Page 1

MITSUBISHI DIGITAL ELECTRONICS

V19 / V21

PWB Level

Troubleshooting Guide

Page 2

V19 / V21

PWB Level Troubleshooting Guide

©2002 Mitsubishi Digital Electronics

9351 Jeronimo Rd.

Irvine, CA 92618

All Rights Reserved

iiii

Page 3

Table of Contents

V19 / V21 PWB Level Troubleshooting Guide

Introduction iii

Printed Circuit Board Layout 1

TROUBLESHOOTING

Shut-Down Problems 2

X-Ray Protection Failures 3

Horizontal Deflection Failures 4

Vertical Deflection Failures 5

TV Microprocessor Diagnostics 6

Color or Video Failures 7

QUICK REFERENCES

Power Supply 8

Main Board 9

Deflection Jungle 9

3DYC Module 10

CRT Drive 10

2HDW Module 11

Digital Module Assembly 12

Convergence Module and IC 13

iii

iiiiii

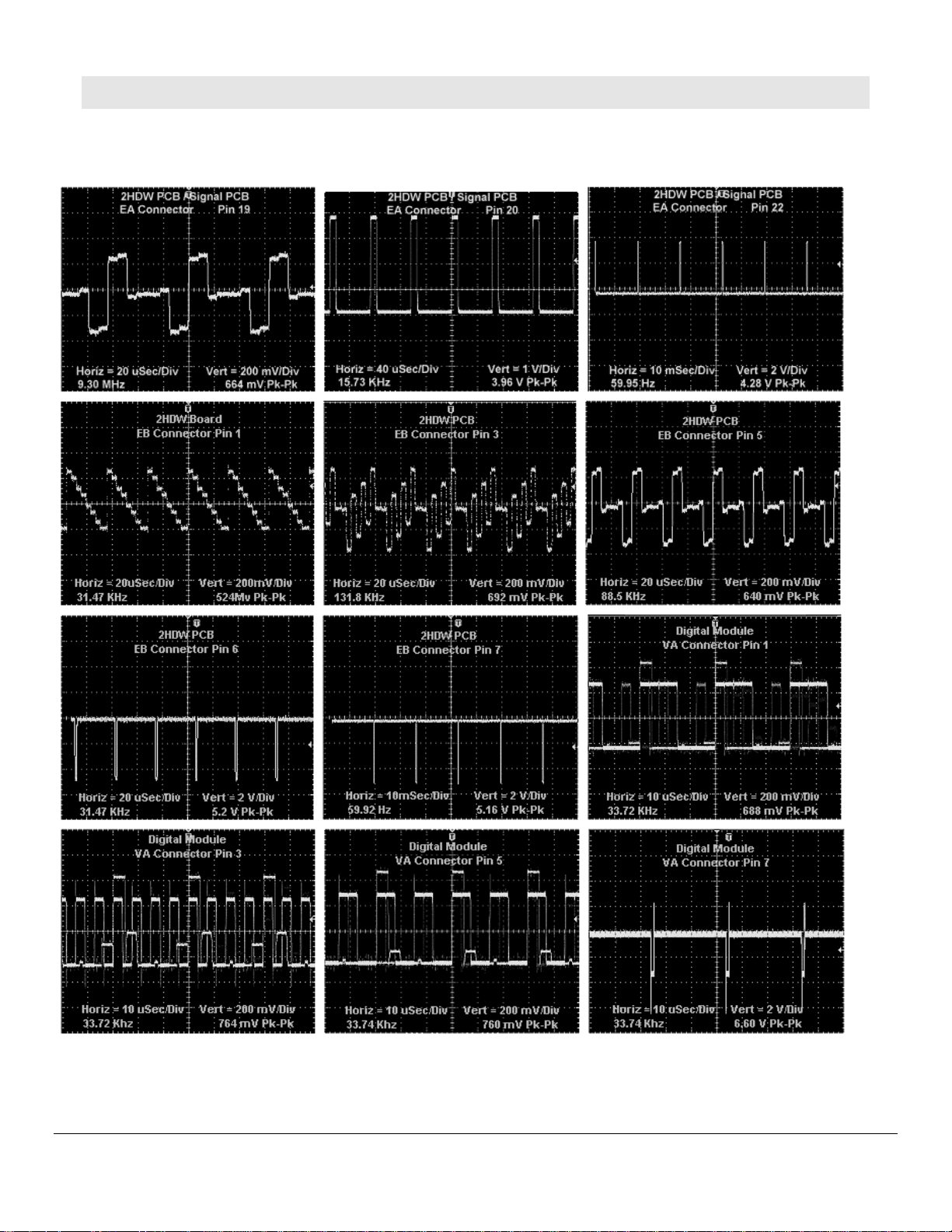

WAVEFORMS

KH, DR, DQ Connectors 14

DQ, EF Connectors 15

EF, RM, EA Connectors 16

EA, EB, VA Connectors 17

VA, DB, VD Connectors 18

VD Connector & IC8C01 19

IC8C01 20

IC8C01, IC9A20, IC9A50 21

ii

ii

iiii

Page 4

V19 / V21 PWB Level Troubleshooting Guide

Introduction

The purpose of this V19 / V21 PWB Level Troubleshooting Guide is to assist the servicer to quickly identify common

chassis test points, and to facilitate efficient servicing procedures in the field or service shop / depot. It is intended for use

in tandem with the Service manual as an aid to troubleshooting a set. Included are many major DC voltage measurements

and AC waveforms pertinent to proper operations of the chassis. In addition, troubleshooting procedures are provided for

some common service issues a Technician may encounter.

