Page 1

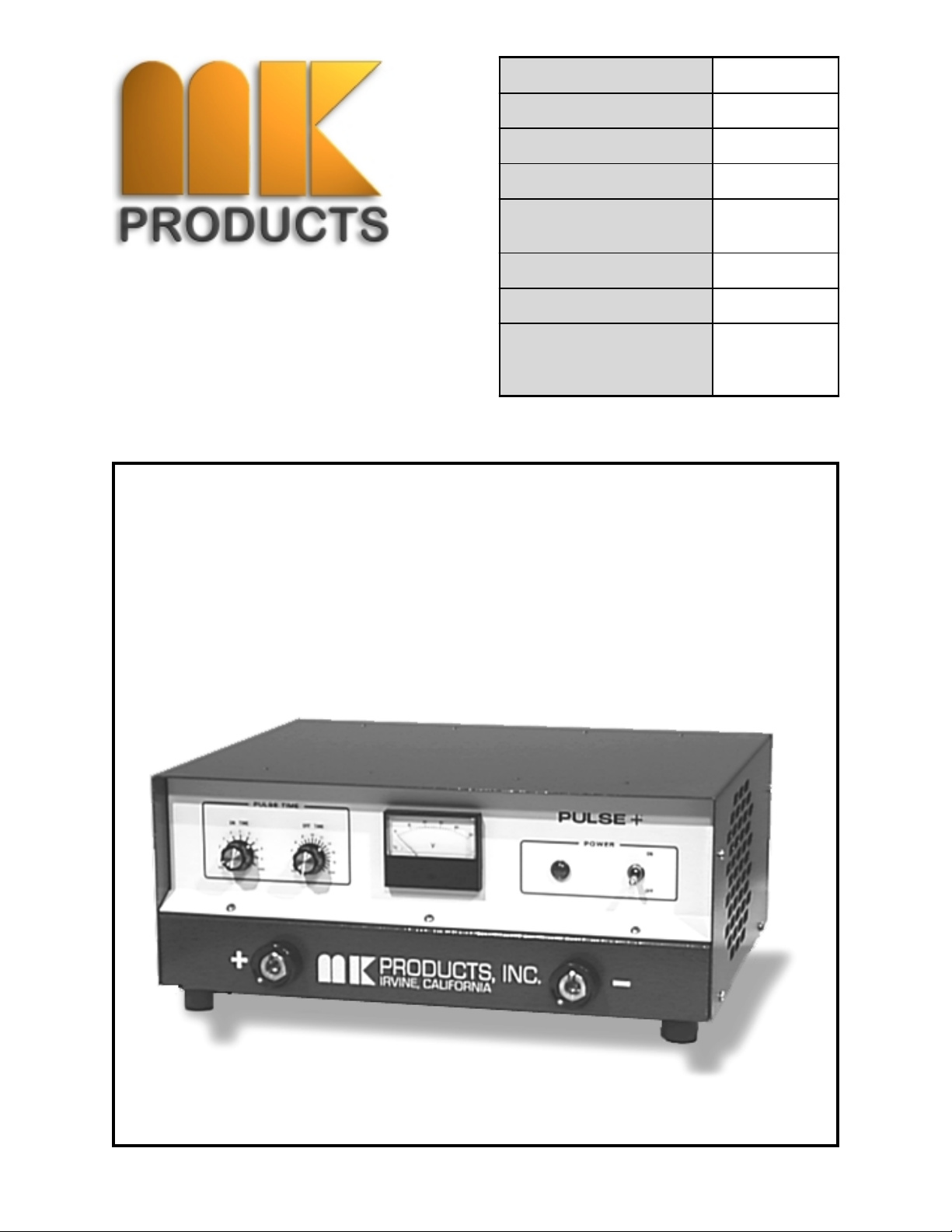

Product Description

Pulse +

MK Ma n ual P a rt Numb er

MK Form Number

NWSA Form Number

Effective wi th Serial

Voltage Ratings

Printing/Rev. Date

This manual applies to

the follow ing Model

Pulse+ Add-on Pulse system

Number

Numbers

091 - 0217

PP/OM

550

0580

115

2/99 rev. A

158-001

OWNERS MANUAL

16882 ARMSTRONG AVE., IRVINE, CALIFORNIA 92606 TEL (949) 863-1234 FAX (949) 474-1428

Page 2

SAFETY CONSIDERATIONS

ELECTRIC ARC WELDING EQUIPMENT

CAUTION : READ BEFORE ATTEMPTING INSTALLATION, OPERATION

OR MAINTENANCE OF THIS EQUIPMENT

1-1 INTRODUCTION

This equipment is intended for ultimate

application by commercial/industrial

users and for operation by persons

trained and experienced in the use and

maintenance of welding equipment.

Operation should not be undertaken

without adequate training in the use of

such equipment. Training is available

from many public and private schools or

similar facilities.

Safe practices in the installation,

operation and maintenance of this

equipment requires proper training in the

art, a careful study of the information

provided with the equipment, and the

use of common sense. Rules for safe

use are generally provided by suppliers

of welding power sources, compressed

gas suppliers, and electrode suppliers.

Careful compliance with these rules will

promote safe use of this equipment.

The following Safety Rules cover some

of the more generally found situations.

READ THEM CAREFULLY. In case of

any doubt, obtain qualified help before

proceeding.

1-2 GENERAL PRECAUTIONS

A. Burn Prevention

ELECTRIC ARC WELDING PRODUCES

HIGH INTENSITY HEAT AND

ULTRAVIOLET RADIANT ENERGY

WHICH MAY CAUSE SERIOUS AND

PERMANENT EYE DAMAGE AND WHICH

MAY DAMAGE ANY EXPOSED SKIN

AREAS.

Wear helmet with safety goggles or

glasses with side shields underneath,

appropriate filter lenses or plates

(protected by clear cover glass). This

is a must for welding or cutting (and

chipping) to protect the eyes from radiant

energy and flying metal. Replace cover

glass when broken, pitted, or spattered.

