Page 1

Page 2

Page 3

MELDAS is a registered trademark of Mitsubishi Electric Corporation.

Other company and product names that appear in this manual are trademarks or registered trademarks of the respective

companies.

Page 4

Page 5

Introduction

CAUTION

This is a setup manual for MITSUBISHI CNC M700VW Series.

This manual is written on the assumption that with all of the MITSUBISHI CNC M700VW Series functions are

added, but the actually delivered NC may not have all optional functions.

Refer to the specifications issued by machine tool builder to confirm the functions available for your NC before

proceeding to operation.

Notes on Reading This Manual

(1) This manual explains general parameters as viewed from the NC.

For information about each machine tool, refer to manuals issued from the machine tool builder.

If the descriptions relating to "restrictions" and "allowable conditions" conflict between this manual and the

machine tool builder's instruction manual, the later has priority over the former.

(2) This manual is intended to contain as much descriptions as possible even about special operations.

The operations to which no reference is made in this manual should be considered "impossible".

(3) The "special display unit" explained in this manual is the display unit incorporated by the machine tool builder,

and is not the MITSUBISHI standard display unit.

(4) This manual is for the machine tool builders who set up the NC system.

If the descriptions relating to the "restrictions" and "allow a ble conditions" conflict between this manual

and the machine tool builder’s instruction manual, the latter has priority over the former.

The operations to which no reference is made in this manual should be considered "impossible".

This manual is complied on the assum ption that your machine is provided with all optional functions. Refer

to the specifications issued by machine tool builder to confirm the functions available for yo ur NC before

proceeding to operation.

In some NC system versions, there may be cases that different pictures appear on the screen, the machine

operates in a different way or some function is not activated.

Page 6

Page 7

Precautions for Safety

DANGER

WARNING

CAUTION

DANGER

WARNING

Always read the specifications issued by the machine tool builder, this manual, related manuals and attached

documents before installation, operation, programming, maintenance or inspection to ensure correct use.

Understand this numerical controlle r, s af et y ite ms an d cau ti o ns be fo re usi n g th e unit.

This manual ranks the safety precautions into "DANGER", "WARNING" and "CAUTION".

When the user may be subject to imminent fatalities or major injuries if handling is

mistaken.

When the user may be subject to fatalities or major injuries if handling is mistaken.

When the user may be subject to injuries or when physical damage may occur if handling

is mistaken.

Note that even items ranked as " CAUTION", may lead to major results depending on the situation. In any case,

important information that must always be observed is described.

Not applicable in this manual.

Do not cancel the emergency stop before confirming the basic operation.

Always set the stroke end and stroke limit. Failure to set this could result in collision with the machine end.

1. Items related to product and manual

If the descriptions relating to the "restrictions" and "allow a ble conditions" conflict between this manual

and the machine tool builder's instruction manual. the latter has priority over the former.

The operations to which no reference is made in this manual should be considered "impossible".

This manual is complied on the assumption that your machine is provided with all optional functions.

Confirm the functions available for your machine before proceeding to op eration by referring to the

specification issued by the machine tool builder.

CAUTION

In some NC system versions. there may be cases that different pictures appear on the screen, the machine

operates in a different way on some function is not activated.

[Continued to next page]

Page 8

2. Items related to faults and abnormalities

CAUTION

If the battery low warning is issued, save the machinin g programs, tool data and parameters in an input/

output device, and then replace the battery. When the battery alarm is issued, the machining programs, tool

data and parameters may have been destroyed. Replace the battery and then reload the data.

3. Items related to setup

Do not adjust the spindle when possible risks associated with adjustment proc edures are not thoroughly

taken into consideration.

Be careful when touching spindle's rotating section, or yo ur hand may be caught in or cut.

4. Items related to maintenance

Do not replace the battery while the power is ON.

Do not short-circuit, charge, overheat, incinerate or disassemble the battery.

Dispose the spent battery according to the local laws.

Do not connect or disconnect the cables between units while the power is ON.

Do not pull the cables when connecting/disconnecting them.

Do not replace the cooling fan while the power is ON.

Dispose the spent cooling fan according to the local laws.

[Continued]

Do not replace the backlight while the power is ON.

Dispose the spent backlight according to the local laws.

Do not touch the backlight while the power is ON. Failure to observe this cou ld result in elec tric shocks d ue

to high voltage.

Do not touch the backlight while the LCD panel is in use. Failure to observe this could result in burns.

Do not apply impact or pressure on the LCD panel or backlight. Failure to observe this could result in

breakage as they are made of glass.

Incorrect connections could cause devices to damage. Connect the cables to designated connectors.

Do not replace the control unit while the power is ON.

Do not replace the display unit while the power is ON.

Do not replace the keyboard unit while the power is ON.

Do not replace the operation panel I/O unit while the power is ON.

Do not replace the hard disk unit while the power is ON.

Dispose the spent hard disk unit according to the local laws.

Hard disk unit is a precision device, so do not drop or apply strong impacts on it.

5. Items related to servo parameters and spindle parameters

Do not adjust or change the parameter settings greatly as operation could become unstable.

In the explanation on bits, set all bits not used, including blank bits, to "0".

Page 9

Disposal

(Note) This symbol mark is for EU countries only.

This symbol mark is according to the directive 2006/66/EC Article 20 Information for end-users and

Annex II.

Your MITSUBISHI ELECTRIC product is designed and manufactured with high quality materials and components

which can be recycled and/or reused.

This symbol means that batteries and accumulators, at their end-of-life, should be disposed of separately from your

household waste.

If a chemical symbol is printed beneath the symbol shown above, this chemical symbol means that the battery or

accumulator contains a heavy metal at a certain concentration. This will be indicated as follows:

Hg: mercury (0,0005%), Cd: cadmium (0,002%), Pb: lead (0,004%)

In the European Union there are separate collection systems for used batteries and accumulators.

Please, dispose of batteries and accumulators correctly at your local community waste collection/recycling centre.

Please, help us to conserve the environment we live in!

Page 10

Page 11

CONTENTS

1 Setup Outline. ... ....................................... ... .... ... ... ....................................... ... ... ... .... .................................... 1

1.1 Device Configuration..............................................................................................................................................2

1.2 Hardware Configuration.........................................................................................................................................3

1.3 Flow of Initial Setup................................................................................................................................................5

2 Connecting and Setting the Hardware............... ........................................................................................ 7

2.1 Connecting and Setting the Drive Unit.................................................................................................................8

2.1.1 Connecting with Servo Drive Unit ................................................................................................................8

2.1.1.1 Connecting with MDS-D/DH Series......................................................................................................9

2.1.1.2 Connecting with MDS-DM Series.......................................................................................................12

2.1.1.3 Connecting with MDS-SVJ3/SPJ3 Series..........................................................................................17

2.1.2 Setting up without Connecting to the Motor/ Drive unit...........................................................................18

2.2 Setting the Rotary and DIP Switches.................................... ..............................................................................19

2.2.1 MDS-D/DH Series...................................................... ........................................ ............................................19

2.2.2 MDS-DM Series........................................... ... ...............................................................................................21

2.2.3 MDS-D-SVJ3/SPJ3 Series................................... ... ......................................................................................23

2.3 Connecting the Batteries......................................................................................................................................24

2.3.1 Control Unit Battery.....................................................................................................................................24

2.3.2 Servo Drive Unit Battery..............................................................................................................................25

2.4 Connecting and Setting the Remote I/O Unit.....................................................................................................27

2.4.1 Outline of the Remote I/O Unit....................................................................................................................27

2.4.2 Connection and Station No. Setting on Remote I/O Unit..........................................................................29

2.4.3 Station No. Setting when Using Multiple Remote I/O Units......................................................................31

2.4.4 Device No. Assignment ............. .. ............................................................................ ....................................35

2.5 Initializing the NC Internal Data (SRAM).............................................................................................................36

3 Setting the Parameters and Date/Time .................................................................................................... 39

3.1 Setting on the System Setup Screen..................................................................................................................40

3.2 Setting the Parameters for the Machine Specifications....................................................................................44

3.3 Setting Date and Time..........................................................................................................................................46

4 Setting Up with HMI Integrated Installer ................................................................... ... ... .... ... .................. 47

4.1 Outline of HMI Integrated Installer.......................................................................................................................48

4.2 Memory Card for Upgrade....................................................................................................................................48

4.3 Operation Methods ...............................................................................................................................................49

5 PLC Program Writing................................................................................................................................. 51

5.1 Setting the Ethernet Communication..................................................................................................................52

5.2 Connecting the Control Unit and a Personal Computer....................................................................................53

5.3 Setting the Communication with GX Developer.................................................................................................54

5.4 Setting the Parameters on GX Developer...........................................................................................................56

5.5 Writing a PLC Program with GX Developer........................................................................................................58

5.6 Writing a PLC Program to ROM with GX Developer..................................... ... ..................................................59

5.7 Setting the PLC Parameters.................................................................................................................................61

6 Confirming the Basic Operation............................................................................................................... 63

6.1 Checking Inputs/Outputs and Alarms.................................................................................................................64

6.2 Confirming Manual Operation..............................................................................................................................65

6.2.1 Using the Manual Pulse Generator.............................................................................................................65

6.2.2 Using JOG Feed ...........................................................................................................................................65

6.2.3 Servo Simplified Adjustment ................................................................. ... ..................................................66

6.2.3.1 First Measure Against Vibration.........................................................................................................66

6.2.3.2 MS Configurator........................................................ ................................. ..........................................67

7 Setting the Position Detection System.................................................................................................... 71

7.1 Marked Point Alignment Method II......................................................................................................................72

Page 12

8 Setting the Tool Entry Prohibited Range ............................................................................................... 75

8.1 Stroke End (H/W OT) ............................................................................................................................................76

8.2 Stored stroke limit (S/W OT)................................................................................................................................ 77

8.2.1 Outline........................................................................................................................................................... 77

8.2.2 Detailed Explanation....................................................................................................................................79

8.2.2.1 Stored Stroke Limit I...........................................................................................................................80

8.2.2.2 Stored Stroke Limit II..........................................................................................................................81

8.2.2.3 Stored Stroke Limit IB.........................................................................................................................83

8.2.2.4 Stored Stroke Limit IC.........................................................................................................................84

8.2.2.5 Movable Range during Inclined Axis Control...................................................................................85

8.2.2.6 Stored Stroke Limit for Rotation Axis...............................................................................................86

8.2.2.7 Precautions......................................... ... ....................................... .......................................................86

9 Confirming the Spindle Operation............................................................................................................ 87

9.1 In Manual Operation (with Manual Numerical Command) ................................................................................ 88

9.2 In MDI Operation................................................................................................................................................... 89

9.3 Confirming the Rotation Speed........................................................................................................................... 89

10 Setting the Credit System ....................................................................................................................... 91

11 Setting the Handy Terminal..................................................................................................................... 95

11.1 Inputting the Data from a Personal Computer........................................................ ......................................... 96

11.2 Inputting the Data from NC................................................................................................................................ 99

12 Setting the Deceleration Check ............................................................................................................ 101

12.1 Function.............................................................................................................................................................102

12.2 Deceleration Check Method.............................................................................................................................103

12.3 Deceleration Check for Opposite Direction Movement Reversal..................................... ... ... ......................105

12.4 Parameter .......................................................................................................................................................... 106

12.5 Precautions....................................................................................................................................................... 108

13 Operating the Auxiliary Axis................................................................................................................. 109

13.1 Preparations......................................................................................................................................................110

13.2 Absolute Position Initial Setting...................................................................................................................... 110

13.3 Test Run ............................................................................................................................................................ 110

13.4 PLC Device........................................................................................................................................................ 111

13.5 Notes.................................................................................................................................................................. 114

14 Data Backup and Restoration............................................................................................................... 115

14.1 All Backup......................................................................................................................................................... 116

14.2 All Restoration.................................................................................................................................................. 119

15 Hardware Replacement Methods........................................................................ .................................. 121

15.1 Durable Parts ....................................................................................................................................................122

15.1.1 Control Unit Battery.................................................................................................................................122

15.1.2 Control Unit Cooling Fan......................................................................................................................... 124

15.1.3 Display Unit Battery............................................................................................. .................................... 125

15.1.4 Display Unit Cooling Fan..................................... ....................................................................................126

15.1.5 Backlight................................................................................................................................................... 127

15.1.6 Touch Panel Protective Sheet.................................................................................................................130

15.2 Control Unit....................................................................................................................................................... 131

15.3 Display Unit....................................................................................................................................................... 133

15.4 Keyboard Unit................................................................................................................................................... 135

15.5 Operation Panel I/O Unit .................................................................................................................................. 136

15.6 Hard Disk Unit...................................................................................................................................................137

15.7 Control Unit CompactFlash (CF) Card ........................................................................................................... 139

15.8 PCMCIA Card .................................................................................................................................................... 140

16 Cables ..................................................................................................................................................... 141

16.1 Precautions when Connecting/Disconnecting Cables..................................................................................142

16.2 Precautions for Using Optical Communication Cable..................................................................................145

16.2.1 Optical Communication Cable Outline and Parts................................................................................. 145

16.2.2 Precautions for Handling Optical Communication Cable....................................................................145

16.2.3 Precautions for Laying Optical Communication Cable........................................................................ 146

Page 13

Appendix 1 Explanation of Parameters .................................................................................................... 147

Appendix 1.1 User Parameters................................................................................................................................148

