Page 1

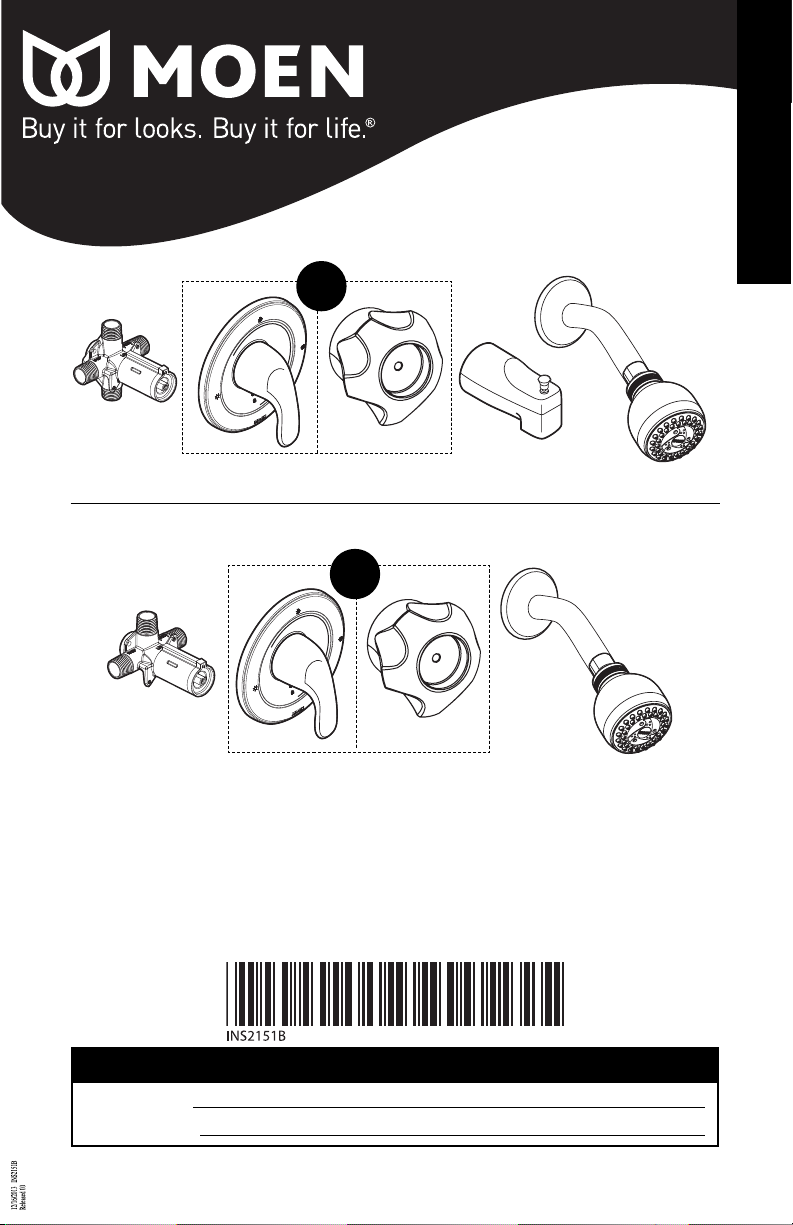

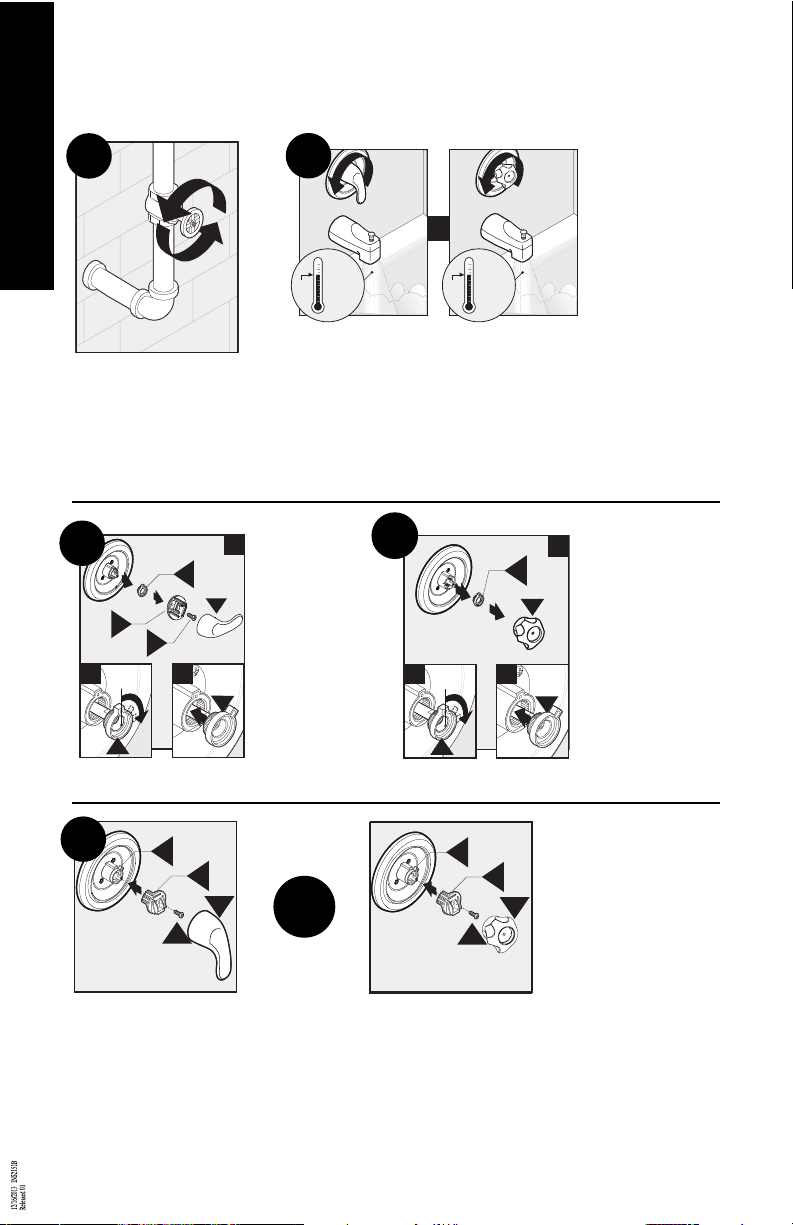

OR

▲

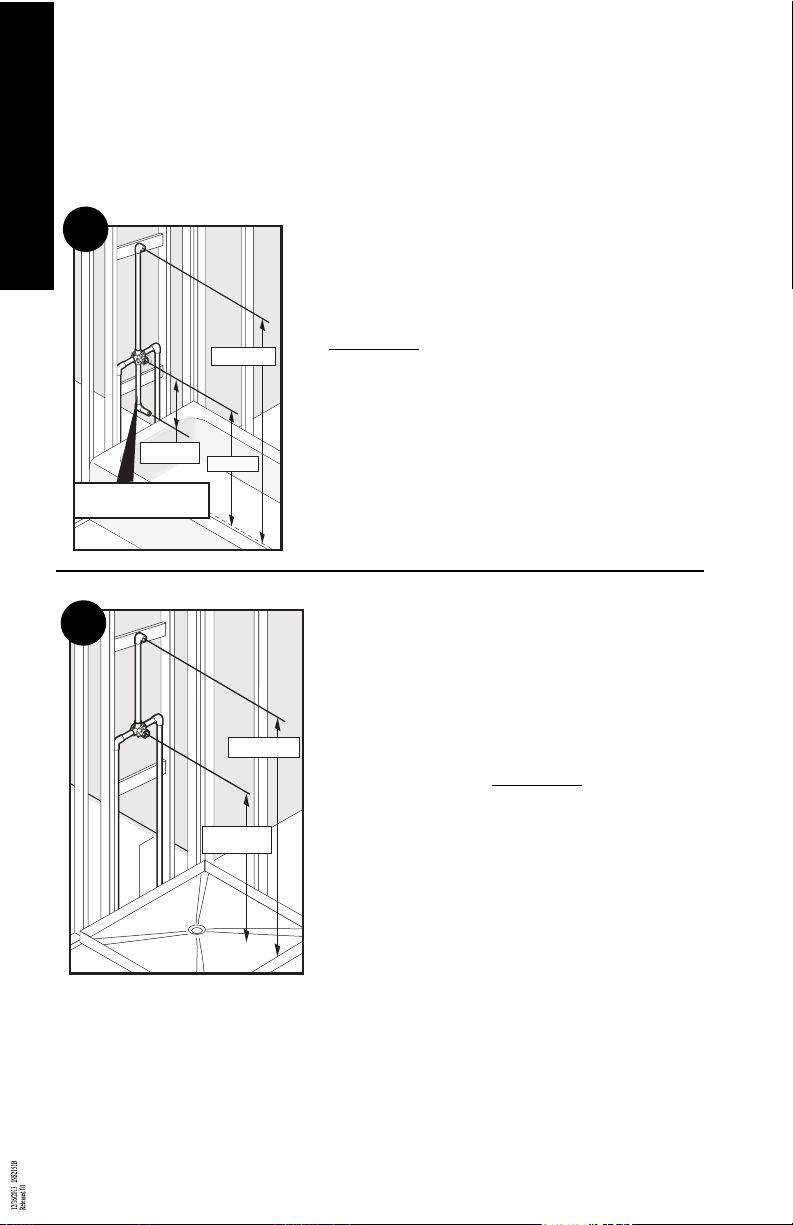

One Handle Tub/Shower Valve Trim

One Handle Shower Only Valve Trim

▲

OR

INS2151B - 8/13

English

Model Number

Installation Date

Installation Instructions

Styles and parts vary by model.

For Warranty Support

E1

Page 2

Thank you for choosing Moen.

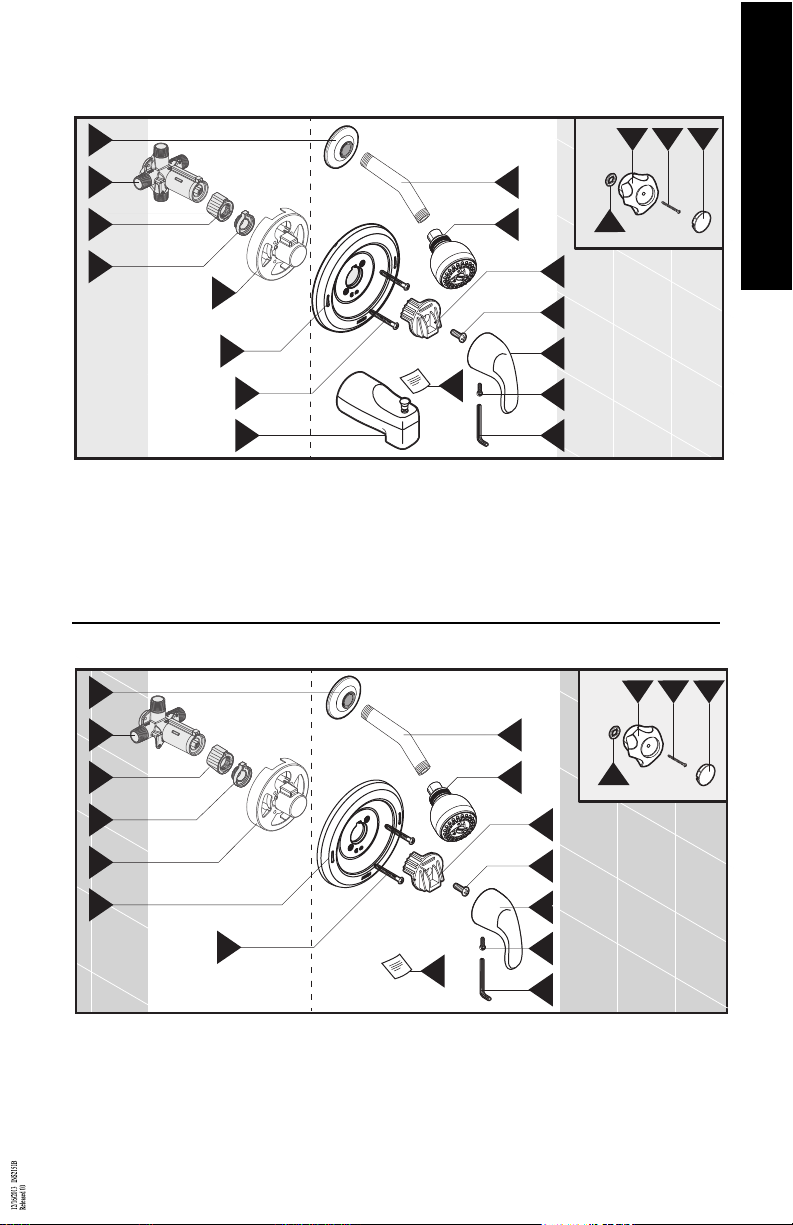

A

K

J

N

H

C

D

E

F

S

R Q P

O

x2

G

I

Z

B

L

Installs behind wall. Installs on wall exterior.

