Page 1

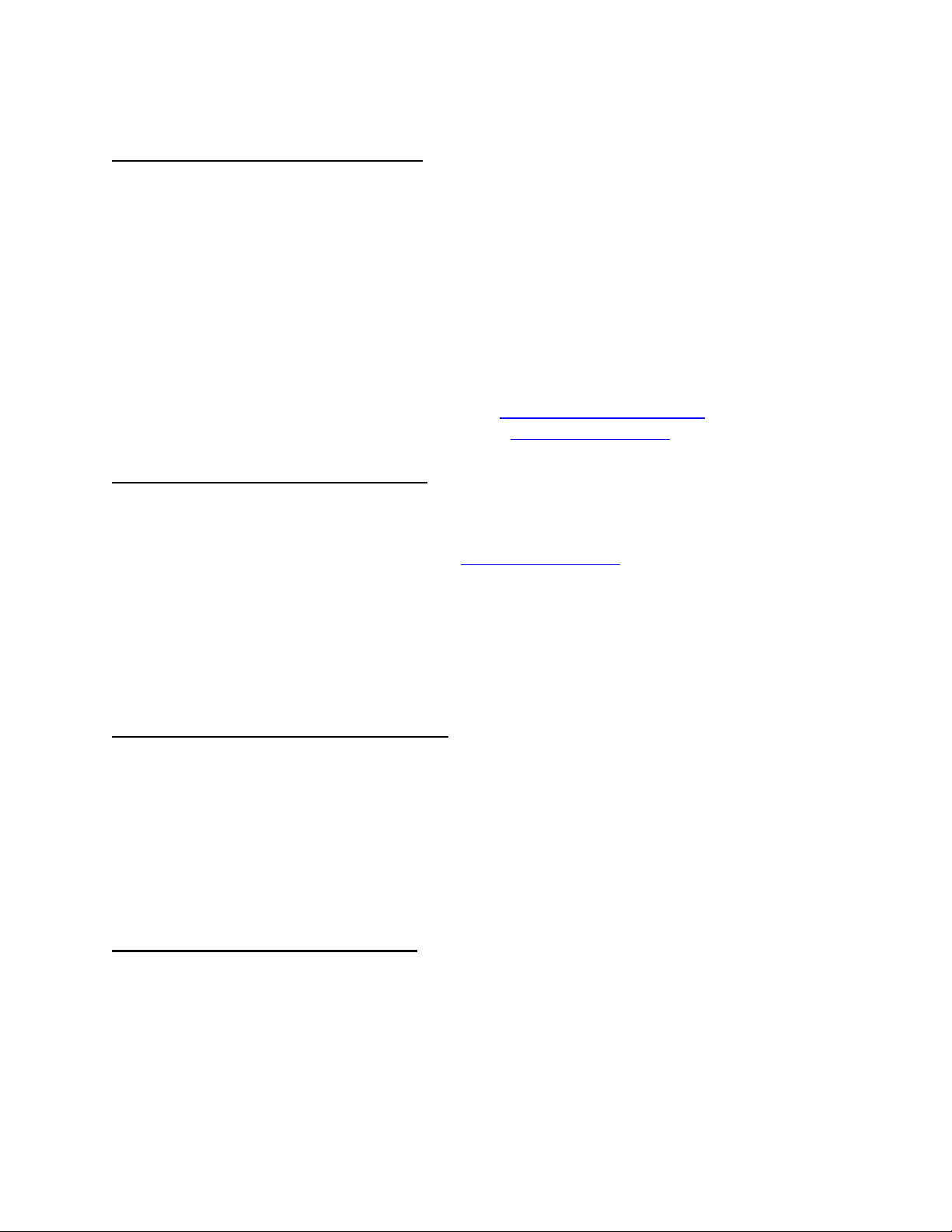

ALLEGRO™

MOBILE IMAGING TABLE

OWNER’S MANUAL

Model 6800

This manual is written in five

languages in the following order:

• (en) English

• (es) Spanish

• (fr) French

• (de) German

• (it) Italian

MIZUHO OSI

30031 AHERN AVENUE • UNION CITY, CA 94587

Bus: 510-429-1500 • Toll Free: 800-777-4674 Fax: • 510-429-8500

WWW.MIZUHOSI.COM ·

MIZUHOSI 2009 NW0510 Rev. D

•

NEWHIPNEWS.COM · •NEWSPINENEWS.COM

Page 2

IMPORTANT NOTICES

CAUTION: To ensure safe operation of the equipment, please READ THESE

INSTRUCTIONS COMPLETELY and keep this manual readily available for future

reference.

Carefully observe and comply with all warnings, cautions and instructions placed on the

equipment or described in this manual.

In this manual, the WARNING symbol is intended to alert the user to the presence

of important operation, maintenance, or safety instructions.

PROTECTION AGAINST ELECTRICAL SHOCK HAZARD:

This symbol indicates this equipment is an applied part, TYPE B in

accordance with IEC 60601-1 and is generally suitable for applications involving

external or internal contact with the patient, excluding the heart. The patient

circuit is connected to protective earth and this equipment should be connected

only to outlets with a protective earth ground.

This symbol indicates the external stud that is at the same potential as the

equipment chassis. If the AC power cable is not connected to an outlet with a

protective earth ground, this external stud should be connected to a protective

earth ground.

WARNING:

Proper preoperative and intraoperative procedures must be followed to prevent

venous stasis and pooling, pressure sore development, neuropathy, improper

electro-surgical tissue grounding, hypotension and hypothermia.

NOTE: The application techniques outlined in these instructions are the manufacturer’s

suggested techniques. The final disposition of each patient’s care as related to the use

of this equipment rests with the attending physician.

THIS DEVICE IS TO BE USED BY TRAINED PERSONNEL ONLY.

MIZUHOSI 2009 NW0510 Rev. D

2

Page 3

TABLE OF CONTENTS

1.0 INTRODUCTION ................................................................................................................................. 5

1.1 General Description.......................................................................................................................5

1.2 Specification .................................................................................................................................. 5

1.2 Specification .................................................................................................................................. 6

2.0 GLOSSARY OF TERMS.....................................................................................................................7

2.1 Basic Assumptions Of Patient Orientation On The Tabletop ........................................................ 7

3.0 COMPONENT IDENTIFICATION .......................................................................................................9

3.1 Table Orientation ........................................................................................................................... 9

3.2 Model Number And Serial Number ...............................................................................................9

4.0 BASIC OPERATION ......................................................................................................................... 10

4.1 Control Operation ........................................................................................................................ 10

4.2 Floor Lock....................................................................................................................................10

4.3 Hand Pendant ............................................................................................................................. 11

4.4 Joystick Control – Interactive Proportional Speed Control™ (IPSC) .......................................... 14

5.0 INSPECTION..................................................................................................................................... 16

5.1 Acceptance And Transfer............................................................................................................ 16

5.2 Inspection And Transfer .............................................................................................................16

6.0 FUNCTION CHECK .......................................................................................................................... 17

6.1 Function Check ........................................................................................................................... 17

7.0 THE ELECTRICAL SYSTEM............................................................................................................20

7.1 Description .................................................................................................................................. 20

7.2 On/Off Circuit Breaker Switch .....................................................................................................20

7.3 Component Circuit Breakers ....................................................................................................... 20

7.4 Power Cord ................................................................................................................................. 20

7.5 Floor Lock System.......................................................................................................................20

7.6 Battery Charging ......................................................................................................................... 21

7.7 Power Supply - AC & DC Operation ...........................................................................................21

7.8 Battery System ........................................................................................................................... 22

8.0 CLEANING........................................................................................................................................24

8.1 Cleaning And Disinfecting ...........................................................................................................24

1. Table exterior ............................................................................................................................... 24

2. Casters ......................................................................................................................................... 24

4. Table tops.....................................................................................................................................25

8.2 Lubrication ................................................................................................................................... 25

1. Table exterior ............................................................................................................................... 25

2. Table interior ................................................................................................................................ 25

8.3 Table Storage .............................................................................................................................. 25

9.0 TROUBLESHOOTING ...................................................................................................................... 26

9.1 Electrical System ......................................................................................................................... 26

9.2 Table Functions ........................................................................................................................... 27

10.0 REMOVAL AND REPLACEMENT OF COMPONENTS .................................................................. 33

10.1 Floor Lock Foot Actuator........................................................................................................... 33

10.2 Floor Lock Pad ..........................................................................................................................34

10.3 Power Supply Tray.................................................................................................................... 35

10.4 Controller Circuit........................................................................................................................36

10.5 10-Amp Motor Control PCB ......................................................................................................37

10.6 Stepper Controller Tray............................................................................................................. 38

10.7 Tilt Sensor Actuator ................................................................................................................... 40

Left Tilt Cover Removal (The Bell Shaped Housing): .......................................................................41

11.0 TECHNICAL DRAWINGS AND PARTS LISTS ............................................................................... 44

11.1 Electrical Interconnect Diagram, 120 VAC................................................................................ 44

11.2 Electrical Interconnect Diagram, 230 VAC................................................................................ 45

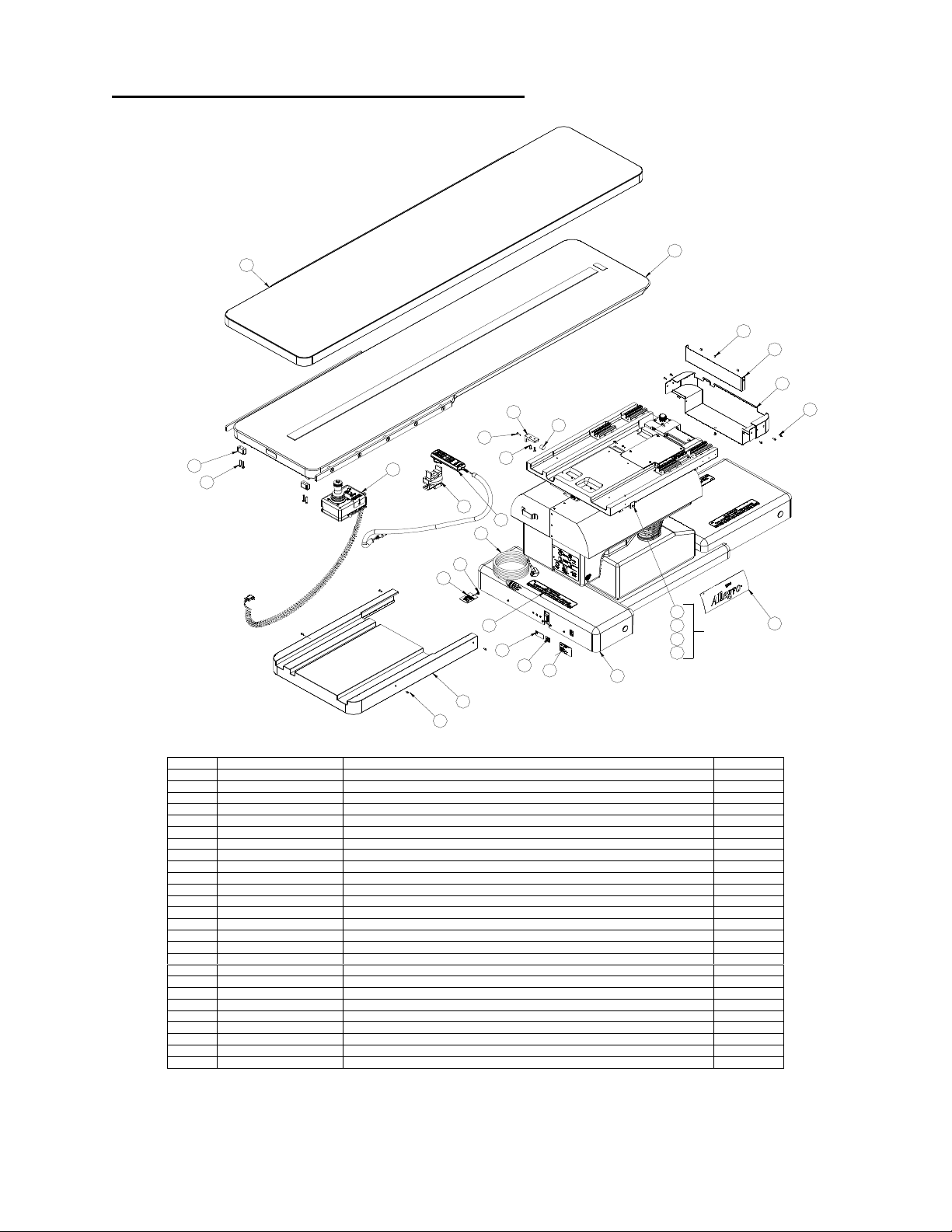

11.3 Top Level Table Assembly Exploded View ...............................................................................46

