Page 1

ADVANCED CONTROL BASE

FOR THE

MODULAR TABLE SYSTEM

OWNER’S MANUAL

Model 5803

This manual is written in five

languages in the following order:

(en) English

(es) Spanish

(fr) French

(de) German

(it) Italian

MIZUHO OSI

30031 AHERN AVENUE UNION CITY, CA 94587

Bus: 510-429-1500 Toll Free: 800-777-4674 Fax: 510-429- 85 0 0

WWW.MIZUHOSI.COM ·

MIZUHOSI 2009 1 NW0498 Rev E

NEWHIPNEWS.COM · NEWSPINENEWS.COM

Page 2

IMPORTANT NOTICES

CAUTION: To ensure safe operation of the equipment, please READ THESE

INSTRUCTIONS COMPLETELY and keep this manual readily available for future

reference.

Carefully observe and comply with all warnings, cautions and instructions placed on the

equipment or described in this manual.

In this manual, the WARNING symbol is intended to alert the user to the presence

of important operation, maintenance, or safety instructions.

PROTECTION AGAINST ELECTRICAL SHOCK HAZARD:

This symbol indicates this equipment is an applied part, TYPE B in

accordance with IEC 60601-1 and is generally suitable for applications involving

external or internal contact with the patient, excluding the heart. The patient

circuit is connected to protective earth and this equipment should be connected

only to outlets with a protective earth ground.

This symbol

indicates the external stud that is at the same potential as the

equipment chassis. If the AC power cable is not connected to an outlet with a

protective earth ground, this external stud should be connected to a protective

earth ground.

WARNING:

Proper preoperative and intraoperative procedures must be followed to prevent

venous stasis and pooling, pressure sore development, neuropathy, improper

electro-surgical tissue grounding, hypotension and hypothermia.

WARNING:

It is important to note that a Jackson Spinal Surgery or Imaging Table Top used

on the model 5803 Advanced Control Base must have gimbals. Earlier versions

of these table tops do not have gimbals. Use of table tops without gimbals on the

5803 Advanced Control Base can result in damage to the table and the base.

WARNING:

Prior to attempting to use the Modular Table Base, one should carefully review

this owners manual and keep a copy on file for further reference. It is

recommended that one also view the appropriate sections of the Modular Table

System instructional video provided with the table top.

This device is to be used by trained personnel only.

MIZUHOSI 2009 NW0498 Rev E

2

Page 3

TABLE OF CONTENTS

1.0 INTRODUCTION..................................................................................................................................................5

1.1 General Description.........................................................................................................................................5

1.2 Specifications....................................................................................................................................................5

1.3 Shipping.............................................................................................................................................................5

1.4 Storage ..............................................................................................................................................................6

1.5 Acceptance & Transfer....................................................................................................................................6

1.6 Inspection and Transfer...................................................................................................................................6

2.0 GLOSSARY of TERMS......................................................................................................................................7

3.0 CONTROLS IDENTIFICATION.........................................................................................................................8

3.1 Base Orientation...............................................................................................................................................9

3.2 Model Number and Serial Number................................................................................................................9

4.0 BASIC OPERATION.........................................................................................................................................10

4.1 Casters.............................................................................................................................................................10

4.2 Hand Pendant.................................................................................................................................................11

4.3 5803 Advanced Base Controls..................................................................................................................... 13

4.3.1 Rotation Safety Lock ..................................................................................................................................13

4.3.2 180° Rotation Lock Indicator.....................................................................................................................14

4.3.3 Tilt Drive Status Indicator...........................................................................................................................14

4.4 Synchronizing The Lateral Tilt Function......................................................................................................15

4.5 Tabletop Coupling Procedure.......................................................................................................................17

4.6 Patient Transfer..............................................................................................................................................19

4.7 Table Top Coupling Procedure With Top In Place....................................................................................19

4.8 Patient Rotation..............................................................................................................................................20

4.9 Rotation Lock System....................................................................................................................................20

4.10 Rotation Procedure......................................................................................................................................20

4.11 Retracting The Base For Storage..............................................................................................................21

4.12 Table Top on the Base................................................................................................................................22

5.0 PRE-OPERATIONAL FUNCTION CHECK...................................................................................................23

6.0 CLEANING and MAINTENANCE...................................................................................................................24

6.1 Cleaning and Disinfecting.............................................................................................................................24

6.2 Lubrication.......................................................................................................................................................24

6.3 Preventative Maintenance ............................................................................................................................25

7.0 THE ELECTRICAL SYSTEM...........................................................................................................................26

7.1 Power Cord.....................................................................................................................................................26

7.2 ON/OFF Power/Circuit-Breaker Switch.......................................................................................................26

7.3 Power ON / Fault / Battery Status Lights....................................................................................................26

7.4 Battery Recharging........................................................................................................................................26

8.0 TROUBLESHOOTING......................................................................................................................................27

8.1 Electrical System............................................................................................................................................27

8.2 Functional Guide............................................................................................................................................28

9.0 REMOVAL and REPLACEMENT of COMPONENTS.................................................................................30

9.1 Head end Cover .............................................................................................................................................30

9.2 Foot End Cover...............................................................................................................................................31

9.3 Hand Pendant Module...................................................................................................................................31

9.4 Batteries...........................................................................................................................................................32

9.5 Power Supply Replacement.........................................................................................................................34

9.6 Controller Circuit Board Replacement.........................................................................................................34

9.7 On-Off Power Switch / Circuit Breaker Replacement...............................................................................35

9.8 Head End Assembly......................................................................................................................................35

9.9 Head End Tilt Motor.......................................................................................................................................35

9.10 Foot End Rotation Safety Lock Motor.......................................................................................................35

9.11 Head End or Foot End Column..................................................................................................................36

9.12 Retractable Center Beam...........................................................................................................................36

9.13 Casters ..........................................................................................................................................................36

MIZUHOSI 2009 NW0498 Rev E

3

Page 4

10.0 ADJUSTMENT of COMPONENTS...............................................................................................................37

HEAD END ............................................................................................................................................................37

10.1 Tilt Actuator Rod End Position...................................................................................................................37

10.2 180° Rotation Lock Sensor.........................................................................................................................37

10.3 Home & Tilt Left/Right Sensors.................................................................................................................. 38

10.4 Head end Slider Adjustment Procedure...................................................................................................39

10.5 Rotation Safety Lock....................................................................................................................................40

10.6 Rotation Safety Lock (Brake) “ON” Sensor Setting.................................................................................41

11.0 Mizuho OSI TECHNICAL SERVICE............................................................................................................42

11.1 Contact for Parts and Service....................................................................................................................42

11.2 Instant Support Value Package ................................................................................................................. 42

11.3 To order Replacement Parts (RP).............................................................................................................42

11.4 To return damaged parts (RGA)................................................................................................................42

11.5 To send a part for repair (RA)....................................................................................................................43

11.6 EC Authorized Representative...................................................................................................................43

11.7 Replacement / Spare Parts List.................................................................................................................44

11.8 Replacement Parts......................................................................................................................................45

11.9 INTERCONNECT DIAGRAM....................................................................................................................46

MIZUHOSI 2009 NW0498 Rev E

4

Page 5

1.0 INTRODUCTION

1.1 General Description

This manual describes the use, maintenance, and repair of the Modular Table System

(MTS) 5803 Advanced Control I-Base, DC (5803 Base). It is the primary component of

the system designed to support patients for a variety of surgical procedures. The 5803

Base is designed to hold a table top that will provide a patient support that is free of any

obstructions that might compete for space with a fluoroscopic C-Arm. There are five

procedure-specific table tops: Jackson Spinal, Radiolucent Imaging, Orthopedic

Trauma, Endourology and Maximum Access Lateral Top available for use on the MTS

Base.

1.2 Specifications

Maximum Patient Weight: Table top specific but not to exceed 500 lbs

Height Range of Base 34 - 48 inches (83.36 – 121 centimeters)

Trendelenburg Range 10 3

Reverse Trendelenburg 10° ±3°

Range

Powered Lateral Roll 25 3

Power Input (configurable)

o 100 VAC at 50/60 Hz

o 120 VAC at 60 Hz

o 230 VAC at 50 Hz

o internal battery power

Compatible Tabletops All MTS tops equipped with gimbals.

Maximum Length 102 inches (259 cm)

Retracted Length 64 inches (162 cm)

Width 32 inches (81 cm)

Maximum tilt torque 55 ft-lb

Maximum brake torque 93 ft-lb

Duty Cycle 4% or 2.5 minutes continuously per hour

1.3 Shipping

The 5803 Base must be shipped in a manner that prevents damage to its structural

elements, caster wheels, electronics, and operating controls. Contact with solid objects

in the environment must be prevented during shipment and storage, except at the four

casters. Banding for lateral constraint is to be limited to the base structure. Additionally,

banding of the head end assembly to prevent movement of the trolley is necessary. It is

also necessary to fully crate the 5803 Base to assure that no impact with foreign solid

objects will be made during transit. The 5803 Base is to be shipped in an environment

within the following limits:

Ambient temperature -4°F to 122°F (-20° C to +50° C)

Relative humidity from 10% to 100%, including condensation

Atmospheric pressure from 50 to 110 kPa.

