Page 1

Orbital Weldhead

Owner’s Manual

Product: Mini Micro

Manual: 091-0510

Serial: 02020001

Voltage Rating: N/A

Revision: May 2002 Rev A

Model Number: 4000

Page 2

Page 3

Safety - Page i

trained and experienced in the use and

without adequate training in the use of

from many public and private schools or

tion and maintenance of this equipment

with the equipment, and the use of

welding power sources, compressed

A.

VIOLET RADIANT ENERGY WHICH

AREAS.

Wear helmet with safety goggles or

tected by clear cover glass). This is a

to protect the eyes from radiant energy

when broken, pitted, or spattered.

the eyes and skin burns.

Wear protective clothing - leather (or

to avoid entry of sparks and slag.

Avoid oily or greasy clothing. A spark

WARNING: The use of this product may

to the State of California to cause cancer

Adequate ventilation. Severe discomfort,

vapors, heat, or oxygen enrichment or

ventilation. NEVER ventilate with oxygen.

welded or cut, may produce harmful con-

that emit toxic fumes should not be heated

Work in a con ned space only while it is

wearing an air-supplied respirator.

the space is safe before reentering it.

Vapors from chlorinated solvents can be

ame) to form PHOSGENE, a highly toxic

welding or cutting atmosphere or where

the radiant energy can penetrate to atmo-

trichloroethylene or perchloroethylene.

ying sparks, hot slag, or heated mate-

through wall or oor openings, out of

free of oil, grease, and (in electrical

to an area free of combustibles. Avoid

Walls touching combustibles on opposite

Walls, ceil in gs , and floor near work

Appreciable combustibles (including

Appreciable combustibles are further

than 35 feet, but can be ign it ed by

oors or walls within 35 feet may expose

After work is done, check that area is

free of sparks, glowing embers, and

ames.

An empty container that held combus-

tibles, or that can produce ammable or

toxic vapors when heated, must never

Page 4

with industry standards.

washing, depending on the combustible’s

Water- lling just below working level may

A cont ainer with unk nown conten ts

to weld or cut.

vented before welding or cutting. They

the regulator was designed.

valve). The following symptoms indicate

faulty regulators for repair to manufac-

turer’s designated repair center, where

valves, or safety devices:

Avoid electr ical circui t cont act with

wires, or welding circuits. They can

to a serious accident. (See 1-3C)

when the cylinder is properly handled.

from FULLS, and return promptly.

wrench to open a cylinder valve that cannot

than that designed for the speci ed gas.

A general hose identi cation rule is: red

for fuel gas, green for oxygen, and black

for inert gases.

Avoid long runs to prevent kinks and abuse.

tangles.

Wipe with a clean, lintless cloth.

for a particular gas or gases to a cylinder

threaded connections, clean and smooth

wrench.

Adapters. Use a CGA adapter (available

from your supplier) between cylinder

two wrenches to tighten adapter marked

for oxygen and left hand threads (with

tor pressure increases slowly. When

than one turn to permit quick emergency

your supplier) for safe and effi ci en t

from service immediately for repair. Read

Page 5

ARC WELDING

A.

from light-colored surfaces, and burn

the skin and eyes. Skin burns resemble

Wear long-sleeve clothing in addition to

when exposed to the electric arc, even

when not looking in the direction of the

Welding helmet or shield containing a

lter plate shade no. 12 or denser must

welding, a separate room or enclosed

tible screens or panels. Allow for free air

Viewing the weld. Provide face shields for

to the outside air. Carbon monoxide can

ash and cause a re.

water, or moi sture betw een body and

the body.

When installing, connect the frames of

the building ground. Conductors must be

two wires of the three-phase line. Do NOT

the thir d (live) wire, or the equipment

will become electrically HOT - a danger-

fatally.

tion to a switch box, connect the ground

three-prong plug is added for connection

to a grounded mating receptacle, the

with a three-prong plug, connect to a

with damaged areas may be taped to

4.

when the power switch of gas metal-arc

welding equipment is ON and welding

welding power source, and pull all 115

volts line-cord plugs.

