Page 1

2004

SerSer

Ser

SerSer

vicevice

vice

vicevice

MITSUBISHI ELECTRIC

ManualManual

Manual

ManualManual

DIGITAL LIGHT PROCESSING™ PROJECTION TV

V26 CHASSIS

MODELS

V26 V26+ V26++

WD-52525 WD-52725 WD-52825

WD-62525 WD-62725 WD-62825

WD-52525

CAUTION:

Before servicing this chassis, it is important that the service person read the "SAFETY PRECAUTIONS" and

"PRODUCT SAFETY NOTICE" contained in this manual.

SPECIFICATIONS

• Power Input : AC 120V, 60Hz

• Power Usage : 275W

• Light Engine : DLP 0.85" 1280 x 720p

• Lamp : 120W VIP Type

• Channel Frequencies : Air - VHF 2 ~ 13 UHF 14 ~ 69

Analog Cable - 1 ~ 125

Digital Cable - 1 ~ 135

• Antenna Input : 2 RF 75Ω unbalanced

• Tuning :

• Cabinet Dimensions : [WD-52xxx] 37.2" x 49.6" x 17.4"

• Weight : [WD-52xxx] 132.4 lbs

• Speakers (10Wx2) : 5" Coaxial x 2

• Input Level : VIDEO IN JACK (RCA Type)

• Design specifications are subject to change without notice.

1 NTSC/ATSC/QAM64&256

1 CableCARD™ Slot

1 NTSC for PIP

[WD-62xxx] 43.7" x 58.3" x 19.9"

[WD-62xxx] 165.5 lbs

1.0Vp-p 75Ω unbalanced

AUDIO IN JACK (RCA Type)

500mV RMS full scale into 43kΩ,

unbalanced

: S-VIDEO IN JACK

(Y/C separate type)

Y:1.0 Vp-p C:0.286Vp-p(BURST)

75Ω unbalanced, 480i

: COMP / Y, Pr, Pb (RCA Type )

Y: 1.0 Vp-p Pr, Pb: 700mVp-p, 480i,

480p, 720p, 1080i

: DTV / Y(G), Pr(R), Pb(B), H, V (RCA

Type) Y: 1.0 Vp-p Pr, Pb: 700mVp-p,

75Ω, H, V: 3.0Vp-p, 480i, 480p,

720p, 1080i

: VGA / R,G,B,V,H (15 pin D) 640x480,

800x600, 1024x768, 720x1280,

60Hz

• Output Level : VIDEO OUT JACK (RCA Type)

1.0Vp-p 75Ω unbalanced

: AUDIO OUT JACK (RCA Type)

500mV RMS

full scale into 4.7kΩ, unbalanced

• Digital : IEEE-1394 I/O Jacks

Interface : AC-3 Digital Audio Output (RCA

Type)

: HDMI

: MonitorLink

: 4 Memory Card Reader Inputs

(+/-200mV)

1.5V RMS

TM

TM

Control/RS-232C

MITSUBISHI DIGITAL ELECTRONICS AMERICA, INC.

9351 Jeronimo Road, Irvine, CA 92618-1904

Copyright © 2004 Mitsubishi Digital Electronics America, Inc.

All Rights Reserved

Page 2

Page 3

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

CONTENTS

INTRODUCTION ................................................................................................................................5

PRODUCT SAFETY NOTICE ...........................................................................................................5

SAFETY PRECAUTIONS .................................................................................................................6

DISASSEMBLY PROCEDURES ......................................................................................................... 7

Cabinet Front Disassembly ............................................................................................................. 7

Cabinet Rear Disassembly .............................................................................................................. 9

ELECTRICAL CHASSIS REPLACEMENT ........................................................................................ 10

OPTICAL ENGINE REPLACEMENT ................................................................................................. 13

DATA COPY PROCEDURE ............................................................................................................... 16

DIAMONDSHIELD™ REPLACEMENT .............................................................................................. 17

SERVICING THE LENTICULAR SCREEN AND FRESNEL LENS ..................................................... 18

INITIAL SETUP ................................................................................................................................ 20

FRONT PANEL LED DIAGNOSTICS ................................................................................................ 22

SERVICE ADJUSTMENTS ............................................................................................................... 24

Equipment .................................................................................................................................... 24

Circuit Adjustment Mode ............................................................................................................... 24

Adjustment Items and Initial Data Settings ................................................................................... 26

Electrical Adjustments .................................................................................................................. 27

Mechanical Adjustments ............................................................................................................... 27

REPLACEMENT PARTS .................................................................................................................. 30

SCREEN ASSEMBLY PARTS .......................................................................................................... 33

CIRCUITRY BLOCK DIAGRAMS ..................................................................................................... 35

PCB INTERCONNECT DIAGRAM

Page 3

Page 4

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

Page 4

Page 5

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

INTRODUCTION

This service manual provides service instructions for PTV Models and Chassis:

V26 Chassis V26+ Chassis V26++ Chassis

WD-52525 WD-52725 WD-52825

WD-62525 WD-62725 WD-62825

This service manual includes:

1. Assembly and disassembly instructions for the front and rear cabinet components.

2. Servicing of the Lenticular Screen and Fresnel Lens.

3. Servicing down to major components, chassis, Optical Engine, Lamp Ballast, etc..

4. Electrical adjustments.

5. Optical Adjustments.

6. Chip parts replacement procedures.

7. Simplified circuit path diagrams.

8. Overall PCB interconnect block diagram.

The parts list section of this service manual includes:

1. Cabinet and screen parts.

2. Electrical parts.

Block diagrams of the above listed models are included in this service manual for better understanding of the circuitry.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in television receivers have special safety related characteristics. These characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily be obtained by

using replacement components rated for higher voltage, wattage, etc.

Replacement parts which have special safety characteristics are identified in this service manual.

Electrical components having such features are identified by shading on the schematic diagram and by bold type in

the parts list of this service manual. Therefore, the replacement for any safety part should be identical in value

and characteristics.

Digital Light Processing, Digital Micromirror Device and DLP are trademarks of Texas Instruments.

CableCARD is a trademark of Cable Television Laboratories, Inc.

HDMI, the HDMI logo and High-Definition Multimedia Interface are trademarks or registered trademarks of HDMI Licensing LLC.

Page 5

Page 6

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

SAFETY PRECAUTIONS

NOTICE: Observe all cautions and safety related notes located inside the receiver cabinet and on the

receiver chassis.

WARNING:

1. Operation of this receiver outside the cabinet or with the cover removed presents a shock hazard

from the receiver's power supplies. Work on the receiver should not be attempted by anyone who is

not thoroughly familiar with the precautions necessary when working on high voltage equipment.

2. When service is required, observe the original lead dress. Extra precaution should be taken to

assure correct lead dress in the high voltage area. Where a short-circuit has occurred, replace those

components that indicate evidence of overheating.

W ARNING: Ultraviolet Rays Hazard!

The lamp used in this product generates high intensity light which contains UV -rays

that can injure your eyes. This high intensity light is then filtered and all UV -rays are

removed before it is displayed on screen.

T o protect your eyes, do not look directly into the lamp or the light coming directly

from the lamp, lens or mirror .

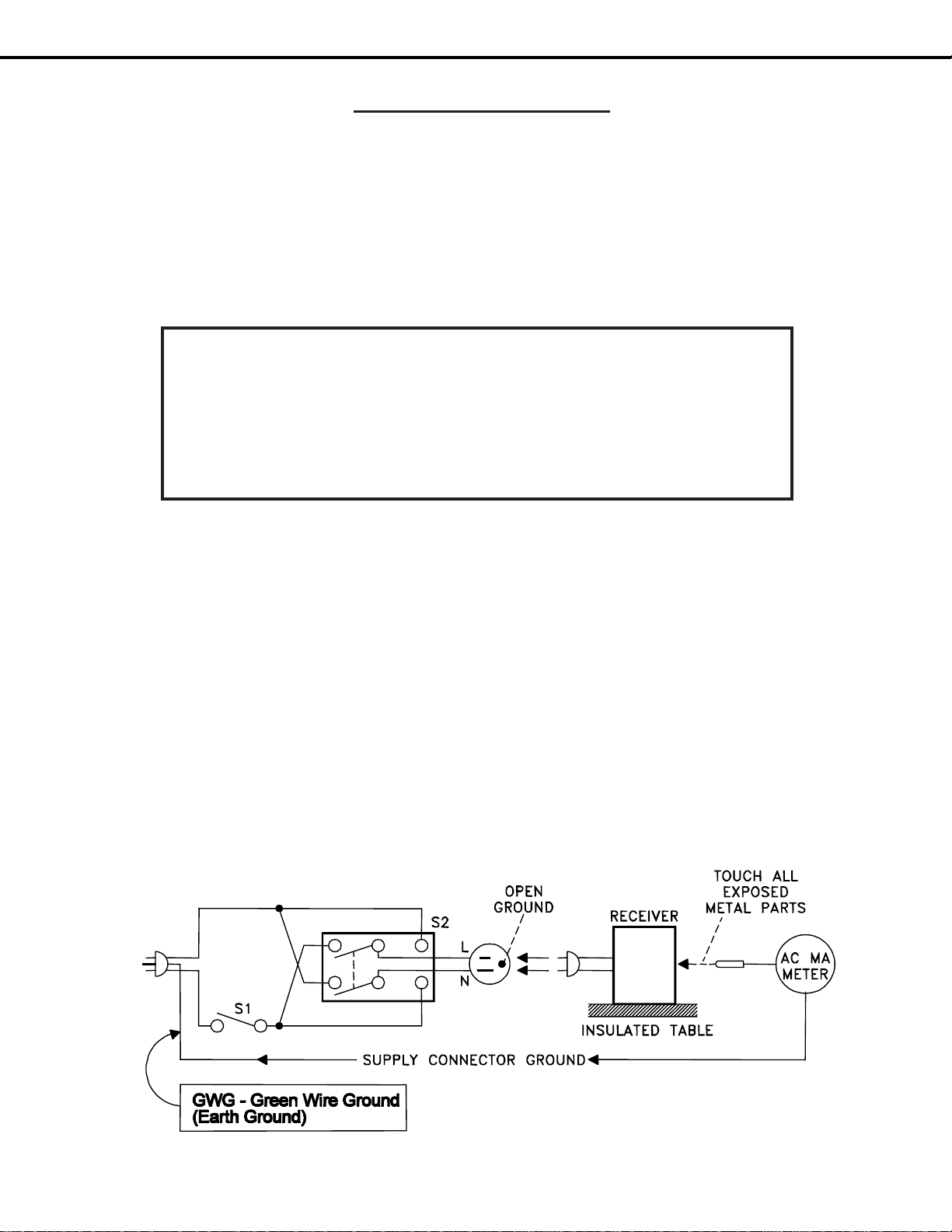

Leakage current check:

Before returning the receiver to the customer, it is recommended that leakage current be measured according to the

following methods.

1. Cold Check

With the alternating current (AC) plug removed from the AC source, place a jumper across the two AC plug

prongs. Connect one lead of an ohm meter to the AC plug and touch the other lead to each exposed metal part

(i.e. antennas, handle bracket, metal cabinet, screw heads, metal overlay , control shaf ts, etc.), particularly any

exposed metal part that has a return path to the chassis. The resistance of the exposed metal parts having a

return path to the chassis should be a minimum of 1Megohm. Any resist ance below this value indicates an

abnormal condition and requires corrective action.

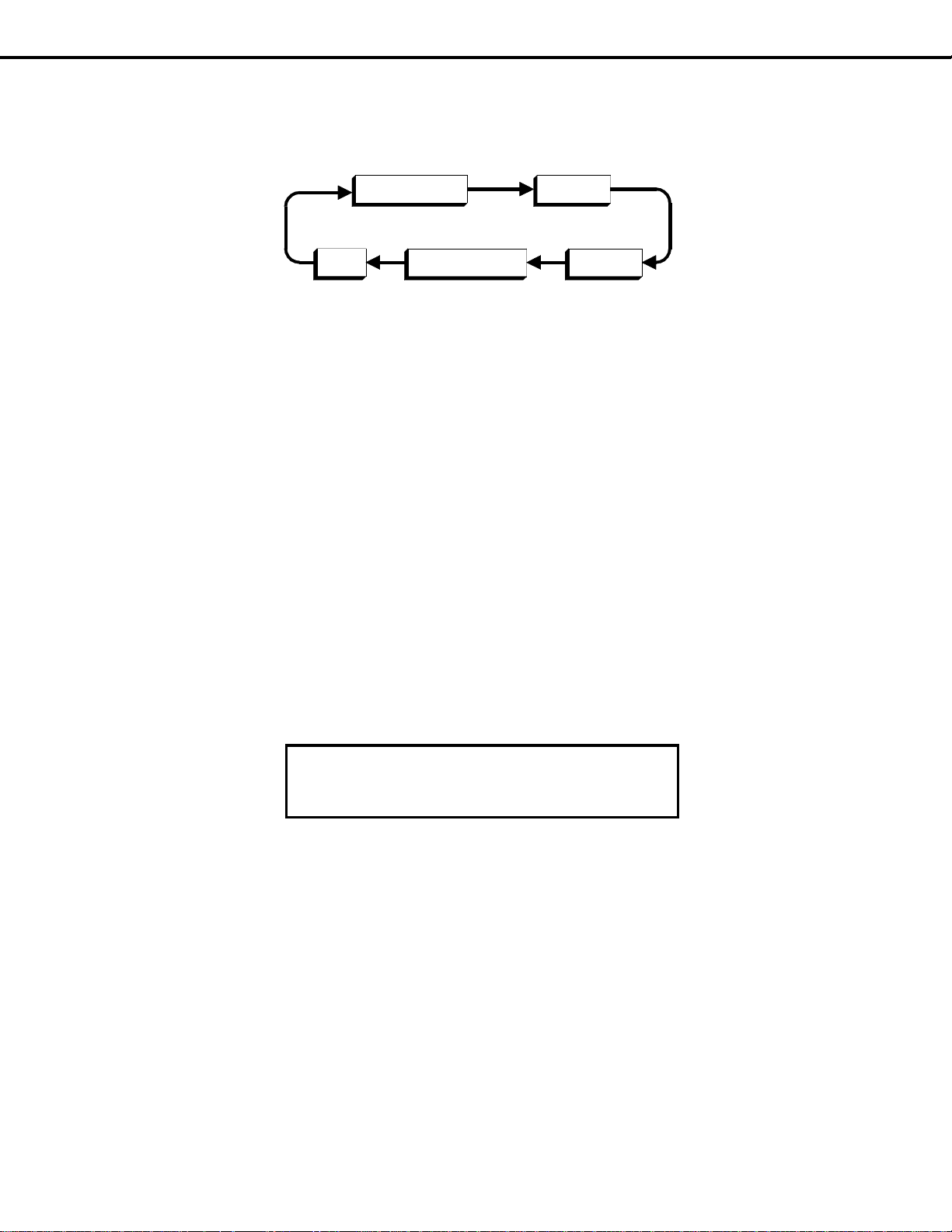

2. Hot Check ...Use the circuit shown below to perform the hot check test.

1. Keep switch S1 open and connect the receiver to the measuring circuit. Immediately after

connection, and with the switching devices of the receiver in their operating positions, measure the

leakage current for both positions of switch S2.

2. Close switch S1, energizing the receiver . Immediately after closing switch S1, and with the

switching devices of the receiver in their operating positions, measure the leakage current for both

positions of switch S2. Repeat the current measurements of items 1 and 2 after the receiver has

reached thermal stabilization. The leakage current must not exceed 0.5 milliampere (mA).

Page 6

Page 7

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

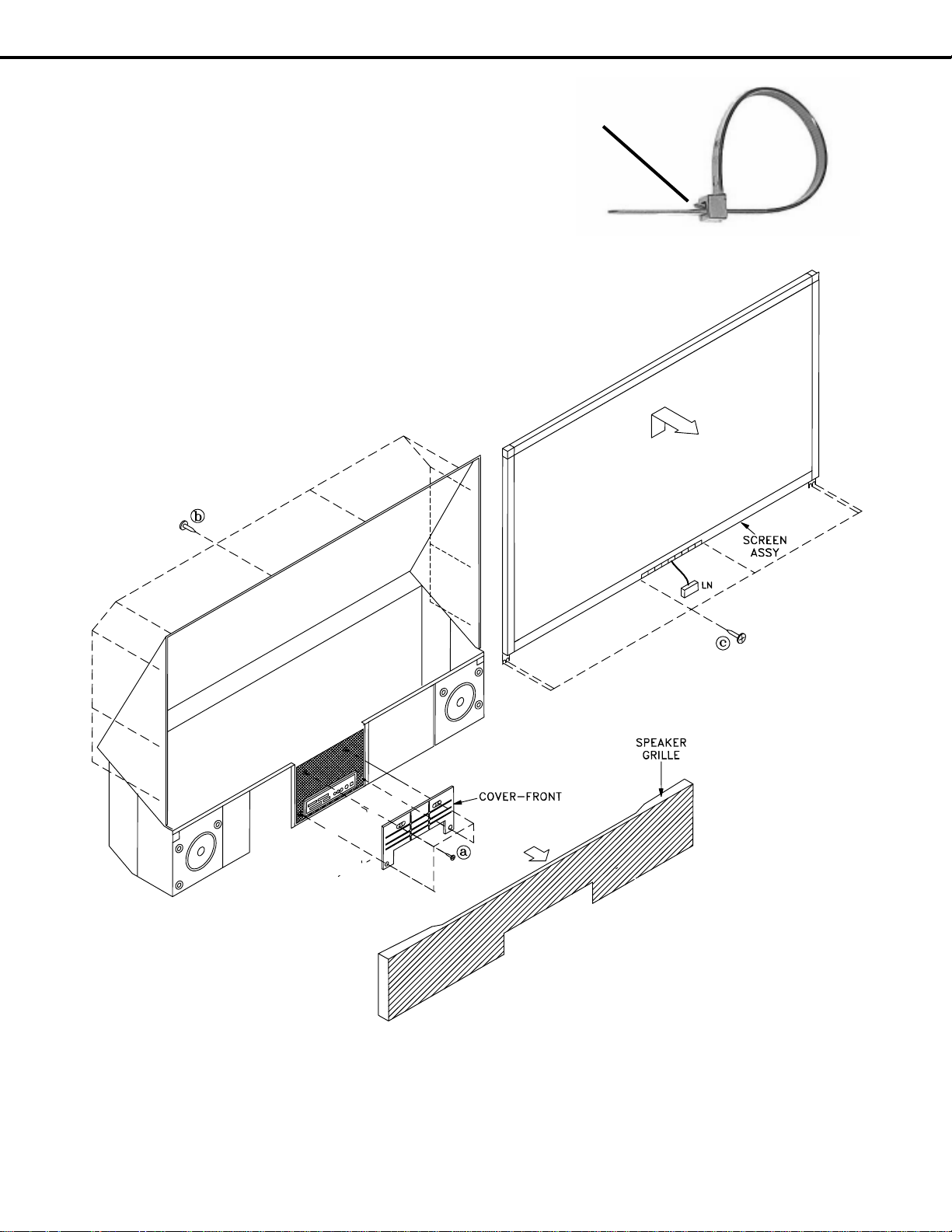

Reusable Wire Ties

Do not cut wire ties during disassembly, reusable

wire ties are used in these models. Lift the tab to release the wire tie. During reassembly, re-use wire ties to

ensure all wiring harnesses are properly bundled and

dressed.

