Page 1

LOSSNAY

HAND BOOK

(For EUROPE and OTHERS)

Issued January 2002 No. U-042

Model:

LGH-15RX

3-E

LGH-25RX

3-E

LGH-35RX

3

-E

LGH-50RX

3-E

LGH-80RX3-E

LGH-100RX

3-E

LGH-100RX

3-E-60

LGH-150RX

3-E

LGH-200RX3-E

LGH-200RX

3-E-60

Notice:

The term of validity is for a year from the issued date.

MITSUBISHI ELECTRIC CORPORATION

Model name

The picture is shown LGH-100RX3-E

FOR DEALERS

Page 2

Contents

Safety precautions........................................................................2

1. Specifications...................................................................... 3~6

2. Dimensions ....................................................................... 7~10

3. Wiring diagrams.............................................................. 11~12

4. Maintenance procedures................................................. 13~19

4-1 Blower Parts................................................................. 13~14

4-2 Damper Movement Motor Part (All units available) ............ 15

4-3 Circuit Board Part......................................................... 15~19

5. Parts list .......................................................................... 20~68

LGH-15RX

3-E............................................................... 21~26

LGH-25RX3-E............................................................... 27~32

LGH-35RX3-E............................................................... 33~38

LGH-50RX3-E............................................................... 39~44

LGH-80RX3-E............................................................... 45~50

LGH-100RX3-E (-60).................................................... 51~56

LGH-150RX

3

-E............................................................. 57~62

LGH-200RX

3-E (-60).................................................... 63~68

Page 3

—2——2—

Electric shock

Prohibited

Instructions must be followed

♦♦

Electric shock

If you have to inspect the circuitry while power

is being conducted, be sure you do not touch

the live parts.

(Failure to heed this warning may

result in electric shock.)

♦♦

Modification is prohibited

Do not modify the unit.

(Failure to heed this warning may result

in electric shock, bodily injury or fire.)

♦♦

Proper electric work

The specified electric wires should be used for

electric work, which should be done in accordance with the "Electrical Installation

Engineering Standard," "Indoor Wiring

Regulations," and the Installation Work Guide.

(Failure to heed this warning may result in electric shock or fire.)

♦♦

Caution for bodily injury

Do not perform any work at a location where your feet are unstable.

(Failure to heed this caution may result in bodily injury.)

♦♦

Shut off the power supply

Be sure to shut off the breaker before disassembling the unit for repair.

(Failure to heed this warning may

result in electric shock.)

♦♦

Use proper parts and tools

For repair, use the parts listed in the service

parts list of the applicable unit model and use

the proper tools.

(Failure to heed this warning may result

in electric shock, bodily injury or fire.)

♦♦

Replace damaged and/or degraded parts

Be sure to replace the power-supply cord and

lead wire in the event that they are damaged

and degraded.

(Failure to heed this warning may

result in electric shock and fire.)

♦♦

Check insulation

Be sure to measure the insulation resistance

once the repair work is completed, and turn on

the power supply after verifying that insulation

resistance of 1 MΩ or more is obtained.

(If an insulation problem exists,

it may result in electric shock.)

Safety precautions

● Please take a time to read the following safety precautions before commencing with the

maintenance work.

● They will help to maintain the Lossnay properly and safely.

Warning

Mis-operation could result in serious injury or death.

Caution

Mis-operation could result in injury and/or damage to property.

The symbols used in have the following meanings.

Warning

Caution

• Inspect the grounding wire and repair it if incomplete.

Request

● Make sure that the product operates correctly after maintenance.

Page 4

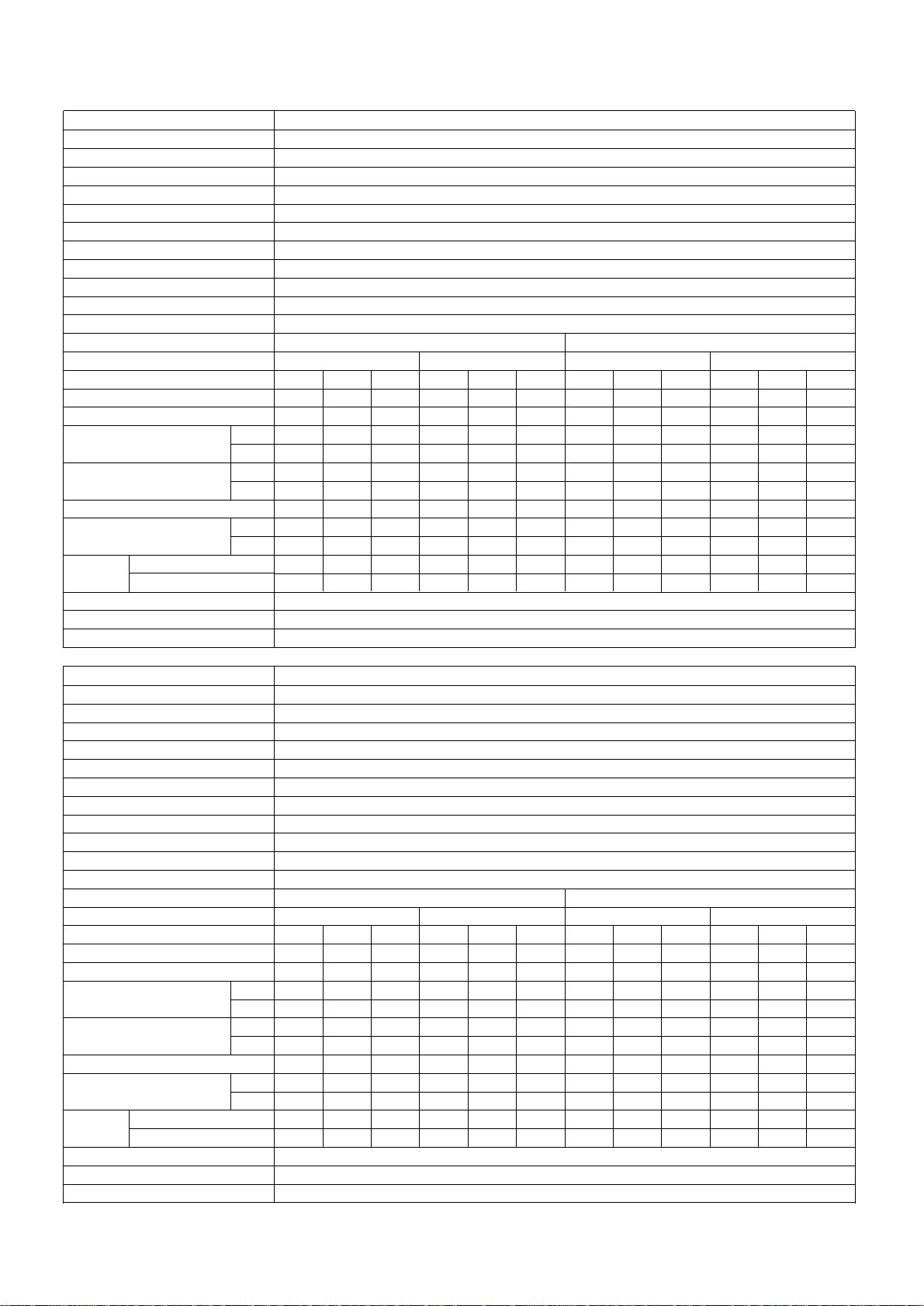

—3——3—

1. Specifications

Model

Control signal

Heat recovery system

Heat recovery module material

Cladding

Heat insulating material

Motor

Blower

Filter material

Operating environment (Supply air)

Functions

Weight

Power supply

Ventilation mode

Fan speed

Current

Power consumption

Air volume

External static pressure

Temperature recovery efficiency

Enthalpy recovery

efficiency (%)

Noise (dB)

Starting current

Insulation resistance

Dielectric strength

LGH-15RX3-E

Serial single communication (M-NET transmission)

Air-to-air total heat (sensible heat + latent heat) recovery

Partition, spacing plate-special treated paper

Galvanized steel sheet

Self-extinguishing urethane foam

Totally enclosed capacitor permanent split-phase induction motor, 4 poles, 2 units

180 mm dia.centrifugal fan

Non-woven fabrics filter (Gravitational method 82 %)

-10 °C to 40 °C, RH 80 % or less (-15 °C (*1) to +40 °C, RH 80 % or less)

Lossnay ventilation/Bypass ventilation High (Extra high)-Low switching

17 kg

Single phase 220-240 V/50 Hz Single phase 220 V/60 Hz

Lossnay ventilation Bypass ventilation Lossnay ventilation Bypass ventilation

Extra high High Low Extra high High Low Extra high High Low Extra high High Low

0.48-0.52 0.34-0.35 0.24-0.25 0.48-0.52 0.34-0.36 0.24-0.25 0.57 0.39 0.27 0.58 0.40 0.27

104-122 74-83 52-59 104-123 74-85 52-59 119 85 58 120 85 58

150 150 120 150 150 120 150 150 110 150 150 110

42 42 33 42 42 33 42 42 31 42 42 31

9.2 4.1 2.6 9.2 4.1 2.6 12.2 6.1 3.6 12.2 6.1 3.6

90 40 25 90 40 25 120 60 35 120 60 35

77 77 80 - - - 77 77 81 - - 69 69 72 - - - 69 69 73 - - -

62.5 62.5 66 - - - 62.5 62.5 67 - - 26-27 24-25 21-22 26-27 24-25 21-22 28 25 22 28 25.5 22

33-34 31-32 26-27 33-34 31-32 26-27 35 32 27 35 32.5 27

Under 0.8/0.7 A or less

10 MΩ or more (500 V megger)

AC 1500 V 1 minute

[A]

[W]

[m3/h]

[L/s]

[mmH2O]

[Pa]

[%]

Heating

Cooling

Measured at 1.5 m under the center of panel

Air outlets

Model

Control signal

Heat recovery system

Heat recovery module material

Cladding

Heat insulating material

Motor

Blower

Filter material

Operating environment (Supply air)

Functions

Weight

Power supply

Ventilation mode

Fan speed

Current

Power consumption

Air volume

External static pressure

Temperature recovery efficiency

Enthalpy recovery

efficiency (%)

Noise (dB)

Starting current

Insulation resistance

Dielectric strength

LGH-25RX3-E

Serial single communication (M-NET transmission)

Air-to-air total heat (sensible heat + latent heat) recovery

Partition, spacing plate-special treated paper

Galvanized steel sheet

Self-extinguishing urethane foam

Totally enclosed capacitor permanent split-phase induction motor, 4 poles, 2 units

180 mm dia.centrifugal fan

Non-woven fabrics filter (Gravitational method 82 %)

-10 °C to 40 °C, RH 80 % or less (-15 °C (*1) to +40 °C, RH 80 % or less)

Lossnay ventilation/Bypass ventilation High (Extra high)-Low switching

21 kg

Single phase 220-240 V/50 Hz Single phase 220 V/60 Hz

Lossnay ventilation Bypass ventilation Lossnay ventilation Bypass ventilation

Extra high High Low Extra high High Low Extra high High Low Extra high High Low

0.51-0.54 0.42-0.44 0.25-0.27 0.52-0.55 0.42-0.45 0.25-0.27 0.63 0.49 0.28 0.63 0.50 0.27

111-128 91-104 54-64 112-130 91-105 54-64 131 106 60 132 107 58

250 250 165 250 250 165 250 250 150 250 250 150

69 69 46 69 69 46 69 69 42 69 69 42

6.6 4.1 2.0 6.6 4.1 2.0 10.2 5.1 2.0 10.2 5.1 2.0

65 40 20 65 40 20 100 50 20 100 50 20

78 78 83 - - - 78 78 84 - - 69 69 74 - - - 69 69 75 - - -

62.5 62.5 68 - - - 62.5 62.5 70 - - -

26.5-27.5 25-26 21-22 27-28 25.5-26.5 21-22 28.5 25.5 21 29 26 21

33.5-34.5 32-33 26-27 34-35 32.5-33.5 26-27 35.5 32.5 26 36 33 26

Under 0.8/0.7 A or less

10 MΩ or more (500 V megger)

AC 1500 V 1 minute

[A]

[W]

[m3/h]

[L/s]

[mmH2O]

[Pa]

[%]

Heating

Cooling

Measured at 1.5 m under the center of panel

Air outlets

Page 5

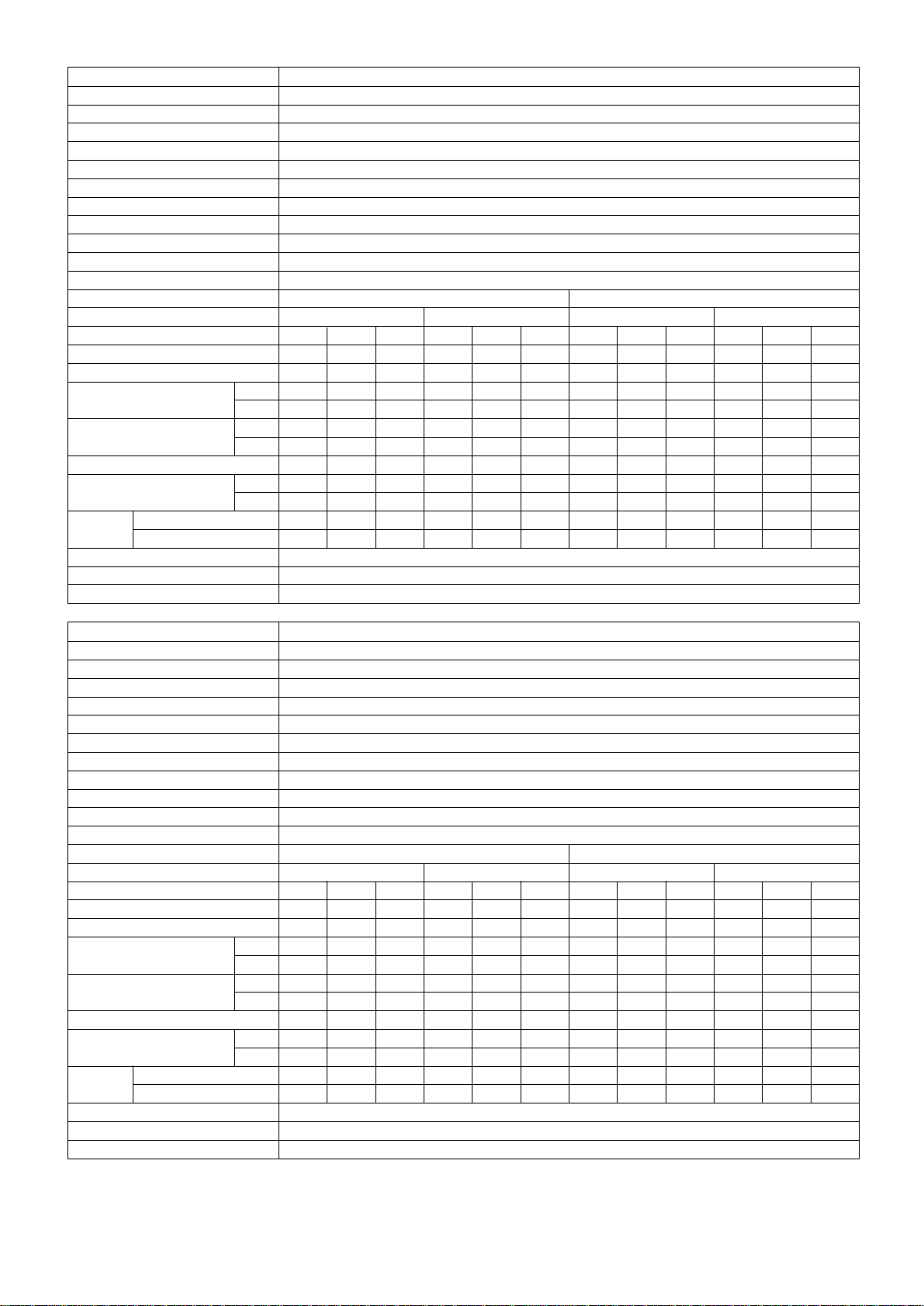

—4——4—

Model

Control signal

Heat recovery system

Heat recovery module material

Cladding

Heat insulating material

Motor

Blower

Filter material

Operating environment (Supply air)

Functions

Weight

Power supply

Ventilation mode

Fan speed

Current

Power consumption

Air volume

External static pressure

Temperature recovery efficiency

Enthalpy recovery

efficiency (%)

Noise (dB)

Starting current

Insulation resistance

Dielectric strength

LGH-35RX3-E

Serial single communication (M-NET transmission)

Air-to-air total heat (sensible heat + latent heat) recovery

Partition, spacing plate-special treated paper

Galvanized steel sheet

Self-extinguishing urethane foam

Totally enclosed capacitor permanent split-phase induction motor, 4 poles, 2 units

220 mm dia.centrifugal fan

Non-woven fabrics filter (Gravitational method 82 %)

-10 °C to 40 °C, RH 80 % or less (-15 °C (*1) to +40 °C, RH 80 % or less)

Lossnay ventilation/Bypass ventilation High (Extra high)-Low switching

30 kg

Single phase 220-240 V/50 Hz Single phase 220 V/60 Hz

Lossnay ventilation Bypass ventilation Lossnay ventilation Bypass ventilation

Extra high High Low Extra high High Low Extra high High Low Extra high High Low

0.78-0.79 0.71-0.71 0.46-0.48 0.81-0.82 0.72-0.73 0.46-0.49 0.99 0.83 0.46 1.00 0.83 0.46

