Page 1

1

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

Models:

AVFL60NIP

AVFL60PIP

Installation Manual

Installation and Appliance Setup

INSTALLER: Leave this manual with party responsible for use and operation.

OWNER: Retain this manual for future reference.

NOTICE: DO NOT discard this manual!

In the Commonwealth of Massachusetts

installation must be performed by a licensed

plumber or gas tter.

See Table of Contents for location of

additional Commonwealth of Massachusetts

requirements.

• DO NOT store or use gasoline or other am-

mable vapors and liquids in the vicinity of this

or any other appliance.

• What to do if you smell gas

- DO NOT try to light any appliance.

- DO NOT touch any electrical switch. DO

NOT use any phone in your building.

- Leave the building immediately.

- Immediately call your gas supplier from

a neighbor’s phone. Follow the gas supplier’s instructions.

- If you cannot reach your gas supplier, call

the re department.

• Installation and service must be performed

by a qualied installer, service agency, or the

gas supplier.

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly

could result in serious injury, death, or

property damage.

ARTISAN

SERIES

This is an unvented gas-red heater. It uses air

(oxygen) from the room in which it is installed.

Provisions for adequate combustion and ventil-

ation air must be provided. Refer to Page 6.

DO NOT install this unit in a bedroom or

bathroom. Please refer to page 6 Section F for

proper unit placement.

Page 2

2

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

Safety Alert Key:

• DANGER! Indicates a hazardous situation which, if not avoided will result in death or serious injury.

• WARNING! Indicates a hazardous situation which, if not avoided could result in death or serious injury.

• CAUTION! Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

• NOTICE: Used to address practices not related to personal injury.

Table of Contents

Installation Standard Work Checklist ....................3

1 Product Specic and Important Safety Information

A. Appliance Certication ............................4

B. BTU Specications ...............................4

C. High Altitude Installations ..........................4

D. Non-Combustible Materials Specication. . . . . . . . . . . . . . 4

E. Combustible Materials Specication ................. 4

F. Electrical Codes .................................4

2 Getting Started

A. Design and Installation Considerations ............... 5

B. Tools and Supplies Needed ........................ 5

C. Inspect Appliance and Components ..................5

D. Getting Started ..................................6

E. Planning the Installation ........................... 6

F. Adequate Combustion Ventilation Air ................. 6

3 Framing and Clearances

A. Fireplace & Framing Dimension Diagrams. . . . . . . . . . . . . 8

B. Clearances and Height Requirements ................9

C. Good Faith Wall Surface TV Guidelines ..............10

D. Constructing the Appliance Chase .................. 11

E. Floor Protection ................................ 11

4 Appliance Preparation

A. Securing and Leveling the Appliance ................12

B. Installing Non-Combustible Facing Material ..........13

5 Gas Information

A. Fuel Type .....................................14

B. Gas Pressure ..................................14

C. Gas Service Access .............................14

D. Connect to Gas ................................16

E. Valve Access ..................................17

F. Check Gas Pressure ............................ 17

G. Gas Connection ................................18

6 Electrical Information

A. General Information .............................19

B. Wiring Requirements ............................20

7 Final Installation

A. Dome Light Bulb Installation ......................22

B. Black Magic Glass Installation .....................22

C. Installation of Air Deection Glass .................. 23

D. Fireglass Only Placement ........................23

E. Glass and Optional Stone Kit Placement ............. 23

F. Placement of Optional Logs .......................24

G. Lighting Instructions (IPI) .........................26

8 Finishing

A. Facing and Finishing Instructions ...................27

B. Operation During a Power Outage ..................29

C. Detailed Component Operating Instructions.—Intellire Plus

ODS .........................................30

D. Troubleshooting ................................ 31

E. Accessories ................................... 33

Page 3

3

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

Installation Standard Work Checklist

Appliance Install Sections 2 and 4 (Pg. 5 & 12)

Verified that the chase is insulated and sealed.

Required non-combustible board is installed.

Gas Section 5 (Pg 14)

Proper appliance for fuel type.

Leak check performed and inlet pressure verified.

Verified proper air shutter setting for installation type.

Customer:

Lot/Address:

Model

(circle one): AVFL60NIP, AVFL60PIP

Date Installed:

Location of Fireplace:

Installer:

Dealer/Distributor Phone #

Serial #:

Comments: Further description of the issues, who is responsible (Installer/ Builder/ Other Trades, etc) and corrective

action needed _____________________________________________________________________________________

Comments Communicated to party responsible ____________________ by ______________________on ___________

(Builder / Gen. Contractor/) (Installer) (Date)

?YHW , ON F I SEY

___________________________

___________________________

___________________________

___________________________

___________________________

Verifi ed clearances to combustibles.

Fireplace is level

ed and secured.

Adequate provisions for combustion and ventilation air have been verified.

___________________________

___________________________

___________________________

___________________________

___________________________

Finishing Section 8 (Pg 27)

Combustible materials not installed in non-combustible areas.

Verifi ed all clearances meet installation manual requirements.

Finishing done correctly using inside fit or overlap fit method.

Bottom finishing template and finishing guards removed.

Mantels and wall projections comply with installation manual requirements.

___________________________

___________________________

___________________________

___________________________

___________________________

___________________________

___________________________

___________________________

___________________________

Manual bag and all of its contents are removed from inside/under

___________________________

___________________________

the appliance and given to party responsible for use and operation.

Started appliance and veried no gas leaks exist.

Lights work in all switched positions (if so equipped). ___________________________

4605-902A 05/17

= Contains updated information.

Hearth & Home Technologies recommends the following:

• Photographing the installation and copying this checklist for your file.

• That this checklist remain visible at all times on the appliance until the installation is complete.

This standard work checklist is to be used by the installer in conjunction with, not instead of, the instructions contained in this

installation manual.

WARNING! Risk of Fire or Explosion! Failure to install appliance according to these instructions could

lead to a fire or explosion.

ATTENTION INSTALLER:

Follow this Standard Work Checklist

Glass & Stone Section 7 (Pg 22-25)

All packaging and protective materials removed (inside & outside of appliance).

Media installed correctly.

Glass assembly installed and secured.

Accessories installed properly.

Electrical Section 6 (Pg 19)

Unswitched power (110-120 VAC) provided to the appliance.

Switch wires properly installed.

Page 4

4

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

This product is listed to ANSI standards for "Unvented

Room Heaters” and applicable sections of "Gas Burning

Heating Appliances for Manufactured Homes" and "Gas

Fired Appliances for Use at High Altitude."

A. Appliance Certication

D. Non-Combustible Materials Specication

Material which will not ignite and burn. Such materials are

those consisting entirely of steel, iron, brick, tile, concrete,

slate, glass or plasters, or any combination thereof.

Materials that are reported as passing ASTM E 136,

Standard Test Method for Behavior of Materials in

a Vertical Tube Furnace at 750 ºC shall be considered

non-combustible materials.

E. Combustible Materials Specication

Materials made of or surfaced with wood, compressed pa-

per, plant bers, plastics, or other material that can ignite

and burn, whether ame proofed or not, or plastered or

unplastered shall be considered combustible materials.

F. Electrical Codes

NOTICE: This appliance must be electrically wired

and grounded in accordance with local codes or, in the

absence of local codes, with National Electric Code

ANSI/NFPA 70-latest edition or the Canadian Electric

Code CSA C22.1.

• A 110-120 VAC circuit for this product must be pro-

tected with ground-fault circuit-interrupter protection,

in compliance with the applicable electrical codes,

when it is installed in locations such as in bathrooms

or near sinks.

NOT INTENDED FOR USE AS A PRIMARY HEAT SOURCE.

This appliance is tested and approved as either supplemen-

tal room heat or as a decorative appliance. It should not be

factored as primary heat in residential heating calculations.

NOTICE: This installation must conform with local codes.

In the absence of local codes you must comply with the

National Fuel Gas Code, ANSI Z223.1-latest edition in

the U.S.A.

1

Product Specic and Important Safety Information

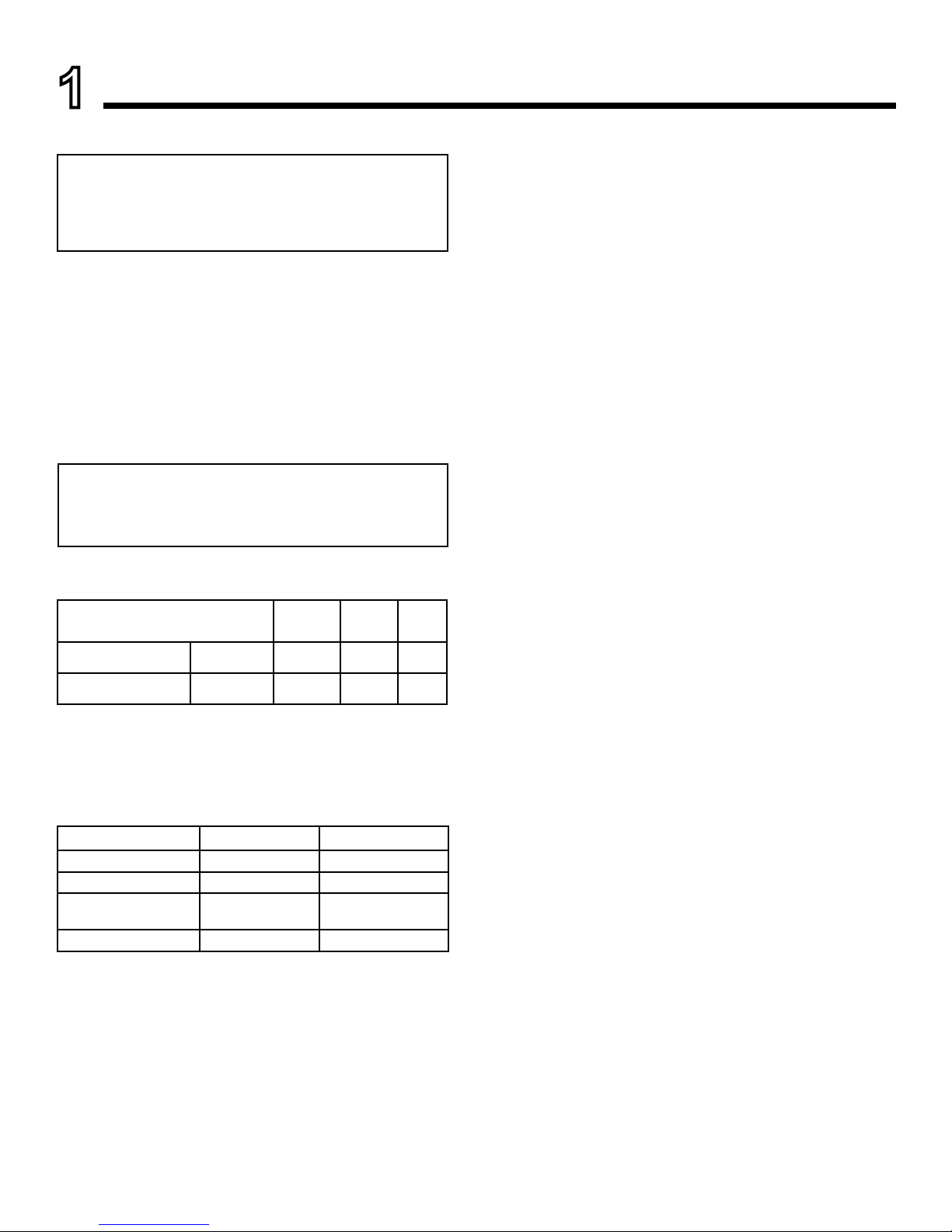

B. BTU Specications

C. High Altitude Installations

NOTICE: If the heating value of the gas has been reduced,

these rules do not apply. Check with your local gas utility

or authorities having jurisdiction.

