LOSSNAY

HANDBOOK

MODELS

VL-220CZGV-E

VL-220CZGV-EB

April 2016 No. U209

Nameplate

Remote controller (Optional)

PZ-61DR-E

PZ-43SMF-E

Filter (Optional)

P-220SHF-E

P-220EMF-E

P-220F-E

Warning:

Repair work must be performed by the manufacturer, its service

agent or a similarly qualified person in order to avoid hazards.

Contents

1. Safety precautions

2. Specifications

3. Names and functions of components

4. Outside dimensions

5. Electrical wiring diagram

6. Circuit board diagrams

7. Troubleshooting

8. Before receiving repair requests

9. Service inspection list

10. Overhauling procedures

11. Parts catalog

VL-220CZGV-E

VL-220CZGV-EB

........................................................................

.......................................................................

...............................................................................

...................................................................

.............................................................

..........................................................

....................................................................

...............................................

................................................................

.......................................................

...............................................................

.............................................................

..........................................

6-8

10-11

12-28

30-38

39-55

40-47

48-55

3

4

5

9

29

29

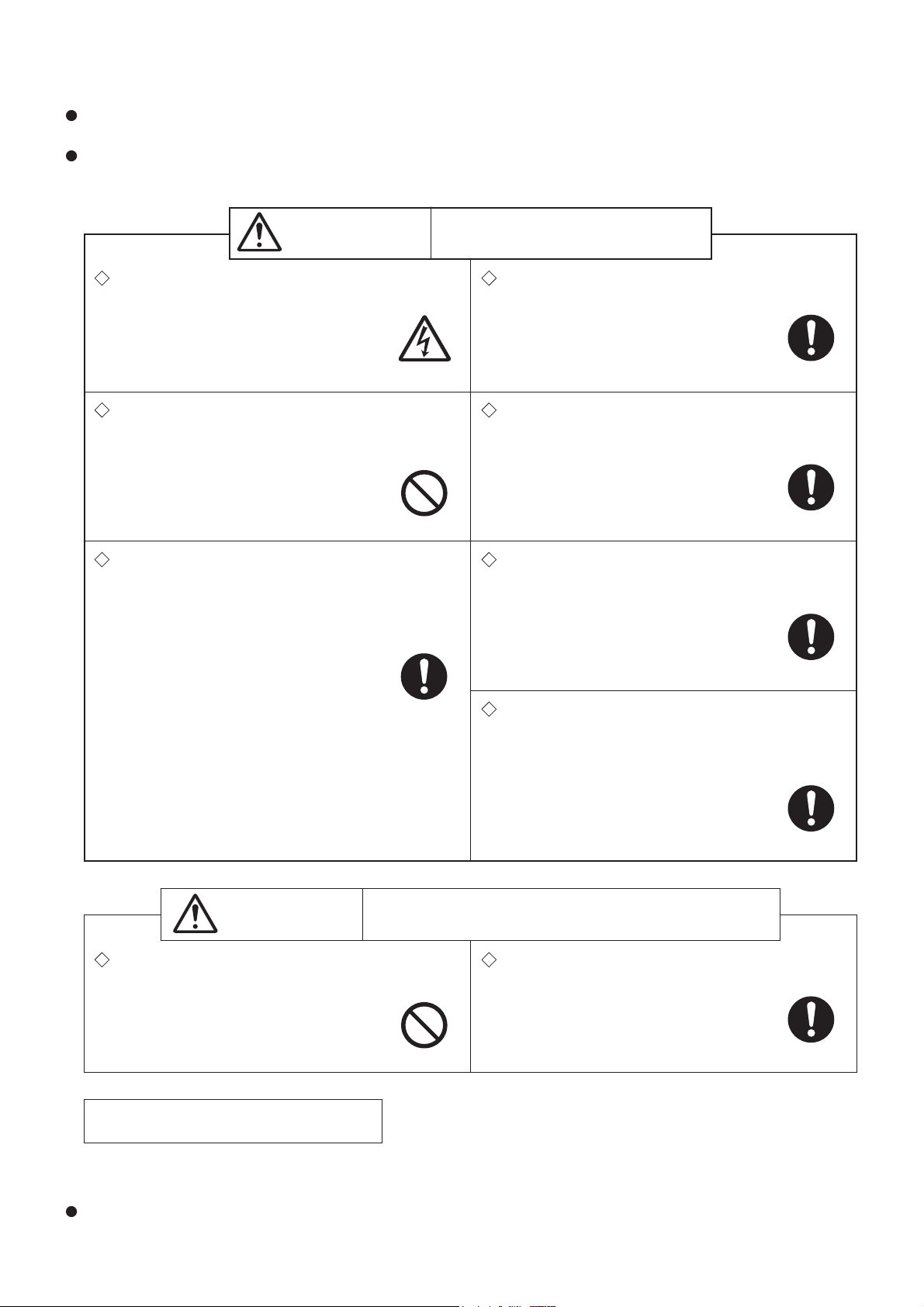

1. Safety precautions

Read the following precautions thoroughly before the maintenance, and then inspect and repair the product in a

safe manner.

The types and levels of danger that may arise if the product is handled incorrectly are described with the warning

symbols shown below.

Incorrect handling of the product may

Warning

result in serious injury or death.

Electric shock

If you must inspect the circuitry while the power is

on, do not touch the live parts.

(Failure to heed this warning may result

in electric shock.)

Caution against

electric shock

Modification is prohibited

Do not modify the unit.

(Failure to heed this warning may result

in electric shock, fire and/or injury.)

Prohibited

Proper electric work

Use the electric wires designated for electric work,

and conduct electric work in accordance with your

local "Electric Installation Engineering Standard",

the "Indoor Wiring Regulations" and the installation

instructions.

(Improper connection or wiring installation

may result in electric shock and/or fire.)

Be sure to follow

this instruction.

Turn off the power supply

Be sure to shut off the power supply isolator before

disassembling the unit for repair.

(Failure to heed this warning may result

in electric shock.)

Be sure to follow

this instruction.

Use proper parts and tools

For repair, be sure to use the parts listed in the

service parts catalog of the applicable model and

use the proper tools.

(Failure to heed this warning may result in

electric shock, fire and/or injury.)

Be sure to follow

this instruction.

Replace damaged and/or degraded parts

Be sure to replace the power cord and lead wires if

they are damaged and/or degraded.

(Failure to heed this warning may result

in electric shock and/or fire.)

Be sure to follow

this instruction.

Check insulation

Upon completing repair work, always measure the

insulation resistance. Verify that it is at least 10 MΩ

(with a 500-V DC insulation resistance tester), and

then turn on the power.

(Inadequate insulation may result in

electric shock.)

Be sure to follow

this instruction.

Incorrect handling of the product may result in injury or

Caution

Caution for injury

Do not work at a location where you do not have a

damage to properties including buildings and equipment.

Wear gloves

Wear gloves when servicing.

sure footing.

(Failure to heed this caution may result in

(Failure to heed this caution may result in

a fall.)

Prohibited

injury to your hands from sharp metal or

other edges.)

Be sure to follow

this instruction.

Notes for servicing

● Inspect the earth condition, and repair it if it is incomplete. Make sure that a power supply isolator or an overload protection device is installed, if it is not installed, recommend the customer to install one.

Make sure that the product operates properly upon completion of repair. Clean the product and the surrounding

area, and then notify the customer of the completion of repair.

