Mitsubishi Electronics WD-62531 User Manual 2

20062006

2006

20062006

SerSer

Ser

SerSer

vicevice

vice

vicevice

MITSUBISHI ELECTRIC

ManualManual

Manual

ManualManual

LCD PROJECTION HDTV

V32/V32L CHASSIS

V32 Chassis

WD-52327

WD-52531

CAUTION:

Before servicing this chassis, it is important that the service person read the "SAFETY PRECAUTIONS" and

"PRODUCT SAFETY NOTICE" contained in this manual.

SPECIFICATIONS

• Power Input : AC 120V, 60Hz

• Power Usage : 225W

• Light Engine : 3 LCD (1280 x 720 pixels)

• Light Source : 132 Watts

• Antenna Input : 2 RF 75Ω unbalanced

• Tuning : 1 NTSC/A TSC/QAM

• Cabinet Dimensions

: [WD-52531]

33.1"(H) x 47.1"(W) x 16.9"(D)

: [WD-62530]

39.1"(H) x 55.9"(W) x 19.2"(D)

: [WD-62531]

39.1"(H) x 55.9"(W) x 19.2"(D)

) W

WD-52531

WD-62531

Pb Solder

• Input Level : VIDEO IN JACK (RCA T ype)

1.0Vp-p 75Ω unbalanced

: AUDIO IN JACK (RCA T ype)

-4.7dBm 43kΩ unbalanced

: S-VIDEO IN JACK

(Y/C separate type)

Y:1.0 Vp-p C:0.286Vp-p(BURST)

75Ω unbalanced

: COMP / Y , Cr, Cb (RCA T ype)

Y: 1.0 Vp-p Cr, Cb: 700mVp-p

• Output Level : VIDEO OUT JACK (RCA T ype)

1.0Vp-p 75Ω unbalanced

: AUDIO OUT JACK (RCA T ype)

-4.7dBm 4.7kΩ unbalanced

V32L Chassis

WD-62530

• Weight : [WD-52531]

82.5 lbs

: [WD-62530] [WD-62531]

99.3 lbs

• Speakers (4 Ohms 10W)

: 2-5 ½ x 2 ¼ inch

• Design specifications are subject to change without notice.

MITSUBISHI DIGITAL ELECTRONICS AMERICA, INC.

9351 Jeronimo Road, Irvine, CA 92618-1904

Copyright © 2006 Mitsubishi Digital Electronics America, Inc.

All Rights Reserved

• Digital : AC-3 Digital Audio Output

(RCA T ype)

TM

: HDMI

: Lead-Free solder PWBs

Pb Solder

.

MODEL: WD-52531 / WD-62531 / WD-62530

CONTENTS

INTRODUCTION ................................................................................................................................5

Dimensions, weight, power usage, etc............................................................................................5

PRODUCT SAFETY NOTICE .............................................................................................................5

SAFETY PRECAUTIONS .................................................................................................................6

DISASSEMBL Y .................................................................................................................................. 7

Rear Cover Removal ........................................................................................................................ 7

Chassis Removal and Disassembly ................................................................................................7

LCD Engine Removal ....................................................................................................................10

Front Disassembly.............................................................................................................. .......... 13

Lenticular Screen and Fresnel Lens Removal and Replacement....................................................14

ADJUSTMENTS ...............................................................................................................................15

Option Menu & Remote Control ....................................................................................................15

Digital Signal Strength................................................................................................................... 15

Front Panel Initialization................................................................................................................ 16

Defaults ........................................................................................................................................17

A/V Defaults .................................................................................................................................18

LED Indicator Diagnostics............................................................................................................. 18

Error Codes Operational Check..................................................................................................... 19

Error Codes List................................................................................................................... 19

Lamp Troubleshooting ................................................................................................................... 20

Lamp Control diagram.......................................................................................................... 21

Lamp Troubleshooting Flow Chart ........................................................................................21

Service Adjustment Mode ............................................................................................................. 22

Service Adjustment Mode Operation ....................................................................................23

Transferring data ..................................................................................................................23

Optical Engine Adjustment............................................................................................................ 23

T est Signal activation ........................................................................................................... 23

Preliminary .......................................................................................................................... 23

Rotation and Keystone Distortion Adjustment ............................................................................... 24

After completing Light Engine Adjustments .......................................................................... 24

Horizontal & V ertical Position............................................................................................... 25

USING LEAD FREE SOLDER .......................................................................................................... 26

CHIP P ARTS REPLACEMENT ......................................................................................................... 27

REPLACEMENT P ARTS .................................................................................................................. 28

Parts Ordering .............................................................................................................................. 28

Critical and Warranty Parts Designation........................................................................................28

Parts T olerance Codes.................................................................................................................. 28

Quick Reference List ........................................................................................................................29

SERVICE PARTS LIST .................................................................................................................... 30

SCREEN ASSEMBL Y PARTS LIST.................................................................................................. 37

CIRCUITRY BLOCK DIAGRAMS ..................................................................................................... 38

Main Power Supply....................................................................................................................... 38

LCD Light Engine & Fan Power Supplies ...................................................................................... 39

DC to DC Supplies........................................................................................................................ 39

Analog Video Signal Path ............................................................................................................. 40

Page 3

MODEL: WD-52531 / WD-62531 / WD-62530

Digital Video Signal Path .............................................................................................................. 41

Sound Signal Path ........................................................................................................................ 42

Overall Control Circuitry ................................................................................................................ 43

Command Input Circuitry............................................................................................................... 44

Lamp Control Circuitry ..................................................................................................................44

LCD Engine Protect Circuitry ........................................................................................................ 45

Short Protect Circuit ..................................................................................................................... 45

Auto Input Detection ..................................................................................................................... 46

SCHEMA TIC DIAGRAMS .....................................................................................................................

Dolby and Dolby digital are registered trademarks of Dolby Laboratories.

DTV Link is a trademark of Consumer Electronics Association

HDMI, the HDMI logo and High-Definition Multimedia Interface are trademarks or registered trademarks of HDMI Licensing, LLC.

Page 4

MODEL: WD-52531 / WD-62531 / WD-62530

INTRODUCTION

This service manual provides service instructions for LCD Projection TV Models WD-52531 and WD-62531 using the

V32 chassis, and WD-62530 using the V32L chassis.

This service manual includes:

1. Assembly and disassembly instructions for the front and rear cabinet components.

2. Servicing of the Lenticular Screen and Fresnel Lens.

3. Servicing down to major components, chassis, PWBs, Light Engine, Lamp Ballast, etc..

4. Electrical adjustments.

5. Optical Adjustments.

6. Lead Free Soldering.

7. Chip parts replacement procedures.

8. Simplified circuit path diagrams.

The parts list section of this service manual includes:

1. Cabinet and screen parts.

2. Electrical parts.

Block diagrams of the above listed models are included in this service manual for better understanding of the circuitry .

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in television receivers have special safety related characteristics. These characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily be obtained by

using replacement components rated for higher voltage, wattage, etc.

Replacement parts which have special safety characteristics are identified in this service manual.

Electrical components having such features are identified by shading on the schematic diagram and by bold type in

the parts list of this service manual. Therefore, the replacement for any safety part should be identical in value

and characteristics.

The PWBs used in the V32 chassis are constructed using Lead-Free solder. When servicing use

Pb Solder

only recommended Lead-Free solder (refer to page 26).

Page 5

MODEL: WD-52531 / WD-62531 / WD-62530

SAFETY PRECAUTIONS

NOTICE: Observe all cautions and safety related notes located inside the receiver cabinet and on the

receiver chassis.

WARNING:

1. Operation of this receiver outside the cabinet or with the cover removed presents a shock hazard

from the receiver's power supplies. Work on the receiver should not be attempted by anyone who is

not thoroughly familiar with the precautions necessary when working on high voltage equipment.

2. When service is required, observe the original lead dress. Extra precaution should be taken to

assure correct lead dress in the high voltage area. Where a short-circuit has occurred, replace those

components that indicate evidence of overheating.