Medical first aid and eye treatment. First

aid facilities and a qualified first aid

person should be available for each shift

unless medical facilities are close by for

immediate treatment of flash burns of

the eyes and skin burns.

Wear protective clothing - leather (or

asbestos) gauntlet gloves, hat, and high

safety-toe shoes. Button shirt collar and

pocket flaps, and wear cuffless trousers

to avoid entry of sparks and slag.

Avoid oily or greasy clothing. A spark

may ignite them.

Flammable hair preparations should not

be used by persons intending to weld or

cut.

Hot metal such as electrode stubs and

work pieces should never be handled

without gloves.

Ear plugs should be worn when working

on overhead or in a confined space. A

hard hat should be worn when others work

overhead.

B. T oxic Fume Prevention

WARNING: The use of this product may

result in exposure to chemicals known to

the State of California to cause cancer and

birth defects or other reproductive harm.

Adequate ventilation. Severe discomfort,

illness or death can result from fumes,

vapors, heat, or oxygen enrichment or

depletion that welding (or cutting) may

produce. Prevent them with adequate

ventilation. NEVER ventilate with oxygen.

Lead-, cadmium-, zinc-, mercury-,

beryllium-bearing and similar materials,

when welded or cut, may produce harmful

concentrations of toxic fumes. Adequate

local exhaust ventilation must be used, or

each person in the area, as well as the

operator, must wear an air-supplied

respirator. For beryllium, both must be used.

Metals coated with or containing materials

that emit toxic fumes should not be heated

unless coating is removed form the work

surface, the area is well ventilated, or the

operator wears an air-supplied respirator.

Work in a confined space only while it is

being ventilated and, if necessary, while

wearing an air-supplied respirator.

Gas leaks in a confined space should be

avoided. Leaked gas in large quantities

can change oxygen concentration

dangerously. Do not bring gas cylinders

into a confined space.

Leaving confined space, shut OFF gas

supply at source to prevent possible

accumulation of gases in the space if

downstream valves have been accidentally

opened or left open. Check to be sure that

the space is safe before reentering it.

Vapors from chlorinated solvents can be

decomposed by the heat of the arc (or

flame) to form PHOSGENE, a highly toxic

gas, and other lung and eye irritating

products. The ultraviolet (radiant) energy

of the arc can also decompose

trichloroethylene and perchloroethylene

vapors to form phosgene. DO NOT WELD

or cut where solvent vapors can be drawn

into the welding or cutting atmosphere or

where the radiant energy can penetrate to

atmospheres containing even minute

amounts of trichloroethylene or

perchloroethylene.

C. Fire and Explosion Prevention

Causes of fire and explosion are:

combustibles reached by the arc, flame,

flying sparks, hot slag, or heated material,

misuse of compressed gases and

cylinders, and short circuits.

BE AWARE THAT flying sparks or falling

slag can pass through cracks, along

pipes, through windows or doors, and

through wall or floor openings, out of

sight of the goggled operator. Sparks

can fly many feet.

To prevent fires and explosion:

Keep equipment clean and operable, free

of oil, grease, and (in electrical parts) of

metallic particles that can cause short

circuits.

If combustibles are in area, do NOT weld

or cut. Move the work if practicable, to

an area free of combustibles. Avoid

paint spray rooms, dip tanks, storage

areas, ventilators. If the work cannot

be moved, move combustibles at least

35 feet away, out of reach of sparks

and heat; or protect against ignition with

suitable and snug-fitting, fire-resistant

covers or shields.

Walls touching combustibles on opposite

sides should not be welded on (or cut).

Walls, ceilings, and floor near work

should be protected by heat-resistant

covers or shields.

Fire watcher must be standing by with

suitable fire extinguishing equipment

during and for some time after welding

or cutting if:

1. Appreciable combustibles (including

building construction) are within 35 feet.

2. Appreciable combustibles are further

than 35 feet, but can be ignited by sparks.

3. Openings (concealed or visible) in

floors or walls within 35 feet may expose

combustibles to sparks.

4. Combustibles adjacent to walls,

ceilings, roofs, or metal partitions can

be ignited by radiant or conducted heat.

Hot work permit should be obtained

before operation to ensure supervisor’s

approval that adequate precautions have

been taken.

After work is done, check that area is

free of sparks, glowing embers, and

flames.

An empty container that held

combustibles, or that can produce

flammable or toxic vapors when heated,

must never be welded on or cut, unless

container has first been cleaned in

accordance with industry standards.

This includes: a thorough steam or

caustic cleaning (or a solvent of water

washing, depending on the

combustible’s solubility), followed by

Pulse+ Owner's Manual

Page 3

purging and inerting with nitrogen or

carbon dioxide, and using protective

equipment.

Water-filling just below working level may

substitute for inerting.

A container with unknown contents

should be cleaned (see paragraph

above). Do NOT depend on sense of

smell or sight to determine if it is safe to

weld or cut.

Hollow castings or containers must be

vented before welding or cutting. They

can explode.

Explosive atmospheres. NEVER weld

or cut where the air may contain

flammable dust, gas, or liquid vapors

(such as gasoline).

D. Compressed Gas Equipment

The safe handling of compressed gas

equipment is detailed in numerous

industry publications. The following

general rules cover many of the most

common situations.

1. Pressure Regulators

Regulator relief valve is designed to

protect only the regulator from

overpressure; it is not intended to

protect any downstream equipment.

Provide such protection with one or more

relief devices.

Never connect a regulator to a cylinder

containing gas other than that for which

the regulator was designed.

Remove faulty regulator from service

immediately for repair (first close cylinder

valve). The following symptoms indicate

a faulty regulator:

Leaks - if gas leaks externally.

Excessive Creep - if delivery pressure

continues to rise with downstream valve

closed.

Faulty Gauge - if gauge pointer does not

move off stop pin when pressurized,

nor returns to stop pin after pressure

release.

Repair. Do NOT attempt repair. Send

faulty regulators for repair to

manufacturer’s designated repair center,

where special techniques and tools are

used by trained personnel.

