Page 1

www.mkdiamond.com

MK-6000 SERIES

OWNER'S MANUAL &

OPERATING INSTRUCTIONS

SINGLE SPEED

THREE SPEED

Kubota Diesel

08.2013Revision 103

Manual Part# 169572

CAUTION: Read all safety and operating instructions

before using this equipment. This manual MUST

accompany the equipment at all times.

Page 2

INTRODUCTION

Congratulations on your purchase of a MK-6000 Concrete Saw. We are certain that you will be

pleased with your purchase. MK Diamond takes pride in producing the nest construction power

tools and diamond blades in the industry.

Operated correctly, your MK-6000 Concrete Saw should provide you with years of service. In order

to help you, we have included this manual. This owners manual contains information necessary to

operate and maintain your

MK-6000 Concrete Saw safely and correctly. Please take the time to familiarize yourself with the MK6000 Concrete Saw by reading and reviewing this manual.

Read and follow all safety, operating and maintenance instructions.

If you should have questions concerning your MK-6000 Concrete Saw, please feel free to call our

friendly customer service department at: 800 421-5830

Regards,

MK Diamond

NOTE THIS INFORMATION FOR FUTURE USE:

MODEL NUMBER:

SERIAL NUMBER:

PURCHASE PLACE:

PURCHASE DATE:

NOTE: For your (1) one year warranty to be effective, complete the warranty card

(including the Serial Number) and mail it in as soon as possible.

22

Page 3

TABLE OF CONTENTS

SAFETY PAGE NO.

Safety Message/Alert Symbols 4

Safety Warnings 5

Rules for Safe Operation & Transportation 6-8

Operation & Safety Decals 10

Safety Decal Locations 11

Console Controls 12

Console Control Descriptions 13

PRODUCT SPECIFICATIONS

Specications 14-16

Saw Features 17

Model Specications 17

Instructions for Changing Blade Speed 18

Single Speed 18

Gear Box 19

INSPECTION & START-UP

Pre-Operation Checklist, Belt & Powerband 20

Schedule Maintenance Quick Reference 21

OPERATION

Blade Mounting Instructions 22-23

Starting Engine, Starting Instructions 24

Saw Guide Alignment and Adjustment, Pointer Alignment 25

Maneuvering the Saw, Dry Cutting, Wet Cutting, Speed Control-Lever Use and Adjustment 26

Engaging the Drive Unit, Water Hook Up 27

Depth Indicator and Depth Stop 28

MAINTENANCE

Engine, Air Cleaner, Arbor, Axle, Drive Unit, & Hydrostatic Drive Unit 29

Maintenance Schedule 30

Troubleshooting 31

GENERAL PRODUCT INFORMATION

Ordering, Return & Packaging 34

Contact Information and Limited Warranty 35

3

Page 4

MK-6000 SAW SAFETY

Safety precautions should be followed at all times when operating this equipment. Failure to read and

understand the Safety Precaution and Operating Instructions could result in injury to yourself and others.

This Operation and Parts Manual has been developed to provide complete instructions for the safe and

efcient operation of the MK-6000 Concrete Saw.

Before using this machine, ensure that the person operating the machine has read and understands all

instructions in this manual.

SAFETY MESSAGE / ALERT SYMBOLS

A safety message alerts you to potential hazards that could hurt you or others. Each safety message is

preceded by a safety alert symbol ( ) and one of three words: DANGER, WARNING, or CAUTION.

DANGER

You WILL be KILLED or SERIOUSLY INJURED if you do not follow directions.

WARNING

You CAN be KILLED or SERIOUSLY INJURED if you do not follow directions.

CAUTION

You CAN be INJURED if you do not follow directions. It may also be used to

alert against unsafe practices.

Each message tells you what the hazard is, what can happen, and what you can do to avoid or reduce injury. Other important messages are preceded by the word NOTICE.

NOTICE

You can cause PROPERTY DAMAGE to your machine if you don’t follow directions.

The safety labels should be periodically inspected and cleaned by the user to maintain good legibility

at a safe viewing distance. If the label is worn, damaged or illegible, it should be replaced.

4

Page 5

MK-6000 SAW SAFETY

SILICA DUST WARNING

Grinding/cutting/drilling of masonry, concrete, metal and other materials can generate dust, mists and

fumes containing chemicals known to cause serious or fatal injury or illness, such as respiratory disease, cancer, birth defects or other reproductive harm. If you are unfamiliar with the risks associated

with the particular process and/or material being cut or the composition of the tool being used, review

the material safety data sheet and/or consult your employer, the material manufacturer/supplier, governmental agencies such as OSHA and NIOSH and other sources on hazardous materials and make

certain to comply with all product warnings and instructions for the safe and effective use of the material being cut. California and some other authorities, for instance, have published lists of substances

known to cause cancer, reproductive toxicity, or other harmful effects.

Control dust, mist and fumes at the source where possible. In this regard use good work practices

and follow the recommendations of the manufacturer/supplier, OSHA/NIOSH, and occupational and

trade associations. Water should be used for dust suppression when wet cutting is feasible. When

the hazards from inhalation of dust, mists and fumes cannot be eliminated through engineering controls such as vacuum and/or water mist, the operator and any bystanders should always wear a respirator approved by NIOSH/MSHA for the material being cut.

CALIFORNIA PROPOSITION 65 MESSAGE

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contain chemicals known (to the State of California) to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead, from lead-based paints

• Crystalline silica, from bricks and cement and other masonry products

• Arsenic and chromium, from chemically treated lumber

For further information, consult the following sources:

http://www.osha.gov/dsg/topics/silicacrystalline/index.html

http://www.cdc.gov/niosh/consilic.html

http://oehha.ca.gov/prop65/law/P65law72003.html

http://www.dir.ca.gov/Title8/sub4.html

Your risk from these exposures varies depending on how often you do this type of work. To reduce

your exposure to these chemicals, work in a well-ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to lter out microscopic particles.

5

Page 6

MK-6000 SAW SAFETY

RULES FOR SAFE OPERATION

DANGER

Failure to follow instructions in this manual may lead to serious injury or even death! This equipment is

to be operated by trained and qualied personnel only! This equipment is for industrial use only.

The following safety guidelines should always be used when operating the saw.

MAINTENANCE SAFETY

• NEVER lubricate components or attempt service on a running machine.

• Keep the machinery in proper running condition. Clean the machine after each day’s use. Follow

instructions for changing accessories. Inspect tool periodically and, if damaged, have repaired by

authorized service facility.

SET UP & TRANSPORTATION SAFETY

• ALWAYS use caution and follow the instructions when lifting and transporting this machine.