WARNING ... RISK OF EYE INJUR Y

Do not look into the light source, lens or mirror when operating the TV

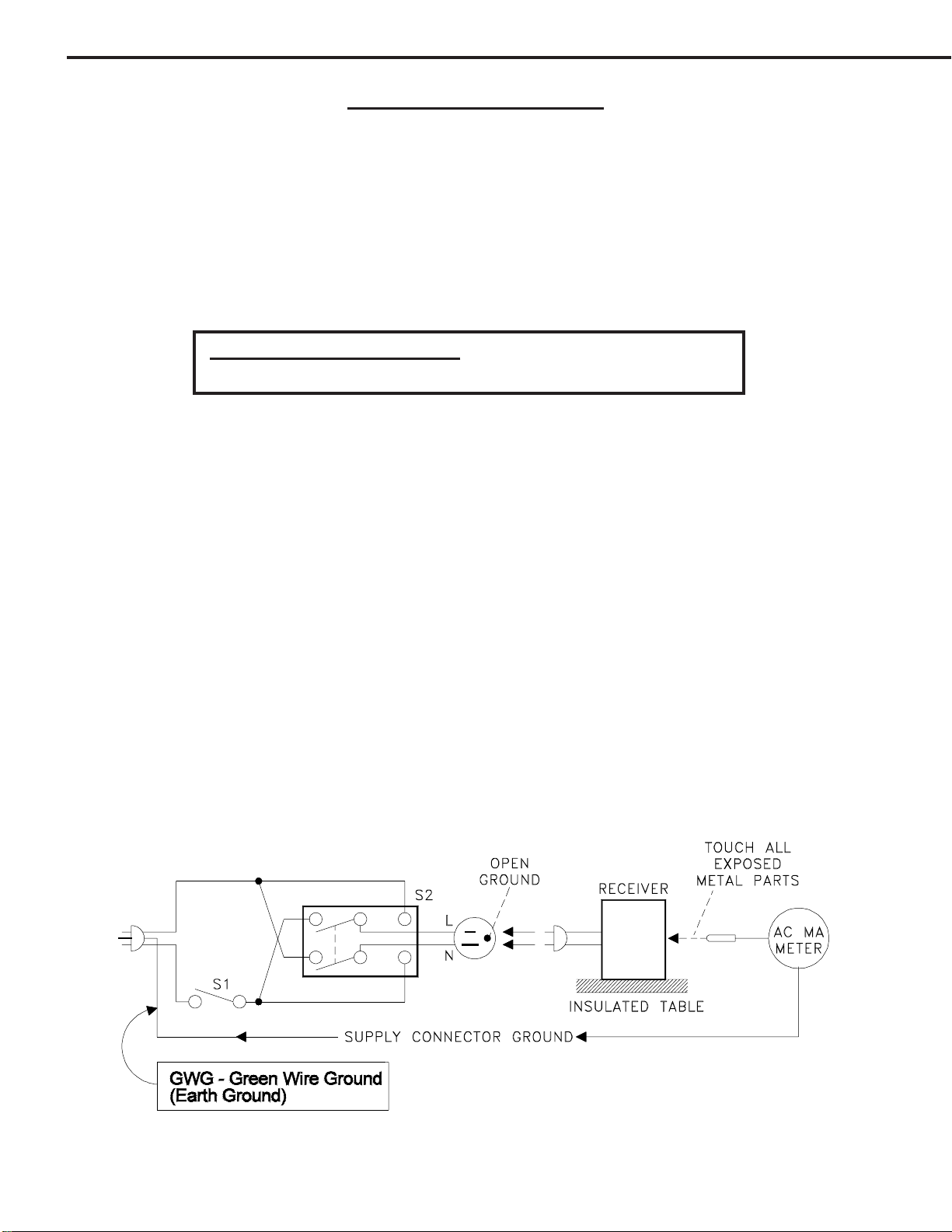

Leakage current check

Before returning the receiver to the customer, it is recommended that leakage current be measured according to the

following methods.

1. Cold Check

With the alternating current (AC) plug removed from the AC source, place a jumper across the two AC plug

prongs. Connect one lead of an ohm meter to the AC plug and touch the other lead to each exposed metal part

(i.e. antennas, handle bracket, metal cabinet, screw heads, metal overlay , control shaf ts, etc.), particularly any

exposed metal part that has a return path to the chassis. The resistance of the exposed metal parts having a

return path to the chassis should be a minimum of 1Meg Ohm. Any resistance below this value indicates an

abnormal condition and requires corrective action.

2. Hot Check ...Use the circuit shown below to perform the hot check test.

1. Keep switch S1 open and connect the receiver to the measuring circuit. Immediately after

connection, and with the switching devices of the receiver in their operating positions, measure the

leakage current for both positions of switch S2.

2. Close switch S1, energizing the receiver . Immediately after closing switch S1, and with the

switching devices of the receiver in their operating positions, measure the leakage current for both

positions of switch S2. Repeat the current measurements of items 1 and 2 after the receiver has

reached thermal stabilization. The leakage current must not exceed 0.5 milliampere (mA).

Page 6

MODEL: WD-52531 / WD-62531 / WD-62530

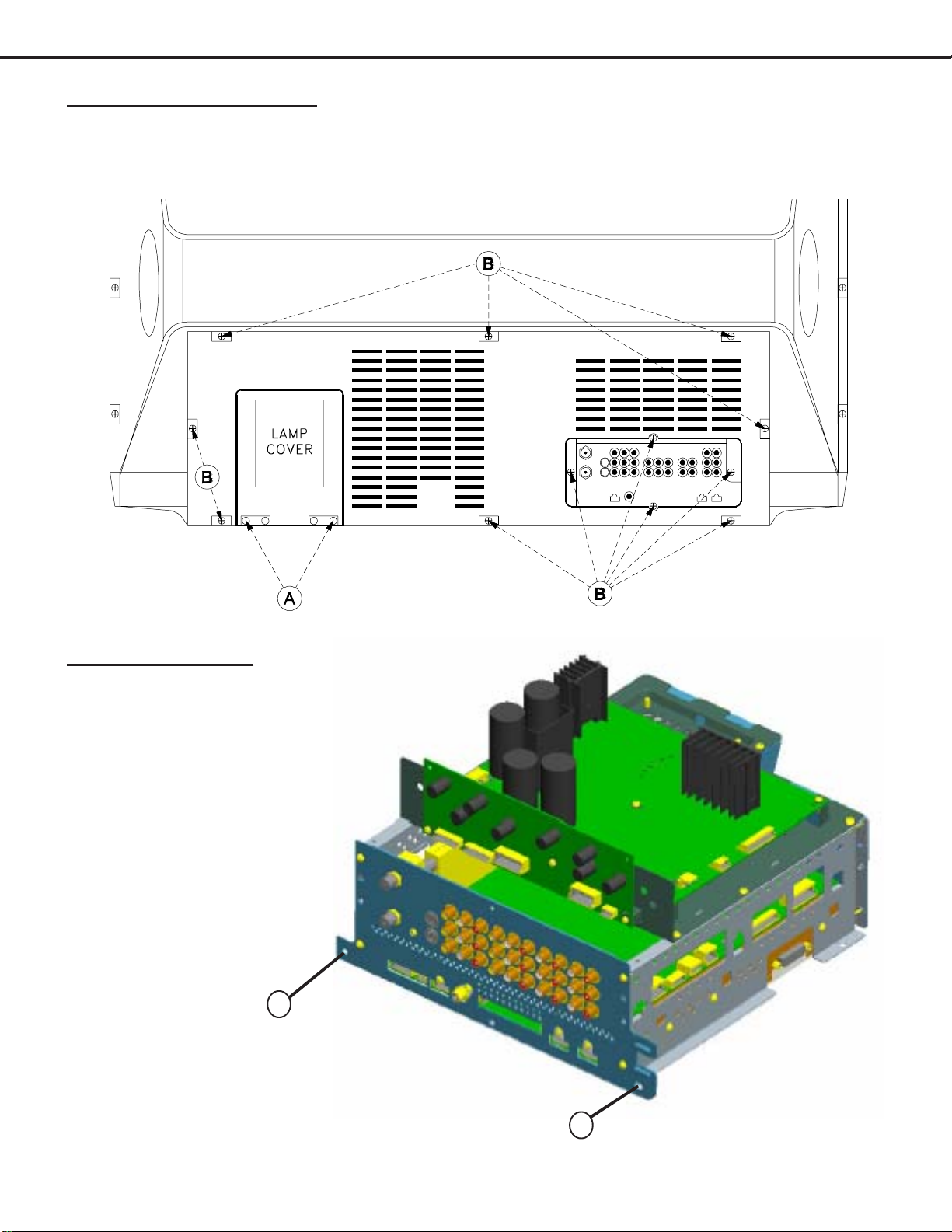

BACK-COVER Removal

1 ) Remove 2 screws (A) to remove the Lamp Cover

2 ) Remove 12 screws (B).

3 ) Pull the COVER-BACK from the cabinet.

NOTE: To operate the TV the Lamp Cover must be reinstalled after the back cover is removed.

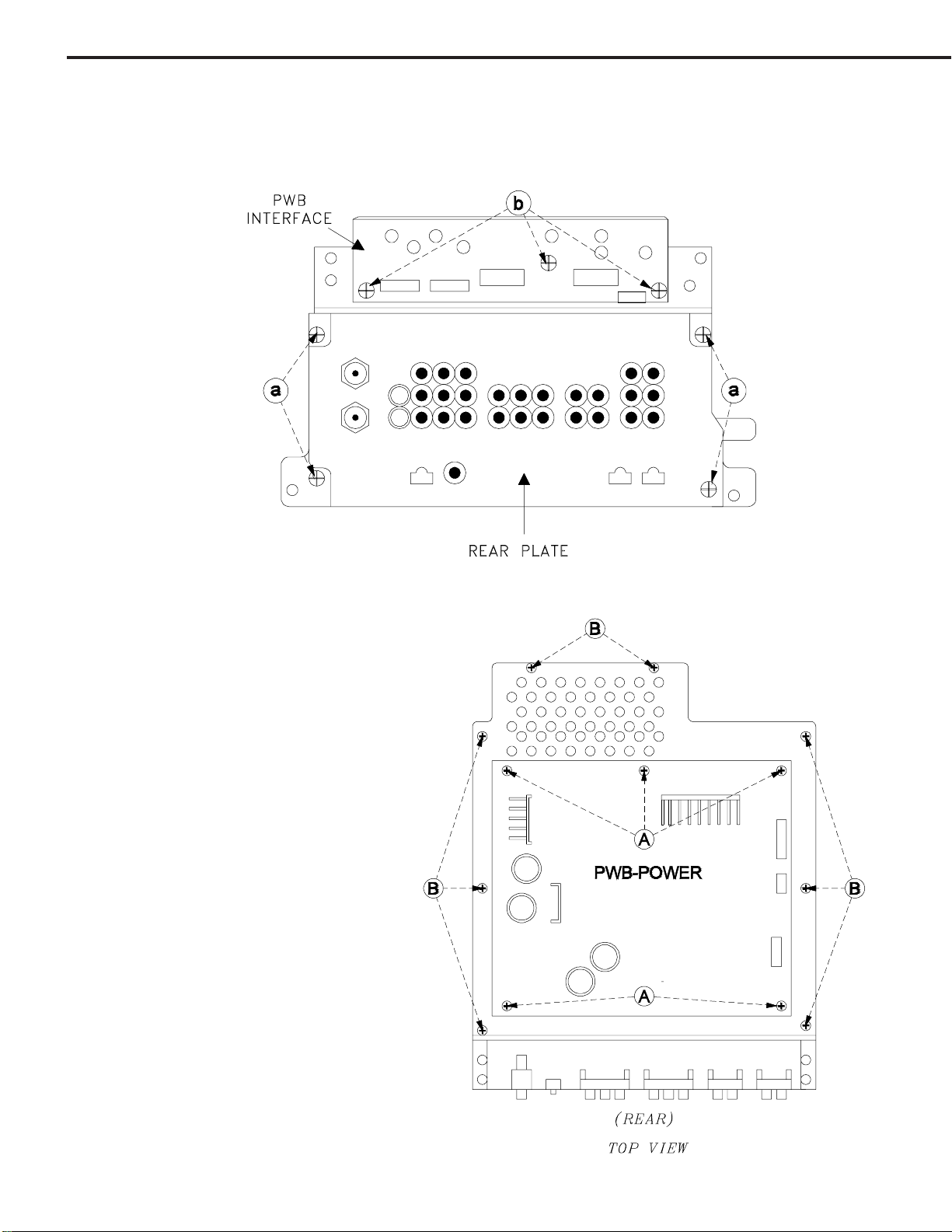

Chassis Removal

1 ) Remove 2 screws (C).

