Page 1

Monarch

9800 Series

Printers

TC9840OH Rev. A 11/98 ©1998 Monarch Marking Systems, Inc. All rights reserved.

Page 2

Each product and program carries a respective written warranty, the only

warranty on which the customer can rely. Monarch reserves the right to make

changes in the product, the programs, and their availability at any time and

without notice. Although Monarch has made every effort to provide complete

and accurate information in this manual, Monarch shall not be liable for any

omissions or inaccuracies. Any update will be incorporated in a later edition of

this manual.

©1998 Monarch Marking Systems, Inc. All rights reserved. No part of this

publication may be reproduced, transmitted, stored in a retrieval system, or

translated into any language in any form by any means, without the prior

written permission of Monarch Marking Systems, Inc.

WARNING

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

CANADIAN D.O.C. WARNING

This digital apparatus does not exceed the Class A limits for radio noise emissions from

digital apparatus set out in the Radio Interference Regulations of the Canadian Department

of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites

applicables aux appareils numériques de la classe A prescrites dans le Réglement sur le

brouillage radioélectrique édicte par le ministère des Communications du Canada.

Trademarks

MONARCH is a registered trademark of Monarch Marking Systems, Inc.

917, 9403, 9805, 9800, 9820, 9830, 9835, 9840 and 9856 are trademarks of Monarch Marking Systems, Inc.

Paxar is a trademark of Paxar Corporation.

Microsoft and MS-DOS are registered trademarks of Microsoft Corporation.

Windows is a registered trademark of Microsoft in the U.S. and other countries.

Centronics is a registered trademark of Centronics Data Computer Corporation.

TrueType is a trademark of Apple Computer, Inc.

Hewlett-Packard is a registered trademark of Hewlett-Packard Company.

Adobe and Acrobat are trademarks of Adobe Systems Incorporated which may be registered in certain

jurisdictions.

Monarch Marking Systems

P.O. Box 608

Dayton, Ohio 45401

Page 3

Page 4

Page 5

TABLE OF CONTENTS

GETTING STARTED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Unpacking the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Printer Online Emulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

9445

Ordering Programmer’s Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Connecting the Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Establishing Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Connecting the Communication Cable . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Setting DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Using the Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Printer Status Lights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Button Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Status Code Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

LOADING SUPPLIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Loading Labels or Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Using the Optional Tear Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

LOADING RIBBON. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Loading Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Using a High Energy Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

High Energy Ribbon Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

PRINTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

On-Demand Mode Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Printing an Error Label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Clearing Batches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Using Batch Separators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Table of Contents i

Page 6

4-2

Adjusting Print Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Printing the Euro-Dollar Symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

CARE AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Clearing Label Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Replacing the Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Adjusting the Wide/Narrow Knobs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Adjusting the Print Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Replacing the Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Printing a Test Label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Data Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Communication Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Data Formatting Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Machine Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Ribbon Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

SETTING DIP SWITCHES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

ii Table of Contents

Page 7

GETTING STARTED 1

The Monarch® 9840 printer lets you print text, graphics, and bar

codes on thermal transfer (ribbon) and thermal direct labels or

tags. The 9840 printer prints labels continuously (in one strip) or

on-demand (one label at a time).

You can print on die cut, black mark, or continuous supplies.

Continuous supply must be used in continuous mode. See

Appendix A, "Specifications," for more information about the

different supply types. See "Setting DIP Switches," to select your

supply type.

This chapter includes information about

u

unpacking the printer.

u

connecting the power cord.

u

connecting the communications cable.

u

using the printer’s control panel.

Audience

The Operator’s Handbook is for the person who prints and applies labels.

Unpacking the Printer

After you unpack the printer, you should have the 9840 printer, a power

cord, and a ribbon take-up core (may already be on take-up reel).

Keep the box and packaging material in case the printer ever needs repair.

Rev. A 10/98

Getting Started 1-1

Page 8

9445 Printer Online Emulation

The 9840 printer supports 94x5 emulation. You can send 94x5

data streams to the 9840 printer.

Refer to your 9445 Programmer’s Manual for information about

94x5 data streams.

Ordering Programmer’s Manuals

The Packet Reference Manual, which describes how to create

format and batch packets for printing labels, how to configure the

printer online, how to diagnose printer error messages, and how

to perform other advanced techniques can be downloaded from

our web site. You can print this manual or order a hard-copy

version (part number TC9800PM).

Connecting the Power Cable

1. Plug the power cable into the socket. Plug the other end of

the cable into a grounded electrical outlet.

2. Turn on the printer. Press ( I ) to turn on and ( O ) to turn off

the printer.

For information about replacing the fuse, see Chapter 5, "Care

and Maintenance."

Establishing Communications

Before the printer can accept print jobs from the host, you must:

u

Connect the communication cable to the printer and to the

host.

u

Set the communication values on the printer to match those at

the host. (Only required if you are using the serial port.)

u

Make sure the printer is off before connecting the cable to the

communication port.

1-2 Getting Started

Rev. A 10/98

Page 9

Ask your System

Administrator which

method you will use to

communicate with the

host:

Parallel Port

Serial Communication

9 to 25 pin cable

(Part #118364)

Power Cable

goes here

Serial Port

25 to 25 pin cable

(Part #118366)

Parallel Communication

IEEE-1284 or

Centronics® mode cable

(Part #118363) See

"Setting DIP Switches" for

more information.

Connecting the Communication Cable

Connect the communication cable into the appropriate port.

Secure the cable with the connecting screws (serial) or spring

clips (parallel).

If you are communicating with the host through the serial port,

make sure the printer’s communication values match those at the

host. The factory default values are 9600 Baud, 8 bit data frame,

1 stop bit, no parity, and DTR flow control.

The printer supports a baud rate up to 38400.

Make sure your host is capable of

communicating at the speed you select for the

printer.

Rev. A 10/98

Getting Started 1-3

Page 10

Setting DIP Switches

To change the DIP switch settings, move the switches to

the desired position and then turn on the printer.

If you select Software Controlled, the parameters in

Packet F will override the communication settings.

Software Controlled uses the last sent Packet F settings

or the defaults. Turning on the printer activates the DIP

switch settings. Make sure the DIP switch settings

match the printer’s setup for ribbon or supply type.

Upper DIP Switches

12345678

Baud Rate

38400

19200

9600

4800

2400

1200

Software Control

Data Bits

7 Data Bits

8 Data Bits

Stop Bits

2 Stop Bits

1 Stop Bit

Parity

Even

Odd

None

Parallel Port

Centronics Mode

IEEE-1284

ON

ON

ON

OFF

OFF

OFF

OFF

ON

OFF

OFF

ON

ON

OFF

OFF

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

OFF

OFF

ON

OFF

OFF

ON

Communication settings at the printer must match those at the host.

Make sure your host is capable of communicating at the speed you

select for the printer.

1-4 Getting Started

Rev. A 10/98

Page 11

Lower DIP Switches

Flow Control

XON/XOFF

RTS/CTS*

DTR

Diagnostics

Normal

Diagnostics Mode

Verifier

No Verifier

Verifier Installed

Supply Type

Die Cut or Edge Apt.

Black Mark (center)

Continuous

Center Apt.

Ribbon

Transfer

Direct

Feed Mode

Disable On-Demand

Enable On-Demand

* Requires a special cable.

