Page 1

Manual No.'18 • SRK-SM-259

SERVICE MANUAL

INVERTER WALL MOUNTED TYPE

RESIDENTIAL AIR-CONDITIONERS

(Split system, air to air heat pump type)

SRK25ZSP-W

SRK35ZSP-W

SRK45ZSP-W

Page 2

Page 3

'18 • SRK-SM-259

CONTENTS

1. OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER ................... 2

(1) Operation control function by wireless remote control

(2) Unit ON/OFF button

................................................................................. 3

............................. 2

................................................................................. 3(3) Auto restart function

(4) Installing two air-conditioners in the same room

...................................... 3

(5) High power operation ............................................................................... 4

(6) Economy operation

.................................................................................. 4

(7) Air flow direction adjustment .................................................................... 4

(8) Timer operation

........................................................................................ 5

(9) Outline of heating operation ..................................................................... 5

(10) Outline of cooling operation ..................................................................... 7

(11) Outline of automatic operation ................................................................. 7

(12) Protection control function

2. MAINTENANCE DATA

(1) Cautions

................................................................................................. 16

................................................................................. 16

....................................................................... 8

(2) Items to check before troubleshooting ................................................... 16

(3) Troubleshooting procedure

(If the air-conditioner does not run at all)

........ 16

(4) Troubleshooting procedure (If the air-conditioner runs)

......................... 17

(5) Self-diagnosis table ............................................................................... 18

(6) Service mode (Trouble mode access function) ..................................... 19

(7) Inspection procedures corresponding to detail of trouble ...................... 27

(8)

Phenomenon observed after short-circuit, wire breakage on sensor

(9) Checking the indoor electrical equipment

.............................................. 32

.......... 31

(10) How to make sure of wireless remote control ........................................ 33

(11) Outdoor unit inspection points ............................................................... 34

3. ELECTRICAL WIRING

(1) Indoor units

........................................................................................... 37

................................................................................. 37

(2) Outdoor units ........................................................................................ 38

4. PIPING SYSTEM

.......................................................................................... 40

-

-

1

Page 4

'18 • SRK-SM-259

1. OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER

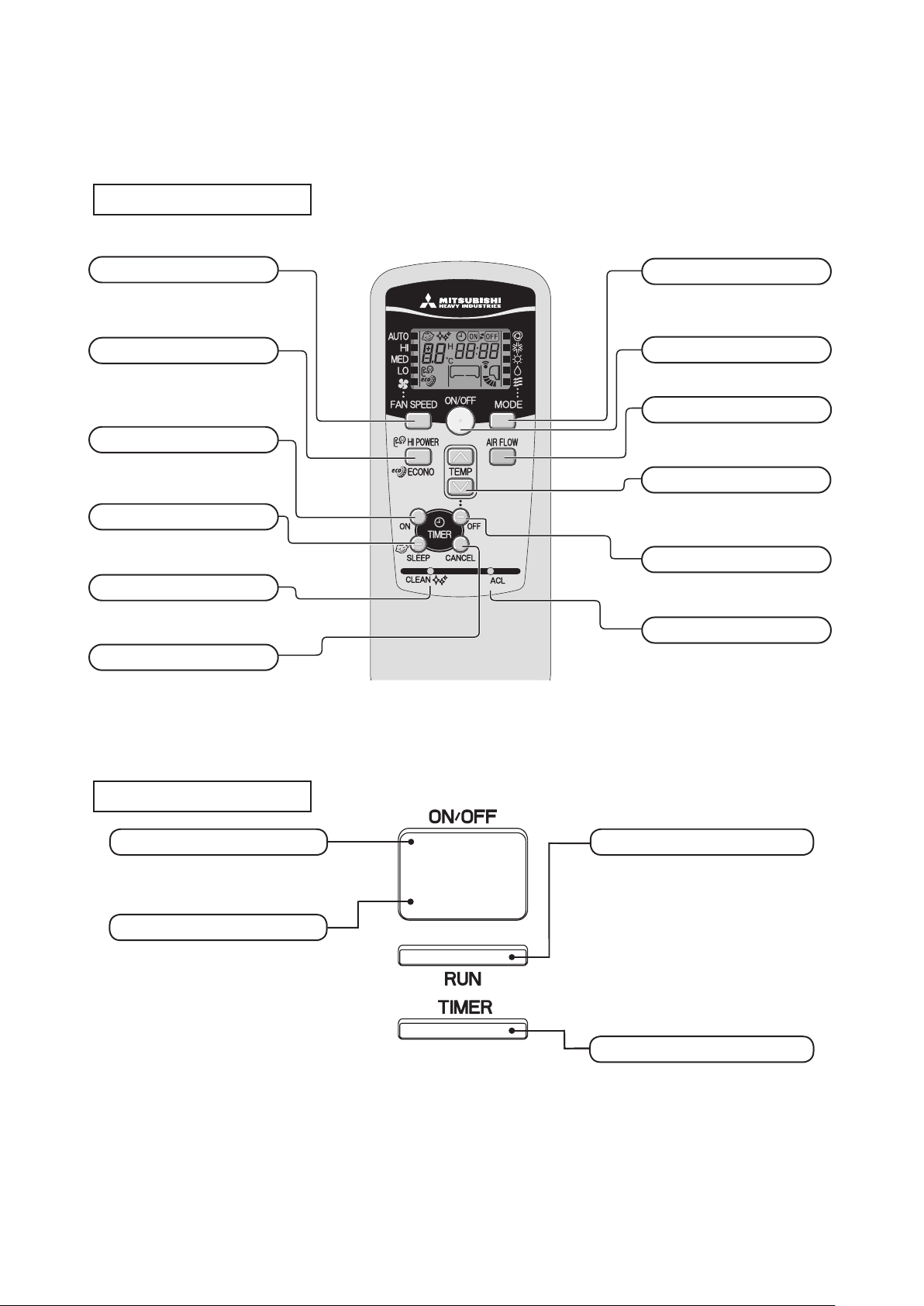

(1) Operation control function by wireless remote control

Remote control

Operation section

◆

FAN SPEED button

Each time the button is pressed, the fan

speed changes.

HI POWER/ECONO button

This button changes the HIGH POWER/

ECONOMY mode.

ON TIMER button

This button selects ON TIMER operation.

SLEEP button

This button selects SLEEP operation.

CLEAN switch

This switch selects the SELF CLEAN

mode.

CANCEL button

This button cancels the ON timer, OFF

timer, and SLEEP operation.

The above illustration shows all controls, but in

•

practice only the relevant parts are shown.

OPERATION MODE select button

Each time the button is pressed, the

mode changes.

ON/OFF (luminous) button

Press to start operation, press again to

stop.

AIR FLOW (UP/DOWN) button

This button changes the air flow

(up/down) direction.

TEMPERATURE button

These buttons set the room temperature.

(These buttons are used for setting the

current time and timer function as well.)

OFF TIMER button

This button selects OFF TIMER

operation.

ACL switch

This switch resets the program to default

state.

Unit display section

Unit ON/OFF button

This button can be used for turning on/off

the unit when a remote control is not available.

Wireless remote control signal receiver

RUN light (green)

• Illuminates during operation.

•

Blinks slowly when SELF CLEAN operation

(3 seconds ON, 1 second OFF).

• Blinks when air flow is stopped to

prevent blowing out of cold air in

heating operation. (1.5 seconds ON,

0.5 seconds OFF)

TIMER light (yellow)

Ⅰlluminates during TIMER operation.

-

-

2

Page 5

'18 • SRK-SM-259

Cut

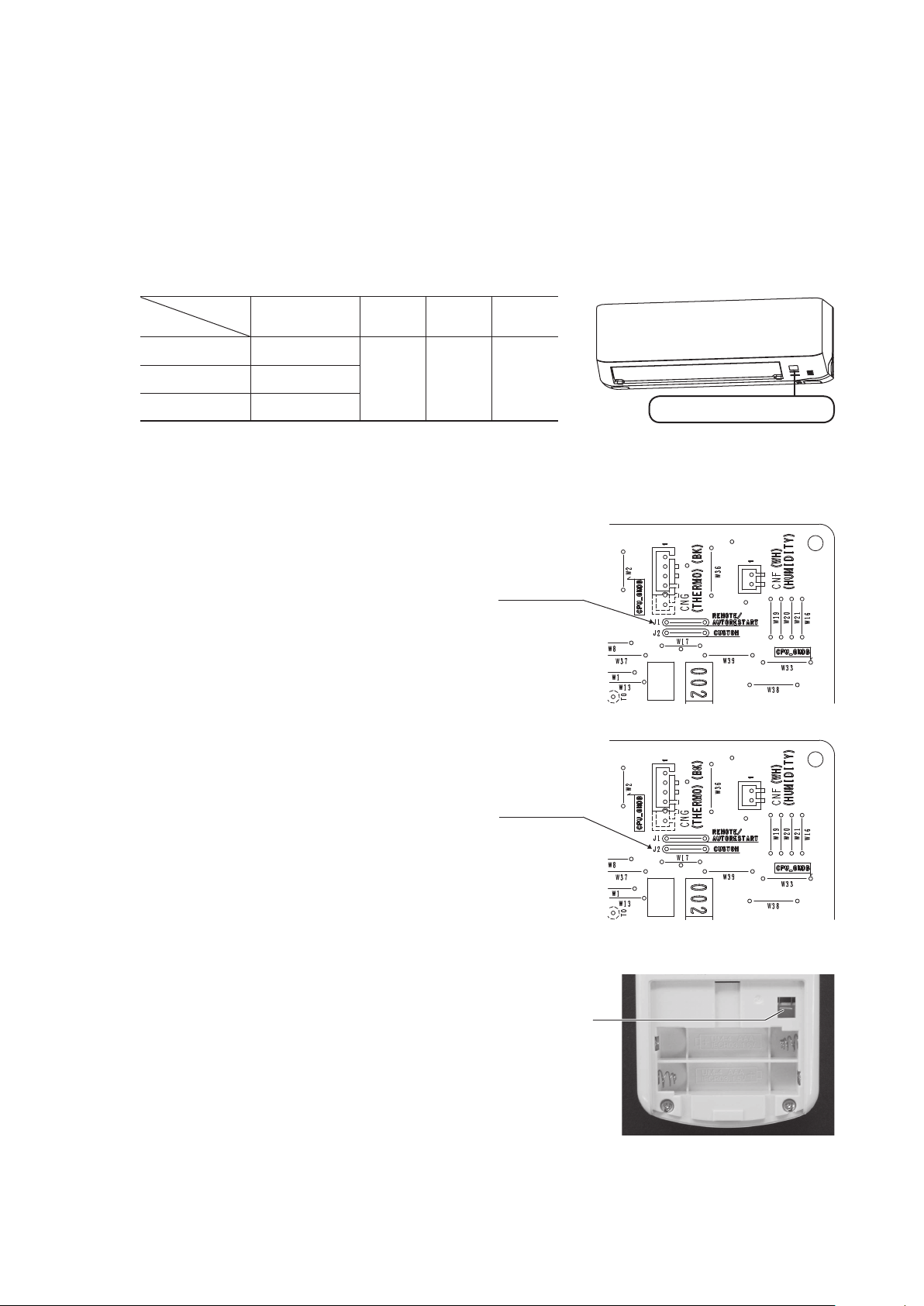

(2) Unit ON/OFF button

When the wireless remote control batteries become weak, or if the wireless remote control is lost or malfunctioning, this

button may be used to turn the unit on and off.

(a) Operation

Push the button once to place the unit in the automatic mode. Push it once more to turn the unit off.

(b) Details of operation

The unit will go into the automatic mode in which it automatically determines, from room temperature (as detected by

sensor), whether to go into the COOL, DRY or Heat modes.