2 ) Disconnect all cables connected to the

chassis.

3 ) Carefully slide the chassis from the

cabinet

C

Page 7

C

MODEL: WD-52531 / WD-62531 / WD-62530

Rear Plate & PWB-INTERFACE Removal

1 ) Remove 4 screws (a) and pull off the rear plate.

2 ) Remove 3 screws (b) to remove the PWB-INTERF ACE

PWB-POWER & Power Bracket

Removal

1 ) Remove 4 screws (A) and lift PWB-

POWER from the chassis.

2 ) Remove 8 screws (B) to remove the

Power Bracket.

Page 8

MODEL: WD-52531 / WD-62531 / WD-62530

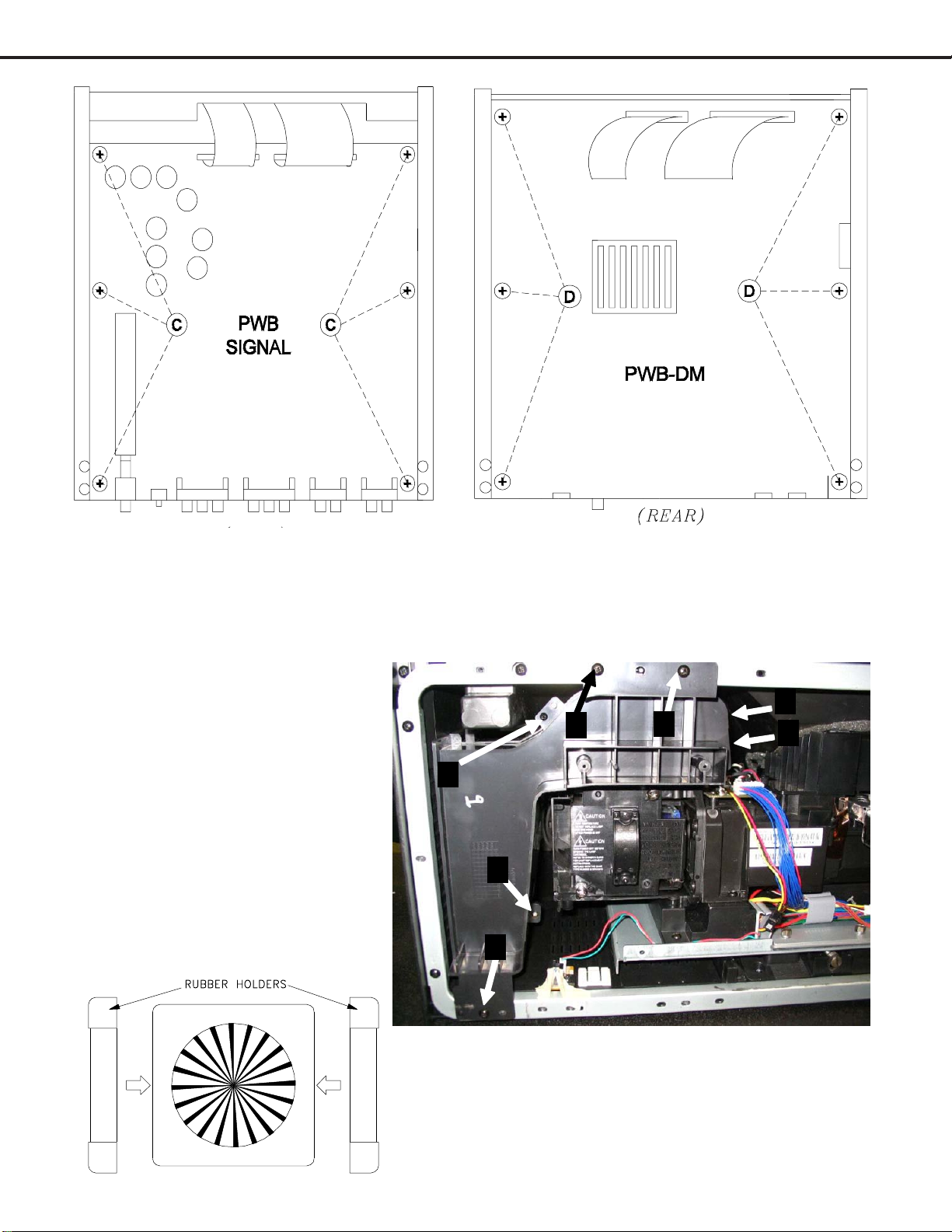

PWB-SIGNAL Removal

1 ) Remove 6 screws (c).

2 ) Unplug all connecting cables.

3) Remove PWB-SIGNAL

If PWB-SIGNAL is replaced, see page 22 to

perform "Download WB Data to FMT"

Exhaust Fan Replacement

1 ) Remove 7 screws (A) to

remove the lamp duct rear

cover.

2 ) Slide the Exhaust Fan from

the duct and unplug the JF

connector . Remove the

rubber fan holders, they do

not come with the replacement fan.

3 ) When installing the fan

insert the fan in the removed cover first.

4 ) Insure the leads come out

the bottom of the fan and

the label on the fan is

facing upwards.

PWB-DM Removal

1) Remove 6 screws (D).

2) Unplug all connecting cables.

3) Lift PWB-DM from the chassis.

If PWB-DM is replaced, see page 22 to

perform "Copy Light Engine E2PROM to DM"

A

A

A

A

A

A

A

Page 9

MODEL: WD-52531 / WD-62531 / WD-62530

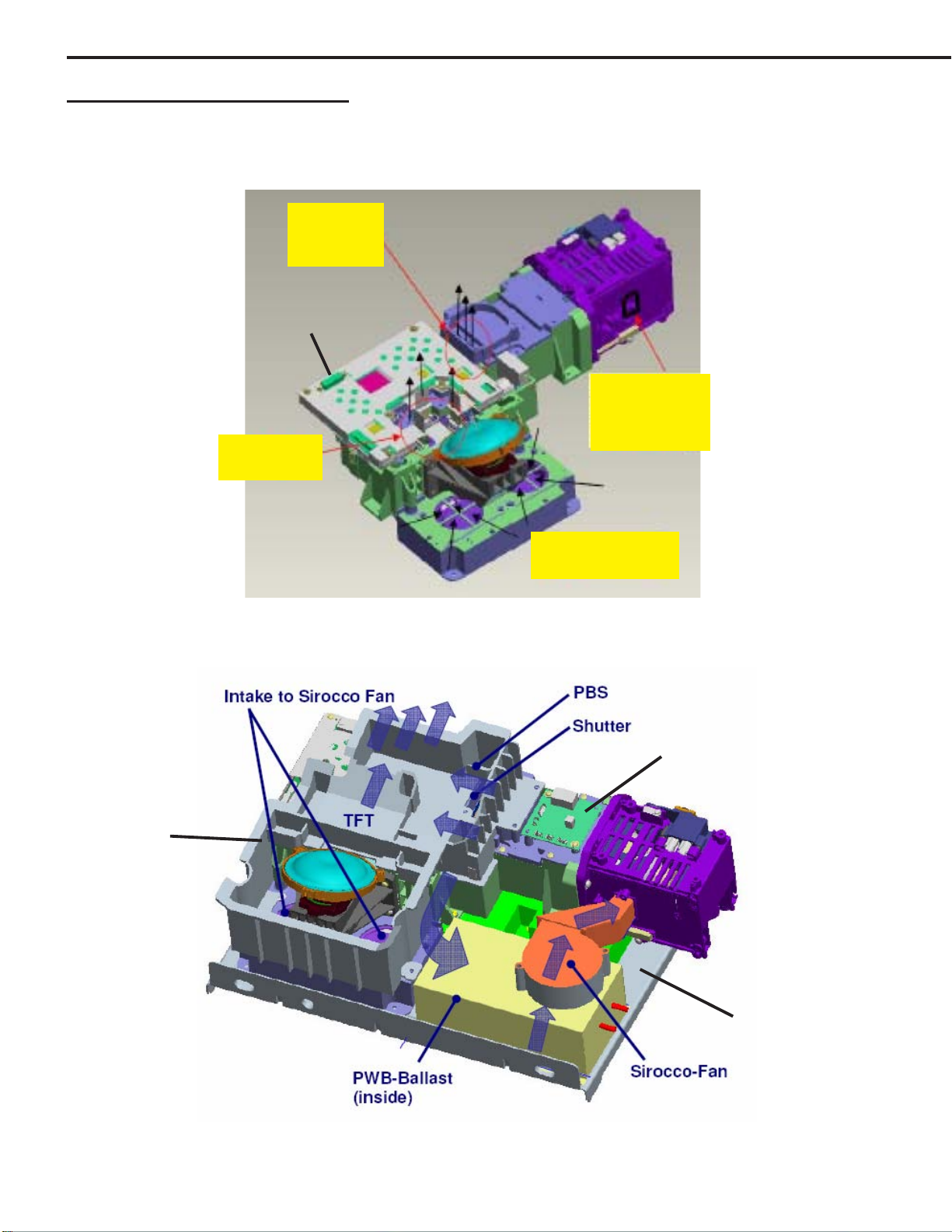

Light Engine Replacement

Light Engine and Associated Components

The picture below shows the LCD Engine without added components, and the bottom picture shows the added

components and the Engine mounted on the Engine Plate.

