Page 1

IMPORTANT INSTRUCTIONS TO THE INSTALLER:

PLEASE READ THESE INSTRUCTIONS, FILL IN THE BLANKS BELOW,

THEN PROVIDE THE INSTRUCTIONS TO THE USER BY SECURELY

TAPING THEM TO THE FLOW HANDLE OR THE ESCUTCHEON.

WARNING: Risk of scalding

Varying the calibration of this thermostatic valve to increase water

temperature increases the risk of injury from scalding. The installer is

responsible for installing the valve and any recalibration of the water

temperature in accordance with the instructions.

CAUTION: Danger of scald injury. Valve can be recalibrated to

provide higher temperature water.

This valve has been preset at the factory to provide a range of water

temperatures. Any change in settings or water inlet conditions from

those used during calibration at the factory may raise the outlet

temperature and may cause scalding. The responsibility for the

proper installation and any recalibration of this valve lies with the

installer.

TWO HANDLE THERMOSTATIC TUB/SHOWER FAUCET

T3428, T3428CP, T3428CPM, T3428STV, T3428NLBL, T3428CGPC,

T3428CGSA, T3429, T3429CP, T3429CPM, T3429STV, 3429NLBL,

T3429CGPC, T3429CGSA, T3431, T3431CP, T3431CPM, T3431STV,

T3431NLBL, T3431CGC, T3134CGSA

ENGLISH

INS235A

THIS THERMOSTATIC VALVE HAS BEEN PRESET

BY

OF

TO A MAXIMUM WATER DISCHARGE TEMPERATURE OF

______ºF. ANY CHANGE TO THIS SETTING MAY RAISE THE

DISCHARGE TEMPERATURE AND COULD CAUSE SCALDING.

DATE:__________

!

Complies with: ASME A112.18.1M, CSA B125, & ASSE 1016

Page 2

1

For Safety and ease of faucet installation, Moen recommends

the use of these helpful tools.

Para la seguridad y facilidad de instalacion de la

mezcladora, Moen recomienda las siguientes herramientas.

Par mesure de sécurité et pour faciliter l’installation, Moen

suggère l’utilisation des outils suivants.

SAFETY GLASSES

HELPFUL TOOLS HERRAMIENTAS UTILES OUTILS UTILES

Questions During

Installation?

1-800-BUY-MOEN

(1-800-289-6636)

Toronto 905-829-3400

Rest of Canada

1-800-465-6130

¿Preguntas durante la

instalación?

1-800-BUY-MOEN

(1-800-289-6636)

Toronto 905-829-3400

Resto del Canadá

1-800-465-6130

Des questions lors de

l’installation?

Toronto :

(905) 829-3400

Ailleurs au Canada :

1 800 465-6130

GAFAS DE SEGURIDAD

LUNETTES DE SÉCURITÉ

FLASHLIGHT

LINTERNA

LAMPE DE POCHE

HEX WRENCH

LLAVE HEXAGONAL

CLÉ HEXAGONALE

PHILLIPS SCREWDRIVER

DESTORNILLADOR DE ESTRELLA

TOURNEVIS À POINTE CRUCIFORME

TEFLON TAPE

CINTA DE TEFLON

RUBAN TÉFLON

MASILLA DE PLOMERO

MASTIC DE PLOMBIER

PIPE WRENCH

LLAVE DE TUBO

CLÉ DE LAVABO

PLUMBER'S PUTTY

Page 3

2

1

2

3

4

5

8

7

ENGLISH

FRANÇAIS

ESPAÑOL

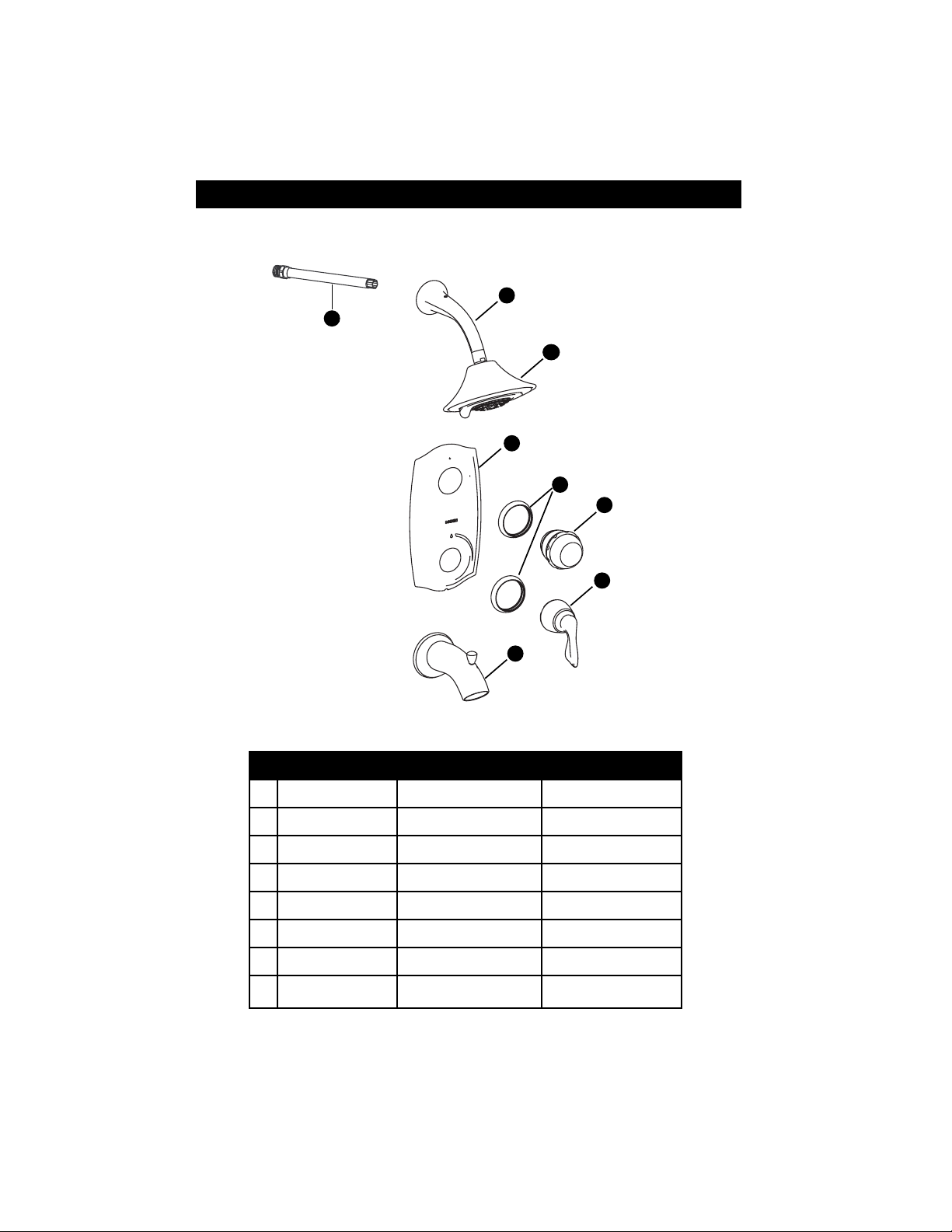

1

Showerhead

Pomme de douche

Cebolleta

2

Arm

Bras de douche

Brazo

3

Shower Arm Adapter

Adapteur de bras de douche

Adaptador el brazo de la regadera

4

Escutcheon

Rosace de base

Chapetón

5

Ring Escutcheon

Rosace d'anneau

Chapetón en anillo

6

Temperature Knob

Bouton de temperature

Perilla de temperatura

7

Flow Knob

Bouton de débit

Perilla de flujo

8

Tub Spout

Bec de la baignoire

Pico de salida de la bañera

PARTS DIAGRAM DESCRIPTIÓN DE PIEZAS TABLEAU DES PIÈCES

6

Page 4

INSTALLATION INSTRUCTIONS

2

3

/4 - 3 3/4"