CABINET DISASSEMBLY (FRONT VIEW)

WD-52525 / WD-62525 / WD-52725 / WD-62725

*Refer to the Parts List for Part Numbers

Lift Tab to Release

Wire Tie

Front Cabinet Disassembly

1. Remove the SPEAKER-GRILLE by pulling forward.

2. Remove screws (a) to remove the COVER-FRONT.

3. Remove screws (b) on the rear of the upper back cover (4 across the top and 3 on each side).

4. Remove the 4 screws (c) holding the bottom of the Screen Assembly.

5. Unplug connector LN from the Control Panel.

6. Lift the Screen Assembly up slightly then pull towards the front to remove the assembly.

Page 7

Page 8

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

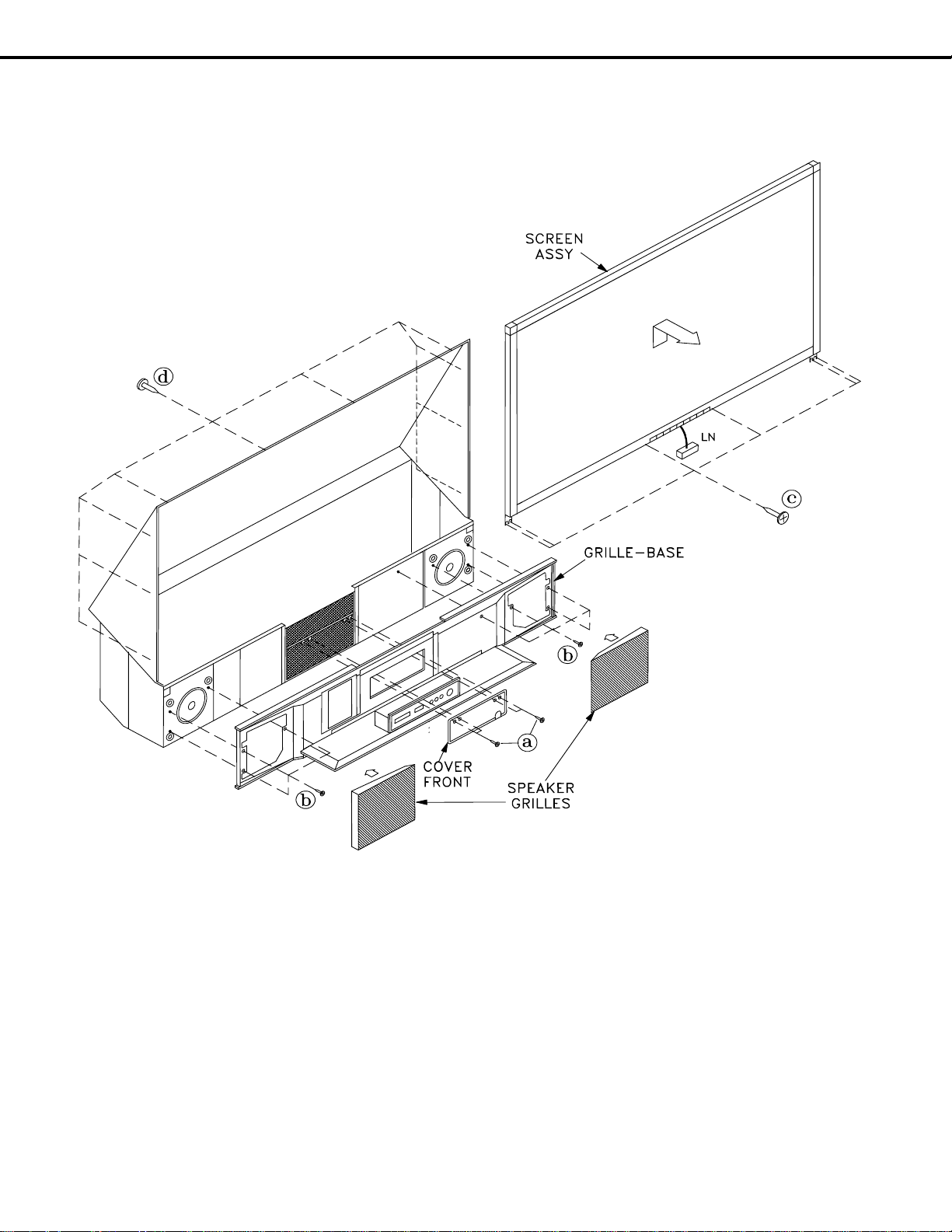

CABINET DISASSEMBLY (FRONT VIEW)

WD-52825 /WD-62825

*Refer to the Parts List for Part Numbers

Front Cabinet Disassembly

1. Remove the SPEAKER-GRILLES by pulling forward.

2. Remove screws (a) to remove the COVER-FRONT.

3. Remove screws (b) to remove the GRILLE-BASE.

4. Remove screws (d) on the rear of the upper back cover (3 on each side and 4 across the top).

5. Remove the 4 screws (c) holding the bottom of the Screen Assembly.

6. Unplug connector LN from the Control Panel.

7. Lift the Screen Assembly up slightly then pull towards the front to remove the assembly

8. To disconnect the Card Reader and the Front Inputs:

• Unplug the Card Reader USB connector from the PCB-DM.

• Unplug the Front 1394 cable from the HDD Module (Hard Drive).

• Unplug the CC connector from the Front Inputs.

Page 8

Page 9

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

(b)

(b)

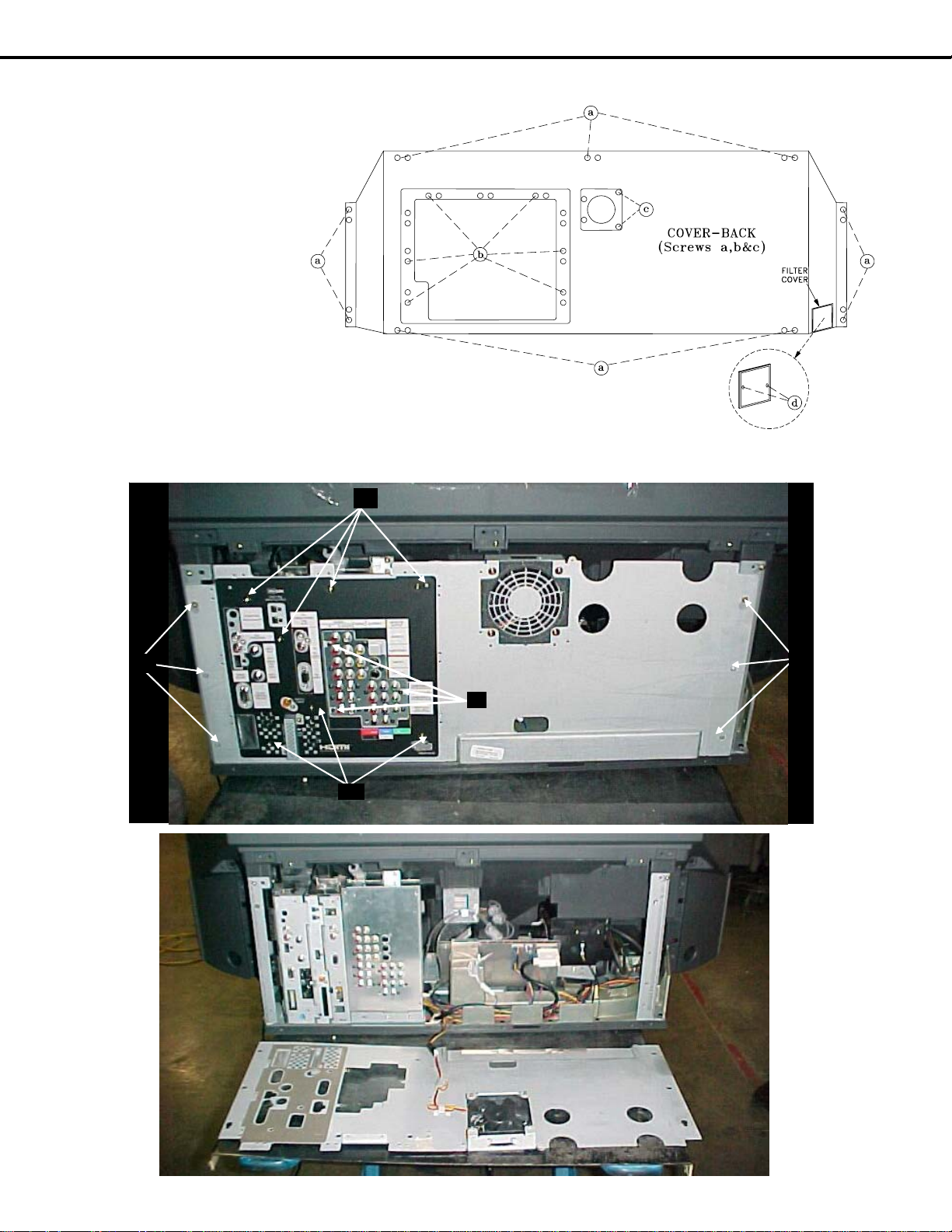

CABINET DISASSEMBLY (REAR VIEW)

FILTER-COVER Removal

Remove 2 screws (d) to remove the Filter Cover.

COVER-BACK Removal

1) Remove 9 screws (a)

2) Remove 5 screws (b)

3) Remove 2 screws (c)

4) Pull the COVER-BACK

from the cabinet.

Rear Plate Removal

1) Remove 6 screws (a)

2 Remove10 screws (b)

3) Pull the Rear Plate from the

cabinet.

NOTE: To operate set with the Cover-Back and Rear Plate removed, re-install the Filter Cover and ensure the Exhaust Fan

is connected.

(a)

(a)

(b)

(b)

(b)

(a)

(a)

Page 9

Page 10

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

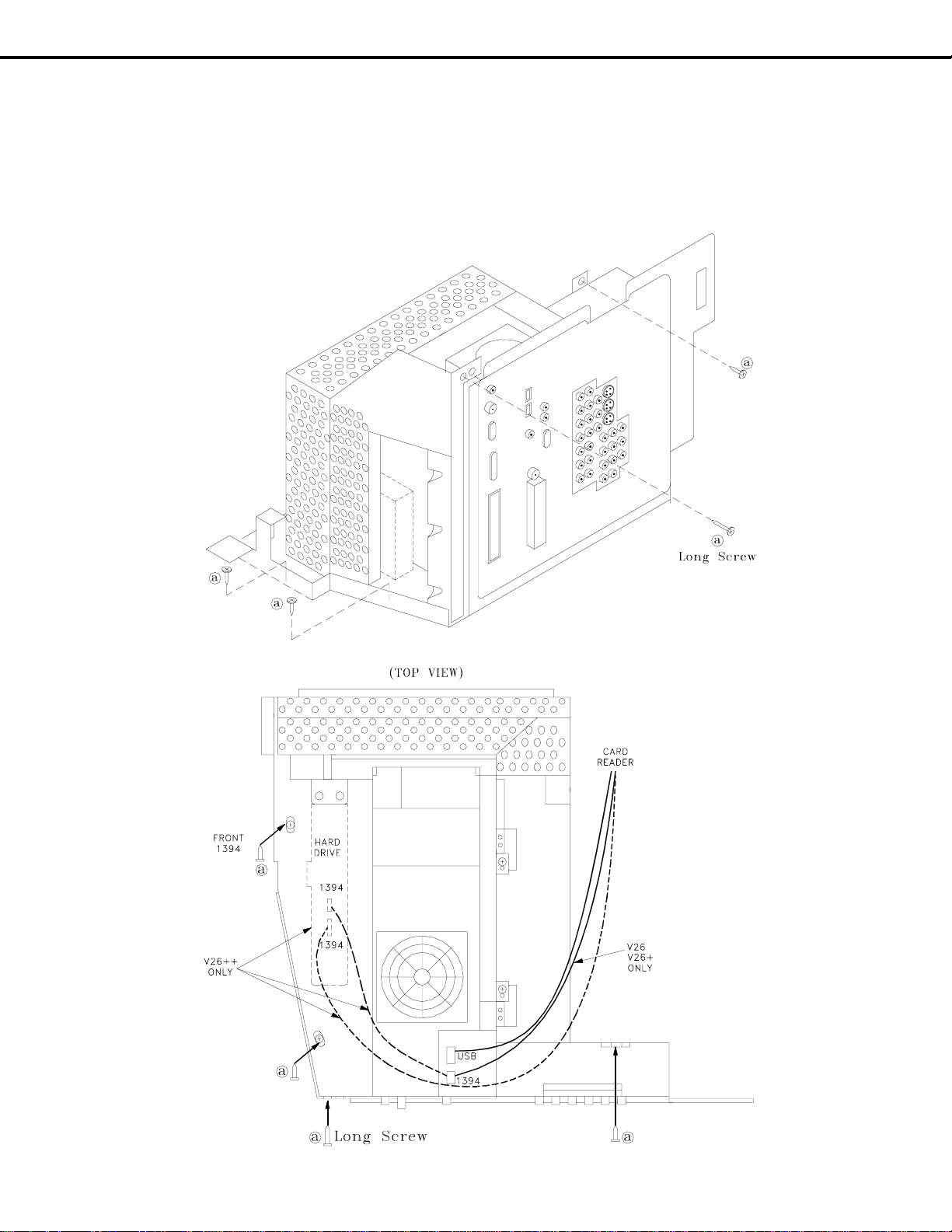

ELECTRICAL CHASSIS REPLACEMENT

1) Remove the 4 black screws (a) securing the chassis shown in the two diagrams below.

2) Unplug the USB and 1394 connectors from the Card Reader.

NOTE: In the V26++ chassis the Card Reader 1394 connector plug into the Hard Drive Module.

3) Disconnect all cables to the front of the cabinet, the Optical Engine and the Lamp Ballast (see next page).

4) Carefully slide the chassis from the cabinet.

5) IMPORTANT: After Electrical Chassis replacement, perform the Data Copy Procedure (page 16).

Page 10

Page 11

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

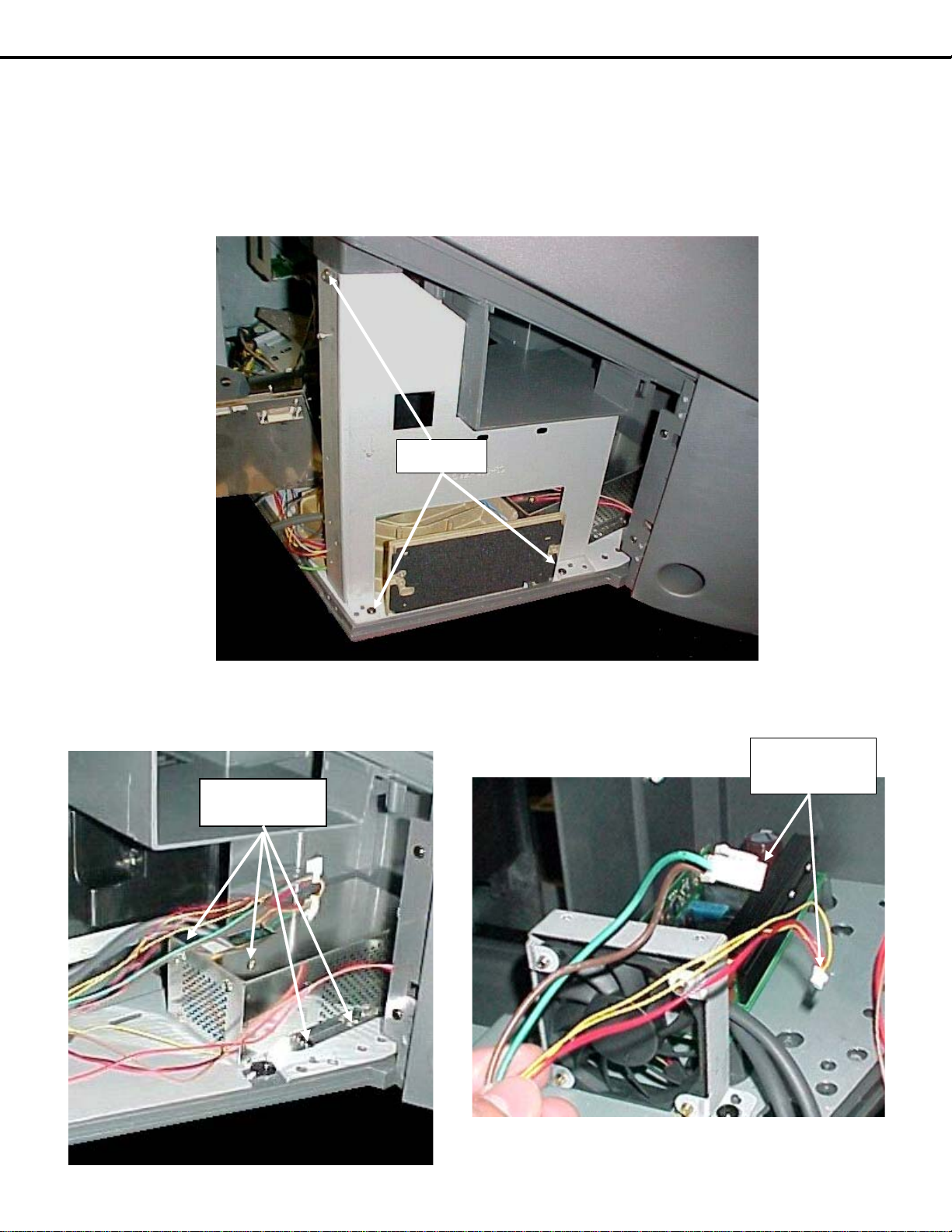

NOTE: To remove the chassis, the two connectors to the Lamp Ballast must be

disconnected at the Lamp Ballast.

Accessing & Disconnecting The Lamp Ballast

Removing the Right Support

Remove the 3 screws shown below.

3 Screws

Removing the Lamp Ballast Shield

(4 screws)

4 Screws

Unplug CN1 & CN2

Connectors

Unplug

Connectors

Page 11

Page 12

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

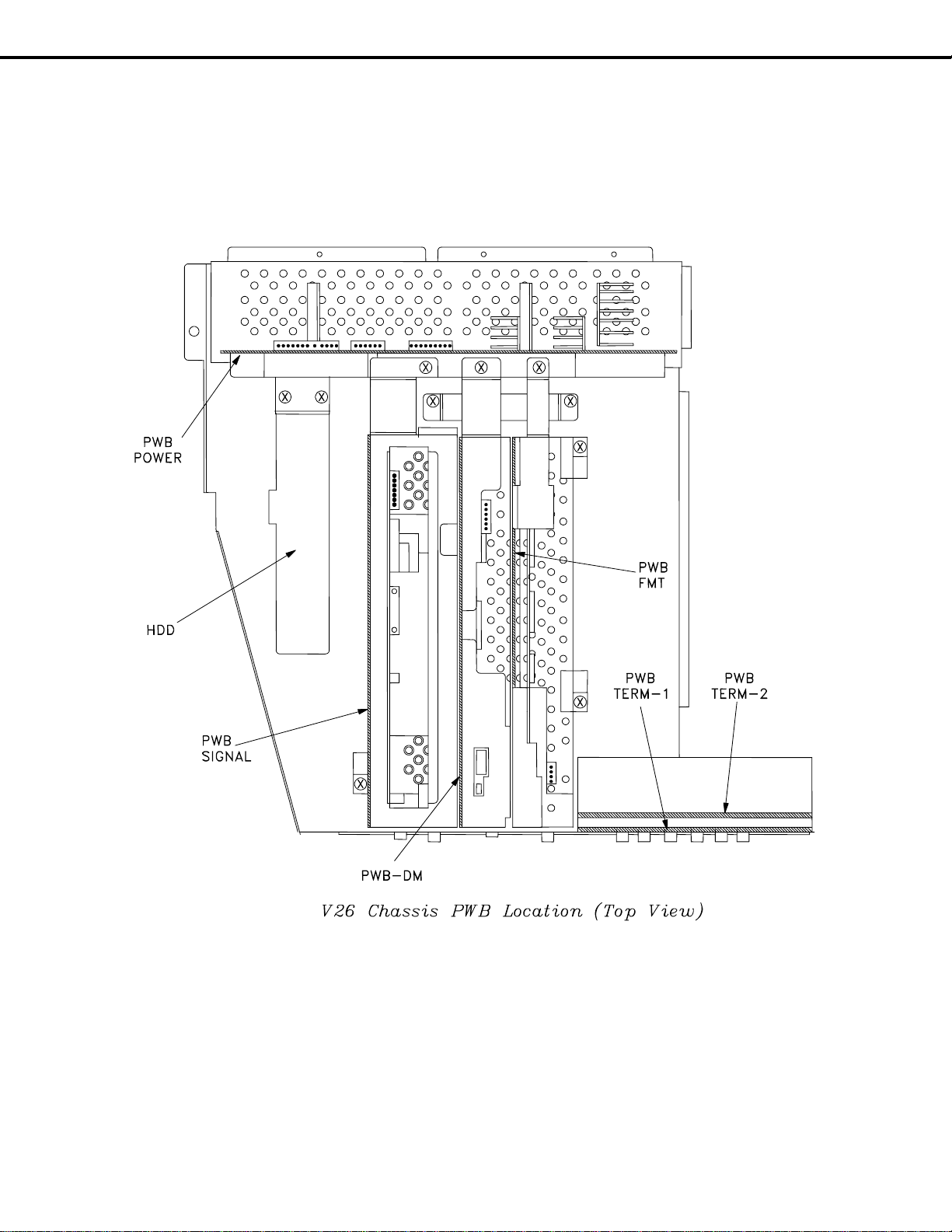

V26 Chassis PWB Locations

NOTE: The HDD is only in the V26++ models.