11.4 Table Sub Assembly Parts List .................................................................................................47

11.5 Table Assembly Exploded View................................................................................................ 48

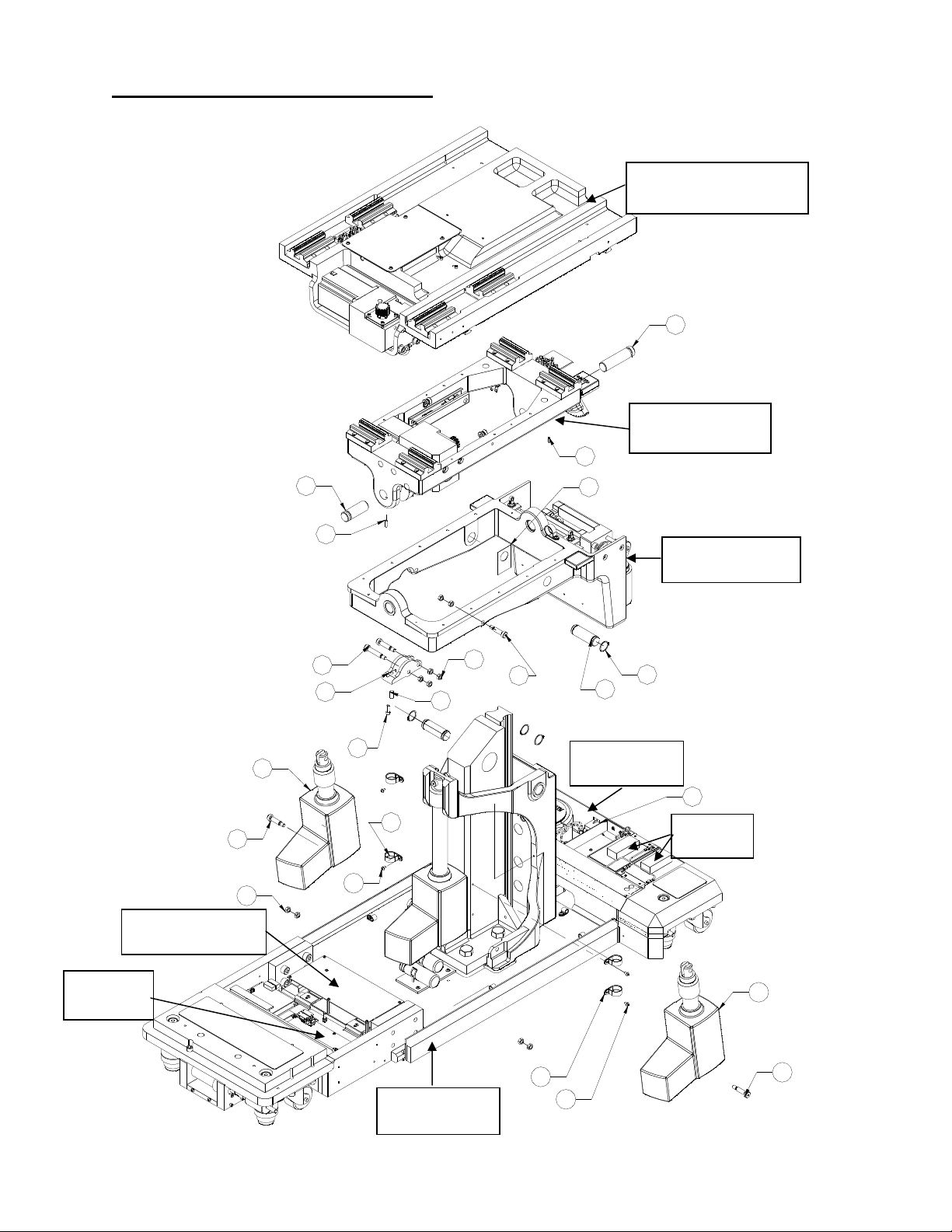

11.6 Base Cover Assembly Exploded View ......................................................................................49

11.7 Base Assembly Exploded View................................................................................................. 50

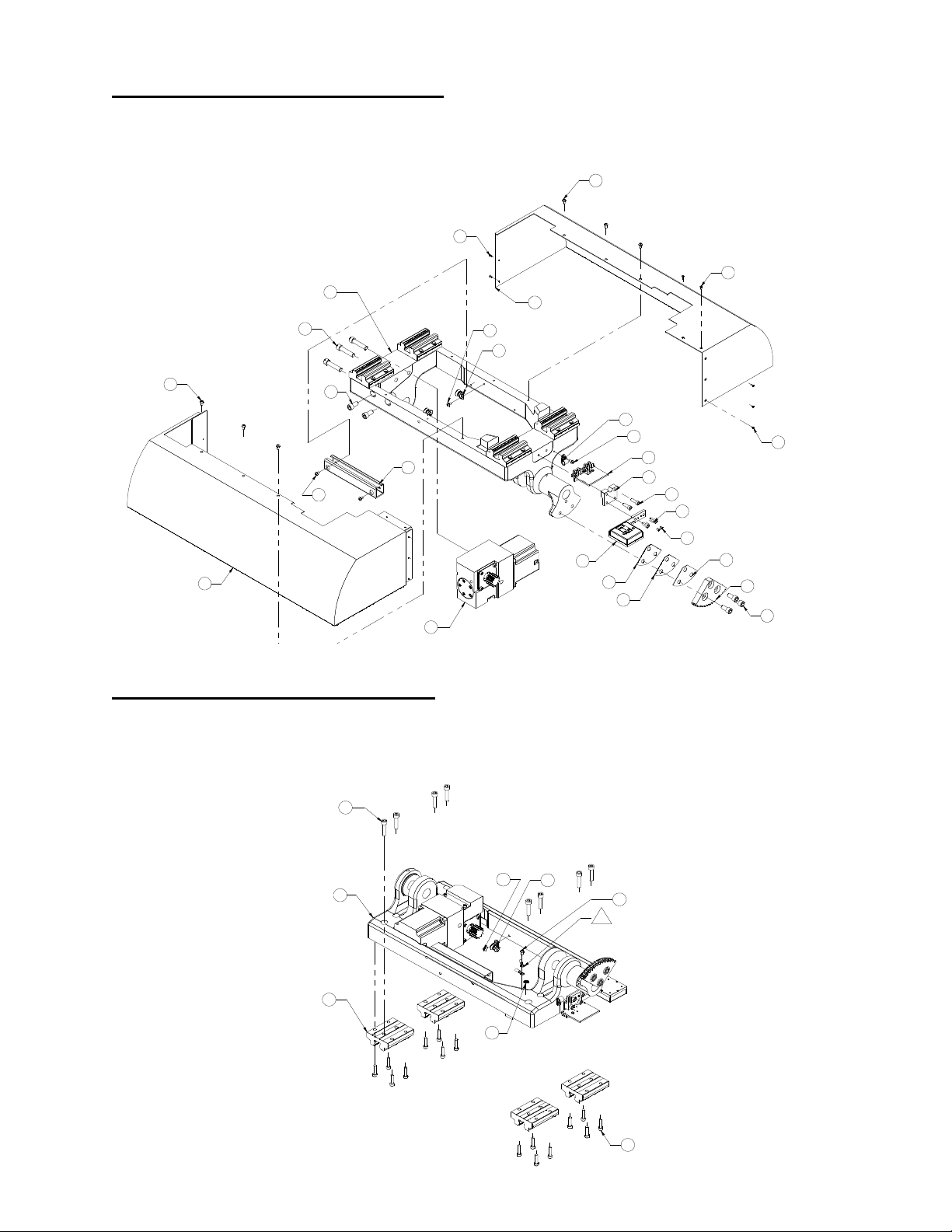

11.8 X-Ring Assembly Exploded View.............................................................................................. 51

MIZUHOSI 2009 NW0510 Rev. D

3

Page 4

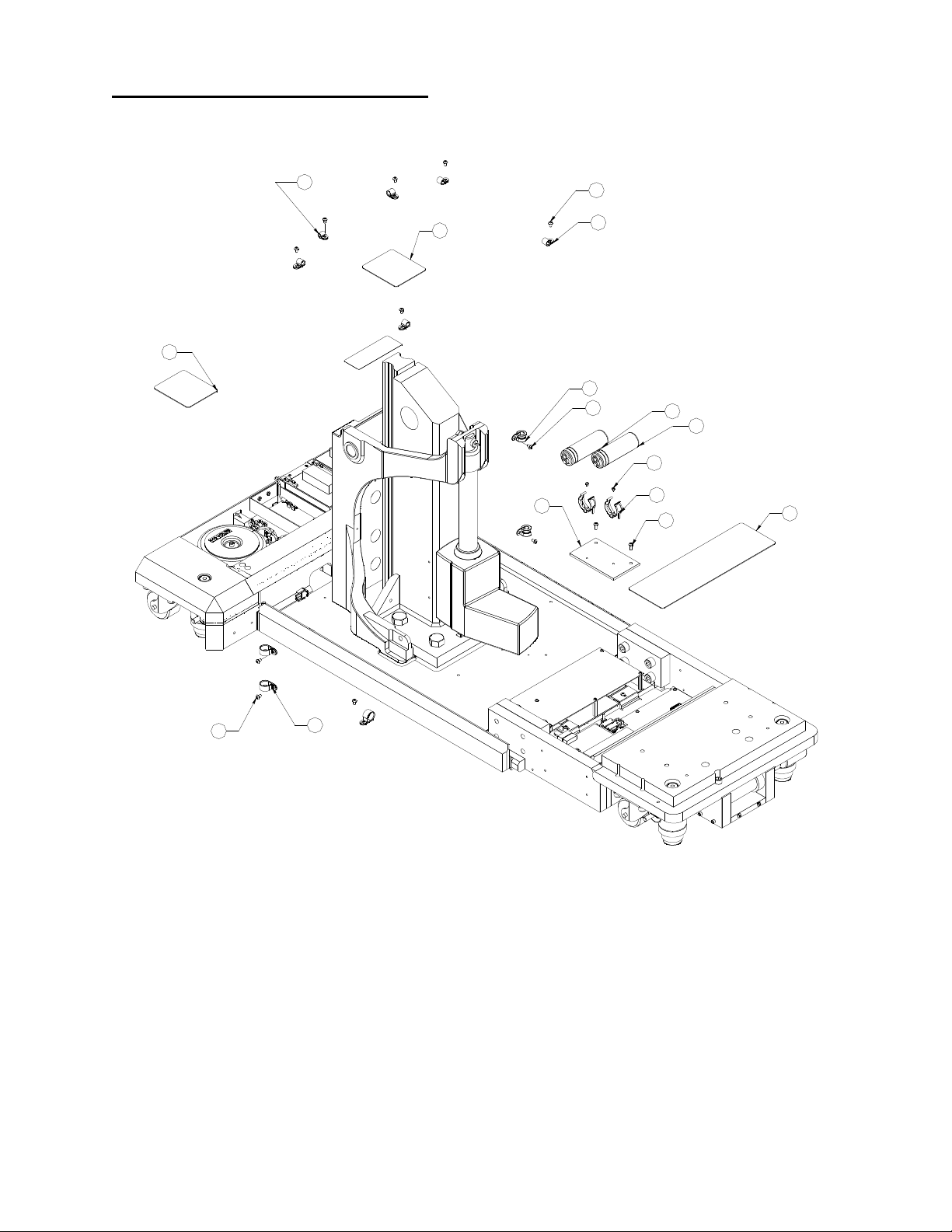

11.9 Y-Ring Assembly Exploded View.............................................................................................. 52

11.10 Y-Ring Assembly Bottom View ...............................................................................................52

11.11 X - Y Coupler Assembly Exploded View .................................................................................53

11.12 X - Y Coupler Assembly Bottom View..................................................................................... 54

11.13 Replacement/Spare Parts List ................................................................................................55

12.0 Mizuho OSI CUSTOMER RESOURCE GROUP .............................................................................56

12.1 Contact For Parts And Service.................................................................................................. 56

12.2 Instant Support Value Package................................................................................................. 56

12.3 To Order Replacement Parts (RP)............................................................................................ 56

12.4 Returns To Mizuho OSI (RGA) .................................................................................................56

12.5 To Send A Part For Repair (RA) ...............................................................................................57

12.6 EC Authorized Representative.................................................................................................. 57

13.0 Mizuho OSI ALLEGRO™ 6800 OPTIONAL ACCESSORIES ........................................................58

MIZUHOSI 2009 NW0510 Rev. D

4

Page 5

1.0 INTRODUCTION

Fig

ure 1

:

Allegro™ 6800 Mobile Imaging

1.1 General Description

The Allegro™ 6800 Mobile Imaging Table is designed to safely hold a patient in the

proper position undergoing radiographic or surgical procedures.

