Page 1

LOSSNAY

HANDBOOK

MODELS

VL-50S2-E

July 2017 No. U224-A

VL-50ES

VL-50SR

Filter

(Optional)

P-50F2-E

P-50HF

Pipe

(Optional)

2-E

P-50P-E

P-50PJ-E

2-E

2-E

Nameplate

Hood

(Optional)

P-50VSQ5-E

Warning:

Repair work must be performed by the manufacturer, its service

agent or a similarly qualified person in order to avoid hazards.

Page 2

Contents

1. Safety precautions

2. Changed points

....................................................................

...........................................................................

3. Names and functions of components

4. Specifications

5. Outside dimensions

6. Electrical wiring diagrams

7. Circuit board diagrams

8. Principles of operation

9. Troubleshooting

10. Before receiving repair requests

11. Service inspection list

12. Overhauling procedures

12-1 VL-50S2-E, VL-50ES2-E

12-2 VL-50SR

...............................................................................

...................................................................

............................................................

..........................................................

...............................................................

....................................................................

...............................................

................................................................

.......................................................

....................................................................

......................................................................................

2-E

3-4

..........................................

7-8

10-11

13-17

18-31

18-24

25-31

4

5

6

9

12

17

18

13. Parts catalog

VL-50S

2-E

VL-50ES

VL-50SR

.........................................................................

.......................................................................

....................................................................

2-E

....................................................................

2-E

32-44

33-36

37-40

41-44

Page 3

1. Safety precautions

Warning

Caution

Caution against

electric shock

Be sure to follow

this instruction.

Be sure to follow

this instruction.

Be sure to follow

this instruction.

Be sure to follow

this instruction.

Be sure to follow

this instruction.

Be sure to follow

this instruction.

Read the following precautions thoroughly before the maintenance, and then inspect and repair the product in a

safe manner.

The types and levels of danger that may arise if the product is handled incorrectly are described with the warning

symbols shown below.

Improper handling of the product may

result in serious injury or death.

Electric shock

If you must inspect the circuitry while the power is

on, do not touch the live parts.

(Failure to observe this warning may

result in electric shock.)

Modification is prohibited

Do not modify the unit.

(

Failure to observe this warning may

result in electric shock, fire and/or injury.

)

Prohibited

Proper electric work

Use the electric wires designated for electric work,

and conduct electric work in accordance with your

local electric work regulations and the installation

manual.

(Improper connection or wiring installation

may result in electric shock and/or fire.)

Turn off the power supply

Be sure to unplug the power cord, or shut off the

circuit breaker before disassembling the unit for

repair.

(Failure to observe this warning may

result in electric shock.)

Use proper parts and tools

For repair, be sure to use the parts listed in the parts

catalog of the applicable model and use the proper

tools.

(Failure to observe this warning may

result in electric shock, fire and/or injury.)

Replace damaged and/or degraded parts

Be sure to replace the power cord and lead wires if

they are damaged and/or degraded.

(Failure to observe this warning may

result in electric shock and/or fire.)

Check insulation

Upon completing repair work, always measure the

insulation resistance. Verify that it is at least 10 MΩ

(with a 500 V DC insulation resistance tester), and

then turn on the power.

(Inadequate insulation may result in

electric shock.)

Improper handling of the product may result in slight injury

or damage to properties including buildings and equipment.

Caution for injury

Do not work at a location where you do not have a

Wear gloves

Wear a pair of gloves when servicing.

sure footing.

(Failure to observe this caution may

(

Failure to observe this caution may result

in a fall.

)

Prohibited

result in injury to your hands from sharp

metal or other edges.)

Notes for servicing

●

Make sure that an earth leakage breaker and an overload protection device are installed, if they are not installed, recommend the customer to install one.

Make sure that the product operates properly upon completion of repair. Clean the product and the surrounding

area, and then notify the customer of the completion of repair.

─ 3 ─

Page 4

Precautions for soldering

Lead-free solder is used for the circuit boards of this product, and " " is marked on the circuit boards.

Observe the following precautions.

● When making repairs on these circuit boards, lead-free solder must be used.

● Make sure to use dedicated soldering irons to lead-free solder. (Do not use soldering irons that are used for

Sn-Pb [tin-lead] eutectic solder)

● It is recommended to use soldering irons having power consumption of 40 W or more.

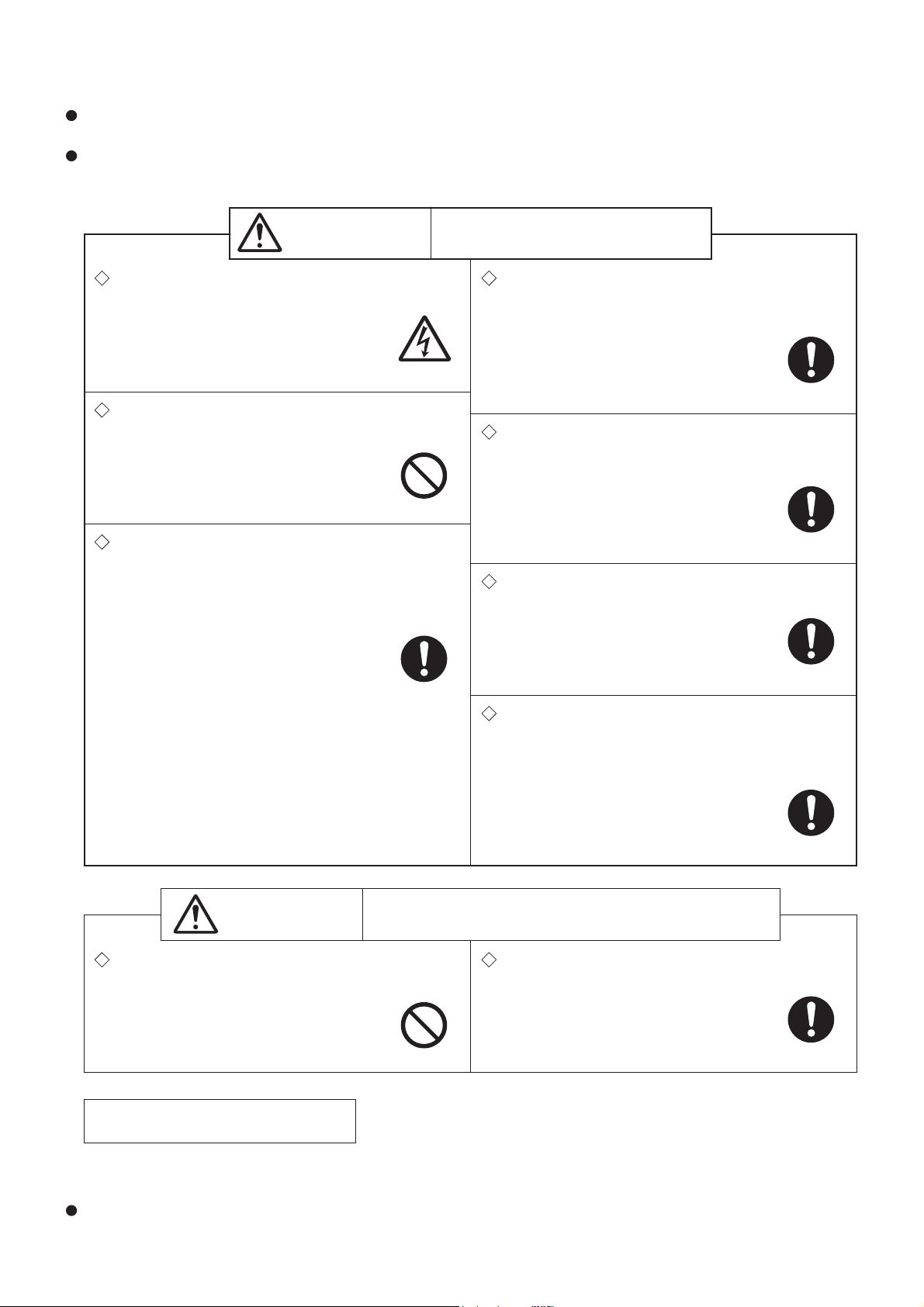

2. Changed points

Item

Operation

means

Shape of

main circuit

board

Wiring for

terminal

block

New model Previous model

VL-50SR2-E VL-50S2-E VL-50ES2-E

Remote controller

Pull cord switch

80x129 mm 80x80 mm

Two wires Three wires

Terminal blockPower cable

L

Control switch

(Wall switch)

Terminal blockPower cable

Display

Operation lamp

Operating mode

selection switch

Remote controller

receiver

Display

─ 4 ─

Operation lamp

Display

Pull cord

(VL-50S

2-E only)

Page 5

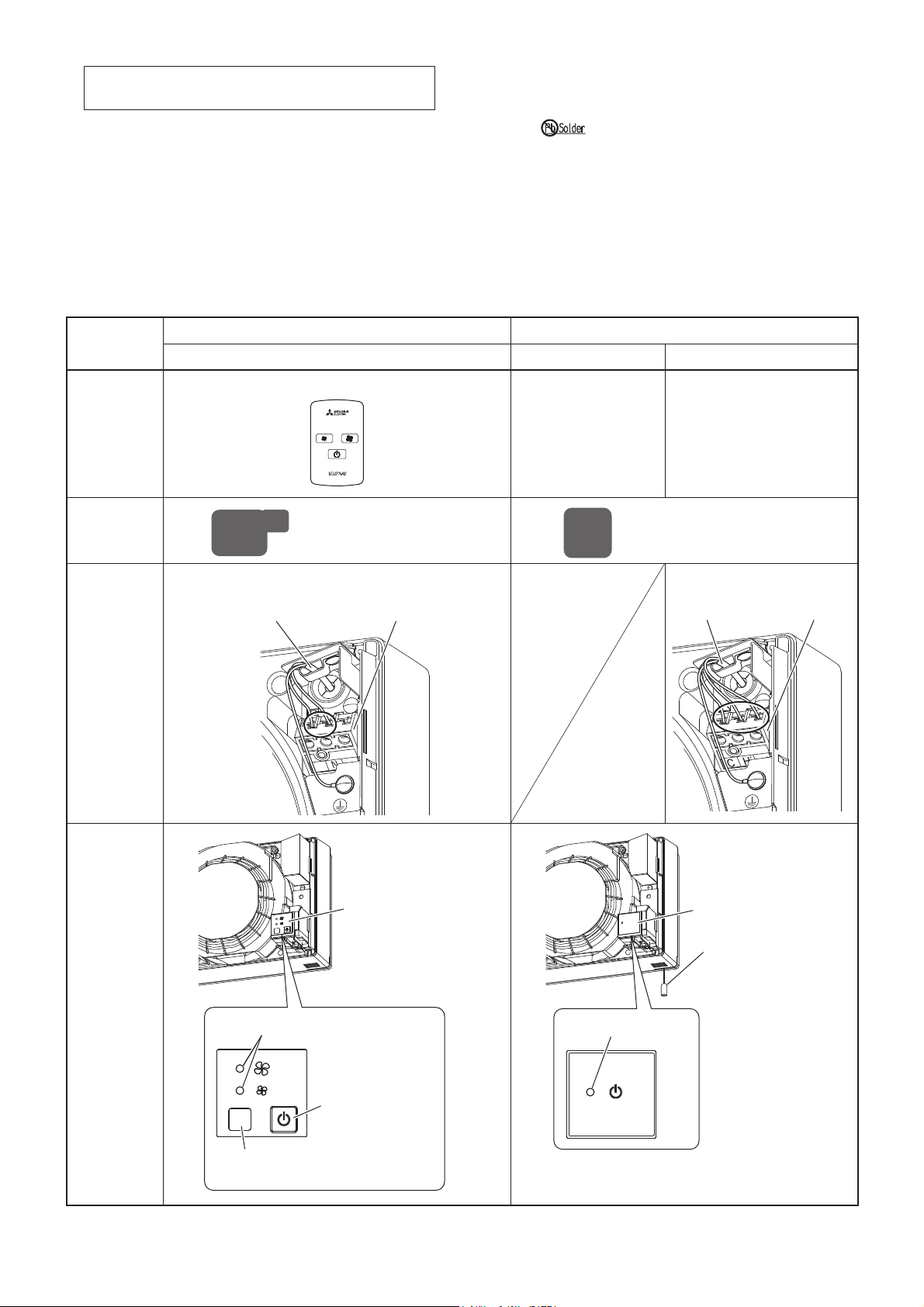

3. Names and functions of components

Panel

<Front panel>

Wire (fall prevention)