─ 3 ─

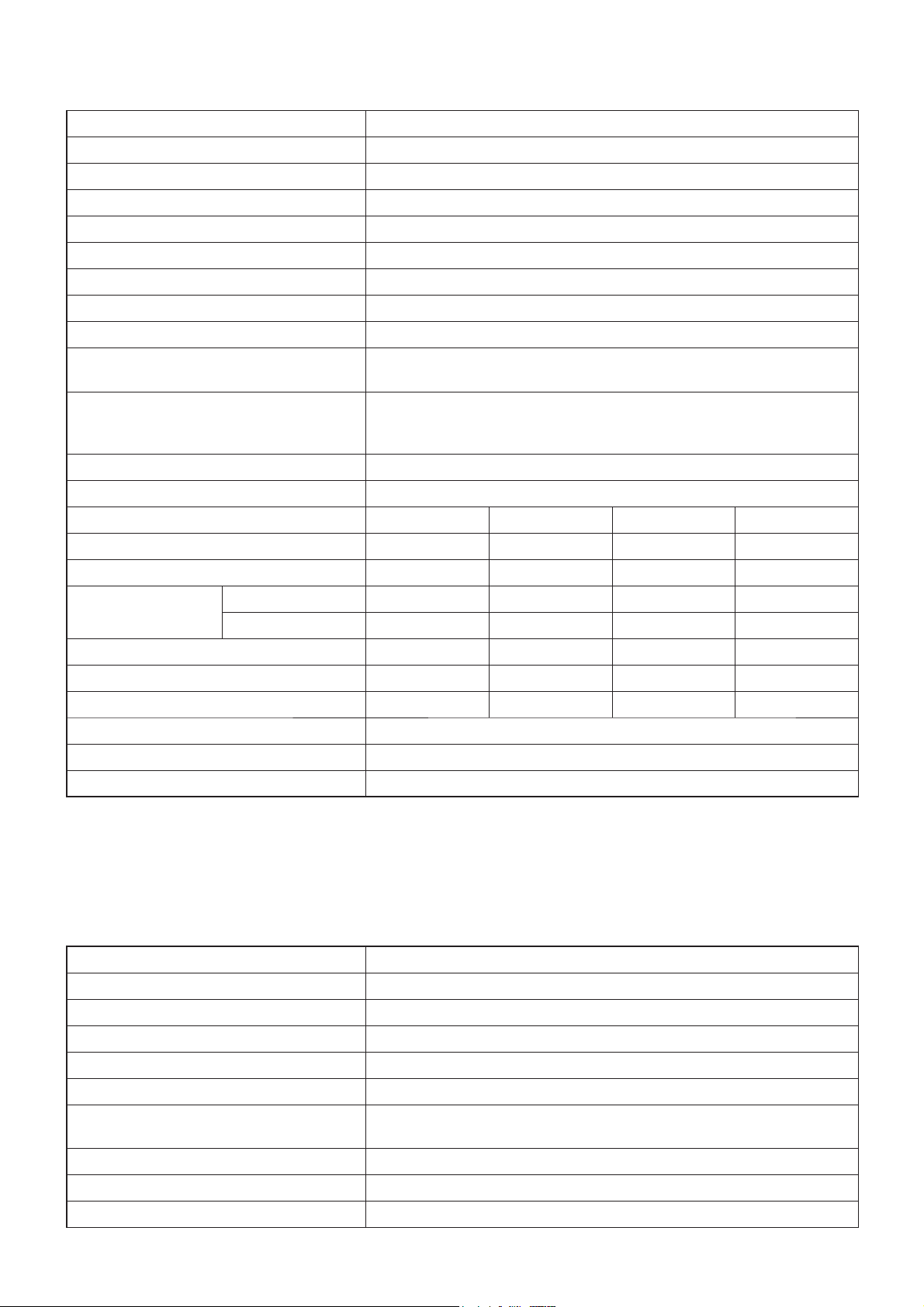

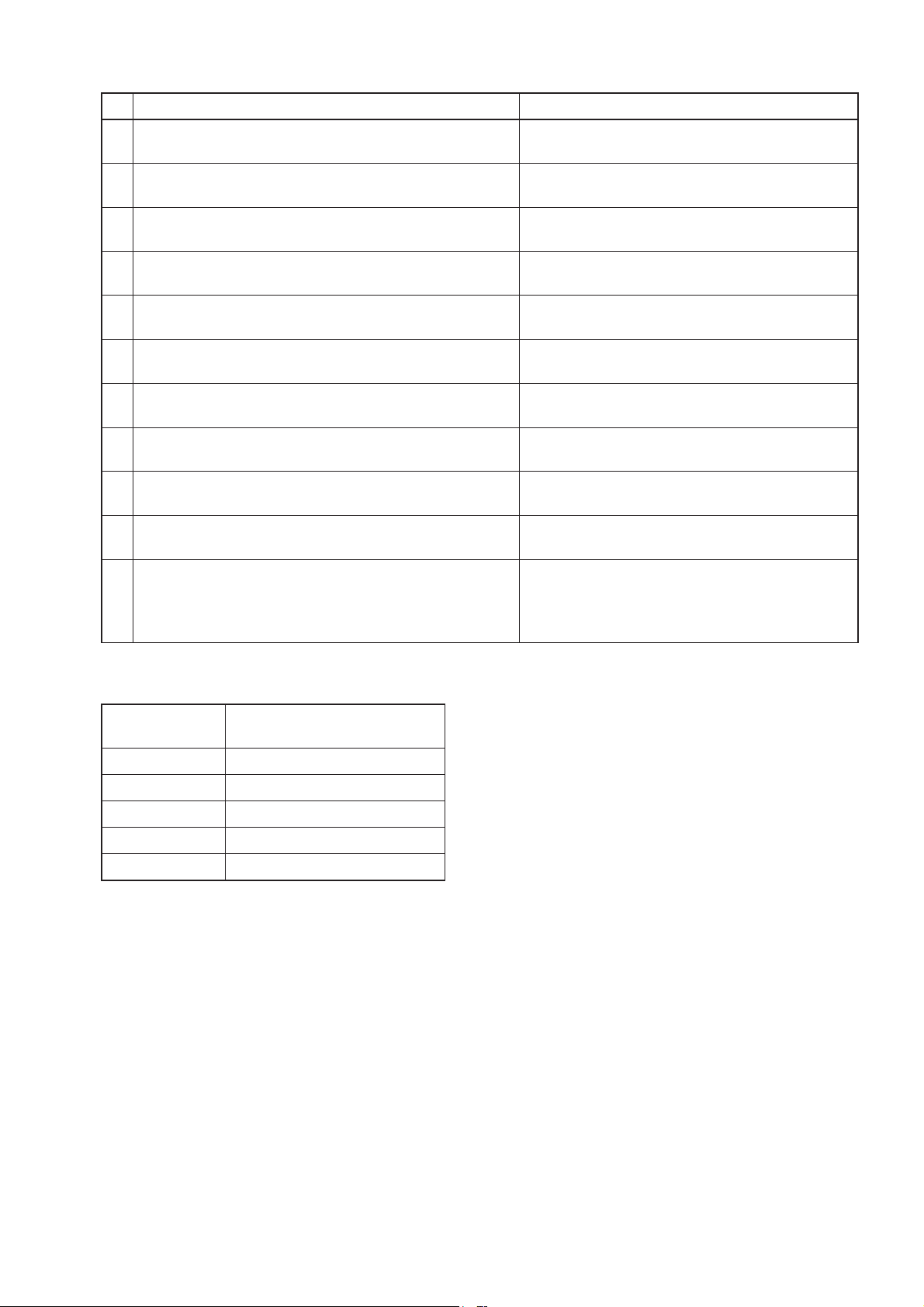

2. Specifications

Model name VL-220CZGV-E, VL-220CZGV-EB

Heat exchange system Heat recovery ventilating system

Heat exchanger material Water-resistant paper sensible heat exchanger

Cladding Galvanized steel sheet

Heat insulation material Noncombustibility polyethylene foam

Motor EC motor

Filter Non-woven fabrics filter (Gravitational method 82%, EN779: 2012: G3)

Surrounding air condition Shall be between 0°C and 40°C, 80%RH or less

Suction air condition Shall be lower than 40°C, 95%RH

Supply fan operation under low outdoor

temperature

Function

Electrical power supply 220-240 V/50 Hz, 220 V/60 Hz

Ventilation mode Heat recovery mode

Fan speed Fan speed 4 Fan speed 3 Fan speed 2 Fan speed 1

0°C to -5°C: Intermittent operation 24 min ON, 6 min OFF

-5°C or less: Continuous supply air stopped

Heat recovery ventilation/ Bypass ventilation, Fan speed 1,2,3,4

( When the optional motorized damper (P-133DUE-E) is used, bypass

ventilation mode can be switched.)

Running current (A) 0.60 0.29 0.18 0.11

Input power (W) 80 35 18.5 8.5

3

/h) 230 165 120 65

(m

Air volume

(L/S) 64 46 33 18

External static pressure (Pa) 164 84 44 13

Temperature exchange efficiency (%) 82 84 85 86

Noise (dB) 31 25 19 14

Weight (kg) VL-220CZGV-E: 31, VL-220CZGV-EB: 32

Insulation resistance 10 MΩ or more

Dielectric strength 1000 V AC 1 minute

Attention:

The running current, the input power, the efficiency and the noise are based on the rating air volume, and 230 V/50 Hz.

•

The noise is measured at 1.5 m under the center of the unit in an anechoic chamber.

• Temperature exchange efficiency (%) is based on winter condition.

• Mitsubishi Electric measures figures in the chart according to Japan Industrial Standard (JIS B 8628), therefore

the characteristic curves are measured by chamber method.

