Page 1

TC0169e

3PIECE HARD TONNEAU COVER

INSTALLATION INSTRUCTIONS

VEHICLE DESCRIPTION: Mitsubishi MN Triton onwards

PLEASE KEEP INSTRUCTIONS IN GLOVE BOX FOR FURTHER USE

29/10/10ISSUE05Page 1 of 13

PLEASE REFER TO PAGE 13, OF THIS INSTRUCTION FOR A LIST OF PARTS AND QUANTITIES.

WARNING!

When in the closed position, Tonneau Cover must be latched and tailgate must be closed! Failure to do so could result in unexpected opening of the

Tonneau Cover from sudden wind gusts, which could cause damage to the vehicle and/or your Tonneau Cover!

MAINTENANCE:

• Only use cleaners, waxes, or products that are labeled safe for use on plastics. Avoid the use of any chemicals to clean your Tonneau Cover unless

labelled safe for plastics. Avoid use of abrasive type cleansers as they may dull the finish.

• The gas struts are self lubricating and should only be cleaned occasionally with a damp cloth. Premature seal failure will result if solvents or

lubricants are used to clean struts.

• The locking mechanisms & Latches only require occasional lubrication with Graphite Powder. DO NOT use any other lubricants or oils.

Using alternative products will VOID Warranty.

• All installation hardware and fasteners must be checked every so often for tightness.

TONNEAU COVER - IMPORTANT:

• Do not stand/sit or rest heavy objects on Tonneau Cover.

• Humans or animals are not to be under the closed Tonneau Cover at any time.

• Securely latch Tonneau Cover before operating vehicle.

• Do not carry open volatile chemicals with Tonneau Cover installed.

• If contact with volatile chemicals occurs clean Tonneau Cover with mild detergent and water solution.

• Read instructions carefully before installation. It is strongly recommended that installation is conducted by an authorized dealer.

• This product must be installed exactly as specified in these instructions. Failure to do so may result in improper fit and/or retention.

• Recommend installation by 2 people.

• Approximate fitting time is 1 ½ hours.

PAINTING INSTRUCTIONS: (IF UNPAINTED)

• Prior to painting, clean all surfaces to be painted using clean water and a mild detergent, do not use lacquer thinner or any solvent based products.

Wipe completely dry.

• Best results will be achieved by wiping the areas to be painted with a tack rag just prior to painting.

• Select a top coat and clear paint that is suitable for ABS (Acrylonitrile-Butadiene-Styrene).

• Automotive paint systems, such as Acrylics or Two Packs, can be applied directly to the components. However, some paints may require a primer.

If recommendations on paint specification are not followed, cracking of the part or degradation to the material may result. In all paint systems,

aromatic hydrocarbons and alkalies are best avoided to reduce damage to the material properties.

• If using a paint system which requires baking, do not expose the product to temperatures above 70° C (155° F).

• Allow a minimum of 8 hours after baking before installation on the vehicle.

