Mitsubishi SRK25ZMP-S, SRK45ZMP-S, SRK35ZMP-S Technical Manual

TECHNICAL MANUAL

INVERTER WALL MOUNTED TYPE

RESIDENTIAL AIR-CONDITIONERS

(Split system, air to air heat pump type)

SRK25ZMP-S

SRK35ZMP-S

SRK45ZMP-S

Manual No.'13•SRK-T-140

-

1

-

'13 • SRK-T-140

'10 • SRK-T-099

CONTENTS

1. SPECIFICATIONS ........................................................................................ 3

(2) Outdoor units ....................................................................................... 7

..................................................... 16

(3) Wireless remote control

...................................................................... 9

......................................................................... 6

(1) Indoor units .......................................................................................... 6

2. EXTERIOR DIMENSIONS

3. ELECTRICAL WIRING .............................................................................. 10

(1) Indoor units .......................................................................................... 10

4. NOISE LEVEL ............................................................................................ 12

(2) Outdoor units ....................................................................................... 11

6. RANGE OF USAGE & LIMITATIONS

................................................................................... 18

7. CAPACITY TABLES

5. PIPING SYSTEM ...................................................................................... 15

.................................................................................. 19

8. APPLICATION DATA

9. OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER ............... 27

(8) Timer operation

.................................................................................. 30

....................................................... 28

(1) Operation control function by remote control

(7) Flap control ........................................................................................ 29

(6) Economy operation

............................................................................. 29

(5) High power operation .......................................................................... 29

(4) Custom cord switching procedure

......................................................................... 28(3) Auto restart function

(2) Unit ON/OFF button

........................................................................... 28

...................................... 27

(9) Outline of heating operation ................................................................ 30

(11) Outline of automatic operation ........................................................... 32

(10) Outline of cooling operation ............................................................... 32

(12) Protection control function

................................................................... 33

..................... 41

............................................................................... 40

(4) Troubleshooting procedure (If the air conditioner runs)

(3) Troubleshooting procedure

(If the air conditioner does not run at all)

........ 40

(1) Cautions

............................................................................................. 40

(2) Items to check before troubleshooting ................................................. 40

(5) Self-diagnosis table ............................................................................. 42

(6) Service mode (Trouble mode access function) ................................... 43

(7) Inspection procedures corresponding to detail of trouble .................... 51

10. MAINTENANCE DATA

-

2

-

'13 • SRK-T-140

'10 • SRK-T-099

(10) How to make sure of wireless remote control ...................................... 57

(11) Outdoor unit inspection points .............................................................. 58

(8)

Phenomenon observed after shortcircuit, wire breakage on sensor

......... 55

(9) Checking the indoor electrical equipment

........................................... 56

■How to read the model name

Example: SRK 25 Z

Series code

Inverter type

Product capacity (Cooling capacity)

Model name SRK : Wall mounted type

SRC : Outdoor unit

MP-S

..................................................................... 60

11. TECHNICAL INFORMATION

-

3

-

'13 • SRK-T-140

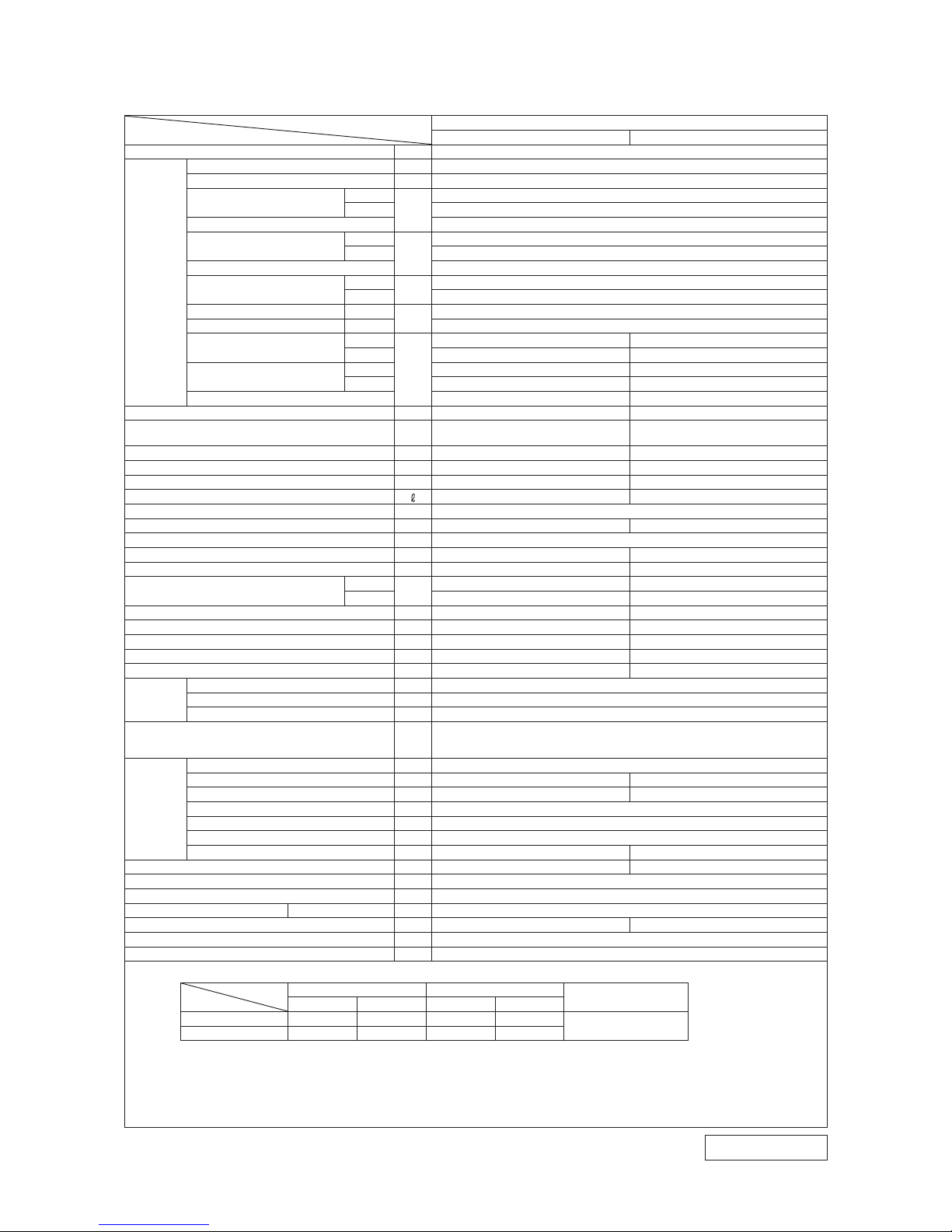

Model SRK25ZMP-S

Model

Item

SRK25ZMP-S

Indoor unit SRK25ZMP-S Outdoor unit SRC25ZMP-S

Power source 1 Phase, 220 - 240V, 50Hz

Operation

data

Nominal cooling capacity (range) kW 2.5 (0.9 (Min.) - 2.8 (Max.))

Nominal heating capacity (range) kW 2.8 (0.8 (Min.) - 3.9 (Max.))

Power

consumption

Cooling

kW

0.780 (0.25 - 1.01)

Heating 0.755 (0.20 - 1.43)

Max power consumption 1.65

Running

current

Cooling

A

3.9 / 3.8 / 3.6 (220 / 230 / 240 V)

Heating 3.8 / 3.7 / 3.5 (22 0 / 230 / 240 V)

Inrush current, max current 3.9 / 3.8 / 3.6 (220 / 230 / 240 V) Max. 9

Power factor

Cooling

%

90

Heating 89

EER Cooling 3.21

COP Heating 3.71

Sound power level

Cooling

dB(A)

59 60

Heating 58 59

Sound pressure level

Cooling Hi: 45 Me: 34 Lo: 23 47

Heating Hi: 43 Me: 34 Lo: 26 45

Silent mode sound pressure level — —

Exterior dimensions (Height x Width x Depth) mm 262 x 769 x 210 540 x 645(+57) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 6.9 25

Compressor type & Q'ty — RM-B5077MDE5(Rotary type) x 1

Compressor motor (Starting method) kW — 0.75 (Inverter driven)

Refrigerant oil (amount, type) — 0.3 (DIAMOND FREEZE MA68)

Refrigerant (Type, amount, pre-charge length) kg R410A 0.655 in outdoor unit (incl. the amount for the piping of 10m)

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Fan type & Q'ty Tangential fan x 1 Propeller fan x 1

Fan motor (stating method) W 30 x1 (Direct drive) 24 x1 (Direct drive)

Air flow

Cooling

m3/min

Hi: 10.1 Me: 7.3 Lo: 4.2 26.0

Heating Hi: 9.5 Me: 7.3 Lo: 5.2 19.7

Available external static pressure Pa 0 0

Outside air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) —

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber sleeve (for fan motor & compressor)

Electric heater — —

Operation

control

Remote control Wireless-Remote control

Room temperature control Microcomputer thermostat

Operation display RUN: Green, TIMER: Yellow

Safety equipments

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection (High pressure control), Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ9.52 (3/8")

Connecting method Flare connection Flare connection

Attached length of piping m Liquid line : 0.39 / Gas line : 0.32 —

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length m Max. 15

Vertical height diff. between O.U. and I.U.

m Max. 10 (Outdoor unit is higher) / Max. 10 (Outdoor unit is lower)

Drain hose

Hose connectable (VP 16) Holes φ20 x 2 pcs

Drain pump, max lift height mm — —

Recommended breaker size A 16

L.R.A. (Locked rotor ampere) A 3.9 / 3.8 / 3.6 (220 / 230 / 240 V)

Interconnecting wires Size x Core number 1.5mm2 x 4 cores (Including earth cable) / Terminal block (Screw fixing type)

IP number IPX0 IPX4

Standard accessories Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

item

operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

ISO5151-T1

Heating 20˚C — 7˚C 6˚C

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound level indicates the value in an anechoic chamber. During operation these value are somewhat

higher due to ambient conditions.

(4) Select the breaker size according to the own national standard.

(5) The refrigerant quantity to be charged includes the refrigerant in 10 m connecting piping.

(purging is not required even for the short piping. )

If the piping length is longer, when it is 10 to 15 m, add 20 g refrigerant per meter.

The pipe length is 7.5m.

1. SPECIFICATIONS

RWA000Z 2 4 9

-

4

-

'13 • SRK-T-140

RWA000Z 2 4 9

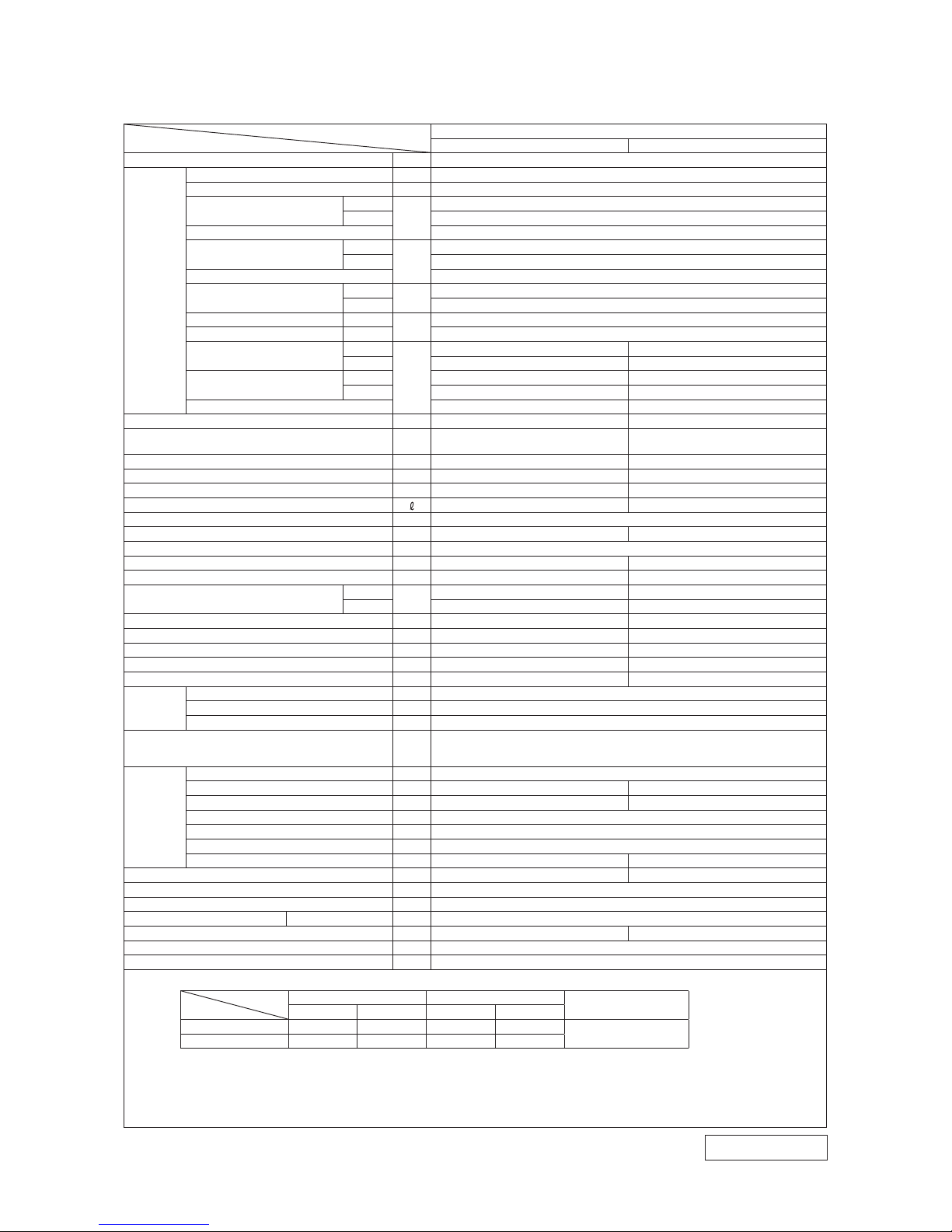

Model SRK35ZMP-S

Model

Item

SRK35ZMP-S

Indoor unit SRK35ZMP-S Outdoor unit SRC35ZMP-S

Power source 1 Phase, 220 - 240V, 50Hz

Operation

data

Nominal cooling capacity (range) kW 3.2 (0.9 (Min.) - 3.5 (Max.))

