Page 1

Monarch

P

u

b

l

i

s

h

e

d

b

y

t

h

e

T

e

c

h

n

i

c

a

l

C

o

m

m

u

n

i

c

a

t

i

o

n

s

D

e

p

a

r

t

m

e

n

t

.

P

r

i

n

t

e

d

i

n

t

h

e

U

.

S

.

A

.

®

9820™/ 9830™/ 9835™

Printers

TC9830SM Rev. B 7/98 ©1996 Monarch Marking Systems, Inc. All rights reserved.

Page 2

Table of Contents

CHAPTER 1 PRINTER OVERVIEW & INSTALLATION---------------------------------------------1

PRINTER FEATURES---------------------------------------------------------------------------------------------------------------1

PRINTER OPTIONS -----------------------------------------------------------------------------------------------------------------1

PRINTER SPECIFICATIONS ------------------------------------------------------------------------------------------------------1

STOCK SPECIFICATIONS---------------------------------------------------------------------------------------------------------2

UNPACKING THE PRINTER ------------------------------------------------------------------------------------------------------3

DOCUMENTATION ------------------------------------------------------------------------------------------------------------------3

SETTING DIP SWITCHES---------------------------------------------------------------------------------------------------------3

FUSE REPLACEMENT--------------------------------------------------------------------------------------------------------------4

CONNECTING TO A HOST--------------------------------------------------------------------------------------------------------4

CHAPTER 2 FUNCTIONAL DESCRIPTION-----------------------------------------------------------7

OVERVIEW OF MODULES --------------------------------------------------------------------------------------------------------7

Power Transformer Assembly --------------------------------------------------------------------------------------------------8

Inlet Power Module -------------------------------------------------------------------------------------------------------------8

Power Transformer -------------------------------------------------------------------------------------------------------------8

Bridge Rectifier ------------------------------------------------------------------------------------------------------------------8

CONTROL BOARD ASSEMBLY--------------------------------------------------------------------------------------------------8

Functional Description ------------------------------------------------------------------------------------------------------------8

Power Conversion --------------------------------------------------------------------------------------------------------------9

Memory----------------------------------------------------------------------------------------------------------------------------9

Flash Memory-----------------------------------------------------------------------------------------------------------------9

DRAM Memory ---------------------------------------------------------------------------------------------------------------9

SRAM Memory ---------------------------------------------------------------------------------------------------------------9

Printer Control -------------------------------------------------------------------------------------------------------------------9

Data Handling-----------------------------------------------------------------------------------------------------------------9

Printhead Thermal Control-------------------------------------------------------------------------------------------------9

Print Imaging------------------------------------------------------------------------------------------------------------------9

Motion Control ----------------------------------------------------------------------------------------------------------------9

Platen Drive Interface -------------------------------------------------------------------------------------------------------9

Ribbon Drive Interface------------------------------------------------------------------------------------------------------9

Analog to Digital Conversion----------------------------------------------------------------------------------------------9

Supply Detection & Tracking System-----------------------------------------------------------------------------------9

Operator Control Panel--------------------------------------------------------------------------------------------------------9

Communications ----------------------------------------------------------------------------------------------------------------9

RS-232 interface -----------------------------------------------------------------------------------------------------------10

Centronics IEEE-1284 Parallel Interface-----------------------------------------------------------------------------10

IEEE 1284 Bi-Directional Parallel Interface -------------------------------------------------------------------------10

Contrast Control---------------------------------------------------------------------------------------------------------------10

Hardware Power-up Settings (DIPS)-------------------------------------------------------------------------------------10

Peel Module Assembly ------------------------------------------------------------------------------------------------------10

PRINT ASSEMBLY-----------------------------------------------------------------------------------------------------------------10

Thermal Printhead------------------------------------------------------------------------------------------------------------10

Ribbon Supply & Take-up Spools-----------------------------------------------------------------------------------------10

Ribbon Transfer Rollers -----------------------------------------------------------------------------------------------------10

Ribbon Spool Drive Motors-------------------------------------------------------------------------------------------------11

Supply Deflector and Bi-Cell Emitter (IR LED) ------------------------------------------------------------------------11

Ribbon Transfer Rollers -----------------------------------------------------------------------------------------------------11

Functional Description ----------------------------------------------------------------------------------------------------------11

Ribbon Drive Operation -----------------------------------------------------------------------------------------------------11

Printing---------------------------------------------------------------------------------------------------------------------------11

i

Page 3

FEED ASSEMBLY------------------------------------------------------------------------------------------------------------------11

Platen Module------------------------------------------------------------------------------------------------------------------11

24VDC Stepper Motor -------------------------------------------------------------------------------------------------------11

Lower Supply Guide and Bi-Cell Sensor --------------------------------------------------------------------------------11

Printhead Latch----------------------------------------------------------------------------------------------------------------11

Functional Description ----------------------------------------------------------------------------------------------------------11

Printhead Locking-------------------------------------------------------------------------------------------------------------12

SUPPLY HOLDER ASSEMBLY -------------------------------------------------------------------------------------------------12

Functional Description ----------------------------------------------------------------------------------------------------------12

CONTROL PANEL ASSEMBLY-------------------------------------------------------------------------------------------------12

Functional Description ----------------------------------------------------------------------------------------------------------12

CHAPTER 3 TROUBLESHOOTING------------------------------------------------------------------- 13

PRELIMINARY CHECK -----------------------------------------------------------------------------------------------------------13

ANALYZING FAILURE DURING POWER UP ------------------------------------------------------------------------------13

EVALUATION OF A 616 ERROR (DOT SHIFTING FAILED)-----------------------------------------------------------13

EVALUATION OF A 704 ERROR (OUT OF SUPPLY)--------------------------------------------------------------------13

EVALUATION OF A 754 ERROR (OUT OF RIBBON)--------------------------------------------------------------------14

EVALUATION OF A 755 ERROR (PRINTHEAD OPEN)-----------------------------------------------------------------14

EVALUATION OF A 765 ERROR (PRINTHEAD FAILURE)-------------------------------------------------------------14

EVALUATION OF THE CONTROL BOARD ASSY. -----------------------------------------------------------------------14

EVALUATION OF COMMUNICATIONS--------------------------------------------------------------------------------------14

GENERAL TROUBLESHOOTING SUGGESTIONS-----------------------------------------------------------------------15

CHAPTER 4 DIAGNOSTICS ---------------------------------------------------------------------------- 19

POWER-UP SELF-TEST---------------------------------------------------------------------------------------------------------19

NV RAM ByteTest----------------------------------------------------------------------------------------------------------------19

Version String Mismatch -------------------------------------------------------------------------------------------------------19

System Restart Condition---------------------------------------------------------------------------------------------------19

Printhead Dot Resistance------------------------------------------------------------------------------------------------------19

TEST LABEL (LEVEL 1) ----------------------------------------------------------------------------------------------------------19

SERVICE DIAGNOSTICS--------------------------------------------------------------------------------------------------------20

Accessing Diagnostic Modes--------------------------------------------------------------------------------------------------20

Data Dump Mode ----------------------------------------------------------------------------------------------------------------20

Serial Loop Back Test-----------------------------------------------------------------------------------------------------------21

Parallel Port Test -----------------------------------------------------------------------------------------------------------------21

Diagnostics Test Mode----------------------------------------------------------------------------------------------------------21

Performing a Virgin Printer Reset-----------------------------------------------------------------------------------------21

Printing a Test Label ---------------------------------------------------------------------------------------------------------21

CHAPTER 5 TESTS AND ADJUSTMENTS--------------------------------------------------------- 23

SERVICE TESTS-------------------------------------------------------------------------------------------------------------------23

CN6 Power Supply------------------------------------------------------------------------------------------------------------23

Continuity Tests ------------------------------------------------------------------------------------------------------------------23

Transformer - Primary Side ------------------------------------------------------------------------------------------------23

Transformer - Secondary Side---------------------------------------------------------------------------------------------23

Bridge Rectifier ----------------------------------------------------------------------------------------------------------------23

Head Open Sensor -----------------------------------------------------------------------------------------------------------23

Displaying Machine/Service Totals---------------------------------------------------------------------------------------23

Print Contrast Adjustment------------------------------------------------------------------------------------------------------24

Platen Motor Gear Adjustment -----------------------------------------------------------------------------------------------24

Ribbon Tension Adjustment---------------------------------------------------------------------------------------------------24

CHECKING SUPPLY QUALITY-------------------------------------------------------------------------------------------------25

ii TC9830SM Rev. B 7/98 Confidential

Page 4

CHAPTER 6 SERVICE PROCEDURES -------------------------------------------------------------- 27

MAINTENANCE OVERVIEW----------------------------------------------------------------------------------------------------27

GENERAL SAFETY TIPS --------------------------------------------------------------------------------------------------------27

CONTROL PANEL REMOVAL--------------------------------------------------------------------------------------------------27

COVER HOUSING REMOVAL--------------------------------------------------------------------------------------------------27

POWER TRANSFORMER ASSEMBLY --------------------------------------------------------------------------------------28

Transformer Removal-----------------------------------------------------------------------------------------------------------28

Bridge Rectifier Removal ------------------------------------------------------------------------------------------------------28

AC Inlet Removal ----------------------------------------------------------------------------------------------------------------28

Control Board Assy. Removal ------------------------------------------------------------------------------------------------29

PRINT ASSEMBLY-----------------------------------------------------------------------------------------------------------------29

Bi-Cell Emitter Removal--------------------------------------------------------------------------------------------------------30

Upper Supply Guide Removal------------------------------------------------------------------------------------------------30

Printhead Module Removal----------------------------------------------------------------------------------------------------30

Ribbon Spool Assembly Removal -------------------------------------------------------------------------------------------30

Ribbon Roller Assembly Removal-------------------------------------------------------------------------------------------30

DC Ribbon Motor Removal----------------------------------------------------------------------------------------------------30

Print Assembly Removal-------------------------------------------------------------------------------------------------------31

FEED ASSEMBLY------------------------------------------------------------------------------------------------------------------31

Latch Fascia Removal----------------------------------------------------------------------------------------------------------31

Platen Module Removal--------------------------------------------------------------------------------------------------------31

Platen Module Replacement --------------------------------------------------------------------------------------------------32

Bi-Cell Sensor Removal--------------------------------------------------------------------------------------------------------32

Lower Supply Guide Removal------------------------------------------------------------------------------------------------32

Bi-Cell Sensor Replacement --------------------------------------------------------------------------------------------------32

Lower Supply Guide-------------------------------------------------------------------------------------------------------------33

Replacement ----------------------------------------------------------------------------------------------------------------------33

SUPPLY HOLDER ------------------------------------------------------------------------------------------------------------------33

Supply Holder Removal --------------------------------------------------------------------------------------------------------33

PLATEN MOTOR-------------------------------------------------------------------------------------------------------------------33

Platen Motor Removal----------------------------------------------------------------------------------------------------------33

PEEL MODULE----------------------------------------------------------------------------------------------------------------------33

Peel Module Removal ----------------------------------------------------------------------------------------------------------33

Peel Motor Replacement-------------------------------------------------------------------------------------------------------33

CHAPTER 7 USING FLASH----------------------------------------------------------------------------- 35

FLASH DOWNLOADING PROCEDURES -----------------------------------------------------------------------------------35

CHAPTER 8 SUPPLY SENSING SYSTEMS -------------------------------------------------------- 37

SUPPLY DETECTION/TRACKING SYSTEM -------------------------------------------------------------------------------37

SUPPLY DEFLECTOR/BI-CELL EMITTER (IR LED) ---------------------------------------------------------------------37

LOWER SUPPLY GUIDE/BI-CELL SENSOR-------------------------------------------------------------------------------38

SUPPLY FEEDING-----------------------------------------------------------------------------------------------------------------38

SUPPLY SENSING-----------------------------------------------------------------------------------------------------------------38

MECHANICAL ADJUSTMENTS ------------------------------------------------------------------------------------------------39

Bi-Cell Sensor Adjustment-----------------------------------------------------------------------------------------------------39

REPLACING A SENSOR ---------------------------------------------------------------------------------------------------------40

SENSOR SETUP WITH VERSION 5.2 OR GREATER-------------------------------------------------------------------41

POWER UP SENSOR RECOGNITION ---------------------------------------------------------------------------------------41

Performing a Sensor Display Test-------------------------------------------------------------------------------------------42

