Page 1

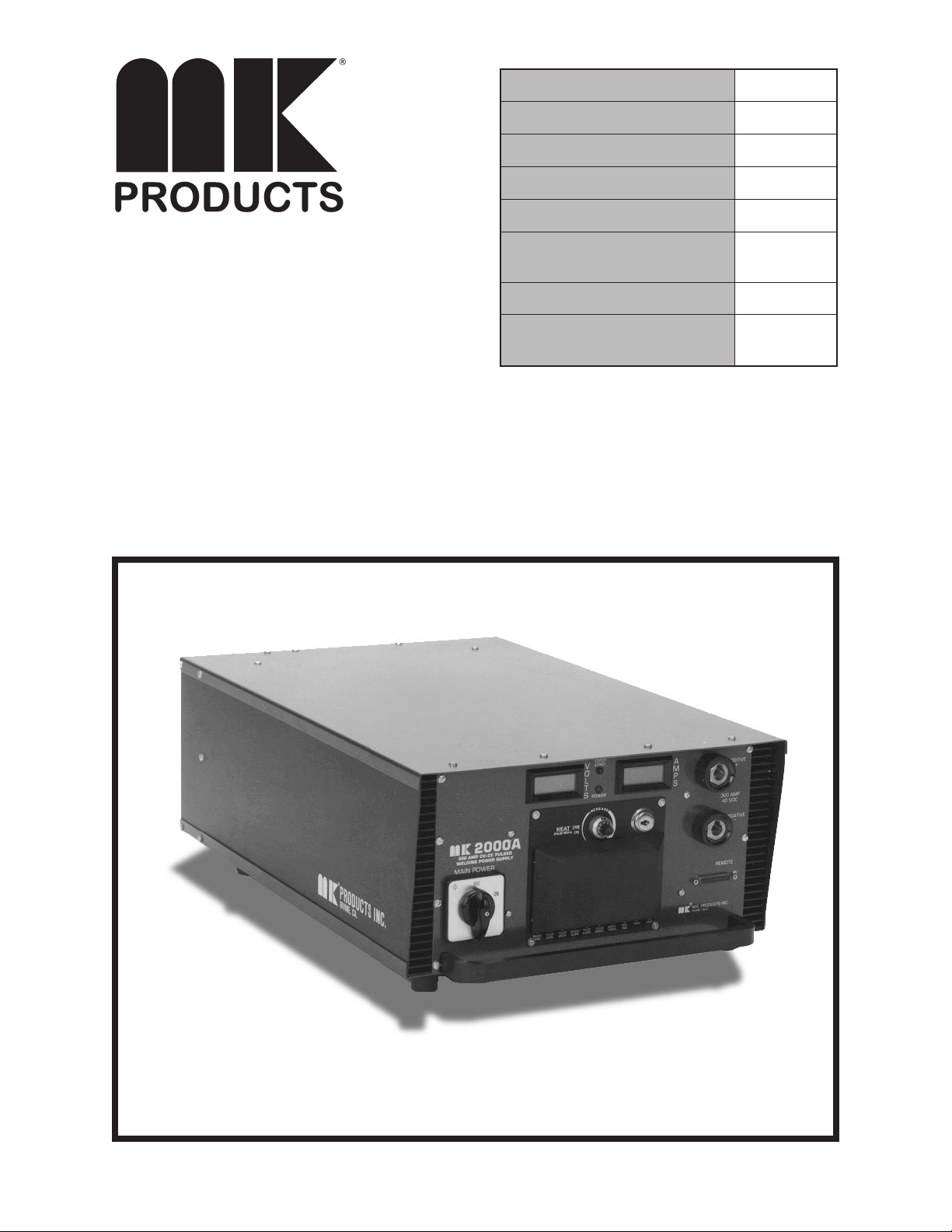

MK2000A Inverter Power Supply

noitpircseDtcudorP noitpircseDtcudorP

noitpircseDtcudorP

noitpircseDtcudorP noitpircseDtcudorP

A0002KM

rebmuNtraPlaunaMKM rebmuNtraPlaunaMKM

rebmuNtraPlaunaMKM

rebmuNtraPlaunaMKM rebmuNtraPlaunaMKM

6220-190

rebmuNmroFKM rebmuNmroFKM

rebmuNmroFKM

rebmuNmroFKM rebmuNmroFKM

A0002KM

rebmuNmroFASWN rebmuNmroFASWN

rebmuNmroFASWN

rebmuNmroFASWN rebmuNmroFASWN

055

rebmuNlaireShtiwevitceffE rebmuNlaireShtiwevitceffE

rebmuNlaireShtiwevitceffE

rebmuNlaireShtiwevitceffE rebmuNlaireShtiwevitceffE

3661

sgnitaRegatloV sgnitaRegatloV

sgnitaRegatloV

sgnitaRegatloV sgnitaRegatloV

.hp3/1V802

.hp3/1V032

etaD.veR/gnitnirP etaD.veR/gnitnirP

etaD.veR/gnitnirP

etaD.veR/gnitnirP etaD.veR/gnitnirP

A1002yluJ

ehtotseilppalaunamsihT ehtotseilppalaunamsihT

ehtotseilppalaunamsihT

ehtotseilppalaunamsihT ehtotseilppalaunamsihT

srebmunledomgniwollof srebmunledomgniwollof

srebmunledomgniwollof

srebmunledomgniwollof srebmunledomgniwollof

100-451

16882 Armstrong Ave., Irvine, CA 92606 TEL (949) 863-1234 FAX (949) 474-1428 www.mkproducts.com

Page 2

SAFETY CONSIDERATIONS

ELECTRIC ARC WELDING EQUIPMENT

CAUTION : READ BEFORE ATTEMPTING INSTALLATION, OPERATION

OR MAINTENANCE OF THIS EQUIPMENT

1-1 INTRODUCTION

This equipment is intended for ultimate

app lication by com mercial/industrial

users and for operation by persons

trained and experienced in the use and

maintenanc e of welding equipment.

Operation should not be under taken

without adequate training in the use of

such equipment. Training is available

from many public and private schools or

similar facilities.

Safe practices in the installation, operation and maintenance of this equipment

requires proper training in the ar t, a

careful study of the information provided

with the equipme nt, and the use of

common sense. Rule s fo r safe use

are generally provided by suppliers of

welding power sources, compressed

gas suppliers, and electrode suppliers.

Careful compliance with these rules will

promote safe use of this equipment.

The following Safety Rules cover some

of the more generally found situations.

READ THEM CAREFULLY. In case of

any doubt, obtain qualied help before

proceeding.

1-2 GENERAL PRECAUTIONS

A. Burn Prevention

ELECTRIC ARC WELDING PRODUCES

HIGH INTENSITY HEAT AND ULTRAVIOLET RADIANT ENERGY WHICH

MAY CAUSE SERIOUS AND PERMANENT EYE DAMAGE AND WHICH

MAY DAMAGE ANY EXPOSED SKIN

AREAS.

Wear helm et with safet y goggles or

glasses with side shields underneath,

appropriate lter lenses or plates (protected by clear cover glass). This is a

must for welding or cutting (and chipping)

to protect the eyes from radiant energy

and ying metal. Replace cover glass

when broken, pitted, or spattered.

Medical rst aid and eye treatment. First

aid fac ilities and a qualified first aid

person should be available for each shift

unless medical facilities are close by for

immediate treatment of ash burns of

the eyes and skin burns.

Wear protective clothing - leather (or

asbestos) gauntlet gloves, hat, and high

safety-toe shoes. Button shirt collar and

pocket aps, and wear cufess trousers

to avoid entry of sparks and slag.

Avoid oily or greasy clothing. A spark

may ignite them.

Flammable hair preparations should not

be used by persons intending to weld

or cut.

Hot metal such as electrode stubs and work

pieces should never be handled without

gloves.

Ear plugs should be worn when working

on overhead or in a conned space. A

hard hat should be worn when others work

overhead.

B. Toxic Fume Prevention

WARNING: The use of this product may

result in exposure to chemicals known

to the State of California to cause cancer

and birth defects or other reproductive

harm.

Adequate ventilation. Severe discomfort,

illness or death can result from fumes,

vapors, heat, or oxygen enrichment or

depletion that welding (or cu tting) may

pro duc e. Prevent them with adequate

ventilation. NEVER ventilate with oxygen.

Lead-, cadmium-, zinc-, mercury-, beryllium-bearing and similar materials, when

welded or cut, may produce harmful concentrations of toxic fumes. Adequate local

exhaust ventilation must be used, or each

person in the area, as well as the operator,

must wear an air-supplied respirator. For

beryllium, both must be used.

