Page 1

Version 3.0 10/13/11

2011

Service

Manual

DLP PROJECTION HDTV

V45C

V45 V45CA

WD-73C11 WD-73640 WD-73CA1

V45+

V45++ V45CB

WD-73740 WD-73840 WD-82CB1

WD-82740

WD-82840

WD-92840

CAUTION:

Before servicing this chassis, it is important that the service person read the "SAFETY PRECAUTIONS" and

"PRODUCT SAFETY NOTICE" contained in this manual.

SPECIFICATIONS

• Power Input : AC 120V, 60Hz

• Light Engine : DLP™ (1080p)

• Light Source : VIP Lamp

• Antenna Input : RF 75unbalanced

• Tuning : NTSC/ATSC/QAM

: Analog Cable - 1~125

Digital Cable - 1~135

• Speakers : 10W x 2 (except V45++)

: 2W x 16 (V45++)

• See Page 5 for additional specifications.

• Design specifications are subject to change without notice.

• Analog Input

Level (RCA Type)

Y/Video: 1.0 Vp-p, Cr, Cb: 700mVp-p

75 unbalanced

: AUDIO IN JACK (RCA Type)

-4.7dBm 43k unbalanced

• Analog Output : AUDIO / SUBWOOFER OUT JACK

Level (RCA Type)

-4.7dBm 4.7kunbalanced

• Digital : AC-3/PCM Digital Audio Output

Inputs/Outputs (RCA Type)

: HDMI™

:

: PC - use HMDI™

:

: Ethernet (V45CB, V45+, V45++)

: Bluetooth (V45++)

: Composite/Component

USB

Wired IR Input/Output (V45++)

MITSUBISHI ELECTRIC VISUAL SOLUTIONS AMERICA, INC.

9351 Jeronimo Road, Irvine, CA 92618-1904

Copyright © 2011 Mitsubishi Electric Visual Solutions America, Inc.

All Rights Reserved

Page 2

Page 3

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

CONTENTS

INTRODUCTION .................................................................................................................................. 5

Dimensions, weight, power usage, etc. ............................................................................................ 5

PRODUCT SAFETY NOTICE .............................................................................................................. 5

SAFETY PRECAUTIONS .................................................................................................................... 6

DISASSEMBLY & PARTS REPLACEMENT ...................................................................................... 7

Back Cover Removal ........................................................................................................................ 7

Chassis Removal ............................................................................................................................ 8

Rear Terminal Cover Removal ......................................................................................................... 8

PWB-POWER Removal ................................................................................................................... 9

PWB-MAIN Removal ........................................................................................................................ 9

PWB-BALLAST Removal ............................................................................................................... 10

Optical Engine Assembly Removal & Disassembly ....................................................................... 10

Optical Engine Replacement .......................................................................................................... 13

Projection Lens Replacement ........................................................................................................ 14

Color Wheel Replacement ............................................................................................................. 15

Screen Replacement ...................................................................................................................... 16

Mirror Replacement ........................................................................................................................ 20

SERVICE PROCEDURES ................................................................................................................. 23

Remote Control .............................................................................................................................. 23

Option Menu ................................................................................................................................... 24

Reset and Initialization ................................................................................................................... 26

LED Indications & Self Diagnostics ................................................................................................ 27

Error Codes .................................................................................................................................... 28

Error Code Log ............................................................................................................................... 28

Sound Projector Transducer Test .................................................................................................. 29

Service Adjustments

Equipment & Test Signals ..................................................................................................... 30

Service Menu ........................................................................................................................ 30

Horizontal & Vertical Position Adjustment ............................................................................. 31

Index Delay Adjustment ........................................................................................................ 31

Manual Geometry Alignment ................................................................................................. 32

Data Transfer Functions ................................................................................................................. 36

Using Lead Free Solder ................................................................................................................. 37

Chip Parts Replacement ................................................................................................................ 38

REPLACEMENT PARTS ................................................................................................................... 39

Safety Critical Parts Designation .................................................................................................... 39

Fuse Replacement Warning ........................................................................................................... 39

Parts Quick Reference ................................................................................................................... 40

Service Parts List ........................................................................................................................... 41

Screen Parts ................................................................................................................................... 46

Mirror Kits & Preparation ................................................................................................................ 48

CIRCUIT BLOCK DIAGRAMS .......................................................................................................... 50

SCHEMATIC DIAGRAMS ................................................................................................................. 56

....................................................................................................................... 30

Version 3.0

Page 3

Page 4

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

Version 3.0

Digital Light Processing®, Digital Micro Mirror Device and DLP® are Trademarks of Texas Instruments.

HDMI, the HDMI logo and High-Definition Multimedia Interface are trademarks or registered trademarks of HDMI Licensing, LLC..

Page 4

Page 5

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

INTRODUCTION

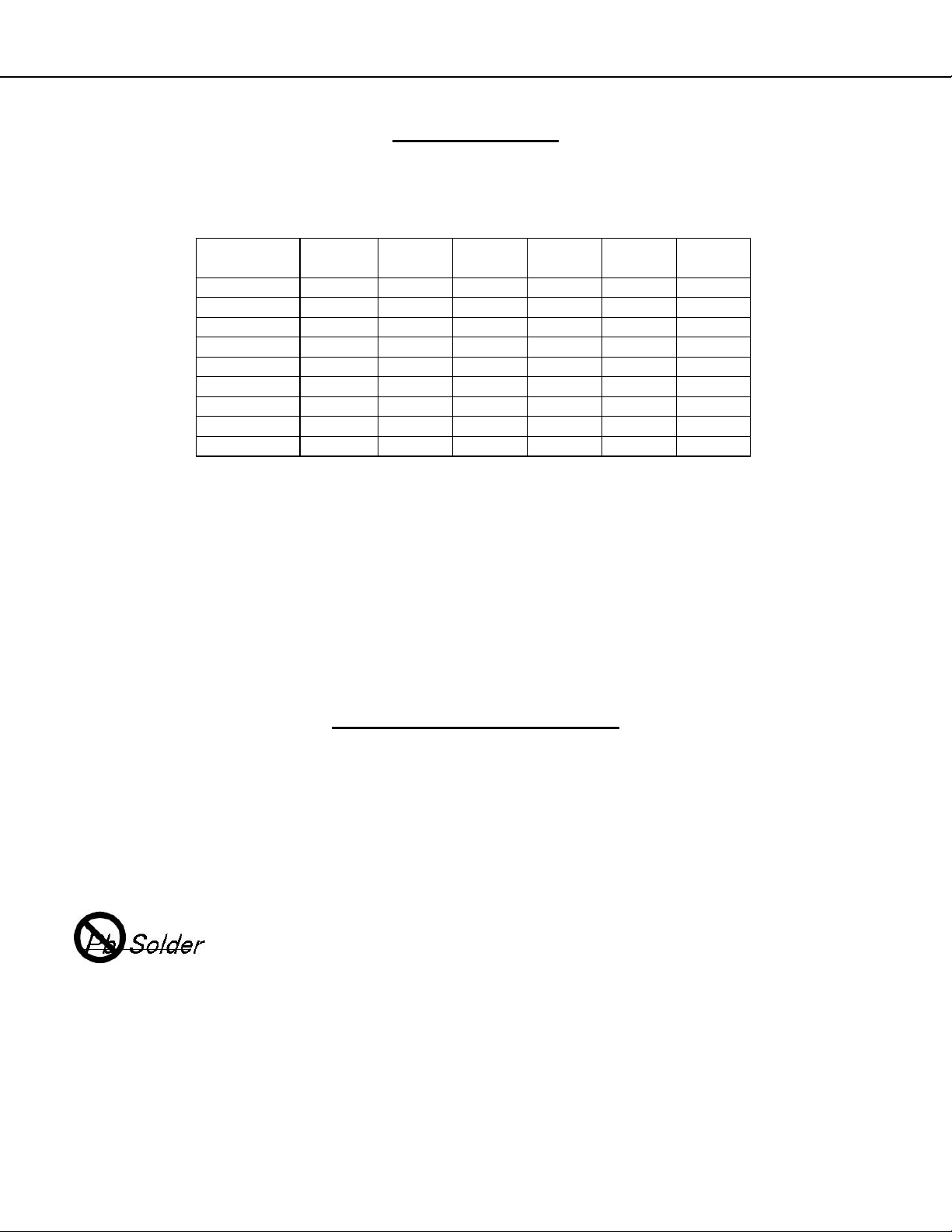

This service manual provides service instructions for the V45C, V45, V45CA, V45+, V45CB and V45++ chassis

types. The specific models for each chassis type, dimensions and weight are listed below. Service personnel should

read this manual thoroughly before servicing these chassis.

This service manual includes:

1. Disassembly & replacement instructions for cabinet and chassis components.

2. Replacing the Lenticular Screen, Fresnel Lens and Mirror.

3. Initial setup and troubleshooting.

4. Service adjustments.

5. Using lead free solder.

6. Chip parts replacement procedures.

7. Replacement part Instructions

8. Replacement parts list

9. Circuit block diagrams

10. Schematic diagrams

MODEL CHASSIS HEIGHT WIDTH DEPTH WEIGHT

WD-73C11 V45C 43.6" 65.0" 17.5" 77.9 lbs 260W

WD-73640 V45 43.6" 65.0" 17.5" 77.9 lbs 260W

WD-73CA1 V45CA 43.6" 65.0" 17.5" 77.9 lbs 270W

WD-73740 V45+ 43.6" 65.0" 17.5" 77.9 lbs 270W

WD-82740 V45+ 48.7" 73.3" 19.8" 129.9 lbs 270W

WD-82CB1 V45CB 48.7" 73.3" 19.8" 129.9 lbs 270W

WD-73840 V45++ 43.6" 65.2" 17.5" 83.6 lbs 290W

WD-82840 V45++ 48.7" 73.2" 19.8" 133.6 lbs 275W

WD-92840 V45++ 54.8" 82.1" 22.0" 195.1 lbs 290W

POWER

USAGE

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in television receivers have special safety related characteristics. These characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc.

Replacement parts which have special safety characteristics are identified on the schem atic diagrams and parts list

of this service manual. The replacement for any safety critical part should be identical in value and character-

istics.

Version 3.0

The PWBs used in this chassis are constructed using Lead-Free Solder. When servicing use

only recommended Lead-Free Solder. Refer to the section “Using Lead Free Solder.”

Page 5

Page 6

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

SAFETY PRECAUTIONS

NOTICE:

Observe all cautions and safety related notes located inside the receiver cabinet and on the receiver chassis.

WARNING:

1. Operation of this receiver outside the cabinet or with the cover removed presents a shock hazard from the

receiver's power supplies. Work on the receiver should not be attempted by anyone who is not thoroughly

familiar with the precautions necessary when working on high volta ge equipment.

2. When service is required, observe the original lead dress. Where a short-circuit has occurred, replace those

components that indicate evidence of overheating.

SAFETY PRECAUTION

To protect your eyes, do not look directly into the lamp, or light coming directly from the lamp, lens or

mirror.

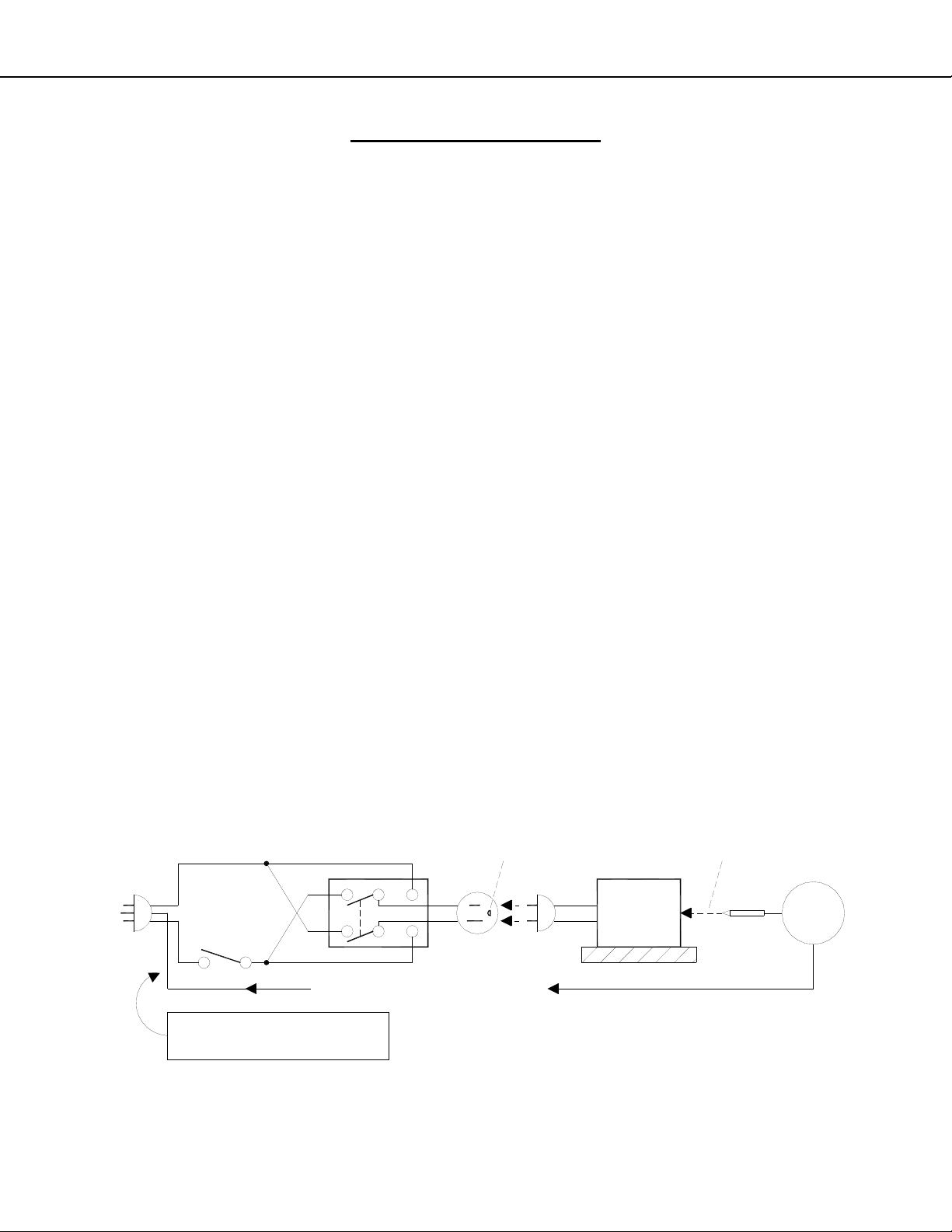

Leakage current check

Before returning the receiver to the customer, it is recommended that leakage current be measured according to the

following methods.

1. Cold Check

With the alternating current (AC) plug removed from the AC source, place a jumper across the two AC plug

prongs. Connect one lead of an ohm meter to the AC plug and touch the other lead to each exposed metal

part (i.e. antennas, handle bracket, metal cabinet, screw heads, metal overlay, control shafts, etc.), particularly

any exposed metal part that has a return path to the chassis. The resistance of the exposed metal parts having a return path to the chassis should be a minimum of 1Meg Ohm. Any resistance below this value indicates an abnormal condition and requires corrective action.

