Page 1

MODEL 6850 ORTHOPEDIC SURGERY TABLE

PROfx

MAINTENANCE and REPAIR MANUAL

OSI 2003

®

30031 Ahern Avenue

Union City, CA 94587-1234

Bus: 510-429-1500 Toll Free: 800-777-4674 Fax: 510-429-8500

NW0424 Rev A

Page 2

TABLE OF CONTENTS

1.0 INTRODUCTION .................................................................................................................................................4

1.1 General Description .............................................................................................................................................4

1.2 Specifications.......................................................................................................................................................4

1.3 Shipping...............................................................................................................................................................4

1.4 Storage .................................................................................................................................................................5

2.0 CONTROLS IDENTIFICATION........................................................................................................................6

2.1 Table Orientation .................................................................................................................................................6

2.2 Major Controls Location......................................................................................................................................6

2.3 Control Panel Identification.................................................................................................................................7

3.0 INSPECTION ........................................................................................................................................................8

3.1 Acceptance and Transfer .....................................................................................................................................8

3.2 Preoperative .........................................................................................................................................................8

3.3 Postoperative .......................................................................................................................................................8

3.4 Annually ..............................................................................................................................................................8

4.0 PRE-OPERATIONAL FUNCTION CHECK ....................................................................................................9

5.0 BASIC OPERATION ..........................................................................................................................................11

5.1 Control Operation ..............................................................................................................................................11

5.2 Floor Lock .........................................................................................................................................................11

5.3 Moving the Table...............................................................................................................................................11

5.4 Hand Pendant Control........................................................................................................................................11

5.5 Leg Spars: ..........................................................................................................................................................12

6.0 THE ELECTRICAL SYSTEM ..........................................................................................................................13

6.1 Description.........................................................................................................................................................13

6.2 On/Off Power Switch ........................................................................................................................................13

6.3 Component Circuit Breaker ...............................................................................................................................13

6.4 Power Cord ........................................................................................................................................................13

6.5 Leakage Current ................................................................................................................................................13

6.6 Floor Lock System.............................................................................................................................................14

6.7 Emergency Backup Battery System...................................................................................................................15

6.8 Troubleshooting .................................................................................................................................................15

7.0 CLEANING and MAINTENANCE...................................................................................................................16

7.1 Cleaning and Disinfecting .................................................................................................................................16

7.2 Maintenance.......................................................................................................................................................16

8.0 REMOVAL and REPLACEMENT of COMPONENTS .................................................................................17

8.1 Floor-lock Actuator ...........................................................................................................................................17

8.2 Floor-lock Pad ...................................................................................................................................................18

8.3 Emergency Backup Battery ...............................................................................................................................19

8.4 10 Amp Motor-control PCB ..............................................................................................................................20

8.5 Power Supply Tray ............................................................................................................................................21

8.6 Stepper-controller Tray......................................................................................................................................22

8.7 Tilt Sensor-Actuator ..........................................................................................................................................23

9.0 TECHNICAL DRAWINGS and PARTS LISTS ..............................................................................................25

9.1 Interconnect Diagram, 110VAC ........................................................................................................................25

9.2 Interconnect Diagram, 220VAC ........................................................................................................................26

9.3 Table Assembly Bill of Materials ......................................................................................................................27

9.4 Replacement / Spare Parts List ..........................................................................................................................27

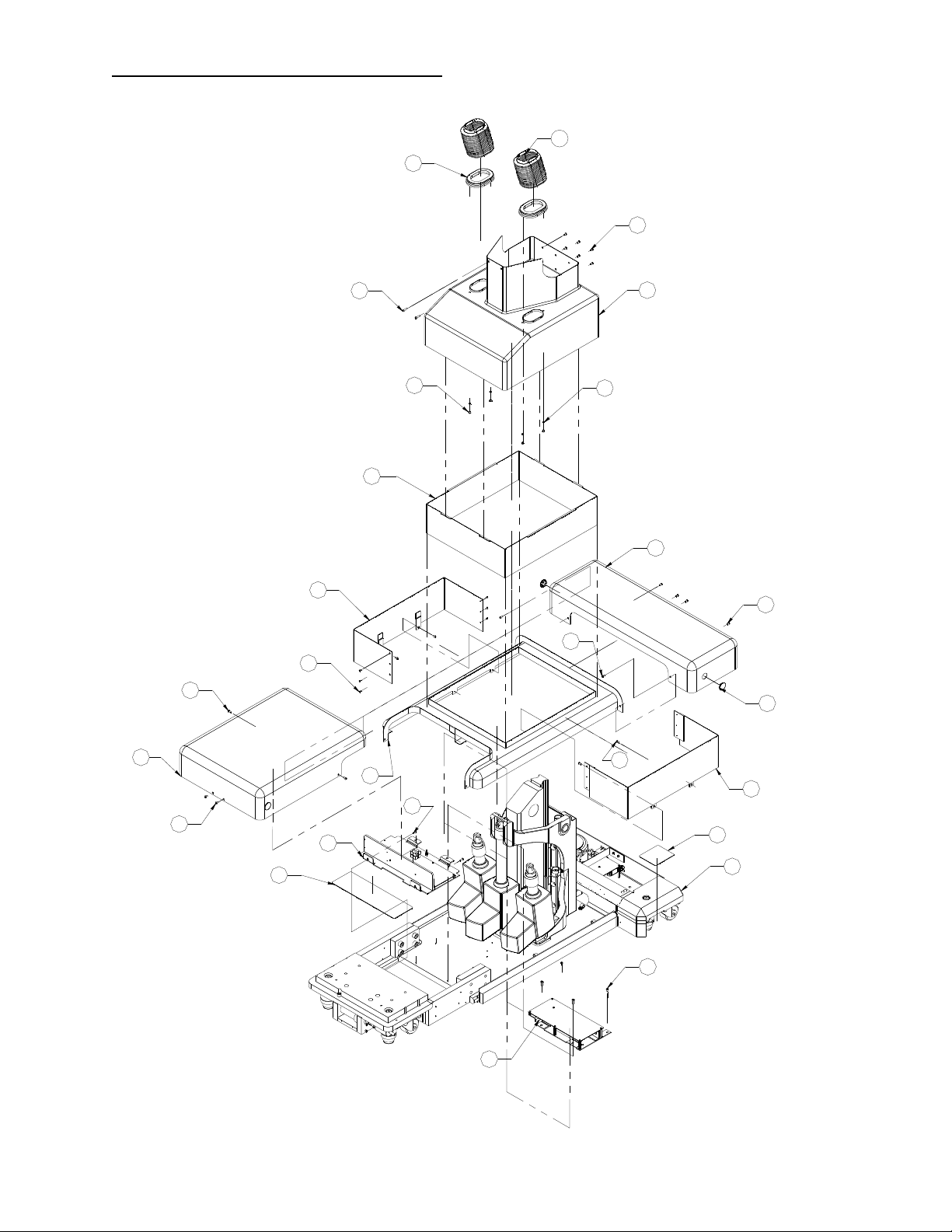

9.5 Table Assembly Exploded View .......................................................................................................................28