M

A

K

J

L

M

N

B

C

D

E

F

O

R Q P

H

I

G

x2

Z

Installs behind wall. Installs on wall exterior.

English

Please Contact Moen First

For Installation Help, Missing or Replacement Parts

USA

1-800-BUY-MOEN

1-800-289-6636

Mon. - Fri. 8:00 a.m. to 8:00 p.m. EST

Sat. 9:00 a.m. to 5:30 p.m. EST

1-800-465-6130

Mon. - Fri. 7:30 a.m. to 8 :00p.m. EST

CANADA

www.moen.ca

www.moen.com

Table of Contents

Tub/Shower Parts Supplied ................................................................................................E3

Shower Only Parts Supplied ..............................................................................................E3

Rough-in Plumbing Variations

Copper ..................................................................................................................................E4

IPS............................................................................................................................................E4

PEX ..........................................................................................................................................E5

CVPC ......................................................................................................................................E5

Helpful Tools..................................................................................................................E4-E5

Installation Schematics ........................................................................................................E6

Thin Wall/Thick Wall and Plaster Ground Installation ........................................E7-E8

Trim Installation................................................................................................................E8-E9

Setting the Temperature Limit Stop ....................................................................E10-E11

Warranty..................................................................................................................................E11

Care Instructions ..................................................................................................................E12

Troubleshooting Guide......................................................................................................E12

E2

Page 3

A

K

J

N

H

C

D

E

F

S

R Q P

O

x2

G

I

Z

B

L

Installs behind wall. Installs on wall exterior.

M

A

K

J

L

M

N

B

C

D

E

F

O

R Q P

H

I

G

x2

Z

Installs behind wall. Installs on wall exterior.

Visit Moen.com for product specific parts diagrams.

Styles and parts vary by model.

Tub/Shower Parts Supplied

A. Shower Arm Flange

B. 4 Port Valve and Stop Tube

C. Key Stop

D. Adjustable Temperature Limit Stop

E. Plaster Ground

F. Escutcheon

G. Escutcheon Screws (2-3/16”)

H. Shower Arm

I. Showerhead

J. Lever Handle Adapter

K. Adapter Screw (1/2”)

L. Lever Handle

M. Hex Screw

Shower Only Parts Supplied

N. 7/64” Hex Wrench

O. Double D Washer

P. Knob

Q. Phillips Screw – Knob (1-1/2”)

R. Knob Cap

S. Tub Spout

Z. Product Identification Label

English

A. Shower Arm Flange

B. 3 Port Valve and Stop Tube

C. Key Stop

D. Adjustable Temperature Limit Stop

E. Plaster Ground

F. Escutcheon

G. Escutcheon Screws (2-3/16”)

H. Shower Arm

I. Showerhead

J. Lever Handle Adapter

K. Adapter Screw (1/2”)

L. Lever Handle

M. Hex Screw

N. 7/64” Hex Wrench

O. Double D Washer

P. Knob

Q. Phillips Screw – Knob (1-1/2”)

R. Knob Cap

Z. Product Identification Label

E3

Page 4

P

i

p

e

J

o

i

n

t

C

o

m

p

o

u

n

d

Wire Brush

Phillips Screwdriver

Tube Cutter

Crescent Wrench

Measuring TapeSafety Glasses

Thermometer

Thread Seal Tape

Lead-free Solder Kit

Torch

Pipe Joint Compound

Flashlight

Key Hole Saw

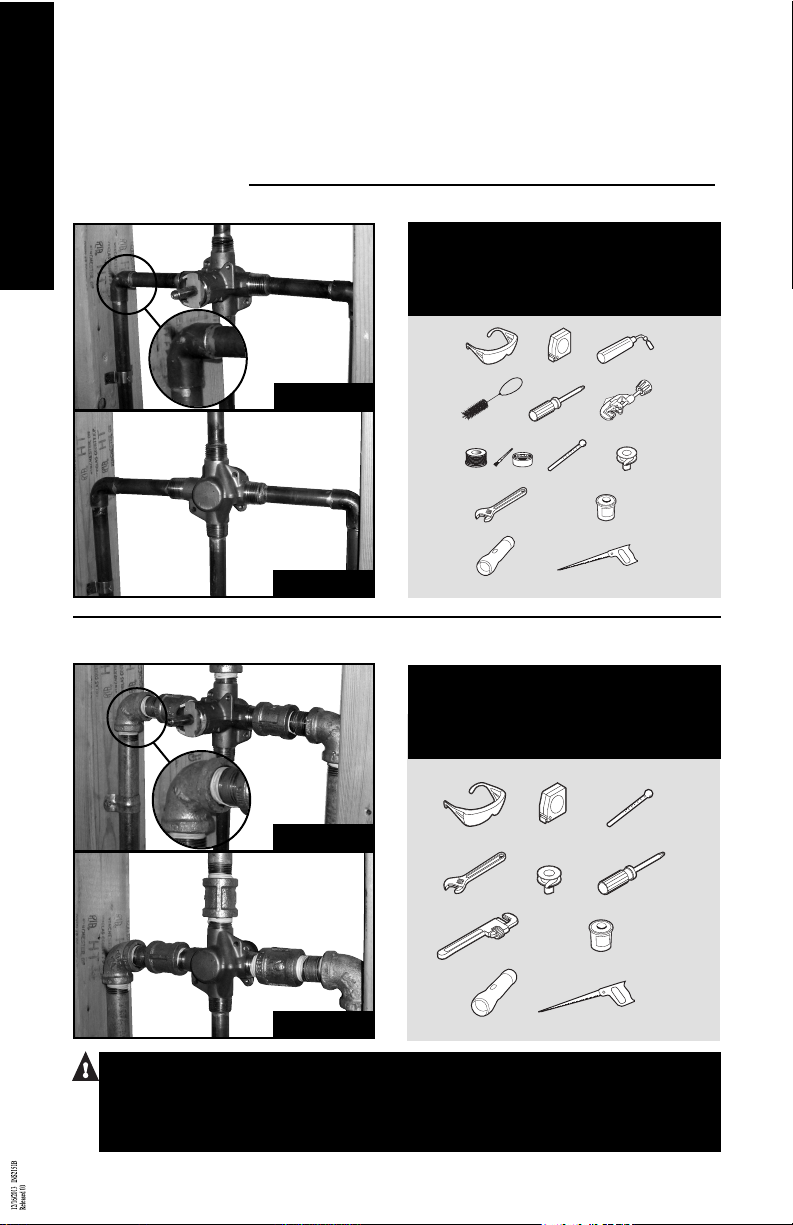

1. Determining Your Existing Rough-In Plumbing Installation

P

i

p

e

J

o

i

n

t

C

o

m

p

o

u

n

d

Phillips Screwdriver

Full Circle Crimping Tool

Flashlight Key Hole Saw

Measuring TapeSafety Glasses

Thermometer Tubing Cutter

Thread Seal Tape

Pipe Joint Compound

Crescent Wrench

C

P

V

C

C

e

m

e

n

t

C

P

V

C

C

l

e

a

n

e

r

P

i

p

e

J

o

i

n

t

C

o

m

p

o

u

n

d

Phillips Screwdriver

CPVC Cement CPVC Cleaner

Measuring TapeSafety Glasses

Thermometer Tubing Cutter

Thread Seal Tape

Pipe Joint Compound

Crescent Wrench

Flashlight Key Hole Saw

P

i

p

e

J

o

i

n

t

C

o

m

p

o

u

n

d

Phillips Screwdriver

Adjustable Wrench

Measuring TapeSafety Glasses

Thermometer

Thread Seal Tape

Pipe Joint Compound

Crescent Wrench

Flashlight Key Hole Saw

If you are replacing your plumbing valve, see below for four common plumbing methods. Specific rough-in fittings are not supplied. These may be

required for installation. Remove existing handle and valve trim before

replacing your valve. Please follow all local building and plumbing codes.

English

Copper

Helpful Tools

For safety and ease of faucet replacement,

Moen recommends the use

of these helpful tools.

Front View

Back View

IPS – (Galvanized Iron Pipe/Threaded Connections)

CAUTION – TURN HOT & COLD WATER SUPPLIES OFF BEFORE REMOV-

ING YOUR CURRENT FAUCET OR DISASSEMBLING YOUR CURRENT

VALVE. OPEN FAUCET HANDLE TO RELIEVE WATER PRESSURE AND

ENSURE COMPLETE WATER SHUT-OFF HAS BEEN ACCOMPLISHED.

Helpful Tools

For safety and ease of faucet replacement,

Moen recommends the use

of these helpful tools.

Front View

Back View

E4

Page 5

P

i

p

e

J

o

i

n

t

C

o

m

p

o

u

n

d

Phillips Screwdriver

Full Circle Crimping Tool

Flashlight Key Hole Saw

Measuring TapeSafety Glasses

Thermometer Tubing Cutter

Thread Seal Tape

Pipe Joint Compound

Crescent Wrench

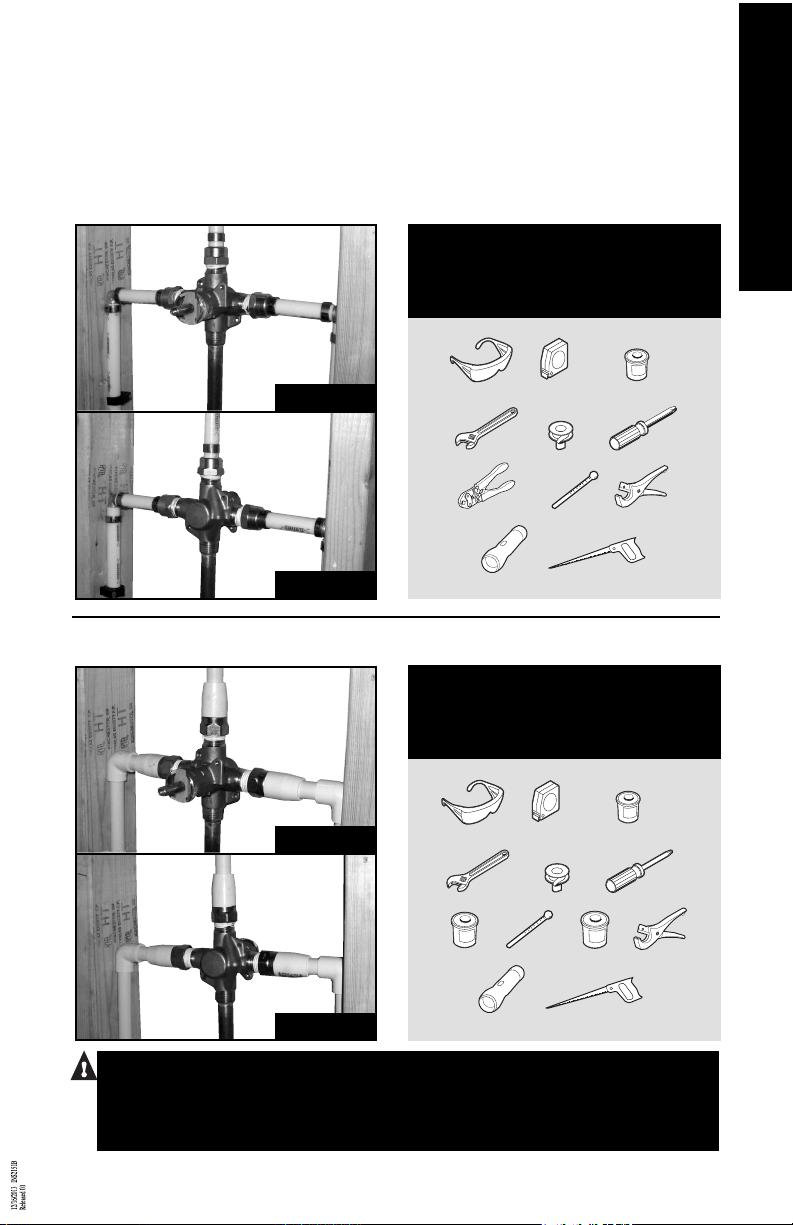

PEX

C

P

V

C

C

e

m

e

n

t

C

P

V

C

C

l

e

a

n

e

r

P

i

p

e

J

o

i

n

t

C

o

m

p

o

u

n

d

Phillips Screwdriver

CPVC Cement CPVC Cleaner

Measuring TapeSafety Glasses

Thermometer Tubing Cutter

Thread Seal Tape

Pipe Joint Compound

Crescent Wrench

Flashlight Key Hole Saw

CPVC

English

Helpful Tools

For safety and ease of faucet replacement,

Moen recommends the use

of these helpful tools.