12345678

OFF

ON

ON

OFF

OFF

OFF

OFF

ON

OFF

ON

OFF

OFF

ON

OFF

OFF

ON

ON

ON

OFF

ON

OFF

ON

Rev. A 10/98

Getting Started 1-5

Page 12

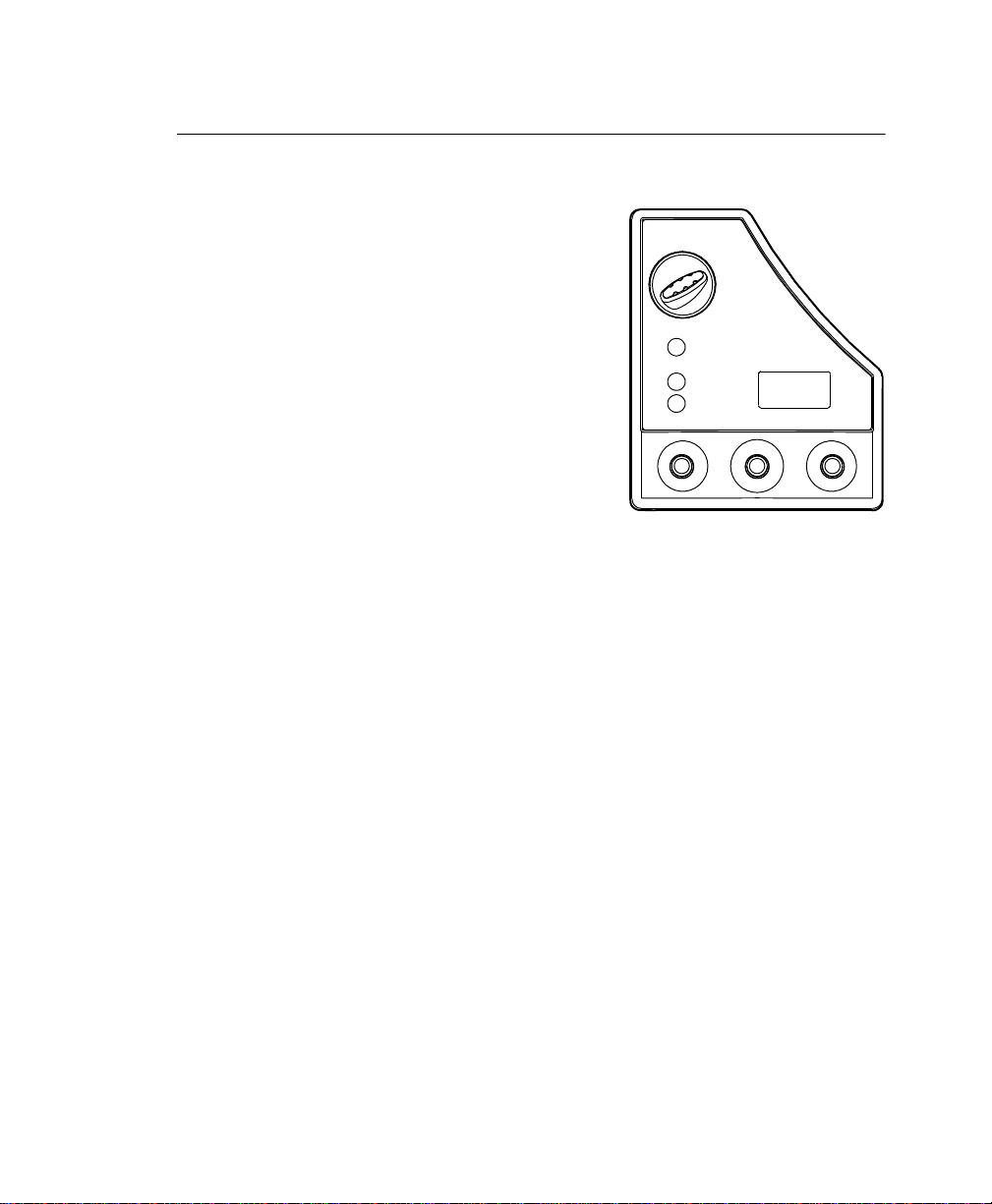

Using the Control Panel

The control panel helps you check printer status, displays error

codes, and allows you to perform some

basic printer functions.

Printer Status Lights

Power: The printer shows

a steady green

light when it is on.

Supplies: The printer shows

a blinking amber

light when it is out

of labels or ribbon,

or when you have a

supply jam.

Paused: The printer shows a steady amber light when

paused.

The printer shows a blinking amber light when

there is a data, communication, or data

formatting error. See the status code box for

the error code.

Printhead

Release

Power

Supplies

Paused

Feed

Status Code

1 2 3

Pause Clear

1-6 Getting Started

The printer also shows a blinking amber light

when it’s ready to print a label in the

on-demand mode. See Chapter 4, "Printing,"

for more information.

Rev. A 10/98

Page 13

Button Functions

Feed:

u

Prints a label in the on-demand mode.

u

Feeds a blank label if there is no print job.

u

Prints a label with error information that is

useful to your System Administrator if an

error is displayed.

u

Cuts the supply when pressed and held for

two seconds if a knife is installed.

Pause: Pauses the current print job or resumes a

paused print job.

Feed and Pause: Prints a test label when you press the buttons

at the same time.

Feed and Clear: Allows you to adjust print positions from

paused mode. See "Adjusting Print

Positions" in Chapter 4 for more information.

u

Clear:

Clears an error.

u

Cancels the current print job.

u

Cancels all queued print jobs if pressed

for two seconds.

To cancel a single or all queued print jobs, the printer must be in

paused mode before Clear is pressed.

Status Code Box

The status code box displays a three-digit error code to identify

any problem the printer may have. For a description of the

problem, look up the error code in Chapter 6, "Troubleshooting."

If there is no error, the display will be blank.

Rev. A 10/98

Getting Started 1-7

Page 14

1-8 Getting Started

Rev. A 10/98

Page 15

LOADING SUPPLIES 2

This chapter describes how to load:

u

a roll of supply

u

fan-fold supply

u

a roll of tag supply.

There are three types of supplies:

Thermal Direct specially treated thermal supplies that do not

use a ribbon for printing.

Thermal Transfer standard supplies that require a ribbon for

printing.

High Energy scratch, chemical, and temperature resistant

supplies that require a ribbon able to

withstand high temperatures. See "Using a

High Energy Ribbon" in Chapter 3 for more

information.

If you are using thermal direct supplies, do not load a ribbon.

If you switch from black mark to die cut supplies, make sure the

DIP switches are set correctly. The System Administrator can also

send the supply setup packet to change the supply type. Refer to

the Packet Reference Manual for more information about sending

the supply setup packet.

Rev. A 10/98

Loading Supplies 2-1

Page 16

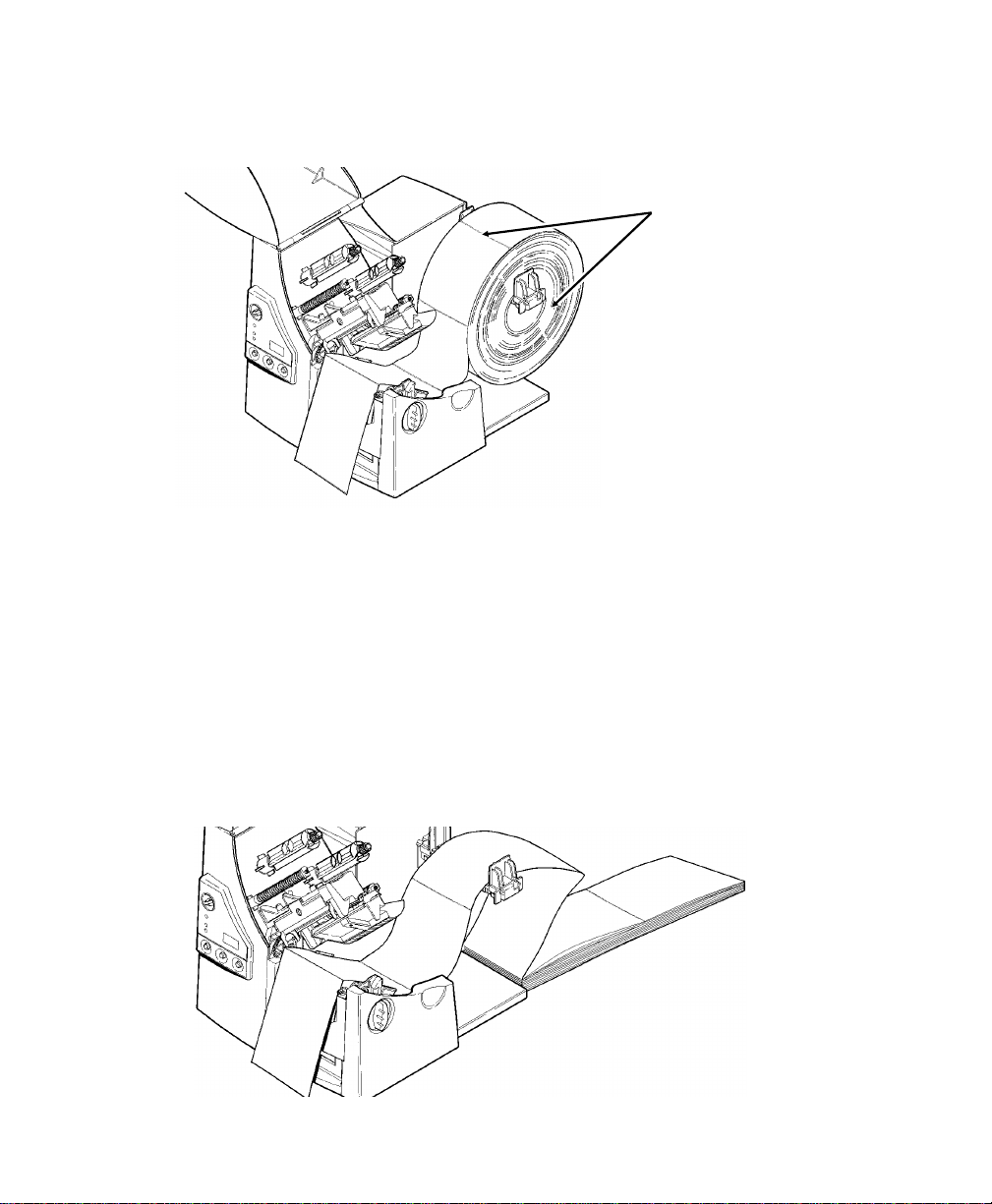

Loading Labels or Tags

Printhead Tab

Deflector Tab

Make sure the printer is configured for the correct supply type.

1. Open the cover.

2. Unlock the printhead by turning the retaining latch.

3. Lift printhead assembly using the printhead tab until the

assembly locks into place.

2-2 Loading Supplies

4. Place the roll of supply on the supply holder. Make sure the

supply unrolls from the top.

Do not pick up the printer

by the supply holder.

Rev. A 10/98

Page 17

5. Adjust the supply holder guides so the sides barely touch the

Supply Holder

Guides

roll. Make sure the supply roll turns freely.

If you are using fan-fold supplies, place the supply stack

behind the printer, label side facing up.

6. Push down on the supply lever to unlock the supply guides.

7. Lay the label strip across the supply guide so that a few

inches extend past the front of the printer. Tuck the supply

under the nibs.

For fan-fold supplies, lay the label strip over the supply

holder and across the supply guide so that a few inches

extend past the front of the printer. Tuck the supply under the

nibs on the supply guide.

Rev. A 10/98

Loading Supplies 2-3

Page 18

For tag supplies using the optional knife, feed the supply

through the knife. Make sure at least 0.5 inches of supply is

past the knife.