TC9830SM Rev. B 7/98 Confidential iii

Page 5

APPENDIX A PRINTER ERROR/STATUS CODES ----------------------------------------------- 43

READING AN ERROR LABEL --------------------------------------------------------------------------------------------------43

DATA ERRORS (001 - 499) ------------------------------------------------------------------------------------------------------43

COMMUNICATION FAILURES (410 - 499)----------------------------------------------------------------------------------47

DATA FORMATTING FAILURES (571 - 619)-------------------------------------------------------------------------------48

MACHINE FAULTS (700 - 766) -------------------------------------------------------------------------------------------------48

HARD PRINTER FAULTS (900 - 910)-----------------------------------------------------------------------------------------50

FLASH FAULTS (930 - 940) -----------------------------------------------------------------------------------------------------50

FAULTS (950 - 999)----------------------------------------------------------------------------------------------------------------50

APPENDIX B CONNECTORS AND CABLES------------------------------------------------------- 51

Daughter Board Connectors---------------------------------------------------------------------------------------------------55

APPENDIX C CONNECTOR LOCATIONS ---------------------------------------------------------- 57

APPENDIX D MODEL 928 STACKER ---------------------------------------------------------------- 59

SPECIFICATIONS------------------------------------------------------------------------------------------------------------------59

FUNCTIONAL DESCRIPTION --------------------------------------------------------------------------------------------------59

INSTALLATION ---------------------------------------------------------------------------------------------------------------------59

TROUBLESHOOTING-------------------------------------------------------------------------------------------------------------60

Error Messages-------------------------------------------------------------------------------------------------------------------60

Alignment --------------------------------------------------------------------------------------------------------------------------60

CABLES AND CONNECTORS --------------------------------------------------------------------------------------------------60

LUBRICATION-----------------------------------------------------------------------------------------------------------------------62

MAINTENANCE PROCEDURES-----------------------------------------------------------------------------------------------62

REPLACE ROLLERS--------------------------------------------------------------------------------------------------------------63

Replacing Transport Assembly -----------------------------------------------------------------------------------------------63

Replace DC Motor ---------------------------------------------------------------------------------------------------------------64

Replace Stepper Motor---------------------------------------------------------------------------------------------------------64

Replace Stacker Sensors ------------------------------------------------------------------------------------------------------64

Replace Power Supply----------------------------------------------------------------------------------------------------------64

Replace Control Board----------------------------------------------------------------------------------------------------------64

APPENDIX E 926 KNIFE ASSEMBLY ---------------------------------------------------------------- 65

KNIFE SPECIFICATIONS--------------------------------------------------------------------------------------------------------65

TAG CUT DIMENSIONS ----------------------------------------------------------------------------------------------------------65

FUNCTIONAL DESCRIPTION --------------------------------------------------------------------------------------------------65

Functional Description ----------------------------------------------------------------------------------------------------------65

TROUBLESHOOTING-------------------------------------------------------------------------------------------------------------65

Evaluation of Error 760---------------------------------------------------------------------------------------------------------65

VOLTAGE TESTS---------------------------------------------------------------------------------------------------------------66

LUBRICATION-----------------------------------------------------------------------------------------------------------------------66

MAINTENANCE OVERVIEW----------------------------------------------------------------------------------------------------66

GENERAL SAFETY TIPS --------------------------------------------------------------------------------------------------------66

Blade Assembly Replacement------------------------------------------------------------------------------------------------68

Drive Board Replacement -----------------------------------------------------------------------------------------------------68

Motor Replacement--------------------------------------------------------------------------------------------------------------68

CONNECTORS AND CABLES --------------------------------------------------------------------------------------------------69

iv TC9830SM Rev. B 7/98 Confidential

Page 6

List Of Tables

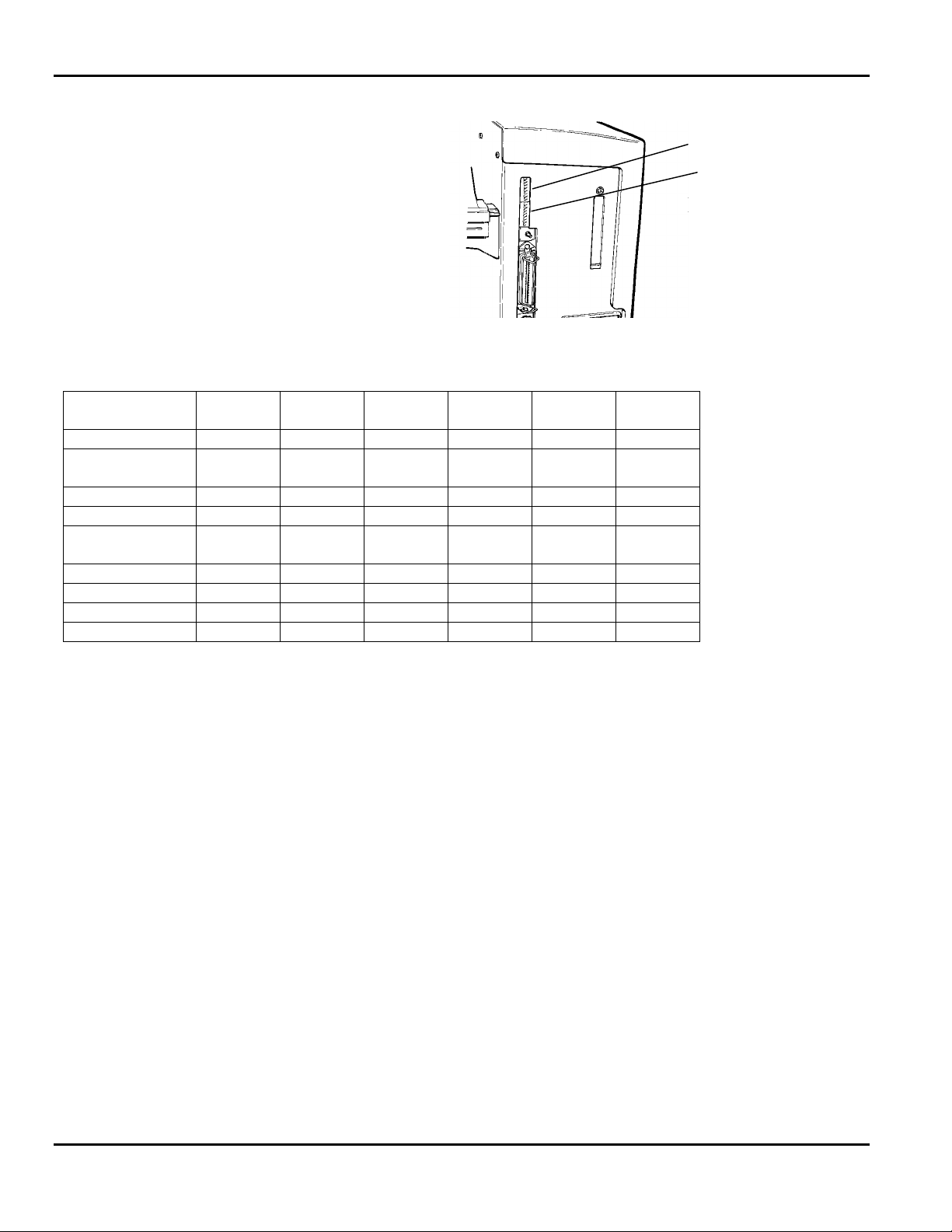

Table 1 – 1 Daughter Board DIP Switches ................................................................................................................ 4

Table 1 - 2. Exterior Rear (SW2 and SW3) DIP Switch Settings .............................................................................. 5

Table 4- 1. Diagnostics Tests.................................................................................................................................. 21

Table D- 1. Stacker Control Harness........................................................................................................................ 60

Table D- 2 Jam/Full Sensor Harness....................................................................................................................... 61

Table D- 3. Extended Motor Interface Harness........................................................................................................ 61

Table D- 4. AC Power Harness. .............................................................................................................................. 61

Table D- 5. Power Supply Connector J2.................................................................................................................. 61

Table D- 6. Power Supply Connector J1.................................................................................................................. 62

Table E- 1. Knife Drive Board Voltages................................................................................................................... 66

Table E- 2. Drive Board Connector J1..................................................................................................................... 69

Table E- 3. Drive Board Connector J2..................................................................................................................... 69

Table E- 4. Knife Drive Board Connector J3............................................................................................................ 69

Table E- 5. Drive Board Connector J4 To 928 Stacker Assembly............................................................................ 69

Table E- 6. Knife Drive Board Connector J5............................................................................................................ 69

List of Figures

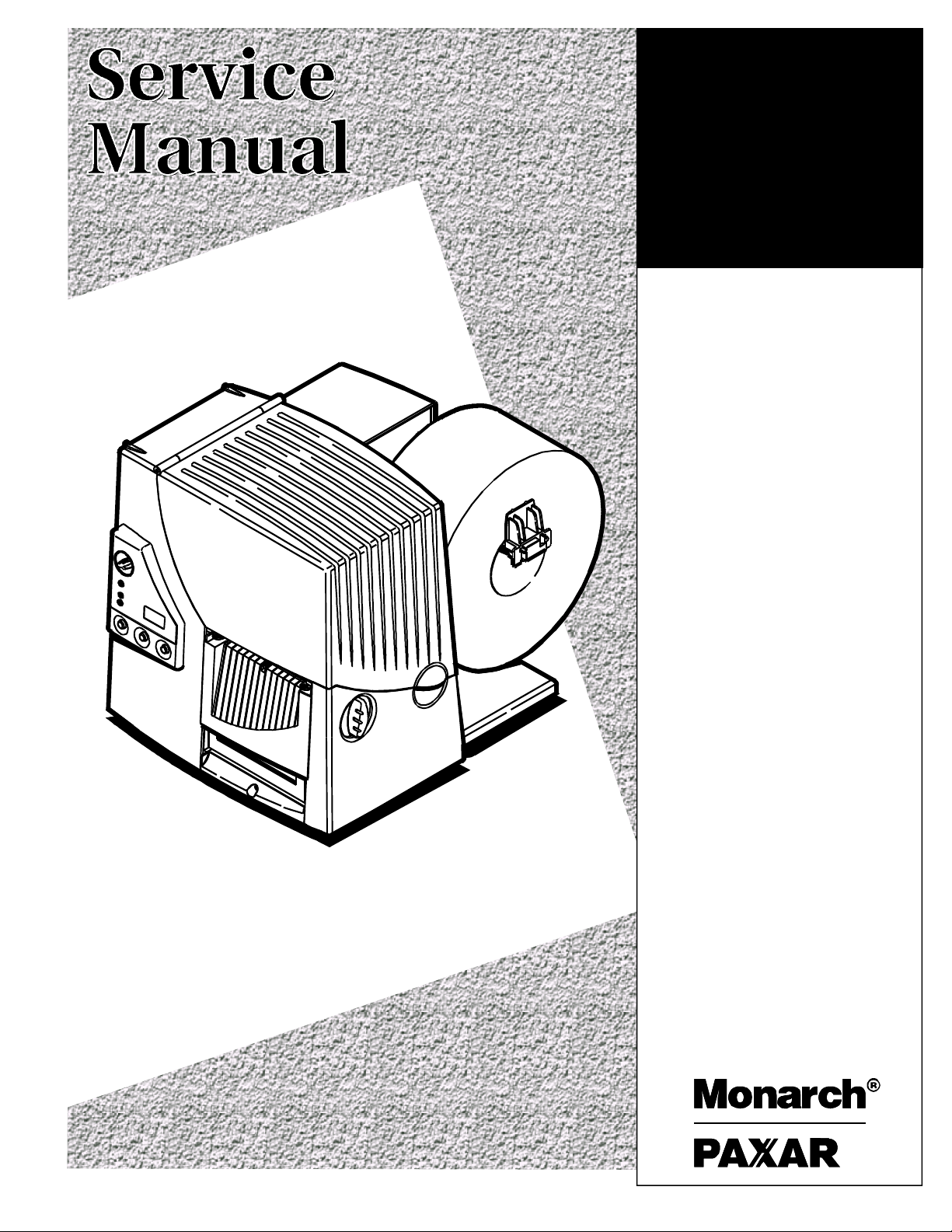

Figure 1 - 1. 9830 Printer (Housing removed) ........................................................................................................... 1