• ALWAYS tie down the machine when transporting. DO NOT tow this machine behind a vehicle.

• NEVER transport with the blade mounted on the machine.

• Lift only from the lift bail.

GENERAL SAFETY

•DONOT operate or service this equipment before reading this entire manual. Read

and understand all warnings, instructions and controls on the machine.

This equipment should not be operated by persons under 18 years of age.

• NEVER operate this equipment when not feeling well due to fatigue, illness or taking medicine.

• NEVER operate this equipment under the inuence of drugs or alcohol.

• Whenever necessary, replace nameplate, operation and safety decals when they become difcult

to read.

•NEVER operate this equipment without proper protective clothing, shatterproof

glasses, steel-toed boots and other protective devices required by the job.

• ALWAYS check the machine for loose bolts before starting.

• ALWAYS wear proper respiratory, head, ear and eye

protection equipment when operating this machine.

• ALWAYS store equipment properly when it is not being used. Equipment should be stored in a

clean, dry location out of the reach of children.

6

Page 7

MK-6000 SAW SAFETY

• CAUTION must be observed while servicing the machine. Rotating parts can cause injury if

contacted. Have all service performed by competent service personnel.

• Operate this machine only in well ventilated areas. ALWAYS ensure that the machine is on level

ground before using.

• NEVER operate this machine in an explosive atmosphere.

• Establish a training program and give a copy of this manual to operators of this equipment. If you

need extra copies, call (800) 421-5830.

SAW BLADE SAFETY

For complete safety information, refer to ANSI Safety Code B7.1 available through the American National

Standards Institute.

• ALWAYS keep area around the machine clear of obstructions and clear the work area of

unnecessary people. Keep all body parts away from the blade and all other moving parts.

• Before starting the machine, check that all guards are in position and correctly tted.

NEVER allow blade exposure from the guard to be more than 180 degrees. DO NOT

operate this machine with any guard removed.

• Inspect the blade, anges and shafts for damage before installing the blade. NEVER use damaged

or worn blade anges.

• The blade shaft anges must be of proper diameter for the size blade being used.

• Inspect the blade, anges and size shown for each blade size. DO NOT exceed maximum blade

speed shown, as excessive speed could result in blade breakage. Use ONLY blades marked with a

maximum operating speed greater than the blade shaft speed. Verify speed and saw drive

conguration by checking blade shaft RPM and pulley diameters and blade ange diameters.

• Use the correct blade for the type of work being done. Use only reinforced abrasive blades or steel

center diamond blades and anges supplied with the saw or manufactured for use on concrete saws.

DO NOT use carbide-tipped blades. Check with the blade manufacturer if you do not know if blade

is correct.

• Make sure the blade and anges are clean and free of dirt and debris before mounting the blade on

the saw. Verify the blade arbor hole matches the machine spindle before mounting the blade.

ALWAYS mount the blade solidly and rmly. Wrench tighten the arbor nut.

7

Page 8

MK-6000 SAW SAFETY

• Make sure the blade is not contacting anything before starting the engine.

• ALWAYS cut in a straight line. DO NOT cut deeper than 1” per pass with a dry blade. Step cut to

achieve deeper cuts. NEVER cock, jam wedge or twist the blade in a cut. DO NOT grind on the side

of the blade.

FUELING SAFETY

ON / OFF

• ALWAYS use caution when handling fuel. Shut off the engine and allow to cool before refueling.

• Move the machine at least 10 feet (3 meters) from the fueling point before starting the engine and

make sure the gas cap is on the machine and the fuel can is properly tightened.

• DO NOT touch a dry cutting blade immediately after use. These blades require several

minutes to cool after each cut. DO NOT use a blade that has been overheated (Core

has bluish color).

TRANSPORT SAW

WARNING

Never attempt to off load the saw on uneven ground of any degree or slope.

1. When transporting the saw from location to location, be sure the transmission drive system is

engaged. The FNR handle must be in the neutral position.

2. Lower the saw completely to relieve the weight on the front axle assembly.

3. For prolonged hauling, the saw should be blocked and chained to prevent undue stress and strain

on the drive system.

8

Page 9

NOTES

9

Page 10

Read entire operatorʼs manual before operating this

machine. Understand all warnings, instructions and

controls. IF YOU DO NOT HAVE AN OPERATORʼS

MANUAL, CALL TOLL FREE 1-800-474-5594

Machinery Hazard - Always keep all guards in place

and in good condition. Always keep all parts of your

body away from blade and all other moving parts.

Never allow blade exposure to exceed 180°.

Always use blades with a rated speed above the

blade shaft speed. Excessive speed can cause blade

breakage. Verify speed by checking blade shaft RPM,

pulley diameters and blade flange diameter.

Never use damaged

blades or equipment.

Never operate this machine

in areas of combustible material.

Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities

contains chemicals known (to the State of California)

to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and

cement and other masonry products

• Arsenic and chromium

from chemically-treated lumber

Always wear safety approved hearing,

eye, head and respiratory protection

WARNING

MK-6000 SAW SAFETY LABELS

SAFETY LABEL

Safety labels contain important safety information. Please read the information contained on each

safety label. These labels are considered a permanent part of your saw. If a label comes off or

becomes hard to read, contact MK Diamond or your dealer for a replacement.

CAUTION

!

!

NOTICE

Keep

hands and

feet clear.

Decal A

Decal C

Overtensioning of belts

will result in premature

crank and/or bearing failure.

Decal B

Decal B

Decal D, E & G

Decal F

Decal I

MK-6000 Concrete Saw Decal Sheet, Part No. 166009

10

Decal H

DANGER

Lethal exhaust

gases. Use only

in well ventilated

areas. DO NOT

use indoors.

