Page 1

VENTILATING FAN

MODEL:

MANUAL AND INSTALLATION PROCEDURE

PRODUCT APPEARANCE

ADDITIONAL PART

SCREW (9 PCS)

REMARK : IS THE ALPHABET OF DEVELOPEMENT NUMBER

CAREFULLY READ INSTALLATION MANUAL AND THE PRODUCT

SHOULD BE INSTALLED BY THE SPECIALIZED TECHNICIAN.

Page 2

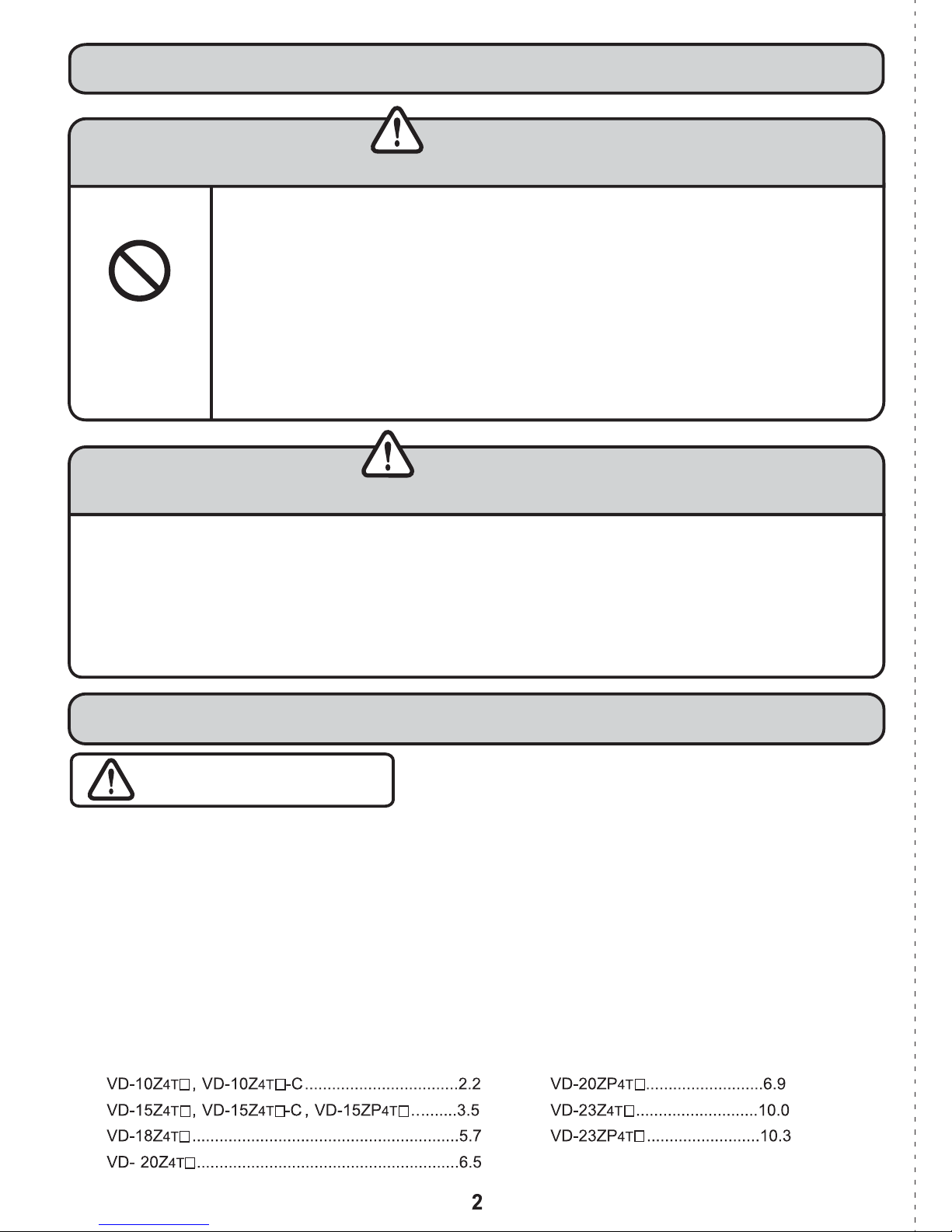

ESSENTIAL SAFETY PRECAUTIONS

WARNING

FAILURE TO COMPLY DEATH OR BODILY INJURY MAY RESULT.