Model name PZ-61DR-E

Power supply requirement 12 V DC (Supplied from Lossnay unit)

Power consumption 0.3 W

2

Transmission cable Non polarized 2-wire (0.3 mm

(AWG22) sheathed cable)

Total wiring length 200 m maximum

Number of controllable Lossnay units 15 Lossnay units maximum (Max. 2 remote controllers installable)

Environmental condition

Temperature: 0 to 40°C, Humidity: 30% to 90% relative humidity (no

condensation)

Size 120 x 120 x 19 mm

Weight 0.25 kg

Color Munsell 1.0Y9.2/0.2

─ 4 ─

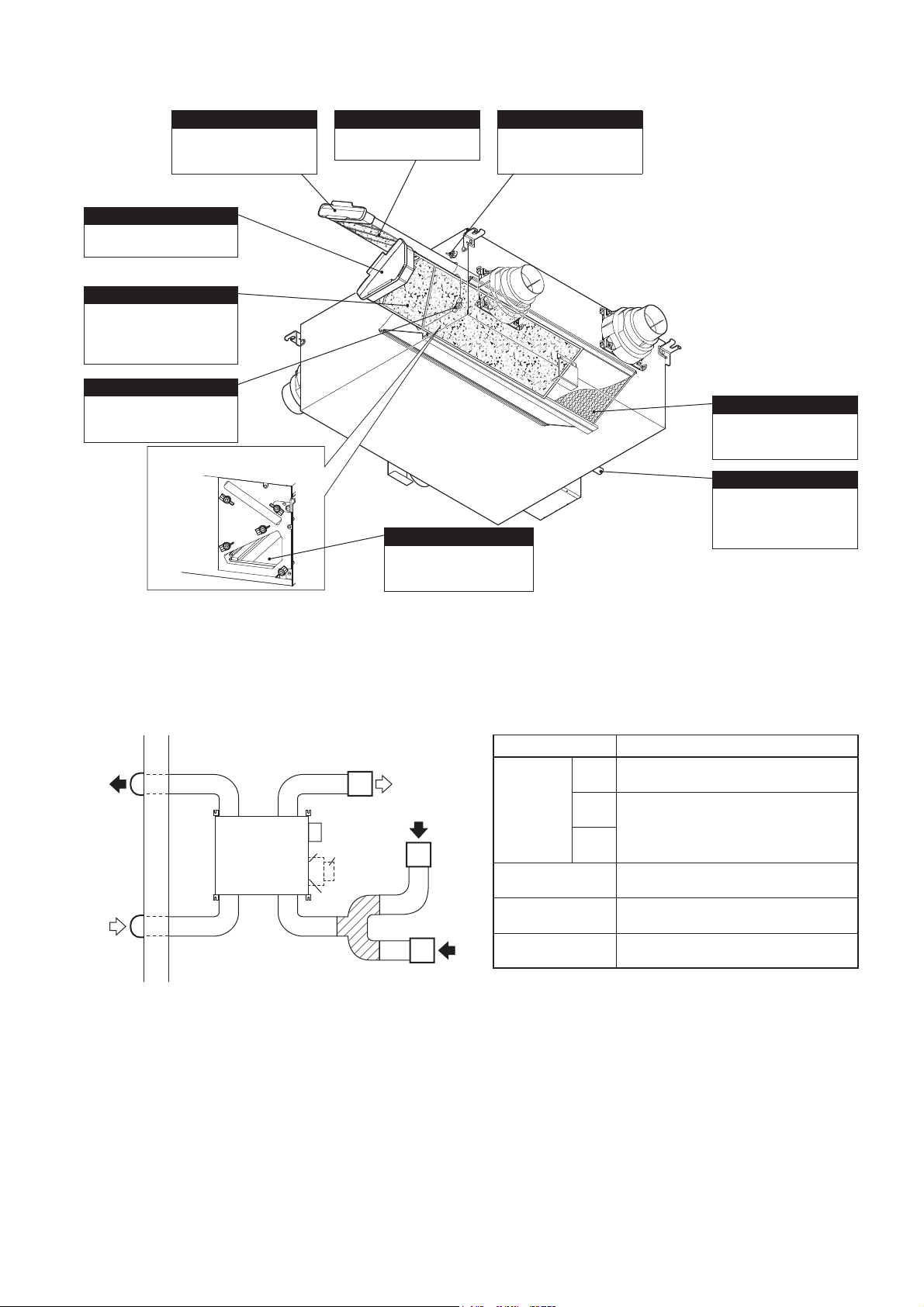

3. Names and functions of components

Exhaust air fi lter case

It holds the exhaust air

fi lter or medium ef

exhaust air fi lter.

Supply air fi lter case

It holds the supply air fi lter or

high effi ciency supply air fi lter.

Supply air fi lter

It removes insects, pollen,

dirt, dust, and other particles

from the outside air that is

taken into the room.

Supply air fi lter fi xing knob

Release it to remove the

supply air fi lter case.

(3 locations)

After the supply air fi lter case is

removed

fi ciency

Exhaust air fi lter

It prevents Lossnay core

from clogging.

Drain pan (supply air side)

It holds dew condensation

water that occurs inside the

Lossnay unit.

Exhaust air fi lter fi xing knob

Release it to remove the

exhaust air fi lter case.

(2 locations)

RA 1

OA

Lossnay core

Lossnay core exchanges

heat between the supply air

and the exhaust air.

Drain outlet

It is for discharging dew

condensation water that has

built up in the drain pan to

outside the room.

Piping example

• When connecting the RA (return air) to a bathroom, be

sure to branch the pipe into two lines and intake return

air from two locations, the bathroom and living room

(kitchen/dining room).

Outdoor

side

EA

(exhaust air)

OA

(outside air)

Indoor

side

Lossnay

RA3

RA2

RA1

(return air)

SA

(supply air)

Air duct

switching damper

(P-133DUE-E)

(Optional)

Bath

(Bathroom)

Kitchen /

dining room

Name of Connection Point

For intake from living room, toilet, wash

RA1

basin, bathroom, etc.

RA

(Return air)

EA

(Exhaust air)

OA

(Outside air)

SA

(Supply air)

For optional air duct switching damper

RA2*

(P-133DUE-E)

Exclusive for intake from living room, toilet,

RA3*

wash basin, bathroom, etc.

For exhaust air of inside air

For intake of outside air

For air supply opening to living room

Connection Location

* When RA2 and RA3 are used, use grills equipped with fi lter.

─ 5 ─

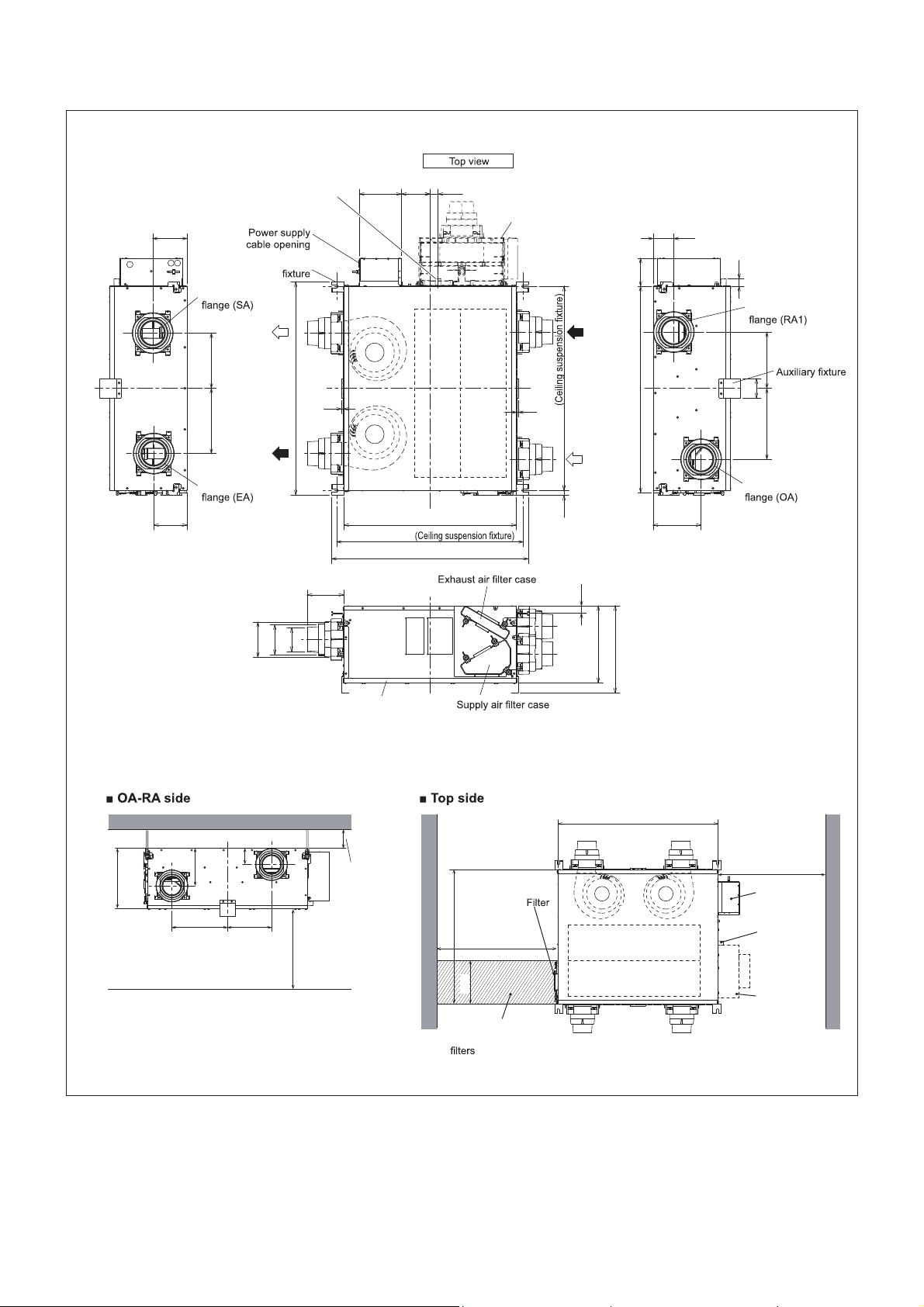

4. Outside dimensions

VL-220CZGV-E

Lossnay unit

139

Ceiling suspension

Duct connecting

SA

(supply

air)

229

271

EA

(exhaust

Duct connecting

air)