Operation mode

COOL

DRY

HEAT

Function

Room temperature

setting

About 24ºC

About 24ºC

About 26ºC

Fan

speed

Flap

Auto Auto

Timer

switch

Continuous

Unit ON/OFF button

(3) Auto restart function

(a)

Auto restart function records the operational status of the air-conditioner immediately prior to be switched off by a

power cut, and then automatically resumes operations after the power has been restored.

(b) The following settings will be cancelled:

(i) Timer settings

(ii) HIGH POWER operation

Jumper wire (J1)

Notes (1) Auto restart function is set at on when the air-conditioner is shipped from the factory. Consult

with your dealer if this function needs to be switched off.

(2) When power failure ocurrs, the timer setting is cancelled. Once power is resumed, reset the timer.

If the jumper wire (J1) “AUTO RESTART” is cut, auto restart is disabled. (See the diagram at right.)

(3)

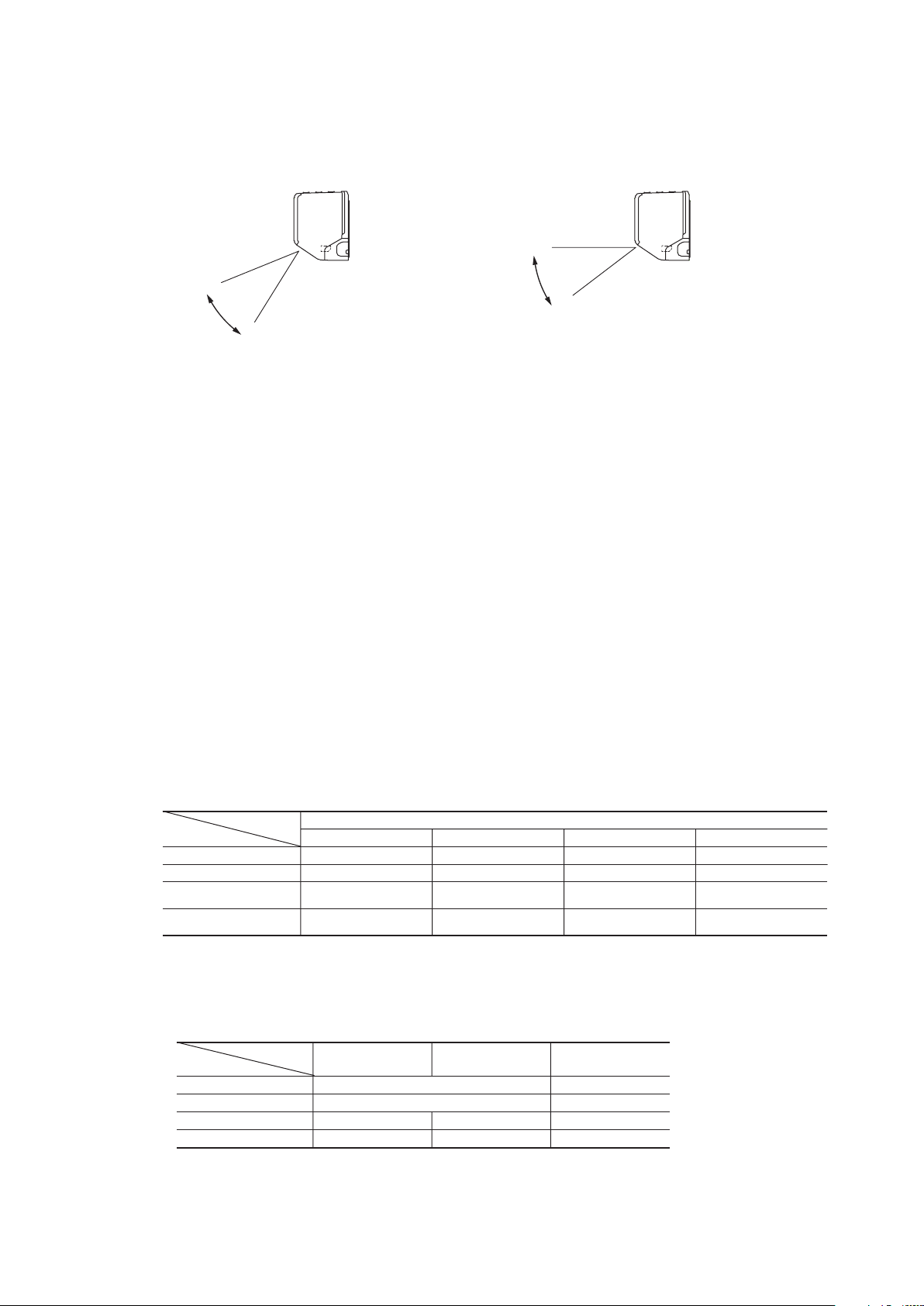

(4) Installing two air-conditioners in the same room

When two air-conditioners are installed in the room, set the wireless

remote contrrol and indoor unit as belows to prevent operating air-condi-

tioners with one wireless remote control.

(a) Setting an indoor unit’s printed circuit board

Jumper wire (J2)

(i) Take out the printed circuit board from the control box.

(ii) Disconnect jumper wire (J2) with wire cutters.

(iii) Install a printed circuit board.

(b) Setting a wireless remote control

(i) Pull out the cover and take out batteries.

(ii) Disconnect the switching line next to the battery with wire cutters.

(iii) Insert batteries. Close the cover.

-

-

3

Page 6

'18 • SRK-SM-259

(5) High power operation

(6) Economy operation

Pressing the HI POWER/ECONO button intensifies the operating power and initiates powerful cooling and heating operation for

15 minutes continuously. The wireless remote control displays HIGH POWER mark and the FAN SPEED display disappears.

(a) During the HIGH POWER operation, the room temperature is not controlled. When it causes an excessive cooling and hea-

ting, press the HI POWER/ECONO button again to cancel the HIGH POWER operation.

(b) HIGH POWER operation is not available during the DRY and the ON timer to OFF timer operations.

(c) When HIGH POWER operation is set after ON TIMER operation, HIGH POWER operation will start from the set time.

(d) When the following operation are set, HIGH POWER operation will be canceled.

① When the HI POWER/ECONO button is pressed again.

② When the operation mode is changed.

③ When it has been 15 minutes since HIGH POWER operation has started.

(e) Not operable while the air-conditioner is OFF.

Pressing the HI POWER/ECONO button initiates a soft operation with the power suppressed in order to avoid an excessive

cooling or heating. The unit operates 1.5℃ higher than the setting temperature during cooling or 2.5℃ lower than that during

heating. The wireless remote control displays ECONO mark and the FAN SPEED display disappears.

(a) It will go into ECONOMY operation at the next time the air-conditioner runs in the following cases.

① When the air-conditioner is stopped by ON/OFF button during ECONOMY operation.

② When the air-conditioner is stopped in SLEEP or OFF TIMER operation during ECONOMY operation.

③ When the operation is retrieved from CLEAN operation.

(b) When the following operation are set, ECONOMY operation will be canceled.

① When the HI POWER/ECONO button is pressed again.

② When the operation mode is changed DRY to FAN.

(c) Not operable while the air-conditioner is OFF.

(d) The setting temperature is adjusted according to the following table.

① at the start of operation.

② one hour after the start of operation.

③ two hours after the start of operation.

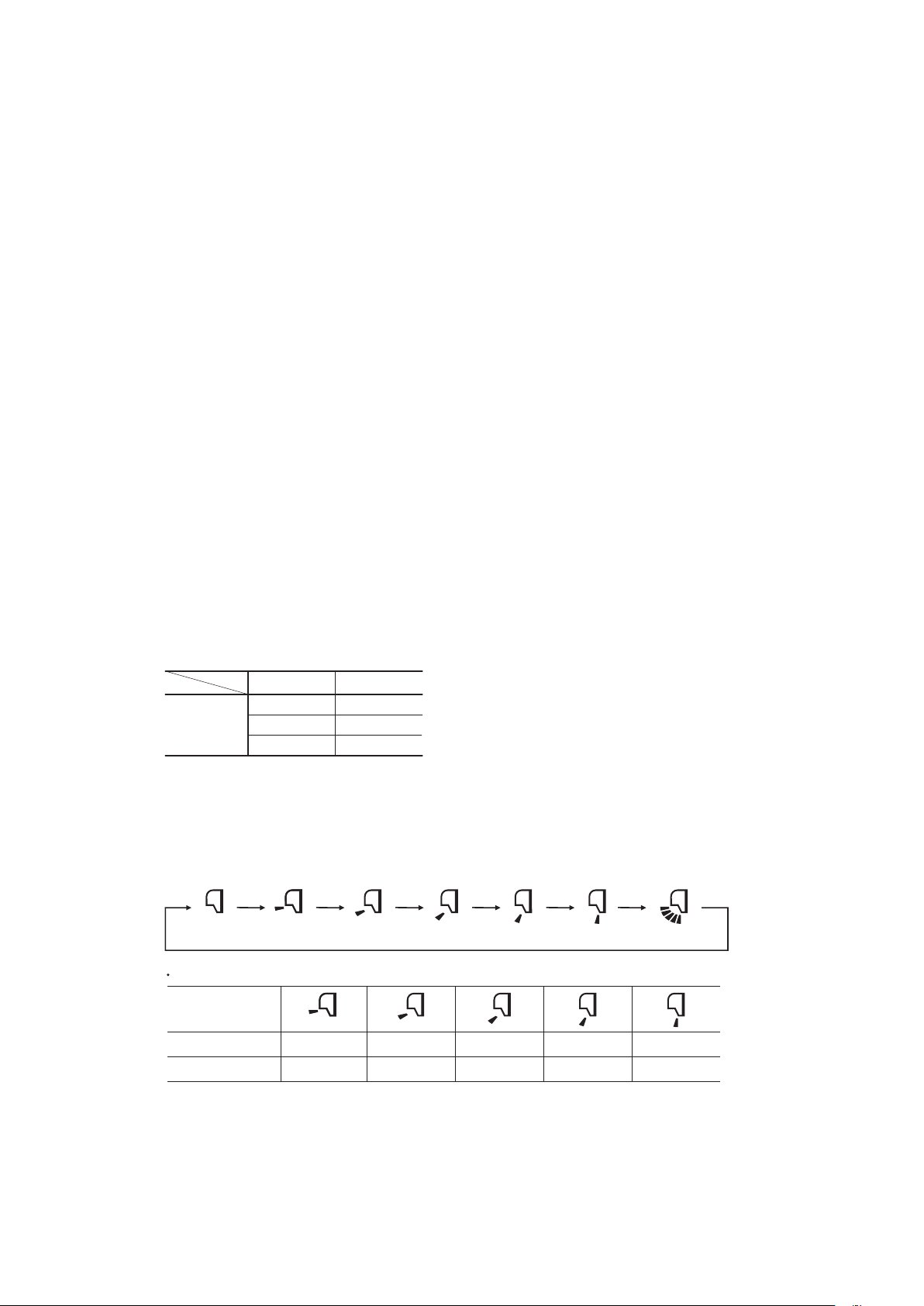

(7) Air flow direction adjustment

Air ow direction can be adjusted with by AIR FLOW

(a) Flap

Item

Temperature

adjustment

Each time when you press the AIR FLOW

Angle of flap from horizontal

Remote control

display

COOL, DRY, FAN

HEAT

Mode

(Flap stopped)

Cooling Heating

①+0.5

②+1.0 ②-2.0

③+1.5 ③-2.5

Approx. 15°

Approx. 25°

①-1.0

Approx. 25°

Approx. 35°

(UP/DOWN) button on the wireless remote control.

(UP/DOWN) button the mode changes as follows.