Appendix 1.2 Base Specifications Parameters ......................................................................................................209

Appendix 1.3 Axis Specifications Parameters.......................................................................................................276

Appendix 1.4 Servo Parameters..............................................................................................................................306

Appendix 1.5 Spindle Parameters...........................................................................................................................339

Appendix 1.6 Rotary Axis Configuration Parameters............................................................................................393

Appendix 1.7 Machine Error Compensation Parameters......................................................................................400

Appendix 1.8 PLC Constants...................................................................................................................................402

Appendix 1.9 Macro List...........................................................................................................................................405

Appendix 1.10 Position Switches............................................................................................................................415

Appendix 1.11 Auxiliary Axis Parameters ..............................................................................................................429

Appendix 1.12 Open Parameters.............................................................................................................................447

Appendix 1.13 Device Open Parameters ................................................................................................................448

Appendix 1.14 SRAM Open Parameters .................................................................................................................449

Appendix 1.15 CC-Link Parameters ........................................................................................................................450

Appendix 1.16 Anshin-net Parameters 2/ MTB-net Parameters 2 ............. ................................. ..........................462

Appendix 1.17 PLC Axis Indexing Parameters.......................................................................................................475

Appendix 1.18 Screen Transition Chart..................................................................................................................486

Appendix 1.19 Unit....................................................................................................................................................487

Appendix 1.20 Inputting the Machine Parameters.................................................................................................487

Appendix 1.21 Machine Error Compensation (Function Details) .......................................................................488

Appendix 1.21.1 Outline.............................................................................................. ........................................488

Appendix 1.21.2 Setting Compensation Data......................................................... ..........................................491

Appendix 1.21.3 Example in Using a Linear Axis as Base Axis......................................................................492

Appendix 1.21.4 Example in Using a Rotary Axis as Base Axis.....................................................................496

Appendix 1.22 Position Switch (Function Details) ................................................................................................497

Appendix 1.22.1 Outline.............................................................................................. ........................................497

Appendix 1.22.2 Setting and Operation Examples of dog1 and dog2............................................................497

Appendix 1.22.3 Canceling the Position Switch...............................................................................................499

Appendix 1.23 Bit Selection Parameters #6449 to #6496......................................................................................500

Appendix 2 Explanation of Alarms............................................................................................................ 503

Appendix 2.1 Operation Errors (M)..........................................................................................................................504

Appendix 2.2 Stop Codes (T)...................................................................................................................................520

Appendix 2.3 Servo/Spindle Alarms (S)..................................................................................................................526

Appendix 2.3.1 Servo Errors (S01/S03/S04)........................................... ...........................................................526

Appendix 2.3.2 Initial Parameter Errors (S02) ..................................................................................................540

Appendix 2.3.3 Parameter Erro rs ( S 51).............................................................................................................541

Appendix 2.3.4 Servo Warnings (S52)................................... ... ... ......................................................................542

Appendix 2.4 MCP Alarms (Y)..................................................................................................................................545

Appendix 2.5 System Alarms (Z).............................................................................................................................555

Appendix 2.6 Absolute Position Detection System Alarms (Z7*).........................................................................561

Appendix 2.7 Distance-coded Reference Scale Errors (Z8*) ................................................................................565

Appendix 2.8 Emergency Stop Alarms (EMG)........................................................................................................567

Appendix 2.9 Auxiliary Axis Alarms (S)..................................................................................................................570

Appendix 2.9.1 Auxiliary Axis Servo Errors/Warnings (S) ..............................................................................570

Appendix 2.9.2 Auxiliary Axis Absolute Position Detection System Alarms (Z)...........................................575

Appendix 2.9.3 Auxiliary Axis Operation Errors (M)........................................................................................576

Appendix 2.9.4 Auxiliary Axis MCP Alarms (Y) ................................................................................................578

Appendix 2.10 Computer Link Errors (L)................................................................................................................580

Appendix 2.11 User PLC Alarms (U) .......................................................................................................................581

Appendix 2.12 Network Service Errors (N).............................................................................................................583

Appendix 2.13 Program Errors (P) ..........................................................................................................................585

Appendix 2.14 Troubleshooting..............................................................................................................................615

Appendix 2.14.1 Troubleshooting at power ON...... ................................................................ ..........................615

Appendix 2.14.2 Troubleshooting for each alarm No. .....................................................................................616

Appendix 2.14.3 Troubleshooting for each warning No..................................................................................648

Appendix 2.14.4 Parameter numbers during initial parameter error..............................................................651

Appendix 2.14.5 Troubleshooting the spindle system when there is no alarm or warning.........................652

