Page 1

MITSUBISHI ELECTRIC

2001

Service

Manual

PROJECTION TELEVISION

VZ9 / VZ9+ CHASSIS

VZ9

MODELS

VS-45609

VS-50609

VS-55609

-

VZ9+

MODELS

VS-60719

VS-70709

VS-60609

CAUTION:

Before servicing this chassis, it is important that the service person read the "SAFETY PRECAUTIONS" and

"PRODUCT SAFETY NOTICE" contained in this manual.

SPECIFICATIONS

• Power Input : AC 120V, 60Hz

• Power : 200W

Consumption

• Frequency : VHF 54 ~ 470MHz

Range UHF 470 ~ 806MHz

• Antenna Input : VHF/UHF 75Ω unbalanced

Single axis input

• CRT Size :7"

• High Voltage : 32.0kV (at 0A)

• Speaker : [VZ9]

4" round type, full range 2 pcs.

(8Ω 10W)

[VZ9+]

5" round type, full range 2 pcs.

(8Ω 10W)

• Cabinet : [Model] (H)x(W)x(D)

Dimensions : [VS-45609] 48"x38.4"x22.2"

: [VS-50609] 50.4"x42.8"x23.8"

: [VS-55609] 54.8"x46.4"x23.7"

: [VS-60609] 60.8"x50.6"x29"

: [VS-60719] 60.8"x50.6"x29"

: [VS-70709] 70.5"x58.7"x29.4"

• Input Level : VIDEO IN JACK (RCA Type)

1.0Vp-p 75Ω unbalanced

: AUDIO IN JACK (RCA Type)

-4.7dBm 43kΩ unbalanced

: S-VIDEO IN JACK

(Y/C separate type)

Y:1.0 Vp-p C:0.286Vp-p(BURST)

75Ω unbalanced

: Component Inputs (RCA Type)

Y: 1.0Vp-p

Cr, Cb: 700mVp-p

• Weight : [VS-45609] 176 lbs

[VS-50609] 198 lbs

[VS-55609] 229 lbs

[VS-60609] 259 lbs

[VS-60719] 253 lbs

[VS-70709] 369 lbs

MITSUBISHI DIGITAL ELECTRONICS AMERICA, INC.

9351 Jeronimo Road, Irvine, CA 92618-1904

Copyright © 2001 Mitsubishi Digital Electronics America, Inc.

• Output Level : VIDEO OUT JACK (RCA Type)

1.0Vp-p 75Ω unbalanced

: AUDIO OUT JACK (RCA Type)

-4.7dBm 4.7kΩ unbalanced

• Weight and dimensions shown are approximate.

• Design specifications are subject to change without notice.

All Rights Reserved

Page 2

Page 3

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

CONTENTS

INTRODUCTION ................................................................................................................................5

PRODUCT SAFETY NOTICE ............................................................................................................. 5

SAFETY PRECAUTIONS ................................................................................................................... 6

DISASSEMBLY .................................................................................................................................. 7

Front Cabinet Components ............................................................................................................. 7

Rear Cabinet Components .............................................................................................................. 8

SERVICING THE LENTICULAR LENS AND FRESNEL SCREEN ....................................................... 9

Removal of the Lenticular Screen and Fresnel Lens ........................................................................ 9

Installation of the Lenticular Screen and Fresnel Lens ................................................................... 10

VS-70709 CABINET SEPARATION PROCEDURE ............................................................................ 11

SERVICING THE DIAMONDSHIELD

DiamondShieldTM Removal ............................................................................................................ 12

DiamondShieldTM Installation ......................................................................................................... 12

SERVICING PCBs ............................................................................................................................ 13

Chassis Removal & PCB Locations .............................................................................................. 13

Major Parts Locations ................................................................................................................... 13

CRT REPLACEMENT ....................................................................................................................... 14

CRT Removal ................................................................................................................................14

CRT Installation ............................................................................................................................ 15

ELECTRICAL ADJUSTMENTS ........................................................................................................ 17

Equipment .................................................................................................................................... 17

Initial Setup ................................................................................................................................... 18

LED Indicator Diagnostics ............................................................................................................. 19

Circuit Adjustment Mode............................................................................................................... 20

Convergence Adjustment Mode ..................................................................................................... 21

Adjustment Items List ................................................................................................................... 24

Test Points Locations ................................................................................................................... 27

Adjustment Procedures ................................................................................................................ 28

Audio Circuit ........................................................................................................................ 28

High Voltage Control ............................................................................................................ 29

Focus Adjustments .............................................................................................................. 29

CRT Adjustments ................................................................................................................. 30

Video Adjustments .............................................................................................................. 32

PIP Adjustments .................................................................................................................. 33

Cb, Cr Offset Adjustment ..................................................................................................... 34

Character Position ............................................................................................................... 34

Deflection/Convergence Geometry Presets .......................................................................... 35

Height and Vertical Linearity Adjustments ............................................................................ 36

Centering and Static Convergence ....................................................................................... 36

Convergence Geometry Adjustments ................................................................................... 37

Convergence Adjustments ................................................................................................... 38

TM

r ........................................................................................... 12

Page 3

Page 4

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

CHIP PARTS REPLACEMENT ......................................................................................................... 40

REPLACEMENT PARTS .................................................................................................................. 41

Parts Ordering .............................................................................................................................. 41

Critical and Warranty Parts Designation........................................................................................ 41

Parts Tolerance Codes .................................................................................................................. 41

Model Abbreviations ...................................................................................................................... 41

Quick Reference List .................................................................................................................... 42

SERVICE PARTS LIST .................................................................................................................... 43

CIRCUITRY BLOCK DIAGRAMS ..................................................................................................... 54

Power Supply ............................................................................................................................... 54

Video/Color Signal Path ................................................................................................................ 55

Sound Circuit ................................................................................................................................ 56

Deflection and High Voltage .......................................................................................................... 56

Protect Circuitry ............................................................................................................................ 57

Convergence Circuitry ................................................................................................................... 57

Control Circuitry ............................................................................................................................ 58

SCHEMATIC DIAGRAMS

PCB LAYOUT DIAGRAMS

Page 4

Page 5

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

INTRODUCTION

This service manual provides service instructions for PTV Models VS-45609, VS-50609, VS-55609 and VS-60609

which use the VZ9 chassis, and PTV Model VS-60719 and VS-70709 which use the VZ9+ chassis. Service personnel

should read this manual thoroughly before servicing these chassis.

This service manual includes:

1. Assembly and disassembly instructions for the front and rear cabinet components.

2. Servicing of the Lenticular Screen and Fresnel Lens.

3. Servicing printed circuit boards (PCBs).

4. CRT replacement procedure.

5. Electrical adjustments.

6. Chip parts replacement procedures.

7. Circuit path diagrams.

The parts list section of this service manual includes:

1. Cabinet and screen parts.

2. Electrical parts.

Schematic and block diagrams of the above listed models are included in this service manual for better understanding of the circuitry. PCB drawings are also included for easy location of parts and test points.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in television receivers have special safety related characteristics. These

characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily be

obtained by using replacement components rated for higher voltage, wattage, etc.

Replacement parts which have special safety characteristics are identified in this service manual.

Electrical components having such features are identified by shading on the schematic diagram and by bold

type in the parts list of this service manual. The replacement for any safety part should be identical in value

and characteristics.

Page 5

Page 6

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

SAFETY PRECAUTIONS

NOTICE: Observe all cautions and safety related notes located inside the receiver cabinet and on the

receiver chassis.

WARNING:

1. Operation of this receiver outside the cabinet or with the cover removed presents a shock hazard

from the receiver's power supplies. Work on the receiver should not be attempted by anyone who is

not thoroughly familiar with the precautions necessary when working on high voltage equipment.

2. Do not install, remove or handle the picture tubes in any manner unless shatterproof goggles are

worn. People not so equipped should be kept away while the picture tube is being handled. Keep

the picture tube away from the body while handling.

3. When service is required, observe the original lead dress. Extra precaution should be taken to

assure correct lead dress in the high voltage area. Where a short-circuit has occurred, replace those

components that indicate evidence of overheating.

X-Radiation warning

The surface of the cathode ray tubes (CRTs) may generate X-Radiation, so take proper precautions when servicing. It is recommended that a lead apron be used for shielding while handling the CRT. Use this method if

possible.

When replacing the CRTs, use only the designated replacement part since it is a critical component with regard to

X-Radiation. High voltage must be set as prescribed under the section titled Electrical Adjustments.

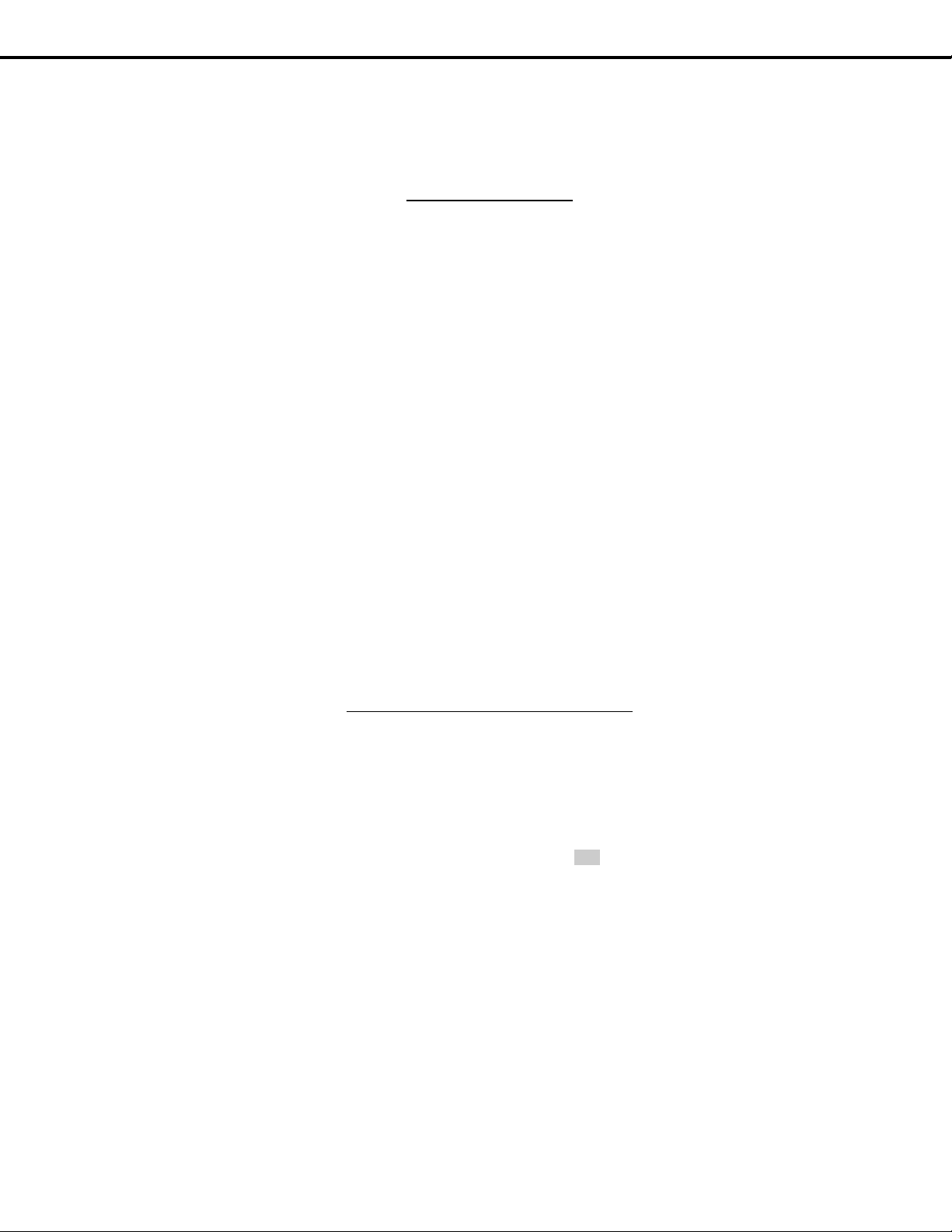

Leakage current check

Before returning the receiver to the customer, it is recommended that leakage current be measured according to

the following methods.

1. Cold Check

With the alternating current (AC) plug removed from the AC source, place a jumper across the two AC plug

prongs. Connect one lead of an ohm meter to the AC plug and touch the other lead to each exposed metal

part (i.e. antennas, handle bracket, metal cabinet, screw heads, metal overlay, control shafts, etc.), particularly any exposed metal part that has a return path to the chassis. The resistance of the exposed metal parts

having a return path to the chassis should be a minimum of 1Mega Ohm. Any resistance below this value

indicates an abnormal condition and requires corrective action.

2. Hot Check ...Use the circuit shown below to perform the hot check test.

1. Keep switch S1 open and connect the receiver to the measuring circuit. Immediately after

connection, and with the switching devices of the receiver in their operating positions, measure

the leakage current for both positions of switch S2.

2. Close switch S1, energizing the receiver. Immediately after closing switch S1, and with the

switching devices of the receiver in their operating positions, measure the leakage current for both

positions of switch S2. Repeat the current measurements of items 1 and 2 after the receiver has

reached thermal stabilization. The leakage current must not exceed 0.5 milliampere (mA).