When installing above 4500 feet elevation: Reduce input

rate 4% for each 1000 feet above 4500 feet.

Check with your local gas utility to determine proper

orice size.

MODEL: AVFL60NIP, AVFL60PIP

LABORATORY: CSA

TYPE: Unvented Room Heaters

STANDARD: ANSI Z21.11.2.2013

Models

Maximum

Input BTU/h

Minimum

Input

BTU/h

Orice

Size

(DMS)

AVFL60NIP (0-4500 FT) 38,000 25,000 #44

AVFL60PIP (0-4500 FT) 37,000 29,000 #54

GAS PRESSURES

NOTE: For LP models an external regulator is required

to reduce supply pressure to a maximum of 13" w.c.

NATURAL PROPANE (LP)

Inlet Minimum 5.0" w.c. 11.0" w.c.

Inlet Maximum 10.5" w.c. 13.0" w.c.

Regulator Pressure

Setting

3.5" w.c. 10" w.c.

Pilot Regulator 3.5" w.c. —

Page 5

5

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

2

Getting Started

A. Design and Installation Considerations

Installation MUST comply with local, regional, state and

national codes and regulations. Consult insurance carrier,

local building inspector, re ofcials or authorities having

jurisdiction over restrictions, installation inspection and

permits.

Before installing, determine the following:

• Where the appliance is to be installed.

• Gas supply piping.

• Electrical wiring requirements.

• Framing and nishing details.

• Whether optional accessories—devices such as a wall

switch or remote control—are desired.

Improper installation, adjustment, alteration, service or

maintenance can cause injury or property damage. For

assistance or additional information, consult a qualied

service technician, service agency or your dealer.

Installation and service of this appliance should

be performed by qualied personnel. Hearth

& Home Technologies recommends HHT

Factory Trained or NFI certied professionals.

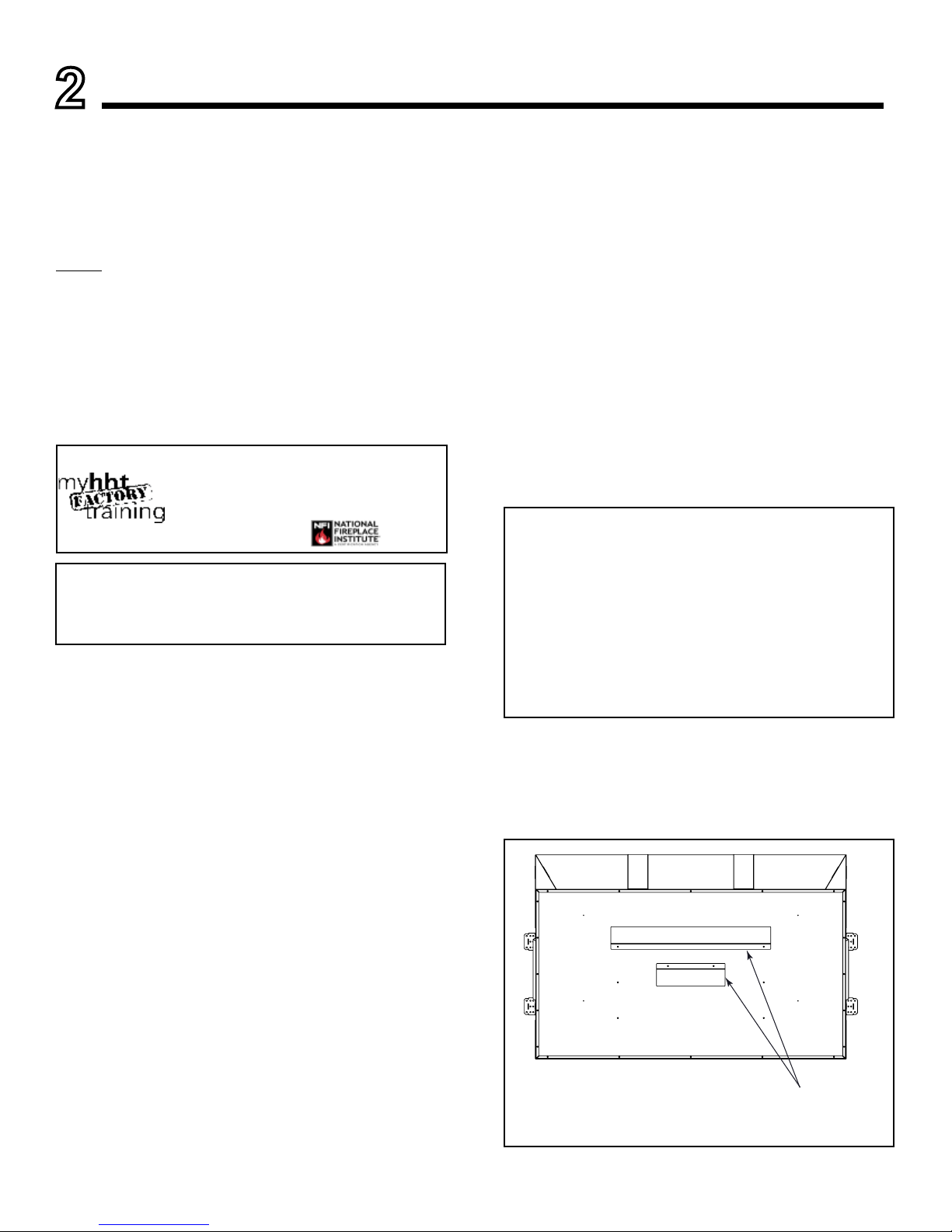

C. Inspect Appliance and Components

• Carefully remove the appliance and components from

the packaging.

• NOTE: Remove rear packaging brackets (2) before

installing unit. See Figure 2.1.

• The accessories and fronts may be shipped in separate

packages.

• Media may be packaged separately.

• Report to your dealer any parts damaged in shipment,

particularly the condition of the glass.

• Read all of the instructions before starting the installation. Follow these instructions carefully during the

installation to ensure maximum safety and benet.

WARNING! Risk of Fire or Explosion! Damaged parts

could impair safe operation. DO NOT install damaged, incomplete or substitute components. Keep appliance dry.

B. Tools and Supplies Needed

Before beginning the installation be sure that the following

tools and building supplies are available.

• Tape measure

• Pliers

• Hammer

• Gloves

• Voltmeter

• Level

• Manometer

• Framing material

• Phillips screwdriver

• Framing square

• Plumb line

• Safety glasses

• Reciprocating saw

• Flat blade screwdriver

• 1/2 - 3/4 in. length, #6 or #8 Self-drilling screws

• Non-corrosive leak check solution

• Electric drill and bits (1/4 in. magnetic)

• External regulator (for propane/LPG only)

• Piping which complies with local codes

• Pipe sealant approved for use with propane/LPG

(Resistant to sulfur compounds)

Hearth & Home Technologies disclaims any responsibility

for, and the warranty will be voided by, the following actions:

• Installation and use of any damaged appliance.

• Modication of the appliance.

• Installation other than as instructed by Hearth & Home

Technologies.

• Installation and/or use of any component part not approved

by Hearth & Home Technologies.

Any such action may cause a re hazard.

WARNING! Risk of Fire, Explosion or Electric Shock!

DO NOT use this appliance if any part has been under

water. Call a qualied service technician to inspect the

appliance and to replace any part of the control system

and/or gas control which has been under water.

• Manual shutoff valve

• Sediment trap

• Tee joint

• Pipe wrench

Rear View

Remove brackets before

installation and replace

screws

Figure 2.1 Bracket Removal

Page 6

6

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

D. Getting Started

Verify that all listed parts have been received. You should

have the following:

• Unvented gas heater

• Two (2) anchoring screws

• Installation and Owner’s instructions

• 6" non-combustible board

• Deector glass

• Five (5) bags reglass

• Two (2) 90 watt bulbs

• RC300 remote control

Carefully inspect the contents for shipping damage. If any

parts are missing or damaged, immediately inform the

dealer from whom you purchased the appliance. Do not

attempt to install any part of the appliance unless you

have all parts in good condition.

F. Adequate Combustion Ventilation Air

This heater shall not be installed in a conned space or

unusually tight construction unless provisions are provided

for adequate combustion and ventilation air.

The National Fuel Gas Code, (ANSI Z223.1/NFPA54),

denes a conned space as a space whose volume is less

than 50 cubic feet per 1,000 BTU per hour (4.8m

3

per kw)

of the aggregate input rating of all appliances installed in

that space, and an unconned space as a space whose

volume is not less than 50 cubic feet per 1,000 BTU per

hour (4.8 m3 per kw) of the aggregate input rating of all

appliances installed in that space. Rooms communicating

directly with the space in which the appliances are installed,

through openings not furnished with doors, are considered

a part of a conned space.

Unusually tight construction is dened as construction

where:

a. Walls and ceilings exposed to the outside atmosphere

have a continuous water vapor retarder with a rating of

1 perm (6 x 10

11

kg per pa/sec-m2) or less with openings

gasketed or sealed, and

b. Weather stripping has been added to windows and

doors, and

c. Caulking or sealants are applied to areas such as joints

around window and door frames, between sole plates

and oors, between wall-ceiling joints, between wall

panels, at penetrations for plumbing, electrical and gas

lines and other openings.