This guide is not intended to be used as a resource for technical training, circuit analysis, or adjustment procedures. Refer

to the V19 / V21 Technical Training guide and/or the Service manual which includes all schematics, parts lists, and

adjustment procedures for these purposes.

iii

iii

iiiiii

Page 5

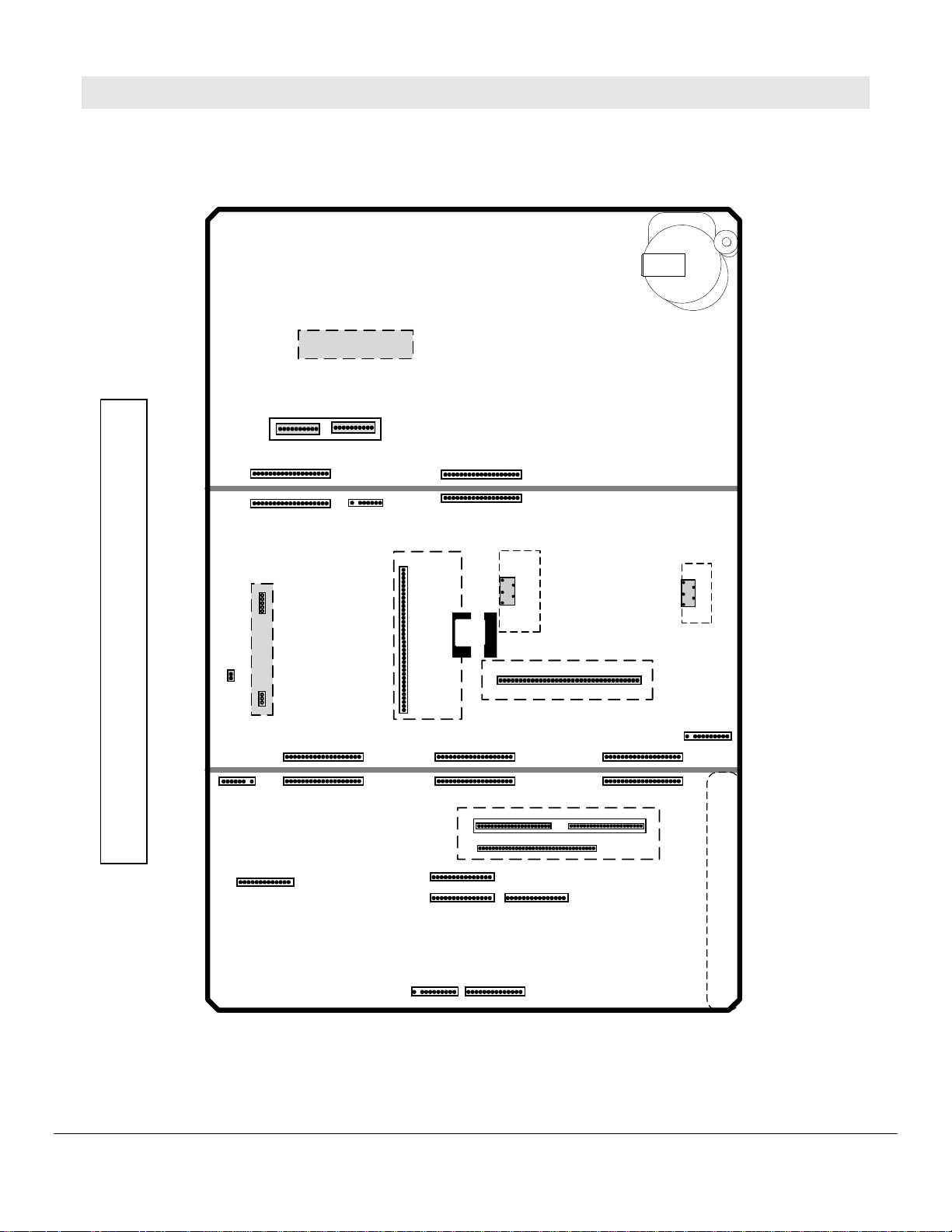

V19 / V21 PWB Level Troubleshooting Guide

DBF-PCB

Printed Circuit Board Diagram

RM

DR

KH KH

KKKA

SVM-PCB

FA

KE

PM

DQ

Jungle Module

KFKF

IC9A50

IC8C01

Heatsink As sy

KD

VD

Generator

Convergence

KC

2HDW-PCB

EB

Shield

Assembly

3DYC-PCB

EF

Shield

EA

IC9A20

Assembly

PF

VA

RF

DB

PCB-Signal PCB-Power PCB-Main

PCB Terminal

DA

1111

Page 6

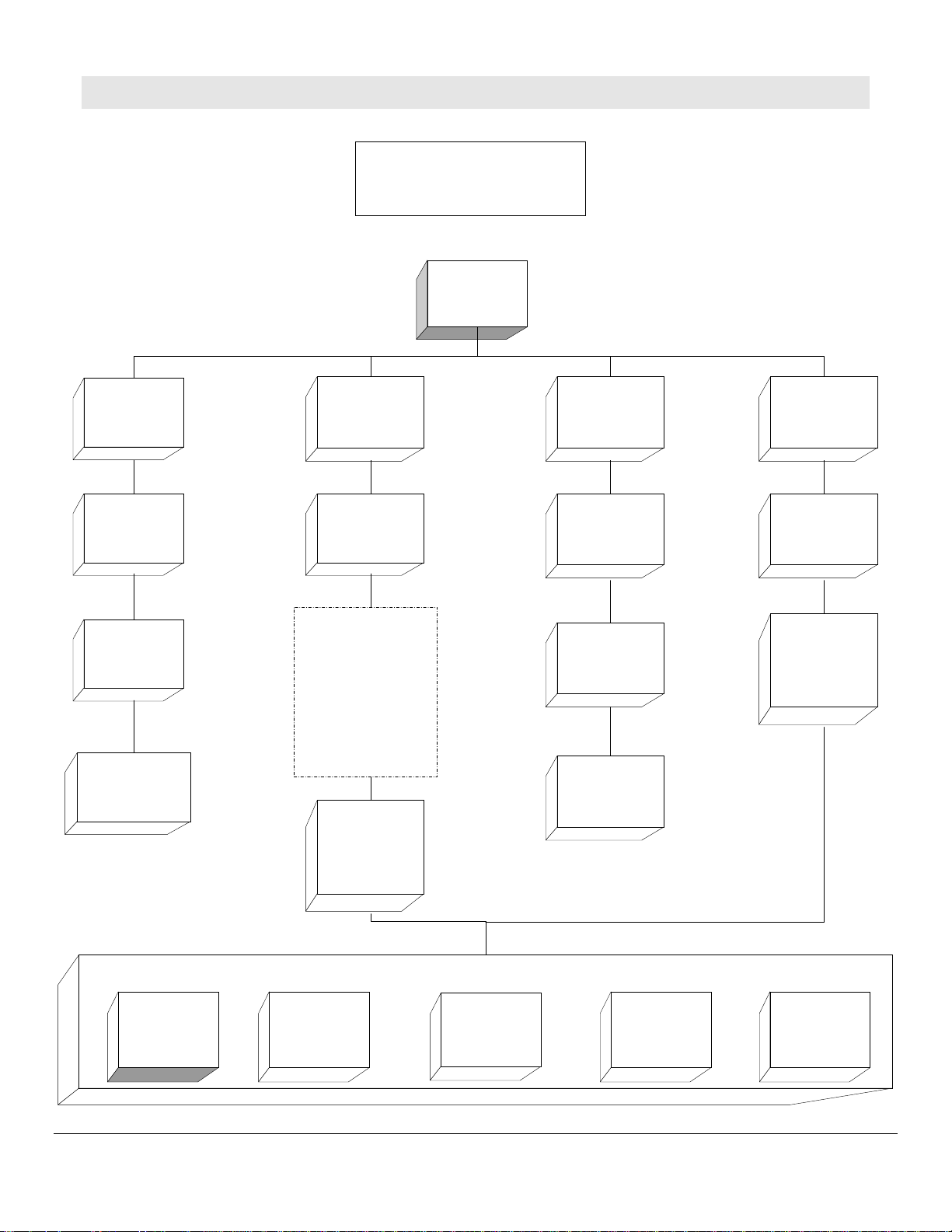

V19 / V21 PWB Level Troubleshooting Guide

Troubleshooting

Shut-Down

Problems

Initial

Front Panel

L.E.D. Status

Power

Applied

Off

Problem in

Standby Power

Supply or TV

Microprocessor

is not running

Check Standby

Supplies

Page 8

Check TV

Microprocessor

IC7A00

Page 6

Fast Blink

70 Seconds

Only

Normal

Operation

If the Light Box is

removed from the

cabinet without the

front panel control

assembly, be sure to

wait 70 seconds prior

to turning on the TV.

There is no visual

indicator to remind you

of the delay while the

DM is in the process of

booting.

If Set Shuts

down after

power-up,

continue Shut-

Down

troubleshooting

Fast Blink

Continuous

TV

Microprocessor is

running, DM

failed to boot.

UnPlug Set, wait

30 seconds and

try again.

Replace DM

Assembly

Slow

Blink

Normal Operation

TV "On" Timer is

active.

If Set Shuts

down upon

power-up,

continue Shut-

Down

troubleshooting

1 then 2 flashes

Normal

Operation

While the set is OFF, Press and hold the Front Panel "Device" and "Menu" Buttons for five seconds

Check the Status of the Flashing L.E.D. on the front panel

2 then 1 flash,

X-Ray Protect

Problem. Go to