2. Hot Check ...Use the circuit shown below to perform the hot check test.

1. Keep switch S1 open and connect the receiver to the measuring circuit. Immediately after connection,

and with the switching devices of the receiver in their operating positions, measure the leakage current

for both positions of switch S2.

2. Close switch S1, energizing the receiver. Immediately after closing switch S1, and with the switching

devices of the receiver in their operating positions, measure the leakage current for both positions of

switch S2. Repeat the current measurements of items 1 and 2 after the receiver has reached therm al

stabilization. The leakage current must not exceed 0.5 milliampere (mA).

Version 3.0

S1

SUPPLY CONNECTOR GROUND

GWG - Green Wire Ground

(Earth Ground)

S2

OPEN

GROUND

L

N

Page 6

TOUCH ALL

EXPOSED

METAL PARTS

RECEIVER

AC MA

METER

INSULATED TABLE

Page 7

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

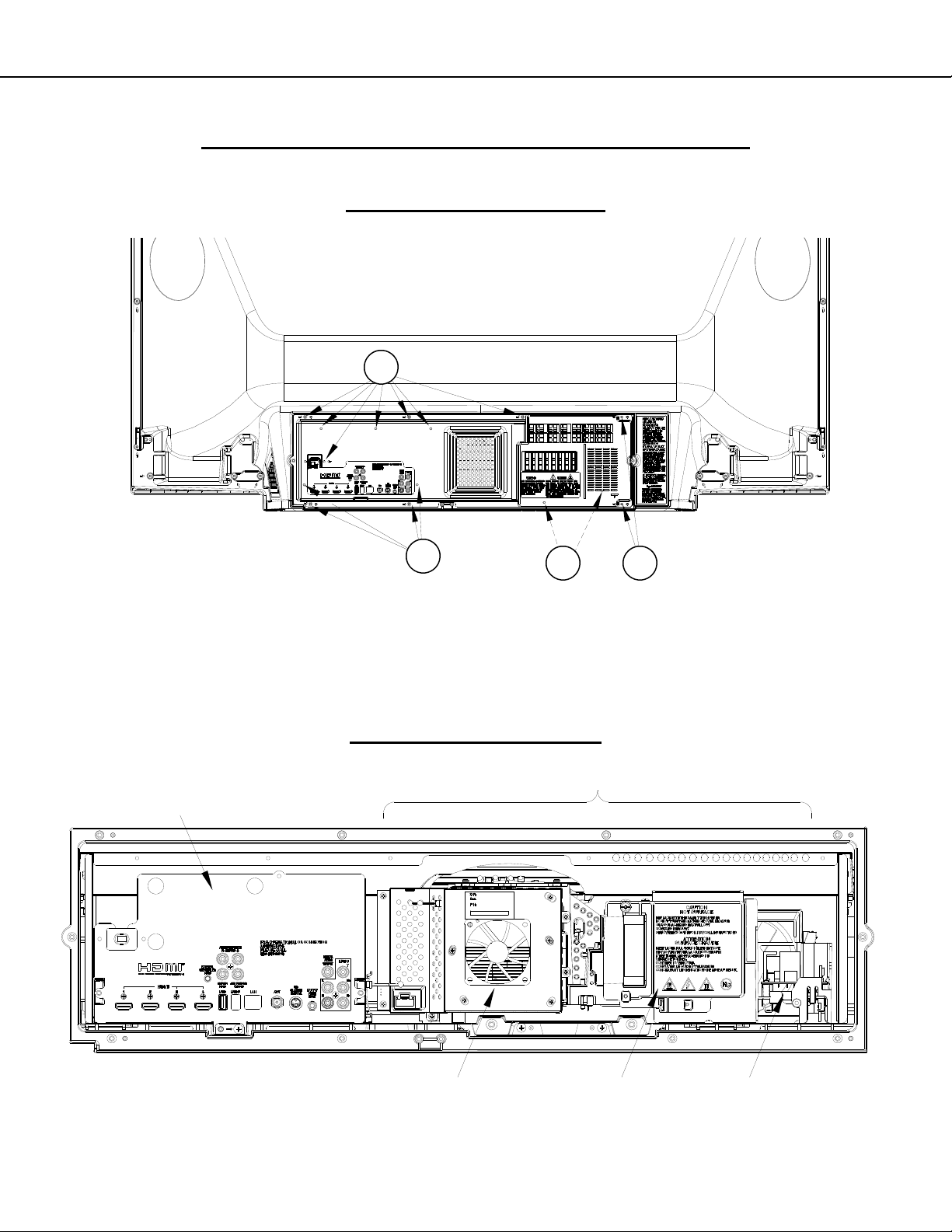

DISASSEMBLY & PARTS REPLACEMENT

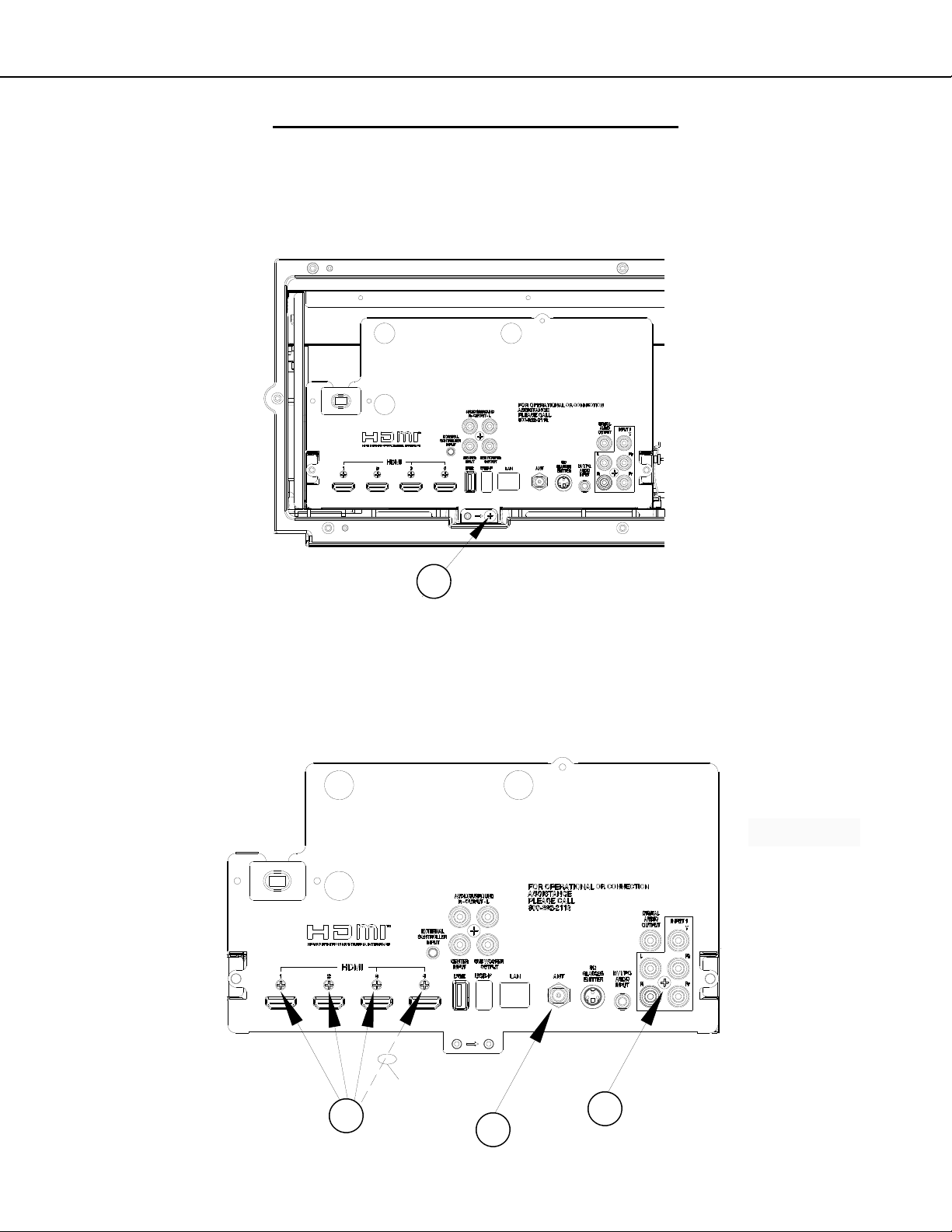

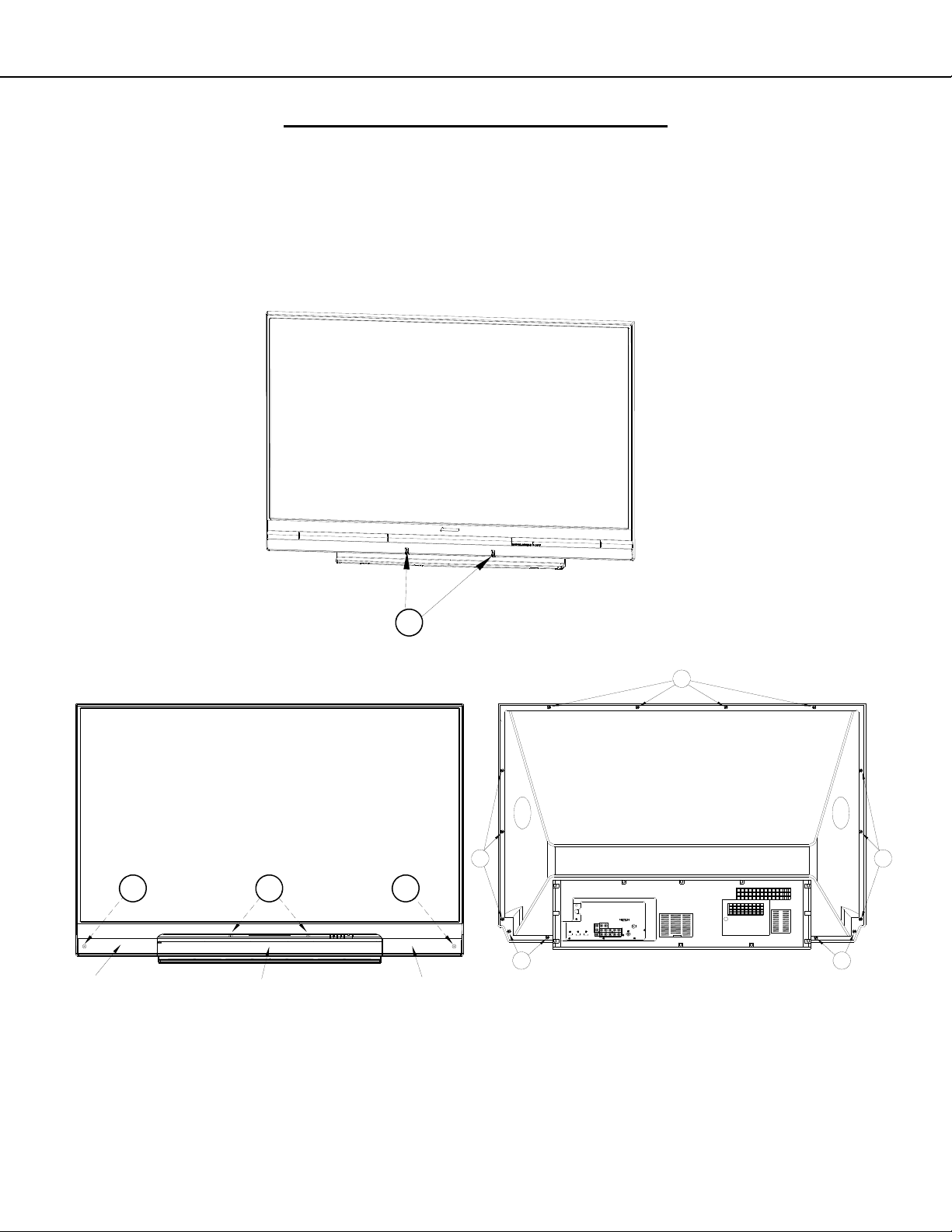

BACK COVER REMOVAL

C

Back Cover Removal

1. Remove screws (A) and remove the Lamp Cover.

2. Remove screws (B) from behind the Lamp Cover.

3. Remove Screws (C).

4. Remove the back cover from the TV.

Version 3.0

C

B

A

CHASSIS

ASSEMBLY LOCATIONS

OPTICAL ENGINE ASSEMBLY

DMD FAN LAMP PWB-BALLAST

Page 7

Page 8

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

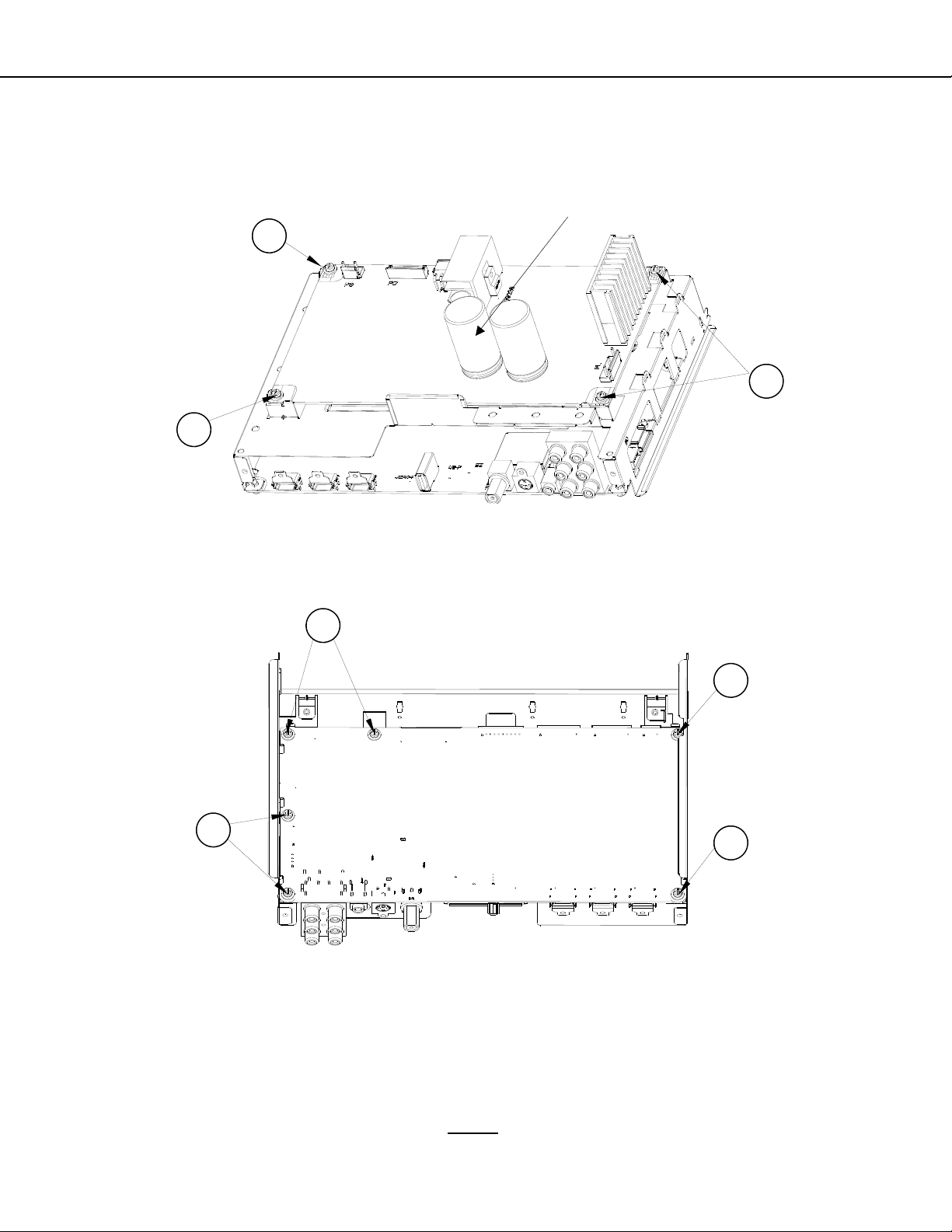

Chassis Removal

1. Remove screws (A).

2. Slide the chassis back and disconnect all cables.

3. Remove the chassis from the cabinet.

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

CHASSIS - REMOVAL & DISASSEMBLY

Version 3.0

A

Rear Terminal Cover Removal (To Replace PWB-MAIN)

