Page 1

20042004

2004

20042004

SerSer

Ser

SerSer

vicevice

vice

vicevice

MITSUBISHI ELECTRIC

ManualManual

Manual

ManualManual

DIGITAL LIGHT PROCESSING™ PROJECTION TV

VK26 CHASSIS

MODELS

WD-52327

CAUTION:

Before servicing this chassis, it is important that the service person read the "SAFETY PRECAUTIONS" and

"PRODUCT SAFETY NOTICE" contained in this manual.

SPECIFICATIONS

• Power Input : AC 120V, 60Hz

• Power Usage : 200W

• Light Engine : DLP (1280 x 720p pixels)

• Light Source : 120W VIP

• Frequency Range : VHF 54 ~ 470MHz

UHF 470 ~ 806MHz

• Antenna Input : VHF/UHF 75Ω unbalanced

2 - NTSC

• Cabinet Dimensions WD-52327

: 37.2"(H) x 49.6"(w) x 17.4"(D)

WD-62327

: 43.7"(H) x 58.3"(W) x 19.9"(D)

• Weight [WD-52327] 110 lbs

[WD-62327] 139 lbs

• Speakers (8 Ohms 10W)

: 2-5 inch Coaxial

• Input Level : VIDEO IN JACK (RCA Type)

• Output Level : VIDEO OUT JACK (RCA Type)

WD-52327

WD-62327

1.0Vp-p 75Ω unbalanced

: AUDIO IN JACK (RCA Type)

-4.7dBm 43kΩ unbalanced

: S-VIDEO IN JACK

(Y/C separate type)

Y:1.0 Vp-p C:0.286Vp-p(BURST)

75Ω unbalanced

: COMP / Y, Cr, Cb (RCA Type)

Y: 1.0 Vp-p Cr, Cb: 700mVp-p

: DTV / Y(G), Pr(R), Pb(B), H, V

Y: 1.0Vp-p with sync 75Ω (BNC)

Pr, Pb: 700mV 75Ω

H, V: 3.0Vp-p 75Ω

1.0Vp-p 75Ω unbalanced

: AUDIO OUT JACK (RCA Type)

-4.7dBm 4.7kΩ unbalanced

• Design specifications are subject to change without notice.

MITSUBISHI DIGITAL ELECTRONICS AMERICA, INC.

9351 Jeronimo Road, Irvine, CA 92618-1904

Copyright © 2004 Mitsubishi Digital Electronics America, Inc.

All Rights Reserved

• Digital : MonitorLink

.

TM

/DVI

Page 2

Page 3

MODEL: WD-52327 / WD-62327

CONTENTS

INTRODUCTION ............................................................................................................................... 5

PRODUCT SAFETY NOTICE ...........................................................................................................5

SAFETY PRECAUTIONS .................................................................................................................6

DISASSEMBLY

WD-52327 & WD-62327

Front Cabinet Components .................................................................................................... 7

Rear Cabinet Components ..................................................................................................... 8

CHASSIS REMOVAL

Chassis removal procedure .................................................................................................... 9

Shield Removal .................................................................................................................... 10

Chassis PWB locations ....................................................................................................... 11

Accessing the Lamp Ballast ................................................................................................ 12

OPTICAL ENGINE REPLACEMENT

Optical Engine Mounting ...................................................................................................... 13

Removing the Optical Engine ............................................................................................... 14

Removing DMD Heat Sensor ................................................................................................ 15

Removing Bottom Plate & Black Support Bracket. ............................................................... 15

Installing the Optical Engine ................................................................................................ 16

SERVICING THE LENTICULAR SCREEN AND FRESNEL LENS

Removal of the Lenticular Screen and Fresnel Lens ............................................................. 17

Installation of the Lenticular Screen and Fresnel Lens .......................................................... 19

ELECTRICAL ADJUSTMENTS

Equipment .................................................................................................................................... 20

Initial Setup (Option Menu) ............................................................................................................ 21

Main Menu Defaults ...................................................................................................................... 21

A/V Memory Defaults .................................................................................................................... 22

LED Indications ............................................................................................................................ 22

LED Dignostic Check .................................................................................................................... 23

Circuit Adjustment Mode ............................................................................................................... 23

Adjustment Items List ................................................................................................................... 25

Activating Internal Test Patterns .................................................................................................... 26

Adjustment Procedures ................................................................................................................ 27

Main & Sub Y level adjustments .......................................................................................... 27

Main & Sub Color level adjustments ..................................................................................... 27

White Balance Adjustments ................................................................................................. 28

Horizontal & Vertical Position adjustments .......................................................................... 28

Mechanical Adjustments ............................................................................................................... 29

Required Front Disassembly ................................................................................................ 29

Required Rear Disassembly ................................................................................................. 29

Picture Rotation Adjustment ............................................................................................... 30

Horizontal & Vertical Keystone Distortion adjustments ......................................................... 31

QUICK REFERENCE PART LIST ..................................................................................................... 32

Service Parts List ........................................................................................................................... 33

Screen Parts List ............................................................................................................................ 41

CIRCUITRY BLOCK DIAGRAMS

Standby power Supplies....................................................................................................... 42

Switched Supplies ...............................................................................................................42

Page 3

Page 4

MODEL: WD-52327 / WD-62327

Switched DC to DC Supplies ............................................................................................... 43

Video/Color Signal Path ....................................................................................................... 44

Sound Signal Path ...............................................................................................................45

Sync Signal Path ................................................................................................................. 46

Control Circuit (Commands, Serial Data & Reset) ................................................................ 47

Control Circuit (Status Inputs, OSD Insert & CCD Insert)...................................................... 48

PWB-FORMAT Block Diagram ............................................................................................ 49

SCHEMATIC DIAGRAMS

BLOCK (PWB INTERCONNECTIONS) ......................................................................................... S1

1

Page 4

Page 5

MODEL: WD-52327 / WD-62327

INTRODUCTION

This service manual provides service instructions for PTV models WD-52327 and WD-62327, using the VK26 chassis.

This service manual includes:

1. Assembly and disassembly instructions for the front and rear cabinet components.

2. Servicing of the Lenticular Screen and Fresnel Lens.

3. Servicing to PWB level. The Optical Engine and Lamp Ballast are considered replaceable components

4. Electrical and Mechanical adjustments.

5. Chip parts replacement procedures.

6. Simplified signal path block diagrams.

The parts list section of this service manual includes:

1. Cabinet and screen parts.

2. Electrical parts.

Block diagrams of the above listed models are included in this service manual for better understanding of the circuitry.

.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in television receivers have special safety related characteristics. These characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily be obtained by

using replacement components rated for higher voltage, wattage, etc.

Replacement parts which have special safety characteristics are identified in this service manual.

Electrical components having such features are identified by shading on the schematic diagram and by bold type in

the parts list of this service manual. Therefore, the replacement for any safety part should be identical in value

and characteristics.

Page 5

Page 6

MODEL: WD-52327 / WD-62327

SAFETY PRECAUTIONS

NOTICE: Observe all cautions and safety related notes located inside the receiver cabinet and on the

receiver chassis.

WARNING:

1. Operation of this receiver outside the cabinet or with the cover removed presents a shock hazard

from the receiver's power supplies. Work on the receiver should not be attempted by anyone who is

not thoroughly familiar with the precautions necessary when working on high voltage equipment.

2. When service is required, observe the original lead dress. Extra precaution should be taken to

assure correct lead dress in the high voltage area. Where a short-circuit has occurred, replace those

components that indicate evidence of overheating.

WARNING ... RISK OF EYE INJURY

Do not look into the light source, Light Engine lens or mirror when operating the TV

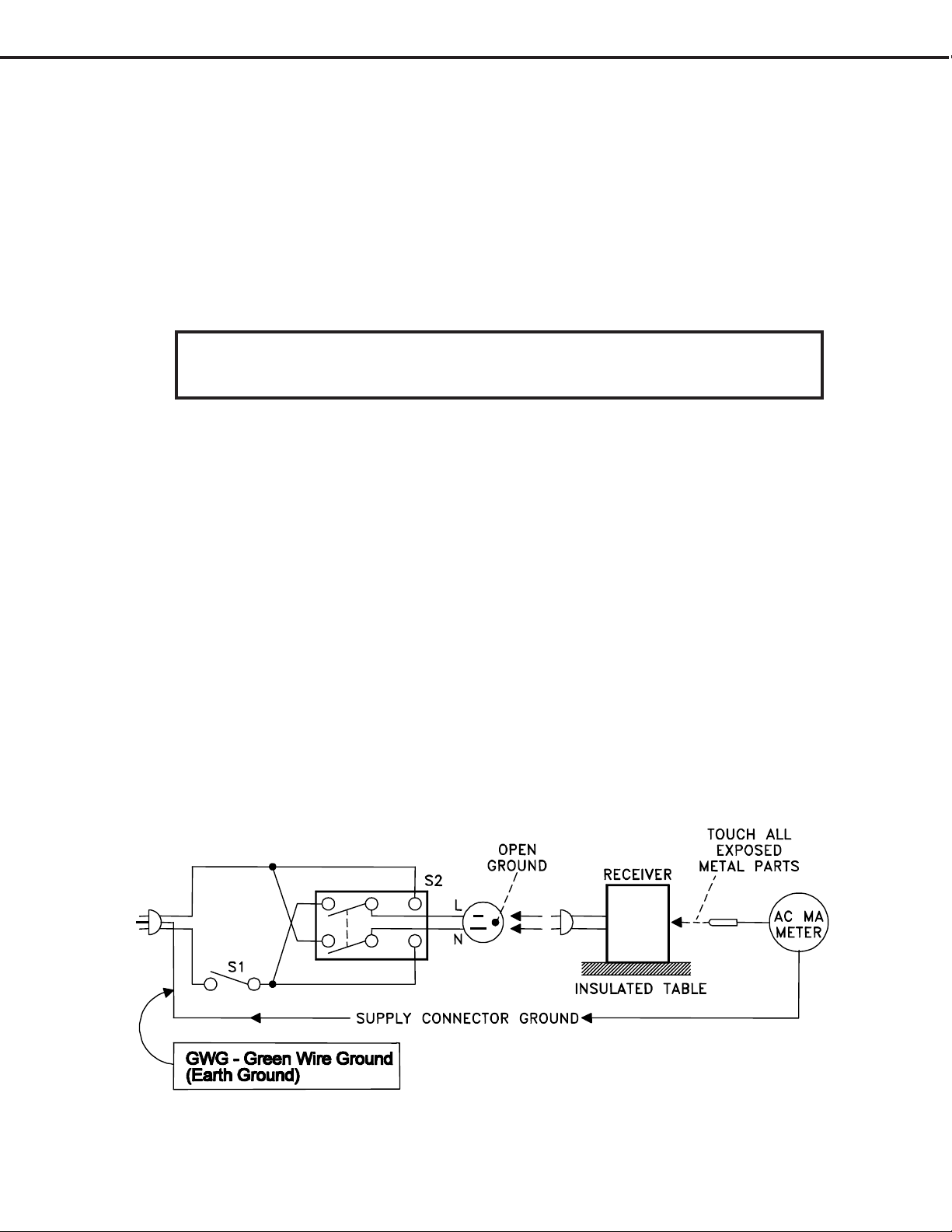

Leakage current check

Before returning the receiver to the customer, it is recommended that leakage current be measured according to the

following methods.

1. Cold Check

With the alternating current (AC) plug removed from the AC source, place a jumper across the two AC plug

prongs. Connect one lead of an ohm meter to the AC plug and touch the other lead to each exposed metal part

(i.e. antennas, handle bracket, metal cabinet, screw heads, metal overlay, control shafts, etc.), particularly any

exposed metal part that has a return path to the chassis. The resistance of the exposed metal parts having a

return path to the chassis should be a minimum of 1Mega Ohm. Any resistance below this value indicates an

abnormal condition and requires corrective action.

2. Hot Check ...Use the circuit shown below to perform the hot check test.

1. Keep switch S1 open and connect the receiver to the measuring circuit. Immediately after

connection, and with the switching devices of the receiver in their operating positions, measure the

leakage current for both positions of switch S2.

2. Close switch S1, energizing the receiver. Immediately after closing switch S1, and with the

switching devices of the receiver in their operating positions, measure the leakage current for both

positions of switch S2. Repeat the current measurements of items 1 and 2 after the receiver has

reached thermal stabilization. The leakage current must not exceed 0.5 milliampere (mA).

Page 6

Page 7

MODEL: WD-52327 / WD-62327

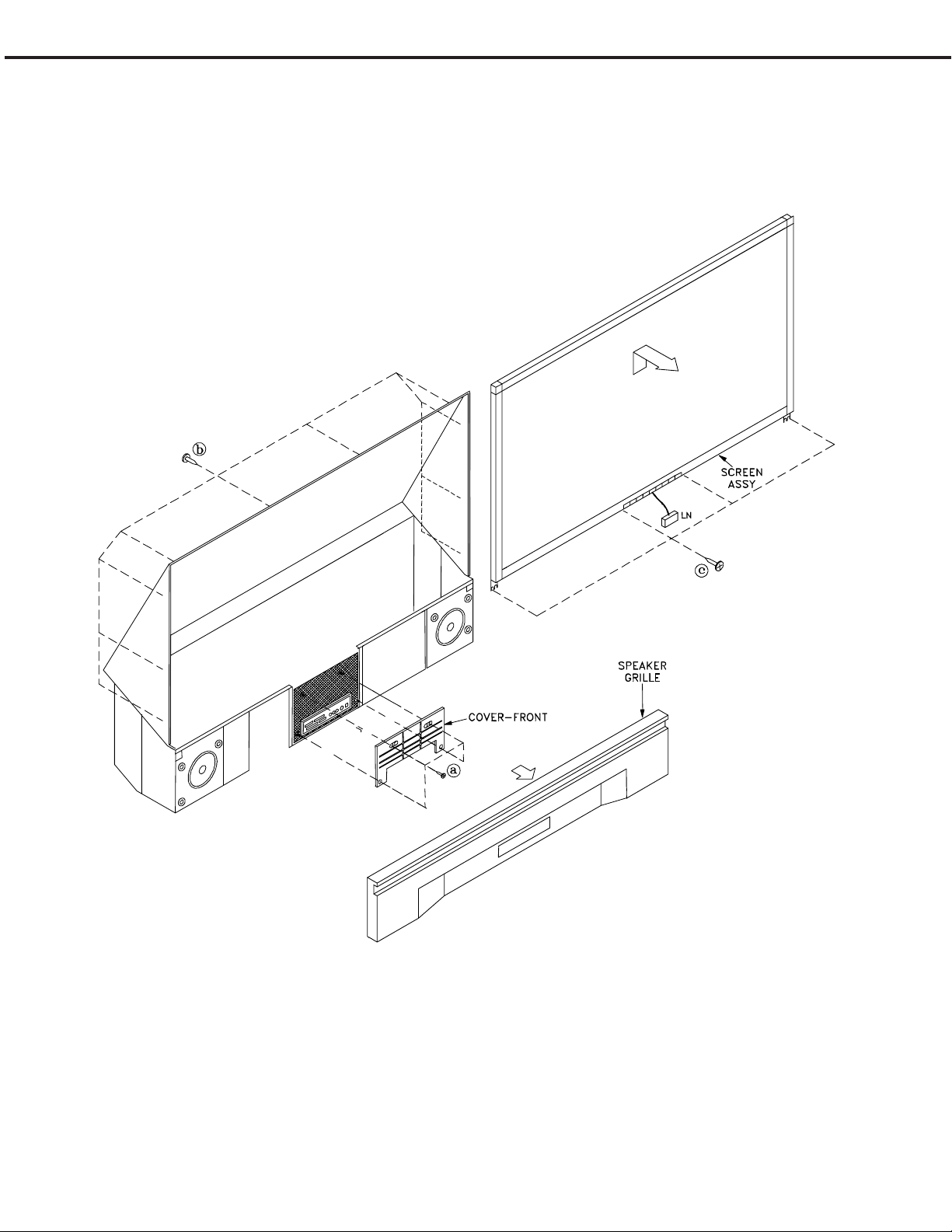

CABINET DISASSEMBLY (FRONT VIEW)