Page 3

2 then 2 flashes,

Short Circuit

Protect. Go to

Power Supply

Page 8

2 then 3 flashes,

Horizontal

Deflection

failure. Go to

Page 4

2222

2 then 4 flashes,

Vertical

Deflection

failure.

Go to Page 5

Page 7

Caution !

V19 / V21 PWB Level Troubleshooting Guide

Troubleshooting Shut-Down Problems

X-Ray Protect

Prior to the diagnostics of these issues, it is imperative that you disable the CRT's to prevent phosphor damage.

Do so by removing Connector SP, which removes filament voltage, or removing each CRT-PCB.

With CRT's disabled

Check HV Block

for arcing

Check Anode

Caps, Spark

Gaps on PCB-

CRT

Unit Shuts

Down

Is there HV

Arcing evident?

NoYes

Check HV

Block for short

or open

N.G. Good

Unit Now

Operates

N.G.

Check High

Voltage

32 KV

Normal High

Check IC5A02

Check IC5A03

Check FBT Pin 8 (2.8 V)

Check Voltage at Cathode

of D5A57 (18.4 V)

Low

Check IC5A00 - IC5A01

Check all Peripheral

Good

Components

Normal

Check CRT-

Sockets. Check

CRT's

Replace HV

Block

Replace Main

PCB

Replace FBT

3333

Page 8

Caution !

V19 / V21 PWB Level Troubleshooting Guide

Troubleshooting Shut-Down Problems

Horizontal Deflection Failure

Do so by removing Connector SP, which removes filament voltage. Also remove D5A13 on the Main PCB to disable the deflection shut-down circuitry

If Missing, Replace

PWB-Signal

Prior to the diagnostics of these issues, it is imperative that you disable the CRT's to prevent phosphor damage.

KE Connector

Pin

17

PWB Signal

Out Out

20 uSec / Div

2.00 V / Div

0.48 V DC

31.5 KHz

4.24 V Pk-Pk

KH Connector

In

Pin

3

PWB Main

If Missing, Replace

PWB-Main

If waveform is missing,

check pin 2 of FB connector

(PWB-Jungle)

Normal

4.4 V

Replace

PWB-Jungle

Low

Replace

PWB-Signal

Waveform

Good

Replace

PWB-Main

20 uSec / Div

2.00 V / Div

4444

31.5 KHz

7.96 V Pk-Pk

3.6 V

DQ Connector

Pin

5

Pin

Out

PWB Jungle

In

3

Page 9

Caution !

