Page 1

BBV400NV/BBV400NE SERIES

B-VENT DECORATIVE GAS APPLIANCE

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

READ THIS MANUAL BEFORE INSTALLING OR OPERATING THIS APPLIANCE. THIS INSTALLATION, OPERATION AND MAINTENANCE

MANUAL

MUST BE LEFT WITH APPLIANCE FOR FUTURE REFERENCE.

WARNING: IF THE INFORMATION IN THIS MANUAL IS NOT FOLLOWED EXACTL Y, A FIRE OR EXPLOSION MAY RESULT

CAUSING

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER

APPLIANCE

PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF LIFE.

.

WHA T TO DO IF YOU SMELL GAS

• DO NOT TRY TO LIGHT ANY APPLIANCE.

• DO NOT TOUCH ANY ELECTRICAL SWITCH; DO NOT USE ANY PHONE IN YOUR BUILDING.

• IMMEDIATELY CALL YOUR GAS SUPPLIER FROM A NEIGHBOR’S PHONE. FOLLOW THE GAS SUPPLIER’S

INSTRUCTIONS

• IF YOU CANNOT REACH YOUR GAS SUPPLIER, CALL THE FIRE DEPARTMENT.

INST ALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED INST ALLER, SERVICE AGENCY OR THE GAS SUPPLIER.

DANGER: FAILURE TO FOLLOW THESE INSTRUCTIONS CAREFULLY AND WITHOUT ERROR, OR FAILURE TO HEED ANY

ALL WARNINGS IN THESE INSTRUCTIONS CAN RESULT IN AN EXPLOSION, FIRE OR THE PRODUCTION OF CARBON

AND

MONOXIDE

GAS WHICH CAN CAUSE PROPERTY DAMAGE, BODILY INJURY OR DEATH.

.

53D9015. Rev. 1 03/03

Page 2

TABLE OF CONTENTS

CONGRATULA TIONS!

You have chosen the finest B-vent gas fireplace system available. Y our fireplace has been designed for

years of decorative viewing enjoyment. Please take time to read this entire manual before installing or

operating your system.

Important Information .......................................................................................................................2-4

Appliance System Components ................................................................................ ..5

Clearances ........................

Installation Preparation

Fireplace and Venting Installation ..................................................................................................9

Venting Requirements ........... .............................................................................................10

Gas Supply Connections .............................. .................................................................11

Electrical Wiring .....................................................................................................................................11

Electronic Ignition ................................................................................... .....................12

Fireplace Setup ....................................................................................................................................13

Operating Instructions .....................................................................................................................14-15

Maintenance Instructions ................................................................................................................15-16

Outside Combustion Air Precautions and Recommendations .............................................................17

Combustion Air Assembly .....................................................................................................................18

Troubleshooting .....................................................................................................................................19

Repair Parts List...................................................................................................................................20

................. .................................. ............................................6

...................................................................................................7-8

LISTING AND CODE APPROVALS

U.S. and Canada Certification

The BBV400NV Series Gas Appliance has been tested in accordance with the ANSI Z21.501998/CSA M2.22-M98 Standard for Vented Gas Fireplaces and have been LISTED by OMNITest Laboratories, Inc. for installation and operation as described in these Installation and

Operating Instructions. All components are UL, AGA, CGA, or CSA safety certified.

Local Codes

Check with your local building code agency prior to installing this appliance to ensure

compliance with local codes, including the need for permits and follow-up inspections. This

installation must conform with local codes or, in the absence of local codes, in the USA with

the National Fuel Gas Code, ANSI Z223.1-latest edition.

2

53D9015. Rev 1 03/03

Page 3

IMPORTANT INFORMATION

2

"Warning: If not installed, operated and maintained in accordance with the manufacturer’s

instructions, this product could expose you to substances in fuel or from fuel combustion which

can cause death or serious illness and which are known to the state of California to cause cancer,

birth defects or other reproductive harm. Also, operation, installation and servicing of this product

could expose you to airborne particles of glass wool fibers known to the state of California to

cause cancer through inhalation."

The gas fireplace must be installed and serviced by a qualified installer to conform with local codes. In the

absence of local codes, install to the current National Fuel Gas Code, ANSI Z223.1.

The fireplace and its individual shutoff valve must be disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of 1/2 psig.

The fireplace must be isolated from the gas supply piping system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psig.

Pressures in excess of 1/2 psig will cause damage to the control valve and may cause damage to the shutoff

valve.

Model BBV400NV (Natural Gas):

Maximum Input: 18,000 BTU Per Hour

Minimum Inlet Gas Supply Pressure: 4.5 inches water column

Maximum Inlet Gas Supply Pressure: 7 inches water column

Manifold Pressure Under Flow Conditions: 3.5 inches water column

Notice: This appliance operates with a yellow, smoky flame. When properly adjusted according

to these instructions, small amounts of carbon (soot) will be deposited on the outlet section of

the air terminal and possibly on surrounding structure. If not properly adjusted and operated

according to these instructions, carbon (soot) will accumulate in larger quantities on the air

terminal and surrounding structure and objects.

Do not attempt to operate the burner at an input rate other than that given by the flame adjustment valve.

Illustrations throughout these instructions reflect typical installations and are for design purposes only. Actual

installation may vary slightly due to individual design preferences. However, minimum and maximum clearances

must be maintained at all times. The illustrations and diagrams in these instructions are not drawn to scale.

Any additions, changes or conversions required in order for the appliance to satisfactorily meet the application

needs must be made by a distributor or dealer using factory specified and approved parts.

This product is manufactured to use natural gas. A natural gas unit can be converted to use propane, but ONLY

if converted by a qualified service technician and ONLY if the Natural Gas to Propane Gas Conversion Kit is

used.

If any assistance is required during installation, please contact your local dealer or the Customer Service

Department.