Ta g

8. Adjust the supply guides so they touch the supply. Push up

on the supply lever to lock the supply guides into place.

2-4 Loading Supplies

Nibs

Supply Lever

Rev. A 10/98

Page 19

9. Hold the printhead assembly by the printhead tab while

pressing down on the printhead release.

10. Close the printhead by pressing down on the thumb well until

you hear it click into place.

Thumb Well

11. Close the cover.

12. Press Feed to position the supply under the printhead.

Rev. A 10/98

Loading Supplies 2-5

Page 20

You may need to adjust the wide/narrow knobs depending on

the width of your supply. See Chapter 5, "Care and

Maintenance," for more information.

For Peel Mode:

In peel mode, the printer separates the backing paper from the

label. The next label is not printed until the completed one is

removed from the printer. Make sure the printer is configured for

on-demand mode and the correct supply type.

The minimum feed length is 1.5 inches for peel mode. Hold the

leading edge of peeled labels when printing on stock longer than

six inches. You must use non-perforated supplies for peel mode.

Follow the steps for loading supplies from the previous section.

Then, follow these steps after you close the printhead.

1. Remove the labels from the first 10 inches of the backing

paper.

2. Press down on the exit cover tabs to open the exit cover on

the front of the printer.

Exit Cover

2-6 Loading Supplies

Rev. A 10/98

Page 21

3. Feed the backing paper over the peel bar.

Peel Bar

Lower Opening

4. Feed the backing paper through the lower opening of the exit

cover. Close the exit cover. Pull down on the backing paper

to remove any slack.

Tear Edge

Backing Paper

When removing the backing paper, pull up across the

saw-toothed tear edge. Make sure the backing paper tears

at the edge.

Rev. A 10/98

Loading Supplies 2-7

Page 22

5. Close the printer’s cover.

6. Press Feed to position the supply under the printhead.

Using the Optional Tear Bar

Tear labels against the tear bar. You cannot tear tags with the

tear bar. Note the following change to loading labels if you have

purchased the optional tear bar:

Slide the supply between the tear bar and peel bar.

Tear Bar

Peel Bar

Do not tear both label and backing paper at the same time.

u

Tear labels against the tear bar.

u

Tear backing paper against the tear edge.

2-8 Loading Supplies

Tear Edge

Backing Paper

Rev. A 10/98

Page 23

LOADING RIBBON 3

This chapter describes how to load a ribbon roll.

There are different ribbon requirements for the three types of

supplies:

Thermal Direct

Supplies

Thermal Transfer

Supplies

High Energy

Supplies

If you are using thermal direct supplies, do not load a ribbon. If

you are using high energy supply, be sure to use a high energy

ribbon. See "Using a High Energy Ribbon" for more information.

If you want to use a high energy ribbon, you must send the supply

setup packet every time the printer is turned on.

do not use a ribbon for printing.

require a ribbon for printing.

require a ribbon able to withstand high

temperatures.

Rev. A 10/98

Loading Ribbon 3-1

Page 24

Loading Ribbon

Make sure the printer is configured to use a ribbon.

To load ribbon:

1. Open the cover.

2. Unlock the printhead by turning the retaining latch.

3. Lift printhead assembly using the printhead tab until the

assembly locks into place.

Printhead Assembly

Deflector Tab

4. Push the deflector tab down.

5. Slide the extra ribbon core on the take-up reel as far as it will

go with the "Monarch" writing facing out. Use your empty

ribbon core as the take-up core. The take-up core only fits on

the take-up reel one way. (An extra take-up core is available

by ordering part number 117961.) See "Accessories" in

Appendix A for more information.

3-2 Loading Ribbon

Rev. A 10/98

Page 25

6. Remove the new ribbon from the package as shown. Do not

Take -up Reel

wrinkle or crush the new ribbon.

7. Slide the ribbon onto the back reel as far as it will go. The

ribbon roll only fits on the reel one way. Carefully unwind a

few inches of ribbon from the bottom of the roll.

8. Carefully feed the ribbon under both ribbon rollers and

printhead as shown.

9. Align the ribbon and make sure it is straight and centered

throughout the path.

10. Tape the ribbon to the take-up core. Do not tape the ribbon

to the take-up reel.

Rev. A 10/98

Take-up Core

Ribbon Rollers

Loading Ribbon 3-3

Page 26

11. Rotate the take-up core until the leader is past the printhead

and remove any slack in the ribbon by turning the take-up reel

clockwise.

12. Hold the printhead assembly by the printhead tab while

pressing down on the printhead release.

13. Close the printhead by pressing down on the thumb well until

you hear it click into place. Close the cover.

Thumb Well

Using a High Energy Ribbon

High energy ribbon is an option for the 9840 printer. It enables

you to print on high energy (TUFF-MARK®) supplies.

When you select high energy ribbon for the printer setting, you

are setting the printer to a higher printing temperature. Select

this setting only after you have loaded a high energy ribbon and

supply or it may damage your printhead. To select a high energy

ribbon, send the supply setup packet everytime you turn on the

printer.

3-4 Loading Ribbon

Rev. A 10/98

Page 27

The high energy setting is lost when you turn

off the printer.

High Energy Ribbon Limitations

When using the high energy ribbon option:

u

Use a print speed of 2.5IPS (inches per second).

u

Printhead warranty is reduced to 100,000 inches.

u

Serial bar codes cannot be printed.

u

Do not use peel mode.

u

No more than 20% of the supply should have print (black

coverage).

CAUTION

The high energy ribbon may break or stick to the

supply when more than 20% of the supply

contains print.

u

Only white high energy supply should be used for bar code

printing.

u

Reverse fonts cannot be used.

u

A non-printing area of at least .1 inch (2.54 mm) must exist on

the left and right edge of the ribbon.

u

Do not print horizontal lines or bars.

u

Graphics are limited.

Rev. A 10/98

Loading Ribbon 3-5

Page 28

3-6 Loading Ribbon

Rev. A 10/98

Page 29

PRINTING 4

This chapter explains how to

u

use on-demand mode printing.

u

print an error label and batch separators.

u

adjust the print positions.

Printing

The host sends online packets containing print jobs to the printer.

1. Turn on the printer.

2. Download a format and a batch. Refer to the Packet

Reference Manual for information on downloading print jobs.

3. The printer prints a strip of labels.

4. Remove the printed labels.

On-Demand Mode Printing

When the 9840 printer is operating in the on-demand mode, the

next label prints when the previous label is removed from the

printer or when Feed is pressed. The Paused light blinks until all

the labels in the batch are printed.

If you have purchased the optional peel module, you must use

on-demand printing with peel mode. If you are using peel mode,

remove the excess backing paper by pulling up across the

saw-toothed tear edge. Make sure the backing paper tears at the

edge. Hold the leading edge of peeled labels when printing on

stock longer than six inches. The minimum feed length for peel

mode is 1.5 inches. You must use non-perforated supplies for

peel mode.

Rev. A 10/98

Printing 4-1

Page 30

Printing an Error Label

If the printer displays a data error (errors

0-499), press Feed to print an error label

and continue printing. See your System

Administrator about the error label.

Clearing Batches

All batches are cleared when the printer is turned on. You can

also clear all or a single batch by pressing Clear after the printer

is paused. See "Using the Control Panel" in Chapter 1 for more

information.

Using Batch Separators

A batch separator is a striped label that prints in between

batches. For non-indexed supply, the batch separator is always

six inches long. If you have the optional 928 stacker installed,

the batch separator is 3.66 inches long. The name of the batch is

shown on the batch separator.

4-2 Printing

To use batch separators, refer to the Packet Reference Manual.

Rev. A 10/98

Page 31

Adjusting Print Positions

You can adjust the supply, print, margin, or cut positions on the

9840 printer by using the control panel buttons. Make sure a

batch is not waiting to print before you adjust the positions.

To change the supply, print, margin, or cut positions:

1. Press Pause.

2. Press Feed and Clear (at the same time) once to select the

supply position, twice to select the print position, three times

to select the margin position, and four times to select the cut

position. These buttons act as toggle switches between the

four (supply, print, margin, and cut) position adjustments.

When you select the position to change, the

current setting is displayed.

3. Press Feed to decrease the current position by one dot or

press Feed for two seconds to decrease the value by 10 dots.

OR

Press Clear to increase the current position by one dot or

press Clear for two seconds to increase the value by 10 dots.

If the position has a negative value, the

supplies light is on.

After you adjust the position (and release the

buttons), the setting is displayed.

4. Press Pause when you are done making adjustments.

Resend the format so these changes take effect. You

cannot change the settings if the printer is paused while

printing a batch. Change the settings after the batch is

done printing.

Review the following definitions for the different print position

adjustments.

Rev. A 10/98

Printing 4-3

Page 32

Supply Position Adjusts the machine to print at the vertical 0,0

point on the supply. Increase the supply

position to move print up, decrease to move

print down on the label. The range is -300 to

300 dots.

The supply position adjustment should only

be made on inital printer setup. For format

adjustments, change the print position.

Print Position Adjusts where data prints vertically on the

supply. Increase the print position to move

print up, decrease to move print down. The

range is -99 to 99 dots.

Margin Position Adjusts where data prints horizontally on the

supply. Increase the margin position to move

print to the right, decrease to move print to

the left. The range is -99 to 99 dots.

Cut Position Adjusts where the tag is cut. The printer

adjusts the cut position according to the black

marks on the supply. You may need to adjust

the cut position up or down for aperture

supplies. Increase the cut position to move

the cut up, decrease to move the cut down.

The range is -300 to 300 dots.