WD-52327 / WD-62327

*Refer to the Parts List for Part Numbers

Front Cabinet Disassembly

1. Remove the SPEAKER-GRILLE by pulling forward.

2. Remove screws (a) to remove the COVER-FRONT.

3. Remove screws (b) on the rear of the upper back cover (4 across the top and 3 on each side).

4. Remove the 4 screws (c) holding the bottom of the Screen Assembly.

5. Unplug connector LN from the Control Panel.

6. Lift the Screen Assembly up slightly then pull towards the front to remove the assembly.

Page 7

Page 8

MODEL: WD-52327 / WD-62327

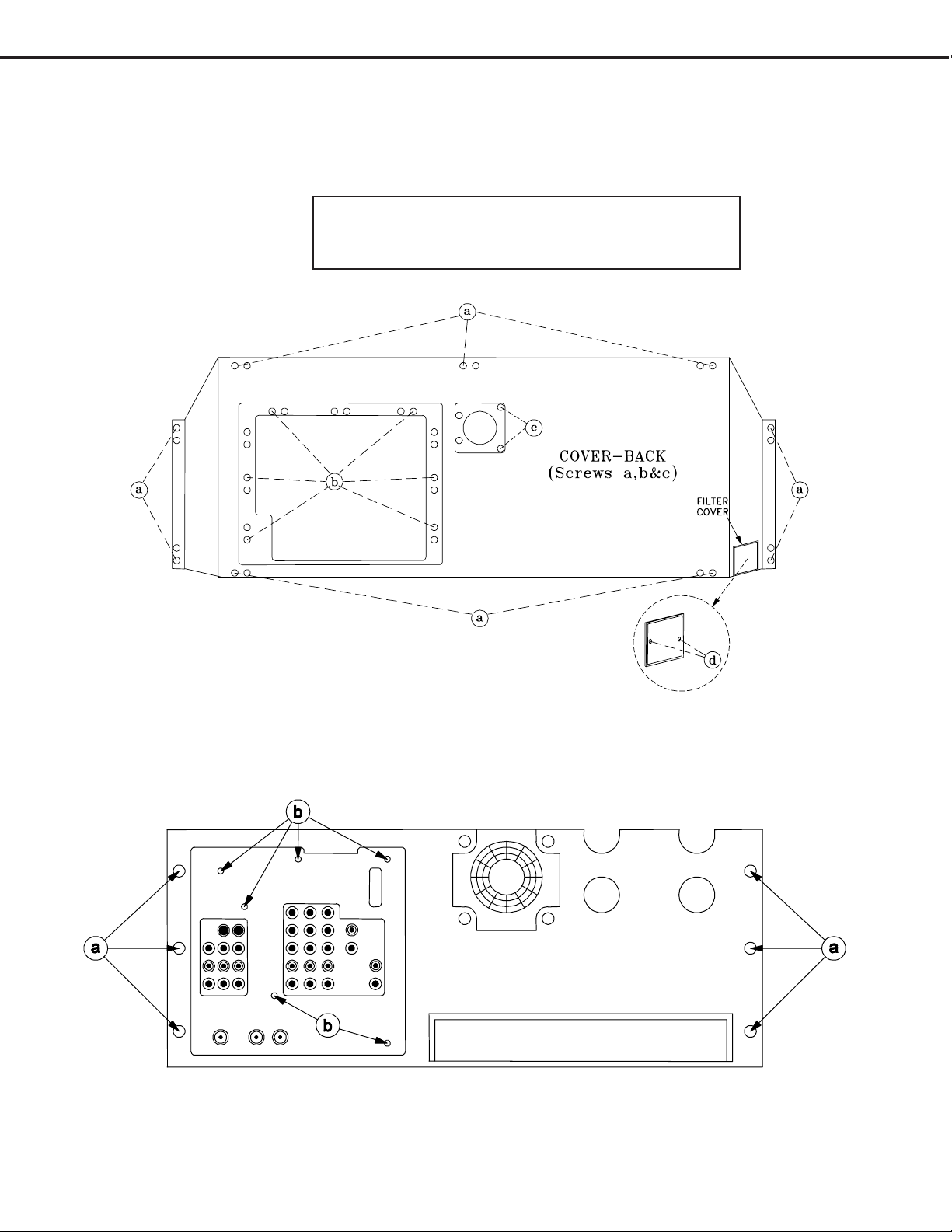

REAR DISASSEMBLY

FILTER-COVER Removal

Remove 2 screws (d) to remove the Filter Cover.

COVER-BACK Removal

1) Remove 9 screws (a)

2) Remove 6 screws (b)

3) Remove 2 screws (c)

4) Pull the COVER-BACK

from the cabinet.

NOTE: To operate the TV with the COVER-BACK removed,

the FILTER-COVER must be reinstalled.

Rear Plate Removal

1) Remove 6 screws (a)

2 Remove 6 screws (b)

3) Pull the COVER-BACK from the cabinet.

4) Lay the Rear Plate down behind the TV.

Page 8

Page 9

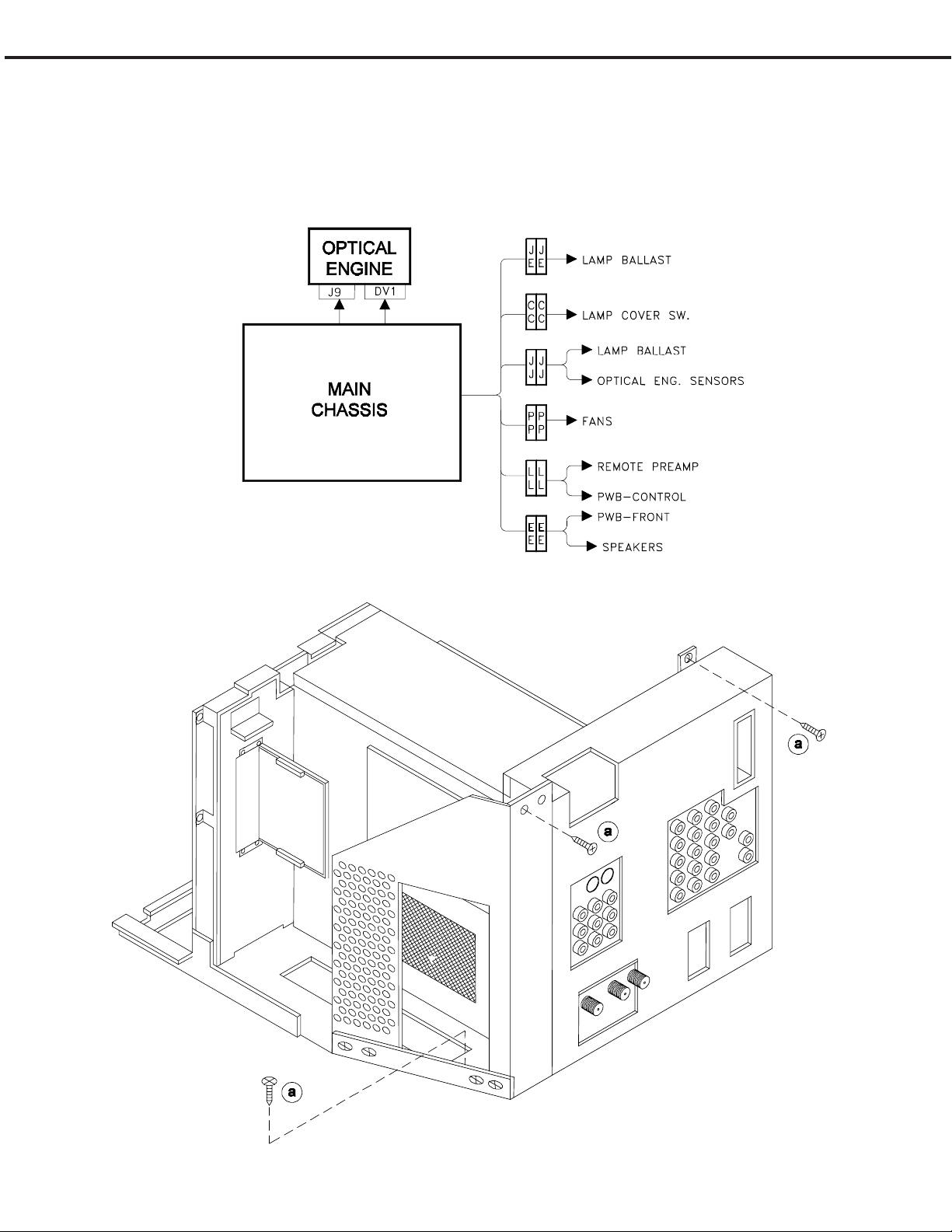

MODEL: WD-52327 / WD-62327

CHASSIS REMOVAL

Chassis Removal Procedure

1) Disconnect all relay connectors shown below (JE, CC, JJ, PP, LL & EE)

2) Disconnect the J9 and DVI connectors at the Optical Engine.

2) Remove three screws (a) securing the chassis.

3) Carefully slide the chassis from the cabinet.

Page 9

Page 10

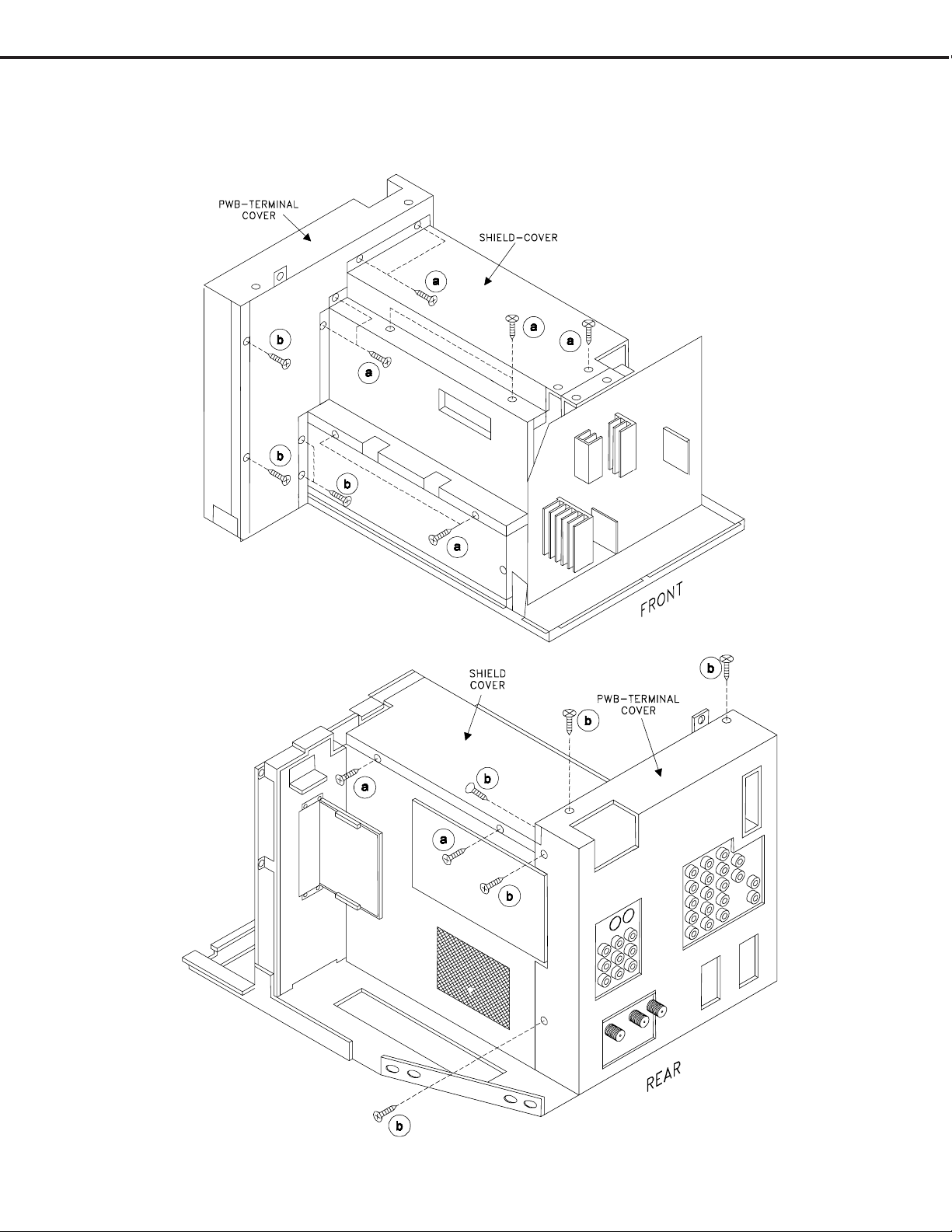

MODEL: WD-52327 / WD-62327

Shield Removal

1) To remove SHIELD-COVER, remove 11 screws (a).

2) To remove PWB-TERMINAL COVER, remove 9 screws (b).

Page 10

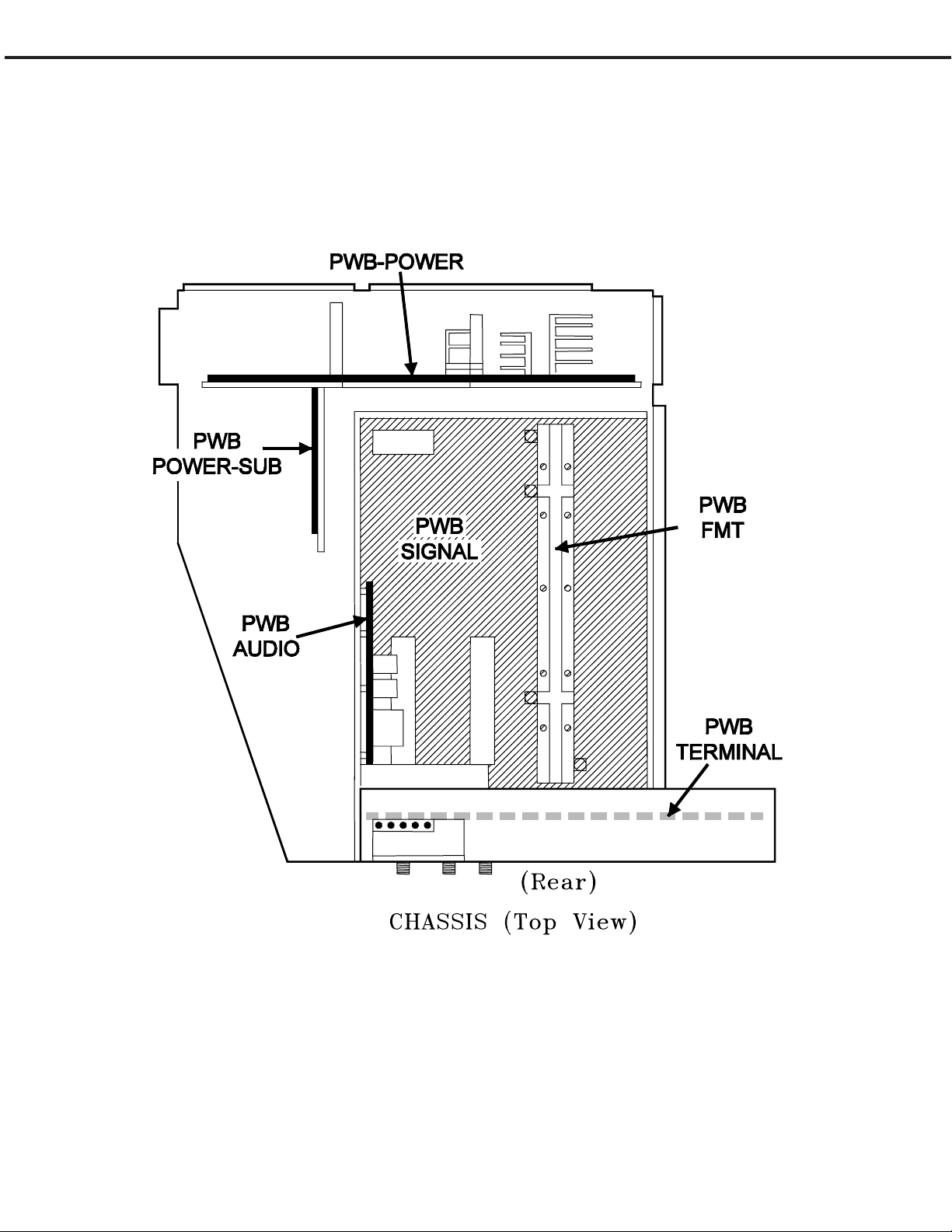

Page 11

MODEL: WD-52327 / WD-62327

VK26 Chassis PWB Locations (Shield-Cover removed)