169-187 154-167 97-110 176-192 156-172 97-111 215 180 97 217 180 97

350 350 230 350 350 230 350 350 210 350 320 210

97 97 64 97 97 64 97 97 58 97 89 58

15.3 7.1 2.6 15.3 7.1 2.7 19.4 5.1 2.0 19.4 5.1 2.0

150 70 25 150 70 26 190 50 20 190 50 20

79 79 84 - - - 79 79 85 - - -

68.5 68.5 75.5 - - - 68.5 68.5 76.5 - - -

65.5 65.5 72 - - - 65.5 65.5 73 - - -

31-32 28-30 23-24 31.5-32.5 28-30 23-24 32.5 27 21 33.5 28 21

39-40 35-37 29-30 39.5-40.5 35-37 29-30 40.5 34 27 41.5 35 27

Under 1.6/1.5 A or less

10 MΩ or more (500 V megger)

AC 1500 V 1 minute

[A]

[W]

[m3/h]

[L/s]

[mmH2O]

[Pa]

[%]

Heating

Cooling

Measured at 1.5 m under the center of panel

Air outlets

Model

Control signal

Heat recovery system

Heat recovery module material

Cladding

Heat insulating material

Motor

Blower

Filter material

Operating environment (Supply air)

Functions

Weight

Power supply

Ventilation mode

Fan speed

Current

Power consumption

Air volume

External static pressure

Temperature recovery efficiency

Enthalpy recovery

efficiency (%)

Noise (dB)

Starting current

Insulation resistance

Dielectric strength

LGH-50RX3-E

Serial single communication (M-NET transmission)

Air-to-air total heat (sensible heat + latent heat) recovery

Partition, spacing plate-special treated paper

Galvanized steel sheet

Self-extinguishing urethane foam

Totally enclosed capacitor permanent split-phase induction motor, 4 poles, 2 units

222 mm dia.centrifugal fan

Non-woven fabrics filter (Gravitational method 82 %)

-10 °C to 40 °C, RH 80 % or less (-15 °C (*1) to +40 °C, RH 80 % or less)

Lossnay ventilation/Bypass ventilation High (Extra high)-Low switching

33 kg

Single phase 220-240 V/50 Hz Single phase 220 V/60 Hz

Lossnay ventilation Bypass ventilation Lossnay ventilation Bypass ventilation

Extra high High Low Extra high High Low Extra high High Low Extra high High Low

0.94-0.95 0.89-0.90 0.57-0.60 0.95-0.96 0.90-0.93 0.58-0.60 1.21 1.05 0.60 1.22 1.05 0.60

204-225 193-214 123-142 206-228 196-221 125-142 262 231 130 263 228 130

500 500 350 500 500 350 500 500 300 500 500 300

139 139 97 139 139 97 139 139 83 139 139 83

15.3 6.1 3.1 15.3 6.1 3.1 20.4 6.1 2.0 20.4 6.1 2.0

150 60 30 150 60 30 200 60 20 200 60 20

77 77 82 - - - 77 77 83.5 - - 67 67 73 - - - 67 67 75 - - -

61.5 61.5 68 - - - 61.5 61.5 70 - - -

32.5-33.5 30-31 23.5-24.5 33.5-34.5 30.5-31.5 23.5-24.5 32.5 28.5 23 33.5 29.5 23

40.5-41.5 38-39 29.5-30.5 41.5-42.5 38.5-39.5 30.5-30.5 40.5 36.5 29 41.5 37.5 29

Under 1.9/1.7 A or less

10 MΩ or more (500 V megger)

AC 1500 V 1 minute

[A]

[W]

[m3/h]

[L/s]

[mmH2O]

[Pa]

[%]

Heating

Cooling

Measured at 1.5 m under the center of panel

Air outlets

Page 6

—5——5—

Model

Control signal

Heat recovery system

Heat recovery module material

Cladding

Heat insulating material

Motor

Blower

Filter material

Operating environment (Supply air)

Functions

Weight

Power supply

Ventilation mode

Fan speed

Current

Power consumption

Air volume

External static pressure

Temperature recovery efficiency

Enthalpy recovery

efficiency (%)

Noise (dB)

Starting current

Insulation resistance

Dielectric strength

LGH-80RX3-E

Serial single communication (M-NET transmission)

Air-to-air total heat (sensible heat + latent heat) recovery

Partition, spacing plate-special treated paper

Galvanized steel sheet

Self-extinguishing urethane foam

Totally enclosed capacitor permanent split-phase induction motor, 4 poles, 2 units

245 mm dia.centrifugal fan

Non-woven fabrics filter (Gravitational method 82%)

-10 °C to 40 °C, RH 80 % or less (-15 °C (*1) to +40 °C, RH 80 % or less)

Lossnay ventilation/Bypass ventilation High (Extra high)-Low switching

61 kg

Single phase 220-240 V/50 Hz Single phase 220 V/60 Hz

Lossnay ventilation Bypass ventilation Lossnay ventilation Bypass ventilation

Extra high High Low Extra high High Low Extra high High Low Extra high High Low

1.8-1.8 1.7-1.7 1.4-1.4 1.7-1.7 1.6-1.6 1.4-1.4 2.1 1.9 1.5 2.0 1.8 1.4

392-418 368-396 304-332 370-394 348-374 298-330 455 405 315 425 390 305

800 800 670 800 800 670 800 800 660 800 800 660

222 222 186 222 222 186 222 222 183 222 222 183

14.3 10.2 7.1 14.3 10.2 7.1 23.5 12.2 8.2 23.5 12.2 8.2

140 100 70 140 100 70 230 120 80 230 120 80

78 78 80.5 - - - 78 78 81 - - 71 71 73 - - - 71 71 73.5 - - -

64.5 64.5 68 - - - 64.5 64.5 68.5 - - -

33.5-34.5 32-33 30-31 34.5-35.5 33-34 30.5-31.5 35 31 29 36 32 29.5

44.5-45.5 43-44 40-41 45.5-46.5 44-45 40.5-41.5 46 42 39 47 43 39.5

Under 3.8/3.1 A or less

10 MΩ or more (500 V megger)

AC 1500 V 1 minute

[A]

[W]

[m3/h]

[L/s]

[mmH2O]

[Pa]

[%]

Heating

Cooling

Measured at 1.5 m under the center of panel

Air outlets

Model

Control signal

Heat recovery system

Heat recovery module material

Cladding

Heat insulating material

Motor

Blower

Filter material

Operating environment (Supply air)

Functions

Weight

Power supply

Ventilation mode

Fan speed

Current

Power consumption

Air volume

External static pressure

Temperature recovery efficiency

Enthalpy recovery

efficiency (%)

Noise (dB)

Starting current

Insulation resistance

Dielectric strength

LGH-100RX3-E,LGH-100RX3-E-60

Serial single communication (M-NET transmission)

Air-to-air total heat (sensible heat + latent heat) recovery

Partition, spacing plate-special treated paper

Galvanized steel sheet

Self-extinguishing urethane foam

Totally enclosed capacitor permanent split-phase induction motor, 4 poles, 2 units

245 mm dia.centrifugal fan

Non-woven fabrics filter (Gravitational method 82 %)

-10 °C to 40 °C, RH 80 % or less (-15 °C (*1) to +40 °C, RH 80 % or less)

Lossnay ventilation/Bypass ventilation High (Extra high)-Low switching

72 kg

Single phase 220-240 V/50 Hz Single phase 220 V/60 Hz

Lossnay ventilation Bypass ventilation Lossnay ventilation Bypass ventilation

Extra high High Low Extra high High Low Extra high High Low Extra high High Low

2.3-2.3 2.3-2.3 2.2-2.2 2.3-2.3 2.3-2.2 2.1-2.1 2.8 2.6 1.7 2.8 2.6 1.7

500-525 495-515 465-475 505-525 500-515 455-485 600 555 365 595 550 365

1000 1000 870 1000 1000 870 1000 1000 720 1000 1000 720

278 278 242 278 278 242 278 278 200 278 278 200

16.3 10.2 8.2 16.3 10.2 8.2 20.4 11.2 6.1 20.4 11.2 6.1

160 100 80 160 100 80 200 110 60 200 110 60

79 79 81 - - - 79 79 83 - - 70 70 73 - - - 70 70 76 - - -

64.5 64.5 67 - - - 64.5 64.5 71 - - -

36-37 34-35 31.5-32.5 37-38 35-36 33-34 36 34 30 37 35 31

47-48 45-46 41.5-42.5 48-49 46-47 43-44 47 45 40 48 46 41

Under 5.7/5.0 A or less

10 MΩ or more (500 V megger)

AC 1500 V 1 minute

[A]

[W]

[m3/h]

[L/s]

[mmH2O]

[Pa]

[%]

Heating

Cooling

Measured at 1.5 m under the center of panel

Air outlets

Page 7

Model

Control signal

Heat recovery system

Heat recovery module material

Cladding

Heat insulating material

Motor

Blower

Filter material

Operating environment (Supply air)

Functions

Weight

Power supply

Ventilation mode

Fan speed

Current

Power consumption

Air volume

External static pressure

Temperature recovery efficiency

Enthalpy recovery

efficiency (%)

Noise (dB)

Measured at 1.5 m under the center of panel

Air outlets

Starting current

Insulation resistance

Dielectric strength

LGH-150RX3-E

Serial single communication (M-NET transmission)

Air-to-air total heat (sensible heat + latent heat) recovery

Partition, spacing plate-special treated paper

Galvanized steel sheet

Self-extinguishing urethane foam

Totally enclosed capacitor permanent split-phase induction motor, 4 poles, 4 units

245 mm dia.centrifugal fan

Non-woven fabrics filter (Gravitational method 82 %)

-10 °C to 40 °C, RH 80 % or less (-15 °C (*1) to +40 °C, RH 80 % or less)

Lossnay ventilation/Bypass ventilation High (Extra high)-Low switching

154 kg

Single phase 220-240 V/50 Hz Single phase 220 V/60 Hz

Lossnay ventilation Bypass ventilation Lossnay ventilation Bypass ventilation

Extra high High Low Extra high High Low Extra high High Low Extra high High Low

3.3-3.3 3.1-3.1 2.7-2.8 3.2-3.2 3.0-3.0 2.6-2.6 4.2 3.7 2.9 4.2 3.7 2.9

[A]

720-785 670-730 585-660 695-760 650-705 565-615 915 805 630 905 800 630

[W]

[m3/h]

[L/s]

[mmH2O]

Heating

Cooling

1500 1500 1200 1500 1500 1200 1500 1500 1200 1500 1500 1200

417 417 333 417 417 333 417 417 333 417 417 333

14.0 10.2 5.1 14.0 10.2 5.1 21.0 12.0 7.0 21.0 12.0 7.0

[Pa]

[%]

137 100 50 137 100 50 206 118 69 206 118 69

79 79 81 - - - 79 79 81 - - 72 72 75 - - - 72 72 75 - - -

65.5 65.5 69 - - - 65.5 65.5 69 - - -

36.5-37.5 35.5-36.5 32.5-33.5 36.5-37.5 35.5-36.5 32.5-33.5 37 36 33 37 36 33

47.5-48.5 46.5-47.5 43.5-44.5 47.5-48.5 46.5-47.5 43.5-44.5 48 47 44 48 47 44

Under 6.8/5.9 A or less

10 MΩ or more (500 V megger)

AC 1500 V 1 minute

Model

Control signal

Heat recovery system

Heat recovery module material

Cladding

Heat insulating material

Motor

Blower

Filter material

Operating environment (Supply air)

Functions

Weight

Power supply

Ventilation mode

Fan speed

Current

Power consumption

Air volume

External static pressure

Temperature recovery efficiency

Enthalpy recovery

efficiency (%)

Noise (dB)

Measured at 1.5 m under the center of panel

Air outlets

Starting current

Insulation resistance

Dielectric strength

LGH-200RX3-E,LGH-200RX3-E-60

Serial single communication (M-NET transmission)

Air-to-air total heat (sensible heat + latent heat) recovery

Partition, spacing plate-special treated paper

Galvanized steel sheet

Self-extinguishing urethane foam

Totally enclosed capacitor permanent split-phase induction motor, 4 poles, 4 units

245 mm dia.centrifugal fan

Non-woven fabrics filter (Gravitational method 82 %)

-10 °C to 40 °C, RH 80 % or less (-15 °C (*1) to +40 °C, RH 80 % or less)

Lossnay ventilation/Bypass ventilation High (Extra high)-Low switching

179 kg

Single phase 220-240 V/50 Hz Single phase 220 V/60 Hz

Lossnay ventilation Bypass ventilation Lossnay ventilation Bypass ventilation

Extra high High Low Extra high High Low Extra high High Low Extra high High Low

4.6-4.3 4.6-4.3 4.1-3.8 4.4-4.2 4.4-4.1 4.1-3.8 5.4 5.2 3.3 5.3 5.0 3.3

[A]

[W]

[m3/h]

[L/s]

[mmH2O]

[Pa]

[%]

