Mitsubishi SRK20ZS-W, SRK 25ZS-WB, SRK20ZS-WB, SRK 25ZS-WT, SRK 35ZS-W Technical Manual

...Page 1

Manual No.'18•SRK-T-250

TECHNICAL MANUAL

INVERTER WALL MOUNTED TYPE

RESIDENTIAL AIR-CONDITIONERS

(Split system, air to air heat pump type)

SRK20ZS-W, -WB, -WT

25ZS-W, -WB, -WT

35ZS-W, -WB, -WT

50ZS-W, -WB, -WT

Page 2

(1) Indoor units ........................................................................................ 16

2. EXTERIOR DIMENSIONS

3. ELECTRICAL WIRING

4. NOISE LEVEL

6. RANGE OF USAGE & LIMITATIONS

7. CAPACITY TABLES

5. PIPING SYSTEM

8. APPLICATION DATA

9. OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER

1. SPECIFICATIONS

(2) Outdoor units......................................................................................... 17

(3) Remote control

'18 • SRK-T-250

CONTENTS

........................................................................................ 3

......................................................................... 16

........................................................................................ 19

.............................................................................. 22

(1) Indoor units ............................................................................................. 22

(2) Outdoor units........................................................................................... 23

................................................................................................. 25

............................................................................................ 43

............................................................. 45

....................................................................................... 47

(1) Installation of indoor unit ......................................................................... 48

(2) Installation of outdoor unit ....................................................................... 56

(3)

Safety precautions in handling air-conditioners with flammable refrigerants

.................................................................................. 48

(1) Operation control function by wireless remote control ............................ 62

(2) Unit ON/OFF button

................................................................................ 63

................................................................................ 63(3) Auto restart function

..................................... 63(4) Installing two air-conditioners in the same room

.... 60

.................. 62

(5) Selection of the annual cooling function.................................................. 64

(6) Heating only function............................................................................... 64

(7) High power operation .............................................................................. 64

(8) Economy operation

................................................................................. 65

(9) Air flow direction adjustment ................................................................... 65

(10) 3D auto operation

(11) Timer operation

................................................................................... 66

....................................................................................... 67

(12) Silent operation....................................................................................... 67

(13) Night setback operation .......................................................................... 67

(14) Air flow range setting .............................................................................. 68

(15) Display brightness adjustment................................................................ 68

(16) Outline of heating operation

(17) Outline of cooling operation

(18) Outline of dehumidifying (DRY) opertaion

(19) Outline of automatic operation

.................................................................... 69

.................................................................... 70

.............................................. 71

................................................................ 71

-

-

1

Page 3

'18 • SRK-T-250

(20) Protective control function

10. MAINTENANCE DATA

(1) Cautions

.................................................................................................. 79

................................................................................... 79

....................................................................... 72

(2) Items to check before troubleshooting .................................................... 79

(3) Troubleshooting procedure

(If the air-conditioner does not run at all)

(4) Troubleshooting procedure (If the air-conditioner runs)

.......................... 80

........... 79

(5) Self-diagnosis table................................................................................. 81

(6) Service mode (Trouble mode access function)....................................... 82

(7) Inspection procedures corresponding to detail of trouble ....................... 90

(8)

Phenomenon observed after short-circuit, wire breakage on sensor

(9) Checking the indoor electrical equipment

.............................................. 95

........... 95

(10) How to make sure of wireless remote control ......................................... 97

(11) Inspection procedure for blown fuse on the indoor and outdoor PCB .... 97

(12) Outdoor unit inspection points ................................................................ 98

11. OPTION PARTS

(1) Wired remote control

........................................................................................... 101

............................................................................ 101

(2) Interface kit (SC-BIKN2-E)

.................................................................... 117

(3) Superlink E board (SC-ADNA-E) ........................................................... 121

12. TECHNICAL INFORMATION

....................................................................... 123

■How to read the model name

Example: SRK 20 Z

S-W

Series code

Inverter type

Product capacity (Cooling capacity : 2.0kW)

Model name SRK : Wall mounted type

SRC : Outdoor unit

-

-

2

Page 4

'18 • SRK-T-250

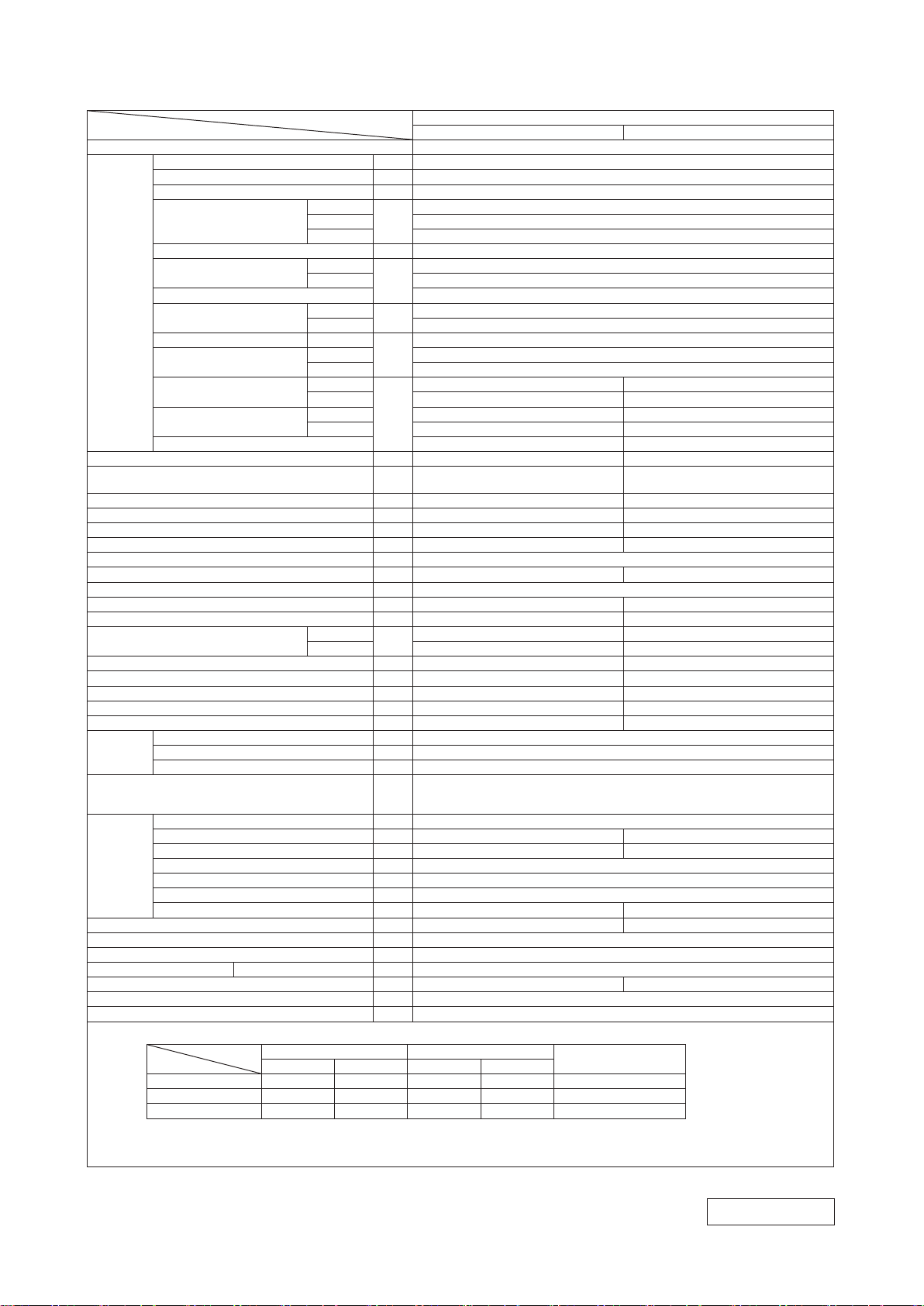

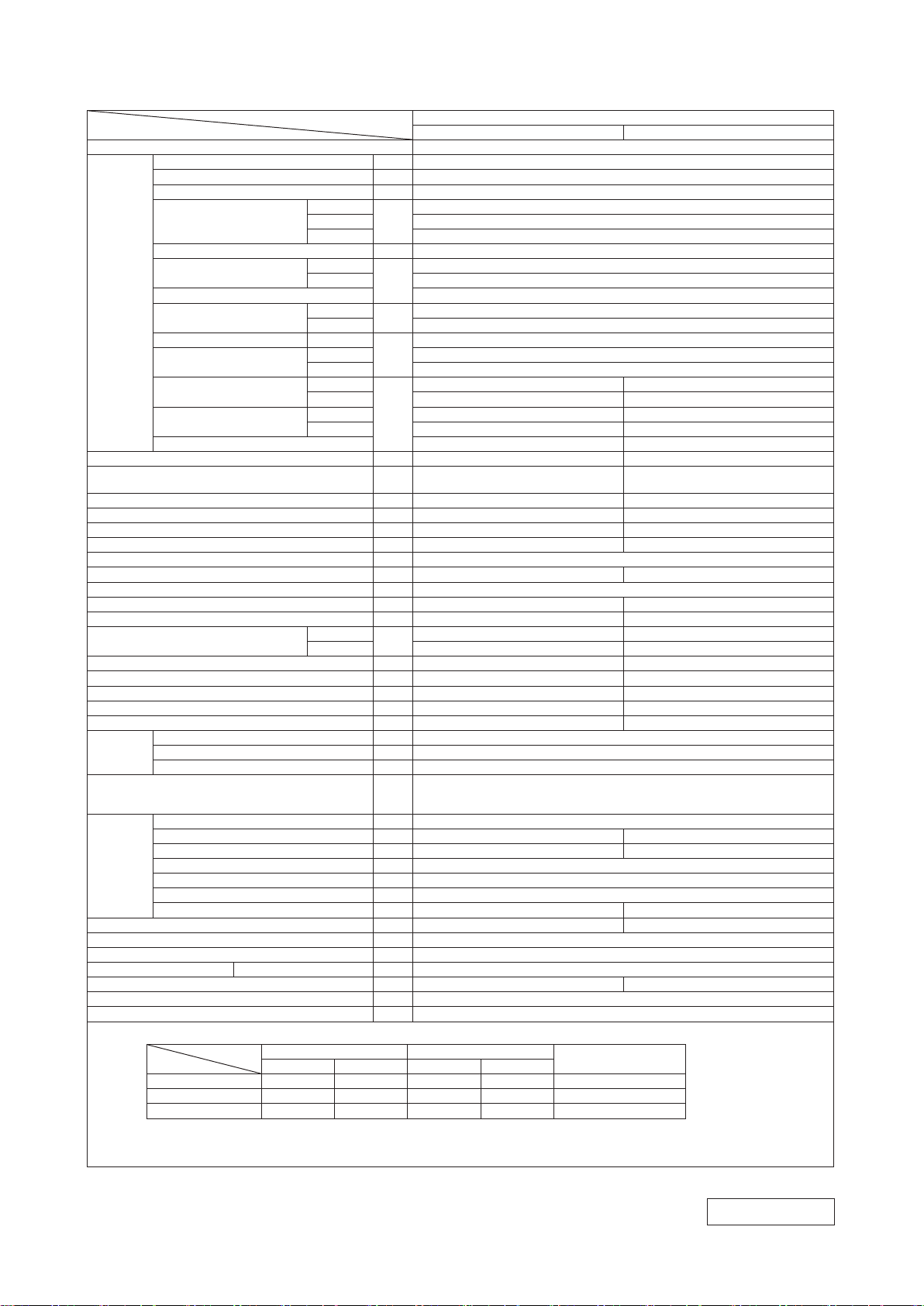

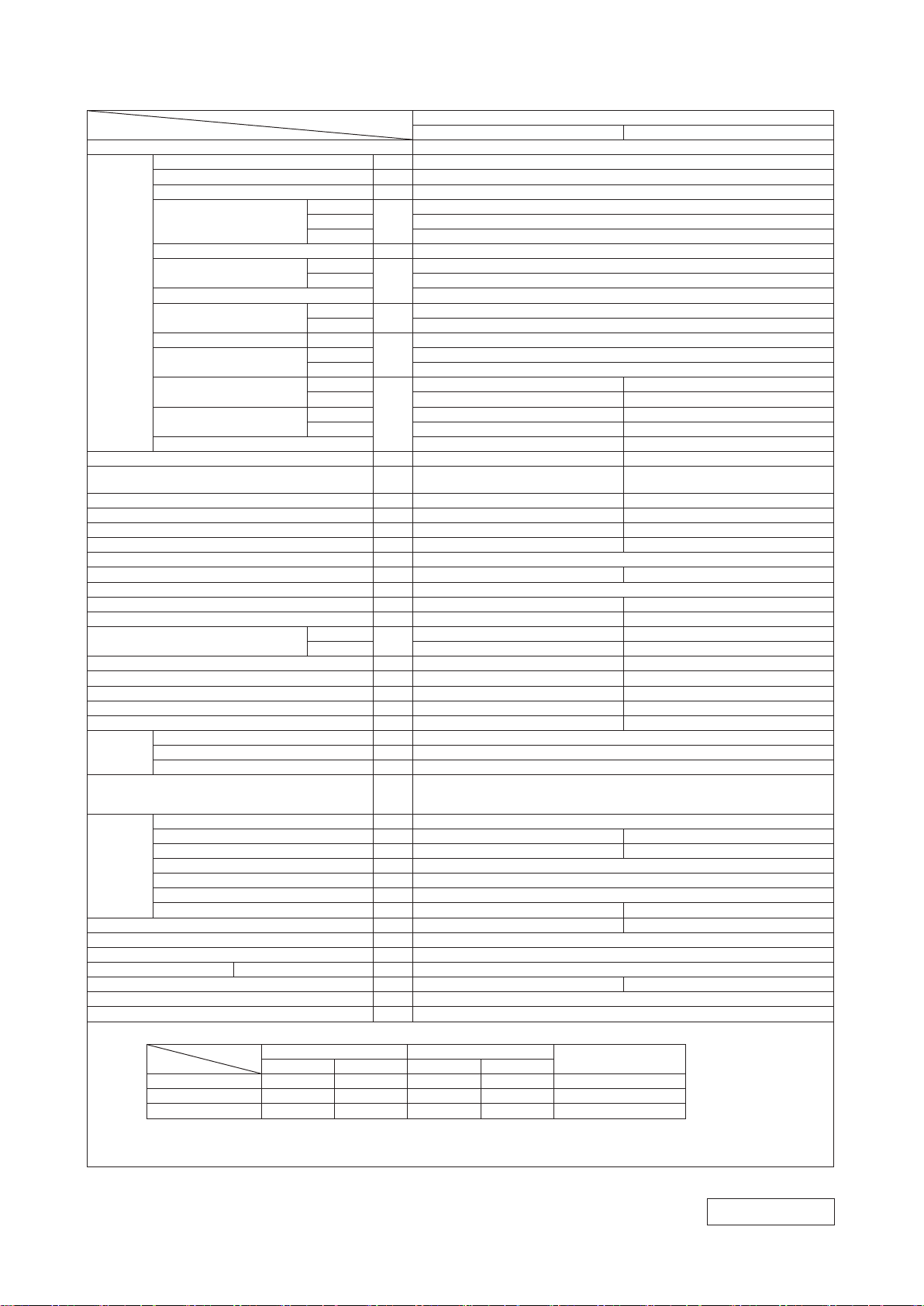

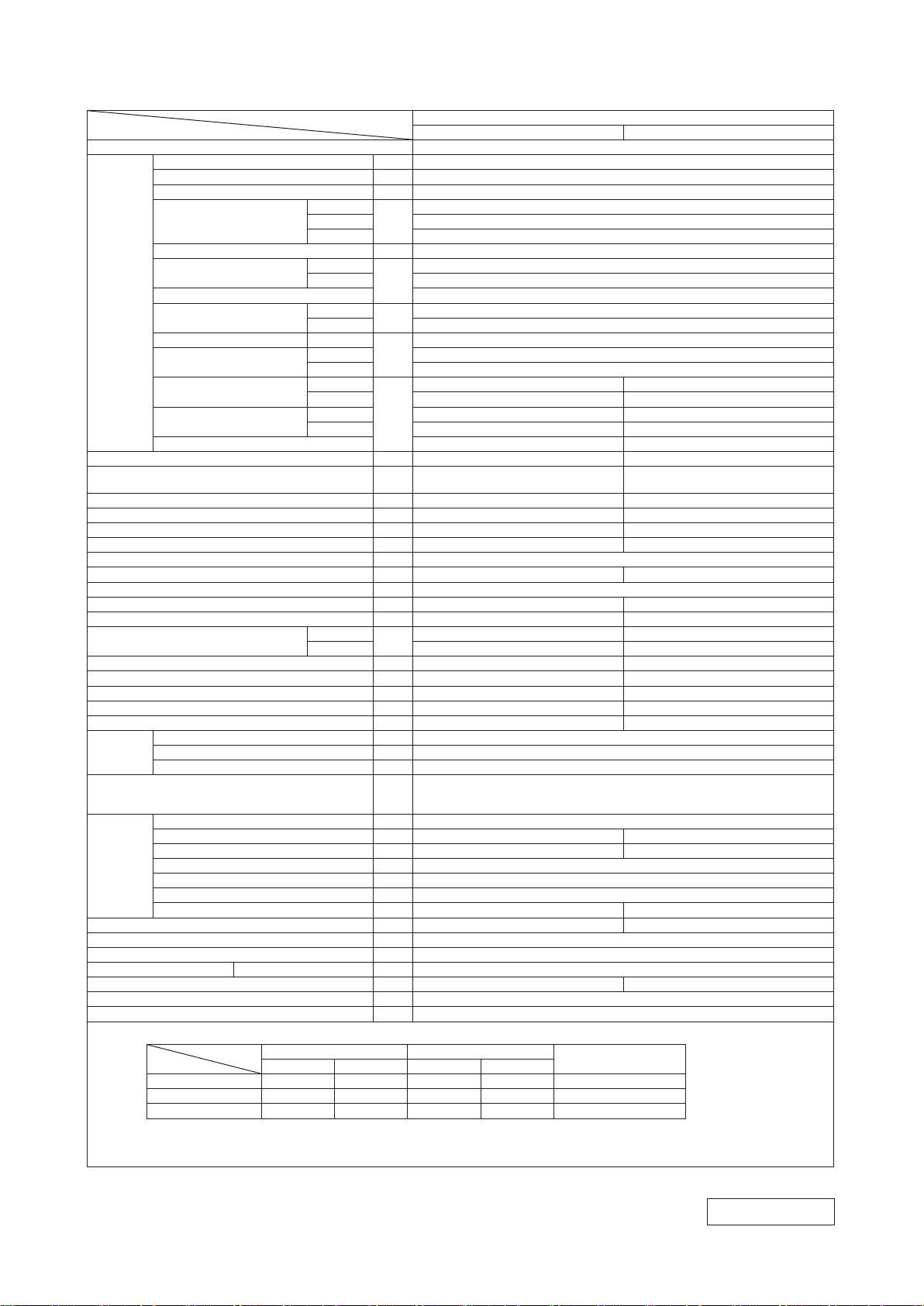

1. SPECIFICATIONS

Item

Power source 1 Phase, 220 - 240V, 50Hz / 220V, 60Hz

Operation

data

Exterior dimensions (Height x Width x Depth) mm 290 x 870 x 230 540 x 780(+62) x 290

Exterior appearance

(Equivalent color : Munsell, RAL)

Net weight kg 9.5 31.5

Compressor type & Quantity — RM-C5077SBE71( Rotary type ) x 1

Compressor motor (Starting method) kW — 0.75 ( Inverter driven )

Refrigerant oil (Amount, type) ℓ — 0.30 ( DIAMOND FREEZE MB75 )

Refrigerant (Type, amount, pre-charge length) kg R32 0.62 in outdoor unit (Incl. the amount for the piping of 15m )

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Fan type & Quantity Tangential fan x 1 Propeller fan x 1

Fan motor (Starting method) W 42 x1 (Direct drive) 24 x1 (Direct drive)

Air flow

Available external static pressure Pa 0 0

Outside air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (Washable) x 2 —

Shock & vibration absorber Rubber sleeve (for fan motor)

Electric heater — —

Operation

control

Safety equipments

Installation

data

Drain pump, max lift height mm — —

Recommended breaker size A 16

L.R.A. (Locked rotor ampere) A 3.2 / 3.0 / 2.9 (220/ 230/ 240V)

Interconnecting wires Size x Core number 1.5mm

IP number IPX0 IPX4

Standard accessories

Option parts Interface kit ( SC-BIKN2-E )

Nominal cooling capacity (range) kW 2.0 ( 0.9 (Min.) - 2.9 (Max.))