Metals coated with or containing materials

that emit toxic fumes should not be heated

unless coating is removed form the work

surface, the area is well ventilated, or the

operator wears an air-supplied respirator.

Work in a conned space only while it is

being ventilated and, if necessary, while

wearing an air-supplied respirator.

Gas leaks in a conned space should be

avoided. Leaked gas in large quantities can

change oxygen concentration dangerously.

Do not bring gas cylinders into a conned

space.

Leaving confined space, shut OFF gas

supply at source to prevent possible accumulation of gases in the space if downstream valves have bee n accide ntally

opened or left open. Check to be sure that

the space is safe before reentering it.

Vapors from chlorinated solvents can be

decomposed by the heat of the arc (or

ame) to form PHOSGENE, a highly toxic

gas, and other lung and eye irritating products. The ultraviolet (radiant) energy of the

arc can also decompose trichloroethylene

and perchl oroethylene vapo rs to form

phosgene. DO NOT WELD or cut where

so lvent vapors can be drawn int o the

welding or cutting atmosphere or where

the radiant energy can penetrate to atmospheres containing even minute amounts of

trichloroethylene or perchloroethylene.

C. Fire and Explosion Prevention

Causes of fire and explosion are: com-

bustibles reac hed by the arc, flame,

ying sparks, hot slag, or heated material, misuse of compressed gases and

cylinders, and short circuits.

BE AWARE THAT ying sparks or falling

slag can pass through cracks, along

pipes, through windows or doors, and

through wall or oor openings, out of

sight of the goggled operator. Sparks

can y many feet.

To prevent res and explosion:

Keep equipment clean and operable,

free of oil, grease, and (in el ectrical

parts) of metallic particles that can cause

short circuits.

If combustibles are in area, do NOT weld

or cut. Move the work if practicable,

to an area free of combustibles. Avoid

paint spray rooms, dip tanks, storage

areas, ventilators. If the work cannot

be moved, move combustibles at least

35 feet away, out of reach of sparks and

heat; or protect against ignition with

suitable and snug-tting, re-resistant

covers or shields.

Walls touching combustibles on opposite

sides should not be welded on (or cut).

Wal ls, ce ilings, and floor nea r work

should be protected by heat-resistant

covers or shields.

Fire watcher must be standing by with

suitable fire extinguishing equipment

during and for some time after welding

or cutting if:

1. Appreciable combustibles (including

building construction) are within 35 feet.

2. Appreciable combustibles are further

th an 35 fee t, but ca n be i gnited by

sparks.

3. Openings (concealed or visible) in

oors or walls within 35 feet may expose

combustibles to sparks.

4. Combustibles adjacent to walls, ceilings, roofs, or metal partitions can be

ignited by radiant or conducted heat.

Hot work permit should be obtained

before operation to ensure supervisor’s

approval that adequate precautions have

been taken.

After work is done, check that area is

free of sparks, glowing embers, and

ames.

An empty container that held combustibles, or that can produce ammable or

toxic vapors when heated, must never

be welded on or cut, unless container

has rst been cleaned in accordance

with industry standards.

This inclu de s: a th orough ste am or

Page 3

caustic cleaning (or a solvent of water

washing, depending on the combustible’s

solubility), followed by purging and inerting with nitrogen or carbon dioxide, and

using protective equipment.

Water-lling just below working level may

substitute for inerting.

A containe r with unknow n contents

should be cleaned (see paragraph

above). Do NOT depend on sense of

smell or sight to determine if it is safe

to weld or cut.

Hollow castings or containers must be

vented before welding or cutting. They

can explode.

Explosive atmospheres. NEVER weld or

cut where the air may contain ammable

dust, gas, or liquid vapors (suc h as

gasoline).

D. Compressed Gas Equipment

The safe handling of compressed gas

eq ui pm ent is det ailed in num er ous

industry publications. The foll owing

general rules cover many of the most

common situations.

1. Pressure Regulators

Regulator relief valve is des igned to

protect only the regulator from overpressure; it is not intended to protect

any downstream equipment. Provide

such protection with one or more relief

devices.

Never connect a regulator to a cylinder

containing gas other than that for which

the regulator was designed.

Remove faulty regulator from service

immediately for repair (rst close cylinder

valve). The following symptoms indicate

a faulty regulator:

Leaks - if gas leaks externally.

Excessive Creep - if delivery pressure

continues to rise with downstream valve

closed.

Faulty Gauge - if gauge pointer does

not move off stop pin when pressurized,

nor returns to stop pin after pressure

release.

Repair. Do NOT attempt repair. Send

faulty regulators for repair to manufacturer’s designated repair center, where

special techniques and tools are used

by trained personnel.

2. Cylinders

Cylinders must be handled carefully to

prevent leaks and damage to their walls,

valves, or safety devices:

Avo id electrical cir cu it contact w ith

cylinders including third rails, electrical

wires, or welding circuits. They can

produced short circuit arcs that may lead

to a serious accident. (See 1-3C)

ICC or DOT marking must be on each

cylinder. It is an assurance of safety

when the cylinder is properly handled.

Identifying gas content. Use only cylinders with name of gas marked on them;

do not rely o n c ol or to ident if y gas

content. Notify supplier if unmarked.

NEVER DEFACE or alter name, number,

or other markings on a cylinder. It is illegal

and hazardous.

Empties: Keep valves closed, replace caps

securely; mark MT; keep them separate

from FULLS, and return promptly.

Prohibited use. Never use a cylinder or its

contents for other than its intended use,

NEVER as a support or roller.

Locate or secure cylinders so they cannot

be knocked over.

Passageways and work areas. Keep cylinders clear of areas where they may be

stuck.

Transporting cylinders. With a crane, use

a secure support such as a platform or

cradle. Do NOT lift cylinders off the ground

by their valves or caps, or by chains, slings,

or magnets.

Do NOT expose cylinders to excessive

heat, sparks, slag, and ame, etc. that may

cause rupture. Do not allow contents to

exceed 55 degrees C (130 degrees F.)

Cool with water spray where such exposure

exists.

Protect cylinders, particularly valves from

bumps, falls, falling objects, and weather.

Replace caps securely when moving cylinders.

Stuck valve. Do NOT use a hammer or

wrench to open a cylinder valve that cannot

be opened by hand. Notify your supplier.

Mixing gases. NEVER try to mix any gases

in a cylinder.

NEVER rell any cylinder.

Cylinder ttings should never be modied

or exchanged.

3. Hose

Pro hib ited use. Never use hose other

than that designed for the specied gas.

A general hose identication rule is: red

for fuel gas, green for oxygen, and black

for inert gases.

Use ferrules or clamps designed for the

hose (not ordinary wire or other substitute)

as a binding to connect hoses to ttings.

No copper tubing splices. Use only standard brass ttings to splice hose.

Avoid long runs to prevent kinks and abuse.

Suspend hose off ground to keep it from

being run over, stepped on, or otherwise

damaged.

Coi l excess hose to prevent kinks and

tangles.

Protect hose from damage by sharp edges,

and by sparks, slag, and open ame.

Examine hose regularly for leaks, wear, and

loose connections. Immerse pressured

hose in water; bubbles indicate leaks

Repair leaky or worn hose by cutting area

out and splicing. Do NOT use tape.

4. Proper Connections

Clean cylinder valve outlet of impurities that

may clog orices and damage seats before

connecting regulator. Except for hydrogen,

crack valve momentarily, pointing outlet

away from people and sources of ignition.

Wipe with a clean, lintless cloth.

Match reg ulator to cylinde r. Before

connecting, check that the regulator label

and cylinder marking agree, and that the

regulator inlet and cylinder outlet match.

NEVER Connect a regulator designed

for a particular gas or gases to a cylinder

containing any other gas.

Tighten connections. When assembling

threaded connections, clean and smooth

sea ts where necessar y. Tighten. If

connection leaks, disassemble, clean,

and retigh te n, usi ng prope rl y fitting

wrench.

Adapters. Use a CGA adapter (available

from your supplier) between cylinder

and regulator, if one is required. Use

two wrenches to tighten adapter marked

RIGHT and LEFT HAND threads.

Regulator outlet (or hose) connections

may be identied by right hand threads

for oxygen and left hand threads (with

grooved hex on nut or shank) for fuel

gas.