146

ij

Drain outlet

885

98

124

ij

ij

151

8

174 119 33

720

775

815

Air duct switching damper

(Optional)

RA1

(return air)

8

848

OA

(outside air)

20

31

320

362

116850

86143

31

Duct connecting

234

80

295

Duct connecting

199

Drain pan

Working space (required space around Lossnay unit)

86

234295

Leave at least

650 mm of space

RA1

Leave at least

100 mm of space

Leave at least

720

900 mm of space

245

Space required for

removing and inserting

320

OA

199

850

EA SA

OA RA1

Leave at least

700 mm of space

Circuit

Drain outlet

Air duct

switching damper

(Optional)

Unit (mm)

─ 6 ─

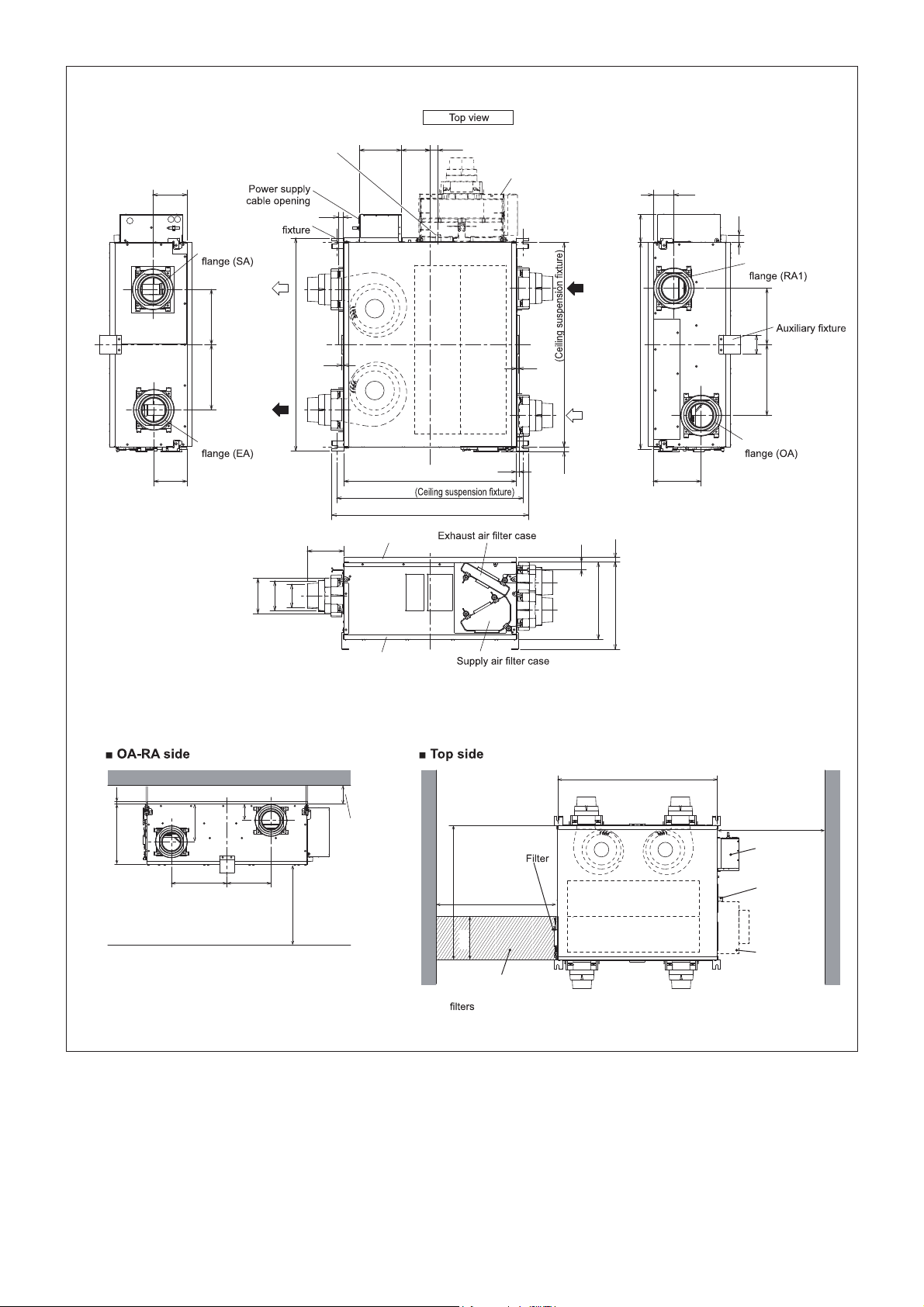

VL-220CZGV-EB

Lossnay unit

139

Ceiling suspension

Duct connecting

SA

(supply

air)

229

271

EA

(exhaust

Duct connecting

air)

Drain outlet

885

151

8

17420119 33

720

775

815

Insulation

Air duct switching damper

(Optional)

RA1

(return air)

8

848

OA

(outside air)

10

20

31

20

116850

86143

31

Duct connecting

234

80

295

Duct connecting

199

124

146

ij 98

ij

ij

Drain pan

Working space (required space around Lossnay unit)

OA

199

320 20

86

234295

Leave at least

650 mm of space

RA1

Leave at least

100 mm of space

Leave at least

720

900 mm of space

245

Space required for

removing and inserting

320

362

850

EA SA

OA RA1

Leave at least

700 mm of space

Circuit

Drain outlet

Air duct

switching damper

(Optional)

Unit (mm)

─ 7 ─

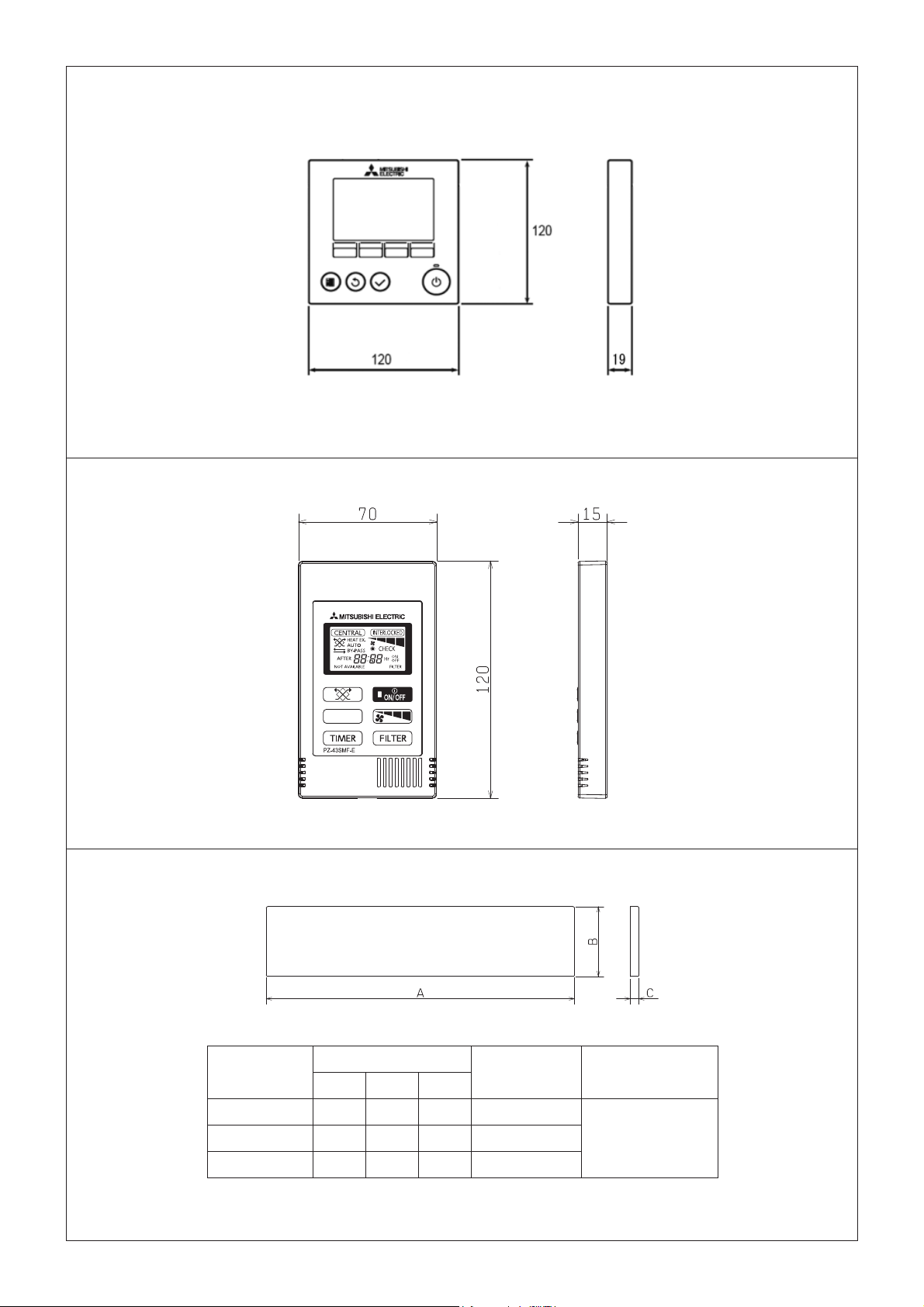

PZ-61DR-E

PZ-43SMF-E

Unit (mm)

P-220SHF-E, P-220EMF-E, P-220F-E

Model

Dimension

ABC

The number of

filters per set

P-220SHF-E 362 189 15 2

P-220EMF-E 353 183 15 2

P-220F-E 355 184 15 2

Note:

• Lossnay unit is provided with one set of the fi lters.