Approx. 35°

Approx. 50°

Approx. 45°

Approx. 59°

Approx. 59°

Approx. 65°

(Swing)

-

-

4

Page 7

'18 • SRK-SM-259

◆ In HEAT operation ◆ In COOL, DRY, FAN operation

Approx. 65°

ON OFF OFF

ON ON OFF

ON

OFF

(few minutes ON)

OFF

ON ON(HOT KEEP) OFF

OFF

OFF

(3 minutes ON)

OFF

OFF

Thermostat ON Thermostat OFF Defrost Failure

Heating

Compressor

Indoor fan motor

Outdoor fan motor

4-way valve

20-115rps 20-100rps

20

-

115rps 20-100rps

20

-

72rps 20-84rps 20-90rps

20

-

54rps 20-62rps 20-58rps

Model

Fan speed

SRK25ZSP-W SRK35ZSP-W SRK45ZSP-W

AUTO

MED

HI

LO

(b) Swing

Flap moves in upward and downward directions continuously.

Approx.

20°

Approx. 35°

Approx. 59°

(c) Memory flap

When you press the AIR FLOW (UP/DOWN) button once while the ap is operating, it stops swinging at the position.

Since this angle is memorized in the microcomputer, the ap will automatically be set at this angle when the next opera-

tion is started.

(d) When not operating

The ap returns to the position of air ow directly below, when operation has stopped.

(8) Timer operation

(a) Comfortable timer setting (ON timer)

If the timer is set at ON when the operation select switch is set at the cooling or heating, or the cooling or heating in

auto mode operation is selected, the comfortable timer starts and determines the starting time of next operation based

on the initial value of 15 minutes and the relationship between the room temperature at the setting time (temperature of

room temperature sensor) and the setting temperature.

(b) Sleep timer operation

Pressing the SLEEP button causes the temperature to be controlled with respect to the set temperature.

(c) OFF timer operation

The Off timer can be set at a specic time (in 10-minute units) within a 24-hour period.

(9) Outline of heating operation

(a) Operation of major functional components in heating mode

(b) Details of control at each operation mode (pattern)

(i) Fuzzy operation

Deviation between the room temperature setting correction temperature and the suction air temperature is calculated in

accordance with the fuzzy rule, and used for control of the air capacity and the compressor speed.

When the defrost operation, protection device, etc. is actuated, operation is performed in the corresponding mode.

-

-

5

Page 8

(ii) Hot keep operation

Outdoor heat exchanger temperature (

TH1

-20

-25

-20 -15 -10 -5 0 5 10

-15

-10

-5

0

Outdoor air temperature (℃)

TH2

Outdoor heat exchanger temperature (℃)

Defrost operation

start

Defrost operation start temperature

Model DXK15Z6-S

1) Fuzzy operation

2) Hot keep operation

ON OFF

ON ON

ON

OFF

(few minutes ON)

ON ON(HOT KEEP)

OFF

OFF

(3 minutes ON)

OFF

OFF

Thermostat ON Thermostat OFF Failure

Heating

Compressor

Indoor fan motor

Outdoor fan motor

4-way valve

(i)

1)

2)

3)

4)

−

≧

−

≦ <

30~115rps

30~115rps

30~76rps

30~46rps

SRK35ZJ-S

23~106rps

23~106rps

23~78rps

23~50rps

SRK50ZJ-S

30~115rps

30~115rps

30~72rps

30~42rps

SRK25ZJ-S

30~115rps

30~115rps

30~66rps

30~40rps

SRK20ZJ-S

Model

Fan speed

Auto

MED

HI

LO

(model DXK12 : 45)

35

35

(model DXK12 : 45)

(model DXK15 : ≧ −2 ࠉ) (model DXK15 : 10 ࠉ)

(model DXK15 : ≧

−2

ࠉ)

5)

<

− −

−

−

1) 2) 3) 5)

(model DXK15 : +10 ࠉ)

higher

met.

(model SRK50 : 35)

(model SRK50 : 35)

'09•SRK-DB-087D

(16)ࠉOutline of heating operation

(a) Operation of major functional components in heating mode

(b) Details of control at each operation mode (pattern)

(i) Fuzzy operation

(ii) Hot keep operation

ON OFF

ON ON

ON

OFF

(few minutes ON)

ON ON(HOT KEEP)*

OFF

OFF

(3 minutes ON)

OFF

OFF

Thermostat ON Thermostat OFF Failure

Heating

Compressor

Indoor fan motor

Outdoor fan motor

4-way valve

(c) Defrost operation

(i)

1)

2)

3)

4)

5)

−

Model

Fan speed

Auto

MED

HI

LO

ULO

*It can be set the indoor fan motor off or the heating thermostat OFF with connecting a wired remote control.

In the case, indoor air temperature is detected by sensor on the wired remote control.

During the heating operation, the indoor fan speed can be controlled based on the temperature of the indoor heat

exchanger (Th2) to prevent blowing out of cold air.

are satisfied.)

(Total compressor operation time)

After finish of defrost operation

C or less for 3 minutes continuously.

(Total compressor operation time)

20~115rps

20~115rps

20~86rps

20~70rps

20~44rps

SRK20ZS-S

20~115rps

20~115rps

20~104rps

20~84rps

20~54rps

SRK25ZS-S

20~115rps

20~115rps

20~108rps

20~96rps

20~60rps

SRK35ZS-S

23~106rps

23~106rps

23~82rps

23~70rps

23~37rps

SRK50ZS-S

is as following.

During the heating operation, the indoor fan speed can be controlled based on the temperature of the indoor heat ex-

changer (Th2) to prevent blowing of cold air.

(c) Defrost operation

(i)

1)

(model SRK35 : 45)

35

2)

35

(model SRK35 : 45)

3)

-

4)

follows.

TH2

•0

•

•TH2

TH2: TH2

℃≦

℃≦

15

-

<

0

<

TH2

: TH2

℃

15

-

-

℃

TH1

≧

: TH2

TH1

-

7

-

≧

Models SRK25, 35, 45ZSP-W

(ii)

1)

2)

0

℃)

-5

-10

TH1

-15

-20

-25

In case satisfied all of following conditions.

-20 -15 -10 -5 0 5 10

• Connect compressor speed 0 rps 10 times or more.

• Satisfy 1), 2) and 3) conditions above.

• Outdoor air temperature is 3°C or less.

Defrost operation start temperature

Outdoor air temperature (℃)

and 30 seconds).

●

Defrost operation

Heating operation

Depends on an operation condition, the time can be longer than 7 minutes.

≦

, TH1

℃

2/15

≧

TH1

, TH1

℃

5

-

Defrost operation

start

TH2

operation

(Mode SRK45: Max.17 minutes and 30 seconds)

Total

Total

or less

℃

7

-

13/15

≦

, TH1

℃

7

+

TH2

×

℃

5

+

TH2

≦

Max. 16 minutes and 50 seconds

-

6

-

'18 • SRK-SM-259

satisfied.

℃

7

-

TH2

×

satisfied.

(SRK45 : 10 )

16

minutes and 50 seconds (model SRK45 : 17 minutes

2-7 minutes

Hot keep operation

is as

Page 9

27.5

25.5

18.0

18

30

(10) Outline of cooling operation

ON OFF OFF

OFF OFF OFF

ON

OFF

(few minutes ON)

OFF

(few minutes ON)

ON ON ON

Thermostat ON Thermostat OFF Failure

Cooling

Compressor

Indoor fan motor

Outdoor fan motor

4-way valve

15-74rps 20-97rps

15-74rps

15-98rps

15-98rps 20-97rps

15-52rps 15-74rps 20-72rps

15-38rps 15-46rps 20-44rps

Model

Fan speed

SRK25ZSP-W SRK35ZSP-W SRK45ZSP-W

AUTO

MED

HI

LO

(a) Operation of major functional components in cooling mode

(b) Detail of control in each mode (Pattern)

(i) Fuzzy operation

During the fuzzy operation, the air ow and the compressor speed are controlled by calculating the difference between

the room temperature setting correction temperature and the suction air temperature.

'18 • SRK-SM-259

(11) Outline of automatic operation

(a) Determination of operation mode

The unit checks the indoor air temperature and the outdoor air temperature, determines the operation mode, and then

begins in the automatic operation.

Cooling

Indoor air temperature (˚C)

A

Heating

Outdoor air temperature (˚C)

Dehumidifying

(b) The unit checks the temperature every hour after the start of operation and, if the result of check is not same as the pre-

vious operation mode, changes the operation mode.

(i) If the setting temperature is changed with the remote control, the operation mode is judged immediately.

(ii) When both the indoor and the outdoor air temperatures are in the range “A”, cooling or heating is switched depending

on the difference between the setting temperature and the indoor air temperature.

(iii) When the operation mode has been judged following the change of setting temperature with the remote control, the hour-

ly judgment of operation mode is cancelled.

(c) When the unit is started again within one hour after the stop of automatic operation or when the automatic operation is

selected during heating, cooling or dehumidifying operation, the unit is operated in the previous operation mode.

(d) Setting temperature can be adjusted within the following range. There is the relationship as shown below between the

signals of the wireless remote control and the setting temperature.

Signals of wireless remote control (Display)

Setting

temperature

Cooling

Dehumidifying

Heating

–6 –5 –4 –3 –2 –1

18 19 20 21 22 23 24 25 26 27 28 29 30

19 20 21 22 23 24 25 26 27 28 29 30 31

20 21 22 23 24 25 26 27 28 29 30 31 32

0 +1 +2 +3 +4 +5 +6

±

(e) When the unit is operated automatically with the wired remote control connected, the cooling operation is controlled ac-

cording to the display temperatures while the setting temperature is compensated by +1˚C during dehumidifying or by

2˚C during heating.

+

-

-

7

Page 10

(12) Protection control function

(a) Dew prevention control Ⅰ [Cooling]

Prevents dewing on the indoor unit.

(i) Operating conditions

When the following conditions have been satised.

1) Humidity is 78% or higher.

(ii) Contents of operation

Maximum compressor speed

SRK25ZSP-W

SRK35ZSP-W

SRK45ZSP-W

68 rps

73 rps

87 rps

(iii) Reset condition

When either of the following condition is satised.

1) Humidity is 73% or less.

2) Dew prevention control Ⅱ has been satised.

(b) Dew prevention control Ⅱ [Cooling]

Prevents dewing on the indoor unit.

(i) Operating conditions

When the following conditions have been satised for more than 30 minutes after starting operation

1) Compressor speed is 32 rps or higher. (SRK25, 35)

2) Humidity is 68% or higher. (SRK45 : 60%)

(ii) Contents of operation

1) Air capacity control

'18 • SRK-SM-259

Model

Item

Upper limit of compressor speed

LO

SRK25,35ZSP-W SRK45ZSP-W

RangeA: 41rps, RangeB: 41rps RangeA: 57rps, RangeB: 39rps

Indoor fan 4th speed (SRK35 : 5th speed)

AUTO,HI,MED

Upper limit of compressor speed

Indoor fan

RangeA: 41rps, RangeB: 41rps RangeA: 57rps, RangeB: 39rps

Adaptable to compressor

speed (Lower limit 4th speed)

Note (1) Ranges A and B are as shown below.

Range B

Range A

68

73

Humidity(%)

2) When this control has continued for more than 30 minutes continuously,the following wind direction control is per-

formed.

a) When the vertical wind direction is set at other than the vertical swing,the aps change to the horizontal position.

b) When the horizontal wind direction is set at other than the horizontal swing,the louver changes to the vertical po-

sition.

(iii) Reset condition

When any of followings is satised.