Page 12

Page 13

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

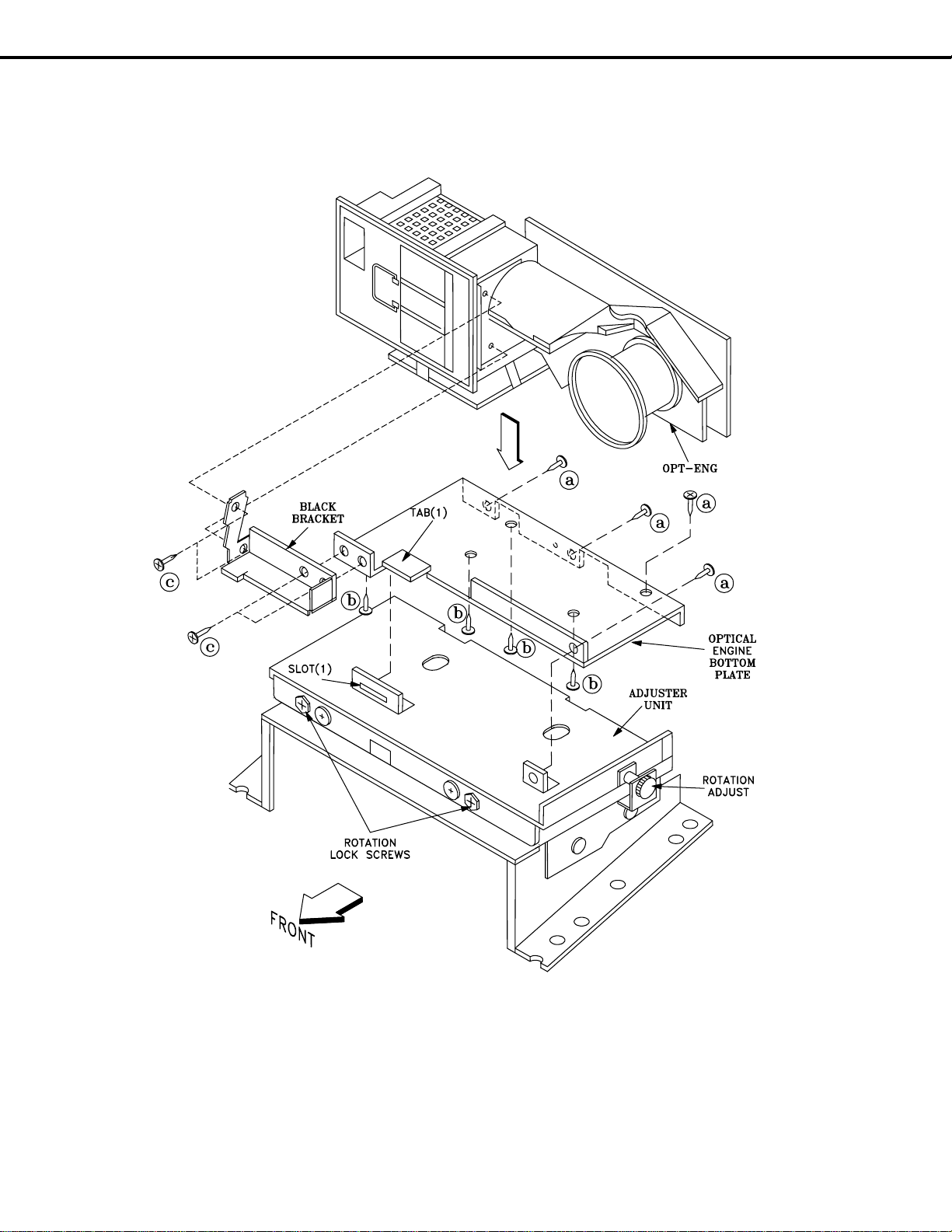

Optical Engine Mounting

Note: The Engine has no individual

service parts available. Attempting

to disassemble the Engine may void

the warranty.

Optical Engine Replacement

The Optical Engine is mounted on the Adjuster assembly as shown in the above diagram.

1) Four screws (a) secure the bottom plate and Optical Engine to the Adjuster assembly.

2) The bottom plate tab (1) slides into slot (1) on the Adjuster.

3) The Optical Engine is secured to the bottom plate by 4 screws (b).

4) The Black Bracket is secured to the bottom plate and the Lamp Box with 4 screws (c).

5) To replace the Optical Engine, the Optical Engine, bottom plate and black bracket need to be removed

together as an assembly. Refer to the following pages for exact replacement instructions.

Page 13

Page 14

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

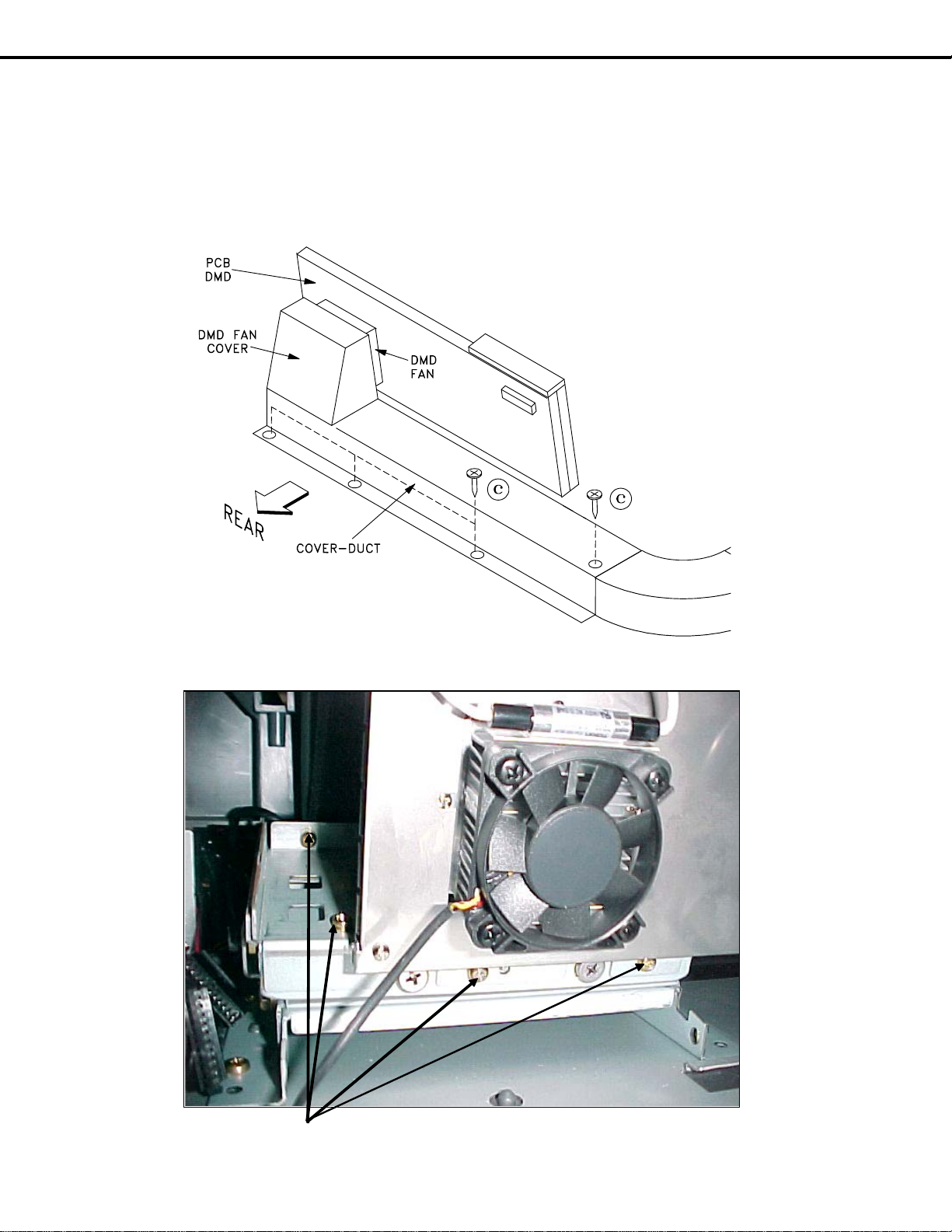

Removing the Optical Engine

1) Remove the Cabinet Back (refer to disassembly instructions).

2) Disconnect all connectors from the Optical Engine, Lamp Cartridge Housing and the PCB-DMD.

3) From the rear of the TV, remove the 4 screws (c), to remove the COVER-DUCT and DMD Fan cover.

4) From the rear of the TV, remove the 4 brass colored screws (a), shown below, securing the bottom plate to

the Adjuster assembly.

5) Slide the Optical Engine/Lamp Cartridge Housing towards the rear to remove from the TV.

(a)

O ptic al Engine (R e a r Vie w / Aird uct & DMD Fa n Cover Re moved)

Page 14

Page 15

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

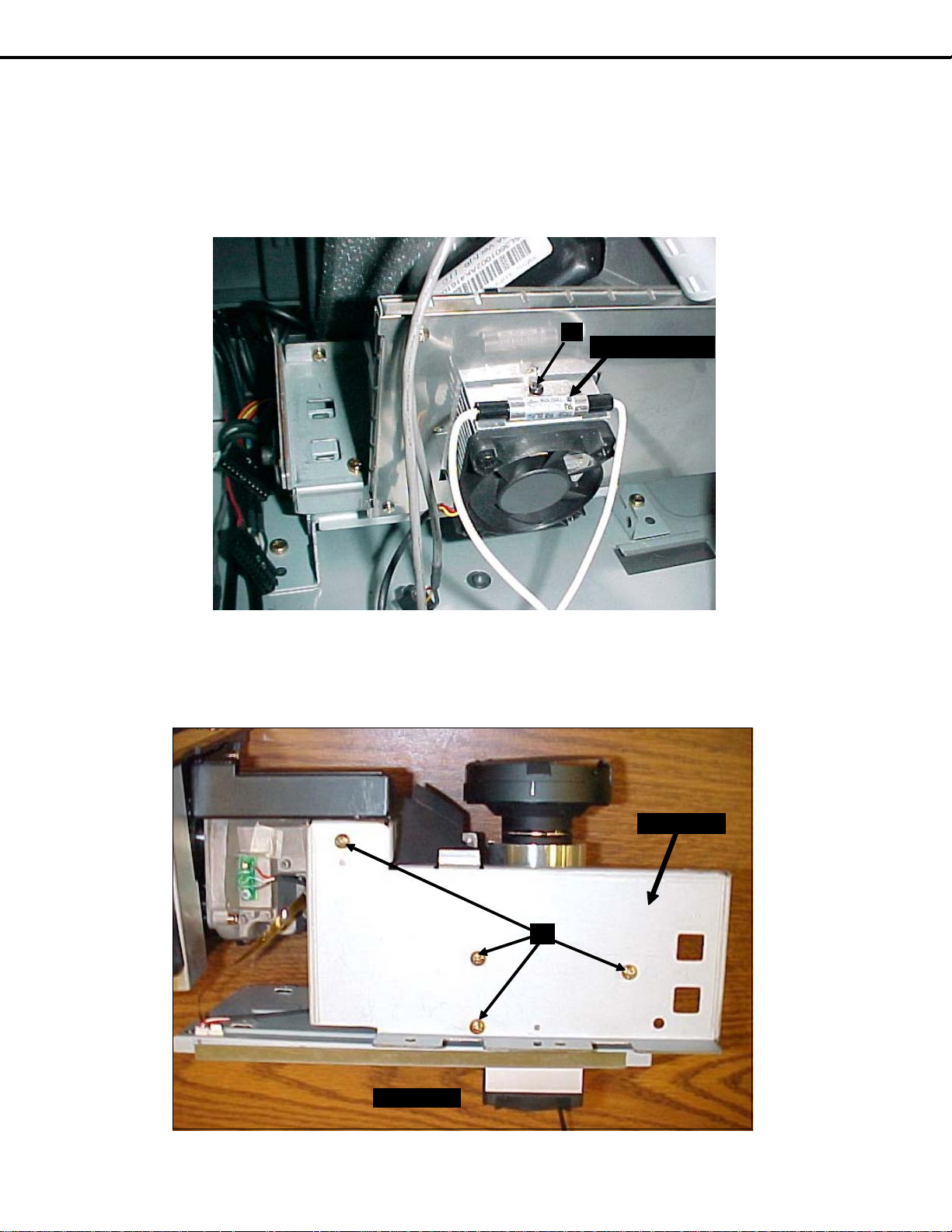

Remove the following parts from the Optical Engine

• DMD Thermal Sensor

• The Optical Engine bottom plate and black bracket

DMD Thermal Sensor Removal (Figure 1)

1) Remove screw (a) on the top of the DMD Fan.

2) Set the Thermal Sensor aside to install on the replacement Optical Engine.

(a)

Figure 1: DMD Thermal Sensor

Bottom Plate & Black Bracket Removal

1) Remove the 4 screws (B) from the Bottom Plate (Figure 2)

2) Remove the two screws (C), holding the Black Bracket to the Lamp Box. (Figure 3)

Heat Sensor

Thermal Sensor

(B)

Bottom V iew

Figure 2: Bottom Plate

Page 15

Bottom Pla te

Page 16

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

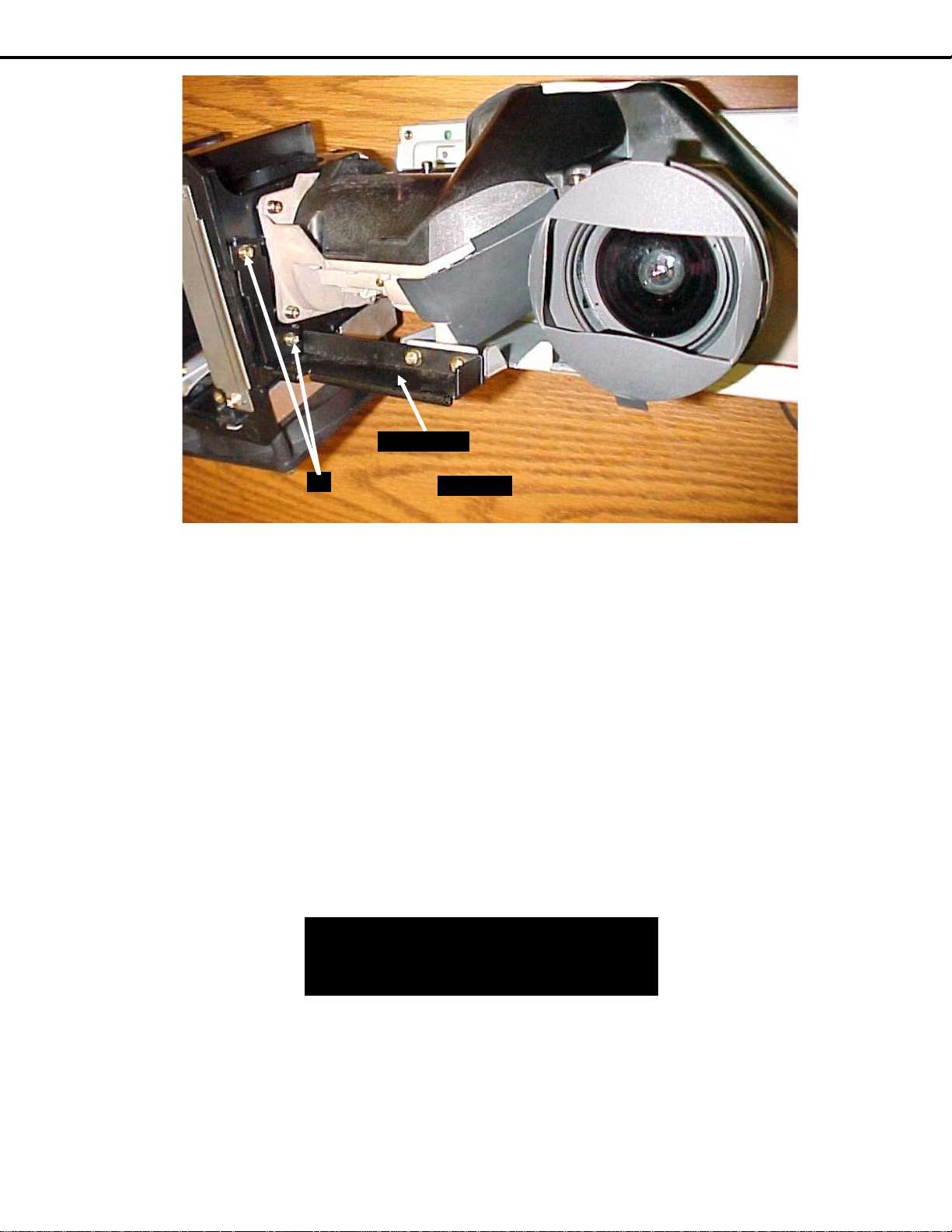

Bla ck Bra cke t

(C)

Front View

Figure 3: Black Support Bracket

Installing the Optical Engine

1) Install the Bottom Plate, Black Support Bracket and the Heat Sensor, removed from the original Optical

Engine, on the replacement Engine

2) Reverse the removal procedure to install the replacement Optical Engine in the cabinet.

3) The following adjustments may have to be performed after the installation. (See Service Manual)

• Horizontal and Vertical Electrical Centering Adjustment.

• Optical Unit Rotation Adjustment

• Optical Unit Keystone Distortion Adjustments.

4) IMPORTANT: After Optical Engine replacement, perform the Data Copy Procedure described below.

Data Copy Procedure

This procedure must be performed after replacing either the Electrical Chassis or Optical Engine.

