Page 1

www.mkdiamond.com

MK-SCARIFIER

OWNER’S MANUAL, PARTS LIST &

OPERATING INSTRUCTIONS

SG-9

SG-5

Revision 105

Manual Part# 158537

Caution: Read all safety and operating instructions

before using this equipment. This owner’s manual

MUST accompany the equipment at all times.

01.2014

Page 2

INTRODUCTION

Congratulations on your purchase of a MK-Scarier. We are certain that you will be pleased with

your purchase. MK Diamond takes pride in producing the nest construction power tools and diamond blades in the industry.

Operated correctly, your MK-Scarier should provide you with years of service. In order to help you,

we have included this manual. This owners manual contains information necessary to operate and

maintain your MK-Scarier safely and correctly. Please take the time to familiarize yourself with the

MK-Scarier by reading and reviewing this manual.

Read and follow all safety, operating and maintenance instructions.

If you should have questions concerning your MK-Scarier please feel free to call our friendly

customer service department at (800) 421-5830.

Regards,

MK Diamond

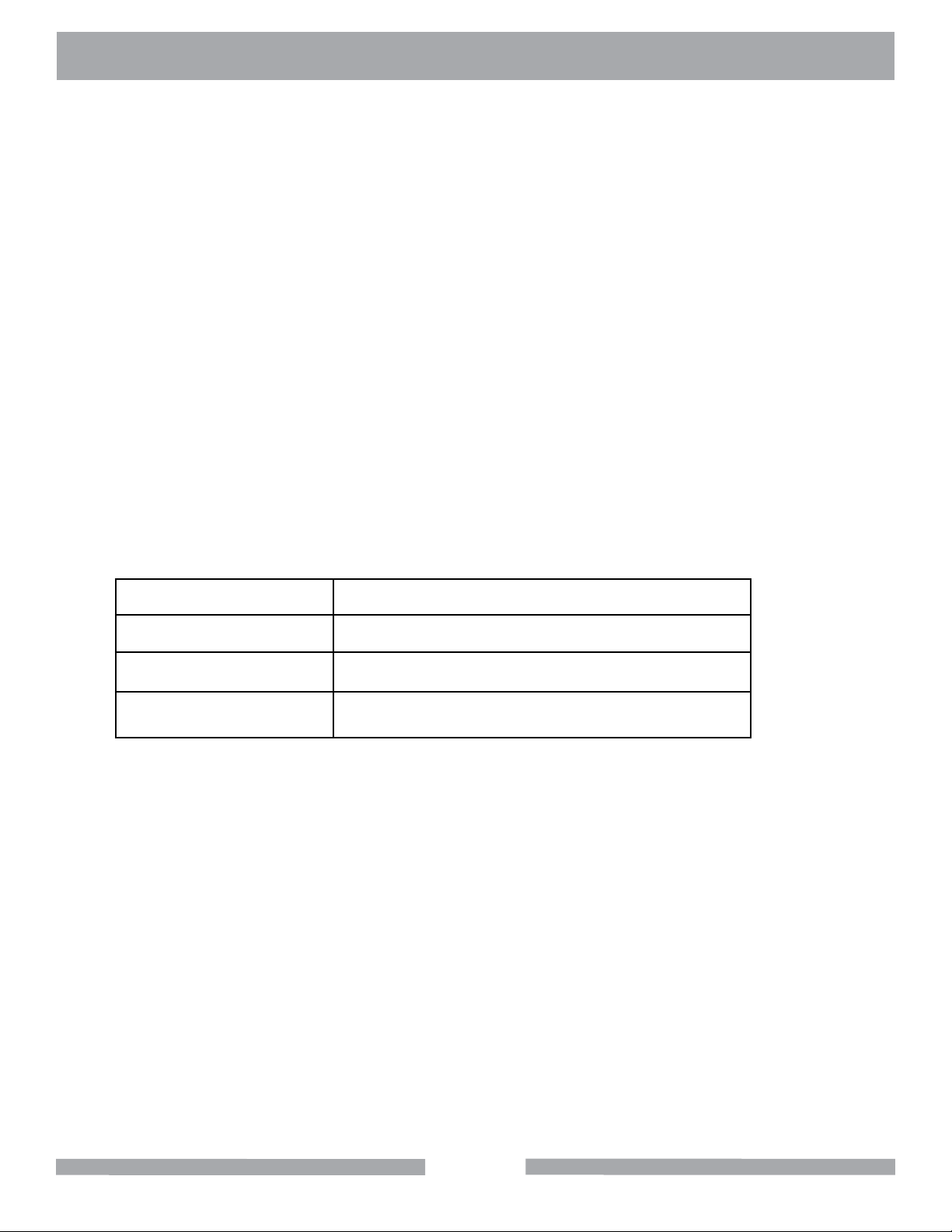

NOTE THIS INFORMATION FOR FUTURE USE:

MODEL NUMBER:

SERIAL NUMBER:

PURCHASE PLACE:

PURCHASE DATE:

NOTE: For your (1) one year warranty to be effective, complete the warranty card

(including the Serial Number) and mail it in as soon as possible.

2

Page 3

TABLE OF CONTENTS

SAFETY PAGE

Safety Messages 4

Damage Prevention Message 4

General Safety Precautions and Hazard Symbols 4-7

California Proposition 65 Message 8

Electrical Requirements and Grounding Instructions 9

Electric Motor Safety 10-11

Safety Label Locations 12

Specic Warnings 13

Product Specications 13

UNPACKING ASSEMBLY

Unpacking 14

Contents 14

Transport 14

Handlebar 15

SCARIFIER DRUM

Scarier Drum Cutter 16

Drum Conguration 17-18

Assembly 19-20

ASSEMBLY

Assembly 21-26

SETUP

Vacuum Setup 26

Pre-start Inspection 27

Setup 28-29

Operation 30-31

Cleanup 31-32

MAINTENANCE

Maintenance 32-48

EXPLODED VIEW & PARTS LIST

Exploded View & Parts List 50-59

DRUM ASSEMBLIES

Exploded View & Parts List 60-63

THEORY

Theory of Scarifying 64

ACCESSORIES

Accessories 65

ORDERING & RETURN INSTRUCTIONS

Ordering Information 66

Return Material Policy 66

CONTACT & LIMITED WARRANTY

Contact 67

Limited Warranty 67

3

Page 4

MK-SCARIFIER SAFETY

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

Read and follow all safety, operating and maintenance instructions. Failure to read and follow

these instructions could result in injury or death to you or others. Failure to read and follow these

instructions could also result in damage and/or reduced equipment life. Safety warnings and

guidelines do not by themselves eliminate danger. They are not substitutes for proper accident

prevention procedures and good judgement.

SAFETY MESSAGES

A safety message alerts you to potential hazards that could hurt you or others. Each safety message is

preceded by a safety alert symbol ( ) and one of three words: DANGER, WARNING, or CAUTION.

DANGER You WILL be KILLED or SERIOUSLY INJURED if you DO NOT follow directions.

WARNING

You CAN be KILLED or SERIOUSLY INJURED if you DO NOT follow directions.

You CAN be INJURED if you DO NOT follow directions. It may also be used to

CAUTION

alert against unsafe practices.

DAMAGE PREVENTION AND INFORMATION MESSAGES

A Damage Prevention Message is to inform the user of important information and/or instructions that

could lead to equipment or other property damage if not followed. Information Messages convey

information that pertains to the equipment being used. Each message will be preceded by the word

NOTE, as in the example below.

NOTE:

Equipment and/or property damage may result if these instructions are not followed.

GENERAL SAFETY PRECAUTIONS AND HAZARD SYMBOLS

In order to prevent injury, the following safety precautions and symbols should be followed at all times!

ALWAYS read this Owner’s Manual before operating the machine. DO NOT operate or

service this equipment before reading this entire manual. Read and understand all warnings, instructions and controls on the machine. Know how to stop the equipment quickly in

case of emergency. It is the operators responsibility to use this machine under safe working conditions and conform with federal, state and local codes or regulations pertaining to

safety, air, pollution, noise etc...

ALWAYS keep the Blade and Belt Guards in place. DO NOT operate this machine with any

guard or safety device removed. A Guard, or any damaged part should be repaired or

replaced immediately.

REMOVE ADJUSTING KEYS AND WRENCHES

Form a habit of checking to see that keys and adjusting wrenches are removed from the

power tool before it is turned on.

KEEP WORK AREA CLEAN

Cluttered work areas and benches invite accidents.

DO NOT USE IN DANGEROUS PLACES

DO NOT use power tools in damp or wet locations nor expose them to rain. Always keep

the work area well lighted.

4

Page 5

MK-SCARIFIER SAFETY

KEEP CHILDREN AWAY

All visitors and children should be kept a safe distance from work area.

MAKE THE WORKSHOP KID PROOF

Make the workshops kid proof by using padlocks, master switches or by removing starter keys.

DO NOT FORCE THE TOOL

A power tool will do a job better and safer operating at the rate for which it was designed.

USE THE RIGHT TOOL

DO NOT force a tool or an attachment, to do a job that it was not designed to do.

USE THE PROPER EXTENSION CORD

If using an extension cord make sure it is in good condition rst. When using an extension

cord, be sure to use one heavy enough to carry the current your product will draw. An undersized cord will cause a drop in line voltage that will result in a loss of power and overheating.

Page 9 shows the correct AWG size to use depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gauge. The smaller the gauge number, the heavier

the cord.

USE PROPER APPAREL

DO NOT wear loose clothing, gloves, neckties, rings, bracelets, or other jewelry that may be

caught in moving parts. Non-slip footwear is recommended. Wear protective hair covering to

contain long hair.

PERSONAL PROTECTIVE EQUIPMENT

ALWAYS wear approved respiratory, head, ear and eye protection

when operating this machine.

SECURE WORK

Clamps or a vise should be used to hold work whenever practical. Keeping your hands free

to operate a power tool is safer.

DO NOT OVERREACH

Keep proper footing and balance at all times by not overreaching.

MAINTAIN TOOLS WITH CARE

Keep tools clean for the best and safest performance. Always follow maintenance instructions for lubricating, and when changing accessories.

DISCONNECT TOOLS

Power tools should always be disconnected before servicing or when changing accessories,

such as blades, bits, cutters, and the like.

ON / OFF

ALWAYS place the power ON/OFF switch in the OFF position when the saw is not in use.

5

Page 6

MK-SCARIFIER SAFETY

USE RECOMMENDED ACCESSORIES

Consult the owner’s manual for recommended accessories. Using improper accessories

may increase the risk of personal or by-stander injury. Unauthorized equipment

modifications will void all warranties. Manufacturer does not assume responsibility for any

accident due to equipment modifications.

AlwAys ensure that the machine is on level ground before using.

NEVER STAND ON THE TOOL

Serious injury could occur if a power tool is tipped, or if a cutting tool is unintentionally contacted.

TRANSPORT

When loading or unloading the machine, use caution. Remove the blade prior to hoisting,

loading and transporting the machine.

CHECK FOR DAMAGED PARTS

Before using a power tool, check for damaged part. A guard or any other part that is damaged

should be carefully checked to determine if would operate properly and perform its intended

function. Always check moving parts for proper alignment or binding. Check for broken parts

and mountings and all other conditions that may affect the operation of the power tool. A

guard, or any damaged part, should be properly repaired or replaced.

DIRECTION OF ROTATION

A blade or cutter should always be installed so that rotation is in the direction of the

arrow imprinted on the side of the blade or cutter. It should correspond with the rotational

direction of the motor. Always feed work into a blade against the direction of rotation.

NEVER LEAVE A TOOL UNATTENDED

TURN POWER OFF - Do not leave a tool until it comes to a complete stop. Always turn a

power tool OFF when leaving the work area, or, when a cut is nished.

NEVER disconnect any "emergency or safety devices". These devices are intended for

operator safety. Disconnection of these devices can cause severe injury, bodily harm, or

even death! Disconnection of any of these devices will void all warranties. Unauthorized

equipment modifications will void all warranties. Manufacturer does not assume

responsibility for any accident due to equipment modifications.

NEVER operate this equipment when not feeling well due to fatigue, illness or taking medicine.

Check the chemical properties of the material to be cut/grinded and follow all EPA/OSHA

Regulations.

6

Page 7

MK-SCARIFIER SAFETY

(

(

)

)

WARNING

Diamond Blades improperly used are dangerous. Comply with American National Standards Institute

Safety Code, B7.1 and, Occupational Safety and Health Act covering Speed, Safety Guards, Flanges,

Mounting Procedures, General Operating Rules, Handling, Storage and General Machine Conditions

ELECTRICAL SHOCK

NEVER touch electrical wires or components while the engine is running. Exposed,

frayed or worn electrical wiring and plugs can be sources of electrical shock which could

cause severe injury or burns. Do not touch the plug with wet hands.

ROTATING PARTS

Keep hands, feet, hair, and clothing away from all moving parts to prevent injury. Never

operate the motor with covers, shrouds, or guards removed.

OVER SPEED

NEVER tamper with the governor components or settings to increase the maximum

speed. Severe personal injury and damage to the engine or equipment can result if operated at speeds above maximum.

DO NOT EXPOSE TO RAIN

DO NOT expose to rain or use in damp locations.

7

Page 8

MK-SCARIFIER SAFETY

SILICA DUST WARNING

Grinding/cutting/drilling of masonry, concrete, metal and other materials with silica in their composition

may give off dust or mists containing crystalline silica. Silica is a basic component of sand, quartz,

brick clay, granite and numerous other minerals and rocks. Repeated and/or substantial inhalation of

airborne crystalline silica can cause serious or fatal respiratory diseases, including silicosis. In addition, California and some other authorities have listed respirable crystalline silica as a substance

known to cause cancer. When cutting such materials, always follow respiratory precautions.

Use appropriate NIOSH-approved respiratory protection where dust hazard may occur. Paper masks

or surgical masks without a NIOSH approval number are not recommended because they do little to

protect the worker. For more information about respirator programs, including what respirators have

received NIOSH approval as safe and effective, please visit the NIOSH website at:

http://www.cdc.gov/niosh/topics/respirators

Observe OSHA regulations for respirator use (29 C.F.R.§1910.134 and §1503.1).

Visit http://www.osha.gov for more information.

CALIFORNIA PROPOSITION 65 MESSAGE

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contain chemicals known (to the State of California) to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead, from lead-based paints

• Crystalline silica from bricks, cement and other masonry products

• Arsenic and chromium, from chemically treated lumber

For further information, consult the following sources:

http://www.osha.gov/dsg/topics/silicacrystalline/index.html

http://www.cdc.gov/niosh/docs/96-112/

http://oehha.ca.gov/prop65/law/P65law72003.html

http://www.dir.ca.gov/Title8/sub4.html

Your risk from these exposures varies depending on how often you do this type of work. To reduce

your exposure to these chemicals, work in a well-ventilated area, and work with approved safety

equipment, such as dust masks that are specially designed to lter out microscopic particles. Where

use of a dust extraction device is possible, it should be used. To achieve a high level of dust collection, use an industrial HEPA vacuum cleaner. Observe OSHA 29 CFR part 1926.57 and 1926.103.

WARNING

Sawing, grinding and drilling generate dust. Excessive airborne particles may cause irritation to eyes,

skin and respiratory tract. To avoid breathing impairment, always employ dust controls and protection

suitable to the material being sawed or drilled; See OSHA (29 CFR Part 1910.1200).

8

Page 9

MK-SCARIFIER SAFETY

ELECTRICAL REQUIREMENTS AND GROUNDING INSTRUCTIONS

In order to prevent potential electrical shock and injury, the following electrical safety precautions and

symbols should be followed at all times!

WARNING

In case of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock. This tool is equipped with an electric cord having an equipment-grounding conductor and a grounding plug. The plug must be plugged into a matching outlet

that is properly installed and grounded in accordance with all local codes and ordinances.