Heating

Cooling

1000-1020

995-1020 900-905 960-995 955-975 885-900 1175 1130 735 1155 1090 720

2000 2000 1400 2000 2000 1400 2000 2000 1400 2000 2000 1400

556 556 389 556 556 389 556 556 389 556 556 389

14.0 8.2 8.5 14.0 8.2 8.5 20.0 9.0 7.0 20.0 9.0 7.0

137 80 83 137 80 83 196 88 69 196 88 69

79 79 83 - - - 79 79 83 - - 70 70 76 - - - 70 70 76 - - -

64.5 64.5 71 - - - 64.5 64.5 71 - - -

39-40 37-38 35.5-36.5 39.5-40.5 37.5-38.5 36-37 38.5 36.5 34.5 38.5 36.5 34.5

50-51 48-49 46.5-47.5 50.5-51.5 48.5-49.5 47-48 49.5 47.5 45.5 49.5 47.5 45.5

Under 13.0/9.7 A or less

10 MΩ or more (500 V megger)

AC 1500 V 1 minute

—6——6—

Page 8

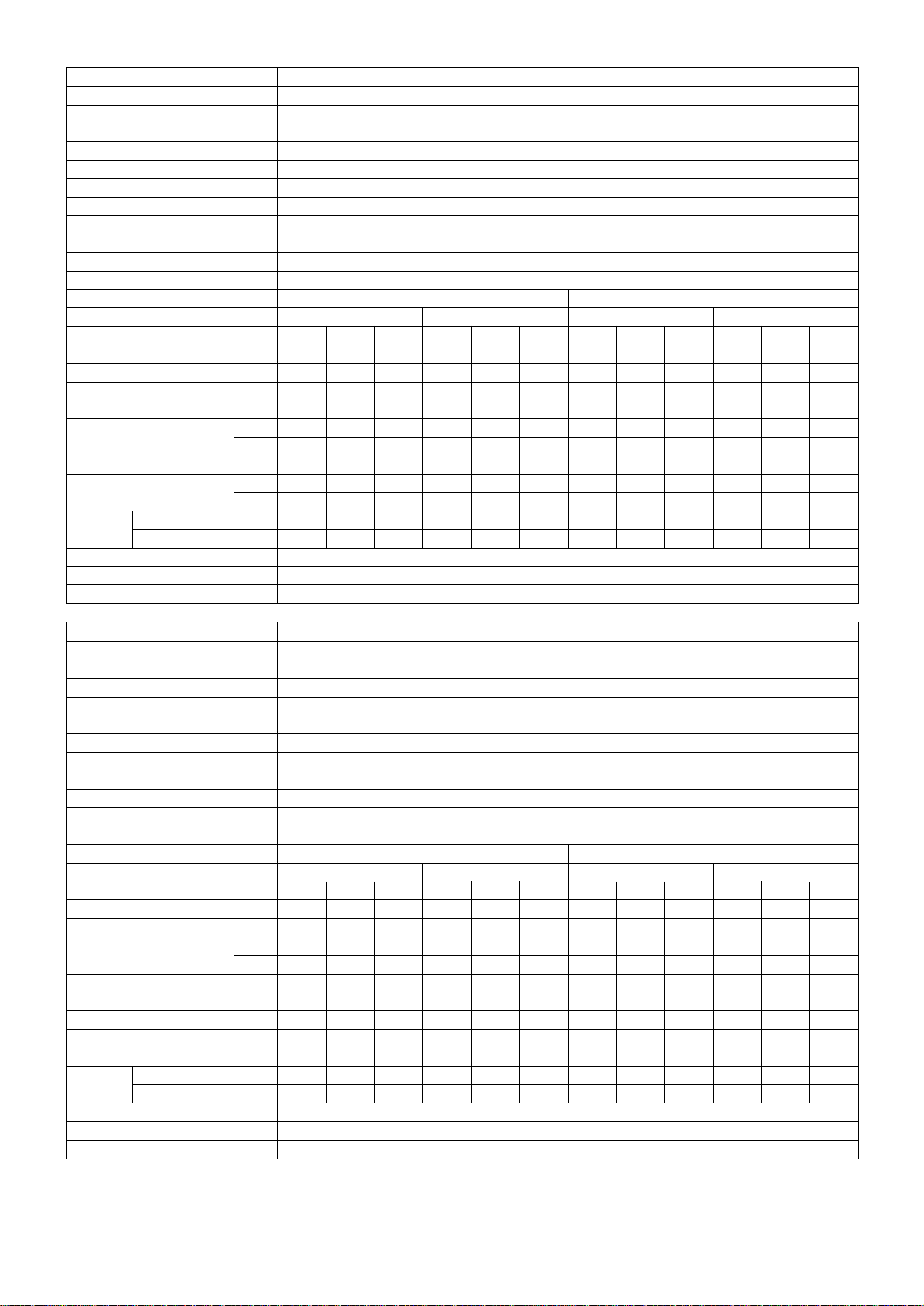

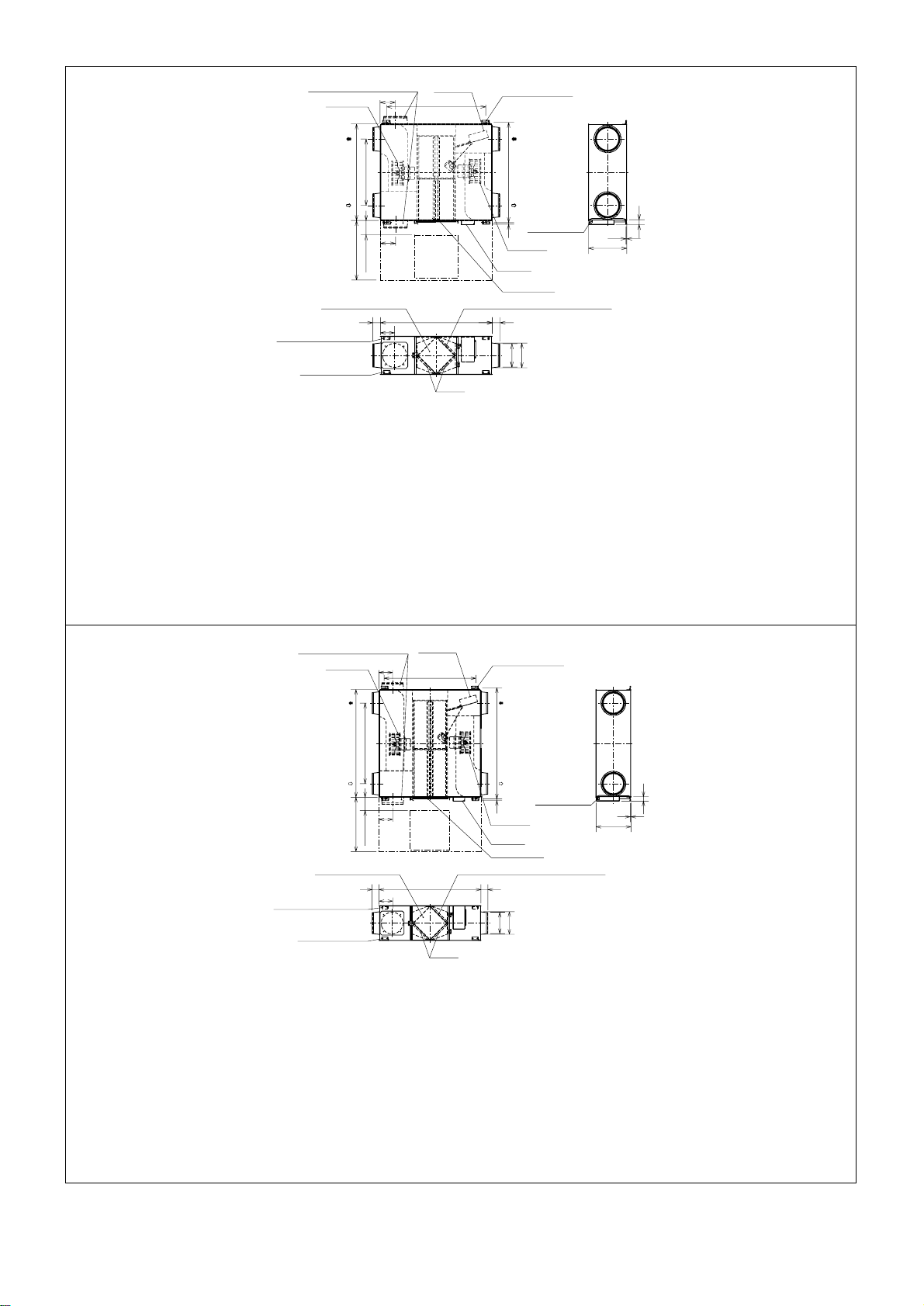

2. Dimensions

SA

(supply air)

RA

(return air)

OA

(outside air)

EA

(exhaust air)

10

Ceiling suspension fixture

Position where Ceiling suspension

fixture is changed

Power cord opening

275

90

Maintenance space for

heat exchanger,

air filters,

and fans

Position where duct direction is changed

High-performance filter (sold separately attachment position)

Heat exchanger (Lossnay core)

Air exhaust fan

Damper plate

Maintenance cover

Control box

Air supply fan

Ceiling suspension fixture

54 780 54

φ 110

φ 97.5

600 or more

450

610

119

150 to 250

119

64122

700

119

Air filters

Inspection

opening

()

102

700

102

735

530

22

765

10

275

90

63 780 63

102

φ 160

φ 142

SA

(supply air)

RA

(return air)

OA

(outside air)

EA

(exhaust air)

Ceiling suspension fixture

Maintenance space for

heat exchanger,

air filters,

and fans

Heat exchanger (Lossnay core)

Air exhaust fan

Damper plate

Maintenance cover

Control box

Air supply fan

Ceiling suspension fixture

600 or more

150 to 250

Air filters

Inspection

opening

Power cord opening

Position where duct direction is changed

High-performance filter (sold separately attachment position)

Position where Ceiling suspension

fixture is changed

()

LGH-15RX3-E

Unit (mm)

Attention

*

1. If condensation is expected to form, heat up the fresh outside air using a duct heater, etc.

2. An inspection port (450 × 450 – 600 × 600 mm) must be installed on the filter and Lossnay core removing side.

3. The two outdoor ducts must be covered with heat-insulating material in order to prevent condensation from forming.

The two indoor ducts may be covered with heat-insulation if Lossnay is to be installed in the circumstance of higher temperature in summer.

4. Installing the duct damper is preferred also to prevent the outdoor air introduced to room if there has strongthern wind,

when the unit operates or stops.

5. The outside ducts must be tilted at a gradient (1/30 or more) down toward the outdoor area from Lossnay unit.

* Specifications subject to change without notice.

LGH-25RX3-E

Attention

*

1. If condensation is expected to form, heat up the fresh outside air using a duct heater, etc.

2. An inspection port (450 × 450 – 600 × 600 mm) must be installed on the filter and Lossnay core removing side.

3. The two outdoor ducts must be covered with heat-insulating material in order to prevent condensation from forming.

Unit (mm)

The two indoor ducts may be covered with heat-insulation if Lossnay is to be installed in the circumstance of higher temperature in summer.

4. Installing the duct damper is preferred also to prevent the outdoor air introduced to room if there has strongthern wind,

when the unit operates or stops.

5. The outside ducts must be tilted at a gradient (1/30 or more) down toward the outdoor area from Lossnay unit.

—7——7—

* Specifications subject to change without notice.

Page 9

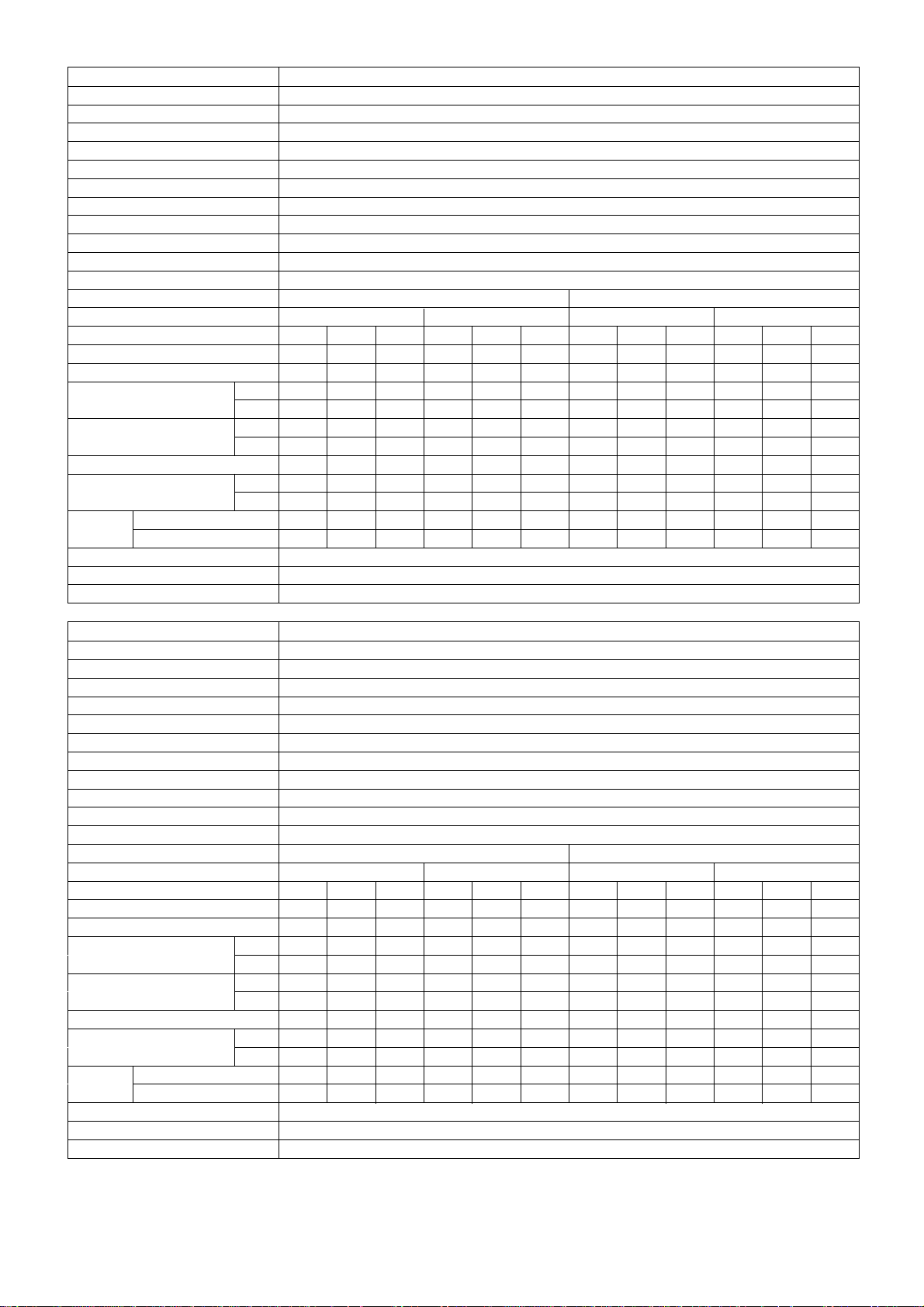

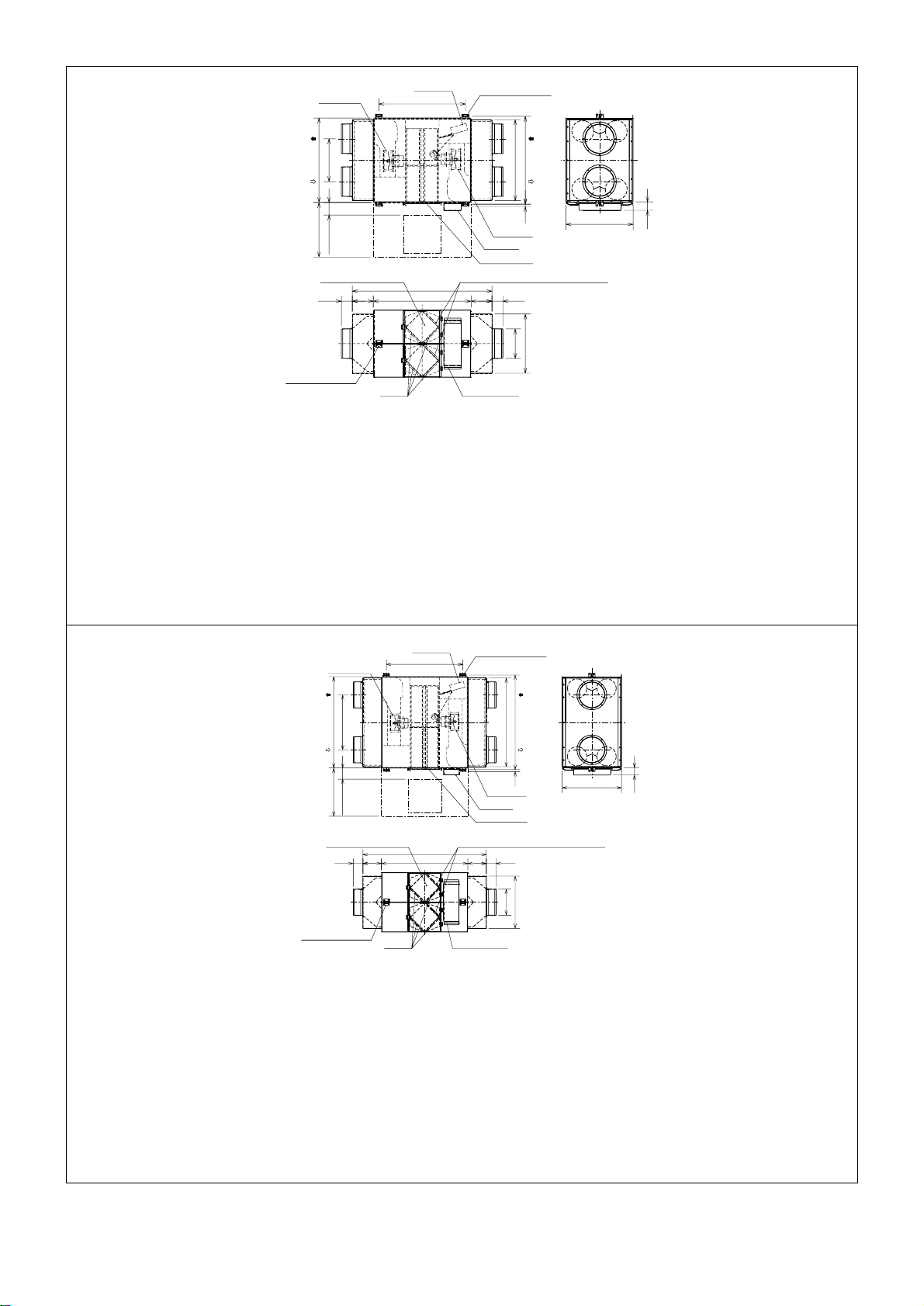

—8——8—

Unit (mm)

Unit (mm)

SA

(supply air)

RA

(return air)

OA

(outside air)

EA

(exhaust air)

40

Ceiling suspension fixture

317

90

Maintenance space for

heat exchanger,

air filters,

and fans

Heat exchanger (Lossnay core)

Air exhaust fan

Damper plate

Maintenance cover

Control box

Air supply fan

Ceiling suspension fixture

63 888 63

φ 160

φ 142

600 or more

650

874

124

150 to 250

124

90622

790

124

Air filters

Inspection

opening

Power cord opening

Position where duct direction is changed

High-performance filter (sold separately attachment position)

Position where Ceiling suspension

fixture is changed

()

SA

(supply air)

RA

(return air)

OA

(outside air)

EA

(exhaust air)

40

317

90

Maintenance space for

heat exchanger,

air filters,

and fans

Air exhaust fan

Damper plate

Maintenance cover

Control box

Air supply fan

Ceiling suspension fixture

79 888 79

φ 208

φ 192

600 or more

745

1016

124

150 to 250

124

104822

790

124

Inspection

opening

Power cord opening

Position where duct direction is changed

Ceiling suspension fixture

Heat exchanger (Lossnay core)

Air filters

High-performance filter (sold separately attachment position)

Position where Ceiling suspension

fixture is changed

()

LGH-35RX3-E

LGH-50RX3-E

*

Attention

1. If condensation is expected to form, heat up the fresh outside air using a duct heater, etc.

2. An inspection port (450 × 450 – 600 × 600 mm) must be installed on the filter and Lossnay core removing side.

3. The two outdoor ducts must be covered with heat-insulating material in order to prevent condensation from forming.

The two indoor ducts may be covered with heat-insulation if Lossnay is to be installed in the circumstance of higher temperature in summer.

4. Installing the duct damper is preferred also to prevent the outdoor air introduced to room if there has strongthern wind,

when the unit operates or stops.

5. The outside ducts must be tilted at a gradient (1/30 or more) down toward the outdoor area from Lossnay unit.

*

Attention

1. If condensation is expected to form, heat up the fresh outside air using a duct heater, etc.

2. An inspection port (450 × 450 – 600 × 600 mm) must be installed on the filter and Lossnay core removing side.

3. The two outdoor ducts must be covered with heat-insulating material in order to prevent condensation from forming.

The two indoor ducts may be covered with heat-insulation if Lossnay is to be installed in the circumstance of higher temperature in summer.

4. Installing the duct damper is preferred also to prevent the outdoor air introduced to room if there has strongthern wind,

when the unit operates or stops.

5. The outside ducts must be tilted at a gradient (1/30 or more) down toward the outdoor area from Lossnay unit.

* Specifications subject to change without notice.

* Specifications subject to change without notice.