5. Pressurizing Steps:

Drain regulator of residual gas through

suitable vent before opening cylinder

(or manifold valve) by turning adjusting

screw in (clockwise). Draining prevents

excessive compression heat at high

pressure seat by allowing seat to open

on pre ss ur ization . Leave adjust ing

screw engaged slightly on single-stage

regulators.

Stand to side of regulator while opening

cylinder valve.

Open cylinder valve slowly so that regulator pressure increases slowly. When

gauge is pressurized (gauge reaches

regulator maximum) leave cylinder valve

in following position: for oxygen and inert

gases, open fully to seal stem against

possible leak; for fuel gas, open to less

than one turn to permit quick emergency

shut-off.

Use pressure charts (availabl e from

your supplier ) for safe and ef ficie nt

recomme nded pre ssure sett ings on

regulators.

Check for leaks on rst pressurization

and regularly thereafter. Br ush with

soap solution. Bubbles indicate leaks.

Clean off soapy water after test; dried

soap is combustible.

E. User Responsibilities

Follow all Safety Rules.

Remove leaky or defective equipment

from service immediately for repair. Read

and follow user manual instructions.

F. Leaving Equipment Unattended

Close gas supply at source and drain

gas.

G. Rope Staging-Support

Rop e staging-suppor t should not be

used for welding or cutting operation;

rope may burn.

1-3 ARC WELDING

Comply with precautions in 1-1, 1-2,

Page 4

and this section. Arc Welding, properly

done, is a safe process, but a careless

operator invites trouble. The equipment

carries high currents at signicant voltages. The arc is very bright and hot.

Sparks y, fumes rise, ultraviolet and

infrared ener gy radiate s, weldments

are hot, and compressed gases may

be used. The wise op erator avoid s

unnecessary risks and protects himself

and others from accidents.

A. Burn Protection

Comply with precautions in 1-2.

The welding arc is intense and visibly

bright. Its radiation can damage eyes,

penetrate lightweight clothing, reflect

from light-colored surfaces, and burn

the skin and eyes. Skin burns resemble

acute sunburn; those from gas-shielded

arcs are more severe and painful. DON’T

GET BURNED; COMPLY WITH PRECAUTIONS.

1. Protective Clothing

Wear long-sleeve clothing in addition to

gloves, hat, and shoes. As necessary,

use additional protective clothing such

as leather jacket or sleeves, ameproof

apron, and re-resistant leggings. Avoid

outer garments of untreated cotton.

Bare skin protection. Wear dark, substantial clothing. Button collar to protect

chest and neck, and button pockets to

prevent entry of sparks.

2. Eye and Head Protection

Protect eyes from exposure to arc. Eyes

may be dama ged by radian t energy

when exposed to the electric arc, even

when not looking in the direction of the

arc. Never look at an electric arc without

protection.

Welding helmet or shield containing a

lter plate shade no. 12 or denser must

be used when welding. Place over face

before striking arc.

Protect filter plate with a clear cover

plate.

Cracke d or broken helmet or shield

should NOT be worn; radiation can be

passed through to cause burns.

Cracked, broken, or loose lter plates

must b e repl aced I MM EDIATELY.

Replace clear cover plate when broken,

pitted, or spattered.

Flash goggles with side shields MUST

be worn under the helmet to give some

protection to the eyes should the helmet

not be lowered over the face before

an arc is stru ck. Looking at an ar c

mo me nt ar il y with u np rotected eyes

(particularly a high intensity gas-shielded

arc) can cause a retinal burn that may

leave a permanent dark area in the eld

of vision.

3. Protection of Nearby Personnel

Enclose the welding area. For production

welding, a separate room or enclosed

bay is best. In open areas, surround the

operation with low-reective, noncombustible screens or panels. Allow for free

air circulation, particularly at oor level.

Viewing the weld. Provide face shields for

all persons who will be looking directly

at the weld.

Others working in area. See that all persons

are wearing ash goggles.

Before starting to weld, make sure that

screen aps or bay doors are closed.

B. Toxic Fume Prevention

Comply with precautions in 1-2B.

Generator engine exhaust must be vented

to the outside air. Carbon monoxide can

kill.

C. Fire and Explosion Prevention

Comply with precautions in 1-2C.

Equipment’s rated capacity. Do not overload

arc welding equipment. It may overheat

cables and cause a re.

Loose cable connections may overheat or

ash and cause are.

Never strike an arc on a cylinder or other

pressure vessel. It creates a brittle area that

can cause a violent rupture or lead to such

a rupture later under rough handling.

D. Compressed Gas Equipment

Comply with precautions in 1-2D.

E. Shock Prevention

Exposed electrically hot conductors or

other bare metal in the welding circuit, or in

ungrounded, electrically-HOT

equipme nt can fatally shock a perso n

whose body becomes a conductor. DO

NOT STAND, SIT, LIE, LEAN ON, OR

TOUCH a wet surface when welding without

suitable protection.

To protect against shock:

Keep body and clothing dry. Never work

in damp area without adequate insulation

against electrical shock. Stay on a dry

duckboard, or rubber mat when dampness

or sweat cannot be avoided. Sweat, sea

water, or moisture between body and

an electrically HOT part - or grounded

metal - reduces the body surface electrical resistance, enabling dangerous and

possibly lethal currents to flow through

the body.

1. Grounding the Equipment

When installing, connect the frames of

each unit such as welding power source,

control, work table, and water circulator to

the building ground. Conductors must be

adequate to carry ground currents safely.

Equipment made electrically HOT by stray

currents may shock, possibly fatally. Do

NOT GROUND to electrical conduit, or to

a pipe carrying ANY gas or a ammable

liquid such as oil or fuel.

Thr ee-phase conne cti on. Check phase

requirement of equipment before installing.

If only three-phase power is avail able,

connect single-phase equipment to only

two wires of the three-phase line. Do NOT

connect the equipment groun d lead to

the third (live) wire, or the equipment will

become electrically HOT - a dangerous

condition that can shock, possibly fatally.

Before welding, check ground for continuity.

Be sure conductors are touching bare

metal of equipment frames at connections.

If a line c ord w it h a ground lea d is

provided with the equipment for connection to a switch box, connect the ground

lead to the grounded switch box. If a

three-prong plug is added for connection

to a grounded mating receptacle, the

ground lead must be connected to the

ground prong only. If the line cord comes

with a three-prong plug, connect to a

gro unded mati ng rece ptacle. Never

remove the ground prong from a plug, or

use a plug with a broken ground prong.

2. Connectors

Fully insu lated lock-type connectors

should be used to join welding cable

lengths.

3. Cables

Fre quently inspec t cabl es for wear,

cracks, and damage. IMMEDIATELY

REPLACE those with excessively worn

or damaged insulation to avoid possibly

lethal shock from bared cable. Cables

with damaged areas may be taped to

give resistance equivalent to original

cable.

Keep cable dry, free of oil and grease,

and protected from hot metal and

sparks.

4. Terminals and Other Exposed Parts

Terminals and other exposed par ts of

electrical units should have insulating

covers secured before operation.

5. Electrode Wire

Electrode wire becomes electrically HOT

when the power switch of gas metal-arc

welding equipment is ON and welding

gun trigger is pressed. Keep hands

and body clear of wire and other HOT

parts.

6. Safety Devices

Safety devices such as interlocks and

circuit breakers should not be disconnected or shunted out.

Before installation, inspection, or service

of equipment, shut OFF all power, and

remove line fuses (or lock or red-tag

switches) to prevent accidental turning

ON of power. Disconnect all cables from

welding power source, and pull all 115

volts line-cord plugs.

Do not open power circuit or change

polarity while welding. If, in an emergency, it must be disconnected, guard

against shock burns or ash from switch

arcing.

Leaving equipment unattended. Always

shut OFF, and disconnect all power to

equipment.

Power disconnect switch must be available near the welding power source.

Page 5

Thank You

For selecting a quality product. We want you to take

pride in operating this product...as much pride as we

have in bringing the product to you!

When this equipment is shipped, title passes to the purchaser upon receipt by the

carrier. Consequently, claims for material damaged in shipment must be made by the

purchaser against the transportation company at the time the shipment is received.

Please record your equipment identification information below for future reference. This

information can be found on your machine nameplate.

Model Name & Number _____________________

Code & Serial Number _____________________

Date of Purchase _____________________

Whenever you request replacements parts for, or information on this equipment always

supply the information you have recorded above.

Please Examine Carton and Equipment For Damage Immediately

Read this Owner’s Manual completely before attempting to use this equipment. Save this manual

and keep it handy for quick reference. Pay particular attention to the safety instructions we

have provided for your protection.

