Page 1

www.mkdiamond.com

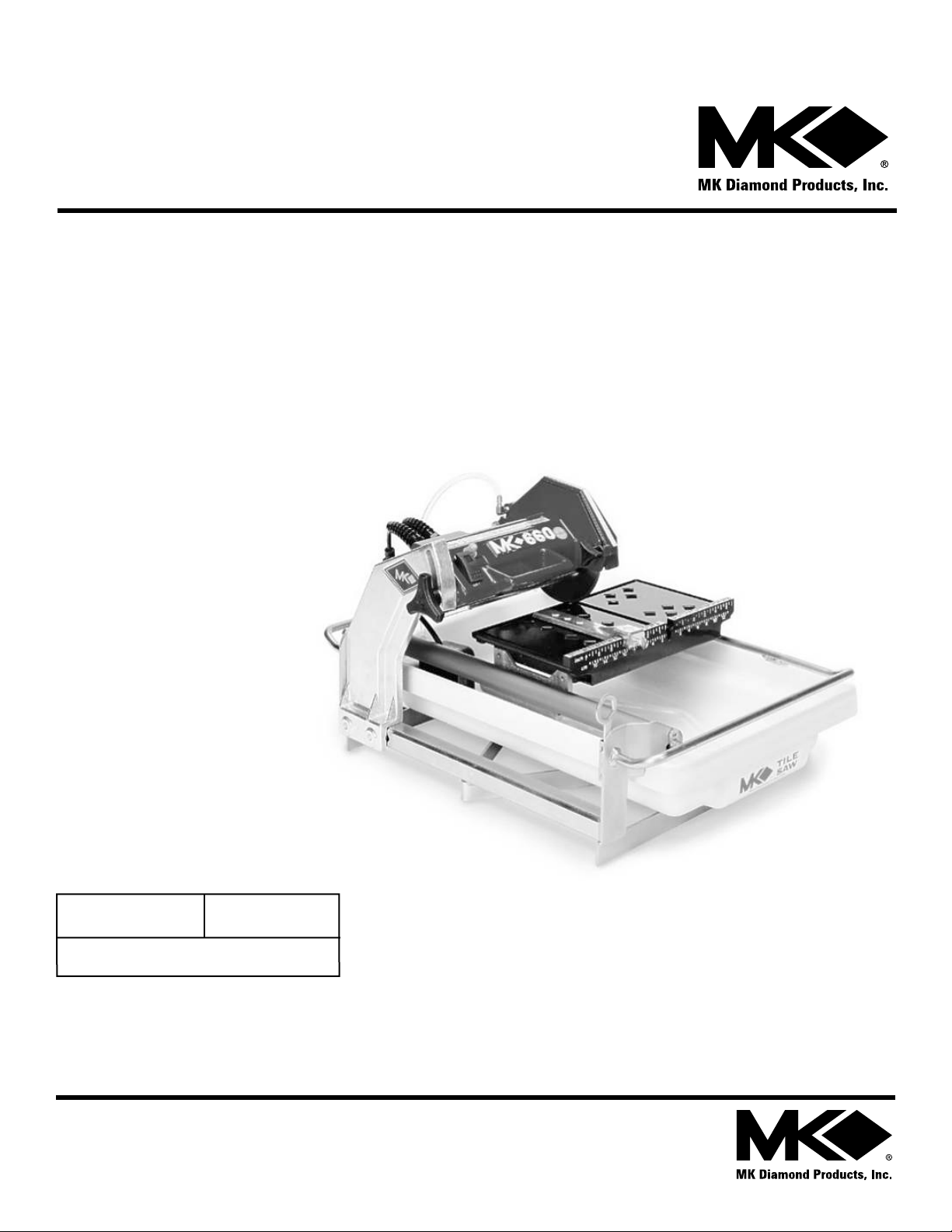

MK-660 TILE SAW

OWNER'S MANUAL

PARTS LIST &

OPERATING INSTRUCTIONS

Revision 103

Manual Part# 153461

Caution: Read all safety and operating instructions

before using this equipment. This parts list MUST

accompany the equipment at all times.

05.2014

Page 2

INTRODUCTION

Congratulations on your purchase of a MK-660 Saw. We are certain that you will be pleased

with your purchase. MK Diamond takes pride in producing the nest construction power tools

and diamond blades in the industry.

Operated correctly, your MK-660 Saw should provide you with years of service. In order to help

you, we have included this manual. This owners manual contains information necessary to

operate and maintain your MK-660 Saw safely and correctly. Please take the time to familiarize

yourself with the MK-660 Saw by reading and reviewing this manual.

Read and follow all safety, operating and maintenance instructions.

If you should have questions concerning your MK-660 Saw, please feel free to call our friendly

customer service department at: 800 421-5830

Regards,

MK Diamond

NOTE THIS INFORMATION FOR FUTURE USE:

MODEL NUMBER:

SERIAL NUMBER:

PURCHASE PLACE:

PURCHASE DATE:

NOTE: For your (1) one year warranty to be effective, complete the warranty card

(including the Serial Number) and mail it in as soon as possible.

2

Page 3

TABLE OF CONTENTS

SAFETY

Rules for Safe Operation 4-7

California Proposition 65 Message 8

Electrical Requirements 9-12

Safety Label Locations 13

Product Specications 14

UNPACKING, TRANSPORT and ASSEMBLY

Unpacking 15

Contents 15

Transport 16

Stand 16

STARTUP, ADJUSTMENT, OPERATION and SHUTDOWN

Cutting Head Installation 17

Diamond Blade Installation 17-18

Adjustable Cutting Guide Installation 18

Splash Guard Installation 19

Water Pump Installation 19

Pre-Start Inspection 19-20

Connecting the Water Pump 21

Water Pump Setup for Operation 21

Recirculation 21

Setup for Operation 22

Portable Generator 22

Operation

Cleanup 27-28

(Cutting Straight edges, Diagonal Cutting, 45° Miter Cutting, Off-Angle Cutting) 23-26

MAINTENANCE AND TROUBLESHOOTING

Maintenance 28-31

Flow adjustment 31

Blade Dressing 32

Diamond Blade Change-Out 33

Troubleshooting 34-36

EXPLODED VIEW AND PARTS LIST

Exploded View & Parts List 38-40

ACCESSORIES ORDERING and RETURN INSTRUCTIONS

Accessories 41

Ordering Information 42

Return Material Policy 42

Packaging Instructions 42

Authorized Service Centers 42

Contact & Warranty 43

3

Page 4

MK-660 TILE SAW SAFETY

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

Read and follow all safety, operating and maintenance instructions. Failure to read and follow

these instructions could result in injury or death to you or others. Failure to read and follow these

instructions could also result in damage and/or reduced equipment life. Safety warnings and

guidelines do not by themselves eliminate danger. They are not substitutes for proper accident

prevention procedures and good judgement.

SAFETY MESSAGES

A safety message alerts you to potential hazards that could hurt you or others. Each safety message is

preceded by a safety alert symbol ( ) and one of three words: DANGER, WARNING, or CAUTION.

DANGER You WILL be KILLED or SERIOUSLY INJURED if you DO NOT follow directions.

WARNING

You CAN be KILLED or SERIOUSLY INJURED if you DO NOT follow directions.

You CAN be INJURED if you DO NOT follow directions. It may also be used to

CAUTION

alert against unsafe practices.

DAMAGE PREVENTION AND INFORMATION MESSAGES

A Damage Prevention Message is to inform the user of important information and/or instructions that

could lead to equipment or other property damage if not followed. Information Messages convey

information that pertains to the equipment being used. Each message will be preceded by the word

NOTE, as in the example below.

NOTE:

Equipment and/or property damage may result if these instructions are not followed.

GENERAL SAFETY PRECAUTIONS AND HAZARD SYMBOLS

In order to prevent injury, the following safety precautions and symbols should be followed at all times!

SAFETY PRECAUTIONS

ALWAYS read this Owner’s Manual before operating the machine. DO NOT operate or

service this equipment before reading this entire manual. Read and understand all warnings, instructions and controls on the machine. Know how to stop the equipment quickly in

case of emergency. It is the operators responsibility to use this machine under safe working conditions and conform with federal, state and local codes or regulations pertaining to

safety, air, pollution, noise etc...

ALWAYS keep the Blade and Belt Guards in place. DO NOT operate this machine with any

guard or safety device removed. A Guard, or any damaged part should be repaired or

replaced immediately.

NEVER operate this equipment without proper protective clothing, shatterproof

glasses, steel-toed boots and other protective devices required by the job. Non-slip

foot wear is recommended.

4

Page 5

MK-660 TILE SAW SAFETY

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

(

(

)

)

(

(

)

)

ON

(

(

)

)

PERSONAL PROTECTIVE EQUIPMENT

ALWAYS wear approved respiratory, head, ear and eye protection

when operating this machine.

ON

ACCIDENTAL STARTS!

Before starting the engine/motor, be sure the ON/OFF switch is in the OFF position to prevent accidental starting. Place the ON/OFF switch in the OFF position before performing any

service operation. ALWAYS place the power ON/OFF switch in the OFF position when the

machine is not in use.

ROTATING PARTS

Keep hands, feet, hair, and clothing away from all moving parts to prevent injury. Never operate the motor with covers, shrouds, or guards, removed.

HOT PARTS!

