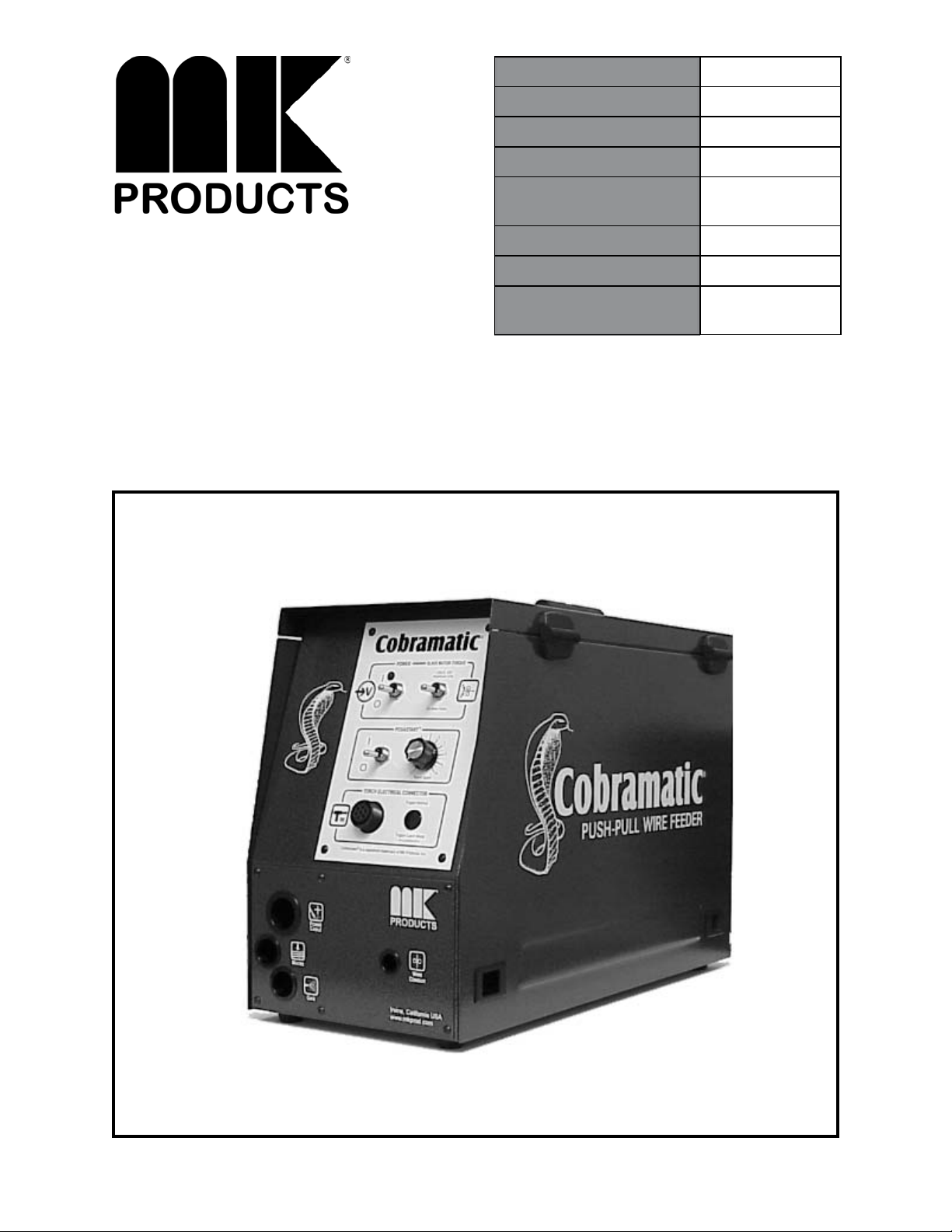

MK Products Cobramatic 120VAC User Manual

Product Description Cobramatic®

MK Manual Part Number 091-0495

MK Form Number CB/OM-5

NWSA Form Number 550

Effective with Serial

Number

Voltage Rating 115 VAC

Printing/Rev. Date August 2002 D

This manual applies to the

following model numbers

12001

150-005

Cobramatic® Wire Feed Cabinet

16882 Armstrong Ave., Irvine, CA 92606 Tel 949/863-1234 Fax 949/474-1428 www.mkproducts.com

SAFETY CONSIDERATIONS

ELECTRIC ARC WELDING EQUIPMENT

CAUTION : READ BEFORE ATTEMPTING INSTALLATION, OPERATION

OR MAINTENANCE OF THIS EQUIPMENT

1-1 INTRODUCTION

This equipment is intended for ultimate

application by commercial/industrial users and

for operation by persons trained and

experienced in the use and maintenance of

welding equipment. Operation should not be

undertaken without adequate training in the

use of such equipment. Training is available

from many public and private schools or similar

facilities.

Safe practices in the installation, operation

and maintenance of this equipment requires

proper training in the art, a careful study of the

information provided with the equipment, and

the use of common sense. Rules for safe use

are generally provided by suppliers of welding

power sources, compressed gas suppliers, and

electrode suppliers. Careful compliance with

these rules will promote safe use of this

equipment.

The following Safety Rules cover some of the

more generally found situations. READ THEM

CAREFULLY. In case of any doubt, obtain

qualifi ed help before proceeding.

1-2 GENERAL PRECAUTIONS

A. B

URN PREVENTION

ELECTRIC ARC WELDING PRODUCES HIGH

INTENSITY HEAT AND ULTRAVIOLET

RADIANT ENERGY WHICH MAY CAUSE

SERIOUS AND PERMANENT EYE DAMAGE

AND WHICH MAY DAMAGE ANY EXPOSED

SKIN AREAS.

Wear helmet with safety goggles or glasses

with side shields underneath, appropriate fi lter

lenses or plates (protected by clear cover

glass). This is a must for welding or cutting

(and chipping) to protect the eyes from radiant

energy and fl ying metal. Replace cover glass

when broken, pitted, or spattered.