Page 6

Page 7

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

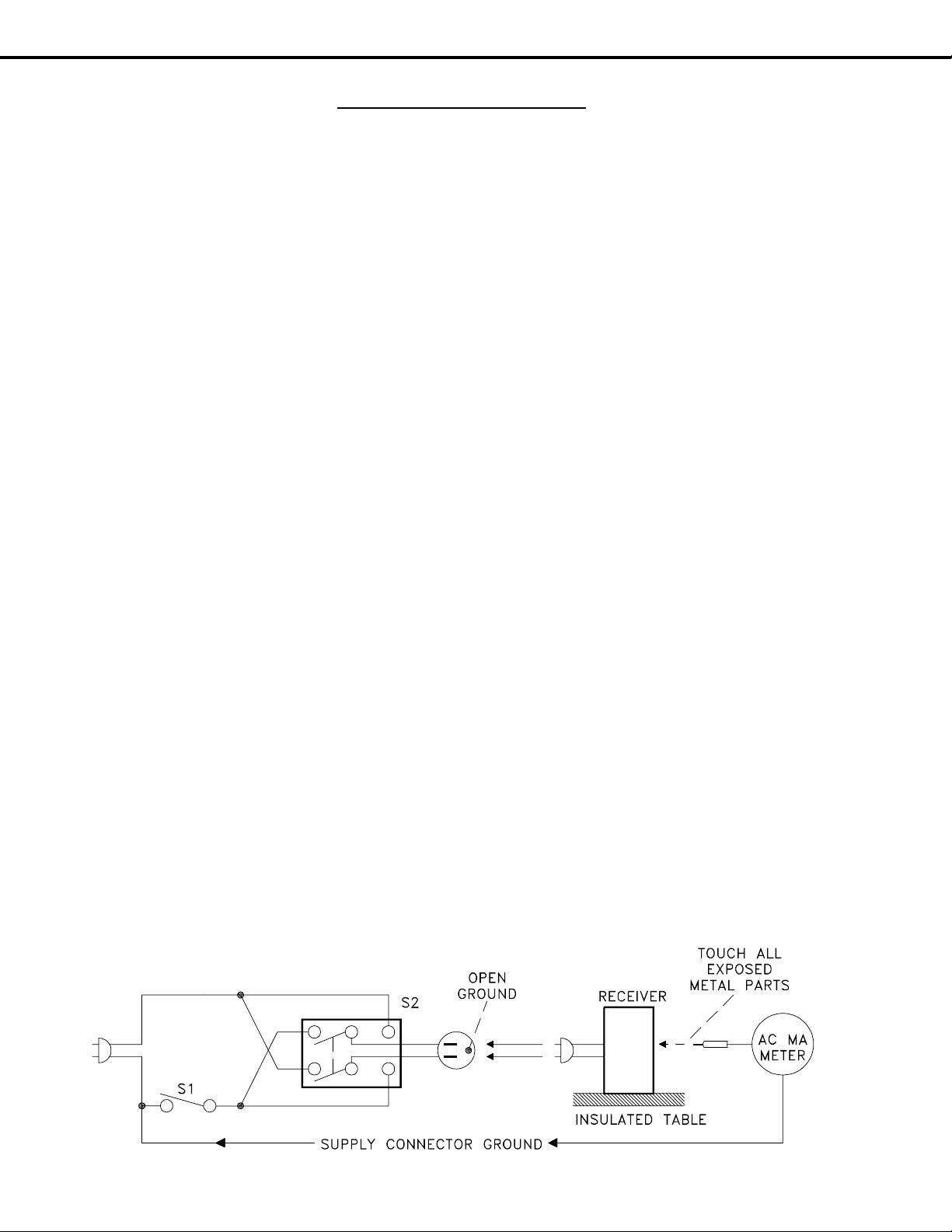

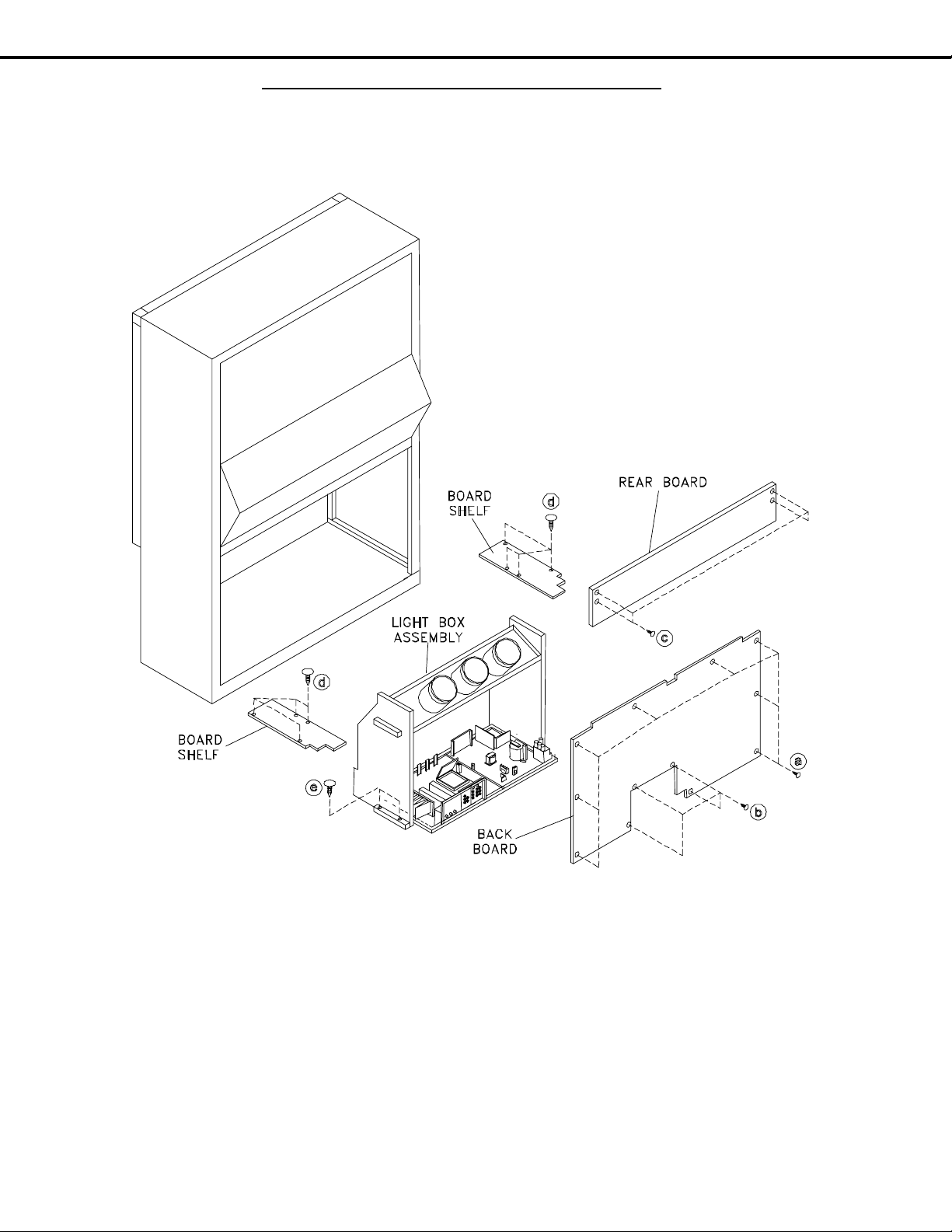

CABINET DISASSEMBLY (FRONT VIEW)

*Refer to PARTS LIST for Part Numbers

1.Front Cabinet Disassembly

1. Remove the Speaker Grille by pulling forward.

2. Remove the Front-Board by removing 4 screws "a".

3. Remove the Screen Assembly by removing screws "b". Disconnect all cable harnesses between the Screen

Assembly and the PCB-Signal.

4. Lift the Screen Assembly and pull up and away from the cabinet as shown.

Page 7

Page 8

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

CABINET DISASSEMBLY (REAR VIEW)

2. Rear Cabinet Disassembly

1. Remove the Back Board by removing 8 screws "a" and 4 screws “b”.

2. Remove the Rear Board-1 by removing 4 screws "c".

3. Remove 4 screws "e" (two not shown) and 8 screws "d" securing the Light Box Assembly and the Board

Shelves.

4. Remove the Board Shelves by lifting up and out.

5. Be certain that all cables and connectors between the Light Box Assembly and external items are disconnected (e.g. speaker plugs).

6. Slide the Light Box Assembly out of the cabinet.

Page 8

Page 9

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

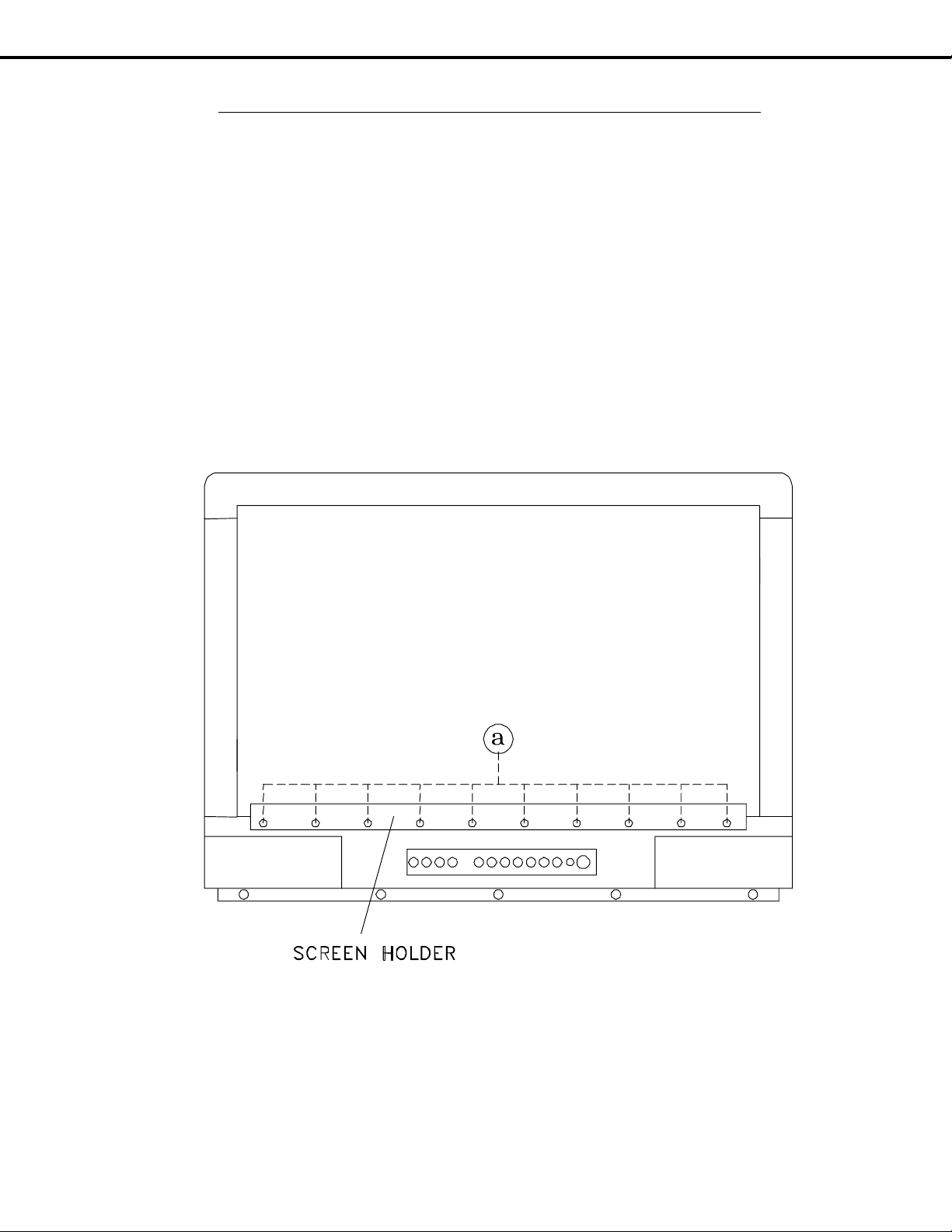

SERVICING THE LENTICULAR SCREEN AND FRESNEL LENS

1. Removal of the Lenticular Screen and Fresnel Lens

CAUTION: Wear gloves when handling the Lenticular Screen and the Fresnel Lens.

This prevents cuts and finger prints. Do not place the Fresnel Lens in the sun.

This may cause fire and heat related injuries.

1. Remove the screen assembly as shown in the Cabinet Disassembly procedure. [Figure 1-1]

2. Remove the Screen Holder by removing screws (a). [Figure 3-1]

3. Slide the Lenticular Screen and Fresnel Lens from the Screen Frame.

Note: When separating the Lenticular Screen from the Fresnel Lens, use caution

while prying the Screen and Lens apart. Use a slot type screw driver, and

remove the pressure sensitive, double sided tape.

Figure 3-1

Page 9

Page 10

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

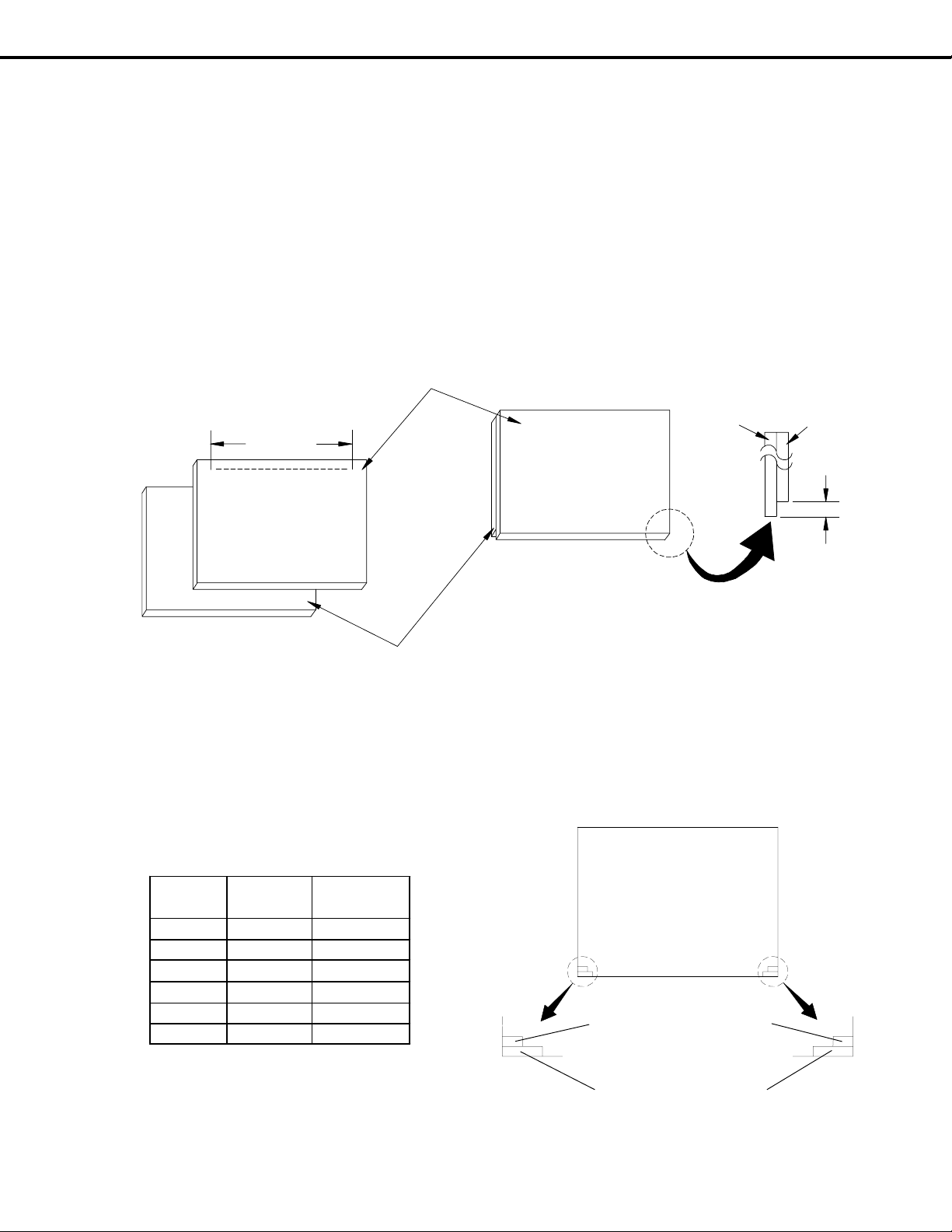

2. Installation of the Lenticular Screen and Fresnel Lens

Note: Store the Lenticular Screen and Fresnel Lens in a cool dry place. High humidity may

deform the Lenticular Screen and Fresnel Lens.