V19 / V21 PWB Level Troubleshooting Guide

Troubleshooting Shut-Down Problems

Vertical Deflection Failure

Do so by removing Connector SP, which removes filament voltage. Also remove D5A13 on the Main PCB to disable the deflection shut-down circuitry

If Missing, Replace

PWB-Signal

Prior to the diagnostics of these issues, it is imperative that you disable the CRT's to prevent phosphor damage.

KE Connector

Pin

18

PWB Signal

Out Out

10 mSec / Div

20 uSec / Div

2.00 V / Div

2.00 V / Div

0.46 V DC

31.5 KHz

59.95 Hz

4.24 V Pk-Pk

4.12 V Pk-Pk

KH Connector

In

PWB Main

If Missing, Replace

PWB-Main

Pin

2

If waveform is missing,

check pin 2 of FB connector

(PWB-Jungle)

Normal

4.4 V

Replace

PWB-Jungle

Low

Replace

PWB-Signal

Waveform

Good

Replace

PWB-Main

4 mSec / Div

20 uSec / Div

200 mV / Div

2.00 V / Div

DR Connector

Pin

2

3.6 V

Out

PWB Jungle

59.95 Hz

31.5 KHz

772 mV Pk-Pk

7.96 V Pk-Pk

5555

In

Pin

6

Page 10

V19 / V21 PWB Level Troubleshooting Guide

TV Microprocessor

Diagnostics

IC7A00

Pin 82

Power Good/ Line

0 V

Pin 99

AVCC

5 V

Pin 5

VCC

Pin 1

Reset

5 V

WatchDog IC

5 V

IC7A02

Pin 2

Gnd

Pin 73

Watch Dog Sense

Pulse Waveform

80

Pin 62

5V Stby.

IC7A00

130

Pin 12

Reset

5V

Pin 4

WatchDog Input Data

Pulse Waveform

Pin 3

Master Reset

5 V

Pin 60 & 61

EEPROM Data & Clock

Pin 16

5V Stby.

4.4 V

Pin 46

Short Sense Line

Pin 20

AC-Off

Pin 13 & 15

10 MHz.Xtal Osc.

2.7 V

Waveform

Page 21

Pin 1

12 V Input

5 V

5 V

50

5 V

Regulator

IC9C00

Pin 2

Gnd

Pin 47

X-Ray Sense Line

5 V

Pin 40 & 41

Stby Clock

and Data

4.4 V

Pin 3

5 V Output

Check the following for a No Start Condition

1) Check 5V Supplies to IC on Pins 16, 62, and 99.

All 5V Supplies are sourced from IC9C00, Pin 3

2) Check Reset Pin 12

3) Check for Oscillator operation on Pins 13 and 15

4) Check AC-Off on pin 20, should be High.

5) Check Power Good line Pin 82. Should be Low.

6) Check clock and data signals, Pins 40, 41, 60, and 61.

7) Check for presence of WatchDog pulse on Pin73

Check the following for a Shut-down Condition

1) Check Pin 47, X-Ray Sense line.

This monitors high voltage and Arc-Protection on

the Main PWB. If there is a defect here, go to

deflection troubleshooting procedures.

2) Check Pin 46, Short-Sense line.

This monitors the + /- 24 supplies from the main

power supply, in addition to a 12 V standby supply.

If there is a defect here, go to the power supply

troubleshooting procedures.

