Page 1

DIGITAL MONOCHROME PRINTER

MODEL

P93DW

P93DE

OPERATION MANUAL

COPY

FEED

LOCK

DOWN

BRT/CONT

UP

BRT

CONT

LOCK

OPEN

THIS OPERATION MANUAL IS IMPORTANT

TO YOU.

PLEASE READ IT BEFORE USING YOUR

DIGITAL MONOCHROME PRINTER.

DIGITAL MONOCHROME

PRINTER

This digital monochrome printer complies with the requirements of the EC Directive 89/

336/EEC, 73/23/EEC, 93/42/EEC and 93/68/EEC.

The electro-magnetic susceptibility has been chosen at a level that gains proper

operation in residential areas, on business and light industrial premises and on smallscale enterprises, inside as well as outside of the buildings. All places of operation are

characterised by their connection to the public low voltage power supply system.

Page 2

FOR THE MODEL P91DW(UB) ONLY

WARNING:

In the USA or Canada, use the AC power cord according to the recommendations as

below, in order to comply with UL2601-1 and CAN/CSA C22.2 No. 601.1.

Case 1. Connect to the 120V receptacle of the room or the host equipment.

The AC power cord should be UL or CSA approved and consist of type SJT, size

16 or 18AWG, length 2.5m or shorter cord with IEC320/C13 type, 125V 10A or

higher rating connector and NEMA 5-15 type, 125V 10A or higher rating, Hospital

Grade plug.

Case 2. Connect to the 230V receptacle of the room or the host equipment.

The AC power cord should be UL or CSA approved and consist of type SJT, size

16 or 18AWG, length 2.5m or shorter cord with IEC320/C13 type, 250V 10A or

higher rating connector and NEMA 6-15 type, 250V 10A or higher rating, Hospital

Grade plug.

Case 3. Connect to the 120V receptacle of the host equipment.

The AC power cord should be UL or CSA approved and consist of type SJT, size

16 or 18AWG, length 2.5m or shorter cord with IEC320/C13 type, 125V 10A or

higher rating connector and IEC320-2.2/E type, 125V 10A or higher rating plug.

Case 4. Connect to the 230V receptacle of the host equipment.

The AC power cord should be UL or CSA approved and consist of type SJT, size

16 or 18AWG, length 2.5m or shorter cord with IEC320/C13 type, 250V 10A or

higher rating connector and IEC320-2.2/E type, 250V 10A or higher rating plug.

CAUTION:

Changes or modifications not expressly approved by the party responsible

for compliance could void the user’s authority to operate the equipment.

NOTE:

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his or her own expense.

Information:

This class A digital apparatus complies with Canadian ICES-003.

"CLASSIFIED BY UNDERWRITERS LABORATORIES INC.®

WITH RESPECT TO ELECTRIC SHOCK, FIRE AND MECHANICAL HAZARDS ONLY IN

ACCORDANCE WITH UL2601-1 AND CAN/CSA C22.2 No. 601.1"

Page 3

CAUTION:

RISK OF ELECTRIC SHOCK DO NOT OPEN.

TO REDUCE THE RISK OF ELECTRIC SHOCK,DO NOT REMOVE COVER (OR

BACK)

NO USER-SERVICEABLE PARTS INSIDE. REFER SERVICING TO QUALIFIED

SERVICE PERSONNEL.

The lightning flash with arrowhead symbol, within an equilateral triangle, is

intended to alert the user to the presence of uninsulated "dangerous voltage"

within the product's enclosure that may be of sufficient magnitude to constitute a

risk of electric shock.

The exclamation point within an equilateral triangle is intended to alert the user

to the presence of important operating and maintenance (servicing) instructions

in the literature accompanying the appliance.

The “Caution, hot surface” symbol indicates that the marked item may be hot

and should not be touched.

The “ON/OFF” symbol indicates connection to or disconnection from the mains,

at least for mains switches.

The “Equipotentiality” symbol identifies the terminals connected each other. The

potential of various parts of equipment or of a system is equalized.

The “Alternating current” symbol indicates that the equipment is suitable for

alternating current only.

When you dispose of the unit or accessories, you must obey the law in the relative area

or country and/or regulation in the relative hospital.

Page 4

WARNING:

Install and use this appliance in accordance with the operation manual for safety and

EMC (Electromagnetic Compatibility). If it is not installed and used in accordance with

the operation manual, it may cause interference to other equipment and/or other risk.

To prevent fire or shock hazard, do not expose this appliance to rain or moisture.

This appliance must be earthed.

In Europe, use the AC power cord according to the recommendations as below, in order

to comply with EN60601-1 and EN60950.

Connect to the 230V receptacle of the room or the host equipment.

The AC power cord should be VDE approved and consist of core size 1mm

length 2.5m or shorter cord with IEC320/C13 type, 250V 10A or higher rating connector

and CEE(7)VII type or IEC 320-2.2/E type, 250V 10A or higher rating plug.

Use the USB cable according to the recommendations as below, in order to comply with

EN60601-1-2.

The USB cable with appropriate plug should be 2 m long or shorter, comply with USB 2.0

standard High speed requirements and USB IF (USB Implementers Forum) approved.

This product is to be employed with medical equipment, just for reference purpose, not

for medical diagnostic purpose.