1) To display the data copy menu press <TV MENU> <2-4-5-7> <0>

2) Use the cursor keys to yellow highlight “Copy Light Engine EEPROM to DM”

3) Press <ENTer>

4) After the copy procedure has been completed, exit the menu by pressing <HOME>

Copy Light Engine EEPROM to DM

Restore backup

UPLOAD TERMINAL BOARD DATA

Page 16

Page 17

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

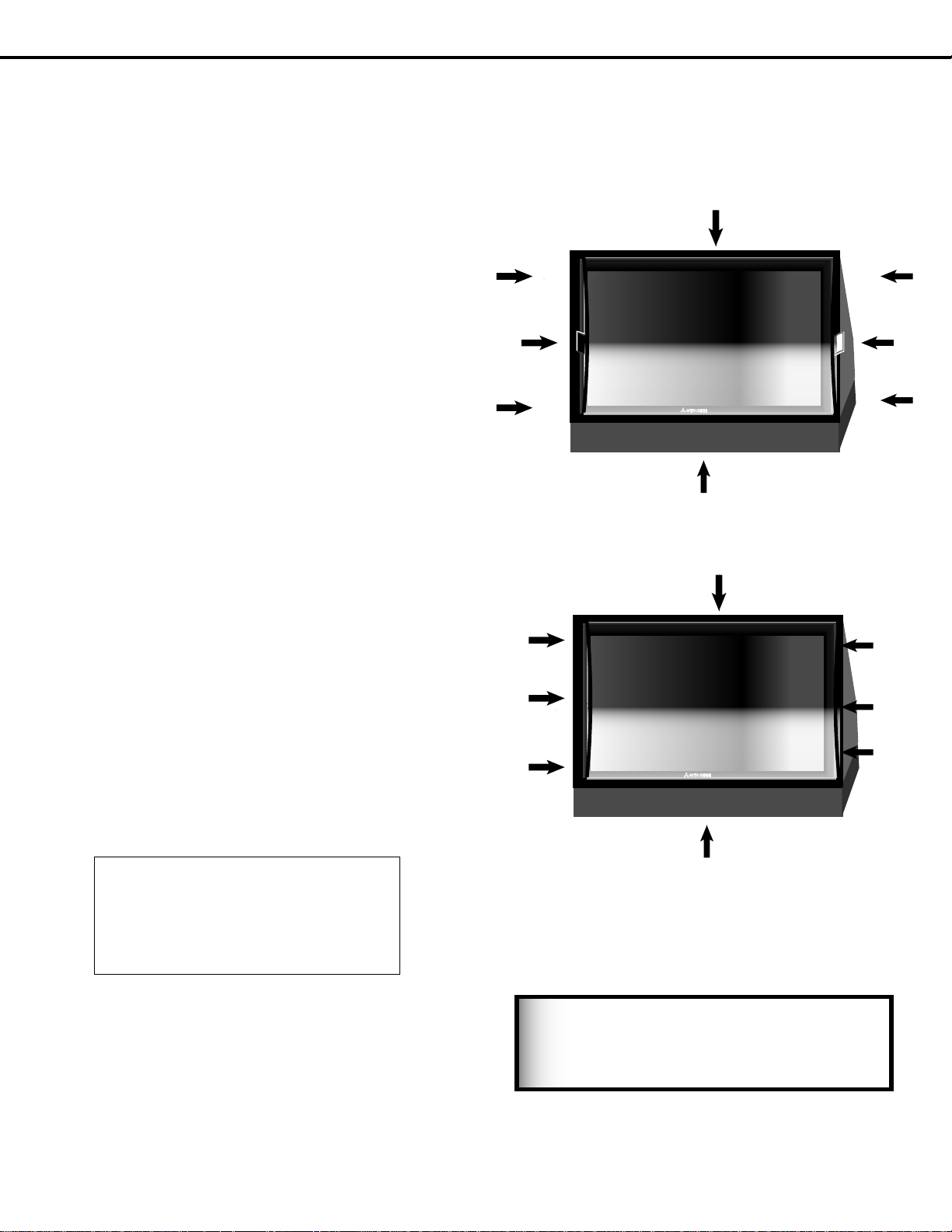

DIAMOND SHIELD REPLACEMENT

To Remove the Diamond Shield:

1. While wearing soft cotton gloves, loosen the

sides of the Diamond Shield by pressing a small

plastic card (the size of a standard credit card or a

clean, plastic, putty knife) into the middle of the

side slot. The Diamond Shield side will snap out

of the top middle and bottom clips. Loosen both

sides before proceeding to step 2.

2. After the sides are free, gently push down on the

top of the Diamond Shield. It will slide out of the

top channel.

3 Carefully pull the screen up to remove it from the

bottom channel. Store the Diamond Shield in a clean,

dust free area, where it will not be scratched.

To Install the Diamond Shield:

4. Slide the Diamond Shield into the bottom channel,

making sure it fits securely.

5. Press gently on the top of the Diamond Shield to

slightly bow the screen towards you. Insert the

top of the Diamond Shield into the top channel. It

should fit securely.

6. At each side, gently press the top, middle and

bottom of the Diamond Shield to snap it back into

place.

2

1

1

1

3

5

6

6

6

1

1

1

6

6

6

WARNING

Sharp edges! Always wear gloves to

handle, lift, install and remove the

Diamond Shield.

4

Page 17

Page 18

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

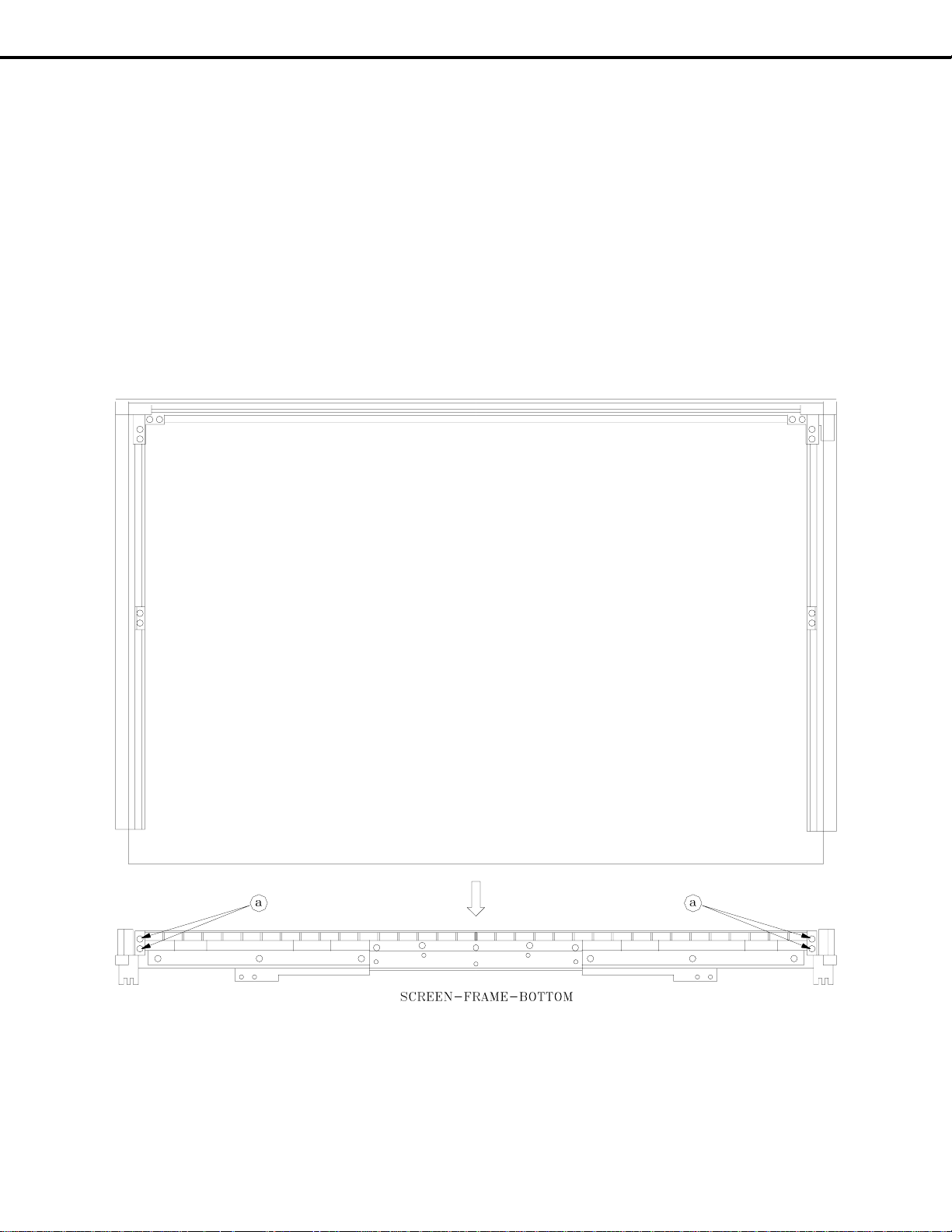

SERVICING THE LENTICULAR SCREEN AND FRESNEL LENS

CAUTION: Wear gloves when handling the Lenticular Screen and Fresnel Lens.

This prevents cuts and finger prints. Do not place Fresnel Lens in the sun.

This may cause fire and heat related injuries.

Lenticular Screen and Fresnel Lens Removal

1. Remove the screen assembly shown in the Cabinet Disassembly procedure.

2. Remove the four screws (a) to remove the bottom of the SCREEN-FRAME-BOTTOM .

3. Carefully slide the Lenticular Screen and Fresnel Lens combination from the Screen Frame assembly.

Note: When separating the Lenticular Screen from the Fresnel Lens, use caution

while prying the Screen and Lens apart. Use a slot type screw driver, and

remove the pressure sensitive double sided tape.

Page 18

Page 19

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

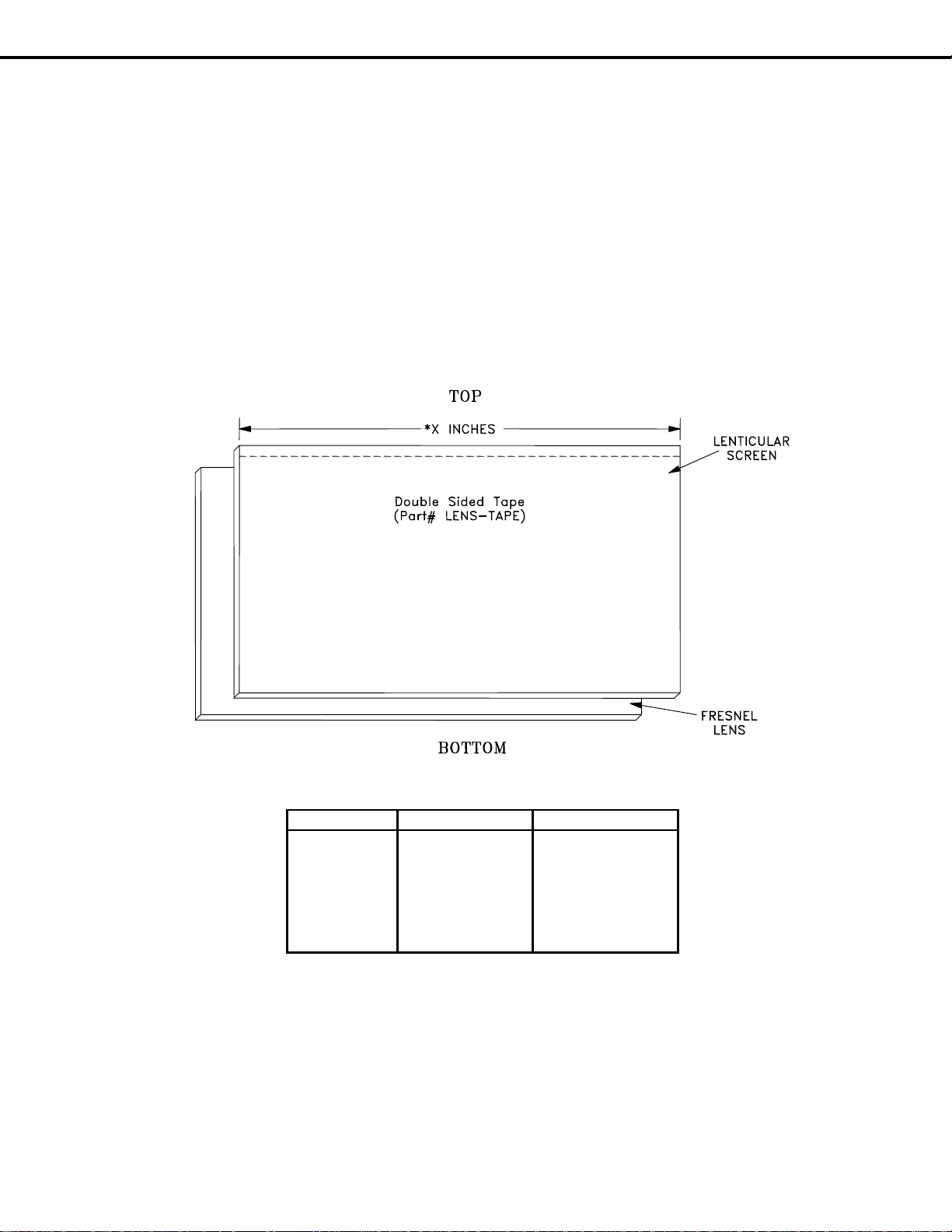

SERVICING THE LENTICULAR SCREEN AND FRESNEL LENS

Lenticular Screen and Fresnel Lens Installation

Note: Store the Lenticular Screen and Fresnel Lens in a cool dry place. High heat and humidity may

deform the Lenticular Screen and Fresnel Lens.

1. Apply double coated tape (Part #LENS-TAPE) along the top rear edge of the Lenticular Screen, as shown

below. Refer to the table below for the tape length.

2. Place the Fresnel Lens on top of the Lenticular Screen and apply pressure at the top edge

to bond them together.

3. Reverse the Screen Removal procedure to insert the screens in the Screen Frame Assembly.

*X INCHES - Refer to the Tape Length in the table below

MODEL SCREEN SIZE TAPE LENGTH

WD-52525 52 Inches 46.3 Inches

WD-52725 " "

WD-52825 " "

WD-62525 62 Inches 55.1 Inches

WD-62725 " "

WD-62825 " "

Page 19

Page 20

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

INITIAL SETUP

OPTION MENU

1. Press the “MENU” button on the remote hand

unit.

2. Press the buttons “2”, “4”, “7” and “0” in order.

(The screen will change to the option menu.)

3. Select “Initialize” and press <ENTer> to restore

all Inital Main Menu Defaults and A/V Reset

Default settings to those listed in the following

two tables.

OPTION MENU <TV MENU> <2-4-7-0>

Initialize

Power Restore: Off

DTV Port: AUTO

Direct Key Mode : Off

NetCommand Software: V26 XXX.XX

Digital Signal Strength: X

00000 00000 00000 00000 00000

Tot al TV

On Time

Current

Lamp

Tim e

Previous

Lamp

Tim e

Previous

Lamp

Tim e 2

Initial Main Menu D efaults

Setup Menu

Language English Programs Not Rated Enable

Combine Channel View -- Movie Rating PG

NetCommand Menu

Edit -- Start 12:00pm

Transport Menu On S top 12:00pm

Default Digital Record Device -Icon Order -- Lock by Time On

Antenna Menu

Antenna 1 Unlock Time 12:00pm

Memorize -- Front B utton Lock Off

Prefer Digital -Channel 3 A/V Memory Res et Ant-1

Memory A dded Settings

Name -SQV -- Bass 50%

Time Me nu

Clock Setting Manual Balanc e 50%

Time 12:00pm Surround Off

Date -- Listen to (Analog Only) Stereo

Time Zone -- Level Sound (Analog Only ) On

Daylight Savings Time -- Language (Digital Only) English

Tim er --

Captions Menu

Analog Captions On if Mute Brightness 50%

Background Gray Sharpness 50%

Digital Caption On if Mute Color 50%

Appearance Default Tint 50%

Digital S ettings Color Temp High

Font Font 3 Video Noise Standard

Siz e Large Film Mode (Auto) On

Color White Define Edge On

Background Black Color Balanc e

Opacity Translucent Video M ute On

Background Opacity Translucent black Enhancem ent On

V-Chip Lock Menu

V-Chip Off

TV Rat i n g TV -P G

FV-Fantas y Violence Enable

D-Sexual Dialog Enable

L-Adult Language Enable

S-Sexual Situations Enable

Page 20

V-Violence Enable

V-Chip Time

Lock by Time

Lock Time 12:00pm

Audio/Video

Audio

Treble 50%

Video

Contrast 100%

TV Speak ers On

TV Volume

PIP Source

PIP Position

POP Position

PIP/POP Format

Format

30%

Ant 1 003

Lower Right

Right Half

Double W indow

Stretch

Previous

Lamp

Tim e 3

Page 21

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

A/V RESET DEFAULT SETTINGS (By Input)

A/V Me mory Ant 1/2

Contrast Max. Max. Max. Max. Max. N/A

Brightness Center Center Center Center Center N/A

Sharpness Center Center Center Center Center N/A

Color Center Center Center Center Center N/A

Tint Center Center Center Center Center N/A

Color Temp. High High High High High N/A

Video Noise Standard Standard Standard N/A N/A N/A

TV Film Mode (Auto) On On On N/A On N/A

TV DefinEdge VS M On On On On On On

Bass Center Center Center Center Center Center

Treble Center Center Center Center Center Center

Balance Center Center Center Center Center Center

Surround OFF OFF OFF OFF OFF N/A

Listen To Stereo N/A N/A N/A N/A Stereo

Level Sound On On On On On N/A

INPUTS

1/2/3

Component

1/2/DTV

1394 w hen

connected

HDMI Card 1~4

A. A/V Memory

Each of the external inputs has its own Audio/Video Memory. A change in an A/V setting at a specific input is

stored in memory for that specific input.

B. A/V Reset

The AV Memory Reset in the user’s menu initializes the selected input’s A/V Memory.

Remote Control Operational Modes

There are two Remote Hand Unit Operational Modes, “Standard” and “NetCommand™”. The Remote is initially

in the “Standard” mode. The “NetCommand” mode is used when controlling Home Theater devices using

NetCommand. To change the Remote Operational Mode:

• Set the Remote to the TV Layer

• Point the Remote away from the TV.

• To change to “Netcommand” ... Hold the “Power” button and press “9-3-5” in sequence.

• To change to “Standard” ... Hold the “Power” button and press “0-0-0” in sequence.

Page 21

Page 22

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

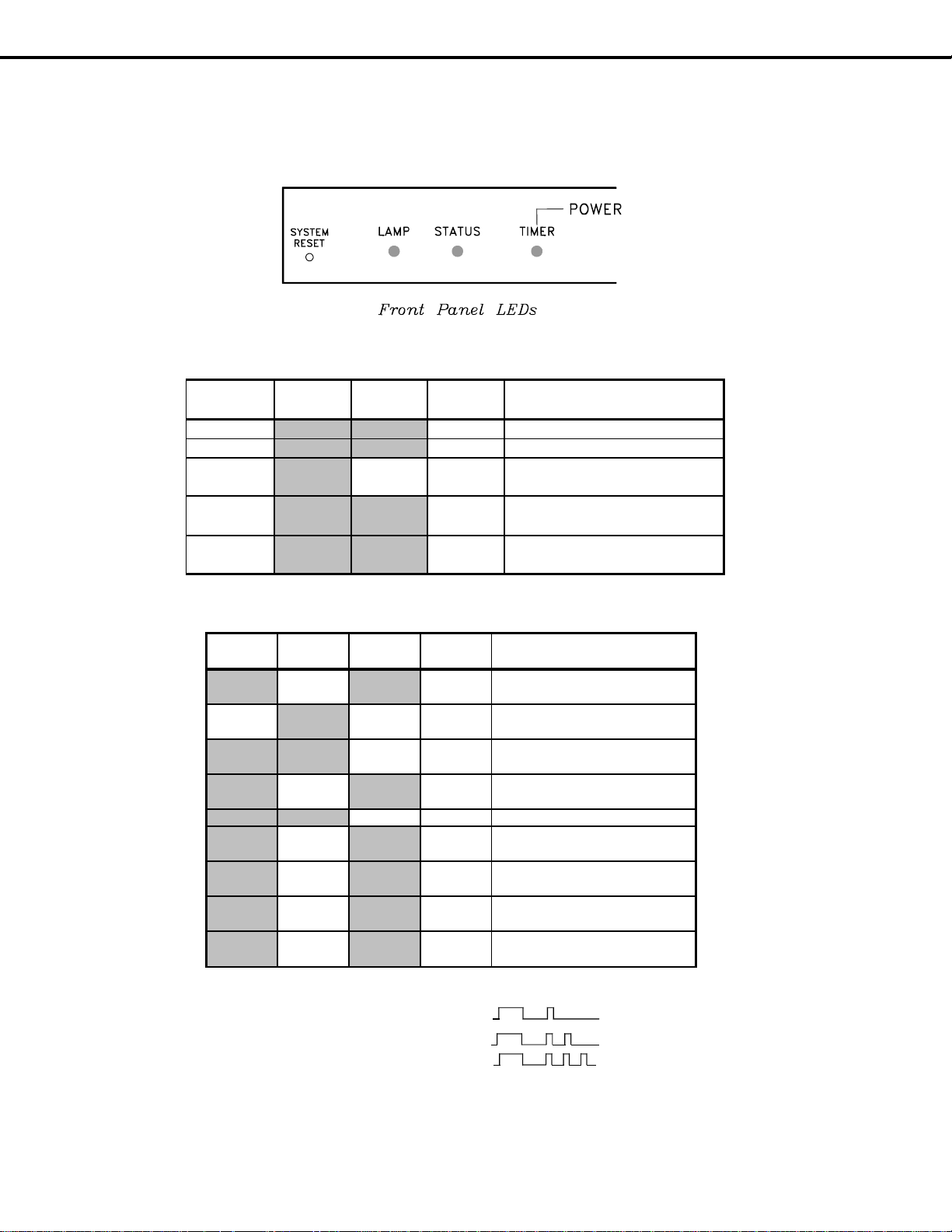

FRONT LED INDICATOR DIAGNOSTICS

The front panel LEDs provide an indication of the sets operation, and the possible cause of a malfunction. There

are three front panel LEDs, “Power”, “Status” and “Lamp”. Which LED is lit, the color, and whether it is blinking or

steady indicate the current status, or a possible malfunction.