6666

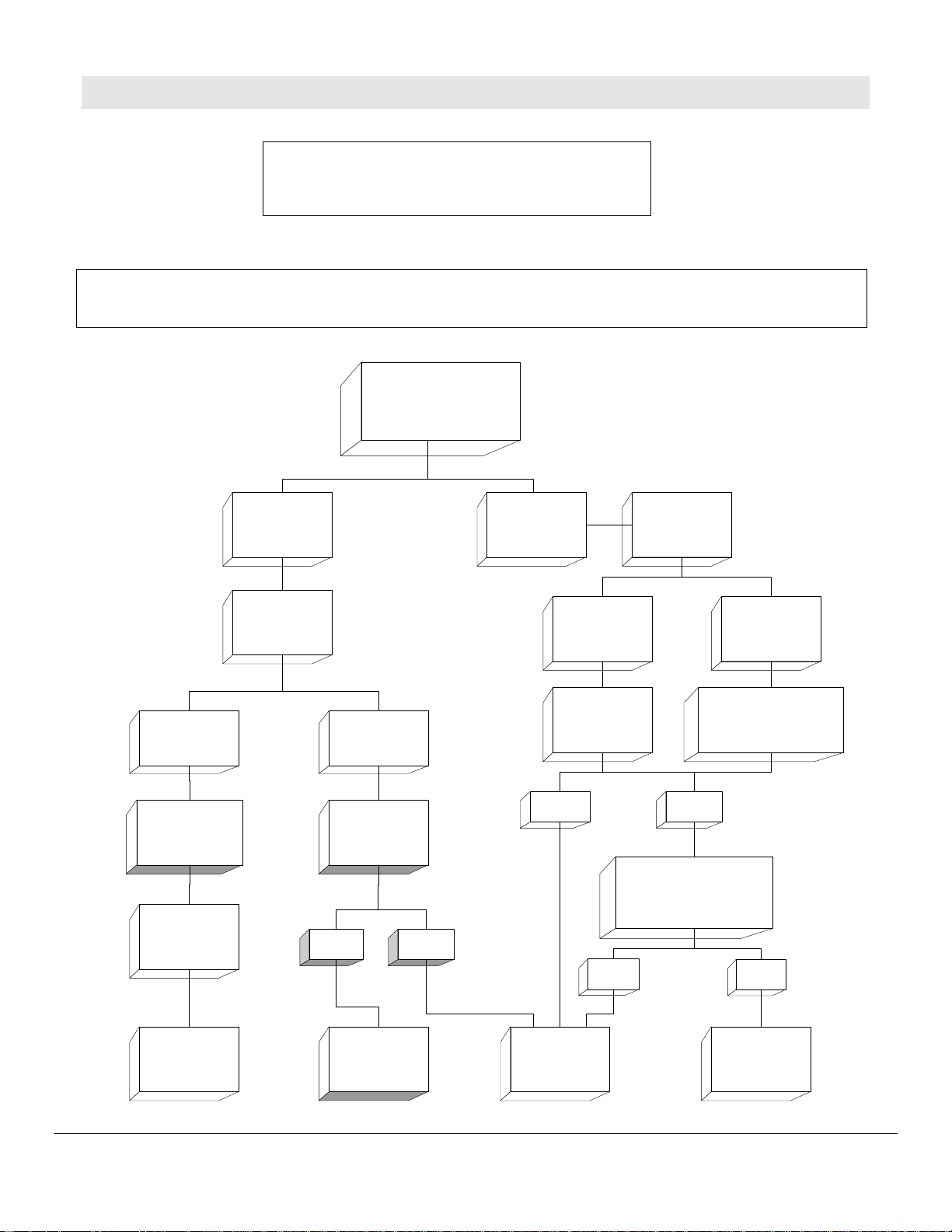

Page 11

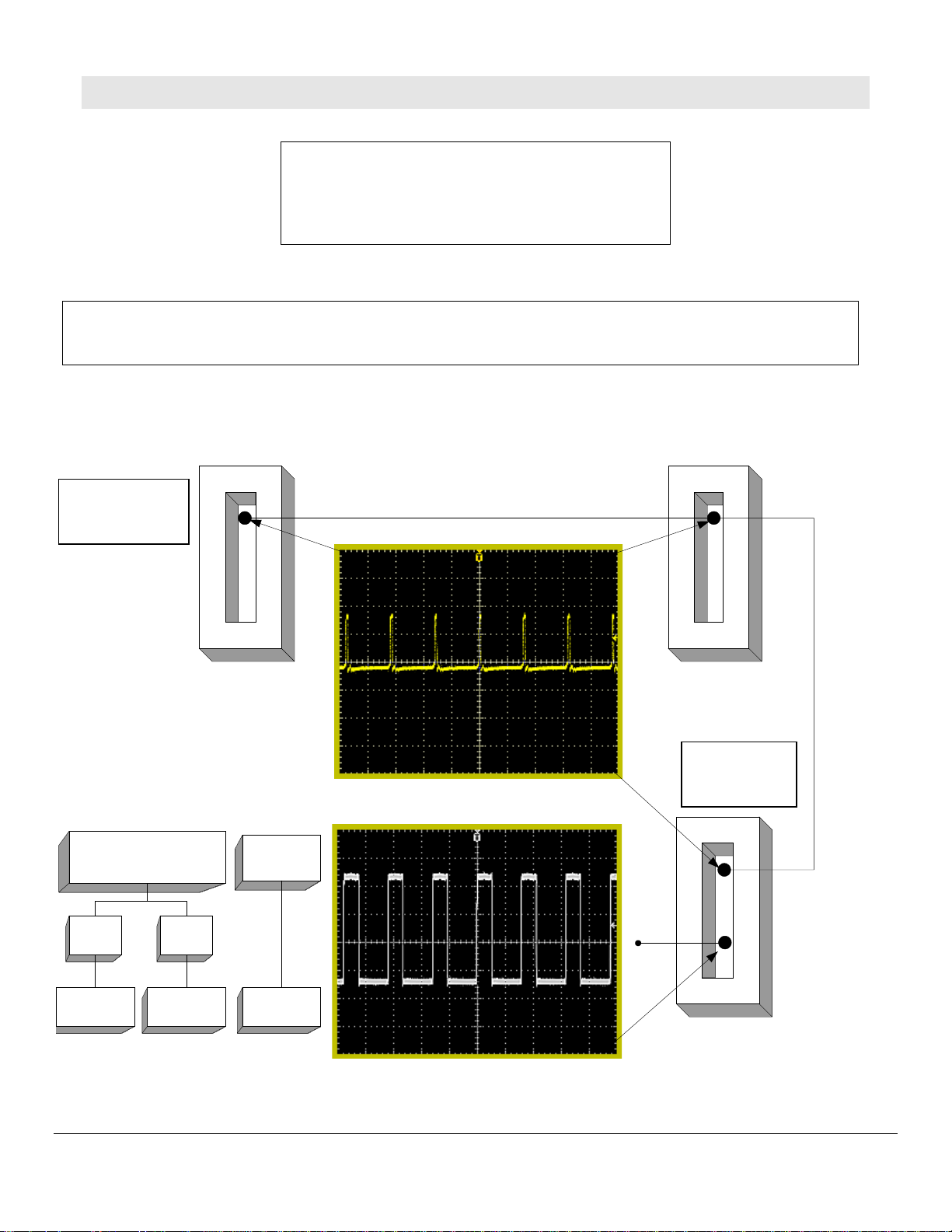

V19 / V21 PWB Level Troubleshooting Guide

Verify

DC Voltages

and Waveforms prior

to PCB replacement

All Inputs

2HDW

Test

Input a 480P signal to a

component input.

Switch screen Format

between "Standard" and

"Narrow".

PCB

Defect in Color or Video

PCB

2HDW

3DYC

Which Video

Source Input

Shows a defect?

Component PIP Tuner Input 1-5

3DYC

Test

Input Tuner A and

Input 1 NTSC 480i

signal source. Invoke

PIP. Compare Main

picture to PIP Picture

Compare ANT-DTV or

IEEE-1394 input to

any other source

Page 4

Page 3

ANT-DTV

IEEE-1394

DM

Test

Both formats N.G.,

Perform DM Test

If DM signal source is

Defective Signal

good,

Standard Format Good,

Defective 2HDW PCB

Standard Format N.G.

