Mitsubishi V45CB WD-82CB1, V45CA WD-73CA1, V45C WD-73C11, WD-92840, WD-73740 User Manual

...Page 1

ECHNICAL

RAINING

T

2011

Technical Training Manual

Including…

Down-to-1

High Speed Troubleshooting

V46

L75-A94

2012

V45

Chassis

DLP

®

V46

Chassis

HOME CINEMA TV

V45C V45 V45CA

WD-73C11 WD-73640 WD-73CA1

V45+

V45++ V45CB

WD-73740 WD-73840 WD-82CB1

WD-82740

WD-82840

WD-92840

Copyright © 2011 Mitsubishi Electric Visual Solutions America, Inc.

All Rights Reserved

Page 2

Page 3

MITSUBISHI ELECTRIC

2011-2012

Technical Training Manual

Table of Contents

Introduction ........................................................................................................................... 5

Product line ......................................................................................................................... 5

Features and Technologies .................................................................................................. 6

New Technologies .............................................................................................................. 8

Chapter 1 - LASERVUE ...................................................................................................... 15

Safety ................................................................................................................................ 15

Disassembly and Parts Replacement ................................................................................ 17

Service Procedures ............................................................................................................ 23

Down-to-1 Troubleshooting ............................................................................................. 31

Chapter 2 - DLP

Disassembly and Parts Replacement ................................................................................ 35

Service Procedures ............................................................................................................ 23

Down-to-1 Troubleshooting ............................................................................................. 57

Circuit Block Diagrams .................................................................................................... 61

®

HOME CINEMA ..................................................................................... 35

3

Page 4

4

Page 5

Introduction

Introduction

DLP

®

HOME CINEMA

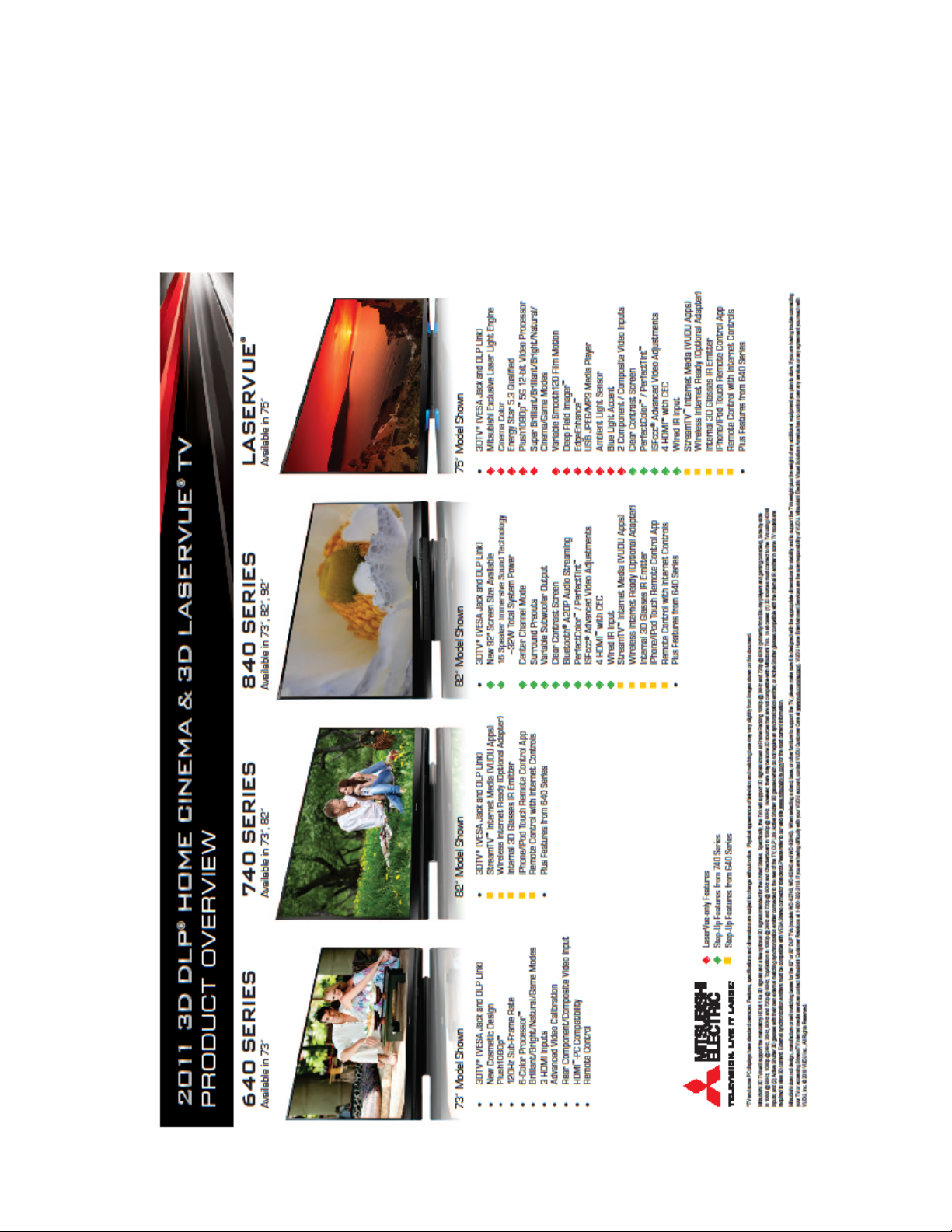

This training manual will cover Mitsubishi’s 2011-2012 TV Product Line shown below broken down by

category, chassis, display technology and light source.

Product Category Chassis Display Technology Light Source

LASERVUE V46 Rear Projection DLP RGB Lasers

DLP Home Cinema V45 Rear Projection DLP High Pressure Discharge Lamp

The full TV Product Line is shown below by size, sub-chassis and model.

LASERVUE

SIZE V46

75” L75-A94

DLP Home Cinema

SIZE V45C V45 V45CA V45+

73” WD-73C11 WD-73640 WD-73CA1 WD-73740

82” WD-82740

92”

5

V45++

WD-73840

WD-82840

WD-92840

V45CB

WD-82CB1

Page 6

Introduction

This Introduction will discuss some of the newest features and technologies. The remainder of the manual is

divided into 2 sections to cover the

LASERVUE and DLP Home Cinema product categories separately. While

this manual can be used as a service aid, always refer to the Service Manual for complete service information

and safety instructions.

FEATURES and TECHNOLOGIES

A matrix of many of the features included in the 2011-2012 product line follows. Also, several of the newest

6

Page 7

Introduction

TECHNOLOGIES

Mitsubishi’s 2011-2012 TV product line includes several technologies either new to the market place or

introduced in the recent past. These technologies include:

3D with built in IR synchronization emitters.

Stream TV™ Internet Media

Wireless Internet Ready and Built-in Wireless Internet

Bluetooth

iPhone

®

A2DP Audio Streaming

®

Remote Control App

In addition, Mitsubishi’s Reliability and Service Technologies have evolved yet again. These technologies

will be discussed further.

3D

2011-2012 Mitsubishi TVs will support the mandatory HDMI 1.4a 3D signals intended for the United

States. However, there may be some 3D sources that are not compatible with the TVs. Specifically, the

TVs will support the 3D signals known as:

Frame Packing 1080p/24Hz and 720p/60Hz (primarily from Blu-ray players and gaming consoles).

Side-by-Side in 1080i/60Hz, 1080p/24Hz/30Hz/60Hz and 720p/60Hz.

Top/Bottom in 1080p/24Hz and 720p/60Hz.

Checkerboard 1080p/60Hz.

In all cases:

(1) 3D sources must connect to the TV using the HDMI inputs or via StreamTV™ Internet Media.

(2) Active Shutter 3D glasses are required in order to view 3D content. They must be synchronized

using either IR or DLP-Link. IR synchronization must use either the TV’s internal IR emitter or an

external IR emitter connected to the rear of the TV.

7

Page 8

Introduction

Stream TV™ Internet Media

Introduced last year, internet media capabilities have been expanded to many more models this year by including an Ethernet port and wireless ready or wireless internet connections. This permits instant access to

an extensive library of high quality entertainment and social media content. StreamTV provides consumers

with over 100 different applications.

Internet services provided by VUDU™ Apps let you access many popular on-line applications. In addition

to free content, VUDU’s movie service lets you buy and rent movies through the TV. Visit VUDU.com to

learn more about available movie titles, prices, and services offered. For a list of recommended routers

and switches, see the Support > FAQ section at VUDU.com.

Requirements for StreamTV internet media:

Broadband internet service (at least 2 Mbps for SD, • 4 Mbps for HD, and 8 Mbps for 1080p HDX)

Internet connection (wired or wireless).

Computer access to the VUDU.com website (required for initial account activation).

A credit card for rental and purchase transactions from VUDU’s movie service.

Wired Internet, Wireless Internet Ready and Built-in Wireless Internet

These technologies are exactly what they say they are. Requirements are as follows:

Wired: Category-5 (CAT-5) Ethernet cable connected from the LAN Port of the TV from either a

router or modem providing high speed internet service.

Wireless Ready: Azurewave AW-NU231 USB wireless adapter plugged into the TV’s USB port.

Note: At this time, these are the only wireless adaptors available on the market that can be used.

More options may be available in the future.

Wireless and Built-in Wireless: IEEE 802.11n compliant wireless network router providing highspeed internet service.

Bluetooth® A2DP Audio Streaming

The Bluetooth specification for basic audio provides a frequency response designed for voice communication. Bluetooth’s Advanced Audio Distribution Profile, or A2DP, allows high-fidelity stereo audio to be

streamed from the customer’s Bluetooth device to the TV. A A2DP enabled Bluetooth device (phone, media player, etc.) is required.

®

iPhone

Remote Control App

Owners of Apple’s iPhone or iPod Touch devices can obtain an optional App (application) that will give

the device remote control capabilities. They can then control their TV over the wireless internet connection.

From a Service Technician’s Point of View…

New technologies always present a challenge to the service technician. The customer expects the technology to work to whatever expectation he has in mind. And if it doesn’t, he expects the service technician to

wave his “magic wand” and make it all better. In most cases, problems are not due to a failure. The customer simply does not understand the feature’s use, capabilities, requirements or set-up. Since the Service

Technician’s primary job is to repair failures, the customer problems have to be eliminated first. When

receiving a customer complaint about a new technology, the best first course of action is to point the customer to Mitsubishi’s Operational Assistance department at 800-332-2119.

8

Page 9

Introduction

9

Page 10

Introduction

Reliability and Serviceability Technologies—Simplified!

If one word could be used to describe the reliability and serviceability technologies in Mitsubishi’s 20112012 TV products, it would be simplified.

LASERVUE

The second generation V42 chassis is a complete redesign of the V40. It is, well... simplified. How?

The Screen is stationary. No motors. No moving parts. No shipping screws.

The Fiber Optic Cables have been eliminated. No optical connectors.

The Mirror is flat.

DLP Home Cinema

The Chassis is held in the cabinet by only 4 screws. And, disassembly is simplified by a reduction

in the number of screws necessary to remove the PWB-MAIN. Comparing the base models V43

to V41 shows a screw reduction of more than 42%. The high end models screw reduction is more

than 32%. And the V41 seemed simple!

The Optical Engine assembly has been redesigned to a more compact design and is held in the

cabinet by only 3 screws.

The PWB-BALLAST is held in place by a single clip.

The screw on DVI Cable has been replaced by a finger locking LVDS Ribbon Cable.

DLP Home Cinema

The Self Diagnostics feature is self activated when the set is in the shut down condition. No pro-

cedure necessary to obtain an Error Code.

The Error Code read-out is now color coded. It’s now simplified to the point where a customer

can read the Error Code.

Software updates can be performed on-line automatically (Internet Media models).

Bluetooth circuit is on a separate PWB to simplify troubleshooting.

Features, specifications and dimensions are subject to change without notice.

Digital Light Processing, Digital Micro mirror Device, and DLP are trademarks or registered trademarks of Texas Instruments.

ENERGY STAR and the ENERGY STAR mark are registered marks owned by the U.S. government. Dolby, Dolby Digital and

Dolby Pro Logic are registered trademarks of Dolby Laboratories. HDMI, the HDMI logo and High-Definition Multimedia

Interface are trademarks or registered trademarks of HDMI Licensing, LLC. “x.v.Color” is a trademark of Sony Corporation.

Bluetooth and the Bluetooth trademarks are owned by Bluetooth SIG, Inc. iPhone is a registered trademark of Apple Inc.

is a registered trademark of Textron.

6-Color Processor™, DeepField Imager™, Easy Connect™, Net Command®, PerfectColor™, PerfecTint™, Plush 1080p®,

EdgeEnhance™, Smooth120Hz™, True120Hz™. True240Hz™, StreamTV™,

Solutions America, Inc.

