Page 1

www.mkdiamond.com

MK-EZ PROFILER

OWNER'S MANUAL, PARTS LIST &

OPERATING INSTRUCTIONS

Revision 100

Manual Part No. 170565-OM

Caution: Read all safety and operating instructions

before using this equipment. This owners manual MUST

accompany the equipment at all times.

12.2013

Page 2

INTRODUCTION

Congratulations on your purchase of a MK-EZ Profiler. We are certain that you will be pleased

with your purchase. MK Diamond takes pride in producing the finest construction power tools and

diamond blades in the industry.

Operated correctly, your MK-EZ Profiler should provide you with years of service. In order to help

you, we have included this manual. This owners manual contains information necessary to operate

and maintain your MK-EZ Profiler safely and correctly. Please take a few minutes to familiarize

yourself with the MK-EZ Profiler by reading and reviewing this manual.

If you should have questions concerning your MK-EZ Profiler, please feel free to call our friendly

customer service department at: 800 421-5830

Regards,

MK Diamond

NOTE THIS INFORMATION FOR FUTURE USE:

MODEL NUMBER:

SERIAL NUMBER:

PURCHASE PLACE:

PURCHASE DATE:

NOTE: For your (1) one year warranty to be effective, complete the warranty card

(including the Serial Number) and mail it in as soon as possible.

2

Page 3

TABLE OF CONTENTS

SAFETY

Safety Messages 4

Damage Prevention Message 4

General Safety Precautions 4-7

California Proposition 65 Message 8

Electrical Requirements 9-12

Safety Label Locations 14

Product Specications 15

UNPACKING, TRANSPORT and ASSEMBLY

Unpacking 16

Contents 16

Transport 16

STARTUP, ADJUSTMENT, OPERATION and SHUTDOWN

Water Pump Installation 17

Cutting Head Installation 17-18

Prole Tool Installation 18

Fence Installation 19

Prole Adjustment 20

Connecting the water 20

Water Setup 21

Pre-Start inspection 21

Water Nozzle Adjustment 22

Proling 22

EXPLODED VIEW AND PARTS LIST

Exploded View & Parts List 24-30

ACCESSORIES

Accessories 32

ORDERING and RETURN INSTRUCTIONS

Ordering Information 34

Return Material Policy 34

Packaging Instructions 34

Authorized Service Centers 35

Contact & Warranty 35

3

Page 4

MK-EZ PROFILER SAFETY

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

Read and follow all safety, operating and maintenance instructions. Failure to read and follow

these instructions could result in injury or death to you or others. Failure to read and follow these

instructions could also result in damage and/or reduced equipment life. Safety warnings and

guidelines do not by themselves eliminate danger. They are not substitutes for proper accident

prevention procedures and good judgement.

SAFETY MESSAGES

A safety message alerts you to potential hazards that could hurt you or others. Each safety message is

preceded by a safety alert symbol ( ) and one of three words: DANGER, WARNING, or CAUTION.

DANGER You WILL be KILLED or SERIOUSLY INJURED if you DO NOT follow directions.

WARNING

You CAN be KILLED or SERIOUSLY INJURED if you DO NOT follow directions.

You CAN be INJURED if you DO NOT follow directions. It may also be used to

CAUTION

alert against unsafe practices.

DAMAGE PREVENTION AND INFORMATION MESSAGES

A Damage Prevention Message is to inform the user of important information and/or instructions that

could lead to equipment or other property damage if not followed. Information Messages convey

information that pertains to the equipment being used. Each message will be preceded by the word

NOTE, as in the example below.

NOTE:

Equipment and/or property damage may result if these instructions are not followed.

GENERAL SAFETY PRECAUTIONS AND HAZARD SYMBOLS

In order to prevent injury, the following safety precautions and symbols should be followed at all times!

SAFETY PRECAUTIONS

ALWAYS read this Owner’s Manual before operating the machine. DO NOT operate or

service this equipment before reading this entire manual. Read and understand all warnings, instructions and controls on the machine. Know how to stop the equipment quickly in

case of emergency. It is the operators responsibility to use this machine under safe working conditions and conform with federal, state and local codes or regulations pertaining to

safety, air, pollution, noise etc...

ALWAYS keep the Blade and Belt Guards in place. DO NOT operate this machine with any

guard or safety device removed. A Guard, or any damaged part should be repaired or

replaced immediately.

NEVER operate this equipment without proper protective clothing, shatterproof

glasses, steel-toed boots and other protective devices required by the job. Non-slip

foot wear is recommended.

4

Page 5

MK-EZ PROFILER SAFETY

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

(

(

)

)

(

(

)

)

ON

(

(

)

)

PERSONAL PROTECTIVE EQUIPMENT

ALWAYS wear approved respiratory, head, ear and eye protection

when operating this machine.

ON

ACCIDENTAL STARTS!

Before starting the engine/motor, be sure the ON/OFF switch is in the OFF position to prevent accidental starting. Place the ON/OFF switch in the OFF position before performing any

service operation. ALWAYS place the power ON/OFF switch in the OFF position when the

machine is not in use.

ROTATING PARTS

Keep hands, feet, hair, and clothing away from all moving parts to prevent injury. Never operate the motor with covers, shrouds, or guards, removed.

HOT PARTS!

Engine components can become extremely hot from operation. To prevent severe burns,

do not touch these areas while the engine is running, or immediately after it is turned off.

Never operate the engine with heat shields removed.

OVER SPEED

)

)

(

(

NEVER tamper with the governor components or settings to increase the maximum speed.

Severe personal injury and damage to the engine or equipment can result if operated at

speeds above maximum.

ELECTRICAL SHOCK

NEVER touch electrical wires or components while the engine is running. Exposed, frayed or

worn electrical wiring and plugs can be sources of electrical shock which could cause severe

injury or burns. Do not touch the plug with wet hands.

ALWAYS avoid inhalation of and skin contact with silica dust and/or mist. Provide proper

dust removal. Use dust-collection system when applicable.

NEVER operate the machine in an explosive atmosphere or near combustible materials.

Sparks from the cutting-action of this machine can ignite flammable materials, liquids, gases

or dust.

This equipment should not be operated by persons under 18 years of age.