1. Do not use the ventilator when damages found on wire or other components. This may

cause fire and electric shock.

2. Do not switch on the ventilator when the assembling is not completed with all

components such as airguide and propeller as bodily injury may result.

3. Do not use the ventilator or its electrical components when they are wet as injury from

PROHIBITED

electric shock may result.

4. Do not contact the ventilator or its electrical components when your hands are wet.

5. Do not modify the ventilator as severe injury may result.

6. Be sure to unplug the ventilator from the main supply prior to cleaning or repairing the

ventilator.

CAUTIONS

FAILURE TO COMPLY BODILY INJURY OR PROPERTY DAMAGE MAY RESULT.

1. It is dangerous to insert fingers or object into the ventilator propeller or rotating component.

2. Do not use harsh cleaners or solvents on the ventilator as this may cause deforming on plastic

components and damaging other components.

3. Do not install the ventilator at the location of heat source such as gas/electric fire nearby; location of

high humidity, location of solvent dampness, as fan damage or fire may result.

4. The appliance is not intended for use by young children or infirm persons unless they been adequately

supervised by a responsible person to ensure that can use the appliance safety.

INSTALLATION

INSTALLATION CAUTIONS

1. Before installation and assembling the Ventilator, please study the manual.

2. The installation might be suggestion from Service Center or Sales Agency.

3. To be install with stable ceiling to bear the weight and vibration of Ventilator.

4. To be installed metal pipe by do not install metal parts contact with conductive material which

be coated on the wooden.

5. The Accessory pipe hood more available to protect insect or bird and rains.

6. Do not install the ventilator and control switch in bathroom or high humidity area may cause electric

short-circuit.

7. Do not install the fan in:

- Area containing high amount of oil, chemical, dust.

- The back-flow of gases into the room the open fuel of gas or other open fire appliances.