1. Remove nut (A) from the ANT input.

2. Remove screws (B) and (C).

3. Disconnect the connectors to the PWB-SOUND (V45++).

4. Remove the Terminal Cover from the chassis.

PWB-SOUND

CONNECTORS

(ON REAR)

V45++ Only

C

V45++ Only

B

A

Page 8

Page 9

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

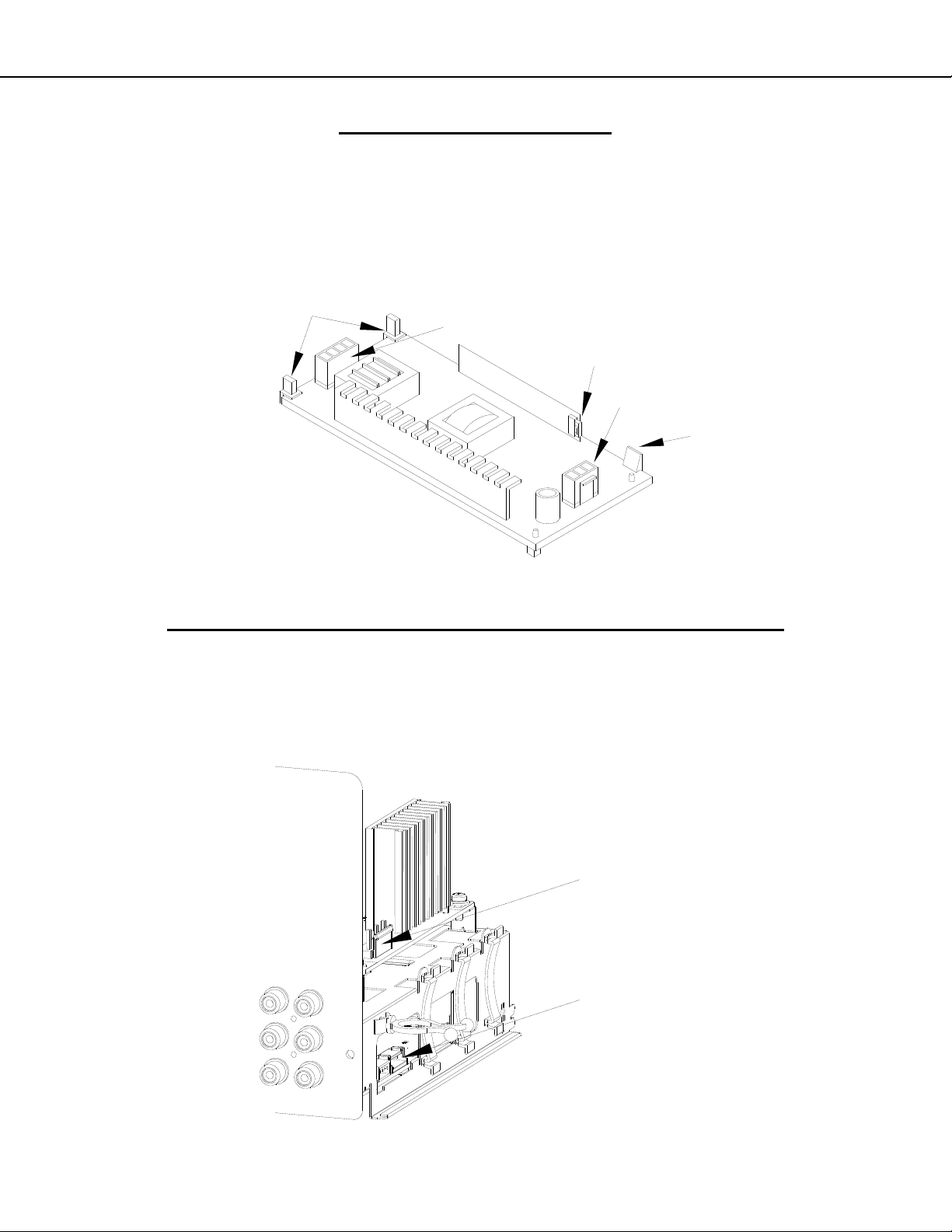

PWB-POWER Removal

1. Disconnect all cables from the PWB-POWER.

2. Remove screws (A).

3. Pinch the Retainer to release the PWB.

4. Lift the PWB-POWER from the chassis.

A

A

Retainer

(Pinch)

Version 3.0

A

PWB-MAIN Removal

1. Disconnect all cables to PWB-MAIN.

2. Remove screws (A) from the bottom of the PWB-MAIN.

3. Lift the PWB-MAIN from the chassis.

A

A

A

A

After PWB-MAIN Replacement

See Data Transfer in Service Procedures section.

1. V45C, V45 & V45CA: Perform “Restore Engine Data From Backup.”

2. V45+, V45++ & V45CB: Perform “Restore Engine Data From Backup” and “Restore Geometry Data From

Backup.”

V45+, V45++, V45CB IMPORTANT REPLACEMENT NOTE: If the customer has subscribed to VUDU (Internet

program provider), the customer must be instructed to contact VUDU to re-activate their account after the replacement PWB has been installed. The original PWB cannot

bishi per policy.

be installed in another TV. It must be returned to Mitsu-

Page 9

Page 10

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

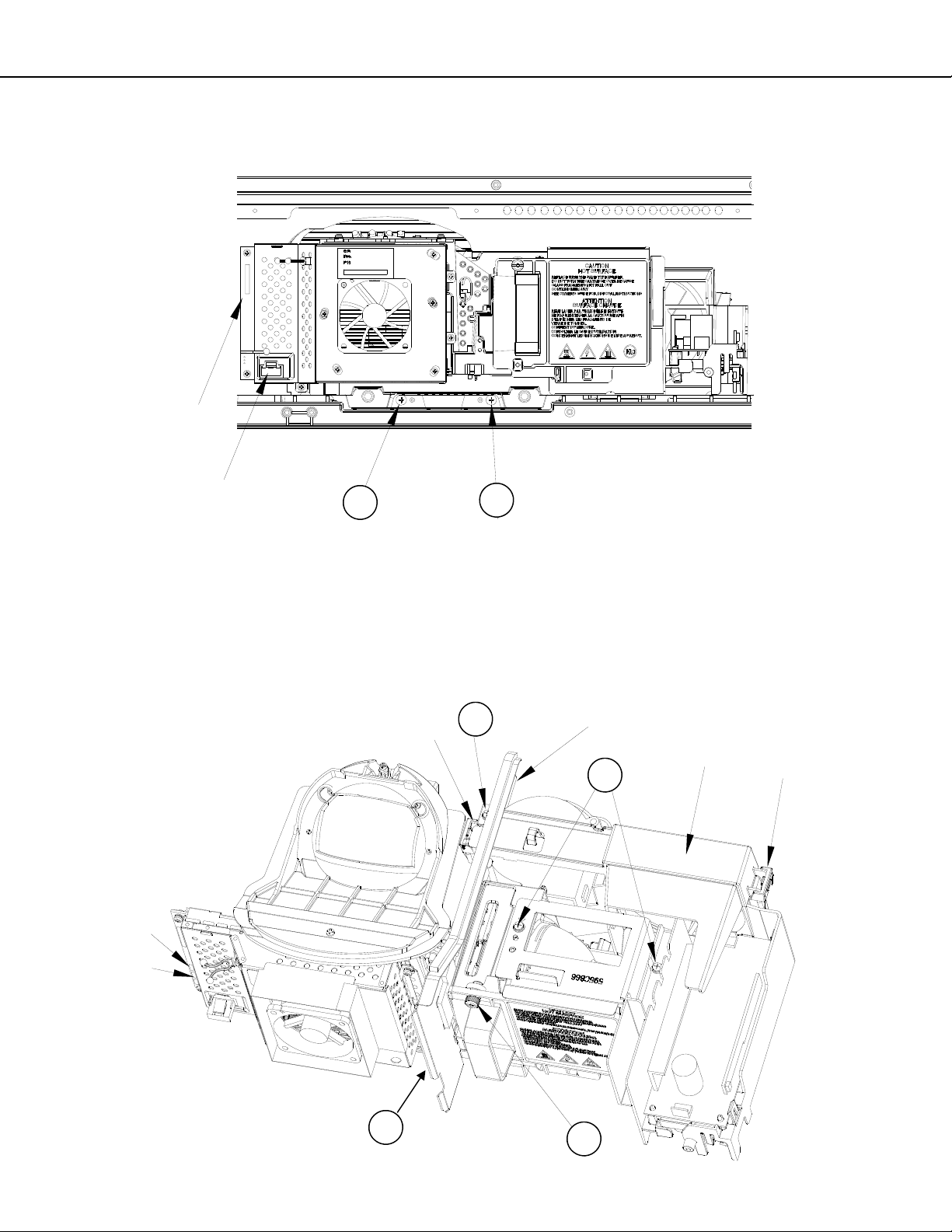

PWB-BALLAST REMOVAL

Note: To remove the PWB-BALLAST, it is not necessary to remove the Engine or Lamp Cartridge.

1. Release the Latch to lift the PWB-BALLAST up from the mounting bracket.

2. Slide the PWB-BALLAST out of the Engine Assembly.

3. Disconnect the electrical locking connectors indicated.

4. To reinstall, first connect the connectors. Then slide the PWB under the Retaining Hooks. Then press the rear

edge of the PWB down onto the guide pins to engage the latch.

RETAINING

HOOKS

CJ4 (HV to Lamp)

CJ3 (Lamp Control)

CJ1 (Lamp Power)

LATCH

Version 3.0

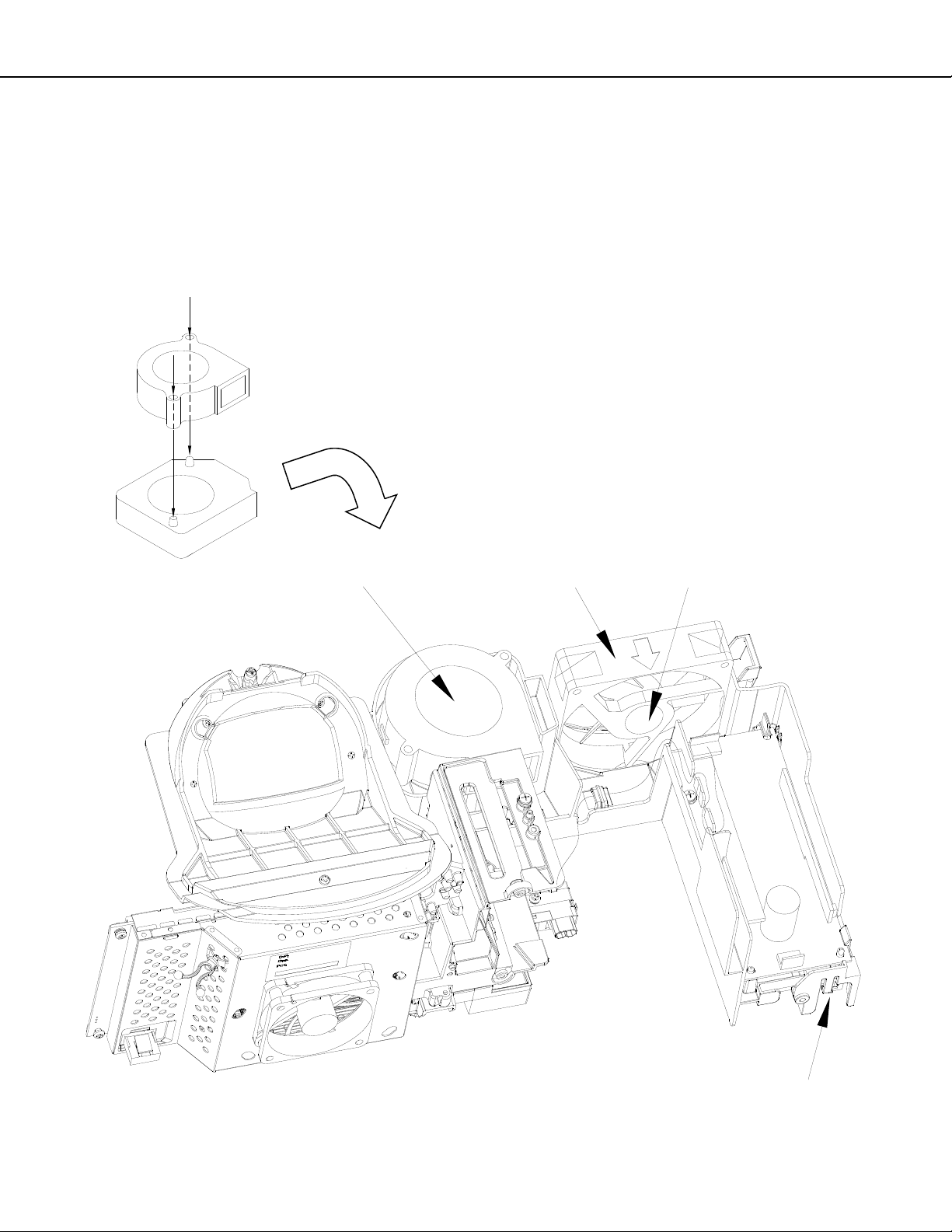

OPTICAL ENGINE ASSEMBLY - REMOVAL & DISASSEMBLY

OPTICAL ENGINE ASSEMBLY REMOVAL

1. Disconnect the PL connector from the side of the PWB-POWER.

2. Disconnect the FB connector from the side of the PWB-MAIN.

3. Loosen the wiring harnesses from the looms.

PL (Lamp Power)

FB

(Lamp Control and Lamp Door Switch)

