Page 1

hana

®

HIP AND KNEE ARTHROPLASTY

SURGERY TABLE

OWNERS MANUAL

Model 6875

This manual is written in five

languages in the following order:

(en) English

(es) Spanish

(fr) French

(de) German

(it) Italian

MIZUHO OSI

30031 AHERN AVENUE UNION CITY, CA 94587

Bus: 510-429-1500 Toll Free: 800-777-4674 Fax: 510-429- 85 00

WWW.MIZUHOSI.COM ·

NEWHIPNEWS.COM · NEWSPINENEWS.COM

MIZUHOSI 2009 1 NW0508 Rev. D

Page 2

TABLE OF CONTENTS

1.0 INTRODUCTION............................................................................................................................4

1.1 Important Notices ......................................................................................................................4

1.2 General Description...................................................................................................................6

1.3 Specifications ............................................................................................................................7

1.4 Shipping ....................................................................................................................................7

1.5 Storage......................................................................................................................................7

1.6 Glossary Of Terms ....................................................................................................................8

2.0 CONTROLS IDENTIFICATION...................................................................................................... 9

2.1 Table Orientation.......................................................................................................................9

2.2 Major Controls Location ............................................................................................................9

2.3 Control Panel Identification .....................................................................................................10

3.0 BASIC OPERATION ....................................................................................................................11

3.1 Control Operation ....................................................................................................................11

3.2 Caster Floor Locks ..................................................................................................................11

3.3 Moving The Table....................................................................................................................11

3.4 Hand Pendant/Control Panel Operation..................................................................................12

3.5 Leg Spars ................................................................................................................................13

4.0 INSPECTION ............................................................................................................................... 15

4.1 Acceptance And Transfer........................................................................................................15

4.2 Inspection And Transfer ........................................................................................................ 15

4.3 Pre-Procedure/Post-Procedure ...............................................................................................15

4.4 Semi-Annual............................................................................................................................15

5.0 FUNCTION CHECK ..................................................................................................................... 16

6.0 THE ELECTRICAL SYSTEM .......................................................................................................18

6.1 Description ..............................................................................................................................18

6.2 On/Off Power Switch ...............................................................................................................18

6.3 Component Circuit Breakers ...................................................................................................18

6.4 Power Cord .............................................................................................................................19

6.5 Battery System ........................................................................................................................19

6.6 Troubleshooting.......................................................................................................................20

7.0 CLEANING AND MAINTENANCE ...............................................................................................21

7.1 Cleaning And Disinfecting .......................................................................................................21

7.2 Preventative Maintenance.......................................................................................................22

8.0 SET-UP OF 6875 hana

®

SURGERY TABLE ...............................................................................23

8.1 Insertion And Removal Of Leg Spars – 6875-350 & 6875-360 ...............................................23

8.2 Removable Femur Jack Mount Assembly...............................................................................24

8.3 Attaching Femur Lift(s) And Femur Lift Foot Pedal 6875-600, 6875-601, 6875-19.................28

8.4 Femoral Hook Support And Femoral Hook(s) Sterilization Guidelines....................................29

8.5 Insertion Of Well Leg Support Adaptor 6875-200....................................................................32

8.6 Optional Patient Transfer Assembly Instructions For Use.......................................................33

8.7 Attaching hana

8.8 Knee Flexion Sterilization Guidelines......................................................................................35

8.9 IM Nailing Femur: Unilateral Skeletal Traction 6875 hana

8.10 IM Nailing Femur: Unilateral Skin Traction 6875 hana

8.11 IM Nailing Femur: Lateral Decubitus Position With Bilateral Skin Traction 6875 hana

Surgery Table Set-Up....................................................................................................................44

8.12 IM Nailing Tibia: Supine With Unilateral Skin Traction 6875 hana

8.13 Hip Pinning: Supine With Unilateral Skin Traction 6875 hana

8.14 Hip Pinning: Supine With Bilateral Skin Traction 6875 hana

8.15 Anterior Approach Total Hip Replacement 6875 hana

8.16 Total Knee Replacement 6875 hana

8.17 Total Knee Replacement 6875 hana

9.0 6875 hana

®

SURGERY TABLE COMPONENTS AND ACCESSORIES .....................................58

9.1 6875 hana

®

Knee Flexion System™ For TKA 6875-230..................................................34

®

Surgery Table Set-Up.................38

®

Surgery Table Set-Up ....................41

®

Surgery Table Set-Up...47

®

Surgery Table Set-Up .........49

®

®

®

Surgery Table Set Up................................................55

®

Surgery Table Set Up................................................57

®

Standard Components........................................................................................58

Surgery Table Set-Up ...........51

Surgery Table Set-Up ....................53

®

MIZUHOSI 2009 2 NW0508 Rev. D

Page 3

10.0 REMOVAL AND REPLACEMENT OF COMPONENTS ............................................................63

10.1 Hand Pendant Control...........................................................................................................63

10.2 Foot Pedal .............................................................................................................................63

10.3 Motion Control Module ..........................................................................................................64

10.4 Internal Batteries ...................................................................................................................65

10.5 Table Lift Assembly ...............................................................................................................67

10.6 Tilt/Trendelenburg Assembly.................................................................................................68

10.7 Femur Lift Assembly, Left/Right ............................................................................................69

10.8 Caster(s)................................................................................................................................69

11.1 Replacement/Spare Parts List...............................................................................................70

11.2 Interconnect Diagram, 100VAC, 120VAC, 230VAC..............................................................72

12.0 TROUBLESHOOTING ...............................................................................................................73

12.1 Table Malfunction ..................................................................................................................73

12.2 Diagnostics Tree ...................................................................................................................73

13.0 MIZUHO OSI CUSTOMER RESOURCE GROUP..................................................................... 76

13.1 Contact For Parts And Service..............................................................................................76

13.2 Instant Support Value Package.............................................................................................76

13.3 To Order Replacement Parts.................................................................................................76

13.4 To Return Damaged Parts ....................................................................................................76

13.5 To Send A Part For Repair....................................................................................................77

13.6 Warranty................................................................................................................................77

13.7 European Union EC Representative .....................................................................................77

MIZUHOSI 2009 3 NW0508 Rev. D

Page 4

1.0 INTRODUCTION

1.1 Important Notices

Caution:

To ensure safe operation of the equipment, please READ THESE INSTRUCTIONS

COMPLETELY and keep this manual readily available for future reference.

Carefully observe and comply with all warnings, cautions and instructions placed on the

equipment or described in this manual.

In this manual, the WARNING symbol is intended to alert the user to the presence

of important operation, maintenance, or safety instructions.

Protection Against Electrical Shock Hazard:

This symbol indicates this equipment is an applied part TYPE B in accordance with IEC

60601-1 and is generally suitable for applications involving external or internal contact with

the patient, excluding the heart. The patient circuit is connected to protective earth and this

equipment should be connected only to hospital grade AC outlets with a protective earth

ground.

This symbol indicates an external ground stud that is required for use when the AC

power cable is not connected to a protective earth ground hospital grade AC outlet in your

operating room or facility.

To protect the patient, hospital staff and the table from possible electrical hazards, an

external ground wire connection is required between the external ground stud and protective

earth ground.

WARNING:

If the integrity of the AC power source is in doubt, the equipment shall be operated

from its internal electrical power source (battery).

WARNING:

Proper preoperative and intra-operative procedures must be followed to prevent

venous stasis and pooling, pressure sore development, neuropathy, improper electro

surgical tissue grounding, hypertension and hypothermia.

NOTE: The application techniques outlined in these instructions are the manufacturer’s

suggested techniques. The final disposition of each patient’s care as related to the use of

this equipment rests with the attending physician.

This symbol indicates a Pinch Point and danger to body extremities.

MIZUHOSI 2009 4 NW0508 Rev. D

Page 5

Disposal of Electrical Components:

In accordance to the WEEE directive, all electrical components, batteries and carbon

composite components must be returned to Mizuho OSI for proper disposal. Please contact

Mizuho OSI Customer Resource Group Service Department at 1-800-777-4674 for further

information regarding this requirement.

THIS DEVICE IS TO BE USED BY TRAINED PROFESSIONAL PERSONNEL ONLY.

MIZUHOSI 2009 5 NW0508 Rev. D

Page 6

1.2 General Description

The Mizuho OSI 6875 hana® Surgery Table is designed to safely hold in proper position a

patient undergoing orthopedic surgical procedures including supine position for the anterior

approach for Total Hip Arthroplasty, Total Knee Arthroplasty, IM Nailing of the Femur or Tibia

and Hip Pinning, and Lateral position for IM Nailing of the Femur.

It is a stand-alone, single-pedestal, AC powered or internal battery powered table designed

to position a patient in a supine or lateral position during surgical procedures.

The table has a 2” (5 cm) MIZUHO OSI Tempur-Pedic® pad. The TEMPUR® used in the

manufacture of MIZUHO OSI pads has viscoelastic properties and is a temperature sensitive

material, becoming softer where the patient’s body is making the most contact with the

surface and remaining firm in areas where less body contact is being made. Pressure is

distributed evenly over the entire surface area. The pad is radiolucent, MR safe and latex

free. The benefits of using MIZUHO OSI Tempur-Pedic® are improved pressure

management, reduced shear forces and enhanced patient comfort.

The hana® Surgery Table has three primary electrically powered functions: height up/down,

left/right lateral roll and trendelenburg/reverse trendelenburg. Electromechanical actuator

motors perform these motions which are controlled by means of a hand pendant or onboard

auxiliary control panel with functions clearly labeled. The table is also equipped with

powered left and right femur lifts that are controlled by a foot pedal providing the surgeon the

ability to raise and lower the femoral hook during the anterior approach total hip arthroplasty.

Four (4) independent, manual caster floor locks are utilized to stabilize the table in the

operating location.

HEAD END

FOOT END

Manual caster floor

locks

Manual caster floor

locks

Figure 1: Mizuho OSI 6875 hana® Surgery Table, right-side view

MIZUHOSI 2009 6 NW0508 Rev. D

Page 7

1.3 Specifications

The table is designed to hold a maximum patient load of 450-pound (205 kg) in a

procedural position at any point within its physical range.

The table has a height range of 29 to 49 inches (74 cm – 124 cm).

The width of the tabletop is 21.5 inches (55 cm) and narrows to 10 inches (25 cm) toward

the foot end and 5 inches (13 cm) at the perineal post.

The length of the tabletop is 48.5 inches (123 cm). The overall length with leg spars

attached is 124 inches (315 cm).

The lateral roll range is +/- 12 degrees and the trendelenburg/reverse trendelenburg

range is +/- 12 degrees.

The leg spars rotate on a spherical joint and are capable of positioning the patients leg in

up to 20 degrees of adduction, 45 degrees of abduction, raise the leg to 28 degrees

above level and lower the leg to 35 degrees below level.

The tabletop has a radiolucent equivalency of less than 1 millimeter of aluminum.

The input power requirement is 100 VAC, 50Hz or 60Hz, 120 VAC, 60Hz or 230 VAC,

50Hz as indicated on the table label.