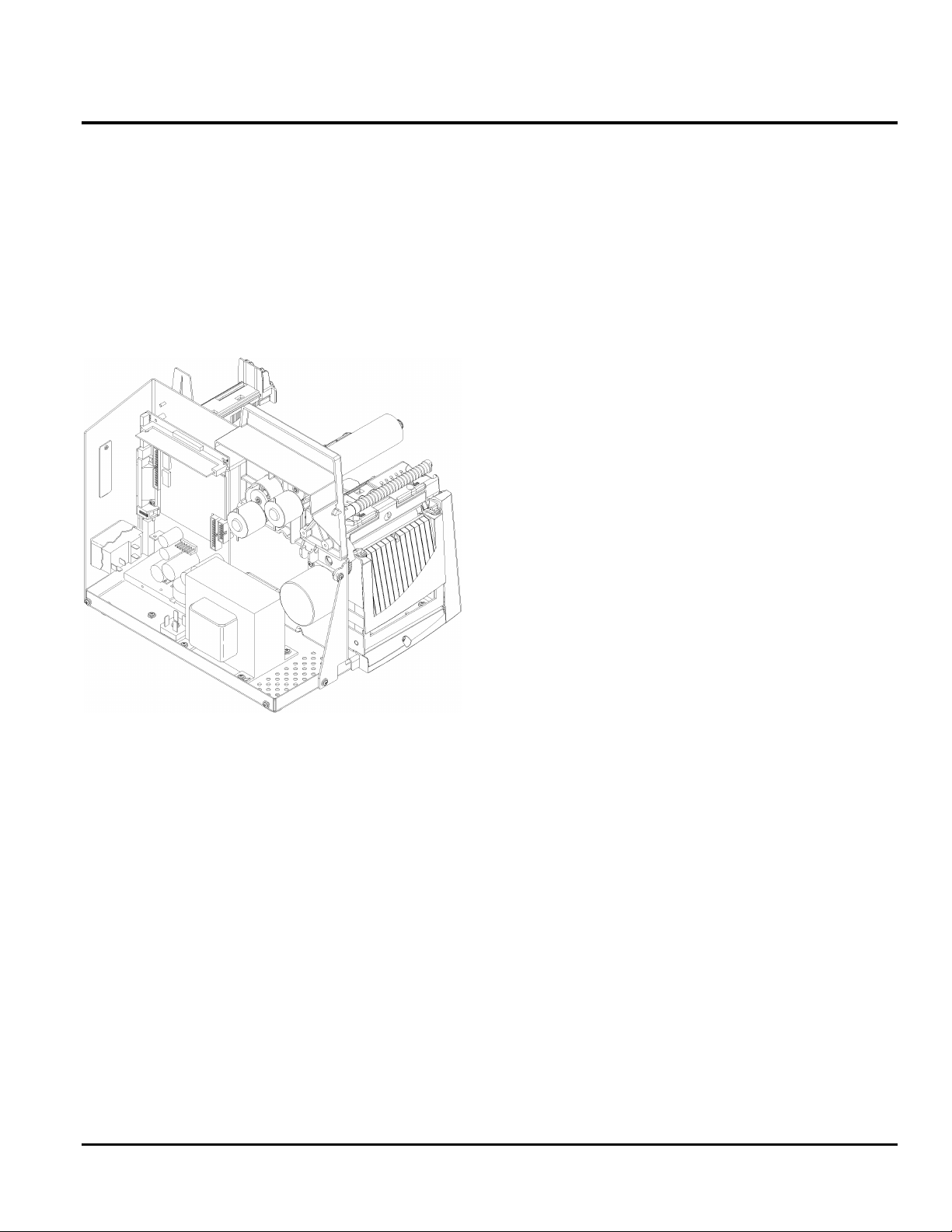

Figure 1 - 2. Printer Unpacking ................................................................................................................................. 3

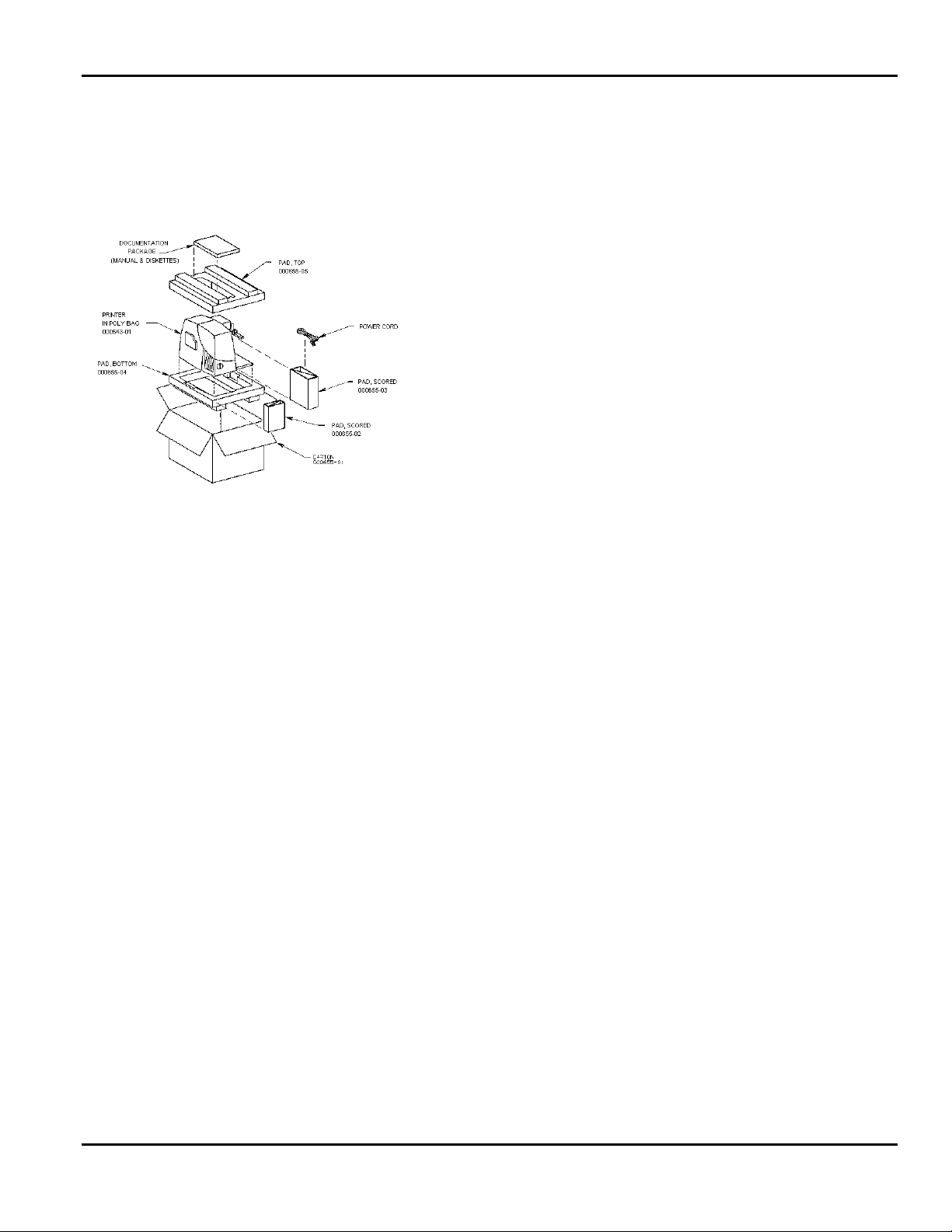

Figure 1 - 3. SW2/SW3 DIP Switch Location ............................................................................................................. 4

Figure 2- 1. Print Assembly ..................................................................................................................................... 10

Figure 2- 2. Feed Assembly.................................................................................................................................... 11

Figure 2- 3. Supply Holder Assembly...................................................................................................................... 12

Figure 2- 4. Control Panel Assembly....................................................................................................................... 12

Figure 4- 1. Test Labels.......................................................................................................................................... 20

Figure 4- 2. Loop Back Plug Wiring......................................................................................................................... 21

Figure 5- 1. Print Contrast Adjustment .................................................................................................................... 24

Figure 5- 2. Platen Motor Gear Adjustment............................................................................................................. 24

Figure 5- 4. Eccentric And Locking Screw............................................................................................................... 25

Figure 6 -1. Transformer Wiring Diagram................................................................................................................ 28

Figure 6 -2 Bridge Rectifier (Four Wires) ................................................................................................................ 28

Figure 6 -3 . Bridge Rectifier (Four Wires) .............................................................................................................. 28

Figure 6 -4.. Print Assembly .................................................................................................................................... 30

Figure 6 -5. BI-Cell Emitter Removal ...................................................................................................................... 30

Figure 6 -6. Print Assembly Plate & Printhead Module............................................................................................ 31

Figure 6 -7. Latch Removal..................................................................................................................................... 31

Figure 6 - 8. Bi-Cell Sensor ..................................................................................................................................... 33

Figure 8 -1. Bi-Cell Sensor Adjustment ................................................................................................................... 40

Figure 8 -2. Sensor Board....................................................................................................................................... 40

Figure B- 1. CN 1 IEEE 1284 Parallel Port............................................................................................................. 51

Figure B- 2. CN 2 Printhead Assembly ................................................................................................................ 51

Figure B- 3. CN 3 Platen Stepper Motor ............................................................................................................. 52

TC9830SM Rev. B 7/98 Confidential v

Page 7

Figure B- 4. CN 4 Control Panel............................................................................................................................. 52

Figure B- 5. CN 5 Coax/Twinax Interface................................................................................................................ 52

Figure B- 6. CN 6 Transformer Output Power ....................................................................................................... 53

Figure B- 7. CN 7 RS-232 Serial Port................................................................................................................. 53

Figure B- 8. CN 8 Supply Sensor (Bi-Cell) .............................................................................................................. 53

Figure.B- 9. CN 10 Board Interface..................................................................................................................... 54

Figure B- 10. CN 11................................................................................................................................................. 55

Figure B- 11. CN 15............................................................................................................................................... 55

Figure B- 12. CN 16................................................................................................................................................ 55

Figure B- 13. CN 19 (to Daughter Board CN3) ....................................................................................................... 55

Figure B- 14. CN 3 To MotherBoard CN 19............................................................................................................ 55

Figure B- 15.. CN 10 Peel Motor............................................................................................................................ 55

Figure B- 16. CN 6 On-Demand Sensor.................................................................................................................. 55

Figure C- 1. Control Board Assy. (Mother Board)................................................................................................... 57

Figure C-2. Control Board Assy. (Daugher Board) ................................................................................................... 58

Figure D- 1. Stacker Control Board......................................................................................................................... 62

Figure D- 2. Stacker Lubrication Points................................................................................................................... 62

Figure D- 3. Model 928 Stacker Assembly. ............................................................................................................. 63

Figure D- 4. Lower Transport Rollers....................................................................................................................... 63

Figure D- 5. Upper Transport Rollers. ..................................................................................................................... 63

Figure D- 6. Power Supply/Control Board................................................................................................................ 64

Figure E -1. Knife Lubrication Points....................................................................................................................... 66

Figure E -2. Location of Connectors........................................................................................................................ 66

Figure E -3. Knife Assembly.................................................................................................................................... 67

Figure E -4. Drive Board Connector Locations. ........................................................................................................ 68

vi TC9830SM Rev. B 7/98 Confidential

Page 8

Safety Summary

Warning and caution messages appear throughout this manual. They alert you to potentially safety hazards or

potential damage to equipment. The messages and there meaning are shown below.

WARNING

Calls attention to practices that could cause

Calls attention to improper practices that could

result in a potentially serious, even lethal injury.

Familiarize yourself with proper procedures before operating or repairing the equipment. Follow these precautions

for your own safety.

Personal Safety

• Treat every circuit as if it is “Live”. If in doubt,

check with a neon tester or voltmeter.

• Know how to turn off power in the work area

and how to obtain help in an emergency.

• Don’t work on equipment under power unless

it’s absolutely necessary. If you must, use

extreme caution.

• Shock. Don’t under estimate the danger of

shock. 12 mA causes hand muscles to

contract, so you cannot free yourself; 24 mA

has proven fatal.

• Tools. Use the right tools for the job. A tool

which slips can cause a short -- or a shock.