Page 10

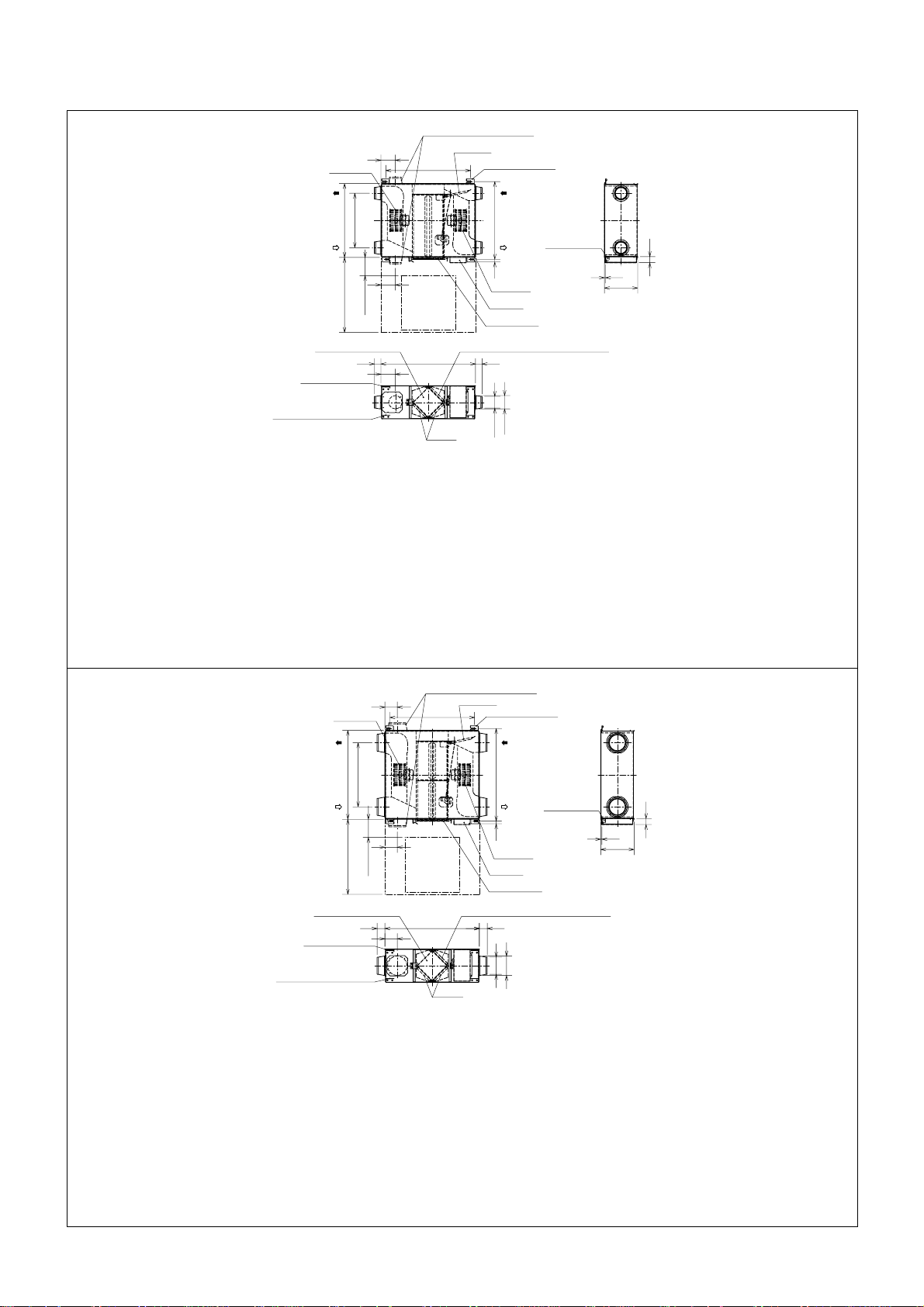

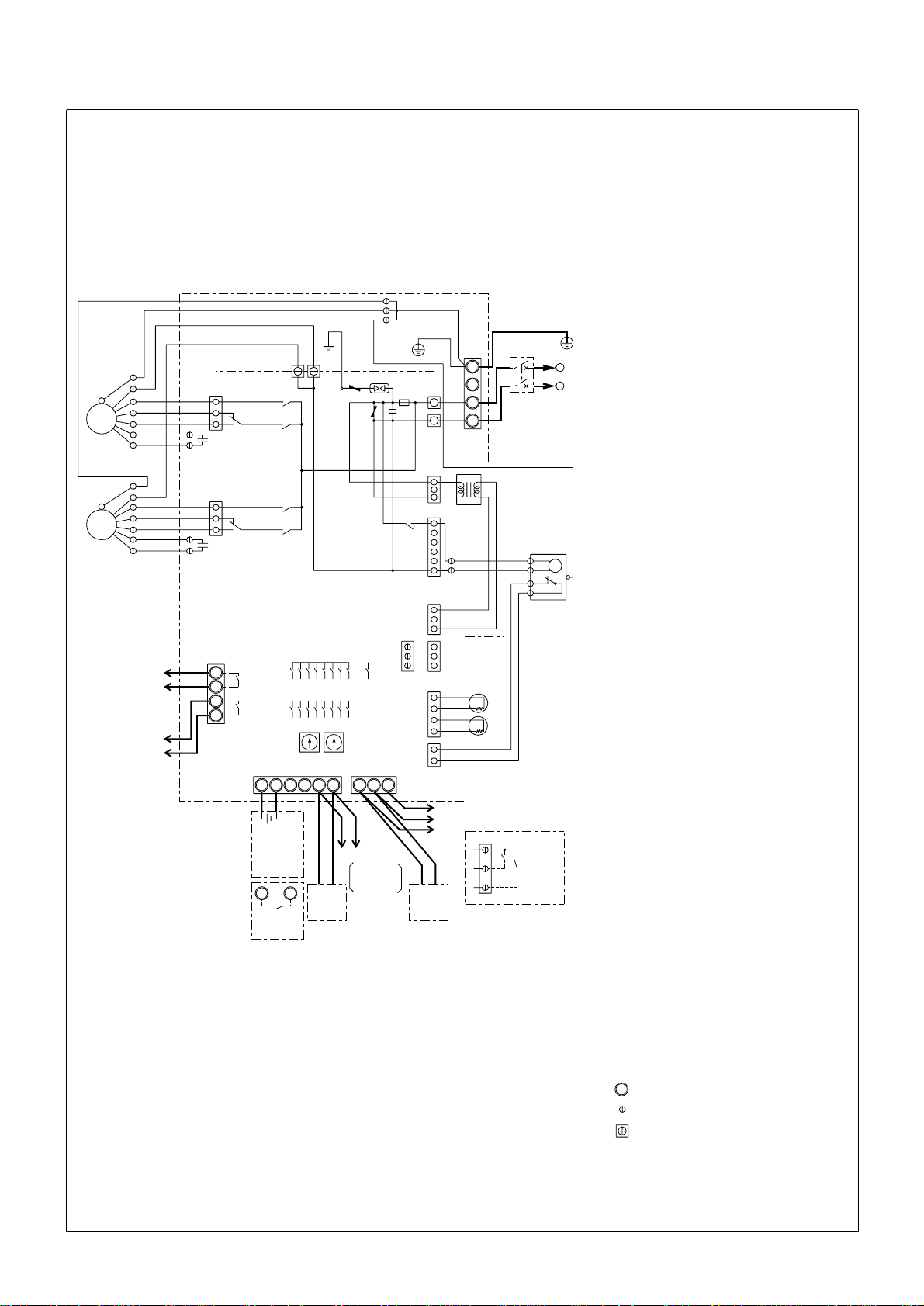

—9——9—

LGH-80RX3-E

LGH-100RX3-E,LGH-100RX3-E-60

*

Attention

1. If condensation is expected to form, heat up the fresh outside air using a duct heater, etc.

2. An inspection port (450 × 450 – 600 × 600 mm) must be installed on the filter and Lossnay core removing side.

3. The two outdoor ducts must be covered with heat-insulating material in order to prevent condensation from forming.

The two indoor ducts may be covered with heat-insulation if Lossnay is to be installed in the circumstance of higher temperature in summer.

4. Installing the duct damper is preferred also to prevent the outdoor air introduced to room if there has strongthern wind,

when the unit operates or stops.

5. The outside ducts must be tilted at a gradient (1/30 or more) down toward the outdoor area from Lossnay unit.

*

Attention

1. If condensation is expected to form, heat up the fresh outside air using a duct heater, etc.

2. An inspection port (450 × 450 – 600 × 600 mm) must be installed on the filter and Lossnay core removing side.

3. The two outdoor ducts must be covered with heat-insulating material in order to prevent condensation from forming.

The two indoor ducts may be covered with heat-insulation if Lossnay is to be installed in the circumstance of higher temperature in summer.

4. Installing the duct damper is preferred also to prevent the outdoor air introduced to room if there has strongthern wind,

when the unit operates or stops.

5. The outside ducts must be tilted at a gradient (1/30 or more) down toward the outdoor area from Lossnay unit.

Unit (mm)

Unit (mm)

* Specifications subject to change without notice.

* Specifications subject to change without notice.

Position where duct direction is changed

Air exhaust fan

149

Damper plate

1030

Ceiling suspension fixture

RA

(return air)

1036

SA

(supply air)

Power cord opening

22

Air supply fan

Control box

Maintenance cover

φ 258

φ 242

90

10

398

EA

(exhaust air)

690

1004

OA

(outside air)

Maintenance space for

heat exchanger,

air filters,

and fans

Heat exchanger (Lossnay core)

Position where Ceiling suspension

()

fixture is changed

Ceiling suspension fixture

149

Inspection

600 or more

150 to 250

79 1164 79

opening

High-performance filter (sold separately attachment position)

149

Air filters

Position where duct direction is changed

Maintenance space for

heat exchanger,

air filters,

and fans

Position where Ceiling suspension

()

fixture is changed

Ceiling suspension fixture

Air exhaust fan

EA

(exhaust air)

920

1231

OA

(outside air)

600 or more

150 to 250

Heat exchanger (Lossnay core)

79 1164 79

Damper plate

149

1030

149

Inspection

opening

149

Air filters

Ceiling suspension fixture

RA

(return air)

1263

SA

(supply air)

Power cord opening

22

Air supply fan

Control box

Maintenance cover

High-performance filter (sold separately attachment position)

φ 258

φ 242

90

10

398

Page 11

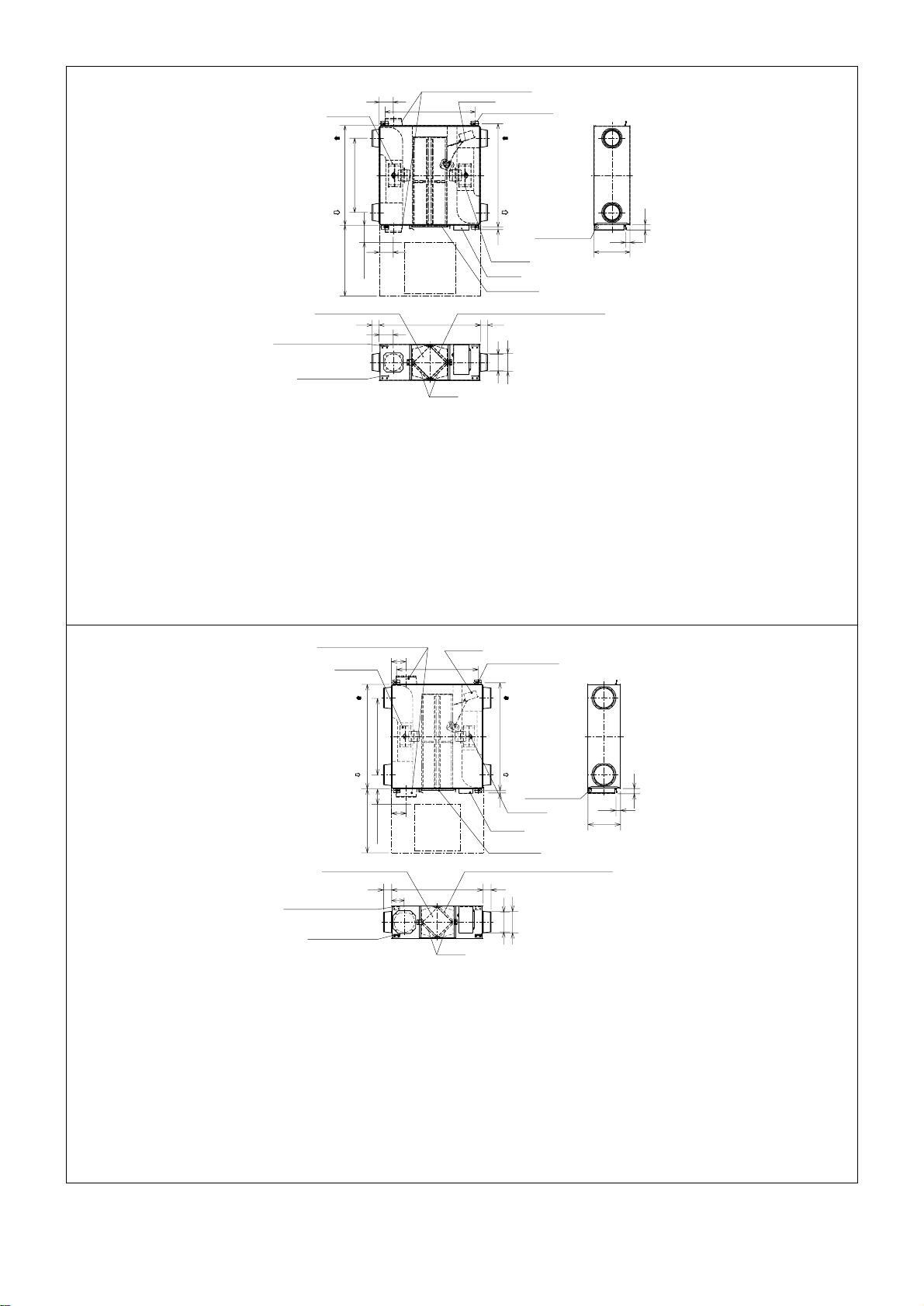

—10——10—

LGH-200RX3-E,LGH-200RX3-E-60

LGH-150RX3-E

*

Attention

1. If condensation is expected to form, heat up the fresh outside air using a duct heater, etc.

2. An inspection port (450 × 450 – 600 × 600 mm) must be installed on the filter and Lossnay core removing side.

3. The two outdoor ducts must be covered with heat-insulating material in order to prevent condensation from forming.

The two indoor ducts may be covered with heat-insulation if Lossnay is to be installed in the circumstance of higher temperature in summer.

4. Installing the duct damper is preferred also to prevent the outdoor air introduced to room if there has strongthern wind,

when the unit operates or stops.

5. The outside ducts must be tilted at a gradient (1/30 or more) down toward the outdoor area from Lossnay unit.

*

Attention

1. If condensation is expected to form, heat up the fresh outside air using a duct heater, etc.

2. An inspection port (450 × 450 – 600 × 600 mm) must be installed on the filter and Lossnay core removing side.

3. The two outdoor ducts must be covered with heat-insulating material in order to prevent condensation from forming.

The two indoor ducts may be covered with heat-insulation if Lossnay is to be installed in the circumstance of higher temperature in summer.

4. Installing the duct damper is preferred also to prevent the outdoor air introduced to room if there has strongthern wind,

when the unit operates or stops.

5. The outside ducts must be tilted at a gradient (1/30 or more) down toward the outdoor area from Lossnay unit.

Unit (mm)

Unit (mm)

* Specifications subject to change without notice.

* Specifications subject to change without notice.