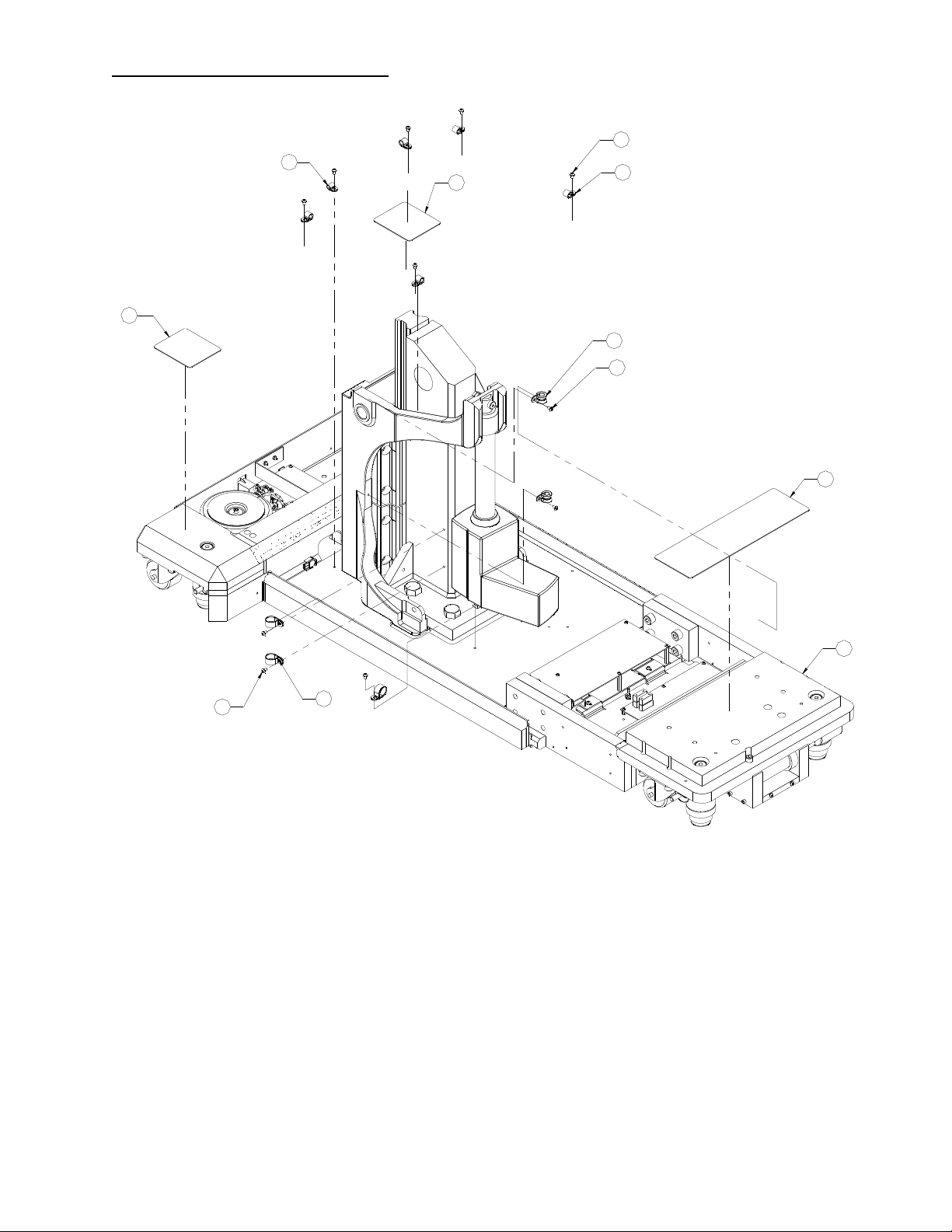

9.6 Base Cover Assembly, Exploded View .............................................................................................................29

9.7 Base Assembly, Exploded View........................................................................................................................30

9.8 X-Ring Assembly Exploded View ....................................................................................................................31

10.0 GLOSSARY OF TERMS..................................................................................................................................32

11.0 OSI TECHNICAL SERVICE...........................................................................................................................33

11.1 Contact for Parts and Service: .........................................................................................................................33

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

1

Page 3

IMPORTANT NOTICES

CAUTION:

To ensure safe operation of the equipment, please READ THESE INSTRUCTIONS

COMPLETELY and keep this manual readily available to OR personnel for future reference.

Carefully observe and comply with all warnings, cautions and instructions placed on the

equipment or described in this manual.

In this manual, the WARNING symbol is intended to alert the user to the presence of

important operation, maintenance, or safety instructions.

Dans ce manuel, le symbole AVERTISSANT est projeté d'alerter l'utilisateur à la

présence d'opération importante, l'entretien, ou les instructions de sûreté.

WARNING

Proper preoperative and intra-operative procedures must be followed to prevent

venous stasis and pooling, pressure sore development, neuropathy, improper

electro surgical tissue grounding, hypertension and hypothermia.

AVERTISSANT

Preoperative propre et les procédures dans opératifs doivent être suivis pour

empêcher venous stasis et pooling, la pression développement endolori, la

neuropathie, electro déplacé mettre à terre de tissu chirurgical, l'hypertension et

hypothermia.

NOTE:

The application techniques outlined in these instructions are the manufacturer’s suggested

techniques. The final disposition of each patient’s care as related to the use of this equipment

rests with the attending physician.

This device is to be used by trained professional personnel only.

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

2

Page 4

Classification and Table Rating

The tables listed above are considered Class I Exempt and has a rating of IPX-0.

PROTECTION AGAINST ELECTRICAL SHOCK HAZARD:

This symbol indicates this equipment is an applied part TYPE B and is

generally suitable for applications involving external or internal contact with the

patient, excluding the heart. The patient circuit is connected to protective earth

and this equipment should be connected only to outlets with a protective earth

ground.

LA PROTECTION CONTRE LE DANGER DE CHOC ELECTRIQUE:

Ce symbole indique que cet équipement est un B DE TYPE de partie appliqué

et est généralement convenable pour les applications contact impliquant,

externes ou internes avec le malade, excluant le coeur. Le circuit patient est

connecté à la terre protective et cet équipement devrait être seulement connecté

aux sorties avec un sol de terre protectif.

WARNING:

If the integrity of the external protective earth conductor is in doubt, the

equipment shall be operated from its internal electrical power source (battery).

AVERTISSANT:

Si l'intégrité de l'externe protectif terre est en doute, l'équipement sera opéré de

son interne électrique pouvoir (pile).

This symbol

indicates an external ground stud that is required for use

when the AC power cable is not connected to a protective earth ground outlet in

your operating room or facility.

To protect the patient, hospital staff and the table from any possible hazards, an

external ground wire connection is required between the external ground stud

and protective earth ground.

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

3

Page 5

1.0 INTRODUCTION

1.1 General Description

The model 6850 PROfx Pelvic Reconstruction Orthopedic Trauma Table (6850 Table) is

designed to safely hold a patient in the proper position undergoing orthopedic or surgical

procedures.

It is a stand-alone, single-pedestal electrically operated table designed to position a patient in a

prone, lateral or supine position during surgical procedures. The table has three primary

electrically powered functions. Up/down, left/right lateral roll, Trendelenburg/Reverse

Trendelenburg tilt. Electromechanical actuator-motors perform these motions.

The table is controlled by means of a hand pendant control with functions clearly labeled.

Positive floor locks are employed to stabilize the table in the operating location.

Figure 1: 6850 Table, right-side view.

1.2 Specifications

The table is designed to safely hold up to a 450-pound patient in the proper procedural position

at any point within its physical range. The table has a height range of 30 to 40 inches. The width

of the tabletop is 21 inches. The length of the tabletop is 62 inches. With leg spars is 125 inches.

The lateral roll range is +/- 20 degrees and the Trendelenburg range is +/- 15 degrees. The

maximum deflection of the tabletop under full load is less than 1 inch at the cantilever end. The

tabletop has a radiolucent equivalency of less that 1-mm of aluminum. The input power

requirement is 110 VAC, 60Hz or 230 VAC AC 50 Hz as indicated on the table label. This is a

Class 1 exempt type B Medical Device with an IPX-0 rating, 10% duty cycle or 6 minutes per

hour.

1.3 Shipping

The 6850 Table must be shipped using appropriate Shipping Crate (OSI part number [p/n] 6800-

400) and Shipping Instructions (p/n NW0408). During shipment the 9650 Table is to be kept in

an environment within the following limits:

1. Ambient temperature -20 degrees C to + 50 degrees C

2. Relative humidity from 10% to 100%, including condensation

3. Atmospheric pressure from 50 to 110 kPa

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

4

Page 6

1.4 Storage

When not in use the table should be stored in a clean dry environment with temperature between

32°F & 120°F.

To insure the battery is always fully charged and ready for use. The table should be stored with

the power plug inserted and attached to an appropriate power source (110VAC or 220VAC) and

the Power Switch turned “ON”.

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

5

Page 7

2.0 CONTROLS IDENTIFICATION

Illuminated Circuit Breaker

2.1 Table Orientation

The major components of the 6850 Table are identified below. The table is described as having

a "head end" and a "foot end". The On/Off Switch, Floor Lock buttons and the Power Cord are

located at the "head end" of the table.

Head-end

Hand Control

Foot-end

Leg Spars

Figure 2: Right-side View with Patient

2.2 Major Controls Location

The Control Panel, On-Off Power Switch, Power Cord receptacle and Model Number/Serial

Number identification label are located at the head-end of the table.