Nominal heating capacity (range) kW 2.7 ( 0.9 (Min.) - 4.3 (Max.))

Heating capacity (H2) kW —

Power consumption

Max power consumption 1.65

Running current

Inrush current, max current 3.2 / 3.0 / 2.9 (220/ 230/ 240V)

Power factor

EER Cooling 4.55

COP

Sound power level

Sound pressure level

Silent mode sound pressure level — Cooling:42 / Heating:43

Remote control Wireless remote control

Room temperature control Microcomputer thermostat

Operation display RUN: Green, TIMER: Yellow

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connection Flare connection

Attached length of piping m Liquid line : 0.54 / Gas line : 0.47 —

Insulation for piping Necessary ( Both sides ), independent

Refrigerant line (one way) length m Max.20

Vertical height diff. between O.U. and I.U. m Max.10 ( Outdoor unit is higher ) / Max.10 ( Outdoor unit is lower )

Drain hose Hose connectable ( VP 16 ) Hole φ20 x 2 pcs

Cooling

Heating 0.59 ( 0.20 - 1.40 )

Heating (H2) —

Cooling

Heating 3.2 / 3.0 / 2.9 (220/ 230/ 240V)

Cooling

Heating 85

Heating 4.58

Heating (H2) —

Cooling

Heating 50 56

Cooling Hi: 34 Me: 25 Lo: 22 ULo: 19 45

Heating Hi: 36 Me: 29 Lo: 23 ULo: 19 45

Cooling

Heating Hi: 10.0 Me: 8.5 Lo: 6.5 ULo: 5.9 23.6

Model

kW

A

%

dB(A)

3

m

/min

Indoor unit SRK20ZS-W Outdoor unit SRC20ZS-W

48 56

Fine snow (Pure white)

( 8.0Y 9.3/0.1 ) , ( 9003 )

Hi: 9.3 Me: 7.0 Lo: 5.9 ULo: 5.0 27.4

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection( High pressure control ), Cooling overload protection

Mounting kit, Clean filter ( Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1 )

Compressor overheat protection, Overcurrent protection,

2

x 4 cores (Including earth cable) / Terminal block (Screw fixing type)

Notes (1) The data are measured at the following conditions.

Indoor air temperature Outdoor air temperature

Operation

Cooling 27˚C 19˚C 35˚C 24˚C ISO5151-T1

Heating 20˚C — 7˚C 6˚C ISO5151-H1

Heating (H2) 20˚C — 2˚C 1˚C ISO5151-H2

Item

DB WB DB WB

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound level indicates the value in an anechoic chamber. During operation these values are somewhat higher due to ambient conditions.

(4) Select the breaker size according to the own national standard.

SRK20ZS-W

0.44 ( 0.19 - 0.80 )

2.6 / 2.5 / 2.4 (220/ 230/ 240V)

79

( 4.2Y 7.5/1.1 ) , ( 7044 )

Rubber sleeve (for fan motor & compressor)

The pipe length is 5m.

Standards

Max. 9

Stucco white

RWA000Z274

-

-

3

Page 5

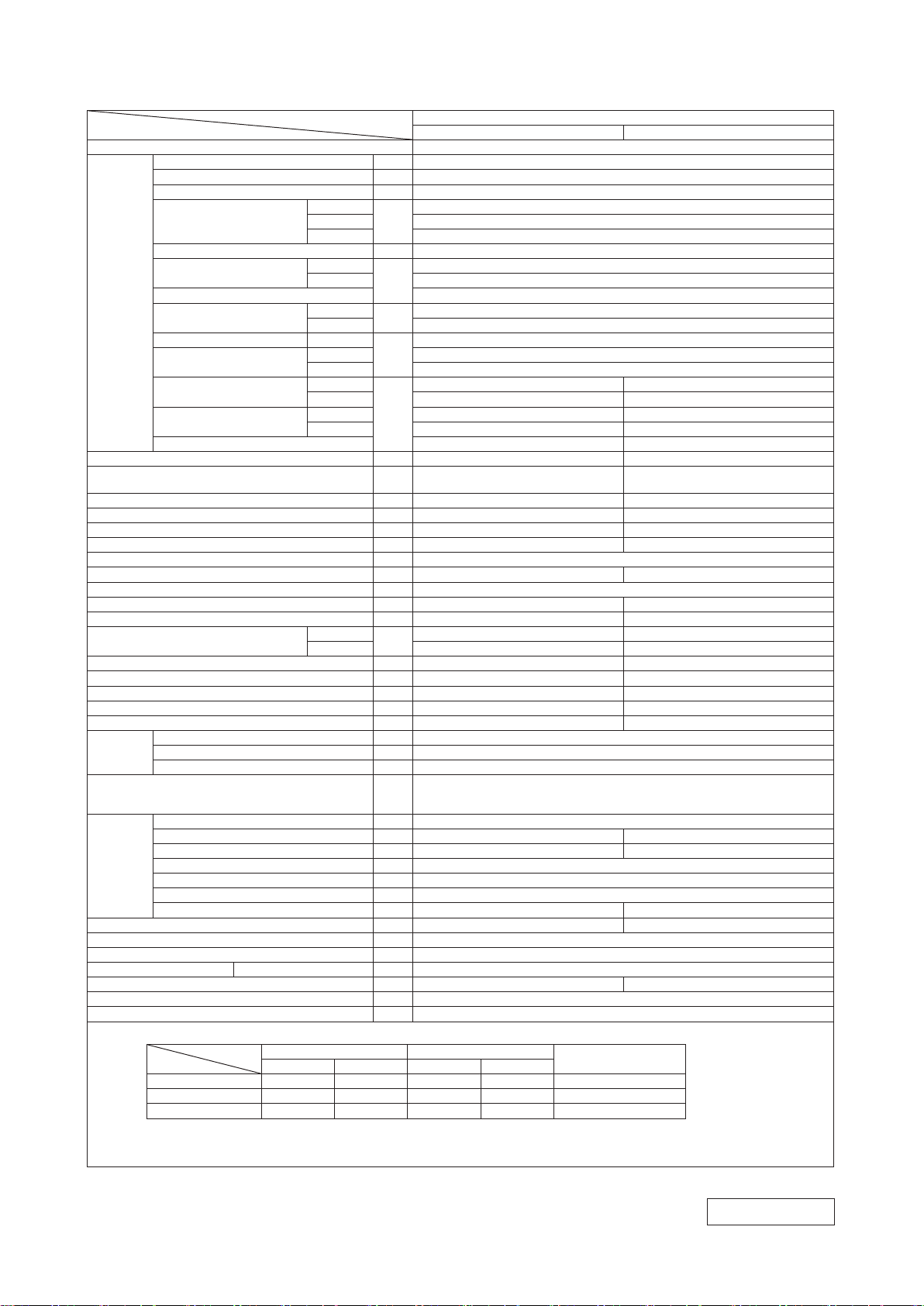

'18 • SRK-T-250

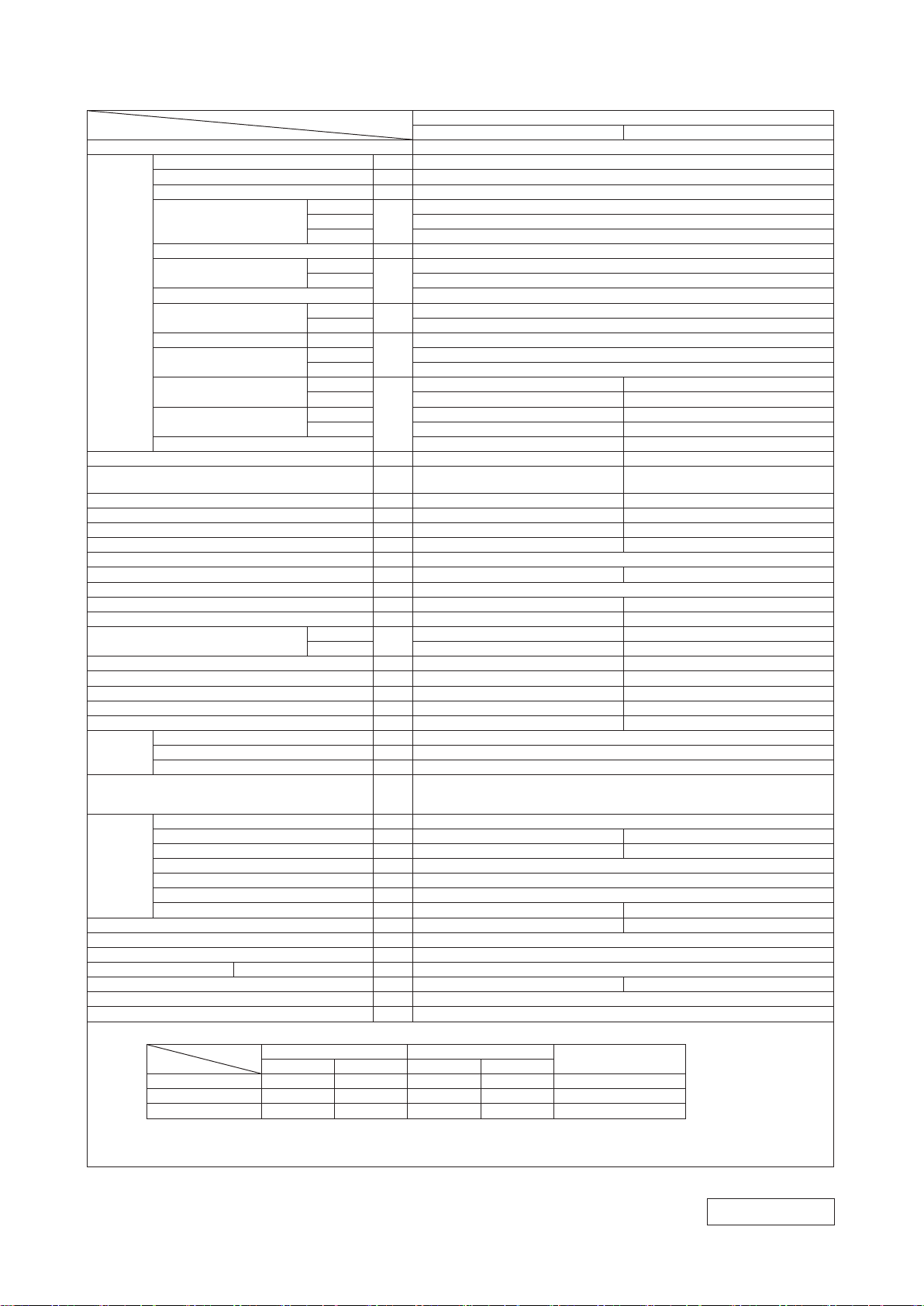

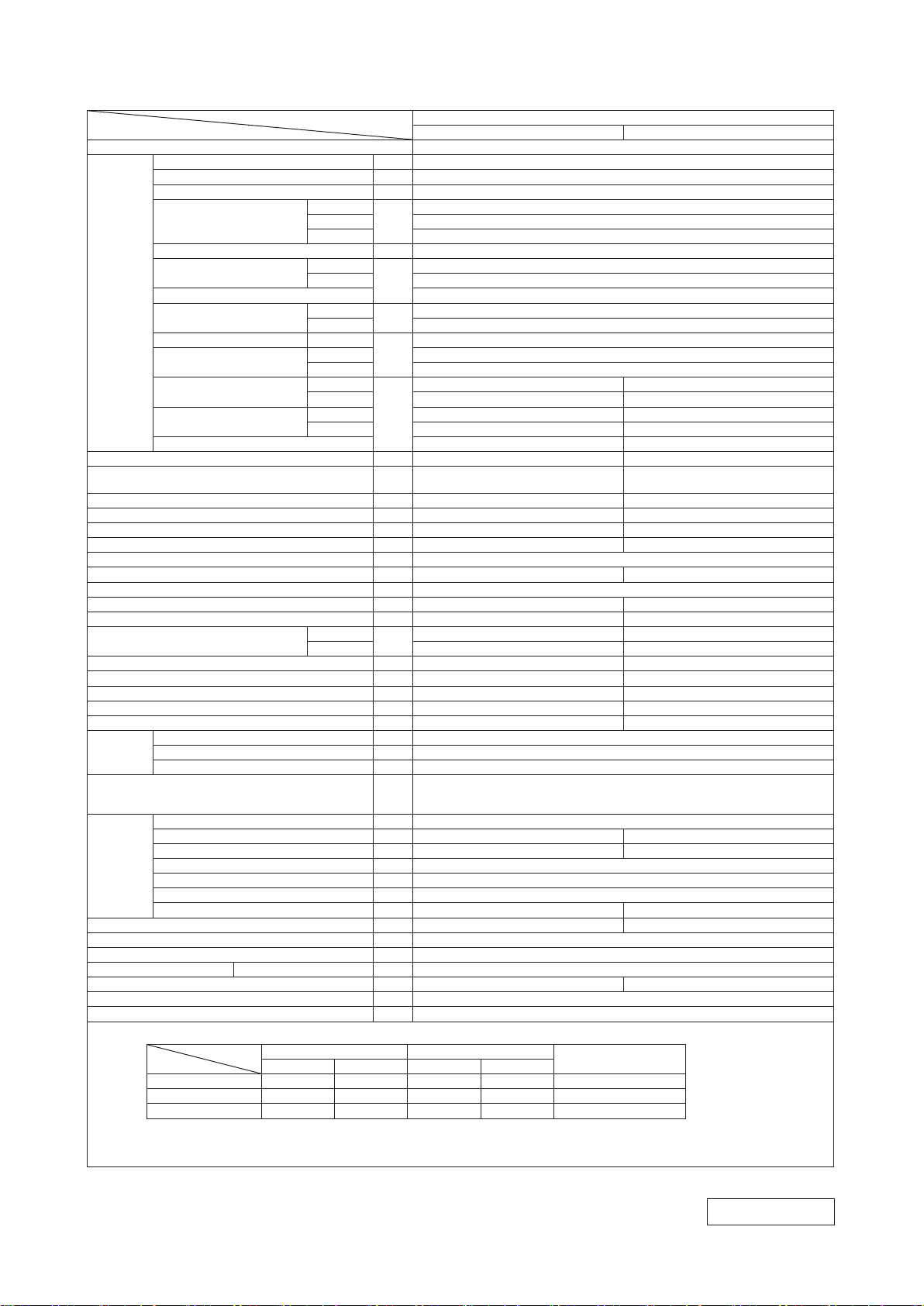

Item

Power source 1 Phase, 220 - 240V, 50Hz / 220V, 60Hz

Operation

data

Exterior dimensions (Height x Width x Depth) mm 290 x 870 x 230 540 x 780(+62) x 290

Exterior appearance

(Equivalent color : Munsell, RAL)

Net weight kg 9.5 31.0

Compressor type & Quantity — RM-C5077SBE71( Rotary type ) x 1

Compressor motor (Starting method) kW — 0.75 ( Inverter driven )

Refrigerant oil (Amount, type) ℓ — 0.30 ( DIAMOND FREEZE MB75 )

Refrigerant (Type, amount, pre-charge length) kg R32 0.62 in outdoor unit (Incl. the amount for the piping of 15m )

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Fan type & Quantity Tangential fan x 1 Propeller fan x 1

Fan motor (Starting method) W 42 x1 (Direct drive) 24 x1 (Direct drive)

Air flow

Available external static pressure Pa 0 0

Outside air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (Washable) x 2 —

Shock & vibration absorber Rubber sleeve (for fan motor)

Electric heater — —

Operation

control

Safety equipments

Installation

data

Drain pump, max lift height mm — —

Recommended breaker size A 16

L.R.A. (Locked rotor ampere) A 3.7 / 3.6 / 3.4 (220/ 230/ 240V)

Interconnecting wires Size x Core number 1.5mm

IP number IPX0 IPX4

Standard accessories

Option parts Interface kit ( SC-BIKN2-E )

Nominal cooling capacity (range) kW 2.5 ( 0.9 (Min.) - 3.1 (Max.))

Nominal heating capacity (range) kW 3.2 ( 0.9 (Min.) - 4.5 (Max.))