Defective Signal PCB

PCB

Narrow Format N.G.

Narrow Format Good

Main Good

PIP N.G.

Perform 2HDW test

Using 480i source

Main picture N.G.

PIP Good

Defective 3DYC PCB

Main Picture N.G.

PIP Picture N.G.

Perform 2HDW Test

7777

DM Source Good

Other Source N.G.

Perform 2HDW test

DM Picture N.G.

Other Source Good

Defective DM

Both Sources N.G.

Defective Signal PCB

or CRT Drive

Page 12

V19 / V21 PWB Level Troubleshooting Guide

Power Supply

Quick Reference

Power-Pcb Signal-PCB

IC9A20

5

4

3

2

1

IC9A50

5

4

3

2

1

StandBy Supplies

Start-up

Resistor

0.7v

R9A22

16.0V

Ground

0V

163 V

Waveform Page

to PCB-Signal

24V

FA

2

Connector

110V

5KAConnector

Note; 12 V Switched, + / - 24 V Supplies are monitored

by the "Short Sense" line to the TV Microprocessor pin 46

T9A20

21

Off-Board Connectors

to SVM-PCB

D9A33

to CRT-PCB's

220V

12V

Connector

13

12V

1

Connector

D9A30

12 Vs

6Vs

PM

KK

Ref 4V

Switched Supplies

Ground

16.9V

163 V

0V

0.7V

Start-up

Resistor

R9A50

Waveform Page

Refer to Page 1, Printed Circuit Board Diagram, for component and connector locations

21

T9A50

8888

12 Stby

6V in

Q9A22

IC9A22

5

2

D9A57

D9A58

D9A56

D9A60

D9A61

Q9A20

3

1

4

C 36.0V

B 32.6V

E 32.0Vs

220V

110V

19V

24V

-24V

12V Switched

P-on2

Timer Recording

Voltages

Out 5V

D9A35

28 Vs

PF Connector

1

3

4

5

6

7

8

9

10

11

Power-PCB

Gnd

Gnd

Gnd

Gnd

Gnd

12Vs

12Vs

12Vs

12Vs

28Vs

DM

KC Connector

KF Connector

Power-PCB

Gnd

1

Gnd

2

Gnd

3

Gnd

4

Gnd

5

Gnd

6

Gnd

7

6Vs

8

6Vs

9

10

5V

5V

11

12V

12

12V

13

12V

14

12Vs

15

12Vs

16

32Vs

17

P-on2

18

P-on1

19

1

2

3

4

12Vs

5

6

24V

7

8

24V

Gnd

9

10

Gnd

11

Gnd

Gnd

12

Gnd

13

Gnd

14

15

16

110V

17

110V

18

110V

19

Main-PCB

Page 13

V19 / V21 PWB Level Troubleshooting Guide

Main-PCB

Jungle-PCB

Quick Reference

Power-PCB

KH Connector

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Main-PCB

ID In/O ut DC Waveform

G n d - - -

VD Out .46 P age 14

HD Out .48 Page 14

FP In 0 -

G n d - - -

VTIM O ut .26 Page 14

SC P O ut .95 Page 14

AC L Out 2.8 -

N /C - - -

VB lank O ut 0 -

X-Ray In 5.0 -

N /C - - -

N /C - - -

SC L-Stby I/O 4.5 Data

H-Pulse Out .51 Page 14

Gnd5 - - -

V-Pulse Out .26 Page 14

SD A-Stby I/O 4.5 D ata

HV -Adj O ut 2.0 -

Waveform DC In/O ut ID

- - - H-Gnd

Page 14 4.0 Out Side_Pin

Page 15 3.6 Out H_Drive

Page 15 .57 In H_Pulse

Page 15 .47 In HD

- 9.0 Out FH_Status

- 5.13 Out F33k

- - - N/C

- 9.0 In 9Vsb

- 9.0 In 9Vsb

Refer to Page 1, Printed Circuit Board Diagram, for component and connector locations

Jungle-PCB

DQ Connector

10

1

2

3

4

5

6

7

8

9

Main-PCB

9999

Waveform DC In /O ut ID

Page 14 .95 In SCP-2H

Page 14 .45 In VD

Page 14 .26 In V_Timing

Page 14 0 Out V_Saw

- - - V -Gn d

Page 14 3.4 Out VDRV -

N/A N/A N/A VDRV+

- 12.0 In 12Vsb

Data 4.4 I/O SDA 5

Data 4.4 I/O SC L5

Jungle-PCB

Main-PCB

DR Connector

1

2

3

4

5

6

7

8

9

10

Page 14

V19 / V21 PWB Level Troubleshooting Guide

3DYC-PCB

CRT Drive

Quick Reference

Signal-PCB

EF Connector

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

3DYC-PCB

ID In /O ut DC Waveform

Gn d - - -

3D_Hsync In .58 Page 15

Gn d - - -

3D_Vsync In .15 Page 15

M _F run - - -

3D_Csync In 4.7 Page 15

NT_Sw In - -

3D_Pb Out 3.0 Page 15

Gn d - - -

3D_Pr Out 3.0 P age 15

Gn d - - -

3D-Y Out 2.8 P age 15

Gn d - - -

SDA-3D I/O 4.4 Data

SCL-3D I/O 4.4 Data

9V-1 In 9.0 -

9V-1 In 9.0 -

Kil In 0 -

3DRst In 5.0 -

5V In 5.0 -

5V In 5.0 -

Gn d - - -

Gn d - - -

VY_3D YC In 3.76 Page 15

Gn d - - -

C_3DY C In 2.62 Page 15

Gn d - - -

Gn d - - -

Gn d - - -

Y-Mon O ut 2.62 Page 15

Gn d - - -

C-Mon O ut 2.6 P age 16

Gn d - - -

Gn d - - -

Gn d - - -

CRT-PCB's

Signal-PCB

RM Connector

1

3

4

5

6

7

8

CRT Drive

Signal-PCB

ID In/Ou t DC Waveform

R_Out Out 2.9 Page 16

- - - -

Gnd - - -

G_Out Out 3.13 Page 16

Gnd - - -

B_Out Out 2.9 Page 16

Gnd - - -

Ik In 2.0 Page 16

Refer to Page 1, Printed Circuit Board Diagram, for component and connector locations