Front View

Back View

CAUTION – TURN HOT & COLD WATER SUPPLIES OFF BEFORE REMOV-

ING YOUR CURRENT FAUCET OR DISASSEMBLING YOUR CURRENT

VALVE. OPEN FAUCET HANDLE TO RELIEVE WATER PRESSURE AND

ENSURE COMPLETE WATER SHUT-OFF HAS BEEN ACCOMPLISHED.

Helpful Tools

For safety and ease of faucet replacement,

Moen recommends the use

of these helpful tools.

Front View

Back View

E5

Page 6

Use 1/2" Copper or

IPS Pipe Only

78" (1981mm)

32" (813mm)

6" (152mm) Min.

11" (229mm) Max.

E

4-1/2"

(114mm)

more than 1/4"

(6mm)

2-1/4" min.

(57mm)

3-1/2" max.

(89mm)

less than 1/4"

(6mm)

3/4"

(19mm)

E

G

B

F

3

2

F

Z

1

E

2. Installation Schematics –

78” (1981mm)

45-48”

(1143-1219mm)

Measuring for Ideal Tub/Shower Performance

Installation of this product at non-recommended measurements may

lead to issues such as water discharge from the showerhead during

English

tub fill mode.

2.1

2.2

Tub/Shower

Position the valve body 32 inches from the floor of the

tub basin. The shower arm should be placed 78 inches

above the floor of the tub basin (recommended installation of the shower arm is with a flanged elbow fitting –

not included – and attached to a wood brace). The tub

spout is to be no less than 6 inches and no greater than

11 inches below the valve. If installing a threaded tub

spout, connect to the valve with 1/2 inch pipe or 1/2 inch

copper tubing with a threaded adapter. If installing a slipfit tub spout, connect to the valve with only copper tubing – no threaded adapter is needed.

See step 4.3 for tub spout tube length.

Shower Only

The center of the valve should be 45 inches to 48 inches

above the shower stall floor. The shower arm should be

placed 78 inches above the floor of the shower stall floor

(recommended installation of the shower arm is with a

flanged elbow fitting – not included – and attached to a

wood brace).

E6

Page 7

E

4-1/2"

(114mm)

more than 1/4"

(6mm)

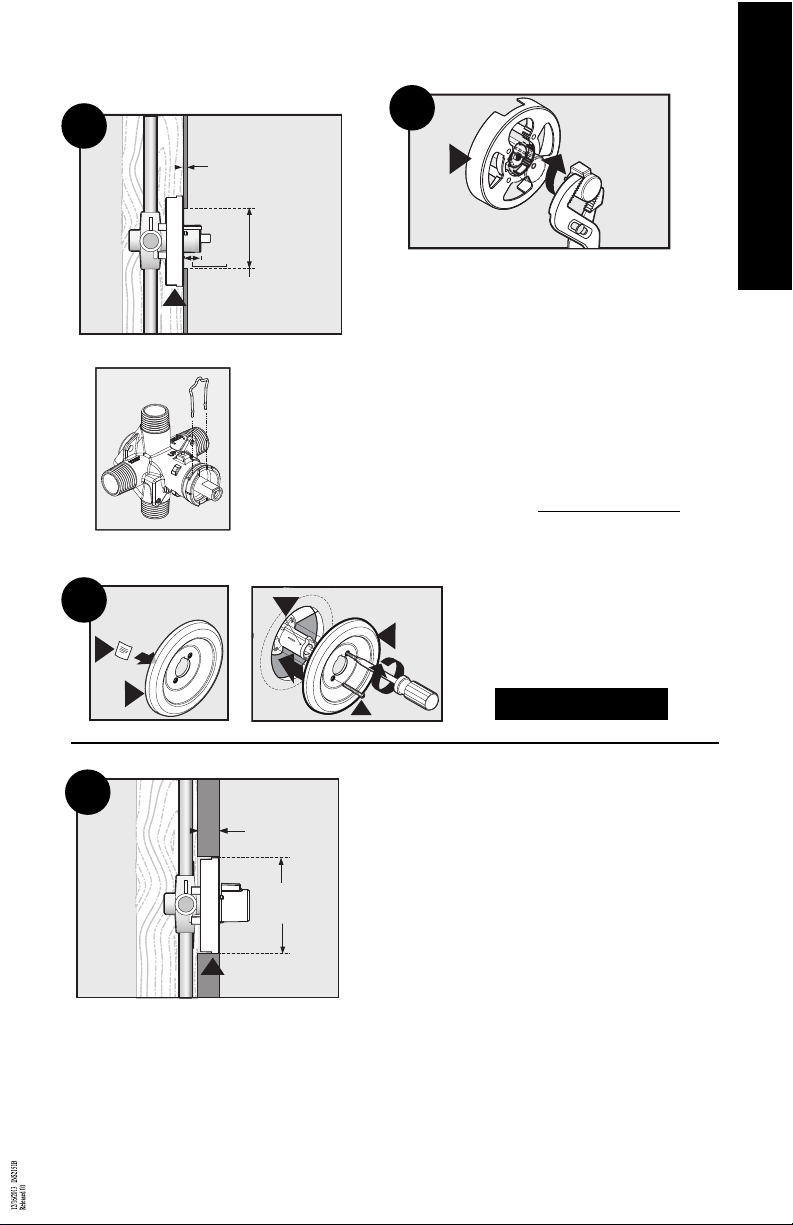

3. Installing Your Valve

2-1/4" min.

(57mm)

3-1/2" max.

(89mm)

less than 1/4"

(6mm)

3/4"

(19mm)

E

G

B

F

3

2

F

Z

1

E

3.1

3.2

English

Thin Wall Installation

1

/4 inch

,

Ensure cartridge

retainer clip is

installed prior to

escutcheon

installation.

For Walls Thinner Than

3.1 The “Thin Wall” method is used when the

tub/shower wall is less than 1/4 inches

thick (such as fiberglass tub surround)

and will be the main source of support for

the valve. The plaster ground (E) remains

attached to the valve. A 2-1/4 inches to 31/2 inches diameter hole is cut thru the wall

for this method.

3.2 Break away the black plastic protective cover

using pliers and rotating clockwise.

3.3 Remove the escutcheon screws (G), place product

identification label (Z) on back of escutcheon

make sure wall is clean, place the escutcheon (F)

over the stop tube (B), then reinstall the screws (G).

A gasket on the back of the escutcheon provides a

seal against the finished wall.

3.3

Go To Step 4.1

Thick Wall Installation

3.4

For Walls Thicker Than

3.4 The “Thick Wall” installation method is used

when the tub/shower wall is greater than 1/4

inches thick. “Thick Walls” are usually built up with

materials such as cement board, drywall, tile, etc. The

valve is secured by straps (not included)holding

the water inlet lines to the framing members (2X4’s)

as shown in steps 2.1 and 2.2. The valve also features

mounting holes to screw the valve to a cross member attached behind the valve if desired.

Attach the plaster ground (E) to the valve body using

the 2-3/16 inches escutcheon screws (G). Keep the

plaster ground (E) attached to the valve until the

valve has been positioned and secured. The plaster

ground (E) is positioned so that it is flush with the finished wall. This ensures that the valve will be at the

correct position to accept the trim.

The hole in the wall should be the same size (4-1/2

inches) as the plaster ground (E). This hole will allow

access for future servicing if necessary.

E7

1

/4 inch

Page 8

Slightly ti ghten

set screw.

5/32"

Hex

Not

Included

No sharp edges/burrs on end of pipe.

2

S

1

1

2

2

1

S

C

D

NO

YES

L

P

F

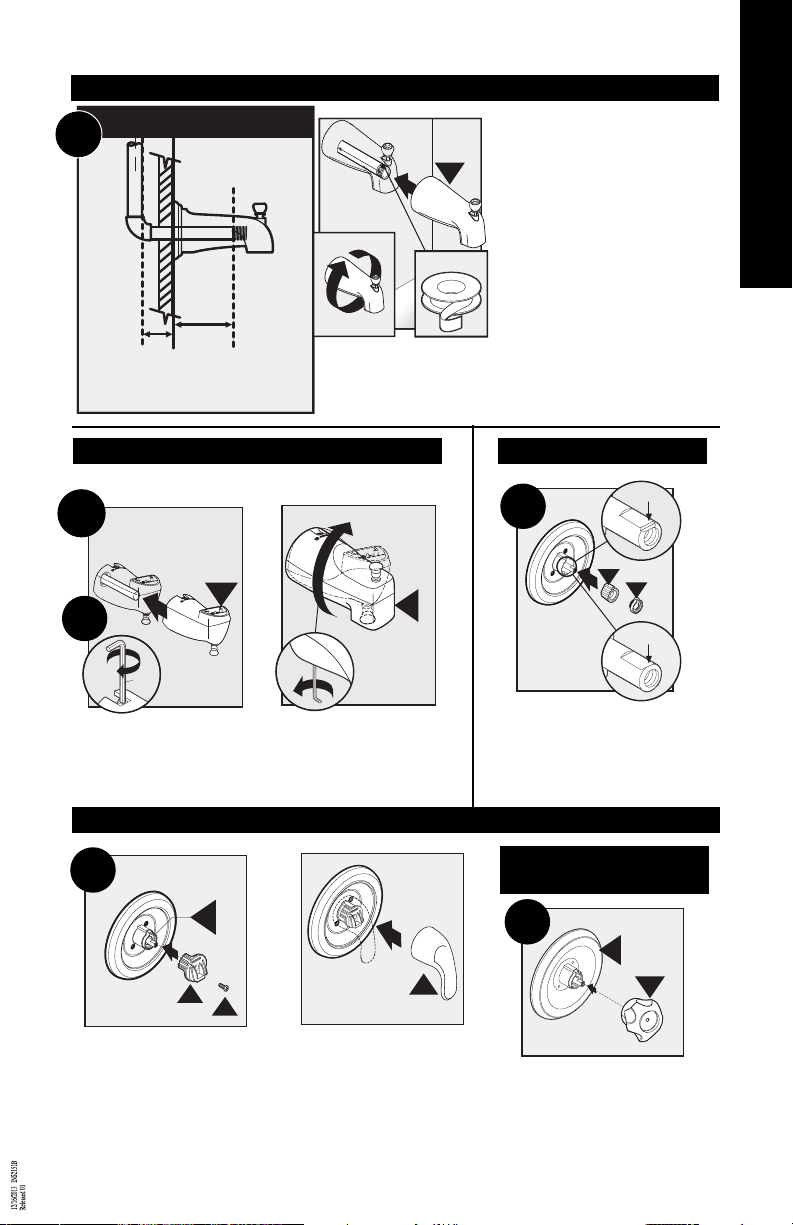

Tub Spout Installation

(y) + (x) + 1/4” = Pipe Length

To determine the proper pipe length, measure from the inside elbow

shoulder to the wall (y) and from the threaded adapter inside of the

tub spout to the base of the tub spout (x), then add 1/4”.