The table may also be operated under battery power. The expected working life of a fully

charged battery is approximately 12 hours at a 10% duty cycle.

WARNING:

This symbol indicates an external ground stud that is required for use when the

AC power cable is not connected to a protective earth ground hospital grade AC outlet

in your operating room or facility.

To protect the patient, hospital staff and the table from possible electrical hazards, an

external ground wire connection is required between the external ground stud and

protective earth ground.

1.4 Shipping

®

The 6875 hana

Surgery Table must be shipped using the appropriate shipping carton.

During shipment the table is to be kept in an environment within the following limits:

1. Ambient temperature -4 °F (-20 °C) to + 122 °F (50 °C).

2. Relative humidity from 10% to 100%, including condensation.

3. Atmospheric pressure from 50 to 110 kPa.

1.5 Storage

When not in use, the hana

®

Surgery Table should be stored in a clean, dry environment with

temperature between 32 °F (0 °C) and 120 °F (49 °C). The table cover provided should be

utilized and serves as a dust cover.

To ensure the battery is always fully charged and ready for use, the table should be stored

with the power cord inserted on the head end control panel and attached to an appropriate,

hospital grade AC outlet (100VAC, 120VAC or 230VAC) and the power switch turned on.

MIZUHOSI 2009 7 NW0508 Rev. D

Page 8

1.6 Glossary Of Terms

This glossary of terms assumes the patient is supine with their head at the head end of table

(toward control panel) and their feet at the foot end of table (toward leg spars). The hand

pendant functions are oriented for this position only.

AUXILIARY CONTROL PANEL is a panel of buttons and lights located on the back of the

pedestal.

FOOT END OF TABLE refers to the leg spar control end of the table.

HEAD END OF TABLE refers to the end of the table where the power cord, on/off power

switch, and auxiliary control panel are located; otherwise referred to as the pedestal end.

HOSPITAL GRADE AC OUTLET refers to specially designated outlets (receptacles) that

include additional grounding reliability, assembly integrity, strength and durability. Hospital

Grade is indicated by a Green Colored Dot on the face of the outlet.

LEFT SIDE OF THE TABLE refers to the side to the patient’s left in the supine position.

This also corresponds to the hand pendant button labeled left lateral roll.

LOWER THE TABLE refers to lowering the height of the table. This corresponds to the hand

pendant button labeled height down.

PEDESTAL refers to the main column structure that supports the tabletop.

RAISE THE TABLE refers to raising the height of the table. This corresponds to the hand

pendant button labeled height up.

RETURN TO LEVEL, OR LEVEL THE TABLE, refers to returning the tabletop to a state of

level regardless of its position. This corresponds to the hand pendant button labeled return to

level. Holding the return to level button longer than approximately three seconds will also

lower the tabletop to its lowest position.

REVERSE TRENDELENBURG refers to raising the height of the head end of the table tilting.

This corresponds to the hand pendant button labeled rev.tren.

RIGHT SIDE OF THE TABLE refers to the side to the patient’s right in the supine position.

This also corresponds to the hand pendant button labeled right lateral roll.

TRENDELENBURG refers to lowering the height of the head end of the table. This

corresponds to the hand pendant button is labeled tren.

MIZUHOSI 2009 8 NW0508 Rev. D

Page 9

2.0 CONTROLS IDENTIFICATION

2.1 Table Orientation

The major components of the 6875 hana® Surgery Table are identified below. The table is

described as having a head end and a foot end. The control panel, on/off switch and the

power cord receptacle are located at the head end of the table.

HEAD END

FOOT END

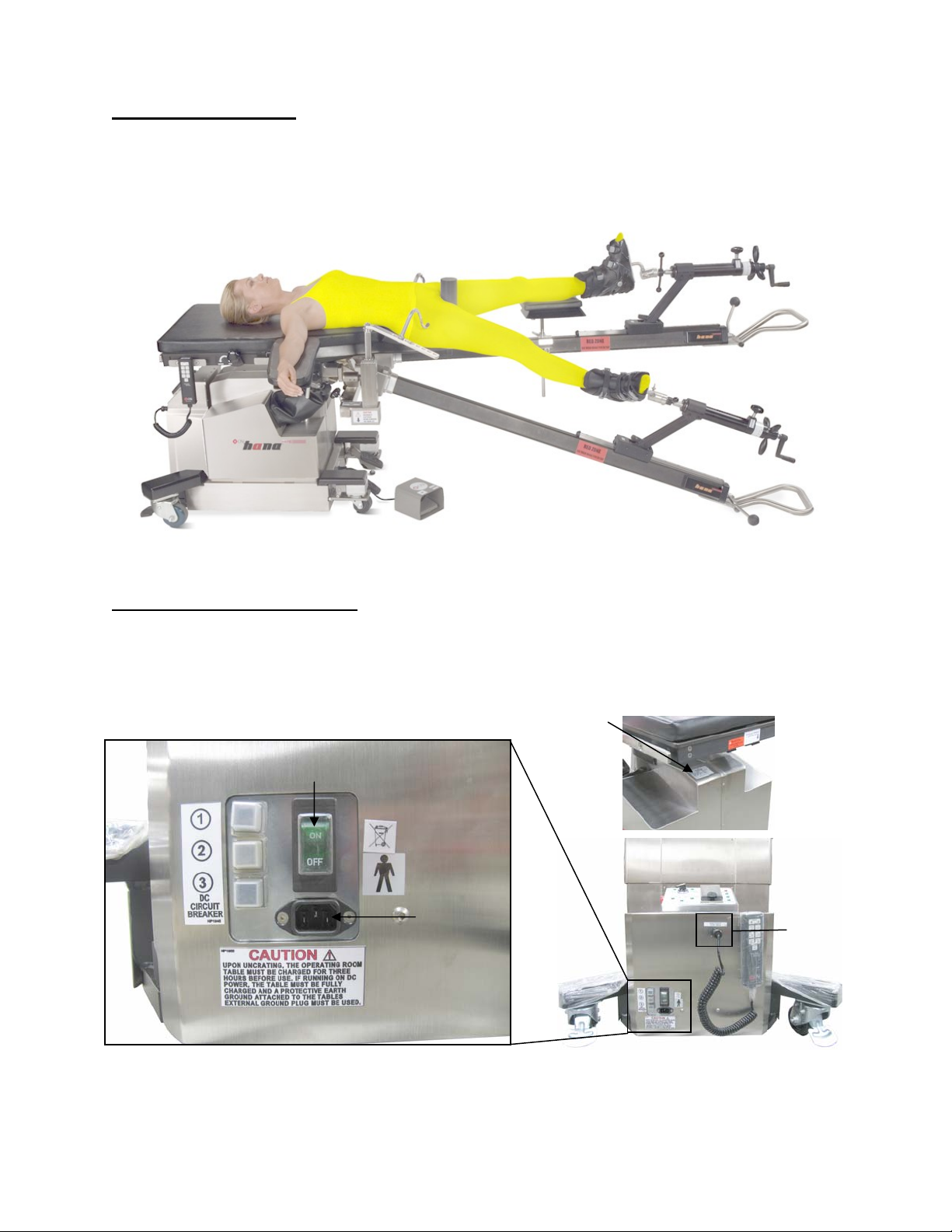

Figure 2: Right-side view with patient in supine position

2.2 Major Controls Location

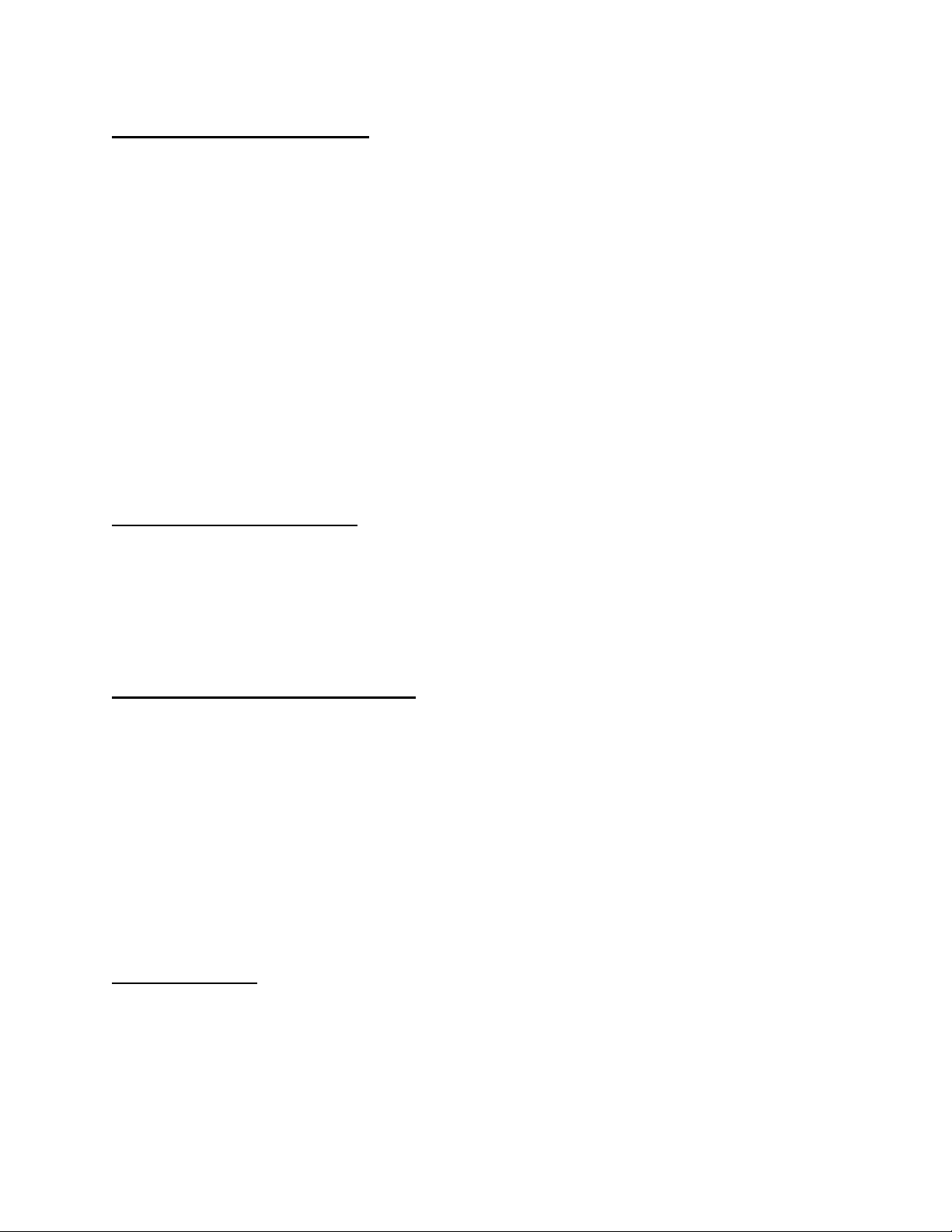

The control panel, on/off power switch, power cord receptacle and model number/serial

number identification label are located at the base of the head end of the table.