For Massachusetts Residences Only:

• This product must be installed by a licensed plumber or gas fitter when installed within the

Commonwealth of Massachusetts. Flexline installation must not exceed 36 inches.

3

53D9015. Rev 1 03/03

Page 4

IMPORTANT INFORMATION

This fireplace is a decorative gas appliance.

Do not burn wood or other materials in this fireplace.

Adults and especially young children should be alerted to the hazards of high temperatures and should stay away

to avoid burns or clothing ignition.

Supervise young children when they are in the same room as the fireplace.

Due to high temperatures, the fireplace should be located out of traffic and away from furniture and draperies.

Clothing or other flammable material should not be placed on or near the fireplace.

The fireplace glass door must be in place when the appliance is operating.

Any safety screen or guard removed for servicing the appliance must be replaced prior to operating the fireplace.

It is imperative that the control compartments, burners and circulating air passageways of the fireplace and

venting system are kept clean.

The fireplace and its venting system should be inspected before use and at least annually by a qualified service

person.

5

More frequent cleaning may be required due to excessive lint from carpeting, bedding material, etc.

The fireplace area must be kept clear and free from combustible materials, gasoline and other flammable vapors

and liquids.

This fireplace must not be connected to a chimney flue servicing a separate solid fuel burning appliance.

Under no circumstances should the fireplace be modified.

The fireplace is not intended for use with a thermostat.

Do not use this appliance if any part has been under water.

Immediately call a qualified service technician to inspect the appliance and to replace any part of the control

system which has been under water.

This appliance must be installed with the draft hood in the same atmospheric pressure zone as the combustion air

inlet to the appliance.

4

53D9015. Rev 1 03/03

Page 5

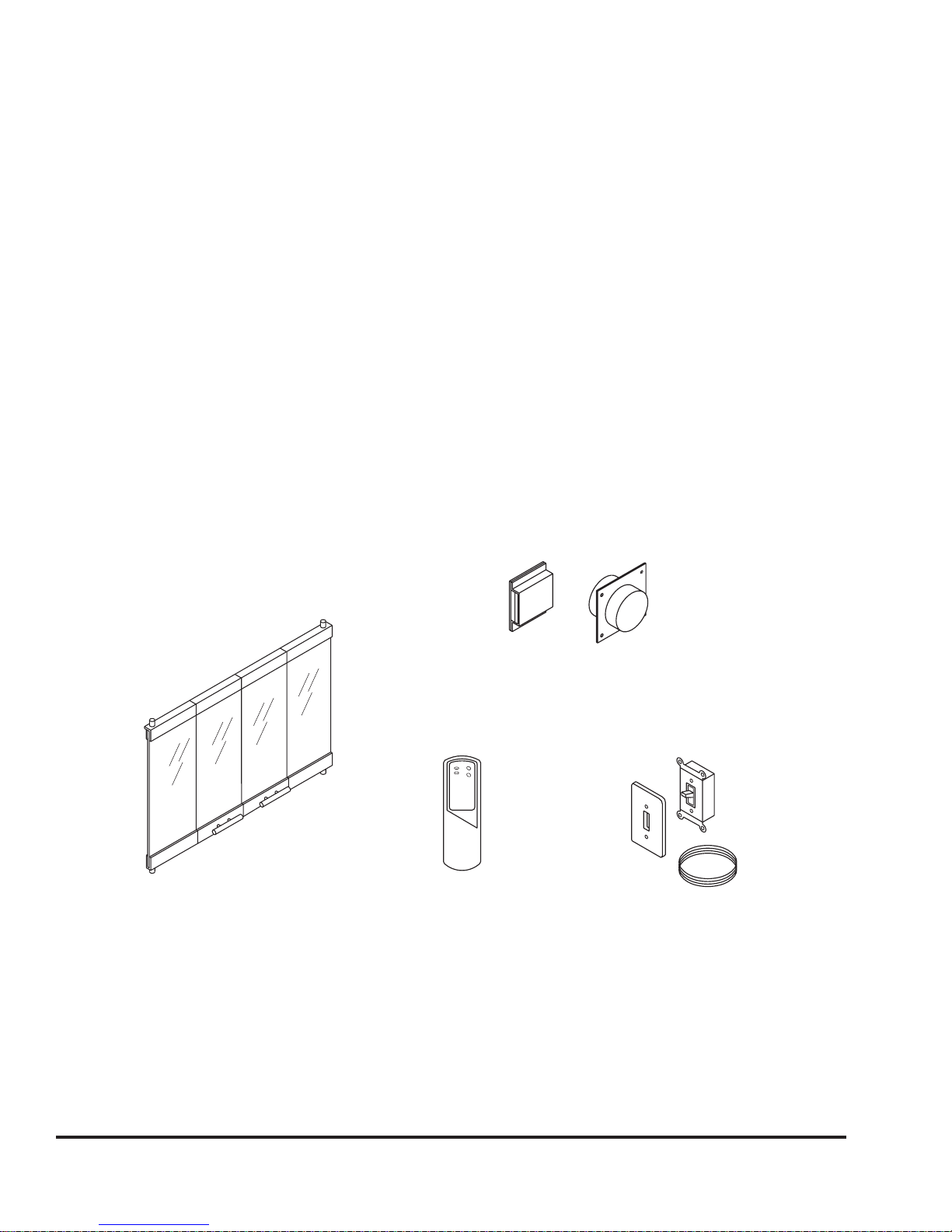

APPLIANCE SYSTEM COMPONENTS

GD36B

GD36PB

OAC4 OUTSIDE

AIR ASSEMBLY

A list of the components that may safely be used with this appliance are listed below.

6

MODELS

BBV400NV Standing Pilot, Natural Gas

BBV400NE Electronic Ignition, Natural Gas

†

Field convertible to propane gas.

Must be installed with one of the glass doors shown below.

GLASS DOORS

GD36PB Polished Brass Glass Door

GD36B Black Finish Glass Door

††

OPTIONAL

Shown below.