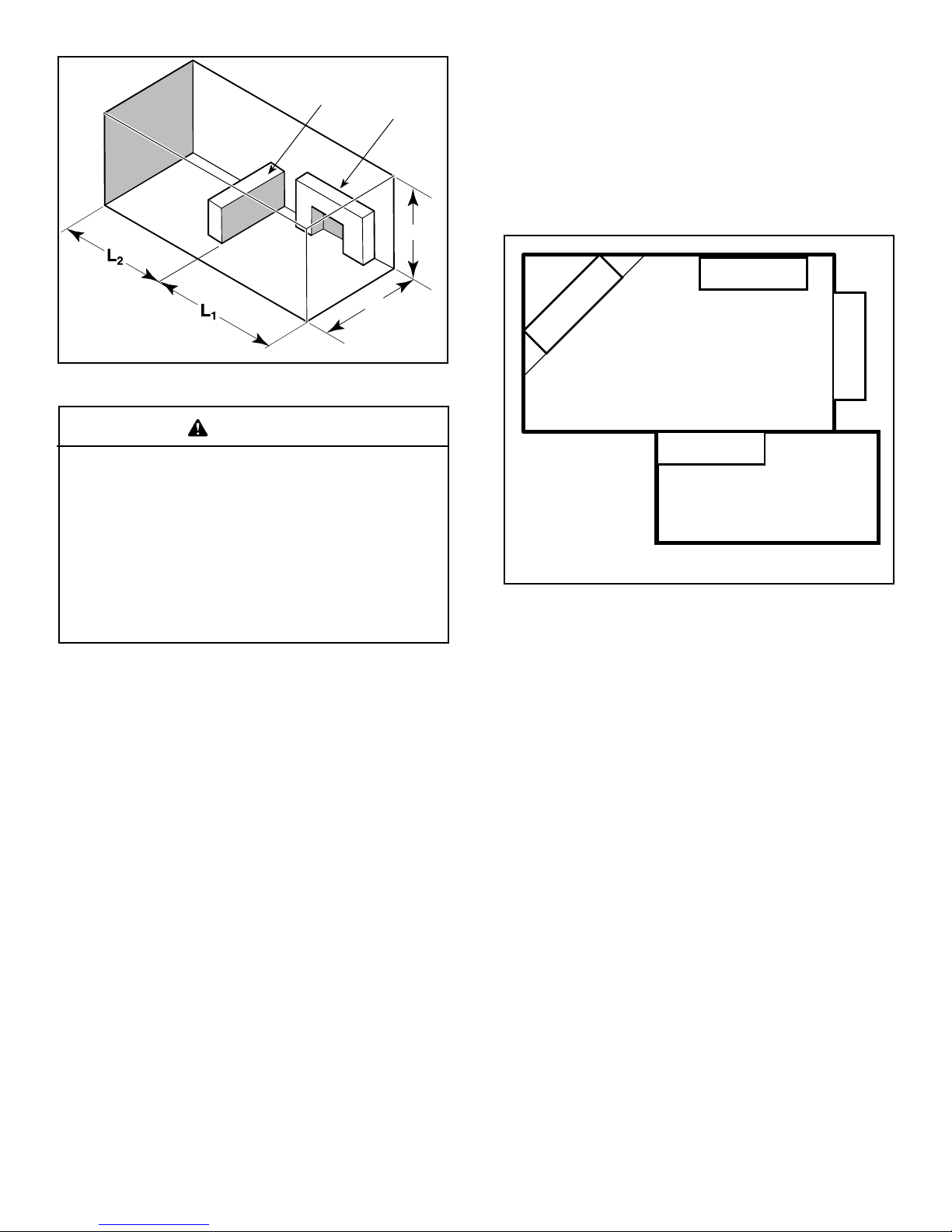

The following formula can be used to determine the maxi-

mum heater rating per the denition of unconned space:

BTU/Hr = (L1 + L2) Ft x (W) Ft x (H) Ft

50

Consider two connecting rooms with an open area

between, with the following dimensions:

L1 = 151/2 Ft., L2 = 12 Ft., W = 12 Ft., H = 8 Ft.

BTU/Hr = (151/2 + 12) x (12) x (8)

50

If there were a door between the two rooms the calculation

would be based only on the room with the heater.

BTU/Hr = (151/2) x (12) x (8)

50

Do not install the heater:

• Where curtains, furniture, clothing, or

other ammable objects are less than

36" from the front of the heater.

• In high trafc areas.

• In windy or drafty areas.

E. Planning the Installation

When planning the installation of the replace it is necessary to determine where the unit is to be installed and

whether optional accessories are desired. Gas supply

piping should also be planned. The following steps represent the normal sequence of installation. Each installation

is unique, however, and might require a different sequence.

1. Position replace in desired location. Refer to the Fire-

place Location (page 8, Figure 3.2) and Clearances

and Height Requirements (page 9, Figures 3.4 and 3.5)

sections and Fireplace and Framing Dimensions (page

8, Figure 3.2) illustration found in this manual.

NOTE: Be sure all packing material has been removed

from under and behind the unit.

2. Install following the instructions found in this manual.

3. Field wire main power supply to junction box. Refer to the

Electrical Installation section (page 19). (Electrical connections should only be performed by an experienced,

licensed certied service person).

4. Plumb gas line. Gas line may be run either through

bottom of unit or left side. There is no right side access.

Refer to the Connect the Gas (page 16, Figure 5.4)

section found in this manual. (Gas connections should

only be performed by an experienced, licensed/certied

service person).

5. Complete nish wall material and/or surround.

WARNING

WARNING

Gloves are recommended when handling

ceramic ber logs to prevent skin irritation

from loose bers. Logs are fragile—handle

with care.

Page 7

7

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

W

H

Counter

Fireplace

If the area in which the heater may be

operated does not meet the required volume

for indoor combustion air, combustion and

ventilation air shall be provided by one

of the methods described in the National

Fuel Gas Code, ANSI Z223.1/NFPA 54, the

International Fuel Gas Code or applicable

local codes.

Figure 2.12

FIREPLACE LOCATION

This unvented gas heater requires no outside venting and

burns cleanly and efciency. As a zero-clearance unvented

gas heater, it can be installed against (or recessed into)

any wall that is accessible to a gas line.

Carefully select the best location for installation of your

unvented replace. The following factors should be taken

into consideration.

• Clearance to side wall, ceiling, woodwork and window

or other combustibles. Refer to Clearance and Height

Requirements section on Page 9. Minimum clearances

to combustibles must be maintained.

• Location must not be affected by drafts caused by

kitchen exhaust fans, ceiling fans, return air registers

for forced air furnaces / air conditioners, windows or

doors.

• Installation must provide adequate ventilation and

combustion air.

• DO NOT INSTALL THIS MODEL IN A BEDROOM

OR BATHROOM.

• Location should be out of high trafc areas and

away from furniture and draperies due to heat from

rebox.

Figure 2.3

• Never obstruct the front opening of the unvented re-

place or restrict the ow of combustion and ventilation

air.

• Minimize modications to existing construction. Refer

to Figure 2.2 below for location suggestions.

• Do not install in the vicinity where gasoline or other

ammable liquids may be stored. The unvented rebox must be kept clear and free from the combustible

materials.

NOTICE: Illustrations reect typical installations and are

FOR DESIGN PURPOSES ONLY. Illustrations/diagrams

are not drawn to scale. Actual installation could vary due

to individual design preference.

It is important to follow the framing and nishing instructions step by step to ensure proper placement of replace

in the surrounding framing/nishing materials.

WARNING

Page 8

8

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

3

Framing and Clearances

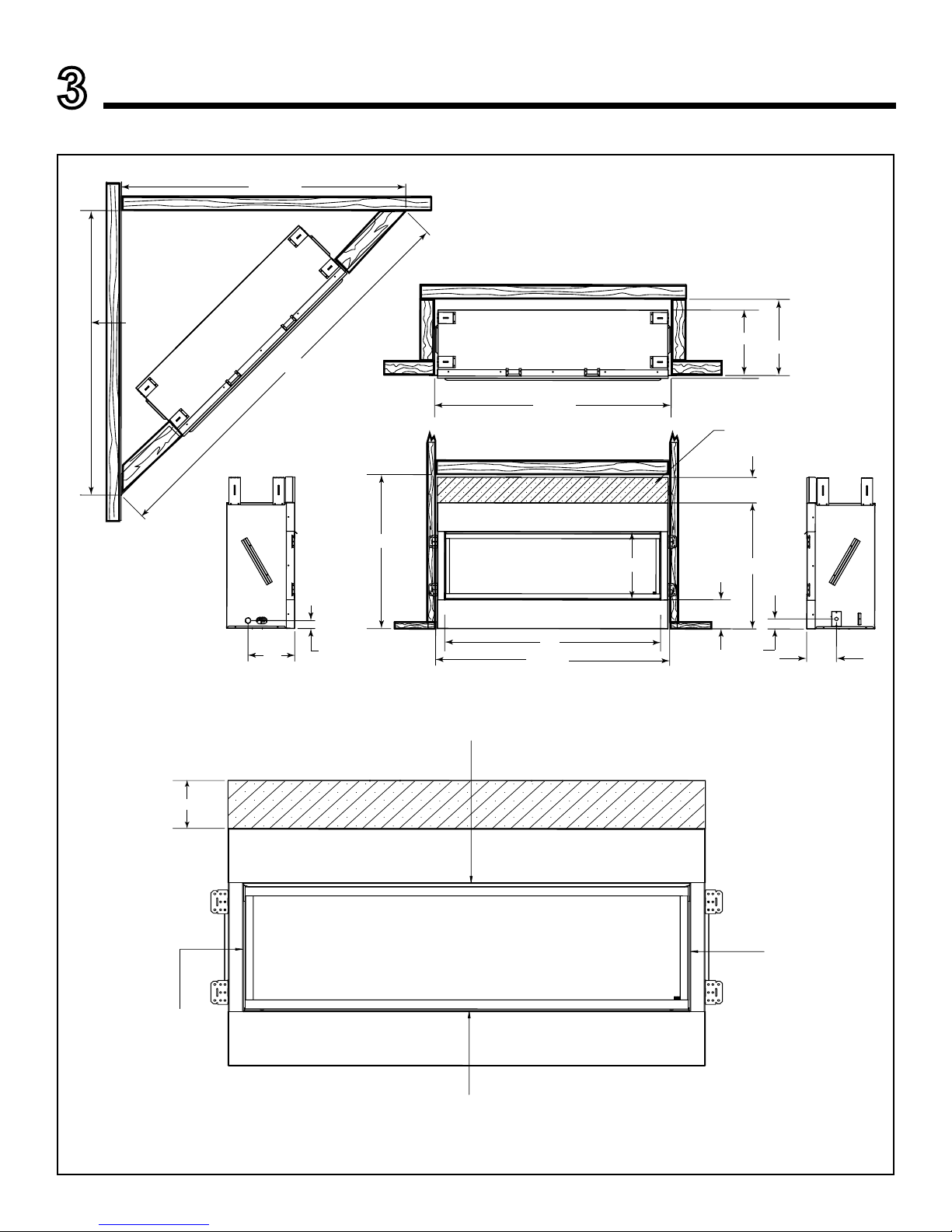

Figure 3.1 Fireplace and Framing Dimensions

A. Fireplace and Framing Dimensions

Figure 3.2 - Optional Facing Installation

"

NON COMBUSTIBLE BOARD

SUPPLIED

16-1/8”

18”

55-7/8”

67-3/16”

67-3/16”

95”

11”

1-7/8”

36-3/8”

51”

55-3/8”

16”

6”

6-7/8”

29-3/4”

2-3/8”

7”

Corner Framing

Gas

Rough

Opening

Height

Rough Opening Width

Rough

Opening

Depth

Actual

Actual

Actual

Electrical

View

NON-COMBUSTIBLE

NON-COMBUSTIBLE

6”

ONLY NON-COMBUSTIBLE

MATERIAL ON FACE OF UNIT.