Page 11

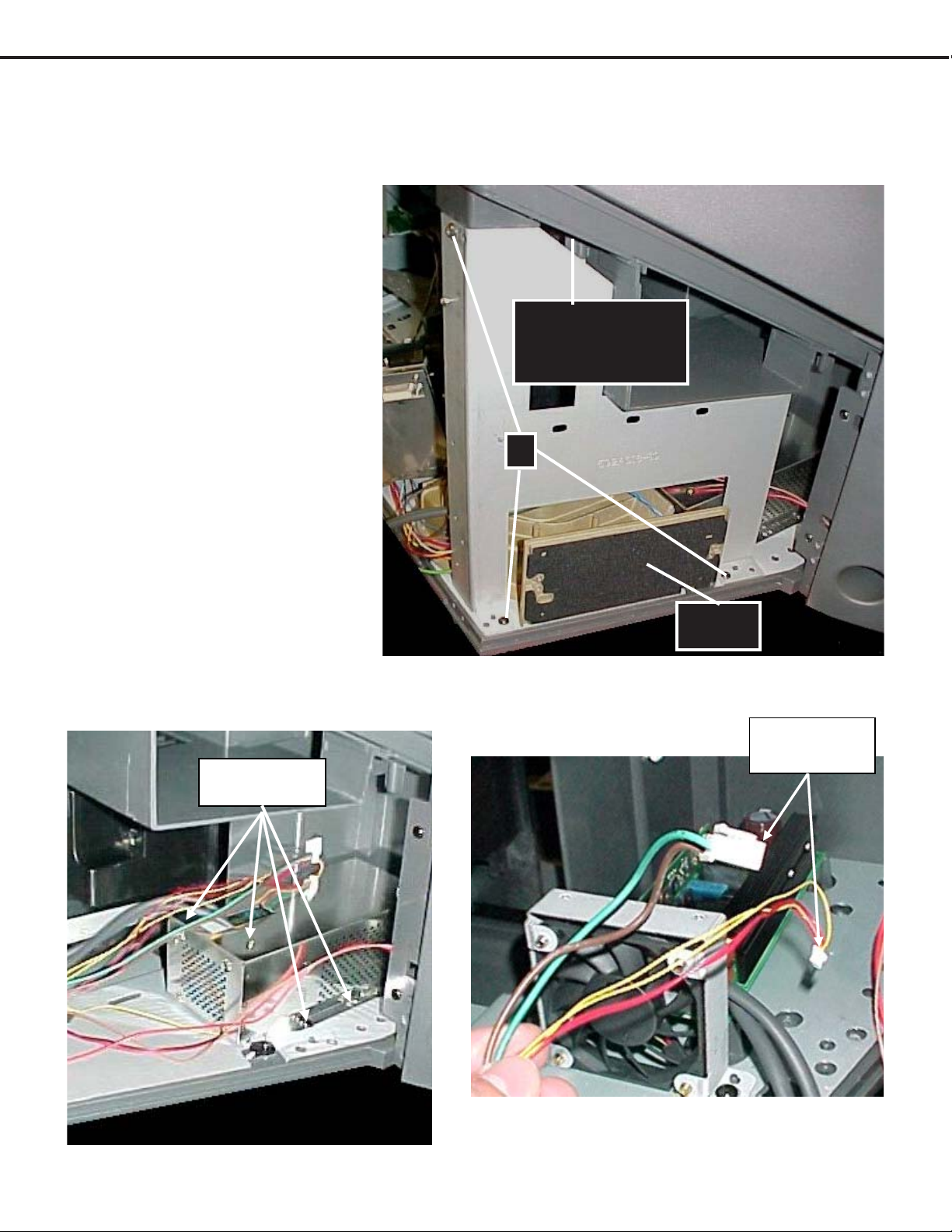

Page 12

MODEL: WD-52327 / WD-62327

Accessing The Lamp Ballast

Removing the Right Support (Rear View)

1) Remove the Air Filter.

2) Remove the 3 screws (a).

3) Lift the upper cabinet slightly

to remove the support bracket.

Lift upper cabinet

slightly to remove

support.

(a)

Removing the Lamp Ballast Shield

(4 screws)

4 Screws

Remove

Air Filter

Unplug CJ3 & CN2

Connectors

Unplug

Connectors

Page 12

Page 13

MODEL: WD-52327 / WD-62327

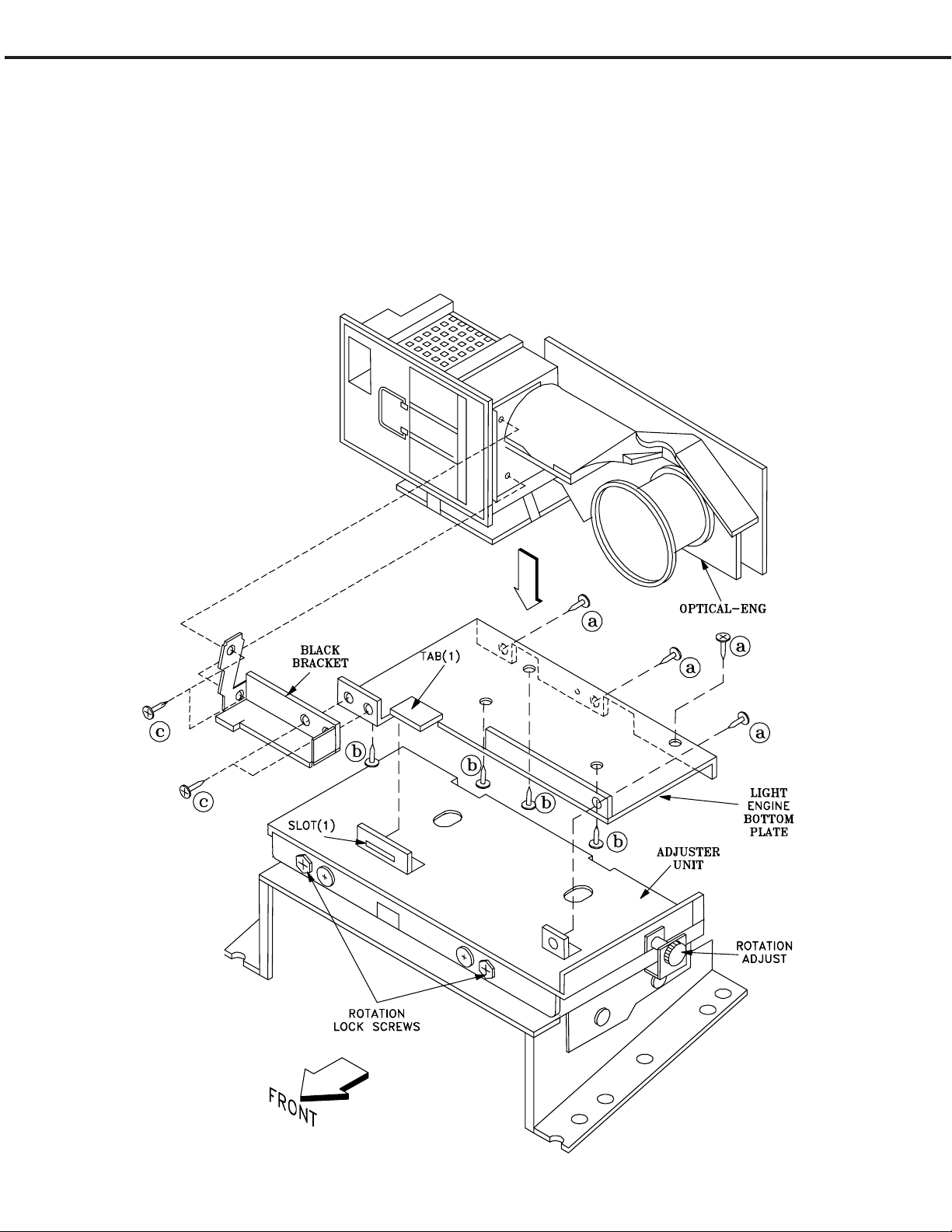

OPTICAL ENGINE REPLACEMENT

Optical Engine is mounted on the Adjuster assembly as shown below.

1) The Optical Engine is secured to the bottom plate with 4 screws (b).

2) The Black Bracket is secured to the bottom plate and the Lamp Cartridge Housing with 4 screws (c).

3) Tab (1) on the bottom plate slides into slot (1) on the Adjuster assembly.

4) 4 screws (a) secure the bottom plate and Optical Engine to the Adjuster assembly.

5) The Optical Engine, the bottom plate, black bracket and the Optical Engine are removed as a unit.

Page 13

Page 14

MODEL: WD-52327 / WD-62327

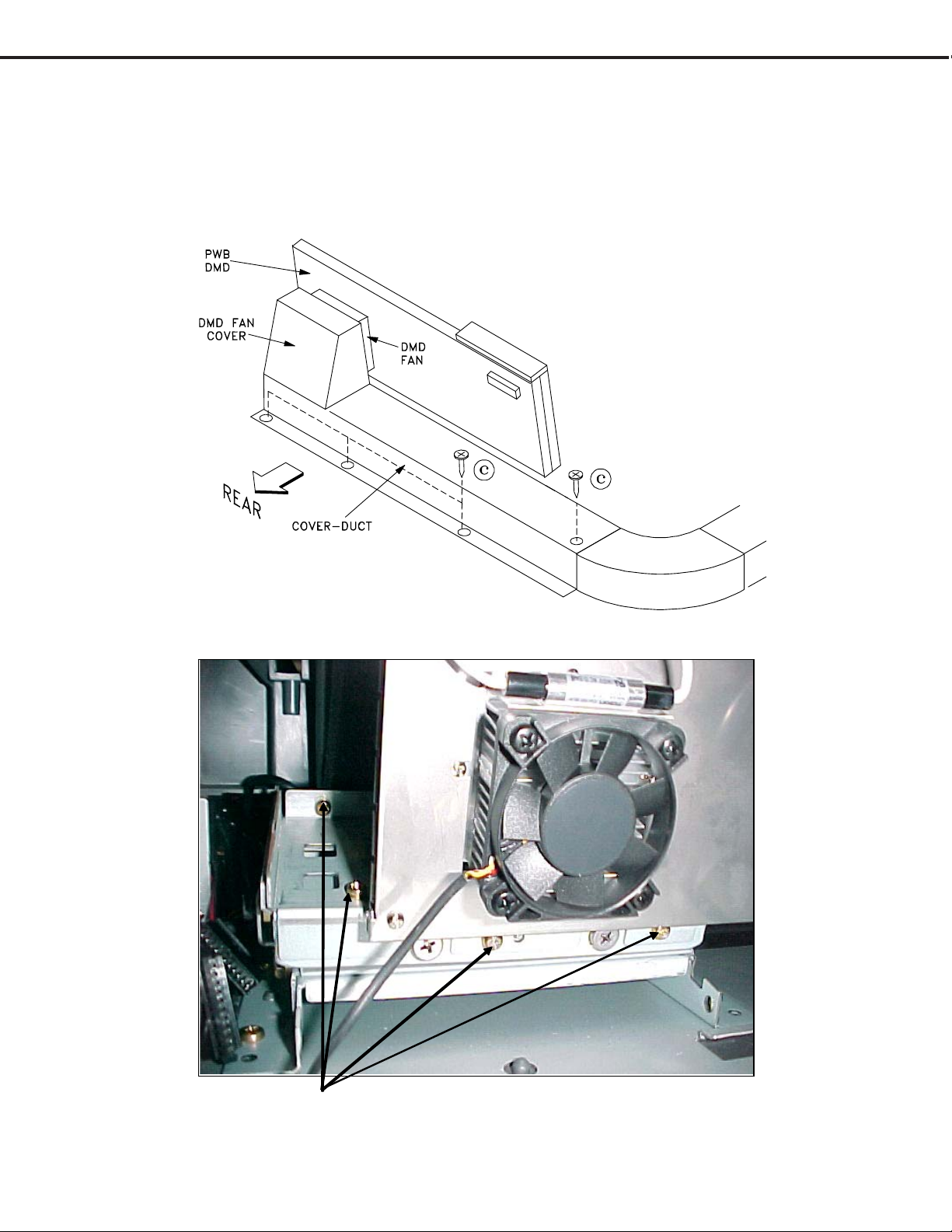

Removing the Optical Engine

1) Remove the Cabinet BACK-BOARD and REAR-PLATE (refer to disassembly instructions).

2) Disconnect all connectors connected to the Engine and the PWB-FORMAT.

3) From the rear of the TV, remove the 4 screws (c), to remove the COVER-DUCT and DMD Fan cover.

4) From the rear of the TV, remove the 4 screws (a), shown below, securing the bottom plate to the Adjuster

assembly.

5) Slide the Optical Engine, PWB-DMD and bottom plate towards the rear to remove the unit from the TV.

(a)

Optical Engin e (Rear View / Aird u ct & DMD Fan Cover Removed)

Page 14

Page 15

MODEL: WD-52327 / WD-62327

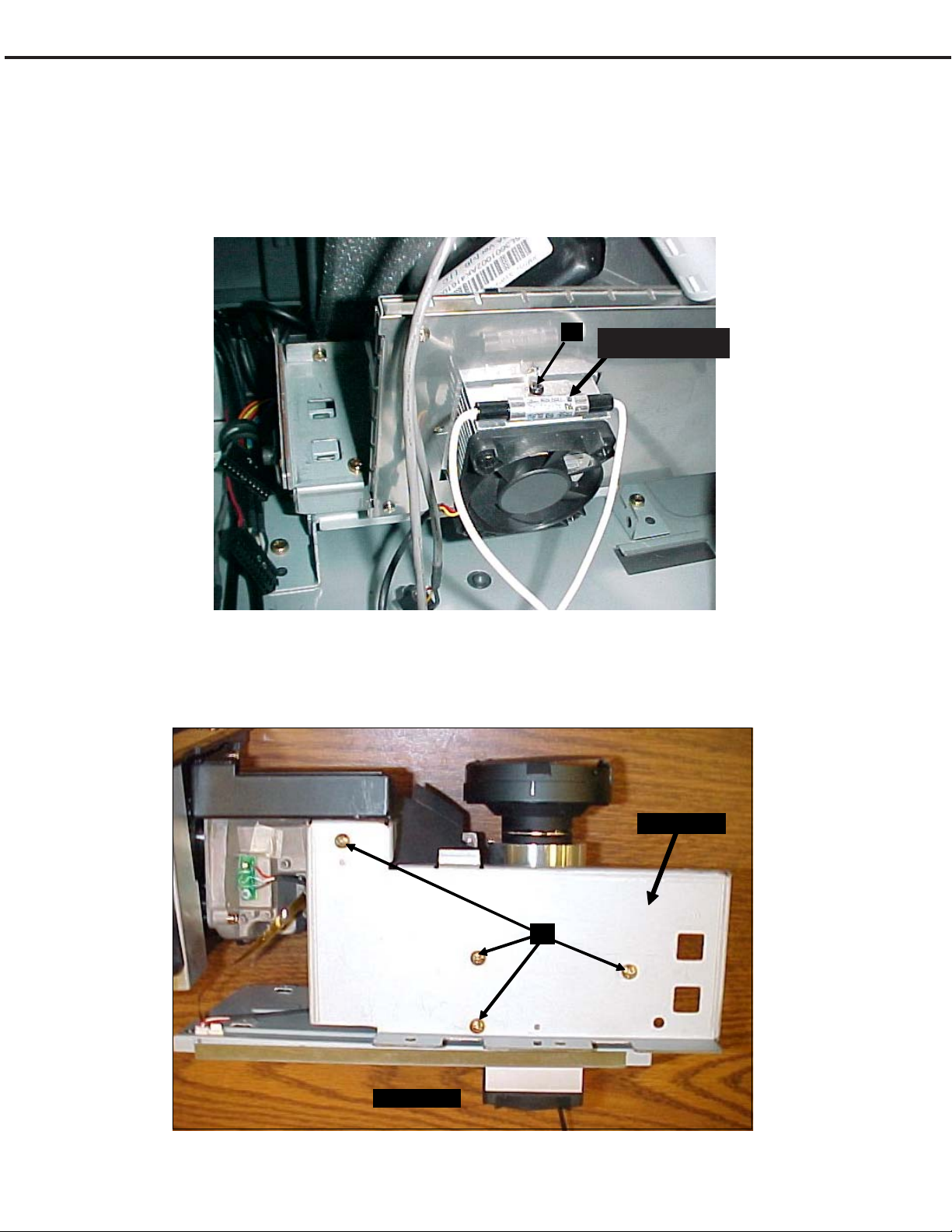

Remove the follolwing parts from the Optical Engine

• DMD Thermal Sensor

• The Optical Engine bottom plate and black bracket

DMD Termal Sensor Removal (Figure 1)

1) Remove screw (a) on the top of the DMD Fan.