KEEP CHILDREN AWAY

All visitors and children should be kept a safe distance from work area. Maintain a safe

operating distance to other personnel.

MAKE THE WORKSHOP KID PROOF

Make the workshops kid proof by using padlocks, master switches or by removing starter keys.

DO NOT FORCE THE TOOL

A power tool will do a job better and safer operating at the rate for which it was designed.

DO NOT force a tool or an attachment to do a job that it was not designed to do.

5

Page 6

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

MK-EZ PROFILER SAFETY

USE PROPER APPAREL

DO NOT wear loose clothing, gloves, neckties, rings, bracelets, or other jewelry that may

be caught in moving parts. Non-slip footwear is recommended. Wear protective hair covering to contain long hair.

SECURE WORK

Clamps or a vise should be used to hold work whenever practical. Keeping your hands free

to operate a power tool is safer.

DO NOT OVERREACH

Keep proper footing and balance at all times by not overreaching.

DISCONNECT TOOLS

Power tools should always be disconnected before servicing, adjusting or when changing

accessories, such as blades, bits, cutters, and the like.

MAINTAIN TOOLS WITH CARE

Keep tools clean and maintained for the best and safest performance. Always follow

maintenance instructions and examine the machine before use. If any abnormal vibrations

or noises occurs, turn off machine immediately and have the problem corrected before

further use.

REMOVE ADJUSTING KEYS AND WRENCHES

Form a habit of checking to see that keys and adjusting wrenches are removed from

the power tool before it is turned on.

KEEP WORK AREA CLEAN

Cluttered work areas and benches invite accidents. Keep area around machine clear of

obstructions which could cause persons to fall.

DO NOT USE IN DANGEROUS PLACES

DO NOT operate equipment in dangerous or hazardous environments. DO NOT use power

tools in damp or wet locations nor expose them to rain. Always keep the work area well

lighted.

USE RECOMMENDED ACCESSORIES

Consult the owner’s manual for recommended accessories. Using improper accessories

may increase the risk of personal or by-stander injury. Unauthorized equipment

modifications will void all warranties. Manufacturer does not assume responsibility for any

accident due to equipment modifications.

ALWAYS ensure that the machine is on level ground before using.

NEVER STAND ON THE TOOL

Serious injury could occur if a power tool is tipped, or if a cutting tool is unintentionally

contacted.

TRANSPORT

When loading or unloading the machine, use caution. Remove the blade prior to hoisting,

loading and transporting the machine.

6

Page 7

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

MK-EZ PROFILER SAFETY

CHECK FOR DAMAGED PARTS

Before using a power tool, check for damaged parts. A guard or any other part that is

damaged should be carefully checked to determine if it would operate properly and

perform its intended function. Always check moving parts for proper alignment or binding.

Check for broken parts and mountings and all other conditions that may affect the

operation of the power tool. A guard, or any damaged part, should be properly repaired or

replaced. Always check the machine for loose bolts before starting.

DIRECTION OF ROTATION

A blade or cutter should always be installed so that rotation is in the direction of the

arrow imprinted on the side of the blade or cutter. It should correspond with the rotational

direction of the motor. Always feed work into a blade against the direction of rotation.

NEVER LEAVE A TOOL UNATTENDED

TURN POWER OFF - Do not leave a tool until it comes to a complete stop. ALWAYS

turn a power tool OFF when leaving the work area, or, when a cut is finished.

NEVER disconnect any "emergency or safety devices". These devices are intended for

operator safety. Disconnection of these devices can cause severe injury, bodily harm, or

even death! Disconnection of any of these devices will void all warranties. Unauthorized

equipment modifications will void all warranties. Manufacturer does not assume

responsibility for any accident due to equipment modifications.

NEVER use this machine with any cutter designed for woodworking.

NEVER operate this equipment when not feeling well due to fatigue, illness or taking medicine.

NEVER operate this equipment under the influence of drugs or alcohol.

On belt driven equipment, overtensioning of belts will result in premature crank and/or bearing

failure.

Whenever necessary, replace nameplate, operation and safety decals when they become

difcult to read.

ALWAYS store equipment properly when it is not being used. Equipment should be stored in

a clean, dry location out of the reach of children

DO NOT lend or rent this equipment without including the Owner's Manual and the Engine/

Motor Manufacturer's Manual.

Check the chemical properties of the material to be cut/grinded and follow all EPA/OSHA

Regulations.

7

Page 8

ON

(

(

)

)

MK-EZ PROFILER SAFETY

SILICA DUST WARNING

Grinding/cutting/drilling of masonry, concrete, metal and other materials with silica in their composition

may give off dust or mists containing crystalline silica. Silica is a basic component of sand, quartz,

brick clay, granite and numerous other minerals and rocks. Repeated and/or substantial inhalation of

airborne crystalline silica can cause serious or fatal respiratory diseases, including silicosis. In addition, California and some other authorities have listed respirable crystalline silica as a substance

known to cause cancer. When cutting such materials, always follow respiratory precautions.

Use appropriate NIOSH-approved respiratory protection where dust hazard may occur. Paper masks

or surgical masks without a NIOSH approval number are not recommended because they do little to

protect the worker. For more information about respirator programs, including what respirators have

received NIOSH approval as safe and effective, please visit the NIOSH website at:

http://www.cdc.gov/niosh/topics/respirators

Observe OSHA regulations for respirator use (29 C.F.R.§1910.134).

Visit http://www.osha.gov for more information.

CALIFORNIA PROPOSITION 65 MESSAGE

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contain chemicals known (to the State of California) to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead, from lead-based paints

• Crystalline silica from bricks, cement and other masonry products

• Arsenic and chromium, from chemically treated lumber

For further information, consult the following sources:

http://www.osha.gov/dsg/topics/silicacrystalline/index.html

http://www.cdc.gov/niosh/docs/96-112/

http://oehha.ca.gov/prop65/law/P65law72003.html

http://www.dir.ca.gov/Title8/sub4.html

Your risk from these exposures varies depending on how often you do this type of work. To reduce

your exposure to these chemicals, work in a well-ventilated area, and work with approved safety

equipment, such as dust masks that are specially designed to lter out microscopic particles. Where

use of a dust extraction device is possible, it should be used. To achieve a high level of dust collection, use an industrial HEPA vacuum cleaner. Observe OSHA 29 CFR part 1926.57 and 1926.103.