Nominal heating capacity (range) kW 3.6 (0.9 (Min.) - 4.3 (Max.))

Power

consumption

Cooling

kW

0.995 (0.23 - 1.32)

Heating 0.995 (0.19 - 1.31)

Max power consumption 1.65

Running

current

Cooling

A

4.9 / 4.7 / 4.5 (220 / 230 / 240 V)

Heating 4.9 / 4.7 / 4.5 (220 / 230 / 240 V)

Inrush current, max current 4.9 / 4.7 / 4.5 (220 / 230 / 240 V) Max. 9

Power factor

Cooling

%

93

Heating 93

EER Cooling 3.22

COP Heating 3.62

Sound power level

Cooling

dB(A)

60 60

Heating 58 60

Sound pressure level

Cooling Hi: 47 Me: 36 Lo: 23 49

Heating Hi: 44 Me: 36 Lo: 28 48

Silent mode sound pressure level — —

Exterior dimensions (Height x Width x Depth) mm 262 x 769 x 210 540 x 645(+57) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 7.2 27

Compressor type & Q'ty — RM-B5077MDE5(Rotary type) x 1

Compressor motor (Starting method) kW — 0.90 (Inverter driven)

Refrigerant oil (amount, type) — 0.3 (DIAMOND FREEZE MA68)

Refrigerant (Type, amount, pre-charge length) kg R410A 0.81 in outdoor unit (incl. the amount for the piping of 15m)

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Fan type & Q'ty Tangential fan x 1 Propeller fan x 1

Fan motor (stating method) W 30 x1 (Direct drive) 24 x1 (Direct drive)

Air flow

Cooling

m3/min

Hi: 9.5 Me: 6.8 Lo: 4.2 25.4

Heating Hi: 9.6 Me: 7.4 Lo: 5.5 20.5

Available external static pressure Pa 0 0

Outside air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) —

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber sleeve (for fan motor & compressor)

Electric heater — —

Operation

control

Remote control Wireless-Remote control

Room temperature control Microcomputer thermostat

Operation display RUN: Green, TIMER: Yellow

Safety equipments

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection (High pressure control), Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ9.52 (3/8")

Connecting method Flare connection Flare connection

Attached length of piping m Liquid line : 0.39 / Gas line : 0.32 —

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length m Max. 15

Vertical height diff. between O.U. and I.U.

m Max. 10 (Outdoor unit is higher) / Max. 10 (Outdoor unit is lower)

Drain hose

Hose connectable (VP 16) Holes φ20 x 2 pcs

Drain pump, max lift height mm — —

Recommended breaker size A 16

L.R.A. (Locked rotor ampere) A 4.9 / 4.7 / 4.5 (220 / 230 / 240 V)

Interconnecting wires Size x Core number 1.5mm2 x 4 cores (Including earth cable) / Terminal block (Screw fixing type)

IP number IPX0 IPX4

Standard accessories Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound level indicates the value in an anechoic chamber. During operation these value are somewhat higher

due to ambient conditions.

(4) Select the breaker size according to the own national standard.

(5) The refrigerant quantity to be charged includes the refrigerant in 15 m connecting piping.

(purging is not required even for the short piping. )

item

operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

ISO5151-T1

Heating 20˚C — 7˚C 6˚C

The pipe length is 7.5m.

-

5

-

'13 • SRK-T-140

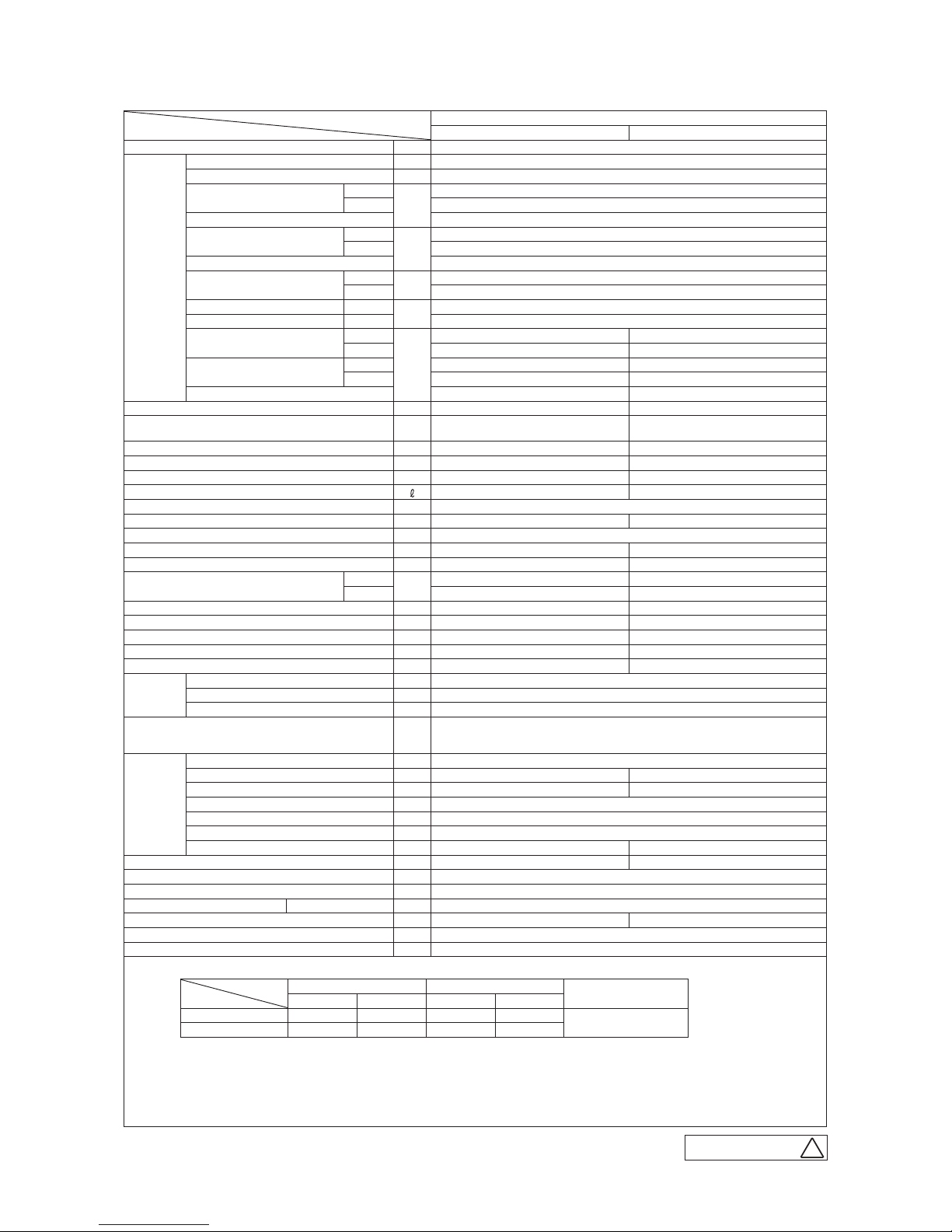

Model SRK45ZMP-S

Model

Item

SRK45ZMP-S

Indoor unit SRK45ZMP-S Outdoor unit SRC45ZMP-S

Power source 1 Phase, 220 - 240V, 50Hz

Operation

data

Nominal cooling capacity (range) kW 4.5 (0.9 (Min.) - 4.8 (Max.))

Nominal heating capacity (range) kW 5.0 (0.8 (Min.) - 5.8 (Max.))

Power

consumption

Cooling

kW

1.495 (0.22-1.98)

Heating 1.385 (0.20-1.86)

Max power consumption 2.68

Running

current

Cooling

A

7.0 / 6.7 / 6.4 (220 / 230 / 240 V)

Heating 6.5 / 6.2 / 6.0 (220 / 230 / 240 V)

Inrush current, max current 7.0 / 6.7 / 6.4 (220 / 230 / 240 V) Max.14

Power factor

Cooling

%

97

Heating 97

EER Cooling 3.01

COP Heating 3.61

Sound power level

Cooling

dB(A)

60 65

Heating 64 65

Sound pressure level

Cooling Hi : 46 Me : 40 Lo : 25 52

Heating Hi : 48 Me : 43 Lo : 32 53

Silent mode sound pressure level — —

Exterior dimensions (Height x Width x Depth) mm 262 x 769 x 210 595 x 780(+62) x 290

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 7.6 40

Compressor type & Q'ty — GKT128MFA (Twin Potary type) x 1

Compressor motor (Starting method) kW — 1.10 (Inverter driven)

Refrigerant oil (amount, type) — 0.45 (FVC68D)

Refrigerant (Type, amount, pre-charge length) kg R410A 1.20 in outdoor unit (incl. the amount for the piping of 15m)

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Fan type & Q'ty Tangential fan x 1 Propeller fan x 1

Fan motor (stating method) W 30 x1 (Direct drive) 24 x1 (Direct drive)

Air flow

Cooling

m3/min

Hi : 9.0 Me : 7.2 Lo : 3.8 35.5

Heating Hi : 12.0 Me : 9.2 Lo : 6.2 33.5

Available external static pressure Pa 0 0

Outside air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) —

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber sleeve (for fan motor & compressor)

Electric heater — —

Operation

control

Remote control Wireless-Remote control

Room temperature control Microcomputer thermostat

Operation display RUN: Green, TIMER: Yellow

Safety equipments

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection (High pressure control), Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ12.7 (1/2")

Connecting method Flare connection Flare connection

Attached length of piping m Liquid line : 0.39 / Gas line : 0.32 —

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length m Max. 25

Vertical height diff. between O.U. and I.U.

m Max. 15 (Outdoor unit is higher) / Max. 15 (Outdoor unit is lower)

Drain hose

Hose connectable (VP 16) Holes φ20 x 2 pcs

Drain pump, max lift height mm — —

Recommended breaker size A 16

L.R.A. (Locked rotor ampere) A 7.0 / 6.7 / 6.4 (220 / 230 / 240 V)

Interconnecting wires Size x Core number 1.5mm2 x 4 cores (Including earth cable) / Terminal block (Screw fixing type)

IP number IPX0 IPX4

Standard accessories Mounting kit

Option parts —

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound level indicates the value in an anechoic chamber. During operation these value are somewhat

higher due to ambient conditions.

(4) Select the breaker size according to the own national standard.

(5) The refrigerant quantity to be charged includes the refrigerant in 15 m connecting piping.

(purging is not required even for the short piping. )

If the piping length is longer, when it is 15 to 25 m, add 20 g refrigerant per meter.

Note (1) The data are measured at the following conditions.

item

operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

ISO5151-T1

Heating 20˚C — 7˚C 6˚C

The pipe length is 7.5m.

A

RWA000Z 2 4 9

-

6

-

'13 • SRK-T-140

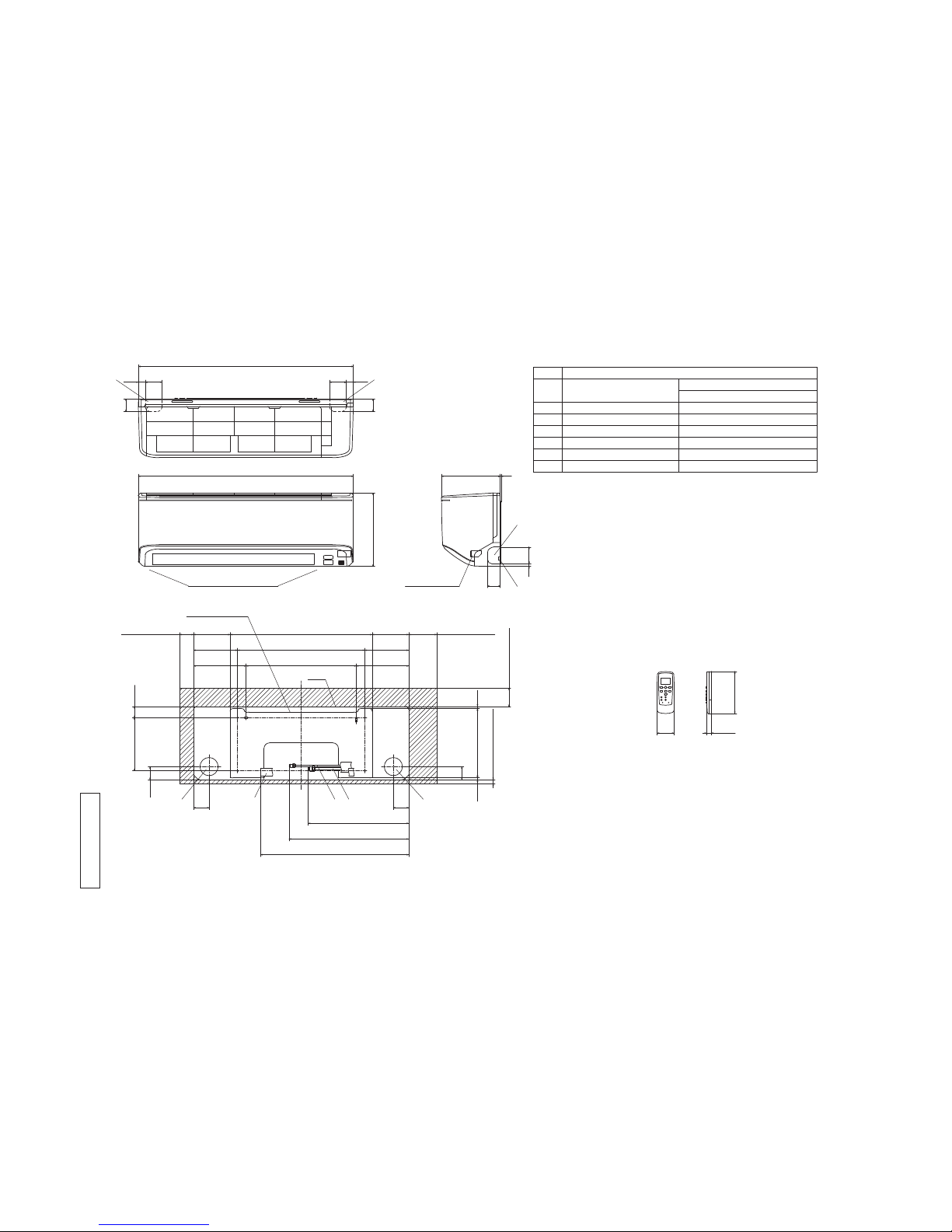

G

Terminal block

F

GG

Unit:mm

Wireless remote control

Outlet for down piping

(Refer to the above view)

Space for installation and service when viewing from the front

D E C

Hole on wall for right rear piping

Hole on wall for left rear piping

Gas piping

Outlet for wiring

Drain hose

Liquid piping

F

E

C

D

B

Symbol

A

( φ65)

VP16

φ6.35(1/4")(Flare)

Content

( φ65)

Outlet for piping(on both side)

G

Model 25,35 φ9.52(3/8")(Flare)

Model 45 φ12.7(1/2")(Flare)

AB

Note(1)The model name label is attached

on the underside of the indoor unit.