Heating capacity (H2) kW —

Power consumption

Max power consumption 1.65

Running current

Inrush current, max current 3.7 / 3.6 / 3.4 (220/ 230/ 240V)

Power factor

EER Cooling 4.03

COP

Sound power level

Sound pressure level

Silent mode sound pressure level — Cooling:42 / Heating:43

Remote control Wireless-remote control

Room temperature control Microcomputer thermostat

Operation display RUN: Green , TIMER: Yellow

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connection Flare connection

Attached length of piping m Liquid line : 0.54 / Gas line : 0.47 —

Insulation for piping Necessary ( Both sides ), independent

Refrigerant line (one way) length m Max.20

Vertical height diff. between O.U. and I.U. m Max.10 ( Outdoor unit is higher ) / Max.10 ( Outdoor unit is lower )

Drain hose Hose connectable ( VP 16 ) Hole φ20 x 2 pcs

Cooling

Heating 0.74 ( 0.20 - 1.42 )

Heating (H2) —

Cooling

Heating 3.7 / 3.6 / 3.4 (220/ 230/ 240V)

Cooling

Heating 90

Heating 4.32

Heating (H2) —

Cooling

Heating 53 58

Cooling Hi: 34 Me: 25 Lo: 22 ULo: 19 46

Heating Hi: 36 Me: 29 Lo: 23 ULo: 19 46

Cooling

Heating Hi: 11.3 Me: 8.7 Lo: 6.7 ULo: 5.9 23.6

Model

kW

A

%

dB(A)

3

m

/min

Indoor unit SRK25ZS-W Outdoor unit SRC25ZS-W

50 56

Fine snow (Pure white)

( 8.0Y 9.3/0.1 ) , ( 9003 )

Hi: 9.9 Me: 8.0 Lo: 5.9 ULo: 5.0 27.4

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection( High pressure control ), Cooling overload protection

Mounting kit, Clean filter ( Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1 )

Compressor overheat protection, Overcurrent protection,

2

x 4 cores (Including earth cable) / Terminal block (Screw fixing type)

Notes (1) The data are measured at the following conditions.

Indoor air temperature Outdoor air temperature

Operation

Cooling 27˚C 19˚C 35˚C 24˚C ISO5151-T1

Heating 20˚C — 7˚C 6˚C ISO5151-H1

Heating (H2) 20˚C — 2˚C 1˚C ISO5151-H2

Item

DB WB DB WB

SRK25ZS-W

0.62 ( 0.19 - 0.90 )

3.3 / 3.1 / 3.0 (220/ 230/ 240V)

86

( 4.2Y 7.5/1.1 ) , ( 7044 )

Rubber sleeve (for fan motor & compressor)

The pipe length is 5m.

Standards

Max. 9

Stucco white

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound level indicates the value in an anechoic chamber. During operation these values are somewhat higher due to ambient conditions.

(4) Select the breaker size according to the own national standard.

RWA000Z274

-

-

4

Page 6

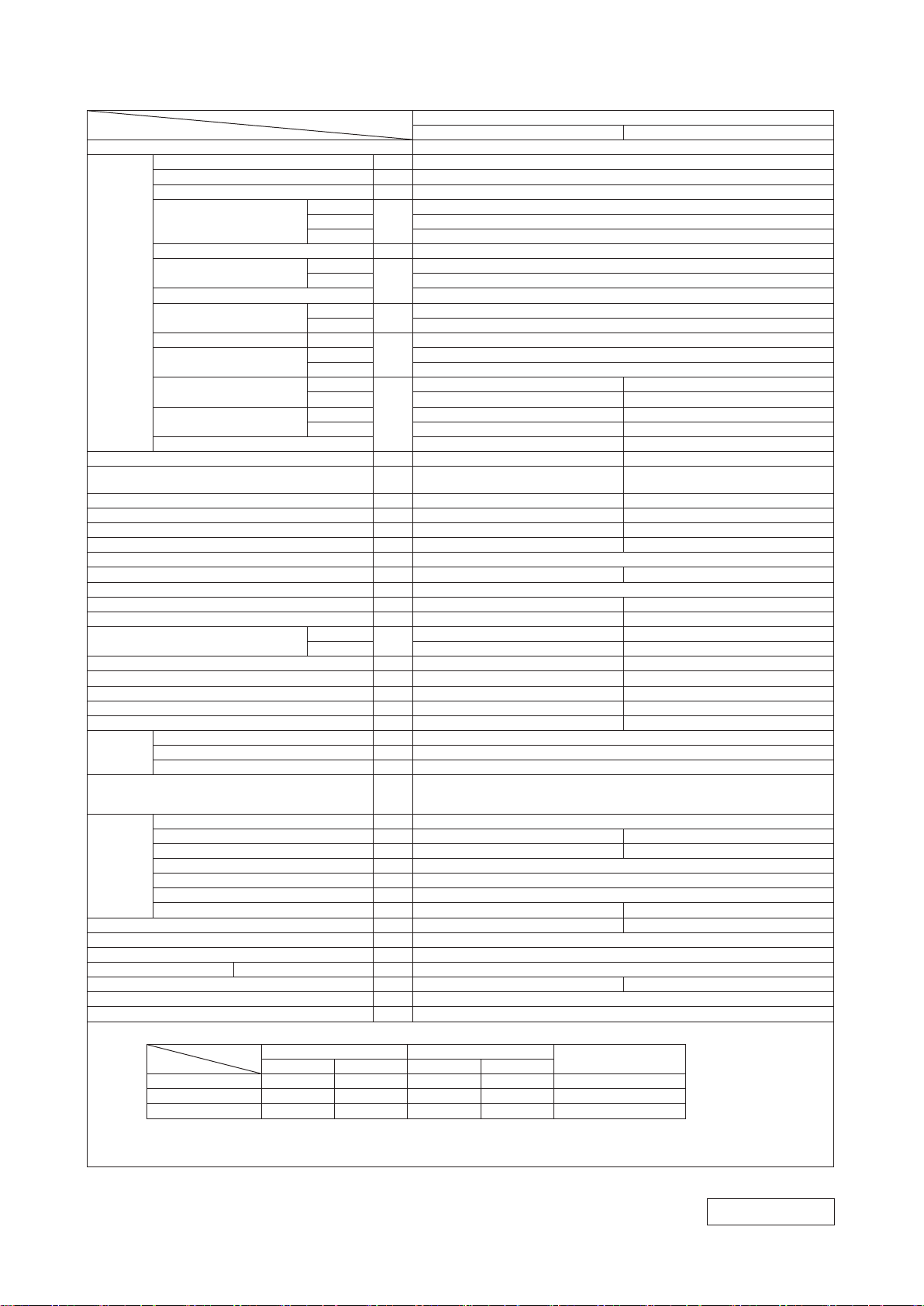

'18 • SRK-T-250

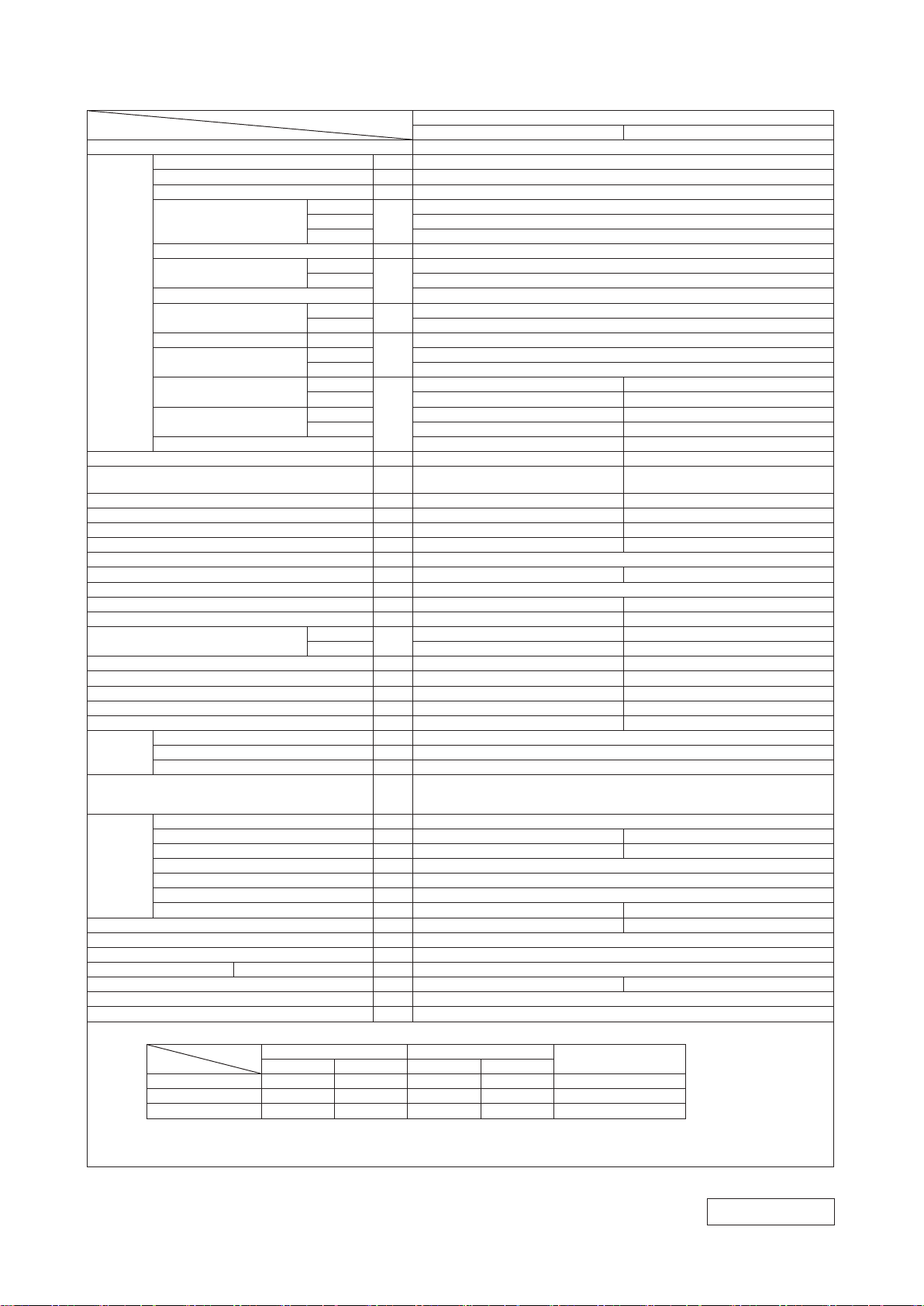

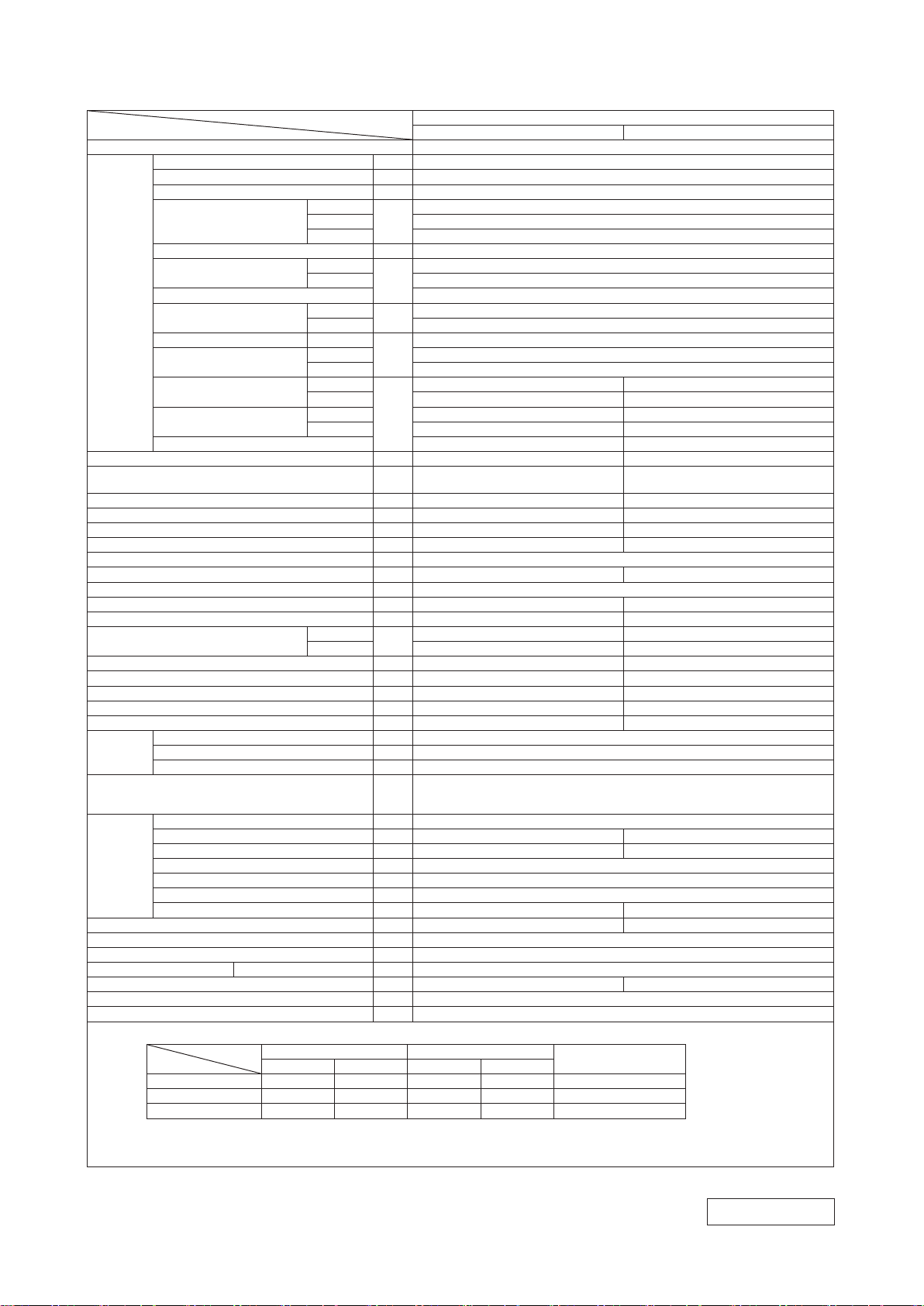

Item

Power source 1 Phase, 220 - 240V, 50Hz / 220V, 60Hz

Operation

data

Exterior dimensions (Height x Width x Depth) mm 290 x 870 x 230 540 x 780(+62) x 290

Exterior appearance

(Equivalent color : Munsell, RAL)

Net weight kg 9.5 34.5

Compressor type & Quantity — RM-B5077SBE2( Rotary type ) x 1

Compressor motor (Starting method) kW — 0.90 ( Inverter driven )

Refrigerant oil (Amount, type) ℓ — 0.30 ( DIAMOND FREEZE MB75 )

Refrigerant (Type, amount, pre-charge length) kg R32 0.78 in outdoor unit (Incl. the amount for the piping of 15m )

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Fan type & Quantity Tangential fan x 1 Propeller fan x 1

Fan motor (Starting method) W 42 x1 (Direct drive) 24 x1 (Direct drive)

Air flow

Available external static pressure Pa 0 0

Outside air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (Washable) x 2 —

Shock & vibration absorber Rubber sleeve (for fan motor)

Electric heater — —

Operation

control

Safety equipments

Installation

data

Drain pump, max lift height mm — —

Recommended breaker size A 16

L.R.A. (Locked rotor ampere) A 4.6 / 4.4 / 4.2 (220/ 230/ 240V)

Interconnecting wires Size x Core number 1.5mm

IP number IPX0 IPX4

Standard accessories

Option parts Interface kit ( SC-BIKN2-E )

Nominal cooling capacity (range) kW 3.5 ( 0.9 (Min.) - 4.0 (Max.))

Nominal heating capacity (range) kW 4.0 ( 0.9 (Min.) - 5.0 (Max.))

Heating capacity (H2) kW —

Power consumption

Max power consumption 1.65

Running current

Inrush current, max current 4.6 / 4.4 / 4.2 (220/ 230/ 240V)

Power factor

EER Cooling 3.93

COP

Sound power level

Sound pressure level

Silent mode sound pressure level — Cooling:45 / Heating:44

Remote control Wireless-remote control

Room temperature control Microcomputer thermostat

Operation display RUN: Green , TIMER: Yellow

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connection Flare connection

Attached length of piping m Liquid line : 0.54 / Gas line : 0.47 —

Insulation for piping Necessary ( Both sides ), independent

Refrigerant line (one way) length m Max.20

Vertical height diff. between O.U. and I.U. m Max.10 ( Outdoor unit is higher ) / Max.10 ( Outdoor unit is lower )

Drain hose Hose connectable ( VP 16 ) Hole φ20 x 2 pcs

Cooling

Heating 0.94 ( 0.19 - 1.45 )

Heating (H2) —

Cooling

Heating 4.6 / 4.4 / 4.2 (220/ 230/ 240V)

Cooling

Heating 93

Heating 4.26

Heating (H2) —

Cooling

Heating 56 61

Cooling Hi: 40 Me: 30 Lo: 26 ULo: 19 50

Heating Hi: 41 Me: 36 Lo: 25 ULo:19 48

Cooling

Heating Hi: 12.3 Me: 11.0 Lo: 7.0 ULo: 5.6 27.8

Model

kW

A

%

dB(A)

3

m

/min

Indoor unit SRK35ZS-W Outdoor unit SRC35ZS-W

54 61

Fine snow (Pure white)

( 8.0Y 9.3/0.1 ) , ( 9003 )

Hi: 11.3 Me: 8.7 Lo: 7.0 ULo: 5.0 31.5

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection( High pressure control ), Cooling overload protection

Mounting kit, Clean filter ( Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1 )

Compressor overheat protection, Overcurrent protection,

2

x 4 cores (Including earth cable) / Terminal block (Screw fixing type)

Notes (1) The data are measured at the following conditions.

Indoor air temperature Outdoor air temperature

Operation

Cooling 27˚C 19˚C 35˚C 24˚C ISO5151-T1

Heating 20˚C — 7˚C 6˚C ISO5151-H1

Heating (H2) 20˚C — 2˚C 1˚C ISO5151-H2

Item

DB WB DB WB

SRK35ZS-W

0.89 ( 0.17 - 1.24 )

4.4 / 4.2 / 4.0 (220/ 230/ 240V)

92

( 4.2Y 7.5/1.1 ) , ( 7044 )

Rubber sleeve (for fan motor & compressor)

The pipe length is 5m.

Standards

Max. 9

Stucco white

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound level indicates the value in an anechoic chamber. During operation these values are somewhat higher due to ambient conditions.

(4) Select the breaker size according to the own national standard.