1) Humidity is less than 63%. (SRK45 : 55%)

-

-

8

Page 11

'09•SRK-DB-087D

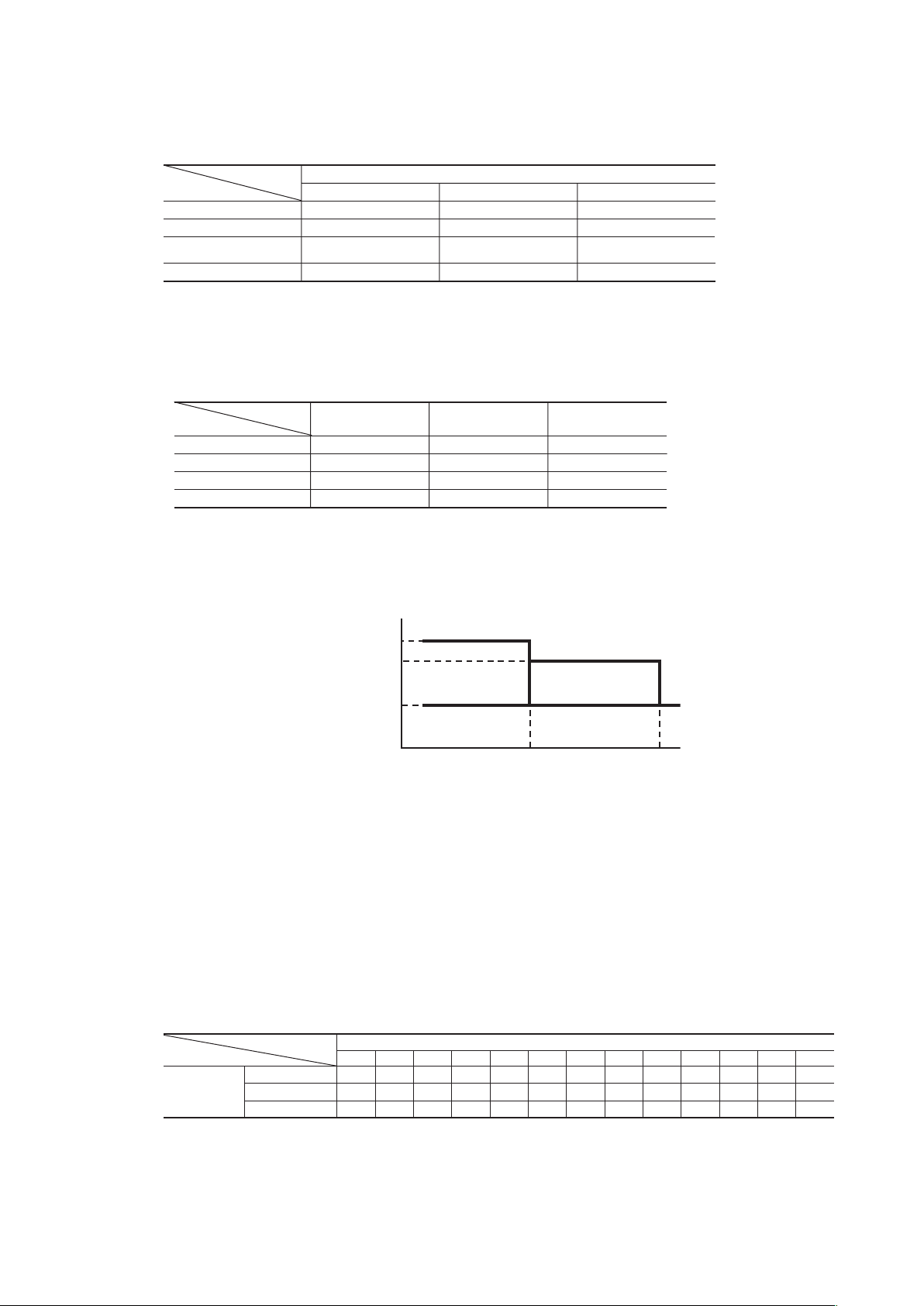

(c) Frost prevention control

A

B

C

Outdoor heat exchanger temperature(°C)

8rps

(1)

8rps

(1)

0rps

After lapse of 20 sec. or over

(3)

After lapse of 20 sec. or over

(3)

After lapse of 20 sec. or over

(3)

(Example) Fuzzy

(i) Operating conditions

1)

2)

(ii) Detail of anti-frost operation

Indoor heat exchanger

Item

Lower limit of compressor speed

Indoor fan

Outdoor fan

4-way valve

temperature

(iii) Reset conditions

1)

2)

5°C or lower 2.5°C or lower

22rps (SRK45 : 23 rps)

compressor

-

-

'18 • SRK-SM-259

compressor

speed

Lower

limit

speed

0 rps

2.55 8

Indoor heat exchanger

temperature (ºC)

(d) Cooling overload protective control

(i) Operating conditions

When the outdoor air temperature (TH2) has become continuously for 30 seconds at 41ºC or more, or 47ºC or more

with the compressor running, the lower limit speed of compressor is brought up.

Model

Item

Outdoor air temperature

Lower limit speed

SRK25, 35ZSP-W SRK45ZSP-W

41°C or more 47°C or more 41°C or more 47°C or more

30 rps 45 rps 27 rps 35 rps

(ii) Detail of operation

1) The outdoor fan is stepped up by 3 speed step. (Upper limit; 8th speed.)

2) The lower limit of compressor speed is set to 30 or 45(model SRK45 : 27 or 35) rps. However, when the thermo

OFF, the speed is reduced to 0 rps.

(iii) Reset conditions

When either of the following condition is satised.

1) The outdoor air temperature is lower than 40ºC.

2) The compressor speed is 0 rps.

(e) Cooling high pressure control

(i) Purpose

Prevents anomalous high pressure operation during cooling.

(ii) Detector

Outdoor heat exchanger sensor (TH1)

(iii) Detail of operation

-

-

9

Page 12

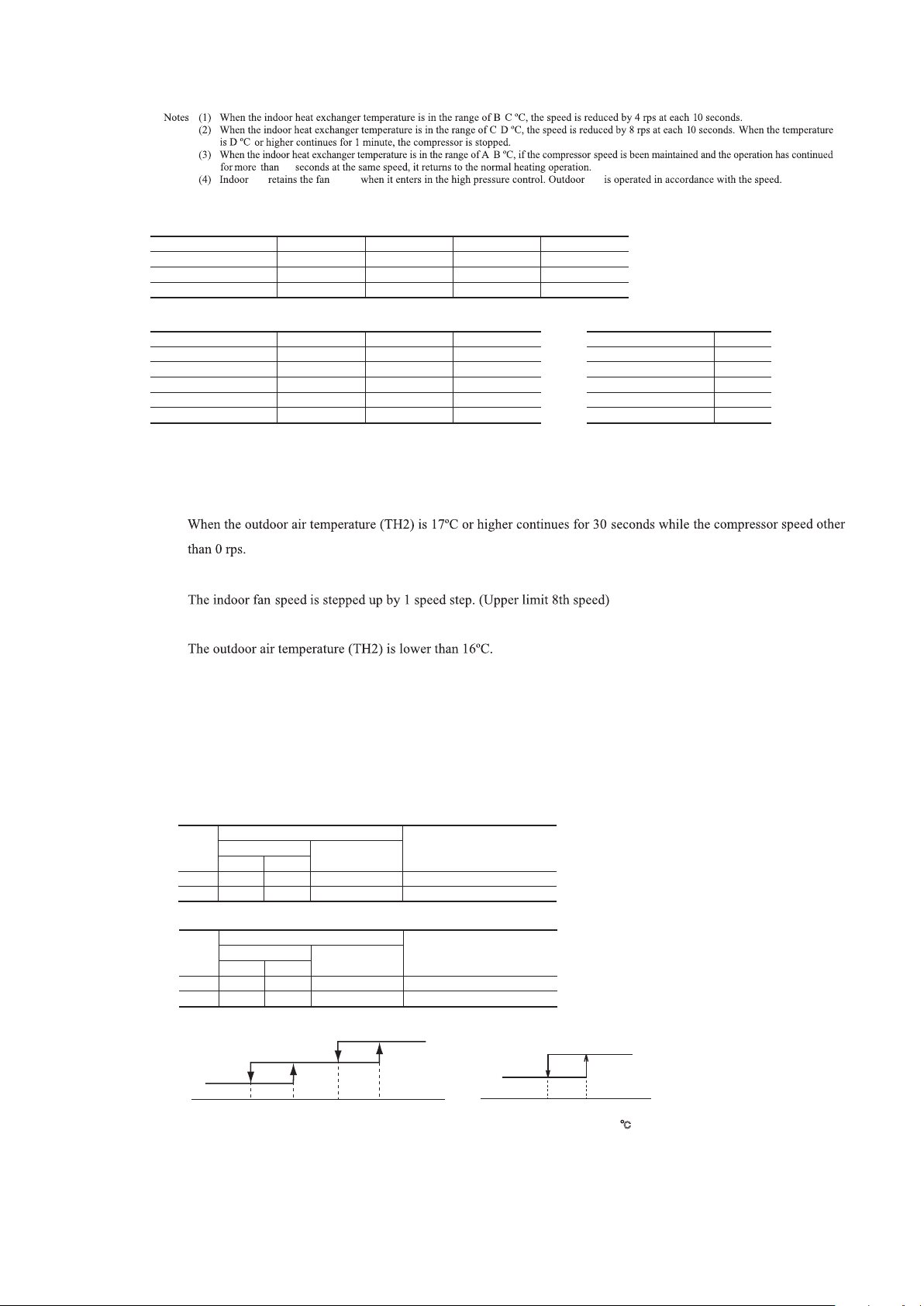

Notes (1) When the outdoor heat exchanger temperature is in the range of B-C ºC, the speed is reduced by 8 rps at each 20 seconds.

'09•SRK-DB-087D

(i) Operating conditions

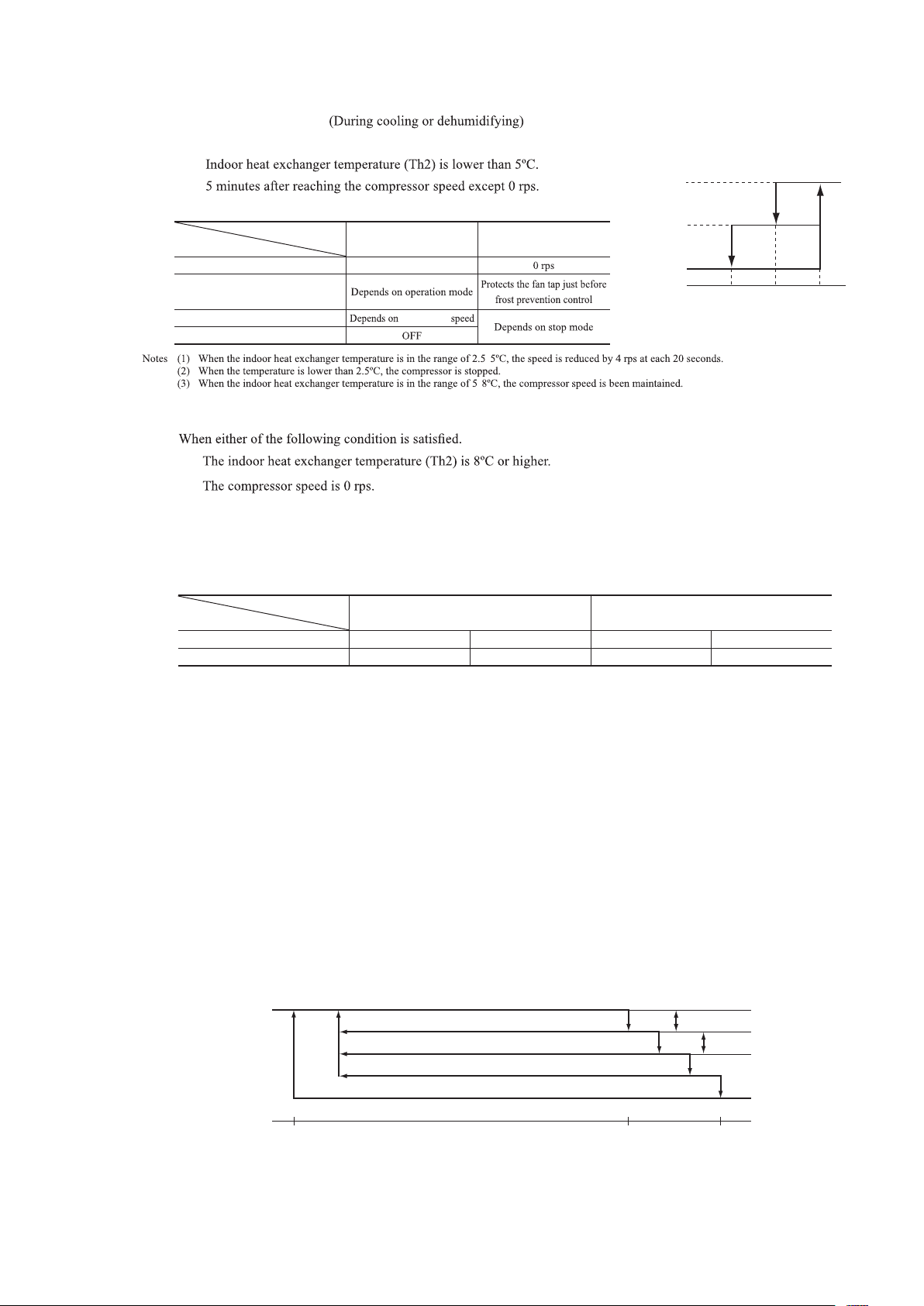

(e) Cooling low outdoor air temperature protective control

(i) Operating conditions

(ii) Detail of operation

When the outdoor air temperature (TH2) is 22°C or lower continues for 20 seconds while the compressor speed is other than 0 rps.