LASERVUE™ are Mitsubishi Electric Visual

TORX

10

Page 11

Chapter 1

SIZE V46

75” L75-A94

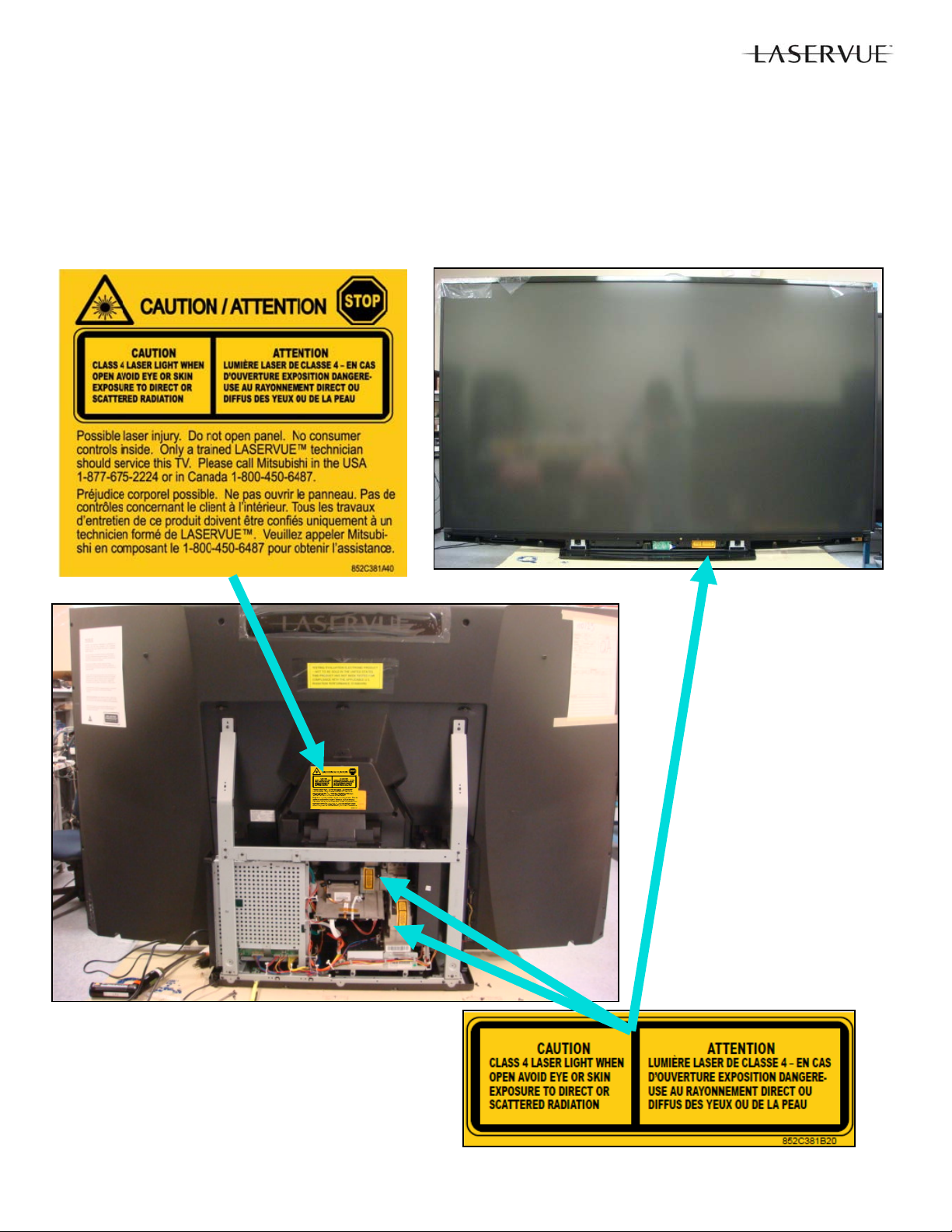

SAFETY

Like the first generation V40 LASERVUE chassis, the V46 chassis includes laser technologies that have

safety requirements that are separate and different than those in other TVs. Prior to servicing this type

product, it is important to read and understand all safety requirements. The V40 Technical Training Manual includes a section on the Fundamentals of Laser and Laser Safety. It is available for download from

new.3diamonds.com. In addition, the laser safety requirements specific to the V46 chassis are repeated

from the Service Manual here. Refer to the Service Manual for all other safety instructions.

11

Page 12

SAFETY PRECAUTIONS

NOTICE: Observe all cautions and safety related notes located inside the receiver cabinet and on the receiver

chassis.

WARNING:

1. Operation of this receiver with the covers removed presents both a shock hazard and a hazard from laser ra diation. Work on the receiver should not be attempted by anyone who is not thoroughly familiar with the precautions necessary when working on high voltage and laser based equipment.

2. When service is required, observe the original lead dress. Where a short-circuit has occurred, replace those

components that indicate evidence of overheating.

CAUTION:

This TV is a CLASS 1 laser product. This TV poses no risk to eyes or skin during normal use. An exposure hazard

may exist only if the protective housing is removed.

This TV contains a CLASS 4 laser device, which by itself may be hazardous. However, this TV incorporates a protective housing, optics and electronics such that there should be no exposure to unsafe levels of laser light during normal

operation and proper service.

This TV is in compliance with the requirements of IEC 60825-1 Ed. 2(2007).

CLASS 1 LASER PRODUCT

Complies with FDA performance standards

for laser products except for deviations

pursuant to Laser Notice No. 50, dated June

24th, 2007.

APPAREIL À LASER DE CLASS 1

Se conforme aux norms de rendement du

FDA relatives aux produits laser sauf en ce

qui concerne les déviations conformément à

La Notice Laser No 50 du 24 Juin 2007

AVIS: Risque de choc electrique. Ne pas ouvrir.

12

Page 13

Caution: Use of controls or adjustments or performance of procedures other than those specified herein may result in

hazardous radiation exposure. Use external or remote controls to operate the product. Connection to signal sources

and power are accomplished through the external connectors.

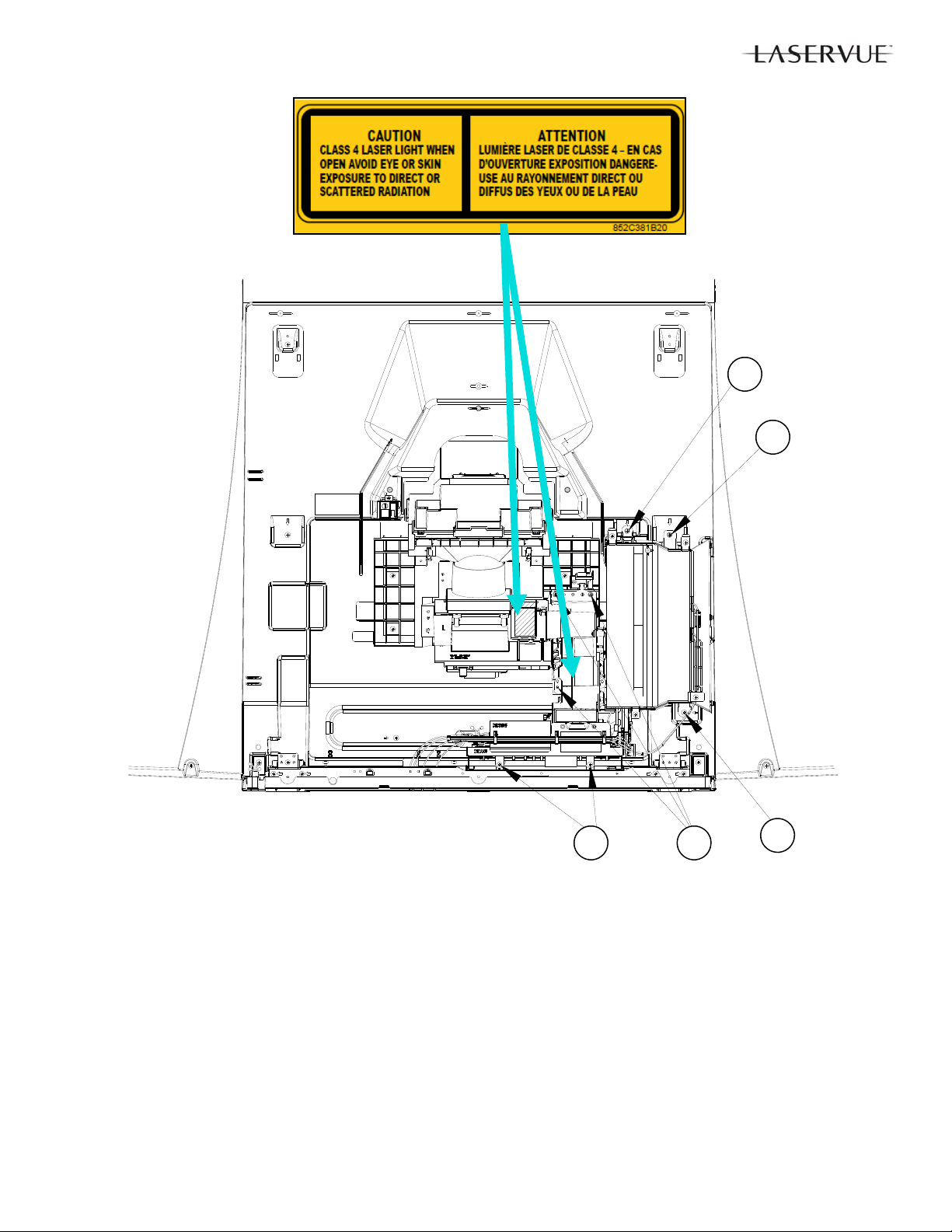

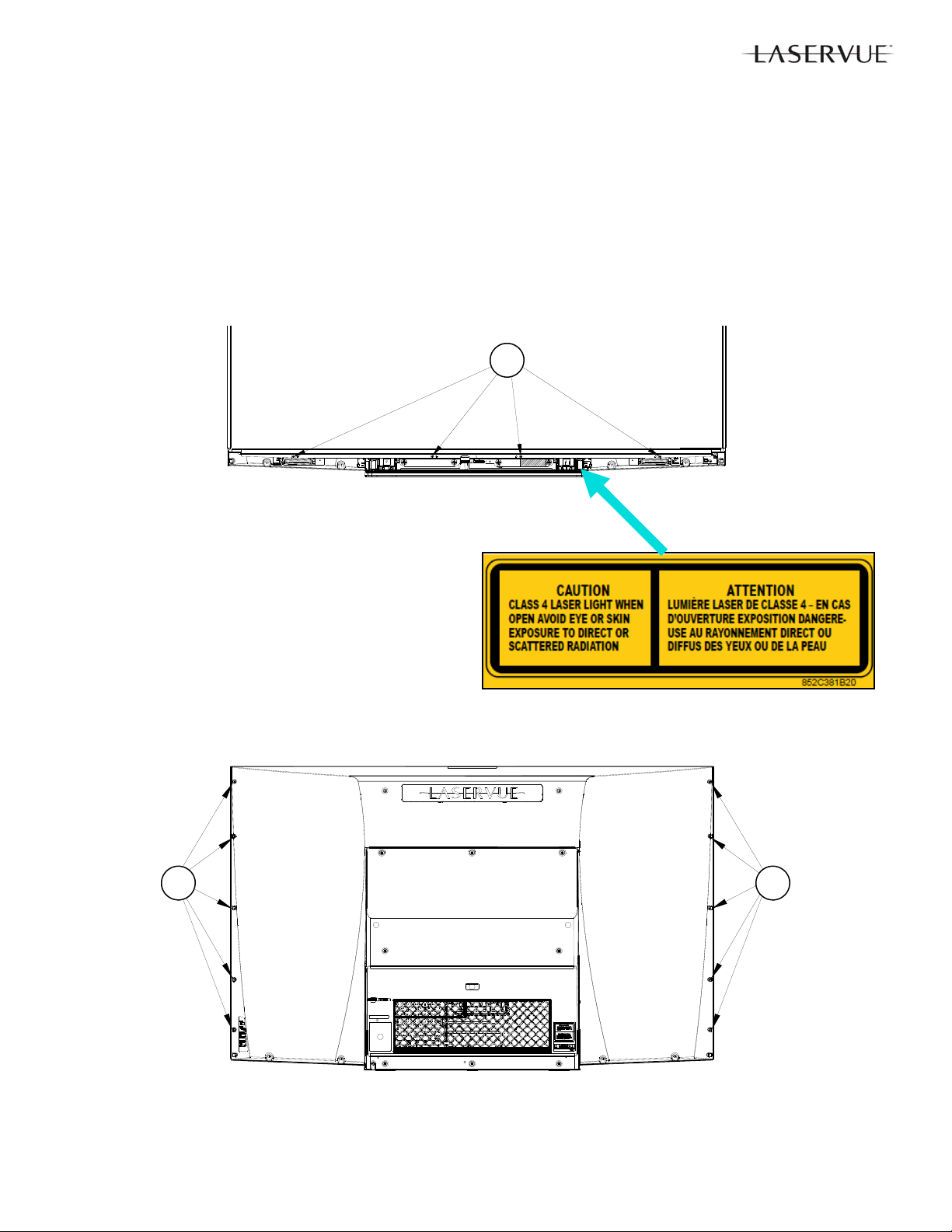

1. The following precautions must be taken to avoid exposure to hazardous laser radiation during service.

Prior to removing items marked with either of the two labels shown below, AC power mu st be removed. AC power

must not be re-applied until the cover(s) are replaced back into their original position and all screws are in place.

The specific Class 4 areas in the V46 chassis include the Scre en Assembly, the Light Source Unit and the Optical

Engine, indicated below.