When working on live circuits, use tools with

insulated handles.

• Safety Devices. Don’t bypass safety devices,

particularly fuses. If a hot wire shorts to an

ungrounded frame, the frame itself becomes

hot and potentially dangerous.

• Electrical Fires Use Type C, BC, or ABC

extinguishers only.

minor injury or that could cause damage to

equipment.

Equipment Safety

Your body is a giant capacitor. It can store several

thousand volts of electricity. Digital equipment is

easily damaged or destroyed by this static

electricity. You don’t have to see a spark to ruin an

IC -- 50 volts is enough. To protect the equipment

from static damage, follow these guidelines:

• Ground yourself before reaching into the

equipment or touching any circuit board or

other electrical component. The Monarch Static

Ground Kit contains everything you need.

• Re-ground whenever you have walked away

and returned to the equipment. Be especially

careful around carpet. Carpet is a major

source of static buildup in the body. Even a

few steps can recharge you.

• The smaller the object, the greater the

precautions must be. A board in the machine

is better protected than one which is not

plugged in; a chip on a board is better

protected than one in your hand.

• Avoid touchings pins coming out of a chip or

the connector edge of circuit boards. These

metal parts have signal and data lines which

are connected directly to fragile circuits.

CAUTION

TC9830SM Rev. B 7/98 Confidential vii

Page 9

viii TC9830SM Rev. B 7/98 Confidential

Page 10

CHAPTER 1 PRINTER OVERVIEW & INSTALLATION

9820/9830/9835 printer operation is controlled online

PRINTER FEATURES

The 9820/9830/9835 printers are on-line table-top

printers that accepts Monarch Printer Control

Language II (MPCLII) data structure.

They use a 203 dpi thermal printhead for printing. The

printhead supports both thermal transfer (heat

activated ribbon) and thermal direct (heat activated

stock) printing.

via an RS-232 port, a Centronics® parallel port,

Ethernet adapter, or a CoAx/TwinAx port. Local

operation is controlled by the Control Panel and DIP

Switch settings and include Printer On/Off,

Diagnostics, On-Demand Mode , Error/Fault Condition

Indication and Clear.

PRINTER OPTIONS

These options are available for all printers:

• TwinAx /CoAx Interface

• Memory Expansion Board

• Ethernet Adapter Plug #117531-01 (10BaseT)

• Ethernet Adapter Plug #117532-02 (10Base2)

The following options are available for the 9835

printer:

• 917 Keypad (for offline batch entry)

• 926 Knife

• 928 Stacker (must be used with knife)

The 9835 printer also supports 9445 emulation,

connection for an optional keyboard, and a verifier.

Service can install the above options on-site.

Figure 1 - 1. 9830 Printer (Housing removed)

The printers have a hinged print assembly for ease in

loading and unloading the supply. The supply spool,

lower paper guide, and ribbon spool are center

justified and can be adjusted by the user to handle

various supply widths.

The printers support fanfold or roll supply. The 9835

supports tag stock to 10 mil thickness. Standard,

smudgeless, durable, and steam resistant ribbon types

are supported by all printers. Ribbon length is 600

meters and is available in core widths of 1.3”, 1.6”,

2.16”, 3.15”, and 4.13”. Used ribbon is collected on a

take-up spool by taping the ribbon leader to an empty

core. One empty core is supplied with the printer.

The 9830/9835 models offer a Service installed tear

bar, Flash ROM programming, and an optional Peel

Module for separation of supply and backing. The

Peel Module is standard on the 9830, optional for the

9835, but not available on the 9820. The 9835

supports either a Peel Module or a knife, but not both.

NOTE: The knife and stacker attachments can be

installed by the customer or Field Service

technicians. Ethernet Adapter Plugs are

not factory installed.

PRINTER SPECIFICATIONS

Height: 12.5 inches (318 mm)

Width: 12 inches (305 mm)

Depth: 13 inches (330 mm)

Weight: 29 pounds (13 kg)

Shipping Wgt: 33 pounds (15 kg)

Power: 115 VAC, 60 Hz

July 1998 TC9830SM Rev. B 7/98 Confidential 1

Page 11

9820/9830/9835 Service Manual Printer Overview and Installation

Fuse, Inlet Module: 4.0 amp, 250 V Slo-Blow®

(1 required)

Fuse, Main PCB 7.0 amp, 125 V Slo-Blow

(Soldered radial leads)

Tear Bar: 9830/9835 (Service Installed)

Programming: Flash

Communications: Parallel Port; IEEE 1284

compliant or

Centronics Mode

Operating With Ribbon

Limits: 40 to 95 degrees F

(4 to 35 degrees C)

Without Ribbon

40 to 104 degrees F

(4 to 40 degrees C)

Storage 15 to 120 degrees F

Limits: (-10 to 49 degrees C)

Relative 5 to 90 % Non Condensing

Humidity:

Display: Liquid Crystal Display

3 numeric digits

Light Emitting Diodes

POWER green

SUPPLIES amber

PAUSED amber

Thermal Thin Film

Printhead: 4.15 inches (105mm) wide

832 dots

203 dots/inch (8 dots/mm)

0.0049 inch dot width,

( 0.1245 mm), center-center

Printing Thermal Transfer

Methods: Thermal Direct

Supply Types: 9820 – labels only

9830 -- labels only

9835 -- labels or tags

Ribbon Types: Roll (Non Cartridge)

Standard

Smudgeless

Durable

Steam Resistant

High Energy (9830/9835)

Ribbon Length 23,600 inches (600 m)

Ribbon Widths: 1.3 inches (33 mm)

1.6 inches (41 mm)

2.16 inches (55 mm)

3.15 inches (80 mm)

4.13 inches (105 mm)

Max Ribbon 3.6 inches (91 mm)

Roll O.D.

Ribbon Storage: 41 to 95 degrees F

(5 to 35 degrees C)

Print Speed: 2D Bar Code

2.5, 4, or 6 inches/sec

Serial Bar Code

2.5 inches/sec

Max Print Image: 4 inches wide (102 mm)

16 inches long (405 mm)

Max Print +/- 0.050 inches (1.3 mm)

Tolerance: (side to side)

Feed Method: On-Demand, Continuous, and

optional Peel Mode

STOCK SPECIFICATIONS

Ribbon: Thermal Transfer

Requirements

Stock Width: 1.2 inches (31mm)

4.25 inches (108mm) max

Version 5.2 or .75 inches (19mm) min

greater width:

Stock Length: 1 inch (25mm) min

16 inches (405mm) max

12 inches (305mm) max 9820

Version 5.2 or .75 inches (19mm) min

greater length:

Cut Length: 1.2 inches (31mm) min with

optional knife installed

Stock 0.007 inches min

Thickness: (0.18mm)

0.010 inches max

(0.25mm)

Stock Roll: Outside Diameter

9.375 inches ( 229 mm)

Inside/Core Diameter

3-4 inches (102 mm)

8100 inches (200 m) long

Stock Output: Roll or Fanfold

Stock Type: Die cut without Black Mark

Black Mark

Continuous

Coated Supplies

Version 5.2 or Die Cut Edge

greater stock type: Black Mark

Continuous

Center or Edge Aperture

2 TC9830SM Rev. B 7/98 Confidential July 1998

Page 12

Printer Overview and Installation 9820/9830/9835 Service Manual

UNPACKING THE PRINTER

1. Clear a work area approximately four feet wide.

2. Open shipping carton top flaps.

3. Remove the Documentation Package. and top

pad 000655-05.

Figure 1 - 2. Printer Unpacking

4. Remove scored pad 000655-02 and scored pad

000655-03 (Figure 1-2).

5. Remove power cord from scored pad 000655-03.

NOTE: The power cord is not included with some

models.

1. Grasp printer at base by inserting hands into

cutouts in bottom pad 000655-04. Lift printer out

of box and set on solid surface.

2. Remove poly bag 000543-01.

3. Put all packing back in the carton and set carton

aside.

4. Inspect printer for damage. Report any damage

following established procedures.

5. Open printer door and remove packing tape from

the printhead assembly.

6. Remove empty four-inch core from ribbon take-up

spool.

7. Install customer’s ribbon roll.

8. Install customer’s supply stock.

DOCUMENTATION

The following Documentation Package (TC9830DP or

TC9835DP) is provided with each printer:

• quick-set Software Diskettes

• Operator’s Handbook

In addition, these documents are available on your

Service CD-ROM as Adobe Acrobat Reader files

(.pdf):

• Service Manual TC9830SM

• Programmer’s Manual TC9800PM

• TwinAx/CoAx Manual TC9800TXCX

The Operator’s Handbook (TC9830OH or TC9835OH)

can be ordered separately.

SETTING DIP SWITCHES

These printers have three sets of DIP switches. Two

sets are located on the back of the printer and

accessed from outside of the printer. They are

designated SW2 (Upper) and SW3 (Lower). The third

set is located on the Control Board Assembly daughter

board and is designated SW1. The printer is

delivered with the SW2 and SW3 DIP Switches set to

the defaults shown in Table 1-2. SW1 switch setting

are shown in Table 1-1.

NOTE: DIP switches are only read at power-up.

Turn off the printer immediately after

changing DIP switch settings.

To change the DIP switch settings:

TOOLS REQUIRED:

Small Flat Blade Screwdriver

NOTE: If software control is enabled (by setting

rear DIP switches 1 thru 3 to OFF), all rear

communications switches are ignored.

Downloaded communications settings

remain in effect until a new packet is sent

or until software control is disabled by

setting rear DIP switches 1 thru 3 to a valid

baud rate. Downloaded communications

settings remain in memory and take effect

when software control is again enabled.

DIP Switches for Version 5.2 or greater are shaded.

July 1998 TC9830SM Rev. B 7/98 Confidential 3

Page 13

9820/9830/9835 Service Manual Printer Overview and Installation

1. Locate Upper or Lower DIP Switch block as

shown in Figure 1-3.

2. Turn printer off and change individual DIP

switches as required. Use Table 1-1 as a guide.

3. Daughter board SW1 settings are factory set.

However, when replacing the Control Board

Assembly, the new board must be set as shown

in Table 1-1.