Page 10

Page 11

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

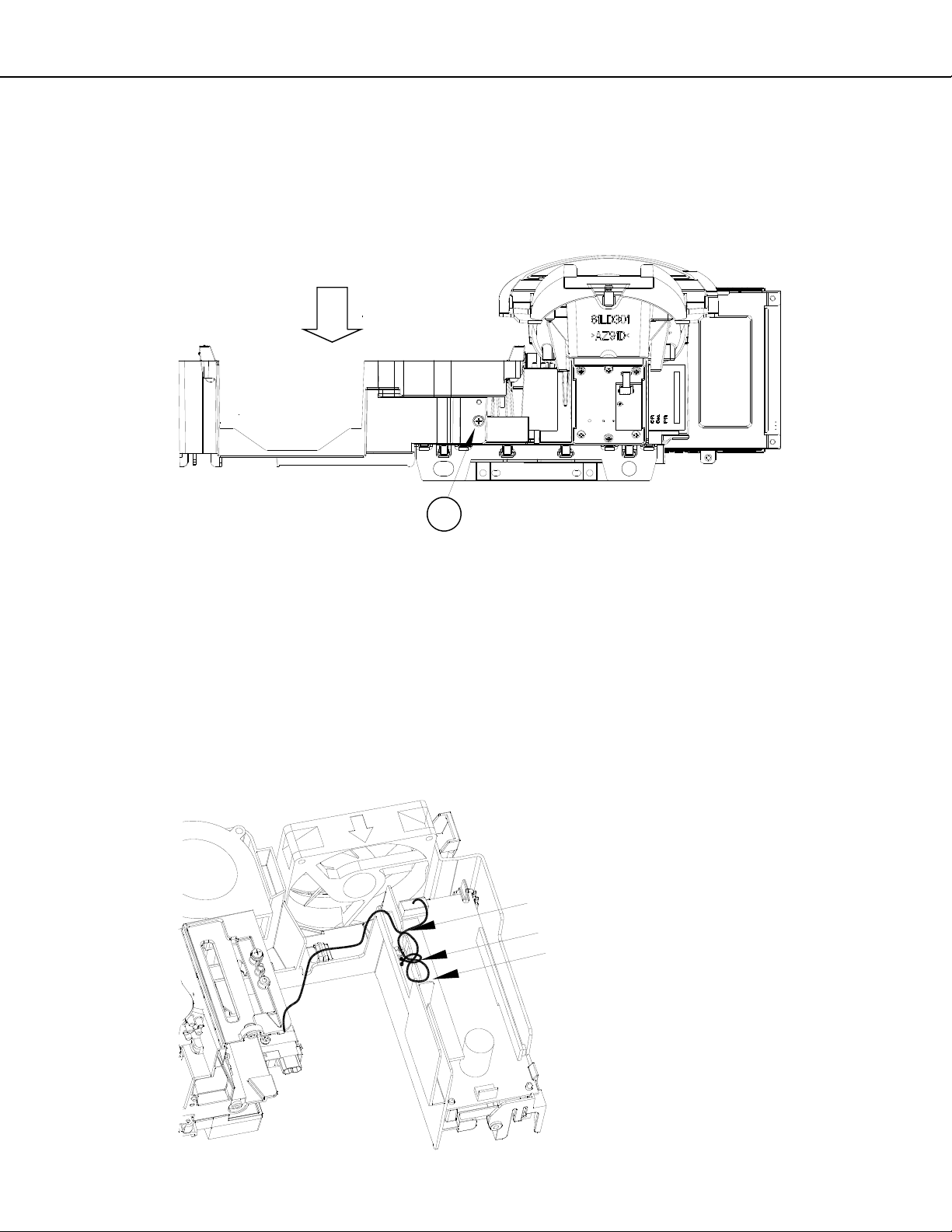

OPTICAL ENGINE ASSEMBLY REMOVAL (Continued)

1. Disconnect the PE and J12 connectors from the Engine.

2. Remove screws (A).

3. Slide the Engine Assembly back out of the cabinet.

J12 (LVDS)

Version 3.0

PE

(Engine Power)

A

A

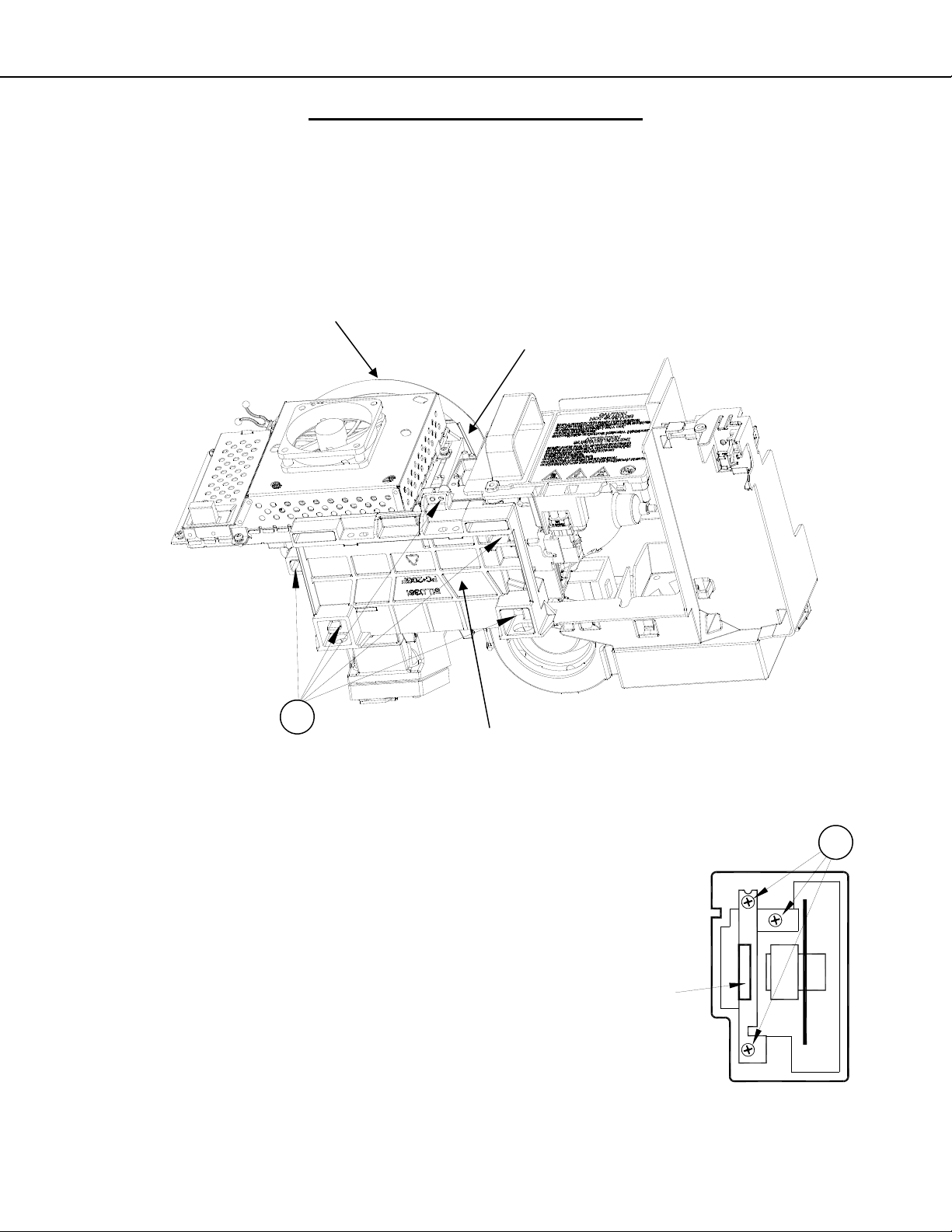

OPTICAL ENGINE ASSEMBLY - Disassembly

1. Loosen screw (A) to remove the Lamp Cartridge.

2. Remove screws (B) and the lamp top cover.

3. Remove screws (C) and the Engine Plate

4. Disconnect the Exhaust and Sirocco Fan Connectors (J4 and J8) from the back of the Engine and loosen the

wiring harnesses from the looms.

5. Release the Latches to remove the Fan Holder.

C

LATCH

ENGINE PLATE

FAN HOLDER

B

J8

(Sirocco Fan)

LATCH

J4

(Exhaust Fan)

C

Page 11

A

Page 12

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

Duct Interior Components

Duct Interior Components are shown below.

Notes:

When replacing the Optical Engine, transfer all Duct and Duct Interior Components from the old Engine to the

new Engine.

The Exhaust Fan must be installed so the Label is facing inside the Duct.

The Sirocco Fan must be installed so the Label is facing up with the Flanges aligned onto the Guide Pins.

Sirocco Fan Flanges

Align Onto Guide Pins

Version 3.0

SIROCCO FAN

(Label Facing Up)

EXHAUST FAN

(Label Facing In)

Page 12

PWB-LAMP DOOR SW

Page 13

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

Lower Duct Removal

1. Remove the Lamp Cartridge, Top Cover, Exhaust Fan and Sirocco Fan.

2. Disconnect the HV Lamp Wiring from the Ballast and loosen it from the guides.

3. Remove screw (A) on the rear of the lower duct.

4. Carefully remove the Lower Duct from the Engine.

LOWER DUCT

Version 3.0

A

OPTICAL ENGINE REPLACEMENT

1. Install Lower Duct and components on the new Engine.

2. Connect the HV Lamp Wiring to the Ballast and dress the wiring through the guides as shown.

3. Remove the Protective Lens Cover from the face of the Lens and place it on the old Engine for return.

4. Install the Engine Assembly in the cabinet.

5. Perform the following procedures as described in the Data Transfer section of the Service Procedures:

“Restore Index Delay”

“Save Engine and Geometry Setting to Backup”

6. As necessary, perform the Horizontal and Vertical Centering Adjustment and Manual Geometry Alignment as

described in the Service Adjustments section of the Service Procedures.

HV LAMP WIRING

Dress Through Guides as Shown

Add VINAL CLAMP at center Guide.

Page 13

Page 14

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

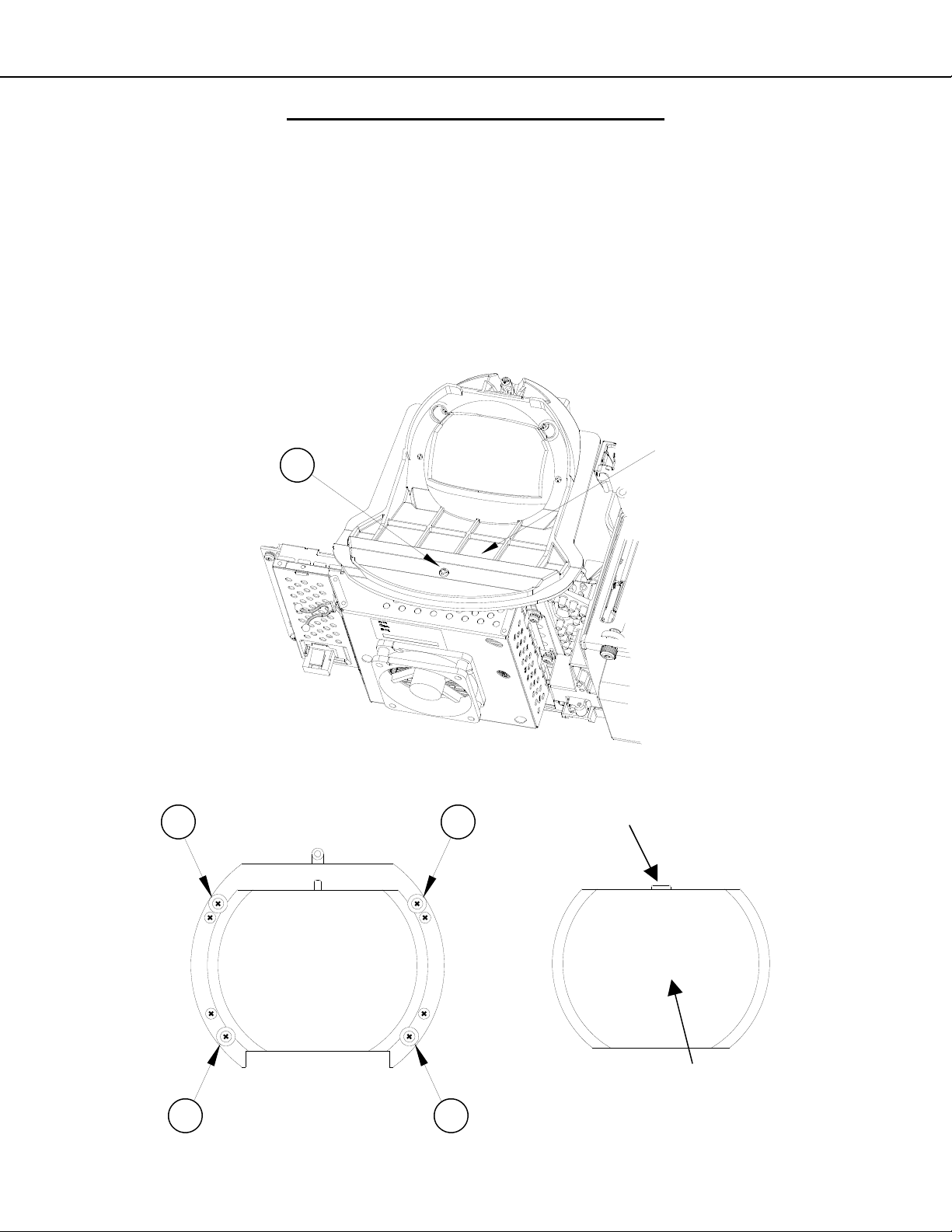

PROJECTION LENS REPLACEMENT

CAUTION: Any dust or fingerprints in the optics can cause abnormalities in the picture.

This procedure should be performed in a dust free environment.

Wear lint free cotton or rubber gloves while performing this procedure.

1. Remove Optical Engine Assembly.

2. Remove screw (A) and remove the Lens Collar.

3. Remove screws (B).

4. Lift out the Projection Lens.

5. Install the replacement lens so the key is oriented towards the top as shown.

LENS

A

COLLAR

Version 3.0

B

B

B

B

Page 14

KEY

LENS

Page 15

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

COLOR WHEEL REPLACEMENT

CAUTION: This procedure should be performed in a dust free environment.

Any dust entering into the optical compartment can cause abnormalities in the picture.

1. Remove the Optical Engine Assembly.

2. Remove the Lens Collar and cover the projection lens to protect it from scratches. See previous page.

3. Disconnect the 2 connectors, J6 & J7, from the front side of the Light Engine. Note the orientation of the

ribbon cable for re-assembly (Silver Contacts towards the Lens).

4. Access the optical compartment by removing screws (A) and the Engine Base from the bottom of the Optical Engine

Version 3.0

LENS COLLAR

A

J6 & J7

(Opposite Side of Formatter PWB)

ENGINE BASE

5. Remove the 3 screws (B) from the Color Wheel Assembly.

6. Use the metal Handle to lift the Color Wheel from the compartment.

7. For installation, reverse the procedure above.

CAUTION: Avoid touching or scratching the Color Wheel.

8. After re-assembly, perform the Index Delay Adjustment described in the

Service Adjustments section.