4-4 Printing

Printing the Euro-Dollar Symbol

You can print the Euro-Dollar symbol (c) online by using ~192

(ASCII) code in the data stream. Your System Administrator can

also select the Euro-Dollar symbol by sending the Monetary

Formatting Packet (packet D). If you have purchased the optional

keypad, you can select Euro-Dollar from the Defaults Monetary

Sign Menu.

Rev. A 10/98

Page 33

Rev. A 10/98

Printing 4-5

Page 34

CARE AND MAINTENANCE 5

This chapter tells you how to

u

clear label jams

u

clean the printhead and platen roller

u

replace a printhead

u

replace a fuse

u

adjust print contrast.

CAUTION

Do not use sharp objects to clean the printhead. This

may damage the printer and void your warranty.

Clearing Label Jams

When you are printing and a jam occurs, the Supplies light on the printer’s

front panel blinks. To clear the jam:

1. Turn off the printer and open the cover and printhead assembly.

2. If necessary, remove the label roll and ribbon.

3. Remove the jammed labels and reload the label roll.

4. Close the printhead assembly and turn on the printer.

5. Press Feed to position the supply under the printhead.

Rev. A 10/98

Care and Maintenance 5-1

Page 35

Cleaning

Platen Roller

The rate and frequency at which you print or how often you

receive supply errors determines how often you must clean the

printer. You may need to clean the printhead, sensor, and platen

roller:

u

if there is any adhesive build-up in

the supply path

u

after printing approximately six rolls of

supply, after using two ribbons, or

whenever you load new supplies

u

daily if your printer is in an excessively

dirty, hot, or humid environment

u

when you see voids in the print as shown.

1. Turn off the printer and open the cover and printhead

assembly.

2. Remove the label roll and ribbon (when cleaning the

printhead).

3. Press down on the exit cover tabs to open the exit cover on

the front of the printer.

4. Moisten a cotton swab with isopropyl alcohol. Turn the platen

5-2 Care and Maintenance

roller with your finger and run the cotton swab across it.

Make sure the platen roller is clean all the way around.

Rev. A 10/98

Page 36

5. Rub the cotton swab across the peel bar, printhead, and

PrintheadPrinthead

supply sensor to remove any build-up.

6. Clean the build-up in the supply path.

7. Let the printer dry before you reload supplies. Close the exit

cover until both latches click into place.

Supply Sensor

8. Close the cover and printhead assembly.

9. Turn on the printer.

10. Press Feed to position the supply under the printhead.

Resend your format, batch, and check digit packets.

Rev. A 10/98

Care and Maintenance 5-3

Page 37

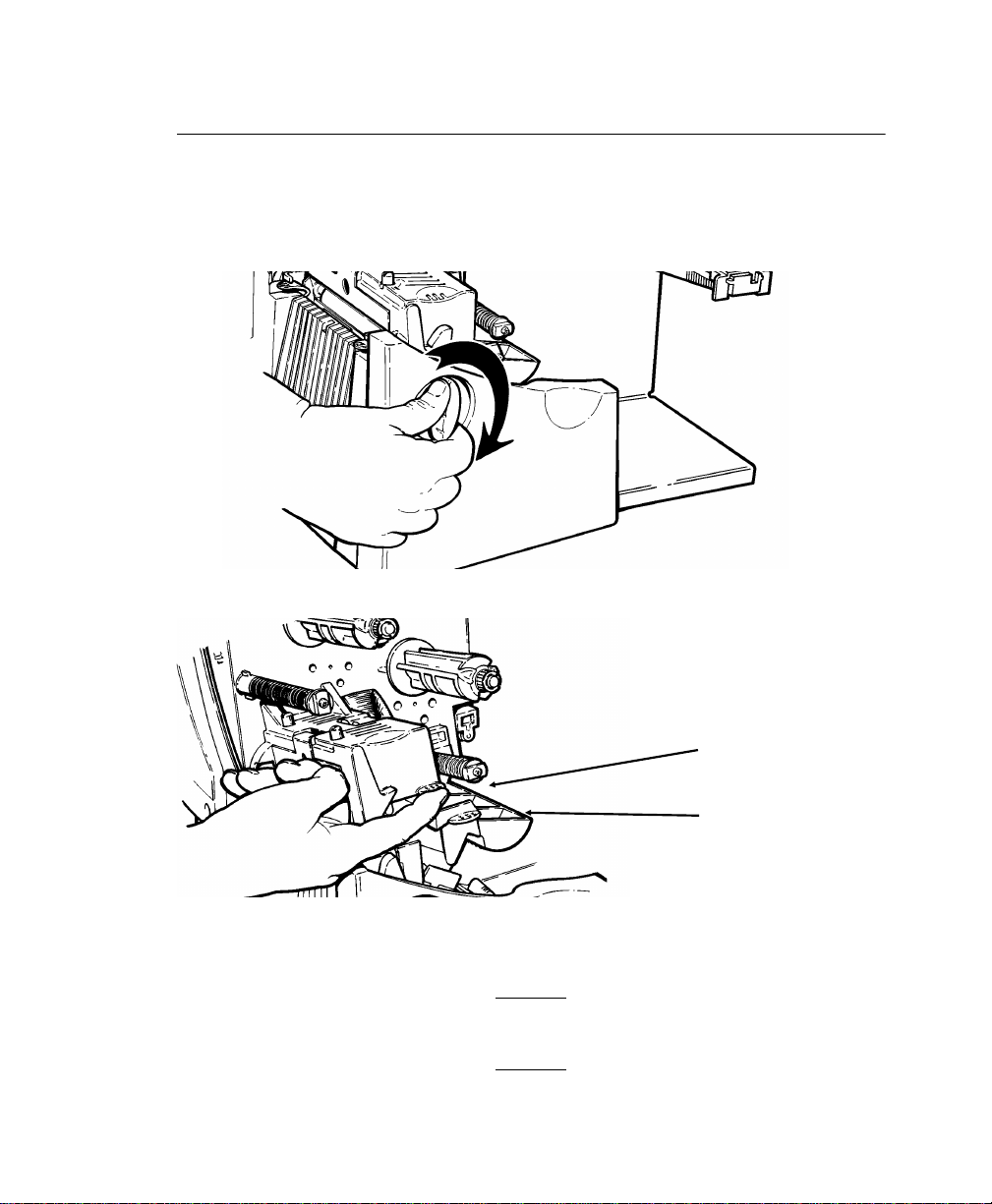

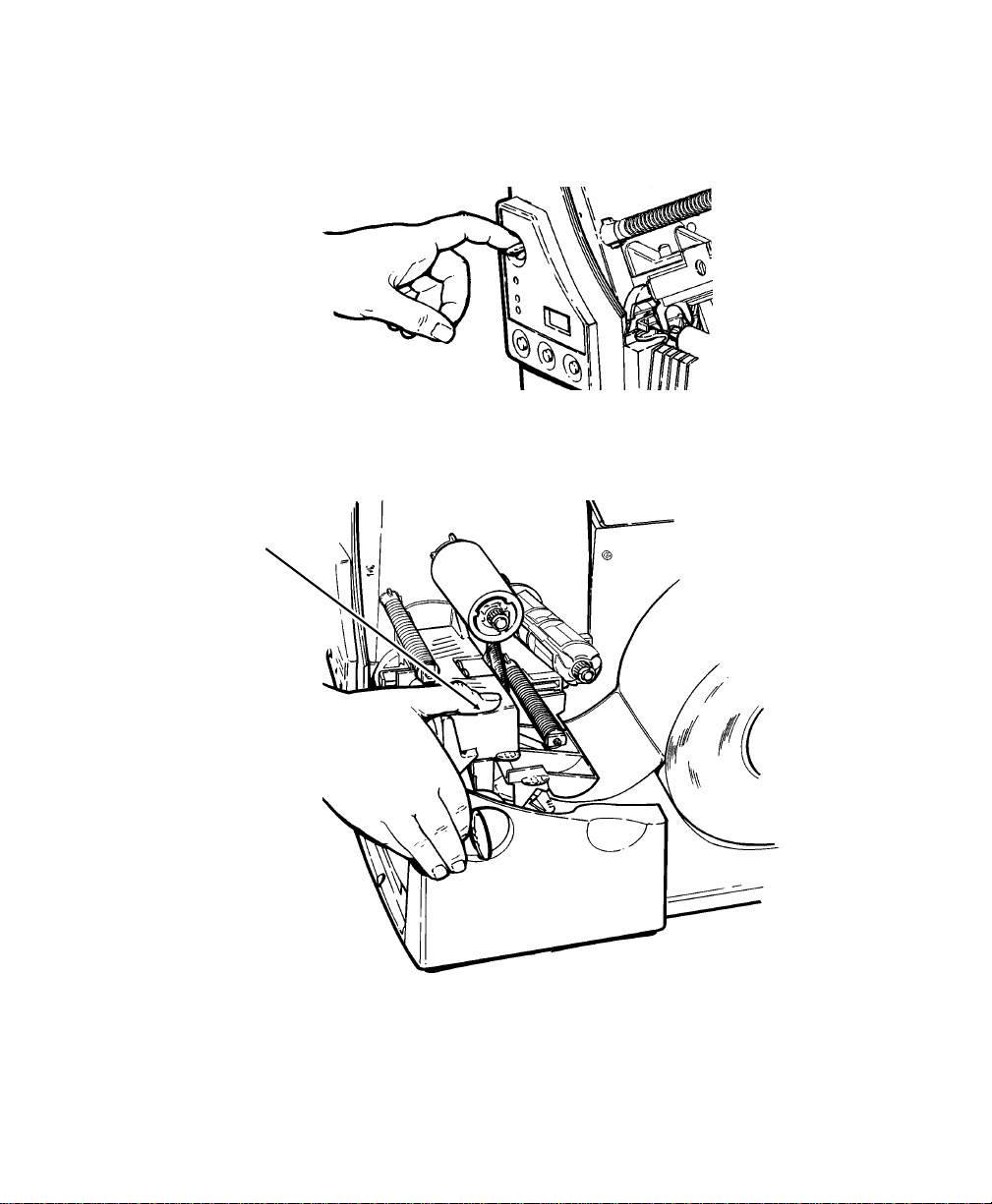

Replacing the Printhead

You may have to replace the printhead if it is damaged or

worn-out. For example, you may see 616 (bad dot or dots) or 765

(printhead failure) error codes. See "Accessories" in Appendix A

for the printhead part number.