2) Set the Thermal Sensor aside to install on the replacement Optical Engine.

(a)

Thermal Sensor

Heat Sensor

Figure 1: DMD Thermal Sensor

Bottom Plate & Black Bracket Removal

1) Remove the 4 screws (B) from the Bottom Plate (Figure 2)

2) Remove the two screws (c), holding the Black Bracket to the Lamp Cartridge Housing. (Figure 3)

Bottom Plate

(B)

Bottom V i e w

Figure 2: Bottom Plate

Page 15

Page 16

MODEL: WD-52327 / WD-62327

Black Bracket

(C)

Front V i ew

Figure 3: Black Support Bracket

Installing the Optical Engine

1) Install the Bottom Plate, Black Support Bracket and the Thermal Sensor from the original Optical Engine, on

the replacement Engine

2) Reverse the removal procedure to install the replacement Optical Engine in the cabinet.

2) The following adjustments may have to be performed after the installation.

• Horizontal and Vertical Electrical Centering Adjustment.

• Optical Unit Rotation Adjustment

• Optical Unit Keystone Distortion Adjustments.

Page 16

Page 17

MODEL: WD-52327 / WD-62327

SERVICING THE LENTICULAR SCREEN AND FRESNEL LENS

CAUTION: Wear gloves when handling the Lenticular Screen and Fresnel Lens.

This prevents cuts and finger prints. Do not place Fresnel Lens in the sun.

This may cause fire and heat related injuries.

Lenticular Screen and Fresnel Lens Removal

1. Remove the screen assembly shown in the Cabinet Disassembly procedure.

2. Remove the four screws (a) to remove the bottom of the SCREEN-FRAME-BOTTOM . (Figure 1)

3. From the front of the screen assembly, slide the BEZEL out the bottom of the Screen Frame. (Figure 2)

4. From the rear of the screen assembly, carefully slide the Lenticular Screen and Fresnel Lens combination

from the Screen Frame. (Figure 3)

Note: When separating the Lenticular Screen from the Fresnel Lens, use caution

while prying the Screen and Lens apart. Use a slot type screw driver, and

remove the pressure sensitive double sided tape.

Figure 1: SCREEN-FRAME-BOTTOM Removal (Rear View)

Page 17

Page 18

MODEL: WD-52327 / WD-62327

Figure 2: BEZEL Removal (Front View)

Figure 3: Lenticular Screen & Fresnel Lens Removal (Rear View)

Page 18

Page 19

MODEL: WD-52327 / WD-62327

SERVICING THE LENTICULAR SCREEN AND FRESNEL LENS

Lenticular Screen and Fresnel Lens Installation

Note: Store the Lenticular Screen and Fresnel Lens in a cool dry place. High humidity may

deform the Lenticular Screen and Fresnel Lens.

1. Apply double coated tape (Part #LENS-TAPE) along the top rear edge of the Lenticular Screen, as shown

below. Refer to the table below for the tape length.

2. Sandwich the Fresnal Lens and Lenticular Screen together. The Lenticular Screen label must be towards

the front and the Fresnel Lens label towards the rear. (Figure 4)

3. Apply pressure at the top edge to bond the screens together.

4. Reverse the Screen Removal procedure and insert the screens in the Screen Fame Assembly.

Figure 4: Installing the Fresnel Lens & Lenticular Screen

*X INCHES - Refer to the Tape Length in the table below

MODEL SCREEN SIZE TAPE LENGTH

WD-52327 52 Inches 46.3 Inches

WD-62327 62 Inches 55.1 Inches

Page 19

Page 20

MODEL: WD-52327 / WD-62327

ELECTRICAL ADJUSTMENTS

Note: Perform only the adjustments required.

Do not attempt an alignment if proper equipment is not available.

Test Equipment

• Oscilloscope (Unless otherwise specified, use 10:1 probes)

• Signal Generator (NTSC Color Bar)

Test Signals

A. Internally Generated Square Pattern Signals

B. Color Bar Signal

Use the color bar signal shown

below, unless otherwise specified

in this manual.

100%

40%

75%

40%

1H

Split-Field Color Bars (100% window)

Page 20

Page 21

MODEL: WD-52327 / WD-62327

V

f

f

Initial Setup

A. Option Menu Setup

Follow the steps below for the initial set-up:

1. Select the "MENU" display by pressing the "MENU" button once.

2. Press the number buttons "5", "7", "7", "0" in sequence to select the "OPTION MENU" display.

3. Press the "ADJUST" button to select "INITIALIZE."

4. Press "ENTER."

NOTE: At this time channel 3 is automatically selected.

OPTION MENU <MENU> <5-7-7-0>

Initialize

Power Restore: Of

DTV Port: AUTO

Direct Key Mode: Of

Lamp Hours: TOTAL CURRNT PREV1 PREV2

0000

Total TV

On Time

Current

Lamp

Time

Previous

Lamp

Time

Previous

Lamp

Time 2

B. Default Settings

K26 M ain M enu Defau lt Settings

Setup Menu

Memorize Channels Ant-A Front Button Lock Off Yellow 50%

Language English Green 50%

Energy Mode Standard V-Chip Off Cyan 50%

Input Assignm e nt Me n u

Antenna-A On FV-Fant asy Violence A llow

Antenna-B On D-Sex ual Dialog Allow A/V Memory Reset A nt-A

DTV YPrP b L-Adult Language Allow TV Speak ers (internal) On

Component-1 Comp-1 S-Sex ual Situation Allow A udio Output Fixed

Component-2 Comp-2 V-Violence Allow

Input-1 Input-1 M ovie Rating PG Bass 50%

Input-2 Input-2 Programs Not Rated Allow Treble 50%

Input-3 Input-3 Balanc e Center

MonitorLink™ MonoLink V-Chip Start Time 12:00am S urrond Off

Clock Me nu

Clock S etting Manual Level Sound Off

Clock Time ../.. Color Balance TV Volume 30%

Set Day Sunday Timer

Time Zone N/A Video M ute On Contrast 50%

Daylight Savings N/A Blac k Enhanc em entt On Brightness 50%

Captions

Closed Captions In Mute Ant-A A uto Color Correction Off Color 50%

CC Back ground Gray PerfectColor™ Tint 50%

Channel Edit Menu

Antenna Ant -A

Channel 003 Timer Off Film Mode (Auto) On

Memory Deleted Set Time 12:00 AM

Name N/A Set Day Everyday PIP Souce Ant-A Ch-3

SQV N/A Input Ant-A PIP Position Lower Rt.

V-Chip Lock Menu

Lock by Time On PIP/POP Format Dble Win.

Lock Time N/A M agenta 50%

Unlock Time N/A Red 50%

V-Chip Menu

TV Rating TV-PG Blue 50%

Audio/Video Settings Menu

Audio S e tti ngs (TV )

V-Chip Hours

V-Chip Start Time 12:00am Listen To Stereo

Advanced Features Menu

Video Settin gs (TV)

Color Balance Me nu

Reset Color for Ant-A Color Temp. High

Timer Menu

Channel 003 P OP Position Rt. Half

PerfectColor™

Sharpness 50%

Video Noise Standard

PIP Menu

Format

Stretch

Page 21

Page 22

MODEL: WD-52327 / WD-62327

A/V Memory Defaults

Function Ant -A/B DTV Comp-1/2 Input 1/2/3 MonoLink

Contrast Maximum Maximum Maximum Maximum Maximum

Brightness Center Center Center Center Center

Sharpness Center Center Center Center Center

Color Center Center Center Center Center

Tint Center Center Center Center Center

Color Temp. High High High High High

Video Noise Standard Standard Standard Standard Standard

Film Mode On On On On On

Bass Center Center Center Center Center

Treble Center Center Center Center Center

Balance Center Center Center Center Center

Surround Off Off Off Off Off

Listen To Stereo N/A N/A N/A N/A

Level Sound Off Off Off Off Off

C. A/V Memory

Each of the external inputs has its’ own Audio/Video Memory. A change in an A/V setting at a specific input is

stored in memory for that specific input.

A/V Reset

1. The front panel AV Reset button initializes all A/V Memories.

2. The AV Reset in the user’s menu initializes only the selected input’s A/V Memory.

LED Indications

The three front panel LEDs provides an indication of the sets operation,

and the possible cause of a malfunction.

Normal LED Indications

LED

Power/Timer Status Lamp Condition

Off Off Off Off (standby)

Green Blink Off Off µPC Initializing (after AC off/on) (1~2 sec)

Off Off Blink green Lamp Fan running (1 min after PTV Off)

Green Off Off Power On

Slow Green Blink Off Off Power On Timer is set.

Abnormal LED Indications

LED

Power/Timer Status Lamp Condition

Off Yellow Off Temp. high - dirty filter/excess room temp.

Off Off Yellow 4000 hrs. Lamp usage warning

Off Off Blink Yellow Lamp Cover open

Off Blink Yellow Off Air Filter Cover open

Off Off Red Lamp failure (failed to turn On or broken)

Off Blink Red Off Fan Stopped

Red Off Circuit failure (short) or DVI cable disconnected

Page 22

Page 23

LED Diagnostic Check

1. Initial Control Circuitry Check

Immediately after the TV is connected to an AC power source:

2. Error Code Operational Check

Pressing the front panel “INPUT” and “MENU” buttons at the same time, and holding for 5 seconds,

activates the Error Code Mode. The ” Power LED” flashes denoting a two digit Error Code, or indicating no problem

has occured since the last Initalization.

Note: The front panel buttons must used, NOT those on the Remote Control.

• The number of flashes indicates the value of the MSD (tens digit) of the Error Code.

• The flashing then pauses for approximately 1/2 second.

• The LED then flashes indicating the value of the LSD (ones digit) of the Error Code.

• The Error Code is repeated a total of 5 times.

Example: If the Error Code is “34”, the LED will flash 3 times, pause, and then flash 4 times.

3. Error Codes

The Error Code designations indicating a malfunction, or no malfunction, are listed below:

ERR0R CODES

Error

Code

12 No Error detected, check Power Supply

32 Lamp Cover is open

33 Air Filter Cover is open

34 Lamp abnormality

36 Light Engine (DMD or LAMP Fan stopped)

37 Exhaust or Lamp Ballast Fan stopped

38 Lamp temperature high

39 DMD temperature high

41 Short is detected

44 DVI cable between FMT & Engine disconnected.

MODEL: WD-52327 / WD-62327

Description

Circuit Adjustment Mode

Most of the adjustments can only be performed using the remote hand unit.

A. Activating the Circuit Adjustment Mode

1. Select the signal source.

2. Press the "MENU" button on a remote hand unit.

3. Press the number buttons "5", "7", "5", "7" in sequence. The screen will change to the Adjustment Mode.

Note: Repeat steps 1 and 2 if the circuit

adjustment mode does not appear

on screen.

Page 23

Page 24

MODEL: WD-52327 / WD-62327

A

B. Selection of adjustment Functions and

Adjustment Items

To select an adjustment item in the circuit adjustment mode, first select the

adjustment function that includes the specific item to be adjusted. Then

select that adjustment item.

Refer to the following pages for the listing of

adjustment functions and adjustment items.

1. Press the "AUDIO" button on a remote hand unit to select an adjustment function. Each time the button is pressed, the Function changes

in the following sequence:

MAIN MATR SUB MATR

Adjustment Functions

DDP FPG

2. Press the “VIDEO” button to select a specific

Adjustment Item. The Item number increases

each time the“VIDEO” button is pressed.

MISCDEV

C. Changing Data

After selecting an adjustment Item, use the “ADJUST UP/DOWN” buttons to

change data.

• Press “ADJUST DOWN” to decrease the data value.

• Press “ADJUST UP” to increase the data value.

D. Saving Adjustment Data

Press “ENTER” to save adjustment data in memory. The character display turns red for approximately one

second in this step.

Note: If the circuit adjustment mode is terminated without pressing “ENTER”, changes in adjustment data

are not saved.

E. Terminating the Circuit Adjustment Mode

Press the “MENU” button on the remote hand unit twice to terminate the adjustment mode.

Note: The circuit adjustment mode can also be terminated by turning power OFF.

Page 24

Page 25

MODEL: WD-52327 / WD-62327

List of Service Adjustment Items

MAIN MATRIX

(Main Decoder) Stored in IC2K02 on PWB-TERMINAL

Item No. Abbrev, Description Data Range Initial Data

39 SCNT Main Y-Gain 0~31 16

41 SCLR Main CB/CR Gain 0~31 22

SUB MATRIX

(Sub Decoder) Stored in IC2K02 on PWB-TERMINAL

Item No. Abbrev, Description Data Range Initial Data

39 SCNT Sub Y-Gain 0~31 15

41 SCLR Sub CB/CR Gain 0~31 21

FPGA Stored in IC7C01 on PWB-SIGNAL

Item No. Abbrev, Description Data Range Initial Data

1 H-DLY Horiz. Position 0~128 74

2 V-DLY Vertical Position 0~55 32

DDP Function

Item # Abbrev. Description Range WD-52327 WD-62327

120 GGH High Temp. Green Gain 000~400 2FA 31F

121 GRH High Temp. Red Gain " 400 400

122 GBH High Temp. Blue Gain " 36D 34F

123 GGM Mid Temp. Green Gain " 2E1 2FE

124 GRM Mid Temp. Red Gain " 400 400

125 GBM Mid Temp. Blue Gain " 320 2FF

126 GGL Low Temp. Green Gain " 2C8 2EC

127 GRL Low Temp. Red Gain " 400 400

128 GBL Low Temp. Blue Gain " 2D4 2C0

NOTE: Data values are in hexadecimal format

Stored in IC2K02 on PWB-TERMINAL

Data

Initial Data

Page 25

Page 26

MODEL: WD-52327 / WD-62327

Activating & Selecting an Internal

Test Signal

1. Select an External Input with no signal.

2. Press the buttons “MENU”-“5”-“7”-“5”-“7” in

sequence. (Activates the Service Menu)

3. Select the “FPGA” function (AUDIO button)

4. Press “1” for Pattern A, or “2” for Pattern B.

.