Decal J

For manuals and parts

lists scan the QR code

with your smart phone

Decal K

Page 11

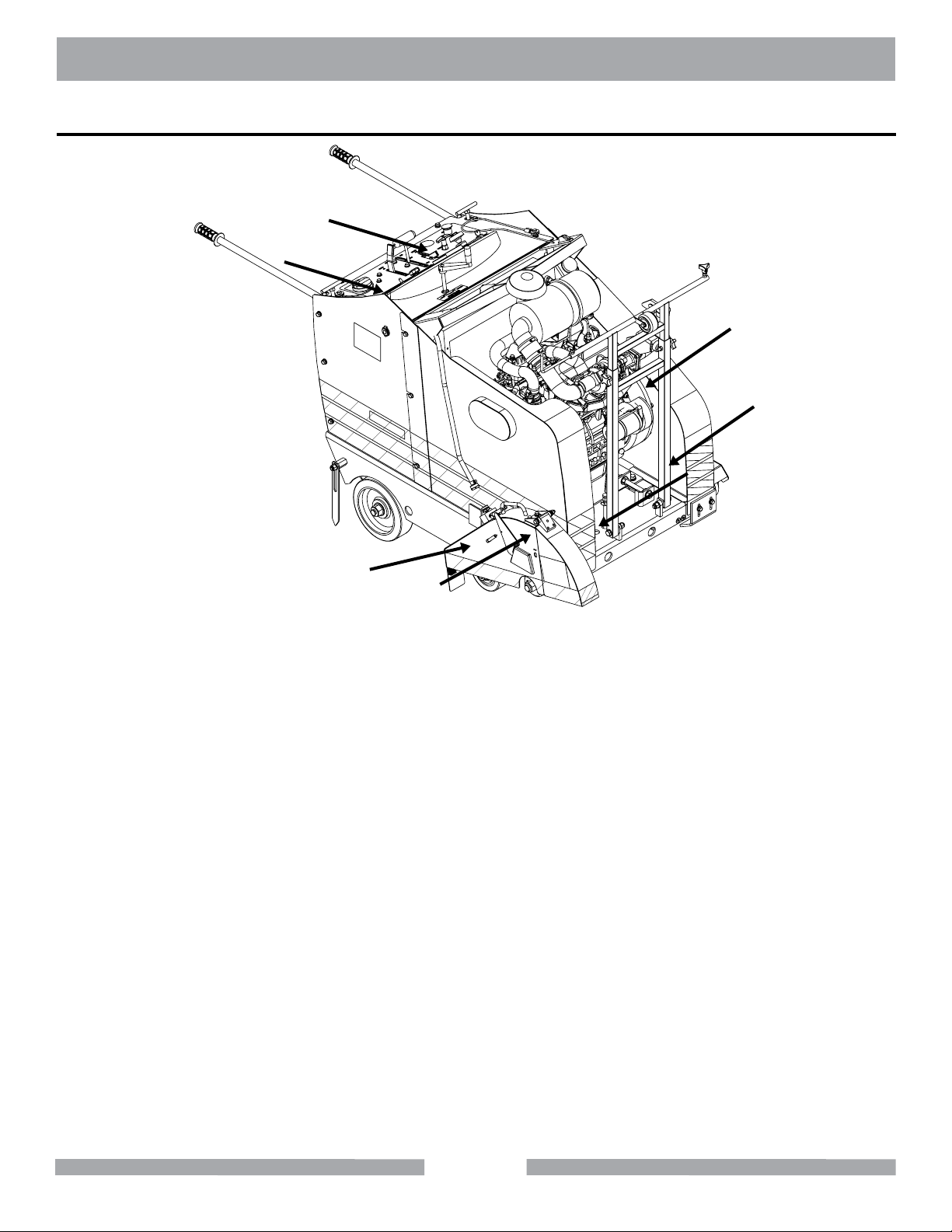

MK-6000 SAW SAFETY DECAL

SAFETY DECAL LOCATIONS

Decal J

Decal I

Decal B, C, D

Decal E

Decal A

Decal G, H

Decal F

MK-6000 Concrete Saw Safety Decal Locations

Decal Location Description

A Machine Front Caution Keep Hands and Feet Clear

B Top of Belt Guard Caution Do Not Overtension Belts

C Top of Belt Guard Caution Do Not Touch Hot Surface

D Top of Belt Guard Caution Do Not Operate with Guard Removed

E Face of Shaft Guard Caution Do Not Operate with Guard Removed

F Top of Blade Guard Blade Rotation Direction

G Side of Blade Guard Caution Do Not Operate with Guard Removed

H Top of Blade Guard Warning Do Not Change to Larger Blade Guard

I Console Warning Reading the manual, Machinery hazard, protect

hearing, seeing, headgear, California Proposition 65 message

J Console Danger Lethal exhaust gases

K Console QR Code for manuals

11

Page 12

MK-6000 SAW CONSOLE CONTROL

CONSOLE CONTROLS

The following is a list of console controls elements:

D

C

Q

U

T

S

R

P

V

A

B

E

I

H

G

J

F

N

M

O

L

Kubota

K

12

Page 13

MK-6000 SAW CONSOLE CONTROL

CONSOLE CONTROL DESCRIPTIONS

Decal Name Function

A Ignition Switch Use to start engine (Glow-OFF-ON-START).

B Engine Throttle Controls engine speed.

C Engine Temp Gauge Shows temperature of engine.

D Lifting Points Used to lift saw.

E Engine Tachometer Shows the engine RPM’s.

F Indicator Lights Indication of Oil Pressure, Charge and Glow Plug.

G Fuel Gauge Shows the level of fuel in the fuel tank.

H Depth Stop Sets the depth stop for repetitive cuts at the same depth.

I Radiator Filled with engine coolant

J Depth Indicator Displays cutting depth.

K T-Handle Knob Use to tighten operator grip handles.

L Handle Grip For operator gripping.

M Fuel Tank Fill Fill the fuel tank at this location.

N Raise/Lower Handle Controls raising and lowering of blade.

O Temp Gauge Reset Must be reset after overheat condition

P FNR Handle Used to set direction of saw (Forward/Neutral/Reverse).

Q Water Valve Lever Controls water ow to blade guard.

R Back Panel Knob 1/4 Turn Fastener to remove back.

S Water Inlet Hook-up for standard water hose.

T E-Stop Stops down engine in an emergency!

U Point Lift Cable Allows operator to lift pointer.

V Neutral Engages Transmission, Turn-To-Lock.