• Do not modify the plug provided – if it will not t the outlet; have the proper outlet installed by a

qualied electrician

• Improper connections of the equipment-grounding conductor can result in a risk of electric

shock. The equipment-grounding conductor is the insulated conductor that has an outer

surface that is green, with or without yellow stripes. If repair or replacement of the electric cord

or plug is necessary, do not connect the equipment-grounding conductor to a live terminal

• Check with a qualied electrician or service personnel if the grounding instructions are not

completely understood, or if in doubt as to whether the tool is properly grounded

• Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles that

accept the tool’s plug

• Repair or replace a damaged or worn cord immediately

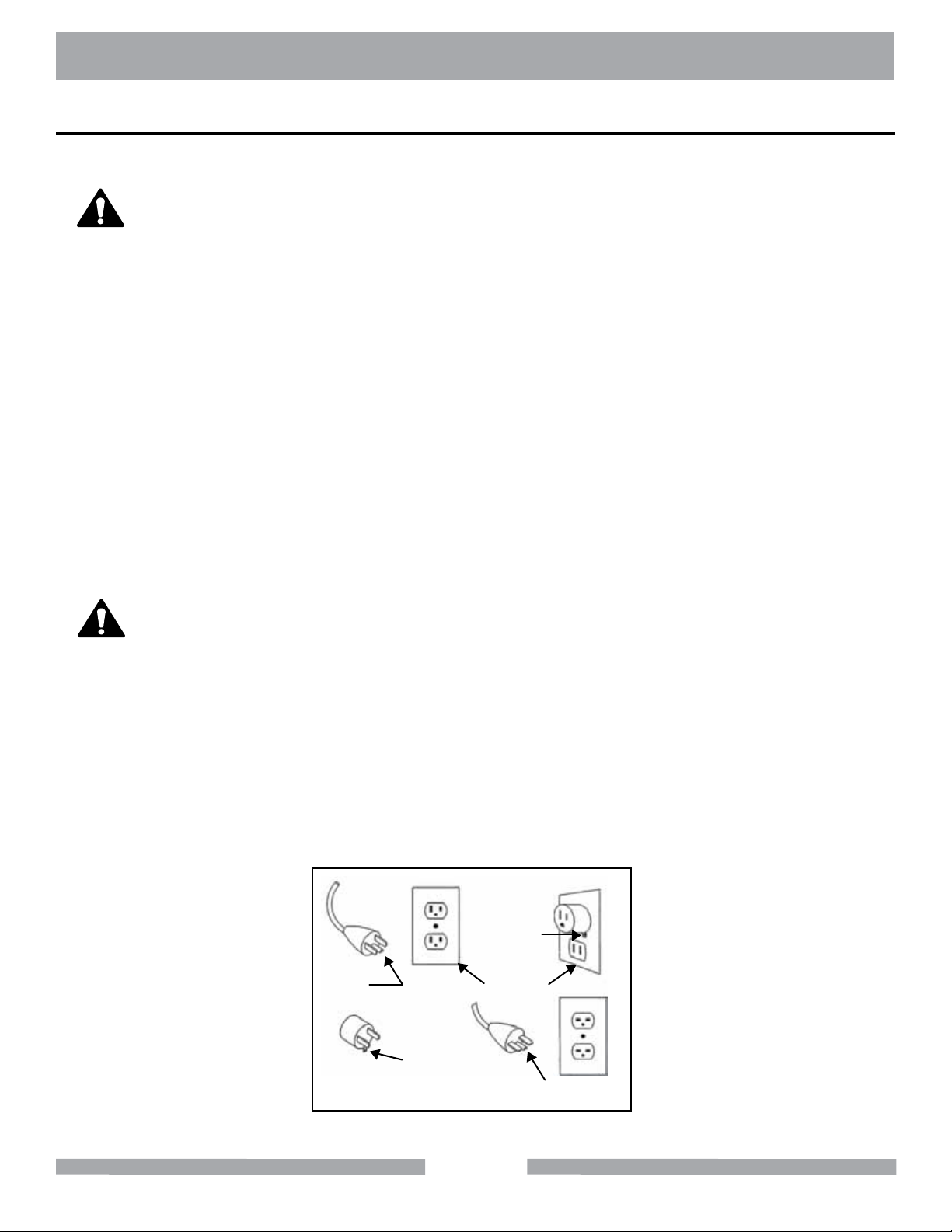

WARNING

This tool is intended for use on a circuit that has an outlet that looks like the one shown in Sketch A.

The tool has a grounding plug that looks like the plug illustrated in Sketch A. A temporary adapter,

which looks like the adapter illustrated in sketches B and C, may be used to connect this plug to a

2-pole receptacle as shown in Sketch B, if a properly grounded outlet is not available. The temporary

adapter should be used only until a properly grounded outlet can be installed by a qualied electrician. The green-colored rigid ear, lug, and the like, extending from the adapter, must be connected to

a permanent ground such as a properly grounded outlet box.

NOTE: Use of a temporary adapter is not permitted in Canada.

Metal Screw

Grounding

Pin

(A)

ADAPTER

Grounding

Means

(C)

Cover of

Grounded

Outlet Box

Grounding

Pin

(B)

(D)

Circuit and Adapter Information

9

Page 10

MK-SCARIFIER SAFETY

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ELECTRIC MOTOR SAFETY

For maintenance care and operation of the electric motor, refer to your electric motor instruction booklet furnished with the electric motor. Protect the electric motor from dust as much as possible and keep

ventilating openings clean. Before plugging in the machine, make sure that the outlet voltage is within

the voltage marked on the machines's data plate.

CAUTION

DO NOT spray water on the electric motor. DO NOT touch the plug with wet hands. To reduce

the risk of electrocution, keep all connections dry and off the ground.

DO NOT operate electric motor in an explosive environment.

DO NOT EXPOSE TO RAIN

DO NOT expose to rain or use in damp locations.

WARNING

If operating the equipment in damp locations is unavoidable, ALWAYS use a Ground Fault

Circuit Interrupter, ALWAYS wear rubber gloves and footwear in damp conditions.

DO NOT abuse the cord. Never use the cord to carry the equipment or to pull the plug from

the outlet. Keep the cord away from heat, sharp edges, and moving parts. Replace damaged cords immediately. Damaged cords increase the risk of electric shock.

WARNING

To reduce the risk of electrocution, keep all connections dry and off the ground. A Ground Fault

Circuit Interrupter (GFCI) should be provided on the circuit(s) or outlet(s) to be used for this

machine. Receptacles are available having built-in GFCI protections and may be used for this

measure of safety. When using an extension cord, GFCI should be installed closest to the power

source, followed by the extension cord and lastly, the machine.

WARNING

The water pump requires a GFCI. To reduce risk of electrical shock when operating the machine

with the pump plugged into the 3-pole receptacle on the motor, connect the saw to a GFCI outlet.

See the pump manual and informational tags enclosed separately for all pump information.

WARNING

To avoid the possibility of the appliance plug or receptacle getting wet, position the machine to one

side of a wall mounted receptacle. This will prevent water from dripping onto the receptacle or plug. A

“drip loop,” shown in the picture below, should be arranged by the user to properly position the power

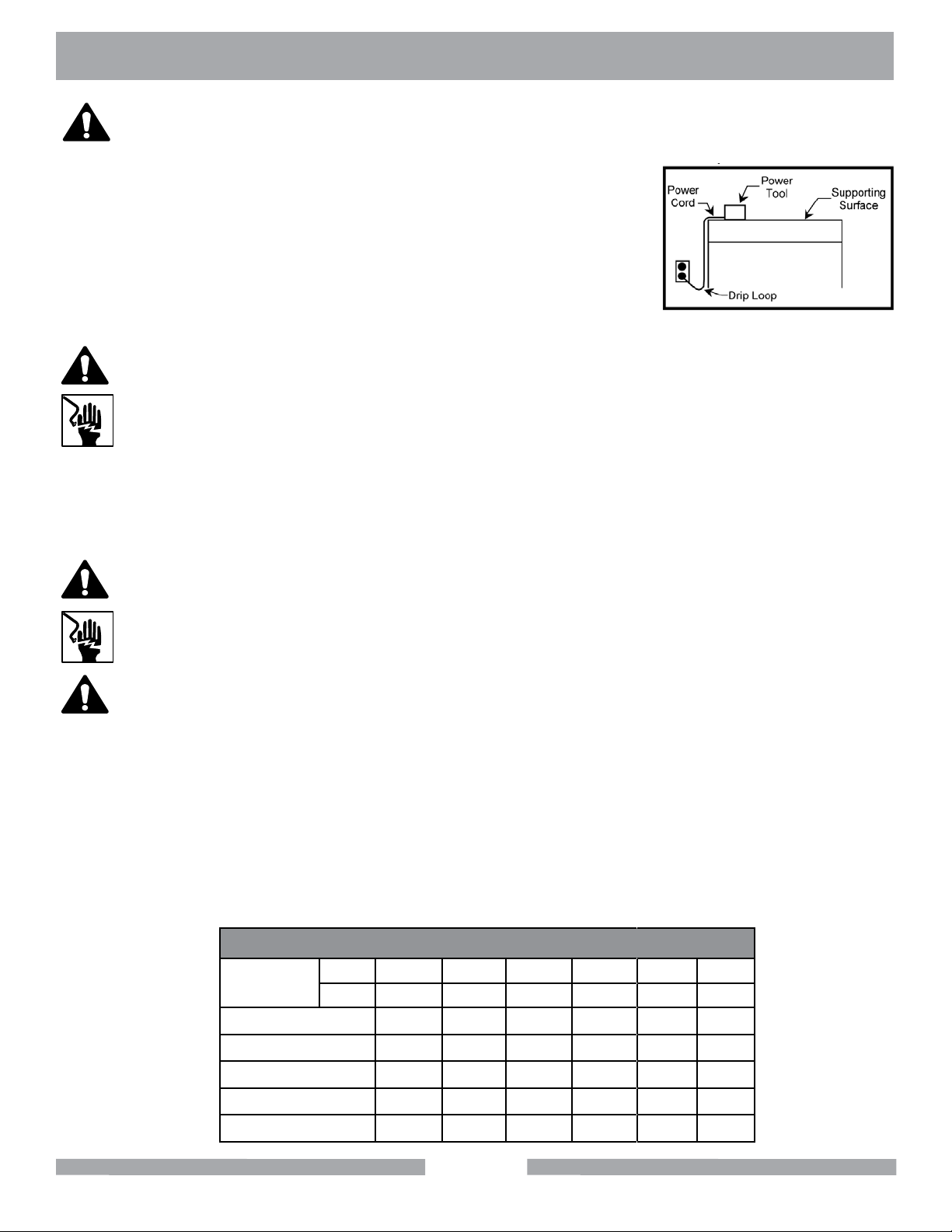

cord relative to the power source.

10

Page 11

MK-SCARIFIER SAFETY

WARNING

The “drip loop” is that part of the cord below the level of the receptacle,

or the connector, if an extension cord is used. This method of positioning the cord prevents the travel of water along the power cord and

coming in contact with the receptacle.

If the plug or receptacle gets wet, DO NOT unplug the cord. Disconnect the fuse or circuit breaker that supplies power to the tool. Then

unplug and examine for presence of water in the receptacle.

WARNING

Use only extension cords that are intended for outdoor use. These extension cords are

identied by a marking “Acceptable for use with outdoor appliances; store indoors while not

in use." Use only extension cords having an electrical rating not less than the rating of the

product. Do not use damaged extension cords. Examine extension cords before using and

replace if damaged. Do not abuse extension cords and do not yank on any cord to disconnect. Keep cords away from heat and sharp edges. Always disconnect the extension cord

from the receptacle before disconnecting the product from the extension cord.

Drip Loop Information

WARNING

To reduce the risk of electrocution, keep all connections dry and off the ground. Do not touch

the plug with wet hands.

WARNING

Use of under sized extension cords result in low voltage to the motor that can result in motor burnout and premature failure. MK Diamond warns that equipment returned to us showing

signs of being run in a low voltage condition, through the use of undersized extension cords will

be repaired or replaced totally at the customer's expense. There will be no warranty claim.

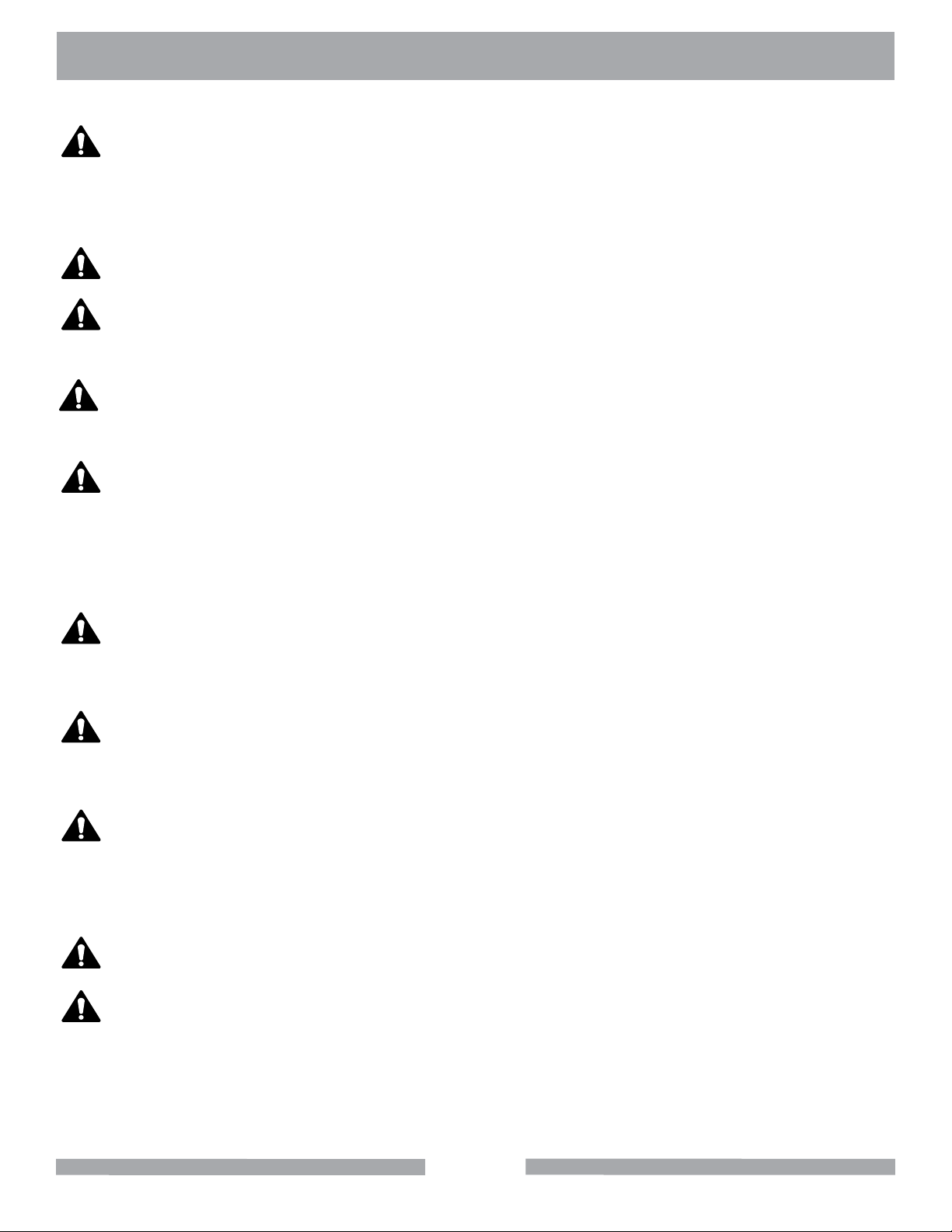

To choose the proper extension cord,

• Locate the length of extension cord needed in the table below.

• Once the proper length is found, move down the column to obtain the correct AWG

size required for that length of extension cord.