WARNING

Sawing, grinding and drilling generate dust. Excessive airborne particles may cause irritation to eyes,

skin and respiratory tract. To avoid breathing impairment, always employ dust controls and protection

suitable to the material being sawed or drilled; See OSHA (29 CFR Part 1910.1200).

8

Page 9

ON

(

(

)

)

MK-EZ PROFILER SAFETY

ELECTRICAL REQUIREMENTS AND GROUNDING INSTRUCTIONS

In order to prevent electrical shock and injury, the following electrical safety precautions and symbols

should be followed at all times!

WARNING

In case of a malfunction or breakdown, grounding provides a path of least resistance for electrical

current to reduce the risk of electric shock. This tool is equipped with an electric cord which has an

equipment-grounding conductor and a grounding plug. The plug must be plugged into a matching

outlet that is properly installed and grounded in accordance with all local codes and ordinances.

• DO NOT modify the plug provided - if it will not t the outlet, have the proper outlet

installed by a qualied electrician.

• Improper connections of the equipment-grounding conductor can result in a risk of electric

shock. The equipment-grounding conductor is the insulated conductor that has an outer

surface that is green, with or without yellow stripes. If repair or replacement of the electric

cord or plug is necessary, DO NOT connect the equipment-grounding conductor to a live

terminal.

• Check with a qualied electrician or service personnel if the grounding instructions are not

completely understood, or if in doubt as to whether the tool is properly grounded.

• Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles

that accept the tool’s plug.

• Repair or replace a damaged or worn cord immediately.

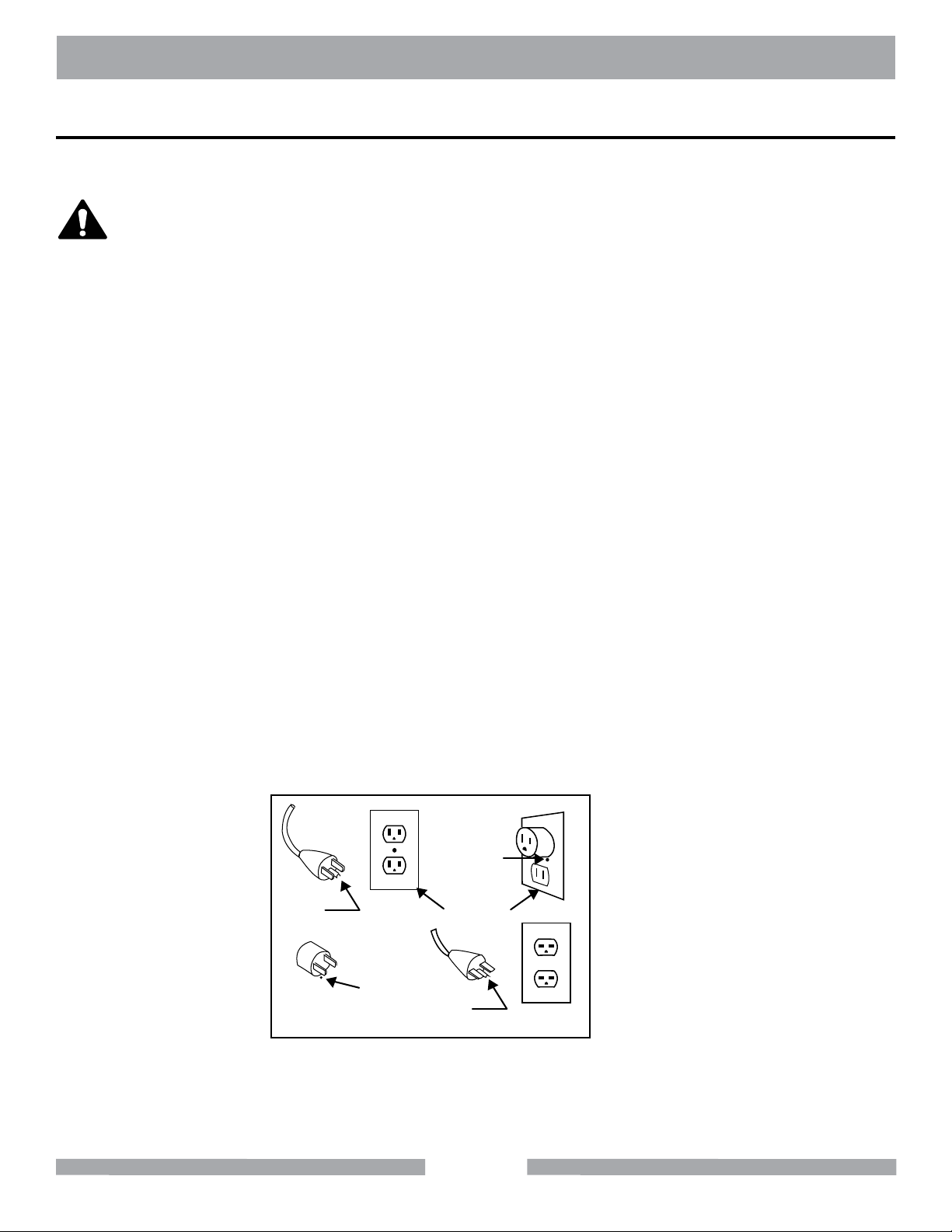

This tool is intended for use on a circuit that has an outlet that looks like the one shown in Sketch A.

The tool has a grounding plug that looks like the plug illustrated in Sketch A. A temporary adapter,

which looks like the adapter illustrated in sketches B and C, may be used to connect this plug to a

2-pole receptacle as shown in Sketch B, if a properly grounded outlet is not available. The temporary

adapter should be used only until a properly grounded outlet can be installed by a qualied electrician. The green-colored rigid ear, plug, and the like, extending from the adapter, must be connected

to a permanent ground, such as a properly grounded outlet box.

Metal Screw

Grounding

Pin

(A)

ADAPTER

Grounding

Means

(C)

Cover of

Grounded

Outlet Box

Grounding

Pin

(B)

(D)

Circuit and Adapter Information

Use of a temporary adapter is not permitted in Canada.NOTE:

NOTE:

If permanently connected this tool should be connected to a grounded metal permanent

wiring system; or to a system having an equipment - grounding conductor.

