Page 1

Page 2

Page 3

MELDAS is a registered trademark of Mitsubishi Electric Corporation.

Other brands and product names throughout this manual are trademarks or registered

trademarks of their respective holders.

Page 4

Page 5

Introduction

This instruction manual describes the methods of using the MITSUBISHI CNC

MULTI-AXIS,MULTI-PART SYSTEM M700L/M700LV/M70L Series mainly for a lathe.

The programming methods for all of the above models are described, so read this manual

thoroughly before starting use.

In respect to the functions related to the multi-axis multi-part system, the programming and

alarm details for each system are the same as the general-purpose (2-axis, 3-axis) lathe.

Explanations in this manual assume that all functions are provided with all of the above

models. However, all options are not necessarily provided with each CNC, so refer to the

specifications issued by the machine manufacturer before starting use.

Thoroughly read the "Precautions for Safety" given on the next page to ensure safe use of

this numerical control unit.

Details described in this manual

(1) This manual gives general explanations from the standpoint of the NC side.

For explanations concerning individual machine tools, refer to the instruction manual

issued by the machine manufacturer.

For items described as "Restrictions, "Usable State", etc., the instruction manual issued by

the machine manufacturer takes precedence over this manual.

(2) While every effort has been made to describe special handling in this manual, items not

described in this manual should be interpreted as "Not Possible".

(3) The multi-part system function is an additional specification. The 3-system model is

explained as an example in this manual, but the number of systems that can be used will

differ according to the model.

Note that the maximum number of spindle axes will also differ according to the model.

Check the specifications before starting use.

(4) Some functions are unavailable depending on the machine model.

CAUTION

For items described in "Restrictions" or "Usable State", the instruction manual issued by the

machine manufacturer takes precedence over this manual.

Items not described in this instruction manual should be interpreted as "Not Possible".

This manual has been writt en on t h e a s s u mptio n t h a t all op t i o n f u n c t ions a r e added.

Refer to the specifications issued by the machine manufacturer before starting use.

Refer to the instruction manual issued by the machine manufacturer for explanations on each

machine tool.

Some screens and functions may differ or may not be usable depending on the NC system

version.

Page 6

Page 7

Precautions for Safety

Always read the specifications issued by the machine maker, this manual, related manuals

and attached documents before installation, operation, programming, maintenance or

inspection to ensure correct use.

Understand this numerical controller, safety items and cautions before using the unit.

This manual ranks the safety precautions into "DANGER", "WARNING" and "CAUTION".

DANGER

WARNING

CAUTION

Note that even items ranked as " CAUTION", may lead to major results depending on the

situation. In any case, important information that must always be observed is described.

When the user may be subject to imminent fatalities or major injuries if

handling is mistaken.

When the user may be subject to fatalities or major injuries if handling is

mistaken.

When the user may be subject to injuries or when physical damage may

occur if handling is mistaken.

DANGER

Not applicable in this manual.

WARNING

Not applicable in this manual.

CAUTION

1. Items related to product and manual

For items described as "Restrictions" or "Usable State" in this manual, the instruction manual

issued by the machine manufacturer takes precedence over this manual.

Items not described in this instruction manual should be interpreted as "Not Possible".

This manual is written on the assumption that all option functions are added. Refer to the

specifications issued by the machine manufacturer before starting use.

Some screens and functions may differ or may not be usable depending on the NC system

version.

Page 8

CAUTION

2. Items related to programming

Because of key chattering etc., during editing, the commands with no value after G become a

"G00" operation during running.

";", "EOB" and "%" "EOR" are expressions used for the explanation. The actual codes are

"; (line feed)" and "%" for ISO, and "EOB" (End Of Block) and "EOR" (End Of Record) for

EIA.

The commands with no value after G become a "G00" operation during running.

Always carry out dry run operation before actual machining, and confirm the machining

program, tool offset amount and workpiece offset amount, etc.

When creating the machining program, select adequate machining conditions, and make

sure not to exceed the machine and NC's performance, capacity and limits. Examples

given in this manual do not take the machining conditions into consideration.

Do not change fixed cycle programs without the prior approval of the machine

manufacturer.

When programming the multi-part system, take special care to the movements of the

programs for other systems.

During the spindle synchronous control mode, do not turn the rotation command for the

slave spindle OFF while the master spindle and slave spindle are chucked on the same

workpiece. This will be hazardous as the slave spindle will stop.

Do not issue another axis name change command before axis name change cancel is

issued once axis name change is commanded.

Page 9

Disposal

(Note) This symbol mark is for EU countries only.

This symbol mark is according to the directive 2006/66/EC Article 20 Information for endusers and Annex II.

Your MITSUBISHI ELECTRIC product is designed and manufactured with high quality materials and

components which can be recycled and/or reused.

This symbol means that batteries and accumulators, at their end-of-life, should be disposed of

separately from your household waste.

If a chemical symbol is printed beneath the symbol shown above, this chemical symbol means that the

battery or accumulator contains a heavy metal at a certain concentration. This will be indicated as

follows:

Hg: mercury (0,0005%), Cd: cadmium (0,002%), Pb: lead (0,004%)

In the European Union there are separate collection systems for used batteries and accumulators.

Please, dispose of batteries and accumulators correctly at your local community waste collection/

recycling centre.

Please, help us to conserve the environment we live in!

Page 10

Page 11

Contents

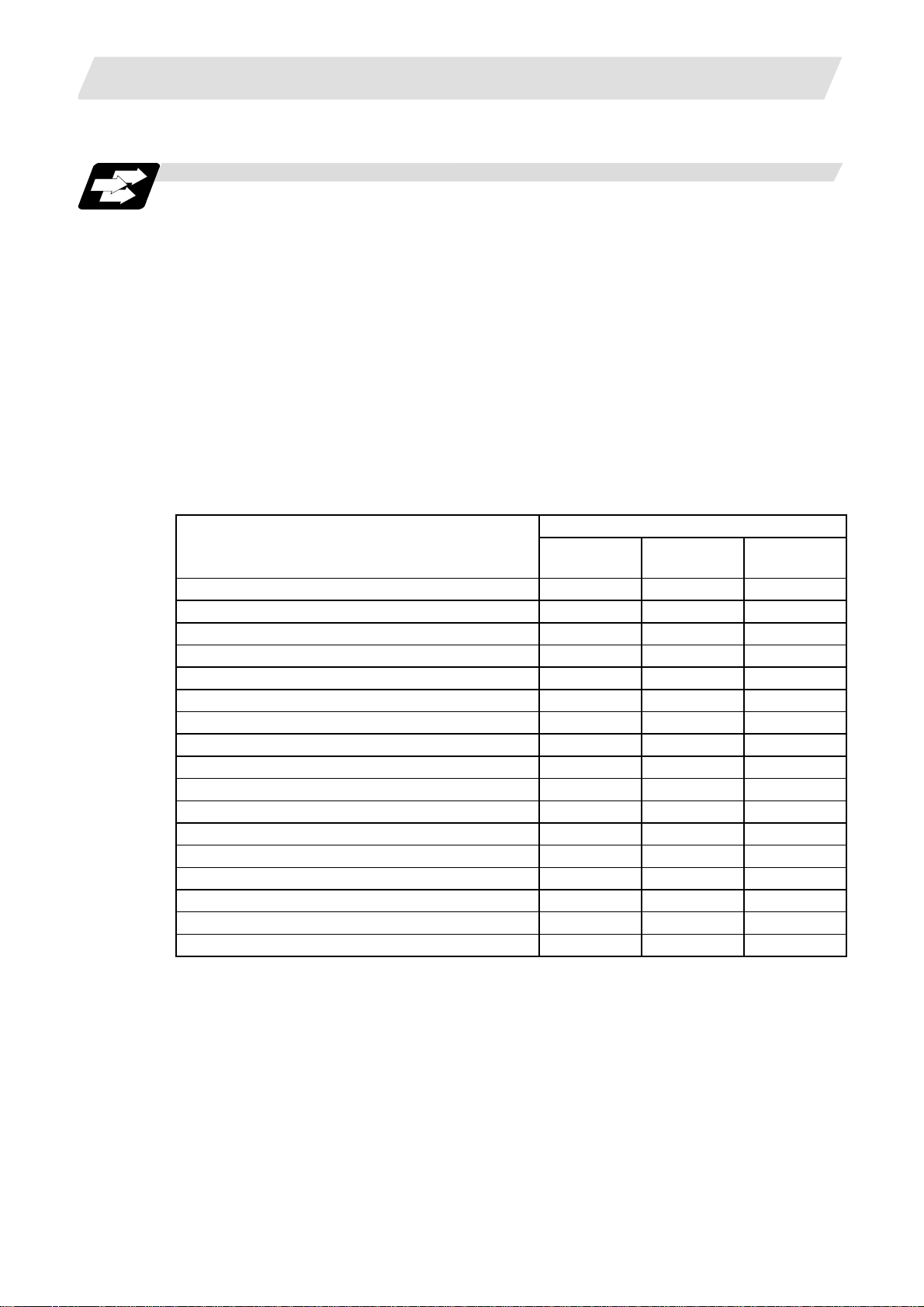

1. CONTROL AXES............................................................................................................................1

1.1 Coordinate Word and Control Axis..........................................................................................1

1.2 Coordinate Systems and Coordinate Zero Point Symbols......................................................2

2. INPUT COMMAND UNITS .............................................................................................................3

2.1 Input Command Units .............................................................................................................3

2.2 Input Setting Units...................................................................................................................3

3. DATA FORMATS ...........................................................................................................................4

3.1 Tape Codes.............................................................................................................................4

3.2 Program Formats ....................................................................................................................6

3.3 Tape Storage Format..............................................................................................................8

3.4 Optional Block Skip.................................................................................................................8

3.5 Program/Sequence/Block Numbers (O, N).............................................................................9

3.6 G Code System.....................................................................................................................10

3.7 Precautions Before Machining ..............................................................................................14

4. BUFFER REGISTER....................................................................................................................15

4.1 Pre-read Buffers....................................................................................................................15

5. POSITION COMMANDS ..............................................................................................................16

5.1 Incremental/Absolute Value Commands...............................................................................16

5.2 Radius/Diameter Commands ................................................................................................18

5.3 Inch/Metric Conversion (G20, G21) ......................................................................................19

5.4 Decimal Point Input...............................................................................................................20

6. INTERPOLATION FUNCTIONS...................................................................................................24

6.1 Positioning (Rapid Traverse); G00........................................................................................24

6.2 Linear Interpolation; G01.......................................................................................................27

6.3 Circular Interpolation; G02, G03 ...........................................................................................29

6.4 R-designated Circular Interpolation; G02, G03.....................................................................33

6.5 Plane Selection; G17, G18, G19...........................................................................................35

6.6 Helical interpolation; G17, G18, G19, and G02, G03............................................................37

6.7 Thread Cutting ......................................................................................................................41

6.7.1 Constant lead thread cutting; G33..................................................................................41