EXTENSION CORD LENGTH

Nameplate

Amperes

0 - 5 16 16 16 14 12 12

115V 25' 50' 75' 100' 150' 200'

250V 50' 100' 150' 200' 300' 400'

5.1 - 8 16 16 14 12 10 •

8.1 - 12 14 14 12 10 • •

12.1 - 15 12 12 10 10 • •

15.1 - 20 10 10 10 • • •

11

Page 12

MK-SCARIFIER SAFETY

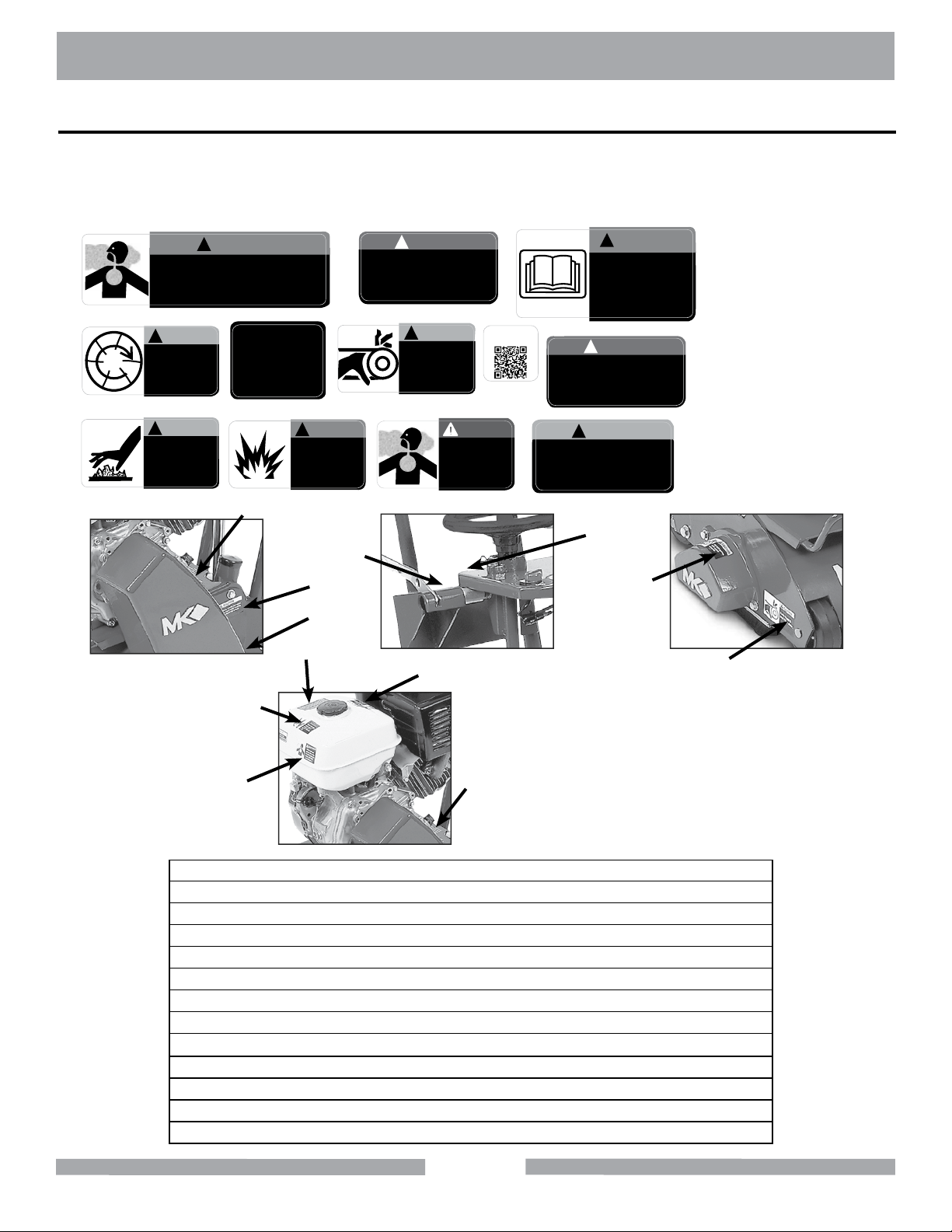

SAFETY LABEL LOCATIONS

Safety labels contain important safety information. Please read the information contained on each

safety label. These labels are considered a permanent part of your saw. If a label comes off or

becomes hard to read, contact MK Diamond or your dealer for a replacement.

Grinding/cutting/drilling of masonry, concrete, metal and other materials with silica in

their composition may give off dust or mists containing crystalline silica. Silica is a basic

component of sand, quartz, brick clay, granite and numerous other minerals and rocks.

Repeated and/or substantial inhalation of airborne crystalline silica can cause serious

or fatal respiratory diseases, including silicosis. In addition, California and some other

authorities have listed respirable crystalline silica as a substance known to cause cancer.

!

Keep

hands and

feet clear.

Label D

!

DO NOT

touch hot

surface.

Label I

Label A

CAUTION

CAUTION

!

WARNING

SERVICE OR

WARRANTY

FOR INFORMATION ON

PLEASE CALL

1-800-474-5594

Label E

WARNING

!

When refueling

stop engine and

allow to cool.

DO NOT overll

tank.

Label J Label K

NOTICE

!

Overtensioning of belts

will result in premature

crank and/or bearing failure.

Label B

CAUTION

!

DO NOT

operate without

guards in place.

Label F

DANGER

Lethal exhaust

gases. Use only

in well ventilated

areas. DO NOT

use indoors.

For manuals and parts

lists scan the QR code

with your smart phone

Label G

The exhaust from this product

contains chemicals known to

the State of California to cause

cancer, birth defects or other

reproductive harm.

Accidental start hazard.

Disconnect spark plug

prior to servicing.

!

DO NOT operate

this equipment

before reading

the owner’s

manual!

Label C

DANGER

!

Label H

CAUTION

!

Label L

WARNING

Warning Sheet

Part # 166010

Label A

Label E

Label C

Label B

Label D

Label G

Label H

Label I

Label F

Label J

Label K

Label L

Decal/Label Location Description

A Belt Guard - Side Warning - Silica Warning

B Belt Guard - Side Notice - Overtension of the belts

C Console Warning - Read Owner’s Manual

D Belt Guard Caution - Keep Hands & Feet Clear

E Console Service or Warranty

F Belt Guard Caution - Guards in place

G Belt Guard QR Code for Manual

H Gas Tank - Top Danger - State of California

I Gas Tank - Top Caution - Do Not Touch

J Gas Tank - Side Warning - Do Not OVerfill Tank

K Gas Tank - Side Danger - Silica Warranty

L Cutting Drum Caution - Spack Plug

12

Page 13

MK-SCARIFIER PRODUCT SPECIFICATIONS

SPECIFIC WARNINGS

• Read Owners Manual

• Wear Protective Gear for Head, Lungs, Ears and Eyes

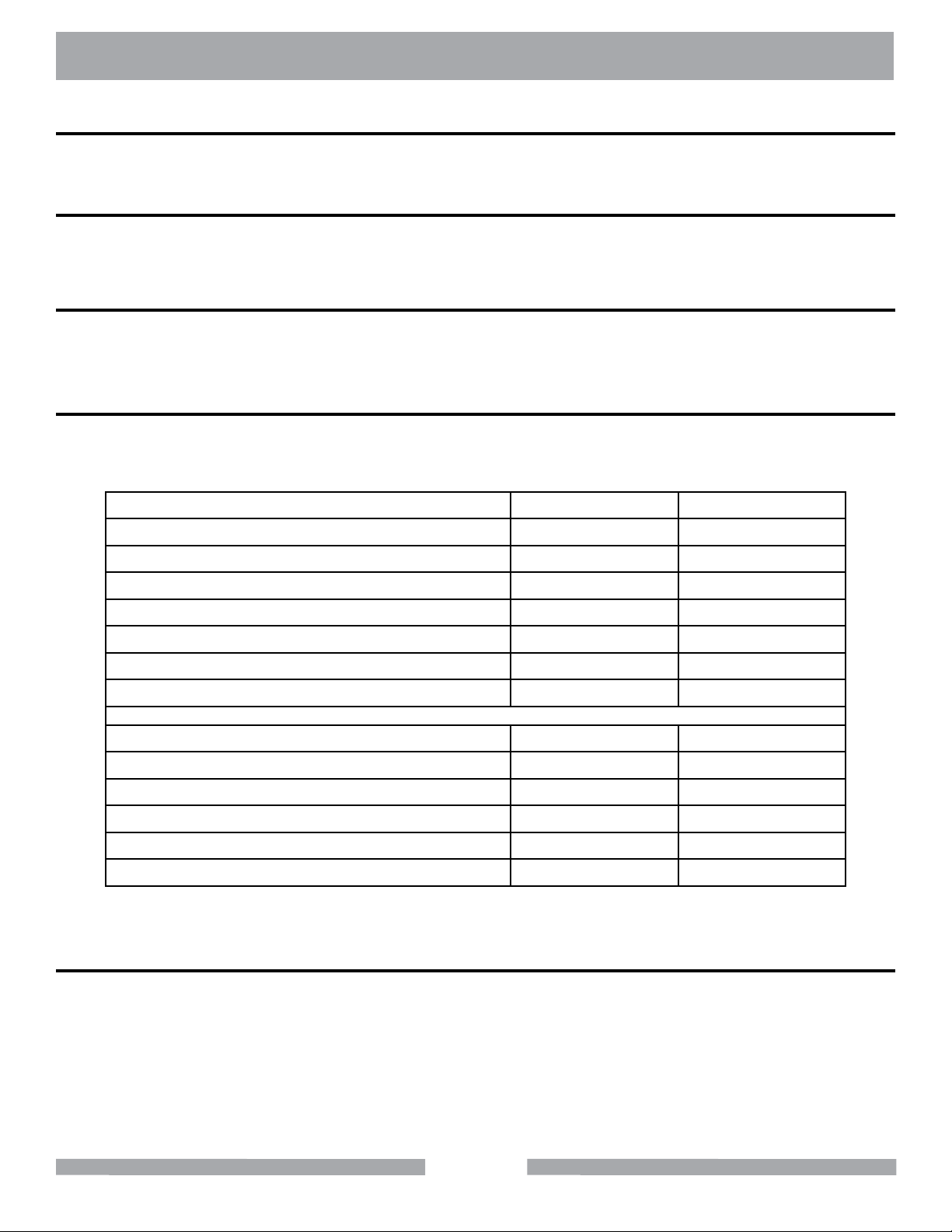

PRODUCT SPECIFICATION

Operated and used according to this manual, the Scarier will provide years of dependable service.

General Description

The Scariers are is engineered with an 8” Cutting Drum. The SG-9 has a Honda engine and the

SG-5 has a Baldor motor. The scarier is designed with ne depth control allowing the operator to

make depth adjustments in 1/16-inch increments.

MotorandWeightSpecications

The Scariers use a 6-inch diameter, 8-inch long cutting drum with 6 hardened steel shafts that will

accommodate the most common cutting discs.

Model MK-SG-9 MK-SG-5

Engine/Motor Honda (Gas) Baldor (Electric)

Power GX270 Cyclone 5 HP 230V

Weight (not including drum) 170 lbs. (77kg) 170 lbs. (77kg)

Drum Dimensions (Dia. x L) 6” x 8” 6” x 8”

Drum Weight 30 lbs. (14 kg) 30 lbs. (14kg)

L x W x H (in) 23” x 20” x 43” 23” x 20” x 43”

L x W x H (mm) 813 x 508 x 1,092 813 x 508 x 1,092

DrumCongurations Part # Part #

Scarier with 5 Point Carbide Drum (no cutters) 158532 158533

Scarier with 5 Point Carbide Drum 158941 165276

Scarier with 6 Point Carbide Drum 158942 165277

Scarier with 18 Point Carbide Drum 158943 165278

Scarier with 12 Point Carbide Drum 158944 165279

Depending on cutting wheel style, production rate varies from 350 to 500 square feet per hour for a 1/8-inch

removal depth.

ScarierUsage

The Scarier is designed to grind surfaces, remove old coatings, prepare surfaces before applying

new coatings, roughen surfaces, groove surfaces and slot surfaces.

Features

• Engage/Disengage Lever allowing the operator to raise or lower the cutting drum without

changing the cutting depth setting.

• Ergonomically designed handlebar to reduce fatigue.

• Poly micro V-belt to ensure maximum power transfer from the engine to the cutting drum.

13

Page 14

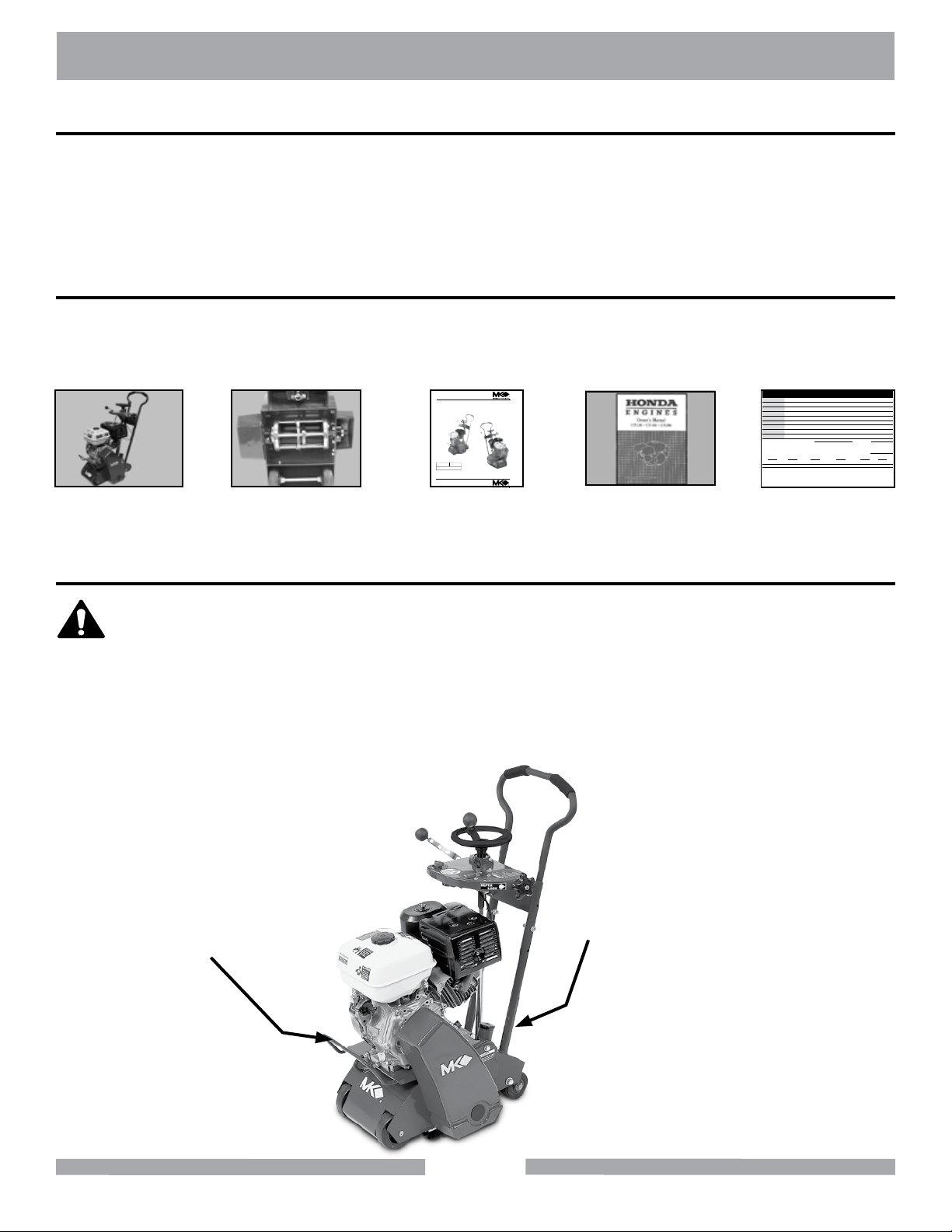

MK-SCARIFIER UNPACKING

UNPACKING

Your Scarier has been shipped from the factory thoroughly inspected. Only minimal assembly is

required.

If not already done, remove the Scarier from the pallet and place it on a at surface (lift the scarier

using the lifting points shown below).

CONTENT

In the containers, you will nd one (1) Scarier, one (1) cutting drum, one (1) owner’s manual, one

(1) Honda owner’s manual and one (1) warranty card.