9

Page 10

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

MK-EZ PROFILER SAFETY

ELECTRIC MOTOR SAFETY

For maintenance care and operation of the electric motor, refer to your electric motor instruction booklet furnished with the electric motor. Protect the electric motor from dust as much as possible and keep

ventilating openings clean. Before plugging in the machine, make sure that the outlet voltage is within

the voltage marked on the machines's data plate.

CAUTION

DO NOT spray water on the electric motor. DO NOT touch the plug with wet hands. To reduce

the risk of electrocution, keep all connections dry and off the ground.

DO NOT operate electric motor in an explosive environment.

DO NOT EXPOSE TO RAIN

DO NOT expose to rain or use in damp locations.

WARNING

If operating the equipment in damp locations is unavoidable, ALWAYS use a Ground Fault

Circuit Interrupter, ALWAYS wear rubber gloves and footwear in damp conditions.

DO NOT abuse the cord. Never use the cord to carry the equipment or to pull the plug from

the outlet. Keep the cord away from heat, sharp edges, and moving parts. Replace damaged cords immediately. Damaged cords increase the risk of electric shock.

WARNING

To reduce the risk of electrocution, keep all connections dry and off the ground. A Ground Fault

Circuit Interrupter (GFCI) should be provided on the circuit(s) or outlet(s) to be used for this

machine. Receptacles are available having built-in GFCI protections and may be used for this

measure of safety. When using an extension cord, GFCI should be installed closest to the power

source, followed by the extension cord and lastly, the machine.

WARNING

The water pump requires a GFCI. To reduce risk of electrical shock when operating the machine

with the pump plugged into the 3-pole receptacle on the motor, connect the machine to a GFCI

outlet. See the pump manual and informational tags enclosed separately for all pump information.

10

Page 11

Surface

ON

(

(

)

)

ON

(

(

)

)

MK-EZ PROFILER SAFETY

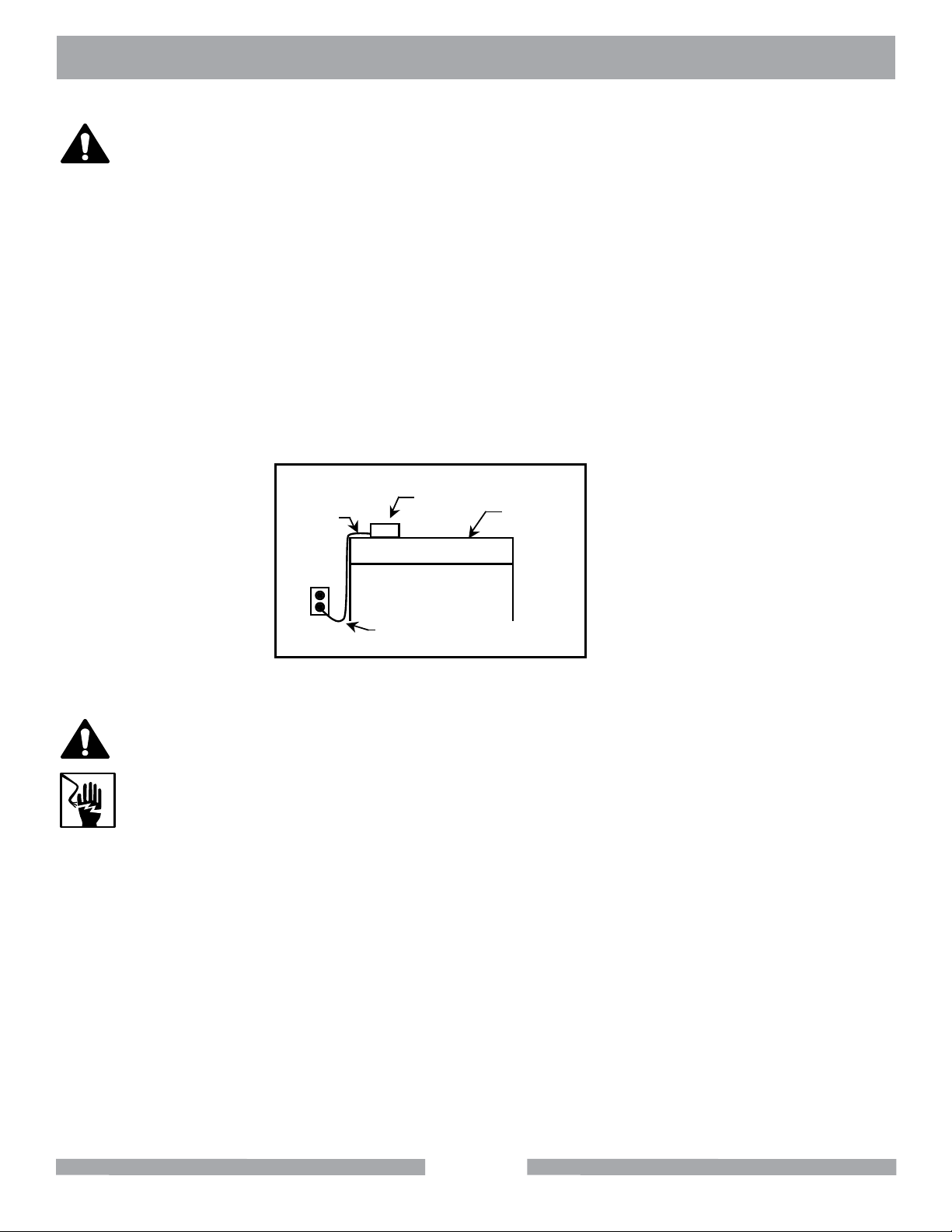

WARNING

To avoid the possibility of the appliance or plug receptacle getting wet, position the machine to one

side of a wall mounted receptacle. This will prevent water from dripping into the receptacle or plug. A

"drip loop," shown in the picture below, should be arranged by the user to properly position the power

cord relative to the power source. Use the drip loop as a way to prevent GFCI and plug from getting

wet.