1. Apply double coated tape (Part # LENS-TAPE) along the top front edge of the Fresnel Lens

as shown in figure 3-2. Refer to Table A for proper tape length.

2. Place the Fresnel Lens on top of the Lenticular Screen and apply pressure at the top edge to

bond them together as shown in figure 3-2.

3. Install CUSHION-CORNER pads at the bottom corners on the back of the Fresnel Lens, as

shown in figure 3-3.

To p

Bottom

( * X ) inch

Double Sided Tape

(Part# LENS-TAPE)

Lenticular Screen

Fresnel Lens

Figure 3-2

Top

Bottom

To p

Fresnel

Lens

Lenticular

Screen

0.16 inch

* Tape Application Guide

MODEL

VS-45609 45" 36"

VS-50609 50" 40"

VS-55609 55" 44"

VS-60609 60" 48"

VS-60719 60" 48"

VS-70709 70" 56"

SCREEN

SIZE

Table A

TAPE

LENGTH

Fresnel Lens

(Rear)

Bottom

CUSHION-CORNER(B)

Part #622D757060

CUSHION-CORNER(A)

Part #622D757050

Figure 3-3

Page 10

Page 11

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

CABINET SEPARATION PROCEDURE (VS-70709)

Model VS-70709 cabinets are assembled in two pieces. These two pieces may be separated to allow easier delivery

and setup.

Note:

ing and installing. DO NOT tilt the cabinet top while resting on the guide pins.

The Guide Pins under the cabinet top may break if mishandled. Keep the cabinet top straight when remov-

1c. VS-70709 Cabinet Separation Precedure

1. Remove the Screen Assembly and disconnect

all cable harnesses between the Frame

Assembly and the PCB-SIGNAL (refer to

Front Cabinet Disassembly

2. Remove 4 screws “a” securing the top and

bottom cabinet sections (Figure 1-3).

3. Lift the cabinet top straight up until the guide

pins are clear.

4. Carefully place the cabinet top on the floor.

5. Place the cabinet bottom in the desired

location.

6. Reverse the procedure and mount the cabinet

top on the cabinet bottom.

7. Reinstall the the Screen Assembly and

connect all cable harnesses between the

Screen Assembly and the PCB-SIGNAL.

).

1a.

Page 11

Figure 1-3

Page 12

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

SERVICING THE DIAMONDSHIELD™

1. DiamondShield™ Removal Procedure

The location of the DiamondShieldTM molding clips may vary between models, top and bottom, or sides. Use

the appropriate disassembly procedure given below.

Note:

Wear gloves when handling the DiamondShield™ to prevent finger prints.

Top & Bottom Molding Clips

1. Gently insert a small screwdriver between the

DiamondShield™ and one end of the clip to pry

the clip loose.

Side Molding Clips

1. Gently insert a small screwdriver between the

DiamondShield™ and one end of the clip to pry

the clip loose.

2. Remove both clips by pulling them toward you.

3. Carefully insert a small screwdriver into the gap

at the top/center point of the Shield and pull the

Shield slightly away from the unit. Place your

hands at the points shown and gently bow the

Shield toward you and remove from the unit.

Then re-install the two clips.

2. DiamondShield™ Installation Procedure

*(See the Parts List for DiamondShield™ part numbers)

To install the DiamondShieldTM, reverse the above Removal Procedure.

2. Remove both clips by pulling them toward you.

3. Carefully insert a small screwdriver into the gap

at the side/center point of the Shield and pull the

Shield slightly away from the unit. Place your

hands at the points shown and gently bow the

Shield toward you and remove from the unit.

Then re-install the two clips.

Page 12

Page 13

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

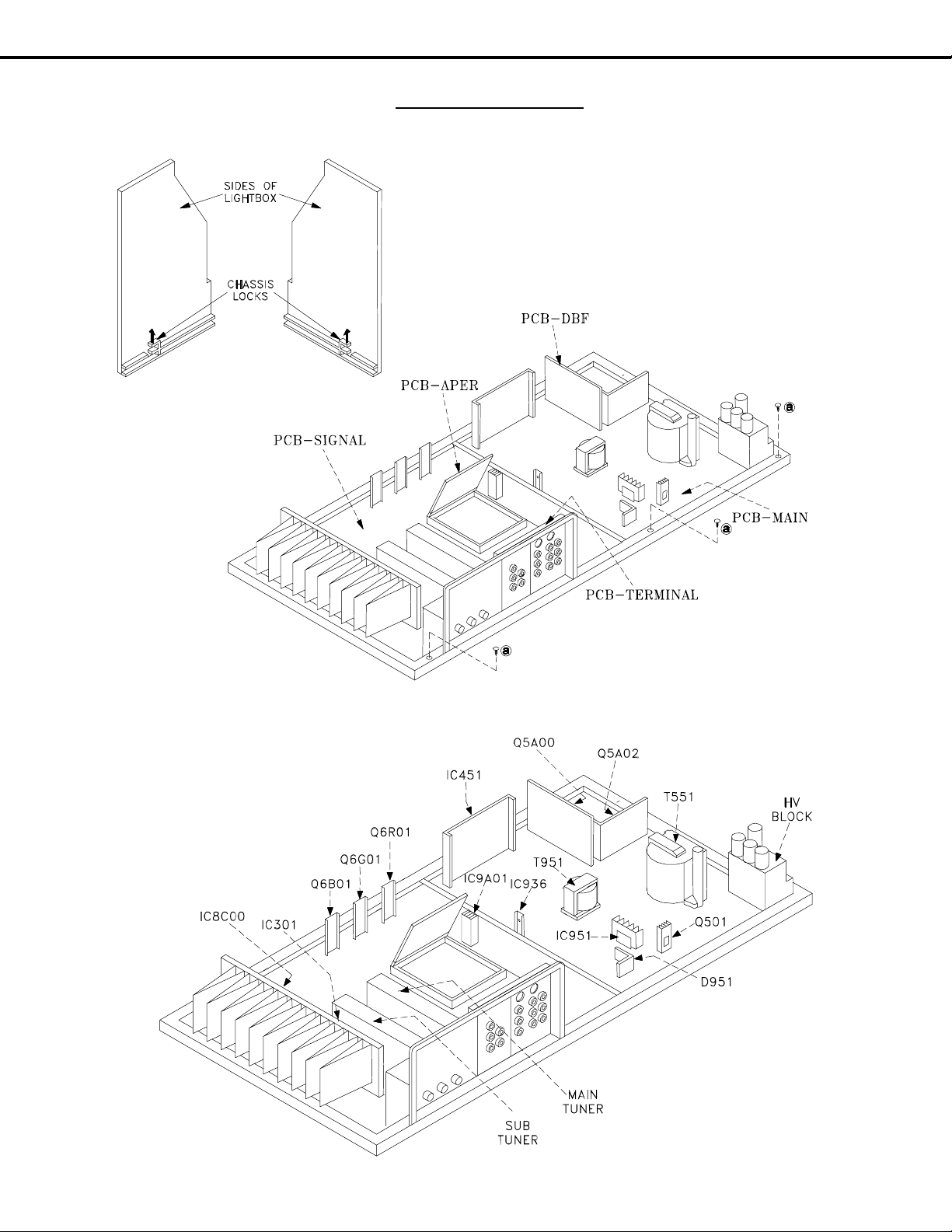

SERVICING PCBs

Chassis Removal and PCB Locations

Chassis Removal

1) Remove 3 screws “a” from the Main Chassis.

2) Raise the two chassis locks on the inner sides of the

Lightbox Assembly and slide the chassis towards the

rear.

Major Parts Locations

Page 13

Page 14

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

CRT REPLACEMENT

1. Removal of the CRT

Caution! High voltage should be completely discharged prior to CRT removal.

Since The CRTs receive high voltage from the CR Block, discharge

by shorting the open end of the respective high voltage cable to

chassis ground.

Note: Refer to figures 1-1 through 2-2 when performing steps 1 through 4.

1. Remove the Speaker Grille, Front Board, and Screen Assy.

2. Remove the Back Board.

3. Remove the Anode Lead Wire from the CR Block.

4. Remove the PCB-CRT.

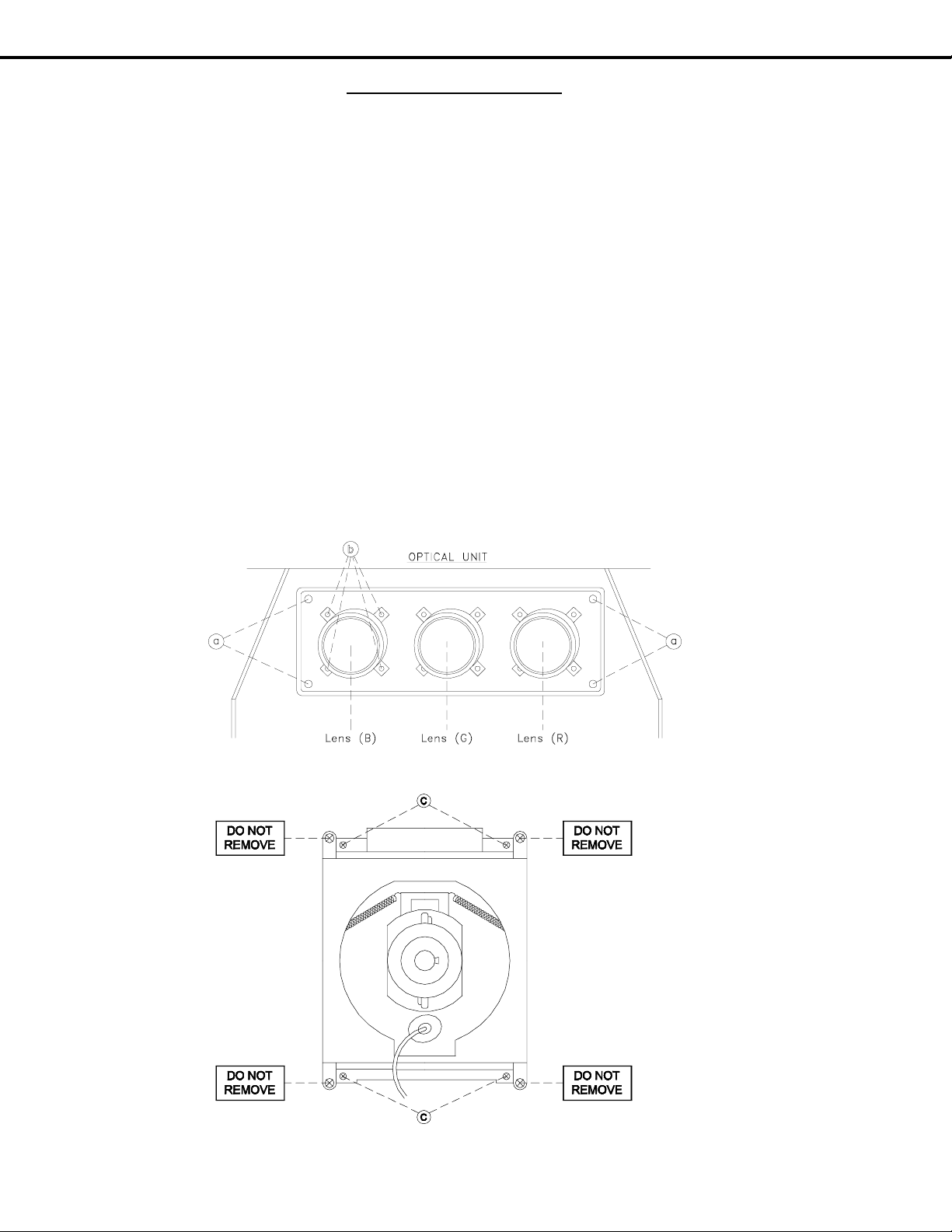

5. Remove 4 hex-screws "a" retaining the Optical Unit. [Figure 5-1]

6. Remove 4 screws "b" retaining the Lens.

Note: DO NOT loosen the RED screws. Doing so will break the seal between the

C-Element and the # 6 Lens, causing leakage of the CRT Coolant.

7. Remove 4 screws "c" retaining the CRT. [Figure 5-2]

8. Remove the Deflection Yoke from the neck of the CRT. [Figure 5-7]

Figure 5-1

Figure 5-2

Note: The 4 spring-loaded screws shown

in Fig 5-2 and labeled as "DO NOT

REMOVE", should not be loosened

under any circumstance. Doing so

will break the seal between the

CRT and the CRT-Spacer, causing

leakage of the CRT Coolant.

Page 14

Page 15

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

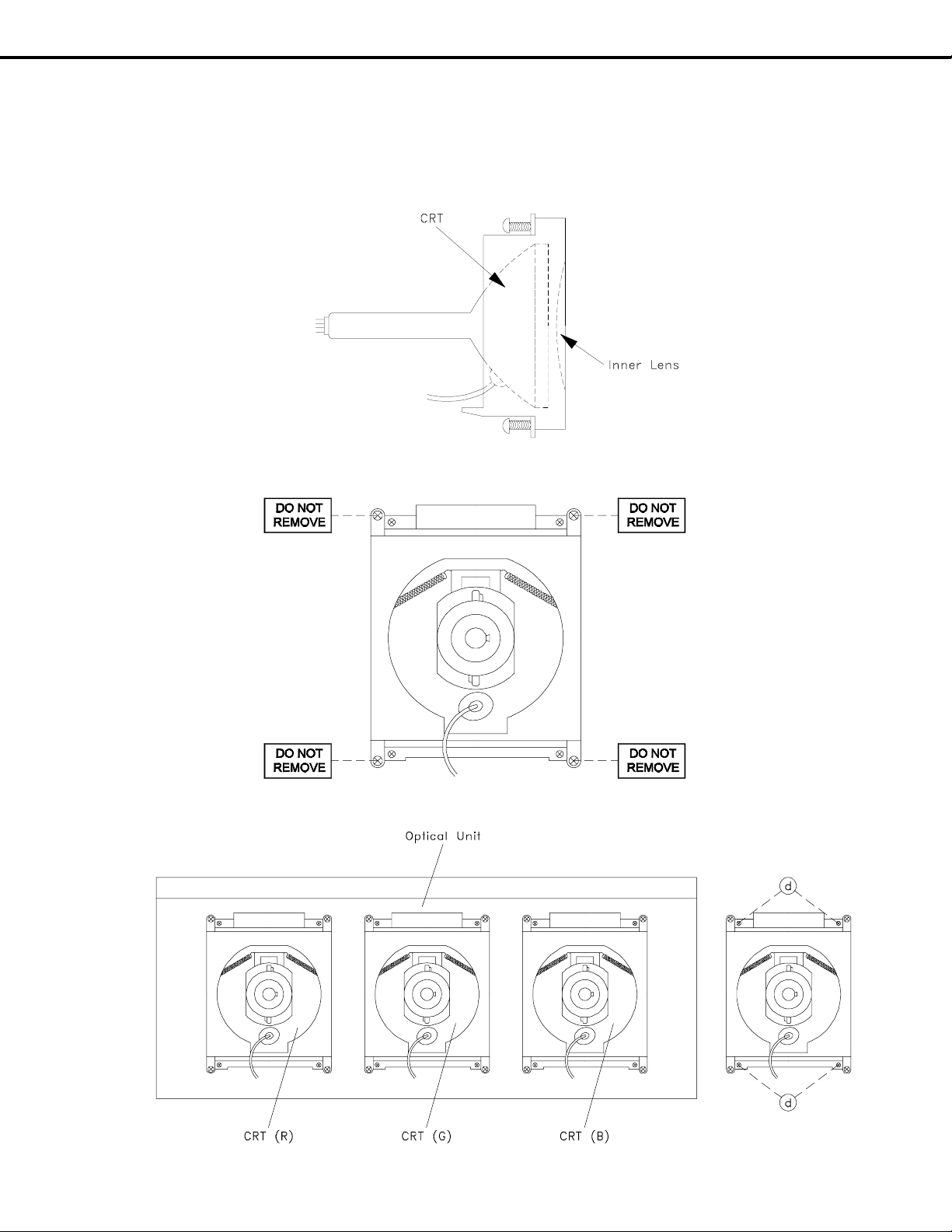

2. Installation of the CRT

Note: The replacement CRT is supplied as an assembly comprised of the CRT and the