Air exhaust fan

Damper plate

1030

Ceiling suspension fixture

964

Air supply fan

φ 350

1046

26

705

RA

(return air)

SA

(supply air)

800

100

EA

(exhaust air)

1004

OA

(outside air)

600 or more

Maintenance space for

heat exchanger,

air filters,

and fans

Ceiling suspension fixture

510

Inspection

Air filters

opening

1662

1164

150 to 250

Heat exchanger (Lossnay core)

249130 249 130

Control box

Maintenance cover

High-performance filter (sold separately attachment position)

Power cord opening

(exhaust air)

(outside air)

Maintenance space for

heat exchanger,

air filters,

and fans

Air exhaust fan

EA

740

1231

OA

600 or more

150 to 250

Heat exchanger (Lossnay core)

Ceiling suspension fixture

Damper plate

1030

Inspection

opening

Air filters

1662

1164

249130 249 130

Ceiling suspension fixture

Air supply fan

Control box

Maintenance cover

High-performance filter (sold separately attachment position)

Power cord opening

1194

RA

(return air)

1273

SA

(supply air)

26

705

φ 350

800

100

Page 12

—11——11—

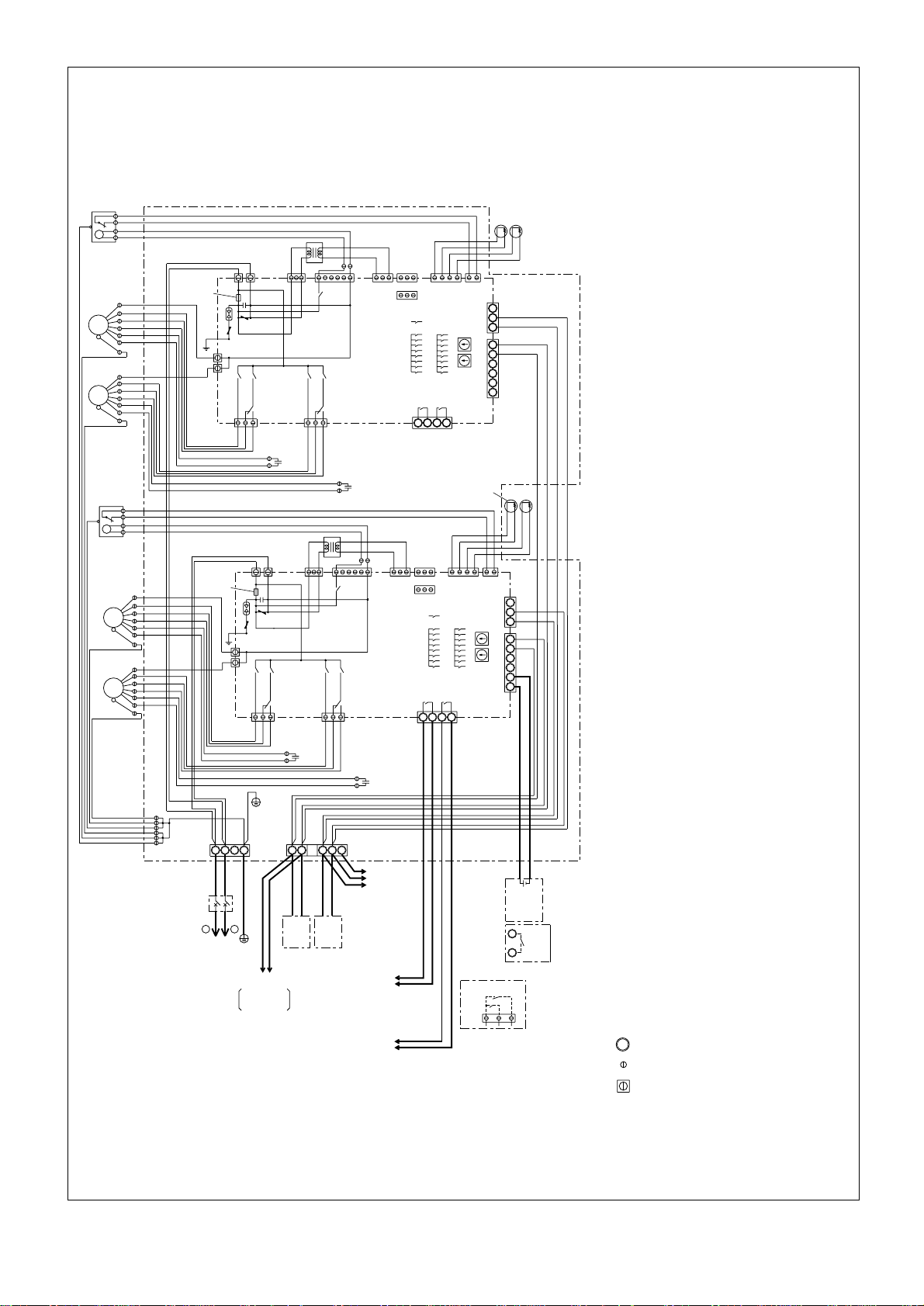

3. Wiring diagrams

GM

231456AB

S

13

9

8

7

M1

M2

Operation monitor output

MAX MIN

AC 240 V 2A AC 220 V 100 mA

DC 24 V 2A DC 5 V 100 mA

Malfunction monitor output

MAX MIN

AC 240 V 1A AC 220 V 100 mA

DC 24 V 1A DC 5 V 100 mA

N

L

PE

SA1

SA2

SW5

SW2

SW1

WHITE

WHITE

BLUE

BLUE

GREY

GREY

ORANGE

ORANGE

BROWN

BROWN

RED

YELLOW

BROWN

BLUE

Breker

TH1(OA)

PZ-41SLB

PZ-52SF

CN16

CN16

High

Low

Unchaged

a-contact

High/Low select connector

CN7

CN2

CN6

CN1

6

1

1

S1

S2

TM1

GREEN/YELLOW

CN32

TB5

Transmission cable

Uncharged

a-contact

12V or

24V DC

(non-polar)

TM2

Shield wire

3

External control input

10

TM3

SW3

X2

X1

X5

High

Extra high

BLUE

Exhaust

fan motor

CN10

CN9

High

Supply

fan motor

WHITE

ORANGE

YELLOW

GREY

BLACK

X4

X3

Extra high

SW4

1

5

1

5

CN8-1

RED

CN8-2

BROWN

ZNR102

DSA1

C101

Fuse

250V 6.3A

ZNR101

C

C

TR

M-NET-transmission cable

LS

CN5

TH2(RA)

Lossnay unit

MAX 15 units

Mr.Slim

X8

X7

N

L

Power supply

220-240 V ~50Hz

220 V ~60Hz

* Specifications subject to change without notice.

■ Symbol explanation

M1 : Motor for exhaust fan

M2 : Motor for supply fan

C : Capacitor

GM : Motor for Bypass movement

LS : Microswitch

TH1 : Thermistor for outside air

TH2 : Thermistor for return air

SW1 : Switch (Main/Sub change)

SW2, 5

: Switch (Function selection)

SW3 : High/E.high select switch

(Exhaust fan)

SW4 : High/E.high select switch

(Supply fan)

TM1 : Terminal block (Power supply)

TM2 : Terminal block (Transmission

cable and external control input)

TM3 : Terminal block (Monitor output)

TB5 : Terminal block

(M-NET Transmission cable)

S1, S2

: Connector (Power supply)

TR : Control circuit transformer

X7 : Relay contact

(For operation monitor output)

X8 : Relay contact

(For malfunction monitor output)

CN1 :

Connector (Transformer primary)

CN2 :

Connector

(Transformer secondary)

CN5 : Connector (Thermistor)

CN6 : Connector (Microswitch)

CN7 : Connector

(Motor for Bypass operation)

CN8-1

: Tab connector (Fan motor)

CN8-2

: Tab connector (Fan motor)

CN9 : Connector (Fan motor)

CN10 : Connector (Fan motor)

CN16 : Connector (High/Low switch)

CN32 :

Connector (Remote control selection)

SA1 : Address setting rotary switch

(10 digit)

SA2 : Address setting rotary switch

(1 digit)

MARK

: Indicates terminal block

: Connector

: Board insertion connector or fas-

tening connector of control board

*1

*1

*1

*

Attention

1. This must be used with Mitsubishi Electric Air-Conditioner Network System. (MELANS)

2. External control input (TM2) is impossible to use on the Lossnay addressed to “Sub” (SW1) unit.

3. PZ-41SLB and PZ-52SF cannot be used simultaneously.

■ NOTE

1. TM1, TM2, TM3, TB5 shown in bold lines are field work.

2. Breaker should be provided by the customer.

3. Be sure to connect the grounding wire.

LGH-15RX

3

-E,LGH-25RX3-E,LGH-35RX3-E,LGH-50RX3-E,LGH-80RX3-E,LGH-100RX3-E,LGH-100RX3-E-60

Page 13

—12——12—

NL

PE

2

3

1

4

5

6

A

B

S

9

87

10

C

Supply

fan motor

Exhaust

fan motor

Supply

fan motor

Exhaust

fan motor

C

M2

M1

M2

M1

ABS65

LS

GM

LS

GM

TM3

CN10 CN9

1

5

1

5

CN8-1

CN8-2

ZNR102

DSA1

C

TB5TM2

TM1

GREEN/YELLOW

BROWN

RED

BLACK

GREY

YELLOW

ORANGE

BLUE

WHITE

GREEN/YELLOW

X3

X4

X1

X2

WHITE

SA1

SA2

SW5SW2

SW1(Main)

CN16

CN7 CN2 CN6

CN1

611

S1 S2

CN32

(TB5)

TM2

3

C101

ZNR101

C

TR

CN5

TH2(RA)

TH1(OA)

BROWN

BLUE

ORANGE

ORANGE

GREY

GREY

BLUE

BLUE

BROWN

BROWN

RED

YELLOW

WHITE

Fuse

250V 6.3A

X5

X7 X8

31

CN16

High

Low

Unchaged

a-contact

High/Low select connector

Uncharged

a-contact

Shield wire

M-NET-transmission

cable

External control input

Transmission

cable

Lossnay unit

MAX 7 units

Breker

Mr.Slim

(non-polar)

24V DC

12V or

PZ-41SLB

PZ-52SF

2

3

1

4

5

6

A

B

S

9

87

10

(TM3)

CN10 CN9

Extra

high

1

5

1

5

CN8-1

CN8-2

ZNR102

DSA1

BROWN

High

Extra

high

High

SW4

BLACK

GREY

YELLOW

ORANGE

BLUE

WHITE

SW3

Extra

high

High

Extra

high

High

SW4 SW3

X3

X4

X1

X2

WHITE

SA1

SA2

SW5SW2

SW1(Sub)

(CN16)

CN7 CN2 CN6

CN1

611

S1 S2

(CN32)

(TB5)

(TM2)

3

C101

ZNR101

TR

CN5

TH2(RA)

TH1(OA)

BROWN

BLUE

ORANGE

ORANGE

GREY

GREY

BLUE

BLUE

BROWN

BROWN

RED

YELLOW

WHITE

Fuse

250V 6.3A

X5

X7 X8

Power supply

220-240 V ~50Hz

220 V ~60Hz

NL

Operation monitor output

MAX MIN

AC 240 V 2A AC 220 V 100 mA

DC 24 V 2A DC 5 V 100 mA

Malfunction monitor output

MAX MIN

AC 240 V 1A AC 220 V 100 mA

DC 24 V 1A DC 5 V 100 mA

* Specifications subject to change without notice.

■ Symbol explanation

M1 : Motor for exhaust fan

M2 : Motor for supply fan

C : Capacitor

GM : Motor for Bypass movement

LS : Microswitch

TH1 : Thermistor for outside air

TH2 : Thermistor for return air

SW1 : Switch (Main/Sub change)

SW2, 5

: Switch (Function selection)

SW3 : High/E.high select switch

(Exhaust fan)

SW4 : High/E.high select switch

(Supply fan)

TM1 : Terminal block (Power supply)

TM2 : Terminal block (Transmission

cable and external control input)

TM3 : Terminal block (Monitor output)

TB5 : Terminal block

(M-NET Transmission cable)

S1, S2

: Connector (Power supply)

TR : Control circuit transformer

X7 : Relay contact

(For operation monitor output)

X8 : Relay contact

(For malfunction monitor output)

CN1 :

Connector (Transformer primary)

CN2 :

Connector

(Transformer secondary)

CN5 : Connector (Thermistor)

CN6 : Connector (Microswitch)

CN7 : Connector

(Motor for Bypass operation)

CN8-1

: Tab connector (Fan motor)

CN8-2

: Tab connector (Fan motor)

CN9 : Connector (Fan motor)

CN10 : Connector (Fan motor)

CN16 : Connector (High/Low switch)

CN32 :

Connector (Remote control selection)

SA1 : Address setting rotary switch

(10 digit)

SA2 : Address setting rotary switch

(1 digit)

MARK

: Indicates terminal block

: Connector

: Board insertion connector or fas-

tening connector of control board

*1

*1

*1

*

Attention

1. This must be used with Mitsubishi Electric Air-Conditioner Network System. (MELANS)

2. External control input (TM2) is impossible to use on the Lossnay addressed to “Sub” (SW1) unit.

3. PZ-41SLB and PZ-52SF cannot be used simultaneously.

■ NOTE 1. TM1, TM2, TM3, TB5 shown in bold lines are field work.

2. Breaker should be provided by the customer.

3. Be sure to connect the grounding wire.

LGH-150RX

3

-E,LGH-200RX3-E,LGH-200RX3-E-60

Page 14

—13——13—

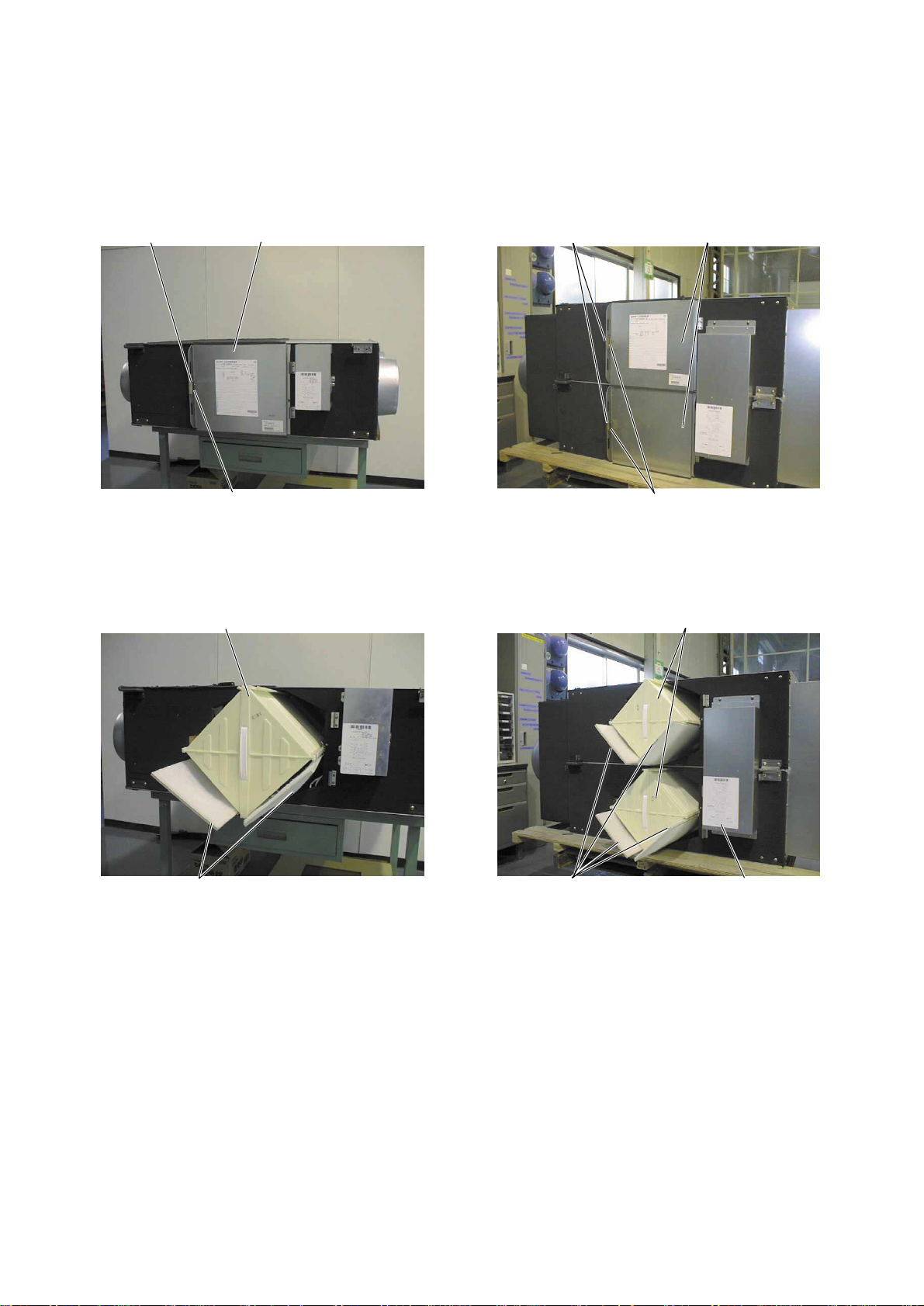

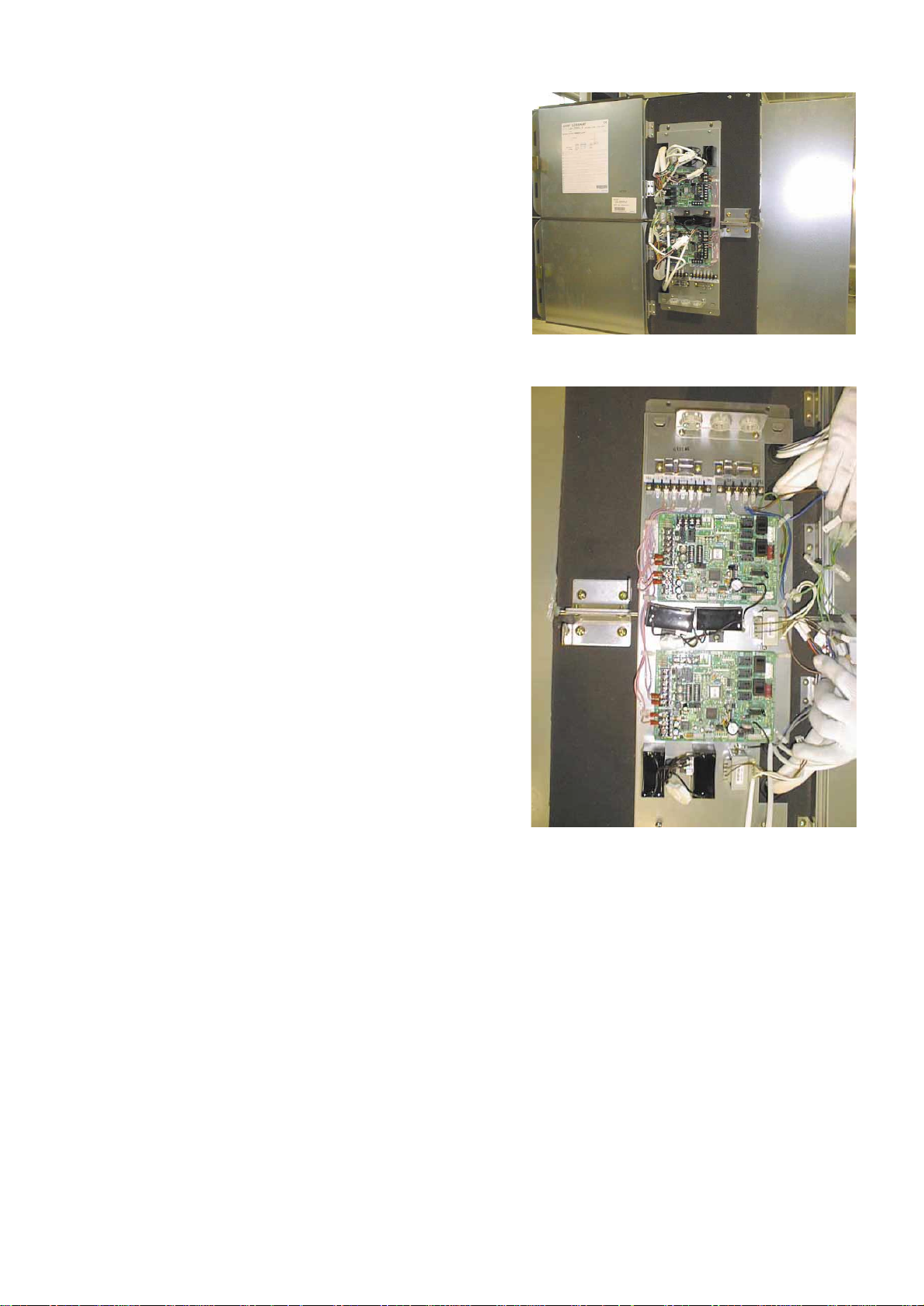

4. Maintenance procedures

4-1 Blower Parts

1Remove the cover fixing screw.

