Page 1

6-Channel Remote Control System

"MC60"

Item no.: 20 72 56

Operating instructions

Version 04/10

Page 2

Table of Contents

1. Introduction ........................................................................................................................................................... 4

2. Intended Use ......................................................................................................................................................... 4

3. Product Description ............................................................................................................................................... 5

4. Scope of Delivery .................................................................................................................................................. 5

5. Symbols................................................................................................................................................................. 5

6. Safety Information ................................................................................................................................................. 6

a) General Information ......................................................................................................................................... 6

b) Operation .......................................................................................................................................................... 7

7. Notes on Batteries and Rechargeable Batteries .................................................................................................. 8

8. Charging Rechargeable Batteries ........................................................................................................................ 9

9. Transmitter Controls............................................................................................................................................ 10

a) Front ............................................................................................................................................................... 10

b) Rear ................................................................................................................................................................ 11

10. Setting up the Transmitter ................................................................................................................................... 12

a) Inserting the Batteries/Rechargeable Batteries ............................................................................................. 12

b) Charging the Rechargeable Transmitter Batteries ......................................................................................... 13

c) Switching on the Transmitter .......................................................................................................................... 14

d) Modifying the Throttle Function ...................................................................................................................... 15

e) Setting the Control Levers .............................................................................................................................. 16

11. Setting up the Receiver ....................................................................................................................................... 16

a) Receiver Connection ...................................................................................................................................... 16

b) Installing the Receiver .................................................................................................................................... 18

c) Installing the Servos ........................................................................................................................................19

d) Checking the Servo Functions ....................................................................................................................... 19

12. Programming the Remote Control ...................................................................................................................... 20

13. The System Menu ............................................................................................................................................... 21

13.1. “MODELSET” (Model Settings) ................................................................................................................. 22

a) “MODEL” (Selection of the Model Memory) .............................................................................................. 22

b) “RENAME” (Model Memory Name)........................................................................................................... 23

c) “SAVE AS” (Copy a Model Memory) ......................................................................................................... 24

d) “RECOVER” (Resetting to the Factory Settings) ...................................................................................... 25

13.2. “MODULATE” (Setting the Transmitter Modulation) ................................................................................. 26

13.3. “PLANE TYPE” (Setting the plane type) ................................................................................................... 27

13.4. “STICK MODE” (Transmitter Lever Settings) ............................................................................................ 28

13.5. “STICK ADJ” (Control Lever Calibration) .................................................................................................. 30

Page

2

Page 3

Page

14. Function Menu .................................................................................................................................................... 31

14.1. “DR” (Servo Path Limiter)........................................................................................................................ 32

14.2. “SUB.TRIM” (Servo Centre Position) ...................................................................................................... 35

14.3. “TRAVEL” (Servo Travel Settings) .......................................................................................................... 36

14.4. “CH.REV” (Reversing the Servo Direction) ............................................................................................ 37

14.5. “SWASH.MIX” (Swash Plate Mixer) ........................................................................................................ 38

14.6. “GYRO.SENS” (Gyro Sensitivity) ............................................................................................................ 40

14.7. “THRO.CURV” (Throttle Curve) .............................................................................................................. 42

14.8. “MONITOR” (Servo Path Display)........................................................................................................... 44

14.9. “PIT.CURV” (Pitch Curve) ....................................................................................................................... 45

14.10. “THRO.HOLD” (Throttle Hold Function) ................................................................................................. 48

14.11. “V-TAIL” (V-Tail Mixer) ............................................................................................................................. 49

14.12. “DELTA MIX” (Delta Mixer)...................................................................................................................... 51

15. Remote Control Operation .................................................................................................................................. 54

16. Crystal Change ................................................................................................................................................... 55

17. Maintenance and Care ....................................................................................................................................... 55

18. Disposal ............................................................................................................................................................... 56

a) General Information ........................................................................................................................................ 56

b) Batteries and Rechargeable Batteries ........................................................................................................... 56

19. Troubleshooting .................................................................................................................................................. 57

20. Technical Data ..................................................................................................................................................... 58

a) Transmitter...................................................................................................................................................... 58

b) Receiver ......................................................................................................................................................... 58

21. Declaration of Conformity (DOC) ........................................................................................................................ 58

3

Page 4

1. Introduction

Dear Customer,

Thank you for purchasing this product.

The product meets the requirements of the current European and national guidelines.

To maintain this status and to ensure safe operation, you as the user must observe these operating instructions!

These operating instructions are part of this product. They contain important information concerning operation and handling. Please bear this in mind in case you pass on the product to any

third party.

Therefore, keep these operating instructions for future reference!

All company names and product names are trademarks of the respective owners. All rights reserved.

In case of any technical inquiries, contact or consult:

2. Intended Use

The remote control is solely designed for private use in the field of model construction and the operating times associated with it. This system is not suitable for industrial use, such as controlling machines or equipment.

Tel. no.: +49 9604 / 40 88 80

Fax. no.: +49 9604 / 40 88 48

E-mail: tkb@conrad.de

Mon. to Thur. 8.00am to 4.30pm, Fri. 8.00am to 2.00pm

Any use other than the one described above damages the product. Moreover, this involves dangers such

as short-circuit, fire, electric shock, etc.

The remote control must not be technically modified or rebuilt!

Observe all safety notes in these operating instructions. They contain important information regarding the

handling of the product.

You are solely responsible for the safe operation of your remote control and your model!

4

Page 5

3. Product Description

The “MC60” remote control system is a radio remote control system ideally suited for model motor planes, model

gliders or model helicopters.

The proportional channels allow you to use the steering function and control function independently from each other.

The remote control also features several mixing and memory functions needed for the different models. The settings

of up to 6 different models can be saved in the remote control system.

The display is easily readable and the easy-to-use buttons allow you to easily, quickly and safely enter data. Thanks to

electronic trimming, the rudders are always in the correct position. The last set position is assumed automatically when

the remote control is switched on!

The ergonomic casing can be held and operated comfortably and allows you to safely control the model.

For operating, 8 mignon batteries (e.g. Conrad item no.: 652507, pack of 4, order 2) or rechargeable batteries are

needed. The receiver requires 4 AA batteries (e.g. Conrad item no.: 652507, pack of 4, order 1) or rechargeable

batteries.

4. Scope of Delivery

• Transmitter

• Receiver

• Operating instructions

5. Explanation of Symbols

The symbol with the exclamation mark points out particular dangers associated with handling, function or

operation.

The “arrow” symbol indicates special advice and operating information.

5

Page 6

6. Safety Information

In case of damage caused by non-compliance with these safety instructions the warranty / guarantee will become void. We do not assume any responsibility for consequential damage!

We do not assume any liability for damage to property or personal injury caused by improper use

or the failure to observe the safety instructions! In such cases the warranty/guarantee is void.

Normal wear and tear in operation and damage due to accidents (like the receiver aerial being torn

off, the receiver housing broken etc.) are excluded from the warranty.

Dear Customer, these safety instructions are not only for the protection of the product but also for your own safety and

that of other people. Therefore, read this chapter very carefully before putting the product into operation!

a) General Information

Caution, important note!

Operating the model may cause damage to property and/or individuals.

Therefore, make sure that you are properly insured when using the model, e.g. by taking out private

liability insurance. If you already have private liability insurance, inquire about whether the operation of the

model is covered before operating it.

• The unauthorized conversion and/or modification of the product is prohibited for safety and approval reasons (CE).

• The product is not a toy and should be kept out of reach of children under 14 years of age.

• The product must not become damp or wet.

• Do not leave packaging material unattended. It may become a dangerous toy for children.

• Do not connect the drive motor to electric models before the receiver system has been installed completely. This

ensures that the drive motor does not start unintentionally.

• Please check the functional safety of your model and of the remote control system each time before you use the

model. Watch out for visible damage such as defective plug connections or damaged cables. All movable parts on

the model have to be running smoothly. However, there must be no tolerance or ‘play’ in the bearing.

• Should questions arise that are not answered with the help of this operating manual, contact us (contact information,

see chapter 1) or another expert.

• The operation and handling of RC models must be learned! If you have never controlled such a model, start especially carefully to get used to how it responds to the remote commands. Do be patient!

6

Page 7

b) Operation

• If you do not yet have sufficient knowledge on how to deal with remote-controlled models, please contact an experienced model sportsman or a model construction club.

• Each time before you use the product, make sure that there are no other models operated within the same range of

frequency or channel as your own remote control. Control over remote controlled vehicles will be lost! Always use

different frequencies/channels.

• When putting the device into operation, always turn on the transmitter first. Then switch on the receiver in the model.

Otherwise, the model might show unpredictable responses! Always pull out the telescopic aerial of the remote

control completely.

• Before operating the model, check whether the stationary model reacts to the commands of the remote control as

expected.

• When you operate the model, always make sure that no parts of your body, other people or objects come within the

dangerous range of the motors or any other rotating drive parts.

• Improper operation can cause serious damage to people and property! Always make sure that the model is in direct

visual contact and do not operate it at night.

• Do not operate your model if your ability to respond is unrestricted. Fatigue or the influence of alcohol or medication

can lead to wrong responses.

• Operate your model in an area where you do not endanger other people, animals or objects. Only operate it on

private sites or in places which are specifically designated for this purpose.

• In case of an error, stop operating your model straight away and remove the cause of malfunction before you

continue to use the model.

• Do not operate your RC system during thunderstorms, under high-voltage power lines or in the proximity of radio

masts.

• Never switch off the remote control (transmitter) while the model is in use. To switch off the model, always switch off

the motor first, then switch off the receiver. Only then may the remote control be switched off.

• Protect the remote control from dampness and heavy dirt.

• Do not expose the remote control to direct sunlight or excessive heat for a long period of time.

• If the batteries (or rechargeable batteries) in the remote control are low the range decreases. If the rechargeable

battery in the receiver is low, the model will not respond correctly to the remote control.

If this is the case, stop flying immediately. Replace the batteries with new ones or recharge the rechargeable batteries.

• Do not take any risks when operating the product! Your own safety and that of your environment depends completely

on your responsible use of the model.

7

Page 8

7. Notes on Batteries and Rechargeable Batteries

• Keep batteries/rechargeable batteries out of the reach of children.

• Do not leave any batteries/rechargeable batteries lying around openly. There is a risk of batteries being swallowed

by children or pets. If swallowed, consult a doctor immediately!

• Batteries/rechargeable batteries must never be short-circuited, disassembled or thrown into fire. There is a danger

of explosion!

• Leaking or damaged batteries/rechargeable batteries may cause acid burns when coming into contact with skin.

Use suitable protective gloves.

• Do not recharge normal batteries. There is a risk of fire and explosion! Only charge rechargeable batteries intended

for this purpose. Use suitable battery chargers.

• Please observe correct polarity (positive/+ and negative/-) when inserting the batteries/rechargeable batteries.