RWA000Z274

-

-

5

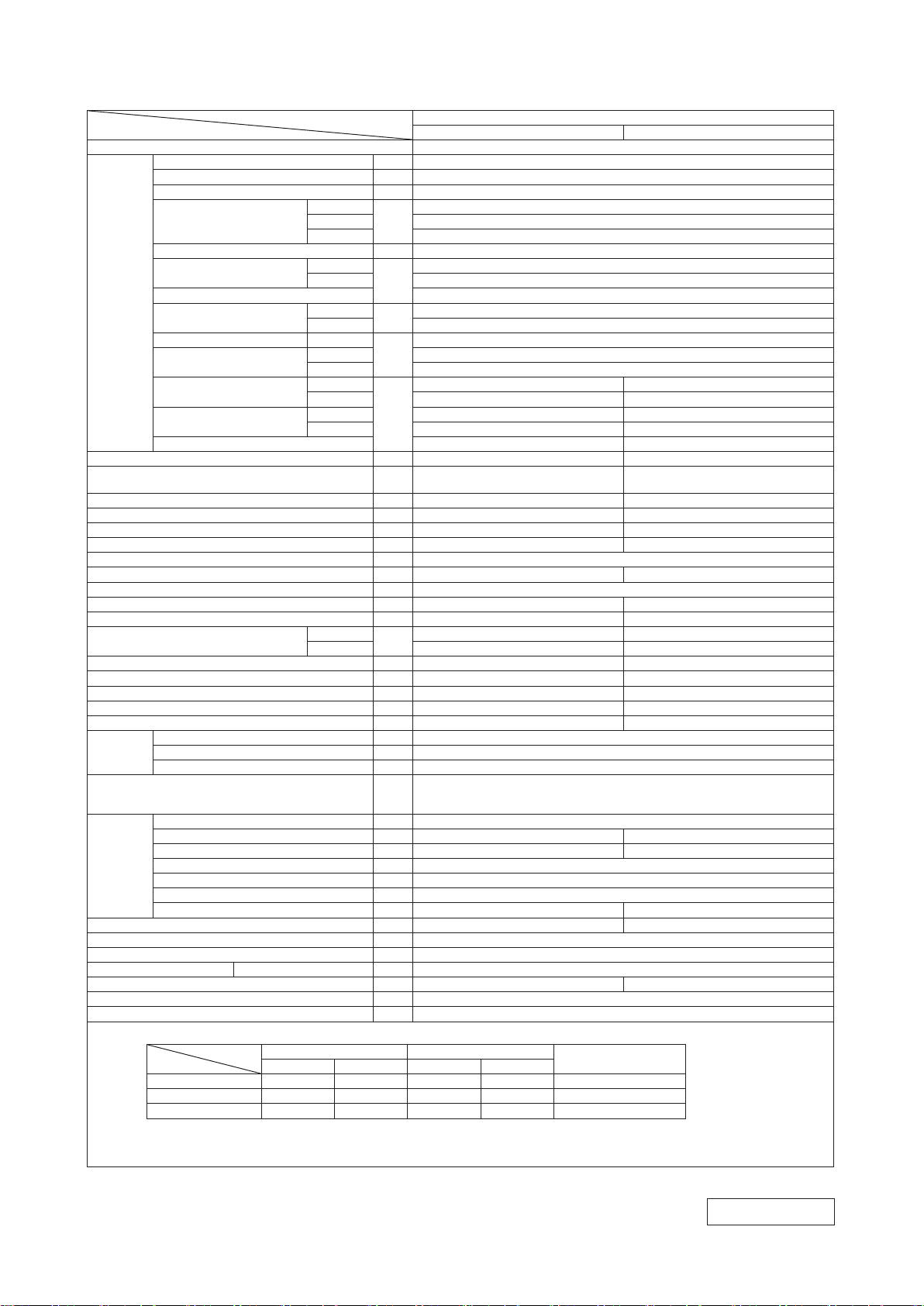

Page 7

'18 • SRK-T-250

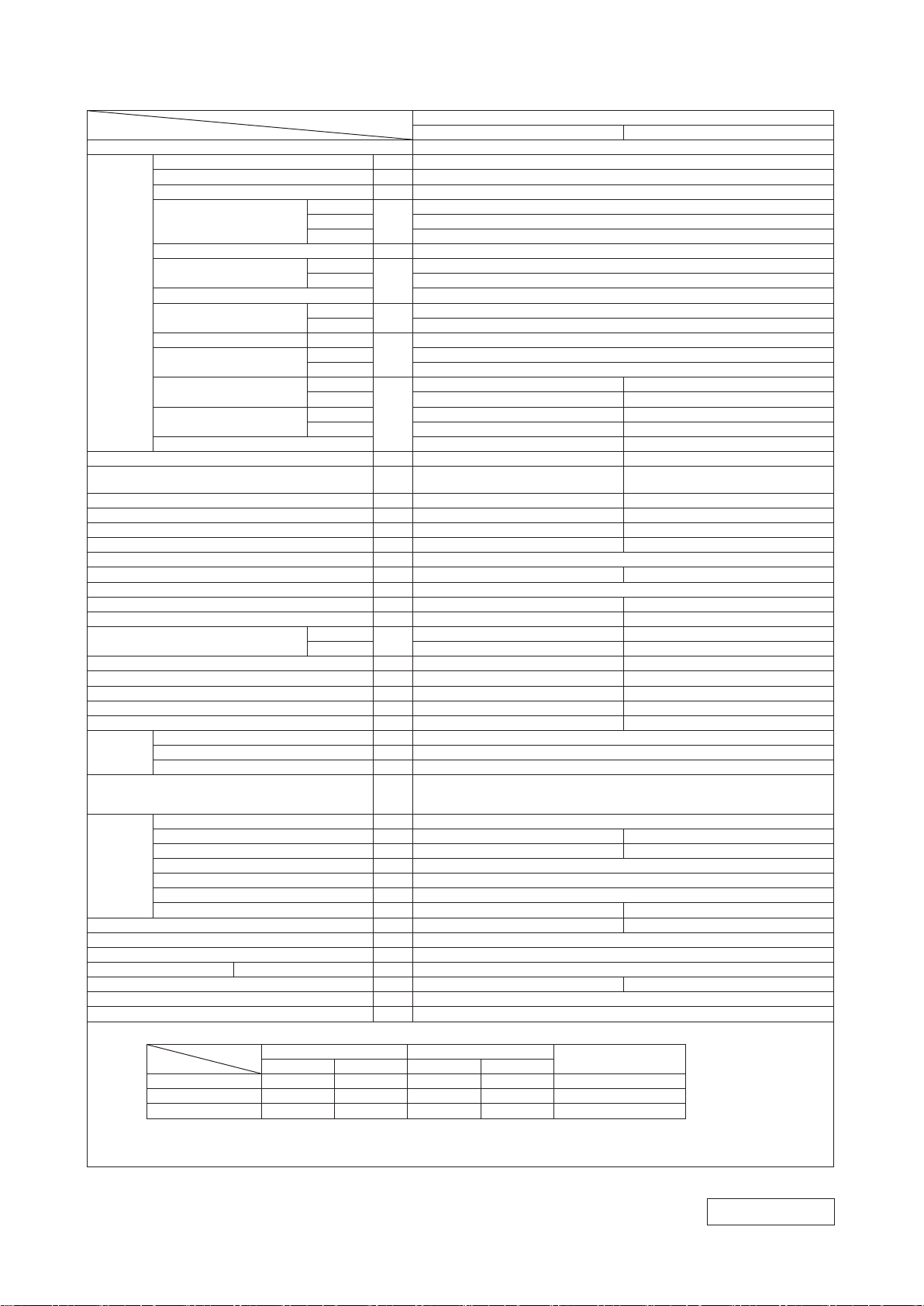

Item

Power source 1 Phase, 220 - 240V, 50Hz / 220V, 60Hz

Operation

data

Exterior dimensions (Height x Width x Depth) mm 290 x 870 x 230 595 x 780(+62) x 290

Exterior appearance

(Equivalent color : Munsell, RAL)

Net weight kg 10.0 36.0

Compressor type & Quantity — 9RS102XDA21( Rotary type ) x 1

Compressor motor (Starting method) kW — 1.50 ( Inverter driven )

Refrigerant oil (Amount, type) ℓ — 0.32 ( FW50S )

Refrigerant (Type, amount, pre-charge length) kg R32 1.05 in outdoor unit (Incl. the amount for the piping of 15m )

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Fan type & Quantity Tangential fan x 1 Propeller fan x 1

Fan motor (Starting method) W 42 x1 (Direct drive) 24 x1 (Direct drive)

Air flow

Available external static pressure Pa 0 0

Outside air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (Washable) x 2 —

Shock & vibration absorber Rubber sleeve (for fan motor)

Electric heater — —

Operation

control

Safety equipments

Installation

data

Drain pump, max lift height mm — —

Recommended breaker size A 20

L.R.A. (Locked rotor ampere) A 7.2 / 6.9 / 6.6 (220/ 230/ 240V)

Interconnecting wires Size x Core number 1.5mm

IP number IPX0 IPX4

Standard accessories

Option parts Interface kit ( SC-BIKN2-E )

Nominal cooling capacity (range) kW 5.0 ( 1.3 (Min.) - 5.5 (Max.))

Nominal heating capacity (range) kW 5.8 ( 1.3 (Min.) - 6.6 (Max.))

Heating capacity (H2) kW —

Power consumption

Max power consumption 2.68

Running current

Inrush current, max current 7.2 / 6.9 / 6.6 (220/ 230/ 240V)

Power factor

EER Cooling 3.70

COP

Sound power level

Sound pressure level

Silent mode sound pressure level — Cooling:43 / Heating:45

Remote control Wireless-remote control

Room temperature control Microcomputer thermostat

Operation display RUN: Green , TIMER: Yellow

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ12.7 (1/2" )

Connecting method Flare connection Flare connection

Attached length of piping m Liquid line : 0.54 / Gas line : 0.47 —

Insulation for piping Necessary ( Both sides ), independent

Refrigerant line (one way) length m Max.25

Vertical height diff. between O.U. and I.U. m Max.15 ( Outdoor unit is higher ) / Max.15 ( Outdoor unit is lower )

Drain hose Hose connectable ( VP 16 ) Hole φ20 x 2 pcs

Cooling

Heating 1.56 ( 0.25 - 1.98 )

Heating (H2) —

Cooling

Heating 7.2 / 6.9 / 6.6 (220/ 230/ 240V)

Cooling

Heating 99

Heating 3.72

Heating (H2) —

Cooling

Heating 60 63

Cooling Hi: 46 Me: 36 Lo: 29 ULo: 22 51

Heating Hi: 46 Me: 37 Lo: 31 ULo: 24 52

Cooling

Heating Hi: 13.9 Me: 11.2 Lo: 9.1 ULo: 7.4 32.8

Model

kW

A

%

dB(A)

3

m

/min

Indoor unit SRK50ZS-W Outdoor unit SRC50ZS-W

59 61

Fine snow (Pure white)

( 8.0Y 9.3/0.1 ) , ( 9003 )

Hi: 12.1 Me: 9.9 Lo: 7.4 ULo: 5.9 32.8

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection( High pressure control ), Cooling overload protection

Mounting kit, Clean filter ( Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1 )

Compressor overheat protection, Overcurrent protection,

2

x 4 cores (Including earth cable) / Terminal block (Screw fixing type)

Notes (1) The data are measured at the following conditions.

Indoor air temperature Outdoor air temperature

Operation

Cooling 27˚C 19˚C 35˚C 24˚C ISO5151-T1

Heating 20˚C — 7˚C 6˚C ISO5151-H1

Heating (H2) 20˚C — 2˚C 1˚C ISO5151-H2

Item

DB WB DB WB

SRK50ZS-W

1.35 ( 0.29 - 1.80 )

6.2 / 5.9 / 5.7 (220/ 230/ 240V)

Max. 14.5

99

The pipe length is 5m.

Standards

( 4.2Y 7.5/1.1 ) , ( 7044 )

Rubber sleeve (for fan motor & compressor)

Stucco white

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound level indicates the value in an anechoic chamber. During operation these values are somewhat higher due to ambient conditions.

(4) Select the breaker size according to the own national standard.

RWA000Z274

-

-

6

Page 8

'18 • SRK-T-250

Item

Power source 1 Phase, 220 - 240V, 50Hz / 220V, 60Hz

Operation

data

Exterior dimensions (Height x Width x Depth) mm 290 x 870 x 230 540 x 780(+62) x 290

Exterior appearance

(Equivalent color : Munsell, RAL)

Net weight kg 9.5 31.0

Compressor type & Quantity — RM-C5077SBE71( Rotary type ) x 1

Compressor motor (Starting method) kW — 0.75 ( Inverter driven )

Refrigerant oil (Amount, type) ℓ — 0.30 ( DIAMOND FREEZE MB75 )

Refrigerant (Type, amount, pre-charge length) kg R32 0.6 in outdoor unit (Incl. the amount for the piping of 15m )

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Fan type & Quantity Tangential fan x 1 Propeller fan x 1

Fan motor (Starting method) W 42 x1 (Direct drive) 24 x1 (Direct drive)

Air flow

Available external static pressure Pa 0 0

Outside air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (Washable) x 2 —

Shock & vibration absorber Rubber sleeve (for fan motor)

Electric heater — —

Operation

control

Safety equipments

Installation

data

Drain pump, max lift height mm — —

Recommended breaker size A 16

L.R.A. (Locked rotor ampere) A 3.2 / 3.0 / 2.9 (220/ 230/ 240V)

Interconnecting wires Size x Core number 1.5mm

IP number IPX0 IPX4

Standard accessories

Option parts Interface kit ( SC-BIKN2-E )

Nominal cooling capacity (range) kW 2.0 ( 0.9 (Min.) - 2.9 (Max.))

Nominal heating capacity (range) kW 2.7 ( 0.9 (Min.) - 4.3 (Max.))

Heating capacity (H2) kW —

Power consumption

Max power consumption 1.65

Running current

Inrush current, max current 3.2 / 3.0 / 2.9 (220/ 230/ 240V)

Power factor

EER Cooling 4.55

COP

Sound power level

Sound pressure level

Silent mode sound pressure level — Cooling:42 / Heating:43

Remote control Wireless-remote control

Room temperature control Microcomputer thermostat

Operation display RUN: Green , TIMER: Yellow

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connection Flare connection

Attached length of piping m Liquid line : 0.54 / Gas line : 0.47 —

Insulation for piping Necessary ( Both sides ), independent

Refrigerant line (one way) length m Max.20

Vertical height diff. between O.U. and I.U. m Max.10 ( Outdoor unit is higher ) / Max.10 ( Outdoor unit is lower )

Drain hose Hose connectable ( VP 16 ) Hole φ20 x 2 pcs

Cooling

Heating 0.59 ( 0.20 - 1.40 )

Heating (H2) —

Cooling

Heating 3.2 / 3.0 / 2.9 (220/ 230/ 240V)

Cooling

Heating 85

Heating 4.58

Heating (H2) —

Cooling

Heating 50 56

Cooling Hi: 34 Me: 25 Lo: 22 ULo: 19 45

Heating Hi: 36 Me: 29 Lo: 23 ULo: 19 45

Cooling

Heating Hi: 10.0 Me: 8.5 Lo: 6.5 ULo: 5.9 23.6

Model

kW

A

%

dB(A)

3

m

/min

Indoor unit SRK20ZS-WB Outdoor unit SRC20ZS-W

48 56

Fine snow ( 8.0Y 9.3/0.1 ) , ( 9003 )

Black ( 4.0PB 2.44/0.25 ) , ( 9011 )

Hi: 9.3 Me: 7.0 Lo: 5.9 ULo: 5.0 27.4

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection( High pressure control ), Cooling overload protection

Mounting kit, Clean filter ( Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1 )

Compressor overheat protection, Overcurrent protection,

2

x 4 cores (Including earth cable) / Terminal block (Screw fixing type)

Notes (1) The data are measured at the following conditions.

Indoor air temperature Outdoor air temperature

Operation

Cooling 27˚C 19˚C 35˚C 24˚C ISO5151-T1

Heating 20˚C — 7˚C 6˚C ISO5151-H1

Heating (H2) 20˚C — 2˚C 1˚C ISO5151-H2

Item

DB WB DB WB

SRK20ZS-WB

0.44 ( 0.19 - 0.80 )

2.6 / 2.5 / 2.4 (220/ 230/ 240V)

79

( 4.2Y 7.5/1.1 ) , ( 7044 )

Rubber sleeve (for fan motor & compressor)

The pipe length is 5m.

Standards

Max. 9

Stucco white

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound level indicates the value in an anechoic chamber. During operation these values are somewhat higher due to ambient conditions.

(4) Select the breaker size according to the own national standard.

RWA000Z274

-

-

7

Page 9

'18 • SRK-T-250

Item

Power source 1 Phase, 220 - 240V, 50Hz / 220V, 60Hz

Operation

data

Exterior dimensions (Height x Width x Depth) mm 290 x 870 x 230 540 x 780(+62) x 290

Exterior appearance

(Equivalent color : Munsell, RAL)

Net weight kg 9.5 31.0

Compressor type & Quantity — RM-C5077SBE71( Rotary type ) x 1

Compressor motor (Starting method) kW — 0.75 ( Inverter driven )

Refrigerant oil (Amount, type) ℓ — 0.30 ( DIAMOND FREEZE MB75 )

Refrigerant (Type, amount, pre-charge length) kg R32 0.62 in outdoor unit (Incl. the amount for the piping of 15m )

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Fan type & Quantity Tangential fan x 1 Propeller fan x 1

Fan motor (Starting method) W 42 x1 (Direct drive) 24 x1 (Direct drive)

Air flow

Available external static pressure Pa 0 0

Outside air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (Washable) x 2 —

Shock & vibration absorber Rubber sleeve (for fan motor)

Electric heater — —

Operation

control

Safety equipments

Installation

data

Drain pump, max lift height mm — —

Recommended breaker size A 16

L.R.A. (Locked rotor ampere) A 3.7 / 3.6 / 3.4 (220/ 230/ 240V)

Interconnecting wires Size x Core number 1.5mm

IP number IPX0 IPX4

Standard accessories

Option parts Interface kit ( SC-BIKN2-E )

Nominal cooling capacity (range) kW 2.5 ( 0.9 (Min.) - 3.1 (Max.))

Nominal heating capacity (range) kW 3.2 ( 0.9 (Min.) - 4.5 (Max.))