2Pull back the hinged clip.

2Open the door and lift off of the hinge brackets.

3Remove Filters from the unit.

4Remove Cores from the unit.

LGH-15RX3-E~LGH-100RX3-E type

Hinge Maintenance Cover

LGH-15RX

3-E~LGH-100RX3-E type

Core

Screw Screw

Filter Filter Control Box Cover

LGH-150RX

3-E,LGH-200RX3-E type

Hinge Maintenance Cover

LGH-150RX

3-E,LGH-200RX3-E type

Core

Page 15

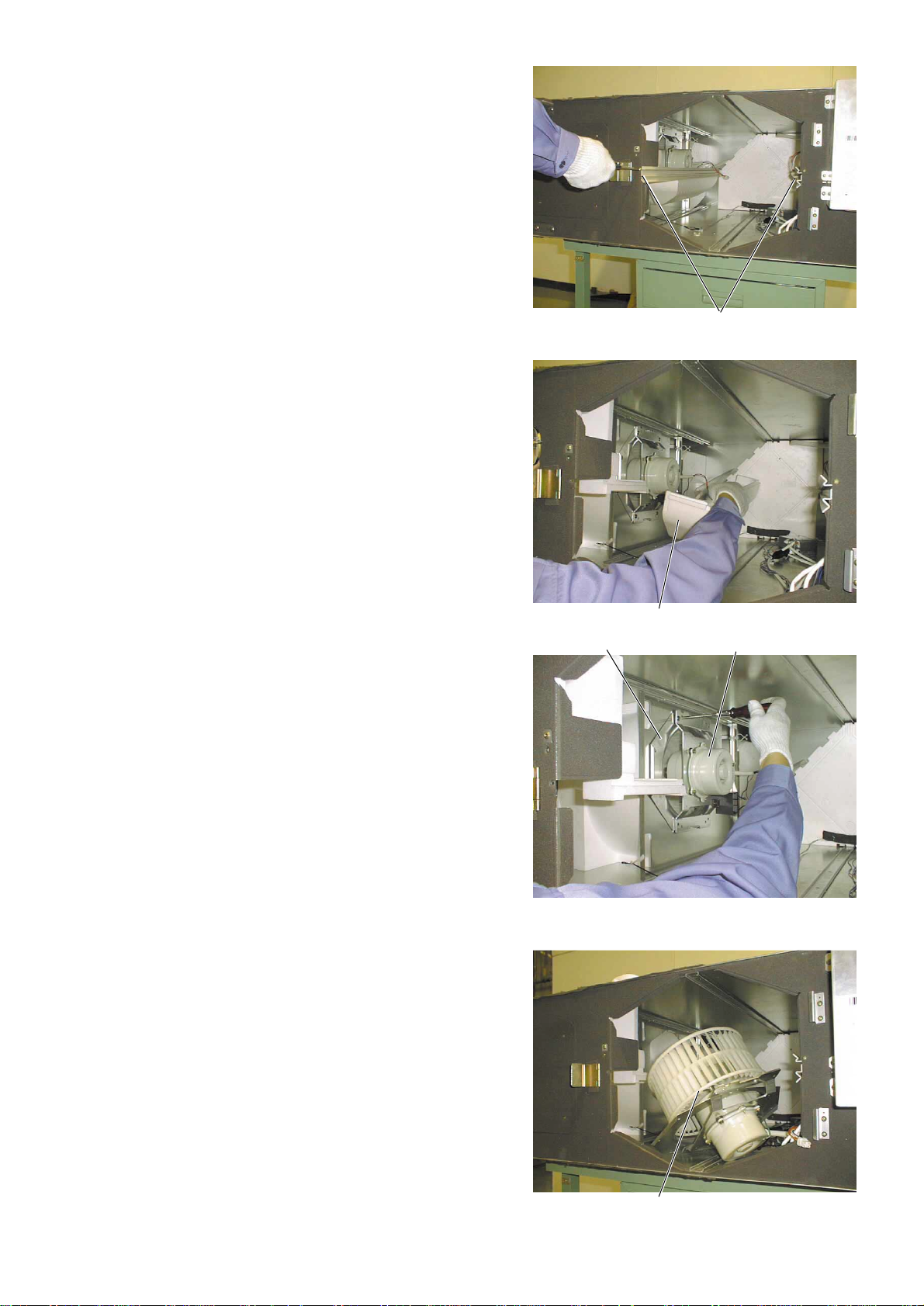

—14——14—

5Remove screw from the core-guide,Remove core-

guide.

6Remove separator from the blower portion.

7Remove screws from the motor base.

8Remove the pre-assembled blower.

Core Guide

Separator

Motor Base Motor

Pre-assembled Blower

Page 16

—15——15—

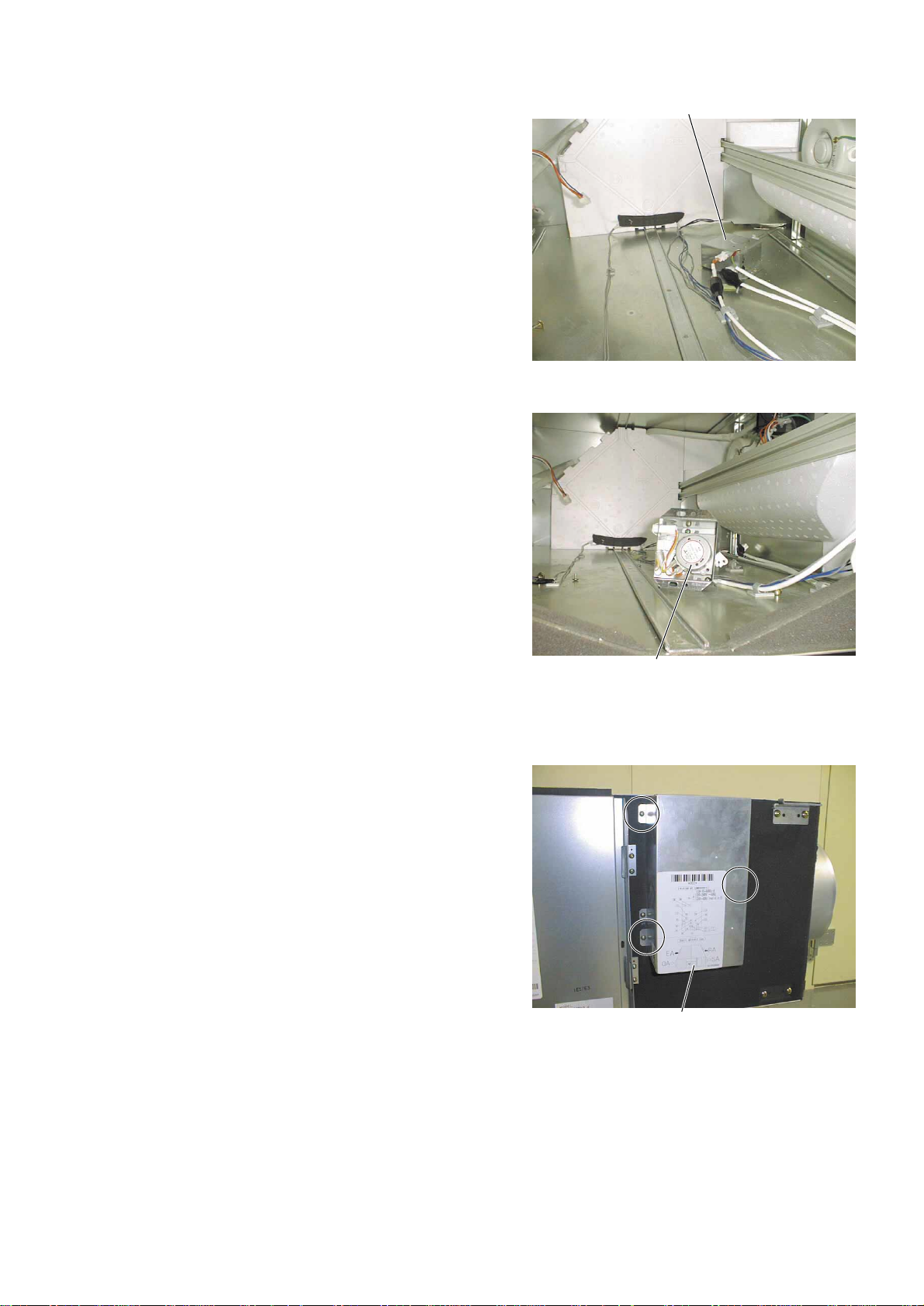

4-2 Damper Movement Motor Part (All units available)

4-3 Circuit Board Part

(1)LGH-15RX3-E~LGH-100RX3-E type

1Remove (3) screws from the control box cover.

1Remove (2) screws out from the damper motor

cover.

2Take the damper movement motor out of the cover.

Damper Motor Cover

Damper Movement Motor

Control Box Cover

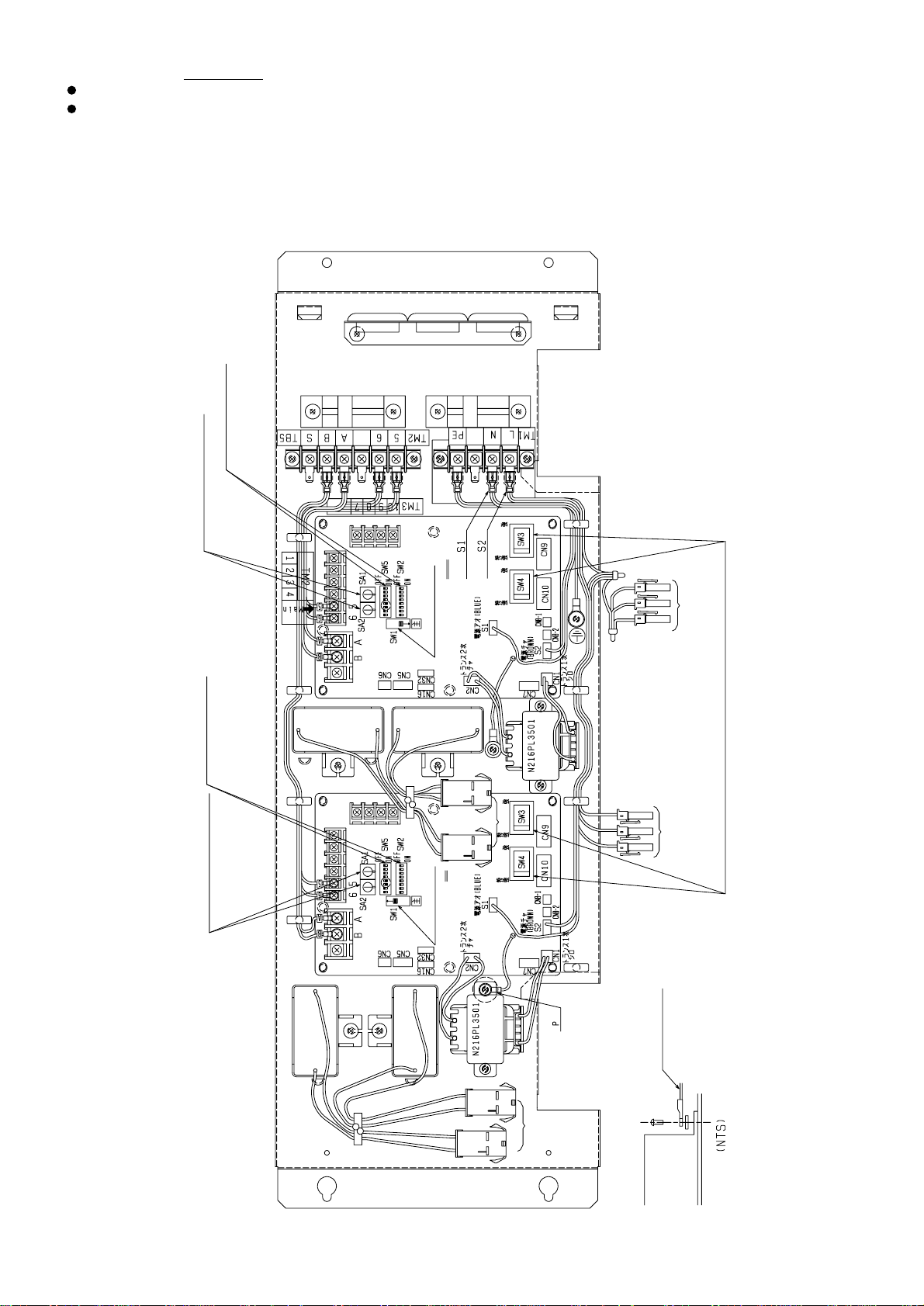

Page 17

—16——16—

2Remove (2) screws from capacitors.

3Remove all harnesses connected to the circuit

board.

4Take the circuit board out.

Capacitors

Circuit Board

Page 18

—17——17—

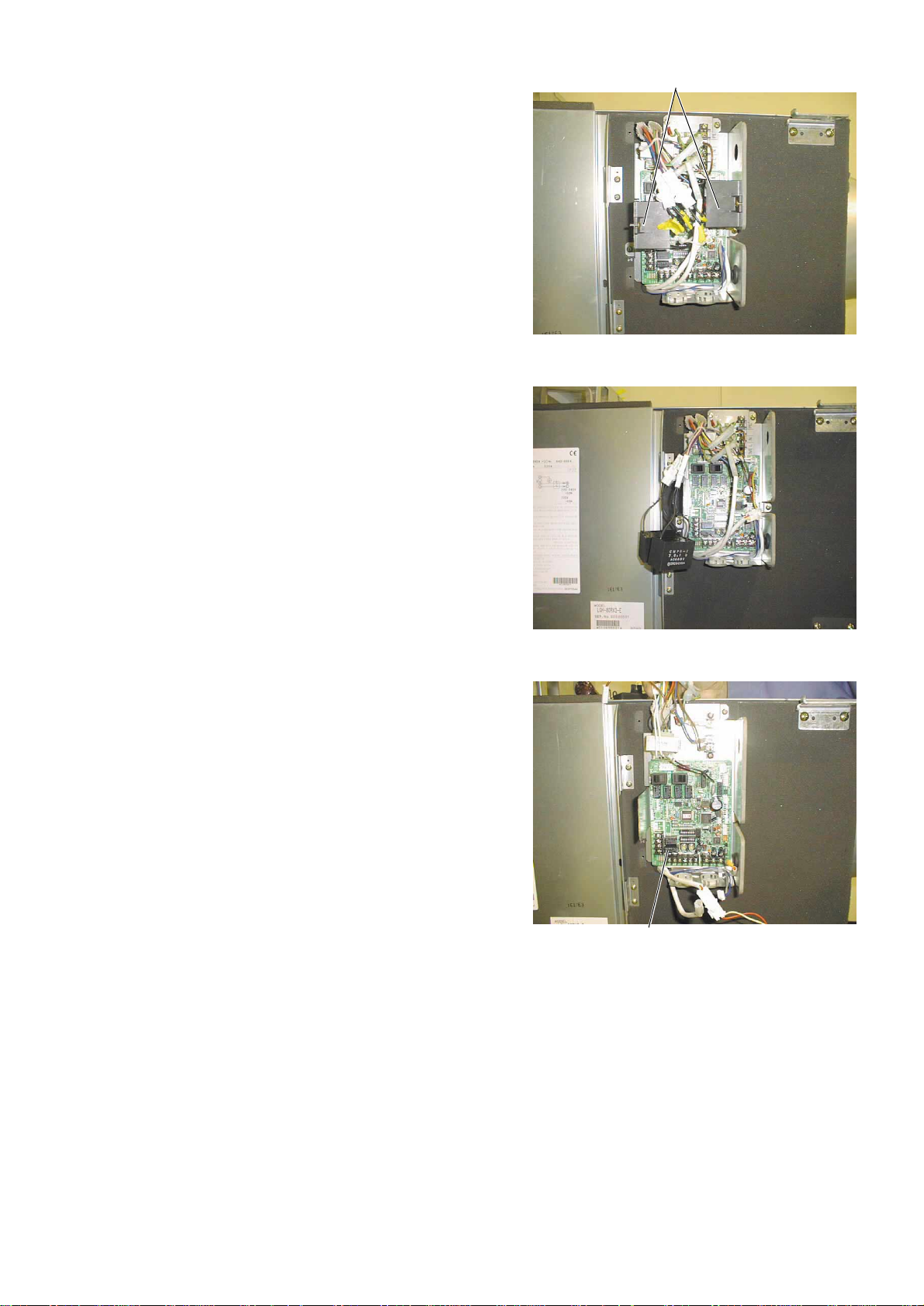

(2)

LGH-150RX3-E,LGH-200RX3-E (-60) type

1Remove (4) screws from the control box cover.