ONLY

NON-COMBUSTIBLE

MATERIAL ON FACE

OF UNIT.

ONLY NON-COMBUSTIBLE

MATERIAL ON FACE OF UNIT.

ONLY

NON-COMBUSTIBLE

MATERIAL ON FACE

OF UNIT.

Page 9

9

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

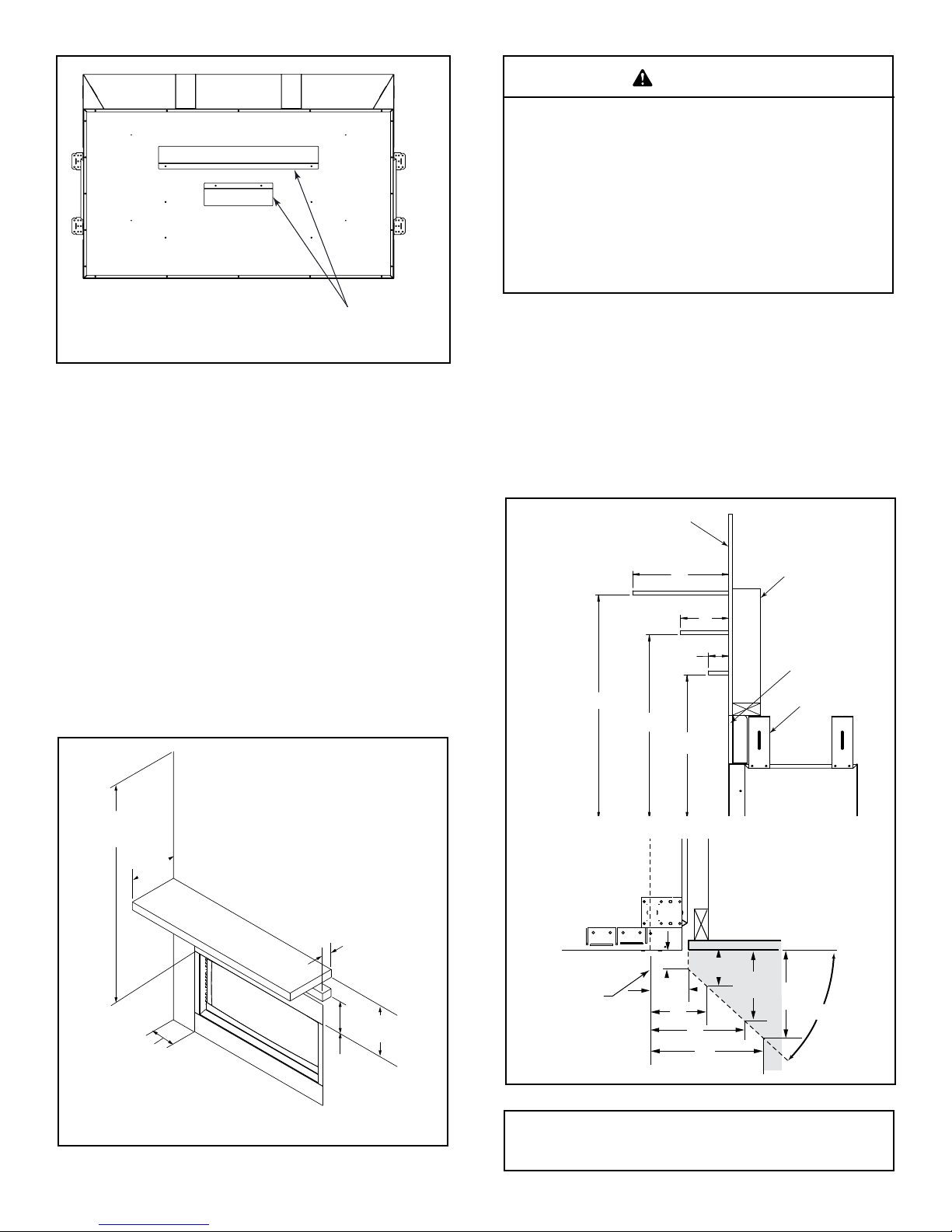

B. Clearances and Height Requirements

Ensure that minimum clearances shown in Figures 3.4

and 3.5 are maintained. Left and right clearances are

determined when facing the front of the rebox.

Follow these instructions carefully to ensure safe installation. Failure to follow these requirements may create a

re hazard.

Sidewall Clearances — The clearance from the inside of

the appliance to any combustible adjacent wall should not

be less than 6". Figure 3.4.

Ceiling Clearance — The ceiling or any other combustible

material must be at least 36" from the rebox opening.

Figure 3.4

Back Wall Clearance — The appliance may be placed

against a combustible back wall.

The dimensions shown in Figures 3.4 and

3.5 are minimum clearances to maintain

when installing this heater. Left and right

clearances are determined when facing the

front of the heater.

Follow these instructions carefully to

ensure safe installation. Failure to follow

instructions exactly can create a re hazard.

Floor Clearance — The replace may be installed directly

on a combustible oor or a raised platform of an appropriate height. Do not place replace on carpeting, vinyl, tile or

other soft oor coverings. It may, however, be placed on at

wood, plywood, particle board or other hard surfaces. Be

sure replace rests on a solid continuous oor or platform

with appropriate framing for support so that no cold air can

enter from under the rebox.

Mantel clearances — Must meet the clearance requirements detailed in Figures 3.4 and 3.5.

Figure 3.4 Sidewall and Ceiling Clearances

Figure 3.5 – Mantel Clearances

28"

6"

18"

12"

23"

Wall

Stud

Insulation

Board

Stando

2-1/2"

SIDE VIEW

6"

5"

3"

4¹⁄₂"

45°

1"

3¹⁄₂"

1¹⁄₂"

2¹⁄₂"

Fireplace

Opening

TOP VIEW

36" Minimum

From Opening

12

" Max.

Depth

2

1

/2" Max

Depth

18

" Min.

From Opening

28

" Min.

From Opening

6

" Min.

Rear View

Remove brackets before

installation and replace

screws

Figure 3.3 Bracket Removal

WARNING

See Good Faith Guidelines for TV Installations on

page 10, Figure 3.6.

Page 10

10

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

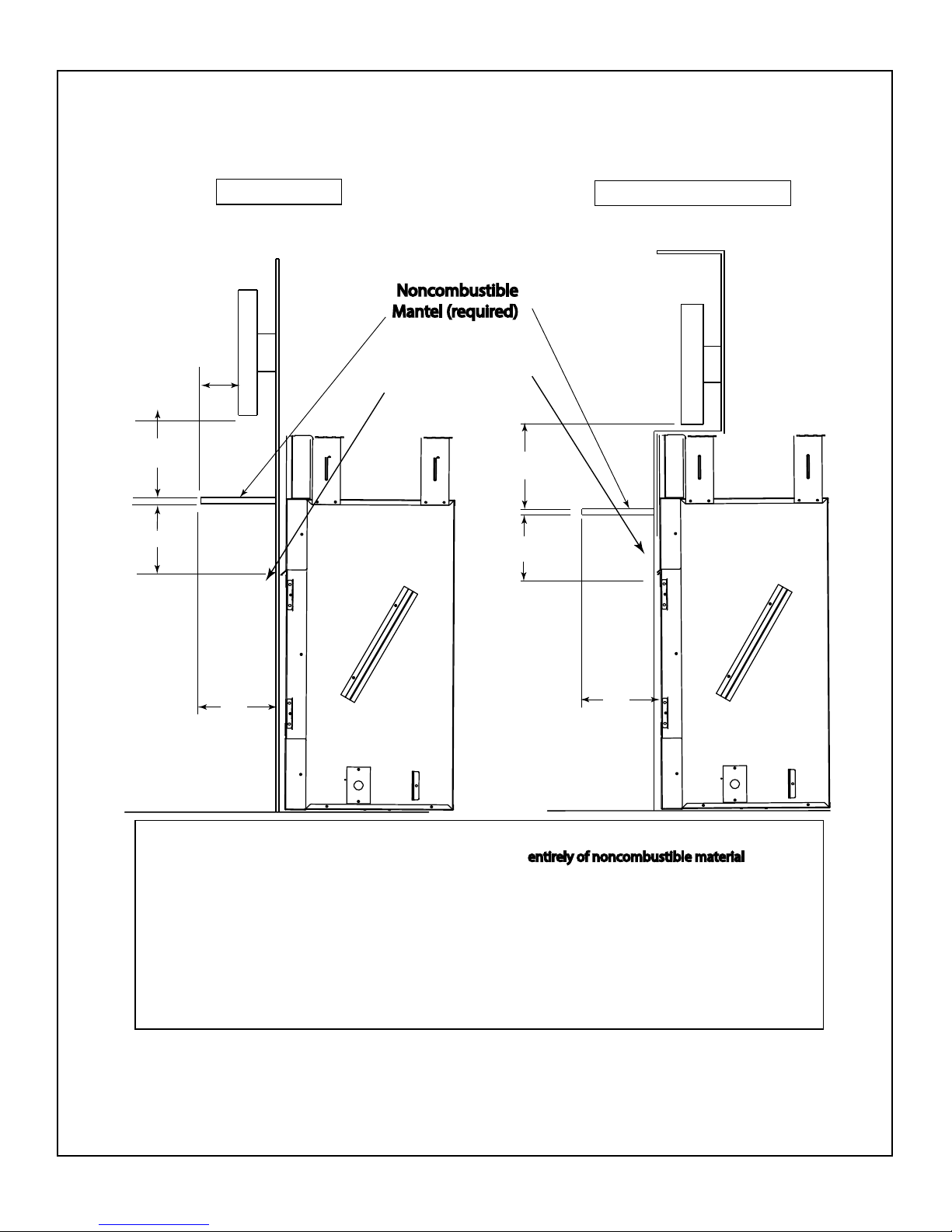

Figure 3.6 Good Faith TV Guidelines

C. Good Faith Wall Surface TV Guidelines

Good Faith Guidelines for TV Installaons above a Typical Gas Fireplace

Notes:

1. TV installation as shown requires the mantel be constructed entirely of noncombustible material

as it is below the allowable height for a combustible mantel.

2. These are good faith recommended clearances only and not a guarantee of compliance with all TV

manufacturers’ maximum allowable operating temperatures.

3. Since every home has unique air ow characteristics and maximum allowable operating temperatures

can vary from manufacturer to manufacturer and from model to model, actual TV temperatures should be

validated at the time of each installation. TVs should not be used in situations where the actual TV

temperature exceeds the manufacturers’ maximum allowable operating temperatures identied in the

TV’s technical specications. Contact the TV’s manufacturer directly if you cannot locate this information

or have questions regarding the information.

TV on the wall

TV recessed into the wall

TV

TV

6” Min.

4” Min.

12”

Min.

28”

4” Min.

28”

12”

Min.

Measured from top

of rebox opening.