MIZUHOSI 2009 NW0498 Rev E

5

Page 6

1.4 Storage

When not in use, store in a clean, dry environment with temperature between 32°F and

120°F (0° C to 49°C).

It is recommended that the 5803 Base be stowed with the power cord plugged into a

proper AC receptacle with the on/off power-switch “on” to assure batteries are fully

charged and ready for service.

If recharge is required, charge a minimum of 3 hours. A full charge should be

available after 18 hours.

1.5 Acceptance & Transfer

Upon receipt of your table, remove the table from the shipping crate following the

unpacking instructions. Visually inspect all surfaces for freight damage. Check each

caster for proper rolling operation.

NOTE: Any freight damage must be reported to the freight carrier immediately upon

delivery. It is the responsibility of the recipient to make freight damage claims.

1. Read the model/serial number identification label found at the head end of the base

(see figure 4) to confirm the serial number and the input power requirements.

2. Perform pre-op function check; see section 5.0.

1.6 Inspection and Transfer

Before use, inspect the device for possible damage, excessive wear or non-functioning

parts. Carefully inspect all critical, inaccessible areas, joints, electrical cords and all

movable parts for possible damage or non-function.

Damaged or defective products should not be used or processed. Contact your local

MIZUHO OSI sales representative for repair or replacement.

MIZUHOSI 2009 NW0498 Rev E

6

Page 7

2.0 GLOSSARY of TERMS

This glossary of terms and technical procedures assume the patient is oriented with

their head at the head end of table and their feet at the foot end of table. The hand

pendant functions are oriented for this position only.

Head end of base, indicates the end of the table where the power cord, "On-Off" switch,

and Control Panel are located.

Foot end of base, indicates the opposite end of the table.

Column, refers to one of two main column structures that support the tabletop.

Left side of the base, refers to the base as you stand at the head end of table.

Right side of the base, refers to the table as you stand at the front of column.

Raise the column, refers to raising the height of the column. This also corresponds to

Height Up.

Lower the column, refers to lowering the height of the column. This also corresponds to

Height Down.

Left lateral roll (tilt), refers to tilting the table top to the left when standing at the head

end of the base facing the foot end.

Right lateral roll (tilt), refers to tilting the table top to the right when standing at the head

end of the base facing the foot end.

Trendelenburg, refers to lowering the head end below the foot end.

Reverse trendelenburg, refers to lowering the foot end below the head end.

Hospital Grade, outlet refers to a 120VAC outlet properly wired with earth ground:

Neutral to Common = 120VAC; Neutral to Ground = 120VAC; Common to Ground less

than zero point five 0.5 VAC.

MIZUHOSI 2009 NW0498 Rev E

7

Page 8

3.0 CONTROLS IDENTIFICATION

m

The major components of the 5803 Advanced Control Base are identified in the

following figures.

Head end

H-Frame

H-Frame in Storage Bracket

Foot End

Center Bea

Locking Caster

Figure 1: 5803 Advanced Control Base - Side View

Tilt Drive

Status Switch

Hand Pendant

Locking

Caster

Figure 2: 5803 Advanced Control Base - Head End View

On/Off Switch – Identification Label

180° Rotation

Lock

Quiver

T-Pin Storage

Power Cord

Storage Wrap

Locking

Caster

Retracting Lock Knob

Steer Caster

Traction Arc

Interlocking

Switch

Quiver

T-Pin Storage

Steer Caster

Figure 3: 5803 Advanced Control Base - Foot End View

Locking Caster

MIZUHOSI 2009 NW0498 Rev E

8

Page 9

3.1 Base Orientation

The control end of the base is considered the head end, and the opposite end is the foot

end. The right side of the base is the side to the operator’s right when standing at the

head end looking toward the foot end. The general nomenclature and orientation of the

base is shown in figure 1, 2 and 3. Refer to the appropriate owners manual supplied

with each table top for table top component Identification and more detailed information

about the use of each table top.

3.2 Model Number and Serial Number

The model number and serial number are printed on the Identification label located at

the head end base. This label is located to the right of the on/off switch as shown

below.

On/Off

Switch

“Battery Status”

“Fault”, & Power lights

Head end

Base

Out Side

Model/Serial

Number

Identification

Label

Figure 4: Head End; Base Outside

Power Cord

Plug In

Reset Button

Circuit Breaker

External Ground

Stud

Head end

Base

Beam Side

Figure 5: Head End; Base Beam Side

MIZUHOSI 2009 NW0498 Rev E

9

Page 10

4.0 BASIC OPERATION

The 5803 Advanced Control Base uses an external AC power source or internal,

rechargeable, battery power for operation. It uses AC power when plugged into a proper

AC receptacle and the on/off power-switch is in the “on” position. When not plugged in,

or AC power is lost, the 5803 Base will automatically switch over to internal battery

power. The batteries are automatically recharged whenever the 5803 Base is plugged

into an AC power source and the on/off power-switch is in the “on” position. Located

next to the on/off power-switch on the head end base (see figure 4) is the power on,

fault, and battery status lights.

WARNING:

When the power cord is removed and/or not plugged into an AC outlet, the

protective earth ground stud near the power entry module must be connected to

a proper earth ground during use.

WARNING:

All Locks must be engaged before a patient transfer is performed.

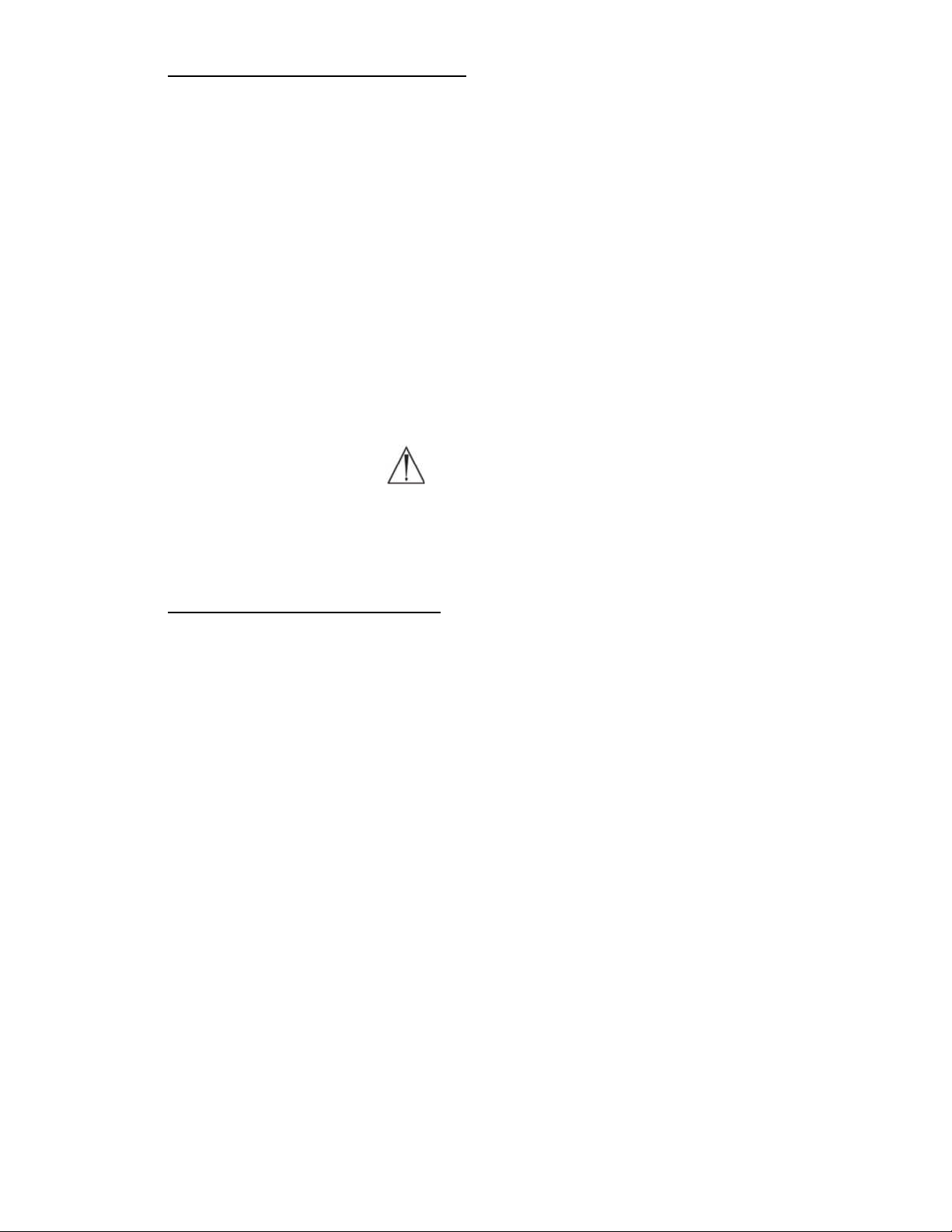

4.1 Casters

Each base is equipped with three (3) locking casters and one (1) steer caster. The

steer caster functions to allow the table to roll along a straight path when pushed from

the head end. The steer caster is located on the right side of the foot end. The steer

caster has a green label marked “Steer”. To lock the table base securely in place, it is

necessary to engage the lock on each of the four (4) casters.

