Page 1

RESIDENTIAL AIR-CONDITIONING

TECHNICAL MANUAL & PARTS LIST

INVERTER WALL MOUNTED TYPE

RESIDENTIAL AIR-CONDITIONER

(Split system, air cooled cooling only type)

SRK10YJV-S, 13YJV-S

Manual No.'10•SRK-T-103

Page 2

TECHNICAL MANUAL

Page 3

-

1

-

'10 • SRK-T-099

CONTENTS

1. SPECIFICATIONS ........................................................................................ 3

(2) Outdoor units ....................................................................................... 6

(3) Wireless remote controller

................................................................... 7

............................................................................ 5

(1) Indoor units .......................................................................................... 5

2. EXTERIOR DIMENSIONS

3. ELECTRICAL WIRING ................................................................................. 8

(1) Indoor units .......................................................................................... 8

(2) Outdoor units ....................................................................................... 9

.......................................................... 11

5. RANGE OF USAGE & LIMITATIONS

4. PIPING SYSTEM ......................................................................................... 10

.................................................................................. 13

6. APPLICATION DATA

7. OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER ............... 22

(6) 3D auto operation

.............................................................................. 25

(7) Timer operation

.................................................................................. 26

....................................................... 23

(1) Operation control function by remote controller

(5) Flap and louver control ...................................................................... 24

(4) Custom cord switching procedure

......................................................................... 23(3) Auto restart function

(2) Unit ON/OFF button

........................................................................... 23

.................................. 22

(8) Installation location setting .................................................................. 26

(10) Outline of automatic operation ........................................................... 27

(9) Outline of cooling operation ............................................................... 27

(11) Protective control function

................................................................... 28

..................... 31

.................................................................................. 30

(4) Troubleshooting procedure (If the air conditioner runs)

(3) Troubleshooting procedure

(If the air conditioner does not run at all)

........ 30

(1) Cautions

............................................................................................. 30

(2) Items to check before troubleshooting ................................................. 30

(5) Self-diagnosis table ............................................................................. 32

(6) Service mode (Trouble mode access function) ................................... 33

(7) Inspection procedures corresponding to detail of trouble .................... 41

8. MAINTENANCE DATA

Page 4

-

2

-

'10 • SRK-T-099

(10) How to make sure of wireless remote controller .................................. 46

(11) Outdoor unit inspection points .............................................................. 47

(8)

Phenomenon observed after shortcircuit, wire breakage on sensor

......... 45

(9) Checking the indoor electrical equipment

........................................... 45

■How to read the model name

Example: SRK 10 Y

Series code

Inverter type

Product capacity

Model name SRK : Wall mounted type

SRC : Outdoor unit

JV-S

Page 5

-

3

-

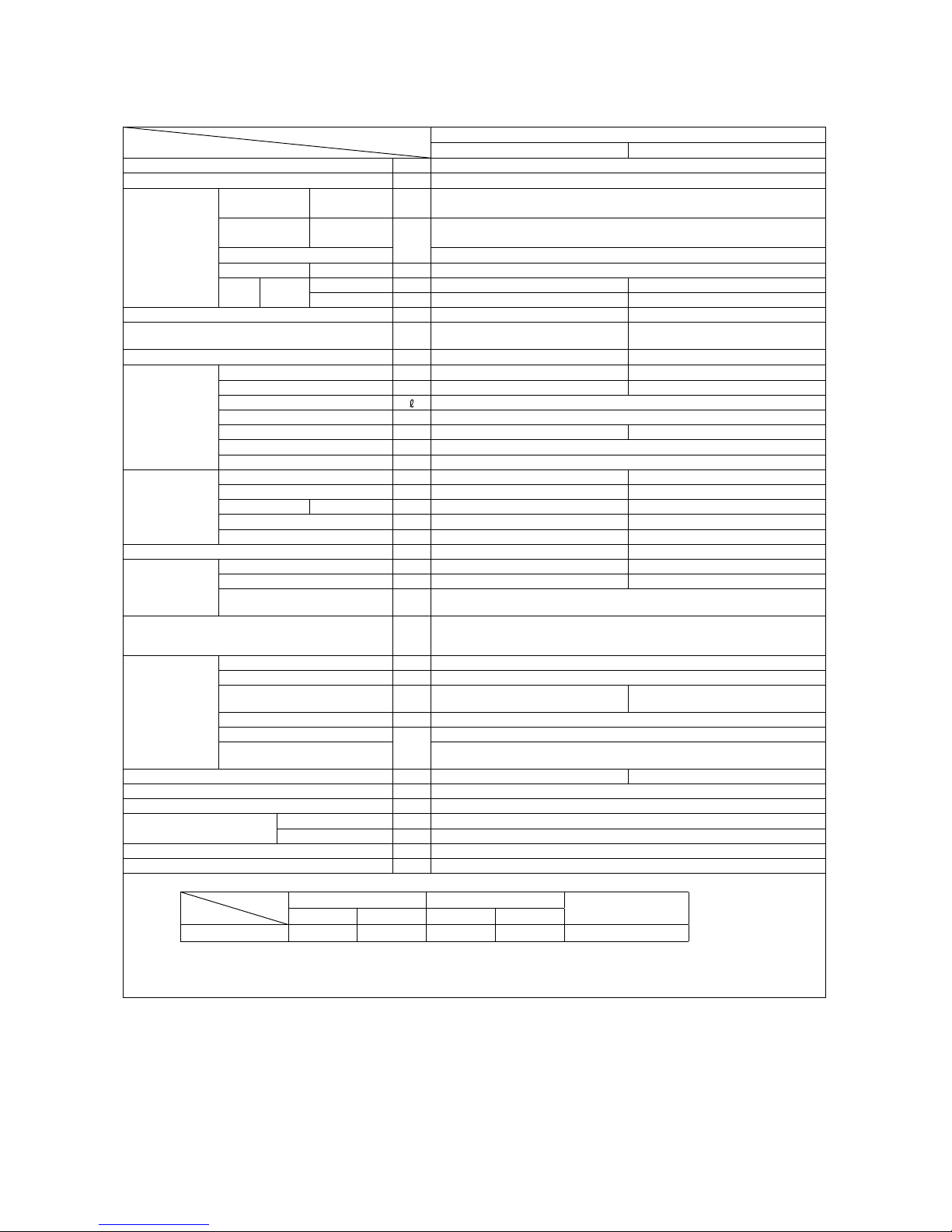

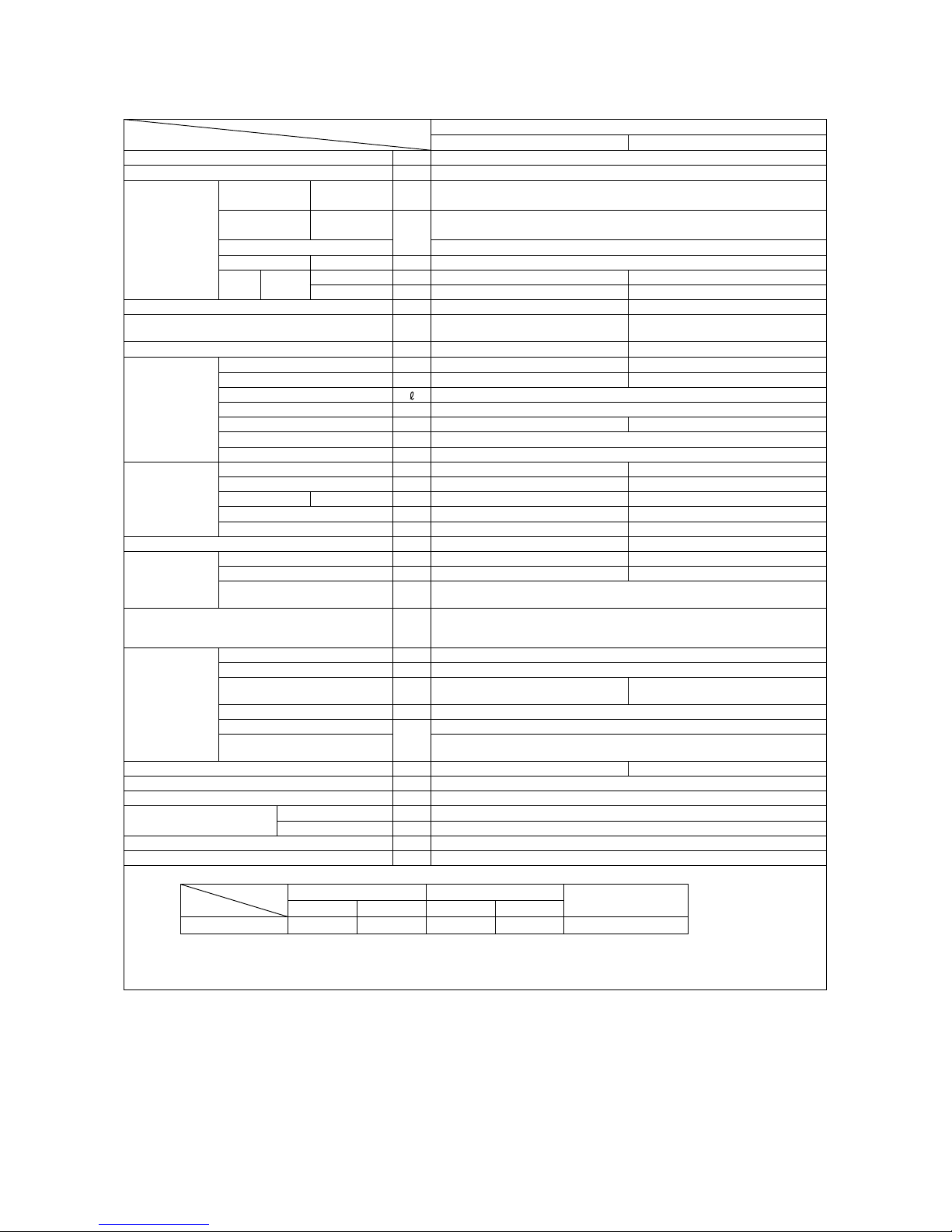

1. SPECIFICATIONS

Model

Item

SRK10YJV-S

Indoor unit SRK10YJV-S Outdoor unit SRC10YJV-S

Cooling capacity (1) W 2500 (1000 (Min.)~2700 (Max.))

Power supply 1 Phase, 220 V, 50Hz

Operation

data (1)

Power

consumption

Cooling kW 0.70 (0.21~0.88)

Running

current

Cooling

A

3.5

Inrush current 3.5

COP Cooling 3.57

Noise

level

Cooling

Sound level dB(A) Hi : 40 Me : 30 Lo : 24 49

Power level dB 56 59

Exterior dimensions (Height x Width x Depth) mm 268 x 790 x 213 540 x 780 (+62) x 290

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 8.5 32

Refrigerant

equipment

Compressor type & Q'ty — RM-B5077MDE1 (Rotary type) x 1

Motor (Starting method) kW — 0.75 (Line starting)

Refrigerant oil 0.35 (DIAMOND FREEZE MA68)

Refrigerant (3) kg R410A 0.75 (Pre-Charged up to the piping length of 10m)

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Deice control Microcomputer control

Air handling

equipment

Fan type & Q'ty Tangential fan x 1 Propeller fan x 1

Motor W 38 24

Air flow Cooling CMM Hi : 8.0 Me : 6.2 Lo : 4.5 29.5

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 2 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display

RUN : Green, TIMER : Yellow, HI POWER : Green,

3D AUTO : Orange

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

connecting method Flare connecting

Attached length of piping m

Liquid line : 0.4

Gas line : 0.33

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.10 (Outdoor unit is higher)

Max.10 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable 2m (3 Cores wih Earth)

Recommended breaker size A 16

Connection wiring

Size x Core number 1.5mm2 x 4 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included)

Mounting kit

Optional parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 10m connecting piping.

(Purging is not required even for the short piping.)

The pipe length is 7.5m.

Adapted to RoHS directive

Page 6

-

4

-

Model

Item

SRK13YJV-S

Indoor unit SRK13YJV-S Outdoor unit SRC13YJV-S

Cooling capacity (1) W 3500 (1000 (Min.)~3700 (Max.))

Power supply 1 Phase, 220 V, 50Hz

Operation

data (1)

Power

consumption

Cooling kW 0.99 (0.21~1.24)

Running

current

Cooling

A

4.7

Inrush current 4.7

COP Cooling 3.54

Noise

level

Cooling

Sound level dB(A) Hi : 46 Me : 34 Lo : 28 50

Power level dB 62 60

Exterior dimensions (Height x Width x Depth) mm 268 x 790 x 213 540 x 780 (+62) x 290

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 8.5 35

Refrigerant

equipment

Compressor type & Q'ty — RM-B5077MDE1 (Rotary type) x 1

Motor (Starting method) kW — 0.90 (Line starting)

Refrigerant oil 0.35 (DIAMOND FREEZE MA68)

Refrigerant (3) kg R410A 1.05 (Pre-Charged up to the piping length of 15m)

Heat exchanger Slit fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Deice control Microcomputer control

Air handling

equipment

Fan type & Q'ty Tangential fan x 1 Propeller fan x 1

Motor W 38 24

Air flow Cooling CMM Hi : 8.5 Me : 6.8 Lo : 4.6 27.8

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 2 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display

RUN : Green, TIMER : Yellow, HI POWER : Green,

3D AUTO : Orange

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ9.52 (3/8")

connecting method Flare connecting

Attached length of piping m

Liquid line : 0.40

Gas line : 0.33

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.10 (Outdoor unit is higher)

Max.10 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable 2m (3 Cores wih Earth)

Recommended breaker size A 16

Connection wiring

Size x Core number 1.5mm2 x 4 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Optional parts —

Adapted to RoHS directive

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1 , JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 15m connecting piping.

(Purging is not required even for the short piping.)

The pipe length is 7.5m.