Exhaust air filter

<Filter>

Lossnay Core

(Heat exchanger)

Vertical mounting joint C

<Joint pipe>

Outside air filter

<Filter>

Hook

Shutter knob

Air supply/exhaust pipes A

<Pipe> (2 pcs.)

Weather cover

Operation lamp

Display

(Remove the provided

protective sheet.)

Pull cord

<Switch>

(VL-50S

2-E only)

Joint pipe B

<Joint pipe>

Note:

The names in the angle brackets < >

show the part names in the parts catalog.

About the filters

For

Exhaust air filter

Outside air filter

(Replacement filter: P-50F2-E)

Outside air filter can be replaced with the following high performance filter.

High performance

filter

(Optional parts)

(P-50HF2-E)

Exhaust

For

Supply

For

Supply

The filter prevents clogging of the internal components.

air

When Lossnay takes in outside air to a room, the

filter collects dust, sand, pollen or the likes from

outside air.

Note: Some fine particles or tiny insects may pass

air

air

through the filter. The high performance filter

is recommended for higher collecting effect.

The filter collects dust more efficiently than the

outside air filter.

Remote controller

(VL-50SR

2-E only)

Features

─ 5 ─

Page 6

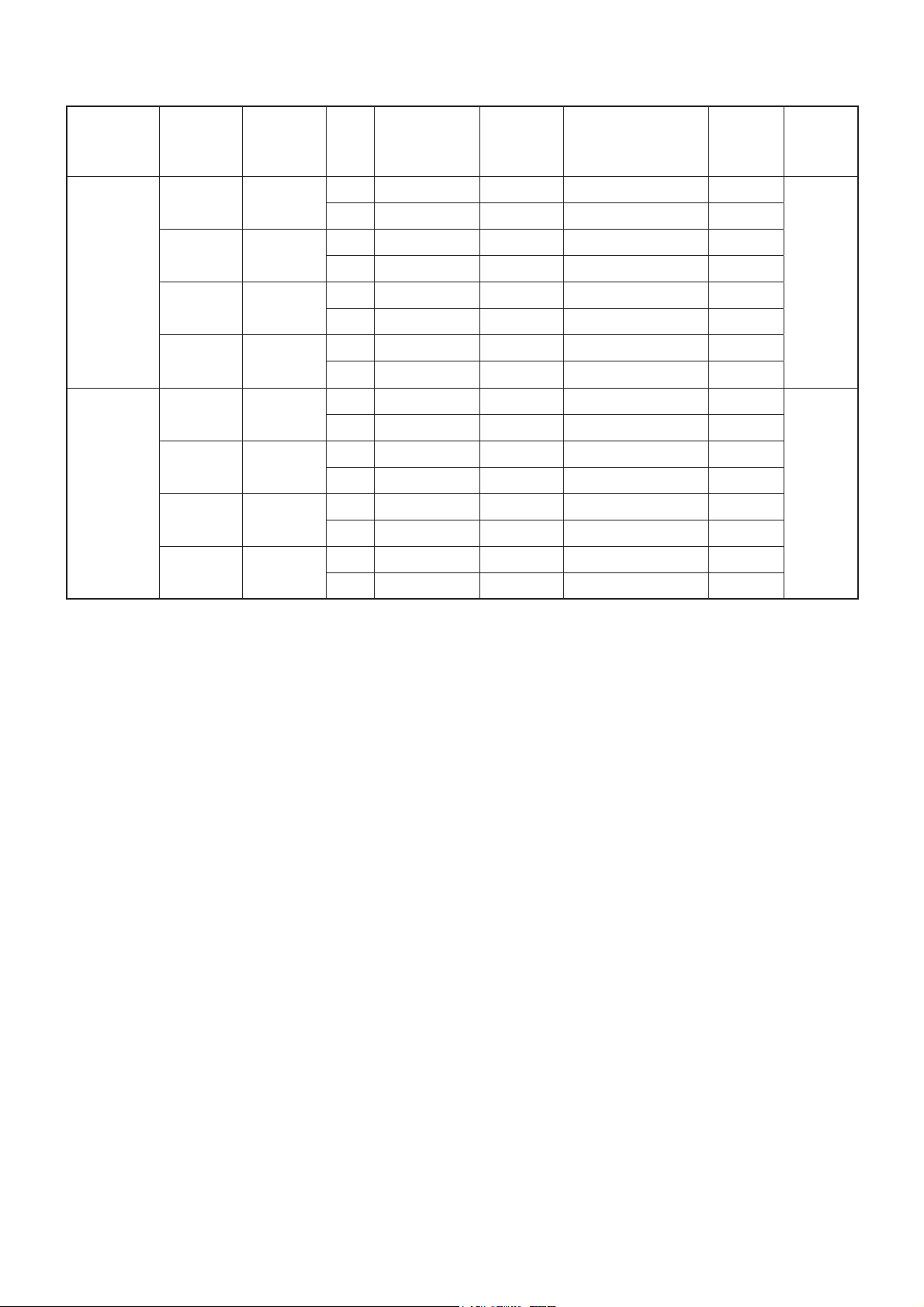

4. Specifications

Model

VL-50S

VL-50ES2-E

VL-50SR

2-E

2-E

Supply

voltage (V)

220 50

230 50

240 50

220 60

220 50

230 50

240 50

220 60

Frequency

(Hz)

Power

Notch

consumption

(W)

HI 19 51 70 36.5

LO 4 15 86 14

HI 20 52.5 69 37

LO 4.5 16 85 15

HI 21 54 68 37.5

LO 5 17 84 15.5

HI 21 54 68 37.5

LO 5.5 17 84 15.5

HI 19 51 70 36.5

LO 4.5 15 86 14

HI 20 52.5 69 37

LO 5 16 85 15

HI 21 54 68 37.5

LO 5.5 17 84 15.5

HI 21 54 68 37.5

LO 6 17 84 15.5

Air volume

3

/h)

(m

Temperature

exchange efficiency

(%)

Noise

(dB)

Weight

(kg)

6.2

6.2

* Noise values may be higher than those listed depending on the structure of the room.

─ 6 ─

Page 7

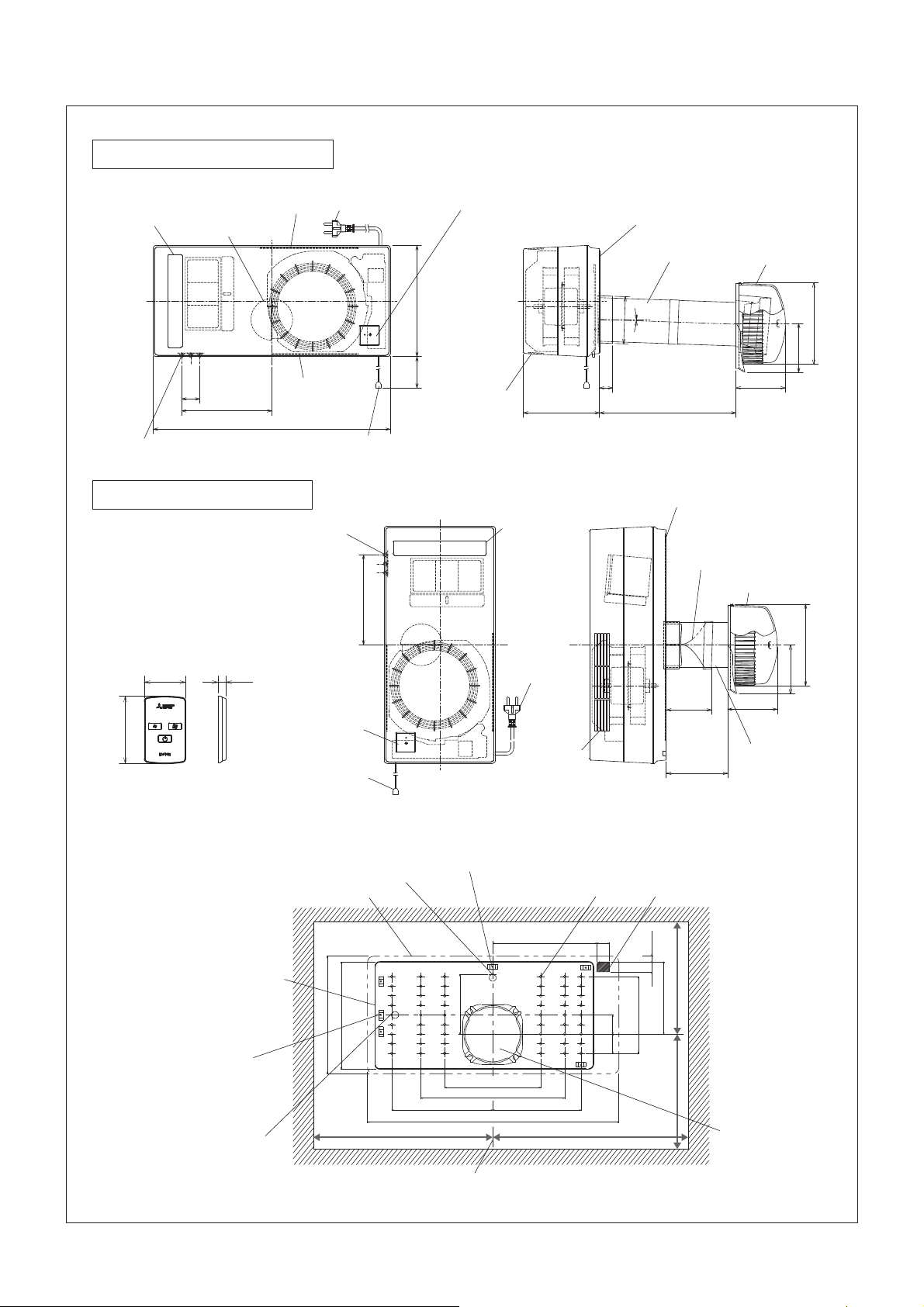

5. Outside dimensions

VL-50S2-E, VL-50ES2-E, VL-50SR2-E

For horizontal mounting

Indoor air

Air supply

hole

Shutter knob

Air supply/

exhaust hole

40

exhaust hole

198.5

522

For vertical mounting

* For vertical mounting, the

display comes to the lower

side. (The unit cannot be

mounted upside down.)