2

or bigger,

Page 5

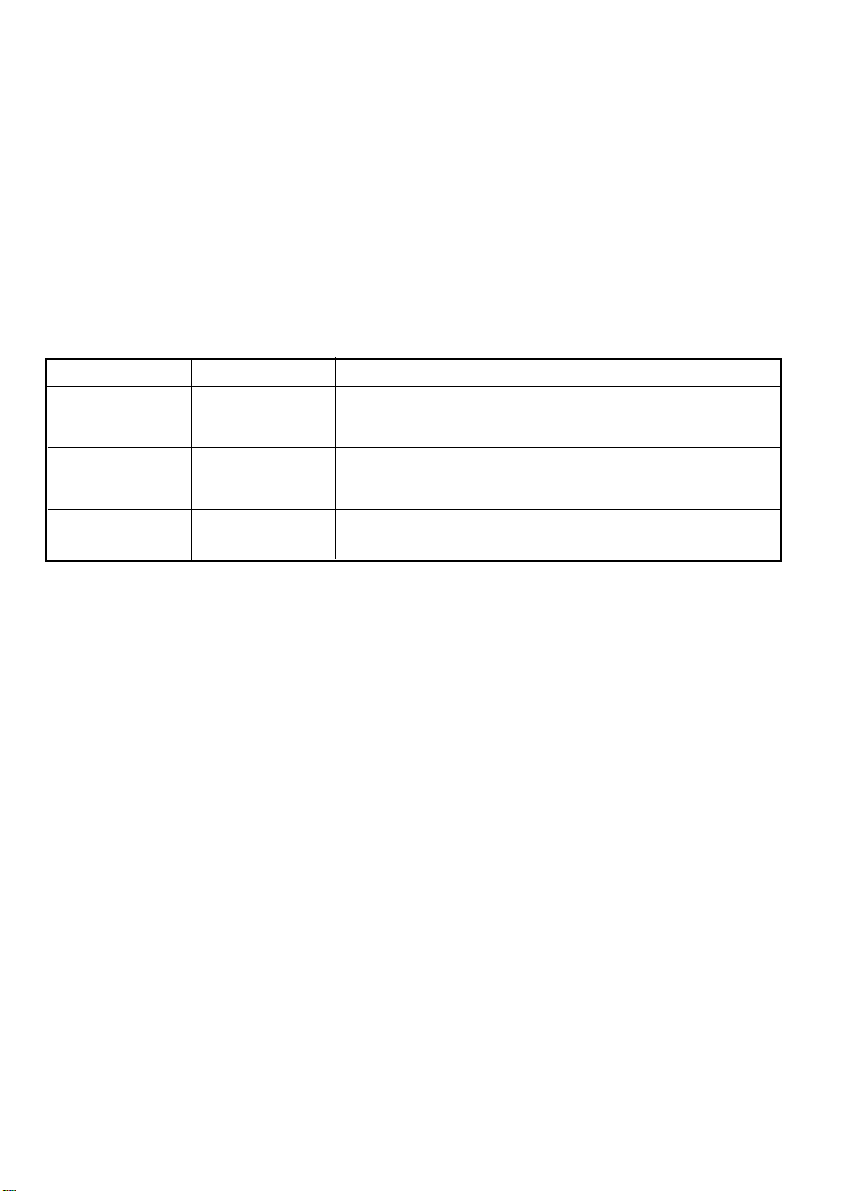

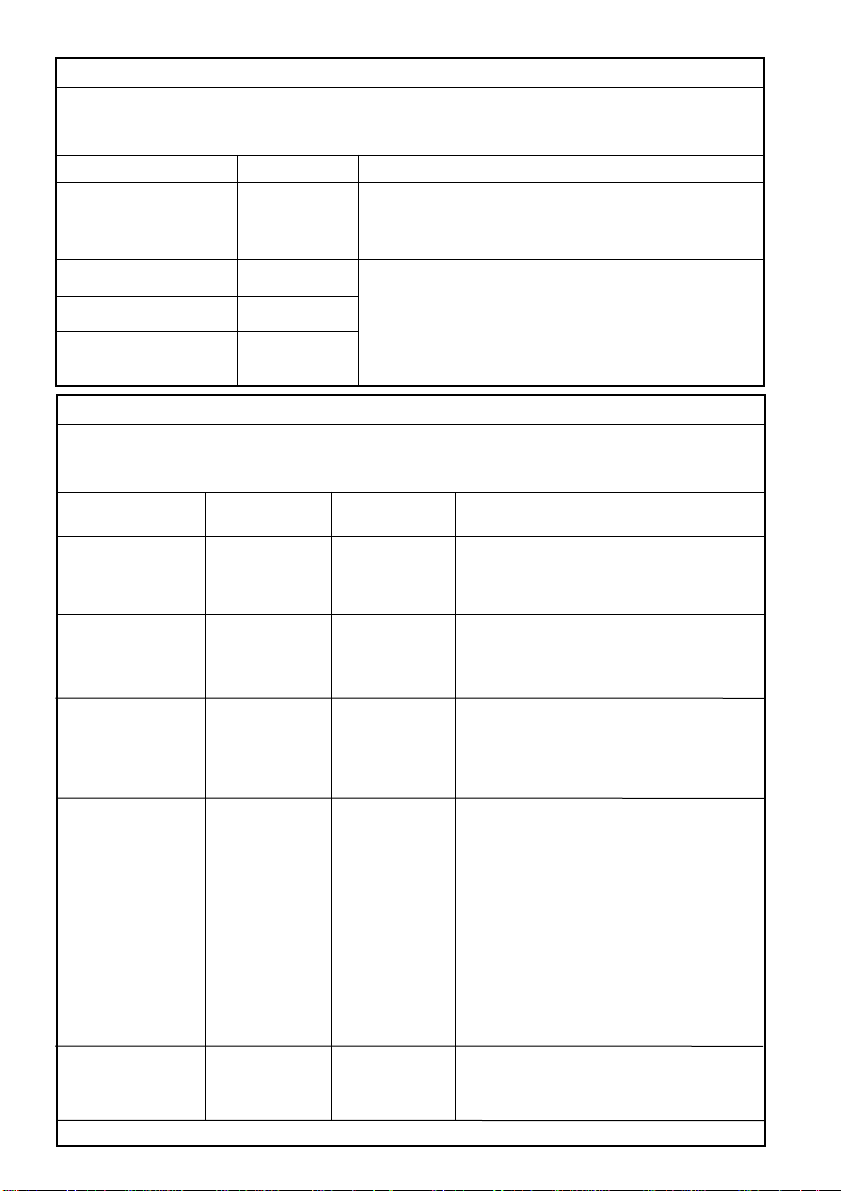

INSTRUCTIONS FOR MEDICAL USE

<according to the Medical Safety/EMC standard IEC/EN 60601-1-2>

MEDICAL ELECTRICAL EQUIPMENT needs special precautions regarding EMC and needs

to be installed and put into service according to the EMC information provided in the ACCOMPANYING DOCUMENTS.

Portable and mobile RF communications equipment can affect MEDICAL ELECTRICAL

EQUIPMENT.

Technical description

List of all cables and maximum length of the cable and transducers and other

ACCECCORIES

Reference page in this operation manual

This page, the previous pages for safety and page 22

for accessories

This page, the previous pages for safety and page 22

for accessories

Page 3 for thermal paper, Page 22 for accessories

AC power cord

USB cable

Thermal paper

Maximum length

2.5 m

2 m

WARNING:

The use of ACCESSORIES, transducers and cables other than those specified, with the

exception of transducers and cables sold by the manufacturer of the Model P93DW/P93DE

as replacement parts for internal components, may result in increased EMISSIONS or

decreased IMMUNITY of the Model P93DW/P93DE.

WARNING:

The Model P93DW/P93DE should not be used adjacent to or stacked with other equipment

and that if adjacent or stacked use is necessary, the Model P93DW/P93DE should be

observed to verify normal operation in the configuration in which it will be used.

Page 6

Guidance and manufacturer's declaration - electromagnetic emissions

The Model P93DW/P93DE is intended for use in the electromagnetic environment specified below.

The customer or user of the Model P93DW/P93DE should assure that it is used in such an

environment.

Emission test

RF emissions

CISPR 11/EN 55011

Compliance

Group 1

Electromagnetic environment - guidance

The Model P93DW/P93DE uses RF energy only for its

internal function. Therefore, its RF emissions are very

low and are not likely to cause interference in nearby

electronic equipment.