Lookout Pipe

Finished Wall

8

3

2

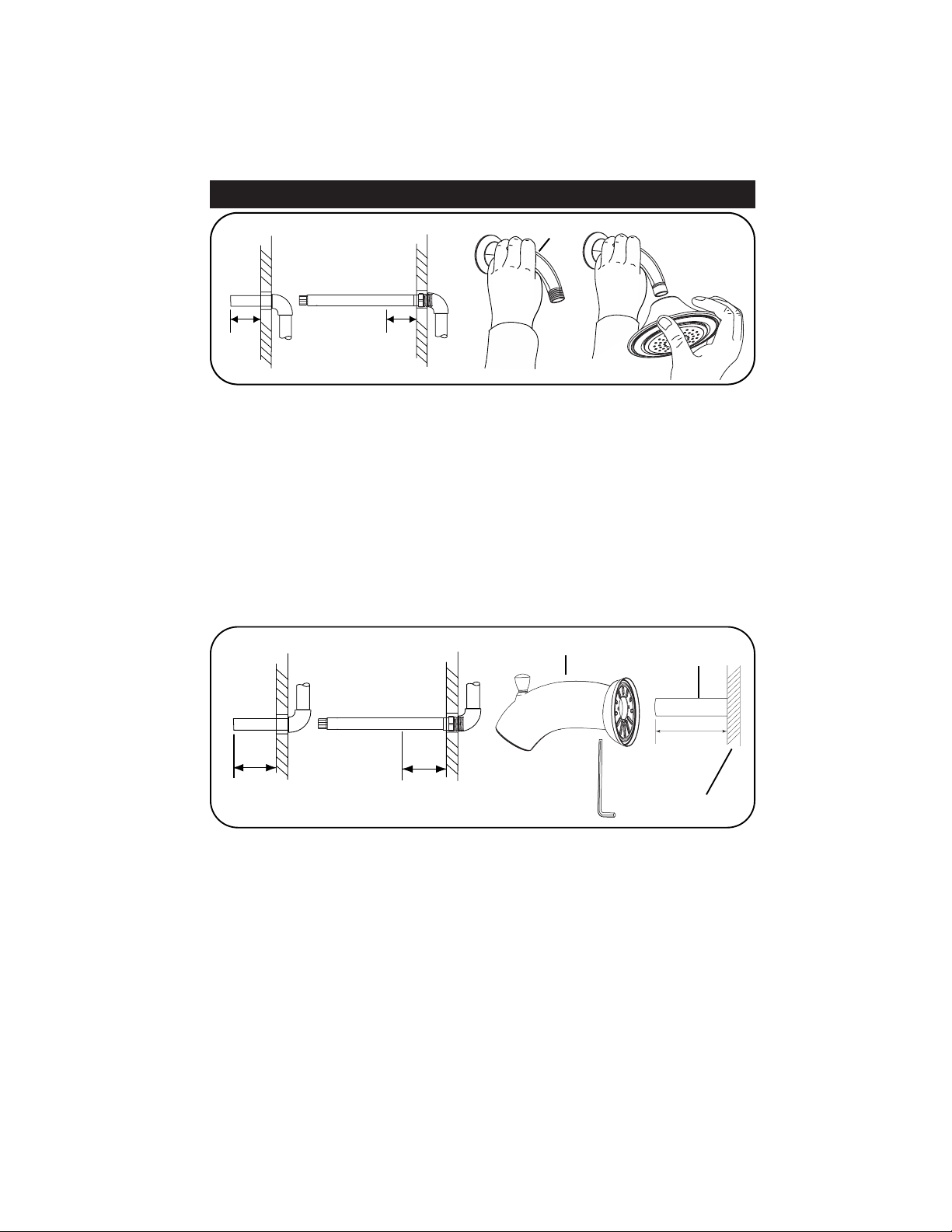

TUB SPOUT INSTALLATION

1/2” copper lookout (pipe protruding from wall)

must be 2 3/4" (70mm) min. to 3 3/4" (95mm)

max. in length and be free of deep scratches,

dents, kinks or bends. The cutoff end must be

free of burrs inside and out. Use of a tubing

cutter is recommended.

IF USING ADAPTER TO INSTALL SPOUT

WITH IPS CONNECTION:

Apply Teflon tape to thread and install into IPS

connection. Tighten with 9/16” socket wrench.

DO NOT use an open end wrench. Cut off 2 3/43 3/4” from finished wall surface. Use of a tubing

cutter is recommended.

TO INSTALL SLIP FIT SPOUT:

Press and twist tub spout (8) onto the lookout

upside down and tightly up against the wall.

Tighten set screw with a 3/32" hex wrench until

it just starts to bind. Turn spout upright into

position against the wall and finish tightening

the set screw. DO NOT OVERTIGHTEN.

INSTALL SHOWER ARM

1/2” copper lookout (pipe protruding from wall)

must be 2” (50mm) min. to 3” (76mm) max. in

length and be free of deep scratches, dents,

kinks or bends. The cutoff end must be free of

burrs inside and out. Use of a tubing cutter is

recommended.

IF USING SHOWER ARM ADAPTER (3) - IPS

to CC: Apply Teflon tape to thread and install

into IPS connection. Tighten with 9/16” socket

wrench; DO NOT use an open end wrench. Cut

off 2-3” from finished wall surface. Use of a

tubing cutter is recommended.

TO INSTALL SLIP FIT SHOWER ARM: Press

and twist shower arm (2) onto the lookout

upside down and tightly up against the wall.

Tighten set screw with a 3/32” hex wrench

until it just starts to bind. Turn shower arm

upright into position against the wall and

finish tightening the setscrew. DO NOT

OVERTIGHTEN.

TO INSTALL SHOWERHEAD

Wrap shower arm thread with teflon tape.

Thread shower head onto shower arm. Tighten

shower head using a wrench on the flats

located on the shower ball. Hold shower arm

with one hand while tightening.

2-3" 2-3"

2 3/4 - 3 3/4 "2

3

/4 - 3 3/4 "

Page 5

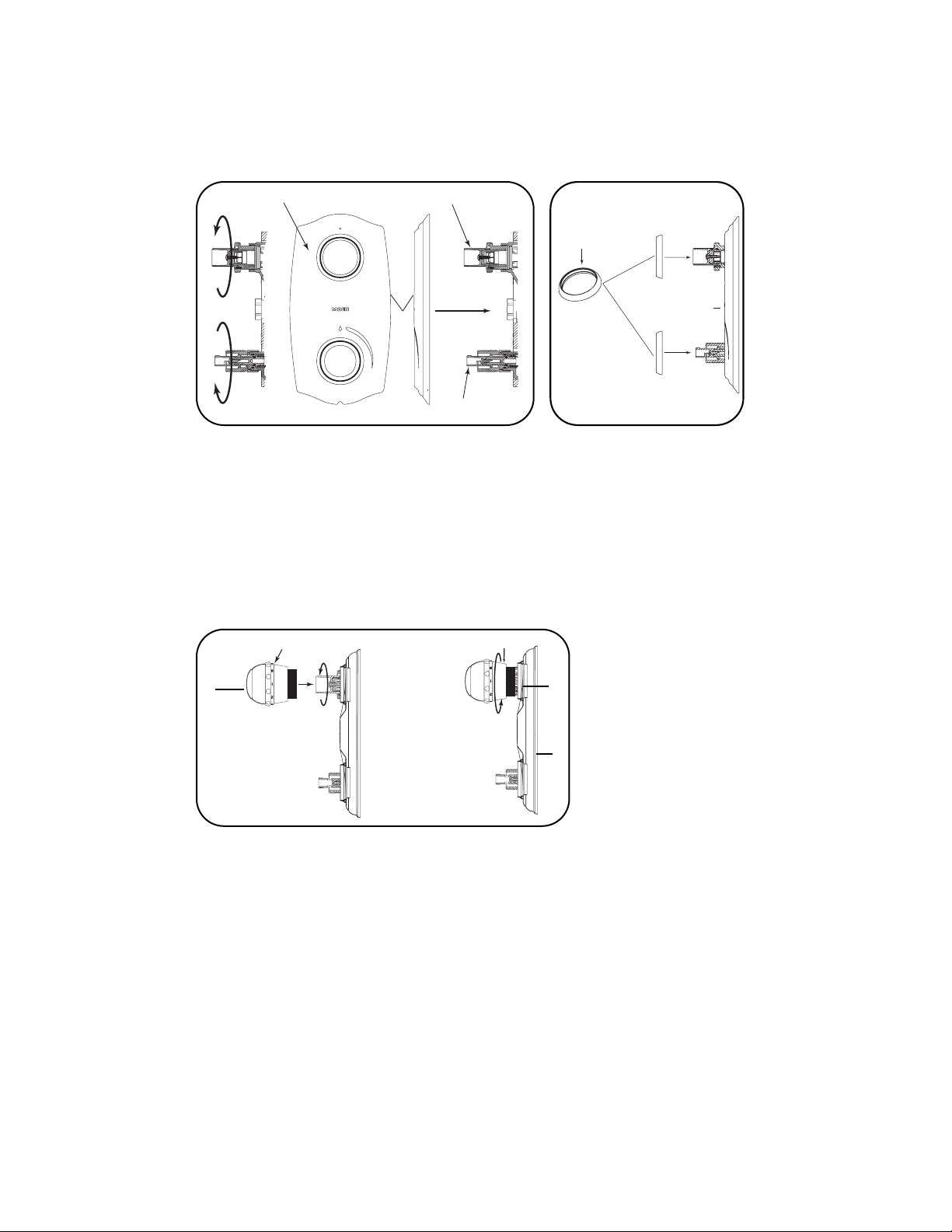

ATTACH BASE ESCUTCHEON:

1. Turn off main hot and cold water supply to

valve.

2. Turn temperature extension near top of valve

body counter-clockwise until it stops (it may

already be in the full counter-clockwise

position).

3. Turn white flow extension near bottom of

valve body clockwise until it stops (it may

already be in the full clockwise position).