• If the device is not used for a longer period of time (e.g. storage), take out the inserted batteries/rechargeable

batteries inserted in the remote control and in the car to avoid damage from leaking batteries/rechargeable batteries.

Recharge the rechargeable batteries about every 3 months, because otherwise there may be a total discharge due

to self-discharge, which makes the rechargeable batteries useless.

• Always replace the entire set of batteries or rechargeable batteries. Never mix fully charged batteries/rechargeable

batteries with partially discharged ones. Always use batteries or rechargeable batteries of the same type and manufacturer.

• Never mix batteries and rechargeable batteries! Either use batteries or rechargeable batteries for the remote control.

The remote control (transmitter) may be operated with rechargeable batteries instead of batteries.

However, the lower voltage (batteries=1.5 V, rechargeable batteries=1.2 V) and the lower capacity of

rechargeable batteries do lead to a decrease of the operating time. Normally this does not matter, since

the operating time of the remote control exceeds that of the model.

If you use batteries in the remote control, we recommend the use of high-quality alkaline batteries.

When rechargeable batteries are used, the range can be reduced.

8

Page 9

8. Charging Rechargeable Batteries

The rechargeable mignon batteries required for the RC system are, in general, empty on delivery and must be charged.

Please note:

Before a rechargeable battery reaches maximum capacity, several complete discharge and charge cycles

are necessary.

Always discharge the rechargeable battery at regular intervals, since charging a “half-full” rechargeable

battery several times can cause a so-called memory effect. This means that the rechargeable battery

loses its capacity. It no longer provides all of its stored energy, and the operating time of the model and the

remote control is reduced.

If you use several rechargeable batteries, purchasing a high-quality charger may be worthwhile. Such a

charger usually has a quick-charging feature.

9

Page 10

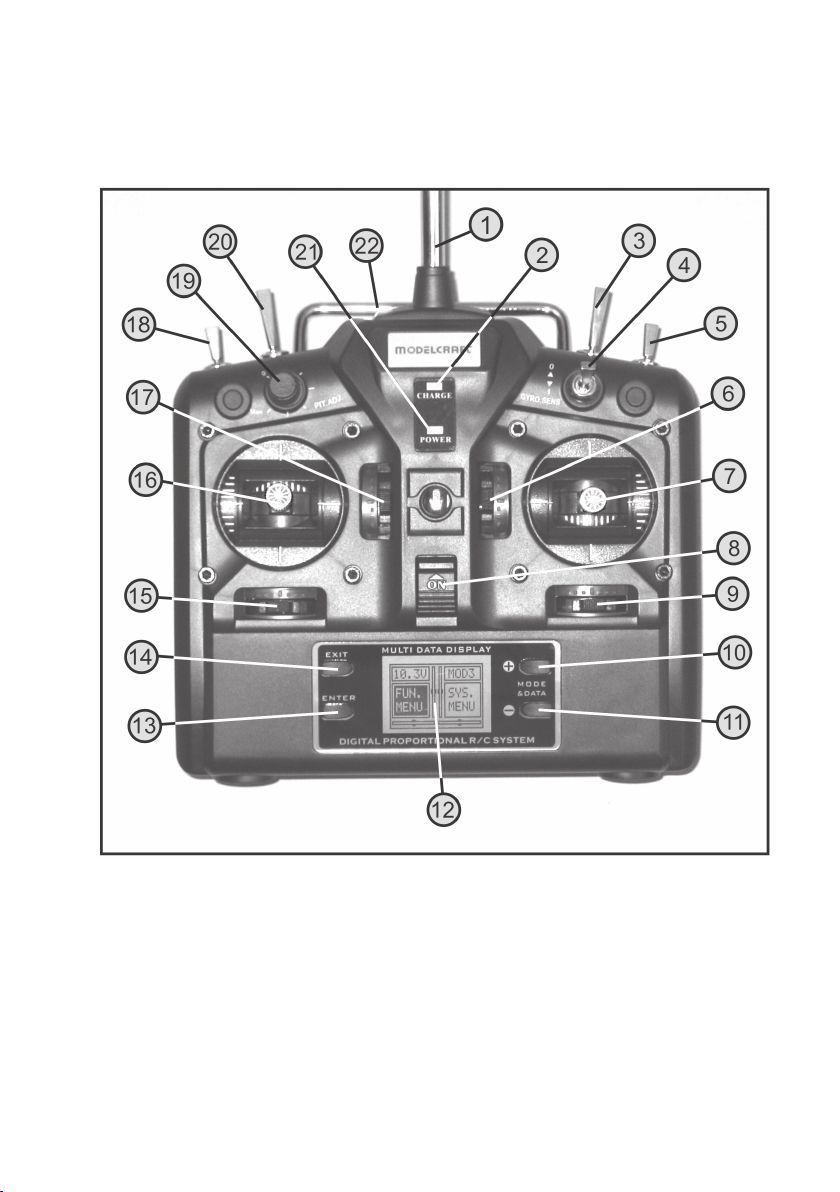

9. Transmitter Controls

a) Front

10

Figure 1

Page 11

1. Transmitter aerial

2. Charge volume indication

3. “AILE D/R” toggle switch

4. “GYRO.SENS” toggle switch

5. “TH.HOLD” toggle switch

6. Trim button for elevator/nod function (in mode II)*

7. Control lever for elevator/nod and aileron/roll function (in mode II)*

8. Function switch

9. Trim button for aileron/roll function (in mode II)*

10. “+” (plus) button

11. “-” (minus) button

12. Multi-functional display

13. “Enter” button

14. “Exit” button

15. Trim button for rudder/tail function (in mode II)*

16. Control lever for rudder/tail and throttle/pitch function (in mode II)*

17. Trim button for throttle/pitch function (in mode II)*

18. “IDLE” toggle switch

19. “PIT.ADJ.” rotary control

20. “ELEV.D/R” toggle switch

21. Operational charge display

22. Carrying handle

* For further information on this, see the chapter “Programming the remote control transmitter” in the “Sytem Menu”

section and the sub-section “STICK MODE”.

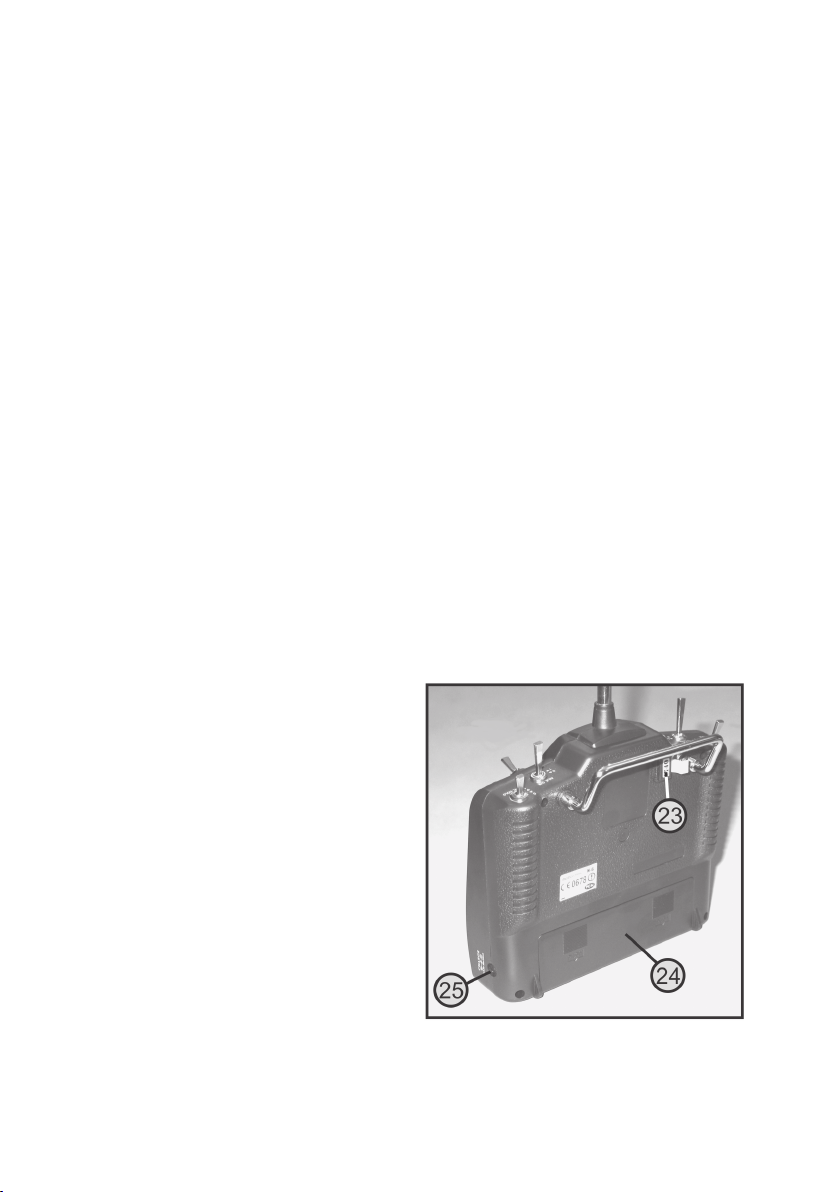

b) Back

23. Transmitter crystal

24. Battery compartment lid

25. Charging jack

Figure 2

11

Page 12

10. Setting up the Transmitter

Important note:

In the operating instructions, the numbers in the text always refer to the figure opposite or the figures within

the section. Cross-references to other figures will be indicated by the corresponding figure number.