Inner Lens with the space between them filled with ethylene glycol. Care should

be taken during handling and installation to prevent shock from disrupting the seal

or alignment between the CRT and Inner Lens. [Figure 5-3]

Figure 5-3

Note: The CRT fixing screws should not be loosened nor should they be removed. [Figure 5-4]

Figure 5-4

1. Carefully position the replacement CRT and fasten in place using 4 screws "d". [Figure 5-6]

Figure 5-6

Figure 5-5

Page 15

Page 16

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

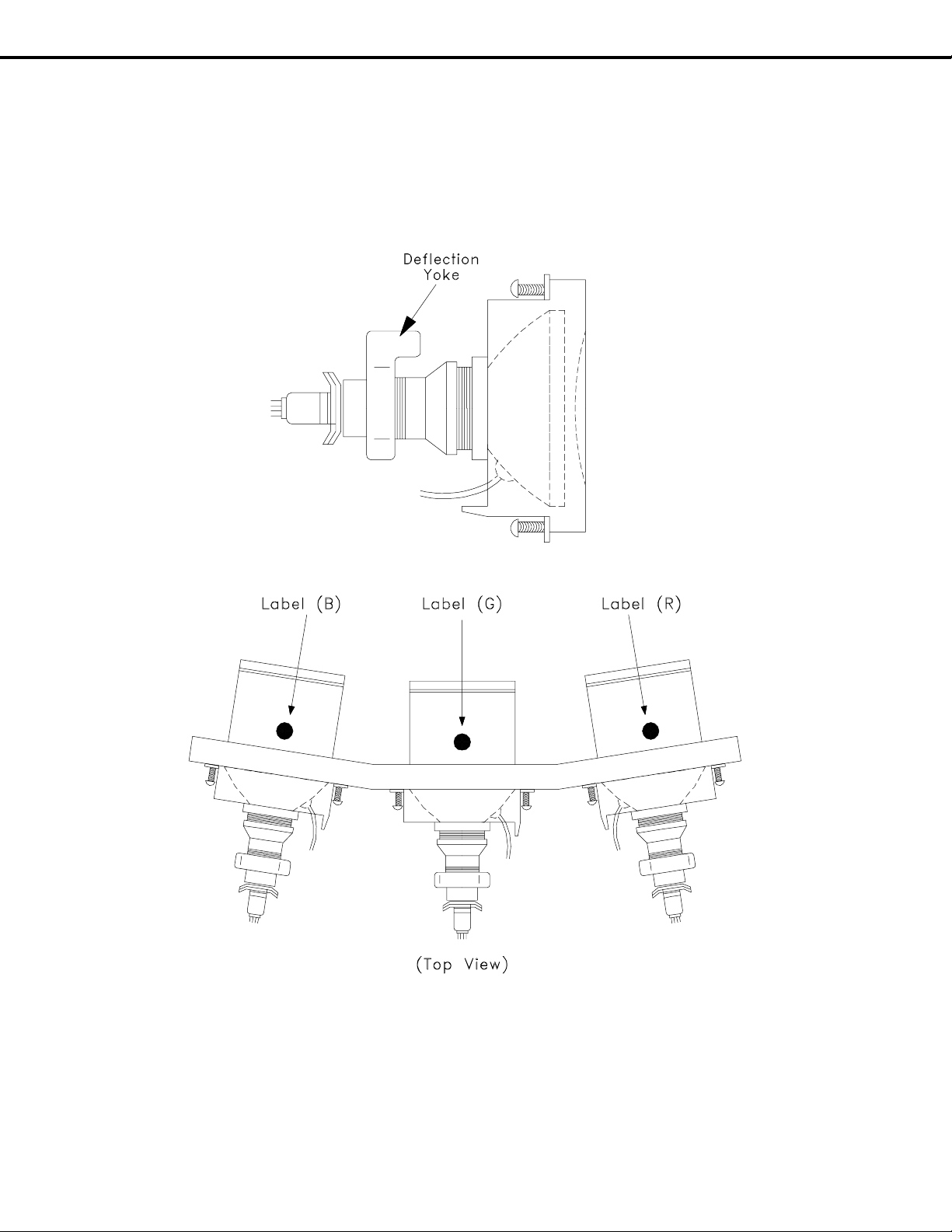

2. Install the Deflection Yoke on the CRT neck. [Figure 5-7]

3. Install the Lens that was removed in steps 5 and 6 of Removal Of The CRT. [ Figures 5-1 and 5-2 ]

a) Position the Lens so that the Label faces the direction shown in Figure 5-8.

b) Install the mounting screws. [Figure 5-1]

4. Install the PCB-CRT.

5. Insert the Optical Unit into the Light Box Assembly.

6. Insert the Anode Lead Wire into the Flyback Transformer.

7. Re-clamp the Lead Wire in its original position.

Figure 5-7

Figure 5-8

Adjustment procedures after replacing the CRT(s)

• CRT Cut Off / White Balance Adjustment

• Static Convergence Adjustment

• Dynamic Convergence Adjustment

Page 16

Page 17

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

ELECTRICAL ADJUSTMENTS

Note: Perform only the adjustments required.

Do not attempt an alignment if proper equipment is not available.

1. Test Equipment

• Oscilloscope (Unless otherwise specified, use 10:1 probes)

• Signal Generator

• Frequency Counter

• Direct Current Voltmeter

Direct Current Power Supply

• Multiplex Audio Signal Generator

• Direct Current Ampere Meter

2. Test Signal

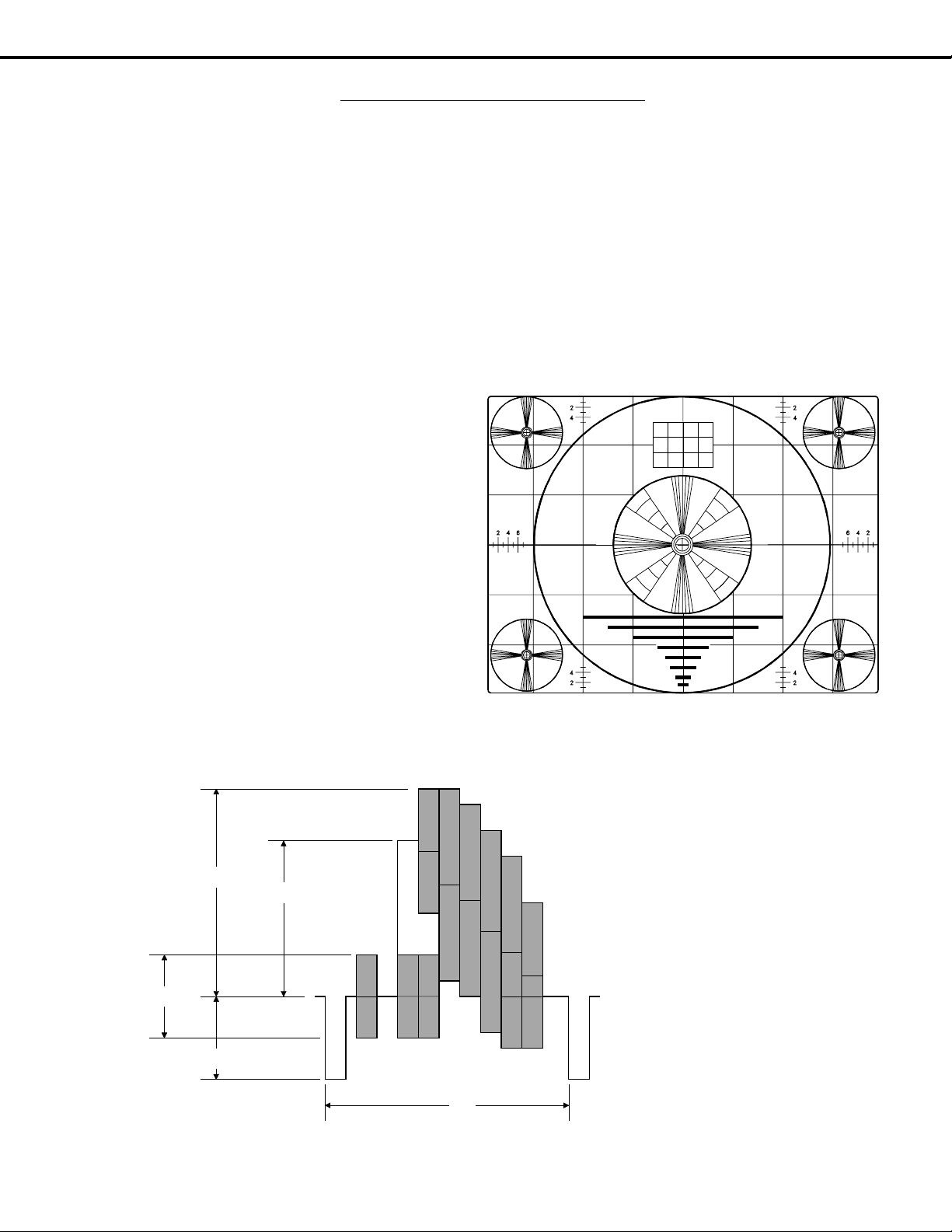

A. Monoscope Signal

Note: If you do not have

a monoscope signal source,

connect the unit to a VCR

and play a Monoscope

*alignment tape.

(* Part Number: 859C568060)

B. Color Bar Signal

Use the color bar signal shown

below, unless otherwise specified

in this manual.

100%

75%

40%

40%

Monoscope Signal

1H

Split-Field Color Bars (100% window)

Page 17

Page 18

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

3. Initial Setup

1. Option Menu Setup

Follow the steps below for the initial set-up:

1. Select the "MENU" display by pressing the "MENU" button once.

2. Press the number buttons "0", "1", "7", "0" in sequence to select the "OPTION MENU" display.

3. Press the "ADJUST" button to select "INITIAL."

4. Press "ENTER."

NOTE: At this time channel 3 is automatically selected.

OPTION MENU

INITIAL

POWER RESTORE :OFF

DIRECT KEY MODE :OFF

VIDEO MUTE TIME OUT :OFF

(MENU-0-1-7-0)

2. Default Settings

INITIAL SETTINGS

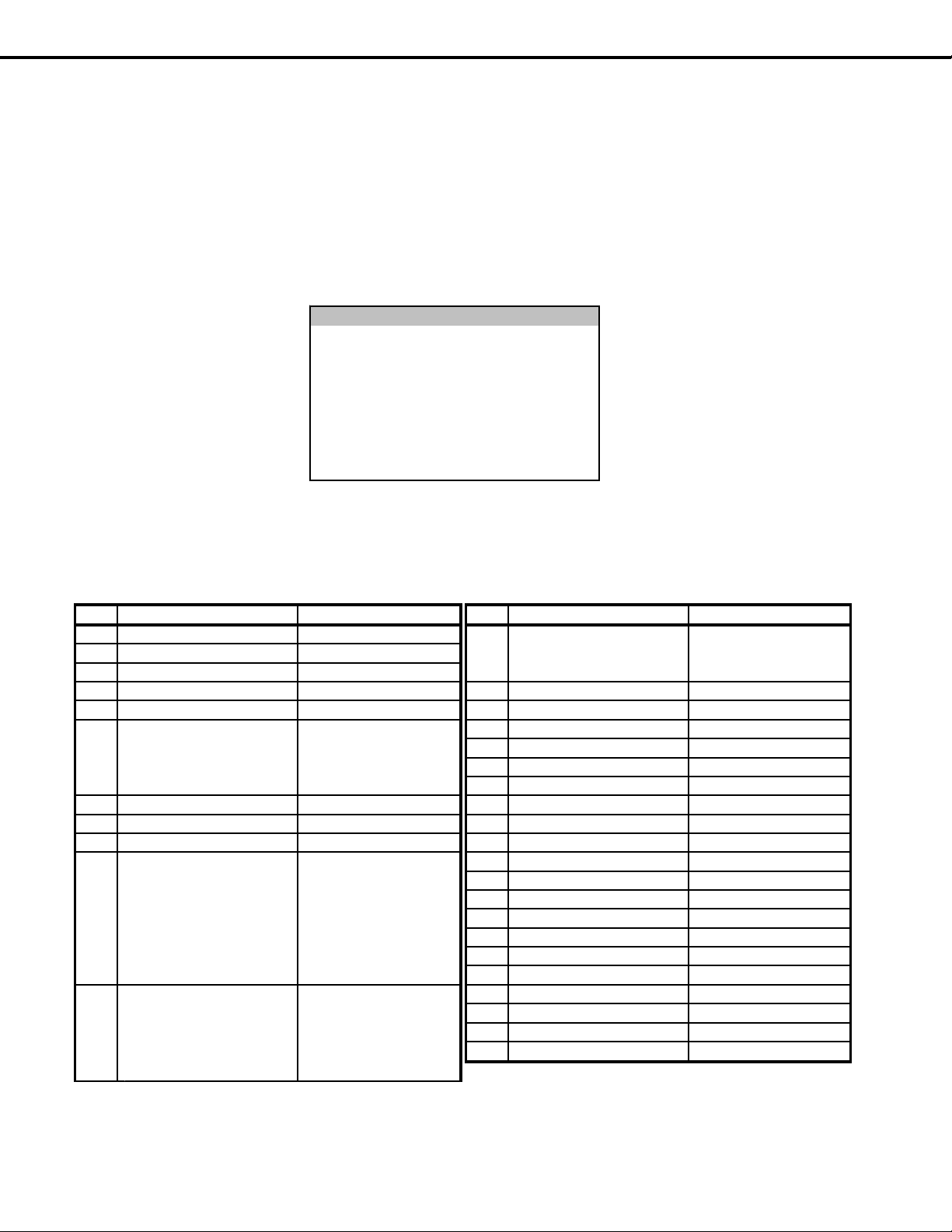

Item Description Initial Setting Item Description Initial Setting

1 Input TV 11 TV Brightness 50%

2 Receiving Channel 003 CH TV Sharpness 50%

3 TV/CATV CATV TV Color 50%

4 QV Recalls previous ch. 12 Speaker ON

5 Channel Memory All CH (0,0) 13 Background Gray

6 V-CHIP LOCK 14 Closed Caption On if Mute

Lock by Time OFF 15 PIP SOURCE TV

Lock Time 12:00 AM 16 PIP POSITION Lower Right

UnlocK Time 12:00 AM 17 VIDEO MUTE OFF

7 Lock Channels OFF 18 INPUT, NAME All inputs name OFF

8 LOCK CODE - - - - 19 TIMER OFF

9 VOLUME 30% 20 SQV All Ch Clear (deleted)

10 AUDIO FUNCTIONS 21 SYSTEM 4* OFF

TV Listen to STEREO 22 LANGUAGE English

TV Bass 50% 23 Name The Channels All Labels Cleared

TV Treble 50% 24 Locked to Input No

TV Balance 50% 25 External Audio System No

TV Surround OFF 26 Vol. change by AV Rec. N/A

TV Level sound OFF 27 Auto Clock Setting OFF

11 VIDEO FUNCTIONS 28 Front Lock Function OFF

TV Tint 50% 29 PIP Demo Mode OFF

TV Color temp High 30 Clock Time - -:- -

TV Noise Reduction OFF 31 Set Day Sunday

TV Contrast 100%

* Note: System 4 in VS-60719 & VS-70709 only

Page 18

Page 19

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

Items in the table below are set to following after Initalization.