2Remove all harnesses connected to the circuit

board.

3Take the circuit board out.

Page 19

—18——18—

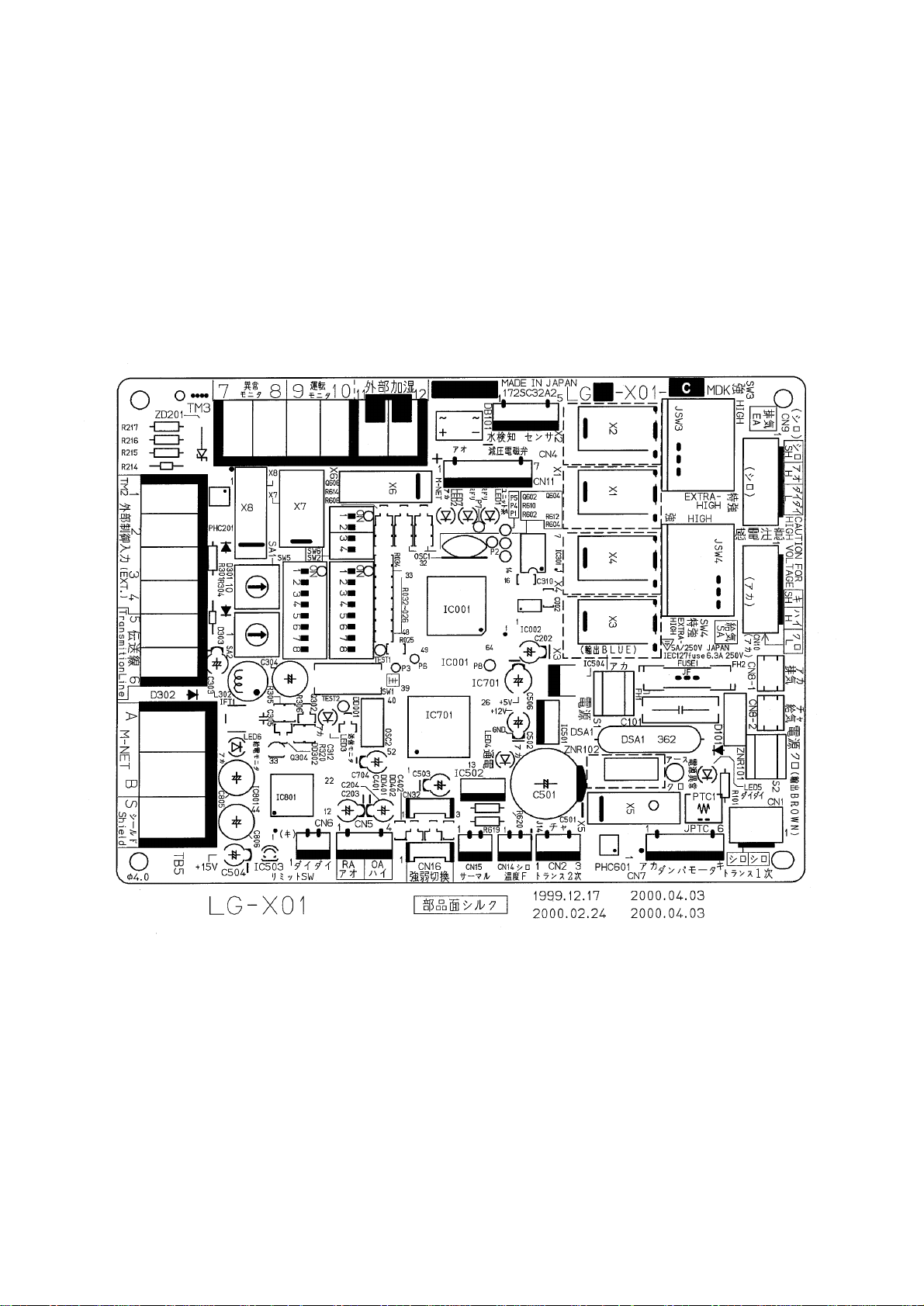

Address setting switches (SA1 and SA2)

(The factory setting is "0".)

Function selection switch

(The factory setting is SW5 and SW6 set to "ON", and all others set to "OFF".)

(Sub)

Blue

To motor (capacitor)

To motor (capacitor)

Transformer

PCB Ground wire

P section

Must be securely grounded.

*When inserting the PCB ASSY into the spacer,

press down on the circuit board near the spacer before inserting it.

To motor and GM ground

Special High/High selection switch

(The factory setting is "Special High".)

To motor and GM ground

Brown

Main/Sub selection switch

(The factory setting is "Sub".)

Main/Sub selection switch

(The factory setting is "Main".)

Function selection switch

(The factory setting is SW5 and SW6 set to "ON", and all others set to "OFF".)

Address setting switches (SA1 and SA2)

(The factory setting is "0".)

CAUTION

Unit : LGH-150RX3-E,LGH-200RX3-E

All settings should be re-set the same as

previous.

a.Main/Sub change switch (SW1)

Upper PCB : Main

Lower PCB : Sub

b.Address switch (SA1,SA2)

c.Function switch (SW2,SW5)

d.Fan speed selection switch (SW3,SW4)

Page 20

—19——19—

Page 21

—20——20—

5. Parts list

Please note the following when using the parts list.

1. To order parts, contact the nearest office of MITSUBISHI ELECTRIC Cor

poration.

2. When ordering parts, always indicate the part number, part name, and number of parts

required.

3. Parts are not always available, and it may take time for you to receive them.

4. There may be specification improvements or prices changes.

5. Specifications and prices are as of January 2002.

6. Parts marked are critical for safety. To maintain safety and performance, always

replace these parts with the parts prescribed.

7. The numbers that are circled in the exploded view are the same as the reference

number for the part being indicated.