Engine components can become extremely hot from operation. To prevent severe burns,

do not touch these areas while the engine is running, or immediately after it is turned off.

Never operate the engine with heat shields removed.

OVER SPEED

)

)

(

(

NEVER tamper with the governor components or settings to increase the maximum speed.

Severe personal injury and damage to the engine or equipment can result if operated at

speeds above maximum.

ELECTRICAL SHOCK

NEVER touch electrical wires or components while the engine is running. Exposed, frayed or

worn electrical wiring and plugs can be sources of electrical shock which could cause severe

injury or burns. Do not touch the plug with wet hands.

ALWAYS avoid inhalation of and skin contact with silica dust and/or mist. Provide proper

dust removal. Use dust-collection system when applicable.

NEVER operate the machine in an explosive atmosphere or near combustible materials.

Sparks from the cutting-action of this machine can ignite flammable materials, liquids, gases

or dust.

This equipment should not be operated by persons under 18 years of age.

KEEP CHILDREN AWAY

All visitors and children should be kept a safe distance from work area. Maintain a safe

operating distance to other personnel.

MAKE THE WORKSHOP KID PROOF

Make the workshops kid proof by using padlocks, master switches or by removing starter keys.

DO NOT FORCE THE TOOL

A power tool will do a job better and safer operating at the rate for which it was designed.

DO NOT force a tool or an attachment to do a job that it was not designed to do.

5

Page 6

MK-660 TILE SAW SAFETY

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

USE PROPER APPAREL

DO NOT wear loose clothing, gloves, neckties, rings, bracelets, or other jewelry that may

be caught in moving parts. Non-slip footwear is recommended. Wear protective hair covering to contain long hair.

SECURE WORK

Clamps or a vise should be used to hold work whenever practical. Keeping your hands free

to operate a power tool is safer.

DO NOT OVERREACH

Keep proper footing and balance at all times by not overreaching.

DISCONNECT TOOLS

Power tools should always be disconnected before servicing, adjusting or when changing

accessories, such as blades, bits, cutters, and the like.

MAINTAIN TOOLS WITH CARE

Keep tools clean and maintained for the best and safest performance. Always follow

maintenance instructions and examine the machine before use. If any abnormal vibrations

or noises occurs, turn off machine immediately and have the problem corrected before

further use.

REMOVE ADJUSTING KEYS AND WRENCHES

Form a habit of checking to see that keys and adjusting wrenches are removed from

the power tool before it is turned on.

KEEP WORK AREA CLEAN

Cluttered work areas and benches invite accidents. Keep area around machine clear of

obstructions which could cause persons to fall.

DO NOT USE IN DANGEROUS PLACES

DO NOT operate equipment in dangerous or hazardous environments. DO NOT use power

tools in damp or wet locations nor expose them to rain. Always keep the work area well

lighted.

USE RECOMMENDED ACCESSORIES

Consult the owner’s manual for recommended accessories. Using improper accessories

may increase the risk of personal or by-stander injury. Unauthorized equipment

modifications will void all warranties. Manufacturer does not assume responsibility for any

accident due to equipment modifications.

ALWAYS ensure that the machine is on level ground before using.

NEVER STAND ON THE TOOL

Serious injury could occur if a power tool is tipped, or if a cutting tool is unintentionally

contacted.

TRANSPORT

When loading or unloading the machine, use caution. Remove the blade prior to hoisting,

loading and transporting the machine.

6

Page 7

MK-660 TILE SAW SAFETY

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

CHECK FOR DAMAGED PARTS

Before using a power tool, check for damaged parts. A guard or any other part that is

damaged should be carefully checked to determine if it would operate properly and

perform its intended function. Always check moving parts for proper alignment or binding.

Check for broken parts and mountings and all other conditions that may affect the

operation of the power tool. A guard, or any damaged part, should be properly repaired or

replaced. Always check the machine for loose bolts before starting.

DIRECTION OF ROTATION

A blade or cutter should always be installed so that rotation is in the direction of the

arrow imprinted on the side of the blade or cutter. It should correspond with the rotational

direction of the motor. Always feed work into a blade against the direction of rotation.

NEVER LEAVE A TOOL UNATTENDED

TURN POWER OFF - Do not leave a tool until it comes to a complete stop. ALWAYS

turn a power tool OFF when leaving the work area, or, when a cut is finished.

NEVER disconnect any "emergency or safety devices". These devices are intended for

operator safety. Disconnection of these devices can cause severe injury, bodily harm, or

even death! Disconnection of any of these devices will void all warranties. Unauthorized

equipment modifications will void all warranties. Manufacturer does not assume

responsibility for any accident due to equipment modifications.

NEVER use this machine with any cutter designed for woodworking.

NEVER operate this equipment when not feeling well due to fatigue, illness or taking medicine.

NEVER operate this equipment under the influence of drugs or alcohol.

On belt driven equipment, overtensioning of belts will result in premature crank and/or bearing

failure.

Whenever necessary, replace nameplate, operation and safety decals when they become

difcult to read.

ALWAYS store equipment properly when it is not being used. Equipment should be stored in

a clean, dry location out of the reach of children

DO NOT lend or rent this equipment without including the Owner's Manual and the Engine/

Motor Manufacturer's Manual.

Check the chemical properties of the material to be cut/grinded and follow all EPA/OSHA

Regulations.

7

Page 8

MK-660 TILE SAW SAFETY

ON

(

(

)

)

SILICA DUST WARNING

Grinding/cutting/drilling of masonry, concrete, metal and other materials with silica in their composition

may give off dust or mists containing crystalline silica. Silica is a basic component of sand, quartz,

brick clay, granite and numerous other minerals and rocks. Repeated and/or substantial inhalation of

airborne crystalline silica can cause serious or fatal respiratory diseases, including silicosis. In addition, California and some other authorities have listed respirable crystalline silica as a substance

known to cause cancer. When cutting such materials, always follow respiratory precautions.

Use appropriate NIOSH-approved respiratory protection where dust hazard may occur. Paper masks

or surgical masks without a NIOSH approval number are not recommended because they do little to

protect the worker. For more information about respirator programs, including what respirators have

received NIOSH approval as safe and effective, please visit the NIOSH website at:

http://www.cdc.gov/niosh/topics/respirators

Observe OSHA regulations for respirator use (29 C.F.R.§1910.134).

Visit http://www.osha.gov for more information.

CALIFORNIA PROPOSITION 65 MESSAGE

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contain chemicals known (to the State of California) to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead, from lead-based paints

• Crystalline silica from bricks, cement and other masonry products

• Arsenic and chromium, from chemically treated lumber

For further information, consult the following sources:

http://www.osha.gov/dsg/topics/silicacrystalline/index.html

http://www.cdc.gov/niosh/docs/96-112/

http://oehha.ca.gov/prop65/law/P65law72003.html

http://www.dir.ca.gov/Title8/sub4.html

Your risk from these exposures varies depending on how often you do this type of work. To reduce

your exposure to these chemicals, work in a well-ventilated area, and work with approved safety

equipment, such as dust masks that are specially designed to lter out microscopic particles. Where

use of a dust extraction device is possible, it should be used. To achieve a high level of dust collection, use an industrial

HEPA vacuum cleaner. Observe OSHA 29 CFR part 1926.57 and 1926.103.

WARNING

Sawing, grinding and drilling generate dust. Excessive airborne particles may cause irritation to eyes, skin and respiratory

tract. To avoid breathing impairment, always employ dust controls and protection suitable to the material being sawed or

drilled; See OSHA (29 CFR Part 1910.1200).

8

Page 9

MK-660 TILE SAW SAFETY

ON

(

(

)

)

ELECTRICAL REQUIREMENTS AND GROUNDING INSTRUCTIONS

In order to prevent electrical shock and injury, the following electrical safety precautions and symbols

should be followed at all times!