IMPORTANT: If part return is required, prevent damage by packing the

color wheel the same way the replacement part was sent to you.

Page 15

HANDLE

B

Page 16

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

SCREEN REPLACEMENT 73” Models

Screen Assembly Removal and Replacement

1. V45C, V45, V45+ - Remove the Screw Caps to access screws (A).

2. V45++ - Remove the ORNAMENT LEFT & RIGHT first by pinching up and pulling away from the bottom.

Then remove the ORNAMENT CENTER using the same method.

3. Remove screws (A).

4. Remove screws (B) around the rear edge of the screen bezel.

5. During re-assembly replace screws in their original locations.

V45C,V45, V45+ (73”)

Version 3.0

V45++ (73”)

A A A

ORNAMENT

CENTER

(Speaker Cover)

A

B

Number and Location of

Screws Varies by Model

B

B

ORNAMENT RIGHT ORNAMENT LEFT

73 INCH

B

B

Page 16

Page 17

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

SCREEN REPLACEMENT 73” Models (continued)

Screen Removal From the Bezel-Front

1) Remove screws (A) and remove the top, bottom and side rails.

NOTE: The number and location of screws vary by model.

2) Lift the Fresnel Lens and Lenticular screen from the Bezel-Front.

3) During re-assembly replace screws in their original locations.

A

Version 3.0

A

Example Diagrams. The number and location of screws varies by model.

73 INCH

(Rear View)

A

Page 17

Page 18

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

SCREEN REPLACEMENT 73” Models (continued)

CAUTION: Wear gloves when handling the Lenticular Screen and Fresnel Lens.

This prevents cuts and finger prints. Do not place Fresnel Lens in the sun.

This may cause fire and heat related injuries.

Lenticular Screen and Fresnel Lens Removal

1. After removing the top, bottom and side HOLDER-SCREEN rails and their cushions from the Bezel, lift the

screens as a single unit from the frame.

2. Separate the Lenticular Screen and Fresnel Lens.

Note: When separating the Lenticular Screen from the Fresnel Lens, use caution

while prying the Screen and Lens apart. Use a slot type screw driver, and

remove the pressure sensitive double sided tape.

Lenticular Screen and Fresnel Lens Replacement

1. Apply LENS-TAPE along the rear top edge of the Lenticular Screen.

2. Place the Fresnel Lens on top of the Lenticular Screen, and apply pressure along the top edge.

3. Place the screens in the screen frame and reinstall the cushions, top, bottom and side rails.

NOTE: The Lenticular Screen label must face the front and the Fresnel Lens label face the rear.

4. Reverse the Screen Removal Procedure and insert the screens in the Bezel.

Version 3.0

LENTICULAR

LENS

FRESNEL

SCREEN

LENS-TAPE

BEZEL FRONT

HOLDER-SCREEN-T

SPACER-SCREEN-T

COVER-HOLDER-T

LABEL

LABEL

HOLDER-SCREEN-B

SPACER-SCREEN-S

HOLDER-SCREEN-S

SPACER-SCREEN-B

Page 18

Page 19

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

SCREEN REPLACEMENT 82” & 92” Models

Screen Assembly Removal

1. Remove screws (A) around the bottom rear edge.

2. (V45+) Remove the Pedestal cover and remove screws (B).

3. (V45++) Pull off ornamental Front Covers and Speaker Grill.

4. Remove the Speaker Box and Pedestal by removing screws (B).

5. Remove screws (C) from the bottom front of the screen assembly.

6. Remove screws (D) from the top rear edge of the cabinet.

NOTE: Leave one screw secured at the top. Then support the assembly to prevent it from falling while

removing the remaining screw.

V45+

WD-82740

WD-82CB1

Version 3.0

A A

V45++

WD-82840

WD-92840

B

PEDESTAL

D D D

SPEAKERBOX

B

A A

B

B

C

PEDESTAL

Page 19

Page 20

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

SCREEN REPLACEMENT 82” & 92” Models (continued)

CAUTION: Wear gloves when handling the Lenticular Screen and Fresnel Lens.

This prevents cuts and finger prints. Do not place Fresnel Lens in the sun.

This may cause fire and heat related injuries.

Lenticular Screen and Fresnel Lens Removal

1. Remove four screws (A) in all four corners of the Screen Bezel.

2. Remove the Screen Bezel components from the Screen/Lens Assembly.

A X4

Version 3.0

CORNER-S-T

CORNER-CAP

TOP-L

HOLDER-SCREEN

S-L

CORNER

B-L

SCREEN/LENS

ASSEMBLY

FRONT

HOLDER-SCREEN-B

COVER-HOLDER-T

CORNER-S-T

CORNER-CAP

TOP-R

HOLDER-SCREEN

S-R

LABEL

CORNER

B-R

Page 20

Page 21

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

SCREEN REPLACEMENT 82” & 92” Models (continued)

Lenticular Screen and Fresnel Lens Disassembly

1. Remove the HOLDER-SCREEN from the top, bottom and sides.

2. Separate the Lenticular Screen and Fresnel Lens.

HOLDER-SCREEN

Version 3.0

LENTICULAR

SCREEN

HOLDER-SCREEN

(TOP/BOTTOM)(SIDES)

FRESNEL

LENS

LENS

FRONT

Label Position

(Facing Outside)

Lenticular Screen and Fresnel Lens Replacement

1. Place the Fresnel Lens on top of the Lenticular Screen with the labels facing outside as shown.

2. Install the HOLDER-SCREEN, top, bottom and sides as shown above.

3. Reverse the disassembly procedure to reassemble and install the screen frame assembly.

NOTE: The Lenticular Screen must face the front and the Fresnel Lens must face the rear.

LENTICULAR

SCREEN

Page 21

Page 22

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

MIRROR REPLACEMENT

MIRROR REPLACEMENT - 73” Models

1. To access the Mirror for replacement, remove the Screen Assembly (See Screen Assembly Removal).

2. The Mirror slides down into the Left, Right and Bottom Brackets inside the cabinet.

3. Then the Top Bracket is installed.

4. See the Mirror Parts section for instructions on preparing a replacement mirror.

TOP BRACKET

(73" Models)

SUPPORT

BRACKETS

Version 3.0

MIRROR REPLACEMENT - 82” & 92” Models

1. To access the Mirror for replacement, remove screws (A) and lift away the Mirror Cover(s). Note: 82” cover is

1 piece, 92” cover is 2 pieces.

2. The Mirror rests in place below the Mirror Cover.

3. See the Mirror Parts section for instructions on preparing a replacement mirror.

A

(2 Piece Cover)

A

92"

MIRROR

(Below Cover)

A

Page 22

Page 23

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

SERVICE PROCEDURES

REMOTE CONTROL

NOTE: The Remote Controls differ between Type 1 and the Type 2 models.

TYPE 1

V45C V45 V45CA

WD-73C11 WD-73640 WD-73CA1

REMOTE CONTROL USE FOR SERVICE

Many service functions and adjustments are accessed using the Remote Control. The Type 1 remote does not have

buttons such as PLAY, FWD and RVW that are associated with operating connected devices. Service Proc edures are

described assuming a Type 1 remote is being used. However, if a Type 2 remote is being used, buttons can optionally

be substituted as follows:

TYPE 2

V45+ V45++ V45CB

WD-73740 WD-73840 WD-82CB1

WD-82740

WD-82840

WD-92840

Type 1

V45C / V45 / V45CA

V45+ / V45++ / V45CB

TYPE1 TYPE 2

<2> <2> or <PLAY>

Type 2

Version 3.0

<CH-UP> <CH-UP> or <FWD>

<CH-DOWN> <CH-DOWN> or <RVW>

Page 23

Page 24

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

OPTION MENU

OPTION MENU

1. Press the <MENU> button on the remote control.

2. Press the buttons <2-4-7-0>. The screen will display the Option Menu.

Option Menu

<MENU><2-4-7-0>

Initialize

Power Restore OFF

Production Mode OFF

Digital Signal Strength <1~9>

NetCommand Software Vxx xxx.xx

Total hours of use 0

Version 3.0

SERVICE LEVEL INITIALIZATION

Service Level Initialization is used to restore all customer menu, video and audio settings to the original factory default

condition.

1. Enter the Option Menu <MENU><2-4-7-0>

2. Select “Initialize” and <ENTER>.

Option Menu

<MENU><2-4-7-0>

Initialize

Power Restore OFF

Production Mode OFF

Digital Signal Strength <1~9>

NetCommand Software Vxx xxx.xx

Total hours of use 0

Page 24

Page 25

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

DIGITAL SIGNAL INFORMATION

Information on the currently selected digital channel can be displayed on screen.

1. Enter the Option / Service Menu <MENU><2-4-7-0>.

Option Menu

<MENU><2-4-7-0>

Initialize

Power Restore OFF

Production Mode OFF

Digital Signal Strength <1~9>

NetCommand Software Vxx xxx.xx

Total hours of use 0

1. Select “Digital Signal Strength” and <ENTER>.

Digital Signal Information

Version 3.0

“Digital Signal Strength” <ENTER>

Tuner

Frequency(MHz) 749

Signal Level <1~9>

Modulation 8VSB Air

Carrier Lock Locked

SNR 29.09

Correctable errors 0

Un Correctable errors 0

Page 25

Page 26

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

RESET / INITIALIZATION

SERVICE TIP:

Many symptoms that are customer generated, intermittent or cannot be verified can be resolved by using the various

Reset and Initialization options. Before visiting the customer’s home ask the customer to 1st perform a System Reset. If

this does not resolve the issue, they can perform an A/V Reset. Then, if necessary, perform a user level Initialization.

The customer should be made aware when settings and/or options will be reset. For more information, see the chart

below.

Reset Name When to use How to use Resulting Action

Remote Control

Reset

TYPE 1 Only

Returns the remote control to normal

operation.

Press and hold the <POWER> button until it flashes twice

1)

then release the button.

Enter the code <0-0-0-0-0>. The <POWER> button will flash

2)

twice

The remote control is reset.

Version 3.0

Remote Control

TV Layer Reset

TYPE 2 Only

Remote Control

TV Volume/

Mute functions

A/V Memory

Reset, by individual input

A/V Reset, all

inputs

System Reset To reset the TV when it does not turn

Returns the remote control TV layer

to normal operation.

Returns the volume and mute functions of the remote control to TV volume and mute for TV, Cable/Sat,

VCR and DVD layers after the Audio

Lock for AV Receiver feature has

been used.

When the audio or video performance

or settings for a single input seem to

be incorrect.

When the audio or video performance

or settings for more than one input

seem to incorrect.

on or off, does not respond to the

remote control, front panel buttons or

has other unusual symptoms.

Select the remote control TV mode.

1)

Press and hold the <POWER> button until it flashes twice

2)

then release the button.

Enter the code <0-0-9-3-5>. The <POWER> button will flash

3)

twice

Select the remote control TV mode.

1)

Press and hold the <POWER> button until it flashes twice

2)

then release the button.

Enter the code <9-9-3>< VOL >. The <POWER> button

3)

will flash four times.

<MENU> “Audio/Video” “AV Reset” <ENTER> All Audio and Video settings

While viewing the TV, press the front panel buttons <INPUT> +

<VOL > at the same time and hold for 10 sec.

Press the <POWER> button on the front panel and hold it for 8

seconds.

The remote control TV layer

is reset.

The remote will now operate

the TV's volume and mute

when the slide switch is in

the TV, CABLE/SAT, VCR

or DVD positions.

for the individual input are

reset except for the Listen

To, Language, Balance and

Closed Caption settings.

All Audio and Video settings

are reset to the factory default settings. No other

menu options are changed.

TV Micro Re-boots. Note:

The changes made during

the current TV-On period

may be lost. All other previous user settings are not

lost.

Initialize User

Level

Initialize - Service Level

V-Chip Password Bypass

Unlock Front

Panel

To reset all customer settings except

V-Chip

To reset all customer settings <MENU><2-4-7-0> "INITIALIZE" <ENTER> All customer menu options

If V-Chip password is not known Press <LAST>+<9> at the same time. Password will be bypassed.

To unlock the front panel if it has

been locked in the V-Chip Menu.

Press <MENU><1-2-3><ENTER> All customer menu options

Press and hold the front panel <INPUT>

button for 10 seconds.

and A/V settings except VChip & locked ISF are reset

to factory default.

and A/V settings are reset

to factory default.

If in the V-Chip menu, enter

a new password.

Front Pan

erational. Other V-Chip

settings not changed. Note:

Cannot be performed while

in the Low Power mode and

the set is Off.

e

l becomes op-

Page 26

Page 27

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

LED INDICATI ONS AND SELF DIAGNOSTICS

The front panel Status LED provides an indication of the set’s operation and the possible cause of a malfunction.

NORMAL INDICATIONS

STATUS LED Indication Condition

Off Off (Standby)

Green Power On

Slow Blinking Green Power Off with Timer Set. Power On normally

Fast Blink Green 80 seconds after Power Off Power Off Lamp cooling. Wait for blinking to

stop to Power On.

Version 3.0

Fast Blinking Green 1 to 3 minutes after Power

Restored from AC interrupt, Power On, System

Reset or Software update.

ABNORMAL INDICATIONS

STATUS LED Indication Condition

Steady Red Lamp Failure (See Error Code 66)

Steady Yellow DMD Temperature Excessive

Blinking Yellow Lamp Cover Open (See Error Code 32)

Blinking Red then Blinking Yellow Circuit Failure (See Self Diagnostics)

Boot-up. Wait for blinking to stop to Power On.

SELF DIAGNOSTICS

A blinking red and yellow Status LED will indicate an Error Code that can help determine the cause of a circuit

failure.

The number of Red blinks indicates the value of the MSD (tens digit) of the Error Code.

The number of Yellow blinks indicates the value of the LSD (ones digit) of the Error Code.

Example: If the Error Code is “37”, the LED will continuously blink Red three times, followed by blinking Yellow

seven times.

See the following page for a list of Error Codes.

To perform a System Reset, press and hold the Power button for 10 seconds. Or, unplug the set for 10 seconds

then restore power.

Number of Red Blinks Number of Yellow Blinks

3 7

Error Code: 37

Page 27

Page 28

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

ERROR CODES

Error Codes, descriptions and the most likely cause of failure are listed below:

ERROR CODES

Code Description Most Likely Cause

Loss of 12V from PWB-POWER to Engine /

17 I2C Communication loss between TV Micro and Engine

Engine will not accept data

18

(ASIC-READY signal from Engine is not detected)

Lamp Cover is open.

32*

Lamp turns Off while the TV is playing.

34**

Lamp Failure

Lamp Enable signal from engine is lost.