y

x

1

Thread seal tape

S

2

E

G

G

B

F

3

2

F

Z

1

3.5

2

H

1

Thread Seal Tape

2

I

1

A

Thread Seal Tape

3

H

2

I

1

A

Thread Seal Tape

3

H

J

D

K

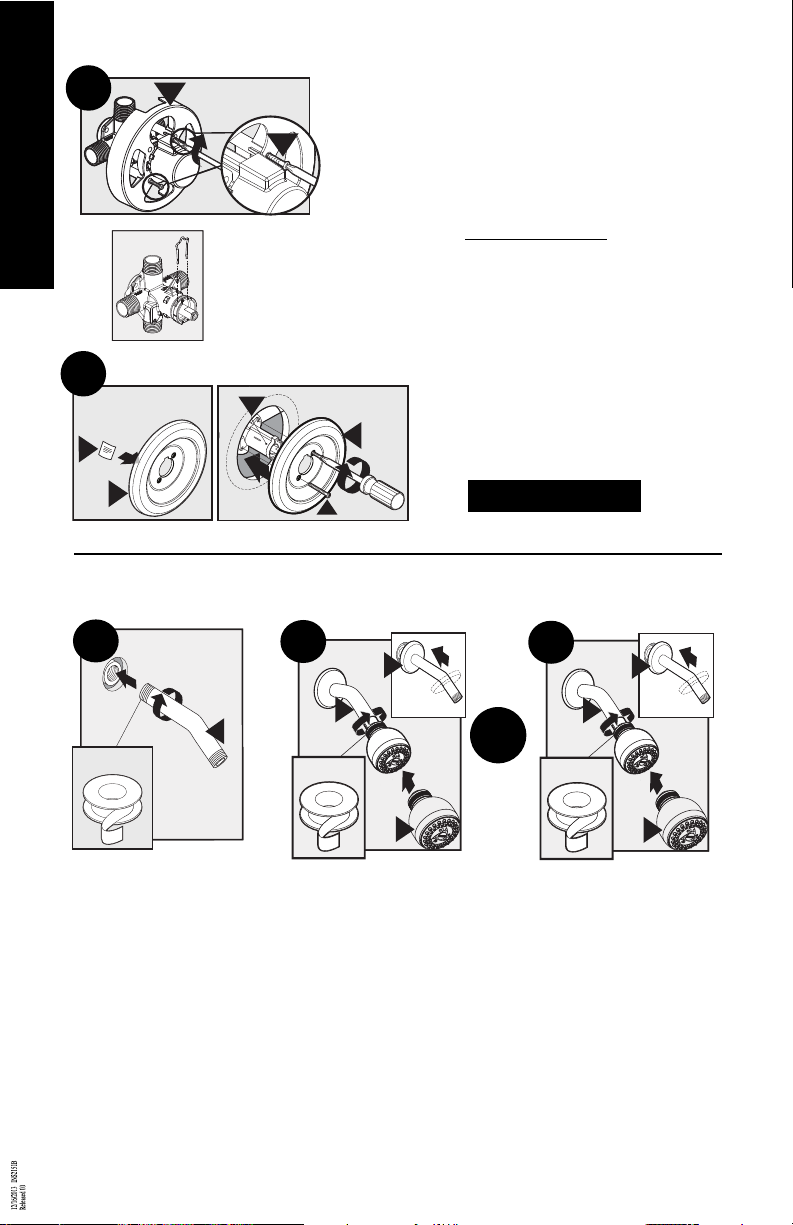

3.5 Once the valve is secured in place,

remove the escutcheon screws

(G) and the plaster ground (E).

Keep the escutcheon screws (G)

for installation of the escutcheon

English

(F) and discard the plaster

ground (E).

3.6 Place product identification label

Ensure cartridge

retainer clip is

installed prior to

escutcheon

installation.

(Z) on back of escutcheon

sure wall is clean, place the

escutcheon (F) over the stop tube

then re-install the screws (G).

(B)

A gasket on the back of the

escutcheon provides a seal

against the wall.

3.6

Go To Step 4.1

4. Installing Your Moen Tub/Shower Trim

, make

4.1

Wrap thread seal tape

around the threads of

the shower arm (H) then

screw the arm into the

threaded connection in

the wall.

If there is a rubber washer

inside the threaded

adapter on the showerhead, continue to step

4.2A. If there is no rubber

washer, then proceed to

step 4.2B.

4.2A

4.2B

OR

4.2A Plastic Shower Ball

Seal around the shower arm

hole with sealant (caulk) then

slide shower flange (A) over

shower arm (H). Remove any

debris from the shower arm

to ensure proper flow. Then,

simply thread showerhead (I)

onto shower arm (H).

E8

4.2B Metal Shower Ball

Seal around the shower arm

hole with sealant (caulk)

then slide shower flange (A)

over shower arm (H). Wrap

thread seal tape around

threads at bottom of shower

arm (H). Remove any debris

from the shower arm to

ensure proper flow. Thread

showerhead (I) onto shower

arm (H).

Page 9

Slightly ti ghten

set screw.

5/32"

Hex

Not

Included

No sharp edges/burrs on end of pipe.

2

S

1

1

2

2

1

S

C

D

NO

YES

L

P

F

Tub Spout Installation

(y) + (x) + 1/4” = Pipe Length

To determine the proper pipe length, measure from the inside elbow

shoulder to the wall (y) and from the threaded adapter inside of the

tub spout to the base of the tub spout (x), then add 1/4”.

y

x

1

Thread seal tape

S

2

4.3A

J

D

K

Threaded Tub Spout Installation

If this is a shower only

installation, skip to step 4.4.

IPS (threaded) spouts are

designed to screw onto a pipe

with 1/2 inch male pipe threads.

To determine the proper pipe

length, measure from the inside

elbow shoulder to the wall (y)

and from the threaded adapter

inside of the tub spout to the

base of the tub spout (x), then

add 1/4”. Place thread seal tape

around the pipe threading and a

sealant (plumbers putty or caulk)

around the base of the pipe to

prevent leaking behind the wall.

English

Slip Fit Tub Spout Installation

4.3B

OR

Some models may feature a slip fit installation with no

threaded adapter in the tub spout. For these installations, slip the tub spout onto pipe pointing up and

slightly tighten the set screw. Rotate tub spout to final

position and fully tighten set screw in place.

For Lever Handles Installed with Plastic Handle Adapter (J)

4.5

If this is a lever handle that

attaches with the lever handle

adapter (J), attach the plastic

handle adapter (J) to the cartridge stem using the 1/2 inch

adapter screw (K). Make sure

the ridges on the back of the

adapter (J) are to the left of the

tab on limit stop (D).

Place the lever (L) on the

lever handle adapter.

E9

Cartridge Orientation

4.4

Now you are ready to attach the

handle. Rotate so the notch at the

end of the stem is facing down

towards the drain. Insert the key

stop (C) and the adjustable limit

stop (D) into stop tube as shown.

Other Possible Handle

Type Installations

4.6

Place the knob handle

(P) – onto the cartridge make sure the indicator

on the knob is pointing

down.

Page 10

2

-

+

D

D

D

J

K

1

1

3

L

D

J

K

L

L

N

M

OR

HOTTEST

120F

(49C)

HOTTEST

120F

(49C)

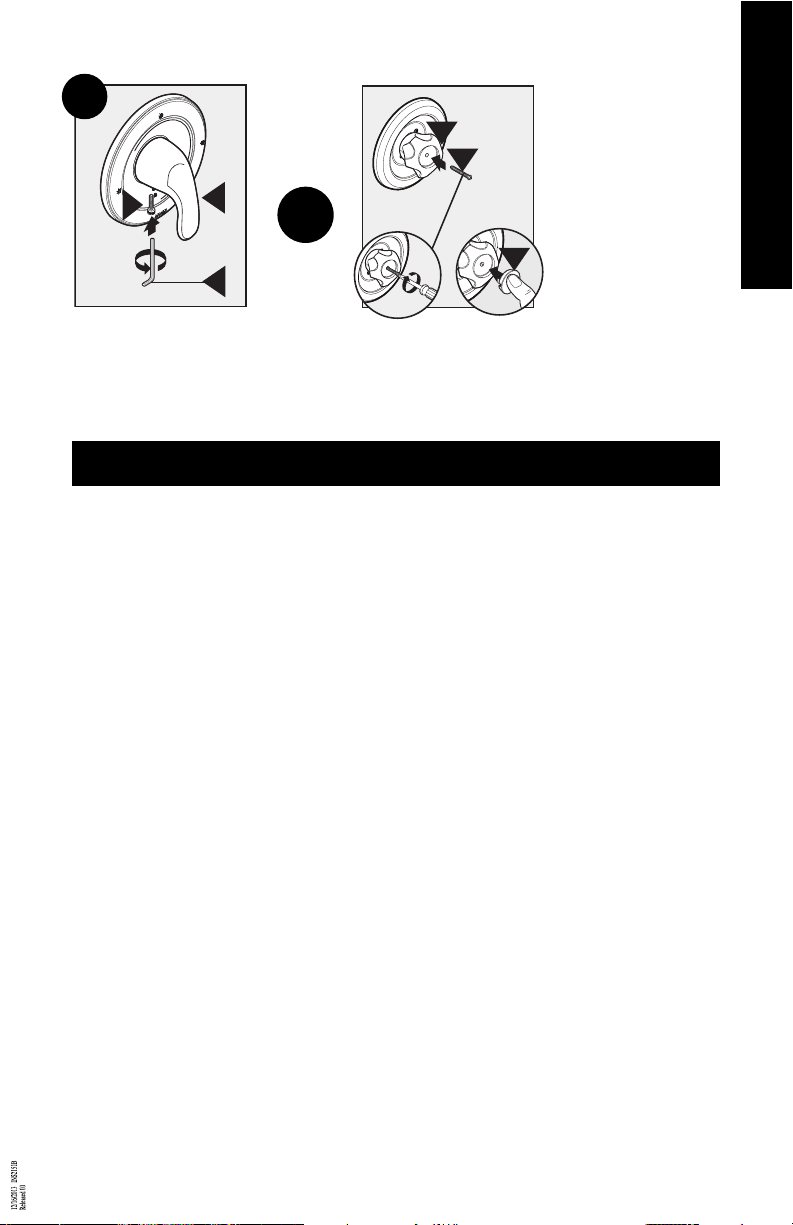

Setting The Temperature Limit Stop and Finishing Your

1

-

+

D

D

D

P

2

1

3

P

Q

R

1

2

D

J

K

L

5.

Tub/Shower Installation

5.1

English

Turn on the hot and cold

water supply to check for

leaks and set temperature

limit stop.

5.3

5.2

Rotate the lever OR knob counterclockwise until the water is to the

maximum desired temperature, not to exceed 120 degrees F

(49 degrees C). Seasonal maintenance of the maximum outlet

temperature may be required due to changes in

groundwater temperature. TURN LEVER OR KNOB TO THE OFF

POSITION ONCE THE TEMPERATURE IS SET.

If temperature exceeds 120 degrees, go to step 5.3.

If temperature is less than 120 degrees, go to step 5.4.

OR

Remove the lever (L)

and lever handle

adapter (J).

Note the position of

the stop. Position the

adjustable temperature limit stop (D) so

the lever or knob stops

at that position. This

prevents the lever or

knob from being

turned into an unsafe

temperature.

Remove the knob handle (P). Note the position of the stop.

Position the adjustable

temperature limit stop

(D) so the lever or knob

stops at that position.

This prevents the lever

or knob from being

turned into an unsafe

temperature.

5.4

OR

After setting the adjustable

temperature limit stop to the

desired position, remove the

lever (L), reattach the lever

handle adapter (J), adapter

screw (K), and lever (L) – make

sure ridges on back of (J) are to

the left of the tab on (D).

After setting the adjustable

temperature limit stop to

the desired position, reattach the double D washer

(O) and knob (P) – make

sure indicator on the knob

is pointing down.

E10

Page 11

L

N

M

5.5

P

Q

R

1

2

English

OR

Using 7/64 inches hex wrench

(N), insert and tighten hex

screw (M) into lever (L).

OR insert 1-1/2 inch Phillips

screw (Q). Tighten screw

and insert cap (R).

Moen Lifetime Limited Warranty

Moen products have been manufactured under the highest standards of quality and

workmanship. Moen warrants to the original consumer purchaser for as long as the original

consumer purchaser owns their home (the “Warranty Period” for homeowners), that this faucet

will be leak- and drip-free during normal use and all parts and finishes of this faucet will be free

from defects in material and manufacturing workmanship. All other purchasers (including

purchasers for industrial, commercial and business use) are warranted for a period of 5 years

from the original date of purchase (the “Warranty Period” for non-homeowners).