ACCESSORIES

CK35E LP Conversion Kit for Electronic Ignition Model

CK35L LP Conversion Kit for Standing Pilot Model

RC2 Hand Held Remote Control

GFWS Wall Switch

OAC4 Outside Air Kit

†

†

††

††

OAC4 OUTSIDE

AIR ASSEMBLY

GD36B

GD36PB

RC2

HAND HELD REMOTE

CONTROL

GFWS

REMOTE WALL SWITCH

This gas appliance has been tested and listed for use with the optional components listed on this page. Many

optional components may be purchased separately and installed at a later date. However, installation of a blower

kit will require electrical power. T o avoid costly reconstruction, electrical power should be connected to the appliance

at the time of initial appliance installation for possible addition of these accessories at a later date.

5

53D9015. Rev 1 03/03

Page 6

CLEARANCES TO COMBUSTIBLE MATERIALS

GAS LINE

KNOCKOUT

JUNCTION BOX

KNOCKOUT

TOP VIEW

FRONT VIEW

SIDE VIEW

15 1/2" MIN.

FRAMING DIM.

1 7/8"

3 1/2"

6 1/8"

5 1/2"

38"

36"

39" MIN.

FRAMING DIM.

MIN.

FRAMING

DIM.

Sides: 1/2 inch Back: 1/2 inch Bottom: 0 inch

Top: 0 to Top of Spacers Front: 24 inches Ceiling: 48 inches

Vent Pipe: As specified by vent manufacturer.

Notice: Spacers are provided on the top of the unit which allow the fireplace to be listed as a "0" clearance

appliance. A ˚" clearance to combustibles must be maintained from the flat surfaces of the sides and back of the

appliance.

When the fireplace is installed directly on carpeting, vinyl tile or other combustible material other than wood

flooring, the fireplace shall be installed on a metal or wood panel extending the full width and depth of the appliance.

Adequate combustion and ventilation air must be provided. Provide adequate accessibility clearance for servicing

and operating the fireplace. Never obstruct the front opening of the fireplace.

F

IGURE 1

36 1/2"

MIN.

FRAMING

DIM.

FRAMING DIM.

FRONT VIEW

TOP VIEW

36"

38"

39" MIN.

7 13/16"

15"

36 1/2"

33"19 5/8"

15 1/2" MIN.

FRAMING DIM.

6 1/8"

3 1/2"

5 1/2"

4 1/8"

1 7/8"

SIDE VIEW

GAS LINE

KNOCKOUT

JUNCTION BOX

KNOCKOUT

6

53D9015. Rev 1 03/03

Page 7

INSTALLATION PREPARATION

This gas fireplace and its components are tested and safe when installed in accordance with this installation

manual. Report your dealer any parts damaged in shipment, particularly the condition of the glass. Do not install

any unit with damaged, incomplete, or substitute parts.

Read all of the instructions before starting the installation. Follow these instructions carefully during the

installation to ensure maximum safety and benefit. Failure to follow these instructions will void the owner’s

warranty and may present a fire hazard.

When planning a fireplace installation, it is necessary to determine:

• Where the unit is to be installed.

• The vent system configuration to be used.

• Gas supply piping requirements.

• Electrical wiring requirements.

• Framing and finishing details.

• Whether optional accessories - devices such as a fan, wall switch, or remote control - are desired.

HIGH ALTITUDE INSTALLATION

For U.S. installation, units are tested and approved for elevations from 0-2000 feet. When installing this unit at an

elevation above 2000 feet, United States codes require a decrease of the input rating by changing the existing

burner orifice to a smaller size. Input should be reduced 4% for each 1000 feet above sea level. Check with the

local gas utility for proper orifice size identification. Consult your local gas company for assistance in determining

the proper orifice for your locality or refer to ANSI Z223.1-the latest edition, Appendix F.

This appliance has been converted for use at an altitude of

Orifice Size Manifold Pressure

Input (Btu/hr) Fuel T ype

Date of Conversion Converted By

7

53D9015. Rev 1 03/03

Page 8

INSTALLATION PREPARATION

61 3/4"

35 1/4"

1/2" MIN. (13 MM)

30 13/16"

15 1/2"

1" MIN. (25 MM)

39"