Description of screw abbreviations

Screw

4 × 16

Abbreviation

PC screw

PRC screw

PP screw

SW · PP screw

PPT screw

PCT screw

PTT screw

PT screw

SET screw

SQ · SET screw

P · SET screw

PMT screw

HS · SET screw

P · R · W screw

P · C · W screw

P · R · C . W screw

R · W screw

PW · PP screw

SW-PW · PP screw

Description

Cross recess flat head machine screw

Cross recess oval head machine screw

Cross recess pan head machine screw

Cross recess pan head screw with spring washer

Cross recess tapping screw

Cross recess flat head tapping screw

Cross recess truss head tapping screw

Cross recess truss head machine screw

Slotted head stop screw

Square head stop screw

Pan head stop screw

Primer truss head screw

Hexagon head stop screw

Cross recess round wood screw

Cross recess flat head wood screw

Cross recess round and flat wood screw

Slotted round wood screw

Cross recess pan head screw with small washer

Cross recess pan head machine screw with spring washer and flat washer

Screw diameter Length

Page 22

—21——21—

Model LGH-15RX3-E

Critical

for safety

22

18

No. Parts No. Name of part

Q’ty

pcs/unit

1. H00 312 007 P T T screw 4×6

2. R50 384 617 Pipe guide 4

3. H00 000 487 P T T screw 4×8

4. R50 091 380 Hanger 4

5. H00 000 391 P T screw 5×88

6. R50 395 707 Maintenance cover 1

7. R50 395 381 Core guide 1

8. Y50 061 717 Filter 2

9. R50 213 710 Lossnay core 1

10. R50 261 381 Core guide 1

11. R50 354 704 Cover 2

12. R50 213 344 Hinge 1

13. M34 074 017 Special screw 4×11 1

14. Y50 029 712 Fix plate 1

15. Y50 061 704 Hanger 4

16. R50 361 717 Sound absorbing material 1

Remarks Price

Page 23

—22—

6 7 8 9 10 11 12 13 14 15 16

1 2 3 4 5

2

4

5

4

8

3

2

2

15

4

Page 24

—23——23—

Model LGH-15RX3-E

Critical

for safety

17

No. Parts No. Name of part

Q’ty

Remarks Price

pcs/unit

21. R50 331 067 Special nut 2

22. M34 398 077 Tab washer 2

23. R50 354 480 Centrifugal fan 2 180

24. R50 028 465 Special washer 2

25. Y50 061 451 Motor 2

26. R50 214 708 Motor fix plate 4

27. H00 000 332 P T T screw 4×10

28. Y50 029 708 Motor base 2

Page 25

—24—

21 22 23 24 25 26 27 28

27

1

1

27

27

28

1

1

27

27

25

24

23

22

21

26

Page 26

—25——25—

Model LGH-15RX3-

E

t

y

r

t

r

r

d

d

d

r

y

E

y

p

No. Parts No. Name of par

Q't

cs/unit

31. Y50 061 693 Damper motor cove

32. R50 213 715 Damper suppor

33. M31 234 089 Special bush 2

34. R50 095 156 Pull spring 1

35. R50 213 713 Dampe

36. Y50 061 260 Damper moto

37. R50 054 225 Bush 2

38. R50 228 150 Ro

39. R50 399 224 Cord clip 3

40. Y50 061 215 Thermistor 1 -30/100゚C

41. R50 399 223 Cord clip 2

42. Y50 061 706 Cover plate 1

43. K83 170 228 Cord ban

44. M45 017 228 Cord ban

45. Y50 047 216 Transformer 1 230WAC

46. R50 385 283 Capacitor 2 2.5µF・440WAC

47. H00 011 008 P T screw 4×8(BS) 1 For earth

48. H00 013 076 Lock washe

49. H00 000 488 P T T screw 4×12 2

50. R50 072 236 Terminal 1 4P

51. Y50 061 226 Insulation plate 1

52. Y50 061 708 PCB fixplate 1

53. H00 000 003 P P screw 4×8 2

54. Y50 061 171 PCB ass

55. X40 139 095 Spacer 4

56. D42 019 095 Spacer 3

57. M35 164 224 Cord clip 1

58. Y50 047 226 Cord bush 2

59. K83 223 225 Bush 1

1

1

1

1 220-240V

1

1

1

2

1 LG-X01-

Critical Remarks Price

for safet

Page 27

53 54 55 56 57 58 59

31 32 33 34 35

36 37 38 39 40 41

42 43 44 45 46 47 48 49 50 51 52

1

1

37

1

41

39

39

3

3

48

3

—26—

Page 28

—27——27—

Model LGH-25RX3-E

Critical

for safety

22

18

No. Parts No. Name of part

Q’ty

pcs/unit

1. H00 312 007 P T T screw 4×6

2. R50 323 609 Pipe guide 4

3. H00 000 487 P T T screw 4×8

4. R50 091 380 Hanger 4

5. H00 000 391 P T screw 5×88

6. R50 395 707 Maintenance cover 1

7. R50 395 382 Core guide 1

8. Y50 061 718 Filter 2

9. R50 214 710 Lossnay core 2

10. R50 395 383 Core guide 1

11. R50 354 704 Cover 2

12. R50 213 344 Hinge 1

13. M34 074 017 Special screw 4×11 1

14. Y50 029 712 Fix plate 1

15. Y50 061 704 Hanger 4

16. R50 354 718 Sound absorbing material 1

Remarks Price

Page 29

—28—

6 7 8 9 10 11 12 13 14 15 16

1 2 3 4 5

2

4

5

4

8

3

2

2

15

4

Page 30

—29——29—

Model LGH-25RX3-E

Critical

for safety

17

No. Parts No. Name of part

Q’ty

Remarks Price

pcs/unit

21. R50 331 067 Special nut 2

22. M34 398 077 Tab washer 2

23. R50 354 480 Centrifugal fan 2 180

24. R50 028 465 Special washer 2

25. Y50 061 452 Motor 2

26. R50 214 708 Motor fix plate 4

27. H00 000 332 P T T screw 4×10

28. Y50 030 707 Motor base 2

Page 31

—30—

21 22 23 24 25 26 27 28

27

1

1

27

27

28

1

1

27

27

25

24

23

22

21

26

Page 32

—31——31—

Model LGH-25RX3-

E

t

y

r

t

r

r

d

d

d

r

y

E

y

p

No. Parts No. Name of par

Q't

cs/unit

31. Y50 061 693 Damper motor cove

32. R50 213 715 Damper suppor

33. M31 234 089 Special bush 2

34. R50 095 156 Pull spring 1

35. R50 213 713 Dampe

36. Y50 061 260 Damper moto

37. R50 054 225 Bush 2

38. R50 230 150 Ro

39. R50 399 224 Cord clip 2

40. Y50 061 216 Thermistor 1

41. R50 399 223 Cord clip 2

42. Y50 061 706 Cover plate 1

43. K83 170 228 Cord ban

44. M45 017 228 Cord ban

45. Y50 047 216 Transformer 1 230WAC

46. R50 385 283 Capacitor 2 2.5µF・440WAC

47. H00 011 008 P T screw 4×8(BS) 1 For earth

48. H00 013 076 Lock washe

49. H00 000 488 P T T screw 4×12 2

50. R50 072 236 Terminal 1 4P

51. Y50 061 226 Insulation plate 1

52. Y50 061 708 PCB fixplate 1

53. H00 000 003 P P screw 4×8 2

54. Y50 061 171 PCB ass

55. X40 139 095 Spacer 4

56. D42 019 095 Spacer 3

57. M35 164 224 Cord clip 1

58. Y50 047 226 Cord bush 2

59. K83 223 225 Bush 1

1

1

1

1 220-240V

1

1

1

2

1 LG-X01-

Critical Remarks Price

for safet

Page 33

—32—

53 54 55 56 57 58 59

31 32 33 34 35

36 37 38 39 40 41

42 43 44 45 46 47 48 49 50 51 52

1

1

37

1

3

3

48

3

Page 34

—33——33—

Model LGH-35RX3-E

Critical

for safety

23

34

No. Parts No. Name of part

Q’ty

pcs/unit

1. H00 312 007 P T T screw 4×6

2. R50 323 609 Pipe guide 4

3. Y50 061 704 Hanger 4

4. H00 000 487 P T T screw 4×8

5. R50 091 380 Hanger 4

6. H00 000 583 P T screw 5×12 8

7. R50 351 707 Maintenance cover 1

8. R50 396 381 Core guide 1

9. Y50 062 717 Filter 2

10. R50 215 710 Lossnay core 2

11. R50 396 382 Core guide 1

12. R50 354 704 Cover 2

13. R50 213 344 Hinge 1

14. M34 074 017 Special screw 4×11 1

15. Y50 029 712 Fix plate 1

16. R50 365 717 Sound absorbing material 1

Remarks Price

Page 35

7 8 9 10 11 12 13 14 15 16

1 2 3 4 5 6

2

3

3

5

2

2

5

4

5

9

—34—

Page 36

—35——35—

Model LGH-35RX3-E

Critical

for safety

20

No. Parts No. Name of part

Q’ty

Remarks Price

pcs/unit

21. R50 331 067 Special nut 2

22. M34 398 077 Tab washer 2

23. R50 351 480 Centrifugal fan 2 220

24. R50 215 708 Fan base 2

25. Y50 062 451 Motor 2

26. R50 351 713 Motor base 2

27. H00 000 390 P T screw 5×10

Page 37

21 22 23 24 25 26 27

27

27

26

25

27

24

23

22

21

—36—

Page 38

—37——37—

Model LGH-35RX3-

E

t

y

r

t

r

r

d

d

d

r

y

E

y

p

No. Parts No. Name of par

Q't

cs/unit

31. Y50 061 693 Damper motor cove

32. R50 069 156 Pull spring 1

33. R50 215 716 Damper suppor

34. M31 234 089 Special bush 2

35. R50 215 715 Dampe

36. Y50 061 260 Damper moto

37. R50 054 225 Bush 2

38. R50 231 150 Ro

39. Y50 062 215 Thermistor 1

40. R50 399 223 Cord clip 2

41. R50 399 224 Cord clip 3

42. Y50 061 706 Cover plate 1

43. K83 170 228 Cord ban

44. M45 017 228 Cord ban

45. Y50 047 216 Transformer 1 230WAC

46. R50 385 283 Capacitor 2 2.5µF・440WAC

47. H00 011 008 P T screw 4×8(BS) 1 For earth

48. H00 013 076 Lock washe

49. H00 000 488 P T T screw 4×12 2

50. R50 072 236 Terminal 1 4P

51. Y50 061 226 Insulation plate 1

52. Y50 061 708 PCB fixplate 1

53. H00 000 003 P P screw 4×8 2

54. Y50 061 171 PCB ass

55. X40 139 095 Spacer 4

56. D42 019 095 Spacer 3

57. M35 164 224 Cord clip 1

58. Y50 047 226 Cord bush 2

59. K83 223 225 Bush 1

1

1

1

1 220-240V

1

1

1

2

1 LG-X01-

Critical Remarks Price

for safet

Page 39

—38—

31 32 33 34 35

36 37 38 39 40 41

1

1

41

40

53 54 55 56 57 58 59

42 43 44 45 46 47 48 49 50 51 52

4

4

48

4

37

Page 40

—39——39—

Model LGH-50RX3-E

Critical

for safety

23

34

No. Parts No. Name of part

Q’ty

pcs/unit

1. H00 312 007 P T T screw 4×6

2. R50 028 610 Flange 4

3. Y50 061 704 Hanger 4

4. H00 000 487 P T T screw 4×8

5. R50 091 380 Hanger 4

6. H00 000 583 P T screw 5×12 8

7. R50 351 707 Maintenance cover 1

8. R50 216 381 Core guide 1

9. Y50 062 718 Filter 2

10. R50 216 710 Lossnay core 2

11. R50 263 381 Core guide 1

12. R50 351 708 Cover 2

13. R50 213 344 Hinge 1

14. M34 074 017 Special screw 4×11 1

15. Y50 029 712 Fix plate 1

16. R50 351 717 Sound absorbing material 1

Remarks Price

Page 41

—40—

7 8 9 10 11 12 13 14 15 16

1 2 3 4 5 6

2

3

3

5

2

2

5

4

5

9

Page 42

—41——41—

Model LGH-50RX3-E

Critical

for safety

20

No. Parts No. Name of part

Q’ty

Remarks Price

pcs/unit

21. R50 331 067 Special nut 2

22. M34 398 077 Tab washer 2

23. R50 351 480 Centrifugal fan 2 220

24. R50 215 708 Motor base 2

25. Y50 062 452 Motor 2

26. R50 351 713 Motor fix plate 2

27. H00 000 390 P T screw 5×10

Page 43

—42—

21 22 23 24 25 26 27

27

27

26

25

27

24

23

22

21

Page 44

—43——43—

Model LGH-50RX3-

E

t

y

r

t

r

r

d

d

d

r

y

E

p

y

No. Parts No. Name of par

Q't

cs/unit

31. Y50 061 693 Damper motor cove

32. R50 069 156 Pull spring 1

33. R50 215 716 Damper suppor

34. M31 234 089 Special bush 2

35. R50 215 715 Dampe

36. Y50 061 260 Damper moto

37. R50 054 225 Bush 2

38. R50 232 150 Ro

39. Y50 062 216 Thermistor 1

40. R50 399 223 Cord clip 2

41. R50 399 224 Cord clip 3

42. Y50 061 706 Cover plate 1

43. K83 170 228 Cord ban

44. M45 017 228 Cord ban

45. Y50 047 216 Transformer 1 230WAC

46. Y50 057 283 Capacitor 2 4µF・440WAC

47. H00 011 008 P T screw 4×8(BS) 1 For earth

48. H00 013 076 Lock washe

49. H00 000 488 P T T screw 4×12 2

50. R50 072 236 Terminal 1 4P

51. Y50 061 226 Insulation plate 1

52. Y50 061 708 PCB fixplate 1

53. H00 000 003 P P screw 4×8 2

54. Y50 061 171 PCB ass

55. X40 139 095 Spacer 4

56. D42 019 095 Spacer 3

57. M35 164 224 Cord clip 1

58. Y50 047 226 Cord bush 2

59. K83 223 225 Bush 1

1

1

1

1 220-240V

1

1

1

2

1 LG-X01-

Critical Remarks Price

for safet

Page 45

—44—

31 32 33 34 35

36 37 38 39 40 41

1

1

41

40

53 54 55 56 57 58 59

42 43 44 45 46 47 48 49 50 51 52

4

4

48

4

37

Page 46

—45——45—

Model LGH-80RX3-E

Critical

for safety

18

16

No. Parts No. Name of part

Q’ty

pcs/unit

1. H00 000 487 P T T screw 4×8

2. Y50 021 609 Flange 4

3. R50 095 380 Hanger 4

4. H00 000 244 P T screw 6×12

5. R50 397 708 Maintenance cover 1

6. R50 218 381 Core guide 1

7. Y50 063 717 Filter 2

8. R50 218 710 Lossnay core 2

9. R50 265 381 Core guide 1

10. R50 358 704 Cover 2

11. R50 213 344 Hinge 1

12. M34 074 017 Special screw 4×11 1

13. Y50 029 712 Fix plate 2

14. R50 358 717 Sound absorbing material 1

Remarks Price

Page 47

5 6 7 8 9 10 11 12 13 14

1 2 3 4

2

3

2

2

3

1

7

3

—46—

Page 48

—47——47—

Model LGH-80RX3-E

Critical

for safety

16

No. Parts No. Name of part

Q’ty

Remarks Price

pcs/unit

21. R50 218 067 Special nut 2

22. K83 466 113 Special washer(12) 2

23. R50 357 480 Centrifugal fan 2 250

24. H00 157 008 P T screw 6×20 8

25. M34 043 080 Special washer 8

26. D40 135 095 Spacer 8

27. R50 217 225 Bush 8

28. Y50 033 707 Fan base 2

29. R50 264 711 Inlet plate 2

30. R50 264 712 Motor base 2

31. H00 189 007 P T T screw 5×10

32. Y50 063 451 Motor 2

33. H00 061 050 Nut (6) 8

Page 49

21 22 23 24 25 26 27 28 29 30 31 32 33

33

30

29

31

32

27

26

28

24

25

23

22

21

—48—

Page 50

—49——49—

Model LGH-80RX3-

E

t

y

r

t

r

r

d

d

d

r

y

E

y

p

No. Parts No. Name of par

Q't

cs/unit

41. Y50 061 693 Damper motor cove

42. H00 312 007 P T T screw 4×6 2

43. R50 074 156 Pull spring 1

44. R50 218 716 Damper suppor

45. M31 234 089 Special bush 2

46. R50 271 715 Dampe

47. Y50 061 260 Damper moto

48. R50 054 225 Bush 2

49. R50 265 150 Ro

50. Y50 063 215 Thermistor 1

51. R50 399 223 Cord clip 4

52. R50 399 224 Cord clip 4

53. Y50 061 706 Cover plate 1

54. K83 170 228 Cord ban

55. M45 017 228 Cord ban

56. H00 000 332 P T T screw 4×10 1

57. Y50 047 216 Transformer 1 230WAC

58. Y50 063 283 Capacitor 2 7.0µF・440WAC

59. H00 011 008 P T screw 4×8(BS) 1 For earth

60. H00 013 076 Lock washe

61. H00 000 488 P T T screw 4×12 2

62. R50 072 236 Terminal 1 4P

63. Y50 061 226 Insulation plate 1

64. Y50 061 708 PCB fixplate 1

65. H00 000 003 P P screw 4×8 2

66. Y50 061 171 PCB ass

67. X40 139 095 Spacer 4

68. D42 019 095 Spacer 3

69. M35 164 224 Cord clip 1

70. Y50 047 226 Cord bush 2

71. K83 223 225 Bush 1

1

1

1

1 220-240V

1

1

1

1

1 LG-X01-

Critical Remarks Price

for safet

Page 51

—50—

41 42 43 44 45 46

47 48 49 50 51 52

42

48

51

51

52

51

65 66 67 68 69 70 71

53 54 55 56 57 58 59 60 61 62 63 64

60

1

Page 52

—51——51—

Model LGH-100RX3-E,LGH-100RX3-E-60

Critical

for safety

No. Parts No. Name of part

Q’ty

pcs/unit

1. H00 000 487 P T T screw 4×8 18

2. Y50 021 609 Flange 4

3. R50 095 380 Hanger 4

4. H00 000 244 P T screw 6×12

5. R50 397 708 Maintenance cover 1

6. R50 219 381 Core guide 1

7. Y50 063 718 Filter 2

8. R50 219 710 Lossnay core 2

9. R50 266 381 Core guide 1

10. R50 358 704 Cover 2

11. R50 213 344 Hinge 1

12. M34 074 017 Special screw 4×11 1

13. Y50 029 712 Fix plate 2

14. R50 358 717 Sound absorbing material 1

Remarks Price

16

Page 53

—52—

5 6 7 8 9 10 11 12 13 14

1 2 3 4

2

3

2

2

3

1

7

3

Page 54

—53——53—

Model LGH-100RX3-E,LGH-100RX3-E-60

Critical

for safety

No. Parts No. Name of part

Q’ty

Remarks Price

pcs/unit

21. R50 218 067 Special nut 2

22. K83 466 113 Special washer(12) 2

23. R50 357 480 Centrifugal fan 2 250

24. H00 157 008 P T screw 6×20

25. M34 043 080 Special washer 8

26. R50 000 095 Spacer 8

27. R50 217 225 Bush 8

28. Y50 033 707 Fan base 2

29. R50 264 711 Inlet plate 2

30. R50 218 712 Motor base 2

31. H00 189 007 P T T screw 5×10

32. Y50 063 452 Motor 2 50Hz

32. Y50 063 453 Motor 2 60Hz

33. H00 061 050 Nut (6)

8

16

8

Page 55

—54—

21 22 23 24 25 26 27 28 29 30 31 32 33

33

30

29

31

32

27

26

28

24

25

23

22

21

Page 56

—55——55—

Model LGH-100RX3-E,LGH-100RX3-E-6

0

t

y

r

t

r

r

d

d

d

r

y

E

y

p

No. Parts No. Name of par

Q't

cs/unit

41. Y50 061 693 Damper motor cove

42. H00 312 007 P T T screw 4×6 2

43. R50 074 156 Pull spring 1

44. R50 218 716 Damper suppor

45. M31 234 089 Special bush 2

46. R50 271 715 Dampe

47. Y50 061 260 Damper moto

48. R50 054 225 Bush 2

49. R50 265 150 Ro

50. Y50 063 216 Thermistor 1

51. R50 399 223 Cord clip 4

52. R50 399 224 Cord clip 4

53. Y50 061 706 Cover plate 1

54. K83 170 228 Cord ban

55. M45 017 228 Cord ban

56. H00 000 332 P T T screw 4×10 1

57. Y50 047 216 Transformer 1 230WAC

58. Y50 063 283 Capacitor 2 7.0µF・440WAC

59. H00 011 008 P T screw 4×8(BS) 1 For earth

60. H00 013 076 Lock washe

61. H00 000 488 P T T screw 4×12 2

62. R50 072 236 Terminal 1 4P

63. Y50 061 226 Insulation plate 1

64. Y50 061 708 PCB fixplate 1

65. H00 000 003 P P screw 4×8 2

66. Y50 061 171 PCB ass

67. X40 139 095 Spacer 4

68. D42 019 095 Spacer 3

69. M35 164 224 Cord clip 1

70. Y50 047 226 Cord bush 2

71. K83 223 225 Bush 1

1

1

1

1 220-240V

1

1

1

1

1 LG-X01-

Critical Remarks Price

for safet

Page 57

—56—

41 42 43 44 45 46

47 48 49 50 51 52

42

48

51

51

52

51

65 66 67 68 69 70 71

53 54 55 56 57 58 59 60 61 62 63 64

60

1

Page 58

—57——57—

Model LGH-150RX3-E

Critical

for safety

35

No. Parts No. Name of part

Q’ty

pcs/unit

1. H00 000 333 P T T screw 4×14 32

2. R50 220 607 Flange 4

3. R50 213 344 Hinge 2

4. R50 111 381 Fix plate 8

5. H00 000 244 P T screw 6×12

6. R50 397 708 Maintenance cover 2

7. R50 218 381 Core guide 2

8. Y50 063 717 Filter 4

9. R50 218 710 Lossnay core 4

10. R50 265 381 Core guide 2

11. H00 000 487 P T T screw 4×8

12. Y50 029 712 Fix plate 4

13. R50 358 717 Sound absorbing material 2

Remarks Price

24

Page 59

6 7 8 9 10 11 12 13

1 2 3 4 5

1

1

4

8

5

5

5

4

4

5

1

1

—58—

Page 60

—59——59—

Model LGH-150RX3-E

Critical

for safety

No. Parts No. Name of part

Q’ty

Remarks Price

pcs/unit

21. R50 218 067 Special nut 4

22. K83 466 113 Special washer(12) 4

23. R50 357 480 Centrifugal fan 4 250

24. H00 157 008 P T screw 6×20 16

25. M34 043 080 Special washer 16

26. D40 135 095 Spacer

27. R50 217 225 Bush

28. Y50 033 707 Fan base 4

29. H00 189 007 P T T screw 5×10

30. R50 264 711 Inlet plate 4

31. R50 264 712 Motor base 4

32. Y50 063 451 Motor 4

33. H00 061 050 Nut (6) 16

16

16

32

Page 61

21 22 23 24 25 26 27 28 29 30 31 32 33

29

33

32

31

29

30

28

25

27

26

24

23

22

21

—60—

Page 62

—61——61—

Model LGH-150RX3-

E

t

y

r

t

r

r

d

d

r

y

E

y

p

No. Parts No. Name of par

Q't

cs/unit

41. Y50 061 693 Damper motor cove

42. H00 312 007 P T T screw 4×6 8

43. R50 074 156 Pull spring 2

44. R50 218 716 Damper suppor

45. M31 234 089 Special bush 4

46. R50 271 715 Dampe

47. Y50 061 260 Damper moto

48. R50 265 150 Ro

49. Y50 064 215 Thermistor 2

50. R50 399 223 Cord clip 8

51. R50 399 224 Cord clip 4

52. Y50 045 707 Cover plate 1

53. K83 170 228 Cord ban

54. Y50 063 283 Capacitor 4 7.0µF・440WAC

55. H00 000 003 P P screw 4×8 5

56. H00 013 076 Lock washe

57. Y50 047 216 Transformer 2 230WAC

58. D42 019 095 Spacer 6

59. M35 164 224 Cord clip 8

60. Y50 064 706 Fix plate 1

61. X40 139 095 Spacer 8

62. R50 072 236 Terminal 1 4P

63. H00 000 488 P T T screw 4×12 4

64. Y50 061 226 Insulation plate 1

65. R50 069 236 Terminal 1 6P

66. D40 058 224 Cord clip 2

67. Y50 047 226 Cord bush 3

68. Y50 064 707 Hanger(cord) 1

69. Y50 061 171 PCB ass

70. R50 054 225 Bush 4

71. H00 011 008 P T screw 4×8(BS) 1

2

2

2

2 220-240V

2

2

4

2 LG-X01-

Critical Remarks Price

for safet

Page 63

—62—

41 42 43 44 45 46

47 48 49 50 51

42

70

50

50

51

50

62 63 64 65 66 67 68 69

52 53 54 55 56 57 58 59 71 60 61

58

11

11

56

11

11

11

53

11

61

61

70

Page 64

—63——63—

Model LGH-200RX3-E,LGH-200RX3-E-60

Critical

for safety

32

No. Parts No. Name of part

Q’ty

pcs/unit

1. H00 000 333 P T T screw 4×14

2. R50 220 607 Flange 4

3. R50 213 344 Hinge 2

4. R50 111 381 Fix plate 8

5. H00 000 244 P T screw 6×12 24

6. R50 397 708 Maintenance cover 2

7. R50 219 381 Core guide 2

8. Y50 063 718 Filter 4

9. R50 219 710 Lossnay core 4

10. R50 266 381 Core guide 2

11. H00 000 487 P T T screw 4×835

12. Y50 029 712 Fix plate 4

13. R50 358 717 Sound absorbing material 2

Remarks Price

Page 65

—64—

6 7 8 9 10 11 12 13

1 2 3 4 5

1

1

4

8

5

5

5

4

4

5

1

1

Page 66

—65——65—

Model LGH-200RX3-E,LGH-200RX3-E-60

Critical

for safety

φ

No. Parts No. Name of part

Q’ty

Remarks Price

pcs/unit

21. R50 218 067 Special nut 4

22. K83 466 113 Special washer(12) 4

23. R50 357 480 Centrifugal fan 4

24. H00 157 008 P T screw 6×20 16

25. M34 043 080 Special washer 16

26. R50 000 095 Spacer 16

27. R50 217 225 Bush 16

28. Y50 033 707 Fan base 4

29. H00 189 007 P T T screw 5×10 32

30. R50 264 711 Inlet plate 4

31. R50 218 712 Motor base 4

32. Y50 063 452 Motor 4 50Hz

32. Y50 063 453 Motor 4 60Hz

33. H00 061 050 Nut(6) 16

250

Page 67

—66—

21 22 23 24 25 26 27 28 29 30 31 32 33

29

33

32

31

29

30

28

25

27

26

24

23

22

21

Page 68

—67——67—

Model LGH-200RX3-E,LGH-200RX3-E-6

0

t

y

r

t

r

r

d

d

r

y

E

p

y

No. Parts No. Name of par

Q't

cs/unit

41. Y50 061 693 Damper motor cove

42. H00 312 007 P T T screw 4×6 8

43. R50 074 156 Pull spring 2

44. R50 218 716 Damper suppor

45. M31 234 089 Special bush 4

46. R50 271 715 Dampe

47. Y50 061 260 Damper moto

48. R50 265 150 Ro

49. Y50 064 216 Thermistor 2

50. R50 399 223 Cord clip 8

51. R50 399 224 Cord clip 4

52. Y50 045 707 Cover plate 1

53. K83 170 228 Cord ban

54. Y50 063 283 Capacitor 4 7.0µF・440WAC

55. H00 000 003 P P screw 4×8 5

56. H00 013 076 Lock washe

57. Y50 047 216 Transformer 2 230WAC

58. D42 019 095 Spacer 6

59. M35 164 224 Cord clip 8

60. Y50 064 706 Fix plate 1

61. X40 139 095 Spacer 8

62. R50 072 236 Terminal 1 4P

63. H00 000 488 P T T screw 4×12 4

64. Y50 061 226 Insulation plate 1

65. R50 069 236 Terminal 1 6P

66. D40 058 224 Cord clip 2

67. Y50 047 226 Cord bush 3

68. Y50 064 707 Hanger(cord) 1

69. Y50 061 171 PCB ass

70. R50 054 225 Bush 4

71. H00 011 008 P T screw 4×8(BS) 1

2

2

2

2 220-240V

2

2

4

2 LG-X01-

Critical Remarks Price

for safet

Page 69

—68—

41 42 43 44 45 46

47 48 49 50 51

42

70

50

50

51

50

62 63 64 65 66 67 68 69

52 53 54 55 56 57 58 59 71 60 61

58

11

11

56

11

11

11

53

11

61

61

70

Page 70

Printed in Japan in January, 2002

100 <MEE>

Loading...

Loading...