Page 7

-

5

-

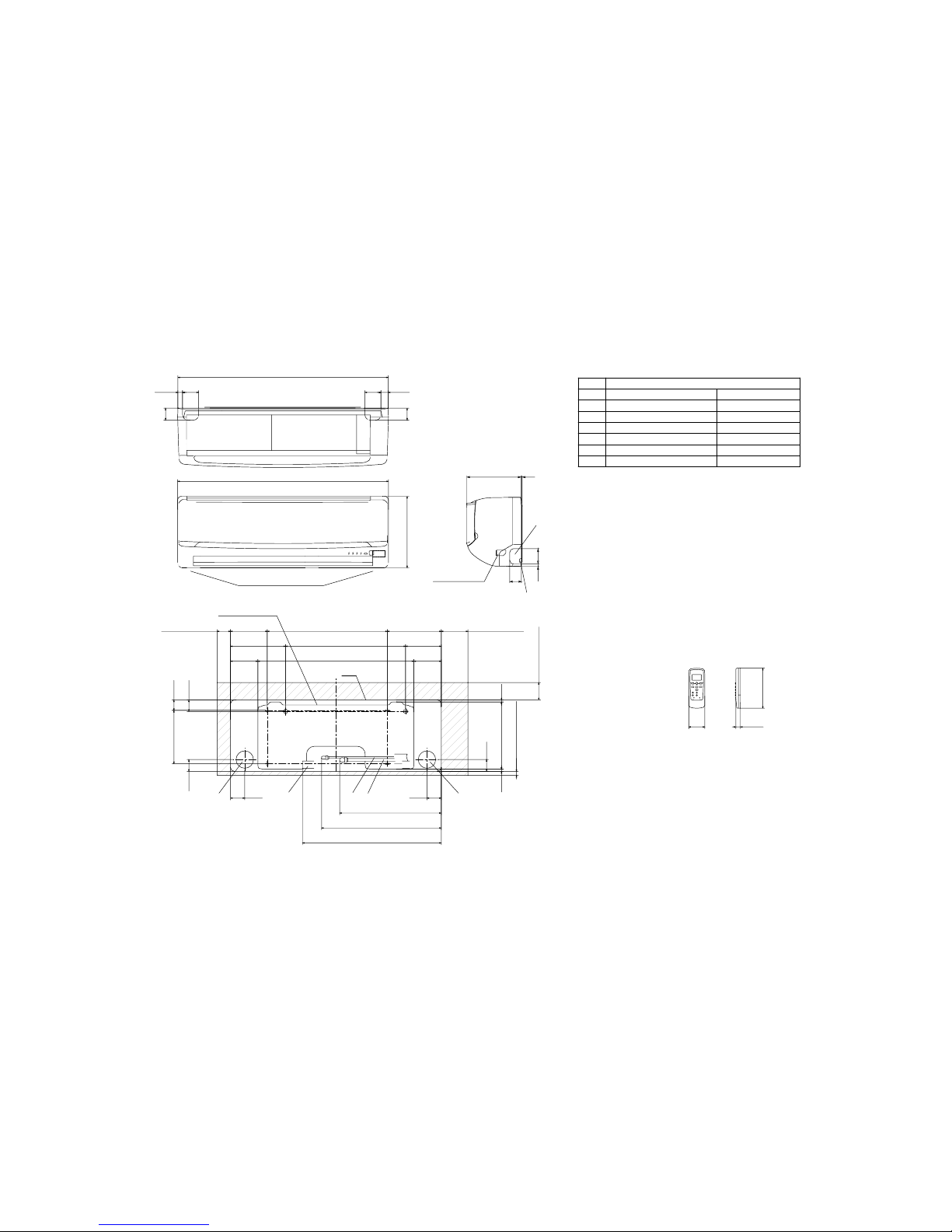

2. EXTERIOR DIMENSIONS

(1) Indoor units

Models SRK10YJV-S, 13YJV-S

Wireless remote controller

Outlet for down piping

㧔Refer to the above view㧕

Space for installation and service when viewing from the front

D A

B

E

C

Hole on wall for right rear piping

Hole on wall for left rear piping

Gas piping

Outlet for wiring

Drain hose

Liquid piping

F

E

C

D

B

Symbol

A

㧔Ǿ65㧕

VP16

Ǿ6.35㧔1㧛4"㧕㧔Flare㧕

Content

㧔Ǿ65㧕

Ǿ9.52㧔3㧛8"㧕㧔Flare㧕

Outlet for piping㧔on both side㧕

G

Note㧔1㧕The model name label is attached

ޓޓޓon the underside of the panel.

60

150

17.3

788

2760

45

60

45

790

268

17.5

200

39.3

43.244.5

102.5 585 102.5

206.5 450 133.5

138 450 202

44.5

7.5252.28.3

㧔Service space㧕

65

㧔Service space㧕

15

50

㧔

Service space

㧕

100

㧔Service space㧕

53.5

380.6

448.6

520

53.5

Installation plate

Unit

Unit:mm

Terminal block

G

F

9

213 3

45

60

Page 8

-

6

-

(2) Outdoor units

Models SRC10YJV-S, 13YJV-S

Notes

㧔1㧕 It must not be surrounded by walls on the four sides.

㧔2㧕 The unit must be fixed with anchor bolts. An anchor bolt must not

protrude more the 15mm.

㧔3㧕 Where the unit is subject to strong winds, lay it in such

a direction that the blower outlet faces perpendicularly

to the dominant wind direction.

㧔4㧕 Leave 1m or more space above the unit.

㧔5㧕 A wall in front of the blower outlet must not exceed the units height.

㧔6㧕 The model name label is attached on the lower right comer of the front panel.