To lock a caster lock, step on the lock tab until you hear an audible click and the tab

remains in the down or locked position (see figure 6). To unlock the caster, push the

unlock button. When the unlock button is pressed, the tab will click back to the original

unlocked position (see figure 7).

To Lock

To Unlock

Lock

Tab

Unlock

Button

Figure 6: Locked Caster Figure 7: Unlocked Caster

MIZUHOSI 2009 NW0498 Rev E

10

Page 11

4.2 Hand Pendant

Each 5803 Advanced Control Base is equipped with a hand-held pendant, which is on a

storage bracket attached to the head end. The hand pendant allows the operator to

manipulate the table into trendelenburg, reverse trendelenburg, and lateral roll (tilt)

positions. The selected function will continue to operate until the button on the hand

pendant is released.

NOTE: It is recommended that a table top always be connected between the head and

foot ends when operating the powered controls.

Indicator

Lights

To raise the table, depress the

height up button on the left side of

the control with the arrow that points

in the “up” direction.

To lower the table, depress the

height down button on the right side

of the control with the arrow that

points in the “down” direction.

Height Up

Trendelenburg

Left Lateral

Roll (Tilt)

Indicator

Lights

Figure 8: Hand Pendant

Height

Down

Reverse

Trendelenburg

Right Lateral

Roll (Tilt)

To trendelenburg the table,

depress the button on the left with

the arrow that indicates foot up until

the desired trendelenburg angle is

achieved. This lowers the head end

column and raises the foot end

column simultaneously. If the table is

in a fully lowered position, only the

foot end will raise to achieve the

desired trendelenburg angle.

To reverse trendelenburg the

table, depress the button on the right

with the arrow that indicates foot

down until the desired reverse

trendelenburg angle is achieved.

This raises the head end column and

lowers the foot end column

simultaneously. If the table is in a

fully raised position, only the foot end

will lower to achieve the proper

reverse trendelenburg angle.

To laterally tilt to the left, depress

the left lateral roll button on the left

side of the control.

To laterally tilt to the right, depress

the right lateral roll button on the

right side of the control.

MIZUHOSI 2009 NW0498 Rev E

11

Page 12

NOTE: In the event a large traction arc 5855-13 is placed on the base, the tilt function

has been made inoperable. However in the event a small traction arc 5848-191 is

placed on the base, the tilt function is still operable.

Battery Status Light:

Green = OK

Red = Needs Recharge

Fault Indicator Light:

Electrical Fault

To unplug and re-attach the Hand Control:

At the end of the hand pendant coiled-cord is a black connector plug. Unscrew the

connector locking nut and pull the connector straight down out of the socket. To reattach, insert the connector into the socket with the notches on the connector lining up

with the slots on the socket. The connector locking nut must be tightened around the

socket to insure proper connection.

If the hand pendant is removed when table power is on, power must be switched off for

10 seconds and then back on after re-attaching the hand pendant for the hand pendant

to function (refer to section 8.0 for additional information).

MIZUHOSI 2009 NW0498 Rev E

12

Page 13

4.3 5803 Advanced Base Controls

The head end base of the 5803 Advanced Control Base is equipped with four indicator

lights (see figure 4). These lights are: 1) on/off AC power switch light, 2) power light, 3)

battery status light, and 4) fault light. Under normal AC operation, the on/off AC power

switch light and battery status light should be lit green and the fault light should be dark.

NOTE: If the fault light on hand pendant or base is lit, the 5803 Advanced Control Base

has detected a fault in the system. Determine fault before use (refer to sections 4.2 &

4.3).

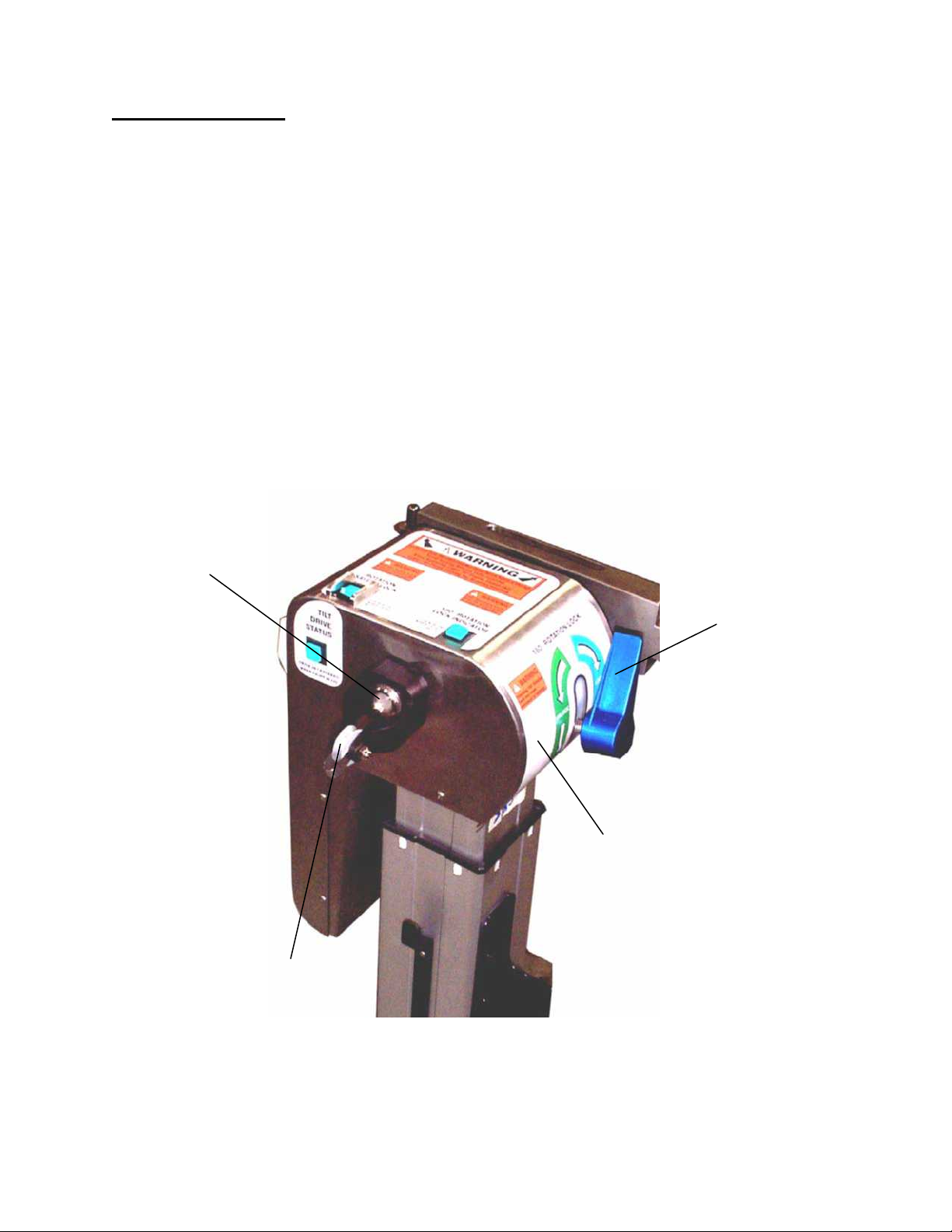

The head end pivot assembly of the 5803 Advanced Control Base is equipped with

three indicator lights. These lights are: 1) 180° rotation lock indicator light, 2) tilt drive

status light and 3) rotation safety lock indicator light. Verify that the rotation safety lock

switch is in the on position and the 180° rotation lock handle is in the locked position.

All three lights must be illuminated before a patient is transferred to the table. These

indicator lights are shown in figure 9.

3) Rotation Safety Lock

Lighted Switch

1) 180° Rotation Lock

Indicator Light

Crossbar

2) Tilt Drive Status

Indicator Light

Traction Pulley

180°° Rotation

Lock Lever (blue)

Figure 9: Head End Pivot Assembly Indicator Lights and Controls

4.3.1 Rotation Safety Lock

The rotation safety lock switch locks out the 180° rotation function. This feature

is designed to prevent unintended rotation of the table top. When the rotation

safety lock switch is illuminated, the table top can still be laterally tilted by

pressing the left or right lateral roll button on the hand pendant. The rotation

safety lock switch should be turned off only when a 180° rotation is to be

performed. If the rotation safety lock switch is not illuminated, press the rocker

switch to the on position.