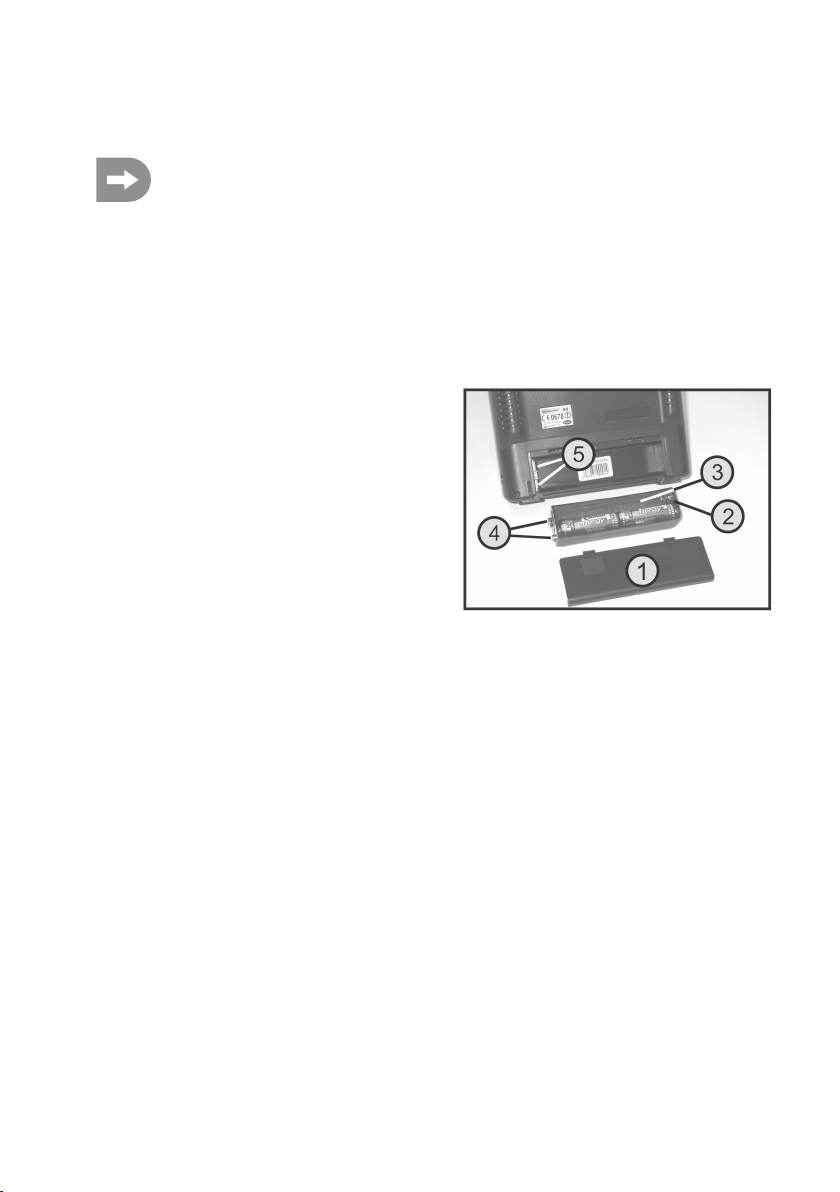

a) Inserting the Batteries/Rechargeable Batteries

The power supply of the transmitter requires 8 alkaline batteries (e.g. Conrad Item No.: 652507, pack of 4, order 2) or

rechargeable batteries. For ecological and also for economical reasons it is recommended to use rechargeable batteries, since they can be recharged in the transmitter via a built-in charging socket (see fig. 2 pos. 25).

To insert the batteries or rechargeable batteries, please proceed as follows:

The battery compartment lid (1) is located on the back of the

transmitter. Press the two corrugated areas and push off the

lid downwards.

Remove the battery holder (2) and place 8 batteries or 8 rechargeable batteries in the battery compartment.

Always make sure the polarity of the batteries is correct. A

corresponding label (3) is located at the bottom of the battery

compartment.

When inserting the filled battery case, ensure that the two

connections of the case (4) have good contact to the coach

springs in the transmitter (5).

Then slide the cover of the battery compartment back on and

let it snap into place.

Figure 3

12

Page 13

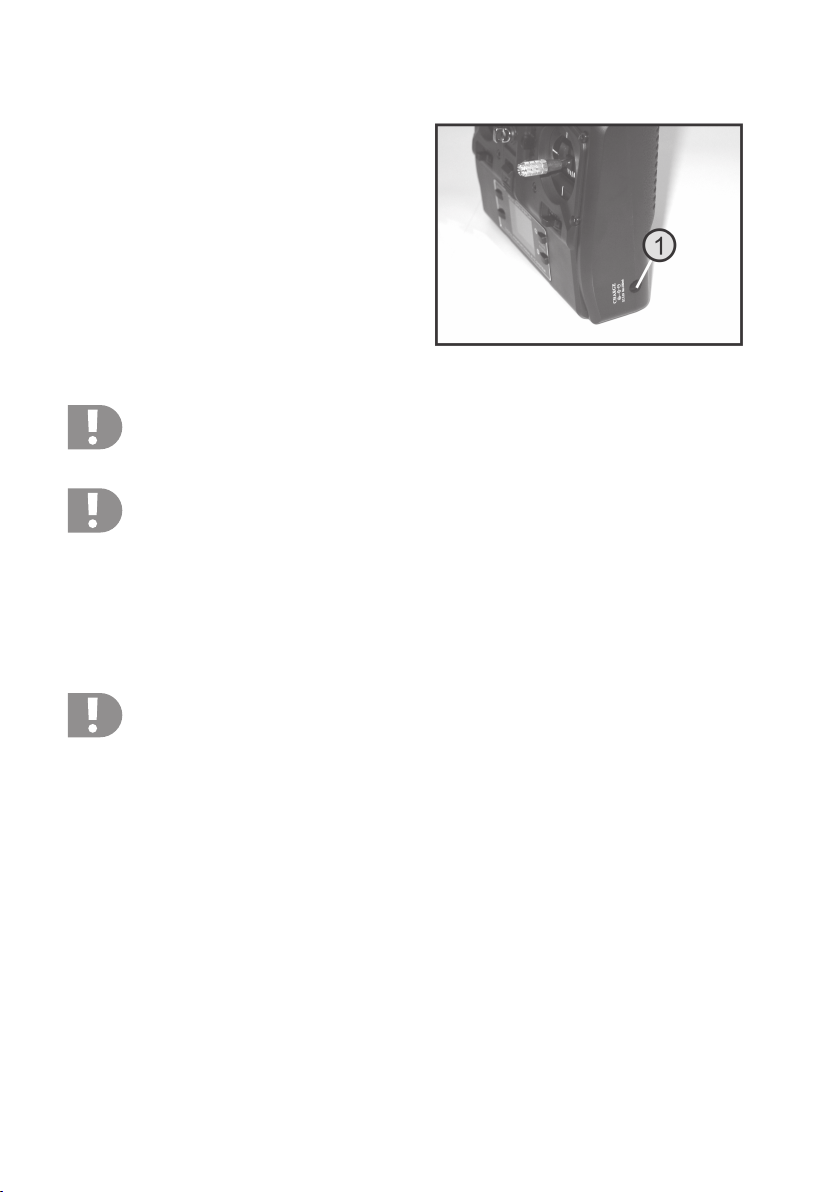

b) Charging the Rechargeable Transmitter Batteries

The charging socket (1) is located on the right side of the transmitter. When rechargeable batteries are inserted, you can

connect the charger cable to charge the rechargeable batteries in the transmitter.

Always make sure the polarity of the connecting plug is correct. The inner contact of the charging socket must be connected to the positive terminal (+) and the outer contact to the

negative terminal (-) of the charger.

The charging current should correspond to approximately 1/

10 of the capacity value of the inserted rechargeable batteries. For rechargeable batteries with a capacity of 2000 mAh,

this corresponds to a charging current of approx. 200 mA and

charging time takes approx. 14 h.

Attention!

Before charging the rechargeable batteries in the transmitter, remove the transmitter crystal from the back

of the transmitter (see fig. 2, pos. 23). Otherwise, charging is not possible.

Caution!

Connect the charger only if rechargeable batteries (1.2V/cell) have been inserted in the transmitter. Never

try to recharge normal batteries (1.5V/cell) with a charger. There is a risk of fire and explosion!

During charging, the operating display appears (see fig. 1, item 12) and the operating voltage (see fig. 1, item 21)

lights up. Additionally, the flashing charging control lamp (see fig. 1, item 2) indicates that the batteries are being

charged. When the rechargeable batteries are fully charged and the charge end voltage was reached, the charge

control lamp goes out.

After the charger is separated from the transmitter, you can push the transmitter crystal back into the casing and check

the system’s function.

Attention!

In order to avoid damage to the internal conductor paths and connections, please do not use any quick

chargers. Charging current should not exceed 200 mA.

As an alternative to charging the rechargeable batteries right in the transmitter, mignon rechargeable batteries can

also be taken from the remote control and charged in a suitable round cell charger.

Figure 4

13

Page 14

c) Switching on the Transmitter

When the rechargeable batteries are fully charged or new batteries have been inserted, completely pull out the remote

control aerial (see fig. 1, pos. 1).

Check the position of the toggle switches. All switches should be in the forward or bottom positions (switch position “0”

or “N”). Now switch on the transmitter using the “on/off” switch (see fig. 1, pos. 8).

The operating voltage indication (see fig. 1, pos. 21) indicates that the transmitter is sufficiently supplied with power.

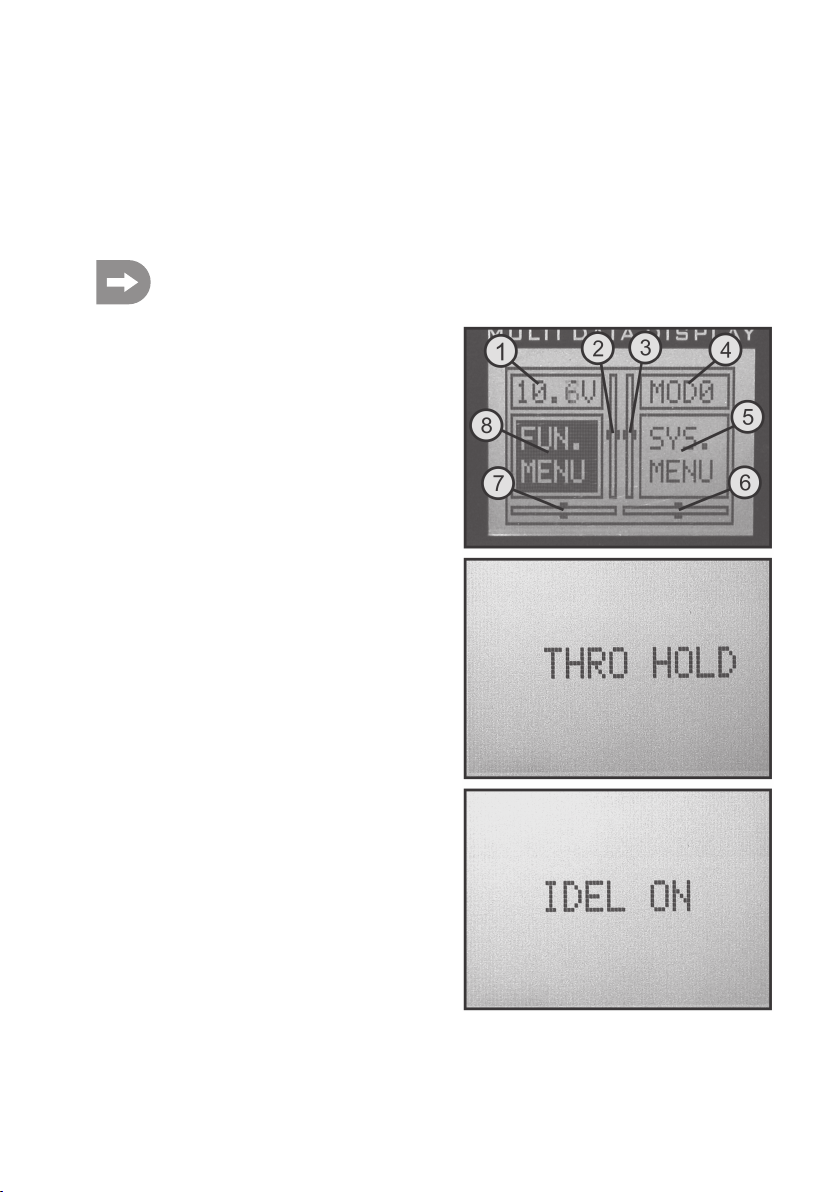

Additionally, an acoustic signal sounds and the display shows the operating display (see figure 5).