6.7.2 Inch thread cutting; G33 .................................................................................................45

6.7.3 Continuous thread cutting...............................................................................................46

6.7.4 Variable lead thread cutting............................................................................................47

6.7.5 Circular thread cutting; G35/G36....................................................................................49

6.8 Milling Interpolation; G12.1/G13.1.........................................................................................55

6.8.1 Selecting milling mode....................................................................................................56

6.8.2 Milling interpolation control and command axes.............................................................57

6.8.3 Selecting a plane during the milling mode......................................................................59

6.8.4 Setting milling coordinate system ...................................................................................61

6.8.5 Preparatory functions......................................................................................................63

6.8.6 Switching from milling mode to turning mode; G13.1 .....................................................68

6.8.7 Feed function ..................................................................................................................68

6.8.8 Program support functions..............................................................................................68

6.8.9 Miscellaneous functions..................................................................................................69

6.8.10 Tool offset functions......................................................................................................70

6.8.11 Interference check ........................................................................................................87

7. FEED FUNCTIONS.......................................................................................................................95

7.1 Rapid Traverse Rate.............................................................................................................95

7.2 Cutting Feedrate ...................................................................................................................95

Page 12

7.3 Synchronous/Asynchronous Feed; G94, G95.......................................................................96

7.4 Feedrate Designation and Effects on Control Axes ..............................................................98

7.5 Thread Cutting Leads..........................................................................................................102

7.6 Automatic Acceleration/Deceleration ..................................................................................103

7.7 Rapid Traverse Constant Inclination Acceleration/Deceleration.........................................104

7.8 Speed Clamp ......................................................................................................................106

7.9 Exact Stop Check; G09.......................................................................................................107

7.10 Exact Stop Check Mode; G61...........................................................................................111

7.11 Cutting Mode; G64............................................................................................................111

7.12 Feed Forward Control .......................................................................................................112

8. DWELL .......................................................................................................................................113

8.1 Dwell Per Second; (G94) G04.............................................................................................113

8.2 Dwell Per Rotation; (G95) G04 ...........................................................................................115

9. MISCELLANEOUS FUNCTIONS...............................................................................................116

9.1 Miscellaneous Functions (M2-digit BCD)............................................................................116

9.2 Miscellaneous Functions (M8-digit).....................................................................................118

9.3 2nd Miscellaneous Functions (A8/B8/C8-digit) ...................................................................118

10. SPINDLE FUNCTIONS.............................................................................................................119

10.1 Spindle Functions (S2-digit BCD) .....................................................................................119

10.2 Spindle Functions (S8-digit)..............................................................................................119

10.3 Constant Surface Speed Control; G96, G97.....................................................................120

10.4 Spindle Clamp Speed Setting; G92 ..................................................................................127

10.5 Spindle Functions (Multiple Spindles)...............................................................................129

10.5.1 Multiple-spindle commands ........................................................................................130

10.6 Second Spindle Control Function......................................................................................132

10.6.1 Second spindle extension selection............................................................................134

11. TOOL FUNCTIONS..................................................................................................................135

11.1 Tool Functions (T4-digit) ...................................................................................................135

11.2 Tool Functions (T8-digit) ...................................................................................................136

11.3 Number of T Command Digits Judgment Function...........................................................137

12. TOOL OFFSET FUNCTIONS...................................................................................................139

12.1 Tool Offset.........................................................................................................................139

12.2 Tool Length Offset.............................................................................................................141

12.3 Tool Nose Wear Offset......................................................................................................143

12.3.1 Wear offset amount hold.............................................................................................144

12.4 Nose R Compensation; G40, G41, G42, G46...................................................................145

12.4.1 Tool nose point and compensation directions ............................................................147

12.4.2 Nose R compensation operations...............................................................................150

12.4.3 Other operations during nose R compensation ..........................................................160

12.4.4 G41/G42 commands and I, J, K designation..............................................................168

12.4.5 Interrupts during nose R compensation......................................................................173

12.4.6 General precautions for nose R compensation...........................................................176

12.4.7 Interference check ......................................................................................................177

12.5 Programmed Tool Offset Input; G10.................................................................................182

12.6 Common System Offset....................................................................................................185

13. PROGRAM SUPPORT FUNCTIONS.......................................................................................186

13.1 Fixed Cycles for Turning ...................................................................................................186

13.1.1 Longitudinal cutting cycle; G77...................................................................................187

13.1.2 Thread cutting cycle; G78...........................................................................................189

13.1.3 Face cutting cycle; G79 ..............................................................................................192

13.2 Compound Fixed Cycles...................................................................................................195

Page 13

13.2.1 Longitudinal rough cutting cycle I; G71.......................................................................196

13.2.2 Face rough cutting cycle I; G72..................................................................................201

13.2.3 Formed material rough cutting cycle; G73..................................................................206

13.2.4 Finishing cycle; G70 ...................................................................................................210

13.2.5 Face cut-off cycle; G74...............................................................................................211

13.2.6 Longitudinal cut-off cycle; G75 ...................................................................................213

13.2.7 Compound thread cutting cycle; G76..........................................................................215

13.2.8 Precautions for compound fixed cycles (G70 to G76) ................................................219

13.3 Hole Drilling Fixed Cycles; G80 to G89.............................................................................221

13.3.1 G83 face deep hole drilling cycle 1 (G87 longitudinal deep hole drilling cycle 1).......225

13.3.2 G84 face tapping cycle (G88 longitudinal tapping cycle)............................................227

13.3.3 G85 face boring cycle (G89 longitudinal boring cycle)................................................232

13.3.4 G80 hole drilling fixed cycle cancel.............................................................................232

13.3.5 Precautions for using hole drilling fixed cycles ...........................................................233

13.4 Deep Hole Drilling Cycle 2; G83.2 ....................................................................................234

13.5 Subprogram Control; M98, M99........................................................................................237

13.6 Variable Commands..........................................................................................................243

13.7 User Macro........................................................................................................................245

13.7.1 User macro commands; G65, G66, G66.1, G67.........................................................245

13.7.2 Macro call instruction..................................................................................................246

13.7.3 G code for macro........................................................................................................253

13.7.4 Variables.....................................................................................................................254

13.7.5 Types of variables.......................................................................................................256

13.7.6 Operation commands..................................................................................................271

13.7.7 Control commands......................................................................................................276

13.7.8 Precautions.................................................................................................................279

13.8 Double-Turret Mirror Image; G68, G69.............................................................................281

13.9 Corner Chamfering, Corner Rounding Function I .............................................................286

13.9.1 Corner chamfering (,C_ )............................................................................................286

13.9.2 Corner rounding (,R_ )................................................................................................288

13.10 Corner Chamfering, Corner Rounding Function II ..........................................................290

13.10.1 Corner chamfering (,C_) ...........................................................................................290

13.10.2 Corner rounding (,R_ )..............................................................................................292

13.10.3 Interrupt during corner chamfering/rounding.............................................................294

13.11 Linear Angle Command ..................................................................................................295

13.12 Geometric Command ......................................................................................................296

13.12.1 Geometric command IA ............................................................................................296

13.13 Program Parameter Input; G10/G11...............................................................................299

13.14 Programmable In-position Check....................................................................................307

13.15 Positioning (G00)/Machine Coordinate System Selection (G53) Feedrate

Designation.....................................................................................................................310

13.16 Inclined Coordinate Rotation; G173................................................................................316

14. COORDINATE SYSTEM SETTING FUNCTIONS....................................................................328

14.1 Coordinate Words and Control Axes.................................................................................328

14.2 Basic Machine, Workpiece and Local Coordinate Systems..............................................329

14.3 Machine Zero Point and 2nd Reference Point (Zero Point) ..............................................330

14.4 Automatic Coordinate System Setting ..............................................................................331

14.5 Machine Coordinate System Selection; G53 ....................................................................332

14.6 Coordinate System Setting; G92.......................................................................................333

14.7 Reference Point Return; G28, G29...................................................................................334

14.8 2nd, 3rd, and 4th Reference (Zero) Point Return; G30.....................................................338

14.9 Reference Point Check; G27 ............................................................................................341

14.10 Workpiece Coordinate System Setting and Offset; G54 to G59 .....................................342

Page 14

14.11 Local Coordinate System Setting; G52...........................................................................347

15. PROTECTION FUNCTIONS.....................................................................................................348

15.1 Chuck Barriers/Tailstock Barriers......................................................................................348

16. MEASUREMENT SUPPORT FUNCTIONS..............................................................................351

16.1 Skip Function; G31............................................................................................................351

16.2 Multi-step Skip Function; G31...........................................................................................356

16.3 Automatic Tool Length Measurement; G37 ......................................................................358

17. MULTI-AXIS, MULTI-PART SYSTEM COMPOUND CONTROL FUNCTIONS.......................361

17.1 Synchronizing Operation between Systems .....................................................................364

17.2 Start Point Designation Synchronizing (Type 1); G115.....................................................369

17.3 Start Point Designation Synchronizing (Type 2); G116.....................................................371

17.4 Balance Cut Command; G15, G14 ...................................................................................373

17.5 Program Call Control.........................................................................................................376

17.6 Cross Axis Control; G110..................................................................................................377

17.7 Control Axis Synchronization ; G125 ................................................................................383

17.8 Spindle Synchronization; G114.1, G113...........................................................................386

17.9 Tool/Spindle Synchronization 1 (Polygon); G114.2, G113................................................393

17.10 Tool/Spindle Synchronization 2 (Hobb Machining); G114.3, G113.................................400

17.11 Control Axis Superimposition; G126 ...............................................................................411

17.12 Spindle Superimposition; G164, G113............................................................................426

17.12.1 Relation with other functions.....................................................................................430

17.12.2 Precautions and restrictions .....................................................................................431

17.13 2-System Simultaneous Thread-cutting Cycle................................................................433

17.13.1 Parameter setting command.....................................................................................433

17.13.2 2-system simultaneous thread-cutting cycle I...........................................................434

17.13.3 2-system simultaneous thread cutting cycle II..........................................................436

18. OTHER MULTI-AXIS, MULTI-PART SYSTEM CONTROL FUNCTIONS................................439

18.1 Miscellaneous Function Output during Axis Movement; G117 .........................................439

18.2 G Code Macros.................................................................................................................441

18.3 Axis Name Change; G111 ................................................................................................442

APPENDIX 1 LIST OF FUNCTION CODES................................................................................450

APPENDIX 2 LIST OF COMMAND VALUES AND SETTING RANGES....................................451

APPENDIX 3 CIRCULAR CUTTING RADIUS ERROR...............................................................452

APPENDIX 4 STANDARD FIXED CYCLE SUBPROGRAMS.....................................................453

APPENDIX 5 LIST OF VARIABLE NUMBERS...........................................................................461

APPENDIX 6 CORRESPONDENCE TABLE OF PROGRAM PARAMETER INPUT N NUMBERS

...............................................................................................................................463

6.1.1 Control parameter.........................................................................................................464