5. Press “9” to return to the Service Menu.

6. Press “MENU” to exit the Service Mode.

CAUTION

DO NOT press “MENU” (or HOME) without

pressing “9” first. (The Video Mute function will

not function properly.)

To correct the Mute function -- remove AC to

the TV, then reapply AC to reset the unit.

Page 26

Page 27

[Video Circuit]

A

MODEL: WD-52327 / WD-62327

Purpose:

To set picture luminance

1. Main/Sub Y Level

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

CIRCUIT ADJ UST MODE

ctivate …….. MENU-5-7-5-7

Func tion … ...………..AU D IO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Sa ve D a ta …. …… … E NTER

Exit …………..MENU (twice)

Oscilloscope

JA-22 & JB-3

------

------

Color Bars

Video Input

Symptom:

Excess or insufficient brightness.

1. Supply a color bar signal to a Video Input (not an RF input).

2. Select the color bar signal for both the main and sub pictures.

3. Connect the oscilloscope to connector JA pin 22. (Main-Y)

4. Activate the Adjustment Mode (MENU-5-7-5-7)

5. Select the “MAIN MTRX” function. (AUDIO button)

6. Select adjustment Item “39 SCNT”. (VIDEO button)

7. Adjust the data for 0.71 ~ 0.76 Vp-p at JA pin 22.

(If it cannot be adjusted within this range, set to the lower value)

8. Move the oscilloscope to connector JB pin 3. (Sub-y)

9. Select the “SUB MTRX” function. (AUDIO button)

10. Select adjustment Item “39 SCNT”. (VIDEO button)

11. Adjust the data to equal the MAIN-Y Gain (+0.0V -0.05V).

12. Press “ENTER” to save data changes.

[Video Circuit]

2. Main/Sub Color Level

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

Oscilloscope

JA-20 & JB-5

------

200mV/div

20usec/div

Color Bars

Video Input

Purpose:

Symptom:

To set the sub picture color level.

Main and sub pictures color levels differs.

1. Supply a color bar signal to a Video Input.

2. Select the color bar signal as the source for both the main and sub picture.

3. Connect an oscilloscope to connector JA pin 20 (main Cr).

3. Activate the Adjustment mode (MENU-5-7-5-7)

4. Select the “MAIN MTRX” function (AUDIO button).

5. Select adjustment item “41 SCLR” (VIDEO button)

6. Adjust the data for 0.81 ~ 0.86 Vp-p min. at JA pin 20.

(If it cannot be adjusted within this range, set to the lower value).

7. Move the oscilloscope to connector JB pin 5 (sub Cr).

8. Select the “SUB MTRX” function (AUDIO button).

9. Select adjustment item “41 SCLR” (VIDEO button).

10. Adjust data so the Sub Cr amplitude equals that of the Main Cr.

11. Press “ENTER to save data changes.

Page 27

Page 28

[Video Circuit]

A

3. White Balance

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

CIRCUIT ADJ UST MODE

ctivate …….. MENU-5-7-5-7

Func tion … ...………..AU D IO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Sa ve D a ta …. …… … E NTER

Exit …………..MENU (twice)

------

------

White Raster

Video Input

MODEL: WD-52327 / WD-62327

Purpose:

Symptom:

1. Supply a 100% white raster to an External Video Input.

3. Activate the Service Mode. (MENU-5-7-5-7)

4. Select the “DDP” function. (AUDIO button)

5. Select adjustment Items with the VIDEO button.

NOTE: Data is displayed in the hexadecimal format.

6. Adjust the data for Items “120 GGH”, “121 GRH and “122 GBH” for optimum

white at the center of the screen.

7. Adjust the data for Items “123 GGM”, “124 GRM and “125 GBM” for optimum

white at the center of the screen.

8. Adjust the data for Items “126 GGL”, “127 GRL and “128 GBL” for optimum

white at the center of the screen.

9. Press “ENTER” to save data changes.

10. Press “MENU” twice to exit the Service Mode.

To set high, mid and low temperature white levels.

White areas have a color tint.

[PICTURE POSITION]

4. Horizontal/Vertical Position

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

----

----

------

-------

Internal Pattern “B”

External Input

Purpose:

Symptom:

To center picture on the screen.

Picture is off center.

NOTE: The TV must be on a flat level surface.

1. Select an External Input with no signal.

2. Press “MENU-5-7-5-7” in sequence (activates the Service Mode).

3. Press “AUDIO” to select the “FPGA” function.

4. Press “2” to activate internal Test Pattern B. (Shown below)

5. Use the “VIDEO” button to select Item “1 H-DLY”.

6. Use the “ADJUST” buttons to center the picture Horizontally..

7. Press “ENTER” to save the adjustment.

8. Use the “VIDEO” button to select Item “2 V-DLY”.

9. Use the “ADJUST” buttons to center the picture Vertically.

10. Press “ENTER” to save the adjustment.

11. Press “9” to terminate the test pattern.

12. Press “Menu” twice to terminate the Adjustment Mode.

CIRCUIT ADJUST MODE

Activate …….. MENU-5-7-5-7

Function …...………..AUDIO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Save Data …. ………ENTER

Exit ………….."9" then "MENU"

Page 28

Page 29

MODEL: WD-52327 / WD-62327

Mechanical Adjustments

• To perform the mechanical adjustments, the TV must be on a flat level surface and a certain amount of disassembly

is required.

• Use internal Test Pattern B for all mechanical adjustments.

Front Disassembly

Refer to the diagram below for the Front Panel removal procedures.

Rear Disassembly

Refer to the to the diagrams below for the COVER-BACK and Rear Plate removal.

NOTE: T o operate the T V with the COVER-BACK removed,

the FIL TER-COVER must be reinstalled and the Exhaust Fan connected.

Page 29

Page 30

MODEL: WD-52327 / WD-62327

Picture Rotation Adjustment

NOTE: The TV must be on a flat level surface.

1. From the front of the TV, lift the foam to access and loosen slightly, the brass Rotation Locking Screws on the Adjuster

Assembly, Figure 4A. (Use a 10mm wrench.)

2. From the rear of the TV, access the black Rotation Adjustment screw and adjust so the test pattern center lines are

parallel to the sides, top and bottom of the screen frame, Figure 4B. (Use a mirror to veiw the picture from the rear of the

set.)

3. Tighten the two Locking Screws. Use Locktite to secure the Adjustment Screw. (If necessary, use the electrical adjustments to center the picture)

Page 30

Page 31

MODEL: WD-52327 / WD-62327

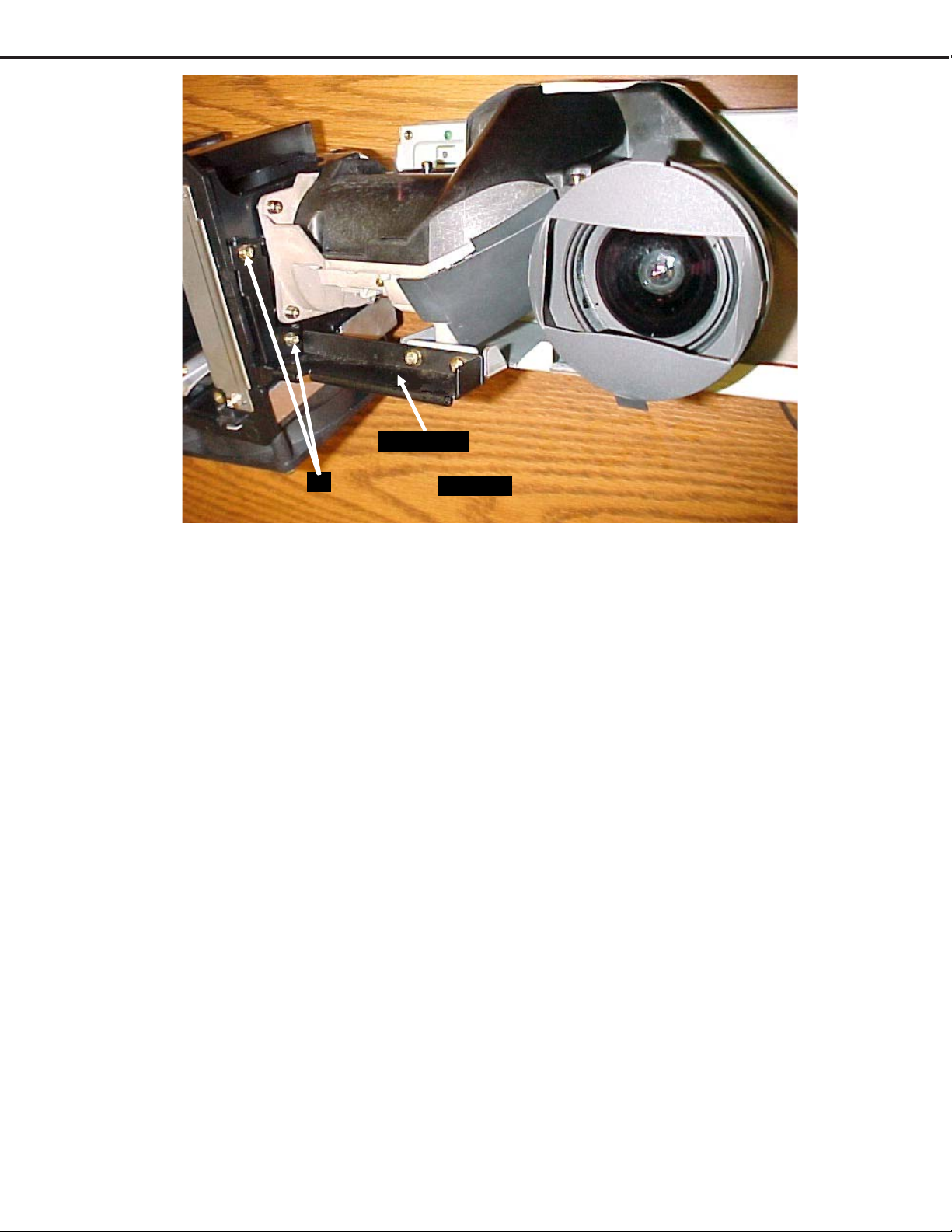

Keystone Adjustment

Horizontal Keystone Distortion

Vertical Keystone Distortion

NOTE: The TV must be on a flat level surface

1. From the front of the TV, loosen the two Keystone Locking Screws in the small mirror assembly. (10mm wrench)

2. From the front of the TV, adjust the Horizontal Keystone Adjustment for minimum distortion.

3. From the front of the TV, adjust the Vertical Keystone Adjustment for minimum distortion.

4. Tighten the Keystone Lock Screws. and secure the adjustment screws with Locktite. (If necessary, use the electrical

adjustments to center the picture)

Horiz

Keystone

Adjust

Locking Screws

Vertical

Keystone

Adjust

Small Mirror Assembly (Front View)

Page 31

Page 32

MODEL: WD-52327 / WD-62327

QUICK REFERENCE FOR COMMON REPLACEMENT PARTS

• Critical Electrical Components are indicated by Bold Type in the Parts List

Customer Replaceable Parts

Part Nam e Description WD-52327 W D-62327

Lam p Cartridge LAMP-CARTRIDGE 915P020010 915P020010

Dust Filter FILTER-DUST 620D144010 620D144010

Remote Control REMOTE 260P116010 260P116010

Service Parts

Part Nam e Description WD-52327 W D-62327

Optic al Engine OPTICAL-ENGINE 939P977010 939P977020

Lam p Balla st UNIT-POW ER-LAMP 939B978010 939B978010

Power PWB ASSY-PWB-POWER 930B929001 930B929001

Signal PW B ASSY-PWB-SIGNAL 930B930001 930B930001

Format PWB ASSY-PWB-FMT 930B931001 930B931001

Terminal PWB ASSY-PWB-TERMINAL 930B932001 930B932001

Sub Power PWB ASSY-PWB-POWER-SUB 934C148001 934C148001

Audio PWB ASSY-PWB-AUDIO 934C149001 934C149001

Remote Preamp ASSY-PWB-PREAMP 935D811001 935D811001

Front PWB ASSY-PWB-FRONT 935D812001 935D812001

Control PWB ASSY-PWB-CONTROL 935D813001 935D813001

Right Speaker PWB ASSY-PWB-SPEAKER-R 935D814001 935D814001

Left Speaker PWB ASSY-PWB-SPEADER-L 935D815001 935D815001

Lam p Fan FAN-LAMP 299P282010 299P282010

DMD Fan FAN-DMD 299P283010 299P283010

Balla st Fan FAN-BALLAST 299P278020 299P278020

Exhaust Fa n FAN-EXHAUST 299P103050 299P103050

DMD Thermal Sensor SENSOR-THERMA L 299P280010 299P280010

Lamp Cover Detect Switch SW -MICRO 436P021010 436P021010

Filter Cover Detect Switch SW-MICRO 436P021010 436P021010

Screen Parts

Part Nam e Description WD-52327 W D-62327

Lenticular Screen LENS-LENTICULAR 491P176030 491P176040

Fresnel Lens LENS-FRESNEL 491P175010 491P175020

Bezel BEZEL-FRONT 761A252010 761A253010

PAGE 32

Page 33

MODEL: WD-52327 / WD-62327

Model Legend: [a] WD-52327, [b] WD-623275

Ref # Part # Part Name & Description [#]

Ref # Part # Part Name & Description [#]

INTEGRATED CIRCUITS

IC2D00 270P974010 IC-C-MOS - SII907B

IC2D02 261P135010 FET-HEX - IRF7313

IC2D04 271P004010 IC - CM1208-08MS

IC2K01 270P623010 IC - CXA2069Q

IC2K02 275P533010 IC-C-MOS - M24C64WM6T

IC2K04 275P718010 IC-C-MOS - TC74HC4053FT

IC2K05 275P718010 IC-C-MOS - TC74HC4053FT

IC2L01 275P937010 IC-C-MOS - MM1519XQ

IC2M01 275P947010 IC-C-MOS - UPD64083

IC2M02 270P992020 IC - BA25BC0FP

IC2MD1 272P379020 IC - LM1881MX (NSC)

IC2N01 275P938010 IC-C-MOS - TA1340F

IC2P01 275P938010 IC-C-MOS - TA1340F

IC2R01 271P005020 IC - AN15851AN

IC3A01 275P731020 IC-C-MOS - MSP3445G-QI-B8-V3

IC3E00 271P080010 IC - TDA8922J

IC3J01 270P838010 IC-C-MOS - NJM2520M

IC3J02 270P838010 IC-C-MOS - NJM2520M

IC3J03 270P838010 IC-C-MOS - NJM2520M

IC3J04 270P838010 IC-C-MOS - NJM2520M

IC7A00 276P017070 IC-C-MOS - M306V7FGFP-VK26

IC7A02 270P706020 IC - MAX823REUK

IC7A03 275P786010 IC-C-MOS - TC7SA08FU

IC7A05 271P023010 IC - SN74CBTD1G125DBVR

IC7A06 271P023010 IC - SN74CBTD1G125DBVR

IC7AAA 275P981010 IC-C-MOS - 24LCS22AT/SN

IC7C01 275P533010 IC-C-MOS - M24C64WM6T

IC7D01 275P278010 IC-C-MOS - TC74LVX14FT

IC7D02 270P818020 IC - CXA3506R

IC7D03 267P172010 HIC - AF-9395A

IC7E00 275P451010 IC-C-MOS - TC74HC4066AFN

IC7E01 275P560010 IC-C-MOS - ADS931E

IC7E02 275P560010 IC-C-MOS - ADS931E

IC7E03 275P560010 IC-C-MOS - ADS931E

IC7H00 275P963010 IC-C-MOS - DPM5

IC7H07 270P992010 IC - BA18BC0FP

IC7M00 275P982010 IC - MT48LC2M32B2-7

IC7N01 270P348010 IC - TLC2932IPW

IC7N11 275P236020 IC-C-MOS - TC74LVX244FT

IC7N21 275P769010 IC-C-MOS - TC74AC157FT

IC7N31 275P769010 IC-C-MOS - TC74AC157FT

IC7N41 274P901010 IC-C-MOS - TC74HCT7007AF

IC7N61 274P901010 IC-C-MOS - TC74HCT7007AF

IC8C03 275P689010 IC-C-MOS - ICS551MT

IC8D01 271P112010 IC - IP00C722

IC8D02 275P982010 IC - MT48LC2M32B2-7

IC8E00 276P107010 IC-C-MOS - SiI164

IC8E02 270P879030 IC - SC1566I5M-2.5TR

IC8E03 270P879030 IC - SC1566I5M-2.5TR

IC8E04 271P010010 IC - RT9172-18CG

IC8E05 271P010010 IC - RT9172-18CG

IC8H01 271P113010 IC - XC2S50E-6PQ208C

IC8H02 271P114020 IC - XCF01SVO20C-K261

IC9A10 267P175010 HIC - STR-W6735

IC9A12 271P081010 IC - BA00CC0WFP

IC9A20 270P816010 IC - NJM431L

IC9A21 270P991010 IC - IRU3037CS

IC9AAA 270P677010 IC - BA033FP

IC9C01 270P928010 IC - BA17809FP

IC9C11 270P928010 IC - BA17809FP

IC9C20 267P164010 HIC - TNY264P

IC9C21 270P677010 IC - BA033FP

IC9C21 270P816010 IC - NJM431L

IC9C31 270P999010 IC - NJM2370R09

IC9C61 270P677010 IC - BA033FP

TRANSISTORS

CHIP Type Transistors (Listed by Part No.)