Page 6

When this equipment is shipped, title passes to the purchaser upon receipt

___________________________________

___________________________________

________________________________________

Whenever requesting replacement parts or information on this equipment,

Page 7

Owner’s Manual - Page 1

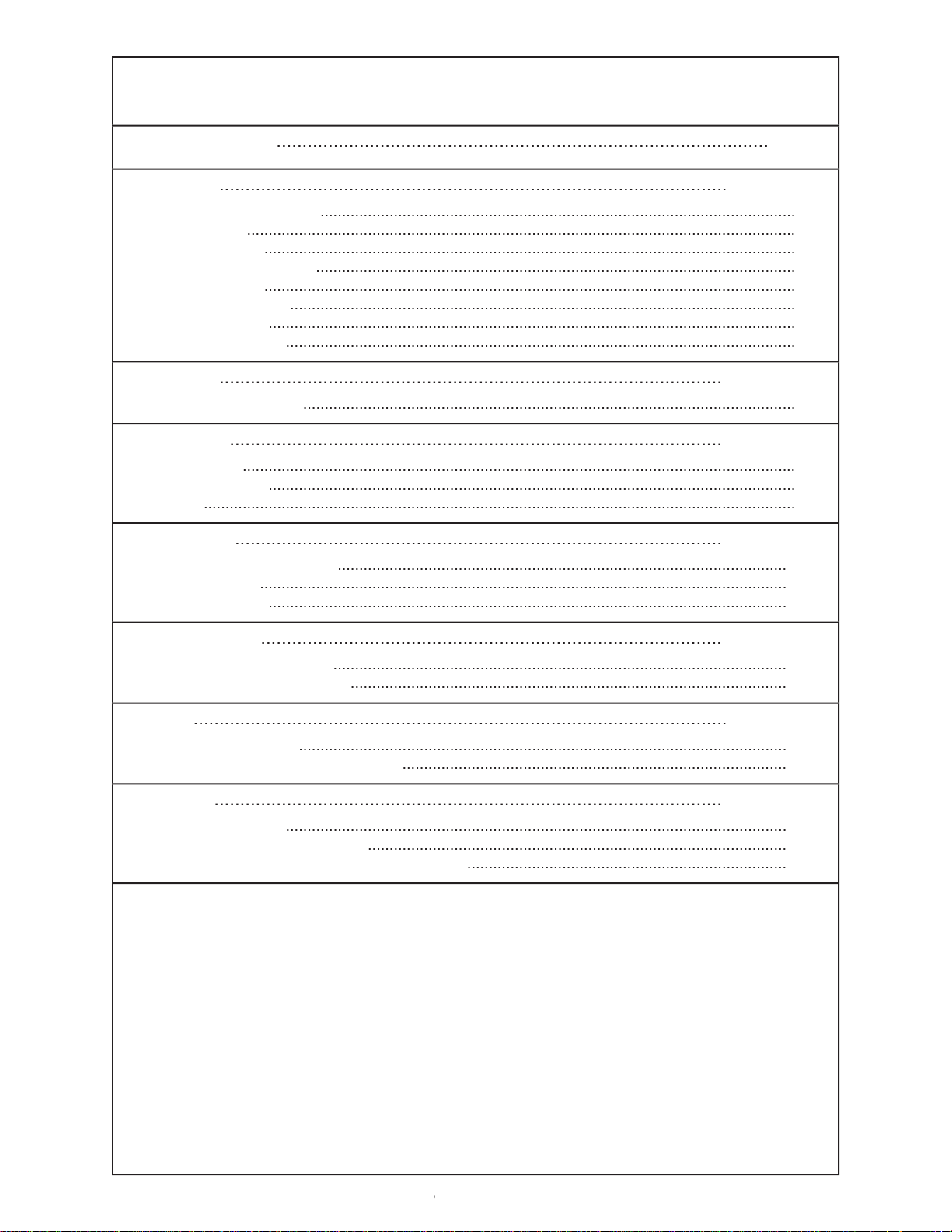

Table of Contents

Weldhead Connections

Weldhead Coolant

Weldhead Calibration

Accessories

Arc Start Troubleshooting

Appendix A Collets

Appendix B Locating Mandrels

Appendix C Pre-Ground Tungsten Electrodes

Warranty

Page 8

Owner’s Manual - Page 2

THIS PAGE INTENTIONALLY BLANK

Page 9

Owner’s Manual - Page 3

#6, 75A, 600V.