Engagement Handle

13

Page 14

MK-6000 SAW SPECIFICATIONS

SINGLE SPEED

59 Hp SerieS

Part # 165149-20 165149-26 165149-30 165149-36

Blade Guard Capacity 20"

Max. Depth of Cut 7-1/2" (191mm) 10-1/2" (267mm) 12-1/2" (318mm) 15" (381mm)

Blade Flange Diameter 4" (102mm) 5" (127mm) 5" (127mm) 6" (152mm)

Blade Shaft RPM 1,980 1,850 1,550 1,300

Engine Type Kubota V2403-M-T Kubota V2403-M-T Kubota V2403-M-T Kubota V2403-M-T

Maximum Horsepower** 59Hp

Displacement 148.5 cu in. (2,434 Liters) 148.5 cu in. (2,434 Liters) 148.5 cu in. (2,434 Liters) 148.5 cu in. (2,434 Liters)

Bore 3.43" (87mm) 3.43" (87mm) 3.43" (87mm) 3.43" (87mm)

Stroke 4.03" (78.4mm) 4.03" (78.4mm) 4.03" (78.4mm) 4.03" (78.4mm)

MK-6020-KB

(508mm) 26" (660mm) 30" (762mm) 36" (914mm)

(44.0kw) 59Hp (44.0kw) 59Hp (44.0kw) 59Hp (44.0kw)

MK-6026KB MK-6030KB MK-6036KB

66 Hp SerieS MK-6620KB MK-6626KB MK-6630KB MK-6636KB

Part # 165147-20 165147-26 165147-30 165147-36

Blade Guard Capacity 20"

Max. Depth of Cut 7-1/2" (191mm) 10-1/2" (267mm) 12-1/2" (318mm) 15" (381mm)

Blade Flange Diameter 4" (102mm) 5" (127mm) 5" (127mm) 6" (152mm)

Blade Shaft RPM 1,980 1,980 1,300 1,300

Engine Type Kubota V2607-DI-T-E3B Kubota V2607-DI-T-E3B Kubota V2607-DI-T-E3B Kubota V2607-DI-T-E3B

Maximum Horsepower** 66Hp

Displacement 159.6 cu in. (2,615 Liters) 159.6 cu in. (2,615 Liters) 159.6 cu in. (2,615 Liters) 159.6 cu in. (2,615 Liters)

Bore 3.43" (87mm) 3.43" (87mm) 3.43" (87mm) 3.43" (87mm)

Stroke 4.33" (109.9mm) 4.33" (109.9mm) 4.33" (109.9mm) 4.33" (109.9mm)

14" Blade Guard Model Available upon Request

(508mm) 26" (660mm) 30" (762mm) 36" (914mm)

(49.2kw) 66Hp (49.2kw) 66Hp (49.2kw) 66Hp (49.2kw)

14

Page 15

MK-6000 SAW SPECIFICATIONS

THREE SPEED

59 Hp SerieS

MK-6020-KBG MK-6026-KBG MK-6030-KBG MK-6036-KBG

Part # 165149-20G 165149-26G 165149-30G 165149-36G

Blade Guard Capacity 20"

(508mm) 26" (660mm) 30" (762mm) 36" (914mm)

Max. Depth of Cut 7-1/2" (191mm) 10-1/2" (267mm) 12-1/2" (318mm) 15" (381mm)

Blade Flange Diameter 4" (102mm) 5" (127mm) 5" (127mm) 6" (152mm)

Blade Shaft RPM* 1100/1700/2500 1100/1700/2500 1100/1700/2500 1100/1700/2500

Engine Type Kubota V2403-M-T Kubota V2403-M-T Kubota V2403-M-T Kubota V2403-M-T

Maximum Horsepower** 59Hp

(44.0kw) 59Hp (44.0kw) 59Hp (44.0kw) 59Hp (44.0kw)

Displacement 148.5 cu in. (2,434 Liters) 148.5 cu in. (2,434 Liters) 148.5 cu in. (2,434 Liters) 148.5 cu in. (2,434 Liters)

Bore 3.43" (87mm) 3.43" (87mm) 3.43" (87mm) 3.43" (87mm)

Stroke 4.03" (78.4mm) 4.03" (78.4mm) 4.03" (78.4mm) 4.03" (78.4mm)

59 Hp SerieS

MK-6042-KBG

14" Blade Guard Model Available upon Request

Part # 165149-42G

Blade Guard Capacity 42"

(1067mm)

Max. Depth of Cut 17-1/2 (495mm)

Blade Flange Diameter 7" (177mm)

Blade Shaft RPM* 1100/1700/2500

Engine Type Kubota V2403-M-T

Maximum Horsepower** 59Hp

(44.0kw)

Displacement 148.5 cu in. (2,434 Liters)

Bore 3.43" (87mm)

Stroke 4.03" (78.4mm)

66 Hp SerieS MK-6620-KBG MK-6626-KBG MK-6630-KBG MK-6636-KBG

Part # 165147-20G 165147-26G 165147-30G 165147-36G

Blade Guard Capacity 20"

Max. Depth of Cut 7-1/2" (191mm) 10-1/2" (267mm) 12-1/2" (318mm) 15" (381mm)

Blade Flange Diameter 4" (102mm) 5" (127mm) 5" (127mm) 6" (152mm)

Blade Shaft RPM* 1100/1700/2500 1100/1700/2500 1100/1700/2500 1100/1700/2500

Engine Type Kubota V2607-DI-T-E3B Kubota V2607-DI-T-E3B Kubota V2607-DI-T-E3B Kubota V2607-DI-T-E3B

Maximum Horsepower** 66Hp

Displacement 159.6 cu in. (2,615 Liters) 159.6 cu in. (2,615 Liters) 159.6 cu in. (2,615 Liters) 159.6 cu in. (2,615 Liters)

Bore 3.43" (87mm) 3.43" (87mm) 3.43" (87mm) 3.43" (87mm)

Stroke 4.33" (109.9mm) 4.33" (109.9mm) 4.33" (109.9mm) 4.33" (109.9mm)

66 Hp SerieS MK-6642-KBG

Part # 165147-42G

Blade Guard Capacity 42"

Max. Depth of Cut 17-1/2 (495mm)

Blade Flange Diameter 7" (177mm)

Blade Shaft RPM* 1100/1700/2500

Engine Type Kubota V2607-DI-T-E3B

Maximum Horsepower** 66Hp

Displacement 159.6 cu in. (2,615 Liters)

Bore 3.43" (87mm)

Stroke 4.33" (109.9mm)

(508mm) 26" (660mm) 30" (762mm) 36" (914mm)

(49.2kw) 66Hp (49.2kw) 66Hp (49.2kw) 66Hp (49.2kw)

*Bold blade shaft RPM indicates correct speed for model listed above

** Engine power ratings are calculated by the individual engine manufacturer and the rating method may vary among engine manufacturers. MK Diamond Products makes no claim, representation or warranty as to the power rating of the engine on this equipment

(1067mm)

(49.2kw)

and disclaims any responsibility or liability of any kind whatsoever with respect to the accuracy or the engine power rating. Users are

advised to consult the engine manufacturer’s owners manual and website for specific information regarding the engine power rating.