Medical fi rst aid and eye treatment. First aid

facilities and a qualifi ed fi rst aid person should

be available for each shift unless medical

facilities are close by for immediate treatment

of fl ash burns of the eyes and skin burns.

Wear protective clothing - leather (or asbestos)

gauntlet gloves, hat, and high safety-toe shoes.

Button shirt collar and pocket fl aps, and wear

cuffl ess trousers to avoid entry of sparks and

slag.

Avoid oily or greasy clothing. A spark may

ignite them.

Flammable hair preparations should not be

used by persons intending to weld or cut.

Hot metal such as electrode stubs and work

pieces should never be handled without gloves.

Ear plugs should be worn when working on

overhead or in a confi ned space. A hard hat should

be worn when others work overhead.

OXIC FUME PREVENTION

B. T

WARNING: The use of this product may result

in exposure to chemicals known to the State of

California to cause cancer and birth defects or

other reproductive harm.

Adequate ventilation. Severe discomfort, illness

or death can result from fumes, vapors, heat, or

oxygen enrichment or depletion that welding (or

cutting) may produce. Prevent them with adequate

ventilation. NEVER ventilate with oxygen.

Lead-, cadmium-, zinc-, mercury-, beryllium-bearing

and similar materials, when welded or cut, may

produce harmful concentrations of toxic fumes.

Adequate local exhaust ventilation must be used, or

each person in the area, as well as the operator,

must wear an air-supplied respirator. For beryllium,

both must be used.

Metals coated with or containing materials that emit

toxic fumes should not be heated unless coating

is removed form the work surface, the area is well

ventilated, or the operator wears an air-supplied

respirator.

Work in a confi ned space only while it is being

ventilated and, if necessary, while wearing an airsupplied respirator.

Gas leaks in a confi ned space should be avoided.

Leaked gas in large quantities can change oxygen

concentration dangerously. Do not bring gas

cylinders into a confi ned space.

Leaving confi ned space, shut OFF gas supply at

source to prevent possible accumulation of gases

in the space if downstream valves have been

accidentally opened or left open. Check to be sure

that the space is safe before reentering it.

Vapors from chlorinated solvents can be

decomposed by the heat of the arc (or fl ame) to

form PHOSGENE, a highly toxic gas, and other

lung and eye irritating products. The ultraviolet

(radiant) energy of the arc can also decompose

trichloroethylene and perchloroethylene vapors to

form phosgene. DO NOT WELD or cut where

solvent vapors can be drawn into the welding or

cutting atmosphere or where the radiant energy can

penetrate to atmospheres containing even minute

amounts of trichloroethylene or perchloroethylene.

C. F

IRE AND EXPLOSION PREVENTION

Causes of fi re and explosion are: combustibles

reached by the arc, fl ame, fl ying sparks, hot slag, or

heated material, misuse of compressed gases and

cylinders, and short circuits.

BE AWARE THA T fl ying sparks or falling slag can

pass through cracks, along pipes, through windows

or doors, and through wall or fl oor openings,

out of sight of the goggled operator. Sparks

can fl y many feet.

To prevent fi res and explosion:

Keep equipment clean and operable, free of

oil, grease, and (in electrical parts) of metallic

particles that can cause short circuits.

If combustibles are in area, do NOT weld or

cut. Move the work if practicable, to an area

free of combustibles. Avoid paint spray rooms,

dip tanks, storage areas, ventilators. If the

work cannot be moved, move combustibles at

least 35 feet away, out of reach of sparks and

heat; or protect against ignition with suitable

and snug-fi tting, fi re-resistant covers or shields.

Walls touching combustibles on opposite sides

should not be welded on (or cut). Walls,

ceilings, and fl oor near work should be

protected by heat-resistant covers or shields.

Fire watcher must be standing by with suitable

fi re extinguishing equipment during and for

some time after welding or cutting if:

1. Appreciable combustibles (including building

construction) are within 35 feet.

2. Appreciable combustibles are further than

35 feet, but can be ignited by sparks.

3. Openings (concealed or visible) in fl oors or

walls within 35 feet may expose combustibles

to sparks.

4. Combustibles adjacent to walls, ceilings,

roofs, or metal partitions can be ignited by

radiant or conducted heat.

Hot work permit should be obtained before

operation to ensure supervisor’s approval that

adequate precautions have been taken.

After work is done, check that area is free of

sparks, glowing embers, and fl ames.

An empty container that held combustibles, or

that can produce fl ammable or toxic vapors

when heated, must never be welded on or

cut, unless container has fi rst been cleaned in

accordance with industry standards.

This includes: a thorough steam or caustic

cleaning (or a solvent of water washing,

depending on the combustible’s solubility),

followed by purging and inerting with nitrogen

or carbon dioxide, and using protective

equipment.

Water-fi lling just below working level may

substitute for inerting.

A container with unknown contents should be

cleaned (see paragraph above). Do NOT

depend on sense of smell or sight to determine

Cobramatic® Safety - page i

if it is safe to weld or cut.

Hollow castings or containers must be vented

before welding or cutting. They can explode.

Explosive atmospheres. NEVER weld or cut

where the air may contain fl ammable dust, gas,

or liquid vapors (such as gasoline).

OMPRESSED GAS EQUIPMENT

D. C

The safe handling of compressed gas

equipment is detailed in numerous industry

publications. The following general rules cover

many of the most common situations.

1. Pressure Regulators

Regulator relief valve is designed to protect

only the regulator from overpressure; it is

not intended to protect any downstream

equipment. Provide such protection with one or

more relief devices.

Never connect a regulator to a cylinder

containing gas other than that for which the

regulator was designed.

Remove faulty regulator from service

immediately for repair (fi rst close cylinder

valve). The following symptoms indicate a

faulty regulator:

Leaks - if gas leaks externally.