Noncombustible

Mantel (required)

Page 11

11

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

E. Floor Protection

NOTICE: Install appliance on hard metal or wood surfaces

extending full width and depth. DO NOT install directly

on carpeting, vinyl, tile or any combustible material other

than wood.

WARNING! Risk of Fire! Maintain specied air space

clearances to appliance and vent pipe:

• Insulation and other materials must be secured to prevent

accidental contact.

• The chase must be properly blocked to prevent blown

insulation or other combustibles from entering and

making contact with replace or chimney.

• Failure to maintain airspace could cause overheating

and re.

Figure 3.7 Floor Protection

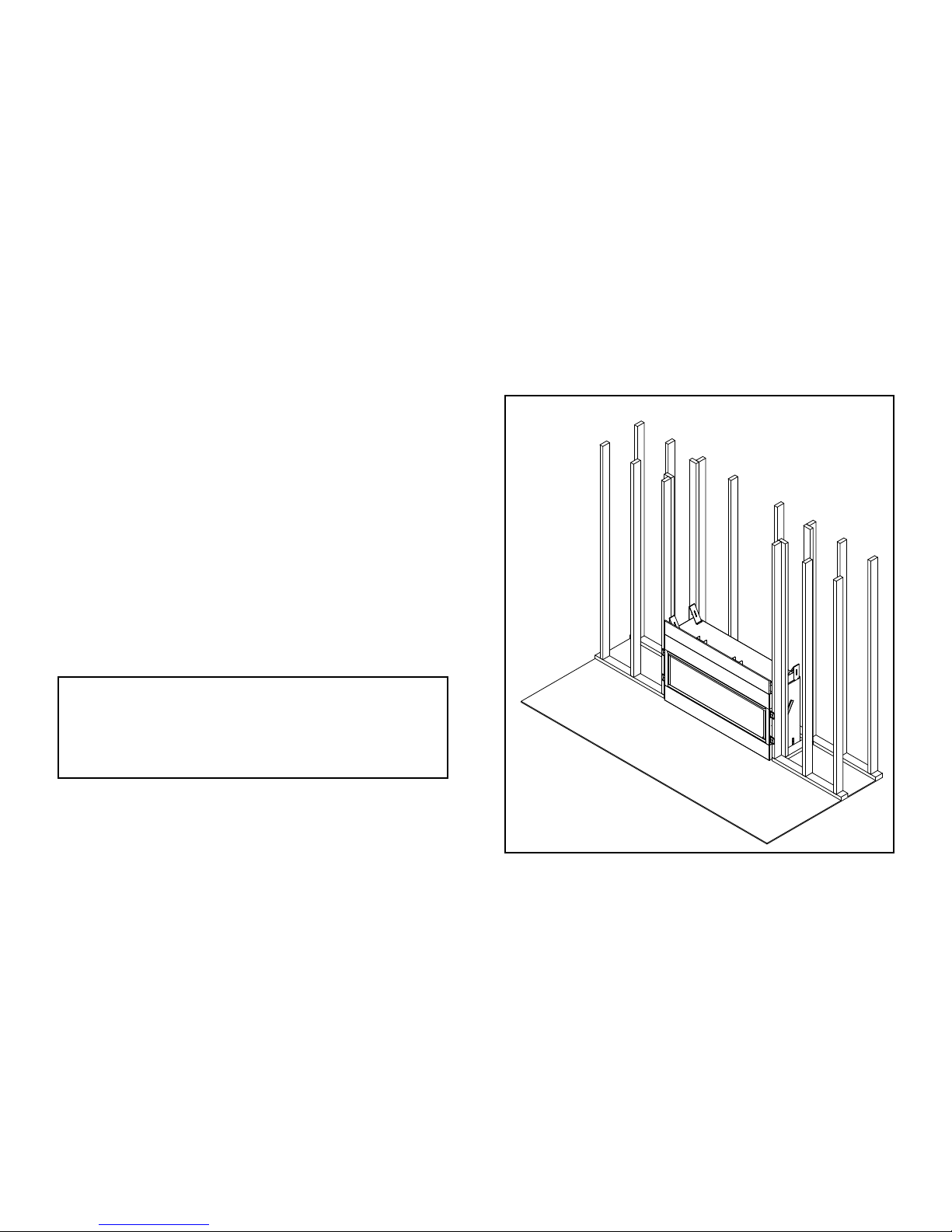

D. Constructing the Appliance Chase

A chase is a vertical box-like structure built to enclose the

gas appliance.

NOTICE: Construction of the chase may vary with the type

of building. These instructions are not substitutes for the

requirements of local building codes. Therefore, you MUST

check local building codes to determine the requirements

to these steps.

Chases should be constructed in the manner of all outside walls of the home to prevent cold air drafting prob-

lems. The chase should not break the outside building

envelope in any manner.

Walls, ceiling, base plate and cantilever oor of the chase

should be insulated. Vapor and air inltration barriers

should be installed in the chase as per regional codes for

the rest of the home. Additionally, in regions where cold

air inltration may be an issue, the inside surfaces may be

sheet rocked and taped (or an equivalent method may be

used) to achieve maximum air tightness.

To further prevent drafts, the wall shield and ceiling re-

stops should be caulked with caulk with a minimum of

300ºF continuous exposure rating to seal gaps. Gas line

holes and other openings should be caulked with caulk

with a minimum of 300ºF continuous exposure rating or

stuffed with unfaced insulation. If the appliance is being

installed on a cement surface, a layer of plywood may be

placed underneath to prevent conducting cold up into the

room.

Note: Figure 3.4 and Figure 3.5, and Figure 3.7 show the

replace installed on the oor. However, this replace can

be elevated off the oor provided that the replace is properly

supported by framing materials and the ceiling clearances are

maintained.

Page 12

12

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

4

Appliance Preparation

A. Securing and Leveling the Appliance

WARNING! Risk of Fire! Prevent contact with:

• Sagging or loose insulation

• Insulation backing or plastic

• Framing and other combustible materials

Block openings into the chase to prevent entry of blownin insulation. Make sure insulation and other materials

are secured.

DO NOT notch the framing around the appliance

standoffs. Failure to maintain air space clearance could

cause overheating and re.

To properly position, level, and secure the appliance, see

below. Nailing tabs are provided to secure the appliance

to the framing members.

• Bend out the two nailing tabs on each side.

• Place the appliance into position.

• Keep nailing tabs ush with the framing. See Figure 4.2.

• Level the appliance from side to side and front to back.

• Shim the appliance as necessary. It is acceptable to use

wood shims underneath the appliance.

• Secure the appliance to the framing by using nails or

screws through the nailing tabs.

Some gures in manual show the replace installed on the

oor. However, this replace can be elevated off the oor

provided that the replace is properly supported by framing

materials and the ceiling clearances are maintained.

Figure 4.2 Securing Fireplace to Framing

Combustible

Material

Framing Members

6 in.

Nailing Flange

Nailing Flange

Nailing Flange

Screws

Screws

Figure 4.1 Noncombustible Facing Installation

6"

MOUNTING

POINTS

55-3/8"

Standoffs

35-3/4"

Framing

55-7/8"

Page 13

13

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

Setting the Fireplace into the Framing

The left and right nailing tabs were designed as a means

to ensure the replace is mounted ush with the framing

materials. See Figures 4.2 and 4.3.

1. Bend out all nailing tabs. The AVFL60 has four nailing

tabs, two on each side in the middle of the unit.

2. Screw each nailing tab to the adjoining framing material. See Figures 3.1-3.7 for framing and clearance

details.

Figure 4.3 Nailing Tabs

Figure 4.4 Install Non-Combustible Facing Material

B. Installing Non-Combustible Facing Material

WARNING! Risk of Fire!

• Follow these instructions exactly.

• Facing materials must be installed properly to prevent

re.

• No materials may be substituted without authorization

by Hearth & Home Technologies.

• Non-Combustible facing material needs to be at least 6”

high and the full width of the unit.

• Attach non-combustible facing material to the framing

members with regular sheetrock screws.

• Use a wet or dry towel or soft brush to remove dust or

dirt from facing material.

• See Section 8 for nishing materials guidelines.

Page 14

14

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

A. Fuel Type

• This appliance is equipped for either natural or propane

gas. Field conversion is not permitted.

• Make sure the appliance is compatible with available gas

types.

B. Gas Pressure

• Optimum appliance performance requires proper input

pressures.

• Gas line sizing requirements will be determined in ANSI

Z223.1 National Fuel Gas Code in the USA.

• Pressure requirements are:

5

Gas Information

Note: Have the gas supply line installed in accordance with

local codes, if any. If not, follow ANSI 223.1. Installation

should be done by a qualied installer approved and/or

licensed as required by the locality. (In the Commonwealth

of Massachusetts installation must be performed by a

licensed plumber or gas tter).

Note: A listed (and Commonwealth of Massachusetts ap-

proved) 1/2 in. (13 mm) T-handle manual shut-off valve

and exible gas connector are connected to the 1/2 in. (13

mm) control valve inlet.

• If substituting for these components, please consult

local codes for compliance.

Fire Risk.

Explosion Hazard.

High pressure will damage valve.

• Disconnect gas supply piping BEFORE

pressure testing gas line at test pressures

above 1/2 psig.

• Close the manual shutoff valve BEFORE

pressure testing gas line at test pressures

equal to or less than 1/2 psig.

WARNING

WARNING! Risk of Fire or Explosion! High pressure

will damage valve. Low pressure could cause explosion.

• Verify inlet pressures. Verify minimum pressures when

other household gas appliances are operating.

• Install regulator upstream of valve if line pressure is

greater than 1/2 psig.

• Valve pressure taps are accessible by removing the

control door. See Figures 5.1 & 5.2.

Figure 5.1. Valve Pressure Tap

NOTE: This appliance does include a manual gas shutoff

valve that is located in the valve compartment. This manual

gas shutoff valve is accessible for service by removing the

con tro l doo r. See Fi gur e 5.2 . The valve is most accessible

if it is located forward in the control cavity of the appliance.

Depending upon local code, an additional manual gas

shutoff, in a readily accessible area may be required and

located upstream from the appliance.

C. Gas Service Access

NATURAL PROPANE (LP)

Inlet Minimum 5.0" w.c. 11.0" w.c.

Inlet Maximum 10.5" w.c. 13.0" w.c.

Regulator Pressure

Setting

3.5" w.c. 10" w.c.

Pilot Regulator 3.5" w.c. —

TEST PORT "A"

Page 15

15

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

Led

Buttons

Valve

Control

Module

ODS

Module

ODS

Adapter

Battery

Backup

Aux

Figure 5.2 Valve Access

Page 16

16

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

D. Connect to Gas

NOTICE: A qualied gas appliance installer must connect

the heater to the gas supply. Consult all local codes.

Use new black iron or steel pipe. Internally

tinned copper or copper tubing can be used

per National Fuel Code, section 2.6.3, providing

gas meets hydrogen sulde limits, and where

permitted by local codes. Gas piping system

must be sized to provide minimum inlet

pressure (Listed on Data Plate) at the maximum

ow rate (BTU/hr). Undue pressure loss will

occur if the pipe is too small.