Accessory

MITSUBISHI

MOTORS

Page 2

MITSUBISHI TRITON 3 PIECE TONNEAU COVER

ISSUE05

FIG. 3

FIG. 2

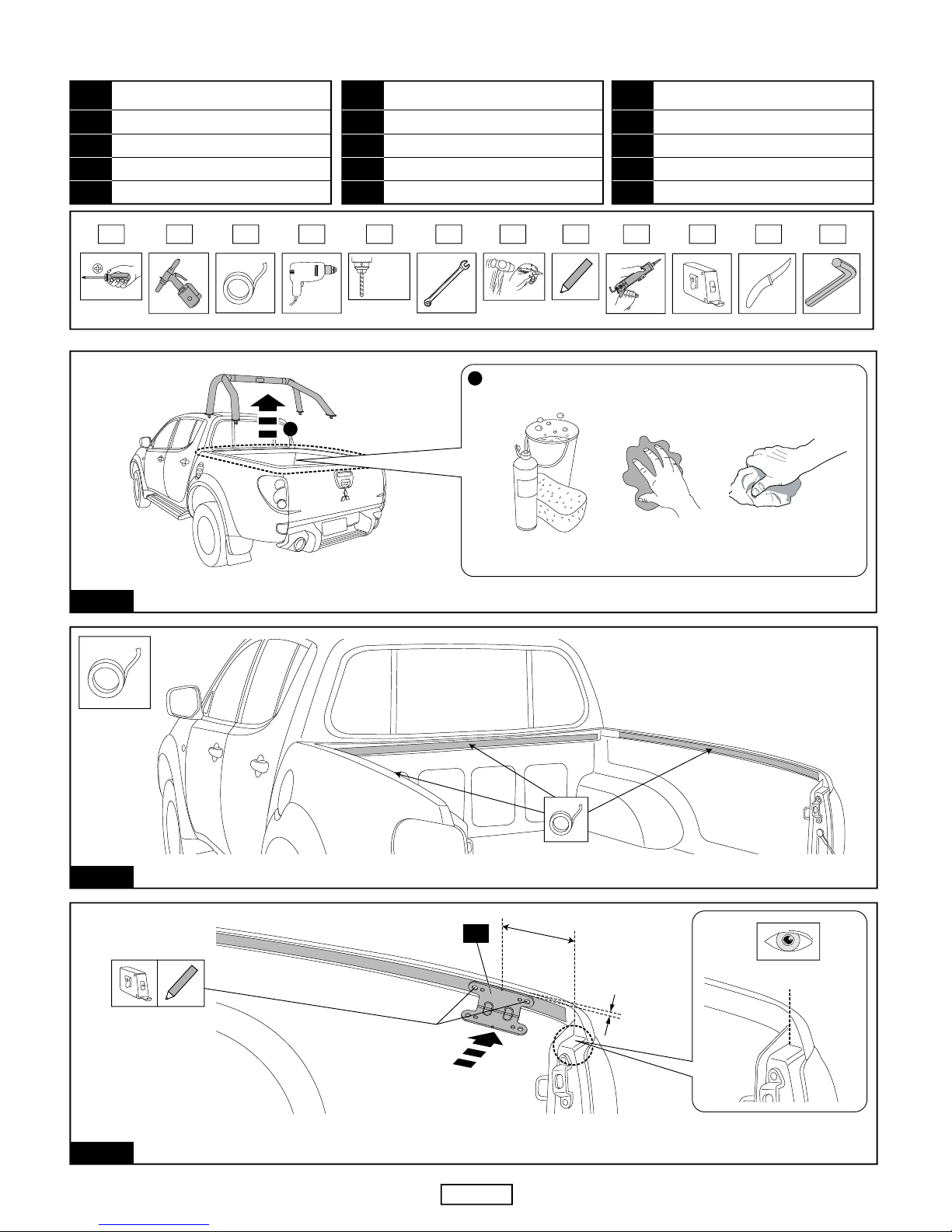

APPLY MASKING TAPE TO THE INNER BEDRAIL AS SHOWN.

FIG. 1

REMOVE SPORTS BAR AND RETAIN ALL HARDWARE. THOROUGHLY CLEAN AND DRY THE INSTALLATION AREA.

TC0169e

29/10/10Page 2 of 13

1

2

MEASURE AND MARK A LINE ON THE SIDE RAIL 108MM FROM THE REAR OF THE SIDE RAIL AS SHOWN. POSITION “FACE B ”

OF LOCK STRIKER BRACKET TO SIDE OF SIDE RAIL 18MM DOWN FROM TOP OF SIDE RAIL. ALIGN NOTCH TO PREVIOUSLY

MARKED CENTRELINE. MARK THE POSITION OF THE TWO (2) LARGER HOLES AS SHOWN. REPEAT FOR THE OTHER SIDE.

108mm

MEASURE FROM REAR

OF FLANGE

18mm

A

B

4

RECOMMENDED TOOLS LIST

TOOL NAME

Caulking Gun & Silicon

Tape Measure

Knife

Allen Key

9

10

11

12

NO.TOOL NAME

Phillips Head Screwdriver

Rivet Gun

Masking Tape

Drill

1

2

3

4

NO. TOOL NAME

Ø5mm & Ø6mm Drill Bit

Spanners & Sockets

Hammer & Centre Punch

Pencil

5

6

7

8

NO.

