Page 1

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

ON/OFF

RESET

TOO

WARM

TOO

COOL

MODE

AUTO COOL

DRY

HEAT

FAN

VANE

SELECT

TIME

h

TECHNICAL & SERVICE MANUAL

No. OC302

Series SLZ

Ceiling Cassettes

R410A

Indoor unit

[Model names] [Service Ref.]

SLZ-A09AR SLZ-A09AR.TH

SLZ-A12AR SLZ-A12AR.TH

SLZ-A18AR SLZ-A18AR.TH

•This manual does not cover

outdoor units. When servicing

them, please refer to the

service manual No.OC304

and this manual in a set.

CONTENTS

1. PART NAMES AND FUNCTIONS ········2

2. SPECIFICATIONS·································3

3. OUTLINES AND DIMENSIONS············5

4. WIRING DIAGRAM ·······························7

5.

REFRIGERANT SYSTEM DIAGRAM

INDOOR UNIT

6. TROUBLESHOOTING ··························9

7. 4-WAY AIR FLOW SYSTEM ···············16

8. DISASSEMBLY PROCEDURE ···········18

9. PARTS LIST········································21

REMOTE CONTROLLER

·········8

Page 2

1

ON/OFF

RESET

TOO

WARM

TOO

COOL

MODE

AUTO COOL

DRY

HEAT

FAN

VANE

SELECT

TIME

h

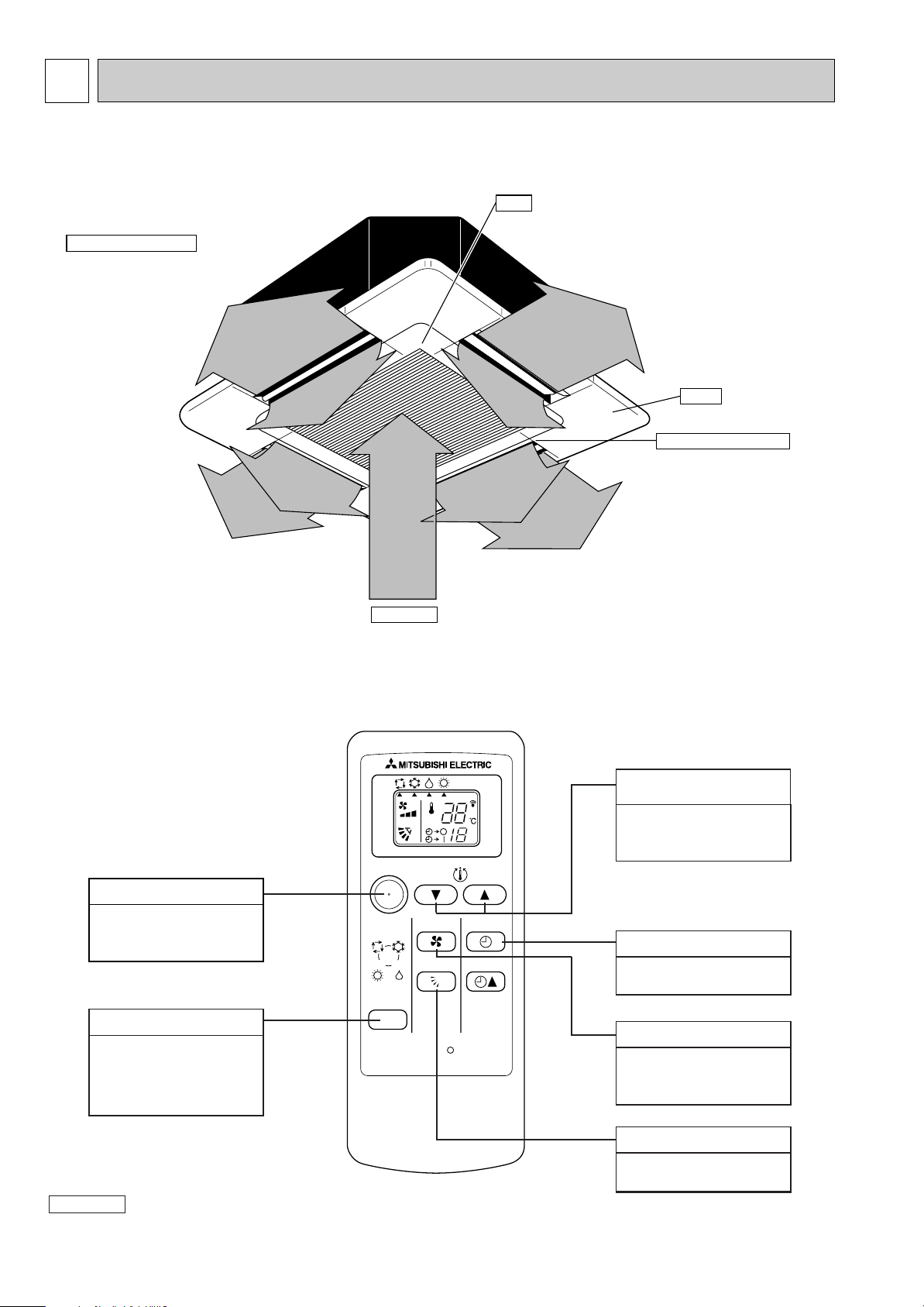

PART NAMES AND FUNCTIONS

Indoor Unit

SLZ-A09AR.TH

SLZ-A12AR.TH

SLZ-A18AR.TH

Horizontal Air Outlet

Sets airflow horizontal automatically

during cooling or dehumidifying.

Filter

Remove dust and pollutants

from inhaled air

Grille

Auto Air Swing Vane

Disperses airflow up and

down and adjusts the angle

of airflow direction.

Air Intake

Inhales air from room.

Remote controller

SET TEMPERATURE

button

SET TEMPERATURE

button sets and any

desired room temperature.

ON / OFF button

Pushing button starts

