Page 1

AXIS JACKSON SYSTEM ®

OWNER’S MANUAL

Model 6977

This manual is written in five

languages in the following order:

• (en) English

• (es) Spanish

• (fr) French

• (de) German

• (it) Italian

MIZUHO OSI

30031 AHERN AVENUE • UNION CITY, CA 94587

Bus: 510-429-1500 • Toll Free: 800-777-4674 Fax: • 510-429-8500

WWW.MIZUHOSI.COM ·

•

NEWHIPNEWS.COM · •NEWSPINENEWS.COM

MIZUHOSI 2009 1 NW0507 Rev G

Page 2

© Copyright 2008, Mizuho OSI. All rights reserved.

Information in this document is subject to change without notice. Mizuho OSI assumes

no responsibility for any errors that may appear in this document. This document is

believed to be complete and accurate at the time of publication. In no event shall

Mizuho OSI be liable for incidental, special, multiple, or consequential damages in

connection with or arising from the use of this document.

NOTICE TO PURCHASER:

MIZUHOSI®, Axis Jackson®, Axis Jackson System®, GentleTouch®, Torso Trolley®,

Advance Control Pad System™, and IVSP™ are trademarks of Mizuho OSI and the

Mizuho Corporation.

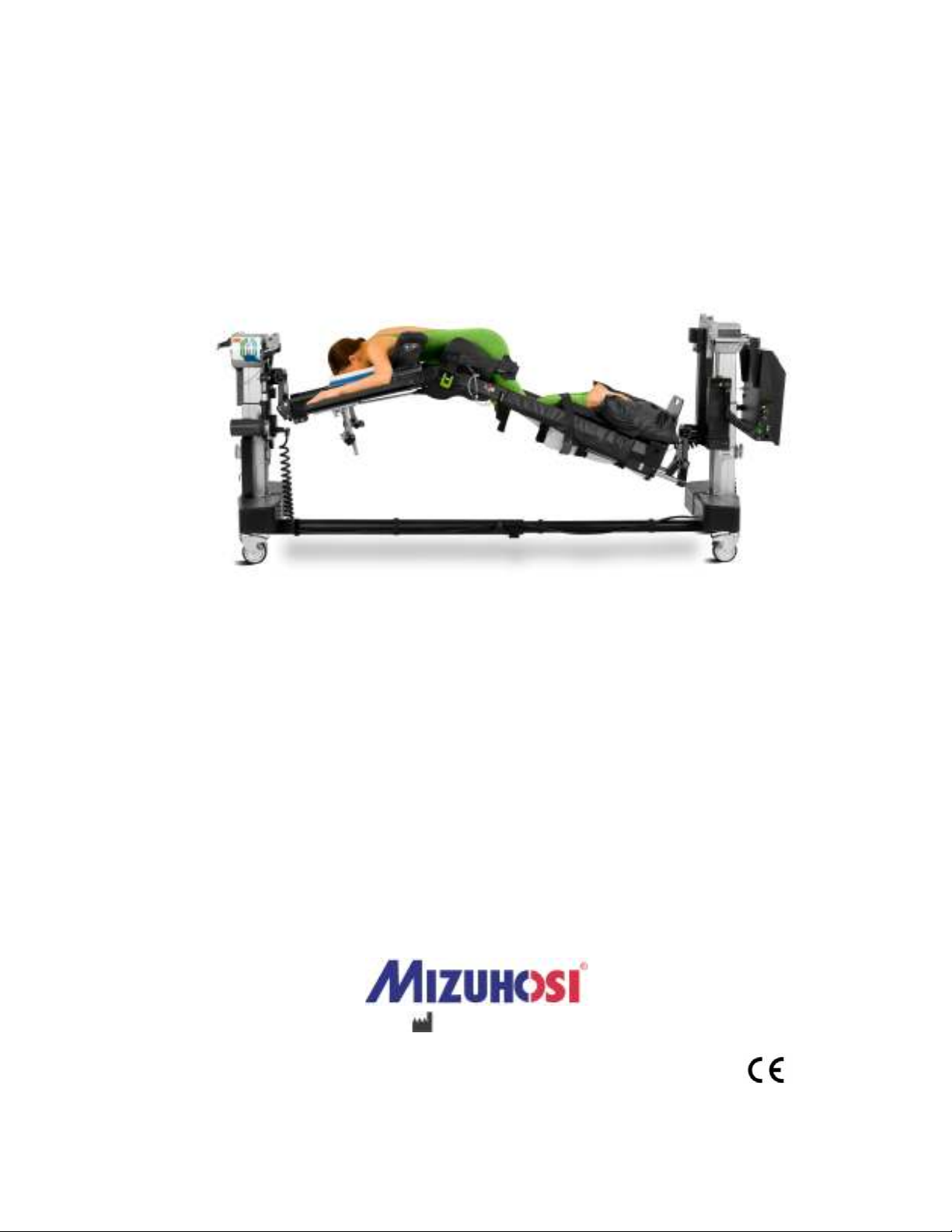

The Axis Jackson System® Model 6977 is a Class II, Exempt Device within the

guidance of 21 CFR Part 860 Medical Device Classification Procedures. The 6977 is

Class I, in accordance with Rule I of the Medical Device Directive Guidance Document

MDDEV 2.4/1, Guidelines for the Classification of Medical Devices.

The Axis Jackson System® Model 6977 is intended for use as a patient positioning

surgical support system for thoracic and lumbar spine procedures. It provides for a wide

range of intra-operative angular movement with the patient positioned prone, supine, or

lateral. Patent pending.

All other trademarks in this document are the sole property of their respective owners.

Printed in the USA, 2009

MIZUHOSI 2009 2 NW0507 Rev G

Page 3

AXIS JACKSON SYSTEM

TABLE OF CONTENTS

Section Page

1.0 SAFETY INFORMATION ..................................................................................... 4

2.0 INTRODUCTION .................................................................................................. 8

3.0 SYSTEM COMPONENTS .................................................................................. 11

4.0 AXIS JACKSON SYSTEM SET-UP................................................................... 14

5.0 PRE-OPERATION FUNCTION CHECKS .......................................................... 34

6.0 OPERATING THE SYSTEM .............................................................................. 36

7.0 PRONE POSITIONING ...................................................................................... 41

8.0 SUPINE AND LATERAL POSITIONING ........................................................... 56

9.0 CLEANING, STORAGE, AND ROUTINE MAINTENANCE............................... 64

10.0 TROUBLESHOOTING GUIDE........................................................................... 68

11.0 REPAIR AND TECHNICAL SERVICE............................................................... 75

12.0 CONTACTING MIZUHOSI ................................................................................. 76

13.0 6977 ELECTRICAL INTERCONNECT DIAGRAM (PAGE 1 OF 2)................... 77

14.0 STANDARD COMPONENTS AND OPTIONAL ACCESSORIES...................... 79

15.0 AXIS JACKSON SYSTEM® OWNER’S MANUAL CHECKLIST ..................... 85

MIZUHOSI 2009 3 NW0507 Rev G

Page 4

1.0 SAFETY INFORMATION

CAUTION

WARNING

DANGER

CAUTION

Safety Conventions Used In This Document

Document Five user attention words may appear in the text of this Mizuho

User Attention OSI Owner’s Manual. Each user attention word implies a

Words particular level of observation or action as described below.

Note: Calls attention to useful information.

IMPORTANT: Indicates information that is necessary for proper product operation.

Indicates a potentially hazardous situation which if not avoided may

result in minor or moderate injury. It may also be used to alert against

unsafe practices.

Indicates a potentially hazardous situation which if not avoided could

result in death or serious injury.

Indicates an imminently hazardous situation which if not avoided will

result in death or serious injury. This signal word is to be limited to the

most extreme situations.

Before Ensure that everyone involved with the use or maintenance

Using This of this product has read the Owner’s Manual.

Product

Avoid using this product in a manner not specified by Mizuho OSI.

IMPORTANT: The positioning techniques and applications outlined in this manual are

the manufacturer’s suggested techniques. The final disposition of

each patient’s care as related to the use of this product rests with the

attending physician.

MIZUHOSI 2009 4 NW0507 Rev G

Page 5

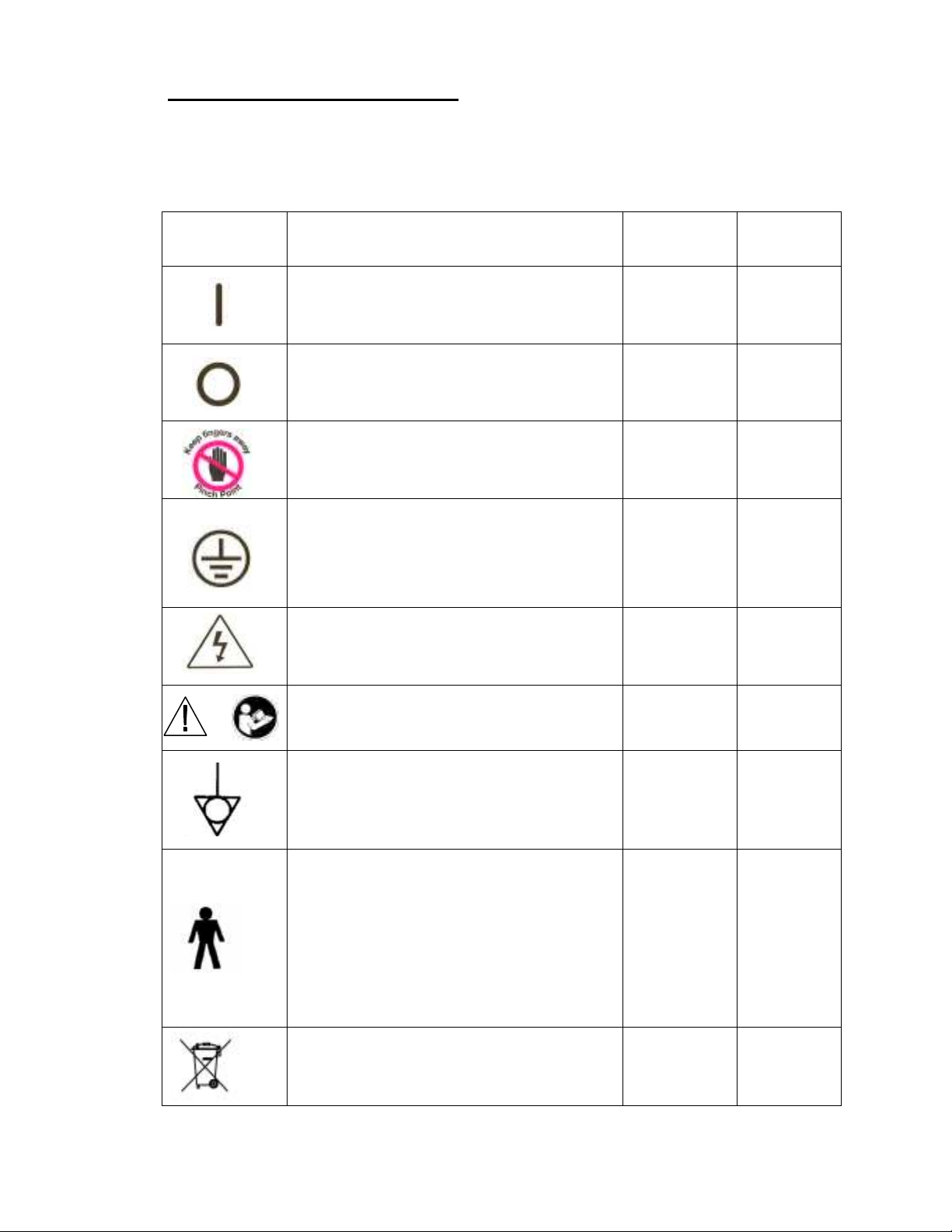

Safety and Health Symbols Used

The following Table (T-1) describes the symbols displayed on the Axis

Jackson System and referenced within this Owner’s Manual.