Page 14

Page 15

1

1

Setup Outline

Page 16

1 Setup Outline

MITSUBISHI CNC

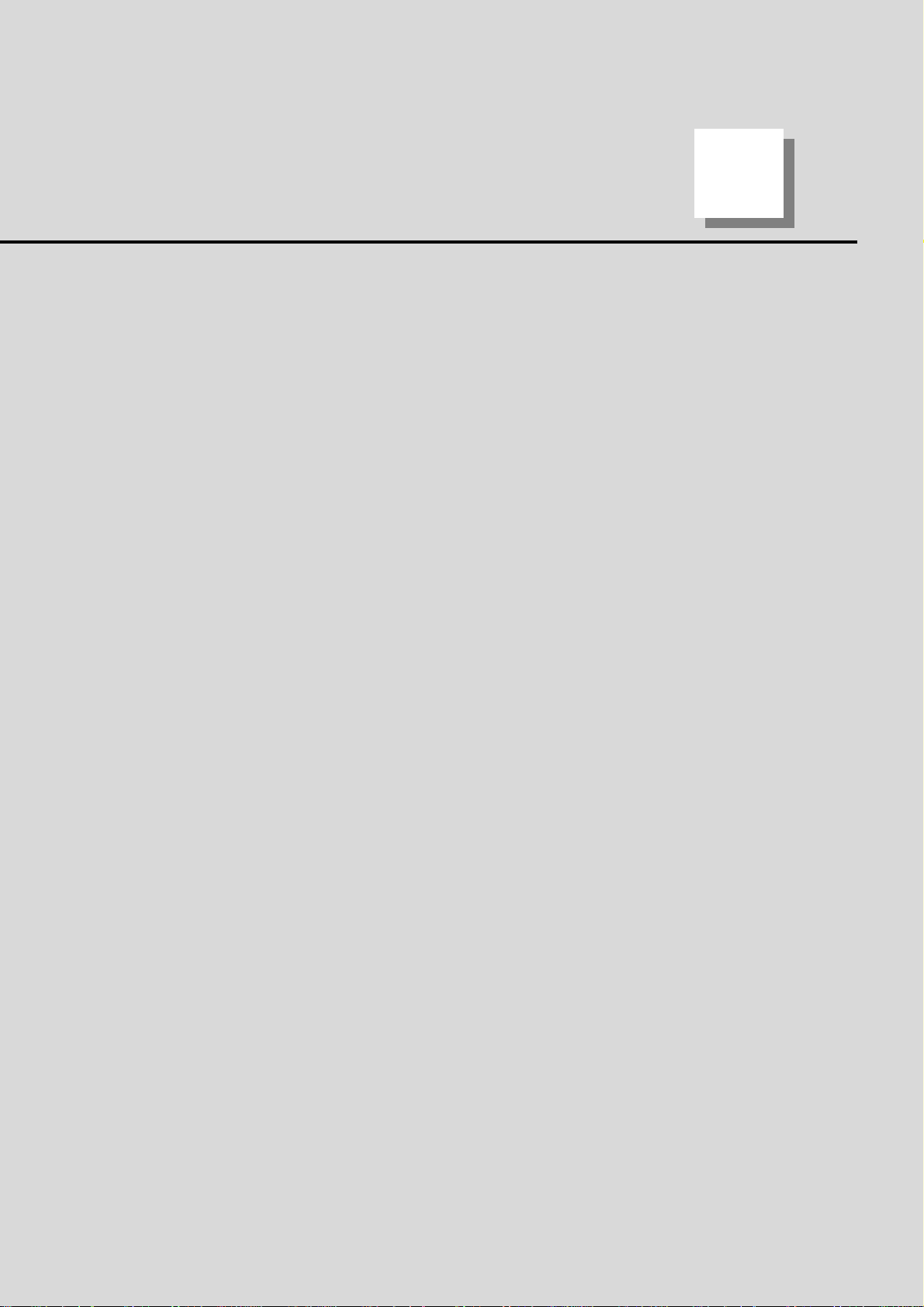

1.1 Device Configuration

Motor group

Auxiliary axis

Servo/Spindle

drive unit

MR-J2-CT/CT4 Series

Auxiliary axis Servo

drive unit

Manual pulse generator

Manual pulse penerator

Expansion unit

Control unit

Display unit

Keyboard unit

Remote I/O unit

Synchronous

feed encoder

Remote I/O unit

Operation panel

I/O unit

MDS-D/DH/DM Series

MDS-D-SVJ3/SPJ3 Series

Expansion card

Hard disk unit

2

Page 17

M700VW Series Setup Manual

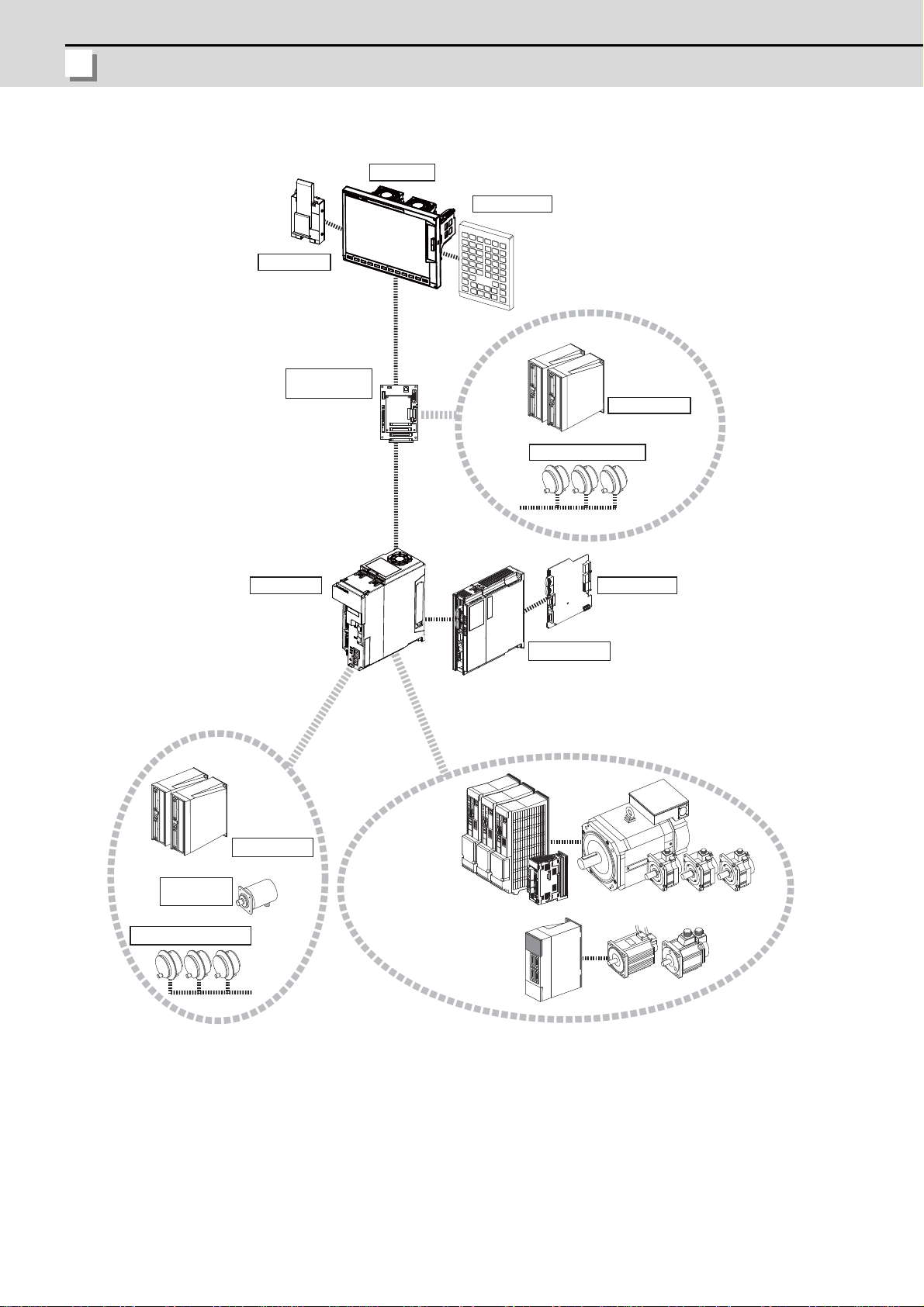

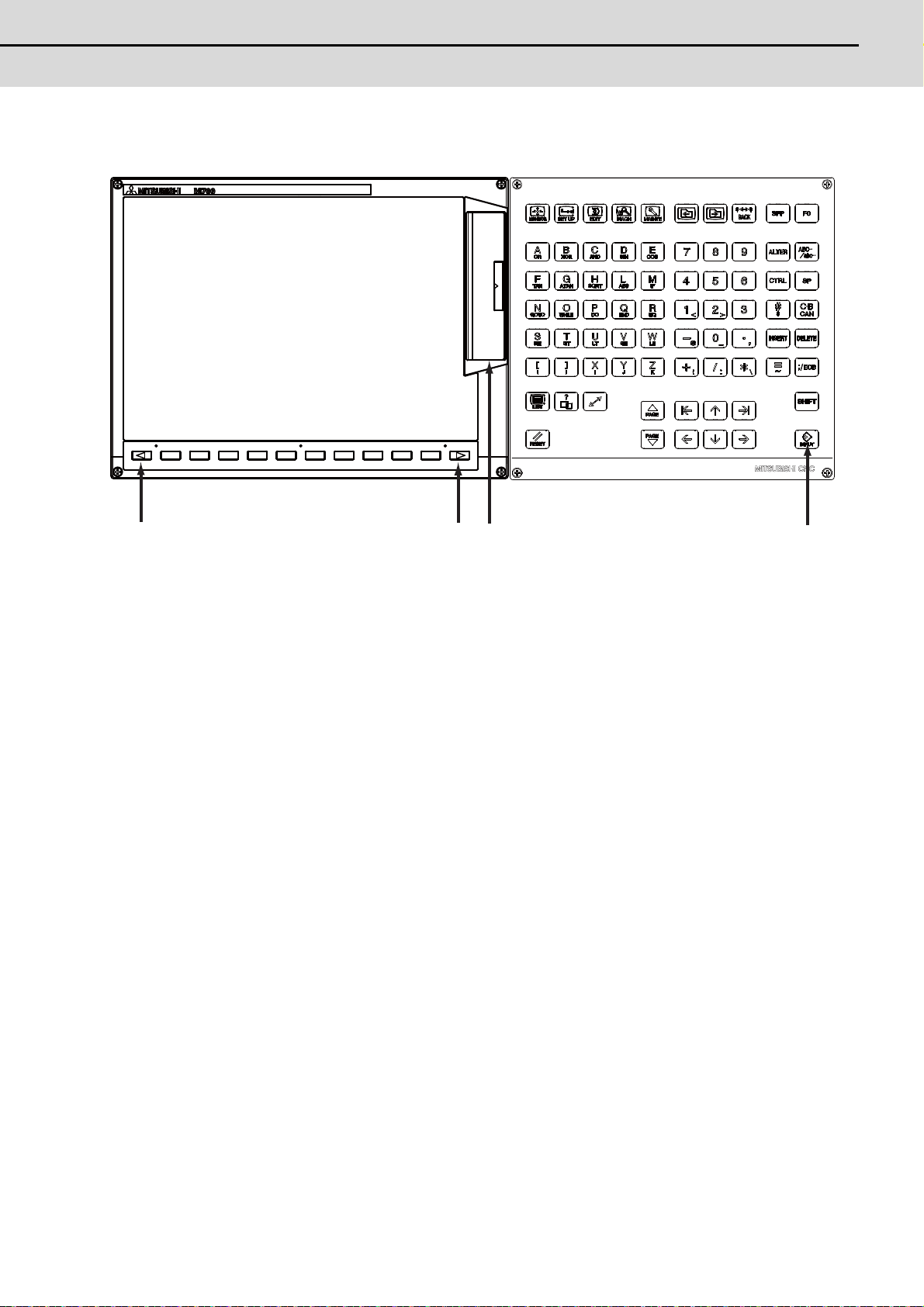

1.2 Hardware Configuration

1.2 Hardware Configuration

(A)

(B) (C)

(D)

The following shows the hardware names used in this manual.

(A) Cancel key

(B) Menu changeover key

(C) Memory card interface on front of display unit

(D) INPUT key

3

Page 18

1 Setup Outline

MITSUBISHI CNC

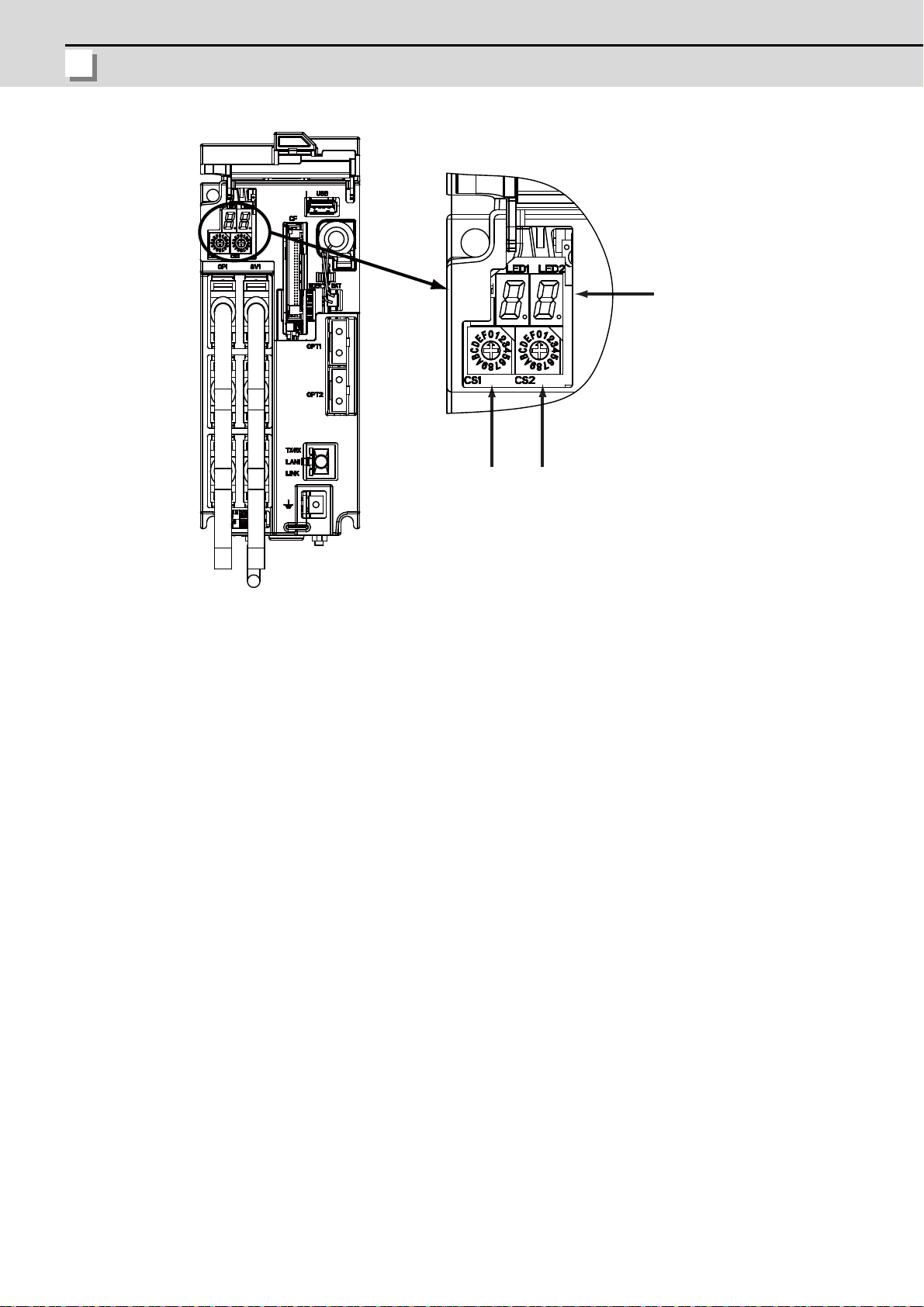

(A) Rotary switch 1

(A)

(B)

(C)

(B) Rotary switch 2

(C) 7-segment LED

4

Page 19

M700VW Series Setup Manual

1.3 Flow of Initial Setup

1.3 Flow of Initial Setup

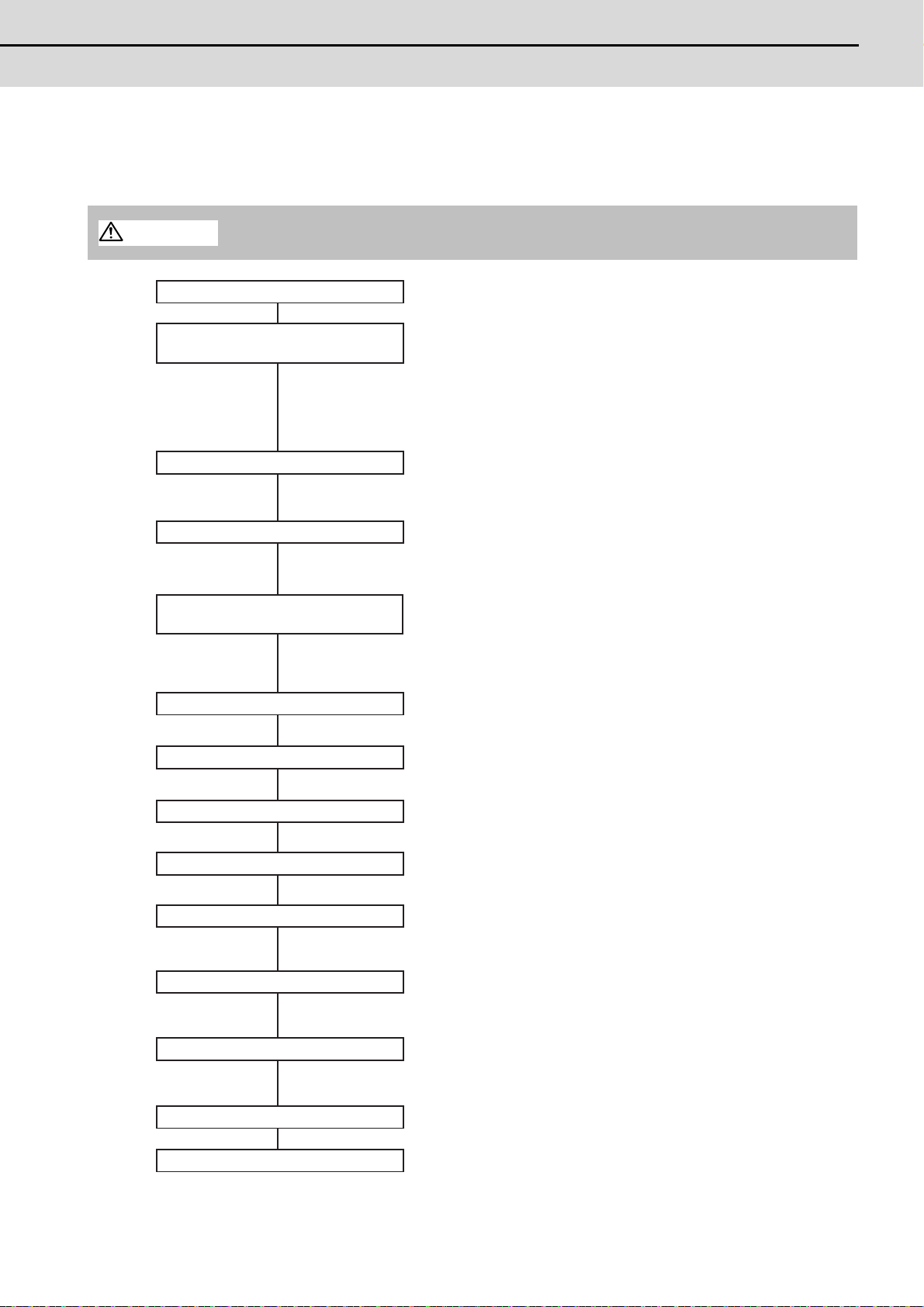

WARNING

Refer to section 2

Refer to section 3

Refer to section 4

Refer to section 5

Refer to section 6

Refer to section 7

Refer to section 9

Refer to the Instruction Manual

Refer to section 8

Points

Is the power supply within a specified range?

Is the power supply polarity correct?

Is the connection of the motor power cable and the detector cable correct?

Is the grounding correct?

Carry out the connecting and setting of drive units, batteries and remote I/O units.

Initialize the NC Internal data (SRAM).

Set the parameters on the system setup screen and the parameter screen.

Set the date and time on the integrated time screen.

Write the created PLC program to NC's ROM using GX Developer.

Confirm input/output of signals, alarm display and manual operation.

Carry out the setting for establishing the reference position (zero point).

Set the tool entry prohibited range.

Confirm that the spindle operates properly in manual/MDI operation.

Confirm the spindle rotation speed as well.

Start

Confirming the connection between

control unit and peripheral devices

Connecting and Setting the Hardware

Setting the Parameters and Date/Time

PLC Program Writing

Confirming the Basic Operation

Setting the Position Detection System

Setting the Stored Stroke Limit

Confirming the Spindle Operation

Inputting the machining program

End

Setting Up with

HMI Integrated Installer

Refer to section 10

Refer to section 11

Input the customized data for the handy terminal.

(Note) This procedure is required only when connecting the handy terminal.

Enable the credit system.

(Note) This procedure is required only when using the credit system.

Install and upgrade "Application of custom release"

with the HMI integrated installer.

If you do not need the installation, go to the next section.

Setting the Handy Terminal

Setting the Credit System

The following flow chart shows the procedures of the initial setup.

(Note) When setting up with backup files, refer to the section of "Data Backup and Restoration".

Do not cancel the emergency stop before confirming the basic operation.