Ŷ Remote controller

(VL-50SR2-E only)

1054

Indoor air

exhaust hole

Shutter

knob

Power cable

(VL-50S

Pull cord

(VL-50S

198.5

2-E only)

2-E only)

245

About

400

Display

(The figure shows

VL-50S

Indoor air

exhaust hole

2-E/VL-50ES2-E.)

Air supply

hole

Power cable

(VL-50S2-E only)

168

Mounting plate

Air supply/exhaust

pipe

114

°

φ

2

28

Wall thickness

50 to 650

Mounting plate

Attach the twisted part of

the vertical mounting joint C

toward the indoor side.

Weather cover

108

109

Weather cover

180

φ

108

180

φ

88

Pull cord

(VL-50S2-E only)

Display

Indoor air

exhaust hole

Ŷ Mounting position diagram (seen from inside)

Mounting plate temporary

fixing hole position (For horizontal mounting)

Edge of main unit Mounting hole 53 – ø6

Mounting plate

245

223.5

Unit hanging screw

position

(For vertical mounting)

Mounting plate

temporary fixing hole

position

(For vertical mounting)

Unit hanging screw position

(For horizontal mounting)

125

200

210.5

min. min.

310 360

Center line

300

522

216

184

26.5

96.5

Wall

thickness

120 to 730

Power and connection

cable pullout area

(VL-50ES

11.5

21

2-E only)

min.

193

151.5

40.539.5

20×8=160

min.

182

109

Air supply/exhaust

pipe

Air supply/exhaust

hole

(ø120 wall hole)

─ 7 ─

Unit (mm)

Page 8

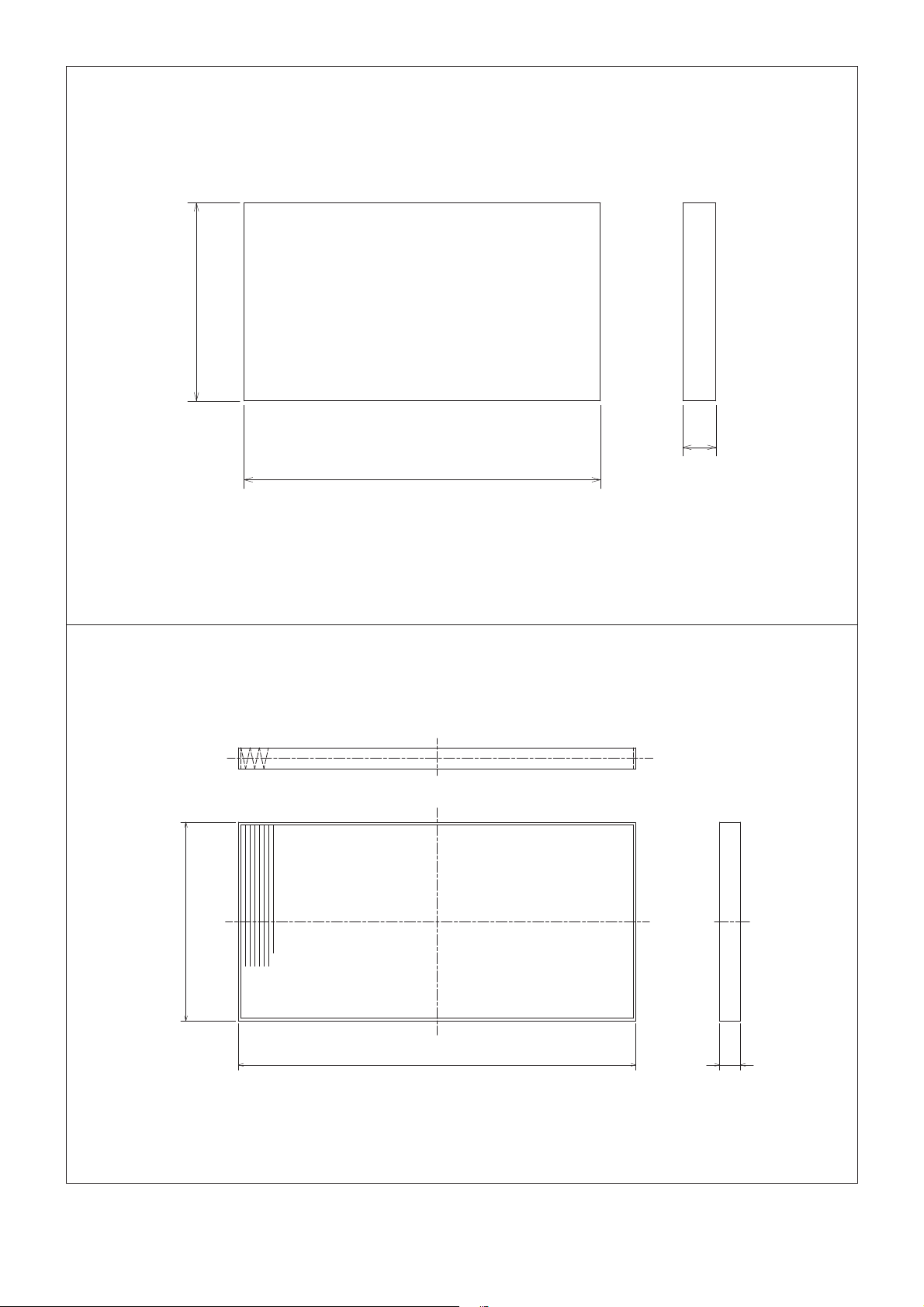

P-50F2-E

76

13

154

P-50HF

2-E

76

153

Unit (mm)

8

─ 8 ─

Unit (mm)