Control Panel

"ON / OFF"

Power Switch and

Power Cord

Receptacle

Floor Lock

Override

(under panel)

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

Model and Serial

Number

Identification

Figure 3: Head-end, Base and Control Panel

6

Floor Lock

Access

(1 of 4)

Page 8

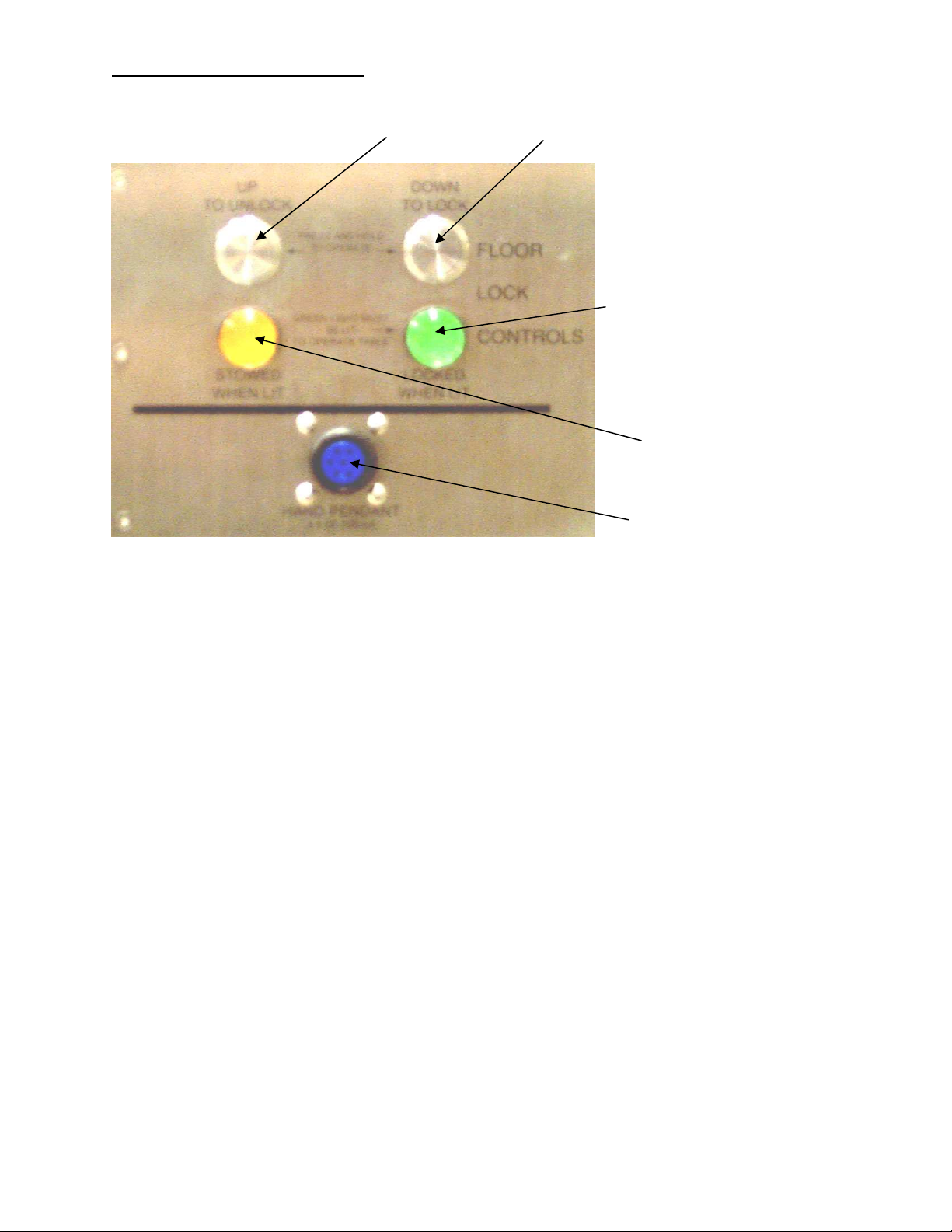

2.3 Control Panel Identification

“DOWN TO LOCK”

Figure 4: Control Panel and Floor Lock Controls

“ UP TO UNLOCK”

Button

Button

“LOCKED WHEN LIT”

Light

“STOWED WHEN LIT”

Light

Hand Control

Receptacle

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

7

Page 9

3.0 INSPECTION

3.1 Acceptance and Transfer

1. Upon receipt of your 6850 Table, remove any protective wrapping or packaging. Visually

inspect all surfaces for freight damage. Check each caster for proper rolling operation.

NOTE: Any freight damage must be reported to the freight carrier immediately upon delivery.

It is the responsibility of the recipient to make freight damage claims.

2. Read the Model/Serial Number Identification Label found at the head end of the base to

confirm the serial number and the input power requirements.

3. Place the 6850 Table, with leg spars attached, in an area with at least 4 feet of clearance on

all sides.

4. Perform Pre-Operational function check.

3.2 Preoperative

Perform Pre-Operational function check.

3.3 Postoperative

Perform Pre-Operational function check.

3.4 Annually

• Inspect and test the 6850 Table as described Pre-Operational function check. Thoroughly

clean the table as described in the CLEANING and MAINTENANCE section of this manual.

Pay special attention to the cleanliness of the controls as excessive soil could affect function.

• Inspect for cuts in the insulation or damage to the connector or power cord.

• On a smooth surface, floor locks engaged, push with minimum of 100lbs force. Table should

not move.

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

8

Page 10

4.0 PRE-OPERATIONAL FUNCTION CHECK

Perform all steps in this procedure. For a complete definition of reference terms used in this

procedure, please refer to the “Glossary of Terms”.

CAUTION: Leg Spars can be damaged if allowed contact with floor. Verify Leg Spars are

raised to maximum, are spread beyond parallel, and all lock handles are

secured.

LA PRUDENCE: les Perches de Jambe peuvent être endommagées si a permis le contact

avec le plancher. Vérifier les Perches de Jambe sont élevées au

maximum, sont étalé au delà de parallèle, et toutes poignées de serrure

sont obtenues.

1. Plug in the Hand Control cable-connector into the "HAND PENDANT" port on the Control

Panel.

2. Plug the power cord into a “hospital grade” power outlet and flip the main “ON/OFF” power

switch to "ON". Verify the switch illuminates; this indicates power is applied to the table.

3. Lockout mode:

3.1. Table is operational when the green “LOCKED WHEN LIT” indicator light, located on

the Control Panel is illuminated and the “FLOOR LOCK STATUS ON” indicator light,

located on the Hand Control, is illuminated.

3.2. With Floor Locks raised, verify that the amber "STOWED WHEN LIT" indicator light

on the Control panel is illuminated and the “FLOOR LOCK STATUS STOWED”

indicator on the Hand Control is illuminated.

3.3. Verify only

the Hand Control operates the Floor Locks when Floor Locks are stowed.

4. Floor lock check using the Control Panel:

4.1. Press and hold “DOWN TO LOCK” button until green “LOCKED WHEN LIT” light is

illuminated. Verify table cannot move on its wheels.

4.2. Press and hold “UP TO UNLOCK” button until amber "STOWED WHEN LIT" light is

illuminated. Verify table is moveable on its wheels.

5. “FLOOR LOCK OVERRIDE" button check:

5.1. Press and hold "FLOOR LOCK OVERRIDE" button located under Control Panel, press

each Hand Control button; Up, Down, Tilt, and Trendelenburg to verify that each

function works without Floor Locks engaged (table locked to the floor).

6. Hand Control check; Cycle all button functions below, to their limits.

6.1. Press and hold "FLOOR LOCK" button. Verify all four locking feet move down and

contact the floor and the green "LOCKED WHEN LIT" light illuminates.

6.2. Press and hold "FLOOR UNLOCK" button. Verify all four locking feet move up and

amber "STOWED WHEN LIT" light illuminates.

6.3. Press and hold "FLOOR LOCK" button to relock table to floor. Verify all four locking

feet move down and contact the floor and the green "LOCKED WHEN LIT" light

illuminates.

6.4. Press and hold "HEIGHT UP" button. Verify Tabletop moves up.

6.5. Press and hold “HEIGHT DOWN" button. Verify Tabletop moves down.

6.6. Press and hold "REV. TREN" button. Verify head-end of tabletop moves up, foot-end

moves down.

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

9

Page 11

6.7. Press and hold "TREN" button. Verify head-end of tabletop moves down, foot-end

moves up.

6.8. Press and hold "LEFT LATERAL ROLL" button. Verify Tabletop rolls to the left.

6.9. Press and hold "RIGHT LATERAL ROLL" button. Verify Tabletop rolls to the right.

6.10. Disorient tabletop by raising height minimum six inches, Left or Right Lateral

Roll the tabletop and Trendelenburg a minimum of five degrees. Press and hold the

"RETURN TO LEVEL" button. Verify Tabletop first levels laterally, levels

Trendelenburg, then after a three-second delay, the tabletop moves down.