APPLIANCE LOCATIONS AND SPACE REQUIREMENTS

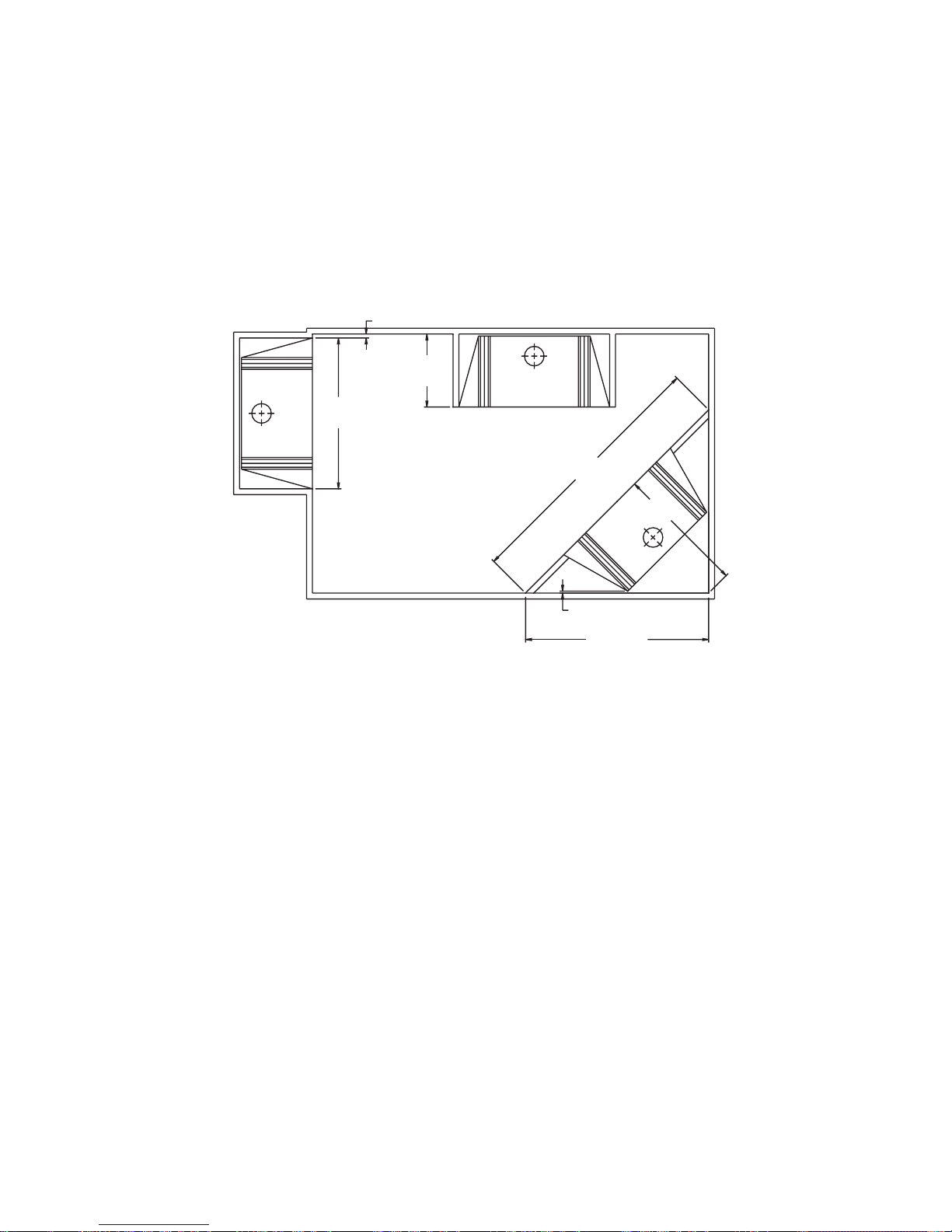

This appliance may be installed along a wall, across a corner or use an exterior chase. The BBV400NV Series

may be installed directly on the floor or on a raised platform to enhance its visual impact. Figure 2 illustrates a

variety of ways the appliance may be located in a room.

Due to high temperatures, the appliance should be located out of traffic and away from furniture and draperies.

1" MIN. (25 MM)

F

IGURE 2

15 1/2"

39"

61 3/4"

30 13/16"

1/2" MIN. (13 MM)

35 1/4"

FRAMING THE ENCLOSURE

Figure 3 shows a typical framing of this appliance assuming combustible materials are used. All required clearances

shown in Figures 1 and 3 to combustibles around the appliance must be adhered to. Any framing at the back and

sides of the appliance must be outside the spacers. Any framing on top of the appliance must be above the top

spacers.

Fireplace framing can be built before or after the fireplace is set in place. Framing should be positioned to

accommodate wall coverings and fireplace facing material.

8

53D9015. Rev 1 03/03

Page 9

12"

MAX.

3 1/2" MIN.

NON-COMBUSTIBLE

MATERIAL

12" MIN. FROM

FIREPLACE OPENING

TO BOTTOM OF

COMBUSTIBLE

MANTEL

2"MIN.

STORM COLLAR

FLASHING

APPROVED COWL

6 FT.

MIN.

AS SPECIFIED BY VENT

MANUFACTURER.

"B" VENT CLEARANCE

MINIMUM CLEARANCE AS

MANUFACTURER.

SPECIFIED BY VENT

SUPPORT

LISTED CEILING

GAS VENT

4" TYPE "B"

WALL

1/2" AIR SPACE TO SIDES

AND REAR OF FIREPLACE.

GAS APPLIANCE

FLOOR

FIREPLACE AND VENTING INSTALLATION

COWL

CHIMNEY

FIGURE 3

APPROVED COWL

STORM COLLAR

FLASHING

4" TYPE "B"

GAS VENT

6 FT.

MIN.

LISTED CEILING

SUPPORT

12" MIN. FROM

FIREPLACE OPENING

TO BOTTOM OF

COMBUSTIBLE

MANTEL

3 1/2" MIN.

NON-COMBUSTIBLE

MATERIAL

12"

MAX.

FLOOR

MINIMUM CLEARANCE AS

SPECIFIED BY VENT

MANUFACTURER.

"B" VENT CLEARANCE

AS SPECIFIED BY VENT

2"MIN.

MANUFACTURER.

1/2" AIR SPACE TO SIDES

AND REAR OF FIREPLACE.

WALL

GAS APPLIANCE

APPROVED

COWL

AS SPECIFIED

BY VENT

MANUFACTURER.

APPROVED THIMBLE FOR

4" TYPE "B" GAS VENT

THROUGH WALL

12" MIN. FROM

FIREPLACE OPENING

TO BOTTOM OF

COMBUSTIBLE

MANTEL

3 1/2" MIN.

NON-COMBUSTIBLE

MATERIAL

FLOOR

12"

MAX.

2" MIN.

SUPPORT

4" TYPE "B" GAS VENT

CHIMNEY

WALL

1/2" AIR SPACE TO SIDES

AND REAR OF FIREPLACE.

GAS APPLIANCE

53D9015. Rev 1 03/03

1 FT.

MIN.

"0" CLEARANCE TO SPACERS

9

Page 10

VENTING REQUIREMENTS

Warning: Do not connect this appliance to a chimney flue serving a separate solid fuel burning appliance.

Carbon deposits (Soot) and creosote from solid fuels can clog the vent from the appliance causing

poisonous carbon monoxide to be released into the room in which the appliance is installed.