Normal LED Indications

POWER

LED

Off Off Off Stby Off

Green Off Off P-0N Power On

Off Off

Blinks

Green

Slow Blinks

Green

STATUS

LED

LAMP

LED

Blinks

Green

Power

Status

After Turn

Off

Condition

Lamp Fan On for 1 minute

Off Off Stby Booting after AC applied

Off Off Stby On Timer is set

Abnormal LED Indications

POWER

LED

Off Yellow Off

Off or On Off Yellow

Off Off

Off

Off Off Red Stby Lamp did not turn On

Off

Off

Off

Off Red Off "

STATUS

LED

Blinks

Yellow

*Blinks

Red

**Blinks

Red

***Blinks

Red

*Blinks = (1 long/1 short)

**Blinks = (1 long/2 short)

***Blinks = (1 long/3 short)

LAMP

LED

Blinks

Yellow

Off " Filter Cover Open

Off

Off "

Off " DMD or Lamp Fan Stopped

Power

Status

Low

Power

No

change

Low

Power

Low

Power

Condition

Excess Temperature

Usage time over 4000 Hrs.

Lamp Cover open

Chassis Fan Stopped

Ballast or Exhaust Fan

Stopped

Short or DVI Cable from FMT

to DMD disconnected

Page 22

Page 23

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

3. Error Code Operational Check

Note: The TV must be in “Shut Down” and not manually switched Off, to perform the Error Code Opera-

tional Check. When the TV is switched Off, the code automatically resets to “12” No Error.

Press the front panel “DEVICE” and “MENU” buttons at the same time, and hold for 5 seconds to

activate the Error Code Operational Check. The LED will then flash denoting a two digit Code.

Note: The front panel buttons must be used, NOT those on the Remote Control.

• The number of flashes indicates the value of the MSD (tens digit) of the Error Code.

• The flashing then pauses for approximately 1/2 second.

• The LED then flashes indicating the value of the LSD (ones digit) of the Error Code.

Example: If the Error Code is “32”, the LED will flash three times, pause, and then flash two times.

• The Error Code is repeated a total of 5 times.

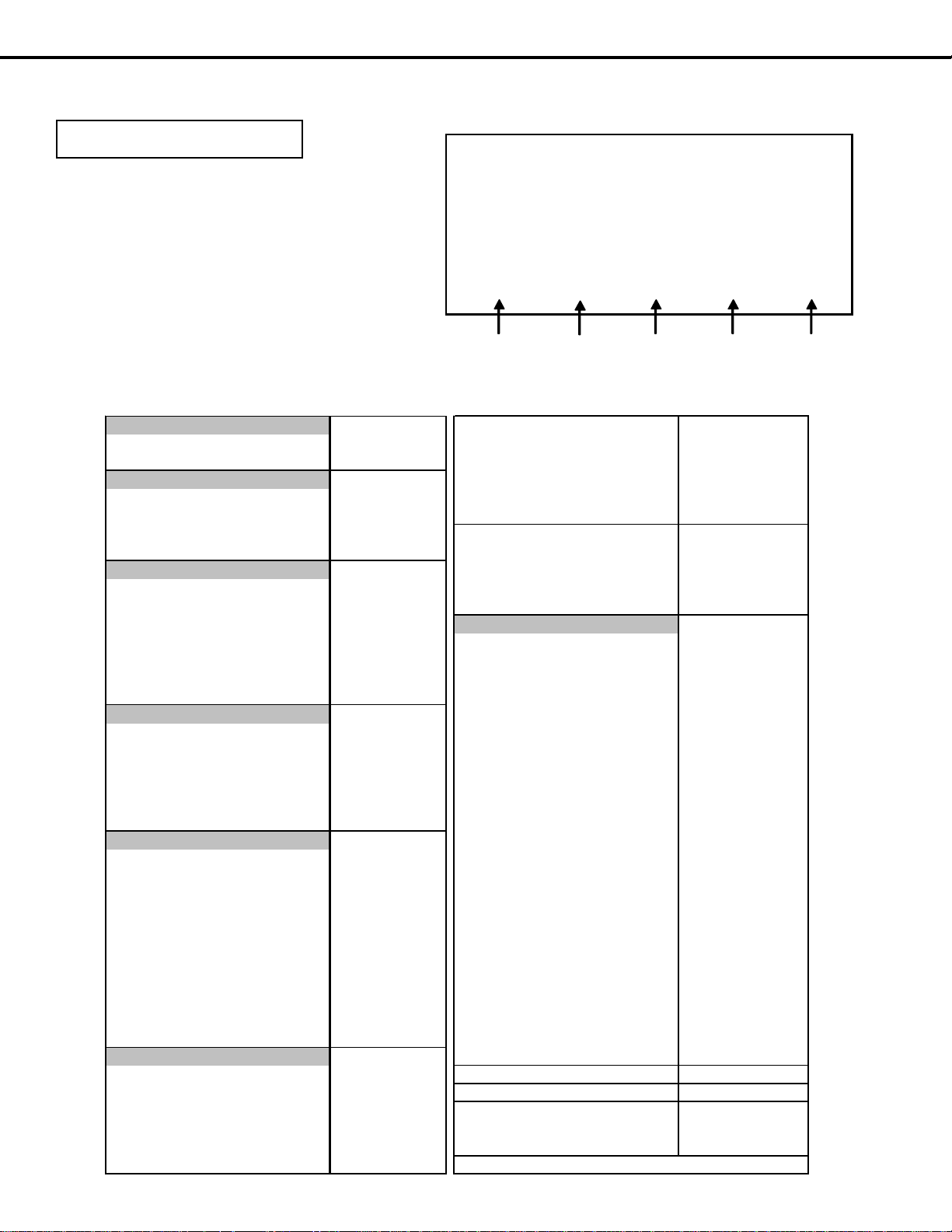

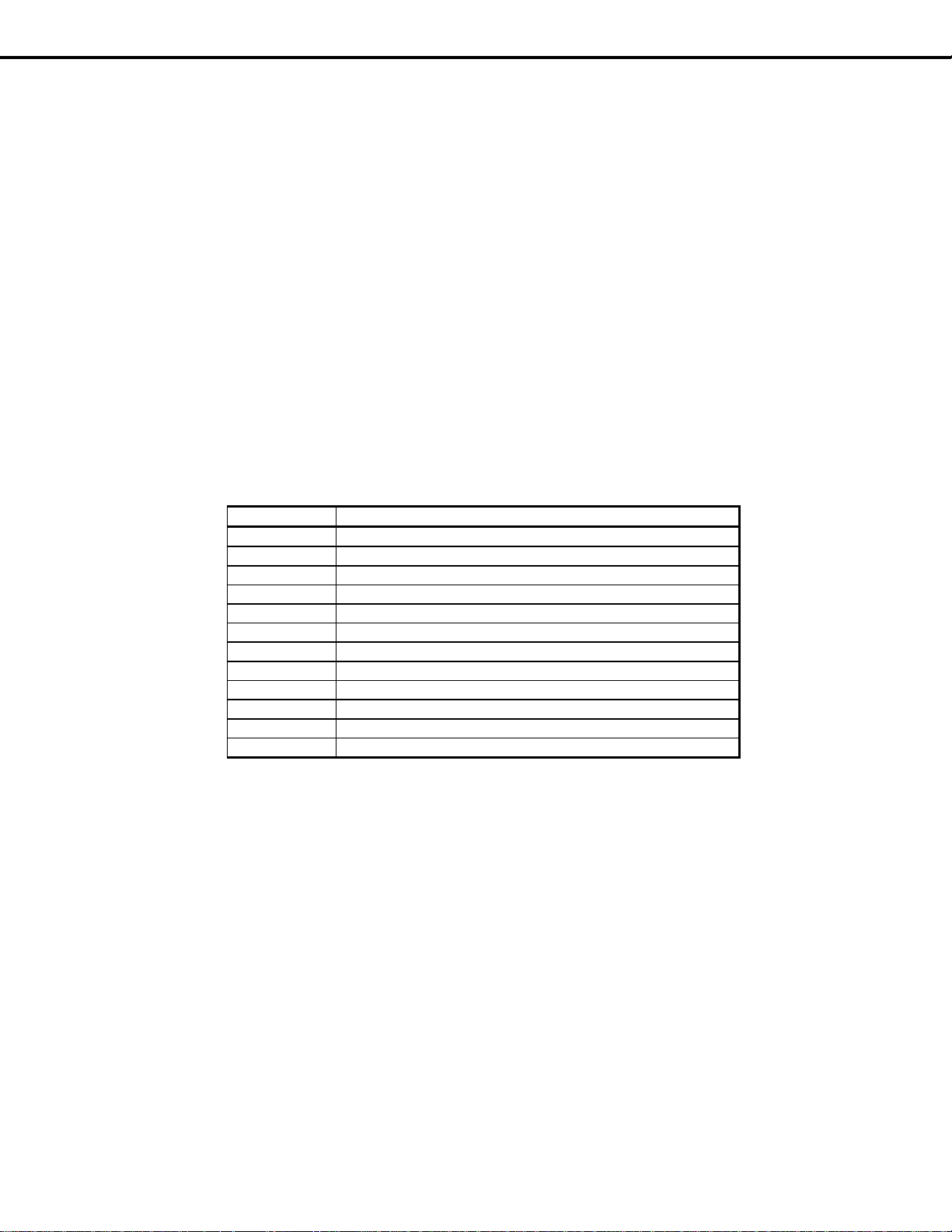

4. Error Codes

The Error Code designations are listed below:

ERROR CODES

Press and Hold "DEVICE" and "MENU" FOR 5 SECONDS

Error Code Probable Cause

12 No error detec ted

22 Recovery from momentary Reset

32 Lamp Cover open

33 Air Filter Cover open

34 Lamp abnormality

35 Chass is Fan failure

36 Ex haust (Back Cover) or Lamp Ballast Fan failure

37 Engine (DMD or Lamp) Fan failure

38 Ex cess Lamp Temperature

39 Ex cess DMD Temperature

41 Short Detected

44 DVI Cable (between Chassis and Engine) disconnected

Page 23

Page 24

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

SERVICE ADJUSTMENTS

There are only 5 Service Adjustments required:

Two Electrical Adjustments

• Horizontal Centering

• Vertical Centering

Three Mechanical Adjustments

• Picture Rotation

• Horizontal Keystone Distortion

• Vertical Keystone Distortion

Tools, Test equipment and Test signals

• Conventional Hand Tools.

• No additional Test Equipment is required.

• Test Signals are internally generated, no external signals are required.

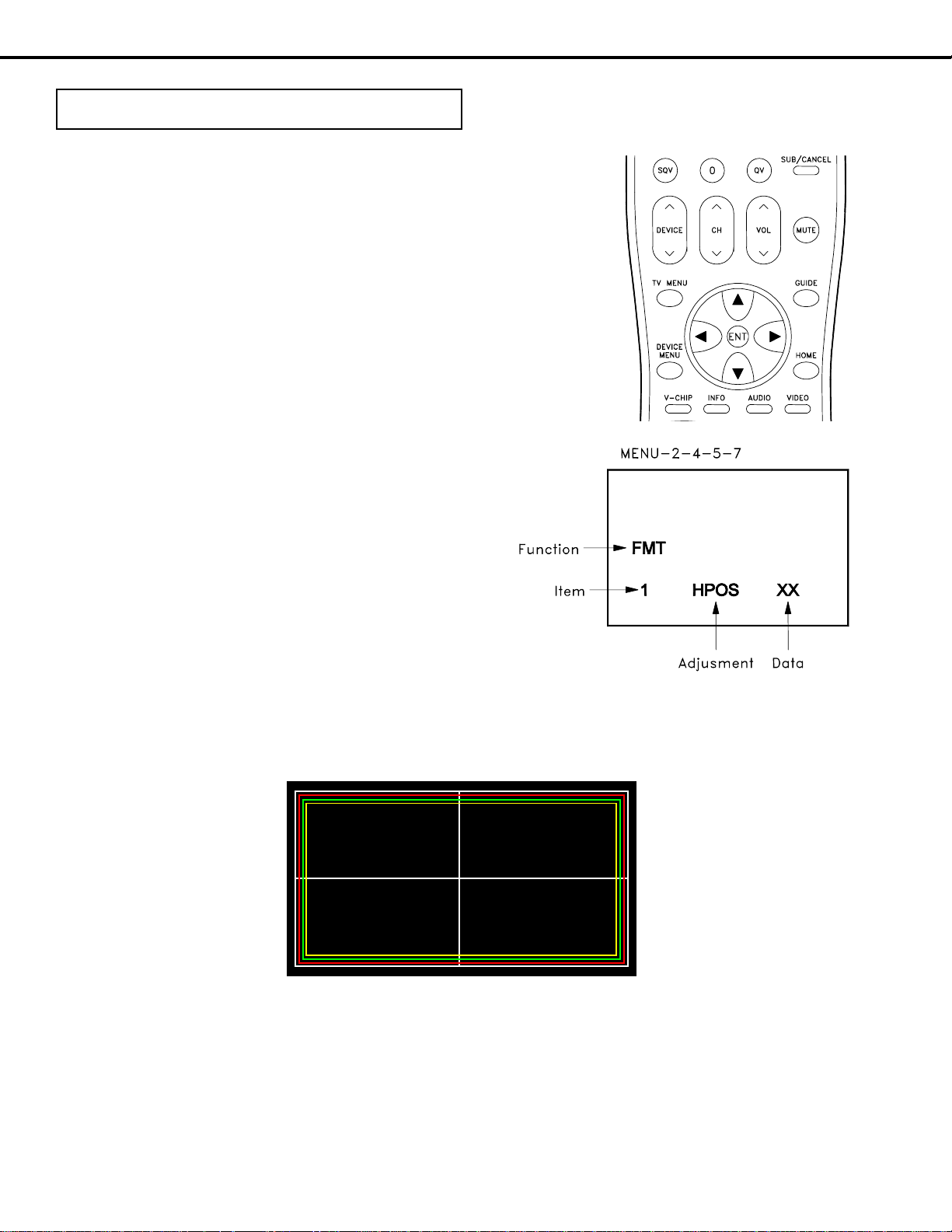

Circuit Adjustment Mode

On these models, the Circuit Adjustment Mode is used only for:

• Test Signal activation

• Horizontal Centering

• Vertical Centering

1. Activating the Circuit Adjustment mode

1. Press the “TV MENU” button on the remote control.

(The Customer Menu will appear.)

2. Press the buttons “2”, “4”, “5” and “7” in that order.

(The screen will change to the adjustment mode.)

If unsucessful, repeat steps 1 and 2.

2. Test Signal Activation

When in the Circuit Adjustment mode, press “REWIND” once on the remote control to activate the test pattern.

This pattern is used for both electrical and mechanical adjustments.

Page 24

Page 25

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

3. Adjustment Function Selection

Use the “AUDIO” button to select a specific Adjustment Function.

AD9883A MMTX

Functions

SMTXlight engfmt

4. Adjusting Data

After selecting an adjustment item, use the UP and DOWN cursor buttons to change adjustment data.

• If the UP button is pressed, the adjustment data increases.

• If the DOWN button is pressed, the adjustment data decreases.

5. Saving data

Press “ENTER” to save the adjustment data in memory.

The display characters go red for about one second in this step.

Note: If the circuit adjustment mode is terminated without pressing

“ENTER”, changes in adjustment data are not saved.

6. Terminating the circuit adjustment mode

Press the “HOME button or the “MENU” button twice on the remote to terminate the adjustment mode.

Note: The adjustment mode can be also terminated by turning the

power off.

Resetting Data to Factory Values

1) Enter the Service Adjustment Mode ... Press “TV MENU” “2-4-5-7”

2) Press “0” when in the Service Mode ... Three choices appear at the top of the screen.

"TV MENU" "2-4-7-0" then "0"

Copy Light Engine EEPROM to DM

Restore backup

UPLOAD TERMINAL BOARD DATA

3) Use UP & DOWN keys to highlight the desired choice, then Press “ENTER”

• Copy Light Engine EEPROM to DM ... required after replacing the Light Engine or Electrical

Chassis.

• Restore Back Up ... resets Service Mode data back to factory values. Use this feature if service

adjustment data has been corrupted or improper adjustments have been performed.

• Up Load Terminal Board Data ... uploads White Balance data from PWB-SIGNAL.

(Do Not Select. This option is for depot level service only.)

Page 25

Page 26

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

A

g

g

SERVICE MODE - Adjustment Items and Initial Data Values

AD9883

Item # Abbrev. Description

12 ROFF Red Offset 0~127

14 BOFF Blue Offset 0~127

Main Matrix (MMTX)

Item # Abbre v. Description

1 TNTM Hue Control 0~63 31

4 COLM Color Gain Control 0~63 19

15 YDRM Y Drive Gain Control 0~31 5

19 VPDM V Signal Pedestal Control 0~15 2

20 UPDM U Signal Pedestal Control 0~15 2

Data

Ran

Data

Range

e

Initial

Data

Sub M a trix (S MTX)

Item # Abbre v. Description

1 TNTS Hue Control 0~63 31

4 COLS Color Gain Control 0~63 16

15 YDRS Y Drive Gain Control 0~31 5

19 VPDS V S ignal Pedestal Control 0~15 2

20 UPDS U Signal Pedes tal Control 0~15 2

Light Engine (light eng)

Item # Abbrev. Description

120 GGH Temp. H Green Gain

121 GRH Temp. H Red Gain

122 GBH Temp. H Blue Gain

123 GGM Temp. M Green Gain

124 GRM Temp. M Red Gain

125 GBM Temp. M Blue Gain

126 GGL Temp. L Green Gain

127 GRL Temp. L Red Gain

128 GBL Temp. L Blue Gain

Data

Range

Initial

Data

Format (fmt)

Item # Abbrev. Description

Data

Ran

e

1 HPOS Horizontal Position 0~255

2 VPOS Vertical Position *0~255

* Do Not

set VPOS Data to 0 or 255 and press Enter.

(Video will be muted and On Screen Menus will no

longer be visible.)