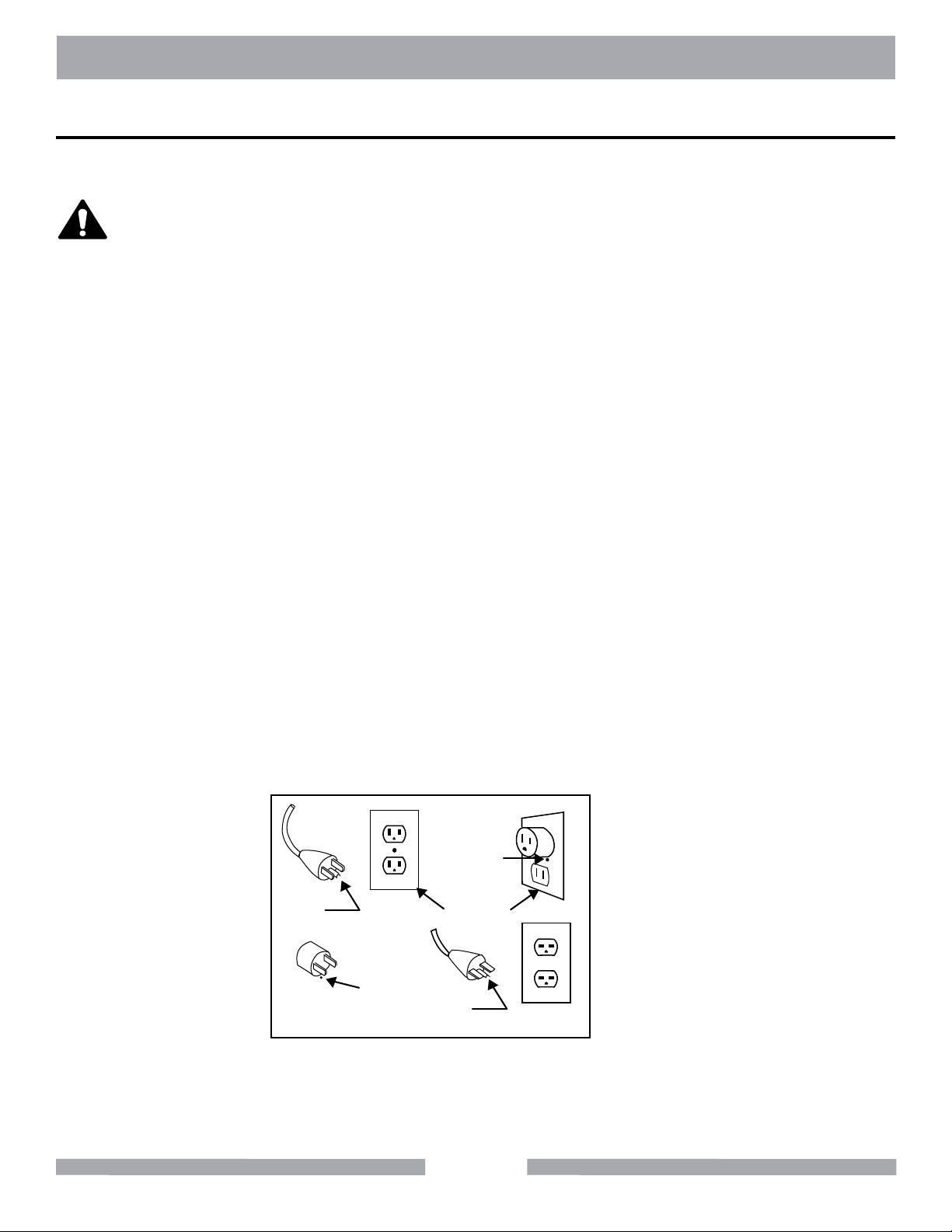

WARNING

In case of a malfunction or breakdown, grounding provides a path of least resistance for electrical

current to reduce the risk of electric shock. This tool is equipped with an electric cord which has an

equipment-grounding conductor and a grounding plug. The plug must be plugged into a matching

outlet that is properly installed and grounded in accordance with all local codes and ordinances.

• DO NOT modify the plug provided - if it will not t the outlet, have the proper outlet

installed by a qualied electrician.

• Improper connections of the equipment-grounding conductor can result in a risk of electric

shock. The equipment-grounding conductor is the insulated conductor that has an outer

surface that is green, with or without yellow stripes. If repair or replacement of the electric

cord or plug is necessary, DO NOT connect the equipment-grounding conductor to a live

terminal.

• Check with a qualied electrician or service personnel if the grounding instructions are not

completely understood, or if in doubt as to whether the tool is properly grounded.

• Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles

that accept the tool’s plug.

• Repair or replace a damaged or worn cord immediately.

This tool is intended for use on a circuit that has an outlet that looks like the one shown in Sketch A.

The tool has a grounding plug that looks like the plug illustrated in Sketch A. A temporary adapter,

which looks like the adapter illustrated in sketches B and C, may be used to connect this plug to a

2-pole receptacle as shown in Sketch B, if a properly grounded outlet is not available. The temporary

adapter should be used only until a properly grounded outlet can be installed by a qualied electrician. The green-colored rigid ear, plug, and the like, extending from the adapter, must be connected

to a permanent ground, such as a properly grounded outlet box.

Metal Screw

Grounding

Pin

(A)

ADAPTER

Grounding

Means

(C)

Cover of

Grounded

Outlet Box

Grounding

Pin

(B)

(D)

Circuit and Adapter Information

Use of a temporary adapter is not permitted in Canada.NOTE:

NOTE:

If permanently connected this tool should be connected to a grounded metal permanent

wiring system; or to a system having an equipment - grounding conductor.

9

Page 10

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

ON

(

(

)

)

MK-660 TILE SAW SAFETY

ELECTRIC MOTOR SAFETY

For maintenance care and operation of the electric motor, refer to your electric motor instruction booklet furnished with the electric motor. Protect the electric motor from dust as much as possible and keep

ventilating openings clean. Before plugging in the machine, make sure that the outlet voltage is within

the voltage marked on the machines's data plate.

CAUTION

DO NOT spray water on the electric motor. DO NOT touch the plug with wet hands. To reduce

the risk of electrocution, keep all connections dry and off the ground.

DO NOT operate electric motor in an explosive environment.

DO NOT EXPOSE TO RAIN

DO NOT expose to rain or use in damp locations.

WARNING

If operating the equipment in damp locations is unavoidable, ALWAYS use a Ground Fault

Circuit Interrupter, ALWAYS wear rubber gloves and footwear in damp conditions.

DO NOT abuse the cord. Never use the cord to carry the equipment or to pull the plug from

the outlet. Keep the cord away from heat, sharp edges, and moving parts. Replace damaged cords immediately. Damaged cords increase the risk of electric shock.

WARNING

To reduce the risk of electrocution, keep all connections dry and off the ground. A Ground Fault

Circuit Interrupter (GFCI) should be provided on the circuit(s) or outlet(s) to be used for this

machine. Receptacles are available having built-in GFCI protections and may be used for this

measure of safety. When using an extension cord, GFCI should be installed closest to the power

source, followed by the extension cord and lastly, the machine.

WARNING

The water pump requires a GFCI. To reduce risk of electrical shock when operating the machine

with the pump plugged into the 3-pole receptacle on the motor, connect the machine to a GFCI

outlet. See the pump manual and informational tags enclosed separately for all pump information.

10

Page 11

Surface

ON

(

(

)

)

ON

(

(

)

)

MK-660 TILE SAW SAFETY

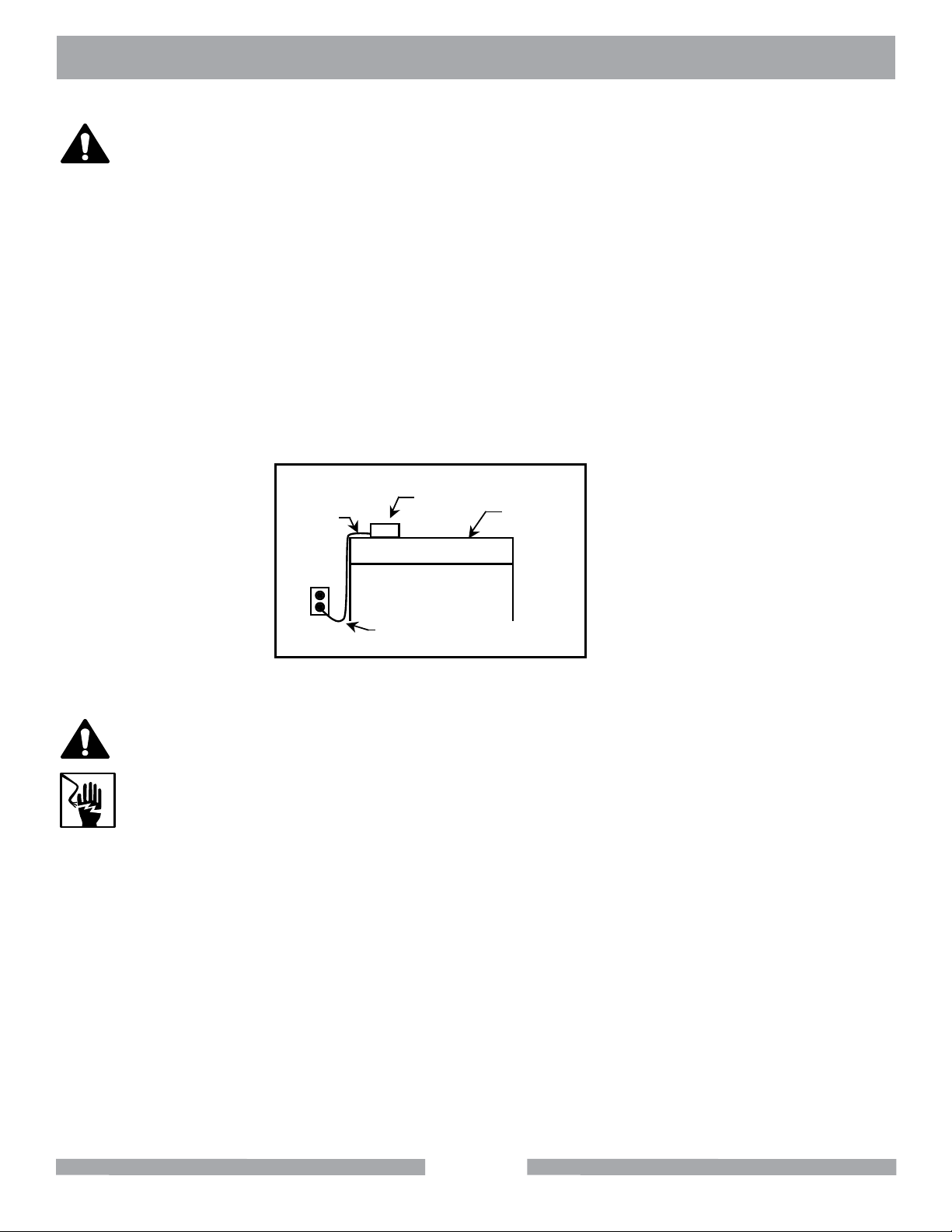

WARNING

To avoid the possibility of the appliance or plug receptacle getting wet, position the machine to one

side of a wall mounted receptacle. This will prevent water from dripping into the receptacle or plug. A

"drip loop," shown in the picture below, should be arranged by the user to properly position the power

cord relative to the power source. Use the drip loop as a way to prevent GFCI and plug from getting

wet.