5

Page 20

1 Setup Outline

MITSUBISHI CNC

For other settings, refer to the following sections:

- Setting the Deceleration Check

- Operating the Auxiliary Axis

- Data Backup and Restoration

6

Page 21

7

2

Connecting and Setting

the Hardware

Page 22

2 Connecting and Setting the Hardware

MITSUBISHI CNC

2.1 Connecting and Setting the Drive Unit

2.1.1 Connecting with Servo Drive Unit

Connect the optical communication cables from the NC to the each drive unit so that they run in a straight

line from the NC to the drive unit that is a final axis. Up to 16 axes can be connected per system. Note that

the number of connected axes is limited by the NC.

(Note) Refer to "Precautions for Using Optical Communication Cable" when handling an d wiring

optical communication cable.

Cable application table

Cable

G396

G395

G380

Panel internal wiring Panel external wiring

Under 10m 10 to 30m 10m or less 10 to 30m

○× × ×

○× ○ ×

○○ ○ ○

(Note) Wiring of over 30m can be applied when relaying the optical signal by Optical Repeater

module. Refer to the specification manual of the drive unit for the details of the Optical

Repeater module.

8

Page 23

M700VW Series Setup Manual

2.1 Connecting and Setting the Drive Unit

2.1.1.1 Connecting with MDS-D/DH Series

CAUTION

POINT

Refer to the

instruction manual

of each NC for

details.

MDS-D/DH-V2

1st/2nd axis

MDS-D/DH-V2

3rd axis

MDS-D/DH-SP

6th axis

(Final axis)

MDS-D/DH-CVMDS-D-SP2

4th/5th axis

Connect the NC and the drive units by the optical communication cables. The distance between the

NC and the final drive unit must be within 30m and the bending radius within 80mm.

Axis Nos. are determined by the rotary switch for setting the axis No. (Refer to the MDS-D/DH Series

Instruction Manual.) The axis No. has no relation to the order for connecting to the NC.

(1) When using one power supply unit

Connect the largest-capacity spindle drive unit to the final axis of the NC communication bus in order to

control the power supply unit. The spindle drive unit must be insta lled adjacent to the power supp ly unit.

In the system with servo only, a servo drive unit for controlling unbalance axis must be installed in the

same manner in the same way.

<Connection>

CN1A: CN1B connector on NC or previous stage's drive unit

CN1B: CN1A connector on next stage's drive unit

CN4: Connector for communication between power supply unit (master side) and drive unit

Connected

to the NC

Optical

communication

cable

CN4

CN4

The optical communication cables from the NC to the

final drive unit must be within 30m.

Connection when using one power supply unit

9

Page 24

2 Connecting and Setting the Hardware

MITSUBISHI CNC

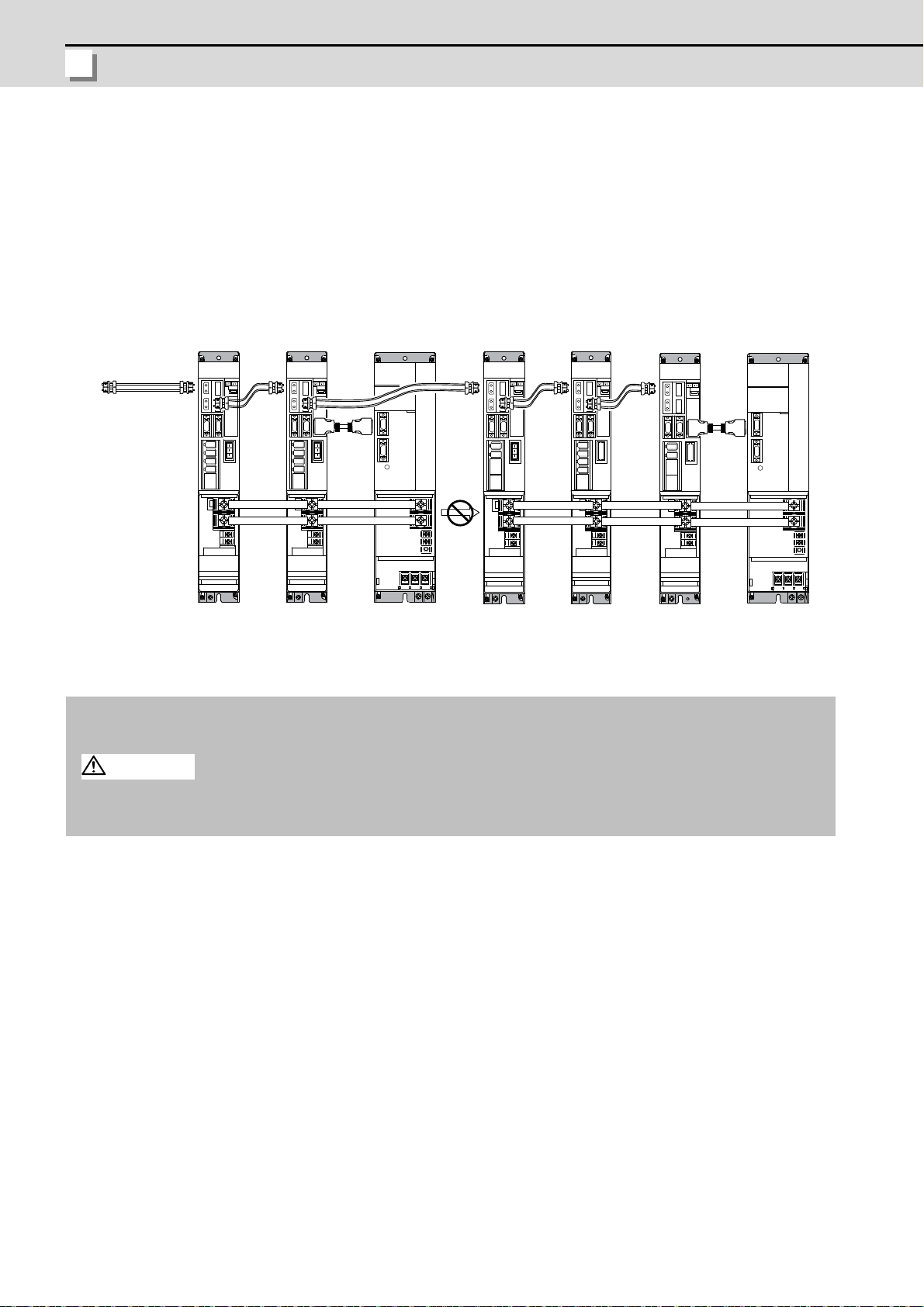

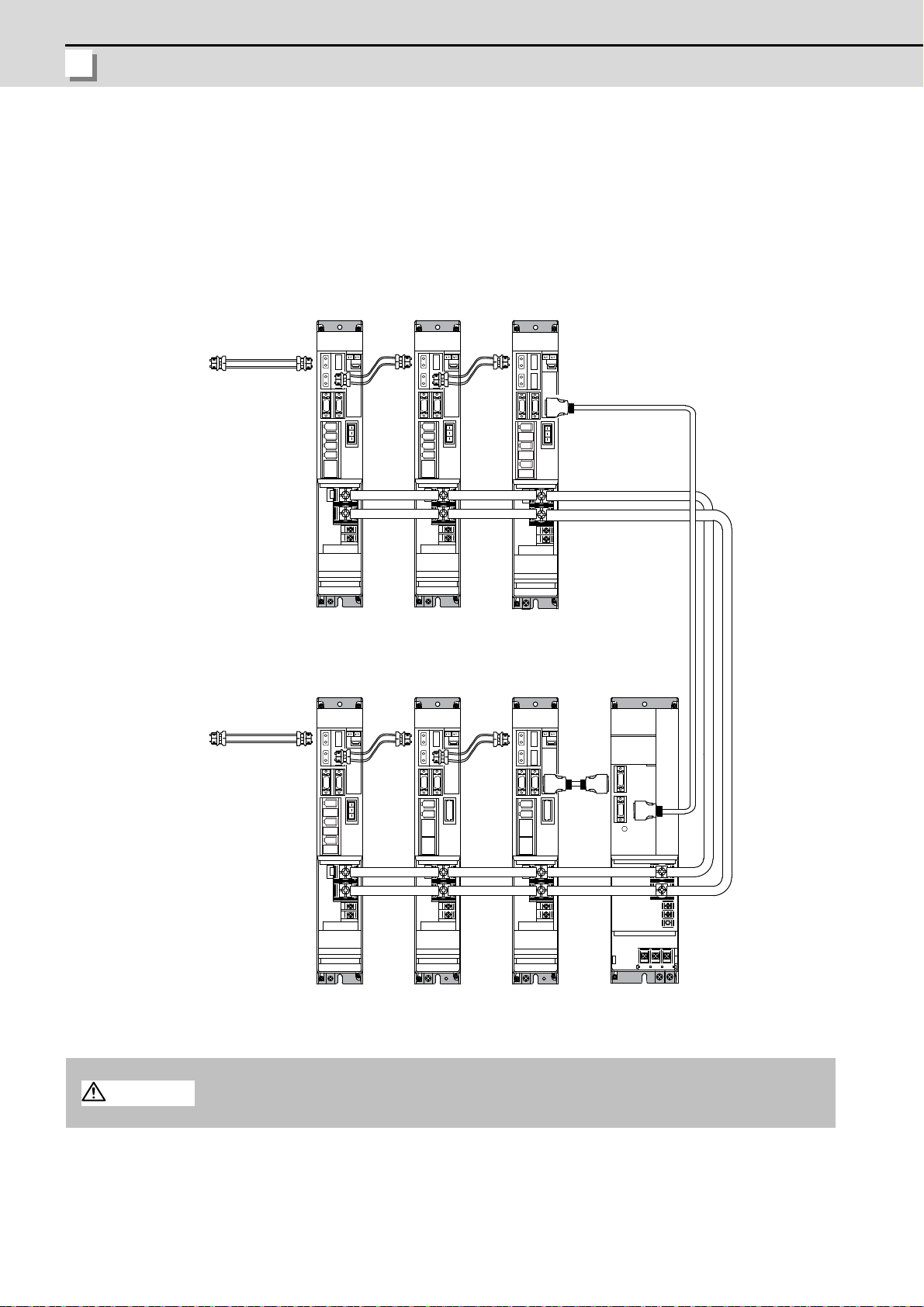

(2) When using two or more power supply units within a single NC communication bus system

Connected to the NC

MDS-D/DH-SP

8thaxis

(CV control axis)

MDS-D/DH-CV

[2]

MDS-D-SP2

6th/7th axis

MDS-D/DH-V2

1st/2nd axis

MDS-D/DH-V2

3rd/4th axis

(CV control axis)

MDS-D/DH-CV

[1]

MDS-D/DH-V1

5th axis

CAUTION

Two or more power supply units may be required within a single NC communication bus system if the

spindle drive unit capacity is large. The drive unit receiving power (L+, L-) from each power supp ly unit

must always have NC communication cable connection at the NC sid e of each pow er supply unit. In the

NC communication bus connection example below, power supply [1] cannot supply power ( L+, L-) to the

5th axis servo drive unit.

For basic connection information, refer to the MDS-D/DH Series Instruction Manual.

Optical

communication

cable

CN4

CN4

Power

cannot be

supplied

CN4

CN4

Connections when using two or more power supply units within a single NC communication bus system

1. The drive unit receiving power (L+, L-) from each power supply unit must always have NC

communication bus connection at the NC side of each power supply unit.

2. If two or more power supply units are connected in the drive system, confirm that the units are not

connected with each other through the L+ and L- lines before turning ON the power. Also make

sure that the total capacity of the drive units connected to the same power supply unit meets the

unit's selected capacity.