Table T-1

Symbol

Indicates pinch point.

Indicates a protective grounding terminal

Indicates the presence of an electrical

Indicates the ON position of a power

switch.

Indicates the OFF position of a power

switch.

that must be connected to earth ground

before any other electrical connections

are made to the product.

shock hazard and to proceed with

appropriate caution.

Description

Used On

Product

√

√

√

Used In

Manual

√

√

Indicates that you should consult the

OR

manual for further information and to

proceed with appropriate caution.

Indicates an external ground stud that is

required for use when the AC power

cable is not connected to a protective

earth ground outlet in your operating

room or facility.

Indicates this equipment is an applied

part, TYPE B in accordance with IEC

60601-1 and is generally suitable for

applications involving external or internal

contact with the patient, excluding the

heart. The patient circuit is connected to

protective earth and this equipment

should be connected only to outlets with a

protective earth ground.

Indicates Waste Disposal information.

√

√

√

√

MIZUHOSI 2009 5 NW0507 Rev G

Page 6

Product Safety Certifications

CAUTION

WARNING

The Axis Jackson System has been independently tested and verified to comply with

the applicable sections of the following:

IEC 60601-1 Medical Electrical Equipment, Part 1: General Requirements for Basic

Safety and Essential Performance.

IEC 60601-1-2 Medical Electrical Equipment, Part 1-2: General Requirements for Safety

– Collateral Standard: Electromagnetic Compatibility – Requirements and Tests.

IEC 60601-2-46 Medical Electrical Equipment – Part 2: Particular Requirements for

Safety – Specification for Operating Tables.

UL60601-1 UL Standard for Safety for Medical Electrical Equipment, Part 1: General

Requirements for Safety.

CAN/CSA C22.2 NO. 601.1-M90 Medical Electrical Equipment - Part 1: General

Requirements for Requirements for Safety.

JIS0601-1 Medical Electrical Equipment, Part 1: General Requirements for Safety.

93/42/EEC Medical Device Directive.

IEC 60529 Degrees of Protection Provided by Enclosures (IP Code).

General Product Setup and Use Precautions

Servicing of the Axis Jackson System is to be performed only by

Mizuho OSI Factory authorized personnel. Failure to comply with

this requirement may result in damage to the product, and injury or

death of personnel.

This equipment is an applied part, TYPE B, in accordance

with IEC 60601-1 and is generally suitable for applications involving

external or internal contact with the patient, excluding the heart.

The patient circuit is connected to protective earth and this

equipment should be connected only to outlets with a protective

earth ground.

MIZUHOSI 2009 6 NW0507 Rev G

Page 7

An external ground stud is required for use when the AC

WARNING

power cable is not connected to a protective earth ground outlet in

your operating room or facility. To protect the patient and hospital

staff from any possible hazards, an external ground wire connection

is required between the external ground stud and protective earth

ground. Failure to comply with this requirement may result in

damage to the product, and injury or death of personnel.

IMPORTANT: Medical electrical equipment needs special precautions regarding EMC

and needs to be installed and put into service according to the EMC

information provided in this manual.

IMPORTANT: Portable and mobile RF communications equipment can affect medical

electrical equipment.

IMPORTANT: This equipment should not be stacked with other equipment. The

equipment should be observed to verify normal operation in the

configuration in which it will be used.

IMPORTANT: The use of accessories, transducers and cables that are not specified

by Mizuho OSI, may result in increased electrical/electronic signal

emissions and/or decreased electronic/electrical signal immunity which

may affect the proper operation of the equipment.

Note: To be in compliance with the European WEEE Directive, all

electrical components, batteries and carbon composite components

that must be disposed shall either be returned directly to Mizuho OSI

or to a Mizuho OSI specified disposal facility for proper disposal.

Please contact Mizuho OSI Customer Resources Department at 1800-777-4674 for further information regarding this requirement.

MIZUHOSI 2009 7 NW0507 Rev G

Page 8

2.0 INTRODUCTION

General Description

The Mizuho OSI Axis Jackson System®, Model 6977, in conjunction with the Mizuho

OSI Advanced Control Modular Table Base, Model 5803 is a patient positioning surgical

support system for thoracic and lumbar spine procedures that provides for a wide range

of intra-operative angular movement.

The Axis Jackson System can be set-up for prone, supine and lateral patient positioning

and is designed to articulate the patient intra-operatively in flexion and extension,

replicating the natural movement of the spine.

The Axis Jackson Hinged Frame is designed to only be mounted on the Mizuho OSI

5803 Advanced Control Modular Table Base. The modular base Hand Pendant controls

the Trendelenburg, Reverse Trendelenburg, and table top height adjustments. The

Hand Pendant for the Axis Jackson controls the table top’s Hinge movement and

Lateral Roll.

The Axis Jackson System incorporates an Advance Control Pad System (ACP) which

supports a patient in the prone position. The pad system is electronically controlled and

pneumatically actuated, providing massage action and periodic pressure point

stimulation through the Bilateral Winged ACP Chest Pad and the Contoured

Combination ACP Hip / Thigh Pads.

Specifications

Hinged Frame 80“ (203 cm)

Total Length

Hinged Frame Head-End 33“ (84 cm) length

Hinged Frame Foot-End 47” (119 cm) length

Hinged Frame Head-End 19“ (48 cm) width

Hinged Frame Width

Hinged Frame Foot-End 19” (48 cm) width

Head-End 30“ (76 cm) length

Two Piece Supine Top Length

Foot-End 43“ (109 cm) length

Head-End 21” (53 cm) width

Supine Top Width

Foot-End 21” (53 cm) width

-20° (± 2°) Hinge Down

Table Articulations

+35° (± 2°) Hinge Up

12° (± 2°) Lateral Roll

Table Top Height Range

24” – 39” (61 cm - 99cm) measured at the HeadEnd of the table frame

Patient Weight Capacity 500 lb (227 kg) maximum

Power Requirements 6977: 100-230 VAC at 50/60 Hz, 9 Amps max.

Duty Cycle of Hinged Frame 10%, (6 minutes continuously per hour)

MIZUHOSI 2009 8 NW0507 Rev G

Page 9

Product Acceptance

Upon receipt of your Axis Jackson System, remove each component from its shipping

crate or packaging. Visually inspect all surfaces for freight damage.

Note: Any freight damage must be reported to the freight carrier immediately upon

delivery. It is the responsibility of the recipient to make freight damage claims.

Glossary of Terms

Foot Elevator, Down A downward motion of the Hinged Frame Foot-End. The

Hinge angle remains neutral.

Foot Elevator, Up An upward motion of the Hinged Frame Foot-End. The

Hinge angle remains neutral. The Foot-End of the frame

does not raise above neutral.

Foot-End Table Top The section of the Hinged Frame where the Removable

Foot Board is attached.

Head-End Table Top The section of the Hinged Frame where the Torso

Trolley® mounts.

Height Down Both Columns of the modular base lower simultaneously

to lower the table top.

Height Up Both Columns of the modular base raise simultaneously

to raise the table top.

Hinge Down The Hinge of the frame moves downward. The Foot

elevator moves upward.

Hinge Up The Hinge of the frame moves upward. The Foot

Elevator moves downward.

Lateral Roll, Left A counter-clockwise motion of the table top about its

longitudinal axis, as viewed from the Head-End Column.

Lateral Roll, Right A clockwise motion of the table top about its longitudinal

axis, as viewed from the Head-End Column.

Left Side of Table Top The left side of the table top, as viewed when standing

at the Head-End Column facing the Foot-End Column.

Return to Home The Hinged Frame returns to level side to side and the

Hinge and Foot Elevator return to neutral positions.

Reverse Trendelenburg A position of the table top and the patient, with the Foot-

End lower than the Head-End. On the modular base,

the Head-End Column raises and the Foot-End Column

lowers simultaneously. If the table is in a fully raised

position, only the Foot-End will lower to achieve the

proper Reverse Trendelenburg angle.

Right Side of Table Top The right side of the table top, as viewed when standing

at the Head-End Column facing the Foot-End Column.

MIZUHOSI 2009 9 NW0507 Rev G

Page 10

Trendelenburg

A position of the table top and the patient, with the Head-End

lower than the Foot-End. On the modular base, the Foot-End

Column raises and the Head-End Column lowers

simultaneously. If the table is in a fully lowered position, only

the Foot-End will raise to achieve the desired Trendelenburg

angle.

V Hinge Down Only the Hinge of the frame moves downward.

V Hinge Up Only the Hinge of the frame moves upward.

MIZUHOSI 2009 10 NW0507 Rev G

Page 11

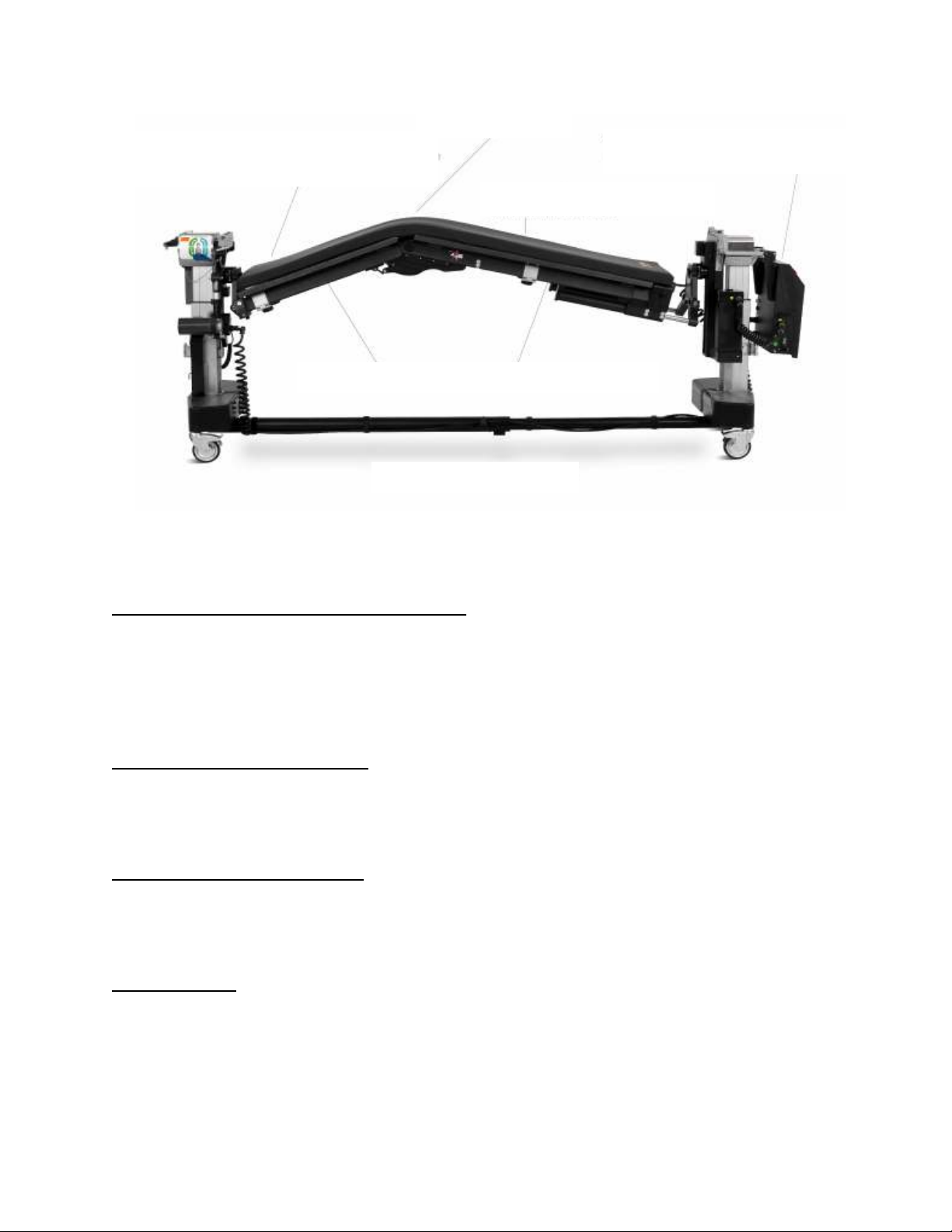

3.0 SYSTEM COMPONENTS

Advanced Control Pad System™ (ACP)

Hinged Frame

Contoured

Bilateral Winged

Torso Trolley™

5-Way Adjustable

The main components of the Axis Jackson System are shown in Figures 1 and 2.