36 Exhaust Fan rotation not detected Check Exhaust Fan / Check J4 circuitry

37 Engine (DMD) fan rotation not detected Check DMD Fan / Check J5 circuitry

42 Sirocco fan (Lamp fan) rotation not detected Check Sirocco Fan / Check J8 circuitry

44 LVDS cable between PWB-MAIN and Engine not detected Check LVDS Cable & circuitry

48 PON-SHORT 3.3V or 5V switched supply short PWB-MAIN Failure

57 Ballast communication problem (ballast to chassis)

16 LAMP-EN Detection

Lamp did not turn on at P-ON sequence

66**

(No Lamp inserted)

(Disconnected cable between ballast and lamp)

(Lamp-Enable goes to PWB-MAIN but not to Ballast)

Check PE & PE2 circuitry

Engine Failure, PWB-MAIN Failure

LDVS circuitry

Engine Failure

Check CD connector

Lamp Cartridge Failure

Loss of 340V from PWB-POWER to Ballast /

Check PL & CJ1 circuitry

Loss of communications between PWB-MAIN

and Ballast / Check FB & CJ3 circuitry

Ballast Failure

Check Color Wheel / Check J6 & J7 circuitry /

Engine Failure

Check CJ4 circuitry

No Lamp Inserted.

HV connection or lead wire to lamp.

Lamp Cartridge Failure

Version 3.0

* Error Code 32 is indicated by a flashing Yellow Status LED. The code is stored in the Error code Log. See below.

** Error Codes 34 & 66 are indicated by a steady Red Status LED. The code is stored in the Error code Log. See

below.

ERROR CODE LOG

The Error Code Log can be used to retrieve the code for an error that occurred in the past.

To access the Error Code Log: Press <MENU> <3-5-6-4>

Error Code Log Definitions

PAGE - Current page number

CURRENT TIME - total hours of operational

use.

USAGE TIME - usage hours when the error

occurred.

CODE - the specific Error Code that oc-

curred.

STATUS: HAPPENED - Indicates an error

was recorded.

Press <CANCEL> to erase the Log.

NOTE: The Error Code Log is intended as a ref-

erence tool and is not meant to be used as a final

Error Code Log

<MENU><3-5-6-4>

***** PAGE (001/001) *****

CURRENT TIME: 01455 HOURS

USAGE TIME CODE STATUS

00413 HRS 44 HAPPENED

00716 HRS 57 HAPPENED Press Up to Previous Page

Press Down to Next Page

Press Right to Top Page

Press Left to Last Page

Press CANCEL to Erase

determination of a defective part.

Press MENU to Exit

Page 28

Page 29

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

SPEAKER TRANSDUCER AND SPEAKER FREQUENCY TEST (V45++ Only)

These procedures will test the TV’s speakers using an internal tone generator.

1. Press the <MENU> button on the remote control. The Customer Menu will appear.

2. Press the <2-4-5-7> buttons. The Service Menu will appear.

3. Press the <0> button. The Data Transfer & Geometry Menu will appear. See below.

Note: Before activating the SPEAKER TEST, be sure that the SOUND is not in STEREO mode.

Use SURROUND, MUSIC or NIGHT m ode.

4. Use the <> buttons to select “SPEAKER TEST” and press <ENTER>. The Speaker Test Transducer

Test Menu will be displayed. A tone will automatically cycle from one speaker to the next as indicated on

screen. Follow the instructions to manually cycle the tone.

5. From the Data Transfer & Geometry Menu, use the <> buttons to “SPEAKER FREQUENCY TEST.”

The Speaker Frequency Test Menu will be displayed. A tone will automatically cycle from one frequency

to the next as indicated on screen. Follow the instructions to manually cycle the frequency tone.

Data Transfer & Geometry Menu <MENU><2-4-5-7><0>

RESTORE ENGINE DATA FROM BACKUP

RESTORE GEOMETRY DATA FROM BACKUP

MANUAL GEOMETRY ALIGNMENT

RESTORE INDEX DELAY

SAVE ENGINE AND GEOMETRY SETTING TO BACKUP

SPEAKER TEST

SPEAKER FREQUENCY TEST

BACKUP AND RESTORE ISF SETTINGS

RED ONLY AND GREEN ONLY

Version 3.0

Page 29

Page 30

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

SERVICE ADJUSTMENTS

Service Adjustments include Adjustment Procedures and Data Transfer Functions.

Electrical Adjustments (there are no mechanical adjustments)

• Horizontal and Vertical Centering Adjustment

• Index Delay Adjustment

• Geometry Alignment

• Data Transfer Functions

Test Equipment and Test Patterns

• Remote Control

• Internally generated Test Patterns

• No external test equipment or pattern generators are required.

SERVICE MENU

The Service Menu is used for all service adjustments.

Service adjustments can only be performed using the remote control.

1. Activating the Service Menu

1. Press the <MENU> button on a remote control. (The Customer Menu will appear.)

2. Press the buttons <2-4-5-7>. (The Service Menu will appear.)

2. Test Pattern Activation

When in the Service Menu, press the <2> or <> key on the remote to activate the internal test patterns (no

indication will be displayed initially). Use <CH-UP/CH-DOWN> or <

<2> or <> a second time and use <CHAN-UP/CHAN-DOWN> or <

Press <2> or <> again to toggle back to the previous patterns.

3. Adjustment Overview—Specific adjustment procedures follow.

1. When in the Service Menu use the <VIDEO> button to toggle to adjustment desired indicated by the

number and abbreviation displayed on screen.

2. For Geometry, from the Service Menu press <0> and select “Manual Geometry Alignment” <ENTER>.

4. Adjusting Data

After selecting an adjustment item, use the Navigation arrows or other buttons indicated in the adjustment

procedure to perform the adjustment.

5. Saving Data

Press <ENTER> to save the adjustment data. The menu display will turn red for approximately one second.

Note: If the circuit adjustment mode is terminated without pressing <ENTER>, changes in adjustment data

are not saved.

6. Exiting the Service Menu

Press <EXIT> to quit.

Service Menu

<MENU> <2-4-5-7>

SERVICE

TVM

1. HVPOS

4

-3

/> to toggle between patterns. Press

/> to access additional patterns.

Version 3.0

Page 30

Page 31

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

ADJUSTMENT PROCEDURES

Horizontal and Vertical Position Adjustment

1. Enter the Service Menu <MENU><2-4-5-7>.

2. Select the Geomet ry Test Pattern shown <2> <CH-DOWN>or <

3. If necessa ry, use the <VIDEO> button to select the adjustment, “1.HVPOS”.

4. After selecting the HVPOS adjustm ent item, use the Navigation <> buttons to center the display.

5. Press <ENTER> to save the adjustment data. The on-screen display will flash red whil e the data is saved.

Vertical & Horizontal Position Adjustment

<MENU><2-4-5-7> <2> <CH-DOWN> or <

Adjustment

SERVICE

TVM

1.HVPOS

-3

4

> x2.

> x2

Data (HPOS)

Data (VPOS)

Version 3.0

Index Delay Adjustment (Perform after color wheel replacement)

1. Enter the Service Menu <MENU><2-4-5-7>.

2. Select the Ramp Pattern shown below <2> <CH-DOWN> or <

3. Use the <VIDEO> button to select the adjustment, “60.IDL”.

4. After selecting the IDL adjustment item, use the Navigation <> buttons to adjust the ramp pattern color

bars for the smoothest transition from dark to bright.

5. Press <ENTER> to save the adjustment data. The on-screen display will turn red while the data is saved.

Index Delay Adjustment

<MENU><2-4-5-7> <2> <CH-DOWN> or <

Adjustment

SERVICE

TVM

60.IDL

201

> x3.

> x3 <VIDEO>

Data

Page 31

Page 32

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

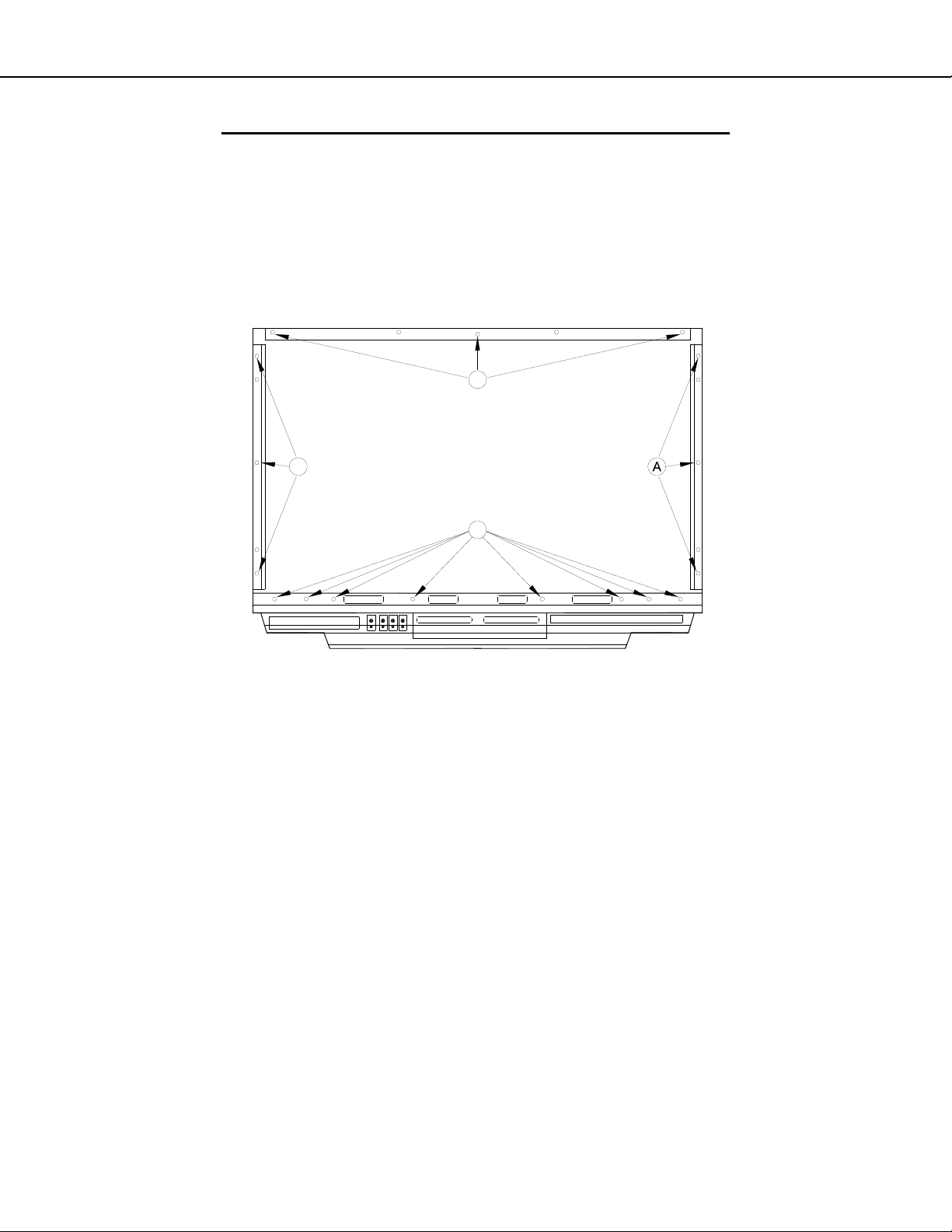

Manual Geometry Alignment

1. Entering the Manual Geometry Alignment Mode

1. Activate the Service Mode <MENU><2-4-5-7>.

2. From the Service Menu, press the <0> button. The Data Transfer & Geometry Menu will appear.

3. Use the <> buttons to select “MANUAL GEOMETRY ALIGNMENT” <ENTER>. The Manual Geometry

Alignment Pattern will appear.

Type 2 Data Transfer & Geometry Menu <MENU><2-4-5-7><0>

RESTORE ENGINE DATA FROM BACKUP

RESTORE GEOMETRY DATA FROM BACKUP

MANUAL GEOMETRY ALIGNMENT

RESTORE INDEX DELAY

SAVE ENGINE AND GEOMETRY SETTING TO BACKUP

BACKUP AND RESTORE ISF SETTINGS

RED ONLY AND GREEN ONLY

Manual Geometry Alignment

Version 3.0

<MENU><2-4-5-7><0> “MANUAL GEOMETRY ALIGNMENT”<ENTER>

Page 32

Page 33

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

C

r

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

2. Manual Geometry Alignment

Note: Upon entering the Manual Geometry Alignment Mode the first time, the geometry may appear distorted

because all factory geometry correction is automatically disabled. Press <EXIT> to quit and re-enable

the factory geometry correction. Pressing <1> <ENTER> and <EXIT> will cause the TV to operate with

out factory geometry correction (distortion will be present).

Note: At any time the original factory geometry data can be restored from backup:

From the Data Transfer & Geometry Menu <MENU><2-4-5-7><0>, select “RESTORE

GEOMETRY DATA FROM BACKUP” <ENTER>.

+

urso

+

Adjustment Points

(16 Total)

Version 3.0

Align Cursor + Flush With Bezel Edge

Phase 1 - 16 Point Geometry Alignment

1. 16 Adjustment Points are indicated by white dots around the edge of the raster. The adjustment position is

indicated by a + cursor.

2. Starting from the upper left corner, use the <> buttons to align the + at each point in a straight line,

flush with the bezel as a reference. See example above.

Note: Only the cursor will move. The Geometry Pattern will not change.

3. After adjusting each point, use the <CH-UP> or <

and repeat until all 16 points have been adjusted.

4. After all 16 points are adjusted and the cursor is returned to the original starting point, press <ENTER> then

<EXIT>. Correction will be automatically calculated and saved and the Manual Geometry Alignment will be

terminated.

5. Re-activate the Manual Geometry Alignment. The geometry pattern will appear with the corrections applied. If

Geometry is acceptable, press <EXIT> to quit. To touchup the raster geometry, proceed to Phase 2.

Phase 2 - Geometry Touch-up Alignment

1. If additional correction is necessary after performing the Manual Geometry Alignment, re-enter the Manual

Geometry Alignment mode.

2. Use the <CH-UP/CH-DOWN> or <

3. Use the <> buttons to indicate the direction and amo unt of correction necessary at the particular

point. Note: Only the cursor will move. The Geometry Pattern will not change.

4. Press the <INFO> button to apply the correction. The Geometry Pattern will now show the correction.

5. Repeat steps 2, 3 and 4 as needed.

6. Press <ENTER> then <EXIT> to save your changes. The Manual Geometry Alignment will be terminated.

7. To proceed to Phase 3, re-activate the Manual Geometry Alignment.

/> buttons to shift the cursor to the point needing correction.

> button to shift the cursor to the next point clockwise

Page 33

Page 34

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

Phase 3 - 4:3 and 16:9 Alignment

1. With the Manual Geometry Alignment activated, press <VIDEO> to enter the 4:3 Alignment Mode. The pattern below will be displayed.

Note: Pressing <VIDEO> will toggle between the 4:3,16:9 (top, top-ce nter, center & bottom) and 16 Point Ge-

ometry Alignment modes.

2. In the 4:3 Alignment Mode, pressing <CH-UP/CH-DOWN> or <

/> will cause the geometry pattern to be

displayed with 11 preset amounts of correction. Toggle through them until you find the one with the straightest Blue 4:3 Lines. It may help to count the patterns as you cycle through them. When you find the pattern

with the straightest Blue 4:3 Lines, press <VIDEO>. The Top 16:9 Alignment Mode will then be activated as

indicated by the Top Red 16:9 Line displayed in the pattern.