60

150

17.3

190 40.1

47

130.5 508 130.5

157 455 157

187.5 394 187.5

47

7.6247.5

6.9

(Service space)

65

(Service space)

15

50

(Service space)

100

(Service space)

55

359.5

427.5

530

55

Installation plate

Unit

6025 60 25

768.1

45

45

769

262

45

609

210 3

RLC000Z003

2. EXTERIOR DIMENSIONS

(1) Indoor units

Models SRK25ZMP-S, 35ZMP-S, 45ZMP-S

-

7

-

'13 • SRK-T-140

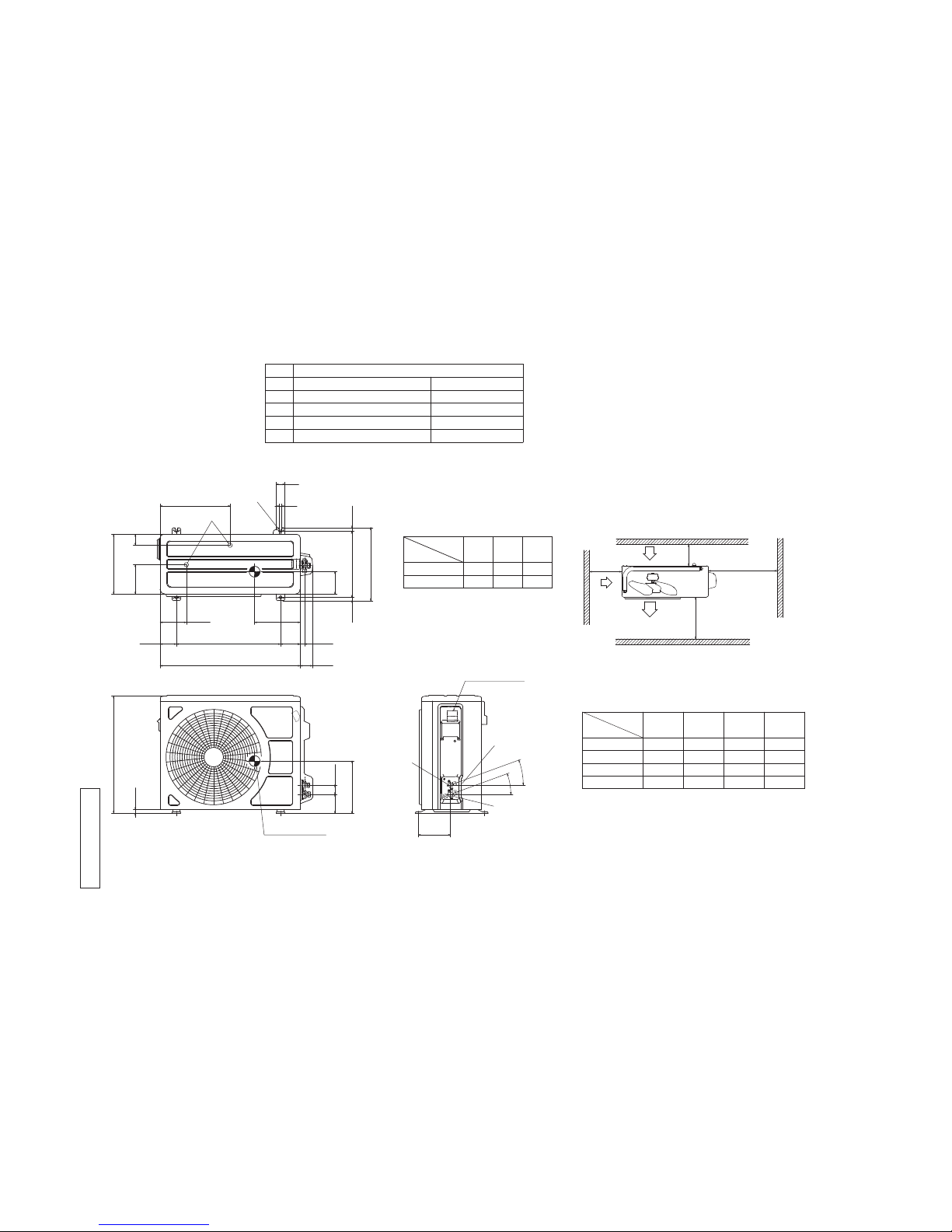

( )

D

E

B

A

C

50

322

135

275

120.5

74.5 480 90.5 20.2

645 57.2

14.8

336

16.8

304.4

12

40

16.5

540

86.3

43.2

147.2

Center of gravity

※3

※1

※2

φ9.52(3/8")(Flare)

Content

C Pipe/cable draw-out hole

D

E Anchor bolt hole

Drain discharge hole

Symbol

B

A Service valve connection(gas side)

M10×4places

φ20×2places

Service valve connection(liquid side)

φ6.35(1/4")(Flare)

Unit:mm

L2

Intake

Outlet

Intake

L3

L1

Minimum installation space

Service

space

L4

L2

L3

L4

L1

100

100

250

Open

I Ⅱ Ⅲ Ⅳ

Open

250

80

280

280

Open

80

100

Examples of

Dimensions

installation

180

Open

80

Open

Terminal block

SRC35ZMP-S

SRC25ZMP-S

220

210

※1

108

103240

240

Dimensions

MODEL

※2 ※3

2

0

゜

2

0

゜

Notes

(1) It must not be surrounded by walls on the four sides.

(2) The unit must be fixed with anchor bolts. An anchor bolt must not

protrude more than 15mm.

(3) Where the unit is subject to strong winds, lay it in such

a direction that the blower outlet faces perpendicularly

to the dominant wind direction.

(4) Leave 1m or more space above the unit.

(5) A wall in front of the blower outlet must not exceed the units height.

(6) The model name label is attached on the right side of the unit.

RCW000Z002

(2) Outdoor units

Models SRC25ZMP-S, 35ZMP-S

-

8

-

'13 • SRK-T-140

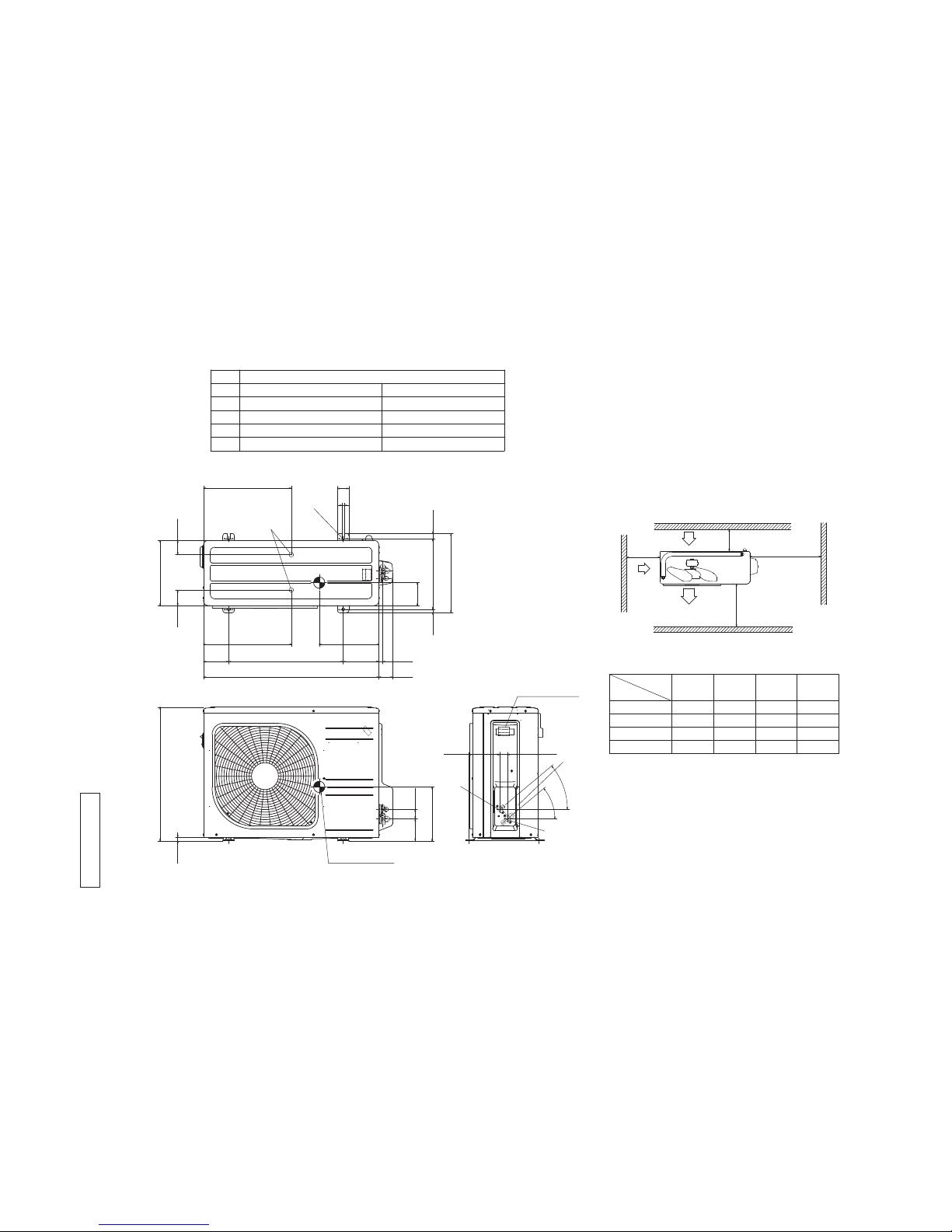

( )

Center of gravity

L2

Intake

Outlet

Intake

L3

L1

Minimum installation space

Service

space

L4

L2

L3

L4

L1

100

100

250

Open

I Ⅱ

Open

250

80

280

Ⅲ

280

Open

80

100

Examples of

Dimensions

installation

Ⅳ

180

Open

80

Open

φ12.7(1/2")(Flare)

Content

CDPipe/cable draw-out hole

E Anchor bolt hole

Drain discharge hole

Symbol

B

A Service valve connection(gas side)

M10×4places

φ20×2places

Service valve connection(liquid side)

φ6.35(1/4")(Flare)

138.4 33.5

Terminal block

C

B

A

97.7 42.5

15.8

595

240

63.4

390.6

390.6

69.4

111.6 510 158.4

780 61.9

17.9

14.8 312.5 24.3

351.6

50.6

12

290

102

265

D

E

Unit:mm

Notes

(1) It must not be surrounded by walls on the four sides.

(2) The unit must be fixed with anchor bolts. An anchor bolt must not

protrude more than 15mm.

(3) Where the unit is subject to strong winds, lay it in such

a direction that the blower outlet faces perpendicularly

to the dominant wind direction.

(4) Leave 1m or more space above the unit.

(5) A wall in front of the blower outlet must not exceed the units height.

(6) The model name label is attached on the lower right corner of the front panel.