10

10

1010

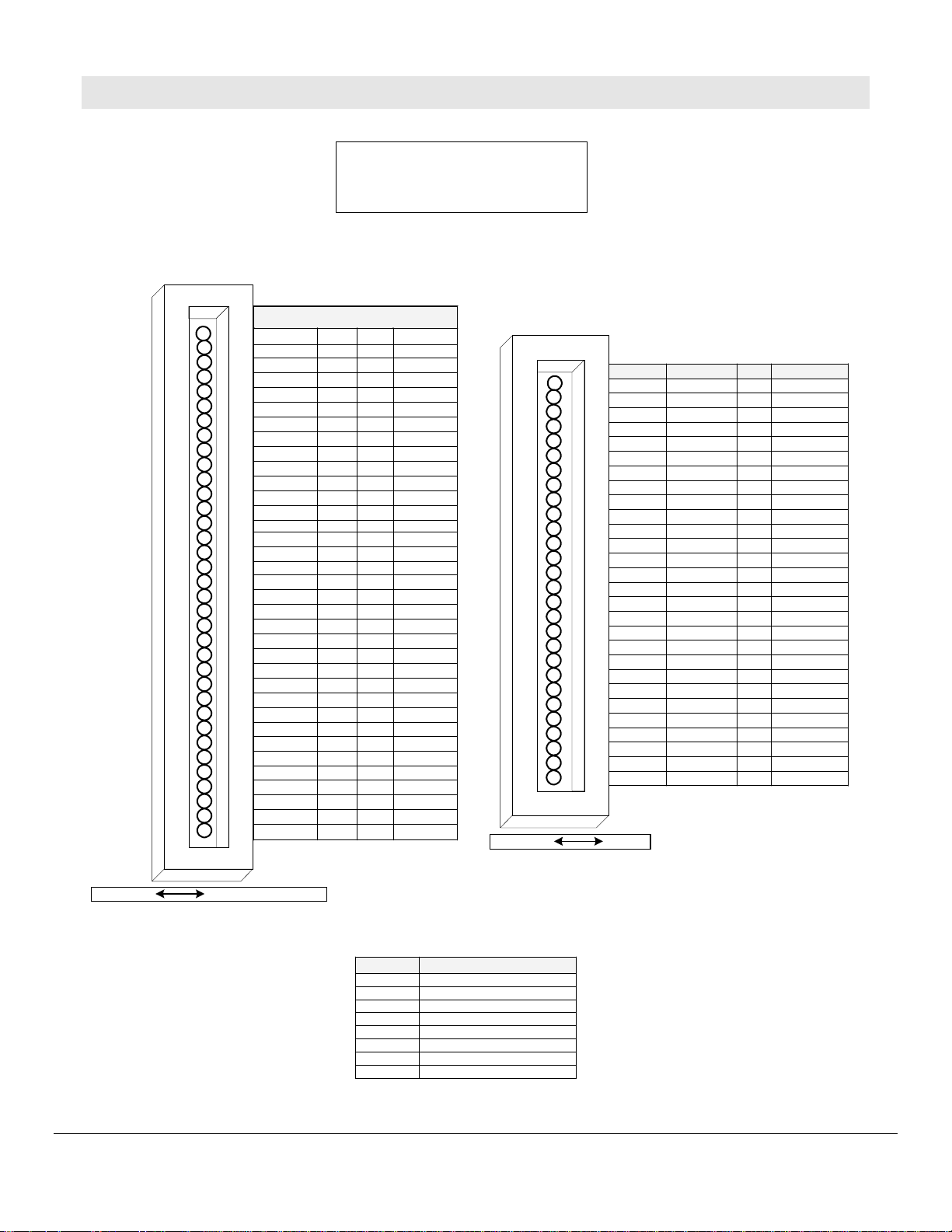

Page 15

EA Connector

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

Signal-PCB

2HDW (Line Doubler) PCB

Quick Reference

ID In/O u t DC Waveform

PIP-Y In 3.0 Page 16

Gnd - - -

PIP-PB In 2.85 Page 16

Gnd - - -

PIP-PR In 2.83 Page 16

PIP-H In .58 Page 16

Gnd - - -

PIP-V In .16 Page 16

3.3V In 3.3 -

3.3V In 3.3 -

Gnd - - -

Gnd - - -

9V-2 In 9.0 -

Gnd - - -

AMDP-Y-In In 2.36 Page 16

Gnd - - -

AMDP-PB-In In 2.2 Page 16

Gnd - - -

AMD-PR-In In 2.2 Page 17

Main-H In .58 Page 17

Gnd - - -

Main-V In .15 Page 17

Waveform DC In/Out ID

2HDW-PCB

Page 17 2.25 Out Y-AMDP

- - Gnd

Page 17 2.65 Out PB-AMDP

- - Gnd

Page 17 2.65 Out PR-AMDP

Page 17 4.5 Out H-AMDP

Page 17 4.8 Out V-AMDP

- - - G nd

- - Out YS-AMDP

- - - G nd

- - Out FP

- - - N /C

- - In 5 V- A

- - In 5V

- - - G nd

Data 3.8 I/O SDA-AMDP

Data 3.8 I/O SCL-AMDP

- - - G nd

Data .18 I/O CS-AMDP

Data 5.0 I/O Clk

Data 3.18 In D _In

Data 5.0 Out D_Out

V19 / V21 PWB Level Troubleshooting Guide

2HDW-PCB

EB Connector

Signal-PCB

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

Refer to Page 1, Printed Circuit Board Diagram, for component and connector locations

