Page 1

DLPTM Display Wall Cube /

LCD Display Wall

Seventy Series

Set-up Manual

REV. 1.3

January 29, 2010

Page 2

Table of Contents

1 OVERVIEW............................................................................................................................................................. 4

1.1 Product lineup................................................................................................................................................................................ 4

1.1.1 Main Products ............................................................................................................................................................................. 4

1.1.2 Optional products...................................................................................................................................................................... 5

1.2 Flowchart.......................................................................................................................................................................................... 6

1.3 Basic operation............................................................................................................................................................................... 8

1.3.1 Remote control unit................................................................................................................................................................... 8

1.3.2 Operation mode ......................................................................................................................................................................... 9

1.3.3 Menus.......................................................................................................................................................................................... 10

1.4 Control panel.................................................................................................................................................................................12

2 CUBE INSTALLATION (CUBE ).............................................................................................................................13

2.1 Safety precaution.........................................................................................................................................................................13

2.2 Preparation ....................................................................................................................................................................................14

2.2.1 Accessories.................................................................................................................................................................................14

2.2.2 Input boards installation........................................................................................................................................................ 14

2.2.3 Front attachment in 80” cabinet..........................................................................................................................................15

2.3 Engine embedding .....................................................................................................................................................................16

2.3.1 Rear ............................................................................................................................................................................................ 16

2.3.2 Front .......................................................................................................................................................................................... 17

2.4 Cube stacking ...............................................................................................................................................................................18

2.4.1 Screen demounting .................................................................................................................................................................18

2.4.2 Base stands and cubes assembling .....................................................................................................................................19

2.4.3 Screen mounting and open/close (Front ) ........................................................................................................................ 20

2.4.4 Screen gaps adjustment.........................................................................................................................................................21

2.4.5 Fixing to the wall and floor....................................................................................................................................................22

3 LCD PANEL INSTALLATION (LCD ).....................................................................................................................23

3.1 Safety precaution.........................................................................................................................................................................23

3.2 Preparation ....................................................................................................................................................................................24

3.2.1 Accessories.................................................................................................................................................................................24

3.2.2 Input boards installation........................................................................................................................................................ 24

3.3 Mounting........................................................................................................................................................................................24

3.3.1 For using commercial wall mount brackets ......................................................................................................................24

3.3.2 For using optional wall mount frame (BR-XM70KK)........................................................................................................ 26

3.3.3 Arrangement.............................................................................................................................................................................27

3.3.4 Wall mount frame attaching.................................................................................................................................................28

3.3.5 Preliminary internal cabling.................................................................................................................................................. 28

3.3.6 LCD panel mounting ...............................................................................................................................................................29

3.3.7 Panel open / close.....................................................................................................................................................................29

3.3.8 Panel gap adjustment............................................................................................................................................................. 30

3.3.9 IR receiver (R-XM70IR) attaching..........................................................................................................................................31

4 ADJUSTMENT......................................................................................................................................................32

4.1 Initial setting..................................................................................................................................................................................32

4.1.1 Connecting................................................................................................................................................................................. 32

4.1.2 Dipswitch setting...................................................................................................................................................................... 33

4.1.3 Power-on ....................................................................................................................................................................................33

4.1.4 Focus adjustment (Cube)...................................................................................................................................................... 33

4.1.5 Wallaby.......................................................................................................................................................................................34

4.2 System memory setting (basic)...............................................................................................................................................36

4.2.1 Basic adjustment items........................................................................................................................................................... 36

4.2.2 System memory saving........................................................................................................................................................... 37

4.3 Geometry adjustment ( Cube ) ................................................................................................................................................38

4.3.1 6-axis adjustment .................................................................................................................................................................... 38

4.3.2 Mirror correction.......................................................................................................................................................................41

4.4 Color balance adjustment.........................................................................................................................................................43

4.4.1 Preparation................................................................................................................................................................................ 43

4.4.2 SENSOR GAIN adjustment (LCD ) .........................................................................................................................................43

4.4.3 BLACK LEVEL adjustment .......................................................................................................................................................44

2 Seventy Series Set-up Manual

Page 3

CSC adjustment ........................................................................................................................................................................44

4.4.4

4.4.5 Light source output adjustment (LED, LCD).................................................................................................................... 45

4.4.6 WHITE BALANCE adjustment ................................................................................................................................................ 46

4.4.7 GRADATION adjustment.........................................................................................................................................................46

4.4.8 TAR GET COLOR ( Lamp ).......................................................................................................................................................... 46

4.4.9 SENSOR .......................................................................................................................................................................................47

4.5 System memory setting (custom)..........................................................................................................................................48

4.6 Input memory setting ................................................................................................................................................................54

4.6.1 Basic setting............................................................................................................................................................................... 54

4.6.2 Custom setting..........................................................................................................................................................................56

4.6.3 Input memory saving ..............................................................................................................................................................58

4.6.4 Input memory calling / deleting...........................................................................................................................................58

4.7 Display memory setting ............................................................................................................................................................59

4.7.1 Available layouts......................................................................................................................................................................59

4.7.2 Layout patterns setting........................................................................................................................................................... 60

4.7.3 Display memory saving ..........................................................................................................................................................63

4.7.4 Display memory calling / deleting .......................................................................................................................................63

5 MAINTENANCE ...................................................................................................................................................64

5.1 Lamp replacement (Lamp)......................................................................................................................................................64

5.1.1 Safety precaution ..................................................................................................................................................................... 64

5.1.2 Procedure ...................................................................................................................................................................................65

5.1.3 Auto-lamp changing function (Changer)........................................................................................................................ 66

5.2 Error indication.............................................................................................................................................................................67

5.2.1 On-screen indicator (Cube) .................................................................................................................................................. 67

5.2.2 Status indicator (Cube)..........................................................................................................................................................67

5.2.3 Side indicator (LCD )................................................................................................................................................................68

5.2.4 Internal temperature warning (LED)..................................................................................................................................68

5.3 Cleaning.......................................................................................................................................................................................... 69

5.4 Securing for delivery ( Cube )...................................................................................................................................................69

5.5 Resetting.........................................................................................................................................................................................69

5.6 About LCD panels (LCD )...........................................................................................................................................................70

6 SPECIFICATIONS .................................................................................................................................................71

6.1 Available input signals ...............................................................................................................................................................71

6.2 Menu trees .....................................................................................................................................................................................72

6.2.1 On-screen menus ..................................................................................................................................................................... 72

6.2.2 Wallaby menu...........................................................................................................................................................................75

6.3 Connectors / switches spec......................................................................................................................................................81

7 REVISION HISTORY.............................................................................................................................................82

* The symbol Changer , Front, etc. refers to lamp changer, front access models etc.

REV 1.3 3

Page 4

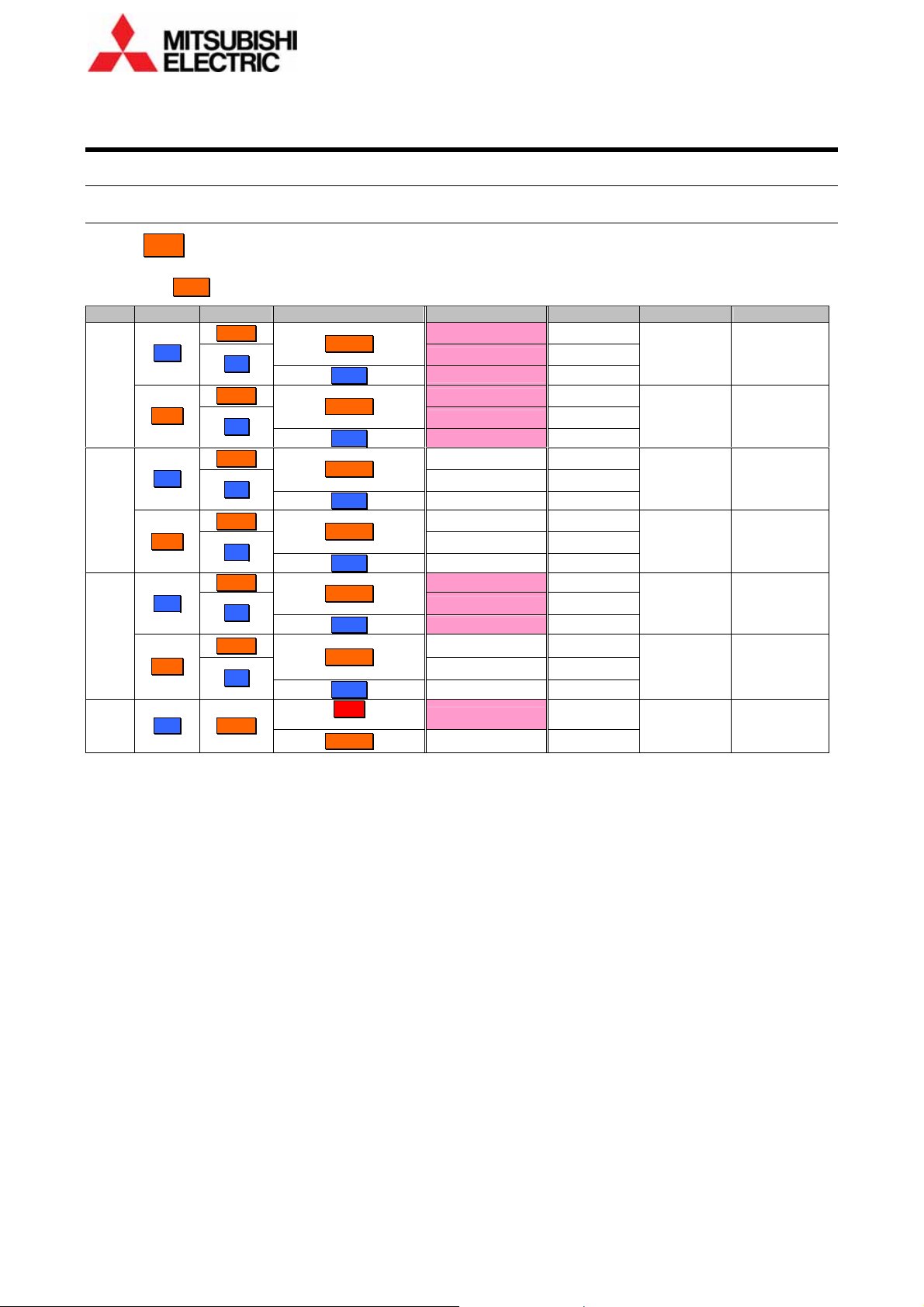

Product lineup

1

1

OOvveerrvviieeww

1

11..1

PPrroodduucctt lliinneeuupp

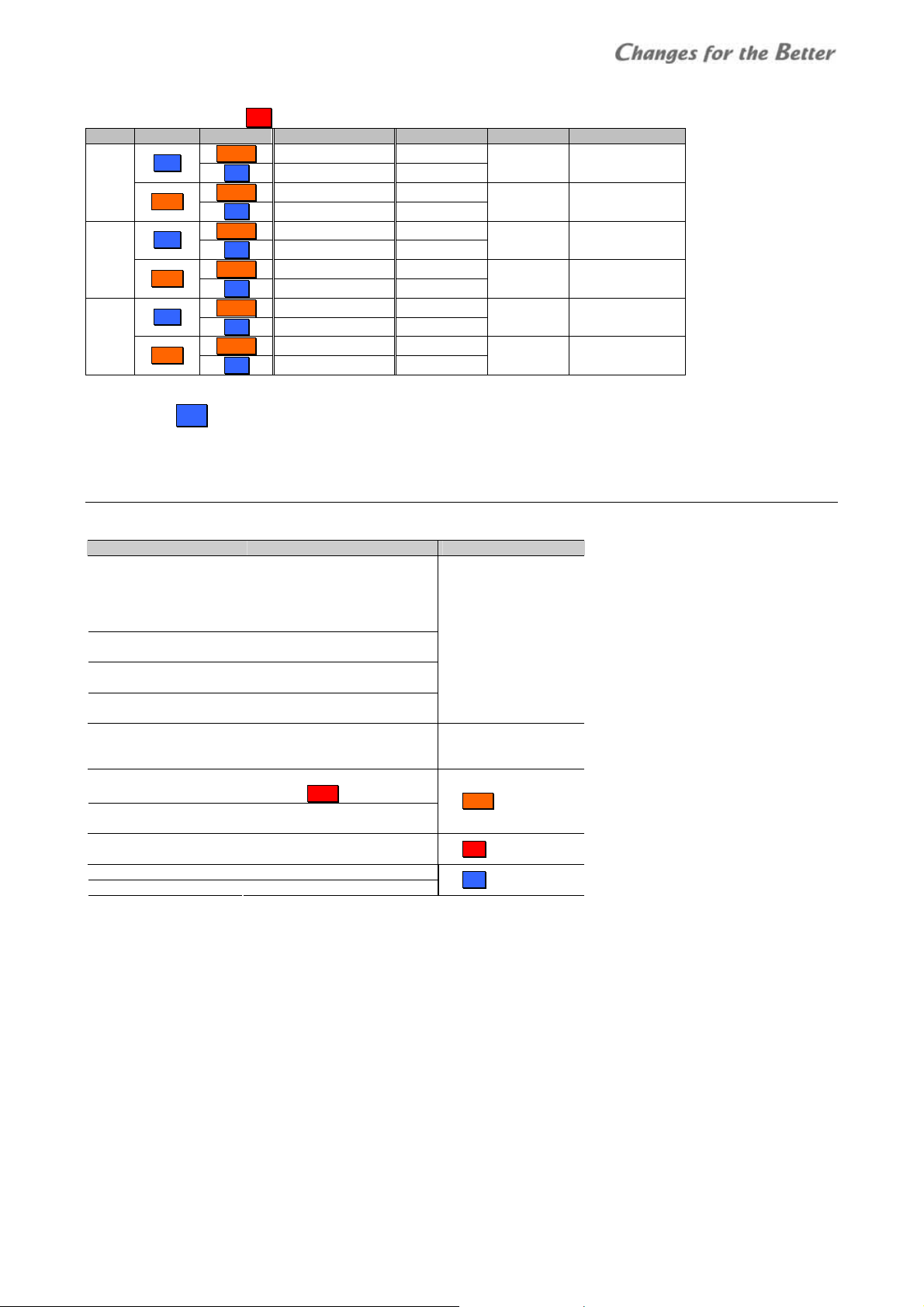

1.1.1 Main Products

Cubes Cube

A variety of cubes can be configured by combining engine units, cabinets, screen units and optional products.

With lamps Lamp

Size Access Resolution Lamp Combined name Engine unit Cabinet Screen unit

VS-50PH70U VS-PH70U

VS-50XH70U VS-XH70U

VS-50XL70U VS-XL70U

VS-50PHF70U VS-PH70U

VS-50XHF70U VS-XH70U

VS-50XLF70U VS-XL70U

VS-60PH70U VS-PH70U

VS-60XH70U VS-XH70U

VS-60XL70U VS-XL70U

VS-60PHF70U VS-PH70U

VS-60XHF70U VS-XH70U

VS-60XLF70U VS-XL70U

VS-67PH70U VS-PH70U

VS-67XH70U VS-XH70U

VS-67XL70U VS-XL70U

VS-67PHF70U VS-PH70U

VS-67XHF70U VS-XH70U

VS-67XLF70U VS-XL70U

VS-80PH75U VS-PH75U

VS-80PH70U VS-PH70U

S-5070CA SC-5070U

S-5070CAF SC-5070UF

S-6070CA SC-6070U

S-6070CAF SC-6070UF

S-6770CA SC-6770U

S-6770CAF SC-6770UF

S-8070CA SC-8070B

50”

60”

67”

80”

SXGA+

Rear

Front

Rear

Front

Rear

Front

Rear SXGA+

XGA

SXGA+

XGA

SXGA+

XGA

SXGA+

XGA

SXGA+

XGA

SXGA+

XGA

Changer

Single

Changer

Single

Changer

Single

Changer

Single

Changer

Single

Changer

Single

PH75

high brightness changer

Changer

• The product names marked in red may be delivered with the projection engine and for 50” also the screen,

already installed. 67” and 80” models always have the screen shipped separately.

