Page 1

AUTOMATIC

TRANSMISSION

V5A51

CONTENTS

GENERAL INFORMATION 23E-0-3................................................

1. SPECIFICATIONS 23E-1-1...................................................

TRANSMISSION MODEL TABLE 23E-1-1....................................

GENERAL SPECIFICATIONS 23E-1-2.......................................

SERVICE SPECIFICATIONS 23E-1-3........................................

VALVE BODY SPRING IDENTIFICATION 23E-1-4.............................

TORQUE SPECIFICATIONS 23E-1-5.........................................

SNAP RING, THRUST RACE, SPACER AND PRESSURE PLATE

FOR ADJUSTMENT 23E-1-7................................................

SEALANTS 23E-1-12.......................................................

LUBRICANTS 23E-1-13.....................................................

2. SPECIAL TOOLS 23E-2-1....................................................

3. TRANSMISSION AND TRANSFER 23E-3-1.....................................

4. TRANSFER CASE ADAPTER 23E-4-1.........................................

5. TRANSMISSION 23E-5-1.....................................................

6. REVERSE AND OVERDRIVE CLUTCH 23E-6-1.................................

7. SECOND BRAKE 23E-7-1....................................................

8. LOW/REVERSE ANNULUS GEAR 23E-8-1.....................................

9. CENTER SUPPORT 23E-9-1..................................................

10. UNDERDRIVE CLUTCH 23E-10-1..............................................

11. VALVE BODY 23E-11-1.......................................................

12. DIRECT ANNULUS GEAR 23E-12-1............................................

13. DIRECT CLUTCH 23E-13-1....................................................

14. OUTPUT SHAFT SUPPORT 23E-14-1..........................................

15. TRANSFER 23E-15-1.........................................................

16. TRANSFER CASE PLATE 23E-16-1............................................

17. INPUT GEAR 23E-17-1........................................................

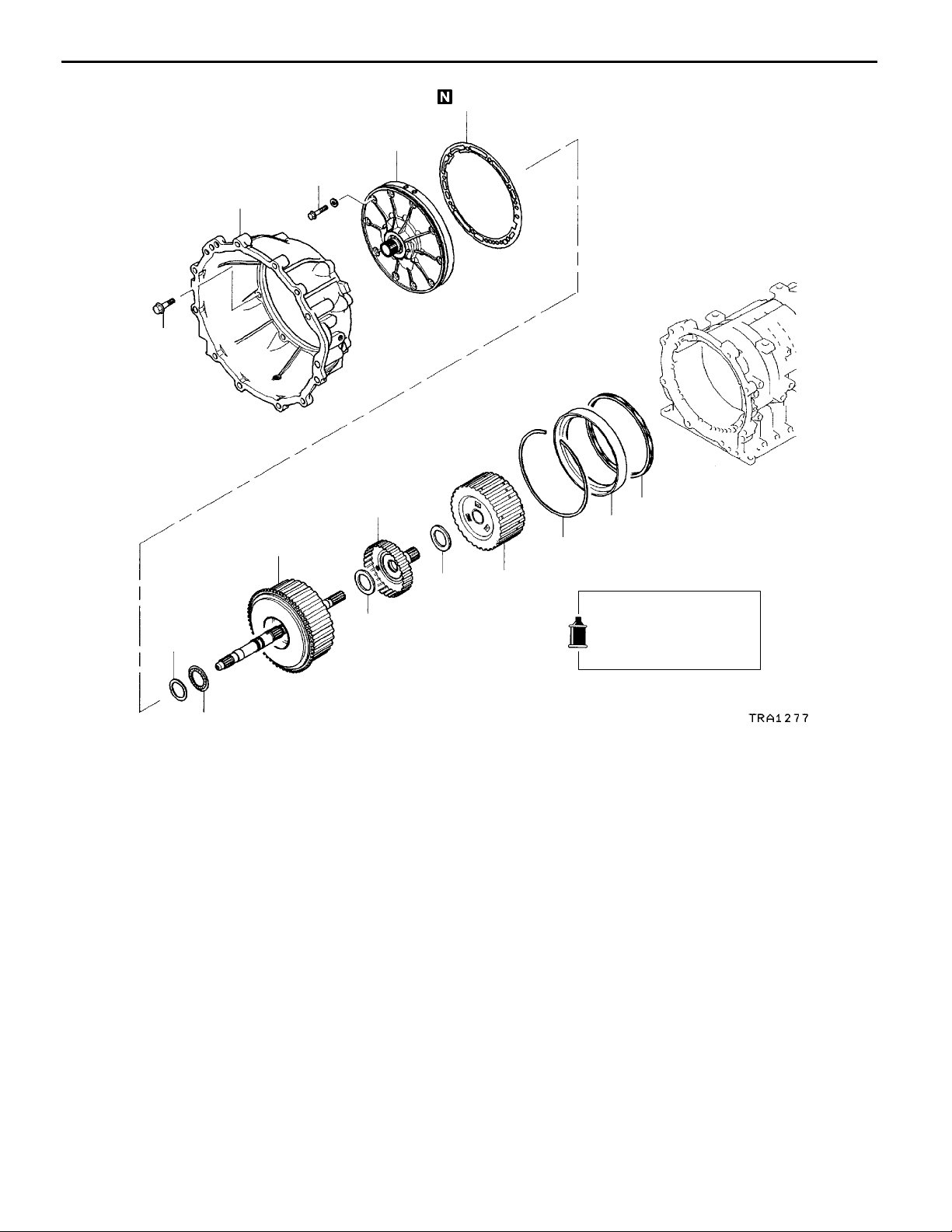

18. COUNTER GEAR 23E-18-1....................................................

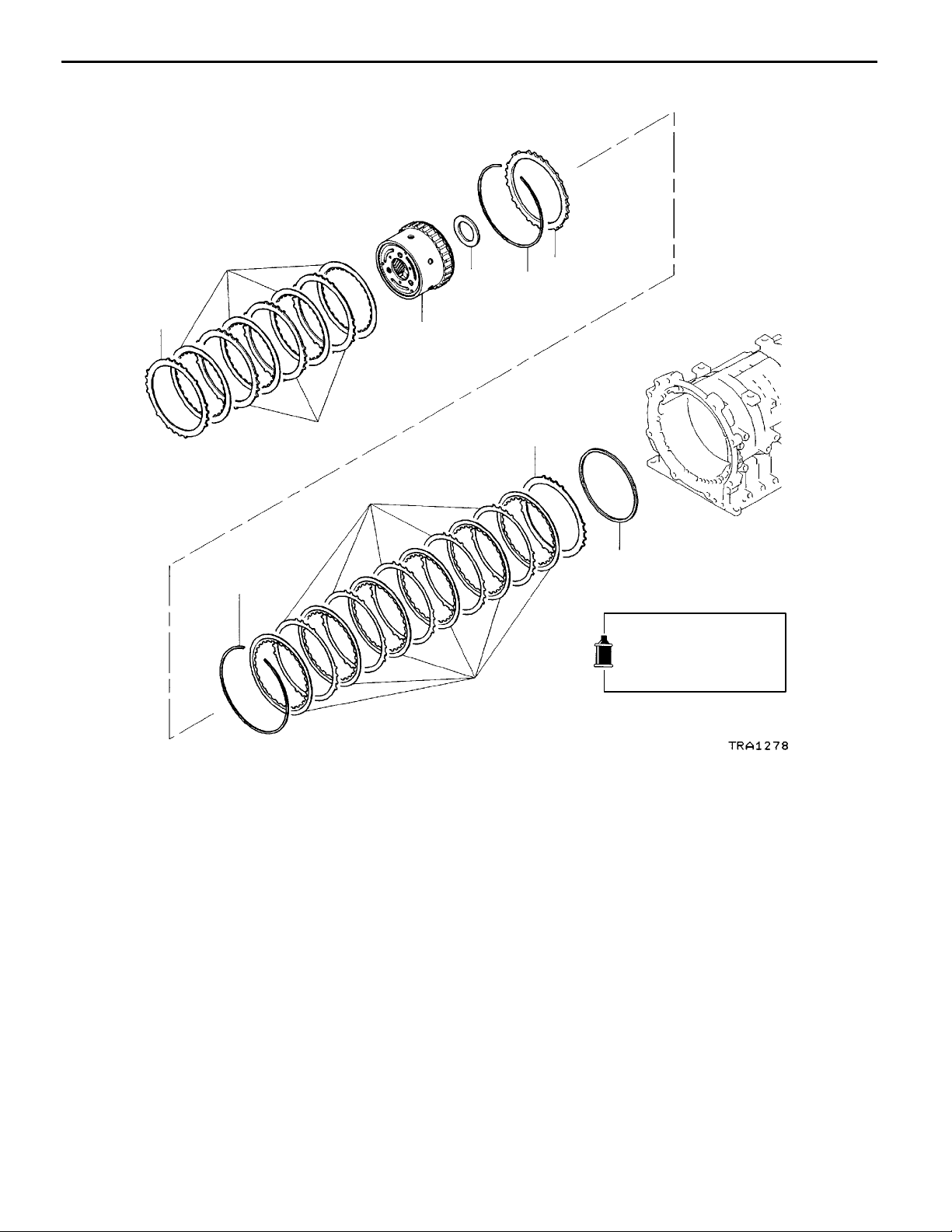

19. REAR OUTPUT SHAFT 23E-19-1..............................................

20. FRONT OUTPUT SHAFT 23E-20-1.............................................

21. TRANSFER DRIVE SHAFT 23E-21-1...........................................

22. SHIFT RAIL DRIVE GEAR 23E-22-1............................................

23. 2-4WD SHIFT RAIL AND H-L SHIFT RAIL 23E-23-1..............................

23E-0-1

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 2

23E-0-2

NOTES

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 3

V5A51 -

General Information

23E-0-3

GENERAL INFORMATION

This transmission is the newly developed 5-speed automatic transmission that merges advanced electronic

technology and mechanical technology.

(1) A hydraulic balance mechanism is incorporated for the transmission clutch, allowing speed changes

at ultra-high speeds to be handled.

(2) The weight has been reduced by using precision sheet metal pressing of the clutch retainer, etc.,

and using aluminum die cast for the oil pump housing, etc.