It is a stand-alone, single-pedestal AC power or battery-operated table designed to

position a patient in a prone, lateral or supine position during radiographic or surgical

procedures.

The table has a 2” (5 cm) MIZUHO OSI® Tempur-Pedic® pad. The TEMPUR® used in

the manufacture of MIZUHO OSI® pads has viscoelastic properties and is a temperature

sensitive material, becoming softer where the patient’s body is making the most contact

with the surface and remaining firm in areas where less body contact is being made.

Pressure is distributed evenly over the entire surface area. The pad is radiolucent, MR

safe and latex free. The benefits of using MIZUHO OSI® Tempur-Pedic® are improved

pressure management, reduced shear forces and enhanced patient comfort.

The table has four primary electrically powered functions; up/down, left/right lateral roll

(tilt), trendelenburg/reverse trendelenburg and X-Y translation. These motions are

performed by electromechanical actuators and electric stepper motors.

The table is controlled by means of a low voltage hand pendant which has the functions

clearly labeled. In addition to the hand pendant, a joystick controls the X-Y translations

of the table top. Positive floor locks are employed to stabilize the table in the operating

location.

Cantilever

end

Pedestal

end

MIZUHOSI 2009 NW0510 Rev. D

5

Page 6

1.2 Specification

• Maximum patient weight 450 lbs (205 kg)

• Height range of table top 30 – 40 inches (76 - 102 cm)

• Trendelenburg range 15°

• Reverse trendelenburg 15°

range

• Powered lateral roll ±20°

• Longitudinal travel 21 inches (53 cm) at speed of 2 to 4 inches

(5 cm – 10 cm) per second

• Lateral travel 10 inches (25 cm) at speed of 2 inches (5 cm)

per second

• Table top length 86 inches (218 cm)

• Width 21 inches (53 cm)

• Duty cycle 10%

• Battery life 5 hours at 10% duty cycle

• Maximum deflection <1 inches (2.5 cm) at cantilever end

• Radiolucent equivalency <1 mm of aluminum

• Class B medical device

• Power input (configurable)

o 120 VAC at 60 Hz

o 230 VAC at 50 Hz

o internal battery power

• IPX-0 rating

MIZUHOSI 2009 NW0510 Rev. D

6

Page 7

2.0 GLOSSARY OF TERMS

NOTE: The following terms are used throughout this owners manual. A thorough

understanding of these terms is necessary to properly operate this table.

2.1 Basic Assumptions Of Patient Orientation On The Tabletop

Our glossary of terms and technical procedures assume the patient is oriented with their

head at the front of table and their feet at the rear of table as described below. The hand

control functions are oriented for this position only.

PEDESTAL END, or rear of table, indicates the power cord end of the table, where the

control panel is located.

CANTILEVER END, or front of table indicates the opposite end of the rear of the table

or, the column pedestal.

PEDESTAL, refers to the main column structure that supports the tabletop.

Left side, of the table refers to the left side of the table as you stand by the pedestal end

and look down the table. This also corresponds to the hand pendent button labeled

LEFT LATERAL ROLL.

Right side, of the table refers to the right side of the table as you stand by the pedestal

end and look down the table. This also corresponds to the hand pendant button labeled

RIGHT LATERAL ROLL.

Raise the table, refers to raising the height of the table. This also corresponds to the

hand pendant button labeled HEIGHT UP.

Lower the table, refers to lowering the height of the table down toward the floor. This

also corresponds to the hand pendant button labeled HEIGHT DOWN.

Reverse trendelenburg, refers to moving the cantilever end of the table up. The

corresponding hand pendant button is labeled REV. TREN.

Trendelenburg, refers to moving the cantilever end of the table down. The

corresponding hand pendant button is labeled TREN.

Return to level, or level the table, refers to returning the tabletop to a state level

regardless of height. The corresponding hand pendant button is labeled return to level.

Holding the RETURN TO LEVEL button longer than approximately three seconds will

lower the tabletop to its lowest position.

Top home, refers to returning the table top to its home position after longitudinal or

lateral travel. The corresponding hand pendant button is labeled TOP HOME. The

tabletop in the home position is centered over the pedestal pads in its side to side travel

and to its extent of travel toward the pedestal end in its longitudinal travel

Unlock the floor locks, raise the floor locks, turn off the floor locks, refers to allowing the

table to freely roll on its wheels once the floor lock feet next to the wheels, raise off the

MIZUHOSI 2009 NW0510 Rev. D

7

Page 8

floor. The floor locks, when down, prevent the table from moving on its wheels. The

corresponding hand pendant buttons labeled FLOOR LOCK.

Control panel, is a panel of buttons and lights located on the pedestal end of the table.

Floor locks and tabletop home can be controlled by depressing the corresponding

button labeled UP TO UNLOCK, DOWN TO LOCK or TABLE TOP HOME.

Hospital grade outlet, refers to a 120VAC outlet properly wired with earth ground.

Generally this is: neutral to common = 120VAC; neutral to ground = 120VAC; common

to ground less than zero point five (0.5)VAC, and will be marked with a green dot.

MIZUHOSI 2009 NW0510 Rev. D

8

Page 9

3.0 COMPONENT IDENTIFICATION

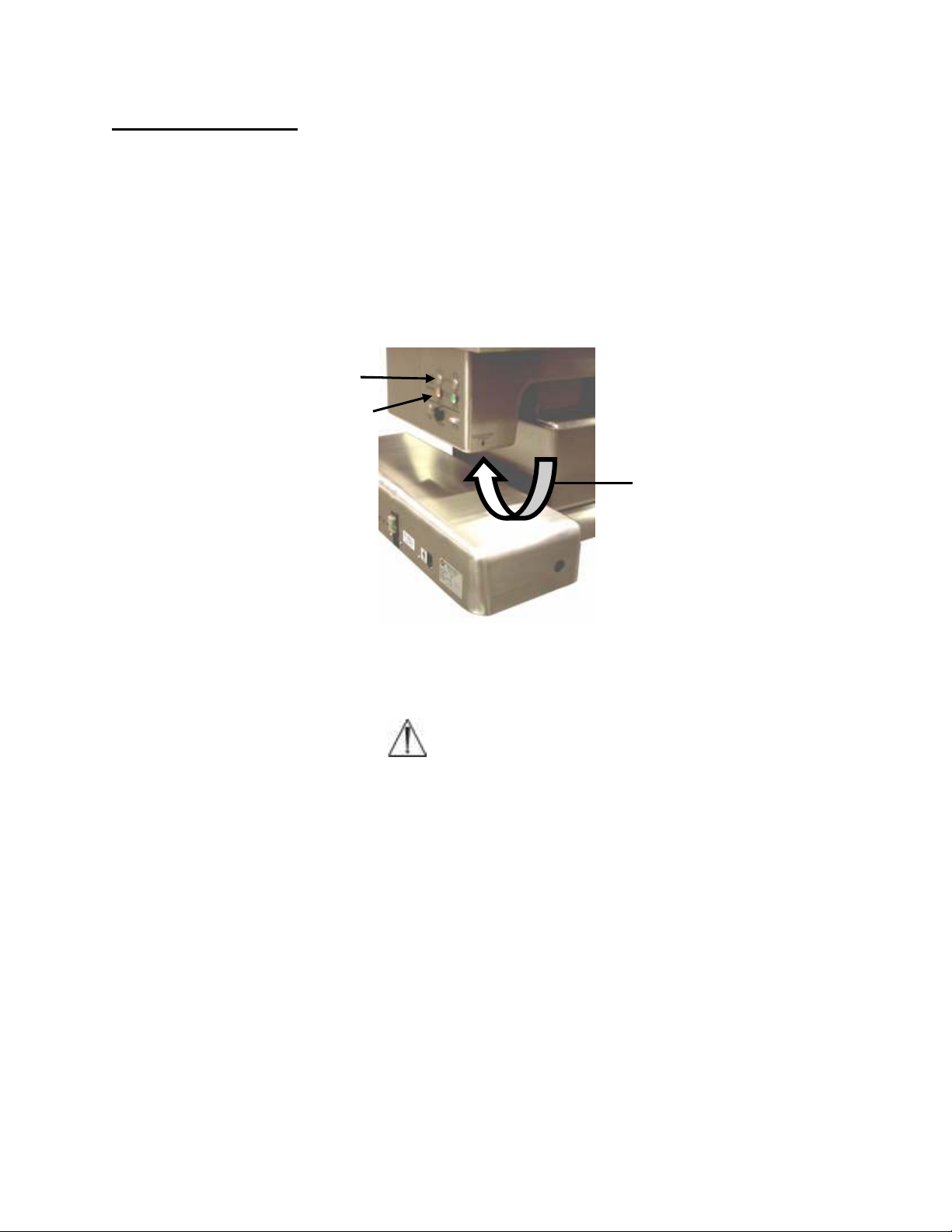

Figure 3:

Component identification

Figure 2:

Component identification of

3.1 Table Orientation

The major components of the Allegro™ 6800 and control panel are shown in figure 2.

The patient’s head can be located at either end of the table, depending on the

procedure. Therefore, the table is described as having a pedestal end and a cantilever

end. The on/off switch, floor lock buttons and the power cord socket are located at the

pedestal end of the table.

Floor lock

indicator lights

Hand pendant

can be hung here

the pedestal end interface

of the control panel

3.2 Model Number And Serial Number

The model number and serial number are printed on the identification label on the

pedestal end of the base.

Hand pendant

can be hung here

MIZUHOSI 2009 NW0510 Rev. D

Component

circuit breakers

On/off

switch

Figure 4: On/ Off switch, serial number/model number/identification label

Power cord

socket

Model No./

Serial No. label

9

Page 10

4.0 BASIC OPERATION

4.1 Control Operation

For use with line power:

Plug the power cord into a properly grounded receptacle. Refer to the label at the

pedestal end of the base for input voltage requirements (see figure 4). Turn on the

power switch and observe the green light in the switch indicating that power is applied

to the table. This rocker switch is a combination on/off power switch, circuit breaker and

pilot light.

WARNING:

Ensure that the battery has been properly charged as outlined in section 7.0.