6.1.2 Axis parameter..............................................................................................................466

6.1.3 Setup parameter ...........................................................................................................467

6.1.4 Setup parameter 2 ........................................................................................................469

6.2.1 Base axis parameter.....................................................................................................470

6.2.2 Base system parameter................................................................................................471

6.2.3 Base common parameter..............................................................................................473

6.2.4 Axis specification parameter.........................................................................................475

6.2.5 Zero point return parameter..........................................................................................476

6.2.6 Absolute position set.....................................................................................................477

6.2.7 Position switch ..............................................................................................................477

6.2.8 Servo parameter ...........................................................................................................478

Page 15

6.2.9 Machine error compensation ........................................................................................478

6.2.10 Machine compensation data.......................................................................................478

6.2.11 Macro list ....................................................................................................................479

6.2.12 Spindle NC parameter ................................................................................................484

6.2.13 Spindle parameter.......................................................................................................485

6.2.14 Spindle type servo parameter.....................................................................................485

6.2.15 PLC constant ..............................................................................................................486

6.2.16 PLC timer....................................................................................................................486

6.2.17 PLC counter................................................................................................................486

6.2.18 Bit selection ................................................................................................................486

APPENDIX 7 SUPPLEMENTARY DETAILS ON INCOMPLETE THREAD AREAS ARISING

DURING THREAD CUTTING................................................................................487

APPENDIX 8 MACRO INTERFACE EXPANSION......................................................................491

8.1 Macro Interface Input ..........................................................................................................492

8.2 Macro Interface Output .......................................................................................................494

APPENDIX 9 SYSTEM COMMON POSITION INFORMATION RETRIEVING VARIABLES......496

APPENDIX 10 PROGRAM ERRORS..........................................................................................498

Page 16

Page 17

1. CONTROL AXES

p

r

r

1. CONTROL AXES

1.1 Coordinate Word and Control Axis

Function and purpose

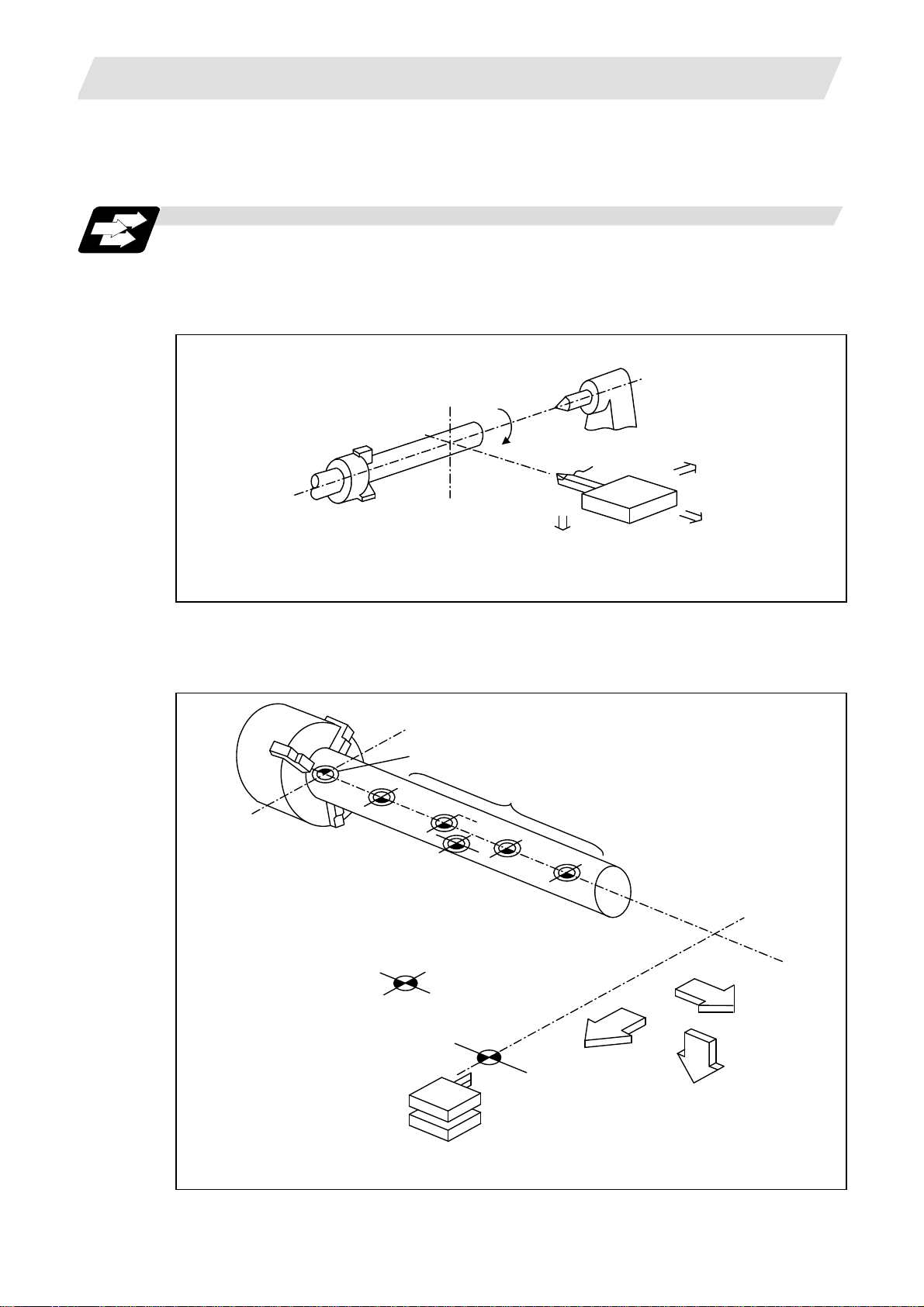

In the case of a lathe, the axis parallel to the spindle is known as the Z axis and its forward

direction is the direction in which the turret moves away from the spindle stock while the axis at

right angles to the Z axis is the X axis and its forward direction is the direction in which it moves

away from the Z axis, as shown in the figure below.

1.1 Coordinate Word and Control Axis

indle stock

S

+Y

Tailstock

Tool

Tu

et

+Z

+X

Coordinate axes and polarities

Since coordinates based on the right hand rule are used with a lathe, the forward direction of the

Y axis in the above figure which is at right angles to the X-Z plane is downward. It should be

borne in mind that an arc on the X-Z plane is expressed as clockwise or counterclockwise as

seen from the forward direction of the Y axis. (Refer to the section on circular interpolation.)

Spindle nose

Machine zero point

G54

G55

G58

G52

Workpiece zero points (G54 to G59)

G59

Local coordinate system

(Valid in G54 to G59)

G30

2nd reference position

+Z

G28

+X

Reference position

(+Y)

Relationship between coordinates

1

Page 18

1. CONTROL AXES

X

X

X

X

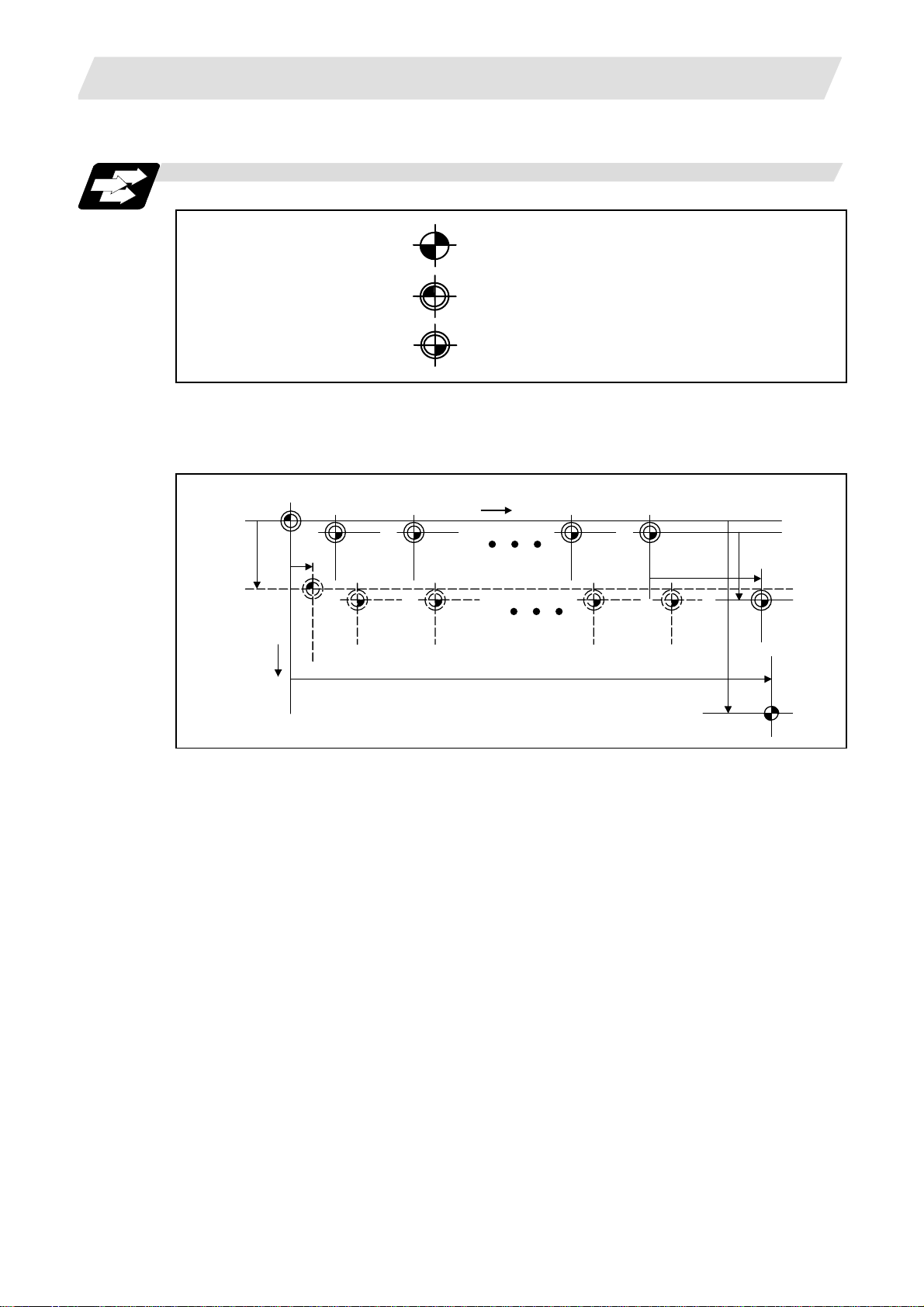

1.2 Coordinate Systems and Coordinate Zero Point Symbols

1.2 Coordinate Systems and Coordinate Zero Point Symbols

Function and purpose

: Reference position

: Machine coordinate origin

: Workpiece coordinate zero points

(G54 to G59)

Upon completion of the reference point return, the parameters are referred to and automatically

set for the basic machine coordinate system and workpiece coordinate systems (G54 to G59).