8. The Installation area might be stable ceiling to bear the weight of ventilator in each model as;

Kg Kg

Kg

Kg

Kg

Kg

Kg

Page 3

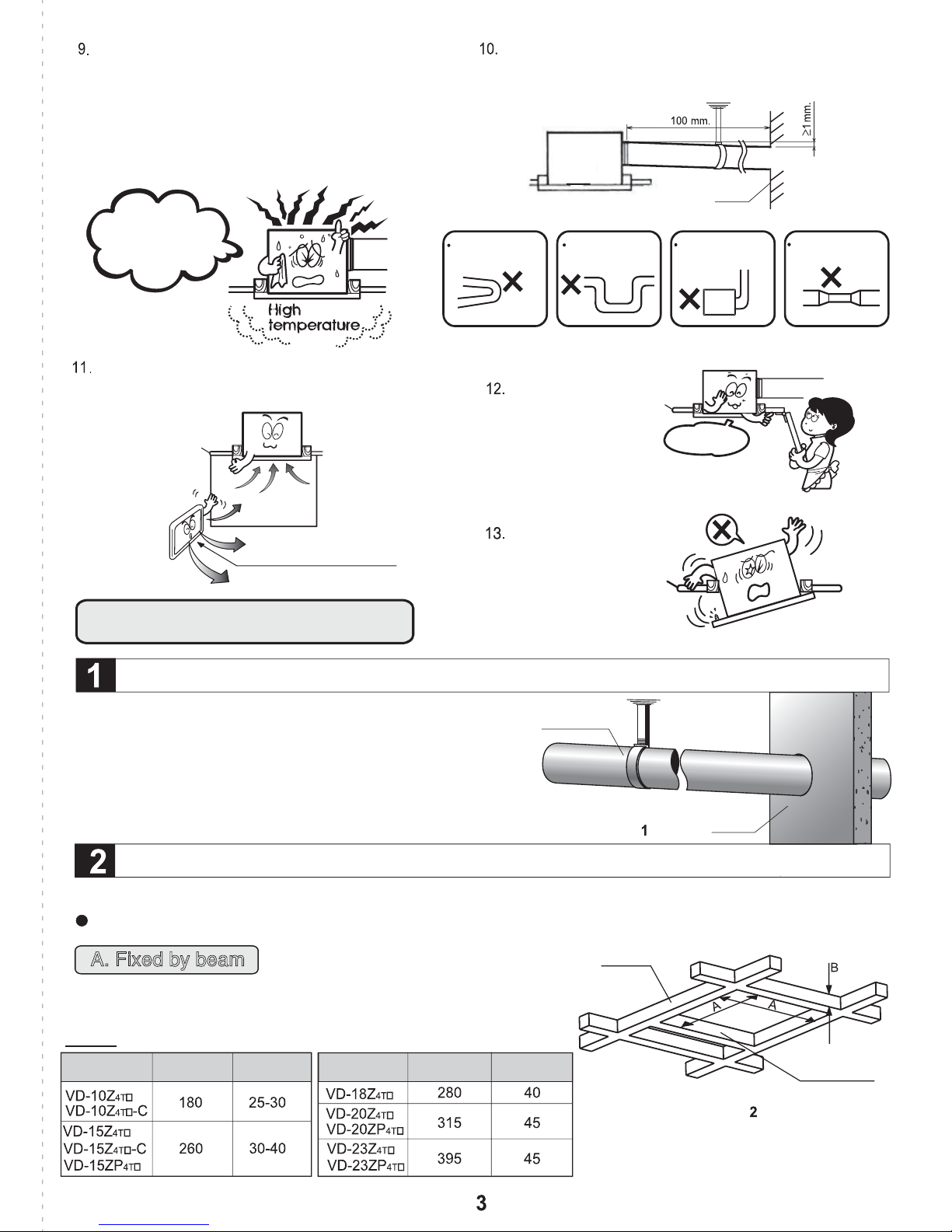

In case of installation at high temperature area, the

capacity of insulator parts such as motor, capacity

might drop and be cause of electric leakage.

Moreover, not well-done lubricated shaft might be

hotter as well as motor. To protect those conditions

do not install the product at the high temperature

area.

Watch out!!

It’s Electric leaking

In the closed building or unable to exhaust the

air area, the hole should be installed to drain in

the fresh air.

Should avoid pipe bending as belows:

SHARP BENDS

Should inclined install smoke pipe by additional duct

higher than smoke pipe on the wall

1mm/100mm to protect the rain water.

WALL

MANY BENDS

The installed

ceiling should be

easy to check

from opened gap.

BEND RIGHT BY

THE AIR OUTLET

OPENED GAP

VERY NARROW

CONNECTION

In case of loosen

AIR DRAIN IN GAP

installation, It’s

might occur

vibration or loud

noise.

INSTALLATION

TO SELECT INSTALLATION AREA AND WALL FOR DRILLING THE AIR-EXHAUSTED HOLE

To Install duct from the air-exhausted hole to

additional duct by fixing it with ceiling to protect the

overload. Diameter of duct is 100 mm(VD-10/15) or

150 mm (VD-18/20/23) made from vinyl chloride,

aluminium, steel. Before Installation Please carefully

read Installation of caution.

VENTILATING FAN INSTALLATION

There are two methods to install the product.

To prevent the contact with the propeller, install the ventilating fan above 2.3 m from the floor.

A. Fixed by beam

DUCT

Figure.

BEAM

WALL

(A1) To make a frame with beam and sub beam as

Figure.2 and dimension in Table 1.

Table.1

Model

Dimension A Dimension B

Model

Dimension A Dimension B

SUB BEAM

Figure.

Unit : mm.