Turn on the power switch. The battery status LED on the hand pendant should be

green, indicating a charged battery. The expected working life of a fully charged

battery is approximately 5 hours at 10% duty cycle. While in storage, it is

desirable that the table be plugged in and the power switch turned on so that the

batteries remain charged. If this is not possible, the batteries must be charged

for at least three hours a week. This can be accomplished when using the table

under line power.

This symbol indicates the external stud that is at the same potential as the

equipment chassis. If the AC power cable is not connected to an outlet with a

protective earth ground, this external stud should be connected to a protective

earth ground.

4.2 Floor Lock

To operate the floor locks via the hand pendant, press and hold the FLOOR LOCK

button until the floor lock is completely deployed. The green indicator light marked

LOCKED WHEN LIT on the control panel and the FLOOR LOCK ON LED located on

the hand pendant will be illuminated when it is locked. To stow the floor locks via the

hand pendant, press and hold the FLOOR UNLOCK button until the floor lock is

completely retracted. The amber indicator light marked STOWED WHEN LIT on the

control panel and the FLOOR LOCK, STOWED LED located on the hand pendant will

be illuminated when they are stowed.

The floor locks can also be operated by the floor lock buttons on the sheet metal

housing of the pedestal as follows. Press the button labeled DOWN TO LOCK, and

hold it until the floor lock is completely deployed. The green indicator light marked

LOCKED WHEN LIT on the control panel (see figure 3) and the FLOOR LOCK ON LED

located on the hand pendant (see figure 6) will be illuminated when it is locked. To

release the floor lock, press the button labeled UP TO UNLOCK and hold it until the

floor lock is completely retracted. The amber indicator light marked STOWED WHEN

LIT on the control panel and the FLOOR LOCK STOWED LED on the hand pendant will

be illuminated when it is stowed.

MIZUHOSI 2009 NW0510 Rev. D

10

Page 11

NOTE: The table will not function until the floor locks are completely deployed.

Floor lock override button:

If floor lock systems fails during table use, press and hold the FLOOR LOCK

OVERRIDE button while simultaneously operating the desired hand pendant function.

When button is released, no functions will be operable and this button must be pressed

again if subsequent table movement is required.

NOTE: This OVERRIDE button only powers the height, trendelenburg and lateral roll

functions via the hand pendant and is intended for emergency situations only.

To restore floor lock system function:

• Verify power cord is plugged into a live power outlet supplying proper voltage and

the power switch is ON and illuminated

• Verify all four floor locks are completely engaged and control panel, green

LOCKED WHEN LIT light illuminates and the FLOOR LOCK ON LED on the

hand pendant is illuminated. The table should not move on its wheels when the

floor locks are engaged.

To manually disengage floor lock for table relocation:

a. Use floor lock crank handle (see Replacement / Spare Parts List) stowed on sheet

metal housing behind control panel for each floor lock.

b. Remove floor lock access hole-plug and insert crank handle to engage floor lock

shaft.

• For floor lock nearest grounding stud/power cord, turn crank handle clockwise to

raise floor lock.

• For all other floor locks, turn crank handle counter-clockwise to raise floor lock.

4.3 Hand Pendant

WARNING:

A hand pendant can be plugged in at the pedestal end (back) or the cantilever end

(front) of the base, or both locations with two hand pendants. If a hand pendant is

removed or added while the table is operational, the table must be shut down for 30

seconds. When turned on, the floor locks must be reengaged. It is best only to plug or

unplug hand pendants when power is turned off.

The table is controlled by means of a low voltage hand pendant which has the functions

clearly labeled (see figure 6). The hand pendant should be plugged into the receptacle

labeled “hand pendant” on either the back or the front of pedestal. The hand pendant is

intended to be hung on the side rail independently, placed either with the swivel mount

or without. The swivel mount allows the hand pendant to be mounted horizontally on

the table. The hand pendant clip slides in the top of the swivel mount and the swivel

mount slides on the side rail or auxiliary clamp.

MIZUHOSI 2009 NW0510 Rev. D

11

Page 12

Height:

To adjust the height of the table press and hold the appropriate HEIGHT UP or HEIGHT

DOWN button until the desired height is achieved.

Lateral roll:

To adjust the lateral roll press and hold the appropriate LATERAL ROLL button. Note

that when lateral roll is within +/- 2° of level the green level indicator will illuminate.

Trendelenburg / reverse trendelenburg:

To adjust the trendelenburg position of the table, press and hold the appropriate TREN

or REV.TREN button. Note that when trendelenburg tilt is within +/- 2° of level the

green level indicator will illuminate.

Table top translation:

The hand pendant is equipped with TOP FORWARD, TOP AFT, TOP LEFT and TOP

RIGHT translation button. When one of the translation buttons is depressed the table

top will translate in the given direction at constant speed.

NOTE: The table can also be translated at variable speeds using the joystick (see

section 4.4).

WARNING:

Battery status: The hand pendant is equipped with a two color battery status

LED. If the indicator is green, the battery is charged and the table is ready for

use. If the indicator is red, the battery must be charged for a minimum of 3 hours

(see section 7.0 for complete Battery Charging instructions).

NOTE: The table can be used on line power if the battery is not fully charged.

MIZUHOSI 2009 NW0510 Rev. D

12

Page 13

Figure

5:

Hand pendant in

TOP HOME

FLOOR LOCK - ON

HEIGHT UP

REVERSE TRENDELENBURG

LEFT LATERAL ROLL

TOP FORWARD

TOP LEFT

FLOOR LOCK - STOWED

HEIGHT DOWN

TRENDELENBURG

TRENDELENBURG - LEVEL

RIGHT LATERAL ROLL

LATERAL ROLL LEVEL

TOP AFT

TOP RIGHT

RETURN TO LEVEL

FLOOR LOCK

FLOOR UNLOCK

BATTERY STATUS

Green = OK

Red = CHARGE

the swivel mount

Figure 6: Hand pendant function buttons

The hand pendant is equipped with a TOP HOME button and a RETURN TO LEVEL

button. The TOP HOME button is used to return the table top to it’s X-Y home position.

The RETURN TO LEVEL button returns all functions to a preset level position. The top

home and the return to level buttons must be depressed and held continuously until the

function is complete.

Return to level:

Press and hold the RETURN TO LEVEL button, this will 1) level lateral roll, 2) level the

trendelenburg and 3) bring the table to its lowest height position. A delay of 3 seconds

is programmed after the trendelenburg function before the table returns to its lowest

height position. The button must be depressed and held continuously for the function to

complete.

MIZUHOSI 2009 NW0510 Rev. D

13

Page 14

The controller considers the table to be level if it is within +/- 2° of 0° level. If the

Joystick

RETURN TO LEVEL button is pressed while the table is within this range, it will not

move. If it is required to adjust the table to a position closer to 0°, simply press the

appropriate function button on the hand pendant until the desired position is achieved.

Top home:

The X-Y home position of the table top can be achieved by pressing the TABLE TOP

HOME button located on the control panel of the pedestal or the TOP HOME button on

the hand pendant. This position is defined as the table top being centered in its side to

side travel and to its extent of travel toward the pedestal end in its longitudinal travel.

4.4 Joystick Control – Interactive Proportional Speed Control™ (IPSC)

The lateral and longitudinal translation movement of the table is controlled by a joystick

control mounted on the side rail or auxiliary clamp on either side of the table top. The

Allegro™ 6800 has 2 speed ranges of operation for longitudinal travel. Lateral travel is

always performed at the normal speed setting. An illuminated green light on the top of

the joystick control indicates which speed is engaged. A speed button on the top of the

joystick control can be pressed once to switch between speeds. It should be noted that

the joystick provides Interactive Proportional Speed Control™ (IPSC). This means that

the Allegro™ 6800 travel speed will increase from stop to full speed within the selected

range in proportion to how far the joystick is pushed.

Activation

button

Normal/high speed

indicator lights

Speed selection

button

Locking

lever

Figure 7: Joystick control

To use the joystick control slide it onto the side rail or auxiliary clamp and plug it into the

receptacle labeled joystick on either end of the pedestal of the Allegro™ 6800. The

locking lever of the joystick control must always be rotated toward the pedestal end of

the table to lock it to the side rail or auxiliary clamp. Correct orientation of this lever

insures that the direction of travel of the Allegro™ 6800 will be consistent with the

direction of the joystick movement.

WARNING:

Failure to engage the joystick locking lever in the proper direction will result in

travel in the direction opposite of the joystick motion.

MIZUHOSI 2009 NW0510 Rev. D

14

Page 15

The joystick control includes an activation button (red button) that must be depressed to

activate the joystick. This feature prevents unintended motion of the Allegro™ 6800 if

the joystick is inadvertently pushed.

To translate the Allegro™ 6800, press and hold down the JOYSTICK ACTIVATION

button and then push the joystick in the intended direction of travel. Release the

joystick when the desired position is achieved. The table will move at a speed that is

proportional to the position of the joystick from the starting center position. Pushing the

joystick further from center moves the table faster in that direction. Releasing the

joystick activation button stops the table in any position.

NOTE: Although the Allegro™ 6800 is designed to travel laterally and longitudinally at

any tilt or trendelenburg angle, it is recommended not to translate the table at high

speed under full load (i.e. 450 lb. patient) when it is at extreme tilt or trendelenburg

angles.

NOTE: If the joystick is moved off center before the joystick activation button is pressed

the table will start moving at that speed proportional to the position of the joystick. This

can result in sudden jerky or rapid movement of the table top. Therefore, do not move

the joystick off of center before pressing the joystick activation button.

Figure 8: Patient supine with head toward pedestal end

MIZUHOSI 2009 NW0510 Rev. D

15

Page 16

5.0 INSPECTION

5.1 Acceptance And Transfer

Upon receipt of your Allegro™ 6800 Mobile Imaging Table, remove the table from the

shipping crate following the unpacking instructions. Visually inspect all surfaces for

freight damage. Check each caster for proper rolling operation.

NOTE: Any freight damage must be reported to the freight carrier immediately upon

delivery. It is the responsibility of the recipient to make freight damage claims.

• Verify receipt of the completeness and test report provided with each Allegro™

6800.

• Read the model/serial number identification label found at the pedestal end of the

base (see figure 4) to confirm the serial number and the input power requirements.

• Place the Allegro™ 6800 in an area with at least 4 feet of clearance on all sides.

• Perform Function Check; see section 6.0.

Pre-procedure/post-procedure and annually perform functional checks:

• Inspect and test the table as described in Function Check section 6.0.

• Thoroughly clean the table as described in the Cleaning section of this manual. Pay

special attention to the cleanliness of the controls, as excessive soil can affect

function.

• Inspect the power cord for cuts in the insulation or damage to the connector.

• Check to see that all fasteners are tight.

• Check the operation and security of the floor lock with and without a patient load in

place.

5.2 Inspection And Transfer

Before use, inspect the device for possible damage, excessive wear or non-functioning

parts. Carefully inspect all critical, inaccessible areas, joints, electrical cords and all

movable parts for possible damage or non-function.

Damaged or defective products should not be used or processed. Contact your local

Mizuho OSI sales representative for repair or replacement.

MIZUHOSI 2009 NW0510 Rev. D

16

Page 17

6.0 FUNCTION CHECK

Perform all steps in this procedure. If you have any questions please feel free to contact

Mizuho OSI Customer Resource Group at 800-777-4674, 7AM to 5PM PST. For a

complete definition of reference terms used in this procedure, please refer to the

Glossary of Terms (Section 2) this owners manual.

6.1 Function Check

1. Plug a hand pendant into the desired location.

NOTE: A hand pendant can be plugged in at the pedestal end (back) or the cantilever

end (front) of the base, or both locations with two hand pendants. If a hand pendant is

removed or added while the table is operational, the table must be shut down for 30

seconds. When turned back on, the floor locks must be reengaged.

2. Plug in and tighten the connector for the joystick into the receptacle labeled

JOYSTICK at either end of the pedestal.