Compressor speed: Upper/lower limit (rps)

Lower 3Upper 2Lower 2

Lower 1

Range BRange A

Upper 1Upper 3

50504430

50

445044

60

6027

Release

Release

50

SRK25, 35

SRK45

1) It controls the upper and lower limit values for the compressor speed according to the following table.

2) It checks the outdoor temperature (TH2) once every hour to judge the operation range.

'09•SRK-DB-087D

(2) When the temperature is C ºC or higher, the compressor is stopped.

(3) When the outdoor heat exchanger temperature is in the range of A-B ºC, if the compressor speed is been maintained and the operation has

●

Temperature list

Outdoor air temperature

Outdoor air temperature <

continued for more than 20 seconds at the same speed, it returns to the normal cooling operation.

SRK25, 35 SRK45

>

=

32 ºC

32 ºC

A B C A B C

53 58 63 48 53 55

40 43 46 53 58 63

(f) Cooling low outdoor air temperature protective control

'18 • SRK-SM-259

Upper limit 50 rps

ON

Lower limit 50ࠝ44ࠞ rps

EF

First time

After the

second times

Upper limit 50 rps

ON

Lower limit 44 rps

Outdoor air temperature (°C)

(iii) Reset conditions

1)

2)

(g)

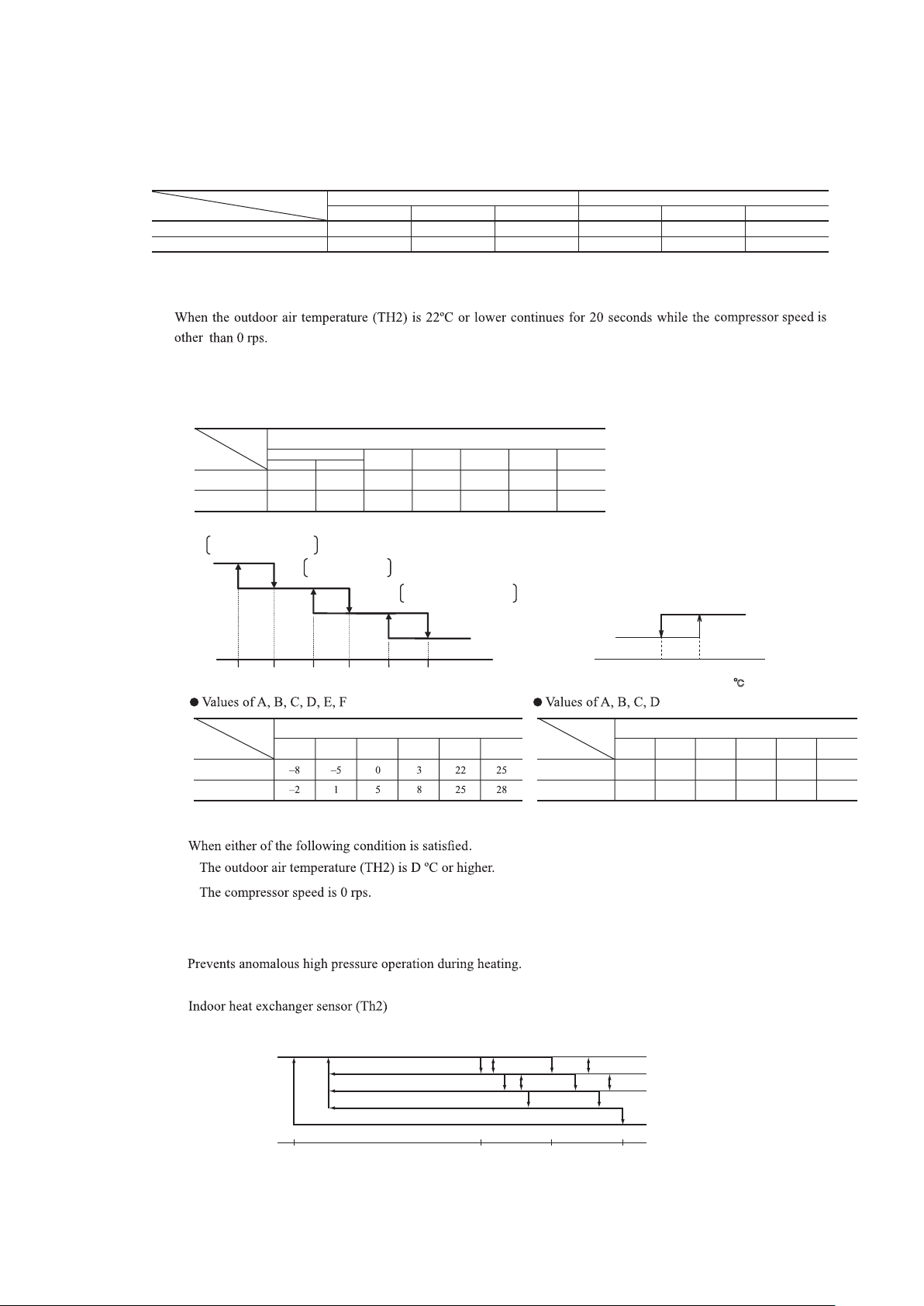

Heating high pressure control

(i) Purpose

(ii) Detector

Upper limit 60 rps

ON

Lower limit 30ࠝ27ࠞ rps

CDAB

(Models SRK25, 35)

Outdoor air temperature (˚C)

ABCDEF

OFF

First time

After the

second times

Range A

Range B

Indoor air temperature ( Υ

2624

)

, E, F (Model SRK45)

Outdoor air temperature (˚C)

E FABCD

0

5721691911252228

25

(iii) Detail of operation

(Example) Fuzzy

After lapse of 10 sec. or over

After lapse of 10 sec. or over

After lapse of 10 sec. or over

A

Indoor heat exchanger temperature(°C)

(3)

(3)

lower limit

(3)

speed 30(35) rps

B

4rps

(1)

(1)

4rps

C

8rps

(2)

8rps

(2)

0rps

D

-

-

10

Page 13

'09•SRK-DB-087D

CDAB

OFF

EF

Upper limit 50 rps

Lower limit 44 rps

ON

ON

Upper limit 50 rps

Lower limit 50ࠝ44ࠞ rps

ON

Upper limit 60 rps

Lower limit 30ࠝ27ࠞ rps

Outdoor air temperature (°C)

Heating high pressure control

A

B

C

D

Indoor heat exchanger temperature(°C)

4rps

(1)

8rps

(2)

8rps

(2)

4rps

(1)

0rps

-

-

After lapse of 10 sec. or over

(3)

After lapse of 10 sec. or over

(3)

After lapse of 10 sec. or over

(3)

lower limit

speed 30(35) rps

First time

After the

second times

Outdoor air temperature (˚C)

ABCDEF

1)

2)

(Models SRK25, 35)

First time

After the

second times

Outdoor air temperature (˚C)

E FABCD

, E, F (Model SRK45)

0

5721691911252228

25

2624

Indoor air temperature ( Υ

)

Range A

Range B

'09•SRK-DB-087D

(h) Heating overload protective control

10

fan fan

●

Temperature list

Models SRK25, 35 Unit : ºC

RPSmin < 50

<

50

RPSmin < 92

=

92

<

RPSmin

=

<

=

115

speed

A B C D

47 52 54 55

47.5 55 57 61

47.5-39.0 55.0-40.0 57.0-42.0 61

-

'18 • SRK-SM-259

Model SRK45 Unit : ºC Unit : ºC

RPSmin < 30

<

30

RPSmin < 40

=

<

40

RPSmin < 80

=

<

80

RPSmin < 90

=

<

90

RPSmin < 100

=

(i) Indoor unit side

1) Operating conditions

2) Detail of operation

3) Reset conditions

(ii) Outdoor unit side

1) Operating conditions

When the outdoor air temperature (TH2) is 22 (11 or 20)ºC or higher continues for 30 seconds while the compressor

speed other than 0 rps.

2) Detail of operation

Upper and lower limits of compressor speed and the outdoor unit fan speed are restricted.

Models SRK25,35

ON1

ON2

Model SRK45

ON1

ON2

A B C

45 49 50

45-49 49-55 50-57

49 55 57

49-48 55-53 57-55

48-37 53-42 55-44

Upper limit

Upper limit

Compressor command speed (rps)

Lower limit

Range A Range B

- - - -

40 Release 60 2nd speed

Compressor command speed (rps)

Lower limit

Range A Range B

35 Release 85 It depends on compressor speed

35 35 55 2nd speed

Outdoor fan speed

Outdoor fan speed

RPSmin < 35

<

35

RPSmin < 40

=

<

40

RPSmin < 80

=

<

80

RPSmin < 95

=

<

95

RPSmin < 100

=

D

55.5

55.5-62

62

62-56

56-50.5

Protective

control

Normal

operation

OFF

ON1

10

Outdoor air temperature(°C)

3) Reset conditions

When the outdoor air temperature drops below 19 (13)ºC.

Note (1) Values in ( ) are for the model SRK45.

22 (20)21 (19)11

ON2

Range A

Range B

Indoor air temperature ( Υ

2321

)

-

-

11

Page 14

b) Detail of operation

c) Reset conditions:

10 11 19 20

Normal operation

Protective control ON1

Protective control ON2

Outdoor air temperature(°C)

21 22

Normal operation

Protective

control

Outdoor air temperature(°C)

• Model 50

i)

ii)

iii)

iv)

Taking the upper limit of compressor command speed range at 60 rps, if the output speed obtained with the fuzzy

calculation exceeds the upper limit, the upper limit value is maintained.

The lower limit of compressor command speed is set to 40 rps and even if the calculated result becomes lower than

that after fuzzy calculation, the speed is kept to 40 rps. However, when thethermo becomes OFF, the speed is

reduced to 0 prs.

rps.

a) Operating conditions :

b) Detail of operation

When the outdoor air temperature (TH2) is 11ºC or higher continues for 30 seconds while

the compressor command speed other than 0 rps.

i)

ii)

iii)

iv)

Taking the upper limit of compressor command speed range at 78 rps, if the output speed obtained with the fuzzy

calculation exceeds the upper limit, the upper limit value is maintained.