All vented gas-fired appliances when operating correctly produce small concentrations of carbon monoxide along

with other combustion products. Should something interfere with the operation of the appliance, it is possible for

the appliance to produce deadly quantities of poisonous carbon monoxide. All flue products from this appliance

must be vented to the outside at all times. Never operate an appliance designed to be vented without a correctly

working vent system connected to the appliance.

Warning: V enting of this appliance is one of the most important parts of the installation. V enting systems

must be installed and inspected according to these instructions and local codes or in the absence of local

codes, according to the National Fuel Gas Code Z223.1 - Latest edition, by a licensed or otherwise qualifed

installer.

Your local gas company should have copies of the National Fuel Code Z223.1 or other installation codes applicable

to your area.

Venting requirements and accepted methods vary greatly depending on the particular installation. It is impossible

to thoroughly define all possible installation circumstances in this manual. The following instructions and illustrations

are general guidelines only . All venting material must be instatlled according to local codes, or in the absence of

such codes, according to the National Fuel Gas Code Z223.1.

Warning: An improperly vented gas-fired appliance can lead to death from carbon monoxide posioning.

Venting materials are not provided with this appliance and must be purchased separately.

This appliance must be installed using 4" type “B” vent that has been listed by a nationally recognized testing

agency..

Attach the vent pipe to the appliance using four (4) sheet metal screws.

Vent must maintain minimum rise of ˘ inch per foot of horizontal run.

Venting terminals shall not be recessed into a wall or siding.

10

53D9015. Rev 1 03/03

Page 11

GAS SUPPLY CONNECTIONS

Both rigid and flexible gas lines are approved for use with these appliances. Consult you local codes for approved

gas piping practices. Some local codes may require the installation of a manual main shut-off valve and union

external to the appliance. Approved components must be used and the union must be of the ground joint type.

1. Knockouts are on each side of the fireplace outer jacket for convenience in running the gas line to the unit.

2. Choose the gas line routing that results in the shortest length of run and requires the least number of fittings

and joints to avoid excessive pressure drop.

3. Connect the gas line to the inlet side of the gas valve.

NOTE: Compounds used on thread joints of gas piping must be resistant to the actions of liquefied

petroleum gases.

A 1/8 inch (3 mm) N.P.T. plugged tapping, accessible for test gauge connection, should be provided in the

gas supply line leading to the unit’s shutoff valve.

4. After gas piping installation is complete, carefully check all piping connections for gas leaks using a leak

detecting solution.

Caution: The gas valve can be damaged if subjected to more than ˚ psig during pressure testing

of the gas piping system. The gas valve must be disconnected or isolated from the piping system

during pressure testing.

ELECTRICAL WIRING

NOTE: This appliance must be electrically wired and grounded in accordance with local codes

and/or with the National Electric Code ANSI/NFPA 70 - Latest Edition, and Canadian Electrical

Code C22.1.

1. Model BBV400NV uses a millivolt standing pilot valve system and does not require a 110 volt supply for

operation.

Warning: Do not connect 110 Vac to millivolt valve. This will cause the unit to malfunction and

destroy the valve control system.

11

53D9015. Rev 1 03/03

Page 12

ELECTRONIC IGNITION

TAP

LIMIT SWITCH

WALL

GAS CONTROL/ELECTRONIC IGNITION ROUTING

PILOT

TO BURNER

GAS LINE-OUT

EQUIVALENT.

WITH SAME OR

DEGREE C. REPLACE

WIRE TYPE 105

SUPPLY

PILOT GAS

GROUND

PILOT BURNER

GND

COMMON

LINE

120V. 60 Hz.

POWER SUPPLY

TRANSFORMER

SWITCH

IGNITION WIRE

TAP

PRESSURE

OUTLET

ELECTRONIC CONTROL

CONTROL ADJUST. SCREW

INLET PRESSURE

IN

GAS CONTROL VALVE

GAS SUPPLY - IN

ON

OFF

MV

PV

PV

MV

SPARK

(OPT)

TH-W

24V

(GND)

24V

(BURNER)

GND

PV

MV/PV

MV

WARNING

PV-1A MAX. MV-1A MAX.

24V, 60 Hz

90 SEC. L.O.

100% SHUTOFF IP

S8600H

device that has been wet - replace it.

it gets wet. Never try to use a

This device can malfunction if

serious injury or death.

Explosion hazard. Can cause

3. Model BBV400NE requires connection to a 110 VAC supply from a remote wall switch to the Junction Box.

Connect the 110 VAC supply to the transformer leads and the receptacle. Insure that the 110 VAC supply is

properly grounded to the unit. Figure 4.

Caution!: Always make sure the power is "OFF" before attempting to install or service any electrical

wiring or components.

FIGURE 4

GAS CONTROL/ELECTRONIC IGNITION ROUTING

PILOT

DEGREE C. REPLACE

WIRE TYPE 105

WITH SAME OR

EQUIVALENT.

GAS LINE-OUT

TO BURNER

PILOT BURNER

GROUND

GAS CONTROL VALVE

GAS SUPPLY - IN

IN

CONTROL ADJUST. SCREW

OUTLET

PRESSURE

TAP

PILOT GAS

SUPPLY

MV

MV

OFF

ON

PV

PV

ELECTRONIC CONTROL

S8600H

100% SHUTOFF IP

90 SEC. L.O.

24V, 60 Hz

PV-1A MAX. MV-1A MAX.

PV

(GND)

24V

24V

GND

(BURNER)

7

6

5

4

IGNITION WIRE

WARNING

Explosion hazard. Can cause

serious injury or death.

This device can malfunction if

it gets wet. Never try to use a

device that has been wet - replace it.

MV

MV/PV

3

21

INLET PRESSURE

TAP

(OPT)

TH-W

8

LIMIT SWITCH

POWER SUPPLY

SPARK

9

WALL

SWITCH

TRANSFORMER

120V. 60 Hz.