Polarized

Beam

Splitter

Side hole for

lamp cooling.

LCD panel

area.

Induction

cover

LCD Engine

Two induction

fans.

Note: The Engine has no individual

service parts available. Attempting

to disassemble the Engine may void

the warranty.

PWB-MTR-DRIVE

(Relay Board)

LCD Engine on engine plate

Page 10

Engine

Plate

MODEL: WD-52531 / WD-62531 / WD-62530

Light Engine & Engine Plate removal from the Cabinet

Preliminary

Refer to the chassis removal procedure and remove the BACK-COVER.

Removal Procedure

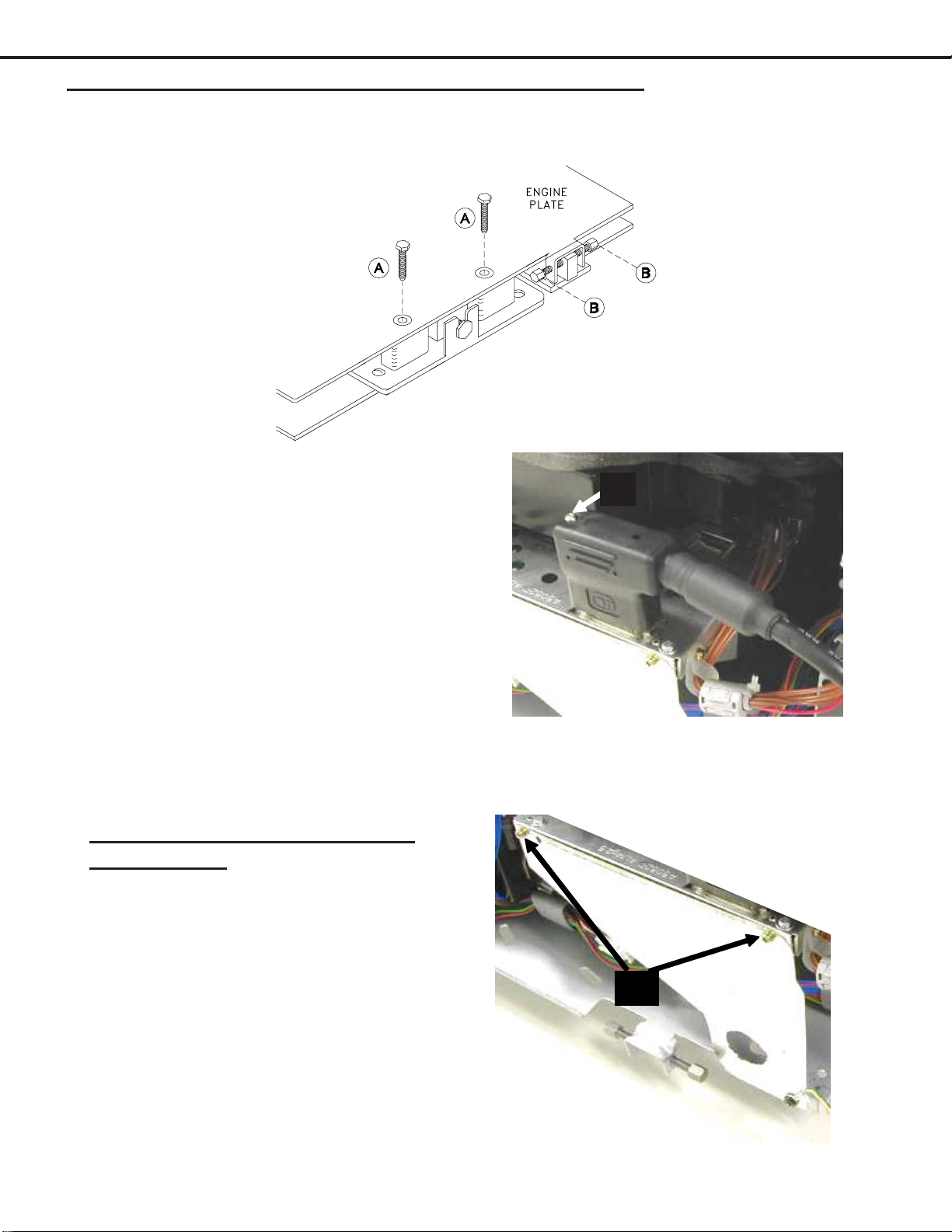

1 ) Remove the 2 locking screwss (A).

2 ) Loosen one (B) adjustment screw.

(With only one (B) screw loose less

adjustment is required when

installing a new Engine.)

3 ) Partially slide the Engine and

bottom plate out of the cabinet.

4 ) Loosen screw (C) and unplug the

DVI cable from the Engine.

5 ) Disconnect all leads to the Engine,

Lamp Box and Ballast.

6 ) Carefully slide the Engine and

bottom plate from the cabinet.

(c)

Light Engine removal from the

Bottom Plate

1 ) Remove 2 screws (D) secure the support plate

to the Engine.

(D)

Page 11

MODEL: WD-52531 / WD-62531 / WD-62530

Light Engine removal from the Bottom Plate (continued)

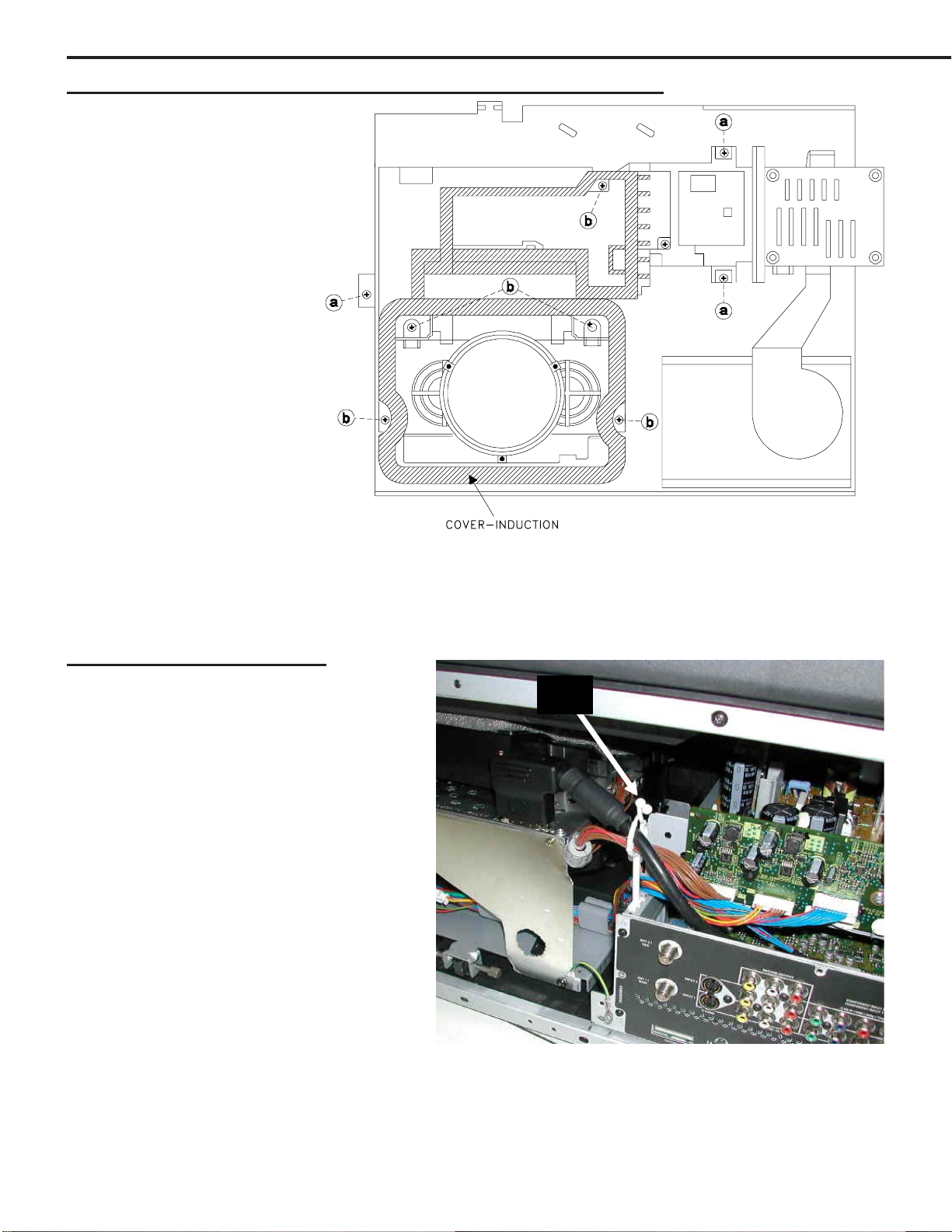

2 ) T o remove the Engine from

the bottom plate, remove 3

screws (a), and carefully lift

the Engine from the bottom

plate.

3) T o remove the COVERINDUCTION from the Engine

5 screws (b).

Light Engine Inst

1) Reverse the removal procedure to

install a new light engine.

2) Tighten the DVI cable screw to 2-4 kgfcm.

3) Route the DVI cable and the KA-CN201

leads through the cable clamp as shown on

the right.