Page 6

TABLE OF CONTENTS

Section 1 Specications ................................................ 8

Section 2 System Controls & Front Panel ............................ 9

Section 3 General.......................................................10

Section 4 Design ........................................................10

Electrical ..........................................................10

Mechanical ........................................................ 11

Section 5 Control Panel

Section 6 Operating Characteristics .................................12

Non-Pulsed Operation ........................................... 12

Remote Connector Pin Assignments ...........................20

Frequency Calculation Procedures.............................24

Section 7 Input Power Connections ..................................25

Page 7

This page intentionally blank

Page 8

Section 1 SPECIFICATIONS

Primary Input Power

50/60 Hz 3 phase 208-277 Volts 36 Amps source must have 15

KVA rating.

3 phase 380-460 Volts 4 wire wye 36 Amps source must

have 15 KVA rating.

1 Phase 208-240 Volts 50 Amps 50% duty cycle on 12 KVA

source 100% duty cycle on 25 KVA source.

Output

DC 6-50 volts

30-300 amperes 100% duty cycle at 10 KVA out (eg. 33 @300a)

Slope Control Flat to Vertical, Provides constant (potential) to

constant current operation.

Inductance Electronically provided 0-3 millihenries

Dual Slope

Capability (eg. CV during normal use - CC during Short circuit

transfer)

Idle Power Unit "On" contactor open - 80 watts (22w with fan off)

Unit "On", contactor closed no arc - 100 watts

Efciency 92% at Full rated power

Pulse Output

Pulse adds to background level setting providing 0 to 100% output during

pulse.

Pulse "On Time" may be 0% to 100% of total pulse interva. Pulse repetition

rate variable from 20 pulse per second to 2000 pulse per second.

Pulse rise time - variable (external only) - 100usec min. - sym rise and fall.

Controls

All functions are calibrated in 0-100% of full scale and may be controlled

remotely with 0-10 volts signals. For use with Robot Control Computers,

desired functions may be commanded from the control computer with

remaining function locally controlled at the power supply.

Size

16-1/4" x 8-1/2" x 24" (41.3 cm x 21.6 cm x 61 cm)

Weight

78 lbs. (35.4 KG)

Maximum Heat Dissipation

900 watts

Environment

-20°F to +110°F (-30°C to + 44°C) 90% humidity without condensation. 0 10,000 ft. elevation. Normal handling for electrical equipment, units may be

stacked or mounted side-by-side. Access required to rear of unit to connect

primary power cable. Cooling air inlet in rear - needs at least 4" clearance

from wall. Auto Over-temp shut down.

MK 2000A - Owner's Manual - Page 8

Page 9

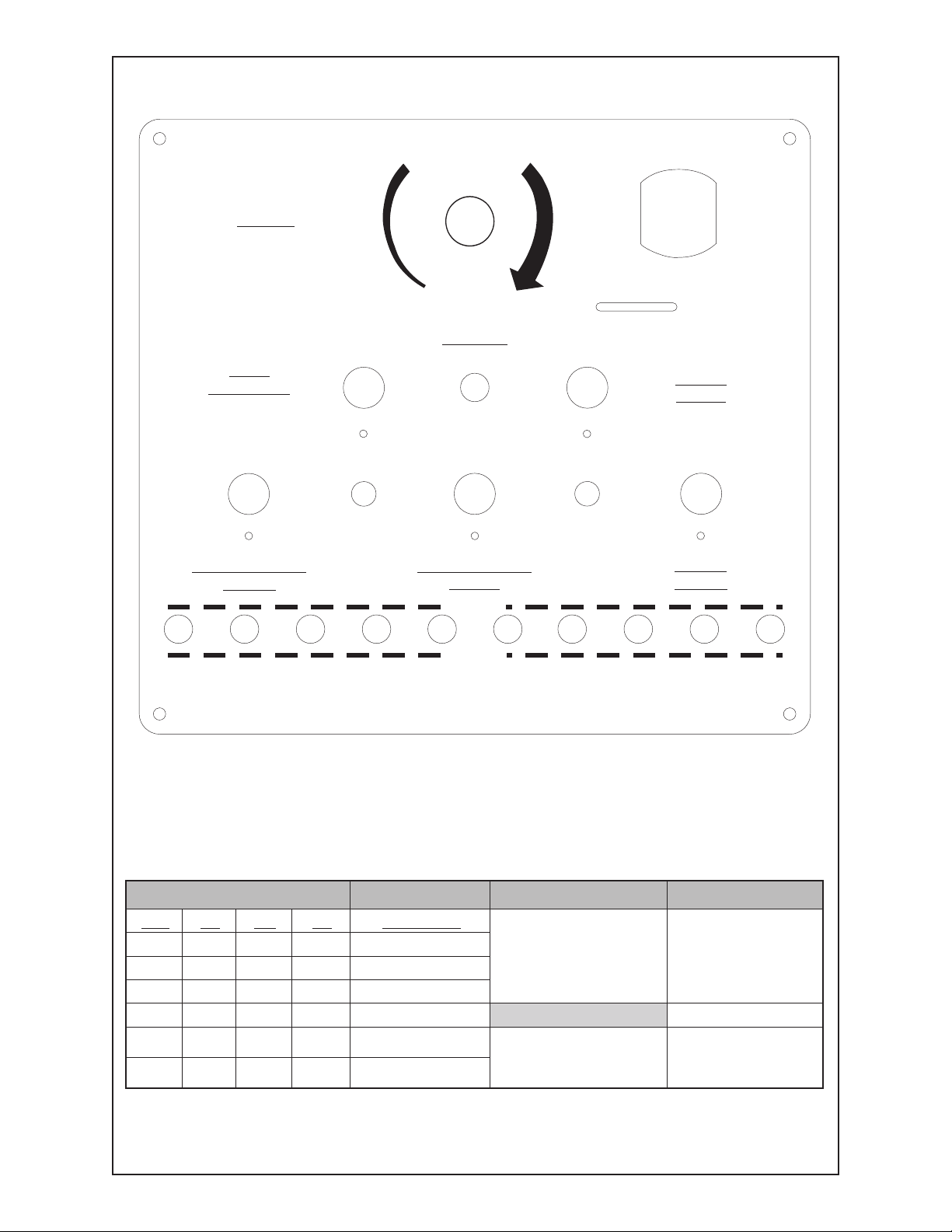

Section 2 SYSTEM CONTROLS AND FRONT PANEL

HEAT

(PULSE WIDTH)

MODE

HEAT

REMOTE

LOCAL

BKGND

LEVEL

PULSE

LEVEL

PULSE

WIDTH

BKGND

SLOPE

PULSE

SLOPE

PULSE

HEIGHT

INDUC-

TANCE

RISE

TIME

FREQ.

HEAT

INDUCTANCE

(NORMAL MIN:CCW)

PULSE HEIGHT

(NORMAL MAX:CW)

(4)

1 2 3 4

7

98 10

5

6

(1)(7)

(6)

(5)

PULSE

LEVEL

BACKGROUND

SLOPE

BACKGROUND

LEVEL

PULSE

SLOPE

WIRE

DIAMETER

(FREQUENCY)

(FREQ-WIDTH)

(9)

(2)

(10)

(3)

I

N

C

R

E

A

S

E

%nIeriW %nIeriW

%nIeriW

%nIeriW %nIeriW ssecorP ssecorP

ssecorP

ssecorP ssecorP leveldnuorgkcaB leveldnuorgkcaB

leveldnuorgkcaB

leveldnuorgkcaB leveldnuorgkcaB teSyrotcaF teSyrotcaF

teSyrotcaF

teSyrotcaF teSyrotcaF

.aiD LA SS TS leveLesluP

%32lairetaMnihT

%62lairetaM.gvA

%23lairetaMkcihT

%51ecnatcudnI

%001emiTesiR

%001thgieHesluP

020. 49 65 52 %06LA3404

%32lairetaMnihT

%62lairetaM.gvA

%23lairetaMkcihT

%51ecnatcudnI

%001emiTesiR

%001thgieHesluP

030. 57 83 22 %17LA6535

%32lairetaMnihT

%62lairetaM.gvA

%23lairetaMkcihT

%51ecnatcudnI

%001emiTesiR

%001thgieHesluP

530. 65 82 02 %57sselniatS

%32lairetaMnihT

%62lairetaM.gvA

%23lairetaMkcihT

%51ecnatcudnI

%001emiTesiR

%001thgieHesluP

540. 83 02 02 %48leetSdliM

epolS epolS

epolS

epolS epolS

250. 82 02 81

%02epolsdnuorgkcaB

%02epolsesluP

roflaunameeS

dnaatadlanoitidda

selpmaxe

260. 81 81 61

%02epolsdnuorgkcaB

%02epolsesluP

roflaunameeS

dnaatadlanoitidda

selpmaxe

Set Mode switch to "HEAT". Set Wire Diameter, Pulse Level (process) and background level per chart.