13

Page 14

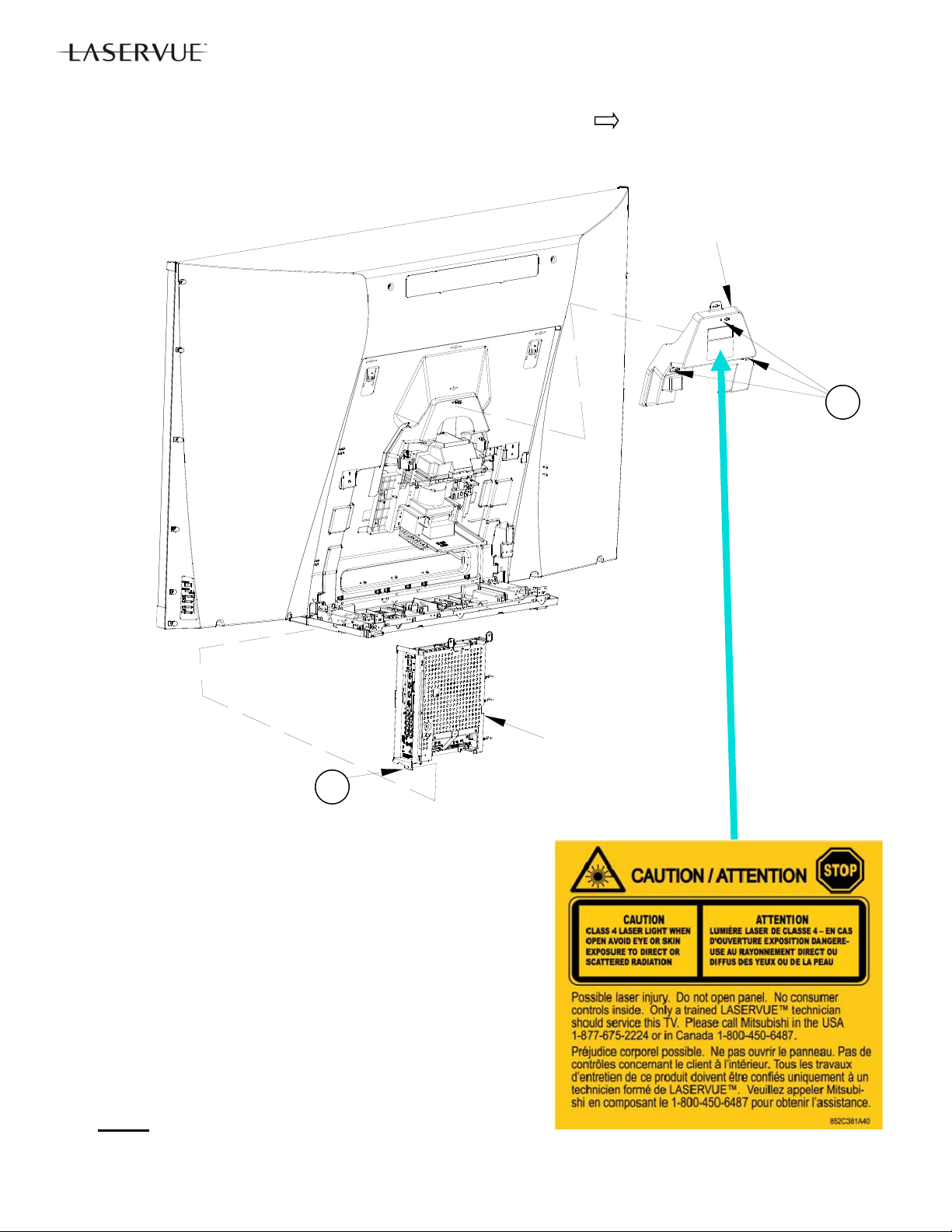

DISASSEMBLY & PARTS REPLACEMENT

CAUTION: Prior to disassembly, remove AC power. Do not re-apply AC power until the set

has been fully re-assembled and inspected for safety as described on page 12.

IMPORTANT NOTES:

1. Disassembly beyond what is shown in this manual is not recommended.

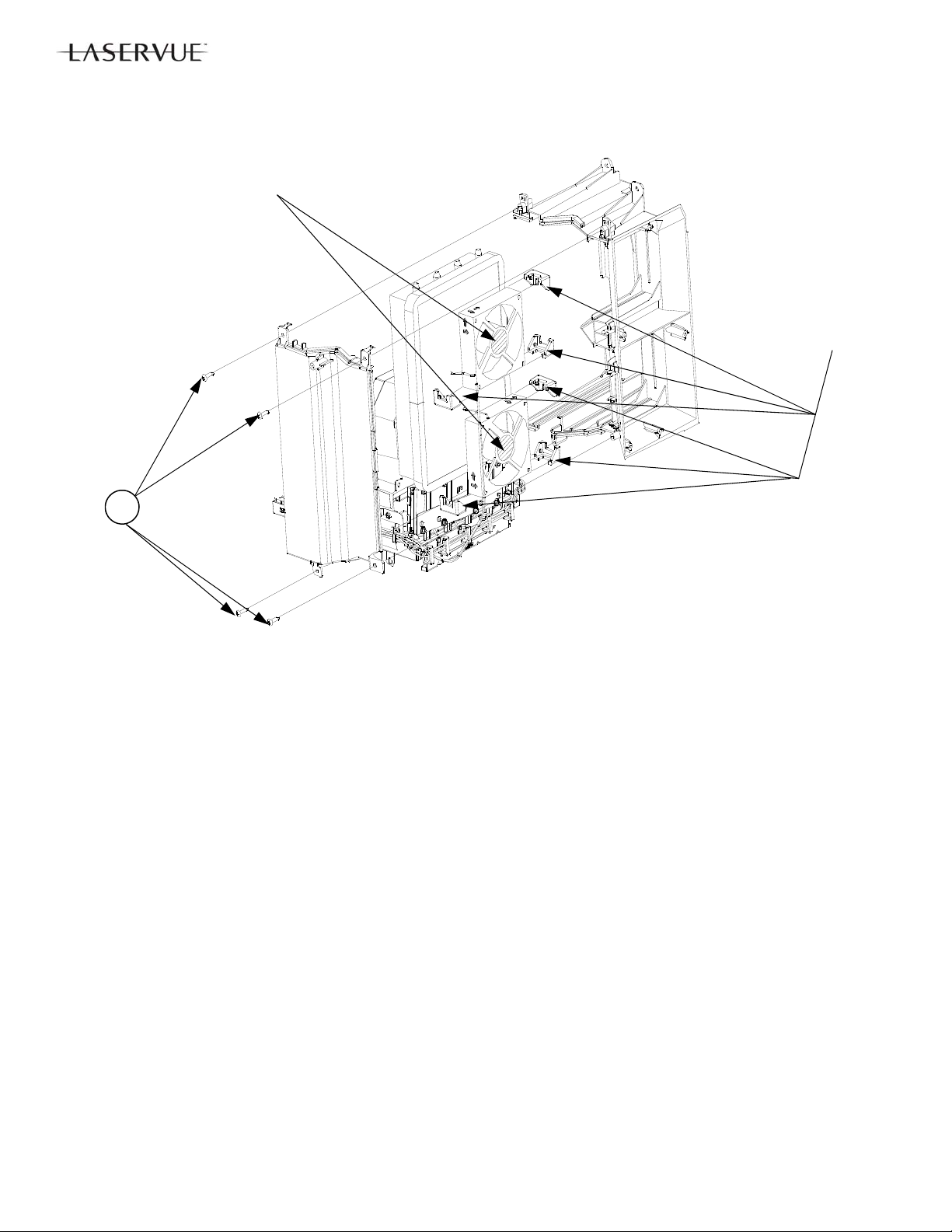

2. The following assemblies are replacement items that should not be disassembled:

Electrical Chassis—Replacement is supplied complete with PWBs. However PWBs can be replaced

individually.

Light Source Unit—Replacement is supplied complete with fans and ducts. However Exhaust Fans can

be replaced individually.

Optical Engine—Replacement is supplied complete with the DMD fan. However the DMD Fan can be

replaced individually.

3. Do not allow the rear of the screen to come into contact with any other surface including cleaning cloths or

fingers. Remove dust or other debris by blowing with a dry air source.

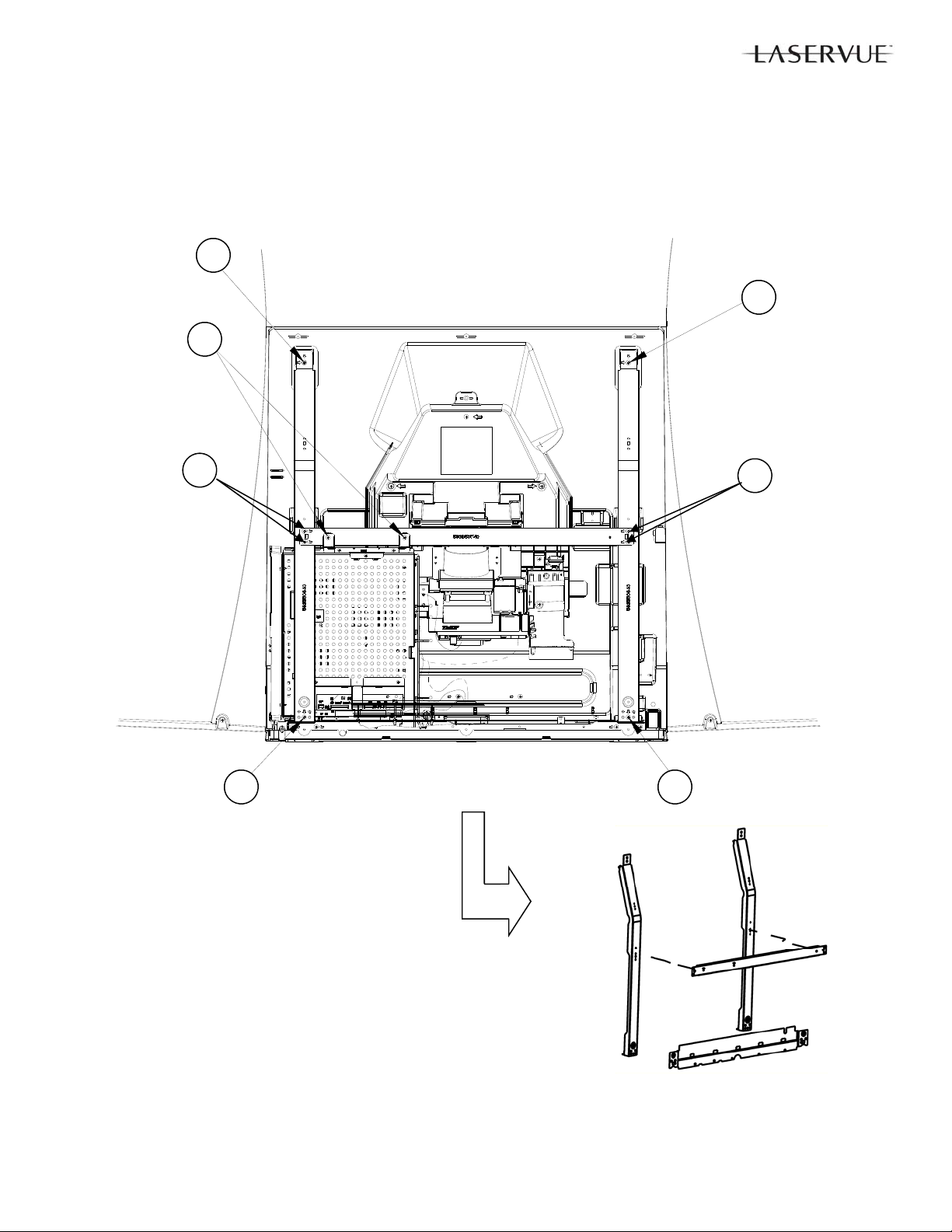

Back Cover Removal

1. Remove screws (A) from the back cover (Star Head/TORX® T20).

2. Remove the back cover from the TV.

A

A

A

A

A

A

14

Page 15

Rear Cabinet Frame Removal

1. Remove screws (A) from the Rear Cabinet Frame.

2. Remove the Rear Cabinet Support Frame from the TV.

A

A

A

A

A

A

A

15

Page 16

Service Cover Removal (For Light Source Unit and Optical Engine Replacement)

1. Remove screws (A) indicated on the Service Cover by the arrows

2. Remove the Service Cover in the direction indicated.

SERVICE

COVER

A

B

Electrical Chassis Removal

1. Disconnect all cables connecting to the chassis.

2. Remove screw (B).

3. Slide the chassis up and out of the cabinet.

Note: After replacing either the Electrical Chassis or PWB-MAIN,

see Data Transfer section and perform the following procedure s:

1. Restore Engine Data From Backup

2. Restore Geometry Data From Backup.

3. Restore ISF Settings From Backup (Only if backup USB

memory device is available).

IMPORTANT REPLACEMENT NOTE: If the customer has subscribed to VUDU (Internet program provider), the customer must be

instructed to contact VUDU to re-activate their account after a replacement CHASSIS or PWB-MAIN has been installed. The original

part cannot

bishi per policy.

be installed in another TV. It must be returned to Mitsu-

16

ELECTRICAL

CHASSIS

Page 17

A

A

A

B

A

Light Source Unit Removal

NOTE: The Light Source Unit is supplied complete with fans and ducts. However the Exhaust Fans can be replaced

individually.