The "drip loop" is that part of the cord below the level of the receptacle (or the connector, if an extension cord is used). This method of positioning the cord prevents the travel of water along the power

cord and coming in contact with the receptacle.

If the plug or receptacle gets wet, DO NOT unplug the cord. Disconnect the fuse or circuit breaker

that supplies power to the tool. Then unplug and examine for presence of water in the receptacle.

Power

Cord

Power

Tool

Drip Loop

Supporting

Drip Loop Information

WARNING

Use only extension cords that are intended for outdoor use. These extension cords are

identied by a marking "Acceptable for use with outdoor appliances; store indoors while not

in use." Use only extension cords having an electrical rating not less than the rating of the

product. DO NOT use damaged extension cords. Examine extension cords before using and

replace if damaged. DO NOT abuse extension cords and DO NOT yank on any cord to disconnect. Keep cords away from heat and sharp edges. Always disconnect the extension cord

from the receptacle before disconnecting the product from the extension cord.

ALWAYS make certain that the power source required for the electric motor is correct and always

use the correct NEMA conguration plug. Motors can burn out when the line voltage falls 10% below

the voltage rating of the motor. Failure to use proper voltage will cause the motor to overheat. Make

certain that the correct size grounded (3-wires) extension cord is used.

11

Page 12

ON

(

(

)

)

MK-EZ PROFILER SAFETY

WARNING

Use of undersized extension cords result in low voltage to the motor that can result in motor burnout

and premature failure. MK Diamond warns that equipment returned to us showing signs of being run

in a low voltage condition, through the use of undersized extension cords,will be repaired or replaced

totally at the customer’s expense. There will be no warranty claim.

To choose the proper extension cord,

• Locate the length of extension cord needed in the table below.

• Once the proper length is found, move down the column to obtain the correct

AWG size required for that length of extension cord.

EXTENSION CORD LENGTH

Nameplate

Amperes

0 - 5 16 16 16 14 12 12

115V 25' 50' 75' 100' 150' 200'

250V 50' 100' 150' 200' 300' 400'

5.1 - 8 16 16 14 12 10 •

8.1 - 12 14 14 12 10 • •

12.1 - 15 12 12 10 10 • •

15.1 - 20 10 10 10 • • •

12

Page 13

NOTES

13

Page 14

MK-EZ PROFILER SAFETY

SAFETY LABEL LOCATIONS

Safety labels contain important safety information. Please read the information contained on each

safety label. These labels are considered a permanent part of your machine. If a label comes off or

becomes hard to read, contact MK Diamond or your dealer for a replacement.

CAUTION

!

Receptacle is for

water pump only.

125V .6 amps max.

Label A

CAUTION

!

This saw is to be used

with a Ground Fault

Circuit Interrupter.

Label B

FOR INFORMATION ON

SERVICE OR

WARRANTY

PLEASE CALL

1-800-474-5594

Label C

For manuals and parts

lists scan the QR code

with your smart phone

Grinding/cutting/drilling of masonry, concrete, metal and other materials with silica in

their composition may give off dust or mists containing crystalline silica. Silica is a basic

component of sand, quartz, brick clay, granite and numerous other minerals and rocks.

Repeated and/or substantial inhalation of airborne crystalline silica can cause serious

or fatal respiratory diseases, including silicosis. In addition, California and some other

authorities have listed respirable crystalline silica as a substance known to cause cancer.

!

NOTICE

Most motor problems are caused by improper

voltage and extension cords. Cord should be

one-piece and short as possible. Cord

selection should match the following table.

1-2 H.P.

115v 230v

Max. Cord Length

25’

100’

Max. Cord Length

50’

150’

Max. Cord Length

75’

250’

Label E Label F

Warning Sheet Part # 166012

WARNING

!

Label D

No. 12 Wire

No. 10 Wire

No. 8 Wire

WARNING

!

DO NOT operate

this equipment

before reading

the owner's

manual!

B

A

Label G

C

Decal/Label Location Description

A Motor - Side Caution - Receptacle is for Water Pump Only

B Motor - Top Caution - Use with GFCI outlet only

C Motor - Mount Service/ Warranty

D Pan - Back Warning - Silica Warning

E Fence - Left Warning - Read Owners Manual

F

G

Pan - Back

Pan - Back

PROFILER SPECIFIC WARNINGS

F

G

D

E

Notice - Voltage/extension cords

QR Code for Manuals

WARNING

Wear eye protection.

Use splash guard for every operation for which it can be used.

Disconnect machine before servicing, when changing tools, and cleaning.

Replace damaged profiling tool before operating.

14

Page 15

MK-EZ PROFILER PRODUCT SPECIFICATIONS

GENERAL DESCRIPTION

Operated and used according to this manual, the MK-EZ Profiler will provide years of dependable

service. The MK-EZ Profiler is engineered as a tabletop unit. The profiler includes a powerful 120v

electric motor. It quickly and easily provides the initial shaping of the material before the follow up

polishing operations.

MOTOR SPECIFICATIONS

Motor specifications for the MK-EZ Profiler are listed in the table below.

Voltage 120v

Overall Amperage 7.4 A

Frequency 50/60Hz

RPM 6000 rpm

Horse Power 1-1/4 hp

TOOL CAPACITY

The MK-EZ Profiler uses wet cutting profiling tools in the 3-1/2" to 4-1/2" diameter range. These

tools have a 5/8"-18 female thread. See the accessories section for a complete list of tools,

compatible with your MK-EZ Profiler, that are available from MK Diamond.

TILE TYPES

The MK-EZ Profiler can profile a variety of material types including stone, ceramic, slate, granite,

marble, porcelain, and lapidary products.

NOTE:

The MK-EZ Profiler is not designed to cut plastic or metals.

15

Page 16

MK-EZ PROFILER UNPACKING

UNPACKING

CAUTION

Use proper lifting techniques when lifting the MK-EZ Profiler

Remove the MK-EZ Profiler and accessory box from the carton.

CONTENTS

One (1) MK-EZ Profiler Pan, Frame and

Table Assembly,

One (1) Cutting Head Assembly

One (1) MK-400BDB 3/8 Radius Profiling Tool

One (1) Electric Water Pump

MK-EZ Profiler Pan,

Frame & Table Assembly

www.mkdiamond.com

MK-EZ PROFILER

OWNER'S MANUAL, PARTS LIST &

OPERATING INSTRUCTIONS

12.2013

Revision 100

Manual Part No. 170565-OM

Caution: Read all safety and operating instructions

before using this equipment. This owners manual MUST

accompany the equipment at all times.