Part No. Description

260P806010 DTA124EK/UN2112

260P817010 2SA1037K-Q

260P817050 2SA1037K-R,S/2SB709AI-R,S

260P817080 2SA1037K-R,S

260P818010 2SC2412K-Q

260P818050 2SC2412K-R,S/2SD601AI-R,S

260P835030 2SC2413K-Q

260P846030 DTC143ZKAT146

TRANSISTORS

Conventional Transistors (By Ref #)

Ref # Part # Part Name & Description

Q9A20 261P135010 FET-HEX - IRF7313

Q9A70 261P101010 TR - PHP21N06T

Q9B70 261P101010 TR - PHP21N06T

DIODES

D2J91 262P075010 DIODE - RSB6.8S

D7A00 264P828010 D-CHIP - DAN202U/MA142WK

D7AAA 262P805050 D-CHIP - UDZS5.1B

D7L20 262P075010 DIODE - RSB6.8S

D7L21 264P212020 D-LED - LN31GPH

D7L22 264P584020 DIODE-LE - SML1216W-C,D

D7L23 264P584020 DIODE-LE - SML1216W-C,D

D7L24 262P075010 DIODE - RSB6.8S

D7L25 262P075010 DIODE - RSB6.8S

D7L26 262P075010 DIODE - RSB6.8S

D7L27 262P075010 DIODE - RSB6.8S

D9A00 262P031010 DIODE - D6SB80

D9A01 262P031010 DIODE - D6SB80

D9A02 264P045080 DIODE - 1S2076A/1S2471OM

D9A03 264P461050 DIODE - EQA02-06B/RD5.6EB3

D9A04 264P045080 DIODE - 1S2076A/1S2471OM

D9A05 264P899010 DIODE - BYV26E

D9A06 264P045080 DIODE - 1S2076A/1S2471OM

D9A18 264P045080 DIODE - 1S2076A/1S2471OM

D9A19 264P045080 DIODE - 1S2076A/1S2471OM

D9A20 264P045080 DIODE - 1S2076A/1S2471OM

D9A23 264P045080 DIODE - 1S2076A/1S2471OM

D9A24 264P045080 DIODE - 1S2076A/1S2471OM

D9A25 264P045080 DIODE - 1S2076A/1S2471OM

D9A26 262P066010 DIODE - RU4A

D9A27 262P066010 DIODE - RU4A

D9A28 264P045080 DIODE - 1S2076A/1S2471OM

D9A29 264P045080 DIODE - 1S2076A/1S2471OM

D9A30 264P470070 DIODE - EQA02-32B/RD33EB3

D9A31 264P828010 D-CHIP - DAN202U/MA142WK

D9A32 264P828010 D-CHIP - DAN202U/MA142WK

PAGE 33

Page 34

MODEL: WD-52327 / WD-62327

[#] Model Legend: [a] WD-52327, [b] WD-62327

Ref # Part # Part Name & Description [#]

Ref # Part # Part Name & Description [#]

D9A33 264P458050 DIODE - RD3.9EB1

D9A34 262P090010 DIODE - M1FP3

D9A41 264P828010 D-CHIP - DAN202U/MA142WK

D9A42 264P828010 D-CHIP - DAN202U/MA142WK

D9A43 264P828010 D-CHIP - DAN202U/MA142WK

D9A44 264P828010 D-CHIP - DAN202U/MA142WK

D9A45 264P828010 D-CHIP - DAN202U/MA142WK

D9A60 264P669030 DIODE - S3L20U

D9A61 264P669030 DIODE - S3L20U

D9A80 264P828010 D-CHIP - DAN202U/MA142WK

D9A81 264P828010 D-CHIP - DAN202U/MA142WK

D9A82 264P828010 D-CHIP - DAN202U/MA142WK

D9A83 264P828010 D-CHIP - DAN202U/MA142WK

D9C22 264P825040 DIODE - ERA15-08

D9C24 264P045080 DIODE - 1S2076A/1S2471OM

D9C30 262P097010 DIODE - 11EQS06N-TA2B5

D9C31 262P097010 DIODE - 11EQS06N-TA2B5

COILS

L1A30 321C114010 COIL-RF - 2200MH-J

L1A31 325C461030 COIL-PEAKING - 10MH-K

L1B30 321C114010 COIL-RF - 2200MH-J

L1B31 325C461030 COIL-PEAKING - 10MH-K

L2AGA 409P864010 EMI-F-CHIP - ACB2012M600

L2AJA 409P864010 EMI-F-CHIP - ACB2012M600

L2AKA 409P864010 EMI-F-CHIP - ACB2012M600

L2ANA 409P864010 EMI-F-CHIP - ACB2012M600

L2APA 409P864010 EMI-F-CHIP - ACB2012M600

L2ARA 409P864010 EMI-F-CHIP - ACB2012M600

L2ATA 409P864010 EMI-F-CHIP - ACB2012M600

L2AYA 409P864010 EMI-F-CHIP - ACB2012M600

L2AZA 409P864010 EMI-F-CHIP - ACB2012M600

L2K05 409P777080 EMI-F-CHIP - BLM21P221S

L2K42 325C461030 COIL-PEAKING - 10MH-K

L2K46 325C462080 COIL-PEAKING - 180MH-J

L2K55 325C462080 COIL-PEAKING - 180MH-J

L2L28 325C461030 COIL-PEAKING - 10MH-K

L2M22 325C461050 COIL-PEAKING - 15MH-K

L2M31 409P777080 EMI-F-CHIP - BLM21P221S

L2M32 325C461050 COIL-PEAKING - 15MH-K

L2M38 409P777080 EMI-F-CHIP - BLM21P221S

L2M45 409P777080 EMI-F-CHIP - BLM21P221S

L2M46 409P777080 EMI-F-CHIP - BLM21P221S

L2M50 325C461000 COIL-PEAKING - 5.6MH-K

L2M53 325C461030 COIL-PEAKING - 10MH-K

L2M81 409P777080 EMI-F-CHIP - BLM21P221S

L2MA0 325C461050 COIL-PEAKING - 15MH-K

L2MA1 325C461030 COIL-PEAKING - 10MH-K

L2MD1 325C461030 COIL-PEAKING - 10MH-K

L2N01 325C461030 COIL-PEAKING - 10MH-K

L2N25 325C462020 COIL-PEAKING - 56MH-K

L2NA1 325C461030 COIL-PEAKING - 10MH-K

L2NA2 325C461080 COIL-PEAKING - 27MH-K

L2NA3 325C461030 COIL-PEAKING - 10MH-K

L2NC0 325C461030 COIL-PEAKING - 10MH-K

L2NC1 325C461080 COIL-PEAKING - 27MH-K

L2P01 325C461030 COIL-PEAKING - 10MH-K

L2P22 325C461050 COIL-PEAKING - 15MH-K

L2P25 325C462020 COIL-PEAKING - 56MH-K

L2P31

325C462020 COIL-PEAKING - 56MH-K

L2P32 325C461050 COIL-PEAKING - 15MH-K

L2P41 325C462020 COIL-PEAKING - 56MH-K

L2R28 325C461030 COIL-PEAKING - 10MH-K

L3A10 409P923060 EMI-F-CHIP - BLM21B272S

L3A49 409P923060 EMI-F-CHIP - BLM21B272S

L3E25 325C502010 COIL-CHIP - SLF12575T-330M3R2-H

L3E26 325C502010 COIL-CHIP - SLF12575T-330M3R2-H

L3E51 411D009020 CORE-FERRITE - ZBF503D-01

L3E52 411D009020 CORE-FERRITE - ZBF503D-01

L3J01 325C461030 COIL-PEAKING - 10MH-K

L3J20 325C461030 COIL-PEAKING - 10MH-K

L3J40 409P777020 EMI-F-CHIP - BLM21A05

L7A16 409P777050 EMI-F-CHIP - BLM21B201S

L7A19 409P777050 EMI-F-CHIP - BLM21B201S

L7A39 409P865060 EMI-F-CHIP - BLM11B141S

L7A42 409P865060 EMI-F-CHIP - BLM11B141S

L7A43 409P865060 EMI-F-CHIP - BLM11B141S

L7A47 409P865060 EMI-F-CHIP - BLM11B141S

L7A49 409P865060 EMI-F-CHIP - BLM11B141S

L7A50 409P865060 EMI-F-CHIP - BLM11B141S

L7A51 409P865060 EMI-F-CHIP - BLM11B141S

L7A52 409P865060 EMI-F-CHIP - BLM11B141S

L7A53 409P865060 EMI-F-CHIP - BLM11B141S

L7A54 409P865060 EMI-F-CHIP - BLM11B141S

L7A55 409P865060 EMI-F-CHIP - BLM11B141S

L7A56 409P865060 EMI-F-CHIP - BLM11B141S

L7A57 409P865060 EMI-F-CHIP - BLM11B141S

L7A58 409P865060 EMI-F-CHIP - BLM11B141S

L7A59 409P865060 EMI-F-CHIP - BLM11B141S

L7A61 409P865060 EMI-F-CHIP - BLM11B141S

L7A62 409P865060 EMI-F-CHIP - BLM11B141S

L7A63 409P865060 EMI-F-CHIP - BLM11B141S

L7A64 409P865060 EMI-F-CHIP - BLM11B141S

L7A65 409P865060 EMI-F-CHIP - BLM11B141S

L7A66 409P865060 EMI-F-CHIP - BLM11B141S

L7A88 409P777050 EMI-F-CHIP - BLM21B201S

L7A91 409P865060 EMI-F-CHIP - BLM11B141S

L7A99 409P777050 EMI-F-CHIP - BLM21B201S

L7ACC 409P777080 EMI-F-CHIP - BLM21P221S

L7D30 325C241030 COIL-CHIP - 10MH-K

L7D31 325C241030 COIL-CHIP - 10MH-K

L7D41 325C241030 COIL-CHIP - 10MH-K

L7D42 409P777080 EMI-F-CHIP - BLM21P221S

L7D90 409P777080 EMI-F-CHIP - BLM21P221S

L7E00 409P777080 EMI-F-CHIP - BLM21P221S

L7E11 409P777080 EMI-F-CHIP - BLM21P221S

L7E12 409P777080 EMI-F-CHIP - BLM21P221S

L7E13 409P777080 EMI-F-CHIP - BLM21P221S

L7E14 409P777080 EMI-F-CHIP - BLM21P221S

L7E15 409P777080 EMI-F-CHIP - BLM21P221S

L7H01 409P777080 EMI-F-CHIP - BLM21P221S

L7H04 409P777080 EMI-F-CHIP - BLM21P221S

L7H29 409P777080 EMI-F-CHIP - BLM21P221S

L7H49 409P777080 EMI-F-CHIP - BLM21P221S

L7H73 409P777080 EMI-F-CHIP - BLM21P221S

L7H76 409P777080 EMI-F-CHIP - BLM21P221S

L7J13 409P777080 EMI-F-CHIP - BLM21P221S

L7J23 409P777080 EMI-F-CHIP - BLM21P221S

L7J38 409P777080 EMI-F-CHIP - BLM21P221S

L7J44 409P777080 EMI-F-CHIP - BLM21P221S

PAGE 34

Page 35

MODEL: WD-52327 / WD-62327

Model Legend: [a] WD-52327, [b] WD-623275

Ref # Part # Part Name & Description [#]

Ref # Part # Part Name & Description [#]

L7K01 409P777080 EMI-F-CHIP - BLM21P221S

L7M90 409P777080 EMI-F-CHIP - BLM21P221S

L7N01 409P777080 EMI-F-CHIP - BLM21P221S

L7N02 409P777080 EMI-F-CHIP - BLM21P221S

L7N11 409P777080 EMI-F-CHIP - BLM21P221S

L7N21 409P777080 EMI-F-CHIP - BLM21P221S

L7N31 409P777080 EMI-F-CHIP - BLM21P221S

L7N41 409P777080 EMI-F-CHIP - BLM21P221S

L7N61 409P777080 EMI-F-CHIP - BLM21P221S

L7RF1 409P777050 EMI-F-CHIP - BLM21B201S

L8C02 409P964010 EMI-F-CHIP - BK2125HS102

L8C04 409P964010 EMI-F-CHIP - BK2125HS102

L8C09 409P938020 EMI-F-CHIP - BK1608 LL121

L8C10 409P938020 EMI-F-CHIP - BK1608 LL121

L8C11 409P938020 EMI-F-CHIP - BK1608 LL121

L8C13 409P938020 EMI-F-CHIP - BK1608 LL121

L8D01 409P777080 EMI-F-CHIP - BLM21P221S

L8D02 409P777080 EMI-F-CHIP - BLM21P221S

L8D03 409P777080 EMI-F-CHIP - BLM21P221S

L8D04 409P964010 EMI-F-CHIP - BK2125HS102

L8E00 409P777080 EMI-F-CHIP - BLM21P221S

L8E01 409P777080 EMI-F-CHIP - BLM21P221S

L8E03 409P777080 EMI-F-CHIP - BLM21P221S

L8E04 409P777080 EMI-F-CHIP - BLM21P221S

L8E05 409P777080 EMI-F-CHIP - BLM21P221S

L8E06 409P777080 EMI-F-CHIP - BLM21P221S

L8E07 409P777080 EMI-F-CHIP - BLM21P221S

L8E08 409P777080 EMI-F-CHIP - BLM21P221S

L8E10 409P777080 EMI-F-CHIP - BLM21P221S

L8E11 409P777080 EMI-F-CHIP - BLM21P221S

L8E12 409P777080 EMI-F-CHIP - BLM21P221S

L8E13 409P777080 EMI-F-CHIP - BLM21P221S

L8H01 409P777080 EMI-F-CHIP - BLM21P221S

L9A01 411P011010 FERITE-BEADS - ZBF-503S-P

L9A02 411P011010 FERITE-BEADS - ZBF-503S-P

L9A10 321C151070 COIL-RF - 22MH-K

L9A19 321C141010 COIL-RF - 6.8MH-M

L9A20 321C141010 COIL-RF - 6.8MH-M

L9A21 321C141010 COIL-RF - 6.8MH-M

L9A22 321C141030 COIL-RF - 10MH-K

L9A23 321C141030

L9A30 321C140060 COIL-RF - 2.7MH-M

L9A31 321C140060 COIL-RF - 2.7MH-M

L9A32 321C140060 COIL-RF - 2.7MH-M

L9A33 351P250010 COIL-CHOKE - GSTC6018-100M

L9A62 321C141010 COIL-RF - 6.8MH-M

L9A63 321C141090 COIL-RF - 33MH-K

L9A64 321C141090 COIL-RF - 33MH-K

L9A70 321C141090 COIL-RF - 33MH-K

L9A71 321C141090 COIL-RF - 33MH-K

L9AAA 325C462020 COIL-PEAKING - 56MH-K

L9B70 321C141090 COIL-RF - 33MH-K

L9C20 321C141070 COIL-RF - 22MH-K

L9C21 321C141070 COIL-RF - 22MH-K

L9D00 351P268010 LINE-FILTER - HF3545-502Y5R0-TXXBH

L9D01 351P268010 LINE-FILTER - HF3545-502Y5R0-TXXBH

L9D02 351P268010 LINE-FILTER - HF3545-502Y5R0-TXXBH

LC1A10 409P875090 EMI-F-CHIP - ELKE103FA

LC1A11 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC1A12 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