Figure 1 - 3. SW2/SW3 DIP Switch Location

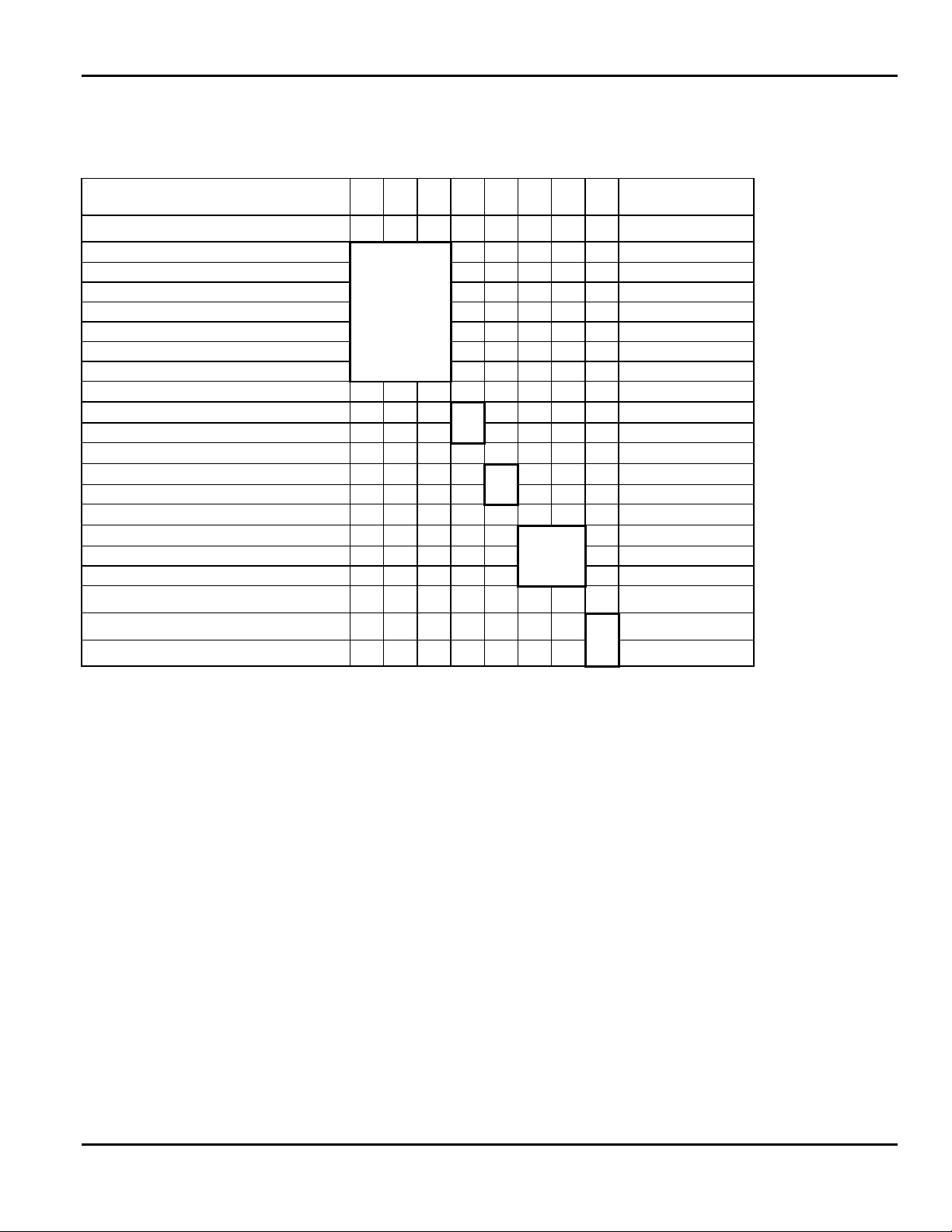

Table 1 - 1. Daughter Board DIP Switches

SW1

Model #

9820 OFF OFF OFF OFF OFF OFF

9820 with new

sensing system

9830 No Peel OFF OFF OFF OFF OFF ON

9830 With Peel OFF ON OFF OFF OFF ON

Fox IV

printer/applicator

Paxar CL OFF ON OFF OFF ON ON

9835 With Peel ON ON OFF OFF OFF ON

9835 With Knife ON OFF OFF OFF OFF ON

9835 No Peel/Knife ON OFF OFF OFF OFF ON

ON OFF OFF OFF OFF OFF

OFF ON OFF ON OFF ON

SW2

Peel

SW3

Not used

SW4

Fox IV

SW5

Paxar CL

Upper DIP Switches

Lower DIP Switches

SW6

Memory

FUSE REPLACEMENT

Refer to the Operator’s Handbook for fuse replacement procedures.

CONNECTING TO A HOST

For instructions on connecting the printer to a host, refer to the Operator’s Handbook.

4 TC9830SM Rev. B 7/98 Confidential July 1998

Page 14

Printer Overview and Installation 9820/9830/9835 Service Manual

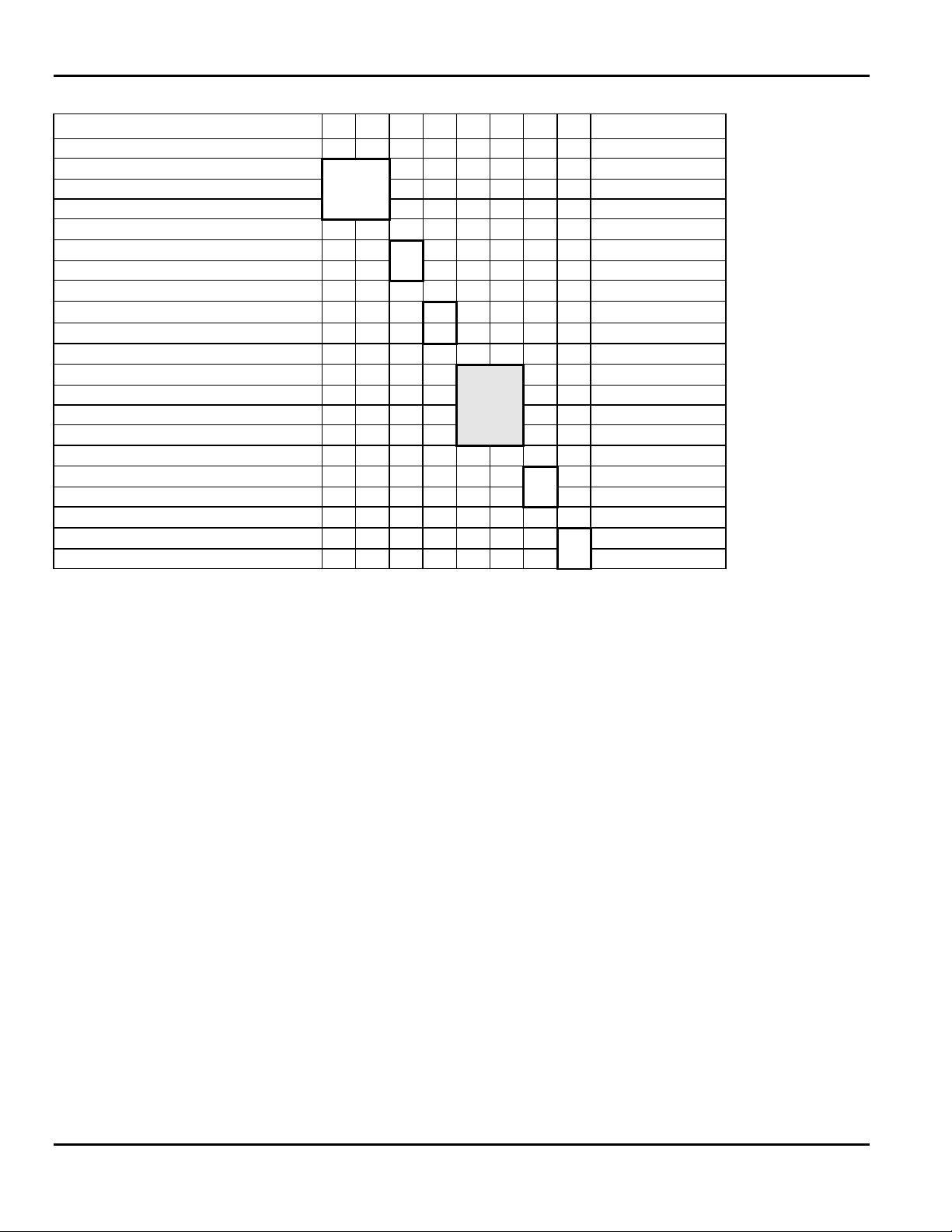

Table 1 - 2. Exterior Rear (SW2 and SW3) DIP Switch Settings

Upper DIP Switches:

SELECTION 1 2 3 4 5 6 7 8 DEFAULT

Baud Rate

38400 ON ON OFF

19200 ON OFF ON

9600 ON OFF OFF 9600

4800 OFF ON ON

2400 OFF ON OFF

1200 OFF OFF ON

Software Ctrl OFF OFF OFF

Data Bits

7 Data Bits ON

8 Data Bits OFF 8 Data Bits

Stop Bits

2 Stop Bits ON

ON Stop Bit OFF 1 Stop Bit

Parity

Even ON OFF

Odd OFF ON

None OFF OFF None

Parallel Port

Centronics Mode

IEEE-1284

OFF Centronics

ON

July 1998 TC9830SM Rev. B 7/98 Confidential 5

Page 15

9820/9830/9835 Service Manual Printer Overview and Installation

Lower DIP Switches:

SELECTION 1 2 3 4 5 6 7 8 DEFAULT

Flow Control

XON/XOFF ON OFF

RTS/CTS OFF ON

DTR OFF OFF DTR

Diagnostics

Normal Run Mode OFF Normal

Diagnostics Mode ON

Verifier

No Verifier

Verifier Installed

Supply Type/ Sensing

Die Cut or Edge Aperture (edge sensor) OFF OFF

Black Mark (center sensor) OFF ON Die Cut

Continuous (no sensor) ON OFF

Center Aperture (center sensor)

Ribbon

Transfer OFF Transfer

Direct ON

Feed Mode

Continuous OFF Continuous

On-Demand ON

OFF No Verifier

ON

ON ON

NOTE: DIP Switches for Version 5.2 or greater are shaded.

6 TC9830SM Rev. B 7/98 Confidential July 1998

Page 16

CHAPTER 2 FUNCTIONAL DESCRIPTION

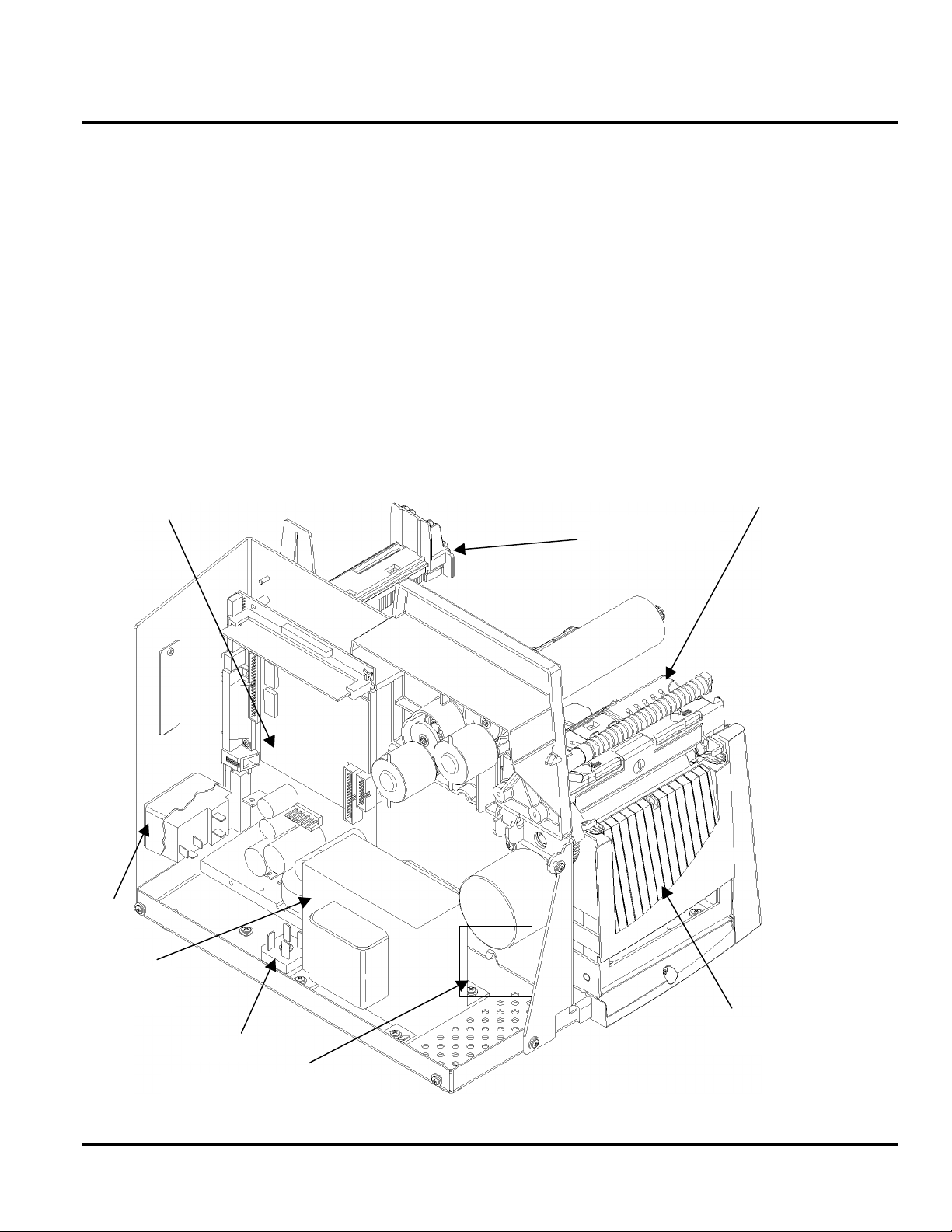

OVERVIEW OF MODULES

• Power Transformer Assembly (Power Supply and Distribution)

• Control Board Assy. (Data Handling and Control)

• Peel Module (Supply/Backing Separation)

• Print Assembly (Thermal Control and Motion Synchronization)

• Feed Assembly (Supply Alignment/Tension)

• Supply Holder Assembly (Supply Guide)

• Control Panel Assembly (Operator Interface)

Control Board

Assy.