Cutting Head

MK-400BDB

One (1) 1" Open End Wrench

One (1) 11/16" Open End Wrench

One (1) Owner's Manual

One (1) Pump Manual

One (1) Warranty Card

Electric Water

Pump

1" & 11/16" Open

End Wrench

Owner's

Manual

Pump

Manual

Warranty

Card

TRANSPORT

CAUTION

1. The MK-EZ Profiler weighs approximately twenty-three (23) pounds; use care when transporting.

2. Never transport the MK-EZ Profiler with water in the Water Pan.

The MK-EZ Profiler is designed with a rigid, lightweight frame making the profiler easily

transportable. To lift the profiler, grasp the left and right of the pan at the lift points shown below.

Lift Point

Lift Point

16

Page 17

MK-EZ PROFILER INSTALLATION

Follow the assembly instructions to prepare your MK-EZ Profiler for operation.

PUMP INSTALLATION

(A)

Remove base (with suction

cups) from water pump (if

included). Pull off front cover,

slide base off of pump, and

replace the cover.

(D)

Place pump in pan.

plugged into the pump attachment plug on the

CUTTING HEAD INSTALLATION

(B)

Remove the Frame Assembly

from the pan, setting it next to

the pan.

(E)

Place the Frame assembly back in the pan

ensuring that the water hose is not pinched,

and pump cord comes out of the pan at

the back of the unit, where it can easily be

motor (once the cutting head is installed).

(C)

Attach the loose end of the

water hose (that is attached to

the water nozzle) to the pump.

(A)

Remove the two bolts and

washers at the back of the

cutting head mount.

(B)

Place the cutting head in position

and replace the bolts and washers,

through the vertical slots in the

cutting head slide.

17

(C)

Slide the head down, until the end

of the vertical adjustment screw

is sitting in the hole in the cutting

head mount.

Page 18

MK-EZ PROFILER ASSEMBLY

(D)

Tighten the screws using a 9/16"

wrench (not included).

PROFILE TOOL INSTALLATION

(A)

Loosen the two screws on the

cutting head slide, and without

using the vertical adjustment

screw, slide the head to its

highest position and retighten

the screws to hold it there.

(E)

Place frame in pan.

(B)

Place the tool on the motor

spindle and spin it on by hand.

(C)

Then using the two wrenches

provided, tighten it up. The

smaller wrench fits the flats

on the motor spindle to hold it

from turning, while the larger 1"

wrench fits the profiling tools.

18

Page 19

MK-EZ PROFILER ASSEMBLY

FENCE ADJUSTMENT

Once a tool has been installed, the fences can be adjusted for use with that particular tool.

(A)

Flip the splash guard brush up

out of the way.

(D)

Loosen the vertical slide bolts,

raise the head so that the middle

of the lower guide bearing on the

tool is level with the table surface

and tighten the bolts.

(B)

Ensure that the fine

horizontal adjustment is

approximately in the center of

its adjustment slot.

(E)

Loosen the two bolts on both

fences and slide them towards

the back of the machine.

(C)

This adjustment operates by

loosening (about a quarter

turn) both of the large knobs

next to the motor, turning the

fine horizontal adjustment knob

in or out as necessary and

retightening the knobs.

(F)

Place a straight edge (at least

24" long) on the table, so that it is

touching the guide bearing on the

tool, and is approximately parallel

with the long direction of the tables.

(G)

Holding the straight edge firmly

in place, slide the left fence into

contact with the straight edge and

tighten the two bolts that hold it.

(H)

Now holding the straight edge in

contact with the left fence (and

guide bearing), bring the right

fence up to touch the straight

edge and tighten it in place.

19

(I)

The two fences should now be

parallel and the straight edge

should be able to slide from one

to the other without bumping or

catching. The profile tool can now

be set for the desired cut.

Page 20

MK-EZ PROFILER SETUP

PROFILE ADJUSTMENT

(A)

Adjust the cutting head vertical

position for the thickness of

the material. Adjustment is

made by loosening the two

slide bolts.

(D)

The tool is now adjusted to make

the maximum profile that the tool

will make. Fine adjustments can

be made to the profile by using the

vertical and horizontal adjustment

knobs (loosening and retightening

their appropriate fixing screws).

(B)

Using the fine vertical

adjustment knob.

(C)

Move the head up or down until

the material to be profiled just

touches the underside of the

profile tool upper guide. Retighten

the slide bolts.

CONNECTING THE WATER PUMP

WARNING

1. To prevent the possibility of electrical shock, the MK-EZ Profiler MUST

be de-energized when connecting the Water Pump.

2. To prevent the possibility of electrical shock, use only MK Diamond

authorized replacement parts.

NOTE:

To prevent pump damage, the Water Pump must be disconnected if cutting dry.

20

Page 21

MK-EZ PROFILER SETUP

WATER PUMP SETUP FOR OPERATION

The Water Pump can be setup for operation in two ways: External Water Source or Re-circulation.

If cutting dry DO NOT connect the water pump.NOTE:

RE-CIRCULATION

NOTE: When using the re-circulation method, the water should be changed often for longer pump life.

(A)

Ensure the Drain Plug is

installed in the Water Basin

Place the Water Pump in the

back of the Water Basin

(B)

PRE-START INSPECTION

Prior to beginning work, a pre-start inspection of the machine should be performed.

CAUTION

1. Before powering or starting, check for damage that could prevent this equipment

from proper operation or performing it’s intended function. Check for binding and

alignment of moving parts. Check for damaged, broken, or missing parts.

2. Verify the On/Off switch is in the OFF position.

3. Before connecting the MK-EZ Proler to a power supply, be sure the voltage, cycle

and phase of the job site power source meet the requirements.