Page 9

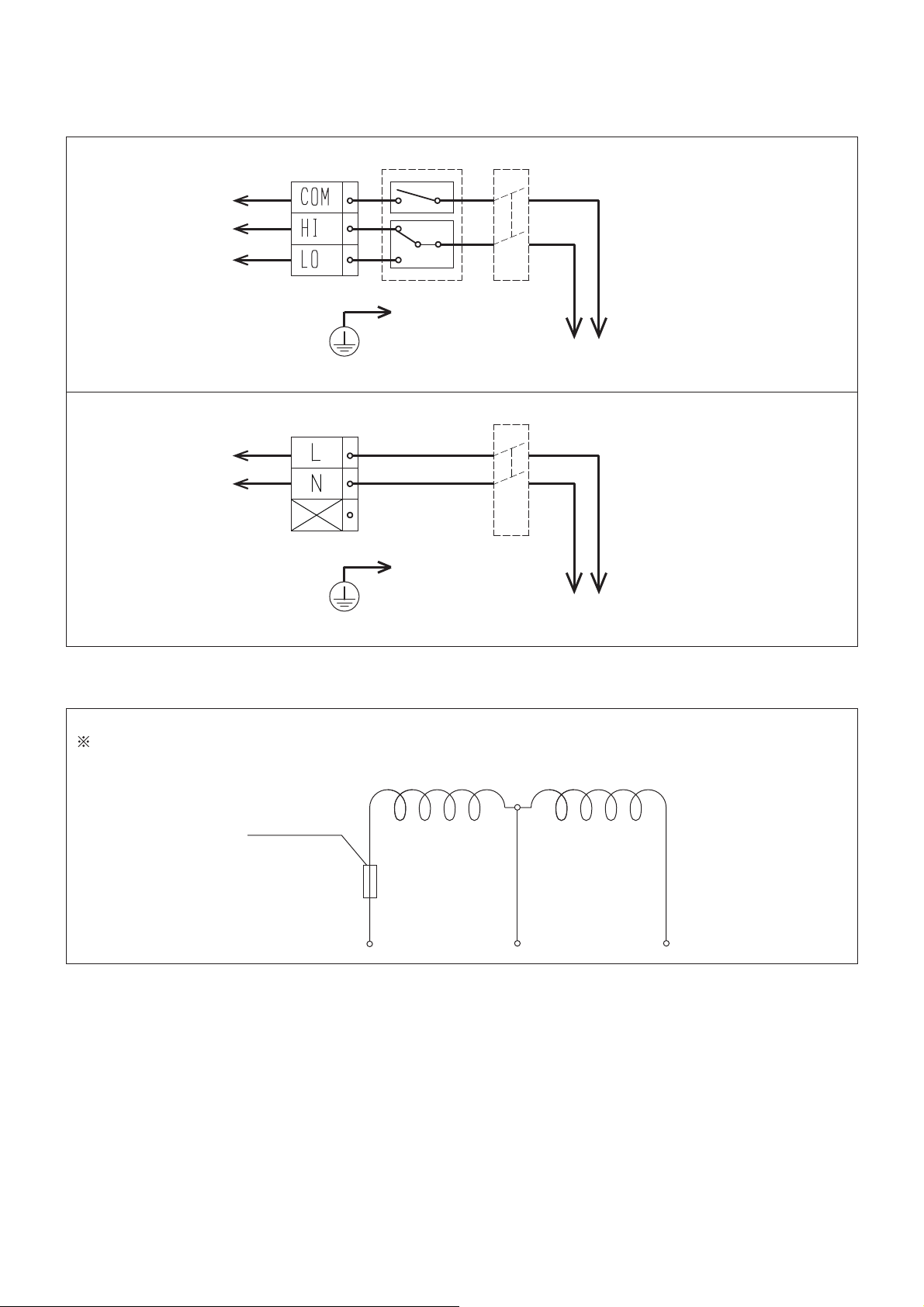

6. Electrical wiring diagrams

(1) Switch wiring diagrams

VL-50ES2-E

Red

White

Blue

Terminal block Switch Circuit breaker

220/230/240 VAC 50 Hz

220 VAC 60 Hz

VL-50SR

2-E

Red

White

Terminal block Circuit breaker

(2) Motor coil diagram

VL-50S2-E, VL-50ES2-E, VL-50SR2-E

Coil resistance at a temperature of 30°C

Thermal fuse

145Υ

220/230/240 VAC 50 Hz

220 VAC 60 Hz

0FRLOȍ6FRLOȍ

White

─ 9 ─

Black

Red

Page 10

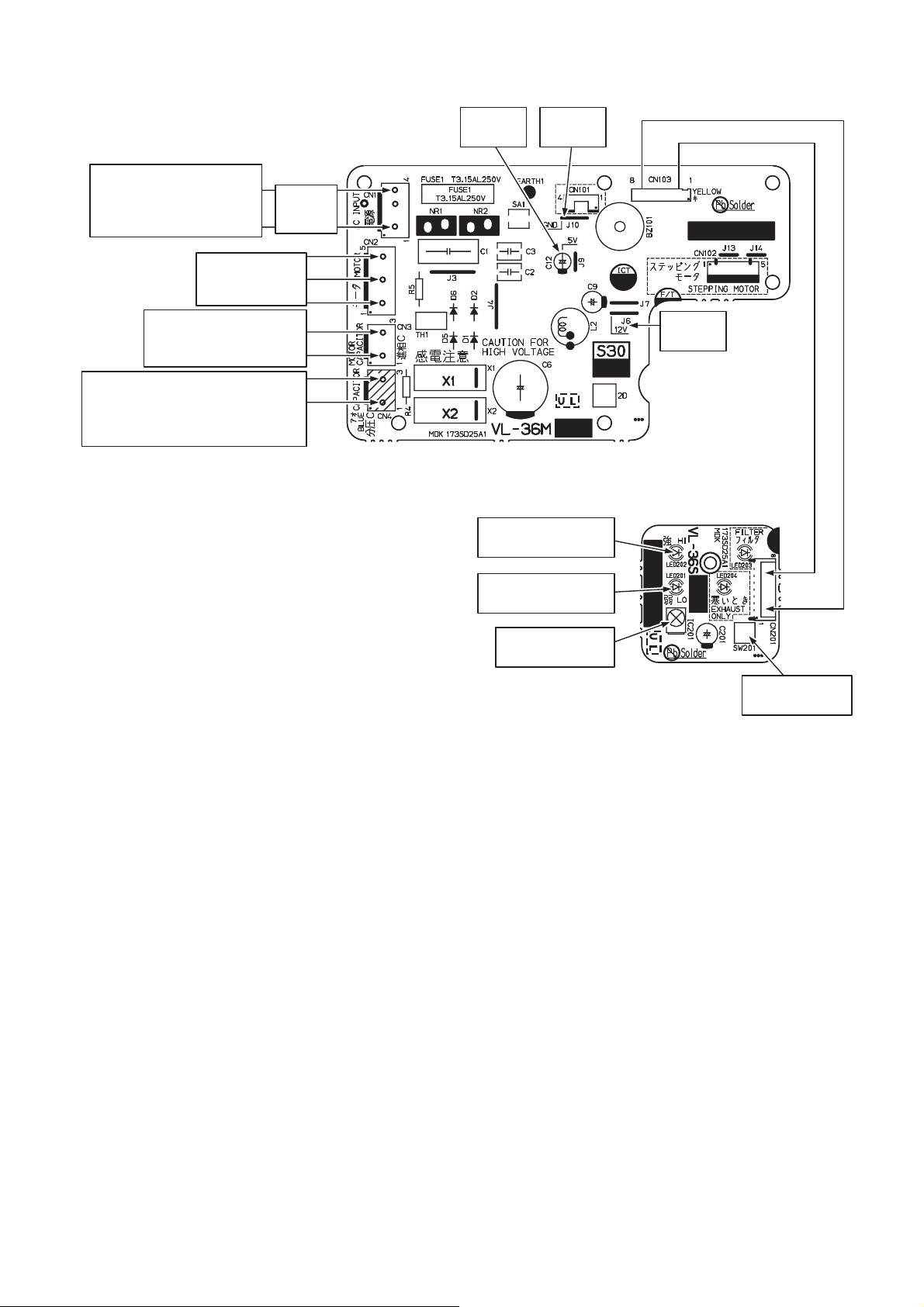

7. Circuit board diagrams

Circuit board diagrams and check points

(1) VL-50S

AC power supply input

220/230/240 VAC 50 Hz

220 VAC 60 Hz

White connector

Phase advance capacitor

White connector

2-E (Pull cord type)

Power cord

Motor

White connector

2 ȝF

Operation lamp

(green)

Not in use

<Display circuit board>

VL-35-B

Voltage-dividing capacitor

<Main circuit board>

VL-35-A

Blue

White

Red

ȝ)ȝ)

White connector

Switch with a pull cord

(2) VL-50ES2-E (Wall switch type)

AC power supply input

220/230/240 VAC 50 Hz

220 VAC 60 Hz

Control switch

Terminal block

Not in use

Motor

White connector

Phase advance capacitor

2 ȝF

White connector

<Display circuit board>

Red

Operation lamp

(green)

VL-35-B

Voltage-dividing capacitor

ȝ)ȝ)

White connector

Blue

White

<Main circuit board>

VL-35-A

─ 10 ─

Not in use

Page 11

(3) VL-50SR2-E (Remote controller type)

AC power supply input

220/230/240 VAC 50 Hz

220 VAC 60 Hz

White connector

White connector

Phase advance capacitor

2 ȝF

White connector

Voltage-dividing capacitor

ȝ)

(1ȝF and 2ȝF capacitors in series)

Blue connector

Motor

Terminal

block

5 V DC

(C12 (+))

<Main circuit board>

VL-36M

GND

(J10)

12 V DC

(J6)

<Display circuit board>

VL-36S

High operation lamp

(Green)

Low operation lamp

(Green)

Remote control

signal receiver IC

Operating mode

selection switch

─ 11 ─

Page 12

8. Principles of operation

(1) VL-50S2-E (Pull cord type)

• Operating mode (fan speed) can be switched from HI (High) to LO (Low) to OFF by using the switch with a

pull cord.

<Lighting status of the operation lamp under each operating mode>

Operating mode of the fan OFF HI LO

Operation lamp (LED1) Off Lit Lit

(2) VL-50ES2-E (Wall switch type)

• Operating mode (fan speed) can be switched by using the control switch. Operations may vary depending

on the switches installed.

220/230/240 V is applied between HI and COM2

220/230/240 V is applied between LO and COM2

<Lighting status of the operation lamp under each operating mode>

Operating mode of the fan OFF HI LO

Operation lamp (LED1) Off Lit Lit

HI (High)

LO (Low)

(3) VL-50SR2-E (Remote controller type)

• Operating mode (fan speed) can be selected from HI (High), LO (Low), and Power ON/OFF by using the

remote controller.

• Operating mode (fan speed) can be switched from HI (High) to LO (Low) to OFF by using the operating

mode selection switch on the main unit.

<Lighting status of the operation lamps under each operating mode>

Operating mode of the fan OFF HI LO

Operation lamp (LED201) Off Off Lit

Operation lamp (LED202) Off Lit Off

─ 12 ─

Page 13

9. Troubleshooting

Work precautions

• When servicing, be sure to recreate the malfunction two or three times before starting repairs.

• When servicing, always take care to keep proper footing.

• Before starting the service, always unplug the power cord from the outlet, or turn off the circuit breaker

when no power cord plug is provided. Sufficient care must be taken to avoid electric shock or injury.

• Make sure to connect the power supply wires correctly.

• When removing the circuit board, always hold it at both ends and remove carefully so as not to apply force

to the surface mounted parts.

• When removing the circuit board, be careful of the metal edges on the board.

• When removing or inserting the connectors for the circuit board, hold the entire housing section. Never pull

on the lead wires.

• When circuit board failure is considered to be a cause, check closely for any broken section on the copper

foil patterns, burning or discoloration of parts.

• After replacing a circuit board, make sure to restore the same settings as before the replacement.

The part names in the text are standardized with the part names in the parts catalog. (There are some

exceptions.)

(1) Service Flowchart

After checking the preliminary check items below, follow troubleshooting 1 and 2 for servicing.

Preliminary check items

1. Condition of trouble

2. Frequency of trouble:

The date of starting

operation and occurrence of trouble

Troubleshooting 1 Lossnay does not operate, or it stops by itself.

Check (2) Initialization checklist.

Troubleshooting 2 Lossnay operates abnormally.

Check (3) Lossnay checklist.

Check "10. Before receiving repair requests."

─ 13 ─

Page 14

(2) Initialization checklist

Troubleshooting 1 Lossnay does not operate, or it stops by itself.

No.

Error Cause Action

1 Lossnay does

not operate.

<VL-50S

• Is the power plug connected to the

power source of the rated voltage?

<VL-50ES2-E, VL-50SR2-E>

2-E>

Supply the rated voltage 220/230/240 VAC.

If a power failure has occurred, wait for power

failure recovery.

• Is the rated voltage 220/230/240 VAC

supplied to the terminal block?

<VL-50ES

2-E, VL-50SR2-E>

Are there any poor connections of the

Check that the circuit breaker is ON.

Connect the lead wires securely.

terminal block?

<VL-50S

Is the following power supply connec-

2-E, VL-50SR2-E>

Connect the connector securely.

tor on the main circuit board securely

connected?

VL-50S2-E: CN2

VL-50SR2-E: CN1

Is the current fuse on the main circuit

board blown?

If the current fuse is blown, determine the

cause of the failure (abnormal voltage applica-

tion or wrong connection), and eliminate the

cause. Then, replace the main circuit board

together with the display circuit board.

Are there any problems with the main

circuit board or display circuit board?

Diagnose the problems of the circuit boards

by checking the Basic checklist for the major

components (Table 1). (See page 16.)

<VL-50S

Is the power cord properly plugged into

2-E>

Plug the power cord properly.

the wall outlet?

<VL-50S

Is the switch with a pull cord turned

2-E>

Turn ON the switch with a pull cord.

ON?