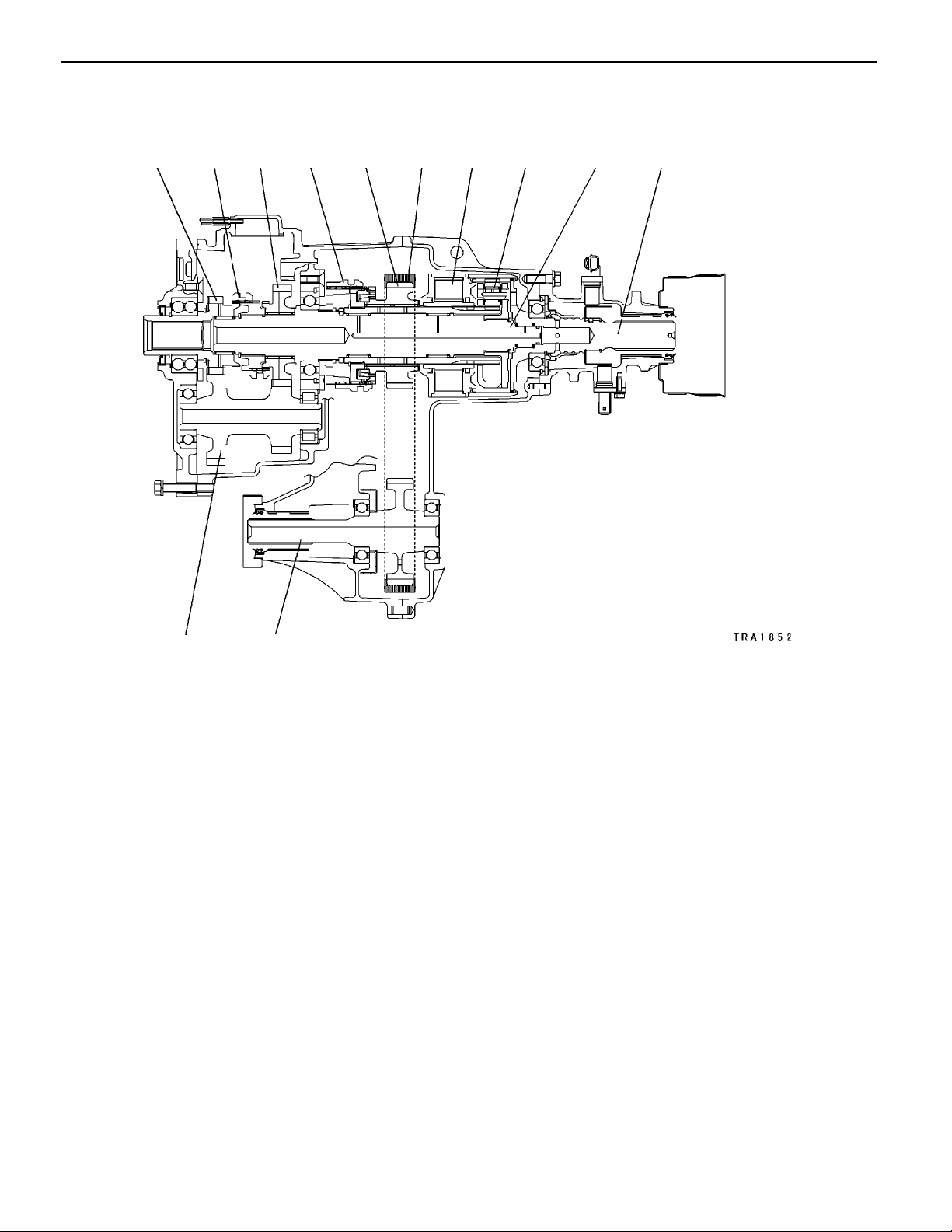

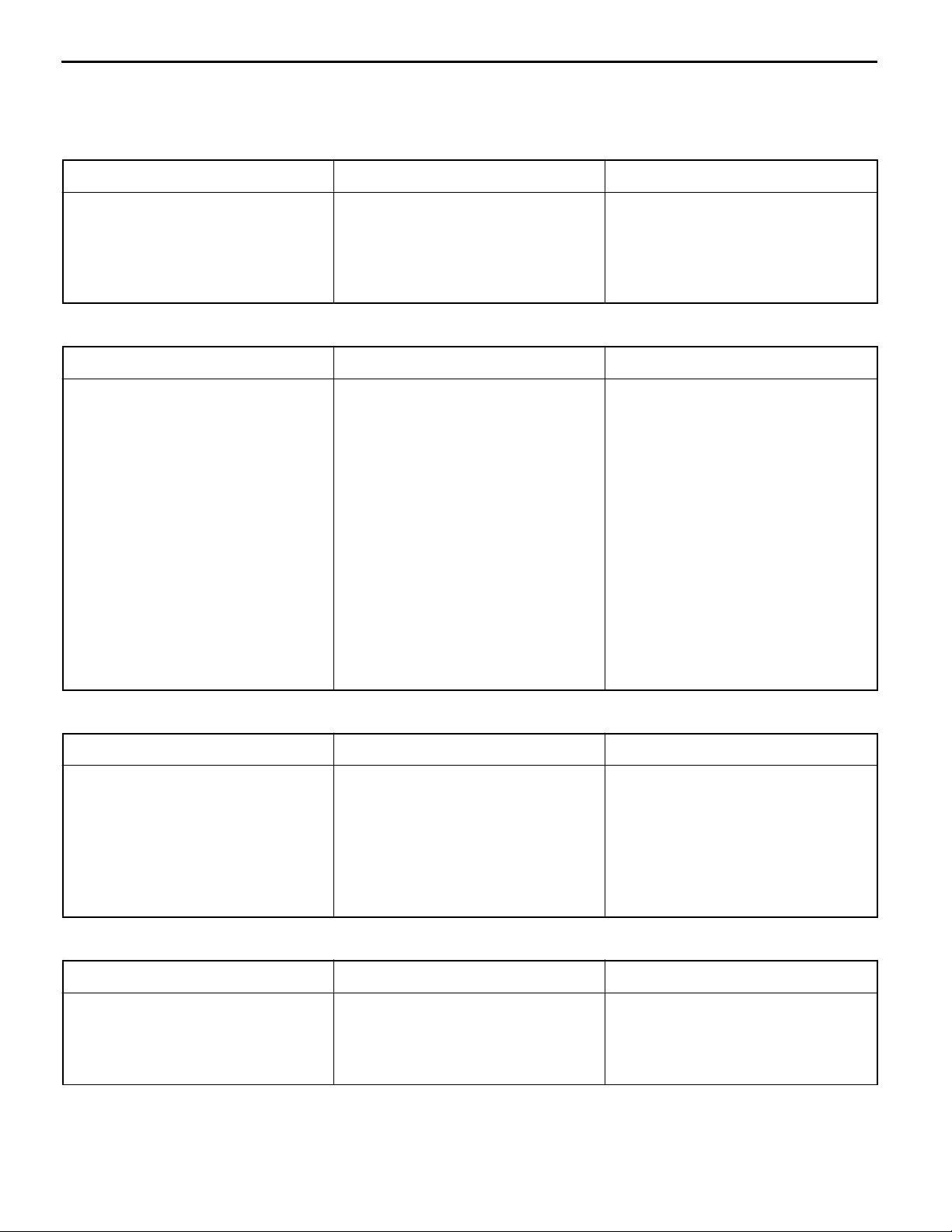

SECTIONAL VIEW <TRANSMISSION>

12345678910111213

19

18

14

17

15

16

1. Torque converter clutch

2. Torque converter

3. Oil pump

4. Overdrive clutch

5. Reverse clutch

6. Overdrive planetary carrier

7. Second brake

8. Output planetary carrier

9. Low/reverse brake

10. One-way clutch

E

Mar. 2000Mitsubishi Motors Corporation

11. Center support

12. Underdrive clutch

13. Output shaft support

14. Parking gear

15. Output shaft

16. One-way clutch

17. Direct clutch

18. Valve body

19. Input shaft

AddedPWEE8920-I

Page 4

23E-0-4

V5A51 -

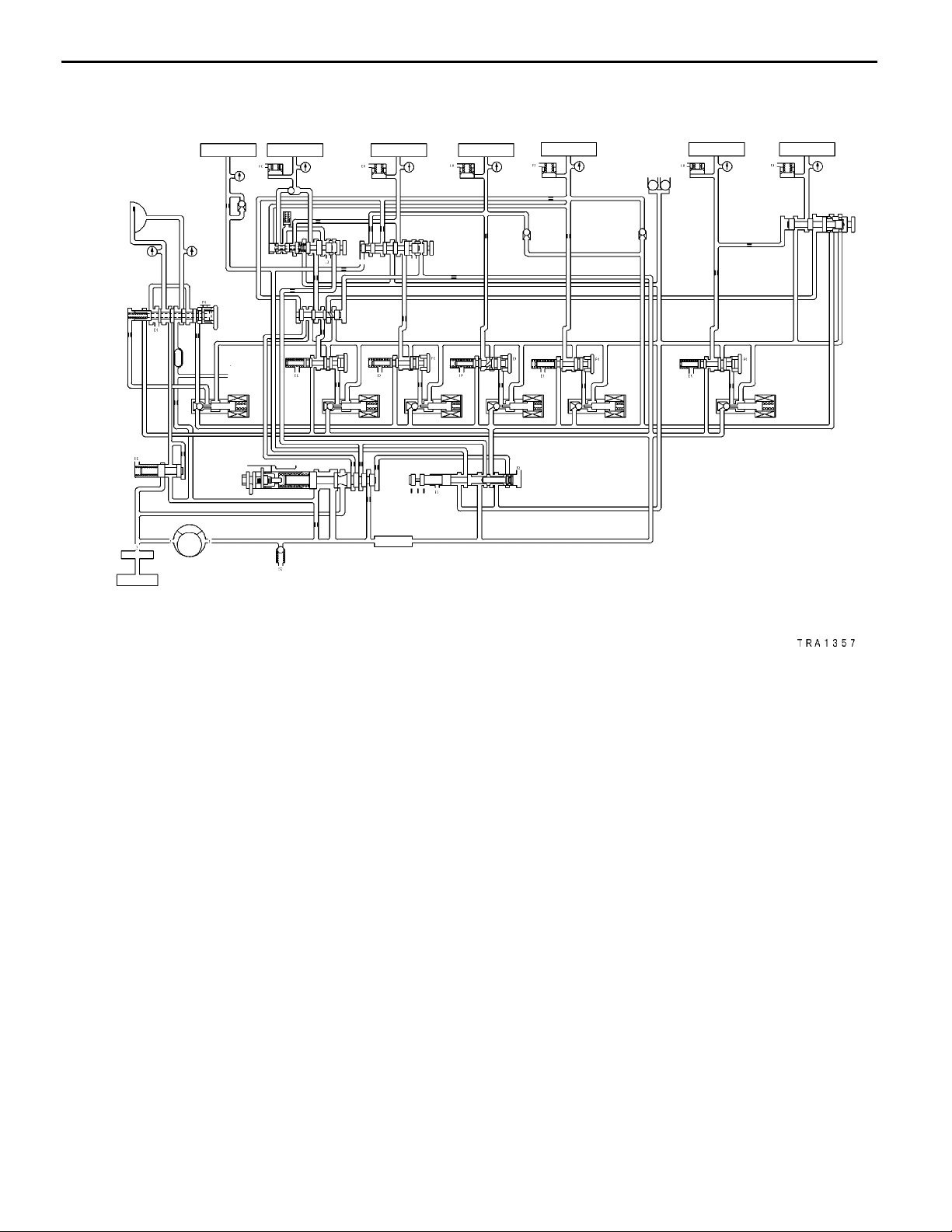

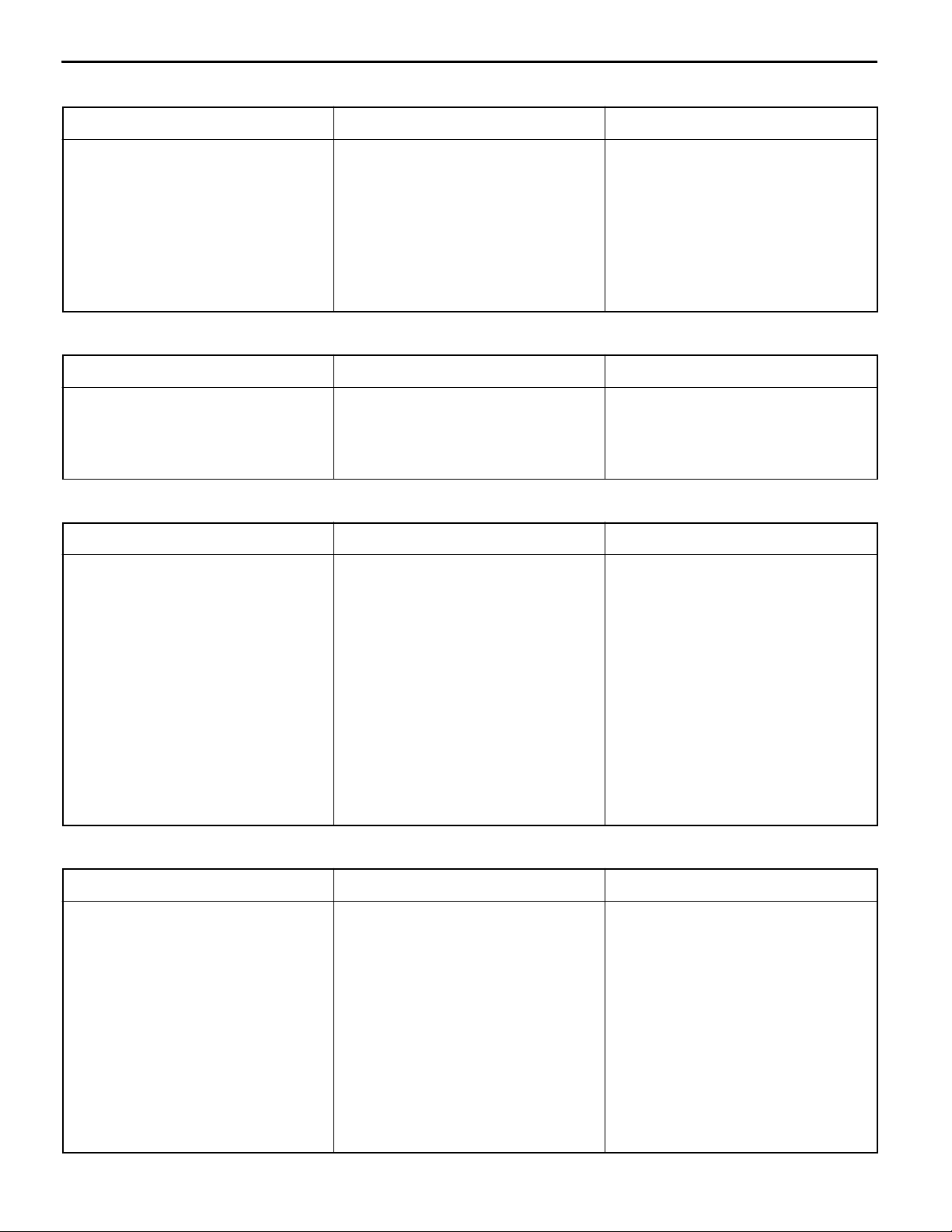

SECTIONAL VIEW <TRANSFER>

1 2 3 4 5 6 7 8 9 10

General Information

12

1. Transfer input gear

2. H-L clutch

3. Low speed gear

4. 2-4WD clutch sleeve

5. Drive sprocket

6. Chain

11

7. Viscous coupling

8. Center differential planetary carrier

9. Transfer drive shaft

10. Rear output shaft

11. Front output shaft

12. Counter shaft gear

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 5

V5A51 -

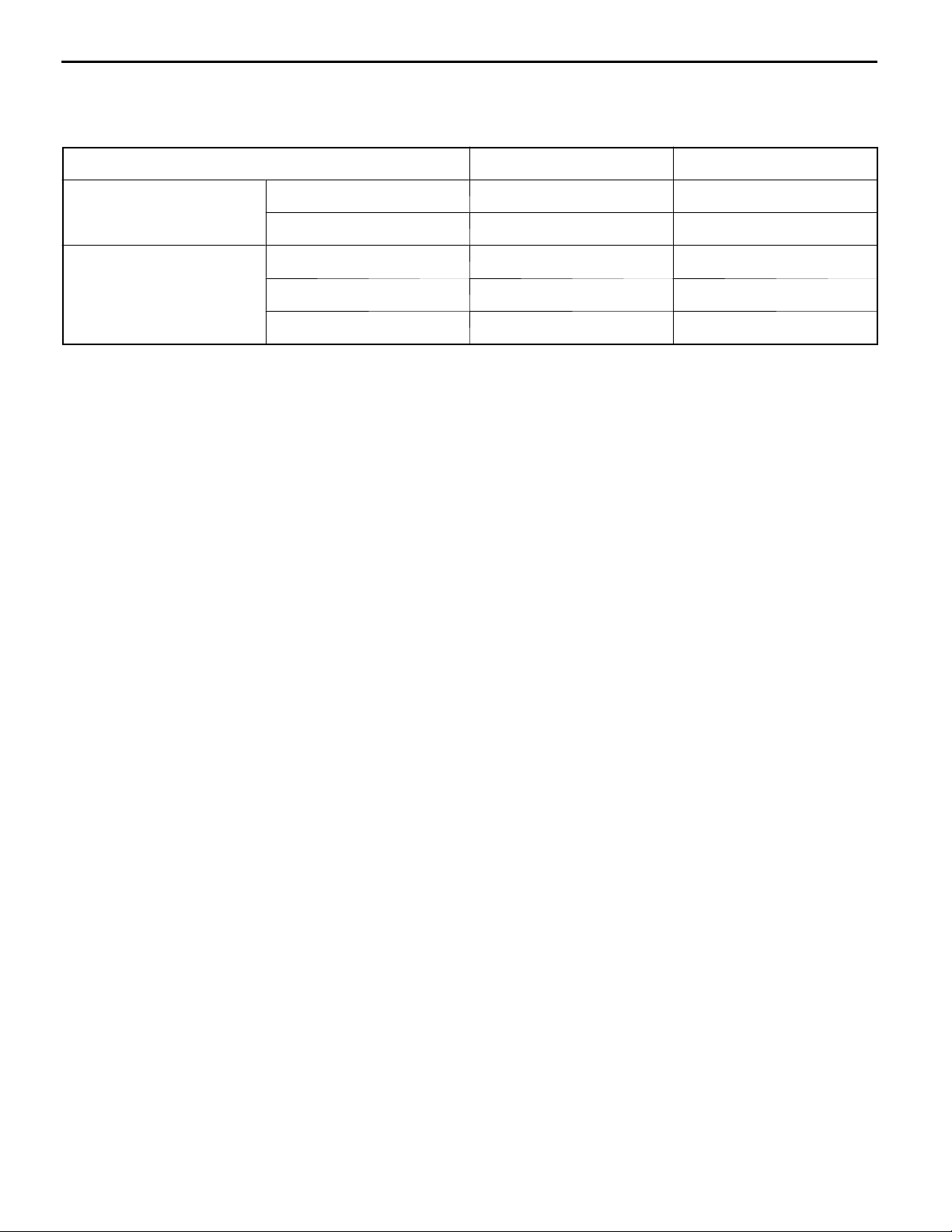

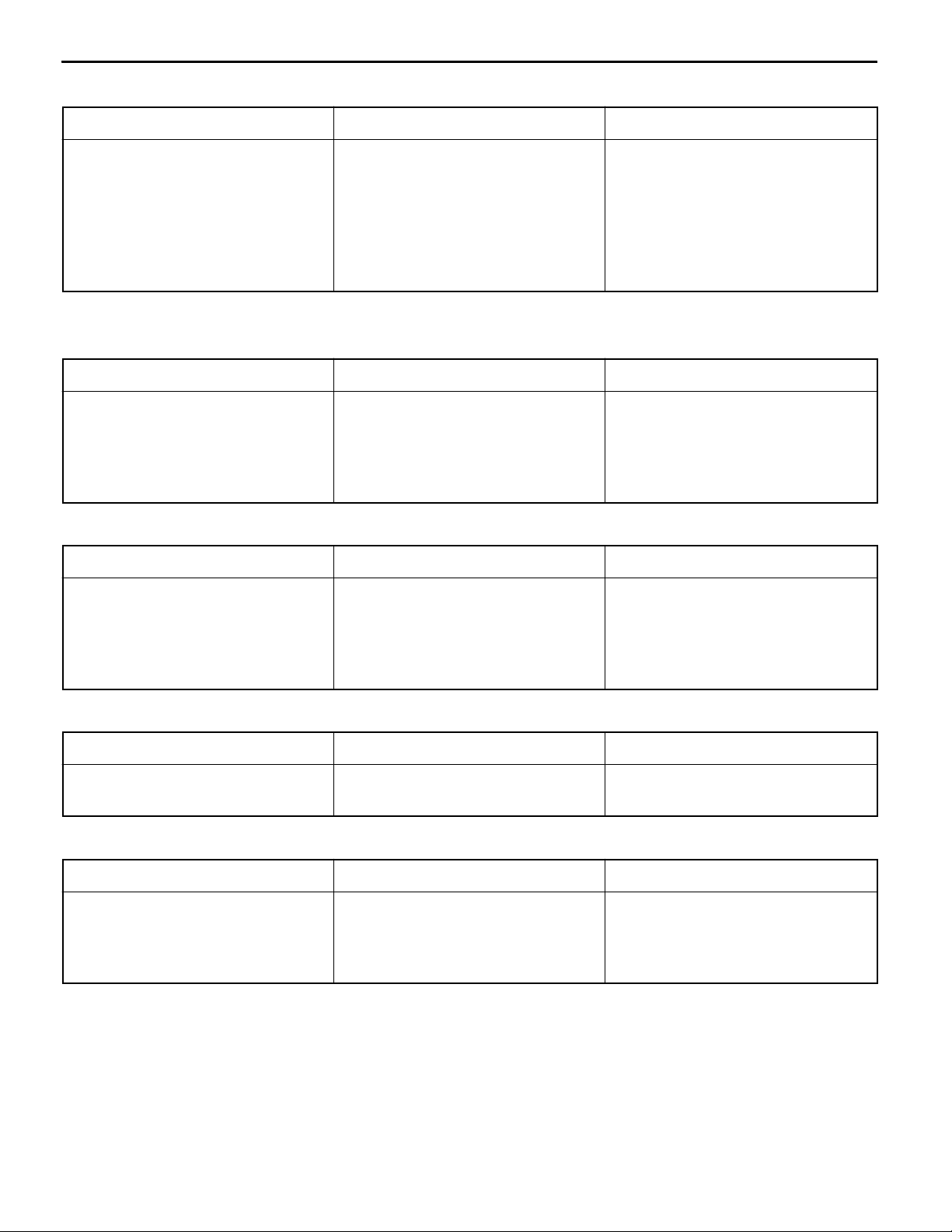

HYDRAULIC CONTROL SYSTEM

General Information

23E-0-5

25

24

21

12 3 4 5

28

6

7

9

10

8

29

30

11

22

16

12

13

14

17 18

19

23

15

20

31

32

26

27

1. Reverse clutch

2. Low/reverse brake

3. Second brake

4. Underdrive clutch

5. Overdrive clutch

6. Torque converter clutch

7. Fail-safe valve A

8. Fail-safe valve B

9. Torque converter clutch control valve

10. Switching valve

11. Cooler

12. Low-reverse brake pressure control

valve

13. Second brake pressure control valve

14. Underdrive clutch pressure control

valve

15. Overdrive clutch pressure control

valve

16. Torque converter clutch control solenoid valve

17. Low-reverse brake solenoid valve

18. Second brake solenoid valve

19. Underdrive clutch solenoid valve

20. Overdrive clutch solenoid valve

21. Torque converter pressure control

valve

22. Regulator valve

23. Manual valve

24. Oil filter

25. Oil pan

26. Oil pump

27. Oil strainer

28. Reduction brake

29. Direct clutch

30. Fail-safe valve C

31. Reduction brake pressure control

valve

32. Reduction brake solenoid valve

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 6

V5A51 -

Specifications

1. SPECIFICATIONS

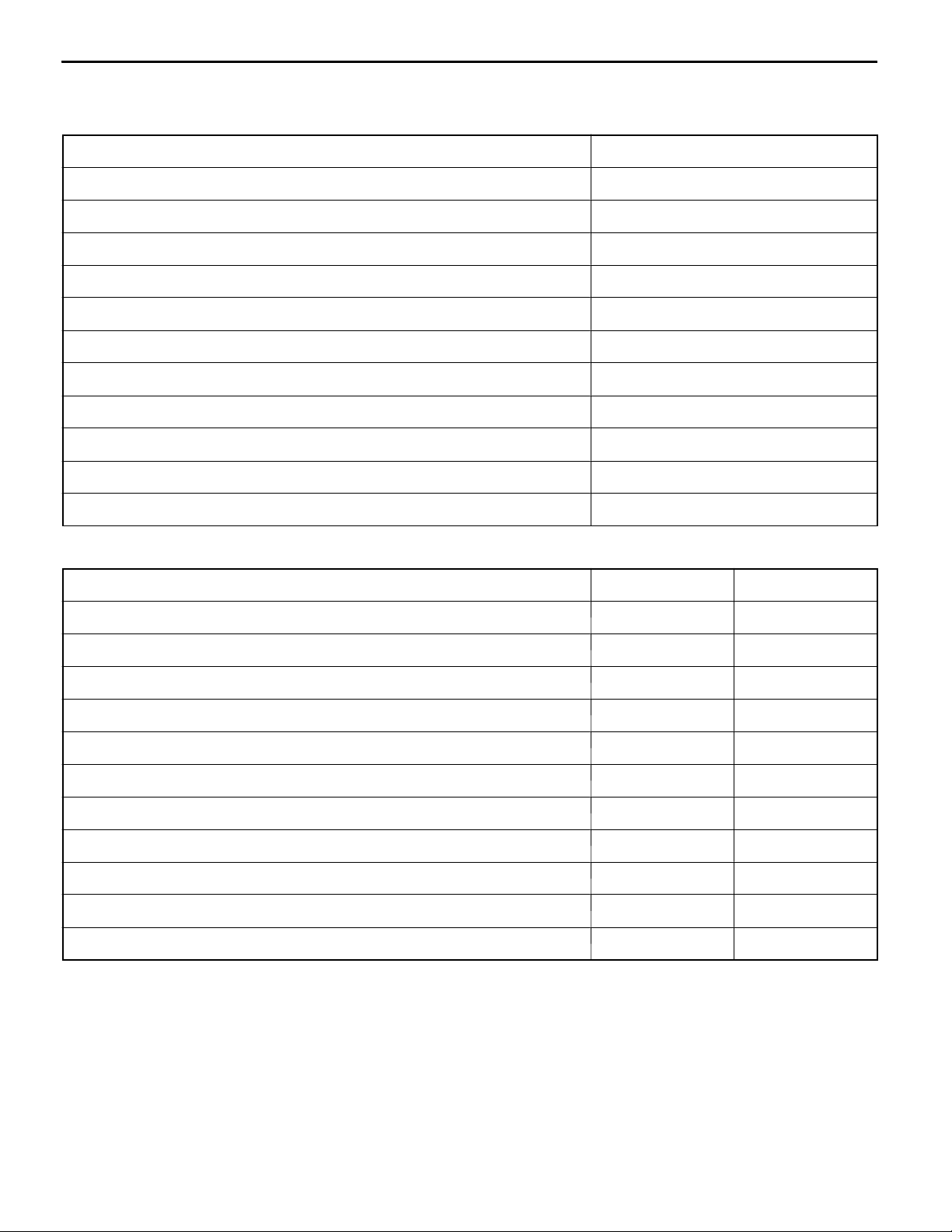

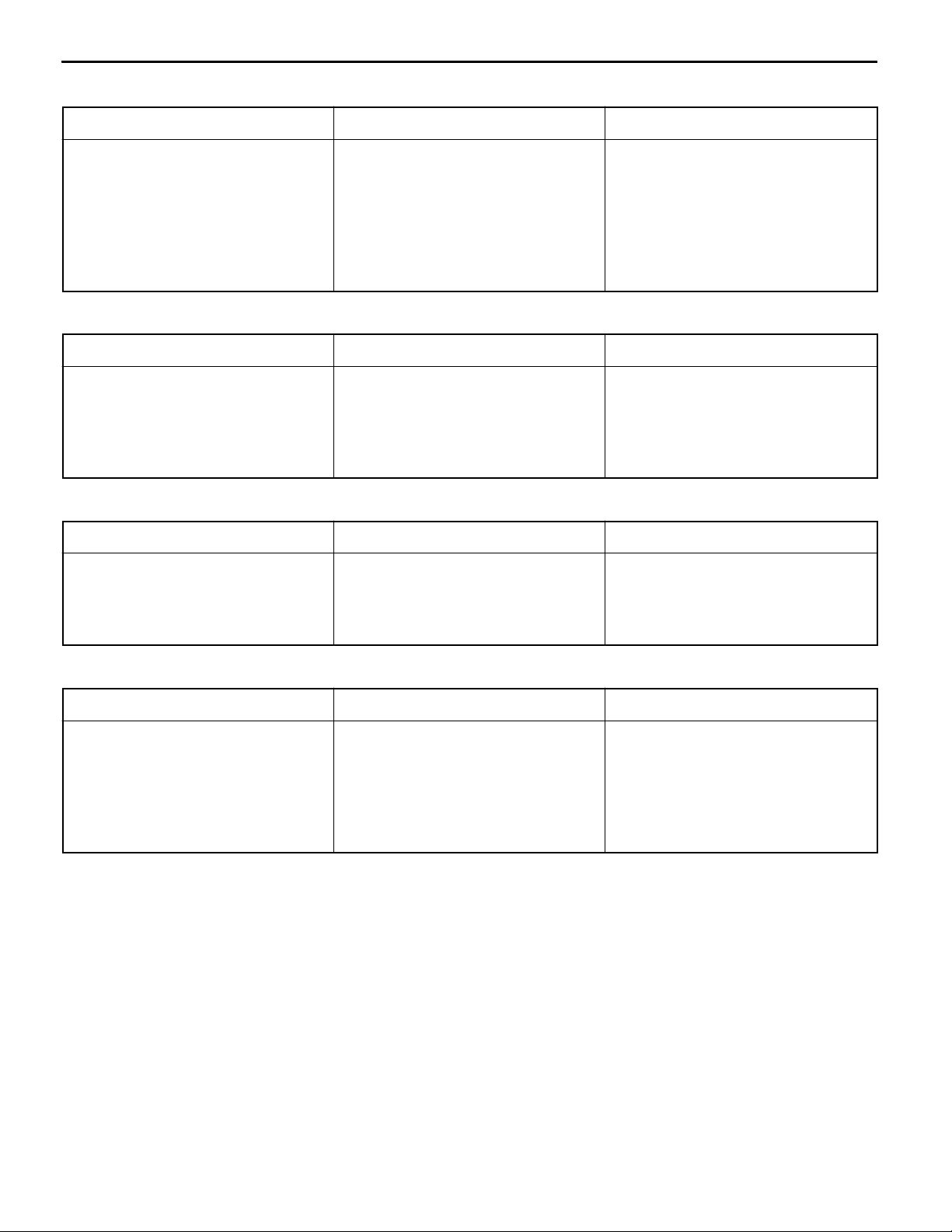

TRANSMISSION MODEL TABLE - MODEL 2001

Transmission models Vehicle model Engine model

EUR V5A51-7-ACA V65W, V75W 6G74

V5A51-7-SDA V68W, V78W 4M41

EXP V5A51-7-CCA1 V75W 6G74

V5A51-7-CCA2 V65W, V75W 6G74

V5A51-7-SDA1 V78W 4M41

23E-1-1

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 7

23E-1-2

V5A51 -

Specifications

GENERAL SPECIFICATIONS

Item V5A51

Torque converter Type 3-element, with torque converter clutch

Transmission Type 5-speed, fully automatic

Gear ratio 1st 3.789

2nd 2.057

3rd 1.421

4th 1.000

5th 0.731

Reverse 3.865

Transfer Type 2-speed constant mesh

Gear ratio High 1.000

Low

1.900

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 8

V5A51 -

Specifications

SERVICE SPECIFICATIONS

TRANSMISSION

Item Standard value

Direct planetary carrier mm 0.25 - 0.55

Underdrive clutch end play mm 1.6 - 1.8

Input shaft end play mm 0.25 - 0.81

Direct clutch end play mm 1.0 - 1.2

Overdrive clutch end play mm 2.0 - 2.2