1 2 3 4 5 6 7 8 9 10

Ø5mm

Ø6mm

11 12

Page 3

FIG. 4

TC0169eMITSUBISHI TRITON 3 PIECE TONNEAU COVER

29/10/10Page 3 of 13

ISSUE05

FIG. 7

FIG. 6

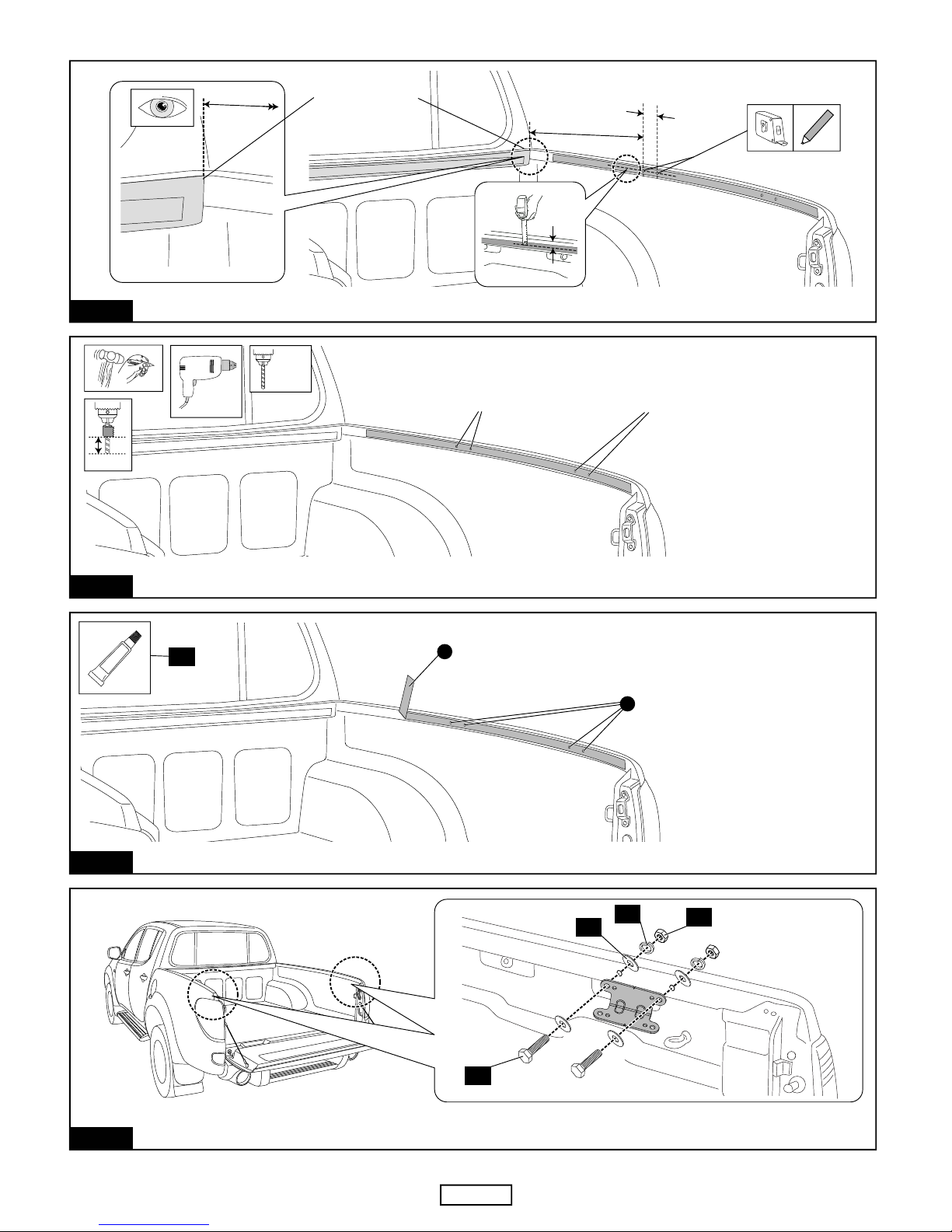

REMOVE THE MASKING TAPE FROM THE INSIDE OF THE SIDE RAILS ONLY. APPLY RUST INHIBITOR TO ALL THE DRILLED HOLES.

FIG. 5

REMOVE MASKING TAPE

APPLY RUST INHIBITOR

1

2

23

ALIGN LOCK STRIKER BRACKETS WITH PREVIOUSLY DRILLED HOLES, ENSURING BRACKETS ARE PARALLEL WITH TOP OF

SIDE RAIL AND SECURE WITH M6 BOLTS, M6 FLAT WASHERS, M6 SPRING WASHERS AND M6 NUTS AS SHOWN.

TIGHTEN TO TORQUE 12Nm.

CENTRE PUNCH THE TWO (2) FRONT HOLE POSITIONS AND DRILL Ø5MM HOLES. CENTRE PUNCH THE TWO (2) REAR

HOLE POSITIONS AND DRILL Ø6MM HOLES. REPEAT FOR THE OTHER SIDE OF THE VEHICLE.

CENTRE PUNCH,

THEN DRILL Ø5MM

HOLES

CENTRE PUNCH,

THEN DRILL Ø6MM

HOLES

Ø5mm

Ø6mm

20mm

ENSURE BRACKET IS

PARALLEL WITH

TOP OF SIDE RAIL

A

B

7

8

9

20

MEASURE FROM THE FRONT RAIL INSIDE OF THE TUB AND MARK THE DISTANCES AS SHOWN. REPEAT FOR THE OTHER SIDE.