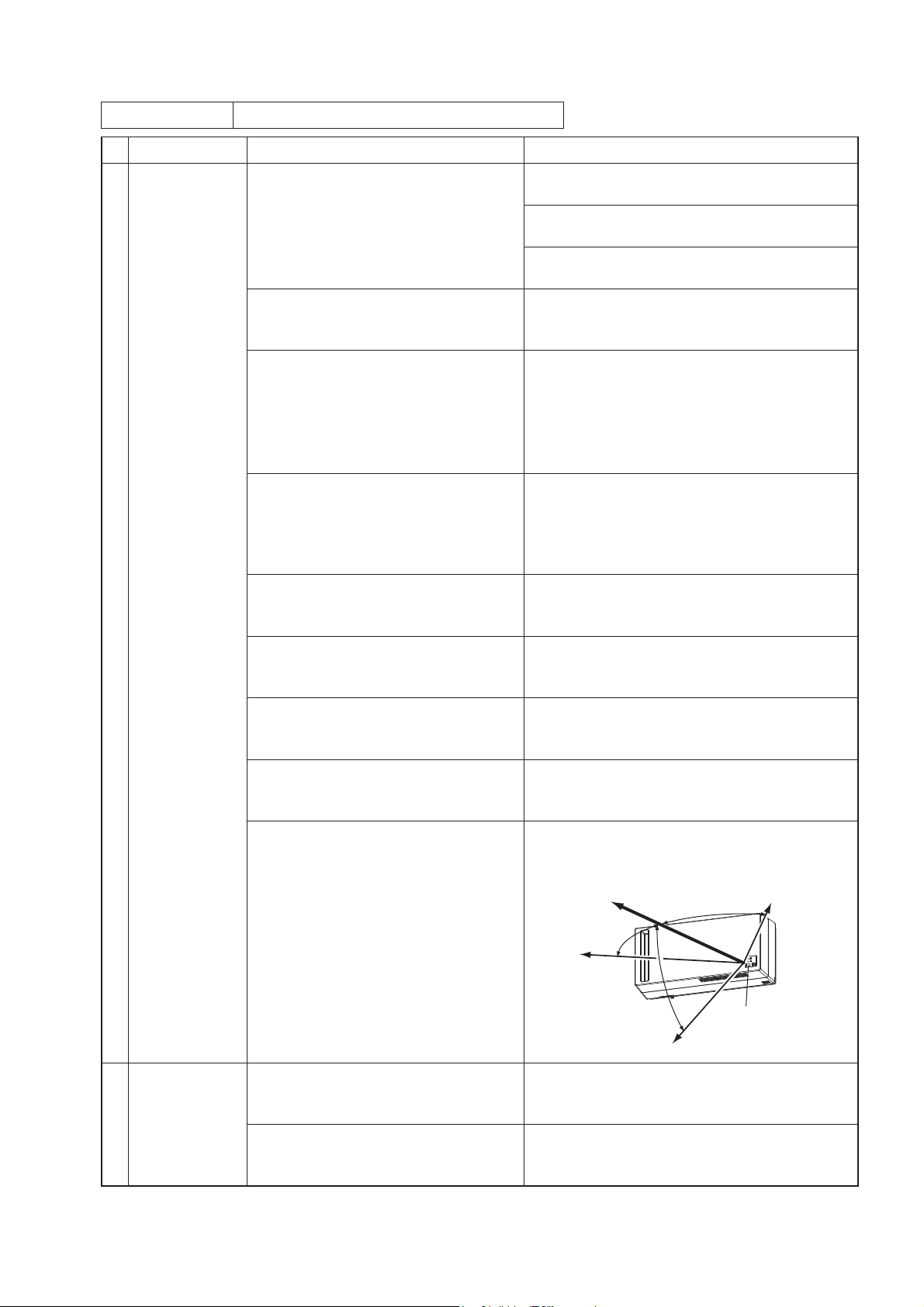

<VL-50SR

2-E>

Is the battery exhausted? Replace it with a commercially available lithium

battery (CR2025).

<VL-50SR

• Is the remote controller operated at

the position too far away from the

main unit?

• Is the remote controller case installed

outside the remote control signal

receiving range?

2-E>

The remote control signal receiving range is

shown below.

Front: 4 m

Left: 3 m

45°

45°

Right: 3 m

2 Lossnay stops

by itself.

<VL-50ES2-E, VL-50SR2-E>

Are there any poor connections of the

terminal block?

Are there any problems with the main

circuit board or display circuit board?

─ 14 ─

45°

Downward: 3 m

Receiver

Connect the lead wires securely.

Diagnose the problems of the circuit boards

by checking the Basic checklist for the major

components (Table 1). (See page 16.)

Page 15

(3) Lossnay checklist

Troubleshooting 2 Lossnay operates abnormally.

No.

Error Cause Action

1 The shutters

do not open or

close.

2 The fans do not

rotate.

3 The fans do not

stop.

4 Operating mode

(fan speed) cannot be switched.

5 An unusual

noise comes

from the fans.

6 The operation

lamp does not

illuminate.

Is there any foreign matter or obstruction

Remove it.

around the shutters?

Are the shutters detached from guide rails

Attach the shutters properly.

of the casing?

Are the following connectors on the main

Connect the connectors securely.

circuit board securely connected ?

VL-50S2-E, VL-50ES2-E: CN3, CN4, CN5

VL-50SR2-E: CN2, CN3, CN4

Do the fan blades touch other components?

Is there any foreign matter around the fans?

Check for any abnormal area.

Replace any abnormal or defective parts.

Remove it.

Are there any problems with the motor? Diagnose the problems of the motor by

checking the Basic checklist for the major

components (Table 1). (See page 16.)

Is the voltage 220/230/240 V AC output

from the main circuit board?

Disconnect the following motor connector to

check the output voltage.

VL-50S

2-E, VL-50ES2-E: CN3

VL-50SR2-E: CN2

(See page 16.)

<VL-50S

Do the fans continue operating even if the

switch with a pull cord is turned OFF?

<VL-50S

Is the switch with a pull cord caught on

2-E>

If the fans do not stop operating, replace the

switch.

2-E>

Eliminate the cause of catching.

some components?

<VL-50S

Does the switch with a pull cord work

properly?

2-E>

Operate the switch to check whether it ob-

tains click feeling. If there are any prob-

lems, replace the switch.

Are there any problems with the main

circuit board or display circuit board?

Diagnose the problems of the circuit boards

by checking the Basic checklist for the major

components (Table 1). (See page 16.)

Is there any foreign matter around the fans?

Are there any odd feelings when rotating

the fan?

Does the motor generate abnormal

noise?

Remove it.

If there are any odd feelings, replace the

motor.

Diagnose the problems of the motor by

checking the Basic checklist for the major

components (Table 1). (See page 16.)

Are the Lossnay core and filters properly

Install the Lossnay core and filters properly.

installed? (Check the installation directions and positions.)

Is the LED on the display circuit board

tilted?

Is the following connector on the display

Attach the LED case cover so that the LED is

positioned in the hole of the LED case cover.

Connect the connector securely.

circuit board securely connected?

VL-50S

VL-50SR

Are there any problems with the main

circuit board or display circuit board?

2-E, VL-50ES2-E: CN1

2-E: CN201

Diagnose the problems of the circuit boards

by checking the Basic checklist for the major

components (Table 1). (See page 16.)

─ 15 ─

Page 16

No.

7 The front

8 Cold air or wind

Error Cause Action

Are the Lossnay core and filters properly

panel cannot be

closed.

installed? (Check the installation directions and positions.)

Are the shutters being kept open when

comes into the

the fans are stopped?

room.

Basic checklist for the major components (Table 1)

No.

Components Judging instructions

1 Motor Check the coil resistance.

Disconnect the following connector from the main circuit board, and then measure

the resistance between the motor lead wires.

VL-50S

2-E, VL-50ES2-E: CN3

VL-50SR2-E: CN2

See Chapter 6. (2) Motor coil diagram (page 9) for the resistance values.

In the case of an open circuit or short circuit, replace the motor.

2 Switch with a pull

cord

(VL-50S

2-E only)

Remove the switch from the main unit. Measure the resistance at the weld for the

wire connection on the backside of the switch.

If the resistance differs from the values listed below, replace the switch.

Install the Lossnay core and filters properly.

Move the shutter knob to the CLOSE posi-

tion.

Color of wires

Red - White High

Red - Blue Low

3 Display circuit

board

[1] Check the appearance.

• Check whether the circuit name is proper.

VL-50S2-E, VL-50ES2-E: VL-35-B

VL-50SR2-E: VL-36S

• Check if any parts are damaged.

• Check if any parts are stained with sticking liquid or the like.

• Check if the solder is cracked.

• Check if the circuit board is cracked.

[2] Check the operating mode selection switch (VL-50SR

• Are the connectors CN201 on the display circuit board and CN103 on the main

circuit board securely connected?

• If the operating mode selection switch does not work, even though the remote controller is operable, replace the display circuit board together with the main circuit

board.

If any of the above items is not satisfied, replace the display circuit board together

with the main circuit board.

4 Main circuit board [1] Check the appearance.

• Check whether the circuit name is proper.

VL-50S

2-E, VL-50ES2-E: VL-35-A

VL-50SR2-E: VL-36M

• Check if any parts are damaged.

• Check if any parts are stained with sticking liquid or the like.

• Check if the solder is cracked.

• Check if the circuit board is cracked.

• Check if the varistors NR1 and NR2 are damaged.

( If they are damaged, it is due to application of an abnormal voltage. (Wrong instal-

lation work))

Operating mode

(fan speed)

Resistance

Short-circuited

2-E only)

─ 16 ─

Page 17

No.

Components Judging instructions

4 Main circuit board [2] Check the motor drive.

• Motor: Measure the voltage between the pins of the following connector.

VL-50S

VL-50SR

2-E, VL-50ES2-E: CN3

2-E: CN2

At high fan speed output: Between 1 and 5 pins: 220/230/240 V AC ± 5 V

At low fan speed output: Between 1 and 5 pins: 80 V AC or more

For details of the above checkpoints, see Chapter 7. Circuit board diagrams.

If any of the above items is not satisfied, replace the main circuit board together with

the display circuit board.

5 Remote controller

(VL-50SR

2-E only)

• Check if the battery is old. (Battery voltage 2.9 V or more is required.)

• If the remote controller does not work, even though the operating mode selection

switch is operable, the remote controller might be broken.

( Take a digital photo of the transmitter part on the remote controller to check

whether infrared rays are emitted from the remote controller.)

10. Before receiving repair requests

Frequently asked question Response

The incoming air feels cold. Has the outside air temperature dropped?

If the outside air temperature has dropped, switch the operating mode to

"Exhaust only mode," or stop the operation and close the shutters.

When switching the operating

mode or adjusting the shutter knob,

there is a noise inside the product.

The product does not operate. [1]

The operation sound becomes

louder.

The air volume is low. If the filters are clogged, clean them in accordance with the operating

No air is coming from the product.

Not much air is coming from the

product.

The front panel cannot be closed. If Lossnay core and filters are not properly installed, reinstall them prop-

When adjusting the shutter knob,

there is a noise inside the product.

Cold air or wind comes in more

than usual when the product is

stopped.

Operation sensitivity of the remote controller is low.

(VL-50SR

2-E only)

This sound is the operation sound of the motor or shutters in the product.

It is not a malfunction.

The power plug is almost detached from the wall outlet. (VL-50S2-E only)

[2] The circuit breaker on the distribution board is OFF.

[3] A power failure has occurred.

[1] If the front panel or the filters are almost detached (or tilted), reinstall

them properly.

[2] If the shutters are closed, adjust the shutter knob to the OPEN position.

[3] If the filters are clogged, clean them in accordance with the operating

instructions.

instructions.

If the shutters are closed, adjust the shutter knob to the OPEN position.

erly. (For example, a component is out of position or inserted backwards.)

This sound is the operation sound of the shutters in the product. It is not a

malfunction.

If the shutters are being kept open, adjust the shutter knob to the CLOSE

position.

[1] Check if the battery is weak. (Replace it with a commercially available

lithium battery (CR2025).)

[2] Check if the remote controller is operated at the position too far away

from the product, or at the improper angle. (See page 14.)

Operation sensitivity of the infrared remote controller can be affected by

[3]

strong light such as sunlight or room illumination. It is not a malfunction.

[4] Electromagnetic waves can affect the operation sensitivity at the loca-

tions in close proximity of electronic devices such as a television. It is

not a malfunction.

─ 17 ─

Page 18

11. Service inspection list

Front panel

Hook

Wire

Front panel

Wire

Hook

Front panel

Front panel

Location Inspection Item Check Result

Electric

wiring

Are the power lead wires securely connected to the terminal block?