If the “TH.HOLD” switch (see figure 1, pos. 5) or the “IDLE” switch (see figure 1, pos. 18) are not in the front

or lower position, a quick series of acoustic signals sounds and the respective switch is indicated in the

display (see fig. 5).

When the switch is put in the correct position, the alarm is

switched off and the operating display goes out.

The operating display consists of the following elements:

1. Operating voltage display

2. Throttle/pitch trimming display (in Mode II)*

3. Elevator/nod trimming display (in Mode II)*

4. Memory display

5. System menu display

6. Aileron/roll trimming display (in Mode II)*

7. Rudder/tail trimming display (in Mode II)*

8. Function menu display

* For further information on this, see chapter “Programming

the Remote Control Transmitter”, section “Sytem Menu”

and sub-section “STICK MODE”.

The respective menu that can be called (function or system

menu) is highlighted with a dark background. To switch between the two menus, press the button “+” (see fig. 1, pos.

10) or the button “-”(see fig. 1, pos. 11). The remote control

emits a signal tone for each press of a button.

If the power supply is not sufficient for faultless operation any

more (at a voltage of less than 8.5 V), a repeating signal tone

and flashing operating voltage display (see fig. 1 item 21) indicates the lack of sufficient battery power.

In this case, you should stop operating your model as quickly

as possible. To continue operating the transmitter, recharge

the batteries or insert new batteries.

14

Figure 5

Page 15

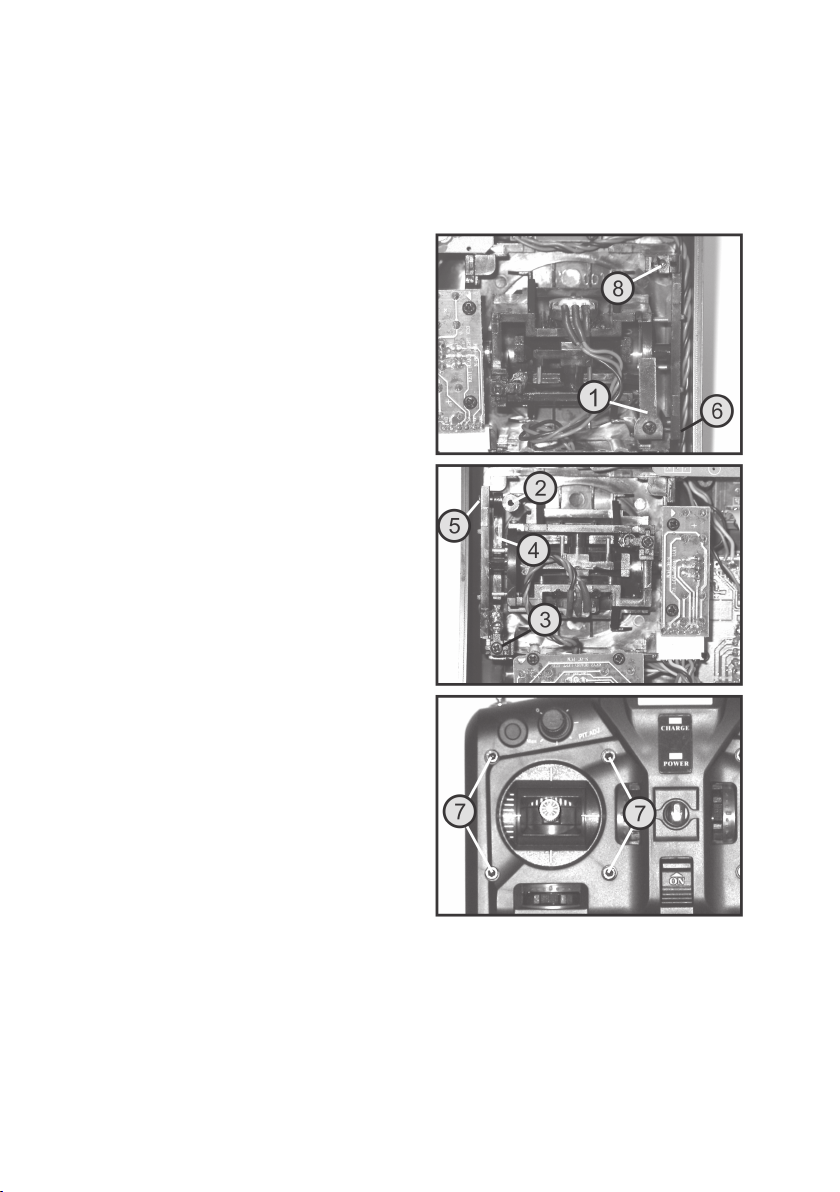

d) Modifying the Throttle Function

If you prefer to have the throttle function on the right instead of the left hand lever, you have the option of swapping the

rest/hold function and the spring return mechanism of the two lever units.

To make the necessary changes, some experience with remote control transmitters is required. Therefore you should

consult an experienced model maker or a model construction club if you do not feel capable of undertaking the

procedures described in the following.

Unscrew the four screws by means of a Phillips-tip screwdriver from the rear panel of the transmitter and lift the rear

panel carefully.

Remove the coach spring (1) from the right lever aggregate

(seen from the rear) and screw it on to the left aggregate’s

spring at the prepared screw hole (2).

Turn the adjustment screw for the lever return force (3) at the

left lever aggregate (seen from the rear) out with a suitable

screw driver until the return spring is completely relieved.

Bend the tip of a pin with fine tongs to form a hook and use it

to unhook the return spring from the adjustment screw hook.

The return spring and adjustment screw can now be removed.

To be able to remove the return lever (4) as well, the retaining

screw (5) must be removed.

To be able to install the return lever reversed mirror-inverted

in the right lever aggregate (seen from the rear), the retaining

screw (5) must be screwed into the prepared bore (6). Remove the four retaining screws (7) of the lever aggregate at

the front of the transmitter and lift it out of the casing until you

can turn in the screw, since the transmitter side is in the way

otherwise. Then, the lever aggregate is attached again.

After hooking the return spring into the return lever, push the

adjusting screw into the prepared bore (8) and attach the return spring to the hook of the adjustment screw.

Then you can check the mechanical function of the lever aggregate and set the desired return force of the control lever.

Figure 6

When attaching the back, ensure that no cables are squeezed and screw on the transmitter’s back cover again. The

electronic modification of the throttle function is done later in the system menu under “STICK MODE”.

15

Page 16

e) Setting the Control Levers

As already shown in section “Modifying the Throttle Function”, the return forces for the control levers can be set

individually. For this, each of the three return springs has a separate adjustment screw (also see figure 5, pos. 3).

When the screw is turned in, the return force is lowered. If the adjustment screw is screwed out, the restoring force is

increased. The control lever length can also be adjusted.

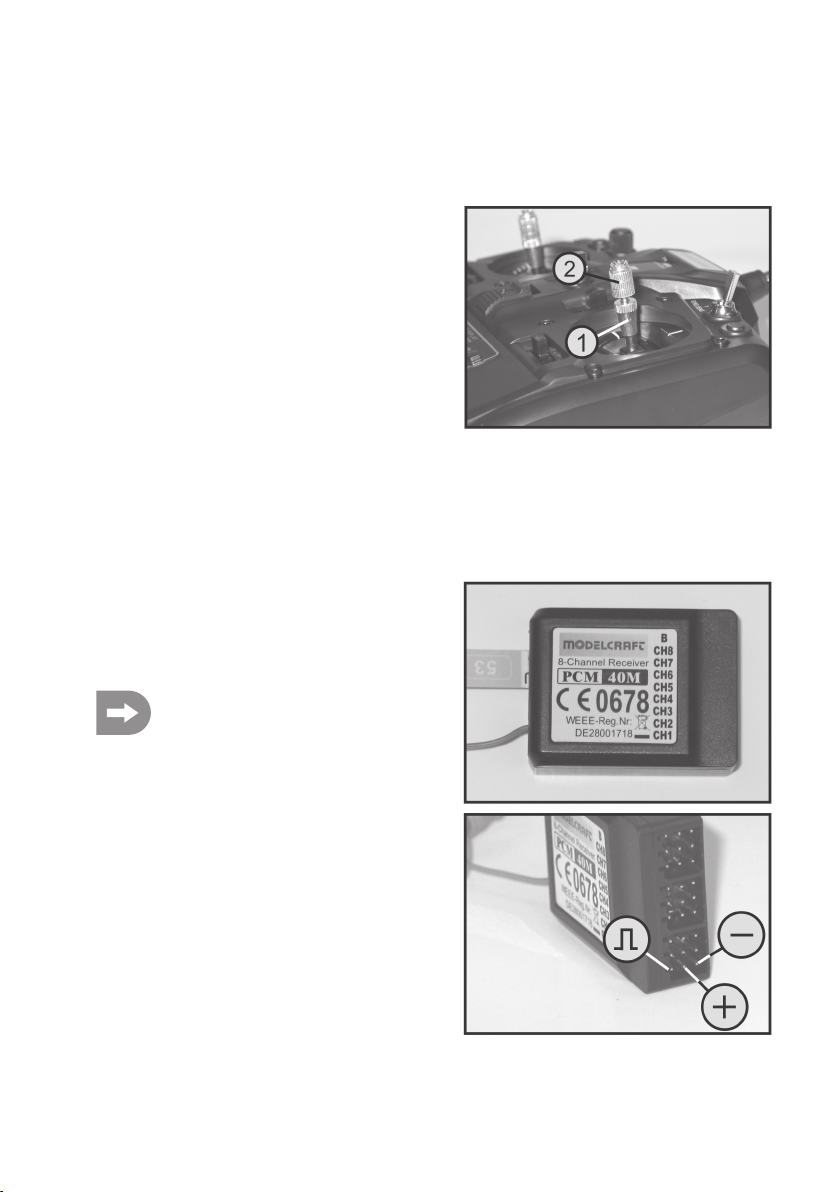

To do so simply hold the bottom part of the grip (1) and turn

the upper part (2) anti-clockwise. You can now set the length

of the control lever by turning the bottom part of the grip.

Finally, tighten the upper part of the grip back up.