RF emissions

CISPR 11/EN 55011

Harmonic emissions

IEC/EN 61000-3-2

Voltage fluctuations /

Class B

Class A

Complies

The Model P93DW/P93DE is suitable for use in all

establishments, including domestic establishments

and those directly connected to public low-voltage

power supply network that supplies buildings used for

domestic purpose.

flicker emissions

IEC/EN 61000-3-3

Guidance and manufacturer's declaration - electromagnetic immunity

The Model P93DW/P93DE is intended for use in the electromagnetic environment specified below.

The customer or user of the Model P93DW/P93DE should assure that it is used in such an

environment.

Immunity test

Electrostatic

discharge (ESD)

IEC/EN 61000-4-2

Electrical fast

transient/burst

IEC/EN 61000-4-4

Surge

IEC/EN 61000-4-5

Voltage dips, short

interruptions and

voltage variations

on power supply

input lines

IEC/EN 61000-4-11

Power frequency

(50/60 Hz)

magnetic field

IEC/EN 61000-4-8

NOTE

U

is the a.c. mains voltage prior to application of the test level.

T

IEC/EN 60601

test level

±6 kV contact

±8 kV air

±2 kV for power

supply lines

±1 kV for input

/output lines

±1 kV

differential

mode

±2 kV common

mode

< 5%

U

T

(> 95% dip in

for 0,5 cycle

40%

U

T

(60% dip in

for 5 cycles

70%

U

T

(30% dip in

for 25 cycles

< 5%

U

T

(> 95% dip in

for 5 sec.

3 A/m

Compliance

level

±6 kV contact

±8 kV air

±2 kV for power

supply lines

±1 kV for input

/output lines

±1 kV

differential

mode

±2 kV common

mode

< 5%

U

)

(> 95% dip in

T

for 0,5 cycle

40%

U

)

(60% dip in

T

for 5 cycles

70%

U

)

(30% dip in

T

for 25 cycles

< 5%

U

)

(> 95% dip in

T

for 5 sec.

3 A/m

Electromagnetic environment - guidance

Floors should be wood, concrete or

ceramic tile. If floors are covered with

synthetic material, the relative humidity

should be at least 30%.

Mains power quality should be that of a

typical commercial or hospital

environment.

Mains power quality should be that of a

typical commercial or hospital

environment.

U

T

U

T

U

T

U

T

Mains power quality should be that of a

typical commercial or hospital

U

)

T

environment. If the user of the Model

P93DW/P93DE requires continued

operation during power mains

U

)

T

interruptions, it is recommended that the

Model P93DW/P93DE be powered from

an uninterruptible power supply or a

battery.

U

)

T

U

)

T

Power frequency magnetic fields should

be at levels characteristic of a typical

commercial or hospital environment.

Page 7

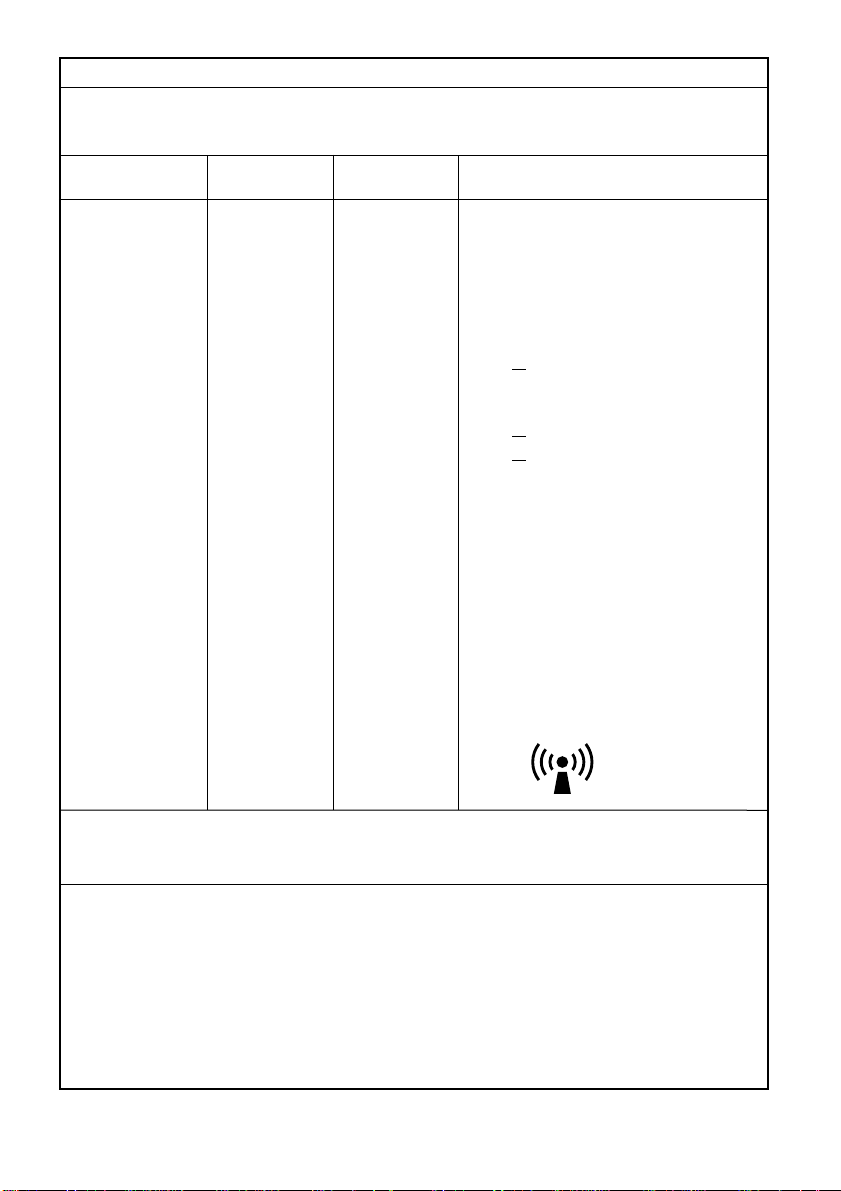

Guidance and manufacturer's declaration - electromagnetic immunity

The Model P93DW/P93DE is intended for use in the electromagnetic environment specified below.

The customer or user of the Model P93DW/P93DE should assure that it is used in such an

environment.

Immunity test

Conducted RF

IEC/EN 61000-4-6

Radiated RF

IEC/EN 61000-4-3

IEC/EN 60601

test level

3 Vrms

150 kHz to 80

MHz

3 V/m

80 MHz to 2,5

GHz

Compliance

level

3 Vrms

3 V/m

Electromagnetic environment - guidance

Portable and mobile RF communications

equipment should be used no closer to

any part of the Model P93DW/P93DE,

including cables, than the recommended

separation distance calculated from the

equation applicable to frequency of the

transmitter.

Recommended separation distance

d=1,2√P

d=1,2√P 80 MHz to 800 MHz

d=2,3√P 800 MHz to 2,5 GHz

where P is the maximum output power

rating of the transmitter in watts (W)

according to the transmitter manufacturer

and d is the recommended separation

distance in meters (m).