3. Attach and correctly orient the locking lever on the joystick. This lever must always

lock in place toward the pedestal end of the table. Correct orientation of this lever

ensures the direction of travel of the Allegro™ 6800 will be consistent with the

direction of the joystick movement.

4. If the table is to be used under battery power, ensure that the battery has been

properly charged and that the battery status LED on the hand pendant is green

when the on/off power switch is on.

5. If the table is to be used under line power, plug in power cord into an appropriate

hospital grade outlet and turn on the main ON/OFF power switch. Note that the

switch illuminates indicating that AC power is on.

6. Lockout mode: The Allegro™ 6800 is only operational if the LOCKED WHEN LIT

green indicator located on the control panel is illuminated and the FLOOR LOCK ON

LED is illuminated on the hand pendant. Verify that the hand pendant functions do

not operate except to activate floor locks.

7. Floor lock check using the control panel:

7.1. Press and hold DOWN TO LOCK button until green locked when lit indicator

is illuminated on the control panel and that the FLOOR LOCK ON LED on the

hand pendant is illuminated. Table is locked if it cannot be moved on its

wheels.

7.2. Press and hold UP TO UNLOCK button until amber indicator is illuminated on

the control panel and the FLOOR LOCK STOWED indicator is illuminated on

the hand pendant. The table is unlocked if it can move on its wheels.

MIZUHOSI 2009 NW0510 Rev. D

17

Page 18

8. Floor lock override button check:

8.1. With floor locks not engaged, press and hold floor lock override button located

under control panel. While holding the floor lock override button, operate the

HEIGHT UP, HEIGHT DOWN, LEFT LATERAL ROLL, RIGHT LATERAL

ROLL, TRENDELENBURG/REVERSE TRENDELENBURG. These should

function without the floor locks being engaged while holding the override

button (see figure 10).

9. Joystick control:

9.1. Move the joystick without pressing the activation button. No movement should

occur.

9.2. Verify Interactive Proportional Speed Control™ (IPSC), variable speed

operation. Press and hold activation button and move joystick. The tabletop

moves in the direction of handle. Small handle movements away from center

result in slow speeds while larger movements result in faster tabletop speeds.

9.3. Press the speed select button, illuminating the high speed indicator light and

deactivating the normal indicator light. Tabletop can move at twice the normal

speed in the long direction.

9.4. Relocate joystick control to other side of table and repeat steps 9.1-9.3 (see

step 3 for more information).

10. Hand pendant check:

10.1. Press and hold FLOOR LOCK button. Listen for locking feet to move down

and contact the floor. Observe on the control panel LOCKED WHEN LIT

green indicator is illuminated and that the FLOOR LOCK ON LED indicator is

illuminated on the hand pendant after floor locks engaged. Observe that all

four feet have moved down and are in contact with the floor.

10.2. Press and hold FLOOR UNLOCK button. Observe that all four locking feet

move up and STOWED WHEN LIT amber indicator is illuminated on the

control panel and that the FLOOR LOCKS STOWED LED is illuminated on

the hand pendant.

10.3. Press and hold HEIGHT UP button. Observe that the tabletop moves up.

10.4. Press and hold HEIGHT DOWN button. Observe that the tabletop moves

down. Complete range.

10.5. Press and hold REV.TREN button. Cantilever end of tabletop moves up.

Complete range.

10.6. Press and hold TREN button. Cantilever of tabletop moves down. Complete

range.

10.7. Press and hold LEFT LATERAL ROLL button. Tabletop tilts to the left.

Complete range.

10.8. Press and hold RIGHT LATERAL ROLL button. Tilt tabletop to the right.

Complete range.

10.9. Press and hold TOP FORWARD button. Tabletop translates forward. Full

distance.

10.10. Press and hold TOP AFT button. Tabletop translates aft. Full distance.

10.11. Press and hold TOP RIGHT button. Tabletop translates right. Full distance.

10.12. Press and hold TOP LEFT button. Tabletop translates left. Full distance.

MIZUHOSI 2009 NW0510 Rev. D

18

Page 19

10.13. Disorient tabletop by raising height approximately two inches, lateral roll

tabletop and performing trendelenburg approximately five degrees. Press and

hold RETURN TO LEVEL button. Tabletop first levels roll and trendelenburg

and then after a three-second delay, the tabletop moves down. Observe that

the table top is level and in its lowest height position when movement stops.

10.14. Use the joystick and move tabletop, forward and laterally. Press and hold

TOP HOME button on hand pendant. Tabletop moves to center and furthest

position toward the pedestal end. Perform this same step but use the TABLE

TOP HOME button on the control panel.

11. Verify the full function of the table system by moving and connecting hand pendant

and joystick to alternate ports. Power should be shut down when changing ports on

joystick or hand pendant (see section 6.1 Note).

MIZUHOSI 2009 NW0510 Rev. D

19

Page 20

7.0 THE ELECTRICAL SYSTEM

7.1 Description

The electrical system provides control of all the table functions and is comprised of a

power cord, an on/off circuit breaker switch, wire harnesses, a power supply, a

controller circuit, a hand pendant, a joystick control, floor lock jackscrews, various

electromechanical actuators, two stepper motors and two batteries. The electric motor

driven leadscrew-type actuators manipulating the height, lateral roll and trendelenburg

functions are controlled by the hand pendant. The floor lock buttons raise and lower the

table floor lock feet to the floor. The translation motion of the table top is controlled by

the joystick control and the hand pendant and driven by the stepper motors. Drawing

number 6800-1003 is the Electrical Wiring Diagram for the Allegro™ 6800 Imaging

Table. The input power requirement for this table is 120 VAC 60Hz, 5 Amp or 230 VAC

50Hz 2.5 Amps as indicated on the serial number label. Drawing number 6800-1004 is

the Electrical Wiring Diagram for the 230 volt model 6800 Imaging Table.

7.2 On/Off Circuit Breaker Switch

An illuminated on/off circuit breaker main switch is located on the back of the pedestal

end of the base of the table (see figure 4). When illuminated, it indicates that the table

is plugged into a live electrical outlet and the power is on, (when the table is turned on

using battery power, this switch will not illuminate). This switch also serves as a circuit

breaker. In the event of an overload condition this switch will trip off. To reset, push to

the off position and then the on position.

NOTE: Determine the source of the overload prior to resetting this switch.

7.3 Component Circuit Breakers

The electrical system includes three individual component circuit breakers that provide

protection for the major components of the system. These circuit breakers are located

in the base at the pedestal end of the table (see figure 4). If a short circuit occurs, the

affected circuit breaker will trip as evidenced by a button protruding from the circuit

breaker access hole. To reset, press the button in and release.

NOTE: Determine the source of the overload prior to resetting this button.

7.4 Power Cord

The table is equipped with a standard IEC power cord with the appropriate hospital

grade connector. The power cord is connected to the table at the IEC power entry

socket located on the base of the pedestal near the on/off switch.

7.5 Floor Lock System

The Allegro™ 6800 Mobile Imaging Table floor lock secures the table by powering 4

jackscrews to lower four legs onto the floor and unloading the swivel casters. It is

operated by depressing the DOWN TO LOCK button located on the control panel or the

FLOOR LOCK button on the hand pendant. The lock button is pressed and held until

the floor lock is completely engaged as evidenced by the illumination of the floor lock

MIZUHOSI 2009 NW0510 Rev. D

20

Page 21

indicator light on the control panel or the hand pendant. This button applies electrical

current to each of the four jackscrew motors. Each leg is monitored by the controller for

contact with the floor. In the case of an uneven floor, it is possible that one or more legs

will continue to extend until firm contact is made with the floor. Complete locking is

evidenced by the illumination of the green LOCKED WHEN LIT indicator located on the

control panel and the FLOOR LOCK ON LED located on the hand pendant. The table

should not move on its wheels when floor locks are engaged.

NOTE: The table controller requires that the floor lock system be completely engaged

before any other function can be operated. If the hand pendant or the joystick will not

operate the table, verify that the floor locks are completely deployed, such that the table

does not move.

To unlock the floor lock, press and hold the UP TO UNLOCK button until the amber

STOWED WHEN LIT indicator on the control panel and the FLOOR LOCK STOWED

LED located on the hand pendant are illuminated indicating that the legs are completely

retracted.

WARNING:

Press and hold DOWN TO LOCK button until green LOCK WHEN LIT light is

illuminated on the control panel, and that the FLOOR LOCK ON LED on the hand

pendant is illuminated. Table is locked if it cannot move on its wheels. Ensure

each floor lock is fully engaged before use.

7.6 Battery Charging

The Allegro™ 6800 Table is designed to use two 12 volt batteries in series to provide 24

volts. When battery status LED on the hand pendant is red, batteries need to be

charged. To charge the batteries, simply plug the power cord into an appropriate

hospital grade outlet and turn the power switch on.

While in storage, it is desirable that the table be plugged in and the power switch turned

on so that the batteries remained charged. If this is not possible, the batteries must be

charged for at least three hours a week. This can be accomplished when using the

table under line power.

To ensure proper battery function, it is recommended that the batteries be charged for

at least 3 hours within the previous 48 hours prior to use. The battery status LED on the

hand pendant must be illuminated green when the table is on. The batteries should be

replaced every 5 years or when they fail to hold a charge.

7.7 Power Supply - AC & DC Operation

The system power supply converts AC power, 120-volt, 60Hz or 230-volt, 50Hz into

24VDC (nominal) operational power. There are four 24VDC output ports, each with a

circuit breaker for thermal and short-circuit protection. Two are unregulated at 10-Amps

with voltage between 36VDC and 22VDC depending on load and one at 15-Amps with

voltage between 36VDC and 22VDC depending on load. The fourth DC output port is

regulated at 24VDC +/- .25 ,and has no circuit protection within the power supply tray.

When powered from an AC source, the batteries in series are constantly being charged

at a variable rate depending on the charged state. Battery charge status is monitored by

MIZUHOSI 2009 NW0510 Rev. D

21

Page 22

the 10-Amp motor controller PCB via a data port on the power supply PCB. A currentsensing circuit switches to DC battery power when it senses no AC power source is

available. The 24VDC battery circuit can power and operate all of the on-board

systems, motors and actuators. When running on DC battery power the power switch

will not illuminate green but LED’s on the hand pendant will illuminate, indicating the

battery circuit powers the table.

7.8 Battery System

The 6800 Allegro™ Table uses two 12-volt batteries in series to provide 24-volts. When

the battery status LED on the hand pendant is red, the batteries require charging. To

charge, plug power cord into an appropriate hospital grade AC outlet and turn the power

switch to on.

WARNING:

While in storage, the batteries should remain charged for a minimum of three (3)

hours a week. Using the table while on AC power will also charge the batteries.

• Normal battery operation is approximately 5 hours at 10% duty cycle.

•

If recharge is required, charge a minimum of three hours. A full charge should be

available after 18 hours.

•

If battery fails to hold a charge it should be replaced. Replace only with identical type

and size battery (see Replacement / Spare Parts List).

•

Replace both batteries at the same time. Also replace foam battery blocks on top of

battery.

•

Batteries should be replaced once every five (5) years.

•

Whenever the battery cover is opened, check battery for signs of corrosion. Battery

terminals should be clean and free from corrosion, oil, grease, dirt, or other

contaminants.

• Battery ordering number: NV0801; failure to use an approved Mizuho OSI battery,

voids warranty and can cause harm to equipment.

1. Turn power switch off, wait 30 seconds for discharge, unplug power cord from wall

outlet.

2. Remove pedestal-end base cover by removing the six screws using 1/8 in hex key.

WARNING:

Disconnect batteries only with power cord unplugged and power switch off.

This symbol indicates the external stud that is at the same potential as the

equipment chassis. If the AC power cable is not connected to an outlet with a

protective earth ground, this external stud should be connected to a protective

earth ground.