1. Disconnect all cables connecting to the Light Source Unit.

2. Remove Screws (A) and (B).

3. Remove the Light Source Unit from the cabinet.

Light Source Unit Replacement

1. After a new Light Source Unit is installed, perform the “Select Calibration Table” procedure as described in

the Service Adjustments section.

17

Page 18

A

Fan Labels

Facing Out

Corner

Cushions

3 Per Fan

Light Source Exhaust Fan Removal

NOTE: Disassemble Duct Assembly for Fan replacement only. Otherwise order the complete Light

Source Unit.

1. Remove Screws (A).

2. Separate the Front and Rear Air Ducts.

IMPORTANT: Do not disassemble the Light Source Unit any further.

18

Page 19

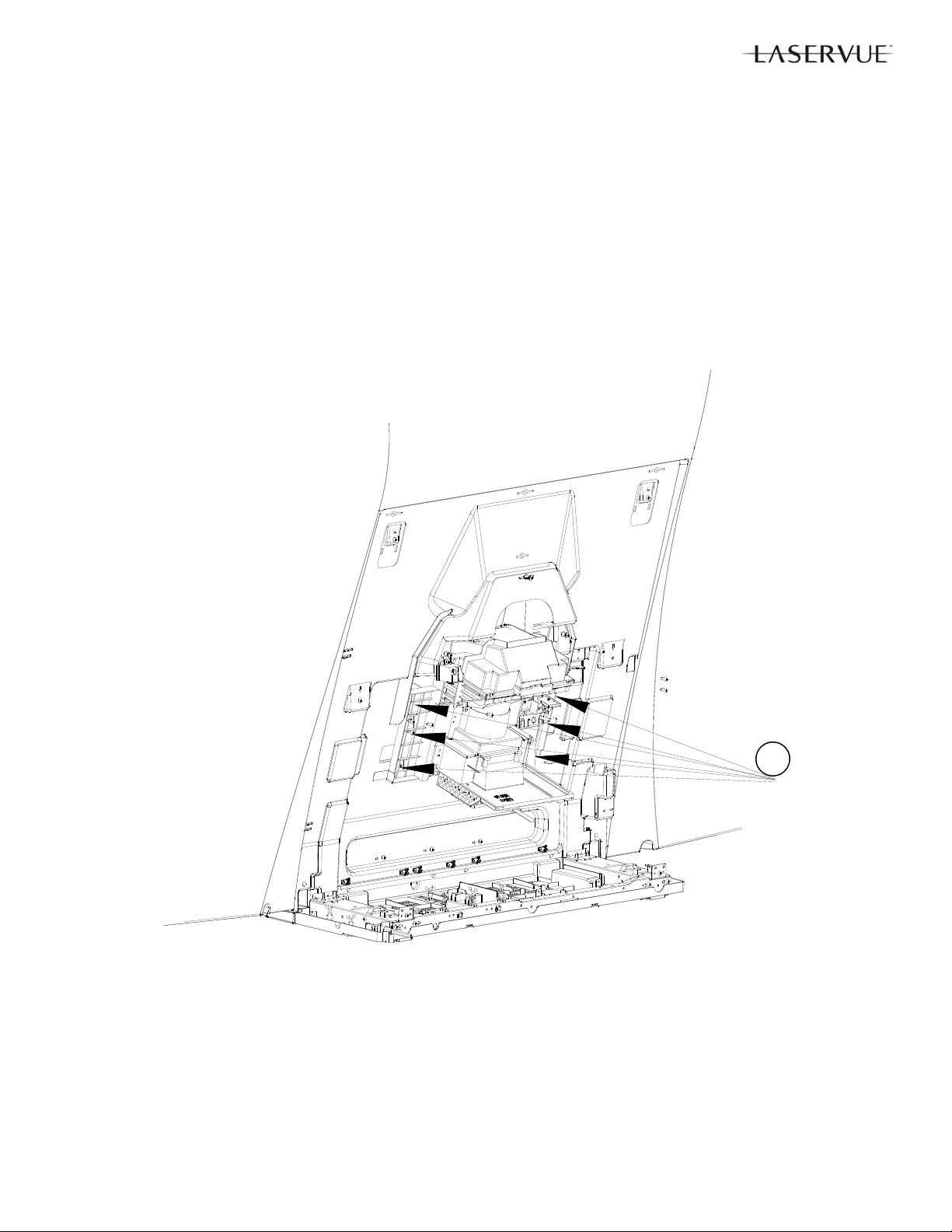

Optical Engine Removal

1. Remove Screws (A).

2. Remove the Optical Engine from the cabinet.

IMPORTANT: Do not disassemble the Optical Engine further than DMD Fan replacement.

Optical Engine Replacement

After a new Optical Engine is installed, perform the following procedures:

1. TSP Alignment as described in the Service Adjustments section.

2. “Save Engine and Geometry Setting to Backup” procedure as described in the Data Transfer section of the

Service Adjustments.

19

A

Page 20

COVER-FRONT Removal

1. Remove Back Cover and remove Screw (A).

2. Remove Screws (B).

3. Pull COVER-FRONT away from the front of the cabinet.

B B

A

COVER-FRONT

(Example)

20

Page 21

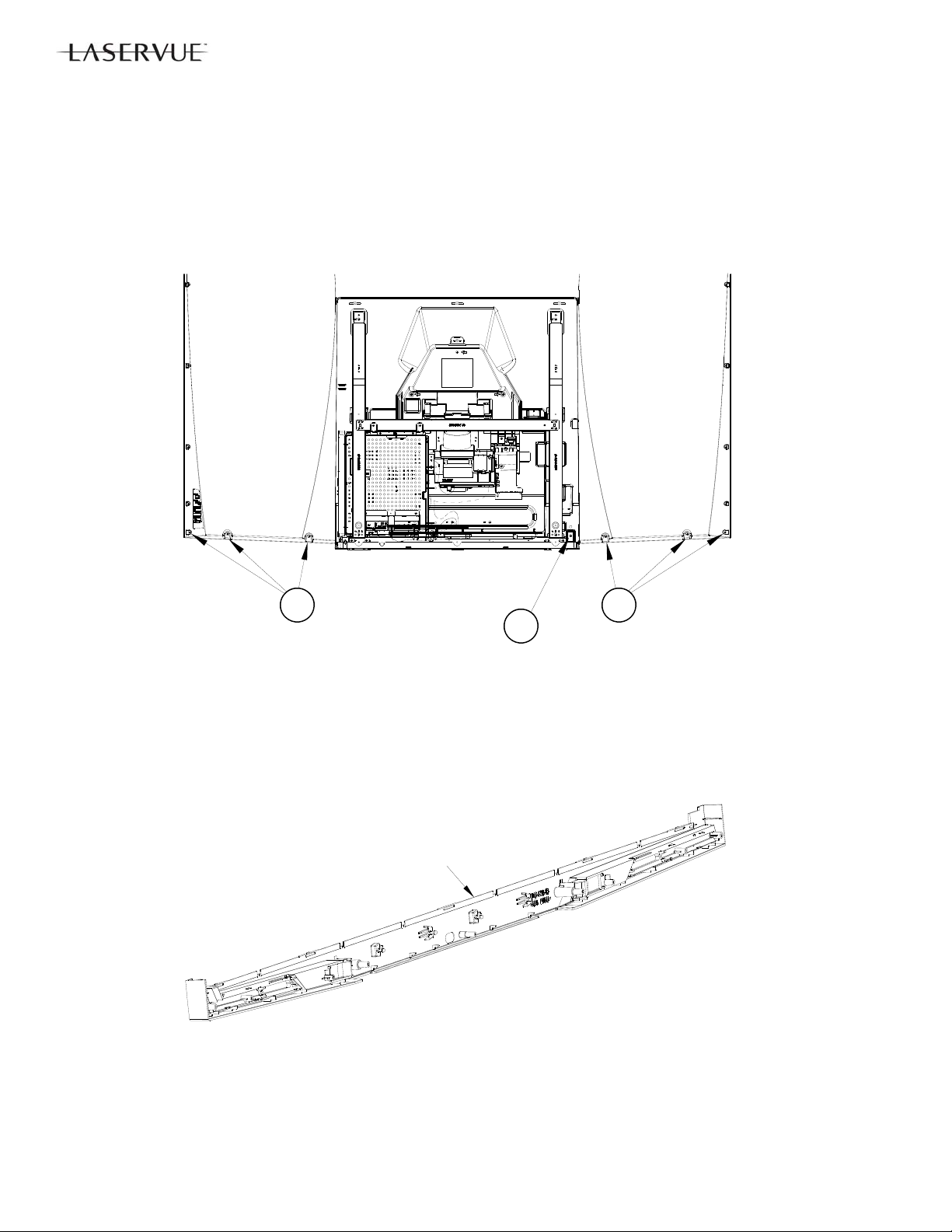

Screen Assembly Removal -

Note: The Screen Assembly and screens are not considered to be field replaceable items.

1. Remove the COVER-FRONT.

2. Remove Screws (A) from the bottom front.

3. Remove Screws (B) from the rear sides.

4. Remove the Screen Assembly from the cabinet.

IMPORTANT: Do not allow the rear of the screen to come into contact with any other surface including cleaning cloths or fingers. Remove dust or other debris by blowing with a dry air source.

IMPORTANT: Do not disassemble the Screen Assembly.

A

B B

21

Page 22

SERVICE PROCEDURES

REMOTE CONTROL USE FOR SERVICE

Many service functions and adjustments are accessed using the Remote Control. See below.

22

Page 23

OPTION MENU

OPTION MENU

1. Press the <MENU> button on the remote control.

2. Press the buttons <2-4-7-0>. The screen will display the Option Menu.

Option Me nu

<MENU><2-4-7-0>

Ini tia lize

Deactivate VUDU

Power Restore OFF

Production Mode OFF

Digital Signal Streng th <1~ 9>

DM Sof twa re Vxx xx x.xx

TV MAC Address xx:xx:xx:xx:xx:xx

Wireless LAN Device ON

Total ho urs of use xxx

Light Sensor xxx

APC Ratio xxx,xxx,xxx

DAC Ratio xxx,xxx,xxx

LM ONTIME [m] xxx

Laser ONTIME R [m] xxx

Laser ONTIM E G [m] xxx

Laser ONTIME B [m] xxx

TEMP [C] xx.xx

Peltier DAC [%] xx.xx

SERVICE LEVEL INITIALIZATION

Service Level Initialization is used to restore all customer menu, video and audio settings to the original factory default

condition.

1. Enter the Option Menu <MENU><2-4-7-0>

2. Select “Initialize” and <ENTER>.

DEACTIVATE VUDU

This feature will deactivate the customer’s VUDU on-line subscription. It should be used before TV ownership is

changed. NOTE: This feature is independent of the Initialize function.

1. Enter the Option Menu <MENU><2-4-7-0>.

2. Select “Deactivate VUDU” and <ENTER>.

3. The “Vudu Reset” text will momentarily turn red.

4. Press <EXIT> to quit.

5. The TV will register as deactivated the next time it is connected to the internet.

23

Page 24

DIGITAL SIGNAL STRENGTH

1. Tune to a Digital Channel.

2. From the Option Menu, scroll down and highlight “Digital Signal Strength.”

3. Press <ENTER>. The screen will display the Digital Signal Strength Menu.

Digital S i gna l S trength Menu

"Di gi t al Si gnal S trength" <E NTER>

Tuner

Frequenc y(MHz) 749

Signal Level <1~9>

Modulation 8VSB Air

Ca rrier Loc k Loc ked

SNR 29.09

Correc t a ble erro rs 0

Un C orrec t a ble errors 0

SNR Recommended Levels:

8VSB = 16 to 33

64 QAM = 22 to 35

256 QAM = 27 to 38

24

Page 25

RESET / INITIALIZATION

SERVICE TIP:

Many symptoms that are customer generated, intermittent or cannot be verified can be resolved by using the various

Reset and Initialization options. Before visiting the customer’s home ask the customer to 1st perform a System Reset by

pressing the <POWER> button on the side panel and holding it for 8 seconds. If this does not resolve the issue, they

can perform an A/V Reset by pressing the side panel <INPUT> + <VOL > buttons at the same time and holding for 10

seconds. Then, if necessary, perform a user level Initialization by pressing <MENU><1-2-3> <ENTER> with the remote.

The customer should be made aware when settings and/or options will be reset. For more information, see the chart.

Reset Name When to use Resulting Action

Remote Control

Reset

A/V Memory

Reset, by individual input

A/V Reset, all

inputs

System Reset To reset the TV when it does not turn

Initialize -

User Level

Initialize -

Service Level

Deactivate

Vudu

V-Chip Password Bypass

Unlock Side

Panel

Returns the remote control to normal

operation.

When the audio or video performance

or settings for a single input seem to

be incorrect.

When the audio or video performance

or settings for more than one input

seem to incorrect.

on or off, does not respond to the

remote control, side panel buttons or

has other unusual symptoms.