4 Seventy Series Set-up Manual

Page 5

With LED light source LED

Size Access Resolution Combined name Engine unit Cabinet Screen unit

VS-50PE70U VS-PE70U

VS-50XE70U VS-XE70U

VS-50PEF70U VS-PE70U

VS-50XEF70U VS-XE70U

VS-60PE70U VS-PE70U

VS-60XE70U VS-XE70U

VS-60PEF70U VS-PE70U

VS-60XEF70U VS-XE70U

VS-67PE70U VS-PE70U

VS-67XE70U VS-XE70U

VS-67PEF70U VS-PE70U

VS-67XEF70U VS-XE70U

S-5070CAF SC-5070UF

S-6070CAF SC-6070UF

S-6770CAF SC-6770UF

S-5070CA SC-5070U

S-6070CA SC-6070U

S-6770CA SC-6770U

50”

60”

67”

Rear

Front

Rear

Front

Rear

Front

SXGA+

XGA

SXGA+

XGA

SXGA+

XGA

SXGA+

XGA

SXGA+

XGA

SXGA+

XGA

LCD panel LCD

VS-L46XM70U

1.1.2 Optional products

The main products are not equipped with any input ports. Arrange optional input boards according to input signals

to be displayed.

Optional products Product names Applicable main products

Input boards VC-B70D2 (for digital inputs)

Wireless / wired

remote control unit

Motorized adjustment tool

*

Motor units

for screen / mirror *

Power cord (3m) JC-PC3MA (for North America)

Spare lamps S-70LA (standard)

Spare color wheels S-703CW (3 segments)

Spare LED light source

module

Wall mount frame BR-XM70KK

IR receiver R-XM70IR

The combination of S-A70E and S-MA70E can be applied to the wall mount frame, which can adjust the gaps

between panels electrically.

VC-B70V2 (for video inputs)

VC-B70G2 (for analog inputs)

VC-B70DC (for daisy chain)

VC-B70SD1 (for SDI/HD-SDI input)

R-XL50TX

S-A70E

S-MA70E

JC-PC3ME (for Europe)

JC-PC3MC (for China)

S-75LA (for PH75)

S-704CW (4 segments)

S-70LE

Common

Common

For Lamp

For LED

For LCD

Product lineup

REV 1.3

5

Page 6

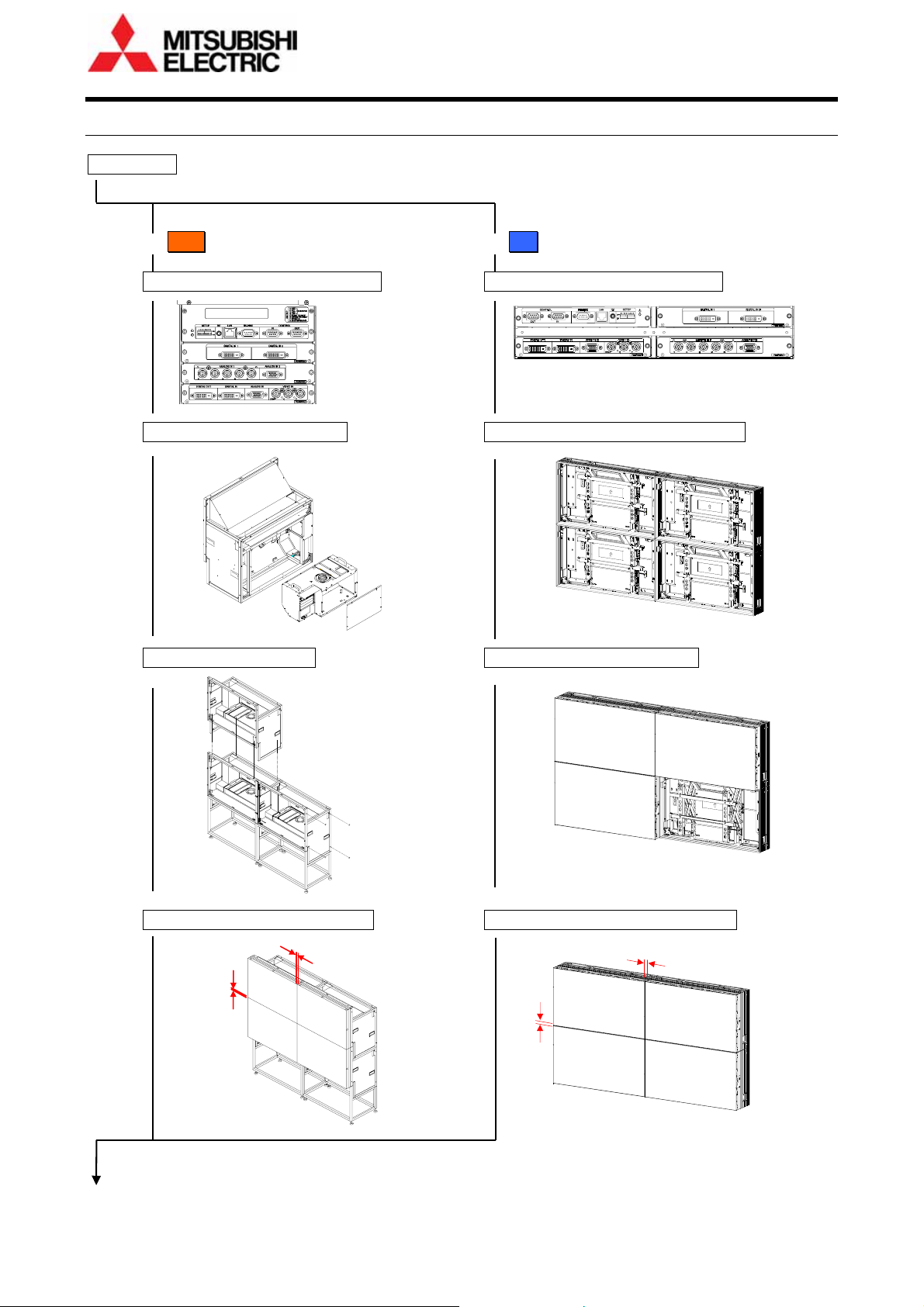

Flowchart

2

11..2

FFlloowwcchhaarrtt

Installation

For Cube (page 13) For LCD (page 23)

Input boards installation (page

Engine embedding (page

Cube stacking (page

( Go to next page)

Screen gap adjustment (page

14) Input boards installation (page 24)

16) Wall mount frame attaching (page 26)

18) LCD panel mounting (page 29)

21) LCD panel gap adjustment (page 30)

6 Seventy Series Set-up Manual

Page 7

Adjustment (page

32)

Initial setting (page

Connecting

Dipswitch setting

Power-on

Focus adjustment Cube

32) Basic system memory setting (page 36)

A1

Unit ID assignment

IP address assignment

H. / V. LOCATION

(IMAGE FLIP)

(SYSTEM SYNC)

Geometory adjustment (page 38) (Cube) Color balance adjustment (page 43)

6-axis adjustment

Mirror correction

Sensor gain adjustment LC D

(BLACK LEVEL)

CSC

LED POWER gain LED

BACKLIGHT DIMMER gain LCD

(WHITE BALANCE)

GRADATION

TAR GET COLO R Lamp

SENSOR

Custom system memory setting (page

LAMP POWER / FRAME LOCK / REDUNDANCY / AMP. GAIN etc.

48)

Input signal adjustment (page

Input port selection

MEMORY SCAN

H. / V. POSITION

CLOCK PHASE

AMP. GAIN

etc.

54) layout pattern adjustment (page 59)

H=1, V=1

H=1, V=2

H=2, V=1

H=2, V=2

Input signal allocation

Position / size setting

Crop / zoom setting

Priority order setting

etc.

Finish

Flowchart

ID 1

MASTER

H=1, V=1

ID 3

SLAVE

H=1, V=2

ID 1

ID 3

ID 2

SLAVE

H=2, V=1

ID 4

SLAVE

H=2, V=2

ID 2

ID 4

REV 1.3 7

Page 8

Basic operation

3

11..3

BBaassiicc ooppeerraattiioonn

The cubes can be operated with the remote control unit or control software, “Wallaby” (page 34).

1.3.1 Remote control unit

In Cube , face the remote control toward the screen on each cube to control. Or facing to the MASTER cube (page

33) directs other cubes. In LCD , face to the IR receptor on the left side of the panel or to the optional IR receiver

(page 31).

It can control the imaging monitors (cubes or LCD panels) also through the cable supplied with the remote control.

Buttons

POWER Switch between power-on and standby state

DISPLAY *1

MUTE *1 -

INPUT A -

INPUT B

VIDEO -

MEM LIST - MEMORY CALL menu -

TEST - Internal test patterns *4

MENU1 - TOP menu Simple menu display

MENU2 -

ESC

ENTER - Enter

Up/down

arrows

Left/right

arrows

R, G, B - Primary color mute/display *5

numbers

NORMAL Switch between normal and advanced mode Value reset

FUNC - Remote ID switch *6

Slide switch - Switch the function between [DISPLAY] and [MUTE]

In normal

mode

Status

information

Switch the contents on the status indicator

Status

information

off

On-screen indicator off (available in light source off) Cube

Recall display memory by number

Status information (press-and-hold for advanced information)

Screen mute

Status bar off (on test patterns)

INPUT SELECT menu WINDOW PRIORITY menu (press-and-hold)

Light path calibration with [INPUT A] + [ESC] +[2-digit unit ID] Lamp

- INPUT MEMORY menu Manual lamp change with [INPUT B] + [ESC] +[2-digit unit ID] (Changer ) *2

SENSOR DATA window with [VIDEO] + [DISPLAY] LCD

SENSOR GAIN: AUTO ADJ. window with [VIDEO] + [ESC] LCD

DISPLAY MEMORY menu

SYSTEM MEMORY menu (press-and-hold)

Cancel, exit

- -

- -

- Remote ID input after [FUNC]

*1. The slide switch switches the function between [DISPLAY] and [MUTE].

*2. It is available even in standby state and blowout mode (page

*3. Specified window image will be muted off/on during DISPLAY > WINDOW 1 – 6 menu display.

*4. Every press of the button switches the test patterns to be displayed.

*5. Regardless of ID setting, the R / G / B button mutes (switches off) the red / green / blue color for the monitors.

When muted / un-muted monitors are mixed in a display wall, pressing R / G / B may just alternate the effect. To

un-mute all of the monitors, press and hold the R / G / B button.

*6. Number keys specify the ID number, or left/right buttons change the number by 1 and up/down buttons by 10.

In advanced mode

In menu off In menu on

*2

Cube

Screen mute

(Window mute)

-

Menu select,

cursor up/down

Option select,

value change

49).

*3

8 Seventy Series Set-up Manual

Page 9

1.3.2 Operation mode

For remote control, the monitors have 2 operation modes: “normal mode” and “advanced mode”. The normal mode is

for usual operation and advanced mode for set-up and adjustment. [NORMAL] button switches the modes when

there is no adjustment menu on screen. This status bar is shown on screen in the advanced mode.

Normal mode

Following operations are available in normal mode.

Button Func tion

[POWER] Switch between power-on and standby state

[DISPLAY] Status information, switch the contents on the status indicator

[ESC] Status information off

[NORMAL] Switch between normal and advanced mode

Numbers Recall a display memory (page 63) by 3-digit number. Press 001 for display memory 1.

Advanced mode

Monitor adjustments such as color balance and input signal adjustments should be done in advanced mode.

Status bar

No. Description No. Description

1 Selected display memory number (page 59)

Input memory number (page

2

foreground window

Foreground window number

3

4 Slot number and input port on foreground window 8

5

Remote ID

An individual monitor can be controlled remotely. Specify it with [FUNC] button followed by 2-digit unit ID number.

Specifying 00 means that all monitors will be controlled. To control only ID 1 monitor, press [FUNC] + [0] + [1].

• Arrow keys after [FUNC] can also specify the ID. Left/right buttons change the ID by 1 and up/down buttons by 10.

• Remote ID switch is available even when the menus are on displayed on the screen.

Test patterns

[TEST] button shows internal test patterns. Every press cycles through the patterns in the following order.

Full-bit white -> Crosshatch -> Adjustment white -> Gradation -> Color bar -> Test pattern off -> (Full-bit white)

icon is shown when the window is displayed in space

coordinates on another monitor.

Image status

• Test pattern name: in internal test pattern displaying

• SCREEN MUTE: in screen mute

• WINDOW MUTE: One of the windows is mute.

• NO SIGNAL: no signal on the foreground window

Press [ENTER] button to confirm.

1 2

3 4

5 6 7 8 9

54) and its comment on the

Redundancy (page

• : BOARD REDUNDANCY mode

• : PORT REDUNDANCY mode (The number shows the slot

6

7 Unit ID number

9

number)

• : COLOR-KEY mode

These indicators are shown when the function is set ON. The color of

indicator or changes to yellow when the signal is switched.

Remote ID indicator

* It is shown when remote controlling is available by remote ID setting.

Monitor status

: In waiting time for lamp calibration (page 52) or for initial sensor

•

data obtaining (page 47) ( Lamp).

The operation will be completed in 5 minutes and then the

indication will disappear.

• : The spare lamp status is not “NEW” (Changer).

• : Adjustment values have been changed.

* It appears when a value is changed automatically by internal

process as well as changed by remote control.

51) and color-key (page 50) setting, status

Basic operation

REV 1.3 9

Page 10

Basic operation

1.3.3 Menus

Basic menu operations

• The up/down arrow buttons on the remote control

move the yellow cursor to select menus.

• The left/right arrow buttons change the value in a

menu with left/right triangle marks.

• In a menu with “>” mark on the right, [ENTER] button

shows its lower layer menu. [ESC] button restores the

original upper menu.

• In a menu with an enter mark on the right, [ENTER]

button confirms or executes the menu.

• When values are changed in a menu,

appears. Save the change according to the necessity.

- In WINDOW PRIORITY menu, the mark appears

when an input memory in any of the windows is

changed.

- In INPUT MEMORY menu, the mark appears when

an input memory in the top window is changed.

• In the menu displaying, [MENU1] button changes the

menu GUI to the simple one. The image area behind

the menu can be observed widely. Re-pressing the

same button restores the original menu.

• Menus are not displayed when the monitors are

controlled by Wallaby.

mark

TOP menu

The TOP menu is displayed by [MENU1] button on the

remote control in the advanced mode. Starting from

the menu, which is the top of the menu tree, lower

menus can be choosen.

• Allocated short-cut buttons directly access each

menu not-through the TOP menu.

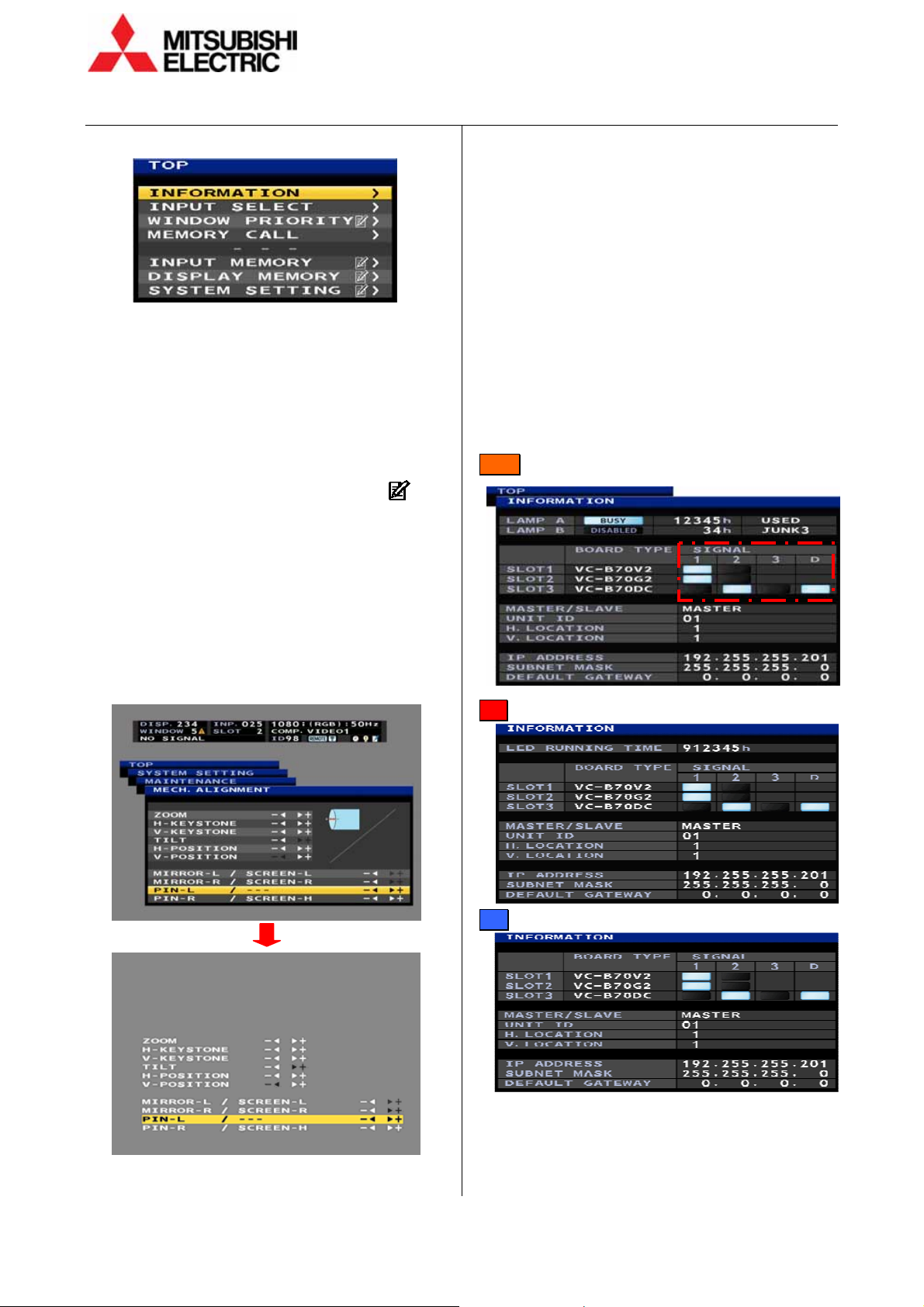

INFORMATION menu

It shows various status information on screen.