4:3 MODE

Version 3.0

Select Straightest Blue Lines

3. In the 16:9 Alignment Mode, pressing <CH-UP/CH-DOWN> or </> will cause the geometry pattern to be

displayed with 15 different preset amounts of correction to the Red Line. Toggle through them until you find

the one with the straightest Red Line. Again, count the patterns as you cycle through them. When you find

the pattern with the straightest line, press <VIDEO>. The Top-Center Red Line will be displayed in the pattern.

4:3 MODE

Select Straightest Red Line (Top)

Page 34

Page 35

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

4. Repeat the process of pressing <CH-UP/CH-DOWN> or </> to display the 15 different preset amounts

of correction to the Top-Center Red Line. When you find the pattern with the straightest line, press

<VIDEO> to proceed to the Center Red Line. Repeat the process for the Center Line, followed by the Bottom Line. Press <ENTER> then <EXIT> to exit and save the 4:3 and 16:9 data.

5. Select the Geometry Test Pattern (See HVPOS). If Geometry is acceptable, press <EXIT> to quit.

Version 3.0

Select Straightest Red Line (Top- Center)

Select Straightest Red Li ne (Center)

4:3 MODE

Select Straightest Red Line (Bottom)

Page 35

Page 36

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

DATA TRANSFER FUNCTIONS

Data Transfer

Service Data is duplicated and stored in separate EEPROMs in two locations.

PWB-MAIN - Working Service Data for TV operation

OPTICAL ENGINE - Backup Service Data

The Optical Engine also includes data for the Index Delay setting for color wheel timing determined at the factory.

The PWB-MAIN also includes User and/or ISF settings. The User/ISF data is not backed up on the Engine. However if

used, it can be backed up onto a USB flash drive.

Data Transfer Procedures should be followed…

After PWB-MAIN Replacement:

1. Restore Engine Data From Backup.

2. Restore Geometry Data From Backup.

3. Restore ISF Settings From Flash Drive. (Only if backup USB flash drive is available).

After OPTICAL ENGINE Replacement:

1. Restore Index Delay.

Version 3.0

Data Transfer Procedure:

1. Enter the Service Mode <MENU><2-4-5-7> Select the Data Transfer & Geometry Menu <0>

Note: Besides MANUAL GEOMETRY ALIGNMENT, six data transfer choices are listed on screen.

RESTORE ENGINE DATA FROM BACKUP - copies backup factory adjustments HVPOS, White Balance

RESTORE GEOMETRY DATA FROM BACKUP - copies backup factory Geometry Alignment data from

RESTORE INDEX DELAY - copies factory Index Delay Adjustment data from the Optical Engine to the

SAVE ENGINE AND GEOMETRY SETTING TO BACKUP - copies all working data from the PWB-MAIN

BACKUP AND RESTORE ISF SETTINGS - allows the ISF (ADV) video settings to be backed up and

RED ONLY AND GREEN ONLY - displays the video in red or green only during ISF Calibration.

2. Use the <> buttons to select the item and press <ENTER>.

3. Follow on-screen instructions if given.

4. Press <EXIT> to quit.

Data Transfer & Geometry Menu <MENU><2-4-5-7><0>

RESTORE ENGINE DATA FROM BACKUP

RESTORE GEOMETRY DATA FROM BACKUP

MANUAL GEOMETRY ALIGNMENT

RESTORE INDEX DELAY

SAVE ENGINE AND GEOMETRY SETTING TO BACKUP

BACKUP AND RESTORE ISF SETTINGS

RED ONLY AND GREEN ONLY

Warning: Only use “SAVE ENGINE AND GEOMETRY SETTING TO BACKUP”

and Index Delay from the Optical Engine to the PWB-MAIN.

the Optical Engine to the PWB-MAIN.

PWB-MAIN.

into backup memory on the Optical Engine.

restored using an external USB flash drive.

Page 36

Page 37

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

Using Lead Free Solder

Pb Solder

The symbol shown above indicates Lead (Pb) Free Solder was used during the construction of PWBs. Only Lead Free

Solder should be used when servicing these PWBs.

Solder must be compatible with that used by the manufacturer. Leaded solder can not be used on PWBs manufactured

with Pb-free solder. The Mitsubishi standard for service requires the use of Tin-Silver-Copper (Sn-96.5, Ag-3.0, Cu-0.5).

It can be obtained through the Parts Department.

Order part number: PB FREE SOLDER

Lead Free Solder has a higher melting point, and does not “wet” as well as leaded solder. This means it does not adhere as readily to the solder iron tip and the surface to be soldered. To counteract this, the flux used is more corrosive.

The following cautions must be taken when using Pb Free Solder.

Higher temperatures can cause the PWB to warp, detaching surface mount components.

Higher temperatures may cause thermal damage to components.

Higher temperatures can cause plastics such as connectors, relays, LEDs, electrolytic capacitors to melt or warp.

Higher temperatures can cause surface oxidation resulting in poor solder spread-ability and wet-ability.

The flux is more corrosive.

The time required for a good solder connection may take longer.

Poor wet-ability can cause solder balls.

Higher temperatures can cause flux spattering.

Soldering iron tip life is shortened.

Dull finish solder joints (not shiny) can appear to be a “cold” solder joint.

In general a tip temperature of 700° F will usually provide good results.

Displays used to indicate Pb-free

PWBs will be marked, indicating the level of Pb-free construction. Table 1 defines the levels by phase and shows the

different symbols that will be displayed on the PWB. Additionally, a PWB constructed using Pb-free solder may be simply

marked LFS.

When possible, the indication will be placed close to the part number that is screened onto the PCB (not the part label).

Version 3.0

Pb-Free

Phase Definition Display

Phase-1 PCB's constructed using

Pb-free solder.

Pb Solder

Phase-2 Solder, PCB surface

Phase-3 Solder, PCB surface

finishing and component

lead plating is Pb-free.

Components may have

internal Pb.

finishing and components

are Pb-free. (100% Pbfree)

Table 1: Pb-Free Phases and Symbols

Pb Joints

Pb PCA

Page 37

Short Display (When the

area is too small)

Pb S

Pb J

Pb P

Page 38

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

Chip Parts Replacement

Some resistors, shorting jumpers (0 Ohm resistors), ceramic capacitors, transistors and diodes are chip parts. The following precautions should be taken when replacing these part s.

Cautions:

1. Use a fine tipped, well insulated soldering iron and tweezers.

2. Melt the solder and remove the chip parts carefully so as not to tear the copper foil from the printed circuit

board.

3. Discard removed chips; do not reuse them.

4. Do not apply heat for more than 3 (three) seconds to new chip parts.

5. Avoid using a rubbing stroke when soldering

6. Take care not to scratch, or damage the chip parts when soldering.

7. Supplementary cementing is not required.

Chip Parts Removal (Resistors, Capacitors, etc.)

1. Grasp the part with tweezers.

2. Melt the solder at both sides alternately, and remove one side of the part with a twisting motion.

3. Melt the solder at the other side and remove the part.

Chip Parts Removal (Transistors)

1. Melt the solder of one lead and lift the side of that lead upward.

2. Simultaneously melt the solder of the other two leads and lift the part from the PCB.

Replacement

1. Pre-solder the contact points on the circuit pattern.

2. Press the part downward with tweezers and apply the soldering iron as shown.

Version 3.0

Page 38

Page 39

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

REPLACEMENT PARTS

Safety Critical Parts Designation

Safety Critical Components are indicated in the Parts List by Bold Type and a

They are indicated in the schem atic diagrams by a red hatch and a

The replacement for any safety critical part should be identical in value and characteristics.

Fuse Replacement Warning

Caution: For continued protection against risk of fire, replace only with the same type fuse. See parts list.

PWB-POWER

V45C, V45, V45CA, V45+, V45CB

F9000

F9004

F9003

125V 10A

125V 5A

125V 5A

Symbol.

symbol.

Version 3.0

F9A01

24V 6.3A

F9003

F9005

F9000

V45++

125V 5A

125V 10A

125V 10A

F9001

125V 5A

PWB-MAIN

Page 39

Page 40

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

[ # ] Model Legend: (a) WD-73640, (b) WD-73740, (c) WD-73840, (d) WD-73C11, (e) WD-7 3CA1, (f) WD-82740,

(g) WD-82840, (h) WD-82CB1, (i) WD-92840

Safety Critical Part - Use exact replacement only

Parts Quick Reference

Description Part Number #

PWB-MAIN 934C407001 ad

PWB-MAIN 934C407002 bf

PWB-MAIN 934C407003 cgi

PWB-MAIN 934C407016

PWB-MAIN 934C407017

PWB-POWER 934C409001 ade

PWB-POWER 934C409002 bfh

PWB-POWER 934C409003 cgi

PWB-SOUND 934C408001 cgi

PWB-CONTROL 934D162001 abdefh

PWB-CONTROL 934D162002 cgi

PWB-PREAMP 934D163001 ade

PWB-PREAMP 934D163002 bcfghi

PWB-SW-LAMP 934D164001

PWB-AUX 934D165001 cgi

BLUETOOTH-MODULE 938P213010 cgi

OPTICAL-ENGINE 938P197040

OPTICAL-ENGINE 938P197060 fgh

OPTICAL-ENGINE 938P197070 i

ASSY-PWB-BALLAST 938P198010

LAMP-CARTRIDGE 915B455011

COLOR-WHEEL 938P215010

PROJECTION-LENS 491P245010

FAN-SCIROCCO 299P321020

EXHAUST-FAN 299P356010

DMD-FAN 299P382010

REMOTE-CONTROL 290P187010 ade

REMOTE-CONTROL 290P187040 bcfghi

SCREEN-LENTICULAR 491P243030 abcde

SCREEN-LENTICULAR 491P243040 fh

SCREEN-LENTICULAR 491P231020 g

SCREEN-LENTICULAR 491P247010 i

LENS-FRESNEL 491P242060 abcde

LENS-FRESNEL 491P232010 fgh

LENS-FRESNEL 491P248010 i

MIRROR 73” KIT-MIR V45 73 abcde

MIRROR 82” KIT-MIR V45 82 fgh

MIRROR 92” KIT-MIR V45 92 i

e

h

abcde

Version 3.0

Page 40

Page 41

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

[#] Model Legend: (a) WD-73640, (b) WD-73740, (c) WD-73840, (d) WD-73C11, (e) WD-73CA1, (f) WD-82740, (g) WD-82840, (h) WD-82CB1, (i) WD-92840

[] Safety Critical Part - Use exact replacement only

Ref # Part # Part Name & Description

INTEGRATED CIRCUITS

IC1B01 271P349010 IC - MIC2005-0.5YM6

IC1B05 271P349010 IC - MIC2005-0.5YM6 cgi

IC1B06 276P578020 IC-C-MOS - MM3376A33NRE cgi

IC1F01 276P963010 IC-C-MOS - Si2153-A40-GM

IC2A01 276P726020 IC-C-MOS - 276P726

IC3A00 271P348010 IC - YDA164 abdefh

IC3F01 276P515010 IC-C-MOS - DIR9001PWR cgi

IC3G01 276P513010 IC-C-MOS - D708E001BRFP266 cgi

IC3H01 276P907010 IC-C-MOS - W9864G6JH-6 cgi

IC3J01 271P326020 IC - NJM2831F05 cgi

IC3J02 271P355010 IC - NJM2781V cgi

IC3J03 271P345010 IC - NJM2753V cgi

IC3J04 276P503010 IC-C-MOS - AK5358AETP cgi

IC3L01 276P828010 IC-C-MOS - PCM1681PWPR cgi

IC3L02 276P828010 IC-C-MOS - PCM1681PWPR cgi

IC3L03 276P741010 IC-C-MOS - AK4420ETP cgi

IC3L05 276P741010 IC-C-MOS - AK4420ETP cgi

IC3M01 276P930010 IC-C-MOS - LM48410SQ cgi

IC3M02 276P930010 IC-C-MOS - LM48410SQ cgi

IC3M03 276P930010 IC-C-MOS - LM48410SQ cgi

IC3M04 276P930010 IC-C-MOS - LM48410SQ cgi

IC3N01 276P930010 IC-C-MOS - LM48410SQ cgi

IC3N02 276P930010 IC-C-MOS - LM48410SQ cgi

IC3N03 276P930010 IC-C-MOS - LM48410SQ cgi

IC3N04 276P930010 IC-C-MOS - LM48410SQ cgi

IC3P01 271P254010 IC - ISL6545ACBZ-TS2698 cgi

IC4A01 276P742020 IC-C-MOS - PST8428NR

IC4A02 276P687030

IC4F01 276P744010 IC-C-MOS - NT5TU64M16DG-AC

IC4F02 271P033020 IC - LP2996LQNOPB

IC4F03 276P744010 IC-C-MOS - NT5TU64M16DG-AC

IC4G01 271P251040 IC - MM1662FHBE

IC4J01 276P950020 IC-C-MOS - TC58NVG0S3ETA00

IC7A01 276P576010

IC7D01 276P962010

IC9010 267P324010 HIC - STR-W6754

IC9020 271P142010 IC - RT9H301C

IC9030 271P315010 HIC - ST R-A6159

IC9031 271P142010 IC - RT9H301C

IC9A01 271P381010 IC - IR3842AMTRPbF

IC9A02 270P950020 IC - NJM78M05DL1A - TE1

IC9A03 271P379010 IC - TPS54326PWPR

IC9A04 271P379010 IC - TPS54326PWPR

IC9A05 271P380010 IC - TPS54426PWPR

IC9A07 271P321010 IC - PST8242NR

IC9A08 276P578020 IC-C-MOS - MM3376A33NRE

IC9A09 270P950010 IC - NJM78M09DL1A(TE1) bcfghi

IC9G80 271P349010 IC - MIC2005-0.5YM6

CHIP Type Transistors (Listed by Part No.)