Overdrive clutch return spring retainer end play mm 0 - 0.09

Second brake end play mm 1.49 - 1.95

Center support end play mm 0 - 0.16

Brake reaction plate end play mm 0 - 0.16

Reverse clutch end play mm 1.5 - 1.7

23E-1-3

Low/reverse brake end play mm 1.65 - 2.11

TRANSFER

Item Standard value Limit

Input gear bearing end play mm 0 - 0.06 -

Countershaft gear end play mm 0 - 0.15 -

Countershaft gear bearing end play mm 0 - 0.08 -

2-4WD clutch hub end play mm 0 - 0.08 -

H-L clutch hub end play mm 0 - 0.08 -

Rear output shaft preload mm 0.12 - 0.24 -

Rear output shaft end play mm 0 - 0.12 -

Rear output shaft bearing end play mm 0 - 0.08 -

Rear output shaft annulus gear end play mm 0 - 0.08 -

Differential lock hub end play mm 0 - 0.08 -

Clearance between outer synchronizer ring and drive sprocket mm - 0.3

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 9

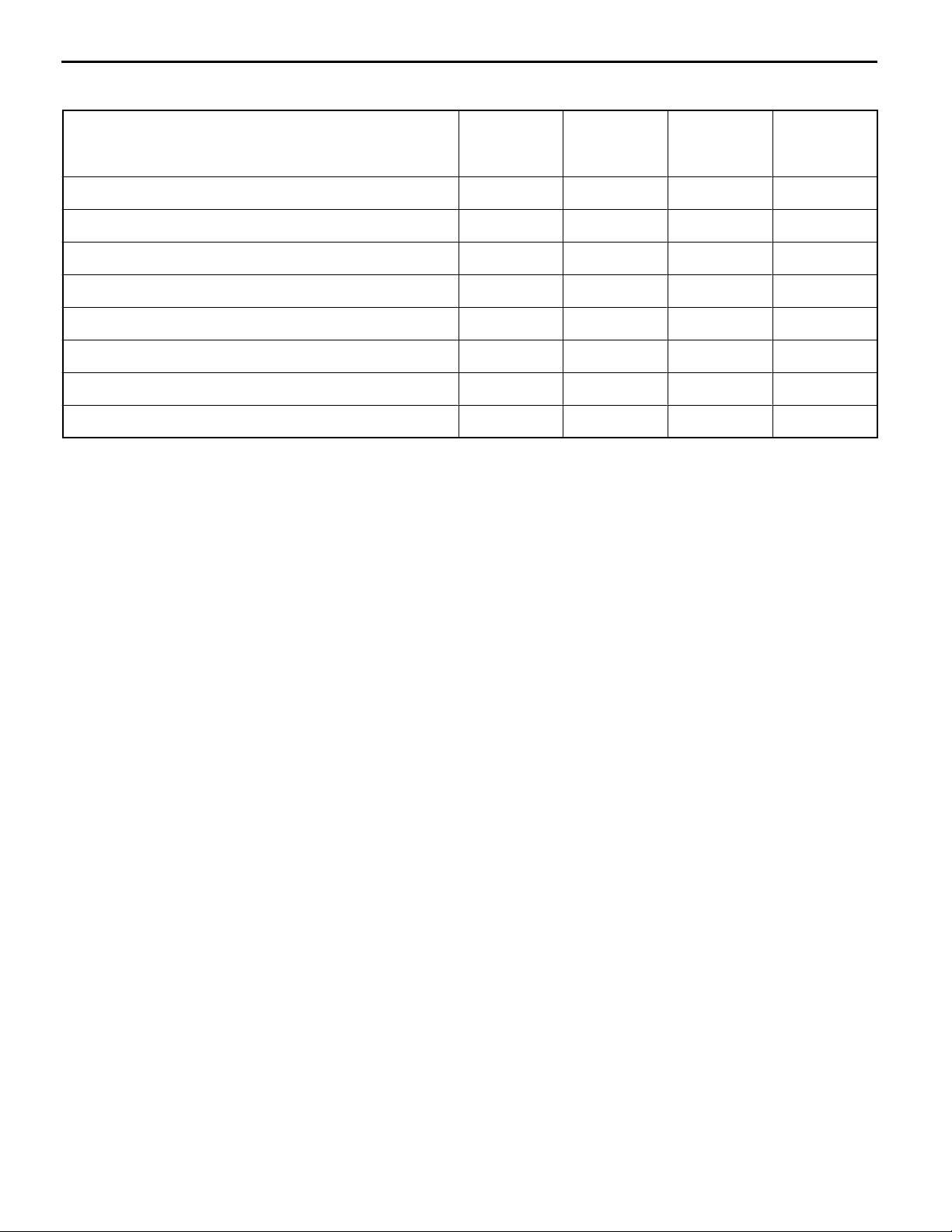

23E-1-4

V5A51 -

VALVE BODY SPRING IDENTIFICATION

Specifications

Item Wire

diameter

mm

Orifice check ball spring 0.5 4.5 15.4 15

Torque converter clutch control valve spring 0.7 5.9 28.1 19

Damping valve spring 1.0 7.7 35.8 17

Torque converter pressure control valve spring 1.6 11.2 29.4 9.5

Fail-safe valve A spring 0.7 8.9 21.9 9.5

Pressure control valve spring 0.7 7.6 37.7 25

Line relief valve spring 1.0 7.0 17.3 10

Regulator valve spring 1.3 13.3 44.6 10.5

Outside

diameter

mm

Free

height

mm

Number of

loops

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 10

V5A51 -

Specifications

TORQUE SPECIFICATIONS

TRANSMISSION

Item Torque Nm

Output shaft support mounting bolt 23 ± 3

Upper valve body mounting bolt 11 ± 1

Park/neutral position switch mounting bolt 11 ± 1

Anchor plug 98 ± 15

Oil pan mounting bolt 11 ± 1

Oil filter mounting bolt 6 ± 1

Oil pump mounting bolt 23 ± 3

Cable end bracket mounting bolt 48 ± 6

Converter housing to transmission case tightening bolt 48 ± 6

Output shaft speed sensor mounting bolt 11 ± 1

23E-1-5

Reduction brake piston nut 19 ± 3

Separating plate mounting bolt 6 ± 1

Solenoid support mounting bolt 6 ± 1

Transfer to transfer case adapter tightening bolt 35 ± 6

Transmission case to transfer case adapter tightening bolt 48 ± 6

Input shaft speed sensor mounting bolt 11 ± 1

V alve body mounting bolt 11 ± 1

Detent spring mounting bolt 6 ± 1

Manual control lever mounting nut 22 ± 3

Lower valve body mounting bolt 11 ± 1

Lower valve body cover mounting bolt 11 ± 1

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 11

23E-1-6

V5A51 -

Specifications

TRANSFER

Item Torque Nm

Dynamic damper 35 ± 6

Transfer case cover tightening bolt 19 ± 2

Input gear bearing retainer mounting bolt 20 ± 2

Transfer case to chain cover tightening bolt 35 ± 6

Rear bearing retainer mounting bolt 20 ± 2

Transfer case plate to transfer case tightening bolt and nut 35 ± 6

Rear cover to chain cover tightening bolt 35 ± 6

Shift actuator mounting bolt 11 ± 1

4LLC switch 35 ± 6

2WD switch 35 ± 6

Center differential lock switch 35 ± 6

4H switch 35 ± 6

2WD-4WD switch 35 ± 6

Vehicle speed sensor mounting bolt 11 ± 1

Front outoput sensor mounting bolt 11 ± 1

Rear output sensor mounting bolt 11 ± 1

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 12

V5A51 -

Specifications

23E-1-7

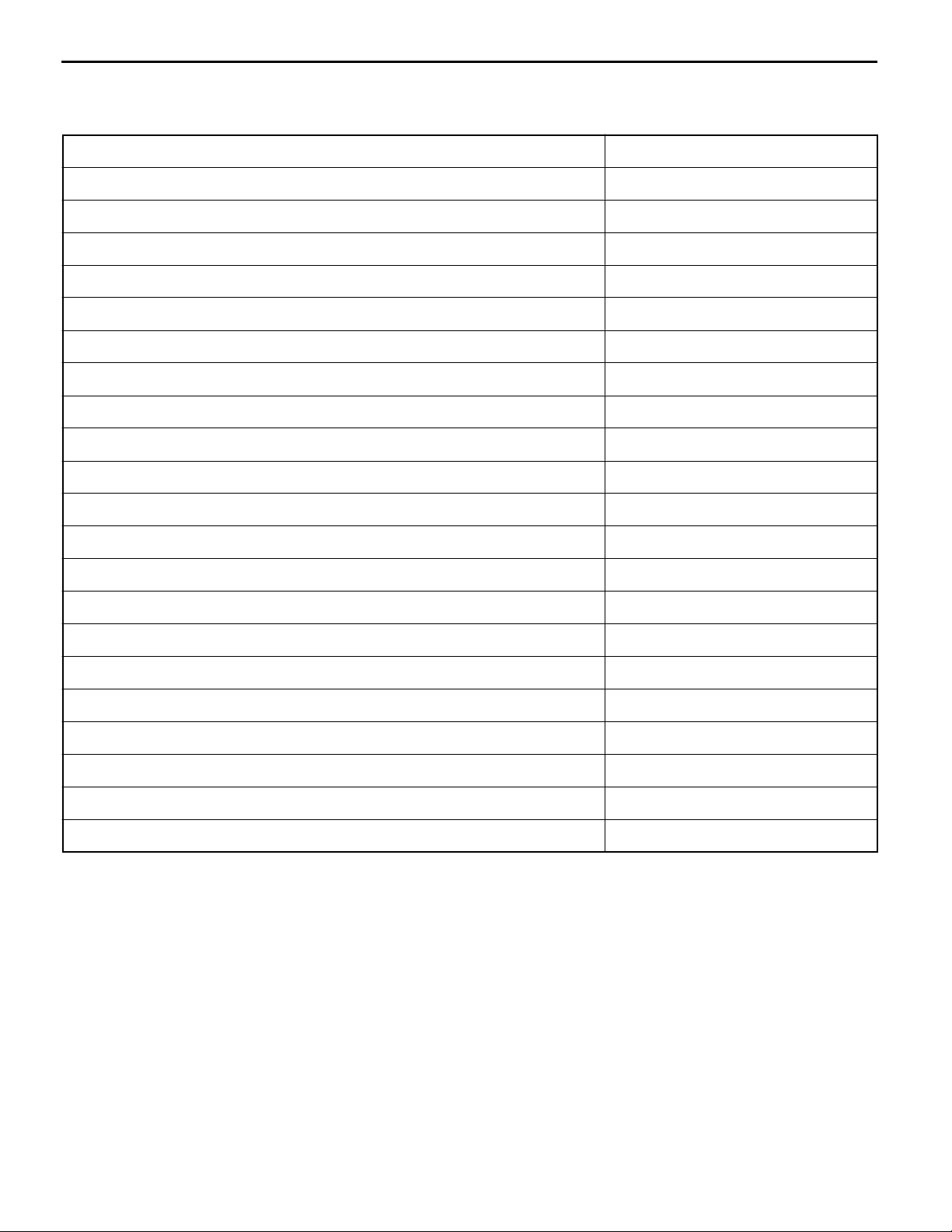

SNAP RING, THRUST RACE, SPACER AND PRESSURE PLATE FOR ADJUSTMENT

TRANSMISSION

Thrust race (for adjustment of direct planetary carrier end play)