LINE

COMMON

GND

12

53D9015. Rev 1 03/03

Page 13

FIREPLACE SETUP

1. Remove the box containing the log from the firebox and discard the two (2) shipping pads. Carefully remove

the log from the box.

2. Position log over burner as shown in Figure 5. Wear protective gloves to place glowing ember meterial in front

and on top of burner tube. The ember material should be separated into small (nickel size) pieces and spread

evenly in front of burner. Lava rock may be placed on the hearth around the ember material.

Warning: Improper log placement may result in production of increased quanities of poisonous

carbon monoxide and soot.

3. Install the glass door assembly supplied separately from this package. The glass door is installed by inserting

the top two (2) pins into the receiving holes above the fireplace opening and then inserting two (2) pins into the

bottom. Use care not to bump or scratch the glass. Glass door assembly model number GD36PB or model

number GD36B must be installed when the fireplace is in use.

IGURE 5

F

BURNER TUBE

EMBER MATERIAL

LAVA ROCK

DO NOT COVER

LARGE PORT HOLES

13

53D9015. Rev 1 03/03

Page 14

GAS VALVE SHOWN IN PILOT POSITION

CONTROL

KNOB

PILOT ADJUSTMENT

SCREW

SUPPLY

GAUGE PORT

MANIFOLD

GAUGE PORT

HI/LO FLAME

ADJUSTMENT KNOB

TP

TH

TP

TH

OPERATING INSTRUCTIONS

A. BEFORE LIGHTING smell all around the appliance area for gas. Be sure to smell

next

to the floor because some gas is heavier than air, and will settle on the f

loor.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in your buil

ding.

Immediately call your gas supplier from a neighbor's phone. Follow th

e supplier's

instructions.

If you cannot reach your gas supplier, cal

l the fire department.

B. Use only your hand to push in or turn knob. Never use tools. If the knob will

not push

in or turn by hand, don't try to repair it; call a qualified service techni

cian Forced or

attempted repair may result in a fire or explosion.

C. Do not use this appliance if any part has been under water. Immediately call aa

qualified service technician to inspect the appliance and to replace any pa

rt of the

control system and any gas control which has been under water.

WARNING!

IF YOU DO NOT FOLLOW THESE INSTRUCTIONS EXACTLY, A FIRE OR

EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL

INJURY OR LOSE IF LIFE.

FOR YOUR SAFTEY READ BEFORE LIGHTING

Warning!: Never operate this unit with the glass removed.

FOR YOUR SAFTEY READ BEFORE LIGHTING

WARNING!

IF YOU DO NOT FOLLOW THESE INSTRUCTIONS EXACTLY, A FIRE OR

EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL

INJURY OR LOSE IF LIFE.

A. BEFORE LIGHTING smell all around the appliance area for gas. Be sure to smell

to the floor because some gas is heavier than air, and will settle on the f

loor.

next

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in your buil

Immediately call your gas supplier from a neighbor's phone. Follow th

ding.

e supplier's

instructions.

If you cannot reach your gas supplier, cal

B. Use only your hand to push in or turn knob. Never use tools. If the knob will

in or turn by hand, don't try to repair it; call a qualified service techni

l the fire department.

not push

cian Forced or

attempted repair may result in a fire or explosion.

C. Do not use this appliance if any part has been under water. Immediately call

qualified service technician to inspect the appliance and to replace any pa

rt of the

control system and any gas control which has been under water.

MILLIVOLT STANDING PILOT SYSTEM

1. If an optional wall mounted switch or appliance mounted On/Off switch was used, switch to the “OFF” position.

2. Turn off all electrical power to the appliance.

3. Open the hinged lower grille. Push in gas control knob slightly and turn clockwise to “OFF”.

4. Wait five (5) minutes to clear out any gas. If you then smell gas do not attempt to light. Follow the instructions

in the warning above. If you do not smell gas proceed to the next step.

5. Depress gas valve control knob partially, and turn counterclockwise to the pilot position. Figure 6.

6. Depress control knob in until it stops and hold

in this position while pushing the red piezo

ignitor button until the pilot lights. The control

knob should be held depressed for a few

seconds. Release the control knob and the

pilot should remain lit.

7. Depress the control knob partially and turn

counterclockwise to the "ON" position.

8. If an optional wall switch or appliance mounted

switch was used, switch to "ON". The main

burner should now be "ON".

9. Close the lower grille.

14

53D9015. Rev 1 03/03

F

IGURE 6

ADJUSTMENT KNOB

TP

TH

TP

TH

PILOT ADJUSTMENT

HI/LO FLAME

SCREW

GAS VALVE SHOWN IN PILOT POSITION

MANIFOLD

GAUGE PORT

L

O

I

H

O

F

F

O

N

CONTROL

KNOB

SUPPLY

GAUGE PORT

P

I

L

O

T

Page 15

OPERATING INSTRUCTIONS

TO TURN OFF GAS TO APPLIANCE

1. TURN GAS CONTROL KNOB

CLOCKWISE TO OFF.

2. TURN OFF ALL ELECTRICAL

POWER TO THE UNIT.

3. SHUT OFF MAIN GAS SUPPLY

VALVE TO THE UNIT.

GAS CONTROL

KNOB

POSITION

INDICATER

ON

OFF

ELECTRONIC IGNITION SYSTEM

1. STOP! Read the safety information at the beginning of this section.

2. Turn off the electric power to the appliance.

3. This appliance is equipped with an ignition device which automatically lights the pilot. Do

NOT try to light the

pilot by hand.

4. Open control access panel.

5. Turn gas control knob clockwise to "OFF". Refer to Figure 7.

F

IGURE 7

POSITION

INDICATER

ON

OFF

GAS CONTROL

KNOB

TO TURN OFF GAS TO APPLIANCE

1. TURN GAS CONTROL KNOB

CLOCKWISE TO OFF.

2. TURN OFF ALL ELECTRICAL

POWER TO THE UNIT.