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

10

Page 12

5.0 BASIC OPERATION

5.1 Control Operation

Plug the Power Cord into the power cord receptacle, located at the head end of the base and into

a properly grounded receptacle. Refer to the Model/Serial Number label on the head end of the

base for input voltage requirements. Turn "ON" the On-Off power rocker switch (On-Off

Power). The green light in the switch illuminates indicating that power is applied to the table.

This On/Off Power switch is a combination on/off power switch, circuit breaker and pilot light.

5.2 Floor Lock

The Floor Lock button is located on the Control Panel at the head end of the table or on the Hand

Control. To lock the table to the floor, press and hold the “LOCK” button until the Floor Lock is

completely deployed. The green “LOCKED WHEN LIT” indicator light will illuminate when it

is locked. To release the Floor Lock, press and hold the “UNLOCK” button until the Floor Lock

is completely retracted. The green “LOCKED WHEN LIT” light will go dark and the amber

“STOWED WHEN LIT” light will illuminate when it is unlocked.

NOTE:

The table will not function until the Floor Lock is completely deployed and green “LOCKED

WHEN LIT” light is illuminated.

5.3 Moving the Table

Once the Floor Locks are unlocked the table can be rolled for relocation. It is best that the table

be rolled with the Head End forward (Leg Spars trailing).

5.4 Hand Pendant Control

See Figure 5.

The 6800 Table is controlled by means of a Hand Control Pendant (Hand Control). The Hand

Control is plugged into the receptacle labeled “HAND PENDANT” on the Control Panel. Plug in

Hand Control connector and rotate screw-locking collar until hand tight. To operate any of the

desired functions, press and hold the appropriate button on the Hand Control until the desired

position is achieved.

The Hand Control is equipped with a "RETURN TO LEVEL" button. This button is used to

level first the lateral roll, second the Trendelenburg, and third brings the table to its lowest

position. A delay of 3 seconds is expected after the Trendelenburg function before returning to

its lowest position.

The controller considers the table to be level if it is within +/- 2 degrees. If the "RETURN TO

LEVEL" button is pressed while the table is within this range, it will not move. If it is required

to adjust the table to a position closer to zero degrees, press the appropriate function button on

the Hand Control until the desired position is achieved.

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

FLOOR LOCK STATUS

11

Page 13

FLOOR LOCK

ON

STOWED

RETURN

TO

LEVEL

FLOOR

FLOOR

UNLOCK

LOCK

Battery Status

Green-OK

Red-Charge

(800) 777-4674

Figure 5: Hand Pendant Control (Hand Control)

5.5 Leg Spars:

The 6850 Table is equipped with two adjustable patient leg spars. Each will articulate

horizontally and vertically to accommodate a variety of patient positions and surgical

procedures. Additional patient leg rotation and traction is available.

CAUTION: Leg Spars can be damaged if allowed contact with floor during table

operation. Clear area of any obstructions or obstacles during table movement.

LA PRUDENCE: les Perches de Jambe peuvent être endommagées si a permis le contact

avec le plancher pendant l'opération de table. Eclaircir de n'importe

quelles obstructions ou de n'importe quels obstacles pendant le

mouvement de table.

Figure 6: 6850 Table with Leg Spars attached.

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

12

Page 14

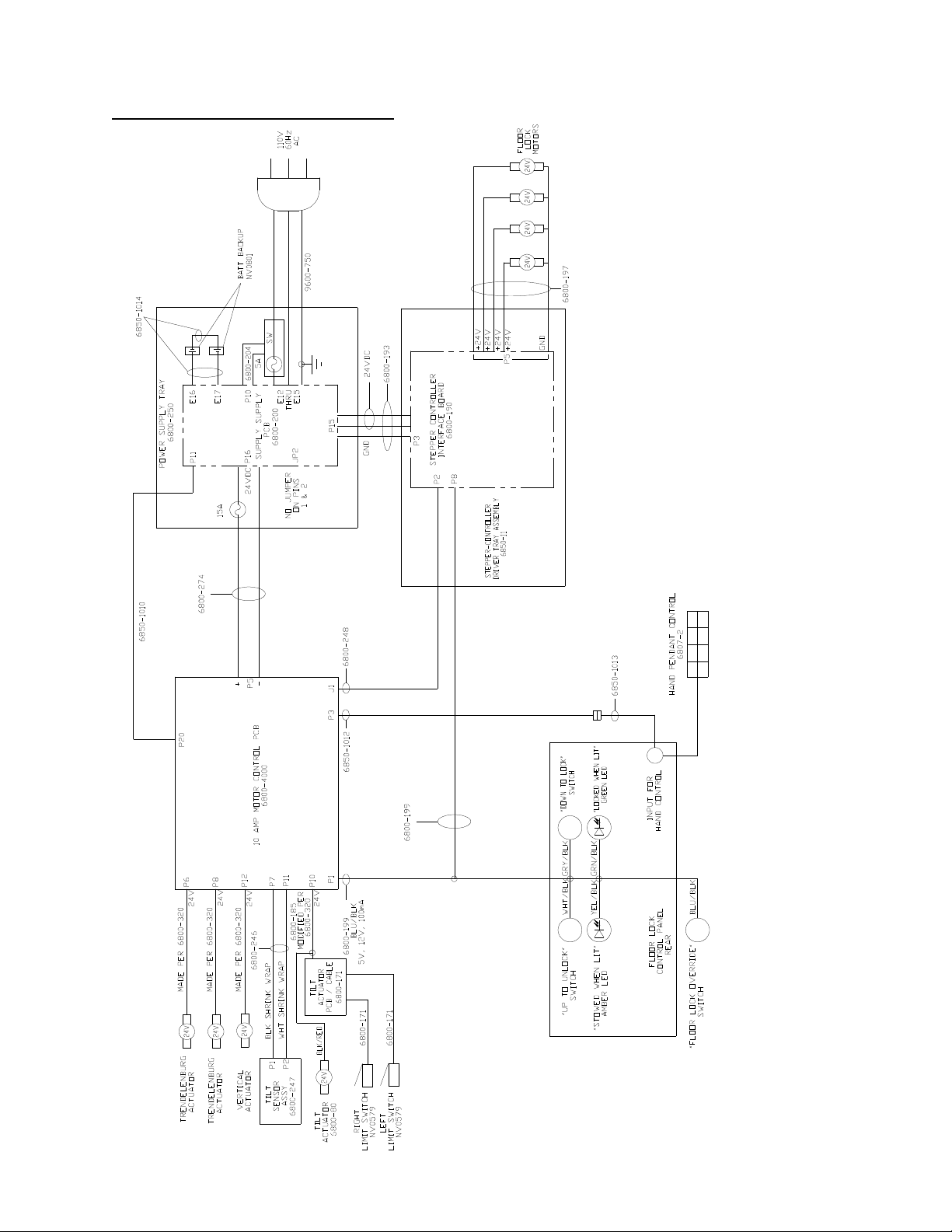

6.0 THE ELECTRICAL SYSTEM

6.1 Description

The electrical system provides control of all table functions and is comprised of a power cord, an

On/Off circuit-breaker switch, wire harnesses, a power supply, a controller circuit, a Hand

Control, floor lock jackscrew-actuators, and various electromechanical actuators. The electric

motor-driven lead-screw type actuators manipulate the table height; the Hand Control controls

lateral roll and trendelenburg functions. The Floor Lock buttons raise and lower the table onto

the floor locks. The input power requirement is 120 VAC 60Hz, 6.5 Amp or 230 VAC 50Hz as

indicated on the Serial Number label. Refer to 6850 Table Electrical Interconnect Diagram

(drawing number 6850-1001).

6.2 On/Off Power Switch

An illuminated On/Off main power switch and circuit breaker is located on the head-end of the

table base. When illuminated, it indicates that the table is plugged into a live electrical outlet and

the power is on. This switch also serves as a high-voltage 120/240-volt circuit breaker. In the

event of an overload condition this switch will trip off. To reset, push circuit-breaker switch to

the "OFF" position and then the "ON" position.

NOTE:

Determine the source of the overload prior to resetting this switch.

6.3 Component Circuit Breaker

The electrical system includes individual component 24-volt circuit breakers, located at the headend of the table base. If a short circuit occurs the low voltage circuit breaker will trip as

indicated by a button protruding from the access hole. To reset, press the button in and release.

NOTE:

Determine the source of the overload prior to resetting this button.

6.4 Power Cord

The table is equipped with a detachable standard EIC power cord with the appropriate 120 VAC

hospital grade connector (230volt versions do not include the power connector). The power cord

is connected to the table at the EIC power entry socket located near the "ON/OFF" switch, at the

pedestal end of the table base.