2. Cylinders

Cylinders must be handled carefully to

prevent leaks and damage to their walls,

valves, or safety devices:

Avoid electrical circuit contact with

cylinders including third rails, electrical

wires, or welding circuits. They can

produced short circuit arcs that may lead

to a serious accident. (See 1-3C)

ICC or DOT marking must be on each

cylinder. It is an assurance of safety

when the cylinder is properly handled.

Identifying gas content. Use only

cylinders with name of gas marked on

them; do not rely on color to identify gas

content. Notify supplier if unmarked.

NEVER DEFACE or alter name, number ,

or other markings on a cylinder . It is illegal

and hazardous.

Empties: Keep valves closed, replace caps

securely; mark MT; keep them separate

from FULLS, and return promptly.

Prohibited use. Never use a cylinder or its

contents for other than its intended use,

NEVER as a support or roller.

Locate or secure cylinders so they cannot

be knocked over.

Passageways and work areas. Keep

cylinders clear of areas where they may

be stuck.

Transporting cylinders. With a crane, use

a secure support such as a platform or

cradle. Do NOT lift cylinders off the ground

by their valves or caps, or by chains, slings,

or magnets.

Do NOT expose cylinders to excessive

heat, sparks, slag, and flame, etc. that may

cause rupture. Do not allow contents to

exceed 55 degrees C (130 degrees F .) Cool

with water spray where such exposure

exists.

Protect cylinders, particularly valves from

bumps, falls, falling objects, and weather.

Replace caps securely when moving

cylinders.

Stuck valve. Do NOT use a hammer or

wrench to open a cylinder valve that

cannot be opened by hand. Notify your

supplier.

Mixing gases. NEVER try to mix any gases

in a cylinder.

NEVER refill any cylinder .

Cylinder fittings should never be modified

or exchanged.

3. Hose

Prohibited use. Never use hose other than

that designed for the specified gas. A

general hose identification rule is: red for

fuel gas, green for oxygen, and black for

inert gases.

Use ferrules or clamps designed for the

hose (not ordinary wire or other substitute)

as a binding to connect hoses to fittings.

No copper tubing splices. Use only

standard brass fittings to splice hose.

Avoid long runs to prevent kinks and abuse.

Suspend hose off ground to keep it from

being run over, stepped on, or otherwise

damaged.

Coil excess hose to prevent kinks and

tangles.

Protect hose from damage by sharp edges,

and by sparks, slag, and open flame.

Examine hose regularly for leaks, wear,

and loose connections. Immerse

pressured hose in water; bubbles indicate

leaks

Repair leaky or worn hose by cutting area

out and splicing. Do NOT use tape.

4. Proper Connections

Clean cylinder valve outlet of impurities that

may clog orifices and damage seats before

connecting regulator. Except for hydrogen,

crack valve momentarily, pointing outlet

away from people and sources of

ignition. Wipe with a clean, lintless cloth.

Match regulator to cylinder. Before

connecting, check that the regulator label

and cylinder marking agree, and that the

regulator inlet and cylinder outlet match.

NEVER Connect a regulator designed for

a particular gas or gases to a cylinder

containing any other gas.

Tighten connections. When assembling

threaded connections, clean and smooth

seats where necessary. Tighten. If

connection leaks, disassemble, clean,

and retighten, using properly fitting

wrench.

Adapters. Use a CGA adapter (available

from your supplier) between cylinder

and regulator, if one is required. Use

two wrenches to tighten adapter marked

RIGHT and LEFT HAND threads.

Regulator outlet (or hose) connections

may be identified by right hand threads

for oxygen and left hand threads (with

grooved hex on nut or shank) for fuel

gas.

5. Pressurizing Steps:

Drain regulator of residual gas through

suitable vent before opening cylinder (or

manifold valve) by turning adjusting

screw in (clockwise). Draining prevents

excessive compression heat at high

pressure seat by allowing seat to open

on pressurization. Leave adjusting

screw engaged slightly on single-stage

regulators.

Stand to side of regulator while opening

cylinder valve.

Open cylinder valve slowly so that

regulator pressure increases slowly.

When gauge is pressurized (gauge

reaches regulator maximum) leave

cylinder valve in following position: for

oxygen and inert gases, open fully to

seal stem against possible leak; for fuel

gas, open to less than one turn to permit

quick emergency shut-off.

Use pressure charts (available from your

supplier) for safe and efficient

recommended pressure settings on

regulators.

Check for leaks on first pressurization

and regularly thereafter. Brush with

soap solution. Bubbles indicate leaks.

Clean off soapy water after test; dried

soap is combustible.

E. User Responsibilities

Follow all Safety Rules.

Remove leaky or defective equipment

from service immediately for repair. Read

and follow user manual instructions.

F . Leaving Equipment Unattended

Close gas supply at source and drain

gas.

G. Rope Staging-Support

Rope staging-support should not be used

for welding or cutting operation; rope

may burn.

Pulse+ Owner's Manual

Page 4

1-3 ARC WELDING

Comply with precautions in 1-1, 1-2, and

this section. Arc Welding, properly done,

is a safe process, but a careless

operator invites trouble. The equipment

carries high currents at significant

voltages. The arc is very bright and hot.

Sparks fly, fumes rise, ultraviolet and

infrared energy radiates, weldments are

hot, and compressed gases may be

used. The wise operator avoids

unnecessary risks and protects himself

and others from accidents.

A. Burn Protection

Comply with precautions in 1-2.

The welding arc is intense and visibly

bright. Its radiation can damage eyes,

penetrate lightweight clothing, reflect

from light-colored surfaces, and burn

the skin and eyes. Skin burns resemble

acute sunburn; those from gas-shielded

arcs are more severe and painful. DON’T

GET BURNED; COMPLY WITH

PRECAUTIONS.

1. Protective Clothing

Wear long-sleeve clothing in addition to

gloves, hat, and shoes. As necessary,

use additional protective clothing such

as leather jacket or sleeves, flameproof

apron, and fire-resistant leggings. Avoid

outer garments of untreated cotton.

Bare skin protection. Wear dark,

substantial clothing. Button collar to

protect chest and neck, and button

pockets to prevent entry of sparks.