4. Place the base escutcheon (4) over the hole

in shower wall with larger hole in

the base escutcheon surrounding the top

threaded extension from the valve. The base

escutcheon will be correctly oriented when

the word “MOEN” is right side up.

5. Place the flat side of the two ring

escutcheons (5) against the base

escutcheon (4): one ring escutcheon over the

temperature extension and one ring

escutcheon over the white flow extension. At

this point, the ring escutcheons and base

escutcheon will be hanging from the

threaded extensions on the valve body.

LARGER HOLE AT TOP

TEMPERATURE EXTENSION

FLOW EXTENSION

5

4

ATTACH TEMPERATURE KNOB:

1. Confirm that the temperature extension near

top of valve body is rotated fully counterclockwise.

2. Align the temperature knob to the

temperature extension with the number “9”

on the grip ring turned upward to the 12

o’clock position.

3. Move the temperature knob (6) towards the

temperature extension until the internal

splines (projections on the inner diameter) in

the temperature knob start to engage the

external splines on the temperature

extension.

4. After splines start to

engage, turn the lower shell

of the temperature knob

clockwise several turns while

holding the rubber grip to

prevent it from turning. This

turning will thread the internal

threads in the temperature

knob onto the threads on the

valve body. Continue turning

the lower shell (you may

release the rubber grip) until

the lower shell compresses

the ring escutcheon (5)

against the base escutcheon (4). It is helpful to

pull the lower shell towards you away from the

shower wall as you turn it to keep the knob from

disassembling. Note that as the temperature

knob nears the base escutcheon, the base

escutcheon and ring escutcheon will have to be

shifted upwards so that the ring escutcheon is

centered on the lower shell and the black plastic

part extending from the bottom of the

temperature knob fits within the hole in the base

escutcheon. Tighten the lower shell hand-tight

only. Verify that the “9” is still at the 12 o’clock

position. This completes the attachment of the

temperature knob.

Turn until "9" is at 12 o'clock position

Temperature extension turned

fully counter-clockwise

6

5

4

4

4

Lower shell

Use your hand to center the ring

escutcheon as the temperature

knob is threaded onto valve stem.

Page 6

5

ATTACH FLOW HANDLE:

1. Confirm that the white flow extension is turned fully clockwise. Align the flow handle (7) to the

flow extension with the handle pointing downwards (6 o’clock position).

2. Move the flow handle towards the flow extension until the internal splines in the flow handle start

to engage the external splines on the flow extension.

3. After the splines start to engage, turn the shell of the flow handle (7) clockwise several turns

while holding the handle to prevent it from rotating. This turning will thread the internal threads

in the flow handle onto the threads on the valve body. Continue turning the shell (you may

release the handle) until it compresses the ring escutcheon (5) against the base escutcheon (4).

It is helpful to pull the shell towards you (away from the shower wall) as you turn it to keep the

knob from disassembling. Again, as the flow handle nears the base escutcheon, the ring

escutcheon will have to be shifted upwards so that the ring escutcheon is centered on the lower

shell. Tighten the shell hand-tight only. This completes the attachment of the flow handle. The

valve trim is now completely assembled and is ready for operation.

Flow extension turned

fully clockwise

Use your hand to center the ring

escutcheon as the handle is

threaded onto valve stem.

7

7

5

4

TESTING FOR PROPER OPERATION:

1. Make sure the flow handle (7) is still in the full down 6 o’clock position.

2. Turn on the hot and cold water supplies.

3. Turn the temperature knob fully counterclockwise so the number “9” is in the vertical 12 o’clock

position. The numbers represent increasing temperature. “9” is the hottest and “1” is the coldest.

4. Turn the flow handle counter-clockwise to start flow from the shower head or tub spout.

5. The thermostatic valve has a temperature range from 85°F (29°C) corresponding to the number

“1” on the temperature knob to 115°F (46°C) corresponding to the number “9” on the temperature

knob. If the temperature when the knob is set at “9” is not approximately 115°F (46°C), or if a

hotter maximum temperature is desired, the temperature range can be recalibrated by following

the instructions in the section “Recalibration Procedure.”

NOTE: Recalibration to a higher maximum temperature will increase the temperature

across the entire range.

CAUTION: RISK OF SCALDING HAZARD

The valve has been calibrated at the factory to provide a maximum water temperature

of 115°F (46°C). Any significant variation in the calibration or any variation in the water

supply temperatures (greater than 5°F or 3°C) from those used at the factory during

the calibration procedure can result in water temperatures that present scalding

dangers. Therefore, it is important to check the water temperature with the

temperature knob set at “9” to determine the maximum temperature of the water. The

responsibility for the proper installation and any recalibration of this valve lies with the

installer.

6. Turn the water off by turning the flow handle fully clockwise.

!

Page 7

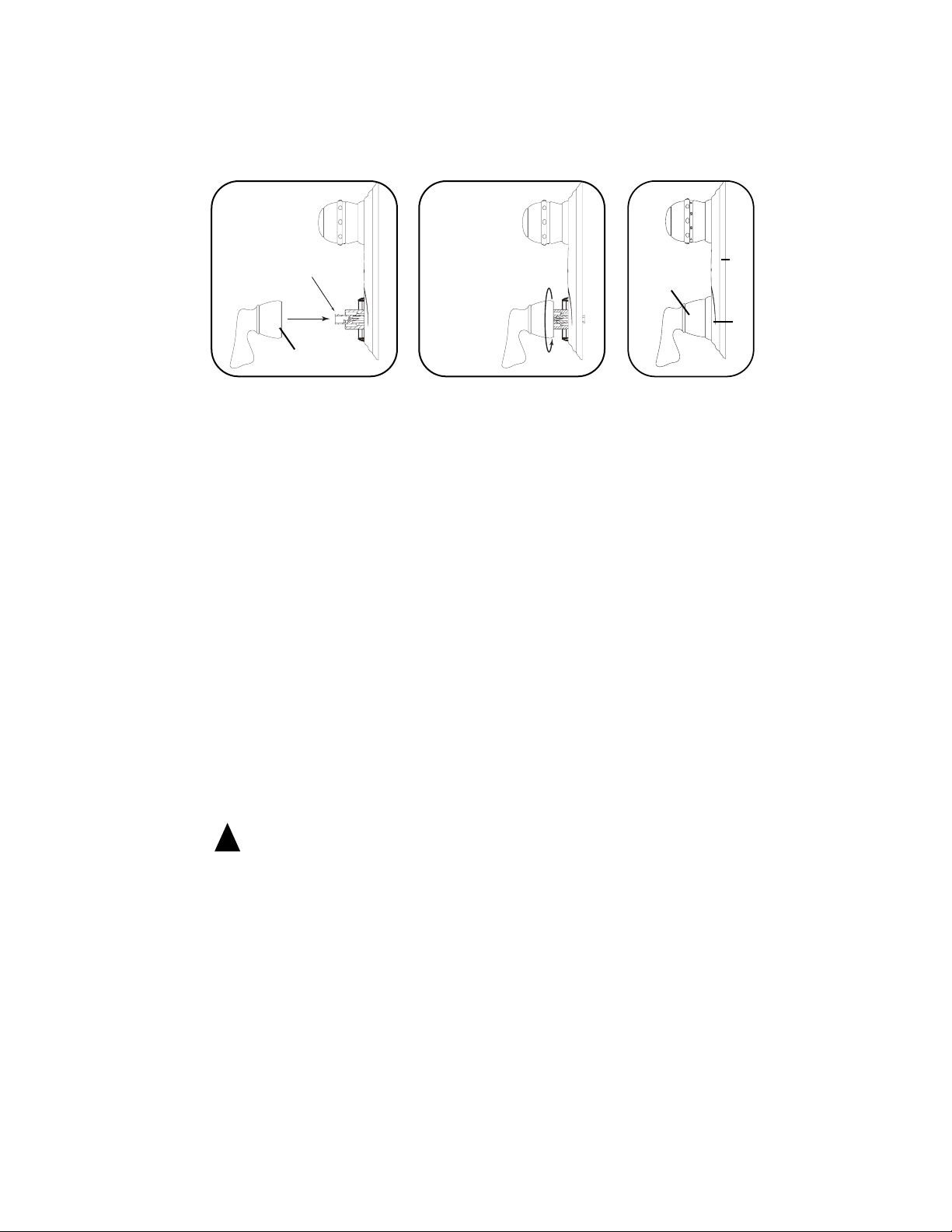

RE-CALIBRATION PROCEDURE

1. To re-calibrate the valve, it is necessary to

gain access to the spindle (located behind

the temperature extension near the top of

the valve).

2. Turn the temperature extension counter-

clockwise until it stops.

3. Loosen and remove the screw in the center

of the temperature extension by turning it

counterclockwise.

4. Carefully remove the temperature extension

without turning it or the spindle behind it.

You have now accessed the spindle.

5. To increase the temperature, rotate the

spindle counter-clockwise one or two

spline(s) past the mark on the retaining nut.

To decrease the temperature, rotate the

spindle clockwise one or two spline(s) past

the mark on the retaining nut.