Thickness mm Identification symbol Part number

1.6

1.8

2.0

2.2

2.3

None

None

None

None

None

MR276705

MR276706

MR276707

MR276708

MR276709

Snap ring (for adjustment of underdrive clutch and overdrive clutch end play)

Thickness mm Identification symbol Part number

1.6

1.7

1.8

1.9

2.0

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

3.0

Brown

None

Blue

Brown

None

Blue

Brown

None

Blue

Brown

None

Blue

Brown

None

Blue

MD759960

MD759961

MD759962

MD758892

MD750841

MD750842

MD750843

MD750844

MD750845

MD750846

MD750847

MD750848

MD750849

MD750850

MD750851

Thrust race (for adjustment of input shaft end play)

Thickness mm Identification symbol Part number

1.4

1.6

1.8

2.0

2.2

2.4

2.6

None

None

None

None

None

None

None

MD723063

MD707267

MD723064

MD707268

MD723065

MD724358

MD754798

Snap ring (for adjustment of overdrive clutch return spring retainer end play)

Thickness mm Identification symbol Part number

1.48

1.53

1.58

1.63

Brown

Black

None

Brown

MR336158

MR336159

MR336160

MR336161

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 13

23E-1-8

V5A51 -

Specifications

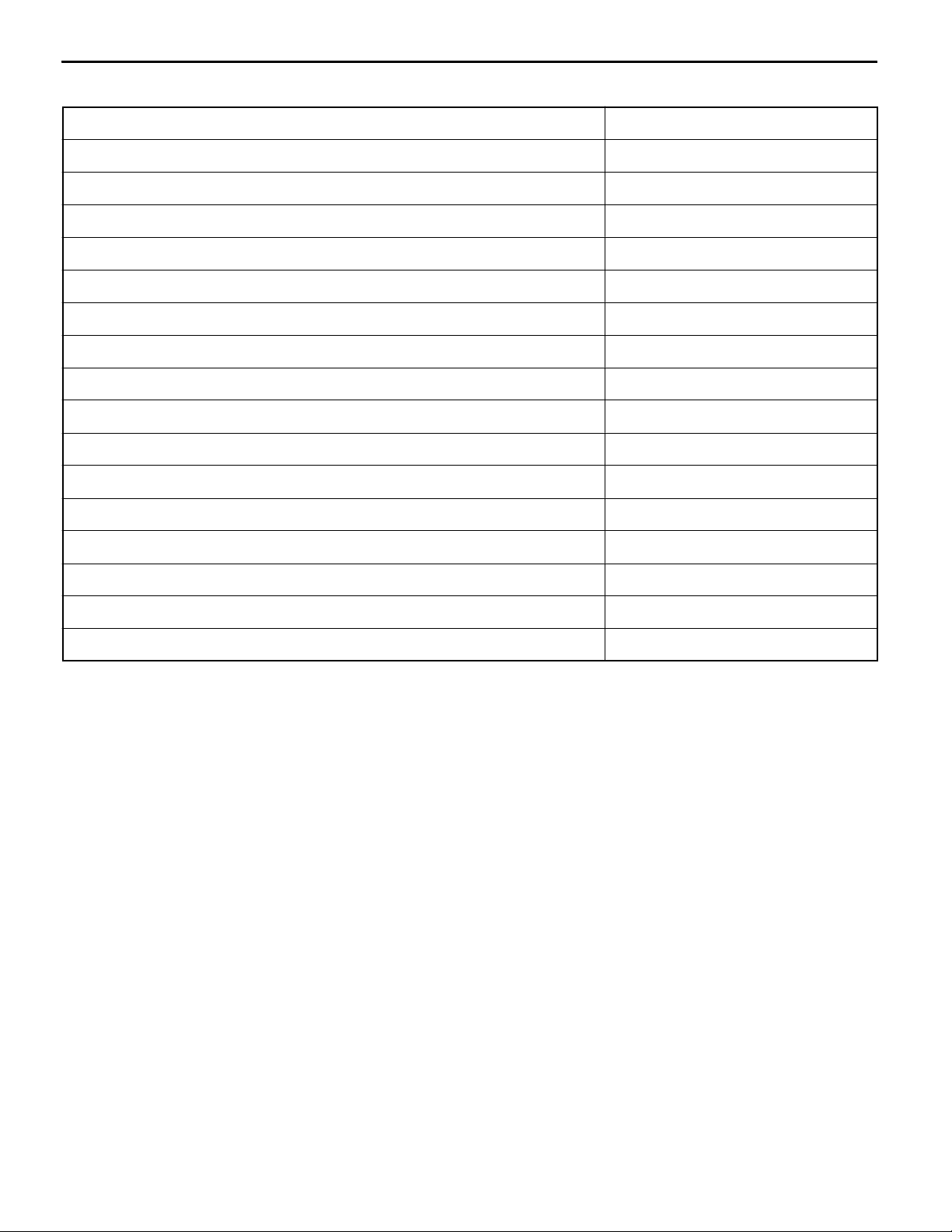

Pressure plate (for adjustment of second brake end play)

Thickness mm Identification symbol Part number

1.6

1.8

2.0

2.2

2.4

2.6

2.8

3.0

F

E

D

C

B

A

0

1

MR336390

MR336391

MR336392

MR336393

MR336394

MR336395

MR336396

MR336397

Snap ring (for adjustment of center support and brake reaction plate end play)

Thickness mm Identification symbol Part number

2.2

2.3

2.4

2.5

None

Blue

Brown

None

MD756784

MD756785

MD758552

MD758553

Snap ring (for adjustment of reverse clutch end play)

Thickness mm Identification symbol Part number

1.6

1.7

1.8

1.9

2.0

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

None

Blue

Brown

None

Blue

Brown

None

Blue

Brown

None

Blue

Brown

None

MD761088

MD761089

MD761090

MD758947

MD756690

MD756691

MD756692

MD756693

MD756694

MD756695

MD756696

MD756697

MD756698

Snap ring (for adjustment of direct clutch end play)

Thickness mm Identification symbol Part number

1.9

2.0

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

3.0

E

Mar. 2000Mitsubishi Motors Corporation

Brown

None

Blue

Brown

None

Blue

Brown

None

Blue

Brown

None

Blue

MD758946

MD753397

MD753398

MD753399

MD753400

MD753401

MD753402

MD753403

MD753404

MD753405

MD753406

MD753497

AddedPWEE8920-I

Page 14

V5A51 -

Specifications

Snap ring (for adjustment of low/reverse brake end play)

Thickness mm Identification symbol Part number

23E-1-9

1.8

2.0

2.2

2.4

2.6

2.8

3.0

E

D

C

B

A

0

1

MD759425

MD759426

MD759427

MD759428

MD759429

MD759430

MD759431

TRANSFER

Spacer (for adjustment of input gear bearing end play)

Thickness mm Identification symbol Part number

2.30

2.35

2.40

2.45

2.50

None

Red

White

Blue

Green

MD704199

MD704200

MD704201

MD704202

MD704203

Spacer (for adjustment of countershaft gear end play)

Thickness mm Identification symbol Part number

1.77

1.91

2.05

2.19

2.33

None

Blue

Brown

White

Red

MB896728

MB896729

MB896730

MB896731

MB896732

Snap ring (for adjustment of countershaft gear bearing end play)

Thickness mm Identification symbol Part number

1.48

1.62

Blue

None

MB919176

MB919177

Snap ring (for adjustment of H-L clutch hub end play)

Thickness mm Identification symbol Part number

2.18

2.25

2.32

2.39

None

None

None

None

MR410928

MR410929

MR410930

MR410931

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 15

23E-1-10

V5A51 -

Specifications

Snap ring (for adjustment of differential lock hub end play)

Thickness mm Identification symbol Part number

2.56

2.63

2.70

2.77

2.84

2.91

2.98

None

Red

White

Blue

Yellow

Green

Brown

MD738386

MD738387

MD738388

MD738389

MD738390

MD738391

MD738392

Snap ring (for adjustment of 2-4WD clutch hub end play)

Thickness mm Identification symbol Part number

2.56

2.63

2.70

2.77

2.84

None

Red

White

Blue

Yellow

MD738393

MD738394

MD738395

MD738396

MD738397

Snap ring (for adjustment of rear output shaft bearing end play)

Thickness mm Identification symbol Part number

2.26

2.33

2.40

2.47

None

Red

White

Blue

MD73431 1

MD734312

MD734313

MD734314

Snap ring (for adjustment of rear output shaft annulus gear end play)

Thickness mm Identification symbol Part number

1.90

1.94

1.98

2.02

2.06

2.10

None

None

None

None

None

None

MR305024

MR305025

MR305026

MR305027

MR305028

MR305029

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 16

V5A51 -

Specifications

Snap ring (for adjustment of rear output shaft preload)

Thickness mm Identification symbol Part number

23E-1-11

1.57

1.63

1.69

1.75

1.81

1.87

1.93

1.99

2.05

2.11

2.17

2.23

2.29

2.35

2.41

2.47

2.53

2.59

2.65

2.71

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

Spacer (for adjustment of rear output shaft end play)

MR486340

MR486341

MR486342

MR486343

MR486344

MR486345

MR486346

MR486347

MR477935

MR477936

MR477937

MR477938

MR477939

MR477940

MR477941

MR477942

MR477943

MR477944

MR477945

MR477946

Thickness mm Identification symbol Part number

2.57

2.63

2.69

2.75

2.81

2.87

2.93

2.99

3.05

3.11

3.17

3.23

3.29

3.35

3.41

3.47

3.53

3.59

3.65

3.71

3.77

3.83

3.89

3.95

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

MR477950

MR477951

MR477952

MR477953

MR477954

MR477955

MR477956

MR477957

MR477958

MR477959

MR477960

MR477961

MR477962

MR477963

MR477964

MR477965

MR477966

MR477967

MR477968

MR486348

MR486349

MR486350

MR486351

MR486352

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 17

23E-1-12

V5A51 -

Specifications

SEALANTS

TRANSMISSION

Item Specified sealant

Oil pan MITSUBISHI genuine sealant part No. MR166584 or

equivalent

Transfer case adapter (transmission side) MITSUBISHI genuine sealant part No. MR166584 or

equivalent

TRANSFER

Item Specified sealant

Bearing retainer mounting bolt MITSUBISHI genuine sealant part No. MD997740 or

equivalent

Chain cover MITSUBISHI genuine sealant part No. MD997740 or

equivalent

Transfer case cover MITSUBISHI genuine sealant part No. MD997740 or

equivalent

Rear cover MITSUBISHI genuine sealant part No. MD997740 or

equivalent

Sealing cap 3MTMAAD part No. 8672 or equivalent

Transfer case plate MITSUBISHI genuine sealant part No. MD997740 or

equivalent

Mar. 2000Mitsubishi Motors Corporation AddedPWEE8920-I

E

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 18

V5A51 -

Specifications

23E-1-13

FORM-IN-PLACE GASKET (FIPG)

The transmission has several areas where the form-in-place gasket (FIPG) is in use. To ensure that

the gasket fully serves its purpose, it is necessary to observe some precautions when applying the gasket.

Bead size, continuity and location are of paramount importance. Too thin a bead could cause leaks.

Too thick a bead, on the other hand, could be squeezed out of location, causing blocking or narrowing

of the fluid feed line. To eliminate the possibility of leaks from a joint, therefore, it is absolutely necessary

to apply the gasket evenly without a break, while observing the correct bead size.

Since the FIPG used in the transmission hardens as it reacts with the moisture in the atmospheric air,

it is normally used in the metallic flange areas.

Disassembly

The parts assembled with the FIPG can be easily disassembled without use of a special method. In

some cases, however, the sealant between the joined surfaces may have broken by lightly striking with

a mallet or similar tool. A flat and thin gasket scraper may be lightly hammered in between the joined

surfaces. In this case, however, care must be taken to prevent damage to the joined surfaces.

Surface preparation

Thoroughly remove all substances deposited on the gasket application surfaces, using a gasket scraper

or wire brush. Check to ensure that the surfaces to which the FIPG is to be applied is flat. Make sure

that there are no oils, greases and foreign substances deposited on the application surfaces. Do not

forget to remove the old FIPG remaining in the bolt holes.

Form-in-place gasket application

When assembling parts with the FIPG, you must observe some precautions, but the procedures is very

simple as in the case of a conventional precut gasket.

Applied FIPG bead should be of the specified size and without breaks. Also be sure to encircle the

bolt hole circumference with a completely continuous bead. The FIPG can be wiped away unless it is

hardened. While the FIPG is still moist (in less than 15 minutes), mount the parts in position. When

the parts are mounted, make sure that the gasket is applied to the required area only. In addition, do

not apply any oil or water to the sealing locations or start the engine until a sufficient amount of time

(about one hour) has passed after installation is completed.

The FIPG application procedure may vary on different areas. Observe the procedure described in the

text when applying the FIPG.