Excessive Creep - if delivery pressure

continues to rise with downstream valve

closed.

Faulty Gauge - if gauge pointer does not move

off stop pin when pressurized, nor returns to

stop pin after pressure release.

Repair. Do NOT attempt repair. Send

faulty regulators for repair to manufacturer’s

designated repair center, where special

techniques and tools are used by trained

personnel.

2. Cylinders

Cylinders must be handled carefully to prevent

leaks and damage to their walls, valves, or

safety devices:

Avoid electrical circuit contact with cylinders

including third rails, electrical wires, or welding

circuits. They can produced short circuit arcs

that may lead to a serious accident. (See 1-3C)

ICC or DOT marking must be on each cylinder.

It is an assurance of safety when the cylinder is

properly handled.

Identifying gas content. Use only cylinders with

name of gas marked on them; do not rely on

color to identify gas content. Notify supplier

if unmarked. NEVER DEFACE or alter name,

number, or other markings on a cylinder. It is

illegal and hazardous.

Empties: Keep valves closed, replace caps

securely; mark MT; keep them separate from

FULLS, and return promptly.

Prohibited use. Never use a cylinder or its

contents for other than its intended use,

NEVER as a support or roller.

Locate or secure cylinders so they cannot be

knocked over.

Passageways and work areas. Keep cylinders clear

of areas where they may be stuck.

Transporting cylinders. With a crane, use a secure

support such as a platform or cradle. Do NOT lift

cylinders off the ground by their valves or caps, or

by chains, slings, or magnets.

Do NOT expose cylinders to excessive heat,

sparks, slag, and fl ame, etc. that may cause

rupture. Do not allow contents to exceed 55

degrees C (130 degrees F.) Cool with water spray

where such exposure exists.

Protect cylinders, particularly valves from bumps,

falls, falling objects, and weather. Replace caps

securely when moving cylinders.

Stuck valve. Do NOT use a hammer or wrench

to open a cylinder valve that cannot be opened by

hand. Notify your supplier.

Mixing gases. NEVER try to mix any gases in a

cylinder.

NEVER refi ll any cylinder.

Cylinder fi ttings should never be modifi ed or

exchanged.

3. Hose

Prohibited use. Never use hose other than that

designed for the specifi ed gas. A general hose

identifi cation rule is: red for fuel gas, green for

oxygen, and black for inert gases.

Use ferrules or clamps designed for the hose (not

ordinary wire or other substitute) as a binding to

connect hoses to fi ttings.

No copper tubing splices. Use only standard brass

fi ttings to splice hose.

Avoid long runs to prevent kinks and abuse.

Suspend hose off ground to keep it from being run

over, stepped on, or otherwise damaged.

Coil excess hose to prevent kinks and tangles.

Protect hose from damage by sharp edges, and by

sparks, slag, and open fl ame.

Examine hose regularly for leaks, wear, and loose

connections. Immerse pressured hose in water;

bubbles indicate leaks

Repair leaky or worn hose by cutting area out and

splicing. Do NOT use tape.

4. Proper Connections

Clean cylinder valve outlet of impurities that may

clog orifi ces and damage seats before connecting

regulator. Except for hydrogen, crack valve

momentarily, pointing outlet away from people and

sources of ignition. Wipe with a clean, lintless

cloth.

Match regulator to cylinder. Before connecting,

check that the regulator label and cylinder marking

agree, and that the regulator inlet and cylinder

outlet match. NEVER Connect a regulator

designed for a particular gas or gases to a cylinder

containing any other gas.

Tighten connections. When assembling threaded

connections, clean and smooth seats where

necessary. Tighten. If connection leaks,

disassemble, clean, and retighten, using properly

fi tting wrench.

Adapters. Use a CGA adapter (available from

your supplier) between cylinder and regulator,

if one is required. Use two wrenches to

tighten adapter marked RIGHT and LEFT

HAND threads.

Regulator outlet (or hose) connections may be

identifi ed by right hand threads for oxygen and

left hand threads (with grooved hex on nut or

shank) for fuel gas.

5. Pressurizing Steps:

Drain regulator of residual gas through suitable

vent before opening cylinder (or manifold

valve) by turning adjusting screw in (clockwise).

Draining prevents excessive compression heat

at high pressure seat by allowing seat to

open on pressurization. Leave adjusting screw

engaged slightly on single-stage regulators.

Stand to side of regulator while opening

cylinder valve.

Open cylinder valve slowly so that regulator

pressure increases slowly. When gauge

is pressurized (gauge reaches regulator

maximum) leave cylinder valve in following

position: for oxygen and inert gases, open fully

to seal stem against possible leak; for fuel gas,

open to less than one turn to permit quick

emergency shut-of

f.

Use pressure charts (available from your

supplier) for safe and effi cient recommended

pressure settings on regulators.

Check for leaks on fi rst pressurization and

regularly thereafter. Brush with soap solution.

Bubbles indicate leaks. Clean off soapy water

after test; dried soap is combustible.

E. U

SER RESPONSIBILITIES

Follow all Safety Rules.

Remove leaky or defective equipment from

service immediately for repair. Read and follow

user manual instructions.

F. L

EAVING EQUIPMENT UNATTENDED

Close gas supply at source and drain gas.

G. ROPE STAGING-SUPPORT

Rope staging-support should not be used for

welding or cutting operation; rope may burn.

1-3 ARC WELDING

Comply with precautions in 1-1, 1-2, and this

section. Arc Welding, properly done, is a

safe process, but a careless operator invites

trouble. The equipment carries high currents

at signifi cant voltages. The arc is very bright

and hot. Sparks fl y, fumes rise, ultraviolet and

infrared energy radiates, weldments are hot,

and compressed gases may be used. The

wise operator avoids unnecessary risks and

protects himself and others from accidents.

A. B

URN PROTECTION

Comply with precautions in 1-2.