6.5 Leakage Current

The 6850 Table is designed and tested not to exceed 100 micro amps of leakage current.

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

13

Page 15

6.6 Floor Lock System

Floor Lock Button

Floor Lock Indicator Lights

Floor Lock Override Button

located under panel

Manual Floor Lock access

for Crank Handle

Figure 7: Head-end Base and Control Panel

The Floor Lock System secures the 6850 Table by powering four (4) jackscrews, lowering four

legs onto the floor and unloading table weight off of the four swivel casters. The controller

monitors each individual Floor Lock for contact with the floor and requires that each Floor Lock

be completely engaged before any other table function can be operated. In the case of an uneven

floor, it is possible that one or more legs will continue to extend until firm contact is made.

To lock the Floor Lock:

Press and hold the Hand Control "FLOOR LOCK" button or Control Panel "DOWN TO LOCK"

button. When locked, the Hand Control "FLOOR LOCK ON" light, and Control Panel, green

“LOCKED WHEN LIT” light illuminates, indicating that all four feet are locked.

To unlock the Floor Lock:

Press and hold the Hand Control “FLOOR UNLOCK” button or Control Panel "UP TO

UNLOCK" button. When unlocked, the Hand Control "FLOOR LOCK STOWED" light and

Control Panel, amber “STOWED WHEN LIT” light illuminates, indicating that all four feet are

completely retracted.

“FLOOR LOCK OVERRIDE” Button:

If Floor Lock System fails during table use, press and hold the “FLOOR LOCK OVERRIDE”

button while simultaneously operating the desired Hand Control function. Once released, no

functions will be operable and this button must be pressed again if subsequent table movement is

required.

NOTE: This Override Button only powers the height, Trendelenburg, and Lateral Roll functions

via the Hand Control and is intended for emergency situations only.

To restore Floor Lock System function:

• Verify Power Cord is plugged into a live power outlet supplying proper voltage and the

"ON/OFF" Power Switch is on and illuminated.

• Verify all four Floor Locks are completely engaged and Control Panel, green “LOCKED

WHEN LIT” light illuminates.

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

14

Page 16

To manually disengage Floor Lock for table relocation:

1. Use Floor Lock Crank Handle (p/n 6800-230) stowed on sheet metal housing behind Control

Panel for each Floor Lock.

2. Remove Floor Lock access hole-plug and insert Crank Handle to engage Floor Lock shaft.

3. For Floor Lock nearest grounding stud/Power Cord, turn Crank Handle clockwise to raise

Floor Lock.

4. For all other Floor Locks, turn Crank Handle counter-clockwise to raise Floor Lock.

6.7 Emergency Backup Battery System

The 6850 Table is equipped with an emergency battery backup system. The system batteries are

automatically charged while the table is plugged into a proper power source and the ON/OFF

power switch is switched "ON".

Battery charge status in shown via a light on the Hand Control labeled "Battery Status".

If illuminated green = OK.

If illuminated red = charge.

Due to the relatively low drains of the 6850 Table, the table could be used only on the backup

batteries for up to several hours of continuous use, but are intended for emergency use during

loss of power.

If recharge is required, charge a minimum of 3 hours. A full charge should be available after 18

hours.

Both batteries should be replaced every five (5) years or as needed. See Emergency Backup

Battery Replacement section.

6.8 Troubleshooting

In the event of a table malfunction:

• Check input power; verify Power Cord is plugged into a live electrical outlet.

• Verify Power Switch is “ON”; the switch illuminates green.

• Verify the Floor Lock is locked to the floor; press the “FLOOR LOCK” button until the

green “LOCKED WHEN LIT” light is illuminated.

• Use the “FLOOR LOCK OVERIDE” button to temporarily bypass the interlock of the Floor

Lock system.

NOTE: This Override Button only powers the height, Trendelenburg, and Lateral Roll

functions via the Hand Control and is intended for emergency situations only.

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

15

Page 17

7.0 CLEANING and MAINTENANCE

7.1 Cleaning and Disinfecting

NOTE: Never pour any liquid directly onto the table. Never subject the 6850 Table to an

equipment washing machine.

USE OF IODOPHORS WILL CAUSE STAINING.

Table Exterior:

1. Exterior surface should be regularly wiped clean with a mild detergent solution and wiped

dry with a soft lint-free cloth.

2. Care should be taken to avoid exposing the table to excessive moisture. Flooding, fogging or

steam cleaning is not recommended.

3. Blood or other fluids, etc., if allowed to remain on the table for a long period of time, will

require special cleaning to remove. A 5% acetic acid solution or white vinegar and water

solution is especially good for this purpose.

4. Cleaning with a good commercial cleaning compound, such as Stainless Steel Magic or

Acme White Finish, and then buffing the surface by hand can correct staining and

discoloration of plated or stainless steel surfaces only.

5. To disinfect exterior surfaces use a quaternary ammonium or similar type disinfectant

compound according to manufacturer's directions for use. Wipe dry with a soft lint-free

cloth.

NOTE: Failure to thoroughly dry surface after cleaning and disinfecting may result in rust.

Casters:

Casters should be cleaned and disinfected in the same manner as table exterior. Access to the

casters is achieved by removing the sheet metal enclosures at each end of the table base.

NOTE: Before removing any sheet metal covers the table must be turned off and unplugged.

Dangerous high voltage may be present in the circuitry under the covers. Only trained

technicians should perform this task.

7.2 Maintenance

Routine table care will assure many years of trouble-free service.

Lubrication:

All components are lubricated for life at the factory and no other lubrication on the table is

necessary.

Preventative Maintenance:

Contact OSI Technical Service for a complete Preventative Maintenance Checklist.

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

16

Page 18

8.0 REMOVAL and REPLACEMENT of COMPONENTS

8.1 Floor-lock Actuator

Floor Lock

(lowered)

Coupling

and Set-screw

Support Block

Floor Lock

(raised)

Crank Handle

Figure 8: Foot-end Base with cover removed, raised with support block and Crank Handle.

1. Flip on

main “ON/OFF” power switch. The switch illuminates, indicating power is to the

table.

2. Lock table to floor; Press and hold “DOWN TO LOCK” button until green "LOCKED

WHEN LIT" light is on.

3. Flip off

main “ON/OFF” power switch. Wait 30 seconds for discharge. Unplug power cord

from properly grounded wall outlet.

4. Remove base-access cover from end of table needing floor lock replacement.

CAUTION: Electrical shock hazard exists with access covers removed; use caution

when working in exposed areas.

LA PRUDENCE: Le danger de choc Electrique existe avec les couvertures d'accès

enlevées; la prudence d'usage en travaillant dans les domaines

exposés.

a. Remove two white-plastic access plugs for the Floor Lock using small slotted

screwdriver.

b. Remove four screws attaching the cover using a 1/8-inch hex key.

c. Remove access cover.

5. Raise end of table using Floor Lock Crank Handle (p/n 6800-230 supplied with table). See

photo above.

6. Place 2-1/2 inch high support-block under Floor Lock motor-mount.

7. Carefully lower table onto support-block using Floor-lock Crank Handle.

CAUTION: Make certain table remains stable.

LA PRUDENCE: Faire la certaine table restes écurie.

8. Raise Floor Lock off the floor to its maximum height, using Floor-lock Crank Handle.

9. Loosen Floor-lock actuator coupling setscrew using 1/8-inch hex key, slide coupling towards

actuator.

10. Remove actuator by removing the two socket-head cap screws using 3/16-inch hex key.

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

17

Page 19

11. Replace Floor-lock Actuator (p/n 6800-217) or Pad (as described below).

M6-1.00 x 35 mm Bolt

12. Reassemble in reverse order.

13. Verify proper function using Pre-Op Function Check.

8.2 Floor-lock Pad

If only the Floor-lock pad requires replacing.

1. Remove Brake Pad (p/n MZC700004B0) by removing M6-1.00 x 20mm socket-head bolt

(p/n MZA00206200) using 5mm hex key.

2. If the standard attachment bolt is bent; the first threads may be damaged requiring

replacement with an optional, longer M6-1.00 x 35mm (p/n AAM6035CAN).

3. Install replacement Brake Pad with attachment bolt and washer using 5mm hex key.

Floor Lock

Actuator Jack

Screw

Figure 9: Floor Lock Actuator Assembly.

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

Floor Lock Pad

18

Page 20

8.3 Emergency Backup Battery

The following information is on the battery replacement-warning label located inside the battery

cover.