L4

L3

L1

Intake

Service

space

Intake

Outlet

Minimum installation space

L2

L2

L3

L4

L1

100

100

250

Open

㧵 㧵㧵

Open

250

80

280

㧵㧵㧵

280

Open

80

75

Examples of

Dimensions

installation

㧵㨂

180

Open

80

Open

Ǿ9.52㧔3㧛8"㧕㧔Flare㧕

Content

C Pipe㧛cable draw-out hole

D

E Anchor bolt hole

Drain discharge hole

Symbol

B

A Service valve connection㧔gas side㧕

M10 × 4places

Ǿ20 × 2places

Service valve connection㧔liquid side㧕

Ǿ6.35㧔1㧛4"㧕㧔Flare㧕

Unit:mm

A

C

Terminal block

B

40°

40°

33.5

138.4

97.7

15.8

540

290

42.5

69.4

63.4

390.6

390.6

111.6 510

158.4

12

50.6

17.9

780 61.9

312.5

351.6

14.8 24.3

D

E

Page 9

-

7

-

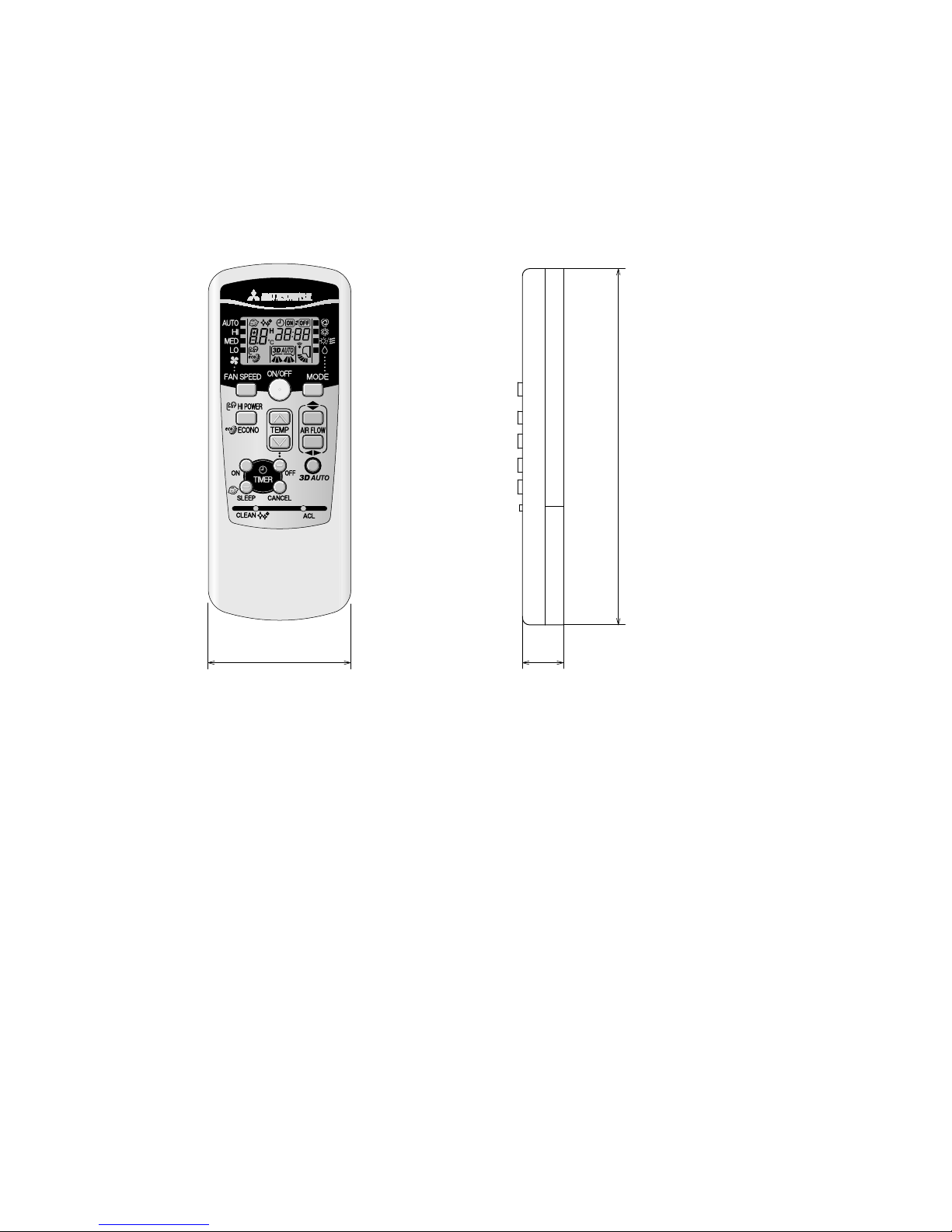

(3) Wireless remote controller

Unit: mm

60

17.3

150

Page 10

-

8

-

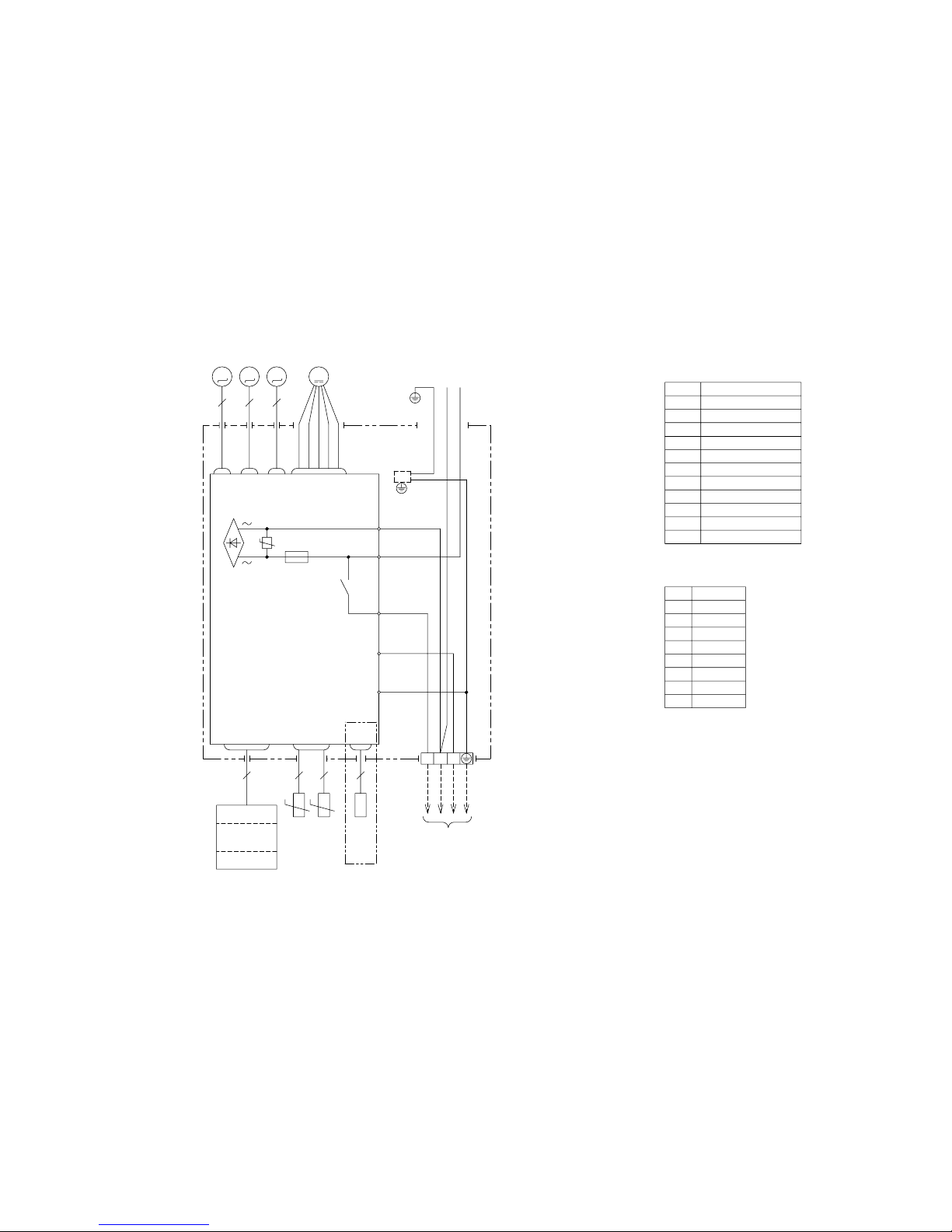

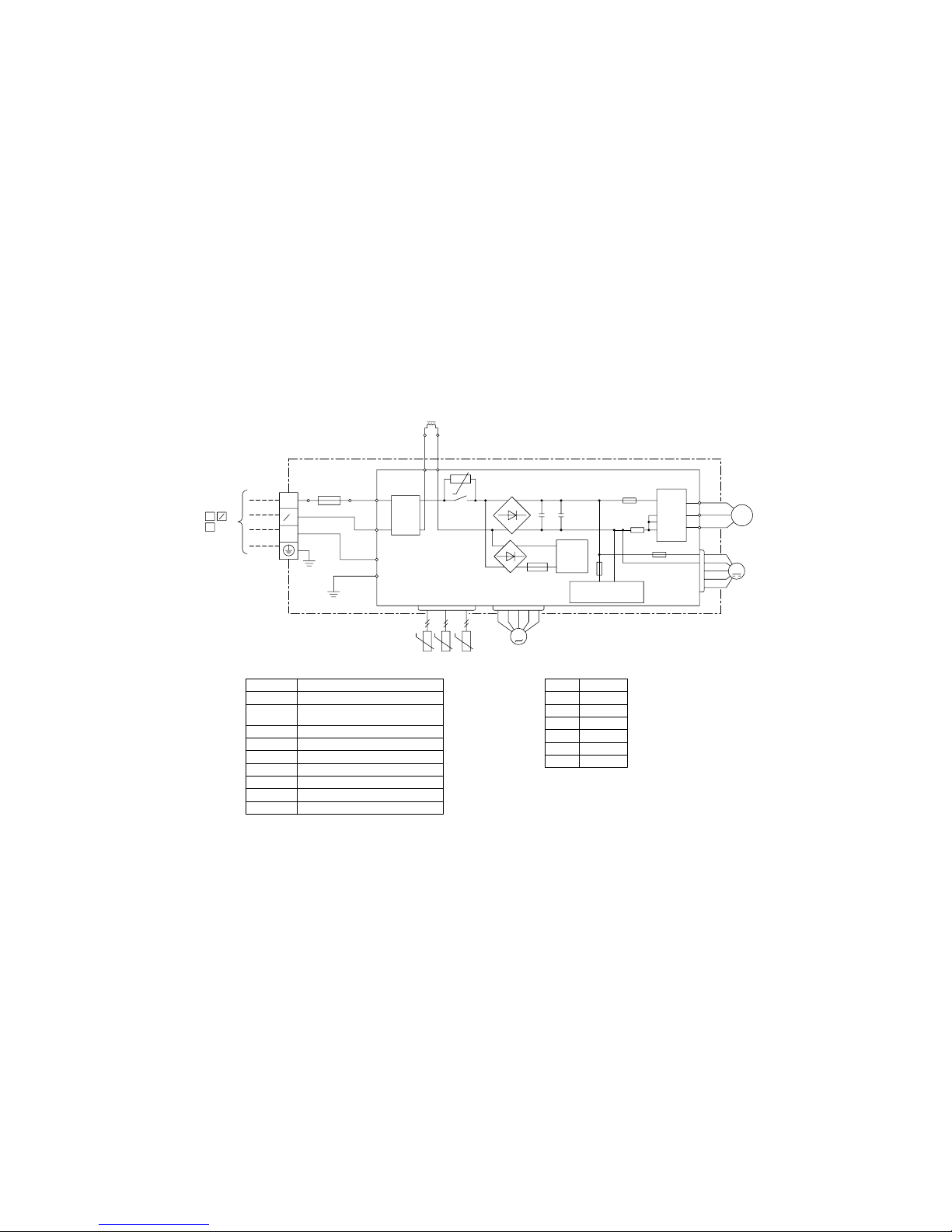

3. ELECTRICAL WIRING

(1) Indoor units

Models SRK10YJV-S, 13YJV-S

G

J

R-AMP

WIRELESS

DISPLAY

N

CNGCNE

250V 3.15A

CNU

52C

52C-3

52C-4

BACK UP SW

U

M

CNF

FM

HD

F

Va

DS

T

※

CNX

5

M

CNY

5

M

LM1 LM2

CNM

5

M

SM

Blue

BlackBK

Red

BL

RD

WhiteWH

Yellow/Green

Y/G

ColorMark

Heat exch. sensor

Fan motor

Room temp. sensor

Flap motor

Diode stackDS

FuseF

Connector

CNE-CNU

FM

Terminal blockT

Description

Item

VaristorVa

SM

Louver motor

LM1,2

ThI

Th2

YellowY

Humidity sensor

HD

BrownBR

Light blueLB

BR

Y/G

RD

Y

WH

Y/G

RD

BK

BOX

CONTROL

3

2/N

WH

6

TO OUTDOOR UNIT

1

BOARD

PRINTED CIRCUIT

~220V 50Hz

POWER SOURCE

BR

LB

Y/G

BK

1 3 4 5

RDBKBL

EXCHANGER

HEAT

WH

8 2 2 2

t゜

※SRK13 MODELS ONLY

ThI Th2

t゜

Page 11

-

9

-

(2) Outdoor units

Models SRC10YJV-S, 13YJV-S

3

1

2

[

]

N

(BK)

C-2

G1

(RD)

(Y/G)

S.IN

(WH)

R.IN

(BK)

(WH)

(RD)

PWB ASSY

250V 20A

F2

F3 250V 1A

++

F4

250V 10A

F1

250V 2A

CIRCUIT

PAM

SWITCHING POWER

CIRCUIT

NW

NV

NU

P

W

V

U

TRANSISTOR

POWER

W

V

U

FILTER

NOISE

CNTH

CNEEV

CNFAN

M

M

3~

250V 15A

(Y/G)

T1

T2

(OR)

(Y)

M

t゜

TH1TH2 TH3

EEV

FMo

CM

t゜ t゜

t゜

L

TERMINAL

N

1

3

2

BLOCK

T

TO INDOOR UNIT

POWER WIRES

SIGNAL WIRE

POWER SOURCE

~220V 50Hz

Color

RD

Mark

OrangeOR

Yellow/Green

Y/G

BlackBK

YellowY

WhiteWH

Red

DescriptionItem

Connector

Electric expansion valve(coil)EEV

Fan motorFMo

ReactorL

Terminal blockT

Compressor motorCM

Heat exchanger sensor(outdoor unit)TH1

Outdoor air temp.sensorTH2

TH3 Discharge pipe temp.sensor

CNTH

CNEE

Page 12

-

10

-

'09•SRK-DB-087D

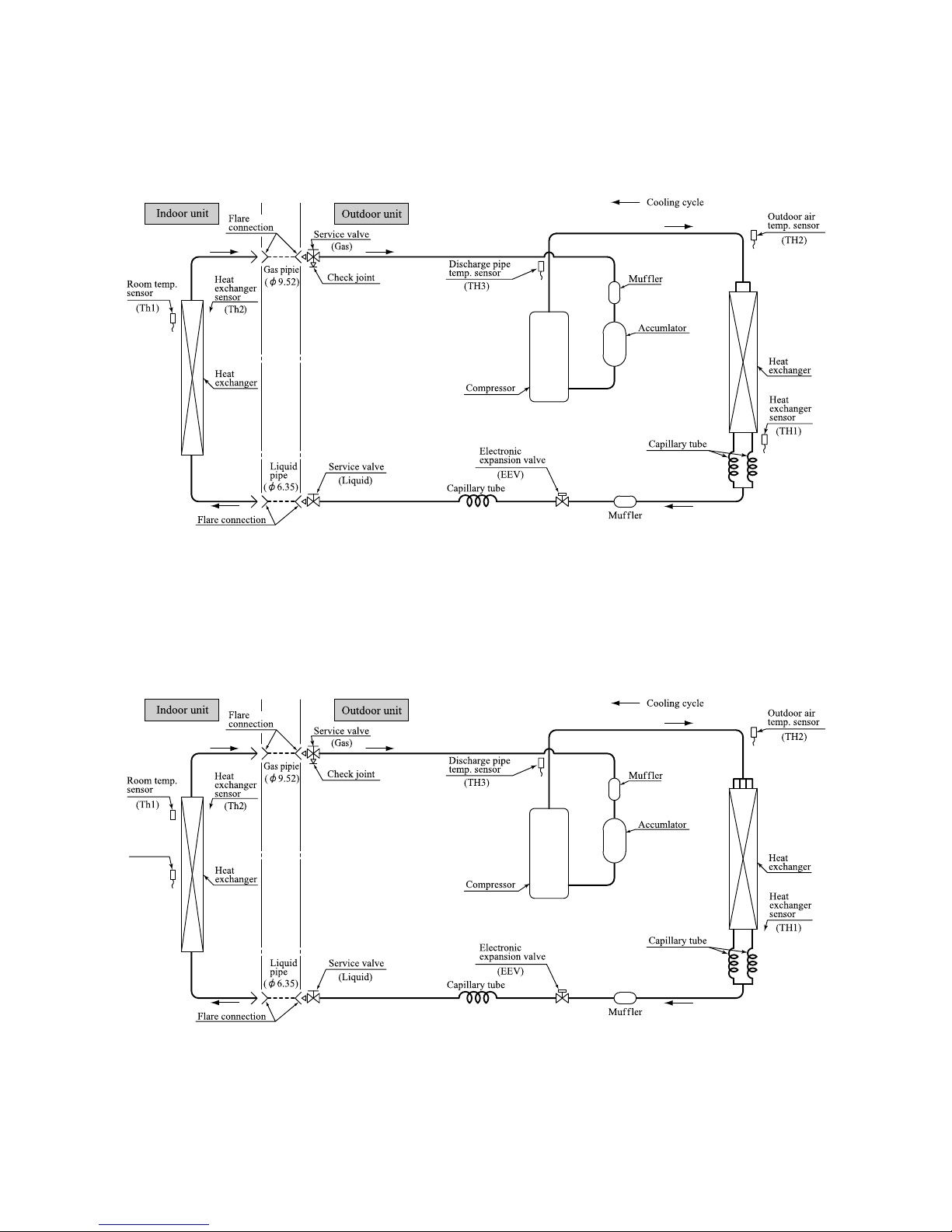

5 PIPING SYSTEM

Models SRK20ZJ-S, 25ZJ-S

Model SRK35ZJ-S

Humidity

sensor

(HD)

4. PIPING SYSTEM

Model SRK10YJV-S

Model SRK13YJV-S

Page 13

-

11

-

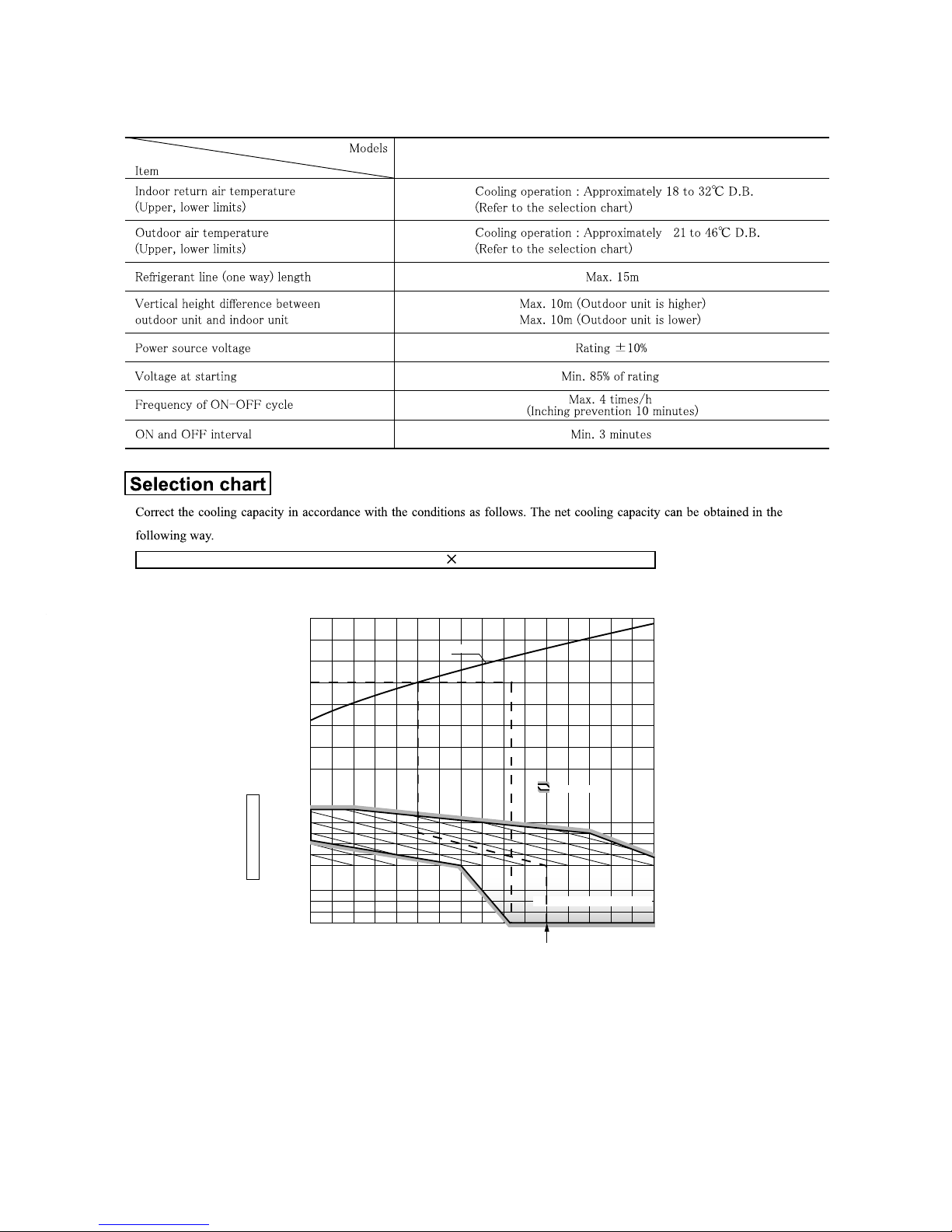

5. RANGE OF USAGE & LIMITATIONS

SRK10YJV-S,13YJV-S

Net capacity = Capacity shown on specification Correction factors as follows.

(1) Coefficient of cooling capacity in relation to temperatures

Cooling

2220181614

0.6

0.7

0.8

0.9

1.0

1.2

1.1

1.3

0

-5

-10

-15

Applicable range

Depends on installed situation

24

26

20

25

30

35

40

46

ISO-T1 Standard Condition

Cooling operation

Outdoor air D.B.

temperature

(°C D. B.)

Coefficient of cooling

capacity in

relation to temperature

Indoor air W.B. temperature °C W.B.