If Light Engine is replaced, see page 22 to perform

"Copy Light Engine E2PROM to DM"

allation

CABLE

CLAMP

Page 12

MODEL: WD-52531 / WD-62531 / WD-62530

Front Disassembly

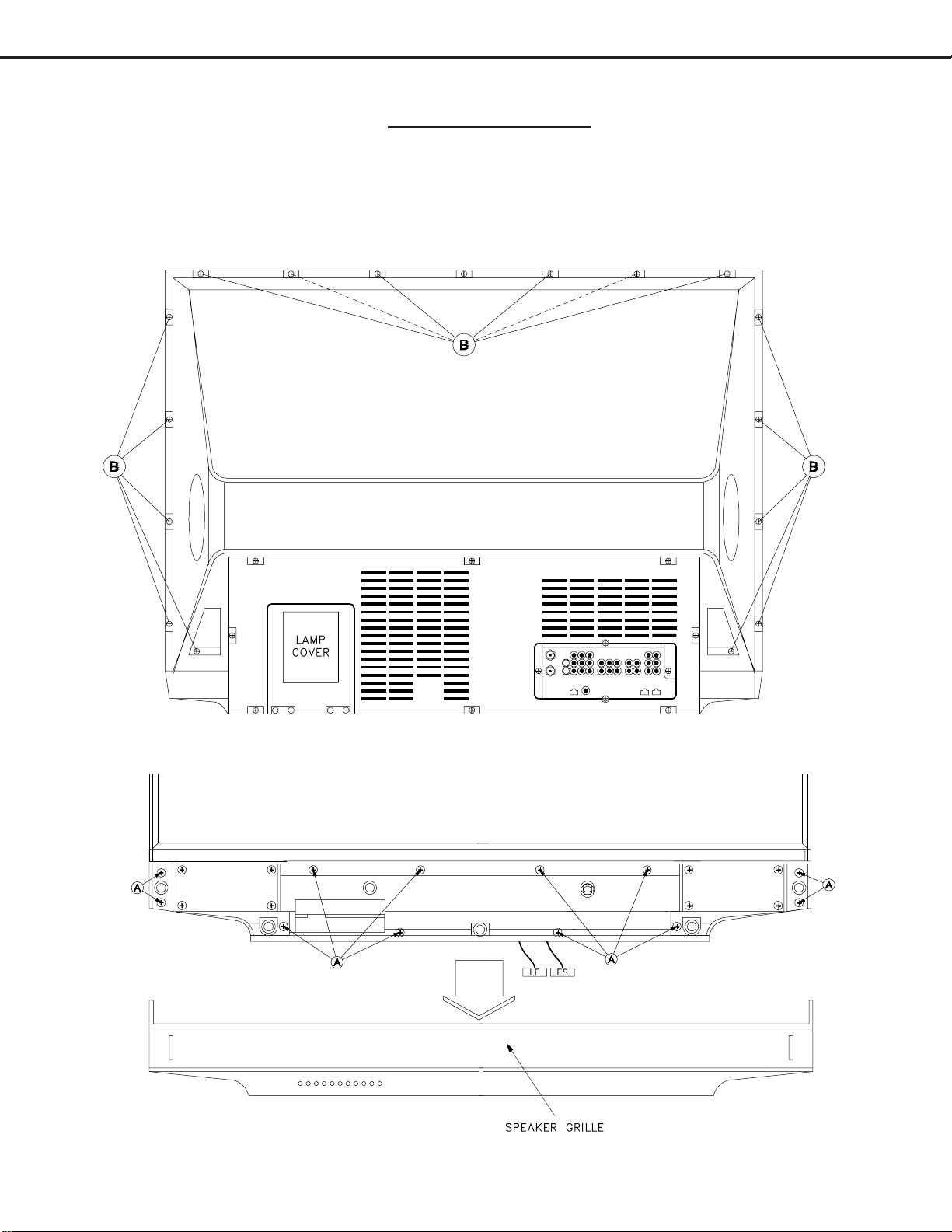

Screen Frame Removal

1 ) Pull off the Speaker Grill.

2 ) Remove all screws (B) from the upper rear cover (except one screw at a upper corner). The remaining screw

supports the screen frame while removing the front screws.

3 ) Remove all screws (A) from the front of the screen frame.

4 ) Carefully pull the Screen Frame from the TV and disconnect the ES and LE connectors.

Page 13

MODEL: WD-52531 / WD-62531 / WD-62530

Screen Replacement

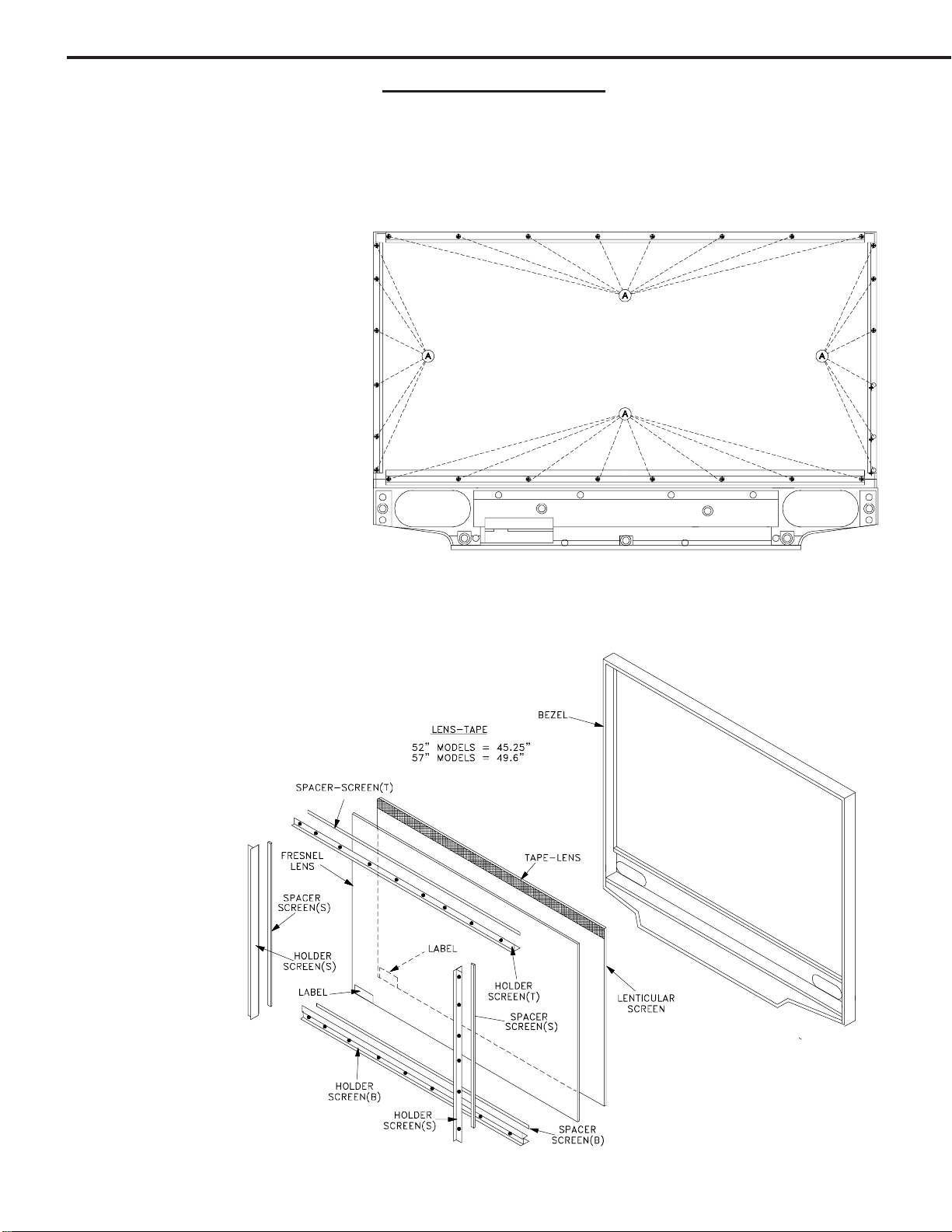

CAUTION: Wear gloves when handling the Lenticular Screen and Fresnel Lens.

This prevents cuts and finger prints. Do not place Fresnel Lens in the sun.

This may cause fire and heat related injuries.

Lenticular Screen and Fresnel Lens Removal

1 ) Remove 28 screws (A) to remove the top, bottom and side HOLDER-SCREEN rails and their SPACERS from

the Screen Frame. (36 screws in the 62” model)

2 ) Lift the screens as a single

unit from the frame.

3 ) Separate the Lenticular Screen

and Fresnel Lens.

Note: When separating the Lenticular

Screen from the Fresnel Lens, use caution

while prying the Screen and Lens apart.

Use a slot type screw driver , and

remove the pressure sensitive double sided

tape.

Lenticular Screen and

Fresnel Lens Replacement

1 ) Apply LENS-TAPE along the rear top edge of the Lenticular Screen.

2 ) Place the Fresnel Lens on top of the Lenticular Screen, and apply pressure along the top edge.

3 ) Place the screens in the screen frame and reinstall the cushions, top, bottom and side rails.

NOTE: The Lenticular Screen label must face the front

and the Fresnel Lens label face the rear.

4 ) Reverse the Screen Removal Procedure and insert the

screens in the Bezel.