2. Eye and Head Protection

Protect eyes from exposure to arc. Eyes

may be damaged by radiant energy

when exposed to the electric arc, even

when not looking in the direction of the

arc. Never look at an electric arc without

protection.

Welding helmet or shield containing a filter

plate shade no. 12 or denser must be

used when welding. Place over face

before striking arc.

Protect filter plate with a clear cover

plate.

Cracked or broken helmet or shield should

NOT be worn; radiation can be passed

through to cause burns.

Cracked, broken, or loose filter plates

must be replaced IMMEDIA TELY . Replace

clear cover plate when broken, pitted,

or spattered.

Flash goggles with side shields MUST

be worn under the helmet to give some

protection to the eyes should the helmet

not be lowered over the face before an

arc is struck. Looking at an arc

momentarily with unprotected eyes

(particularly a high intensity gas-shielded

arc) can cause a retinal burn that may

leave a permanent dark area in the field

of vision.

3. Protection of Nearby Personnel

Enclose the welding area. For production

welding, a separate room or enclosed

bay is best. In open areas, surround the

operation with low-reflective,

noncombustible screens or panels. Allow

for free air circulation, particularly at floor

level.

Viewing the weld. Provide face shields for

all persons who will be looking directly at

the weld.

Others working in area. See that all persons

are wearing flash goggles.

Before starting to weld, make sure that

screen flaps or bay doors are closed.

B. Toxic Fume Prevention

Comply with precautions in 1-2B.

Generator engine exhaust must be vented

to the outside air. Carbon monoxide can

kill.

C. Fire and Explosion Prevention

Comply with precautions in 1-2C.

Equipment’s rated capacity . Do not overload

arc welding equipment. It may overheat

cables and cause a fire.

Loose cable connections may overheat or

flash and cause afire.

Never strike an arc on a cylinder or other

pressure vessel. It creates a brittle area

that can cause a violent rupture or lead to

such a rupture later under rough handling.

D. Compressed Gas Equipment

Comply with precautions in 1-2D.

E. Shock Prevention

Exposed electrically hot conductors or other

bare metal in the welding circuit, or in

ungrounded, electrically-HOT equipment

can fatally shock a person whose body

becomes a conductor. DO NOT STAND,

SIT, LIE, LEAN ON, OR TOUCH a wet

surface when welding without suitable

protection.

To protect against shock:

Keep body and clothing dry . Never work in

damp area without adequate insulation

against electrical shock. Stay on a dry

duckboard, or rubber mat when dampness

or sweat cannot be avoided. Sweat, sea

water, or moisture between body and an

electrically HOT part - or grounded metal reduces the body surface electrical

resistance, enabling dangerous and

possibly lethal currents to flow through the

body.

1. Grounding the Equipment

When installing, connect the frames of each

unit such as welding power source,

control, work table, and water circulator to

the building ground. Conductors must be

adequate to carry ground currents safely.

Equipment made electrically HOT by stray

currents may shock, possibly fatally. Do

NOT GROUND to electrical conduit, or to a

pipe carrying ANY gas or a flammable liquid

such as oil or fuel.

Three-phase connection. Check phase

requirement of equipment before installing.

If only three-phase power is available,

connect single-phase equipment to only

two wires of the three-phase line. Do NOT

connect the equipment ground lead to

the third (live) wire, or the equipment

will become electrically HOT - a

dangerous condition that can shock,

possibly fatally.

Before welding, check ground for

continuity. Be sure conductors are

touching bare metal of equipment frames

at connections.

If a line cord with a ground lead is

provided with the equipment for

connection to a switch box, connect the

ground lead to the grounded switch box.

If a three-prong plug is added for

connection to a grounded mating

receptacle, the ground lead must be

connected to the ground prong only. If

the line cord comes with a three-prong

plug, connect to a grounded mating

receptacle. Never remove the ground

prong from a plug, or use a plug with a

broken ground prong.

2. Connectors

Fully insulated lock-type connectors

should be used to join welding cable

lengths.

3. Cables

Frequently inspect cables for wear,

cracks, and damage. IMMEDIATELY

REPLACE those with excessively worn

or damaged insulation to avoid possibly

lethal shock from bared cable. Cables

with damaged areas may be taped to

give resistance equivalent to original

cable.

Keep cable dry, free of oil and grease,

and protected from hot metal and sparks.

4. Terminals & Other Exposed Parts

Terminals and other exposed parts of

electrical units should have insulating

covers secured before operation.

5. Electrode Wire

Electrode wire becomes electrically HOT

when the power switch of gas metalarc welding equipment is ON and welding

gun trigger is pressed. Keep hands and

body clear of wire and other HOT parts.

6. Safety Devices

Safety devices such as interlocks and

circuit breakers should not be

disconnected or shunted out.

Before installation, inspection, or service

of equipment, shut OFF all power, and

remove line fuses (or lock or red-tag

switches) to prevent accidental turning

ON of power. Disconnect all cables from

welding power source, and pull all 115

volts line-cord plugs.

Do not open power circuit or change

polarity while welding. If, in an

emergency, it must be disconnected,

guard against shock burns or flash from

switch arcing.

Leaving equipment unattended. Always

shut OFF, and disconnect all power to

equipment.

Power disconnect switch must be

available near the welding power

source.

Pulse+ Owner's Manual

Page 5

MK Products, Inc.

Printed in the U.S.A.