Supply Holder Assy.

Print Assembly

AC Inlet

Module

Power

Transformer

Assy.

Rectifier

Peel Module

(inside door of 9830)

Control Panel Assembly (Mounted

to printer housing- not shown)

July 1998 TC9830SM Rev. B 7/98 Confidential

Page 17

9820/9830/9835 Service Manual Functional Description

Power Transformer Assembly

The power transformer assembly is located beneath

the printer’s back cover and includes three

components:

Inlet Power Module

The power module is attached to the printer’s rear

panel just in front of the Control Board Assy. Its face

plate partially extends through the rear panel to allow

users access to the power receptacle, fuse box/power

selector and the on/off switch. It has wire attachments

to ground the Power Transformer.

This module includes the following components:

• International line cord receptacle

• 4.0 Amp, 250VAC Slo-Blow fuse

Line voltage enters at the cord receptacle and passes

through a slow-blow fuse. The slow-blow fuse protects

the system from damage by power surges. Line

ground is provided to the printer via a ground harness

connected to the bottom frame.

Power Transformer

The power transformer is available in three voltages:

110V, 115V, or 220V. It is attached to the frame base

just below the print module. The transformer gets AC

line voltage from the inlet power module and converts

it to two AC output voltages. The first is sent directly

to the Control Board Assembly for futher conditioning.

The second output is sent to the bridge rectifier for

additional conversion.

The power transformer assembly outputs the required

AC and DC voltages for operation of the printer and

sends both voltages directly to the Control Board

Assy. Further conversion and/or distribution is made

by the Control Board Assy. Major functions of the

power transformer include providing power to the Inlet

Power Module, Power Transformer, and to the Bridge

Rectifier.

Bridge Rectifier

The bridge rectifier is a 1” x 1” assembly fastened to

the printer frame base left of the power transformer. It

has wire attachments to ground, the power

transformer, and the Control Board Assy.

The bridge rectifier accepts the AC from the power

transformer and converts it to DC. This voltage is

then supplied to the Control Board Assembly for

further conversion.

CONTROL BOARD

ASSEMBLY

The Control Board Assembly is located on the back

side of the printer frame wall beneath the printer’s

back cover. It consists of a mother board and a

daughter board. The two boards are replaced as a

single assembly. The board assembly is mounted on

six quick-release aluminum standoffs. Three of the

standoffs are threaded for retainer screws.

The board has three connectors (serial port, parallel

port, and bar code verifier), the print contrast control,

and three DIP switch assemblies. Two are mounted

on the long vertical side allowing for external access.

The third DIP switch is located on the daughter board.

There is a connector across the top of the board and a

hall effect sensor at the top right corner of the board to

sense a “Head Open” condition. Eight additional

connectors accept cabling to other printer assemblies.

The daughter board has a connector for cabling to the

mother board, and two connectors for functional

expansion.

Functional Description

The Control Board Assy. controls all electrical

requirements for the printer and contains interfaces for

controlling all printer functions, including Ribbon

Supply and Take-up motors, Stepper Motor, Peel

motor, Knife motor, and the Printhead. A single

microcomputing unit consisting of a 32-bit RISC

processor, 256K OTPROM (16 bits), and 256K (16

bits) of Dynamic RAM (DRAM) controls the interfaces.

Major functions of the Control Board Assy. are:

• Power Conversion

• Memory

• Printer Control

• Operator Panel Control

• Communications

• Contrast Control

• Hardware Power-up Settings (DIP Switches)

• Peel Motor Control

• On-Demand Sensor Interface

• Knife Motor

8 TC9830SM Rev. B 7/98 Confidential July 1998

Page 18

Functional Description 9820/9830/9835 Service Manual

Power Conversion

Power conversion interface receives AC and DC

voltage from the Power Transformer assembly.

35VAC is converted to +12VDC and -12VDC, while

the 40VDC input is converted to +25VDC and +5VDC.

Memory

Control Board Assebmly contains three types of

memory: Flash, DRAM and SRAM.

Flash Memory

Flash memory contains the necessary BOOT code

and Operating System functions for I/O routines used

for communications, the application program, fonts,

formats, and the Kernel/Library functions.

DRAM Memory

DRAM is used for variable storage, buffers, and image

memory. The base memory configuration for the

printer is 256K (16 bits).

SRAM Memory

SRAM (32K of non-volatile static RAM ) is used to

store system parameters and machine totals. All

relevant information is automatically stored in the

SRAM when the printer is turned off.

Printer Control

Control Board Assembly controls all printer functions.

It use a high performance, 32-bit, RISC based,

integrated microcontroller. The microcontroller

performs imaging and provides interfaces to printer

control operations. Major functions of the board are:

Data Handling

During operation, communication with both the RS232 port and the High Speed parallel port is

maintained. MPCL data received is transferred to

Dynamic RAM (DRAM)

Printhead Thermal Control

Printhead thermal control operation is a dynamic

closed loop servo circuit that adjusts the on/off duty

cycle in response to a continuously monitored

Printhead operating temperature and resistance.

Print Imaging

The Thermal Printhead Interface is controlled by the

microcontroller. Page image data is transferred from

Dynamic RAM to the thermal printhead as a serial

data stream.

Motion Control

Motion control sub-system controls four DC motors.

Two DC motors drive the Ribbon control, a stepper

motor controls the platen drive, and a fourth motor

drives the Peel Module.

Platen Drive Interface

Control Board Assembly controls the platen drive

motor’s torque, speed and direction through the use of

four phased 25Vdc output signals. Motor torque and

direction is controlled by changing the sequence and

pattern of the four signals. Motor speed is controlled

by increasing or decreasing the speed of the digital

pulse that make up the four phased signals.

Ribbon Drive Interface

Electronically controlled DC motors drive the ribbon

over the printhead. The motors, and associated

control software, control the tension of the ribbon web

as the ribbon spools from the supply side to the takeup side. A speed-detection method using BEMF

(Back Electromagnetic Motor Force) provides

accurate ribbon tension control.

Analog to Digital Conversion

An ML2255 A/D converter, in conjunction with the

microcontroller, monitors system functions. The A/D

converter combines an 8-Bit A/D converter, 8-channel

analog multiplexer, and a microcontroller-compatible,

8-bit parallel interface and control logic. The A/D

converter monitors various system functions and

provides information to the printers firmware to control

the supply motion, print quality, etc.

Supply Detection & Tracking System

See Chapter 8, “Supply Sensing Systems” for more

information.

Operator Control Panel

Printer Control Board uses a Peripheral Interface Unit

(PIU) to control the operator control panel interface

comprised of a three digit display, three push-button

keys and three LEDs.

An optional 917 Keypad is available for the 9835

printer (offline batch entry).

Communications

RS-232 interface and the Centronics/IEEE 1284

compliant parallel interfaces are mounted on the

Control Board Assy. Both are located on the left edge

of the board and accessed by the user at the rear of

the printer near the supply roll.

July 1998 TC9830SM Rev. B 7/98 Confidential 9

Page 19

9820/9830/9835 Service Manual Functional Description

RS-232 interface

This interface allows connection to devices capable of

RS-232 communications. The interface is incorporated

in the microcontroller and has DIP switches to set

communications parameters. The DIP switches can

be set manually by the user or through software

control.

Centronics IEEE-1284 Parallel Interface

This interface accommodates high data rates, up to

2M Bits/Second.

IEEE 1284 Bi-Directional Parallel Interface

An IEEE 1284 High Speed Bi-directional Parallel

interface provides parallel communications. The

microcontroller directly controls the port. The

interface allows compatibility with the Centronics

interface as well as allowing for High Speed Bidirectional communications.

NOTE: Third party LAN devices are connected

through the parallel interface to allow the

printer to interface different LAN networks.

Contrast Control

A manual contrast control, located at the edge of the

Control Board Assy., extends out of the rear cover. It

is used for fine adjustments to the print contrast

values.

Hardware Power-up Settings (DIPS)

Two 8-switch DIP switches, located on the back panel

of the printer above the contrast adjustment, control

the default power-up configuration of the printer.

Settings include the serial port settings, diagnostics,

ribbon setup, printer mode and supply type.

Peel Module Assembly

The peel module separates the supply from the

backing paper. It consists of an on-demand sensor,

rollers, and a 12Vdc motor drive. Dip SW1 (switch 2)

located on the daughter board enables and disables

the peel function.

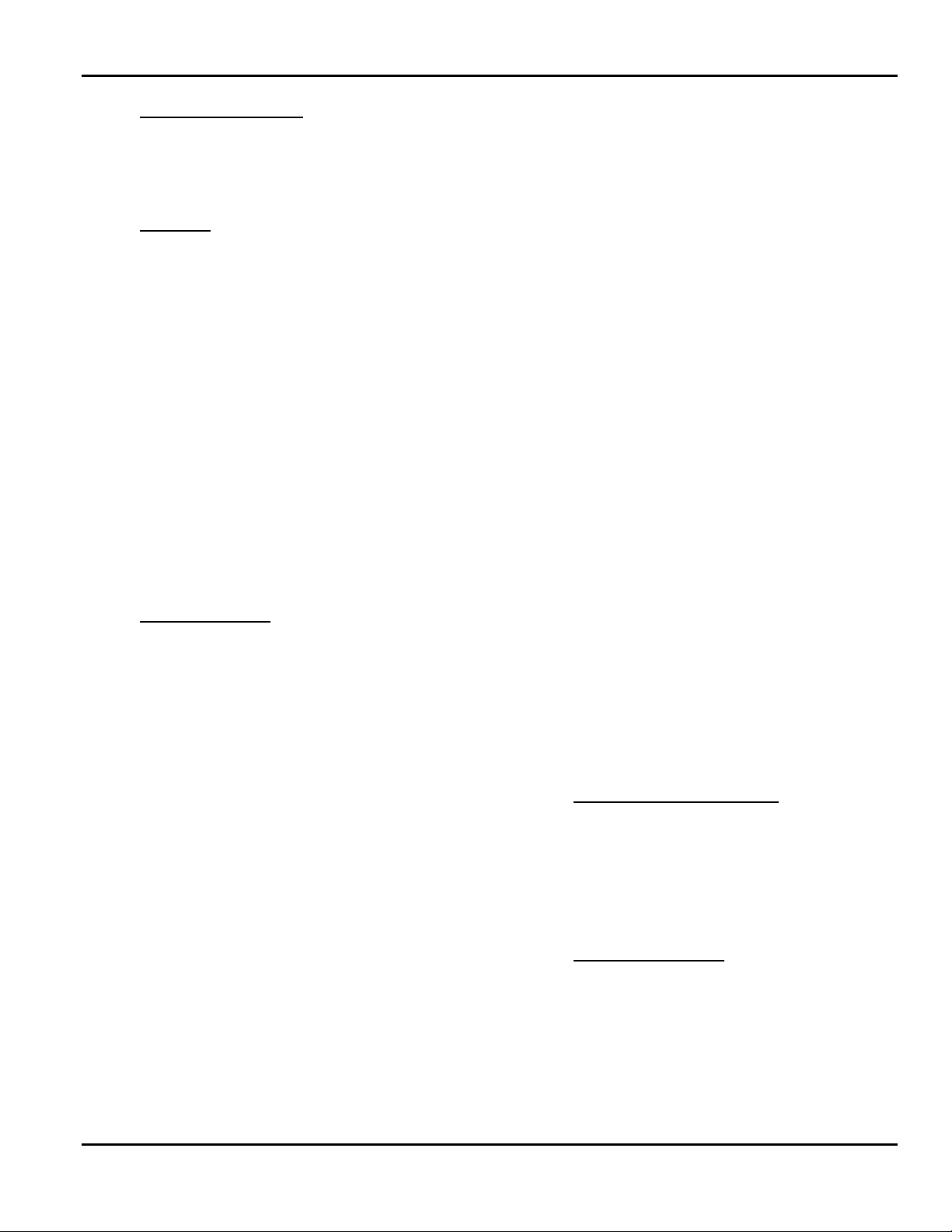

PRINT ASSEMBLY

This Print Module is a plastic casting located inside

the printer’s hood. It is attached to the mid frame by

two bearing blocks which capture studs on the module

back plate. Components of the Print Module are:

Figure 2- 1. Print Assembly

Thermal Printhead

The printhead is located at the bottom front of the

module. It is held in place by a plastic carrier which

acts as an interlock to a formed metal bracket. The

bracket is center-mounted and pivots to ensure an

even pressure on the supply. The printhead bracket

has two alignment loops which slip over the platen

roller to assure dot row to platen roller alignment. The

printhead mount also has two spring loaded

adjustment knobs to adjust printhead pressure for

wide or narrow supplies. A 30 pin ribbon cable

connects the printhead to the Control Board Assy

Ribbon Supply & Take-up Spools

The ribbon supply and ribbon take-up spools are

located on the supply side of the module. Each spool

shaft extends through the module wall and connects to

its own DC drive motor. The spools are designed to

handle a detented ribbon core so when ribbons of

various widths are installed they maintain center

justification.