The "drip loop" is that part of the cord below the level of the receptacle (or the connector, if an extension cord is used). This method of positioning the cord prevents the travel of water along the power

cord and coming in contact with the receptacle.

If the plug or receptacle gets wet, DO NOT unplug the cord. Disconnect the fuse or circuit breaker

that supplies power to the tool. Then unplug and examine for presence of water in the receptacle.

Power

Cord

Power

Tool

Drip Loop

Supporting

Drip Loop Information

WARNING

Use only extension cords that are intended for outdoor use. These extension cords are

identied by a marking "Acceptable for use with outdoor appliances; store indoors while not

in use." Use only extension cords having an electrical rating not less than the rating of the

product. DO NOT use damaged extension cords. Examine extension cords before using and

replace if damaged. DO NOT abuse extension cords and DO NOT yank on any cord to disconnect. Keep cords away from heat and sharp edges. Always disconnect the extension cord

from the receptacle before disconnecting the product from the extension cord.

ALWAYS make certain that the power source required for the electric motor is correct and always

use the correct NEMA conguration plug. Motors can burn out when the line voltage falls 10% below

the voltage rating of the motor. Failure to use proper voltage will cause the motor to overheat. Make

certain that the correct size grounded (3-wires) extension cord is used.

11

Page 12

MK-660 TILE SAW SAFETY

ON

(

(

)

)

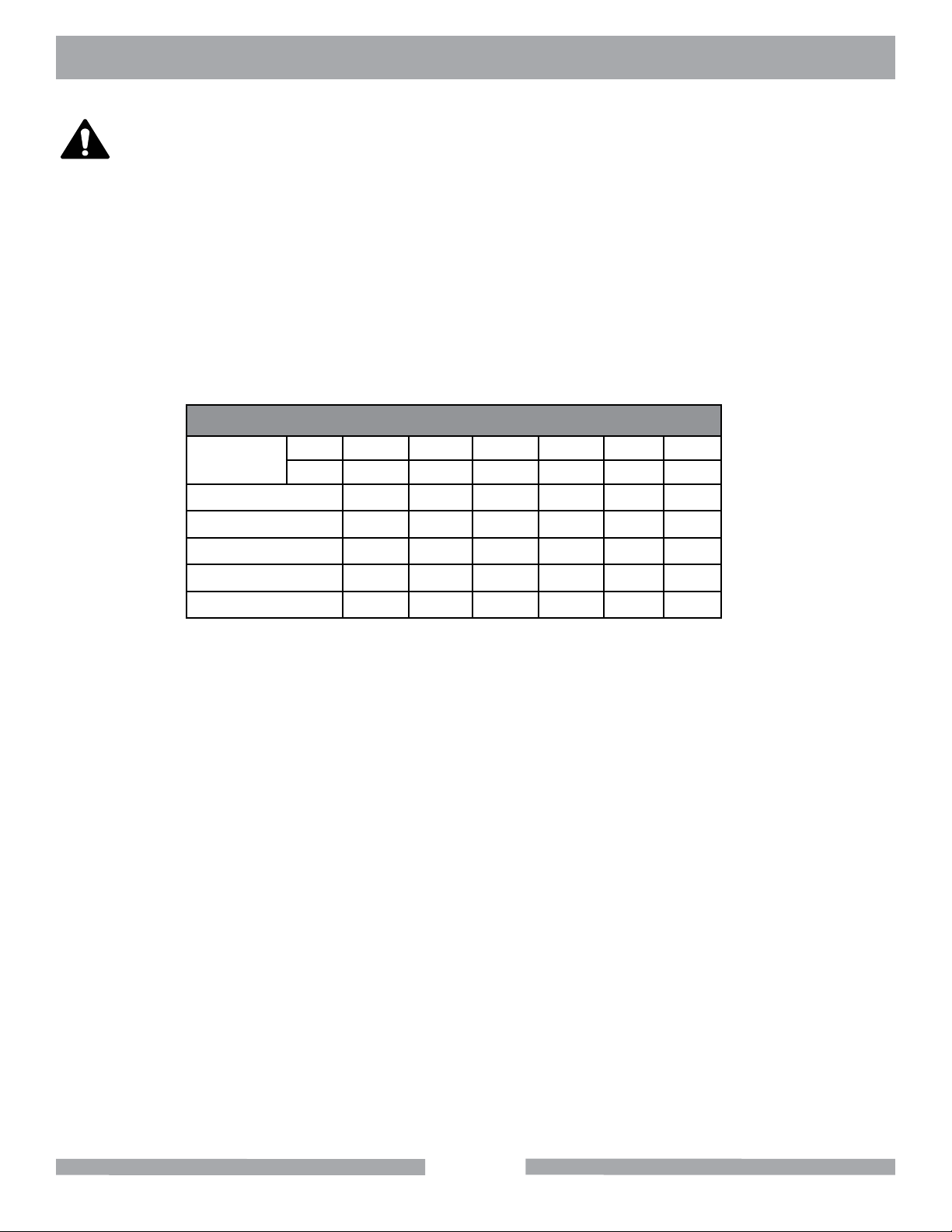

WARNING

Use of undersized extension cords result in low voltage to the motor that can result in motor burnout

and premature failure. MK Diamond warns that equipment returned to us showing signs of being run

in a low voltage condition, through the use of undersized extension cords,will be repaired or replaced

totally at the customer’s expense. There will be no warranty claim.

To choose the proper extension cord,

• Locate the length of extension cord needed in the table below.

• Once the proper length is found, move down the column to obtain the correct

AWG size required for that length of extension cord.

EXTENSION CORD LENGTH

Nameplate

Amperes

0 - 5 16 16 16 14 12 12

115V 25' 50' 75' 100' 150' 200'

250V 50' 100' 150' 200' 300' 400'

5.1 - 8 16 16 14 12 10 •

8.1 - 12 14 14 12 10 • •

12.1 - 15 12 12 10 10 • •

15.1 - 20 10 10 10 • • •

12

Page 13

MK-660 TILE SAW SAFETY

SAFETY LABEL LOCATIONS

The warning labels contain important safety information. Please read the information contained on

each safety label. These labels are considered a permanent part of your saw. If a label comes off or

becomes hard to read, contact MK Diamond or your dealer for a replacement.

Label A

!

WARNING

For Your Own Safety Read Instruction Manual

Before Operating Saw.

Wear Eye Protection.

Disconnect Saw Before Servicing, when Changing

Cutting Wheels and Cleaning.

Use Tool Only with Smooth Edge Cutting Wheels

Free of Openings and Grooves.

Replace Damaged Cutting Wheel Before Operating.

Do Not Fill Water Bath Above Water Fill Line.

See Manual for Pump Replacement.

Label A

!

NOTICE

Most Motor Problems are caused by improper

voltage and extension cords. Cord should be

one-piece and short as possible. Cord

selection should match the following table.

1-2 H.P.

115v 230v

25’

100’

50’

150’

75’

250’

Max. Cord Length

Max. Cord Length

Max. Cord Length

No. 12 Wire

No. 10 Wire

No. 8 Wire

Label B

FOR INFORMATIONON

SERVICE OR

WARRANTY

PLEASE CALL

1-800-474-5594

Label DLabel C

Tile Master Label Sheet Part#166012

Label C

Grinding/cutting/drilling of masonry, concrete, metal and other materials with silica in

their composition may give off dust or mists containing crystalline silica. Silica is a basic

component of sand, quartz, brick clay, granite and numerous other minerals and rocks.

Repeated and/or substantial inhalation of airborne crystalline silica can cause serious

or fatal respiratory diseases, including silicosis. In addition,California and some other

authorities have listed respirable crystalline silica as a substance known to cause cancer.

Label D Label E Label F

!

WARNING

Label B

For manuals and parts

lists scan the QR code

with your smart phone

Label G

CAUTION

!

This saw is to be used

with a Ground Fault

Circuit Interrupter.

CAUTION

!

Receptacle is for

water pump only.

125V, .6 amps max.

Label E Label F

Decal/Label Location Description

A Cutting Head Front Warning - Read Owner's Manual

B Cutting Head Front Warning - Silica Warning

C Cutting Head Back Notice - Voltage / extension cords

D Cutting Head Back Service / Warranty

E Cutting Head Back Caution - Use with GFCI only

F Cutting Head Back Caution - Receptacle for water pump

G Frame QR Manuals (Not Shown)

13

Page 14

MK-660 TILE SAW SAFETY

PRODUCT SPECIFICATIONS

The MK-660 Saw is a versatile Tile Saw. Operated and used according to this manual, the

MK-660 will provide years of dependable service.