Page 4

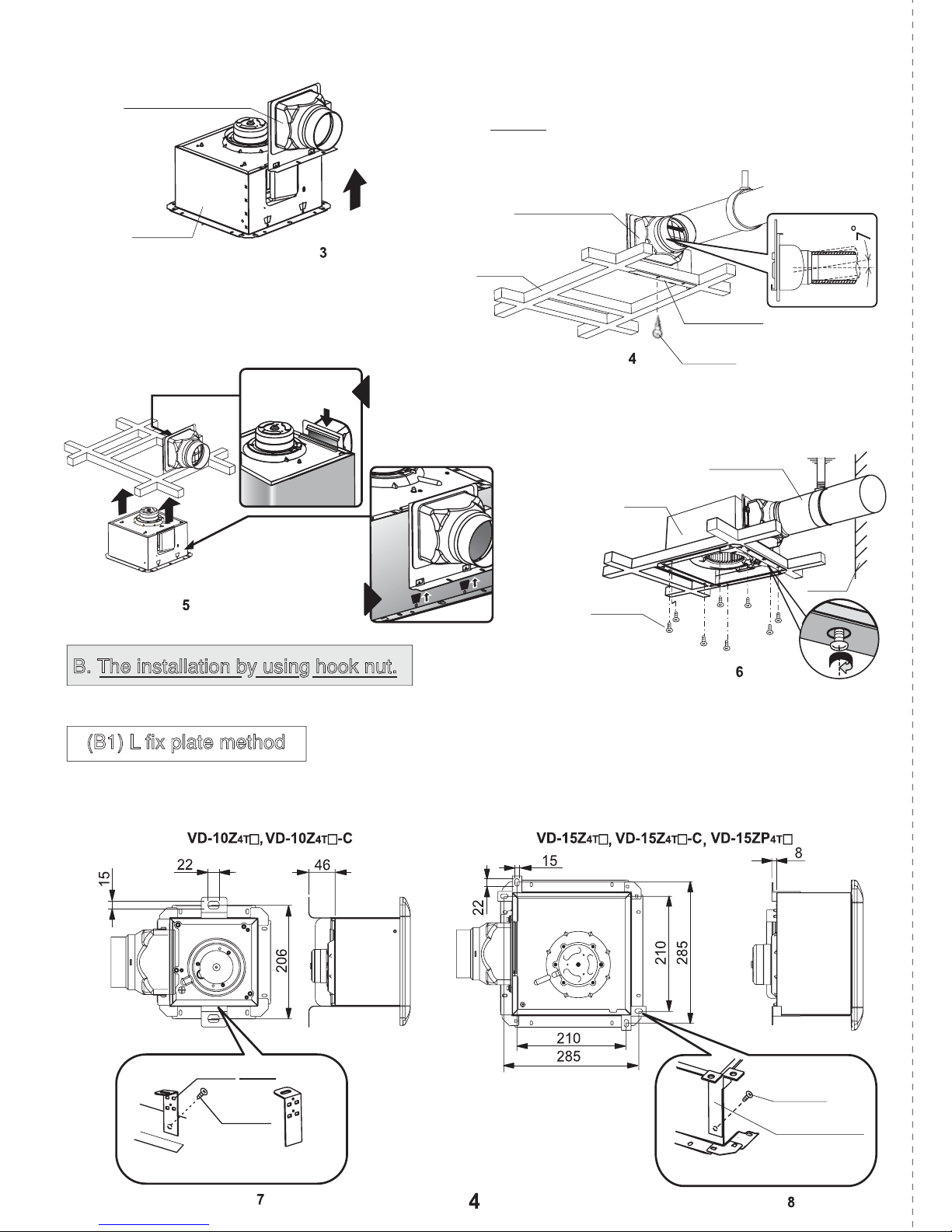

(A2) To take off additional duct as the arrow

direction as Figure.3

(A3) To install the wing of additional duct under sub

beam and fix additional duct with main duct. Then

fix additional duct with sub beam at “A” position with

ADDITIONAL DUCT

screw as Figure.4

Remark

In case of vinyl chloride duct, the inclination from the

product to ended-duct should not greater than 7 degree.