If battery fails to hold a charge it should be replaced. Replace only with identical type and size

battery. Replace both batteries at the same time. Also replace foam battery blocks on top of

battery. Batteries should be replaced once every five (5) years. Whenever this cover is opened,

check battery for signs of corrosion. Battery terminals should be clean and free from corrosion,

oil, grease, dirt, or other contaminants. Install batteries per included diagram.

WARNING:

Connect batteries only with power cord unplugged and main switch “OFF”

.

Connect battery terminals as follows:

Red Wire: Positive terminal of battery “A” to terminal E16 on power supply.

Yellow Wire: Negative terminal of battery “A” to positive terminal of battery “B”.

Black Wire: Negative terminal of battery “B” to terminal E17 on power supply.

Perform the following test:

Make sure power cord is unplugged

.

Turn “ON” main power (utilizing battery power).

Observe all LED lights on Hand Control turn on and off sequentially.

Note: If this does not happen, turn “OFF” main power immediately and check if connection of

battery is correct and Hand Control is fully connected to the receptacle on the table, then

try above test again. If this does not solve the problem, contact OSI Technical Support at

800-777-4674 for further assistance.

When correctly connected and main power switch is “ON” and power cord unplugged, battery

status indicator light on Hand Control will show green or red.

A green battery-status light indicates batteries are charged and installed correctly.

A red battery-status light indicates batteries are connected correctly but are in need of charging.

Charge for at least three (3) hours by plugging power cord into wall receptacle and turn table

power “ON”. Make sure green indicator on circuit breaker in on (AC is provided to the charger).

Battery Type: Gel cell LED acid batteries, 12 Volt 12 Amp-hour rating.

Battery Size: 150mm long, 98mm wide, 100mm deep.

Battery OSI ordering number: NVO801

Foam battery block OSI ordering number: 6850-195

Figure 10: Head-end base, cover removed, Power Supply Assembly

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

19

Page 21

8.4 10 Amp Motor-control PCB

See 9.5 Table Assembly, Exploded View.

1. Flip off the main “ON/OFF” power switch, and wait 30 seconds

cord from wall outlet.

2. Remove foot end base cover by removing the four screws using 1/8 in hex key.

3. Lift off foot end base cover.

4. Unplug cables from 10 Amp Motor-controller PCB. See Interconnect Diagram.

CAUTION: Cable connectors are not marked, mark as needed.

a. J1 "TO STEPPER CONTROLLER" -

b. P1 "TO INTERUPT" - to Stepper Controller/Component Interface.

c. P2 "TO PC" - no connection.

d. P3 "KEYPAD" - Extension Cable (p/n NV0564) to Hand Control.

e. P4 "OUTPUT" - no connection.

f. P5 "POWER IN" - Power Cable (p/n 6800-274) to DC Power Supply.

g. P6 - white marked cable to Trendelenburg Actuators.

h. P7 - to Tilt Sensor Assy. (p/n6800-247).

i. P8 - blue marked cable to Trendelenburg Actuators.

j. P10 - orange marked cable to Tilt Actuator.

k. P11 - to Tilt Sensor Assy. (p/n6800-247).

l. P12 - yellow marked cable to Vertical Actuator.

m. P13, P15, P17 - no connection.

n. P18 "INPUT" - no connection.

o. P20 – to Power Supply P11, battery feedback monitor.

5. Remove the two #10 socket-head screws attaching the 10 Amp Motor-controller PCB

mounting bracket (located under the PCB).

6. Lift the mid-section base cover and remove the two #10 socket-head screws attaching the 10

Amp Motor-controller PCB mounting bracket.

7. Carefully lift out the two #10 socket-head screws attaching the 10 Amp Motor-controller

PCB assy.

8. Reassemble in reverse order.

for discharge. Unplug power

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

20

Page 22

8.5 Power Supply Tray

See 9.5 Table Assembly, Exploded View.

Figure 11: Head-end base with cover removed, Power Supply removal.

1. Flip off

cord from wall outlet.

2. Remove head end base cover by removing the six screws using 1/8 in hex key.

3. Unplug small 3-wire connector P11.

4. Unplug 3-wire connector P 15.

5. Unplug 2-wire connector P 16.

6. Remove 3/8-inch hex bolt from ground stud using 9/16-inch wrench and remove top two

green / yellow striped wires.

7. Remove three socket-head screws on each side of power supply tray and loosen two socket-

head screws at front of tray using 5/32-inch hex key.

8. Remove Power Supply Tray by carefully lifting out of base casting.

9. Install in reverse order.

the main “On/Off” power switch, and wait 30 seconds for discharge. Unplug power

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

21

Page 23

8.6 Stepper-controller Tray

See 9.5 Table Assembly, Exploded View.

Figure 12: Stepper-controller Tray Assembly

1. Flip off

cord from wall outlet.

2. Remove foot end base cover by removing the six screws using 1/8-inch hex key.

3. Lift off cover.

4. Unplug cables from Stepper Controller PCB. See Interconnect Diagram.

CAUTION: Cable connectors are not marked, mark as needed.

LA PRUDENCE: les connecteurs de câble ne sont pas marqués, la marque comme

nécessaire.

a. J1 and J2 - no connection.

b. P1 - no connection.

c. P2 - Com Port.

d. P3 - Power In.

e. P4 - Power Out.

f. P6 - Senders

g. P7 - Analog I/O

h. P8 - Digital I/O

5. Remove ground wires from the ground stud using 3/8-inch wrench.

6. Remove two socket-head screws attaching the tray, closest to the table pedestal, using 5/16-

inch hex key.

7. Loosen two, horizontal, socket-head screws, attaching the tray, using 5/16-inch hex key.

8. Carefully lift out the Controller Tray.

9. Install in reverse order.

the main “On/Off” power switch, and wait 30 seconds for discharge. Unplug power

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

22

Page 24

8.7 Tilt Sensor-Actuator

1. Flip on

main “ON/OFF” power switch. The switch illuminates, indicating power is in the

table.

2. Press and hold “DOWN TO LOCK” button until green "LOCKED WHEN LIT" light is lit.

3. Move tabletop to highest position using Hand Control.

4. Flip off

main “ON/OFF” power switch. Wait 30 seconds for discharge.

5. Pivot both Leg Spars outward to their maximum limits.

6. Remove left and right Leg Spars per User Guide procedures.

Pivot Frame Cover Removal:

See Figure 13.

1. Remove left and right “Spar Position” crank handles using 1/8-inch hex key.

2. Remove left and right ‘Spar Position Lock” handle-knobs by firmly rotating counter-

clockwise.

3. Remove “Accessory Bracket Remove/Attach” crank handle using 3/16-inch hex key.

4. Remove four button-head screws, located at top of cover using 1/8-inch hex key.

5. Carefully remove Pivot Frame Cover.

Left and Right “Pivot Frame Front” Cover Removal:

Not shown, but located at far end from Pivot Frame Cover.

1. Carefully pry off each cover (held in place with double-backed tape).

Left Bell Cover Removal:

See Figure 13.

1. Remove seven flat-head screws, located on top, front and back, using 1/16 hex key.

2. Remove two screws, located on top surface of cover, using 1/8 hex key

3. Remove cover.

CAUTION: To prevent damage to the sensors use care removing or replacing this

cover.

LA PRUDENCE: Empêcher des dommages au soin d'usage de détecteurs pour enlever

ou remplacer cette couverture.

“Spar Position Lock”

Handle

“Spar Position”

Crank Handle

“Accessory Bracket

Remove/Attach”

Handle

Pivot Frame

Cover

Bell Cover,

Left

Bell Cover,

Right

Figure 13: Head-end - Pivot Frame and Bell Covers, Spar Lock Handles.

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

23

Page 25

Tilt Sensor removal:

1. Cut any cable ties holding the existing tilt sensor wire-harness to the tilt sensor bracket.

2. Gently pull the two sets of wires from the tilt sensor.

NOTE: The color-coding, white-marked connector into white-marked "Tilt Adjust" socket,

black-marked connector into black-marked "Trend Adjust" socket.

3. Remove original tilt sensor by removing two 1/4-20x1/2 in. cap-head screws using 3/16 hex

key.

Replacement Tilt Sensor installation:

1. Using 3/16 hex key, attach the replacement tilt sensor with the two ¼-20 screws.

2. Plug in wire harnesses connecting to tilt sensor. Connect the white shrink-tube-marked

connector into white-marked "Tilt Adjust" socket, black shrink-tube-marked connector into

black-marked "Trend Adjust" socket.

3. Attach harness to sensor bracket, as needed, with small nylon cable tie. “Do not over tighten

wires” Use care to prevent possible damage by moving parts.