4

0

゜

4

0

゜

RCV000Z016

Model SRC45ZMP-S

-

9

-

'13 • SRK-T-140

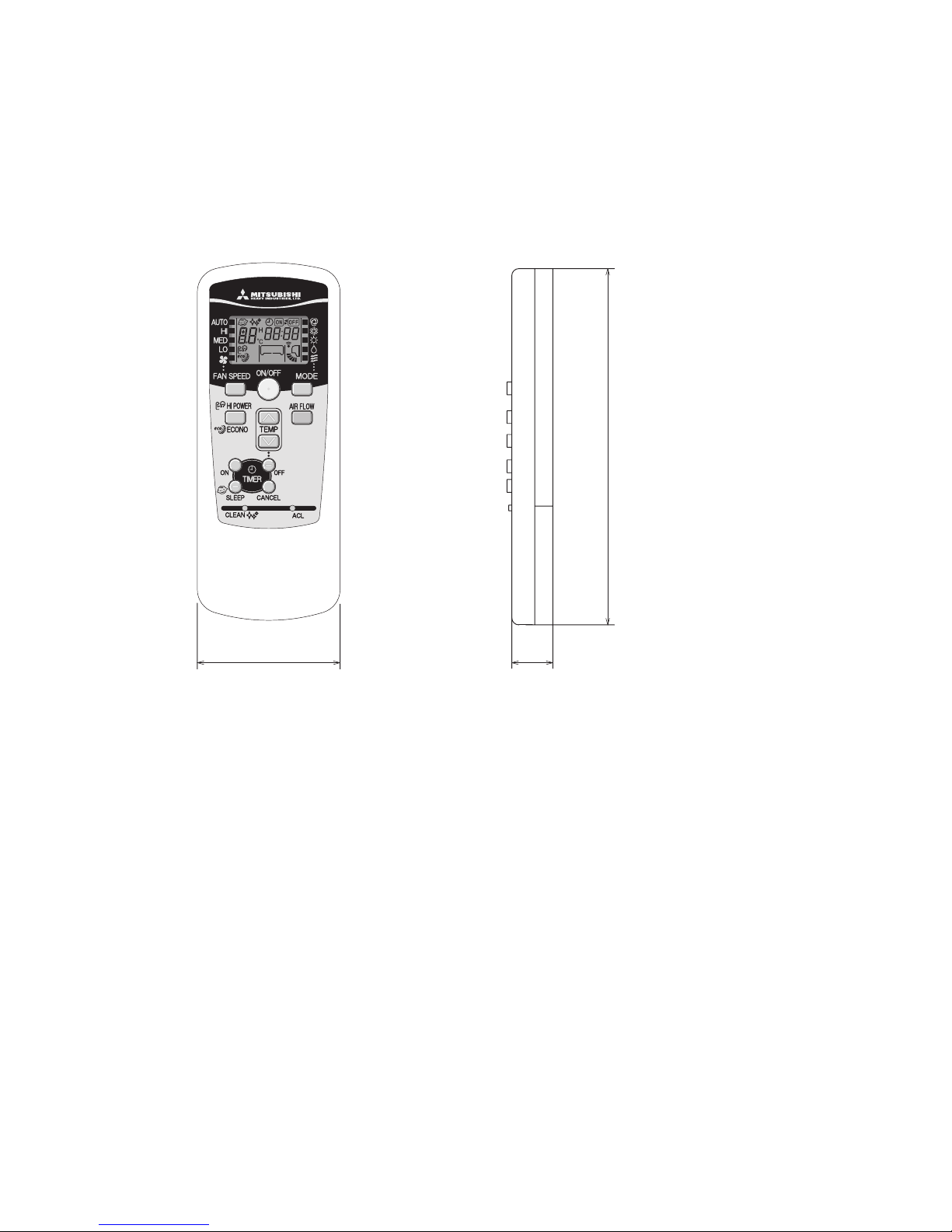

Unit: mm

60

17.3

150

(3) Wireless remote control

-

10

-

'13 • SRK-T-140

G

J

WIRELESS

R-AMP

DISPLAY

S/N

CNGCNE

250V 3.15A

CNU

CNM

BACK UP SW

5

U

M

M

CNF

F M

S M

F

Va

DS

L

Blue

BlackBK

Red

BL

RD

WhiteWH

Yellow/GreenY/G

ColorMark

Heat exch. sensor

Fan motor

Room temp. sensor

Flap motor

Diode stackDS

FuseF

ConnectorCNE

FM

Terminal blockTB

Description

Item

VaristorVa

SM

Th

I

Th

2

YellowY

Humidity sensor

HD

CNF

CNG

CNM

CNU

BK

Y/G

RD

Y

WH

Y/G

RD

BK

BOX,

CONTROL

3

2/N

WH

6

TO OUTDOOR UNIT

1

1 3 4 5

RDBKBL

HEAT

EXCHANGER

WH

6 2 2 2

ThITh

2

TB

t゜

t゜

HD

HEAT

EXCHANGER

PWB ASSY

RW A 0 00Z25 0

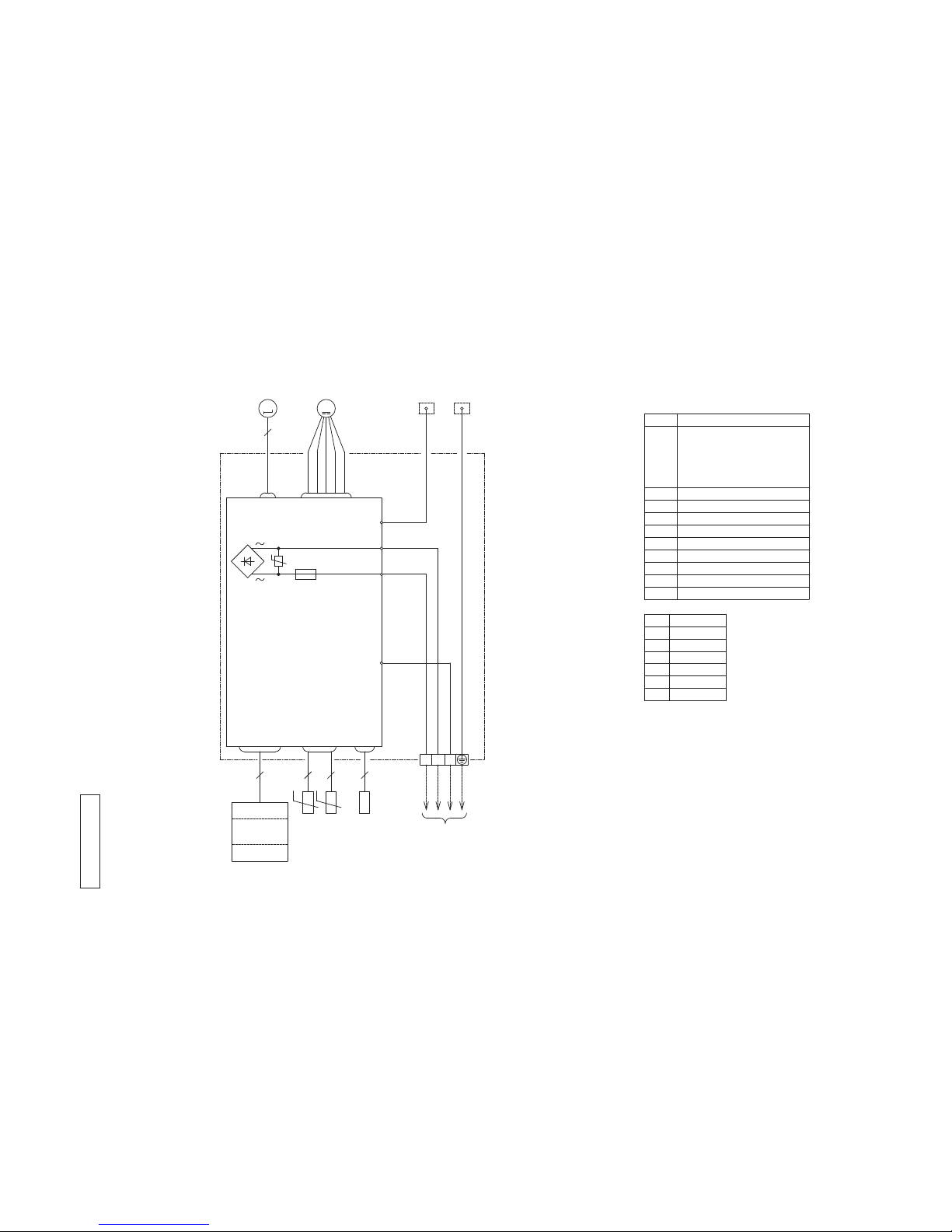

3. ELECTRICAL WIRING

(1) Indoor units

Models SRK25ZMP-S, 35ZMP-S, 45ZMP-S

-

11

-

'13 • SRK-T-140

[ ]

Color

RD

Mark

OrangeOR

Yellow/GreenY/G

BlackBK

YellowY

WhiteWH

Red

DescriptionItem

Connector

Electric expansion valve(coil)

EEV

Fan motor

FMo

Reactor

L

Terminal block

TB

Compressor motor

CM

Solenoid coil for 4 way valve

20S

Heat exchanger sensor(outdoor unit)

TH1

Outdoor air temp. sensor

TH2

TH3

Discharge pipe temp. sensor

CN20S

CNEEV

CNFAN

CNTH

25

Model

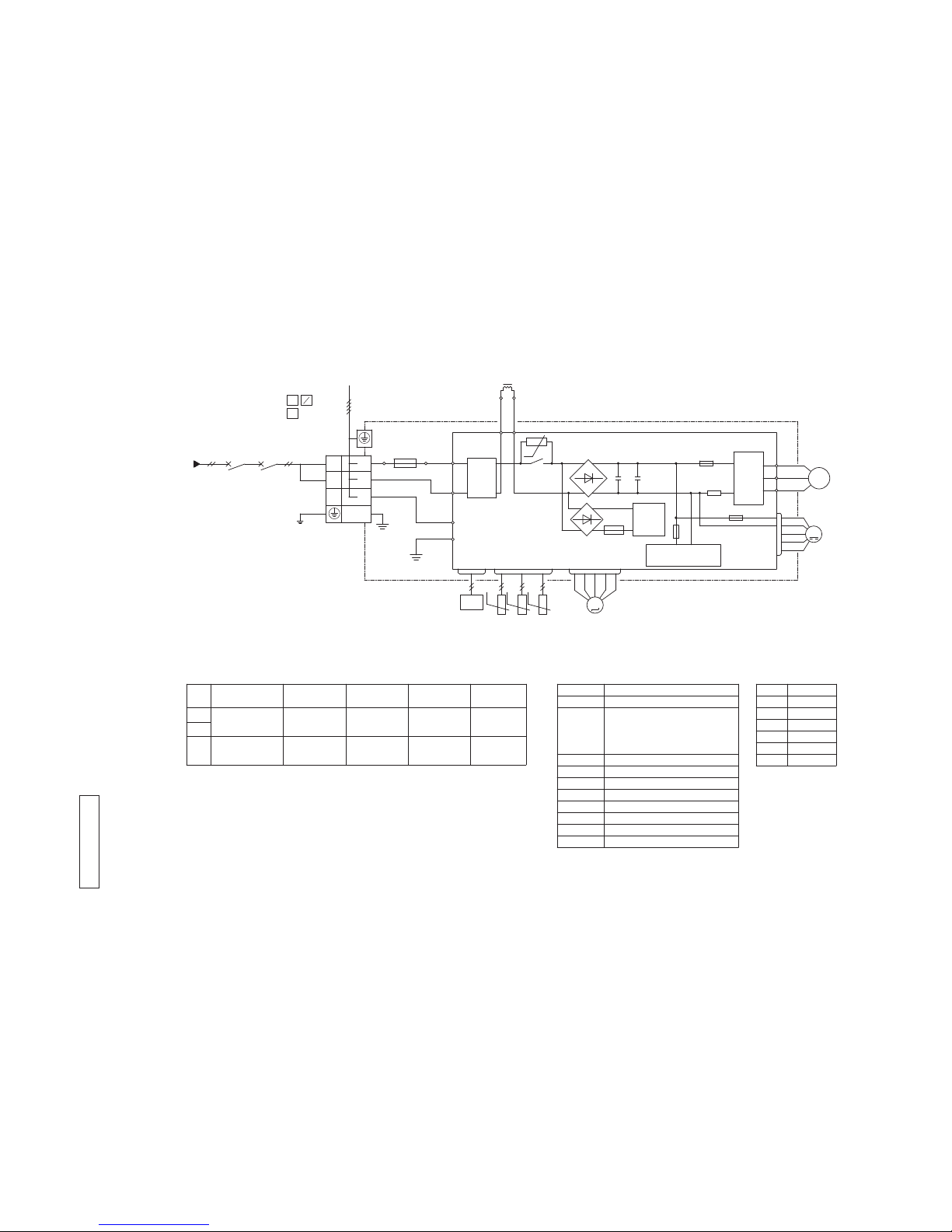

Power cable, indoor-outdoor connecting wires

●

The specifications shown in the above table are for units without heaters. For units with heaters, refer

to the installation instructions or the construction instructions of the indoor unit.

●

Switchgear of Circuit breaker capacity which is calculated from MAX. over current should be chosen

along the regulations in each country.

●

The cable specifications are based on the assumption that a metal or plastic conduit is used with no

more than three cables contained in a conduit and a voltage drop is 2%. For an installation falling

outside of these conditions, please follow the internal cabling regulations. Adapt it to the regulation

in effect in each country.