ADDITIONAL

BODY

Push up

DUCT

Figure.

(A4) To install the product with additional duct and

BEAM

push product until lock point of additional duct

lock hook of product as Figure.5

To lock

product with

upper

additional duct.

(A5) To check the completeness and install

product with beam by screwing with 8 screws.

as Figure.6

Figure.

LETTER “A”

HOLE

SCREW

ADDITIONAL

DUCT

BODY

To lock product

with lower

additional duct

Figure.

as picture.

B. The installation by using hook nut.

There are two methods, using L fix plate, and sub frame

SCREW

Figure.

WALL

SCREW

(LETTER “A” HOLE)

(B1) L fix plate method

(B1.1) To set hook nut with ceiling and install L fix plate with the product as the Figure.7, 8 and 9

Model : Model :

L fix plate

SCREW

Q.14UL3)BEEJUJPOBM!QBSU*

Figure.

SCREW

L fix plate

Q.16UL)BEEJUJPOBM!QBSU*

Figure.

Page 5

Table shown dimension of position of “L” Fix plate

each model as followed

MODEL

DimensionADimensionBDimension

C

Unit:mm.

As shown at Figure.9

L fix plate

P-08TK (ADDITIONAL PART)

(B1.2) To fix the product with hook nut and

horizontal install the product as right

picture. as Figure.10

SCREW

L FIX PLATE

Figure.

HOOK NUT

NUT

WASHER

(B2) To use SUB FRAME

(B2.1) Install HOOK NUT with the ceiling and

install sub frame with the Body.

The sub frame of model

Figure.11

Caution

2 Central holes to be use.

HOLE

Table shown each SUB FRAME model dimension

MODEL

Figure.

The sub frame of model

SUB FRAME

Dimension

A

Dimension

RUBBER

WASHER

Figure.12

HOLE

Figure.

DimensionCDimension

B

D

Unit :mm.

Figure.

Unit:mm.

Page 6

(B2.2) To set 2 wooden parts with sub frame

by using screws as the Figure.13

(B2.3) To Install sub frame to ceiling with Hook nut as

the Figure.14

Caution

SCREW

as Figure.15.

ADDITIONAL

DUCT

BODY

:Do not obstruct hook nut-hole on sub frame.

Figure.

SUB FRAME

WOODEN

PUSH UP

Figure.

HOOK-NUT

SUB FRAME

Figure.

(B2.5)

To set the product by turning the front to open air hole to

exhaust the air from the wall and fix the additional duct

with sub frame by screwing through “A” letter hole as

Figure.16

ADDITIONAL DUCT

SCREW

HOOK NUT

WOODEN

SUB FRAME

Figure.

(B2.6) To set the product with additional duct with

hook of product and additional duct Figure.17

SUB FRAME

BODY

ADDITIONAL DUCT

Figure.

as Figure.19

SUB FRAME

MODEL NAME

as Figure.18

SUGGESTION

ADDITIONAL

DUCT

WOODEN

Figure.

SCREW

(B2.9) After installed ceiling board, to hammer from the

inside for protecting the slide of sub frame and

ceiling as Figure.20

SUB FRAME

WOODEN

BEAM

TAPE

Figure.

Unit:mm.

NAIL NAIL

SUB FRAME

Figure.

Page 7

TO INSTALL PIPE FROM BODY TO WELL EXHAUST PIPE

To adhere aluminium tape at connecting point

between exhaust pipe and additional duct to

protect air leakage as Figure.21

TAPE

DUCT

Figure.

ADDITIONAL PART(NOT INCLUDE ON PRODUCT)

“L” fix plate, Sub frame, Duct (Iron, plastic, Aluminium, Stainless steel), Hood.

TO INSTALL LEAD WIRE SHOULD BE DONE AS NECESSARY

LEAD WIRE INATALLATION CAUTION

1.Fan and lead wire installation should be suggested by service center or specialize

technician.

2.Before installation and Assembling the fan please read installation manual carefully.

3.Installation leadwire carefully, in case missing occure may cause circuit-shorten.