COIL-RF - 10MH-K

LC1A13 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC1A14 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC1A15 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC1A16 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC1A17 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC1A18 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC1A19 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC1A20 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC2A21 409P875090 EMI-F-CHIP - ELKE103FA

LC2A24 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC2A25 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC2A26 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC2A27 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC2A28 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC2A31 409P875090 EMI-F-CHIP - ELKE103FA

LC2J40 409P777020 EMI-F-CHIP - BLM21A05

LC2J41 409P777020 EMI-F-CHIP - BLM21A05

LC2J42 409P777020 EMI-F-CHIP - BLM21A05

LC2J43 409P777020 EMI-F-CHIP - BLM21A05

LC3A10 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC3A11 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC3A12 409P875090 EMI-F-CHIP - ELKE103FA

LC3A13 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC3A14 409P876020

LC3A15 409P875090 EMI-F-CHIP - ELKE103FA

LC3A16 409P875090 EMI-F-CHIP - ELKE103FA

LC3A20 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC3J41 409P777020 EMI-F-CHIP - BLM21A05

LC7A00 409P865060 EMI-F-CHIP - BLM11B141S

LC7A01 409P865060 EMI-F-CHIP - BLM11B141S

LC7A02 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC7A03 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC7A04 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC7A05 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC7A06 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC7A07 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC7A08 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC7A19 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC7A20 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC7A21 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC7A22 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC7A23 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC7A24 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC7A26 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC7A27 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC7D02 409P777080 EMI-F-CHIP - BLM21P221S

LC7D10 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC7D11 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC7D12 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC7D13 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC7D14 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC7E10 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC7E11 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC7E12 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC7E13 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC7E14 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC8E02 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC8E03 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC8E05 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC8E06 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

PAGE 35

Page 36

MODEL: WD-52327 / WD-62327

[#] Model Legend: [a] WD-52327, [b] WD-62327

Ref # Part # Part Name & Description [#]

Ref # Part # Part Name & Description [#]

LC8E07 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC8E08 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC8E09 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC8E22 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC8E23 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC8E24 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC8E25 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC8E26 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC8E27 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC8E28 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC8E29 409P875090 EMI-F-CHIP - ELKE103FA

LC8E30 409P875090 EMI-F-CHIP - ELKE103FA

LC8E31 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC8E32 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC9A10 409P875090 EMI-F-CHIP - ELKE103FA

LC9A11 409P875090 EMI-F-CHIP - ELKE103FA

LC9A12 409P875090 EMI-F-CHIP - ELKE103FA

LC9A13 409P875090 EMI-F-CHIP - ELKE103FA

LC9A14 409P875090 EMI-F-CHIP - ELKE103FA

LC9A15 409P875090 EMI-F-CHIP - ELKE103FA

LC9A16 409P875090 EMI-F-CHIP - ELKE103FA

LC9A17 409P875090 EMI-F-CHIP - ELKE103FA

TRANSFORMERS

T9A10 350P830010 TRANS-PWR - SRW39LEC-U10V117

T9C20 350P806010 TRANS-PWR - ETS19AB1R5BG

VARIABLE RESISTORS

RV9D00 265P100020 VAR - ERZV10D271CS

RV9D01 265P100020 VAR - ERZV10D271CS

RESISTORS

CHIP Type Resistors (Listed by Value)

Part No. Value Part No. Value

103P509050 1/16W 0OHM 103P492060 1/16W 1.1K-F

103P508040 1/16W 2.2-J 103P502060 1/16W 1.2K-J

103P509000 1/16W 6.8-J 103P492080 1/16W 1.3K-F

103P400050 1/10W 22-J 103P492090 1/16W 1.5K-F

103P910050 1/16W 22-J 103P502070 1/16W 1.5K-J

103P500050 1/16W 22-J 103P472090 1/8W 1.5K-F

103P500070 1/16W 33-J 103P493000 1/16W 1.6K-F

103P500080 1/16W 39-J 103P502080 1/16W 1.8K-J

103P910090 1/16W 47-J 103P493020 1/16W 2K-F

103P400090 1/10W 47-J 103P493030 1/16W 2.2K-F

103P500090 1/16W 47-J 103P502090 1/16W 2.2K-J

103P501000 1/16W 56-J 103P493050 1/16W 2.7K-F

103P501010 1/16W 68-J 103P503000 1/16W 2.7K-J

103P794060 1/16W 75-F 103P493060 1/16W 3K-F

103P509090 1/16W 75-J 103P493070 1/16W 3.3K-F

103P501020 1/16W 82-J 103P503010 1/16W 3.3K-J

103P401030 1/10W 100-J 103P493090 1/16W 3.9K-F

103P501030 1/16W 100-J 103P503020 1/16W 3.9K-J

103P501040 1/16W 120-J 103P503030 1/16W 4.7K-J

103P401050 1/10W 150-J 103P494030 1/16W 5.6K-F

103P490050 1/16W 150-F 103P503040 1/16W 5.6K-J

103P501050 1/16W 150-J 103P503050 1/16W 6.8K-J

103P501060 1/16W 180-J 103P503060 1/16W 8.2K-J

103P501070 1/16W 220-J 103P494080 1/16W 9.1K-F

103P470090 1/8W 220-F 103P494090 1/16W 10K-F

103P491000 1/16W 240-F 103P503070 1/16W 10K-J

103P501080

103P401080 1/10W 270-J 103P503080 1/16W 12K-J

103P491020 1/16W 300-F 103P503090 1/16W 15K-J

103P501090 1/16W 330-J 103P504000 1/16W 18K-J

103P491040 1/16W 360-F 103P504010 1/16W 22K-J

103P491050 1/16W 390-F 103P496000 1/16W 30K-F

103P502000 1/16W 390-J 103P496010 1/16W 33K-F

103P491060 1/16W 430-F 103P504030 1/16W 33K-J

103P491070 1/16W 470-F 103P504040 1/16W 39K-J

103P502010 1/16W 470-J 103P504050 1/16W 47K-J

103P491090 1/16W 560-F 103P504060 1/16W 56K-J

103P502020 1/16W 560-J 103P504070 1/16W 68K-J

103P492000 1/16W 620-F 103P504080 1/16W 82K-J

103P492010 1/16W 680-F 103P504090 1/16W 100K-J

103P502030 1/16W 680-J 103P505000 1/16W 120K-J

103P505090 1/16W 680K-J 103P505010 1/16W 150K-J

103P492030 1/16W 820-F 103P505050 1/16W 330K-J

103P502040 1/16W 820-J 103P506000 1/16W 820K-J

103P492050 1/16W 1K-F 103P506010 1/16W 1M-J

103P502050 1/16W 1K-J

1/16W 270-J 103P495010 1/16W 12K-F

RESISTORS

Conventional Resistors (By Ref #)

Ref # Part # Part Name & Description [#]

R2J21 109D151050 R-CARBON - 1/4W 75-J

R2J31 109D151050 R-CARBON - 1/4W 75-J

R3E27 109D151030 R-CARBON - 1/4W 4.7-J

R3E28 103C170050 R-METAL - 1W 22-J

R3E29 109D151030 R-CARBON - 1/4W 4.7-J

R3E30 109D151030 R-CARBON - 1/4W 4.7-J

R3E31 109D151030 R-CARBON - 1/4W 4.7-J

R3E32 103C170050 R-METAL - 1W 22-J

R9A01 109P179010 R-CEMENT-PLATE - 6.8-J

R9A02 109P179010 R-CEMENT-PLATE - 6.8-J

R9A03 109C010010 R-COMP - 1/2W 1M-K

R9A05 109C010010 R-COMP - 1/2W 1M-K

R9A06 109C010010 R-COMP - 1/2W 1M-K

R9A09 103P145030 R-CARBON - 1/2W 220K-J

R9A11 103P145030 R-CARBON - 1/2W 220K-J

R9A13 103C194090 R-METAL - 3W 100K-J

R9A14 103C194090 R-METAL - 3W 100K-J

R9A15 103C394020 R-METAL-P - 3W 27K

R9A16 103P145020 R-CARBON - 1/2W 180K-J

R9A17 103P145020 R-CARBON - 1/2W 180K-J

R9A18 103P145020 R-CARBON - 1/2W 180K-J

R9A19 103P144020 R-CARBON - 1/2W 27K-J

R9A20 103P144020 R-CARBON - 1/2W 27K-J

R9A21 103C177040 R-METAL - 1W 0.33-J

R9A22 103C177040 R-METAL - 1W 0.33-J

R9A25 103P142050 R-CARBON - 1/2W 1K-J

R9A26 109D151060 R-CARBON - 1/4W 68-J

R9A27 109D151050 R-CARBON - 1/4W 75-J

R9A66 103P712000 R-CARBON - 1/4W 390-J

R9A67 103P712000 R-CARBON - 1/4W 390-J

R9A68 103P712000 R-CARBON - 1/4W 390-J

R9A69 103P712000 R-CARBON - 1/4W 390-J

R9A76 103C392010 R-METAL-P - 3W 470-J

R9A77 103C392010 R-METAL-P - 3W 470-J

PAGE 36

Page 37

MODEL: WD-52327 / WD-62327

Model Legend: [a] WD-52327, [b] WD-623275

Ref # Part # Part Name & Description [#]

Ref # Part # Part Name & Description [#]

R9A89 103P141090 R-CARBON 1/2W 330-J

R9A90 103C394020 R-METAL-P - 3W 27K

R9A91 103C394020 R-METAL-P - 3W 27K

R9A92 103C288040 R-METAL-CP - 2W 2.2-J

R9C20 103C391020 R-METAL-P - 3W 82-J

R9C21 103P712050 R-CARBON - 1/4W 1K-J

R9C23 103P710090 R-CARBON - 1/4W 47-J

R9C24 103P142070 R-CARBON - 1/2W 1.5K-J

R9C25 103P462050 R-METAL - 1/4W 1K-F

R9C26 103P462050 R-METAL - 1/4W 1K-F

R9C27 103P712050 R-CARBON - 1/4W 1K-J

R9C28 103P713070 R-CARBON - 1/4W 10K-J

R9C29 103P711030 R-CARBON - 1/4W 100-J

R9C30 103P710080 R-CARBON - 1/4W 39-J

R9D00 109D036020 R-COMP - 1/2W 4.7M-K

CAPACITORS

CHIP Type Capacitors (Listed by Value)

Part No. Value Part No. Value

154P340040 50V 3P-C 141P143080 F50V 0.01M-Z

154P341010 CH50V 10P-C 141P133080 F50V 0.01M-Z

154P351020 SL50V 10P-J 141P132030 B50V 0.015M-K

154P341030 CH50V 12P-J 141P142090 B25V 0.047M-K

154P341050 CH50V 15P-J 141P143020 B16V 0.082M-K

154P341090 CH50V 22P-J 141P143030 B16V 0.1M-K

154P342010 CH50V 27P-J 141P144020 F25V 0.1M-Z

154P342030 CH50V 33P-J 141P134090 F50V 0.1M-Z

154P342070 CH50V 47P-J 141P139030 B25V 0.1M-K

154P342090 CH50V 56P-J 141P146040 B10V 0.22M-K

154P353000 SL50V 56P-J 141P138080 B25V 0.33M-K

154P343050 CH50V 100P-J 141P146080 B10V 0.47M-K

141P140010 B50V 220P-K 141P139090 B16V 0.47M-K

154P344050 CH50V 270P-J 181P526010 50V 1M-M

154P344070 CH50V 330P-J 141P147020 B10V/6.3V 1M-K

141P140050 B50V 470P-K 141P134070 B16V 1M-K

141P140060 B50V 560P-K 181P526020 50V 2.2M-M

154P345030 CH25V 560P-J 181P532030 16V 10M-M

154P345050 CH25V 680P-J 181P508080 16V 10M-M

154P345070 CH25V 820P-J 181P522030 16V 10M-M 105C

154P345010 CH50V 470P-J 181P530030 6.3V 47M-M

141P140090 B50V 1000P-K 181P520030 6.3V 47M-M

154P345090 CH25V 1000P-J 181P522060 6V 47M-M

141P141010 B50V 1500P-K 181P502070 16V 100M-M

141P141030 B50V 2200P-K 181P520040 6.3V 100M-M

181P500060 6.3V 220M-M

CAPACITORS AND TRIMMERS

Conventional Capacitors (By Ref #)

Ref # Part # Part Name & Description [#]

C1A13 181P352040 C-ELEC - 16V 100M-M

C1A21 181P352040 C-ELEC - 16V 100M-M

C1A24 181P352040 C-ELEC - 16V 100M-M

C1A26 172P262010 C-M-POLY - 50V 0.047M-J

C1B13 181P355090 C-ELEC - 50V 100M-M

C1B21 181P352040 C-ELEC - 16V 100M-M

C1B24 181P352040 C-ELEC - 16V 100M-M

C1B26 172P262010 C-M-POLY - 50V 0.047M-J

C2AGC 155P239040 C-CER - CH50V 100P-J

C2AGD 142P024060 C-CER - BF50V 0.1M-Z

C2AJB 142P024060 C-CER - BF50V 0.1M-Z

C2AJD 155P239040 C-CER - CH50V 100P-J

C2AKC 181P352040 C-ELEC - 16V 100M-M

C2AKD 155P239040 C-CER - CH50V 100P-J

C2ANC 142P024060 C-CER - BF50V 0.1M-Z

C2AND 155P239040 C-CER - CH50V 100P-J

C2APC 181P352040 C-ELEC - 16V 100M-M

C2APD 155P239040 C-CER - CH50V 100P-J

C2ARC 142P024060 C-CER - BF50V 0.1M-Z

C2ARD 155P239040 C-CER - CH50V 100P-J

C2ATC 142P024060 C-CER - BF50V 0.1M-Z

C2ATD 155P239040 C-CER - CH50V 100P-J

C2AYC 142P024060 C-CER - BF50V 0.1M-Z

C2AYD 155P239040 C-CER - CH50V 100P-J

C2AZC 142P024060 C-CER - BF50V 0.1M-Z

C2AZE 181P355050 C-ELEC - 50V 10M-M

C2AZF 155P239040 C-CER - CH50V 100P-J

C2K01 181P355050 C-ELEC - 50V 10M-M

C2K03 181P355050 C-ELEC - 50V 10M-M

C2K08 181P355050 C-ELEC - 50V 10M-M

C2K10 181P355050 C-ELEC - 50V 10M-M

C2K15 181P355050 C-ELEC - 50V 10M-M

C2K17 181P355050 C-ELEC - 50V 10M-M

C2K18 181P351060 C-ELEC - 10V 330M-M

C2K22 181P355050 C-ELEC - 50V 10M-M

C2K27 181P355050 C-ELEC - 50V 10M-M

C2K43 181P352030 C-ELEC - 16V 47M-M

C2K48 181P352030 C-ELEC - 16V 47M-M

C2K50 181P355050 C-ELEC - 50V 10M-M

C2K63 181P355050 C-ELEC - 50V 10M-M

C2K71 181P352030 C-ELEC - 16V 47M-M

C2K75 181P352030 C-ELEC - 16V 47M-M

C2L29 181P352030 C-ELEC - 16V 47M-M

C2L52 181P352030 C-ELEC - 16V 47M-M

C2M28 181P351080 C-ELEC - 10V 1000M-M

C2M29 181P351080 C-ELEC - 10V 1000M-M

C2M31 181P352030 C-ELEC - 16V 47M-M

C2M34 181P352030 C-ELEC - 16V 47M-M

C2M36 181P352030 C-ELEC - 16V 47M-M

C2M38 181P352030 C-ELEC - 16V 47M-M

C2M43 181P352030 C-ELEC - 16V 47M-M

C2M44 181P352030 C-ELEC - 16V 47M-M

C2M54 181P355050 C-ELEC - 50V 10M-M

C2M64 181P352030 C-ELEC - 16V 47M-M

C2M80 181P352030 C-ELEC - 16V 47M-M

C2M88 181P355010 C-ELEC - 50V 1M-M

C2M89 181P352030 C-ELEC - 16V 47M-M

C2M98 181P355050 C-ELEC - 50V 10M-M

C2MA4 181P352030 C-ELEC - 16V 47M-M

C2MA6 181P352030 C-ELEC - 16V 47M-M

C2MA9 181P352030 C-ELEC - 16V 47M-M

C2MC4 181P352030 C-ELEC - 16V 47M-M

C2MC8 181P352040 C-ELEC - 16V 100M-M

C2MD6 181P352040 C-ELEC - 16V 100M-M

C2MD7 181P352040 C-ELEC - 16V 100M-M

C2N03 181P352070 C-ELEC - 16V 470M-M

C2N27 181P350060 C-ELEC - 3V 1000M-M

C2NA6 181P355050 C-ELEC - 50V 10M-M

C2NC5 181P355050 C-ELEC - 50V 10M-M

C2P01 181P352070 C-ELEC - 16V 470M-M

PAGE 37

Page 38

MODEL: WD-52327 / WD-62327

[#] Model Legend: [a] WD-52327, [b] WD-62327

Ref # Part # Part Name & Description [#]