Page 14

MODEL: WD-52531 / WD-62531 / WD-62530

Tuner 0 Tuner 1 OOB Tuner

Frequency(MHz): 597 0

Signal Level: 8 0

Modulation: 256 QAM Unknown

Carrier Lock: Locked Unknown

SQI: 100 0

SNR: 34.3 0

Correctable errors: 0 0

UnCorrectable errors: 0 0

Previous Model Name

New Name

HOME EXIT

PIP/POP SPLIT

SQV FAV

DEVICE INPUT

V32/v32L Remote Button Name Changes

OPTION MENU

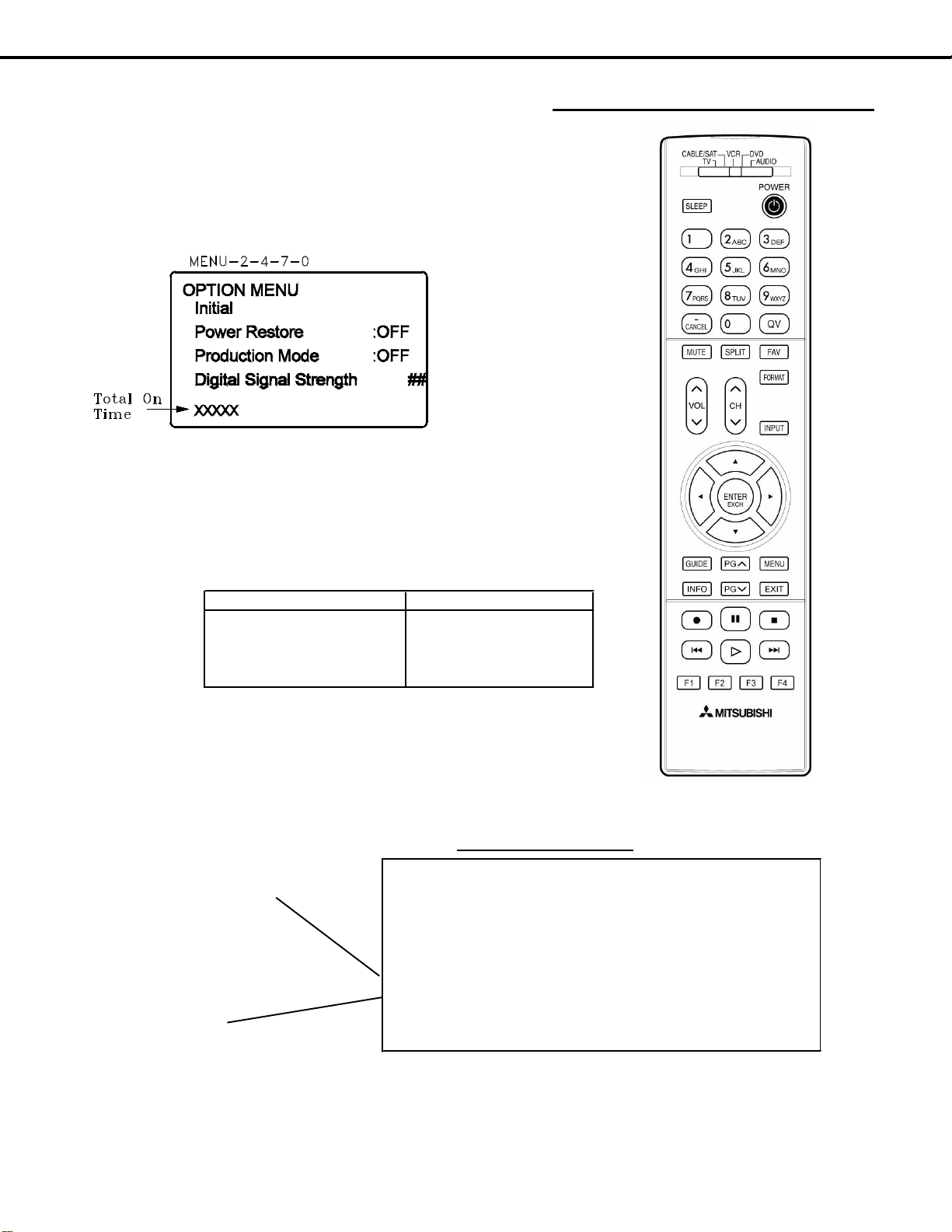

1. Press the MENU button on the remote hand unit.

2. Press the buttons 2, 4, 7 and 0 in order.

(The screen will change to the option menu.)

V32/V32L REMOTE CONTROL

Digital Signal Strength

1. Tune to a Digital Channel

2. From the Option menu scroll down and highlight Digital

Signal Strength

3. Press Enter

Signal Quality

Index (0-100)

Signal Noise

Ratio

SNR Recommended Levels:

VSB = 15 to 35

64 QAM = 22 to 34

256 QAM = 27 to 37

Example using on ANT1

Page 15

MODEL: WD-52531 / WD-62531 / WD-62530

A

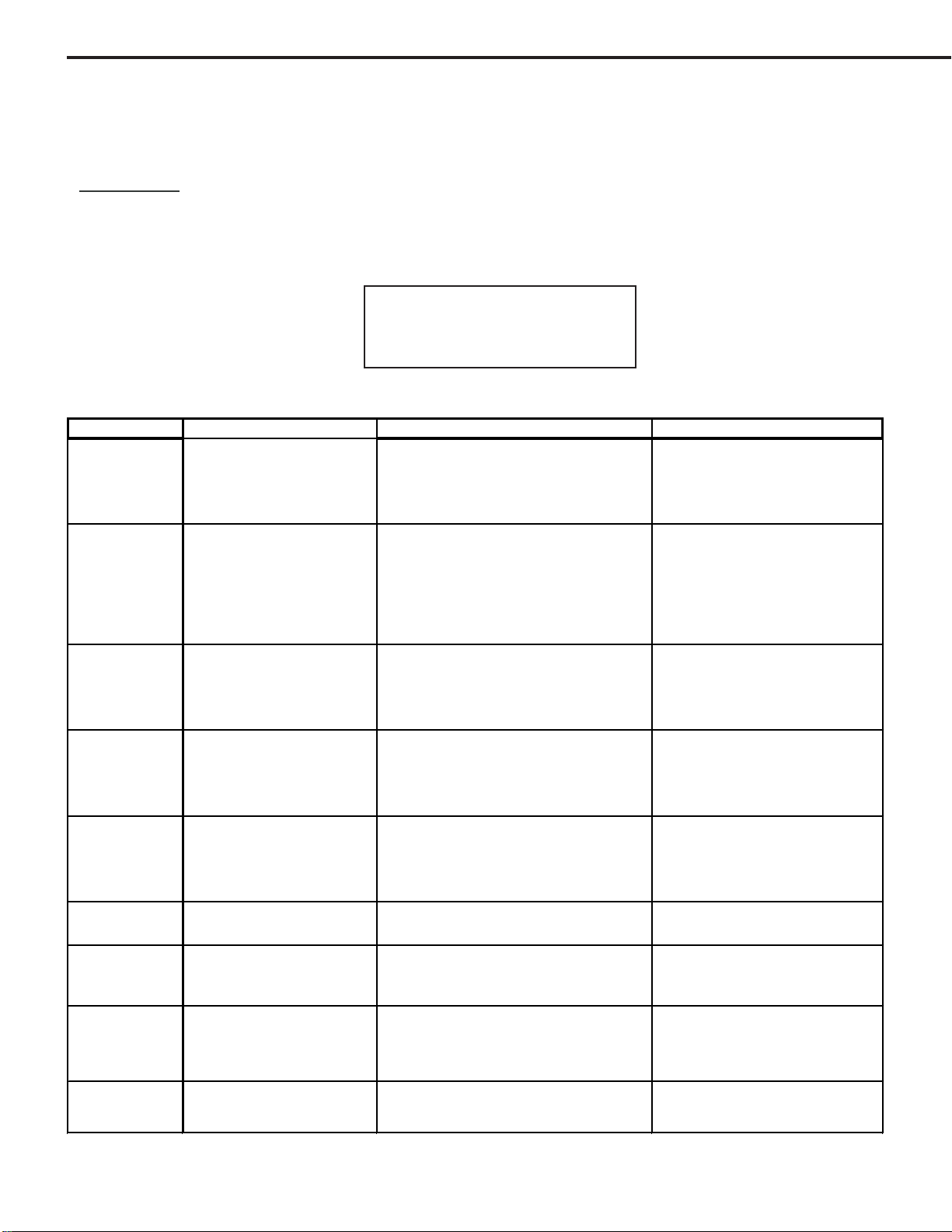

Front Panel Initialization

While the unit is ON, pressing the FORMA T and INPUT buttons simultaneously will immediately start the Initialization

sequence. The TV will reboot once the initialization sequence is completed. Front Panel Initialization will reset A LL

user settings to the factory setting.

SERVICE TIP:

Many customer generated symptoms, intermittent symptoms or no symptom found can be resolved by system reset

or initialization. Before visiting the customer’s home ask the customer 1

control panel and if this does not resolve the issue, then they can use the front panel initialization by pressing the

FORMA T and INPUT buttons simultaneously

NOTE: During Initialization, the set will

reboot. Wait until the Power LED stops

flashing before unplugging or powering

ON the TV .

RESET / INITIALIZE GUIDE

Reset Name When to use How to use Result in g Action

Remote Co n trol TV

Layer Reset

Returns th e rem o te c o ntro l T V

layer to normal operation.

(1)

Set the slide switch to TV posi t ion.

(2)

Press and hold the

(3)

flashes twice then release the button.

(3)

Enter the code

POWER

0 0 9 3 5

st

to try the System Reset button on the

Once the valid code has been entered

button until it

.

and confirmed, the remote control has

been reset.

Remote Co n trol TV

Volume/Mute

functions

/V Memory Reset,

single in put

A/V Reset, all

inputs

System Reset To reset the TV when it does not

TV Reset To reset all customer settings

Initialize - User

Level

Returns the volume and mute

functions of the remote control to

TV volume and mute for TV,

Cable/Sat, VCR and DVD layers

after the audio lock for AV

Receivers feature has been used.

When the audio and or video

settings for a single input seems

to incorrect

To reset audio and video

adjustments for all inputs to the

original factory settings.

turn on or off, does not respond

to the remote control, front panel

buttons or has audio but no

video.

To reset all consumer adjusted

settings and memories to the

original factory defaults.

(1)

Set the slide switch to TV posi t ion.