– automatically

stimulates patient pressure points on chest, hips and thighs

Chest Pad

- integrates

patient movement with hinge

translation

Arm Boards

Carbon Fiber Frame Construction

– supports spine

biomechanics and improves

surgeon access

Removable Foot Board

Hip/ Thigh Pads

Adjustable Leg Sling

Hinged Frame

6977 Axis Jackson Hinged Frame with 5803 Advanced Control Modular Base

MIZUHOSI 2009 11 NW0507 Rev G

Figure 1: Axis Jackson System

Page 12

Axis Jackson™ System Controller

Tempur

-

Med® 2

-

in, Table Pad

P

rone and Supine Table Tops

–

mount on dual column 5803 Advanced Control

Base

Hinge Angle Plus 35°

with Translation Slide

-

controls hinged frame

Carbon Fiber Removable Two Piece Imaging Top

Two Piece Supine Top

Figure 2: Axis Jackson System

6977 Axis Jackson Hinged Frame w/Two-Piece Supine Top and 5803 Advanced Control Modular Base

Head-End and Foot-End Column Sliders

The Axis Jackson System cannot be used without first installing both the Head-End and

Foot-End Column Sliders. The Column Sliders (P/N 6977-640 & 6977-641) are key

structural components of the system. The Column Sliders mount on the 5803 Advanced

Control Base Head-End and Foot-End Columns.

Head-End Support Assembly

The Head-End Support Assembly (P/N 6977-601) attaches to the Head-End Column

Slider and provides structural support for the Hinged Frame.

Foot-End Support Assembly

The Foot-End Support Assembly (P/N 6977-600) attaches to the Foot-End Column

Slider and provides structural support for the Hinged Frame.

Hinged Frame

The Hinged Frame (P/N 6977-100) is the primary structural member of the Axis

Jackson. It directly supports the patient weight while articulating about the Hinge point

just above the patient’s hips. The frame is constructed of carbon fiber tube elements

with aluminum Hinge and end fittings, and it includes a length-compensation element to

handle the foreshortening of the frame when it is flexed. The Hinge drive motor is

incorporated into the Hinged Frame.

MIZUHOSI 2009 12 NW0507 Rev G

Page 13

Axis Jackson Controller with Cable Set

The Controller (P/N 6977-4006, 120V or 6977-4005I, 230V) supplies power to the

various components of the Axis Jackson System. The table top On/Off switch is located

on the Controller. The Controller also includes the air pump and controls for the

Advance Control Pad System (ACP).

Hand Pendant with Junction Box

The Axis Jackson Hand Pendant (P/N 6807-5) mounts in the Holster (P/N 6977-4162)

with the 5803 Advanced Control Base Hand Pendant and should be hung on the HeadEnd Column of the base for easy access. It is used to manipulate the Hinge of the

frame up and down as well as control Lateral Roll of the Hinged Frame.

Two-Piece Supine Imaging Top

The Two-Piece Supine Top (P/N 6977-955 and P/N 6977-956) is of carbon fiber

construction and mounts above and below the Hinge of the frame to allow for

articulation of the Hinge when the patient is positioned in the supine or lateral position.

A 2” (5 cm) MIZUHO OSI Tempur-Pedic® pad (P/N 6977-7000) is provided for use with

the Two-Piece Supine Imaging Top. The TEMPUR® used in the manufacture of

MIZUHO OSI pads has viscoelastic properties and is a temperature sensitive material,

becoming softer where the patient’s body is making the most contact with the surface

and remaining firm in areas where less body contact is being made. Pressure is

distributed evenly over the entire surface area. The pad is radiolucent, MR safe and

latex free. The benefits of using MIZUHO OSI Tempur-Pedic are improved pressure

management, reduced shear forces and enhanced patient comfort.

The Supine Top Translation Sheet (P/N 6977-927) interfaces with the Supine Top and

Tempur-med® Pad to allow support and movement.

MIZUHOSI 2009 13 NW0507 Rev G

Page 14

4.0 AXIS JACKSON SYSTEM SET-UP

IMPORTANT: It is recommended that two people work together when installing

or uninstalling the system components.

Note: If you have purchased a 6977 Axis Jackson System already mounted on a

5803 Advanced Control Base at the factory, the base has been prepared and

the frame mounted. It remains important, however, that Section 4.0 Axis

Jackson System Set-Up be read to form an understanding about how the

applicable components are installed and function.

The Mizuho OSI Axis Jackson System is designed to only mount and be utilized on the

5803 Advanced Control Modular Table Base.

Note: For complete instructions on the 5803 Advanced Control Modular Table Base

operation and functions, please refer to the Owner’s Manual supplied with the

Advanced Control Modular Table Base (P/N NW0498). A thorough

understanding of the operation of the 5803 Advanced Control Base is required

before continuing.

Preparing the 5803 Advanced Control Base for Mounting 6977 Axis Jackson System

Complete the following steps prior to mounting the Axis Jackson® Hinged Frame

1. Move and position the 5803 Advanced Control Base where it will be used.

2. Ensure the retractable I beam is fully extended and locked in place

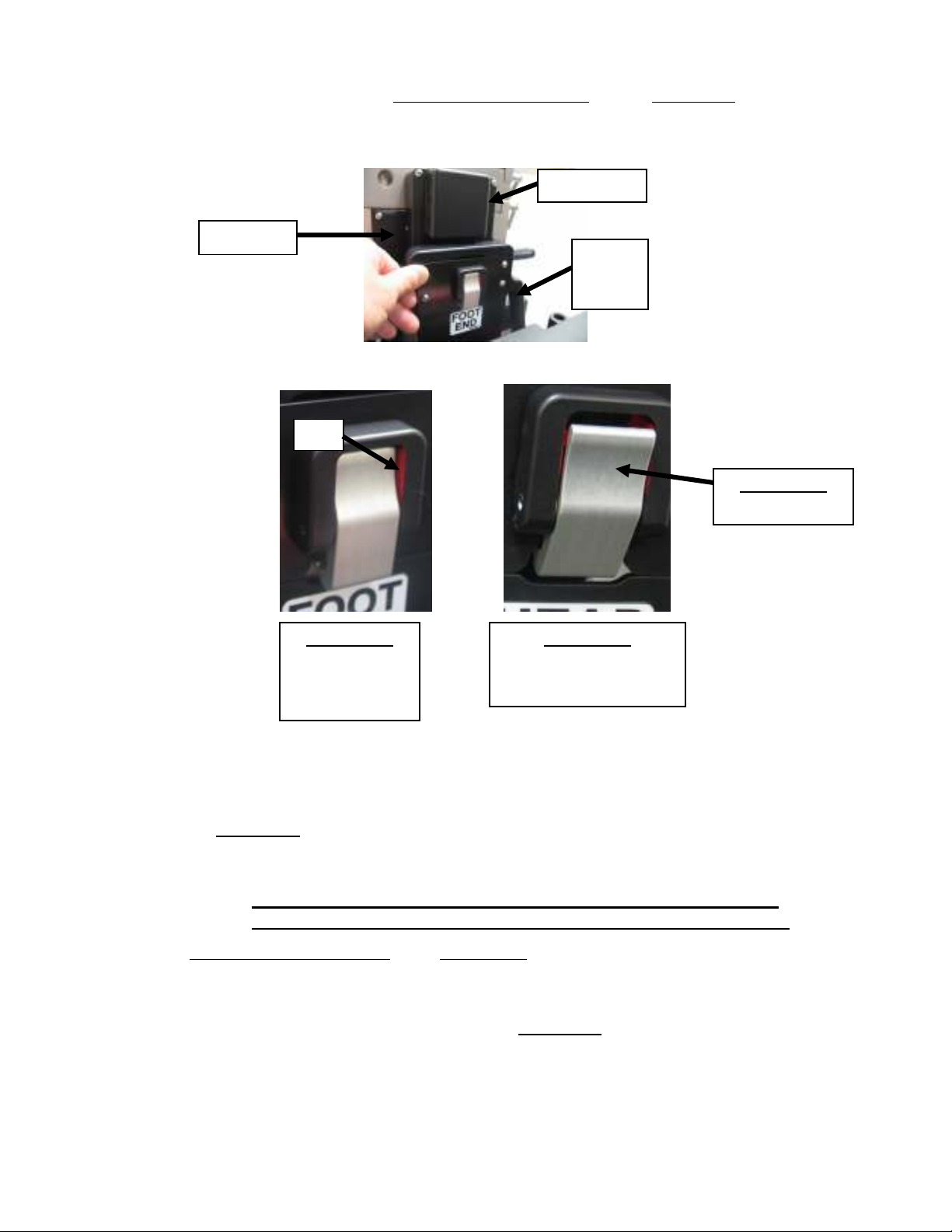

Rotation Safety

Lock Switch / Indicator

Light

Tilt Drive Status

Indicator Light

Traction Pulley

180° Rotation Lock

Indicator Light

Crossbar

180° Rotation

Lock Lever

Figure 3A: Indicator Lights on the Head-End Column of 5803 Advanced Control Base

3. Lock all 4 caster locks on the base

MIZUHOSI 2009 14 NW0507 Rev G

Page 15

4. Verify the Head-End and Foot-End crossbars are level, that the Rotation Safety Lock

Switch is in the ON position, and the 180 degree Rotation Lock Lever is in the locked

position. All three indicator lights on the Head-End Column must be lit (the 180°

Rotation Lock Indicator light, the Tilt Drive Status light and the Rotation Safety

Indicator light).

5. Using a hex wrench, remove the H-frame storage brackets which are mounted on

the base of both the Head-End Column and the Foot-End Column of the 5803 Base.