Heating capacity (H2) kW —

Power consumption

Max power consumption 1.65

Running current

Inrush current, max current 3.7 / 3.6 / 3.4 (220/ 230/ 240V)

Power factor

EER Cooling 4.03

COP

Sound power level

Sound pressure level

Silent mode sound pressure level — Cooling:42 / Heating:43

Remote control Wireless-remote control

Room temperature control Microcomputer thermostat

Operation display RUN: Green , TIMER: Yellow

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connection Flare connection

Attached length of piping m Liquid line : 0.54 / Gas line : 0.47 —

Insulation for piping Necessary ( Both sides ), independent

Refrigerant line (one way) length m Max.20

Vertical height diff. between O.U. and I.U. m Max.10 ( Outdoor unit is higher ) / Max.10 ( Outdoor unit is lower )

Drain hose Hose connectable ( VP 16 ) Hole φ20 x 2 pcs

Cooling

Heating 0.74 ( 0.20 - 1.42 )

Heating (H2) —

Cooling

Heating 3.7 / 3.6 / 3.4 (220/ 230/ 240V)

Cooling

Heating 90

Heating 4.32

Heating (H2) —

Cooling

Heating 53 58

Cooling Hi: 36 Me: 28 Lo: 23 ULo: 19 46

Heating Hi: 39 Me: 30 Lo: 24 ULo: 19 46

Cooling

Heating Hi: 11.3 Me: 8.7 Lo: 6.7 ULo: 5.9 23.6

Model

kW

A

%

dB(A)

3

m

/min

Indoor unit SRK25ZS-WB Outdoor unit SRC25ZS-W

50 56

Fine snow ( 8.0Y 9.3/0.1 ) , ( 9003 )

Black ( 4.0PB 2.44/0.25 ) , ( 9011 )

Hi: 9.9 Me: 8.0 Lo: 5.9 ULo: 5.0 27.4

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection( High pressure control ), Cooling overload protection

Mounting kit, Clean filter ( Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1 )

Compressor overheat protection, Overcurrent protection,

2

x 4 cores (Including earth cable) / Terminal block (Screw fixing type)

Notes (1) The data are measured at the following conditions.

Indoor air temperature Outdoor air temperature

Operation

Cooling 27˚C 19˚C 35˚C 24˚C ISO5151-T1

Heating 20˚C — 7˚C 6˚C ISO5151-H1

Heating (H2) 20˚C — 2˚C 1˚C ISO5151-H2

Item

DB WB DB WB

SRK25ZS-WB

0.62 ( 0.19 - 0.90 )

3.3 / 3.1 / 3.0 (220/ 230/ 240V)

86

( 4.2Y 7.5/1.1 ) , ( 7044 )

Rubber sleeve (for fan motor & compressor)

The pipe length is 5m.

Standards

Max. 9

Stucco white

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound level indicates the value in an anechoic chamber. During operation these values are somewhat higher due to ambient conditions.

(4) Select the breaker size according to the own national standard.

RWA000Z274

-

-

8

Page 10

'18 • SRK-T-250

Item

Power source 1 Phase, 220 - 240V, 50Hz / 220V, 60Hz

Operation

data

Exterior dimensions (Height x Width x Depth) mm 290 x 870 x 230 540 x 780(+62) x 290

Exterior appearance

(Equivalent color : Munsell, RAL)

Net weight kg 9.5 34.5

Compressor type & Quantity — RM-B5077SBE2( Rotary type ) x 1

Compressor motor (Starting method) kW — 0.90 ( Inverter driven )

Refrigerant oil (Amount, type) ℓ — 0.30 ( DIAMOND FREEZE MB75 )

Refrigerant (Type, amount, pre-charge length) kg R32 0.78 in outdoor unit (Incl. the amount for the piping of 15m )

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Fan type & Quantity Tangential fan x 1 Propeller fan x 1

Fan motor (Starting method) W 42 x1 (Direct drive) 24 x1 (Direct drive)

Air flow

Available external static pressure Pa 0 0

Outside air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (Washable) x 2 —

Shock & vibration absorber Rubber sleeve (for fan motor)

Electric heater — —

Operation

control

Safety equipments

Installation

data

Drain pump, max lift height mm — —

Recommended breaker size A 16

L.R.A. (Locked rotor ampere) A 4.6 / 4.4 / 4.2 (220/ 230/ 240V)

Interconnecting wires Size x Core number 1.5mm

IP number IPX0 IPX4

Standard accessories

Option parts Interface kit ( SC-BIKN2-E )

Nominal cooling capacity (range) kW 3.5 ( 0.9 (Min.) - 4.0 (Max.))

Nominal heating capacity (range) kW 4.0 ( 0.9 (Min.) - 5.0 (Max.))

Heating capacity (H2) kW —

Power consumption

Max power consumption 1.65

Running current

Inrush current, max current 4.6 / 4.4 / 4.2 (220/ 230/ 240V)

Power factor

EER Cooling 3.93

COP

Sound power level

Sound pressure level

Silent mode sound pressure level — Cooling:45 / Heating:44

Remote control Wireless-remote control

Room temperature control Microcomputer thermostat

Operation display RUN: Green , TIMER: Yellow

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connection Flare connection

Attached length of piping m Liquid line : 0.54 / Gas line : 0.47 —

Insulation for piping Necessary ( Both sides ), independent

Refrigerant line (one way) length m Max.20

Vertical height diff. between O.U. and I.U. m Max.10 ( Outdoor unit is higher ) / Max.10 ( Outdoor unit is lower )

Drain hose Hose connectable ( VP 16 ) Hole φ20 x 2 pcs

Cooling

Heating 0.94 ( 0.19 - 1.45 )

Heating (H2) —

Cooling

Heating 4.6 / 4.4 / 4.2 (220/ 230/ 240V)

Cooling

Heating 93

Heating 4.26

Heating (H2) —

Cooling

Heating 56 61

Cooling Hi: 40 Me: 30 Lo: 26 ULo: 19 50

Heating Hi: 41 Me: 36 Lo: 25 ULo:19 48

Cooling

Heating Hi: 12.3 Me: 11.0 Lo: 7.0 ULo: 5.6 27.8

Model

kW

A

%

dB(A)

3

m

/min

Indoor unit SRK35ZS-WB Outdoor unit SRC35ZS-W

54 61

Fine snow ( 8.0Y 9.3/0.1 ) , ( 9003 )

Black ( 4.0PB 2.44/0.25 ) , ( 9011 )

Hi: 11.3 Me: 8.7 Lo: 7.0 ULo: 5.0 31.5

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection( High pressure control ), Cooling overload protection

Mounting kit, Clean filter ( Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1 )

Compressor overheat protection, Overcurrent protection,

2

x 4 cores (Including earth cable) / Terminal block (Screw fixing type)

Notes (1) The data are measured at the following conditions.

Indoor air temperature Outdoor air temperature

Operation

Cooling 27˚C 19˚C 35˚C 24˚C ISO5151-T1

Heating 20˚C — 7˚C 6˚C ISO5151-H1

Heating (H2) 20˚C — 2˚C 1˚C ISO5151-H2

Item

DB WB DB WB

SRK35ZS-WB

0.89 ( 0.17 - 1.24 )

4.4 / 4.2 / 4.0 (220/ 230/ 240V)

92

( 4.2Y 7.5/1.1 ) , ( 7044 )

Rubber sleeve (for fan motor & compressor)

The pipe length is 5m.

Standards

Max. 9

Stucco white

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound level indicates the value in an anechoic chamber. During operation these values are somewhat higher due to ambient conditions.

(4) Select the breaker size according to the own national standard.

RWA000Z274

-

-

9

Page 11

'18 • SRK-T-250

Item

Power source 1 Phase, 220 - 240V, 50Hz / 220V, 60Hz

Operation

data

Exterior dimensions (Height x Width x Depth) mm 290 x 870 x 230 595 x 780(+62) x 290

Exterior appearance

(Equivalent color : Munsell, RAL)

Net weight kg 10.0 36.0

Compressor type & Quantity — 9RS102XDA21( Rotary type ) x 1

Compressor motor (Starting method) kW — 1.50 ( Inverter driven )

Refrigerant oil (Amount, type) ℓ — 0.32 ( FW50S )

Refrigerant (Type, amount, pre-charge length) kg R32 1.05 in outdoor unit (Incl. the amount for the piping of 15m )

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Fan type & Quantity Tangential fan x 1 Propeller fan x 1

Fan motor (Starting method) W 42 x1 (Direct drive) 24 x1 (Direct drive)

Air flow

Available external static pressure Pa 0 0

Outside air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (Washable) x 2 —

Shock & vibration absorber Rubber sleeve (for fan motor)

Electric heater — —

Operation

control

Safety equipments

Installation

data

Drain pump, max lift height mm — —

Recommended breaker size A 20

L.R.A. (Locked rotor ampere) A 7.2 / 6.9 / 6.6 (220/ 230/ 240V)

Interconnecting wires Size x Core number 1.5mm

IP number IPX0 IPX4

Standard accessories

Option parts Interface kit ( SC-BIKN2-E )

Nominal cooling capacity (range) kW 5.0 ( 1.3 (Min.) - 5.5 (Max.))

Nominal heating capacity (range) kW 5.8 ( 1.3 (Min.) - 6.6 (Max.))

Heating capacity (H2) kW —

Power consumption

Max power consumption 2.68

Running current

Inrush current, max current 7.2 / 6.9 / 6.6 (220/ 230/ 240V)

Power factor

EER Cooling 3.70

COP

Sound power level

Sound pressure level

Silent mode sound pressure level — Cooling:43 / Heating:45

Remote control Wireless-remote control

Room temperature control Microcomputer thermostat

Operation display RUN: Green , TIMER: Yellow

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ12.7 (1/2" )

Connecting method Flare connection Flare connection

Attached length of piping m Liquid line : 0.54 / Gas line : 0.47 —

Insulation for piping Necessary ( Both sides ), independent

Refrigerant line (one way) length m Max.25

Vertical height diff. between O.U. and I.U. m Max.15 ( Outdoor unit is higher ) / Max.15 ( Outdoor unit is lower )

Drain hose Hose connectable ( VP 16 ) Hole φ20 x 2 pcs

Cooling

Heating 1.56 ( 0.25 - 1.98 )

Heating (H2) —

Cooling

Heating 7.2 / 6.9 / 6.6 (220/ 230/ 240V)

Cooling

Heating 99

Heating 3.72

Heating (H2) —

Cooling

Heating 60 63

Cooling Hi: 46 Me: 36 Lo: 29 ULo: 22 51

Heating Hi: 46 Me: 37 Lo: 31 ULo: 24 52

Cooling

Heating Hi: 13.9 Me: 11.2 Lo: 9.1 ULo: 7.4 32.8

Model

kW

A

%

dB(A)

3

m

/min

Indoor unit SRK50ZS-WB Outdoor unit SRC50ZS-W

59 61

Fine snow ( 8.0Y 9.3/0.1 ) , ( 9003 )

Black ( 4.0PB 2.44/0.25 ) , ( 9011 )

Hi: 12.1 Me: 9.9 Lo: 7.4 ULo: 5.9 32.8

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection( High pressure control ), Cooling overload protection

Mounting kit, Clean filter ( Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1 )

Compressor overheat protection, Overcurrent protection,

2

x 4 cores (Including earth cable) / Terminal block (Screw fixing type)

Notes (1) The data are measured at the following conditions.

Indoor air temperature Outdoor air temperature

Operation

Cooling 27˚C 19˚C 35˚C 24˚C ISO5151-T1

Heating 20˚C — 7˚C 6˚C ISO5151-H1

Heating (H2) 20˚C — 2˚C 1˚C ISO5151-H2

Item

DB WB DB WB

SRK50ZS-WB

1.35 ( 0.29 - 1.80 )

6.2 / 5.9 / 5.7 (220/ 230/ 240V)

Max. 14.5

99

The pipe length is 5m.

Standards

( 4.2Y 7.5/1.1 ) , ( 7044 )

Rubber sleeve (for fan motor & compressor)

Stucco white

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound level indicates the value in an anechoic chamber. During operation these values are somewhat higher due to ambient conditions.

(4) Select the breaker size according to the own national standard.

-

10

RWA000Z274

-

Page 12

'18 • SRK-T-250

Item

Power source 1 Phase, 220 - 240V, 50Hz / 220V, 60Hz

Operation

data

Exterior dimensions (Height x Width x Depth) mm 290 x 870 x 230 540 x 780(+62) x 290

Exterior appearance

(Equivalent color : Munsell, RAL)

Net weight kg 9.5 31.0

Compressor type & Quantity — 9RS102XDA21( Rotary type ) x 1

Compressor motor (Starting method) kW — 1.50 ( Inverter driven )

Refrigerant oil (Amount, type) ℓ — 0.32 ( FW50S )

Refrigerant (Type, amount, pre-charge length) kg R32 0.62 in outdoor unit (Incl. the amount for the piping of 15m )

Heat exchanger 0 M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Fan type & Quantity Tangential fan x 1 Propeller fan x 1

Fan motor (Starting method) W 42 x1 (Direct drive) 24 x1 (Direct drive)

Air flow

Available external static pressure Pa 0 0

Outside air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (Washable) x 2 —

Shock & vibration absorber Rubber sleeve (for fan motor)

Electric heater — —

Operation

control

Safety equipments

Installation

data

Drain pump, max lift height mm — —

Recommended breaker size A 16

L.R.A. (Locked rotor ampere) A 3.2 / 3.0 / 2.9 (220/ 230/ 240V)

Interconnecting wires Size x Core number 1.5mm

IP number IPX0 IPX4

Standard accessories

Option parts Interface kit ( SC-BIKN2-E )

Nominal cooling capacity (range) kW 2.0 ( 0.9 (Min.) - 2.9 (Max.))

Nominal heating capacity (range) kW 2.7 ( 0.9 (Min.) - 4.3 (Max.))

Heating capacity (H2) kW —

Power consumption

Max power consumption 1.65

Running current

Inrush current, max current 3.2 / 3.0 / 2.9 (220/ 230/ 240V)

Power factor

EER Cooling 4.55

COP

Sound power level

Sound pressure level

Silent mode sound pressure level — Cooling:43 / Heating:45

Remote control Wireless-remote control

Room temperature control Microcomputer thermostat

Operation display RUN: Green , TIMER: Yellow

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connection Flare connection

Attached length of piping m Liquid line : 0.54 / Gas line : 0.47 —

Insulation for piping Necessary ( Both sides ), independent

Refrigerant line (one way) length m Max.20

Vertical height diff. between O.U. and I.U. m Max.10 ( Outdoor unit is higher ) / Max.10 ( Outdoor unit is lower )

Drain hose Hose connectable ( VP 16 ) Hole φ20 x 2 pcs

Cooling

Heating 0.59 ( 0.20 - 1.40 )

Heating (H2) —

Cooling

Heating 3.2 / 3.0 / 2.9 (220/ 230/ 240V)

Cooling

Heating 85

Heating 4.58

Heating (H2) —

Cooling

Heating 50 56

Cooling Hi: 34 Me: 25 Lo: 22 ULo: 19 45

Heating Hi: 36 Me: 29 Lo: 23 ULo: 19 45

Cooling

Heating Hi: 10.0 Me: 8.5 Lo: 6.5 ULo: 5.9 23.6

Model

kW

A

%

dB(A)

3

m

/min

Indoor unit SRK20ZS-WT Outdoor unit SRC20ZS-W

48 56

Titanium gray ( 1.6Y 6.59/0.63 ) , ( 7048 )

Black ( 4.0PB 2.44/0.25 ) , ( 9011 )

Hi: 9.3 Me: 7.0 Lo: 5.9 ULo: 5.0 27.4

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection( High pressure control ), Cooling overload protection

Mounting kit, Clean filter ( Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1 )

Compressor overheat protection, Overcurrent protection,

2

x 4 cores (Including earth cable) / Terminal block (Screw fixing type)

Notes (1) The data are measured at the following conditions.

Indoor air temperature Outdoor air temperature

Operation

Cooling 27˚C 19˚C 35˚C 24˚C ISO5151-T1

Heating 20˚C — 7˚C 6˚C ISO5151-H1

Heating (H2) 20˚C — 2˚C 1˚C ISO5151-H2

Item

DB WB DB WB

SRK20ZS-WT

0.44 ( 0.19 - 0.80 )

2.6 / 2.5 / 2.4 (220/ 230/ 240V)

79

( 4.2Y 7.5/1.1 ) , ( 7044 )

Rubber sleeve (for fan motor & compressor)

The pipe length is 5m.

Standards

Max. 9

Stucco white

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound level indicates the value in an anechoic chamber. During operation these values are somewhat higher due to ambient conditions.

(4) Select the breaker size according to the own national standard.

-

11

RWA000Z274

-

Page 13

'18 • SRK-T-250

Item

Power source 1 Phase, 220 - 240V, 50Hz / 220V, 60Hz

Operation

data

Exterior dimensions (Height x Width x Depth) mm 290 x 870 x 230 540 x 780(+62) x 290

Exterior appearance

(Equivalent color : Munsell, RAL)

Net weight kg 9.5 31.0

Compressor type & Quantity — RM-C5077SBE71( Rotary type )

Compressor motor (Starting method) kW — 0.75 ( Inverter driven )

Refrigerant oil (Amount, type) ℓ — 0.30 ( DIAMOND FREEZE MB75 )

Refrigerant (Type, amount, pre-charge length) kg R32 0.62 in outdoor unit (Incl. the amount for the piping of 15m )

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Fan type & Quantity Tangential fan x 1 Propeller fan x 1

Fan motor (Starting method) W 42 x1 (Direct drive) 24 x1 (Direct drive)

Air flow

Available external static pressure Pa 0 0

Outside air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (Washable) x 2 —

Shock & vibration absorber Rubber sleeve (for fan motor)

Electric heater — —

Operation

control

Safety equipments

Installation

data

Drain pump, max lift height mm — —

Recommended breaker size A 16

L.R.A. (Locked rotor ampere) A 3.2 / 3.0 / 2.9 (220/ 230/ 240V)

Interconnecting wires Size x Core number 1.5mm

IP number IPX0 IPX4

Standard accessories

Option parts Interface kit ( SC-BIKN2-E )

Nominal cooling capacity (range) kW 2.5 ( 0.9 (Min.) - 3.1 (Max.))

Nominal heating capacity (range) kW 3.2 ( 0.9 (Min.) - 4.5 (Max.))