operation. Pushing again

stops operation.

MODE SELECT button

This button is used to change

between auto, cooling,

heating and drying operation

modes. (SLZ)

Attention :

● Avoid operation of buttons with fingernails or other sharp objects. Sharp objects may scratch remote controller.

TIMER SELECT button

Used for selecting timed

starting or stopping.

FAN SPEED button

This button is used to set

fan speed to low, medium

or high.

VANE CONTROL button

Used to change the airflow

direction.

2

Page 3

2

SLZ-A09AR.TH SLZ-A12AR.TH

Indoor model

Function

Power supply

Single phase

230V, 50Hz

600/540/480

10

0.18

40

0.014

0.18

PK6V15-LA

4

38/35/32

650/580/530

3

10

10

10

MPPC

Cooling

91

Heating

92

Single phase

230V, 50Hz

660/600/540

10

0.23

52

0.014

0.23

PK6V20-LE

4

39/37/34

690/630/570

3

10

10

10

MPPC

Cooling

94

Heating

95

Air flow (High/Med./Low)

Power outlet

Running current ✽1

Power input Rated frequency

Dew prevention heater

Power factor ✽1

Fan motor current ✽1

Model

Winding

resistance (at20:)

Width

Height

Depth

Weight

Air direction

Sound level(High/Med./Low)

Fan speed(High/Med./Low)

Fan speed regulator

Thermistor RT11(at25:)

Thermistor RT12(at25:)

Thermistor RT13(at25:)

Remote controller model

K /h

A

A

W

(kW)

%

A

"

mm(in)

mm(in)

mm(in)

kg

dB(A)

rpm

k"

k"

k"

Electrical

data

Fan

motor

Special

remarks

Capacity

Dimensions

WHT-BLK : 407 BLK-BLU : 55

BLU-YLW : 31 YLW-BRN : 30

BRN-RED : 165

UNIT : 570(22-7/16) PANEL : 650(25-9/16)

UNIT : 208(8-3/16) PANEL : 20(13/16)

UNIT : 570(22-7/16) PANEL : 650(25-9/16)