(2)

Press and hold the

(3)

flashes twice then release the button.

(3)

Enter the code

MENU --> Audio/Video--> AV Reset All Audio and Video settings for the

While viewing the TV, press the front panel

GUIDE

buttons

time.

Press the

front panel with a pointed object such as

the point of pencil or end tip of a paperclip.

Press

Press

front control panel at the same time.

SYSTEM RESET

MENU-1-2-3-ENTER All customer settings except V-Chip are

FORMAT

POWER

9 9 3 VOL UP

FORMAT

and

INPUT

and

button until it

.

at the same

button on the

buttons on the

The remote will now operate the TV's

volume and mute when the slide switch

is in the TV, CABL E/SAT, VCR or DVD

positions.

individual input are reset except for the

Listen To

Balance

All Audio and Video settings including

Listen To

Captions

are returned to the original factory

settings.

The changes you made most recently,

before using the SYSTEM RESET, may

be lost. Changes you made previously,

howev er, are not los t.

reset.

All memories and settings outlined in

the Owner's Guide will need to be set

again.

Language,

and

Closed Caption

and

Language, Closed

and

settings and

Format

audio

settings.

settings

Initialize - Service

Level

Factory Restore To recover from data/adjustment

To reset all consumer adjusted

settings and memories to the

original factory defaults.

errors in the ISF menu

MENU + 2470

press

MENU + 2457 + 0

FACTORY DEFAULTS and press ENTER

. Highlight

ENTER

INITIALIZE

. Highlight RESTORE

and

All memories and settings outlined in

the Owner's Guide will need to be set

again. Also erases V-CHIP password

All service, user, ISF data is set back to

factory defaults.

Page 16

MODEL: WD-52531 / WD-62531 / WD-62530

f

f

V

V

f

V

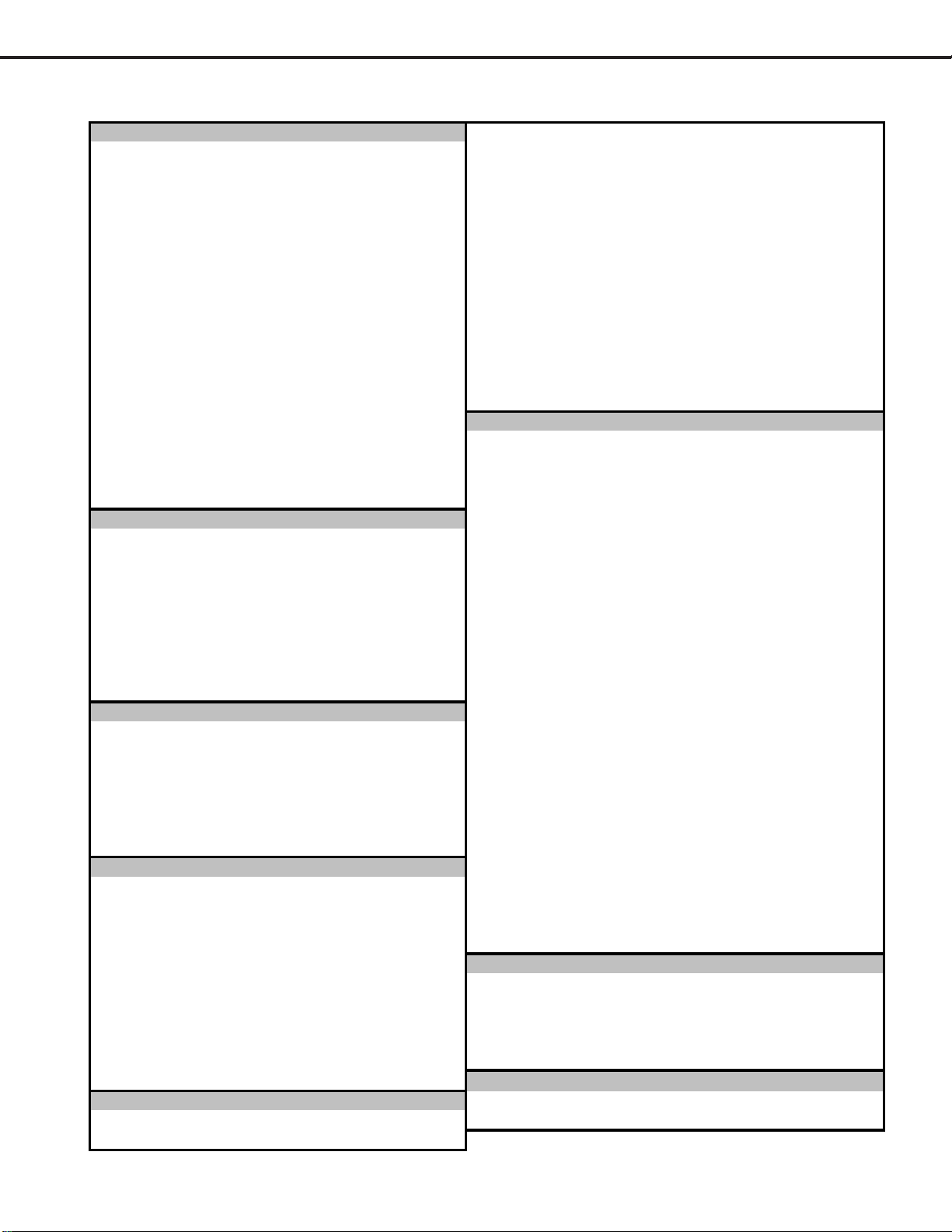

DEFAULTS AFTER INITIALIZATION

Setup Menu

Language :English

Memorize Channels -- D-Sexual Dialog --

Ant1 Air -- L-Adult Language - Ant1 Cable -- S-Sexual Situations - Ant2 Air -- V-Violence - Ant2 Cable -- Programs not rated --

Clock

Clock Setting Manual V-Chip Time

Time 12:00pm Start :12:00pm

Date 1/01/04 Stop :12:00pm

Time Zone :Eastern

Daylight Savings :Applies Lock Time :12:00pm

Timer

Timer :Off From Butt on Lock :Of

Day :Everyday

Time :12:00pm A/V Memory Reset :Ant1

Device :Ant1

Channel :2 Bass :50%

Software Version V32 xxx.xx Treble :50%

Record

Record

Channel :2 Listen To :Stereo

Record to -- Level Sound :Off

Duration :1 hr Language (Digital Signal Only) :English

Start Ti me - Day -- Picture Mode : Brillant

Record List -Default Record Device :Gray out Brillant Contrast :100%

Analog Recordings :Anamorphic

Channel

Antenna :1

Prefer Digital Sharpness :50%

Channel :2

Memory :Added Color :Manual Center

Name

FAV

Signal Strength :Digital only TV Speakers :On

Captions Menu

Analog Captions :On if Mute PIP Source Ant1 002

Background :Gray PIP Position :Lower Right

Digital Captions :On if Mute POP Position :Right Hal

Appearance :Default PIP/POP Format Double Window

Digital Settings

Font :Font 3 Ant 1 or 2 480i/480p :Stretch

Size :Large Ant 1 or 2 HD Digital :Standard

Color : White I nput 1, 2, 3 :Standard

Background :Black Comp 1, 2 :Standard

Opacity :Translucent HDMI 1, 2 (Only HDMI 1 in V32L) :Standard

Backgroung Opacitry :Translucent

Parental Lock

-Chip Componet 1, 2 :On

US Ratings :Off

:Gray Out

TV Rating :TV-PG

FV-Fantasy/Violence --

Movie Rating PG

Lock by Time :Of

Unlock Time :12:00pm

Audio/Video

Audio/Video

Balance :50%

Surround :Off

ideo

Bright/Natural :Bright

Brillant Brightness :50%

Color :50%

Tint :50%

Brillant Color Temp :High

Video Noise :Standard

ideo Mute :On

TV Volume :30%

Format

Auto Input Detect

Input 1, 2, 3 :On

Page 17

MODEL: WD-52531 / WD-62531 / WD-62530

A

V

AV RESET DEFAULTS

A/V Memory Antenna 1&2 Input 1/2/3

Brillant/Bright/Natural Bright Bright Bright Bright

Bright Contrast

Bright Brightness Center Center Center Center

Color

Tint Center Center Center Center

Sharpness

Color Temp. High High High High

Perfect Color

ideo Noise Standard Standard Standard N/A

Bass

Treble Center Center Center Center

Balance

Surround Off Off Off Off

Listen To

Level Sound On On N/A N/A

Language**

* HDMI 2 in V32 only.

Maximum Maximum Maximum Maximum

Center Center Center Center

Center Center Center Center

Manual Center Manual Center Manual Center Manual Center

Center Center Center Center

Center Center Center Center

Stereo N/A N/A N/A

English N/A N/A N/A

Component

1/2

HDMI 1/*2

A. A/V Memory

Each of the external inputs has its’ own Audio/Video Memory. A change in an A/V setting at a specific input is

stored in memory for that specific input.

B. A/V Reset

1. The front panel AV Reset (pressing the “Guide” and “Format” buttons at the same time) initializes all A/V

Memories.