The basic machine coordinate system is set so that the first reference point is at the position

designated by the parameter from the basic machine coordinate zero point (machine zero point).

Basic mac hine

coordinate system

Hypothetical machine

coordinate system

(shifted by G92)

+

2

Z2

Machine zero point

Workpiece

coordinate

system

1 (G54)

Workpiece

coordinate

system

2 (G55)

+Z

Workpiece

coordinate

system

5 (G58)

Workpiece

coordinate

system6

(G59) Z

3

Z

3

Local

coordinate

system

1

(G52)

1

1st reference position

The local coordinate system (G52) is valid on the coordinate systems designated by the

commands for the workpiece coordinate systems 1 to 6.

Using the G92 command, the basic machine coordinate system can be shifted and made the

hypothetical machine coordinate system. At the same time, workpiece coordinate systems 1 to 6

are also shifted.

2

Page 19

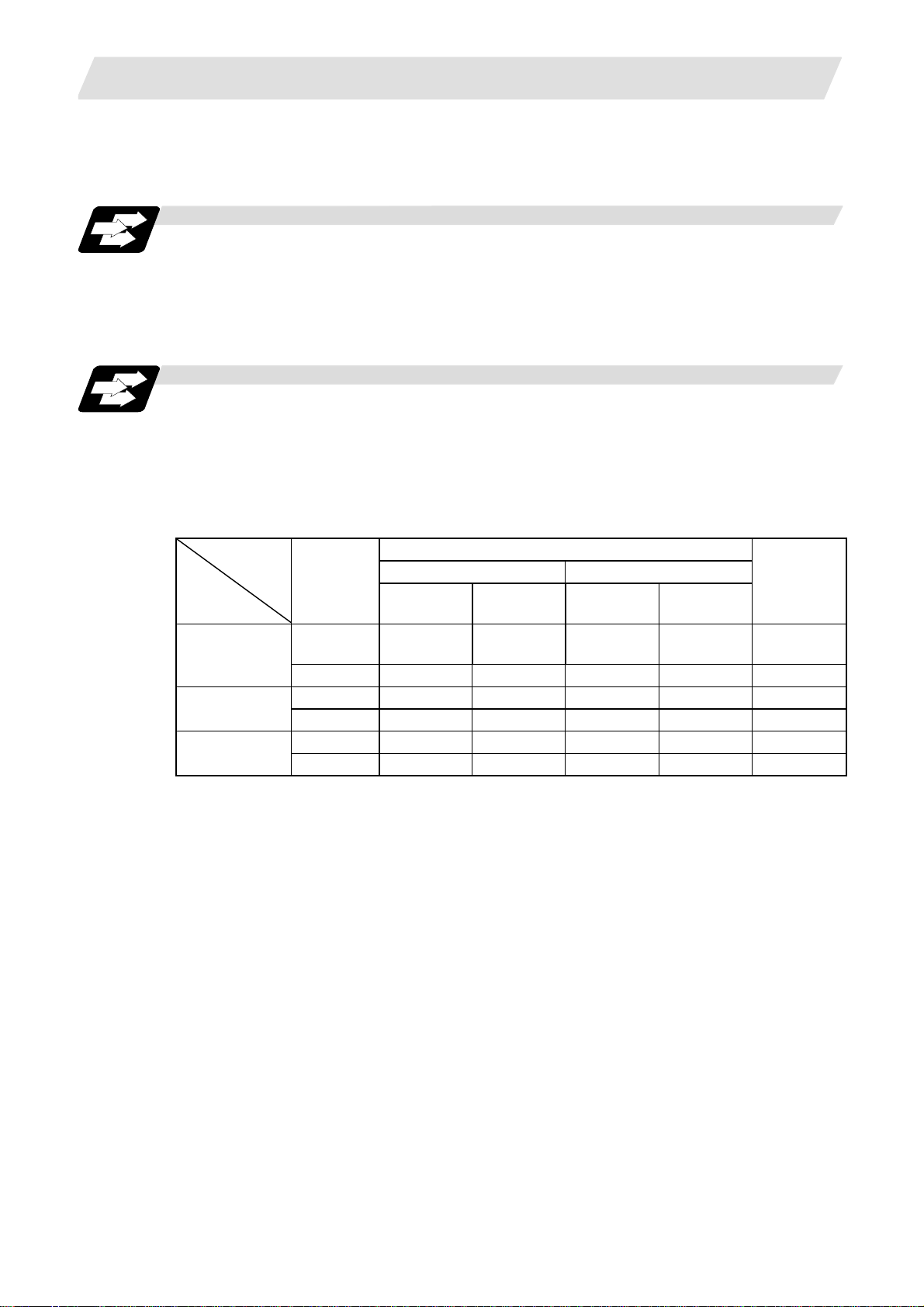

2. INPUT COMMAND UNITS

2. INPUT COMMAND UNITS

2.1 Input Command Units

2.2 Input Setting Units

Function and purpose

These are the units used for the movement amounts in the program as commanded by the MDI

input. They are expressed in millimeters, inches or degrees (°).

Function and purpose

These are the units of setting data which are used, as with the compensation amounts, in

common for all axes.

The input command unit can be selected for each axis and input setting units can be selected in

common for the axes by parameters from among the following types. (For further details on

settings, refer to the sections about control.)