MK DiaMonD Warranty CarD

www.mkdiamond.com

SG-9

Revision 103

08.2013

Manual Part# 158537

Caution: Read all safety and operating instructions

before using this equipment. This owner’s manual

MUST accompany the equipment at all times.

MK-SCARIFIER

OWNER’S MANUAL, PARTS LIST &

OPERATING INSTRUCTIONS

SG-5

SG-9

SG-5

Name

address

City

state zip Code

phoNe Fax

e-mail

produCt model

part NumBer

maChiNe serial#

where did you purChase this saw From ? N a me

q tile distriButor q home CeNter q equipmeNt supply house

q tool supply q Bldg material supply q reNtal equipmeNt house

q or CoNtraCtor q IF so, what type? tile q masoNry q other

are you a do-it-yourselFer

what Criteria was importaNt iN ChoosiNg this saw? (rate From 1 to 5, 5 BeiNg the most importaNt)

power preCisioN portaBility availaBility other

priCe

CommeNts or suggestioNs:

mK diamoNd warraNty

1315 Storm Parkway, Torrance, CA 90509 USA | www.mkdiamond.com | 1.800.421.5830 | 1.310.539.5158

If within one (1) Year from the date of purchase, this MK Diamond saw fails due to defect in material or workmanship, MK will repair it, free of charge when the unit is returned to the dealer where it was purchased. This warranty DOES NOT cover normal wear or damage resulting from operator abuse. In no event shall MK Diamond Products,

Inc. be liable for consequential damages arising out of the failure of any product if operated improperly. MK Diamond Products may act as a warranty station for motor/engine repairs based on an individual agreement with the manufacturer. This warranty is in lieu of all other warranties express or implied.

©2010 All Rights reserved. MK Diamond Products, Inc. • P/N 155037 MK Warranty Card (02/10)

date purChased

Scarier Cutting Drum Owner’s Manual Motor/Engine

Manual

Warranty

Card

TRANSPORT

1. The Scarier weighs approximately one hundred and eighty-ve (185)

CAUTION

pounds (with the Cutting Drum assembled the scarier weighs approximately

230 pounds), use care when transporting.

2. Two people are required to transport the Scarier.

To lift the scarier, each person will stand on opposite sides of the Scarier and grasp the rear Handlebar and the front Handle/Stand to lift, as shown below.

Handlebar

Lift Point

Handle/

Stand

Lift Point

14

Page 15

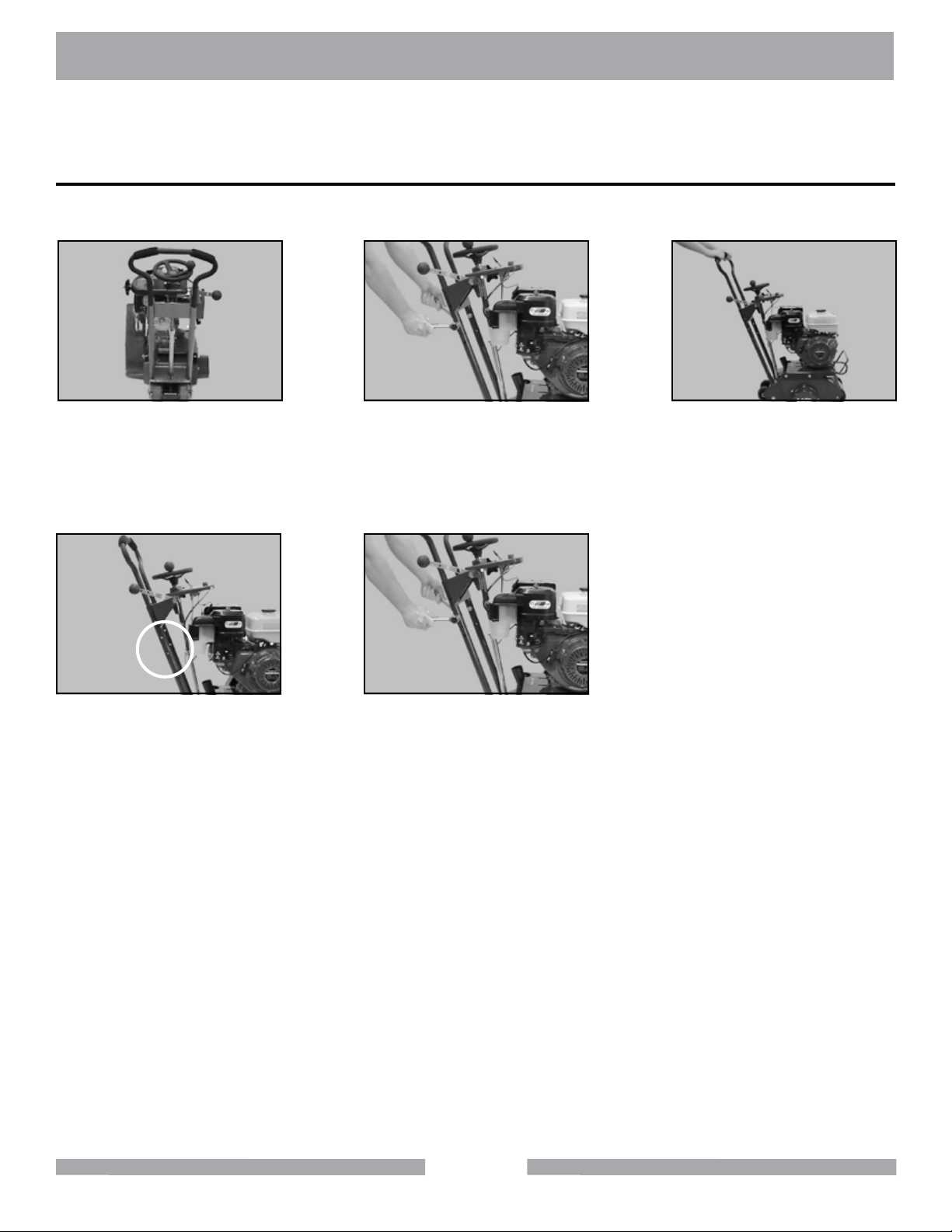

MK-SCARIFIER HANDLEBAR ASSEMBLY

Follow the assembly instructions to prepare your Scarier for operation.

Handlebar Adjustment

Adjust the Handlebar for for ease of operation and comfort of the user.

(A)

Locate the Handlebar retain-

ing bolts.

(D)

Align one set of Retaining

Bolt holes in the Handlebar to

the holes in Scarier Frame.

Remove the Retaining Bolts

using 9/16 wrenches and/or

Install the Retaining Bolts

and tighten using 9/16

wrenches and/or sockets.

(B)

Raise or lower the Handle-

sockets.

(E)

NOTE: Do not rotate saw to rest on handlebar. Engine damage will result.

(C)

bar as needed.

15

Page 16

MK-SCARIFIER SCARIFIER DRUM

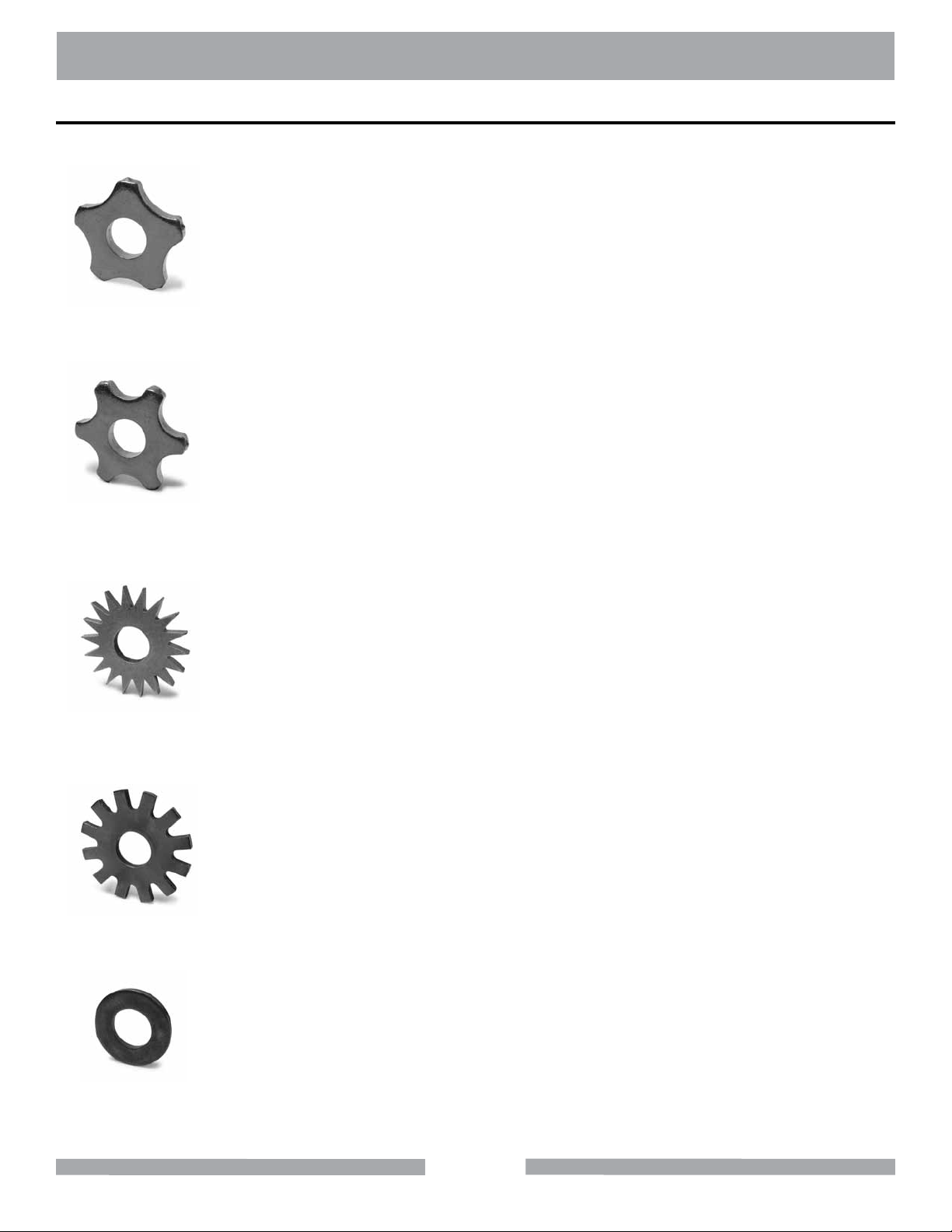

ScarierDrumCutters

Five Tooth Carbide Tip Star

• Used for grinding, leveling, grooving, cleaning, and preparing concrete

• Five-point carbide tips (1-3/4” OD x 5/8” ID x 1/4”)

• Longer life than steel tooth cutters, average of 6000 to 8000 square feet

• Maximum cutting rate is 1/8” per pass

Six Tooth Carbide Tip Star

• Used for grinding, leveling, grooving, cleaning, and preparing concrete

• Five-point carbide tips (1-3/4” OD x 5/8” ID x 1/4”)

• Exceptional life, average of 8000 to 10000 square feet

• Maximum cutting rate is 1/8” per pass

18 Tooth Steel Sharp Tooth Cutter

• Used for general cleaning of concrete or asphalt including removal of

paint, epoxy, urethane, adhesive, and heavy dirt, grease and oil deposits

• 18 tooth hardened steel, (2” OD x 5/8” ID x 1/4”)

• Average life of 500 to 800 square feet

• Maximum cutting rate is 1/16” per pass

Part # 158583

Part # 158584

Part # 158585

12 Tooth Steel Blunt Tooth Cutter

• Used for paint and oil removal, trafc and shop oor safety-line removal,

cleaning and concrete preparation

• 12 tooth, hardened steel (2” OD x 9/16” ID x 1/4”)