6. Replace the temperature extension,

positioned fully counter-clockwise with the

tab as close as possible to the clockwise

side of the pin in the retaining nut. This

should be done without rotating the spindle.

Do not install the screw at this time.

7. Turn the flow handle counter-clockwise to

start the flow of water.

8. After the water temperature has stabilized,

check the temperature. This will be the new

maximum temperature. If the temperature is

not suitable, remove the temperature

extension as described above and repeat

this procedure to further adjust the water

temperature.

9. When the maximum temperature is

acceptable, re-install the screw in the

temperature extension and tighten.

10. Refer to “Attach Temperature Knob”

instructions on how to re-attach the

temperature knob.

Turn fully CCW

Temperature

extension tab

Temperature extension

Spindle

Retaining nut pin

Loosen and remove screw

6

Spindle with

temperature

extension in place

Increase temperature

Decrease temperature

Retaining nut pin

Spindle w/ temperature

extension removed

Page 8

7

MOEN LIFETIME LIMITED WARRANTY

CONSUMER INFORMATION

Moen products have been manufactured under the highest standards of quality and workmanship. Moen

warrants to the original consumer purchaser for as long as the original consumer purchaser owns their home

(the “Warranty Period” for homeowners), that this faucet will be leak and drip-free during normal use and all

parts and finishes of this faucet will be free from defects in material and manufacturing workmanship. All other

purchasers (including purchasers for industrial, commercial and business use) are warranted for a period of 5

years from the original date of purchase (the “Warranty Period” for non-homeowners).

If this faucet should ever develop a leak or drip during the Warranty Period, Moen will FREE OF CHARGE

provide the parts necessary to put the faucet back in good working condition and will replace FREE OF CHARGE,

any part or finish that proves defective in material and manufacturing workmanship, under normal installation,

use and service. Replacement parts may be obtained by calling 1-800-289-6636 (Canada 1-800-465-6130),

or by writing to the address shown. Proof of purchase (original sales receipt) from the original consumer

purchaser must accompany all warranty claims. Defects or damage caused by the use of other than genuine

Moen parts are not covered by this warranty. This warranty is applicable only to faucets purchased after

December 1995 and shall be effective from the date of purchase as shown on purchaser’s receipt.

This warranty is extensive in that it covers replacement of all defective parts and finishes. However, damage

due to installation error, product abuse, product misuse, or use of cleaners containing abrasives, alcohol or

other organic solvents, whether performed by a contractor, service company, or yourself, are excluded from this

warranty. Moen will not be responsible for labor charges and/or damage incurred in installation, repair or

replacement, nor for any indirect, incidental or consequential damages, losses, injury or costs of any nature

relating to this faucet. Except as provided by law, this warranty is in lieu of and excludes all other warranties,

conditions and guarantees, whether expressed or implied, statutory or otherwise, including without restriction

those of merchantability or of fitness for use.

Some states, provinces and nations do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitations or exclusions may not apply to you. This warranty gives you specific legal

rights and you may also have other rights which vary from state to state, province to province, nation to nation.

Moen will advise you of the procedure to follow in making warranty claims. Simply write to Moen Incorporated

using the address below. Explain the defect and include proof of purchase and your name, address, area code

and telephone number.

Faucets made of leaded brass alloys may contribute small amounts of lead to water that is allowed

to stand in contact with the brass. The amount of lead contributed by any faucet is highest when the

faucet is new. The following steps may reduce potential exposure to lead from faucets and other

parts of the plumbing system:

• Always run the water for a few seconds prior to use for drinking or cooking

• Use only cold water for drinking or cooking

• If you wish to flush the entire plumbing system of water that has been standing in the pipes or

other fittings, run the cold water until the temperature of the water drops, indicating water coming

from the outside main

• If you are concerned about lead in your water, have your water tested by a certified laboratory in

your area

HELPLINE:

1 (800) BUY-MOEN

[289-6636]

In the U.S. call our toll free Helpline number

for answers to any product, installation, or

warranty questions.

In Canada:

Toronto: 905-829-3400;

Rest of Canada: 1-800-465-6130

In Mexico:

(84) 88-08-26, 88-08-27,

o 91-800-84-345

Page 9

DIRECTIVES IMPORTANTES À L'ATTENTION DE L’INSTALLATEUR :

VEUILLEZ LIRE CES DIRECTIVES ATTENTIVEMENT, REMPLIR LES

RENSEIGNEMENTS MANQUANTS CI-DESSOUS PUIS ATTACHER LES

DIRECTIVES À LA POIGNÉE DE DÉBIT OU À LA ROSACE POUR QUE

L’UTILISATEUR LES VOIT.

AVERTISSEMENT : Risque de brûlure

Le réétalonnage de ce robinet thermostatique pour augmenter la température

de l’eau accroît le risque de brûlure. L’installateur est responsable de

l’installation du robinet et de tout réétalonnage de la température de l’eau

conformément aux directives fournies.

Attention : Risque de brûlure. Le robinet peut être réétalonné pour

augmenter la température de l’eau.

Ce robinet a été préréglé en usine pour fournir une certaine plage de

températures d’eau. Tout changement apporté aux réglages ou aux

conditions d’entrée de l’eau définis en usine peut augmenter la

température de l’eau sortant et causer des brûlures. L’installateur est

responsable d’installer et de réétalonner correctement (au besoin) ce

robinet.

FRANÇAIS

INS235A

CE ROBINET THERMOSTATIQUE A ÉTÉ PRÉRÉGLÉ

PAR ________________________________________________

DE _________________________________________________

POUR QUE LA TEMPÉRATURE MAXIMALE DE L’EAU SOIT DE

____°C. TOUT CHANGEMENT APPORTÉ AUX RÉGLAGES

PEUT AUGMENTER LA TEMPÉRATURE DE L’EAU DÉVERSÉE

ET PEUT CAUSER DES BLESSURES.

DATE : _________

!

Respecte ASME A112.18.1M, CSA B125 et ASSE 1016

ROBINET DE DOUCHE/BAIGNOIRE THERMOSTATIQUE

À DEUX POIGNÉES

T3428, T3428CP, T3428CPM, T3428STV, T3428NLBL, T3428CGPC,

T3428CGSA, T3429, T3429CP, T3429CPM, T3429STV, 3429NLBL,

T3429CGPC, T3429CGSA, T3431, T3431CP, T3431CPM, T3431STV,

T3431NLBL, T3431CGC, T3134CGSA

Page 10

INSTRUCCIONES DE INSTALACIÓN

Para herramientas until ver pagina 1

Para description de piezas ver pagina 2

2

INSTALACIÓN DEL SURTIDOR DE LA TINA

La tubería o niple de cobre de 1/2" (13 mm.)

que sobresale de la pared debe tener una

longitud mínima. de 2 3/4" (70 mm) y máxima

de 3 3/4" (95 mm) y estar libre de raspaduras,

abolladuras o pliegues. El borde debe estar

libre de rebabas tanto por dentro como por

fuera. Se recomienda el uso de un cortador de

tubos.

SI SE UTILIZA UN ADAPTADOR CON

CONEXIÓN IPS PARA INSTALAR EL

SURTIDOR: Aplique cinta de Teflón a la parte

roscada e instale dentro de la conexión IPS.

Apriete con una llave de cubo de 9/16" (15

mm);NO use una llave de boca abierta. Corte a

2-3" (5,8 cm a 7,62 cm) de la superficie de la

pared terminada. Se recomienda el uso de un

cortador de tubos.

INSTALACIÓN DEL SURTIDOR DE LA TINA:

Presione y gire el surtidor de la tina (18)

invertido por sobre el niple en la pared hasta

que quede firme contra la misma. Ajuste el

tornillo de sujeción con una llave hexagonal de

3/32" (2,38 mm) hasta que apenas comience a

apretar. Haga girar el surtidor de la tina hacia su

posición correcta contra la pared y termine de

ajustar el tornillo. NO AJUSTE DEMASIADO.

INSTALACIÓN DEL BRAZO DE LA

REGADERA

La tubería o niple de cobre de 1/2" (13 mm.)

que sobresale de la pared debe tener una

longitud mínima. de 2" (50 mm) y máxima de 3"

(76 mm) y estar libre de raspaduras,

abolladuras o pliegues. El borde debe estar

libre de rebabas tanto por dentro como por

fuera. Se recomienda el uso de un cortador de

tubos.

SI SE UTILIZA UN ADAPTADOR IPS a CC (3)

PARAEL BRAZO DE LA REGADERA: Aplique

cinta de Teflón a la parte roscada e instale

dentro de la conexión IPS. Apriete con una llave

de cubo de 9/16" (15 mm);NO use una llave de

boca abierta. Corte a 2-3" (5,8 cm a 7,62 cm) de

la superficie de la pared terminada. Se

recomienda el uso de un cortador de tubos.

INSTALACIÓN DEL BRAZO DE LA

REGADERA: Presione y gire el brazo de la

regadera (2) invertido por sobre el niple en la

pared hasta que quede firme contra la misma.