On/off power

switch

Number/serial

model

Power cord

receptacle

Hand

pendant

Figure 3: Head end power supply box and control panel

MIZUHOSI 2009 9 NW0508 Rev. D

Page 10

2.3 Control Panel Identification

The control panel is divided into 3 sections:

Section 1: Femur lift control section. Selection switch changes between right and left femur

lift operation. Indicator displays status of femur lift connection (left, right). Indicator displays

status of foot pedal connection. (Indicator illuminated: Parts are connected, Indicator not

illuminated: Parts not connected)

Section 2: Control pad section. The control pad and the hand pendant control table

up/down, lateral tilt and trendelenburg; see section 3.4 for operation of the hand pendant and

control pad.

Section 3: Power indicator section. LED indicators notify user of the following conditions

when illuminated:

1. Battery condition

a. BATTERY CHARGE: Battery power low or no battery installed.

b. BATTERY OK: Battery has sufficient power to operate table

c. AC POWER: Indicates table is running on line (100, 120, 230 VAC) power from

wall receptacle.

d. BATTERY POWER: Indicates table is running from internal battery power.

Femur lift

control

1

section

Control pad

2

section

Figure 4: Control panel

Release

button

Power

indicator

3

section

MIZUHOSI 2009 10 NW0508 Rev. D

Page 11

3.0 BASIC OPERATION

3.1 Control Operation

Refer to the model/serial number label on the head end of the table for input voltage

requirements. Plug the power cord into the power cord receptacle, located at the head end

of the table and into a properly grounded receptacle. Turn on the on/off power switch. The

green light in the power switch illuminates, indicating that AC power is applied to the table.

This switch functions as a combination on/off power switch, circuit breaker and pilot light.

NOTE: A startup self-diagnostic routine is initiated each time the table is plugged in and

turned on.

3.2 Caster Floor Locks

Prior to transferring a patient onto the table and at all times when the table is in use, ensure

all four (4) independent, manual caster floor locks are in the locked position. To engage the

caster lock, step on the foot pad and depress to the floor. To unlock, slide foot under pad

and lift to disengage lock.

LOCK

Figure 5: Floor lock in the unlocked position Figure 6: Floor lock in the locked position

Location of external

ground stud

UNLOCK

®

NOTE: The casters and locks installed on your hana

Surgery Table may look different than

those depicted above but they will operate in the same manner that is described.

3.3 Moving The Table

After all four (4) floor locks are unlocked, the table can be rolled for relocation. It is best that

the table be rolled with the foot end pointed in the direction of travel. The 6875 hana®

Surgery Table is heavy and a minimum of two people should move it, one at the head end,

one at the foot end, and care should be taken to control it when rolling.

WARNING:

If the table is allowed to roll too fast, it may be difficult to stop or turn. Impact of the

table top with a stationary object may cause serious damage to the table top. If an

impact occurs the table must be visually inspected for visible damage, and a Function

Check must be performed (see section 5.0 of this manual). If damage is discovered or

the table does not pass the Function Check call your Mizuho OSI service

representative.

MIZUHOSI 2009 11 NW0508 Rev. D

Page 12

3.4 Hand Pendant/Control Panel Operation

The 6875 hana® Surgery Table is controlled by means of a hand pendant, alternate control,

via control panel built into power supply. The hand pendant is plugged into the receptacle

labeled hand pendant on the control panel (see figure 3). To activate a desired function,

press and hold the appropriate button on the hand pendant until the desired position is

achieved.

The hand pendant is equipped with a return to level button. This button functions to first level

the lateral roll, second level the trendelenburg, third re-level lateral roll and fourth brings the

table to its lowest position. A delay of 3 seconds is programmed after the leveling functions

are completed before returning to its lowest position. To achieve the final position, this

button must be held continuously until motion stops. The controller considers the table to be

level if it is within +/- 2 degrees of horizontal. If the return to level button is pressed while the

table is within this range, it may not move. If it is required to adjust the table to a position

closer to zero degrees, press the appropriate function button on the hand pendant until the

desired position is achieved.

Height Up

Trendelenburg

Left Lateral Roll

Figure 7: hana

Height Down

Reverse

Trendelenburg

Right Lateral Roll

®

Surgery Table 6807-4 hand pendant

Height Up

Trendelenburg

Left Lateral Roll

Height Down

Reverse

Trendelenburg

Right Lateral

Roll

Figure 8: Head end control panel

WARNING:

When installing a hand pendant, turn the power switch off, then plug in hand pendant

connector and rotate locking collar clockwise until hand tight. To operate any of the

desired functions, turn the power switch on and wait for 20 seconds for the table to

power up and run its self diagnostics.

MIZUHOSI 2009 12 NW0508 Rev. D

Page 13

3.5 Leg Spars

The 6875 hana® Surgery Table is equipped with two adjustable leg spars. Each leg spar is

designed to support the foot in the traction boot and allow for traction, abduction, adduction,

raising or lowering of the leg. When the leg is in a desired position, the spar can be locked to

maintain that position. A dial is provided to gauge the degree of internal and external rotation

and should be zeroed out and locked in place utilizing the thumb screw when the foot is in

the neutral position. Gross and fine traction are also controlled near the foot end of the spar.

Rotation lock

Foot rotation

Fine traction

Spar lock

handle

Internal/external

rotation dial

Gross

traction

Figure 9: 6875 Spar controls

To unlock the spar for abduction, adduction or height adjustment, hold the spar with one

hand by the loop handle and move the spar lock handle (knobbed lever) from the locked to

unlocked position (refer to picture below). When you have positioned the leg where needed,

lock the spar by rotating the spar lock handle clockwise to the locked position. If the spar will

not hold position, rotate lock handle further toward the locked position. The spar should be

held securely by the looped handle at all times when it is not locked.

Figure 10: Spar ball joint lock/unlock loop handle of leg spar

Unlock

Lock

Loop handle

WARNING:

Failure to lock the spar lock handle can cause the spar to drop when not held in place.

WARNING:

Leg spars can be damaged if allowed to contact the floor during table operation. Clear

area of any obstructions or obstacles during table movement.

MIZUHOSI 2009 13 NW0508 Rev. D

Page 14

Figure 11: 6875 hana® Surgery Table with leg spars attached & set up for bilateral anterior approach total hip

replacement

MIZUHOSI 2009 14 NW0508 Rev. D

Page 15

4.0 INSPECTION

4.1 Acceptance And Transfer

1. Upon receipt of your Mizuho OSI 6875 hana® Surgery Table, remove it from the shipping

carton by following the provided instructions. Remove any protective wrapping or

packaging. Visually inspect all surfaces for freight damage. Check each caster for proper

rolling operation.

NOTE: Any freight damage must be reported to the freight carrier immediately upon delivery.

It is the responsibility of the recipient to make freight damage claims.

2. Read the model/serial number identification label found at the head end of the table to

confirm the serial number and the input power requirements.

3. Place the 6875 hana® Surgery Table in an area with at least 4 feet of clearance on all

sides.

4. Perform Function Check; see section 5.0.

4.2 Inspection And Transfer

Before use, inspect the device for possible damage, excessive wear or non-functioning parts.

Visually inspect all accessible areas, electrical cords and all movable parts for possible

damage that may adversely affect the proper operation of the hana® Surgical Table.

Damaged or defective products should not be used or processed. Contact your local Mizuho

OSI sales representative for repair or replacement.

4.3 Pre-Procedure/Post-Procedure

Inspect and test the table as described in Function Check section 5.0.

Thoroughly clean the table as described in the Cleaning and Maintenance section 7.0.

Pay special attention to the cleanliness of the controls as excessive soil can affect

function.

Inspect the power cord for cuts in the insulation or damage to the connector.

On a smooth surface with the caster locks engaged, push the table. The table should not

move.

4.4 Semi-Annual

It is recommended to perform a Preventative Maintenance (PM) check on your 6875 hana

®

Surgery Table (see section 7.0 Cleaning and Maintenance).

A PM checklist is available from Mizuho OSI Customer Resource Group (800-777-4674).

MIZUHOSI 2009 15 NW0508 Rev. D

Page 16

5.0 FUNCTION CHECK

Perform all steps in this procedure before using the table. For a complete definition of terms

used in this procedure, please refer to the Glossary of Terms in section 1.6 of the manual.

1. Turn the power switch off. Plug in the hand pendant cable connector into the hand

pendant receptacle on the control panel.

2. If the table is to be used under battery power, put the power switch in the on position and

wait for 20 seconds for the table to power up and run its self diagnostics. The battery

power lamp on the control panel should illuminate.

WARNING:

This symbol indicates an external ground stud that is required for use when the

AC power cable is not connected to a protective earth ground hospital grade AC outlet

in your operating room or facility.

To protect the patient, hospital staff and the table from possible electrical hazards, an

external ground wire connection is required between the external ground stud and

protective earth ground.

3. Battery operation check:

3.1 Observe table battery power status light in the power indicator section of the control

panel or on the hand pendant. A green light indicates the table is set for battery

power operation.

3.1.1 If green battery Ok light is on, the table is ready to operate normally.

3.1.2 If red battery charge light is on, the battery must be charged prior to using the

table. To charge the battery, make sure the power cord is plugged into a live

receptacle and turn on the power switch. This switch will illuminate indicating

that appropriate power is applied to the table. The table must remain plugged in

and switched on for a minimum of 3 hours to insure sufficient charging of the

battery to operate the table.

3.1.3 If red check battery light remains on after 3 hours, continue to charge battery for

up to 18 hours.

3.1.4 If green battery ok light does not illuminate after 18 hours, refer to section 6.5 of

this manual.

NOTE: The table may be used with AC power even if the battery status light is red, indicating

batteries need charging.

4. If the table is to be used under line power, plug power cord into an appropriate hospital

grade AC outlet and turn on the power switch. Note that the power switch illuminates

indicating the AC power on. The AC power lamps on the control panel and hand pendant

should illuminate.

5. Hand pendant check:

5.1 Press and hold HEIGHT UP button. Observe that the tabletop moves up.

5.2 Press and hold HEIGHT DOWN button. Observe that the tabletop moves down.

5.3 Press and hold REVERSE.TRENDELENBURG button. Foot end of tabletop becomes

lower than the head end

MIZUHOSI 2009 16 NW0508 Rev. D

Page 17

5.4 Press and hold TRENDELENBURG button. Head end of tabletop becomes lower

than the foot end

5.5 Press and hold LEFT LATERAL ROLL button. Observe that the tabletop tilts to the

left.

5.6 Press and hold RIGHT LATERAL ROLL button. Observe that the tabletop tilts to the

right.

5.7 Move tabletop out of level in both tilt and trendelenburg by 5 degrees and raise table

at least 2 inches from lowest position. Press and hold RETURN TO LEVEL button.

The tabletop first levels roll and trendelenburg and then after a three-second delay,

the tabletop moves down to its lowest height position. Observe that the table top is

level and in its lowest height position.