This is required to allow for installation of the Column Sliders (P/N 6977-640, 6977-

641). The H-frame storage brackets can be re-attached should you desire when not

utilizing the Axis Jackson System

6. Where the brackets were removed, install the Table Base Joint Cover (P/N 6977-

853) and the H-Frame Hangar Bracket (P/N 6977-852) provided in the Axis Jackson

Conversion Kit (P/N 6977-850). Also provided in the kit is the Cable Attachment

Post (P/N 6977-209) and mounting hardware, install at the foot end of the 5803

base, location as shown in 3B below.

Figure 3B

Installing the Column Sliders

To attach the Column Sliders to the Head-End and Foot-End Columns of the 5803

base, complete the following steps:

1. Ensure the base has been prepared for mounting the Axis Jackson as instructed in

the previous section.

2. Ensure all 3 indicator lights on the Head-End Column are illuminated. If not, refer to

the 5803 Advance Control Base Owner’s Manual and complete the steps required.

3. Depress the Height Up button on the 5803 Base Hand Pendant and raise the

Columns of the base to half-way in their height range

4. Unlatch the Head-End Column Slider and slide between the quiver and the Column.

The Column Slider will rest on the foot of the modular base. Enclose the Column

with the Slider, latch and tighten the knob.

5. Unlatch the Foot-End Column Slider and slide between the quiver and the Foot-End

Column. The Column Slider will rest on the foot of the modular base. Enclose the

Column with the Slider, latch and tighten the knob.

MIZUHOSI 2009 15 NW0507 Rev G

Page 16

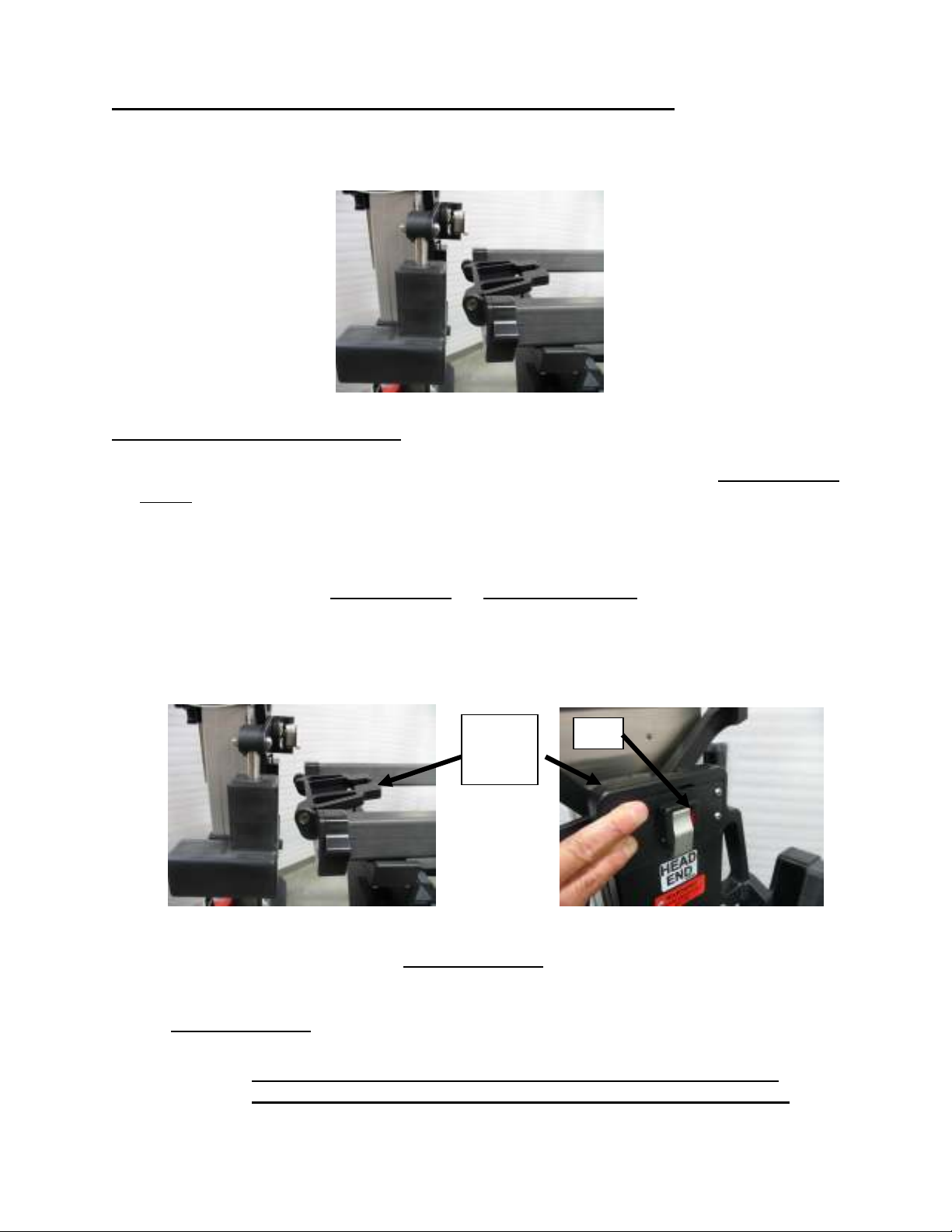

6. When installed correctly, the labels on the Column Sliders will be legible as shown

WARNING

below.

Figure 4: Installing the Column Sliders

Installing the Head-End Support Assembly

To install the Head-End Support Assembly, complete the following steps:

1. Lift the Head-End Support Assembly’s catch mechanism up under the Head-End

Column crossbar.

2. Align the catch with the dowel pins on the cross bar and install a T-pin (P/N 5840-

361) to secure it in place.

3. To attach the Head-End Support Assembly to the Head-End Column Slider, slide the

latch mechanism to engage the pin on the back side of the assembly. An audible

“click” confirms the latch mechanism is secured in place.

T-pin (handle end)

Figure 5: Installing the Head-End Support Assembly

T-pin (drop lock end)

Verify that the T-pin is inserted and passes completely through the

Head-End Support Assembly and Crossbar. Verify the T-pin drop lock

is in sight and pivots freely (see Figure 5 illustration). Failure to do so

may result in the patient and table assembly being dropped and may

result in serious injury to the patient and others.

MIZUHOSI 2009 16 NW0507 Rev G

Page 17

Failure to follow the prescribed procedures for securing the Head-End

WARNING

Support Assembly to the Crossbar, may result in the patient and table

assembly being dropped and may result in serious injury to the patient

and others.

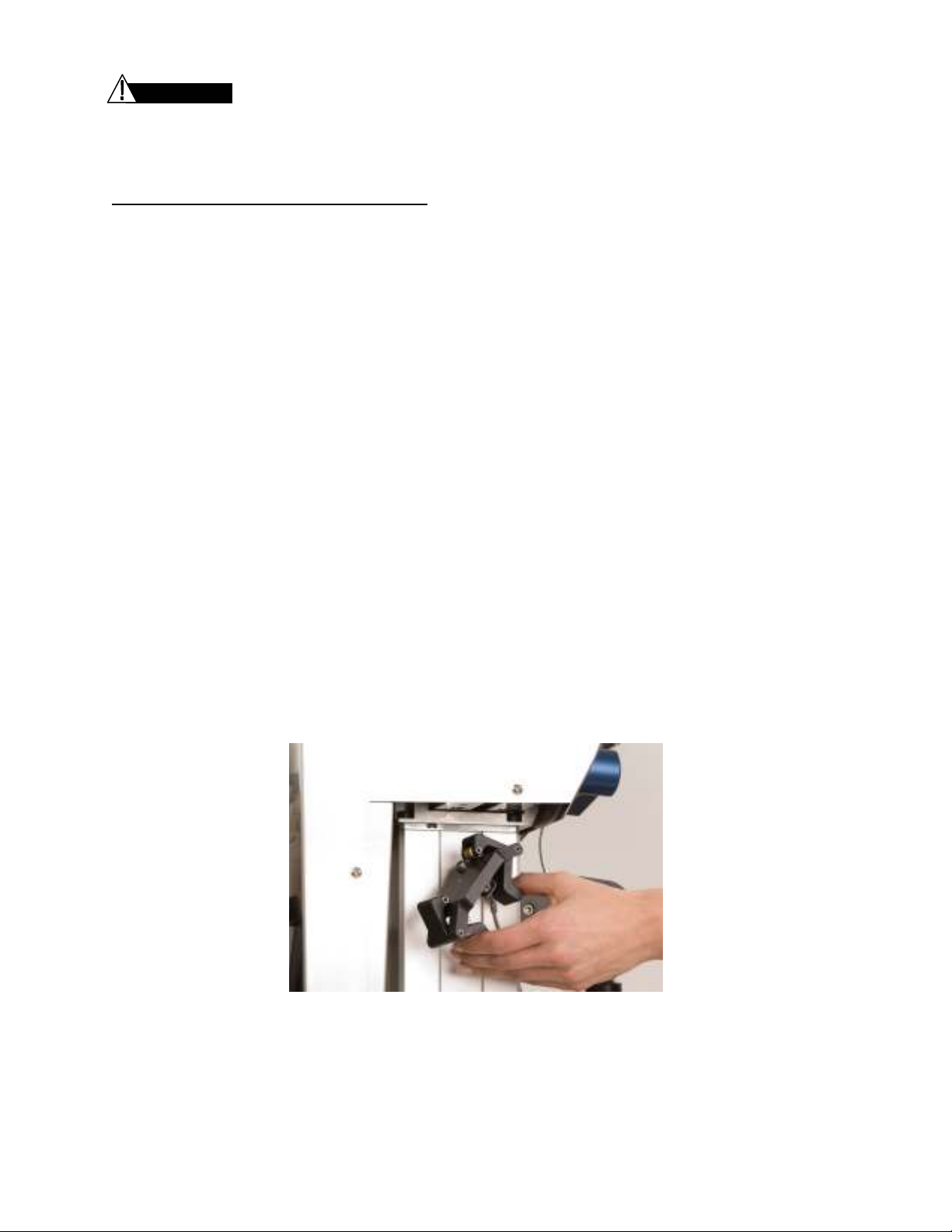

Installing the Head Lock-Out Clamp

When mounting the Axis Jackson System, the Head-End Lock-out Clamp (P/N 6977-

830) is required to be installed. The clamp prevents the sliding movement of the Head-

End Column of the 5803 Base which is allowed when other modular tops are utilized.

1. Verify that the 4 caster locks on the 5803 Advanced Control Base are locked in

position.

2. Standing at the Head-End of the base, pull the top of the Head-End Column toward

you and away from the center of the base.

3. Align the pins on the top of the Clamp (P/N 6977-830) with the holes under the top of

the Head-End Column. The label on the top of the clamp should be facing outward.

4. Pinch the clamp lever-arms and allow the jaws of the Clamp to grab the underside of

the Head-End Column. When properly positioned, release the clamp lever arms and

the clamp will seat itself. The red label should not be visible.

5. Confirm the Clamp is installed correctly:

a) Pull on the lanyard with moderate force (5-10 lbs/2.5 – 5 kg) – the Clamp should

remain in place.

b) Attempt to move the Head-End Column forward and backward - no motion

should be detected.

If the red label is visible, the Clamp did not remain in place, and/or motion in the

Head-End Column is detected, remove the Clamp and re-install following steps 1-5.