If this faucet should ever develop a leak or drip during the Warranty Period, Moen will FREE OF

CHARGE provide the parts necessary to put the faucet back in good working condition and will

replace FREE OF CHARGE any part or finish that proves defective in material and manufacturing

workmanship, under normal installation, use and service. Replacement parts may be obtained

by calling 1-800-289-6636 (Canada 1-800-465-6130), or by writing to the address shown. Proof

of purchase (original sales receipt) from the original consumer purchaser must accompany all

warranty claims. Defects or damage caused by the use of other than genuine Moen parts is not

covered by this warranty. This warranty is applicable only to faucets purchased after December,

1995 and shall be effective from the date of purchase as shown on purchaser’s receipt.

This warranty is extensive in that it covers replacement of all defective parts and finishes.

However, damage due to installation error, product abuse, product misuse, or use of cleaners

containing abrasives, alcohol or other organic solvents, whether performed by a contractor,

service company, or yourself, are excluded from this warranty. Moen will not be responsible for

labor charges and/or damage incurred in installation, repair or replacement, nor for any indirect,

incidental or consequential damages, losses, injury or costs of any nature relating to this faucet.

Except as provided by law, this warranty is in lieu of and excludes all other warranties, conditions

and guarantees, whether expressed or implied, statutory or otherwise, including without

restriction those of merchantability or of fitness for use.

Some states, provinces and nations do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitations or exclusions may not apply to you. This

warranty gives you specific legal rights and you may also have other rights which vary from

state to state, province to province, nation to nation. Moen will advise you of the procedure to

follow in making warranty claims. Simply write to Moen Incorporated using the address below.

Explain the defect and include proof of purchase and your name, address, area code and

telephone number.

25300 Al Moen Drive, North Olmsted, Ohio 44070-8022 U.S.A.

Moen Incorporated

E11

Page 12

Care Instructions

To preserve the finish on the metallic parts of your Moen faucet, apply non-abrasive wax, such as car wax. Any

cleaners should be rinsed off immediately.

English

6. Post Installation - Troubleshooting Guide

Problem Possible To Diagnose Remedy

Cause

Hot/cold reversed

No water/low flow One or both No water/low flow Turn both water supply valves

Leak or drip Grommets not Leak/drip from spout Replace cartridge

from spout sealing properly

Only hot/no cold – Balancing spool Only hot/no cold – Replace cartridge

Only cold/no hot stuck Only cold/no hot

Stacking (Water Choice of pipe/ Water comes out of spout Change pipe to IPS or

comes out of the distance between and showerhead at the copper/distance from

showerhead during valve and showerhead same time showerhead and valve

tub fill mode) less than 46"/multiple moved to at least 46"/

Restricted Handle (more In the off position, able to Remove handle, rotate 180˚,

temperature range common in knob turn the handle both re-install

Not able to install Valve installed too far Handle does not install Contact Moen for assistance.

handle/handle back from finished

rubs up against wall

escutcheon

Handle is hard Cartridge stem is Difficult movement from Replace cartridge

to turn difficult to rotate handle or lubricate

Lines reversed/ Hot/cold reversed Rotate cartridge stem 180˚

cartridge installed

upside down down towards the drain.

supplies not on counterclockwise to the on

to the unit position

elbows/anything change or remove anything

restricting flow of restrictive

water exiting valve

Flow restriction Water comes out of spout Remove tub spout and flush

between valve and and showerhead at the out debris – Replace

tub spout same time causing undersized line or fittings

Valve installed Remove cartridge and verify Remove valve and reinstall

upside down that the outlet hole is in in the proper orientation

models) is installed clockwise and

upside down counterclockwise

Temperature limit Remove handle and Position temperature limit

stop out of position see Step 5.3 stop to desired temperature

restriction

proper location (should be

down). "Up" is on the top

of the valve

so that the notch is facing

position

For further assistance, contact Moen at:

USA: 1-800-289-6636 or visit www.moen.com

Canada: 1-800-465-6130 or visit www.moen.ca

INS2151B - 8/13 ©2013 Moen Incorporated www.moen.com

E12

Page 13

Cómprelo por apariencia. Cómprelo para toda la vida.

INS2151B - 8/13

O

▲

Un regulador de válvula con manija para tina/regadera

Un regulador de válvula con manija sólo para regadera

▲

O

Español

Instrucciones de instalación

Los estilos y las piezas varían según el modelo.

Para soporte de la garantía

Número de modelo

Fecha de instalación

S1

Page 14

A

K

J

N

H

C

D

E

F

S

R Q P

O

x2

G

I

Z

B

L

Installs behind wall. Installs on wall exterior.

M

A

K

J

L

M

N

B

C

D

E

F

O

R Q P

H

I

G

x2

Z

Installs behind wall. Installs on wall exterior.

Gracias por elegir Moen.

Español

Primero póngase en contacto con Moen

Para recibir ayuda de instalación o ausencia de piezas de repuesto

EE.UU.

1-800-BUY-MOEN

1-800-289-6636

Lunes a viernes de 8:00 a.m. a 8:00 p.m. EST

www.moen.com

Lunes a viernes de 7:30 a.m. a 8:00 p.m. EST

CANADÁ

1-800-465-6130

www.moen.ca

Tabla de contenido

Piezas suministradas para la tina/regadera..................................................................S3

Piezas suministradas sólo para la regadera..................................................................S3

Variaciones de las tuberías de plomería

Cobre......................................................................................................................................S4

IPS............................................................................................................................................S4

PEX ..........................................................................................................................................S5

CVPC ......................................................................................................................................S5

Herramientas útiles ....................................................................................................S4-S5

Esquemas de instalación ....................................................................................................S6

Instalación en pared delgada/pared gruesa y plantilla de yeso ....................S7-S8

Instalación del regulador ..............................................................................................S8-S9

Establecer el tope del límite de temperatura ..................................................S10-S11

Garantía ..................................................................................................................................S11

Instrucciones para el cuidado ........................................................................................S12

Guía para solucionar problemas ....................................................................................S12

S2

Page 15

A

K

J

N

H

C

D

E

F

S

R Q P

O

x2

G

I

Z

B

L

Installs behind wall. Installs on wall exterior.

M

A

K

J

L

M

N

B

C

D

E

F

O

R Q P

H

I

G

x2

Z

Installs behind wall. Installs on wall exterior.

Visite Moen.com para ver los diagramas de

piezas específicas del producto.

Los estilos y las piezas varían según el modelo.

Piezas suministradas para la tina/regadera

Español

A. Brida del brazo de la regadera

B. Válvula de 4 puertos y tubo de tope

C. Tope clave

D. Tope ajustable del límite de temperatura

E. Plantilla de yeso

F. Escudete

G. Tornillos del escudete (2-3/16”)

H. Brazo de la regadera

I. Cabezal de la regadera

J. Adaptador de la manija estilo palanca

K. Tornillo del adaptador (1/2”)

Piezas suministradas sólo para la regadera

A. Brida del brazo de la regadera

B. Válvula de 3 puertos y tubo de tope

C. Tope clave

D. Tope ajustable del límite de temperatura

E. Plantilla de yeso

F. Escudete

G. Tornillos del escudete (2-3/16”)

H. Brazo de la regadera

I. Cabezal de la regadera

J. Adaptador de la manija estilo palanca

L. Manija estilo palanca

M. Tornillo hexagonal

N. Llave hexagonal de 7/64”

O. Arandela doble D

P. Perilla

Q. Tornillo de cruz – Perilla (1-1/2”)

R. Tapón de la perilla

S. Surtidor de la tina

Z. Etiqueta de identificación del producto

K. Tornillo del adaptador (1/2”)

L. Manija estilo palanca

M. Tornillo hexagonal

N. Llave hexagonal de 7/64”

O. Arandela doble D

P. Perilla

Q. Tornillo de cruz – Perilla (1-1/2”)

R. Tapón de la perilla

Z. Etiqueta de identificación del producto

S3

Page 16

P

i

p

e

J

o

i

n

t

C

o

m

p

o

u

n

d

Cepillo de alambre

Desarmador de cruz

Cortatubos

Llave ajustable

Cinta métrica

Gafas de

seguridad

Termómetro

Cinta para sellar roscas

Kit para soldar

sin plomo

Soplete

Compuesto para

juntas de tuberías

Linterna

Sierra de punta

1. Determinar la instalación existente de sus tuberías de plomería

P

i

p

e

J

o

i

n

t

C

o

m

p

o

u

n

d

Desarmador de cruz

Llave ajustable

Cinta métricaGafas de seguridad

Termómetro

Cinta para

sellar roscas

Compuesto para

juntas de tuberías

Llave ajustable

Linterna Sierra de punta

P

i

p

e

J

o

i

n

t

C

o

m

p

o

u

n

d

Desarmador de cruz

erramienta engarzadora

de círculo completo

Linterna Sierra de punta

Cinta métricaGafas de

seguridad

Termómetro Cortador de tubos

Cinta para

sellar roscas

Compuesto para

juntas de tuberías

Llave ajustable

C

P

V

C

C

e

m

e

n

t

C

P

V

C

C

l

e

a

n

e

r

P

i

p

e

J

o

i

n

t

C

o

m

p

o

u

n

d

Desarmador de cruz

Cemento

CPVC

CPVC Limpiador

para CPVC

Cinta métricaGafas de

seguridad

Termómetro Cortador de tubos

Cinta para s

ellar roscas

Compuesto para

juntas de tuberías

Llave ajustable

Linterna Sierra de punta

Si va a reemplazar su válvula de plomería, ve a continuación los cuatro

métodos comunes de plomería. Los accesorios específicos de tubería no se

suministran. Estos pueden ser necesarios para la instalación. Retire la manija

y el regulador de la válvula existentes antes de reemplazar la válvula. Siga

Español

todos los códigos locales de construcción y plomería.

Cobre

Herramientas útiles

Por seguridad y facilidad de reemplazo del

grifo, Moen recomienda usar estas

herramientas útiles.

Vista delantera

Vista trasera

IPS – (Tubo de hierro galvanizado/Conexiones roscadas)

PRECAUCIÓN: CIERRE LOS SUMINISTROS DE AGUA CALIENTE Y FRÍA ANTES

DE QUITAR SU GRIFO ACTUAL O DESMONTAR SU VÁLVULA ACTUAL. ABRA LA

LLAVE DEL GRIFO PARA LIBERAR LA PRESIÓN Y ASEGÚRESE DE QUE EL

Herramientas útiles

Por seguridad y facilidad de reemplazo del

grifo, Moen recomienda usar estas

herramientas útiles.

Vista delantera

Vista trasera

CIERRE COMPLETO DEL AGUA SE HAYA LOGRADO.

S4

Page 17

P

i

p

e

J

o

i

n

t

C

o

m

p

o

u

n

d

Desarmador de cruz

erramienta engarzadora

de círculo completo

Linterna Sierra de punta

Cinta métricaGafas de

seguridad

Termómetro Cortador de tubos

Cinta para

sellar roscas

Compuesto para

juntas de tuberías

Llave ajustable

PEX

C

P

V

C

C

e

m

e

n

t

C

P

V

C

C

l

e

a

n

e

r

P

i

p

e

J

o

i

n

t

C

o

m

p

o

u

n

d

Desarmador de cruz

Cemento

CPVC

CPVC Limpiador

para CPVC

Cinta métricaGafas de

seguridad

Termómetro Cortador de tubos

Cinta para s

ellar roscas

Compuesto para

juntas de tuberías

Llave ajustable

Linterna Sierra de punta

CPVC

Español

Herramientas útiles

Por seguridad y facilidad de reemplazo del

grifo, Moen recomienda usar estas

herramientas útiles.

Vista delantera

Vista trasera

PRECAUCIÓN: CIERRE LOS SUMINISTROS DE AGUA CALIENTE Y FRÍA ANTES

DE QUITAR SU GRIFO ACTUAL O DESMONTAR SU VÁLVULA ACTUAL. ABRA LA

LLAVE DEL GRIFO PARA LIBERAR LA PRESIÓN Y ASEGÚRESE DE QUE EL

Herramientas útiles

Por seguridad y facilidad de reemplazo del

grifo, Moen recomienda usar estas

Vista delantera

Vista trasera

CIERRE COMPLETO DEL AGUA SE HAYA LOGRADO.

S5

herramientas útiles.