MIZUHOSI 2009 NW0510 Rev. D

22

Page 23

3. Connect battery terminals as follows (see figure below):

a. Red wire: Battery A positive terminal to power supply terminal E16.

b. Yellow wire: Battery A negative terminal to battery B positive terminal.

c. Black wire: Battery B negative terminal to power supply terminal E17.

Figure 9: Battery orientation and wiring

Perform the following test to confirm proper battery connection:

1. Verify power cord is unplugged from AC wall outlet.

2. Turn power switch on (utilizing battery power) and verify all hand pendant LED’s

illuminate on and off in sequence.

3. With properly connected batteries, the hand pendant battery status light illuminates

green or red.

• A green battery-status light indicates batteries are charged and installed

correctly.

• A red battery-status light indicates batteries are connected correctly but are in

need of charging. If a charge is required, plug power cord into wall receptacle;

turn power switch on, verify it illuminates green (AC is provided to the charger).

Charge for at least three (3) hours.

NOTE: If this does not happen, immediately turn power switch off; verify proper battery

connections, verify hand pendant is fully connected to table receptacle. Repeat test

again. If problem continues, contact Mizuho OSI Customer Resource Group at 800-7774674 for further assistance.

MIZUHOSI 2009 NW0510 Rev. D

23

Page 24

8.0 CLEANING

8.1 Cleaning And Disinfecting

NOTE: Never pour any liquid directly onto the table. Never subject the Allegro™ 6800

Mobile Imaging Table to any cart or equipment washer.

1. Table exterior

• Exterior surface should be regularly wiped clean with a mild detergent solution and

wiped dry with a soft lint-free cloth.

NOTE: Do not wipe the support rails for the translating table top. These should remain

with a light coat of oil at all times.

• Care should be taken to avoid exposing the table to excessive moisture. Flooding,

fogging or steam cleaning is not recommended.

• Blood or other fluids, etc., if allowed to remain on the table for a long period of time,

will require special cleaning to remove. A 5% acetic acid solution or white vinegar

and water solution is especially good for this purpose.

• Staining and discoloration of plated or stainless steel surfaces can be corrected by

cleaning with a good commercial cleaning compound, such as Stainless Steel Magic

or Acme White Finish, and then buffing the surface by hand.

• To disinfect exterior surface use a quaternary ammonium or similar type disinfectant

compound according to manufacturer's directions for use. Wipe dry with a soft lintfree cloth.

USE OF IODOPHORS WILL CAUSE STAINING

NOTE: Failure to thoroughly dry surface after cleaning and disinfecting may result in

rust.

2. Casters

• Casters should be cleaned and disinfected in the same manner as table exterior.

Access to the casters is achieved by removing the sheet metal enclosures at each

end of the table base.

NOTE: Before removing any sheet metal covers the table must be turned off and

unplugged. Dangerous high voltage may be present in the circuitry under the covers.

This task should be performed by trained technicians only.

3. Table Pad

MIZUHO OSI® Tempur-med® Pad

IMPORTANT: The MIZUHO OSI® Tempur-Pedic® pad should always be stored in a

flat position. It can actually get stiff in cold temperatures and can crack

and break if in a rolled position. It is important that you allow the pad to

warm to room temperature before attempting to utilize or handle it.

• When handling always grasp by the entire thickness of the pad.

MIZUHOSI 2009 NW0510 Rev. D

24

Page 25

• Do not lift, slide or carry MIZUHO OSI® Tempur-med® pads by grabbing the fabric.

The cover may tear or rip.

• The pad is intended to be cleaned in place. It does not need to be rotated or flipped.

• Clean with standard hospital disinfectants labeled for use on table pads. Always

dilute and rinse per manufacturer’s label instructions. Wipe dry with a lint free cloth.

Do not soak or autoclave pads. The continued use of bleach or highly concentrated

chemicals will void the warranty on the cover.

• When cleaning the bottom of the pad or the table top, simply lift one end of the pad,

and fold it over onto the other end. Clean the pad or the table top then return the

pad to flat on the table top.

4. Table tops

• Disinfect surfaces of table tops according to standard hospital procedure.

8.2 Lubrication

1. Table exterior

No lubrication is necessary.

2. Table interior

The translation and height adjustment sliding mechanisms of the 6800 Imaging Table

require periodic lubrication. There are ten sliders in all and each should be lubricated

with Thomson Linear Lube grease (or equivalent) once a year. Four sliders are on the

lateral translation rails, four are on the longitudinal translation rails and two are on the

main table column. Apply the grease through the zerk fittings located on each slide

bearing housing. Do not over lubricate.

All other components are lubricated for life at the factory and no other lubrication on the

table is necessary.

8.3 Table Storage

When not in use the table should be stored in a clean dry environment with temperature

between 32 °F & 120 °F (0 °C & 49 °C).

MIZUHOSI 2009 NW0510 Rev. D

25

Page 26

9.0 TROUBLESHOOTING

9.1 Electrical System

In the advent of a table malfunction, the first item to investigate is the input power. Be

certain that the power cord is plugged into a live electrical outlet and the power switch is

on. This is evidenced by an illuminated on/off switch.

If none of the functions are operating, the floor lock may not be completely deployed.

Press the FLOOR LOCK button until the green LOCKED WHEN LIT indicator is

illuminated.

Floor lock button

Floor lock indicator lights

Figure 10: Floor lock override button

Floor lock override button

(under this surface)

WARNING:

If the floor lock is deployed as evidenced by visual inspection, all four floor lock

feet should be in contact with the floor. Table should not move whether or not

the green indicator is illuminated, and the up/down, lateral roll or trendelenburg

functions do not operate. The floor lock override button can be used to

temporarily bypass the interlock on the floor lock system. This button is located

on the underside of the sheet metal housing at the FLOOR LOCK buttons (see

figure 10). Press and hold this button while simultaneously operating the desired

function on the hand pendant. Once released, no functions will be operable and

this button must be pressed again if subsequent table movement is required.

This override button only powers the height, trendelenburg and lateral roll

functions on the hand pendant and is intended for emergency situations only. If

it becomes necessary to use this feature, call Mizuho OSI Customer Resource

Group immediately to arrange for table service.

MIZUHOSI 2009 NW0510 Rev. D

26

Page 27

CAUTION: Electrical shock hazard exists with access covers removed; use

caution when working in exposed areas.

1. Measure voltage at wall outlet to verify proper AC input is available (120V or 230V).

2. Inspect power supply cord for physical damage, continuity, and adequate resistance.

3. Inspect power switch/circuit breaker:

a. Plastic boot is in good condition.

b. Switch locks in the on and off positions.

c. Green light illuminates when switched on.

4. Verify proper voltage at output ports:

a. Refer to specifications (described above) and interconnect diagram.

5. Verify switchover from AC (mains) to battery operation:

a. With charged battery (24 volts or higher with power switch off) turn power switch

on.

b. Operate up/down function and pull power cord connector from table power-entry-

socket while motor is running.

c. The table should keep moving with only a minor slow-down of motor speed.

6. Repair option for damaged or non-functioning power supply is replacing entire power

supply tray assembly with new unit (see Replacement/Spare Parts List). Field repair

is not recommended.

9.2 Table Functions

Table is “dead”; no functions are operational:

• Verify power cord is plugged into an appropriate AC receptacle and into the power

cord socket (located at the back end of pedestal).

• Verify power switch (located on back end of pedestal) is on. If illuminated, table is

connected to live AC power. If no illumination, table may still operate on internal

battery power (hand pendant control buttons and lights will be illuminated).

• Verify circuit breaker (part of power switch located on table-base panel) is not

tripped off (indicating table power overload condition. Find overload source prior to

resetting). To reset, switch power switch/circuit breaker off, then on.

• Verify component circuit breakers (located on table-base panel) are not tripped off

(indicating component power overload condition. Find overload source prior to

resetting). Observe the three component circuit breaker buttons are not protruding

from circuit breaker access holes.

• Verify floor locks are deployed (all four locking feet make firm contact with the floor).

Observe LOCKED WHEN LIT green light on control panel or FLOOR LOCK ON LED

on hand pendant illuminates.

Floor lock button on control panel not functioning:

• Using the control panel, press and hold the DOWN TO LOCK control button. Verify

the LOCKED WHEN LIT green indicator on the control panel or FLOOR LOCK ON

LED on the hand pendant illuminates.

• Verify the floor locks are deployed (all four locking feet make firm contact with the

floor). Using the control panel, press and hold the DOWN TO LOCK button on the

control panel. Try pressing the UP TO UNLOCK button and then repeat press and

hold the DOWN TO LOCK button.

MIZUHOSI 2009 NW0510 Rev. D

27

Page 28

• Verify power cord is plugged into a properly grounded AC receptacle.

• If on battery power, verify proper charge; observe battery status LED illuminates

green.

• Verify table power switch is on.

• Activate floor lock override; press and hold FLOOR LOCK OVERRIDE button

(located under control panel). While holding floor lock override control button, press

and hold any hand pendant control button for height up, height down, trendelenburg,

reverse trendelenburg, left lateral roll or right lateral roll. Verify function.

Floor lock button on hand pendant not functioning:

• Using the hand pendant, press and hold the FLOOR LOCK button. Verify the

LOCKED WHEN LIT green indicator on the control panel or the FLOOR LOCK ON

LED on the hand pendant illuminates.

• Verify the floor locks are deployed (all four locking feet make firm contact with the

floor). Using the hand pendant, press and hold the FLOOR LOCK button. Try

pressing the FLOOR UNLOCK button and repeat press and hold the FLOOR LOCK

button.

• Verify power cord is plugged into a properly grounded AC receptacle.

• If on battery power, verify proper charge; observe battery status LED illuminates

green.

• Verify the table power switch is on.

• Activate floor lock override; press and hold the FLOOR LOCK OVERRIDE control

button (located under control panel). While holding the FLOOR LOCK OVERRIDE

control button, press and hold any hand pendant control button for height up, height

down, trendelenburg, reverse trendelenburg, left lateral roll or right lateral roll. Verify

function.

Height up or height down not functioning:

• Press and hold the hand pendant HEIGHT UP or HEIGHT DOWN control button.

Observe tabletop movement.

• Verify the hand pendant is properly plugged into a hand pendant receptacle.

Observe hand pendant buttons illuminate green.

NOTE: The table power switch must be turned off before disconnecting or

connecting the hand pendant. Once reconnected, turn power on and deploy floor

locks (all four locking feet make firm contact with the floor).

• With the power switch off, plug the hand pendant into the other hand pendant

receptacle. Turn power switch on. Observe hand pendant buttons illuminate green.

• Verify the power cord is plugged into a properly grounded AC receptacle.

• If on battery power, verify proper charge. Observe battery status LED illuminates

green.

• Verify power switch is on.

• Verify floor locks are deployed (all four locking feet make firm contact with the floor).

Observe LOCKED WHEN LIT illuminates green on the control panel or FLOOR

LOCK ON, LED illuminates on the hand pendant.

• Verify if other hand pendant buttons are functional. If not, replace the hand pendant.

MIZUHOSI 2009 NW0510 Rev. D

28

Page 29

• Call Mizuho OSI Customer Resource Group for service or parts (possible hand

pendant and/or 10 Amp motor-control PCB).

Trendelenburg or reverse trendelenburg not functioning:

• Press and the hold hand pendant TREN or REV.TREN button. Observe tabletop

movement.

• Verify the hand pendant is properly plugged into a hand pendant receptacle.

Observe hand pendant buttons illuminate green.

NOTE: The table power switch must be turned off before disconnecting or

connecting the hand pendant. Once reconnected, turn power on and deploy floor

locks (all four locking feet make firm contact with the floor).

• With the power switch off, plug the hand pendant into the other hand pendant

receptacle. Turn power switch on. Observe hand pendant buttons illuminate green.

• Verify power cord is plugged into a properly grounded AC receptacle.

• If on battery power, verify proper charge; observe battery status LED illuminates

green on the hand pendant.