─ 8 ─

Unit (mm)

Applicable model

VL-220CZGV-E

VL-220CZGV-EB

Unit (mm)

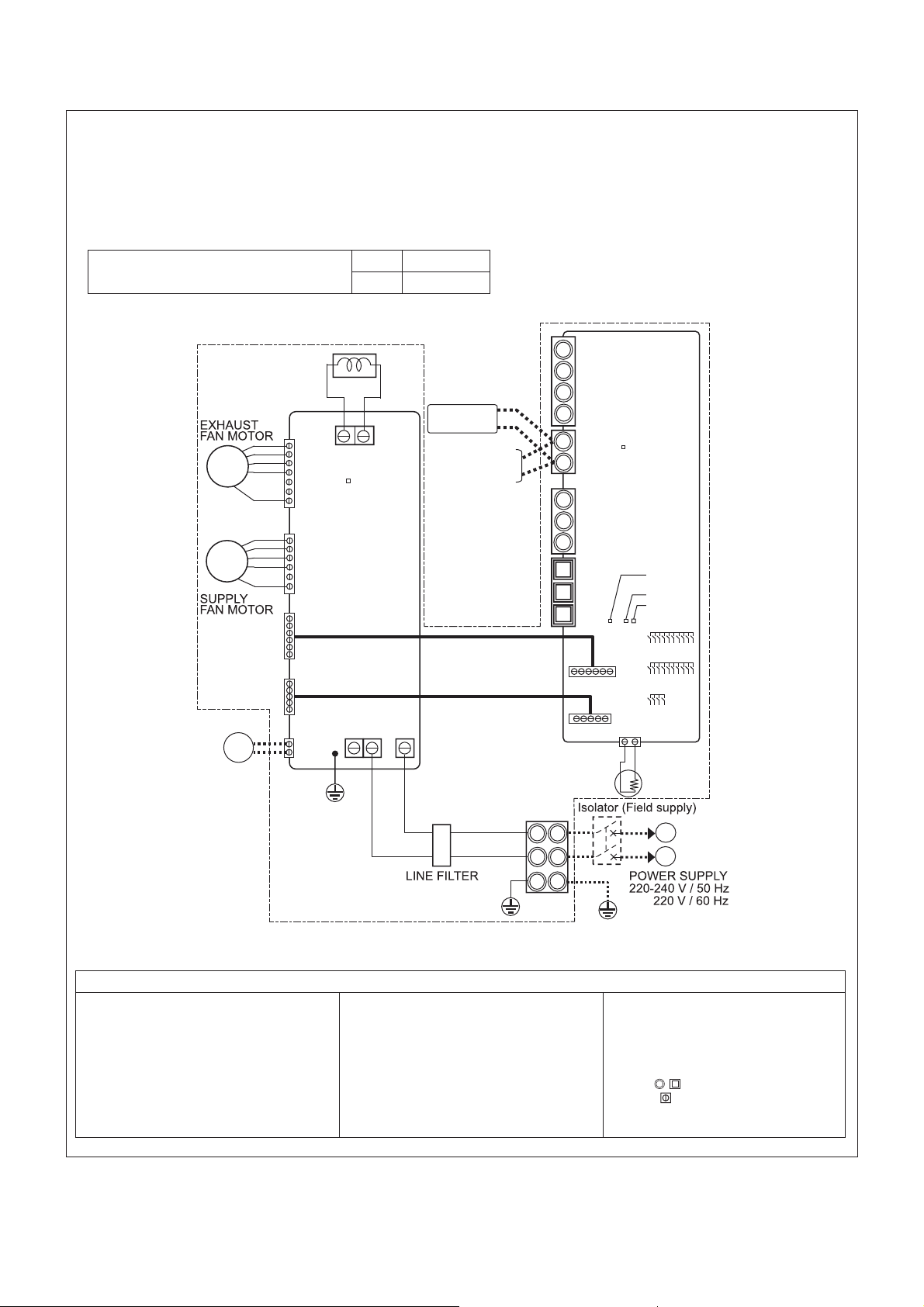

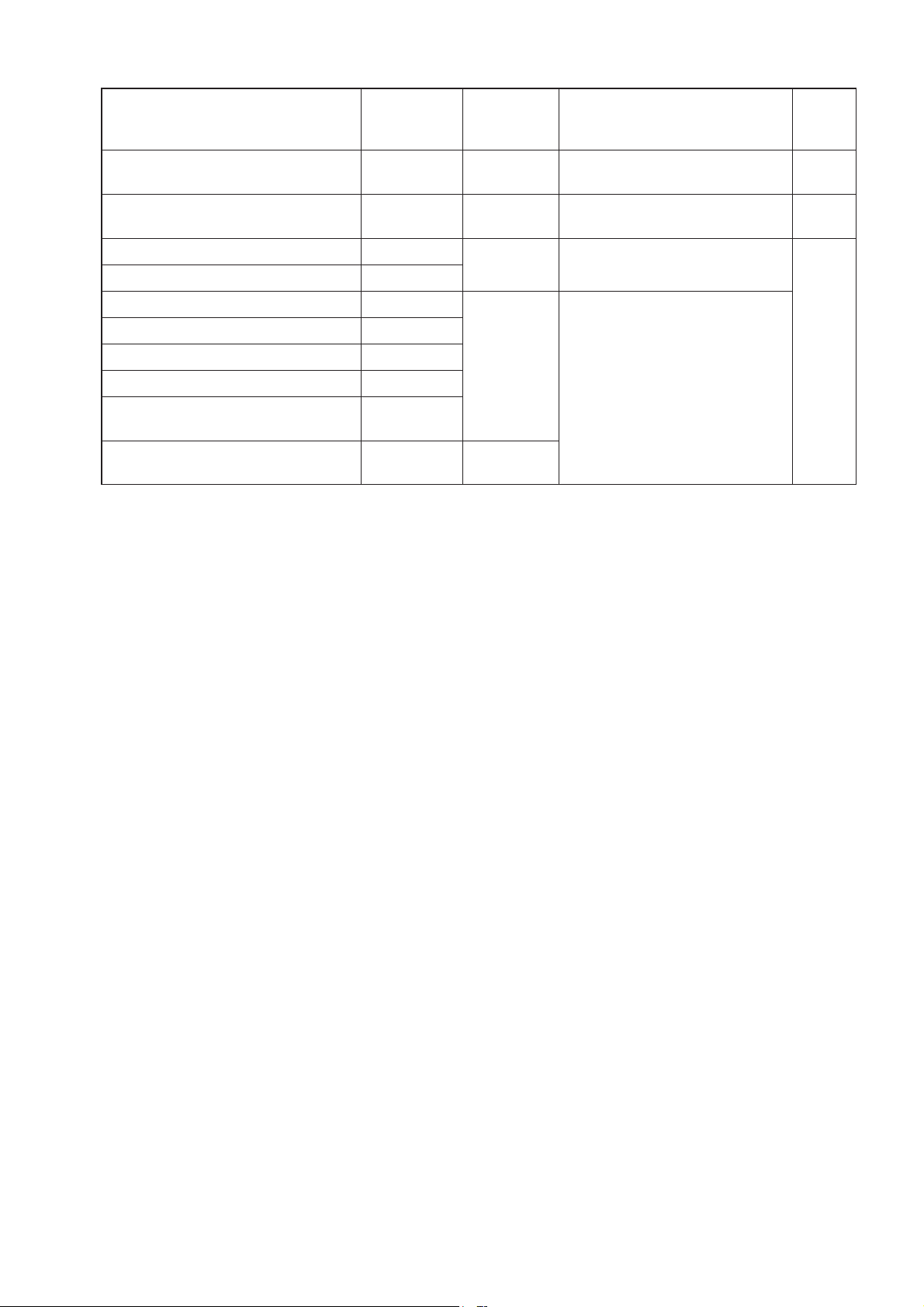

5. Electrical wiring diagram

VL-220CZGV-E, VL-220CZGV-EB

* TM1, TM4 shown in dotted lines are fi eld work.

* CN7 (DAMPER) is optional.

* Be sure to connect the earth wire.

* A power supply isolator must be installed.

* Always use an isolator for the main switch power connection.

* Select proper circuit breaker according to the electrical current information in the chart below.