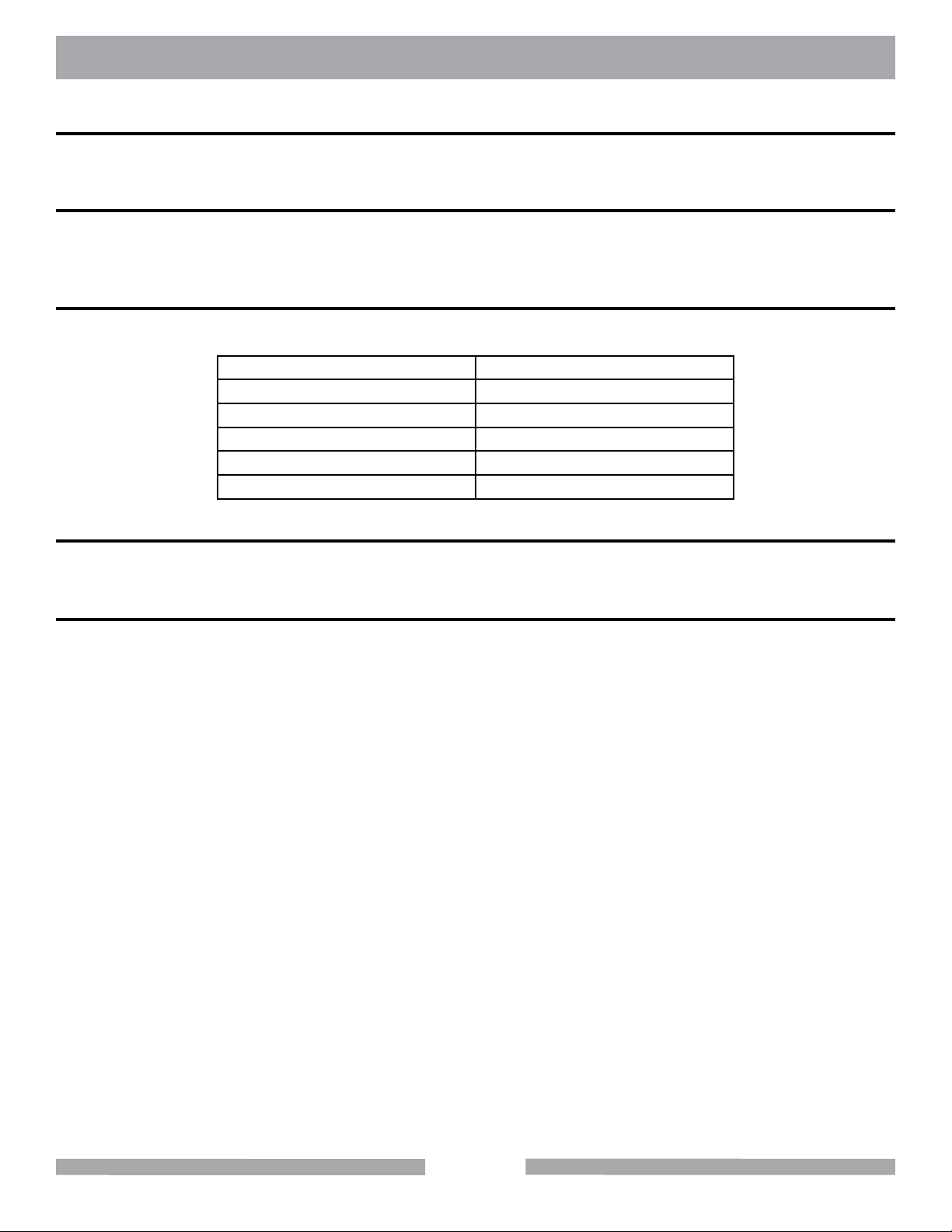

GENERAL DESCRIPTION

The MK-660 Saw is engineered as a tabletop or stand mounted wet tile saw. The saw includes a

powerful 120v electric motor. The saw is capable of cutting tile up to fourteen (14) inches in length.

The saw can cut an object two (2) inches thick in one pass.

MOTOR SPECIFICATIONS

Motor specifications for the MK-660 Saw are listed in the table below:

Voltage 120v

Motor Only Amperage 8.8 a

Frequency 60Hz

RPM 3500 rpm

Horse Power 3/4 hp

Weight 53 lbs.

BLADE CAPACITY

The MK-660 Saw uses a seven (7) inch (178mm) diameter, wet cutting continuous rim, MK Diamond

blade with a five-eighths (5/8) inch (15.875 mm) arbor.

TILE TYPES

The MK-660 Saw can cut a variety of tile types including stone, masonry, and lapidary products.

NOTE:

The MK-660 Saw is not designed to cut plastic or metals.

14

Page 15

MK-660 TILE SAW UNPACKING

UNPACKING

Your MK-660 Saw has been shipped from the factory thoroughly inspected. Only minimal assembly

is required.

CAUTION

Use proper lifting techniques when lifting the MK-660 Saw.

If not done, remove the MK-660 Saw, Cutting Head and accessory box from the carton.

CONTENTS

In your container, you will find one (1) MK-660 Frame and Water Pan, one (1) MK-660 Cutting Head,

(1) Cutting Head Height Adjusting Knob, (1) Height Adjusting Knob Flat Washer, one (1) 7-inch Wet

Cutting Continuous Rim Diamond Blade, one (1) Adjustable Cutting Guide, one (1) Electric Water

Pump, one (1) Pump Discharge Fitting, one (1) Cooling Transfer Tube, one (1) Flow Adjusting

Clamp, one (1) Drain Plug, one (1) Blade Wrench, one (1) Table Clip, one (1) Inner Flange Wrench,

(1) Splash Guard, one (1) Owner's Manual, one (1) Pump Manual and one (1) Warranty Card.

MK-660 Frame

and Water Pan

MK-660 Cutting

Head

Height Adjusting

Knob

Height Adjusting

Knob Flat Washer

Diamond Blade

Adjustable

Cutting Guide

Electric Water

Pump

Drain Plug Blade Wrench

and Table Clip

MK DiaMonD Warranty CarD

Name

address

City

state zip Code

phoNe Fax

e-mail

produCt model

part NumBer

maChiNe serial#

where did you purChase this saw From ? N a me

q tile distriButor q home CeNter q equipmeNt supply house

q tool supply q Bldg material supply q reNtal equipmeNt house

are you a do-it-yourselFer

q or CoNtraCtor q IF so, what type? tile q masoNry q other

what Criteria was importaNt iN ChoosiNg this saw? (rate From 1 to 5, 5 BeiNg the most importaNt)

power preCisioN por taBility availaBility other

priCe

CommeNts or suggestioNs:

mK diamoNd warraNty

1315 Storm Parkway, Torrance, CA 90509 USA | www.mkdiamond.com | 1.800.421.5830 | 1.310.539.5158

If within one (1) Year from the date of purchase, this MK Diamond saw fails due to defect in material or workmanship, MK will repair it, free of charge when the unit is returned to the dealer where it was purchased. This warranty DOES NOT cover normal wear or damage resulting from operator abuse. In no event shall MK Diamond Products,

Inc. be liable for consequential damages arising out of the failure of any product if operated improperly. MK Diamond Products may act as a warranty station for motor/engine repairs based on an individual agreement with the manufacturer. This warranty is in lieu of all other warranties express or implied.

©2010 All Rights reserved. MK Diamond Products, Inc. • P/N 155037 MK Warranty Card (02/10)

date purChased

Pump Manual Warranty Card

Pump Discharge

Fitting

Inner Flange

Wrench

15

Cooling Transfer

Tube

Flow Adjusting

Clamp

www.mkdiamond.com

www.mkdiamond.com

Revision 100

Revision 100

Manual Part# 153461

Manual Part# 153461

Caution: Read all safety and operating instructions

Caution: Read all safety and operating instructions

before using this equipment. This parts list MUST

before using this equipment. This parts list MUST

accompany the equipment at all times.

accompany the equipment at all times.

04.2010

04.2010

MK-660 SERIES

MK-660 SERIES

OWNERS MANUAL

OWNERS MANUAL

PARTS LIST &

PARTS LIST &

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

Splash Guard Owner's Manual

Page 16

MK-660 TILE SAW TRANSPORT

TRANSPORT

CAUTION

1. The MK-660 Saw weighs approximately fifty-three (53) pounds; use care when transporting.

2. Never transport the MK-660 Saw with water in the Water Pan.

The MK-660 Saw is designed with a rigid frame and removable Cutting Head. Always use proper

lifting techniques when lifting the MK-660 Saw.

To lift the saw, grasp the front and back of the frame at the lift points shown below.

Cutting Head

Lift Point

Lift Point

STAND (Optional)

CAUTION

The MK-660 Saw weighs fifty-three (53) pounds; follow the guidelines in the TRANSPORT

section when placing it on the stand (MK Diamond Part# 151889).

NOTE:

Open the stand and place on

If using the Optional MK Diamond Stand, follow these steps:

(A)

at surface

(B)

Remove Water Basin,

place saw on stand

(C)

Ensure saw frame is

positioned properly

(D)

Reinstall the Water Basin

16

Page 17

MK-660 TILE SAW ASSEMBLY

CUTTING HEAD INSTALLATION

Follow the assembly instructions to prepare your MK-660 Saw for operation.