Heating capacity (H2) kW —

Power consumption

Max power consumption 1.65

Running current

Inrush current, max current 3.7 / 3.6 / 3.4 (220/ 230/ 240V)

Power factor

EER Cooling 4.03

COP

Sound power level

Sound pressure level

Silent mode sound pressure level — Cooling:42 / Heating:43

Remote control Wireless-remote control

Room temperature control Microcomputer thermostat

Operation display RUN: Green , TIMER: Yellow

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connection Flare connection

Attached length of piping m Liquid line : 0.54 / Gas line : 0.47 —

Insulation for piping Necessary ( Both sides ), independent

Refrigerant line (one way) length m Max.20

Vertical height diff. between O.U. and I.U. m Max.10 ( Outdoor unit is higher ) / Max.10 ( Outdoor unit is lower )

Drain hose Hose connectable ( VP 16 ) Hole φ20 x 2 pcs

Cooling

Heating 0.74 ( 0.20 - 1.42 )

Heating (H2) —

Cooling

Heating 3.7 / 3.6 / 3.4 (220/ 230/ 240V)

Cooling

Heating 90

Heating 4.32

Heating (H2) —

Cooling

Heating 53 58

Cooling Hi: 36 Me: 28 Lo: 23 ULo: 19 46

Heating Hi: 39 Me: 30 Lo: 24 ULo: 19 46

Cooling

Heating Hi: 11.3 Me: 8.7 Lo: 6.7 ULo: 5.9 23.6

Model

kW

A

%

dB(A)

3

m

/min

Indoor unit SRK25ZS-WT Outdoor unit SRC25ZS-W

50 56

Titanium gray ( 1.6Y 6.59/0.63 ) , ( 7048 )

Black ( 4.0PB 2.44/0.25 ) , ( 9011 )

Hi: 9.9 Me: 8.0 Lo: 5.9 ULo: 5.0 27.4

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection( High pressure control ), Cooling overload protection

Mounting kit, Clean filter ( Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1 )

Compressor overheat protection, Overcurrent protection,

2

x 4 cores (Including earth cable) / Terminal block (Screw fixing type)

Notes (1) The data are measured at the following conditions.

Indoor air temperature Outdoor air temperature

Operation

Cooling 27˚C 19˚C 35˚C 24˚C ISO5151-T1

Heating 20˚C — 7˚C 6˚C ISO5151-H1

Heating (H2) 20˚C — 2˚C 1˚C ISO5151-H2

Item

DB WB DB WB

SRK25ZS-WT

0.62 ( 0.19 - 0.90 )

3.3 / 3.1 / 3.0 (220/ 230/ 240V)

86

( 4.2Y 7.5/1.1 ) , ( 7044 )

Rubber sleeve (for fan motor & compressor)

The pipe length is 5m.

Standards

Max. 9

Stucco white

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound level indicates the value in an anechoic chamber. During operation these values are somewhat higher due to ambient conditions.

(4) Select the breaker size according to the own national standard.

-

12

RWA000Z274

-

Page 14

'18 • SRK-T-250

Item

Power source 1 Phase, 220 - 240V, 50Hz / 220V, 60Hz

Operation

data

Exterior dimensions (Height x Width x Depth) mm 290 x 870 x 230 540 x 780(+62) x 290

Exterior appearance

(Equivalent color : Munsell, RAL)

Net weight kg 9.5 34.5

Compressor type & Quantity — RM-B5077SBE2( Rotary type ) x 1

Compressor motor (Starting method) kW — 0.90 ( Inverter driven )

Refrigerant oil (Amount, type) ℓ — 0.30 ( DIAMOND FREEZE MB75 )

Refrigerant (Type, amount, pre-charge length) kg R32 0.78 in outdoor unit (Incl. the amount for the piping of 15m )

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Fan type & Quantity Tangential fan x 1 Propeller fan x 1

Fan motor (Starting method) W 42 x1 (Direct drive) 24 x1 (Direct drive)

Air flow

Available external static pressure Pa 0 0

Outside air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (Washable) x 2 —

Shock & vibration absorber Rubber sleeve (for fan motor)

Electric heater — —

Operation

control

Safety equipments

Installation

data

Drain pump, max lift height mm — —

Recommended breaker size A 16

L.R.A. (Locked rotor ampere) A 4.6 / 4.4 / 4.2 (220/ 230/ 240 V)

Interconnecting wires Size x Core number 1.5mm

IP number IPX0 IPX4

Standard accessories

Option parts Interface kit ( SC-BIKN2-E )

Nominal cooling capacity (range) kW 3.5 ( 0.9 (Min.) - 4.0 (Max.))

Nominal heating capacity (range) kW 4.0 ( 0.9 (Min.) - 5.0 (Max.))

Heating capacity (H2) kW —

Power consumption

Max power consumption 1.65

Running current

Inrush current, max current 4.6 / 4.4 / 4.2 (220/ 230/ 240 V) Max. 9

Power factor

EER Cooling 3.93

COP

Sound power level

Sound pressure level

Silent mode sound pressure level — Cooling:45 / Heating:44

Remote control Wireless-remote control

Room temperature control Microcomputer thermostat

Operation display RUN: Green , TIMER: Yellow

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connection Flare connection

Attached length of piping m Liquid line : 0.54 / Gas line : 0.47 —

Insulation for piping Necessary ( Both sides ), independent

Refrigerant line (one way) length m Max.20

Vertical height diff. between O.U. and I.U. m Max.10 ( Outdoor unit is higher ) / Max.10 ( Outdoor unit is lower )

Drain hose Hose connectable ( VP 16 ) Hole φ20 x 2 pcs

Cooling

Heating 0.94 ( 0.19 - 1.45 )

Heating (H2) —

Cooling

Heating 4.6 / 4.4 / 4.2 (220/ 230/ 240V)

Cooling

Heating 93

Heating 4.26

Heating (H2) —

Cooling

Heating 56 61

Cooling Hi: 40 Me: 30 Lo: 26 ULo: 19 50

Heating Hi: 41 Me: 36 Lo: 25 ULo:19 48

Cooling

Heating Hi: 12.3 Me: 11.0 Lo: 7.0 ULo: 5.6 27.8

Model

kW

A

%

dB(A)

3

m

/min

Indoor unit SRK35ZS-WT Outdoor unit SRC35ZS-W

54 61

Titanium gray ( 1.6Y 6.59/0.63 ) , ( 7048 )

Black ( 4.0PB 2.44/0.25 ) , ( 9011 )

Hi: 11.3 Me: 8.7 Lo: 7.0 ULo: 5.0 31.5

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection( High pressure control ), Cooling overload protection

Mounting kit, Clean filter ( Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1 )

Compressor overheat protection, Overcurrent protection,

2

x 4 cores (Including earth cable) / Terminal block (Screw fixing type)

Notes (1) The data are measured at the following conditions.

Indoor air temperature Outdoor air temperature

Operation

Cooling 27˚C 19˚C 35˚C 24˚C ISO5151-T1

Heating 20˚C — 7˚C 6˚C ISO5151-H1

Heating (H2) 20˚C — 2˚C 1˚C ISO5151-H2

Item

DB WB DB WB

SRK35ZS-WT

0.89 ( 0.17 - 1.24 )

4.4 / 4.2 / 4.0 (220/ 230/ 240V)

92

( 4.2Y 7.5/1.1 ) , ( 7044 )

Rubber sleeve (for fan motor & compressor)

The pipe length is 5m.

Standards

Stucco white

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound level indicates the value in an anechoic chamber. During operation these values are somewhat higher due to ambient conditions.

(4) Select the breaker size according to the own national standard.

-

13

RWA000Z274

-

Page 15

'18 • SRK-T-250

Item

Power source 1 Phase, 220 - 240V, 50Hz / 220V, 60Hz

Operation

data

Exterior dimensions (Height x Width x Depth) mm 290 x 870 x 230 595 x 780(+62) x 290

Exterior appearance

(Equivalent color : Munsell, RAL)

Net weight kg 10.0 36.0

Compressor type & Quantity — 9RS102XDA21( Rotary type ) x 1

Compressor motor (Starting method) kW — 1.50 ( Inverter driven )

Refrigerant oil (Amount, type) ℓ — 0.32 ( FW50S )

Refrigerant (Type, amount, pre-charge length) kg R32 1.05 in outdoor unit (Incl. the amount for the piping of 15m )

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Fan type & Quantity Tangential fan x 1 Propeller fan x 1

Fan motor (Starting method) W 42 x1 (Direct drive) 24 x1 (Direct drive)

Air flow

Available external static pressure Pa 0 0

Outside air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (Washable) x 2 —

Shock & vibration absorber Rubber sleeve (for fan motor)

Electric heater — —

Operation

control

Safety equipments

Installation

data

Drain pump, max lift height mm — —

Recommended breaker size A 16

L.R.A. (Locked rotor ampere) A 7.2 / 6.9 / 6.6 (220/ 230/ 240V)

Interconnecting wires Size x Core number 1.5mm

IP number IPX0 IPX4

Standard accessories

Option parts Interface kit ( SC-BIKN2-E )

Nominal cooling capacity (range) kW 5.0 ( 1.3 (Min.) - 5.5 (Max.))

Nominal heating capacity (range) kW 5.8 ( 1.3 (Min.) - 6.6 (Max.))

Heating capacity (H2) kW —

Power consumption

Max power consumption 2.68

Running current

Inrush current, max current 7.2 / 6.9 / 6.6 (220/ 230/ 240V) Max. 14.5

Power factor

EER Cooling 3.70

COP

Sound power level

Sound pressure level

Silent mode sound pressure level — Cooling:45 / Heating:44

Remote control Wireless-remote control

Room temperature control Microcomputer thermostat

Operation display RUN: Green , TIMER: Yellow

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ12.7 (1/2" )

Connecting method Flare connection Flare connection

Attached length of piping m Liquid line : 0.54 / Gas line : 0.47 —

Insulation for piping Necessary ( Both sides ), independent

Refrigerant line (one way) length m Max.25

Vertical height diff. between O.U. and I.U. m Max.15 ( Outdoor unit is higher ) / Max.15 ( Outdoor unit is lower )

Drain hose Hose connectable ( VP 16 ) Hole φ20 x 2 pcs

Cooling

Heating 1.56 ( 0.25 - 1.98 )

Heating (H2) —

Cooling

Heating 7.2 / 6.9 / 6.6 (220/ 230/ 240V)

Cooling

Heating 99

Heating 3.72

Heating (H2) —

Cooling

Heating 60 63

Cooling Hi: 46 Me: 36 Lo: 29 ULo: 22 51

Heating Hi: 46 Me: 37 Lo: 31 ULo: 24 52

Cooling

Heating Hi: 13.9 Me: 11.2 Lo: 9.1 ULo: 7.4 32.8

Model

kW

A

%

dB(A)

3

m

/min

Indoor unit SRK50ZS-WT Outdoor unit SRC50ZS-W

59 61

Titanium gray ( 1.6Y 6.59/0.63 ) , ( 7048 )

Black ( 4.0PB 2.44/0.25 ) , ( 9011 )

Hi: 12.1 Me: 9.9 Lo: 7.4 ULo: 5.9 32.8

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection( High pressure control ), Cooling overload protection

Mounting kit, Clean filter ( Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1 )

Compressor overheat protection, Overcurrent protection,

2

x 4 cores (Including earth cable) / Terminal block (Screw fixing type)

Notes (1) The data are measured at the following conditions.

Indoor air temperature Outdoor air temperature

Operation

Cooling 27˚C 19˚C 35˚C 24˚C ISO5151-T1

Heating 20˚C — 7˚C 6˚C ISO5151-H1

Heating (H2) 20˚C — 2˚C 1˚C ISO5151-H2

Item

DB WB DB WB

SRK50ZS-WT

1.35 ( 0.29 - 1.80 )

6.2 / 5.9 / 5.7 (220/ 230/ 240V)

99

( 4.2Y 7.5/1.1 ) , ( 7044 )

Rubber sleeve (for fan motor & compressor)

The pipe length is 5m.

Standards

Stucco white

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound level indicates the value in an anechoic chamber. During operation these values are somewhat higher due to ambient conditions.

(4) Select the breaker size according to the own national standard.

-

14

RWA000Z274

-

Page 16

'18 • SRK-T-250

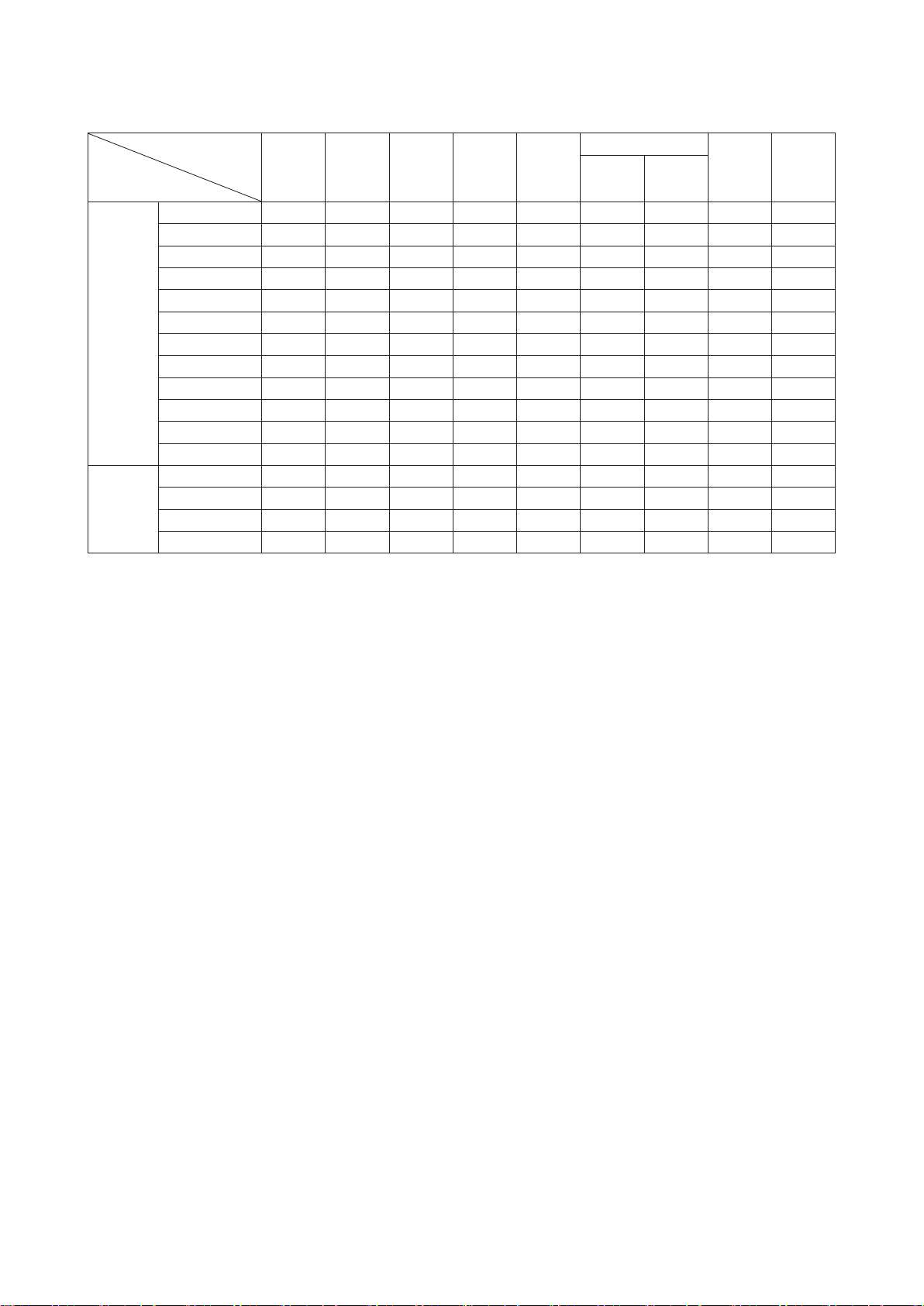

Packing material weight list

Material

Model

SRK20ZS-W 11.5 1.21 0.00 0.33 0.88 0.00 0.00 0.00 0.00

SRK25ZS-W 11.5 1.21 0.00 0.33 0.88 0.00 0.00 0.00 0.00

SRK35ZS-W 11.5 1.21 0.00 0.33 0.88 0.00 0.00 0.00 0.00

SRK50ZS-W 12.0 1.21 0.00 0.33 0.88 0.00 0.00 0.00 0.00

SRK20ZS-WB 11.5 1.21 0.00 0.33 0.88 0.00 0.00 0.00 0.00

Indoor

Outdoor

SRK25ZS-WB 11.5 1.21 0.00 0.33 0.88 0.00 0.00 0.00 0.00

SRK35ZS-WB 11.5 1.21 0.00 0.33 0.88 0.00 0.00 0.00 0.00

SRK50ZS-WB 12.0 1.21 0.00 0.33 0.88 0.00 0.00 0.00 0.00

SRK20ZS-WT 11.5 1.21 0.00 0.33 0.88 0.00 0.00 0.00 0.00

SRK25ZS-WT 11.5 1.21 0.00 0.33 0.88 0.00 0.00 0.00 0.00

SRK35ZS-WT 11.5 1.21 0.00 0.33 0.88 0.00 0.00 0.00 0.00

SRK50ZS-WT 12.0 1.21 0.00 0.33 0.88 0.00 0.00 0.00 0.00

SRC20ZS-W 32.5 2.04 0.00 0.35 1.69 0.00 0.00 0.00 0.00

SRC25ZS-W 32.5 2.04 0.00 0.35 1.69 0.00 0.00 0.00 0.00

SRC35ZS-W 36.0 2.04 0.00 0.35 1.69 0.00 0.00 0.00 0.00

SRC50ZS-W 38.0 2.13 0.00 0.35 1.78 0.00 0.00 0.00 0.00

Gross

Weight

Packing

Parts

weight

(Total)