Page 18

Use 1/2" Copper or

IPS Pipe Only

78" (1981mm)

32" (813mm)

6" (152mm) Min.

11" (229mm) Max.

78” (1981mm)

45-48”

(1143-1219mm)

2. Esquemas de instalación: medir para lograr el

2-1/4" mín.

(57mm)

3-1/2" máx.

(89mm)

menos de 1/4"

(6mm)

3/4"

(19mm)

E

G

B

F

3

2

F

Z

1

E E

E

4-1/2"

(114mm)

más de 1/4"

(6mm)

rendimiento ideal de la tina/regadera

La instalación de este producto en medidas no recomendadas puede

dar lugar a problemas como la descarga de agua del cabezal de la

Español

regadera en el modo de llenado de la tina.

2.1

2.2

Tina/regadera

Coloque el cuerpo de la válvula a 32 pulgadas del piso de

la cuenca de la tina. El brazo de la regadera se debe

colocar 78 pulgadas sobre el suelo de la cuenca de la tina

(la instalación recomendada del brazo de la regadera es

con un codo de brida - no incluido - y unido a un

refuerzo de madera). El surtidor de la tina no debe ser

menor de 6 pulgadas y no mayor de 11 pulgadas debajo

de la válvula. Si va a instalar un surtidor de la tina con

rosca, conéctelo a la válvula con un tubo de 1/2 pulgada o

un tubo de cobre de 1/2 pulgada con un adaptador de

rosca. Si va a instalar un surtidor de la tina deslizable,

conéctelo a la válvula sólo con tubería de cobre - no se

necesita un adaptador de rosca.

Vea el paso 4.3 para conocer la longitud del tubo del

surtidor de la tina.

Sólo regadera

El brazo de la regadera se debe colocar 78 pulgadas sobre

el suelo de la cabina de la regadera (la instalación

recomendada del brazo de la regadera es con un codo de

brida - no incluido - y unido a un refuerzo de madera).

S6

Page 19

2-1/4" mín.

(57mm)

3-1/2" máx.

(89mm)

menos de 1/4"

(6mm)

3/4"

(19mm)

E

G

B

F

3

2

F

Z

1

E E

E

4-1/2"

(114mm)

más de 1/4"

(6mm)

3. Instalar la válvula

Español

3.1

3.3

Asegúrese de que

el clip de retención del cartucho

se haya instalado

antes de instalar

el escudete.

3.2

Instalación en paredes delgadas

Para paredes más delgadas de 1/4 de pulgada

3.1 El método de "pared delgada" se utiliza

cuando la pared de la tina/regadera tiene

menos de 1/4 de pulgada de grosor (como el

área circundante de la tina de fibra de vidrio)

y va a ser la fuente de apoyo principal para la

válvula. La plantilla de yeso (E) permanece

unida a la válvula. Un orificio de 2-1/4 a 3-1/2

pulgadas de diámetro se corta a través de la

pared para este método.

3.2 Rompa la cubierta protectora de plástico negro

con unos alicates y gire a la derecha.

3.3 Quite los tornillos del escudete (G), coloque la etiqueta

de identificación del producto (Z) en la parte posterior

del escudete, asegúrese de que la pared esté limpia,

coloque el escudete (F) sobre el tubo de tope

(B) y vuelva a instalar los tornillos (G). Una

junta en la parte posterior del escudete

proporciona un sello contra la pared acabada.

Vaya al Paso 4.1

3.4

Instalación en paredes gruesas

Para paredes más gruesas de 1/4 de pulgada

3.4 El método de instalación de "pared gruesa" se utiliza

cuando la pared de la tina/regadera tiene más de 1/4 de

pulgada de grosor. Las "paredes gruesas" generalmente se

construyen con materiales como placas de cemento, yeso,

azulejo, etc. La válvula es asegurada con correas (no incluidas)

sujetando las líneas de entrada de agua a los miembros de la

estructura (2X4) como se muestra en los pasos 2.1 y 2.2. La

válvula también cuenta con orificios de montaje para atornillar

la válvula a un travesaño unido detrás de la válvula si se desea.

Una la plantilla de yeso (E) al cuerpo de la válvula con los

tornillos del escudete de 2-3/16 pulgadas (G). Mantenga la

plantilla de yeso (E) unida a la válvula hasta que la válvula se

haya colocado y asegurado. La plantilla de yeso (E) se coloca de

manera que quede al ras con la pared acabada. Esto asegura

que la válvula esté en la posición correcta para aceptar el

regulador.

El orificio en la pared debe ser del mismo tamaño (4-1/2

pulgadas) como la plantilla de yeso (E). Este orificio permite el

acceso para el mantenimiento futuro de ser necesario.

S7

Page 20

1

S

Apriete ligeram ente

el tornillo de jación.

5/32"

hexagonal

No

incluido

Sin bordes alados/rebabas

en el extremo del tubo.

2

1

2

2

1

S

C

D

NO

Sí

L

P

F

2

H

1

Cinta para sellar roscas

2

I

1

A

Cinta para sellar roscas

3

H

2

I

1

A

Cinta para sellar roscas

3

H

J

D

K

E

G

G

B

F

3

2

F

Z

1

3.5

Instalación del surtidor de la tina

(y) + (x) + 1/4" de longitud de la tubería

Para determinar la longitud adecuada de la tubería,

mida desde el codo-hombro interior a la pared (y) y

del adaptador de rosca dentro del surtidor de la tina a la base

del surtidor de la tina (x), luego agregue 1/4".

y

x

1

S

2

Cinta para sellar roscas

3.5 Una vez que la válvula esté asegurada

en su lugar, quite los tornillos del

escudete (G) y la plantilla de yeso (E).

Mantenga los tornillos del escudete

(G) para la instalación del escudete

Español

(F) y deseche la plantilla de yeso (E).

3.6 Coloque la etiqueta de identificación

del producto (Z) en la parte posterior

Asegúrese de que el

clip de retención del

cartucho se haya

instalado antes de

instalar el escudete.

del escudete, asegúrese de que la

pared esté limpia, coloque el escudete

(F) sobre el tubo de tope (B) y luego

vuelva a instalar los tornillos (G). Una

junta en la parte posterior del

escudete proporciona un sello

contra la pared.

3.6

Vaya al Paso 4.1

Moen sugiere que realice pruebas de funcionalidad y detección de fugas antes de sellar las paredes.

Se recomienda un panel de acceso detrás de la válvula.

4. Instalar el regulador Moen para la tina/regadera

4.1

Envuelva cinta para sellar roscas alrededor de

las roscas del brazo de

la regadera (H) y luego

atornilla el brazo en la

conexión roscada en la

pared.

Si hay una arandela de

goma en el interior del

adaptador de rosca en

el cabezal de la

regadera, continúe con

el paso 4.2A. Si no hay

una arandela de goma,

entonces continúe con

el paso 4.2B.

4.2A

4.2B

O

4.2A Esfera de plástico de

la regadera

Selle alrededor del orificio

del brazo de la regadera con

sellador (masilla) y luego

deslice la brida de la

regadera (A) sobre el brazo

de la regadera (H). Elimine

los residuos del brazo de la

regadera para asegurar el

flujo adecuado. Luego,

rosque el cabezal de la

regadera (I) en el brazo de la

regadera (H).

S8

4.2B Esfera de metal de la

regadera

Selle alrededor del orificio del

brazo de la regadera con

sellador (masilla) y luego

deslice la brida de la regadera

(A) sobre el brazo de la

regadera (H). Envuelva la cinta

para sellar roscas alrededor de

las roscas en la parte inferior

del brazo de la regadera (H).

Elimine los residuos del brazo

de la regadera para asegurar

el flujo adecuado. Rosque el

cabezal de la regadera (I) en el

brazo de la regadera (H).

Page 21

1

S

Apriete ligeram ente

el tornillo de jación.

5/32"

hexagonal

No

incluido

Sin bordes alados/rebabas

en el extremo del tubo.

2

1

2

2

1

S

C

D

NO

Sí

L

P

F

J

D

K

Instalación del surtidor de la tina

(y) + (x) + 1/4" de longitud de la tubería

Para determinar la longitud adecuada de la tubería,

mida desde el codo-hombro interior a la pared (y) y

del adaptador de rosca dentro del surtidor de la tina a la base

del surtidor de la tina (x), luego agregue 1/4".

y

x

1

S

2

Cinta para sellar roscas

4.3A

Instalación del surtidor de la tina con rosca

Si se trata de una instalación

sólo para la regadera, vaya al

paso 4.4.

Los surtidores IPS (roscados)

están diseñados para

atornillarse en un tubo con

roscas macho de tubos de 1/2

pulgada. Para determinar la longitud adecuada de la tubería,

mida desde el codo-hombro

interior a la pared (y) y del

adaptador de rosca dentro del

surtidor de la tina a la base del

surtidor de la tina (x), luego

agregue 1/4". Coloque la cinta

para sellar roscas alrededor de

la rosca de tubos y un sellador

(masilla de plomería o masilla)

alrededor de la base del tubo

para evitar fugas detrás de la

pared.

Español

Instalación del surtidor de la tina

deslizable

4.3B

O

Algunos modelos pueden disponer de una instalación

deslizable sin adaptador de rosca en el surtidor de la tina.

Para estas instalaciones, deslice el surtidor de la tina en el

tubo hacia arriba y apriete ligeramente el tornillo de

fijación. Gire el surtidor de la tina a la posición final y apriete el tornillo de fijación en su lugar.

Para manijas estilo palanca instaladas con adaptador de plástico de la manija (J)

4.5

Orientación del

cartucho

4.4

Ahora está listo para colocar la

manija. Gire para que la muesca en

el extremo del vástago esté boca

abajo hacia el drenaje. Inserte el

tope clave (C) y el tope del límite

ajustable (D) en el tubo de tope

como se muestra.

Otras posibles

instalaciones de tipo

manija

4.6

Si se trata de una manija estilo palanca

que se conecta con el adaptador de la

manija estilo palanca (J), coloque el

adaptador de plástico de la manija (J) en

el vástago del cartucho con el tornillo del

adaptador de 1/2 pulgada (K). Asegúrese

de que las estrías en la parte posterior

del adaptador (J) estén a la izquierda de

la pestaña en el tope del límite (D).

Coloque la palanca (L)

en el adaptador de la

manija.

S9

Coloque la manija de la

perilla (P) – en el cartucho - asegúrese de que

el indicador en la perilla

esté apuntando hacia

abajo.

Page 22

D

J

K

L

L

N

M

1

-

+

D

D

D

P

2

1

3

P

Q

R

1

2

D

J

K

L

MÁS

CALIENTE

120F

(49C)

5.

1

2

-

+

D

D

D

J

K

1

3

L

Establecer el tope del límite de temperatura y terminar la

instalación de su tina/regadera

5.1

Español

Abra el suministro de

agua caliente y fría para

comprobar si hay fugas

y establezca el tope del

límite de temperatura.

5.3

Gire la palanca a la izquierda hasta

5.2

que el agua esté a la temperatura

máxima deseada, sin exceder los

120 grados F (49 grados C). El

mantenimiento estacional de la

temperatura de salida máxima

puede ser necesario debido a los

cambios en la temperatura de las

aguas subterráneas.

GIRE LA PALANCA A LA POSICIÓN

DE CERRADO EN CUANTO LA

TEMPERATURA SE HAYA

ESTABLECIDO.

Si la temperatura supera los 120 grados, vaya al paso 5.3.

Si la temperatura es inferior a los 120 grados, vaya al paso 5.4.

Retire la palanca

(L) y el adaptador

de la manija estilo

palanca (J). Tenga

en cuenta la

posición del tope.

Coloque el tope

del límite de

temperatura

ajustable (D) para

que la palanca se

detenga en esa

posición. Esto evita

que la palanca se

cambie a una

temperatura

insegura.

O

Retire la manija de la

perilla (P). Tenga en

cuenta la

posición del tope.

Coloque el tope del

límite de

temperatura ajustable

(D) para que la palanca

o perilla se detenga en

esa posición. Esto evita

que la palanca o perilla

se cambien a una

temperatura insegura.

5.4

O

Después de establecer el tope del

límite de temperatura ajustable en

la posición deseada, retire la

palanca (L), vuelva a conectar el

adaptador de la manija estilo

palanca (J), el tornillo del adaptador

(K) y la palanca (L) - asegúrese de

que las estrías en la parte posterior

de (J) estén a la izquierda de la

pestaña en (D).