21

Page 22

MK-EZ PROFILER SETUP

WATER NOZZLE ADJUSTMENT

NOTE:

The best water nozzle adjustment depends on

several factors, including the material thickness and

profile tool used. The water pump receptacle cord,

that comes out of the motor, turns on and off along

with the motor. The pump can be plugged into a

receptacle or extension cord to test the aim of the

(A)

The water nozzle can be

pivoted to provide the best

aim for delivering water to

the contact area between the

material and the tool.

water stream, and to make adjustments without the

motor and tool running.

PROFILING

Once everything is set up, profiling is performed by sliding the material through the Profiling Tool

from Left to Right.

NOTE:

Most profiles can be cut in one pass. If the material

comes away from the fence while profiling, less than

the full amount of material will be removed and a

second pass will finish up the profile.

(A)

Flip the splash guard brush down

onto the table, turn on the motor and

proceed with a test cut.

22

Page 23

NOTES

23

Page 24

MK-EZ PROFILER EXPLODED VIEW

MK-EZ PROFILER PART # 170565

2

13

1

16

20

7

15

8

5

9

4

17

24

19

Page 25

MK-EZ PROFILER PARTS LIST

MK-EZ PROFILER PART # 170565

ITEM DESCRIPTION PART# OTY.

1 HOSE, VINYL, 1/4 X 3/8 (6.0') 132951 1

2 PUMP, WATER 115V/60HZ UL/CSA 151271-VP 1

3 CARTON, 13-1/2 X 12-1 X 9 - 3/4 152565 1

4 WRENCH, TILESAW, 11/16 OPEN END 153450 1

5 SCREW, SOCKET HEAD CAP 3/8 - 16 X 1 154685 2

6 CARD, WARRANTY REGISTER SAW 155037 1

7 TAG, SERIAL NUMBER, BLANK 157500-RW 1

8 SCREW, SOCKET HEAD CAP 3/8 - 16 X 1-14 157529 2

9 DRAIN PLUG, W/RING 159529 1

10 MASONRY LABEL SHEET (NOT SHOWN) 166011 1

11 CARTON, MK100/101 SERIES PL KR 166621-01PL 1

12 CARTON, TRAY, MK-100/101 166621-05 1

13 ADAPTER, 1/2 NPT X 1/4 BARB 168261 1

14 OWNERS MANUAL, MK-EZ PROFILER 170565-OM 1

15 ASSY, MOTOR, 120V, EZPR 170650 1

16 ASSY, FRAME AND TABLE, EZPR 170754 1

17 WRENCH, 1" OPEN END, THIN 170799 1

18 SHEET, LABEL, EZPR 170801 1

19 ASSY, PAN, EZPR 170805 1

20 MMK-400BDB 3-1/2 X 5.8-18 3/8R 400038-18 1

25

Page 26

MK-EZ PROFILER EXPLODED VIEW

MK-EZ PROFILER ASSY, MOTOR PART # 170650

7

2

1

1

15

9

5

18

10

13

12

16

17

4

6

14

3

8

19

6

20

11

26

Page 27

MK-EZ PROFILER PARTS LIST

MK-EZ PROFILER ASSY, MOTOR PART # 170650

ITEM DESCRIPTION PART# OTY.

1 WASHER, FLAT, USS, 3/8 101360 4

2 SCREW, 3/8-16 X 1-1/4 HEX HEAD CAP 150774 2

3 CLAMP, CUSHION LOOP 3/8 152592 1

4 SCREW, FLAT HEAD 1-32 X 5/ 8" 153902 4

5 MTR, ELECT, 7.4 AMP 120V 156428-R 1

6 SCREW, 8 -32 X 3/8 PAN HEAD PHILLIPS 156614 4

7 KNOB, TRI PLASTIC, 1" 156770-01 2

8 FITTING, 1/4 FNPT X 1/4 BARB 162601 1

9 SCREW, 1/4-20 X 1/2 SOCKET HEAD CAP 162778 1

10 NUT, HEX, NYL, 8-32 165227 2

11 CASTING, BASE, EZPR, COMP 170656 1

12 CASTING, SLIDE, EZPR, COMP 170658 1

13 CASTING, MTR MOUNT, EZPR, COMP 170660 1

14 KNOB, 3/8-16 X 3, EZPR 170741 1

15 KNOB, 1/4-20 X 2, EZPR 170742 1

16 SPRING, EXTEN, .250 X 1.0 X .023 170743 1

17 BRACKET, BRUSH MNT, EZPR 170793 2

18 ASSY, BRUSH, EZPR 170794 1

19 FITTING, 1/4 MNPT X LOC-LINE 170797 1

20 NOZZLE, LOC-LINE, 1/8" 170798 1

27

Page 28

MK-EZ PROFILER EXPLODED VIEW & PARTS VIEW

MK-EZ PROFILER ASSY, FRAME & TABLE PART # 170754

8

7

2

1

9

3

6

5

4

ITEM DESCRIPTION PART# OTY.

1 WASHER, FLAT, USS, 3/8 101360 4

2 SCREW, HEX, 3/8-16 X 3/4 153527 4

3 PLUG, PLASTIC, 1 SQ-14-20 GA 160727-1 4

4 FRAME, EZ PROFILER 170649 1

5 TABLE, LEFT, EZPR, COMP 170651 1

6 TABLE, RIGHT, EZPR, COMP 170652 1

7 STRAP, TABLE, EZPR 170653 3

8 SCREW, HEX HD, 1/4- 0 X 2-1/4 170752 9

9 ASST, FENCE, EZPR 170755 2

28

Page 29

MK-EZ PROFILER EXPLODED VIEW

MK-EZ PROFILER ASSY, FRAME & TABLE PART # 170755

2

1

3

ITEM DESCRIPTION PART# OTY.

1 SCREW, FLAT HEAD CAP #8-32 X 3/8 165437 5

2 FENCE, EZPR 170654 1

3 STRIP, DELRIN, 1/4 X 5/8 X 12, COMP 170753 1

29

Page 30

MK-EZ PROFILER EXPLODED VIEW & PARTS VIEW

MK-EZ PROFILER PAN PART # 170805

2

1

5

3

6

4

ITEM DESCRIPTION PART# OTY.