The lower limit of compressor command speed is set to 30 rps and even if the calculated result becomes lower than

that after fuzzy calculation, the speed is kept to 30 rps. However, when thethermo becomes OFF, the speed is

reduced to 0 prs.

rps.

.

c) Reset conditions:

.

30

Protective

control

NO1

NO2

Item

Compressor command speed

Low limit

30 rps

30 rps

Upper limit

78 rps

51 rps

It depends on compressor command speed

Outdoor fan speed

2nd

10

(i) Heating low outdoor temperature protective control

(i) Protective control I

1) Operating conditions

2 (-8)

lower

'18 • SRK-SM-259

2) Detail of operation

Models SRK25, 35

-10 -8 204

Outdoor air temperature(°C )

3) Reset conditions

a)

b)

Note (1) Values in ( ) are for the model SRK35.

(j) Compressor overheat protection

(i) Purpose

It is designed to prevent deterioration of oil, burnout of motor coil and other trouble resulting from the compressor over-

heat.

(ii) Detail of operation

1) Speeds are controlled with temperature detected by the sensor mounted on the discharge pipe.

(Example) Fuzzy

changed as shown in the figure below.

Lower limit 45(55) rps

Lower limit 40 rps

Lower limit 38(40) rps

Normal operation

Model SRK45

-8 -6

Outdoor air temperature(°C )

Lower limit 27 rps

Normal operation

4 (-6)

After lapse of 60 seconds. or over

After lapse of 60 seconds. or over

After lapse of 60 seconds. or over

(3)

(3)

(3)

(1)

4 rps

Lower limit

4 rps

(4)

0 rps

90 100 110

Discharge pipe temperature (˚C)

Notes (1) When the discharge pipe temperature is in the range of 100 to 110 ºC, the speed is reduced by 4 rps.

(2) When the discharge pipe temperature is raised and continues operation for 20 seconds without changing, then the speed is reduced again by 4

rps.

(3) If the discharge pipe temperature is in the range of 90-100ºC even when the compressor speed is maintained for 60 second when the tempera-

ture is in the range of 90-100ºC, the speed is raised by 1 rps and kept at that speed for 60 second. This process is repeated until the compres-

sor speed is reached.

(4) Lower limit speed

Cooling Heating

Models SRK25, 35

Model SRK45

15 rps 20 rps

20 rps 30rps

-

-

12

Page 15

'18 • SRK-SM-259

(p) Rotor lock

2) If the temperature of 110ºC is detected by the sensor on the discharge pipe, then the compressor will stop immediately.

When the discharge pipe temperature drops and 3 minutes has elapsed, the unit starts again within 1 hour but there

is no start at the third time.

(k) Current safe

(i) Purpose

Current is controlled not to exceed the upper limit of the setting operation current.

(ii) Detail of operation

Input current to the converter is monitored with the current sensor xed on the printed circuit board of the outdoor

unit and, if the operation current value reaches the limiting current value, the compressor speed is reduced.

If the mechanism is actuated when the compressor speed is less than 30 rps, the compressor is stopped immediately.

Operation starts again after 3 minutes.

(l) Current cut

(i) Purpose

Inverter is protected from overcurrent.

(ii) Detail of operation

Output current from the inverter is monitored with a shunt resistor and, if the current exceeds the setting value, the

compressor is stopped immediately. Operation starts again after 3 minutes.

(m) Outdoor unit failure

This is a function for determining when there is trouble with the outdoor unit during air-conditioning.

The compressor is stopped if any one of the following in item (i), (ii) is satised. Once the unit is stopped by this func-

tion, it is not restarted.

(i) When the input current is measured at 1 A or less for 3 continuous minutes or more.

(ii) If the outdoor unit sends a 0 rps signal to the indoor unit 3 times or more within 20 minutes of the power being turned on.

(n) Indoor fan motor protection

When the air-conditioner is operating and the indoor fan motor is turned ON, if the indoor fan motor has operated at 300

-1

or under for more than 30 seconds, the unit enters rst in the stop mode and then stops the entire system.

min

(o) Serial signal transmission error protection

(i) Purpose

(ii) Detail of operation

(q) Outdoor fan motor protection

min

-1

-

-

13

Page 16

(p) Rotor lock

(q) Outdoor fan motor protection

(r) Outdoor fan control at low outdoor temperature

(i)

min

-1

Cooling

1) Operating conditions

2) Detail of operation

Outdoor temperature > 10˚C

<

Outdoor temperature

=

10˚C

a)

b)

-

'18 • SRK-SM-259

Outdoor fan

-

c)

3) Reset conditions

a)

b)

(ii)

Heating

1) Operating conditions

2) Detail of operation

model

SRK45 : 8th speed)

SRK25, 35

ON1

ON2

Values in ( ) are for the model SRK35.

Th1<21℃

8th speed

9th(8th) speed

>

21℃

Th1

=

8th speed

8th speed

24

(model SRK45:0 )

; models SRK25, 35 : refer to belows,

ON2

ON1

OFF

-1 1 4 6

Outdoor air temperature(°C )

3) Reset conditions

a)

b)

(model SRK45:2 )

-

-

14

Page 17

(q) Outdoor fan motor protection

(r) Outdoor fan control at low outdoor temperature

Cooling

1) Operating conditions

2) Detail of operation

3) Reset conditions

Heating

1) Operating conditions

2) Detail of operation

3) Reset conditions

Outdoor temperature > 10˚C

Outdoor temperature

<

=

10˚C

Outdoor fan

a)

b)

a)

b)

a)

b)

c)

(i)

(ii)

Values in ( ) are for the model SRK35.

(model SRK45:0 )

min

-1

-

-

(model SRK45:2 )

; models SRK25, 35 : refer to belows,

model

SRK45 : 8th speed)

Th1<21℃

SRK25, 35

8th speed

9th(8th) speed

Th1

21℃

8th speed

8th speed

ON1

ON2

>

=

-1 1 4 6

Outdoor air temperature(°C )

ON1

ON2

OFF

24

(s) Refrigeration cycle system protection

(i) Starting conditions

1)

When 5 minutes have elapsed after the compressor ON or the completion of the defrost operation

2)

Other than the defrost operation

3)

When, after satisfying the conditions of 1) and 2) above, the compressor speed, indoor air temperature (Th1) and indoor

heat exchanger temperature (Th2) have satisfied the conditions in the following table for 10 (SRK45:5) minutes:

'18 • SRK-SM-259

(iii) Reset condition

Compressor speed (N)Operation mode

<

Cooling

Heating(1)

Except that the fan speed is HI in heating operation.

(ii) Contents of control

1)

When the conditions of (i) above are satisfied, the compressor stops.

2)

Error stop occurs when the compressor has stopped 3 times within 60 minutes.

50 N

=

<

50 N

=

Indoor air temperature (Th1)

<=<

10 Th1 40

=

<=<

0 Th1 40

=

When the compressor has been turned OFF.

Room temperature (Th1)/

Indoor heat exchanger temperature (Th2)

Th1−4<Th2

Th2<Th1+6

-

15

-

Page 18

2. MAINTENANCE DATA

YES

YES

YES

NO

NO

NO

NO

YES

(1) Cautions

(a) If you are disassembling and checking an air-conditioner, be sure to turn off the power before beginning. When working on

indoor units, let the unit sit for about 1 minute after turning off the power before you begin work. When working on an out-

door unit, there may be an electrical charge applied to the main circuit (electrolytic condenser), so begin work only after

discharging this electrical charge (to DC 10 V or lower).

(b) When taking out printed circuit boards, be sure to do so without exerting force on the circuit boards or package components.

(c) When disconnecting and connecting connectors, take hold of the connector housing and do not pull on the lead wires.

(2) Items to check before troubleshooting

(a) Have you thoroughly investigated the details of the trouble which the customer is complaining about?

(b) Is the air-conditioner running? Is it displaying any self-diagnosis information?

(c) Is a power source with the correct voltage connected?

(d) Are the control lines connecting the indoor and outdoor units wired correctly and connected securely?

(e) Is the outdoor unit’s service valve open?

(3) Troubleshooting procedure (If the air-conditioner does not run at all)

If the air-conditioner does not run at all, diagnose the trouble using the following troubleshooting procedure. If the air-condi-

tioner is running but breaks down, proceed to troubleshooting step (4).

Important

When all the following conditions are satised, we say that the air-conditioner will not run at all.

(a) The RUN light does not light up.

(b) The aps do not open.

(c) The indoor unit fan motors do not run.

(d) The self-diagnosis display does not function.

'18 • SRK-SM-259

Troubleshooting procedure (If the air-conditioner does not run at all)

Is the correct voltage

connected for the power

source?

With the power off, do

the aps open manually,

then close again when

the power is turned on?

Is there a reception sound

emitted from the unit

when it is operated by the

wireless remote control?

Replace the indoor unit PCB

and perform an operation

check.

Make sure the correct voltage is connected, then perform an operation check.

Is the current fuse on the indoor unit PCB blown?

Proceed to the indoor unit

PCB check.

Proceed to the wireless remote

control troubleshooting procedure.

* If the voltage is correct, it will be

within the following voltage range.

AC 198-264 V

If the package components

are not damaged, replace

the fuse and perform an operation check again.

-

16

-

Page 19

(4) Troubleshooting procedure (If the air-conditioner runs)

NO

NO

NO

NO

YES

YES

YES

YES

Conrm the contents of the customer complaint.

The cause of the trouble can

be specically identied.

'18 • SRK-SM-259

Check the self-diagnosis display.

See page 18.

Is an error code displayed by

the self-diagnosis function?

Identify the faulty component by using the check

procedure corresponding to the content of the trouble.

Eliminate the cause of the trouble and perform an

operation check.

Using the service mode, access the self-diagnosis

displays generated in the past.

See pages 19-25.

Is there a history of self-diagnosis display items?

Using the service mode, access the stop history due

to protection control generated in the past.

See pages 19-25.

Is there a history of stops due

to protection control?

(1)

Replace the faulty component, then perform an

The air-conditioning system is operating normally.

operation check.

Note (1) Even in cases where only intermittent stop data are generated, the air-conditioning system is normal. However, if the same protective operation

recurs repeatedly (3 or more times), it will lead to customer complaints. Judge the conditions in comparison with the contents of the complaints.

-

-

17

Page 20

'18 • SRK-SM-259

(5) Self-diagnosis table

When this air-conditioner performs an emergency stop, the reason why the emergency stop occurred is displayed by the ash-

ing of display lights. If the air-conditioner is operated using the wireless remote control 3 minutes or more after the emergen-

cy stop, the trouble display stops and the air-conditioner resumes operation.

(1)

Indoor unit display section

RUN

light

1‐time

flash

2‐time

flash

5‐time

flash

6‐time

flash

7‐time

flash

Keeps

flashing

Keeps

flashing

Keeps

flashing

ON

ON

ON

ON

ON

ON

TIMER

light

ON

ON

ON

ON

ON

1‐time

flash

2‐time

flash

4‐time

flash

1‐time

flash

2‐time

flash

3‐time

flash

4‐time

flash

5‐time

flash

6‐time

flash

Description

of trouble

Indoor heat exchanger

sensor error

Room

temperature

sensor error

Active filter

voltage error

Indoor fan

motor error

Refrigeration

cycle system

protective

control

Outdoor air

temperature

sensor error

Outdoor heat

exchanger

sensor error

Discharge pipe

sensor error

Current cut

Trouble of

outdoor unit

Current safe

stop

Power transistor

error

Over heat of

compressor

Error of signal

transmission

Cause Display (flashing) condition

• Broken heat exchanger sensor

wire, poor connector

connection

• Indoor unit PCB is faulty

• Broken room temperature

sensor wire, poor connector

connection

• Indoor unit PCB is faulty

• Defective active filter

• Defective fan motor, poor

connector connection

• Service valve is closed.