(VL-50ES

Is the wiring correct?

Is the product securely mounted?

Does Lossnay operate as described in the operating Instructions when operating the switch?

2-E and VL-50SR2-E only)

Appliance

Is the fan rotating?

Are the connectors securely connected?

Do the shutters work?

Does Lossnay operate without abnormal vibration or noise?

12. Overhauling procedures

Work precautions

• Before replacing parts, follow the instructions described in the troubleshooting.

• When servicing, always keep proper footing.

• When servicing, always unplug the power cord from the outlet, or turn off the circuit breaker. Pay sufficient

attention to avoid electric shock or injury.

• Always connect the power wires properly.

• Pay attention not to drop the parts or components.

• After completing repairs, check that the product operates properly.

Always wear a pair of gloves when servicing.

The part names in the text are standardized with the part names in the parts catalog. (There are some exceptions.)

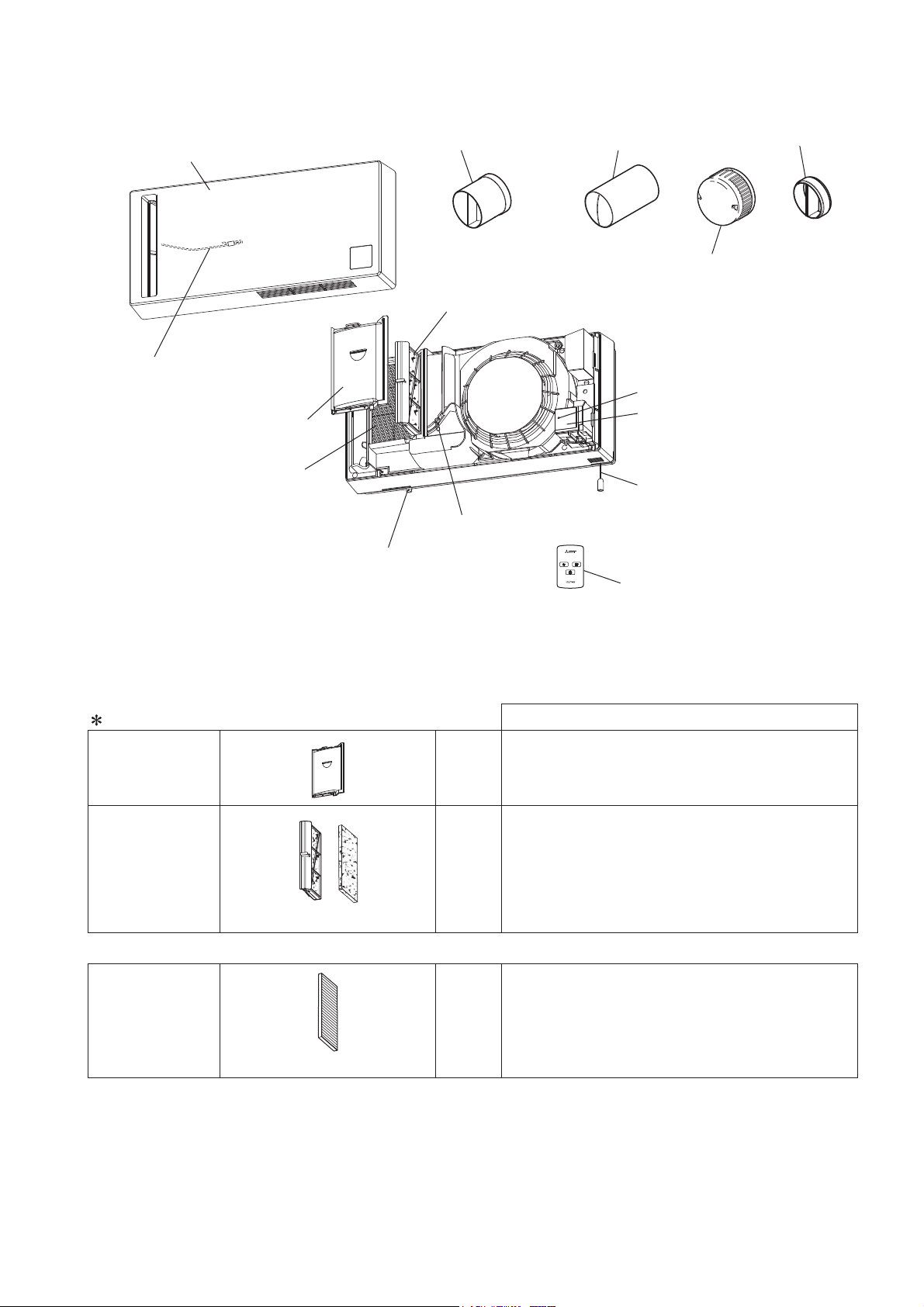

12-1 VL-50S2-E, VL-50ES2-E

(1) Turn off the power.

[1] Stop the operation by turning off the switch.

[2] Turn off the circuit breaker on the distribution board, or unplug the power cord.

(2) Remove the front panel.

[1] Hold both ends of the front panel, and pull it forward.

[2] Suspend the detached front panel by using the wire.

Precautions

• When removing the front panel from the main unit, hold the hook to disengage the wire.

• Do not shake the suspended front panel. (The wallpaper could be damaged.)

<When the unit is installed vertically><When the unit is installed horizontally>

─ 18 ─

Page 19

Terminal block

Bush

Ground cable

Ground screw

Cord clamp

Lead-in opening

Power cable

Mounting

plate

Main unit

PCB case cover

(3) Dismount the main unit.

For VL-50ES2-E

[1] Remove the PCB case cover.

Unscrew the screws (one PTT screw 4×8, indicated by

Reassembly precaution

Tightening torque for the screws: 1.1 N.m

[2] Disconnect the power cable and ground cable

from the main unit.

, and one PP screw 3×8, indicated by ).

For both models

[3] Unscrew the screws (four special screws 4x10.5,

indicated by ), and dismount the main unit.

Precaution

Pay attention to unhook the main unit from the

unit fixing screw (one special screw 4x10.5, indicated by

) on the mounting plate.

Reassembly precaution

Tightening torque for the screws: 1.1 N.m

* The figure shows VL-50ES2-E.

─ 19 ─

Page 20

(4) Remove the display circuit board (VL-35-B).

[1] Unscrew the screw (one PTT screw 4x12, indi-

cated by

parts together with the LED case cover and LED

case.

Reassembly precaution

Tightening torque for the screw: 1.1 N.m

[2] Remove the LED case cover, and unscrew the

screw (one PPT screw 3x8, indicated by ).

Reassembly precaution

Tightening torque for the screw: 0.7 N.m

), and remove the display circuit board

LED case cover

LED case

[3] Disconnect the connector from the display circuit

board, and remove the circuit board (VL-35-B).

Reassembly precaution

Securely connect the connector to the display

circuit board.

ConnectorDisplay circuit board (VL-35-B)

─ 20 ─

Page 21

Insert

Fan side

Lossnay Core

Guide

Marking

Guide rail

Marking on the

Lossnay core

Exhaust air filter

Outside air filter

Filter frame

Tab

Outside air filter

bb

aa

Tab

Press

Lossnay Core

(5) Remove the Lossnay core and filters.

[1] Remove the exhaust air filter from the main unit.

a. Hold the filter as shown in the figure.

b. Unhook the top part of the filter, and pull for-

ward to remove it.

[2] Hold the knob of the outside air filter to pull it out,

and remove it from the main unit.

[3] Remove the outside air filter from the filter frame.

a. Press the tabs (two locations) to open the filter

frame.

b. Remove the outside air filter.

[4] Pull out the Lossnay core.

Reassembly precautions

• When installing the Lossnay core, pay attention

not to curl the packing.

• Deeply insert the Lossnay core.

• Reinstall the Lossnay core as before.

* To install the Lossnay core in the correct direc-

tion, check the marking on the Lossnay core:

Insert" and " Fan side."

"

* Insert the guide of the Lossnay core into the

guide rails of the main unit.

─ 21 ─

Page 22

PCB cover

PCB case

(6) Remove the fan guard and fan casing (front).

[1] Unscrew the screws (three PTT screws 4x25,

indicated by

), and remove the fan guard.

Reassembly precaution

Tightening torque for the screws: 1.1 N.m

[2] Unscrew the screws (two PTT screws 4x14, indi-

cated by ), and remove the fan casing (front).

Reassembly precautions

• When attaching or removing the fan casing

(front), make sure to prevent it from contacting

with the part of the PCB box indicated by

.

• Tightening torque for the screws: 1.1 N.m

Reassembly precaution

When attaching the fan casing (front), fit its hole

onto the damper shaft that is assembled on the

fan casing.

Fan casing (front)

Fan casing (front)

Hole of the fan

casing (front)

Damper shaft

PCB box

Fan guard

(7) Remove the main circuit board (VL-35-A).

[1] Disengage the PCB box from the hook parts of

the casing (two locations, indicated by ).

[2] Unscrew the screw (one PT screw 4x8, indicated

), and remove the PCB cover.

by

Reassembly precaution

Tightening torque for the screw: 1.1 N.m

Damper

PCB box

─ 22 ─

* The figure shows VL-50S

2-E.

Page 23

[3] Remove the rivets (four pieces, indicated by ),

and remove the main circuit board (VL-35-A).

Reassembly precautions

• Fasten the motor lead tube, ground wire for the

motor, and power cord with the lead wire clip.

• Make sure that the lead wires for the display

circuit board come out from the cutout of the

PCB case (indicated by

).

Motor lead tube

Ground wire

for the motor

Power cord

Lead wire clip

PCB case

For VL-50S2-E

Reassembly precaution

The pull cord for the switch must be drawn out

to the left side of the spacer as shown in the

picture.

(8) Remove the centrifugal fans and motor.

[1] Remove the damper.

Main circuit board

(VL-35-A)

* The figure shows VL-50S

Lead wires for the

display circuit board

Pull cord

2-E.

Spacer

[2] Unscrew the clamping screw for the motor fix

plate (one PTT screw 4x12, indicated by

).

Reassembly precaution

Tightening torque for the screw: 1.1 N.m

─ 23 ─

Damper

Motor fix plate

Page 24

Centrifugal fan

(Air exhaust fan)

Centrifugal fan

(Air supply fan)

Motor

Lead cover

White

Black

Shutter (for supply air)

Casing

Shutter (for exhaust air)

Reassembly precautions

• Attach the damper to the fan casing so that the damper shaft is not tilted.

•

Insert the protrusion of the damper shaft (indicated by ) into the hole of the fan casing (front). (See page 22.)

Damper

[3] Remove the special nut (M8) and tab washer (one

each, indicated by ), and remove the centrifugal fan together with the special washer (8) (one

each, indicated by ).

Reassembly precaution

Tightening torque for the nut: 2.0 N.m

[4] Unscrew the screws (two PTT screws 4x10, indi-

cated by ), and remove the lead cover.