Control weld heat with "HEAT" control. Trim arc length with wire feeder rate control.

MK 2000A - Owner's Manual - Page 9

Page 10

Section 3 GENERAL

The MK2000A Electronic Pulsed Welding Power Supply is designed to

provide precision controlled, highly efcient welding power in a compact,

extremely reliable form.

The demands of modern fabrication techniques, with well- designed parts

accurately tted together, require exceptionally well controlled welding wire

feed and welding power control. The MK Cobramatic Wire Feed Systems,

long known for precision wire feeding for critical applications are now

matched with a precision power supply. The combination is exceptionally

well suited for xtured or robotic welding, although the exceptionally stable

characteristics also make hand welding much easier.

The welding engineer will appreciate the exibility to utilize constant voltage,

constant current, pulsed welding and unique combinations of all in a single

compact, efcient unit.

Section 4 DESIGN

Electrical

The MK2000A is a transistorized inverter power supply intended for use on

three phase 208 to 277 volt and 380 to 460 volt, 4 wire wye (with neutral),

50/60 Hertz supply circuits. (See page 24 for more details) The unit will also

operate on single phase 208 to 277 volt circuits, although the reduced power

factor may require limiting the duty cycle based on the volt ampere capacity

of the primary wiring.

The input power is converted to direct current and a switching inverter utilized

to generate alternating current at 20,000 hertz.

A compact, low-loss transformer steps the high voltage down to the welding

voltage range where it is rectied and ltered for output.

The inverter is controlled by a digital/analog control system which permits an

exceptional range of voltage, current and waveform controls.

For constant voltage (CV) operation, the output voltage is sensed and

compared with a digital reference. The inverter switch is controlled on a cycle

by cycle basis to hold the output at the reference value over the entire load

range. To provide spatter free welding conditions, slope may be added so

that the output voltage decreases with increasing current. Any slope from 0

volts per 100 amperes to vertical (constant current) may be set.

For constant current (CC) operation, the output current is sensed and

compared with a digital reference. The inverter switch is controlled on a

cycle by cycle basis to hold the output at the reference value over the entire

load range.

Pulsed operation is provided whereby the background voltage set by the

background level control is increased periodically. These pulses may

increase the output by any amount up to 100% of the power supply capacity.

Pulse rates may be any frequency from 20 pulses per second to 2000 pulses

per second. This, of course, includes the common pulse frequencies of 60

and 120 pulses per second available from thyristor supplies operated at line

frequency. Pulse widths may be any value from 0 to 100% of the pulse

period. In addition, the pulse shape may be controlled to provide a gradual

rise and fall (symmetrical), when an external control computer is used.

An exceptional capability is provided by the MK2000A through the use of

the Pulse Level and Pulse Slope controls in conjunction with the Background

Level and Background Slope. These two sets of controls function identically

cept that the pulse modulation is only added to the Background Control.

MK 2000A - Owner's Manual - Page 10

Page 11

The combination may be used to create a wide range of welding

characteristics. For example, when welding thick aluminum sections, CC

operation is often desired due to the increased penetration. In this instance

the Background Level is set to the desired operating voltage (e.g. 20 volts)

and the Background Slope set to a typical CV slope of 4 volts per 100

amperes (19% on dial); the welding condition will be standard CV. To limit

the current increase during the short circuit transfer interval, the Pulse Level

may be set to the desired maximum current (e.g. 240 amps) with a Pulse

Slope of 32 volts per 100 amps (66% on dial) or typically CC.

Another application of the Pulse Level Control is Pulsed Welding Operation.

Conventional pulsed supplies provide increased voltage during the pulse

interval, resulting in a current peak. Since the operating mode is that of

constant voltage, the actual current peak depends very critically on the load

impedance (wire feed rate and tip-to-work distance).

Using the Pulse Level Control with the Pulse Slope set for Constant Current

operation, the pulses on the pulse height may be set to 100%, permitting the

power supply to go to maximum output voltage. The pulse current is then

controlled by the Pulse Level, which is set to the desired peak current. Under

these conditions, the welding condition during the pulse is constant current,

and largely independent of wire feed rate and tip-to-work distance.

The MK2000A has built in protective circuitry to protect it from excessively

high or low input voltage and from any load condition. Under overload

conditions, the unit will automatically shut down and reset when conditions

are normal.

The physical layout logically separates input, switching, output and control

functions for ease of fault isolation and sub-assembly replacement. All

components are very conservatively rated and reliability is exceptional.

Mechanical

Careful attention has been given to the mechanical and thermal design of the

power supply. Recognizing the difcult environment in which such equipment

must operate, the MK2000A utilizes a heat exchanger design to eliminate

dust and dirt from the electronic components.

Although the circuit design is exceptionally efcient, it is necessary to remove

heat from the high current devices. This is accomplished by mounting the

input and output rectiers, switching transistors, main transformer and output

inductor on nned aluminum heat sinks which conduct the heat directly out

of the enclosure and into the air stream from a rear mounted cooling fan.

Outside air is not passed through the electronic enclosure.

All components are securely mounted to insure circuit integrity in spite of the

inevitable rough handling.

The compact size and light weight of this ten kilowatt power supply makes

handling much easier - never requiring hoists or fork lifts to position the unit.

Section 5 MK2000A CONTROL PANEL **

Background Level: Relates to the background level. This is background

voltage for a slope setting of ‘O‘ (CV) and background current for a slope

setting of 100 (CC).

Pulse Level: Also relates to the background level and slope. It is normally set

to establish a limiting value of current (slope near 100) when in short circuit

transfer mode or in pulse mode.

Pulse Width: This control may be set to make the actual pulse length 0% to

100% of the pulse interval.

MK 2000A - Owner's Manual - Page 11

Page 12

Background Slope: Adjustable from Constant Voltage to Constant Current.

Pulse Slope: Adjustable from Constant Voltage to Constant Current.

Pulse Height: This control determines the height of the output pulse. The

pulse is added on top of the background level so the total output during

the pulse is the sum of the Background Level setting plus the Pulse Height

setting.

Inductance: This control creates the electronic equivalent of output

inductance. This limits the rate of rise of current during short circuit transfer

without limiting the peak current. This control is factory set to 15%; however,

when -0- inductance is required, it may be disabled by placing the inductance

switch to remote.

Pulse Rise Time: This control determines the rise (and symmetrical fall) time

of the pulse. It may be used to change the rectangular pulse to a trapezoidal

or triangular shape. This control is adjustable through an external control

computer only.

Pulse Frequency: This control may be set to provide pulses at any repetition

rate from 20 pulses per second to 2000 pulses per second.

Heat: This control adjusts the pulse frequency while maintaining a preset

pulse width. The "ON TIME" (pulse width) is determined by the wire diameter

control.

Mode Selector: The mode selector switch allows the frequency and

pulse width to be controlled independently of each other or operate in the

“Heat” Mode.

** See Control Panel Detail (Section 2)

Section 6 OPERATING CHARACTERISTICS

The operating characteristics of the MK2000A cover a very wide spectrum,

however the operation may be easily understood by considering it in

relationship to conventional supplies.

Non-Pulsed Operation

Constant Voltage

Operation as a Constant Voltage (potential) power supply is shown in

Figure 1. This is the operation obtained when the Pulse Height control is set

to -0- and the Pulse Level is disabled by setting it to 100% with the Pulse

Slope set to -0-.

With the Background Slope control set to -0-, the Background Level control

MK 2000A - Owner's Manual - Page 12

Page 13

sets the power supply voltage output. This is shown as line ‘A’ as set to 24

volts. There is no slope and thus the voltage remains constant from below

50 amperes to over 300 amperes. The resulting harsh arc may be softened

by providing some slope as shown in lines ‘B’ & ‘C’. Setting the Background

slope to 15% results in a slope of just slightly more than 3 volts per 100

amperes - a commonly used value (line B). The slope may be increased

continuously until at 100% on the Background Slope control the line becomes

vertical and the power supply is operating as a very stiff Constant Current

(CC) source.