4.Installing lead wire in pipe should be use the standard piping accesories (available from

hardware store),and then connect to the terminal.

TERMINAL DIAGRAM AND LEAD WIRE CONNECTION

Separate each model group as followed

VENTILATOR MAIN UNIT

VVF

LEAD WIRE

1.6 mm or

2.0 mm

Thermal

fuse

WALL

SWITCH

CIRCUIT

BREAKER

*

VVF

LEAD WIRE

1.6 mm or

2.0 mm

VENTILATOR MAIN UNIT VENTILATOR MAIN UNIT

Thermal

fuse

WALL

*

SWITCH

CIRCUIT

BREAKER

VVF

LEAD WIRE

1.6 mm or

2.0 mm

Thermal

fuse

WALL

SWITCH

CIRCUIT

BREAKER

*

Figure.

Page 8

VENTILATOR MAIN UNIT

Thermal

fuse

VVF

LEAD WIRE

1.6 mm or

2.0 mm

WALL

*

SWITCH

157

HOOK

SLIDE COVER

*

WALL SWITCH is obtained from hardware store.

Remark :

1. Installation location of circuit breaker should be easy

to operation and shut off.

2. The circuit breaker shall have a contact separation in

all poles and provide full disconnection under

overvoltage category III condition in accordance

with the wiring rules.

CIRCUIT

BREAKER

Pay attention to connect the wire,1 wire

from power supply especially common

wire connect with the “N(COM)” terminal.

Figure.

CAUTION

Continue

Leadwire size for installation

1. Must use indoor wiring VVF cable Ø1.6 mm or Ø2.0 mm

2

2

2. In case of install ground wiring must install ground at least

1.0 mm and must install to Industrial Standard

Ground Rod by specialized technician.

2

General connector and electric line procedure

Do not connect the ground wire to Gas duct, Water pipe

Lightning rod or Telephone line because may

occur electric shock.

To peel off lead wire 10 mm.

To pull wiring approx. 150 mm from the product.

To separate wiring from connecting board, then push

red button on connecting board and pull each wiring

with Screw Driver.

Lead wire connector method

Figure.

CAUTION

LEAD WIRE

CONDUCTOR

Insert the tip of the flathead

screwdriver here.

SCREW

TERMINAL

COVER

STRIPPED WIRE

Model :

(1) Remove screw and unlock cover, weave VVF (Ø1.6, Ø2.0)

through rubber button until it can be completely passed.

(2) The product is used in high humidity area, the ground wiring

should be installed.

(3) To lock the cover and fix to screw.

Model :

(1) Remove screw and unlock cover, weave VVF (Ø1.6, Ø2.0)

through rubber button until it can be completely passed.

(2) The product is used in high humidity area, the ground wiring

should be installed.

(3) To lock the cover and fix to screw.

(as Figure. )

as Figure.

GROUND

TERMINAL

TERMINAL

COVER

LEAD WIRE

GROUND

TERMINAL

TERMINAL

Figure.

SCREW

STRIPPED WIRE

TERMINAL

Figure.

Page 9

Model:

as Figure.

(1) Remove screw and unlock cover, weave VVF (Ø1.6, Ø2.0)

through rubber button until it can be completely passed.

(2) The product is used in high humidity area, the ground wiring

should be installed.

(3) To lock the cover and fix to screw.

GROUNDING

TERMINAL

STRIPPED WIRE

SCREW

TERMINAL

COVER

LEAD WIRE

Figure.

Model:

as Figure.

(1) Remove screw and unlock cover, weave VVF (Ø1.6, Ø2.0)

through rubber button until it can be completely passed.

(2) The product is used in high humidity area, the ground wiring

should be installed.

(3) To lock the cover and fix to screw.

GROUNDING

TERMINAL

STRIPPED WIRE

TO INSTALL CEILING BOARD AND CEILING

Caution

To leave a gap between the product and

ceiling board approx. 2-3 mm.

Figure.