Figure 7

11. Setting up the Receiver

a) Receiver Connection

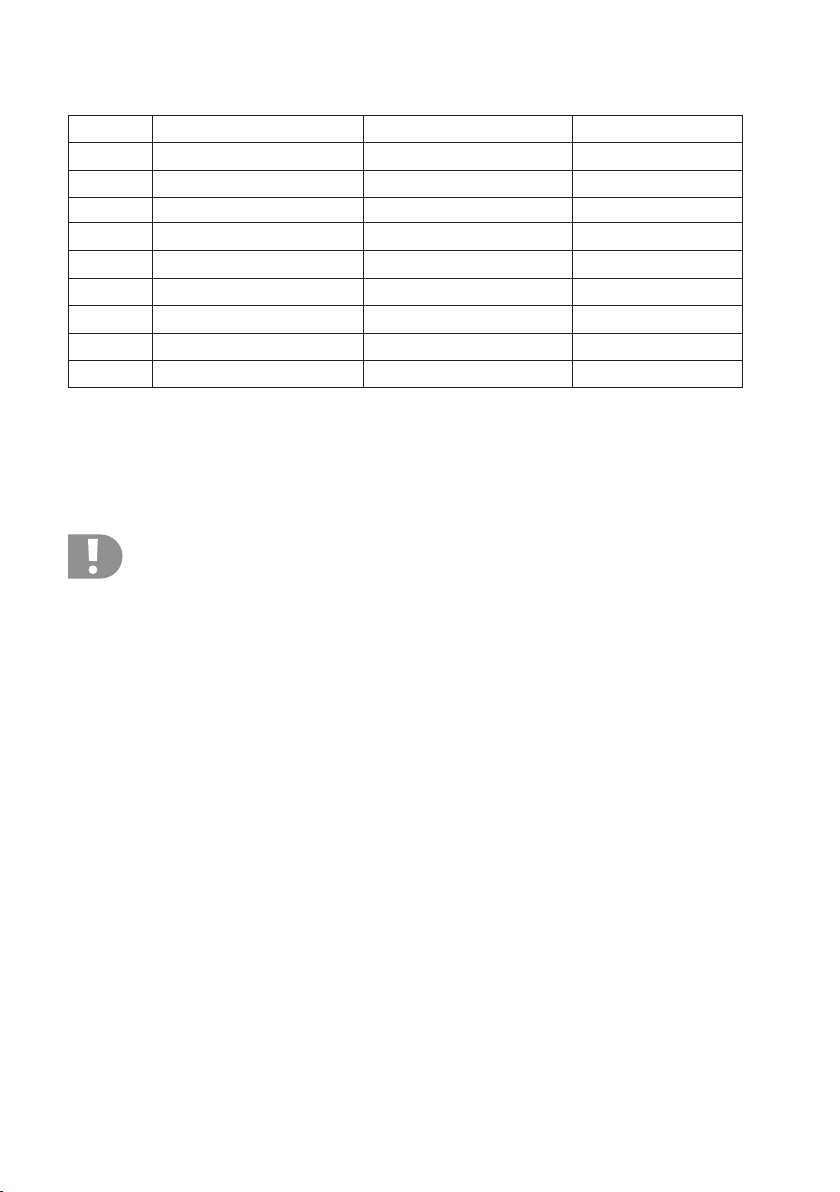

On its right hand side the receiver offers the option of connecting up to 8 servos with Futaba or JR plugs (CH1 to CH8).

The receiver battery is connected to connection “B”.

When connecting servos and speed or flight

controllers, always make sure to pay close attention to the correct polarity of the plug connectors.

For Futaba plug connectors protected against

polarity reversal the positive lead (yellow, white or

orange, depending on the manufacturer) must be

connected to the left of the three aligned contacts.

The plug contact for the negative line (black or

brown, depending on the manufacturer) must be

connected to the right pin contact.

16

Figure 8

Page 17

The receiver outputs are assigned as follows:

Output Helicopter Motor model plane Model glider

CH1 Roll servo Aileron servo Aileron servo

CH2 Nod servo Elevator servo Elevator servo

CH3 Throttle servo/speed controller Throttle servo/speed controller Spoiler servo

CH4 Tail servo Rudder servo Rudder servo

CH5 Gyro sensitivity Undercarriage servo * Free channel *

CH6 Pitch servo Free channel ** Free channel **

CH7 Not available Not available Not available

CH8 Not available Not available Not available

B Battery connection *** Battery connection *** Battery connection ***

* A servo connected here reacts to the rotary control “PIT.ADJ” (see figure 1, pos. 19).

** A servo connected here reacts to the toggle switch “GYRO SENS” (see figure 1, pos. 4).

*** Electric models with an electronic speed controller only require a separate rechargeable receiver battery if the

speed controller used does not have a BEC circuit. For further information, refer to the technical documents of the

controller.

Important!

It is recommended to use a pair of tweezers or long-nosed pliers to disconnect the connection. To prevent

cable breaks, you should always pull on the plastic casing of the plug to disconnect the connection. Never

pull on the cables.

17

Page 18

b) Installing the Receiver

Installation of the receiver depends on the model. For this reason, you should always follow the recommendations of

the model manufacturer regarding the installation.

With electric models, make sure to keep sufficient distance to electronic speed controllers as the speed controller can

have a negative effect on the reception quality. Regardless of the model, you should always try to install the receiver

so that it is protected from dirt, moisture, heat, and vibration in the best possible way.

Two-sided adhesive foam (servo tape) or rubber rings that hold the foam-wrapped receiver securely in place are

suitable for fastening.

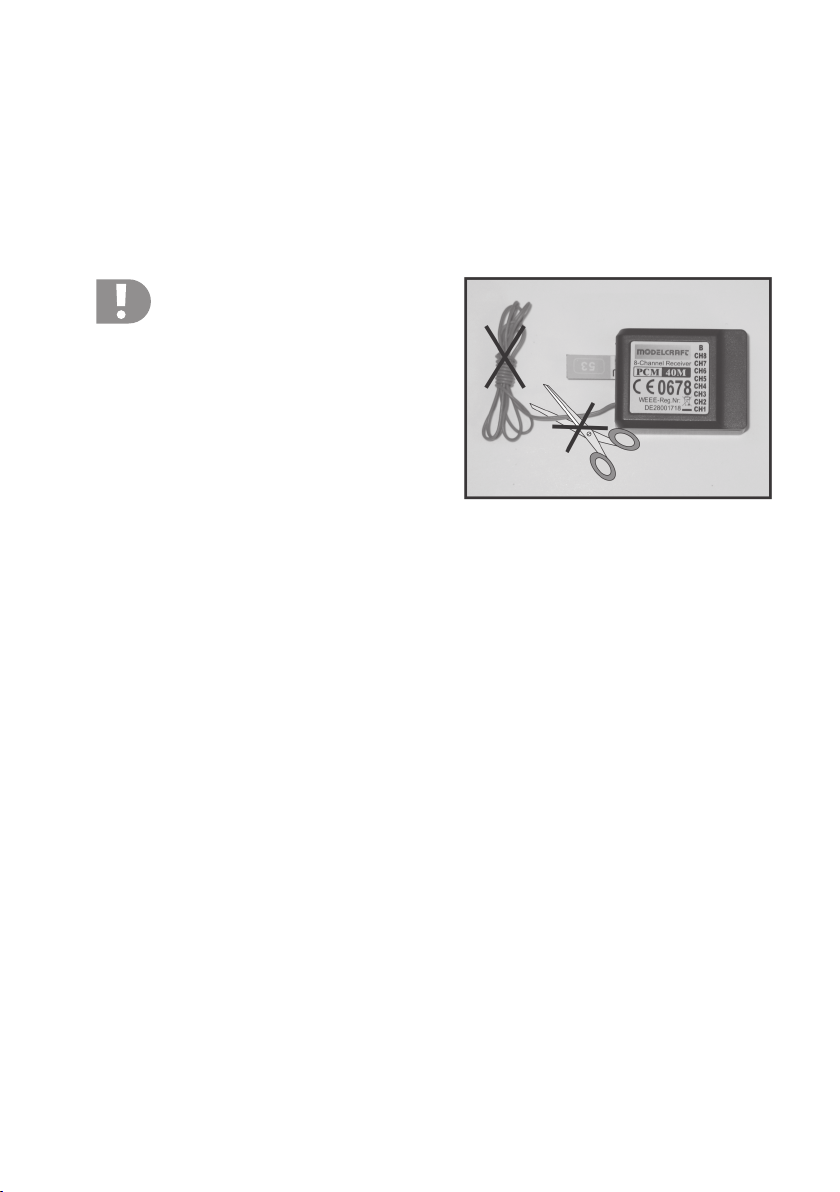

Attention!

The aerial wire has a precisely determined length.

For this reason, you must not roll up the wire, form

it into a loop or cut it off.

This would decrease the range significantly and

thus pose a considerable safety risk.

Figure 9

Pull the aerial wire out of the model through an opening in the body directly behind the receiver. To do so, you should

ideally use an aerial tube, which may be supplied with the model or which can be obtained as an accessory.

With model planes, the aerial wire can be attached to the tail, and with model helicopters, it can be attached along the

landing strut towards the tail boom.

18

Page 19

c) Installing the Servos

To install the servos (1) please use the rubber elements (2)

supplied with the servos and the screw grommet (3).

The rubber elements are intended to protect the servos from

shocks to the model during operation. Therefore, the servo

casing must be able to swing freely. It must not have direct

contact to the model.

Linkages and servo arms of servos installed next to each other

must not obstruct one another even at full deflection.

When servo arms or linkages are obstructed, the servos cannot assume the required positions. This causes higher power

consumption and the model cannot be controlled properly.

Always mount the servo lever at a 90° angle to the linkage

rods (see sketch A).

The rudder or steering travel will not be equal on both sides if

the servo lever is mounted at an angle to the linkage rod

(sketches B and C).

A slight tilt of the servo levers can later be electronically balanced out according to chapter “Programming the Remote

Control Transmitter” in the “Function Menu” section and the

sub-section “Servo Centre Position”.

2

3

A

SERVO SERVO

1

B

2

3

Figure 10

C

SERVO

Figure 11

d) Checking the Servo Functions

To run a test, connect the servos used to the receiver. Pay attention to the assignment of the receiver outputs as

described above.

Switch on the remote control, then the receiver. If attached correctly, the servos should react to movement of the

control levers at outputs 1 - 4. The servos at the outlets 5 and 6 react depending on the models programmed to the

transmitter and/or the activated switches and controllers.

Important information!

Always switch on the transmitter first, then the receiver. When you switch off the devices, always switch off

the receiver first, then the transmitter.

Never switch off the remote control as long as the receiver is in operation. This can lead to unexpected

reactions by the model!