• Verify power switch is on.

• Verify floor locks are deployed (all four locking feet make firm contact with the floor);

observe LOCKED WHEN LIT indicator illuminates green on the control panel and

the FLOOR LOCK ON LED illuminates on the hand pendant.

• Verify if other hand pendant buttons are functional. If not, replace hand pendant.

• Call Mizuho OSI Customer Resource Group for service or parts (possible hand

pendant and/or 10 Amp motor-control PCB).

Left lateral roll or right lateral roll not functioning:

• Press and hold hand pendant LEFT LATERAL ROLL or RIGHT LATERAL ROLL

control button. Observe tabletop movement.

• Verify hand pendant is properly plugged into a hand pendant receptacle; observe

hand pendant control buttons illuminate green.

NOTE: The table power switch must be turned off before disconnecting or

connecting the hand pendant. Once reconnected, turn power on and deploy floor

locks (all four locking feet make firm contact with the floor).

• With the power switch off, plug the hand pendant into the other hand pendant

receptacle. Turn power switch on. Observe hand pendant buttons illuminate green.

• Verify the power cord is plugged into a properly grounded AC receptacle.

• If on battery power, verify proper charge. Observe battery status LED illuminates

green on the hand pendant.

• Verify power switch is on.

• Verify floor locks are deployed (all four locking feet make firm contact with the floor);

observe LOCKED WHEN LIT indicator illuminates green on the control panel and

the FLOOR LOCK ON, LED illuminates on the hand pendant.

• Verify if other hand pendant buttons are functional. If not, replace the hand pendant.

MIZUHOSI 2009 NW0510 Rev. D

29

Page 30

• Call Mizuho OSI Customer Resource Group for service or parts (possible hand

pendant and/or 10 Amp motor-control PCB).

Top forward or top aft not functioning:

• Press and hold hand pendant TOP FORWARD or TOP AFT control button. Observe

tabletop movement.

• Verify the hand pendant is properly plugged into a hand pendant receptacle.

Observe hand pendant buttons illuminate green.

NOTE: The table power switch must be turned off before disconnecting or

connecting the hand pendant. Once reconnected, turn power on and deploy floor

locks (all four locking feet make firm contact with the floor).

• With the power switch off, plug the hand pendant into the other hand pendant

receptacle. Turn power switch on. Observe hand pendant buttons illuminate green.

• Verify the power cord is plugged into a properly grounded AC receptacle.

• If on battery power, verify proper charge; observe battery status LED illuminates

green on the hand pendant.

• Verify power switch is on.

• Verify floor locks are deployed (all four locking feet make firm contact with the floor);

observe locked when lit light illuminates green.

• Verify if other hand pendant buttons are functional. If not, replace hand pendant.

• Call Mizuho OSI Customer Resource Group for service or parts (possible hand

pendant and/or 10 Amp motor-control PCB).

Top left or top right not functioning:

• Press and hold hand pendant TOP LEFT or TOP RIGHT control button. Observe

tabletop movement.

• Verify hand pendant is properly plugged into a hand pendant receptacle; hand

pendant buttons illuminate green.

NOTE: The table power switch must be turned off before disconnecting or

connecting the hand pendant. Once reconnected, turn power on and deploy floor

locks (all four locking feet make firm contact with the floor).

• With the power switch off, plug the hand pendant into the other hand pendant

receptacle. Turn power switch on. Observe hand pendant buttons illuminate green.

• Verify the power cord is plugged into a properly grounded AC receptacle.

• If on battery power, verify proper charge; observe battery status LED illuminates

green on the hand pendant.

• Verify power switch is on.

• Verify floor locks are deployed (all four locking feet make firm contact with the floor);

observe locked when lit light illuminates green.

• Verify if other hand pendant control buttons are functional. If not, replace the hand

pendant.

• Call Mizuho OSI Customer Service Resource Group for service or parts (possible

hand pendant and/or 10 Amp motor-control PCB).

MIZUHOSI 2009 NW0510 Rev. D

30

Page 31

Top home not functioning on the hand pendant:

• Press and hold hand pendant TOP HOME button. Observe tabletop movement.

• Call Mizuho OSI Customer Resource Group for service or parts (possible hand

pendant and/or 10 Amp motor-control PCB).

Table top home not functioning on the control panel:

• Press and hold TABLE TOP HOME button. Observe tabletop movement.

• Call Mizuho OSI Customer Resource Group for service or parts (possible hand

pendant and/or 10 Amp motor-control PCB).

Return to level not functioning:

• Press and hold hand pendant RETURN TO LEVEL button. Observe tabletop

movement.

• Disorient tabletop by raising height approximately two inches, lateral roll tabletop

and activating trendelenburg approximately five degrees.

• Press and hold hand pendant RETURN TO LEVEL button. Observe roll and

trendelenburg functions level first, and after a three-second delay, tabletop moves

down to its lowest height position and is level.

• Call Mizuho OSI Customer Resource Group for service or parts (possible hand

pendant and/or 10 Amp motor-control PCB).

Battery status LED illuminates red:

• Table battery system requires charging. Charge batteries minimum three (3) hours;

plug power cord into appropriate AC outlet.

NOTE: Power switch must be switched on.

Battery status LED remains illuminated red after battery charging:

• Call Mizuho OSI Customer Resource Group for service or parts.

Joystick control not functioning (allowing longitudinal and lateral tabletop

movement):

• Press and hold ACTIVATION button; red button (black on older tables) must be

activated for joystick operation. Verify function.

• Verify joystick cable-connector is properly plugged into either joystick receptacle.

Observe normal high speed indicator lights illuminate green when corresponding

button pushed.

• Verify Joystick locking lever is completely locked toward pedestal-end to move

tabletop in same direction.

Joystick control moving tabletop in opposite direction:

• Verify joystick locking lever is locked in proper direction, toward pedestal end.

MIZUHOSI 2009 NW0510 Rev. D

31

Page 32

Joystick variable speed operation not functioning:

• Call Mizuho OSI Customer Resource Group for service or parts.

Joystick speed select button not functioning:

• Call Mizuho OSI Customer Resource Group for service or parts.

Joystick:

1. Perform all indicated functions per functional check.

2. If there is no joystick response, inspect for physical damage:

a. Inspect coiled cord for cuts or other damage.

b. Inspect the coiled cord connector pins; verify that they are not bent or broken.

c. Verify the joystick handle provides firm resistance to motion in all directions and

returns to vertical when pushed to one side and released.

d. Inspect the joystick handle support rod (hidden under the rubber boot) for bends.

e. Inspect the red activation-button for damage; verify firm resistance to being

pressed with smooth up and down motion; the button should provide an audible

click at or near the bottom of its stroke.

3. If there is no physical damage:

a. Verify non-function when plugged into either access port.

b. Bypass the internal wiring by plugging the joystick directly into the stepper-

controller PCB DB9-type socket marked joystick.

c. If the table responds properly, the internal table wiring is at fault.

4. Repair option for damaged or non-functioning joystick is replacing entire unit. Field

disassembly is not recommended.

MIZUHOSI 2009 NW0510 Rev. D

32

Page 33

10.0 REMOVAL AND REPLACEMENT OF COMPONENTS

10.1 Floor Lock Foot Actuator

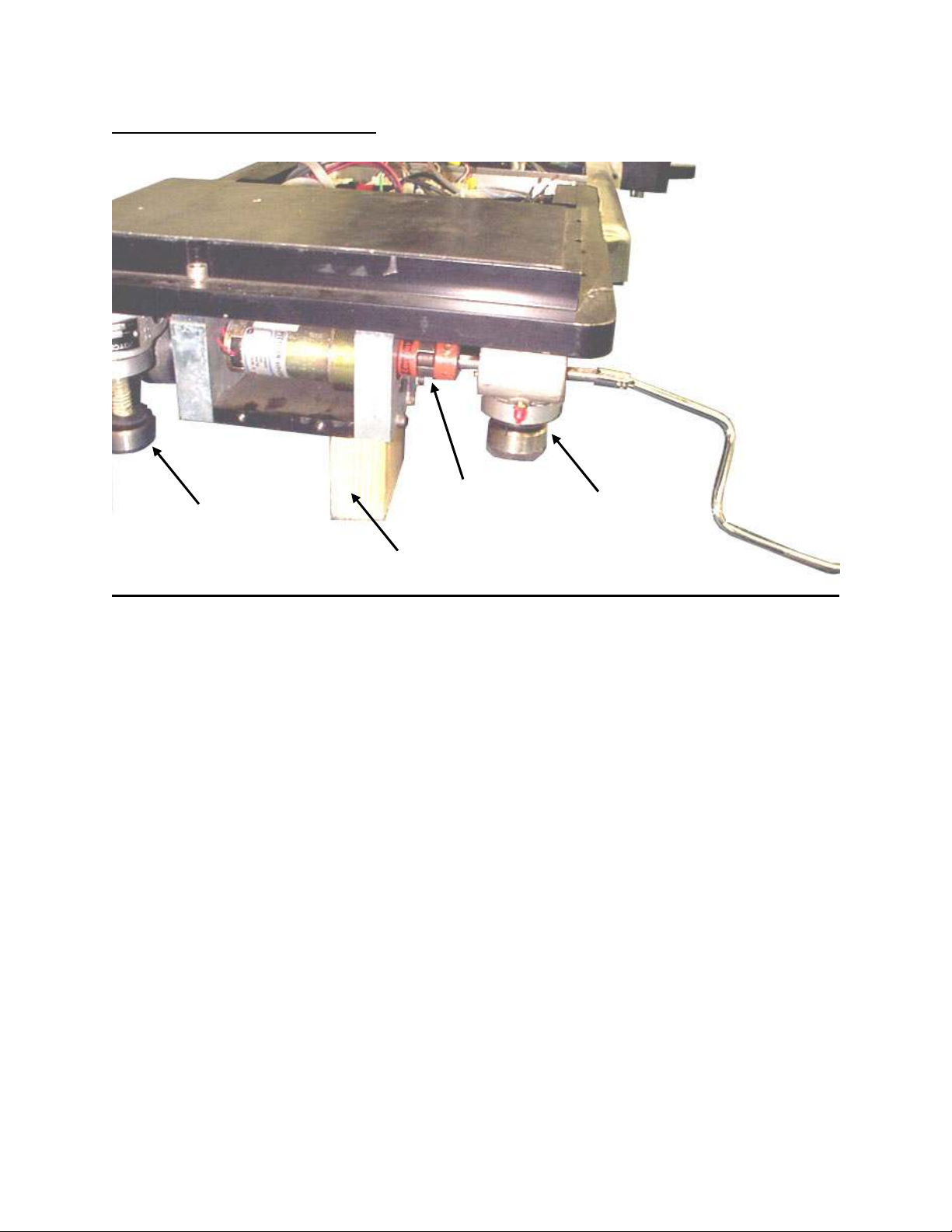

Coupling

Floor lock

(lowered)

and set-screw

Floor lock

(raised)

Crank handle

Support block

Figure 11: Foot end base: Cover removed, raised with support block and crank handle

Replacement procedure:

1. Turn power switch on. The switch illuminates indicating power is to the table.

2. Lock table to floor; press and hold DOWN TO LOCK button until green LOCKED

WHEN LIT light is on.

3. Turn power switch off. Wait 30 seconds for discharge then unplug power cord from

wall outlet.

4. Remove base-access cover from end of table needing replacement.

CAUTION: Electrical shock hazard exists with access covers removed; use

caution when working in exposed areas.

a. Pry off two white plastic access plugs for the floor lock jackscrew using a small

screwdriver.

b. Remove four screws attaching the cover using a 1/8 inch hex key.

c. Remove access cover.

5. Disconnect red wire from battery A positive terminal.

6. Raise end of table using floor lock crank handle (supplied with table).

7. Place 2-1/2 inch high support block under jackscrew floor lock motor mount.

8. Carefully lower table onto support block using floor lock crank handle.

CAUTION: Make certain table remains stable.