AV MEMORY

AV MEMORY All Inputs

TINT 31

COLOR 31

CONTRAST 63

BRIGHTNESS 31

SHARPNESS 31

COLOR TEMP HIGH

BASS 31

TREBLE 31

BALANCE 31

SURROUND OFF

LEVEL SOUND OFF

4. LED Indicator Diagnostics

The “Power ON LED” provides an indication of the sets operation, and the possible cause of a malfunction.

1. Initial Control Circuitry Check

Immediately after the TV is connected to an AC power source:

• The LED flashes three times ... indicating the Microprocessor has initialized and is functioning

properly.

• If the LED does not flash ... the Microprocessor is NOT functioning.

2. Error Code Operational Check

Pressing the front panel “INPUT” and “MENU” buttons at the same time, and holding for 5 seconds,

activates the Error Code Mode. The LED flashes denoting a two digit Error Code, or indicating no problem

has occured since the last Initalization.

Note: The front panel buttons must used, NOT those on the Remote Control.

• The number of flashes indicates the value of the MSD (tens digit) of the Error Code.

• The flashing then pauses for approximately 1/2 second.

• The LED then flashes indicating the value of the LSD (ones digit) of the Error Code.

• The Error Code is repeated a total of 5 times.

Example: If the Error Code is “24”, the LED will flash two times, pause, and then flash four

times.

3. Error Codes

The Error Code designations indicating a malfunction, or no malfunction, are listed below:

“12” ... indicates no error has occured.

“21” ... X-Ray Protect circuit.

“22” ... Short Protect circuit.

“23” ... Horizontal Deflection failure.

“24” ... Vertical Deflection failure.

Page 19

Page 20

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

1

2

3

5

6

789

0

SQV

QV

4

POWER

HOME

PAUSE

REC

FF/FWDREW/REV

PLAY

STOP

VOLUME

INFO

CANCEL

MENU

PIP/POP

PIP SIZE

PIP CH

INPUT

SLEEP

VIDEO

AUDIO

MUTE

CHANNEL

ENTER

PIP INPUT

EXCH

GUIDE

TV

AUDIO

CABLE/DBS

DVD

VCR

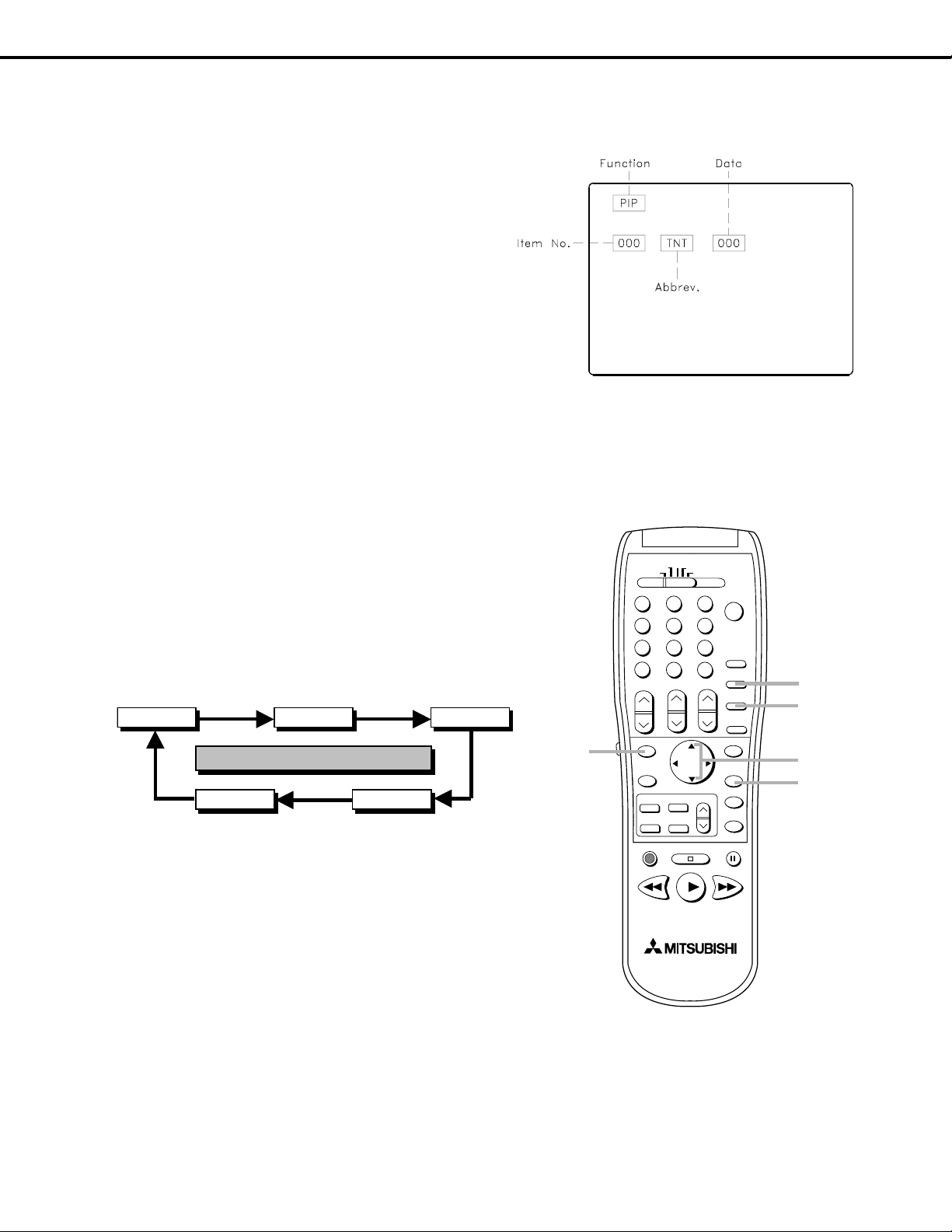

5. Circuit Adjustment Mode

Except for the following, all adjustment items must be performed

using the remote hand unit.

• Lens Focus

• Electrostatic Focus

A. Activating the Circuit Adjustment Mode

1. Press the "MENU" button on a remote hand unit.

2. Press the number buttons "0", "1", "5", "7" in sequence.

The screen will change to the Adjustment Mode.

Note: Repeat steps 1 and 2 if the circuit

adjustment mode does not appear

on screen

B. Selection of adjustment Functions and

Adjustment Items

To select an adjustment item in the circuit adjustment mode,

first select the adjustment function that includes the specific

adjustment item to be selected. Then, select the adjustment

item.

Refer to the following pages for the listing of adjustment

functions and adjustment items.

1. Press the "AUDIO" button on a remote hand unit to

2. Press the “VIDEO” button to select a specific

C. Changing Data

After selecting an adjustment Item, use the “ADJUST

UP/DOWN” button to change data.

• Press “ADJUST DOWN” to decrease the data value.

• Press “ADJUST UP” to increase the data value.

select an adjustment function. Each time the button

is pressed, the Function changes in the following

sequence:

VCJ AUDIO YUV

Adjustment Functions

PIP HR

Adjustment Item. The Item number increases each

time the “VIDEO” button is pressed.

ENTER

VIDEO

AUDIO

ADJUST

UP/DN

MENU

Page 20

Page 21

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

D. Saving Adjustment Data

Press “ENTER” to save adjustment data in memory. The character display turns red for

approximately one second in this step.

Note: If the circuit adjustment mode is terminated without pressing “ENTER”, changes

in adjustment data are not saved.

E. Terminating the Circuit Adjustment Mode

Press the “MENU” button on the remote hand unit twice to terminate the adjustment mode.

Note: The circuit adjustment mode can also be terminated by turning power OFF.

7. Convergence Adjustment Mode

The Convergence mode is used to perform raster geometry correction, and convergence adjustments as

specified in Adjustment Procedures 15, 17, 18, 19 and 20.

A. Convergence Mode Activation

1. Press MENU-0-1-5-9

2. When the Convergence Mode is activated, the display at

the right appears on a Green Crosshatch.

B. Convergence Mode Functions

In the Convergence Mode there are three main Functions (Categories).

• Pressing “6” activates CONV MISC

• Pressing “5” activates COARSE CONV

• Pressing “4” activates FINE CONV

C. CONV MISC (Press 6)

This mode is used to preset data values controlling the Convergence Generator, and to perform the HV

Regulation adjustment.

1. Use the VIDEO button to select an item.

2. Use the ADJUST buttons to change data.

Note: When Item “1 HVOL” is selected the screen goes black except for the data display.

This occurs since a black screen is required when making the HV Regulation adjustment.

D. COARSE CONV (Press 5)

There are four Sub Functions in the Coarse mode, COARSE GREEN, COARSE RED, COARSE BLUE and

DF.

• COARSE GREEN .... used to make Coarse Raster Geometry Adjustments.

• COARSE RED ... used to make Coarse Red Convergence Adjustments.

• COARSE BLUE ... used to make Coarse Blue Convergence Adjustments.

• DF ... used to preset data values controlling the Dynamic Beam Focus circuit drive signal.

Page 21

Page 22

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

1. Use AUDIO button to select a Sub Function

2. Use the VIDEO button to select an Adjustment Item.

3. Use the ADJUST buttons to change data.

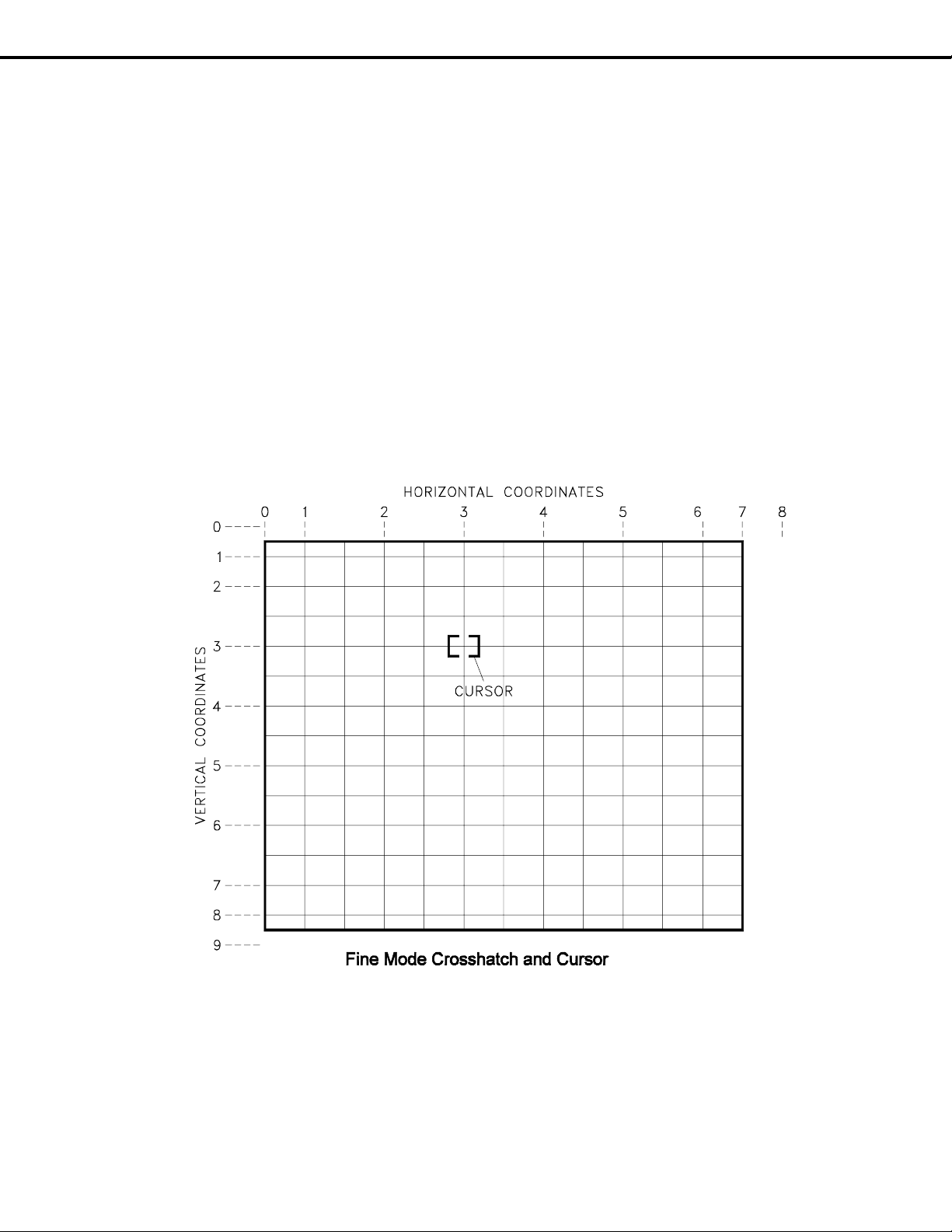

E. FINE CONV (Press 4)

Sub Functions

This mode is used to perform Fine Raster Correction, and Fine Red and Blue Convergence Adjustments.