UNIT : 16.5 PANEL : 3

WHT-BLK : 384 BLK-BLU : 111

BLU-YLW : 49 YLW-BRN : 46

BRN-RED : 311

SLZ-A18AR.TH

Single phase

230V, 50Hz

660/600/540

20

0.24

53

0.014

0.24

PK6V20-LF

4

40/38/35

710/650/590

3

10

10

10

MPPC

Cooling

97

Heating

97

WHT-BLK : 317 BLK-BLU : 88

BLU-YLW : 52 YLW-BRN : 45

BRN-RED : 301

1.5+ 440V

250V 3.15A

MSBPC20 12V 250"

POWER SUPPLY : 3P TO OUTDOOR UNIT : 4P

G4A-1A-E-PS 12V DC

145:i2:

240V AC 15W

INDOOR UNIT

Item

Model

Indoor fan capacitor

Fuse

Vane motor

Terminal block

Contactor

Indoor fan motor thermal fuse

Cord Heater

SLZ-A09AR.TH SLZ-A12AR.TH SLZ-A18AR.TH

(C1)

(F11)

(MV)

(TB)

(52C)

(H2)

SPECIFICATIONS

NOTE : Test conditions are based on ISO 5151

Cooling : Indoor D.B. 27: W.B. 19:

Heating : Indoor D.B. 20: W.B. 15:

Refrigerant piping length (one way): 5m

✽1 Measured under rated operating frequency.

Specifications and rating conditions of main electric parts

Outdoor D.B. 35: W.B. 24:

Outdoor D.B. 7: W.B. 6:

3

Page 4

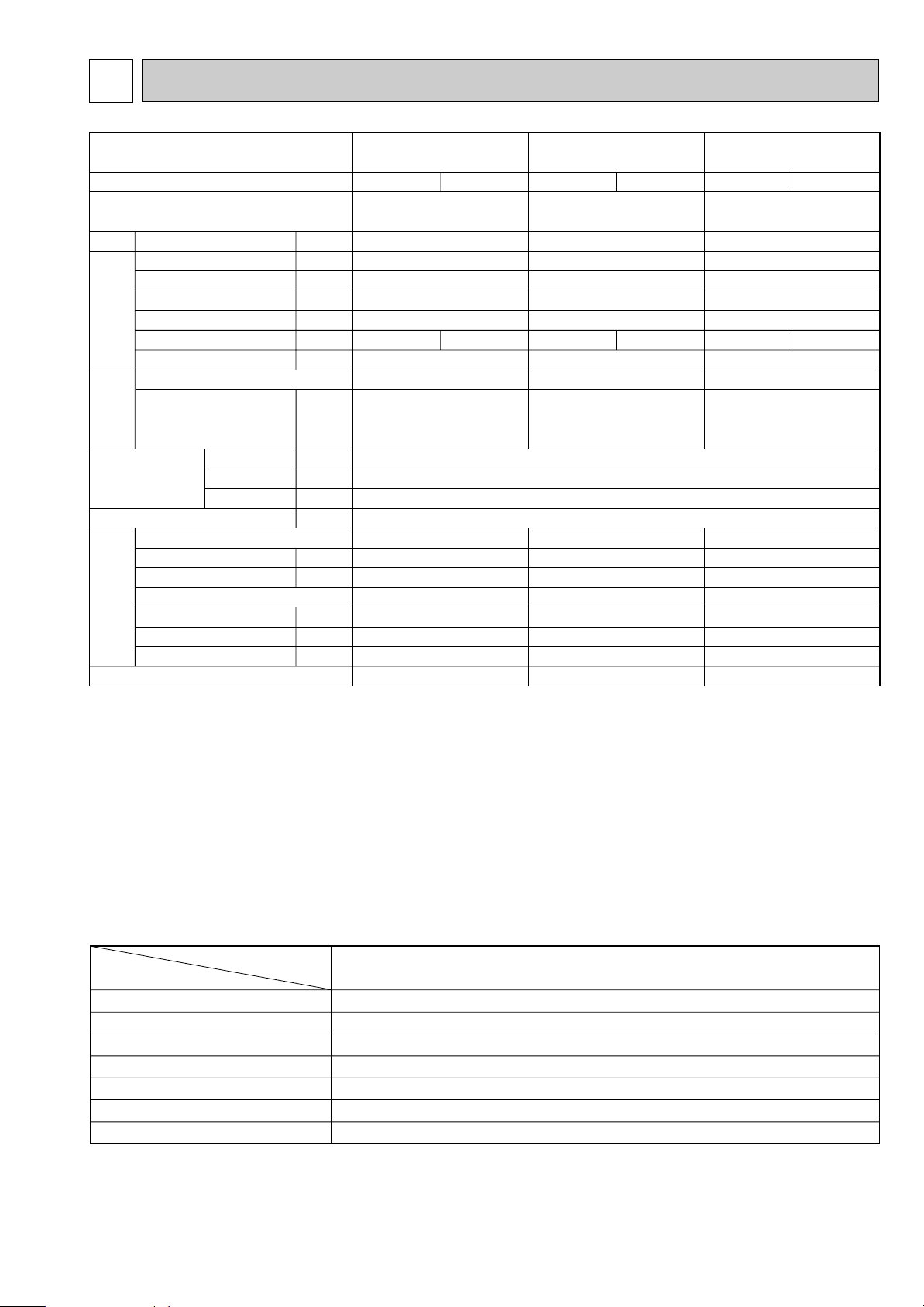

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

SLZ-A12AR.TH

Hi

Me

39

SPL(dB)37LINE

<50Hz>

NOTCH

Lo

34

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

SLZ-A09AR.TH

Hi

Me

38

SPL(dB)35LINE

<50Hz>

NOTCH

Lo

32

NOISE CRITERION CURVES

UNIT

1.5m

MICROPHONE

CEILING

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

SLZ-A18AR.TH

Hi

Me

40

SPL(dB)38LINE

<50Hz>

NOTCH

Lo

35

4

NOTE: The sound level is measured in an anechoic room where echoes are few, when compressor stops. The sound

may be bigger than displayed level under actual installation condition by surrounding echoes. The sound level

can be higher by about 2 dB than the displayed level during cooling and heating operation.