MEASURE FROM

FRONT RAIL

INSIDE OF THE TUB

37mm

738mm

738mm

28mm

Page 4

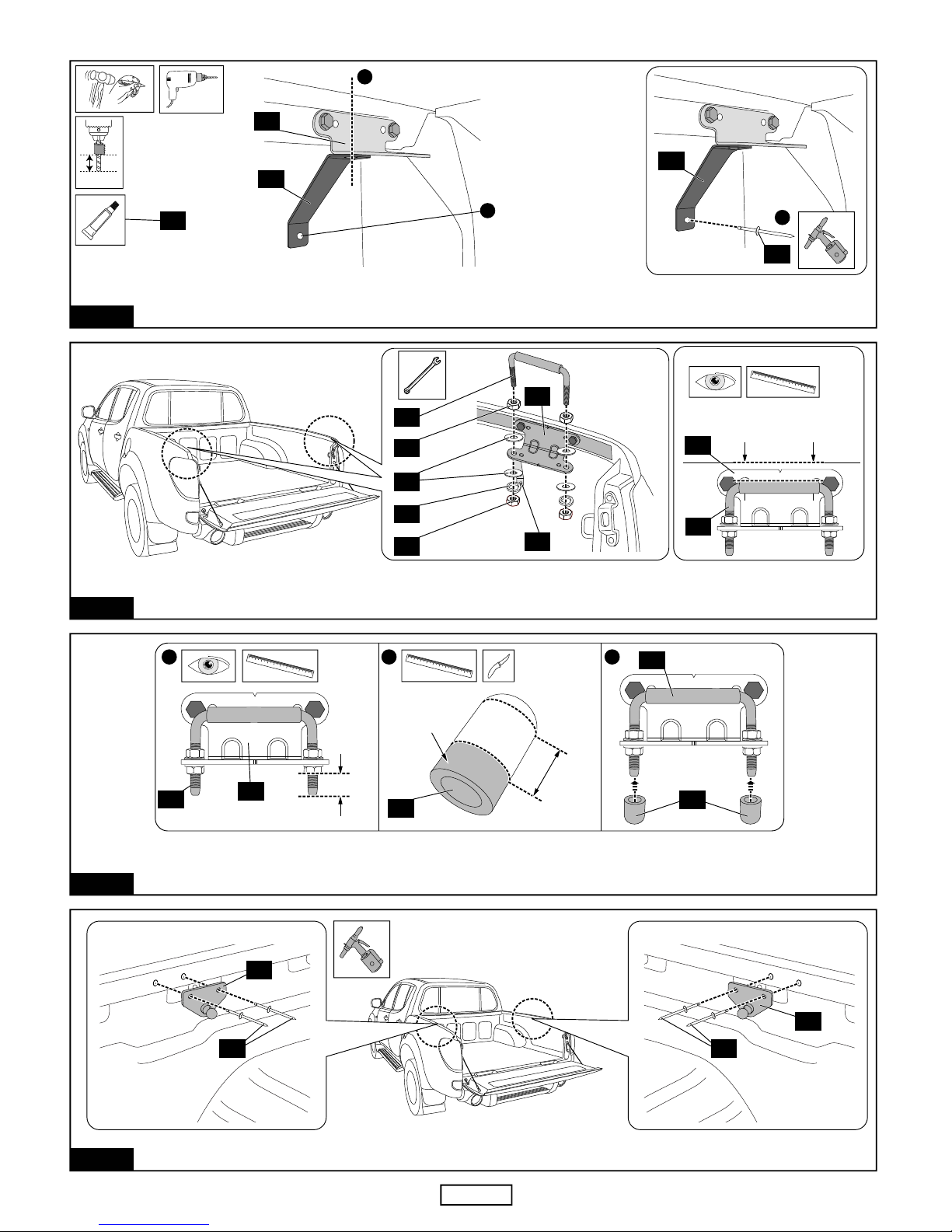

ATTACH THE GAS STRUT BRACKETS (BOTH SIDES) TO THE SIDE RAILS USING POP RIVETS AS SHOWN.

MEASURE THE LENGTH OF EXPOSED THREAD (X MM) FROM THE BOTTOM OF THE NUT TO THE END OF THE THREAD.

MEASURE LENGTH (X MM) ON THE RUBBER THREAD CAP AND CUT TO LENGTH AS SHOWN.

REPEAT FOR FOUR (4) RUBBER THREAD CAPS AND FIT TO THREADS.

ASSEMBLE U BOLT, WASHERS AND NUTS ONTO LOCK STRIKER AND LOCK STRIKER SUPPORT BRACKETS AS SHOWN. ADJUST

SO THE TOP OF THE U BOLT IS 13MM DOWN FROM THE TOP OF THE SIDE RAIL. LAY STRAIGHT EDGE ACROSS THE CORNER OF

THE TUBE AND TAILGATE TO ASSIST MEASUREMENT OF U BOL TS. TIGHTEN ENSURING THE 13MM TO THE TOP OF THE SIDE

RAIL IS MAINTAINED.

10

5

CENTRAL POSITION OF BED

DRIVER’S SIDE

10

5

PASSENGER’S SIDE

SIDE VIEW

MEASURE FROM TOP OF

SIDE RAIL

X (mm)

CUT AW AY

SHADED

AREA

0m

m

10

20

30

40

50

60

70

80

90

0mm 10

20

30

40

50

60

70

80

90

0mm

10 20 30

40 50

60

70

80 90

1 2 3

22

13mm 13mm

4

21

4

22

X (mm)

B

B

B

FIG. 8

TC0169eMITSUBISHI TRITON 3 PIECE TONNEAU COVER

29/10/10Page 4 of 13

ISSUE05

FIG. 11

FIG. 10

FIG. 9

23

POSITION LOCK STRIKER SUPPORT BRACKET UNDER THE LOCK STRIKER BRACKET AND ALIGN THE HOLES CLOSEST TO THE

FRONT OF THE VEHICLE AS SHOWN. MARK AND CENTRE PUNCH HOLE POSITION IN THE SIDE OF THE TUB. DRILL Ø5mm HOLE

AND APPLY RUST INHIBITOR. REPOSITION LOCK STRIKER SUPPORT BRACKET AND SECURE TO THE TUB WITH A RIVET.