To reset all customer settings except

V-Chip

To reset all customer settings

To deactivate the customer’s on-line

Vudu subscription when TV ownership is changed.

If V-Chip password is not known Press <LAST>+<9> at the same time. Password will be bypassed.

To unlock the side panel if it has been

locked in the V-Chip Menu.

1) Press and hold <POWER> until it flashes twice then release.

2) Enter <0-0-0-0-0>. The <POWER> button will flash twice

<MENU> “Audio/Video” “AV Reset” <ENTER> All Audio and Video settings

While viewing the TV, press the side panel buttons <INPUT> +

<VOL > at the same time and hold for 10 sec.

Press and hold the side panel <POWER> button for 8 seconds.

Press <MENU><1-2-3><ENTER> All customer menu options

<MENU><2-4-7-0> Select "INITIALIZE" <ENTER>

<MENU><2-4-7-0> Select "Deactivate VUDU" <ENTER>

Press and hold the side panel <INPUT> button for 10 seconds.

How to use

The remote control is reset.

for the individual input are

reset except for the Listen

To, Language, Balance and

Closed Caption settings.

All Audio and Video settings

are reset to the factory default settings. No other

menu options are changed.

TV Micro Re-boots. Note:

The changes made during

the current TV-On period

may be lost. All other previous user settings are not

lost.

and A/V settings except VChip, locked ISF & Vudu

subscription are reset to

factory default.

All customer menu options

and A/V settings except

Vudu subscription are reset

to factory default.

Vudu subscription is deactivated.

If in the V-Chip menu, enter

a new password.

Side Panel becomes operational. Other V-Chip settings

not changed. Note: Cannot

be performed while in the

Low Power mode and the

set is Off.

25

Page 26

LED INDICATIONS AND SELF DIAGNOSTICS

The front panel Power LED provides an indication of the set’s operation and the possible cause of a malfunction.

NORMAL INDICATIONS

STATUS LED Indication Condition

Off Off (Standby)

Green Power On

Slow Blinking Green Power Off with Timer Set. Power On normally

Fast Blinking Green 1 to 3 minutes after Power

Restored from AC interrupt, Power On, System

Reset or Software update.

ABNORMAL INDICATIONS

STATUS LED Indication Condition

Blinking Red then Blinking Yellow Circuit Failure (See Self Diagnostics)

Boot-up. Wait for blinking to stop to Power On.

SELF DIAGNOSTICS

A blinking red and yellow Status LED will indicate an Error Code that can help determine the cause of a circuit

failure.

The number of Red blinks indicates the value of the MSD (tens digit) of the Error Code.

The number of Yellow blinks indicates the value of the LSD (ones digit) of the Error Code.

Example: If the Error Code is “37”, the LED will continuously blink Red three times, followed by blinking Yellow

seven times.

See the following page for a list of Error Codes.

To perform a System Reset, press and hold the Power button for 10 seconds. Or, unplug the set for 10 seconds

then restore power.

Number of Red Blinks Number of Yellow Blinks

3 7

Error Code: 37

26

Page 27

ERROR CODES

Error Codes, descriptions and corrective actions for the error are listed below:

Error

Code

12

13 Cover-4 (Laser Unit) i s open. Contact MDEA Technical S upp ort 1-800-552-832 4

15 Strobe signal abnormal detection

17

18 ASIC-ready from engine is not detected.

23 Cover-1 (Back Cover) is open. Contact MDEA Technica l Su pport 1- 800-552-832 4

25 Abnormal High ambient temperature Check and Clean Air Vents / Replace PWB-TEMP2 if defective

26 Laser FAN1 or 2 sto p

29

33 Cover-2 (Front Cover) is open. C ont act MDEA Technica l Su pport 1- 800-552-832 4

37 DMD- FAN stops.

38* Laser uni t tem peratu re is abn ormall y high. Check and Clean A ir Path / Repla ce Las er Unit

39

45 Diffuser motor stops. Check JS ci rcu itry / Replace Engin e

46 Peltier temperature is abnormally high.

No serious erro r sinc e last main pow er on or

last micro initialization.

Engine I2C bus commun ica tion er ror is detected

Com m un ica tion er ror betw een Laser micro

and temp sensor (ambient, peltier, heat pipe)

Com m un ica tion er ror betw een Laser micro

and EEPROM

Com m un ica tion er ror betw een Laser micro

and LASER module therm istor.

Abnormal low ambient temperature

Description Corrective Actions

Check J V-J 6C00 circuitry or its Lea d Wir e / Ch eck if Flat cable is damaged / Repla ce Engine or Chassis

Check J V-J 6C00 circuitry or its Lea d Wir e / Ch eck if Flat cable is damaged / Repla ce Engine or Chassis

Check PE–PE circuitry or its lead wire / Check JV-J6C00 circuitry or its

Lead Wire / C heck if Flat cable is damag ed / R eplace Engine or Chassis

Check L D X or LD Y ci rcuitry & wirin g / Replace Laser Unit Fans if defective

Check communication as follows:

Ambient temp sensor : Check LE-ST2 circuitry & wiring / Replace PWBTEMP2

Peltier temp sensor : Check ST-ST1 circuitry & wiring / Replace PWBTEMP1

EEPR O M : C heck FA-FA circuitry & wiring / R eplace Laser Un its

LASER module ther m istor : Che ck FB-FB circuitry & wiri ng / R eplace

Laser U nit

Check JM circuitry & wiring / Replace DMD FAN if defective / Replace

Engine.

All ow TV t o warm to room te m per atur e / Replac e PWB-TEMP 2 if defective

Check and Clean Air Path / Check FA-FA circuitry & wiring (PEL_EN) /

Repl a ce Laser Un i t

48 P-ON shor t Replace Chassis

49* Laser abnormal brightness (more than limit) Replace Laser Unit

56

57

66* Laser abnormal brightness (less than limit) Check FB-FB connector or its Lead Wire / Replace Laser Unit

67 Peltier control abnormal Check FA-FA circuitry & wiring (PEL_EN) / Replace Laser Unit

68 Cover-3 (Service Cover above Engine) open. Contact MDEA Technical S upp ort 1-800-552-832 4

FPGA communication error with laser micro

FPGA configuration failure

Com m un ica tion er ror betw een TV micro and

Laser micr o

Check J V-J 6C00 circuitry or its Lea d Wir e / Ch eck if Flat cable is damaged / Repla ce Laser U nit or Chassis

Replace Chassis

* After 3 occurrences, the TV will be locked out and will not respond to Power On commands. After repair, use

the following procedure to unlock the TV.

1. Perform a System Reset by removing and re-applying AC.

2. Press and hold the side panel <INPUT> + <VOL > buttons at the same time un t il the Status LED returns

to normal (about 5 seconds).

27

Page 28

ERROR CODE LOG

The Error Code Log may be helpful to retrieve the code for an error that occurred in the past.

To access the Error Code Log: Press <MENU> <3-5-6-4>

Error Code Log

<MENU> <3-5-6-4>

***** PAGE (001/001) *****

CURRENT TIME: 01455 HOURS

USAGE TIME CODE STATUS

00413 HRS 56 HAPPENE D

00716 HRS 57 HAPPENE D Press U p to Prev ious Page

Press Dow n to Next Page

Press Right to Top Page

Press Left to Last Page

Press CAN CEL to Erase

Error Code Log Definitions

PAGE - Current page number

CURRENT TIME - total hours of operational use.

USAGE TIME - usage hours when the error occurred.

CODE - the specific Error Code that occurred.

STATUS: HAPPENED - Indicates an error was recorded.

Press <CANCEL> to erase the Log.

Press M ENU t o Exit

NOTE: The Error Code Log is intended as a reference tool and is not meant to be used as a final determination of a

defective part.

28

Page 29

SERVICE ADJUSTMENTS

There are 2 Types of Service Adjustments, electrical and mechanical:

Electrical Adjustments

Horizontal and Vertical Centering Adjustment

Index Delay Adjustment

Geometry Alignment

Data Transfer Functions

Mechanical Adjustment

Top Mirror Adjustment

ELECTRICAL ADJUSTMENTS

Overview—Specific Adjust Procedures follow

Service adjustments are performed using the remote control.

The Service Menu is used for all service adjustments.

Test Patterns are generated internally.

1. Activating the Service Menu

1. Press the <MENU> button on a remote control. (The “MENU” display will appear.)

2. Press the buttons <2-4-5-7>. (The Service Menu On Screen Display will appear.)

If no display appears, press <EXIT> and repeat steps 1 and 2.

2. Test Pattern Activation

1. When in the Service Menu, press Play <> to activate the internal test patterns (no indication will be displayed initially). Use FWD <

2. Press Play <

3. Press Play <

3. Adjustment Selection

When in the Service Menu use the <VIDEO> button to toggle to the adjustment desired as indicated by the number and abbreviation displayed on screen, i.e. “1.HVPOS.”

4. Adjusting Data

After selecting an adjustment item, use the Navigation <> buttons to perform the adjustment.

5. Saving Data

Press <ENTER> to save the adjustment data. The menu display will turn red for approximately one se con d.

Note: If the circuit adjustment mode is terminated without pressing <ENTER>, changes in adjustment data

are not saved.

6. Data Transfer & Geometry Menu

While in the Service Menu, press the <0> button to activate the Data Transfer & Geometry Menu.

7. Exiting the Service Menu

Press <EXIT> to quit.

SERVICE MENU <MENU><2-4-5-7>

Adjustment

SERVICE

TVM

Data (HPOS)

1.HVPOS

> and RWD <> to toggle between patterns.

> a second time and use FWD <> and RWD <> to access additional patterns.

> again to toggle back to the previous patterns.

-3

4

Data (VPOS)

29

Page 30

Horizontal and Vertical Position Adjustment

D

A

t

D

1. Enter the Service Menu <MENU><2-4-5-7 > .

2. Select the Geometry Test Pattern shown

Play <

> Rewind <> x2.

3. If necessary, select the adjustment, “1.HVPOS”

<VIDEO>.

4. After selecting the HVPOS adjustment item,

use the Navigation <

> buttons to center

the display.

• If a Up/Down <

> button is pressed,

the vertical position and VPOS adjustment

data changes.

• If a Left/Right <

>button is pressed, the

horizontal position and HPOS adjustment

data changes.

5. Press <ENTER> to save the adjustment data.

TSP Alignment (after Optical Engine replacement)

1. Enter the Service Menu <MENU-<2-4-5-7 >.

2. Select the TSP Test Pattern by pressing

PLAY <

<

shown appears.

3. Use the <VIDEO> button to select

“2.TSP”.

4. Use the DIRECTION <

straighten the horizontal lines, see example.

5. Press <ENTER> to save the adjustment.

> once, then FAST FORWARD

> or REWIND <> until the pattern

> buttons to

SERVICE

TVM

1.HVPOS -3

djustmen

ata (HPOS)

ata (VPOS)

4

Before

Adjustment

After

Adjustment

30

Page 31

Select Calibration Table (after Light Source Unit replacement)

1. In the Customer’s Video Settings Menu select COLOR TEMP: HIGH

2. Enter the Service Menu <MENU-<2-4-5-7>.

3. Use the <VIDEO> button to select the adjustment, “61.BCMH” and note the data value (0, 1, 2, 3 or 4).

4. Select the Green Double Ramp Pattern by pressing PLAY <

REWIND <

5. Check the pattern for smoothness of graduation from dark to light and for the presence any vertical contour

lines.

6. Use the DIRECTION <

As necessary, press PLAY <

twice to return to the pattern.

7. Select the data value 0, 1, 2, 3 or 4 that gives the best results. No higher data value should be used.

8. Press <ENTER> to save the adjustment.

> until the pattern below appears.

> buttons to alternately change the Data Value of “61.BCMH” to 0, 1, 2, 3 or 4.

> once to observe the Service Menu on screen display and press PLAY <>

> twice, then FAST FORWARD <> or

Before

Adjustment

After

Adjustment

Manual Geometry Alignment

1. Activate the Service Mode <MENU><2-4-5-7>. From the Service Menu, press the <0> button. The Data Tran sfer & Geometry Menu will appear.

2. Use the <

3. The Manual Geometry Alignment Pattern will appear. See below.

4. Prepare for the alignment by resetting the geometry data. Press <1> then <ENTER>. The previous men u will be

displayed. Select “MANUAL GEOMETRY ALIGNMENT” and press <ENTER> again to proceed.

Note 1: Upon entering the Manual Geometry Alignment Mode the first time, the geometry may appear distorted

because all factory geometry correction is automatically disabled. Press <EXIT> to quit and re-ena ble

the factory geometry correction. Pressing <1> <ENTE R> and <EXIT> will cause the TV to operate with

out factory geometry correction (distortion will be present).

Note 2: At any time the original factory geometry data can be restored from backup:

> buttons to select “MANUAL GEOMETRY ALIGNMENT” and press <ENTER>.

From the Data Transfer & Geometry Menu <MENU><2-4-5-7><0>, select “RESTORE GEOMETRY

DATA FROM BACKUP” <ENTER>.