There are three Sub Adjustment Functions, selected with the AUDIO button:

• FINE GREEN .... a Green Crosshatch is displayed, for Fine Raster Corrections.

• FINE RED .... a White Crosshatch is displayed, for Fine Red Convergence Adjustments.

• FINE BLUE .... a White Crosshatch is displayed, for Fine Blue Convergence Adjustments.

Cursor

In the Fine mode a Cursor is added to the Crosshatch. The ENTER button toggles the Cursor between

two modes:

• MOVE (blinking Cursor) .... use the ADJUST buttons to select any of 64 points on the

Crosshatch.

• ADJUST (Non blinking Cursor) .... the ADJUST buttons adjust the active color at the current

Cursor position, horizontally or vertically.

Cursor Coordinates

Specific intersections in the Crosshatch are assigned vertical and horizontal coordinates.

These are shown in the above diagram. The Cursor can only be moved to those positions that

have coordinates assigned. If the Cursor is at coordinates outside the screen area, the Cursor will not be

visible. Use the ADJUST buttons to move the Cursor to an intersection on the screen.

Page 22

Page 23

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

Display

The on-screen display changes in the Fine mode, as shown below. The display shows the vertical and

horizontal data for the current Cursor Position, and the horizontal and vertical coordinates for

that position.

F. Saving Data and Exiting the Convergence Mode

Press MENU twice to exit the Convergence mode, data is automatically saved.

Note: If power is interrupted prior to properly exiting the Convergence Mode, changes in adjustment

data will not be saved.

Page 23

Page 24

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

ADJUSTMENT ITEMS LIST

When Replacing the EEPROM (IC701)

The EEPROMs (IC701 and IC801) store the adjustment data. After replacing the EEPROM, readjust the data to the

values given in the following tables. If good performance is not obtained with these values, perform the Adjustment

Procedure(s) given in the Notes column.

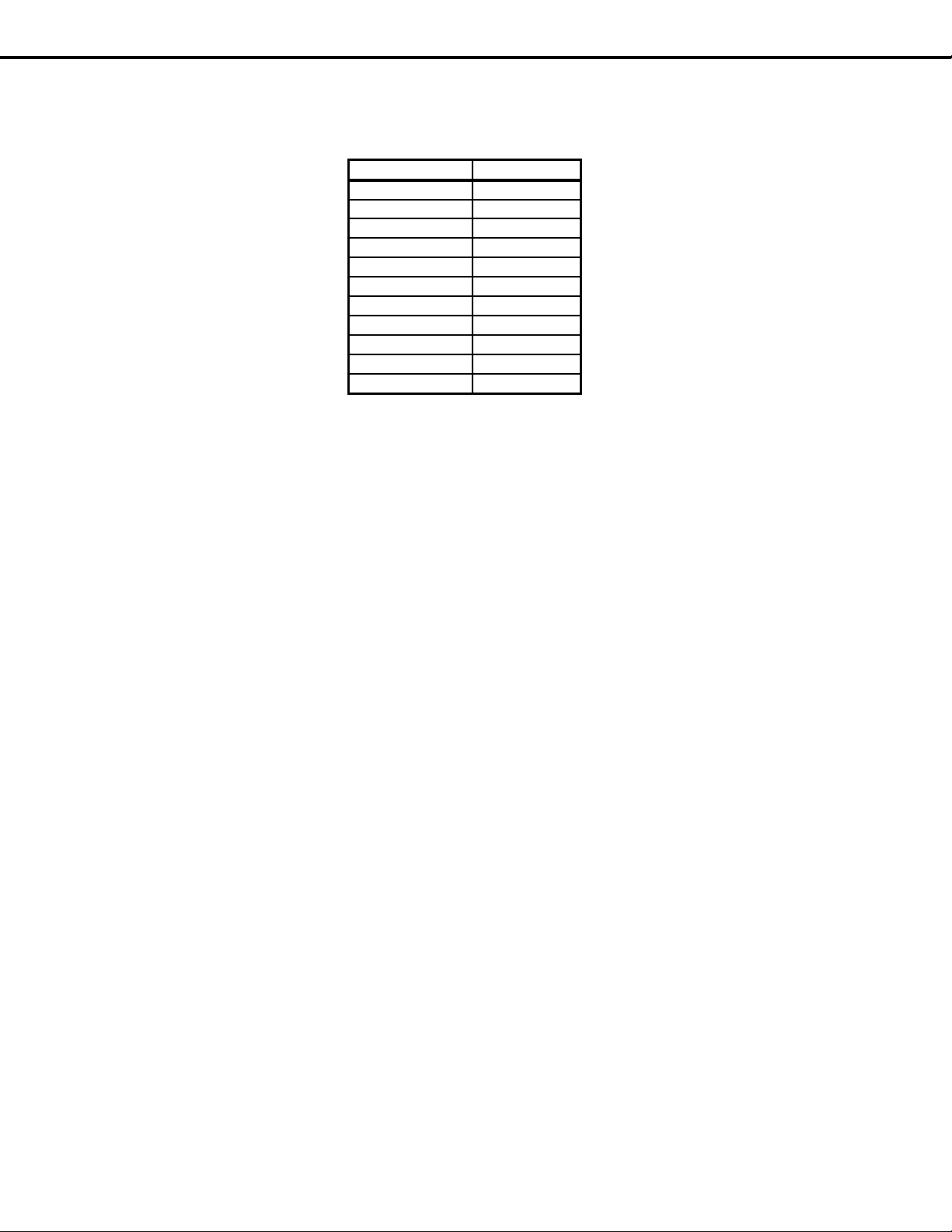

VCJ Function

Item No. Abbrev. Description

1 SCT Sub Contrast 63 55 Sub Contrast

2 VHGT Height 63 31 Vertical Height

3 SCOR S-Distortion 15 7

4 VLIN Vertical Linearity 15 7 Vertical Linearity

5 UPVL Top Vertical Linearity 15 0

6 LOVL Bottom Vertical Linearity 15 0

7 BRTH Brightness Control (high) 63 31 Black Level

8 CTRH Red Cutoff (high temp.) 15 7 White Balance (high)

9 CTGH Green Cutoff (high temp.) 15 10 CRT Cutoff

10 CTBH Blue Cutoff (high temp.) 15 7 White Balance (high)

11 RDRH Red Drive (high temp.) 63 31 White Balance (high)

12 GDR Green Drive 63 51

13 BDRH Blue Drive (high temp.) 63 31 White Balance (high)

14 CTRL Red Cutoff (low temp) 15 7 White Balance (low)

15 CTGL Green Cutoff (low temp) 15 10

16 CTBL Blue Cutoff (low temp) 15 7 White Balance (low)

17 RDRL Red Drive (low temp.) 63 31 White Balance (low)

18 BDRL Blue Drive (low temp.) 63 31 White Balance (low)

23 CBOF Cb Offset 15 7 Cb, Cr Offset

24 CROF Cr Of fset 15 7 Cb, Cr Offset

25 SHUE Sub Hue Control 15 7

26 SCOL Sub Color Gain 15 12

27 SCON Sub Contrast Control 15 7

28 AG-1 Aging Mode On/Off 1 0

30 COLH Color Gain high 63 27 Cb, Cr Offset

51 VPOS V-Drive DC bias 63 31

55 HPOS Horiz. Position 63 34

Range

0 ~ •••

Initial

Data

Service Adjustment

AUDIO Function

Item No. Abbrev. Description

Range

0 ~ •••

1 INP Input Level 15 7 Audio Input Level

2 AUT Auto Alignment Off/On Sw. 1 0

3 WDE Wideband Separation 31 16 Separation

4 SPC Spectral Separation 31 16 Separation

Initial

Data

Service Adjustment

PIP Function

Item No. Abbrev. Description

1 HUE Sub Picture Hue 63 0 Sub Picture Tint

2 CSAT Sub Picture Color Saturation 15 0 Sub Picture Color

3 CONT Sub Picture Contrast 15 7 Sub Picture Contrast

4

5 BLKG GREEN Output Pdestal Level 15 0

6 BLKB BLUE Output Pdestal Level 15 0

7 BRIT Sub Picture Brightness 15 0

8 PON PIP On/Off 1 0

BLKR RED Output Pdestal Level 15 0

Range

0~…

Page 24

Initial

Data

Service Adjustment

Page 25

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

YUV Function

Item No. Abbrev. Description

28 PEAK Peaking Amplitude Adjust 63 40

Range 0

~ •••

Initial

Data

Service Adjustment

HR Function

Item No. Abbrev. Description

1 HR OSD Horiz. Position 15 7 Display Centering

Range 0

~ •••

Initial

Data

Service Adjustment

CONVERGENCE MODE ITEMS

CONV MISC

Item Abbr. Data Description

1 HVOL 200 High Voltage Control

2 VCNT 62 Vertical correction signal increment per line

3 VSTR 0 Start point of vertical correction

4 VOFS 0 V Offset

5 STLN 20 Horiz. Correction signal start line number

6 FPHS 300 Fine H-phase of correction signal

7 CPHS 15 Coarse H-phase of correction signal

8 HOFS 16 H Offset

9 DPHS 13 Dynamic Focus H-phase

10 D0FS 0 Dynamic Focus Offset

11 TPHS 50 Test pattern H-phase

12 TPVO 13 Test pattern V-position

13 ODEV 24 Odd/Even detection

14 HRTC 1 Horizontal Retrace

15 DRTC 1 DBF retrace

16 EPWP 0 EEPROM write protection

CONV GREEN

Item Abbr. Data Description

1 HSTA* 0 Horiz. Position

2 VSTA* 0 Vertical Position

3 SKEW 0 Skew (Y axis rotation)

4 TILT 0 Tilt (X axis rotation)

5HWID30 Width

6 HLIN 0 Horizontal Linearity

7 SPCC -125 Side Pin Cushion Correction

8 HKEY 30 Horizontal Keystone

9 TBPC -230 Top/Bottom Pin Cushion Correction

10 VKEY -10 Vertical Keystone Correction

11 VWID 0 Height

12 VLIN 0 Vertical Linearity

*HSTA & VSTA data should not exceed ±100

Page 25

Page 26

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

CONV RED

Item Abbr. Data Description

1 HSTA* 100 Horiz. Position

2 VSTA* 0 Vertical Position

3 SKEW 0 Skew (Y axis rotation)

4 TILT 0 Tilt (X axis rotation)

5 HLIN -270 Horizontal Linearity

6 HWID -60 Width

7 VKEY -170 Vertical Keystone Correction

8 VWID 0 Height

9 VLIN 0 Vertical Linearity

10 TBPC 0 Top/Bottom Pincushion Correction

11 SDBW 80 Horizontal Bow

*HSTA & VSTA data should not exceed ±100

CONV BLUE

Item Abbr. Data Description

1 HSTA* -100 Horiz. Position

2 VSTA* 0 Vertical Position

3 SKEW 0 Skew (Y axis rotation)

4 TILT 0 Tilt (X axis rotation)

5 HLIN 280 Horizontal Linearity

6 HWID -50 Width

7 VKEY 150 Vertical Keystone Correction

8 VWID 0 Height

9 VLIN 0 Vertical Linearity

10 TBPC 0 Top/Bottom Pincushion Correction

11 SDBW -70 Horizontal Bow

*HSTA & VSTA data should not exceed ±100

DF Function

Item Abbr. Data Description

0 DFH 200 Dynamic Focus (Horizontal)

1 DFV 100 Dynamic Focus (Vertical)

Page 26

Page 27

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

Location of Test Points and Adjustments

Page 27

Page 28

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

[Audio Circuit]

1. Input Level

Purpose:

Symptom:

Set the input signal level to the MCS circuit.

Distorted sound during a stereo broadcast.

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

Oscilloscope

TP14A, TP15A

------

50mV/Div

RF Monaural

300 Hz modulation

RF Input

1. Supply an RF monaural signal to the Ant A input, 300 Hz at 100% modulation

(25 kHz deviation).

2. Connect the oscilloscope to TP15A (Right Channel). (Junction of

R2K64 and R3A38)

3. Enter the Adjustment Mode and select the Audio Function.

4. Verify that the Audio Function items are set to the data values given the

table below.

5. Adjust Item “1 INP” for 1.55 ±0.06 Vp-p at TP15A.

6. Connect the oscilloscope to TP14A. (Junction of R2K62 and R3A15)

7. Confirm that the left channel output at TP14A is 1.55 ±0.06 Vp-p.

Note:

Adjustment 2 (Stereo Separation) must be performed after this adjustment)

AUDIO Function

SERVICE MODE

Activate …….. MENU-0-1-5-7

Function …...………..AUDIO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Save Data …. ………ENTER

Exit …………..MENU (twice)

Item Abbrev. Data

1INP 7

2AUT 0

3WDE 16

4 SPC 16

15 MZX 1

16 VZX 1

20 ATK 1

[Audio Circuit]

2. Separation

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

Oscilloscope

TP14A, TP15A

------

10mV/Div

RF Stereo

RF Input

Purpose:

Symptom:

Note:

This adjustment must follow Adjustment 1 (Input Level)

Adjust for optimum stereo separation.

Poor stereo separation

1. Supply a RF Stereo Signal to the Ant. A input.

• Left Channel = 300 Hz modulation

• Right Channel = no modulation signal

2. Connect the oscilloscope to TP15A (right channel). (Junction of

R2K64 and R3A38)

3. Enter the Service Mode and select the Audio Function.

4. Adjust Item “3 WDE” for minimum signal at TP15A.

5. Change the modulation frequency to 3 kHz.

6. Adjust Item “4 SPC” for minimum signal at TP15A.

SERVICE MODE

Activate …….. MENU-0-1-5-7

Function …...………..AUDIO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Save Data …. ………ENTER

Exit …………..MENU (twice)

Page 28

Page 29

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

[High Voltage Circuit]

Purpose:

To set the CRTs anode voltages

3. High Voltage Control

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

DC Voltmeter

+ Lead to DT #5

- Lead to DT #4

------

-------

Monoscope

Video Input

Symptom:

Dark picture.

1. Supply a Monoscope signal to a Video Input.

2. Connect a DC Voltmeter to pins 4 and 5 of the DT connector.

• Positive Lead to DT #5

• Negative Lead to DT #4

3. Set Contrast to maximum, and Brightness to the center position.

4. Enter the Service Mode and check that Item “7 BRTH” under the VCJ Function is

set at 31.

5. Press Enter and Exit the Service Mode.

6. Enter the Convergence Mode and select the Conv. Misc Function.

7. Select Item “1 HVOL” (screen goes black).

8. Adjust “1 HVOL” for 0.15 ±0.01 V on the meter.

9. Exit the Convergence Mode and verify that the meter reading does not exceed

0.85V.

Note:

HV must be reset if E2RESET is activated.