NOTE: If the Cutting Head is installed, go to step next step.

(A)

Place the Flat Washer onto

the Height Adjusting Knob

(D)

Install the Adjusting Knob

DIAMOND BLADE INSTALLATION

NOTE:

When installing the Retaining Screw, do not “cross-thread" and DO NOT over tighten the

screw.

(B)

Align Cutting Head Pivot

Hole to the Post, Pivot Shaft

(C)

Verify the Cutting Head is

completely installed and seated

on the Pivot Shaft

(A)

Loosen the Blade Guard

Retaining Screw

(B)

Open the Outer Blade Guard to

expose the Retaining Nut and

Flanges

17

(C)

Using the Blade Nut Wrench,

loosen and then remove the

Retaining Nut and Outer Flange

Page 18

MK-660 TILE SAW ASSEMBLY

(D)

Locate the Inner Flange

Wrench Retaining Holes

(G)

Install the Retaining Nut and Outer

Flange. Hold the Shaft using the

Inner Flange Retaining Wrench

and tighten using the Blade

Wrench

Install Diamond Blade

onto Blade Shaft

Close the Outer Blade Guard

and tighten the Blade Guard

Retaining Screw

ADJUSTABLE CUTTING GUIDE INSTALLATION

(E)

(H)

(F)

Verify the Blade is seated on the

Blade Shaft and direction

of rotation is correct

(I)

Tighten the Outer Blade Guard

Pivot Screw

(A)

Loosen adjustable Cutting

Guide retaining thumbscrew and

place it over the movable

Cutting Table Ruler/Stop

(B)

Place the adjustable Cutting

Guide onto the movable Cutting

Table Ruler/Stop and tighten the

retaining thumbscrew

18

Page 19

MK-660 TILE SAW ASSEMBLY

SPLASH GUARD INSTALLATION

Follow the assembly instructions to prepare your MK-660 Saw for operation.

(A)

Install the retaining thumbscrew

through the washer and Splash

Guard, then align to the hole

WATER PUMP INSTALLATION

(A)

Install Water Pump Discharge

Fitting

PRE-START INSPECTION

(B)

Install the Splash Guard

onto the Blade Guard

(B)

Press one end of the Cooling

Transfer Tube onto the Water

Pump Discharge Fitting

(C)

Slide Cooling Flow Adjusting Clamp

onto the Cooling Transfer Tube

Prior to beginning work, a pre-start inspection of the saw should be preformed.

(A)

Ensure the ON/OFF Switch is in

the OFF position

Verify the movable Cutting

Table moves freely

(B)

Inspect the Diamond Blade for

damage - verify the blade is correct

for the material being cut

19

(C)

Page 20

MK-660 TILE SAW ASSEMBLY

(D)

Inspect the Pump Assembly for

damage - ensure the cord is free

of cracks or cuts

Inspect the MK-660 for dam-

age - ensure the cord is free

of cracks or cuts

(E)

CONNECTING THE WATER PUMP

Prior to beginning work, a pre-start inspection of the saw should be preformed.

WARNING

1. To prevent the possibility of electrical shock, the MK-660 Saw MUST be de-energized

when connecting the Water Pump.

2. To prevent the possibility of electrical shock, use only MK Diamond qualied

replacement parts.

NOTE:

To prevent pump damage, the Water Pump must be disconnected if cutting with a Dry Blade.

(A)

Connect the Coolant Transfer

Tube to the inlet connection of

the Blade Guard

(B)

Connect the Water Pump power

cord to the connection found on

the back of the motor

20

Page 21

MK-660 TILE SAW ASSEMBLY

WATER PUMP SETUP FOR OPERATION

The Water Pump can be setup for operation in two ways, External Water Source or Re-circulation.

NOTE:

To prevent pump damage, the Water Pump must be disconnected if cutting with a Dry Blade.

(A)

Remove the Drain Plug

(B)

Place the Water Pump

in an external container

(C)

Fill the external container until

water completely covers the

Water Pump suction

(A)

Place an external catch Basin

below the Water Pan drain

hole

RECIRCULATION

NOTE: When using the re-circulation method, the water should be changed often for longer pump life.

(A)

Ensure the Drain Plug is in-

stalled in the Water Pan

Place the Water Pump in the

back of the Water Pan

(B)

(C)

Fill the Water Pan until water

completely covers the Water

Pump suction

21

Page 22

MK-660 TILE SAW OPERATION

MK-660 SAW SETUP FOR OPERATION

CAUTION

NOTE:

1. Check for damaged, broken, or missing parts.

2. Verify the On/Off switch is in the OFF position.

3. Before connecting the MK-660 Saw to a power supply, be sure the voltage, cycle

and phase of the job site power source meet the requirements of the table below:

VOLTAGE: 120v

CYCLE: 60hz

PHASE: 1-phase

4. If using an extension power cord, make sure the length and wire gauge

correspond to the requirements listed in the table on page 10. An extension

power cord that is too small in wire gauge (diameter), or too long in length, will

cause the motor to overheat and could cause premature failure.

5. Use an approved Ground Fault Circuit Interrupter (GFCI).

6. Do not cover the motor vents as this could lead to motor overheating.

In order to avoid breaker tripping, a 20-amp circuit breaker should be used.

(A) Ensure the ON/OFF Switch is in the OFF position

(B) Plug MK-660 Saw into the GFCI

(C) Plug the GFCI into the power source

NOTE:

PORTABLE GENERATOR

If using a portable generator to provide power, ensure the generator meets the following minimum

requirements:

MK Diamond has available, as an accessory item, (Part # 152610) a plug-in GFCI that

may be plugged into a properly installed and grounded 3-pole outlet.

8 KW 120/240 volts 66.7/33.3 amps Single Phase

22

Page 23

MK-660 TILE SAW OPERATION

CUTTING STRAIGHT EDGES

CAUTION

DO NOT FORCE THE TOOL. It will do the job better and safer at the rate for

which it was designed.

(A)

Loosen the adjustable Cutting

Guide retaining thumbscrew

(B)

Position the adjustable Cutting

Guide to desired cut length

indicated inside the diamond

(C)

Tighten the retaining thumbscrew

(D)

Place the tile against the

Ruler/Stop and Cutting Guide

(G)

Perform the cut

(E)

Turn the motor ON

(H)

Turn the motor OFF when

work is complete

(F)

Verify ow on both sides of the

blade (See Maintenance Section

to adjust ow)

23

Page 24

MK-660 TILE SAW OPERATION

DIAGONAL CUTTING

NOTE:

To cut 45º Diagonals, the 45º Flat Angle Guide (MK Diamond Part No. 134577-MK) should be

used.

CAUTION

(A)

Remove the adjustable Cut-

ting Guide

NOTE:

If cutting the tile in two equal halves, align the tile in the V-notch of the movable Cutting Table Ruler/Stop.

DO NOT FORCE THE TOOL. It will do the job better and safer at the rate for

which it was designed.

(B)

Place the Dual 45° Flat Angle

Guide on the Ruler/Stop

Position the Dual 45° Flat Angle

Guide and tighten the retaining

(C)

thumbscrew

(D)

Position the tile against the

Dual 45° Flat Angle Guide

and the Ruler/Stop

(G)

Perform the cut

(E)

Turn the motor ON

(H)

Turn the motor OFF when

work is complete

24

(F)

Verify cooling ow on both sides

of the blade (See Maintenance

Section to adjust ow)

Page 25

MK-660 TILE SAW OPERATION

45° MITER CUTTING

NOTE:

To cut 45º Miters, the 45º Bullnose Miter Guide (MK Diamond Part No. 153201-MK) should be

used.

CAUTION

(A)

Remove the adjustable Cut-

ting Guide

DO NOT FORCE THE TOOL. It will do the job better and safer at the rate for

which it was designed.

(B)

Place the 45° Bullnose Miter

Guide on the Ruler/Stop

Position the 45° Bullnose Miter

Guide and tighten the retaining

(C)

thumbscrew

(D)

Position the tile on the 45°

Bullnose Miter Guide and the

Ruler/Stop

(G)

Perform the cut

(E)

Turn the motor ON

(H)

Turn the motor OFF when

work is complete

25

(F)

Verify cooling ow on both sides

of the blade (See Maintenance

Section to adjust ow)

Page 26

MK-660 TILE SAW OPERATION

OFF-ANGLE CUTTING

NOTE:

To cut angles other than 45º angles, a Protractor (MK Diamond Part No. 134569-MK) should be

used.

CAUTION

DO NOT FORCE THE TOOL. It will do the job better and safer at the rate for

which it was designed.

(A)

Remove the adjustable Cut-

ting Guide

(B)

Place the Protractor on the

Ruler/Stop

(C)

Set the desired angle and tighten

the thumbscrew

(D)

Position the Protractor cutting

guide to the desired cut length

indicated inside the diamond

(G)

Turn the motor ON

(E)

Tighten the retaining

thumbscrew

(H)

Verify ow on both sides of the

blade (See Maintenance Sec-

tion to adjust ow)

26

(F)

Position the tile against the Pro-

tractor and the Ruler/Stop

(I)

Perform the cut

Page 27

MK-660 TILE SAW CLEANUP

(J)

Turn the motor OFF when

work is complete

CLEANUP

NOTE: 1. If an external water source was used, steps A through C may be skipped.