A manual shutoff valve must be installed

upstream of the appliance. Union tee and

plugged 1⁄8" NPT pressure tapping point should

be installed upstream of the appliance. Figure

5.3

A sediment trap should be installed upstream

to prevent moisture and contaminants from

passing through the pipe to appliance controls

and burners. Failure to do so could prevent the

appliance from operating reliable. Figure 5.3

IMPORTANT: Loosen the pipe adapter on the ex tube

before installing to the system piping.

Always use an external regulator for all propane/LPG heat-

ers only, to reduce the supply tank pressure to a maximum

of 13" w.c. This is in addition to the internal regulator in the

heater valve.

When tightening the joint to the valve, hold the valve

securely to prevent movement.

Test all gas joints from the gas meter to the heater valve for

leaks using a gas analyzer or soap and water solution after

completing connection. DO NOT USE AN OPEN FLAME.

CHECK GAS TYPE: The gas supply must be the

same as stated on the heater’s rating plate. If

the gas supply is different, DO NOT INSTALL

THE HEATER. Contact your dealer for the

correct model.

Connecting directly to an unregulated

propane/LP tank can cause an explosion.

DO NOT USE OPEN FLAME TO CHECK

FOR GAS LEAKS.

GAS LINE IN

GAS LINE IN

Figure 5.3 Gas Line In

When an appliance is connected to a xed piping system, the installation must conform with local codes,or in

the absence of local codes with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 or International Fuel Gas

Code.

THIS APPLIANCE IS EQUIPPED FOR

EITHER NATURAL OR PROPANE GAS.

FIELD CONVERSION IS NOT PERMITTED.

WARNING

WARNING

WARNING

WARNING

Page 17

17

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

E. Valve Access

The valve and controls are located in the appliance con-

trol box. See Figure 5.4.

The control box and controls can be accessed by lifting

engine assembly and shown in Figure 5.4.

• Make sure unit is off and cool.

• Remove media and deection glass panel from

hearth pan.

• Remove two (2) screws securing burner assembly to

appliance, set aside.

• Lift the burner assembly and place the two engine

supports, provided under the Engine, against lower

front space at the bottom of the face, and slide into

the slots at the bottom of the engine assembly. See

Figure 5.4.

• Locate valve on face of engine assembly.

• Gas line sizing requirements will be determined in

ANSI Z233.1 National Fuel Gas Code in the USA.

• Pressure requirements are:

These pressures can be veried by lifting engine and

removing control cover to reveal the valve.

When an appliance is connected to a xed piping sys-

tem, the installation must conform with local codes,or in

the absence of local codes with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 or International Fuel Gas

Code.

Engine Support

Figure 5.4 Valve Access

F. Check Gas Pressure

Check the gas pressure with the appliance burning and

the control set to HIGH.

Open control access door at bottom front of unit to nd

valve and regulator referred to below.

The valve regulator controls the burner pressure which

should be checked at the pressure test point.

Turn captured screw counterclockwise two or three turns

and then place tubing to pressure gauge over test point.

Use test point “A” closest to gas inlet. After taking pres-

sure reading, be sure and turn captured screw clockwise

rmly to reseal. Do not over torque. Check for gas leaks.

See Figure 5.5.

TEST PORT 'A'

Figure 5.5 Pressure Test Point Location

Screen

Access

Panel

Figure 5.6 Gas and Electrical Access - Remove Screen

Page 18

18

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

Figure 5.7 Gas Fitting Access

G. Gas Connection

• Refer to Figure 5.7 for location of gas ex line access in

appliance.

• Gas line may be run through the left side or right bottom

of the appliance. See Figure 5.3.

• The gap between supply piping and gas access hole

may be caulked with caulk with a minimum of 300ºF

continuous exposure rating or stuffed with noncombustible, unfaced insulation to prevent cold air

inltration.

• Ensure that gas line does not come in contact with outer

wrap of the appliance. Follow local codes.

• Pipe incoming gas line into valve compartment.

• Connect incoming gas line to the 1/2 in. (13 mm)

connection on manual shutoff valve.

WARNING! Risk of Fire or Explosion! Support control

when attaching pipe to prevent bending gas line.

• A small amount of air will be in the gas supply lines.

WARNING! Risk of Fire or Explosion! Gas build-up during line purge could ignite.

• Purge should be performed by qualified service

technician.

• Ensure adequate ventilation.

• Ensure there are no ignition sources such as sparks

or open ames.

H. High Altitude Installations

NOTICE: If the heating value of the gas has been reduced,

these rules do not apply. Check with your local gas utility

or authorities having jurisdiction.

When installing above 4500 feet elevation reduce input

4% for each 1000 feet above 4500 feet.

Check with your local gas utility to determine proper ori-

ce size.

Gas

Valve

Control

Module

Battery

Backup

Light the appliance. It will take a short time for air to purge

from lines. When purging is complete the appliance will

light and operate normally.

WARNING! Risk of Fire, Explosion or Asphyxiation!

Check all ttings and connections with a non-corrosive

commercially available leak-check solution. DO NOT use

open ame. Fittings and connections could have loosened during shipping and handling.

WARNING! Risk of Fire! DO NOT change valve settings.

This valve has been preset at the factory.

18" Flex Line

Page 19

19

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

A. General Information

WARNING! Risk of Shock or Explosion! DO NOT wire

110-120 VAC to the valve or to the appliance wall switch.

Incorrect wiring will damage controls.

NOTICE: This appliance must be electrically wired and

grounded in accordance with local codes or, in the absence

of local codes, with National Electric Code ANSI/NFPA

70-latest edition.

• Wire the appliance junction box to unswitched 110-

120 VAC. This is required for proper operation of the

appliance.

• A 110-120 VAC circuit for this product must be protected

with ground-fault circuit-interrupter protection, in

compliance with the applicable electrical codes, when

it is installed in locations such as in bathrooms or near

sinks.

• Low voltage and 110/120 VAC voltage cannot be shared

within the same wall box.

6

Electrical Information

Electrical Service and Repair

WARNING! Risk of Shock! Label all wires prior to disconnection when servicing controls. Wiring errors can

cause improper and dangerous operation. Verify proper

operation after servicing.

WARNING! Risk of Shock! Replace damaged wire with

type 105º C rated wire. Wire must have high temperature

insulation.

Junction Box Installation

WARNING! Risk of Shock! Label all wires prior to disconnection when servicing controls. Wiring errors can

cause improper and dangerous operation. Verify proper

operation after servicing.

WARNING! Risk of Shock! Replace damaged wire with

type 105° C rated wire. Wire must have high temperature

insulation.

Accessories Requirements

• This appliance may be used with a wall switch, or optional

wall mounted thermostat and/or a remote control.

Wiring for optional Hearth & Home Technologies approved

accessories should be done now to avoid reconstruction.

Follow instructions that come with those accessories.

Figure 6.1 Cover Plate for Junction Box

Junction Box Wiring

1. This should be done before framing the replace. Wire

the receptacle into an electrical circuit.

2. The junction box cover has a Romex style strain relief

connector located in the Owner’s Manual. After con-

necting the wires, route the wire leads through this

connector. Refer to the wiring diagram in Figure 6.2.

Electrical connections should only be performed

by a qualied, licensed electrician. Main power

must be off when connecting to main electrical

power supply or performing service. All wiring

shall be in compliance with all local, city and

state codes. The appliance, when installed,

must be electrically grounded in accordance

with local codes or in the absence of local

codes, with the National Electrical Code ANSI/

NFPA 70 (latest edition) and Canadian Electrical

Code, CSA C22.1.

CAUTION

Label all wires before disconnecting when

servicing controls. Wiring errors can cause

improper and dangerous operation.

Do not connect wall switch to 110 V circuit.

Figure 6.2 - Junction Box Wiring Diagram

120V AC

60Hz

Factory Supplied

Not Supplied

Junction Box

WARNING

WARNING

Page 20

20

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

Figure 6.3 IntelliFire™ Plus ODS Wiring Diagram

B. Wiring Requirements

Intellire™ Plus ODS Ignition System Wiring

NOTICE: Batteries should only be used as a power source

in the event of an emergency power outage. Batteries

should not be used as a primary long-term power source.

Battery polarity must be correct when installing batteries.

When using batteries as a power source, the 6-volt

transformer must be unplugged from the receptacle.

Do not store batteries in the battery pack when the

appliance is powered by the 6 volt transformer connected

to permanent electrical service.

• Wire the appliance junction box to 110-120 VAC for

proper operation of the appliance.

WARNING! Risk of Shock or Explosion! DO NOT wire

IFP ODS controlled appliance junction box to a switched

circuit. Incorrect wiring will override IFP ODS safety lockout.

• Refer to Figure 6.3 or 6.4, IFP ODS Wiring Diagram.

• This appliance is equipped with an Intellire™ Plus

control valve which operates on a 6 volt/1.5 AMP system.

• Plug the 6 volt transformer plug into the appliance junction

box to supply power to the unit OR install 4 AA cell

batteries (not included) into the battery pack before use.

Accessories Requirements

• This appliance ships standard with a remote control.

Wiring for optional Hearth & Home Technologies approved

accessories should be done now to avoid reconstruction.

Follow instructions that come with those accessories.

TO JUNCTION

BOX (120V)

I

S

RC300 4.5V DC

(AAA X 3)

TO JUNCTION

BOX 120VAC

TO OPTIONAL

COMPONENTS

GROUND

ORANGE

(PILOT)

GREEN

(MAIN)

BROWN

BLACK

RED

BROWN/RED

OPTIONAL ON/OFF

SWITCH

BATTERY PACK

6V DC

FLAME

MODULATION

AUX300 MODULE

AUX 1

AUX 2

FAN

WHITE

ORANGE

CONTROL MODULE

6V DC

SUPPLY

PILOT

THERMOCOUPLE MODULE

19026-GM931 Control Box ODS

19093-Thermalcouple Module Wire

K19084 8K-1 Adapter Box

K99085 GM8K-1

ODS Adapter Box

THERMOCOUPLE

THERMOCOUPLE

SENSOR

SENSOR

Page 21

21

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

Figure 6.4 Wiring Diagram

LED STRIP

LED STRIP

TRANSFORMER

CONTROL

MODULE

JUNCTION BOX

TOP BUTTON

ON/HI/MED/LO/OFF

BOTTOM BUTTON

Color Selection

RED

WHITE

YELLOW

BLACK

RED

BLACK

BLACK

BLACK

BLACK

BLACK

Page 22

22

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

7

Final Installation

A. Dome Light Bulb Installation

NOTE: This unit is shipped without bulbs installed to pre-

vent any damage to the bulb lament during transport. This

unit is shipped with a total of two (2) 90W bulbs.

Dome Light Bulb Installation

CAUTION

Turn OFF the main power supply before performing any service work on the unit, including install-

ing or replacing light bulbs.

1. Remove three screws holding the left dome light

cover in place. See Figure 7.2.