• Refrigerant is insufficient

• Broken outdoor air temperature

sensor wire, poor connector

connection

• Outdoor unit PCB is faulty

• Broken heat exchanger sensor

wire, poor connector

connection

• Outdoor unit PCB is faulty

• Broken discharge pipe sensor

wire, poor connector

connection

• Outdoor unit PCB is faulty

• Compressor locking, open

phase on compressor output,

shortcircuit on power

transistor, closed service valve

• Broken compressor wire

• Compressor blockage

• Overload operation

• Overcharge

• Compressor locking

• Broken power transistor

• Gas shortage, defective

discharge pipe sensor, closed

service valve

• Defective power source,

Broken signal wire, defective

indoor/outdoor unit PCB

When a heat exchanger sensor wire disconnection is detected while operation is

stopped. (If a temperature of –28ºC or lower is detected for 15 seconds, it is

judged that the wire is disconnected.)

(Not displayed during operation.)

When a room temperature sensor wire disconnection is detected while operation

is stopped. (If a temperature of –45ºC or lower is detected for 15 seconds, it is

judged that the wire is disconnected.)

(Not displayed during operation.)

When the wrong voltage connected for the power source.

When the outdoor unit PCB is faulty.

When conditions for turning the indoor unit’s fan motor on exist during airconditioner operation, an indoor unit fan motor speed of 300 min

measured for 30 seconds or longer. (The air-conditioner stops.)

When refrigeration cycle system protective control operates.

-55℃ or lower is detected for 5 seconds continuously 3 times within 40 minutes

after initial detection of this anomalous temperature.

Or -55℃ or higher is detected for within 20 seconds after power ON.

(The compressor is stopped.)

-55℃ or lower is detected for 5 seconds continuously 3 times within 40 minutes

after initial detection of this anomalous temperature.

Or -55℃ or higher is detected for within 20 seconds after power ON.

(The compressor is stopped.)

-25℃ or lower is detected for 5 seconds continuously 3 times within 40 minutes

after initial detection of this anomalous temperature.

(The compressor is stopped.)

The compressor output current (compressor motor current) exceeds the set value

during compressor start.

(The air-conditioner stops.)

When there is an emergency stop caused by trouble in the outdoor unit, or the

input current value is found to be lower than the set value.

(The air-conditioner stops.)

When the compressor speed is lower than the set value and the current safe has

operated. (The compressor is stopped.)

When there is an emergency stop caused by trouble in the outdoor unit, or the

input current value is found to be lower than the set value continuously for 3

minutes or longer.

(The compressor is stopped.)

When the value of the discharge pipe sensor exceeds the set value.

(The air-conditioner stops.)

When there is no signal between the indoor unit PCB and outdoor unit PCB for

10 seconds or longer (when the power is turned on), or when there is no signal

for 7 minutes 35 seconds or longer (during operation)

(The compressor is stopped).

-1

or lower is

7‐time

ON

ON

2‐time

flash

Note (1) The air-conditioner cannot be restarted using the wireless remote control for 3 minutes after operation stops.

flash

Keeps

flashing

2‐time

flash

Outdoor fan

motor error

Cooling high

pressure

protection

Rotor lock

• Defective fan motor, poor

connector connection

• Overload operation, overcharge

• Broken outdoor heat exchange

sensor wire

• Service valve is closed.

• Defective compressor

• Open phase on compressor

• Defective outdoor unit PCB

-

18

When the outdoor unit’s fan motor sped continues for 30 seconds or longer at

-1

or lower. (3 times) (The air-conditioner stops.)

75 min

When the value of the outdoor heat exchanger sensor exceeds the set value.

If the compressor motor’s magnetic pole positions cannot be correctly detected

when the compressor starts.

(The air-conditioner stops.)

-

Page 21

'18 • SRK-SM-259

NO

NO

(*1)

YES

YES

(6) Service mode (Trouble mode access function)

This air-conditioner is capable of recording error displays and protective stops (service data) which have occurred in the

past. If self-diagnosis displays cannot be conrmed, it is possible to get a grasp of the conditions at the time trouble occurred by checking these service data.

(a) Explanation of terms

Term

Explanation

Service mode

The service mode is the mode where service data are displayed by flashing of the display lights

when the operations in item (b) below are performed with the indoor control.

These are the contents of error displays and protective stops which occurred in the past in the airconditioner system. Error display contents and protective stop data from past anomalous

Service data

operations of the air-conditioner system are saved in the indoor unit control’s non-volatile

memory (memory which is not erased when the power goes off). There are two types of data,

self-diagnosis data and stop data, described below.

These are the data which display the reason why a stop occurred when an error display (selfdiagnosis display) occurred in an indoor unit. Data are recorded for up to 5 previous occurrences.

Data which are older than the 5th previous occurrence are erased.

Self-diagnosis data

In addition, data on the temperature of each sensor (room temperature, indoor heat exchanger,

outdoor heat exchanger, outdoor air temperature, discharge pipe), wireless remote control

information (operation switching, fan speed switching) are recorded when trouble occurs, so more

detailed information can be checked.

These are the data which display the reason by a stop occurred when the air-conditioning system

performed protective stops, etc. in the past. Even if stop data alone are generated, the system

restarts automatically. (After executing the stop mode while the display is normal, the system

Stop data

restarts automatically.) Data for up to 10 previous occasions are stored. Data older than the 10th

previous occasion are erased.

( Important) In cases where transient stop data only are generated, the air-conditioner system

may still be normal. However, if the same protective stop occurs frequently (3 or

more times), it could lead to customer complaints.

(b) Service mode display procedure

Start

Turn off the air-conditioner’s power once, then

wait 1 minute or longer.

Turn the air-conditioner’s power on again while

pressing the unit ON/OFF button.

Did a buzzer located in

the indoor unit sound?

Within 1 minute after turning the air-conditioner’s power on, signals will be sent from the

remote control.

(*2)

Count the number of times the RUN light and

TIMER light ash

(*3)

, and check the contents of the

error, etc. from the table. (See pages 22.)

Are other data displayed?

Change the wireless remote control settings based

on the instructions in the table

(*4)

. (See page 20.)

*1: If the buzzer does not sound no matter how

many times you repeat the operation, the

unit ON/OFF button may be faulty.

*2: Set the wireless remote control’s settings on

“Cooling operation,” “Fan speed: MED” and

“Set temperature: 21ºC.”

Turn off the air-conditioner’s power to terminate the

service mode. If you are going to turn the power on

again, wait 1 minute or longer after turning it off.

-

19

-

Page 22

'18 • SRK-SM-259

Remote control setting

Contents of output data

Fan speed switching

MED

HI

AUTO

LO

MED

HI

AUTO

Displays the reason for stopping display in the past (error code).

Displays the room temperature sensor temperature at the time the error code was displayed in the past.

Displays the indoor heat exchanger sensor temperature at the time the error code was displayed in the past.

Displays the remote control information at the time the error code was displayed in the past.

Displays the outdoor air temperature sensor temperature at the time the error code was displayed in the past.

Displays the outdoor heat exchanger sensor temperature at the time the error code was displayed in the past.

Displays the discharge pipe sensor temperature at the time the error code was displayed in the past.

Cooling

Operation switching

Heating

Remote control setting

Indicates the number of

occasions previous to the present

the error display data are from.

Temperature setting

21ºC

22ºC

23ºC

24ºC

25ºC

1 time previous (previous time)

2 times previous

3 times previous

4 times previous

5 times previous

Remote control setting

Fan speed

switching

Operation

switching

Displayed data

Temperature

setting

21ºC

22ºC

23ºC

24ºC

25ºC

Displays the reason for the stop (error code) the previous time an error was displayed.

Displays the reason for the stop (error code) 2 times previous when an error was displayed.

Displays the reason for the stop (error code) 3 times previous when an error was displayed.

Displays the reason for the stop (error code) 4 times previous when an error was displayed.

Displays the reason for the stop (error code) 5 times previous when an error was displayed.

Cooling MED

0.5 sec.

1.5 sec.

RUN light

(10’s digit)

TIMER light

(1’s digit)

11-second interval

0.5 sec.

OFF

ON

OFF

ON

• In the case of current cut (example: stop code “42”)

The RUN light (10’s digit) flashes 4 times and the TIMER light (1’s digit) flashes 2 times.

4 × 10 + 2 × 1 = 42 → From the table, read the instructions for error code 42, “current cut”.

*3: To count the number of ashes in the service mode, count the number of ashes after the light lights up for 1.5 second

initially (start signal). (The time that the light lights up for 1.5 second (start signal) is not counted in the number of

ashes.)

When in the service mode, when the remote control settings (operation switching, fan speed switching, temperature

*4:

setting) are set as shown in the following table and sent to the air-conditioner unit, the unit switches to display of service data.

Self-diagnosis data

①

What are Self-diagnosis data?

These are control data (reasons for stops, temperature at each sensor, wireless remote control information) from the time when

there were error displays (abnormal stops) in the indoor unit in the past. Data from up to 5 previous occasions are stored in

memory. Data older than the 5th previous occasion are erased. The temperature setting indicates how many occasions previous

to the present setting the error display data are and the operation switching and fan speed switching data show the type of data.

(Example)

-

20

-

Page 23

Stop data

②

Operation

switching

Cooling LO

Remote control setting

Fan speed

Temperature

switching

setting

21ºC

22ºC

23ºC

24ºC

25ºC

26ºC

27ºC

28ºC

29ºC

30ºC

'18 • SRK-SM-259

Displayed data

Displays the reason for the stop (stop code) the previous time when the air-conditioner was stopped by protective stop control.

Displays the reason for the stop (stop code) 2 times previous when the air-conditioner was stopped by protective stop control.

Displays the reason for the stop (stop code) 3 times previous when the air-conditioner was stopped by protective stop control.

Displays the reason for the stop (stop code) 4 times previous when the air-conditioner was stopped by protective stop control.

Displays the reason for the stop (stop code) 5 times previous when the air-conditioner was stopped by protective stop control.

Displays the reason for the stop (stop code) 6 times previous when the air-conditioner was stopped by protective stop control.

Displays the reason for the stop (stop code) 7 times previous when the air-conditioner was stopped by protective stop control.

Displays the reason for the stop (stop code) 8 times previous when the air-conditioner was stopped by protective stop control.

Displays the reason for the stop (stop code) 9 times previous when the air-conditioner was stopped by protective stop control.

Displays the reason for the stop (stop code) 10 times previous when the air-conditioner was stopped by protective stop control.

-

21

-

Page 24

'18 • SRK-SM-259

'09•SRK-DB-087D

(c) Error code, stop code table

Number of flashes when in

service mode

RUN

light

(10's digit)

(1's digit)

OFF

3time

flash

4

time

flash

5

time

flash

6

time

flash

8

time

flash

TIMER

light

OFF

5time

flash

5time

flash

6time

flash

7time

flash

8time

flash

9time

flash

2time

flash

7time

flash

8time

flash

1time

flash

7time

flash

8time

flash

9time

flash

OFF

1time

flash

2time

flash

OFF

2time

flash

4time

flash

5time

flash

6time

flash

Stop coad

or

Error coad

0 Normal

Can not receive signals for 35

05

seconds

(if communications have recovered)

Cooling high pressure control

35

36

Compressor

Outdoor heat exchanger sensor

37

is abnormal

Outdoor air temperature sensor

38

is abnormal

Discharge pipe sensor is

39

abnormal (anomalous stop)

Current cut

42

47

Active filter voltage error

Outdoor unit's fan motor is

48

abnormal

Short circuit in the power

transistor (high side)

51

Current cut circuit breakdown

Refrigeration cycle system

57

protective control

58

Current safe

Compressor wiring is unconnection

V

oltage drop

59

Low speed protective control

60

Rotor lock

Connection lines between the

61

indoor and outdoor units are

faulty

62

Serial transmission error

Indoor unit's fan motor is

80

abnormal

Indoor heat exchanger sensor

82

is abnormal (anomalous stop)

84

Anti-condensation control

85

Anti-frost control

86

Heating high pressure control

Error content Cause Occurrence conditions

overheat

110°C

Power source is faulty.