6. Control panel check:

6.1 Repeat steps 5.1 through 5.7 using the control panel buttons.

7. Femur lift control and foot pedal check:

7.1 With femur lift connected with electrical connectivity, the corresponding light on the

control panel should illuminate indicating a good connection. See section 8.3 for

proper installation of femur lift and foot pedal.

7.2 With femur lifts and foot pedal connected and connectivity indicator lights green,

position the control knob located in section 1 of the control panel (see figure 4) to

either the left femur lift or right femur lift. Test femur lift foot pedal function for

operation of the indicated femur lift. Repeat for opposite side.

MIZUHOSI 2009 17 NW0508 Rev. D

Page 18

6.0 THE ELECTRICAL SYSTEM

6.1 Description

The electrical system provides control of all table functions and is comprised of a power cord,

an on/off circuit-breaker switch, wire harnesses, a power supply, a controller circuit, a hand

pendant, floor lock jackscrew-actuators, and various electromechanical actuators. Electric

motor-driven lead-screw actuators manipulate the table height, lateral roll and trendelenburg

functions. The input power requirement is 100 VAC 50/60Hz, 4 Amp, 120 VAC 60Hz, 4 Amp

or 230 VAC 50Hz, 2 Amp, 10%/6 minute duty cycle as indicated on the serial number label.

Refer to 6875 hana® Surgery Table Electrical Interconnect Diagram in section 11.2 for details

of the electrical system.

The primary components of the electrical control system are contained in the power supply

box at the head end of the table.

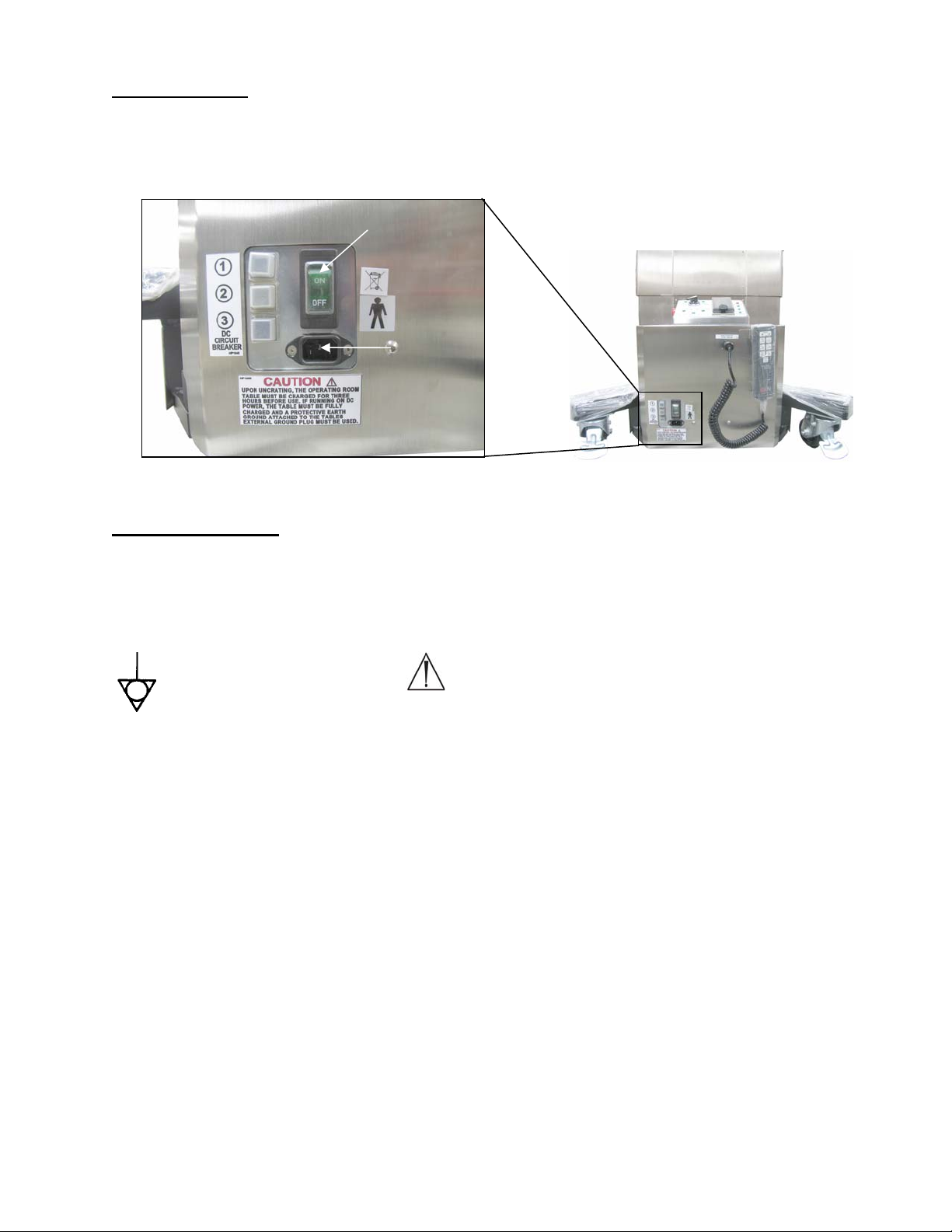

6.2 On/Off Power Switch

An illuminated on/off power switch and circuit breaker is located on the head end of the table.

When illuminated, it indicates that the table is plugged into a live electrical Hospital Grade AC

outlet and the power is on. (When the table is turned on using battery power, this switch will

not illuminate). This switch also serves as a circuit breaker. In the event of an overload

condition this switch will trip off. To reset, push to the off position and then the on position.

6.3 Component Circuit Breakers

The electrical system includes individual component 24-VDC circuit breakers located at the

head end of the table. If a short circuit occurs in the low voltage circuit, the breaker will trip

as indicated by a button protruding from the access hole. To reset, press the button in and

release.

WARNING:

Determine the source of the overload prior to resetting this switch. If unable to

determine and fix the source of failure, contact Mizuho OSI for additional support.

MIZUHOSI 2009 18 NW0508 Rev. D

Page 19

6.4 Power Cord

The table is equipped with a detachable standard IEC power cord connector. The power cord

is connected to the table at the IEC power entry socket located below the on/off switch, at the

head end control panel.

On/off power

switch

Power

cord

receptacle

Figure 12: Head end power supply box and control panel

6.5 Battery System

The 6875 hana® Surgery Table is equipped with a battery system that provides power to all

functions, and consists of two batteries (NV0801). Due to the relatively low power

consumption of the 6875 hana® Surgery Table, the table can be used on battery power for up

to 12 hours at 10% duty cycle.

WARNING:

This symbol indicates an external ground stud that is required for use when the

AC power cable is not connected to a protective earth ground hospital grade AC outlet

in your operating room or facility.

To protect the patient, hospital staff and the table from possible electrical hazards, an

external ground wire connection is required between the external ground stud and

protective earth ground.

Battery charge status is shown via a LED on the hand pendant labeled battery status and in

the power indicator section of the control panel.

On the hand pendant:

If illuminated green = OK.

If illuminated red = charge required

If a recharge is required, charging the batteries is necessary for a minimum of 3 hours. Fully

discharged batteries will require 18 hours for a complete charge. To charge the batteries,

simply plug the power cord into an appropriate hospital grade AC outlet and turn the power

switch on. It is important to plug in the table as soon as possible after the battery status LED

is illuminated red.

MIZUHOSI 2009 19 NW0508 Rev. D

Page 20

WARNING:

Life of the batteries can be shortened if the table remains unplugged and turned on for

extended period of time with the red battery charge light illuminated. While in storage

it is desirable that the table be plugged in and the power switch turned on so that the

batteries remain charged. If this is not possible, the batteries must be charged for at

least three hours per week under normal use conditions. This can be accomplished

when using the table under AC power since the system batteries are automatically

charged while the table is plugged in and turned on.

Both batteries should be replaced every five (5) years or when they fail to hold a charge.

6.6 Troubleshooting

In the event of a table malfunction:

Check input power, verify the power cord is plugged into a live hospital grade AC

electrical outlet.

Verify the power switch is on; the switch illuminates green.

Check hand pendant is plugged in and lights illuminated.

Switch main power to off, wait 30 seconds and turn to on position.

Contact Mizuho OSI Customer Resource Group if table function is not restored, please

note what functions are working as well as those not working when you call (see section

13.0 of this manual for more information on Customer Resource Group).

MIZUHOSI 2009 20 NW0508 Rev. D

Page 21

7.0 CLEANING AND MAINTENANCE

7.1 Cleaning And Disinfecting

NOTE: Never pour any liquid directly onto the table. Never subject the 6875 hana® Surgery

Table to an equipment washing machine.

Use of iodophors will cause staining.

Table exterior:

The exterior surface should be regularly wiped clean with a mild detergent solution and

wiped dry with a soft lint-free cloth. This includes the table pad and table top.

Care should be taken to avoid exposing the table to excessive moisture. Flooding, fogging

or steam cleaning is not recommended.

Blood or other fluids, etc., if allowed to remain on the table for a long period of time, will

require special cleaning to remove. A 5% acetic acid solution or white vinegar and water

solution is especially good for this purpose.

Clean with a good commercial cleaning compound, such as Stainless Steel Magic or Acme

White Finish, and then buff the surface by hand to correct staining and discoloration of plated

or stainless steel surfaces only.

To disinfect exterior surfaces, use a quaternary ammonium compound or similar type

disinfectant compound according to manufacturer's directions for use. Wipe dry with a soft

lint-free cloth.

NOTE: Failure to thoroughly dry the surface after cleaning and disinfecting may result in

rust.

Table Pad:

®

MIZUHO OSI

Tempur-med® Pad

IMPORTANT: The MIZUHO OSI Tempur-Pedic

®

pad should always be stored in a flat

position. It can actually get stiff in cold temperatures and can crack and

break if in a rolled position. It is important that you allow the pad to warm to

room temperature before attempting to utilize or handle it.

When handling always grasp by the entire thickness of the pad.

Do not lift, slide or carry MIZUHO OSI Tempur-med

®

pads by grabbing the fabric. The cover

may tear or rip.

The pad is intended to be cleaned in place. It does not need to be rotated or flipped.

Clean with standard hospital disinfectants labeled for use on table pads. Always dilute and

rinse per manufacturer’s label instructions. Wipe dry with a lint free cloth. Do not soak or

MIZUHOSI 2009 21 NW0508 Rev. D

Page 22

autoclave pads. The continued use of bleach or highly concentrated chemicals will void the

warranty on the cover.

When cleaning the bottom of the pad or the table top, simply lift one end of the pad, and fold

it over onto the other end. Clean the pad or the table top then return to pad to flat on the

table top.

7.2 Preventative Maintenance

Routine table care will assure many years of trouble-free service.

Lubrication:

All components are lubricated for life at the factory and no other lubrication for the table is

required.

Preventative Maintenance:

Contact OSI Technical Service for a complete preventative maintenance checklist.