Page 26

Page 27

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

Electrical Adjustments

[PICTURE POSITION]

1. Horizontal/Vertical Position

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input

----

----

------

-------

None

ANT-DTV

Purpose:

Symptom:

To center picture on the screen.

Picture is off center.

NOTE: The TV should be placed on a flat level surface.

Improper installation can affect raster geometry.

1. Select the ANT-DTV Input, no signal.

2. Press “TV MENU-2-4-5-7” in sequence

3. Press “REWIND” to activate the Test Pattern shown above.

4. Press “AUDIO” to select “FMT” function.

5. Use the “VIDEO” button to select “1 HPOS”.

6. Use the “ADJUST” buttons to center the picture Horizontally.

7. Press “ENTER” to save the adjustment.

8. Use the “VIDEO” button to select “2 VPOS”.

9. Use the “ADJUST” buttons to center the picture Vertically.

10. Press “ENTER” to save the adjustment.

CAUTION: DO NOT set VPOS data to “0” or “255” and press ENTER.

Video will be muted and On Screen Menus will no longer be visible.

11. Press “HOME” or “TV MENU” twice to terminate the Adjustment Mode.

Mechanical Adjustments

Picture Rotation Adjustment

NOTE: The TV should be placed on a flat level surface.

Improper installation can affect raster geometry.

1. Refer to the Disassembly Preocedures on Pages 7, 8, and 9 to remove the Speaker Grille, Front Cover, Back Cover and

Inner Cover.

2. From the front of the TV, lift the sponge to access and slightly loosen the brass Rotation Locking Screws on the Adjuster

Assembly, Figure 4A. (Use a 10mm wrench.)

3. From the rear of the TV, access the black Rotation Adjustment screw (4mm allen wrench) and adjust so the test pattern

center lines are parallel to the sides, top and bottom of the screen frame, Figure 4B. (Use a mirror to view the picture

from the rear of the set.)

4. Tighten the two Locking Screws. Use Locktite to secure the Adjustment Screw. (If necessary, use the electrical

adjustments to center the picture)

Page 27

Page 28

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 /WD-62825

Page 28

Page 29

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

A

A

Keystone Adjustment

NOTE: The TV should be placed on a flat level surface.

Improper installation can affect raster geometry.

Horizontal Keystone Distortion

Vertical Keystone Distortion

1. From the front of the TV, loosen the two Keystone Locking Screws in the small mirror assembly. (10mm box wrench)

2. From the front of the TV, adjust the Horizontal Keystone Adjustment for minimum distortion. (4mm allen wrench)

3. From the front of the TV, adjust the Vertical Keystone Adjustment for minimum distortion.

Note: There may be some inter-action between the Keystone and Rotation Adjustments.

4. Tighten the Keystone Lock Screws. and secure the adjustment screws with Locktite.

Horiz

Keystone

djust

Locking Screws

Vertical

Keystone

djust

Small Mirror Assembly (Front View)

Page 29

Page 30

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

p

A

p

p

REPLACEMENT PARTS

Critical Electrical Components are indicated by Bold Type in the Parts List.

QUICK REFERENCE FOR COMMON REPLACEMENT PARTS

Customer Replaceable Parts

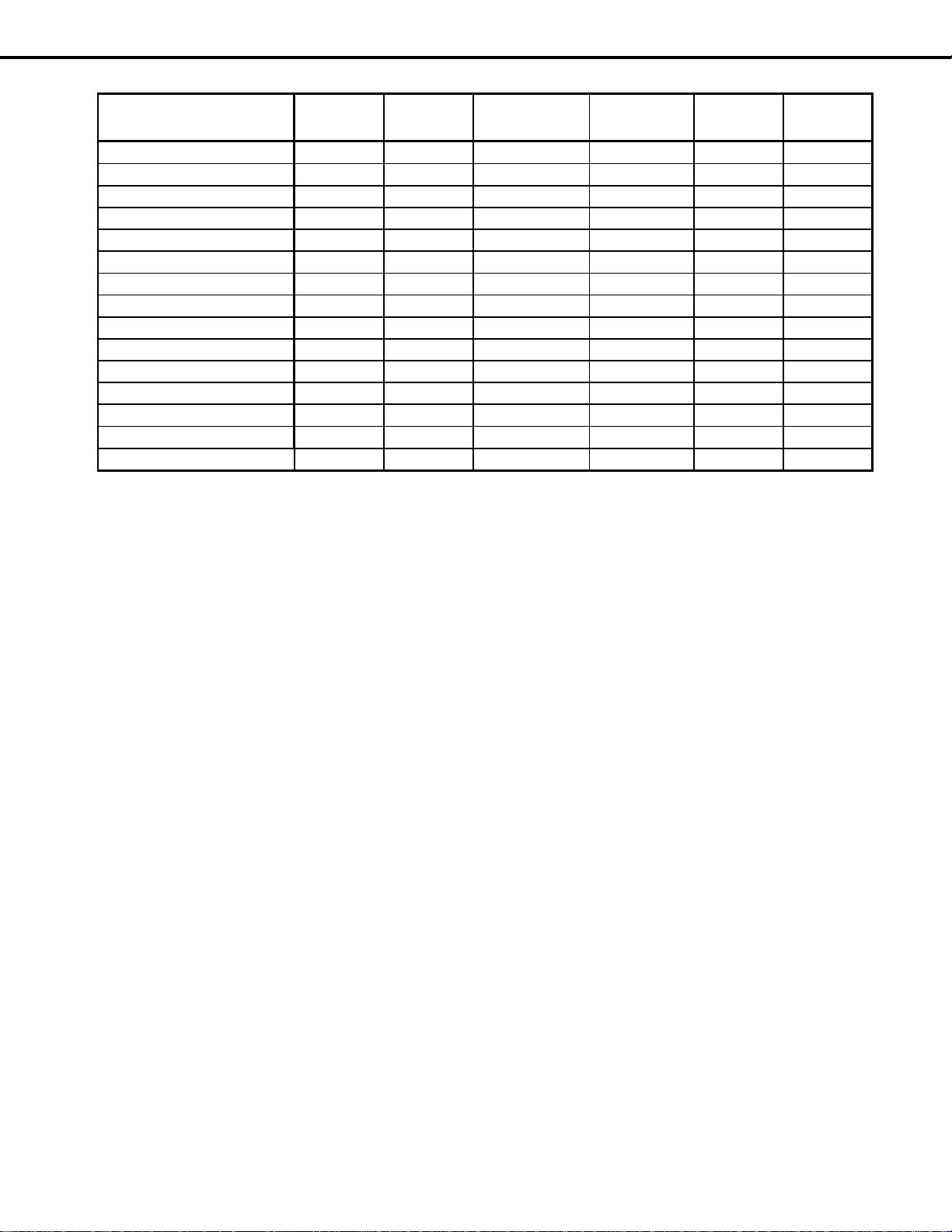

Part Name Description WD-52525 WD-62525 WD-52725 WD-62725 WD-52825 WD-62825

Lamp Cartridge LAMP - CARTRIDGE

Dust Filter FILTER - DUST 620D144010 620D144010 620D144010 620D144010 620D144010 620D144010

Remote Control REMOTE 290P123010 290P123010 290P123020 290P123020 290P123020 290P123020

Part Name Descri

Optical Engine OPTICAL-ENGINE 939P977010 939P977020 939P977010 939P977020 939P977010 939P977020

Electrical Chassis

Lamp Ballast PCB UNIT-POWER-LAMP 939P978010 939P978010 939P978010 939P978010 939P978010 939P978010

Memory Card PCB

Preamp PCB ASSY-PWB-PREAMP 935D774001 935D774001 935D774001 935D774001 935D774001 935D774001

Front PCB ASSY-PWB-FRONT 935D775001 935D775001 935D775001 935D775001 935D779001 935D779001

Control PCB ASSY-PWB-CONTROL 935D776001 935D776001 935D776001 935D776001 935D776001 935D776001

Right Speaker PCB ASSY-PWB-SPEAKER-R 935D806001 935D806001 935D806001 935D806001 935D806001 935D806001

Left Speaker PCB ASSY-PWB-SPEAKER-L 935D807001 935D807001 935D807001 935D807001 935D807001 935D807001

Hard Disk DriveASSY-HDD-UNIT ----939P989010 939P989010

Lamp Ballast Fan FAN-BALLAST 299P278020 299P278020 299P278020 299P278020 299P278020 299P278020

Lamp Fan FAN-LAMP

DMD Fan FAN-DMD 299P283010 299P283010 299P283010 299P283010 299P283010 299P283010

Chassis Fan FAN-COOLING 299P103050 299P103050 299P103050 299P103050 299P103050 299P103050

Exhaust Fan FAN-COOLING

Lamp Cover Detect Switch SW-MICRO 436P021010 436P021010 436P021010 436P021010 436P021010 436P021010

Filter Cover Detect Switch SW-MICRO 436P021010 436P021010 436P021010 436P021010 436P021010 436P021010

DMD Thermal Sensor SENSOR – THERMAL 299P280010 299P280010 299P280010 299P280010 299P280010 299P280010

Lamp Thermal Sensor

Bold Type = Safety Critical

(Complete)

SSY-CHASSIS 955B298001 955B298001 955B298002 955B298002 955B298003 955B298003

MEMORY -CARD-RE ADER-P WB 299P271010 299P271010 299P271010 299P271010 299P271010 299P271010

SENSOR-THERMAL (LAMP) 299P285010 299P285010 299P285010 299P285010 299P285010 299P285010

tion WD-52525 WD-62525 WD-52725 WD-62725 WD-52825 WD-62825

915P020010 915P020010 915P020010 915P020010 915P020010 915P020010

Service Parts

299P282010 299P282010 299P282010 299P282010 299P282010 299P282010

299P103050 299P103050 299P103050 299P103050 299P103050 299P103050

Screen Parts

Part Name Descri

DiamondShield

Lenticular Screen

Fresnel Lens

PWB Name Descri

Power

Signal PWB-SIGNAL 930B923002 930B923002 930B923001 930B923001 930B923003 930B923003

Format PWB-FMT 930B924002 930B924002 930B924003 930B924003 930B924001 930B924001

DM PWB-DM 934C116002 934C116002 934C116003 934C116003 934C116001 934C116001

Terminal-1 PWB-TERMINAL 1 934C117001 934C117001 934C117001 934C117001 934C117002 934C117002

Terminal-2 PWG-TERMINAL-2 934C118001 934C118001 934C118001 934C118001 934C118001 934C118001

DIAMOND - SHIELD

LENS - LENTICULAR

LENS - FRESNEL

PWB-POW ER

tion WD-52525 WD-62525 WD-52725 WD-62725 WD-52825 WD-62825

KIT-WD52525 DS KIT-WD62525 DS KIT-W D52725 DS KIT-W D62725 DS KIT-W D52825 DS KIT-WD62825 DS

491P178020 491P174020 491P178020 491P176020 491P178020 491P176020

491P177020 491P173020 491P177020 491P175020 491P177020 491P175020

Chassis PWBs

tion WD-52525 WD-62525 WD-52725 WD-62725 WD-52825 WD-62825

930B921002 930B921002 930B921002 930B921002 930B921001 930B921001

Note: The DiamondShield includes the Shield, Logo, Side and Bottom Clips.

PAGE 30

Page 31

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

[#] Model Legend: [a] WD-52525, [b] WD-52725, [c] WD-52825, [d] WD-62525, [e] WD-62725, [f] WD-62825

Ref # Part # Part Name & Description [#]

Ref # Part # Part Name & Description [#]

INTEGRATED CIRCUITS

IC2000 276P090010 IC-C-MOS - SiI9993

IC2010 261P829010 TR-CHIP - NDC7002N

IC2020 275P981010 IC-C-MOS - 24LCS22AT/SN

IC2030 271P069010 IC-C-MOS - CM1210-08MS

IC2040 271P071010 IC - BA033SFP

IC2C00 275P989010 IC-C-MOS - MAX3223ECAP

IC2C01 276P020010 IC-C-MOS - SN74LVC2G14DBVR

IC2C02 276P064010 IC-C-MOS - SN74LVC1G125DBV

IC2C03 276P064010 IC-C-MOS - SN74LVC1G125DBV

IC2K01 271P061010 IC - CXA2189Q

IC2L00 271P078010 IC - MM1566AJBE

IC2M01 275P947010 IC-C-MOS - UPD64083

IC2M02 272P379020 IC - LM1881MX (NSC)

IC3E00 271P080010 IC - TDA8922J

IC3J01 271P060010 IC - CXA2188Q

IC7A00 276P017020 IC-C-MOS - M306V7MG

IC7A01 275P533010 IC-C-MOS - M24C64WM6T

IC7A02 270P706020 IC - MAX823REUK

IC7A03 275P786010 IC-C-MOS - TC7SA08FU

IC7A05 271P023010 IC - SN74CBTD1G125DBVR

IC7A06 271P023010 IC - SN74CBTD1G125DBVR

IC7D00 275P278010 IC-C-MOS - TC74LVX14FT

IC7D01 270P818020 IC - CXA3506R

IC7DA1 267P176010 HIC - AF-9412

IC7DB0 270P677010 IC - BA033FP

IC7DC0 270P992010 IC - BA18BC0FP

IC7E01 275P894010 IC-C-MOS - AD9883AKST-110

IC7E02 275P663030 IC-C-MOS - M4A3-32/32-5VC-48

IC7H00 276P106010 IC-C-MOS - MB87M1823PFV-ES-BND

IC7K21 270P831010 IC-C-MOS - OPA2350PA

IC7M00 276P091010 IC-C-MOS - M12L64322A-6T

IC7N01 275P682010 IC-C-MOS - TC74VCX16244FT

IC7N02 275P682010 IC-C-MOS - TC74VCX16244FT

IC7P01 275P943030 IC-C-MOS - PIC18F252T-I/SO030

IC7P03 263P154010 IC-C-MOS - SN74HC132DB

IC7P04 271P023010 IC - SN74CBTD1G125DBVR

IC8001 276P030020 IC-C-MOS - 215H31AGA12 be

IC8001 276P030030 IC-C-MOS - 215H31AGA12H

IC8002 270P706020 IC - MAX823REUK

IC8003 276P064010 IC-C-MOS - SN74LVC1G125DBV cf

IC8003 276P064010 IC-C-MOS - SN74LVC1G125DBV

IC80E1 275P657050 IC-C-MOS - 24LC256T-I/SN

IC80E2 276P174010 IC-C-MOS - AT24C512N-10S1-2.7

IC80E3 270P880010 IC - 24LC64I/SN

IC8101 271P033010 IC - LP2996MRX

IC8102 276P029020 IC-C-MOS - NT5DS16M16BT-5T

IC8103 276P029020 IC-C-MOS - NT5DS16M16BT-5T

IC8104 276P029020 IC-C-MOS - NT5DS16M16BT-5T

IC8105 276P029020 IC-C-MOS - NT5DS16M16BT-5T

IC81A1 270P991010 IC - IRU3037CS

IC81A2 261P135010 FET-HEX - IRF7313

IC81A3 270P879030 IC - SC1566I5M-2.5TR

IC81A4 270P992010 IC - BA18BC0FP

IC81A5 270P879030 IC - SC1566I5M-2.5TR

IC81A6 270P037020 IC - MIC29301-5.0BU

IC81A7 270P999010 IC - NJM2370R09

IC81A8 271P081010 IC - BA00CC0WFP

IC8205 276P042010 IC-C-MOS - MIC2544-1BM

IC8211 276P029020 IC-C-MOS - NT5DS16M16BT-5T

IC8212 276P029020 IC-C-MOS - NT5DS16M16BT-5T

IC8280 275P955010 IC-C-MOS - RTC-8564JE

IC8301 275P677010 IC-C-MOS - SN74LVC573APWR

IC8302 275P677010 IC-C-MOS - SN74LVC573APWR

IC8303 275P677010 IC-C-MOS - SN74LVC573APWR

IC8305 275P956010 IC-C-MOS - MD2811-D16-V3

IC8305 275P956020 IC-C-MOS - MD2811-D32-V3

IC8307 275P983010 IC-C-MOS - XR16L2750CM

IC8308 276P077010 IC-C-MOS - ST013T

IC8309 275P660020 IC-C-MOS - CS4341-KSR

IC8310 275P270010 IC-C-MOS - M66010GP

IC8311 275P769010 IC-C-MOS - TC74AC157FT

IC8312 270P938010 IC - MC33202D

IC8313 275P731020 IC-C-MOS - MSP3445G-QI-B8-V3

IC8314 275P677010 IC-C-MOS - SN74LVC573APWR

IC8315 275P464010 IC-C-MOS - TC7WH14FK

IC8316 276P064010 IC-C-MOS - SN74LVC1G125DBV

IC8401 275P624010 IC-C-MOS - TSB42AA4

IC8402 275P686010 IC-C-MOS - TSB41AB3PFP

IC8501 275P679010 IC-C-MOS - TC74LCX74FT

IC8502 275P124040 IC-C-MOS - SN74LVC245APWR

IC8503 275P677010 IC-C-MOS - SN74LVC573APWR

IC8504 271P036020 IC - TPS2221PWPR

IC8505 275P677010 IC-C-MOS - SN74LVC573APWR

IC8506 276P065020 IC-C-MOS - CIMAX(103563)

IC8507 275P680010 IC-C-MOS - TC74VCX257FT

IC8508 275P675010 IC-C-MOS - SN74LV125APWR

IC8509 271P036020 IC - TPS2221PWPR

IC8600 275P983010 IC-C-MOS - XR16L2750CM

IC8601 275P122020 IC-C-MOS - SN74LV32APWR

IC8602 275P676010 IC-C-MOS - SN74LVC139APWR

IC8705 275P769010 IC-C-MOS - TC74AC157FT

IC8706 275P731020 IC-C-MOS - MSP3445G-QI-B8-V3

IC8707 276P089010 IC-C-MOS - TC7W66FU

IC8708 270P037020 IC - MIC29301-5.0BU

IC8709 271P082010 IC - LD1117DT12

IC8710 271P072010 IC - LD29150DT25

IC8711 295P527010 TUNER-NTSC DEMODULATOR

IC8712 276P109010 IC-C-MOS - CS4334-KS

IC8713 270P938010 IC - MC33202D

IC8719 271P023010 IC - SN74CBTD1G125DBVR

IC8720 271P023010 IC - SN74CBTD1G125DBVR

IC8722 271P064010 IC - TA75S01F

IC8723 275P278010 IC-C-MOS - TC74LVX14FT

IC8800 270P877010 I C - UPC3217GV

IC8801 270P877010 I C - UPC3217GV

IC8802 275P464010 IC-C-MOS - TC7WH14FK

IC8805 270P988010 IC-OP AMP - LM358M

IC8806 271P039010 IC-C-MOS - NXT2003 100C

IC8A00 275P980010 IC-C-MOS - SAA7115HL cf

IC8A01 275P982020 IC IC8A02 276P111010 IC-C-MOS - AK5353VT cf

IC8A03 276P112010 IC-C-MOS - BCM7040 KQL cf

IC8B01 275P278010 IC-C-MOS - TC74LVX14FT

IC8B02 270P818020 IC - CXA3506R

IC8B03 270P915020 IC - RT9161A-33CG

IC8B04 270P537010 IC - M52347FP cf

IC8B04 270P537010 IC - M52347FP abde

IC8B05 275P981010 IC-C-MOS - 24LCS22AT/SN

C-MOS - MT48LC2M32B2P-7 c f

PAGE 31

Page 32

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

[#] Model Legend: [a] WD-52525, [b] WD-52725, [c] WD-52825, [d] WD-62525, [e] WD-62725, [f] WD-62825

Ref # Part # Part Name & Description [#]

Ref # Part # Part Name & Description [#]