2. Dispose of wastewater in accordance with applicable Federal, State and Local laws.

(A)

Clean the Water Pump suc-

tion of all debris

CAUTION

Ensure the saw is disconnected before completing the remnder of the cleanup

process.

(D)

Ensure the ON/OFF switch is

in the OFF position

(B)

Place the Water Pump in an

external container

(E)

Unplug the GFCI from the

power source

(C)

Run the MK-660 Saw until clear

water is seen at the blade coolant

ports (Approx. one (1) minute)

(F)

Unplug MK-660 from the

GFCI

27

Page 28

MK-660 TILE SAW CLEANUP

(G)

Clean the MK-660 Saw with

soap and clean water

CAUTION

Clean the movable Cutting

Table Guide Bar

Ensure water is not forced into the motor casing when cleaning.

(J)

Remove the Water Pan from

the MK-660 Saw

Clean the movable Cutting

Table Roller Wheel Frame

(H)

(K)

Support

(I)

Clean the Water Pan

(L)

Clean the remainder of the

MK-660 Saw

MAINTENANCE FOLLOWING USE

To extend the life of the MK-660 Saw, the following procedure should be performed after each use.

Lubricate all points listed below with light oils such as, 3 in 1, WD-40, etc.

(A)

Ensure the ON/OFF switch is

in the OFF position

(B)

Unplug MK-660 Saw

28

(C)

Lubricate the Guide Bar

Page 29

MK-660 TILE SAW MAINTENANCE

(D)

Lubricate the Roller Wheel

Assembly

MONTHLY MAINTENANCE

The following maintenance should be performed monthly.

(A)

Remove the Diamond Blade

(D)

Remove the Inner Flange

(B)

Lubricate the Outer Flange and

Retaining Nut

(E)

Clean around the Motor Shaft

and clean the Inner Flange

(C)

Remove the Outer Blade

Guard

(F)

Lubricate the Motor Shaft

and Inner Flange

29

Page 30

MK-660 TILE SAW MAINTENANCE

(G)

Locate the Motor Shaft Align-

ment Pin

(J)

Install the Outer Blade Guard

(H)

Align the Alignment Slot of the

Inner Flange to the Motor Shaft

Alignment Pin and install the

Inner Flange

(K)

Remove the Cutting Head

(I)

Lubricate the Outer Blade

Guard Pivot Shaft

(L)

Lubricate the Cutting Head

Pivot Shaft

(M)

Lubricate the Cutting Head

Adjustment Knob

(N)

Lubricate the Cutting Head Ad-

justment Knob retaining holes

30

(O)

Lubricate the Cutting Head

Pivot Hole

Page 31

MK-660 TILE SAW MAINTENANCE

(P)

Verify the Cutting Table Roller

Wheel Assembly is tight

FLOW ADJUSTMENT

NOTE:

If ow to the Diamond Blade requires adjustment, perform the following actions:

(A)

Increase cooling ow by

releasing the Flow Adjusting

Clamp

(B)

Reduce cooling ow by Press-

ing down on the Flow Adjusting

Clamp

31

Page 32

MK-660 TILE SAW MAINTENANCE

BLADE DRESSING

Like most cutting instruments, a Diamond Blade performs best when it is dressed. Over time and

use, diamonds on the outer edge of the blade will become smoothed or "glazed" over. This will

reduce grinding efficiency and may cause the blade to "wander" or bend giving the illusion of an

alignment problem. When this occurs, the blade will need to be dressed. The Diamond Blade can be

dressed using the MK Dressing Stick (part# 152972) and by following the steps below.

(A)

Setup the MK-660 Saw for

operation (see Setup, Adjust-

ment and Operation)

(D)

Turn the motor ON

(B)

Set the adjustable Cutting

Guide to cut a 1/16-strip

(E)

Verify ow on both sides of

the blade (See Maintenance

Section to adjust ow)

(C)

Position the Dressing Stick

(F)

Cut the Dressing Stick

seven (7) or eight (8) times

to dress the Blade

(G)

Ensure the ON/OFF switch is

in the OFF position

32

Page 33

MK-660 TILE SAW MAINTENANCE

DIAMOND BLADE CHANGE-OUT

NOTE:

When installing the Retaining Screw, do not "cross-thread" and DO NOT over tighten the screw.

(A)

Open the Outer Blade

Remove Retaining Nut and

(B)

Outer Flange

(C)

Remove Diamond Blade

from Blade Shaft

(D)

Install the Diamond Blade

onto Blade Shaft

(G)

Close the Outer Blade Guard

and tighten the Blade Guard

Retaining Screw

(E)

Verify the Blade is seated on

the Blade Shaft and direction of

rotation is correct

(H)

Tighten the Outer Blade Guard

Pivot Screw

(F)

Install the Retaining Nut and Outer

Flange. Hold the Blade Shaft

using the Inner Flange Retain-

ing Wrench and tighten using the

Blade Wrench

33

Page 34

MK-660 TILE SAW TROUBLESHOOTING

BLADE WILL NOT CUT PROPERLY

(A)

Check for Smoothness or

“Glazing" (Dress blade if

needed)

(D)

Verify the blade is correct for

the material being used

Check for proper rotation

(B)

MOVABLE CUTTING TABLE DOES NOT MOVE CORRECTLY

(C)

Ensure the Blade Core is not

bent and Arbor is not out of

round

(A)

Check that the Guide Bar is

clean – clean if dirty

(B)

Check the movable Cutting

Table Roller Wheel for wear

replace if necessary

34

Page 35

MK-660 TILE SAW TROUBLESHOOTING

COOLING FLOW

(A)

Check Flow Adjusting

Clamp is open. If flow exists,

go to Step B

(D)

Remove the Transfer Tube

and check flow. If flow exists,

go to Step F

(B)

Remove the Transfer Tube

from the Blade Guard inlet,

go to Step C

(E)

Remove the Pump Discharge

Fitting and check flow. If flow

exists, go to Step F.

(C)

Place Pump into a bucket of

water and check flow. If flow

exists, go to Step D

Intake Screen

(F)

Remove the Pump Intake

Screen and check for debris.

If flow exists, go to Step G.

(G)

Remove the Blade Guard

Intake Fitting, go to Step H.

NOTE:

“Rodding" coolant channels is performed by inserting a small wire rod through

the inlet on top of the Blade Guard and directing the rod out through each of the

flow tubes located on the underside of the Blade Guard. The channels should

be “rodded" until all ports are free of foreign debris.

(H)

Clean the Blade Guard

Intake Fitting, go to Step I.

35

(I)

Rod Cooling Channels and

recheck flow

Page 36

MK-660 TILE SAW TROUBLESHOOTING

BLADE STOPS TURNING

(A)

Allow motor to cool and

depress motor Overload

Reset Switch

(D)

Verify circuit breaker at least

20 amps - if not, move to

20-amp circuit

NOTE:

Using the proper blade when cutting any material will insure that additional drag

is not induced on the motor thus increasing the amperage draw. Too much drag/

amperage draw can overheat the motor. A sign that the incorrect blade is being

used for the material being cut is if user trips the circuit breaker at the power

supply when cutting the material.

(B)

Verify all plugs fully installed

(E)

Verify circuit breaker not

tripped if tripped, reset once

(C)

Check Ground Fault Circuit

Interrupter (GFCI) is not tripped

(F)