For detailed repair information or to order replacement parts, call or contact via the web the

OSI technical services department:

1-800-777-4674 Extension 2

techsvcs@mizuhosi.com

www.mizuhosi.com

Technical services is available from 7am – 5pm PST Monday – Friday. Please leave a

message at the extension after normal business hours.

MIZUHOSI 2009 22 NW0508 Rev. D

Page 23

8.0 SET-UP OF 6875 hana® SURGERY TABLE

Instructions are provided for the following components to the 6875 hana® Surgery Table:

Leg spars 6875-350

Femur lift(s) and foot pedal assembly 6875-600, 6875-601, 6875-19

Femoral support and femoral hook(s) 6850-110.6850-919, 6850-918

Well leg support adaptor 6875-201

hana® Knee Flexion System™ for TKA 6875-230

8.1 Insertion And Removal Of Leg Spars – 6875-350 & 6875-360

Raise the height of the table to be able to easily access the spar mount. Insure the spar

locking knob is in the unlocked position by turning counterclockwise. Prior to mounting the

spar, ensure the spar ball joint handle is in the locked position. One person needs to support

the distal (foot) end of the spar holding the loop handle, while another person supports the

spar as it slides into the spar mount on the table. Slide the end of the spar forward until it is

fully engaged, and a defined click should be heard when spar post is inserted past the safety

latch. Lock in place by turning the spar locking knob clockwise until tight. Slight movement

of spar up and down while tightening knob will insure a tighter lock. While continuing to

support the distal (foot) end of the spar holding the loop handle, move the spar lock handle to

the unlocked position. Reposition the spar as needed and then return the spar ball joint

handle to the locked position.

Spar mount

Spar

Figure 13: Mounting the leg spar

Spar locking knob

Unlock

Lock

Safety latch

Figure 14: Locking and unlocking the leg spar

To remove the spar from the table, one person should support the distal (foot) end of the

spar with the loop handle and one person should turn the spar locking knob counterclockwise

MIZUHOSI 2009 23 NW0508 Rev. D

Page 24

to unlock the spar. Release the safety latch by lifting it to allow the spar to be removed.

Slide the spar out of the spar mount.

8.2 Removable Femur Jack Mount Assembly

WARNING:

To ensure safe operation of the equipment, READ THESE INSTRUCTIONS

COMPLETELY and keep this instruction sheet readily available to operating room

personnel for future reference. Carefully observe and comply with all warnings,

cautions and instructions placed on the equipment or described in this manual.

Before use, inspect the device for possible damage, excessive wear or non-functioning parts.

Visually inspect all accessible areas, electrical cords and all movable parts for possible

damage that may adversely affect the proper operation of the hana® Surgical Table.

Damaged or defective products should not be used or processed. Contact your local Mizuho

OSI sales representative for repair or replacement.

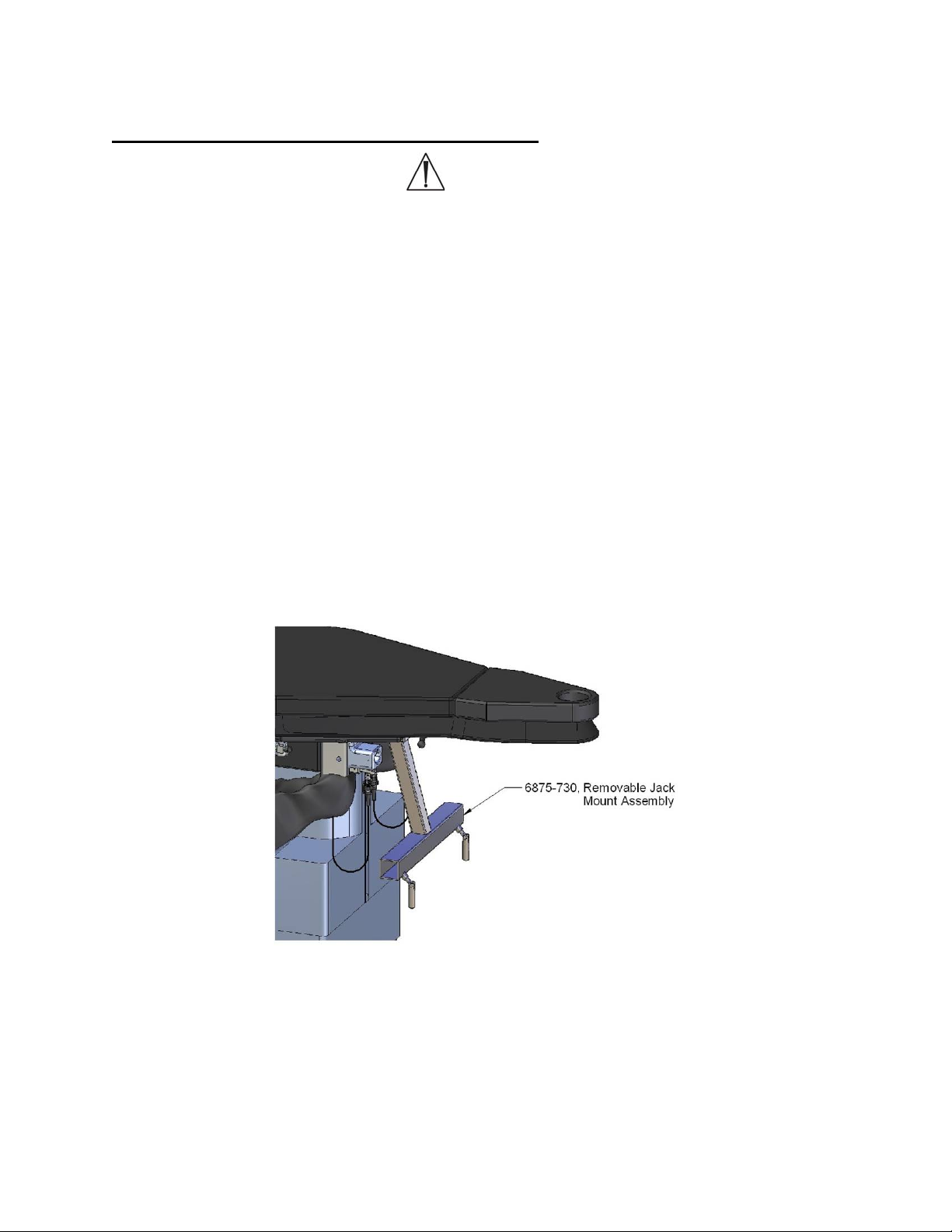

The 6875-730, removable jack mount assembly is designed to allow for removal and

reinstallation as needed depending on the type of surgical procedures being performed.

Removing the removable jack mount allows for C-arm access during hip arthroscopy and

certain fracture procedures. If C-arm access and certain fracture procedures are not

required, the removable jack mount may remain on the table.

The removable jack mount is located directly underneath the foot end of the hana® Surgical

Table top between the removable leg spars (figure 20).

Figure 15: Spars are not shown for clarification purposes

MIZUHOSI 2009 24 NW0508 Rev. D

Page 25

Removal:

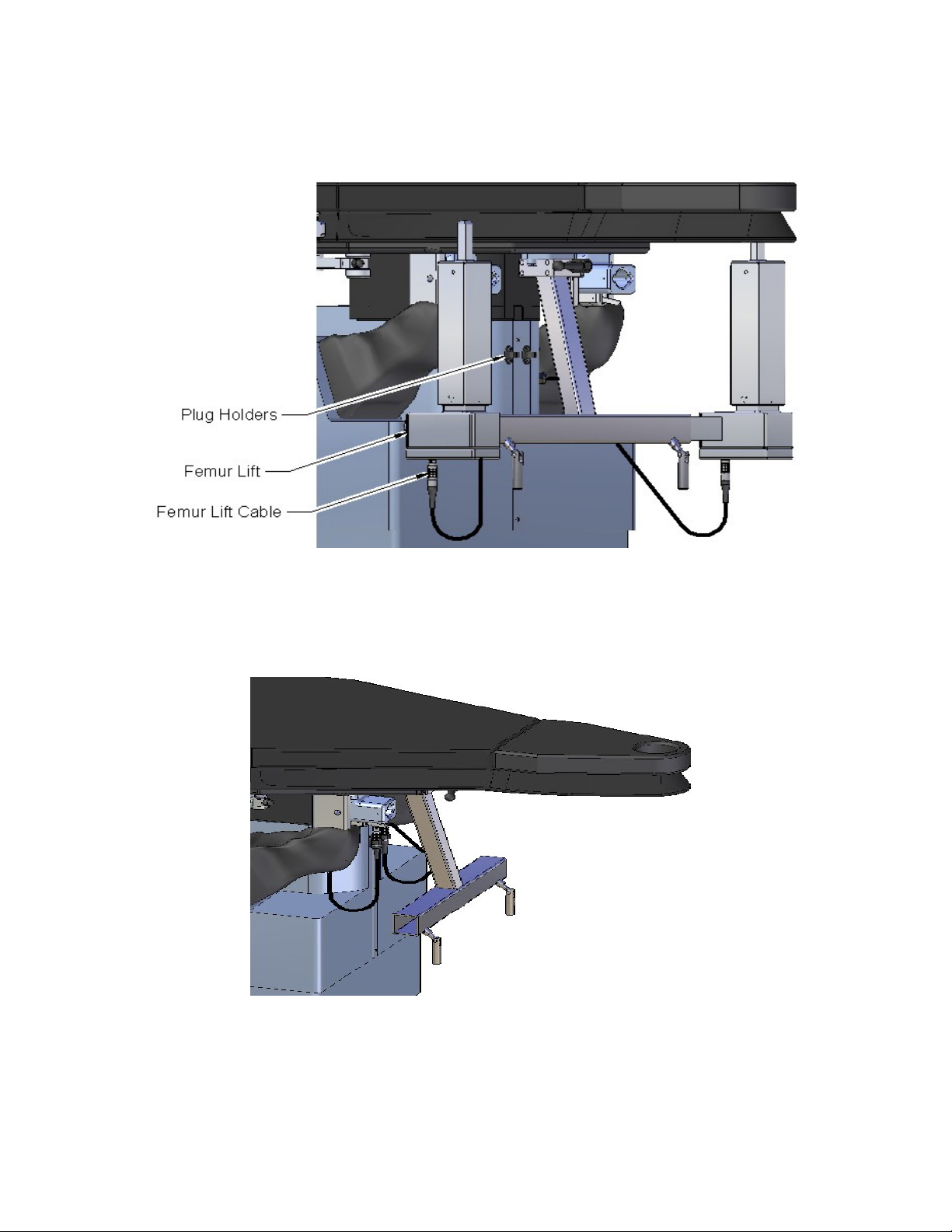

Step 1: Unplug both femur lift cables and click the plugs into its holders (figure 16).

Step 2: Remove both femur lifts from the removable jack mount (figure 17).

Figure 16: Locking and unlocking the removable jack mount

NOTE: Steps 1 and 2 must be completed before moving to step 3 (figure 18).