MIZUHOSI 2009 NW0498 Rev E

13

Page 14

4.3.2 180° Rotation Lock Indicator

When illuminated, the 180° rotation lock indicator light indicates the lock is

engaged and the table cannot be rotated 180°. If the 180° rotation lock indicator

is not illuminated, turn the rotation lock lever clockwise until the light is

illuminated.

NOTE: If a 180° patient rotation is to be performed, the rotation lock lever should

be rotated counterclockwise approximately one half rotation past the point that

the rotation lock indicator light goes out. Rotating the lock lever to this point

lessens the drag of the friction control, thereby allowing the table tops to rotate

more freely during the rotation. If even less friction is desired, the lock lever may

be rotated further counterclockwise, as necessary. If more friction is desired,

rotate handle clockwise.

After the patient rotation is complete, rotate the rotation lock lever clockwise until

the rotation lock indicator light is illuminated.

WARNING:

When the rotation lock indicator light is not illuminated, the table top is

UNLOCKED regardless of how much the lock lever has been turned clockwise or

counterclockwise. Always turn the lock lever until the rotation lock indicator light

is illuminated after a 180° rotation.

4.3.3 Tilt Drive Status Indicator

The tilt drive status indicator light is illuminated when the powered lateral tilt drive

mechanism is in the center position of the +/- 25- lateral tilt range. If the tilt drive

status indicator is not illuminated, operate the lateral tilt function using the hand

pendant in the appropriate direction until the indicator is illuminated. The head

end crossbar should be horizontal when the tilt drive status indicator is

illuminated. If the head end crossbar is not horizontal, the internal power tilt

mechanism is out of synchronization with the crossbar. Refer to section 4.4

synchronizing the lateral tilt function to reset this function.

MIZUHOSI 2009 NW0498 Rev E

14

Page 15

4.4 Synchronizing The Lateral Tilt Function

Normally, the head end crossbar and tilt drive mechanism are synchronized so that the

tilt drive is in the middle of its travel range when the crossbar is level. It is possible for

the crossbar and tilt drive to become unsynchronized if the crossbar is rotated manually.

Also, the head end crossbar and foot end crossbar can become unsynchronized (not at

the same tilt angle) if a crossbar is rotated manually or the 5803 Advanced Control Base

is operated without a table top in place. The crossbars must be synchronized to each

other, as well as to the tilt drive mechanism.

WARNING:

Never attempt to attach a Table Top to the 5803 Advanced Control Base if the

head and foot end crossbars are not horizontal and level. Doing so may cause

damage to the table top or the tilt drive system.

To verify synchronization of the tilt drive and head end crossbar:

1. Confirm that the 180° rotation lock is engaged and Indicator light / switch illuminated.

2. Confirm that the rotation safety lock is engaged and Indicator light / switch

illuminated.

3. Use the hand pendant lateral roll buttons to rotate the head end crossbar until it is

level.

4. Confirm the tilt drive status indicator light illuminates (on hand pendant or head end

pivot assembly) indicating proper synchronization.

If the light will not illuminate, the head end crossbar and tilt drive are not

synchronized.

If the head end crossbar will not level using the hand pendant lateral roll buttons,

then the head end crossbar and tilt drive are not synchronized.

To re-synchronize the tilt drive and head end crossbar:

Different techniques are used depending on whether a table top is attached to the base

or not. Choose from the following cases.

Case 1: Table top is

coupled to the base

1. Confirm table top is attac hed to H-frame and securely locked in place with the T- pin.

No patient or load should be on table top.

2. Turn power switch on.

3. Turn off the rotation safety lock. The switch should not be illuminated.

4. Rotate the 180° rotation lock lever counter-clockwise until it is disengaged. Be

careful – this allows the table top to swing freely.

5. The tilt drive mechanism will automatically return to the middle of its range. While

this occurs, you will hear the tilt motor running, but the table top will only rotate a

little (if at all).

6. When the tilt motor stops, observe the tilt drive status light. If it is illuminated, then

the drive is in the middle of its travel range.

7. Verify that the head end and foot end crossbars are level.

8. Turn on the rotation safety lock. The indicator light should illuminate.

MIZUHOSI 2009 NW0498 Rev E

15

Page 16

9. Rotate the 180° rotation lock handle clockwise until it is engaged (lock indicator light

is illuminated).

10. The tilt drive is now synchronized to the crossbars, and the crossbars are

synchronized to each other.

Case 2: A table top is not coupled to the base

1. Turn power switch on.

2. Turn off the rotation safety lock. The switch should not be illuminated.

CAUTION: This allows the foot end crossbar to rotate freely; any load on the

crossbar can make it swing.

3. Rotate the 180° rotation lock lever counter-clockwise until it is disengaged.

CAUTION: This allows the head end crossbar to rotate freely; any load on the

crossbar can make it swing.

4. The tilt drive mechanism will automatically return to the middle of its range. While

this occurs, you will hear the tilt motor running, and the head end crossbar may

rotate.

5. When the tilt motor stops, observe the tilt drive status light. If it is illuminated, then

the tilt drive is in the middle of its travel range.

6. Manually level the head end crossbar.

7. Manually level the foot end crossbar.

8. Turn on the rotation safety lock switch. The switch should illuminate.

9. Rotate the 180° rotation lock lever, clockwise, until it is engaged (lock Indicator light

is illuminated).

10. The tilt drive is now synchronized to the crossbars and the crossbars are

synchronized to each other.

MIZUHOSI 2009 NW0498 Rev E

16

Page 17

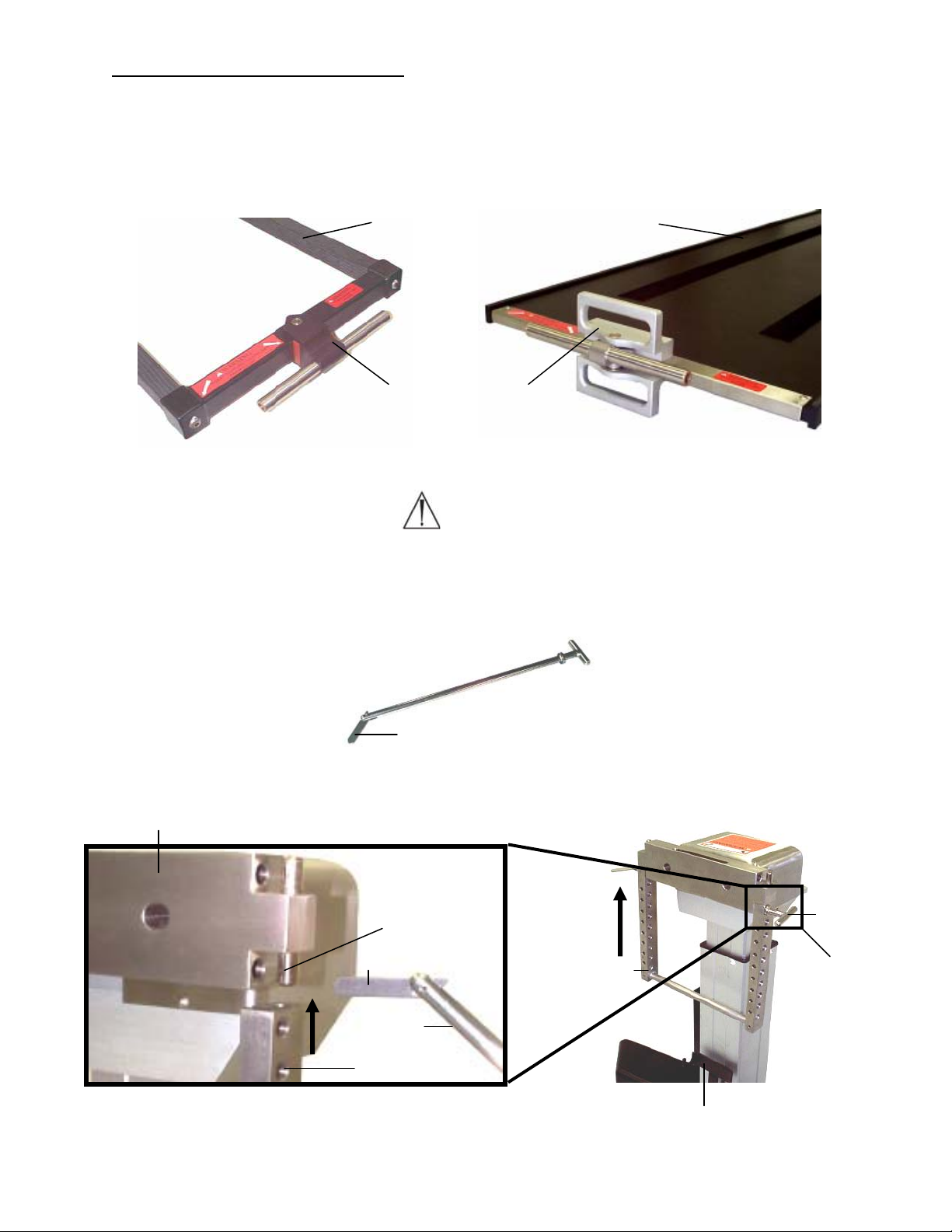

4.5 Tabletop Coupling Procedure

k

The modular table tops may be interchanged and coupled to the 5803 Advanced

Control Base as needed to provide flexibility and specific procedural capability. Position

the 5803 Base and engage all four caster locks. When using trendelenburg with tilt,

only table tops with gimbals may be used with the 5803 Base.