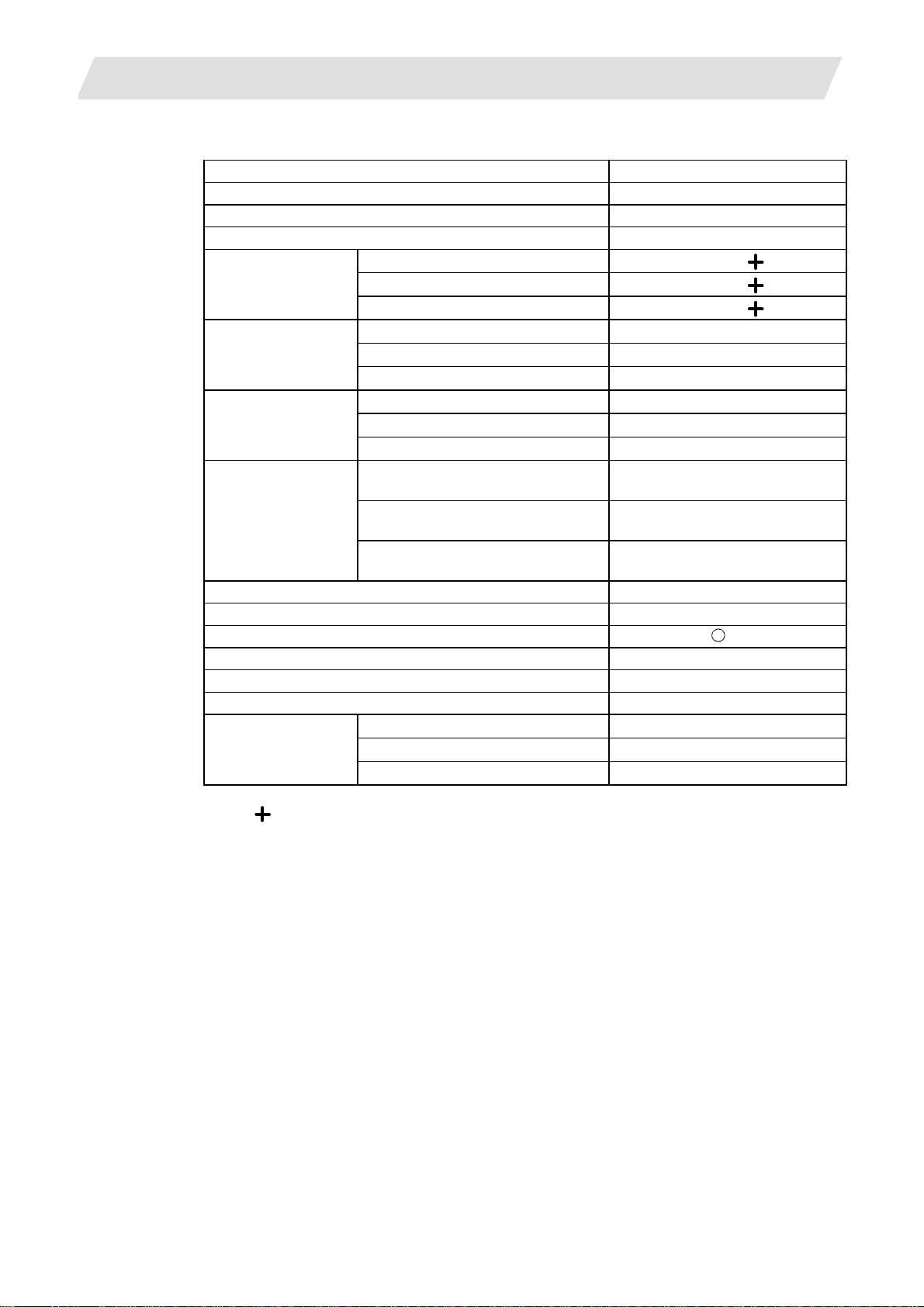

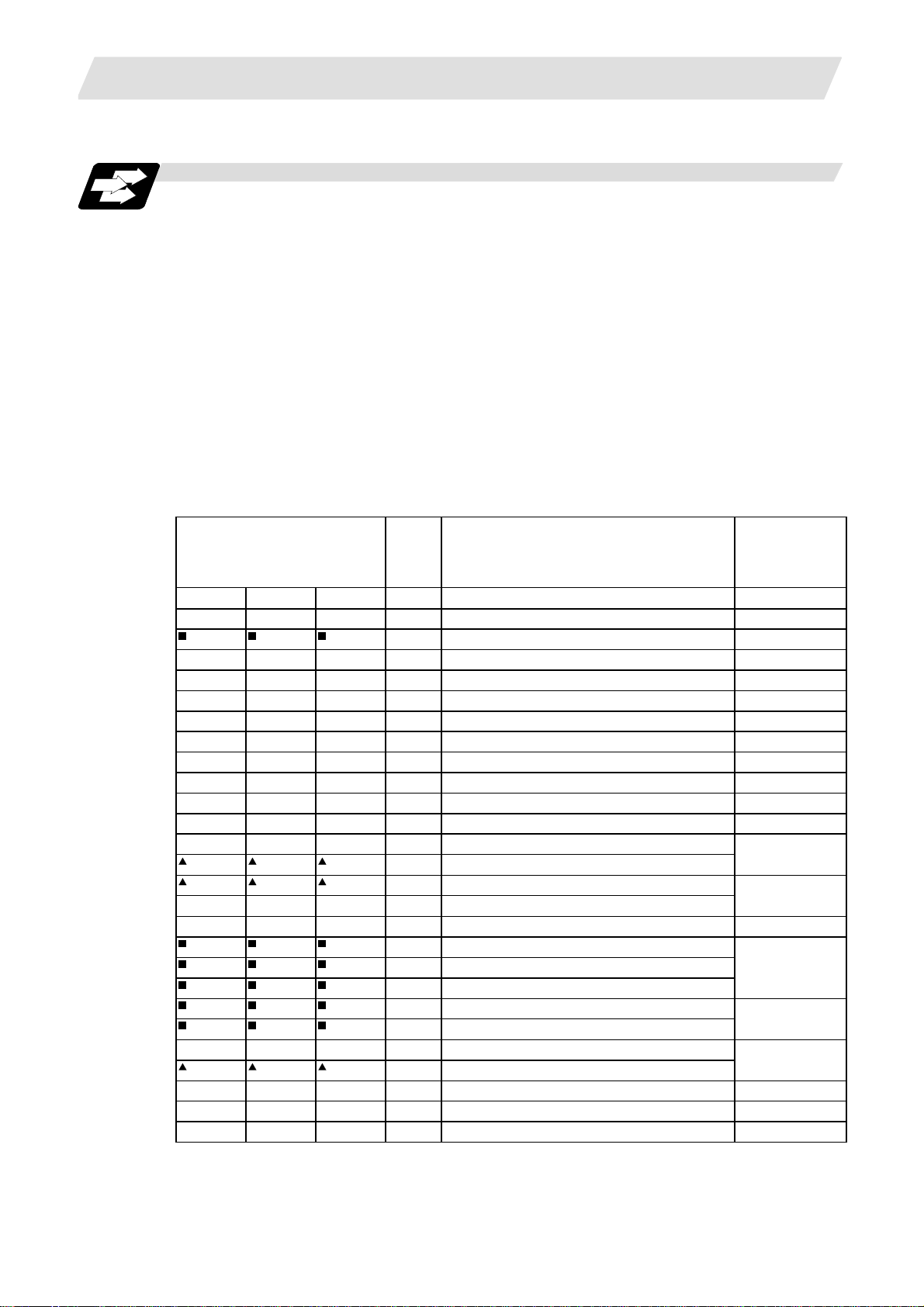

Type

Input

command unit

Min. movement

unit

Input setting

unit

(Note 1) Inch/metric conversion is performed in either of 2 ways: conversion from the Parameter

screen ("Initial inch": valid only when the power is turned ON) and conversion using the

G command (G20 or G21).

However, when a G command is used for the conversion, the conversion applies only to

the input command units and not to the input setting units.

Consequently, the tool offset amounts and other compensation amounts as well as the

variable data should be preset to correspond to input setting unit.

#1003

cunit=10

=1 0.0001 0.0001 0.00001 0.00001 0.0001

IS-B 0.0005 0.001 0.0005 0.0001 0.001

IS-C 0.00005 0.0001 0.00005 0.00001 0.0001

IS-B 0.001 0.001 0.0001 0.0001 0.001

IS-C 0.0001 0.0001 0.00001 0.00001 0.0001

2.1 Input Command Units

Linear axis

Millimeter Inch

Diametrical

command

0.001 0.001 0.0001 0.0001 0.001

Radial

command

Diametrical

command

Radial

command

Rotation

axis

(°)

(Note 2) The millimeter and inch systems cannot be used together.

3

Page 20

3. DATA FORMATS

3. DATA FORMATS

3.1 Tape Codes

Function and purpose

The tape command codes used for this NC are combinations of alphabet letters (A, B, C...Z),

numbers (0, 1, 2...9) and signs ( +, –, /...). These alphabet letters, numbers and signs are referred

to as characters. Each character is represented by a combination of 8 holes which may, or may

not, be present.

These combinations make up what is called codes.

This NC employs the ISO code (R-840).

CAUTION

";", "EOB" and "%" "EOR" are expressions used for the explanation. The actual codes are "line

feed" and "%" for ISO.

Detailed description

(1) For the sake of convenience, a ";" has been used in the NC display to indicate End Of Block

(EOB/LF) which separates one block from another. Do not use the ";" key, however, in actual

programming but use the keys in the following table instead.

EOB/EOR keys and displays

3.1 Tape Codes

Code used

Key used

End Of Block LF or NL ;

End Of Record % %

(Note 1) If a code not given in Table of tape codes is assigned during operation, an Illegal

address error "P32" will result.

(Note 2) The following codes which exist with ISO can be designated by parameter:

[ (left square parenthesis)

] (right square parenthesis)

# (sharp sign)

∗ (asterisk)

= (equals sign)

: (colon)

! (exclamation mark) = (queuing code)

$ (dollar sign) = (code designating system number)

Any codes which overlap with existing codes or codes which result in parity H cannot be

designated.

ISO NC display

4

Page 21

3. DATA FORMATS

G

R

•

•••••••

•

•••

•

• •

•

•••••••••

•

•••••••

•

•

•••••••••••••••••

•

•

•

•••••••••••••••

•

•

•••••••••

(2) Significant data section (label skip function)

(3) Control out, control in

3.1 Tape Codes

All data up to the first EOB (;), after the power has been turned ON or after operation has

been reset, are ignored during automatic operation based on tape, memory loading

operation or during a search operation. In other words, the significant data section of a tape

extends from the character or number code after the first EOB (;) code after resetting to the

point where the reset command is issued.

When the ISO code is used, all data between control out "(" and control in ")" are ignored by

the NC, although these data appear on the setting display unit. Consequently, the command

tape name, number and other such data not directly related to control can be inserted in this

section.

This information will also be loaded, however, during tape loading.

The system is set to the "control in" mode when the power is turned ON.

Example of ISO code

••

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

•• •••

•

•• •••

•

•

•

Operator information print-out example

L C S L

00X-85000Y-64000 (CUTTE

F R

• •

•• ••

••

•

• •• •

Information in this section is ignored and nothing is executed.

RE T URN)

P

• • •

• •• •

••• • ••

•••

•

•

••••••

••• • • •

F

••

•••••

•

(4) EOR (%) code

Generally, End Of Record is punched at both ends of the tape. It has the following functions:

(a) Rewind stop when rewinding tape (with tape handler)

(b) Rewind start during tape search (with tape handler)

(c) Completion of loading during tape loading

5

Page 22

3. DATA FORMATS

3.2 Program Formats

Function and purpose

The prescribed arrangement used when assigning control information to the NC unit is known as

the "program format", and the format used with the NC is called the "word address format."

Detailed description

(1) Word and address

A word is a collection of characters arranged in a specific sequence. This entity is used as

the unit for processing data and for causing the NC to execute specific operations.

Each word used for the NC consists of an alphabet letter and a number of several digits

(sometimes with a "+" or "–" sign placed at the head of the number).

Word

Numerical (word data)

Alphabet (address)

3.2 Program Formats

------

Word configuration

The alphabet letter at the head of the word is the address. It defines the meaning of the

numerical information which follows it.

With the NC, "S

=" can be commanded for a multiple number of spindle commands

although this applies only to address S.

For details of the types of words and the number of significant digits of numbers used for this

NC, refer to Table 1 Format details and abbreviations.

(2) Blocks

A block is a collection of words. It includes the information which is required for the NC to

execute one specific operation. One block unit constitutes a complete command. The end of

each block is marked with an EOB (End-Of-Block) code.

(3) Programs

A program is a collection of several blocks.

(Note 1) If there is no number after the alphabetic character in the actual program, the value

following the alphabetic character will be handled as 0.

(Example) G28XYZ; → G28X0Y0Z0;

6

Page 23

3. DATA FORMATS

(Note 1) "

3.2 Program Formats

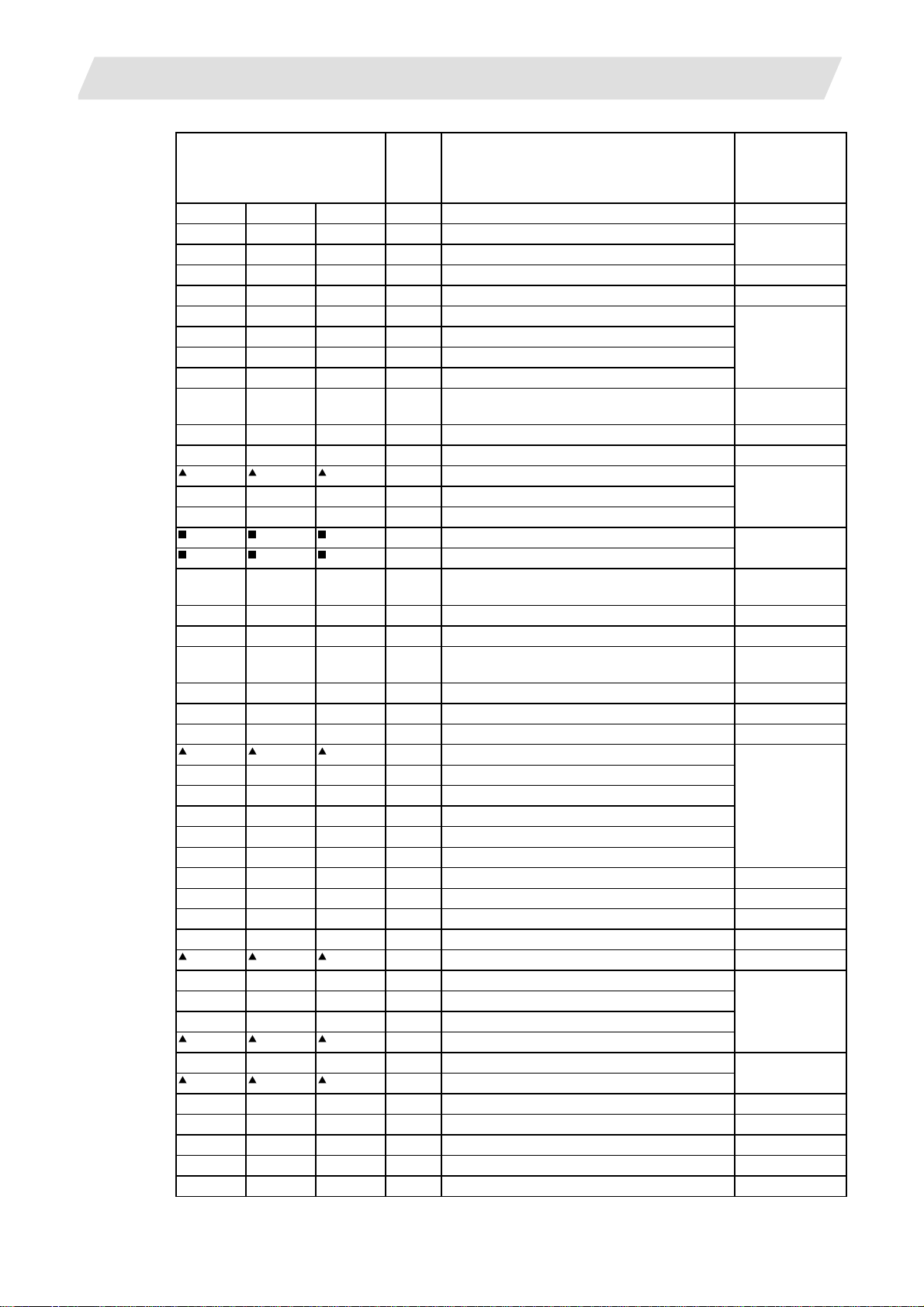

Table 1 Format details and abbreviations

Item Abbreviation

Program number O8

Sequence number N5

Preparatory function G3/G21

Movement

command

Movement

command, circular,

cutter radius

Dwell

Feed function

Input setting unit A 0.01°, mm

Input setting unit B 0.001°, mm

Input setting unit C 0.0001°, mm

Input setting unit A 0.01°, mm

Input setting unit B 0.001°, mm

Input setting unit C 0.0001°, mm

Input setting unit A 0.01°, mm

Input setting unit B 0.001°, mm

Input setting unit C 0.0001°, mm

Input setting unit A 0.01°, mm

X + 62 Z + 62

X + 53 Z + 53

X + 44 Z + 44

I + 62 K + 62

I + 53 K + 53

I + 44 K + 44

X + 53 P8

X + 53 P8

X + 53 P8

F62 (feed per minute)