Tilt Sensor Calibration:

NOTE: Use bubble level, resting on the tabletop, as level gauge. The level sensor adjustment

screws are accessed from top of unit. A two-degree maximum dead-band exists for axis.

For "Return-to-level" to function, tabletop must be outside of this dead-band.

1. Flip on

table.

2. Press and hold “DOWN TO LOCK” button until green "LOCKED WHEN LIT" light

illuminates.

3. Raise the tabletop to a comfortable level.

4. Push " LEFT LATERAL ROLL" or "RIGHT LATERAL ROLL" buttons to level tabletop.

5. Push "LEFT LATERAL ROLL" button to lateral roll tabletop more than five degrees.

6. Push "RETURN-TO-LEVEL" button to level tabletop; note degree of level.

7. Push "RIGHT LATERAL ROLL" button to lateral roll tabletop more than five degrees.

8. Push and hold "RETURN-TO-LEVEL" button to level tabletop; note degree of level.

9. Turn the "Tilt Adjust" screw a partial turn.

NOTE: Clockwise will stop tabletop more to the right, counter-clockwise will stop tabletop

10. Test the adjustment by:

10.1. Push "LEFT LATERAL ROLL" button to tilt tabletop to maximum.

10.2. Push "RETURN-TO-LEVEL" button to level tabletop; note the degree of level.

10.3. Push "RIGHT LATERAL ROLL" button to tilt tabletop to maximum.

10.4. Push "RETURN-TO-LEVEL" button to level tabletop; note the degree of level.

11. Continue adjustments until tabletop stops from either maximum lateral roll at same offset

from zero.

12. Trendelenburg / Reverse-Trendelenburg calibration.

12.1. Repeat steps of "Left and Right Lateral Roll" calibration using "Trendelenburg /

13. Push the illuminated "ON/OFF" switch to off

discharge

14. Reattach Left Bell Cover with seven screws using a 1/16-inch hex key.

CAUTION: Use care replacing this cover to prevent damage to the sensors.

LA PRUDENCE: le soin d'Usage pour remplacer cette couverture pour empêcher des

dommages aux détecteurs.

main “ON/OFF” power switch. The switch illuminates, indicating power is in the

more to the left. Tabletop will overshoot each stopping point, requiring "splitting

the difference" to adjust for proper balance.

Reverse-Trendelenburg".