IC8C01 275P994010 IC-C-MOS - S1L52502B24S000

IC8C03 275P689010 IC-C-MOS - ICS551MT

IC8C04 275P680010 IC-C-MOS - TC74VCX257FT

IC8D01 275P997010 IC-C-MOS - IP00C720

IC8D02 275P982020 IC-C-MOS - MT48LC2M32B2P-7

IC8D03 276P113040 IC-C-MOS - XC9572XL-8D03

IC8E00 276P107010 IC-C-MOS - SiI164

IC8E01 276P113030 IC-C-MOS - XC9572XL-10TQ100C-8E0102

IC8E02 276P113030 IC-C-MOS - XC9572XL-10TQ100C-8E0102

IC8F01 276P156010 IC-C-MOS - M30826MH-092GP

IC8F02 275P657050 IC-C-MOS - 24LC256T-I/SN

IC8F03 274P503020 IC-C-MOS - 74ACT245MTC

IC8F04 271P010010 IC - RT9172-18CG cf

IC8F05 271P009010 IC - RT9172-25CG

IC8F06 270P677020 IC - BA05FP

IC8F07 261P135010 FET-HEX - IRF7313

IC8F08 270P991010 IC - IRU3037CS

IC8F09 270P915020 IC - RT9161A-33CG

IC8F10 275P786010 IC-C-MOS - TC7SA08FU

IC8F11 275P124040 IC-C-MOS - SN74LVC245APWR

IC8F12 275P124040 IC-C-MOS - SN74LVC245APWR

IC8F13 275P124040 IC-C-MOS - SN74LVC245APWR

IC8F14 275P124040 IC-C-MOS - SN74LVC245APWR

IC8F15 275P124040 IC-C-MOS - SN74LVC245APWR

IC8F16 260P846030 TR-CHIP - DTC143ZKAT146

IC8F17 270P696010 IC - BA05SFP bcef

IC8G00 276P108020 IC-C-MOS - M306H2MC-517FP be

IC8G00 276P108030 IC-C-MOS - M306H2FCFP-V261 cf

IC8G01 270P706010 IC - MAX823 bcef

IC8G02 271P023010 IC - SN74CBTD1G125DBVR bcef

IC8G03 276P020010 IC-C-MOS - SN74LVC2G14DBVR bcef

IC8G04 271P023010 IC - SN74CBTD1G125DBVR bcef

IC8G05 275P443010 IC-C-MOS - TC7SET08H bcef

IC8G06 271P023010 IC - SN74CBTD1G125DBVR bcef

IC8H01 270P658030 IC - CXA2019AQ/T4

IC8H02 271P079010 IC - CXA2181Q

IC8H10 271P071020 IC - BA09SFP

IC8H20 270P696010 IC - BA05SFP bcef

IC8T01 270P658030 IC - CXA2019AQ/T4

IC8T02 271P079010 IC - CXA2181Q

IC8T10 271P023010 IC - SN74CBTD1G125DBVR

IC8T11 271P023010 IC - SN74CBTD1G125DBVR

IC9A10 267P175010 HIC - STR-W6735

IC9A11 270P696010 IC - BA05SFP

IC9A12 271P081010 IC - BA00CC0WFP

IC9A20 270P816010 IC - NJM431L

IC9A21 270P991010 IC - IRU3037CS

IC9C01 271P071020 IC - BA09SFP

IC9C21 271P072020 IC - LD29150DT33

IC9C41 271P072030 IC - LD29150DT50

IC9M01 270P677010 IC - BA033FP

IC9M02 270P992020 IC - BA25BC0FP

IC9M03 271P071020 IC - BA09SFP

IC9M04 270P696010 IC - BA05SFP

TRANSISTORS

CHIP Type Transistors (Listed by Part No.)

Part No. Description

260P806010 DTA124EK/UN2112

260P809010 DTC114YK

260P817030 2SA1037K-S

260P817050 2SA1037K-R,S/2SB709AI-R,S

260P817080 2SA1037K-R,S

260P818030 2SC2412K-S

260P818050 2SC2412K-R,S/2SD601AI-R,S

260P818080 2SC2412K-R,S

260P836090 2SC3326-A,B

260P846030 DTC143ZKAT146

261P005010 2SC3123

TRANSISTORS

Conventional Transistors (By Ref #)

Ref # Part # Part Name & Description [#]

Q7E03 261P114010 TR - 2SA1585STPR

Q8800 261P026010 TR - 2SC3356

Q9A20 261P135010 FET-HEX - IRF7313

Q9A70 261P101010 TR - PHP21N06T

Q9F01 260C004010 TR - 2SC1740S-R,S/2SC3311A-R,S

Q9F02 260P741010 TR - 2SA1020-0,Y

Q9F03 260C604010 TR - DTC124ES/UN4212

Q9F04 260C604010 TR - DTC124ES/UN4212

Q9F05 260C604010 TR - DTC124ES/UN4212

Q9F06 260C604010 TR - DTC124ES/UN4212

DIODES

D2760 264P828010 D-CHIP - DAN202U/MA142WK

D2761 264P828010 D-CHIP - DAN202U/MA142WK

D2770 262P805050 D-CHIP - UDZS5.1B

D2771 264P828010 D-CHIP - DAN202U/MA142WK

D2J00 264P458050 DIODE - RD3.9EB1

D2J01 264P458050 DIODE - RD3.9EB1

D2J91 262P075010 DIODE - RSB6.8S abde

D2J92 262P075010 DIODE - RSB6.8S cf

D2L80 262P075010 DIODE - RSB6.8S

D2L81 262P075010 DIODE - RSB6.8S

D7A00 264P828010 D-CHIP - DAN202U/MA142WK

D7A01 264P828010 D-CHIP - DAN202U/MA142WK

D7E00 262P075010 DIODE - RSB6.8S

D7E01 262P075010 DIODE - RSB6.8S

D7K21 268P100010 DIODE-PHOTO - SFH235FA

D7K22 264P045080 DIODE - 1S2076A/1S2471OM

D7L20 262P075010 DIODE - RSB6.8S

D7L21 264P212020 D-LED - LN31GPH

D7L22 264P584020 DIODE-LE - SML1216W-C,D

D7L23 264P584020 DIODE-LE - SML1216W-C,D

D7L24 262P075010 DIODE - RSB6.8S

D7L25 262P075010 DIODE - RSB6.8S

D7L26 262P075010 DIODE - RSB6.8S

PAGE 32

Page 33

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

[#] Model Legend: [a] WD-52525, [b] WD-52725, [c] WD-52825, [d] WD-62525, [e] WD-62725, [f] WD-62825

Ref # Part # Part Name & Description [#]

Ref # Part # Part Name & Description [#]

D7L27 262P075010 DIODE - RSB6.8S

D81A2 264P828010 D-CHIP - DAN202U/MA142WK

D81A3 264P828010 D-CHIP - DAN202U/MA142WK

D81A4 262P090010 DIODE - M1FP3

D81A5 264P458050 DIODE - RD3.9EB1

D8201 264P846010 DIODE-CHIP - MA732

D8202 264P846010 DIODE-CHIP - MA732

D8203 264P846010 DIODE-CHIP - MA732

D8204 264P846010 DIODE-CHIP - MA732

D8280 264P808010 DIODE-CHIP - DAN202K

D8701 262P132010 DIODE - MA2Z077

D8702 262P132010 DIODE - MA2Z077

D8703 262P132010 DIODE - MA2Z077

D8704 262P132010 DIODE - MA2Z077

D8800 262P089010 DIODE - MA2S728

D8801 262P071070 DIODE-LE - SML-210FT

D8802 262P071070 DIODE-LE - SML-210FT

D8803 262P071070 DIODE-LE - SML-210FT

D8B00 264P882010 D-CHIP - HSB123

D8B01 264P882010 D-CHIP - HSB123

D8B02 264P882010 D-CHIP - HSB123

D8B03 264P878020 D-CHIP - HZM6.2ZWA

D8B04 264P828010 D-CHIP - DAN202U/MA142WK bcef

D8B04 264P828010 D-CHIP - DAN202U/MA142WK

D8B09 264P878020 D-CHIP - HZM6.2ZWA

D8F00 264P828010 D-CHIP - DAN202U/MA142WK bcef

D8F00 264P828010 D-CHIP - DAN202U/MA142WK

D8F01 264P828010 D-CHIP - DAN202U/MA142WK bcef

D8F01 264P828010 D-CHIP - DAN202U/MA142WK

D8F03 262P090010 DIODE - M1FP3

D8F04 264P458050 DIODE - RD3.9EB1

D8F05 264P828010 D-CHIP - DAN202U/MA142WK

D9A00 262P031010 DIODE - D6SB80

D9A01 262P031010DIODE - D6SB80

D9A02 264P045080 DIODE - 1S2076A/1S2471OM

D9A03 264P461050 DIODE - EQA02-06B/RD5.6EB3

D9A04 264P045080 DIODE - 1S2076A/1S2471OM

D9A05 264P899010 DIODE - BYV26E

D9A18 264P045080 DIODE - 1S2076A/1S2471OM

D9A19 264P045080 DIODE - 1S2076A/1S2471OM

D9A20 264P045080 DIODE - 1S2076A/1S2471OM

D9A23 264P045080 DIODE - 1S2076A/1S2471OM

D9A24 264P045080 DIODE - 1S2076A/1S2471OM

D9A25 264P045080 DIODE - 1S2076A/1S2471OM

D9A26 262P066010 DIODE - RU4A

D9A27 262P066010 DIODE - RU4A

D9A28 264P045080 DIODE - 1S2076A/1S2471OM

D9A29 264P045080 DIODE - 1S2076A/1S2471OM

D9A30 264P470070 DIODE - EQA02-32B/RD33EB3

D9A31 264P828010 D-CHIP - DAN202U/MA142WK

D9A32 264P828010 D-CHIP - DAN202U/MA142WK

D9A33 264P458050 DIODE - RD3.9EB1

D9A34 262P090010 DIODE - M1FP3

D9A41 264P828010 D-CHIP - DAN202U/MA142WK

D9A42 264P828010 D-CHIP - DAN202U/MA142WK

D9A43 264P828010 D-CHIP - DAN202U/MA142WK

D9A44 264P828010 D-CHIP - DAN202U/MA142WK

D9A45 264P828010 D-CHIP - DAN202U/MA142WK

D9A60 264P669030 DIODE - S3L20U

D9A61 264P669030 DIODE - S3L20U

D9A80 264P828010 D-CHIP - DAN202U/MA142WK

D9A81 264P828010 D-CHIP - DAN202U/MA142WK

D9A82 264P828010 D-CHIP - DAN202U/MA142WK

D9C40 262P090010 DIODE - M1FP3

D9F01 264P212020 D-LED - LN31GPH

L1H01 321C114010 COIL-RF - 2200MH-J

L1H02 325C461030 COIL-PEAKING - 10MH-K

L1H51 321C114010 COIL-RF - 2200MH-J

L1H52 325C461030 COIL-PEAKING - 10MH-K

L2011 409P777080 EMI-F-CHIP - BLM21P221S

L2012 409P777080 EMI-F-CHIP - BLM21P221S

L2061 409P777080 EMI-F-CHIP - BLM21P221S

L2071 409P777080 EMI-F-CHIP - BLM21P221S

L2111 409P777080 EMI-F-CHIP - BLM21P221S

L2121 409P777080 EMI-F-CHIP - BLM21P221S

L2141 409P777080 EMI-F-CHIP - BLM21P221S

L2151 409P777080 EMI-F-CHIP - BLM21P221S

L2231 409P777080 EMI-F-CHIP - BLM21P221S

L2272 409P955020 EMI-F-CHIP - BLM18BB220SN1

L2301 409P955020 EMI-F-CHIP - BLM18BB220SN1

L2311 409P955020 EMI-F-CHIP - BLM18BB220SN1

L2321 409P955020 EMI-F-CHIP - BLM18BB220SN1

L2331 409P955020 EMI-F-CHIP - BLM18BB220SN1

L2341 409P955020 EMI-F-CHIP - BLM18BB220SN1

L2761 409P777080 EMI-F-CHIP - BLM21P221S

L2801 409P777080 EMI-F-CHIP - BLM21P221S

L2821 409P777080 EMI-F-CHIP - BLM21P221S

L2C03 325C146090 COIL-CHIP - 33MH-J

L2K01 325C461030 COIL-PEAKING - 10MH-K

L2K09 325C461030 COIL-PEAKING - 10MH-K

L2K25 321C141090 COIL-RF - 33MH-K

L2K58 325C461030 COIL-PEAKING - 10MH-K

L2K67 325C461030 COIL-PEAKING - 10MH-K

L2K71 325C461030 COIL-PEAKING - 10MH-K

L2K80 409P777080 EMI-F-CHIP - BLM21P221S

L2K81 409P777080 EMI-F-CHIP - BLM21P221S

L2K90 325C461030 COIL-PEAKING - 10MH-K

L2K91 325C461030 COIL-PEAKING - 10MH-K

L2K99 409P777080 EMI-F-CHIP - BLM21P221S

L2L12 409P777080 EMI-F-CHIP - BLM21P221S

L2L13 409P777080 EMI-F-CHIP - BLM21P221S

L2L80 409P923060 EMI-F-CHIP - BLM21B272S

L2L81 409P923060 EMI-F-CHIP - BLM21B272S

L2L82 409P923060 EMI-F-CHIP - BLM21B272S

L2L83 409P923060 EMI-F-CHIP - BLM21B272S

L2L84 409P923060 EMI-F-CHIP - BLM21B272S

L2L85 409P923060 EMI-F-CHIP - BLM21B272S

L2M21 325C461030 COIL-PEAKING - 10MH-K

L2M30 409P777080 EMI-F-CHIP - BLM21P221S

L2M31 409P777080 EMI-F-CHIP - BLM21P221S

L2M35 325C461050 COIL-PEAKING - 15MH-K

L2M36 325C461030 COIL-PEAKING - 10MH-K

L2M38 409P777080 EMI-F-CHIP - BLM21P221S

L2M40 325C461030 COIL-PEAKING - 10MH-K

L2M41 325C461080 COIL-PEAKING - 27MH-K

COILS

PAGE 33

Page 34

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

[#] Model Legend: [a] WD-52525, [b] WD-52725, [c] WD-52825, [d] WD-62525, [e] WD-62725, [f] WD-62825

Ref # Part # Part Name & Description [#]

Ref # Part # Part Name & Description [#]

L2M42 325C461030 COIL-PEAKING - 10MH-K

L2M45 409P777080 EMI-F-CHIP - BLM21P221S

L2M46 409P777080 EMI-F-CHIP - BLM21P221S

L2M50 325C461000 COIL-PEAKING - 5.6MH-K

L2M53 325C461030 COIL-PEAKING - 10MH-K

L2M70 325C461030 COIL-PEAKING - 10MH-K

L2M71 325C461080 COIL-PEAKING - 27MH-K

L2M77 325C461030 COIL-PEAKING - 10MH-K

L2M81 409P777080 EMI-F-CHIP - BLM21P221S

L3E25 325C502010 COIL-CHIP - SLF12575T-330M3R2-H

L3E26 325C502010 COIL-CHIP - SLF12575T-330M3R2-H

L3E51 411D009020 CORE-FERRITE - ZBF503D-01

L3E52 411D009020 CORE-FERRITE - ZBF503D-01

L3J00 409P777080 EMI-F-CHIP - BLM21P221S

L7A16 409P777050 EMI-F-CHIP - BLM21B201S bcef

L7A19 409P865060 EMI-F-CHIP - BLM11B141S bcef

L7A19 409P865060 EMI-F-CHIP - BLM11B141S

L7A39 409P865060 EMI-F-CHIP - BLM11B141S bcef

L7A39 409P865060 EMI-F-CHIP - BLM11B141S

L7A42 409P865060 EMI-F-CHIP - BLM11B141S bcef

L7A42 409P865060 EMI-F-CHIP - BLM11B141S

L7A43 409P865060 EMI-F-CHIP - BLM11B141S bcef

L7A43 409P865060 EMI-F-CHIP - BLM11B141S

L7A47 409P865060 EMI-F-CHIP - BLM11B141S bcef

L7A47 409P865060 EMI-F-CHIP - BLM11B141S

L7A49 409P865060 EMI-F-CHIP - BLM11B141S bcef

L7A49 409P865060 EMI-F-CHIP - BLM11B141S

L7A50 409P865060 EMI-F-CHIP - BLM11B141S bcef

L7A50 409P865060 EMI-F-CHIP - BLM11B141S

L7A51 409P865060 EMI-F-CHIP - BLM11B141S bcef

L7A51 409P865060 EMI-F-CHIP - BLM11B141S

L7A52 409P865060 EMI-F-CHIP - BLM11B141S bcef

L7A52 409P865060 EMI-F-CHIP - BLM11B141S

L7A53 409P865060

L7A53 409P865060 EMI-F-CHIP - BLM11B141S

L7A54 409P865060 EMI-F-CHIP - BLM11B141S bcef

L7A54 409P865060 EMI-F-CHIP - BLM11B141S

L7A55 409P865060 EMI-F-CHIP - BLM11B141S bcef

L7A55 409P865060 EMI-F-CHIP - BLM11B141S

L7A56 409P865060 EMI-F-CHIP - BLM11B141S bcef

L7A56 409P865060 EMI-F-CHIP - BLM11B141S

L7A57 409P865060 EMI-F-CHIP - BLM11B141S bcef

L7A57 409P865060 EMI-F-CHIP - BLM11B141S

L7A58 409P865060 EMI-F-CHIP - BLM11B141S bcef

L7A58 409P865060 EMI-F-CHIP - BLM11B141S

L7A59 409P865060 EMI-F-CHIP - BLM11B141S bcef

L7A59 409P865060 EMI-F-CHIP - BLM11B141S

L7A60 409P865060 EMI-F-CHIP - BLM11B141S cf

L7A61 409P865060 EMI-F-CHIP - BLM11B141S bcef

L7A61 409P865060 EMI-F-CHIP - BLM11B141S

L7A62 409P865060 EMI-F-CHIP - BLM11B141S bcef

L7A62 409P865060 EMI-F-CHIP - BLM11B141S

L7A63 409P865060 EMI-F-CHIP - BLM11B141S bcef

L7A63 409P865060 EMI-F-CHIP - BLM11B141S

L7A64 409P865060 EMI-F-CHIP - BLM11B141S bcef

L7A64 409P865060 EMI-F-CHIP - BLM11B141S

L7A65 409P865060 EMI-F-CHIP - BLM11B141S bcef

L7A65 409P865060 EMI-F-CHIP - BLM11B141S

L7A66 409P865060 EMI-F-CHIP - BLM11B141S bcef

L7A66 409P865060 EMI-F-CHIP - BLM11B141S

EMI-F-CHIP - BLM11B141S bcef

L7A67 409P865060 EMI-F-CHIP - BLM11B141S bcef

L7A67 409P865060 EMI-F-CHIP - BLM11B141S

L7A88 409P777050 EMI-F-CHIP - BLM21B201S bcef

L7A90 409P865060 EMI-F-CHIP - BLM11B141S bcef

L7A90 409P865060 EMI-F-CHIP - BLM11B141S

L7A91 409P865060 EMI-F-CHIP - BLM11B141S bcef

L7A91 409P865060 EMI-F-CHIP - BLM11B141S

L7A92 409P865060 EMI-F-CHIP - BLM11B141S bcef

L7A92 409P865060 EMI-F-CHIP - BLM11B141S

L7A99 409P777050 EMI-F-CHIP - BLM21B201S bcef

L7D16 325C420070 COIL-CHIP - 10MH-K

L7DA7 325C420070 COIL-CHIP - 10MH-K

L7DF4 409P777080 EMI-F-CHIP - BLM21P221S

L7DF8 325C420070 COIL-CHIP - 10MH-K

L7E00 409P876040 EMI-F-CHIP - CNF20C221S/CKD510JB1H221S

L7E01 409P777080 EMI-F-CHIP - BLM21P221S

L7E01 409P876040 EMI-F-CHIP - CNF20C221S/CKD510JB1H221S

L7E34 409P777080 EMI-F-CHIP - BLM21P221S

L7E42 409P777080 EMI-F-CHIP - BLM21P221S

L7E69 409P777080 EMI-F-CHIP - BLM21P221S

L7H01 409P777080 EMI-F-CHIP - BLM21P221S

L7H04 409P777080 EMI-F-CHIP - BLM21P221S

L7H29 409P777080 EMI-F-CHIP - BLM21P221S

L7H49 409P777080 EMI-F-CHIP - BLM21P221S

L7H66 409P777080 EMI-F-CHIP - BLM21P221S

L7H73 409P777080 EMI-F-CHIP - BLM21P221S

L7H76 409P777080 EMI-F-CHIP - BLM21P221S

L7J13 409P777080 EMI-F-CHIP - BLM21P221S

L7J38 409P777080 EMI-F-CHIP - BLM21P221S

L7J44 409P777080 EMI-F-CHIP - BLM21P221S

L7K01 409P777080 EMI-F-CHIP - BLM21P221S

L7M90 409P777080 EMI-F-CHIP - BLM21P221S

L7N01 409P777080 EMI-F-CHIP - BLM21P221S

L7N41 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N42 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N43 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N44 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N45 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N46 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N47 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N48 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N49 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N50 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N51 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N52 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N53 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N54 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N55 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N56 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N57 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N58 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N59 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N60 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N61 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N62 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N63 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N64 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N65 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N66 409P936090 EMI-F-CHIP - BK1608 HS102