14" Blade Guard Model Available upon Request

15

Page 16

MK-6000 SAW SPECIFICATIONS

GENERAL SPECIFICATIONS

Arbor Size 1"

Blade Shaft Diameter 2" (58 mm)

Blade Shaft Bearings Oil Bath

Blade Shaft Drive 1 Ten Rib Powerband

Blade Guard Attachment Quick Detach Bayonet

Blade Control Electro-Hydraulic

Axle - Front 1"

Axle - Rear 1" (25mm)

Wheels - Front 6" x 2-1/2" x 1" (152 x 64 x 25mm)

Wheels - Rear 10" x 3" x 1" (254 x 77 x 25mm)

Handle Bars/Adjustment Length 32-1/2" (826mm)

Transmission Eaton Hydrostatic

Rear End/Differential Differential

Control Forward/Reverse Control, Engage/Disengaged Controls and Differential Lock

Speed 0-222 FPM (Forward) 0-100 FPM (Reverse)

Chassis Heavy Duty jig-welded box frame

Power Source Diesel Turbo Charged

Cylinders Four Cylinder Turbo Diesel

Fuel Capacity 10 Gal

Oil Capacity MK-6000 10 Qt. (9.4 liter)

MK-6600

Air Filter Three Stage Sy-Klone

Starter Electric

Travel Speed 0-220 FPM Forward, 0-100 FPM Reverse

Engine Cooling Liquid Cooled

(25.4mm) w/ 3/8" Drive Pin

(25mm)

(34 liter)

10.75 Qt.

(10.2 liter)

16

Page 17

MK-6000 SAW SPECIFICATIONS

SAW DIMENSIONS

C

BD

A

E

G

K F

Item Description Inches (mm)

Height 53-1/2" (1,359)

A

Minimum Saw Length 70" (1,778)

B

Maximum Overall Length 140-1/2" (3,568)

C

Handle Extension

D

Maximum Pointer Extension 62" (1,574)

E

Frame Width 31-1/2" (800)

F

Frame Length

G

25" (635)

50" (1,270)

L

J

H

Saw Width 39-1/2" (1,010)

H

Outside to Outside Wheel Width - Front 28" (711)

J

Outside to Outside Wheel Width - Rear 32" (812)

K

Blade to Wall 2-1/4" (57)

L

Wheel Base Length 20-1/2" (570)

M

Maximum Overall Height (Pointer Up) 56" (1,422)

N

17

14"

20"

26"

30"

36"

4.75"

7.5"

10.5"

12.5" 15"

Page 18

MK-6000 SAW PRODUCT SPECIFICATIONS

INSTRUCTIONS FOR CHANGING BLADE SPEED FOR SINGLE SPEED SAWS

WARNING

Do not exceed blade shaft speed shown for each blade size. Excessive blade speed could result in

blade failure and serious personal injury.

NOTICE

Changing Blade Guard size MUST be accompanied by changing Pulleys to achieve the correct blade speed.

SINGLE SPEED SAWS

Blade

Size

26"

Model #

Kubota

MK-6026KB

Single Speed

Includes

26" Blade Guard Assembly

5" Flange Set

3.2" Engine Pulley

4.8" Blade Shaft Pulley

10 Rib Powerband

Blade Shaft

Speed

(Engine RPM

= 2800)

1850 RPM

Blade

Speed

(FPM)

18" = 8700

20" = 9700

22" = 10650

24" = 11600

26" = 12600

30" Blade Guard Assembly

30"

36"

MK-6030KB

Single Speed

MK-6036KB

Single Speed

5" Flange Set

3.2" Engine Pulley

5.8" Blade Shaft Pulley

10 Rib Powerband

36" Blade Guard Assembly

6" Flange Set

3.2" Engine Pulley

6.8" Blade Shaft Pulley

10 Rib Powerband

36" Frame Corner

1550 RPM

1310 RPM

NOTICE

As shown on the chart, some blade guards accept more than one size blade.

BLADE GUARDS AND BLADE SIZES

BLADE SIZE THAT CAN

BLADE GUARD

BE USED WITH BLADE

GUARD

24" = 9750

26" = 10550

28" = 11350

30" = 12200

30" = 10300

26" = 11000

28" = 11650

30" = 12350

26" 20" up to 26"

30" 26" up to 30"

36" 30" up to 36"

18

Page 19

MK-6000 SAW GEAR BOX

INSTRUCTIONS FOR CHANGING BLADE SPEED FOR THREE SPEED SAWS

DANGER!

Turn off saw before changing gears. Engage the E-Stop button for additional safety.

CAUTION

Never shift the Gearbox with the engine running. Only shift the Gearbox with the engine OFF.

Gearbox damage could occur.

NOTE:

The engine speed on this saw does not need to be changed from the factory

set speed. The maximum RPM should be 2800, no load.

The 3-speed gearbox provides correct blade speed for different blade sizes. Determine gearbox

speed based on the chart below.

Selected

Gear

High

Blade Diameter/

Blade Guard

14" - 20"

RPM

2500

Medium 22" - 30" 1700

Low 36" - 42" 1100

L

H

M

NOTE:

Gears are not sequential. High speed is in

middle position.

Gears are indicated by "L",

"M", and "H"

Move lever up to unlock gears

NOTE:

Blade may need to be rotated slightly so gears

align and lever slides to desired position/gear.

Place lever in desired position Move lever all the way down to

lock in gear selection

19

Page 20

MK-6000 SAW INSPECTION & START-UP

BELT AND POWERBAND INSPECTION AND TENSION ADJUSTMENT

The MK-6000 is designed with a transmission belt and a 10 rib powerband. The transmission belt and

powerband should be inspected, adjusted and/or replaced periodically. Inspect the belt and powerband

daily for cracks, fraying, separation and wear.

Powerband Tension

Check powerband tension by applying pressure by

pushing down rmly with nger in the middle of the

belt; approximately 1/8” deection is correct.

To Tension Powerband

Loosen 4 bolts on the two retain-

ing caps so gearbox can rotate

Loosen locknut on tension bar Apply tension to belt by turning

tension screw clockwise,

increasing tension

When correct tension has been obtained, retighten locknut and retaining caps. Replace belt guard.

Transmission Belt Tension

B

A

A. Lock Nut

B. Breaker arm hole

Check transmission belt tension

by applying pressure by push-

ingdownrmlywithngerinthe

middle of the belt; approximately

3/8”deectioniscorrect.

To Tension Belt: Loosen locknut

on tension arm. Apply tension

with ½” drive breaker bar.

Retighten locknut and check deection is correct. Replace belt guard.

20

Page 21

MK-6000 SAW INSPECTION & START-UP

PRE-OPERATION CHECKLIST

WARNING

Before leaving our factory, every machine is thoroughly tested. Follow instructions strictly and your

machine will give you long service in normal operating conditions.