LUBRICANTS

TRANSFER

Item Specified lubricant

Lip of transfer case oil seal MITSUBISHI genuine grease part No. 0101011 or

equivalent

Lip of transfer case plate oil seal

Lip of rear cover oil seal

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 19

V5A51 -

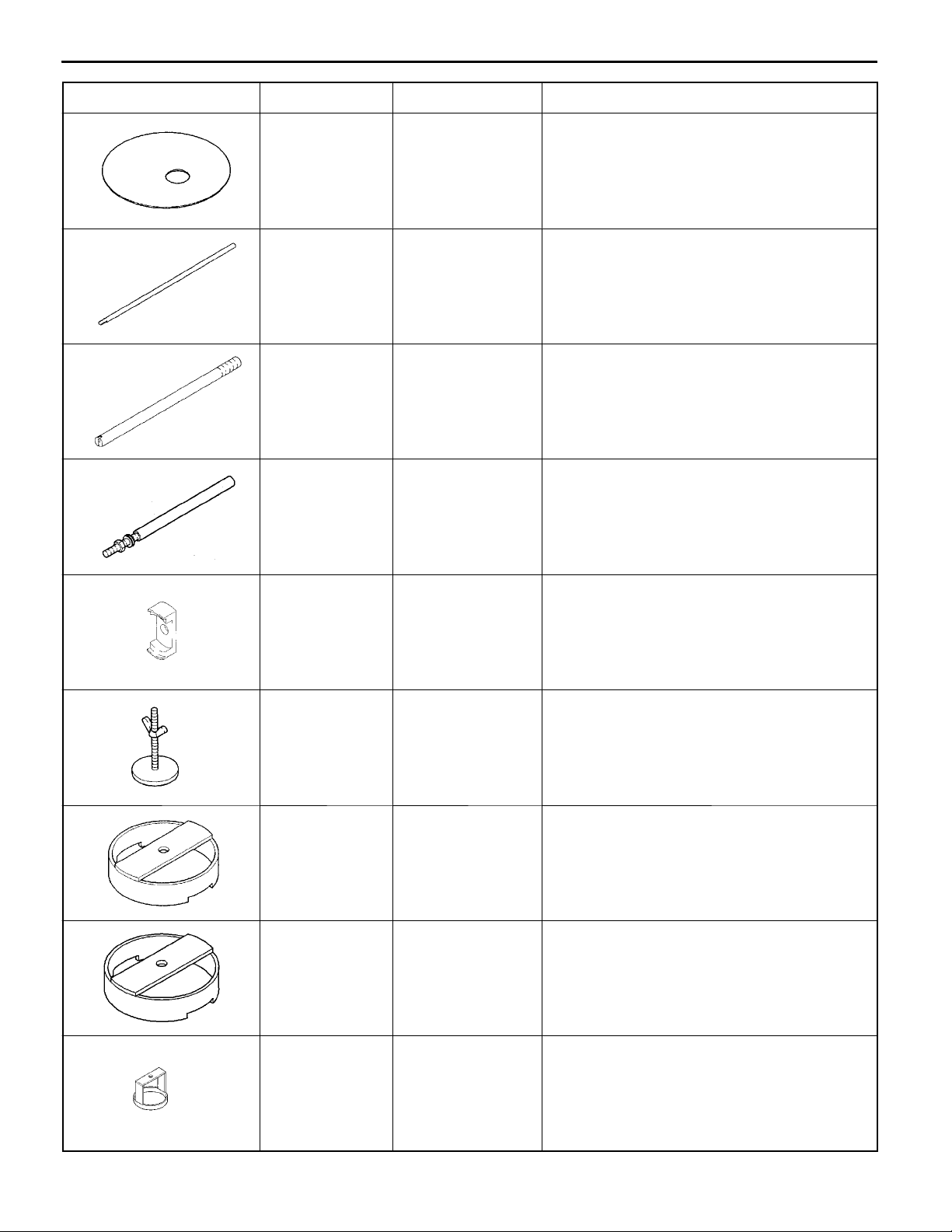

Special Tools

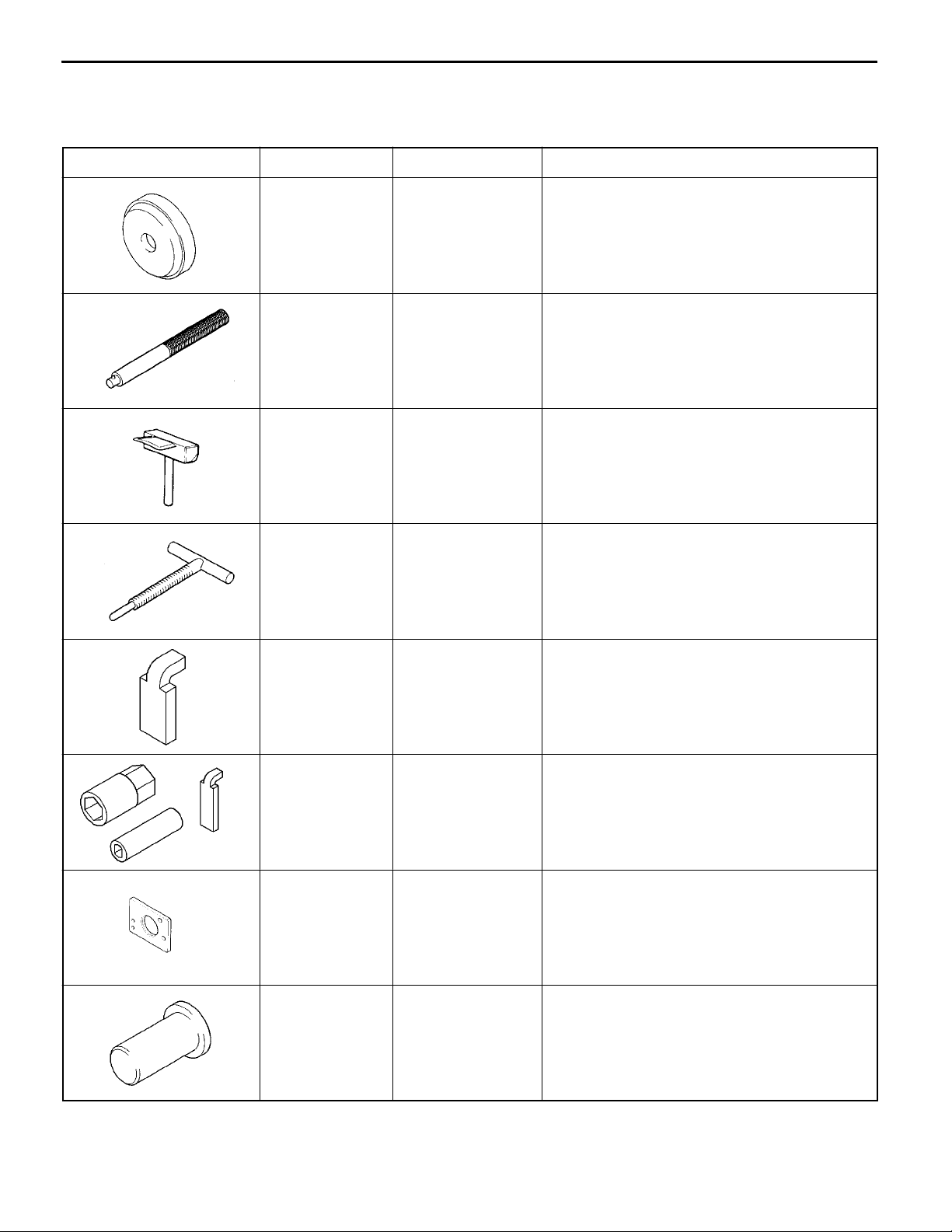

2. SPECIAL TOOLS

TRANSMISSION

Tool Number Name Use

MB990929 Installer adapter Installation of transfer case adapter oil seal

MB990938 Handle Use with installer adapter

MD998727 Oil pan remover Removal of oil pan

23E-2-1

MD998333 Oil pump remover Removal of oil pump

MB991693 Reduction brake

stopper

MB991633 Reduction brake

wrench set

MB991603 Bearing installer

stopper

Adjustment reduction brake piston

Adjustment reduction brake piston

Measurement of direct planetary carrier and

center support end plays

MD998304 Oil seal installer Measurement of direct planetary carrier end

play

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 20

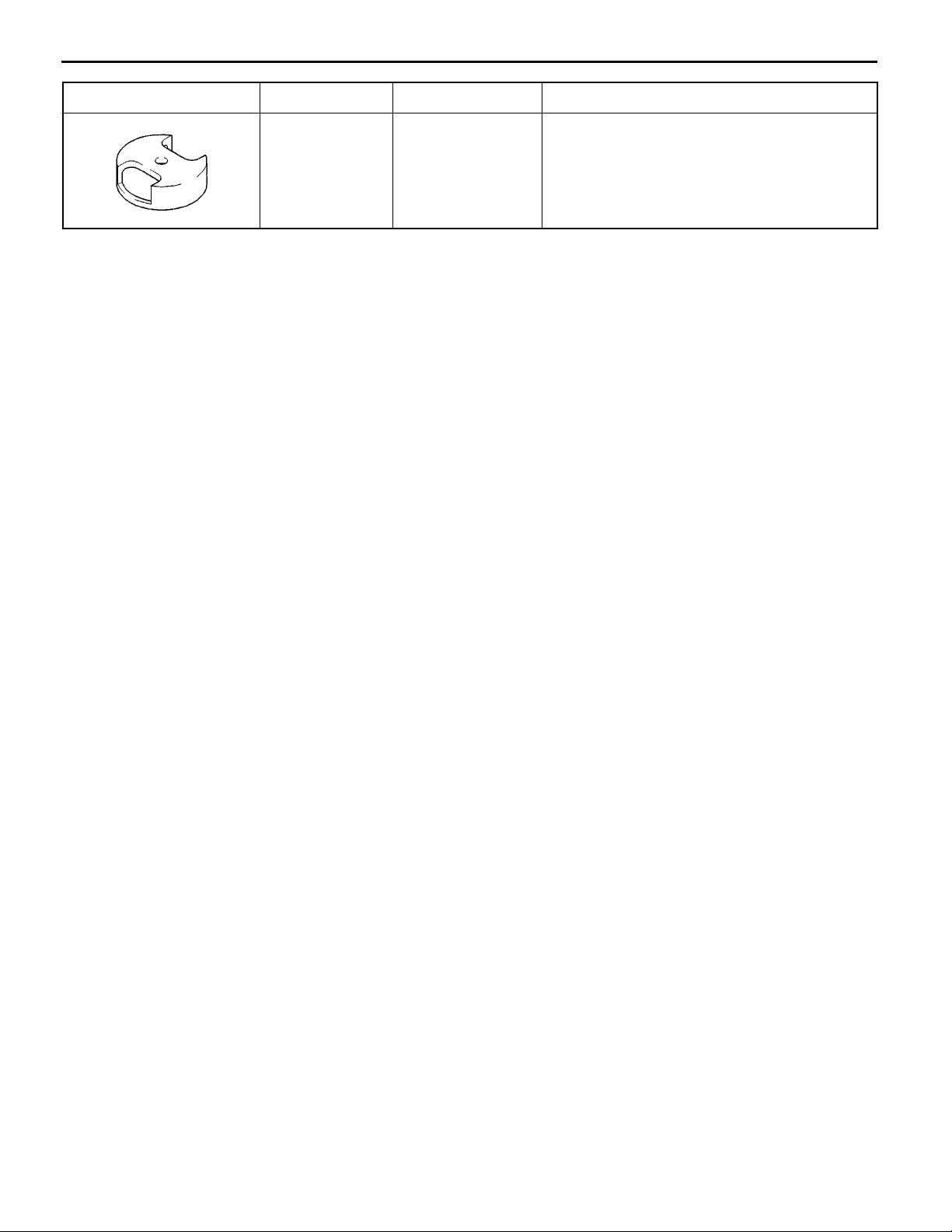

23E-2-2

Tool UseNameNumber

V5A51 -

Special Tools

MB991632 Clearance dummy

plate

MD998913 Dial gauge exten-

sion

MD998412 Guide Installation of oil pump

MD998316 Dial gauge support Measurement of input shaft end play

Measurement of brake reaction plate, second

brake and low/reverse brake end plays

Measurement of brake reaction plate, second

brake and low/reverse brake end plays

MD999590 Spring compressor Removal and installation of reverse and

overdrive clutch spring retainer snap ring

MD998924 Spring compressor

retainer

MB991629 Spring compressor Measurement of overdrive clutch and under-

MB991789 Spring compressor Adjustment reverse clutch end play

Use with spring compressor

drive clutch end plays

MB991630 Spring compressor Removal and installation of center support

snap ring and direct clutch snap ring

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 21

Tool UseNameNumber

MD998907 Spring compressor Removal and installation of underdrive clutch

V5A51 -

Special Tools

spring retainer snap ring

23E-2-3

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 22

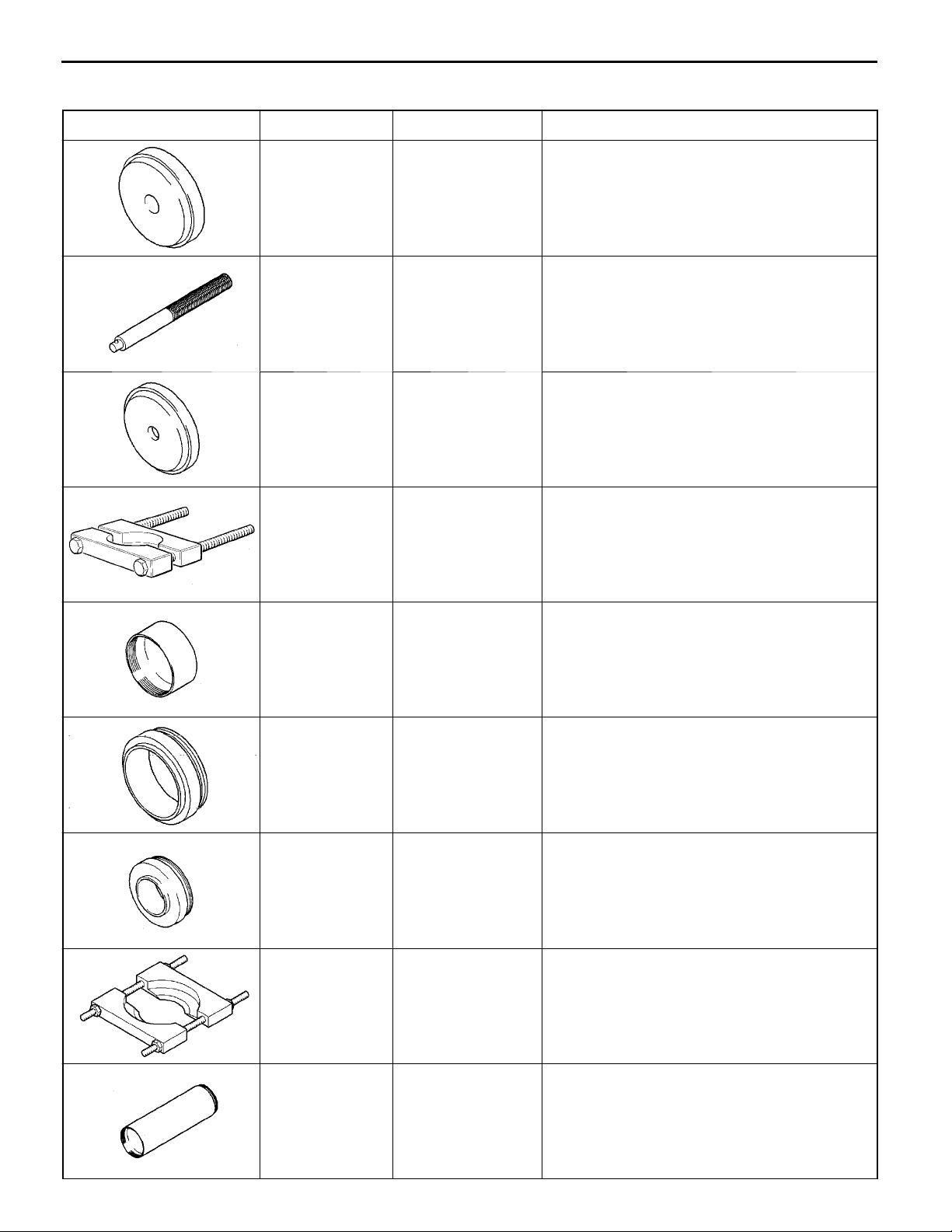

23E-2-4

V5A51 -

Special Tools

TRANSFER

Tool Number Name Use

MB990932 Installer adapter Installation of oil seal

MB990938 Handle Use with installer adapter

MB990936 Installer adapter Installation of oil seal

MD998801 Bearing remover Removal and installation of bearing

MD998812 Installer cap Use with installer and installer adapter

MD998826 Installer adapter

(52)

MD998818 Installer adapter

(38)

Installation of transfer input gear bearing

Installation of countershaft gear bearing, front

output shaft bearing

MD998917 Bearing remover Removal and installation of bearing

MD998814 Installer-200 Use with installer cap and installer adapter

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

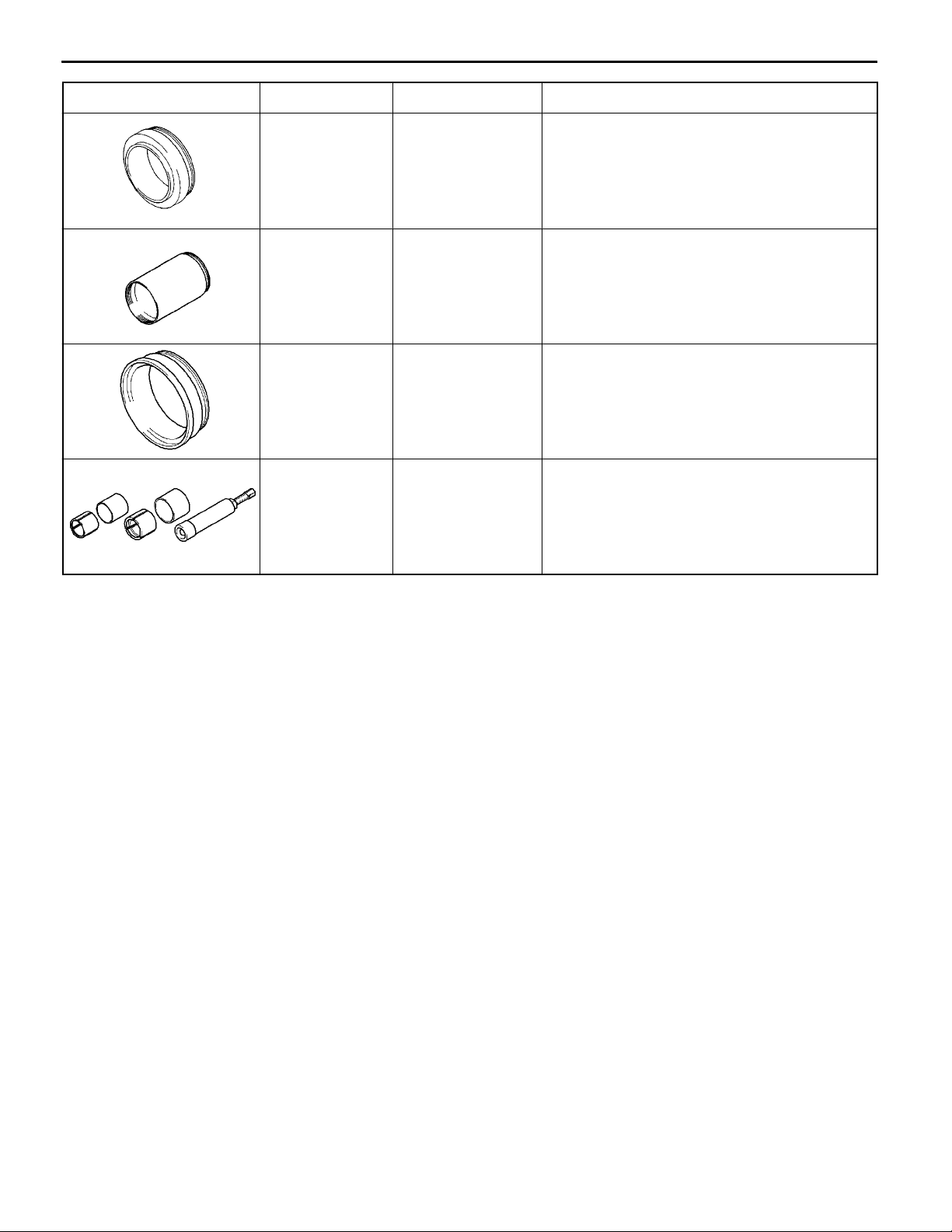

Page 23

Tool UseNameNumber

V5A51 -

Special Tools

23E-2-5

MD998824 Installer adapter

(50)

MD998813 Installer-100 Use with installer cap and installer adapter

MD998830 Installer adapter

(66)