Field strengths from fixed RF

transmitters, as determined by an

electromagnetic site survey,

less than the compliance level in each

frequency range.

b

a

should be

Interference may occur in the vicinity of

equipment marked with the following

symbol:

NOTE1. At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE2. These guidelines may not apply in all situations. Electromagnetic propagation is

affected by absorption and reflection from structures, objects and people.

a

Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless)

telephones and land mobile radios, amateur radio, AM and FM radio broadcast and TV

broadcast cannot be predicted theoretically with accuracy. To assess the electromagnetic

environment due to fixed RF transmitters, an electromagnetic site survey should be

considered. If the measured field strength in the location in which the Model P93DW/P93DE

is used exceeds the applicable RF compliance level above, the Model P93DW/P93DE

should be observed to verify normal operation. If abnormal performance is observed,

additional measures may be necessary, such as reorienting or relocating the Model

P93DW/P93DE.

b

Over the frequency range 150 kHz to 80 MHz, field strength should be less than 3 V/m.

Page 8

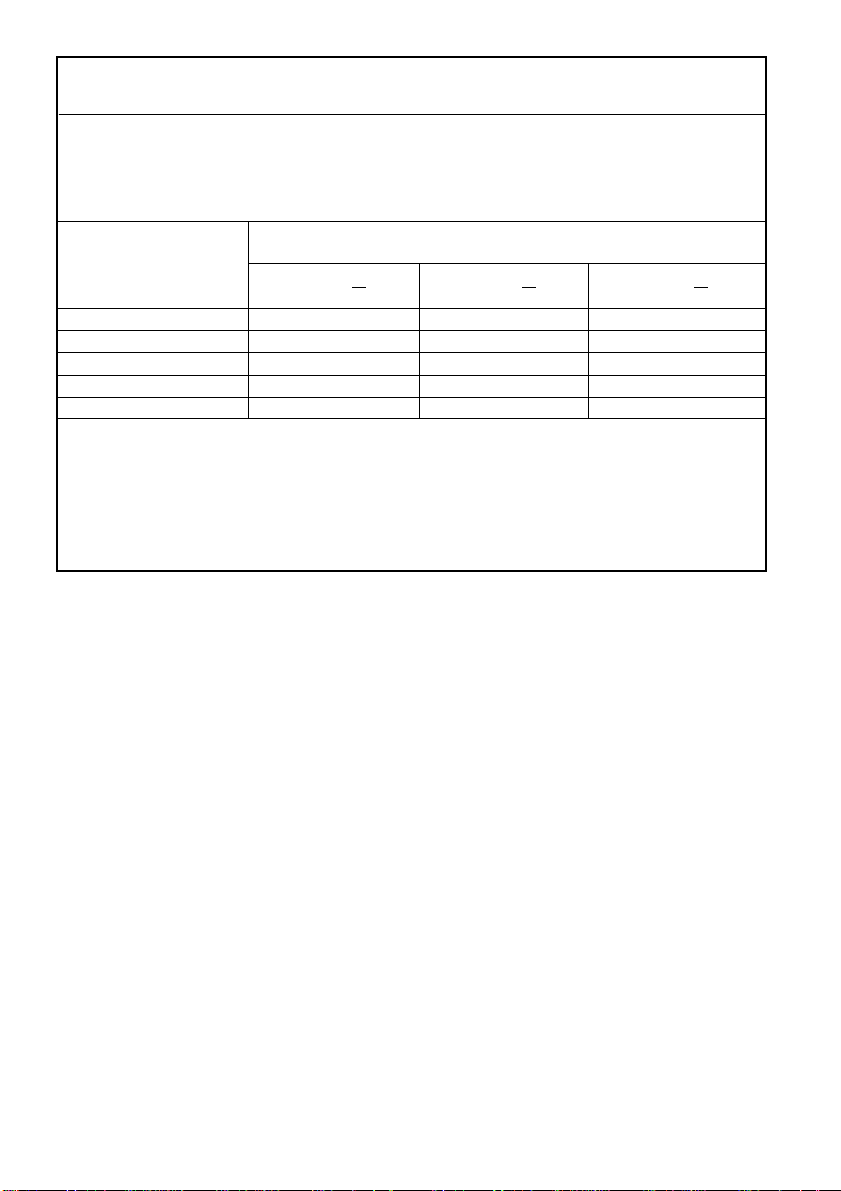

Recommended separation distances between

Portable and mobile RF communications equipment and the Model P93DW/P93DE

The Model P93DW/P93DE is intended for use in the electromagnetic environment in which

radiated RF disturbances are controlled. The customer or user of the Model P93DW/P93DE can

help prevent electromagnetic interference by maintaining a minimum distance between portable

and mobile RF communications equipment (transmitters) and the Model P93DW/P93DE as

recommended below, according to the maximum output power of the communications equipment.

Rated maximum output

power of transmitter

W

0,01

0,1

1

10

100

For transmitters rated at maximum output power not listed above, the recommended separation

distance d in meters (m) can be estimated using the equation applicable to the frequency of the

transmitter, where P is the maximum output power rating of the transmitter in watts (W)

according to the transmitter manufacturer.

NOTE1. At 80 MHz and 800 MHz, the separation distance for higher frequency range applies.

NOTE2. These guidelines may not apply in all situations. Electromagnetic propagation is

affected by absorption and reflection from structures, objects and people.

Separation distance according to frequency of transmitter

150 kHz to 80 MHz

d=1,2√P

0,12

0,38

1,2

3,8

12

m

80 MHz to 800 MHz

d=1,2√P

0,12

0,38

1,2

3,8

12

800 MHz to 2,5 GHz

d=2,3√P

0,23

0,73

2,3

7,3

23

Page 9

CONTENTS

CONTENTS ................................................................. 1

PRECAUTIONS..................................................... 2 - 4

UNPACKING................................................................ 5

FEATURES AND FUNCTIONS .............................. 6 - 7

Front Panel..........................................................................................6

Rear Panel ...........................................................................................7

INSTALLATION OF PAPER ................................... 8 - 9

EXAMPLE OF CONNECTION /

SETTING OF SWITCHES.......................................... 10

PRINTING........................................................... 11 - 12

ADJUSTMENT OF PRINT PICTURE................. 13 - 15

ERROR DISPLAY ............................................... 16 - 18

ST ATUS AND MODES .............................................. 19

USE OF CLEANING PAPER ..................................... 20

MAINTENANCE......................................................... 21

SPECIFICATIONS ..................................................... 22

11

1

11

22

2

22

33

3

33

44

4

44

55

5

55

66

6

66

77

7

77

88

8

88

99

9

99

AA

A

AA

BB

B

BB

CC

C

CC

DD

D

DD

1

1

Page 10

2

PRECAUTIONS

In the interest of safety, please observe the following

precautions:

POWER REQUIREMENT

This digital monochrome printer is designed for operation

on 100-240V AC 50/60Hz. Never connect to any outlet or

power supply having a different voltage or frequency.

PROTECTIVE MEASURES

IF ABNORMALITIES ARISE, . . .