10

Page 25

M700VW Series Setup Manual

2.1 Connecting and Setting the Drive Unit

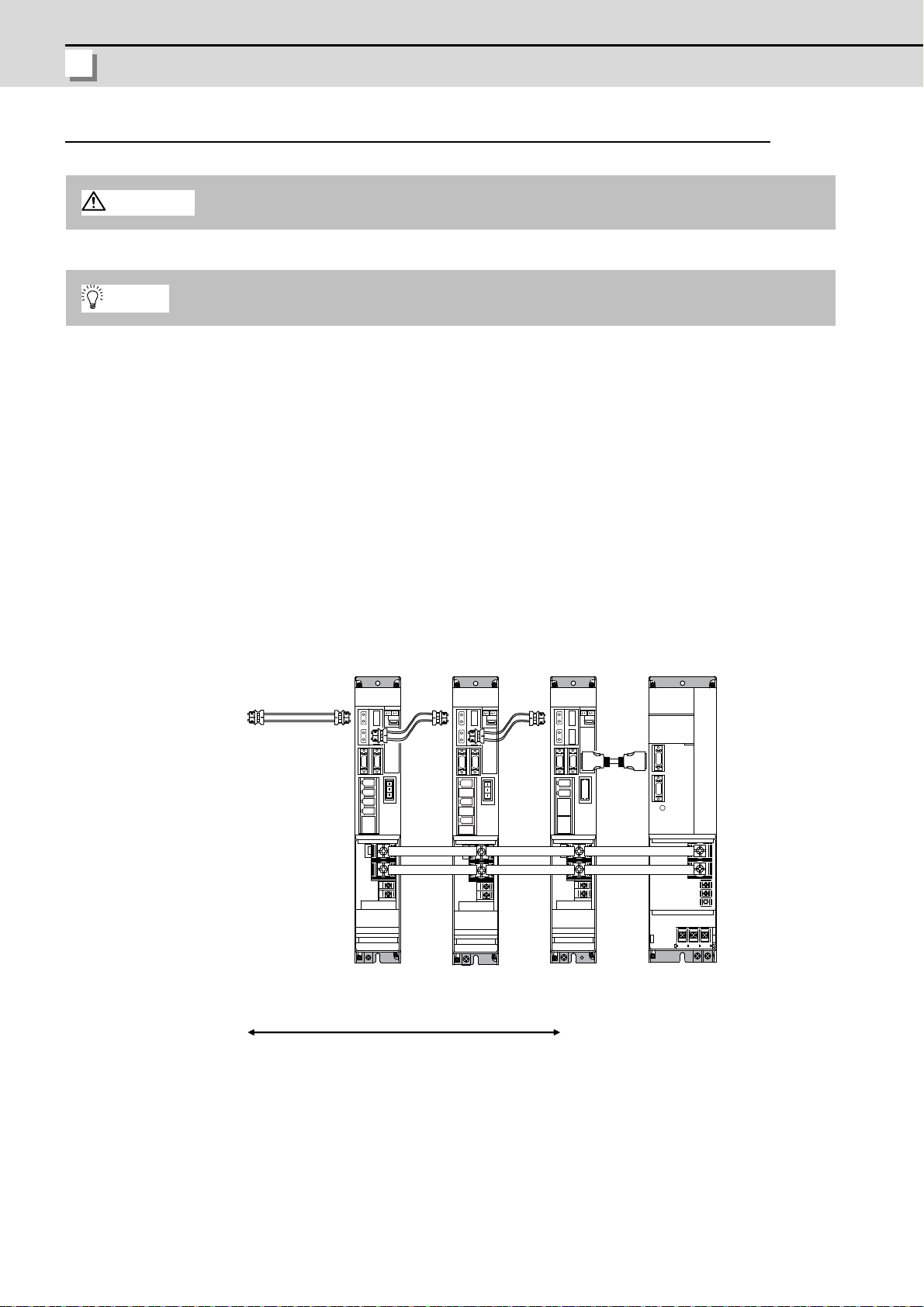

(3) When using one power supply shared unit by two NC communication bus systems

(

(

)

CAUTION

In systems employing a number of small-capacity drive units, a single power supply unit can be shared

by two NC communication bus systems. In this case, a power supply control axis must be set for each

axis of each NC communication bus.

For basic connection information, refer to the MDS-D/DH Series Instruction Manual.

Connected to the NC

(1st part system)

Optical

communication

cable

Connected to the NC

2nd part system

MDS-D/DH-V2

1st/2nd axis

MDS-D/DH-V2

8th/9th axis

MDS- D/DH -V2

3rd/4th axis

MDS-D/DH-V1

10th axis

MDS-D/DH-V2

5th/6th axis

MDS-D-SP2

11th/12th axis

MDS-D/DH-V1

7th axis

(CV control axis)

CN4

MDS-D/DH-SP

13th axis

CV control axis)

MDS-D/DH-CV

(Shared)

Optical

communication

cable

CN4

CN4

CN9

Connections when using one power supply shared by two NC communication bus systems

If the two NC communication bus systems include a spindle drive unit, connect the power supply

unit's CN4 connector to the CN4 connector of the largest capacity spindle drive unit. If there is no

spindle drive unit, connect to the unbalance-axis servo drive unit.

11

Page 26

2 Connecting and Setting the Hardware

MITSUBISHI CNC

2.1.1.2 Connecting with MDS-DM Series

CAUTION

POINT

Connect the NC and the drive units by the optical communication cables. The distance between the

NC and the final drive unit must be within 30m and the bending radius within 80mm.

Axis Nos. are determined by the rotary switch for setting the axis No. (Refer to the MDS-DM Series

Instruction Manual.) The axis No. has no relation to the order for connecting to the NC.

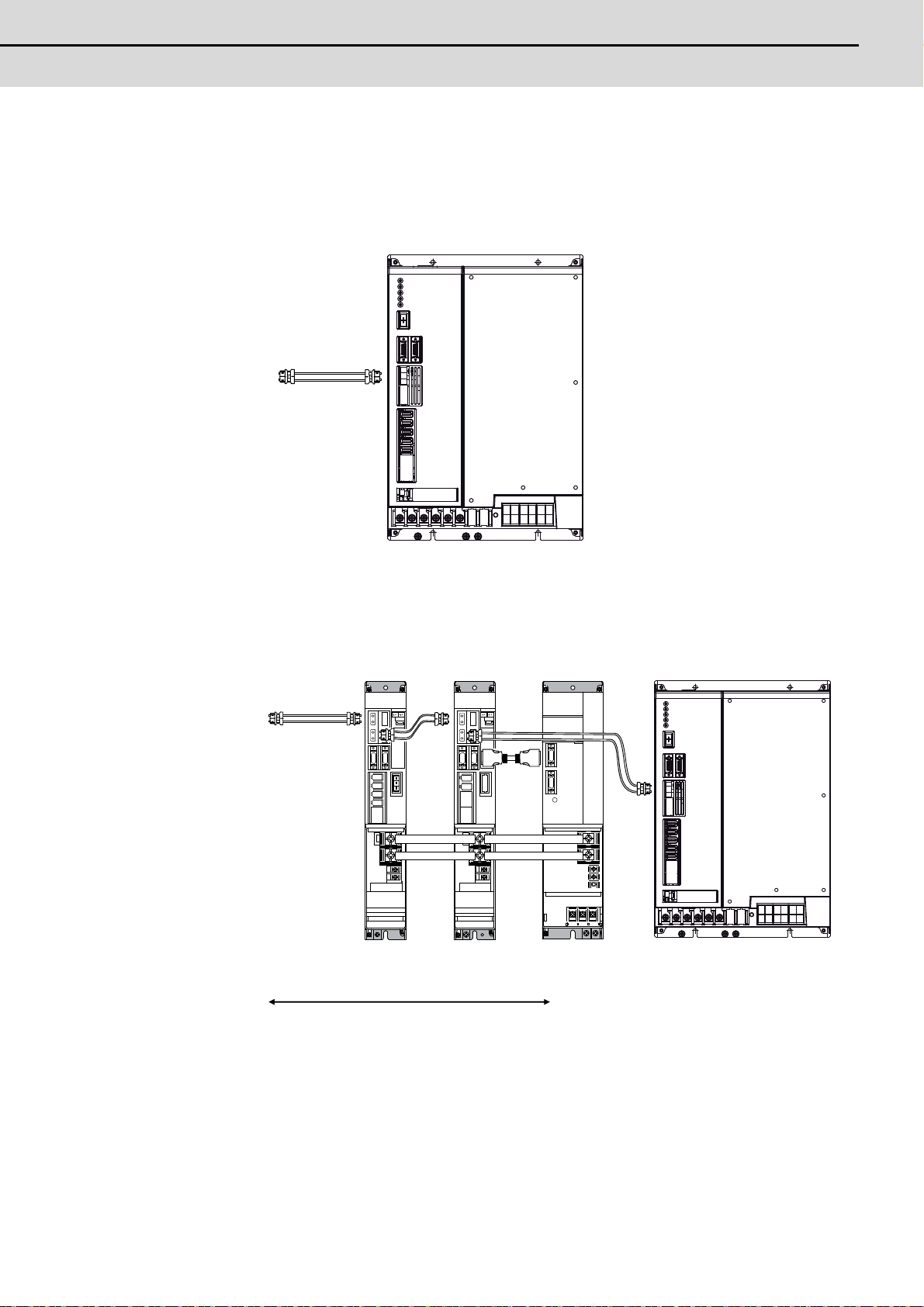

(1) Connecting the MDS-DM-V3

(a) When using one power supply unit

Connect the largest-capacity spindle drive unit to the final axis of the NC communication bus in

order to control the power supply unit. The spindle drive unit must be installed adjacent to the

power supply unit. In the system with servo only, a servo drive unit for controlling unbalance axis

must be installed in the same manner in the same way.

<Connection>

CN1A: CN1B connector on NC or previous stage's drive unit

CN1B: CN1A connector on next stage's drive unit

CN4: Connector for communication between power supply unit (master side) and drive unit

Connected

to the NC

Optical

communication

cable

MDS-D-V2

1st/2nd axis

MDS-DM-V3

3rd/4th/5th axis

MDS-D-SP

6th axis

(Final axis)

CN4

MDS-D-CV

CN4

12

The optical communication cables from the NC to the

final drive unit must be within 30m.

Connection when using one power supply unit

Page 27

M700VW Series Setup Manual

2.1 Connecting and Setting the Drive Unit

(b) When using two or more power supply units within a single NC communication bus system

7th axis

(CV control axis)

6th axis

1st/2nd axis

(CV control axis)

3rd/4th/5th axis

[2][1]

MDS-DM-V3

MDS-D-V2

MDS-D-CV MDS-D-V1 MDS-D-SP

MDS-D-CV

Power

cannot be

supplied

CAUTION

Two or more power supply units may be required within a single NC communication bus system if

the spindle drive unit capacity is large. The drive unit receiving power (L+, L-) from each power

supply unit must always have NC communication cable connection at the NC side of each power

supply unit. In the NC communication bus connection example below, power supply [1] cannot

supply power (L+, L-) to the 6th axis servo drive unit.

For basic connection information, refer to the MDS-DM Series Instruction Manual.

Connected to the NC

Optical

communication

cable

CN4

CN4

CN4

CN4

Connections when using two or more power supply units within a single NC communication bus system

The drive unit receiving power (L+, L-) from each power supply unit must always have NC

communication bus connection at the NC side of each power supply unit.

13

Page 28

2 Connecting and Setting the Hardware

MITSUBISHI CNC

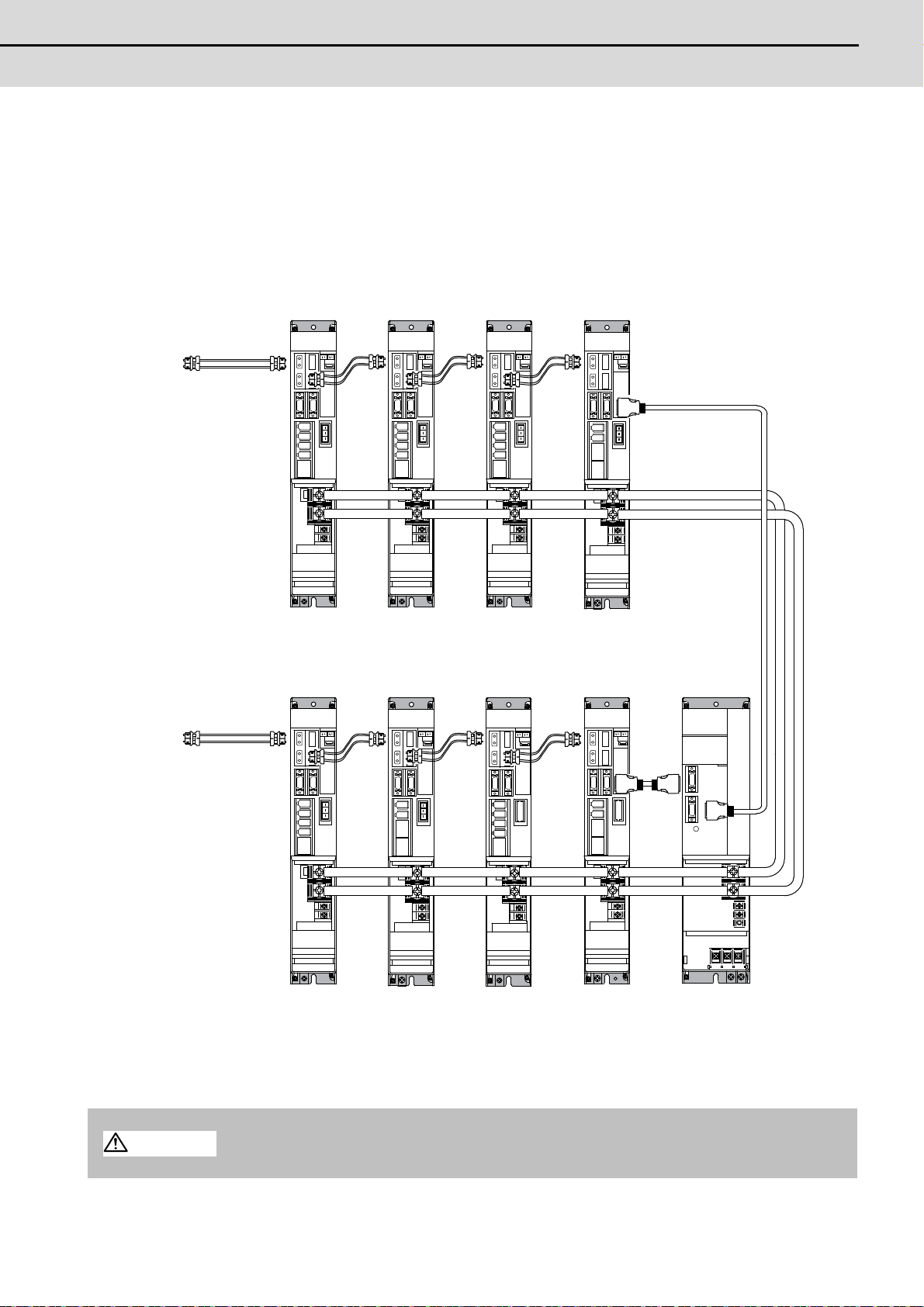

(c) When using one power supply shared unit by two NC communication bus systems

5th/6th/7th axis

(CV control axis)

1st/2nd axis th axis3rd/4

Connected to the NC

(1st part system)

12th axis

(CV control axis)

(Shared)11th axis

8th/9th/10th axis

Connected to the NC

(2nd part system)

communication

Optical

cable

MDS-DM-V3

MDS-DM-V3

MDS-D-V2 MDS-D-V2

MDS-D-SP

MDS-D-SP MDS-D-CV

CAUTION

In systems employing a number of small-capacity drive units, a single power supply unit can be

shared by two NC communication bus systems. In this case, a power supply control axis must be

set for each axis of each NC communication bus.