Glass Plastic

Paper

and

board

Metal

Aluminium

Steel

Unit: kg

Wood Other

-

15

-

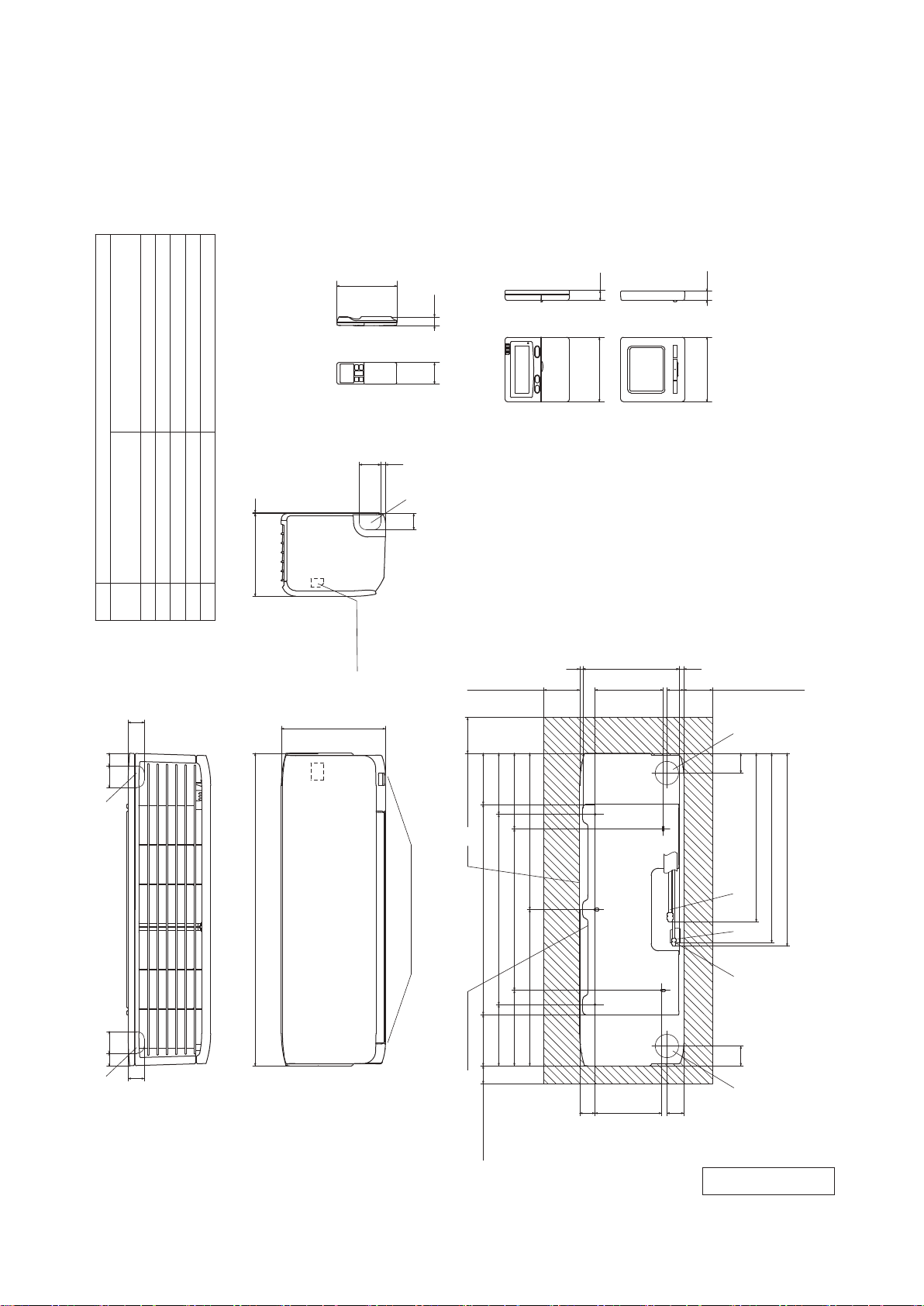

Page 17

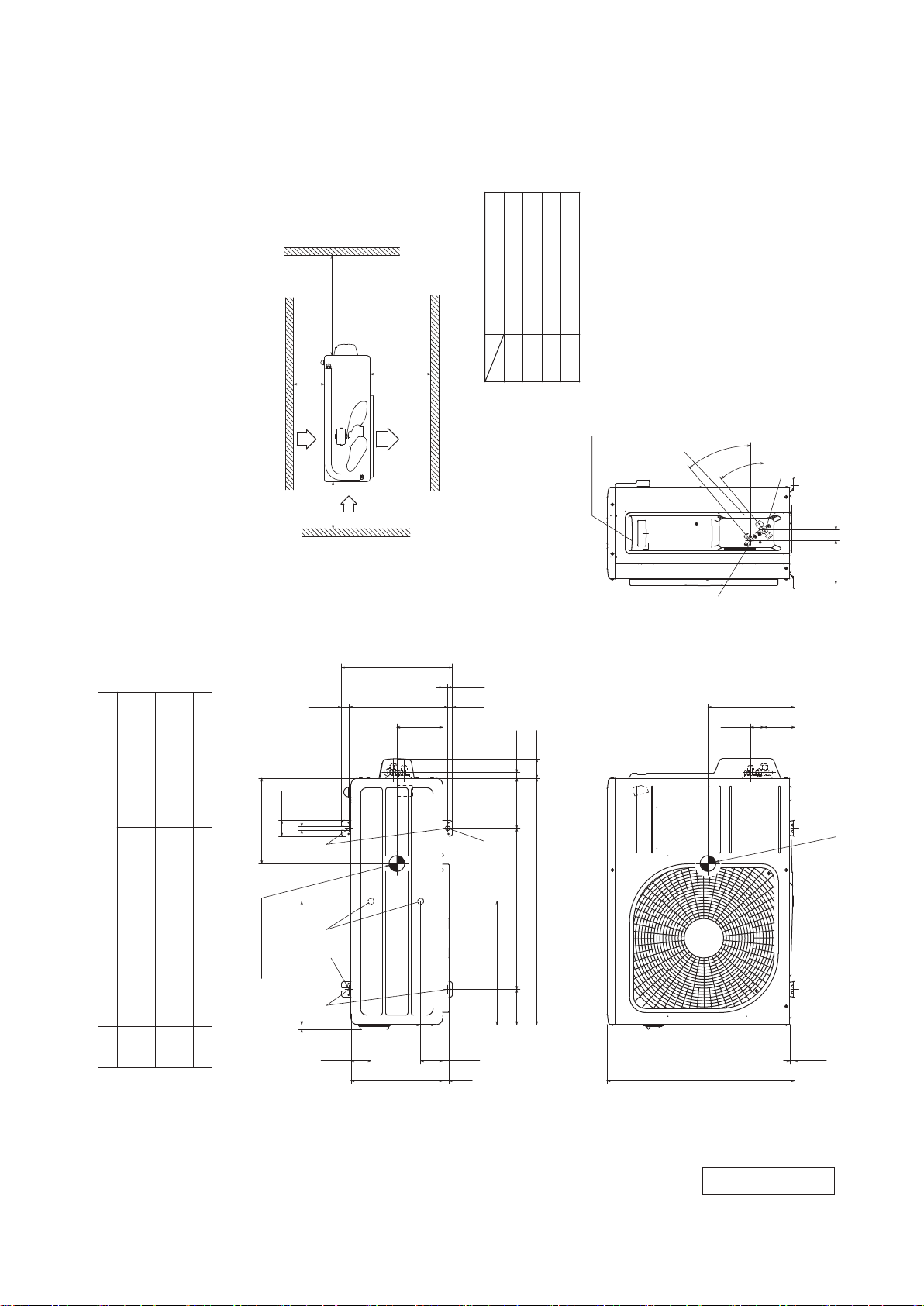

Space for installation and service when viewing from the front

2. EXTERIOR DIMENSIONS

(1) Indoor units

Models SRK20ZS-W, 25ZS-W, 35ZS-W, 50ZS-W

SRK20ZS-WB, 25ZS-WB, 35ZS-WB, 50ZS-WB

SRK20ZS-WT, 25ZS-WT, 35ZS-WT, 50ZS-WT

'18 • SRK-T-250

SRK20, 25, 35 φ9.52(3/8")(Flare)

Content

Gas piping

A

Symbol

SRK50 φ12.7(1/2")(Flare)

Liquid piping

B

45

VP16

φ6.35(1/4")(Flare)

(φ65)

(φ65)

230 3

Hole on wall for right rear piping

Hole on wall for left rear piping

Outlet for piping(on both side)

Drain hose

F

ECD

167

60 24

Wireless remote control

6013

F

45

Terminal block

290

(Option)

Wired remote control

9

(Service space)

100

19

□120

268

190

Unit:mm

□120 19

Notes(1)The model name label is attached

on the right side of the unit.

(2)To connect the wired remote control,

the interface kit(SC-BIKN2-E)is required.

13

47

80 100

(Service space)

C

60 3535 60

170

210

(Service space)

528

Unit

SRK 20,25,35 :469

537

SRK 50 :475

A

870

(Refer to the top view)

Outlet for downward piping

45

F F

530

450

585

435 435

210

170

142.5 142.5

Installation board

50

(Service space)

B

55 55

D E

185

43

47

RLF000Z103

-

16

-

Page 18

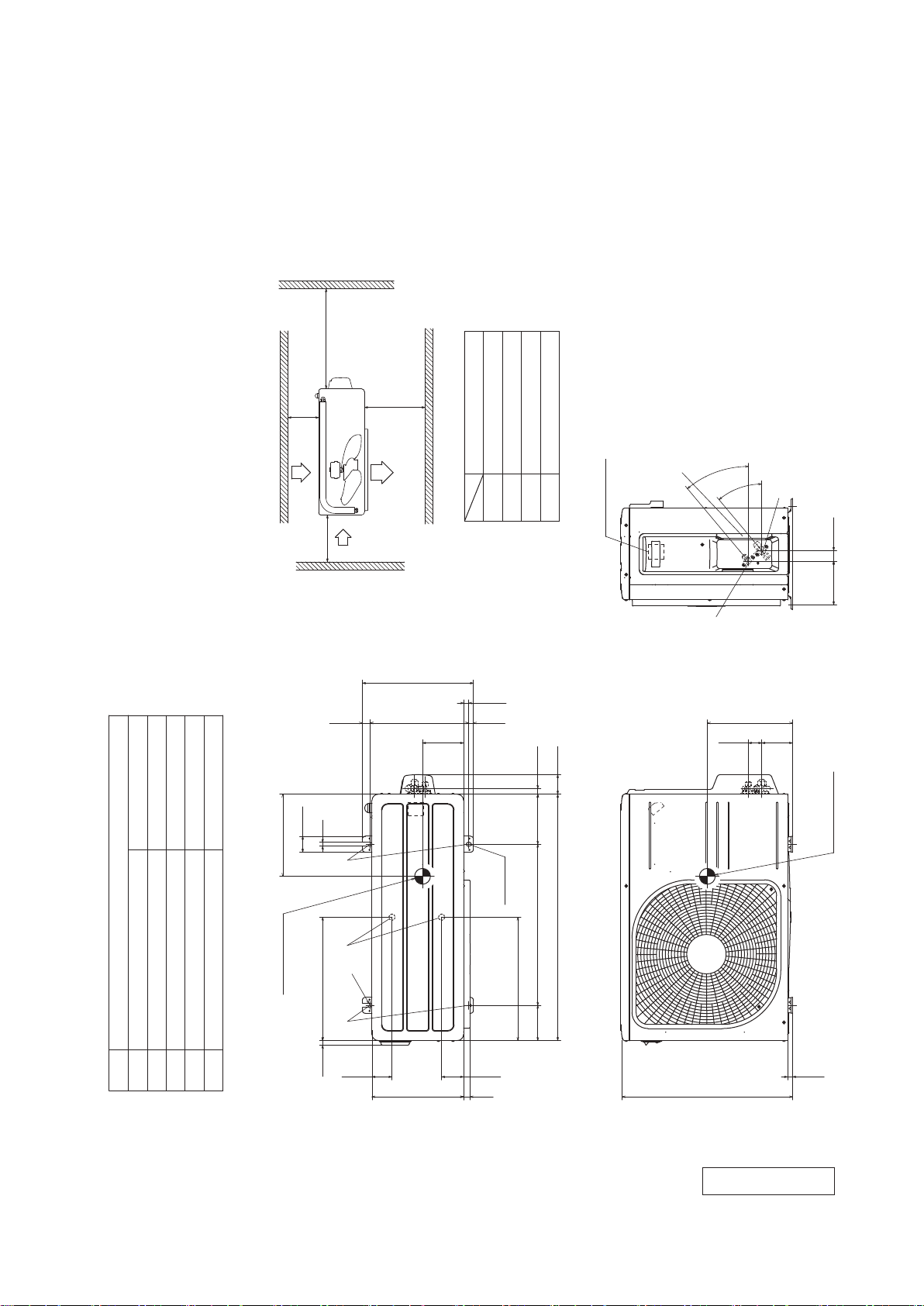

(2) Outdoor units

Models SRC20ZS-W, 25ZS-W, 35ZS-W

L4

Service

space

( )

'18 • SRK-T-250

Unit:mm

L3

Inlet

L2

protrude more than 15mm.

strong winds, place the unit such that the direction of air from the

(2) The unit must be fixed with anchor bolts. An anchor bolt must not

(1) The unit must not be surrounded by walls on the four sides.

Notes

(Flare)

φ9.52(3/8")

outlet gets perpendicular to the wind direction.

(3) If the unit is installed in the location where there is a possibility of

(Flare)

φ6.35(1/4")

(4) Leave 200mm or more space above the unit.

(5) The wall height on the outlet side should be 1200mm or less.

(6) The model name label is attached on the right side of the unit.

φ20×2 places

M10-12×4 places

260

50.6

12

L1

Outlet

Inlet

351.6

E

100 or more

280 or more

Installation space

L2L3L4

L1

16.4

14.8 312.5 24.3

130

80 or more

250 or more

17.9

Terminal block

C

40°

B

40°

A

138.4 33.5

270

97.7 42.5

Center of gravity

Content

A Service valve connection(gas side)

Symbol

Service valve connection(liquid side)

Drain discharge hole

B

E Anchor bolt hole

D

C Pipe/cable draw-out hole

D

Center of gravity

390.6

E

14.6

2-R

63.4

290540 20

-

-

17

2-12×16

Slot hole

390.6

69.4

780 61.9

111.6 510 158.4

15.8

RCV000Z036

Page 19

Model SRC50ZS-W

'18 • SRK-T-250

L4

Service

space

( )

L3

Inlet

L2

(1) The unit must not be surrounded by walls on the four sides.

(2) The unit must be fixed with anchor bolts. An anchor bolt must not

protrude more than 15mm.

(3) If the unit is installed in the location where there is a possibility of

strong winds, place the unit such that the direction of air from the

outlet gets perpendicular to the wind direction.

(4) Leave 200mm or more space above the unit.

(5) The wall height on the outlet side should be 1200mm or less.

Notes

(6) The model name label is attached on the right side of the unit.

L1

Outlet

Inlet

351.6

145

80 or more

100 or more

280 or more

Installation space

L2L3L4

L1

16.4

14.8 312.5 24.3

17.9

250 or more

Terminal block

C

40°

Unit:mm

40°

A

138.4 33.5

B

275

97.7 42.5

φ12.7(1/2")(Flare)

Content

A Service valve connection(gas side)

Symbol

φ20×2 places

M10-12×4 places

φ6.35(1/4")(Flare)

Drain discharge hole

Service valve connection(liquid side)