Weldhead Connections

with the CobraCooler™ installed

®

150 or the

Advanced Color Logic™ (ACL) orbital power-supply. The cable assembly

ow, and recirculating coolant ow (see Figure 1).

®

150 or the ACL

®

150

®

150 orbital power-supply

with a CobraCooler™ installed

with its integrated 12 foot cable.

Page 10

Owner’s Manual - Page 4

Welding Leads

®

150.

female connector connects to the receptacle labeled “GROUND”.

Welding functions of the weldhead transfer through this connector.

Water Hoses

that prevent

ow or leakage

face plate of the weldhead and maintain the weld joint alignment of the parts

to be welded. The collets are manufactured to correspond with the outside

two sides and one bottom. Two sets of collets are needed to weld two tubes

together.

through the use of brass-tipped setscrews, referred to as plungers, in the

top Collet halves. These plungers not only make up the diameter difference

the grounding path between the weldhead and the tube or pipe to be welded.

the bored Collet surface.

Adjust the latching mechanism of the weldhead to ensure a tight, but not

Alternately adjust the plungers on one side of the weldhead until contact

4.

At this point the tube should be rmly held in place. The tube should not

turn if attempting to rotate it by hand.

A Cont.

Page 11

Owner’s Manual - Page 5

the same Collet.

Appendix C gives the MK part numbers for pre-ground tungsten electrodes

the rotor while using a large arc gap.

welding procedure is established.

that should be de ned during procedure development.

the electrode is to be hand ground, use a dedicated diamond wheel. The

weld and tungsten inclusions in the weld bead.

A Cont.

Page 12

Owner’s Manual - Page 6

All tungsten supplied by MK Products, Inc. is prepared using the latest

the tungsten set screw are visible in the top of the rotor. Loosen the tungsten

tighten the setscrew. Be sure to set the appropriate arc gap prior to welding.

welding equipment. Improper arc gap can cause arc strikes to occur to your

weld current level, but not so short as to ‘crash’ or touch the weld being

thumb is as follows:

Arc Gap = (Wall Thickness x 0.5) + .010”

Any length of tungsten that is protruding out the back of the rotor will jam with

the meshing gears inside the weldhead. This will push the tungsten into the

weld being made and inevitably cause an ARC FAULT.

foreign matter, or a piece of tungsten electrode has fallen within the gear

A Cont.

Page 13

Owner’s Manual - Page 7

®

150. Flow rates higher than 25 CFH can create

turbulence within the weldhead chamber and blow the arc about.

Weldhead Coolant

®

weldhead. Use a name-brand additive, (which does not contain reactive

A solution of:

And will Void the Warranty.

Weldhead Calibration

weldhead rotor speed and motor controller calibration. This calibration

the operator) for one revolution at each speed. The start and end of each

the weldhead. The rotation is clocked by the computer and, by process of

®

150 welding power-supply.

150 welding power-supply.

A Cont.