Figure 6: Installing the Head-End Lock-out Clamp

MIZUHOSI 2009 17 NW0507 Rev G

Page 18

WARNING

WARNING

WARNING

Installing the Foot-End Support Assembly

IMPORTANT: The Foot-End Column Slider must be installed prior to installing the

Foot-End Support Assembly.

To install the Foot-End Support Assembly, two people working together should

complete the following steps:

1. Lift the Foot-End Support Assembly and place it onto the table base.

2. Lift and align the catch with the dowel pins on the Foot-End Crossbar and install a T

Pin (P/N 5840-361) to secure it in place.

3. To attach the Foot-End Support Assembly to the Foot-End Column Slider, slide the

catch mechanism to engage the pin on the back side of the assembly. An audible

“click” confirms the latch mechanism is secured in place.

T-pin (drop lock end)

T-pin (handle end)

T-pin (handle end)

Figure 7: Installing the Foot-End Support Assembly

Verify that the T-pin is inserted and passes completely through the

Foot-End Support Assembly and Crossbar. Verify the T-pin drop lock is

in sight and pivots freely (see Figure 7 illustration). Failure to do so

may result in the patient and table assembly being dropped and may

result in serious injury to the patient and others.

T-pin (drop lock end)

Failure to follow the prescribed procedures for securing the Foot-End

Support Assembly to the Crossbar, may result in the patient and table

assembly being dropped and may result in serious injury to the patient

and others.

Axis Jackson

®

System Hinged Frame Installation Cart

Mounting the Hinged Frame on the 5803 Advanced Control Base for Use

The Installation Cart is not intended for patient transport.

MIZUHOSI 2009 18 NW0507 Rev G

Page 19

CAUTION

CAUTION

Caster Guard, Foot End

5803 Center Beam

WARNING

The Hinged Frame should not be utilized for patient positioning when in

place on the Installation Cart.

Avoid using this product in a manner not specified by Mizuho OSI.

IMPORTANT: It is recommended that two people work together when using the

Installation Cart with the Hinged Frame.

Always keep body parts, hands, fingers, etc. clear of moving parts and

pinch points when completing this procedure.

5803 Base Preparation:

Prior to mounting the Hinged Frame on the 5803 Advanced Control Base, complete the

steps outlined previously in this manual to prepare the base. i.e. install the Column

Sliders, Head-End Support and Foot-End Support Assemblies.

Lock the (4) caster locks of the Advanced Control Base.

Move columns of the base to maximum height up:

•

On the 5803 Hand Pendant depress and hold the Height Up button until the columns

of the Base travel to full extent of travel.

Installation Cart Positioning:

Maneuver the Installation Cart (Cart) next to and parallel to the 5803 base (Base) by

placing it into a position between the columns on the Rotation Lock (blue handle) side of

the Head-End column.

•

Cart labels Head-End and Foot-End should align with the orientation of the columns.

•

Cart should remain parallel to the Base as it is rolled into position.

•

Roll the Cart into its final position: the Bumper on the Foot-End of the Cart must be

in contact with the Foot-End of the Base and the two caster guards in contact the

5803’s center beam as shown. Note the Head-End bumper, not shown, does not

contact the base.

Foot End Bumper

Lock the (2) caster locks of the Installation Cart.

MIZUHOSI 2009 19 NW0507 Rev G

Page 20

Clearance 1

Clearance 2

Foot-End Head

-

End

Prior to moving the Cart Slider into position between the columns of the Base ensure the

Hinged Frame is centered (has clearance) between the Foot and Head-End Support

Assemblies.

Foot End

Frame Bracket

Clearance 1 can be easily adjusted by sliding the Hinged Frame toward the Foot-End.

Note increasing clearance 1 causes the Foot-End Frame Bracket to become more vertical.

Move to the opposite side of the base, locate and lift the Release Handle of the Installation

Cart and pull the Cart Slider towards you until it reaches its full extent of travel.

The Cart Slider should lock in place when the Release Handle returns to its neutral

position.

IMPORTANT: THE HINGED FRAME FOOT-END IS ALWAYS “FIRST ON, LAST OFF”.

Hinged Frame Foot-End Installation Preparation:

Rotate the dovetail plate to a level position as shown.

Center the Hinged Frame to the dovetail plate as shown. (If necessary, slide the

Hinged Frame laterally or toward the Head-End or Foot-End as needed to center the

frame between the Head-End and Foot-End Support Assemblies. There is some lateral

free play in the Cart Slider to assist in centering.

Pivot Block

Dovetail

Plate and

Frame

Centered

and Frame

NOT Aligned

MIZUHOSI 2009 20 NW0507 Rev G

Page 21

Frame

Clearance 3

CAUTION

Adjust frame until the Foot-End Bracket has sufficient clearance to mate with the

dovetail plate as shown. (Typically, when the Foot-End Bracket just touches the FootEnd of the Hinged Frame at the angle shown.)

Foot-End Frame

Foot-End

Bracket

pocket for

dovetail plate

engagement

Foot-End

Bracket in

contact with

Foot-End

Always keep body parts, hands, fingers, etc. clear of moving parts and

pinch points when completing this procedure.

Install the Hinged Frame onto the Foot-End Support Assembly:

Utilizing the 5803 Hand Pendant:

•

Use a second person to observe the Foot-End of the Hinged Frame, ensuring there

is adequate clearance for the moving parts.

o

If there is an interference between parts, return the column to its full height up

position. After motion has stopped adjust the Hinged Frame and dovetail plate

as needed to obtain adequate clearance. It may be necessary to slide the frame

toward the Head-End Column in order to angle the Foot-End Bracket away from

the Foot-End Support Assembly.

•

Depress and hold the Reverse-Trendelenburg button, to lower the Foot-End Column

until dovetail plate is aligned with pocket in the Foot-End Bracket.

MIZUHOSI 2009 21 NW0507 Rev G

Page 22

VISIBLE

• Adjust the dovetail plate using Reverse Trendelenburg and/or Height Up buttons

until the top of the Foot-End Bracket is just below the shield cover.

Shield Cover

Clearance

Foot-

End

Bracket

Red

Frame Latch

(silver button)

Frame Latch

DISENGAGED

POSITION

NOTE-

Frame Latch

ENGAGED POSITION

NOTE- RED COLOR IS

COVERED BY LATCH

• Press the Foot-End Bracket against the dovetail plate until the Latch is FULLY

DISENGAGED, as shown above.

• Depress Height Up so the dovetail plate of the Foot-End Support Assembly latches

into the Foot-End Bracket of the Hinged Frame.

IMPORTANT: if the Foot-End of the Frame begins to lift off the Cart Slider

before the Frame Latch is FULLY ENGAGED, STOP MOTION.

Use the Reverse Trendelenburg and Height Up buttons to adjust the dovetail plate

height, realign the frame to the pivot block and repeat the process indicated above.

• When the Latch is fully engaged the Foot-End of the Hinged Frame can be raised off

the Cart Slider by depressing and holding the Height Up button

•

Depress the Height Up button to raise the Foot-End Column to its full extent of

travel.

MIZUHOSI 2009 22 NW0507 Rev G

Page 23

Install the Hinged Frame onto the Head End Support Assembly:

Rotate the Head-End Bracket of the hinged frame toward the hinge.

Utilizing the 5803 Hand Pendant:

• Lower the Head-End dovetail plate by depressing and holding the Trendelenburg

button until it is approximately 2.5 “(6cm) above the Head-End Bracket.

• Raise the Head-End Bracket to engage the dovetail plate and press the Head-End

Bracket against the dovetail plate until the Latch is FULLY DISENGAGED, as shown

below. (See above for description of fully disengaged Latch.) If the Latch is not fully

disengaged, then use Trendelenburg or Height Up buttons to readjust the dovetail

plate height until the Latch is fully disengaged. It may be necessary to slide the

Head-End of the frame laterally toward the Foot-End in order to align the Head-End

Bracket with the dovetail plate.

Head-

End

Bracket

Red

• When properly aligned depress Height Up button so the dovetail plate of the HeadEnd Support Assembly latches into the Head-End Bracket of the Hinged Frame. The

Head-End of the Hinged Frame can now be raised off the Cart Slider by depressing

the Height Up button.

IMPORTANT: If the Head-End of the frame begins to lift off the Cart Slider

before the Frame Latch is FULLY ENGAGED, STOP MOTION.

MIZUHOSI 2009 23 NW0507 Rev G

Page 24

Use the Trendelenburg and Height Up buttons to adjust the dovetail plate height, realign

the frame to the pivot block and repeat the process indicated above.

• Depress and hold the Height Up button raising the Foot-End Column to its full extent

of travel.

The Hinged Frame should now be fully supported by the Head-End and Foot-End Columns

of the base and positioned at its maximum height with the Head-End and Foot-End Latches

fully engaged.

Remove Installation Cart:

Prior to retracting the Cart Slider, be sure there is clearance between the Cart Slider and

the hinged frame.

• Lift the Release Handle of the Installation Cart and push the Cart Slider over into its

stored position.

• An audible click will be heard confirming the Cart Slider is locked in the stored

position. Manually test the Cart Slider top to ensure it is securely locked into

position at both ends of the cart.

• Unlock the (2) caster locks of the Installation Cart and move away from the base.

Continue the installation procedure by following the steps in “Connecting the Axis

Jackson ® Controller and the Hinged Frame”

MIZUHOSI 2009 24 NW0507 Rev G

Page 25

CAUTION

CAUTION

WARNING

WARNING

Removing the Hinged Frame from the 5803 Advanced Control Base for Storage

The Installation Cart is not intended for patient transport.

The Hinged Frame should not be utilized for patient positioning when in

place on the Installation Cart.

Avoid using this product in a manner not specified by Mizuho OSI.

IMPORTANT: It is recommended that two people work together when using the

Installation Cart with the Hinged Frame

Always keep body parts, hands, fingers, etc. clear of moving parts and

pinch points when completing this procedure.

Lock the (4) caster locks of the 5803 Advanced Control Base.

Ensure all components have been removed from the Hinged Frame and are stored on

the Component Cart prior to removing the Hinged Frame.

Confirm the Hinged Frame is in the neutral “HOME” position by checking the 6977

Hand Pendant, the display should read +00 and the 3 LED’s should be lit. If necessary,

utilize the Hand Pendant “Return to Home” button to return the Hinged Frame to the

neutral “HOME” position and the display reads +00.

Raise frame: (to maximum height by utilizing the 5803 Hand Pendant)

• Depress and hold the Height Up button until the columns of the base travel to full

extent of travel.

Remove Cables:

• Disconnect the Blue, White and Brown cables from the Hinged Frame, Controller,

Head-End Support Assembly and Foot-End Support Assembly. Place in the storage

area on the Installation Cart.

Installation Cart Positioning:

Maneuver the Installation Cart (Cart) next to and parallel to the 5803 base (Base) by

placing it into a position between the columns on the Rotation Lock (blue handle) side of

the Head-End column.

• Cart labels Head-End and Foot-End should align with the orientation of the columns.

• Cart should remain parallel to the Base as it is rolled into position.

• Roll the Cart into its final position: the Bumper on the Foot-End of the Cart must be

in contact with the Foot-End of the Base and the two caster guards in contact the

5803’s center beam as shown. Note the Head-End bumper, not shown, does not

contact the base.

MIZUHOSI 2009 25 NW0507 Rev G

Page 26

Caster Guard, Foot End

5803 Center Beam

Foot End Bumper

Lock the (2) caster locks of the Installation Cart.