261P842080 2SC3052-T112-1E;F

Q9012 261P227010 TR - FQPF27P06 bcfghi

261P844010 RT1N436C-T112-1

261P845010 RT1P241C-T1112-1

261P874010 FDS8896 cgi

261P875010 FDS8984

261P876010 FDS6298 cgi

261P877010 FDC655BN

261P878010 RT3Y97M-T111-1 cgi

261P937010 2SC3440-T112-F bcfghi

IC-C-MOS - BCM3549SLKFSB5G(B2)

IC-C-MOS - UPD78F1178GF(S)-GAT-AX

IC-C-MOS - uPD78F9500MA(S)-CAC-E2-A

TRANSISTORS

TRANSISTORS

Conventional Transistors (By Ref #)

[#]

bcfghi

Ref # Part # Part Name & Description

DIODES

D2A11 262P904070 DIODE-CHIP - DZ2J051M0L

D2A12 262P830010 D-CHIP - MC2850-T111-1

D2A13 262P830010 D-CHIP - MC2850-T111-1

D2A21 262P904070 DIODE-CHIP - DZ2J051M0L

D2A22 262P830010 D-CHIP - MC2850-T111-1

D2A23 262P830010 D-CHIP - MC2850-T111-1

D2A31 262P904070 DIODE-CHIP - DZ2J051M0L

D2A32 262P830010 D-CHIP - MC2850-T111-1

D2A33 262P830010 D-CHIP - MC2850-T111-1

D2A41 262P904070 DIODE-CHIP - DZ2J051M0L cgi

D2A42 262P830010 D-CHIP - MC2850-T111-1 cgi

D2A43 262P830010 D-CHIP - MC2850-T111-1 cgi

D4A05 262P830010 D-CHIP - MC2850-T111-1

D4A06 262P830010 D-CHIP - MC2850-T111-1

D7A04 262P828020 D-CHIP - MC2836-T112-1

D7E00 262P830010 D-CHIP - MC2850-T111-1 cgi

D8000 264P584020 DIODE-LE - SML1216W-C,D

D8305 262P230020 DIODE-LE - SID1G307C bcfghi

D8306 262P230020 DIODE-LE - SID1G307C bcfghi

D8307 262P230020 DIODE-LE - SID1G307C bcfghi

D9005 262P170010 DIODE - SARS01

D9006 262P203070 DIODE - UF4007

D9009 262P201060 DIODE - 1N4006

D9010 262P201060 DIODE - 1N4006

D9013 262P084010 DIODE - 31DQ06

D9014 264P774020 DIODE - MTZJ4.7A,B,CQLF

D9015 262P085010 DIODE - 11EFS2N-TA2B5

D9018 264P045080 DIODE - 1S2076A/1S2471OM

D9019 264P045080 DIODE - 1S2076A/1S2471OM

D9020 264P045080 DIODE - 1S2076A/1S2471OM

D9022 264P775080 DIODE - MTZJ6.2CQLF

D9023 262P085010 DIODE - 11EFS2N-TA2B5

D9024 262P085010 DIODE - 11EFS2N-TA2B5

D9026 262P208010 DIODE - FCHS10A12-15A

D9207 262P200010 DIODE - D6SB80-7001

D9A03 262P828010 D-CHIP - MC2838-T112-1

D9A04 262P900020 DIODE - FLZ5V6C T&R 2500/reel

D9A05 262P809010 D-CHIP - M1FS4-5063

D9A06 262P900010 DIODE - FLZ3V9A T&R 2500/reel

D9A08 262P900010 DIODE - FLZ3V9A T&R 2500/reel

D9A09 262P900010 DIODE - FLZ3V9A T&R 2500/reel

D9A12 262P828010 D-CHIP - MC2838-T112-1

D9A15 262P828010 D-CHIP - MC2838-T112-1

COILS

L1B01 409P975010 CHIP BEADS - MPZ2012S221A

L1B02 409P975010 CHIP BEADS - MPZ2012S221A

L1B03 409P985010 FILTER - MCZ1210AH900TA0G

L1B04 409P975010 CHIP BEADS - MPZ2012S221A cgi

L1B05 409P975010 CHIP BEADS - MPZ2012S221A cgi

L1B06 409P985010 FILTER - MCZ1210AH900TA0G cgi

L1B07 409P975010 CHIP BEADS - MPZ2012S221A cgi

L1B09 409P975010 CHIP BEADS - MPZ2012S221A cgi

L1D01 409P974010 CHIP BEADS - MMZ1608S601A bcfghi

L1F01 325C509020 COIL-CHIP - SDCL1005CR27JTDF

L1F02 325C509010 COIL-CHIP - SDCL1005CR22JTDF

L1F03 409P975010 CHIP BEADS - MPZ2012S221A

L1F04 409P975010 CHIP BEADS - MPZ2012S221A

L1F05 409P974010 CHIP BEADS - MMZ1608S601A

L1F06 409P974010 CHIP BEADS - MMZ1608S601A

L1F07 409P974010 CHIP BEADS - MMZ1608S601A

L2A01 409P974010 CHIP BEADS - MMZ1608S601A

L2A92 409P975010 CHIP BEADS - MPZ2012S221A

[#]

Page 41

Version 3.0

Page 42

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

[#] Model Legend: (a) WD-73640, (b) WD-73740, (c) WD-73840, (d) WD-73C11, (e) WD-73CA1, (f) WD-82740, (g) WD-82840, (h) WD-82CB1, (i) WD-92840

[] Safety Critical Part - Use exact replacement only

Ref # Part # Part Name & Description

L3A01 409P974010 CHIP BEADS - MMZ1608S601A abdefh

L3A02 409P974010 CHIP BEADS - MMZ1608S601A abdefh

L3A25 351P317070

L3A26 351P317070

L3A27 351P317070

L3A28 351P317070

L3F05 409P974010 CHIP BEADS - MMZ1608S601A cgi

L3F14 409P974010 CHIP BEADS - MMZ1608S601A cgi

L3F24 409P974010 CHIP BEADS - MMZ1608S601A cgi

L3G08 409P975010 CHIP BEADS - MPZ2012S221A cgi

L3G27 409P974010 CHIP BEADS - MMZ1608S601A cgi

L3H01 409P974010 CHIP BEADS - MMZ1608S601A cgi

L3J01 409P974010 CHIP BEADS - MMZ1608S601A cgi

L3J02 409P974010 CHIP BEADS - MMZ1608S601A cgi

L3J03 409P974010 CHIP BEADS - MMZ1608S601A cgi

L3J04 409P974010 CHIP BEADS - MMZ1608S601A cgi

L3K36 409P974010 CHIP BEADS - MMZ1608S601A cgi

L3L02 409P974010 CHIP BEADS - MMZ1608S601A cgi

L3L03 409P974010 CHIP BEADS - MMZ1608S601A cgi

L3L08 409P974010 CHIP BEADS - MMZ1608S601A cgi

L3L09 409P974010 CHIP BEADS - MMZ1608S601A cgi

L3L13 409P974010 CHIP BEADS - MMZ1608S601A cgi

L3L43 409P974010 CHIP BEADS - MMZ1608S601A cgi

L3M06 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3M07 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3M09 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3M10 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3M16 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3M17 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3M19 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3M20 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3M26 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3M27 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3M29 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3M30 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3M36 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3M37 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3M39 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3M40 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3N06 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3N07 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3N09 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3N10 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3N16 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3N17 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3N19 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3N20 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3N26 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3N27 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3N29 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3N30 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3N36 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3N37 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3N39 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3N40 409P975020 CHIP BEADS - MPZ2012S102A cgi

L3P01 409P975010 CHIP BEADS - MPZ2012S221A cgi

L3P02 409P975010 CHIP BEADS - MPZ2012S221A cgi

L3P03 409P975010 CHIP BEADS - MPZ2012S221A cgi

L3P04 409P975010 CHIP BEADS - MPZ2012S221A cgi

L3P06 409P975010 CHIP BEADS - MPZ2012S221A cgi

L3P08 409P975010 CHIP BEADS - MPZ2012S221A cgi

L3P09 409P975010 CHIP BEADS - MPZ2012S221A cgi

L3P12 351P314010

COIL-CHOKE-CHIP - PLC-1055-150S

COIL-CHOKE-CHIP - PLC-1055-150S

COIL-CHOKE-CHIP - PLC-1055-150S

COIL-CHOKE-CHIP - PLC-1055-150S

COIL-CHOKE-CHIP - MPLC1040L2R2

[#]

abdefh

abdefh

abdefh

abdefh

cgi

Ref # Part # Part Name & Description

L4A01 325C505060 COIL-CHIP - MLF2012A2R7J

L4B00 409P974010 CHIP BEADS - MMZ1608S601A

L4B01 409P974010 CHIP BEADS - MMZ1608S601A

L4B02 409P974010 CHIP BEADS - MMZ1608S601A

L4B03 409P974010 CHIP BEADS - MMZ1608S601A

L4B04 409P974010 CHIP BEADS - MMZ1608S601A

L4B05 409P974010 CHIP BEADS - MMZ1608S601A

L4B06 409P974010 CHIP BEADS - MMZ1608S601A

L4B07 409P974010 CHIP BEADS - MMZ1608S601A

L4B08 409P974010 CHIP BEADS - MMZ1608S601A

L4B09 409P974010 CHIP BEADS - MMZ1608S601A

L4B10 409P974010 CHIP BEADS - MMZ1608S601A

L4B11 409P974010 CHIP BEADS - MMZ1608S601A

L4F01 409P974010 CHIP BEADS - MMZ1608S601A

L4F02 409P974010 CHIP BEADS - MMZ1608S601A

L4G01 409P975010 CHIP BEADS - MPZ2012S221A

L4G02 409P975010 CHIP BEADS - MPZ2012S221A

L4G03 409P975020 CHIP BEADS - MPZ2012S102A

L4G04 409P975010 CHIP BEADS - MPZ2012S221A

L4G05 409P975010 CHIP BEADS - MPZ2012S221A

L4G06 409P975010 CHIP BEADS - MPZ2012S221A

L4G07 409P975010 CHIP BEADS - MPZ2012S221A

L4G08 409P975010 CHIP BEADS - MPZ2012S221A

L4G09 409P974010 CHIP BEADS - MMZ1608S601A

L4G10 409P974010 CHIP BEADS - MMZ1608S601A

L4G11 409P974010 CHIP BEADS - MMZ1608S601A

L4G12 409P974010 CHIP BEADS - MMZ1608S601A

L4G13 409P974010 CHIP BEADS - MMZ1608S601A

L4G14 409P974010 CHIP BEADS - MMZ1608S601A

L4G15 409P974010 CHIP BEADS - MMZ1608S601A

L4G16 409P974010 CHIP BEADS - MMZ1608S601A

L4G17 409P974010 CHIP BEADS - MMZ1608S601A

L4G18 409P974010 CHIP BEADS - MMZ1608S601A

L4G19 409P974010 CHIP BEADS - MMZ1608S601A

L4G20 409P974010 CHIP BEADS - MMZ1608S601A

L4G21 409P974010 CHIP BEADS - MMZ1608S601A

L4G22 409P974010 CHIP BEADS - MMZ1608S601A

L4G23 409P974010 CHIP BEADS - MMZ1608S601A

L4G24 409P974010 CHIP BEADS - MMZ1608S601A

L4G25 325C421020 COIL-CHIP - 68MH-K LOW-R

L4G26 409P974010 CHIP BEADS - MMZ1608S601A

L4G27 409P975010 CHIP BEADS - MPZ2012S221A

L7A01 409P974010 CHIP BEADS - MMZ1608S601A

L7A02 409P974010 CHIP BEADS - MMZ1608S601A

L8300 409P975010 CHIP BEADS - MPZ2012S221A

L9001 351P351010 LINE-FILTER - SC22-05-70J abdefh

L9001 351P387010 LINE-FILTER - SC22-06-60J cgi

L9002 351P351010 LINE-FILTER - SC22-06-70J abdefh

L9002 351P387010 LINE-FILTER - SC22-06-60J cgi

L9A01 351P350010

L9A03 409P975010 CHIP BEADS - MPZ2012S221A

L9A04 409P975010 CHIP BEADS - MPZ2012S221A

L9A05 351P370010

L9A07 409P975010 CHIP BEADS - MPZ2012S221A

L9A08 409P975010 CHIP BEADS - MPZ2012S221A

L9A09 351P370010

L9A10 409P975010 CHIP BEADS - MPZ2012S221A

L9A11 409P975010 CHIP BEADS - MPZ2012S221A

L9A12 409P975010 CHIP BEADS - MPZ2012S221A

L9A13 351P370010

L9A16 409P974010 CHIP BEADS - MMZ1608S601A

L9A17 409P974010 CHIP BEADS - MMZ1608S601A

L9A18 409P974010 CHIP BEADS - MMZ1608S601A

COIL-CHOKE-CHIP - CDRH105RNP-2R2NC

COIL-CHOKE-CHIP - VLP8040T-2R2N

COIL-CHOKE-CHIP - VLP8040T-2R2N

COIL-CHOKE-CHIP - VLP8040T-2R2N

[#]

Page 42

Version 3.0

Page 43

MODELS: WD-73640 / WD-73740 / WD-73840 / WD-73C11 / WD-73CA1 /

WD-82740 / WD-82840 / WD-82CB1 / WD-92840

[#] Model Legend: (a) WD-73640, (b) WD-73740, (c) WD-73840, (d) WD-73C11, (e) WD-73CA1, (f) WD-82740, (g) WD-82840, (h) WD-82CB1, (i) WD-92840

[] Safety Critical Part - Use exact replacement only

Ref # Part # Part Name & Description

L9A19 409P974010 CHIP BEADS - MMZ1608S601A

L9A20 409P974010 CHIP BEADS - MMZ1608S601A

L9A21 409P974010 CHIP BEADS - MMZ1608S601A

L9A22 409P974010 CHIP BEADS - MMZ1608S601A

L9A23 409P974010 CHIP BEADS - MMZ1608S601A

L9A26 409P974010 CHIP BEADS - MMZ1608S601A bcfghi

L9G80 409P975010 CHIP BEADS - MPZ2012S221A

L9G81 409P974010 CHIP BEADS - MMZ1608S601A

TRANSFORMERS

T1F01 339P013010

T4J01 409P984010 FILTER - MCZ2010AH121T000

T4J02 409P984010 FILTER - MCZ2010AH121T000

T4J03 409P984010 FILTER - MCZ2010AH121T000

T4J04 409P984010 FILTER - MCZ2010AH121T000

T4J05 409P984010 FILTER - MCZ2010AH121T000

T4J06 409P984010 FILTER - MCZ2010AH121T000

T9010 350P887010

T9020 350P879010

T9030 350P867010 TRANS-PWR - SRW16ESU37V014

RV9000 265P100040 VARISTOR - ERZV10D471CS

RV9001 265P100040 VARISTOR - ERZV10D471CS

103P401030 1/10W 100-J

103P400010 1/10W 10-J

103P408040 1/10W 2.2-J cgi

103P400050 1/10W 22-J

103P709050 1/16W 0 (max 1A) cgi

103P509050 1/16W 0OHM

103P692070 1/16W 1.2K-F

103P702070 1/16W 1.5K-J

103P701030 1/16W 100-J

103P501030 1/16W 100-J

103P701030 1/16W 100-J

103P501030 1/16W 100-J

103P701030 1/16W 100-J

103P697030 1/16W 100K-F

103P704090 1/16W 100K-J cgi

103P700010 1/16W 10-J cgi

103P694090 1/16W 10K-F

103P494090 1/16W 10K-F

103P694090 1/16W 10K-F

103P703070 1/16W 10K-J abdefh

103P503070 1/16W 10K-J bcfghi

103P703070 1/16W 10K-J

103P690030 1/16W 120-F

103P701040 1/16W 120-J

103P697050 1/16W 120K-F

103P705000 1/16W 120K-J

103P703080 1/16W 12K-J

103P690050 1/16W 150-F

103P703090 1/16W 15K-J cgi

103P701060 1/16W 180-J

103P495050 1/16W 18K-F

103P695050 1/16W 18K-F

103P692050 1/16W 1K-F cgi

103P492050

103P692050

103P702050 1/16W 1K-J cgi

103P502050 1/16W 1K-J cgi

TRANSFORMER - BW21S7511A01TF

TRANS-PWR - SRW2630EG-U10V015

TRANS-POWER - SRW2833EG-U06V016

VARIABLE RESISTORS

RESISTORS

CHIP Type Resistors (Listed by Value)

1/16W 1K-F