+ 62

+ 53

+ 44

F43 (feed per rotation)

Input setting unit B 0.001°, mm

F53 (feed per minute)

F34 (feed per rotation)

Input setting unit C 0.0001°, mm

F54 (feed per minute)

F25 (feed per rotation)

Tool offset T1/T2

Miscellaneous function M2/M8

Spindle function S2/S5/S8 or S = n

Tool function T2/T8

2nd miscellaneous function A8/B8/C8

Subprogram P8H5L4

Fixed cycle

Input setting unit A 0.01°, mm

Input setting unit B 0.001°, mm

Input setting unit C 0.0001°, mm

R + 62 Q62 P8 L4

R + 53 Q53 P8 L4

R + 44 Q44 P8 L4

" denotes the A, B, C, Y, P or R.

(Note 2) The number of digits in the words is checked by the maximum number of digits in the

addresses.

7

Page 24

3. DATA FORMATS

3.3 Tape Storage Format

Function and purpose

(1) Storage tape and storage sections

The section which is stored into the memory extends from the character following the head

EOB after resetting as far as the EOR code.

The significant codes listed in Table of tape codes in Section 3.1 are the codes in the above

storage section which are actually stored into the memory. All other codes are ignored and

are not stored.

The data between control out "(" and control in ")" are stored into the memory.

3.4 Optional Block Skip

Function and purpose

This function selectively ignores specific blocks in a machining program which starts with the "/"

(slash) code.

Detailed description

(1) Provided that the optional block skip switch is ON, blocks starting with the "/" code are

ignored. They are executed if the switch is OFF.

Parity check is valid regardless of whether the optional block skip switch is ON or OFF.

When, for instance, all blocks are to be executed for one workpiece but specific blocks are

not to be executed for another workpiece, the same command tape can be used to machine

different parts by inserting the "/ " code at the head of those specific blocks.

Precautions for using optional block skip

(1) Put the "/" code at the head of the block. When inserted in a block, this is handled as a

division sign.

3.3 Tape Storage Format

(Example) N20G1X25./Z25.;............. NG

(This will be handled as 25. /0, so the error P283

"Divided by zero" will occur.)

/N20G1X25.Z25.;............. OK

(2) Parity checks (H and V) are conducted regardless of the optional block skip switch state.

(3) The optional block skip is processed immediately before the pre-read buffer.

Consequently, it is not possible to skip up to the block which has been read into the pre-read

buffer.

(4) This function is valid even during a sequence number search.

(5) AII blocks with the "/" code are also input and output during tape storing and tape output,

regardless of the state of the optional block skip switch.

8

Page 25

3. DATA FORMATS

3.5 Program/Sequence/Block Numbers (O, N)

3.5 Program/Sequence/Block Numbers (O, N)

Function and purpose

These numbers are used for monitoring the execution of the machining programs and for calling

both machining programs and specific stages in machining programs.

(1) Program numbers are classified by workpiece correspondence or by subprogram units, and

they are designated by the address "O" followed by a number with up to 8 digits.

(2) Sequence numbers are attached where appropriate to command blocks which configure

machining programs, and they are designated by the address "N" followed by a number with

up to 5 digits.

(3) Block numbers are automatically provided inside the NC itself. They are preset to "0" every

time a program number or sequence number is read, and they are counted up one at a time

unless program numbers or sequence numbers are commanded in blocks which are

subsequently read.

Consequently, all the blocks of the machining programs given in the table below can be

determined without further consideration by combinations of program numbers, sequence

numbers and block numbers.

NC input machining program

O12345678 (DEMO.PROG); 12345678 0 0

N100 G00 G90 X120. Z100.; 12345678 100 0

G94 S1000; 12345678 100 1

N102 G71 P210 Q220 I0.2 K0.2 D0.5 F600; 12345678 102 0

N200 G94 S1200 F300; 12345678 200 0

N210 G01 X0 Z95.; 12345678 210 0

G01 X20.; 12345678 210 1

G03 X50. Z80. K–15.; 12345678 210 2

G01 Z55.; 12345678 210 3

G02 X80. Z40. I15.; 12345678 210 4

G01 X100.; 12345678 210 5

G01 Z30.; 12345678 210 6

G02 Z10. K–15.; 12345678 210 7

N220 G01 Z0; 12345678 220 0

N230 G00 X120. Z150.; 12345678 230 0

N240 M02; 12345678 240 0

% 12345678 240 0

Program

No.

NC monitor display

Sequence

No.

Block

No.

9

Page 26

3. DATA FORMATS

3.6 G Code System

Function and purpose

These numbers are used to monitor the execution status of the machining program, or to call a

machining program or a specific process in the machining program.

There are 3 G code systems: 1, 2 and 3. Parameters "G code type 1", "G code type 2" and "G

code type 3" are used to set the applicable system.

G code system 3 is an additional specification.

The description of the G functions is based on G code system 2 which serves as the standard.

(Note 1) An alarm results when a G code not listed in the table is commanded. ("P34": Illegal G

code)

(Note 2) An alarm results when a G code not included in the additional specifications is

commanded.

(Example) An alarm ("P50 No spec: Inch/mm") occurs when the inch command G

3.6 G Code System

code (G20) is commanded although the inch/mm specifications have not

been provided.

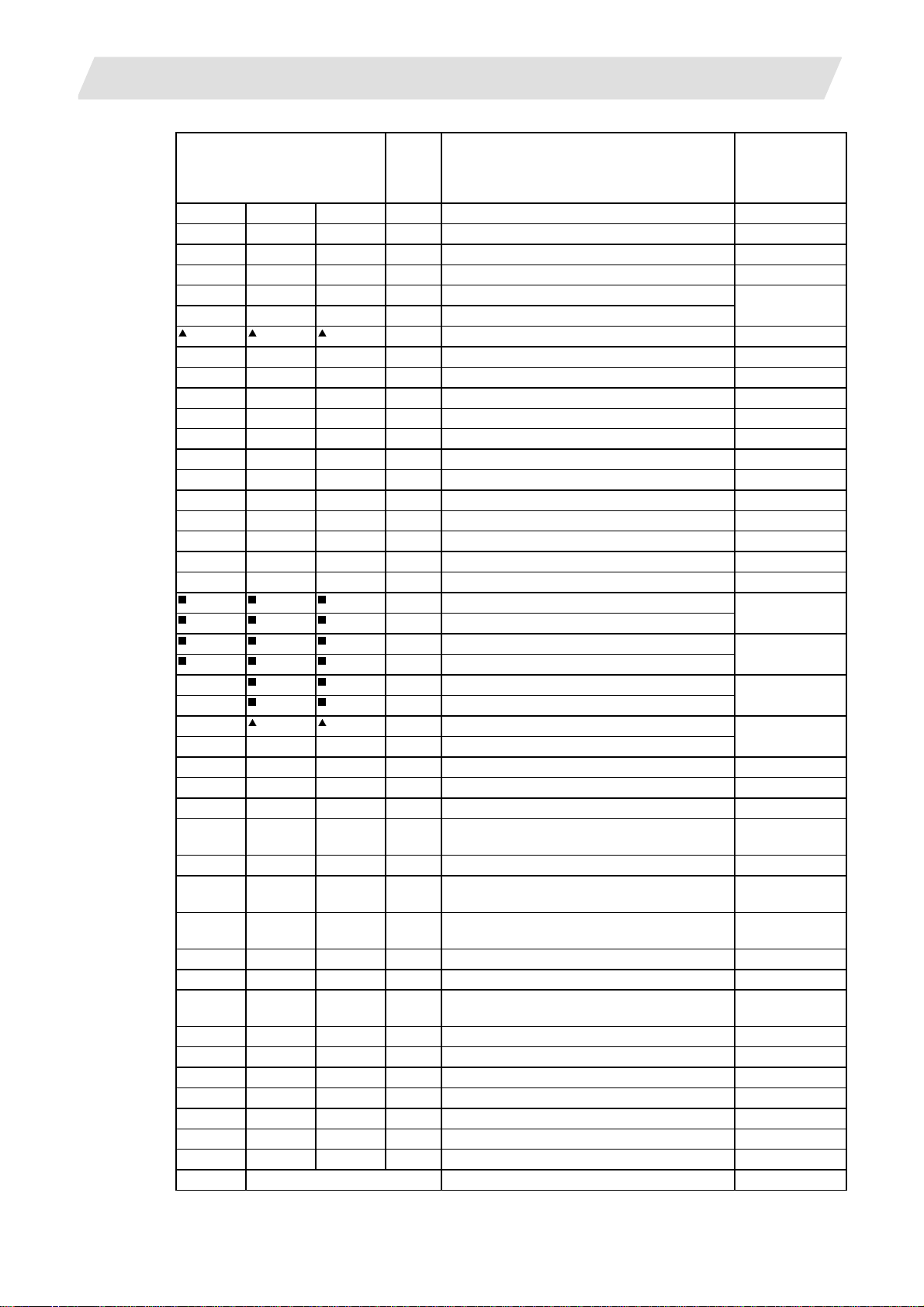

Table of G code systems

Reference

G code system (standard = 2) Group Function name

1 2 3

G00 G00 G00 01 Positioning 6.1

G01 G01 G01 01 Linear interpolation 6.2

G02 G02 G02 01 Circular interpolation (clockwise) 6.3, 6.4

G03 G03 G03 01 Circular interpolation (counterclockwise) 6.3, 6.4

G04 G04 G04 00 Dwell 8.1, 8.2

G09 G09 G09 00 Exact stop 7.8

G10 G10 G10 00 Data setting 12.5

G11 G11 G11 00 Data setting mode cancel 12.1

G12.1 G12.1 G12.1 19 Milling mode ON 6.8

G13.1 G13.1 G13.1 19 Milling mode OFF

G14 G14 G14 18 Balance cut OFF 17.4

G15 G15 G15 18 Balance cut ON

G16

G17 G17 G17 02 X-Y plane selection 6.5

G18 G18 G18 02 Z-X plane selection

G19 G19 G19 02 Y-Z plane selection

G20 G20 G70 06 Inch command

G21 G21 G71 06 Metric command

G22 G22 G22 04 Barrier check ON 15.1

G23 G23 G23 04 Barrier check OFF

G16 G16 02 Y-Z cylindrical plane selection 6.8

section in this

manual

(Section)