Short-cut: [DISPLAY] button

1 and 2 in SIGNAL column represent with or without

signals on each input port (The signal from the SDI

input board is shown only in 1). In the case of the daisy

chain board, it shows following signals.

1: digital in, 2: analog in, 3: video in, D: digital out

Lamp

LED

LCD

10 Seventy Series Set-up Manual

Page 11

T

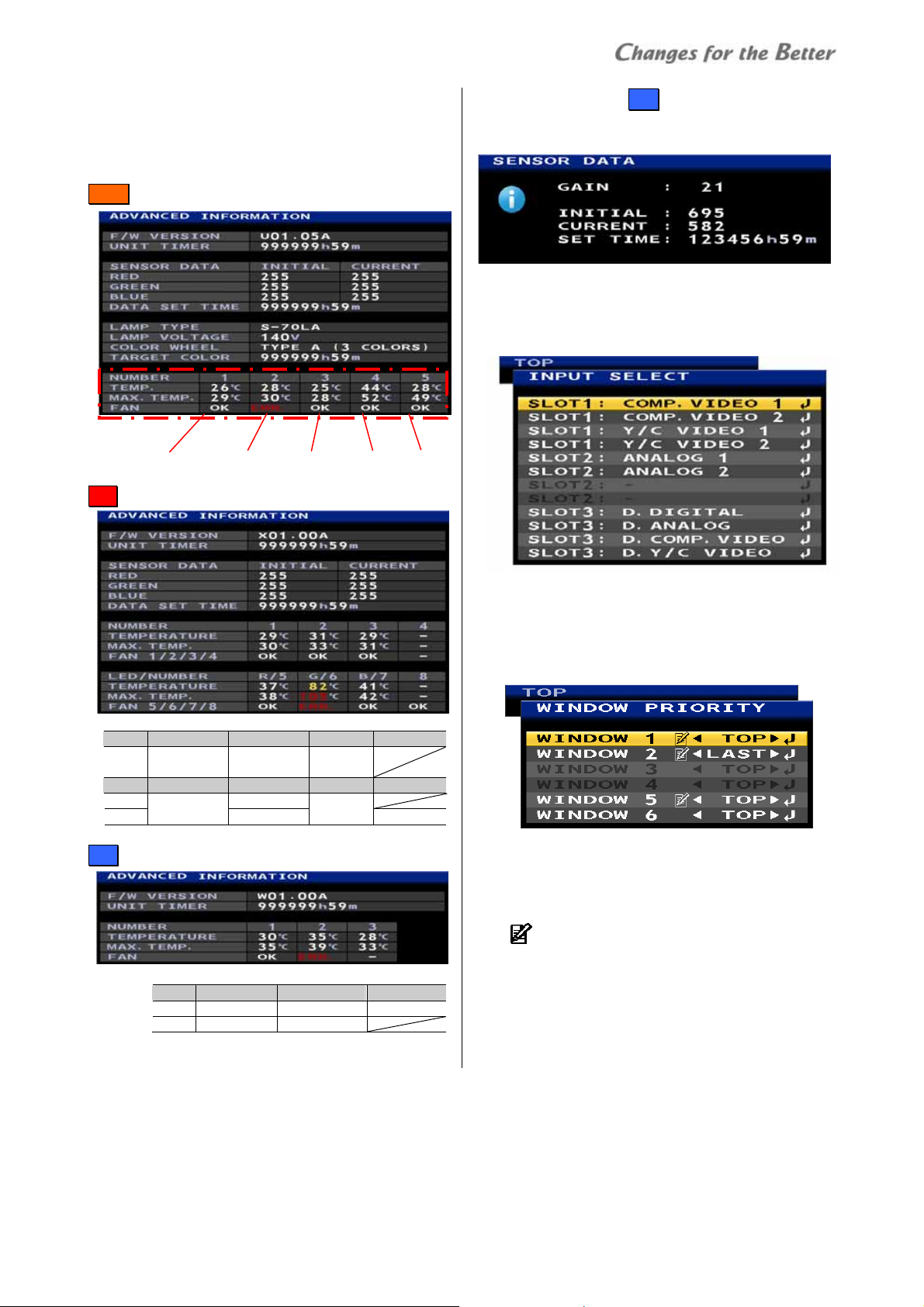

ADVANCED INFORMATION menu

Pressing-and-holding [DISPLAY] button on the status

information displays the advanced information. The

NUMBER section shows temperetures and fan status in

the following positions.

Lamp

Power PCB 1 Power PCB 2 DLP

M

chip Lamp A Lamp B

LED

No. 1 2 3 4

Tem p.

Power PCB 1 Power PCB 2

/ fan

No. 5 6 7 8

Temp. Green LED

Red LED

Fan

Green LED 1

DLPTM

chip

Blue LED

Green LED 2

LCD

No. 1 2 3

Temp. Power PCB 1 Power PCB 2 Sensor PCB

Fan Fan 2 (left) * Fan 2 (ri ght) *

* Seen from the panel front

SENSOR DATA menu LC D

Pressing [VIDEO] + [DISPLAY] button in the advanced

mode shows the light sensor data.

INPUT SELECT menu

It can select input ports to be adjusted (page 54).

Selected input signal will be displayed on top.

Short-cut: [INPUT A] button

WINDOW PRIORITY menu

It can set the window overlay priority order. The

designated window will be displayed on top or last

behind other windows.

Short-cut: Press-and-hold [INPUT A] button

It shows the priority order list and can set the order all

together, unlike PRIORITY menu (page

memory which should enter in each window menu to

set. To save the order, enter DISPLAY MEMORY menu

and save in a display memory (page

The

mark appears when an input memory in the

window is changed. To save the change, move the

window priority to the top and save the input memory.

62) in display

63).

Basic operation

REV 1.3 11

Page 12

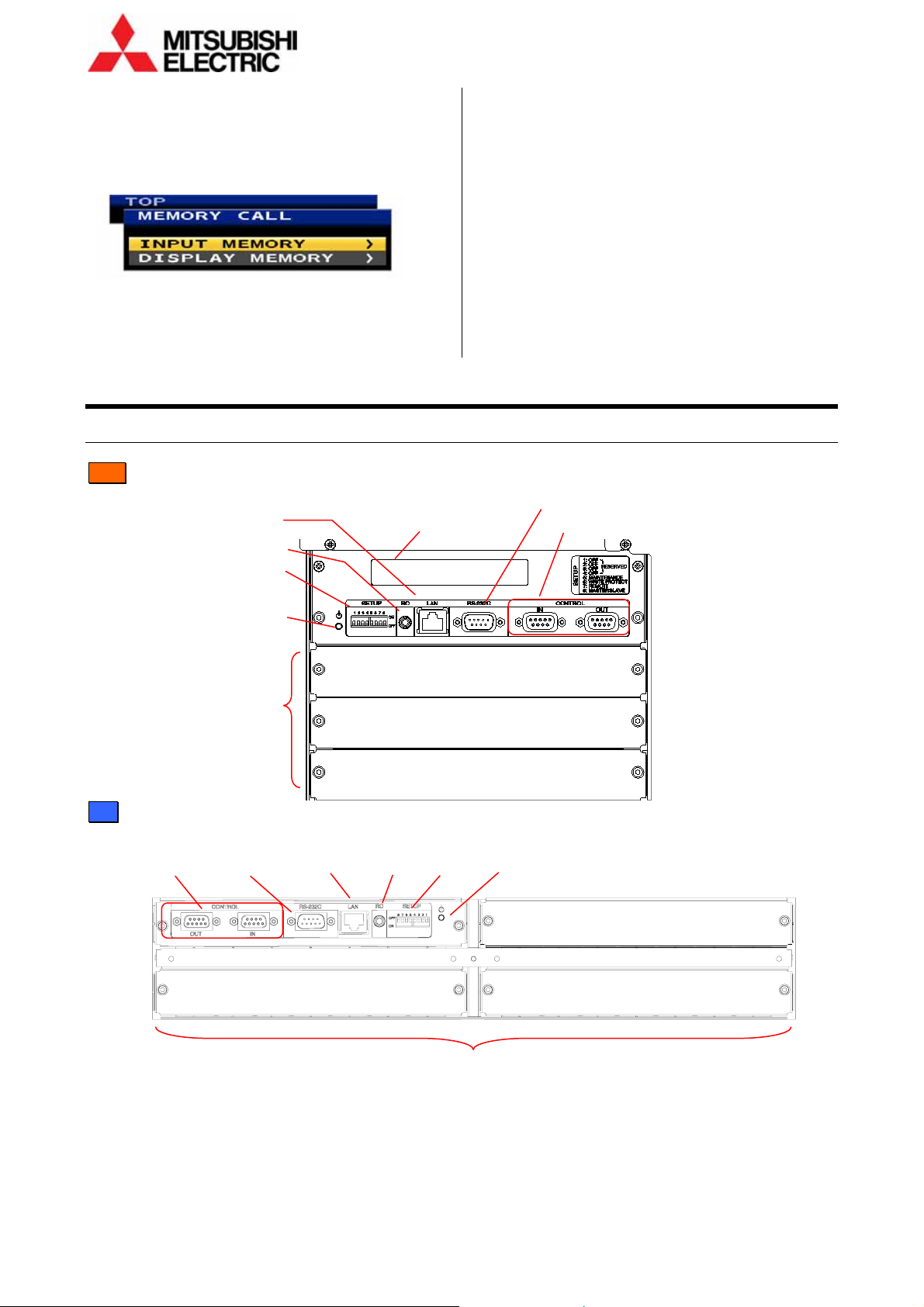

Control panel

MEMORY CALL menu

Registered input memories / display memories can be

called (page

58, 63).

Short-cut: [MEM LIST] button

INPUT MEMORY menu

It can set input signals. See on page 54 for detail. The

setting can be memorized in 128 input memories.

Short-cut: [INPUT B] button

DISPLAY MEMORY menu

It can set display layout patterns. See on page 59 for

detail. The setting can be memorized in 256 display

memories.

Short-cut: [MENU2] button

SYSTEM SETTING menu

It can set an entire monitor / screen condition. See on

36 and 48 for detail. One condition is memorized

page

in the monitor.

Short-cut: Press-and-hold [MENU2] button.

4

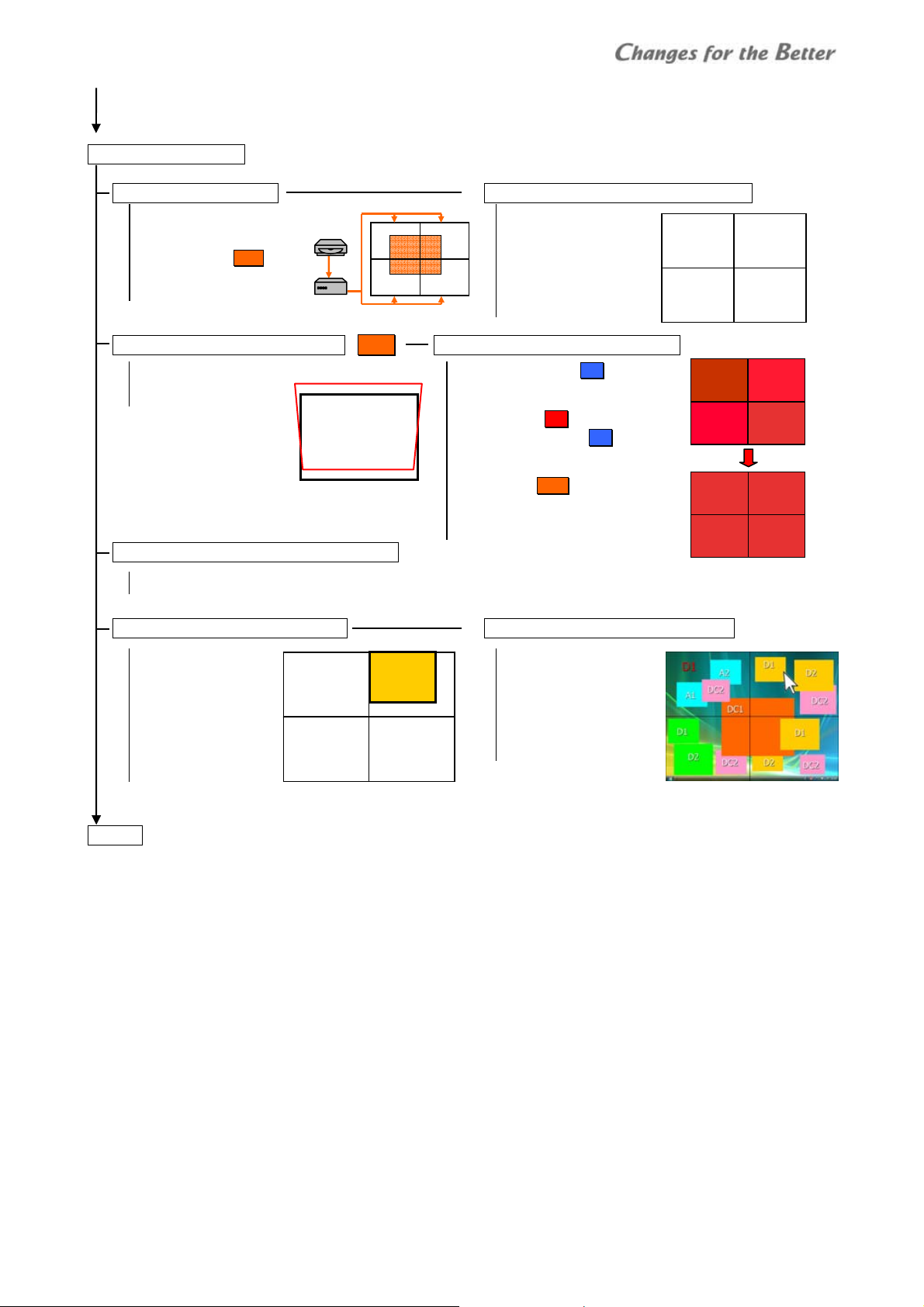

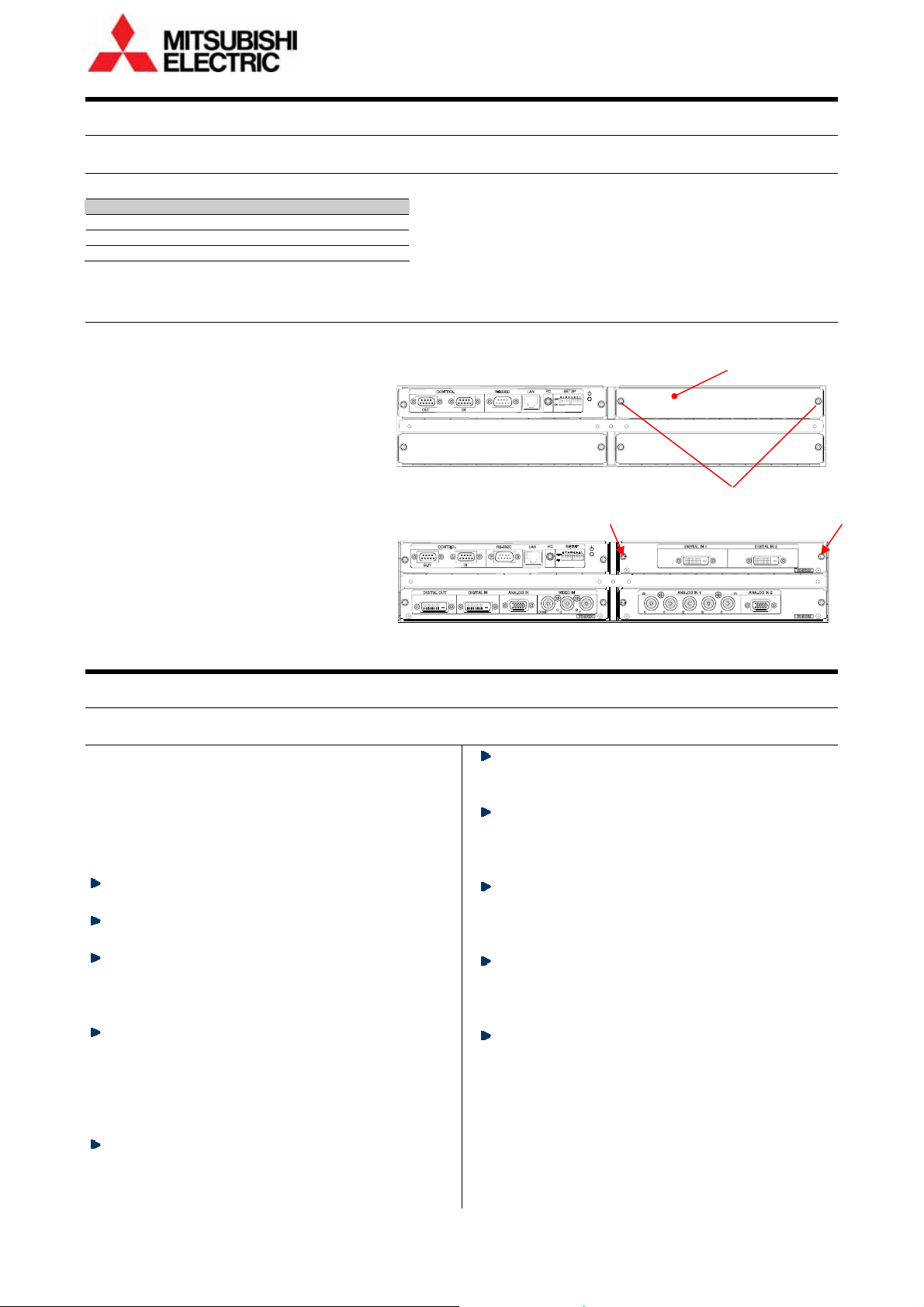

11..4

CCoonnttrrooll ppaanneell

The control panel has the following functions.