11

11

1111

Page 16

V19 / V21 PWB Level Troubleshooting Guide

Digital Module

Quick Reference

Signal-PCB

Signal-PCB

DM Assembly

VA Connector

1

2

3

4

5

6

7

8

9

10

11

12

13

DA Connector

1

2

3

4

5

6

7

8

9

10

11

12

13

14

ID In/Out DC Waveform

DM-G Out 2.4 Page 17

Gnd - - -

DM-B Out 2.4 Page 17

Gnd - - -

DM-R Out 2.4 Page 17

Gnd - - -

DM-H Out 3 .11 Page 17

DM-V Out 3 .22 Page 18

Gnd - - -

DSP-H In .44 Page 18

DSP-V In 0 Page 18

Gnd - - -

Masking Out 0 High = OSD on

DM Assembly

ID

L-DM Out HD Audio

Gnd - - -

R-DM Out HD Audio

Gnd - - -

DM _Reset In 0V -

Powergood Out 0V

TV-DM_RTS I/O Data

TV-DM_CTS I/O Data

DM_Rxd I/O Data

Gnd - - -

TV-DM_Txd I/O Data

DMDetect Out 0V

IR_In_Busy Out Data

IR_Out_ENA In Data

In/Ou t DC Waveform

DM Assembly

Waveform DC In/O ut ID

Page 1 8 .9 In Ma in -Y

- - - G nd

Page 18 2.2 In M ain-CB

- - - G nd

Page 18 2.2 In M ain-CR

- - - G nd

Page 18 4.7 In Main_Sync

- - - N /C

- - - G nd

- 5.0 Out TV_Reset

- - - G nd

Page* 18 .9* Out Y-DM

- - - G nd

Page* 18 .9* O ut C-DM

- - - G nd

* Available in HDTV or

OSD Modes Only

DM Assembly

Power-PCB

PF Connector

Gnd

1

3

Gnd

4

Gnd

Gnd

5

Gnd

6

12Vs

12Vs

12Vs

12Vs

32Vs

7

8

9

10

11

Signal-PCB

DB Connector

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Voltages and Waveforms taken in 480i mode except where indicated

Refer to Page 1, Printed Circuit Board Diagram, for component and connector locations

12

12

1212

Page 17

Convergence Generator

VD Connector

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

C_E2Reset In 5.0 -

C_Mute In 5.0 -

C-Reset In 5.0 -

C_Busy I/O 4.5 -

HPulse In .56 Page 18

HV-Adj In 1.8 -

VPulse In .25 Page 18

C_OSDr Out 0 -

C_OSDg Out 0 -

C_OSDb Out 0 -

Convergence

Quick Reference

ID In /

N/C - - -

12V In 12.0 -

C_Ack I/O 4.8 -

C-Sda I/O 4.2 Data

C_Scl I/O 4.2 Data

N/C - - -

Gn d - - Gn d - - -

N/C - - -

N/C - - -

C_Blk Out - -

5V In 5.0 -

N/C - - -

Gn d - - -

Gn d - - -

Gn d - - -

9V In 9.0V -

DF Out -1.7 Page 18

-9V In -9 .0 -

BV O ut .12 Pag e 19

GV Out 0 Page 19

RV Out 0 Page 19

BH O ut .5 Page 1 9

GH O ut .14 Pag e 19

RH O ut .15 Pag e 19

Out

DC Waveform

V19 / V21 PWB Level Troubleshooting Guide

Convergence IC

IC8C01

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Power-PCB

ID In / Ou t DC Waveform

BH In .257 Page 19

-BH Yoke Return .257 Page 19

+BH Out .45 Page 19

+GH Out .20 P age 19

-GH Yoke Return 0 Page 19

GH In 0 Page 19

RH In .28 Page 20

_RH Yoke Return .28 Page 20

+RH Out 0 Page 20

-VCC In -24 -

N/C - - -

VCC In 24 -

Pre+VCC In 24 -

Gnd - - -

Pre-VCC In -24 -

-VCC2 In -24 -

Gnd - - -

Vcc2 In 24 -

Mute In 5.0 -

+RV Out 0 Page 20

-RV Yoke Return 0 Page 20

RV In 0 Page 20

GV In 0 Page 20

-GV Yoke Return .1 Page 20

+GV Out 0 Page 20

+BV Out .1 Page 21

-BV Yoke Return .2 Page 21

BV In .2 Page 21

IC8C01

Power-PCB

Convergence Generator

Partial Glossary

ID Definition

C_E2Reset Reset Pulse from EEPROM

C_Ack Convergence Acknowledge

C_SDA Conver gence Serial Data

C_SCL Convergence Serial Clock

HPulse Horizontal Pulse

VPulse Vertical Pulse

C_OSD Convergence On Screen Display

DF Dynamic B eam Forming Pulse

Refer to Page 1, Printed Circuit Board Diagram, for component and connector locations

13

13

1313

Page 18

V19 / V21 PWB Level Troubleshooting Guide

14

14

1414

Page 19

V19 / V21 PWB Level Troubleshooting Guide

15

15

1515

Page 20

V19 / V21 PWB Level Troubleshooting Guide

16

16

1616

Page 21

V19 / V21 PWB Level Troubleshooting Guide

17

17

1717

Page 22

V19 / V21 PWB Level Troubleshooting Guide

18

18

1818

Page 23

V19 / V21 PWB Level Troubleshooting Guide

19

19

1919

Page 24

V19 / V21 PWB Level Troubleshooting Guide

20

19

1919

Page 25

V19 / V21 PWB Level Troubleshooting Guide

Loading...

Loading...