Reassembly precautions

• Insert the lead cover

under the motor when

attaching it. (Indicated by

)

• Tightening torque for the screws: 1.6 N.m

[5] Unscrew the screws (four PTT screws 4x10, indi-

cated by

Reassembly precaution

Tightening torque for the screws: 1.6 N.m

), and remove the motor.

Lead cover

Fan casing

Damper

(9) Remove the shutters.

• Remove the shutters (for supply/exhaust air) from

the casing.

Reassembly precautions

• Make sure that the shutter (for exhaust air) is

securely hooked on the claws and hollows of

the casing. (Three locations, indicated by

• Make sure that the shutter (for supply air) is securely hooked on the claws and protrusions of

the casing and shutter (for exhaust air). (Three

locations, indicated by )

When reassembling

Reassemble the unit in the reverse order of disassembly.

After reassembly, always make a test run to make

sure that the unit operates properly.

)

─ 24 ─

Page 25

12-2 VL-50SR2-E

Front panel

Hook

Wire

Front panel

Wire

Hook

Front panel

Front panel

Terminal block

Bush

Ground cable

Ground screw

Cord clamp

Lead-in opening

Power cable

PCB case cover

(1) Turn off the power.

[1] Stop the operation.

[2] Turn off the circuit breaker on the distribution board.

(2) Remove the front panel.

[1] Hold both ends of the front panel, and pull it forward.

[2] Suspend the detached front panel by using the wire.

Precautions

• When removing the front panel from the main unit, hold the hook to disengage the wire.

• Do not shake the suspended front panel. (The wallpaper could be damaged.)

<When the unit is installed vertically><When the unit is installed horizontally>

(3) Dismount the main unit.

[1] Remove the PCB case cover.

Unscrew the screws (one PTT screw 4×8, indicated by , and one PP screw 3×8, indicated by ).

Reassembly precaution

Tightening torque for the screws: 1.1 N.m

[2] Disconnect the power cable and ground cable

from the main unit.

─ 25 ─

Page 26

Mounting

plate

Main unit

[3] Unscrew the screws (four special screws 4x10.5,

indicated by ), and dismount the main unit.

Precaution

Pay attention to unhook the main unit from the

unit fixing screw (one special screw 4x10.5, indicated by

Reassembly precaution

Tightening torque for the screws: 1.1 N.m

) on the mounting plate.

(4) Remove the display circuit board (VL-36S).

[1] Unscrew the screw (one PTT screw 4x12, indi-

cated by

parts together with the LED case cover and LED

case.

Reassembly precaution

Tightening torque for the screw: 1.1 N.m

[2] Remove the LED case cover, and unscrew the

screw (one PPT screw 3x8, indicated by ).

Reassembly precaution

Tightening torque for the screw: 0.7 N.m

), and remove the display circuit board

LED case cover

LED case

[3] Disconnect the connector from the display circuit

board, and remove the circuit board (VL-36S).

Reassembly precaution

Securely connect the connector to the display

circuit board.

─ 26 ─

ConnectorDisplay circuit board (VL-36S)

Page 27

Insert

Fan side

Lossnay Core

Guide

Marking

Guide rail

Marking on the

Lossnay core

Exhaust air filter

Outside air filter

Filter frame

Tab

Outside air filter

bb

aa

Tab

Press

Lossnay Core

(5) Remove the Lossnay core and filters.

[1] Remove the exhaust air filter from the main unit.

a. Hold the filter as shown in the figure.

b. Unhook the top part of the filter, and pull for-

ward to remove it.

[2] Hold the knob of the outside air filter to pull it out,

and remove it from the main unit.

[3] Remove the outside air filter from the filter frame.

a. Press the tabs (two locations) to open the filter

frame.

b. Remove the outside air filter.

[4] Pull out the Lossnay core.

Reassembly precautions

• When installing the Lossnay core, pay attention

not to curl the packing.

• Deeply insert the Lossnay core.

• Reinstall the Lossnay core as before.

* To install the Lossnay core in the correct direc-

tion, check the marking on the Lossnay core:

Insert" and " Fan side."

"

* Insert the guide of the Lossnay core into the

guide rails of the main unit.

─ 27 ─

Page 28

PCB cover

PCB case

(6) Remove the fan guard and fan casing (front).

[1] Unscrew the screws (three PTT screws 4x25,

indicated by

Reassembly precaution

Tightening torque for the screws: 1.1 N.m

[2] Unscrew the screws (two PTT screws 4x14, indi-

cated by ), and remove the fan casing (front).

Reassembly precautions

• When attaching or removing the fan casing

(front), make sure to prevent it from contacting

with the part of the PCB box indicated by

• Tightening torque for the screws: 1.1 N.m

Reassembly precaution

When attaching the fan casing (front), fit its hole

onto the damper shaft that is assembled on the

fan casing.

), and remove the fan guard.

.

Fan casing (front)

Fan casing (front)

Hole of the fan

casing (front)

Damper shaft

PCB box

Fan guard

(7) Remove the main circuit board (VL-36M).

[1] Disengage the PCB box from the hook parts of

the casing (two locations, indicated by ).

[2] Unscrew the screw (one PT screw 4x8, indicated

by ), and remove the PCB cover.

Reassembly precaution

Tightening torque for the screw: 1.1 N.m

Damper

PCB box

─ 28 ─

Page 29

[3] Turn over the insulator sheet

Lead wires for

the display circuit board

Insulator

sheet

Motor

lead tube

Ground wire

for the motor

Lead wire clip

Insulator sheet

[4] Remove the rivets (six pieces, indicated by ),

and remove the main circuit board (VL-36M).

Reassembly precaution

Make sure that the lead wires for the display circuit board come out from the cutout of the PCB

case (indicated by

).

Reassembly precaution

Fasten the motor lead tube and ground wire with

the lead wire clip.

Main circuit board

(VL-36M)

PCB case

Lead wires for the

display circuit board

─ 29 ─

Page 30

Centrifugal fan

(Air exhaust fan)

Centrifugal fan

(Air supply fan)

Motor

Lead cover

White

Black

(8) Remove the centrifugal fans and motor.

[1] Remove the damper.

[2] Unscrew the clamping screw for the motor fix

plate (one PTT screw 4x12, indicated by

Reassembly precaution

Tightening torque for the screw: 1.1 N.m

Reassembly precautions

Attach the damper to the fan casing so that the damper shaft is not tilted.

•

•

Insert the protrusion of the damper shaft (indicated by

(See page 28.)

).

) into the hole of the fan casing (front).

Damper Motor fix plate

Damper

[3] Remove the special nut (M8) and tab washer (one

each, indicated by

), and remove the centrifugal fan together with the special washer (8) (one

each, indicated by

).

Reassembly precaution

Tightening torque for the nut: 2.0 N.m

[4] Unscrew the screws (two PTT screws 4x10, indi-

cated by

), and remove the lead cover.

Reassembly precautions

• Insert the lead cover

under the motor when

attaching it. (Indicated by

)

Lead cover

• Tightening torque for the screws: 1.6 N.m

[5] Unscrew the screws (four PTT screws 4x10, indi-

cated by

Reassembly precaution

), and remove the motor.

Tightening torque for the screws: 1.6 N.m

─ 30 ─

Fan casing

Damper

Page 31

Shutter (for supply air)

Casing

Shutter (for exhaust air)

(9) Remove the shutters.

• Remove the shutters (for supply/exhaust air) from

the casing.

Reassembly precautions

• Make sure that the shutter (for exhaust air) is

securely hooked on the claws and hollows of

the casing. (Three locations, indicated by

• Make sure that the shutter (for supply air) is securely hooked on the claws and protrusions of

the casing and shutter (for exhaust air). (Three

locations, indicated by )

When reassembling

Reassemble the unit in the reverse order of disas-

sembly.

After reassembly, always make a test run to make

sure that the unit operates properly.

)

─ 31 ─

Page 32

13. Parts catalog

Please note the following when using the parts catalog.

1. When ordering parts, always indicate the part number, part name, and the number of

parts required.

2. It may take time for you to receive the parts. Make an inquiry about a rush order.

3. No further notice if the specification changes.

4. Parts marked with and are critical for safety.

5. To maintain safety and performance, always replace the parts with the parts prescribed.

Description of screw abbreviations

Screw

Abbreviation Description

PC screw Cross recess fl at head machine screw

PRC screw Cross recess oval head machine screw

PP screw Cross recess pan head machine screw

SW · PP screw Cross recess pan head screw with spring washer

PPT screw Cross recess tapping screw

PCT screw Cross recess fl at head tapping screw

PTT screw Cross recess truss head tapping screw

PT screw Cross recess truss head machine screw

SET screw Slotted head stop screw

SQ · SET screw Square head stop screw

P · SET screw Pan head stop screw

PMT screw Primer truss head screw

HS · SET screw Hexagon head stop screw

P · R · W screw Cross recess round wood screw

4

×

Screw diameter Length

16

P · C · W screw Cross recess fl at head wood screw

P · R · C · W screw Cross recess round and fl at wood screw

R · W screw Slotted round wood screw

PW · PP screw Cross recess pan head screw with small washer

SW-PW · PP screw Cross recess pan head machine screw with spring washer and fl at washer

─ 32 ─

Page 33

20

22 23

14

15

16

17

8

9

1

2

3

4

5

6

7

18

19

1615

21

24

25

26

e

e

a

(

2 pcs.

)

b

f

d

g

(

3 pcs.

)

(

6 pcs.

)

(

5 pcs.

)

c

1 pc.

3 pcs.

5 pcs.6 pcs.

(

2 pcs.

)

VL-50S2-E

<Standard screws>

Symbol Screw name

a PTT screw 4x14

b PTT screw 4x8

c PTT screw 4x12

d PTT screw 3x8

e PTT screw 4x12

f PP screw 3x8

g PTT screw 4x25

VL-50S2-E

─ 33 ─

shows accessory parts.

Page 34

VL-50S2-E

Q'ty

pcs/unit

1 Front panel Y36 011 719 1

2 Wire M36 357 343 1

3 Special washer M34 225 091 1

4 Filter M36 357 718 1 Exhaust air

5 Lossnay core Y36 011 710 1

6 Filter Y36 013 717 1 Supply air

7 Filter frame M36 357 717 1 Supply air

8 Fan guard Y36 011 717 1

9 PCB case cover Y36 011 706 1

14 Casing M36 428 830 1

15 Special screw 3.5x32 M34 863 045 6

16 Special screw 4x10.5 M36 182 045 5

17 Mounting plate M36 169 706 1

18 Power cord Y36 011 220 1 3200mm

19 Cord clip Y36 011 223 1

20 Pipe M36 428 313 2 (Air supply/Exhaust)

21 Flange M36 169 719 1

22 Packing (flange) M36 172 718 1 153X5mm

23 Aluminium tape M36 428 389 3 450mm

24 Weather cover Y36 011 720 1

25 Joint pipe Y36 011 313 1

26 Joint pipe Y36 011 712 1

Critical

for

safety

RemarksNo. Name of part Parts No.