ALIGN HOLES

21

21

10mm

Ø5mm

1

MARK, CENTRE PUNCH,

DRILL Ø5mm HOLE

APPLY RUST INHIBITOR

2

16

4

16

10

A

B

4

21

9

20

8

9

16

3

Page 5

FIG. 12

TC0169eMITSUBISHI TRITON 3 PIECE TONNEAU COVER

29/10/10Page 5 of 13

CENTRE PUNCH AND DRILL Ø5MM HOLES AT THE PREVIOUSLY MARKED POSITIONS.

POSITION THE BOTTOM HINGES ON THE HEADER RAIL, ALIGNING THEM WITH THE PREVIOUSLY MARKED POSITIONS AS SHOWN.

MARK THE THREE (3) HOLE POSITIONS OF EACH HINGE AND REMOVE THEM FROM THE VEHICLE.

MEASURE AND MARK THE POSITIONS AS INDICATED ABOVE FROM THE CENTRE OF THE BED FOR THE PLACEMENT OF

THE BOTTOM HINGES. WARNING:- RECHECK DIMENSIONS TO ENSURE CORRECT MEASUREMENT.

FIND THE CENTRE OF THE BED AND MARK THE POSITION.

ISSUE05

FIG. 15

FIG. 14

FIG. 13

A

B

A = B (CENTRAL POSITION)

FIND CENTRE AND

MARK POSITION

382.5mm

382.5mm

CENTRAL POSITION OF BED

MARK POSITIONS ON

TOP OF HEADER RAIL

1

ALIGN HINGE

WITH PREVIOUSLY

MARKED POSITION

MARK THREE (3)

HOLE POSITIONS

x2

11

2

11

Ø5mm

20mm

CENTRE PUNCH,

THEN DRILL Ø5MM

HOLES (x6)

Page 6

FIG. 16

TC0169eMITSUBISHI TRITON 3 PIECE TONNEAU COVER

29/10/10Page 6 of 13

PLACE RETAINER CLIPS (WITH TAG FACING LEFT) OVER FRONT OF BOTTOM HINGES. SECURE THE BOTTOM HINGES AND THE

RETAINER CLIPS TO THE HEADER RAIL USING POP RIVETS AS SHOWN.

APPLY SILICON TO THE UNDERSIDE OF THE BOTTOM HINGES AS SHOWN AND POSITION THEM ON THE HEADER RAIL.

REMOVE THE MASKING TAPE FROM THE HEADER RAIL AND APPLY RUST INHIBITOR TO DRILLED HOLES.

ISSUE05

FIG. 19

FIG. 18

FIG. 17

2

11

APPLY RUST

INHIBITOR

REMOVE

MASKING

TAPE

1

2

23

11

11

1

11

12

10

NOT SUPPLIED

CLEAN HEADER RAIL AND HINGES (WHERE EXTRUSION WILL SIT) WITH ALCOHOL WIPES PROVIDED AND WIPE AWAY RESIDUE

WITH A DRY CLEAN CLOTH. PLACE THE EXTRUSION TAPE SEAL ALONG THE TOP OF THE HEADER RAIL WITH THE SEALING

LIP FACING TOWARDS THE TAILGATE. START THE EXTRUSION AT THE EDGE OF THE SIDE RAIL. IMPORTANT: POSITION

EXTRUSION AS CLOSE TO THE HEADER RAIL REAR RADIUS. RUB DOWN FIRMLY TO ENSURE MAXIMUM ADHESION.

18

24

11

18

12

REAR

NOTE: SEALING LIP

MUST FACE TAILGATE

REAR OF VEHICLE

START EXTRUSION

AT EDGE OF SIDE RAIL

POSITION EXTRUSION

AS CLOSE TO REAR RADIUS

18

12

11

HEADER

RAIL

Page 7

23

FIG. 20

TC0169eMITSUBISHI TRITON 3 PIECE TONNEAU COVER

29/10/10Page 7 of 13

PLACE THE CORNER PIECES OVER THE ENDS OF THE SPORTS BAR LEGS. LOOSELY ATTACH THEM TO THE SPORTS BAR USING

THE M6x40mm BOLTS, SPACERS AND LARGE M6 FLAT WASHERS AS SHOWN. DO NOT TIGHTEN FULLY AT THIS STAGE.

ISSUE05

FIG. 23

LOOSELY PRE-ASSEMBLE ONE (1) M8x50MM BOLT AND TWO (2) M8 HEX NUTS TO THE JACKING BRACKET AS SHOWN.

ALIGN JACKING BRACKET WITH PREVIOUSLY DRILLED HOLES, ENSURING BRACKET IS PARALLEL WITH TOP OF SIDE RAIL AND

SECURE WITH M6 BOLTS, M6 FLAT WASHERS, M6 SPRING WASHERS AND M6 NUTS AS SHOWN. TIGHTEN TO TORQUE 12Nm.

REPEAT FOR THE OTHER SIDE OF THE VEHICLE.