Figure 17: Locking and unlocking the removable jack mount

MIZUHOSI 2009 25 NW0508 Rev. D

Page 26

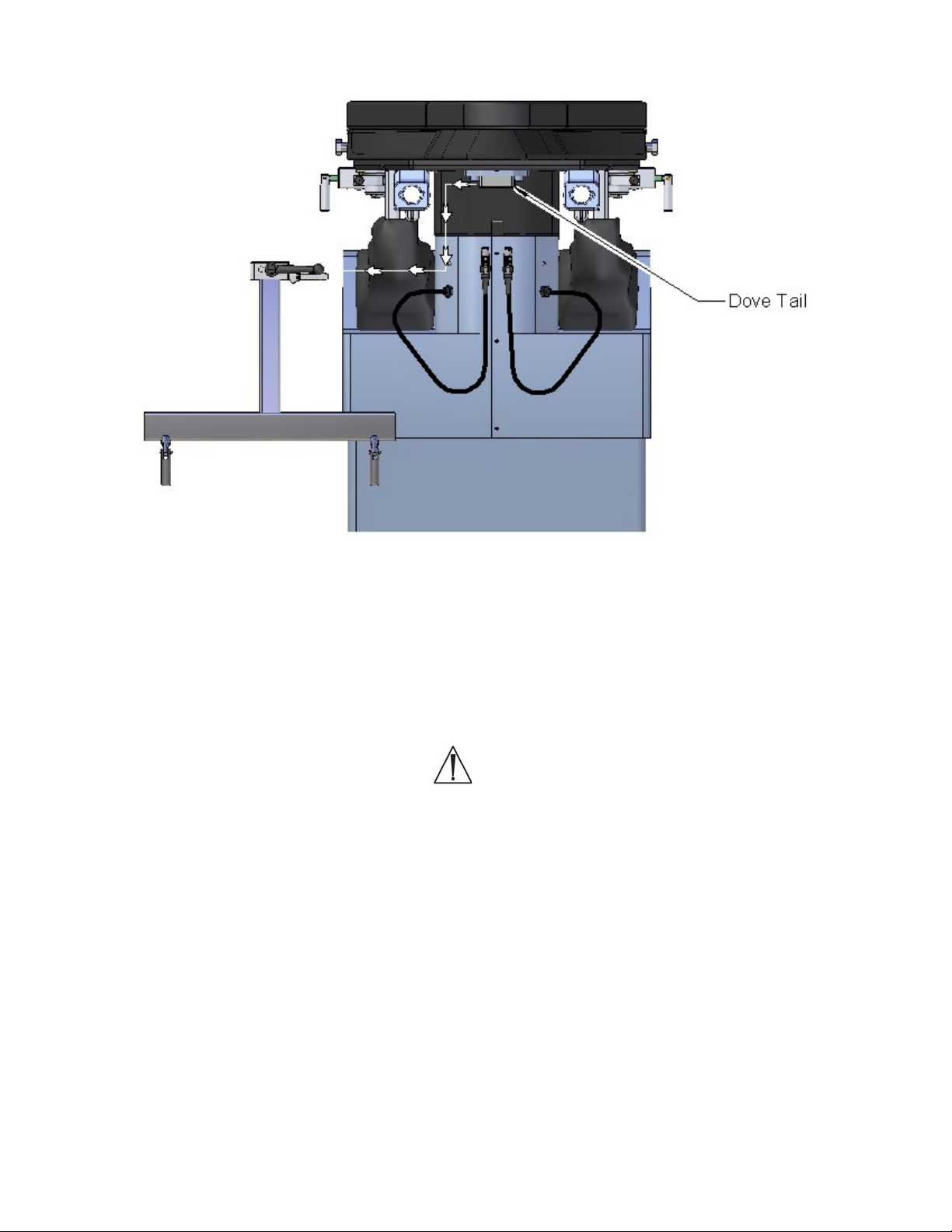

Step 3: Locate and loosen the ratchet black lever handle by rotating it counter-clockwise until

loose (figure 18). The ratchet black lever handle operates by rotating it within its full range of

motion, depressing the center button, pulling the lever back the opposite direction then

releasing the button and rotating it within its full range of motion once again.

Figure 18: Locking and unlocking the removable jack mount

Step 4: Push the silver lock lever up towards the table top (figures 18 & 19)

Figure 19: Locking and unlocking the removable jack mount

While holding the silver lock handle, slide the entire bracket assembly to the left until the

dove tail disengages (figure 20).

MIZUHOSI 2009 26 NW0508 Rev. D

Page 27

Figure 20: Locking and unlocking the removable jack mount

Installation:

To reinstall the removable jack mount, place the assembly to the left of the attachment point,

align the dove tail then slide the assembly from left to right until the silver lock lever drops

into place (figure 18). Tighten the ratchet black lever handle by clockwise rotation until fully

tightened. Do not attempt to reinstall the removable jack mount with the femur lifts attached.

WARNING:

Before every use, visually inspect that the silver lock lever is fully engaged by noting

the handle is pointing downwards and the ratchet black lever handle is tight (figure

18). Failure to perform these actions can result in the removable jack mount falling off

while the table is being tilted and cause injury to the patient.

MIZUHOSI 2009 27 NW0508 Rev. D

Page 28

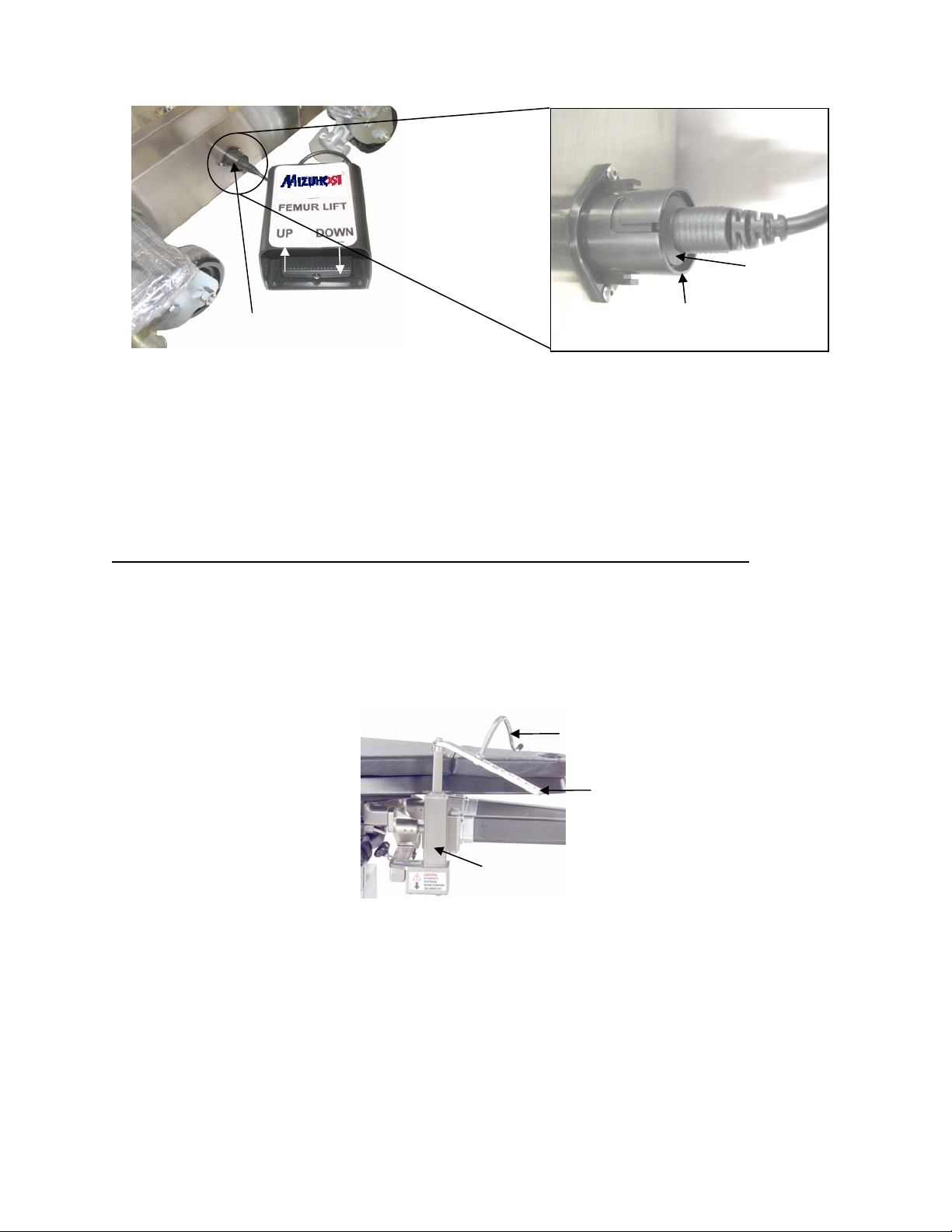

8.3 Attaching Femur Lift(s) And Femur Lift Foot Pedal 6875-600, 6875-601, 6875-19

A single foot pedal is used to operate both left and right femur lifts. Switching operation from

one to the other is accomplished by rotating the femur lift control on the control panel in the

desired direction (see figure 4).

Attach the right or left femur lift to the corresponding mounting bracket by sliding into the

bracket and secure by turning the locking knob clockwise until hand tight.

Pull down and

then pull

connector out

of socket

Locking

knob

Power cord

connector

Figure 21: Removing the power cord connector

Attach the power cord connector extending from the mounting bracket to the port on the

bottom of the femur lift. Align the red dot on the power cord connector with the red dot on the

receptacle, and it will snap in place when properly aligned.

To remove power connector, pull down on the metal checkered jacket of connector.

WARNING:

Failure to properly disconnect connector can damage device.

MIZUHOSI 2009 28 NW0508 Rev. D

Page 29

Plug the foot pedal into the port at the foot end of the table base. (The flange should be flush

or below surface of receptacle).

Flange

Foot pedal

port

Figure 22: Plugging in the foot pedal

Below this

surface

Ensure the foot pedal and femur lift function correctly. On the control panel, (see figure 4)

verify the femur lift is connected by the corresponding LED illuminating when the appropriate

lift is selected. Depress the foot pedal, up side and observe the lift rise to its fullest height

and then depress down side and observe the lift lower to its lowest position. Complete this

process for both the right and left femur lifts.

8.4 Femoral Hook Support And Femoral Hook(s) Sterilization Guidelines

The femoral hook(s) (6850-919, 6850-918) and femoral hook support (6850-110) are

designed for use with only the Mizuho OSI 6850 PROfx® Orthopedic Surgery Table or the

Mizuho OSI 6875 hana® Surgery Table. They are utilized during the Single Incision Tissue

Sparing (SITS) Anterior Approach Total Hip Arthroplasty. The hooks are imprinted with an L

and R to designate left and right.

6850-918/919 Femoral

hook

6850-110 Hook

support

Lift

Figure 23: The femur lift is in place for use with the femoral hook support 6850-110

Proper cleaning, handling and sterilization will ensure that the femoral hook(s) and femoral

hook support perform as intended.