Page 6

Table of Contents

INTRODUCTION....................................................................... 2

Section 1 SPECIFICATIONS .................................................. 9

Section 2 INSTALLATION INSTRUCTIONS ........................... 10

2.1 LOCATION .....................................................................10

2.2 AUXILIARY POWER REQUIREMENTS ................................ 10

2.3 WELD CABLE CONNECTIONS ........................................... 10

Section 3 CABLE CONNECTIONS......................................... 11

Section 4 OPERATION ........................................................ 12

4.1 POWER SWITCH..............................................................1 2

4.2 VOLTMETER.................................................................... 12

4.3 PULSE OPERATION ......................................................... 12

Section 5 PARAMETER SET-UP ........................................... 15

5.1 Peak Level .......................................................................15

5.2 “ON” Time ...................................................................... 15

5.3 "OFF” Time ..................................................................... 15

Section 6 TROUBLE SHOOTING .......................................... 17

6.1 TESTING THE CURRENT SWITCH .................................... 18

6.2 TESTING THE PC BOARD ................................................ 18

6.3 TESTING THE THERMOSTAT ........................................... 18

6.4 TESTING CR1 AND R1..................................................... 18

Section 7 PARTS LIST - PULSE+ WITH METER .................... 19

Pulse+ Owner's Manual Page 6

Page 7

THIS P AGE INTENTIONALLY BLANK

Pulse+ Owner's Manual Page 7

Page 8

INTRODUCTION

MK Products’ patented Pulse+ is a transistorized pulse-generating

attachment which converts a conventional constant voltage (CV) D.C.

power supply into a variable pulsed arc welding machine.

The Pulse+ is exceptionally simple to operate and may be used with any

conventional constant voltage (CV) machine, up to 60 open circuit volts

and 300 amperes continuous current output. It provides pulse rates

continuously variable from 500 pulse per second, down to approximately

30 pulses per second. This of course, includes the frequencies of 60 and

120 pulse per second, available from thyristor supplies operating at line

frequencies.

The power supply voltage control set the peak voltage, and the background

level is a fixed value by design. The “On time” control is used to adjust the

length of the pulse during metal transfer and can be used to apply more

heat to the weld. The “Off time” control regulates how close the “on”

pulses are together, which can reduce the amount of heat into the weld.

The Pulsed-arc process is a transfer process wherein spray transfer occurs

at regular intervals rather than at random intervals. The welding current

rapidly switches from high pulsed current to low background current level.

The background current sustains the arc, while each pulse supplies just

enough power to free one droplet from the wire tip. In the time between

pulses, the welding current is reduced, and no metal transfer occurs.

Pulsed spray uses a lower average current than in regular spray transfer.

This lower average current makes it possible to weld out of position. By

using a lower average, less heat is put into the metal, causing less distortion of the material being welded. Thin metal sections may also be welded

more easily with pulsed spray, and it creates very little metal spatter. In

addition, the pulse agitation aids in cleaning action and outgasing, which

reduces porosity.

The pulsed spray transfer method can use larger diameter electrode wire

and still produce a small weld. This is a great advantage, because larger

diameter electrode are less expensive than smaller ones. Also, nonferrous

wire of a larger diameter can be fed through the wire feeder much easier

without risk of bending or jamming. This also allows using one size wire for

a variety of jobs using many different thicknesses of metal and joint

designs with just one setup in the wire feeder!

At MK Products, we stand behind every product manufactured and ensure

that it is free from defects and will perform to the specification contained in this manual. If for ANY reason you are not completely satisfied

with your purchase, we will make every effort to repair, replace, or refund

your purchase.

That is my guarantee.

Douglas M Kensrue

President

MK Products

Pulse+ Owner's Manual Page 8

Page 9

Section 1 SPECIFICATIONS

PRIMARY POWER INPUT - 1 15V AC 50-60 Hz 1 Ampere

WELDING POWER INPUT - D.C. 10-60 Volts 0 to 300 Amperes

WELDING POWER OUTPUT - D.C. 10-58 Volts 0 to 300 Amperes

PULSE CAP ACITY - Pulsed “On” Period - 1 to 10 milliseconds

SI Z E - 18”W x &-3/4”H x 14”L

WE IGHT - 31 lbs.

ENVIRONMENT - 20 to 105 degrees F , 90% humidity without

AREA REQUIRED - Access required both front and back for

- Pulse “Off” Period - 1 to 20 milliseconds

- Pulse Frequency V ariable from 30 - 500 pps

condensation 0 - 10,000 feet elevation.

Units may be stacked vertically up to four

high.

connectors and four inches on sides for air

circulation.

PULSE OUTPUT VOL T AGE - Equals connected power supply output

voltage, minus approximately a two volt

drop.

BACKGROUND LEVEL - Is automatically adjusted depending on

connected power supply output voltage, wire

characteristics, wire feed rate, and other

welding characteristics. It will typically be

30 to 130 amperes.

CONTROLS -

On/Off Switch

Pulse “On” Time - Controls high current

density pulse duration which should be

adjusted to achieve welding metal droplet

formation, detachment, and axial transfer

to work.

- Pulse “Off” Time - Controls the average

welding heat (energy) and should be ad

justed to be consistent with wire feed speed

used.

- Voltmeter - Reads average voltage while

welding.

Pulse+ Owner's Manual Page 9

Page 10

Section 2 INSTALLATION INSTRUCTIONS

2.1 LOCATION

The Pulse+ should be located to provide adequate ventilation for cooling. There

should be a minimum of four inches on each side.

CAUTION: Overheating of unit can cause possible damage

to internal components.

There should be access to both the front and rear of the unit to allow quick

disconnection of welding cables for applications not requiring pulse capabilities. For standard welding, the connectors can be locked together , thus

removing the Pulse+ from the circuit.

CAUTION: DO NOT operate the Pulse+ in the OFF position.

Doing so will cause damage to internal parts.

2.2 AUXILIARY POWER REQUIREMENTS

The Pulse+ is designed to operate on 220 volt 1 Ampere 50-60 Hz circuit. This

circuit could be a wall outlet or from an outlet on the power supply , if one is

provided.

2.3 WELD CABLE CONNECTIONS

Provided with the Pulse+ are two Dinse 400 Amp male weld cable connectors

(P/N 153-0755) and two Dinse 400 Amp female weld cable connectors (P/N

153-0813).

Select adequate size welding cable for the anticipated maximum weld current.

Keep the cables as short as possible and as close together as possible.

Excessive cable length adds resistance which may reduce the output.

To install the connectors, use Fig. 1 for proper part orientation.

NOTE: Place the connector boot over the cable before cutting back the insulation.

This will keep the copper strands from becoming frayed.

CONNECTOR P ART ORIENTA TION - Fig. 1

Pulse+ Owner's Manual Page 10

Page 11

Section 3 CABLE CONNECTIONS

Connect the Pulse+ in series with the power source as show in Figure 2.