FIG. 22

CENTRE PUNCH THE TWO (2) HOLE POSITIONS AND DRILL Ø6MM HOLES. REPEAT FOR THE OTHER SIDE OF THE VEHICLE.

APPLY RUST INHIBITOR TO ALL THE DRILLED HOLES.

FIG. 21

ALIGN EDGE OF JACKING BRACKET TO EDGE OF GAS STRUT BRACKET ON SIDE RAIL AS SHOWN, 20MM DOWN FROM TOP OF

SIDE RAIL. MARK THE POSITION OF THE TWO (2) HOLES AS SHOWN. REPEAT FOR THE OTHER SIDE.

NO POWER TOOLS

20mm

ALIGN EDGE OF JACKING BRACKET

WITH EDGE OF GAS STRUT BRACKET

5

17

Ø6mm

20mm

APPLY RUST

INHIBITOR

1

2

1

CENTRE PUNCH,

THEN DRILL Ø6MM

HOLES

17

15

14

SIDE VIEW

8

9

20

17

7

2/3

19

19

27

2/3

26

26

Page 8

POSITION THE SPORTS BAR AND CORNER PIECES ON THE VEHICLE. ATTACH THE LEGS OF THE SPORTS BAR USING THE

RETAINED HARDWARE. NOTE: PUSH DOWN ON THE SPORTS BAR AND LIGHTLY TIGHTEN HARDWARE.

TC0169eMITSUBISHI TRITON 3 PIECE TONNEAU COVER

29/10/10Page 8 of 13

FIG. 24

ISSUE05

NO POWER TOOLS

SIDE VIEW

SPORTS BAR HARDWARE

SPORTS BAR

2

3

FIG. 27

FIG. 26

CLEAN THE PREVIOUSLY NOTED AREAS ON TUB WITH ALCOHOL WIPE PROVIDED AND WIPE AWAY RESIDUE WITH A DRY CLEAN

CLOTH. POSITION CLEAR ANTI-RUB PADS AT THESE AREAS ON THE TUB.

FIG. 25

NOTE THE AREA WHERE CORNER PIECE CONTACTS THE VEHICLE TUB AS SHOWN.

MARK THE EDGES AS SHOWN WITH A PENCIL OR NON-PERMANENT MARKER. REPEAT PROCESS FOR THE OTHER SIDE.

REMOVE SPORTSBAR AND CORNER PIECES FROM TUB.

RE-POSITION THE SPORTS BAR AND CORNER PIECES ON THE VEHICLE. ATTACH THE LEGS OF THE SPORTS BAR USING THE

RETAINED HARDWARE. NOTE: PUSH DOWN ON THE SPORTS BAR BEFORE TIGHTENING HARDWARE.

NO POWER TOOLS

SIDE VIEW

SPORTS BAR HARDWARE

SPORTS BAR

2

3

MARK THESE 2 EDGES

ON THE TUB

28

Page 9

TC0169eMITSUBISHI TRITON 3 PIECE TONNEAU COVER

29/10/10Page 9 of 13

FIG. 31

CHECK THAT THE SURFACES OF THE TONNEAU COVER AND CORNER PIECES ARE EVEN. ADJUST THE JACKING BOLTS

UNDERNEATH THE CORNER PIECES IF NECESSARY. ENSURE CLEARANCE BETWEEN CORNER PIECE AND TUB, ESPECIALLY

FRONT AND REAR, TO AVOID PAINT DAMAGE TO TUB.

ONCE IN THE CORRECT POSITION, LOCK THE M8 NUTS INTO

POSITION AGAINST THE BRACKET USING A SPANNER. REPEAT FOR THE OTHER SIDE OF THE VEHICLE.

IMPORTANT: TIGHTEN ALL CORNER PIECE M6 BOLTS TO 4Nm.

ISSUE05

NO POWER TOOLS

12/3

2/3

17

15

14

FIG. 28

FIG. 29

REMOVE INSPECTION COVER BY REMOVING SCRIVETS AND ROTATING COVER ANTI-CLOCKWISE. RELEASE PLASTIC RETAINER

CLIPS AND UNCLIP RODS AS SHOWN. LOOSEN THE FOUR (4) LATCH MECHANISM SCREWS, SO THE LATCH CAN MOVE FREELY

FOR TONNEAU ADJUSTMENT IN THE NEXT STEP.

INSPECTION

COVER

PLASTIC RETAINER

CLIPS

RODS

RELEASE PLASTIC

RETAINER CLIPS

REMOVE

INSPECTION

COVER

21

UNCLIP RODS FROM

PLASTIC RETAINER

CLIPS

LOOSEN SCREWS

3 4

SCREWS

FIG. 30

NEXT STEP

2

ENSURE

CLEARANCE

TO TUB

RUBBER SPACER

1

RE-TORQUE 5Nm

LOOSEN HINGE SCREWS

TO ADJUST TONNEAU

POSITION IF NECESSARY

2

IMPORTANT: THE TONNEAU COMES FITTED WITH TWO (2) RUBBER SPACERS TO ASSIST IN ALIGNMENT TO THE TUB.