Jackson

Spinal Top

Imaging Top

Gimbal Coupling

Device

Figure 10: Jackson Spinal Top & Radiolucent Imaging Top with Gimbal Mounting Assemblies.

WARNING:

Verify that the Jackson Spinal Top or the Imaging Top being used has gimbals.

Never attach a Jackson Spinal Top or Imaging Top to the 5803 Advanced Control

Base that does not have gimbals.

Crossbar

Drop Loc

Figure - T-Pin Assembly

Foot End

Mounting Stud

ON

Drop Lock

H-Frame

T-Pin

T-Pin

See detail

at left

Detail

Figure 11: H-Frame Installed - Foot End Column

H-Frame

H-Frame

Storage Bracket

MIZUHOSI 2009 NW0498 Rev E

17

Page 18

The following procedure assumes the foot end and head end columns do not have table

tops coupled in place. The coupling procedure is as follows:

1. Remove the H-frame from the H-frame storage bracket located on the foot end

column. Install the H-frame to the foot end crossbar and secure it with a T-pin. The

T-pins are stored in the T-pin quiver located adjacent to each column. The T-pin

must extend completely through both sides of the H-frame and the drop lock should

be in sight and pivot freely (see figure 11).

2. Remove the H-frame from the H-frame storage bracket located on the head end

column. Install the H-frame to head end crossbar and secure with a T-pin. The Tpins are stored in the T-pin quiver located adjacent to each column. The T-pin must

extend completely through both sides of the H-frame and the drop lock should be in

sight and pivot freely (see figure 11). The head end crossbar is attached to a sliding

assembly that adjusts superiorly and inferiorly to accommodate trendelenburg and

reverse trendelenburg length compensation. Fully retract the head end H-frame

against the head end column.

NOTE: If the H-frame is not aligned with the mounting studs, it may bind. Do not force

it. Lower the H-frame off and repeat until it mounts easily.

Head end

Sliding Assembly

T-Pin

ON

T-Pin Quiver

H-Frame

H-Frame Storage

Figure 12: Head End Pivot Assembly, H-Frame Installed

NOTE: Two people are required to complete the following sequence.

3. Select the appropriate mounting hole position on the H-frame to support the table

top. Hole selection will differ depending on the table top selected, the patients’ size

and the procedure to be performed. Further information on hole selection is available

in each of the table top owners manuals. On the foot end, align the table coupling

device with the hole in the H-frame and push the T-pin completely through.

MIZUHOSI 2009 NW0498 Rev E

18

Page 19

WARNING:

Verify that the T-pin is inserted through the H-frame, passes completely through

the table mounting tube, and through the opposite side of the H-frame and the Tpin drop lock is in sight and pivots freely.

4. To couple the head end of the table top, slide the H-frame and crossbar away from

the foot end as necessary to accommodate the length of the table top. Align the

holes in the head end H-frame and the table coupling device. Push the T-pin

completely through both sides of the H-frame and the coupling device making

certain that the drop lock is in sight and pivots freely. The head end and the foot end

of the table top are normally coupled at the same hole in the H-frame. The only

exception is when extreme trendelenburg is needed.

WARNING:

Failure to follow the above-prescribed procedures regarding securing the H-frame

to the crossbars and T-pin to the H-frame may result in the patient being dropped.

WARNING:

Prior to rotation, verify that all table coupling devices and H-frames are properly

installed and the T-pins pass completely through the H-frames and crossbars

with the drop lock in sight and pivots freely. Two (2) T-pins and drop locks should

be visible and checked at each end of the table.

4.6 Patient Transfer

Turn the power switch to on position. Prior to patient transfer, confirm that the desired

table top is secured by the H-frames and T-pins. Refer to specific table top coupling

procedure on page 16 of this Owners Manual for detailed information on attaching the

table tops. All three indicator lights should now be illuminated. If the tilt drive indicator

light is not lit, see synchronizing the lateral tilt function procedure on page 13.

WARNING:

If all three lights are not illuminated, do not use the base. Verify that the rotation

safety lock switch is in the on position and the 180° rotation lock lever is in the

locked position.

4.7 Table Top Coupling Procedure With Top In Place

When one table top is already coupled to the 5803 Advanced Control Base and you are

coupling a second top in order to change tops or facilitate a 180° tabletop rotation, the

slide mechanism of the head end sliding assembly will be held in a fixed position due to

the fixed length of the first top. This requires a different procedure to couple the second

top.

MIZUHOSI 2009 NW0498 Rev E

19

Page 20

With two people holding the second top,

1. Attach the head end H-frame as described above to the table top at the desired

mounting hole.

2. Position the second table top and attach the head end H-frame to the head end

crossbar.

3. Attach the foot end H-frame to the foot end crossbar surrounding the table top

coupling device.

4. Connect the table top coupling device to the foot end H-frame at the desired

mounting hole. Verify that the table top is coupled at the desired height at the head

end.

4.8 Patient Rotation

The MTS provides the capability of rotating a patient 180° to transfer the patient from

the supine to the prone position or vise-versa. This is a manually activated function. The

rotation is performed and controlled by the operating room personnel. Refer to the

Jackson Spinal Surgery and Imaging Table Owners Manual, Section 7.0 Rotation

Procedures for detailed instruction for a patient rotation.

NOTE: At least two people are required to hold and control the rotating motion of the

table tops. One additional person should be assigned to monitor the patient’s head

during the rotation.

4.9 Rotation Lock System

The 5803 Advanced Control Base is designed to engage the rotation safety lock

automatically whenever the on/off power switch is turned “OFF”. Automatic rotation

safety lock engagement ensures that the table top cannot unintentionally rotate laterally

without power.

4.10 Rotation Procedure

With an attendant at the head end of the table:

1. Patient is securely strapped to table system.

2. Release the 180° rotation lock by rotating the lever counterclockwise until the 180°

rotation lock indicator light goes out.

3. Advise the attendants holding the tabletops that the rotation safety lock is about to

be released.

4. Release the rotation safety lock by pressing the rocker switch to the off position.

Observe that the indicator light goes out.

5. Rotate the tabletops.

NOTE: The attendant performing the rotation must rotate the tabletops 180° toward

himself or herself without stopping until the complete 180° rotation is achieved.

After the rotation:

1. Immediately engage the rotation safety lock by pressing the rocker switch to the on

position and observe that the indicator light is illuminated.

2. Lock the 180° rotation lock by rotating the lever clockwise until the 180° rotation lock

indicator light is illuminated.

NOTE: The attendant performing the rotation may now release the table tops.

MIZUHOSI 2009 NW0498 Rev E

20

Page 21

4.11 Retracting The Base For Storage

The 5803 Advanced Control Base retracts for storage (refer to Section 1.2 for Length

and Width specifications).

To retract the base:

1. Lock the head end casters and unlock the foot end casters.

2. Loosen the retracting locking knob on the center beam (see figure 13).

NOTE: This knob will become completely separated from the base if rotated many

times.

3. Push the foot end of the base toward the head end of the base until the foot end is

retracted to its minimum length.

4. Tighten the locking knob.

Head end Foot End

Retract

Figure 13: Retracting the 5803 Advanced Control Base

Retracting

Lock Knob

MIZUHOSI 2009 NW0498 Rev E

21

Page 22

4.12 Table Top on the Base

It may be desirable to store a table top on a collapsed 5803 Advanced Control Base.

The table top storage bracket is an optional accessory and can be ordered from

customer service.

1. Remove the table top from H-frame.

2. Retract the base (refer to section 4.11).

3. If the head end H-frame is in the H-frame storage bracket, remove it and attach

to the head end crossbar.

4. Attach the table top storage bracket (optional accessory) to the foot end crossbar

using the gold handle.

5. Using the hand control, depress trendelenburg button which will raise the foot

end column to its highest position.

6. Place the coupling device of the table top in the head end H-frame storage

bracket.

7. Place the table top on the table top storage bracket on the foot end crossbar.

8. Unplug the power cord and store it on the cord wrap.

9. Push the foot end of the table toward the head end of the table until the foot end

is retracted to its minimum length.

The base and table top are now ready for storage.

MIZUHOSI 2009 NW0498 Rev E

22

Page 23

5.0 PRE-OPERATIONAL FUNCTION CHECK

After reading the basic operation (Section 4.0), perform all the steps in this procedure.

1. Plug in the hand pendant cable-connector into the receptacle located at the head

end column.

2. Plug the power cord into a hospital grade power outlet and flip the main on/of f power

switch to on. Verify the switch illuminates; this indicates power is applied to the table.