• Average life of 500 to 800 square feet

• Maximum cutting rate is 1/16” per pass

Hardened Steel Spacer

• Used to ll empty space between the cutting discs

• 1/2” ID hardened steel

16

Part # 158586

Part # 158575

Page 17

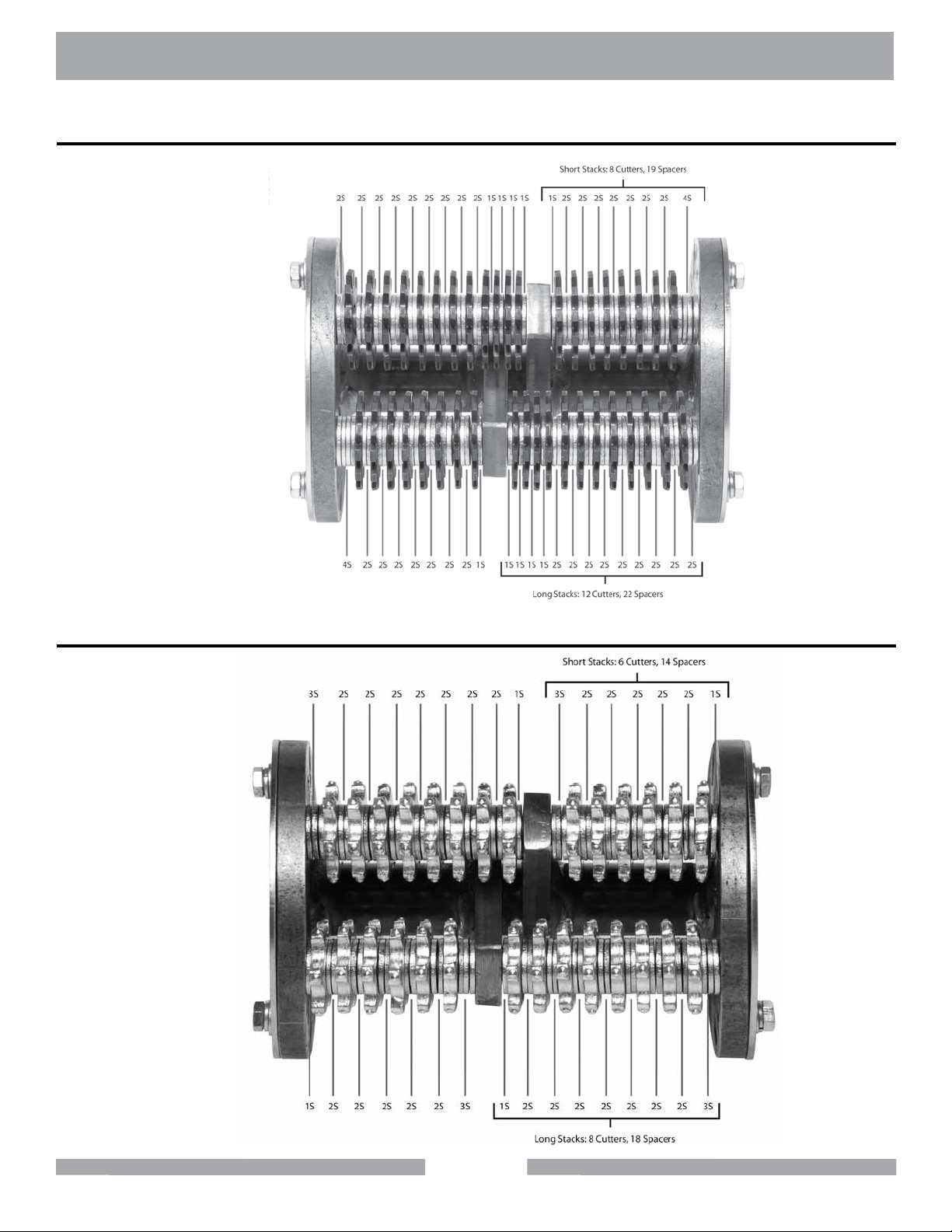

MK-SCARIFIER DRUM CONFIGURATIONS

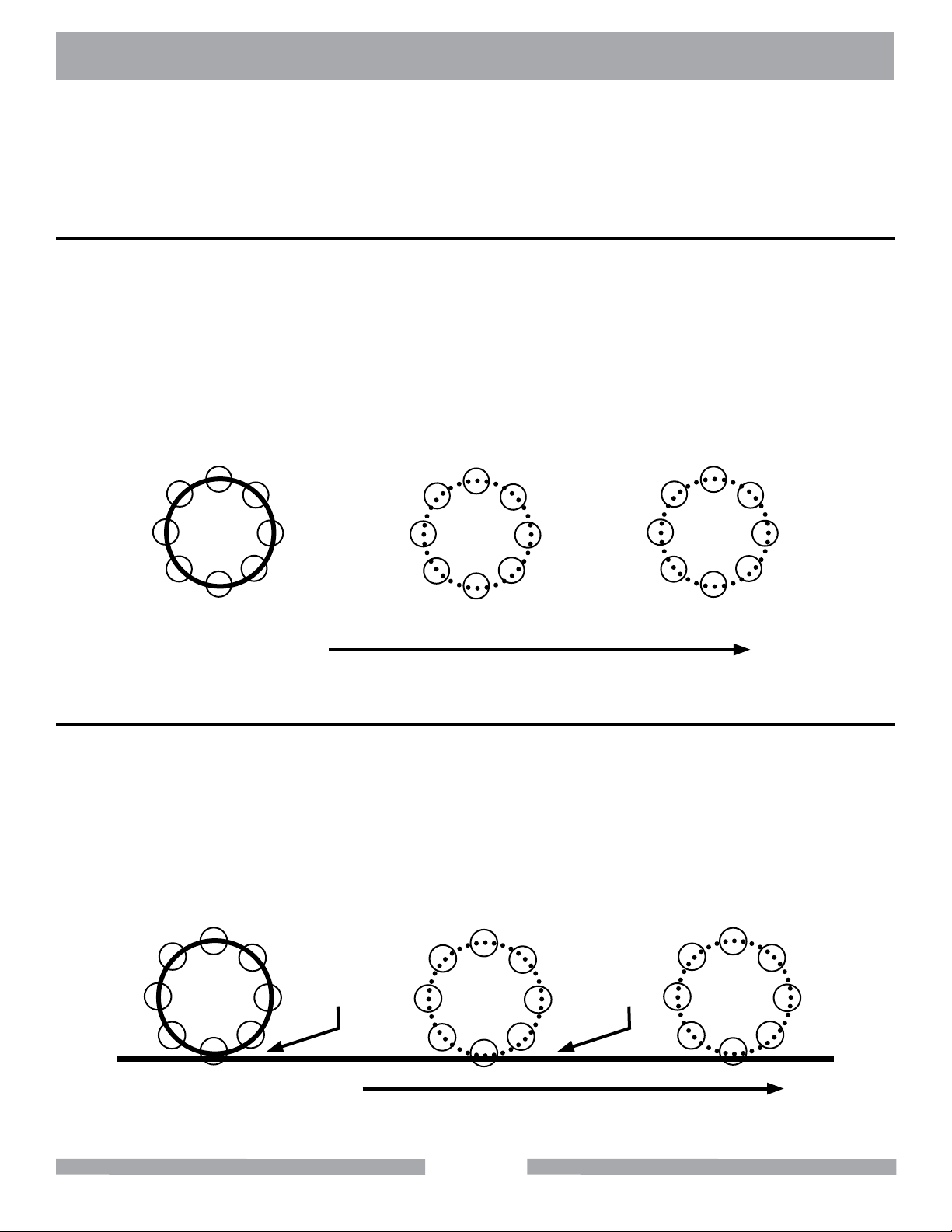

SteelDrumCongurationforRemoval

120 Steel Cutters

246 Spacers (S)

6 Shafts

GeneralPurpose/CleaningDrumConguration

84 Carbide Stars

192 Spacers (S)

6 Shafts

17

Page 18

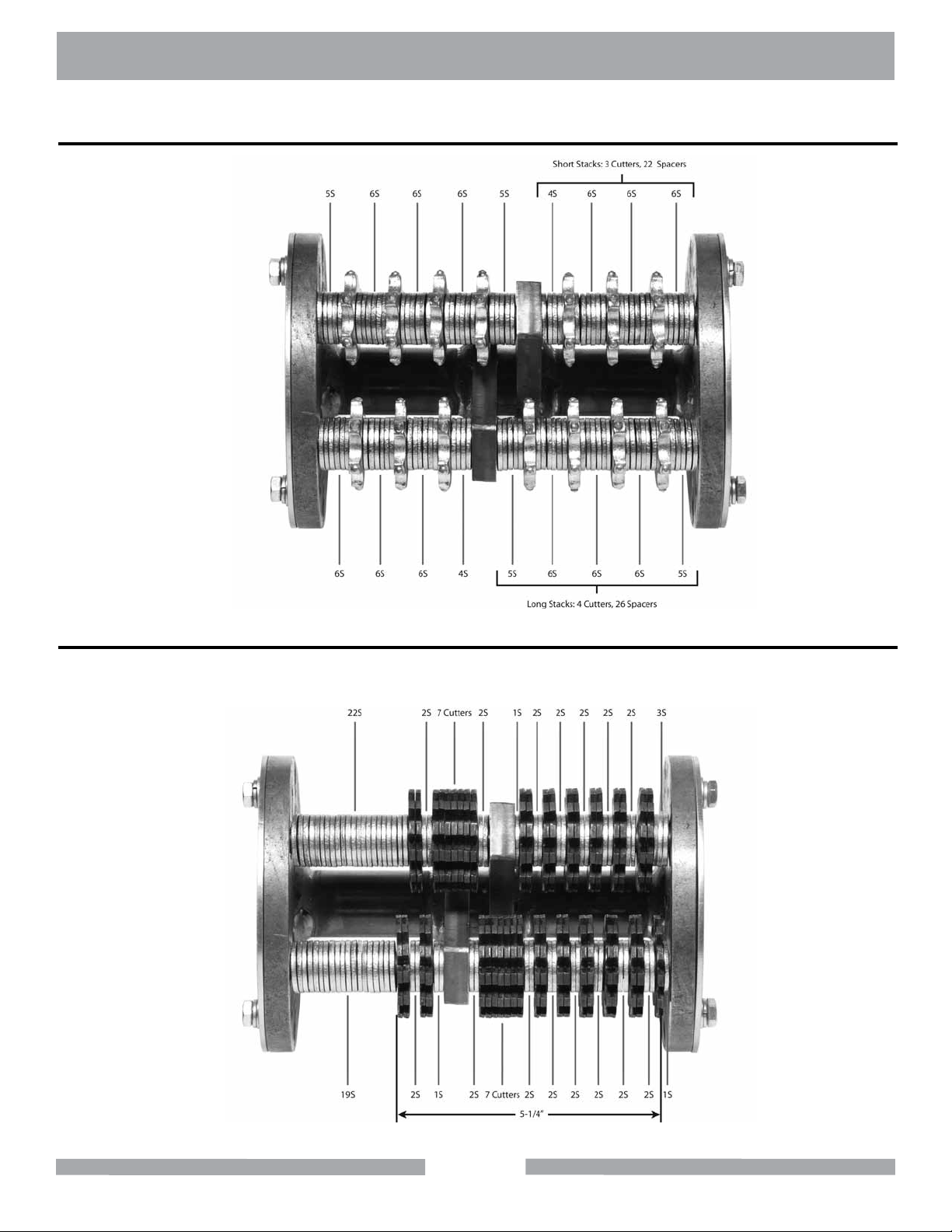

MK-SCARIFIER DRUM CONFIGURATIONS

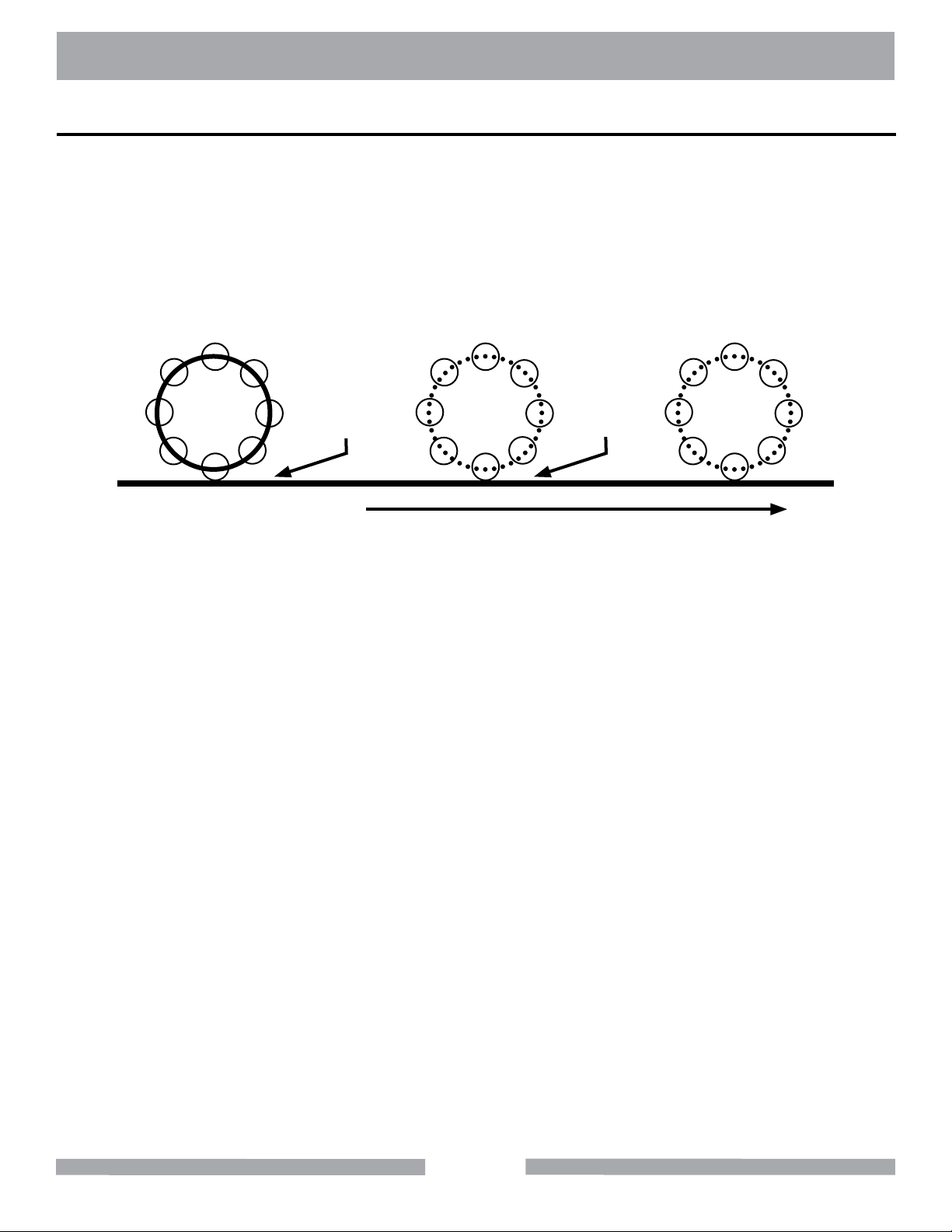

1”GrooveDrumConguration

42 Carbide Stars

288 Spacers (S)

6 Shafts

5”Stripe/LineDrumConguration

123 Steel Cutters

231 Spacers (S)

6 Shafts

18

Page 19

MK-SCARIFIER ASSEMBLY

NOTE:

Leveling a Surface

The Height Adjustment Hand-wheel will adjust the depth (up or down) of the Cutting Drum

by 1/16 of an inch per turn.

A) Congure the Cutting Drum for Grooving

B) Locate the lowest spot and highest spot on the surface

C) Adjust the height of the Cutting Drum to remove approximately 1/16 of an inch from the

high spot

D) Set the Vibration Lock

E) Move the Scarier in a smooth forward motion.

F) When the Cutting Discs are no longer contacting the surface, return the Scarier to the

starting position

G) Repeat Steps A through E until the Surface is level (See Figure 1)

Set 1/16 –

inch below

the surface

High Point

Direction of Movement

Cutting/Grooving a Surface

A) Congure the Cutting Drum for Grooving

B) Adjust the Cutting Drum Depth until the Scarier is cutting grooves approximately 1/8 of

an inch

C) Move the Scarier in a smooth forward motion

D) Should the Cutting Discs loose contact with the surface, repeat Step B and continue

forward motion

E) Repeat Steps A through D until the desired number of grooves are cut (See Figure 2)

Set 1/8 – inch

below the

surface

Figure 1

Maintain

set cutting

depth

Direction of Movement

Figure 2

19

Page 20

MK-SCARIFIER ASSEMBLY

Roughening or Preparing a Surface

A) Congure the Cutting Drum for Surface Prep.

B) Adjust the Cutting Drum Depth until the Cutting Discs are contacting the surface (increase

the depth of the Cutting Drum as necessary to increase the “roughness of the surface”

C) Scarier in a smooth forward motion

D) Should the Cutting Discs loose contact with the surface, repeat Step B and continue for-

ward motion

E) Repeat Steps A through D until the desired roughness is achieved. (See Figure 3)

Set depth to

contact the

surface

Direction of Movement

Maintain

set cutting

depth

Figure 3

20

Page 21

MK-SCARIFIER ASSEMBLY

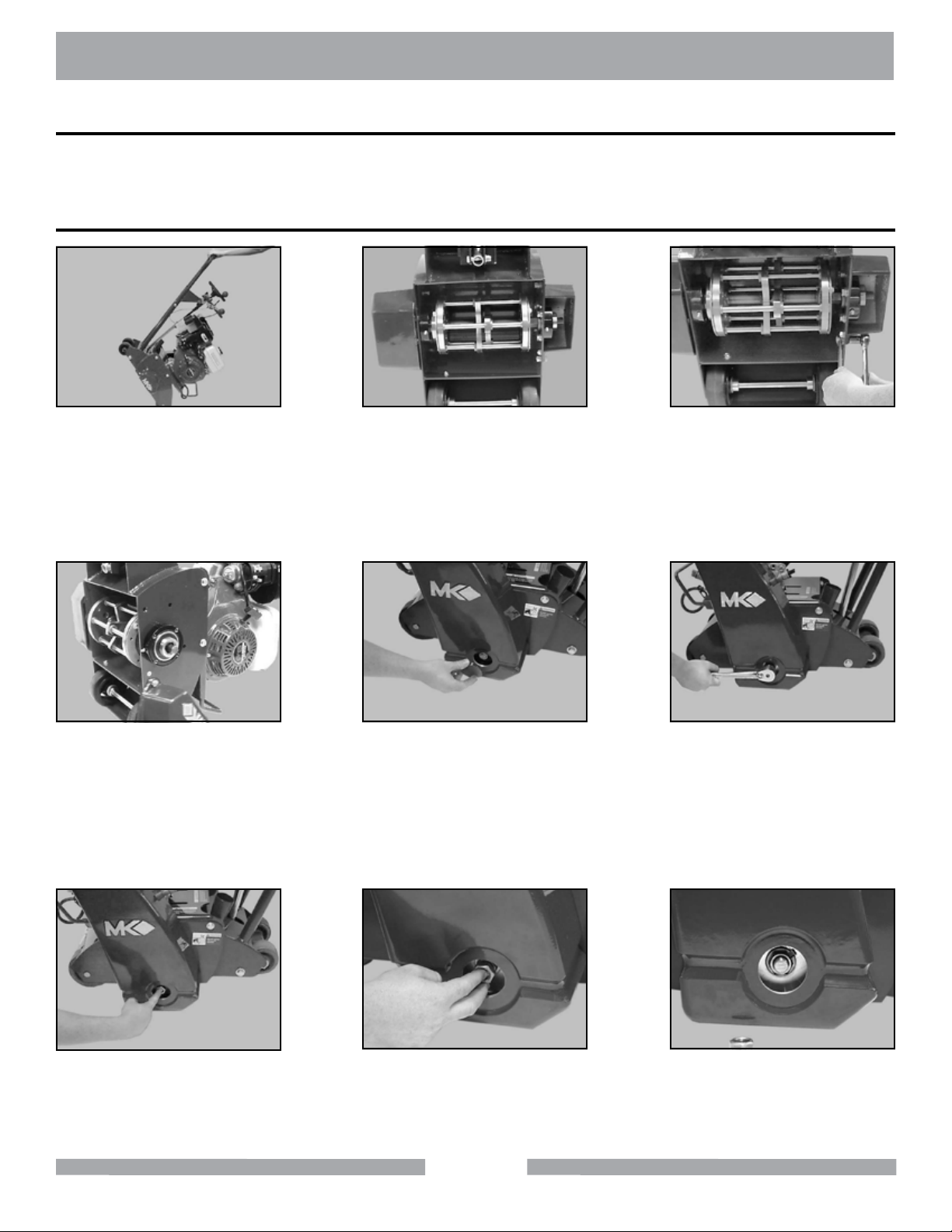

CUTTING DRUM ASSEMBLY

Because the Cutting Drum assembly is a complex process, the assembly procedure will be broken

into several parts.