Use of the unit during emission of smoke or abnormal

sounds (without adopting countermeasures) is

dangerous. In such a case, unplug the power cord from

the source outlet immediately, and request maintenance services from the sales dealer.

NEVER INSERT ANY OBJECT INTO THE UNIT

Foreign objects of any kind inserted into this unit constitute

a safety hazard and can cause extensive damage.

If any object should be inserted into the unit, unplug the

power cord, then contact the sales dealer.

DO NOT PLACE ANYTHING ON THE UNIT

Heavy objects placed on the unit can cause damage or

obstruct proper ventilation.

PROTECT THE POWER CORD

Damage to the power cord may cause fire or shock

hazard. When unplugging, hold by the plug only and

remove carefully.

Never put heavy objects on the power cord. The cord may

be damaged causing a fire or electric shock.

DO NOT PLACE WATER CONTAINERS ON THE UNIT

Do not place flower vases, and other water-holding containers on the unit. If, for some reason, water seeps to the

inside of the unit, unplug the power cord from the

source outlet, and contact the sales dealer. If used without

corrective measures, the unit may be damaged.

WARNING : THIS APPARATUS MUST BE EARTHED.

AVERTISSEMENT : CET APPAREIL DOIT ETRE MIS A

LA TERRE.

This equipment is classified as class 1, according to the

type of protection against electric shock.

DO NOT REMOVE THE CABINET

Touching internal parts is dangerous or may lead to

malfunction. Contact the sales dealer to carry out internal checks and/or adjustments. Before opening the

cover to clear a paper jam, etc., be sure to disconnect

the power cord plug.

DO NOT ATTACH A SCREW MORE THAN 6MM LONG

ON THE BOTTOM

If a screw more than 6 mm long is attached on the bottom

of the printer, it may cause internal damage.

PROTECT AGAINST DEW FORMATION

In extremely cold regions, if the unit is moved quickly from

an extremely cold place to a warmer one, dew is likely to

be formed. If dew is formed, printing is not possible.

OPERATING AMBIENT TEMPERATURE RANGE

The operating ambient temperature range is 5°C-40°C

(41°F-104°F), and humidity of 20-80%.

BE CAREFUL AROUND PRINT PAPER EXIT SLOT

Do not insert your hand or any material into the paper exit

slot during printing.

Do not touch the cutter blade inside the paper exit slot.

Otherwise, your finger will be injured.

DO NOT TOUCH THE THERMAL HEAD AND CUTTER

Do not touch the thermal head (located inside the unit)

and the cutter blade.

The thermal head is heated to high temperature.

This may cause injury.

INSTALLATION LOCATIONS

MAINTAIN GOOD VENTILATION

Ventilation slots and holes are provided on sides of this

unit.

Place the unit on a hard and level surface and locate at

least 4" (10cm) from walls to ensure proper ventilation.

UNSUITABLE LOCATIONS

Avoid shaky places or hot-springs areas where hydrogen

sulfide and acidic ions are likely to be generated.

PLACES WITH HIGH HUMIDITY AND DUST

Do not place the unit at locations with high humidity and/

or dust. They can cause extensive damage.

Avoid places where the unit is likely to contact oily fumes

and vapors.

PLACES LIKELY TO BE EXTREMELY HOT

Places exposed to direct sunlight, or near heating

appliances can attain extremely high temperatures,

which may deform the cabinet, or can become a

prime cause of damage.

SET THE UNIT ON A FLAT SURFACE

Do not use the unit when inclined ±20° in vertical or

horizontal direction, or in an unstable place.

Uneven surfaces may disturb paper feeding or ventilation, or affect the performance of the unit.

2

Page 11

FOR LONG OPERATING LIFE

UNSUITABLE MATERIALS FOR THE UNIT

Many plastic components are used in the unit.

Coat flaking and deformation are likely to occur if the

unit is wiped with chemical dusters, benzine, thinner or

any other solvent, if rubber or PVC items are left in

contact with the unit for extended duration, or if the unit

is sprayed with insecticide.

CARE OF THE CABINET

Unplug and clean with a soft cloth slightly moistened

with a mild soap and water solution. Allow to dry completely before operating. Never use petroleum base

solutions or abrasive cleaners.

HEAD ABRASION

The thermal head, like the video head, wears out.

When it is abraded, it becomes hard to print out fine

details of the picture. In such a case, it is necessary to

replace the thermal head. Consult with the sales dealer

for replacing the head.

THERMAL PAPER

2

Thermal papers listed in the page of SPECIFICATIONS are available.

2

When the remaining length of the paper is about10"

(25cm), a color belt appears at the paper end.

Prepare for replacement of the paper. If the

remaining paper length is less than 10" (25cm),

printing becomes uneven due to the uneven

paper core surface.

2

When the Printed paper is touched by wet hand,

the print may be discolored.

2

When the paper runs out during printing, the printing

operation stops and "EP" is displayed by the indicator

on the front panel. Install new paper at this time.

2

Store the printed paper in a place with low humidity

free from a direct sunlight.

2

If the paper absorbs non-volatile organic solvents

(alcohol, ester, katone, etc.) the print may be

discolored.

Particularly, if the paper comes in contact with soft

vinyl chloride such as a transparent tape, it quickens

discoloration.

2

Do not use paper other than the specified types.

2

Immediately after the paper is replaced, 2-3 images

may be printed with a blank part due to hand's dust

or oil.

2

Avoid direct sunlight or places near heaters, etc.,

and store the paper in a place with 30°C ( 86°F)

or lower temperature and 35-80% RH.

WHEN A DEFECT IS FOUND

If you detect smoke or other smell from the unit, disconnect immediately the power cord plug from a wall socket

and ask the agent for repair. It may be dangerous to

operate the unit under these conditions.

CONNECTION DEVICES

Read thoroughly "Operating Precautions" of the instruction booklets for the devices connected with the digital

monochrome printer.

Do not disconnect the power cord during printing.

CAUTION ON RELOCATING

When transporting this unit, make sure it is not likely to

be subjected to impacts. They can be a prime cause for

damage. Further, make sure to disconnect the power

cord from the power outlet, and the cables from the

connected devices.

UNPLUG THE POWER CORD DURING A LONG

ABSENCE

Turn off the MAIN power switch and unplug the power

cord during a long absence.

2When the paper is rapidly transferred from a cool

place to a hot place, a vapor or a dew is generated

on the paper surface causing paper jam or degraded

printing quality.

2

A finger print or dust on the paper surface may

degrade the printing quality.

Note:

Mitsubishi brand thermal paper is specially treated

with an anti-static coating against thermal head

damage caused by static-electricity discharge.

The use of non-treated paper may cause premature

head failure in your product.

3

Page 12

SAFETY TECHNICAL CHECKS

Periods: According to the recommendations of the manufacturer of medical device.

Scope: a) Visual check

Housing, cables, operator controls, readout device ( displays, LED etc.), labels,

accessories, instruction manual.

b) Function test

Performance check acc. instruction manual, also unity and applicability of set

and accessory test.

c) Electrical check

Safety electrical test of the configuration in accordance with EN60601-1.