3. SHUT OFF MAIN GAS SUPPLY

VALVE TO THE UNIT.

6. Wait five (5) minutes to clear out any gas. If you then smell gas, STOP! Follow the instructions in the warning

on page 14. If you do not smell gas, go to next step.

7. Turn gas control knob counterclockwise to "ON".

8. Close control access panel.

9. Turn on all electric power to the appliance.

10. If the appliance will not operate, follow the instructions "To Turn Of f Gas To Appliance" and call your service

technician or gas supplier.

MAINTENANCE INSTRUCTIONS

1. Control Compartment - Keep the control compartment clean by brushing and vacuuming at least once a year.

Always turn off the gas valve and all electrical power to the unit before cleaning.

2. Checking Flame Patterns - The burner flame pattern should be checked periodically. The flames should be

steady and not lifting. See Figure 8.

3. Vent System Inspection - The appliance and vent system should be inspected at least annually. A qualified

service person should check vent pipe and all connections for tightness and to make sure there is no blockage

at the termination, no unusual corrosion or other damage.

4. The appliance area must be kept clear and free from combustible materials, gasoline and other flammable

vapors and liquids.

15

53D9015. Rev 1 03/03

Page 16

RED GLOWING EMBERS

1. LOOK DOWN BETWWEN THE LOGS TO SEE THE BURNER.

THE FLAMES SHOULD BE STABLE ON THE BURNER.

2. THE FLAMES SHOULD BE BLUE AT THE BURNER AND

YELLOW AT THE TOP.

3. INSURE THAT THE PILOT FLAME IS STABLE AND

CONTACTING THE THERMOPILE.

YELLOW TIPPED FLAMES

LOW MASS

THERMOCOUPLE

THERMOCOUPLE

PILOT

MAINTENANCE INSTRUCTIONS

YELLOW TIPPED FLAMES

FIGURE 8

1. LOOK DOWN BETWWEN THE LOGS TO SEE THE BURNER.

THE FLAMES SHOULD BE STABLE ON THE BURNER.

2. THE FLAMES SHOULD BE BLUE AT THE BURNER AND

YELLOW AT THE TOP.

3. INSURE THAT THE PILOT FLAME IS STABLE AND

CONTACTING THE THERMOPILE.

RED GLOWING EMBERS

THERMOCOUPLE

PILOT

LOW MASS

THERMOCOUPLE

5. Insure that the flow of combustion and ventilation air is not obstructed.

6. Do not use this appliance if any part has been under water. Immediately call a qualified service technician to

inspect the appliance and to replace any part of the control system and any gas control which has been under

water.

7. This appliance must only be operated with glass door model number GD36PB or model number GD36B

properly installed per the Fireplace Setup instruction section of this manual. If the door is damaged or broken,

it may only be replaced by a complete assembly as supplied by the manufacturer. See the Repair Parts List.

8. Never attempt to replace the glass panel with another piece of glass or use any other substitute materials.

9. Never attempt to operate this appliance with a broken glass door.

10. When removing or replacing the glass door for cleaning or inspection, care must be taken not to abuse the

glass panel by striking, slamming shut, or scratching against other surfaces.

11. Only trim kits and other optional accessories supplied by the manufacturer may be used with this appliance.

Draft relief openings must never be covered or blocked.

12. Cleaning the glass - Wear gloves while handling the glass door assembly. DO NOT REMOVE GLASS DOOR

WHEN HOT. Handle the glass door with care to avoid striking or scratching the glass. Clean the inside and

outside surfaces of the glass panel using a mild detergent and water solution with a soft cloth. Do

abrasive cleansers which might scratch the glass surface. Do not attempt to clean the glass when the surface

is hot. The glass door must be properly reinstalled after cleaning. Do not operate this appliance without the

glass door properly in place.

13. Service - Any service to the burner/gas control system or electrical system and its components, must only be

performed by a qualified service technician.

16

53D9015. Rev 1 03/03

not use

Page 17

OUTSIDE COMBUSTION AIR PRECAUTIONS & RECOMMENDATIONS

CONCRETE SLAB INSTALLATION

(OPTIONAL OUTSIDE AIR RUNS)

INLET GRILLE

IN SOFFIT

(OVERHANG)

8' MAX.

TO OUTSIDE WALL

DUCT EXTENDED

TO MISS JOIST

NOTE: The use of outside air for combustion is optional unless required by building codes. It is only necessary

to supply outside combustion air to one side of the fireplace. Use the model OAC4 combustion air kit.

1. Extremely long runs and numerous turns in the duct leading from the fireplace to the combustion air assembly

should be avoided. These conditions will increase the resistance to the free flow of air through the duct.

Refer to Figure 9 for methods of installing the outside air for combustion assemblies.

2. The combustion air assembly should be located at an exterior location, which is not likely to be accidentally

blocked in any manner. The assembly should be located above the snow line to prevent blockage by snow

accumulation.

3. The combustion air inlet assembly should never be mounted in a garage or storage area where combustible

fumes such as gasoline might be drawn into the fireplace.

4. Combustion air can be drawn from the crawl space under a house when an adequate supply of air is

provided by open ventilation.

5. Do not take combustion air from attic space or garage space.

DUCT EXTENDED

TO MISS JOIST

TO OUTSIDE WALL

INSTALLATION ABOVE BASEMENT

OR CRAWL SPACE

FIGURE 9

INLET GRILLE

8' MAX.

IN SOFFIT

(OVERHANG)

CONCRETE SLAB INSTALLATION

(OPTIONAL OUTSIDE AIR RUNS)

17

53D9015. Rev 1 03/03

Page 18

LONGER LENGTH OF THE TUBE

TO OUTSIDE.

INSERT SHORTEST SIDE OF

THE TUBE THROUGH THE

FIREPLACE OUTER WRAP.