19

Page 20

12. Programming the Remote Control

To perfectly adjust the remote control to your model, the remote control has two different menus:

1. System menu (“SYS.MENU”)

2. Function menu (“FUN.MENU”)

In the system menu, the general settings are made first and the model is selected.

In the function menu, the settings for the respective model type are then made.

Depending on the model type (helicopter or plane model) selected in the system menu, the function menu

will offer different functions.

The engine emits a short signal tone for each admissible press of a button or movement of the control

lever.

The selected menu item, the called up function or the settable value is always highlighted with a dark

background in the display.

The settings are made with the four input buttons and the

control levers. They have the following functions:

“+” button (see also fig. 1, pos. 10)

With this button, you can increase the set value or switch between menu items.

“-” button (see also fig. 1, pos. 11)

With this button, you can decrease the set value or switch

between menu items.

“ENTER” button (see also fig. 1, pos. 13)

With this button you can activate selected menu items or save

the changed settings.

“EXIT” button (see also fig. 1, pos. 14)

With this button you can exit the currently selected menu or

sub-menu without saving the changed values. Every press of

this button takes you a step back until you reach the operational display.

Figure 12

In some menus, you need to use the control lever for the rudder/tail function or the elevator/nod function to switch.

With the factory settings (Mode II)*, the left control lever reacts to left/right movement and the right one to up/down

movement.

* For further information on this, see the chapter “Programming the Remote Control Transmitter” in the “Sytem

Menu” section and the sub-section “STICK MODE”.

Important!

If you activated a different stick mode, the control levers react according to the different assignment.

20

Page 21

13. The System Menu

The following menu items are available to you in the system menu:

1. “MODEL.SET” (Model settings)

a) “MODEL” (Selection of the model memory)

b) “RENAME” (Model memory name)

c) “SAVE AS” (Copy a model memory)

d) “RECOVER” (Resetting to the factory settings)

2. “MODULATE” (Setting the transmitter modulation)

3. “PLANE TYPE” (Setting the plane type)

4. “STICK MODE” (Transmitter lever settings)

5. “STICK ADJ” (Control lever calibration)

Calling the system menu

To call the system menu, proceed as follows:

• Switch on the transmitter.

The display shows the operating display and the display for the function

menu (“FUN.MENU”) is highlighted with a dark background.

• Press button “-”.

The display changes from the function menu to the system menu

(“SYS.MENU”).

• Press “ENTER” button.

The different sub-items of the system menu are displayed and can be

switched with the “+” and “-” buttons.

Figure 13

21

Page 22

13.1. “MODEL.SET” (Model Settings)

a) “MODEL” (Selection of the Model Memory)

The remote control system has 6 model memories which allow you to save the data for your respective models

independently of one another.

Selection of the model memory

• Call the system menu and select the menu item “MODEL.SET” with the

“+” and “-” buttons.

• Activate the selected menu item with the “ENTER” button.

The display shows the model settings display. To the right of the model

memory display (“MODEL”), you can see the name of the currently active model memory (e.g. “MOD0” – “MOD5”) highlighted with a dark

background.

• Use the rudder/tail function control lever to switch between the different

model memories.

• Confirm your selection with the “ENTER” button. The data of the model

memory called is then loaded.

• Press the “EXIT” button repeatedly to exit the menu again and switch

back to the operating display. The model memory called is displayed.

22

Figure 14

Page 23

b) “RENAME” (Model Memory Name)

In order to be able to discern between model memories more easily it makes sense to give the memories the abbreviated name of the corresponding models. The name can consist of a combination of up to 4 letters or numbers.

You can only change the currently active model memory name.

Setting the model memory name

• Call the system menu and select the menu item “MODEL.SET” with the

“+” and “-” buttons.

• Activate the selected menu item with the “ENTER” button.

The display shows the model settings display. To the right of the model

memory display (“MODEL”), you can see the name of the currently active model memory (e.g. “MOD0” – “MOD5”) highlighted with a dark

background.

• Select the menu item “RENAME” with the elevator/nod function lever.

• Activate the selected menu item with the “ENTER” button.

The upper right of the display shows the name of the currently active

model memory. The first of the four name signs and the number “0” in

the numbers/letters box below it are highlighted with a dark background.

• Use the elevator/nod and the rudder/tail function levers to select the

first name abbreviation in the numbers/letters box.

• When pressing the “ENTER” button, the selected character is accepted

and the second name character is highlighted.

• Repeat the procedure until you have set all four digits of the model

memory name as desired.

• Press the “EXIT” button repeatedly to exit the menu again and switch

back to the operating display.

Figure 15

23

Page 24

c) “SAVE AS” (Copy a Model Memory)

For simple programming of the system you have the option of copying data from one model memory to another. This

helps to easily transfer basic settings between similar models and you only need to adjust the settings values to the

new model.

Important!

Before copying model data, you need to call the model memory from which the data is to be copied

(source memory).

Copying model data

• Call the system menu and select the menu item “MODEL.SET” with the

“+” and “-” buttons.

• Activate the selected menu item with the “ENTER” button.

• The display shows the model settings display. To the right of the model

memory display (“MODEL”), you can see the name of the currently active model memory (e.g. “MOD0” – “MOD5”) highlighted with a dark

background.

• Select the menu item “SAVE AS” with the elevator/nod function lever.

• Activate the selected menu item with the “ENTER” button.

The display shows the target memory display.

• Use the rudder/tail function control lever to select the desired target

memory.

• Press “ENTER” to copy the data. “SAVING” appears in the display.

• Press the “EXIT” button repeatedly to exit the menu again and switch

back to the operating display.

• Then call the model memory to which the data was copied and check

the correct servo function.

The copying function only transfers the transmitter’s setting

values. The target memory name is not changed.

24

Figure 16

Page 25

d) “RECOVER” (Resetting to Factory Settings)

With this function you have the option of deleting all the data in a model memory or even to reset all model memories

back to their factory settings.

Important!

Before resetting a model memory to factory settings, you need to call the respective model memory.

Resetting to the factory settings

• Call the system menu and select the menu item “MODEL.SET” with the

“+” and “-” buttons.

• Activate the selected menu item with the “ENTER” button.

The display shows the model settings display. To the right of the model

memory display (“MODEL”), you can see the name of the currently active model memory (e.g. “MOD0” – “MOD5”) highlighted with a dark

background.

• Select the menu item “RECOVER” with the elevator/nod function lever.

• Activate the selected menu item with the “ENTER” button.

The display for resetting the model memory appears.

• Press the “EXIT” button repeatedly to exit the menu again and switch

back to the operating display.

When resetting, only the setting values of the memory are set

to the factory parameters. The model memory name is not

changed.

Figure 17

25

Page 26

13.2. “MODULATE” (Setting the Transmitter Modulation)

The position of the individual control sticks, controls and switches is read by the transmitter. The corresponding resistance values are converted to electric pulses. The electric pulses of all control elements are transmitted one after

another to the high-frequency element as a pulse sequence.

The positive pulses always have the same width. The control information is in the pauses between the individual

pulses. Depending on the position of the control stick, the pauses become longer or shorter. The technical term for this

procedure is also known as pulse pause modulation or pulse position modulation (PPM).

The pulse code modulation (PCM) digitalises signals and routes them to the RF stage as a coded data signal.

Important!

The modulation type set on the transmitter depends on the receiver used. A PPM receiver can only be

controlled by a PPM-modulated transmitter signal. A PCM receiver requires a PCM transmitter signal.

As opposed to PCM transmission, which generally only works with components of the same manufacturer,

PPM transmission allows you to use receivers of different manufacturers.

Setting the modulation

• Call the system menu and select the menu item “MODULATE” with the

“+” and “-” buttons.

• Activate the selected menu item with the “ENTER” button.

The display shows the model settings display. The currently active modu-

lation type is highlighted with a dark background.

• Use the rudder/tail function control lever to switch between the two

modulation types “PPM” and “PCM” or to set the desired value.

• Activate the selected modulation type with the “ENTER” button.

• Press the “EXIT” button repeatedly to exit the menu again and switch

back to the operating display.

26

Figure 18

Page 27

13.3. “PLANE TYPE” (Setting the Plane Type)

As there are different functions available for each of the respective model types, such as mixers or switching functions,

it is necessary to enter the right model type during programming.

You can select either helicopters (“HELIC”), flight models (“PLANE”), flight models with a v-tail (“V-TAI”) or delta flight

models (“DELTA”).

Setting the model type

• Call the system menu and select the menu item “PLANE TYPE” with

the “+” and “-” buttons.

• Activate the selected menu item with the “ENTER” button.

The display shows the model selection display. The currently active

model type is highlighted with a dark background.

• Use the rudder/tail function control lever to switch between the different

model types or to set the desired type.

• Activate the selected model type with the “ENTER” button.

• Press the “EXIT” button repeatedly to exit the menu again and switch

back to the operating display.

Important!

Depending on the model type set, the function menu

(“FUN.MENU”) will display different menu items later.

Figure 19

27

Page 28

13.4. “STICK MODE” (Transmitter Lever Settings)

As described previously for the receiver connection, the individual receiver outlets (channels) have specific functions

or servos assigned to them.

The first four outputs are assigned as follows:

CH1 = channel 1 (aileron/roll function)

CH2 = channel 2 (elevator/nod function)

CH3 = channel 3 (throttle servo/pitch function)

CH4 = channel 4 (rudder/tail function)

When setting the control stick assignment, you can exactly determine to

which control stick outputs 1 - 4 should be assigned.

Setting the stick assignment

• Call the system menu and select the menu item “STICK MODE” with

the “+” and “-” buttons.

• Activate the selected menu item with the “ENTER” button.

The display for the currently set lever assignment appears in the dis-

play. At the same time, the two control levers are indicated as crosses

with the respective control functions. The following abbreviations are

used:

Aileron/roll function = “AI” (= “Aileron”)

Elevator/nod function = “EL” (= “Elevator”

Throttle servo/pitch function = “TH” (= “Throttle”)

Rudder/ tail function = “RU” (= “Rudder”)

• Use buttons “+” and “-” to switch between the different lever assignments (“MODE1” – “MODE4”) or set the desired lever settings.

• Activate the selected modulation type with the “ENTER” button.

• Press the “EXIT” button repeatedly to exit the menu again and switch

back to the operating display.