For basic connection information, refer to the MDS-DM Series Instruction Manual.

Optical

communication

cable

CN4

Connections when using one power supply shared by two NC communication bus systems

CN4

CN4

CN9

14

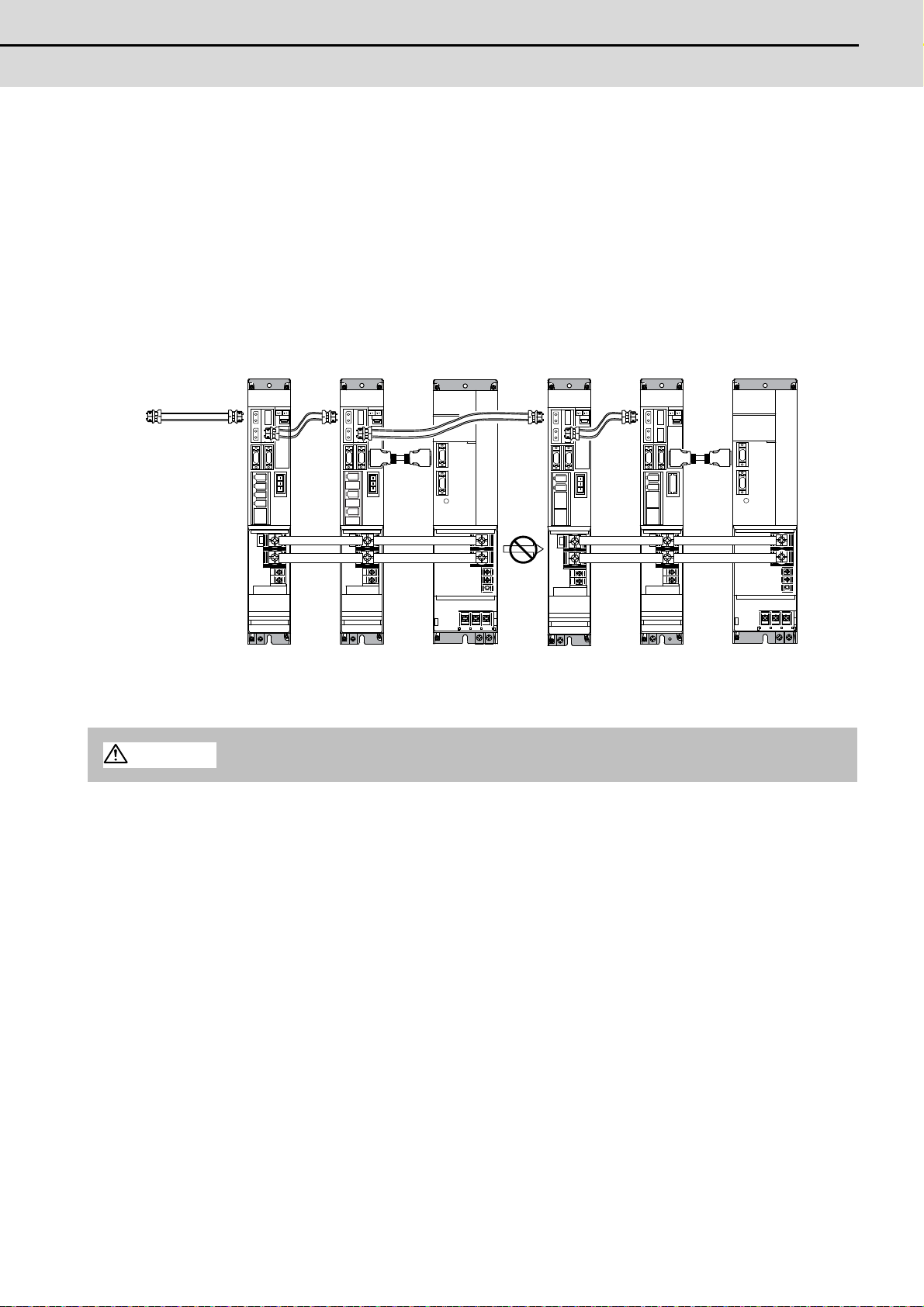

If the two NC communication bus systems include a spindle drive unit, connect the power supply

unit's CN4 connector to the CN4 connector of the largest capacity spindle drive unit. If there is no

spindle drive unit, connect to the unbalance-axis servo drive unit.

Page 29

M700VW Series Setup Manual

2.1 Connecting and Setting the Drive Unit

(2) Connecting the MDS-DM-SPV2/SPV3

Spindle:1st axis

Servo:2nd/3rd/4th axis

to the NC

Connected

communication

Optical

cable

MDS-DM-SPV3

(a) When using only MDS-DM-SPV3

(b) When using the MDS-D unit together

Connected

to the NC

MDS-D-SP

(Final axis)

CN4

CN4

MDS-D-V2

5th/6th axis 7th axis

Optical

communication

cable

The optical communicationcables from the NC to the

final drive unit must be within 30m.

MDS-D-CV

MDS-DM-SPV3

Spindle:1st axis

Servo:2nd/3rd/4th axis

15

Page 30

2 Connecting and Setting the Hardware

MITSUBISHI CNC

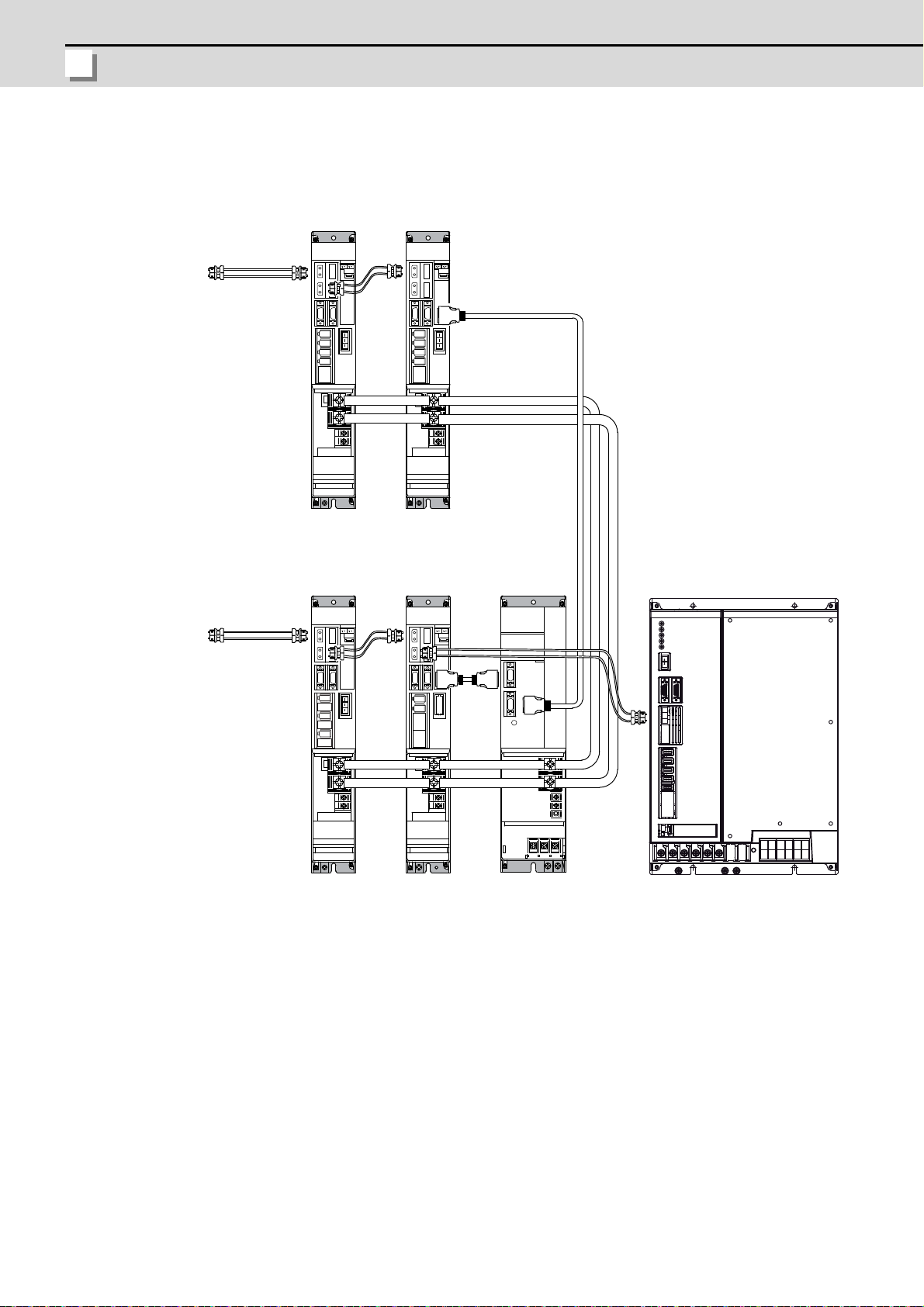

(c) When using one power supply shared unit by two NC communication bus systems

(

)

Connected to the NC

(1st part system)

Optical

communication

cable

Connected to the NC

2nd part system

MDS-D-V2

5th/6th axis

MDS-DM-V3

9th/10th/11th axis

MDS-D-V2

7th/8th axis

(CV control axis)

12th axis

(CV control axis)

CN4

MDS-D-CVMDS-D-SP

(Shared)

MDS-DM-SPV3

Spindle:1st axis

Servo:2nd/3rd/4th axis

Optical

communication

cable

CN4

CN4

CN9

16

Page 31

M700VW Series Setup Manual

2.1 Connecting and Setting the Drive Unit

2.1.1.3 Connecting with MDS-SVJ3/SPJ3 Series

CAUTION

POINT

Connected

to the NC

Optical

communication

cable

MDS-D-SVJ3

1st axis

MDS-D-SVJ3

2nd axis

MDS-D-SVJ3

3rd axis

MDS-D-SPJ3

4th axis

The optical communication cable up to 5m can be used in G396 series, and up to 20m in G380 series.

Connect the NC and the drive units by the optical communication cables. The bending radius must be

within 50mm.

Axis Nos. are determined by the rotary switch for setting the axis No. (Refer to the MDS-SVJ3/SPJ3

Series Instruction Manual.) The axis No. has no relation to the order for connecting to the NC.

<Connection>

CN1A: CN1B connector on NC or previous stage's drive unit

CN1B: CN1A connector on next stage's drive unit

17

Page 32

2 Connecting and Setting the Hardware

MITSUBISHI CNC

2.1.2 Setting up without Connecting to the Motor/ Drive unit

When connecting the motor or drive unit after setting up the system, set the axis data beforehand to enable

the operation without the motor or drive unit. The following shows the procedures.

Setting up without Connecting to the Motor

The axis detach function can be used for servo axis. The detach function cannot be used for spindle.

(1) Set the drive unit rotary switch and "#1021 mcp_no" for the axis that is not connected to the motor.

(2) Set "1" to the parameter "#1070 axoff" for the axis that is not connected to the motor.

(3) Do (a) or (b).

(a) Set "1" to parameter "#8201 AX. RELEASE" for the axis that is not connected to the motor.

(b) Turn ON the control axis detach signal (Y780) for the axis that is not connected to the motor.

Setting up without Connecting to the Drive unit

Set the following parameters.

(1) Set "#1021 mcp_no" (for the servo axis) or "#3031 smcp_n o" (for the spindle axis) to th e axis that is no t

connected to the drive unit.

(2) Set the following parameters to the axis that is not connected to the drive unit.

For the servo axis: Set "1" to "#2018 no_srv".

For the spindle axis: Set "0" to "#3024 sout".

After connecting to the drive unit, make sure to set "#2018 no_srv" to "0" and "#3024 sout" to "1".

18

Page 33

M700VW Series Setup Manual

2.2 Setting the Rotary and DIP Switches

2.2 Setting the Rotary and DIP Switches

L axis

M axis

1-axis

Servo drive unit

(MDS-D/DH -V1)

1-axis

spindle drive unit

(MDS-D/DH-SP)

2-axis

spindle drive unit

(MDS-D-SP2)

2.2.1 MDS-D/DH Series

(1) Setting the rotary switch

Set the axis number with the rotary switch.

2-axis

Servo drive unit

(MDS-D/DH -V2)

#

$

%

&

'

(

#

$

%

&

'

(

#

$

%

&

'

(

MDS-D/DH-V1/V2/SP/SP2 setting

Rotary switch setting Axis No.