5.3

10

Page 27

3. DATA FORMATS

G code system (standard = 2) Group Function name

G27 G27 G27 00 Reference point return check 14.9

G28 G28 G28 00 Reference point return 14.7

G29 G29 G29 00 Return from reference point

G30 G30 G30 00 2nd reference point return 14.8

G31 G31 G31 00 Skip function 16.1

G32 G33 G33 01 Thread cutting 6.7

G34 G34 G34 01 Variable lead thread cutting

G35 G35 G35 01 Circular thread cutting (CW)

G36 G36 G36 01 Circular thread cutting (CCW)

G37 G37 G37 00

G40 G40 G40 07 Tool nose R compensation cancel 12.4

G41 G41 G41 07 Tool nose R compensation left

G42 G42 G42 07 Tool nose R compensation right

G43 G43 G43 08 2nd spindle control OFF 10.6

G44 G44 G44 08 2nd spindle control ON

G46 G46 G46 07

G50 G92 G92 00

G52 G52 G52 00 Local coordinate system setting 14.11

G53 G53 G53 00 Machine coordinate system selection 14.5

G54 G54 G54 12 Workpiece coordinate system selection 1 14.10

G55 G55 G55 12 Workpiece coordinate system selection 2

G56 G56 G56 12 Workpiece coordinate system selection 3

G57 G57 G57 12 Workpiece coordinate system selection 4

G58 G58 G58 12 Workpiece coordinate system selection 5

G59 G59 G59 12 Workpiece coordinate system selection 6

G61 G61 G61 13 Exact stop check mode 7.9

G64 G64 G64 13 Cutting mode 7.10

G65 G65 G65 00 Macro call 13.7.1

G66 G66 G66 14 Macro modal call A

G66.1 G66.1 G66.1 14 Macro modal call B

G67 G67 G67 14 Macro modal call cancel

G68 G68 G68 15 Facing turret mirror image ON 13.8

G69 G69 G69 15 Facing turret mirror image OFF

G70 G70 G72 09 Finishing cycle 13.2.4

G71 G71 G73 09 Longitudinal rough cutting cycle 13.2.1

G72 G72 G74 09 Face rough cutting cycle 13.2.2

G73 G73 G75 09 Stock removal in rough cutting cycle 13.2.3

3.6 G Code System

Reference

section in this

manual

(Section)

Automatic tool length offset, automatic tool

length measurement

Tool nose R compensation

(automatic selection of direction) ON

Coordinate system setting

Spindle clamp speed setting

16.3

12.4

14.6

10.4

11

Page 28

3. DATA FORMATS

G code system (standard = 2) Group Function name

G74 G74 G76 09 Face cut-off cycle 13.2.5

G75 G75 G77 09 Longitudinal cut-off cycle 13.2.6

G76 G76 G78 09 Compound thread cutting cycle 13.2.7

G76.1 G76.1 G76.1 09 2-system simultaneous thread cutting cycle 1 17.13

G76.2 G76.2 G76.2 09 2-system simultaneous thread cutting cycle 2

G80 G80 G80 09 Hole drilling cycle cancel 13.3.4

G83 G83 G83 09 Deep hole drilling cycle 1 (Z axis) 13.3.1

G79 G83.2 G83.2 09 Deep hole drilling cycle 2 13.4

G84 G84 G84 09 Tap cycle (Z axis) 13.3.2

G85 G85 G85 09 Boring cycle (Z axis) 13.3.3

G87 G87 G87 09 Deep hole drilling cycle (X axis) 13.3.1

G88 G88 G88 09 Tap cycle (X axis) 13.3.2

G89 G89 G89 09 Boring cycle (X axis) 13.3.3

G90 G77 G20 09 Longitudinal cutting fixed cycle 13.1.1

G92 G78 G21 09 Thread cutting fixed cycle 13.1.2

G94 G79 G24 09 Face cutting fixed cycle 13.1.3

G96 G96 G96 17 Constant surface speed control 10.3

G97 G97 G97 17 Constant surface speed control cancel

G98 G94 G94 05 Asynchronous feed 7.3

G99 G95 G95 05 Synchronous feed

G110 G110 G110 00 Cross machining command 17.6

G111 G111 G111 00 Axis name change 18.3

G113 G113 G113 00

G114.1 G114.1 G114.1 00 Spindle synchronization 17.8

G114.2 G114.2 G114.2 00

G114.3 G114.3 G114.3 00

G115 G115 G115 00 Waiting at designated start point 1 17.2

G116 G116 G116 00 Waiting at designated start point 2 17.3

G117 G117 G117 00

G125 G125 G125 00 Control axis synchronization 17.7

G126 G126 G126 00 Control axis superimposition 17.11

G164 G164 G164 00 Spindle superimposition 17.12

G173 G173 G173 00 Inclined coordinate rotation control 13.16

G200 to G200 to G999 G macro call 18.3

3.6 G Code System

Reference

section in this

manual

(Section)

– G90 G90 03 Absolute value command

– G91 G91 03 Incremental value command

– G98 G98 10 Hole drilling cycle initial return 13.3

– G99 G99 10 Hole drilling cycle reference point return

Spindle synchronization, tool/spindle

synchronization cancel

Tool/spindle synchronization 1 (polygon

machining)

Tool/spindle synchronization 2 (hobb

machining)

Miscellaneous function output during axis

movement

5.1

17.8-17.12

17.9

17.10

18.1, 18.2

12

Page 29

3. DATA FORMATS

(Note 1) The " " mark denotes a G code which is selected within each group when the power

3.6 G Code System

is turned ON or when resetting that initializes the modal commands is executed.

(Note 2) The "

" mark denotes a G code for which a parameter can be selected as the initial

status when the power is turned ON or when resetting that initializes the modal

commands is executed. Note that the inch/metric conversion can be made only when

the power is turned ON.

CAUTION

The commands with "no value after G", will be handled as "G00" during operation.

13

Page 30

3. DATA FORMATS

3.7 Precautions Before Machining

Precautions before machining

CAUTION

Before starting actual machining, always carry out dry operation to confirm the machining

program, tool offset amount and workpiece offset amount, etc.

When creating the machining program, select the appropriate machining conditions, and make

sure that the performance, capacity and limits of the machine and NC are not exceeded. The

examples do not consider the machining conditions.

3.7 Precautions Before Machining

14

Page 31

4. BUFFER REGISTER

A

A

4. BUFFER REGISTER

4.1 Pre-read Buffers

Function and purpose

During automatic processing, the contents of 1 block are normally pre-read so that program

analysis processing is conducted smoothly. However, during nose R compensation, a maximum

of 5 blocks are pre-read for the intersection point calculation including interference check.

The specifications of pre-read buffer are as follows:

(1) The data of 1 block are stored in this buffer.

(2) Only the significant data in the significant data section are stored into the pre-read buffer.

(3) When codes are sandwiched in the control in or control out mode and the optional block skip

function is ON, the data extending from the "/" (slash) code up to the EOB code are not read

into the pre-read buffer.

(4) The pre-read buffer contents are cleared with resetting.

(5) When the single block function is ON during continuous operation, the pre-read buffer stores

the following block data and then stops operation.

4.1 Pre-read Buffers

nalysis processin g

Max. 5 execution blocks

Pre-read

buffer 5

Buffer 4

Mode

Memory

Keyboard

MDI data

switching

Buffer 3

Buffer 2

Buffer 1

(Note)

Data equivalent to 1 block are stored

in 1 pre-read buffer.

rithmetic

processing

15

Page 32

5. POSITION COMMANDS

5. POSITION COMMANDS

5.1 Incremental/Absolute Value Commands

Function and purpose

There are 2 methods of issuing tool movement amount commands: the incremental value

command and the absolute value command.

The incremental value method applies for coordinates of a point which is to be moved and it

issues a command using the distance from the present point, on the other hand, the absolute

value method issues a command using the distance from the coordinate zero point. The following

figure shows what happens when the tool is moved from point P1 to point P2.

5.1 Incremental/Absolute Value Commands

Spindle

The incremental and absolute value commands for the X and Z axes are identified by addresses

when control parameter "#6 ABS/INC Addr." is ON and by G codes (G90/G91) when it is OFF.

Similarly, even with additional axes (C or Y axis), they are differentiated by addresses, or G

code.

X axis

Z

P2

Workpiece coordinate zero point

Incremental and absolute value commands

W

P1

U

2

X

Z axis

Absolute

value

Incremental

value

(Example)

X_____ W _____ ;

X axis Address X

Z axis Address Z

C/Y axis Address C/Y

X axis Address U

Z axis Address W

C/Y axis Address H/V

Command

system

Incremental value command for Z axis

Absolute value command for X axis

16

Remarks

For setting correspondence between addresses

and axes into machine parameters.

Absolute and incremental values can be used

together in the same block.

Page 33

5. POSITION COMMANDS

5.1 Incremental/Absolute Value Commands

Precautions

(1) Coordinate values can be omitted, in which case they are treated as "0".

The absolute and incremental value commands can be differentiated for any axis by the G90

and G91 commands.

G91 X___ W___ C___;

(Example) When the C axis has been differentiated by G90/G91.

(when incremental addresses have not been set)

Incremental value command for C axis

Incremental value command for Z axis

Absolute value command for X axis

17

Page 34

5. POSITION COMMANDS

r2r

5.2 Radius/Diameter Commands

Function and purpose

The cross sections of workpieces machined on a lathe are circular, and the diameter or radius

value of those circles can be used for movement commands in the X-axis direction. A radius

command will move the tool by the commanded amount only, but a diameter command will move

the tool both in the X-axis direction by an amount equivalent to one-half the command amount

only and in the Z-axis direction by the commanded amount only.

This system permits radius or diameter commands to be issued, depending on the parameter

setting. The figure below shows the command procedure when the tool is to be moved from point

P1 to point P2.

X axis

5.2 Radius/Diameter Commands

P1

Spindle

P2

Workpiece coordinate zero point

1

Z axis

X command U command Remarks

Radius Diameter Radius Diameter

X = r1 X = 2r1 U = r2 U = 2r2

Even when a diameter command has been

selected, only the U command can be

made a radius command by parameter.

Radius and diameter commands

Precautions

(1) In the above example, the tool moves from P1 to P2 in the minus direction of the X axis and

so when an incremental value is issued, the minus sign is given to the numerical value being

commanded.

(2) In this manual, diameter commands are used in descriptions of both the X and U axes for the

sake of convenience.