L7N67 409P955020 EMI-F-CHIP - BLM18BB220SN1

PAGE 34

Page 35

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

[#] Model Legend: [a] WD-52525, [b] WD-52725, [c] WD-52825, [d] WD-62525, [e] WD-62725, [f] WD-62825

Ref # Part # Part Name & Description [#]

Ref # Part # Part Name & Description [#]

L7N68 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N70 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N71 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7P00 409P923060 EMI-F-CHIP - BLM21B272S

L7P14 409P777050 EMI-F-CHIP - BLM21B201S

L7P20 409P777050 EMI-F-CHIP - BLM21B201S

L8001 409P865080 EMI-F-CHIP - BLM18PG6

L8002 409P865080 EMI-F-CHIP - BLM18PG6

L8003 409P865080 EMI-F-CHIP - BLM18PG6

L8004 409P865080 EMI-F-CHIP - BLM18PG6

L8005 409P865080 EMI-F-CHIP - BLM18PG6

L8006 409P865080 EMI-F-CHIP - BLM18PG6

L8007 409P865080 EMI-F-CHIP - BLM18PG6

L8008 409P865080 EMI-F-CHIP - BLM18PG6

L8009 409P777080 EMI-F-CHIP - BLM21P221S

L8012 409P865080 EMI-F-CHIP - BLM18PG6

L8013 409P865080 EMI-F-CHIP - BLM18PG6

L8017 409P865020 EMI-F-CHIP - BLM11A601S

L8018 409P865020 EMI-F-CHIP - BLM11A601S

L81A1 321C140060 COIL-RF - 2.7MH-M

L81A2 351P250010 COIL-CHOKE - GSTC6018-100M

L81A3 409P777080 EMI-F-CHIP - BLM21P221S

L81A4 321C140060 COIL-RF - 2.7MH-M

L81A5 321C140060 COIL-RF - 2.7MH-M

L81A6 409P777080 EMI-F-CHIP - BLM21P221S

L81A7 409P865080 EMI-F-CHIP - BLM18PG6

L81A8 409P777080 EMI-F-CHIP - BLM21P221S

L81A9 409P777080 EMI-F-CHIP - BLM21P221S

L8202 409P777080 EMI-F-CHIP - BLM21P221S

L8203 409P777080 EMI-F-CHIP - BLM21P221S

L8204 409P777080 EMI-F-CHIP - BLM21P221S

L8205 409P777080 EMI-F-CHIP - BLM21P221S

L8206 351P265010 COIL-CHOKE-CHIP - ACM2012

L8207 351P265010 COIL-CHOKE-CHIP - ACM2012

L8280 409P865080 EMI-F-CHIP - BLM18PG6

L8301 409P865080 EMI-F-CHIP - BLM18PG6

L8304 325C501010 COIL-CHIP - ALQM21NNR47K10

L8305 325C501010 COIL-CHIP - ALQM21NNR47K10

L8307 409P865080 EMI-F-CHIP - BLM18PG6

L8307 409P865080 EMI-F-CHIP - BLM18PG6 be

L8309 409P865080 EMI-F-CHIP - BLM18PG6

L8309 409P865080 EMI-F-CHIP - BLM18PG6 be

L8310 409P865080 EMI-F-CHIP - BLM18PG6

L8310 409P865080

L8311 409P865080 EMI-F-CHIP - BLM18PG6

L8311 409P865080 EMI-F-CHIP - BLM18PG6 be

L8312 409P865080 EMI-F-CHIP - BLM18PG6

L8312 409P865080 EMI-F-CHIP - BLM18PG6 be

L8313 409P865080 EMI-F-CHIP - BLM18PG6

L8313 409P865080 EMI-F-CHIP - BLM18PG6 be

L8314 409P865080 EMI-F-CHIP - BLM18PG6

L8314 409P865080 EMI-F-CHIP - BLM18PG6 be

L8315 409P865080 EMI-F-CHIP - BLM18PG6

L8315 409P865080 EMI-F-CHIP - BLM18PG6 be

L8320 409P865080 EMI-F-CHIP - BLM18PG6

L8320 409P865080 EMI-F-CHIP - BLM18PG6 be

L8321 409P865080 EMI-F-CHIP - BLM18PG6

L8321 409P865080 EMI-F-CHIP - BLM18PG6 be

L8322 409P865080 EMI-F-CHIP - BLM18PG6

L8322 409P865080 EMI-F-CHIP - BLM18PG6 be

EMI-F-CHIP - BLM18PG6 be

L8323 409P865080 EMI-F-CHIP - BLM18PG6

L8323 409P865080 EMI-F-CHIP - BLM18PG6 be

L8324 409P865080 EMI-F-CHIP - BLM18PG6

L8324 409P865080 EMI-F-CHIP - BLM18PG6 be

L8326 409P865080 EMI-F-CHIP - BLM18PG6

L8326 409P865080 EMI-F-CHIP - BLM18PG6 be

L8329 409P865080 EMI-F-CHIP - BLM18PG6

L8329 409P865080 EMI-F-CHIP - BLM18PG6 be

L8331 409P865080 EMI-F-CHIP - BLM18PG6

L8331 409P865080 EMI-F-CHIP - BLM18PG6 be

L8332 409P865080 EMI-F-CHIP - BLM18PG6

L8332 409P865080 EMI-F-CHIP - BLM18PG6 be

L8333 409P865080 EMI-F-CHIP - BLM18PG6

L8401 409P865080 EMI-F-CHIP - BLM18PG6

L8403 409P777080 EMI-F-CHIP - BLM21P221S

L8404 409P777080 EMI-F-CHIP - BLM21P221S

L8411 351P265020 COIL-CHIP - ACM2012-201-2P

L8412 351P265020 COIL-CHIP - ACM2012-201-2P

L8413 351P265020 COIL-CHIP - ACM2012-201-2P

L8414 351P265020 COIL-CHIP - ACM2012-201-2P

L8415 351P265020 COIL-CHIP - ACM2012-201-2P

L8416 351P265020 COIL-CHIP - ACM2012-201-2P

L8501 409P865080 EMI-F-CHIP - BLM18PG6

L8502 409P777080 EMI-F-CHIP - BLM21P221S

L8503 409P865080 EMI-F-CHIP - BLM18PG6

L8504 409P777080 EMI-F-CHIP - BLM21P221S

L8505 409P865080 EMI-F-CHIP - BLM18PG6

L8506 409P777080 EMI-F-CHIP - BLM21P221S

L8507 409P865080 EMI-F-CHIP - BLM18PG6

L8508 409P865080 EMI-F-CHIP - BLM18PG6

L8509 409P865080 EMI-F-CHIP - BLM18PG6

L8510 409P865080 EMI-F-CHIP - BLM18PG6

L8510 409P865080 EMI-F-CHIP - BLM18PG6 be

L8700 325C412050 COIL-CHIP - 100MH-J

L8701 325C420030 COIL-CHIP - 2.2MH-M

L8702 325C420030 COIL-CHIP - 2.2MH-M

L8703 325C420030 COIL-CHIP - 2.2MH-M

L8704 325C420030 COIL-CHIP - 2.2MH-M

L8705 325C412050 COIL-CHIP - 100MH-J

L8706 409P923060 EMI-F-CHIP - BLM21B272S

L8707 409P923060 EMI-F-CHIP - BLM21B272S

L8717 325C420030 COIL-CHIP - 2.2MH-M

L8718 325C420030 COIL-CHIP - 2.2MH-M

L8719 409P777080 EMI-F-CHIP - BLM21P221S

L8722 325C420030 COIL-CHIP - 2.2MH-M

L8723 409P923060 EMI-F-CHIP - BLM21B272S

L8725 409P923060 EMI-F-CHIP - BLM21B272S

L8726 409P923060 EMI-F-CHIP - BLM21B272S

L8727 409P923060 EMI-F-CHIP - BLM21B272S

L8729 409P923060 EMI-F-CHIP - BLM21B272S

L8730 409P923060 EMI-F-CHIP - BLM21B272S

L8736 409P923060 EMI-F-CHIP - BLM21B272S

L8737 409P865080 EMI-F-CHIP - BLM18PG6

L8738 409P923060 EMI-F-CHIP - BLM21B272S

L8739 409P923060 EMI-F-CHIP - BLM21B272S

L8800 409P936050 EMI-F-CHIP - HS800

L8801 409P936050 EMI-F-CHIP - HS800

L8802 409P936050 EMI-F-CHIP - HS800

L8803 409P936050 EMI-F-CHIP - HS800

L8804 409P936050 EMI-F-CHIP - HS800

PAGE 35

Page 36

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

[#] Model Legend: [a] WD-52525, [b] WD-52725, [c] WD-52825, [d] WD-62525, [e] WD-62725, [f] WD-62825

Ref # Part # Part Name & Description [#]

Ref # Part # Part Name & Description [#]

L8807 325C414090 COIL-CHIP - 0.68MH-J

L8809 325C410040 COIL-CHIP - 1.8MH-J

L8834 409P865060 EMI-F-CHIP - BLM11B141S

L8835 409P865060 EMI-F-CHIP - BLM11B141S

L8863 409P865060 EMI-F-CHIP - BLM11B141S

L8A00 409P777080 EMI-F-CHIP - BLM21P221S c f

L8A01 409P777080 EMI-F-CHIP - BLM21P221S c f

L8A02 409P777080 EMI-F-CHIP - BLM21P221S c f

L8A03 409P777080 EMI-F-CHIP - BLM21P221S c f

L8A04 409P777080 EMI-F-CHIP - BLM21P221S c f

L8A05 409P777080 EMI-F-CHIP - BLM21P221S c f

L8A06 409P777080 EMI-F-CHIP - BLM21P221S c f

L8A07 409P777080 EMI-F-CHIP - BLM21P221S c f

L8A08 409P777080 EMI-F-CHIP - BLM21P221S c f

L8A11 325C241030 COIL-CHIP - 10MH-K cf

L8B00 409P865040 EMI-F-CHIP - BLM11B050SA

L8B01 409P865040 EMI-F-CHIP - BLM11B050SA

L8B02 409P865040 EMI-F-CHIP - BLM11B050SA

L8B03 409P865060 EMI-F-CHIP - BLM11B141S

L8B04 409P865060 EMI-F-CHIP - BLM11B141S

L8B05 409P865020 EMI-F-CHIP - BLM11A601S

L8B08 409P865020 EMI-F-CHIP - BLM11A601S

L8B09 325C241030 COIL-CHIP - 10MH-K

L8B10 409P865020 EMI-F-CHIP - BLM11A601S

L8B13 325C241030 COIL-CHIP - 10MH-K

L8B14 409P865060 EMI-F-CHIP - BLM11B141S

L8B15 409P865060 EMI-F-CHIP - BLM11B141S

L8C01 409P964010 EMI-F-CHIP - BK2125HS102

L8C02 409P964010 EMI-F-CHIP - BK2125HS102

L8C04 409P964010 EMI-F-CHIP - BK2125HS102

L8C05 409P964010 EMI-F-CHIP - BK2125HS102

L8C06 409P938020 EMI-F-CHIP - BK1608 LL121 bcef

L8C06 409P938020 EMI-F-CHIP - BK1608 LL121

L8C07 409P938020 EMI-F-CHIP - BK1608 LL121 bcef

L8C07 409P938020 EMI-F-CHIP - BK1608 LL121

L8C08 409P956040 EMI-F-CHIP - BLM18PG330SN1 bcef

L8C08 409P956040 EMI-F-CHIP - BLM18PG330SN1

L8C09 409P956040 EMI-F-CHIP - BLM18PG330SN1

L8C10 409P938020 EMI-F-CHIP - BK1608 LL121

L8C11 409P956040 EMI-F-CHIP - BLM18PG330SN1

L8C12 409P938020 EMI-F-CHIP - BK1608 LL121

L8C13 409P938020 EMI-F-CHIP - BK1608 LL121

L8D01 409P777080 EMI-F-CHIP - BLM21P221S

L8D02 409P777080 EMI-F-CHIP - BLM21P221S

L8D03 409P777080 EMI-F-CHIP - BLM21P221S bcef

L8D03 409P777080 EMI-F-CHIP - BLM21P221S

L8D04 409P964010 EMI-F-CHIP - BK2125HS102

L8D05 409P777080 EMI-F-CHIP - BLM21P221S

L8E00 409P777080 EMI-F-CHIP - BLM21P221S

L8E01 409P777080 EMI-F-CHIP - BLM21P221S

L8E03 409P777080 EMI-F-CHIP - BLM21P221S bcef

L8E04 409P777080 EMI-F-CHIP - BLM21P221S

L8E05 409P777080 EMI-F-CHIP - BLM21P221S

L8E06 409P777080 EMI-F-CHIP - BLM21P221S

L8E07 409P777080 EMI-F-CHIP - BLM21P221S

L8E08 409P777080

L8E09 409P777080 EMI-F-CHIP - BLM21P221S

L8E10 409P777080 EMI-F-CHIP - BLM21P221S

L8F01 409P777080 EMI-F-CHIP - BLM21P221S

EMI-F-CHIP - BLM21P221S

L8F02 321C140060 COIL-RF - 2.7MH-M

L8F03 321C140060 COIL-RF - 2.7MH-M

L8F04 351P250010 COIL-CHOKE - GSTC6018-100M

L8F05 321C140060 COIL-RF - 2.7MH-M

L8F06 409P777080 EMI-F-CHIP - BLM21P221S

L8F07 409P777080 EMI-F-CHIP - BLM21P221S

L8F08 409P777080 EMI-F-CHIP - BLM21P221S

L8F09 409P777080 EMI-F-CHIP - BLM21P221S

L8F10 409P777080 EMI-F-CHIP - BLM21P221S

L8F12 409P777080 EMI-F-CHIP - BLM21P221S

L8F13 409P777080 EMI-F-CHIP - BLM21P221S

L8F14 409P777080 EMI-F-CHIP - BLM21P221S

L8F15 409P777080 EMI-F-CHIP - BLM21P221S

L8F16 409P777080 EMI-F-CHIP - BLM21P221S

L8F17 409P777080 EMI-F-CHIP - BLM21P221S

L8F18 409P777080 EMI-F-CHIP - BLM21P221S

L8F19 409P777080 EMI-F-CHIP - BLM21P221S

L8F20 409P777080 EMI-F-CHIP - BLM21P221S

L8G00 409P777080 EMI-F-CHIP - BLM21P221S bcef

L8G01 409P777080 EMI-F-CHIP - BLM21P221S bcef

L8H00 409P777080 EMI-F-CHIP - BLM21P221S bcef

L8H00 409P777080 EMI-F-CHIP - BLM21P221S

L8H01 409P777080 EMI-F-CHIP - BLM21P221S

L8H03 409P777080 EMI-F-CHIP - BLM21P221S

L8H05 409P777080 EMI-F-CHIP - BLM21P221S

L8H10 409P777080 EMI-F-CHIP - BLM21P221S bcef

L8H11 409P777080

L8H13 409P777080 EMI-F-CHIP - BLM21P221S

L8H24 409P777080 EMI-F-CHIP - BLM21P221S

L8H25 409P777080 EMI-F-CHIP - BLM21P221S

L8H32 409P777080 EMI-F-CHIP - BLM21P221S

L8H82 409P777080 EMI-F-CHIP - BLM21P221S

L8H83 409P777080 EMI-F-CHIP - BLM21P221S

L8H84 409P777080 EMI-F-CHIP - BLM21P221S

L8H85 409P777080 EMI-F-CHIP - BLM21P221S

L8H87 409P777080 EMI-F-CHIP - BLM21P221S

L8H88 409P777080 EMI-F-CHIP - BLM21P221S

L8H90 409P777080 EMI-F-CHIP - BLM21P221S

L8H91 409P777080 EMI-F-CHIP - BLM21P221S

L8T03 409P777080 EMI-F-CHIP - BLM21P221S

L8T05 409P777080 EMI-F-CHIP - BLM21P221S

L8T13 409P777080 EMI-F-CHIP - BLM21P221S

L8T24 409P777080 EMI-F-CHIP - BLM21P221S

L8T25 409P777080 EMI-F-CHIP - BLM21P221S

L8T32 409P777080 EMI-F-CHIP - BLM21P221S

L9A10 321C151070 COIL-RF - 22MH-K

L9A19 321C141010 COIL-RF - 6.8MH-M

L9A20 321C141010 COIL-RF - 6.8MH-M

L9A21 321C141010 COIL-RF - 6.8MH-M

L9A22 321C141030 COIL-RF - 10MH-K

L9A23 321C141030 COIL-RF - 10MH-K

L9A30 321C140060 COIL-RF - 2.7MH-M

L9A31 321C140060 COIL-RF - 2.7MH-M

L9A32 321C140060 COIL-RF - 2.7MH-M

L9A33 351P250010 COIL-CHOKE - GSTC6018-100M

L9A62 321C141010 COIL-RF - 6.8MH-M

L9A63 321C141090 COIL-RF - 33MH-K

L9A64 321C141090 COIL-RF - 33MH-K

L9A70 321C141090 COIL-RF - 33MH-K

L9A71 321C141090 COIL-RF - 33MH-K

EMI-F-CHIP - BLM21P221S

PAGE 36

Page 37

MODEL: WD-52525 / WD-52725 / WD-52825 / WD-62525 / WD-62725 / WD-62825

[#] Model Legend: [a] WD-52525, [b] WD-52725, [c] WD-52825, [d] WD-62525, [e] WD-62725, [f] WD-62825

Ref # Part # Part Name & Description [#]

Ref # Part # Part Name & Description [#]

L9D00 351P268010 LINE-FILTER - HF3545-502Y5R0-TXXBH

L9D01 351P268010 LINE-FILTER - HF3545-502Y5R0-TXXBH

L9D02 351P268010 LINE-FILTER - HF3545-502Y5R0-TXXBH

LC2C02 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC2C03 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC2C07 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC8001 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8002 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC81A1 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8300 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8301 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8302 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8303 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8304 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8305 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8306 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8307 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8308 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8309 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8310 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8312 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8313 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8314 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8315 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8316 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8317 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8318 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8319 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8501 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8502 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8503 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8504 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8505 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8506 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8507 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8508 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8509 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8511 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8512 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8514 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8515 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8516 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8517 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8518 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8519 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8520 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8521 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8522 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8523 409P945010 EMI-F-CHIP - NFL21SP506X13CD