Connect between any conventional D.C. constant voltage power source (with a maximum output

voltage of 60 volts) and the wire feeder. Plug Pulse+ into a 115 V . AC outlet.

Pulse+ Owner's Manual Page 11

Page 12

Section 4 OPERATION

CAUTION: DO NOT ATTEMPT TO WELD WITH THE PULSE+ TURNED OFF

For non-pulsed operation, the connectors can be locked together, thus removing

4.1 POWER SWITCH

Placing the power switch in the On position energizes the fan and control

circuitry . The red indicator lamp should be on at this time.

CAUTION: If the fan does not operate when the power switch is in the On position,

DO NOT attempt to weld. Without proper air flow, unit can overheat and cause

4.2 VOLTMETER

The voltmeter on the front of the Pulse+ will read average voltage during

welding. Average amperage can be read off of the power supply amp meter .

4.3 PULSE OPERATION

In pulsed spray welding, the current is varied from the background level to a

peak level. The background level is well below the transition current, while the

peak level is well into the spray arc region, Figure 3. During the peak level,

one droplet is transferred to the work. The current then drops to the background level, which allows the puddle to cool, at which time no metal is

transferred.

the Pulse+ from the circuit.

damage to internal parts.

Pulse+ Owner's Manual Page 12

Page 13

4.3.1. Peak Level

The peak level is set by the voltage control at the power supply . Because the

peak level must be well into the spray arc region, it must be set substantially

higher than non-pulsed operation (typically 30-40 volts).

4.3.2. Background Level

The background level (typically 30 to 130 amps) is the result of the fixed design

values in the Pulse+, together with the power supply input voltage, wire feed

rate, and other parameters.

4.3.3. “On Time”

T o obtain the one drop transfer during the peak level, the “On” time must be

varied, depending on the wire diameter . As the wire size is increased, so must

the “On” time be increased to burn off the larger size wire, Figure 4.

The “On” time is variable from 1 to 10 Ms.

4.3.4. “Off Time”

With the “On” time set to provide a smooth transfer, the “Of f” time is used to

control the amount of heat. Decreasing the “Off” time moves the pulses closer

together (more heat), while increasing the “Off” time moves the pulses further

apart (less heat), Figure 5.

The “Off” time is variable from 1 to 20 ms.

Pulse+ Owner's Manual Page 13

Page 14

4.3.5. Pulse Frequency

The pulse frequency is determined by adding the “On” time and the “Off” time

and dividing it into 1000. Pulse frequency is measured in pulses per second

(PPS). For example:

3 ms on and 5 ms off equals 1000/3+5 = 1000/8 = 125 pps

Pulse+ Owner's Manual Page 14

Page 15

Section 5 PARAMETER SET-UP

5.1 Peak Level

The voltage control on the power supply is used to set the peak level. The

melting temperature of the filler wire used determines at what point the voltage

should be set. For example, 4043 aluminum may require as little as 30 peak

welding volts, whereas steel and stainless may require 35-38 peak welding

volts, Figure 7. When trying to weld thin material the peak voltage should be

kept as low as possible without losing the spray transfer.

5.2 “ON” Time

The “On” time dial is used to obtain a smooth transfer . Start with an “On” time

of 2 ms, and adjust until the correct transfer is achieved.

5.3 “OFF” Time

Start with an “Off” time of 6 ms. If the weld is too cold, decrease the “Off” time.

If the weld is too hot, increase the “Off” time. Remember that the wire feed

speed must also be increased and decreased accordingly

NOTE: The required open circuit voltage (OCV) may vary from one power supply to

another, depending on the slope of the power supply. Sample parameters can be

found on the nest page.

Pulse+ Owner's Manual Page 15

Page 16

SAMPLE WELDING PARAMETERS

WIRE

SIZE

WIRE

TYPE

WIRE

IPM

WELDING

VOLTS

AVERAGE

VOLTS

WELD

AMPS

.030 4043 228 29.5 16.8 52

.035 4043 200 29.5 17.9 67

.035 4043 220 31 18.7 89

3/64 4043 180 33 19.1 108

3/64 4043 214 33 20.3 117

1/16 4043 15 36 22.5 187

.030 5356 308 30 20 59

.035 5356 360 30 18 80

.035 5356 390 30 17.5 88

3/64 5356 250 34 19.5 110

3/64 5356 300 35 20 125

PULSEONPULSE

OFF

1 10

2 11

2 8

3 8

3 5

4 2

1 6

2 10

2 8

3 8

3 5

PLATE

THICKNESS

BASE

METAL

.060 6061 Argon

.090 6061 Argon

1/8 6061 Argon

1/8 6061 Argon

1/4 6061 Argon

3/8 6061 Argon

.060 6061 Argon

.090 6061 Argon

1/8 6061 Argon

1/8 6061 Argon

1/4 6061 Argon

GAS

USED

1/16 5356 260 36 23.5 190

.030 E70S-3 190 33 18.5 65

.035 E70S-3 211 34 19.8 99

.045 E70S-3 150 36 21.8 133

.030 308L 279 34 20.3 78

.035 308L 268 34 20.3 105

.045 308L 145 34 20.9 123

4 2

1.5 15

2 9

3 5

2 8

2.75 6

3 5

3/8 6061 Argon

.050 Steel 98-2

.060 Steel 98-2

3/16 Steel 98-2

.060 S/S 98-2

.080 S/S 98-2

1/8 S/S 98-2

Pulse+ Owner's Manual Page 16

Page 17

Section 6 TROUBLE SHOOTING

SOME F ACTORS TO CONSIDER:

The Pulse+ can only

be sure the CV power supply is operating properly without the Pulse+.

The power supply sets the peak level and, therefore, must be set substantially

higher than non-pulsed operation.

When an arc is initiated, the Pulse+ is always in the pulse “on” mode to

provide maximum current to initiate the arc. After welding current is flowing, a

current switch is utilized to start the pulse timer.

If there appears to be too little output to weld with, be sure the pulse “on” is at

the proper value (or increase it) and that the pulse “off” is not excessive.