The welding arc is intense and visibly bright.

Its radiation can damage eyes, penetrate

lightweight clothing, refl ect from light-colored

surfaces, and burn the skin and eyes.

Skin burns resemble acute sunburn; those

from gas-shielded arcs are more severe and

Cobramatic® Safety - page ii

painful. DON’T GET BURNED; COMPLY

WITH PRECAUTIONS.

1. Protective Clothing

Wear long-sleeve clothing in addition to gloves,

hat, and shoes. As necessary, use additional

protective clothing such as leather jacket or

sleeves, fl ameproof apron, and fi re-resistant

leggings. Avoid outer garments of untreated

cotton.

Bare skin protection. Wear dark, substantial

clothing. Button collar to protect chest and

neck, and button pockets to prevent entry of

sparks.

2. Eye and Head Protection

Protect eyes from exposure to arc. Eyes may

be damaged by radiant energy when exposed

to the electric arc, even when not looking in the

direction of the arc. Never look at an electric

arc without protection.

Welding helmet or shield containing a fi lter

plate shade no. 12 or denser must be used

when welding. Place over face before striking

arc.

Protect fi lter plate with a clear cover plate.

Cracked or broken helmet or shield should

NOT be worn; radiation can be passed through

to cause burns.

Cracked, broken, or loose fi lter plates must be

replaced IMMEDIATELY. Replace clear cover

plate when broken, pitted, or spattered.

Flash goggles with side shields MUST be worn

under the helmet to give some protection to the

eyes should the helmet not be lowered over the

face before an arc is struck. Looking at an arc

momentarily with unprotected eyes (particularly

a high intensity gas-shielded arc) can cause a

retinal burn that may leave a permanent dark

area in the fi eld of vision.

3. Protection of Nearby Personnel

Enclose the welding area. For production

welding, a separate room or enclosed bay is

best. In open areas, surround the operation

with low-refl ective, noncombustible screens or

panels. Allow for free air circulation, particularly

at fl oor level.

Viewing the weld. Provide face shields for all

persons who will be looking directly at the weld.

Others working in area. See that all persons

are wearing fl ash goggles.

Before starting to weld, make sure that screen

fl aps or bay doors are closed.

OXIC FUME PREVENTION

B. T

Comply with precautions in 1-2B.

Generator engine exhaust must be vented to

the outside air. Carbon monoxide can kill.

C. F

IRE AND EXPLOSION PREVENTION

Comply with precautions in 1-2C.

Equipment’s rated capacity. Do not overload

arc welding equipment. It may overheat cables

and cause a fi re.

Loose cable connections may overheat or fl ash

and cause afi re.

Never strike an arc on a cylinder or other pressure

vessel. It creates a brittle area that can cause a

violent rupture or lead to such a rupture later under

rough handling.

OMPRESSED GAS EQUIPMENT

D. C

Comply with precautions in 1-2D.

E. S

HOCK PREVENTION

Exposed electrically hot conductors or other bare

metal in the welding circuit, or in ungrounded,

electrically-HOT

equipment can fatally shock a person whose body

becomes a conductor. DO NOT STAND, SIT, LIE,

LEAN ON, OR TOUCH a wet surface when welding

without suitable protection.

To protect against shock:

Keep body and clothing dry. Never work in damp

area without adequate insulation against electrical

shock. Stay on a dry duckboard, or rubber mat

when dampness or sweat cannot be avoided.

Sweat, sea water, or moisture between body and

an electrically HOT part - or grounded metal reduces the body surface electrical resistance,

enabling dangerous and possibly lethal currents to

fl ow through the body.

1. Grounding the Equipment

When installing, connect the frames of each unit

such as welding power source, control, work

table, and water circulator to the building ground.

Conductors must be adequate to carry ground

currents safely. Equipment made electrically HOT

by stray currents may shock, possibly fatally. Do

NOT GROUND to electrical conduit, or to a pipe

carrying ANY gas or a fl ammable liquid such as oil

or fuel.

Three-phase connection. Check phase requirement

of equipment before installing. If only three-phase

power is available, connect single-phase equipment

to only two wires of the three-phase line. Do

NOT connect the equipment ground lead to the

third (live) wire, or the equipment will become

electrically HOT - a dangerous condition that can

shock, possibly fatally.

Before welding, check ground for continuity. Be

sure conductors are touching bare metal of

equipment frames at connections.

If a line cord with a ground lead is provided with the

equipment for connection to a switch box, connect

the ground lead to the grounded switch box. If

a three-prong plug is added for connection to a

grounded mating receptacle, the ground lead must

be connected to the ground prong only. If the line

cord comes with a three-prong plug, connect to a

grounded mating receptacle. Never remove the

ground prong from a plug, or use a plug with a

broken ground prong.

2. Connectors

Fully insulated lock-type connectors should be used

to join welding cable lengths.

3. Cables

Frequently inspect cables for wear, cracks, and

damage. IMMEDIATELY REPLACE those with

excessively worn or damaged insulation to avoid

possibly lethal shock from bared cable. Cables

with damaged areas may be taped to give

resistance equivalent to original cable.

Keep cable dry, free of oil and grease, and

protected from hot metal and sparks.

4. Terminals and Other Exposed Parts

Terminals and other exposed parts of electrical

units should have insulating covers secured

before operation.

5. Electrode Wire

Electrode wire becomes electrically HOT when

the power switch of gas metal-arc welding

equipment is ON and welding gun trigger is

pressed. Keep hands and body clear of wire

and other HOT parts.

6. Safety Devices

Safety devices such as interlocks and circuit

breakers should not be disconnected or

shunted out.

Before installation, inspection, or service of

equipment, shut OFF all power, and remove

line fuses (or lock or red-tag switches) to

prevent accidental turning ON of power.

Disconnect all cables from welding power

source, and pull all 115 volts line-cord plugs.