Page 14

Owner’s Manual - Page 8

ACL

A report is generated showing the ‘measured’ time for each revolution of the

weldhead. The two readings are averaged together to give the ‘actual’ time

to convert the speed demanded by the procedure into a speed, which will

to calibrate the weldhead before each weld where environmental changes

Actual

Actual

Actual

When a new or repaired weldhead is received, a calibration should be run to

then be used to compare prior calibration reports to determine the condition

than .5 rpm off of the benchmark calibration then the weldhead should be

Page 15

Owner’s Manual - Page 9

Actual

Actual

Tachometer: Gain error = -4.1% / Zero error = 0.13 RPM

Actual

®

150

ACL, however; it does show some very important information. It shows both

the MOTOR and TACH gain values. The calibration and adjustment is still the

TACH gain:

TACH gain:

Accessories

to manipulate parts within the weldhead, which requires the use of a

Page 16

Owner’s Manual - Page 10

When longer weldhead cables are needed, a weldhead extension cable

®

150: welding leads, gas, coolant supply and return and control

A set of Collets is de ned as 3 each 120° segments for each side of the

weldhead. Typically, 2 sets are required per each weldhead (See Appendix A

for Part Numbers.

Weld uniformity depends on the accuracy of the position of the rotor during

welding. Rotor rotation should be circular in motion in a plane at right angles

to the tube and concentric with the center of the tube to be welded. Any

the weld.

An electrical measurement should be made to determine continuity from the

to the jaws on the weldhead.

A measurement should also be made to verify that no conductivity

when measured

A visual inspection should be made to determine the condition of the

weldhead and the cable assembly. If there are damaged or worn items, the

weldhead should be returned for factory service.

Page 17

Owner’s Manual - Page 11

Arc Start Troubleshooting

your Side Plate Clamp or Collets.

tungsten,

around the tungsten (reference Figure 3).

tungsten can cause poor arc starts and tungsten inclusions.

Avoid any tooling that might have sharp edges or points or this will cause

the smaller the tube in a given size weldhead; the longer the pre-purge

time.

with a ne abrasive pad or cover it with appropriate insulating tape.

when the ‘Home’ switch is pressed; the Reed Switch is most likely defective.

®

weldhead must be returned to the factory for any

Page 18

Owner’s Manual - Page 12

THIS PAGE INTENTIONALLY BLANK

Page 19

Owner’s Manual - Page 13

Page 20

Owner’s Manual - Page 14

Page 21

Owner’s Manual - Page 15

Page 22

Owner’s Manual - Page 16

THIS PAGE INTENTIONALLY BLANK

Page 23

Owner’s Manual - Page 17

Appendix A Collets

Appendix B Locating Mandrels

Appendix C Pre-Ground Tungsten Electrodes

Page 24

Owner’s Manual - Page 18

THIS PAGE INTENTIONALLY BLANK

Page 25

Owner’s Manual - Page 19

Appendix A Collets and Jaws

®

Collets:

Collets:

Description Part Number Description Part Number

Appendix B Locating Mandrels

Description Part Number

Appendix C Pre-Ground Tungsten Electrodes

Page 26

Owner’s Manual - Page 20

Page 27

Owner’s Manual - Page 21

Page 28

Owner’s Manual - Page 22

THIS PAGE INTENTIONALLY BLANK

Page 29

- MK Products,Inc.,Irvine,California

warrants that all new and unused equipment furnished by MK

from defect in workmanship or material.

with respect to the quality of any goods, the exclusive remedies

therefore shall be at MK Products’ option:

repair

replacement

where authorized in writing by MK Products, the reasonable

payment of or credit for the purchase price (less reasonable

warranty claim procedures to be followed.

As a matter of general policy only, MK Products may honor

following periods from the date of delivery of equipment

to the original user:

Water Recirculators

All Other Equipment

A copy of the invoice showing the date of sale must accompany

All equipment returned to MK Products for service must be

from shipping.

foreign markets.

ANY EXPRESS WARRANTY NOT PROVIDED HEREIN AND

ANY IMPLIED WARRANTY, GUARANTY, OR REPRESENTA-

ABILITY OR OF FITNESS FOR PARTICULAR PURPOSE,

WITH RESPECT TO ANY AND ALL EQUIPMENT FURNISHED

WRITING, MK PRODUCTS ARE INTENDED FOR ULTIMATE

www.mkproducts.com

Page 30

WWW.MKPRODUCTS.COM

Loading...

Loading...