Cube

Wired remote port (page 8)

Network port

(page 32)

Dipswitches

(page 32)

Standby switch

(page 33)

Status indicator”

(page 66)

RS-232 port (page 32)

Control ports (page 32)

Slot 1

Input board slots

(page 15)

Slot 2

Slot 3

LCD

Control

ports

(page 32)

RS-232

port

(page 32)

Network

port

(page 32)

Wired remote

port

(page 8)

Dipswitches

(page 32)

Standby

switch

(page 33)

Slot 1

Slot 2Slot 3

12 Seventy Series Set-up Manual

Input board slots (page 24)

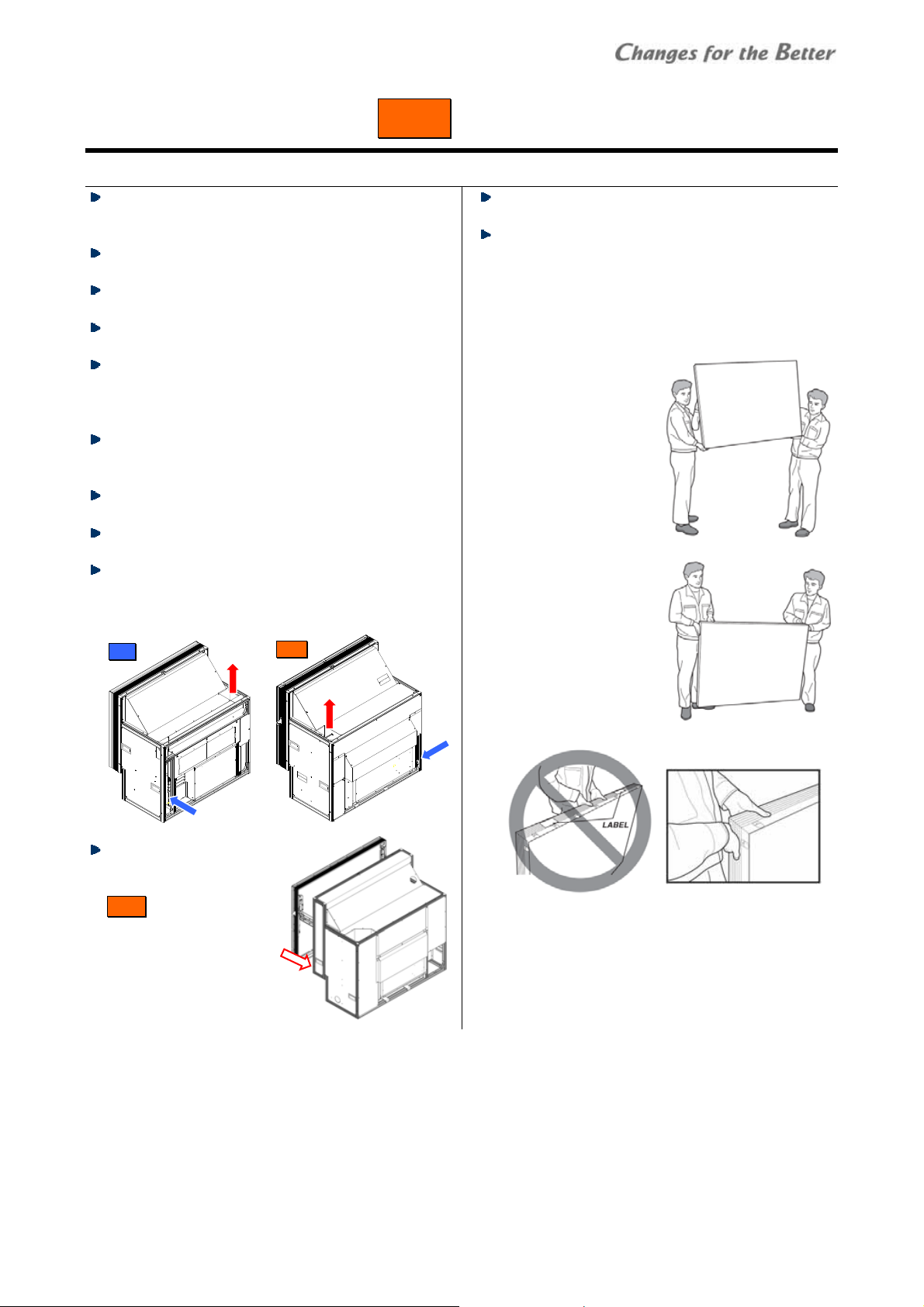

Page 13

2

2

CCuubbee iinnssttaallllaattiioonn (

1

22..1

SSaaffeettyy pprreeccaauuttiioon

This product requires special installation to prevent

falling or toppling. This should be done by

installation specialists.

Be sure to read this manual and the user’s manual for

your safety before starting assembly or installation.

Be sure to use supplied accessories for assembly or

installation.

Attach all the screws and fixtures specified in this

manual securely.

Reinforce the wall surface and floor so that it can

support the total weights of the products

permanently and resist earthquakes, possible

vibrations, and external forces.

Ensure that the safety factor is more than 10 (or

ensure that the total bolts can bear ten times the

weight of products and the brackets).

Inspect the mounting fixings more than once in a

year as needed.

Do not use the product near a heater or in a humid,

dusty or smoky location.

Do not install the product with its intakes, exhaust

slots and ventilation holes blocked. The unit may

overheat and cause a fire or breakdown.

Rear

Be careful not to pinch

your fingers while sliding

the screen holding arms

(Front ).

n

Front

(

CCuubbe

e

))

Be sure that a lighting or sunlight does not leak into

the screens.

Be sure to mount/demount the screen by 2 or more

people. These works may be perilous particularly on

a height or a narrow scaffold.

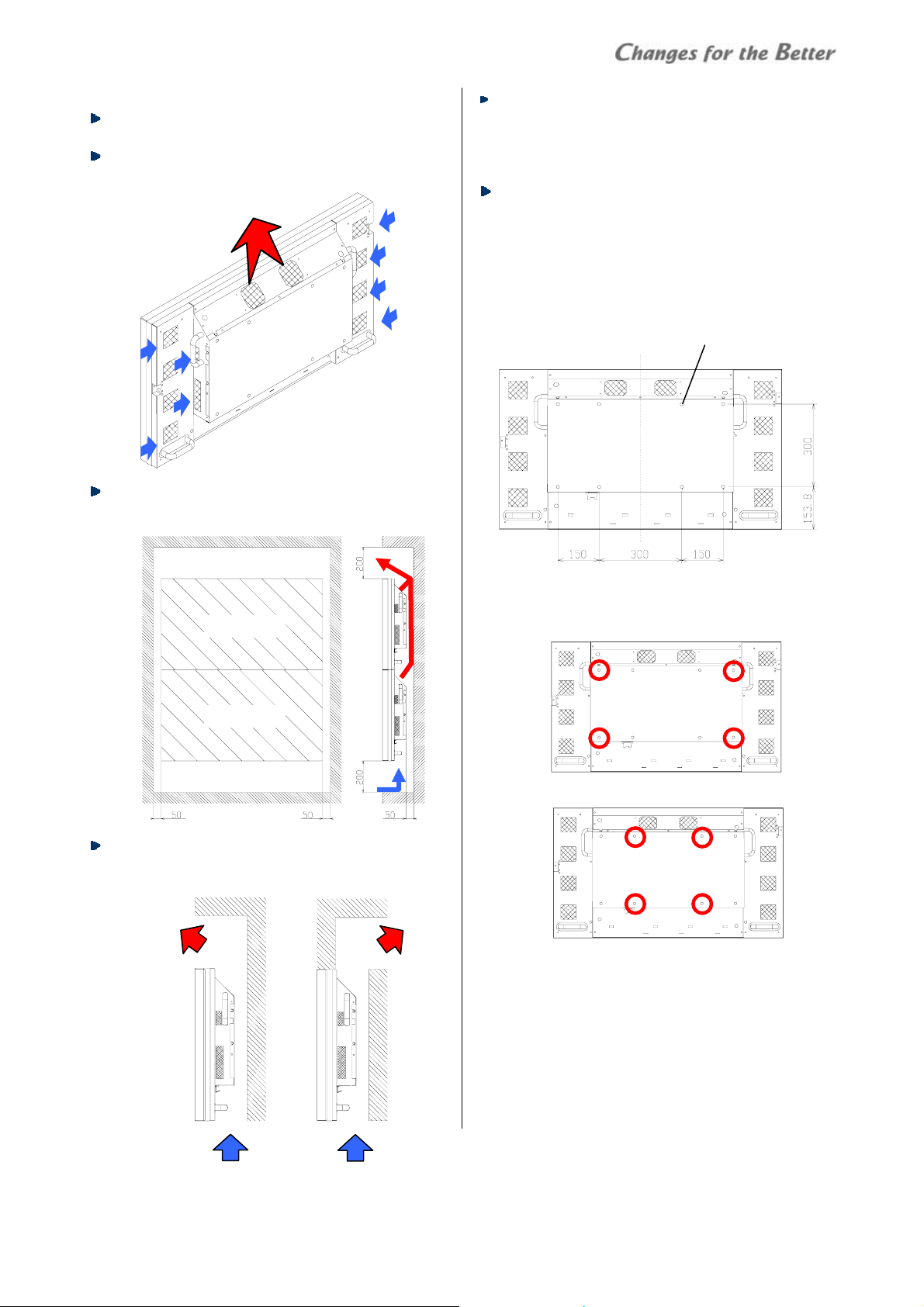

Handling instructions for 80” screen

Because 80” screens are large and heavy, the screens

should be held carefully.

• To prevent the screen

from damage or

breakage, carry the

screen by two or more

people.

• Hold the short sides of

the screen frame or the

corners when picking

up the screen. Holding

the center of the long

sides of the frame

(between labels) may

damage the screen

edge due to its heavy

weight.

• Do not lay the screen with face up on the floor or

table. The screen frames may not support the heavy

and large screen surface.

Safety precaution

REV 1.3 13

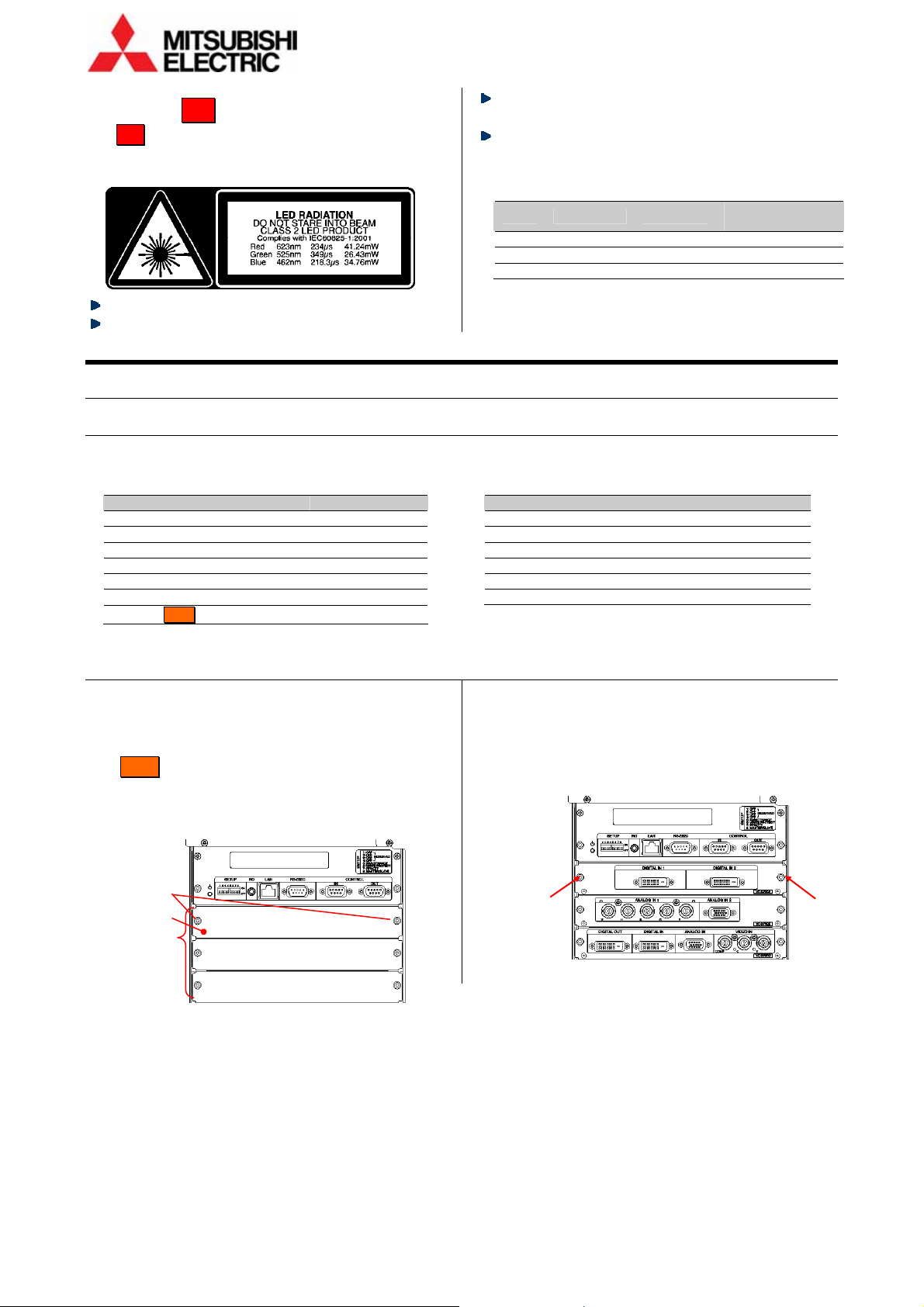

Page 14

Preparation

LED Safety LED

The LED engines are CLASS 2 LED products.

An exposure hazard may exist only if the protective

housing is removed.

Do not look into the LED light directly.

eyesight.

Use of controls, adjustments or performance of

procedures other than those specified herein may

result in hazardous radiation exposure.

• Specification of the LEDs

LED Wave length Pulse width

Red 623 nm 234 μs 41.24 mW

Green 525 nm 349 μs 26.43 mW

Blue 462 nm 218.3 μs 34.76 mW

• The LED light irradiation window is the projection

lens on the upper-center of the engine products.