+

Page 14

-

12

-

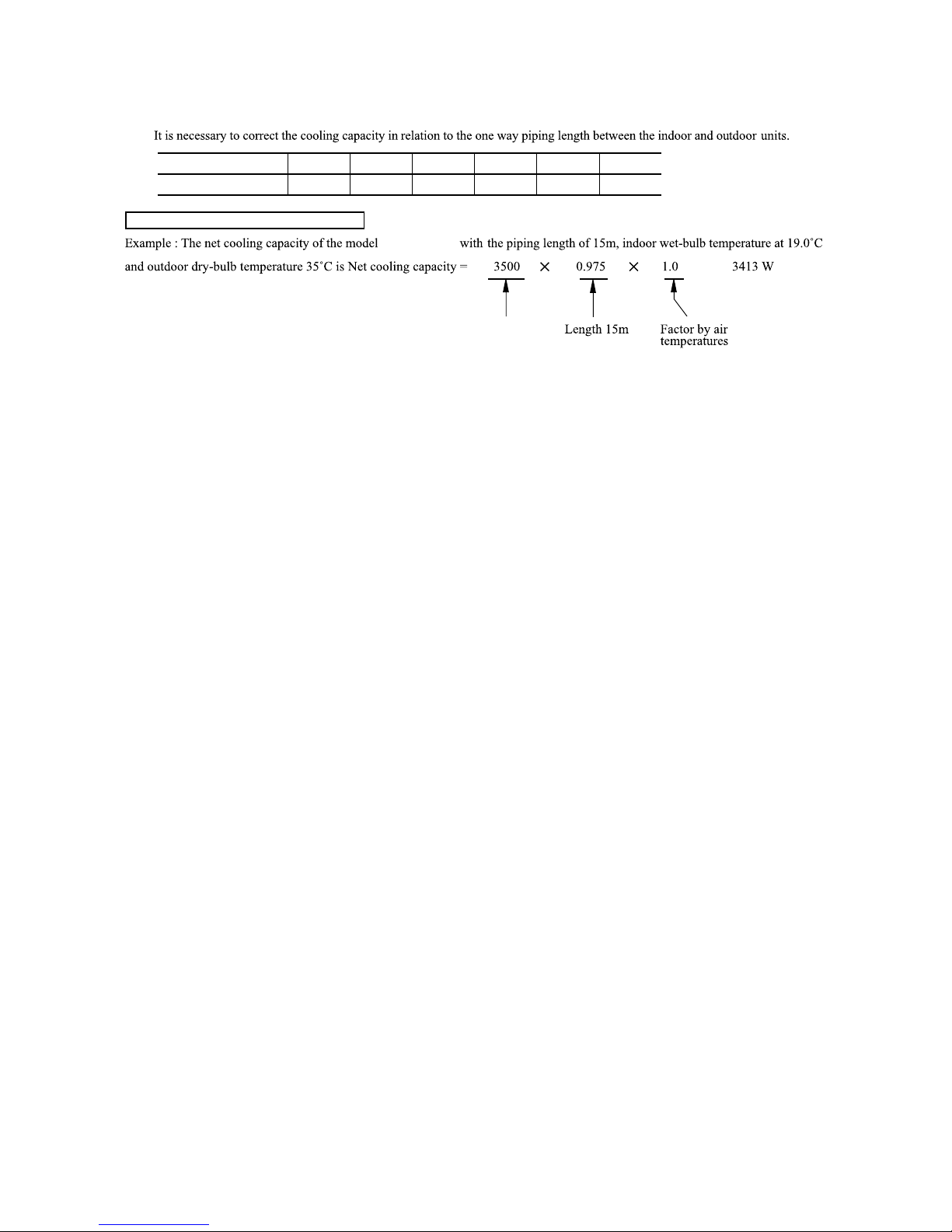

(2) Correction of cooling capacity in relation to one way length of refrigerant piping

How to obtain the cooling capacity

=

Piping length [m]

Cooling

7

1.0

10

0.99

15

0.975

20

0.965

25

0.95

30

0.935

SRK13YJV-S

SRK13YJV-S

Page 15

-

13

-

6. APPLICATION DATA

Safety precautions

• When install the unit, be sure to check whether the selection of installation place, power supply specifications, usage limitation (piping

length, height differences between in door and outdoor un its, power supply voltage and etc.) and installation spaces.

• We recommend you to read this “SAFETY PRECAUTIONS” carefully before the installation work in order to gain full advantage of the functions of the unit and to avoid malfunction due to mishandling.

• The precautions described below are divided into

WARNING and CAUTION . The matters with possibilities leading to serious conse-

quences such as death or serious personal injury due to erroneous handling are listed in the

WARNING and the matters with possibilities

leading to personal injury or damage of the unit due to erroneous handling including probability leading to serious consequences in some cases

are listed in

CAUTION . These are very important precautions for safety. Be sure to observe all of them without fail.

• Be sure to confirm no anomaly on the equipment by commissioning after completed installation and explain the operating methods as well as the

maintenance methods of this equipment to the user according to the owner’s manual.

• Keep the installation manual together with owner’s manual at a place where any user can read at any time. Moreover if necessary, ask to hand

them to a new user.

• For installing qualified personnel, take precautions in respect to themselves by using suitable protective clothing, groves, etc., and then perform

the installation works.

• Please pay attention not to fall down the tools, etc. when installing the unit at the high position.

• If unusual noise can be heard during operation, consult the dealer.

• Symbols which appear frequently in the text have the following meaning:

Observe instructions

with great care

Strictly prohibited Provide proper earthing

WARNING

• I nstallatio n must be carried o ut by the qualified installer.

If you install the sys tem by yourself, it may cause ser ious trouble su ch as

water le aks, ele ctric sho cks, fire and per sonal in jury, as a result of a system

malfunct ion.

• I nstall the system i n full acc ordance w ith the in struction manual.

Incorrec t installat ion may cau se bursts, personal in jury, wate r leaks, el ectric

shocks an d fire.

• B e sure to use only for househ old and r esidence.

If t his applian ce is inst alled in inferio r env ironment such as mach ine s hop

and etc. , it can c ause malf unction.

•

Use the orig inal accesso ries and the sp ecified com ponents for in stallation.

If parts o ther than t hose presc ribed by us are used, I t may cause water leak s,

electric shocks, f ire and pe rsonal injury.

• I nstall the unit in a location with goo d support.

Unsuitab le installat ion locatio ns can cause th e unit to fall and cause mate rial

damage a nd persona l injury.

• E nsure th e unit is stable w hen installed, so t hat it can withstand earthquakes a nd strong winds.

Unsuitab le installat ion locatio ns can cause th e unit to fall and cause mate rial

damage a nd persona l injury.

• V entilate the worki ng area well in the even t of ref rigerant leakage d uring insta llation.

If the re frigerant comes into contact with nak ed flames, poisonous gas is

produced .

• W hen install ing in smal l rooms, ta ke preventi on measure s not to exc eed

the dens ity limit of refrige rant in the even t of leaka ge.

Consult the expe rt ab out p revention me asures. If the density o f ref rigerant

exceeds the limit in the event of leakage , lac k of oxygen can occu r, whi ch

can caus e serious accidents .

•

After comp leted insta llation, ch eck that no ref rigerant le aks from the s ystem.

If refrigerant leaks into the room a nd comes into co ntact with a n o ven or

other ho t surface, poisonou s gas is p roduced.

• U se the pre scribed p ipes, flar e nuts an d tools fo r R410A.

Using ex isting parts ( for R22 or R407C) can ca use the unit fail ure and serious acci dents due to burst o f the ref rigerant c ircuit.

• T ighten the flare nu t by torqu e wrench w ith specified me thod.

If the flare nut w ere tightened with excess torque, this may cause bu rst and

refriger ant leakag e after a long peri od.

• D o not open th e operat ion val ves for liquid line and gas lin e until completed r efrigerant piping w ork, air t ightness t est and evacuati on.

If the c ompressor is operated in s tate of o pening operation valves before

complete d connec tion of refrigerant pi ping work, ai r can be sucke d into refrigeran t circuit, whi ch can cause bust or personal inj ury due to anomal ously

high pre ssure in t he refrig erant.

• D o not put th e drainage pipe di rectly int o drainage channels w here poisonous g ases such as sulphid e gas can occur.

Poisonou s gases will flo w into the room through drai nage pipe and s eriously

affect t he user’s health an d safety.

• E nsure t hat no air enters in the refriger ant cir cuit w hen the unit is installed a nd removed.

If a ir en ters in the refr igerant circuit, the pr essure in the refrigerant circuit

becomes too high, which can cause bur st and pe rsonal inj ury.

• D o not proc essing, splice th e po wer c ord, or sh are a socket with other

power plu gs.

This may cause fire or electric shock due to defect ing contact, de fecting insulation and over- current e tc.

• T he el ectrical installation must be carried out by the qualifi ed el ectrician in accor dance with “th e n orm for electrical work” and “na tional

wiring regulation”, and the s ystem must be conne cted t o the dedicated

circuit.

Power s upply with in sufficien t capaci ty and incorrect fun ction do ne by improper w ork can ca use elect ric shocks and fire .

• B e sure to shut off the power before st arting ele ctrical work.

Failure t o shut off the power can cause electric s hocks, uni t failure or incorrect fun ction of e quipment.

• B e s ure to use the cab les confo rmed to sa fety stan dard and cab le

ampacity for power distribut ion work.

Unconfor mable cables can cause electr ic leak, anomal ous heat production or

fire.

• T his app liance m ust be conne cted to main power suppl y by means of a

circuit br eaker or switc h (fuse:16A ) with a contac t separation of at least

3mm.

• W hen p lugg ing t his ap pli anc e, a p lug conf ormi ng to t he no rm

IEC60884 -1 must be used.

• U se the pre scribed cables for electrical connection, tighten the cables

securely i n terminal block a nd relieve the cabl es correctly to pre vent

overload ing the te rminal bl ocks.

Loose conn ections or ca ble mountin gs can cause a nomalous hea t production

or fire.

• A rrange the w iring in the co ntrol box so t hat it canno t be pushed up

further into the b ox. Instal l the service pa nel correc tly.

Incorrec t installa tion may result in overheatin g and fire.

• B e sure to fix up the service panels.

Incorrec t fixing can cause e lectric shocks or fi re due to intrusion of dust or

water.

• B e sure to switch off the power supply in the event of installation , inspection or servicing.

If the powe r s upply is not shut off, the re is a risk of el ectric shocks, unit

failure or persona l injury due to the unexpect ed start o f fan.

• S top the comp ressor before disconnecting refrigeran t pipes in case of

pump dow n operatio n.

If disconne cting refri gerant pipes in state of openin g operation valves before

compress or sto pping, air can b e suck ed, wh ich ca n cause b urst o r pers onal

injury d ue to anom alously h igh pressu re in the refrigera nt circui t

• O nly use presc ribed optio nal parts. T he installa tion must be c arried out

by the q ualified i nstaller.

If you ins tall the sys tem by your self, it can c ause serious trouble such as

water le aks, elect ric shock s, fire.

• D o not bundling, win ding or processing f or the power cord. Or, do not

deformin g the powe r plug du e to tread it.

This may cause fir e or heat ing.

• D o not ven t R410A i nto the a tmosphere : R410A is a fluorinated greenhouse g as, cove red by the Kyoto Pro tocol wi th Globa l Warming Pot ential (GWP )=1975.

• D o not run the unit with remov ed panels or protec tions.

Touching rotati ng equi pments, hot surfaces or high vo ltage p arts ca n cause

personal injury du e to entra pment, burn or e lectric sh ocks.

•

Do not perfor m any change of prot ective devic e itself or it s setup condit ion.

The forced ope ration by short- circuitin g protective dev ice of pressure switch

and temp erature c ontroller or the use of no n specifi ed compon ent can cause

fire or burst.

• C arry out t he electr ical work for groun d lead wit h care.

Do not co nnect the ground le ad to the gas line, water lin e, lightni ng conduc tor or tel ephone lin e’s ground lead. Incorrect groundin g can caus e unit fa ults such

as elect ric shocks due to sh ort-circu iting.

Page 16

-

14

-

CAUTION

• U se the cir cuit brea ker with s ufficient breaking capacity.

If the breaker does not have sufficient breaking capacit y, it can cause the unit

malfunct ion and fi re.

• E arth leaka ge breake r must be installed .

If the ea rth leakage brea ker is not installe d, it can cause elec tric shocks.

• I nstall isolator o r dis connect switch on the pow er su pply wiring in accordance with the local code s and regulation s.

• B e su re to install indo or unit proper ly a ccording to the instruc tion

manual i n order to run off the draina ge smooth ly.

Improper installa tion of i ndoor uni t can ca use dropp ing water into the room

and dama ging perso nal prope rty.

• I nstall the draina ge pi pe to run off drai nage securely according to the

installa tion manua l.

Incorrec t installa tion of the dra inage pipe can caus e dropping water into the

room and damaging personal property.

• B e s ure to insta ll the drainage pipe with de scending slope of 1/100 or

more, an d not to m ake traps and air-b leedings.

Check if the drai nage runs off secu rely during comm issioning and ensure the

space fo r inspecti on and ma intenance.

• A fter maintenanc e, all w iring, wiring ties and the li ke, sh ould be returned t o their o riginal s tate and wiring route, a nd the ne cessary c learance fro m all meta l parts s hould be s ecured.

• S ecure a space fo r install ation, i nspection and maintenanc e specifi ed in

the manu al.

Insuffic ient space can resul t in accident such as per sonal injury due to falling

from the installat ion place .

• T ake care w hen carry ing the un it by hand .

If th e unit weigh ts mor e than 20kg, it must be carried by two o r more persons. Do not carry by the plasti c str aps, a lways use the carry handl e whe n

carrying th e u nit by hand. Us e g loves to mini mize the risk of cuts by t he

aluminum fins.

• D ispose of any packi ng materia ls correc tly.

Any remaining packing materials can c ause personal injury as it contains

nails and woo d. And to avoid dan ger of suffoca tion, be sure to kee p the plastic wrap per away f rom child ren and to dispose after tear it up.

• F or installation work, be careful not to g et injured with t he heat e xchanger, piping fl are porti on or scre ws etc.

• B e sure to insulate t he refrig erant pipe s so as no t to cond ense the a mbient air m oisture on them.

Insuffic ient insulation can cause c ondensatio n, wh ich c an lead to moisture

damage o n the ceil ing, floo r, furnitu re and an y other va luables.

• W hen pe rform the air conditioner operation (cool ing o r dry ing op eration) in which ventil ator is installed in the room. I n this case, using the

air conditio ner in parallel with the vent ilator, there is the possibility that

drain water may bac kflow in accorda nce w ith the room lapse into the

negative pressur e status . Theref ore, set up th e openin g port such as incorporat e the air into the room that may app ropriate to ventilation (For

example; Open the door a little). I n addition, just as above , so set up the

opening por t if the room lapse in to negative pre ssure status due to register of t he wind fo r the hig h rise apa rtment et c.