3. In succession, press and hold each of the six buttons on the hand pendant and

confirm the operation of the following functions:

3.1. Height up

3.2. Height down

3.3. Trendelenburg

3.4. Reverse trendelenburg

3.5. Tilt left

3.6. Tilt right

3.7. Engage the rotation safety lock (switch to on) and the 180° rotation locks (blue

handle clockwise, indicator light illuminates).

3.8. Release the rotation safety and 180° rotation locks.

3.9. Confirm head end and foot end crossbars are unlocked by rotating each one

complete revolution.

3.10. Re-engage both the rotation safety and 180° rotation locks.

3.11. Confirm head end and foot end crossbars are locked; both crossbars firmly

resist rotation.

3.12. Using the hand control, press and hold left lateral roll (TILT) button to end of

travel. Confirm the foot end crossbar rotates freely.

3.13. Using the hand pendant, press and hold right lateral roll (TILT) button to end of

travel. Confirm the foot end crossbar rotates freely.

Report any malfunction to your Mizuho OSI representative immediately.

MIZUHOSI 2009 NW0498 Rev E

23

Page 24

6.0 CLEANING and MAINTENANCE

6.1 Cleaning and Disinfecting

After completion of each surgery, wipe the 5803 Advanced Control Base with a

quaternary disinfectant. Dry the base completely.

NOTE: The head end and foot end columns of the 5803 Advanced Control Base are

not sealed, therefore:

Never pour any liquid directly onto the table.

Never allow any liquid to enter the extensile joint of the columns.

Never subject the 5803 Advanced Control Base to an equipment washing machine.

Failure to thoroughly dry any surface after cleaning and disinfecting may result in rust.

It is important to dry the base to prevent rusting. Rust formation can prematurely

shorten the useful life expectancy of the 5803 Base.

USE OF IODOPHORS WILL CAUSE STAINING:

Base Exterior:

Exterior surface should be regularly wiped clean with a mild detergent solution and

wiped dry with a soft lint-free cloth.

Care should be taken to avoid exposing the base to excessive moisture. Flooding,

fogging or steam cleaning is not recommended and will void any warranty.

Blood or other fluids, etc., if allowed to remain on the base for a long period of time,

will require special cleaning to remove. A 5% acetic acid solution or white vinegar

and water solution is especially good for this purpose.

Cleaning with a good commercial cleaning compound, such as stainless steel Magic

or acme white finish, and then buffing the surface by hand can correct staining and

discoloration of plated or stainless steel surfaces.

To dis infect exterior surface use a quaternary ammonium or similar type disinfectant

compound according to manufacturer's directions for use. Wipe dry with a soft lintfree cloth.

Casters should be cleaned and disinfected in the same manner as base exterior.

6.2 Lubrication

Base Exterior:

Following a thorough cleaning and decontamination of the base, silic one lubricant spray

may be used on most of the exposed inner head and foot columns and inner retractable

beam. No other lubrication is necessary.

Base Interior:

All of the internal moving parts of the 5803 base receive factory lubrication which, under

normal use, provides lubrication for the life of the equipment.

MIZUHOSI 2009 NW0498 Rev E

24

Page 25

6.3 Preventative Maintenance

Contact Mizuho OSI Technical Service for a complete Preventative Maintenance

Checklist.

For detailed repair information or to order replacement parts, call or contact via the web

the Mizuho OSI technical services department

1-800-777-4674 Extension 2

techsvcs@mizuhosi.com

www.mizuhosi.com

Technical services is available from 7am – 5pm PST Monday – Friday. Please leave a

message at the extension after normal business hours.

MIZUHOSI 2009 NW0498 Rev E

25

Page 26

7.0 THE ELECTRICAL SYSTEM

7.1 Power Cord

The base is equipped with a standard EIC power cord with the appropriate 120 VAC

hospital grade connector (100 VAC & 230 VAC versions do not include the power

connector).

7.2 ON/OFF Power/Circuit-Breaker Switch

An on/off power switch is at the head end of the base. This switch also serves as a

circuit breaker and in the event of an overload condition this switch will trip off. To reset,

push to the off position and then the on position. Next to it a green power on light

illuminates indicating that the base power is on.

NOTE: Determine the source of the overload prior to resetting this switch.

7.3 Power ON / Fault / Battery Status Lights

Next to the on/off power switch is a small panel of three lights:

Green = Power on (AC power or battery power).

Red = Fault light (Electrical fault, determine source of fault prior to using table).

White = Battery status.

o When illuminated Green = installed properly and charged

o When illuminated Red = recharging required

7.4 Battery Recharging

The batteries in the 5803 Base are automatically charged whenever the table is in an

operational condition (plugged into AC power source and on/off power switch in the on

position). No additional procedures are needed to assure maintenance of the batteries.

The battery status lamp, next to the on/off power switch on the head end base casting,

indicates battery charge condition. If lit, the red battery status lamp indicates that the

batteries require recharging and the table must be plugged into an AC outlet. If the

battery status lamp remains illuminated red after three (3) hours, do not attempt to

operate the base under battery power and call for service (the 5803 Base should remain

functional under AC power). It is recommended that, prior to use, the 5803 Base be

plugged into a proper AC receptacle with the on/off switch in the on position for a

minimum of three (3) hours to ensure that the batteries are fully charged.

MIZUHOSI 2009 NW0498 Rev E

26

Page 27

8.0 TROUBLESHOOTING

8.1 Electrical System

In the advent of a base malfunction, the first item to investigate is the input power. Be

certain that the power cord is plugged into a live electrical outlet and the power switch is

switched on. A green "Power On" light illuminates indicates this.

WARNING:

Before removing any sheet metal covers the base must be turned off and

unplugged. Dangerous high voltage may be present in the circuitry under the

covers. Only trained technicians should perform this task.

SYMPTOM INSPECT ACTION

No column function

either end.

No column function

Head end

No column function

Foot end

Rotation friction control

won’t stop Rotation-Head end

Or Foot End.

Caster won’t lock/unlock Check caster for damage. Replace caster.

Check power.

Check that circuit breaker (light is

green).

Check hand pendant module and

cord.

Check electrical connector at

base of head or foot end Column.

Check hand pendant.

Check electrical connector at

base of head end column.

Check hand pendant module and

cord. Check electrical connector

at the base of foot end column.

Tighten lever to max. Check

brake band.

Plug in.

Reset breaker, turn on.

Plug in connector.

Plug in connector.

Plug in connector.

Adjust brake tension.

Adjust handle to proper range.

Replace if necessary.

MIZUHOSI 2009 NW0498 Rev E

27

Page 28

8.2 Functional Guide

FUNCTION GUIDE

Command: Result: If not, determine if

(Hand pendant) height up Both columns up

Height down Both columns down Same as for Height Up

Base power is off.

Power to PC board is not

connected.

Hand pendant is non-operative,

or not plugged in.

Cable from PC board to column

is not connected, or has failed.

If none of these are the problem

then the column or the PC board

has failed.

Trendelenburg Head end column down and foot

end column up

Reverse trendelenburg Foot end column down and head

end column up

Lateral roll (tilt) left or right

w/rotation safety lock switch off

Rotation safety lock switch off Brake releases

Tilt motor drives

Same as for Height Up

Same as for Height Up

Base power is off

Power supply is not operating

correctly

Power to PC board is not

connected

Hand pendant is non-operative

Hand pendant is not plugged in

PC board is non-operative

Cabling is not connected or has

failed

Tilt motor has failed, or brake-on

sensor is closed

Brake-on sense wire is shorted

Either limit switch has failed.

Either limit switch is open

Limit switch wiring is

disconnected

Base power is off

Power to PC board is not

connected

Power supply is not operating

Cable from PC board to column

is not connected

Cable to column has failed.

Brake off switch has failed

Wire connection to switch has

failed.

Traction arc switch closed

Traction arc switch wiring

shorted

Limit switch has failed

Mechanical error

MIZUHOSI 2009 NW0498 Rev E

28

Page 29

Rotation safety lock switch on Brake engages

Same as rotation safety lock

switch off.

Also verify switch, wiring, and

mounting of brake on sensor if

brake is weak, brake force

adjustment is incorrect

Lateral roll (tilt) left of right w/

rotation safety lock switch on

Release lateral roll (tilt) button Tilt motor ceases; brake engages

Release button. (all functions

except tilt when rocker switch is

on)

Traction arc switch closed

Lateral roll (tilt) left or right

Rotation safety lock switch off Brake motor disabled Same.

Handle loose Tilt motor drives until tilt drive

Brake releases; tilt motor drives

Immediate cessation of above.