Be sure there is a good ground connection to the work and a good cable

connection to the Wire Feeder .

reduce the power supply output voltage and current, so

TROUBLE SHOOTING PROCEDURE

Trouble Cause Remedy/Explanati on

Have weld ing output

but no pulse

Pilot lamp works , Fan

works , No we ld o utput

Completely Inoperative Open line fuse (F1) Replace fuse 2A 250V

Current switch failure or bad

PC board

J2 connector disconnected

from PC board

Thermostat open Check Thermostat for continuity

Po we r S upp ly voltag e to o low Increas e sup p ly voltag e

Open CR1 or R1, Bad PC

board

The current switch, connected to J4, is

located on the negati ve buss bar next to the

capactitor bank. Disconnect J4 and short

between pins. If the unit now pulses,

replace the current switch. If it does not

pulse, check PC board.

Replace J2 on board

Disconnect 115 vac. With a ohm-meter

check resistance between input + and

output + terminals. Should read 5 ohms. If

open, check CR1 and R1 separate. If OK,

check PC board.

Defective power swi tch (S1) Replace switch

Improp e r li ne vo lta ge Che ck li ne vo lta g e for 115 vac

Pulse+ Owner's Manual Page 17

Page 18

6.1 TESTING THE CURRENT SWITCH

When current flows through the buss bar, it creates a magnetic field. This

magnetic field causes the current switch, which is normally open, to close and

turn on the pulse timer circuit. To test, remove the current switch from the unit.

Using an ohm meter on Rx1 scale, check to see that the switch is open,

indicating no continuity . Using a common magnet, move it to within one to

one-half inch from the current switch while watching the ohm meter . As the

magnet nears the current switch, it should close, and continuity should be read

on the meter .

6.2 TESTING THE PC BOARD

An oscilloscope is required to test the PC board. Set the oscilloscope second/div to 2 ms and the volts/div to 5V . Place the negative lead on pin 7 of the

transformer and the positive lead to connector J2 pin 3. The current switch

must be closed so jumper between pins 1 and 2 on the J4 connector, or place

a magnet next to the current switch, if you know it works correctly. Turn the

Pulse+ on. A square wave should appear on the oscilloscope. The “on” and

“off” time controls should vary the wave form on the oscilloscope. A bad

thermostat will also prevent the PC board from operating.

6.3 TESTING THE THERMOSTAT

The thermostat is located on the back of the heat sink and is connected to J5.

It is normally closed and, if the fan malfunctions or if the duty cycle is exceeded, the thermostat will open at 180 degrees F and shut down the unit. To

test, use an ohm meter to check for continuity across the thermostat leads.

6.4 TESTING CR1 AND R1

CR1 is the main diode coming off the + input and mounts to the heat sink. R1

is the power resistor inside the heat sink. If either is open, the Pulse+ will not

operate. To test, place an ohm meter on DC+ in the Rx1 scale. Attach the

positive lead to the + input and the negative lead to the + output. The meter

should read from 4 to 5 ohms. If open, check CR1 and R1 separately .

NOTE: The following conditions were used through-out the above test.

WELDING GAS: Aluminum (Argon), Steel & Stainless (98% Argon -

2% Oxygen)

POWER SUPPLY: Flat Slope C.V.

WELD PO SITION: Flat

WELD TYPE: Fillet

Pulse+ Owner's Manual Page 18

Page 19

Section 7 PARTS LIST - PULSE+ WITH METER

ITEM PART NO. DESCRIPTION

1 003-0661 Assy. - Top & Bottom Heat Sinks

2 003-0666 Assy. - Cover

3 003-0481 PCB Ctrl Mod.

4 325-0225 10-32 x 3/8 Pan. HD. Scr

5 333-0007 #10 Lock Washer

6 341-0008 #10-32 Hex Nut

7 328-0229 10-32 x 1/2 Soc. Hd. Scr.

8 331-0044 #10 Flat Washer

9 333-0045 #10 Lock Washer

10 435-0821 Connector Strip

11 104-0051 Capacitor - 25,000 mf

12 151-0001 Fuse 2 Amp.

13 152-0058 Fuse Holder

14 153-0809 Connector - Male

15 315-0696 Strain Relief

16 844-0019 A.C. Power Cable 6ft bare leads

17 328-0236 8 - 32 x 3/8 Sosc. HD. cr.

18 333-0006 #8 Lock Washer

19 843-0272 Cable Assy

20 003-0780 Sensor Assembly

21 333-0024 #8 Lock Washer

22 327-0073 8 - 32 x 1/4 Self Tapping Scr.

23 435-0830 Bus Bar

24 325-0167 8 - 32 x 3/8 Pan. Hd. Scr.

25 333-0024 #8 Lock Washer

26 153-0754 Connector - Female

27 329-0221 M-10 Hx. Hd. Scr. (Metric)

28 185-0082 Ring Lug #8 Hole, 12 Ga. Wire

29 845-0100 12 Ga. Wire (Black) 10” Lg.

30 124-0062 Diode - VHE804

31 447-0006 1/4 - 20 x 1/2 Hex Hd. Scr. Brass

32 333-0072 1/4” Lock Washer (Silicon Bronze)

33 435-0827 Diode Plate

34 435-0005 Base

35 003-0561 Assy. - Front Panel

36 325-0167 8 - 32 x 3/8 Pan Hd. Scr.

37 333-0044 #8 Lock Washer

38 301-0104 Rubber Feet

39 325-0230 10 - 32 x 3/4 Pan Hd. Scr.

40 333-0025 #10 Lock Washer

41 201-0005 Fan - 220 volts A.C.

42 324-0135 6 - 32 x 1/2 Flt. Hd. Scr.

43 341-0005 6 - 32 Hex Nut

44 333-0023 #6 Lock Washer

45 327-0112 #10 x 1/2 Self T apping Scr .

46 333-0045 #10 Lock Washer

47 435-0831 Fan Mounting Bracket

48 327-0110 6 - 32 x 3/8 Selft Tappin Scr.

49 333-0023 #6 Lock Washer

50 342-0372 Standoff 7/8” Lg.