Page 5

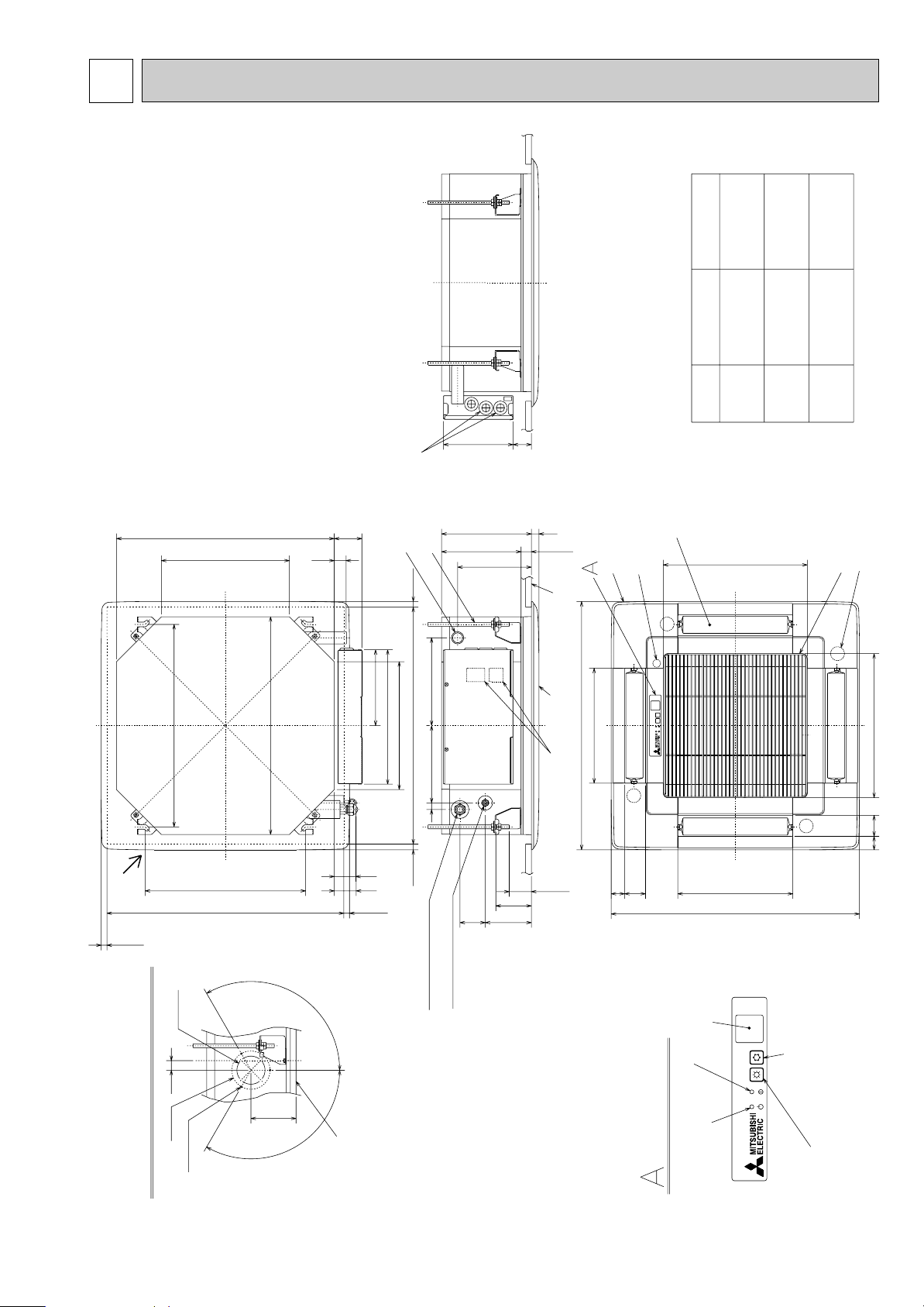

3

Suspension bolt

M10 or 3/8

(procure locally)

1/4F

flared connection

[6.35mm

1/4F

flared connection

[6.35mm

[9.52mm

flared connection

3/8F

1/2F

flared connection

SLZ-A18AR

SLZ-A12AR

Refrigerent pipe (liquid)

Refrigerent pipe (gas)

Models

SLZ-A09AR

[6.35mm

flared connection

1/4F

Refrigerent pipe

(liquid)

Refrigerent pipe

(gas)

[12.7mm

[9.52mm

flared connection

3/8F

15~37 15~37

576~620

570

530

Grille

Fresh air

intake

Drain pipe

VP-25 connection

(O.D.[32)

Vane motor

Drain hole

V/M

V/M

V/M

V/M

Air intake grille

55 35

35 55

Auto vane

Grille

Air intake hole

Air intake hole

Air outlet hole

Air outlet hole

301

301

Emergency operation

switch(cooling)

Emergency operation switch(heating)

Operation lamp

(WIRELESS PANEL)