31

Page 32

RESTORE ENGINE DATA FROM BACKUP

RESTORE GEOMETRY DATA FROM BACKUP

MANUAL GEOMETRY ALIGNMENT

SAVE ENGINE AND GEOME TRY SETTING TO BACKUP

BACKUP AND RESTORE ISF SETTINGS

RED ONLY AND GREEN ONLY

Cursor

+

+

Adjustment Points

(20 Total)

Al i gn Cursor + Flush Wit h B ezel Edge

Phase 1 - 20 Point Geometry Alignment

1. 20 Adjustment Points are indicated by white dots around the edge of the raster. The adjustment positio n is

indicated by a + cursor.

2. Starting from the upper left corner, use the <

flush with the bezel as a reference. See example above.

Note: Only the cursor will move. The Geometry Pattern will not change.

3. After adjusting each point, use the <

all 20 points have been adjusted.

4. After all 20 points are adjusted and the cursor is returned to the original starting point, press <ENTER>.

Correction will be automatically calculated and saved and the Manual Geometry Alignment will be terminated.

5. Press <ENTER> to re-activate the Manual Geometry Alignment. The geometry pattern will appear with th e

corrections applied.

> button to shift the cursor to the next point clockwise and repeat until

> buttons to align the + at each point in a straight line,

32

Page 33

Phase 2 - 4:3 and 16:9 Alignment

1. With the Manual Geometry Alignment activated, press <VIDEO> to enter the Left 4:3 Alignment Mode. The

pattern below will be displayed.

Note: Pressing <VIDEO> will toggle between the Left 4:3, Right 4:3, Top 16:9, Bottom 16:9 and the 20 Point

Geometry Alignment modes.

2. In the Left 4:3 Alignment Mode, pressing <

12 preset amounts of correction. Toggle through them until you find the one with the straightest Blue 4:3 Line.

It may help to count the patterns as you cycle through them. When you find the pattern with the straightest

Blue 4:3 Line, press <VIDEO>. The pattern will be displayed with a Right Blue 4:3 Line.

> or <> will cause the geometry pattern to be displayed with

4:3 MODE

Select Straightest Blue Line

3. In the Right 4:3 Alignment Mode, pressing <> or <> will cause the geometry pattern to be displayed

with 12 preset amounts of correction. Toggle through them until you find the one with the straightest Blue 4:3

Line. Again, count the patterns as you cycle through them. When you find the pattern with the straightest

line, press <VIDEO>. The Top Red Line will be displayed in the pattern.

4:3 MODE

Select Straightest Blue Line

33

Page 34

4:3 MODE

Select Straightest Re d L ine (Top )

4. In the Top 16:9 Alignment Mode, pressing <> or <> will cause the geometry pattern to be displayed

with 30 different preset amounts of correction to the Top Red Line. Toggle through them until you find the one

with the straightest Red Line. Again, count the patterns as you cycle through them. When you find the pattern with the straightest line, press <VIDEO>. The Center Red Line will be displayed in the pattern.

Select Straightest R ed Lin e (Center)

5. In the Center 16:9 Alignment Mode, pressing <

> or <> will cause the geometry pattern to be displayed

with 30 different preset amounts of correction to the Center Red Line. Toggle through them until you find the

one with the straightest Red Line. Again, count the patterns as you cycle through them. When you find the

pattern with the straightest line, press <VIDEO>. The Bottom Red Line will be displayed in the pattern.

4:3 MODE

Select Straightest Re d L ine (Bo t to m)

6. In the Bottom 16:9 Alignment Mode, pressing <

> or <> will cause the geometry pattern to be dis-

played with 30 different preset amounts of correction to the Bottom Red Line. Toggle through them until you

find the one with the straightest Red Line. When you find the pattern with the straightest line, press

<VIDEO>. Press <ENTER> then <EXIT> to exit and save the 4:3 and 16:9 data.

7. Select the Geometry Test Pattern (See HVPOS). If Geometry is acceptable, press <EXIT> to quit.

34

Page 35

Data Transfer

Service Data is duplicated and stored in separate EEPROMs in two locations.

PWB-MAIN - Working data for TV operation

OPTICAL ENGINE - Backup data

Procedure:

1. Enter the Service Mode <MENU><2-4-5-7> Select the Data Transfer & Geometry Menu <0>

Da t a Transfer & Geo met ry Menu

RESTORE ENGINE DATA FROM BACKUP

RESTORE GEOMETRY DATA FROM BACKUP

MANUAL GEOMETRY ALIGNMENT

SAVE E NG INE AND G E OM ETR Y S E TTI N G TO BACKUP

BACKUP AND RESTORE ISF SETTINGS

RED ONLY AND GREEN ONLY

Warning

- Only use "SAVE ENGINE AND GEOMETRY SETTING TO BACKUP"

after Optical Engine replacement.

<MENU><2-4-5-7><0>

Note: Besides MANUAL GEOMETRY ALIGNMENT, six data transfer choices are listed on screen.

RESTORE ENGINE DATA FROM BACKUP - copies backup factory adjustments HVPOS, White Balance

and Index Delay from the Optical Engine to the PWB-MAIN.

RESTORE GEOMETRY DATA FROM BACKUP -

the Optical Engine to the PWB-MAIN.

SAVE ENGINE AND GEOMETRY SETTING TO BACKUP

into backup memory on the Optical Engine.

BACKUP AND RESTORE ISF SETTINGS - allows the ISF (ADV) video settings to be backed up and

restored using an external USB memory device.

RED ONLY AND GREEN ONLY - displays the video in red or green only.

2. Use the <

3. Follow on-screen instructions if given.

4. Press <EXIT> to quit.

After Optical Engine Replacement:

1.

Save Engine and Geometry Setting to Backup

After Electrical Chassis (PWB-MAIN) Replacement:

1.

Restore Engine Data From Backup

2. Restore Geometry Data From Backup.

3. Restore ISF Settings From Backup

> buttons to select the item and press <ENTER>.

(Only if backup USB memory device is available).

copies backup factory Geometry Alignment data from

- copies all working data from the PWB-MAIN

35

Page 36

MECHANICAL ADJUSTMENTS

Top Mirror Adjustment

Note: After Top Mirror Adjustment, perform the Manual Geometry Alignment procedure.

1. Activate the Service Menu <MENU><2-4-5-7>. From the Service Menu, press PLAY <

internal test patterns (no indication will be given), then use

Pattern (see Horizontal and Vertical Position Adjustment).

2. Press the <0> button. The Data Selection Menu will appear.

3. Use the <

The Manual Geometry Alignment Pattern will appear.

4. Perform a reset - Press <1> <ENTER>. This will null all correction data, exit the Manual Geometry

Alignment and return to the Geometry Test Pattern. Use the Geometry Test Pattern for the remainder of the

Top Mirror Adjustment procedure.

5. To remove the Top Mirror Adjustment Cover from the rear of the TV, gently release the points indicated.

> buttons to select “MANUAL GEOMETRY ALIGNMENT” and press <ENTER>.

<> or <> to select the Geometry Test

> to activate the

6. Loosen the 3 locking screws (A).

A A A

Release Points for

Top Mirror Adjustment Cover

36

Page 37

B

B

7. Rotate the Mirror Adjustment Screws (B) in the direction indicated so the geometry is as square as possible in

relation to the bottom edge of the bezel.

8. After adjustment, tighten the 3 Mirror Locking Screws and replace the Top Mirror Adjustment Cover.

9. Perform the Manual Geometry Alignment procedure.

37

Page 38

Down to 1 TROUBLESHOOTING

The Down to 1 strategy is to have set troubleshooting methods that will best ensure an accurate diagnosis

as quickly as possible. The following troubleshooting methods will help the service technician gain the

Down to 1 advantage.

USER LEVEL RESETS AND INITIALIZATION

As in previous models, many symptoms (customer generated or intermittent) may be resolved by performing a reset or initialization. Many of these functions are available to the customer. Asking the user

to perform these resets may eliminate the need for a service call. If the exact nature of a symptom is unknown, it’s best to have the customer perform the procedures in a specific order to minimize the number

of settings that will be affected. The procedures, order and method are:

1. System Reset - Press and hold the <POWER> button for 8 seconds. Or remove and re-apply

power.

2. A/V Reset by Input - Select the Input to be reset. Press remote <MENU> Select “Audio/Video”

Select “AV Reset “ <ENTER>

3. A/V Reset all Inputs - Press side panel <INPUT> and <VOL > buttons at the same time and

hold for 10 seconds.

4. Initialize (User Level) - Press remote <MENU><1-2-3><ENTER>.

If a user level reset does not correct the problem, it may be necessary to perform a Service Level Initialization from the Option Menu as part of a service call.

PICTURE PERFORMANCE COMPLAINTS

Like many Mitsubishi models, the V46 chassis has a “Test Picture” that can be accessed from the customer menu. Press <MENU> select “Global” then “Test Picture.” A photograph of the “Lady” will be

displayed. If a TV picture performance problem exists, it should be evident. Otherwise, the test picture

will have demonstrated that the set is capable of a quality display and the problem is likely due to a signal source or other external cause.

38

Page 39

Chapter 2

DLP® HOME CINEMA

DLP

SIZE V45C V45 V45CA V45+

73” WD-73C11 WD-73640 WD-73CA1 WD-73740

82” WD-82740

92”

DISASSEMBLY & PARTS REPLACEMENT

®

HOME CINEMA

DLP Home Cinema

BACK COVER REMOVAL

C

V45++

WD-73840

WD-82840

WD-92840

V45CB

WD-82CB1

Back Cover Removal

1. Remove screws (A) and remove the Lamp Cover.

2. Remove screws (B) from behind the Lamp Cover.

3. Remove Screws (C).

4. Remove the back cover from the TV.

ASSEMBLY LOCATIONS

CHASSIS

C

A B

OPTICAL ENGINE ASSEMBLY

DMD FAN LAMP PWB-BALLAST

39

Page 40

DLP® HOME CINEMA

CHASSIS - REMOVAL & DISASSEMBLY

Chassis Removal

1. Remove screws (A).

2. Slide the chassis back and disconnect all cables.

3. Remove the chassis from the cabinet.

A

Rear Terminal Cover Removal (To Replace PWB-MAIN)

1. Remove nut (A) from the ANT input.

2. Remove screws (B) and (C).

3. Disconnect the connectors to the PWB-SOUND (V45++).

4. Remove the Terminal Cover from the chassis.

PWB-SOUND

CONNECTORS

(ON REAR)

V45++ Only

C

V45++ Only

B

A

40

Page 41

PWB-POWER Removal

1. Disconnect all cables from the PWB-POWER.

2. Remove screws (A).

3. Pinch the Retainer to release the PWB.

4. Lift the PWB-POWER from the chassis.

A

A

DLP® HOME CINEMA

Retainer

(Pinch)

A

PWB-MAIN Removal

1. Disconnect all cables to PWB-MAIN.

2. Remove screws (A) from the bottom of the PWB-MAIN.

3. Lift the PWB-MAIN from the chassis.

A

A

A

A

After PWB-MAIN Replacement

See Data Transfer in Service Procedures section.

1. V45C, V45 & V45CA: Perform “Restore Engine Data From Backup.”

2. V45+, V45++ & V45CB: Perform “Restore Engine Data From Backup” and “Restore Geometry Data From

Backup.”

V45+, V45++, V45CB IMPORTANT REPLACEMENT NOTE: If the customer has subscribed to VUDU (Internet

program provider), the customer must be instructed to contact VUDU to re-activate their account after the replacement PWB has been installed. The original PWB cannot

bishi per policy.

be installed in another TV. It must be returned to Mitsu-

41

Page 42

DLP® HOME CINEMA

PWB-BALLAST REMOVAL

Note: To remove the PWB-BALLAST, it is not necessary to remove the Engine or Lamp Cartridge.

1. Release the Latch to lift the PWB-BALLAST up from the mounting bracket.

2. Slide the PWB-BALLAST out of the Engine Assembly.

3. Disconnect the electrical locking connectors indicated.

4. To reinstall, first connect the connectors. Then slide the PWB under the Retaining Hooks. Then press the re ar

edge of the PWB down onto the guide pins to engage the latch.

RETAINING

HOOKS

CJ4 (HV to Lamp)

CJ3 (Lamp Control)

CJ1 (Lamp Power)

LATCH

OPTICAL ENGINE ASSEMBLY - REMOVAL & DISASSEMBLY

OPTICAL ENGINE ASSEMBLY REMOVAL

1. Disconnect the PL connector from the side of the PWB-POWER.

2. Disconnect the FB connector from the side of the PWB-MAIN.

3. Loosen the wiring harnesses from the looms.

PL (Lamp Power)

FB

(Lamp Control and Lamp Door Switch)

42

Page 43

OPTICAL ENGINE ASSEMBLY REMOVAL (Continued)

1. Disconnect the PE and J12 connectors from the Engine.

2. Remove screws (A).

3. Slide the Engine Assembly back out of the cabinet.

J12 (LVDS)

DLP® HOME CINEMA

PE

(Engine Power)

A

A

OPTICAL ENGINE ASSEMBLY - Disassembly

1. Loosen screw (A) to remove the Lamp Cartridge.

2. Remove screws (B) and the lamp top cover.

3. Remove screws (C) and the Engine Plate

4. Disconnect the Exhaust and Sirocco Fan Connectors (J4 and J8) from the back of the Engine and loosen the

wiring harnesses from the looms.