Do not lens the LED light at anyone.

Looking at the LED light directly may damage

2

22..2

PPrreeppaarraattiioonn

2.2.1 Accessories

• Remove desiccant taped on the products. (no desiccant in engine integrated cubes)

• Remove a shipping protection sheet tucked in the lamp replacement door (page

• Make sure that all of the following items are supplied. • Prepare following tools.

Supplied accessories Q’ty per unit

Hex socket head bolts (M6) 8 (12 for 80”)

Flat washers (for M6) 8 (12 for 80”)

Spring washers (for M6) 8 (12 for 80”)

Seals for Joint holes 1

Control cable 1

User’s manual 1

Cable ties (Front )

6 (50”), 10 (60”, 67”)

Necessary tools

Hex keys 2mm, 2.5mm, 3mm, 4mm, 5mm

Phillips screwdrivers #0, #2

Level

Stepladder

Spacers (for screen gaps)

Wrenches (for base stands)

65).

Maximum

illumination power

2.2.2 Input boards installation

Install input boards into the slots according to input

signal configurations.

• Be sure to turn off the main power switch before

installation.

• In Front , open the screen unit (page 20). The input

board slots are located inside the cubes.

1 Unscrew the 2 screws on the slots evenly with a hex

key (2.5mm) to remove the cover panels.

Screws

Cover panels

Input board slots

2 Insert input boards into the slots along their guide

rails.

3 Firmly fix the boards until the end by evenly and

alternately tightening the screws on both sides

removed in the step 1 (suggested torque: 0.7Nm). For

uninstalling the boards, reverse the procedure.

14 Seventy Series Set-up Manual

Page 15

2.2.3 Front attachment in 80” cabinet

This work is normally unnecessary.

When you pass the cubes through a narrow gate or

door, you can shorten the depth of the 80” cabinet by

separating the front attachment.

1 Remove the nylon washer with “C” shape on each

screen fixing bolt.

Screen fixing

bolt

2 Pull out the 4 screen fixing bolts from rear. Be sure

not to drop the washers attached to the tip of the

bolts.

Washe r

Nylon

washer

Front

attachment

3 Unscrew 4 hexagon socket head bolts (5mm) to

detach the front attachment.

Front attachment

Hexagon socket

head bolt

4 After passing through, reverse the procedure to

restore.

• Inside the front attachment, there are 4 connecting

plates which can be used as additional cube

connecting holes when making a curved display wall.

Prepare proper bolts, nuts and washers to connect

the cubes together through these holes. Unlike other

connecting plates on the main cabinet (page

19),

there is no castle nut inside the attachment.

Connecting plate

Preparation

REV 1.3 15

Page 16

Engine embedding

3

22..3

EEnnggiinnee eemmbbeeddddiinngg

Embed the engine units before cube installation (page 18) for separately supplied units.

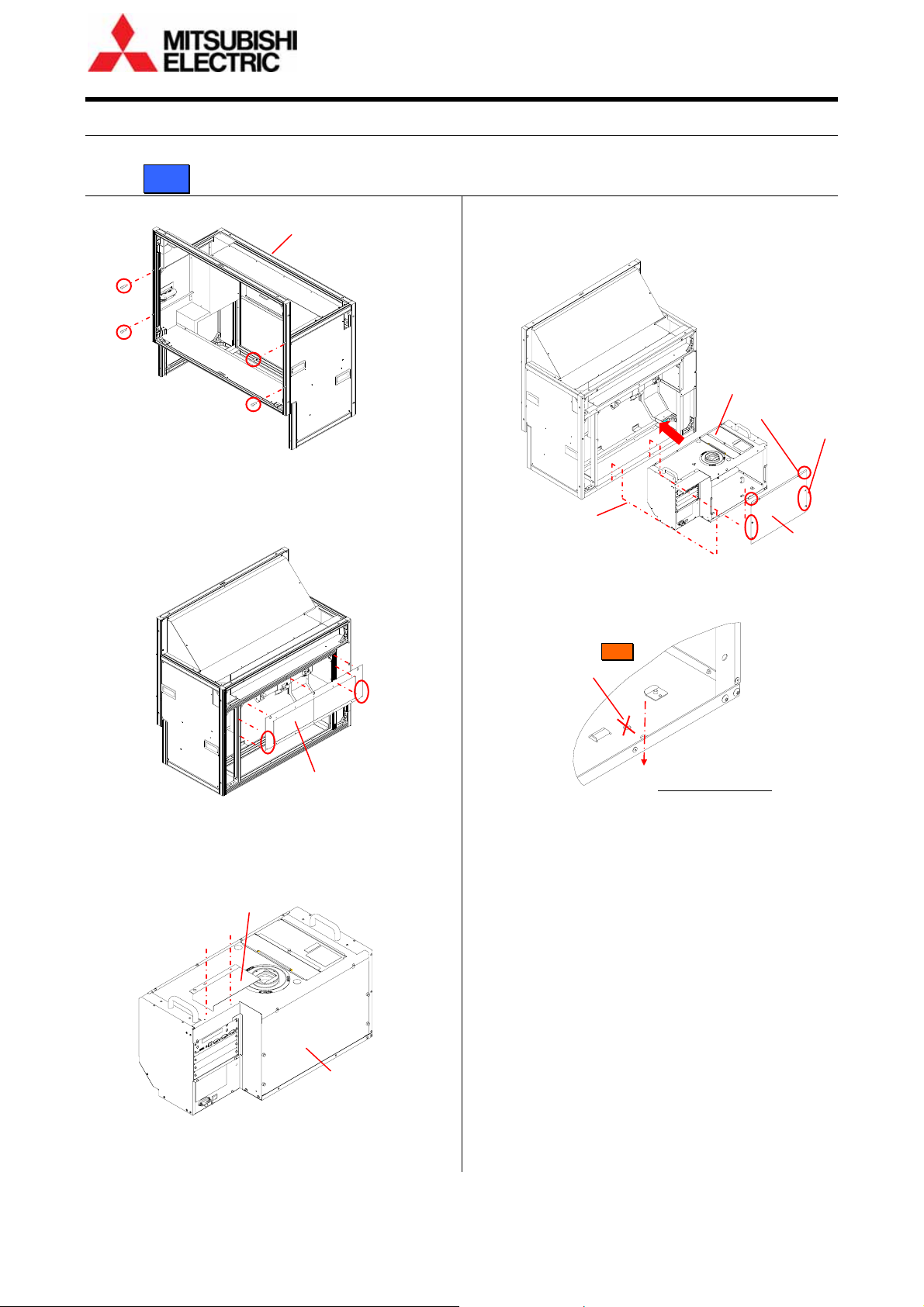

2.3.1 Rear

1 Remove 4 bolt caps from the cabinet.

Cabinet

Bolt caps

2 Loosen screws on the bottom edges of the rear panel

and lift the panel to remove.

• Three screws on the top edge are hooks and need

not to be loosened.

3 Attach a chassis cover, which is supplied with the

cabinet, on the top panel of the engine unit with 2

screws.

Chassis cover

Rear panel

Engine unit

4 Remove the rear panel of the engine unit.

Loosen 2 screws on the top edge, release 4 latches

and lift the panel to remove.

5 Insert the engine unit into the cabinet fully and fix it

with supplied 2 hex socket head bolts on both sides.

6 Put back the rear panels on both the engine unit and

the cabinet.

2 hex socket bolts

Holes for Front

(not in use)

Bottom of engine unit

Engine unit

2 screws

4 latches

Rear panel

2 hex socket bolts

(on left and right sides)

16 Seventy Series Set-up Manual

Page 17

2.3.2 Front

1 Loosen screws on the rear panel and lift the panel to

remove. There is no need to unscrew them.

For 50”: Loosen 2 “A” screws and unscrew 7 “B” screws.

There is no need to unscrew “A” screws.

A

B B B

B

2 Remove the rear panel of the engine unit.

Loosen 2 screws on the top edge, release 4 latches

and lift the panel to remove.

2 screws

Rear panel

2 hex socket bolts

A

B

B

B

4 latches

Engine unit

3 Insert the engine unit into the cabinet fully and fix 2

metal brackets, which are supplied with the cabinet,

with 2 screws each.

2 brackets

Bracket shape

for 50"

4 Fix the engine with supplied 2 hex socket head bolts

on both sides.

Holes for Rear

(not in use)

2 hex socket

bolts

Bottom of engine unit

5 Put back the rear panels of both the engine unit and

the cabinet.

• The engine unit can be embedded from the screen

side as well.

1 In the same manner as above step 3, fix the 2 metal

brackets from the rear side.

2 Put the engine unit in the cabinet from the front side.

Be careful not to touch the mirror.

3 Fix the bottom of the engine unit on the cabinet in

the same manner as above step 4.

4 Put back the rear panel of the engine unit.

Engine embedding

REV 1.3 17

Page 18

T

T

Cube stacking

4

22..4

CCuubbee ssttaacckkiinngg

2.4.1 Screen demounting

Rear:

Loosen screen fixing bolts to demount the screen (in

screen integrated models).

Screen unit

Fixing

bolts

Front :

Unlocking

Release delivery locking before screen demounting /

mounting.

• Screen-holding arms (in screen separated models)

Peel off tapes from the screen-holding arms.

ape

• Shipping lock bolts (in screen integrated models)

remove 2 shipping lock bolts (M5-45mm, white hex

socket bolts).

Shipping lock bolts

Screen-holding arm

ape

Demounting

1 Pull up the screen handles on both sides to draw the

screen unit till locked and put the handles back to

the original positions.

Screen-drawing

handles

(1)

(2)

2 While pressing the release buttons on both sides to

the end, lift up the screen unit till it surely touches

the guides on both sides. Open the lower part of the

screen (about 15°) to pull it down on the skew.

Guide (on

both sides)

(2)

(1)

Release button

(on both sides)

(4)

(3)

3 Put back the screen-holding arms into the cabinet by

pressing down the slide lock lever (only on the right

side).

(2)

(1)

Slide lock lever

Screen-holding arm

18 Seventy Series Set-up Manual

Page 19

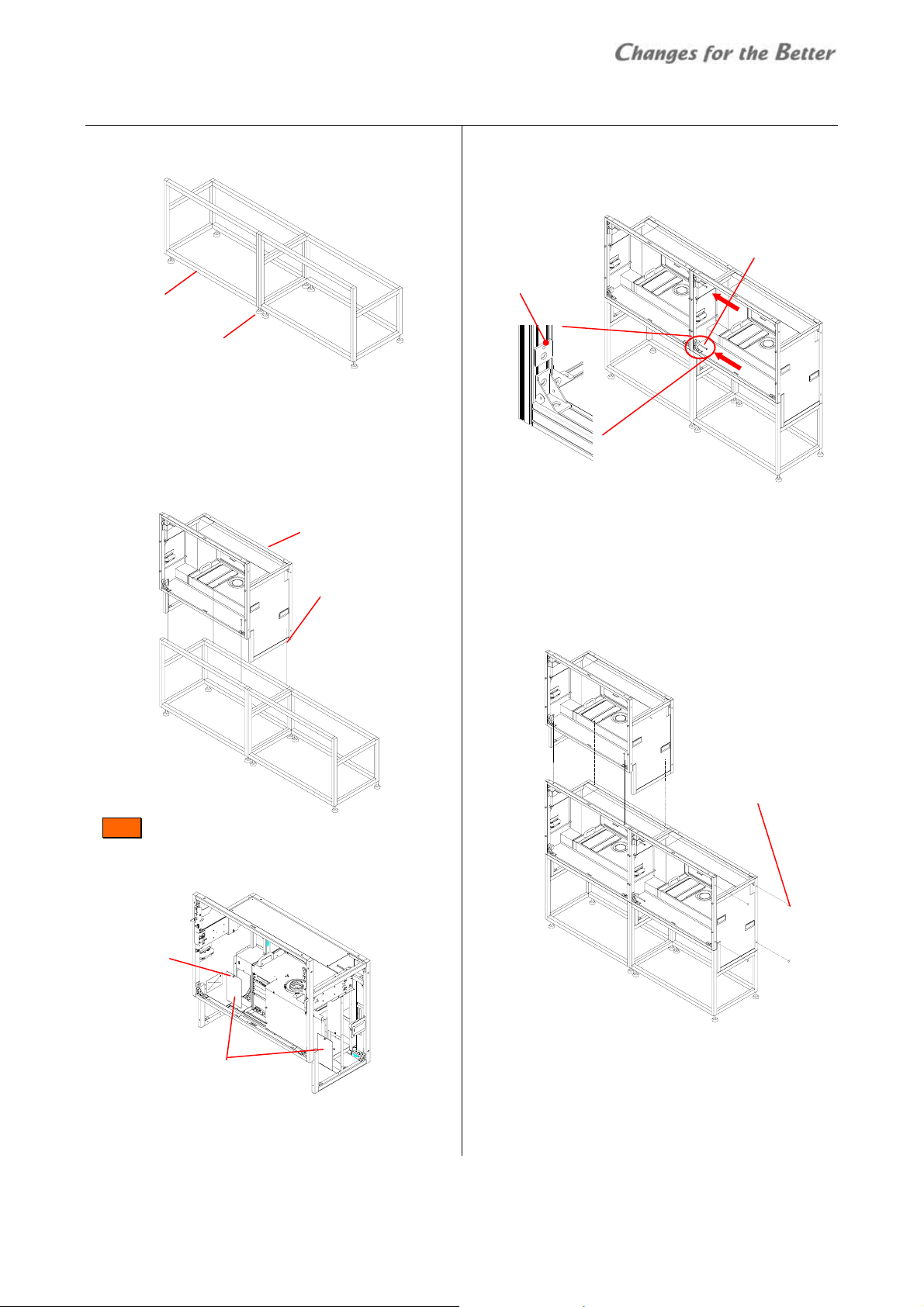

2.4.2 Base stands and cubes assembling

1 Make base stands both level and plumb by means of

a level.

2 Place a cube in the bottom row on the base stand.

3 Fix the cube at 4 points (8 points for 80”) with

4 Place a next bottom row cube on the base stand and

Base stands

Adjusters

supplied hex socket head bolts, spring washers and

flat washers.

• Tighten the bolts with appropriate force

(suggested torque: 3.9Nm).

Cube

Hex socket bolts

Spring washers

Flat washers

Front :

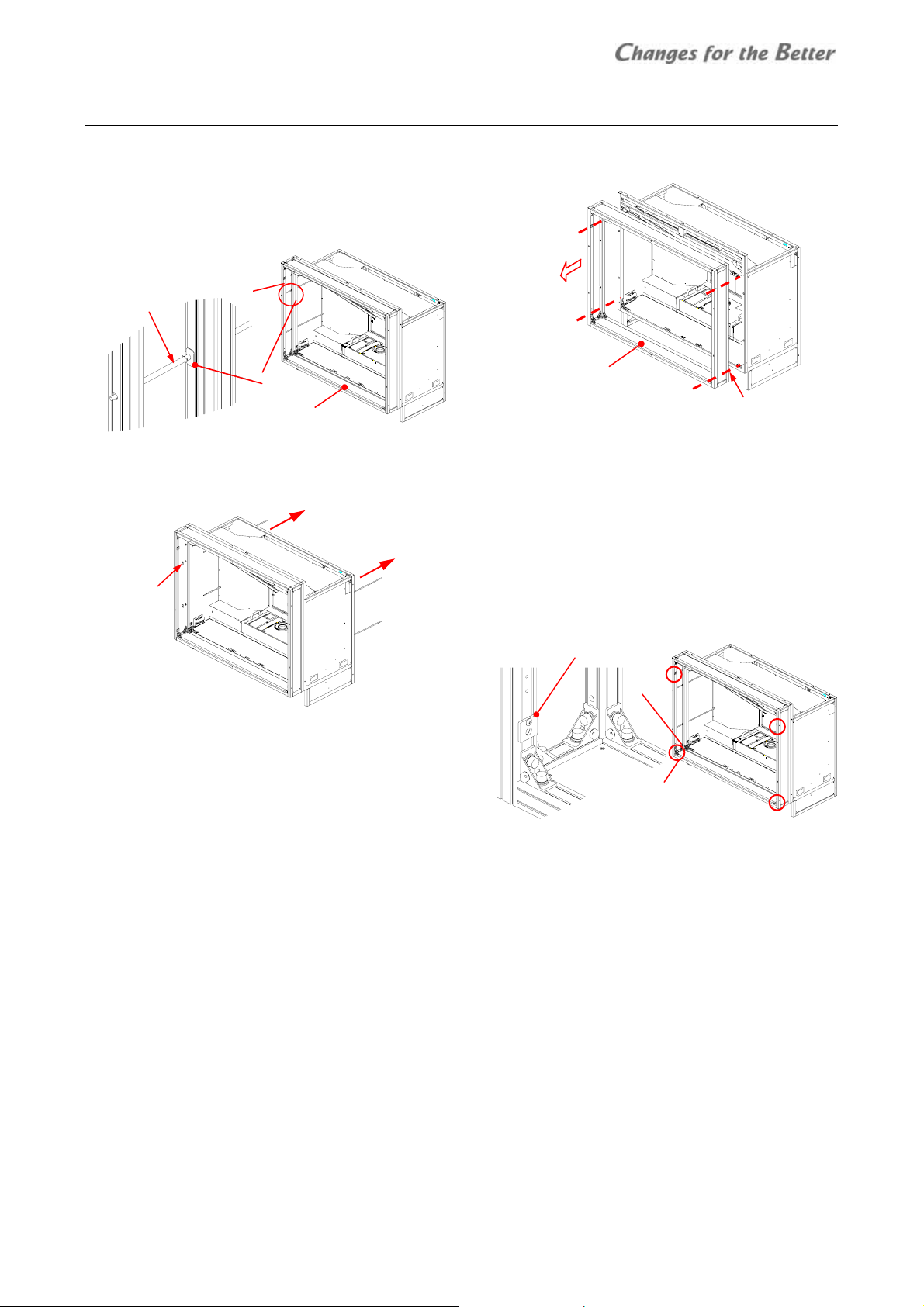

To access the rear fixing points, open the duct covers

on both sides by pulling the latch.