Ribbon Transfer Rollers

Two ribbon transfer rollers are located on the supply

side of the module. The rollers are ribbed and

attached to metal shafts by retainer screws. One sits

at the very front of the module wall above the

printhead while the other is positioned just above the

supply deflector.

10 TC9830SM Rev. B 7/98 Confidential July 1998

Page 20

Functional Description 9820/9830/9835 Service Manual

Ribbon Spool Drive Motors

wo DC ribbon drive motors are mounded to the back

of the module wall. Each motor drives a ribbon spool.

The motors are connected directly to the Control

Board Assembly via separate two-wire harness.

Supply Deflector and Bi-Cell Emitter

(IR LED)

See Chapter 8, “Supply Sensing Systems” for more

information.

Ribbon Transfer Rollers

The two ribbon transfer rollers allow ribbon tension

adjustments. Each roller has an eccentric which

allows slight skew adjustments to each, which in turn

affects the ribbon tension.

Functional Description

The print module, performs ribbon drive operations,

provides mechanical ribbon tension adjustments,

performs print functions, helps maintain supplies

tracking, and houses half of the sensor assembly. It is

controlled by the Control Board Assembly.

Ribbon Drive Operation

The ribbon drive operation is made up of two ribbon

spools, two 25Vdc drive motors, and two ribbon

transfer rollers. It is controlled by the Control Board

Assy. Each drive motor sends continuous information

to the Control Board Assy. where it is used to evaluate

ribbon conditions, maintain optimum ribbon tension,

and sense the end of ribbon condition. This system

eliminates the need for ribbon sensors.

Printing

The printhead has a line array of 832 dot elements

sized to produce 203 dots per inch. Printing occurs by

sending image data to the printhead one line at a

time. Each time a line of data is received,

corresponding dots on the printhead are heated to

create an image line on the stock. Successive image

lines generated across moving stock make up the total

image. The Control Board Assy. controls all image

data sent to the printhead, and regulates the energy

level of the printhead. Energy levels are raised and

lowered to create darker or lighter print respectively.

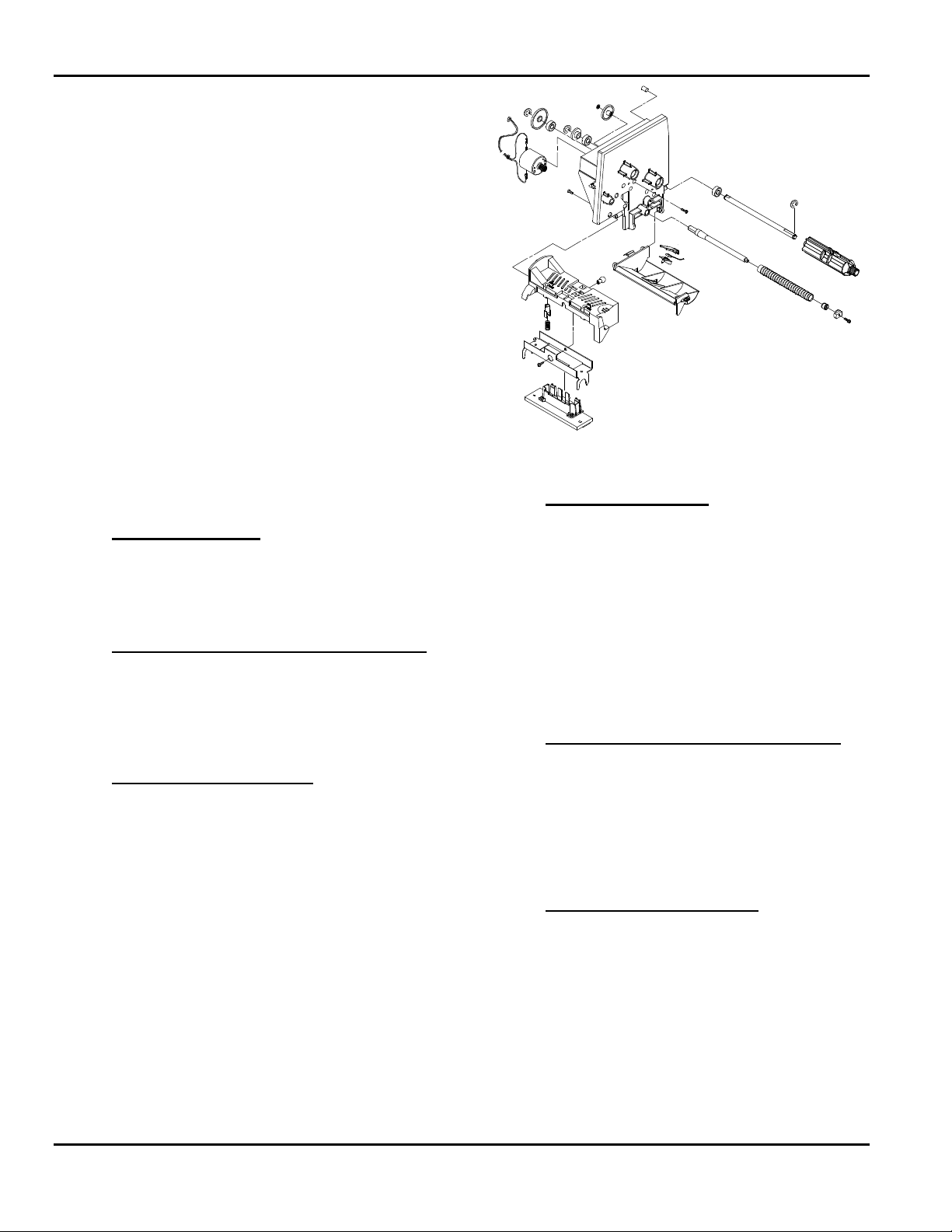

FEED ASSEMBLY

The feed module components are mounted on a metal

frame positioned beneath the Print module and

fastened to the printer base. Components of the feed

module are:

Bearing

Blocks

Spring

Latch

Figure 2- 2. Feed Assembly

Platen Module

The platen rollers are on top of the feed module frame

just beneath the printhead. It is held in place by two

bearing blocks latched on the frame sides. The inner

side of the platen roller shaft extends through the

inside wall of the feed module where a drive gear is

attached.

24VDC Stepper Motor

The stepper motor is located behind the mid-frame of

the printer. Its drive shaft and gear extends through to

the space between the printer mid-frame and the feed

module frame.

Lower Supply Guide and Bi-Cell

Sensor

See Chapter 8, “Supply Sensing Systems” for more

information.

Printhead Latch

The printhead latch is spring loaded and mounted on

the outside of the feed module frame; within the latch

fascia. It locks the printhead in position.

Functional Description

The feed module transports supply through the printer

and across the printhead. It also maintaining proper

alignment, tension, and speed. This is accomplished

by sensing the stock position while securing the

printhead down onto the platen roller. Major functions

are supply feeding and supply sensing. See Chapter

8, “Supply Sensing Systems” for more information.

July 1998 TC9830SM Rev. B 7/98 Confidential 11

Page 21

9820/9830/9835 Service Manual Functional Description

Printhead Locking

Printhead release knob is used to release the print

module from its open position.

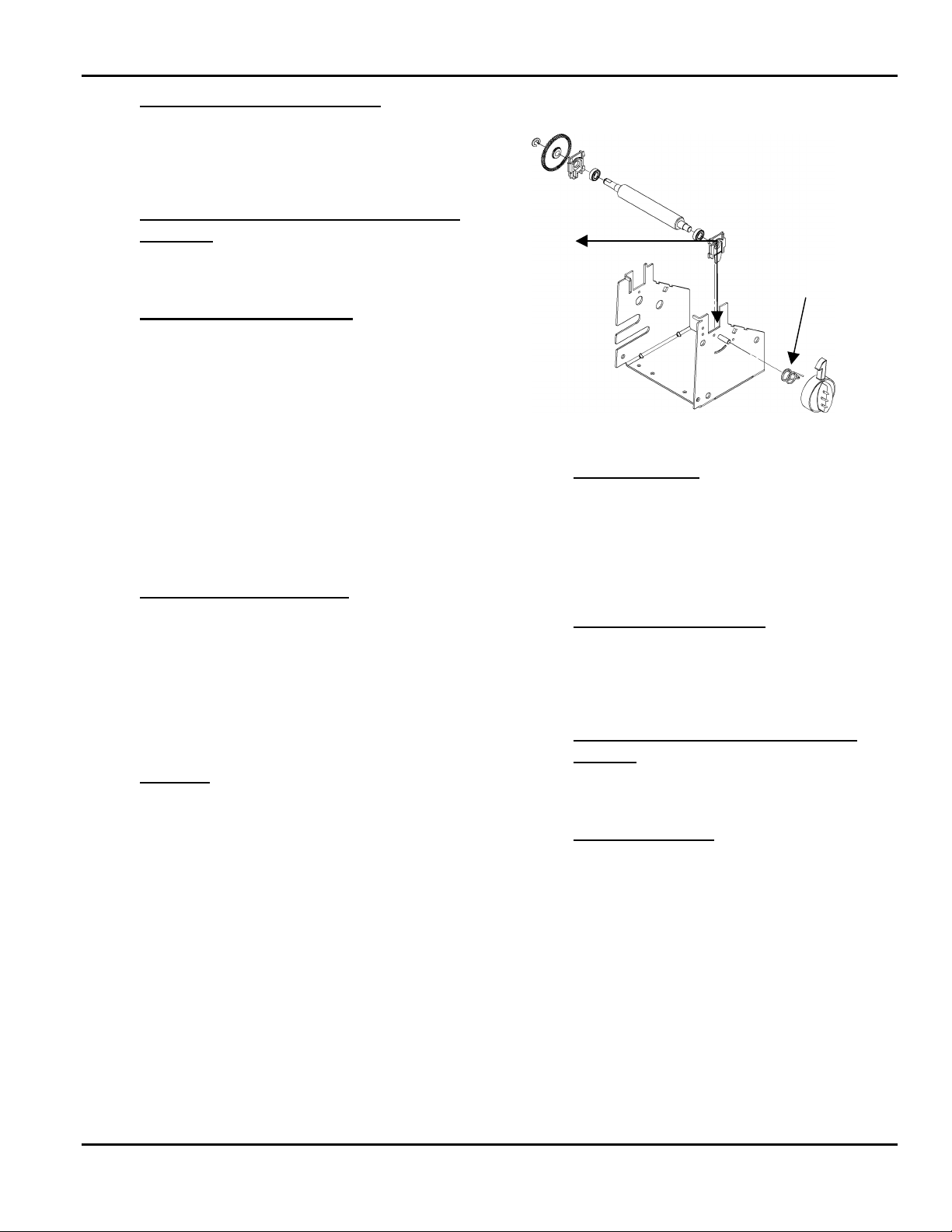

SUPPLY HOLDER ASSEMBLY

Inner Guide

Outer Guide

Figure 2- 4. Control Panel Assembly

Functional Description

Figure 2- 3. Supply Holder Assembly

Functional Description

The supply holder module holds the supply roll in a

center-justified position to ensure optimum supply

tracking. The guides are gently pushed inward until

they center the roll and back off to the next detent

position when released.

The front guide pivots down for supply

loading/unloading. When loading fanfold supply, the

stack is placed behind the printer or under the table

and fed through the supply holder guides.