Cutting Drum Removal

(A)

Rotate the Scarier to rest on

the Handle/Stand. Never rest

on back handle bar.

(D)

Pivot the Shaft Cover to

expose the end of the Cutting

Drum Shaft.

(B)

Locate the Shaft Cover, Re-

taining Bolts.

(E)

Remove the Shaft, Retaining Nut Cover from the Belt

Guard to expose the Shaft,

Retaining Nuts.

(C)

Remove the Shaft Cover,

Rear Retaining Bolt and

loosen the Front Retaining

Bolt using 9/16 wrenches

and/or sockets.

(F)

Rotate counterclockwise to

using a 15/16-inch socket,

loosen the Outer Shaft, Re-

taining Nut.

(G)

Place an index nger on the

end of the Cutting Drum,

Shaft

Remove the Outer Shaft, Retaining Nut using your middle

nger as shown

(H)

21

(I)

Repeat Step H for the Inner

Shaft, Retaining Nut

Page 22

MK-SCARIFIER ASSEMBLY

(J)

Grasp the Cutting Drum

as shown.

(M)

Remove the Cutting Drum

and Shaft.

(K)

Push the Cutting Drum away

from the belt side to loosen

the Shaft.

Place a rod in the hole on the

end of the Shaft, and while

holding the Cutting Drum,

remove the Shaft.

NOTE: Assembly is opposite of disassembly

(L)

22

Page 23

MK-SCARIFIER ASSEMBLY

CUTTING DRUM DISASSEMBLY

The Cutting Drum may be disassembled from either end.NOTE:

(A)

Rotate the Cutting Drum onto

either end and locate the

Retaining Ring, Retaining

Screws.

(D)

If present, remove the three

Flat Washer Spacers.

(B)

Remove the 3 Retaining

Screws using a 7/16-inch

wrench.

(E)

Place the Retaining Ring and

Flat Washer Spacers in a

secure location.

(C)

Remove the Drum Retaining

Ring.

23

Page 24

MK-SCARIFIER ASSEMBLY

CUTTING DRUM ASSEMBLY

The Cutting Drum may be disassembled from either end.NOTE:

(A)

Pull the Cutting Disc Shafts

out the open side of the Cut-

ting Drum as shown.

(D)

Place the Cutting Drum on

the closed end, with the open

end facing upward.

(B)

Assemble the Cutting Drum

using Cutting Discs and Disc

Spacers (See Cutting Drum

Conguration).

(E)

Obtain the Retaining Ring

and Flat Washer Spacers.

(C)

Continue with Step B until

the Cutting Drum assembly is

complete.

(F)

Install the 3 Flat Washer

Spacers (if used) over the

3 Retaining Ring, Retaining

Screw holes.

(G)

Place the Retaining Ring

onto the end of the Cutting

Drum, aligning the Retaining

Screw Holes.

Install the 3 Retaining Screws

into the Cutting Drum (do not

cross-thread the screws).

(H)

24

(I)

Tighten the 3 Retaining

Screws using a 7/16-inch

wrench.

Page 25

MK-SCARIFIER ASSEMBLY

CUTTING DRUM INSTALLATION

The Cutting Drum may be disassembled from either end.NOTE:

(A)

Install the Cutting Drum; align

the Cutting Drum with the

Shaft-side Bearing and install

the Cutting Drum, Shaft.

(D)

Using a 15/16-inch socket

tighten the Shaft, Inner

Retaining Nut, counterclock-

wise.

(B)

Verify the Cutting Drum and

Shaft are fully installed and

seated.

(E)

Obtain the Shaft, Outer

Retaining Nut.

(C)

Install the Shaft, Inner Re-

taining Nut.

(F)

Install the Shaft, Outer

Retaining Nut.

(G)

Using a 15/16-inch socket

tighten the Shaft, Outer

Retaining Nut.

Install the Shaft, Retaining Nut

Cover onto the Belt Guard.

(H)

(I)

Pivot the Shaft Guard Cover

into position and install the

Rear Retaining Bolt.

FILLING OIL RESERVOIR

NOTE:

SAE 10W-30 is recommended for general use in temperatures of – 4ºF (20ºC) and above.

Engine Oil Capacity is 1.16 US qt (1.1l). Refer to Engine Manual for details.

25

Page 26

MK-SCARIFIER ASSEMBLY

FILLING FUEL TANK

WARNING

1. Gasoline is highly ammable and explosive. You can be burned or seriously

injured when handling fuel.

2. To fuel, stop engine if running, and allow it to cool.

3. Refuel in a well-ventilated area.

4. Keep gasoline away from appliance pilot lights, barbecues, electric

appliances, power tools, etc.

5. Wipe up spills immediately.

NOTES:

1. Fuel can damage paint and plastic. Be careful not to spill fuel when lling the fuel

tank. Damage caused by spilled fuel IS NOT covered under the warranty.

2. DO NOT use stale or contaminated gasoline, or an oil/gasoline mixture.

3. Use unleaded gasoline with a pump octane rating of 86 or higher.

NOTE:

Refer to Engine Manual for details.

VACUUM SETUP FOR OPERATION

The Scarier is designed for use with a vacuum. MK Diamond recommends using a vacuum to reduce the amount of dust generated during operation.

MK Diamond does not endorse any specic vacuum type, but does recommend the customer use the

Scarier with a dry dust collector (designed for wood dust) as opposed to a standard wet/dry vacuum.

(A)

Obtain a vacuum or dust

collection system.

Verify the hose connections

are secure at the Scarier

and the Vacuum.

(D)

Remove the Cap from the

Vacuum Connection Point.

(B)

Using a 2 1/2-inch hose,

connect the Vacuum to the

Scarier at the Vacuum

Connection Point.

26

(C)

Page 27

MK-SCARIFIER SETUP

Pre-start Inspection

The pre-start inspection should be performed before beginning any job. If Cutting Discs are worn, or

are missing carbide inserts (carbide cutting discs only), replace the discs before starting work.

NOTE:

• DO NOT rotate Scarier to rest on handlebar. Engine damage will result.

• The carbide tips on carbide cutting discs are approximately 1/4-inch in length. When

the carbide disc is worn to the end of the carbide tip, the tip may fall out leaving a small

hole.

(A)

Inspect the Cutting Discs for

excessive wear and missing

tips.

(B)

Inspect Engine for leaks.

(C)

Inspect the Scarier for

general damage and/or loose

hardware.

(D)

Verify the Height Adjust-

ing Wheel moves freely

and moves up and down

smoothly.

(G)

Check for proper fuel level

(See Engine Manual).

Verify the Scarier rolls freely.

Check Air Filter for cleanliness

(See Engine Manual).

(E)

(H)

27

(F)

Check for proper oil level

(See Engine Manual).

Page 28

MK-SCARIFIER SETUP

STARTUP

WARNING

1. Carbon monoxide gas is toxic, breathing it can cause unconsciousness and/

or death.

2. Avoid any areas or actions that expose you to carbon monoxide.

NOTE:

Verify the Engage/Disengage

Lever is in the “Lift” position.

If restarting a warm engine, leave the Choke Lever in the OPEN position.

(A)

(B)

Raise the Cutting Drum to the

highest position.

(C)

Place Fuel Valve in the

ON position.

(D)

Place Choke Lever in the

CLOSED position.

(G)

Pull Starter Cord slowly, until

slack is removed and

resistance is felt.

Move the Throttle Lever to

Pull Starter Cord straight

back in a smooth

(E)

1/3rd open.

(H)

fast motion.

28

(F)

Place Engine Switch in the

ON position.

(I)

Place Choke Lever in the

OPEN position when engine

is warm.

Page 29

MK-SCARIFIER SETUP

STARTUP

The Scarier is capable of performing several different operations simply by changing drum conguration. The following steps describe how it is operated in any conguration.

(A)

Start the Scarier in accor-

dance with Engine Start, Step

1 of the STARTUP section,

page 24.

(D)

Adjust the height of the Cut-

ting Drum for the Job being

performed (See Basic Grind-

ing Techniques).

(B)

Raise the Cutting Drum to the

highest position.

(E)

Locate the Vibration Lock.

(C)

Place the Engage/Disengage

Lever in the “Lower” position.

(F)

Lock the height of the drum

using the Vibration Lock.

When turning the Scarier, lift the Rear Wheels off the ground, and pivot the it on the Front Wheels.

NOTE:

(G)

Adjust the speed

by using the Throttle,

as desired.

Push the Scarier at a

smooth, even pace to per-

(H)

form the cut.

29

(I)

Place the Engage/Disengage

Lever in the “Lift” when the

cut is complete.

Page 30

MK-SCARIFIER OPERATION

Normal Engine Shutdown

(A)

Verify the Engage/Disengage

Lever is in the “Lift” position.

(D)

Place Engine Master Switch

in the OFF position.

(B)

Raise the Cutting Drum to the

highest position.

(E)

Place Fuel Valve in

the OFF position.

(C)

Move the Throttle Lever to

lower blade speed.

30

Page 31

MK-SCARIFIER OPERATION

Emergency Engine Shutdown

(A)

Place Engine Master Switch

in the OFF position.

(D)

Verify the Engage/Disengage

Lever is in the “Lift” position.

(B)

Move the Throttle Lever to

lower blade speed.

(E)

Raise the Cutting Drum to the

highest position.

Place Fuel Valve in the

(C)

OFF position.

CLEANUP

Engine parts are extremely hot following use, allow engine to cool 1/2-hour before cleaning. Use care

during cleanup to avoid injury.

NOTES:

1. To extend operating life, the scarier should be cleaned following every use.

2. Using a garden hose or pressure washer can force water into the air cleaner or

mufer opening.

3. Use care when cleaning around electrical components.

(A)

Clean the Scarier with soap

and water.

Verify the engine is off and cool

before beginning to clean.

(B)

31

(C)

Clean around the Depth Con-

trol Wheel bearing.

Page 32

MK-SCARIFIER CLEANUP

(D)

Clean the Depth

Control Screw.

(G)

Remove the Cutting Drum

(See Setup Section).

Clean the remainder of the

exterior surface of the scari-

er (except the engine).

Clean the Shaft Penetration

Hole of the Cutting Drum.

(E)

(H)

New Maintenance

Perform the following after initial purchase and operation of the saw.

(F)

Clean engine throttle linkage

with a dry cloth.

(I)

Clean the Cutting Drum,

Shaft.

(A)

Change engine oil after 1st

month or 1st 20 operating

hours (See Engine Manual).

Check and adjust tension on

all V-belts following 1st 48

hours of operation (See V-

belt Inspection).

(B)

32

Page 33

MK-SCARIFIER MAINTENANCE

Maintenance Following Use

The following maintenance should be performed following each use. Use Light oil, such as WD-40 or

3 in 1 when lubricating parts.

NOTES:

Due to the material used in the Cutting Drum and Shaft, it is critical that Steps C and D

be performed.

(A)

Shutdown the Engine (See

Normal Engine Shutdown).

(B)

Check Air Filter for cleanliness

(See Engine Manual).

(C)

Lubricate arbor in drum.

Clean engine throttle linkage

with a dry cloth.

(D)

Lubricate the Cutting Drum

Shaft.

(G)

Lubricate the Front Wheel

Assembly.

Reinstall the Cutting Drum.

Lubricate the Rear Wheel

(E)

(H)

Assembly.

33

(F)

Lubricate the outer surface of

the Cutting Drum.

(I)

Lubricate the Engage/ Disen-

gage Pivot Shaft.

Page 34

MK-SCARIFIER MAINTENANCE

(J)

Lubricate and clean the

Depth Control Screw.

Lubricate engine Throttle

(K)

Linkage.

Monthly Maintenance

The following should be performed monthly. Items should be lubricated using a waterproof grease.

(A)

Verify the tightness of all bolts

and screws.

Lubricate the Height Adjusting

Wheel Bearing.

(B)

(C)

Lubricate the Depth Control

Screw.

(D)

Lubricate the Cutting Drum,

Shaft Bearings.

Lubricate the Front Wheel

Assembly Bearings.

(E)

34

(F)

Clean engine Air Filter (See En-

gine Air Filter Inspection Cleaning

and Replacement).

Page 35

MK-SCARIFIER MAINTENANCE

Six (6) Month Maintenance

Perform the following maintenance every six months.

(A)

Change engine oil

(See Engine Manual).

Clean Fuel Sediment Cup

(See Fuel Sediment Cup

Yearly and Two-Year Maintenance

Perform the following maintenance every year.

(A)

Replace engine Air Filter

(See Engine Manual).

Replace Spark Plug

(See Engine Manual).

(B)

Cleaning).

(B)

(C)

Clean and Readjust engine

Spark Plug

(See Engine Manual).

(C)

Inspect V-belts

(See V-Belt Inspection, Adjust-

ment and Replacement).

(D)

Check/Adjust Idle Speed

Check/Adjust Valve Clear-

ance (Shop Maintenance

Required).

Check Fuel Line (2-Year

Maintenance Only, Shop

Maintenance Required).

(E)

35

Page 36

MK-SCARIFIER MAINTENANCE

Check Fuel Level

WARNING

NOTES: 1. Fuel can damage paint and plastic. Be careful not to spill fuel when lling the fuel tank.

Damage caused by spilled fuel is not covered under the warranty.

2. DO NOT use stale or contaminated gasoline or an oil/gasoline mixture.

3. Use unleaded gasoline with a pump octane rating of 86 or higher.

NOTE:

Checking Oil Level

NOTES: 1. Engine Oil Capacity is 1.16 US qt (1.1 l).

2. When installing the Oil Dipstick, ensure the threads are aligned with the threads of the

Refer to Engine Manual for details.

Oil Reservoir so as not to “cross-thread.”

1. Gasoline is highly ammable and explosive. You can be burned or seriously

injured when handling fuel.

2. To fuel, stop engine if running and allow it to cool.

3. Refuel in a well-ventilated area.

4. Keep gasoline away from appliance pilot lights, barbecues, electric appliances,

power tools, etc.

5. Wipe up spills immediately.

NOTE:

Refer to Engine Manual for details.

36

Page 37

MK-SCARIFIER MAINTENANCE

100ºF

-20ºF

0ºF

20ºF

40ºF

60ºF

80ºF

10W-30

5W-30

30

-20ºC

-10ºC

0ºC

10ºC

20ºC

30ºC

40ºC

-30ºC

Changing Oil

Oil is a major factor affecting performance and service life. Use 4-stroke automotive detergent oil.

Refer to Engine Manual for specic procedures. SAE 10W-30 is recommended for general use. Other

viscosity oil shown in the chart below may be used when the average temperature in your area is

within the recommended range.

NOTES:

1. Drain used oil while the engine is warm.

2. Conform to Federal, State and Local laws, codes and ordinances relative to

environmental protection for oil disposal.

NOTE: Refer to Engine Manual for details.

(A)

Lower the Scarier to its low-

est position.

Free the Oil Drain Line.

(B)

(C)

Place a catch basin below

the Oil Drain Line and re-

move the Drain Cap using

two 1/2 –inch wrenches.

(D)

Drain Oil the engine oil (con-

form to Federal, State and

Local laws for disposal).

(E)

Using two 1/2 – inch

wrenches, install the Drain

Cap onto the Oil Drain Line

(Ensure the Cap is tight).

37

(F)

Fill the Oil Reservoir

(See Engine Manual).