Light cover

screws

Figure 7.1– Dome Light Position

Figure 7.2– Dome Light Screws

TOP LIGHT LOCATION

The Black Magic Glass liner is packaged and shipped

with the unit. Before install, remove the glass panels and

place on a at, clean surface and inspect for damage.

NOTE: Before beginning installation remove the two L

shaped brackets from the manual pack along with two #8

phillips head screws.

NOTE: After gas and electric are connected and the unit

has been test red the glass can be installed.

1. Place the rear glass panel against the rear wall of the

rebox, resting on top of the engine base. The dimples

in the glass will face the rebox.

2. Place the left side panel between the engine base

and rebox, resting on the botton of the rebox ledge.

Secure with supplied L bracket to the top of the rebox

witht the supplied screw.

3. Repeat step 2 on the right side.

NOTE: When removing the black glass from the unit, be

cautious of the rear panel falling forward once the side

panels are removed.

B. Black Magic Glass Installation

Figure 7.3 Black Magic Glass Installation

2. Insert (1) bulb provided into socket

3. Replace dome light cover with three screws

4. Repeat on right side light cover

Page 23

23

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

C. Installation of Air Deection Glass

NOTE: If installing optional driftwood logs be sure to

install log pin brackets prior to installing air deection

glass or reglass. See pages 24 and 25 for instructions.

NOTE: The air deection glass must be installed prior

to placing any reglass or stone media on the burner. To

install the air deection glass simply place the edge of

the deection glass into the two position tabs (located at

the front of the engine base) and slide into ngers until

reaching the bottom of the tab slots, in front of the burner

ports. The glass should stand upright, neither leaning

forward nor backward.

NOTE: The optional stone kit and log kit are to be installed

alone and never in combination.

D. Fireglass Only Placement

NOTE: Five (5) bags of reglass are supplied with the

replace.

Figure 7.4– Air Deection Glass and Stone Placement

Both bags may be used to cover the entire oor and burner.

We advise against using additional reglass as too much

can cut off the proper amount of air the burner needs to

burn cleanly. This may cause sooting.

1. Spread reglass evenly in one layer over the entire oor

and burner. It is important to not have the reglass too

thick on ported area (single layer only).

2. Turn burner on and adjust reglass over ported areas

to achieve an even, clean ame.

E. Glass and Optional Stone Kit Placement

1. For best results, spread reglass evenly over the entire

oor and burner making sure the glass is not too thick

over the burner ports (single layer only). See Figure 7.4.

2. Place the stones randomly in front of and behind the

burner. CAUTION: Do not allow stones to sit directly

on burner or in ame. See Figure 7.4 and 7.5.

3. Turn burner on and adjust reglass over the ported area

to achieve an even, clean ame.

Example of stone accessory placement

Burner surface. DO NOT place stones in the gray shaded area.

Air deflection glass

Deection glass tabs

Page 24

24

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

F. Placement of Optional Logs

WARNING: Turn off replace and allow to cool completely before beginning installation.

Kit Contents:

• Three driftwood logs

• Support pin brackets

• #8 bracket mounting screws

NOTE — Do not handle logs with your bare hands. Always

wear gloves to prevent skin irritation from logs. After

handling the logs, wash your hands with soap and water

to remove any traces of bers.

NOTE: Prior to installing the log set, you must rst install the

pin brackets on the burner. Fireglass and the air deection

glass should only be installed after the pin brackets are in

place. The logs must then be placed in the unit after the

reglass and air deection glass. If the optional logs are

added after the air deection glass and reglass are in use,

move the reglass away from the areas in Figure 7.6 and

install the support brackets, then arrange reglass evenly

across burner again.

The positioning of the logs is critical to the safe

and clean operation of this heater. Sooting and

other problems may result if the logs are not

properly and rmly positioned in the appliance.

Never add additional logs or embellishments

such as pine cones, vermiculite or rock wool to

the heater. Only use the logs supplied with the

optional log kit (AVFL60DLS).

Failure to position the parts in accordance with

diagrams below or to use only parts specically

approved for this heater may result in property

damage or personal injury.

1. Mount the four log support pin brackets using mounting holes and screws provided in locations indicated

in Figure 7.7.

2. Place the large rear log (#1) by aligning the holes in

the bottom of each log with the four pins at the back

of the burner. Logs are marked “Rear Left” and “Rear

Right” for easy identication.

Figure 7.5– Stone Placement

Figure 7.6– Log Pin Assembly

PIN PLACEMENT FOR

REAR LOGS

AIR DEFLECTION

GLASS

REAR

FRONT

Figure 7.7– Pin Placement for Accessory Logs

WARNING

Page 25

25

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

3. The front driftwood log does not utilize a pin bracket.

This log can be placed behind the front deection glass

with the area marked on the gure below. THIS LOG

CAN ONLY BE PLACED WITHIN THIS AREA. The

log cannot be placed on the burner area. It can be

adjusted left to right as desired. See Figure 7.8.

FRONT LOG

PLACEMENT

AREA

DO NOT PLACE LOGS

IN THIS AREA

REAR LOG

PINS

REAR

FRONT

Figure 7.8– Log Placement

Page 26

26

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

G. Lighting Instructions (IPI)

4604-200

FOR YOUR SAFETY READ BEFORE LIGHTING

TO TURN OFF GAS TO APPLIANCE

1. Equipped with wall switch: Turn ON/OFF switch to OFF.

Equipped with remote or wall control: Press OFF button.

Equipped with thermostat: Set temperature to lowest setting.

WARNI NG: If you do not follow these instructions exactly, a fi re or explosion may result causing property damage, personal injury or loss of life.

GAS

VALVE

A. This appliance is equipped with an intermittent pilot ignition (IPI) device which

automatically lights the burner. DO NOT try to light the burner by hand.

B. BEFORE LIGHTING, smell all around the appliance area for gas. Be sure to smell

next to the fl oor because some gas is heavier than air and will settle on the fl oor.

WHAT TO DO IF YOU SMELL GAS

• DO NOT try to light any appliance.

• DO NOT touch any electric switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fi re department.

C. DO NOT use this appliance if any part has been under water. Immediately call

a qualifi ed service technician to inspect the appliance and to replace any part of

the control system and any gas control which has been under water.

LIGHTING INSTRUCTIONS (IPI)

2. Wait fi ve (5) minutes to clear out any gas. Then smell for gas, including near the

fl oor. If you smell gas, STOP! Follow “B” in the Safety Information located on the

top of this label. If you do not smell gas, go to next step.

3. To light the burner:

Equipped

with wall switch: Turn ON/OFF switch to ON.

Equipped with remote or wall control: Press ON or FLAME button.

Equipped with thermostat: Set temperature to desired setting.

4. If the appliance does not light after three tries, call your service technician or gas

supplier.

2. Service technician should turn off electric power to the control when performing

service.

1. This appliance is equipped with an ignition device which automatically

lights the burner. DO NOT try to light the burner by hand.

4604-201

.

WARNING:

NOT FOR USE WITH SOLID FUEL

DO NOT CONNECT LINE VOLTAGE (110/120 VAC OR 220/240 VAC) TO THE CONTROL VALVE.

Improper installation, adjustment, alteration, service or maintenance can cause

injury or property damage. Refer to the owner’s information manual provided with

this appliance. For assistance or additional information, consult a qualifi ed installer,

service agency or the gas supplier.

This appliance needs fresh air for safe operation and must be installed so there are

provisions for adequate combustion and ventilation air.

Keep burner and control compartment clean. See installation and operating instructions accompanying appliance.

Hot while in operation. DO NOT touch. Keep children, clothing, furniture, gasoline

and other liquids having fl ammable vapors away.

,enon fi ;yna fi ,sedoc lacol htiw ecnadrocca ni dellatsni eb tsum ecnailppa sihT

follow the National Fuel Gas Code, ANSIZ223.1/ NFPA 54, or the National Gas and

Propane Installation code, CSA B149.1.

CAUTION:

For additional information on operating your

Hearth & Home Technologies fi replace, please refer to www.fi replaces.com.

Page 27

27

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

8

Finishing

A. Facing and Finishing Instructions

WARNING! Risk of Fire! Comply with all minimum clear-

ances to combustibles as specied. Framing closer than the

minimums listed must be constructed entirely of noncombustible materials (i.e., steel studs, concrete board, etc.).

Finishing Instructions

It is important to follow the framing and nishing instructions to ensure proper placement of replace into the surrounding framing/nishing materials.

Wall sheathing materials 1/2 in. thick are specied in

this installation manual to properly align with the non-

combustible material.

WARNING! Risk of Fire! Non-combustible board MUST

be installed. DO NOT remove or cover it with combustible

material, such as:

• Drywall (gypsum board)

• Plywood

• Materials that do not meet the ASTM E 136 Non-combustibility standard (below).

Removal of installed, non-combustible board and/or use

of materials not meeting the ASTM E 136 standard could

cause re.

Non-Combustible Materials Specication

Material which will not ignite and burn. Such materials are

those consisting entirely of steel, iron, brick, tile, concrete,

slate, glass or plasters, or any combination thereof.

Materials that are reported as passing ASTM E 136,

Standard Test Method for Behavior of Materials in a

Vertical Tube Furnace at 750 ºC.

WARNING! Risk of Fire! Maintain specied air space

clearances to combustibles. Inadequate air space could

cause overheating and re.

NOTICE: The maximum nishing material not only includes

the decorative nish materials (marble, tile, slate, etc) but

also the thin set, lath, and adhesive used to attach the

decorative nish material.

Finishing Materials

This section discusses installation details associated

with the Inside and Overlap Fit methods and species

additional non-combustible materials required.

NOTICE: Surface temperatures around the appliance will

become warm while the appliance is in operation. Ensure

finishing materials used for all surfaces (floor, walls,

mantels, etc.) will withstand temperatures up to 190°F.

Tape wall board joints around the replace opening with

berglass-mesh tape. It will provide a more crack-resistant joint than paper tape. Fill, smooth and nish wall

joints with chemically setting-type joint compound. It will

provide a more crack-resistant joint than air-drying light-

weight compound.

Finish and Sealing Joints

All joints between the nished wall sheathing and the appliance must be sealed with non-combustible materials.

Sealants, such as caulk or mastic used to seal the gap

between the wall and the replace, should be rated at a

minimum continuous exposure to 300ºF.

Painting

If desired nishing includes a painted wall, 100% acrylic

latex with compatible primer is recommended around this

appliance. Oil-based or standard acrylic paints may discolor due to heat exposure.

The appliance is designed to mate with 1/2 in. wall

sheathing materials such as drywall, plywood, wood

composites, or non-combustible materials.

• Finishing Around Perimeter of Unit (Install Option

#1)

Gypsum wallboard (drywall) joints can be nished up to

the perimeter of the left, right and bottom edge of the unit

ush with the face. The 6” of suppied nom-combustible

must be used at the top of the unit where the gypsum

board can then be nished to the left, right and top edge

of the non-combustible board.