Después de establecer el tope

del límite de temperatura

ajustable a la posición

deseada, vuelva a colocar la

arandela doble D (O) y la

perilla (P) - asegúrese de que

el indicador en la perilla esté

apuntando hacia abajo.

S10

Page 23

L

N

M

5.5

P

Q

R

1

2

Español

O

Utilizando una llave hexagonal

de 7/64 pulgadas (N), inserte y

apriete los el tornillo hexagonal

(M) en la palanca (L).

O inserte un tornillo de cruz

de 1-1/2 pulgadas (Q).

Apriete el tornillo e inserte

el tapón (R).

Garantía limitada de por vida de Moen

Los productos Moen han sido fabricados bajo las más estrictas normas de calidad y mano de obra.

Moen le garantiza al consumidor-comprador original durante todo el tiempo que el consumidorcomprador original sea dueño de su casa (el "Período de Garantía" para los propietarios de vivienda),

que este grifo estará libre de fugas y goteo durante el uso normal y que todas las piezas y acabados de

este grifo estarán libres de defectos en materiales y mano de obra. Todos los demás compradores

(incluyendo compradores para uso industrial, comercial y de negocios) se garantizan por un período

de 5 años a partir de la fecha original de compra (el "Período de Garantía" para los no propietarios de

vivienda).

Si este grifo llegara a producir una fuga o goteo durante el Período de Garantía, Moen proporcionará

SIN COSTO las piezas necesarias para volver a poner el grifo en buen estado de funcionamiento y

reemplazará GRATUITAMENTE cualquier pieza o acabado que muestre tener defectos en cuanto a

material y mano de obra de fabricación, bajo condiciones normales de instalación, uso y servicio. Las

piezas de repuesto se pueden obtener llamando al 1-800-289-6636 (Canadá 1-800-465-6130), o

escribiendo a la dirección indicada. El comprobante de compra (recibo original de la venta) del

consumidor-comprador original debe acompañar todas las reclamaciones de garantía. Esta garantía no

ampara los defectos o daños ocasionados por el uso de otras piezas distintas a las genuinas de Moen.

Esta garantía se extiende solamente a los grifos adquiridos después de diciembre de 1995 y entrará en

vigor a partir de la fecha de compra que aparece en el recibo del comprador.

Esta garantía es amplia puesto que cubre el reemplazo de todas las piezas y acabados defectuosos. Sin

embargo, los daños debidos a errores de instalación, abuso del producto, mal uso del producto o el

uso de limpiadores que contengan abrasivos, alcohol u otros solventes orgánicos, ya sean realizados

por un contratista, compañía de servicios o usted mismo, están excluidos de esta garantía. Moen no se

hará responsable de costos laborales y/o daños producidos durante la instalación, reparación o

reemplazo, ni de ningún daño indirecto, incidental o consecuente, pérdidas, daños o gastos de

cualquier naturaleza relacionados con este grifo. Salvo lo dispuesto por la ley, esta garantía reemplaza

y excluye todas las demás garantías, condiciones y afirmaciones, ya sean expresas o implícitas, legales

u otras, incluyendo sin limitación las garantías de comercialización o de adecuación para el uso.

Algunos estados, provincias y países no permiten la exclusión o limitación de daños incidentales o

consecuentes, de modo que las limitaciones o exclusiones anteriores pueden no aplicarse a usted. Esta

garantía le otorga derechos legales específicos y usted también puede tener otros derechos que

cambian de un estado a otro, de una provincia a otra o de un país a otro. Moen le informará el

procedimiento a seguir para hacer válida la garantía. Simplemente escriba a Moen Incorporated a la

dirección indicada más abajo. Explique el defecto e incluya el comprobante de compra y su nombre,

dirección, código de área y número de teléfono.

25300 Al Moen Drive, North Olmsted, Ohio 44070-8022 U.S.A.

Moen Incorporated

S11

Page 24

Cómprelo por apariencia. Cómprelo para toda la vida.

Cómprelo por apariencia. Cómprelo para toda la vida.

Instrucciones para el cuidado

Para conservar el acabado de las piezas metálicas de su grifo Moen, aplique cera no abrasiva, como una cera para

autos. Cualquier limpiador deberá enjuagarse inmediatamente.

6. Después de la instalación -

Español

Guía para solucionar problemas

Problema Causa probable Para diagnosticar Solución

Agua caliente/fría invertida Líneas invertidas/el cartucho

No hay agua/bajo caudal Uno o ambos suministros no

Fugas o goteo en el

surtidor

Sólo agua caliente/no fría Sólo agua fría/no caliente

Effet de colonne (l’eau sort

de la pomme de douche

durant le remplissage en

mode baignoire)

se instaló al revés

están en la unidad

La arandela no sella

correctamente

Carrete de equilibrio pegado Sólo agua caliente/no

Elección de tubo/ distancia

entre la válvula y el cabezal

de la regadera a menos de

46"/codos múltiples/cualquier

cosa que restringe el flujo de

la válvula de salida de agua

Agua caliente/fría invertida Gire 180ºel vástago del

No hay agua/bajo caudal Abra las dos válvulas de

Fugas/goteo en el surtidor Reemplace el cartucho

fría - Sólo agua fría/no

caliente

El agua sale del surtidor de la

tina y del cabezal de la

regadera al mismo tiempo

cartucho de manera que la

muesca quede hacia abajo

hacia el drenaje.

suministro de agua hacia la

izquierda a la posición de

abierto

Reemplace el cartucho

Cambie el tubo a IPS o

cobre/la distancia del

cabezal de la regadera y la

válvula se trasladó a al

menos 46"/cambie o retire

cualquier restricción

El tope del límite de temperatura está fuera de su

posición

Válvula instalada demasiado

lejos de la pared acabada

Rango de temperatura

restringido

No se puede instalar la

manija/la manija hace fricción contra el escudete

Es difícil girar la manija El vástago del cartucho es

La manija (más común en los

modelos de perilla) está

instalada al revés

Le limiteur de température n’est

pas à la position appropriée

Válvula instalada demasiado

lejos de la pared acabada

difícil de girar

Para obtener asistencia adicional, póngase en contacto Moen en:

INS2151B - 8/13

©2013 Moen Incorporated www.moen.com

El agua sale del surtidor de la

tina y del cabezal de la

regadera al mismo tiempo

ocasionando restricción

Retire el cartucho y

compruebe que el orificio de

salida esté en un lugar

adecuado (debe ser hacia

abajo). "Up" (Arriba) está en la

parte superior de la válvula

En la posición de cerrado,

debe poder girar la palanca a

la derecha y a la izquierda

Quite la manija y vea

el Paso 5.3

La manija no se puede

instalar

Movimiento difícil de la

manija

Retire el surtidor de la tina y

enjuague los residuos Reemplace el tubo o las

juntas de tamaño reducido

Retire la válvula y vuelva a

instalar en la orientación

correcta

Retire la manija, gire 180°,

vuelva a instalar

Coloque el tope del límite de

temperatura en la posición

deseada de temperatura

Póngase en contacto con

Moen para obtener

asistencia.

Cambie el cartucho o

lubrique

EE.UU.: 1-800-289-6636 o visite www.moen.com

Canadá: 1-800-465-6130 o visite www.moen.ca

S12

Page 25

INS2151B - 8/13

On l'achète pour le style. On l'achète pour la vie.®

OU

▲

Garniture de soupape de douche/baignoire à une poignée

Garniture de soupape de douche à une poignée seulement

▲

OU

Français

Directives d’installation

Les styles et les pièces peuvent varier selon le modèle choisi.

Pour obtenir un soutien de garantie

Numéro de modèle

Date d’installation

F1

Page 26

A

K

J

N

H

C

D

E

F

S

R Q P

O

x2

G

I

Z

B

L

Installation sur le mur

Installation derrière le mur

M

A

K

J

L

M

N

B

C

D

E

F

O

R Q P

H

I

G

x2

Z

Installation sur le murInstallation derrière le mur

Nous vous remercions d’avoir choisi Moen.

Veuillez d’abord contacter Moen

en cas de problèmes avec l’installation, ou pour obtenir toute

Français

pièce manquante ou de rechange

CANADA

1-800-465-6130

Du lundi au vendredi : De 7 h 30 à 20 h (HE)

www.moen.ca

1-800-BUY-MOEN

1-800-289-6636

Du lundi au vendredi : De 8 h à 20 h (HE)

É.-U. :

Samedi : De 9 h à 20 h 30 h (HE)

www.moen.com

Table des matières

Pièces de douche/baignoire fournies ............................................................................F3

Pièces fournies pour douche seulement ......................................................................F3

Modèles de plomberie brute

Cuivre ....................................................................................................................................F4

IPS............................................................................................................................................F4

PEX ..........................................................................................................................................F5

PVC-C......................................................................................................................................F5

Outils utiles....................................................................................................................F4-F5

Schéma d’installation............................................................................................................F6

Installations pour mur mince, épais ou en plâtre ................................................F7-F8

Installation de la garniture ..........................................................................................F8-F9

Définition du limiteur de température ..............................................................F10-F11

Garantie ..................................................................................................................................F11

Directives d’entretien ........................................................................................................F12

Guide de dépannage..........................................................................................................F12

F2

Page 27

A

K

J

N

H

C

D

E

F

S

R Q P

O

x2

G

I

Z

B

L

Installation sur le mur

Installation derrière le mur

M

A

K

J

L

M

N

B

C

D

E

F

O

R Q P

H

I

G

x2

Z

Installation sur le murInstallation derrière le mur

Visiter Moen.com pour obtenir les diagrammes de pièces

particulières du produit.

Les styles et les pièces peuvent varier selon le modèle choisi.

Pièces de douche/baignoire fournies

Français

A. Bride de bras de douche

B. Soupape à 4 orifices et tube d’arrêt

C. Butée de clé

D. Limiteur de température réglable

E. Arrêt d’enduit

F. Rosace

G. Vis de rosace (2 3/16 po)

H. Bras de douche

I. Pomme de douche

J. Adaptateur de poignée à levier

K. Vis d’adaptateur (1/2 po)

L. Poignée à levier

M. Vis à tête hexagonale

N. Clé hexagonale de 7/64 po

O. Rondelle « D » double

P. Bouton

Q. Vis à tête hexagonale - bouton (1 1/2 po)

R. Capuchon de bouton

S. Bec de baignoire

Z. Étiquette d’identification du produit

Pièces fournies pour douche seulement

A. Bride de bras de douche

B. Soupape à 3 orifices et tube d’arrêt

C. Butée de clé

D. Limiteur de température réglable

E. Arrêt d’enduit

F. Rosace

G. Vis de rosace (2 3/16 po)

H. Bras de douche

I. Pomme de douche

F3

J. Adaptateur de poignée à levier

K. Vis d’adaptateur (1/2 po)

L. Poignée à levier

M. Vis à tête hexagonale

N. Clé hexagonale de 7/64 po

O. Rondelle « D » double

P. Bouton

Q. Vis à tête hexagonale – bouton (1 1/2 po)

R. Capuchon de bouton

Z. Étiquette d’identification du produit

Page 28

P

i

p

e

J

o

i

n

t

C

o

m

p

o

u

n

d

Brosse métallique

Tournevis à

pointe cruciforme

Coupe-tube

Clé à molette Crescent

Ruban à mesurerLunettes de

sécurité

Thermomètre

Ruban d’étanchéité

pour joints

Trousse de soudure

sans plomb

Chalumeau

Pâte à joints

Lampe de poche

Scie à guichet

1. Détermination du type d’installation de la plomberie brute existante

P

i

p

e

J

o

i

n

t

C

o

m

p

o

u

n

d

Tournevis à

pointe cruciforme

Clé anglaise

Ruban à mesurerLunettes de

sécurité

Thermomètre

Ruban d’étanchéité

pour joints letés

Pâte à joints

Clé à molette

Crescent

Lampe de poche Scie à guichet

Tournevis à pointe

cruciforme

Pince à sertir

circulaire

Lampe de poche Scie à guichet

Ruban à mesureLunettes de

sécurité

Thermomètre Coupe -tube

Ruban d’étanchéité

pour joints letés

Pâte à joints

Clé à molette

Crescent

P

i

p

e

J

o

i

n

t

C

o

m

p

o

u

n

d

C

P

V

C

C

e

m

e

n

t

C

P

V

C

C

l

e

a

n

e

r

P

i

p

e

J

o

i

n

t

C

o

m

p

o

u

n

d

Tournevis à pointe

cruciforme

Ciment à

PVC-C

Nettoyeur

de PVC-C

Ruban à mesurerLunettes de

sécurité

Thermomètre Coupe -tube

Ruban d’étanchéité

pour joints letés

Pâte à joints

Clé à molette

Crescent

Lampe de poche Scie à guichet

Avant de remplacer la soupape de plomberie, voir ci-dessous les quatre modèles de plomberie

les plus courants. Les raccords de plomberie brute qui leur sont propres ne sont pas fournis. Ils

seront peut-être nécessaires pour l’installation. Enlever la poignée et la garniture de soupape

existantes avant de remplacer votre soupape. Veuillez vous conformer aux codes de

plomberie et de construction locaux.

