Moniteur 40 User Manual

Installation and Operating Instructions

Moniteur

Series 40 Positioners

INSTALLATION & OPERATING INSTRUCTIONS

SERIES 40 Positioners

Form IO2-0406

Installation and Operating Instructions

Moniteur

Description of Device

Moniteur's Series 40 pneumatic (3-15psi) and electropneumatic (4-20mA) positioners are advanced control

devices for rotary or linear valves which provide

unparalleled stability in difficult environments.

! Rugged Aluminum Housing With a Triple Corrosion-

Resistant Interior and Exterior Coating stands up to

harsh environments

! Reduced Bleed Pilot Valve reduces air consumption by

more than 50%

! Precise Calibration with simple SPAN and ZERO

adjustments.

! Magnetic 4-20 mA I/P Converter provides automatic

compensation for supply pressure, atmospheric

pressure and ambient temperature changes, and is

unaffected by EMF.

! Zero-Hysteresis Coupling System provides superior

accuracy and repeatability by eliminating "slop".

! Vibration Resistant Design maintains consistent

performance in poor conditions - no resonance effects

from 5 - 200Hz

! Stainless Steel Gauges

Series 40 Positioners

CAUTION: To reduce the risk of ignition of

hazardous atmospheres, disconnect the

device from the supply circuit before

opening. Keep assembly tightly closed

during operation.

Positioning

Moniteur Series 40 positioners can be mounted in any

position.

Mounting Brackets

For the installation of the rotary positioner, a mounting

bracket has been designed for actuators with the 80 x

30 mm NAMUR accessory pattern. For the 130 x 30

pattern, the block-type mounting bracket is available.

See diagrams below:

Bracket for the 80 x 30 NAMUR pattern

! Optional Limit Switches and 4-20mA Feedback

! Each Positoner Performance Tested - Test results are

included with each positioner

Bracket for the 130 x 30 NAMUR pattern

Part Number System

The series and part number are located on the nameplate. The part number can be deciphered in the table below.

4 N1

Series 40 Shaft Rating Pilot Feedback Gauges Indicator

Description

Series:

Pneumatic

Electro-Pneumatic

Shaft

Rotary NAMUR

Linear 10-80mm

Linear 80-150 mm

Code

40

41

N

L

S

-

E 1 S

Description

Electrical Ratings

Standard / None

Ex md IIT6

Intrinsically Safe

Pilot Valve

Standard Orifice

Small Orifice

Extra-Small Orifice

N

Code

S

E

I

1

2

3

-

F

Description

Position Feedback

None

4-20 mA

2 SPDT Limit Switches

Gauges

None

Standard

Indication

Flat Dial

Dome

Code

N

T

S

N

S

F

D

MONITEUR DEVICES INCORPORATED

36 Commerce Road, Cedar Grove, NJ 07009 Tel. (973) 857-1600 Fax (973) 857-7289

www.moniteurdevices.com

Page 1

Installation and Operating Instructions

Moniteur

Specifications -3-15 psi Pneumatic

Input Signal 3 - 15 psig

Split Range Available

Impedance N/A

Stroke Range: 0 - 90°

Supply Range: 20 to 100 PSIG

Air Delivery: 7 SCFM

Air Consumption: 0.26 SCFM

Operating Temperature: -4° to +158° F

Linearity +/- 1%

Hysteresis 1% max.

Sensitivity +/- 0.5%

Repeatability +/- 0.5%

Pneumatic Connections: 1/8 NPT - Gauge Ports

1/4 NPT - Supply / Outlet

Series 40 Positioners

Specifications - 4-20 mA Electro-Pneumatic

Input Signal 4 - 20 mA @ 24 VDC

Split Range Available

Impedance 250 +/- 15 ohms

Stroke Range: 0 - 90°

Supply Range: 20 to 100 PSIG

Air Delivery: 7 SCFM

Air Consumption: 0.15 SCFM

Operating Temperature: -4° to +158° F

Linearity +/- 1%

Hysteresis 1% max.

Sensitivity +/- 0.5%

Repeatability +/- 0.5%

Pneumatic Connections: 1/8 NPT - Gauge Ports

1/4 NPT - Supply / Outlet

Enclosure: Designed to NEMA 4, 4X

Enclosure Weight: Approx. 4.8 lbs.