Do not open power circuit or change polarity

while welding. If, in an emergency, it must

be disconnected, guard against shock burns or

fl ash from switch arcing.

Leaving equipment unattended. Always shut

OFF, and disconnect all power to equipment.

Power disconnect switch must be available

near the welding power source.

Cobramatic® Safety - page iii

For selecting a quality product. We want you to take

Thank You

pride in operating this product...as much pride as we

have in bringing the product to you!

Please Examine Carton and Equipment For Damage Immediately

When this equipment is shipped, title passes to the purchaser upon receipt by the

carrier. Consequently, claims for material damaged in shipment must be made by the

purchaser against the transportation company at the time the shipment is received.

Please record your equipment identification information below for future reference. This

information can be found on your machine nameplate.

Model Name & Number _____________________

Code & Serial Number _____________________

Date of Purchase _____________________

Whenever you request replacements parts for, or information on this equipment always

supply the information you have recorded above.

Read this Owner’s Manual completely before attempting to use this equipment. Save this manual

and keep it handy for quick reference. Pay particular attention to the safety instructions we

have provided for your protection.

Cobramatic® Owner’s Manual - page iv

Table of Contents

Saftey Guidelines

Installation .........................................................................Section A

Technical Specifi cations .......................................................................1

Machine Grounding .............................................................................1

Machine Location ................................................................................1

Input Power Connections .....................................................................1

Wire Threading Procedure ...................................................................2

Welding Torch Connections ..................................................................4

Operation............................................................................Section B

General Description .............................................................................4

Recommended Processes and Equiment ...............................................4

Controls and Settings ..........................................................................4

POSA Start Operating Procedure...........................................................5

Accessories .........................................................................Section C

Optional Kits .......................................................................................7

Maintenance .......................................................................Section D

Routine Maintenance ...........................................................................7

Testing the Feeder...............................................................................8

Testing the Torch ................................................................................9

Troubleshooting .................................................................Section E

Troubleshooting Guide .......................................................................10

Diagrams/Parts List ..........................................................Section F

Main PC Boards .................................................................................13

Mechanical .......................................................................................14

Electrical ...........................................................................................25

Warranty Repair Stations

Safety Warnings

Warranty

Cobramatic® Owner’s Manual

This page intentionally blank

Cobramatic® Owner’s Manual

Section A Installation

Technical Specifi cations

Wire Diameter Capacity .......................................030 - 1/16” ALL Types

Wire Spool Capacity ...........................................12” Standard

(Insulated or Non-Insulated)

Power Input ......................................................... 115 VAC 50/60 Hz,

............................................................................... 150 Watts Peak (1.3 amps)

Weight ..................................................................41 pounds

Shipping Weight .................................................46 pounds

For Use with torch prefi x number .....................14X, 16X, 21X & 22X

Support Equipment Required

C.V. or C.C. Power Source of Suffi cient Capacity for

Regulated Gas Supply and Hoses.

Properly Sized Power Leads from Power Source to Wire Feeder and Ground.

Coolant Recommendations

Coolant Recirculator and Hose Capable of Providing a Minimum of 1 qt/min.

at 45 p.s.i. when using water cooled torches.

Use a name-brand additive which does not contain reactive sulphur or

chlorine and does not react with copper, brass, or aluminum.

Check coolant periodically to remain within limits of the following:

A. Coolant Flow rate - 1 quart/minute at 45 p.s.i.

B. Resistivity - 10K ohms/centimeter

C. Ph Range - 5.5-8.5

D. Particle Size - .005”

MK Recommended Coolant Solution:

1 part ethylene glycol

3 parts distilled water

1 teaspoon liquid glycerin

Your Needs.

Machine Grounding

The Cobramatic® and GMAW wire feeders are ground to the power source

through the input cable. The power source grounding terminal must be

properly connected to electrical ground per the power source operating

manual.

Mounting Location

The cabinet should be placed in a location where it can be protected from

damage. Lead lengths and accessibility must also be considered when

installing the cabinet.

Input Connections

(See Cabinet and Torch Hook-Up in the Appendix)

115 VAC

Your Wire Feeder comes factory ready with a standard 3-prong plug ready

to connect into any standard 120VAC, 15

wired harnesses are available for different power supplies. See part numbers

and description of each in the OPTIONAL KITS section of this manual.

The 115 VAC is connected to the PC Board on terminal strip J5 #1 (neutral)

and #2 (hot) and Ground to the Cabinet chassis. See diagram in the

appendix.

Cobramatic® Owner’s Manual - page 1

A receptacle. Several optional, pre-

Shielding Gas

In accordance with the required support equipment, the customer must

provide a cylinder of shielding gas, a pressure regulator, a fl ow control valve,

and a hose from the fl ow control valve to the left bottom-most fi tting on the

power block.

The end of the hose must have a male connector to fi t the female 5/8-18

brass fi tting. Use a 11/16” wrench to tighten.

Coolant Supply and Return (if used)

Using a recirculator with properly mixed coolant, as previously described,

connect the coolant RETURN hose to the left middle fi tting on the power

block. Connect the coolant SUPPL

Y hose to the left top-most fi tting on the

power block.

The coolant hoses must have a male 5/8-18 left-hand thread to connect to the

power block fi ttings. Use an 11/16” wrench to tighten.

Welding Power

The electrode cable coming from the welding power supply should be affi xed

with a 1/2” copper ring lug. Using a 9/16” wrench, remove the 3/8” bolt and

washer from the bottom of the power block. Use a 9/16” wrench to tighten.

It is recommended to make this connection last, after connecting the gas and

coolant hoses. Reference Input Connections fi gure in the

Appendix.

Wire Threading Procedure

Wire Spool Installation

Release latches, and open right side door of cabinet.

Remove spool retainer from spindle hub.

Raise wire retainer bar to latched position.