MD998192 Bearing puller Installation of transfer drive shaft bearing

Installation of rear output shaft bearing

Installation of transfer drive shaft bearing

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 24

V5A51 -

Transmission and Transfer

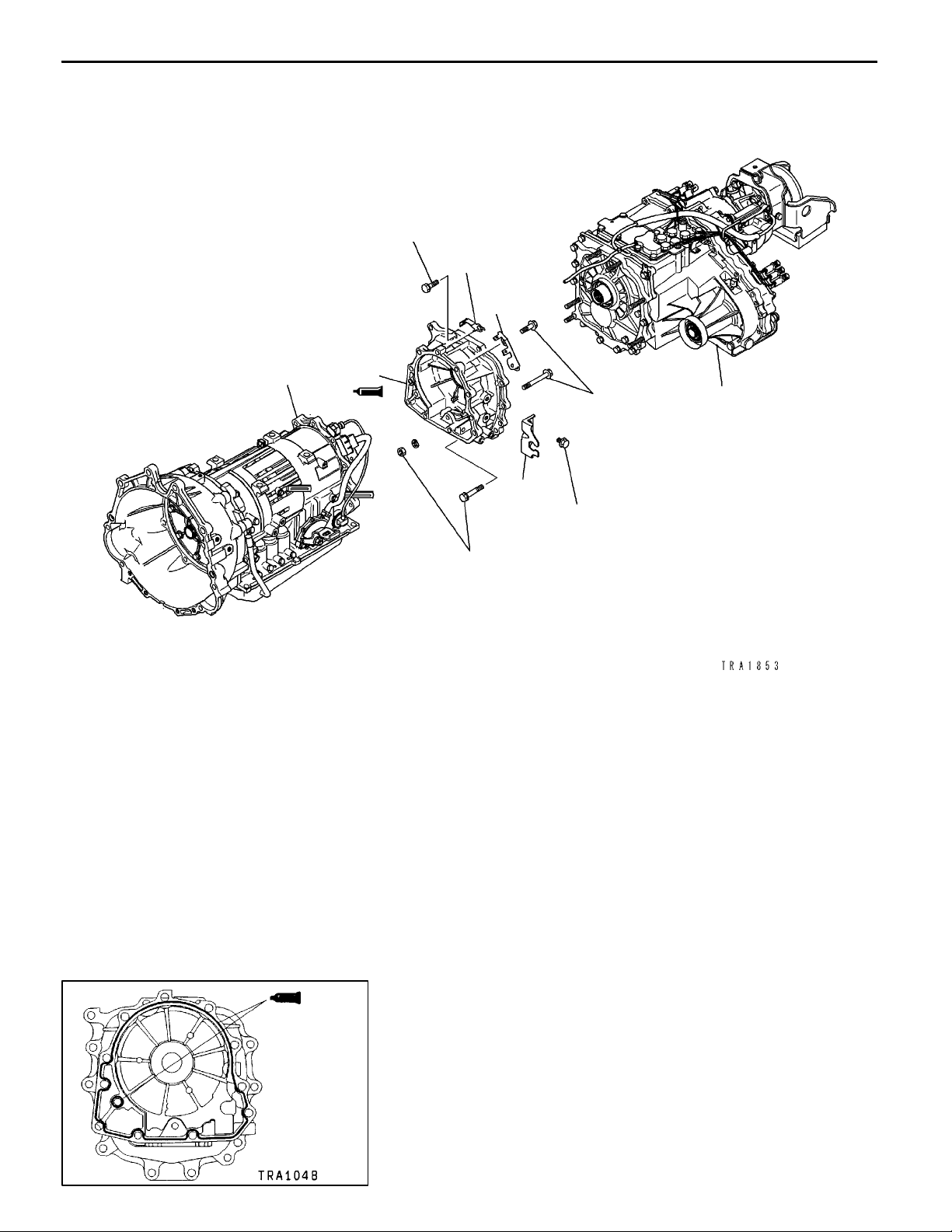

3. TRANSMISSION AND TRANSFER

DISASSEMBLY AND ASSEMBLY

35±6Nm

4

23E-3-1

3

6

Disassembly steps

1. Transfer

2. Cable end bracket

3. Harness bracket

4. Harness bracket

"AA 5. Transfer case adapter

6. Transmission

5

48±6Nm

1

2

48±6Nm

35±6Nm

ASSEMBLY SERVICE POINT

"AA

After squeezing out and applying sealant on the transfer case

3mm

diameter

adapter at the section indicated in the illustration, install onto

the transmission case.

Specified sealant:

Caution

D

E

Mar. 2000Mitsubishi Motors Corporation

TRANSFER CASE ADAPTER INSTALLATION

MITSUBISHI genuine sealant part No. MR166584 or

equivalent

Evenly squeeze out and apply the sealant so that

it is not excessive and does not ooze out.

AddedPWEE8920-I

Page 25

V5A51 -

Transfer Case Adapter

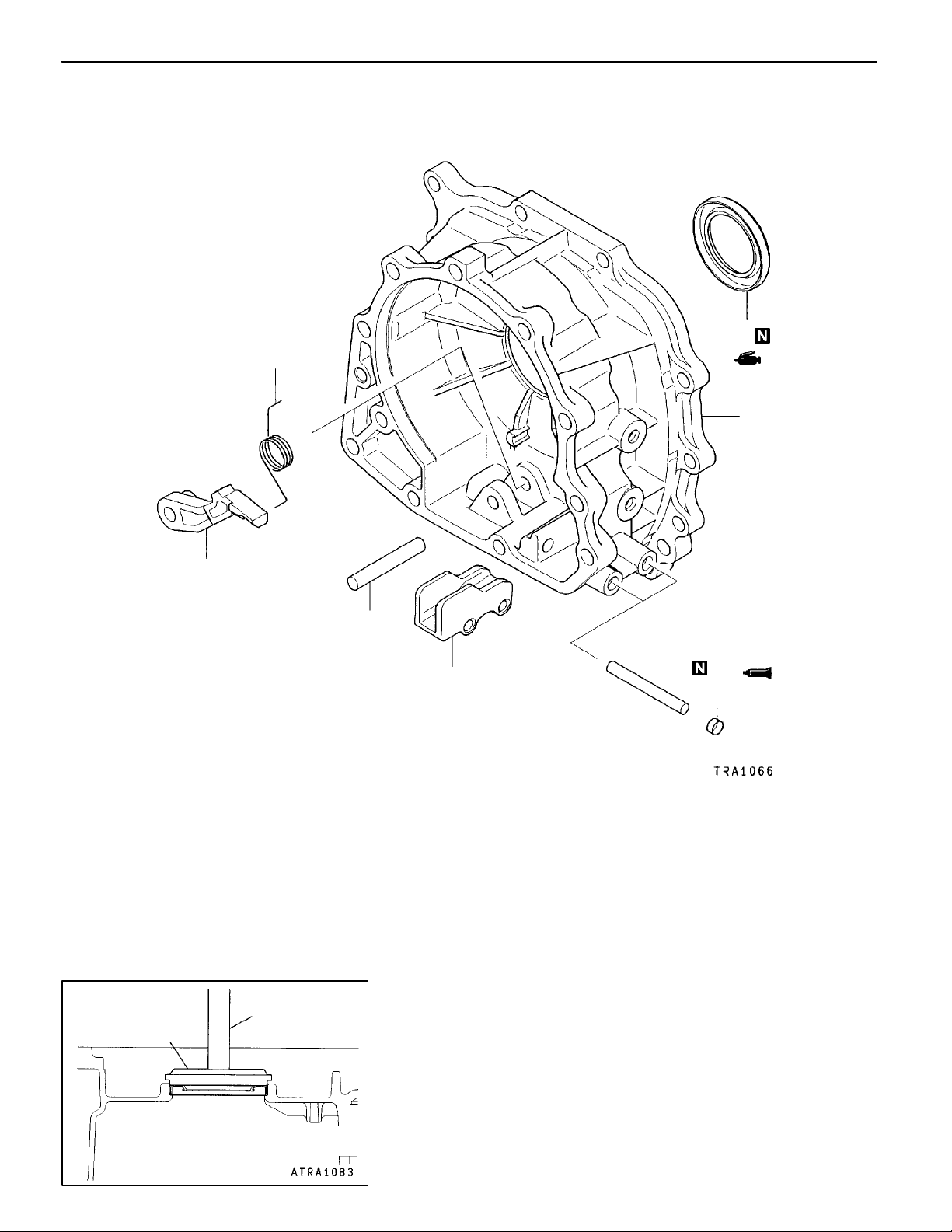

4. TRANSFER CASE ADAPTER

DISASSEMBLY AND ASSEMBLY

2

23E-4-1

7

8

3

Disassembly steps

1. Parking sprag shaft

"CA 2. Parking sprag spring

3. Parking sprag

"BA 4. Sealing cap

5. Parking roller support shaft

6. Parking roller support

"AA 7. Oil seal

8. Transfer case adapter

MB990938

MB990929

1

6

ASSEMBLY SERVICE POINTS

"AA

Use the special tools to install the oil seal.

OIL SEAL INSTALLATION

5

4

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 26

23E-4-2

V5A51 -

Transfer Case Adapter

Sealing cap

1.5 mm

1.5 mm

"BA

SEALING CAP INSTALLATION

1. Press the sealing caps into the dimensions shown in

the illustration so that they are not slanted.

2. Apply sealant as shown in the illustration.

Specified sealant:

TM

"CA

3M

PARKING SPRAG SPRING INSTALLATION

AAD part No. 8672 or equivalent

Attach the end of the spring to the position shown in the

illustration.

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 27

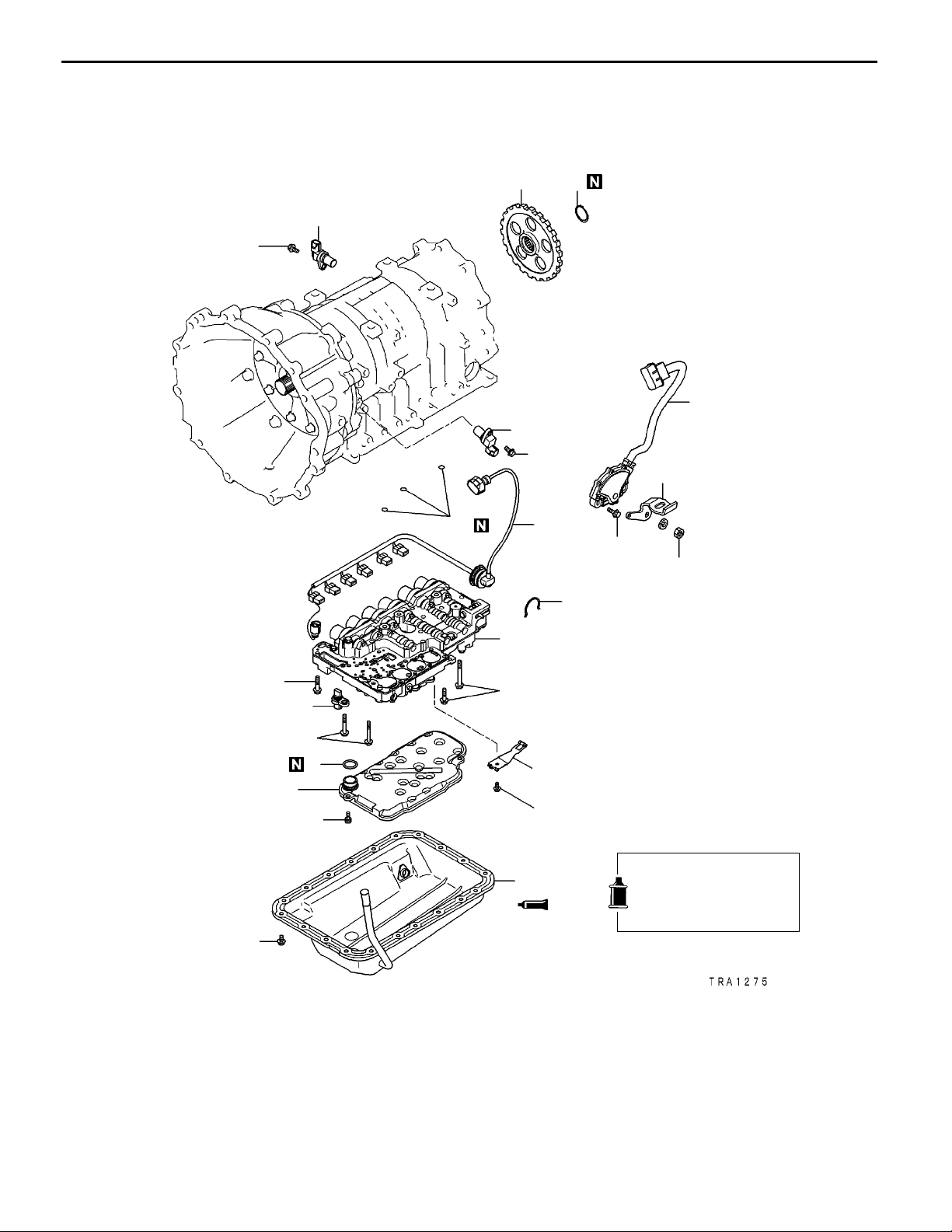

V5A51 -

5. TRANSMISSION

DISASSEMBLY AND ASSEMBLY

Transmission

23E-5-1

11±1Nm

6

5

2

4

1

11±1Nm

3

13

15

11±1Nm

22±3Nm

14

11±1Nm

11

11±1Nm

9

8

6±1Nm

11±1Nm

1. Input shaft speed sensor

2. Output shaft speed sensor

3. Manual control lever

4. Park/neutral position switch

5. Snap ring

6. Parking gear

7. Oil pan

8. Oil filter

12

11±1Nm

10

6±1Nm

7

Apply automatic

transmission fluid to

all moving parts

before installation.

9. O-ring

10. Detent spring

11. Oil temperature sensor

12. Valve body

13. O-ring

14. Snap ring

15. Solenoid valve harness

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

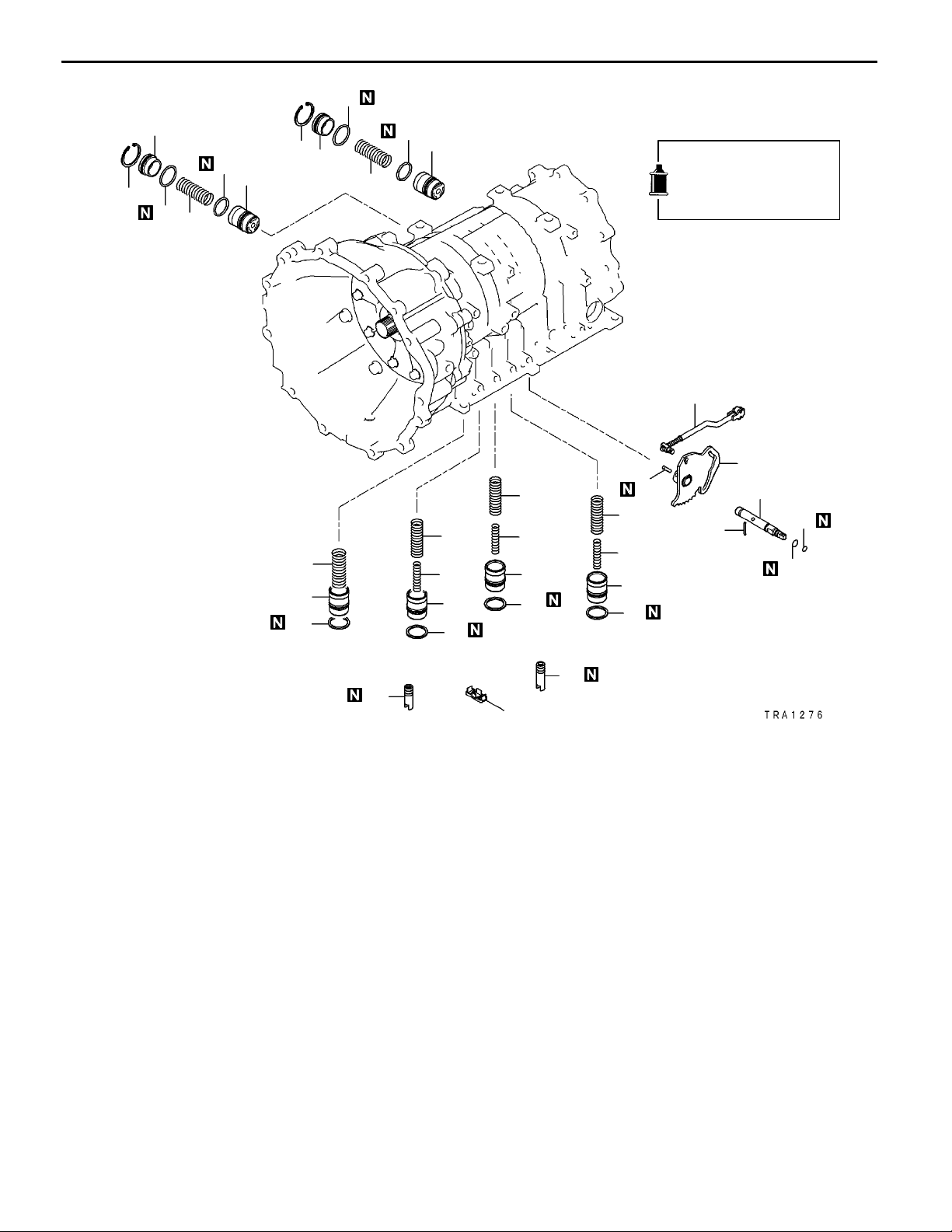

Page 28

23E-5-2

V5A51 -

33

Transmission

31

32

33

34

37

36

31

21

20

19

32

34

37

35

27

24

26

23 25

22

19

19

30

29

28

19

Apply automatic

transmission fluid to

all moving parts

before installation.

44

38

39

43

40

41

42

16. Oil seal

17. Oil seal

18. Oil strainer

19. Seal ring

20. Accumulator piston

(for overdrive clutch)

21. Accumulator spring

22. Accumulator piston

(for second brake)

23. Inner spring

24. Outer spring

25. Accumulator piston

(for low/reverse brake)

26. Inner spring

27. Outer spring

28. Accumulator piston

(for underdrive clutch)

29. Inner spring

17

16

18

30. Outer spring

31. Snap ring

32. Accumulator cover

33. O-ring

34. Accumulator spring

35. Accumulator piston

(for reduction brake)

36. Accumulator piston

(for direct clutch)

37. Seal ring

38. Spring pin

39. Pin

40. Manual control shaft

41. O-ring

42. O-ring

43. Detent lever

44. Parking roller rod

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 29

48±6Nm

45

23±3Nm

V5A51 -

46

Transmission

47

23E-5-3

52

50

51

48

49

45. Converter housing

46. Oil pump

47. Oil pump gasket

48. Thrust race No.1

49. Thrust bearing No.2

50. Reverse and overdrive clutch

51. Thrust bearing No.3

53

57

56

55

54

Apply automatic

transmission fluid to

all moving parts

before installation.

52. Overdrive clutch hub

53. Thrust bearing No.4

54. Reverse sun gear

55. Snap ring

56. Second brake

57. Return spring

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 30

23E-5-4

V5A51 -

Transmission

58

60

65

59

66

61

62

64

63

68

69

Apply automatic

transmission fluid to

all moving parts

before installation.