35

9 2.0 32

1.5mm2x 4 1.5

3

1

2

N

~220-240V 50Hz

POWER SOURCE

45 14 2.0 18

1.5mm2x 4 1.5

(BK)

C-2

G1

(RD)

(Y/G)

S.IN(WH)

R.IN

(BK)

(WH)

(RD)

PWB ASSY

250V 20A

F2

F3 250V 1A

++

F4

250V 10A

F1

250V 2A

CIRCUIT

PAM

SWITCHING POWER

CIRCUIT

P

W

V

U

TRANSISTOR

POWER

W

V

U

FILTER

NOISE

CN20S

CNTH

CNEEV

CNFAN

M

M

3~

250V 15A

(Y/G)

T1

T2

(OR)

(Y)

M

TH1 TH2 TH3

EEV

FMo

CM

t゜

LN1

3

2

TB

TO INDOOR UNIT

POWER WIRES

SIGNAL WIRE

20S

L

N

t゜t゜t゜

MAX running current

Power cable size

(mm2)

(A)

Power cable length

(m)

indoor-outdoor

wire size x number

Earth wire size

(mm2)

RW C 0 00Z26 1

(2) Outdoor units

Models SRC25ZMP-S, 35ZMP-S, 45ZMP-S

-

12

-

'13 • SRK-T-140

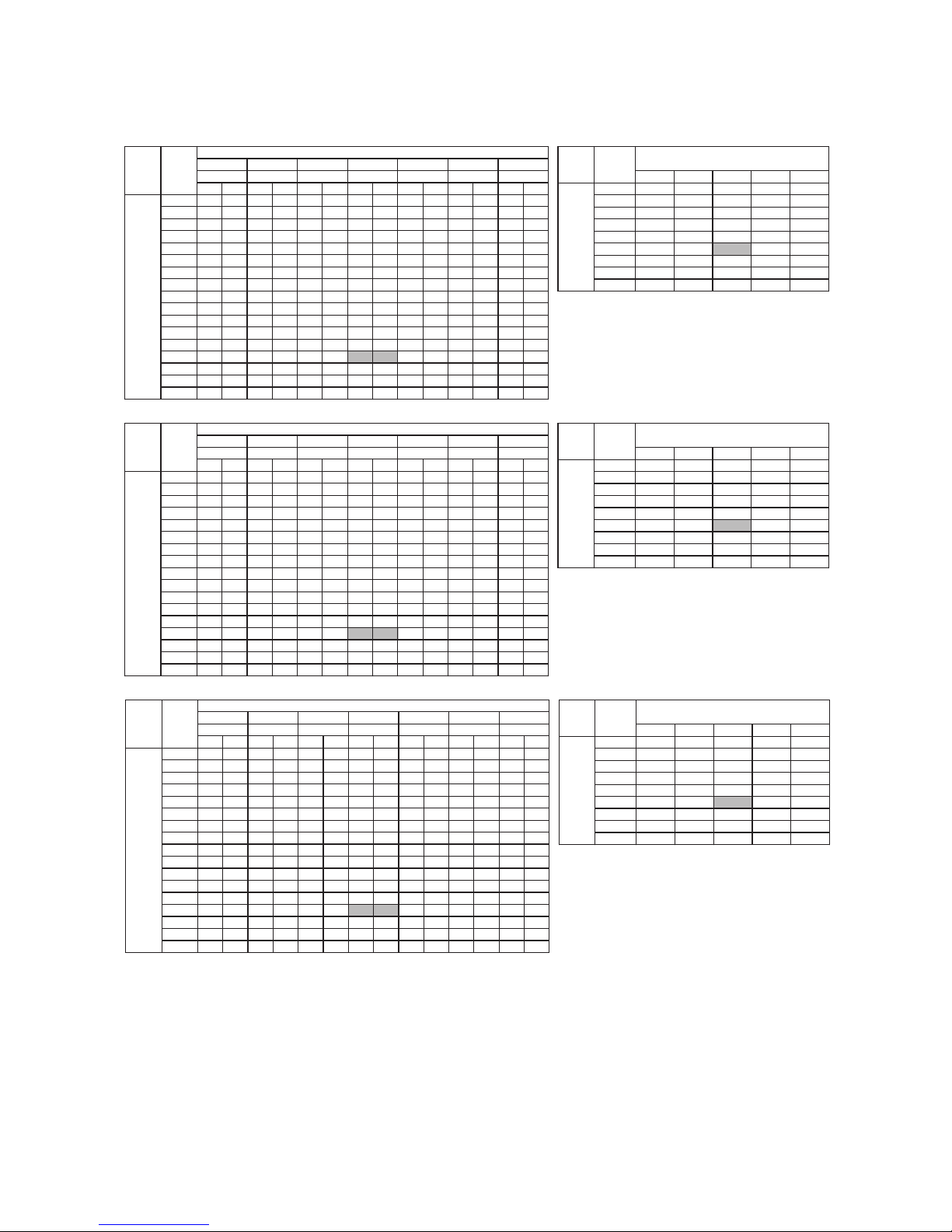

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

Mid Octave Band frequency(Hz)

10

20

30

40

50

60

70

N50

N30

N40

N60

N70

N20

Sound Pressure Level (dB)

(Standard 2 10

-5

Pa)

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

Mid Octave Band frequency(Hz)

10

20

30

40

50

60

70

N50

N30

N40

N60

N70

N20

Sound Pressure Level (dB)

(Standard 2 10

-5

Pa)

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

Mid Octave Band Frequency(Hz)

10

20

30

40

50

60

70

N50

N30

N40

N60

N70

N20

Sound Pressure Level (dB)

(Standard 2 10

-5

Pa)

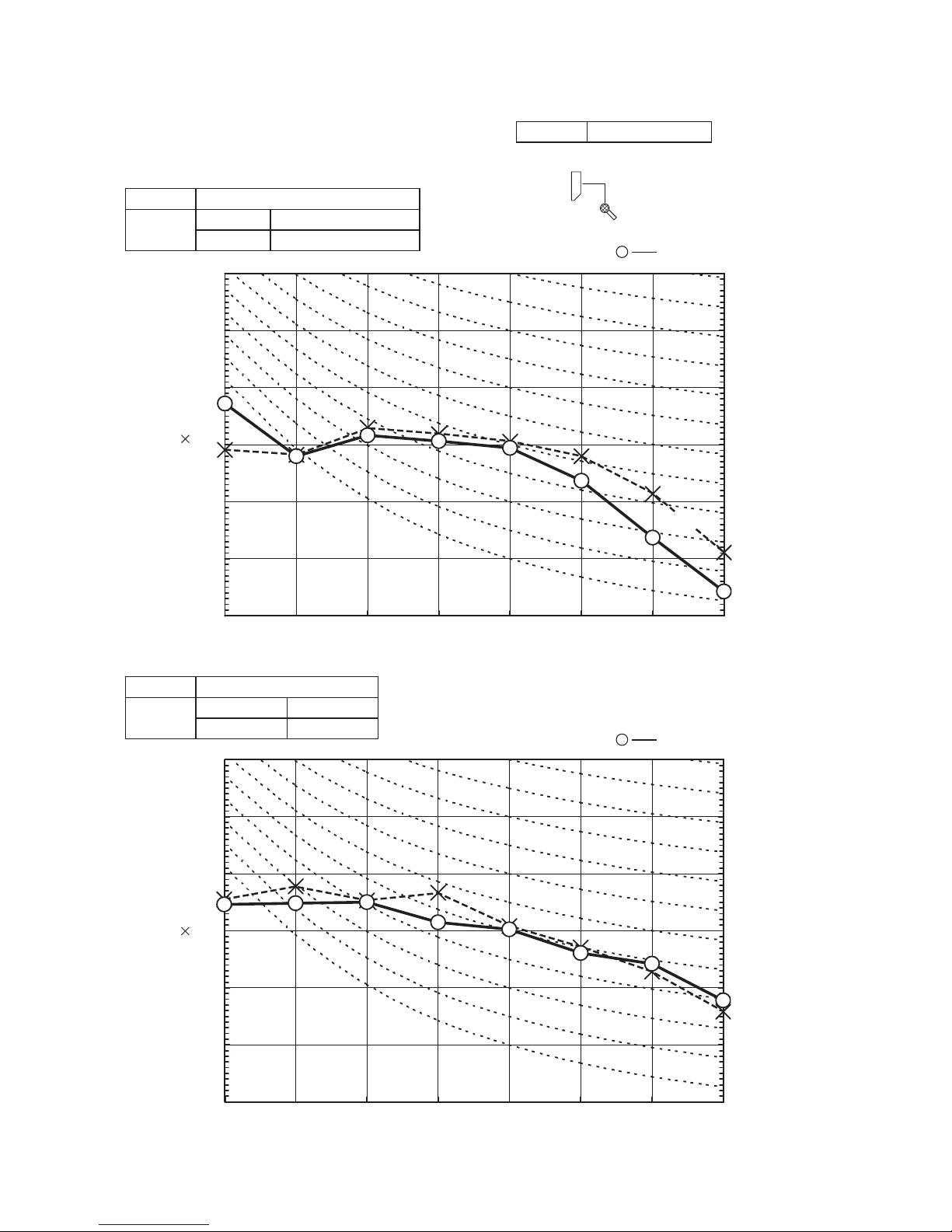

(Outdoor Unit)

Model SRC25ZMP-S

Noise

Level

Cooling 47 dB(A)

Heating 45 dB(A)

(Indoor Unit)

Model SRK25ZMP-S

Noise

Level

Cooling 45 dB(A)

Heating 43 dB(A)

×

......

Cooling Heating

×

......

Cooling Heating

Condition ISO-T1,JIS C 9612

●

Mike position

0.8m

1m

Unit

Mike position

(Center & Low points)

4. NOISE LEVEL

Model SRK25ZMP-S

●

Mike position: at highest noise level in position as mentioned below

Distance from front side 1m

-

13

-

'13 • SRK-T-140

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

Mid Octave Band Frequency(Hz)

10

20

30

40

50

60

70

N50

N30

N40

N60

N70

N20

Sound Pressure Level (dB)

(Standard 2 10

-5

Pa)

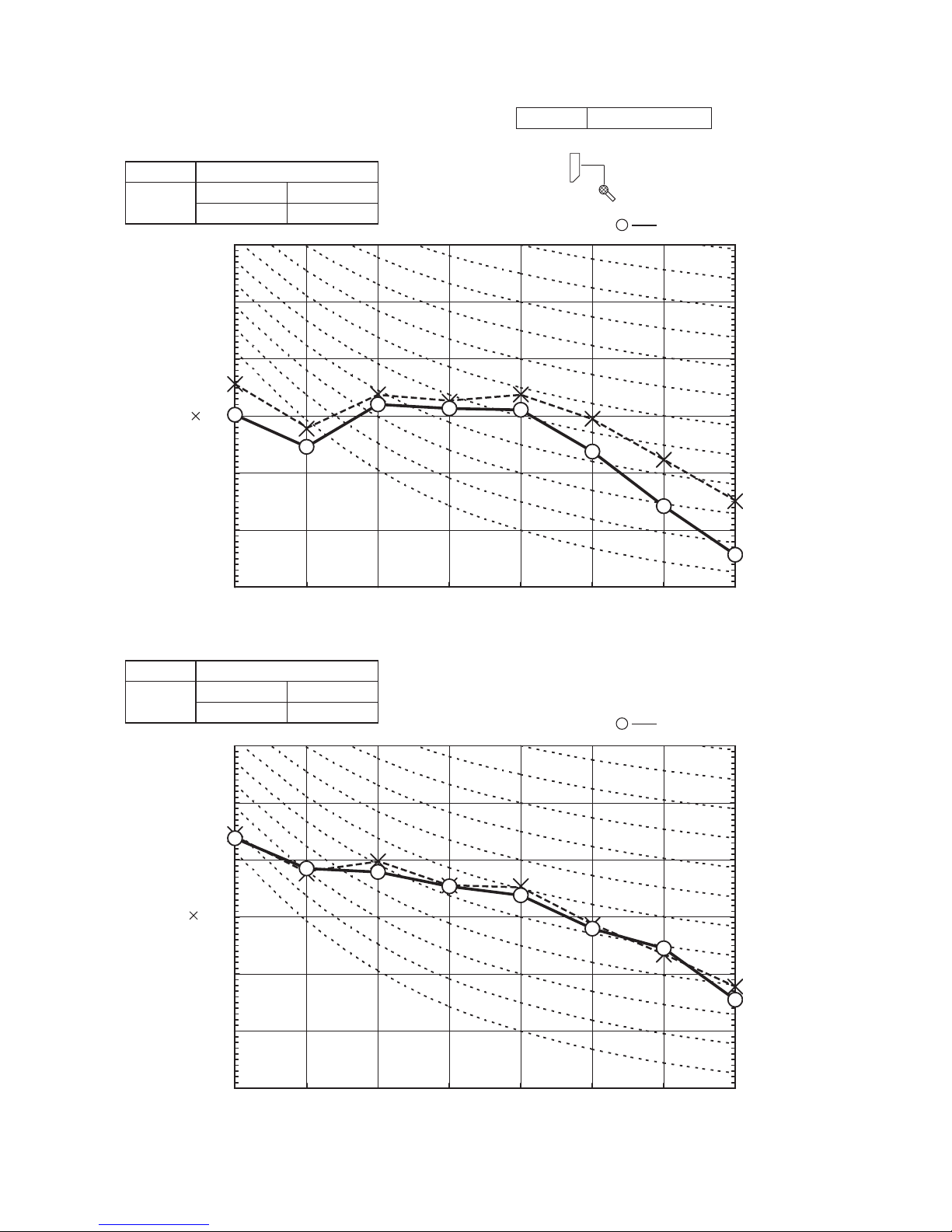

(Outdoor Unit)

Model SRC35ZMP-S

Noise

Level

Cooling 49 dB(A)

Heating 48 dB(A)

×

......

Cooling Heating

(Indoor Unit)

Model SRK35ZMP-S

Noise

Level

Cooling 47 dB(A)

Heating 44 dB(A)

×

......

Cooling Heating

Condition ISO-T1,JIS C 9612

●

Mike position

0.8m

1m

Unit

Mike position

(Center & Low points)

Model SRK35ZMP-S

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

Mid Octave Band Frequency(Hz)

10

20

30

40

50

60

70

N50

N30

N40

N60

N70

N20

Sound Pressure Level (dB)

(Standard 2 10

-5

Pa)

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

Mid Octave Band Frequency(Hz)

10

20

30

40

50

60

70

N50

N30

N40

N60

N70

N20

Sound Pressure Level (dB)

(Standard 2 10

-5

Pa)

●

Mike position: at highest noise level in position as mentioned below

Distance from front side 1m

-

14

-

'13 • SRK-T-140

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

Mid Octave Band Frequency(Hz)

10

20

30

40

50

60

70

N50

N30

N40

N60

N70

N20

Sound Pressure Level (dB)

(Standard 2 10

-5

Pa)

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

Mid Octave Band Frequency(Hz)

10

20

30

40

50

60

70

N50

N30

N40

N60

N70

N20

Sound Pressure Level (dB)

(Standard 2 10

-5

Pa)

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

Mid Octave Band Frequency(Hz)

10

20

30

40

50

60

70

N50

N30

N40

N60

N70

N20

Sound Pressure Level (dB)

(Standard 2 10

-5

Pa)

(Indoor Unit)

Model SRK45ZMP-S

Noise

Level

Cooling 46 dB(A)

Heating 48 dB(A)

×

......