01st axis

1 2nd axis

23rd axis

34th axis

45th axis

56th axis

67th axis

78th axis

89th axis

9 10th axis

A 11th axis

B 12th axis

C 13th axis

D 14th axis

E 15th axis

F 16th axis

$

%

&

#

'

(

Power supply un it

(MDS-D/DH -CV)

#

$

%

&

'

(

#

$

%

&

'

(

$

%

&

#

'

(

MDS-D/DH-CV setting

When not using the external emergency stop: Set SW1 to "0"

When using the external emergency stop: Set SW1 to "4"

*Any other settings are prohibited.

19

Page 34

2 Connecting and Setting the Hardware

MITSUBISHI CNC

(2) Setting the DIP switch

(A) (B)

As a standard setting, turn the all DIP switches OFF.

The switches are OFF when facing bottom as illustrated.

Turning these switches ON sets the corresponding axis to the unused axis.

Carry out the unused axis setting when you use the multi-axes drive unit that has any unused axis.

(A) Used to set L axis to an unused axis

(B) Used to set M axis to an unused axis

20

Page 35

M700VW Series Setup Manual

2.2 Setting the Rotary and DIP Switches

2.2.2 MDS-DM Series

<MDS-DM-V3 Series>

(1) Rotary switch settings

Before turning on the power, the axis No. must be set with the rotary switch. The rotary switch settings

will be validated when the drive units are turned ON.

3-axis

Servo drive unit

(MDS-DM-V3)

L axis

8

79

6A

5B

4C

3D

2E

1F

0

M axis

8

79

6A

5B

4C

3D

2E

1F

0

Spindle drive unit

S axis

8

79

6A

5B

4C

3D

2E

1F

0

(MDS-D-SP

8

79

6A

5B

4C

3D

2E

1F

0

Rotary switch setting Axis No.

01st axis

1 2nd axis

23rd axis

34th axis

45th axis

56th axis

67th axis

78th axis

89th axis

9 10th axis

A 11th axis

B 12th axis

C 13th axis

D 14th axis

E 15th axis

F 16th axis

21

Page 36

2 Connecting and Setting the Hardware

MITSUBISHI CNC

(2) Setting the DIP switch

(A)(B) (C)

As a standard setting, turn the all DIP switches OFF.

The switches are OFF when facing bottom as illustrated.

Turning these switches ON sets the corresponding axis to the unused axis.

Carry out the unused axis setting when you use the multi-axes drive unit that has any unused axis.

(A) Used to set L axis to an unused axis

(B) Used to set M axis to an unused axis

(C) Used to set S axis to an unused axis.

<MDS-DM-SPV2/SPV3 Series>

The setting of the axis number is fixed as follows in the MDS-DM-SPV2/SPV3 Series.

Setting the MDS-DM-SPVx Details

1st axis Spindle axis

2nd axis L-axis

3rd axis M-axis

4th axis S-axis (Only MDS-DM-SPV3)

When using the MDS-DM-SPV2/SPV3, MDS-D and MDS-DM-V3 together, the axis numbers for the

MDS-DM-SPV2/SPV3 are fixed as above. Set the axis numbers from 4th axis or 5th axis.

22

Page 37

M700VW Series Setup Manual

2.2 Setting the Rotary and DIP Switches

2.2.3 MDS-D-SVJ3/SPJ3 Series

MDS-D-SVJ3 MDS-D-SPJ3

Set the axis number with the rotary switch.

8

79

6A

5B

4C

3D

2E

1F

0

Rotary switch setting Axis No.

01st axis

1 2nd axis

23rd axis

34th axis

45th axis

56th axis

67th axis

78th axis

89th axis

9 10th axis

A 11th axis

B 12th axis

C 13th axis

D 14th axis

E 15th axis

F 16th axis

4C

8

79

6A

5B

3D

2E

1F

0

23

Page 38

2 Connecting and Setting the Hardware

MITSUBISHI CNC

2.3 Connecting the Batteries

Front cover

Battery holder

Battery

Battery

connector

BAT connector

CAUTION

2.3.1 Control Unit Battery

The battery is not connected when the machine is delivered. Be sure to connect the battery before

starting up.

A lithium battery in the control unit battery holder retains parameter settings, machining programs and the

like, which requires to be backed up at the power OFF.

Battery Q6BAT

Battery cumulative data holding time

Battery life Approx. 5 years (from date of battery manufacture)

[Installation method]

(1) Check that the machine power is turned OFF. (If the power is not OFF, turn it OFF.)

(2) Confirm that the control unit LED, 7-segment display, etc., are all OFF.

(3) Open the battery cover of the control unit. Pull the right side of the battery cover toward front.

(4) Fit the new battery into the battery holder.

(5) Insert the connector connected to the new battery into the BAT connector. Pay attention to the

connector orientation: do not insert backwards.

(6) Close the front cover of the control unit. At this time, confirm that the cover is closed by listening for

the "click" sound when the latch catches.

45,000 hours (At 0 to 45°C. The life will be shorter if the temperature is high.)

[Precautions for handling battery]

24

(1) Do not disassemble the battery .

(2) Do not place the battery in flames or water.

(3) Do not pressurize and deform the battery.

(4) This is a primary battery so do not charge it.

Do not short-circuit, charge, overheat, incinerate or disassemble the battery.

Page 39

M700VW Series Setup Manual

2.3 Connecting the Batteries

2.3.2 Servo Drive Unit Battery

BT1

Battery

To battery holder

Battery connector

Battery connector connection part magnified figure

Connector for

connecting cell battery

Connect the cell battery with BT1.

(Note) The battery connection is not necessary unless the drive unit employs absolute position detection.

(Spindle drive unit does not require the battery, because the unit does not employ ab solute position

detection.)

MDS-D/DH-V1/V2 and MDS-DM-V3

Connect the battery connector to the connector of the dr ive unit.

BTA

1 2 1

1 2

BTB

(Note) There are different types of battery. Refer to the drive unit's specification manual for details.

Type ER6V-C119B A6BAT(MR-BAT)

Installation

type

Hazard class Not applicable

Number of

connectable

Drive unit with battery holder

type

Up to 2 axes

Dedicated case type

Not applicable

(24 or less)

Up to 8 axes

(When using dedicated

axes

case)

MDS-A-BT- □□

Unit and battery integration

type

Class9

(excluding MDS-A-BT-2)

2 to 8 axes Up to 6 axes

Battery change Possible Possible Not possible Possible

(2)

(1)

Battery connector

Appearance

To the battery

holder

バッテリ

Battery

ER6V-C119B

Battery

A6BAT

(MR-BAT)

Dedicated case

MDS-BTCASE

(3)

FCU6-BTBOX-36

Unit and battery integration

type

Not applicable

(4)

25

Page 40

2 Connecting and Setting the Hardware

MITSUBISHI CNC

MDS-DM-SPV2/SPV3

BT1

Battery

To battery holder

Battery

connector

Battery connector connection part magnified figure

Connector for

connecting cell battery

Connect the cell battery with BT1.

BAT

Connect the battery connector to the connector of the drive unit.

BTA

12

12

MDS-D-SVJ3

Connect the battery connector to the connector BAT of the drive unit.

Remove

Install

26

Page 41

M700VW Series Setup Manual

2.4 Connecting and Setting the Remote I/O Unit

2.4 Connecting and Setting the Remote I/O Unit

(F)

DX10* DX11*/12* DX14*

A

2.4.1 Outline of the Remote I/O Unit

There are eight types of remote I/O unit (FCUA-DX***): DX10*, DX11*, DX12* and DX14* (* is "0" or "1").

Specifications are different as shown below. Each unit has one or two rotary switch(es) for unit No. setting,

which links the device Nos. (with X/Y).

Front

(H)

(A)

(A)

(E)

(A)

(B)

(C)

(D)

(B)

(C)

(D)

(A) Left input connector

(B) DIO specification switch

Currently not used. Always set to "OFF".

Front view View from A direction

OFF

(C),(F) Rotary switch

(D) Left output connector

(E) Right input connector

(G) Right output connector

(H) Analog input/output connector

(F)

(G)

(B)

(C)

(D)

27

Page 42

2 Connecting and Setting the Hardware

MITSUBISHI CNC

Bottom

(A)

(B)

(C)

(A) RIO1 (From controller)

(B) RIO2 (To terminating resister or to next RIO unit)

(C) DCIN (24VDC input)

Number of

occupied

stations

Unit type

DX10* (FCUA-DX10*)

DX11* (FCUA-DX11*)

DX12* (FCUA-DX12*)

DX14* (FCUA-DX14*)

Machine control signals that can be

handled

Digital input signal (DI) (Photocoupler

insulation)

Digital output signal (DO) (Non-insulated) 32 points - 32 points

Digital input signal (DI) (Photocoupler

insulation)

Digital output signal (DO) (Non-insulated) 32 points 16 points 48 points

Digital input signal (DI) (Photocoupler

insulation)

Digital output signal (DO) (Non-insulated) 32 points 16 points 48 points

Analog output (AO) - 1 point 1 point

Digital input signal (DI) (Photocoupler

insulation)

Digital output signal (DO) (Non-insulated) 32 points - 32 points

Analog input (AI) - 4 points 4 points

Analog output (AO) - 1 point 1 point

Left Right Total

32 points - 32 points

32 points 32 points 64 points

32 points 32 points 64 points

32 points - 32 points

(Note) "*" in the table is "0" when the output is sink type, and is "1" when the output is source type. The

input is changeable.

1

2

2

2

28

Page 43

M700VW Series Setup Manual

2.4 Connecting and Setting the Remote I/O Unit

2.4.2 Connection and Station No. Setting on Remote I/O Unit

㨪

㨪

RIO1

RIO2

FCUA-R211/SH41

FCUA-R211/SH41

FCU7-MU031/041

FCU7-MA041

FCUA-DX1**

FCUA-DX1**

Station No.1 - 8

Remote I/O unit

Control unit

Station No.1 - 8

Remote I/O 2ch

Max. 8 channels

Max. input: 256 points (X000 to X0FF)

Max. output: 256 points (Y000 to Y0FF)

Max. 8 channels

Max. input: 256 points (X100 to X1FF)

Max. output: 256 points (Y100 to Y1FF)

Remote I/O 1ch

When connecting directly to the control unit

(Note) A remote I/O unit has one or two rotary switch(es) for unit No. setting, which links the device

Nos. (with X/Y).The rotary switch setting is as follows, from "0" to "7".

Station

No.

10

21

32

43

54

65

76

87

Rotary switch

29

Page 44

2 Connecting and Setting the Hardware

MITSUBISHI CNC

When connecting to the operation panel I/O unit

㨪

㨪

FCU7-DX670/671

FCUA-R211/SH41

RIO3

RIO3

G018

OPI

FCUA-R211/SH41

G018

㨪

㨪

FCU7-DX770/771

FCU7-MU031/041, FCU7-MA041

Control unit

Operation panel I/O unit

Max. 5 stations

Max. input: 160 points (X200 to X2BF)

Max. output: 160 points (Y200 to Y2BF)

Max. 4 stations

Max. input: 128 points (X200 to X2BF)

Max. output: 128 points (Y200 to Y2BF)

Remote I/O unit

Input: 32 points (X200 to X2BF)

Output: 32 points (Y200 to Y2BF)

FCUA-DX1**

Input: 64 points (X200 to X2BF)

Output: 64 points (Y200 to Y2BF)

Set one station among

station No. 1 to 6

No. 7 and 8 are

occupied

Set two stations among

station No. 1 to 6

No. 7 and 8 are

occupied

Remote I/O 3ch

Remote I/O 3ch

Max. 5 stations

among No. 1 to 6

Max. 4 stations

among No. 1 to 6

0

1

F

2 E

D

3

4 C

B

5

6 A

7 9

8

0

1

F

D

B

8

0

1

F

2 E

3

4 C

5

6 A

7 9

2 E

D

3

4 C

B

5

6 A

7 9

8

(Note) Operation panel I/O unit occupies one or two stations among station No. 1 to 6. (Station No. 7

0

1

F

2 E

3

D

4 C

5

B

6 A

7 9

8

0

1

F

2 E

3

D

4 C

5

B

6 A

7 9

8

0

1

F

D

B

8

0

1

F

2 E

6 A

7 9

2 E

3

D

4 C

5

3

4 C

B

5

6 A

7 9

8

and 8 are reserved for manual pulse generator.)

Therefore, RIO3 can use five or four stations from No. 1 to 6.

30

Page 45

M700VW Series Setup Manual

2.4 Connecting and Setting the Remote I/O Unit

2.4.3 Station No. Setting when Using Multiple Remote I/O Units

0

㧗

FCUA-DX100/101

0

1

2

㧗

㧗

FCUA-DX100/101

FCUA-DX110/111

or

FCUA-DX120/121

Multiple remote I/O units can be used, as long as the total No. of occupied stations connected with serial

links is eight or less. (four/five or less when connected to the operation panel I/O unit).

Unit type Number of occupied stations

FCUA-DX10* 1

FCUA-DX11* 2

FCUA-DX12* 2

FCUA-DX14* 2

When using multiple remote I/O units, a characteristic station No. must be set for each unit. The FCUADX10* unit has one rotary switch, FCUA-DX11*, DX12* and DX14* unit have two. Each of these

switches must be set to a characteristic station No. within a range of 0 to 7 (0 to 5 when connected to

the operation panel I/O unit).