MIZUHOSI 2009 29 NW0508 Rev. D

Page 30

How supplied:

Mizuho OSI's femoral hook(s) and femoral hook support are supplied non-sterile. Cleaning

and sterilizing of the instrument(s) is required before each use according to your hospital’s

washing, decontamination and sterilization procedures.

Contraindications:

The use of these surgical instruments is contraindicated when, in the judgment of the

physician, their use would be contrary to the best interest of the patient.

Precautions:

The Mizuho OSI's femoral hook(s) and femoral hook support are surgical instruments that

require special handling to prevent damage. Misuse can cause excessive stress or strain

that can result in damage that can adversely affect their intended use. Use caution during

cleaning and sterilization. The femoral hook(s) are approved for use only in combination with

the femoral hook support in conjunction with the Mizuho OSI 6850 PROfx® Table or Mizuho

OSI 6875 hana® Surgery Table .

Care and handling: Inspection

Before each use, inspect the femoral hook(s) and femoral hook support for damage, wear

and functionality (check for nicks, burrs or bent parts).

Damaged or nonfunctioning instruments should not be used or processed. Contact your local

Mizuho OSI sales representative or Mizuho OSI Customer Resource Group for repair or

replacement.

WARNING:

Use of damaged instruments may increase the risk of tissue trauma, infection and

length of operative procedures.

Cleaning, disinfection, preparation for sterilization:

Prior to each patient use inspect, clean, disinfect and sterilize the femoral hook(s) and

femoral hook support per hospital protocol for reprocessing surgical instruments.

Do not use steel wool, wire brushes, pipe cleaners or abrasive detergents. Use of

anything other than high quality brushes designed for surgical instrument cleaning may

result in damage.

Disassembly of the femoral hook support before cleaning is generally not necessary

unless severely soiled or dictated by hospital policy.

Do not use high acid (pH 4 or lower) or high alkaline (pH 10 or higher) products for

disinfectants, such as bleach and bi-chloride of mercury.

MIZUHOSI 2009 30 NW0508 Rev. D

Page 31

Sterilization:

NOTE: Mizuho OSI does not recommend the 6850-919, 6850-918 femoral hooks, left & right

or 6850-110 femoral hook support to be sterilized by flash or chemical sterilization.

Sterilization of the femoral hook(s) and femoral hook support is accomplished by steam. To

achieve a sterility assurance level of 10-6, Mizuho OSI recommends the sterilization

parameters listed below:

Sterilization Method Temperature Containment Type

Minimum Exposure

Time Range

Gravity Steam 270°F/134°C Wrapped 10-25 Minutes

NOTE: Other sterilization cycles may also be suitable. However, individuals or hospitals not

using the recommended methods are advised to validate any alternative methods using

current good laboratory practices (cGLP).

Storage:

1. Store the Mizuho OSI femoral hook(s) and femoral hook support with care to prevent

damage.

2. Keep stored instruments on carts or shelving in a storage area free of dust, insects,

chemical vapors and extreme changes in temperature and humidity.

Maintenance and repair of femoral hooks and femoral hook support:

WARNING:

Instruments returned to Mizuho OSI for repair require a certificate of disinfection

which testifies that each instrument has been thoroughly cleaned and disinfected.

Failure to supply a certificate of cleaning and disinfection will result in a cleaning

charge and delayed processing of your instrument repair.

1. Repair of the femoral hook(s) and femoral support hook by parties other than Mizuho OSI

will void the above warranty.

2. If the device requires repair or maintenance contact your local Mizuho OSI sales

representative or Mizuho OSI Customer Resource Group for repair or replacement.

Utilization:

Prior to the anterior approach total hip arthroplasty procedure, the appropriate right or left

femoral hook (6850-919 or 6850-918) and femoral hook support should be cleaned,

disinfected and sterilized according to the hospital’s recommended guidelines. During the

surgical procedure, the surgeon will drape the femur lift and place the sterile, femoral hook

support and sterile, femoral hook in the desired position. The height of the femoral hook

support is raised and lowered by depressing the foot pedal.

MIZUHOSI 2009 31 NW0508 Rev. D

Page 32

8.5 Insertion Of Well Leg Support Adaptor 6875-200

The well leg support adaptor attaches to the spar mount and works in conjunction with the

articulating bracket, 6300-92, and well leg support, 5855-838, for positioning the nonoperative leg. Align end of well leg support adaptor with the appropriate spar mount on table

(left or right). Slide forward until fully engaged and lock in place.

6875-200 Well leg support adaptor

Figure 24: 6875-200 Well leg support adaptor locked in place

5855-838 Well leg

support

Figure 25: Well leg support mounted on hana

®

MIZUHOSI 2009 32 NW0508 Rev. D

Page 33

8.6 Optional Patient Transfer Assembly Instructions For Use

Figure 26: Patient transfer assembly

The optional 6875-742, patient transfer assembly is intended for use while placing a patient

®

on a hana

Surgery Table. The torso of the patient should be placed on the main table top of

the hana® Surgery Table and the leg is to rest on the 6875-742, patient transfer assembly

before the foot is put into the boot.

WARNING:

The transfer board is designed only to safely support 60 lb. Placing the entire weight

of the patient on the transfer board will cause a failure of this product and could result

in injury to the patient or healthcare worker.

Setup:

The patient transfer accessory will clamp on either (left or right) spar. Clamp the device to the

side of the table from which the patient will be transferred to the table. Using the long handle

on the double bar clamp adjust the transfer board to best support only the leg or legs of the

patient. Secure the board in the desired orientation by tightening the handle (clock wise

rotation).

Use:

Transfer the patient to the table and rest the torso of the patient on the table top in a stable

position prior to lowering the leg or legs onto the transfer board. Lower the patient’s leg to

the transfer board and place the foot or feet into the boots. After properly adjusting the

boots place the hook on the boot in the holder on the traction device in accordance with this

owners manual.

Remove the transfer board from the table when not using it to transfer a patient.

Clean exterior surfaces with a mild detergent solution and wipe dry with a soft lint-free cloth.

MIZUHOSI 2009 33 NW0508 Rev. D

Page 34

8.7 Attaching hana® Knee Flexion System™ For TKA 6875-230

The hana® Knee Flexion System™ is designed to mount on the operative leg spar to support

and position the leg as needed during Total Knee Arthroplasty (TKA). It allows for full

flexion/extension of the leg and knee as well as internal/external rotation and planter/dorsal

flexion of the foot.

This device is intended to be used above the drapes in the sterile field.

Mizuho OSI's Knee Flexion System™ are supplied non-sterile. Cleaning and sterilizing of the

instrument(s) are required before each use according to your hospital’s washing,

decontamination and sterilization procedures.

Figure 27: 6875 hana® Knee Flexion System™ (6875-230) attachment detail, spar un-draped

Clamp knob

Fine traction

upright

Figure 27: 6875 hana® Knee Flexion System™ (6875-230) attachment detail, spar un-draped

Gross traction

adjustment

NOTE: Prior to draping, the fine traction must be adjusted fully towards the foot end of the

leg spar by rotating the traction handle clockwise until it stops.

Figure 28: 6875 hana® Hip and Knee Arthroplasty Table set up for right TKA spar draped

Prior to use, drape the operative side leg spar prior to attachment of the sterile Knee Flexion

System™ device. Maintaining sterile technique, position the distal end base onto the post

above the gross traction adjustment with the clamp around the fine traction upright and

tighten screw knob until secure (refer to figure 27).

MIZUHOSI 2009 34 NW0508 Rev. D

Page 35

Figure 29: 6875 hana® Knee Flexion System™ (6875-230) attachment detail spar draped

8.8 Knee Flexion Sterilization Guidelines

The knee flexion (6875-230) are designed for use with only the Mizuho OSI 6875 hana®

Surgery Table. They are utilized during the total knee arthroplasty.

Clamp knob

Fine traction

upright

Figure 30: Knee Flexion System™

Gross traction

adjustment

Proper cleaning, handling and sterilization will ensure that the Knee Flexion System

™

performs as intended.

How supplied:

Mizuho OSI's knee flexion are supplied non-sterile. Cleaning and sterilizing of the

instrument(s) are required before each use according to your hospital’s washing,

decontamination and sterilization procedures.

Contraindications:

The use of these surgical instruments is contraindicated when, in the judgment of the

physician, their use would be contrary to the best interest of the patient.

MIZUHOSI 2009 35 NW0508 Rev. D

Page 36

Precautions:

The Mizuho OSI's knee flexion are surgical instruments that require special handling to

prevent damage. Do not apply excessive stress or strain at the joints; misuse will result in

damage. Use caution during cleaning and sterilization. The knee flexion are approved for use

®

only in combination with the Mizuho OSI 6875 hana

Surgery Table.

Care and handling: Inspection

Before each use, inspect the knee flexion for damage, wear and functionality (check for

nicks, burrs or bent parts).

Damaged or nonfunctioning instruments should not be used or processed. Contact your local

Mizuho OSI sales representative or Mizuho OSI Customer Resource Group for repair or

replacement.

WARNING:

Use of damaged instruments may increase the risk of tissue trauma, infection and

length of operative procedures.

Cleaning, disinfection, preparation for sterilization:

Prior to each patient use inspect, clean, disinfect and sterilize the knee flexion and per

hospital protocol for reprocessing surgical instruments.

Do not use steel wool, wire brushes, pipe cleaners or abrasive detergents. Use of anything

other than high quality brushes designed for surgical instrument cleaning may result in

damage.

Disassembly of the knee flexion support before cleaning is generally not necessary unless

severely soiled or dictated by hospital policy.

Do not use high acid (pH 4 or lower) or high alkaline (pH 10 or higher) products for

disinfectants, such as bleach and bi-chloride of mercury.

Sterilization:

NOTE: Mizuho OSI does not recommend the knee flexion to be sterilized by flash or

chemical sterilization.

MIZUHOSI 2009 36 NW0508 Rev. D

Page 37

Sterilization of the knee flexion is accomplished by steam. To achieve a sterility assurance

level of 10-6, Mizuho OSI recommends the sterilization parameters listed below:

Sterilization Method Temperature Containment Type

Minimum Exposure

Time Range

Gravity Steam 270°F/134°C Wrapped 10-25 Minutes

NOTE: Other sterilization cycles may also be suitable. However, individuals or hospitals not

using the recommended methods are advised to validate any alternative methods using

Current Good Laboratory Practices (cGLP).

Storage:

1. Store the Mizuho OSI knee flexion with care to prevent damage.

2. Keep stored instruments on carts or shelving in a storage area free of dust, insects,

chemical vapors and extreme changes in temperature and humidity.

MIZUHOSI 2009 37 NW0508 Rev. D

Page 38

8.9 IM Nailing Femur: Unilateral Skeletal Traction 6875 hana® Surgery Table Set-Up

Figure 31: Patient positioned for Right IM Nailing Femur supine with skeletal traction and well leg retained in

traction boot

Instructions provided are for suggested set-ups. Final determination of patient positioning

and set-up is at the discretion of the surgeon and surgical team.