A notable feature of the MK2000A is that the slope control is referenced to the

diagonal ‘control line’ so that the operating voltage stays relatively constant

when the slope is changed. Therefore, there is no need to calculate open

circuit voltage regardless of the slope setting.

While welding, the output voltage and current follow the appropriate line

(A,B,C,etc.) up to the full 360 ampere capability of the supply.

Constant Current

Operation as a Constant Current power supply is shown in Figure 2. This

is the operation obtained when the Pulse Height control is set to -0- and the

Pulse Level disabled by setting it to 100% with the Pulse Slope set to -0-.

With the Background Slope control set to 100%, the Background Level control

sets the power supply current output. This is shown as line “A” as set to

170 amperes. There is no slope and the current remains constant from

short circuit conditions (zero volts) to the maximum capability of the power

supply at 50 volts. A more typical “drooper” curve is obtained by setting the

Background Slope control to less than 100% as shown in curves “B” and

“C”. Curve “C” at approximately 33 volts per 100 amperes is obtained with a

Background Slope setting of 66%.

The output characteristic curves just described for CV and CC welding may

be compared with “typical” curves representing the majority of presently

available CV and CC welding power sources, as obtained from supplier

catalogs, actual equipment measurements and the AWS Welding Handbook.

Typical curves are shown in Figure 3.

The Constant Current supplies usually start with a high open circuit voltage

and ‘droop’ steeply on the volt/ampere plot. As the output current setting is

decreased, the slope tends to become steeper. Supplies with lower open

circuit voltages (eg 60 volts) have substantially less slope, particularly at

higher currents.

The MK2000A may be set to closely match any of the slopes shown within

the limits of 50 volts and 360 amperes, since the slope is electronically

controlled and not just the result of a high open circuit voltage combined with

a high resistance circuit.

The conventional constant voltage supplies provide an open circuit voltage

MK 2000A - Owner's Manual - Page 13

Page 14

slightly higher than the desired welding voltage. A small amount of circuit

resistance is utilized to provide the desired slope. This is a power absorbing

element and reduces the efciency of the supply.

The MK2000A achieves its slope by an electronic control which does not add

loss to the circuit. It is thus substantially more efcient than the conventional

supply. The output voltage is set along the diagonal ‘control line’ and thus is

much more representative of the desired welding voltage. As may be seen,

changing the slope has a smaller effect on the output voltage at welding

current, although signicant changes in slope may require output voltage

readjustment.

With a CV power supply, it is often necessary to use more slope than

desired to avoid excessive current surges during arc initiation and short

circuit transfer. Some supplies are provided with a variable (or tapped)

inductor which limits the rate of change of current, however this makes the

supply both larger and more expensive. The MK2000A has an ‘electronic

inductor’ which provides the same output waveform, under short circuit

conditions, as would exist with an iron cored inductor. The inductor covers the

equivalent range of 0 to 3 millihenries.

A second method exists to provide for current limiting on short circuit - called

Dual Slope control. This is shown in Figure 4. The Background Slope

control is set for CV operation at 3 volts per 100 amperes (15%) and the

Background Level at the desired welding voltage - here shown as 18 volts

at pivot point ‘A’.

MK 2000A - Owner's Manual - Page 14

Page 15

The ‘Pulse Slope’ is set for CC operation at 38 volts/100 amperes (70%) and

the Pulse Level is set to 175 amperes at pivot point “B”.

Welding at these settings results in a CV operating mode with wire feed

rates adjusted to provide any current between about l00 and 200 amperes.

Short circuit current, however, is limited to 250 amperes by the Pulse Level

setting.

The Pulse Level and Slope may also be adjusted to any desired values, and

are independent of the Background Level and Slope. It is not necessary for

point “B” to be set above point “A”, although this will normally be the case.

The only difference in operation between the Background Level/Background

Slope and the Pulse Level/Pulse Slope is that pulse operation adds to the

Background Level and does not change the Pulse Level.

Inductance may be used with any combination of other settings.

Pulse Operation

The MK2000A provides a range of operating capabilities not available in any

general purpose welding power supply.

Pulse operation is used to provide a measure of independence in the control

of heat input, current density during material transfer, and arc voltage which

effects both heat and cleaning capability.

The majority of available pulsed welding power supplies operate with a

background voltage and then induce extended ring of one or two thyristors

to provide voltage pulses at 60 or 120 pulses per second. (360 pps with three

phase operation) The current resulting from these voltages depends on the

ring point which, in turn, controls the pulse duration (width). It is usually

described in terms of the peak current value.

MK2000A Parameter Set-Up

In pulsed spray welding the current is varied from the background level to a

peak level. The background level is well below the transition current while

the peak level is well into the spray arc region, Figure 5. During the peak

level one droplet is transferred to the work. The current then drops to the

background level which allows the puddle to cool, at which time no metal

is transferred.

MK 2000A - Owner's Manual - Page 15

Page 16

Wire Diameter

To obtain the smooth one drop transfer during the peak level the “On” time

(pulse width) must be varied, depending on the wire diameter. For example,

.030 requires 1/2 of a millisecond and .045 requires 1-1/2 milliseconds. The

WIRE DIAMETER Control on the MK 2000A therefore sets the "ON TIME"

(pulse width).

Pulse Level

Because different alloys melt at different temperatures, the height of the pulse

must also be varied. The PULSE LEVEL therefore limits the height of the

pulse depending on the alloy. For example, the Pulse Level for 4043 is set

to 60 (60% of 300 Amps = 180 Amps) whereas 5356 with its higher melting

temperature is set to 71 (71% of 300 Amps = 213 Amps Max.).

Heat

When changing plate size or for ne tuning, the “HEAT” Control may be

adjusted. With the "ON TIME" (pulse width) preset by the Wire Diameter

control the Heat control moves the pulses closer together (more heat) or

further apart (less heat) without changing the pulse width. Figure 6. Keep in

mind that when you increase your heat you must also increase wire speed.

Note: When operating in the Frequency Width mode the frequency and pulse

width are set independently of each other. Increasing the frequency in this

mode decreases the "ON TIME" (pulse width) proportionately.

MK 2000A - Owner's Manual - Page 16

Page 17

Background Level

When the pulse drops to the background level, it must be at a point high

enough to maintain an arc yet low enough to cool the puddle. Normally the

thickness of the material will determine the Background Level.

Slope

The MK 2000A is capable of operating in either constant voltage (CV) or

constant current (CC). Because of the problems associated with CC Mig

welding, CV operation is most common. A power supply with no slope would

produce a very harsh arc with excessive spatter. Adding slope reduces the

voltage for the same amount of amperage, thereby softening the arc. Setting

the MK2000A’s slope controls to 20% will provide a common slope of 4V/100

Amps.

Inductance

Inductance added to the MK2000A tends to round off the falling pulse. This

increases the “arc on” time which makes the puddle more uid. Because

aluminum solidies so quickly, it is recommended to add 15% (7 turns)

inductance when welding aluminum whereas steel and stainless steel require

little or no inductance. The MK2000A is factory set at 15% inductance. When

-0- inductance is needed place the inductance switch on remote.

Pulse Height

By leaving the Pulse Height Control at 100%, we can limit the height of the

pulse with the Pulse Level Control.

Figure 7 shows the output voltage into a constant load. The pulse period

is the reciprocal of the pulse frequency (16.6 milliseconds at 60 pulses per

second).

MK 2000A - Owner's Manual - Page 17

Page 18

The effect that Rise Time has on the pulse is shown in (Figure 8). At 100%

the pulse is rectangular, but by turning the rise time toward 0%, the leading

and trailing edges become increasingly tapered. Slow rise times and narrow

pulses will result in the output voltage never reaching the maximum voltage.

In this operating mode, the welding engineer has almost complete control of

the welding conditions throughout the entire heat and metal transfer portions

of the weld

Control Characteristics

All controls are calibrated to provide -0- to 100% of the controlled parameter

maximum value. Thus the Background Slope control provides a slope of -0volts per ampere when set to CV (0%) and -0- amperes per volt when set

to CC (100%).

With 0% slope (CV) the Background Level control provides 0-50 V output.

For example 18 volts is 36% of 50 volts, or 36.0 on the dial.

With 100% slope (CC) the Background Level control provides 0-300 amperes

output. For example 180 amperes is 60% of 300 amperes or 60.0 on the

dial.