• D o not inst all the u nit in the locations listed below.

• L ocations where carb on fiber, metal pow der or an y powder i s floatin g.

• L ocations where any substances that can affect the unit such as s ulphide

gas, chl oride gas, acid and alkaline can occur .

• V ehicles a nd ships.

• L ocations where cosm etic or special sprays are often us ed.

• L ocations with direct exposure of oil mist and steam such as kit chen and

machine plant.

• L ocations where any mach ines whic h generat e high frequency harmonics

are used .

• L ocations with salty atmospheres suc h as coast lines.

• L ocations wi th heavy snow (If installed, be sure to provide base flame and

snow hoo d mentione d in the manual).

• L ocations where the unit is exposed to chimney smoke.

• L ocations at high al titude (more tha n 1000m hi gh).

• L ocations with ammon ic atmospheres.

• L ocations where heat radiation from other heat source c an affect the unit.

• L ocations without go od air circulati on.

• L ocations with any obstac les which can pre vent inle t and ou tlet air of the

unit.

• L ocations where short circ uit of a ir c an o ccur (in case of mul tiple units

installa tion).

• L ocations where stro ng air bl ows agains t the air outlet of outdoor unit.

It ca n cause remar kable decrease in performa nce, co rrosion and damage of

componen ts, malfun ction and fire.

• D o no t i nstall the ind oor unit in the locations listed below (Be sure to

instal l the indoor unit according to the installat ion m anual for each

model be cause each indoor un it has each limi tation).

• L ocations with any obstac les which can pre vent inle t and ou tlet air of the

unit.

• L ocations w here vibra tion can be amplified due to insu fficient s trength of

structur e.

• L ocations where the infrared receiver is exposed to the dir ect sun light or

the stro ng light b eam (in c ase of the infrared specifica tion unit ).

• L ocations where an eq uipment affected by high ha rmonics is plac ed (TV

set or r adio recei ver is pl aced withi n 1m).

• L ocations where drai nage cann ot run off safely.

It can a ffect perf ormance o r function and etc.

• D o not inst all the o utdoor uni t in the l ocations listed bel ow.

• L ocations w here disch arged hot a ir or opera ting sound of the outd oor unit

can both er neighbo rhood.

• L ocations where outl et air of the outdo or unit b lows direc tly to pl ants.

• L ocations whe re vibration can be amplified and transmitte d due to insuffi-

cient st rength of structure .

• L ocations where vibra tion an d opera tion s ound ge nerated by the out door

unit can affect se riously ( on the wal l or at t he place n ear bed r oom).

• L ocations where an eq uipment affected by high ha rmonics is plac ed (TV

set or r adio recei ver is pl aced withi n 1m).

• L ocations where drai nage cann ot run off safely.

It can a ffect surr ounding e nvironment and caus e a claim.

• D o not install the unit near the l ocation where l eakage of combus tible

gases ca n occur.

If leake d gases ac cumulate around the unit, it can cause fire.

• D o not inst all t he un it wh ere c orrosive gas (suc h as sulfurous acid gas

etc.) or comb ustible gas (s uch as thinner and petroleum gases) can accu mulate or co llect, or whe re volatile combustibl e substance s are handled .

Corrosiv e gas can cause corrosion of heat e xchanger, breakage of plastic

parts an d etc. And combusti ble gas ca n cause f ire.

• D o not use the indo or unit at the place whe re water splashes may oc cur

such as i n laundries.

Since the indoor un it is not w aterproof, it can cau se electri c shocks a nd fire.

• D o not install nor use the s ystem c lose to the equipment tha t gener ates

electrom agnetic fi elds or h igh freque ncy harmon ics.

Equipmen t such as inverters , standby generators, medical high frequency

equipmen ts a nd t elecommun ication equipments can aff ect the system , an d

cause malfunc tions and breakdowns. The system can also affect medical

equipmen t a nd telecommun ication equipment, and obstruct its function or

cause jam ming.

• D o not pla ce any va riables w hich will be damag ed by get ting wet under

the indo or unit.

When th e relati ve humid ity is higher t han 80% or drainage pipe is clogged,

condensa tion or drainage water can drop and it can cause the damage of valuables.

• D o not inst all the r emote cont rol at the direct sunlight .

It can c ause malfu nction or deformati on of the remote co ntrol.

• D o not use the unit fo r sp ecial purposes s uch a s st oring foods, cool ing

precisio n instrume nts and p reservatio n of anima ls, plants or ar t.

It can c ause the d amage of the items.

• D o not install the outdoor un it in a location where in sects and small animals can inhabit.

Insects and small anim als ca n ent er the elec tric p arts and ca use d amage or

fire. In struct the user to keep the s urroundin gs clean.

• D o not use the base flam e for outdoor unit which is corroded or da maged due to long p eriods of operation .

Using an old an d d amage base fla me can cause the un it falling down and

cause per sonal injury.

• D o not use any materials other than a fuse with t he correct r ating in the

location where fus es are to be used.

Connecti ng the circ uit with co pper wire or other metal thread can cause unit

failure and fire.

• D o not touc h any but tons with wet hands .

It can ca use electric sho cks.

• D o not t ouch any refr igerant pipes wi th your hands when the syst em is

in opera tion.

During operation the refri gerant pipes be come extremely h ot or extremely

cold depe nding the o perating c ondition, a nd it can ca use burn injury or frost

injury.

• D o not touc h the suc tion or al uminum fin on the outdoor unit.

This may cause inj ury.

• D o not put anything on the out door unit and opera ting unit .

This may cause dam age the o bjects or injury du e to falli ng to the object.

Page 17

-

15

-

Necessary tools for the installation work

1 Plus headed driver (Phillips screwdriver)

2 Knife

3 Saw

4 Tape measure

5 Hammer

6 Spanner wrench

7 Torque wrench

8 Hole core drill (65mm in diameter)

9 Wrench key (Hexagon)

[4m/m]

10 Vacuum pump

11

Vacuum pump adapter

(Anti-reverse flow type)

12 Gauge manifold

13 Change hose

14 Flaring tool set

15 Gas leak detector

16

Gauge for projection adjustment (Used when flare

is made by using conventional flare tool)

17 Pipe bender

( )

Standard accessories

(Installation kit) Q'ty

Accessories for indoor unit

1

Installation board

1

(Attached to the rear of the indoor unit)

2 Wireless remote control 1

3 Remote contorol holder 1

4

Tapping screws

5

(for installation board 4dia. by 25mm)

5

Wood screw

2

(for remote contorol switch holder 3.5dia. by 16mm)

6

Baterry [R03 (AAA, Micro) 1.5V]

2

7 Air-cleaning filters 2

8

Filter holders

2

(Attached to the front panel of the indoor unit)

Option parts Q'ty

a Sealing plate 1

b Sleeve 1

c Inclination plate 1

d Putty 1

e Drain hose (extention hose) 1

f

Piping cover (for insulation of

1

connection piping)

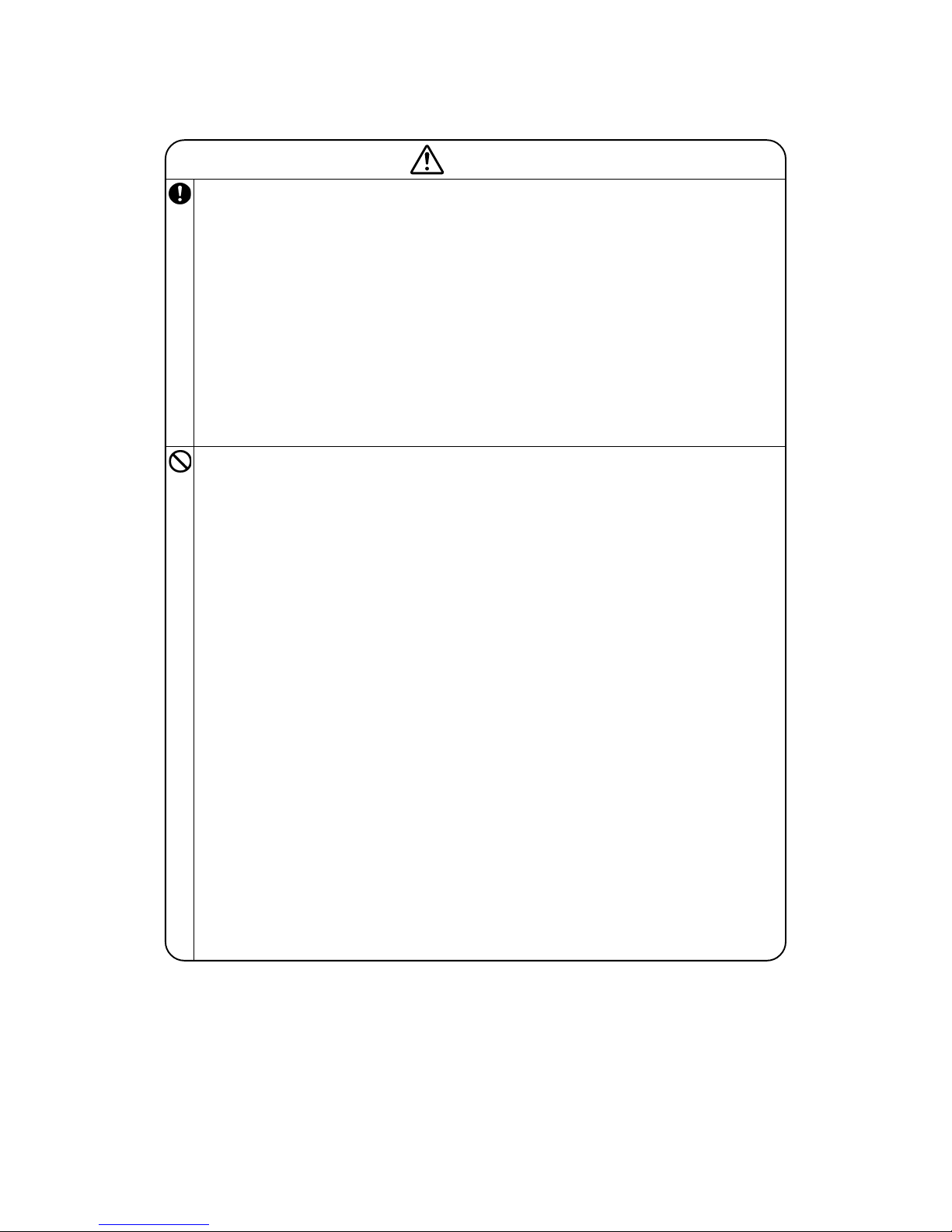

1 A place where good air circulation can be obtained and where rain,

snow or sunshine will not directly strike the unit.

2 A place where discharged hot air or unit’s operating sound will not

be a nuisance to the neighborhood.

3 A place where servicing space can be secured.

4 A place where vibration will not be enlarged.

*Avoid installing in the following places.

•A place near the bedroom and the like, so that the operation

noise will cause no trouble.

•

A place where there is possibility of flammable gas leakage.

•A place exposed to strong wind.

5 Blowing out port and suction port on the back side of the unit can

be installed at a distance of 10cm from walls.

In case the barrier is 1.2m or above in height, or is overhead, the

sufficient space between the unit and wall shall be secured.

6 When the unit is installed, the space of the following dimension

and above shall be secured.

OUTDOOR UNIT

Note (1) If the wall is higher than 1.2 m or a ceiling is

present, distances larger than indicated in the

above table must be provided.

Selection of installation location

1 Where there is no obstructions to the air flow and where the

cooled air can be evenly distributed.

2 A solid place where the unit or the wall will not vibrate.

3 A place where there will be enough space for servicing. (Where

space mentioned right can be secured)

4 Where wiring and the piping work will be easy to conduct.

5 The place where receiving part is not exposed to the direct rays

of the sun or the strong rays of the street lighting.

6 A place where it can be easily drained.

7 A place separated at least 1m away from the television or the

radio.

(To prevent interfence to images and sounds.)

INDOOR UNIT

6.5 cm

5 cm

10 cm

Left

side

14.0 ~ 6 2.0N · m

(1.4 ~ 6 .2kgf · m)

( )

Designed specifica lly

for R410 A

( )

Designed specifica lly

for R410 A

( )

Designed specifica lly

for R410 A

( )

Designed specifica lly

for R410 A

( )

Designed specifica lly

for R410 A

60 cm MIN

Air intake

10 cm MIN

10 cm

MIN

Air outlet

Air

intake

No obstacles

(Service space

for electrical

parts)

Right

side

( )