Remove the Hinged Frame from the Head-End Support Assembly:

Utilizing the 5803 Hand Pendant:

Depress and hold the Trendelenburg button, simultaneously a second person should

depress the silver button on the Head-End Bracket of the frame. These actions will

result in lowering the Head-End Column of the base and allowing the Head-End of the

Hinged Frame to be released from the Head-End Support Assembly and rest on the

Cart Slider.

Hold the Head-End Bracket of the Hinged Frame away from the dovetail support of the

Head-End Support Assembly, simultaneously depress and hold the Height Up button

raising the Head-End Column to its extent of travel.

Remove the Hinged Frame from the Foot-End Support Assembly:

Utilizing the 5803 Hand Pendant:

Depress and hold the Reverse Trendelenburg button, simultaneously a second person

should depress the silver button on the Foot-End Bracket of the frame. These actions

will result in lowering the Foot-End Column of the base and allowing the Foot-End of the

Hinged Frame to be released and rest on the Cart Slider.

Hold the Foot-End Bracket of the Hinged Frame away from the dovetail plate support of

the Foot-End Support Assembly, simultaneously depress and hold the Height Up

button raising the Foot-End Column to its extent of travel.

The Hinged Frame should now be fully supported on the Cart Slider of the Installation

Cart.

MIZUHOSI 2009 26 NW0507 Rev G

Page 27

Remove Installation Cart:

Prior to retracting the Cart Slider, be sure there is clearance between the Cart Slider and

the hinged frame.

• Locate and lift the Release Handle of the Installation Cart and push the Cart Slider

with Hinged Frame over into its stored position.

• An audible click will be heard confirming the Cart Slider is locked in the stored

position. Manually test the Cart Slider top to ensure it is securely locked into

position at both ends of the cart.

• Unlock the (2) caster locks of the Installation Cart and move away from the base.

Remove Components from Base:

Remove the Axis Jackson Controller, Foot-End Support Assembly, Head-End Support

Assembly and Column Sliders and store in the appropriate area on the cart.

Cover Installation Cart:

Cover the Installation Cart with the dust cover provided and move to the storage

location.

MIZUHOSI 2009 27 NW0507 Rev G

Page 28

Connecting the Axis Jackson Controller and the Hinged Frame

Serial Number

Tag

Brown Cable

ACP Tubing Port

(Unused)

Blue Cable

Controller On/Off

Switch

White Cable

Controller Power

Cord Receptacle

Figure 8a and 8b: Controller Cable Connections

To connect the Controller:

1. Mount the Axis Jackson Controller on the Foot-End Column by sliding the handle

over the top of the Column crossbar.

2. Secure by inserting a T-pin through the mounting handle and crossbar.

3. Prior to connecting the Controller: run the Cable (P/N 6977-4110, color coded white)

under the Foot-End Column between the wheels. Wrap the Cable around the I-beam

of the base and secure with attached Velcro™ straps. The Cable should be secured

to the beam so it does not contact the floor if the base needs to be moved. Connect

the Head-End Frame Support Assembly 90 degree end of the Cable to the HeadEnd Support Assembly and the other end of the Cable color coded white to the

corresponding white labeled port on the Controller.

4. Connect the Foot-Elevator Cable (P/N 6977-4140, color coded brown) to the FootEnd Support Assembly and the corresponding color coded brown labeled port on the

Controller.

5. Connect the Hinged Frame Cable (P/N 6977-4130, color coded blue) to the Hinged

Frame and the corresponding color coded blue labeled port on the Controller.

6. Connect the Axis Jackson Controller power cord to the Controller and to an electrical

outlet.

MIZUHOSI 2009 28 NW0507 Rev G

Page 29

CAUTION

An external ground stud is required for use when the AC

power cable is not connected to a protective earth ground outlet in

your operating room or facility. To protect the patient and hospital

staff from any possible hazards, an external ground wire connection

is required between the external ground stud and protective earth

ground. Failure to comply with this requirement may result in

damage to the product, and injury or death of personnel.

7. If the electrical outlet being utilized is not grounded, connect the external ground

stud to a protective earth ground.

Hand Pendant with Junction Box (P/N 6807-5)

1. To connect the Axis Jackson Hand Pendant, plug the long cable extending from the

Junction Box on the Hand Pendant into the port on the Head-End Support

Assembly.

2. Connect the short lead from the Junction Box to the 5803 Head-End Column Hand

Pendant port.

3. Connect the 5803 Hand Pendant to the remaining receptacle on the Junction Box.

5803 Base Hand Pendant and 6977 Axis Jackson System Hand Pendant

When the Axis Jackson System is utilized it requires the use of both the 5803 Advanced

Control Base Hand Pendant and the 6977 Axis Jackson Hand Pendant. The two Hand

Pendants are intended to be placed in the Holster (P/N 6977-4162) provided with the

Axis System for easy access and simultaneous use. The 5803 Hand Pendant controls

table top height adjustment, Trendelenburg and Reverse Trendelenburg positions. The

6977 Hand Pendant controls the Hinged Frame movement, Foot Elevator and Lateral

Roll.

MIZUHOSI 2009 29 NW0507 Rev G

Page 30

Figure 9: The 6977 Axis Jackson Hand Pendant and 5803 Advanced Control Hand Pendant

(Shown mounted in Holster)

Hinge Angle Digital

Display

Hinge Up

V Hinge Up

Foot Elevator

Down

Hinge Down

V Hinge Down

Foot Elevator

Up

Left Lateral

Roll

Right Lateral

Roll

Return To Home

Memory Position 1

& 2

Memory Store

Indicator Lights

(3 places)

Figure 10: The Axis Jackson Hand Pendant

MIZUHOSI 2009 30 NW0507 Rev G

Page 31

Axis Jackson Hand Pendant Operation

To control the angle of the Hinge and transition from a neutral or 00° position up to +35°

Hinge up or -20° Hinge down, depress the appropriate button on the Hand Pendant.

The selected function will continue to operate until the button is released or the Hinged

Frame has reached the extent of its travel. The angle of the Hinge is displayed on the

digital display. The readout will display +00 when the Hinge is in the neutral position and

the table top is level.

To raise the Hinge and lower the Foot-End of the table top simultaneously, depress the

Hinge Up button (on the left side of the control with the arrows that point up in the

middle and down at the foot).

To lower the Hinge, depress the Hinge Down button (on the right side of the control with

the arrows that point down in the middle and up at the foot).

To raise the Hinge only without lowering the Foot-End of the table top, depress the V

Hinge Up button (on the left side of the control, with the arrow that points up in the

middle).

To lower the Hinge only, depress the V Hinge Down button (on the right side of the

control with the arrow that points down in the middle).

To lower the Foot-End of the table top, depress the Foot Elevator Down button (on the

left side of the control, with the arrow that points down at the foot).

To raise the Foot-End of the table top depress the Foot Elevator Up button (on the right

side of the control with the arrow that points up at the foot). The Foot Elevator can only

be raised if lower than the neutral or starting position.

To Lateral Roll the table top to the left, depress the Left Lateral Roll button (on the left

side of the control).

To Lateral Roll the table top to the right, depress the Right Lateral Roll button (on the

right side of the control).

Hinge Position Memory

A Hinge angle position can be stored in memory for ease of returning to the desired

position. To save a position in memory, transition the Hinged Frame to the desired

position, depress and hold the Memory Store (MEM STORE) button; then depress one

of the numbered memory buttons. Continue to depress both buttons until the Indicator

Lights on the hand pendant flash, confirming the position is stored in memory.

To transition the frame to a stored position, depress and hold the pre-programmed

Memory 1 or Memory 2 button. The table top will transition to the position in memory.

To re-program the position stored as Memory 1 or Memory 2, repeat the above

programming process.

NOTE: Lateral Roll, Height, Trendelenburg and Rev Trendelenberg positions can not be

saved to Memory 1 or Memory 2.

MIZUHOSI 2009 31 NW0507 Rev G

Page 32

Hinge Angle Digital Display

The Axis Jackson Hand Pendant displays the position of the Hinge of the frame.

• When the Hinge of the frame is neutral, the table top level, the Hinge angle

displayed is 00°.

• When the Hinge is raised, the Hinge angle displayed is +1° to +35°.

• When the Hinge is lowered, the Hinge angle displayed is -1° to -20°.

Should the Hinge angle display read 106 or 107, the Hinged Frame needs recalibration.

Axis Jackson Hinged Frame Calibration Procedure

1. On the Axis Jackson Controller, toggle the main Power Switch to OFF and then to ON.

2. The Hand Pendant will display a number. Once the number is displayed,

immediately (within 20 seconds) press and release the Mem Store and Hinge Up

buttons simultaneously (the top left and bottom left buttons) once. The system will

enter calibration mode and the Hand Pendant display will begin flashing +35.

3. Using the Hand Pendant, press the V Hinge Up button until the Hinge is raised to its

extent of travel and stops.

4. Simultaneously press and release the Mem Store and Hinge Up buttons once. The

Hand Pendant display will begin flashing +00.

5. Using the Hand Pendant, press the V Hinge Down button until the Hinge lowers to

its neutral or level Hinge position.

6. Simultaneously press and release the Mem Store and Hinge Up buttons once. The

Hand Pendant display will begin flashing -20.

7. Using the Hand Pendant, press the V Hinge Down button until the Hinge lowers from

neutral position to its extent of travel and stops.

8. Simultaneously press and release the Mem Store and Hinge Up buttons once. The

Hand Pendant will briefly display +77 to indicate that the calibration was completed

successfully. Following the display +77, the Hand Pendant will return to normal use

mode and display -20.

9. If the calibration process was unsuccessful, the Hand Pendant will display a blinking

error code either 106 or 107.

Repeat Steps 1-8 to re-calibrate. If re-calibration is unsuccessful a second time, contact

Technical Service.

LED Indicators

The Axis Jackson Hand Pendant has three Indicator Lights located between the Foot

Elevator, Hinge and Lateral Roll buttons.

Foot Elevator Indicator is illuminated when the foot elevator has returned to its home

position, level with the Hinge.

Hinge Indicator is illuminated when the Hinge has returned to its neutral, 00° position.

Lateral Roll Indicator is illuminated when the table top is level side to side.

MIZUHOSI 2009 32 NW0507 Rev G

Page 33

5803 Hand Pendant Operation (see 5803 Owner’s Manual for detailed instructions)

Press a button on 5803 Hand Pendant to adjust the table top. The selected function will

continue to operate until the button is released or the extent of travel of the Columns is

reached.

To raise the table, depress the Height Up button, both Columns raise simultaneously to

raise the height of the table top

To lower the table, depress the Height Down button, both Columns lower

simultaneously to lower the height of the table top.

To move the table top into a Trendelenburg position, depress the Trendelenburg button

until the desired angle is reached. This function lowers the Head-End Column of the

base and raises the Foot-End Column base simultaneously.

To move the table top into a reverse Trendelenburg position, depress the Reverse

Trendelenburg button until the desired angle is achieved. This function raises the HeadEnd Column and lowers the Foot-End Column of the base simultaneously.

Note: The Lateral Roll/Tilt buttons on the 5803 Hand Pendant are inoperable when

the Axis Jackson System is installed. Lateral Roll is provided and controlled

through the 6977 Axis Jackson System Hand Pendant.

MIZUHOSI 2009 33 NW0507 Rev G

Page 34

5.0 PRE-OPERATION FUNCTION CHECKS

Checking the Advanced Control Base

Perform all the steps in this procedure to verify correct base operation.