Inrush current after power supply ON

REACTOR

M

1

M

2

GM

DAMPER

(Option)

10 ms 6.1 A

100 ms 3.6 A

TAB3,4

CN9

LED6

Lower Printed

Circuit Board

(Power circuit board)

CN10

CN119

CN118

TAB2TAB5 TAB1

CN7

PZ-61DR-E

PZ-43SMF-E

2nd Lossnay unit

(Max. 2 units)

TM3

7

8

9

10

1

TM4

2

Upper Printed

Circuit Board

(Control circuit board)

A

TB5

B

S

TM2

1

2

3

CN19

CN18

LED3

LED4

LED2

LED1

SW6

CN22

TH1(OA)

SW2

SW5

M1: Motor for exhaust fan

M2: Motor for supply fan

GM: Motor for By-pass damper

TH1: Thermistor for outside air

SW2,5: Switch (Function selection)

SW6: Switch (Motorized damper (option) selector)

TM1: Terminal block (Power supply)

TM2: Not in use

TM3: Not in use

TM4: Terminal block (Transmission cable)

L

N

PE

TM1

Defi nition of symbols

TB5: Not in use

TAB1, TAB2, (TAB5): Connector (Power supply)

TAB3,TAB4: Connector (Reactor)

CN7: Connector (Motor for By-pass damper)(Option)

CN9: Connector (Fan motor)

CN10: Connector (Fan motor)

CN18: Connector

CN118: Connector

─ 9 ─

L

N

CN19: Connector

CN119: Connector

CN22: Connector (Thermistor OA)

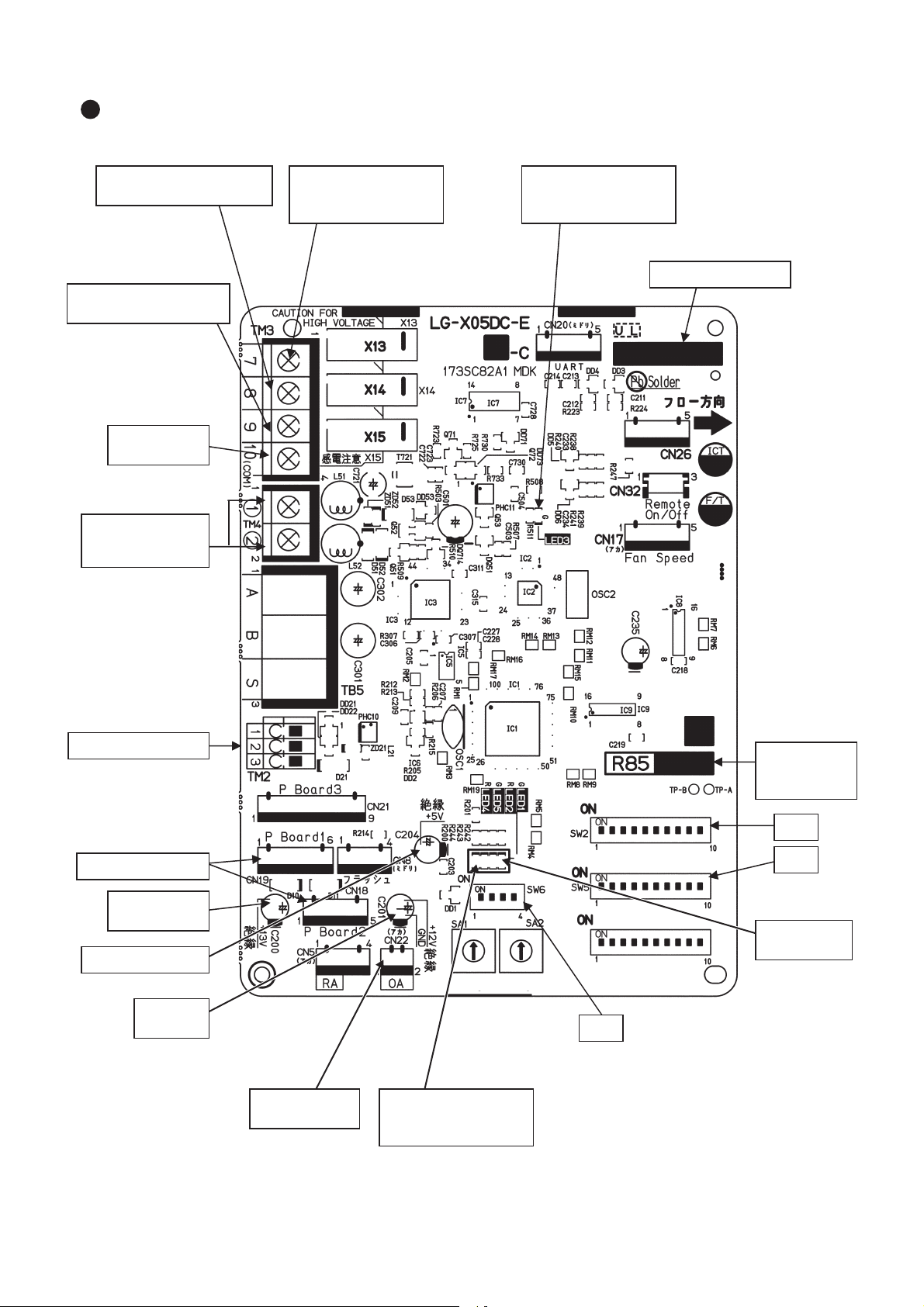

LED1: Inspection indicator lamp

LED3:

Remote controller power supply indicator lamp

LED4, LED6: Power supply indicator lamp

SYMBOL

: Terminal block

: Connector on PCB

1s digit10s digit

Fed with power: lit

Not fed with power: unlit

Lot number indication

Remote controller

power supply indicator

(LED3 Green)

Bypass monitor output

Pre-heater output

(Between 7 and 0)

During bypass mode: 0 ȍ

During heat recovery mode: ȍ

Malfunction monitor output

(Between 8 and 0)

Error: 0 ȍ

Normal: ȍ

Operation monitor output

(Between 9 and 0)

When Lossnay is operating: 0 ȍ

When Lossnay is stopped:

ȍ

Monitor output

COM

Remote controller

(PZ-61DR-E, etc.)

10 to 13 V DC

External control input

Power circuit board

5 V DC (Insulated)

Power for the circuit

12 to 14 V DC

(Insulated)

GND

(Insulated)

Fed with power: lit

Not fed with power: unlit

SW6

Air duct switching damper selector

(Only when the air duct

switching damper (P-133DUE-E)

is installed)

SW2

SW5

Function selection

switch

Indication of the

microcomputer

software version

Error indicator

(LED1 Green)

Normal: unlit

Error: blinking

During delay operation: lit

Power supply indicator

for the circuit

(LED4 Red)

Outdoor air (OA)

thermistor

6. Circuit board diagrams

Circuit board diagram and check points

(1)

Control circuit board

─ 10 ─

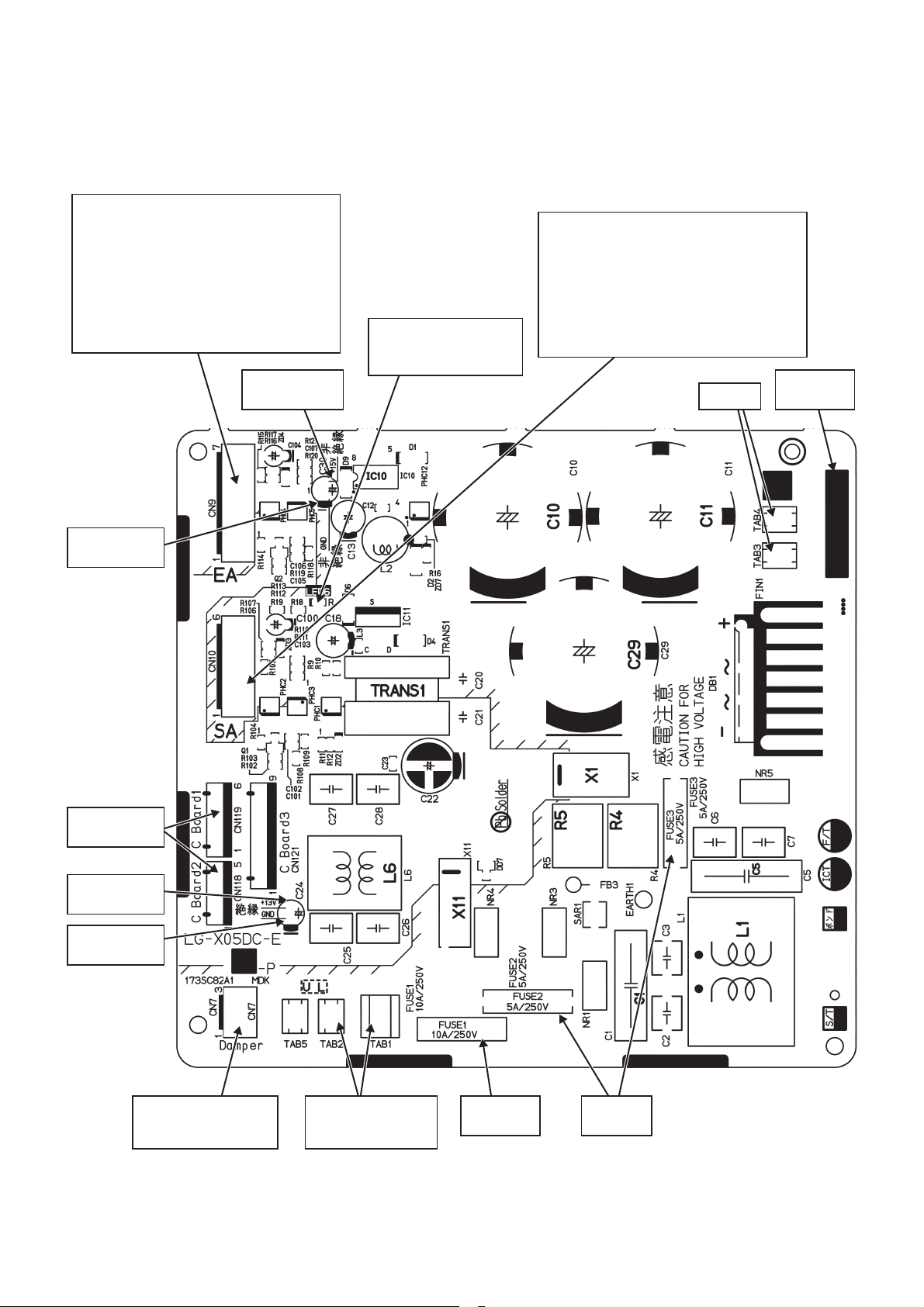

(2)

Power circuit board

Caution:

The power circuit board is not insulated from the power line (high voltage part), except for the connection part

(CN118 and CN119) with the control circuit board. Also, even when the power supply is cut off, the capacitor is

charged. Therefore, wait for at least five minutes before starting work.