Install wire spool onto spindle hub so that wire feeds from bottom of spool

towards slave motor. Make sure that the hole in the spool aligns with pin

on spindle hub. The white dot on the end of the spindle hub will aid in

this alignment.

Replace the spool retainer nut.

Lower the wire retainer bar onto the spool.

Wire Spool Drag Setting

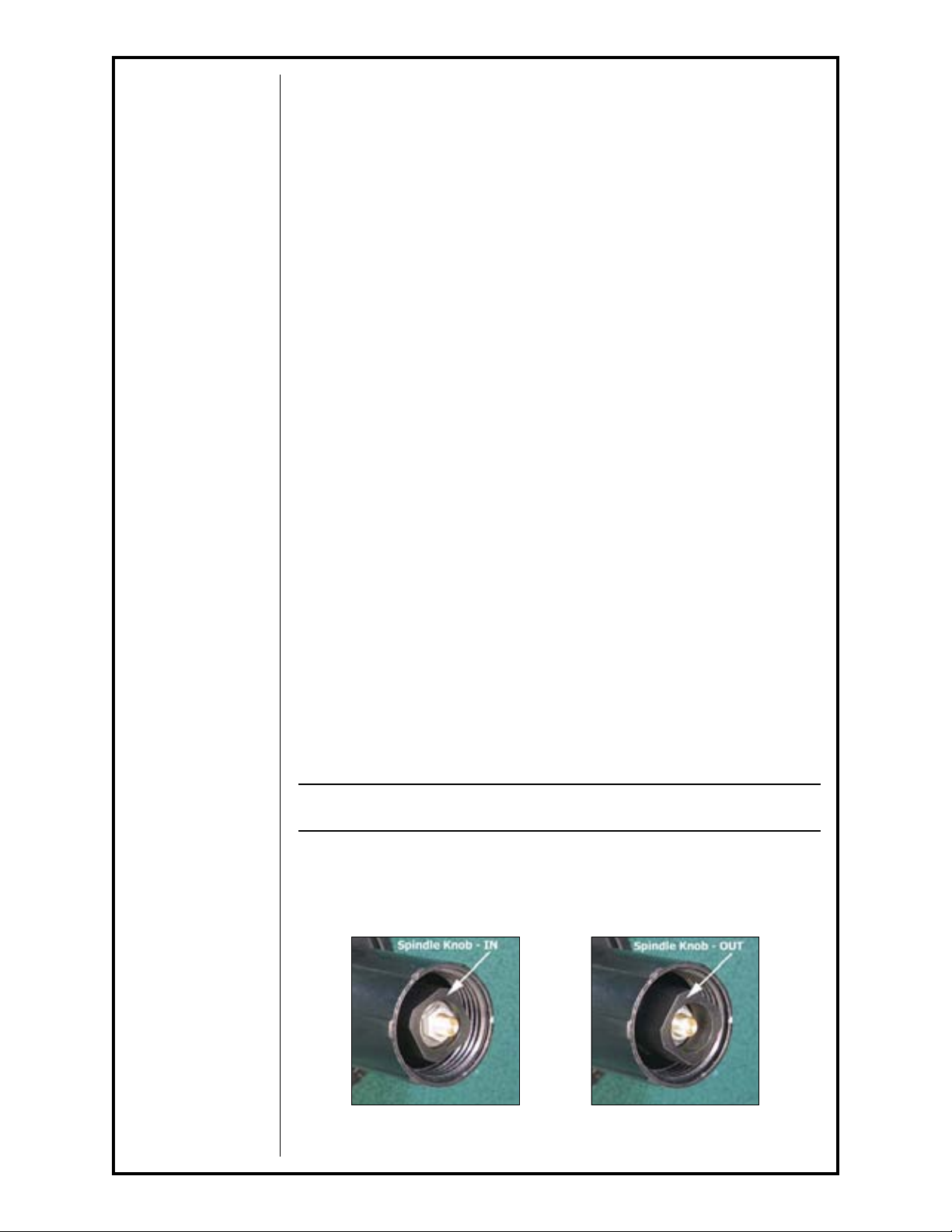

NOTE:

Standard factory setting of the Spindle T

ension Knob is set for All Other Wires.

There are two visible position settings for this Knob, IN - All Other Wires

(Fig. 1) and, OUT - .030/.035 Al Only (Fig. 2). The Spindle Tension Knob

must be set to match the Wire Size Selector Switch on the Cobramatic®

front panel.

IN - All other wires

Figure 1

Cobramatic® Owner’s Manual - page 2

OUT - .030/.035 Aluminum ONLY

Figure 2

To change this setting, it is easier done without the spool of wire on the spindle. Remove the wire spool retainer and re-install it reversed back onto the

Spindle Tension Knob (Fig. 3). In the “Tool Mode”, the square shaped end of

the retainer fi ts onto the Knob. Grab the retainer and turn in the COUNTER-

CLOCKWISE direction until it stops. The Knob is now set to the OUT position (.030/.035 AL Only).

Wire Spool Retainer In "Tool Mode";

used to change spindle drag.

Figure 3

To reset the Knob back to the factory setting of All Other Wires, use the

retainer as described above, and turn in the CLOCKWISE direction until it

stops. The Knob is now set to the IN position. Turning the retainer and

Knob in this direction may require more effort, since turning CLOCKWISE is

working against a spring.

Load wire spool onto spindle according to the previous instructions.

Replace the spool retainer nut.

Lower the wire retainer bar onto the spool.

Threading Procedure

Place wire size selector switch on front panel to the correct position for the

wire being used.

Loosen end of wire from spool and cut off any kinked or bent portions.

Unreel and straighten out fi

rst 6” to 8” of wire.

Raise wire type lever to center position.

Route wire into inlet guide, along drive roll groove, and into wire conduit.

Flip wire type lever to show type of wire being used.

Tighten the torch pressure adjusting knob so the wire will be picked up and

fed through the contact tip. Proper tension is achieved when wire does not

slip if a small amount of pressure is added to the wire as it exits the tip.