When connecting directly to the control unit

Setting example 1

Total number of occupied stations: 1

Setting example 2

Number of occupied stations: 1 2

Total number of occupied stations: 3

31

Page 46

2 Connecting and Setting the Hardware

MITSUBISHI CNC

Setting example 3

0 1

㧗 㧗 㧗

㧗

2 3

4 5

6 7

FCUA-DX110/111

or

FCUA-DX120/121

Number of occupied stations: 2 2 2 2

Total number of occupied stations: 8 (Maximum configuration)

32

Page 47

M700VW Series Setup Manual

2.4 Connecting and Setting the Remote I/O Unit

When connecting to the operation panel I/O unit

㧗

FCUA-DX100/101

1

FCU7-DX670/671

4

5

2

3

FCU7-DX670/671

㧗

㧗

FCUA-DX110/111

or

FCUA-DX120/121

FCUA-DX110/111

or

FCUA-DX120/121

㧗

FCUA-DX100/101

1

Operation panel I/O unit occupies one or two stations among station No. 1 to 6. (Station No. 7 and 8 are

reserved for manual pulse generator.)

Therefore, RIO3 can occupy up to five or four stations, as shown below.

Operation panel I/O unit

type

Max. number of stations

(RIO3 connection)

Max. number of I/O

points (RIO3

connection)

Remote I/O

Rotary switch

Setting range

FCU7-DX670/671 5 channels 160 points/160 points 0 to 5

FCU7-DX770/771 4 channels 128 points/128 points 0 to 5

Setting example 1

0

1

0

1

F

2 E

3

D

4 C

5

B

6 A

7 9

8

F

2 E

D

3

4 C

B

5

6 A

7 9

8

Number of occupied stations: 1

Total number of occupied stations: 1

Setting example 2

0

1

0

1

F

2 E

3

D

4 C

5

B

6 A

7 9

8

F

2 E

D

3

4 C

B

5

6 A

7 9

8

Number of occupied stations: 1 2 2

Total number of occupied stations: 5 (Maximum configuration)

33

Page 48

2 Connecting and Setting the Hardware

MITSUBISHI CNC

Setting example 3

㧗

4

5

FCU7-DX770/771

FCUA-DX110/111

or

FCUA-DX120/121

㧗

FCUA-DX110/111

or

FCUA-DX120/121

2

3

0

1

0

1

F

2 E

3

D

4 C

5

B

6 A

7 9

8

0

1

F

2 E

3

D

4 C

5

B

6 A

7 9

8

F

2 E

3

D

4 C

5

B

6 A

7 9

8

0

1

F

2 E

D

3

4 C

B

5

6 A

7 9

8

Number of occupied stations: 2 2

Total number of occupied stations: 4 (Maximum configuration)

34

Page 49

M700VW Series Setup Manual

2.4 Connecting and Setting the Remote I/O Unit

2.4.4 Device No. Assignment

The devices used by the PLC are determined as follows after the station Nos. are set with the rotary

switches.

Rotary switch No.

0 X00 to X1F Y00 to Y1F(Y0F)

1 X20 to X3F Y20 to Y3F(Y2F)

2 X40 to X5F Y40 to Y5F(Y4F)

3 X60 to X7F Y60 to Y7F(Y6F)

4 X80 to X9F Y80 to Y9F(Y8F)

5 XA0 to XBF YA0 to YBF(YAF)

6 XC0 to XDF YC0 to YDF(YCF)

7 XE0 to XFF YE0 to YFF(YEF)

Rotary switch No.

0 X100 to X11F Y100 to Y11F(Y10F)

1 X120 to X13F Y120 to Y13F(Y12F)

2 X140 to X15F Y140 to Y15F(Y14F)

3 X160 to X17F Y160 to Y17F(Y16F)

4 X180 to X19F Y180 to Y19F(Y18F)

5 X1A0 to X1BF Y1A0 to Y1BF(Y1AF)

6 X1C0 to X1DF Y1C0 to Y1DF(Y1CF)

7 X1E0 to X1FF Y1E0 to Y1FF(Y1EF)

Device No. read in Output device No. Analog output (AO)

RIO channel 1 RIO channel 1 RIO channel 1

The rotary switches

correspond to the file

registers R200 to R207 in

order of small numbers.

Device No. read in Output device No. Analog output (AO)

RIO channel 2 RIO channel 2 RIO channel 2

The rotary switches

correspond to the file

registers R200 to R207 in

order of small numbers.

Rotary switch No.

0 X200 to X21F Y200 to Y21F(Y20F)

1 X220 to X23F Y220 to Y23F(Y22F)

2 X240 to X25F Y240 to Y25F(Y24F)

3 X260 to X27F Y260 to Y27F(Y26F)

4 X280 to X29F Y280 to Y29F(Y28F)

5 X2A0 to X2BF Y2A0 to Y2BF(Y2AF)

6-7--

Device No. read in Output device No. Analog output (AO)

RIO channel 3 RIO channel 3 RIO channel 3

The rotary switches

correspond to the file

registers R200 to R205 in

order of small numbers.

The values shown in parentheses are the device range of the card mounted to the right side of the unit.

(Note) When the analog output is equipped to several RIO channels, maximum of four RIO channels will

be valid in the following order of priority.

(1) RIO channel 1, (2) RIO channel 2, (3) RIO channel 3

35

Page 50

2 Connecting and Setting the Hardware

MITSUBISHI CNC

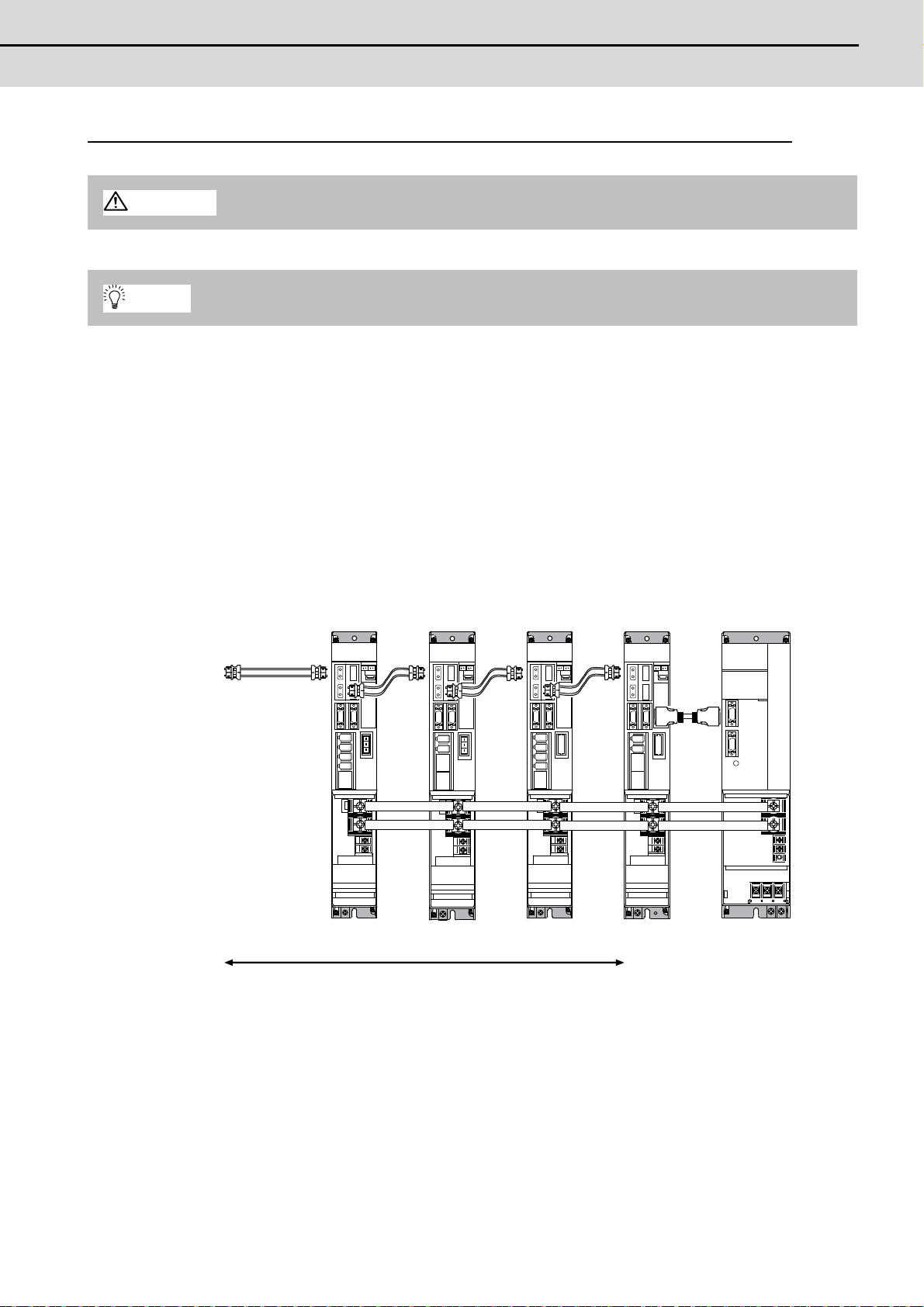

2.5 Initializing the NC Internal Data (SRAM)

A

A

A

A

The initialization does not affect the settings of the option parameters.

(1) With the NC power OFF, turn the left rotary switch (CS1) to "0" and the right rotary switch (CS2) to "C".

Then, turn the power ON.

LED1 LED2

0

1

F

D

B

2 E

3

4 C

5

6

7 9

8

CS1 CS2

0

1

F

D

B

2 E

3

4 C

5

6

7 9

8

(2) The LED display will change to "08." -> "00" -> "01" -> ... "08". The process is completed when "0Y" is

displayed.

LED1 LED2

(3) Turn the NC power OFF.

(4) Set the right rotary switch (CS2) to "0".

D

B

LED1 LED2

0

1

F

7 9

8

0

1

F

2 E

D

3

4 C

B

5

6

2 E

3

4 C

5

6

7 9

8

CS1 CS2

(5) Turn the power ON again.

36

Page 51

M700VW Series Setup Manual

2.5 Initializing the NC Internal Data (SRAM)

(Note 1) After the initializing and the NC power ON, the IP address is initialized as follows.

<Base specification parameter>

#1934 Local IP address: 192.168.100. 1

Failure to communicate with the screen may be caused by inconsistency between the parameter

value and the "C:\WINDOWS\melcfg.ini" setting value. Confirm that "C:\WINDOWS\melcfg.ini" is

set as shown below.

Last line of C:\WINDOWS\melcfg.ini

...

[HOSTS]

TCP1=192.168.100.1,683

(Note 2) The initial screen after the initialization is displayed in English. Refer to "Setting on the System

Setup Screen" for how to set a language to display.

37

Page 52

2 Connecting and Setting the Hardware

MITSUBISHI CNC

38

Page 53

39

3

Setting the Parameters

and Date/Time

Page 54

3 Setting the Parameters and Date/Time

MITSUBISHI CNC

Confirm the emergency stop state before carrying out the steps in this chapter.

WARNING

3.1 Setting on the System Setup Screen

Set the following items on the system setup screen.

- Displayed language and the number of spindle connections

- Number of axes and command type for each part system

- Servo I/F connection channel and rotary switch setting for each spindle, as well as types of the

motor and the power supply connected to each spindle drive

- Servo I/F connection channel and rotary switch setting for each servo axis, as well as types of the

motor, encoder, and the power supply connected to each servo drive

(1) Enter the password on the Mainte screen.

(a) On the Mainte screen, select [Mainte] and then [Psswd input].

(b) Enter "MPARA" in the setting area and press the INPUT key.

(Note 1) To enter the character "A", press the shift key and then "A" key. Do not press both keys at the

same time.

(2) Select a displayed language.

(a) Press the cancel key to return to the Mainte screen. Select [Mainte] and then [System Setup].

(b) Set the No. of the language to display in "language displayed".

40

Page 55

M700VW Series Setup Manual

3.1 Setting on the System Setup Screen

(3) Carry out the spindle and servo axis settings. Set the following items.

Common setting

Number of spindles:

Set the number of spindles connected to the NC. This setting is registered at "#1039 spinno

(Number of spindles)".

Number of MR-J2-CT:

Set the number of auxiliary axes connected to the NC. This setting is registered at "#1044

auxno".

Setting by system

Number of axes:

Set the number of axes for each part system and PLC. This setting is registered at "#1002

axisno (Number of axes)".

(Note) A setting error occurs if a value "1" or higher is set for any of the 2nd to 4th part

systems while the setting for the previous part system is "0".

Command type:

Set the command type for each part system. This setting is registered at "#1037 cmdtyp

(Command type)".

(Note) Although this can be set individually for each part system, it will be shared by the

entire part system if specified for the machining center.

Setting by spindle area

Ch / Rotary SW No.:

Set the servo I/F connection channel and the rotary switch No. (2-digit value) for each spindle

drive unit. This setting is registered at "#3031 smcp_no (Drive unit I/F channel No. (spindle))".

1st digit: Servo I/F connection channel

2nd digit: Rotary switch No.

Motor type:

Set the motor types that are connected to each spindle. Input the values as indicated at the

guidance display area. The input values are not converted to motor types.

Power Supply type:

Set the power supply types that are connected to each spindle drive unit.

Input the values as indicated at the guidance display area. The input value s are then converted

to, and displayed as, power supply types. "0" means "No connection".

Setting by servo

Ch / Rotary SW No.:

Set the servo I/F connection channel and the rotary switch No. (2-digit value) for each servo

drive unit. This setting is registered at "#1021 mcp_no (Drive unit I/F channel No. (servo))".