Before starting up the machine, make sure you read the entire Operation Manual and Engine

Manual so you are familiar with the operation of the machine.

Machine Cold

1. Check engine oil. See Engine Owner’s Manual for type and quantity.

2. Connect battery cables.

3. Check hydrostatic transmission uid level.

4. Test hydraulic operations. Raise and lower.

5. Check the engine air cleaner.

SCHEDULE MAINTENANCE QUICK REFERENCE

1-2 Hour Operation Checklist

WARNING

ALWAYS locate machine on a level surface with the engine “OFF” and the ignition switch set in the

“OFF” position before performing any maintenance. Let the machine cool down prior to any service.

1. Check the engine air cleaner hose clamps. Tighten as required.

2. Tension the blade drive V-belts. DO NOT overtension.

WARNING

Before performing any maintenance, ALWAYS locate machine on a level surface with the engine

“OFF” and the ignition switch set in the “OFF” position.

Service Daily

1. Check engine oil level.

2. Check blade guard for damage.

3. Check hoses and clamps for damage or looseness. Tighten or replace as necessary.

4. Check air cleaner for restriction. Replace air lters at regular intervals.

Interval Service

See the Maintenance Schedule Table on Page 30.

21

Page 22

MK-6000 SAW OPERATION

NOTICE

Before mounting the blade, machine should be turned “OFF”. Clean the blade collars and stub shaft.

BLADE MOUNTING INSTRUCTIONS

1. Remove Blade Guard.

A. Unscrew the hose tting to disconnect hose.

B. Hold the Blade Guard by the handle. Release the inner latch.

C. Pull the guard up and off the Saw.

Unscrew Hose Fitting

2. Remove arbor bolt. If blade is mounted on right side saw,

the bolt has left hand threads. To remove turn clockwise.

If the blade is mounted on left side of saw, bolt has right

hand threads. To remove, turn counter-clockwise.

3. Pull off vi-lock washers and outer ange.

4. Install new blade.

5. Slide the outer ange in place.

6. Slide on the vi-lock washers. Ensure the stepped

ridges face each other.

7. Tighten the arbor bolt.

8. Install the blade guard in place. Make sure that the

guard locks in place and connect the hose.

Release Inner Latch

Remove arbor bolt

Replace Washers

22

Install Blade Guard

Page 23

MK-6000 SAW OPERATION

BLADE MOUNTING INSTRUCTIONS CONTINUED

WARNING

Observe the rotation arrow on blade and DO NOT exceed maximum RPM stamped on the blade. To

set proper RPM, consult the Blade Guards and Blade Sizes.

NOTICE

To meet ANSI safety standards, larger diameter blade anges are required for large diameter blades.

Information is available upon request or for complete safety information refer to ANSI Safety Code B7.1

NOTICE

We recommend the use of MK Diamond Products diamond blades with these saws.

FLANGE DIAMETER BLADE DIAMETER

4" 20"

5" 26" up to 30"

6" 36"

7" 42"

POSITIONING THE SAW

Position the handles to suit the operator and conditions. The saw may be pivoted like a wheelbarrow

by lifting the rear wheels and rotating the saw into position. If moving the saw more than a few feet

or up and down ramps, start the engine and drive.

23

Page 24

MK-6000 SAW OPERATION

STARTING ENGINE

NOTICE

Read the engine instructions manual before starting.

WARNING

Be sure blade is unobstructed and not resting on ground.

WARNING

Be sure hands and feet are clear of blade.

1. Check engine oil. Add oil if low.

2. Check fuel level. Add fuel if low.

3. Check cooling air intake areas and external surfaces of engine. Make sure surfaces are clean

and unobstructed.

4. Check that air cleaner components and all shrouds, equipment covers and guards are in place

and securely fastened.

STARTING INSTRUCTIONS

1. Place FNR Handle in NEUTRAL.

2. Verify Neutral Engagement Handle is down, in NEUTRAL.

3. Pull Engine Throttle Handle out half-way.

4. Start engine by rotating Ignition Switch to the right.

NOTICE

DO NOT crank engine for more than 30 seconds at a time. If engine fails to start, wait about 2 min-

utes between cranking periods to prevent starter from overheating.

NOTICE

Allow engine to warm up at least 3 minutes before applying load.

5. When engine is warm, throttle may be used out to maximum position.

6. To stop engine, push throttle to idle, rotate ignition switch to “OFF” position.

NOTICE

If the engine has been running hard and is hot, do not shut engine off abruptly. Cool engine by removing load and allowing engine to run idle for 3 to 5 minutes.

24

Page 25

MK-6000 SAW OPERATION

SAW GUIDE ALIGNMENT AND ADJUSTMENT

WARNING

This operation is performed with the engine “OFF”!

The front and rear pointers are set in line at the factory. However, the pointers should be checked

for proper alignment with the blade after every use. The following are the procedures for aligning the

pointers with the blade, with the engine shut off.

1. Using a straight edge, carefully mark a line 12 feet long on a smooth level concrete surface.

2. Place the saw parallel to the line. Lower the blade and center it over the line.

3. FRONT: With the blade centered over the line and the saw frame parallel to the line, lower the front

pointer assembly and position the pointer over the line.

4. REAR: With the blade centered over the line and the saw frame parallel to the line, loosen the

pointer and adjust up or down and ensure that it touches the line.

5. Finally, roll the saw along the entire length of the line. The saw should lead off no more than 6 inches to

the left in 12 feet of forward travel. Adjust the pointer in or out if the lead-off is outside this parameter.

6. Secure hardware.

25

Page 26

MK-6000 SAW OPERATION

MANEUVERINGTHESAW

WARNING

The blade is spinning whenever the saw is running. Raise the blade as high as possible when maneuvering so that the blade will not strike the pavement.

DRY CUTTING

Dry cutting blades have been specially designed for use with concrete saws. Ensure that the blade

you are using is clearly marked for dry cutting.

When dry cutting, it is important to keep the air lter clean. Check the condition of the lter at least

every four (4) hours of operation. Clean the pre-lter (wash in soapy water and re-oil) and change the

paper lters as soon as it becomes clogged. Concrete dust is very abrasive and will quickly damage

internal engine parts, causing loss of compression and eventual engine failure.

Saw only as deep as the specications and job conditions require. Remember airow helps to cool

the blade during dry cutting. Cutting too deep with one pass, or exerting excessive forward or side

pressure can be dangerous. Step cut in increments of 1 inch (25 mm) or less, for the best results.