DEFROST/STAND BY lamp

Receiver

Detail drawing of fresh air intake

Ceiling surface

Cut out hole

[73.4

Burring hole

3-[2.8 hole

[100

118

25

120°

120°

377

377

650

650

Suspension

bolt lower edge

230

18248

Wiring entry

Terminal block

Ceiling surface

235

208

27

+5

0

193

20

93

38~58

66121

17 202

56

57

72

31

Ceiling hole

Suspension bolt pitch

15~37

15~37

576~620

420

570

335

199

352

335

Suspension bolt

pitch

Ceiling hole

OUTLINES AND DIMENSIONS

SLZ-A09AR.TH

SLZ-A12AR.TH

SLZ-A18AR.TH

Unit : mm

5

Page 6

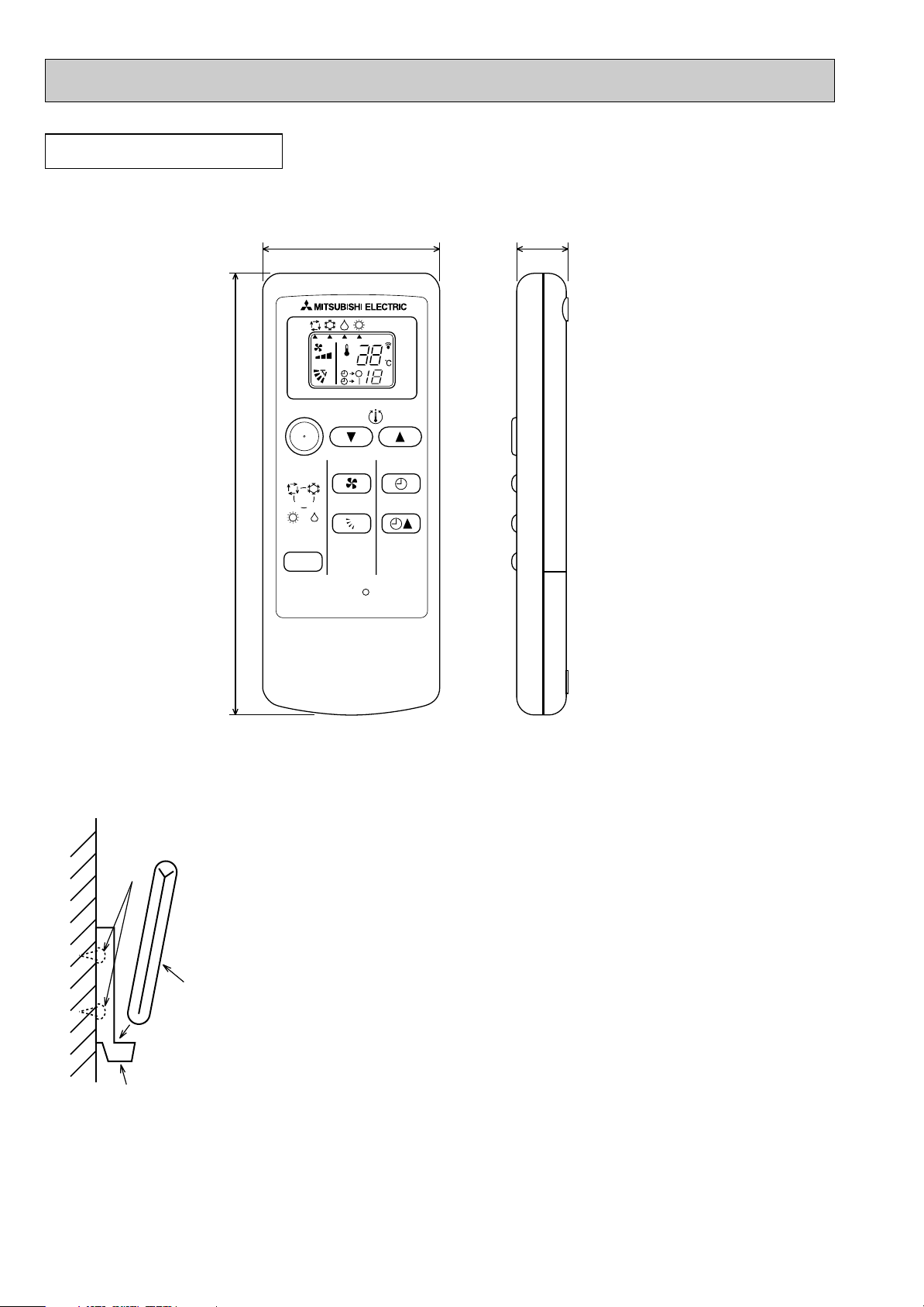

REMOTE CONTROLLER

Installation area

• Area in which the remote controller is not exposed direct sunshine.

• Area in which there is no nearby heating source.

• Area in which the remote controller is not exposed to cold (or hot) winds.

• Area in which the remote controller can be operated easily

• Area in which the remote controller is beyond the reach of children.

Installation method

1 Attach the remote controller holder to the desired location using two tapping screws.

2 Place the lower end of the controller into the holder.

A Wireless remote controller (Accessory)

B Wall

C Remote controller holder (Accessory)

D Fixing screw (Accessory)

• The signal can travel up to approximately 7 meters (in a straight line) within 45

degrees to both right and left of the center line of the receiver.

In addition, the signal may not be received if there is interference of light of fluorescent

lights or strong sunlight.