No additional function

Tilt motor disabled, brake motor

disabled

status indicator lights

Same as tilt with rocker switch

off

Additionally: brake motor faulty

or wiring not connected

Hand pendant has failed, PC

board has failed

Same as for tilt w/rocker on

Hand pendant has failed

PC board has failed

Faulty switch,

broken wiring connection,

switch adjustment incorrect,

PC board has failed

Power off

Power to PC board not

connected

Power supply non-op, PC board

non-op

Cable from PC board to tilt motor

not connected

Tilt motor non-op

Home sensor has failed

Home sensor wiring shorted

Sensor misadjusted,

1/r sensor has failed, 1/r sensor

wiring shorted or disconnected

Sensor misadjusted

Lock sensor has failed

Lock sensor wiring disconnected

Traction arc switch closed

Traction arc switch wiring shorted

Rotation safety lock switch on.

Foot end crossbar tilted left or

right

Rotation safety lock off.

Power down

MIZUHOSI 2009 NW0498 Rev E

Tilt left or right disabled

Brake engages. LED turns on for

15-25 seconds later, LED off

29

Tilt left or right limit switch has

failed

Wiring disconnected

PC board has failed

Motor has failed

Wiring to motor disconnected

LED has failed; wiring

disconnected

PC board has failed

No battery power

Page 30

9.0 REMOVAL and REPLACEMENT of COMPONENTS

9.1 Head end Cover

1. Switch off the base at the circuit breaker and disconnect the power cord from the

source. Allow 45 seconds for discharge.

NOTE: Hand pendant backlights will go dark.

2. Disconnect hand pendant.

3. Remove 1st external retaining ring. Remove traction pulley assembly. Remove 2nd

retaining ring.

4. Remove 180° Rotation lock handle by rotating it counterclockwise until it is free.

5. Using a small screwdriver, pry out 180° indicator light to prevent damage.

6. Remove the cover screws on both sides of the cover except the lower screws.

7. Remove lower screws on both sides of the cover, and remove head end cover inside

panel.

8. Carefully slide the cover away from the base, along the tilt axis.

Caution: Wires still connect the switches and lights on the cover to the base.

Disconnect 16 pin connector.

External retaining ring

180°Rotation Lock

Handle

Head End Cover

Traction Pulley Assy

Figure 14: Head End Cover Removal

MIZUHOSI 2009 NW0498 Rev E

30

Page 31

9.2 Foot End Cover

1. Switch off the base at the circuit breaker and disconnect the power cord from the

source.

2. Remove the foot end base covers.

3. Disconnect the negative wires at the battery terminals.

4. Remove the foot end cover screws.

5. Carefully lift foot end cover up and off.

Screws

Foot End Base Cover

Screws

Figure 15: Foot End Cover Removal

9.3 Hand Pendant Module

1. Switch off the base at the circuit breaker and disconnect the power cord from the

source.

2. Unscrew hand pendant cord-connector from base receptacle.

3. Unplug hand pendant cord connector from the base.

MIZUHOSI 2009 NW0498 Rev E

31

Page 32

9.4 Batteries

WARNING:

Improperly installed batteries can leak, causing equipment damage or injury. See

photo below to assure correct installation of replacement batteries.

1. Rechargeable lead-acid batteries contain toxic materials

. Batteries should be fully

discharged prior to handling, or the terminals should be isolated to prevent

accidental discharge.

2. Batteries contain sulfuric acid. In the event of a leak in the battery or fire, dilute

spilled fluid with water. In case of skin contact, wash areas with water. In the event

of eye contact, flush eyes with water for 15 minutes and consult a physician

immediately.

3. Batteries should only be replaced with Mizuho OSI approved parts. Contact Mizuho

OSI to obtain correct replacement batteries.

4. Incorrectly connected batteries can caus e damage to equipment or injury. Bridging

(shorting) of battery terminals can cause explosion of the battery or fire.

5. Do not attempt to connect AC power to the 5803 Base until correct battery

connection is confirmed.

6. Always dispose of batteries properly. Do not incinerate batteries. Do not place

rechargeable 12V batteries into a metal trashcan, toolbox, drawer or parts bin.

7. Always take the following precautions when removing the battery compartment

covers:

Remove metal jewelry and wristwatches when in proximity to batteries.

Always cover at least one terminal of each battery with insulating material if

connectors are removed.

Use caution when employing metal tools in proximity to batteries. Metal tools

create circuit bridges (electrical shorts) upon contact. When possible, use tools

with insulated handles and ends.

Never place anything on top of batteries, whether batteries are mounted or

removed from product.

MIZUHOSI 2009 NW0498 Rev E

32

Page 33

Battery Charging and Inspection

r

Charge for minimum three (3) hours (Power cord plugged into power source and on/off

power-switch “ON”). If battery fails to hold a charge it should be replaced. Replace only

with identical type and size battery. Replace both batteries at the same time. Batteries

should be replaced once every five (5) years. Whenever the battery cover is opened,

check battery for signs of corrosion. Battery terminals should be clean and free from

corrosion, oil, grease, dirt, or other contaminants.

Battery Mizuho OSI ordering number: NV0801, failure to use an approved Mizuho OSI

battery terminates warranty.

Negative

Te

minal

Jumper

Wire

Positive

Terminal

Connection wires

to columns

Battery “B”

Battery “A”

Figure 16: Battery Placement

Battery Removal

1. Switch on/off power-switch to off, disconnect the power cord from power source (AC

outlet).

2. Remove the foot end base covers.

3. Disconnect the wires at the battery terminals. Cover at least one terminal of each

battery with insulating material.

4. Carefully lift batteries out of base.

Battery Replacement

1. Place replacement batteries in base as shown.

2. Install adhesive-backed loop closure (Velcro).

3. Attach battery wires as shown:

Red wire to positive terminal of battery “A”.

Jumper wire from battery “A” to battery “B”.

Black wire to negative terminal of battery “B”.

Batteries must be properly disposed of, and in accordance with domestic and

international standards and requirements.

MIZUHOSI 2009 NW0498 Rev E

33

Page 34

Battery Function Check

1. Verify power cord is disconnected from power source (AC outlet).

2. Turn on/off power-switch to “ON” (utilizing battery power).

3. Verify all hand pendant lights illuminate on and off sequentially.

4. Verify hand pendant and base panel battery status lights:

Green = batteries installed correctly and charged.

Red = batteries need charging.

5. Fault Light on and battery status light red = batteries not connected properly, or

completely discharged. Turn on/off power-switch “OFF” immediately and check:

Batteries connected properly.

Batteries have been charged.

Repeat test to verify that all lights on hand pendant illuminate on and off

sequentially and battery fault light is dark. If not, contact Mizuho OSI technical

service.

9.5 Power Supply Replacement

1. Switch off the base at the circuit breaker and disconnect the power cord from the

source.

2. Remove the 10-32 screws holding the input plate and circuit breaker plates to the

cover.

3. Remove the head end base covers.

4. Disconnect the negative battery wire.

5. Disconnect all cables from power supply and line filter. Remove transformer wires

from power entry module.

6. Remove the three power supply tray assembly mounting screws and remove tray

assembly.

7. Install replacement in the reverse order.

9.6 Controller Circuit Board Replacement

1. Switch off the base at the circuit breaker and disconnect the power cord from the

source.

2. Remove the 10-32 screws holding the input plate and circuit breaker plates to the

head end base covers.

3. Remove the head end base covers.

4. Disconnect the negative battery wire.

5. Disconnect all cables from controller circuit board

6. Remove the three 10-32 screws mounting the controller circuit board tray and

remove tray assembly.

7. Install replacement in the reverse order.

MIZUHOSI 2009 NW0498 Rev E

34

Page 35

9.7 On-Off Power Switch / Circuit Breaker Replacement

1. Switch off the base at the circuit breaker and disconnect the power cord from the

source.

2. Remove the 10-32 screws holding the input plate and circuit breaker plates to the

head end base covers.

3. Remove the head end base covers.

4. Disconnect the negative battery wire.

5. Disconnect the wires from circuit beaker / on-off switch terminals.

6. Remove the circuit beaker / on-off switch.

7. Install replacement in the reverse order.

9.8 Head End Assembly

1. Switch off the base at the circuit breaker and disconnect the power cord from the

source.

2. Remove the foot end base covers and disconnect the negative wire at a battery

terminal.

3. Remove the 180° Rotation lock handle.

4. Remove gr ip ring from crossbar shaft and slide the traction pulley bracket, from the

shaft.

5. Remove the 8-32 screws from rear of cover.

6. Remove the 2 screws from the front cover and slide inside cover down and away.

Disconnect the electrical cable attached to the cover.

7. Remove the remaining screw at the front cover, and take the cover off by rotating it

to the right.

8. Remove the ground wire screw.

9. Disconnect the electrical cable at the top of the column.

10. Remove the 10-32 screw underneath of the trolley in the groove at front.

11. Slide the head end assembly away from you and remove it from base.

12. Install replacement in the reverse order.

9.9 Head End Tilt Motor

1. Disconnect the motor wire from the wire harness.

2. Remove the E-ring from the pivot axle at the actuator rod joint end.

3. Slide the pivot axle out of the assembly.

4. Loosen and remove the shoulder screw (or E-rings on newer tables) at the base of

the actuators and remove the actuator.