Latch

Duct covers

fix it in the same way.

5 Connect these cubes together at 4 points with

supplied hex socket head bolts, spring washers and

flat washers.

Connecting plate

Hex socket bolts

Spring washers

Flat washers

• When making a curved display wall and you have

to remove the connecting plates, put substitute

washers with equivalent strength on the holes.

6 Place other cubes for the upper row on the row of

cubes.

7 Connect these cubes vertically and horizontally in

the same manner as step 3 and 5.

Seals for Joint holes

• To prevent cubes from falling, make sure the cubes

are stably assembled by checking that they are

level.

8 After all cubes are joined together, stop up unused

holes on both sides of the cubes with supplied seals

for joint holes.

Cube stacking

REV 1.3 19

Page 20

Cube stacking

2.4.3 Screen mounting and open/close (Front )

Screen mounting

1 Draw the screen-holding arms from the cabinet till

locked while pressing down the slide lock lever (only

on the right side).

(1)

2 Mount a screen unit onto the cabinet.

Lift up the screen unit on a skew (about 15°) till the

part B surely touches the part A (guides) on both

sides. Make the screen upright rounding on the part

A to hang it on the arms.

(1)

3 Push the screen unit along the rails till the end while

pressing down the slide lock lever (only on the right

side).

(1)

(2)

Screen-holding arm

Slide lock lever

A B

(3)

(2)

(2)

Slide lock lever

Screen opening

1 Pull up the screen handles on both sides to draw the

2 Press down the open switch on the left at first which

About one-meter space is needed in front of the

screens for the opening. Prior to work, make sure

that there is no object such as steps in the working

space.

Open/close the screen units one-by-one in a display

wall with making sure if adjacent screens are surely

shut so as not to shift the center of gravity too much.

To prevent cubes from toppling during screen

open/close, use the support base contained in the

cube carton boxes when the cubes are not fixed to a

base stand or other cubes.

Support base

Be careful not to trap your fingers during the work.

screen unit till locked and put the handles back to

the original positions.

Screen-drawing

handles

(1)

(2)

will be locked. While pressing down the other open

switch on the right, pull up the lower part of the

screen to open.

Open switch

(left)

(1)

(3)

(2)

Open switch

(right)

20 Seventy Series Set-up Manual

Page 21

Screen closing

Be careful not to trap your fingers during the work.

1 Push down the lower part of the screen lightly till

locked.

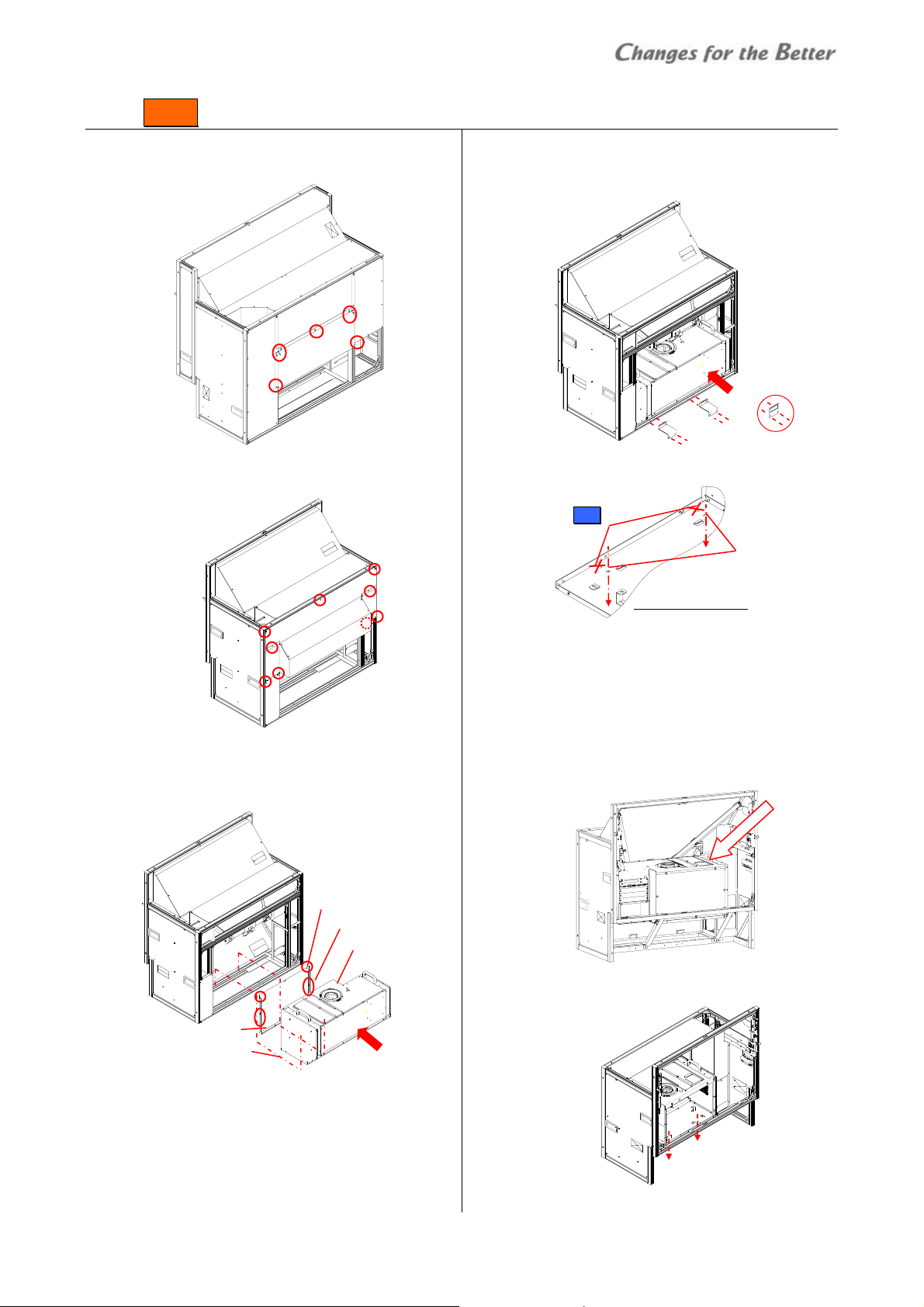

2.4.4 Screen gaps adjustment

Rear:

1 Lightly fix a screen unit on the cabinet with 4

screen-fixing screws.

2 Adjust the screen gaps with spacers to be as follows:

50”: 1mm / 60”: 1.5mm / 67”: 2mm / 80”: 3mm

Screen gap

3 Tighten the 4 screen-fixing screws with appropriate

force (suggested torque: 3.9Nm).

Screen unit

Fixing screws

Screen gap

2 Push the screen unit along the rails till the end while

pressing down the slide lock lever (only on the right

side).

(1)

(2)

Slide lock lever

• The screen unit may touch adjacent screens

depending on the screen gap adjustment. Adjust the

gaps appropriately.

Front :

1 Open the screen unit.

2 Loosen 5 fixing screws for screen adjustment with a

hex key (3mm) (fixing screws: 1 for horizontal, 2 for

vertical on each side).

3 Optional motor unit (S-MA70E) allows you to adjust

the screen gaps by remote control. Connect the

motor unit to the cube in reference to “Mirror

correction (page

41).

Motor units

L

R

PR

H. fixing screw

2 V. fixing screws

(on both sides)

Drive unit

Cube stacking

REV 1.3 21

Page 22

Cube stacking

4 Snap the motor units in the screen adjustment

screws.

• The motor unit of PL is not used for the gap

adjustment.

Screw Motor unit Menu

Vertical (left) L SCREEN-L

Vertical (right) R SCREEN-R

Horizontal PR SCREEN-H

H adjusting screw

V. adjusting screws (on both sides)

5 Display SYSTEM SETTING > MAINTENANCE > MECH

ALIGNMENT menu.

6 Shift the screen position from side to side and up

and down so that the screen gaps will be as follows:

50”: 2mm / 60”: 2.5mm / 67”: 3mm

• The screen is rotated by different travel distance on

both vertical adjustment screws.

7 After the adjustment, tighten the 5 fixing screws

which have been loosened in the step 2.

• The screen unit may touch adjacent screens

depending on the gap adjustment. Adjust the

gaps appropriately.

Manual adjustment

The gaps can be adjusted manually as well. Turn the

adjustment screws with a hex key (4mm) instead of the

motor units. One turn of the screws shifts the screen

approximately 0.8mm.

Close the screen unit to check the gap and repeat the

steps until being appropriate. Tighten the 5 fixing

screws after the adjustment.

2.4.5 Fixing to the wall and floor

1 Firmly fix the base stands onto the floor by means of fixing brackets and/or anchor bolts.

2 Fix the upper back part of the cubes to the wall behind by means of fixing brackets.

To prevent the cubes from falling due to unpredictable events such as earthquakes or shocks, fix them firmly to

the wall and floor. Furthermore, carefully confirm the strength of the fixing areas (wall and floor) of the installation

room. The fixing method differs depending on the number of cubes.

Adjusters

After the completion, proceed to “Adjustment” (page

Bolts

Anchors

Floor-fixing brackets

32).

Wall-fixing brackets

Bolts

22 Seventy Series Set-up Manual

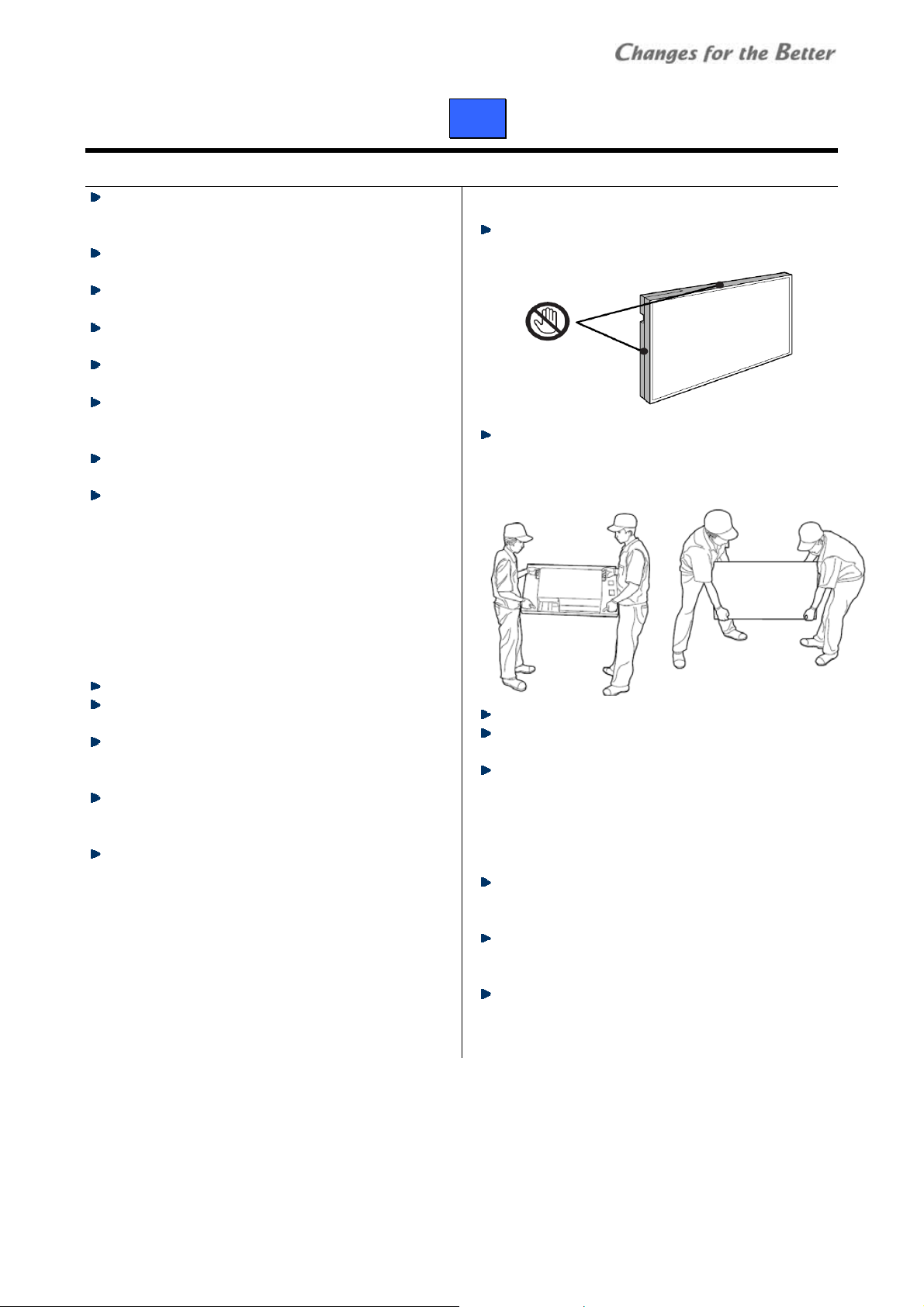

Page 23

3

3

LLCCDD ppaanneell iinnssttaallllaattiioonn (

1

33..1

SSaaffeettyy pprreeccaauuttiioon

This product requires special installation to prevent

falling or toppling. This should be done by

installation specialists.

Be sure to read this manual and the user’s manual for

your safety before starting assembly or installation.

Be sure to use supplied accessories for assembly or

installation.

Attach all the screws and fixtures specified in this

manual securely.

Do not dissolve or revamp the product except the

areas which are specified in this manual.

Do not install this product on an inclined place or

unstable place. The product may drop or fall over

which may cause injury.

Do not install this product on its side, upside down,

on its rear, face down, or in a slanting position.

Do not use the product under the following

circumstances, which may cause fire or electric

shock.

• in a dusty or humid place

• a place where airstream from something like air

conditioning directly blows to an exhaust vent in

the product.

• in a oily, smoky or damp place

• near a heater

• in a vibratory area

Do not use this product outdoors.

Inspect the mounting fixings more than once in a

year as needed.

Do not install the product with its intakes, exhaust

slots and ventilation holes blocked. The unit may

overheat and cause a fire or breakdown.

Be sure to mount/demount the screen by 2 or more

people. These works may be perilous particularly on

a height or a narrow scaffold.

Unplug immediately if there is something wrong

with your product.

n

(

LLCCD

D

))

How to handle the LCD panels

Do not touch the top surface or left-hand surface as

viewed from the front surface of the product. Doing

so may cause failure.

When carrying the product, make sure to have two

people carry it while holding onto the handles. In

addition, being careful not to tough the panel screen,

cautiously support the bottom surface of the panel.

Be careful not to twist or bend the product.

Be careful not to bump or apply pressure on the

panel.

When laying the product flat, be sure to place the

panel on a flat surface with a something soft like a

blanket underneath, and be careful not to scratch

the surface of the panel or allow the panel to be

subjected to excessive pressure. Also do not leave

the panel face-down for a long while.

Protect the panel from static electricity.

To keep static buildup to a minimum, remove the

protective sheet on the panel surface slowly.