If reinforced abrasive blades are used for cured concrete, it is usually better to saw only 1 inch deep

per pass. If deeper cuts are required, cut in multiple passes.

Thinner Diamond Blades are especially advantageous when cutting dry.

WET CUTTING

The water used on the blade is to provide coolant during cutting and to ush the concrete cutting from

the cut. Turn the water control to full “ON” when using wet cutting blades. The required ow rate is 5

to 8 gallons per minute.

FNR HANDLE

The FNR Handle moves the saw forward by pushing the lever away from the operator and moves the

saw in reverse by pulling the lever toward the operator. The further you push this lever, the faster the

saw travels.

WARNING

Before starting the engine, place this lever in NEUTRAL.

RAISE/LOWER HANDLE

The raise/lower handle controls the depth of the blade. When pulled back, the electric/hydraulic pump

will raise the blade out of the cut. When pushed forward the blade will lower. The lowering speed is

faster, the farther forward the lever is pressed.

26

Page 27

MK-6000 SAW OPERATION

ENGAGINGTHEDRIVEUNIT

This saw is driven by a hydrostatic transmission. To engage the transmission, PULL the Neutral Engagement Handle up and turn to either direction to lock.

NOTICE

DO NOT engage the unit unless FNR Handle is on NEUTRAL.

Neutral

Engagement

Handle

Engage transmission

FNR Handle

To disengage the transmission, twist the Neutral Engagement Handle to unlock, and PUSH down.

WATER HOOK UP

Prior to starting the engine, you should hook up the water hose to the Water Inlet and visually inspect

it to make sure that water is owing to the blade. Hook up the hose to the unit and turn on the water

source. Open the water valve.

NOTICE

Water ow volume can be metered by opening the water valve partially.

Next, lift the front of the blade guard and visually inspect to make sure water is owing out of each of

the tubes. If any of the holes are blocked, ush impurities from the tube.

Water

Valve

Water Inlet

Water Hook Up

27

Page 28

MK-6000 SAW OPERATION

DEPTH INDICATOR AND DEPTH STOP

The saw is equipped with a Depth Indicator and a Depth Stop. The Depth Indicator tells you

approximately how deep you are in the cut. To set the indicator, you need to rst lower the blade until

it is just touching the ground and then rotate the Depth Indicator knob to 0.

The Depth Stop is used for several cuts at the same depth. It is set by nding the desired depth and

then turning the knob until it is tight. This will prevent cutting below the “locked” level to provide a consistent depth with every cut.

Depth Stop

Depth Indicator and Depth Stop

Depth Indicator

STEP CUTTING

1. Follow general instructions outlined in the section Operating the Saw pages 20.

2. When deep sawing (more than 4”) or concrete with hard aggregate, sawing to full depth in

several cuts should be made in incremental steps of 1-1/2 to 2 inches until the desired depth of

cut is reached. In softer aggregates or asphalt, it may be possible to saw full depth in two passes.

3. Gradually move the speed control lever forward to increase the cutting speed. If the blade stalls in

the cut (which can happen when deep sawing) immediately raise blade from cut. If not done

at once, the belts will spin freely and burn. Check belts for proper tension and continue sawing at

a slower rate of speed.

4. On nal pass, lower the blade until it hits the sub-base (sandy color will appear in the water being

discharged from the cut). Raise blade approximately 1/2” from bottom. The sand and gravel

particles of the sub-base may cause premature wear or damage to the saw blade.

5. It is common, on the nal pass of the cut, for pavement to wedge blade, particularly on a hot day.

When this happens, immediately stop engine. If the blade is wedged, remove the Blade Shaft Bolt

and Outside Collar and move the saw away from the blade. To remove a wedged blade from the

concrete, use a jack hammer and carefully chip out concrete around the blade. (Pounding or

twisting the blade may cause severe damage).

6. Go slowly with a new blade until it “opens up” that is, until you can see and feel the diamonds.

7. Small corrections can be made by leaning on handles.

Deep sawing is very hard on saws and blades. Experienced operators soon get a “feel” for the

saw and are constantly on guard to slow down when they hit excessive steel or hard aggregate.

28

Page 29

MK-6000 SAW MAINTENANCE

ENGINE

The operation and life of the engine depends on proper maintenance. Do not start engine until en-

gine pre-check is complete. The engine pre-check consists of checking the oil, fuel level, air lter and

greasing the wheel, axle, drive unit and arbor bearings. Basic engine maintenance is shown in Maintenance Schedule Table on the next page. For more detailed information, please refer to the Engine

Operator Maintenance Manual and Warranty provided with the saw.

NOTICE

When breaking-in a new saw, we recommend running the engine for one hour with no load prior to

actual use on the job.

AIR CLEANER

Due to the dusty conditions created by sawing, it is essential to check the engine air cleaner element

daily. Remove the element and shake out the accumulated dust and dirt. Wipe out dirt from the inside

cover and from the housing. Check the engine manual for washing instructions. Stocking replacement

lters is strongly recommended.

ARBOR,AXLE,DRIVEUNITANDWHEELBEARINGS

Blades shaft, Axle, Drive Unit, and Wheel Bearings should be greased according to the Maintenance

Schedule table on the next page.

WARNING

DO NOT inspect when the engine is running.

Use of high quality detergent oil of API (American Petroleum Institute) service class SF or SG. Select

the viscosity based on the air temperature at the time of operation. For temperatures below 0ºF, 5W20 or 5W-30 oil is recommended. For temperatures above 0º, 10W-30 oe 10W-40 oil is recommended. Check your engine manual for other recommendations.

HYDROSTATICDRIVEUNIT&TRANSMISSIONGEARBOX

The uid shipped in your hydrostatic transmission is a uid having a viscosity equivalent to SAE

20W20. Mobil uid 300 or any other oil equivalent to SAE 20W20 is preferred by Eaton Transmission. The expansion tank (Marker A) is marked for proper uid level. It should be checked when unit

is cold. DO NOT allow the unit to run low on oil. If the unit is low, you can add oil by removing the cap

(Marker B). Remove plug (Marker C) and ll transmission gearbox with 80-90 SAE Gear Oil to lower

edge of ll hole.