A control line may be drawn on a graph of voltage vs. current which connects

the origin (-0- volts, -0- amperes) with the maximum (50 V., 300 A.). The

operating volt-ampere line will always cross this control line at the value

corresponding to the dial setting. For example, an output dial setting of 60%

will provide a volt-ampere line passing through 30 volts (.60 X 50V) and

180 amperes (.60 X 300A). As shown in Figure 1 and Figure 2, changing

the background slope rotates this volt-ampere line around the set point and

controls the no load and short circuit values of voltage and current.

The Pulse Level and Pulse Slope controls operate in an identical manner

(except that the pulse operation adds to the Background Level control setting

only). Both Background and Pulse controls may be used simultaneously to

create an operating volt-ampere line such as shown in Figure 4.

The Inductance Control shapes the output current to approximately match

that of an inductor of -0- to 3 millihenries. This is most useful in welding steel

or similar metals to control the rate of use of arc current.

The Pulse Controls include Repetition Rate (frequency), Height, Width, and

Rise Time. The Repetition Rate may be varied from 20 to 2000 pulses per

second (pps), thus 60 pps is 3% of 2000 and 120 pps is 6% of 2000 (or 6

on the dial). The pulse Height adds to the Background level control so that,

in the CV mode, the pulse height may be -0- to 50 volts. For example, if the

Background Level is at 30% (15V) and the Pulse Height is set to 40% (20V)

the “background” will be 15 volts and the pulses will be 35 volts (15 + 20).

The discussion of current limit on the output applies equally to the output

plus pulse levels.

With the Background Slope set to CC conditions (nearer 100% slope) the

pulse height still adds to the background level and represents a current

controlled pulse rather than a voltage controlled pulse. As indicated

previously, the Pulse Level and Slope may be used to provide a constant

current condition during the pulse with a constant voltage background.

The Pulse Width control provides pulse widths from nearly 0% to 100% of

the pulse interval. Of course at -0- width there is no pulse and at 100%

there is no background level. Within rather wide limits, the heat in the weld

may be controlled by adjusting the pulse width with minimum effect on other

parameters.

The Pulse Rise Time may be used to limit the rate of voltage or current

rise during the pulse. The leading and trailing edges of the pulse are

MK 2000A - Owner's Manual - Page 18

Page 19

symmetrically controlled. Excessive rise time may result in the pulse never

reaching the set value. With the width set at a high percentage, excessive

rise time will prevent the output from dropping back to the “background” value.

All functions may be remotely controlled by application of a -0- to 10 V. Direct

Current level to the appropriate pins of the remote connector and placing the

control switch in the “Remote” position. (See Page 20)

Control Summary - 0% to 100% dial settings (Calibration is in percent of

maximum value given).

Background Level 0 to 50 volts, 0-300 amperes

Background Slope 0 volts per ampere (CV) to 0 amperes per volt (CC)

Pulse Level 0 to 50 volts, 0-300 amperes

Pulse Slope 0 volts per ampere (CV) to 0 amperes per volt (CC)

Inductance 0 to 3 millihenries equivalent

Pulse Rate 20 to 2000 pulses per second

Pulse Height 0 to 50 volts, 0 to 300 amperes

Pulse Width 0 to l/pulse frequency

Pulse Time 200 msec to no rise

(see graph)

The following Figures show control characteristics:

Figure 9 Background Slopw & Pulse Slope

Figure 10 Background Level & Pulse Level

Figure 11 Output Wave Form - 50% Pulse Width vs Frequency

Figure 12 Pulse Rise Time vs Dial Settings

The MK2000A and the C1-A Remote Control

The 25 pin D connector on the front panel of the MK2000A enables the power

supply to be remotely controlled through 0 to 10V analog commands. To use

an existing C1-A Pendant, P/N 001-0002, with the MK2000A, the following

25 pin "D" connector cable assembly must be used: P/N 843-0306. When

the C1-A pendant is used in conjunction with the MK2000A, several operating

modes are avialable.

Remote Heat Only

Set desired parameter on power supply, insuring that the mode selector

switch is in the “heat” position. Placing switch 10 in the remote position now

removes the heat control from the front panel to the C1-A pendant.

Full Pendant Operation

Placing switches 1 - 10 in remote provides full C1-A type operation.

NOTE:

Because the C1-A is calibrated to the MK2000’s 40 volt range rather than the

MK2000A’s 50 volt range, it may be necessary to recalibrate the C1-A Pendant.

When recalibration is necessary, consult the factory for procedure instructions.

MK 2000A - Owner's Manual - Page 19

Page 20

REMOTE CONNECTOR PIN ASSIGNMENTS

PIN FUNCTION

1 Pulse Width / Heat

2 Pulse Frequency

3 Pulse Level

4 Rise Time

5 Pulse Height

6 Pulse Slope

7 Background Slope

8 Background Level

9 Contactor - Closing Contacts

10 Spare

11 Arc Establish *

12 Inductance

13 Spare

14 Ground

15 + 10V (Source) (Contactor)

16 Spare

17 Amps Ref.

18 Volts Ref.

19 Spare

20 Spare

21 Spare

22 Spare

23 Spare

24 + 12V Aux. Output

25 Aux. Common Output

NOTE:

Contactor may be closed through 25 pin “D” connector

with “closing contact only” (no 115 VAC) on pins 9 & 15.

* ARC EST. (PIN 11) is a logic type signal that goes from open to +10 VDC when the power

supply is deliver 30 Amps or more. The load on this pin must not exceed more than 10 MA. (1000

OHMS minimum) referenced to Pin 14.

MK 2000A - Owner's Manual - Page 20

Page 21

Volts per

1

00 Amps

Slope Dial Setting

Operating

Lev

el

(P

ivot

Point)

Voltage

(V

olts)

Level Dial Setting

Operating

Lev

el (Pivot Point)

Current

(Am

peres

)

Fig. 9

Fig. 10

MK 2000A - Owner's Manual - Page 21

Page 22

Fig. 11

Volts

Time in Milliseconds

Rise

Time in Microseconds

Rise Time Dial In Percent

Fig. 12

MK 2000A - Owner's Manual - Page 22

Page 23

noisrevnoCA0002KMot0002KM

foepolSAroF foepolSAroF

foepolSAroF

foepolSAroF foepolSAroF

A001/V A001/V

A001/V

A001/V A001/V

oTlaiDepolSteS oTlaiDepolSteS

oTlaiDepolSteS

oTlaiDepolSteS oTlaiDepolSteS

otlevelteS otlevelteS

otlevelteS

otlevelteS otlevelteS

yb.tlum0002KM yb.tlum0002KM

yb.tlum0002KM

yb.tlum0002KM yb.tlum0002KM

tuptuOteS tuptuOteS

tuptuOteS

tuptuOteS tuptuOteS

%otepolS %otepolS

%otepolS

%otepolS %otepolS

gniviGnwohS gniviGnwohS

gniviGnwohS

gniviGnwohS gniviGnwohS

stloVderiseD stloVderiseD

stloVderiseD

stloVderiseD stloVderiseD

001rep 001rep

001rep

001rep 001rep

serepmA serepmA

serepmA

serepmA serepmA

0002 A0002

% % 08.

A0002KMteS

otleveLtuptuO

leveL0002KM

ehtybdeilpitlum

enilnorebmun

.desuepolShtiw

timiLroftaepeR

.leveLdnaepolS

2 31 11 28.

A0002KMteS

otleveLtuptuO

leveL0002KM

ehtybdeilpitlum

enilnorebmun

.desuepolShtiw

timiLroftaepeR

.leveLdnaepolS

4 32 91 48.

A0002KMteS

otleveLtuptuO

leveL0002KM

ehtybdeilpitlum

enilnorebmun

.desuepolShtiw

timiLroftaepeR

.leveLdnaepolS

6 13 621 58.

A0002KMteS

otleveLtuptuO

leveL0002KM

ehtybdeilpitlum

enilnorebmun

.desuepolShtiw

timiLroftaepeR

.leveLdnaepolS

8 83 23 68.

A0002KMteS

otleveLtuptuO

leveL0002KM

ehtybdeilpitlum

enilnorebmun

.desuepolShtiw

timiLroftaepeR

.leveLdnaepolS

01 34 83 88.

A0002KMteS

otleveLtuptuO

leveL0002KM

ehtybdeilpitlum

enilnorebmun

.desuepolShtiw

timiLroftaepeR

.leveLdnaepolS

21 74 24 88.

A0002KMteS

otleveLtuptuO

leveL0002KM

ehtybdeilpitlum

enilnorebmun

.desuepolShtiw

timiLroftaepeR

.leveLdnaepolS

41 15 64 98.