51 325-0229 10 - 32 x 5/8 Pan Hd. Scr.

52 332-0004 #10 Flat Washer

53 332-0018 Shoulder Washer

Pulse+ Owner's Manual Page 19

Page 20

54 003-0494 S/A Diode

55 124-0022 Diode Rectifier - R610

56 003-0662 Assy. Diode Heatsink

57 333-0072 1/4” Lock Washer (Silicon Bronze)

58 449-0001 1/4 - 20 Hex Nut (Brass)

59 843-0256 Cable Assy.

60 003-0660 As sy. - Heat Sink

61 113-0045 Resistor .3 ohm

62 435-0828 Resistor Mounting Bracket

63 435-0836 Contactor Bar

64 113-0042 Resistor 50 ohm

65 327-0109 #4 x 1/4 Self T apping Screw

66 333-0041 #4 Lock Washer

67 843-0254 Cable Assy.

68 327-011 1 #8 x 1/4 Self T apping Screw

69 333-0044 #8 Lcok Washer

70 170-0003 T emperature Sensor

71 843-0255 Cable Assy . - Temp. Sensor

72 327-0108 #2 1/4 Self Tapping Scr.

73 333-0039 #2 Lock Washer

74 186-0164 T erminal Strip

75 325-0137 6 - 32 x 5/8 PN Hd. Scr.

76 333-0043 #6 Lock Washer

77 341-0005 6 -32 Hex Nut

78 159-0051 “ON - “OFF” Switch

79 333-0154 Lock Washer

80 117-0060 200K Potentiometer

81 401-0012 Knob

82 333-0156 Lock Washer

83 341-0050 Nut

84 117-0002 100K Potentiometer

85 431-1251 Back-up Plate

86 169-0043 Volt Meter

87 003-0547 220v pilot lamp

88 327-0022 #8 x 3/8 Self T apping Screw

Pulse+ Owner's Manual Page 20

Page 21

Pulse+ Owner's Manual Page 22

Page 22

Pulse+ Owner's Manual Page 21

Page 23

Pulse+ Owner's Manual Page 23

Page 24

Effective April 1, 1998

This warranty supersedes all previous MK Products warranties and is

exclusive, with no other guarantees or warranties expressed or implied.

LIMITED WARRANTY - MK Products,Inc.,Irvine,California

warrants that all new and unused equipment furnished by MK

Products is free from defect in workmanship and material as

of the time and place of delivery by MK Products. No warranty

is made by MK Products with respect to trade accessories or

other items manufactured by others. Such trade accessories

and other items are sold subject to the warranties of their

respective manufacturers, if any.

MK Products’ warranty does not apply to components having

normal useful life of less than one (1) year, such as relay points,

wire conduit, tungsten, and welding torch parts that come in

contact with the welding wire, including nozzles, nozzle

insulators, and contact tips where failure does not result from

defect in workmanship or material.

In the case of MK Products’ breach of warranty or any other

duty with respect to the quality of any goods, the exclusive

remedies therefore shall be at MK Products’ option: (1) repair;

(2) replacement; (3) where authorized in writing by MK

Products, the reasonable cost of repair or replacement at our

Irvine, California plant; or (4) payment of or credit for the

purchase price (less reasonable depreciation based upon

actual use) upon return of the goods at customer’s risk and

expense. Upon receipt of notice of apparent defect or failure,

MK Products shall instruct the claimant on the warranty claim

procedures to be followed.

As a matter of general policy only, MK Products may honor an

original user’s warranty claims on warranted equipment in the

event of failure resulting from a defect within the following

periods from the date of delivery of equipment to the original

user:

1. Torches and Weldheads ........................ 1 year

2. All Other Equipment .............................. 3 years

3. Repairs ................................................. 90 days

Classification of any item into the foregoing categories shall be

at the sole discretion of MK Products. Notification of any failure

must be made in writing within 30 days of such failure.

A copy of the invoice showing the date of sale must

accompany products returned for warranty repair or

replacement.

All equipment returned to MK Products for service must be

properly packaged to guard against damage from shipping. MK

Products will not be responsible for any damages resulting

from shipping.

Normal surface transportation charges (both ways) for

products returned for warranty repair or replacement will be

borne by MK Products, except for products sold to foreign

markets.

ANY EXPRESS WARRANTY NOT PROVIDED HEREIN AND

ANY IMPLIED WARRANTY, GUARANTY, OR

REPRESENTATION AS TO PERFORMANCE, AND ANY REMEDY

FOR BREACH OF CONTRACT WHICH, BUT FOR THIS

PROVISION, MIGHT ARISE BY IMPLICATION, OPERATION OF

LAW, CUSTOM OF TRADE, OR COURSE OF DEALING,

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY

OR OF FITNESS FOR PARTICULAR PURPOSE, WITH RESPECT

TO ANY AND ALL EQUIPMENT FURNISHED BY MK PRODUCTS,

IS EXCLUDED AND DISCLAIMED BY MK PRODUCTS.

EXCEPT AS EXPRESSLY PROVIDED BY MK PRODUCTS IN

WRITING, MK PRODUCTS ARE INTENDED FOR ULTIMATE

PURCHASE BY COMMERCIAL/INDUSTRIAL USERS AND FOR

OPERATION BY PERSONS TRAINED AND EXPERIENCED IN THE

USE AND MAINTENANCE OF WELDING EQUIPMENT AND NOT

FOR CONSUMERS OR CONSUMER USE. MK PRODUCTS

WARRANTIES DO NOT EXTEND TO, AND NO RE-SELLER IS

AUTHORIZED TO EXTEND MK PRODUCTS’ WARRANTIES TO

ANY CONSUMER.

MK PRODUCTS, INC.

16882 ARMSTRONG AVE.

IRVINE, CA 92606

TEL (949) 863-1234

FAX (949) 474-1428

FORM : LW-8

DATE : April 1, 1998

Page 25

MK Products, Inc.

16882 Armstrong Ave.

Irvine, CA 92606

tel 949/863-1234

fax 949/474-1428

Loading...

Loading...