Ensure the 5803 Hand Pendant cable is securely plugged into the 6977 Hand

Pendant Junction Box.

Ensure the base power cord is connected to a hospital grade power outlet and

toggle the main on/off power switch to ON. Verify the switch illuminates; this

indicates power is applied to the modular base.

Verify the Hand Pendant battery status indicator is lit, and fault indicator is not lit.

Press and hold the Hand Pendant Height Up button. Verify the table moves up.

Press and hold the Hand Pendant Height Down button. Verify the table moves

down.

Press and hold the Hand Pendant Trendelenburg button. Verify the table moves

into a Trendelenburg position.

Press and hold the Hand Pendant Reverse Trendelenburg button. Verify the table

moves into a reverse Trendelenburg position.

The Tilt/Roll function of the base is Locked Out when the Axis Jackson Controller

is installed. The Tilt status indicator on the Head-End Column should remain

illuminated

Checking the Axis Jackson Hinged Frame

Perform all the steps in this procedure to verify correct Axis Jackson operation.

Confirm the Axis Jackson Hand Pendant cable is inserted into the port located on the

side of the Head-End Frame Support Assembly.

Confirm the Axis Jackson Controller power cord is plugged into a hospital grade

power outlet and the ON/OFF power switch is toggled to the ON position. Verify

the switch illuminates; this indicates power is applied to the table top.

Depress and hold the Axis Jackson Hand Pendant Hinge Up button. Verify the

Hinge of the frame moves up and the Foot-End of the frame moves down.

Continue to depress the Hinge Up button until motion stops. Verify the Hinge angle

displayed on the Hand Pendant is +35° (±2°).

Depress and hold the Hand Pendant Hinge Down button. Verify the Hinge of the

frame moves down.

Continue to depress the Hinge Down button until motion stops. Verify the Hinge

angle displayed on the Hand Pendant is -20° (±2°).

Press and hold the Hand Pendant V Hinge Up button. Verify the Hinge of the frame

moves up.

Continue to depress the V Hinge Up button until motion stops. Verify the Hinge

angle displayed on the Hand Pendant is +35° (±2°).

MIZUHOSI 2009 34 NW0507 Rev G

Page 35

Press and hold the Hand Pendant V Hinge Down button. Verify the Hinge of the

frame moves down.

Continue to depress the V Hinge Down button until motion stops. Verify the Hinge

angle displayed on the Hand Pendant is -20° (±2°).

Press and hold the Hand Pendant Foot Elevator Down button. Verify the Foot-End

of the frame moves down.

Press and hold the Hand Pendant Foot Elevator Up button. Verify the Foot-End of

the frame moves up.

Note: The Foot-End of the frame moves up unless it is at the neutral (level) position.

Press and hold the Hand Pendant Lateral Roll Left button. Verify the Hinge frame

rolls to the left when standing at the Head-End of the frame and facing the FootEnd Column.

Press and hold the Hand Pendant Lateral Roll Right button. Verify the Hinge frame

rolls to the right when standing at the Head-End of the frame and facing the FootEnd Column.

Move the Hinge Up or Hinge Down and translate the frame to Lateral Roll Right or

Left. Now, press and hold the Hand Pendant ‘Return To Home button’. Verify the

Hinged Frame rolls back to level and then returns the Hinge to the neutral position.

Verify the Hinge angle displayed on the Hand Pendant is 00°. All three LEDs

corresponding to the Hinge, Foot Elevator and Lateral Roll should all be

illuminated when the frame is in the neutral position.

Toggle the ON/OFF switch for the Advance Control Pad System to the ON position

Verify that air comes out of the tubing connector port on the Controller.

Press the Cycle Selection button on the ACP Control Panel and confirm the cycles

change accordingly.

Press the red E-Stop button in. An audible beep should be heard. The red LED

should flash. To reset, turn the red button in the direction of the arrows to reset.

MIZUHOSI 2009 35 NW0507 Rev G

Page 36

6.0 OPERATING THE SYSTEM

Axis Jackson Controller:

Power On/Off

Serial Number

Tag

Brown Cable

Controller On/Off

Switch

Controller Power

Cord Receptacle

Figure 11: Controller ON/OFF Switch

The Axis Jackson Controller (P/N 6977-4006, 120V or 6977-4005I, 230V) has a power

ON/OFF switch. This switch also serves as a circuit breaker and in the event of an

overload condition the switch will trip. To reset the circuit breaker, toggle the switch to

the OFF position and then to the ON position.

IMPORTANT: Determine and correct the source of the overload prior to resetting this

switch.

MIZUHOSI 2009 36 NW0507 Rev G

Page 37

Emergency Stop (E-Stop) and Reset

To immediately interrupt the power to the Axis Jackson System, press the Emergency

Stop Button. An audible beep will be heard from the Controller and the red LED will

illuminate and flash to indicate that the power has been interrupted

To reset the system, turn the Emergency Stop Button in the direction of the arrows until

it returns to the original position.

Figure 12: Axis Jackson Controller Emergency Stop

Advance Control Pad System

Figure 13: ACP Control Panel

The Axis Jackson System includes the Advance Control Pad System (ACP) with

Tempur-med®. Tempur-med® Axis Jackson ACP Pads provided are:

(1) Left Contoured, ACP Combination Hip and Thigh Pad (P/N 6977-710)

(1) Right Contoured, ACP Combination Hip and Thigh Pad (P/N 6977-720)

(1) Bilateral Winged ACP Chest Pad (P/N 6977-700)

MIZUHOSI 2009 37 NW0507 Rev G

Page 38

The pads are designed specifically with Tempur-med® material for use with the Axis

Jackson Hinged Frame and Controller. Air cells within the pads inflate and deflate with

varying degrees of frequency and duration providing massage action and periodic

pressure point stimulation to the patient’s chest, hips and thighs.

At the discretion of the physician, the pads can be used for patient support on the Axis

Jackson Hinged Frame without the massage action being activated.

The Axis Jackson Controller must be turned on at its main power switch in order to use

the built-in Advance Control Pad System. The ACP Control Panel is located on the front

of the Controller. Turn on the ACP System by toggling the On/Off switch to the ON

position. The ACP panel LEDs will light up and air flow can be felt at the tubing

connection port at the back of the Controller.

ACP Tubing Port

(Unused)

Blue Cable

White Cable

1.0 Figure 14: Port to Connect ACP Tubing

Prior to patient use, the ACP Quick Connect Tubing needs to be connected to the pads

and the Controller.

After the Chest Pad and Hip/Thigh Pad are in place on the frame, the tubing can be

connected to the pads. Align the tubing with the long end directed to the pad furthest

away from the Controller port.

Secure the ACP tubing with the Velcro™ and the clips along the frame. Ensure the

tubing is secure and out of the way such that the tubing will be able to move when the

Hinged Frame is moved. Utilize the Hand Pendant and move the Hinge Up and Hinge

Down to the extent of its travel. Re-adjust the ACP tubing as may be required.

IMPORTANT: Verify the ACP tubing will not be stretched or pinched during hinge

movement which may interrupt or obstruct air flow to the pads. Failure

to do so may result in ACP malfunction.

MIZUHOSI 2009 38 NW0507 Rev G

Page 39

Cycles at 5 sec intervals

CAUTION

Cycle Selector and Cycle Indicator

The ACP Control Panel graphically illustrates 4 pre-programmed cycles. The graphic

shown in Figure 15 illustrates the frequency and duration of the air cells movement.

Choice of cycles is at the discretion of the user and whether or not more or less frequent

massage is preferred.

Cycles at 10 sec intervals

Cycles at 60 sec intervals

Cycles at 5 sec intervals

for 25 sec, rest for 30 sec

1.1.1 Figure 15: ACP Control Panel Cycle Selector and Cycle Indicator

Pressing the Cycle Selector Button changes the frequency at which the cells in the pads

inflate and deflate. Pressing the Button once moves the selected mode from 1 to 2,

once more from 2 to 3, next 3 to 4, the next press changes the cycle from 4 to 1.

Cycle Indicators (2) are located on the ACP Control Panel. The Cycle Indicators

provide visual confirmation that ACP system is alternating cycles.

Note: The Advance Control Pad System is not utilized with the Supine Tops and one

piece table pad and the ACP control switch can remain in the OFF position.

However the ON/OFF switch to the Controller needs to remain in the ON

position at any time the Hip/Thigh and Chest Pad will be utilized for prone

positioning.

Axis Jackson System Manual Operation

In the event of a power failure, the Hinge and the Foot Elevator may be operated

manually to return the Hinged Frame to a level position to facilitate patient transfer.

To manually operate the Hinge:

1. Turn the power off at the Controller and unplug the AC power cord. Disconnect

Cable, color coded blue, to Hinged Frame.

Failing to turn off the power and unplug the cord may cause a potential

safety hazard that may result in injury to the operator.

MIZUHOSI 2009 39 NW0507 Rev G

Page 40

2. Use the Gearbox Crank Handle (P/N 6977-886) which is stored on the side of the

Foot Elevator.

3. Remove the 1.25” (3.2 cm) Black Cover Plug (P/N NB0339) and the 3/4” (1.9 cm)

Black Cover Plug (P/N NB0363) from either the right or left side of the Foot-End of

the Hinged Frame and insert the Gearbox with Crank Handle into the socket.

4. Turn the Gearbox Crank Handle to raise the Hinge to the level position or to lower

the Hinge to a level position.

5. Return the Gearbox Crank Handle to the storage location on the side of the Foot

Elevator.

6. Recap the openings on the side of the Foot-End of the Hinged Frame with the Black

Cover Plugs.

To manually operate the Foot Elevator:

1. Turn the power off at the Controller and unplug the AC power cord.

2. Use the Crank Handle (P/N 6977-679) which is stored on the back of the Controller.

3. Remove the 1” (2.5 cm) Black Cover Plug (P/N NB0360) on top of the Foot Elevator

and insert the Crank Handle into the socket to begin manual operation.

4. Turn the Crank Handle clockwise to raise the Foot-End of the Hinged Frame back to

a level position.

5. Return the Crank Handle to the storage location on the back of the Controller. Clip

into place.

6. Recap the opening on the top of the Foot Elevator with the Black Cover Plug.

MIZUHOSI 2009 40 NW0507 Rev G

Page 41

Advanced

Control Pad System™ (ACP)

Hinged Fram

e

Contoured

Bilateral Winged

Torso Trolley™

5-Way Adjustable Arm

7.0 PRONE POSITIONING

Prone Set-up On Hinged Frame

stimulates patient pressure points on chest, hips and thighs

– automatically

Chest Pad

- integrates

patient movement with hinge

translation

Boards

Carbon Fiber Frame Construction

– supports spine

biomechanics and improves

surgeon access

Removable Foot Board

Hip/Thigh Pads

Adjustable Leg Sling

Hinged Frame

Figure 16: Axis Jackson for Prone Procedures

The Axis Jackson System can be set-up for prone patient positioning according to the

following procedure:

Move the table to the desired location and lock the base by engaging the (4) caster

locks

Confirm that the Axis Jackson Hinged Frame is correctly mounted on the base and the

Controller is plugged in and turned on. The Axis Jackson Hand Pendant will illuminate

displaying the current Hinge angle. It should read 00°. If it does not, confirm the Hand

Pendant is connected, power to the frame is turned on and depress Return to Home

Confirm that the 5803 modular base is plugged in and turned on. The 5803 Hand

Pendant indicator lights will be illuminated as well as the Head-End Column indicator

lights for the Rotation Safety Lock, the Rotation Lock and the Tilt Drive Status will be

illuminated.