• Finishing Around Opening of Unit (Install Option #2)

NOTE: With this installation option, the unit must be

recessed to the depth of the non-combustible being used

to ensure nish is ush with surrounding wall. This is

the recommended install option for all trim kits such as

the AVFL60TKI, AVFL60CFCV, AVFL60CFBT. Refer

to Trim Kit instructions for Option #2 installation before

starting.

The 6” non-combustible must rst be installed above

the unit in the same manor as insatllation option #1,

ush with the top face of the unit. In this option, non-

combustible is required for all material covering the face

of the unit. The non-combustible may be installed up to

the rebox opening but must not overlap which would

impede the removal of the screen. When installing

material around the rebox opening, install the sheet

with a pre-cut hole for the rebox opening in a single

sheet, if possible. This will minimize joints across the

replace face and reduce cracking.

Page 28

28

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

To Reduce the Risk of Sheetrock Cracking:

DO

Use all purpose joint compound.

Use eggshell paint

(100% acrylic latex paint, gloss or semi-gloss).

To Avoid Sheetrock Cracking:

DO NOT

Use a quick set or light weight joint compound.

Use at paint.

In extreme cases, lab tests have shown yellow pigments

fading out of paints over time due to heat. Vent run and

installation location will have an effect on wall temperature

and fading. If fading occurs, consider avoiding paint that

contains yellow pigment.

In regards to the sheetrock mud, apply a smooth, even

layer, covering a wide area of the wall for the best results.

For best results, follow the tips below.

WARNING! Risk of Fire! DO NOT apply combustible

materials beyond the minimum clearances. Comply with

all minimum clearances to combustibles as specied in

this manual. Overlapping materials could ignite and will

interfere with proper operation of doors and louvers.

WARNING! Risk of Fire! DO NOT install drywall or

other combustible materials directly onto the installed

non-combustible board. Overlapping materials could

ignite.

Finish with non-combustible

up to unit opening. Cannot

cover the opening so that

screen can be removed.

NON-COMBUSTABLE

NON-COMBUSTABLE

6”

Install

Option #2

Install

Option #1

Install

Option #1

Install

Option #2

Install

Option #1

(page 27)

Install

Option #2

(page 27)

Install

Option #1

Install

Option #2

Figure 8.1 - Finishing Around Unit

Page 29

29

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

NOTICE: Some functionality will be lost when using

battery backup including remote control, lights, or any

other auxiliary functions that require household 110-120

VAC power.

B. Operation During A Power Outage

NOTICE: Batteries should only be used as a power source

in the event of an emergency power outage. Batteries

should not be used as a primary long-term power source.

The IntelliFire™ Plus ODS intermittent pilot ignition system

comes with a battery backup system that enables the

system to operate in a power outage. The system offers

seamless transition from household AC power to battery

backup. A factory-installed battery pack is located in the

control cavity of the appliance. See Figure 8.2. Battery

longevity and performance will be affected by long term

exposure to the service temperatures of this appliance.

To Operate Fireplace Using Battery Power (DC):

1. Access the control cavity of the appliance. See

Figure 8.2 for location. Lift the screen frame off of

the appliance and lift the access panel out of the front

edge of the unit..

2. Locate the battery tray and insert four AA cell batteries.

See Figure 8.2. Battery polarity must be correct or

module damage will occur. A complete wiring diagram

is included in the Electrical section of the appliance

Installation Manual.

3. Turn the appliance on according to the instructions

below for the appropriate type of control:

Standard Wall Switch or Factory-Installed ON/OFF

Switch:

• Toggle the switch as you would under normal

circumstances.

Wireless Remote:

• Remote receiver is integrated into the ignition module

• Use the remote to turn the appliance on.

• To preserve battery life, do not use the HI/LO ame or

THERMOSTAT options.

Ignition Module:

• Remove screws on left and right sides of component

heat shield and lift it out of the control cavity.

• Locate the ignition module in the control cavity.

• Slide the ON/REMOTE/OFF switch to the ON position.

• Reinstall component heat shield.

To Return to Operation Using Electrical (AC) Power

CAUTION! Risk of Overheating! Component heat shield

MUST be installed before operating appliance. Electrical

components will be damaged.

Standard Wall Switch or Factory-Installed ON/OFF

Switch:

• Remove screws on left and right sides of component

heat shield and lift it out of the control cavity.

• Toggle the switch to OFF.

• Remove the batteries from the battery tray.

• Reinstall component heat shield.

• Replace bottom glass shield and decorative front on

appliance.

Wireless Remote:

• Remove screws on left and right sides of component

heat shield and lift it out of the control cavity.

• Slide the ON/REMOTE/OFF switch to the REMOTE

position.

• Remove the batteries from the battery tray.

• Reinstall component heat shield.

• . Replace bottom glass shield and decorative front on

appliance.

Ignition Module:

• Remove screws on left and right sides of component

heat shield and lift it out of the control cavity.

• Slide the ON/REMOTE/OFF switch to the REMOTE

position.

• Remove the batteries from the battery tray.

• Reinstall component heat shield.

• . Replace bottom glass shield and decorative front on

appliance.

Control Cavity

(shown in gray)

Battery Tray

Control Module

Figure 8.2– Control Cavity Location

Page 30

30

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

Figure 8.3 Control Module

Control Module Operation

1. The control module has an ON/OFF/REMOTE selector

switch that must be set. See Figure 8.3.

OFF Position: Appliance will ignore all power inputs and

will not respond to any commands from a wall switch or

remote. The unit should be in the OFF position during

installation, service, battery installation, fuel conversion,

and in the event that the control goes into LOCK-OUT

mode as a result of an error code.

ON Position: Appliance will ignite and run continuously

in the HI ame setting, with no adjustment in ame

output. This mode of operation is primarily used for

initial installation or power outage operation with battery

backup.

REMOTE Position: Appliance will initiate commands

from an optional wired wall switch and/or the wireless

remote (RC300).

2. If using a wired wall switch with the module in REMOTE

mode, the ame output can be adjusted with the HI/LO

selector switch on the module. See Figure 8.3. Note

that the ame HI/LO selector switch will become inactive

once an optional remote control (RC200/RC300) is

programmed to the control module. Note that the control

module will always ignite the replace on HI and remain

so for the initial 10 seconds of operation. If the HI/LO

is switched to the LO position, the ame output will

automatically drop to the lowest setting after the ame

has been established for 10 sec. After this 10 second

period, the ame can be adjusted from HI to LO with

the switch.

3. The control module has safety feature that automatically

shuts down the replace after 9 hours of continuous

operation without receiving a command from the RC300

remote.

4. If you intend to use both an optional wired wall switch

and the RC300 remote control to operate your replace,

the wall switch will override any commands given by

the remote.

5. Module Reset

This module may lock-out under certain conditions.

When this occurs, the appliance will not ignite or

respond to commands. The module will go into

lock-out mode by emitting three audible beeps, then

continuously displaying a RED/GREEN error code at

its status indicator LED.

• Check battery tray. Remove batteries if installed.

Batteries should only be installed for use during power

outages.

• Locate the module selector switch. (See Figure 8.3).

• Set the module selector switch to the OFF position.

• Wait ve (5) minutes to allow possible accumulated gas

to clear.

• Set the module selector switch to ON or REMOTE

position.

• Start the appliance.

WARNING! Risk of Explosion! DO NOT press the mod-

ule reset switch more than one time within a ve minute time period. Gas could accumulate in rebox. Call a

qualied service technician.

Nine Hour Safety Shutdown Feature

The appliance has a safety feature that automatically

shuts down the replace after nine hours of continuous

operation without receiving a command from the wall

switch or optional remote.

NG/LP GAS-TYPE

SELECTOR SWITCH

SELECTOR

SWITCH

FLAME HI/LOW

SWITCH

STATUS

INDICATOR LED

MODULE

Appliance ON/OFF

Use the IntelliFire™ Plus Remote Control to control the

ON/OFF function of the appliance. Follow instructions

included with the remote control. If desired, a wall switch

may be installed to control the ON/OFF function of the

appliance.

C. Detailed Component Operating Instruc-

tions— Intellire™ Plus ODS

Page 31

31

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

With proper installation, operation, and maintenance your gas appliance will provide years of trouble-free service. If you do

experience a problem, this troubleshooting guide will assist a qualied service technician in the diagnosis of a problem and

the corrective action to be taken. This troubleshooting guide can only be used by a qualied service technician. Contact

your dealer to arrange a service call by a qualied service technician.

D. Troubleshooting

IntelliFire™ Plus ODS Ignition System

Symptom Possible Cause Corrective Action

1. Pilot won’t light.

The ignitor/module

makes noise, but no

spark.

A. Incorrect wiring. Verify “S” wire (white) for sensor and “I” wire (orange) for ignitor are

connected to correct terminals on module and pilot assembly.

B. Loose connections or electrical

shorts in the wiring.

Verify no loose connections or electrical shorts in wiring from module to pilot assembly. Verify connections underneath pilot assembly

are tight; also verify igniter and ame sense wires are not grounding

out to metal chassis, pilot burner, pilot enclosure, mesh screen if

present, or any other metal object.

C. Ignitor gap is too large. Verify gap of igniter to right side of pilot hood. The gap should be

approximately .095 in. (2.41 mm) to .135 in. (3.43 mm).

2. Pilot won’t light,

there is no noise or

spark.

A. No power, transformer installed

incorrectly, or depleted batteries.

Verify that transformer is installed and plugged into module. Check

voltage of transformer at connection to module. Acceptable readings of a good transformer are between 6.4 and 6.6 volts DC. Battery power supply voltage must be at least 4 volts. If less than 4

volts, replace batteries.

B. A shorted or loose connection in

wiring conguration or wiring harness.

Remove and reinstall the wiring harness that plugs into module.

Verify there is a tight t. Verify pilot assembly wiring to module. Remove and verify continuity of each wire in wiring harness. Replace

any damaged components.

C. Improper wall switch wiring. Verify that 110-120 VAC power is “ON” to junction box.

D. Module not grounded. Verify black ground wire from module wire harness is grounded to

metal chassis of appliance.

3. Pilot sparks, but

pilot will not light.

A. Gas supply is off or lacking pres-

sure.

Verify that incoming gas line ball valve is “open." Verify that inlet

pressure reading is within acceptable limits.

B. Ignitor gap is too large. Verify gap of igniter to right side of pilot hood. The gap should be

approximately .095 in. (2.41 mm) to .135 in. (3.43 mm).

C. Module is not grounded. Verify module is securely grounded to metal chassis of appliance.

D. Pilot valve solenoid voltage is out

of spec.

Verify that 1.5 to 1.8 VDC is supplied to pilot solenoid from module.

If below 1.5 volts, replace module. If 1.5 volts or greater, replace

valve.

Page 32

32

Monessen • AVFL60 Installation Manual • 4605-901 Rev. A • 05/17

Intellire™ Plus Ignition System - (continued)

Symptom Possible Cause Corrective Action

4. Pilot lights but continues to spark, and main

burner will not ignite.

(If the pilot continues

to spark after the

pilot ame has been lit,