9. Raise floor lock off the floor to its maximum height, using floor lock crank handle.

MIZUHOSI 2009 NW0510 Rev. D

33

Page 34

10. Loosen floor lock actuator coupling setscrew using 1/8-inch hex key. Slide coupling

towards actuator.

11. Remove actuator by removing the two socket-head cap screws using 3/16-inch hex

key.

12. Replace floor lock actuator assembly (see Replacement/Spare Parts List section) or

pad as described below.

13. Reassemble in reverse order.

14. Verify proper function using pre-op function check.

10.2 Floor Lock Pad

If only the floor-lock pad requires replacing, perform the following:

1. Remove brake pad by removing M6-1.00 x 20mm socket-head bolt using 5mm hex

key.

2. If the standard attachment bolt is bent; the first threads may be damaged requiring

replacement with an optional, longer M6-1.00 x 35mm (see Replacement / Spare

Parts List).

3. Install replacement floor lock pad (see Replacement / Spare Parts List) with

attachment bolt and washer using 5mm hex key.

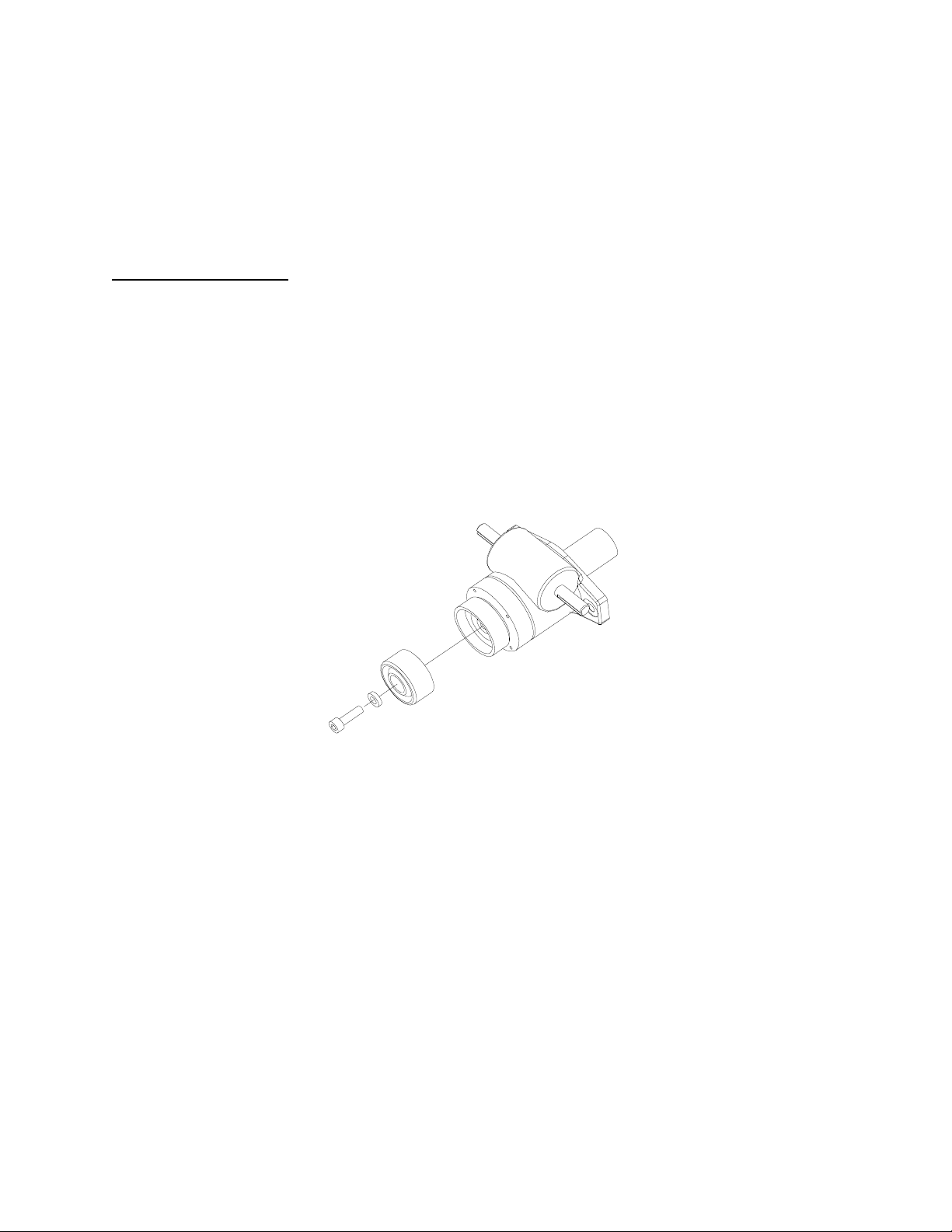

Figure 12: Floor lock actuator assembly

MIZUHOSI 2009 NW0510 Rev. D

34

Page 35

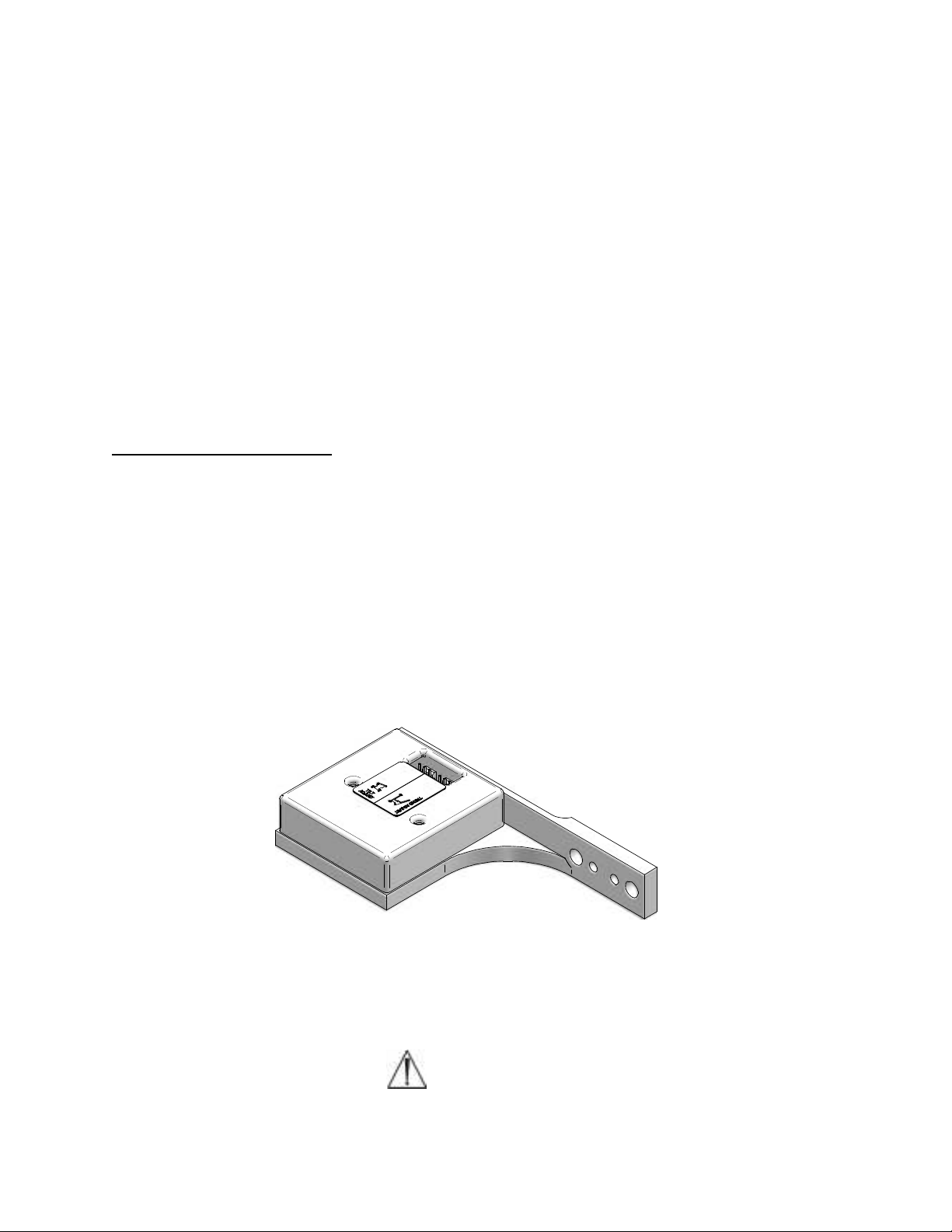

10.3 Power Supply Tray

Battery

-A

Battery

-B

The power supply tray contains the system power supply PCB, transformer, DC

batteries, power switch/circuit breaker, component circuit breakers and power cord

receptacle.

Figure 13: Power supply tray, base cover removed

Figure 14: Base cover and power supply tray removal

MIZUHOSI 2009 NW0510 Rev. D

35

Page 36

Replacement procedure:

1. Turn power switch off. Wait 30 seconds for discharge, then unplug power cord from

wall outlet.

2. Remove pedestal end base cover by removing the six screws using 1/8 in hex key.

CAUTION: Electrical shock hazard exists with access covers removed; use

caution when working in exposed areas.

3. Disconnect red wire from battery A positive terminal.

4. Unplug small 3-wire connector P 11.

5. Unplug 3-wire connector P 15.

6. Unplug 2-wire connector P 16.

7. Remove 3/8-inch hex bolt from ground stud using 9/16-inch wrench and remove top

two green / yellow striped wires.

8. Remove three socket head screws on each side of power supply tray and loosen

two socket-head screws at front of tray using 5/32-inch hex key.

9. Remove power supply tray by carefully lifting out of base casting.

10. Install in reverse order.

10.4 Controller Circuit

The table functions are controlled by input voltage signals from the hand pendant or

control panel to the 10-Amp motor control and stepper controller PCBs located in the

cantilever-end of the base assembly. Voltage from the power supply also is fed to these

controller boards. Interconnect diagrams are given in section 11 for reference.

10-Amp motor control

PCB assembly

Stepper control tray

PCB assembly

Figure 15: 10-Amp motor control PCB and stepper controller tray assemblies

MIZUHOSI 2009 NW0510 Rev. D

36

Page 37

10.5 10-Amp Motor Control PCB

Replacement procedure:

1. Turn the power switch off. Wait 30 seconds for discharge, then unplug power cord

from wall outlet.

2. Remove pedestal end base cover by removing the six screws using 1/8 in hex key.

CAUTION: Electrical shock hazard exists with access covers removed; use

caution when working in exposed areas.

3. Disconnect red wire from battery A positive terminal.

4. Remove cantilever end base cover by removing the four screws using 1/8 hex key.

CAUTION: Electrical shock hazard exists with access covers removed; use

caution when working in exposed areas.

5. Remove cables from 10 Amp motor controller PCB.

NOTE: Cable connectors are not marked, mark as needed.

a. J1 - To stepper controller

b. P1 - To interrupt - to stepper controller/component Interface.

c. P2 - To pc - no connection.

d. P3 - Keypad - extension cable to hand pendant.

e. P4 - Output - no connection.

f. P5 - Power in - power cable to DC power supply.

g. P6 - White marked cable to trendelenburg actuators.

h. P7 - To tilt sensor assembly.

i. P8 - Blue marked cable to trendelenburg actuators.

j. P10 - Orange marked cable to tilt actuator.

k. P11 - To tilt sensor assembly.

l. P12 - Yellow marked cable to vertical actuator.

m. P13 - No connection.

n. P15 - No connection.

o. P17 - No connection.

p. P18 - Input - no connection.

6. Remove the two #10 socket head screws attaching the 10 Amp motor controller

PCB mounting bracket, located under the PCB.

7. Lift the mid section base cover and remove the two #10 socket head screws

attaching the 10-Amp motor controller PCB mounting bracket.