Cooling Heating

Condition ISO-T1,JIS C 9612

●

Mike position

0.8m

1m

Unit

Mike position

(Center & Low points)

(Outdoor Unit)

Model SRC45ZMP-S

Noise

Level

Cooling 52 dB(A)

Heating 53 dB(A)

×

......

Cooling Heating

Model SRK45ZMP-S

●

Mike position: at highest noise level in position as mentioned below

Distance from front side 1m

-

15

-

'13 • SRK-T-140

'09•SRK-DB-087D

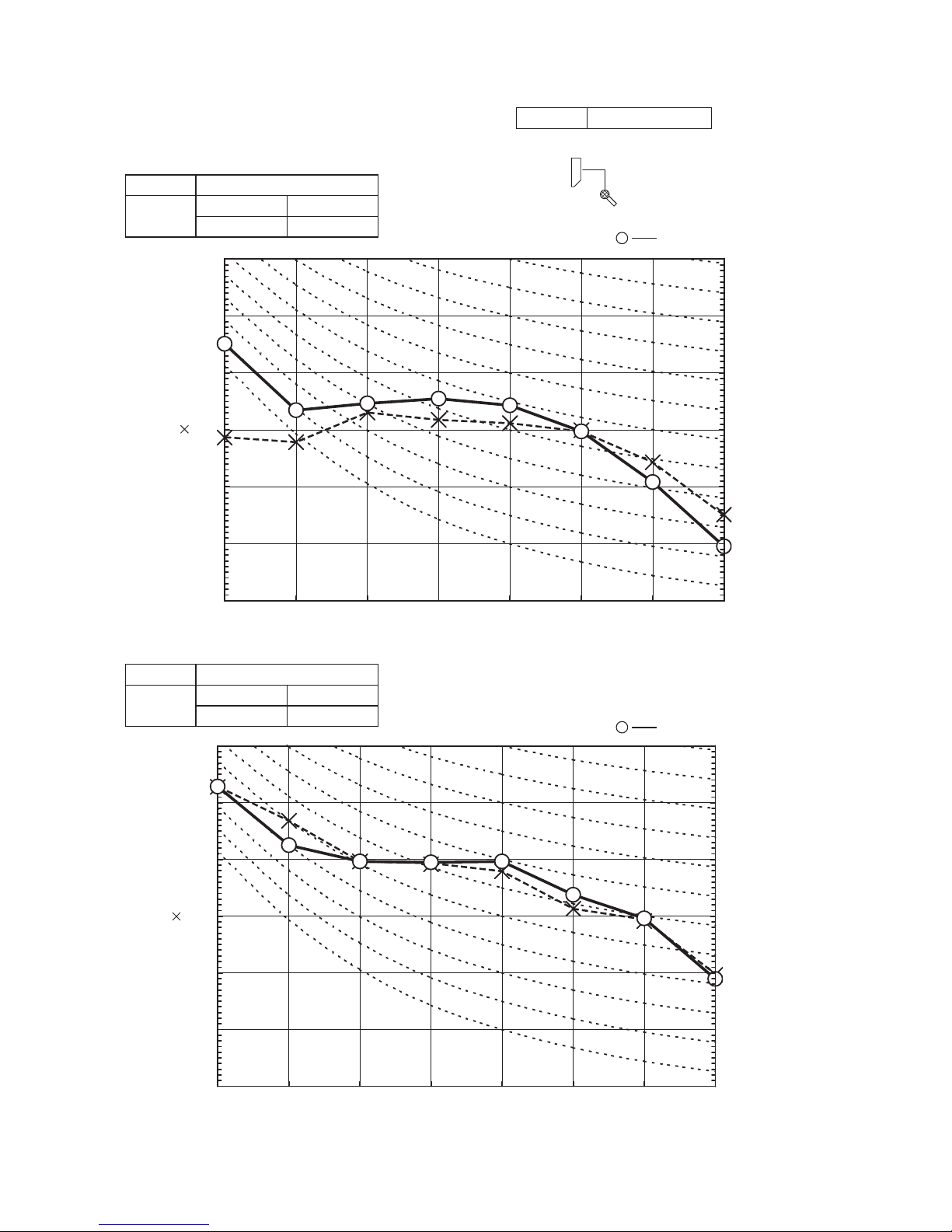

5 PIPING SYSTEM

Models SRK20ZJ-S, 25ZJ-S

Accumulator

Model SRK35ZJ-S

Accumulator

HD

Humidity

sensor

HD

Humidity

sensor

12.7

Case of

SRK35ZMP-S

Case of

SRK25ZMP-S

5. PIPING SYSTEM

Models SRK25ZMP-S, 35ZMP-S

Model SRK45ZMP-S

-

16

-

'13 • SRK-T-140

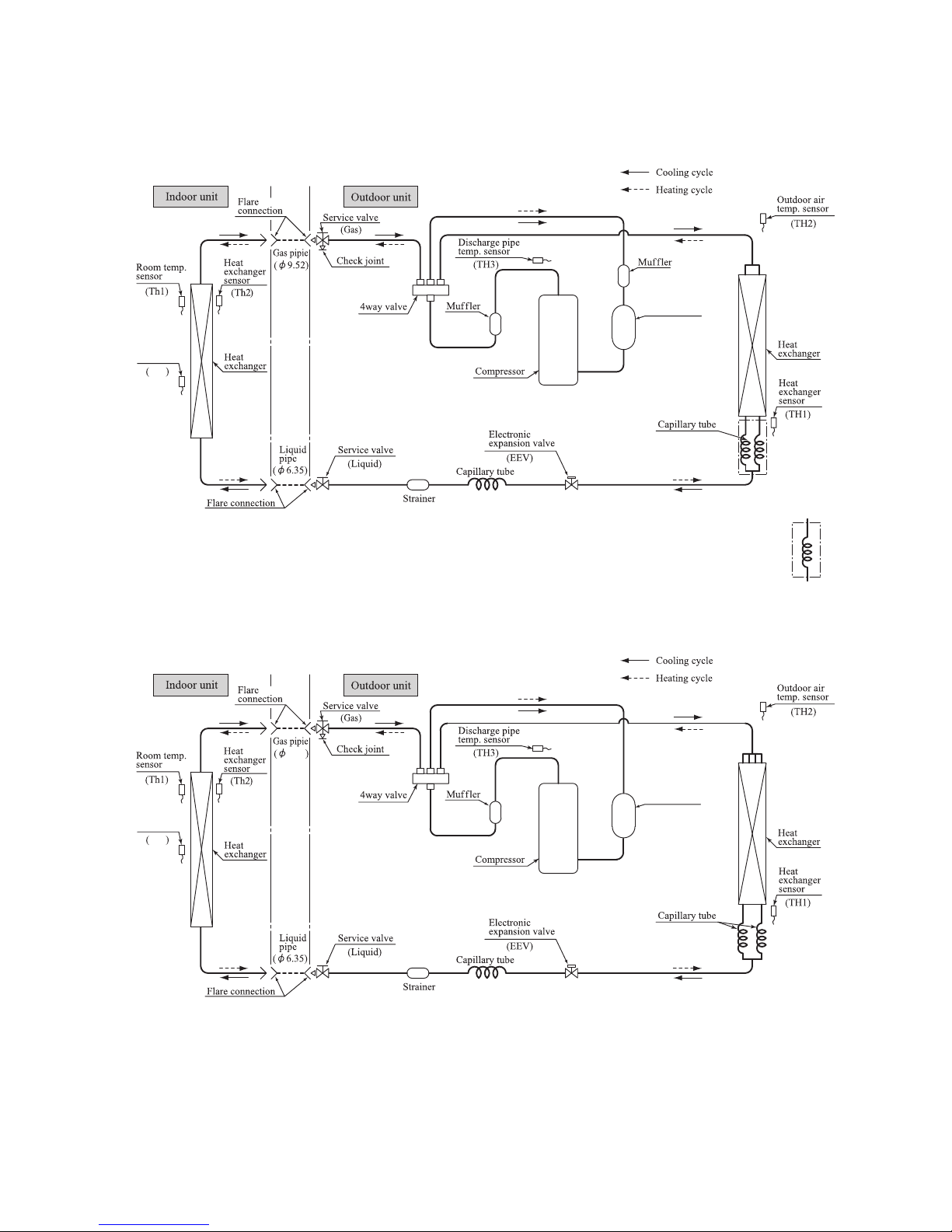

6. RANGE OF USAGE & LIMITATIONS

SRK25ZMP-S, 35ZMP-S SRK45ZMP-S

Net capacity = Capacity shown on specification Correction factors as follows.

(1) Coefficient of cooling and heating capacity in relation to temperatures

0.6

0.7

0.8

0.9

1.0

1.2

1.1

1.3

0

-5

-10

-15

24

26

20

25

30

35

40

46

15

20

25

30

Outdoor air W.B. temperature °C W.B.

-10 -5 0 5 10 15

.

Cooling operation

Outdoor air D.B.

temperature

°C D. B.

Coefficient of cooling

&

Heating capacity in

relation to temperature

Heating operation

Indoor air D.B.

temperature

°C D. B.

ISO-T1 Standard Condition

Depends on installed situation

ISO-T1 Standard Condition

2220181614

Indoor air W.B. temperature °C W.B

Applicable range

Cooling

Heating

-

17

-

'13 • SRK-T-140

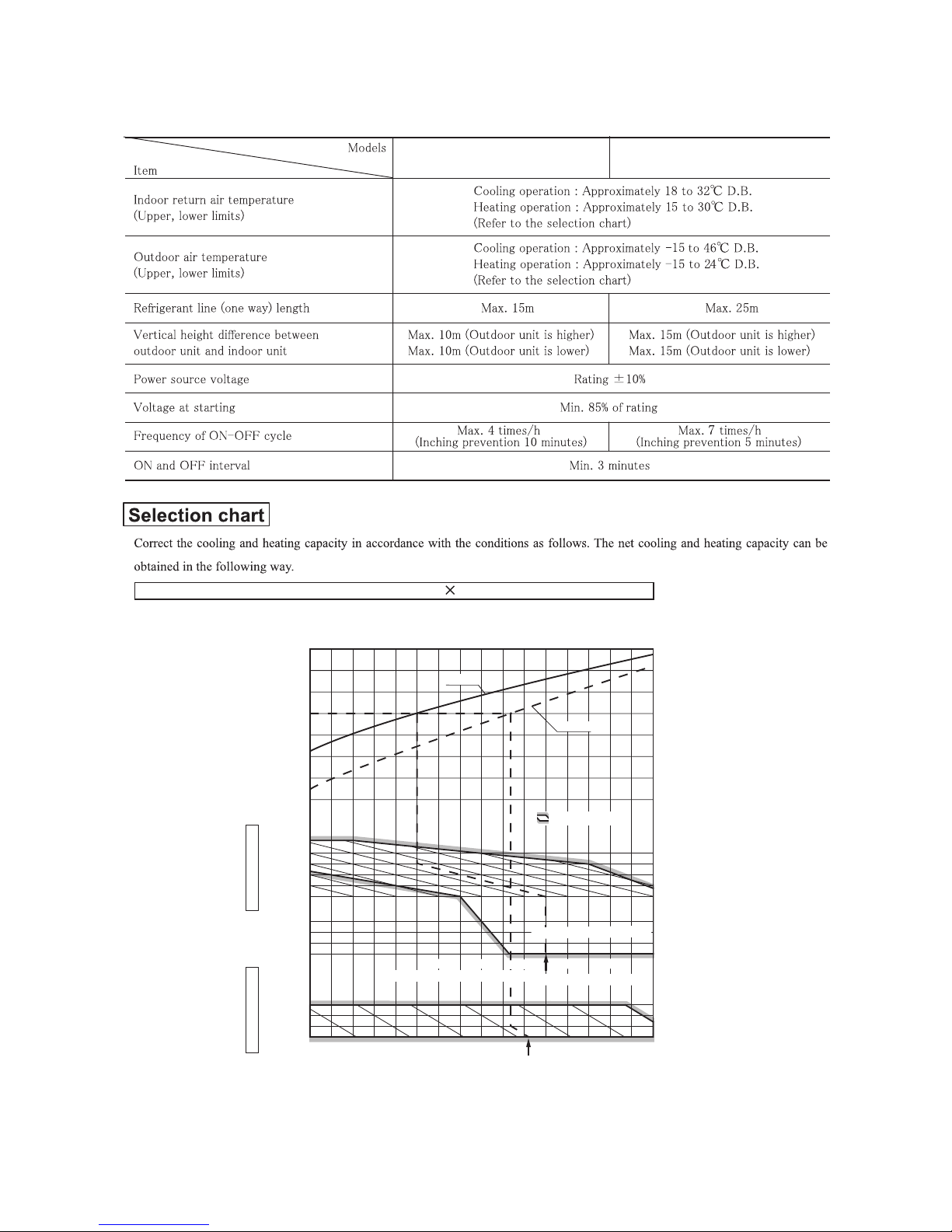

(2) Correction of cooling and heating capacity in relation to one way length of refrigerant piping

(3) Correction relative to frosting on outdoor heat exchanger during heating

How to obtain the cooling and heating capacity

≒

Piping length [m]

Cooling

Heating

7

1.0

1.0

10

0.99

1.0

15

0.975

1.0

20

0.965

1.0

25

0.95

1.0

30

0.935

1.0

Air inlet temperature of

SRK35ZMP-S

SRK35ZMP-S

outdoor unit in °C WB

Adjustment coefficient

-15

0.95 0.95 0.94 0.93 0.91 0.88 0.86 0.87 0.92 1.00

-10 -9 -7 -5 -3 -1 1 3

5 or more

3.2 3.1kW

-

18

-

'13 • SRK-T-140

7. CAPACITY TABLES

Note(1) These data show average statuses.

Note(1) Depending on the system control, there may be ranges where the operation

is not conducted continuously.

Note(1)

These data show the case where the operation frequency of a compressor is

fixed.