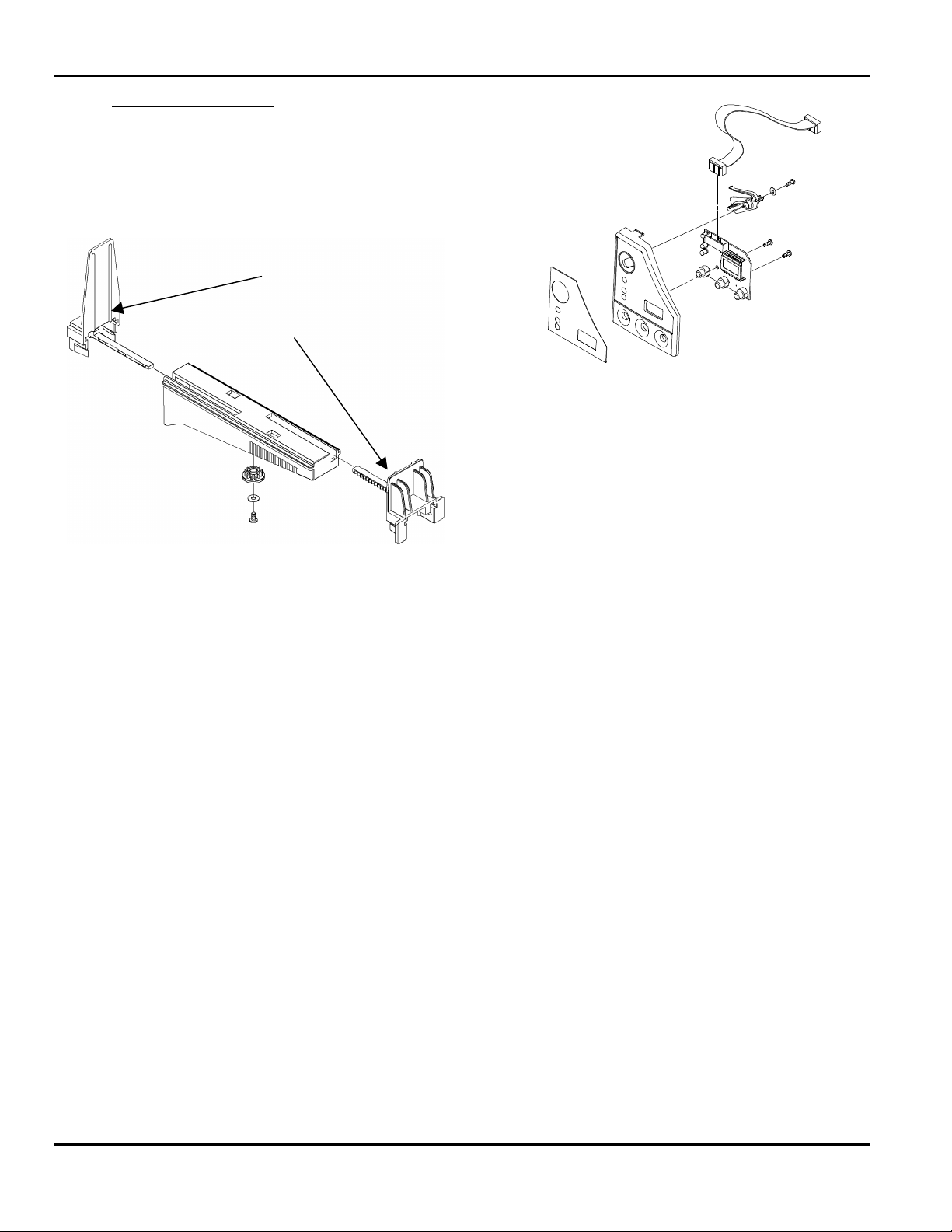

CONTROL PANEL ASSEMBLY

The Control Panel Assembly is mounted on the front

of the printer. The associated electronic components

are mounted on a circuit board behind the panel

fascia. A ground wire connects the board to the

chassis ground and a single wire harness connects it

to the Control Board Assy.

LEDs

LCD

Feed

Pause

Clear

Feed + Pause

Feed + Clear

The three LEDs indicate general printer

status and activity.

The three-character LCD identifies

specific printer conditions through the

use of numeric codes. These codes are

listed and described in Appendix A.

In Normal mode, advances a label from

the printer. In Offline mode or Online

Diagnostic mode, prints a test label.

Stops the current batch from printing.

Printing resumes when Pause is

pressed a second time.

Cancels the current batch from being

printed if pressed for only a moment.

Cancels all batches associated with the

current format if pressed and held for

two seconds. Cancels some error

codes that appear on the LCD.

In Normal mode, prints a test

label.

In Diagnostics mode, places the

printer in data dump mode. See

Chapter 4, “Diagnostics” for

more information.

12 TC9830SM Rev. B 7/98 Confidential July 1998

Page 22

CHAPTER 3 TROUBLESHOOTING

This chapter contains suggestions for diagnostic and repair actions.

PRELIMINARY CHECK

The following checks should be made before going further:

1. Are the DIP switches set properly to match communication values and existing supply?

See Chapter 1 for DIP Switch settings and procedures.

2. Ensure that the proper fuse has been installed. See the Operator’s Handbook.

3. Inspect printhead to ensure it is locked in place.

4. Ensure stock and ribbon are properly loaded. Refer to the Operator’s Handbook for printer loading instructions.

ANALYZING FAILURE DURING POWER UP

Each time the printer is turned on, it runs Power-up Diagnostics. These Level 0 Diagnostic Tests are described in

detail in Chapter 4. If any of the first eight tests result in a fault condition, a three digit status code is indicated on the

Control Panel LCD. As shown in Figure 4-2, if any of the following status codes are indicated, the printer will stop

operating, and remain in a “hold mode” until CLEAR is pressed:

909 Memory Failure 765 Printhead Test Failure

911 Virgin Reset

NOTE: These error codes only appear during a power-up test sequence. If a “765” status code is indicated during

the power on tests, the printer is still operational but may not be able to print all of the commanded label

images.

The Control Panel is tested during the power-up tests by blanking the three digit LCD display momentarily. This is the

final Level 0 test, and would be noticed only if a “765” status code were previously indicated.

EVALUATION OF A 616 ERROR (DOT SHIFTING FAILED)

This error occurs if at least one dot element is non-functional. Shifting the image pattern will not work. You must

replace the printhead.

EVALUATION OF A 704 ERROR (OUT OF SUPPLY)

This error occurs when the sensor is not sensing the supply. This can happen if there is a problem with the supply or

with the sensor. Perform the following procedure:

1. Verify stock is loaded and properly aligned in the supply guide.

2. Verify that DIP switches and online settings are set for proper supply type.

3. Check Bi-cell alignment using gray scale, and check operation using diagnostic procedures (be sure to check

the harness). See Sensor Tests and Bi-Cell Sensor Adjustment, in Chapter 8, for instructions.

4. Verify Emitter is operational (including the harness) by using an infrared detector probe.

July 1998 TC9830SM Rev. B 7/98 Confidential 13

Page 23

9820/9830/9835 Service Manual Troubleshooting

EVALUATION OF A 754 ERROR (OUT OF RIBBON)

This error occurs whenever the ribbon stops turning. This can happen if the motors are not working, the stock is

binding, the platen is sticky, or if any condition is present that prevents ribbon rotation. Perform the following

procedure:

1. Verify Ribbon Motors are turning. If they are not, check connectors to the Control Board Assy. and the

connections to the motors.

2. Verify Platen Motor is feeding. If is is not, check the connections.

EVALUATION OF A 755 ERROR (PRINTHEAD OPEN)

This error occurs if the printhead is not functioning properly. Perform the following procedure:

1. Ensure the printhead is properly latched.

2. Verify that the magnet is present and inserted properly.

3. Verify that sensor is functioning properly.

EVALUATION OF A 765 ERROR (PRINTHEAD FAILURE)

This error occurs if a dot is out of specification. This error can occur even if print quality is not visibly affected.

Operation can be continued until the problem is corrected. Perform the following procedure:

1. Check connections to the printhead.

2. Check the printhead harness.

3. Check the printhead itself and replace if necessary.

EVALUATION OF THE CONTROL BOARD ASSY.

The following status codes indicate the Control Board Assembly has a fault.

900 RAM Test Failure 905 Illegal Interrupt

901 ROM/EPROM Test Failure 906 Power Failure

902 Timer Failure 907 No Application Memory

903 Interrupt Test Failure 908 NVRAM Checksum Failure

904 No Kernel Memory 910 Warm Restart

1. To determine if this fault is permanent or temporary, turn the printer off, wait 15 seconds then turn the printer on

again. If any of these status codes are repeated, turn off the printer and replace the Control Board Assy.

2. Print a test label. See Test Label (Level 1), in Chapter 4, for instructions on printing a test label.

3. Place the printer in Data Dump mode and send data to the printer.

EVALUATION OF COMMUNICATIONS

If the printer functions properly off-line, examine communications. There are two communication paths for the

printer. The RS-232 serial path uses a 25 position connector. The IEEE-1284 parallel path consists of an external

36 position connector, CN1, and an internal 40 position connector, CN5, that is used to support the Coax/TwinAx

Interface. CN1 also supports an external Ethernet adapter.

14 TC9830SM Rev. B 7/98 Confidential July 1998

Page 24

Troubleshooting 9820/9830/9835 Service Manual

The external Coax/TwinAx Interface is a 15 position connector into which is plugged either a Coax adapter cable or a

TwinAx adapter cable. (All electronic activity for the serial port is limited to the Control Board Assembly. All

electronic activity through CN1 is limited to the Control Board Assy.) There is a small circuit board mounted on the

inside rear printer wall that interconnects the 15 position external connector with the internal CN5. Both CN1 and

CN5 share common PCB electronics.

1. Make sure the printer is plugged in and connected to a host with the proper cables. See Connecting to a Host,

in Chapter 1.

2. Compare host communication values to values reported on the test label. See Test Label (Level 1), in Chapter

4, for instructions on printing a test label.

3. Check printer ports using SENDFILE to send an ENQ.

GENERAL TROUBLESHOOTING SUGGESTIONS

There are a number of printer self-reporting fault detection/fault isolation avenues built into the 9820/9830/9835

printers. Three digit status codes, detailed in Appendix A, all help to pinpoint the problem. In addition, the printer

provides status information in the two test labels, in the SENDFILE service diagnostics tests, and in information

labels printed in response to a FEED command following a status code between 571 through 619.

PROBLEM SUGGESTED ACTION

Printer does not print test labels Check for status code on LCD.

Verify stock is installed correctly.

Verify ribbon is installed correctly.

Verify printer voltage measurements.

Verify printhead is installed correctly.

Verify printhead harness connection is on PCB.

Verify DIP switch settings.

Confirm supply feed operation.

Confirm ribbon feed operation.

Perform sensor display service test using SENDFILE.

Perform test label immediate command.

Replace control panel.

Replace printhead.

Replace Control Board Assy.

Printer only prints test labels Check for status code on LCD.

Verify comm DIP switch settings.

Perform serial /parallel comm test.

Perform data transfer immediate commands.

Transfer format using Windows Terminal.

July 1998 TC9830SM Rev. B 7/98 Confidential 15

Page 25

9820/9830/9835 Service Manual Troubleshooting

PROBLEM SUGGESTED ACTION

Partially printed data Check for status code on LCD.

Verify wide/narrow printhead adjustment.

Perform sensor display service test.

Verify ribbon installed correctly.

Confirm ribbon feed operation.

Clean printhead.

Confirm supply sensor operation.

Send a packet you know has no syntax errors.

Printing shadows or smears Check status code on LCD.

Verify wide/narrow printhead adjustment.

Perform contrast sensor display service test using SENDFILE.

Verify supply installed correctly.

Verify ribbon installed correctly.

Confirm stock feed operation.

Confirm ribbon feed operation.

Clean printhead.

Light printing Check status code on LCD.

Verify wide/narrow printhead adjustment.

Perform contrast sensor display service test using SENDFILE.

Adjust contrast.

Verify ribbon installed correctly.

Confirm ribbon feed operation.

Check platen roller surface.

Clean printhead.

Heavy printing Check status code on LCD.

Perform contrast sensor display service test using SENDFILE.

Adjust contrast.

Verify correct stock/ribbon installed correctly.

Clean printhead.

Voids in printing Check status code on LCD.

Confirm test label printhead operation.

Perform printhead sensor display service test using

SENDFILE.

Replace printhead.

Confirm fault via immediate command service test.

Confirm test label printer config parameters.