28

Figure 20

Page 29

Overview of available stick assignments:

Mode 1:

Right control lever up/down: Throttle servo/pitch function (CH3)

Right control lever left/right: Aileron/left+right function (CH1)

Left control lever up/down: Elevator/forward+backward function (CH2)

Left control lever left/right: Rudder/tail function (CH4)

Mode 2:

Right control lever up/down: Elevator/forward+backward function (CH2)

Right control lever left/right: Aileron/left+right function (CH1)

Left control lever up/down: Throttle servo/pitch function (CH3)

Left control lever left/right: Rudder/tail function (CH4)

Mode 3:

Right control lever up/down: Throttle servo/pitch function (CH3)

Right control lever left/right: Rudder/tail function (CH4)

Left control lever up/down: Elevator/forward+backward function (CH2)

Left control lever left/right: Aileron/left+right function (CH1)

Mode 4:

Right control lever up/down: Elevator/forward+backward function (CH2)

Right control lever left/right: Rudder/tail function (CH4)

Left control lever up/down: Throttle servo/pitch function (CH3)

Left control lever left/right: Aileron/left+right function (CH1)

29

Page 30

13.5. “STICK ADJ” (Control Lever Calibration)

The control lever calibration serves for aligning the mechanical and electronic centre positions. This way, mechanical

deflection of the control lever in either direction will cause the same amount of electronic change.

Important!

Before calibrating the control lever, both control levers and the displays for the electronic control must be

at their exact centre positions.

Performing control lever calibration

• Call the system menu and select the menu item “STICK ADJ” with the

“+” and “-” buttons.

• Activate the selected menu item with the “ENTER” button.

The display asks if you really want to perform calibration.

• Use the “+” or “-” buttons to switch from “NO” to “YES”.

• Then press the “ENTER” button to start calibration. When calibration is

completed, the display returns to the system menu.

• Press the “EXIT” button repeatedly to exit the menu again and switch

back to the operating display.

30

Figure 21

Page 31

14. Function Menu

Depending on the model type (helicopter or plane model) selected in the system menu, the function menu will offer

different functions.

The following table offers an overview of the function menu’s menu items:

Helicopter Airplane model Flight model with V-tail Delta flight model

(“HELIC”) (“PLANE”) (“V-TAI”) (“DELTA”)

DR DR DR DR

SUB.TRIM SUB.TRIM SUB.TRIM SUB.TRIM

TRAVEL TRAVEL TRAVEL TRAVEL

CH.REV CH.REV CH.REV CH.REV

SWASH.MIX MONITOR MONITOR MONITOR

GYRO.SENS V-TAIL DELTA-MIX

THRO.CURV

MONITOR

PIT.CURV

THRO.HOLD

The abbreviations stand for the following terms:

DR (“Dual rate”) = Servo path limiter

SUB.TRIM (“Sub Trim”) = Servo centre position

TRAVEL (“Travel”) = Servo travel setting

CH.REV (“Channel reverse”) = Reversing the servo direction

SWASH.MIX (“Swash Mix”) = Swash plate mixer

GYRO.SENS (“Gyro Sensitivity”) = Gyro sensitivity

THRO.CURV (“Throttle Curve”) = Throttle curve

MONITOR (“Monitoring”) = Servo path display

PIT.CURV (“Pitch Curve”) = Pitch curve

THRO.HOLD (“Throttle hold”) = Throttle hold function

V-TAIL (“V-Tail-Mix”) = V-Tail-mixer

DELTA-MIX (“Delta-Mix”) = Delta mixer

31

Page 32

14.1. “DR” (Servo Path Limiter)

The dual rate function allows you to limit servo travel with a switch. You can do this to simply and easily reduce the

reaction sensitivity of a model which reacts too aggressively at full extension. Especially for beginners, models with

reduced rudder deflections are a lot easier to control.

When a model is used for the first time, it might not yet be clear how sensitively it responds to the control commands.

Therefore it is a proven method to reduce the deflections during flight.

Your remote control also offers the possibility of setting a different value for the maximum deflection of either side of the

servo path “H” and “L”.

The dual rate values can be individually adjusted for the aileron/roll function (AILE) and the elevator/(nod

function (ELEV). Use the toggle switches “AILE D/R” (see figure 1, pos. 3) and “ELEV.D/R” (see figure 1,

pos. 20) to switch between the standard servo deflection without path limiter and the reduced dual rate

values or between different dual rate values.

Important!

Before setting the servo path limiter, ensure that the right value is set for the servo path in the menu item

“TRAVEL”.

Setting the servo path limit

• Turn on the transmitter using the function switch and then the “ENTER”

button.

• Use the “+” and “-” buttons to select the “DR” menu item and activate

the menu item with the “ENTER” button.

• On the left of the display, the dual rate values for the aileron/roll function

are displayed, with the set value “H” already highlighted with a dark

background. It can be adjusted with the “+” and “-” buttons if required. At

the same time you can read the settings for the toggle switch

“AILE D/R” (“AILE0” or “AILE1”) in the upper right of the display.

To better display the different settings options, the right half of the display also shows the control curve for the aileron/roll function as a graph.

This also makes changes to the settings well visible.

The current position of the control lever for the aileron function is displayed as a vertical line in the graphics. The ratio of lever position to

curve value can be read from the values “I” (= “IN”) and “O” (= “OUT”).

• Now you can use the “+” and “-” buttons to set the upper dual rate set

value “H” for the servo path. The toggle switch “AILE D/R” should be in

the lower/front position for this, so that the switch position “AILE0” is

displayed. The changed values are stored at once.

32

Figure 22a

Page 33

• Then use the elevator/nod function control lever to switch to the lower

set value “L” and again use the “+” and “-” buttons for setting the desired

servo path.

• Move the control lever for the aileron/roll function to the stop to check

the set servo path for either side and to adjust it.

We recommend setting the servo path for the “AILE0” position so that the rudder or servo lever deflections given by the

model’s manufacturer are achieved.

• Operate the toggle switch “AILE D/R” so that the display switches to

“AILE1”.

• Now set the reduced servo paths for the aileron/roll function according

to the same procedure as described above.

• If you move the aileron/roll function control lever to the stop for test

purposes and leave it in this position, you can see the different servo or

rudder deflections well when operating the “AILE D/R toggle switch.

Figure 22b

Figure 23

33

Page 34

• Press the “ENTER” button to switch to elevator/nod function. Again, the

position of the toggle switch “ELEV D/R” is displayed as “ELEV0” or

“ELEV1”.

• The dual rate values for the two switch positions are set according to

the same procedure as for the aileron/roll function.

• Press the “EXIT” button repeatedly to exit the menu again and switch

back to the operating display.

Figure 24

34

Page 35

14.2. “SUB.TRIM” (Servo Centre Position)

As previously mentioned when installing the servo, always mount the servo lever at a 90° angle to the linkage rods

(see fig. 11). The bar display for the trim button on the transmitter must be in the central position in this case. Only then

will you be able to perform fine trimming in both directions using the trim buttons during flight (see fig. 1, pos. 6, 9, 15

and 17)

However, the cog teeth on servo levers are often so large that the exact 90° angle cannot be set. This is why the servo

centre position helps to set the correct position of the servo arm without the need to adjust the trim buttons.

Important!

Before you set the servo centre position, consult the operational display to check whether the four trim

buttons are in the exact middle position (longer signal tone when the button is pressed).

Setting the servo centre position

• Turn on the transmitter using the function switch and then the “ENTER”

button.

• Use the “+” and “-” buttons to select the “SUB.TRIM” menu item and

activate the menu item with the “ENTER” button.

• The trimming values for the aileron/roll function (“AILE”), the elevator/

nod function (“ELEV”) and the throttle function (“THRO”) are displayed.

The set values for the aileron/roll trimming is already highlighted with a

dark background and can be set.

• Use the “+” and “-” buttons to set the aileron/roll servo centre position.

The value can be set from -100 and 100.

• Press the “ENTER” button to switch to the elevator/nod servo. Set the

values according to the same procedure as above.

• Repeat this process until you have set the exact centre position for all

six servos/functions.

• Press the “EXIT” button repeatedly to exit the menu again and switch

back to the operating display.

Figure 25

35

Page 36

14.3. “TRAVEL” (Servo Travel Settings)

Using the servo travel setting you can precisely define the maximum size of servo travel that is permitted on each side.

This function is typically used to protect servos from mechanically hitting an obstacle when deflecting to the full extent.

You can set a value from 0 to 120. The smaller the value, the shorter the servo travel.

Always try to select the linkage points on the servo and the rudder levers so that they reach maximum

rudder/servo deflections at the factory preset value of 100.

The linked rods or levers should not hit anything or be under any mechanical tension. This ensures that

this function is only required to make minimal adjustments.

The rudder travel values given in the model operating instructions which may be less than the maximum

possible rudder travel values can be reduced later on with the dual rate function.

Setting the servo paths

• Turn on the transmitter using the function switch and then the “ENTER”

button.

• Use the “+” and “-” buttons to select the “TRAVEL” menu item and activate the menu item with the “ENTER” button.

The deflection values for the aileron/roll function (“AILE”), the elevator/

nod function (“ELEV”) and the throttle function (“THRO”) are displayed.

The deflection value for one side of the aileron servo (“AILE”) is already

highlighted with a dark background and can be set.

• Use the “+” and “-” buttons to set the maximum servo path for the aileron/roll servo on one side. The value ´can be set between 0 and 120.

• Then use the rudder/tail function control lever to switch to the other side

and again use the “+” and “-” buttons for setting the desired maximum

servo path.

• Press the “ENTER” button to switch to the elevator/nod function (“ELEV”).

Set the values according to the same procedure as above.

• Repeat this process until you have set the maximum servo path for all

six servos/functions.

• Press the “EXIT” button repeatedly to exit the menu again and switch

back to the operating display.

When connecting electronic speed or flight controllers, you

should not change the factory-preset value of 100 for the

throttle function (“THRO”) to achieve a fine control.

36

Figure 26

Page 37

14.4. “CH.REV” (Reversing the Servo Direction)

Depending on the position of the servos and linkages, a control movement to the left on the transmitter may invoke a

steering movement to the right.

This is why the transmitter allows you to individually set and save the running direction of every servo.

Setting the servo directions of travel

• Turn on the transmitter using the function switch and then the “ENTER”

button.

• Use the “+” and “-” buttons to select the “CH.REV” menu item and activate the menu item with the “ENTER” button.

• In the display you will see six control channels with the respective servo

travel directions currently set. The receiver outlet or channel which is

currently able to be adjusted is highlighted with a dark background.

• Use the “+” and “-” buttons to set the servo travel direction for the receiver output 1 (aileron/roll servo) if required. The indication then switches

from the “NOR” (normal) to the “REV” (reverse) setting or back.

• Press the “ENTER” button to switch to the second receiver output

(elevator/nod servo). Set the values according to the same procedure

as above.

• Repeat the process until all connected servos have the right travel direction.

• Press the “EXIT” button repeatedly to exit the menu again and switch

back to the operating display.

Figure 27

37

Page 38

14.5. “SWASH.MIX” (Swash Plate Mixer)

You can use the swash plate mixer to individually adjust the

mixing ratio of the three swash plate servos. In this way you

can perfectly set the correct movement direction and the required angle of deflection or shift path of the swash plate in

reaction to the transmitter control signals.

For correct function, the swash plate servos must be aligned

according to the adjacent figures.