(2) Capacities are based on the following conditions.

(2) Corresponding refrigerant piping length :7m

(2) Level difference of Zero.

(3) Symbols are as follows.

TC : Total cooling capacity (kW)

SHC : Sensible heat capacity (kW)

HC : Heating capacity (kW)

Heating Mode(HC)

Air flow Outdoor 21˚CDB 23˚C DB 26 ˚CDB 27˚C DB 28˚C DB 31˚CDB

Outdoor

air temp.

14˚C WB 16˚CWB 18˚CWB 19˚CWB 20˚CWB 22˚CWB

33˚CDB

24˚CWB

Air flow air temp. Indoor air temp

61

CHSCTCHSCTCHSCTCHSCTCHSCTCHSCTCHSCT

18˚CDB 20˚CDB 22˚CDB 24˚CDB

10 2.82 2.36 2.95 2.32 3.06 2.42 3.11 2.39 3.16 2.36 3.26 2.46 3.34 2.39

˚CWB 1.72 1.69 1.65 1.61 1.58

12 2.77 2.34 2.90 2.30 3.01 2.40 3.07 2.37 3.12 2.35 3.22 2.45 3.31 2.38

˚CWB 1.95 1.91 1.89 1.84 1.80

14 2.71 2.31 2.85 2.27 2.97 2.39 3.03 2.36 3.08 2.33 3.18 2.43 3.28 2.37

˚CWB 2.11 2.08 2.04 2.02 1.98

16 2.66 2.28 2.80 2.25 2.92 2.37 2.98 2.35 3.04 2.32 3.15 2.42 3.24 2.36

˚CWB 2.21 2.18 2.14 2.12 2.09

18 2.60 2.26 2.74 2.23 2.88 2.35 2.94 2.33 2.99 2.31 3.11 2.41 3.20 2.35

˚CWB 2.82 2.79 2.77 2.72 2.68

20 2.55 2.23 2.68 2.21 2.83 2.33 2.89 2.31 2.95 2.29 3.07 2.39 3.17 2.34

(

m

3

/

min

)

˚C

Hi 22 2.49 2.20 2.63 2.18 2.78 2.31 2.84 2.29 2.90 2.27 3.02 2.38 3.13 2.32

˚CWB 3.04 3.02 3.00 2.96 2.93

10.1 24 2.43 2.18 2.57 2.15 2.72 2.29 2.80 2.27 2.85 2.25 2.98 2.36 3.08 2.31

˚CWB 3.31 3.28 3.26 3.23 3.20

(

m3/min

)

26 2.37 2.14 2.51 2.13 2.67 2.27 2.74 2.25 2.80 2.23 2.93 2.35 3.04 2.29

˚CWB 3.56 3.53 3.52 3.48 3.45

28 2.31 2.12 2.44 2.10 2.61 2.24 2.69 2.23 2.75 2.21 2.89 2.33 3.00 2.28

30 2.24 2.09 2.38 2.07 2.56 2.22 2.64 2.21 2.70 2.19 2.84 2.31 2.95 2.27

32 2.18 2.06 2.31 2.04 2.50 2.20 2.58 2.19 2.64 2.17 2.79 2.30 2.90 2.25

34 2.11 2.03 2.25 2.01 2.44 2.18 2.53 2.17 2.59 2.15 2.74 2.28 2.85 2.24

36 2.04 1.99 2.18 1.98 2.38 2.15 2.47 2.14 2.53 2.13 2.69 2.26 2.80 2.22

38 1.97 1.97 2.11 1.95 2.32 2.12 2.41 2.12 2.47 2.11 2.63 2.24 2.75 2.20

39 1.94 1.94 2.07 1.94 2.28 2.11 2.38 2.11 2.44 2.10 2.61 2.23 2.72 2.20

Heating Mode(HC)

Outdoor

Air flow air temp. Indoor air temp

61

CHSCTCHSCTCHSCTCHSCTCHSCTCHSCTCHSCT

˚CDB

10 3.61 2.75 3.77 2.70 3.91 2.80 3.98 2.76 4.05 2.72 4.17 2.79 4.28 2.70

˚CWB 2.21 2.17 2.12 2.07 2.03

12 3.54 2.72 3.71 2.67 3.86 2.77 3.93 2.73 4.00 2.70 4.12 2.77 4.24 2.68

˚CWB 2.51 2.46 2.43 2.37 2.32

14 3.47 2.69 3.65 2.64 3.80 2.74 3.87 2.71 3.94 2.67 4.08 2.75 4.19 2.67

˚CWB 2.71 2.68 2.62 2.59 2.55

16 3.40 2.65 3.58 2.61 3.74 2.72 3.82 2.68 3.89 2.64 4.03 2.74 4.15 2.65

˚CWB 2.85 2.80 2.76 2.72 2.68

18 3.33 2.61 3.51 2.57 3.68 2.68 3.76 2.66 3.83 2.62 3.98 2.71 4.10 2.64

˚CWB 3.63 3.58 3.56 3.49 3.44

20 3.26 2.58 3.44 2.54 3.62 2.66 3.70 2.63 3.78 2.60 3.92 2.69 4.05 2.61

(

m

3

/

min

)

˚C

Hi 22 3.19 2.54 3.36 2.51 3.55 2.63 3.64 2.61 3.71 2.58 3.87 2.68 4.00 2.59

˚CWB 3.91 3.88 3.85 3.80 3.76

9.5 24 3.11 2.50 3.29 2.47 3.49 2.60 3.58 2.58 3.65 2.56 3.81 2.64 3.95 2.58

˚CWB 4.26 4.22 4.19 4.15 4.11

(

m3/min

)

26 3.03 2.46 3.21 2.43 3.42 2.57 3.51 2.55 3.59 2.53 3.76 2.62 3.89 2.56

˚CWB 4.58 4.54 4.52 4.47 4.43

28 2.95 2.42 3.13 2.39 3.35 2.54 3.45 2.53 3.52 2.50 3.70 2.61 3.84 2.55

30 2.87 2.38 3.05 2.35 3.27 2.51 3.38 2.50 3.45 2.47 3.64 2.59 3.78 2.52

32 2.79 2.34 2.96 2.32 3.20 2.48 3.31 2.47 3.38 2.45 3.57 2.56 3.72 2.51

34 2.70 2.30 2.88 2.28 3.12 2.45 3.24 2.44 3.31 2.42 3.51 2.54 3.65 2.48

36 2.61 2.25 2.79 2.24 3.04 2.41 3.16 2.41 3.24 2.39 3.44 2.51 3.59 2.46

38 2.52 2.21 2.70 2.20 2.96 2.38 3.09 2.38 3.16 2.36 3.37 2.49 3.52 2.44

39 2.48 2.19 2.65 2.18 2.92 2.36 3.05 2.36 3.12 2.34 3.34 2.48 3.49 2.43

Indoor air temp

Indoor air temp

35 2.66 2.27 2.83 2.26 3.08 2.43 3.20 2.43 3.28 2.40 3.47 2.52 3.62 2.47

WB 3.68 3.64 3.60 3.55 3.51

35 2.08 2.01 2.21 2.00 2.41 2.16 2.50 2.16 2.56 2.14 2.71 2.27 2.83 2.23

WB 2.87 2.83 2.80 2.76 2.73

(kW)

(kW)

(kW)

(kW)

(kW)

(kW)

-15

-10

-5

Hi 0

9.5 5

10

15

20

15

-10

-5

Hi 0

9.6 5

6

10

15

20

˚CDB 23˚C DB 26˚C DB 27 ˚CDB 28˚CDB 31˚CDB

˚CWB 16˚CWB 18˚CWB 19˚CWB 20˚CWB 22˚CWB

33˚CDB

24˚CWB

˚CDB

18˚CDB 20˚CDB 22˚CDB 24˚CDB

6

Heating Mode(HC)

Air flow Outdoor 21 ℃DB 23 ℃DB 26 ℃DB 27 ℃DB 28 ℃DB 31 ℃DB 33 ℃DB

Outdoor

air temp. 14 ℃WB 16 ℃WB 18 ℃WB 19 ℃WB 20 ℃WB 22 ℃WB 24 ℃WB

Air flow air temp. Indoor air temp

61

CHSCTCHSCTCHSCTCHSCTCHSCTCHSCTCHSCT

℃ DB 18℃ DB 20℃ DB 22℃ DB 24℃ DB

10 5.07 3.57 5.31 3.52 5.50 3.58 5.59 3.53 5.69 3.47 5.86 3.50 6.02 3.36

℃WB 3.08 3.01 2.94 2.88 2.81

12 4.98 3.52 5.22 3.47 5.42 3.54 5.52 3.49 5.62 3.43 5.80 3.47 5.96 3.34

℃WB 3.48 3.42 3.37 3.29 3.22

14 4.88 3.47 5.13 3.42 5.34 3.50 5.45 3.45 5.55 3.40 5.73 3.43 5.90 3.31

℃WB 3.77 3.72 3.64 3.60 3.54

16 4.79 3.41 5.03 3.37 5.26 3.45 5.37 3.41 5.47 3.36 5.66 3.41 5.83 3.29

℃WB 3.95 3.89 3.83 3.78 3.73

18 4.69 3.35 4.93 3.31 5.18 3.41 5.29 3.37 5.39 3.32 5.59 3.38 5.77 3.26

℃WB 5.04 4.98 4.95 4.85 4.78

20 4.59 3.30 4.83 3.26 5.09 3.36 5.20 3.32 5.31 3.28 5.52 3.34 5.70 3.23

(

m

3

/

min

)

6

℃WB 5.12 5.06 5.00 4.94 4.88

Hi 22 4.48 3.23 4.73 3.20 5.00 3.31 5.12 3.28 5.22 3.24 5.44 3.31 5.63 3.20

℃WB 5.44 5.38 5.35 5.28 5.23

9.0 24 4.37 3.18 4.62 3.14 4.90 3.27 5.03 3.24 5.14 3.20 5.36 3.27 5.55 3.17

12.0

℃WB 5.92 5.87 5.82 5.76 5.71

(

m3/min

)

26 4.26 3.11 4.51 3.08 4.80 3.22 4.94 3.20 5.05 3.16 5.28 3.24 5.48 3.14

℃WB 6.36 6.31 6.28 6.21 6.16

28 4.15 3.05 4.40 3.02 4.70 3.17 4.85 3.15 4.95 3.12 5.20 3.20 5.40 3.10

30 4.04 2.98 4.28 2.96 4.60 3.12 4.75 3.11 4.86 3.07 5.11 3.16 5.31 3.08

32 3.92 2.92 4.16 2.90 4.50 3.06 4.65 3.06 4.76 3.02 5.02 3.13 5.23 3.04

34 3.80 2.85 4.04 2.84 4.39 3.02 4.55 3.01 4.66 2.98 4.93 3.09 5.14 3.01

36 3.67 2.79 3.92 2.78 4.28 2.96 4.45 2.96 4.55 2.93 4.84 3.05 5.05 2.98

38 3.55 2.72 3.79 2.71 4.17 2.91 4.34 2.92 4.45 2.89 4.74 3.01 4.95 2.94

39 3.48 2.69 3.73 2.68 4.11 2.88 4.29 2.89 4.39 2.86 4.69 2.99 4.90 2.92

Indoor air temp

35 3.74 2.82 3.98 2.80 4.34 2.99 4.50 2.99 4.61 2.96 4.88 3.07 5.09 3.00

Air flow Outdoor 21

air temp.