9.10 Foot End Rotation Safety Lock Motor

1. Remove the shoulder screws holding the actuator to the brake pivot arm, and foot

pivot base.

2. Install in reverse order.

3. Adjust rotation safety lock (refer to rotation safety lock adjustment).

MIZUHOSI 2009 NW0498 Rev E

35

Page 36

9.11 Head End or Foot End Column

1. Remove any tabletop and H-frame(s).

2. Switch off the base at the circuit breaker and disconnect the power cord from the

source.

3. Remove the foot end base covers and disc onnect the negative wires at the battery

terminals.

4. Remove the foot end base cover by removing the mounting screws.

5. Remove the head end assembly or foot end.

6. Remove head end base cover: Remove the 10-32 screws holding the input plate

and circuit breaker plates to the head end base covers. Remove cover.

7. Remove foot end base cover: Remove the 10-32 screws holding the cover. Remove

cover.

8. Unplug the connectors at the base of each head end and foot end column.

9. Remove four socket head screws attaching the column to the retractable beam.

10. Lift out of the base the column.

11. Install replacement in the reverse order.

12. Adjust rotation safety lock per rotation safety lock adjustment.

NOTE: Before tightening the mounting screws upon installation stand the base upright

and attach a tabletop between the head end and foot end crossbar. With the screws

loose, rotate the top slowly several times to align the head end and foot ends. Reach

under the head end and foot end base and tighten the mounting screws before

removing the tabletop.

9.12 Retractable Center Beam

1. Remove any tabletop and H-frame.

2. Switch off the base at the circuit breaker and disconnect the power cord from the

source.

3. Remove the foot end base covers and disconnect the negative wire at a battery

terminal.

4. Remove head end covers.

5. Unplug beam cables.

6. Remove the head and foot columns.

7. Remove the ¼-20 inch screws attaching the beam to head end and foot end bases.

8. Remove the center beam.

9. Install replacement in the reverse order.

9.13 Casters

1. Remove the ½-inch bolt from the outside of the base plate.

MIZUHOSI 2009 NW0498 Rev E

36

Page 37

10.0 ADJUSTMENT of COMPONENTS

HEAD END

10.1 Tilt Actuator Rod End Position

1. Loosen lock nut on actuator rod end.

2. Rotate actuator rod until six threads are showing on the rod end.

3. Tighten lock nut.

4. Disconnect the actuator from the base wiring and connect an external power

controller to the actuator.

5. Drive the tilt mechanism all the way right (actuator ex tended). Watch for clearance

between the actuator rod and the pillow block at the end of actuator travel.

6. If the actuator rod touches the pillow block, re-loosen the locknut and turn the

actuator rod as many turns as necessary to ensure clearance. Retighten the rod

end.

7. Once complete, disconnect the tilt actuator from the external controller and connect

to the base wiring.

10.2 180° Rotation Lock Sensor

1. Remove the blue 180° rotation lock handle.

2. Remove head end cover per procedure; do not unplug electrical connector, hang

cover on table base power cord storage bracket.

3. Loosen 8-32 button head screw securing the 180° rotation sensor ( micro switch)

mounting bracket. This is mounted just to the left of the blue 180° rotation lock

handle (see figure 17).

4. Tighten the blue 180° rotation lock handle until rotating crossbar resists 95 ft/lbs

of rotational force in both directions using torque wrench and rotational test bar

(p/n T5890-21/23).

5. Adjust the 180° rotation sensor (micro switch) mounting bracket until the micro

switch clicks on. The "180° Rotation lock indicator" light should be illuminated

blue. Tighten 8-32 button head screw.

6. Test by unscrewing 180° Rotation lock handle until "180° Rotation lock indicator"

goes out. Retighten 180° Rotation lock handle until "180° Rotation lock Indicator"

lights.

7. Retest that rotating crossbar resists 95 ft/lbs of rotational force in both directions

using torque wrench and rotation test bar.

8. If test fails, repeat adjustment procedure.

9. If test passes continue.

10. Install covers per procedure.

11. Install "180° Rotation lock" handle and tighten until "180° Rotation lock indicator"

light illuminates blue.

12. Retest that rotating crossbar resists 95 ft/lbs of rotational force in both directions

using torque wrench and rotation test bar P/N T5890-21-23

13. If test fails, repeat adjustment procedure.

14. If test passes adjustment is complete.

MIZUHOSI 2009 NW0498 Rev E

37

Page 38

10.3 Home & Tilt Left/Right Sensors

1. Turn the base power on.

2. Tighten the 180° Rotation lock handle, and make sure that the indicator light is lit.

3. Using the hand pendant, drive the tilt mechanism to the right.

4. Loosen the 6-32 cap head screw beneath the sensor bracket and move the bracket

closer to the pillow block until the left/right sensor switch clicks.

5. Using the hand pendant, drive the tilt mechanism to the left. Stop when the home

sensor clicks. The indicator light should light up to confirm that the tilt drive is at

home.

6. Tighten the 6-32 cap head screw.

7. Using the hand pendant, drive the tilt mechanism to the right for about three

seconds.

8. Loosen the 180° Rotat ion lock handle. The tilt mechanism should drive to the center

and stop.

9. If it drives towards the center but stops before true level, the sensor switch is too

close to the pillow block. Tighten the 180° Rotation lock handle. Loosen the 6-32

cap head screw beneath the sensor bracket and move the bracket away from the

pillow block slightly. Re-tighten the 6-32. Check this readjustment by repeating

steps.

10. If it drives to the center but does not stop, either rocking back and forth or continuing

past lever, the sensor switch is too far from the pillow block slightly. Re-tighten the

6-32 screw. Check this readjustment by repeating steps.

11. If it does not drive at all when the 180° Rotation lock handle is loosened, there is an

electronic fault in the base. Check the wiring to the head end, and if this does not

alter the condition of the base, replace the controller PC board.

Sensor Switch

and Bracket

180° Rotation

Lock Handle

Figure 17: 180° Rotation Lock Indicator Light Limit Switch and Lock Handle

MIZUHOSI 2009 NW0498 Rev E

38

Page 39

10.4 Head end Slider Adjustment Procedure

Overview:

With one of the Mizuho OSI modular (interchangeable) table tops attached to the 5803

Advanced Control Base, in-line movement of the head end slider (or trolley assembly) is

required to accommodate trendelenburg and reverse trendelenburg positioning.

Periodic adjustment may be needed to maintain proper friction of movement.

Tools Required:

Hex (Allen) Key, 5/64-inch

Force Gauge, to 25-pounds pushing force.

Procedure:

1. Turn on/off power switch to off, disconnect power cord from power source (AC wall

outlet), allow 30 seconds for discharge.

2. Remove head end pivot assembly cover per procedure.

3. Some models may have a set screw installed in front of the spring plunger. This

screw must be removed prior to adjustment. Using 5/64-inch hex key, adjust Slider

spring plunger (shown below) as needed.

4. Using force gauge pushing on rotating crossbar, verify head end slider assembly

(without any top attached) moves in-line to its stops, in both directions, uniformly,

with 20 to 25 pounds of force applied.

Figure 18: Head End Pivot Assembly, Left Side (cover removed)

MIZUHOSI 2009 NW0498 Rev E

39

Page 40

FOOT END

10.5 Rotation Safety Lock

As the safety lock wears, adjustment may be required to achieve complete locking. The

adjustment for this is as follows:

1. The 5803 Advanced Control Base should be upright.

2. Supply power to the base and turn the circuit breaker on.

3. Remove the foot end cover.

4. If the sensor is not indicating that the rotation safety lock is on when crossbar is

secure, loosen the lock nut by one turn, then turn the adjustment setscrew counter

clockwise, while maintaining the setscrew position, and tighten the lock nut. Verify

operation of the rotation safety lock by turning it off and then on again.

5. If the crossbar is not adequately secure when the sensor indicat es that the rotation

safety lock is on, loosen the lock nut and turn the adjustment setscrew clockwise.

Then, while maintaining the setscrew orientation, tighten the lock nut. Verify

operation of the rotation safety lock by turning it off and back on again.

6. The crossbar is secure when it resists 93 foot-pounds of torque without slippage,

using torque wrench and rotation test bar P/N 5890-21-23.

7. Replace the cover.

Crossbar

Adjustment Setscrew

Lock Nut

Figure 19: Foot End Assembly

MIZUHOSI 2009 NW0498 Rev E

40

Page 41

10.6 Rotation Safety Lock (Brake) “ON” Sensor Setting

1. Remove the foot end base covers.

2. Disconnect the battery wire.

3. Turn off the rotation safety lock switch on the head end cover.

4. Supply power to the base and turn the circuit breaker on. Verify brake off sensor is

closed. If it is not, the system may have an electronic fault.

5. Back out the setscrew that locates the brake clamp all the way (see figure 18

adjustment setscrew).

6. Turn off the power to the base (either unplug or turn off the circuit breaker). Wait

until all the system lights go out.

7. Locate the brake on sensor. Loosen the screw that holds the mount plate for the

sensor to the brake lever.