Ajuste el tornillo de sujeción con una llave

hexagonal de 3/32" (2,38 mm) hasta que

apenas comience a apretar. Haga girar el brazo

de la regadera hacia su posición correcta contra

la pared y termine de ajustar el tornillo. NO

AJUSTE DEMASIADO.

2

3

/4 - 3 3/4"

Tubería o niple

Pared terminada

8

9

2-3" 2-3"

2 3/4 - 3 3/4 "2

3

/4 - 3 3/4 "

Page 11

INSTALACIÓN DE LA BASE DEL CHAPETÓN:

1. Cierre las válvulas de suministro principales para el

agua caliente y fría.

2. Voltee la extensión de temperatura cerca de la

parte superior del cuerpo de la válvula en sentido

contrario de las manecillas del reloj hasta que se

detenga (puede ya encontrarse en la posición de

una vuelta entera en sentido contrario de las

manecillas del reloj).

3. Voltee la extensión blanca del flujo cerca de la parte

inferior del cuerpo de la válvula en sentido de las

manecillas del reloj hasta que se detenga (puede

ya encontrarse en la posición de una vuelta entera

en sentido de las manecillas del reloj).

4. Coloque la base del chapetón (4) sobre el hoyo en

la pared de la ducha con el hoyo más grande en la

base del chapetón rodeando la extensión roscada

de arriba de la válvula. La base del chapetón

estará correctamente situada cuando la palabra

"MOEN" esté derecha.

5. Coloque el lado plano de los dos anillos del

chapetón (5) contra la base del chapetón (4): un

anillo del chapetón sobre la extensión de la

temperatura y otro anillo del chapetón sobre la

extensión blanca del flujo. En este punto, los

anillos del chapetón y la base del chapetón estarán

colgando de las extensiones roscadas en el cuerpo

de la válvula.

LARGER HOLE AT TOP

TEMPERATURE EXTENSION

FLOW EXTENSION

5

4

HOYO MÁS GRANDE EN

PARTE SUPERIOR

EXTENSIÓN DE TEMPERATURA

EXTENSIÓN DE FLUJO

10

INSTALACIÓN DE LA PERILLA DE

TEMPERATURA:

1. Confirme que la extensión de temperatura cerca

de la parte superior del cuerpo de la válvula está

virada completamente a la posición contraria a

las manecillas del reloj.

2. Alinee la perilla de temperatura a la extensión

de temperatura con el número "9" en el anillo de

agarre volteado hacia arriba a la posición de las

12 en punto.

3. Mueva la perilla de temperatura (6) hacia la

extensión de temperatura hasta que las ranuras

internas (proyecciones en el diámetro interno)

en la perilla de temperatura empiecen a

acoplarse con las ranuras externas en la

extensión de temperatura.

4. Después que las ranuras empiecen a acoplarse,

voltee el caparazón inferior de

la perilla de temperatura en

sentido de las manecillas del

reloj varias veces mientras

sujeta la agarradera de hule

para prevenir que se volteé.

Esta acción de voltear

enroscará las roscas internas

en la perilla de temperatura a

las roscas en el cuerpo de la

válvula. Continúe volteando el

caparazón inferior (usted

puede soltar la agarradera de

hule) hasta que el caparazón

inferior comprima el anillo del

chapetón (5), contra la base del chapetón (4). Es

útil tirar de el caparazón inferior hacia usted lejos

de la pared de la ducha conforme usted lo voltea

para evitar que la perilla se desarme. Note que

conforme la perilla de la temperatura se acerca a la

base del chapetón, la base del chapetón y el anillo

del chapetón tendrán que ser haber sido

reposicionados hacia arriba de modo que el anillo

del chapetón esté centrado sobre el caparazón

inferior y la parte de plástico negro que se extiende

desde el fondo de la perilla de temperatura quepa

en el hoyo en la base del chapetón. Apriete el

caparazón inferior con sólo un ajuste de manos.

Verifique que el "9" esté aún en la posición de las

"12" en punto. Esto completa la instalación de la

perilla de temperatura.

Turn until "9" is at 12 o'clock position

Temperature extension turned

fully counter-clockwise

6

5

4

Voltee hasta que el "9" esté en la

posición de las 12 en punto.

Extensión de temperatura

volteada completamente en

sentido contrario a las

manecillas del reloj.

Use su mano para centrar el

anillo del chapetón conforme la

perilla de temperatura se va

enroscando en el vástago de la

válvula.

Caparazón inferior

4

Lower shell

Use your hand to center the ring

escutcheon as the temperature

knob is threaded onto valve stem.

Page 12

11

INSTALACIÓN DE LA MANIJA DE FLUJO:

1. Confirme que la extensión blanca de flujo esté volteada completamente en sentido de las manecillas

del reloj. Alinee la manija de flujo (7) a la extensión de flujo con la manija apuntando hacia abajo

(posición de las 6 en punto).

2. Mueva la manija de flujo hacia la extensión de flujo hasta que las ranuras internas en la manija de

flujo empiecen a acoplarse con las ranuras externas en la extensión de flujo.

3. Después que las ranuras empiecen a acoplarse, voltee el caparazón de la manija de flujo (7) en

sentido de las manecillas del reloj varias veces mientras sujeta la manija para prevenir que se volteé.

Esta acción de voltear enroscará las roscas internas en la manija de flujo a las roscas en el cuerpo de

la válvula. Continúe volteando el caparazón (usted puede soltar la manija) hasta que ésta comprima

el anillo del chapetón (5) contra la base del chapetón (4). Es útil tirar de el caparazón hacia usted

(lejos de la pared de la ducha) conforme usted la voltea para evitar que la perilla se desarme. De

nuevo, conforme la manija de flujo se acerca a la base del chapetón, el anillo del chapetón tendrá que

haber sido reposicionado hacia arriba de modo que el anillo del chapetón esté centrado sobre el

caparazón inferior. Apriete el caparazón con sólo un ajuste de manos. Esto completa la instalación de

la manija de flujo. Los accesorios decorativos de la válvula están completamente instalados y la

válvula está lista para operar.

Flow extension turned

fully clockwise

Use your hand to center the ring

escutcheon as the handle is

threaded onto valve stem.

7

7

5

4

Extensión de flujo volteada

completamente en sentido de

las manecillas del reloj.

Use su mano para centrar el

anillo del chapetón conforme la

manija se va enroscando en el

vástago de la válvula.

PRUEBA PARA CONTROLAR EL FUNCIONAMIENTO CORRECTO:

1. Asegurase que la manija del flujo de agua (7) esté todavía completamente girada hacia abajo, en la

posición de las 6 horas.

2. Abrir la provisión de agua caliente y fría .

3. Girar la manija de la temperatura totalmente en sentido antihorario de manera que el número "9" quede

en la posición vertical de las 12 horas. Los números representan el aumento de la temperatura, "9" es la

más caliente y "1" es la más fría.

4. Girar la manija del flujo de agua en sentido antihorario para que empiece a correr el agua ya sea del pico

de la bañera o de la cebolleta de la ducha.

5. La válvula termostática tiene una gama de temperatura que va desde los 85ºF (29ºC) que corresponden

al número "1" en la perilla de temperatura, hasta los 115ºF (48ºC) que corresponden al número "9" en la

perilla de temperatura. Si, cuando la perilla está posicionada en el "9", la temperatura no es de

aproximadamente 115ª F (48ªC), o si se desea una temperatura máxima más caliente, se puede volver

a calibrar la gama de temperatura siguiendo las instrucciones de la sección "Procedimiento para volver a

efectuar la calibración".

NOTA: Una nueva calibración a una mayor temperatura máxima, hará que toda la gama de

temperatura aumente.

PRECAUCIÓN: PELIGRO DE RIESGO DE ESCALDADURA

La válvula ha sido calibrada en la fábrica para proveer una temperatura máxima del agua de 118ºF

(46ºC). Cualquier variación importante en la calibración de las temperaturas de provisión de agua

(mayor de 5ºF o 3ºC), en relación a las que se determinaron en la fábrica durante el procedimiento de

calibración, puede dar como resultado temperaturas del agua que pueden causar escaldaduras. Por

lo tanto, es importante controlar la temperatura del agua con la perilla de temperatura ubicada en "9"

para determinar la temperatura máxima del agua. El instalador es el único responsable de la

instalación apropiada de esta válvula así como de cualquier nueva calibración que de ella se efectúe.

6. Cierre el agua girando completamente la manija del flujo de agua en sentido horario.

!

Page 13

PROCEDIMIENTO PARA VOLVER A EFECTUAR

LA CALIBRACIÓN

1. Para volver a calibrar la válvula es necesario

acceder al vástago (ubicado detrás de la pieza

para variación de temperatura cerca de la parte

superior de la válvula).

2. Girar la pieza para variación de temperatura en

sentido antihorario hasta que se detenga.

3. Aflojar y sacar el tornillo del centro de la pieza

para variación de temperatura haciéndolo girar en

sentido antihorario.