5. Release the Latches to remove the Fan Holder.

C

LATCH

ENGINE PLATE

FAN HOLDER

B

J8

(Sirocco Fan)

LATCH

J4

(Exhaust Fan)

C

A

43

Page 44

DLP® HOME CINEMA

Duct Interior Components

Duct Interior Components are shown below.

Notes:

When replacing the Optical Engine, transfer all Duct and Duct Interior Components from the ol d Engine to the

new Engine.

The Exhaust Fan must be installed so the Label is facing inside the Duct.

The Sirocco Fan must be installed so the Label is facing up with the Flanges aligned onto the Guide Pins.

Sirocco Fan Flanges

Align Onto Guide Pins

SIROCCO FAN

(Label Facing Up)

EXHAUST FAN

(Label Facing In)

44

PWB-LAMP DOOR SW

Page 45

Lower Duct Removal

1. Remove the Lamp Cartridge, Top Cover, Exhaust Fan and Sirocco Fan.

2. Disconnect the HV Lamp Wiring from the Ballast and loosen it from the guides.

3. Remove screw (A) on the rear of the lower duct.

4. Carefully remove the Lower Duct from the Engine.

LOWER DUCT

DLP® HOME CINEMA

A

OPTICAL ENGINE REPLACEMENT

1. Install Lower Duct and components on the new Engine.

2. Connect the HV Lamp Wiring to the Ballast and dress the wiring through the guides as shown.

3. Remove the Protective Lens Cover from the face of the Lens and place it on the old Engine for return.

4. Install the Engine Assembly in the cabinet.

5. After a new Engine is installed, as necessary perform the Horizontal and Vertical Centering Adjustment and

Manual Geometry Alignment as described in the Service Adjustments section of the Service Procedures.

6. Perform the following procedures as described in the Data Transfer section of the Service Procedures:

“Restore Index Delay”

“Save Engine and Geometry Setting to Backup”

HV LAMP WIRING

Dress Through Guides as Shown

Add Vinyl Clamp at center Guide.

45

Page 46

DLP® HOME CINEMA

PROJECTION LENS REPLACEMENT

CAUTION: Any dust or fingerprints in the optics can cause abnormalities in the picture.

This procedure should be performed in a dust free environment.

Wear lint free cotton or rubber gloves while performing this procedure.

1. Remove Optical Engine Assembly.

2. Remove screw (A) and remove the Lens Collar.

3. Remove screws (B).

4. Lift out the Projection Lens.

5. Install the replacement lens so the key is oriented towards the top as shown.

A

LENS

COLLAR

B

B

B

B

46

KEY

LENS

Page 47

DLP® HOME CINEMA

COLOR WHEEL REPLACEMENT

CAUTION: This procedure should be performed in a dust free environment.

Any dust entering into the optical compartment can cause abnormalities in the picture.

1. Remove the Optical Engine Assembly.

2. Remove the Lens Collar and cover the projection lens to protect it from scratches. See previous page.

3. Disconnect the 2 connectors, J6 & J7, from the front side of the Light Engine. Note the orientation of the

ribbon cable for re-assembly (Silver Contacts towards the Lens).

4. Access the optical compartment by removing screws (A) and the Engine Base from the bottom of the Optical Engine

LENS COLLAR

A

J6 & J7

(Opposite Side of Formatter PWB)

ENGINE BASE

5. Remove the 3 screws (B) from the Color Wheel Assembly.

6. Use the metal Handle to lift the Color Wheel from the compartment.

7. For installation, reverse the procedure above.

CAUTION: Avoid touching or scratching the Color Wheel.

8. After re-assembly, perform the Index Delay Adjustment described in the

Service Adjustments section.

IMPORTANT: If part return is required, prevent damage by packing the

color wheel the same way the replacement part was sent to you.

HANDLE

47

B

Page 48

DLP® HOME CINEMA

SCREEN REPLACEMENT 73” Models

Screen Assembly Removal and Replacement

1. V45C, V45, V45+ - Remove the Screw Caps to access scre w s (A ).

2. V45++ - Remove the ORNAMENT LEFT & RIGHT first by pinching up and pulling away from the bottom.

Then remove the ORNAMENT CENTER using the same method.

3. Remove screws (A).

4. Remove screws (B) around the rear edge of the screen bezel.

5. During re-assembly replace screws in their original locations.

V45C,V45, V45+ (73”)

V45++ (73”)

A A A

ORNAMENT

CENTER

(Speaker Cover)

A

B

Number and Location of

Screws Varies by Model

B

B

ORNAMENT RIGHT ORNAMENT LEFT

73 INCH

B

B

48

Page 49

SCREEN REPLACEMENT 73” Models (continued)

Screen Removal From the Bezel-Front

1) Remove screws (A) and remove the top, bottom and side rails.

NOTE: The number and location of screws vary by model.

2) Lift the Fresnel Lens and Lenticular screen from the Bezel-Front.

3) During re-assembly replace screws in their original locations.

A

DLP® HOME CINEMA

A

Example Diagrams. The number and location of screws varies by model.

73 INCH

(Rear View)

A

49

Page 50

DLP® HOME CINEMA

SCREEN REPLACEMENT 73” Models (continued)

CAUTION: Wear gloves when handling the Lenticular Screen and Fresnel Lens.

This prevents cuts and finger prints. Do not place Fresnel Lens in the sun.

This may cause fire and heat related injuries.

Lenticular Screen and Fresnel Lens Removal

1. After removing the top, bottom and side HOLDER-SCREEN rails and their cushions from the Bezel, lift the

screens as a single unit from the frame.

2. Separate the Lenticular Screen and Fresnel Lens.

Note: When separating the Lenticular Screen from the Fresnel Lens, use caution

while prying the Screen and Lens apart. Use a slot type screw driver, and

remove the pressure sensitive double sided tape.

Lenticular Screen and Fresnel Lens Replacement

1. Apply LENS-TAPE along the rear top edge of the Lenticular Screen.

2. Place the Fresnel Lens on top of the Lenticular Screen, and apply pressure along the top edge.

3. Place the screens in the screen frame and reinstall the cushions, top, bottom and side rails.

NOTE: The Lenticular Screen label must face the front and the Fresnel Lens labe l face the rea r.

4. Reverse the Screen Removal Procedure and insert the screens in the Bezel.

LENTICULAR

LENS

FRESNEL

SCREEN

LENS-TAPE

BEZEL FRONT

HOLDER-SCREEN-T

SPACER-SCREEN-T

COVER-HOLDER-T

LABEL

LABEL

HOLDER-SCREEN-B

SPACER-SCREEN-S

HOLDER-SCREEN-S

SPACER-SCREEN-B

50

Page 51

DLP® HOME CINEMA

SCREEN REPLACEMENT 82” & 92” Models

Screen Assembly Removal

1. Remove screws (A) around the bottom rear edge.

2. (V45+) Remove the Pedestal cover and remove screws (B).

3. (V45++) Pull off ornamental Front Covers and Speaker Grill.

4. Remove the Speaker Box and Pedestal by removing screws (B).

5. Remove screws (C) from the bottom front of the screen assembly.

6. Remove screws (D) from the top rear edge of the cabinet.

NOTE: Leave one screw secured at the top. Then support the assembly to prevent it from falling while

removing the remaining screw.

V45+

WD-82740

WD-82CB1

A A

V45++

WD-82840

WD-92840

B

PEDESTAL

D D D

SPEAKERBOX

B

A A

B

B

C

PEDESTAL

51

Page 52

DLP® HOME CINEMA

SCREEN REPLACEMENT 82” & 92” Models (continued)

CAUTION: Wear gloves when handling the Lenticular Screen and Fresnel Lens.

This prevents cuts and finger prints. Do not place Fresnel Lens in the sun.

This may cause fire and heat related injuries.

Lenticular Screen and Fresnel Lens Removal

1. Remove four screws (A) in all four corners of the Screen Bezel.

2. Remove the Screen Bezel components from the Screen/Lens Assembly.

A X4

CORNER-S-T

CORNER-CAP

TOP-L

HOLDER-SCREEN

S-L

CORNER

B-L

SCREEN/LENS

ASSEMBLY

FRONT

HOLDER-SCREEN-B

COVER-HOLDER-T

CORNER-S-T

CORNER-CAP

TOP-R

HOLDER-SCREEN

S-R

LABEL

CORNER

B-R

52

Page 53

SCREEN REPLACEMENT 82” & 92” Models (continued)

Lenticular Screen and Fresnel Lens Disassembly

1. Remove the HOLDER-SCREEN from the top, bottom and sides.

2. Separate the Lenticular Screen and Fresnel Lens.

HOLDER-SCREEN

DLP® HOME CINEMA

LENTICULAR

SCREEN

HOLDER-SCREEN

(TOP/BOTTOM)(SIDES)

FRESNEL

LENS

LENS

FRONT

Label Position

(Facing Outside)

Lenticular Screen and Fresnel Lens Replacement

1. Place the Fresnel Lens on top of the Lenticular Screen with the labels facing outside as shown.

2. Install the HOLDER-SCREEN, top, bottom and sides as shown above.

3. Reverse the disassembly procedure to reassemble and install the screen frame assembly.

NOTE: The Lenticular Screen must face the front and the Fresnel Lens must face the rear.

LENTICULAR

SCREEN

53

Page 54

DLP® HOME CINEMA

MIRROR REPLACEMENT

MIRROR REPLACEMENT - 73” Models

1. To access the Mirror for replacement, remove the Screen Assembly (See Screen Assembly Removal).

2. The Mirror slides down into the Left, Right and Bottom Brackets inside the cabinet.

3. Then a Top Bracket is installed.

4. See the Mirror Parts section for instructions on preparing a replacement mirror.

TOP BRACKET

(73" Models)

SUPPORT

BRACKETS

MIRROR REPLACEMENT - 82” & 92” Models

1. To access the Mirror for replacement, remove screws (A) and lift away the Mirror Cover(s). Note: 82” cover is

1 piece, 92” cover is 2 pieces.

2. The Mirror rests in place below the Mirror Cover.

3. See the Mirror Parts section for instructions on preparing a replacement mirror.

A

(2 Piece Cover)

A

92"

MIRROR

(Below Cover)

A

54

Page 55

SERVICE PROCEDURES

REMOTE CONTROL

NOTE: The Remote Controls differ between Type 1 and the Type 2 models.

DLP® HOME CINEMA

TYPE 1

V45C V45 V45CA

WD-73C11 WD-73640 WD-73CA1

REMOTE CONTROL USE FOR SERVICE

Many service functions and adjustments are accessed using the Remote Control. The Type 1 remote does not have

buttons such as PLAY, FWD and RVW that are associated with operating connected devi ces. Service Pro c edures are

described assuming a Type 1 remote is being used. However, if a Type 2 remote is being used, buttons can optionally

be substituted as follows:

TYPE 2

V45+ V45++ V45CB

WD-73740 WD-73840 WD-82CB1

WD-82740

WD-82840

WD-92840

Type 1

V45C / V45 / V45CA

V45+ / V45++ / V45CB

TYPE1 TYPE 2

<2> <2> or <PLAY>

<CH-UP> <CH-UP> or <FWD>

<CH-DOWN> <CH-DOWN> or <RVW>

Type 2

55

Page 56

DLP® HOME CINEMA

OPTION MENU

OPTION MENU

1. Press the <MENU> button on the remote control.

2. Press the buttons <2-4-7-0>. The screen will display the Option Menu.

Option Menu

<MENU><2-4-7-0>

Initialize

Power Restore OFF

Production Mode OFF

Digital Signal Strength <1~9>

NetCommand Software Vxx xxx.xx

Total hours of use 0

SERVICE LEVEL INITIALIZATION

Service Level Initialization is used to restore all customer menu, video and audio settings to the original fa ctory default

condition.

1. Enter the Option Menu <MENU><2-4-7-0>

2. Select “Initialize” and <ENTER>.

Option Menu

<MENU><2-4-7-0>

Initialize

Power Restore OFF

Production Mode OFF

Digital Signal Strength <1~9>

NetCommand Software Vxx xxx.xx

Total hours of use 0

56

Page 57

DIGITAL SIGNAL INFORMATION

Information on the currently selected digital channel can be displayed on screen.

1. Enter the Option / Service Menu <MENU><2-4-7-0>.

Option Menu

<MENU><2-4-7-0>

Initialize

Power Restore OFF

Production Mode OFF

Digital Signal Strength <1~9>

NetCommand Software Vxx xxx.xx

Total hours of use 0

DLP® HOME CINEMA

1. Select “Digital Signal Strength” and <ENTER>.

Digital Signal Information

“Digital Signal Strength” <ENTER>

Tuner

Frequency(MHz) 749

Signal Level <1~9>

Modulation 8VSB Air

Carrier Lock Locked

SNR 29.09

Correctable errors 0

Un Correctable errors 0

57

Page 58

DLP® HOME CINEMA

SERVICE ADJUSTMENTS

Service Adjustments include Adjustment Procedures and Data Transfer Functions.

Electrical Adjustments (there are no mechanical adjustments)

• Horizontal and Vertical Centering Adjustment

• Index Delay Adjustment

• Geometry Alignment

• Data Transfer Functions

Test Equipment and Test Patterns

• Remote Control

• Internally generated Test Patterns

• No external test equipment or pattern generators are required.