1. Ensure all (4) caster floor locks are in the locked position.

2. Attach radiolucent leg spars (6875-360) right & (6875-350) left to the table and lock in

place. Refer to section 8.1.

3. Place pelvic pad (6875-7129) onto table. Attach lower leg support (6850-170) to nonoperative leg spar with accessory clamp (5855-61) and lock in place.

4. Attach optional patient transfer board (6875-742) by clamping the device to the leg

spar on the side of the table from which the patient will be transferred to the table.

Refer to section 8.6.

5. Adjust table height to appropriate position to transfer patient from patient stretcher.

6. Attach appropriate traction boot (6850-485) small, or (6850-486) large to patients’

non-operative foot while on patient stretcher.

7. Transfer patient to the table in supine position, insert well padded perineal post (6850-

413), move the patient to establish firm contact with the perineal post, and secure with

patient safety strap (5840-44).

8. Place non-operative leg traction boot into traction mount on the non-operative leg

spar.

9. Install arm board with pad (6875-292) to each side of the table and position patient’s

arms out to the side or attach arm board with pad (6875-292) to the non operative side

of the table and optional cross arm support (5857) using clark socket (5393) to the

non-operative side of the table and secure the patient’s arms.

10. Attach a pin holder (not provided) to the traction mount on the operative leg spar using

the traction device hook (6850-114) and traction hook extension (6875-399). Position

the patient’s leg.

11. Remove patient transfer assembly (6875-742) by unclamping it from the leg spar and

sliding it out from underneath the fully positioned patient.

MIZUHOSI 2009 38 NW0508 Rev. D

Page 39

12. Trial position the C-arm unit on the non-operative side.

13. Install the head end drape rod assembly (6875-474) at the head end of the table and

the foot end drape rod assembly (6875-750) on the appropriate leg spar at the foot

end of the table with hole on the outside. Adjust to the appropriate height and lock.

MIZUHOSI 2009 39 NW0508 Rev. D

Page 40

Table set up for Right IM Nailing Femur supine with skeletal traction and well leg retained in traction boot

Radiolucent leg spars (2)

Right: 6875-360

Left: 6875-350

Pelvic pad

6875-7129

Lower leg support

6850-170

Accessory clamp

5855-61

Patient transfer board

6875-742

Traction boot (pair)

Large: 6850-486

Small: 6850-485

Perineal post and pad

6850-413

Patient safety strap

5840-44

Arm boards with pad (2)

6875-292

Cross arm support

5857

Clark socket

5393

Traction device hook

6850-114

Traction hook extender

6875-399

Head end drape rod

assembly

6875-747

Foot end drape rod

assembly

6875-750

MIZUHOSI 2009 40 NW0508 Rev. D

Page 41

8.10 IM Nailing Femur: Unilateral Skin Traction 6875 hana® Surgery Table Set-Up

Figure 32: Patient positioned for a right IM Nailing Femur supine with unilateral skin traction and well leg

supported in leg holder

Instructions provided are for suggested set-ups. Final determination of patient positioning

and set-up is at the discretion of the surgeon and surgical team.

1. Ensure all (4) caster floor locks are in the locked position.

2. Attach appropriate radiolucent leg spar (6875-360) right or (6875-350) left to the table

on the operative side and lock in place. Refer to section 8.1.

3. Place pelvic pad (6875-7129) onto table.

4. Attach optional patient transfer board (6875-742) by clamping the device to the leg

spar on the side of the table from which the patient will be transferred to the table.

Refer to section 8.6.

5. Slide the patient safety strap (5840-44) into place.

6. Adjust table height to appropriate position to transfer patient from patient stretcher.

7. Attach appropriate traction boot (6850-485) small, or (6850-486) large to patient’s

operative foot while on the patient stretcher.

8. Transfer patient to the table in supine position, place boot into traction mount on leg

spar, insert well padded perineal post (6850-413) move the patient to establish firm

contact with the perineal post and secure with patient safety strap (5840-44).

9. Attach well leg support adaptor (6875-200) refer to section 8.5 into the leg spar mount

on the non-operative side of the table and lock into position.

10. Attach well leg holder (5855-838) to the well leg support arm (6850-280) using

articulating bracket (6300-92) and secure patients leg.

11. Install arm boards with pad (6875-292) to each side of the table and position patient’s

arms out to the side, or attach arm boards with pad (6875-292) to the non operative

side of the table and optional cross arm support (5857) using clark socket (5393) to

the non-operative side of the table and secure the patients arms.

MIZUHOSI 2009 41 NW0508 Rev. D

Page 42

12. Remove patient transfer board (6875-742) by unclamping it from the leg spar and

sliding it out from underneath the fully positioned patient.

13. Trial-position the C-arm unit on non-operative side.

14. Install the head end drape rod assembly (6875-747) at the head end of the table and

the foot end drape rod assembly (6875-750) on the appropriate leg spar at the foot

end of the table with hole on the outside. Adjust to the appropriate height and lock.

MIZUHOSI 2009 42 NW0508 Rev. D

Page 43

Table set up for a right IM Nailing Femur supine with unilateral skin traction and well leg supported in leg holder

Radiolucent leg spars (2)

Right: 6875-360

Left: 6875-350

Pelvic pad

6875-7129

Patient transfer board

6875-742

Patient safety strap

5840-44

Traction boot (pair)

Large: 6850-486

Small: 6850-485

Perineal post and pad

6850-413

Well leg support adaptor

6875-200

Well leg support assembly

5855-838

Articulating bracket

6300-92

Arm boards with pad (2)

6875-292

Cross arm support

5857

Clark socket

5393

Head end drape rod

assembly

6875-747

Foot end drape rod

assembly

6875-750

MIZUHOSI 2009 43 NW0508 Rev. D

Page 44

8.11 IM Nailing Femur: Lateral Decubitus Position With Bilateral Skin Traction 6875

hana® Surgery Table Set-Up

Figure 33: hana® Surgery Table set-up for IM Nailing Femur, patient in lateral decubitus position with bilateral

skin traction

Instructions provided are for suggested set-ups. Final determination of patient positioning

and set-up is at the discretion of the surgeon and surgical team.

1. Ensure all (4) caster floor locks are in the locked position.

2. Attach radiolucent leg spars (6875-360) right & (6875-350) left to the table and lock in

place. Refer to section 8.1.

3. Attach the lateral perineal post and pad assembly (6875-250) to table top by sliding

into position and inserting the plug into the standard perineal post hole on the table

top.

4. Position patient safety strap (5840-44) in place.

5. Attach optional patient transfer board (6875-742) by clamping the device to the leg

spar on the side of the table from which the patient will be transferred to the table.

Refer to section 8.6.

6. Adjust table height to appropriate level to transfer patient from patient stretcher.

7. Place traction boots (6850-485) small, or (6850-486) large onto patient and secure

while still on the patient stretcher.

8. Transfer patient to the table in the supine position.

9. Reposition patient into lateral decubitus position. At this time an attendant should be

assigned to support the patient until patient is safely positioned.

10. Slide the patient toward the foot end of the table until firmly positioned against the

perineal post and secure with a patient safety strap (5840-44) (It is recommended that

this set up includes lower leg support (6850-170) to non-operative leg spar with

accessory clamp (5855-61).)

11. Attach well leg traction boot to the traction mount on the operative side leg spar.

12. Attach the operative leg traction boot to the traction mount on the well side leg spar.

MIZUHOSI 2009 44 NW0508 Rev. D

Page 45

13. Attach lower leg support (6850-170) to operative side leg spar using an ACCESSORY

CLAMP (5855-61).

14. Install the arm boards with pad (6875-292) and optional cross arm support (5857)

using a clark socket (5393) to the non-operative side of the table and secure the

patient’s arms.

15. Remove patient transfer board (6875-742) by unclamping it from the leg spar and

sliding it out from underneath the fully positioned patient.

16. Trial position the C-arm unit on the non-operative side.

17. Install the head end drape rod assembly (6875-747) at the head end of the table and

the foot end drape rod assembly (6875-750) on the appropriate leg spar at the foot

end of the table with hole on the outside. Adjust to the appropriate height and lock.

MIZUHOSI 2009 45 NW0508 Rev. D

Page 46

Table set-up for IM Nailing Femur, lateral decubitus position with bilateral skin traction

Radiolucent leg spars (2)

Right: 6875-360

Left: 6875-350

Lateral perineal post and

pad assembly

6875-250

Patient safety strap

5840-44

Patient transfer board

6875-742

Traction boot (pair)

Large: 6850-486

Small: 6850-485

Lower leg support

6850-170

Accessory clamp

5855-61

Arm boards with pad (2)

6875-292

Cross arm support

5857

Clark socket

5393

Head end drape rod

assembly

6875-747

Foot end drape rod

assembly

6875-750

MIZUHOSI 2009 46 NW0508 Rev. D

Page 47

8.12 IM Nailing Tibia: Supine With Unilateral Skin Traction 6875 hana® Surgery

Table Set-Up

Figure 34: Patient positioned for Right IM Nailing Tibia in supine position with unilateral skin traction

Instructions provided are for suggested set-ups. Final determination of patient positioning

and set-up is at the discretion of the surgeon and surgical team.

1. Ensure all (4) caster floor locks are in the locked position.

2. If not already attached install the removable jack mount assembly (6875-730) refer to

section 8.2. Insert the appropriate femur lift (6875-600) right or (6875-601) left to the

operative side of the table. Refer to section 8.3.

3. Attach appropriate radiolucent leg spar (6875-360) right or (6875-350) left to the table

and lock in place. Refer to section 8.1.

4. Attach the lateral perineal post and pad assembly (6875-250) to table top by sliding

into position and inserting the plug into the standard perineal post opening on the

table top after removing the ilium post and lateral perineal post assembly. Attach well

leg support adaptor (6875-200) refer to section 8.5 into the leg spar mount on the nonoperative side of the table and lock into position.

5. Slide patient safety strap (5840-44) in place.

6. Attach optional patient transfer board (6875-742) by clamping the device to the leg

spar on the side of the table from which the patient will be transferred to the table.

Refer to section 8.6.

7. Adjust table height to appropriate position to transfer patient from patient stretcher.

8. Transfer patient to the table in a supine position and secure with patient safety strap

(5840-44).

9. Attach lateral perineal post (6850-400) to the traction lifter with the mounting bracket

lateral perineal post (6850-180) and position patient’s leg over the lateral perineal

post.

10. Attach well leg holder (5855-838) to the well leg support adaptor (6875-200) using the

articulating bracket (6300-92) and secure patient’s leg.

11. Install arm boards with pad (6875-292) to each side of the table and position patient’s

arms out to the side, or attach arm boards with pad (6875-292) to the non operative

side of the table and optional cross arm support (5857) using clark socket (5393) to

the non-operative side of the table and secure the patient’s arms.

12. Remove patient transfer board (6875-742) by unclamping it from the leg spar and

sliding it out from underneath the fully positioned patient.

13. Trial position the C-arm unit.

MIZUHOSI 2009 47 NW0508 Rev. D

Page 48