Français

Cuivre

Outils utiles

Par mesure de sécurité et pour faciliter

l’installation, Moen suggère l’utilisation des

outils suivants.

Vue frontale

Vue arrière

IPS – (tuyau en acier galvanisé/raccords filetés)

MISE EN GARDE – COUPER L’ALIMENTATION EN EAU FROIDE ET EN EAU CHAUDE

AVANT D’ENLEVER LE ROBINET EXISTANT OU DE DÉMONTER LA SOUPAPE EXIS-

TANTE. OUVRIR LE ROBINET POUR ÉLIMINER LA PRESSION D’EAU ET VOUS

ASSURER QUE L’ALIMENTATION EN EAU A ÉTÉ COMPLÈTEMENT COUPÉE.

Outils utiles

Par mesure de sécurité et pour faciliter

l’installation, Moen suggère l’utilisation des

outils suivants.

Vue frontale

Vue arrière

F4

Page 29

Tournevis à pointe

cruciforme

Pince à sertir

circulaire

Lampe de poche Scie à guichet

Ruban à mesureLunettes de

sécurité

Thermomètre Coupe -tube

Ruban d’étanchéité

pour joints letés

Pâte à joints

Clé à molette

Crescent

P

i

p

e

J

o

i

n

t

C

o

m

p

o

u

n

d

PEX

C

P

V

C

C

e

m

e

n

t

C

P

V

C

C

l

e

a

n

e

r

P

i

p

e

J

o

i

n

t

C

o

m

p

o

u

n

d

Tournevis à pointe

cruciforme

Ciment à

PVC-C

Nettoyeur

de PVC-C

Ruban à mesurerLunettes de

sécurité

Thermomètre Coupe -tube

Ruban d’étanchéité

pour joints letés

Pâte à joints

Clé à molette

Crescent

Lampe de poche Scie à guichet

PVC-C

Français

Outils utiles

Par mesure de sécurité et pour faciliter

l’installation, Moen suggère l’utilisation des

outils suivants.

Vue frontale

Vue arrière

MISE EN GARDE – COUPER L’ALIMENTATION EN EAU FROIDE ET EN EAU CHAUDE

AVANT D’ENLEVER LE ROBINET EXISTANT OU DE DÉMONTER LA SOUPAPE EXIS-

TANTE. OUVRIR LE ROBINET POUR ÉLIMINER LA PRESSION D’EAU ET VOUS

ASSURER QUE L’ALIMENTATION EN EAU A ÉTÉ COMPLÈTEMENT COUPÉE.

Outils utiles

Par mesure de sécurité et pour faciliter

l’installation, Moen suggère l’utilisation des

outils suivants.

Vue frontale

Vue arrière

F5

Page 30

Use 1/2" Copper or

IPS Pipe Only

78" (1981mm)

32" (813mm)

6" (152mm) Min.

11" (229mm) Max.

78” (1981mm)

45-48”

(1143-1219mm)

2. Schéma d’installation - Mesures pour un

2-1/4" min.

(57mm)

3-1/2" max.

(89mm)

Moins de 1/4 po

(6mm)

3/4"

(19mm)

E

G

B

F

3

2

F

Z

1

E

4-1/2"

(114mm)

(6mm)

E

plus de 1/4 po

rendement idéal de la douche/baignoire

Le fait d’installer ce produit sans respecter les mesures recommandées

peut causer des problèmes, comme l’écoulement de l’eau par la

Français

pomme de douche durant le mode de remplissage de la baignoire.

2.1

2.2

Douche/Baignoire

Placer le corps de la soupape à 32 po du plancher ou du

fond de la baignoire. Le bras de douche doit être placé à

78 po au-dessus du fond de la baignoire (l’installation

recommandée du bras de douche comporte un raccord

de coude à bride – non inclus – et fixé à un support de

bois). Le bec de la baignoire doit être positionné au

minimum à 6 po et au maximum à 11 po sous la soupape.

Pour installer un bec de baignoire fileté, le raccorder à la

soupape à l’aide d’un tuyau de 1/2 po ou d’un tube en

cuivre de 1/2 po doté d’un adaptateur fileté. Pour installer

un bec de baignoire à glissement rapide, le raccorder à la

soupape uniquement à l’aide d’un tube en cuivre – aucun

adaptateur fileté requis.

Voir étape 4.3 pour connaître la longueur du tube de

bec de baignoire.

Douche seulement

Le centre de la soupape doit être situé de 45 à 48 po

au-dessus du plancher de la douche. Le bras de douche

doit être placé à 78 po au-dessus du plancher de la

douche (l’installation recommandée du bras de douche

comporte un raccord de coude à bride – non inclus – et

fixé à un support de bois).

F6

Page 31

2-1/4" min.

(57mm)

3-1/2" max.

(89mm)

Moins de 1/4 po

(6mm)

3/4"

(19mm)

E

G

B

F

3

2

F

Z

1

E

4-1/2"

(114mm)

(6mm)

E

plus de 1/4 po

3. Installation de la soupape

Français

3.1

3.3

Vous assurer

que l'étrier de la

cartouche est

installé avant

d'installer la

rosace.

3.2

Installation dans un mur mince

Pour les murs de moins de 1/4 po

3.1 La méthode du « mur mince » est utilisée

lorsque l’épaisseur du mur de la

douche/baignoire est inférieure à 1/4 po

(comme dans le cas des cabines de

baignoire en fibre de verre) et que ce mur

constituera le support principal de la

soupape. L’enduit de plâtre (E) reste fixé à la

soupape. Un trou de 2 1/4 à 3 1/2 po de

diamètre doit être coupé dans le mur pour

cette méthode.

3.2 Casser le couvercle protecteur en plastique

noir à l’aide de pinces et le faisant pivoter dans

le sens horaire.

3.3 Enlever les vis de la rosace (G), placer l’étiquette

d’identification du produit (Z) au dos de la rosace

en vous assurant que le mur est propre,

placer la rosace (F) sur le tube d’arrêt (B),

puis réinstaller les vis (G). Un joint

d’étanchéité situé au dos de la rosace

fournit l’étanchéité nécessaire avec le mur fini.

Aller à l'étape 4.1

,

Installation dans un mur épais

3.4

Pour les murs de plus de 1/4 po

3.4 La méthode d’installation sur un « mur épais » est

utilisée lorsque l’épaisseur des parois de la

douche/baignoire est supérieure à 1/4 po. Les murs

épais sont normalement fabriqués à partir de

matériaux comme les panneaux de ciment, la cloison

sèche, le carrelage, etc. La soupape est fixée à l’aide de

courroies (non incluses) retenant les conduites d’entrée

sur les éléments d’ossature (2 x 4), comme illustré aux

étapes 2.1 et 2.2. La soupape est aussi dotée de trous

pour la visser sur une traverse de cadre fixé derrière la

soupape, si désiré.

Fixer l’enduit de plâtre (E) sur le corps de la soupape en

utilisant des vis de rosace de 2 3/16 po (G). Garder

l’enduit de plâtre (E) fixé sur la soupape jusqu’à ce

qu’elle soit positionnée et bien fixée. L’enduit de plâtre

(E) est positionné pour être de niveau avec le mur fini.

Ainsi, la soupape sera à la bonne position pour y

installer la garniture plus tard.

Le trou dans le mur doit être de la même taille

(4 1/2 po) que l'enduit de plâtre (E). Ce trou offre un

accès en cas de besoin de toute réparation future.

F7

Page 32

2

H

1

Ruban d'étanchéité

C

D

NO

OUI

1

S

Serrer légèr ement

la vis de pre ssion.

5/32"

Hex

Non

inclus

Aucune arête vive ni bavure

à l’extrémité du tuyau

2

1

2

2

1

S

2

I

1

A

Ruban d'étanchéité

3

H

2

I

1

A

Ruban d'étanchéité

3

H

E

G

G

B

F

3

2

F

Z

1

3.5

Installation du bec de baignoire

y) + (x) + 1/4 po = longueur du tuyau

Pour déterminer la bonne longueur du tuyau, prendre

la mesure à partir de l’intérieur du pli du coude jusqu’au mur (y),

puis de l’adaptateur leté à l’intérieur du bec de baignoire jusqu’à la base

du bec de baignoire (x), puis ajouter 1/4 po.

y

x

1

S

2

Ruban d'étanchéité

3.5 Lorsque la soupape est bien fixée,

enlever les vis de rosace (G) et

l’enduit de plâtre (E). Garder les

vis de rosace (G) pour

l’installation de la rosace (F) et

Français

jeter l’enduit de plâtre (E).

3.6 Placer l’étiquette d’identification

Vous assurer

que l'étrier de la

cartouche est

installé avant

d'installer la

rosace.

du produit (Z)

en vous assurant que le mur est

propre, placer la rosace (F) sur le

tube d’arrêt (B), puis réinstaller les

vis (G). Un joint d’étanchéité situé

au dos de la rosace fournit

l’étanchéité nécessaire au mur.

au dos de la rosace

3.6

Aller à l'étape 4.1

Moen suggère de procéder à un test pour confirmer le bon fonctionnement de l’installation et pour

déceler la présence de toute fuite, avant de fermer les murs. Il est recommandé d’avoir un panneau

d’accès derrière la soupape.

4. Installation de la garniture de douche/baignoire Moen

,

4.1

Envelopper de ruban

d’étanchéité pour joints

filetés les filetages du

bras de douche (H), puis

visser le bras dans le

raccord fileté du mur.

S’il y a une rondelle en

caoutchouc dans

l’adaptateur fileté de la

pomme de douche,

passer à l’étape 4.2A. S’il

n’y a pas de rondelle en

caoutchouc, passer à

l’étape 4.2B.

4.2A

4.2A Sphère de douche en

plastique

Sceller le pourtour de l’orifice

du bras de douche avec un

agent scellant (calfeutrage),

puis faire glisser la bride de

douche (A) sur le bras de

douche (H). Enlever tous

débris du bras de douche

pour vous assurer que le

débit ne sera pas obstrué.

Puis, visser simplement la

pomme de douche (I) sur le

bras de douche (H).

F8

4.2B

OU

4.2B Sphère de douche

métallique

Sceller le pourtour de

l’orifice du bras de douche

avec un agent scellant

(calfeutrage), puis faire

glisser la bride de douche (A)

sur le bras de douche (H).

Envelopper de ruban

d’étanchéité pour joints filetés

les filetages du bas du bras de

douche (H). Enlever tous

débris du bras de douche

pour vous assurer que le débit

ne sera pas obstrué. Visser la

pomme de douche (I) sur le

bras de douche (H).

Page 33

C

D

NO

OUI

1

S

Serrer légèr ement

la vis de pre ssion.

5/32"

Hex

Non

inclus

Aucune arête vive ni bavure

à l’extrémité du tuyau

2

1

2

2

1

S

Installation du bec de baignoire

y) + (x) + 1/4 po = longueur du tuyau

Pour déterminer la bonne longueur du tuyau, prendre

la mesure à partir de l’intérieur du pli du coude jusqu’au mur (y),

puis de l’adaptateur leté à l’intérieur du bec de baignoire jusqu’à la base

du bec de baignoire (x), puis ajouter 1/4 po.

y

x

1

S

2

Ruban d'étanchéité

4.3A

Installation d’un bec de baignoire fileté

S’il s’agit de l’installation pour douche seulement,

passer à l’étape 4.4.