14

-15

-10

-5

Hi 0

5

10

15

20

Model SRK35ZMP-S

Cooling Mode

Model SRK25ZMP-S

Cooling Mode

Model SRK45ZMP-S

Cooling Mode

-

19

-

'13 • SRK-T-140

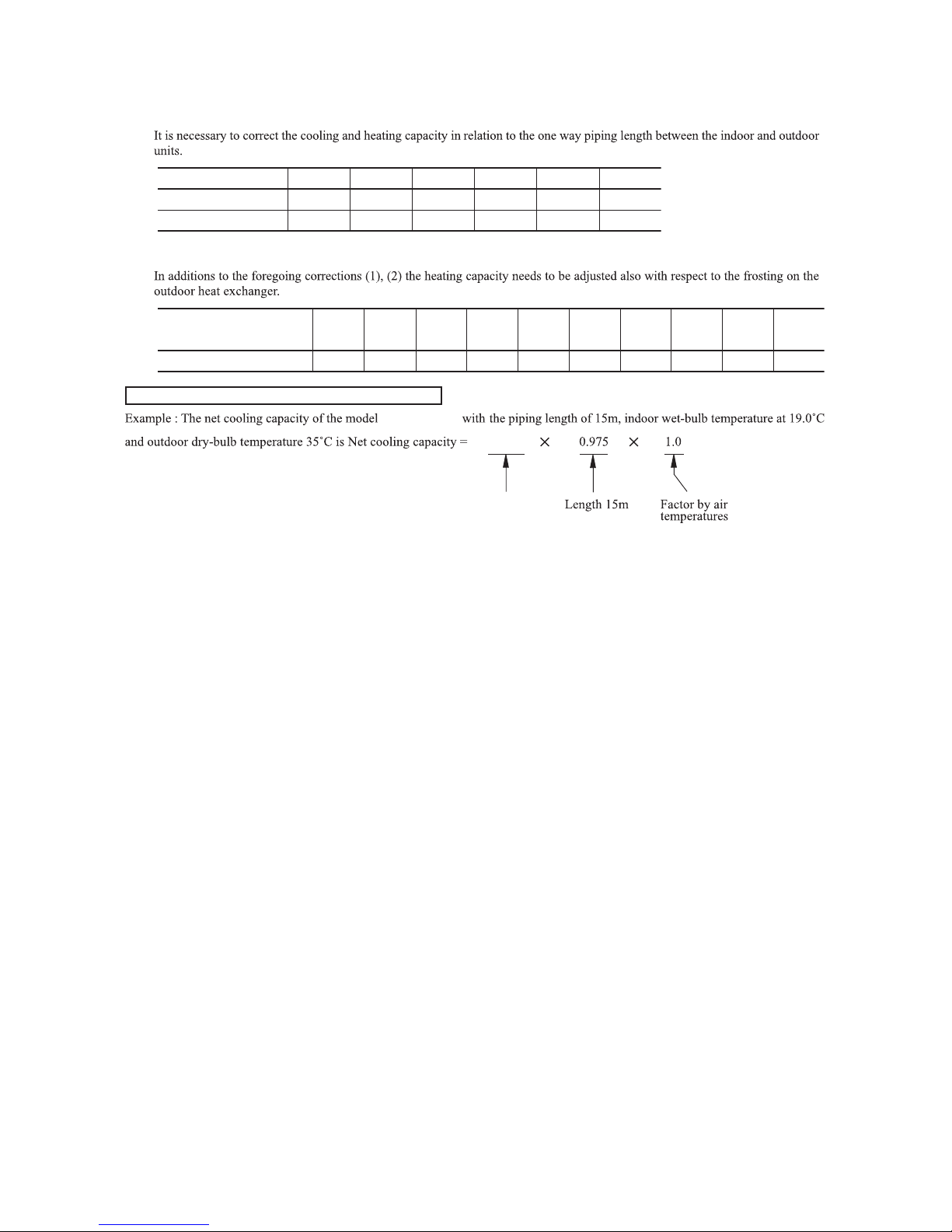

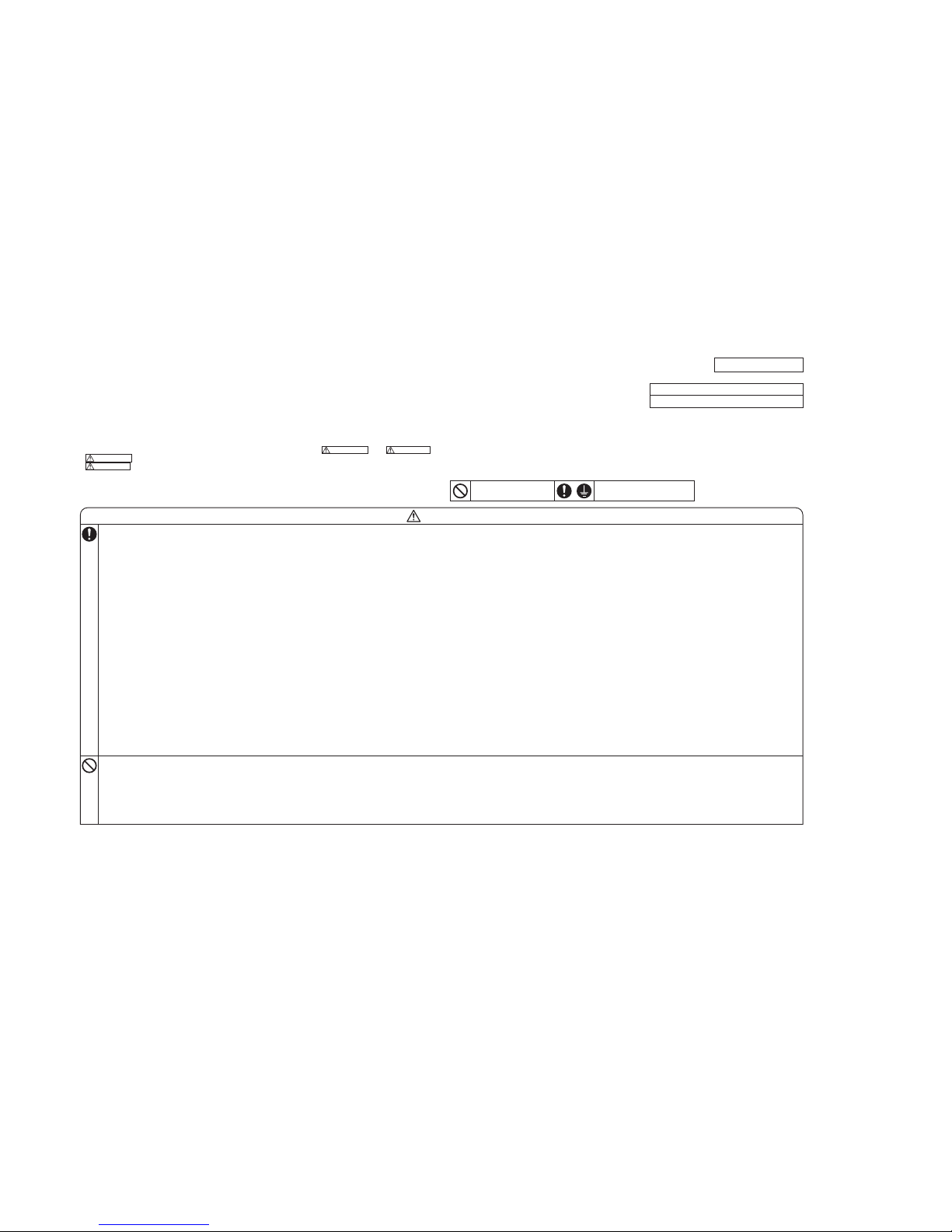

SELECTION OF INSTALLATION LOCATION

Indoor unit

Outdoor unit

(Install at location that meets the following conditions, after getting approval from the customer)

○Where there is no obstructions to the air flow and where the cooled and heated air can be evenly distributed.

○A solid place where the unit or the wall will not vibrate.

○A place where there will be enough space for servicing. (Where space mentioned right can be secured)

○Where wiring and the piping work will be easy to conduct.

○The place where receiving part is not exposed to the direct rays of the sun or the strong rays of the street

lighting.

○A place where it can be easily drained.

○A place separated at least 1m away from the TV or the radio. (To prevent interference to images and

sounds.)

○Places where this unit is not affected by the high frequency equipment or electric equipment.

○Avoid installing this unit in place where there is much oil mist.

○Places where there is no electric equipment or household under the installing unit.

○A place where the air conditioner can be received the signal surely during operating the wireless remote

control.

○Places where there is no affected by the TV and radio etc.

○Do not place where exposed to direct sunlight or near heat devices such as a stove.

○Where air is not trapped.

○Where the installation fittings can be firmly installed.

○Where wind does not hinder the intake and outlet pipes.

○Out of the heat range of other heat sources.

○A place where stringent regulation of electric noises is applicable.

○Where it is safe for the drain water to be discharged.

○Where noise and hot air will not bother neighboring residents.

○Where snow will not accumulate.

○Where strong winds will not blow against the outlet pipe.

○

When the unit is installed, the space of the following dimension and above shall be secured.

In case the barrier is 1.2m or above in height, or is overhead, the sufficient space between

the unit and wall shall be secured.

RLC012A001A

WALL TYPE AIR CONDITIONER

R410A REFRIGERANT USED

Wireless remote control

WA

RNING

• Installation must be carried out by the qualified installer.

If you install the system by yourself, it may cause serious trouble such as water leaks,

electric shocks, fire and personal injury, as a result of a system malfunction. Do not carry

out the installation and maintenance work except the by qualified installer.

• Install the system in full accordance with the installation manual.

Incorrect installation may cause bursts, personal injury, water leaks, electric shocks and fire.

• Be sure to use only for household and residence.

If this appliance is installed in inferior environment such as machine shop and etc., it can

cause malfunction.

• Use the original accessories and the specified components for installation.

If parts other than those prescribed by us are used, It may cause water leaks, electric

shocks, fire and personal injury.

• Install the unit in a location with good support.

Unsuitable installation locations can cause the unit to fall and cause material damage and

personal injury.

• Ensure the unit is stable when installed, so that it can withstand

earthquakes and strong winds.

Unsuitable installation locations can cause the unit to fall and cause material damage and

personal injury.

• Ventilate the working area well in the event of refrigerant leakage during

installation.

If the density of refrigerant exceeds the limit, please consult the dealer and install the

ventilation system, otherwise lack of oxygen can occur, which can cause serious

accident.

• When installing in small rooms, take prevention measures not to exceed

the density limit of refrigerant in the event of leakage, referred by the

formula (accordance with ISO5149).

If the density of refrigerant exceeds the limit, please consult the dealer and install the

ventilation system, otherwise lack of oxygen can occur, which can cause serious accident.

• After completed installation, checkthat no refrigerant leaks from the system.

If refrigerant leaks into the room and comes into contact with an oven or other hot

surface, poisonous gas is produced.

• Use the prescribed pipes, flare nuts and tools for R410A.

Using existing parts (for R22 or R407C) can cause the unit failure and serious accidents

due to burst of the refrigerant circuit.

• Tighten the flare nut by torque wrench with specified method.

If the flare nut were tightened with excess torque, this may cause burst and refrigerant

leakage after a long period.

• Do not open the operation valves for liquid line and gas line until

completed refrigerant piping work, air tightness test and evacuation.

If the compressor is operated in state of opening operation valves before completed

connection of refrigerant piping work, air can be sucked into refrigerant circuit, which can

cause burst or personal injury due to anomalously high pressure in the refrigerant.

• The electrical installation must be carried out by the qualified electrician in

accordance with “the norm for electrical work” and “national wiring

regulation”, and the system must be connected to the dedicated circuit.

Power supply with insufficient capacity and incorrect function done by improper work

can cause electric shocks and fire.

• Be sure to shut off the power before starting electrical work.

Failure to shut off the power can cause electric shocks, unit failure or incorrect function

of equipment.

• Be sure to use the cables conformed to safety standard and cable ampacity

for power distribution work.

Unconformable cables can cause electric leak, anomalous heat production or fire.

• This appliance must be connected to main power supply by means of a circuit

breaker or switch (fuse:16A) with acontact separation of at least3mm.

• When plugging this appliance, a plug conforming to the norm IEC60884-1

must be used.

• Use the prescribed cables for electrical connection, tighten the cables

securely in terminal block and relieve the cables correctly to prevent

overloading the terminal blocks.

Loose connections or cable mountings can cause anomalous heat production or fire.

• Arrange the wiring in the control box so that it cannot be pushed up further

into the box. Install the service panel correctly.

Incorrect installation may result in overheating and fire.

• Be sure to fix up the service panels.

Incorrect fixing can cause electric shocks or fire due to intrusion of dust or water.

• Be sure to switch off the power supply in the event of installation,

inspection or servicing.

If the power supply is not shut off, there is a risk of electric shocks, unit failure or

personal injury due to the unexpected start of fan.

• Stop the compressor before removing the pipe after shutting the service

valve on pump down work.

If the pipe is removed when the compressor is in operation with the service valve open,

air would be mixed in the refrigeration circuit and it could cause explosion and injuries

due to abnormal high pressure in the cooling cycle.

• Only use prescribed option parts. The installation must be carried out by

the qualified installer.

If you install the system by yourself, it can cause serious trouble such as water leaks,

electric shocks, fire.

• Be sure to wear protective goggles and gloves while at work.

• Earth leakage breaker must be installed.

If the earth leakage breaker is not installed, it can cause electric shocks.

• Do not put the drainage pipe directly into drainage channels where

poisonous gases such as sulphide gas can occur.

Poisonous gases will flow into the room through drainage pipe and seriously affect the

user’s health and safety. This can also cause the corrosion of the indoor unit and a

resultant unit failure or refrigerant leak.

• Ensure that no air enters in the refrigerant circuit when the unit is installed

and removed.

If air enters in the refrigerant circuit, the pressure in the refrigerant circuit becomes too

high, which can cause burst and personal injury.

• Do not processing, splice the power cord, or share a socket with other

power plugs.

This may cause fire or electric shock due to defecting contact, defecting insulation and

over-current etc.

• Do not bundling, winding or processing for the power cord. Or, do not

deforming the power plug due to tread it.

This may cause fire or heating.

• Do not ventR410A into the atmosphere: R410A is a fluorinated greenhouse

gas, covered by the KyotoProtocol with Global Warming Potential(GWP)=1975.

• Do not run the unit with removed panels or protections.

T

ouching rotating equipments, hot surfaces or high voltage parts can cause personal

injury due to entrapment, burn or electric shocks.

• Do not perform any change of protective device itself or its setup condition.

The forced operation by short-circuiting protective device of pressure switch and

temperature controller or the use of non specified component can cause fire or burst.

SAFETY PRECAUTIONS

• Read the “SAFETY PRECAUTIONS” carefully first of all and strictly follow it during the installation work in order to

protect yourself.

• The precautionary items mentioned below are distinguished into two levels, and .

: Wrong installation would cause serious consequences such as injuries or death.

: Wrong installation might cause serious consequences depending on circumstances.

Both mentions the important items to protect your health and safety so strictly follow them by any means.

• Be sure to confirm no anomaly on the equipment by commissioning after completed installation and explain the operating methods aswell as the maintenance methods of this equipment to the user according to the owner’s manual.

• Keep the installation manual together with owner’s manual at a place where any user can read at any time.

Moreover if necessary, ask to hand them to a new user.

• For installing qualified personnel, take precautions in respect to themselves by using suitable protective clothing,

groves, etc., and then perform the installation works.

• Please pay attention not to fall down the tools, etc. when installing the unit at the high position.

• If unusual noise can be heard during operation, consult the dealer.

• The meanings of “Marks” used here are shown as follows:

CAUTIONWARNING

CAUTION

WARNING

Never do it under any

circumstances.

Always do it according to the

instruction.

INSTALLATION MANUAL

• When install the unit, be sure to check whether the selection of installation

place, power supply specifications, usage limitation (piping length, height

differences between indoor and outdoor units, power supply voltage and etc.)

and installation spaces.

Intake

The height of a wall is 1200mm or less.

(

service

space

)

L3

L2

L4

Example installation

Size

8. APPLICATION DATA

Models SRK25ZMP-S, 35ZMP-S, 45ZMP-S

Loading...

Loading...