CAUTION

The printhead is sensitive to static electricity, which can

damage the printhead or reduce its life. Ground yourself

by touching some metal, such as the printer’s metal base,

before touching the printhead. Clean the printhead to

remove any salt or oil left from handling prior to operation.

To replace the printhead:

1. Turn off the printer.

2. Open the cover.

3. Unlock the printhead by turning the retaining latch.

4. Press forward and down on the two latches on top of the

printhead assembly as shown. The printhead will drop down.

5. Lift the printhead assembly using the printhead tab and push

back until the printhead assembly clicks into place.

5-4 Care and Maintenance

Rev. A 10/98

Page 38

6. Carefully unplug the cable from the printhead as shown. The

printhead is sensitive to static electricity, which can damage

the printhead or reduce its life. Ground yourself by touching

some metal, such as the printer’s metal base, before touching

the printhead.

7. Carefully plug the cable into the new printhead.

8. Align the new printhead with the tabs.

9. Snap the printhead into place.

Do not

touch here

Rev. A 10/98

Care and Maintenance 5-5

Page 39

Make sure the printhead cable does not touch the ribbon roll.

10. Clean the new printhead with a cotton swab dipped in

isopropyl alcohol to remove any salt or oil left from handling.

11. Let the printhead dry and reload your supplies.

12. Close the printhead assembly and the cover. Turn on the

printer.

13. Press Feed to position the supply under the printhead.

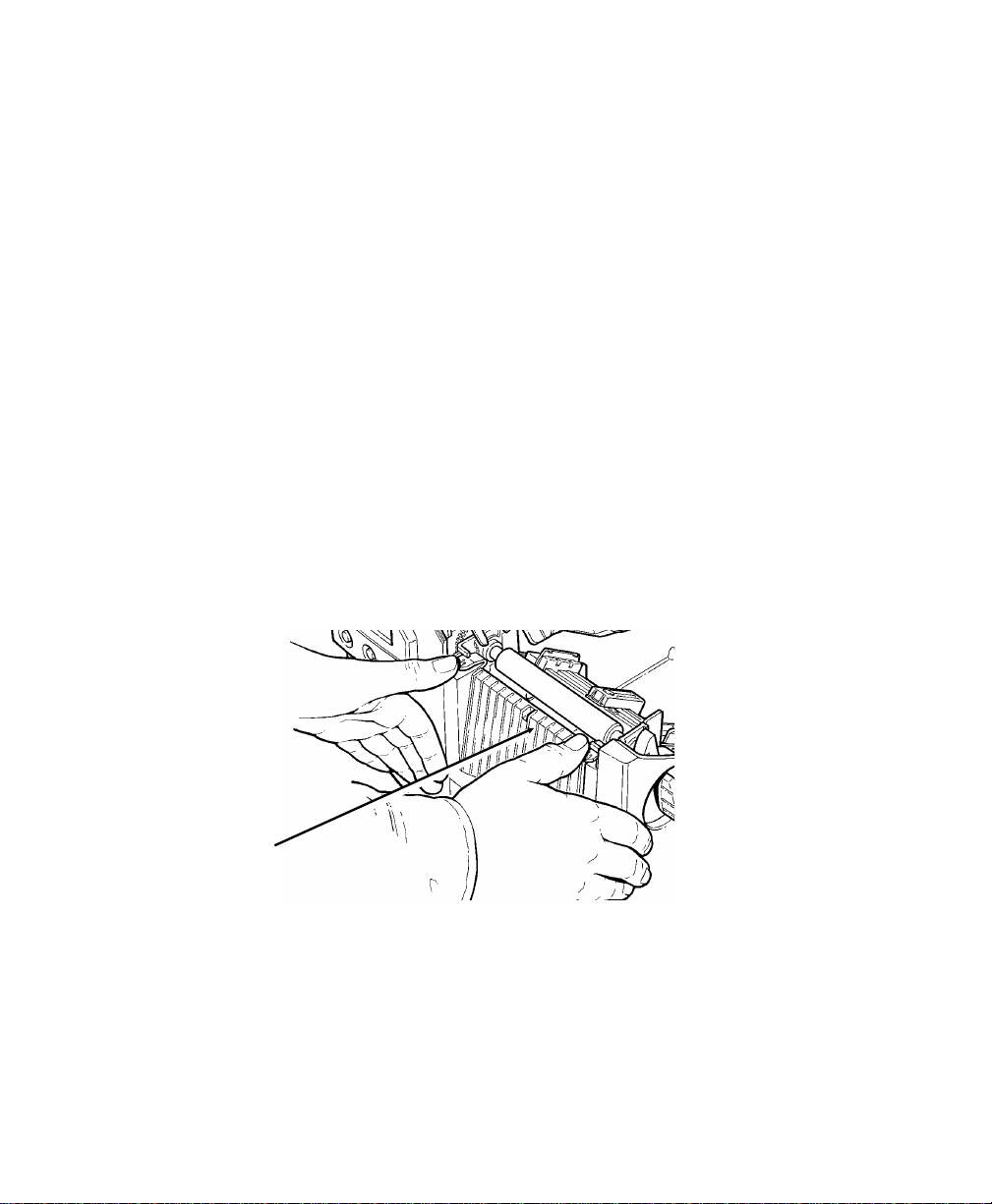

Adjusting the Wide/Narrow Knobs

You may need to adjust the two wide/narrow knobs according to

the width of your supply. For supply that is more than two inches,

adjust the knobs to the wide setting. For supply that is two inches

or less, adjust the knobs to the narrow setting. For wide supplies,

push down and turn the wide/narrow knobs clockwise with a

screwdriver. For narrow supplies, turn the wide/narrow knobs

counter-clockwise with a screwdriver until it pops back up.

You must adjust both of the knobs to the same position.

The adjustment is shown in the wide position.

5-6 Care and Maintenance

Rev. A 10/98

Page 40

Adjusting the Print Contrast

You may need to adjust the print contrast if the printing is too light

or too dark. Having the correct print contrast is important

because it affects how well your bar codes scan and how long

your printhead lasts.

We recommend you check the bar code print

quality with a bar code verifier.

Using a thin screwdriver, turn contrast knob clockwise for darker

print; turn counter-clockwise for lighter print.

Contrast Knob

You only have to turn the contrast

adjuster slightly.

Your System Administrator can adjust the print contrast by

sending the print control packet. See the Packet Reference

Manual for more information.