Ref # Part # Part Name & Description [#]

C2P26 181P350060 C-ELEC - 3V 1000M-M

C2P32 181P352030 C-ELEC - 16V 47M-M

C2P42 181P352030 C-ELEC - 16V 47M-M

C2R29 181P352030 C-ELEC - 16V 47M-M

C3A14 181P355050 C-ELEC - 50V 10M-M

C3A20 181P355050 C-ELEC - 50V 10M-M

C3A21 181P355050 C-ELEC - 50V 10M-M

C3A28 181P355050 C-ELEC - 50V 10M-M

C3A29 181P355050 C-ELEC - 50V 10M-M

C3A32 181P355050 C-ELEC - 50V 10M-M

C3A33 181P355050 C-ELEC - 50V 10M-M

C3A34 181P355030 C-ELEC - 50V 3.3M-M

C3A46 181P355050 C-ELEC - 50V 10M-M

C3A49 181P355050 C-ELEC - 50V 10M-M

C3E50 181P358070 C-ELEC - 63V 22M-M

C3E51 181P354090 C-ELEC - 35V 470M-M

C3E52 181P354090 C-ELEC - 35V 470M-M

C3E53 181P354090 C-ELEC - 35V 470M-M

C3E54 181P354090 C-ELEC - 35V 470M-M

C3F91 181P375050 C-ELE-BP-AUDIO - 25V 1000M-M

C3F92 181P375050 C-ELE-BP-AUDIO - 25V 1000M-M

C3J01 181P352030 C-ELEC - 16V 47M-M

C3J05 181P355050 C-ELEC - 50V 10M-M

C3J06 181P122070 C-ELEC-NP - 25V 10M-M

C3J09 181P355050 C-ELEC - 50V 10M-M

C3J10 181P122070 C-ELEC-NP - 25V 10M-M

C3J24 181P352030 C-ELEC - 16V 47M-M

C3K02 181P355010 C-ELEC - 50V 1M-M

C3K04 181P355010 C-ELEC - 50V 1M-M

C3K09 181P355010 C-ELEC - 50V 1M-M

C3K11 181P355010 C-ELEC - 50V 1M-M

C3K16 181P355010 C-ELEC - 50V 1M-M

C3K18 181P355010 C-ELEC - 50V 1M-M

C3K23 181P355010 C-ELEC - 50V 1M-M

C3K25 181P355010 C-ELEC - 50V 1M-M

C3K29 181P355010 C-ELEC - 50V 1M-M

C3K31 181P355010 C-ELEC - 50V 1M-M

C3K62 181P355010 C-ELEC - 50V 1M-M

C3K64 181P355010 C-ELEC - 50V 1M-M

C7A00 154P345050 C-CER-CHIP - CH25V 680P-J

C7A16 181P352030 C-ELEC - 16V 47M-M

C7A99 181P352030 C-ELEC - 16V 47M-M

C7ACB 181P355050 C-ELEC - 50V 10M-M

C7B02 181P355020 C-ELEC - 50V 2.2M-M

C7B88 181P355050 C-ELEC - 50V 10M-M

C7B96 181P355020 C-ELEC - 50V 2.2M-M

C7C56 181P352030 C-ELEC - 16V 47M-M

C7C57 181P352030 C-ELEC - 16V 47M-M

C7D00 181P352040 C-ELEC - 16V 100M-M

C7D97 181P352040 C-ELEC - 16V 100M-M

C7K01 181P352030 C-ELEC - 16V 47M-M

C7RF2 181P355050 C-ELEC - 50V 10M-M

C7S03 181P352030 C-ELEC - 16V 47M-M

C9A00 189P185090 C-CER - AC250V E2200P-M

C9A01 189P185090 C-CER - AC250V E2200P-M

C9A02 185D122050 C-ELEC - H200V 1000M-M

C9A03 185D122050 C-ELEC - H200V 1000M-M

C9A04 185D127040 C-ELEC - H450V 150M-M 105C

C9A05 189P185090 C-CER - AC250V E2200P-M

C9A06 189P185090 C-CER - AC250V E2200P-M

C9A08 189P185090 C-CER - AC250V E2200P-M

C9A09 189P185090 C-CER - AC250V E2200P-M

C9A10 189P185090 C-CER - AC250V E2200P-M

C9A11 189P185090 C-CER - AC250V E2200P-M

C9A12 189P153010 C-M-POLY - AC125/250V 0.33M-M

C9A13 189P152070 C-M-POLY - 250VAC 0.01M-M

C9A14 189P152070 C-M-POLY - 250VAC 0.01M-M

C9A15 189P185070 C-CER - AC250V E1000P-M

C9A16 189P185070 C-CER - AC250V E1000P-M

C9A20 154P262070 C-CER - R2KV820P-K

C9A21 181P185060 C-ELEC - 50V 10M-M 105C

C9A25 172P138010 C-POLY - 50V 4700P-J

C9A26 185D122050 C-ELEC - H200V 1000M-M

C9A27 185D122050 C-ELEC - H200V 1000M-M

C9A29 181P185060 C-ELEC - 50V 10M-M 105C

C9A30 181P185060 C-ELEC - 50V 10M-M 105C

C9A32 181P735040 C-ELEC - 25V 1500M-M

C9A33 181P735040 C-ELEC - 25V 1500M-M

C9A35 181P735010 C-ELEC - 25V 470M-M

C9A37 181P732040 C-ELEC - 10V 3300M-M 105C

C9A38 181P732040 C-ELEC - 10V 3300M-M 105C

C9A39 181P184070 C-ELEC - 35V 2200M-M

C9A40 181P184070 C-ELEC - 35V 2200M-M

C9A41 181P732010 C-ELEC - 10V 1000M-M 105C

C9A43 172P262050 C-M-POLY - 50V 0.1M-J

C9A45 181P182030 C-ELEC - 16V 1000M-M 105C

C9A46 142P010090 C-CER - B500V 470P-K

C9A47 142P010090 C-CER - B500V 470P-K

C9A51 181P182030

C9A52 181P182030 C-ELEC - 16V 1000M-M 105C

C9A61 181P182030 C-ELEC - 16V 1000M-M 105C

C9A62 181P182030 C-ELEC - 16V 1000M-M 105C

C9A64 181P181000 C-ELEC - 10V 330M-M 105C

C9A71 181P183010 C-ELEC - 25V 100M-M

C9A73 181P735020 C-ELEC - 25V 1000M-M 105C

C9A77 181P183010 C-ELEC - 25V 100M-M

C9A79 181P183010 C-ELEC - 25V 100M-M

C9A82 181P183010 C-ELEC - 25V 100M-M

C9AAB 181P351070 C-ELEC - 10V 470M-M

C9ABA 181P352040 C-ELEC - 16V 100M-M

C9B71 181P183010 C-ELEC - 25V 100M-M

C9B73 181P735020 C-ELEC - 25V 1000M-M 105C

C9C01 181P352030 C-ELEC - 16V 47M-M

C9C02 181P352030 C-ELEC - 16V 47M-M

C9C11 181P352030 C-ELEC - 16V 47M-M

C9C12 181P352030 C-ELEC - 16V 47M-M

C9C15 181P355010 C-ELEC - 50V 1M-M

C9C16 189P185070 C-CER - AC250V E1000P-M

C9C17 189P185070 C-CER - AC250V E1000P-M

C9C21 181P352030 C-ELEC - 16V 47M-M

C9C22 181P199080 C-ELEC - 200V 47M-M/Q

C9C22 181P352040 C-ELEC - 16V 100M-M

C9C25 172P262050 C-M-POLY - 50V 0.1M-J

C9C27 154P270050 C-CER - SL1KV 22P-J

C9C28 172P262050 C-M-POLY - 50V 0.1M-J

C9C29 142P010090 C-CER - B500V 470P-K

C9C30 142P010090 C-CER - B500V 470P-K

C9C31 181P743040 C-ELEC - 16V 330M-M

C9C32 181P352040 C-ELEC - 16V 100M-M

C9C33 181P354060 C-ELEC - 35V 100M-M

C-ELEC - 16V 1000M-M 105C

PAGE 38

Page 39

MODEL: WD-52327 / WD-62327

Model Legend: [a] WD-52327, [b] WD-623275

Ref # Part # Part Name & Description [#]

Ref # Part # Part Name & Description [#]

C9C34 181P354060 C-ELEC - 35V 100M-M

C9C35 181P355050 C-ELEC - 50V 10M-M

C9C38 181P355050 C-ELEC - 50V 10M-M

C9C61 181P352030 C-ELEC - 16V 47M-M

C9C62 181P352040 C-ELEC - 16V 100M-M

C9C80 181P355050 C-ELEC - 50V 10M-M

C9C81 181P355050 C-ELEC - 50V 10M-M

C9C82 181P355050 C-ELEC - 50V 10M-M

C9C83 181P352030 C-ELEC - 16V 47M-M

C9C84 181P352030 C-ELEC - 16V 47M-M

C9C85 181P352030 C-ELEC - 16V 47M-M

C9C86 181P352030 C-ELEC - 16V 47M-M

C9C90 181P355050 C-ELEC - 50V 10M-M

C9C91 181P355050 C-ELEC - 50V 10M-M

C9C92 181P355050 C-ELEC - 50V 10M-M

C9C93 181P355050 C-ELEC - 50V 10M-M

C9D00 189P153040 C-M-POLY - 250VAC 0.1M-M

C9D01 189P153040 C-M-POLY - 250VAC 0.1M-M

C9D02 189P153040 C-M-POLY - 250VAC 0.1M-M

C9D03 189P153040 C-M-POLY - 250VAC 0.1M-M

C9D06 189P153040 C-M-POLY - 250VAC 0.1M-M

CF2N10 299P267010 RESONATOR-CER - CSBLA503KECZF30-B0

CF2P10 299P267010 RESONATOR-CER - CSBLA503KECZF30-B0

SWITCHES

S7L21 432P109010 SW-KEY BOARD - KSHS611BT

S7L22 432P109010 SW-KEY BOARD - KSHS611BT

S7L23 432P109010 SW-KEY BOARD - KSHS611BT

S7L24 432P109010 SW-KEY BOARD - KSHS611BT

S7L25 432P109010 SW-KEY BOARD - KSHS611BT

S7L26 432P109010 SW-KEY BOARD - KSHS611BT

S7L27 432P109010 SW-KEY BOARD - KSHS611BT

S7L28 432P109010 SW-KEY BOARD - KSHS611BT

S7L29 432P109010 SW-KEY BOARD - KSHS611BT

MISCELLANEOUS

096Z465080 TAPE-LENS

246C501020 CABLE - DVI to DVI

299P103050 FAN - MMF-04B12-DL-RB1 (Exhaust Fan)

299P278020 FAN - EFB06121A-R00 (Ballast Fan)

299P280010 SENSOR - THERMAL

299P282010 FAN - LAMP

299P283010 FAN - DMD

299P285010 SWITCH - THERMAL

305P702030 2RF-SW

411D044020 CORE-FERRITE - ZCAT2032-0930

411D062010 CORE-FERRITE - ZCAT1518-0730

411D063020 CORE-FERRITE - CAT3035

411P026010 CORE-FERRITE - ZCAT2017

436P021010 SW-MICRO

480P077010 SPEAKER - COAXIAL

592A032020 PLATE-REAR

620D144010 FILTER - DUST

622C208010 MIRROR - HOLDER - TOP a

622C208020 MIRROR - HOLDER - TOP b

622C209010 MIRROR - HOLDER - BOTTOM a

623D252010 MIRROR - HOLDER - BOTTOM b

622C220010 COVER - LAMP - VENT

622C247010 COVER-SW

635B114010 MIRROR - BRACKET - TOP a

635B114020 MIRROR - BRACKET - TOP b

635B115010 FRAME-LOCK - PLATE a

635B115020 FRAME-LOCK - PLATE b

641B991010 MIRROR - HOLDER - SIDE a

641B993010 COVER - FRONT

641B999010 MIRROR - HOLDER - SIDE b

704B205010 KNOB CONTROL a

704B205020 KNOB CONTROL b

704B207010 BUTTON - RESET

752B142010 COVER - FILTER

752B143010 COVER - LAMP

761C736010 DOOR

767D075010 MIRROR (52") a

767D075020 MIRROR (BIG) b

767D076010 MIRROR (SMALL)

915P020010 LAMP - CARTRIDGE

939P977010 OPTICAL-ENGINE a

939P977020 OPTICAL-ENGINE b

939P978010 UNIT-POWER-LAMP

AG9D00299P220020 SURGE-SUPPRESSOR

F7A00 283P128040 FUSE-CHIP - AC125/100V 3.15A

F7A01 283P128040 FUSE-CHIP - AC125/100V 3.15A

F9A01 283P144080 FUSE - 125V 5A

F9A02 283P144040 FUSE - 32V 15A

F9A03 283P144040 FUSE - 32V 15A

F9A04 283P144080 FUSE - 125V 5A

F9A05 283P144080 FUSE - 125V 5A

F9A06 283P128050 FUSE-CHIP - AC125/100V 4A

F9A07 283P128050 FUSE-CHIP - AC125/100V 4A

F9A08 283P144070 FUSE - 125V 3A

F9A09 283P127060 FUSE-CHIP - AC125/100V 630MA

F9B08 283P144070 FUSE - 125V 3A

F9D00 283D131040 FUSE - S10A 125A

J2AAA 452C385010 CONNECTOR-DVI

J8E00 452C385010 CONNECTOR-DVI

K9A10 287P111010 RELAY-POWER - LKS1AF-5V

K9A11 287P111010 RELAY-POWER - LKS1AF-5V

K9A20 287P111010 RELAY-POWER - LKS1AF-5V

K9A21 287P111010 RELAY-POWER - LKS1AF-5V

PC9A10 268P058020 PHOTO-COUPLER - ON3131-R/ON3161-R