Exhaust fan motor (CN9)

Pin No. of the connector

1Power for the motor: 280 to 360 V DC

2Not used

3Not used

4GND

5Power for motor control: 14 to 16 V DC

6Speed command voltage: 0 to 6 V DC

7Rotational speed pulse

14 to 16 V DC

(Not insulated)

Power supply indicator

for motor control

(LED6 Red)

Fed with power: lit

Not fed with power: unlit

Supply fan motor (CN10)

Pin No. of the connector

1Power for the motor: 280 to 360 V DC

2Not used

3GND

4Power for motor control: 14 to 16 V DC

5Speed command voltage: 0 to 6 V DC

6Rotational speed pulse

Reactor

Lot number

indication

GND

(Not insulated)

Control circuit

board

12 to 14 V DC

(Insulated)

GND

(Insulated)

Damper motor output

220 to 240 V/50 Hz

220 V/60 Hz

(Only when the air duct

switching damper (P-133DUE-E)

is installed)

Power supply input

220 to 240 V/50 Hz

220 V/60 Hz

Fuse

10 A/250 V

─ 11 ─

Fuse

5 A/250 V

7. Troubleshooting

Work precautions

•

When removing or touching the cables, circuit board or other parts, make sure to turn off the power supply isolator.

• Even after the power supply isolator is turned off, the capacitor on the circuit board retains high voltage for a

while. Therefore, before servicing, wait for at least five minutes, and then use a tester to check that the voltage has dropped.

•

Once the power supply is turned off, be sure to wait for at least five minutes before turning the power back on again.

• When servicing, be sure to recreate the malfunction two or three times before starting repairs.

• When servicing, always take care to keep proper footing.

• Before starting the service, always turn off the power supply isolator. Sufficient care must be taken to avoid

electric shock or injury.

• Make sure to connect the power supply wires correctly.

• When removing the circuit board, always hold it at both ends and remove carefully so as not to apply force

to the surface mounted parts.

• When removing the circuit board, be careful of the metal edges on the board.

• When removing or inserting the connectors for the circuit board, hold the entire housing section. Never pull

on the lead wires.

• If it is thought that there is a circuit board malfunction, check for disconnected wires in the print pattern,

burnt parts or discoloration.

•

If the circuit board is replaced, make sure that the switch settings on the new board are the same as the old board.

The part names in the texts are standardized with the part names in the parts catalog. (There are some

exceptions.)

7-1 Service flowchart

After checking the check items below, follow the troubleshooting for servicing.

Applicable Device Applicable Model

Lossnay Heat Recovery Ventilator VL-220CZGV-E, VL-220CZGV-EB

Lossnay Remote Controller PZ-61DR-E, PZ-43SMF-E

Air Duct Switching Damper

(Lossnay Heat Recovery Ventilator System Component)

Note: This device (VL-220CZGV-E, VL-220CZGV-EB) is not compatible with M-NET. When connected to

M-NET, a malfunction may occur or an error code may be displayed.

No. Preliminary check item Details

1 Product information • Model name of the product

• Serial number of the product, manufacturing lot number of the circuit board

• Microcomputer software version marked on the circuit board

2 Fault status • Fault status (For example, the fan does not operate.)

• Error code display on the remote controller

• Operation setting of the remote controller (ventilation mode setting, fan

speed setting, etc.)

3 Frequency of fault occur-

rence

4 Timing of fault occurrence • Remote controller operation performed before fault occurrence

5 System settings • Function selection switch settings of the product

6 System drawings • System Configuration

• Frequency of fault occurrence (frequency of date and time of occurrence,

regularity of occurrence, etc.)

• Operating time up to fault occurrence

• Date of start of use, date of fault occurrence

• Operating status, etc.

• Model name of the Lossnay remote controller, and whether the air duct

switching damper is installed or not

• Function settings on PZ-61DR-E when PZ-61DR-E is used

• Wiring

• Record of the Lossnay function setting statuses

─ 12 ─

P-133DUE-E

Lossnay does not work after installation

is completed.

Lossnay does not work in the trial operation after installation is completed, or

Lossnay works abnormally during use.

(1) Failure mode 1: Lossnay does not work, or

Lossnay works abnormally.

The remote controller does not work

after installation is completed.

Operations such as ON/OFF, fan speed

or ventilation mode switching are

disabled on the remote controller after

installation is completed.

Lossnay does not work properly after

installation is completed.

• An error code is displayed on the

remote controller.

• LEDs on the circuit board blink or light.

Water leaks from the Lossnay unit. (6) Failure mode 6:

(2) Failure mode 2: The remote controller does not

(3) Failure mode 3: Operations on the remote control-

(4) Failure mode 4:

(5) Failure mode 5: Error code and LED display

7-2 Check Details

(1) Failure mode 1: Lossnay does not work.

Initial Check Items

Check the following details if Lossnay does not work after installation is completed.

work.

ler are disabled.

Lossnay does not work properly.

Water leaks from the Lossnay unit.

1 Power supply

No. Check Item Corrective action

1 Is the main power supply on? Turn the main power supply on.

2 Is the current capacity of the power supply isolator

appropriate?

3 Is the designated cable used for the power supply

cable?

4 Is the specified power supply supplied to the power

supply terminal (TM1)?

220-240 V/50 Hz, 220 V/60 Hz

5 Is the power supply cable incorrectly wired, is there

a faulty connection or are screws loose?

6 Is there a faulty connection on the power supply

terminals (TM1, TAB1, and TAB2)?

7 Is there a faulty connection on the reactor terminals

(TAB3 and TAB4)?

8 Are the power supply indicator lamps (LED4 and

LED6, red) lit?

Use an appropriate power supply isolator.

Use the designated cable.

Supply the designated power supply.

Connect the cable securely and correctly, and

tighten the screws firmly.

Connect the lead wires securely.

Connect the lead wires securely.

Check the above items.

─ 13 ─

2 Transmission cables (remote controller transmission cable, and external input/output signal cable)

No. Check Item Corrective action

1 Are the designated cables used for the remote control-

Use the designated transmission cables.

ler transmission cable? (See Table 2-1.)

2 Are the designated cables used for the external input/

Use the designated cables.

output signal cable? (See Table 2-2.)

3 Are the transmission cables wired using multicore

Use the designated transmission cables.

cables?

4 Are multiple transmission cables wired in the same pip-

ing duct?

5 Is the power supply cable wired at least 5 cm away

from transmission cables?

6 Are the transmission cables connected to the desig-

nated terminal block? (See Table 2-1.)

7 Are the transmission cables incorrectly wired, is there a

faulty connection or are screws loose?

8 Is the wiring length of the transmission cable within the

Wire the transmission cable away from one

another.

Wire the power supply cable at least 5 cm away

from the transmission cables.

Connect the transmission cables to the designated terminal blocks.

Connect the cable securely and correctly, and

tighten the screws firmly.

Wire the cables within the regulations.

regulations? (See Table 2-1.)

9 Does the external input signal match the specifica-

Input the signal that matches the specifications.

tions? (See Table 2-2.)

10 Is the external input signal input to the Lossnay set as

the main Lossnay?

11 Is the function selection for the external output signal

set correctly?

Input the signal to the Lossnay set as the main

Lossnay (SW5-10 ON).

Set the function selection switches (SW2-8, 5-2,

and 5-6) on the circuit board correctly.

Set the function settings (No. 57 and 58) of PZ61DR-E correctly.