Wire Retainer Bar

The design of the patented Cobramatic® Wire Retainer Bar performs two

very important and very basic functions of the wire feeder: a) spool drag

tension, and b) wire maintenance on the spool.

The spool drag tension is set by lowering the wire retainer bar onto the wire

inside of the spool. The spring tension of the wire retainer bar applies enough

pressure on the spool so that when the torch trigger is released, engaging the

brake pall, the spool does not overrun kicking wire of

f the spool.

Wire maintenance on the spool is performed by the applied pressure of the

wire retainer bar spread across the coiled wire on the spool. The replaceable

pad (P/N 437-0255) of the wire retainer bar is designed to hold the wire on

the spool, maintaining the smooth layering of the wire and keeping it from

jumping off, and possibly, electrically shorting to the cabinet chassis.

Cobramatic® Owner’s Manual - page 3

Welding Torch Connections

Work Cable

Connect a work lead of suffi cient size and length (see table below) between

the proper output stud on the power source and the work. Be sure the

connection to the work makes tight metal to metal electrical contact. Poor

work lead connections can result in poor arc initiation, poor weld results and

activation of the ground lead protector

Work Lead Lengths

Current 60% Up to 50ft. 10-100ft.

Duty Cycle (15.2m) (15.2-30.4m)

300A 0 (53mm) 0 (67mm)

400A 00 (67mm) 00 (85mm)

500A 00 (67mm) 00 (85mm)

600A 000 (85mm) 000 (107mm)

Control Cable

The 7-Pin “W” Clocked connector screws onto the mating receptacle on the

front panel of the wire feeder.

voltage, potentiometer control & trigger) to and from the feeder to the torch.

Wire Conduit Inlet

Front panel access to attach conduit to front of slave motor assembly.

Power Cable Inlet

Front panel access to attach power cable (air or water) to top of power block.

This provides all electrical signals (motor

.

Gas Inlet

Front panel access to attach gas hose to bottom fi tting of power block.

Water Inlet (For Water Cooled Torches)

Front panel access to connect the water hose to the middle fi tting on the

power block.

Section B Operation

General

The AC slave motor in the feeder runs at a fast, constant speed, but has very

low torque. It is always trying to feed more wire than the torch motor wants,

and when the motor gets all it wants, it slows the slave motor preventing a

bird’s nest. Because of the low torque produced by the slave motor, a brake

system is used to prevent wire overrun rather than tension. The spool drag

tension is produced by the patented Wire Retainer Bar mechanism to keep

the wire slightly taut. The 24 VDC torch pull motor is controlled by a solid

state speed control and a potentiometer located in the torch.

Recommended Processes and Equipment

The Cobramatic® is recommended for use in the GMAW and FCAW welding

applications. It is recommended for use with constant voltage power sources.

The Cobramatic® is capable of feeding wires (diameter capacity) ranging

from .023” through .045” solid/cored and .030” through 1/16” aluminum.

Controls and Settings

On/Off Switch

Placing the switch in the “ON” position energizes the feeder circuitry and the

power indicator light.

Wire Size Selector Switch

The wire size selector switch changes the torque of the slave motor for the

wire you are using. When in the .030-.035 aluminum only position, the slave

Cobramatic® Owner’s Manual - page 4

motor produces approximately 1 1/2 lbs. inches and approximately 4 1/2 lbs.

inches when in the all other wires position.

NOTE:

Operating the cabinet with the switch in the wrong

position will cause wir

e feed diffi culties.

Posa Start Controls

The Posa Start Run-in Speed Control, located on the front panel, provides

adjustment for slow wire run-in. Once the arc has been established, the

wire feed speed is automatically changed from the slow run-in speed to the

welding speed set on the torch potentiometer.

Posa Start Operating Procedure

General

The Posa Start Run-in Speed Control, located on the front panel, provides

adjustment for slow wire run-in. Once the arc has been established, the

wire feed speed is automatically changed from the slow run-in speed to the

welding speed set on the torch potentiometer.

The Posa Start feature allows the Cobramatic® to be used in combination

with constant current DC welding power sources of open circuit voltage in

excess of 55 volts - also, any constant voltage welding power source capable

of a minimum of 50 amps.

Main Board Con

fi guration

Factory supplied, this switch will be shipped in the CV (Constant Voltage)

position. This designates the type of welding power supply the Cobramatic

is connected to. If the the power supply is a Constant Current type (CC), the

switch should be moved to the CC position.

This switch is designed to confi

gure the main board so that the OCV (Open

CIrcuit Voltage) and welding current (measured at J1 current sensor) properly engages the PosaStart

®

cirtcuit to tranfer from the run-in wire speed to

welding wire speed.

If the position of the switch does not match that of the power supply, the

PosaStart

®

circuit will not engage and wire speed transfer will not occur.

Cobramatic® Owner’s Manual - page 5

Note:

Reverse polarity MUST be used.

Posa Start Connections

Attach the #14 single black lead which extends from the back of the cabinet

to the negative terminal of the power supply or work ground. The Posa Start

lead is internally connected to the P

.C. board on terminal strip J6, terminal 2.

CV Posa Start Operations

Attach Cobramatic® to CV power source according to the installation instructions.

Turn the Cobramatic® to the

“ON” position and the Posa Start to the “OFF”

position.

Adjust power source to desired voltage for your weld condition.

Depress gun trigger and adjust wire feed speed at gun to match voltage set-

ting. If approximate wire feed is not known, it is better to start with excess

wire feed rather than too little, in order to prevent a “burn-back”.

Turn the Posa Start switch to the “ON” position. Press torch trigger and,

using Run-in Speed Control, adjust wire feed rate to approximately 10% of

welding wire speed set at torch.

Strike an arc, and adjust wire feed rate at gun until correct condition is

achieved.