Page 38

MK-SCARIFIER MAINTENANCE

Fuel Sediment Cup Cleaning

WARNING

NOTES:

1. Conform to Federal, State and Local laws for the proper disposal of fuel

2. Fuel can damage paint and plastic. Be careful not to spill fuel when lling the fuel

tank. Damage caused by spilled fuel IS NOT covered under the warranty.

3. DO NOT use stale or contaminated gasoline or an oil/gasoline mixture.

4. When installing the Sediment Cup retaining bolt, ensure the threads of the bolt are

aligned with the threads on the Fuel Valve so as not to “cross-thread the nut.”

1. Gasoline is highly ammable and explosive. You can be burned or seriously

injured when handling fuel.

2. To fuel, stop engine if running and allow it to cool.

3. Refuel in a well-ventilated area

4. Keep gasoline away from appliance pilot lights, barbecues, electric

appliances, power tools, etc.

5. Wipe up spills immediately.

(A)

Place Fuel Valve in the OFF

position.

Loosen the Fuel

Sediment Cup. (See Engine

Manual for details)

(B)

Spark Plug Adjustment and Replacement

CAUTION

NOTES:

DO NOT work around the engine while hot.

1. When installing the Spark Plug, ensure the threads of the plug are aligned

with the threads in the engine so as not to “cross-thread” the plug.

2. See Engine Manual for specic details.

38

Page 39

MK-SCARIFIER MAINTENANCE

Engine Air Filter Inspection Cleaning and Replacement

Refer to Engine Manual.

Cutting Drum Change-out

WARNING

NOTE:

(A)

Remove the Shaft Cover,

Rear Retaining Bolt and

loosen the Front Retaining

Bolt using 9/16 wrenches

and/or sockets.

blades, bits, cutters, and the like.

DO NOT Rotate saw to rest on handlebar. Engine damage will result.

Disconnect the tool before servicing and when changing accessories, such as

(B)

Remove the Shaft, Retaining Nut Cover from the Belt

Guard to expose the Shaft,

Retaining Nuts.

(C)

Using a 15/16-inch socket,

loosen the Outer Shaft, Re-

taining Nut. Retaining Nuts are

left hand threaded.

(D)

Place an Index Finger on the

end of the Cutting Drum, Shaft.

(G)

Remove the Cutting

Drum and Shaft.

Remove the Outer Shaft, Retaining Nut using your Middle

Finger as shown.

Recongure the Cutting

Drum as needed.

(E)

(H)

39

(F)

Repeat Step C through E for

the Inner Shaft, Retaining Nut.

(I)

Install the Cutting Drum into the

Scarier; align the Cutting Drum

with the Shaft-side Bearing and

install the Cutting Drum, Shaft.

Page 40

MK-SCARIFIER MAINTENANCE

(J)

Verify the Cutting Drum and

Shaft are fully installed and

seated.

(M)

Obtain the Shaft, Outer

Retaining Nut.

(K)

Install the Shaft, Inner Re-

taining Nut.

(N)

Install the Shaft, Outer

Retaining Nut.

(L)

Using a 15/16-inch socket

tighten the Shaft, Inner

Retaining Nut.

(O)

Using a 15/16-inch socket

tighten the Shaft, Outer

Retaining Nut.

(P)

Install the Shaft, Retaining

Nut Cover onto the

Belt Guard.

Pivot the Shaft Guard Cover

into position and install the

Rear Retaining Bolt.

(Q)

(R)

Tighten the Shaft Guard Cover

Retaining Bolts using 9/16

wrenches and/or sockets.

40

Page 41

MK-SCARIFIER MAINTENANCE

ReconguretheCuttingDrum

(A)

Remove the Cutting

Drum (See Cutting Drum

Change-out).

(D)

If present, remove the three

Flat Washer Spacers.

(B)

Place the Cutting Drum

on end and remove the 3

Retaining Screws using a

7/16-inch wrench.

(E)

Place the Retaining Ring and

the 3 Flat Washer Spacers in

a secure location.

(C)

Remove the Retaining Ring

from the Cutting Drum.

(F)

Pull the Cutting Disc Shafts

and remove the Cutting Discs

and Disc Spacers.

(G)

Assemble the Cutting Drum

using Cutting Discs and Disc

Spacers (See Cutting Drum

Conguration).

Continue with Step B

until the Cutting Drum as-

sembly is complete.

(H)

41

(I)

Place the Cutting Drum on

the closed end, with the open

end facing upward.

Page 42

MK-SCARIFIER MAINTENANCE

(J)

Obtain the Retaining Ring

and Flat Washer Spacers.

(M)

Install the 3 Retaining Screws

into the Cutting Drum (do not

cross-thread the screws).

(K)

Install the 3 Flat Washer

Spacers (if used) over the

3 Retaining Ring, Retaining

Screw holes.

(N)

Tighten the 3 Retaining

Screws using a 7/16-inch

wrench.

(L)

Place the Retaining Ring

onto the end of the Cutting

Drum, aligning the Retaining

Screw Holes.

(O)

Install the Cutting Drum

(See Cutting Drum Change-

out).

42

Page 43

MK-SCARIFIER MAINTENANCE

Dust Screen Brush Change Out

NOTE: The four (4) Brushes should be replaced at the same time (MK Diamond Part # 160300).

(A)

Inspect the Dust Screen

Brushes for wear.

(D)

Obtain Replacement

Brushes.

(B)

Loosen the end of each

Brush Holder with a Flat

Blade Screwdriver.

(E)

Slide the new Brushes into

the Brush Holders.

(C)

Slide each Brush out of its

Brush Holder.

(F)

Pinch the end of the Brush

Holders to hold each Brush in

place.

43

Page 44

MK-SCARIFIER MAINTENANCE

Front Wheel Change Out

NOTE: The two (2) Front Wheels should be replaced at the same time (MK Diamond Part # 138529).

(A)

Rotate the Scarier to rest on

the Handle/Stand.

(D)

Obtain 2 replacement Wheels

and remove the Dust Cover

from one side of each Wheel.

(B)

Loosen the Retaining Collar

of each Wheel using a 5/32-

inch Allen Wrench.

(E)

Seat the Front Wheels into

the Wheel-well with the Dust

Cover side

facing inward.

(C)

Move the Retaining Collars

toward the center of the Axle

and then slide the Axle out of

the Scarier.

(F)

Slide the Axle through one

Wheel, Install the 2 Retain-

ing Collars and then slide

the Axle through the second

Wheel.

(G)

Push the Retaining Collars

against the Front Wheels

and then tighten them with a

5/32-inch Allen Wrench.

44

Page 45

MK-SCARIFIER MAINTENANCE

Rear Wheel Change Out

NOTE: The two (2) Rear Wheels should be replaced at the same time (MK Diamond Part # 158520).

(A)

Rotate to rest on the Handle/

Stand.

(D)

Remove the Rear

Wheel Truck Assembly Re-

taining Bolts.

(B)

Locate the Rear Wheel

Truck Assembly.

(E)

Lower the Rear Wheel Truck

Assembly.

(C)

Remove the Rear Wheel

Truck Assembly Retain-

ing Nuts using 3/4-inch

wrenches.

(F)

Remove the Rear Wheel

Retaining Cotter Pin, Shim

Washer and Rear Wheel from

each side of the Assembly.

(G)

Obtain replacement wheels.

Install the new Rear Wheel,

Shim Washer and Cotter Pin

on each side of the Assem-

(H)

bly.

45

(I)

Install the Rear Wheel Truck

Assembly Retaining Nuts and

Bolts removed in Steps C

and D using

3/4-inch wrenches.

Page 46

MK-SCARIFIER MAINTENANCE

V-Belt Inspection, Adjustment and Replacement

In order to ensure the Scarier operates at peak efciency, the power transmission V-belt should be

inspected monthly and changed if any signs of damage and/or excessive wear is observed.

NOTE: When a new belt is installed, it should be inspected and re-tensioned after the rst forty-eight

(48) hours of operation.

(A)

Remove the Cutting

Drum (See Cutting Drum

Change-out).

(D)

Inspect the V-belt for exces-

sive wear, cracks and cuts –

if worn, proceed to step F.

(B)

Locate and remove the Belt

Guard Retaining Screws us-

ing a 9/16-wrench.

(E)

Check V-belt for proper ten-

sion, if tension correct, go to

step O (proper tension is 1/2-

inch deection of the belt).

(C)

Remove the Belt Guard.

(F)

Locate the Engine Mounting

Plate Bolts on both sides.

(G)

Loosen the Front Engine

Mounting Plate Bolts on

both sides using a 9/16-inch

wrench.

Loosen the Rear Engine

Mounting Plate Bolts on

both sides using a 9/16-inch

(H)

wrench.

46

(I)

Locate the V-belt Adjusting

Screw Lock Nut inside

the Cutting Drum Well.

Loosen the nut using a

9/16-inch wrench.

Page 47

MK-SCARIFIER MAINTENANCE

(J)

Locate the V-belt Adjust-

ing Screw inside the Cut-

ting Drum Well. Loosen the

screw using a 9/16-inch

wrench.

(M)

Obtain and install a new

V-belt onto the Engine and

Cutting Drum Pulleys.

(K)

Remove the V-belt from the

Engine and Cutting Drum

Pulleys.

(N)

Verify the V-belt is seated in

all grooves of the Engine and

Cutting Drum Pulleys.

(L)

Clean and verify the align-

ment of the Engine and Cut-

ting Drum Pulleys.

(O)

Pull the front of the Engine

Mounting Plate away from

the Frame to tension the

V-belt.

(P)

Tighten the V-belt Adjust-

ing Screw one turn using a

9/16-inch wrench.

Verify the tension of the

V-belt (proper tension is

1/2-inch deection of

(Q)

the belt).

47

(R)

Repeat Steps P and Q until

proper tension has been

reached (proper tension is

1/2-inch deection of the

belt).

Page 48

MK-SCARIFIER MAINTENANCE

(S)

Tighten the V-belt Adjust-

ing Screw Lock Nut using a

9/16-inch wrench.

(V)

Tighten the Belt

Guard Retaining Screws us-

ing a 9/16-wrench.

(T)

Tighten the Engine Mounting

Plate Bolts on both sides us-

ing a 9/16-inch wrench.

(W)

Install the Cutting Drum; (See

Cutting Drum Change-out).

(U)

Install the Belt Guard.

48

Page 49

NOTES

49

Page 50

MK-SCARIFIER EXPLODED VIEW

50

Page 51

MK-SCARIFIER EXPLODED VIEW

51

Page 52

MK-SCARIFIER PARTS LIST

ITEM DESCRIPTION PART# QTY.

A ASSEMBLY, ACCESSORIES n/a -

A1 PALLET, SHIPPING (NOT SHOWN) 158535 1

A2 CARTON, MK SCARIFIER SHIPPING (NOT SHOWN) 158536 1

A3 CARTON, SCARIFIER DRUM (NOT SHOWN) 158825 1

A4 MANUAL, OWNER’S (NOT SHOWN) 158537 1

A5 TUBE, OWNER’S MANUAL (NOT SHOWN) 155419 1

A6 (REFERENCE ONLY) SPACER, HARDEN STEEL 158575 A7 (REFERENCE ONLY) STAR, 5 POINT CARBIDE TIP (1 ¾ OD X 5/8” ID) 158492 A8 (REFERENCE ONLY) STAR, 6 POINT CARBIDE TIP (1 ¾ OD X 5/8”ID) 158493 A9 (REFERENCE ONLY) CUTTER, 18 SHARP TOOTH STEEL (2” OD X 9/16”ID) 158494 -

A10 (REFERENCE ONLY) CUTTER, 12 BLUNT TOOTH STEEL (2” OD X 5/8”ID) 158495 -

B ASSEMBLY, FRAME 158609 -

B1

BA1

B2 PLATE, SERIAL NUMBER 157458 1

B3 #7 X 5/16 DRIVE SCREW 227214 4

B4 CAP, 2”OD VINYL 158914 1

B5 LABEL, 1 ¾ X 5” MK LOGO 154335 1

B6 LABEL, CAUTION, HANDS AND FEET 155585 1

B7 LABEL, CAUTION, DO NOT OPERATE WITH GUARDS REMOVED 155587 1

FRAME WELDMENT (MK RED)

FRAME WELDMENT (ORANGE)

158098

158098-OR

1

1

C ASSEMBLY, FRAME DUST SCREEN n/a -

C1 SCREEN, RIGHT SIDE, FRAME DUST 158594 1

C2 SCREEN, LEFT SIDE, FRAME DUST 158595 1

C3 SCREEN, FRONT / BACK, FRAME DUST 158596 2

C4 SCREW, 1/4-20 X 1/2 PAN HEAD PHILLIPS CAP 155452 4

C5 SCREW, 1/4-20 X 1/2 FLAT HEAD PHILLIPS CAP 155812 4

C6 NUT, 1/4-20 KEPS 153941 8

C7 WASHER, 1/4 SAE FLAT 151915 8

D ASSEMBLY, FRONT AXLE n/a -

D1 WHEEL, FRONT, 5 DIA. X 2 138537 2

D2 COLLAR, 3/4 SET 153814 2

D3 AXLE, 3/4 DIA. FRONT 158522 1

E ASSEMBLY, TRUCK n/a 1

E1 TRUCK, WELDMENT 158099 1

E2 WASHER, 3/4 SHIM 153699 ~

E3 WHEEL, 4 DIA. X 2 158520 2

E4 PIN, COTTER, 1/8 X 1 ½ 153861 2

E5 BOLT, 1/2-13 X 4 HEX HEAD TAP 156626 2

E6 WASHER, 1/2 SAE FLAT 150924 4

E7 NUT, 1/2-13 TOP LOCK, HEX 153943 2

52

Page 53

MK-SCARIFIER PARTS LIST

ITEM DESCRIPTION PART# QTY.

F ASSEMBLY, CONSOLE n/a -

F1

FA1

F2 LABEL, CONTROL 158287 1

F3 LABEL, DEPTH LOCK 155577 1

G ASSEMBLY, STANDARD WIRE HARNESS N/A 1

G WIRE HARNESS, STANDARD, HONDA 158232 1

G SWITCH, ENGINE ON/OFF 157851 1

H ASSEMBLY, THROTTLE HONDA - -

H1 SCREW, 10-24 X 1/2 PAN HEAD PHILLIPS CAP 151744 2

H2 NUT, 10-24 CLIP 155407 2

H3 ASSEMBLY, THROTTLE HEAD 155406 1

H4 CABLE, THROTTLE, HONDA 154158 1

J ASSEMBLY, DEPTH CONTROL - -

- SUBASSEMBLY, DEPTH CONTROL WHEEL 155457 1

J1 WHEEL, DEPTH CONTROL 158574 1

J2 SCREW, 3/8-16 X 1/2 SOCKET HEAD SET 153710 1

J3 KNOB, 1” BALL 158519 1

J4 SCREW, 1/2 X 3/4 SOCKET HEAD SHOULDER, W/ 3/8-16 X 5/8 THREAD 156177 1

- SUBASSEMBLY, DEPTH CONTROL TUBE 155460 1

J5 TUBE, DEPTH CONTROL 155049 1

J6 NUT, 3/8-16 NYLOCK HEX 152505 1

J7 SCREW, 3/8-16 X 2 HEX HEAD CAP 153485 1

J8 BEARING, FLANGE, W/ ZERK FITTING 155151 1

J9 SCREW, 3/8-16 X 1 1/4 HEX HEAD CAP 150774 2

J10 WASHER, 3/8 SAE FLAT 150923 1

J11 NUT, 3/8-16 NYLOCK HEX 152505 2

J12 SPACER, 1.5” DEPTH CONTROL 155161 1

J13 SCREW, 15” DEPTH CONTROL 158521 1

WELDMENT, CONSOLE (MK RED)

WELDMENT, CONSOLE (ORANGE)

158100

158100-OR

1

1

K ASSEMBLY, DEPTH LOCK N/A -

K1 LOCK, 8-7/8 DEPTH CONTROL 157846 1

K2 KNOB, DEPTH LOCK 155845 1

K3 THRUST WASHER 155238 1

K4 NUT, 3/8-16 NYLOCK HEX 152505 1

L ASSEMBLY, QUICK LIFT AND LOWERING LEVER N/A -

L1 LEVER 158102 1

L2 KNOB, 2” BALL 158519 1

L3 SCREW, 3/8-24 X 1 HEX HEAD CAP 157803 1

L4 WASHER, 3/8 SAE FLAT 150923 1

L5 WASHER, 3/8 SPLIT LOCK 150925 1

L6 PIVOT, SHAFT 158288 1

53

Page 54

MK-SCARIFIER PARTS LIST

ITEM DESCRIPTION PART# QTY.