Rev. A 10/98

Care and Maintenance 5-7

Page 41

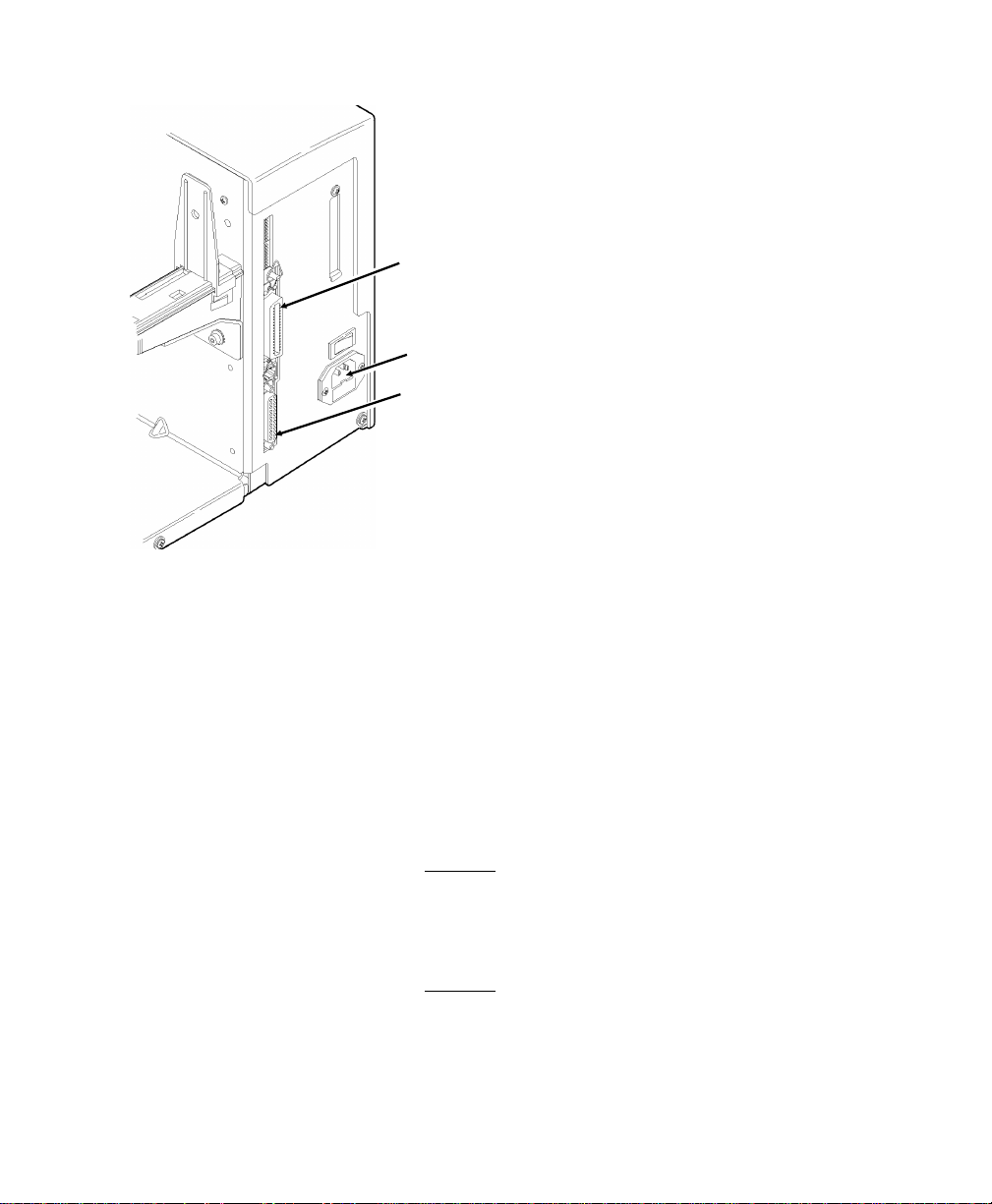

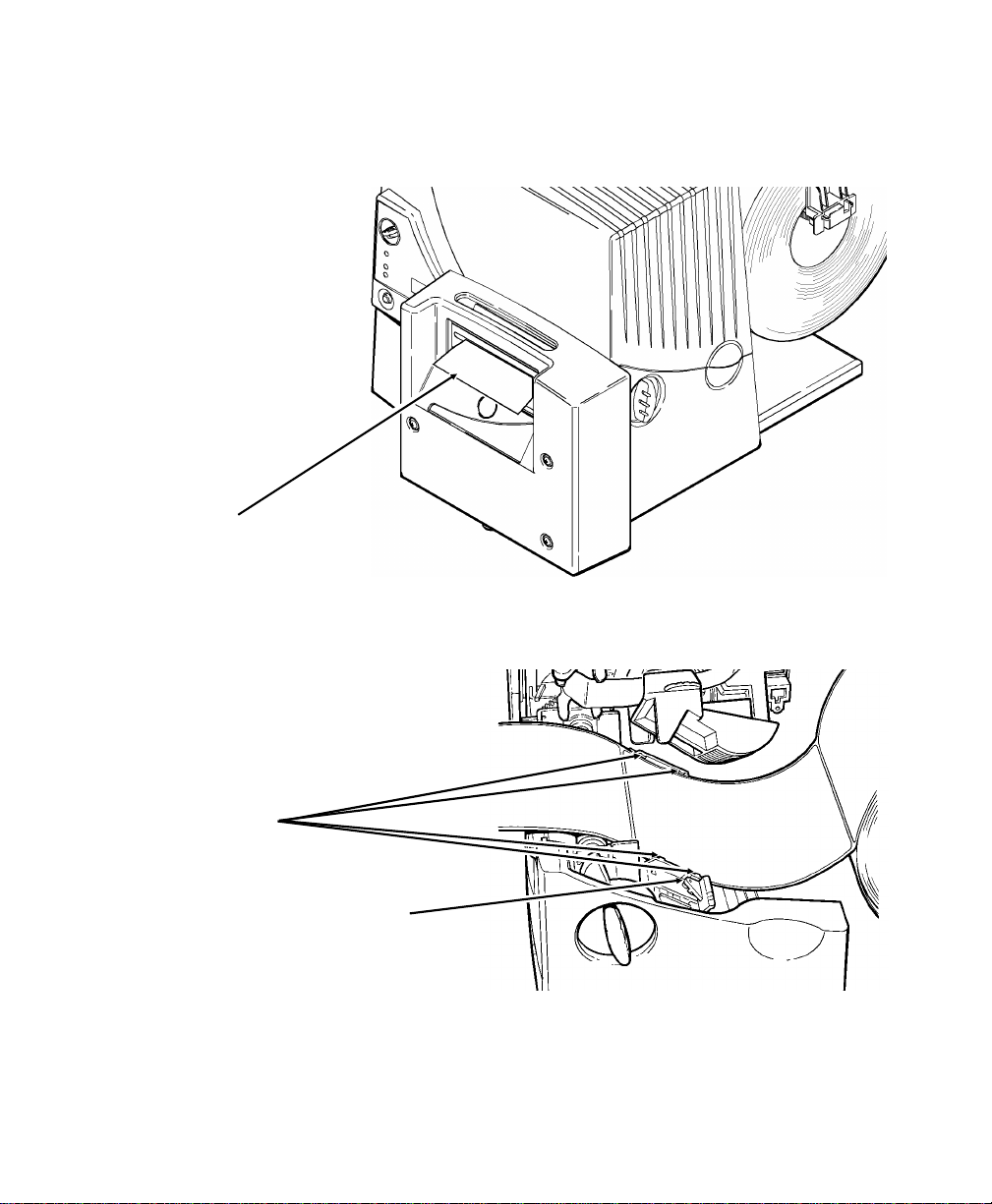

Replacing the Fuse

The printer is shipped with a 115 volt or a 230 volt fuse.

To replace the fuse:

1. Disconnect the printer from the power source.

2. Use a screwdriver to pry open the fuse box in the back of the

printer.

3. Remove the old fuse and insert a new one as shown.

4. Slide the fuse box back into the printer.

5-8 Care and Maintenance

Fuse

Fuse Box

Rev. A 10/98

Page 42

TROUBLESHOOTING 6

This chapter provides

u

information about printing a test label.

u

solutions to minor printing problems.

u

explanations of error messages you may receive while

using the printer.

u

a list of common error messages and their solutions.

Printing a Test Label

Press Feed and Pause simultaneously. Hold for one second and release.

Labels similar to these print:

The first label shows the printer’s configuration by packet (A-G). The

second label shows the model number, software version, stock count,

voltage, print contrast, printhead resistance, number of bad dots, installed

options, and DIP switch settings. The test label also shows an inch count

for the high energy ribbon. If test labels do not print, press Feed and try

again.

Rev. A 10/98

Troubleshooting 6-1

Page 43

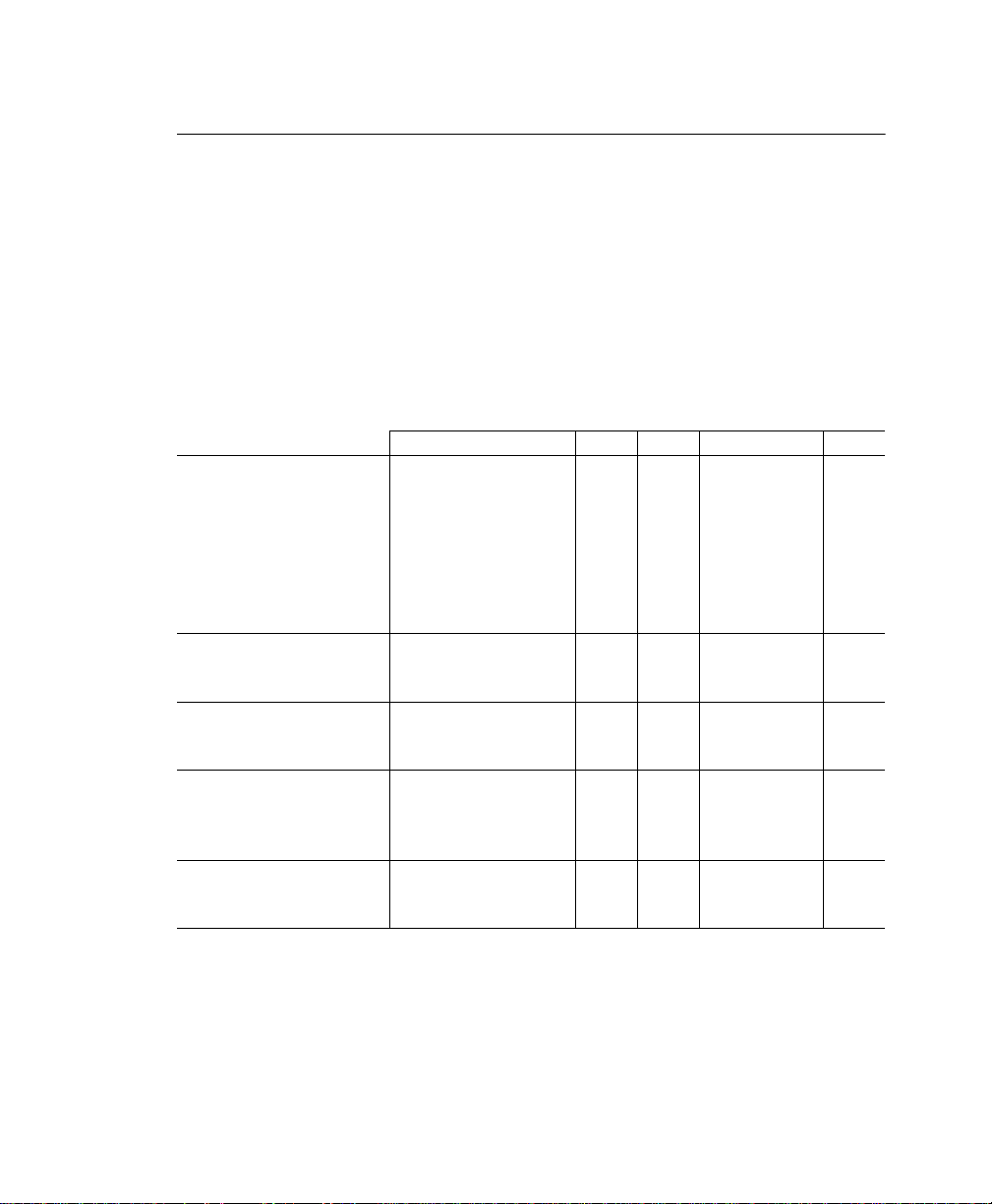

Troubleshooting

This section helps you correct some problems that may occur.