A

C

B

D

ON/OFF

RESET

TOO

WARM

TOO

COOL

MODE

AUTO COOL

DRY

HEAT

FAN

VANE

SELECT

TIME

h

57 17.5

140

Unit : mm

6

Page 7

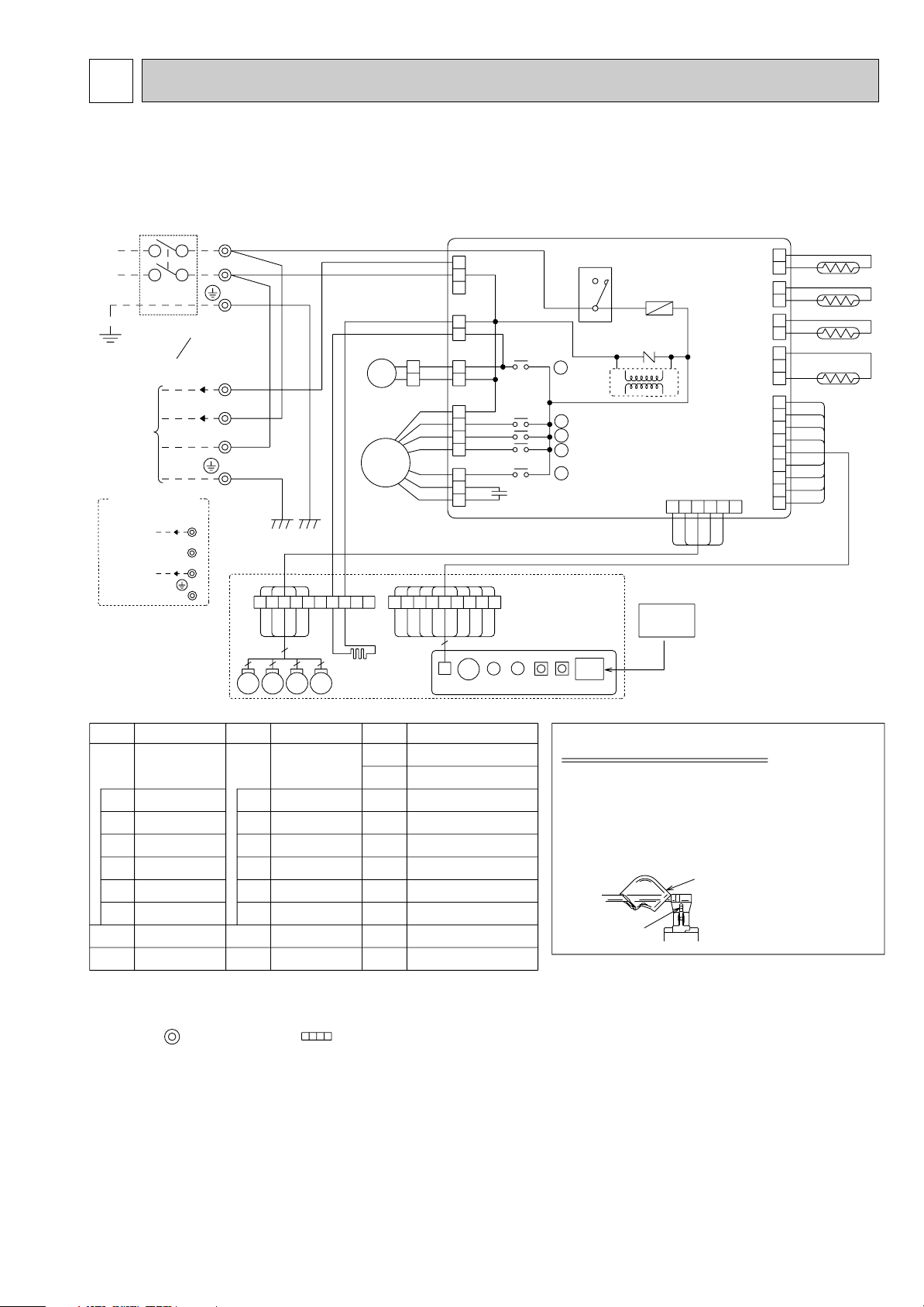

4

GRILLE

FOR A18 (1:1 SYSTEM)

OR MULTI SYSTEM

FOR A09/12

★

★

(1:1 SYSTEM)

TO OUTDOOR

UNIT

CONNECTING

CONDENSER/EVAPORATOR

TEMPERATURE THERMISTOR

RT13

RT13

3

12VDC

★ The 12V DC is NOT always against the ground.