BEAM

CEILING

To prevent the contact with the propeller,

install the ventilating fan above 2.3 m from

the floor.

2-3 mm.

SCREW

TERMINAL

COVER

LOW

HIGH

COM

Figure.

More than 2.3 m

from the floor.

FLOOR.

TO INSTALL GRILLE

To hold grille’s spring of both side and insert to

elliptical hole of product then, release spring and

push cover to fix with the product as Figure.29.

Remarks:

Grille of VD-10Z4T -C, VD-15Z4T -C, VD-18Z4T ,

VD-20Z

4T , VD-20ZP4T , VD-23Z4T , VD-23ZP4T

can be reverse 90 ° by changing SPRING.

Spring grille assembling

MODELMODEL

Put SPRING in

Insert

SPRING

Insert PIN

Twist to CLOSE

locking with PLIERS

Figure.

ELLIPTICAL

HOLE

SPRING

GRILLE

Figure.

MODEL

SPRING

PLIERS

CATCH

Page 10

USAGE

4T

For VD-10Z

, VD-10Z

CAUTION USAGE

In case of installed in restroom having hot bathtub,

after draining the hot water, please cover bathtub

to prevent the evaporation of hot stream.

Be Quick

Close it

Figure. Figure.

OPERATING PROCEDURE

Switch boarded exclude the product, Use switch which be sold generally.

4T

-C, VD-15Z

Yep

4T ,

VD-15Z

4T

-C, VD-15ZP

Various parts are made from plastic material, do not

bring flammable objects to be near them that they

might possibly be deformed or melted.

4T

.

Remark : Installation location

of switch should be easy to

operate and shut off.

Air volume selector is available

Only this followed model

VD-20ZP4T2,VD23Z4T2,VD-23ZP4T2

START TO EXHAUST THE AIR

Switch on the wall. Switch on the wall.

OFF

SET THE AIR VOLUME SELECTOR

SWITCH TO “HIGH.”

LOW

ON

HIGH

STOP TO EXHAUST THE AIR

OFF

SET THE AIR VOLUME SELECTOR

SWITCH TO “LOW.”

LOW

ON

HIGH

MAINTENANCE

1. Be always turn switch off or pull the circuit breaker down before cleaning and

musn’t wet the motor or other electrical parts.

2. Cleaning the dirty part with water/neutral detergent damped-cloth to protect

water driping into electrical part, and then wipe with a dry cloth.

3. Do not use any chemical to clean the plastic part it may cuase damage to

product.

4. In case of intensive dirt on the grille, the air blow will be less causing loud

noise. To protect such condition, should often clean the grille.

5. To remove the grille, pull the grille, then squeeze the spring and take it from

the elliptical hole of fix spring as Figure.29 in page 9.

6. Disconnect the power when not in use.

Page 11

REPAIRING PRODUCT

1. This product must not be assembled under any circumstances. Only authorized repair technicians are

qualified to conduct diassembly and repairs.

(Failure to heed this warning may result infire, electric shock or injury.)

2. Must use genuine spare part from Service center or Sales Agency.

3. Do not modify any electric part, if failure to heed this warning may cause injury.

DIMENSIONS

NPEFM!;

HOLE FOR FIX

SCREW(8POINT)

LEAD WIRE

Unit : mm.

INSERT HOLE

NPEFM!;

Unit : mm.

NPEFM!;

HOLE FOR FIX

SCREW(8POINT)

LEAD WIRE

INSERT HOLE

Unit : mm.

Dimension table was shown

at Page.12

HOLE FOR FIX

SCREW(8POINT)

LEAD WIRE

INSERT HOLE

Page 12

TABLE:

No.

Each part dimension of

PART NAME

PART NAME

PICTURE

PLASTIC

MODEL

METAL

ADDITIONAL

DUCT

BODY

PROPELLER

FAN

AIR GUIDE

ORIFICE

GRILLE

ALL MODEL

ALL MODEL

REMARK :

NOT HAVE ORIFICE (No. 5) IN THIS FOLLOWED MODEL

K0588N41401

Loading...

Loading...