Problem Action

Error message appears

during startup.

Does not print. Check supply.

Does not feed. Set wide/narrow knobs correctly.

Partially printed data. Clean the printhead.

Printing shadows or

smears.

Light printing. Change supply.

Heavy printing. Clean the printhead.

Voids in printing. Clean the printhead.

Serial bar codes do not

scan.

Backing paper is

wrapped around platen

or peel roller.

Turn off the printer, wait fifteen seconds and

then turn on the printer. Call Technical

Support if the error message reappears.

Check ribbon.

Send a corrected format and batch packet.

Send a corrected format packet.

Clean the printhead.

Change supply.

Check ribbon.

Adjust the print contrast.

Check wide/narrow knobs.

Check ribbon.

Change supply.

Adjust the print contrast.

Check wide/narrow knobs.

Check ribbon.

Change supply type.

Check ribbon.

Use a print speed of 2.5 IPS.

Adjust the print contrast.

Carefully remove the backing paper. Make

sure the backing paper tears at the

saw-toothed tear edge when using backfeed

and peel mode.

If you cannot fix a problem, call Technical Support.

6-2 Troubleshooting

Rev. A 10/98

Page 44

Error Messages

You may receive the following types of error messages:

u

Data Errors

u

Communication Errors

Some errors numbered 400-438 and 500-574 are internal

software errors. Errors numbered 900-999 are hard printer

failures. If you cannot clear an error, turn off the printer, wait

several seconds and then turn on the printer. Call Technical

Support if you receive any error message not listed in this chapter.

Data Errors

Errors 001 to 405 and 429 to 435 are data errors. This type of

error indicates that incorrect data was sent to the printer, and the

printer is ignoring it. Your System Administrator should correct

the packet and send it back to the printer.

Error Description/Action

001 Format ID number must be 1 to 999.

002 Name must be 1 to 8 characters inside quotes.

003 Action must be A (add) or C (clear).

004 Supply length is invalid.

005 Supply width is invalid.

006 Storage device must be R (volatile RAM).

007 Unit of measure must be E (English), M (Metric), or G

(Dots).

010 Field ID number is outside the range 0 to 999.

011 Field length exceeds 2710.

Rev. A 10/98

Troubleshooting 6-3

Page 45

012 Row field position is greater than the maximum stock

dimension.

013 Column field position is greater than the maximum stock

dimension.

014 Font selector is invalid.

015 Character rotation must be 0 (0 degree), 1 (90 degree),

2 (180 degree), or 3 (270 degree).

016 Field rotation must be 0 (0 degree), 1 (90 degree), 2

(180 degree), or 3 (270 degree).

017 Field restriction must be V (variable) or F (fixed).

018 Code page selection defined in the field must be 0

(Internal), 1 (ANSI), 2 (DOS 437), or 3 (DOS 850).

020 Vertical magnification must be 1 to 7.

021 Horizontal magnification must be 1 to 7.

022 Color must be B, D, O, R, or W.

023 Intercharacter gap must be 0 to 99 dots.

024 Field justification must be B (balanced), C (centered), E

025 Data length is too long.

030 Bar code height must be at least 20 (English), 51

031 Human readable option must be 0, 1, 5, 6, 7, or 8.

032 Bar code type is invalid.

033 Bar code density is invalid.

040 Line thickness must be 0 to 99 dots.

6-4 Troubleshooting

(end), L (left), or R (right).

(Metric), 40 (Dots), or is not within the supply

dimensions.

Rev. A 10/98

Page 46

041 Line direction must be 0, 90, 180, or 270.

042 The line segment or box end row is defined outside of

printable area.

043 The line segment or box end column is defined outside

of printable area.

044 Dot pattern for line or box must be "".

045 Line length is defined beyond the maximum length.

046 Line type must be S (segment) or V (vector).

051 Imaging mode in the graphic header must be 0.

101 Format referenced by batch not in memory.

102 Print quantity is outside the range 0 to 32000.

104 Batch mode must be N (new) or U (update).

105 Batch separator must be 0 (Off) or 1 (On) in the batch

control field.

106 Print multiple is outside the range 1 to 999.

107 Cut multiple is outside the range 0 to 999.

108 Multiple part supply is outside the range 1 to 5.

109 Reserved for knife usage.

200 Option number must be 1, 4, 30, 31, 42, 50, 60, or 61.

201 Copy length is outside the range 0 to 2710.

202 Copy start position must be 1 to 2710.

203 Destination start position must be 1 to 2710.

204 Source field must be 0 to 999.

Rev. A 10/98

Troubleshooting 6-5

Page 47

205 Copy type must be 1 (Copy after rules) or 2 (Copy

before rules).

206 Increment/Decrement selection must be I (increment) or

D (decrement).

207 Incrementing start position must be 0 to 2710.

208 Incrementing end position must be 0 to 2710.

209 The incrementing amount must be 0 to 999.

210 Security value for a PDF417 bar code must be 0 to 8.

211 Narrow element value is less than 1 or greater than 99.

212 Wide element value is less than 1 or greater than 99.

213 Dimension must be 1 to 30 for a column or 3 to 90 for a

row.

214 Truncation code must be S (standard) or T (truncated

bar code).

215 Aspect code must be C (columns) or R (rows).

216 Option definition must be S (set) or T (template).

217 Input device must be D (Default), H (Host), K

218 Pad direction must be L (from left) or R (from right).

219 Pad character is outside the range 0 to 255.

220 Check digit selection must be G to generate check digit.

221 Primary or secondary price format is outside the range

222 Data type restriction is outside the range of 1 to 6.

223 Option is not valid for the field.

6-6 Troubleshooting

(Keyboard), N (None), or S (Scanner).

1 to 15.

Rev. A 10/98

Page 48

224 Bar code Intercharacter gap must be 0 to 99 in printer

dots.

251 Power up mode must be 0 (online) or 1 (offline).

252 Language selection must be 0 (English).

253 Batch separator code must be 0 (off) or 1 (on) in the

system setup packet.

254 Slash zero selection must be 0 (standard zero) or 1

(slash zero).

255 Supply type must be 0 (black mark) or 1 (die cut).

256 Ribbon selection must be 0 (direct) or 1 (transfer).

257 Feed mode must be 0 (continuous) or 1 (on-demand).

258 Supply position is outside the range.

259 Contrast adjustment must be -390 to 156 dots.

260 Print adjustment must be -99 to 99 dots.

261 Margin adjustment must be -99 to 99 dots.

262 Speed adjustment is invalid.

263 Primary monetary symbol is invalid.

264 Secondary symbol selection must be 0 (none) or 1

(print secondary sign).

265 Monetary decimal places must be 0 to 3.

266 Character string length in Packet E must be 5 (MPCL

control characters) or 7 (ENQ/IMD command character).

267 Baud rate selection must be 0 (1200), 1 (2400), 2

(4800), 3 (9600), 4 (19.2), or 5 (38.4).

268 Word length selection must be 0 (7 bits) or 1 (8 bits).

Rev. A 10/98

Troubleshooting 6-7

Page 49

269 Stop bits selection must be 0 (1 bit) or 1 (2 bits).

270 Parity selection must be 0 (none), 1 (odd), or 2 (even).

271 Flow control selection must be 0 (none), 1 (DTR/DSR),

2 (CTS/RTS), or 3 (XON/XOFF).

272 Internal code page selection must be 0 (Internal), 1

(ANSI), 2 (DOS 437), or 3 (DOS 850).

273 Cut adjustment must be -300 to 300 dots.

282 RS232 Trailer string is too long. Use a maximum of 3

characters.

283 ENQ Trailer string is too long. Use a maximum of 3

characters.

284 The buffer type must be T (transmit), R (receive), I

(image), F (format, batch data, and graphics), D

(downloadable fonts), or V (vector/scalable fonts).

285 The storage device type must be N (non-volatile RAM)

or R (volatile RAM).

286 The buffer size is invalid.

287 The printhead width is invalid.

290 Action must be 0 (disable) or 1 (enable) for Backfeed

291 Dispense position must be 50 to 200 dots and/or the

292 Backfeed distance must be 10 to 200 dots.

310 Check digit scheme number must be 1 to 10.

311 Modulus must be 2 to 11.

314 Check digit algorithm must be D (sum of digits) or P

6-8 Troubleshooting

Control.

backfeed distance is greater than the dispense position.

(sum of products).

Rev. A 10/98

Page 50

325 Duplicating direction must be 0 or 1.

327 Amount of row adjustment must be 0 to 999.

328 Duplicate count must be 0 to 999.

340 Bitmap line encoding must be H (Hex) or R (Run length).

350 Font selector must be 1 to 9999.

351 Font data length must be 68 to 16384.

352 Insufficient font memory is available for the downloaded

font.