4. Remover cuidadosamente la pieza para variación

de temperatura sin girarla y sin girar el vástago

que está detrás de la misma. Ahora usted tiene

acceso al vástago.

5. Para aumentar la temperatura, rotar el vástago en

sentido antihorario una o dos ranura(s) pasada la

marca de la tuerca de retención. Para disminuir la

temperatura, rotar el vástago en sentido horario

una o dos ranura(s) pasada la marca de la tuerca

de retención.

6. Volver a colocar la pieza para variación de

temperatura posicionada totalmente en sentido

antihorario, con la lengüeta tan cerrada como sea

posible hacia el lado horario del pasador en la

tuerca de retención. Esto debe hacerse sin rotar

el vástago. No colocar el tornillo todavía.

7. Girar la manija del flujo de agua en sentido

antihorario para iniciar el flujo de agua.

8. Una vez que la temperatura del agua se ha

estabilizado, controlar la temperatura. Esta será la

nueva temperatura máxima. Si la temperatura no

es la adecuada, quite la pieza para variación de

temperatura como se indicó arriba y repita el

procedimiento para ajustar aun más la

temperatura del agua.

9. Cuando la temperatura máxima resulta aceptable,

colocar nuevamente el tornillo en la pieza para

variación de temperatura y ajustarlo.

10. Para volver a colocar la perilla de la temperatura,

dirigirse a las instrucciones sobre "Cómo colocar

la perilla de la temperatura".

12

Turn fully CCW

Temperature

extension tab

Temperature extension

Spindle

Retaining nut pin

Loosen and remove screw

Gire completamente

en sentido antihorario.

Afloje y saque el tornillo

Lengüeta de la

pieza para variación

de temperatura

Pieza para variación de temperatura

Vástago con la pieza para

variación de temperatura

en su lugar

Aumentar la temperatura

Pasador de la tuerca de retención

Vástago una vez que se

quitó la pieza para

variación de temperatura

Disminuir la temperatura

Vástago

Pasador de la tuerca de retención

Spindle with

temperature

extension in place

Increase temperature

Decrease temperature

Retaining nut pin

Spindle w/ temperature

extension removed

Page 14

13

MOEN GARANTIA LIMITADA DE VIDA

Los productos Moen han sido elaborados bajo los más estrictos standard de calidad y mano de obra. Moen

garantiza al consumidor - comprador original por todo el tiempo que el consumidor - comprador original esté

en posesión de su casa (el “Período de Garantia” del propietario de casa), que esta mezcladora será libre de

infiltraciones y goteo durante su uso normal y que todas las piezas y el acabado de esta mezcladora serán libres

de defectos de material y mano de obra de fabricación. Todos los otros compradores (incluyendo compras para

uso industrial comercial y profesional) se garantizan por un período de 5 años desde la fecha original de

compra (el “Período de Garantía” para los que no son propietarios de casa).

En caso que esta mezcladora empiece en algún momento a gotear o infiltrarse durante el Período de

Garantía, Moen suministrará LIBRE DE CARGO las piezas que se necesiten para reponer la mezcladora en buena

condición de funcionamiento y reemplazará LIBRE DE CARGO, cualquier pieza o acabado que resulte ser

defectuoso en cuanto a material y elaboración, bajo instalación, uso y servicio normal. Las piezas de repuesto

se pueden obtener llamando al 1-800-289-6636 (Canadá 1-800-465-6130), o escribiendo a la dirección

indicada. El comprobante de compra (recibo original de la venta) del consumidor - comprador de origen debe

acompañar todas las reclamaciones de garantía. Esta garantía no ampara los defectos o daños ocasionados

por un uso otro que de piezas genuinas Moen. Esta garantía se extiende solamente a mezcladoras compradas

después de Diciembre 1995 y será en efectividad desde la fecha de la compra como indique el recibo del

comprador.

Esta garantía es amplia puesto que cubre el repuesto de todas piezas y acabados defectuosos. Sin embargo,

los daños causados por un error de instalación, abuso del producto, mal uso del producto o el uso de

limpiadores que contengan abrasivos, alcohol u otros solventes orgánicos, ya sean ejecutados por un

contratista, Cía. de servicio o Ud. mismo se excluyen de esta garantía. Moen no será responsable de costos

laborales y/o daños producidos durante la instalación, reparación o cualquier daño incidental o consiguiente,

pérdidas, heridas u costos de cualquier naturaleza relacionados con esta mezcladora. Salvo como previsto por

la ley, esta garantía reemplaza y excluye todas las otras garantías, condiciones y afirmaciones, ya sea

expresadas o implícitas, legales u otras, incluyendo sin restricción alguna aquellas de comercialización o

aptitud para el uso.

Algunos estados, provincias y naciones no permiten la exclusión o limitación de daños incidentales o

consiguientes, y por este motivo las sobrecitadas limitaciones posiblemente no le afectan. Esta garantía le otorga

derechos legales expecíficos y Ud. posiblemente también tiene otros derechos que cambian de un estado a otro,

de una provincia a otra, de una nación a otra. Moen le avisará cual procedimiento debe seguir en cuanto haga

una reclamación bajo garantía. Escriba nada más a Moen Incorporated a la dirección indicada a continuación.

Explique el defecto e incluya la prueba de compra así como su nombre, dirección, código y número de teléfono.

Mezcladoras fabricadas con aleaciones de latón de plomo podrían contribuir pequeñas contidades

de plomo al agua que está en contacto con el latón. La cantidad de plomo contribuida en cualquier

mezcladora es mayor cuando esta mezcladora es nueva. Los siquientes pasos podrían reducir la

exposición potencial al plomo de las mezcladoras y otras piezas del sistema de plomeria:

• Siempre deje correr el agua por unos segundos antes de usaria para tomar o cocinar

• Solamente use agua fría para tomar o cocinar

• Si usted desea limpiar el sistema completo de plomeria de agua estancada en las tuberías y

otros accessorios, deje correr el agua hasta que la temperatura de ésta baje, indicando de que

esta agua viene del suministro de afuera.

• Si usted tiene interés sobre el plomo en su agua, haga examinar su agua por un laboratorio

certificado en su área

LINEAS TELEFONICAS

DE SERVICIO:

Para Aclarar sus dudas relacionadas con la instalacion,

refacciones, partes y/o garantia de nuestras llaves,

llamenos por cobrar a los siquientes telefonos: (84) 88-0826, 88-08-27, o 91-800-84-345. FAX (84) 88-08-04.

En los Estados Unidos: 1-800-289-6636

INFORMACION AL CONSUMIDOR

Page 15

INSTRUCCIONES IMPORTANTES A LA PERSONA QUE INSTALA:

POR FAVOR LEA ESTAS INSTRUCCIONES, LLENE LOS ESPACIOS

EN BLANCO ABAJO, LUEGO PROVEA LAS INSTRUCCIONES AL

USUARIO PEGÁNDOLAS DE MODO SEGURO A LA MANIJA DE

FLUJO O AL CHAPETÓN.

ADVERTENCIA: Riesgo de escaldadura

La variación del calibraje de esta válvula termostática para aumentar la

temperatura del agua aumenta el riesgo de lesión por escaldadura. La persona

que instala es responsable de instalar la válvula y de cualquier recalibraje de la

temperatura del agua de acuerdo con las instrucciones.

PRECAUCIÓN: Peligro de lesión por escaldadura. La válvula puede ser

recalibrada para suministrar agua de temperatura más alta.

Esta válvula ha sido prefijada en la fábrica para proveer un rango de

temperaturas de agua. Cualquier cambio en los ajustes o en las condiciones de

suministro a aquellos usados durante el calibraje hecho en la fábrica podría

elevar la temperatura de la salida y causar escaldaduras. La responsabilidad de

la instalación apropiada y de cualquier recalibraje de esta válvula yace en la

persona a cargo de la instalación.

ESPAÑOL

INS235A

ESTA VÁLVULA TERMOSTÁTICA HA SIDO AJUSTADA

POR___________________________________________

DE____________________________________________

A UNA DESCARGA MÁXIMA DE TEMPERATURA DEL

AGUA DE ________C° (F°). CUALQUIER CAMBIO DE

ESTE AJUSTE PUEDE ELEVAR LA TEMPERATURA DE

DESCARGA Y PODRÍA CAUSAR ESCALDADURAS.

FECHA:_________

!

Cumple con: ASME A112.18.1M, CSA B125, & ASSE 1016

MEZCLADORA TERMOSTÁTICA DE DOS MANIJAS

PARA BAÑERA/DUCHA

T3428, T3428CP, T3428CPM, T3428STV, T3428NLBL, T3428CGPC,

T3428CGSA, T3429, T3429CP, T3429CPM, T3429STV, 3429NLBL,

T3429CGPC, T3429CGSA, T3431, T3431CP, T3431CPM, T3431STV,

T3431NLBL, T3431CGC, T3134CGSA

Page 16

INSTALLATION DU BRAS DE DOUCHE

Le demi-raccord mâle de 12,7 mm (tuyau en saillie

du mur) doit mesurer entre 50 mm et 76 mm et ne

doit comporter aucune rayure profonde, bosselure,

courbe ou pliure. L’extrémité coupée doit être libre

de toute bavure à l’intérieur comme à l’extérieur.