Page 18

-

16

-

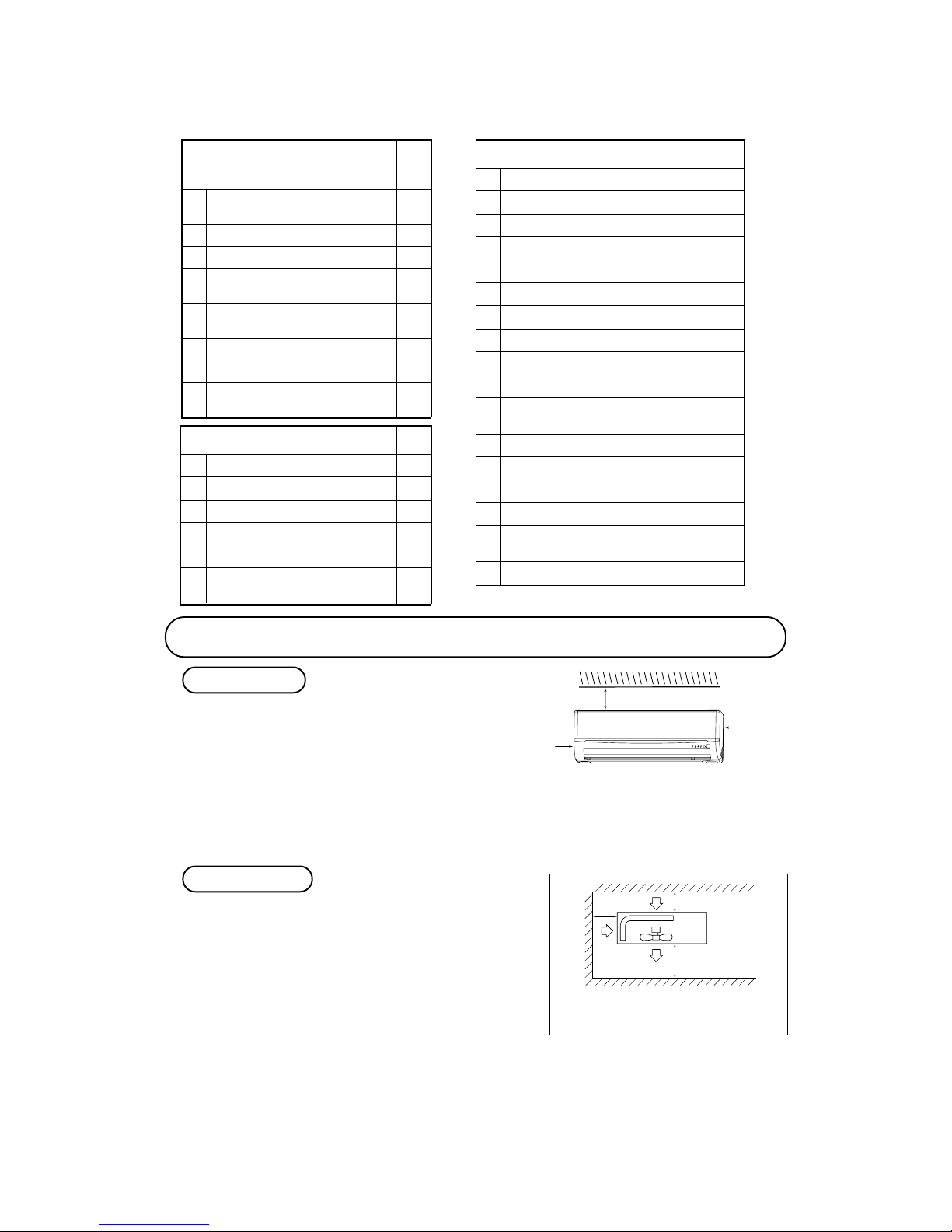

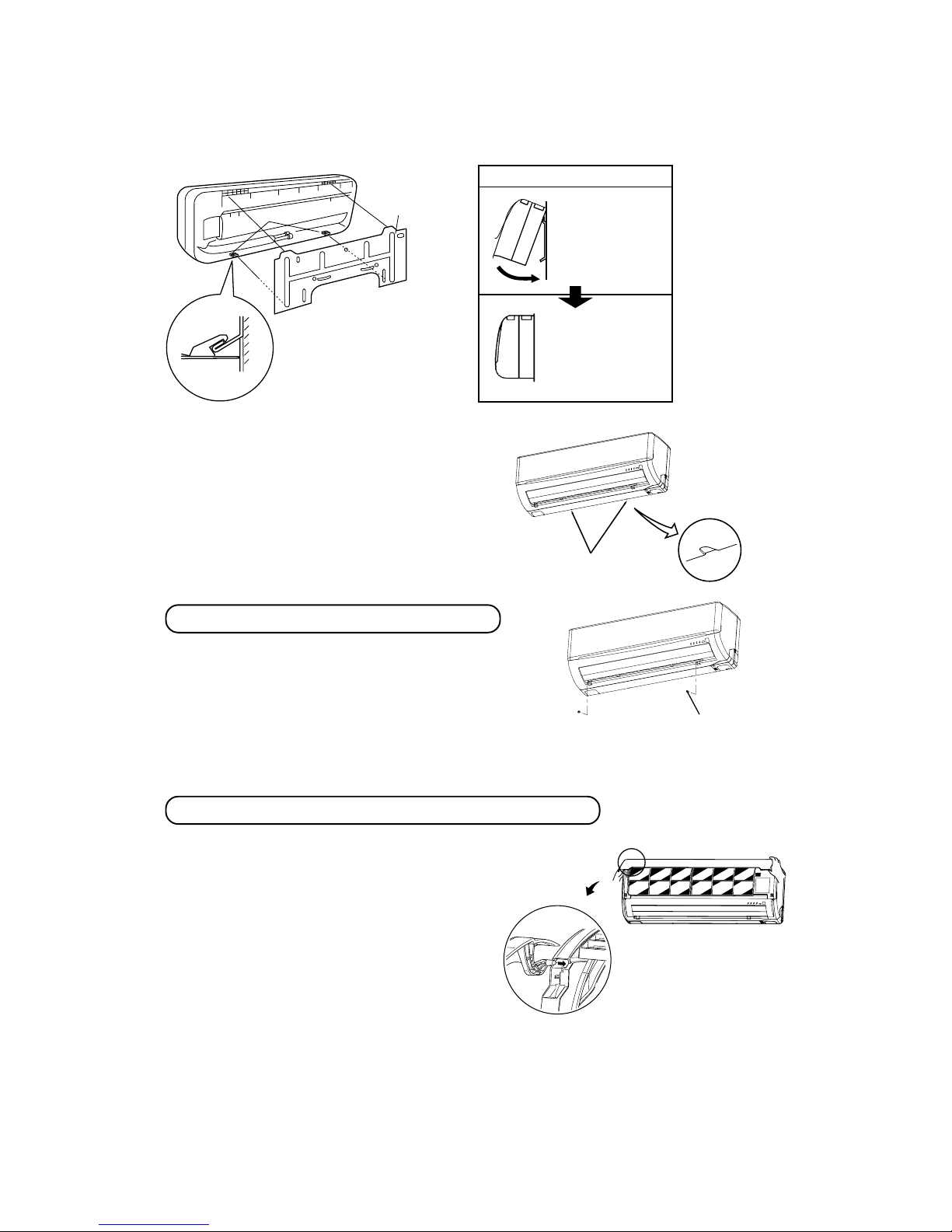

Installation of indoor unit

Installation of installation board

• Adjustment of the installation board in the horizontal

direction is to be conducted with five screws in a

temporary tightened state.

• Adjust so that board will be level by turning the board

with the standard hole as the center.

Standard hole

Look for the inside wall structures (Intersediate support or

pillar and firaly install the unit after level surface has been

checked.)

Mating mark for level surface

450

INSTALLATION SPACE (INDOOR UNIT) (FRONT VIEW)

Unit : mm

Piping hole( 65) Piping hole( 65)

Installation board

Indoor unit

53.5

Piping for Gas 380.6

Piping for Liquid 448.6

Drain hose 520( 16)

53.5

Space *

for service

Space

for service

44.5

252.2

7.5

8.3

Space for

service

50

Space for

service

100

102.5

585

102.5

133.5

450206.5

202450138

44.5

43.2

39.3

200

65

15

Limitations for one way piping length and vertical height difference

Model

SRK10YJV-S

Item

SRK13YJV-S

Total one way piping length (R) Max. 15 m

Vertical height difference (h) Max. 10 m

r

h

Drilling of holes and fixture sleeve (Option parts)

(Insertin g sleeve)

Note (1) Drill a hole with incline of 5 degree from

indoor si de to outd oor side.

Indoor side Outdoor side

Cut off the sleeve

col lar in cas e of

dr aw in g p ipin g

out to re ar.

Cut off the sleeve

collar that can be

seen from beneath

the unit.

Wall thic kness

+ 1.5 cm

Indoor side Outdoor side

Turn t o

tighten

Paste

View of sleeve when installed

In cl ined

flange

Seal ing

plate

Sleeve

Indoor side Outdoor side

(*Sleeve + *Incline d + *Seali ng plate)

Drill a hole with 65 whole core drill Adjusting sleeve length

Install the sleeve

*Leave e xtra space on the r ight side to enable removal o f the lid screw.

Page 19

-

17

-

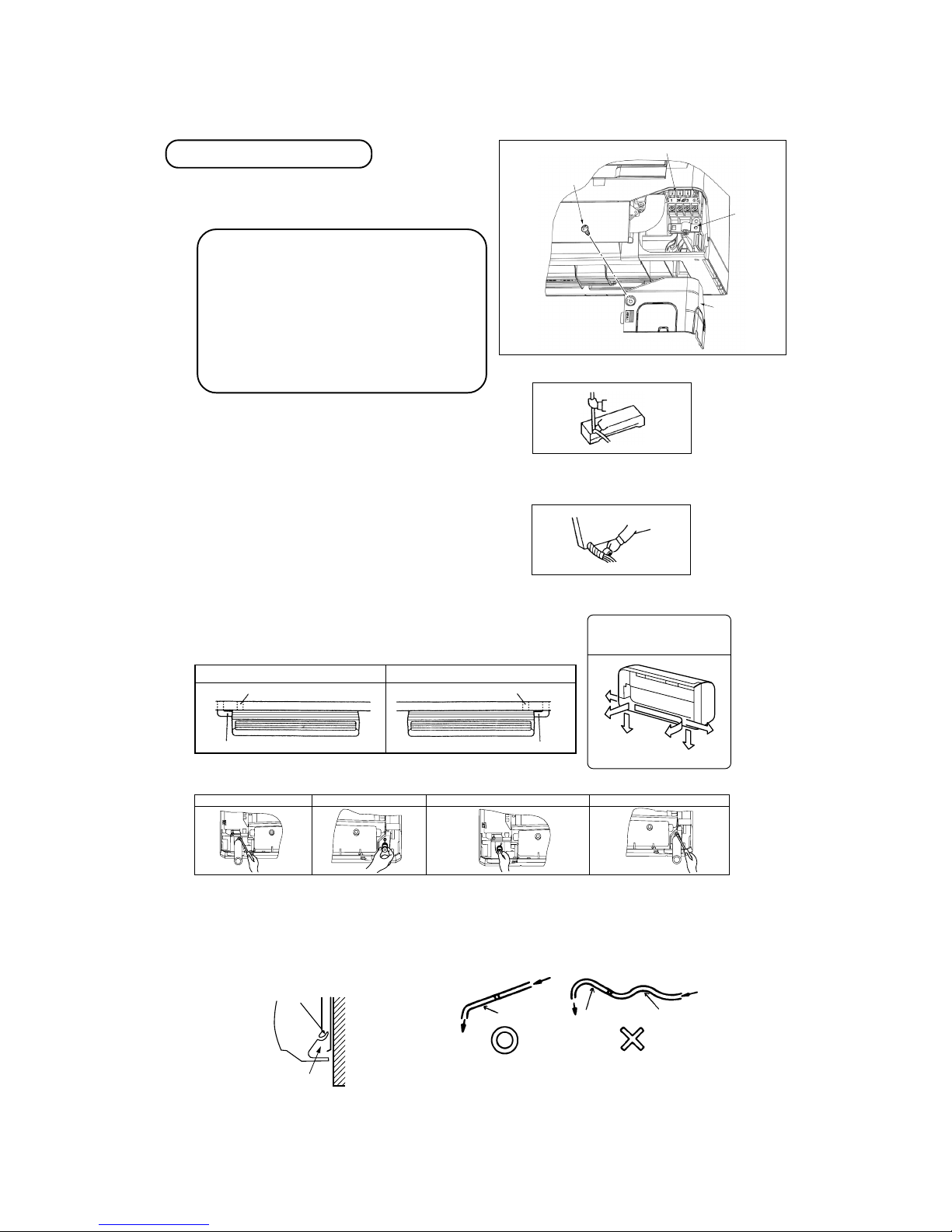

Preparation of indoor unit

Pipe

Drain hose

1. Remove the drain hose. 2. Remove the drain cap. 3. Insert the drain cap. 4. Connect the drain hose.

1 Mounting of connecting wires

a Remove the lid.

b Remove the wiring clamp.

c Connect the connecting wire securely to the terminal block.

Use cable for interconnection wiring to avoid loosening of the

wires.

CENELEC code for cables Required field cables.

H05RNR3G1.5 (Example) or 245IEC57

H Harmonized cable type

05 300/500 volts

R Natural-and/or synth. rubber wire insulation

N Polychloroprene rubber conductors insulation

R Standed core

4or5 Number of conductors

G One conductor of the cables is the earth conductor (yel-

low/green)

1.5 Section of copper wire (mm

2

)

• Connect the connection wire securely to the terminal block.

If the wire is not affixed completely, contact will be poor,

and it is dangerous as the terminal block may heat up and

catch fire.

• Take care not to confuse the terminal numbers for indoor

and outdoor connections.

• Earth lead wire shall be longer than the other lead wires for

the electrical safety in case of the slipping out of the cord

from the anchorage.

• The earth line of power cord must be properly earthed.

• Affix the connection wire using the wiring clamp.

d Fix the connecting wire by wiring clamp.

e Attach the lid.

f Close the air inlet panel.

2 Shaping the pipe

3 Taping of the exterior

• Hold the botto m of the pipe and change it s directio n before

stretchi ng it and shaping it .

• Tape only t he portio n that run s through the wall.

Always t ape the cr ossover wi res with the pip e.

4 Cautions when piping from the left and the rear center of the unit

[ Top View ]

• Remove the sc rew and

drain hose, making it

rotate.

• Remove it with hand

or plier s.

•

Inser t the drain cap which was removed at procedure “2” secure ly using a h exagonal wrench et c.

Note: Be carefu l th at I f it is not Inserted securel y, water leakage may

occur.

•

Insert the drain hose se curely,

making rotate. An d inst all t he

screw.

Note: Be care ful that If it is

not Inser ted sec urely , water

leakage may occur .

Left Side Piping Right Side Piping

Right rear pipingLeft rear piping

Left side piping Right side piping

[Drain hose changing procedures]

Left downward

Right

Rear

Downward

Left rear

Left

Piping is possi ble in the rea r, left,

left rear, left downw ard, right or

downward direction .

• Do n ot place the power supply cords above the gutter,

because the air condition er is structured in a way where

condensa tion on th e back side is c ollected in to the drain

pan befo re drainag e.

• Do not make traps in the drain hose line .

* Leave space t o allow

removal of this scr ew

after ins tallation .

Wall

Gutter

Pipes storage area

Declinin g slope

Inverted slipe

Trap

Terminal block

Clamp

Lid (R)

Screw*

Page 20

-

18

-

Installing steps

1.Hook the upper part

of the indoor unit to

the installation board.

2.The unit can be installed

simply by gently pushing in the lower part.

5 Securing the indoor unit to the installation board

Wall

Indoor u nit

base low er latch

Installa tion

board

Latch ( 2 locati ons)

Installa tion

board

Indoor u nit

•

How to remove the indoor unit from the installation board

1 Push up at the marked portion of the indoor unit

base lower latch, and slightly pull it toward you.

(both right and left hand sides)

(The indoor unit base lower latch can be removed

from the installation board)

2 Push up the indoor unit upward. So the indoor unit

will be removed from the installation board.