The surface of the panel is rather fragile and can be

damaged easily. Do not push down hard on it or

scratch it.

Immediately wipe away any drops of water or oil that

adhere to the panel. Allowing water or oil to remain

on the panel for long periods of time may result in

the panel becoming stained or changing color.

Safety precaution

REV 1.3 23

Page 24

Preparation

2

33..2

PPrreeppaarraattiioonn

3.2.1 Accessories

Make sure that all of the following items are supplied.

Supplied accessories Q’ty per unit

Control cable 1

User’s manual 1

Cable ties 5

3.2.2 Input boards installation

Install input boards into the slots according to input signal configurations

• Be sure to turn off the main power switch before installation.

1 Place the panel on a flat surface with a

something soft like a mattress or blanket

underneath.

• Do not leave the panel face-down for a

long while.

2 Unscrew the 2 screws on the slots evenly

with a hex key (2.5mm) to remove the

cover panels.

3 Insert input boards into the slots along

their guide rails.

4 Firmly fix the boards until the end by

evenly and alternately tightening the

screws on both sides removed in the step 1

(suggested torque: 0.7Nm). For

uninstalling the boards, reverse the

procedure.

Slot 3

Cover panel

Slot 1

Slot 2

Screws

3

33..3

MMoouunnttiinngg

3.3.1 For using commercial wall mount brackets

The product is equipped with screw holes on its back

side to be fixed with a commercially available wall

mount brackets. You can use a bracket which is

compliant with VESA300.

Caution for installation

Mechanical structure

Be sure to read “safety precaution” in this manual

23) and follow the instruction.

(page

Be sure to read the bracket’s instruction manual and

installation procedure as well as this manual.

Use a bracket which can bear 4 times or more weight

of the product. When the strength is unsure, put a

90kg weight on the product and check if it is held

stably for 1 minute.

Before mounting, check the strength of the wall.

Mount on a wall which safety factor is more than 10

(or ensure that it can bear ten times the weight of

products and the brackets). When it is not sufficient,

reinforce the wall surface. (The weight of

VS-L46XM70U: about 30kg)

Carefully install onto the wall not to get loose due to

vibration etc. Wrong installation or installation with

insufficient strength causes the product to fall

resulting in a serious accident or injury.

The weights shall be borne by a sturdy structural

material such as a joist. Secure the bracket using

bolts, spring washers, washers, and nuts.

Don’t install the bracket directly on a wall having

insufficient strength, or don’t install it using wooden

screws or anchor screws. Also don’t install it on

wooden structural materials or blocks.

Ensure that the safety factor per bolt is more than 10

(or ensure that the total bolts bear the weight ten

times the sum of the weights of the products and the

brackets).

Install the products not to touch with adjacent

panels. The outer circumference of the panels is quite

weak and hard pressure or impact may cause

damage.

For future maintenance, it is recommended that the

product be installed so that it can be taken out of the

bracket easily.

24 Seventy Series Set-up Manual

Page 25

Ventilation

Refer to “Image persistence” (page 70) for ventilation

concept.

Don’t block the ventilation holes. The temperature

inside the product rises high causing a fire or

breakdown.

Exhaust

Intake

Intake

To ensure a proper airflow for cooling, create a space

around the products at least as shown below (unit:

mm).

Panel

Panel

Exhaust hot air gets stacked above the product.

Design the structure so as to release it and flow

enough fresh air in from the bottom as shown below.

Exhaust

Intake

In high configurations, the temperature condition

gets worse in the upper panels. The recommended

stack number is up to 6. When over that

configuration, it requires an additional ventilation

way to enhance the efficiency.

Operate under the range of 5 to 30 centigrade

conditions when the panels are used in BRIGHT

mode (page

48).

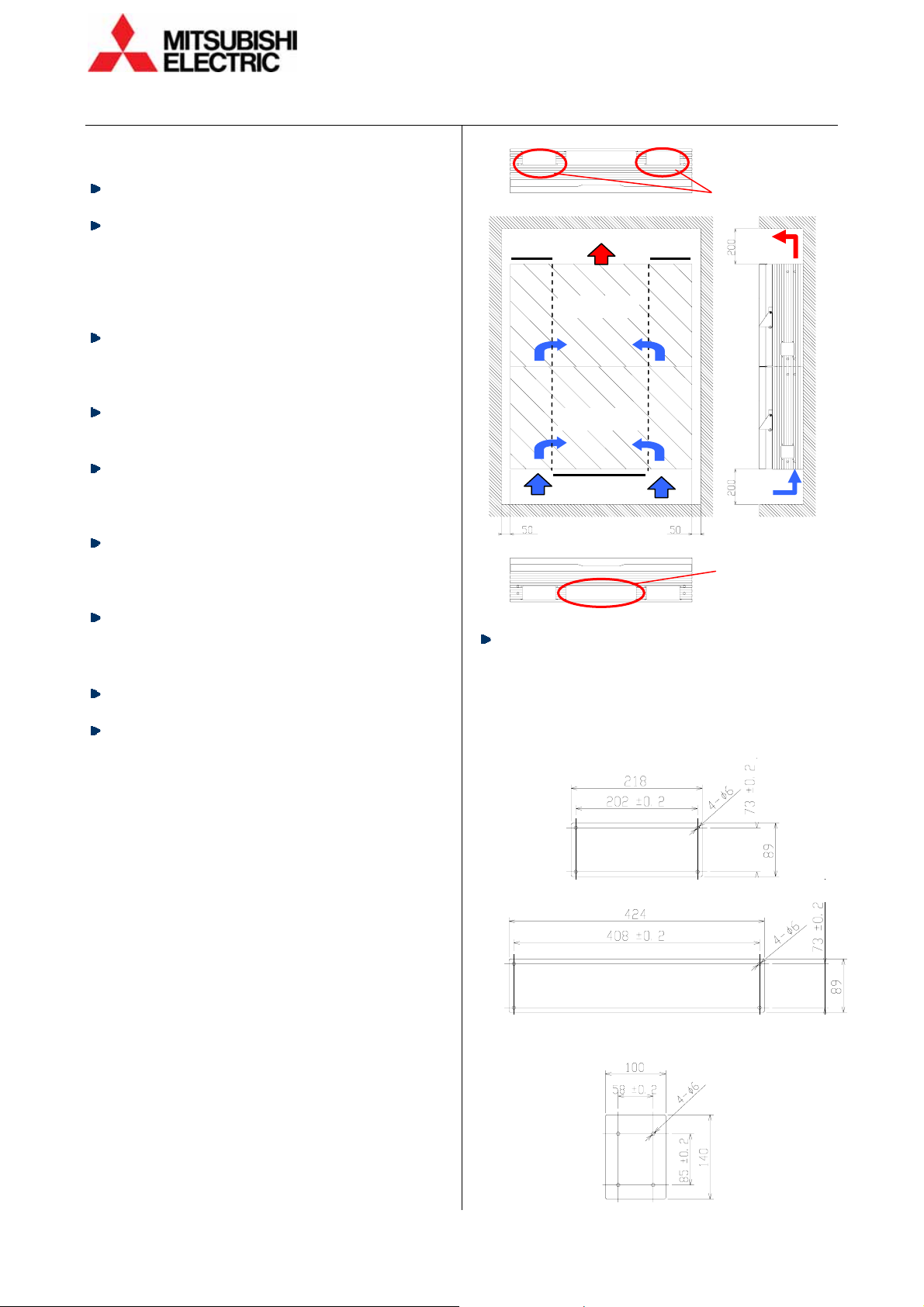

Mount holes for brackets

You can use a bracket which is compliant with VESA300.

Utilizing 8 screw holes (M6, 10mm depth) on the back

of the product, mount it on a bracket.

• At least use 4 screw holes to mount as shown below.

To prevent from drop-off, it is recommended to use

rest of holes as well.

4 points outside

Or 4 points inside

• Use appropriate screws with 10mm or less.

Otherwise, it may be imperfect fixing or it may

damage the nuts inside the products.

Proceed to “IR receiver attaching” (page

8 screws

31).

Mounting

REV 1.3 25

Page 26

Mounting

3.3.2 For using optional wall mount frame (BR-XM70KK)

Caution for installation

Mechanical structure

Be sure to read “safety precaution” in this manual

23) and follow the instruction.

(page

Before mounting, check the strength of the wall.

Mount on a wall which safety factor is more than 10

(or ensure that it can bear ten times the weight of

products and the wall mount frames). When it is not

sufficient, reinforce the wall surface. (The weight of

VS-L46XM70U: about 30kg, BR-XM70KK: about 25kg)

Carefully install onto the wall not to get loose due to

vibration etc. Wrong installation or installation with

insufficient strength causes the product to fall

resulting in a serious accident or injury.

The weights shall be borne by a sturdy structural

material such as a joist. Secure the wall mount frame

using bolts, spring washers, washers, and nuts.

Don’t install the wall mount frame directly on a wall

having insufficient strength, or don’t install it using

wooden screws or anchor screws. Also don’t install it

on wooden structural materials or blocks.

Ensure that the safety factor per bolt is more than 10

(or ensure that the total bolts bear the weight ten

times the sum of the weights of the products and the

wall mount frame).

Before installation, calculate cable length for external

connection and prepare them. Inappropriate length

may make the wiring difficult.

Ventilation

Refer to “Image persistence” (page 70) for ventilation

concept.

To ensure a proper airflow for cooling, create a space

around the products at least as shown in the right

top figure (unit: mm). Also block 2 exhaust vents on

each frame of the top row and one intake vent per

frame on the bottom row.

Prepare the covers by yourself in reference to the

figures below (unit: mm). They can be fixed with 4

screws (M4, 10mm or more length) through holes on

the wall mount frame (suggested torque: 0.7Nm). Do

not block other vents.

Material (example): aluminum or steel plate with

1mm thickness

• Top cover

• Bottom cover

• Side cover (if you cover unused cabling holes on

both sides of the display wall)

Panel

Panel

Blocked 2 exhaust

vents (only on the

top row)

Blocked intake

vent (only on the

bottom row)

26 Seventy Series Set-up Manual

Page 27

Exhaust hot air gets stacked above the product.

Design the structure so as to release it and flow

enough fresh air in from the bottom as shown below.

Exhaust

Intake

In high configurations, the temperature condition

gets worse in the upper panels. The recommended

stack number is up to 6. When over that

configuration, it requires an additional ventilation

way to enhance the efficiency.

3.3.3 Arrangement

1 Create following mount holes on the wall (unit: mm).

4 M6 holes for wall mount frame

Wall mount frame outline

2 Remove 6 shipping lock bolts (both sides), 2 handles

and 2 joint brackets.

2 joint brackets

2 handles

6 shipping lock bolts

3 Place the panel on a flat surface with a something

soft like a mattress or blanket underneath.

• Do not leave the panel face-down for a long while.

2 dia. 6mm guide holes

4 M6 holes

for hooks

Operate under the range of 5 to 30 centigrade

conditions when the panels are used in BRIGHT

mode (page

48).

Accessories

Make sure that all of the following items are supplied

with the wall mount frame.

Supplied accessories Q’ty per unit

Hooks 2

Hook fixing screws (M6x12) 4

Fixing bolts (M6x30) 4

Fixing washers (dia. 25mm) 4

Link bolts (M6x45) 4

Cable ties 10

User’s manual 1

Prepare following tools.

Necessary tools

Hex keys 4mm, 5mm

Phillips screwdrivers #2

Wrench (8mm)

Level

Stepladder

4 Attach the joint brackets on the panel, which

brackets have been removed in the previous step.

Use removed 3 shipping lock bolts each to fix them.

• Carefully work not to bear down on the LCD panel

hardly.

Joint bracket

(on both sides)

5 Likewise, attach the removed handles on the panel

sides with the screws that fixed them on the wall

mount frame. When attaching, contact inside the

handle with the side of the panel closely.

6 Attach the 2 hooks per panel on the wall with

suppied hook fixing screws.

Hook

Hook fixing screws

Handle

(on both sides)