“ In the interest of safety, avoid the handling of liquids beside the set.”

RESPONSIBILITY OF THE MANUFACTURER

The manufacturer, assembler, installer or importer considers himself responsible for the

effects on safety, reliability and performance of the EQUIPMENT only if:

– assembly operations, extensions, re-adjustments, modifications or repairs are carried out

by persons authorized by him, and

– the electrical installation of the relevant room complies with the IEC requirements

– the EQUIPMENT is used in accordance with the instructions for use.

• Any service after expiration of the warranty period will be chargeable. Consult your dealer

for advice.

TECHNICAL DESCRIPTION

The supplier will make available on request such circuit diagrams, component part lists,

descriptions, calibration instructions or other information which will assist the USER's ap-

propriately qualified technical personnel to repair those parts of the EQUIPMENT which

are classified by the manufacturer as repairable.

The use of ACCESSORY equipment not complying with the equivalent safety requirements

of this equipment may lead to a reduced level of safety of the resulting system. Consider-

ation relating to the choice shall include:

– use of the accessory in the PATIENT VICINITY

– evidence that the safety certification of the ACCESSORY has been performed in accor-

dance to the appropriate EN60601-1 and/or EN60601-1-1 harmonized national standard.

The transportation and storage environmental conditions are:

Temperature : -20°C - +60°C (-4°F - +140°F)

Humidity : 90%RH or less at 40°C (104°F)

Note : The above transportation environmental conditions indicate the storage environmental conditions during transport.

4

Page 13

UNPACKING

3

Take the unit out of the box by the following procedures. Make sure to check the

contents.

11

1

Open the top of the box.

2

11

22

22

Remove

the cushion above the unit.

33

3

Take the unit out of the box carefully.

33

• Make sure to

keep the unit

horizontal.

44

4 Unwrap the unit.

44

Accessories

Thermal paper

AC power cord

Cleaning paper

Operation manual

Printer driver (1 CD-ROM)

5

Page 14

4

FEATURES AND FUNCTIONS

Front Panel

1

3

245

BRT/CONT

BRT

CONT

LOCK

678 9

DOWN

LOCK

UP

FEED

COPY

A

B

Name

Power switch Turns on/off the power.

1

Indicator

2

Indicator (BRT/CONT/LOCK)

3

BRT(brightness)/

4

CONT(contrast) button

DOWN button

5

UP button

6

LOCK button

7

FEED button 12

8

COPY button

9

Print exit/Cutter

A

Lever

B

OPEN

Function

Displays stand-by, functions and error

messages.

Displays the settings of brightness,

contrast and button function lock

Makes fine adjustments of the brightness and contrast of the print image.

Press to decrease the setting value.

Press to increase the setting value.

Locks the button functions

Press to feed the paper.

Press to print additional copies of the

previous print-out.

Printed paper will come out through this

slot./ Cut the printed paper here.

Switch to open the door.

Reference

Page

11 • 20

11•14•16-19

10•13

13

14

14

15

11

8•11•20

8•20

6

Page 15

Rear Panel

C

1 2 3 4

ON

OFF

DIP SW

DIP SW FUNCTION TABLE

NO. 1 2 3 4

FUNCTION LOCK

SW-ON

SW-OFF

D

USB

ON

OFF

Name

C

DIP switch

D

USB terminal

Power terminal (AC LINE)

E

Potential equalization terminal

F

AC LINE

E

POTENTIAL EQUALIZATION

F

TERMINAL

This is used to equalize the potential of the

equipment connected to this unit.

For details refer to the installation

instruction of equipment to be

connected.

Function

Selects special functions.

Connects to the device equipped

with USB interface such as personal

computer.

Connect the power cord to this

terminal.

Makes the connected equipment

potential equal.

Reference

Page

10

10

10

-

7

Page 16

5

INSTALLATION OF PAPER

Moisture, fingerprints or dust on the

paper surface may cause a noise at

printing or deterioration in print

quality. Set the paper by the following procedure to prevent adhesion

of fingerprint or dust on the paper

surface.

1Open the door.

• Switch the lever

located on the

N

E

P

O

left side to the

“OPEN” position.

The door opens.

2Load the paper roll.

• Place the paper roll

in the printer.

3Pull out the paper end.

• Pull out the first 1520cm (6 in. - 9 in.) of

the paper to remove

any slack in the roll.

4Close the door.

5Cut the paper end.

printing side

INCORRECT

CORRECT

Note: The printing surface is the outside.

Place the paper with the thermosensitive side (printing side) up.

When the paper roll is placed

inversely, images can not be printed.

cutter

• Cut the paper end with the cutter by

pulling the paper upwards against the

cutter blade.

8

Page 17

When setting the paper, observe the following

precautions to prevent paper jam.

Do not use defective paper.

Adjust the paper position correctly.

Do not allow slack in the paper roll.

Do not use bent or wrinkled

paper.

When the paper is fed out skewed

from the print exit, adjust the paper

position so that it is fed out straight.

Set the paper tightly to remove any

slack.

If the side of the print paper is uneven or the core is sticking out, the amount of paper feeding

after printing may vary.

When the side of paper is uneven or the core is sticking out, install the print paper after

making the paper side even.

The core is sticking out.

INCORRECT

The paper is uneven.

CORRECT

Make the paper side even.

CAUTION

• Keep the high-density paper away from fingerprint, dust or moisture when storing it.

• Do not touch the rubber roller. Do not stain or damage the roller surface.

• Do not touch the thermal head (located behind the cutter). When printing, the thermal

head is heated to high temperature.

• Do not touch the cutter blade.

9

Page 18

6

ON

OFF

DIP SW

1 2 3 4

EXAMPLE OF CONNECTION / SETTING OF SWITCHES

Connecting to various equipment with USB interface such as

medical equipment and personal computer.

Connection

Connect the digital monochrome printer with PC or medical

equipment through a USB cable.

Personal computer or

medical equipment

To USB

terminal

ON

OFF

USB

AC LINE

Connect

Power cord

Rear panel

Setting of Switches

Set the DIP switches on the rear panel.

• When setting the switch No. 1 to ON, DOWN, UP, and LOCK buttons

will be locked. (The functions will not be available.) At this time, the

LOCK indicator illuminates.

Set the switches other than No. 1 to OFF.

Installing printer driver

Printer driver is required to print the data from a personal computer connected with this printer.

The printer driver for Windows®2000/XP is supplied with this printer.

Refer to the “Read me” for installing the printer driver in the CD-ROM supplied with this unit.

22

2

How to open the ReadMe file

22

11

1

Install the CD-ROM in the CD-ROM drive on your PC.

11

22

2

Double-click on the CD-ROM icon.

22

33

3

Double-click on the ReadMe_E.pdf.

33

44

4

44

Microsoft® Windows®2000, and Windows® XP are the registered trademarks of Microsoft

Corporation in the U.S.A and other countries.

Adobe, Acrobat Reader and Adobe Reader are registered trademark of Adobe Systems

Incorporated.