18

Page 35

5. POSITION COMMANDS

5.3 Inch/Metric Conversion (G20, G21)

Function and purpose

These G commands are used to switch between the inch and millimeter (metric) systems.

Command format

G20/G21;

G20 Inch command

G21 Metric command

Detailed description

The G20 and G21 commands merely select the command units. They do not select the Input

units.

G20 and G21 selection is meaningful only for linear axes and it is meaningless for rotation axes.

(Example) Relationship between input command units and G20/G21 commands (with decimal

point input type I)

5.3 Inch/Metric Conversion (G20, G21)

command unit

"cunit"

10

1

Axis type

Linear axes X100; 0.100mm 0.254mm 0.0039 inch 0.0100 inch

Rotation axes C100;

Linear axes X100; 0.0100mm 0.0254mm 0.00039 inch 0.00100 inch

Rotation axes C100;

Command

example

"Initial inch" OFF "Initial inch" ON Input

G21 G20 G21 G20

0.100° 0.100° 0.100° 0.100°

0.0100° 0.0100° 0.0100° 0.0100°

19

Page 36

5. POSITION COMMANDS

5.4 Decimal Point Input

Function and purpose

This function enables the decimal point command to be input. It assigns the zero point in

millimeter or inch units for the machining program input information that defines the tool paths,

distances and speeds.

A parameter selects whether type I (minimum input command unit) or type II (zero point) is to

apply for the least significant digit of data without a decimal point.

Command format

. Inch system

. Metric system

Detailed description

(1) The decimal point command is valid for the distances, angles, times and speeds in

machining programs.

5.4 Decimal Point Input

(2) Refer to the table "Addresses used and valid/invalid decimal point commands" for details on

the valid addresses for the decimal point commands.

(3) The number of significant digits in a decimal point command is shown below (for input

command unit CS-B).

Movement

Integer

MM

(milli-

meter)

INCH

(inch)

command (linear)

part

0 to

99999.

0 to

9999.

Decimal

part

.000

to .999

.0000

to .9999

Movement command

(rotation)

Integer

part

0 to

99999.

99999.

(359.)

Decimal

part

.000

to .999

.0 to .999

Feedrate Dwell (X)

Integer part Decimal part Integer part

0 to 60000. .000 to .999

0 to 999. .0000 to .9999

0 to 2362. .0000 to .9999

0 to 99.

.000000

to .999999

0. to 99999. .000 to .999

0 to 99. .000 to .999

Decimal

part

(Note) The top row of Feedrate is for feed per minute and the bottom row is for feed per

rotation.

(4) The decimal point command is valid even for commands defining the variable data used in

subprograms, etc.

(5) Decimal point commands for decimal point invalid addresses are processed as integer data

only and everything below the decimal point is ignored. Addresses which are invalid for the

decimal point are D, H, L, M, N, O, P, S and T. All variable commands, however, are treated

as data with decimal points.

Precautions

(1) If an arithmetic operator is inserted, the data will be handled as data with a decimal point.

(Example) G00 X123+0;........... This is the X axis 123mm command. It will not be 123μm.

20

Page 37

5. POSITION COMMANDS

Example of program

(1) Example of program for decimal point valid address

5.4 Decimal Point Input

Specification

division

Decimal point command 1

When 1 = 1μm When 1 = 10μm

Decimal point

command 2

1 = 1mm

Program example

G0 X123.45

(decimal points are all

X123.450mm X123.450mm X123.450mm

mm points)

X12.345mm

G0 X12345

(last digit is 1μm

X123.450mm X12345.000mm

unit)

#111=123, #112=5.55

X#111 Z#112

#113=#111+#112

(addition)

#114=#111–#112

(subtraction)

#115=#111∗#112

(multiplication)

#116=#111/#112

#117=#112/#111

(division)

X123.000mm,

Z5.550mm

X123.000mm,

Z5.550mm

X123.000mm,

Z5.550mm

#113 = 128.550 #113 = 128.550 #113 = 128.550

#114 = 117.450 #114 = 117.450 #114 = 117.450

#115 = 682.650 #115 = 682.650 #115 = 682.650

#116 = 22.162,

#117 = 0.045

#116 = 22.162,

#117 = 0.045

#116 = 22.162,

#117 = 0.045

21

Page 38

5. POSITION COMMANDS

Addresses used and valid/invalid decimal point commands

Add-

Decimal

ress

(Note 1) Decimal points are all valid in user macro arguments.

point

com-

mand

Valid Coordinate position data

A

Invalid 2nd miscellaneous function

Valid Angle data

Invalid MRC program number

Invalid Data setting, axis number

Valid Deep hole drilling cycle (2)

Valid Coordinate position data B

Invalid 2nd miscellaneous function

Valid Coordinate position data

C

Invalid 2nd miscellaneous function

Valid Corner chamfering amount ,C

Valid Program tool compensation

Valid Automatic tool length

D

Invalid Data setting, byte type data

E Valid Inch threads

Valid Feedrate F

Valid Thread lead

G Valid Preparatory function code

Valid Coordinate position data

H

Invalid Sequence numbers in

Invalid Data setting, bit type data

Valid Circular center coordinates

I

Valid Nose R compensation/tool

Valid Deep hole drilling cycle (2)

Valid Circular center coordinates

J

Valid Nose R compensation/

Invalid Deep hole drilling cycle (2)

Application

code

Safety distance

code

data

input

Nose R compensation

amount (incremental)

measurement,

deceleration range d

Precision thread lead

subprograms

radius compensation vector

components

First cut amount

nose radius compensation

vector components

Dwell at return point

Re-

marks

5.4 Decimal Point Input

Decimal

Add-

ress

point

com-

mand

Valid Circular center coordinates

K

Valid Nose R compensation/tool

Invalid Hole drilling cycle

Valid Deep hole drilling cycle (2)

Invalid Subprogram

L

Invalid Program tool compensation

Invalid Data setting selection L50

Invalid Data setting

M Invalid Miscellaneous function

Invalid Sequence numbers N

Invalid Data setting, data numbers

O Invalid Program numbers

Invalid Dwell time

P

Invalid Subprogram call program

Invalid 2nd reference point number

Invalid Constant surface speed

Invalid MRC finishing shape start

Valid Cut-off cycle

Invalid Compound thread cutting

Valid Compound thread cutting

Invalid Program tool compensation

Invalid Data setting, broad

Invalid Return sequence number

Valid Coordinate position data

Application

radius compensation vector

components

Number of repetitions

Second and subsequent cut

amounts

Number of repetitions

input type selection

2-word type data

codes

numbers

control, axis number

sequence number

Shift amount/cut amount

cycle, number of cutting

passes, chamfering, tool

nose angle

cycle

Thread height

input/ Offset number

classification number

from subprogram

Re-

marks

L2,

L10,

L11

4 bytes

22

Page 39

5. POSITION COMMANDS

Add-

Decimal

ress

point

command

Invalid Minimum spindle clamp

Q

Invalid MRC finishing shape end

Valid Cut-off cycle

Valid Compound thread cutting

Valid Compound thread cutting

Valid Deep hole drilling cycle (1)

Invalid Program tool compensation

Invalid Deep hole drilling cycle (2)

Valid R-designated arc radius

R

Valid Corner rounding circular

Valid Automatic tool length

Valid MRC longitudinal/face

Invalid MRC shaping division

Valid Cut-off cycle, return amount

Valid Cut-off cycle, escape

Valid Compound thread cutting

Valid Compound thread cutting

Valid Hole drilling cycle/deep

Valid Program tool radius

Valid Coordinate position data

Application

speed

sequence number

Shift amount/cut amount

cycle

Minimum cut amount

cycle

First cut amount

Cut amount of each pass

input

Hypothetical tool nose point

number

Dwell at cut point

radius

measurement, deceleration

range r

escape amount

number

amount

cycle, finishing allowance

cycle/turning cycle, taper

difference

hole drilling cycle (2),

distance to reference point

compensation input

Nose R compensation

amount (absolute)

Re-

marks

,R

5.4 Decimal Point Input

Decimal

Add-

ress

point

com-

mand

Invalid Spindle function codes

S

Invalid Maximum spindle clamp

Invalid Constant surface speed

Invalid Data setting, word type data 2 bytes

T Invalid Tool function codes

Valid Coordinate position data

U

Invalid 2nd miscellaneous function

Valid Program tool compensation

Valid Coordinate position data

V

Invalid 2nd miscellaneous function

Valid Program tool offset input

Valid Coordinate position data

W

Invalid 2nd miscellaneous function

Valid Program tool compensation

Valid Coordinate position data

X

Valid Dwell

Invalid 2nd miscellaneous function

Valid Program tool compensation

Valid Coordinate position data

Y

Invalid 2nd miscellaneous function

Valid Program tool compensation

Valid Coordinate position data

Z

Invalid 2nd miscellaneous function

Valid Program tool compensation

Application

speed

control, surface speed

codes

input

codes

codes

input

codes

input

codes

input

codes

input

Re-

marks

23

Page 40

6. INTERPOLATION FUNCTIONS

6. INTERPOLATION FUNCTIONS

6.1 Positioning (Rapid Traverse); G00

Function and purpose

This command is accompanied by coordinate words. It positions the tool along a linear or

non-linear path from the present point as the start point to the end point which is specified by the

coordinate words.

Command format

G00 Xx/Uu Zz/Ww;

x, u, z, w Coordinate values

The command addresses are valid for all additional axes.

Detailed description

(1) Once this command has been issued, the G00 mode is retained until it is changed by

another G function or until the G01, G02, G03 or G33 command in the 01 group is issued. If

the next command is G00, all that is required is simply that the coordinate words be

specified.

6.1 Positioning (Rapid Traverse); G00

(2) In the G00 mode, the tool is always accelerated at the start point of the block and

decelerated at the end point. Execution proceeds to the next block after it has been

confirmed that the command pulse of the present block is 0 and that the tracking error of the

acceleration/deceleration circuit is 0. The in-position width is set by parameter.

(3) Any G function (G83 to G89) in the 09 group is cancelled (G80) by the G00 command.

(4) Whether the tool moves along a linear or non-linear path is determined by parameter, but the

positioning time does not change.

(a) Linear path................ This is the same as linear interpolation (G01), and the speed is

limited by the rapid traverse rate of each axis.

(b) Non-linear path ......... The tool is positioned at the rapid traverse rate independently for

each axis.

(5) When no number following the G address, this is treated as G00.

CAUTION

The commands with "no value after G" will be handled as "G00" during operation.

24

Page 41

6. INTERPOLATION FUNCTIONS

Example of program

6.1 Positioning (Rapid Traverse); G00

+X

Turret

Start point

(+180, +300)

End point (+100, +150)

Workpiece

+Z

(Unit : mm)

Chuck

G00 X100000 Z150000; Absolute value command

G00 U-80000 W-150000; Incremental value command

(With an input setting unit of 0.001mm)

(Note 1) When the "G0 interpolation OFF" user parameter is OFF, the path along which the tool