CONVERGENCE MODE

SERVICE MODE

Activate …….. MENU-0-1-5-7

Function …...………..AUDIO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Save Data …. ………ENTER

Exit …………..MENU (twice)

Activate ……..MENU-0-1-5-9

Misc. ……………….……"6"

Coarse………………..…."5"

Fine ……………………..."4"

Color (R,G B or DF)...AUDIO

Item No………….…..VIDEO

Adjust/Move……….ADJUST

Cursor Toggle….…..ENTER

Save & Exit…..MENU (twice)

[Focus]

4. Dynamic Focus

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

------

--------

------

-------

Monoscope

Video Input

Purpose:

Symptom:

To improve edge focus

Blurred picture at the edges of the screen.

1. Supply a Monoscope signal to the Video Input.

2. Enter the Coarse Convergence Mode and select the DF Function.

3. Verify that the data values are set as indicated in the table below.

4. Exit the Convergence Mode.

CONVERGENCE MODE

DF Function

Item Abbrev. Data

0 DFH 200

1 DFV 100

Activate ……..MENU-0-1-5-9

Misc. ……………….……"6"

Coarse………………..…."5"

Fine ……………………..."4"

Color (R,G B or DF)...AUDIO

Item No………….…..VIDEO

Adjust/Move……….ADJUST

Cursor Toggle….…..ENTER

Save & Exit…..MENU (twice)

Page 29

Page 30

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

[Focus]

5. Electrostatic Focus

Purpose:

Symptom:

To set focus to the optimum point.

Blurred picture.

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

CONVERGENCE MODE

COLOR PRESS

GREEN 2

--------

RQ Connector

------

-------

Monoscope/Crosshatch

Video Input

(MENU-0-1-5-9)

RED 1

BLUE 3

Note:

These adjustments must be performed after Sub Contrast Adjustment.

General

1. Reset the AV Functions

2. Red, green or blue rasters can be activated by using the Convergence Mode

(Table 1).

Electrostatic Focus

1. Supply a Monoscope signal to the Video Input. (Do Not use a Crosshatch.)

2. Activate a red raster.

3. Adjust the Red VR-FOCUS for optimum focus.

4. Repeat steps 2 and 3 for green and blue rasters.

Focus Verification

1. Supply a Crosshatch signal to the Video Input.

2. Verify good focus on the Crosshatch

3. If necessary, readjust focus using the Monoscope pattern.

[Focus]

6. Lens Focus

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

--------

--------

------

-------

Monoscope

Video Input

Purpose:

Symptom:

Note:

This adjustment must follow item 6 (Electrostatic Focus). Perform this

To set the Lens position for optimum focus

Blurred picture.

adjustment for RED, GREEN, and BLUE monochrome pictures.

1. Supply a VIDEO signal (Monoscope).

2. Cover the Red and Blue Lens (producing a green raster).

3. Adjust the Green Lens for best focus at the center of the Monoscope pattern.

Note:

Attach a white paper to the screen center. During adjustment,

observe the picture on the screen from inside for easier adjustment.

4. Repeat Steps 2 and 3 for the Red and Blue monochrome pictures.

5. Supply a crosshatch pattern and confirm the crosshatch lines at all four sides

are the same width.

6. If not, check the Centering and Static Convergence adjustments.

Page 30

Page 31

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

[CRT Circuit]

Purpose:

To set the cutoff point for all three CRTs.

7. CRT Cutoff

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

Activate …….. MENU-0-1-5-7

Function …...………..AUDIO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Save Data …. ………ENTER

Exit …………..MENU (twice)

Oscilloscope

TP6R, TP6G, TP6B

------

50V per division/ 2 msec

None

Video Input

SERVICE MODE

Symptom:

Monchrome has a color tint, or incorrect brightness.

1. Select an External Input with no signal.

2. Enter the Service Mode, VCJ Function.

3. Set the data to the values given for the Items listed in the Table.

4. Connect the oscilloscope to TP6R.

5. Adjust the Red SCREEN VR so the black level is 200V, as shown below, or to

206 ±1VDC using a DC Voltmeter.

6. Repeat Steps 4 and 5 to set the Blue and Green SCREEN VRs, using TP6G

and TP6B.

Note:

The White Balance Adjustment must be performed after Cutoff Adjustment.

VCJ Function

ITEM ABBR. DATA

7BRTH31

8CTRH7

9CTGH10

10 CTBH 7

[CRT Circuit]

8. White Balance

(High Color Temperature)

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

Activate …….. MENU-0-1-5-7

Function …...………..AUDIO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Save Data …. ………ENTER

Exit …………..MENU (twice)

DC Meter

R6G30, R6B30

------

-------

Full White Raster

Video Input

SERVICE MODE

Purpose:

Symptom:

Note:

This adjustment must be performed after the CRT Cutoff and Focus

To set the CRTs white level

Monchrome has a color tint.

Adjustments.

High Color Temperature White Balance

1. Supply a Full White Raster signal to the Video Input.

2. Enter the Service Mode, VCJ Function.

3. Adjust Items “11 RDRH” and “13 BDRH” for optimum white at the center of the

screen.

Note:

If the Cutoff level changes during the adjustment, use Items “8 CTRH”

and “10 CTBH” to touch up the Cutoff level. Then readjust “RDRH” and

“BDRH”.

4. Save data and exit the Service Mode.

5. Use a DC Current Meter to measure each CRT’s current.

• The meters internal resistance must be less than 30 Ohms.

• Lead length must be less than 30 CM.

6. Connect the meter, in sequence, across each of the following resistors to read

the current for that respective CRT.

• Green CRT ... across R6G30

• Blue CRT ...... across R6B30

7. The Green and Blue CRT current must not exceed the values given in Table 1.

Maximun CRT Current

CRT CURRENT

Green 580 ua

Blue 530 ua

Table 1

Page 31

Page 32

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

[CRT Circuit]

Purpose:

To set the CRTs white level at Low Color Temperature.

9. White Balance

(Low Color Temperature)

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

Activate …….. MENU-0-1-5-7

Function …...………..AUD IO

Item No. ……….…….VIDEO

Adjus t D ata ….…….ADJUST

Save Data …. ………ENTER

Exit …………..MENU (twice)

--------

--------

------

-------

Full White Raster

Video Input

SERVICE MODE

Symptom:

Note:

This adjustment should be performed after the High temperature White

Monchrome has a color tint.

Balance Adjustment.

Low Color Temperature White Balance

1. Supply a Full White Raster signal to the Video Input.

2. Enter the Service Mode, VCJ Function.

3. Adjust Item “17 RDRL” and “18 BDRL” for optimum white at the center of the

picture.

Note:

If the Cutoff level changes during the adjustment, use Items “14 CTRL”

and “16 CTBL” to touch up the Cutoff level. Then readjust “RFRL” and

“BDRL”.

4. Save data and exit the Service Mode.

[Video Circuit]

10. Black Level

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

SERVICE MODE

Activate …….. MENU-0-1-5-7

Function …...………..AUDIO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Save Data …. ………ENTER

Exit …………..MENU (twice)

--------

--------

------

-------

Monoscope

Video Input

Purpose:

Symptom:

Note:

This adjustment should be performed after the Cutoff and White Balance

To set black level of the picture.

Excessive or insufficient contrast.

Adjustments.

1. Supply a Monoscope signal to the Video Input.

2. Enter the Service Mode, VCJ Function.

3. Adjust Item “7 BRTH” so the 0% and 10% gradation levels on the Monoscope pattern are the same. (Data should be within 31 ±4 range)

4. Save the data and exit the Service Mode.

40% 30% 20% 10%

50% 0% 0% 0%

60% 70% 80% 90%

GRADATION SCALE

Page 32

Page 33

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

[Video Circuit]

11. Sub Contrast

Purpose:

Symptom:

To set the beam current to its’ optimum level.

Excessive or insufficient contrast.

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

DC milliammeter

+ DT #3

- DT #1

------

3 MA

Grayscale

Video Input

SERVICE MODE

Activate …….. MENU-0-1-5-7

Function …...………..AUDIO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Save Data …. ………ENTER

Exit …………..MENU (twice)

Note:

This adjustment must follow the Black Level Adjustment.

1. Supply a Grayscale signal to the Video Input.

2. Enter the Service Mode, VCJ Function.

3. Select Item “1 SCT”, before going to Step 4.

4. Connect the DC milliammeter to the DT connector.

• Positive lead to pin 3

• Negative lead to pin 1

5. Adjust Item “1 SCT” to set the total CRT current value to 860 ±15ua.

6. Disconnect the meter.

7. Save data and exit the Service Mode.

[PIP Circuit]

12. Color and Tint

(PIP Insert Picture)

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

Activate …….. MENU-0-1-5-7

Function …...………..AUDIO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Save Data …. ………ENTER

Exit …………..MENU (twice)

-----

-----

------

-----

Color Bars

Video or RF Input

SERVICE MODE

Purpose:

Symptom:

To match the main and sub pictures color.

Different color between the main and sub pictures.

1. Supply a Color Bar signal to the Video or RF Input.

2. Select the Color Bars as the source for the main picture (Input button).

3. Activate the single insert PIP mode .

4. Select the Color Bars as the PIP source.

5. Exit the PIP mode (PIP button)

6. Enter the Service Mode, PIP Function.

7. Select Item “3 SCL1” (the single insert is displayed)

8. Use Items “2 CSAT” and “1 HUE” to match the color of the sub picture to that

of the main picture.

9. Save data and exit the Service Mode.

Page 33

Page 34

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

[Cb, Cr Circuit]

13. Cb, Cr Offset

Purpose:

Symptom:

To match the match grays between color and monochrome

pictures.

Grays have a color tint.

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

-----

-----

------

-----

White Raster @ 25%

NTSC Input

SERVICE MODE

Activate …….. MENU-0-1-5-7

Function …...………..AUDIO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Save Data …. ………ENTER

Exit …………..MENU (twice)

1. Supply an NTSC White Raster with 25% luminance.

2. Activate the Service Mode, VCJ Function.

3. Set the data for item “30 COLH” to 63.

4. Adjust items “23 CBOF” and “24 CROF” for optimum gray.

5. Set the data for item “30 COLH” back to 31.

6. Save the data and exit the Service Mode.

[On Screen Display Circuit]

14. Character Position

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

SERVICE MODE

Activate …….. MENU-0-1-5-7

Function …...………..AUDIO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Save Data …. ………ENTER

Exit …………..MENU (twice)

-----

-----

------

-----

Monoscope

RF or Video

Purpose:

Symptom:

To position the on-screen display.

On-screen display is not positioned correctly.

1. Supply a Monoscope signal to the Video or RF Input.

2. Select the Monoscope as the source for the main picture (Input button).

3. Activate the Service Mode, HR Function.

4. Use the Adjust Right/Left buttons to center the display horizontally.

(A = B)

5. Save data and exit the Service Mode.

Page 34

Page 35

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

[Defl/Conv Circuits]

Purpose:

To preset data values controlling raster geometry.

15. Geometry Preset

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

CONVERGENCE MODE

Activate ……..MENU-0-1-5-9

Misc. ……………….……"6"

Coarse………………..…."5"

Fine ……………………..."4"

Color (R,G B or DF)...AUDIO

Item No………….…..VIDEO

Adjust/Move……….ADJUST

Cursor Toggle….…..ENTER

Save & Exit…..MENU (twice)

-----

-----

------

-----

NTSC RF or Video

Video or RF Input

Symptom:

Note:

This procedure us usually only necessary if:

Raster Distortion

• An E2PROM is replaced in the Control or Convergence circuits.

• E2RESET or Convergence Reset has been activated.

Deflection Circuit

1. Supply NTSC Video signal to the Video or RF Input.

2. Select the NTSC signal as the source (Input button).

3. Enter the Service Mode, VCJ Function.

4. Insure all data values correspond to those in the VCJ Table shown in

5. Save the data and exit the Service Mode.

SERVICE MODE

Activate …….. MENU-0-1-5-7

Function …...………..AUDIO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Save Data …. ………ENTER

Exit …………..MENU (twice)

Convergence Circuit

1. Enter the Convergence Coarse Mode.

2. Set the data in Red, Green and Blue Coarse Convergence Functions to the

data values given in

3. Exit the Convergence Mode.

Tables 2, 3 and 4.

Table 1.

VCJ Function CONV GREEN

Item Abbr. Data Item Abbr. Data

2 VHGT 31 1 HSTA* 0

3 SCOR 7 2 VSTA* 0

4 VLIN 7 3 SKEW 0

51 VPOS 31 4 TILT 0

55 HPOS 34 5 HWID 30

Table 1

6HLIN0

7 SPCC -125

8 HKEY 30

9 TBPC -230

10 VKEY -10

11 VWID 0

12 VLIN 0

* Data should not exceed ±100

Table 2

CONV RED CONV BLUE

Item Abbr. Data Item Abbr. Data

1 HSTA* 100 1 HSTA* -100

2 VSTA* 0 2 VSTA* 0

3 SKEW 0 3 SKEW 0

4TILT0 4TILT0

5 HLIN -270 5 HLIN 280

6HWID-60 6HWID-50

7 VKEY -170 7 VKEY 150

8VWID0 8VWID0

9VLIN0 9VLIN0

10 TPBC 0 10 TPBC 0

11 SDBW 80 11 SDBW -70

* Data should not exceed ±100 * Data should not exceed ±100

Table 3 Table 4

Page 35

Page 36

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

[Deflection Circuit]

16. Height and Vert. Linearity

Purpose:

Symptom:

To set the vertical height and linearity.

Incorrect height and/or vertical non-linearity.

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

-----

-----

------

-----

Monoscope

Video or RF Input

SERVICE MODE

Activate …….. MENU-0-1-5-7

Function …...………..AUDIO

Item No. ……….…….VIDEO

Adjust Data ….…….ADJUST

Save Data …. ………ENTER

Exit …………..MENU (twice)

1. Supply a Monoscope signal to the Video or RF Input.

2. Activate the Service Mode, VCJ Function.

3. Adjust Item “2 VHT” so the sum of the vertical markers is 4.

4. Adjust Item “4 VLR” so the large Monoscope circle is round.

5. Save the data and exit the Service Mode.

[Convergence Circuit]

17. Static Convergence

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

CONVERGENCE MODE

Activate ……..MENU-0-1-5-9

Misc. ……………….……"6"

Coarse………………..…."5"

Fine ……………………..."4"

Color (R,G B or DF)...AUDIO

Item No………….…..VIDEO

Adjust/Move……….ADJUST

Cursor Toggle….…..ENTER

Save & Exit…..MENU (twice)

-----

-----

------

-----

Monoscope/Crosshatch

Video or RF Input

Purpose:

Symptom:

Note:

If not correct, preset Vertical Linearity, Service Mode, VCJ Function, Item

Converge red, green and blue at the screen center.

Color edging over most of the picture.

“4 VLIN”.

Preliminary:

Degauss the shield cover and bracket unit of the CRT assembly and chassis sheet

metal. Do Not degauss the CPM Assemblies.