®

Adobe

Reader® or Adobe® Acrobat® Reader® is required to open ReadMe_E.pdf file.

You can download Adobe Reader and Acrobat Reader free from the Web site of Adobe

Systems Incorporated (http://www.adobe.com/products/acrobat/).

Install the printer driver by following the instruction in the file.

10

Page 19

7

FEED

COPY

1

PRINTING

Turn on the power.

•

Press the

POWER

switch to turn

on the power.

3

Cut the printed paper.

cutter

• Cut the printed

paper with the

cutter by

tearing off the

paper in the

upper right

direction.

2

Print a picture displayed on the screen.

Print a picture with an application

software. The image data is transferred

through USB interface.

Copy Printing

2

You can set the number of copies by pressing

the COPY button on the front panel. (Setting

range : 1 to 200)

You can copy the same picture as many times

as you desire until a new image data is printed.

2

The set number of copy printing and the

number of the remainings are displayed on the

indicator as shown right.

2

The number of copy print setting is not memorized.

2

When pressing the UP button during copy

printing, continuous printing is available.

Cancel of Copy Printing

2

When pressing the FEED button during copy

printing, the copy printing is cancelled upon

completion of the current copy.

• Do not pull the paper in the horizontal

direction. The paper inside the unit may

be displaced and printing may not be

carried out correctly.

Indicator

Number of copy printing /

remainings

1 - 99

100 - 199

Continuous printing

200

11

Page 20

Paper Feeding

FEED

2

To feed the paper, press the FEED button on the

front panel.

Precautions on Printing

When dark pictures are printed consecutively, the digital monochrome printer may become

overheated and the indicator blinks.

In this case, wait for a while until the unit has cooled down.

Avoid pulling out or holding the paper during printing or copying to prevent paper jam.

Do not touch the paper until printing or copying finishes.

12

Page 21

8

ADJUSTMENT OF PRINT PICTURE

Adjustment of Printer Brightness/Printer Contrast

You can make fine adjustment of printer brightness and

printer contrast of the printed picture.

Control panel

COPY

FEED

BRT

CONT

LOCK

BRT/CONT

DOWN

LOCK

UP

• For adjustment, use the BRT/CONT button "

1Press the BRT/CONT button.

COPY

FEED

LOCK

DOWN

BRT/CONT

BRT/CONT

UP

COPY

FEED

LOCK

DOWN

UP

BRT

CONT

LOCK

OPEN

BRT

CONT

LOCK

OPEN

BRT/CONT

", UP button "UP" and DOWN button "

Press the BRT/CONT button "

once to adjust the printer brightness.

• The BRT indicator lights up.

Press the BRT/CONT button "

twice to adjust the contrast.

• The CONT indicator lights up.

BRT/CONT

BRT/CONT

"

"

DOWN

".

13

Page 22

2Change the setting.

3Store the set value.

UP

• Press the UP button to

increase the value.

DOWN

• Press the DOWN button

to decrease the value.

The setting value is displayed by the

indicator.

(example)

Setting range is -19 to +19.

By pressing the BRT/CONT button

again, the setting value is memorized.

The memorized value will not be lost

even when the power is turned off.

14

Page 23

Automatic restoration to the standby status from the adjustment or setting mode

When left without any operation of buttons, and switches

under the following conditions for more than 20 seconds,

this unit automatically returns to the standby status (Indicator display : ).

In this case, the newly set value is not memorized and the

setting goes back to the value that was set before change.

• While adjusting the printer brightness or printer contrast

Resetting the values

You can reset the values of printer brightness and printer

contrast.

1

Turn off the power.

2

While pressing the FEED button, turn on the power.

3

The display by the indicator changes from

default setting.

to , and the values are reset to the

Locking the button functions

You can lock the function of UP and DOWN buttons on the

control panel.

To lock the button functions

1

Hold the LOCK button for approx. 1 second until a "Peep" sounds.

2

The functions of UP and DOWN buttons are locked and the LOCK indicator illuminates.

When the UP or DOWN button is pressed on this status, " " is displayed on the

indicator. Whenever the BRT/CONT buttons is pressed, each set value of brightness

and contrast can be checked.

To unlock the button functions

1

Hold the LOCK button for approx. 1 second until a "Peep" sounds.

2

The functions of UP and DOWN buttons are unlocked and the LOCK indicator goes

off.

If the DIP switch No. 1 is set to ON, this function is not available. (The LOCK button

becomes invalid.)

15

Page 24

ERROR DISPLAY

9

In case of an error in the unit during operation, you are warned

by an alarm tone or the LED indicator.

Cause/Error display

11

1

Overheat

11

Symptom/Remedy

[Symptom]

• When the head gets overheated, the indicator blinks.

When overheat occurs while more than one copy is being processed, printing starts as soon as the error is solved.

If some images are waiting to be processed, the following buttons

function as described below.

COPY button

• Each time the COPY button is pressed, the number displayed by

the indicator increases as

• After the error is solved, copy printing starts automatically.

FEED button

• When the number of copies has been set to more than one,

outstanding copies are cancelled.

When no image remains to be processed, the buttons are valid

during overheat status. After the error is solved, copy printing starts

automatically.

[Remedy]

Wait until the head cools down.

.

16

Page 25

Cause/Error display

22

2

No paper

22

Symptom/Remedy

[Symptom]

• When the paper runs out or the paper is not installed, printing

becomes impossible and an alarm tone is heard.

In this case, all the buttons become invalid.

• If this error occurs while more than one copy is being printed or

there are images waiting to be processed, printing is cancelled

at the occurrence of the error.

[Remedy]

Install a new roll of paper according to "5. INSTALLATION OF

PAPER" on page 8.

When the paper is correctly installed while the printing of more than

one copy has been suspended or there are images waiting to be

processed, an alarm tone is heard. Then, the paper is fed automatically about 15 cm and printing resumes.

After the error is resolved, the unit resumes printing from the interrupted image and finishes printing all the outstanding images.

Cause/Error display

33

3

Button input

33

error

Symptom/Remedy

[Symptom]

• The button becomes invalid and an alarm tone is heard in the

following cases.

• During adjusting the printer brightness or the printer contrast,

the UP button is pressed exceeding the upper limit value (LED

display :

) or the DOWN button is pressed exceeding the

lower limit value (LED display : )

• The UP or DOWN button is pressed when the button func-

tions are locked with the LOCK button or the DIP switch No. 1.

The indicator displays “ ” for one second and return to the status

before the error occurred.

17

Page 26

Cause/Error display

44

4

Door error

44

Symptom/Remedy

[Symptom]

• When the door opens, an alarm tone is heard.

The indicator displays " " for one second.

In this case, all the buttons and switches become invalid.

• If this error occurs while more than one copy is being printed,

printing is cancelled at the occurrence of the error.

[Remedy]

Close the door.

When the door is closed while the printing of more than one copy is

being printed, an alarm tone is heard.

After the error is resolved, the unit resumes printing from the

interrupted image and finishes printing all the outstanding images.