STEP 1: SECURE OUTSIDE AIR STARTING

COLLAR TO LEFT SIDE OF FIREPLACE WITH

FOUR SHEET METAL SCREWS PROVIDED.

STEP 2: SECURE OUTSIDE

DUCT TO STARTING COLLAR

WITH DUCT CLAMP OR SCREWS.

SCREWS

6" DIA. HOLE FOR OAC4

NAIL

HOLES

COMBUSTION AIR ASSEMBLY

MODEL OAC-4 COMBUSTION AIR ASSEMBLY

1. Remove the cover plate from the 4-inch outlet opening location on the left outside of the fireplace. DO NOT

remove the cover if the outside air will not be connected.

2. Place the starting collar (4 inch) into the hole on the left side of the fireplace. Fasten it in place with the four

sheet metal screws provided.

3. Cut a 6-inch diameter opening for model OAC-4 in the outside wall covering where the outside vent is to be

located.

4. Select and cut a piece of duct sufficient length to attach to the fireplace and protrude at least three inches

beyond the face of the wall to which the inlet air vent will be attached. The duct may be cut with a standard

pocket knife (use FP-4 U duct for maximum efficiency and safety). Do not use a combustible duct. Always

use UL Listed Class 0 or 1 duct material. If it is necessary to splice the duct, a Model 403 duct connector

should be used to splice duct sections.

5. If the duct is the insulated type, push the insulation back from one end of the duct approximately two

inches.

6. Slip the exposed end of the duct over the starting collar on the fireplace.

7. Using the sheet metal screws or duct clamps, secure the duct to the starting collar and to the outside vent.

8. Nail or screw the outside vent to the surface of the wall.

FIGURE 10

SCREWS

INSERT SHORTEST SIDE OF

THE TUBE THROUGH THE

FIREPLACE OUTER WRAP.

6" DIA. HOLE FOR OAC4

NAIL

HOLES

STEP 1: SECURE OUTSIDE AIR STARTING

COLLAR TO LEFT SIDE OF FIREPLACE WITH

FOUR SHEET METAL SCREWS PROVIDED.

18

53D9015. Rev 1 03/03

LONGER LENGTH OF THE TUBE

TO OUTSIDE.

STEP 2: SECURE OUTSIDE

DUCT TO STARTING COLLAR

WITH DUCT CLAMP OR SCREWS.

Page 19

TROUBLESHOOTING

While the manufacturer has made every reasonable effort to insure that this heater operates properly and

satisfactorily , sometimes problems do arise. The following troubleshooting chart lists several problems with their

probable cause and solution. Any adjustments and/or replacements must be made by a qualified person. Do not

replace any component with a different type. Only use components supplied by the manufacturer of this heater .

Problem

Flame too large.

Noisy flame.

Yellow excessive flame.

Floating flame.

Delayed ignition.

Cause

Pressure regulator set too high.

Defective regulator on heater.

Burner orifice too large. Replace with correct size.

Noisy pilot.

Burr in orifice.

Too little primary air.

Clogged burner ports.

Misaligned orifice.

Clogged vent system

Blocked venting.

Insufficient primary air .

Improper pilot location.

Pilot flame too small.

Burner ports clogged. Clean ports.

Solution

Reset, using manometer.

Replace.

Reduce pilot gas.

Remove burr or replace.

Clean air intake to burners..

Clean ports.

Realign or replace burner .

Clean.

Clean.

Clean intake to burners.

Reposition pilot.

Check orifice, increase gas.

Failure to ignite.

Main burner won’t turn OFF .

Main burner won’t turn ON.

Burner and pilot flame go

out.

Low pressure. Adjust pressure regulator.

Main gas OFF . Open manual valve.

Defect in gas valve.

Defective auto. pilot valve.

Defective auto. valve.

Defective auto. valve.

Defective thermocouple.

Defective switch.

Poorly functioning vent system

Gas supply interrupted.

Defective thermocouple or control

Replace.

Clean or replace.

Replace.

Replace.

Repair or replace.

Replace.

If pilot can be relit but main burner and pilot go

off after ignition, have vent system checked and

corrected immediately .

Attempt to relight pilot and main burner. If unable

to relight pilot, check thermocouple and/or control.

Replace.

19

53D9015. Rev 1 03/03

Page 20

PARTS LIST

Part

077155A

077154A

077101A

073728A

066308A

077403A

073390A

073391A

057958A

057955A

057956A

060874A

053297A

053298A

Description

All repair part orders should be placed through your local dealer. To ensure prompt and accurate service, please

provide the following information when placing a repair part order: Model number of your Appliance, Part Name,

Part Number, and Quantity of parts needed.

Technical Service Department

2813 W. Mall Drive, Unit B.

Florence, Alabama 35630.

Tel. - 1-866-500-5671

www.monessenhearth.com

Description

Glass Door Brass

Glass Door Black

Log Set

Burner

Orifice (Natural #45)

Orfice (LP #55)

Pilot (Standing Piiot Natural)

Pilot (Standing Pilot LP)

Piezo Ignitor

Gas Valve (Standing Pilot Natural)

Gas Valve (Standing Pilot LP)

Pilot (Electronic Ignitor)

Gas Valve (Electronic Ignitor)

Transformer Assembly

Electronic Ignitor Module

Part

077155A

077154A

077101A

073728A

066308A

077403A

073390A

073391A

057958A

057955A

057956A

060874A

053297A

053298A

052139A

20

53D9015. Rev 1 03/03

Page 21

NOTES

21

53D9015. Rev 1 03/03

Page 22

NOTES

22

53D9015. Rev 1 03/03

Page 23

NOTES

23

53D9015. Rev 1 03/03

Page 24

ATTENTION

APPLIANCE

INSTALLER

PLEASE RETURN THESE OPERATING

AND

INSTALLATION INSTRUCTIONS

TO THE APPLIANCE FOR

53D9015. REV 1 03/03

CONSUMER USE.

Loading...

Loading...