L7 SCREW, 1/2-13 X 1 1/4 HEX HEAD CAP 153532 1

L8 WASHER, 1/2 SPLIT LOCK 153524 1

L9 WASHER, 1/2 SAE FLAT 150924 1

M ASSEMBLY, ENGINE MOUNT N/A -

M1

MA1

M2 BOLT, 3/8-16 X 1 HEX HEAD CAP 152507 4

M3 WASHER, 3/8 SAE FLAT 150923 9

M4 WASHER, 3/8 SPLIT LOCK 150925 3

M5 NUT, 3/8-16 NYLOCK HEX 152505 2

M6 NUT, 3/8-16 HEX 101188 3

M7 BOLT, 3/8-16 X 3 HEX HEAD TAP 155830 1

M8 LABEL, CAUTION, BELT TENSION 155583 1

M9 LABEL, CAUTION, SPARKPLUG 155579 1

N ASSEMBLY, ENGINE, 9HP HONDA 155396-MK 1

N1 ENGINE, HONDA GX240 9 HP W/ CYCLONE FILTER 155396 1

N2 DEFLECTOR, HONDA 155375 1

N3 SCREW, 6-32 X 3/8 PAN HEAD PHILLIPS SELF-TAPPING CAP 153466 3

N4 PULLEY, 2 ½”OD, POLY-V 158470 1

N5 POLLY-V-BELT (350J16) 158469 1

N6 NUT, 3/8-16 HEX 101188 4

N7 WASHER, 3/8 SPLIT LOCK 150925 4

N8 WASHER, 3/8 SAE FLAT 150923 8

N9 SCREW, 3/8-16 X 2 HEX HEAD CAP 153485 4

N10 PIN, THROTTLE CONTROL 151284 1

N11 SCREW, 8-32 X 1/2 PAN HEAD PHILLIPS CAP 152517 1

N12 PIN, COTTER, 1/16 X ¾ 152518 1

N13 PLUG, ¾ FLUSH HEAD BUTTON 156615 1

N14 OIL DRAIN, M12 X 3/8 PUSH 157577-02 1

N15 LABEL, CAUTION, HOT SURFACE, 1.5 X 3.0 155578 1

N16 LABEL, WARNING, REFUELING, 1.5 X 3.0 155580 1

N17 LABEL, DANGER, CALIFORNIA, 1.5 X 3.0 155581 1

N18 LABEL, DANGER, LETHAL EXHAUST, 1.5 X 3.0 155582 1

ENGINE, MOUNT (MK RED)

ENGINE, MOUNT (ORANGE)

158101

158101-OR

1

1

P ASSEMBLY, BELT GUARD N/A -

P1

PA1

P2 SCREW, 3/8-16 X 1 HEX HEAD CAP 152507 3

P3 WASHER, 3/8 SAE FLAT 150923 3

P4 WASHER, 3/8 SPLIT LOCK 150925 3

P5 PLUG, 2” DIA REMOVABLE 158538 1

P6 LABEL, CAUTION, BELT TENSION 155583 1

P7 LABEL, CAUTION, GUARDS IN PLACE 155587 1

GUARD, BELT (MK RED)

GUARD, BELT (ORANGE)

158104

158104-OR

54

1

1

Page 55

MK-SCARIFIER PARTS LIST

ITEM DESCRIPTION PART# QTY.

Q ASSEMBLY, SHAFT GUARD N/A -

Q1

QA1

Q2 SCREW, 3/8-16 X 1 1/4 HEX HEAD CAP 150774 2

Q3 WASHER, 3/8 SAE FLAT 150923 4

Q4 WASHER, 3/8 SPLIT LOCK 150925 2

Q5 NUT, 3/8-16 HEX 101188 2

R ASSEMBLY, DRUM BEARING N/A -

R1 HOUSING, BEARING 158467 2

R2 BEARING 158468 1

R3 BEARING, 1” HEX ID 160834 1

R4 SHAFT, PULLEY 158466 1

R5 SCREW, 3/8-24 X 3/4 SOC HEAD CAP 158496 4

R6 PULLEY, 4.0”OD, POLY-V (16J40 X 1 ¼ BORE) 158472 1

R7 SCREW, 3/8-24 X 1 HEX HEAD CAP 157803 8

R8 WASHER, 3/8 SAE FLAT 150923 8

R9 WASHER, 3/8 SPLIT LOCK 150925 8

GUARD, SHAFT (MK RED)

GUARD, SHAFT (ORANGE)

158581

158581-OR

1

1

S ASSEMBLY, 8” DRUM 158460 1

S1 DRUM, WELDMENT, 8” 158461 1

S2 BUSHING, DRUM (.515 ID) OR (33/64 ID) 158462 18

S3 SHAFT, 8” HARDEN STEEL 158463 6

S4 RING, DRUM RETAINING 158464 2

S5 SCREW, 5/16-18 X ¾ TAP, 151369 6

S6 WASHER, 5/16 SPLIT LOCK 151747 6

S7 WASHER, 5/16 FLAT SAE 151754 6

S8 BUSHING, FLANGED (.515 ID) OR (33/64 ID) 165248 12

T ASSEMBLY, 8” DRUM, DRIVE SHAFT N/A -

T1 SHAFT, 8” DRUM, DRIVE 158465 1

T2 NUT, 5/8-11 HEX JAM (LEFT HAND THREAD) 158577 2

U ASSEMBLY, HANDLEBAR N/A -

U1 HANDLEBAR 158359 1

U2 HANDGRIP 150842 2

U3 SCREW, 3/8-16 X 1 HEX HEAD CAP 156602 2

U4 WASHER, 3/8 SPLIT LOCK 150925 4

U5 WASHER, 3/8 SAE FLAT 150923 4

55

Page 56

MK-SCARIFIER EXPLODED VIEW

MK SG-5PH 220 V NO DRUM PART # 170573

15

9

5

3

2

7

14

1

10

6

8

3

2

5

16

12

4

11

13

ITEM DESCRIPTION PART# QTY.

1 KEY, 1/4 SQR X 1 - 3/4 150796 1

2 WASHER, FLAT, SAE, 3/8 150923 11

3 WASHER, LOCK, SPLIT, 3.8 150925 11

4 WASHER, FLAT, SAE, 1/4 151915 2

5 SCREW, HEX HD CAP, 3.8 - 16 X 1 152507 11

6 WASHER, LOCK, SPLIT, 1/4 152591 2

7 SCREW, 5/16 - 18 X 1/2 SOCKET HEAD SET 152607 4

8 SCREW, HEX HD, TAP, 1/4 - 20 X 1 152676 2

9 MTR, 5PH 230V 1PH 50PZ 152759 1

10 PLATE, MOTOR MOUNT (COMP) 155824 1

11 GUARD, BELT (COMP) 158104 1

12 BELT, 16J350 158469 1

13 PLUG, 2” DIA, REMOVABLE 158538 1

14 PULLEY, 16J25 X 1 - 1/8 BORE 160411 1

15 LABEL, 230V 168652 1

16 MK-SG-II LESS ENGINE 170578 1

56

Page 57

MK-SCARIFIER EXPLODED VIEW

MK SG-II LESS ENGINE PART # 170578

12

22

19

17

9

1

10

2

4

18

21

3

23

14

2

11

13

4

6

5

8

15

4

2

2

16

20

ITEM DESCRIPTION PART# QTY.

1 SCREW, 3/8 - 16 X 1 - 1/4 HEX HEAD CAP 150774 6

2 WASHER, FLAT, SAE 3/8 150923 25

3 WASHER, LOCK, SPLIT, 3/8 150925 15

4 NUT, HEX, NYLK, 3/8 - 16 152505 8

5 WASHER, 1/2 SPLIT LOCK 152524 1

6 SCREW, 1/2 - 13 X 1 - 1/4 HEX HEAD CAP 153532 1

7 NUT, 1/2 - 13 HEX 153943 2

8 LINKAGE, DEPTH FEED 1600/9000 155049 1

9 BEARING, FHSLF 204 - 12G FLANGE 155151 1

10 SPACER, DEPTH CONTROL 155161 1

11 WASHER, THRUST 155238 1

12 ASSY, CRANK WHEEL, 3/4 - 10 155457 1

13 KNOB, AD, 5 PRONG COMP 155845 1

14 SCREW, HEX HD, 3/8 - 24 X 1 157803 9

15 LOCK, DEPTH CONTROL, 8-7/8 157846 1

16 WELDMENT, MAIN FRAME 158098 1

17 WELDMENT, CONSOLE 158100 1

18 LEVER, ENGAGEMENT 158102 1

19 PIVOT BAR, ENGAGEMENT 158288 1

20 HANDLEBAR 158359 1

21 KNOB, BALL, 2”, 3/8 - 16 INSERT 158519 1

22 STUD, 3/4 - 10 X 17” 158521 1

23 GRIP, HANDLE 229413 2

57

Page 58

MK-SCARIFIER EXPLODED VIEW

MK SG-II LESS ENGINE PART # 170578

26

30

14

27

11

11

15

31

11

3

5

34

25

9

17

10

35

8

5

7

22

5

38

16

37

1

7

36

19

20

7

22

6

5

21

29

13

28

23

2

32

4

33

12

24

18

58

Page 59

MK-SCARIFIER PARTS LIST

MK SG-II LESS ENGINE PART # 170578

ITEM DESCRIPTION PART# QTY.

1 NUT, HEX, 3/8 - 16 101188 2

2 WHEEL, FRONT 5” x 2” W 138537 2

3 SCREW, 3/8 - 16 X 1 - 1/4 HEX HEAD CAP 150774 2

4 KEY, 1/4 SQR X 1 - 3/4 150796 1

5 WASHER, FLAT, SAE, 3/8 150923 12

6 WASHER, 1/2 SAE FLAT 150924 4

7 WASHER, LOCK, SPLIT, 3/8 150925 10

8 WASHER, FLAT, SAE, 1/4 151915 8

9 NUT, HEX, NYLK, 3/8 - 16 152505 1

10 SCREW, HEX HD, CAP, 3/8 - 16 X 2 153485 1

11 SHIM, .045 THK .750 ID 1.250 OD 153699 6

12 SCREW, SET, SOC, CUP, 3/8 - 16 X 1/2 153710 2

13 COLLAR, SET, 3/4” 153814 2

14 FITTING, 1/4 - 28 GREASE 153852 2

15 PIN, COTTER 18 X 1 - 1/2 153861 2

16 NUT, HEX, TW, 1/4 - 20 153941 8

17 NUT, 1/2 -13 HEX 153943 2

18 LINKAGE, DEPTH FEED 1600/9000 155049 1

19 SCREW, PAN HD, CAP, 1/4 - 20 X 1/2 155452 4

20 SCREW, FLAT HEAD, 1/4 - 20 X /12 PHIL 155812 4

21 SCREW, HEX HD, TAP, 1/2 - 13 X 4 156626 2

22 SCREW, HEX HD, 3/8 - 24 X 1 157803 8

23 WELDMENT, MAIN FRAME 158098 1

24 WELDMENT, TRUCK, SCARIFIER 158099 1

25 SHAFT, DRUM HEX, SCARIFIER 158465 1

26 SHAFT, PULLEY 158466 1

27 HOUSING, BEARING 158467 2

28 BEARING, 207 SERIES 158468 1

29 PULLEY, 16J40 X 1 -1/4 BORE 158472 1

30 SCREW, SOC, HD, CAP, 3/8 - 24 X 3/4 158496 4

31 WHEEL, 4” DIA X 2” W, 3/4 ID BEARING 158520 2

32 AXLE, FRONT 158522 1

33 NUT, HEX JAM 5/8 - 11 UNC LH 158577 2

34 GUARD, SHAFT (COMP) 158581 1

35 ASSY, DUST SCREEN, RIGHT SIDE 158594 1

36 ASSY, DUST SCREEN, LEFT SIDE 158595 1

37 SCREEN, FRONT/BACK, DUST 158596 2

38 BEARING, 1” ID - UCS207 - 1” HEX 160834 1

59

Page 60

MK-SCARIFIER DRUM ASSEMBLIES

ITEM DESCRIPTION PART# QTY.

ASSEMBLY, 8” DRUM, 84 X 5-POINT CARBIDE STAR 158583

1 Assembly, 8” Drum 158460 1

2 Cutter, 5 Point Carbide 158492 84

3 Spacer, 1/2 Harden Steel 158575 192

60

Page 61

MK-SCARIFIER DRUM ASSEMBLIES

LONG STACKS: 8 CUTTERS, 18 SPACERS (3 OUTSIDE, 1 INSIDE, 2 BETWEEN EACH CUTTER)

2

3

1

SHORT STACKS: 6 CUTTERS, 14 SPACERS (3 INSIDE, 1 OUTSIDE, 2 BETWEEN EACH CUTTER).

ITEM DESCRIPTION PART# QTY.

Assembly, 8” Drum, 84 x 6-Point Carbide Star 158584

1 Assembly, 8” Drum 158460 1

2 Star, 6 Point Carbide 158493 84

3 Spacer, 1/2 Harden Steel 158575 192

61

Page 62

MK-SCARIFIER DRUM ASSEMBLIES

ITEM DESCRIPTION PART# QTY.

Assembly, 8” Drum, 114 x 18 Sharp Tooth Cutter 158585 -

1 Assembly, 8” Drum 158460 1

2 Cutter, 18 Sharp Tooth Steel 158494 114

3 Spacer, 1/2 Harden Steel 158575 216

62

Page 63

MK-SCARIFIER DRUM ASSEMBLIES

ITEM DESCRIPTION PART# QTY.

Assembly, 8” Drum, 114 x 12 Blunt Tooth Cutter 158586 -

1 Assembly, 8” Drum 158460 1

2 Cutter, 12 Blunt Tooth Steel 158495 114

3 Spacer, 1/2 Harden Steel 158575 234

63

Page 64

MK-SCARIFIER THEORY

THEORY OF SCARIFYING

The purpose of scarifying is to make scratches, supercial incisions or roughen a surface. There

are a number of ways in which a concrete surface can be roughened, the advantage of a scarifying

machine is that it allows the user to control the amount of material removed over a large area.

A scarier can be used to clean, level, roughen, groove, slot, or prepare a concrete surface for coating. The scarier is able to perform each of these operations by using different types of cutting discs

that are setup in different congurations on a cutting drum.

By varying the type of cutting disc and conguration of the cutting drum, a user can:

• Clean a surface of oil, grease, or paint prior to applying a coating or sealer

• Level high spots or misaligned joints

• Remove carpet or tile adhesives as well as paint

• Roughen or create non-slip surfaces

• Slot concrete surfaces for overlays

• Cut safety grooves to minimize slippage

Scarier cutting discs are either carbide tipped or steel, and are star-shaped in design. Cutting discs

may have ve or more “points,” and the ends may be round, pointed or blunt depending on application.

Cutting discs designed with carbide inserts tend to be the most commonly used due to their extended

life. As the disc is used, more of the carbide insert is exposed until the disc is worn below the bottom

of the insert. Once worn below the insert, the disc must be replaced.

64

Page 65

MK-SCARIFIER ACCESSORIES

ITEM

1.

2.

3.

4.

NUMBER DESCRIPTION

Five Point Carbide Tip Cutting Disc

Used for grinding, leveling, grooving, clean-

158492

ing and surface preparation

Average Life: 6000 to 8000 Sq Ft

Six Point Carbide Tip Cutting Disc

Used for grinding, leveling, grooving, clean-

158493

ing and surface preparation

Average Life: 8000 to 10000 Sq Ft

Eighteen Point Sharp Tooth Steel Disc

Used for roughening, oil removal, carpet and

158494

tile adhesive removal, cleaning and surface

preparation

Average Life: 500 to 800 Sq Ft