Check power source voltage

is 120v - if not 120v, move to

another circuit

36

Page 37

NOTES

37

Page 38

MK-660 TILE SAW EXPLODED VIEW

38

Page 39

MK-660 TILE SAW PARTS LIST

ITEM DESCRIPTION QTY PART #

A Accessories 1 n/a

A1 Carton, Accessory Pack, 660 1 153498

A3 Wrench, 15/16 Closed End 1 134684

A4 Wrench, Spanner, 660 1 154362

A5 Curtain, Splash 1 134841

A6 Bracket, Splash Curtain 1 152571

A7 Wing-screw, 1/4-20 x 1/2 1 151888

A8 Washer, 1/4 SAE Flat 1 151915

A9 Pump, Water, G-150A 1 151271

A10 Fitting, Plastic, 1/4 FNPT x 1/4 BARB 1 128397

A11 Hose, Vinyl, 1/4 ID 2’ 132951

A12 Clamp, Flow, 1/4-1/2 1 154394

A13 Owner’s Manual, Water Pump 1 155745

A14

Screw, 1/4-20 x 3/4 Thumb

A15

A16 Owner’s Manual, 660 1 153461

A19 Blade, 7 x 060 x 5/8, MK-100 1 153441

Large Bullnose Accessory

Screw, 1/4-20 x 3/4 Thumb

Rip Guide

1

1

1

2

134551

150991

153201

150991

B Blade Guard, 7”, Assembly 1 154811-MK

B1 Guard, 7”Blade 1 151731

B2 Elbow, 1/8 MNPT x 1/4 BARB 90ϒ Brass 1 154652

B3 Knob, Davies 1 151681

B4 Washer, 5/16 SAE Flat 2 151754

B5 Wing-nut, 5/16-18 Nylock 1 151746

D Cutting Head (less blade guard) 1 n/a

D1 Cutting Head, 660 1 154291

D2 Cover, Cutting Head, 660 1 154293

D3 Gasket, Cover, 660 1 154381

D4 Screw, 10-24 x 5/8 Pan Head Phillips Self-Tapping Machine 8 153681

D5 Screw, 5/16-18 x 2 1/2 Hex Head Cap, Fully Threaded 1 151748

D6 Washer, 5/16 Split Lock 1 151747

D7 Motor, 3/4 HP 115V FWR, 660 1 154292

D7A Motor, 3/4 HP 230V FWR, 660 1 153497

D8 Gasket, Thermal, 660 1 154346

D9 Screw, 10-24 x 5/8 Flat Head Phillips Machine 4 154295

D10 Flange, Inner, 660 1 154194

D11 Pin, 1/8 x 3/8 Spring 1 154982

D12 Flange, Outer 1 135830

D13 Nut, 5/8-18 UNF Hex 1 135848

D14

D15

D16 Wire Harness, 660 1 153415

D17 Screw, 10-24 x 3/8 Pan Head Phillips Self-Tapping Machine 1 151262

D18 Resistor, 660 1 153535

D19 Tack, 1/4 Head 4 155659

D20 Switch, Thermal Overload, 660 1 167982

Cord, AC Power 120V (16/3 SJTW x 10’, w/ molded 5-15P and Heyco

3251 Strain Relief)

Cord, Pump Pigtail, 16/3 SJTW x 1’, w/ molded 5-15R and Heyco 3251

Strain Relief

1 153419

1 154446

39

Page 40

MK-660 TILE SAW PARTS LIST

ITEM DESCRIPTION QTY PART #

D21 Boot, Thermal Overload Switch 1 167983

D22 Switch, 15A\125V Lighted Rocker 1 153421

D23 Rectier, 40 Amp 1 153677

D24 Screw, 10-24 x 3/4 Fillister Head Machine 1 151750

D25 Wire-nut, 3/#16 AWG (Blue) 1 155492

D26 Tag, 660 Serial Number 1 156561

D27 Label, Caution Strip 1 155214

D28 Label, When Motor Cools… 1 154409

E Frame 1 n/a

E1 Frame 1 153322

E2 Pan, Plastic 1 151736

E3 Plug, Water Drain 1 153439

E4 Plate, Adjustment 2 151758

E5 Pin, Rolled 2 151783

F Guide Bar, 5/8 Dia. 1 151739-MK

F1 Bar, Guide, 5/8 Dia. 1 151739

F2 Cover, Guide Bar 1 151740

F3 Spacer, 5/8 Guide Bar Cover 2 151755

F4 Screw, 5/16-18 x 1 Hex Head Cap 2 151743

F5 Washer, 5/16 Split Lock 2 151747

F6 Washer, 5/16 SAE Flat 2 151754

G Linear Bearing 1 151737-MK

G1 Casting, Bearing, Linear 1 151737

G1a Bearing, Multi-Lube 2

G2 Screw, 5/16-18 x 1 Hex Head Cap 2 151743

G3 Washer, 5/16 Split Lock 2 151747

G4 Washer, 5/16 SAE Flat 2 151754

H Post 1 n/a

H1

H2 Screw, 3/8-16 x 2 Hex Head Cap 2 153485

H3 Screw, 3/8-16 x 1 Hex Head Cap 1 152507

H4 Washer, 3/8 Split Lock 3 150925

H5 Washer, 3/8 SAE Flat 4 150923

H6 Knob, 3/8-16 x 1-1/2 MK Adjustment 1 156770-02

J Roller Wheel 1 151756

J1 Bracket, Roller Wheel 1 154021

J2 Wheel, Roller 1 151799

J3 Screw, 1/4-20 x 1 1/2 Hex Head Cap 1 151914

J4 Washer, 1/4 SAE Flat 1 151915

J5 Nut, 1/4-20 Hex 1 151893

Post, Rear, 660

Shaft, 5/8 Pivot, 660

1

1

151781

153451

153452

K Table, 660 1 n/a

K1 Table, 660 1 152680

K2 Screw, 5/16-18 x 1 Hex Head Cap 2 151743

K3 Washer, 5/16 Split Lock 2 151747

K4 Washer, 5/16 SAE Flat 2 151754

40

Page 41

MK-660 TILE SAW ACCESSORIES

ITEM NUMBER DESCRIPTION

1. 158434 MK-225, 7 x 5/8 Arbor

2. 139311 MK-215, 7 x 5/8 Arbor

3. 153293 MK-315, 7 x 5/8 Arbor

4. 134577-MK Dual 45° Flat Angle Guide

5. 134569-MK 90° Protractor

6. 152792 Dressing Stone

7. 152601 Ground Fault circuit Interrupter

8. 153201-MK 45° Miter

9. 151889 Saw Stand

41

Page 42

MK-660 TILE SAW ORDERING & RETURN INSTRUCTION

ORDERING INFORMATION

You may order MK Diamond products through your local MK Diamond distributor or, you may order

direct from MK Diamond.

When ordering direct from MK Diamond, please have the following information ready before calling:

• The Model Number of the saw

• The Serial Number of the saw

• Where the saw was purchased and when

• The Part Number for the part(s) being ordered

• The Part Description for the part(s) being ordered

NOTE: There is a $25.00 minimum order when ordering direct from MK Diamond. A $6.00 charge will

be added to orders having a net billing value under $50.00. All purchases must be made using VISA,

MasterCard or American Express.

All parts may be ordered by calling toll free to – 800 421-5830 or 310 539-5221 and asking for

Customer Service. For technical questions, call – 800 474-5594.

RETURN MATERIALS POLICY

To expedite the service relative to the return of a product purchased through MK Diamond, please

observe the following:

NOTE: When returning all items, they must have been purchased within the previous twelve (12)

months.

• Have the Model Number of the saw

• Have the Serial Number of the saw

• Have the location of where the saw was purchased

• Have the date when the saw was purchased

• Contact Customer Service for approval to return the item(s)

• Obtain a Returned Goods Number (RGA) authorizing the return

• Follow the packaging instructions in the following section

• Ensure your item(s) are prepaid to the destination

For returned items, call toll free to – 800 421-5830 or 310 539-5221 and ask for Customer Service.

For technical questions, call – 800 474-5594 or 310 257-2845.

PACKAGING INSTRUCTIONS

• Remove the Cutting Head and Support Angle Assembly

• Dry the saw before shipping

• When packing, include the following: Saw, Diamond Blade, Blade Guard and Support Angle

Assembly and Adjustable Cutting Guide (Other Accessories are not required)

• Package the unit in its original container or one of comparable size (do not ship the unit partially

exposed)

• Ensure all parts are secured in the packaging to prevent moving

AUTHORIZED SERVICE CENTERS

For quicker repair time, you may contact MK Diamond Customer Service, toll free, at 800 421-5830

or 310 539-5221 for the Authorized Service Center closest too you or visit our web site at

www.mkdiamond.com. For technical questions, call – 800 474-5594.

42

Page 43

MK-660 TILE SAW CONTACT & WARRANTY

CONTACT

Please contact MK Diamond Products, Inc. Customer Service Department with any questions you

might have regarding distributors, parts or service.

Telephone: (800) 421-5830

Fax: (310) 539-5158

E-mail: Customer_Service@MKDiamond.com

Customer Service Hours: Monday through Friday, 6AM-4PM PST

MK Diamond Products, Inc.

1315 Storm Parkway

Torrance, CA 90501

MK DIAMOND PRODUCTS, INC. LIMITED WARRANTY

MK DIAMOND PRODUCTS, INC. will guarantee every machine they build, to be free from defects in

material and workmanship for (1) one year from date of purchase. The obligation of MK DIAMOND

PRODUCTS, INC. under this warranty is limited to the repair or replacement of any parts which,

under normal use, prove to be defective in material or workmanship. The parts involved or the unit

in question should be returned to MK DIAMOND PRODUCTS, INC. or to a point designated by us,

transportation prepaid.

This warranty does not obligate us to bear the cost of labor or transportation charges in connection

with replacement or repair of defective parts. Likewise, it shall NOT apply to any unit which has been

subjected to misuse, neglect or accident. This warranty does NOT apply to any machine which has

been repaired or altered outside our factory.

This warranty does NOT obligate MK DIAMOND PRODUCTS, INC., with respect to items not of our

manufacture, such as engines, motors, hydraulics, etc., which are subject to their own guarantees and

warranties.

We shall in no event be liable for consequential damages or contingent liabilities arising out of failure

of any equipment or parts to operate properly.

© COPYRIGHT 2014, MK DIAMOND PRODUCTS, INC. ALL RIGHTS RESERVED.

The MK Diamond logo is a registered trademark of MK Diamond Products, Inc. and may not be used,

reproduced, or altered without written permission. All other trademarks are the property of their respective owners and used with permission.

MK Diamond may have patents, patent applications, trade marks, copyrights of other intellectual

property right covering this product in this document.

This manual MUST accompany the equipment at all times. This manual is considered a permanent

part of the equipment and should remain with the unit if resold.

The information and specications included in this publication were in effect at the time of approval for

printing.

43

Page 44

MK-660 TILE SAW

OWNER'S MANUAL, PARTS LIST

& OPERATING INSTRUCTIONS

MK Diamond Products, Inc.

1315 Storm Parkway

Torrance, CA 90501

Toll-Free: (800) 421-5830

Phone: (310) 539-5221

Fax: (310) 539-5158

www.mkdiamond.com

Loading...

Loading...