The marked portion of the

Indoor unit bese lower latch

Lid

Removal and installation of the front panel

Open/close and detachment/attachment of air inlet panel

Set scre ws

1 Removing

• Remove the 2 set screws.

• Move the lower part of the panel forward and push upwards to

remove. (Remove the 3 latches in the upper section.)

2 Fitting

• Do remove the air filter.

• Cover the body with the front panel.

• Tighten the 2 set screws.

• Fit the air filter. Carry out in the above order.

1 To open, pull the panel at both ends of lower part and release

latches, then pull up the panel until you feel resistance. (The

air inlet panel stops at approx. 60˚ open position.)

2 To close, hold the panel at both ends of lower part to lower

downward and push it slightly until the latch works, then

push the center portion slightly.

3 To remove, pull up the panel to the position shown in right

illustration and pull it toward you.

4 To install, insert the air inlet panel arm into the slot on the

front panel from the position shown in right illustration, hold

the panel at both ends of lower part, lower it downward

slowly, then push it slightly until the latch works and further

push the center portion slightly.

Page 21

-

19

-

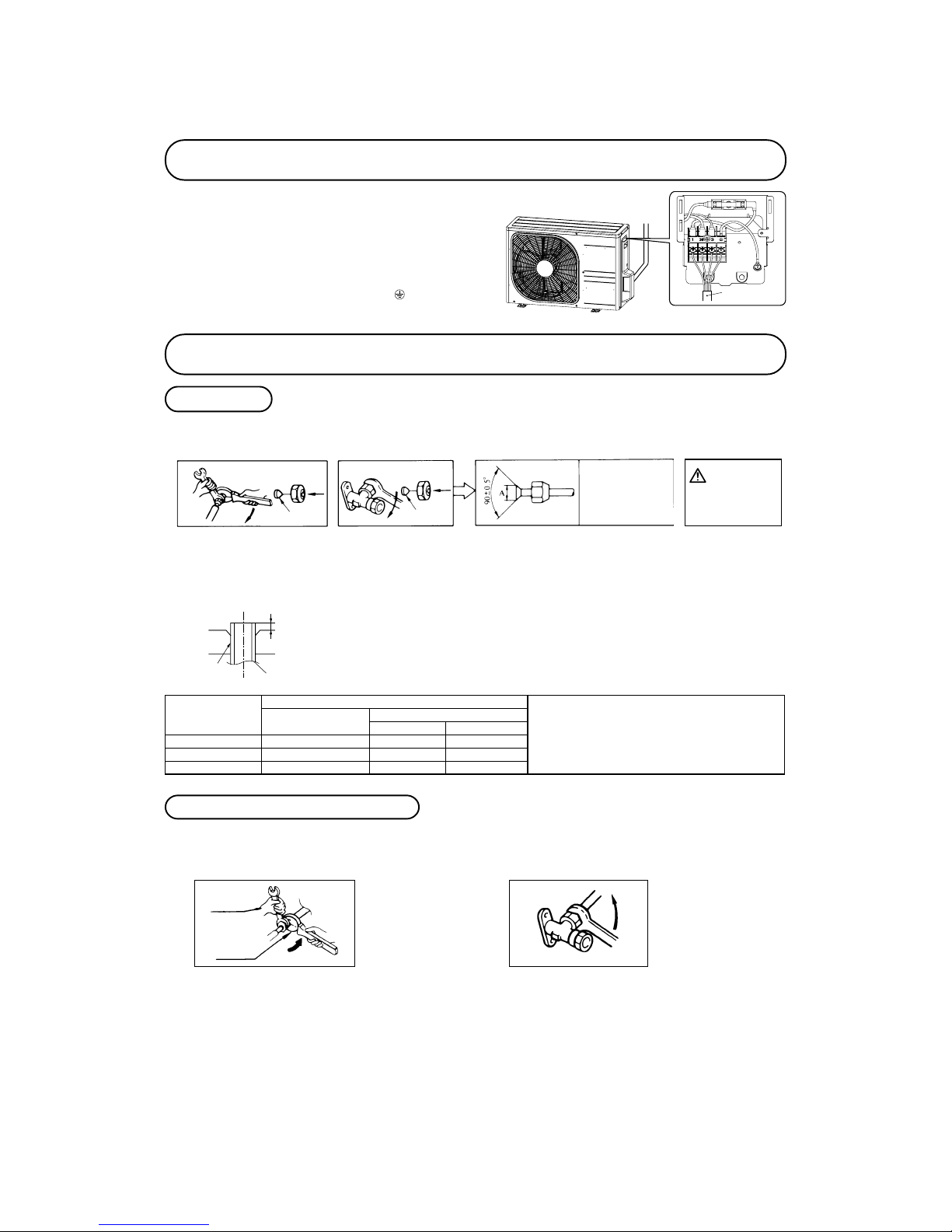

Installation of outdoor unit

1 Make sure that the unit is stable in installation. Fix the

unit to stable base.

2 Perfrom wiring, making wire terminal numbers conform

to terminal numbers of indoor unit terminal block.

3 Earth lead wire shall be longer than the other lead wires

for the electrical safety in case of the slipping out of the

cord from the anchorage.

Connect using ground screw located near mark.

Connection of refrigerant pipings

Preparation

Connection of refrigerant piping

Keep the openings of the pipes covered with tapes etc. to prevent dust, sand, etc. from entering them.

• Specified torquing value:

Liquid side (ø6.35) : 14~18N·m (1.4~1.8kgf·m)

Gas side (ø9.52) : 34~42N·m (3.4~4.2kgf·m)

Gas side (ø12.7) : 49~62N·m (4.9~6.2kgf·m)

• Use one more spanner to fix the valve.

¡ Remov e the flar ed nuts.

(on both liquid an d gas sid es)

¡ Remov e the flared nuts.

(on bo th liquid and gas

sides)

¡ Instal l the removed fl ared nuts to the pipes to

be conne cted, then flare th e pipes.

Dimensio n A

Liquid si de

(ø6.35): 9.0 dia

Gas side

(ø9.52): 13.0 dia

(ø12.7): 16.2 dia

Press

Remove

Remove

(Do not

turn)

Spanner

for fixi ng

the pipin g)

Torque

wrench

• Specified torquing value:

Liquid side (ø6.35) : 14~18N·m (1.4~1.8kgf·m)

Gas side (ø9.52) : 34~42N·m (3.4~4.2kgf·m)

Gas side (ø12.7) : 49~62N·m (4.9~6.2kgf·m)

1 Indoor unit side

2 Outdoor unit side

1 Indoor unit side 2 Outdoor unit side

• Connect firmly gas and liquid side

pipings by Torque wrench.

• Connect firmly gas and liquid side

pipings by Torque wrench.

• Always use a Torque wrench and back up spanner to tighten the flare nut.

Use a flare tool designed for R410A or a conventional flare tool.

Please note that measurement B (protrusion from the flaring

block) will vary depending on the type of a flare tool in use.

If a conventional flare tool is used, please use a copper pipe

gauge or a similar instrument to check protrusion so that you can

keep measurement B to a correct value.

Copper pipe diameter

Clutch type flare tool f or

R410A

Conventional (R22) flare tool

Clutch type Wing nut type

Measurement B (mm)

ø6.35

ø9.52

ø12.7

0.0 ~ 0.5

0.0 ~ 0.5

0.0 ~ 0.5

1.0 ~ 1.5

1.0 ~ 1.5

1.0 ~

1.5

1.5 ~ 2.0

1.5 ~ 2.0

2.0 ~ 2.5

Do not apply refrigerating

machine oil to the flared

surface.

CAUTION

Measurement B

Flaring block

Copper pipe

¡Flaring work

Indoor - Outdoor

connecting wire

Page 22

-

20

-

Insulation of connecting portion

1 Cover the connection portion of the refrigerant piping with the

pipe cover and seal them.

If neglecting to do so, moisture occurs on the piping and water

will drip out.

2 Finishing and fixing

a Tie up the piping with wrapping tape, and shape it so that it conforms

to which the pipe is attached.

b Fix them with clamps as right figure.

Vinyl tap e

To cov er the connecting portion with insulation materi als, cut upper port ion and then seal

it with i nsulation materials .

Cover the exte rior portion wit h covering tape and shape the pi ping so it

will matc h the cont ours of th e route

that t he pip ing to take. Also fix the

wiring and pipings to the w all wit h

clamps.

Insulati on

Refriger ant piping

Electric al wiring

Covering tape

Drain hos e

Tapping s crew

♦ Additional refrigerant charge

Air purge

1 Tighten all flare nuts in the pipings both

indoor and outside wa ll so as not to

cause leak.

2 Connect serv ice valve, char ge hose,

manifold valve and vacuum pump as is

illustrated below.

3 Open manifold valve handle Lo to its

fu ll wid th, and per fo rm vacu um or

evacuation.

Continue the vacuum or evacuation operation for 15 min utes or more and

che ck to see tha t the vacuum gau ge

reads – 0.1 MPa (– 76 cmHg).

4 After comp leting vac uum operat ion,

fully open service valve (Both gas and

li qu id sid es ) w it h hexa go n head ed

wrench.

5 Detach the charge hoses.

6 Check for possible leakage of gas in the

connection parts of both indoor and outdoor.

(three-way valve)

Charge hose (Designed specifically for R410A)

Compound pressure gauge

Pressure gauge

Gauge manifold

(Designed specifically for R410A)

Handle Hi

Vacuum pump

Vacuum pump adapter

(Anti-reverse flow type)

(Designed specifically for R410A)

Charge hose

(Designed specifically for R410A)

Check joint

-0.1MPa

(-76cmHg)

Handle Lo

Operation valve

Operation valve

(two-way valve)

Operation valve

cap

Operation valve

cap

Operation valve cap

tightening torque (N•m)

Check joint blind nut

tightening torque (N•m)

ø6.35 (1/4")

ø9.52 (3/8") 10~12

ø12.7 (1/2") 25~35

20~30

Operation valve size

(mm)

Securely tighten the operation valve cap and the check joint blind nut after adjustment.

¡Since the system uses check joints differing in diameter from those found on the conventional models, a charge hose (for R22) presently in use is

not applicable.

Please use one designed specifically for R410A.

¡Please use an anti-reverse flow type vacuum pump adapter so as to prevent vacuum pump oil from running back into the system.

Oil running back into an air-conditioning system may cause the refrigerant cycle to break down.

Model SRK/C10YJV-S SRK/C13YJV-S

Additional refrigerant

Less than 10m : Not required

More than 10m : 20g/m

Not required

How to relocate or dispose of the unit

• In order to protect the environment, be sure to pump down (recovery of

refrigerant).

• Pump down is the method of recovering refrigerant from the indoor unit

to the outdoor unit when the pipes are removed from the unit.

<How to pump down>

1 Connect charge hose to check joint.

2 Liquid side : Close the liquid valve with hexagon wrench key.

Gas side : Fully open the gas valve.

Carry out cooling operation. (If indoor temperatur e is low, operate

forced cooling operation.)

3 After low pressure gauge become 0.01MPa, stop cooling operation and

close the gas valve.

¡Forced cooling operation

Turn on a power supply again after a while after turn

off a power supply. Then press continually the ON/

OFF button 5 seconds or more.

Unit ON/OFF button

Page 23

-

21

-

Installation of remote control switch

Mounting method of battery

Earthing work

-

-

+

+

• Uncover the remote control switch, and mount the batteries [R03(AAA, Micro)× 2 pieces] in the body regularly.

(Fit the poles with the indication marks, , & . without

fail)

• Earth work shall be carried out without fail in order to prevent electric shock and noise generation.

• The connection of the earth cable to the following substances causes dangerous failures, therefore it shall never be done.

City water pipe, Town gas pipe, TV antenna, lightning conductor, telephone line, etc.

Trial run and operation

1 Conduct trial run after confirming that there is no gas leaks.

2 When conducting trial run set the remote control thermostat to continuous operation position. However when the power source

is cut off or when the unit’s operation switch is turned off or was turned to fan operation position, the unit will not go into

operation in order to protect the compressor.

3 Explain to the customer on the correct usage of the air-conditioner in simple layman’s terms.

4 Make sure that drain flows properly.

Battery

Cover

Fixing to pillar or wall

• Conventionally, operate the wireless remote control

by holding in your hand.

• Avoid installing it on a clay wall etc.

Screws

CAUTION

Do not use new and

old batteries together.

Installations test check points

Check the following points again after completion of the installation, and before turning on the power. Conduct a test run again and

ensure that the unit operates properly.

At the same time, explain to the customer how to use the unit and how to take care of the unit following the instruction manual.

After installation

The power supply voltage is correct as the rating.

No gas leaks from the joints of the operation valve.

Power cables and crossover wires are securely fixed

to the terminal board.

Operation valve is fully open.

The pipe joints for indoor and outdoor pipes have

been insulated.

Test run

Air conditioning operation is normal.

No abnormal noise.

Water drains smoothly.

Protective functions are not working.

The remote control is normal.

Operation of the unit has been explained to the customer.

(Three-minute restart preventive timer)

When the air conditioner is restarted or when changing the operation, the unit will not start operating for approximately 3 minutes.

This is to protect the unit and it is not a malfunction.

Page 24

-

22

-

Remote controller

7.

OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER

(1) Operation control function by remote controller

S

Operation section

Operation and indication section for remote control

Operation section

SRK10YJV-S

SRK13YJV-S

FAN SPEED button

Each time the button is pushed, the

indicator is switche d over in t urn.

•

The above illustrati on shows al l controls, but in pra ctice

only the r elevant pa rts are sho wn.

OPERATION MODE select button

Each time the button pushed, th e

indicator is switche d over in t urn.

ON/OFF (luminous) button

Press for starting o peration, p ress again

for stoppi ng.

HI POWER/ECONO button

This butt on ch anges th e HIG H POWER/

ECONOMY mo de.

Page 14

AIR FLOW (UP/DOWN) button

This butto n changes the air flo w (up/down) mode.

This butto n changes the air flo w (left/rig ht) mode.

Page 10

SLEEP button

This butto n changes to SLEEP op eration.

Page 11

CLEAN switch

This switc h changes the CLEAN m ode.

Page 15

ON TIMER button

This butto n selects ON TIMER op eration.

Page 12

AIR FLOW (LEFT/RIGHT) button

Page 10

3D AUTO button

Thi s b utto n set s 3 D AU TO op erat ion.