2. The AV Reset in the user’s menu initializes only the selected input’s A/V Memory.

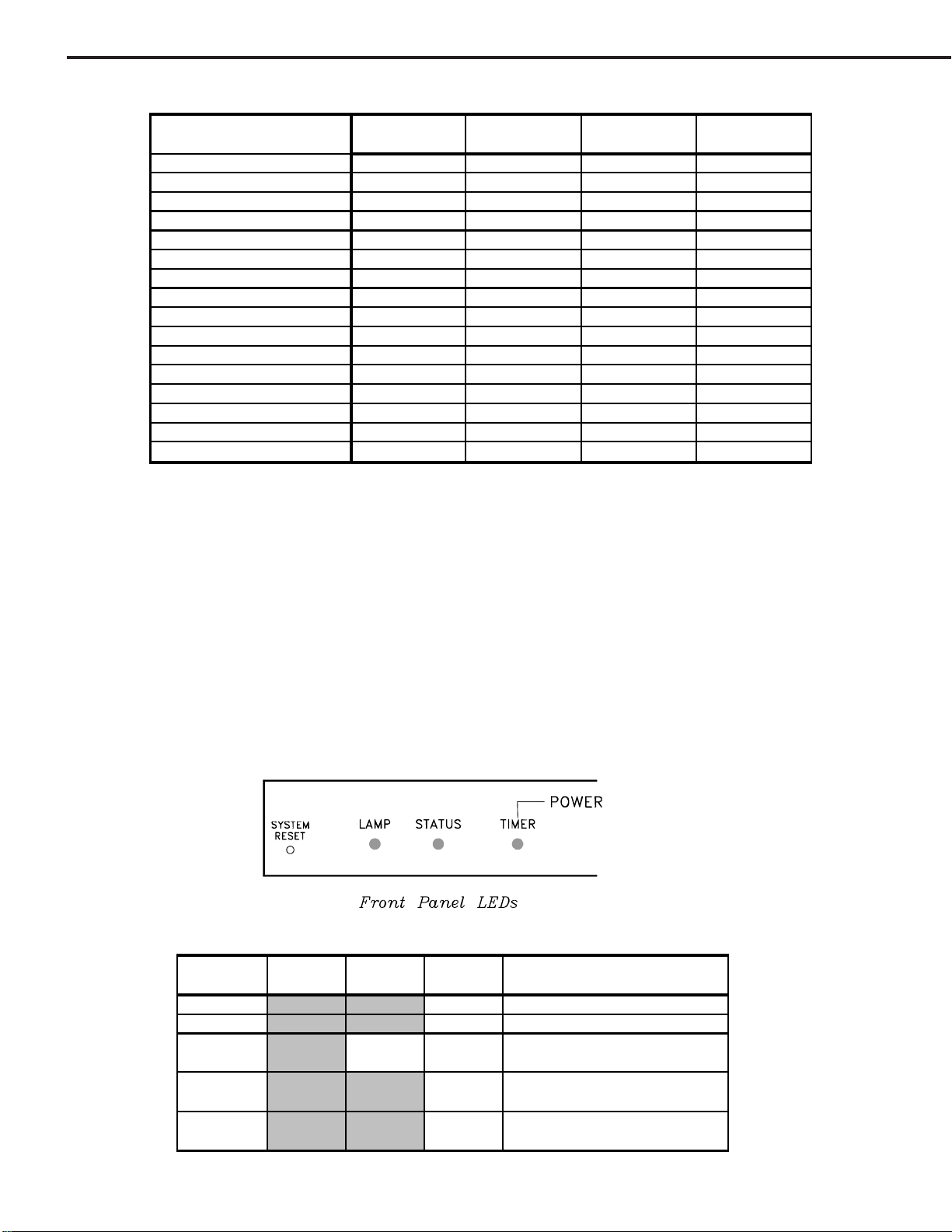

LED Indicator Diagnostics

The front panel LEDs provide an indication of the sets operation, and the possible cause of a malfunction. There

are three front panel LEDs, “Power”, “Status” and “Lamp”. Which LED is lit, the color and whether it is blinking or

steady indicate the current status, or a possible malfunction.

Normal LED Indications

POWER

LED

Off O ff Off Stby Off

Green Off Off P-0N Power On

Off Off

Blinks

Green

Slow Blinks

Green

STATUS

LED

Off Off Stby Booting after AC applied

Off Off St b y On Timer is set

LAMP

LED

Blinks

Green

Power

Status

fter Turn

Off

Condition

Lamp Fan On for 1 minute

Page 18

MODEL: WD-52531 / WD-62531 / WD-62530

ABNORMAL LED INDICATIONS

Power/Timer

Indicator

Off Yellow Off

Off Off Yellow Lamp usage warning (over 5000 hours)

Off Off Blinking yellow Lamp cover is open.

Off Blinking Red Off Fan Stop

Off Red. Off DVI cable between DM and Engine disconnected

3. Error Code Operational Check

Note: The TV must be in “Shut Down” and not have been switched Off, to perform the Error Code Opera-

Pressing the front panel “DEVICE” and “MENU” buttons at the same time, and holding for 5 seconds,

activates the Error Code Mode. The LED flashes denoting a two digit Error Code, or indicating no problem

has occurred since the last Initialization.

Note: The front panel buttons must be used, NOT those on the Remote Control.

Status Indicator Lamp Indicator Condition

Temperature high – room temperature too hot.

Temperature sensor is disconnected.

Off Red Lamp fails to turn on

Circuit failure

Ballast problem detected by ballast UART (temperature,

short circuit, did not ignite, low voltage)

tional Check. When the TV is switched Off, the code automatically resets to “12” No Error.

(short)

• The number of flashes indicates the value of the MSD (tens digit) of the Error Code.

• The flashing then pauses for approximately 1/2 second.

• The LED then flashes indicating the value of the LSD (ones digit) of the Error Code.

• The Error Code is repeated a total of 5 times.

Example: If the Error Code is “23”, the LED will flash two times, pause, and then flash three times.

4. Error Codes

The Error Code designations indicating malfunction, or no malfunction, are listed below:

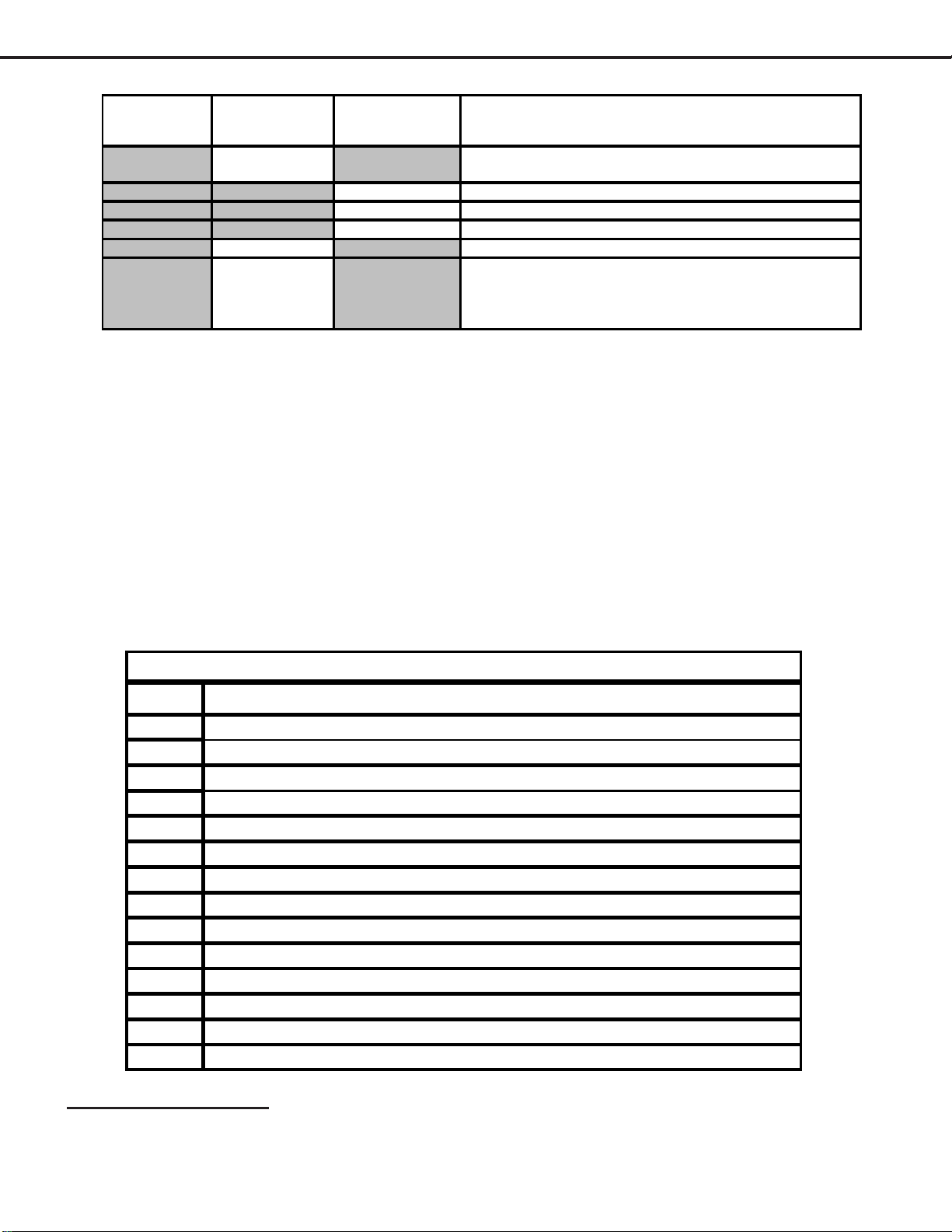

ERROR CODES

Code

12

32

34

36

37

38

39

41

42

44

45

46

48

66

No Er ror found

Lamp cover is open.

Lamp turns Off while the TV is playing.

Lamp ballast fan failed.

Red/Green LCD-PBS fan failed.

Lamp temperature abnormally high.

LCD Intake temperature abnormally high.

Standby Short Detected.

Exhaust (lamp) fan failed.

Check for disconnected DVI cable betw een PWB-DM and Eng in e.

BLUE LCD fan fa iled.

LCD Intake Temperature sensor not detected.

Engin e power supply shor t is detec ted. (P - ON short)

Lamp did not turn on at P-ON sequence

Lamp Troubleshooting

Use the above Error Code T able, and the Lamp Control Block diagram and T roubleshooting flow chart on the following pages

to determine the cause of a lamp problem.

Description

Page 19

Loading...

Loading...