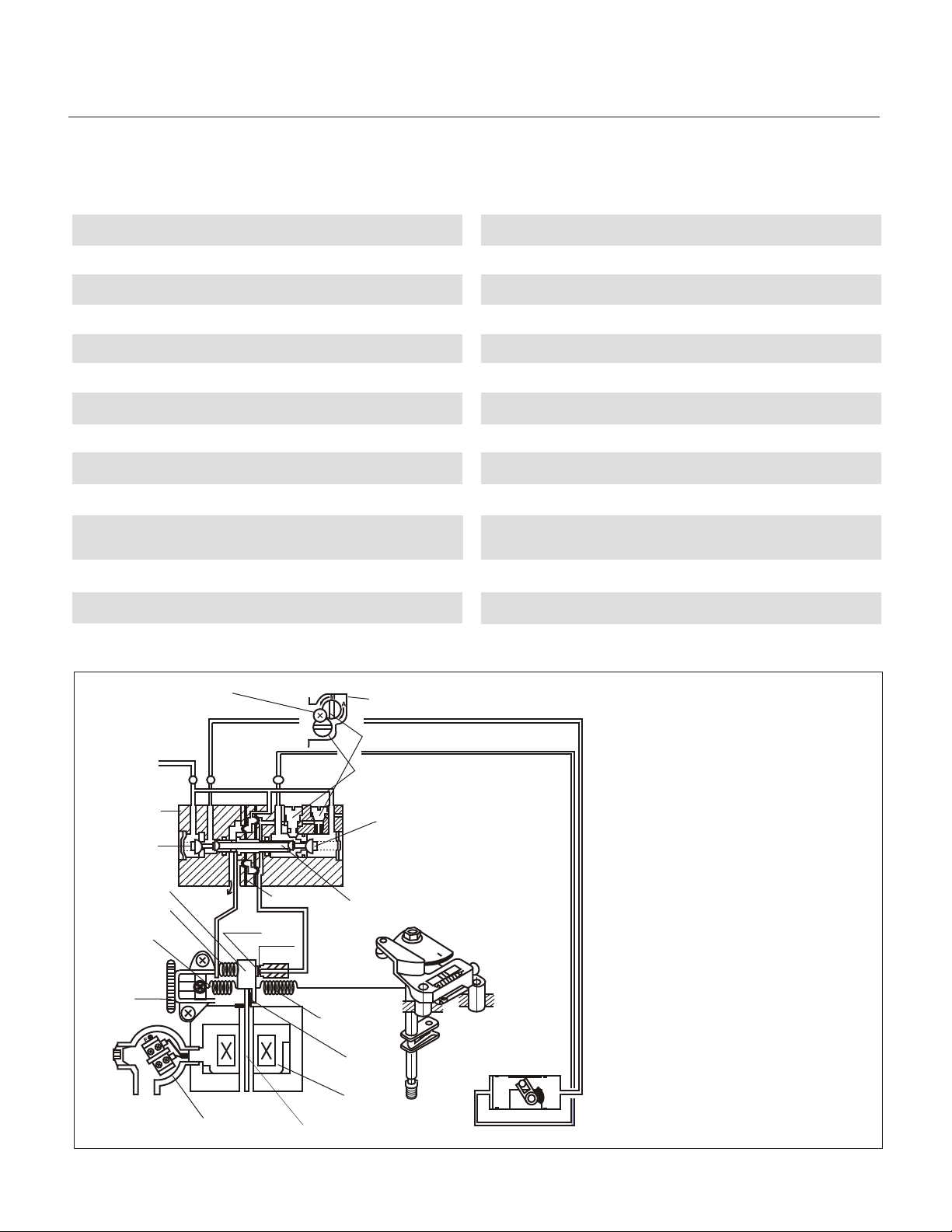

Principle Of Operation

Automatic

Manual

Change-over screw

(Built-in bleed restriction)

Sensitivity adjusting screw

(Adjusts GAIN)

Inlet Valve A

Exhaust Valve

Plate

Spring

Torque

Motor

Air Supply

Pilot Valve

Inlet Valve B

Counter Weight

Compensation

Spring

Zero

adjusting

Spring

Zero

adjusting

Screw

Stopper Screw

Do not move

Terminal Box

Flapper

Diaphragm

Nozzle

Feedback

Spring

Armature

Enclosure: Designed to NEMA 4, 4X

Enclosure Weight: Approx. 6.5 lbs.

OUT 1

As the signal current from the controller

increases, the plate spring of the torque

motor works as a pivot. As the armature

receives the rotary torque in the counter-

OUT 2

clockwise direction, the counter-weight

is pushed to the left, the clearance

between the nozzle and the flapper will

increase, and the nozzle back pressure

will decrease. As a result, the exhaust

valve of the pilot valve moves to the

right, and the output pressure of OUT1

increases (as OUT 2 decreases) to

move the actuator.

The movement of the actuator in turn

rotates the feedback shaft and spring.

The actuator stays in the position where

the spring force is balanced with the

force generated by the input current in

the torque motor. The compensation

spring is for direct feedback of the

Actuator

motion of the exhaust valve, and is

connected to the counter weight to

enhance the stability of the loop. The

zero point is adjusted by changing the

zero adjustment spring tension.

Page 2

MONITEUR DEVICES INCORPORATED

36 Commerce Road, Cedar Grove, NJ 07009 Tel. (973) 857-1600 Fax (973) 857-7289

www.moniteurdevices.com

Loading...

Loading...