3 Servos 120°

Front

ELEV (Ch2)

AILE

(Ch1)

3 Servos 120°

AILE

(Ch1)

PITH

(Ch6)

Front

PITH

(Ch6)

ELEV (Ch2)

Figure 28

38

Page 39

Setting the swash plate mixer

• Turn on the transmitter using the function switch and then the “ENTER”

button.

• Use the “+” and “-” buttons to select the “SWASH.MIX” menu item and

activate the menu item with the “ENTER” button.

The currently set values for the roll control function (“AILE”), the pitch

control function (“PITH”) and the nod control function (“ELEV”) are displayed. The set value for the roll function is already highlighted with a

dark background and can be set at once if required.

• Use the “+” and “-” buttons to set the servo travel direction and deflection value for the roll function if required. The value can be adjusted

between -100 and +100, and the travel direction is indicated by the

prefix.

• Press the “ENTER” button to switch to the pitch function. Set the pitch

values according to the same procedure as above.

• Press the “ENTER” button again to switch to the nod function and to

perform the servo path settings here as well.

• To complete the settings, press the “ENTER” button again to store the

set values.

• Press the “EXIT” button repeatedly to exit the menu again and switch

back to the operating display.

Practical advice:

Usually, the swash plate must tilt to the side into which you

move the control at the transmitter (forwards, backwards, left,

right).

Figure 29

39

Page 40

14.6. “GYRO.SENS” (Gyro Sensitivity)

So-called gyroscope (or gyro) systems are used in order to stabilise the tail of the helicopter in the air. There is a

connection between the receiver and the tail servo.

If the tail turns sideways as a result of a wind gust or other external influences, this is recognised by the gyro and a

corresponding control command is sent to the tail servo to counter the turn.

Gyroscope systems that have an additional controller input can be preset to two different sensitivity levels and these

can be selected during flight using a toggle switch. This requires the controller input for the gyro to be connected to

output 5 (CH5) of the receiver.

Standard and AVCS/Heading lock gyroscope systems

A standard gyroscope only adjusts the tail servo within the timeframe required for the positional electronics of the

gyroscope to recognise a movement.

An AVCS/heading lock gyro controls the tail servo until the tail has returned to its original position, where it was prior to

the gyro control process initiation. As an AVCS heading lock gyro can also be operated in standard mode, the sensitivity control of the two systems is slightly different.

If sensitivity control were carried out with a slide control, the

control range for a standard gyro would be linear from min. to

max. sensitivity with the middle setting of the slide control would

correspond to 50% of the sensitivity.

In an AVCS/heading lock gyro, in contrast, the centre position

of the slider corresponds to the minimum gyro sensitivity. The

two end settings of the slider correspond to the respective

max. settings for gyro sensitivity in the standard or AVCS mode

(see sketch).

For further information, refer to the design documents of the

gyro system.

100%

50%

0%

LINEAR

100%

50%

0%

Normal-Modus

Figure 30

100%

50%

AVCS-Modus

0%

50%

Normal-Modus

100%

40

Page 41

Setting the Gyro Sensitivity

• Turn on the transmitter using the function switch and then the “ENTER”

button.

• Use the “+” and “-” buttons to select the “GYRO.SENS” menu item and

activate the menu item with the “ENTER” button.

• The display shows the two values (“POS0” and “POS1”) for gyro sensitivity.

Depending on the toggle switch “GYRO.SENS” (see figure 1, pos. 4),

either the upper or lower value is highlighted with a dark background.

• Now use the “+” and “-” buttons to set the required value for gyro sensitivity in the switch position (“POS0”). The value can be adjusted from 100 to +100, with 0 corresponding to the centre position of the slider.

• Then use the “GYRO.SENS” toggle switch for switching to the (“POS1”)

switch position and again set the desired value with the “+” and “-” buttons.

• Press the “EXIT” button repeatedly to exit the menu again and switch

back to the operating display.

Figure 31

The required values for gyro sensitivity can generally be found in the gyroscope instructions. You can

easily check the settings exactly by taking a few test flights.

In practice it has proven to be helpful to set a slightly higher gyro sensitivity for hovering (“POS0”) than for

circling (“POS1”).

41

Page 42

14.7. “THRO.CURV” (Throttle Curve)

In a proportional remote control unit the control lever and the

corresponding servo maintain linear reactions.

This means: Moving the control element from one side to the

other results in the corresponding servo arm moving from one

side to the other.

If the throttle/pitch control lever (or stick) on the transmitter is

in the lowest position (L), the throttle flap must be almost fully

closed.

If the control lever is then moved to the middle position (2),

the throttle flap should be approx. 50% open.

If the control lever is in the uppermost position (H), the throttle

should be fully open so that the motor can run at full power.

The throttle curve thus corresponds with a straight line (see

the adjacent figure 32).

Using the throttle curve setting you have the option of changing the shape of the throttle curve at five different points

(L, 1, 2, 3 and H) and to change and save the curve specifically for each flight mode (“NOR”, “IDLE0” and “IDLE1”).

Setting the throttle curve

• Turn on the transmitter using the function switch and then the “ENTER”

button.

• Use the “+” and “-” buttons to select the “THRO.CURV” menu item and

activate the menu item with the “ENTER” button.

The left side of the display shows the current “IDLE” flight mode toggle

switch setting “NOR”, “IDLE0” or “IDLE1” (see figure 1, pos. 18) and the

set values for the throttle curve and the control lever position.

For better illustration, the right half of the display shows the control curve

for the throttle function as a graph. The current position of the control

lever for the throttle-pitch function is displayed as a vertical line in the

graphics. The ratio of lever position to throttle curve value can be read

from the values “I” (“IN”) and “O” (“OUT”).

• Put the “IDLE” toggle switch into the lower position so that “NOR” is

displayed.

This flight mode should be used for starting the motor.

• The “+” and “-” buttons can now be used to set the desired value for “L”

(see lower left of the display) for the throttle curve. The value can be set

from 0 to 100. The effect of the setting you make is immediately visible

in the throttle curve on the right half of the display.

100%

75%

50%

25%

0%

L

Stick

Servo

Stick

Servo

1

2

3

H

Figure 32

42

Figure 33a

Page 43

• Then use the “ENTER” button to switch to the second point on the throttle

curve “1” and use the “+” and “-” buttons again to set the desired value.

• Repeat his process until you have set all five throttle curve points as

desired.

• Put the “IDLE” toggle switch into the middle position so that “IDLE0” is

displayed.

In practice it has proven useful to use this setting for circling. This places

the lower half of the throttle curve to hovering flight level.

If you wish to decrease height while circling and thus reduce the rotor

blade angle of attack, the rotor head stays at the set revs and the motor

does not reduce power.

• The setting of the throttle curve for flight mode “IDLE0” is carried out in

the same way as for flight mode “NOR”.

• Then put the “IDLE” toggle switch into its back/upper position so that

“IDLE1” is displayed.

In practice it has proven useful to use this setting for aerobatics. The

throttle curve is v-shaped in this case.

In connection with a correspondingly high negative angle of attack of

the rotor blades, this makes inverted hovering possible.

• The setting of the throttle curve for flight mode “IDLE1” is carried out in

the same way as for flight mode “IDLE0”.

• When the throttle curves for all three flight modes have been set, press

the “EXIT” button to leave the menu and return to the operating display.

Important information!

The set values for the throttle function shown in the photographs only serve for correct understanding of the function

and not as base values for the first flight. Concerning the values to be set, stick to the values indicated by the model manufacturer.

Figure 33b

Figure 34

Figure 35

43

Page 44

14.8. “MONITOR” (Servo Path Display)

In this menu you can graphically display the servo control settings for all 6 channels and simultaneously check the

individual control functions with all mixers. Especially with helicopter models you can easily very quickly make mixer

errors for swash plate control.

Calling the servo path display

• Turn on the transmitter using the function switch and then the “ENTER”

button.

• Use the “+” and “-” buttons to select the “MONITOR” menu item and

activate the menu item with the “ENTER” button.

In the display you will see display items for the six control functions with

the respective servo positions. The display bars go up to 120 both on

the right and left, and the value 100 is marked.

• Move the control lever according to the function to be tested and observe the changes in the display. At the same time you can follow the

reactions of the servos in the model.

• Press the “EXIT” button repeatedly to exit the menu again and switch

back to the operating display.

44

Figure 36

Page 45

14.9. “PIT.CURV” (Pitch curve)

In a proportional remote control unit the control lever and the

corresponding servos maintain linear reactions.

This means: When you move the lever from one side to the

other, the lever of the respective swash plate servo will also

move from one side to the other correspondingly.

If the throttle/pitch control lever (or stick) on the transmitter is

in the lowest position (L), the rotor blades exhibit a negative

angle of attack.

If the control lever is in the middle position (M), the rotor blades

should exhibit a neutral angle of attack - neither a positive nor

a negative angle of attack.

If the control lever is in the uppermost position (H), the rotor

blades exhibit a positive angle of attack.

The pitch curve thus corresponds with a straight line (see the

adjacent figure 37).

Using the pitch curve setting you have the option of changing the shape of the pitch curve at five different points (L, 1,

2, 3 and H) and to change and save the curve specifically for each flight mode (“NOR”, “IDLE0” and “IDLE1”).

Important!

Before setting the pitch curve, ensure that the rotary control “PIT.ADJ” (see fig. 1, pos. 19) is in the centre

position. Use this control to slightly increase or lower the pitch curve later. This way, you will be able to vary

the pitch values slightly without any great programming effort.

Setting the pitch curve

• Turn on the transmitter using the function switch and then the “ENTER”

button.

• Use the “+” and “-” buttons to select the “PIT.CURV” menu item and

activate the menu item with the “ENTER” button.

The left side of the display shows the current “IDLE” flight mode toggle

switch setting “NOR”, “IDLE0” or “IDLE1” (see figure 1, pos. 18) and the

set values for the pitch curve and the control lever position.

For better illustration, the right half of the display shows the control curve

for the pitch function as a graph. The current position of the control lever

for the throttle-pitch function is displayed as a vertical line in the graphics. The ratio of lever position to pitch curve value can be read from the

values “I” (“IN”) and “O” (“OUT”).

• Put the “IDLE” toggle switch into the lower position so that “NOR” is

displayed.

100%

75%

50%

25%

0%

L

Stick

Servo

Stick

Servo

1

3

2

H

Figure 37

Figure 38a

45

Page 46

• The “+” and “-” buttons can now be used to set the desired pitch curve

value for “L” (see lower left of the display). The value can be adjusted

between 0 and 100. The effect of the setting you make is immediately

visible in the pitch curve on the right half of the display.

• Then use the “ENTER” button to switch to the second point on the pitch

curve (“1”) and use the “+” and “-” buttons again to set the desired value.

• Keep repeating this procedure until all five points on the pitch curve

have been adjusted to your wishes.