CLOSE TONNEAU COVER AND CHECK THAT IT IS CENTRAL ON BED. LOOSEN HINGE SCREWS - DO NOT ADJUST HINGES WHILE

GAS STRUTS ARE CONNECTED. CHECK LH & RH LATCHES ARE ENGAGED. MOVE TONNEAU TO ENSURE EVEN CLEARANCE LHS

TO RHS BETWEEN TUB AND SPACERS. MOVE TONNEAU TO ENSURE FORE & AFT POSITION IS CORRECT BY ENSURING

CLEARANCE AT REAR OF TUB SIDE. RE-TIGHTEN (12) HINGE SCREWS WHILE TONNEAU IS IN CORRECT POSITION TO

TORQUE 5Nm. RE-TIGHTEN LATCHES WHILE TONNEAU IS IN CORRECT POSITION TO TORQUE 4Nm. IMPORTANT: ENSURE

TAILGATE REMAINS OPEN AND SPACERS ARE REMOVED AFTER ALIGNMENT IS COMPLETE.

OPEN TAILGATE. FIT THE TONNEAU COVER TO THE VEHICLE. SECURE THE HINGES USING THE HINGE PINS AS SHOWN.

IMPORTANT: ENSURE TAILGATE REMAINS OPEN. DO NOT REMOVE THE TWO (2) RUBBER SPACERS FROM THE TONNEAU

SIDES (AT THE REAR), THESE WILL BE REQUIRED FOR ALIGNMENT LATER ON.

2

1

1

RHS SHOWN

“CLICK”

3

RHS SHOWN

2

6

12

6

12

RUBBER

SPACER’S

Page 10

CLOSE TONNEAU AND INSPECT LOCKING MECHANISM. ENSURE LATCH HITS THE U BOLT CENTRALLY. IF IT DOES NOT, ADJUST THE U BOLT

ACCORDINGLY BY LOOSENING THE M6 NUTS AND MOVING THE U BOLT UP OR DOWN AS SHOWN. ONCE ADJUSTMENT IS COMPLETE, TIGHTEN

THE M6 NUTS. IMPORTANT: TONNEAU HAS 2 STAGE LOCKS. ENSURE TONNEAU ENGAGES WITH SECOND STAGE OF THE LATCH.

FIG. 33

TC0169eMITSUBISHI TRITON 3 PIECE TONNEAU COVER

29/10/10Page 10 of 13

ISSUE05

1

ATTACH GAS STRUTS. ENSURE THE NARROW END MOUNTS TO THE VEHICLE.

FIG. 32

ENSURE NARROW

END OF GAS STRUT

MOUNTS TO VEHICLE

TO REMOVE:

13

13

5

FIG. 34

OPEN TONNEAU AND ENGAGE LOCK BY PRESSING UPWARDS ON LATCH. ADJUST PULLRODS TO FIT INTO RETAINER CLIPS BY ROTATING THEM

CLOCKWISE TO SHORTEN OR ANTI-CLOCKWISE TO LENGTHEN. CLIP PULLRODS AND RETAINER CLIPS BACK INTO POSITION. TEST LOCK BY

PRESSING THE BUTTON ON TOP OF TONNEAU COVER. IF LATCH MECHANISM DOES NOT RELEASE, RETURN TO STEP 3 AND SHORTEN THE

PULLRODS. FINALLY, RE-CONFIRM THE OPEN-CLOSE-OPEN OPERATION OF TONNEAU WITH THE TAILGATE CLOSED. MAKE FURTHER

ADJUSTMENTS IF NECESSARY BY RETURNING TO FIGURE 29, 33 AND 34. FINALLY REPLACE INSPECTION COVER.

1

ENGAGE LOCK

LATCH MECHANISM

PRESS LATCH

UPWARDS

“CLICK”

2 4 6

TEST LOCKING MECHANISM

5

ROTATE PULLRODS

CLOCKWISE = SHORTEN

ANTI-CLOCKWISE = LENGTHEN

ADJUST LENGTH OF

PULLRODS BY ROTATION

3

RETAINER CLIPS

LOCK PLASTIC RETAINER

CLIPS BACK IN POSITION

REPLACE

INSPECTION COVER

INSPECTION

COVER

INCORRECT

INSPECT LATCH

ENGAGEMENT

CORRECT

2

ADJUST U-BOLT

USE A RULER TO ENSURE

U-BOLT REMAINS PARALLEL

TO LOCK STRIKER

3

TORQUE 10Nm

4

0mm102030405060708090

21

22

FIG. 35

NEXT STEP

2

1

RE-TORQUE 5Nm

LOOSEN HINGE SCREWS

TO ADJUST TONNEAU

POSITION IF NECESSARY

2

CLOSE TAILGATE AND TONNEAU COVER AND RE-CHECK CLEARANCES.

LOOSEN HINGE SCREWS AND ADJUST TONNEAU FORE & AFT IF REQUIRED.

DO NOT ADJUST HINGES WHILE GAS STRUTS ARE CONNECTED. RE-TIGHTEN HINGE SCREWS TO TORQUE 5Nm.