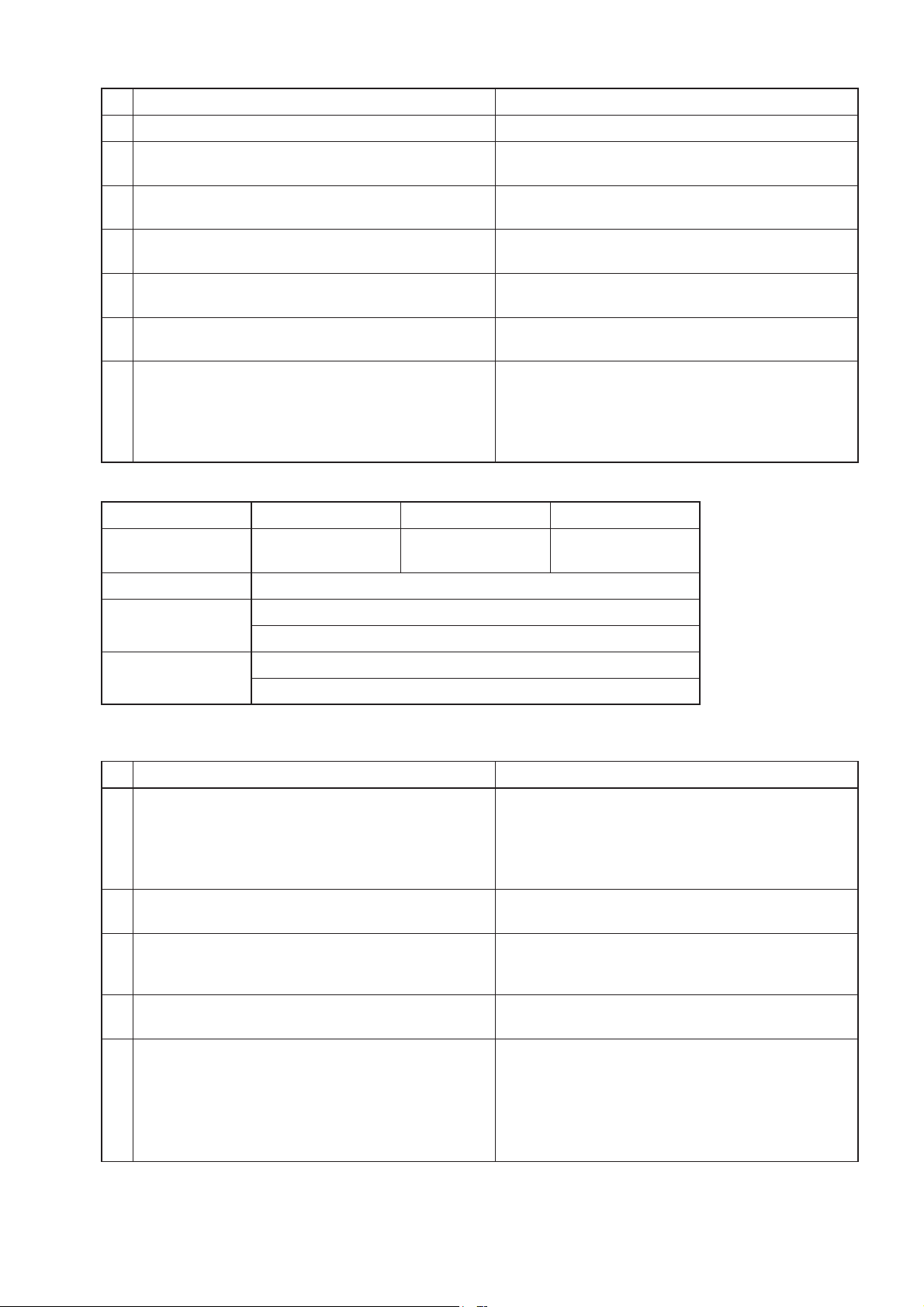

Table 2-1

Remote controller transmission cable specifications

Cable

PZ-61DR-E or PZ-43SMF-E

transmission cable

Type Sheathed cable

Number of cores 2-core cable

2

Cable diameter 0. 3 mm

(AWG22)

Total extension 200 m

Terminal block

TM4 12

─ 14 ─

Table 2-2 External input/output specifications

Function Name

External control input

(volt-free contact)

External control input

(12 V DC, 24 V DC)

Remote/local switching

Remote ON/OFF input

Fan speed 4 input (volt-free contact)

Fan speed 3 input (volt-free contact)

Fan speed 2 input (volt-free contact)

Fan speed 1 input (volt-free contact)

Bypass mode input (volt-free contact)

*Only when P-133DUE-E is installed

Fan speed switching input

(0 to 10 V DC)

Terminal or

connector on

the circuit board

TM2 13

TM2 12

CN32 13

CN32 12

CN17 12

CN17 13

CN17 14

CN17 15

CN26 12

CN26 45

Signal

specifications

Level/pulse

(Note 1)

Level/pulse

(Note 1)

Level

(Note 1)

Level

(Note 1)

Analog

Materials Used

Single-lead 0.8 to 1.2 mm dia. or

twisted lead 0.5 to 1.5 mm

2

Single-lead 0.8 to 1.2 mm dia. or

twisted lead 0.5 to 1.5 mm

2

Remote ON/OFF adaptor

(PAC-SE55RA-E)

Remote display adaptor

(PAC-SA88HA-E)

Total

extension

500 m

(Note 2)

10 m

<Caution>

• When connecting two Lossnay units and using external input/output, input the signals to the Lossnay (SW510 ON, with the smallest address setting) set as the main Lossnay.

(Note 1) The input signal must conform to the following specifications:

Level signal Volt-free contact, 12 V DC, 24 V DC, the duration of ON and OFF should be 10-second

or more.

Pulse signal Volt-free contact, 12 V DC, 24 V DC, the duration of ON should be 200 msec. or more,

and minimum 10-second absence is necessary to the next pulse .

In the case of relay contact input, use a relay having a contact rating of 15 V DC/0.1 A or higher and a

minimum applicable load of 1 mA or less.

(Note 2) Check the specifications of the external device.

─ 15 ─

3 Monitor output signal cable

No. Check Item Corrective action

1 Is the signal cable wired by multicore cable? Wire the cable using a 2-core cable.

2 Are the signal cables and transmission cables wired

in the same piping duct?

3 Is the power supply cable wired at least 5 cm away

from signal cables?

4 Is the signal cable connected to the designated

terminal block? (See Table 3-1.)

5 Is the signal cable incorrectly wired, is there a faulty

connection or are screws loose?

6 Is the output capacity of the signal cable within rat-

Wire the signal cables away from the transmission

cables.

Wire the power supply cable at least 5 cm away

from the signal cables.

Connect the signal cable to the designated terminal

block.

Connect the cable securely and correctly, and

tighten the screws firmly.

Use the signal cable within rating.

ing? (See Table 3-1.)

7 Is the function selection for the external output

signal set correctly?

Set the function selection switches (SW2-8, 5-2,

and 5-6) on the circuit board correctly.

Set the function settings (No. 57 and 58) of PZ61DR-E correctly.

(See the Lossnay technical manual.)

Table 3-1 Monitor Output Specifications

Terminal block

Function Name

TM3 90 TM3 80 TM3 70

Operation monitor

After-heater

Malfunction monitor Bypass monitor

Signal specifications Volt-free contact

240 V AC, 1 A

Output rating

24 V DC, 1 A

220 V AC, 100 mA

Min. applicable load

5 V DC, 100 mA

4 Function setting (See the Lossnay technical manual for details.)

No. Check Item Corrective action

1 Is the main Lossnay set correctly? Check the function selection switch (SW5-10) on

the circuit board.

When an external signal is input to two Lossnay

units, set one of the units as the main Lossnay

(SW5-10 ON).

2 Are the function selection switches on the circuit

board set correctly to suit the required application?

3 Is the applicable model used as the Lossnay re-

mote controller?

Set the function selection switches (SW2 and SW5)

on the circuit board correctly.

Use PZ-61DR-E or PZ-43SMF-E.

(The air conditioner remote controller including

PAR-31MAA cannot be used.)

4 When PZ-61DR-E is used, are the function selec-

Set the function selections correctly.

tions set correctly to suit the required application?

5 Was a function set with the function selection

switches on the circuit board after the function is set

with PZ-61DR-E?

Set the function again with PZ-61DR-E.

For the function that can be set with both PZ61DR-E and the function selection switches, if the

function is set to other than "DIP-SW priority" with

PZ-61DR-E, setting with the function selection

switches is disabled.

─ 16 ─

5 LED Indications on the circuit board

No. LED Contents Check Item Corrective action

1 LED1

(green)

Lossnay main unit

error indicator

Blinking: Starting up, or error occurred

See Failure Mode 5.

Lit: During delay operation Lossnay operates after the delay time

has passed.

Unlit: Other than above It is normal.

2 LED2

(red)

3 LED3

(green)

4 LED4

(red)

M-NET System

error indicator

Remote controller power supply

indicator

Power supply

indicator (control

Unlit It is normal.

Lit: Power supplied to the remote

controller (Main Lossnay)

Unlit: Power not supplied to the

remote controller (Sub Lossnay)

The LED goes out when power is supplied to the remote controller from another Lossnay unit in the case of using

two Lossnay units.

Check that this LED is lit The LED lights while power is being

supplied to the control circuit board.

circuit board)

5 LED6

(red)

Power supply

indicator (power

circuit board)

Check that this LED is lit The LED lights while power is being

supplied to the power circuit board.

(Do not touch components on the circuit

board when the LED is lit.)

─ 17 ─

Loading...

Loading...