1 WASHER, FLAT, SAE, 1/4 151915 4

2 SCREW, HEX, HD, TAP, 1/4-20 X 1 152676 4

3 BUMPER, 1/4 HD, TAP, 1/4-20 X 1 154496 4

4 NUT, HEX, NYLK, 1/4-20 159857 4

5 WASHER, 1/4 RUBBER FENDER 164593 4

6 PAN, PLASTIC, EZPR 170804 1

30

Page 31

NOTES

31

Page 32

ACCESSORIES

V

MK Diamond Prole Bits are designed to achieve a quality nish on

all prole and bevel shapes. They are for proling tile, marble, granite, and all types of stone with superior performance and durability.

MK-400BDB Brazed Diamond Profile Bits

Diameter Profile/Radius Diameter Nut Part #

3-1/2" A - 3/8" 3-1/2" 5/8" - 18 400038-18

3-1/2" A - 3/16" 3-1/2" 5/8" - 18 400039-18

3-1/2" B - 1/2" 3-1/2" 5/8" - 18 400012-18

4" C - 3/4" 4" 5/8" - 18 400034-18

4" E - 45° Bevel 4" 5/8" - 18 400040-18

MK-480SDR Segmented Diamond Profile Bits

Shape Profile/Size Diameter Nut Part #

Half Bullnose B-10mm 3-1/2" 5/8" - 18 480010-18

Half Bullnose B-15mm 3-3/4" 5/8" - 18 480015-18

Half Bullnose B-20mm 3-3/4" 5/8" - 18 480020-18

Ogee F-20mm 3-1/2" 5/8" - 18 480120-18

A B C E

F

32

Page 33

NOTES

33

Page 34

MK-EZ PROFILER ORDERING & RETURN INSTRUCTIONS

ORDERING INFORMATION

You may order MK Diamond products through your local MK Diamond distributor or, you may order

direct from MK Diamond.

When ordering direct from MK Diamond, please have the following information ready before calling:

• The Model Number of the equipment

• The Serial Number of the equipment

• Where the equipment was purchased and when

• The Part Number for the part(s) being ordered

• The Part Description for the part(s) being ordered

NOTE: There is a $25.00 minimum order when ordering direct from MK Diamond. A $6.00 charge will

be added to orders having a net billing value under $50.00. All purchases must be made using VISA,

MasterCard or American Express.

All parts may be ordered by calling toll free to – 800 421-5830 or 310 539-5221 and asking for

Customer Service. For technical questions, call – 800 474-5594.

RETURN MATERIALS POLICY

To expedite the service relative to the return of a product purchased through MK Diamond, please

observe the following:

NOTE: When returning all items, they must have been purchased within the previous twelve (12)

months.

• Have the Model Number of the equipment

• Have the Serial Number of the equipment

• Have the location of where the equpiment was purchased

• Have the date when the equipment was purchased

• Contact Customer Service for approval to return the item(s)

• Obtain a Returned Goods Number (RGA) authorizing the return

• Follow the packaging instructions in the following section

• Ensure your item(s) are prepaid to the destination

For returned items, call toll free to – 800 421-5830 or 310 539-5221 and ask for Customer Service.

For technical questions, call – 800 474-5594 or 310 257-2845.

PACKAGING INSTRUCTIONS

• Remove the Cutting Head

• Dry the equipment before shipping

• When packing, include the following: Proler, Diamond Tool and Frame Assembly

• Package the unit in its original container or one of comparable size (do not ship the unit partially

exposed)

• Ensure all parts are secured in the packaging to prevent moving

AUTHORIZED SERVICE CENTERS

For quicker repair time, you may contact MK Diamond Customer Service, toll free, at 800 421-5830

or 310 539-5221 for the Authorized Service Center closest too you or visit our web site at

www.mkdiamond.com. For technical questions, call – 800 474-5594.

34

Page 35

MK-EZ PROFILER ORDERING & RETURN INSTRUCTIONS

CONTACT:

Please contact MK Diamond Products, Inc. Customer Service Department with any questions you

might have regarding distributors, parts or service.

Telephone: (800) 421-5830

Fax: (310) 539-5158

E-mail: Customer_Service@MKDiamond.com

Customer Service Hours: Monday through Friday, 6AM-4PM PST

MK Diamond Products, Inc.

1315 Storm Parkway

Torrance, CA 90501

MK DIAMOND PRODUCTS, INC. LIMITED WARRANTY

MK DIAMOND PRODUCTS, INC. will guarantee every machine they build, to be free from defects in

material and workmanship for (1) one year from date of purchase. The obligation of MK DIAMOND

PRODUCTS, INC. under this warranty is limited to the repair or replacement of any parts which,

under normal use, prove to be defective in material or workmanship. The parts involved or the unit

in question should be returned to MK DIAMOND PRODUCTS, INC. or to a point designated by us,

transportation prepaid.

This warranty does not obligate us to bear the cost of labor or transportation charges in connection

with replacement or repair of defective parts. Likewise, it shall NOT apply to any unit which has been

subjected to misuse, neglect or accident. This warranty does NOT apply to any machine which has

been repaired or altered outside our factory.

This warranty does NOT obligate MK DIAMOND PRODUCTS, INC., with respect to items not of our

manufacture, such as engines, motors, hydraulics, etc., which are subject to their own guarantees and

warranties.

We shall in no event be liable for consequential damages or contingent liabilities arising out of failure

of any equipment or parts to operate properly.

© COPYRIGHT 2013, MK DIAMOND PRODUCTS, INC. ALL RIGHTS RESERVED.

The MK Diamond logo is a registered trademark of MK Diamond Products, Inc. and may not be used,

reproduced, or altered without written permission. All other trademarks are the property of their respective owners and used with permission.

MK Diamond may have patents, patent applications, trade marks, copyrights of other intellectual

property right covering this product in this document.

This manual MUST accompany the equipment at all times. This manual is considered a permanent

part of the equipment and should remain with the unit if resold.

The information and specications included in this publication were in effect at the time of approval for

printing.

35

Page 36

MK-EZ PROFILER

OWNER'S MANUAL, PARTS LIST

& OPERATING INSTRUCTIONS

MK Diamond Products, Inc.

1315 Storm Parkway

Torrance, CA 90501

Toll-Free: (800) 421-5830

Phone: (310) 539-5221

Fax: (310) 539-5158

www.mkdiamond.com

Loading...

Loading...