L’utilisation d’un coupe-tube est recommandée.

SI ON UTILISE L’ADAPTATEUR DE BRAS DE

DOUCHE (3) - IPS À CC

Apposer du ruban Téflon sur le filetage et installer

dans le raccord IPS. Serrer à l’aide d’une clé à

douilles de 14,3 mm. NE PAS UTILISER une clé à

fourche. Couper à 2 ou 3 po de la surface murale

finie. L’utilisation d’un coupe tube est

recommandée.

INSTALLATION DU BRAS DE DOUCHE À

GLISSEMENT RAPIDE

Appuyer sur le bras de douche (2) et le faire pivoter

dans le demi-raccord pour qu’il pointe vers le bas

et bien le serrer contre le mur. Serrer la vis d’arrêt

à l’aide d’une clé hexagonale de 2,38 mm jusqu’à

ce qu’elle commence à s’engager contre le mur.

Faire pivoter le bras de douche dans sa position

normale contre le mur et finir de serrer la vis

d’arrêt. NE PAS TROP SERRER.

INSTALLATION DE LA POMME DE DOUCHE

Envelopper le filetage du bras de douche avec du

ruban Téflon. Fileter la pomme de douche sur le

bras de douche. Serrer la pomme de douche à

l'aide d'une clé sur les côtés plats situés sur la

sphère de douche. Tenir le bras de douche d'une

main tout en serrant.

DIRECTIVES D’INSTALLATION

Pour savior quels sont les outils utiles voir la page 1.

Pour consulter le Tableau des pièces voir la page 2

2

3

/4 - 3 3/4"

Demi-raccord mâle

Mur Fini

8

2

INSTALLATION DU BEC DE BAIGNOIRE

Le demi-raccord mâle de 12,7 mm (tuyau en

saillie du mur) doit mesurer entre 70 mm et 95

mm et ne doit comporter aucune rayure profonde,

bosselure, courbe ou pliure. L’extrémité coupée

doit être libre de toute bavure à l’intérieur comme

à l’extérieur. L’utilisation d’un coupe-tube est

recommandée.

SI ON UTILISE UN ADAPTATEUR POUR

INSTALLER UN BEC AVEC UN RACCORD IPS

Apposer du ruban Téflon sur le filetage et installer

dans le raccord IPS. Serrer à l’aide d’une clé à

douilles de 14,3 mm. NE PAS UTILISER une clé

à fourche. Couper à 2 ou 3 po de la surface

murale finie. L’utilisation d’un coupe tube est

recommandée.

INSTALLATION DU BEC À GLISSEMENT

RAPIDE

Appuyer et faire pivoter le bec de baignoire (8)

dans le demi-raccord pour qu’il pointe vers le

haut et bien le serrer contre le mur. Serrer la vis

d’arrêt à l’aide d’une clé hexagonale de 2,38 mm

jusqu’à ce qu’elle commence à s’engager contre

le mur. Faire pivoter le bec de baignoire dans sa

position normale contre le mur et finir de serrer la

vis d’arrêt. NE PAS TROP SERRER.

15

2-3" 2-3"

2 3/4 - 3 3/4 "2

3

/4 - 3 3/4 "

Page 17

LARGER HOLE AT TOP

TEMPERATURE EXTENSION

FLOW EXTENSION

5

4

Plus grande ouverture en haut Rallonge de température

Rallonge de débit

16

FIXATION DU BOUTON DE TEMPÉRATURE

1. S’assurer que la rallonge de température près

du haut du corps du robinet est tournée

entièrement dans le sens contraire des aiguilles

d’une montre.

2. Aligner le bouton de température avec la

rallonge de température en s’assurant que le

« 9 » sur l’anneau de prise est tourné vers le

haut, à la position 12 h.

3. Déplacer le bouton de température (6) vers la

rallonge de température jusqu’à ce que les

cannelures internes (projections sur le diamètre

interne) dans le bouton de température

commencent à engager les cannelures externes

de la rallonge de température.

4. Après que les cannelures commencent à

s’engager, faire pivoter de

plusieurs tours, la coquille

inférieure du bouton de

température dans le sens des

aiguilles d’une montre en tenant

la prise en caoutchouc pour

l’empêcher de tourner. Ce

pivotement filètera les filetages

intérieurs du bouton de

température dans les filetages

du corps du robinet. Continuer à

tourner la coquille inférieure

(libérer la prise en caoutchouc)

jusqu’à ce que la coquille

inférieure comprime la rosace

d’anneau (5) sur la rosace de base

(4). Pour que ce soit plus facile, tirer la coquille

inférieure vers soi en l’éloignant du mur de douche

et la tourner pour empêcher que le bouton se

désassemble. Noter que lorsque le bouton de

température se rapproche de la rosace de base, la

rosace de base et la rosace d’anneau devront être

déplacées vers le haut pour que la rosace d’anneau

soit centrée sur la coquille inférieure et que la partie

en plastique noir se prolongeant du bas du bouton

de température puisse passer par l’ouverture dans

la rosace de base. Serrer la coquille inférieure à la

main seulement. Vérifier que le « 9 » est toujours à

la position de 12 h. La fixation du bouton de

température est maintenant terminée.

Turn until "9" is at 12 o'clock position

Temperature extension turned

fully counter-clockwise

6

5

4

Pivoter jusqu’à ce que le « 9 » soit

à la position 12 h

Coquille inférieure

La rallonge de température

pivotée entièrement dans le

sens contraire des aiguilles

d’une montre.

Maintenir à la main la rosace

d’anneau au centre pendant le

filetage du bouton de température

dans la tige du robinet.

FIXATION DE LA ROSACE DE BASE

1. Fermer l’alimentation principale en eau chaude

et froide du robinet.

2. Pivoter la rallonge de température, près du haut

du corps du robinet, dans le sens contraire des

aiguilles d’une montre jusqu’à ce qu’elle s’arrête

(il se peut qu'elle soit déjà en position complète

du sens contraire des aiguilles d’une montre).

3. Pivoter la rallonge de débit blanche, près du bas

du corps du robinet, dans le sens des aiguilles

d’une montre jusqu’à ce qu’elle s’arrête (il se

peut qu'elle soit déjà en position complète du

sens des aiguilles d’une montre).

4. Placer la rosace de base (4) sur l’ouverture du

mur de la douche en s’assurant que la plus

grande ouverture de la rosace de base entoure

la rallonge filetée supérieure du robinet. La

rosace de base est correctement placée lorsque

le mot « Moen » est à l’endroit.

5. Placer le côté plat des deux rosaces d’anneau

(5) contre la rosace de base (4) : une rosace

d’anneau sur la rallonge de température et une

autre sur la rallonge de débit blanche. Les

rosaces d’anneau et la rosace de base seront

accrochées aux rallonges filetées du corps du

robinet.

4

Lower shell

Use your hand to center the ring

escutcheon as the temperature

knob is threaded onto valve stem.

Page 18

17

FIXATION DE LA POIGNÉE DE DÉBIT

1. S'assurer que la rallonge de débit blanche est tournée entièrement dans le sens des aiguilles d’une

montre. Aligner la poignée de débit (7) sur la rallonge de débit en s’assurant que la poignée pointe vers

le bas (position de 6 h).

2. Déplacer la poignée de débit vers la rallonge de débit jusqu’à ce que les cannelures internes dans la

poignée de débit commencent à engager les cannelures externes de la rallonge de débit.

3. Après que les cannelures commencent à s’engager, faire pivoter de plusieurs tours, la coquille de la

poignée de débit (7) dans le sens des aiguilles d’une montre en empêchant la poignée de tourner. Ce

pivotement filètera les filetages internes dans la poignée de débit sur les filetages du corps du robinet.

Continuer à tourner la coquille (lâcher la poignée) jusqu’à ce qu’elle comprime la rosace d’anneau (5)

sur la rosace de base (4). Pour que ce soit plus facile, tirer la coquille vers soi (en l’éloignant du mur

de la douche) en la tournant pour empêcher le bouton de se désassembler. Lorsque la poignée de débit

se rapproche de la rosace de base, la rosace d’anneau devra être déplacée vers le haut pour qu'elle

soit centrée sur la coquille inférieure. Serrer la coquille à la main seulement. La fixation de la poignée

de débit est maintenant terminée. La garniture de robinet est maintenant complètement assemblée et

le tout est prêt à fonctionner.

Flow extension turned

fully clockwise

Use your hand to center the ring

escutcheon as the handle is

threaded onto valve stem.

7

7

5

4

La rallonge de débit pivotée

entièrement dans le sens des

aiguilles d’une montre.

Centrer la rosace d’anneau à la

main pendant que la poignée est

filetée dans la tige du robinet.