Cause/Error display

55

5

Gear lock error

55

Symptom/Remedy

[Symptom]

• When the thermal head does not automatically go down at the start

of printing or paper feeding, an alarm tone is heard.

• When the thermal head does not automatically go up at the end of

printing or paper feeding, an alarm tone is heard.

The indicator displays "

" and all the buttons become invalid.

• If this error occurs while more than one copy is being printed or

there are images waiting to be processed, printing is cancelled at

the occurrence of the error.

[Remedy]

Turn the power off. Then turn it on again.

Printing of the interrupted image or all the images saved in the

memory that are waiting to be processed is cancelled.

18

Page 27

10

STATUS AND MODES

Set state/Mode

Power off

Stand-by

During data receiving

Print state

Printer brightness mode

Printer contrast mode

Error detect state

LED display

Contents of LED display

Power off

During data receiving

Remaining number of copies /

number of copies

1 to 99

100 to 199

200

Continuous copy printing

Fine adjustment of the picture brightness

Fine adjustment of the picture contrast

No paper

Button input error

Door is open.

Gear lock

19

Page 28

11

USE OF CLEANING PAPER

When the thermal head is dirty with dust, etc., white spots or stripes may appear on the

print. In this case, clean the thermal head by the following procedure BY USING THE

SUPPLIED CLEANING PAPER.

11

1

Turn on the power.

11

22

2

Open the door.

22

Press the POWER

switch to turn on the

power.

44

4

Close the door.

44

Close the door

without taking out

the cleaning paper.

Switch the left side

OPEN

lever to the OPEN

position.

The door opens.

55

5

Press the FEED button.

55

FEED

Keep pressing the

FEED button until

33

3

Insert the cleaning paper.

33

you hear a beep.

Roll the cleaning

paper and install

into the set.

66

6

Take out the cleaning paper.

66

Open the door.

Take out the

Cleaning paper

N

E

P

O

cleaning paper.

!

Red mark

Adjust the red mark

on the cleaning

paper parallel to the

platen roller.

77

7

Repeat the steps

77

Do not pull out the

cleaning paper while

the door is closed.

33

66

3

-

6

by 2 or 3 times,

33

66

and print 1-2 sheets to verify the

cleaning effect.

Platen roller

Cleaning paper

CAUTION

0

It is recommended that after printing 10 rolls of paper the unit be cleaned using the supplied cleaning paper.

0

If the symptom of the dirty head is not corrected even after cleaning, your set needs repairing, contact your dealer.

0

Do not pull out the sheet and the cleaning paper while the door is closed.

This may cause extensive damage to the unit.

0

Never use other cleaning papers. It may cause damage to the thermal head.

0

This cleaning paper should be used only for cleaning the thermal head. Do not use it for other purpose.

20

Page 29

12

MAINTENANCE

Turn off the power for maintenance.

Maintenance of Main Unit

Wipe off stains of the front panel with a soft cloth.

When the panel is heavily stained, wipe with a cloth moistened

with neutral cleanser diluted by water and finish with a dry

cloth.

Maintenance of Rubber Roller

When the rubber roller is dirty with dust, etc., a blank spot may

appear on the print.

In this case, eliminate the dust on to the rubber roller with a

blower or a brush.

The regular cleaning using a lint-free cloth, etc., which is

moistened with ethyl alcohol is recommended.

Rubber roller

Cleaning of Thermal Head

When the thermal head is dirty with dust, etc., white spots or

stripes may appear on the print.

In this case, clean the thermal head according to "11. USE OF

CLEANING PAPER".

Note: After installation of new roll of paper, dust on the paper will

generally require 2 to 3 prints to be made before the dust

is eliminated.

21

Page 30

13

Type: Digital Monochrome Printer

Model: P93DW/P93DE

Power supply and

power consumption: 100-240V AC, 50/60Hz, 1.5 - 0.8A

Connection terminal: USB interface (Series "B" receptacle)

Resolution: 1280 x 1280 pixels (Standard)

Gradation: 256 gradations

Printing speed: 5.0 sec (Standard)

Print size: 4" x 4" (100 mm x 100 mm) (Standard)

Operating conditions: Temperature 41 - 104˚F (5-40˚C)

External dimensions: 6.1" x 3.5" x 10.1" (154mm x 89.5mm x 256mm); W x H x D

SPECIFICATIONS

Hi-Speed USB (Ver. 2.0) supported

(Max. 1280 x 5760 pixels)

(Max. 4" x 17.7" (100 mm x 450 mm))

Humidity 20 - 80% RH (No dewing)

Weight: 6.2 lbs (2.8 kg)

Standard accessories: AC power cord ........................................................... 1 piece

Thermal paper KP65HM-CE .......................................... 1 roll

Cleaning paper .......................................................... 1 sheet

Printer driver ........................................................ 1 CD-ROM

Optional accessory: Thermal paper KP65HM-CE, KP65H-CE, KP61S-CE,

KP61B-CE, KP91HG-CE

SERVICE INFORMATION

Before requesting service please review this operation manual to correct minor complaints.

If you are unable to correct the problem, consult your MITSUBISHI Dealer or MITSUBISHI

Service Department.

DO NOT ADJUST ANY CONTROLS NOT DESCRIBED IN THIS OPERATION MANUAL.

DO NOT REMOVE THE PROTECTIVE ENCLOSURE OF THIS UNIT.

22

Page 31

MITSUBISHI DIGITAL ELECTRONICS AMERICA, INC.

9351 Jeronimo Road, Irvine, CA 92618

Phone 949-465-6000

Mitsubishi Electric Europe B.V.

UK Branch

Travellers Lane, Hatfield, Herts. AL10 8XB, England, U.K.

Phone (0) 1707 276100 FAX (0) 1707 278755

German Branch

Gothaer Strasse 8, 40880 Ratingen ; Postfach 1548, 40835 Ratingen ; Germany

Phone 02102/ 486-9250 FAX 02102/ 486-7320

French Branch

25, Boulevard des Bouvets - 92741 NANTERRE cedex

Phone (01) 55.68.55.00 FAX (01) 55.68.57.31

Italian Branch

Centro Direzionale Colleoni, Palazzo Perseo-Ingresso 2,

Via Paracelso 12, 20041 Agrate Brianza, (Milano) Italy

Phone (039) 60531 FAX (039) 6057694

Benelux Branch

Nijverheidsweg 23 A, 3641 RP. Postbus 222, 3640 AE Mijdrecht

Phone 0297-282461 FAX 0297-283936

Spanish Branch (Barcelona)

Sucursal en españa

Ctra. Rubí, 76-80, 08190 Sant Cugat del Vallés

Ap. de Correos 420

BARCELONA (SPAIN)

Phone +34 93 565 3154 FAX +34 93 589 4388

Manufactured by Mitsubishi Electric Corporation

1 Zusho Baba, Nagaokakyo-City, Kyoto Japan

871C596A20

Made from recycled paper

PRINTED IN MALAYSIA

Loading...

Loading...