380 Job request is outside the range 0 to 4.

400 Invalid character following {.

401 Internal software failure. Call Technical Support.

402 Field separator is not in the expected location.

403 Field separator was not found.

404 The number or string that is currently being processed

is too long.

405 Too many fields exist in the format.

Communication Failures

Errors 409 to 413 usually indicate a communication failure.

These errors happen when the host and the printer cannot

communicate. Ask your System Administrator for help.

Error Description/Action

409 Printer memory is full.

410 Parity mismatch.

Rev. A 10/98

Troubleshooting 6-9

Page 51

411 Framing error (baud rate mismatch).

412 Flow control mismatch.

413 Receive buffer is full. Check flow control settings.

414 Internal keyboard buffer is full or you need a new

keypad.

427 Format name must be 1 to 8 characters inside quotes or

a printer-assigned name ("").

428 Batch name is invalid or graphic not found.

429 A field number appears more than once in a format.

430 The format uses a graphic file that cannot be found.

433 The batch references a field number that does not exist

in the format.

497 Error occurred during the parallel port loop back test.

499 Error occurred during the serial port loop back test.

Data Formatting Errors

Errors 571 to 618 are data formatting errors. This type of error

happens when a field prints incorrectly. Your System

Administrator can correct the format, batch, or graphic packet and

send the print job again. For errors 571 to 614, the printer will

still print, but the data may be incomplete, missing, or wrong.

Error Description/Action

571 UPC or EAN bar code data length in the batch doesn’t

572 Batch data doesn’t fit the format, the field contains

6-10 Troubleshooting

fit the format.

blanks, or data mismatch.

Rev. A 10/98

Page 52

573 Batch data in price field doesn’t fit the format or the

field contains blanks.

574 Batch data in check digit scheme doesn’t fit the format,

or, the field contains blanks.

575 The graphic included in your format could not be found.

600 Imaging error because the batch was refused.

601 An error occurred while the batch was imaging.

602 The batch was not found during imaging.

611 Font, bar code, or density in the batch doesn’t fit the

format.

612 Batch data is missing or doesn’t match the format.

613 Reference point off tag.

614 Portion of field off tag.

615 Bar code width is greater than 16 inches, or keywords

on PDF 417 bar code exceed 928.

616 A bad dot falls on a bar code and the dot cannot be

shifted. Call Customer Service to order a new

printhead or printhead kit.

618 Magnification must be 1 to 7.

Machine Faults

Errors 700 to 765 happen when there is a problem with the printer.

Error Description/Action

700 An error is pending, and the printer cannot continue

with the batch.

Rev. A 10/98

Troubleshooting 6-11

Page 53

701 Printer received a command that it cannot execute

while it is running.

702 Check your printer’s SETUP settings.

703 The printer sensed a calibration of different-sized black

marks.

704 Printer didn’t detect a sense mark within the maximum

feed length or is out of supplies. Check or load

supplies.

705 Invalid batch received.

750 Printhead is overheated, turn off the printer to let it cool.

751 Printer didn’t detect a sense mark when expected.

752 Printer detected a sense mark in the wrong place.

753 Printer detected a sense mark that is too long.

754 Out of ribbon or ribbon jam. Check or load ribbon.

Remove any slack in the ribbon by turning the take-up

reel clockwise.

755 Printhead is open. Close the printhead.

756 Out of supplies. Load supplies.

757 Reload supplies (supply length mismatch).

758 The supply was not seen or the on-demand sensor is

759 Knife is not moving. Call Technical Support.

760 Knife jam. Remove any jammed tags from the knife.

6-12 Troubleshooting

not working correctly. Check for a supply jam, clear the

supply path, or reload supplies. This error may occur if

you remove a label too quickly in the on-demand mode.

The printer does not recalibrate after this error.

Call Technical Support.

Rev. A 10/98

Page 54

761 Stacker is full or jammed. Empty the stacker or clear

the jam before continuing. The printer does not

recalibrate after this error.

762 Low battery. Recharge the battery.

763 Waiting to dispense label. Press Feed.

764 Verifier failure. Press Clear to clear the error and

continue printing. A blank label feeds and the last label

reprints.

765 Printhead failure. Call Customer Service to order a new

printhead or printhead kit.

768 Printhead has more than 10 bad dots or is not

connected. Make sure the printhead is connected. If

necessary, call Customer Service to order a new

printhead or printhead kit.

770 The print motor is not ready. Call Technical Support.

771 The format specified by the application was not found.

Reload your application and format and try again.

790 The printer is busy. Wait until the printer is idle (not

receiving data or no batch waiting to print) before you

send any packets. This error may occur when you try

to print a test label if the printer is busy.

791 The printer has an error pending. Turn off the printer.

Wait 15 seconds and turn it back on. Resend the

packets.

792 The printer is not initialized. Call Technical Support.

793 The printer job queue is full. Turn off the printer. Wait

15 seconds and turn it back on. Resend the packets.

Errors numbered 900-999 are hard printer failures. Call Service if

you receive these messages.

Rev. A 10/98

Troubleshooting 6-13

Page 55

6-14 Troubleshooting

Rev. A 10/98

Page 56

SPECIFICATIONS A

Printer

Height: 12.5 inches (318 mm)

Width: 12 inches (305 mm)

Depth: 13 inches (330 mm)

Weight: 30 lb. (13.4 kg)

Shipping Weight: 34 lb. (15.4 kg)

Power: 115 Vac, 60Hz, 100 Vac, 50/60 Hz, 230 Vac, 50Hz

Operating Limits: For Thermal Transfer (ribbon) 40° to 95° F

(4° to 35° C)

For Thermal Direct 40° to 104° F

(4° to 40° C)

Printhead: Thermal at 4 inches (102 mm) wide

203 dpi (8.0 dots per mm)

Printing Method: Thermal Transfer (ribbon) or Thermal Direct

Supplies

For high temperature or high humidity environments, contact Monarch for

supply recommendations. Continuous supply does not have perforations or

black marks and must be used in continuous mode.

Supply Types: Thermal Transfer or Direct

Supply Widths: 1.2 inches (31 mm) minimum

4.25 inches (108 mm) maximum

Supply Lengths: .75 inch (19 mm) minimum

16.0 inches (406 mm) maximum

Rev. A 10/98

Specifications A-1

Page 57

Ribbon Specification

Do not leave ribbon in sunlight, high temperatures or humidity.

Print Speed: 2.5 IPS (64 mm) for all serial bar codes

2.5 IPS (64 mm), 4.0 IPS (102 mm), or 6.0

IPS (152 mm) for other operations

We recommend a print speed of 2.5 IPS for

labels less than two inches long using

backfeed or on-demand mode printing.

Ribbon Type: Standard or High Energy

Ribbon Widths: 1.3 inches (33 mm)

1.6 inches (41 mm)

2.16 inches (55 mm)

3.15 inches (80 mm)

4.13 inches (105 mm)

Ribbon Length: 23,600 inches (600 meters)

Accessories

u

Internal TwinAx/CoAx Protocol Converter Part # 117532

u

LAN Print Server RJ-45 Connector (10BaseT) Part # 11753101

BNC Connector (10Base2) Part # 11753102

u

Printhead Assembly Kit Part # 117971

u

Ribbon Take-up Core Part # 117961-20, -30, or -40 (available

in two, three, or four inches)

u

High Energy Ribbon

u

917 Keypad, 926 Knife, or 928 Stacker

u

Peel mode with on-demand sensor

u

Te a r B a r

u

Metal Cover

You can use either the optional knife or peel mode, but not both.

A-2 Specifications

Rev. A 10/98

Page 58

Rev. A 10/98

Specifications A-3

Page 59

SETTING DIP SWITCHES B

To change the DIP switch settings, move the switches to the

desired position and then turn on the printer.

Upper Dip

Switches

Lower Dip

Switches

1=ON, 0=OFF

If you select Software Controlled, the parameters in Packet F will

override the communication settings. Software Controlled uses

the last sent Packet F settings or the defaults. Turning on the

printer activates the DIP switch settings. Make sure the DIP

switch settings match the printer’s setup for ribbon or supply type.

Rev. 12/97

Setting Dip Switches B-1

Page 60

DIP Switches

Upper DIP Switches

Baud Rate

38400

19200

9600

4800

2400

1200

Software Control

Data Bits

7 Data Bits

8 Data Bits

Stop Bits

2 Stop Bits

1 Stop Bit

Parity

Even

Odd

None

Parallel Port

Centronics Mode

IEEE-1284

12345678

1

1

1

0

0

0

0

1

0

0

1

1

0

0

0

1

0

1

0

1

0

1

0

1

0

1

0

0

0

1

0

0

1

B-2 Setting Dip Switches

Rev. 12/97

Page 61

Lower DIP Switches

12345678

Flow Control

XON/XOFF

RTS/CTS*

DTR

Diagnostics

Normal

Diagnostics Mode

Verifier

No Verifier

Verifier Installed

Supply Type

Continuous

Die Cut

Black Mark

Ribbon

Transfer

Direct

Feed Mode

Disable On-Demand

Enable On-Demand

* Requires a special cable.

1

0

0

0

1

0

0

1

0

1

1

0

0

0

0

1

0

1

0

1

Rev. 12/97

Setting Dip Switches B-3

Page 62

B-4 Setting Dip Switches

Rev. 12/97

Page 63

Page 64

www.monarch.com

Loading...

Loading...