Mounting

REV 1.3 27

Page 28

Mounting

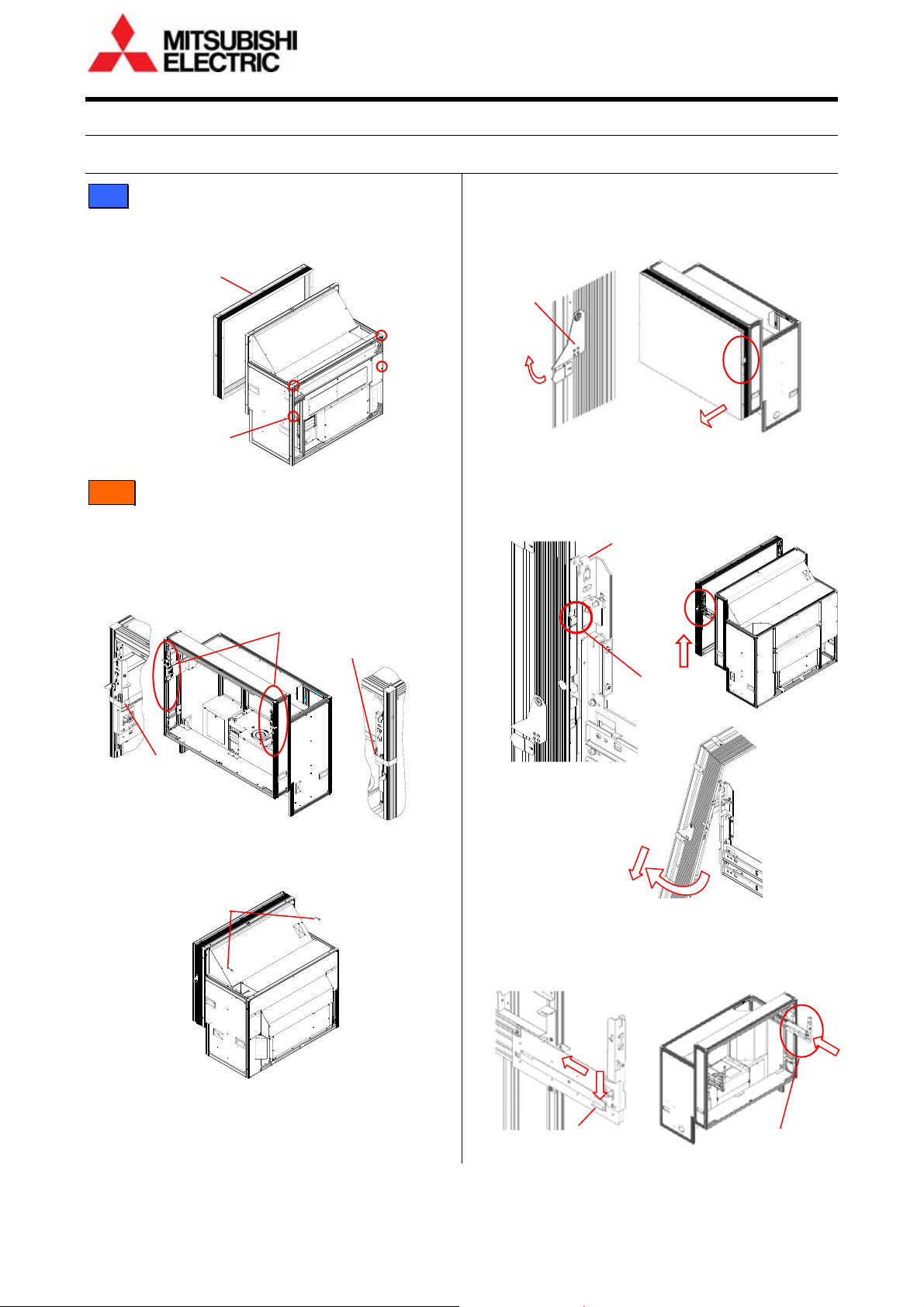

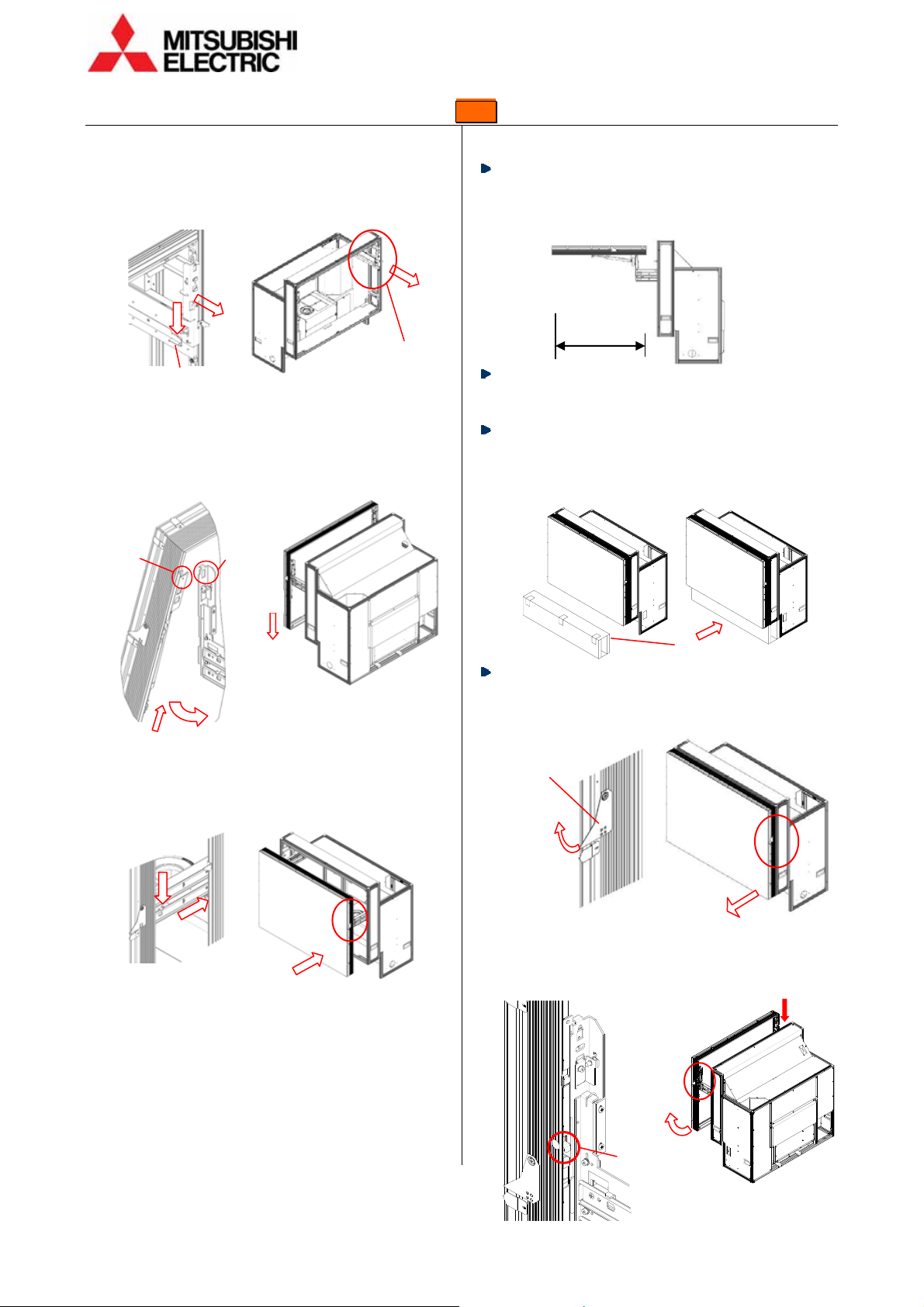

3.3.4 Wall mount frame attaching

At first, attach the frame at the center of bottom row,

then its both sides and go to upper rows.

(7) (8)

(4) (5)

(1)

(1) (2)

1 Hang the frame at the center of bottom row (1) on

the hooks.

2 Shift the position of the frame to fit the guide holes

on the wall. Take a level of the frame. If M6 screw is

inserted at the bottom of each hook, it can lift the

frame to tweak the vertical position.

• Remove the screws after adjustment.

Guide hole Hook

3 Fix the frame on the wall with supplied 4 fixing bolts

and washers.

(9)

(6)

(3)

M6

screw

4 In the same manner as step 1, hang the mount

frames on the both sides ((2) and (3)) on the hooks.

Align the level and height with the center frame (1),

and fix them on the wall temporaliry.

• If M6 screw is inserted at the bottom of each hook,

it can lift the frame to tweak the vertical position.

Remove the screws after adjustment.

5 Connect these frames each other with supplied link

bolts then fix them firmly on the wall.

6 Also in the same manner, attach the frame at the

center of upper row (4). Connect with the lower

frame and fix firmly on the wall.

7 Attach the frames on the both sides of it ((5) and (6)).

Align the horizontal positions with the lower frames

and connect with them and the side frames as well.

Fix them on the wall firmly.

8 Repeat the procedure to attach all frames. Make sure

that they are aligned vertically and horizontally also

their front surfaces are in one flat plane.

3.3.5 Preliminary internal cabling

Before mountig the LCD panels, pre-arrange the cables for all panels in

reference to “Connecting” (page

located on both sides of the frames in consideration of the redundant cable

length for the panel slide distance to the front.

Divide the cable lines as appropriate according to the cable number and length.

Basically signal cables are left side and power cords are right side.

• If you clamp the cables to fix on the inside the frame with supplied cable ties,

it facilitates smooth panel open / close (page

• The cable holes on top and bottom also have a function of airflow vents.

When the cables occupy the opening, tie them in the vicinity of the hole for

space-saving.

28 Seventy Series Set-up Manual

32). Run the cables through the cable holes

29).

Cable holes

Cable holes

Cable ties

Page 29

T

p

T

p

(7)

(3) (5) (8)

3.3.6 LCD panel mounting

At first, attach the panel at the center of middle row,

then spread it out to adjacent panels on both sides and

top / bottom. Lastly attach the ones in other areas.

(1) (2)

(1)

(4) (6)

1 Press the unlock switches on both sides of the wall

mount frame.

2 Draw the front bar to the front until locked.

Unlock

switches

Front bar

3 Hang the joint brackets in the back of the panel on

the front bar so as to fit the hole and the protrusion

toghether.

• Carefully treat the panel not to touch with adjacent

panels.

(9)

Hole

Protrusion

Fixing bolts

and washers

(both sides)

4 Temporaliry fix the panel with fixing bolts and

washers which were on the joint brackets.

• Screen gaps could not be adjusted if you fix it

firmly.

5 Connect the cables to the panels.

6 Not to run the cables off the bottom edge when the

panel is closed, tie the cables with supplied cable

ties.

o clam

o clam

Power cord Cable ties

Cables

Mounting

3.3.7 Panel open / close

Panel closing

Push the panel lightly to slide till locked at the end

while turning the unlock knob clockwise located on

the right side of the wall mount frame.

• Close it carefully not to touch adjacent panels.

• Make sure that the closed panel doesn’t pinch the

internal cables.

Unlock knob

Panel opening

Pull up the handes on both sides 90 degrees to draw

the panel till locked.

Put the handles back to the original positions after

drawing.

Handles

(both sides)

REV 1.3 29

Page 30

T

T

Mounting

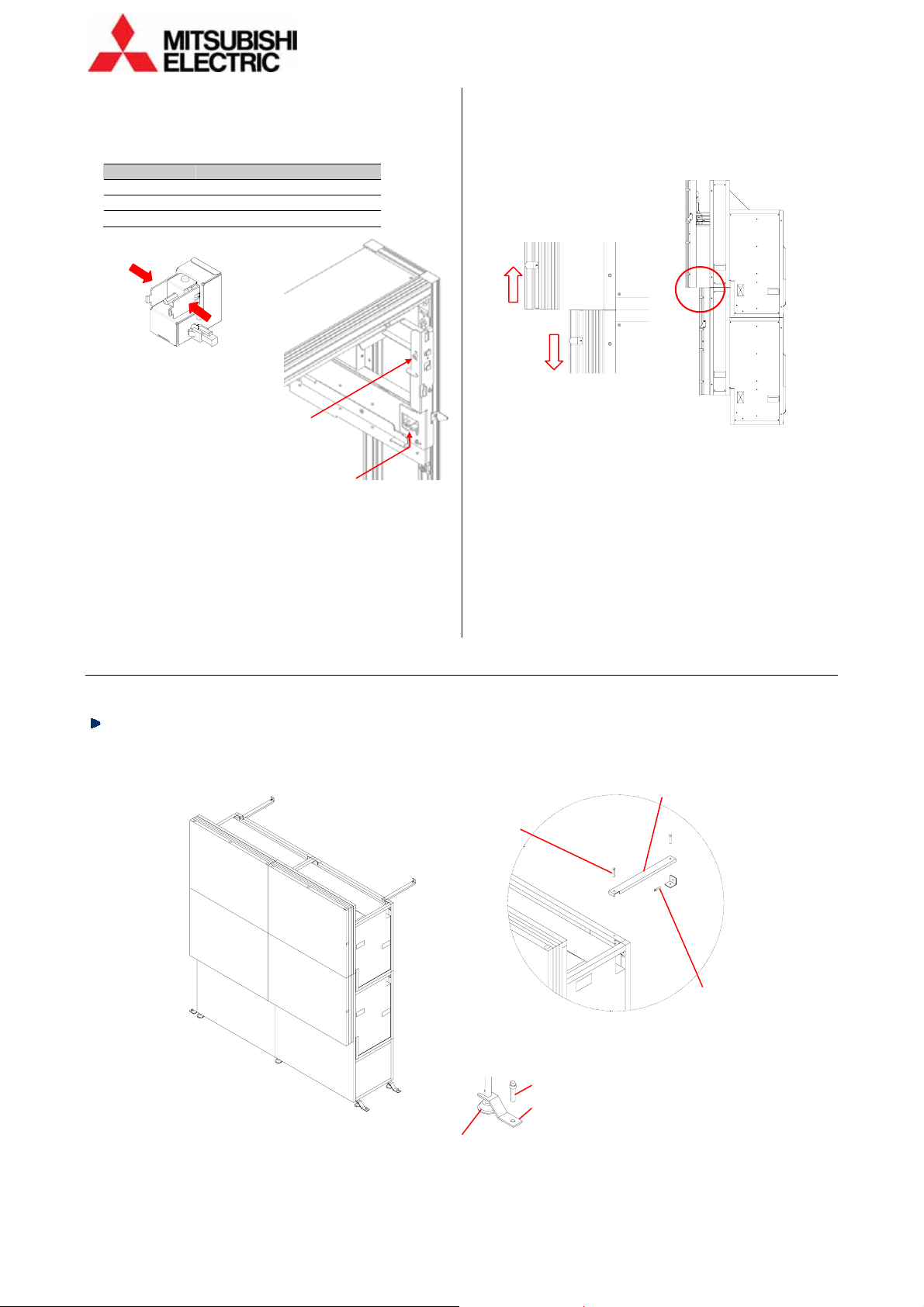

3.3.8 Panel gap adjustment

Flat surface shift

Utilizing optional adjustment tool (the combination of

motor units (S-MA70E) and motorized adjustment tool

(MAT: S-A70E)), the gaps between the panels can be

adjusted by remote control or Wallaby.

1 Set the slide switch to [OPE] on the drive unit of the

MAT (S-A70E).

• Switch them before connection to panels.

• No need to change the switch on the left side.

2 Loosen the screw in the lid for adjustment tool on

back side of the panel, and open the lid by 90 degree

rotation. You don’t need to remove the screw.

3 Connect the drive unit to the connector inside the lid

with a supplied cable with the MAT as well as to the

motor units.

4 Attach the motor units of R, L and PR on the

following points. By pinching metals on the motor

units, snap the tips of them into rectangular holes

beside the adjusting screws.

• The motor unit of PL is not used for the gap

adjustment.

Screw Motor unit Menu

Vertical (left) L SCREEN-L

Vertical (right) R SCREEN-R

Horizontal PR SCREEN-H

REAR WRITE OPE FRONT

Connector for MAT

o motor units

o panel

V. posi tion

(both sides)

H. position:

PR

V. posi tion : R

(other side: L)

• Not to be pinched by panel open / close, carefully

arrange the cables as below.

PR

R

L

5 Display SYSTEM SETTING > MAINTENANCE > MECH

ALIGNMENT menu.

6 Shift the panel position from side to side and up and

down to adjust the gap width.

• The panel is rotated by different travel distance on

both vertical adjustment screws.

• Keep appropriate gaps so that the panel can slide

back and forth. The wall mount frame is designed

1mm bigger (0.5mm each on 4 edges) than the

panel outer dimension.

7 After the adjustment, take out the MAT and surely

close the lid of its connection port by tightening the

screw on it.

Manual adjustment

The gaps can be adjusted manually as well. Turn the

adjustment screws with a hex key (4mm) instead of the

motor units. One turn of the screws shifts the panel

approximately 0.8mm.

Close the panel to check the gap and repeat the steps

until being appropriate.

30 Seventy Series Set-up Manual

Page 31

Front / back direction

Loosen the nuts on the adjustment screws before

adjustment. Turn the screws with a hex key (4mm).

There are 4 screws in total on both sides. One turn of

the screws shifts the panel approximately 1.5mm.

Tighten the nuts after the adjustment.

• The shifting direction is opposite on upper and

lower screws. By clockwise turning, the upper

screws shift the panel to the back and lower screws

to the front.

3.3.9 IR receiver (R-XM70IR) attaching

Optional IR receiver allows you to control the panel by

remote control wirelessy.

• There is no need to change the dipswitch setting on

the panel.

• The IR receptor on the left side of the panel cannot

receive the signal from the panel front.

• Even without the receiver, the supplied cable with

the remote control can be connected to the wired

remote control port on the panel to control it

directly.

Accessories

Make sure that all of the following items are supplied

with the IR receiver.

Supplied accessories Q’ty per unit

Cable (2m): JC-RC2M 1

Screws (M4x10) 2

Attaching

1 Connect a connect port on IR receiver and the wired

remote port on the MASTER panel (page

supplied cable. The Master panel directs other panels

through the control cables.

• The receiver has 2 ports. You can use any of them.

The other one will be a wired remore control port.

Connect ports

Acceptance surface

33) with the

Fixing bolts and washers

(both sides)

Nuts

Adjusting screws

(4 points)

After all adjustment, firmly tighten the fixing bolts and

washers on the joint brackets on both sides which have

been fixed temporarily.

2 Fix the receiver as its acceptance surface faces to the

front on a surrounding structure or at the screw

holes on each edge of the panel (There are 5 holes

on each top / bottom and 3 holes on each side) with

supplied screws. Carefully work not to put an

execcive pressure on the bezels.

IR receiver

(example)

Wired remote control port

Mounting

REV 1.3 31

Page 32

Initial setting

4

4

AAddjjuussttmmeenntt

1

44..1

IInniittiiaall sseettttiinngg

4.1.1 Connecting

Internal control cables connection

From the MASTER monitor (page 33), cascade

CONTROL OUT and CONTROL IN ports between

monitors in sequence with supplied control cables.

Communication between monitors automatically

corrects the brightness for uniformity (SENSOR

function: page

by remote control can control other SLAVE monitors

through the line.

Master

Slave

• Up to 98 monitors can be connected.

• Do not connect to a closed-loop.

• Connect the control cables even when controlling

monitors through network.

47). Also the MASTER monitor directed

To n ext CO NTROL

IN port

Slave

Slave

External control cables connection

External controllers such as personal computers in

which adjustment software, Wallaby has been installed

can control monitors.

• Through RS-232:

Connect the external controller to the MASTER monitor

33) with RS-232 cross-over cable. The controller

(page

will be able to control the monitors individually

through the internal control line.

• Through the network:

Connect external controllers to all monitors through a

network. A unique IP address can be assigned to each

monitor (page

36).

Master

Slave

Slave

Slave

192.168.100.32

192.168.100.34

192.168.100.33

192.168.100.35

Image signals connection

Connect image input sources to monitors according to

input signal configurations to be displayed. Refer to

Display memory setting” (page 59) for the detail of

“

available image window layout patterns.

Internal cabling (Front )

Run cables through the cable covers located on both

sides and top/bottom of a cabinet.

Punch a hole in the center slit of the covers at

necessary points for the cabling.

Mount

base

Clamps

(60”, 67”)

Mount

base

• To block dust, do not break the covers on the outer

sides of a display wall.

For the safety reason, do not leave a power strip

inside the cabinet.

For vertical cabling:

Draw supplied plastic cable ties through the holes in 3

units of mount bases located on the left surface inside

the cabinets and fasten the cables with them. For 60”

and 67” cabinets, fasten with 2 additional ties in the

middle of the cables in the air.

For horizontal cabling:

Draw the ties through the holes in 5 units (3 units for

50”) of mount bases on inside the skirt part and fasten

the cables with them.

Covers

32 Seventy Series Set-up Manual

Page 33

4.1.2 Dipswitch setting

Set the dipswitches

adequately according

1 2 3 4 5 6 7 8

to system

configurations.

• The switches No. 1 through 3, 5 and 6 normally don't

need to be changed. (The function of each switch is

mentioned on page

81.)