, green light goes out. Wait 30 seconds for

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

24

Page 26

9.0 TECHNICAL DRAWINGS and PARTS LISTS

9.1 Interconnect Diagram, 120VAC

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

25

Page 27

9.2 Interconnect Diagram, 220VAC

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

26

Page 28

9.3 Table Assembly Bill of Materials

50 AAAT031AAC #10-32 X .31 SST BTN HD SKT SCR 24

49 AAAT025HJA #10-32 X .25 SELF LOCKING SKT SET SCR 2

48 AAAT025AAC #10-32 X .25 SST BTN HD SKT SCR 4

47 AAAM037CAC #6-32 X .37 SST CAP HD SKT SCR 1

46 AAAK025AAC #5-40 X .25 SST BTNHD SKT SCR 4

45 AAAH031BAC #4-40 UNC X .31 FLAT HEAD SOCKET SCREW, SS 16

44 AAAH018BAC #4-40 UNC X .188 FLAT HEAD SOCKET SCREW, SS 6

43 9650-231 1/2 IN RUBBER CUSHIONED STEEL LOOP CLAMP 6

42 9650-227 .375 INCH PLASTIC CABLE CLAMP 9

41 6800-271 BELLOWS MOUNT 2

40 6800-270 TILT COVER , RIGHT 1

39 6800-269 TILT COVER, LEFT 1

38 6800-268 COLUMN SKIRT, FIXED, RIGHT 1

37 6800-267 COLUMN SKIRT, FIXED, LEFT 1

36 6800-263 X-RING COVER , RIGHT 1

35 6800-262 X-RING CO VER, LEFT 1

34 6800-260 BELLOWS SUPPORT 2

33 6800-259 BELLOWS 2

32 6840-11 CONTROLLER TRAY ASSEMBLY 1

31 6800-250 POWER SUPPLY TRA Y ASSEMBLY 1

30 6800-249 TILT SENSOR SPACER 1

29 6800-247 T ILT SENSOR ASSEMBLY 1

28 6800-239 ASSY, 10 AMP MOTOR CONTROL 1

27 6800-230 ASSEMB LY, MANUAL FLOOR LOCK CRANK 1

26 6800-229 X-RING WITH BUSHINGS ASSY 1

25 6800-208 FLOOR LOCK LED YELLOW 1

24 6800-207 FLOOR LOCK LED GREEN 1

23 6800-171 TILT MOTOR LIMIT SWITCH ASSY 1

22 6800-174 BRKT, TILT MTR LIM SW MNT 2

21 6800-173 PC BOARD MOUNT, TILT MOTOR 1

20 6800-133 BASE COVER, FRONT 1

19 6800-132 BASE COVER, BACK 1

18 6800-130 BASE COVER, MID SECTION 1

17 6800-129 COLUMN SKIRT FLOATING 1

16 6800-127 COLUMN SLIDER COVER 1

15 6800-99 PIN , TRENDELENBURG 2

14 6800-98 PIN ,TILT, BACK 1

13 6800-97 PIN, TILT, FRONT 1

12 6800-96 SWIVEL BRACKET MOUNT WASHER 2

11 6800-95 PRESSURE PLATE, TILT ACTUATOR MOUNT 1

10 6800-94 SWIVEL BRACKET ADJUSTMENT BRACKET 1

9 6800-90 SWIVEL BRACKET WELDMENT, TILT 1

8 6800-80 ASSEMBLY, TILT ACTUATOR 1

7 6800-79 TILT AXIS WORM GEAR 1

6 6800-77 TILT WORM GEAR SHIM, .010 2

5 6800-75 TILT WORM GEAR SHIM, .002 1

4 6800-54 SHIM, 1.00 DIA PIN 6

3 6800-38 Y-RING MACHINED 1

2 6800-37 TRENDELENBURG ADJUSTMENT LEVER, X-RING 1

1 6800-7 BASE FEET AND COLUMN SUBASSEMBLY 1

ITEM PART NO. DESCRIPTION QTY

98 NV0711 MOLEX SOCKET CRIMP 28-22 AWG 16

97 NV0630 CON NECTOR HOUSING , MALE , 8 CIRCUIT 39-01-2080 4

96 6800-76 TILT WORM GEAR SHIM, .005 1

95 6800-274 10 A MOTOR CONTROL POWER CABLE 1

94 6800-248 CABLE ASSY., FLAT RIBBON M-F DB9 1

93 6800-246 TILT SENSOR WIRE HARNESS 1

92 6800-199 DIGITAL I/O W IRE HARNESS 1

91 6800-197 FLOOR LOCK HARNESS ASSY. 1

90 6800-193 CABLE ASS Y, PWR SPL TO STEPPER CONTROLER 1

89 6800-119 TILT WORM GEAR SHIM .O239 THICK 2

88 6800-118 TILT WORM GEAR SHIM .OO7 THICK 2

87 9650-225 .25 INCH PLASTIC CABLE CLAMP 1

86 NV0649 .75 INCH PLASTIC CABLE CLAMP 3

85 6800-185 ACTUATOR POWER CORD 1

84 NV0650 1 INCH PLASTIC CABLE CLAMP 5

83 NV0587 STAINLESS STEEL BUTTON 4

82 NV0259 3/8 IN RUBBER CUSHIONED STEEL LOOP CLAMP 3

81 NL1255 ACTUA TOR, ELEC., 100mm, LINAK 2

80 NG0752 #10-32 PEM SELF CLINCHING SS 8

79 NB0339 EAGLE P LASTIC NYLON HOLE PLUG Ø1.00 4

78 KA0060400 1/16 X 4 1/2 NEOPRENE RUBBER W/ADH 24 "

77 AJ0117 RETAINING RING EXTE RNAL 1" DIA, BLK PHS 4

76 AE019050KF SHOULDER WASHER #10 NYLON 4

75 AE018037D STAR LOCK WASHER, INTERNAL, .18 X .37 3

74 MZA30108030 8 mm HEX NUT 10

73 ADATA #10-32 HEX NUT 3

72 NV0564 CABLE , HANDSET EXTENSION 2.4 M LONG 1

71 AC012025 POP RIVE T, .12 X .25 LG 8

70 AAM10045FA 10mm DIA. X 45mm LG, SKT HD SHLDR SCR 1

69 AAM10035FA 10mm DIA. X 35mm LG, SKT HD SHLDR SCR 1

68 AAM10030FA 10mm DIA. X 30mm LG, SKT HD SHLDR SCR 3

67 AABF125CA 1/2-13 X1.25 CAP HD SKT SCR 2

66 AABB075HA 3/8-16 X .75 SCK SET SCR 1

65 AABB175DD A 3/8 -16 X 1.75 HEX HEAD CAP SCREW GRADE 8 1

64 AABB075CAA 3/8-1 6 X .75 CAP HD SKT SCR GRADE 8 3

63 AAAY350DD 5/16 -18 X 3.5 HEX HEAD CAP SCREW 2

62 AAAW125CA 1/4-20 X 1.25 CAP HD SKT SC R, 2

61 AAAW075CA 1/4-20 X .75 CAP HD SKT SCR 3

60 9600-450 T-CABLE ASSEMBLY, HANDSET 1

59 AAAW050CA S CREW, CAP, HEX, 1/4-20 UNC-2A X .50L 2

58 AAAW050BAC 1/4 X 20 FLAT HEAD SOCKET SCREW 4

57 AAAT075HA #10-32 X .25 SST SKT SET SCR 1

56 9650-431A CABLE, HANDSET EXTENSION 20 IN 1

55 AAAT075AAC #10 -32 X .75 SST BTN HD SKT SCR 4

54 AAAT050HAC #10-32 X .50 SST SKT SET SC R 1

53 AAAT050BAC #10-32 X .50 SST FLHD SKT SCR 2

52 AAAT050AAC #10 -32 X .50 SST BTN HD SKT SCR 10

51 AAAT037AAC #10 -32 X .37 SST BTN HD SKT SCR 51

9.4 Replacement / Spare Parts List

Hand Control…………….…………………..………………..p/n (part number) 6800-238

Power Supply Tray Assembly…………..………………………….…..…….p/n 6800-250

Power Cord, Right Angle………......….….………………………….…...….p/n 9600-750

Power Cord Receptacle………………………………...……………….……..p/n NV0585

LED (Light Assembly), Amber……………………….…………….....……..p/n 6800-208

LED (Light Assembly), Green……………………….…….………......…….p/n 6800-207

Floor Lock Assembly……………………………………...……………..…..p/n 6800-210

Floor Lock Pad…………………………………...………..……....….p/n MCZ700004B0

10 Amp Motor-Controller PCB Assembly………..….……………....…..….p/n 6800-239

Stepper-Controller/Driver PCB Tray Assembly……………………..………..p/n 6840-11

Tilt Actuator Motor Assembly…………….…..………….……………..….…p/n 6800-80

Tilt Sensor Assembly……..………………….………………………………p/n 6800-247

Emergency Backup Battery (two required)……………….……………….….p/n NV0801

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

27

Page 29

9.5 Table Assembly Exploded View

3

13

57

14

Y-Ring Assembly

54

4

26

X-Ring Assembly

10 Amp-Controller

Stepper-Controller

66

74

68

77 4X

15 2X

70

2

61

812X

Power Supply

682X

744X

84 4X

31

504X

81 (REF)

84

50

68

Base Assembly

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

28

Page 30

9.6 Base Cover Assembly, Exploded View

412X

33

51 6X

552X

484X

17

38

512X

456X

512X

16

76 4X

19

51 4X

79 4X

20

18

522X

514X

32

78REF

28

51 2X

37

78 REF

1

51 4X

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

29

Page 31

9.7 Base Assembly, Exploded View

87

78

50 6X

78

42 5X

43 2X

50 2X

78

1

503X

86 3X

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

30

Page 32

9.8 X-Ring Assembly Exploded View

34

80 4X

445X

50

26

34

516X

80 4X

35

514X

714X

33

50

84

532X

43

50

42

21

47

23

433X

50 3X

33

823X

10

50 2X

65

62

42 2X

51 9X

75 3X

73 3X

45 5X

36

9

67

8

11

63 2X

22 2X

58

27

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

31

Page 33

10.0 GLOSSARY OF TERMS

Basic assumptions of patient orientation on the tabletop: our glossary of terms and technical

procedures assume the patient is normally oriented with their head at the “head end of table”

(toward Control Panel) and their feet at the “foot end of table” (toward Leg Spars). The Hand

Control functions are oriented for this position only.

“Head end of table” refers to the end of the table where the power cord, "ON/OFF" power

switch, and Control Panel are located; otherwise referred to as the “pedestal end”.

“Foot end of table” refers to the opposite end of the table also referred to the “leg spar end".

“Control Panel” is a panel of buttons and lights located on the head end of the table.

“Pedestal” refers to the main column structure that supports the tabletop.

“Left side of the table” refers to the table as you stand at the head end of table.

This also corresponds to the Hand Control button labeled “LEFT LATERAL ROLL”.

“Right side of the table refers to the table as you stand at the head end of table.

This also corresponds to the Hand Control button labeled “RIGHT LATERAL ROLL”.

“Raise the table” refers to raising the height of the table.

This also corresponds to the Hand Control button labeled “HEIGHT UP”.

“Lower the table” refers to lowering the height of the table.

This also corresponds to the Hand Control button labeled “HEIGHT DOWN”.

“Raise the foot end of the table” refers to raising the height of the foot end of the tabletop or leg

spars. The corresponding Hand Control button is labeled “TREN” (Trendelenburg).

“Raise the head end of the table” refers to raising the height of the head end of the tabletop.

The corresponding Hand Control button is labeled “REV TREN” (Reverse Trendelenburg).

“Level the table” refers to leveling the tabletop regardless of height. The corresponding Hand

Control button is labeled “RETURN TO LEVEL”. Holding the “RETURN TO LEVEL” button

longer than approximately three seconds will also lower the tabletop to its lowest position.

"Lock the floor locks" refers to lowering the floor locks. The floor locks, when locked down,

will prevent the table from rolling and enable all other table functions. The corresponding Hand

Control button is "FLOOR LOCK" and the "FLOOR LOCK ON" light will illuminate or Control

Panel button is labeled “DOWN TO LOCK” and the green "LOCKED WHEN LIT" light will

illuminate.

“Unlock the floor locks” refers to rising the floor locks up 1/2-inch off the floor, allowing the

table to freely roll on its wheels. The corresponding Hand Control button is "FLOOR UNLOCK"

and the "FLOOR LOCK STOWED" light will illuminate or Control Panel button is labeled “UP

TO UNLOCK” and the amber "STOWED WHEN LIT" light will illuminate.

“Hospital Grade" outlet refers to a 120VAC outlet properly wired with earth ground: Neutral to

Common = 120VAC; Neutral to Ground = 120VAC; Common to Ground less than zero point

five (0.5) VAC.

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

32

Page 34

11.0 OSI TECHNICAL SERVICE

11.1 Contact for Parts and Service:

For detailed repair information or to order replacement parts, call the OSI Technical Services

Department:

A Technical Services representative is available from 7AM-5PM PST, Monday through Friday.

Please leave a message before or after business hours.

Please state; your name, phone number, facility name and city, affected equipment model

number and nature of problem.

OSI Telephone: 800-777-4674

An e-mail message may be left anytime at techsvcs@osisosi.com or through the Technical

Service icon in our web site: www.osiosi.com.

To order Replacement Parts (RP):

If unable to identify part - telephone, fax or E-mail to Technical Service.

If part is known - telephone, fax or E-mail part number and description to Customer Service for

price and availability.

To place Replacement Parts (RP) order - telephone, fax or E-mail part number, description,

price, customer number and method of shipment to Customer Service with purchase order.

Indicate that order is for Replacement Parts (RP).

To return damaged parts (RGA):

Identify parts to be returned.

Telephone, fax or E-mail part number and description of parts for return to Customer Service for

Return Goods Authorization (RGA) number and Certificate of Disinfection.

Return ship parts with RGA number clearly marked on outside of package.

Clean (disinfect) parts prior to shipping.

To send a part or item for OSI to repair (RA):

If unable to identify part - call, fax or E-mail to Technical Service.

If part is known - telephone, fax or E-mail part number and description to Technical Service for

Repair Authorization (RA) number and Certificate of Disinfection.

Clean (disinfect) parts prior to shipping.

Ship part with RA number clearly marked on outside of package.

Part will be evaluated and customer will be contacted with the cost of repair.

After customer approval of repair cost, part will be repaired and return shipped to customer.

End

6850 PROfx Maint. & Repair Manual NW0424 Rev. A

33

Loading...

Loading...