Page 11

TC0169eMITSUBISHI TRITON 3 PIECE TONNEAU COVER

29/10/10Page 11 of 13

ISSUE05

IMPORTANT:

HTC LATCH & STRIKER U-BOLT FREEPLAY, SHOULD BE CHECKED AND ADJUSTED

(AS PER STEPS 29, 33 & 34) AFTER 1500 Km’s (TO ACCOUNT FOR SEAL SETTLING).

KEY IDENTIFICATION CODE

XXXXX

MITSUBISHI MN TRITON ONWARDS 3 PIECE HARD TONNEAU COVER

Please write your key identification code in the boxes above and retain.

Replacement keys can be purchased from your local Mitsubishi dealer.

CLOSE TONNEAU AND CHECK CLOSING EFFORT WITH TAILGATE CLOSED. IF REQUIRED, ADJUST THE U BOLT ACCORDINGLY BY LOOSENING

THE M6 NUTS AND MOVING THE U BOLT UP OR DOWN. ONCE ADJUSTMENT IS COMPLETE, TIGHTEN THE M6 NUTS.

FIG. 36

1

ADJUST U-BOLT

USE A RULER TO ENSURE

U-BOLT REMAINS PARALLEL

TO LOCK STRIKER

TORQUE 10Nm

4

0mm102030405060708090

21

22

2

Page 12

OPEN TONNEAU COVER AND DETACH GAS STRUTS BY INSERTING A SMALL SCREW DRIVER AND ADJUSTING THE SPRING CLIP ON THE

STRUT AS SHOWN. NOTE: DO NOT REMOVE THE SPRING CLIP. ONLY A SMALL AMOUNT OF LEVERING IS REQUIRED TO DETACH.

TO REMOVE:

6

12

TC0169eMITSUBISHI TRITON 3 PIECE TONNEAU COVER

29/10/10Page 12 of 13

ISSUE05

REMOVAL OF TONNEAU COVER

FIG. 2

REMOVE HINGE PINS AND REMOVE THE TONNEAU COVER AS SHOWN.

FIG. 1

RHS SHOWN

2 3

RHS SHOWN

1

TO REPLACE THE TONNEAU COVER:

Reverse the sequence and the procedures of the two (2) Figures above.

13

13

5

6

12

Page 13

TC0169eMITSUBISHI TRITON 3 PIECE TONNEAU COVER

29/10/10Page 13 of 13

ISSUE05

1 25

10

16

Tonneau Cover

Qty - 1

PARTS IN MAIN CARTON

Lock Keys

(Attached to

Tonneau)

Qty - 2

3

RHS Corner

Piece

Qty - 1

2

LHS Corner

Piece

Qty - 1

Fitting Kit

(KIT031386)

Qty - 1

5 6 7 8 9

A

B

Gas Strut

Bracket

(CLIP2034-1)

Qty - 2

Hinge Pin

(MISC2267)

Qty - 2

M6x15 Hex

Head Bolt

(SCRW0633)

Qty - 8

M6 Flat

Washer

(WASH0153)

Qty - 24

M6Hex Nut

(NUTS0161)

Qty - 16

Pop Rivet

(FAST0505)

Qty - 12

11 12 13 14 15

21

Bottom Hinge

(CLIP1805-1)

Qty - 2

Hinge Retainer

Clip

(CLIP2673)

Qty - 2

Gas Strut

(STRT0003-2)

Qty - 2

M8x50 Hex

Head Bolt

(SCRW0789)

Qty - 2

M8Hex Nut

(NUTS0217)

Qty - 4

Jacking

Bracket

(CLIP2353-3)

Qty - 2

Extrusion

Tape Roll

(MISC2600)

Qty - 1

M6 Large

Flat Washer

(WASH0036)

Qty - 4

Striker U-Bolt

(LOCK0006)

Qty - 2

Lock Striker

Support Bracket

(CLIP2613PC)

Qty - 2

PARTS IN FITTING KIT (KIT031386)

17 18 19 20

M6 Spring

Washer

(WASH0103)

Qty - 12

PARTS CHECK SHEET MITSUBISHI TRITON 3 PIECE HARD TONNEAU COVER

4

Lock Striker

Bracket

(CLIP2499-PC)

Qty - 2

AUTOMOTIVE

SURFACE CLEANER

IMPREGNATED WITH 70% ISOPROPYL ALCOHOL

For use in cleaning painted metal,

glass and other vehicle surfaces.

For external use only.

Dispose of properly after use.

22 28

Rust Inhibitor

(MISC2776)

Qty - 1

Alcohol Wipe

(MISC0052)

Qty - 4

M6x40 Allen

Key Bolt

(SCRW0517)

Qty - 4

Anti-Rub Pad

(TAPE0011)

Qty - 2

Rubber

Thread Cap

(MISC2532)

Qty - 4

Fitting Instruction

(FIT-TC0169)

Qty - 1

23 24 26 27

Spacer

(MISC3095)

Qty - 4

Fitting

Instructions

Loading...

Loading...