Centering and Static Convergence

1. Supply a Monoscope signal to the Video or RF Input.

2. Enter the Coarse Convergence Mode

3. Press “2” (green Monoscope is displayed)

3. Press “7” (removes HSTA and VSTA drive from the Convergence circuit).

4. Use the Green Centering Magnet to center the green monoscope on the screen.

6. Rotate the Green Yoke to correct any tilt.

7. Exit the Convergence Mode.

Note: If the green raster centering shifts when exiting the Convergence Mode,

use Coarse Green Items “1 HSTA” and “2 VSTA” to correct centering.

8. Supply an External Crosshatch Pattern

9. Use the Red Centering Magnet to

converge the red crosshatch on the

green at the center of the screen, and

remove any red tilt by rotating the Red

Yoke.

10. Repeat Step 9 for the blue crosshatch,

using the Blue Centering Magnet and

Blue Yoke.

Page 36

Page 37

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

[Convergence Circuit]

Purpose:

To set the Convergence circuit geometry adjustments.

18. Geometry Adjustment

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

CONVERGENCE MODE

Activate ……..MENU-0-1-5-9

Misc. ……………….……"6"

Coarse………………..…."5"

Fine ……………………..."4"

Color (R,G B or DF)...AUDIO

Item No………….…..VIDEO

Adjust/Move……….ADJUST

Cursor Toggle….…..ENTER

Save & Exit…..MENU (twice)

-----

-----

------

-----

Monoscope

RF or Video

Symptom:

Note:

Vertical Height and Vertical Linearity Adjustments must be performed before

Raster distortion at the top, bottom or sides of the picture.

this adjustment.

Coarse Adjustment

1. Supply a Monoscope signal to the RF or Video Input.

2. Select the Monoscope as the signal source (Input button).

3. Activate the Convergence Mode, Coarse Green Function

4. Adjust Item “5 HWID” so the sum of the horizontal markers is 7.6.

5. Set the data of the following items for straight crosshatch lines.

• “3 SKEW” ... Skew

• “4 TILT” ... Tilt

• “6 HLIN” ... Horizontal Linearity

• “7 SPCC” ... Side Pin Cushion Correction

• “8 HKEY” ... Horizontal Keystone

• “9 TBPC” ... Top/Bottom Pin Cushion

• “10 VKEY” ... Vertical Keystone

• “11 VWID” ... Height

• “12 VLIN” ... Vertical Linearity.

Note: If the raster centering changes during the adjustments, correct the

centering using Items “1 HSTA” and “2 VSTA”.

Fine Adjustment

6. Activate the Fine Green Convergence Mode. (Press 4)

7. Use the Cursor to adjust for straight crosshatch lines.

8. Exit the Convergence Mode.

Page 37

Page 38

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

[Convergence Circuit]

Purpose:

To Converge red and blue on green.

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

-----

-----

------

-----

None

Video Input

Symptom:

Color edging at the top, bottom and sides of the picture.19: Coarse Convergence

1. Select an External Input (no signal)

2. Enter the Convergence Mode.

3. Select the Coarse Red Function.

4. Set the Adjustments shown below to converge red on the green.

5. Select the Coarse Blue Function

6. Set the Adjustments shown below to converge blue on the green.

7. Exit the Convergence Mode

Note:

If Static Convergence shifts, use HSTA and VSTA to correct convergence at

the center of the screen. (HSTA and VSTA data values must not exceed 200)

CONVERGENCE MODE

Activate ……..MENU-0-1-5-9

Misc. ……………….……"6"

Coarse………………..…."5"

Fine ……………………..."4"

Color (R,G B or DF)...AUDIO

Item No………….…..VIDEO

Adjust/Move……….ADJUST

Cursor Toggle….…..ENTER

Save & Exit…..MENU (twice)

Page 38

Page 39

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

[Convergence Circuit]

Purpose:

To Converge red and blue on green.

20. Fine Convergence

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

CONVERGENCE MODE

Activate ……..MENU-0-1-5-9

Misc. ……………….……"6"

Coarse………………..…."5"

Fine ……………………..."4"

Color (R,G B or DF)...AUDIO

Item No………….…..VIDEO

Adjust/Move……….ADJUST

Cursor Toggle….…..ENTER

Save & Exit…..MENU (twice)

-----

-----

------

-----

None

Video Input

Symptom:

Color edging at the top, bottom and sides of the picture.

1. Select an External Input (no signal).

2. Enter the Fine Convergence Mode.

3. Select the Fine Red Function.

4. Use the Cursor to converge red on the green.

5. Select the Fine Blue Function.

6. Use the Cursor to converge blue on the green.

7. Exit the Convergence Mode.

Page 39

Page 40

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

CHIP PARTS REPLACEMENT

Some resistors, shorting jumpers (0 Ohm resistors),

ceramic capacitors, transistors and diodes are chip parts.

The following precautions should be taken when replacing

these parts.

Cautions:

1. Use a fine tipped, well insulated soldering iron

(approximately 30 watts), and tweezers.

2. Melt the solder and remove the chip parts

carefully so as not to tear the copper foil from

the printed circuit board.

3. Discard removed chips; do not reuse them.

4. Do not apply heat for more than 3 (three)

seconds to new chip parts.

5. Avoid using a rubbing stroke when soldering.

6. Take care not to scratch, or damage the chip

parts when soldering.

7. Supplementary cementing is not required.

Chip Parts Removal (Resistors, Capacitors, etc.)

1. Grasp the part with tweezers. Melt the solder

at both sides alternately, and remove one side

of the part with a twisting motion.

2. Melt the solder at the other side and remove

the part.

Chip Parts Removal (Transistors)

1. Melt the solder of one lead and lift the side of

that lead upward.

2. Simultaneously melt the solder of the other

two leads and lift the part from the PCB.

Replacement

1. Presolder the contact points on the circuit

pattern.

2. Press the part downward with tweezers and

apply the soldering iron as shown.

PAGE 40

Page 41

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

RELACEMENT PARTS

Parts Ordering

To expedite delivery of replacement parts orders, specify the following:

1. Model Number/Serial Number

2. Part Number and description

3. Quantity

Note: Unless complete information is supplied, delay in processing of orders will result.

Critical and Warranty Parts Designation

Critical Electrical Components are indicated by Bold Type in the Parts List, and in the schematic

diagrams by shading.

Warranty Return Parts are indicated in the Parts List with an (*).

Parts Tolerance Codes

Refer to the following chart for tolerance characteristics of electrical components.

MARK B C D F G J K

Tolerance % ± 0.1 ± 0.25 ± 0.5 ± 1 ± 2 ± 5 ± 10

MARK M N V X Z P Q

Tolerance %

MARK M N V X Z

Tolerance (pF) ± 0.1 ± 0.25 ± 0.5 ± 1 ± 2

Model Abbreviations

45609 VS-45609

50609 VS-50609

55609 VS-55609

60609 VS-60609

60719 VS-60719

70709 VS-70709

± 20 ± 30 ± 10 + 40 + 80 + 100 + 30

-20 -20 - 0 -10

PAGE 41

Page 42

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

QUICK REFERENCE FOR COMMON REPLACEMENT PARTS

CRT ASSEMBLIES

MODEL ASSY-CRT-RED ASSY-CRT-GREEN ASSY-CRT-BLUE

VS-45609 251C210010 251C210020 251C210030

VS-50609 251C210040 251C210050 251C210060

VS-55609 251C210070 251C210080 251C210090

VS-60609 251C211010 251C211020 251C211030

VS-60719 251C211040 251C211050 251C211060

VS-70709 251C211070 251C211080 251C211090

REMOTE CONTROL

290P103030 REMOTE CONTROL 45609 / 50609 / 55609 / 60609

290P103040 REMOTE CONTROL 60719 / 70709

HIGH VOLTAGE / DEFLECTION COMPONENTS

Q5A02 261P120010 HV-OUT TRANSISTOR 2SC5689

T551 334P278030 TRANS-FLYBACK

920P016010 HV-BLOCK

129P059050 VR-FOCUS

330P284010 DEFL-YOKE

453B035010 CAP-ANODE (Red)

453B035020 CAP-ANODE (Green & Blue)

MISCELLANEOUS

MODEL MIRROR

VS-45609

VS-50609

VS-55609

VS-60609

VS-60719

VS-70709

767D055010 491P075010 491P076010

767D055020 491P099010 491P100010

767D055030 491P101010 491P102010

767D048050 491P109010 491P110010

767D048050 491P109010 491P110010

767D048080 491P107020 491P108020

LENTICULAR

SCREEN

FRESNEL LENS

PAGE 42

Page 43

MODELS: VS-45609 / VS-50609 / VS-55609 / VS-60609 / VS-60719 / VS-70709

[#] Model Legend: (1) VS-45609, (2) VS-50609, (3) VS-55609, (4) VS-60609, (5) VS-60719. (6) VS-70709

Ref # Part # Part Name & Description [#]

Ref # Part # Part Name & Description [#]

TUBES

* 251C210010 ASSY-CRT-RED 1

* 251C210020 ASSY-CRT-GREEN 1

* 251C210030 ASSY-CRT-BLUE 1

* 251C210040 ASSY-CRT-RED 2

* 251C210050 ASSY-CRT-GREEN 2

* 251C210060 ASSY-CRT-BLUE 2

* 251C210070 ASSY-CRT-RED 3

* 251C210080 ASSY-CRT-GREEN 3

* 251C210090 ASSY-CRT-BLUE 3

* 251C211010 ASSY-CRT-RED 4

* 251C211020 ASSY-CRT-GREEN 4

* 251C211030 ASSY-CRT-BLUE 4

* 251C211040 ASSY-CRT-RED 5

* 251C211050 ASSY-CRT-GREEN 5

* 251C211060 ASSY-CRT-BLUE 5

* 251C211070 ASSY-CRT-RED 6

* 251C211080 ASSY-CRT-GREEN 6

* 251C211090 ASSY-CRT-BLUE 6

INTEGRATED CIRCUITS

IC2C01 275P496010 IC-C-MOS - UPD64082GF-3BA

IC2C02 275P531010 IC-C-MOS - MSM54V16258B-45TS-K

IC2E00 272P951010 IC - BA7046F

IC2K01 270P623010 IC - CXA2069Q

IC2P20 267P131010 HIC - SI-3033C

IC2P30 270P210010 IC - NJM7809FA/AN7809F

IC2V00 270P851010 IC - CXA2142BS

IC2V40 274P378010 IC-C-MOS - TC74HC4053AF

IC2Y00 270P852010 IC - TDA9178TD

IC2Y70 272P773010 IC - SN74LS221NS

IC301 270P750010 IC - LA4663

IC3A01 270P467010 IC - TDA9855

IC451 270P064030 IC - LA7845N

IC501 272P237010 IC - LA6324N

IC502 266P154010 IC - UPC393C

IC503 270P704010 IC - LM4040BIZ-10.0

IC6P00 275P593010 IC-C-MOS - SDA9589X

IC6Y50 272P302010 IC - PA0030

IC6Y51 270P650010 IC - MM1031XM

IC700 275P363040 IC-C-MOS - M306V0EEFP

IC701 275P222020 IC-C-MOS - M24C32MN6T

IC702 266P130060 IC - PST993E

IC703 274P378010 IC-C-MOS - TC74HC4053AF

IC704 275P656010 IC-C-MOS - TC7W02FU

IC7K21 270P831010 IC-C-MOS - OPA2350PA 5&6

IC800 275P595010 IC-C-MOS - CM0022AF

IC801 275P222020 IC-C-MOS - M24C32MN6T

IC802 270P751010 IC - TL084CD

IC803 270P751010 IC - TL084CD

IC804 270P751010 IC - TL084CD

IC805 270P817010 IC - L4931CDT33-TR

IC8C00 267P155010 HIC - STK393-110

IC8E01 263P408020 IC-C-MOS - UPD6376GS

IC8E02 263P408020 IC-C-MOS - UPD6376GS

IC8E03 263P408020 IC-C-MOS - UPD6376GS

IC935 270P472060 IC - NJM7805FA

IC936 270P210010 IC - NJM7809FA/AN7809F

IC951 267P140020 HIC - STR-F6628

IC952 267P126010 HIC - SE130N

IC9A01 270P472060 IC - NJM7805FA

TRANSISTORS

TR-CHIP Type (Listed by Generic Number)

Type Part No. Description

TR-CHIP 260P807030 DTC124EKAT146

TR-CHIP 260P817030 2SA1037K-S

TR-CHIP 260P818030 2SC2412K-S

TR-CHIP 261P810010 2SK664

Conventional Transistors (By Ref#)

Ref# Part No. Description [#]

Q401 260P559030 TR - 2SC1740S-S

Q501 260P420010 TR - 2SC2073-B,C

Q502 260P559030 TR - 2SC1740S-S

Q521 260P559030 TR - 2SC1740S-S

Q522 260P559030 TR - 2SC1740S-S

Q523 260P560040 TR - 2SA933S-S

Q524 260P559030 TR - 2SC1740S-S

Q530 260P560040 TR - 2SA933S-S

Q531 260P422010 TR - 2SC2482

Q532 260P422010 TR - 2SC2482

Q533 260P559030 TR - 2SC1740S-S

Q5A00 261P120010 TR - 2SC5689

Q5A02 261P120010 TR - 2SC5689

Q5K00 260P664030 TR - 2SC4636

Q5K02 260P559050 TR - 2SC1740S-E

Q5K03 260P560040 TR - 2SA933S-S

Q600 260P560040 TR - 2SA933S-S

Q6B00 260P385020 TR - 2SC2229-Y

Q6B01 261P004010 TR - 2SC3271F-N,P

Q6B02 260P469030 TR - 2SA1321

Q6B03 260P307020 TR - 2SC3334

Q6G00 260P385020 TR - 2SC2229-Y

Q6G01 261P004010 TR - 2SC3271F-N,P

Q6G02 260P469030 TR - 2SA1321

Q6G03 260P307020 TR - 2SC3334

Q6R00 260P385020 TR - 2SC2229-Y

Q6R01 261P004010 TR - 2SC3271F-N,P

Q6R02 260P469030 TR - 2SA1321

Q6R03 260P307020 TR - 2SC3334

Q7A91 261P114010 TR - 2SA1585STPR 5&6

Q7K21 260P559030 TR - 2SC1740S-S 5&6

Q971 260P559030 TR - 2SC1740S-S

Q972 260C676040 TR - 2SC3311A-R,S

Q973 260P559030 TR - 2SC1740S-S

Q975 260P560040 TR - 2SA933S-S

Q979 260P416030 TR - 2SC2274-F,K-F

Q980 260P559030 TR - 2SC1740S-S

DIODES

D2J11 264P485060 DIODE - RD7.5FB2

D2J12 264P485060 DIODE - RD7.5FB2

D2J21 264P485060 DIODE - RD7.5FB2

D2J22 264P485060 DIODE - RD7.5FB2

D2K19 264P485060 DIODE - RD7.5FB2

D2K21 264P485060 DIODE - RD7.5FB2

D2K23 264P485060 DIODE - RD7.5FB2