BB

A

Expansion Tank and Cap

29

C

Page 30

MK-6000 SAW MAINTENANCE

MAINTENANCE SCHEDULE

MAINTENANCE SCHEDULE DAILY

Check Engine Oil Level

Check Air Filter

Check Air Intake, Clean if Necessary

Grease Rear Wheel Pillow Blocks

Grease Front Wheel Bearings

Check Drive Transmission Oil, Add if Low

Check Bladeshaft Gearbox, Add if Low

Check Power Unit Fluid, Add if Low

Large Road Saw Air Cleaner Element

Change Engine Oil

Change Engine Oil Filter

Check Engine Compression

Inspect Fuel Filter, Replace if Dirty

Inspect Spark Plugs and Ignition System

X

X

X

25

HOURS

X

X

X

X

X

X

50

HOURS

X

X

250

HOURS

X

X

X

Inspect Cooling System and Clean

Inspect Starting Motor

Gearbox Oil Level

X

X

X

30

Page 31

MK-6000 SAW MAINTENANCE

TROUBLESHOOTING

When trouble occurs, be sure to check the simple causes which, at rst, may seem too obvious to be

considered. Refer to the table below for problems and their possible causes.

TRANSMISSION

Problem

Cause

Problem

Transmission

jerky when

starting

Transmission

operates in

one direction

Transmission

operating hot

Oil color is

black

Oil color is

milky

Cause

Loose

Transmission

Linkage

X X X

X

X X X X

No

Fuel

Improper

Fuel

Oil

Level

Dirt in

Fuel

Line

Cooling

Fan

Water in

Oil

Reservoir

X X

X

Fuse

Burned

Out

Incorrect

Oil Level

Dirty

Cooling

Fans

Dirty

Air

Filter

Loose

Drive

Chain

Faulty

Spark

Plugs

ENGINE

OTHER

Will not start

Hard starting

Stops suddenly

Lacks power

Operates erratically

Knocks or pings

Skips or misres

Back res

Overheats

High Fuel Consumption

Cause

Problem

Reduced blade life

Excessive belt wear

X X X X X

X X X X X

X X X X

X X X X X

X X X X

X X

X X X

X X X

X X X

X X

Improper Blade for the

Application

Improper Belt

Tension

Damage Caused by

External Objects

X X

X X

31

Page 32

NOTES

32

Page 33

NOTES

33

Page 34

MK-6000 SAW ORDERING, RETURN, & PACKAGING

ORDERING INFORMATION

You may order MK Diamond products through your local MK Diamond distributor or, you may order

direct from MK Diamond.

When ordering direct from MK Diamond, please have the following information ready before calling:

• The Model Number of the saw

• The Serial Number of the saw

• Where the saw was purchased and when

• The Part Number for the part(s) being ordered

• The Part Description for the part(s) being ordered

NOTE: There is a $25.00 minimum order when ordering direct from MK Diamond. A $5.00 charge will

be added to orders having a net billing value under $50.00. All purchases must be made using VISA,

MasterCard or American Express.

All parts may be ordered by calling toll free to – 800 421-5830 or 310 539-5221 and asking for

Customer Service. For technical questions, call – 800 474-5594.

RETURN MATERIALS POLICY

To expedite the service relative to the return of a product purchased through MK Diamond, please

observe the following:

NOTE: When returning all items, they must have been purchased within the previous twelve (12)

months.

• Have the Model Number of the saw

• Have the Serial Number of the saw

• Have the location of where the saw was purchased

• Have the date when the saw was purchased

• Contact Customer Service for approval to return the item(s)

• Obtain a Returned Goods Number (RGA) authorizing the return

• Follow the packaging instructions in the following section

• Ensure your item(s) are prepaid to the destination

For returned items, call toll free to – 800 421-5830 or 310 539-5221 and ask for Customer Service.

For technical questions, call – 800 474-5594 or 310 257-2845.

PACKAGING INSTRUCTIONS

• Remove the Cutting Head and Support Angle Assembly

• Dry the saw before shipping

• When packing, include the following: MK-6000 and Guard Blade (Other Accessories are not

required)

• Package the unit in its original container or one of comparable size (do not ship the unit partially

exposed)

• Ensure all parts are secured in the packaging to prevent moving

AUTHORIZEDSERVICECENTERS

For quicker repair time, you may contact MK Diamond Customer Service, toll free, at 800 421-5830

or 310 539-5221 for the Authorized Service Center closest too you or visit our web site at www.mkdiamond.com. For technical questions, call – 800 474-5594.

34

Page 35

MK-6000 SAW CONTACT & LIMITED WARRANTY

CONTACT

Please contact MK Diamond Products, Inc. Customer Service Department with any questions you

might have regarding distributors, parts or service.

Telephone: (800) 421-5830

Fax: (310) 539-5158

E-mail: Customer_Service@MKDiamond.com

Customer Service Hours: Monday through Friday, 6AM-4PM PST

MK Diamond Products, Inc.

1315 Storm Parkway

Torrance, CA 90501

MK DIAMOND PRODUCTS, INC. LIMITED WARRANTY

MK DIAMOND PRODUCTS, INC. will guarantee every machine they build, to be free from defects in

material and workmanship for (1) one year from date of purchase. The obligation of MK DIAMOND

PRODUCTS, INC. under this warranty is limited to the repair or replacement of any parts which,

under normal use, prove to be defective in material or workmanship. The parts involved or the unit

in question should be returned to MK DIAMOND PRODUCTS, INC. or to a point designated by us,

transportation prepaid.

This warranty does not obligate us to bear the cost of labor or transportation charges in connection

with replacement or repair of defective parts. Likewise, it shall NOT apply to any unit which has been

subjected to misuse, neglect or accident. This warranty does NOT apply to any machine which has

been repaired or altered outside our factory.

This warranty does NOT obligate MK DIAMOND PRODUCTS, INC., with respect to items not of our

manufacture, such as engines, motors, hydraulics, etc., which are subject to their own guarantees and

warranties.

We shall in no event be liable for consequential damages or contingent liabilities arising out of failure

of any equipment or parts to operate properly.

©COPYRIGHT2011,MKDIAMONDPRODUCTS,INC.ALLRIGHTSRESERVED.

The MK Diamond logo is a registered trademark of MK Diamond Products, Inc. and may not be used,

reproduced, or altered without written permission. All other trademarks are the property of their respective owners and used with permission.

MK Diamond may have patents, patent applications, trade marks, copyrights of other intellectual

property right covering this product in this document.

This manual MUST accompany the equipment at all times. This manual is considered a permanent

part of the equipment and should remain with the unit if resold.

The information and specications included in this publication were in effect at the time of approval for

printing.

35

Page 36

MK-6000 SAW

OWNER'S MANUAL & OPERATING INSTRUCTIONS

MK Diamond Products, Inc.

1315 Storm Parkway

Torrance, CA 90501

Toll-Free: (800) 421-5830

Phone: (310) 539-5221

Fax: (310) 539-5158

www.mkdiamond.com

Loading...

Loading...