SERVICE MENU

The Service Menu is used for all service adjustments.

Service adjustments can only be performed using the remote control.

1. Activating the Service Menu

1. Press the <MENU> button on a remote control. (The Customer Menu will app ear.)

2. Press the buttons <2-4-5-7>. (The Service Menu will appear. )

2. Test Pattern Activation

When in the Service Menu, press the <2> or <

indication will be displayed initially). Use <CH-UP/CH-DOWN> or <

<2> or <

Press <2> or <

3. Adjustment Overview—Specific adjustment procedures follow.

1. When in the Service Menu use the <VIDEO> button to toggle to adjustment desired indicated by the

number and abbreviation displayed on screen.

2. For Geometry, from the Service Menu press <0> and select “Manual Geometry Alignment” <ENTER>.

4. Adjusting Data

After selecting an adjustment item, use the Navigation arrows or other button s indicated in the adjustment

procedure to perform the adjustment.

5. Saving Data

Press <ENTER> to save the adjustment data. The menu display will turn red for approximately one second.

Note: If the circuit adjustment mode is terminated without pressing <ENTER>, changes in adjustment data

are not saved.

6. Exiting the Service Menu

Press <EXIT> to quit.

> a second time and use <CHAN-UP/CHAN-DOWN> or </> to access additional patterns.

> again to toggle back to the previous patterns.

Service Menu

<MENU> <2-4-5-7>

SERVICE

TVM

1. HVPOS

> key on the remote to activate the internal test patterns (no

-3

4

/> to toggle between patterns. Press

58

Page 59

DLP® HOME CINEMA

ADJUSTMENT PROCEDURES

Horizontal and Vertical Position Adjustment

1. Enter the Service Menu <MENU><2-4-5-7>.

4

<> x2.

<> x2

Data (HPOS)

Data (VPOS)

> buttons to center the display.

2. Select the Geometry Test Pattern shown <2> <CH-DOWN>or

3. If necessary, use the <VIDEO> button to select the adjustment, “1.HVPOS”.

4. After selecting the HVPOS adjustment item, use the Navigation <

5. Press <ENTER> to save the adjustment data. The on-screen display will flash red while the data is sa ved.

Vertical & Horizontal Position Adjustment

<MENU><2-4-5-7> <2> <CH-DOWN> or

Adjustment

SERVICE

TVM

1.HVPOS

-3

Index Delay Adjustment (Perform after color wheel replacement)

1. Enter the Service Menu <MENU><2-4-5-7>.

2. Select the Ramp Pattern shown below <2> <CH-DOWN> or

3. Use the <VIDEO> button to select the adjustment, “60.IDL”.

4. After selecting the IDL adjustment item, use the Navigation <

bars for the smoothest transition from dark to bright.

5. Press <ENTER> to save the adjustment data. The on-screen display will turn red while the data is saved.

Index Delay Adjustment

<MENU><2-4-5-7> <2> <CH-DOWN> or <> x3 <VIDEO>

Adjustment

SERVICE

TVM

60.IDL

201

<> x3.

Data

> buttons to adjust the ramp pattern color

59

Page 60

DLP® HOME CINEMA

Manual Geometry Alignment

1. Entering the Manual Geometry Alignment Mode

1. Activate the Service Mode <MENU><2-4-5-7>.

2. From the Service Menu, press the <0> button. The Data Transfer & Geometry Menu will appear.

3. Use the <

Alignment Pattern will appear.

Type 2 Data Transfer & Geometry Menu <MENU><2-4-5-7><0>

RESTORE ENGINE DATA FROM BACKUP

RESTORE GEOMETRY DATA FROM BACKUP

MANUAL GEOMETRY ALIGNMENT

RESTORE INDEX DELAY

SAVE ENGINE AND GEOMETRY SETTING TO BACKUP

BACKUP AND RESTORE ISF SETTINGS

RED ONLY AND GREEN ONLY

> buttons to select “MANUAL GEOMETRY ALIGNMENT” <ENTER>. The Manual Geometry

Manual Geometry Alignment

<MENU><2-4-5-7><0> “MANUAL GEOMETRY ALIGNMENT”<ENTER>

60

Page 61

DLP® HOME CINEMA

C

r

2. Manual Geometry Alignment

Note: Upon entering the Manual Geometry Alignment Mode the first time, the geometry may appear distorted

because all factory geometry correction is automatically disabled. Press <EXIT> to quit and re-ena ble

the factory geometry correction. Pressing <1> <ENTER> and <EXIT> will cause the TV to operate with

out factory geometry correction (distortion will be present).

Note: At any time the original factory geometry data can be restored from backup:

From the Data Transfer & Geometry Menu <MENU><2-4-5-7><0>, select “RESTORE

GEOMETRY DATA FROM BACKUP” <ENTER>.

+

urso

+

Adjustm ent Points

(16 Total)

Align Cursor + Flush With Bezel Edge

Phase 1 - 16 Point Geometry Alignment

1. 16 Adjustment Points are indicated by white dots around the edge of the raster. The adjustment position is

indicated by a + cursor.

2. Starting from the upper left corner, use the <

flush with the bezel as a reference. See example above.

Note: Only the cursor will move. The Geometry Pattern will not change.

3. After adjusting each point, use the <CH-UP> or <

and repeat until all 16 points have been adjusted.

4. After all 16 points are adjusted and the cursor is returned to the original starting point, press <ENTER> the n

<EXIT>. Correction will be automatically calculated and saved and the Manual Geometry Alignment will be

terminated.

5. Re-activate the Manual Geometry Alignment. The geometry pattern will appear with the corrections applied. If

Geometry is acceptable, press <EXIT> to quit. To touchup the raster geometry, proceed to Phase 2.

Phase 2 - Geometry Touch-up Alignment

1. If additional correction is necessary after performing the Manual Geometry Alignment, re-enter the Manual

Geometry Alignment mode.

2. Use the <CH-UP/CH-DOWN> or <

3. Use the <

point. Note: Only the cursor will move. The Geometry Pattern will not change.

4. Press the <INFO> button to apply the correction. The Geometry Pattern will now show the correction.

5. Repeat steps 2, 3 and 4 as needed.

6. Press <ENTER> then <EXIT> to save your changes. The Manual Geometry Alignment will be terminated.

7. To proceed to Phase 3, re-activate the Manual Geometry Alignment.

> buttons to indicate the direction and amount of correction necessary at the particular

/> buttons to shift the cursor to the point needing correction.

> buttons to align the + at each point in a straight line,

> button to shift the cursor to the next point clockwise

61

Page 62

DLP® HOME CINEMA

Phase 3 - 4:3 and 16:9 Alignment

1. With the Manual Geometry Alignment activated, press <VIDEO> to enter the 4:3 Alignment Mode. The pattern below will be displayed.

Note: Pressing <VIDEO> will toggle between the 4:3,16:9 (top, top-center, center & bottom) and 16 Point Ge-

ometry Alignment modes.

2. In the 4:3 Alignment Mode, pressing <CH-UP/CH-DOWN> or <

displayed with 11 preset amounts of correction. Toggle through them until you find the one with the straightest Blue 4:3 Lines. It may help to count the patterns as you cycle through them. When you find the pattern

with the straightest Blue 4:3 Lines, press <VIDEO>. The Top 16:9 Alignment Mode will then be activated as

indicated by the Top Red 16:9 Line displayed in the pattern.

4:3 MODE

/> will cause the geometry pattern to be

Select Straightest Blue Lines

3. In the 16:9 Alignment Mode, pressing <CH-UP/CH-DOWN> or </> will cause the geometry pattern to be

displayed with 15 different preset amounts of correction to the Red Line. Toggle through them until you find

the one with the straightest Red Line. Again, count the patterns as you cycle through them. When you find

the pattern with the straightest line, press <VIDEO>. The Top-Center Red Line will be displayed in the pattern.

4:3 MODE

Select Straightest Red Line (Top)

62

Page 63

DLP® HOME CINEMA

4. Repeat the process of pressing <CH-UP/CH-DOWN> or </> to display the 15 different preset amounts

of correction to the Top-Center Red Line. When you find the pattern with the straightest line, press

<VIDEO> to proceed to the Center Red Line. Repeat the process for the Center Line, followed by the Bottom Line. Press <ENTER> then <EXIT> to exit and save the 4:3 and 16:9 data.

5. Select the Geometry Test Pattern (See HVPOS). If Geometry is acceptable, press <EXIT> to quit.

Select Straight est Red Line ( Top- C ent er)

Select Strai ght est Red Line (Cent er)

4:3 MODE

Select Straightest Red Line (Bottom)

63

Page 64

DLP® HOME CINEMA

DATA TRANSFER FUNCTIONS

Data Transfer

Service Data is duplicated and stored in separate EEPROMs in two locations.

PWB-MAIN - Working Service Data for TV operation

OPTICAL ENGINE - Backup Service Data

The Optical Engine also includes data for the Index Delay setting for color wheel timing determined at the factory.

The PWB-MAIN also includes User and/or ISF settings. The User/ISF data is not backed up on the Engine. However if used, it can

be backed up onto a USB flash drive.

Data Transfer Procedures should be followed…

After PWB-MAIN Replacement:

1. Restore Engine Data From Backup.

2. Restore Geometry Data From Backup.

3. Restore ISF Settings From Flash Drive

After OPTICAL ENGINE Replacement:

1. Restore Index Delay.

2. Save Engine and Geometry Setting to Backup

Geometry Adjustments).

. (Only if backup USB flash drive is available).

(After performing any necessary H&V Position and

Data Transfer Procedure:

1. Enter the Service Mode <MENU><2-4-5-7> Select the Data Transfer & Geometry Menu <0>

Note: Besides MANUAL GEOMETRY ALIGNMENT, six data transfer choices are listed on screen.

RESTORE ENGINE DATA FROM BACKUP - copies backup factory adjustments HVPOS, White Balance

RESTORE GEOMETRY DATA FROM BACKUP -

RESTORE INDEX DELAY -

SAVE ENGINE AND GEOMETRY SETTING TO BACKUP - copies all working data from the PWB-MAIN

BACKUP AND RESTORE ISF SETTINGS - allows the ISF (ADV) video settings to be backed up and

RED ONLY AND GREEN ONLY - displays the video in red or green only during ISF Calibrat ion.

2. Use the <

3. Follow on-screen instructions if given.

4. Press <EXIT> to quit.

Data Transfer & Geometry Menu <MENU><2-4-5-7><0>

RESTORE ENGINE DATA FROM BACKUP

RESTORE GEOMETRY DATA FROM BACKUP

MANUAL GEOMETRY ALIGNMENT

RESTORE INDEX DELAY

SAVE ENGINE AND GEOMETRY SETTING TO BACKUP

BACKUP AND RESTORE ISF SETTINGS

RED ONLY AND GREEN ONLY

Warning: Only use “SAVE ENGINE AND GEOMETRY SETTING TO BACKUP”

after Optical Engine Replacement.

and Index Delay from the Optical Engine to the PWB-MAIN.

copies backup factory Geometry Alignment data from

the Optical Engine to the PWB-MAIN.

copies factory Index Delay Adjustment data from the Optical Engine to the

PWB-MAIN.

into backup memory on the Optical Engine.

restored using an external USB flash drive.

> buttons to select the item and press <ENTER>.

64

Page 65

DLP® HOME CINEMA

RESET / INITIALIZATION

SERVICE TIP:

Many symptoms that are customer generated, intermittent or cannot be verified can be resolved by using the various

Reset and Initialization options. Before visiting the customer’s home ask the customer to 1st perform a System Reset. If

this does not resolve the issue, they can perform an A/V Reset. Then, if necessary, perform a user level Initialization.

The customer should be made aware when settings and/or options will be reset. For more information, see the chart

below.

Reset Name When to use How to use Resulting Action

Remote Control

Reset

TYPE 1 Only

Returns the remote control to normal

operation.

1)

Press and hold the <POWER> button until it flashes twice

then release the button.

2)

Enter the code <0-0-0-0-0>. The <POWER> button will flash

twice

The remote control is reset.

Remote Control

TV Layer Reset

TYPE 2 Only

Remote Control

TV Volume/

Mute functions

A/V Memory

Reset, by individual input

A/V Reset, all

inputs

System Reset To reset the TV when it does not turn

Returns the remote control TV layer

to normal operation.

Returns the volume and mute functions of the remote control to TV volume and mute for TV, Cable/Sat,

VCR and DVD layers after the Audio

Lock for AV Receiver feature has

been used.

When the audio or video performance

or settings for a single input seem to

be incorrect.

When the audio or video performance

or settings for more than one input

seem to incorrect.

on or off, does not respond to the

remote control, front panel buttons or

has other unusual symptoms.

1)

Select the remote control TV mode.

2)

Press and hold the <POWER> button until it flashes twice

then release the button.

3)

Enter the code <0-0-9-3-5>. The <POWER> button will flash

twice

1)

Select the remote control TV mode.

2)

Press and hold the <POWER> button until it flashes twice

then release the button.

3)

Enter the code <9-9-3>< VOL >. The <POWER> button

will flash four times.

<MENU> “Audio/Video” “AV Reset” <ENTER> All Audio and Video settings

While viewing the TV, press the front panel buttons <INPUT> +

<VOL > at the same time and hold for 10 sec.