ESSAI DE FONCTIONNEMENT

1. S’assurer que la poignée de débit (7) est complètement à la position de 6 h.

2. Ouvrir les alimentations en eau chaude et froide.

3. Faire pivoter le bouton de température complètement dans le sens contraire des aiguilles d’une montre

pour que le « 9 » soit à la verticale, soit à la position 12 h. Les chiffres représentent l’augmentation de

température : « 9 » est le plus chaud et « 1 » le plus froid.

4. Pivoter la poignée de débit dans le sens contraire des aiguilles d’une montre pour ouvrir le débit de la

pomme de douche ou du bec de baignoire.

5. Les températures du robinet thermostatique sont réglées pour passer de 29 °C, le « 1 » du bouton de

température, à 46 °C, le « 9 » du bouton de température. Si la température n’est pas d’environ 46 °C

lorsque le bouton est défini à « 9 », ou si on veut une température maximale plus élevée, il est possible

de réétalonner la plage de températures en suivant les directives de la section « Procédure de

réétalonnage ».

NOTE : Le réétalonnage visant à augmenter la température maximale peut aussi augmenter

toutes les températures de la plage.

ATTENTION : RISQUE DE BRÛLURE

Le robinet a été étalonné en usine pour fournir une température d’eau maximale de 46 °C.

Tout écart important de l’étalonnage des températures de l’alimentation de l’eau (de plus de

3 °C) par rapport à la température préréglée en usine durant la procédure d’étalonnage

peuvent poser des risques de brûlure. Il est donc important de vérifier la température de

l’eau avec le bouton de température défini à « 9 » pour déterminer la température maximale.

L’installateur est responsable d’installer et de réétalonner correctement ce robinet.

6. Fermer l’eau en tournant la poignée de débit complètement dans le sens des aiguilles d’une montre.

!

Page 19

Turn fully CCW

Temperature

extension tab

Temperature extension

Spindle

Retaining nut pin

Loosen and remove screw

PROCÉDURE DE RÉÉTALONNAGE

1. Pour réétalonner le robinet, il faut avoir accès à

la tige (située derrière la rallonge de

température, près du haut du robinet).

2. Pivoter la rallonge de température dans le sens

contraire des aiguilles d’une montre jusqu’à ce

qu’elle s’arrête.

3. Dévisser et enlever la vis au centre de la

rallonge de température en la tournant dans le

sens contraire des aiguilles d’une montre.

4. Enlever délicatement la rallonge de température

sans tourner la rallonge ou la tige derrière elle.

Vous avez maintenant accès à la tige.

5. Pour augmenter la température, pivoter la tige

dans le sens contraire des aiguilles d’une

montre une ou deux cannelures après la marque

de l’écrou de retenue. Pour diminuer la

température, pivoter la tige dans le sens des

aiguilles d’une montre une ou deux cannelures

après la marque de l’écrou de retenue.

6. Replacer la rallonge de température tournée

complètement dans le sens contraire des

aiguilles d’une montre en s’assurant que l’onglet

est aussi près que possible du côté droit de la

broche dans l’écrou de retenue, sans faire

pivoter la tige. Ne pas installer la vis.

7. Pivoter la poignée de débit dans le sens

contraire des aiguilles d’une montre pour ouvrir

le débit d’eau.

8. Après que la température d’eau a été stabilisée,

vérifier la température. La nouvelle température

maximale est maintenant définie. Si la

température ne convient pas, enlever la rallonge

de température comme décrit ci-dessus et

reprenez les étapes pour régler la température

de l’eau.

9. Lorsque la température maximale est celle qui

est voulue, réinstaller la vis dans la rallonge de

température et serrer.

10. Suivre les directives de « Fixation du bouton de

température » pour réinstaller le bouton de

température.

18

Pivoter complètement

vers la gauche.

Dévisser et enlever la vis

Tige

Broche d’écrou de retenue

Rallonge de température

Tige avec la rallonge de

température en place

Augmenter la température

Diminuer la température

Tige avec rallonge de

température enlevée

Broche d’écrou de retenue

Onglet de la

rallonge de

température

Spindle with

temperature

extension in place

Increase temperature

Decrease temperature

Retaining nut pin

Spindle w/ temperature

extension removed

Page 20

Moen Incorporated • 25300 Al Moen Drive • North Olmsted, OH 44070-8022 U.S.A.

In Canada Moen Inc. • 2816 Bristol Circle • Oakville, Ontario L6H5s7

Robinets fabriqués à partir d'alliages de laiton de plomb pourraient contribuer des petites quantités de plomb à

l'eau qu'on laisse stagner en contact avec ledit laiton. La quantité de plomb contribuée par n'importe quel robinet

est supérieure lorsque le robinet est neuf. Les procédés qui suivent peuvent réduire l'exposition au plomb

provenant de robinets et autres pièces du système de tuyauterie:

• Toujours faire couler l'eau pendant quelques secondes avant de s'en servir pour boire ou cuire

• Utiliser uniquement l'eau froide pour boire ou cuire

• En cas ou l'on désire purger le sysème entier de plomberie de l'eau stagnante dans les tuyaux ou autres

montages, laisser couleur l'eau jusqu'à ce que la température de l'eau tombe, indicant ainsi que l'eau provient

du conduit extérieur

• Si la teneur en plomb de votre eau vous inquiète, la faire tester par un laboratoire régional certifié.

Les produits Moen ont été fabriqués selon les normes de qualité et de main-d’œuvre les plus élevées. Moen

garantit à la personne ayant acheté le robinet originalement, aussi longtemps qu’elle reste propriétaire de la maison,

(période de garantie pour propriétaires), que ce robinet sera libre de toute fuite ou d’égouttement pendant son usage

normal et que toutes les pièces et tous les finis de ce robinet ne présenteront aucun défaut de matériel et de maind’œuvre en usine. L’achat par tout autre consommateur (acheteur à des fins industriels, commerciales et d’affaires)

sera garanti pendant 5 ans à compter de la date d’achat originale (période de garantie pour non-propriétaires).

Si ce robinet fuit ou dégoutte durant la période de garantie, Moen remplacera GRATUITEMENT les pièces de

remplacement requises pour remettre le robinet en parfait état et remplacera GRATUITEMENT toute pièce ou tout fini

dont le matériel, la fabrication ou la main-d’œuvre, lors d’une installation, d’un usage et d’un service normaux,

s’avère défectueux. On peut obtenir les pièces de remplacement en composant le 1 800 465-6130, ou en écrivant

à l’adresse indiquée sous la preuve d’achat. Le reçu de vente original du consommateur ayant acheté le robinet

initialement, doit accompagner toute réclamation. Les défauts ou les dommages causés par l’utilisation de pièces

non fournies par Moen ne sont pas couvertes par cette garantie. Cette garantie s’applique uniquement aux robinets

achetés après décembre 1995 et entre en vigueur à compter de la date d’achat indiquée sur le reçu de caisse du

consommateur.

Cette garantie est vaste car elle couvre le remplacement de toute pièce ou de tout fini défectueux. Cependant, les

dommages causés par une erreur l’installation, un abus du produit, une mauvaise utilisation du produit ou

l’utilisation de nettoyeurs contenant des agents abrasifs, de l’alcool ou des solvants organiques, qu’ils soient utilisés

par un entrepreneur, une entreprise de service ou le consommateur, sont exclus de cette garantie. Moen n’est pas

responsable des frais de main-d’œuvre ni de tous dommages survenus durant l’installation, la réparation ou le

remplacement, ni des dommages indirects ou consécutifs, des pertes, des blessures ou des coûts connexes à ce

robinet. Sauf lorsque prévu par la loi, cette garantie remplace et exclut toute autre garantie et condition, qu’elles

soient exprimées ou sous-entendues, obligatoires ou autres, y compris sans restriction, celle de commercialisation

ou d’aptitude d’utilisation.

Certains pays, certains États et certaines provinces, ne permettent aucune exclusion, ni limitation suite aux

dommages indirects ou consécutifs. Les limitations ou les exclusions ne s’appliquent donc pas dans ces cas. Cette

garantie accorde des droits juridiques et il est possible que d’autres droits soient applicables selon l’état, la province

ou le pays précis. Moen avisera le consommateur de la procédure à suivre pour soumettre une réclamation. Il suffit

d’écrire à Moen incorporée, d’expliquer le défaut et d’inclure une preuve d’achat, d’inscrire son nom, adresse ainsi

que code régional et numéro de téléphone.

APPELER SANS FRAIS NOTRE

SERVICE À LA CLIENTÈLE

Appeler notre Service à la clientèle pour obtenir des

renseignements sur nos produits, leur l’installation ou sur

notre garantie.

Toronto : (905) 829-3400

Ailleurs au Canada : 1 800 465-6130

Aux É.-U. :1 800 289-6636

Au Mexique :

(84) 88-08-26, 88-08-27,

o 91-800-84-345

GARANTIE À VIE LIMITÉE DE MOEN

INFORMATION POUR LE CONSOMMATEUR

© MOEN INCORPORATED 2000

PRINTED IN USA

INS235A MAY 00

Loading...

Loading...