A0002KMteS

otleveLtuptuO

leveL0002KM

ehtybdeilpitlum

enilnorebmun

.desuepolShtiw

timiLroftaepeR

.leveLdnaepolS

61 55 94 09.

A0002KMteS

otleveLtuptuO

leveL0002KM

ehtybdeilpitlum

enilnorebmun

.desuepolShtiw

timiLroftaepeR

.leveLdnaepolS

81 75 25 09.

A0002KMteS

otleveLtuptuO

leveL0002KM

ehtybdeilpitlum

enilnorebmun

.desuepolShtiw

timiLroftaepeR

.leveLdnaepolS

02 06 55 19.

A0002KMteS

otleveLtuptuO

leveL0002KM

ehtybdeilpitlum

enilnorebmun

.desuepolShtiw

timiLroftaepeR

.leveLdnaepolS

MK 2000A - Owner's Manual - Page 23

Page 24

FREQUENCY CALCULATION PROCEDURES

Given: Wire Diameter Dial Setting ...................................38%

Heat Setting .........................................................30%

Convert "Wire Diameter" to pulse width using chart. For example, 38%

equals 1.47 milliseconds.

Formula= HEAT DIAL X 10 = 30 X 10 = 300 = 204 PPS

PULSE WIDTH (ms) 1.47 1.47

WIRE PULSE WIDTH

DIAMETER IN

DIAL SETTING M.SEC

.02 ...........................................25.25

.04 ...........................................12.74

.06 ............................................8.57

.08 ............................................6.48

.10 ............................................5.23

.12 ............................................4.39

.14 ............................................3.79

.16 ............................................3.34

.18 ............................................2.98

.20 ............................................2.70

.22 ............................................2.47

.24 ............................................2.27

.26 ............................................2.11

.28 ............................................1.97

.30 ............................................1.84

.32 ............................................1.73

.34 ............................................1.64

.36 ............................................1.55

.38 ............................................1.47

.40 ............................................1.40

.42 ............................................1.34

.44 ............................................1.28

.46 ............................................1.22

.48 ............................................1.17

.50 ............................................1.13

.52 ............................................1.08

.54 ............................................1.04

.56 ............................................1.00

.58 ............................................0.97

.60 ............................................0.93

.62 ............................................0.90

.64 ............................................0.87

.66 ............................................0.84

.68 ............................................0.82

.70 ............................................0.79

.72 ............................................0.76

.74 ............................................0.74

.76 ............................................0.72

.78 ............................................0.70

.80 ............................................0.68

.82 ............................................0.65

.84 ............................................0.64

.86 ............................................0.62

.88 ............................................0.60

.90 ............................................0.58

.92 ............................................0.56

.94 ............................................0.55

.96 ............................................0.53

.98 ............................................0.52

1.00 ...........................................0.50

MK 2000A - Owner's Manual - Page 24

Page 25

Section 7 INPUT POWER CONNECTIONS

Regardless of what type of input power that you use for the MK2000A,

you must provide a protected line (fused) disconnect in accordance with

all applicable electrical codes. The MK2000A is equipped with an internal

primary switch, but no fuses are provided. Line fuses should be 60 ampere

maximum (Buss non-60 recommended). Connection cables must be sized to

conform to national and local electrical code requirements.

WARNING:

THE 2000A COMES SETUP FOR 208-230VAC SINGLE OR THREE PHASE

(SEE BELOW). FOR HOOKUP OF 480VAC 4 WIRE WYE PLUS GROUND YOU

WILL NEED A SPECIAL PLATE. CONTACT MK PRODUCTS TECHNICAL

SERVICE FOR INSTRUCTION.

1 PHASE 208-230 VAC

When connecting Single (1) Phase

208-230VAC, you will use only the X, Y and

Ground terminals, DO NOT use the Z or

NEUTRAL terminal with this input power.

208-230 VAC ONLY

SINGLE OR 3 PHASE

Rear connection panel on MK2000A

X Y Z NEUTRAL

3 PHASE 208-230 VAC

When connecting 3 Phase 208-230VAC, you

will use the X, Y ,Z and Ground terminals,

DO NOT use the NEUTRAL terminal with

this input power.

208-230 VAC ONLY

SINGLE OR 3 PHASE

Rear connection panel on MK2000A

X Y Z NEUTRAL

CUSTOMER PROVIDED FUSED

DISCONNECT

NON-SHARED

MK 2000A - Owner's Manual - Page 25

GROUND

#12 green

wire

GROUND

#12 green

wire

CUSTOMER PROVIDED FUSED

DISCONNECT

NON-SHARED

Page 26

MK 2000A - Owner's Manual - Page 26

Page 27

MK 2000A - Owner's Manual - Page 27

Page 28

Effective March 1, 2001

This warranty supersedes all previous MK Products warranties and is

exclusive, with no other guarantees or warranties expressed or implied.

LIMITED WARRANTY - MK Products,Inc.,Irvine,California

warrants that all new and unused equipment furnished by MK

Products is free from defect in workmanship and material as

of the time and place of delivery by MK Products. No warranty

is made by MK Products with respect to trade accessories or

other items manufactured by others. Such trade accessories

and other items are sold subject to the warranties of their

respective manufacturers, if any.

MK Products’ warranty does not apply to components having

normal useful life of less than one (1) year, such as relay

points, wire conduit, tungsten, and welding torch parts that

come in contact with the welding wire, including nozzles, nozzle

insulators, and contact tips where failure does not result from

defect in workmanship or material.

In the case of MK Products’ breach of warranty or any other

duty with respect to the quality of any goods, the exclusive

remedies therefore shall be at MK Products’ option: (1) repair;

(2) replacement; (3) where authorized in writing by MK Products,

the reasonable cost of repair or replacement at our Irvine,

California plant; or (4) payment of or credit for the purchase

price (less reasonable depreciation based upon actual use)

upon return of the goods at customer’s risk and expense.

Upon receipt of notice of apparent defect or failure, MK

Products shall instruct the claimant on the warranty claim

procedures to be followed.

As a matter of general policy only, MK Products may honor

an original user’s warranty claims on warranted equipment

in the event of failure resulting from a defect within the

following periods from the date of delivery of equipment to

the original user:

1. Torches, Weldheads, and Water Recirculators........... 1 year

2. All Other Equipment ................................................. 3 years

3. Repairs ....................................................................90 days

Classication of any item into the foregoing categories shall be

at the sole discretion of MK Products. Notication of any failure

must be made in writing within 30 days of such failure.

A copy of the invoice showing the date of sale must accompany

products returned for warranty repair or replacement.

All equipment returned to MK Products for service must be

properly packaged to guard against damage from shipping.

MK Products will not be responsible for any damages resulting

from shipping.

Normal surface transportation charges (both ways) for products

returned for warranty repair or replacement will be borne by MK

Products, except for products sold to foreign markets.

ANY EXPRESS WARRANTY NOT PROVIDED HEREIN AND

ANY IMPLIED WARRANTY, GUARANTY, OR REPRESENTATION AS TO PERFORMANCE, AND ANY REMEDY FOR

BREACH OF CONTRACT WHICH, BUT FOR THIS PROVISION,

MIGHT ARISE BY IMPLICATION, OPERATION OF LAW,

CUSTOM OF TRADE, OR COURSE OF DEALING, INCLUDING

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR OF

FITNESS FOR PARTICULAR PURPOSE, WITH RESPECT TO

ANY AND ALL EQUIPMENT FURNISHED BY MK PRODUCTS,

IS EXCLUDED AND DISCLAIMED BY MK PRODUCTS.

EXCEPT AS EXPRESSLY PROVIDED BY MK PRODUCTS

IN WR IT IN G, MK P RODU CT S A RE INTEN DE D F OR

ULTIMATE PURCHASE BY COMMERCIAL/INDUSTRIAL

USERS AND FOR OPERATION BY PERSONS TRAINED

AND EXPERIENCED IN THE USE AND MAINTENANCE OF

WELDING EQUIPMENT AND NOT FOR CONSUMERS OR

CONSUMER USE. MK PRODUCTS WARRANTIES DO

NOT EXTEND TO, AND NO RE-SELLER IS AUTHORIZED

TO EXTEND MK PRODUCTS’ WARRA NTIES TO AN Y

CONSUMER.

MK Products, Inc.

16882 Armstrong Ave.

Irvine, CA 92606

Tel (949)863-1234

Fax (949)474-1428

DATE : March 1, 2001

Page 29

MK Products, Inc.

16882 Armstrong Avenue

Irvine, California 92606

Tel 949/863-1234

Fax 949/474-1428

Loading...

Loading...