67

58. Pressure plate

59. Brake plate

60. Brake disc

61. Low/reverse annulus gear

62. Thrust bearing No.7

63. Snap ring

E

Mar. 2000Mitsubishi Motors Corporation

64. Reaction plate

65. Snap ring

66. Brake plate

67. Brake disc

68. Pressure plate

69. Wave spring

AddedPWEE8920-I

Page 31

Apply automatic

transmission fluid to

all moving parts

before installation.

V5A51 -

74

75

Transmission

98±15 Nm

91

94

23E-5-5

23±3Nm

70

77

71

72

76

73

78

88

89

90

95

92

85

19±3Nm

82

93

87

86

84

83

81

80

79

70. Snap ring

71. Center support

72. Thrust race No.8

73. Thrust bearing No.9

74. Direct annulus gear

75. Thrust bearing No.12

76. Direct planetary carrier

77. Seal ring

78. Seal ring

79. Snap ring

80. Reduction brake cover

81. O-ring

82. Snap ring

83. Reduction brake piston nut

84. Reduction brake piston

85. Seal ring

86. Reduction brake piston adjusting rod

87. Reduction brake spring

88. Direct clutch

89. Thrust bearing No.13

90. Reduction brake band

91. Anchor plug

92. O-ring

93. Output shaft support

94. Output shaft support gasket

95. Transmission case

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 32

23E-5-6

V5A51 -

DISASSEMBLY

Caution

D

D

D

D

D

Transmission

Because the automatic transmission is manufactured

from high-precision parts, sufficient care must be

taken not to scratch or damage these parts during

disassembly and reassembly.

During the work, always use bare hands or vinyl

gloves. Do not use cotton gloves. Use nylon cloth

or paper towels when necessary. Do not use shop

towel.

Parts which have been disassembled should all be

cleaned. Metal parts can be cleaned with normal

detergent, but they should be dried completely using

compressed air.

Clutch discs, plastic thrust race and rubber parts

should be cleaned with ATF automatic transmission

fluid so that they do not become dirty.

If the transmission body has been damaged,

disassemble and clean the cooler system also.

Manual control lever

1. Remove the input shaft speed sensor.

2. Remove the output shaft speed sensor.

3. Remove the manual control lever, and then remove the

park/neutral position switch.

Park/neutral position

switch

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 33

Snap ring

Parking gear

MD998727

V5A51 -

4. Remove the snap ring, and remove the parking gear

5. Remove the twenty oil pan mounting bolts and then

Transmission

23E-5-7

using a puller (corresponding load approximately 9,800

N).

NOTE

The parking gear may be removed without using a puller.

remove the oil p an using the special tool.

Caution

D

Carefully hammer the special tool so that the oil

pan mounting surface is not damaged.

O-ring

Oil filter

6. Remove the oil filter and O-ring.

7. Remove the detent spring.

8. Disconnect the harness connectors of the valve body.

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 34

23E-5-8

Oil temperature

sensor

O-rings

V5A51 -

9. Remove the twenty valve body mounting bolts a n d then

Transmission

remove the valve body, three O-rings and oil temperature

sensor.

NOTE

The twenty valve body mounting bolts are plated bolts.

NOTE

The O-rings are mounted on the transmission case side

as shown in the illustration. However there may be cases

where they will come off with the valve body.

Oil seals

Oil strainer

Snap ring

10. Remove the snap ring and disconnect the solenoid valve

harness.

11. Remove the oil strainer and two oil seals.

12. Remove each accumulator piston, seal ring and spring.

Remove the snap ring, then remove the accumulator

cover, O-ring and spring.

No. Name

1 For overdrive clutch

2 For second brake

3 For low/reverse brake

4 For underdrive clutch

5 For reduction brake

1234

E

Mar. 2000Mitsubishi Motors Corporation

6 For direct clutch

AddedPWEE8920-I

Page 35

V5A51 -

Transmission

23E-5-9

NOTE

To make assembly easier, attach an identification tag

on the removed accumulator piston.

6

Spring pin

Parking

roller rod

5

Pin

Manual

control shaft

Detent

lever

13. Remove the detent lever spring pin.

14. Remove the pin, and then remove the manual control

shaft, two O-rings, detent lever an d parking roller rod.

15. Remove the eight converter housing mounting bolts, an d

then converter housing.

16. Remove the te n oil pump mounting bolts.

17. Install the special tool into the bolt hole shown in the

illustration.

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 36

23E-5-10

MD998333

V5A51 -

18. While screwing in the special tool evenly, remove the

19. Remove the oil pump gasket.

Transmission

oil pump.

Thrust

bearing

No.2

Reverse and overdrive

clutch

Overdrive

clutch hub

Thrust race

No.1

Thrust

bearing No.3

20. Remove t he reverse a nd overdrive clutch, thrust race

No.1 an d thrust bearing No.2.

NOTE

The thrust race No.1 may be attached to the oil pump.

21. Remove the overdrive clutch hub and thrust bearing No.3.

22. Remove the thrust bearing No.4.

NOTE

The thrust bearing No.4 may be attached to the overdrive

clutch hub.

23. Remove the reverse sun gear.

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 37

V5A51 -

24. Remove the snap ring.

25. Remove the second brake an d return spring.

Transmission

23E-5-11

Thrust

bearing

No.7

26. Remove the pressure plate, brake plates and brake discs.

27. Remove the low/reverse annulus gear.

28. Remove the thrust bearing No.7.

NOTE

The thrust bearing No.7 may be attached to the

low/reverse annulus gear.

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 38

23E-5-12

V5A51 -

29. Remove the snap ring.

30. Remove the reaction plate and one brake disc.

Transmission

31. Remove the snap ring.

32. Remove the brake plates, brake discs, and pressure plate.

33. Remove the wave spring.

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 39

Snap ring

Center support

V5A51 -

34. Remove the snap ring and center support.

Transmission

23E-5-13

Thrust bearing

No.9

Direct planetary

carrier

35. Remove the thrust race No.8 and thrust bearing No.9.

NOTE

The thrust race No.8 may be attached to the center

support.

Thrust race

No.8

36. Remove the direct annulus gear.

37. Remove the thrust bearing No.12 and direct planetary

carrier.

NOTE

The thrust bearing No.12 may be attached to the direct

annulus gear.

E

Seal rings

Thrust bearing

No.12

Seal

rings

Mar. 2000Mitsubishi Motors Corporation

38. Remove the two large and two small seal rings from the

direct planetary carrier.

AddedPWEE8920-I

Page 40

23E-5-14

V5A51 -

Transmission

Snap ring

Reduction brake

piston cover

Snap ring

Reduction brake

piston

39. Remove the snap ring and then the reduction brake piston

cover and O-ring.

40. Remove the snap ring and then the nut, reduction brake

piston, seal ring, adjusting rod and spring.

41. Remove the direct clutch.

42. Remove the thrust bearing No.13.

NOTE

The thrust bearing No.13 may be attached to the direct

clutch.

43. Remove the reduction brake band.

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 41

Output shaft

support

V5A51 -

44. Remove the anchor plug and the O-ring.

45. Remove the eight output shaft support mounting bolts,

Transmission

23E-5-15

and then remove the output shaft support and gasket.

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 42

23E-5-16

V5A51 -

ASSEMBLY

Caution

D

D

D

D

D

D

D

Transmission

Never reuse the gasket, O-ring, oil seal, etc. Always

replace with a new one when reassembling.

Never use grease other than blue petrolatum jelly

and white Vaseline.

Apply ATF to friction components, rotating parts, and

sliding parts before installation. Immerse a new clutch

disc or brake disc in ATF for at least two hours before

assembling them.

Never apply sealant or adhesive to gaskets.

When replacing a bushing, replace the assembly

which it belongs to.

During the work, always use bare hands or vinyl

gloves. Do not use cotton gloves. Use nylon cloth

or paper towels when necessary. Do not use shop

towel.

Change the oil in the cooler system.

Output shaft

support

1. Install a new gasket and output shaft support.

Caution

D

Never reuse a gasket.

2. Tighten the eight output shaft support mounting bolts

to the specified torque.

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 43

V5A51 -

Transmission

Identification of thrust bearings and thrust races

23E-5-17

No.1 No.2 No.3 No.4 No.5 No.6 No.7 No.8 No.9 No.10 No.11 No.12 No.13

Symbol OD mm ID mm Thickness mm Part No.

No.1 48.9 37 1.4 MD723063

1.6 MD707267

1.8 MD723064

2.0 MD707268

2.2 MD723065

2.4 MD724358

2.6 MD754798

No.2 59 37 2.8 MR305718

No.3 57 38.5 4.12 MD758556

No.4 57 38.5 4.12 MD758556

No.5 54.4 38.5 3.3 MD761683

No.6 57 38.5 4.12 MD758556

No.7 70 48.8 4.0 MR222902

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 44

23E-5-18

Symbol OD mm ID mm Thickness mm Part No.

No.8 73 60 1.6 MR276705

No.9 71.4 57 2.78 MR276587

No.10 71.9 48 4.6 MR263281

No.11 54.1 34 3.83 MR276588

No.12 57 38.5 4.62 MR222936

No.13 58 37.5 4.8 MD758555

V5A51 -

Transmission

1.8 MR276706

2.0 MR276707

2.2 MR276708

2.4 MR276709

Anchor bracket hole

Anchor plug

Apply bracket

Reduction brake piston

adjusting rod hole

3. Install a new O-ring on the anchor plug and tighten the

anchor plug to the specified torque.

4. Install the reduction brake band.

Fit the anchor bracket hole of the brake band onto the

anchor plug tip, and then insert the apply bracket part

into the hole for reduction brake piston adjusting rod.

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 45

V5A51 -

Transmission

23E-5-19

Thrust bearing

No.13

Direct clutch

retainer

Thrust bearing

No.13

5. Install the thrust bearing No.13 onto the direct clutch

retainer.

Caution

D

Take care not to mistake the thrust bearing No.13

mounting direction.

6. Install the direct clutch.

Caution

D

Take care that the reduction brake band does not

come off the anchor plug and the hole for the

reduction brake piston adjusting rod.

7. Install th e reduction brake spring.

8. Screw the reduction brake piston adjusting rod into the

reduction brake piston manually to the full.

9. Install new seal ring on the piston.

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 46

23E-5-20

Snap ring

Reduction brake piston

V5A51 -

10. Press the reduction brake piston into the transmission

11. Tighten the reduction brake piston adjusting rod manually

Transmission

case, and then install the snap ring.

NOTE

Set the open of the snap ring at indicated location.

to th e full.

MB991693

MB991633

(Socket)

12 Adjust the reduction brake piston by the following

procedure.

(1) Mount the special tool so that the reduction brake

piston does not rotate.

(2) Mount the torque wrench to the special tool (Socket),

and after repeating tightening and turning back with

a torque of 10 Nm twice, tighten the reduction brake

piston adjusting rod to the specified torque of 5 Nm.

Then turn the reduction brake piston adjusting rod

1

/2to 53/4turns back.

5

(3) Remove the special tool and tighten the reduction

brake piston nut manually.

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 47

V5A51 -

Transmission

23E-5-21

MB991633

(Socket)

MB991633

(Wrench)

Snap ring

Reduction brake

piston cover

Seal

rings

(small)

(4) Tighten the reduction brake piston nut to the specified

torque of 19 ± 3 Nm using the special tool (Wrench)

while fixing the special tool (Socket) so as not to

rotate.

13. Install a new O-ring on the reduction brake piston cover,

and then install the cover and the snap ring on the

transmission case.

14. Install new seal rings (two large pieces) onto the front

end of the direct planetary carrier, and new seal rings

(two small pieces) onto the shaft of the direct planetary

carrier.

15. Insert the direct planetary carrier into the output shaft

support.

Seal rings (large)

Thrust bearing No.12

Direct

planetary

carrier

16. Apply Vaseline or petrolatum jelly on the thrust bearing

No.12, and then install on the front end of the direct

planetary carrier.

Caution

D

Take care not to mistake the thrust bearing No.12

mounting direction.

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 48

23E-5-22

V5A51 -

17. Install the direct annulus gear.

18. Apply Vaseline or petrolatum jelly to the thrust bearing

Transmission

Caution

D

Confirm that the thrust bearing No.10 in the direct

annulus gear is still at the specified location.

No.9, and then install on the direct annulus gear.

Thrust

bearing No.9

Direct annulus

gear

Thrust race No.8

Caution

D

Take care not to mistake the thrust bearing No.9

mounting direction.

19. Apply Vaseline or blue petrolatum jelly on the thrust race

No.8 removed, and then install it on the rear side of the

center support.

Caution

D

Measure and record the thickness of the thrust

race No.8 before assembling.

20. Install the center support.

Caution

D

Install the center support so that the oil hole shown

in the illustration faces the lower side of the

transmission case.

D

Use care that the thrust race No.8 attached to

the rear side of the center support does not fall

off.

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 49

MB991603

Cable end

bracket

V5A51 -

21. Using the transfer case adapter bolt, install special tool

Transmission

23E-5-23

MB991603.

Caution

D

Install the cable end bracket together with the

special tool.

Direct planetary

carrier

MB991603

Thrust race

No.8

End play

MD998304

Direct

annulus

gear

Thrust

bearing No.9

22. Select the thrust race No.8 with the following procedure:

(1) Fix a dial gauge to the special tool.

(2) Push the direct planetary carrier and direct annulus

gear in alternately, and measure the end play of th e

direct planetary carrier.

NOTE

(1) When pushing in the direct planetary carrier, make

sure that the center support does not move.

(2) When pushing in the direct annulus gear, use

the special tool.

(3) Replace the thrust race No.8 installed in step 19 with

a suitable one which can bring th e end play of the

direct planetary carrier to the standard value. Then,

reassemble.

NOTE

Refer to the thickness recorded in step 19.

Standard value: 0.25 - 0.55 mm

(4) Measure the end play again, and confirm that it is

within the standard value.

NOTE

Carry this step out with the special tool and dial gauge

installed.

Snap ring

E

23. Using the following steps, select a suitable snap ring

for fixing the center support.

(1) Install the snap ring which has been used for fixing

the center support.

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 50

23E-5-24

V5A51 -

Transmission

Direct planetary

carrier

MB991603

Standard value

Snap ring

Low/reverse

brake piston

Center support

Center support

(2) Alternately push in the direct planetary carrier an d

center support, and measure the end play of the

center support.

NOTE

Be sure to push the direct planetary carrier in fully

until the center support contacts the snap ring.

(3) Replace the snap ring for fixing the center support

installed in step 23 (1) with a suitable one so that

the end play of the center support is at the standard

value. Then, reassemble.

Standard value: 0 - 0.16 mm

(4) Measure the end play again, and confirm that it is

within the standard value.

24. Using the following steps, select a snap ring for adjusting

the brake reaction plate end play an d second brake end

play, and a pressure plate for adjusting the low/reverse

brake e nd play.

(1) Install the wave spring onto the low/reverse brake

piston.

MB991632

MB991632

E

MD998913

Snap ring

Snap ring

End play

Mar. 2000Mitsubishi Motors Corporation

(2) Install the special tool in the position shown in the

illustration instead of the pressure plate for the

low/reverse brake. Install the brake discs, brake plates

and snap ring.

(3) Install the reaction plate and snap ring that was used.

Caution

D

Take care to the assembly direction of the

reaction plate.

(4) Install a dial gauge onto special tool (MD998913)

so that the tool end contacts the brake reaction plate.

Measure the end play by moving special tool

(MB991632).

(5) Replace the snap ring installed in step 24 (3) with

a suitable one so that the end play may fall within

the standard value. Then, reassemble.

Standard value: 0 - 0.16 mm

(6) Measure the end play again, and confirm that it is

within the standard value.

AddedPWEE8920-I

Page 51

Second brake

Snap ring

V5A51 -

Transmission

23E-5-25

(7) Next, install the special tool instead of the pressure

plate for the second brake. Install the four brake discs

and three brake plates.

Caution

D

MB991632

Return

spring

A

(8) Install the return spring, second brake and snap ring.

(9) Install a dial gauge onto special tool (MD998913)

MD998913

so that the end contacts the special tool (MB991632).

Move special tool (MB991632) and measure the

moving amount.

Select a pressure plate with a thickness that

MB991632

Moving

amount

corresponds to the measured moving amount from

the following table.

End play standard value (reference):

Moving amount mm Pressure plate

Thickness mm ID Symbol Part No.

Take care to the shape and assembly direction

of the brake plates installed at section “A”

shown in the illustration.

1.49 - 1.95 mm

1.2 or more - less than 1.4 1.6 F MR336390

1.4 or more - less than 1.6 1.8 E MR336391

1.6 or more - less than 1.8 2.0 D MR336392

1.8 or more - less than 2.0 2.2 C MR336393

2.0 or more - less than 2.2 2.4 B MR336394

2.2 or more - less than 2.4 2.6 A MR336395

2.4 or more - less than 2.6 2.8 0 MR336396

2.6 or more - less than 2.8 3.0 1 MR336397

(10)Remove the snap ring, second brake, return spring

and special tool installed in step (8).

(11) Install the pressure plate selected in step (9), and

install the return spring, second brake and snap ring

again.

(12)Install a dial gauge onto special tool (MD998913)

MD998913

so that the end contacts the special tool (MB991632).

Move special tool (MB991632) and measure the

moving amount.

Select a pressure plate with a thickness that

corresponds to the measured moving amount from

the following table.

A

MB991632

End play standard value (reference):

1.65 - 2.11 mm

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 52

23E-5-26

Moving amount mm Pressure plate

1.5 or more - less than 1.7 1.8 E MD759425

1.7 or more - less than 1.9 2.0 D MD759426

1.9 or more - less than 2.1 2.2 C MD759427

2.1 or more - less than 2.3 2.4 B MD759428

2.3 or more - less than 2.5 2.6 A MD759429

2.5 or more - less than 2.7 2.8 0 MD759430

2.7 or more - less than 2.9 3.0 1 MD759431

V5A51 -

Thickness mm ID symbol Part No.