MIZUHOSI 2009 41 NW0507 Rev G

Page 42

WARNING

Torso Trolley®

The Torso Trolley® consists of a Chest Slide (P/N 6977-503) to which the Bilateral

Winged ACP Chest Pad and 5 way Adjustable Armboards are mounted. To install the

Chest Slide on the Hinged Frame, first ensure the Hinged Frame is in the neutral

position, Hinge angle 00° and table level side to side.

Linkage Bar

Figure 17: Rail Assembly

Lock/Unlock

1. Slide the Right Rail Assembly (P/N 6977-501) and Left Rail Assembly (6977-502)

onto the corresponding torso section of the Hinged Frame and lock into position.

(Refer to pictures A-D).

A B

C D

Verify the Left and Right Rail Assemblies are locked in position to

eliminate unintended Torso Trolley® movement and the potential for

injury to the patient.

2. Connect the linkage bar of the Rail Assembly to the Hinge by removing the bar from

its storage position and securing the green end over the Hinge knob. (Refer to

pictures E-F).

E F

3. Position the Chest Slide over the brackets and place into position. The post of the

Rail Assembly will slip into position within the slide. After it is placed, you should

confirm operation by simultaneously depressing the green handles and pushing

outward. This releases the pins on the slide and should allow the Chest Slide to be

moved toward the head of the table and back toward the foot of the table. The 1-12

scale mounted on each Rail Assembly assists in identifying where the slide is in its

range of movement.

MIZUHOSI 2009 42 NW0507 Rev G

Page 43

Underside of

Chest Slide,

Insert Armboard

Mounting Bracket

Armboard Mounting

Bracket Inserted

Figure 18: Armboard Mounting Brackets

T-handle

4. Secure the Chest Slide by installing the Armboard Mounting Brackets (P/N 6977-

570). Insert the Armboard Mounting Brackets into the corresponding underside of

the Chest Slide and secure with the locking T-handle.

Figure 19: Torso Trolley® w/Bilateral Winged ACP Chest Pad

5. To attach the Bilateral Winged ACP Chest Pad (P/N 6977-700) to the Chest Slide,

slide the wings under the black tab (see Figure 20). The indentation for the suprasternal notch should be at the Head-End.

MIZUHOSI 2009 43 NW0507 Rev G

Page 44

Black Tab

Figure 20: Black Tab and Sliding Chest Pad in Place

6. The Bilateral Winged ACP Chest Pad is designed specifically for use with the Axis

Jackson System. Air cells within the center of the Tempur-med® pad inflate and

deflate with varying degrees of frequency and duration, providing massage action

and periodic pressure point stimulation to the patient’s chest. At the discretion of the

physician, the pad can be used for patient support without the pneumatic action.

Also at the discretion of the physician, additional foam or padding can be placed

between the patient and the sides of the pad as needed to accommodate varying

sizes and needs of patients.

7. Connect the tubing from the chest pad to the ACP Quick Connect Single Use

Tubing. Insert the white nipple on the disposable tubing into the black/gray port of

the tubing from the chest pad. To disconnect the tubing depress the gray portion of

the port and remove the white nipple.

8. Secure the ACP tubing with the Velcro™ and the clips along the frame. Ensure the

tubing is secure and out of the way such that the tubing will be able to move when

the Hinged Frame is moved. Utilize the Hand Pendant and move the Hinge Up and

Hinge Down to the extent of its travel. Re-adjust the ACP tubing as may be required.

IMPORTANT: Verify the ACP tubing will not be stretched or pinched during hinge

movement which may interrupt or obstruct air flow to the pads. Failure

to do so may result in ACP malfunction.

MIZUHOSI 2009 44 NW0507 Rev G

Page 45

5-Way Adjustable Armboards

The 5-way Adjustable Armboards (P/N 6977-980) are integral to the Torso Trolley®, and

when in place, move with the trolley when the Hinge is articulated.

Figure 21: 5-way Adjustable Armboard Mounting Bracket

Figure 22: Armboard Mounted on the Torso Trolley®

Mount the 5-way Adjustable Armboard unit by sliding the pivoting bracket into the

mounting bracket and securing the locking T handle. To adjust the Armboards, turn the

black knob until there is free movement of the pivoting arm, this allows for height

adjustment, lateral movement and pivoting of the Armboard. The Armboards can be

installed and pivoted out of the way for transfer of the patient on and off the frame.

When in place, the Armboards can also be translated toward the Head-End or Foot-End

depending on the positioning needs of the patient. To release the Armboard and allow

for translation towards the Head-End or Foot-End of the Hinged Frame, pull down on

the silver knob at the underside of the Armboard to release. Move into the desired

position and then return the silver knob to the locked position.

MIZUHOSI 2009 45 NW0507 Rev G

Page 46

Contoured Combination ACP Hip/Thigh Pads

Attach the Right and Left Contoured Combination ACP Hip/Thigh Pads (P/N 6977-720

and P/N 6977-710) at the Hinge.

The pads are designed to be right and left sided and are labeled accordingly. The pads

must be oriented to the patient when the patient is positioned prone on them. Confirm

the pads are applied to the appropriate side of the Hinged Frame. When properly

installed, the pads should slope down toward the Foot-End of the table and the green

latch will be on the outside of the frame.

Figure 23: Un-Latched Hip/thigh Pad on Hinged Frame

Figure 24: Left Hip/Thigh Pad Latched in Place at the Hinge with ACP Tubing Connected

To mount, hold the appropriate Hip/Thigh Pad with the green latch in the open position

over the Foot-End section of the frame. Place the inside of the pad bracket over the top

of the frame to engage the inside of the rail on the Hinge Cover. Slide the pad towards

the Hinge for the full length of the rail. It will come to a stop. Close the green latch

down on the rail. The pad should be secure on the rail in Position 1. Using both hands,

attempt to pull the pad toward the Foot-End of the frame - it should not move. If it is not

latched securely, remove the pad and repeat the process.

MIZUHOSI 2009 46 NW0507 Rev G

Page 47

WARNING

WARNING

IMPORTANT: The Hip/Thigh Pads are recommended to be latched in Position 1,

(closest to the Hinge) for the majority of patient heights less than 7 feet

(213 cm) tall. Moving the Hip/Thigh Pads to an alternate position (away

from the Hinge) should be done only at the discretion of the attending

physician.

Connect the tubing from the Hip/Thigh Pads to the ACP Quick Connect Single Use

Tubing. Insert the white nipple on the disposable tubing into the black/gray port at the

end the tubing from the Hip/Thigh Pads. To disconnect the tubing depress the gray

portion of the port and remove the white nipple.

Secure the ACP tubing with the clips along the frame. Ensure the

tubing is secured so that it is out of the way but will not be stretched or

pinched which may obstruct air flow.

Verify that the Hip/Thigh Pad green locking levers are latched securely

in place to eliminate unwanted Pad movement.

Leg Sling

Figure 25: Leg Sling (P/N 5840-450)

To install the adjustable Leg Sling (P/N 5840-450), place the sling over the trunk section

of the Hinged Frame. Feed the four straps through their respective buckles on the

opposite side of the sling and secure. The sling should be adjusted for each patient.

The straps on the sling consist of a double-sided hook closure that allows for infinite

adjustment along the length of the strap. The hook end of the strap may be folded over

onto the loop portion of the strap to allow for greater adjustability. The strap may be

folded over itself again to shorten, thereby raising the sling and decreasing the hip

flexion angle of the patient.

Place two (2) or three (3) pillows in the leg sling approximately where the patient’s lower

legs will rest to help achieve the desired amount of knee flexion and support.

MIZUHOSI 2009 47 NW0507 Rev G

Page 48

Foot Board

A removable Foot Board (P/N 6977-990) is provided for placement at the Foot-End of

the Hinged Frame. It allows for positioning pillows to be free of any contact with the

Foot-End Support Assembly.

Figure 26: Removable Foot Board

Retractor Adaptor for Axis Jackson Hinged Frame

The Retractor Adaptor (P/N 6977-939) mounts on the Hinged Frame and provides 6

inches (15 cm) of side rail for mounting retractors.

Patient Care Kits – GentleTouch and ProneView®

The GentleTouch and ProneView® Patient Care Kits may be used with the Axis

Jackson.

IMPORTANT: The choice of which Patient Care Kit best meets the positioning needs

of the patient is at the discretion of the attending physician.

GentleTouch Patient Care Kit

The GentleTouch Patient Care Kit (P/N/ 6980) includes a GentleTouch Face Pillow,

Chest Pad Cover, Hip/Thigh Pad Covers with Hinge Aprons and Foam Arm Cradles.

The components should be utilized as described in the Patient Care Kit instruction sheet

included in every kit.

ProneView® Patient Care Kit

®

The ProneView

Patient Care Kit (6980PV) includes a ProneView® Cushion Insert,

Chest Pad Cover, Hip/Thigh Pad Covers with Hinge Aprons and Foam Arm Cradles.

The components should be utilized as described in the Patient Care Kit instruction sheet

included in every kit.

MIZUHOSI 2009 48 NW0507 Rev G

Page 49

WARNING

The ProneView® Patient Care Kit works with the provided ProneView® Helmet and

Mirror System. The system is designed by the manufacturer to support the patient’s

head while in the prone position. Additionally, the position of the patient’s facial

alignment with the Helmet can be readily viewed while in the prone position.

The ProneView® Helmet and Mirror System includes:

1 reusable Adjustable Mirror Platform (P/N D28590CE)

1 reusable Helmet (P/N D28501CE)

1 single-use Cushion Insert (Cushion Inserts are provided in each Patient Kit)

Remove the ProneView® Helmet and Mirror System components from its packaging and

visually inspect the components for any damage. Do not use damaged goods.

IMPORTANT: Before installing and using the ProneView® Helmet and Mirror System

read all instructions and warnings in this Owner’s Manual and the

ProneView® Helmet and Mirror System instructions.

Note: The Adjustable Mirror Platform is a rectangular shaped device with a square

shaped mounting post pattern. The Adjustable Mirror Platform can be mounted

to the Chest Slide such that the ‘longer’ side of the platform can be oriented

either parallel or perpendicular to the overall length of the table. Mounting of

the Adjustable Mirror Platform with the longer side perpendicular to the overall

length of the table will provide the most available clearance between the

Helmet and the Head-End of the table.

Ensure that the Adjustable Mirror Platform Posts are in their lowest position by turning

the Posts clockwise until the base of the Adjustable Posts comes to rest on the

Adjustable Mirror Platform. This action will allow the Helmet Legs to easily engage the

Adjustable Mirror Platform Posts during patient transfer.

With the Adjustable Posts facing up, place the Adjustable Mirror Platform onto the Chest

Slide of the Axis Jackson. Figure 27 illustrates the Adjustable Mirror Platform mounted

to the Chest Slide. Figure 28 illustrates the ProneView® Mirror and Helmet System.

Verify there is adequate space between the Helmet and the Head End

Assembly to accommodate anticipated range of motion. The Axis

Jackson Chest Slide is designed to move simultaneously when the

Hinged Frame is translated to ‘Hinge-Up or Hinge-Down’. Failure to

verify may result in patient injury.