Power source cables and signal lines are improperly wired.

Indoor or outdoor unit PCB are faulty.

Cooling overload operation.

Outdoor unit fan speed drops.

Outdoor heat exchanger sensor is short circuit.

Refrigerant is insufficient.

Discharge pipe sensor is faulty.

Service valve is closed.

Outdoor heat exchanger sensor wire is

disconnected.

Connector connections are poor.

Outdoor unit PCB is faulty.

Outdoor air temperature sensor wire is

disconnected.

Connector connections are poor.

Outdoor PCB is faulty.

Discharge pipe sensor wire is

disconnected.

Connector connections are poor.

Outdoor unit PCB is faulty.

Compressor lock.

Compressor wiring short circuit.

Compressor output is open phase.

Outdoor unit PCB is faulty.

Service valve is closed.

Electronic expansion valve is faulty.

Compressor is faulty.

Defective active filter.

Outdoor fan motor is faulty.

Connector connections are poor.

Outdoor unit PCB is faulty.

Outdoor unit PCB is faulty.

Power transistor is damaged.

Service valve is closed.

Refrigerant is insufficient.

Refrigerant is overcharge.

Compressor lock.

Overload operation.

Compressor wiring is disconnected.

Power transistor is damaged.

Power source construction is defective.

Outdoor unit PCB is faulty.

Compressor is faulty.

Compressor is faulty.

Compressor output is open phase.

Electronic expansion valve is faulty.

Overload operation.

Outdoor unit PCB is faulty.

Connection lines are faulty.

Indoor or outdoor unit PCB are faulty.

Indoor or outdoor unit PCB are faulty.

Noise is causing faulty operation.

Indoor fan motor is faulty.

Connector connections are poor.

Indoor unit PCB is faulty.

Indoor heat exchanger sensor wire is

disconnected.

Connector connections are poor.

High humidity condition.

Humidity sensor is faulty.

Indoor unit fan speed drops.

Indoor heat exchanger sensor is broken wire.

Heating overload operation.

Indoor unit fan speed drops.

Indoor heat exchanger sensor is short-circuit.

When 35 seconds passes without

communications signals from either the outdoor unit or

the indoor unit being detected correctly.

When the outdoor heat exchanger sensor's value exceeds

the set value.

When the discharge pipe sensor's value exceeds the set

value.

–55°C or lower is detected for 5 seconds continuously 3 times

within 40 minutes after initial detection of this anomalous

temperature.

Or–55°C higher is detected for 5 seconds continuously

within 20 seconds after power ON.

–55°C or lower is detected for 5 seconds continuously 3 times

within 40 minutes after initial detection of this anomalous

temperature.

Or–55°C higher is detected for 5 seconds continuously

within 20 seconds after power ON.

–25°C or lower is detected for 5 seconds continuously 3 times

within 40 minutes after initial detection of this anomalous

temperature.

Compressor start fails 42 times in succession and the

reason for the final failure is current cut.

When the wrong voltage connected for the power source.

When the outdoor unit PCB is faulty.

-1

When a fan speed of 75 min

seconds or longer.

When it is judged that the power transistor was

damaged at the time the compressor started.

When refrigeration cycle system protective control

operates.

When there is a current safe stop during operation.

When the current is 1A or less at the time the

compressor started.

When the power source voltage drops during operation.

When the compressor command speed is lower than 32

rps for 60 minutes.

After the compressor starts, when the compressor stops

due to rotor lock.

When 10 seconds passes after the power is turned on

without communications signals from the indoor or

outdoor unit being detected correctly.

When 7 minutes 35 seconds passes without

communications signals from either the outdoor unit or

the indoor unit being detected correctly.

When the indoor unit's fan motor is detected to be running

at 300 min-1 or lower speed with the fan motor in the ON

condition while the air-conditioner is running.

When a temperature of –28°C or lower is sensed

continuously for 40 minutes during heating operation.

(The compressor stops.)

Anti-condensation prevention control is operating.

When the anti-frost control operates and the compressor

stops during cooling operation.

When high pressure control operates during heating

operation and the compressor stops.

or lower continues for 30

Error

display

(5 times)

(2 times)

(3 times)

(3 times)

(3 times)

(2 times)

(3 times)

(3 times)

(2 times)

Auto

recovery

-

22

-

Page 25

'18 • SRK-SM-259

0.5 sec.

1.5 sec.

RUN light

(10’s digit)

TIMER light

(1’s digit)

11-second interval

0.5 sec.

OFF

ON

OFF

ON

• In the case of current cut (example: stop code “42”)

The RUN light (10’s digit) flashes 4 times and the TIMER light (1’s digit) flashes 2 times.

4 × 10 + 2 × 1 = 42 → From the table, read the instructions for error code 42, “Current cut”.

RUN light

(Operation switching)

Display pattern when

in service mode

Operation switching

when there is an

abnormal stop

0

1

2

3

4

AUTO

DRY

COOL

FA N

HEAT

TIMER light

(Fan speed switching)

Display pattern when

in service mode

Fan speed

switching when

there is an

abnormal stop

0

2

3

4

6

7

AUTO

HI

MED

LO

HI POWER

ECONO

0.5 sec.

1.5 sec.

RUN light

(10’s digit)

TIMER light

(1’s digit)

11-second interval

0.5 sec.

OFF

ON

OFF

ON

Notes (1) The number of ashes when in the service mode do not include the 1.5 second period when the lights light up at rst (start signal). (See the ex-

ample shown below.)

Notes (2) Abnormal Stop:

If there is a ( ) displayed, the error display shows the number of times that an automatic recovery occurred for the same

If no ( ) is displayed, the error display shows that the trouble has occurred once.

Notes (3) Automatic Recovery:

-

Is not displayed. (automatic recovery only)

Displayed.

○

reason has reached the number of times in ( ).

-

Does not occur.

Automatic recovery occurs.

○

(d) Wireless remote control information tables

1) Operation switching

2) Fan speed switching

* If no data are recorded (error code is normal), the information display in the wireless remote control becomes as follows.

Wireless remote control setting

Operation switching

Fan speed switching

Display when error code is normal.

AUTO

AUTO

(Example): Operation switching, fan speed switching, cooling HI

-

23

-

Page 26

'18 • SRK-SM-259

Sensor name

Room temperature sensor temperature

Indoor heat exchanger sensor temperature

Outdoor air temperature sensor temperature

Outdoor heat exchanger sensor temperature

Sensor value displayed when the error code is normal

-19ºC

-64ºC

-64ºC

-64ºC

Unit: ºC

0.5 sec.

0.1 sec.

1.5 sec.

Buzzer sound

If the temperature is < 0, the buzzer sounds.

If the temperature is

>

=

0, the buzzer does not sound.

11-second interval

0.5 sec.

OFF

ON

OFF

ON

OFF

ON

RUN light

(10’s digit)

TIMER light

(1’s digit)

(e) Room temperature sensor temperature, indoor heat exchanger sensor temperature, outdoor air tem-

perature sensor temperature, outdoor heat exchanger sensor temperature table

TIMER light

(1’s digit)

RUN light

(10’s digit)

Buzzer sound

0 1 2 3 4 5 6 7 8 9

(sounds for 0.1 second)

Yes

No

(does not sound)

6

5

4

3

2

1

0

0

1

2

3

4

5

6

7

8

9

-60

-50

-40

-30

-20

-10

10

20

30

40

50

60

70

80

90

-61

-62

-63

-64

-51

-52

-53

-54

-41

-42

-43

-44

-31

-32

-33

-34

-21

-22

-23

-24

-11

-12

-13

-14

-1

-2

-3

-4

0

1

2

3

4

11

12

13

14

21

22

23

24

31

32

33

34

41

42

43

44

51

52

53

54

61

62

63

64

71

72

73

74

81

82

83

84

91

92

93

94

* If no data are recorded (error code is normal), the display for each sensor becomes as shown below.

-55

-45

-35

-25

-15

-5

5

15

25

35

45

55

65

75

85

95

-56

-46

-36

-26

-16

-6

6

16

26

36

46

56

66

76

86

96

-57

-47

-37

-27

-17

-7

7

17

27

37

47

57

67

77

87

97

-58

-48

-38

-28

-18

-8

8

18

28

38

48

58

68

78

88

98

-59

-49

-39

-29

-19

-9

9

19

29

39

49

59

69

79

89

99

(Example) Room temperature, indoor heat exchanger, outdoor air temperature, outdoor heat exchanger: “-9ºC”

-

-

24

Page 27

(f) Discharge pipe temperature table

Unit: ºC

Sensor name

Discharge pipe sensor temperature

Sensor value displayed when the error code is normal

-64ºC

0.5 sec.

0.1 sec.

1.5 sec.

11-second interval

0.5 sec.

OFF

ON

OFF

ON

OFF

ON

Buzzer sound

If the temperature is < 0, the buzzer sounds.

If the temperature is

>

=

0, the buzzer does not sound.

RUN light

(10’s digit)

TIMER light

(1’s digit)

RUN light

(10’s digit)

Buzzer sound

Yes

(sounds for 0.1 second)

No

(does not sound)

TIMER light

(1’s digit)

3

2

1

0

0

1

2

3

4

5

6

7

'18 • SRK-SM-259

0 1 2 3 4 5 6 7 8 9

-60

-62

-64

-40

-42

-44

-46

-48

-50

-52

-54

-56

-20

-22

-24

-26

-28

-30

-32

-34

-36

-2

-4

-6

-8

-10

-12

-14

-16

0

2

4

6

8

10

12

14

16

20

22

24

26

28

30

32

34

36

40

42

44

46

48

50

52

54

56

60

62

64

66

68

70

72

74

76

80

82

84

86

88

90

92

94

96

100

102

104

106

108

110

112

114

116

120

122

124

126

128

130

132

134

136

140

142

144

146

148

150

-58

-38

-18

18

38

58

78

98

118

138

* If no data are recorded (error code is normal), the display for sensor becomes as shown below.

(Example) Discharge pipe temperature: “122ºC”

* In the case of discharge pipe data, multiply the reading value by 2. (Below, 61 x 2 = “122ºC”)

-

-

25

Page 28

Service data record form

Customer

Date of investigation

Machine name

Error code on previous occasion.

Room temperature sensor temperature on previous occasion.

Indoor heat exchanger sensor temperature on previous occasion.

Remote control information on previous occasion.

Outdoor air temperature sensor temperature on previous occasion.

Outdoor heat exchanger sensor temperature on previous occasion.

Discharge pipe sensor temperature on previous occasion.

Error code on second previous occasion.

Room temperature sensor temperature on second previous occasion.

Indoor heat exchanger sensor temperature on second previous occasion.

Remote control information on second previous occasion.

Outdoor air temperature sensor temperature on second previous occasion.

Outdoor heat exchanger sensor temperature on second previous occasion.

Discharge pipe sensor temperature on second previous occasion.

Error code on third previous occasion.

Room temperature sensor temperature on third previous occasion.

Indoor heat exchanger sensor temperature on third previous occasion.

Remote control information on third previous occasion.

Outdoor air temperature sensor temperature on third previous occasion.

Outdoor heat exchanger sensor temperature on third previous occasion.

Discharge pipe sensor temperature on third previous occasion.

Error code on fourth previous occasion.

Room temperature sensor temperature on fourth previous occasion.

Indoor heat exchanger sensor temperature on fourth previous occasion.