Transmission

(13)Remove the parts installed in steps 24 (1) to (12).

Thrust

bearing No.7

Thrust bearing

No.7

25. Apply Vaseline or petrolatum jelly on the thrust bearing

No.7, a n d then install the bearing on the rear side of

the low/reverse annulus gear.

Caution

D

Take care not to mistake the thrust bearing No.7

mounting direction.

26. Install the low/reverse annulus gear.

Caution

D

Make sure that the thrust bearing No.7 attached

to the rear side of the low/reverse annulus gear

does not fall off.

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 53

V5A51 -

27. Install the reverse sun gear.

28. Install the wave spring onto the low/reverse brake piston.

Transmission

23E-5-27

29. Install the pressure plate selected in step 24 (12), brake

discs and brake plates.

30. Install the snap ring.

31. Install the reaction plate.

Caution

D

Take care not to mistake the reaction plate

installation direction.

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 54

23E-5-28

Reaction

plate

Pressure plate

Brake plate

V5A51 -

32. Install the snap ring selected in step 24 (5).

33. Install the brake discs, brake plates and pressure plate

Transmission

selected in step 24 (9).

Caution

D

Take care not to mistake the brake plate (reaction

plate side) installation direction.

Second brake

Return spring

Flat side

34. Install the return spring a n d second brake.

Caution

D

Install the return spring so that the flat side faces

the back of the transmission.

35. Install the snap ring.

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 55

V5A51 -

Transmission

23E-5-29

Thrust bearing

No.4

Thrust

bearing

No.4

Overdrive

clutch hub

Thrust

bearing

No.3

36. Apply Vaseline or petrolatum jelly on the thrust bearing

No.4, and then install on the reverse sun gear.

Caution

D

Take care not to mistake the thrust bearing No.4

installation direction.

37. Apply Vaseline or petrolatum jelly on the thrust bearing

No.3, and then install on the overdrive clutch hub.

38. Install the overdrive clutch hub.

Thrust

bearing

No.3

Reverse and overdrive clutch

Thrust bearing No.2

E

Caution

D

Take care not to mistake the thrust bearing No.3

mounting direction.

39. Install the reverse and overdrive clutch.

40. Apply Vaseline or petrolatum jelly on the thrust bearing

No.2, and then install on the reverse and overdrive clutch.

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 56

23E-5-30

Thrust bearing No.2

V5A51 -

Transmission

Caution

D

Take care not to mistake the thrust bearing No.2

mounting direction.

MD998316

Thrust race

No.1

MD998412

41. Apply Vaseline or petrolatum jelly on the thrust race No.1,

and then install on the oil pump.

42. Install the special tool at the position shown in the

illustration, and using this as a guide, install the oil pump

and gasket.

Caution

D

Never reuse the gasket.

43. Tighten the ten oil pump mounting bolts to the specified

torque.

44. Using the special tool, set a dial gauge as shown in the

illustration. Measure the end play of the input shaft, and

replace the thrust race installed in step 41 with a suitable

one so that the end play may meet the standard value.

Then, reassemble.

Standard value: 0.25 - 0.81 mm

45. Measure the end play again, and confirm that it is within

the standard value.

46. Install the converter housing.

47. Tighten the eight converter housing mounting bolts to

the specified torque.

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 57

Parking roller rod

O-rings

Detent

lever

V5A51 -

48. Install the parking roller rod to the detent lever.

49. Install two new O-rings to the manual control shaft, and

Transmission

23E-5-31

assemble onto the transmission case together with the

detent lever and parking roller rod.

Manual

control

shaft

50. Install the pin.

Pin

51. Hammer in the spring pin so that its slit is perpendicular

to the axial direction of the manual control shaft.

Spring pin

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 58

23E-5-32

Inner springs

Outer springs

V5A51 -

Transmission

52. Install a new seal ring onto each accumulator piston.

53. Install each accumulator piston a nd spring, then install

accumulator cover with O-ring and snap ring.

NOTE

(1) Install the accumulator pistons to the original positions

following the identification tags attached when they

were removed.

1, 5, 6234

(2) The springs are identified by paint application position

as shown below. Assemble following this table.

No. Name Identification paint

application position

1 For overdrive

clutch

2 For second

brake

1234

6

5

3 For

low/reverse

brake

4 For underdrive

clutch

5 For reduction

brake

6 For direct

clutch

None

Inner Applied on all surfaces

including both ends

Outer Applied on half of surface

including both ends

Inner Applied on half of surface

including both ends

Outer Applied on entire surface

of one side

Inner Applied on half of surface

including both ends

Outer Applied on half of surface

including both ends

None

None

54. Install the oil strainer an d two new oil seals. Install the

Oil seals

oil seals so that the notched section is oriented as shown

in the illustration.

Caution

D

Take care to the installation direction of the oil

seal.

Oil strainer

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 59

V5A51 -

Transmission

23E-5-33

Manual

valve pin

O-ring

Snap ring

55. Install the solenoid valve harness, and then secure the

snap ring to connector groove.

NOTE

Install the harness so that it is oriented as shown in the

illustration.

56. Install new three O-rings onto the transmission case at

the positions shown in the illustration.

57. Install the valve body while inserting the manual valve

pin into the detent lever groove.

Oil temperature

sensor

E

D

E

Detent lever

58. Install the oil temperature sensor.

59. Tighten the twenty valve body mounting bolts to the

specified torque.

D

Bolt Length mm

A 25

B

B 30

C

D

A

DC

Mar. 2000Mitsubishi Motors Corporation

C 40

D 45

E 55

AddedPWEE8920-I

Page 60

23E-5-34

V5A51 -

60. Connect the connector to the valve body.

61. Install the detent spring.

62. Tighten the detent spring mounting bolt to the specified

Transmission

torque.

O-ring

3 mm diameter

Oil filter

63. Install the oil filter and a new O-ring.

64. Apply sealant on the oil pan.

Specified sealant:

MITSUBISHI genuine sealant part No. MR166584

or equivalent

Caution

D

Evenly squeeze out the sealant so that it is not

insufficient or excessive.

65. Install the oil pan.

66. Tighten the oil pan mounting bolts to the specified torque.

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 61

Transmission

side

Snap ring

Parking

gear

V5A51 -

67. Install the parking gear and snap ring.

Transmission

23E-5-35

Caution

D

Install the parking gear so that the side without

the spline cut faces the transmission side.

D

Heat the parking gear to 160 - 180_C, and shrink

fit up to the stepped section of the output shaft.

Manual control lever

Park/neutral

position switch

68. Install the park/neutral position switch and manual control

lever.

69. Install the output shaft speed sensor.

70. Install the input shaft speed sensor.

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 62

V5A51 -

Reverse and Overdrive Clutch

6. REVERSE AND OVERDRIVE CLUTCH

DISASSEMBLY AND ASSEMBLY

23E-6-1

Apply automatic

transmission fluid to

all moving parts

before installation.

22

1

3

10

21

19

20

14

17

12

13

15

18

16

6

2

8

9

4

5

7

11

Disassembly steps

1. Seal ring

2. Snap ring

3. Input shaft

"HA 4. Snap ring

"GA 5. Reaction plate

"GA 6. Clutch disc

"GA 7. Clutch plate

"FA 8. Snap ring

"EA 9. Reaction plate

"EA 10. Clutch disc

"EA 11. Clutch plate

17

14

8

10

22

21

20

6

15

12

18

12

13

3

16

19

AA""DA 12. Snap ring

11

9

13. Spring retainer

"AA 14. D-ring

"CA 15. Return spring

16. Overdrive clutch piston

"AA 17. D-ring

"BA 18. Reverse clutch piston

"AA 19. D-ring

"AA 20. D-ring

"AA 21. D-ring

22. Reverse clutch retainer

4

5

7

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 63

23E-6-2

V5A51 -

Reverse and Overdrive Clutch

MD999590

Hole “A”

MD998924

Snap ring

Hole “B”

DISASSEMBLY SERVICE POINT

AA"

1. Set the special tools as shown in t he illustration.

2. Compress the return spring, and remove the snap ring.

SNAP RING REMOVAL

ASSEMBLY SERVICE POINTS

"AA

1. Apply ATF to the D-ring.

2. Install the D-rings in the reverse clutch retainer, piston,

"BA

Align the holes (“A” and “B”) in t he reverse clutch piston

and reverse clutch retainer and then assemble.

D-RING INSTALLATION

overdrive clutch piston and spring retainer grooves. Make

sure that they are not twisted or damaged when installing.

REVERSE CLUTCH PISTON INSTALLATION

MD999590

E

MD998924

Snap ring

Mar. 2000Mitsubishi Motors Corporation

"CA

RETURN SPRING INSTALLATION

Align the two return spring holes with the two projections

on the overdrive clutch piston, and then assemble the return

springs.

"DA

SNAP RING INSTALLATION

1. Set the special tools as shown in t he illustration.

2. Tighten the special tool nut, and press the spring retainer

against the reverse clutch retainer.

3. Install the thickest snap ring that can be fitted in the

snap ring groove of the reverse clutch retainer.

4. Confirm that clearance between the snap ring and spring

retainer is the standard value.

Standard value: 0 - 0.09 mm

AddedPWEE8920-I

Page 64

V5A51 -

Reverse and Overdrive Clutch

23E-6-3

Clutch plates

Clutch discs

MD998924

Rounded edge

Reaction

plate

“R1”

stamp

MB991629

"EA

CLUTCH PLATE / CLUTCH DISC / REACTION

PLATE INSTALLATION

1. Alternately assemble the clutch discs and clutch plates

in the reverse clutch piston.

2. Install the reaction plate so that it is oriented as shown

in the illustration.

"FA

SNAP RING INSTALLATION

1. Install the snap ring in the reverse clutch piston groove.

2. Set the special tools as shown in the illustration, and

compress the clutch element.

3. Confirm that the clearance between the snap ring and

reaction plate (overdrive clutch end play) is the standard

value. If the clearance is not at the standard value, select

a suitable snap ring and adjust so that the clearance

is within the standard value.

Standard value: 2.0 - 2.2 mm

Clutch

plates

Reaction plate

A

Rounded edge

Snap ring

End play

B

Reaction

plate

“R” stamp

"GA

CLUTCH PLATE / CLUTCH DISC/REACTION

PLATE INSTALLATION

1. Alternately assemble the clutch plates and clutch discs

in the reverse clutch retainer.

When assembling th e clutch plates, align the section

having no teeth (A in the illustration) with the reverse

clutch retainer hole (B in the illustration).

2. Install the reaction plate so that it is oriented as shown

in the illustration.

Assemble in the same manner as the clutch plate so

that the section with no teeth (“A” in the illustration)

matches the retainer hole (“B” in the illustration).

Clutch discs

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 65

23E-6-4

V5A51 -

Reverse and Overdrive Clutch

End play

MB991789

MD998924

"HA

SNAP RING INSTALLATION

1. Install the snap ring in the reverse clutch retainer groove.

2. Set the special tools as shown in the illustration, and

compress the clutch element.

3. Check that the clearance between the snap ring and

reaction plate (reverse clutch end play) is the standard

value.

If the clearance is not at the standard value, select a

suitable snap ring an d adjust so that the clearance is

within the standard value.

Standard value: 1.5 - 1.7 mm

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 66

V5A51 -

7. SECOND BRAKE

DISASSEMBLY AND ASSEMBLY

4

1

Second Brake

23E-7-1

Disassembly steps

1. Second brake retainer

2. Second brake piston

"AA 3. D-ring

"AA 4. D-ring

2

3

ASSEMBLY SERVICE POINT

"AA

1. Apply ATF to the D-ring.

2. Install the D-ring in the groove on the outer an d inner

E

Mar. 2000Mitsubishi Motors Corporation

D-RING INSTALLATION

periphery of the piston. Make sure that the D-ring is not

twisted or damaged when installing.

AddedPWEE8920-I

Page 67

V5A51 -

Low/reverse Annulus Gear

8. LOW/REVERSE ANNULUS GEAR

DISASSEMBLY AND ASSEMBLY

Apply automatic

transmission fluid to

all moving parts

before installation.

23E-8-1

7

8

2

3

1

Disassembly steps

1. Snap ring

2. Overdrive planetary carrier

"DA 3. Thrust bearing No.5

4. Underdrive sun gear

"CA 5. Thrust bearing No.6

6. Output planetary carrier

"BA 7. Stopper plate

"AA 8. One-way clutch

9. Snap ring

10. Low/reverse annulus gear

4

9

10

5

6

ASSEMBLY SERVICE POINTS

"AA

Install the one-way clutch so that the arrow stamp is oriented

as shown in the illustration.

Arrow

E

Mar. 2000Mitsubishi Motors Corporation

ONE-WAY CLUTCH INSTALLATION

AddedPWEE8920-I

Page 68

23E-8-2

V5A51 -

Low/reverse Annulus Gear

Stopper

plate

Claw

Groove

Output planetary

carrier side

"BA

STOPPER PLATE INSTALLATION

Install the stopper plate onto the low/reverse annulus gear.

Make sure that the stopper plate claws are securely engaged

in the annulus gear groove.

"CA

THRUST BEARING NO.6 INSTALLATION

Apply Vaseline or petrolatum jelly on the thrust bearing No.6,

and then install on the output planetary carrier.

Caution

D

Take care not to mistake the thrust bearing No.6

mounting direction.

"DA

THRUST BEARING NO.5 INSTALLATION

Overdrive

planetary

carrier side

Apply Vaseline or petrolatum jelly on the thrust bearing No.5,

and then install on the overdrive planetary carrier.

Caution

D

Take care not to mistake the thrust bearing No.5

mounting direction.

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 69

V5A51 -

9. CENTER SUPPORT

DISASSEMBLY AND ASSEMBLY

Apply automatic

transmission fluid to

all moving parts

before installation.

5

Center Support

23E-9-1

3

2

1

Disassembly steps

AA""CA 1. Snap ring

2. Plate

3. One-way clutch inner race

"BA 4. O-ring

5. Spring retainer

4

9

8

7

6

6. Return spring

7. Low/reverse brake piston

"AA 8. D-ring

"AA 9. D-ring

10. Center support

10

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 70

23E-9-2

V5A51 -

Center Support

MD998924

MB991630

Snap

ring

DISASSEMBLY SERVICE POINT

AA"

1. Set the special tools as shown in the illustration so that

2. Screw in the special tool nut, and lightly press against

3. Remove the snap ring.

SNAP RING REMOVAL

they are pressed against the inner race of the one-way

clutch.

the inner race of the one-way clutch.

ASSEMBLY SERVICE POINTS

"AA

1. Apply ATF to the D-ring.

2. Install the D-ring in the groove on the outer an d inner

"BA

Install the O-ring onto the center support at the position shown

in the illustration.

D-RING INSTALLATION

periphery of the piston. Make sure that the D-ring is not

twisted or damaged when installing.

O-RING INSTALLATION

O-ring

MD998924

MB991630

Snap

ring

"CA

SNAP RING INSTALLATION

1. Set the special tools as shown in t he illustration.

2. Screw in the special tool nut, and lightly press against

the inner race of the one-way clutch.

3. Install the snap ring.

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 71

V5A51 -

10. UNDERDRIVE CLUTCH

DISASSEMBLY AND ASSEMBLY

Apply automatic

transmission fluid to

all moving parts

before installation.

2

1

Underdrive Clutch

4

3

23E-10-1

11

12

10

9

8

7

1

5

6

5

11

3

7

10

8

13

12

9

6

2

4

E

Mar. 2000Mitsubishi Motors Corporation

13

AddedPWEE8920-I

Page 72

23E-10-2

Disassembly steps

"EA 1. Snap ring

"DA 2. Reaction plate

"DA 3. Clutch disc

"DA 4. Clutch plate

AA""CA 5. Snap ring

6. Snap retainer

"AA 7. D-ring

V5A51 -

Underdrive Clutch

"BA 8. Return spring

9. Underdrive clutch piston

"AA 10. D-ring

"AA 11. D-ring

"AA 12. D-ring

13. Underdrive clutch retainer

MD998924

Snap ring

MD998907

DISASSEMBLY SERVICE POINT

AA"

1. Set the special tools as shown in t he illustration.

2. Compress the return spring, and remove the snap ring.

SNAP RING REMOVAL

ASSEMBLY SERVICE POINTS

"AA

1. Apply ATF to the D-ring.

2. Install th e D-ring in the groove of the underdrive clutch

"BA

Align the two return spring holes with the two projections

on the underdrive clutch piston, and then assemble the return

springs.

D-RING INSTALLATION

retainer and spring retainer. Make sure that the D-ring

is not twisted or damaged when installing.

RETURN SPRING INSTALLATION

MD998924

MD998907

"CA

SNAP RING INSTALLATION

1. Set the special tools as shown in t he illustration.

2. Compress the return spring, and install the snap ring.

Snap ring

E

Mar. 2000Mitsubishi Motors Corporation

AddedPWEE8920-I

Page 73

V5A51 -

Underdrive Clutch

23E-10-3

“W”

stamp

Reaction

plate

MD998924

MB991629

A

Clutch discs

B

"DA

CLUTCH PLATE / CLUTCH DISC / REACTION

PLATE INSTALLATION

1. Alternately assemble the clutch plates and clutch discs

in the underdrive clutch retainer.

When assembling the four clutch plates, align the seciton

having no teeth (A in the illustration) with the underdrive

clutch retainer hole (B in the illustration).

Clutch platesRounded edge

2. Install the reaction plate so that it is oriented as shown

in the illustration.

Assemble in the same manner as the clutch plate so

that the section with no teeth (“A” in the illustration)

matches the retainer hole (“B” in the illustration).

"EA

SNAP RING INSTALLATION

1. Install the snap ring in the groove of the underdrive clutch

retainer.

2. Set the special tools as shown in the illustration, and

compress the clutch element.