─34─

Page 35

31

32

33

34

34

35

36

37

39

38

40

41

42

43

44

45

46

48

49

47

52

53

31

32

44

54

55

50

51

51

56

58

59

57

Air supply fan

Air exhaust fan

For exhaust air

For supply air

61

60

62

j

m

(

4 pcs.

)

m (2 pcs.

)

c

b

(

2 pcs.

)

b (2 pcs.

)

(

4 pcs.

)

p

p

p

k

c

h

<Standard screws>

Symbol Screw name

b PTT screw 4x8

c PTT screw 4x12

h PTT screw 3x8

j PP screw 4x10

k PTT screw 4x30

m PTT screw 4x10

p PT screw 4x8

VL-50S2-E

─ 35 ─

Page 36

VL-50S2-E

No. Name of part Parts No.

31 Special nut (M8) Y36 011 067 2

32 Tab washer M36 130 077 2

33 Centrifugal fan M36 357 481 1 φ170・Black

34 Special washer (8) M34 365 080 2 φ16 (Outer dia.)

35 Motor fix plate M36 357 704 1

36 Lead cover M36 357 705 1

37 Motor Y36 011 453 1

38 Centrifugal fan M36 357 480 1 φ170・Natural

39 Damper M36 357 715 1

40 Fan casing M36 360 830 1

41 Shutter M36 357 716 1

42 Shutter M36 360 715 1

43 Drain pan M36 360 721 1

44 Fix piece M36 230 345 2

45 PCB cover Y36 011 708 1

46 Spacer Y36 011 095 1

47 Switch Y36 004 255 1 With a pull cord

48 Circuit board Y36 011 171 1 VL-35-A・35-B

49 Insulator sheet Y36 011 390 1

50 PT screw 4x6 BS H00 009 008 2

51 Spring washer (4) H00 056 075 2

52 Lead wire clip M30 409 356 1

53 Capacitor cover M35 275 652 1

54 Capacitor Y36 013 231 1 2.0 μF・250 VAC

55 Capacitor case M35 768 653 1

56 Cord bush M45 649 226 1

57 Rivet M35 744 095 4

58 Capacitor assembly Y36 011 232 1 1.0 μF/2.0 μF

59 PCB case Y36 011 707 1

60 Decoration sheet Y36 011 369 1

61 LED case cover Y36 011 711 1

62 LED case Y36 011 709 1

Q'ty

pcs/unit

Critical

for

safety

Remarks

─36─

Page 37

14

15

16

17

8

9

1

2

3

4

5

6

7

18

20 21

1615

19

22

23

24

a

(

2 pcs.

)

b

f

d

g

(

3 pcs.

)

(

6 pcs.

)

(

5 pcs.

)

e

e

1 pc.

3 pcs.

5 pcs.6 pcs.

(

2 pcs.

)

VL-50ES2-E

<Standard screws>

Symbol Screw name

a PTT screw 4x14

b PTT screw 4x8

c PTT screw 4x12

d PTT screw 3x8

e PTT screw 4x12

f PP screw 3x8

g PTT screw 4x25

VL-50ES2-E

─ 37 ─

shows accessory parts.

Page 38

VL-50ES2-E

No. Name of part Parts No.

1 Front panel Y36 011 719 1

2 Wire M36 357 343 1

3 Special washer M34 225 091 1

4 Filter M36 357 718 1 Exhaust air

5 Lossnay core Y36 011 710 1

6 Filter Y36 013 717 1 Supply air

7 Filter frame M36 357 717 1 Supply air

8 Fan guard Y36 011 717 1

9 PCB case cover Y36 012 706 1

14 Casing M36 357 830 1

15 Special screw 3.5x32 M34 863 045 6

16 Special screw 4x10.5 M36 182 045 5

17 Mounting plate M36 169 706 1

18 Pipe M36 428 313 2 (Air supply/Exhaust)

19 Flange M36 169 719 1

20 Packing (flange) M36 172 718 1 153X5mm

21 Aluminium tape M36 428 389 3 450mm

22 Weather cover Y36 011 720 1

23 Joint pipe Y36 011 313 1

24 Joint pipe Y36 011 712 1

Q'ty

pcs/unit

Critical

for

safety

Remarks

─38─

Page 39

31

32

33

34

34

35

36

37

39

38

40

41

42

43

44

45

46

47

50

51

31

32

44

52

53

48

49

54

57

56

55

58

59

61

60

Air supply fan

Air exhaust fan

For exhaust air

For supply air

48

49

63

62

64

j

m

(

4 pcs.

)

m (2 pcs.

)

c

b

(

2 pcs.

)

b (2 pcs.

)

(

4 pcs.

)

k

k

k

k

k

c

h

<Standard screws>

Symbol Screw name

b PTT screw 4x8

c PTT screw 4x12

h PTT screw 3x8

j PP screw 3x20

k PT screw 4x8

m PTT screw 4x10

VL-50ES

2-E

─ 39 ─

Page 40

VL-50ES2-E

No. Name of part Parts No.

31 Special nut (M8) Y36 011 067 2

32 Tab washer M36 130 077 2

33 Centrifugal fan M36 357 481 1 Φ170・Black

34 Special washer (8) M34 365 080 2 φ16 (Outer dia.)

35 Motor fix plate M36 357 704 1

36 Lead cover M36 357 705 1

37 Motor Y36 011 453 1

38 Centrifugal fan M36 357 480 1 Φ170・Natural

39 Damper M36 357 715 1

40 Fan casing M36 360 830 1

41 Shutter M36 357 716 1

42 Shutter M36 360 715 1

43 Drain pan M36 360 721 1

44 Fix piece M36 230 345 2

45 PCB cover Y36 011 708 1

46 Circuit board Y36 011 171 1 VL-35-A・35-B

47 Insulator sheet Y36 011 390 1

48 PT screw 4X6 BS H00 009 008 2

49 Spring washer (4) H00 056 075 2

50 Lead wire clip M30 409 356 1

51 Capacitor cover M35 275 652 1

52 Capacitor Y36 013 231 1 2.0 μF・250 VAC

53 Capacitor case M35 768 653 1

54 Cord bush M45 649 226 1

55 Rivet M35 744 095 4

56 PCB case Y36 012 707 1

57 Capacitor assembly Y36 011 232 1 1.0 μF/2.0 μF

58 Bush M35 460 225 1

59 TB fix plate Y36 012 708 1

60 Cord clip H00 143 223 1

61 Terminal block Y36 005 242 1 3P

62 Decoration sheet Y36 011 369 1

63 LED case cover Y36 011 711 1

64 LED case Y36 011 709 1

Q'ty

pcs/unit

Critical

for

safety

Remarks

─40─

Page 41

※

※

※

10

11

12

13

8

9

1

2

3

4

5

6

7

17

19 20

1211

18

21

22

23

15

14

16

(2 pcs.

)

a

(

2 pcs.

)

b

f

d

g

(

3 pcs.

)

(

6 pcs.

)

(

5 pcs.

)

e

e

1 pc.

3 pcs.

5 pcs.6 pcs.

(

2 pcs.

)

VL-50SR2-E

<Standard screws>

Symbol Screw name

a PTT screw 4x14

b PTT screw 4x8

c PTT screw 4x12

d PTT screw 3x8

e PTT screw 4x12

f PP screw 3x8

g PTT screw 4x25

VL-50SR2-E

─ 41 ─

shows accessory parts.

Page 42

VL-50SR2-E

No. Name of part Parts No.

1 Front panel Y36 011 719 1

2 Wire M36 357 343 1

3 Special washer M34 225 091 1

4 Filter M36 357 718 1 Exhaust air

5 Lossnay core Y36 011 710 1

6 Filter Y36 013 717 1 Supply air

7 Filter frame M36 357 717 1 Supply air

8 Fan guard Y36 011 717 1

9 PCB case cover Y36 012 706 1

10 Casing M36 357 830 1

11 Special screw 3.5x32 M34 863 045 6

12 Special screw 4x10.5 M36 182 045 5

13 Mounting plate M36 169 706 1

14 Remote controller Y36 013 171 1

15 Controller case M33 342 572 1

16 PRW screw 4.5×20 H00 059 030 2

17 Pipe M36 428 313 2 (Air supply/Exhaust)

18 Flange M36 169 719 1

19 Packing (flange) M36 172 718 1 153X5mm

20 Aluminium tape M36 428 389 3 450mm

21 Weather cover Y36 011 720 1

22 Joint pipe Y36 011 313 1

23 Joint pipe Y36 011 712 1

Q'ty

pcs/unit

Critical

for

safety

Remarks

─42─

Page 43

31

32

33

34

34

35

36

37

39

38

40

41

42

43

44

45

46

47

50

51

31

32

44

52

53

48

49

54

57

56

55

58

59

61

60

Air supply fan

Air exhaust fan

For exhaust air

For supply air

48

49

63

62

64

j

m (4 pcs.

)

m (2 pcs.

)

c

b

(

2 pcs.

)

b (2 pcs.

)

(

6 pcs.

)

k

k

k

k

k

c

h

<Standard screws>

Symbol Screw name

b PTT screw 4x8

c PTT screw 4x12

h PTT screw 3x8

j PP screw 3x20

k PT screw 4x8

m PTT screw 4x10

VL-50SR

2-E

─ 43 ─

Page 44

VL-50SR2-E

No. Name of part Parts No.

31 Special nut (M8) Y36 011 067 2

32 Tab washer M36 130 077 2

33 Centrifugal fan M36 357 481 1 φ170・Black

34 Special washer (8) M34 365 080 2 φ16 (Outer dia.)

35 Motor fix plate M36 357 704 1

36 Lead cover M36 357 705 1

37 Motor Y36 011 453 1

38 Centrifugal fan M36 357 480 1 φ170・Natural

39 Damper M36 357 715 1

40 Fan casing M36 360 830 1

41 Shutter M36 357 716 1

42 Shutter M36 360 715 1

43 Drain pan M36 360 721 1

44 Fix piece M36 230 345 2

45 PCB cover Y36 011 708 1

46 Circuit board Y36 013 172 1 VL-36M・36S

47 Insulator sheet Y36 013 390 1

48 PT screw 4X6 BS H00 009 008 3

49 Spring washer (4) H00 056 075 3

50 Lead wire clip M30 409 356 1

51 Capacitor cover M35 275 652 1

52 Capacitor Y36 013 231 1 2.0 μF・250 VAC

53 Capacitor case M35 768 653 1

54 Cord bush M45 649 226 1

55 Rivet M35 744 095 6

56 PCB case Y36 013 706 1

57 Capacitor assembly Y36 013 232 1 1.0 μF/2.0 μF

58 Bush M35 460 225 1

59 TB fix plate Y36 012 708 1

60 Cord clip H00 143 223 1

61 Terminal block Y36 013 233 1 3P・With leads

62 Decoration sheet Y36 013 369 1

63 LED case cover Y36 011 711 1

64 LED case Y36 011 709 1

Q'ty

pcs/unit

Critical

for

safety

Remarks

─44─

Loading...

Loading...