CC Posa Start Operation

Attach the Cobramatic® to a CC power source according to the installation

instructions.

Insure power supply high frequency switch is in the “OFF” position, and

power supply is set to DC reverse polarity.

The power supply contactor should be set to “Remote”

or “Tig” and the

amperage control set to “Panel” or “Standard” depending on power supply.

Turn the Cobramatic® power switch to the “ON” position and the Posa Start

switch to the “OFF” position.

Adjust power source to desired amperage for your weld condition.

Press gun trigger and adjust wire feed speed at gun to match current setting.

If approximate wire feed speed is not known, it is better to start with excess

wire feed rather than too little, in order to prevent possible damage to the

contact tip.

Turn Posa Start switch to the “ON” position. Press torch trigger and, using

Run-in Speed Control, adjust wire feed speed to approximately 10% of welding wire speed set at torch.

Strike an arc; if the wire stubs out, reduce wire feed rate at gun, or increase

amperage setting on power source.

NOTE:

Because the Posa Start Run-in Speed always remains a per

centage

of the actual welding wire feed rate, the Posa Start run-in speed

will always slow down or speed up proportional to any

adjustment you now make at the gun. Therefore, if you slow down

the welding wire feed speed, you will have to increase

the Run-in Speed setting.

Cobramatic® Owner’s Manual - page 6

Section C OPTIONAL KITS

The following is a list of Optional Kits available for the Cobramatic® Wire

Feeder.

A detailed description of each kit is given later in this section.

P/N Description

005-0316 8ft Interface Cable for Miller 14-Pin, 115VAC

005-0658 25ft Interface Cable for Miller 14-Pin, 115VAC

005-0608 8ft Interface Cable for Lincoln 14-Pin, 115VAC

005-0659 25ft Interface Cable for Lincoln 14-Pin, 115VAC

005-0674 Gas Purge/Trigger Latch Kit

005-0630 8ft Interface Cable for Thermal Arc 19-Pin, 1115VAC

005-0614 8ft Interface Cable for ESAB 19-Pin, 1115VAC

005-0316 8ft Interface Cable for Miller 14-Pin, 115VAC

005-0658 25ft Interface Cable for Miller 14-Pin, 115VAC

When properly connected, these interface cables will supply all the necessary signals and power needed, from most Miller welding power supplies: a

Closing Contact signal and 115V

005-0608 8ft Interface Cable for Lincoln 14-Pin, 115VAC

005-0659 25ft Interface Cable for Lincoln 14-Pin, 115VAC

When properly connected, these interface cables will supply all the necessary signals and power needed, from most Lincoln Electric welding power

supplies: a Closing Contact signal, Posa-Start Voltage Sensing and 1

input power.

AC input power.

15VAC

005-0630 8ft Interface Cable for Thermal Arc 19-Pin, 1115VAC

When properly connected, these interface cables will supply all the necessary signals and power needed, from most Miller welding power supplies: a

Closing Contact signal and 115V

005-0614 8ft Interface Cable for ESAB 19-Pin, 1115VAC

When properly connected, these interface cables will supply all the necessary signals and power needed, from most Lincoln Electric welding power

supplies: a Closing Contact signal, Posa-Start Voltage Sensing and 1

input power.

005-0674 Gas Purge/Trigger Latch Kit

The Gas Purge/Trigger Latch Kit is a dual function kit. The kit includes an

easy to install interface control PC board, a 24VAC solenoid for pre and post

purge control, a modifi

switch for activating the Trigger Latch mechanism.

The gas control times have been preset to 0.5 seconds pre-purge and 1.0

seconds post-purge. This offers an optimum amount of inert gas shielding

prior to striking the arc and after the arc has been extinguished.

The Trigger Latch mechanism gives the operator the fl exibility of normal

trigger operation (pull trigger to weld - release trigger to stop). This also

offers the comfort of latched trigger operation (pull trigger once to latch and

weld - pull trigger again to unlatch and stop).

ed valve stem for the welding torch and, a front panel

AC input power.

15VAC

Section D Maintenance

Routine Maintenance

Maintenance of the torch will normally consist of a general cleaning of the

wire guide system, including tubes, drive rolls, and conduits at regular intervals.

Cobramatic® Owner’s Manual - page 7

Remove spatter build-up from inside of nozzles with a hardwood stick.

The only parts on the Cobramatic® system that are subject to normal wear

are the conduit, contact tips, gas cups, front body liners, wire guides, drive

and idler rolls. A supply of these parts should be maintained on hand.

If repairs do become necessary, any part can easily be replaced by qualifi ed

maintenance personnel.

Your Cobramatic® is designed to provide years of reliable service. Normal

wear and component failure may require occasional service.

The number of units in operation and the importance of minimal “down time”

will determine to what extent spare parts should be stocked on hand.

Testing the Feeder

Relay K2 Operation

When the torch trigger is pressed, 24VAC is sent to the coil of relay K2.

When K2 is energized, AC is sent to the slave motor, spool brake, and the

AC contactor. Relay K2 is also responsible for sending 24VAC to the speed

control circuit and shorting the torch motor leads together when the trigger is

released for the dynamic braking system. K2 also provides the closing contactor signal.

Testing the Input Power Circuits

The AC circuits are protected by fuse F3. If F3 continually blows, disconnect

J4 (Brake Solenoid), J7 (Slave Motor) and J5-3 & 4 - if connected (AC Contactor Out.) from the PC board. Replace fuse and re-trigger system. If fuse

does not blow, isolate problem by reconnecting J4, J7 and J5-3 & 4 one at a

time until the fuse blows.

Testing the Speed Control

NOTE:

The torch should be tested fi rst and the amphenol must be connected to the

Cobramatic® to perform this test.

Place a voltmeter across diode D10

- 24VDC should be observed, as the torch potentiometer varied.

and press torch trigger.

A reading of 0

Cobramatic® Owner’s Manual - page 8

Loading...

Loading...