Thi s b utto n can cel s th e ON time r, OF F

timer, and SLEEP ope ration.

CANCEL button

RESET switch

Switch for resetting microcompu ter and

setting ti me.

Page 13, 17

OFF TIMER button

This butto n selects OFF TIMER o peration.

Page 11

TEMPERATURE button

This butto n sets the room tempe rature.

(This butt on changes the presen t time and

TIMER time .)

Page 10

Unit indication section

SRK10YJV-S

SRK13YJV-S

3D AUTO light (green)

Illuminate s during 3 D AUTO oper ation.

HI POWER light (green)

Illuminate s during H IGH POWER o peration.

RUN light (green)

Illuminate s during o peration

and CLEAN operation .

TIMER light (yellow)

Illuminate s during T IMER operat ion.

Unit display section

Page 25

-

23

-

(2) Unit ON/OFF button

When the remote controller batteries become weak, or if the remote controller is lost or malfunctioning, this button may be used to

turn the unit on and off.

(a) Operation

Push the button once to place the unit in the automatic mode. Push it once more to turn the unit off.

(b) Details of operation

The unit will go into the automatic mode in which it automatically determines, from room temperature (as detected by sensor),

whether to go into the cooling or thermal dry modes.

(3) Auto restart function

(a) Auto restart function records the operational status of the air-conditioner immediately prior to be switched off by a power cut,

and then automatically resumes operations after the power has been restored.

(b) The following settings will be cancelled:

1)

Timer settings

2)

HIGH POWER operations

Notes (1) Auto restart function is set at on when the air-conditioner is shipped from the factory. Consult

with your dealer if this function needs to be switched off.

(2) When power failure ocurrs, the timer setting is cancelled. Once power is resumed, reset the timer.

(3)

If the jumper wire (J12) “AUTO RESTART” is cut, auto restart is disabled. (See the diagram at right)

(4) Custom cord switching procedure

If two wireless remote controller are installed in one room, in order to prevent wrong operation

due to mixed signals, please modify the printed circuit board in the indoor unit’s control box

and the remote controller using the following procedure. Be sure to modify both boards. If

only one board is modied, receiving (and operation) cannot be done.

(a) Modifying the indoor unit’s printed circuit board

Take out the printed circuit board from the control box and cut off jumper wire (J13)

using wire cutters.

After cutting of the jumper wire, take measures to prevent contact with the other the lead

wires, etc.

(b) Modifying the wireless remote controller

1) Remove the battery.

2) Cut the jumper wire shown in the gure at right.

Jumper wire (J12)

Jumper wire (J13)

Cut

Function

Operation mode

Room temperature

setting

Fan speed

Flap

Timer switch

Cooling

About 24ºC

Auto Auto Continuous

Thermal dry

About 24ºC

Unit ON/OFF button

In emergen cies, this button c an be used for turni ng on/off the unit when

remote con trol is not availab le.

Page 15

RUN light (green)

Illuminate s during operation

and CLEAN operation.

TIMER light (yellow)

Illuminate s during TIMER oper ation.

Unit ON/OFF button

Page 26

-

24

-

'09•SRK-DB-087D

(5)ޓFlap and louver control

(a) Flap

(b) Louver

(c) Swing

1)

2)

(c) Memory flap (Flap or Louver stopped)

(d) When not operating

COOL , DRY, FAN

Remote controller

display

Approx. 10° Approx. 20° Approx. 30°

(Swing)

(Flap stopped)

Approx. 45° Approx. 60°

Angle of Flap from Horizontal

Center installation

Remote controller

display

Right end installation

Left end installation

Angle of Louver

Left Approx. 45°

Left Approx. 45°

Left Approx. 20°

Left Approx. 30°

Center

Left Approx. 20°

Right Approx. 20°

Center

Right Approx. 45°

Right Approx. 20°

Left Approx. 20°

Center

Right Approx. 20° Right Approx. 30° Right Approx. 45°

(Louver stopped)

(Swing) (Spot) (Wide)

In COOL, DRY, FAN operation

Approx.

10°

Approx. 60°

'09•SRK-DB-087D

(6)ޓ3D auto operation

(a)

1)

2)

(b)

At cooling

Air flow selection

Operation mode

AUTO HI MED LO

Indoor temp. – Setting temp. >5°C

Indoor temp. – Setting temp. 5°C

HIGH POWER AUTO

HI MED LO

<

=

Flap

Louver

Cooling

Up/down Swing

Wide (Fixed)

Flap

Louver

Cooling

Left/right Swing

Horizontal blowing (Fixed)

Flap

Louver

Cooling

Up/down Swing

Center (Fixed)

Wide (Fixed)

Flap

Louver

Cooling

Horizontal blowing (Fixed)

Operation mode

Indoor temp. – Setting temp. 2°C

At cooling

Air flow direction contorol

2°C <

Indoor

temp.

–

Setting temp. 5°C

Indoor temp. – Setting temp. > 5°C

The control in d) continues. Control returns to the control in b). Control returns to the control in a).

<

=

<

=

Wide (Fixed)

Flap

Air flow selection

Louver

According to DRY operation.

Horizontal blowing (Fixed)

a)

b)

c)

d)

e)

c

d

Page 27

-

25

-

'09•SRK-DB-087D

(6)ޓ3D auto operation

(a)

1)

2)

(b)

At cooling

Air flow selection

Operation mode

AUTO HI MED LO

Indoor temp. – Setting temp. >5°C

Indoor temp. – Setting temp. 5°C

HIGH POWER AUTO

HI MED LO

<

=

Flap

Louver

Cooling

Up/down Swing

Wide (Fixed)

Flap

Louver

Cooling

Left/right Swing

Horizontal blowing (Fixed)

Flap

Louver

Cooling

Up/down Swing

Center (Fixed)

Wide (Fixed)

Flap

Louver

Cooling

Horizontal blowing (Fixed)

Operation mode

Indoor temp. – Setting temp. 2°C

At cooling

Air flow direction contorol

2°C <

Indoor

temp.

–

Setting temp. 5°C

Indoor temp. – Setting temp. > 5°C

The control in d) continues. Control returns to the control in b). Control returns to the control in a).

<

=

<

=

Wide (Fixed)

Flap

Air flow selection

Louver

According to DRY operation.

Horizontal blowing (Fixed)

a)

b)

c)

d)

e)

c

d

Page 28

-

26

-

'09•SRK-DB-087D

(b) Sleep timer operation

(7)ޓTimer operation

(a) Comfortable timer setting (ON timer)

(c) OFF timer operation

(8)ޓInstallation location setting

(a) Setting

1)

If the air conditioning unit is running, press the ON/OFF button to stop.

2) Press the AIR FLOW (UP/DOWN) button and the

AIR FLOW (LEFT/RIGHT) button together for 5 seconds

or more.

3) Setting the air-conditioning installation location.

4) Press the ON/OFF button.

Airf low range Airf low rangeAirf low range

(Left End Installation) (Center Installation) (Right End Installation)

(Center Installation) (Right End Installation) (Left End Installation)

,

Installation location setting

3

Setting the air-conditioning installation location.

Each time the AIR FLOW (LEFT/RIGHT) button is pressed, the

indicator is switched in the order of:

Press the AIR FLOW (LEFT/RIGHT) button and adjust to the

desired location.

Take the air conditioning unit’s location into account and adjust the left/right airflow range to maximize air-conditioning.

(Center Installation) (Right End Installation) (Left End Installation)

2

Press the AIR FLOW (UP/DOWN) button and the

AIRFLOW (LEFT/RIGHT) button together for 5 seconds

or more.

The installation location display illuminates.

1

If the air conditioning unit is running, press the ON/OFF

button to stop.

The installation location setting cannot be made while the unit is running.

Page 29

-

27

-

27.5

25.5

19.5

18

30

(9) Outline of cooling operation

(a) Operation of major functional components in Cooling mode

(b) Detail of control in each mode (Pattern)

1) Fuzzy operation

During the fuzzy operation, the air ow and the compressor command speed are controlled by calculating the difference

between the room temperature setting correction temperature and the suction air temperature.

ON OFF OFF

ON

OFF

(few minutes ON)

OFF

(few minutes ON)

ON ON ON

Thermostat ON Thermostat OFF Failure

Cooling

Compressor

Indoor fan motor

Outdoor fan motor

20~74rps

20~74rps

20~98rps

20~98rps

20~52rps 20~74rps

20~38rps 20~46rps

Model

Fan speed

SRK10YJV-S SRK13YJV-S

Auto

MED

HI

LO

(10) Outline of automatic operation

(a) Determination of operation mode

The unit checks the indoor air temperature and the outdoor air temperature, determines the operation mode, and then begins in

the automatic operation.

Dehumidifying

Cooling

Indoor air temperature (˚C)

Outdoor air temperature (˚C)

(b)

The unit checks the temperature every hour after the start of operation and, if the result of check is not same as the previous op

-

eration mode, changes the operation mode.

(c)

When the unit is started again within one hour after the stop of automatic operation or when the automatic operation is selected

during cooling or dehumidifying operation, the unit is operated in the previous operation mode.

(d)

Setting temperature can be adjusted within the following range. There is the relationship as shown below between the signals of

the wireless remote controller and the setting temperature.

Signals of wireless remote controller (Display)

–6 –5 –4 –3 –2 –1

±

0 +1 +2 +3 +4 +5 +6

Setting

Cooling

18 19 20 21 22 23 24 25 26 27 28 29 30

temperature

Dehumidifying

19 20 21 22 23 24 25 26 27 28 29 30 31

Page 30

-

28

-

(11) Protective control function

(a) Frost prevention for indoor heat exchanger

(During cooling or dehumidifying)

1) Operating conditions

a) Indoor heat exchanger temperature (Th2) is lower than 5ºC.

b) 8 minutes after reaching the compressor command speed except 0 rps.

2) Detail of anti-frost operation

5°C or lower 2.5°C or lower

Item

model 10 : 44 rps

Upper limit speed

model 13 : 70 rps

0rps

Indoor fan

Depends on operation mode

Protects the fan tap just before

frost prevention control

Outdoor fan

Depends on operation mode Depends on stop mode

3) Reset conditions:

The indoor heat exchanger temperature (Th2) is 8ºC or higher after 5 minutes of operation following

control of the compressor command speed upper is 0 rps.

Indoor heat exchanger

temperature

Indoor heat exchanger

temperature (ºC)

2.5 5 8

0 rps

Upper

limit

speed

Compressor

command

speed

(b) Cooling overload protective control

1) Operating conditions:

When the outdoor unit is operating with the compressor command speed of other than 0 rps, and when

the outdoor air temperature sensor (TH2) becomes 41ºC or over for 30 seconds continuously.

2) Detail of operation

a) Outdoor fan is stepped up by 3 speed step. (Upper limit speed is 7th speed.)

b) The lower limit of compressor command speed is set to 30 rps and even if the calculated result becomes lower than that

after fuzzy calculation, the speed is kept to 30 rps. However, when the thermo becomes OFF, the speed is reduced to 0 rps.

3)

Reset conditions:

When either of the following condition is satised.

a) When the outdoor air temperature becomes 40ºC or less.

b) When the compressor command speed is 0rps.

(c) Compressor overheat protection

1) Purpose:

It is designed to prevent deterioration of oil, burnout of motor coil and other trouble resulting from the com

-

pressor overheat.

2) Detail of operation

a)

Speeds are controlled with temperature detected by the sensor mounted on the discharge pipe.

(Example) Fuzzy

Notes (1) When the discharge pipe temperature is in the range of 100 to 110ºC, the speed is reduced by 4 rps.

(2) When the discharge pipe temperature is raised and continues operation for 20 seconds without changing, then the speed is reduced again by 4 rps.

(3) If the discharge pipe temperature is still 90ºC or greater but less than 100ºC even when the compressor command speed is maintained for 3 minutes

when the temperature is 90ºC or greater but less than 100ºC, the speed is raised by 2 rps and kept at that speed for 3 minutes. This process is

repeated until the compressor command speed is reached.

(4) Lower limit speed

Cooling

Models 10, 13

20 rps

b)

If the temperature of 110ºC is detected by the sensor on the discharge pipe, then the compressor will stop immediately.

When the discharge pipe temperature drops and the time delay of 3 minutes is over, the unit starts again within 1 hour

but there is no start at the third time.

Discharge pipe temperature (˚C)

Lower limit

(4)

After lapse of 3 min. or over

(3)

After lapse of 3 min. or over

(3)

After lapse of 3 min. or over

(3)

4 rps

4 rps

(1)

0 rps

90 100 110

Page 31

-

29

-

(d) Current safe

1) Purpose:

Current is controlled not to exceed the upper limit of the setting operation current.

2) Detail of operation:

Input current to the converter is monitored with the current sensor xed on the printed circuit board

of the outdoor unit and, if the operation current value reaches the limiting current value, the compressor

command speed is reduced.

If the mechanism is actuated when the speed of compressor command is less than 30 rps, the

compressor is stopped immediately. Operation starts again after a delay time of 3 minutes.

(e) Current cut

1) Purpose:

Inverter is protected from overcurrent.

2) Detail of operation:

Output current from the converter is monitored with a shunt resistor and, if the current exceeds the

setting value, the compressor is stopped immediately. Operation starts again after a delay time of

3 minutes.

(f) Outdoor unit failure

This is a function for determining when there is trouble with the outdoor unit during air conditioning.

The compressor is stopped if any one of the following in item 1), 2) is satised. Once the unit is stopped by this function, it is not

restarted.

1) When the input current is measured at 1 A or less for 3 continuous minutes or more.

2) If the compressor command sends a 0 rps signal to the indoor unit 3 times or more within 20 minutes of the power being

turned on.

(g) Inching prevention

When the compressor goes into the thermo operation within 10 minutes since operation start or becomes various dehumidifying

operations, the operation is continued with the lower limit speed forcibly.

(h) Indoor fan motor protection

When the air conditioner is operating and the indoor fan motor is turned ON, if the indoor fan motor has operated at 300 rpm or

under for more than 30 seconds, the unit enters rst in the stop mode and then stops the entire system.

(i) Serial signal transmission error protection

1) Purpose:

Prevents malfunction resulting from error on the indoor ↔ outdoor signals.

2) Detail of operation

a)

When the outdoor unit controller cannot receive signals from the indoor unit

If the compressor is operating and a serial signal cannot be received from the indoor control with outdoor control hav-

ing serial signals continuously for 1 minute and 55 seconds, the compressor is stopped.