E Anchor bolt hole

D

B

C Pipe/cable draw-out hole

50.6

12

270

EDE

Center of gravity

390.6

14.6

2-R

63.4

29020

-

18

2-12×16

Slot hole

390.6

69.4

-

Center of gravity

780 61.9

111.6 510 158.4

15.8

595

RCV000Z037

Page 20

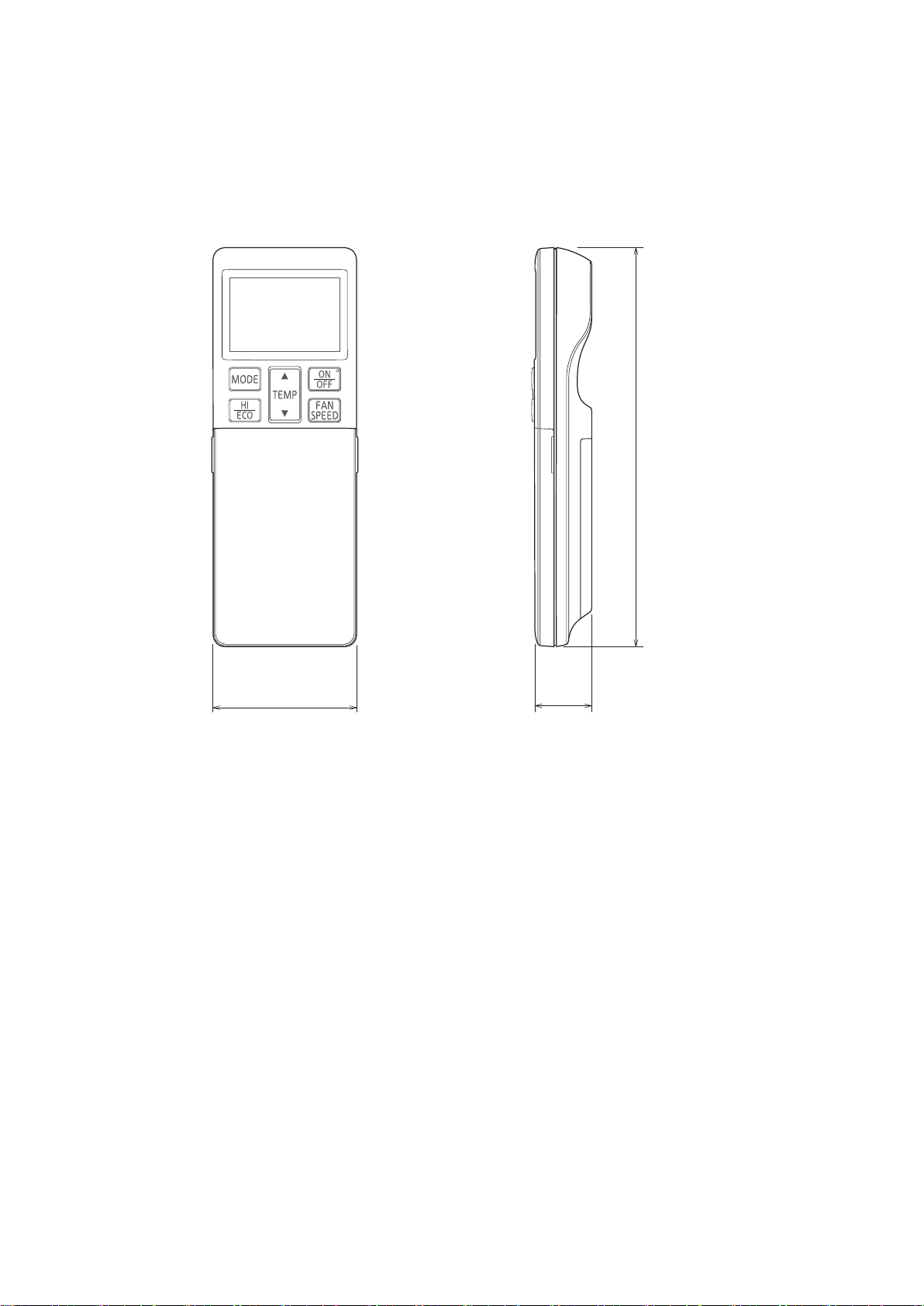

(3) Remote control

(a) Wireless remote control

'18 • SRK-T-250

Unit : mm

167

60

24

-

19

-

Page 21

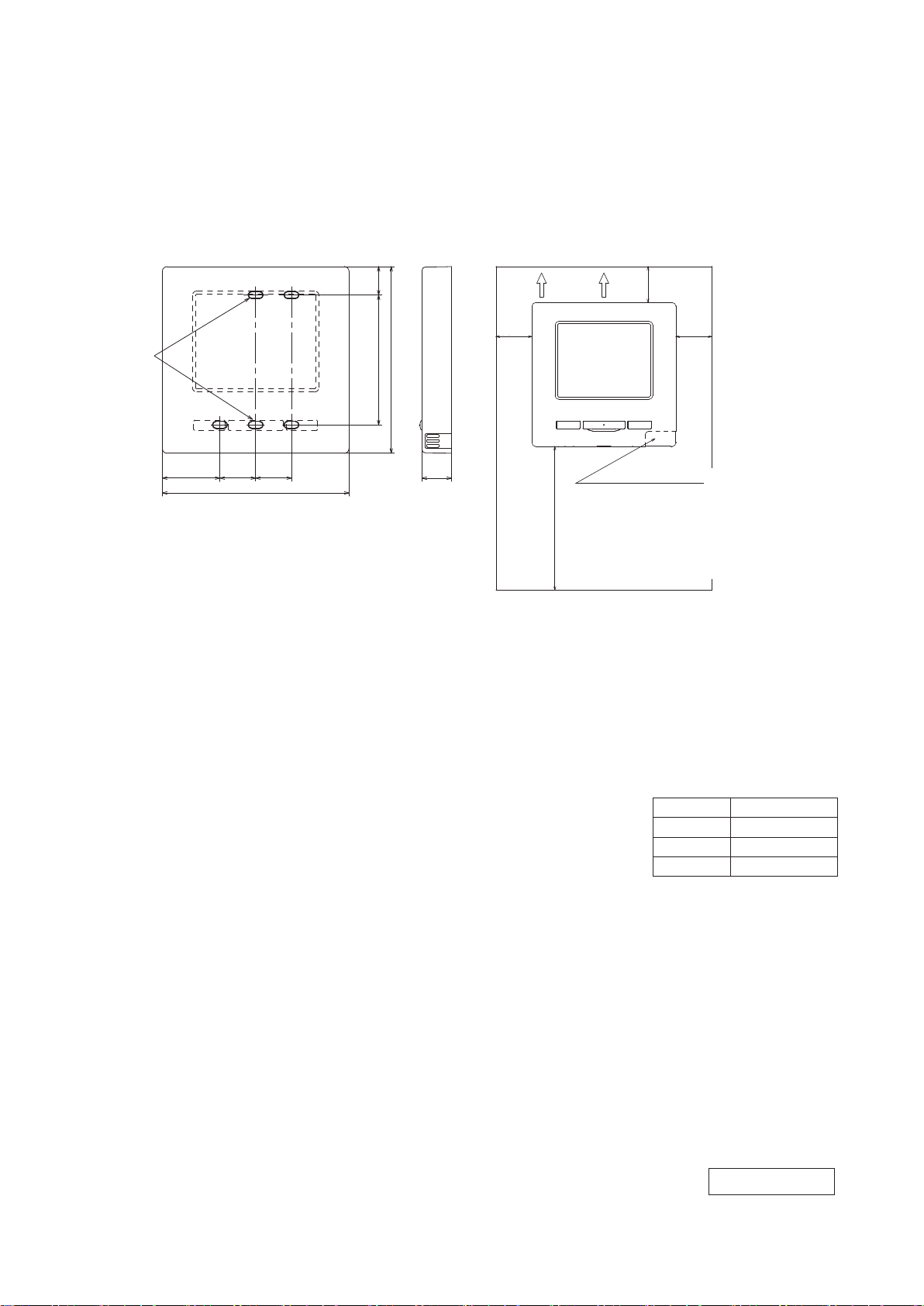

(b) Wired remote control (Option parts)

Interface kit (SC-BIKN2-E) is required to use the wired remote control.

Model RC-EX3A

'18 • SRK-T-250

Fixing holes

固定穴

Dimensions (Viewed from front)

37 23 23

37 23 23

120

120

18.3

18.383.5

120

83.5

120

19

19

Installation space

配線

Wiring

30mm

30mm

120mm

120mm

● Do not install the remote control at following places.

(1) It could cause break-down or deformation of remote control.

・Where it is exposed to direct sunlight

・Where the ambient temperature becomes 0 °C or below, or 40 °C or above

・Where the surface is not flat

・Where the strength of installation area is insufficient

(2) Moisture may be attached to internal parts of the remote control, resulting in a display failure.

・Place with high humidity where condensation occurs on the remote control

・Where the remote control gets wet

(3) Accurate room temperature may not be detected using the temperature sensor of the remote

control.

・Where the average room temperature cannot be detected

・Place near the equipment to generate heat

・Place affected by outside air in opening/closing the door

・Place exposed to direct sunlight or wind from air-conditioner

・Where the difference between wall and room temperature is large

(4) When you are using the automatic grille up and down panel in the IU, you may not be able to

confirm the up and down motion.

・Where the IU cannot be visually confirmed

30mm

30mm

30mm

30mm

R/C temperature sensor

Secure minimum spaces for disassembling the case.

Upper left and Upper right sides

……30mm or more

Bottom side…120mm or more

If using L-shaped screwdriver, 50mm or more is

available.

2

R/C cable:0.3mm

When the cable length is longer than 100 m,

the max size for wires used in the R/C case

is 0.5 mm2 . Connect them to wires of larger

size near the outside of R/C. When wires are

connected, take measures to prevent water,

etc. from entering inside.

200 m 0.5 mm

≦

300m 0.75 mm

≦

400m 1.25 mm

≦

600m 2.0 mm

≦

x2 cores

2

x 2 cores

2

x 2 cores

2

x 2 cores

2

x 2 cores

● When installing the unit at a hospital, telecommunication facility, etc., take

measures to suppress electric noises.

It could cause malfunction or break-down due to hazardous effects on the inverter, private power

generator, high frequency medical equipment, radio communication equipment, etc.

The influences transmitted from the remote control to medical or communication equipment could

disrupt medical activities, video broadcasting or cause noise interference.

-

-

20

Adapted RoHS directive

PJZ000Z333

Page 22

'18 • SRK-T-250

Wiring outlet

Model RC-E5

Exposed mounting

0.3mm2×2 cores

In case of pulling out

from upper left

L C D

48

In case of pulling out

from center

TEMP ON/OFF

ڧ120

Pearl whiteExterior appearance

(Munsell color) (N8.5) near equivalent

Embedded mounting

Cut off the upper thin part of remote control lower case with a nipper or knife,

and grind burrs with a file etc.

X, Y Terminal block

Attach M3 screw

with washer

The peeling-off length of sheath

Pulling out from upper left

Remote control installation dimensions

In case of pulling out

from upper left

Upper

Board

XY

Lower

In case of pulling out from

upper left

X wiring : 215mm

Y wiring : 195mm

In case of pulling out

from center

Upper part

Lower case

Lower part

Sheath

Upper cace

Wiring

Pulling out from center

X wiring : 170mm

Y wiring : 190mm

Upper

In case of pulling out from center

Sheath

Board

YX

Lower

Wiring

The peeling-off length

of sheath

Upper cace

Wall surface

Wiring

Electrical box

䠄Not included䠅

Remote

control

outline

83.5

Wiring oulet

12×7 Slot hole

42

120

46

23

44

11.5 11

9.5×5 Slot hole 䠄4 places䠅

Tighten the screws after

cutting off the thin part of

screw mounting part.

120

45

Installation hole

䠄1䠅 Installation screw for remote control

19

M4 screw (2 pieces)

Wiring specifications

(1) If the prolongation is over 100m, change to the size below.

But, wiring in the remote control case should be under 0.5mm

the case according to wire connecting. Waterproof treatment is necessary at the wire connecting

section. Be careful about contact failure.

2

. Change the wire size outside of

Unit:mm

Length Wiring thickness

100 to 200m

Under 300m

Under 400m

Under 600m

0.5mm

0.75mm

1.25mm

2.0mm

2

×2 cores

2

×2 cores

2

×2 cores

2

×2 cores

-

21

PJZ000Z295

-

Page 23

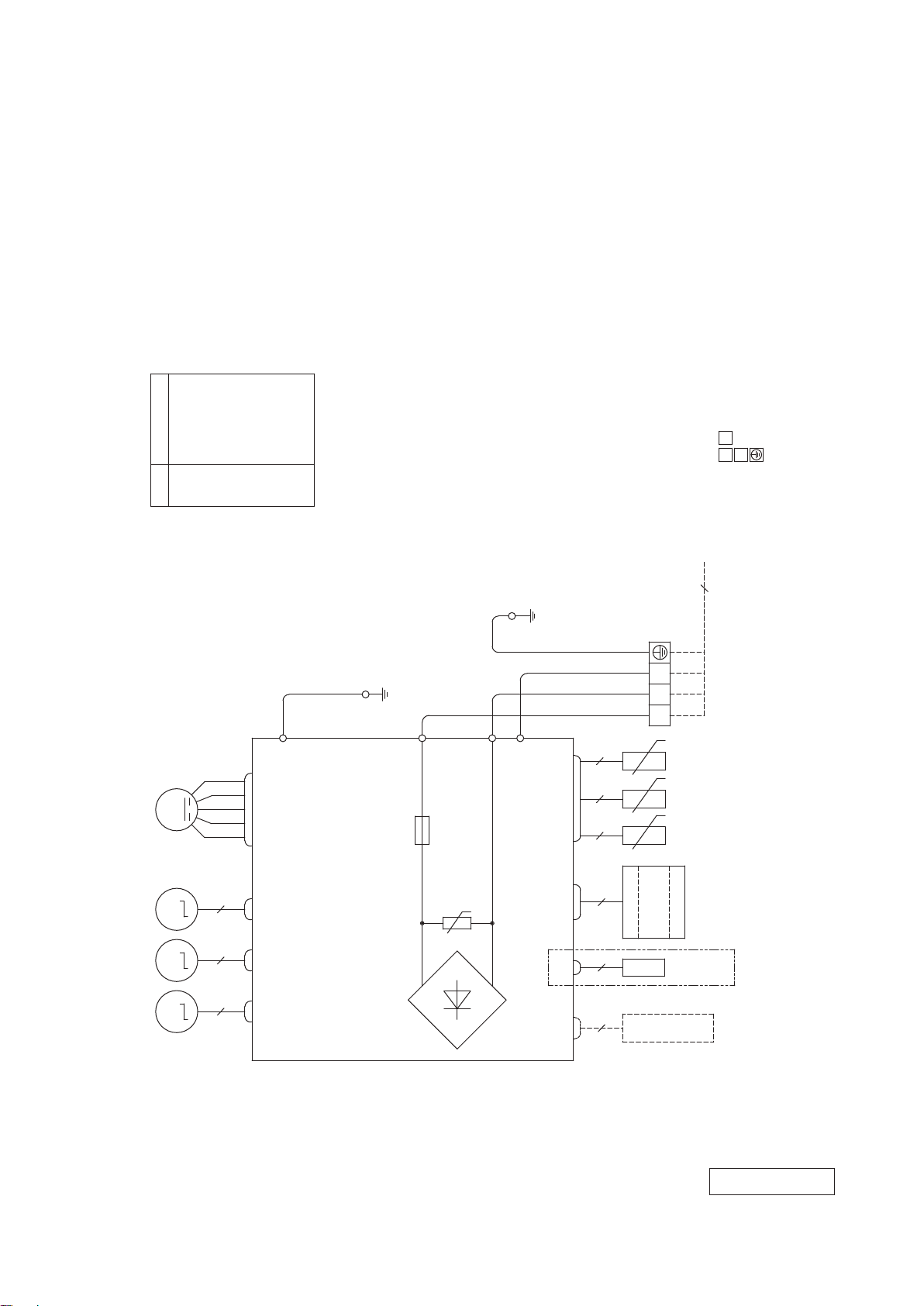

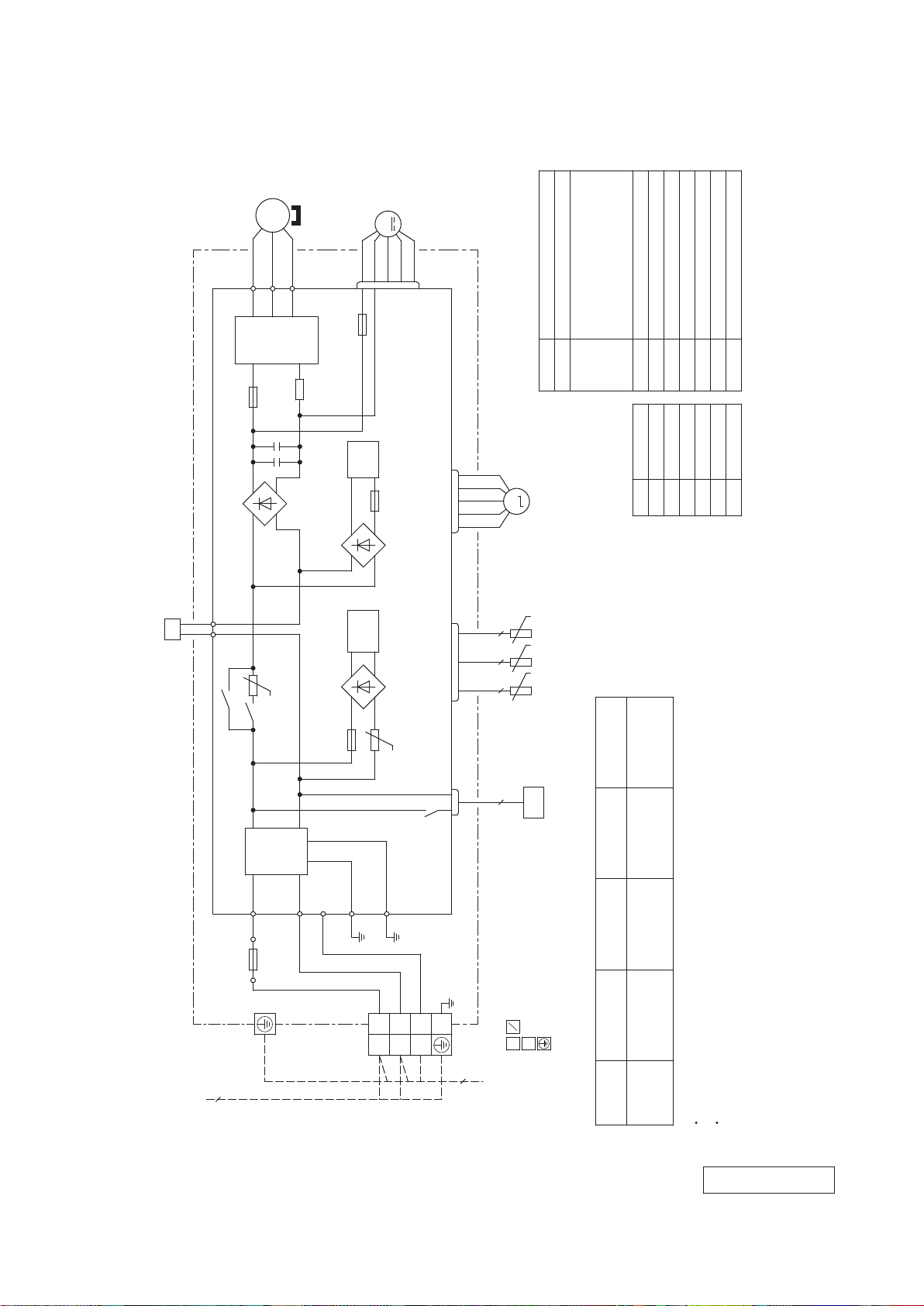

3. ELECTRICAL WIRING

(1) Indoor units

Models SRK20ZS-W, 25ZS-W, 35ZS-W, 50ZS-W

SRK20ZS-WB, 25ZS-WB, 35ZS-WB, 50ZS-WB

SRK20ZS-WT, 25ZS-WT, 35ZS-WT, 50ZS-WT

'18 • SRK-T-250

DescriptionItem

ConnectorCNE

CNF

CNG

CNM

CNS

CNU

CNX

CNY

Power source

1 Phase

220-240V 50Hz

HEAT

EXCHANGER

YELLOW/GREEN

HEAT

EXCHANGER

G

BLUE

YELLOW

4

FAN

MOTOR

WHITE

BLACK

RED

CNU

1 3 65

L

FUSE

F 3.15A L 250V

J

S/N

2 2

CNG

2

BLOCK

TERMINAL

YELLOW/GREEN

3

RED

WHITE

2/N

1

BLACK

t

o

t

o

t

o

2

3

1

220V 60Hz

POWER CABLE

SIGNAL WIRE

EARTH WIRE

TO OUTDOOR UNIT

4

[ ]

SENSOR

ROOM TEMP.

SENSOR 2

HEAT EXCHANGER

SENSOR 1

HEAT EXCHANGER

FLAP

MOTOR

LEFT

MOTOR

LOUVER

RIGHT

MOTOR

LOUVER

M

M M M

VARISTOR

~

U

R-AMP

DISPLAY

WIRELESS

BACK-UP SW

SENSOR

HUMIDITY

※

INTERFACE KIT

ONLY

※SRK35,50ZS-W

~

2 6

CNF CNE

5

CNS

5

CNM

CNX

5 5

CNY

BOARD

CIRCUIT

PRINTED

DIODE

STACK

RWA000Z416

-

-

22

Page 24

Switchgear or circuit breaker capacity should be chosen according to national or regional electricity

The power cable specifications are based on the assumption that a metal or plastic conduit is used

with no more than three cables contained in a conduit and a voltage drop is 2

falling outside of these conditions, please follow the national or regional electricity regulations.

(2) Outdoor units

Models SRC20ZS-W, 25ZS-W, 35ZS-W

PCB ASSY PCB1

POWER

TRANSISTOR

F2

(RD)

U

UP

MS

3~

(WH)

V

V

250V 20A

'18 • SRK-T-250

CM

(BK)

W

W

N

F3

T 1A L 250V

M

FMo

CNFAN

(WH)

Item Description

Meaning of marks

CN20S Connector

20S 4-way valve(coil)

CNFAN

CNEEV

L Reactor

FMo Fan motor

EEV Electric expansion valve(coil)

CM Compressor motor

CNTH

TH4 Discharge pipe temp. sensor

TH3 Outdoor air temp. sensor

TH2 Heat exchanger sensor

+

+

+

-

DIODE

STACK2

~

~

L

T1 T2

(YE) (OR)

t゜

NOISE

FILTER

DIODE

STACK1

DIODE

STACK4

PAM

+

~

SWITCHING

+

~

F1

F 3.15A L 250V

CIRCUIT

F4

POWER

CIRCUIT

250V 10A

-

~

-

~

t゜

(RD)

(WH)