Terminal 3 has 12V DC against terminal N.

However, between 3 and 2, these terminals are NOT electrically insulated by the transformer or other device.

TO OUTDOOR

UNIT

CONNECTING

2

N

TB

TERMINAL BLOCK

MV MV MV MV

CNB

BZ

LED2

LED1

SW1

SW2

RU

W.B

POWER SUPPLY

~/N

220-240V 220V

50Hz 60Hz

FAN MOTOR

CAPACITOR

C1

5

5

5

5

H2

5

BLK

DC13.1V

TRANS

X5

X5

W.R

REMOTE

CONTROLLER

TB

: Connector

: Terminal block

(For field wiring)

2.Use copper conductors only.

3.Symbols below indicate.

PIPE TEMPERATURE

THERMISTOR / LIQUID

RT12

W.R

WIRELESS REMOTE

CONTROLLER

RT11

ROOM TEMPERATURE

THERMISTOR

VANE MOTORMV

FAN MOTOR

MF

DEW PREVENTION

HEATER

H2

DRAIN SENSOR

DRAIN-UP

MACHINE

DP

DS

FUSE

FUSE(3.15A)

w WHT

3

N

2

220-240V~

12VDC

L

3

4

52C

ZNR1

DP

MF

X1

X2

X3

X4

X4

X3

X2

X1

w RED

w BLU

GRN/YLW

w WHT

N

GRN/YLW

TB

CIRCUIT BREAKER

w BLU

1.About the outdoor side electric wiring refer to the outdoor unit electlic wiring diagram for servicing.

How to remove the terminals

shown at "

w " mark.

" w " shows the terminals with a lock mechanism,

so they cannot be removed when you pull the

lead wire. Be sure to pull the wire by pushing

the locking lever (projected part) of the

terminal with a finger.

locking lever

1 Slide the sleeve.

2 Pull the wire

while pushing

the locking lever.

sleeve

NOTES:

9

BUZZER

ZNR1

VARISTOR

NAME

SYMBOLSYMBOL

NAME

SYMBOL

NAME

X1

X2-X5

RELAY(D.PUMP

/D.HEATER)

RELAY

(FAN MOTOR)

COMPRESSOR

CONTACTOR

52C

BZ

LED1

LED2

SW1

SW2

I.B

INDOOR

CONTROLLER

BOARD

W.B

WIRELESS REMOTE

CONTROLLER

BOARD

RU

LED

(RUN INDICATOR)

LED

(HOT ADJUST)

SWITCH

(HEATING ON/OFF)

SWITCH

(COOLING ON/OFF)

RECEVING UNIT

[LEGEND]

FUSE

C1

I.B

RT11

RT12

DS

(2 PHASE)

1

2

BLK

CN29

1

3

1

3

BRN

RED

ORN

YLW

BLU

VLT

GRY

PINK

SKY BLU

YLW

YLW

RED

ORN

YLW

WHT

BLU

1

745

10

89

ORN

RED

BRN

YLW

BLU

WHT

YLW

YLW

BLU

RED

WHT

RED

GRN

WHT

WHT

1

3

5

7

1

3

1

3

5

5

3

1

CNP(PUMP)

CNC

CND(POWER)

RED

CN31

CN20

CN21

(DRAIN)

(INTAKE)

(LIQUID)

CN90

(WIRELESS)

CN6V

(VANE)

(HEATER)

1

2

3

1

1

2

2

12345

1

2

3

4

5

6

7

8

9

FAN2(FAN)

FAN1(FAN)

BLU

WHT

ORN

RED

YLW

6

WHT

WHT

SKY BLU

PINK

GRY

VLT

BLU

YLW

ORN

RED

BRN

YLW

YLW

236

123456789

w

WIRING DIAGRAM

SLZ-A09AR.TH

SLZ-A12AR.TH

SLZ-A18AR.TH

7

Page 8

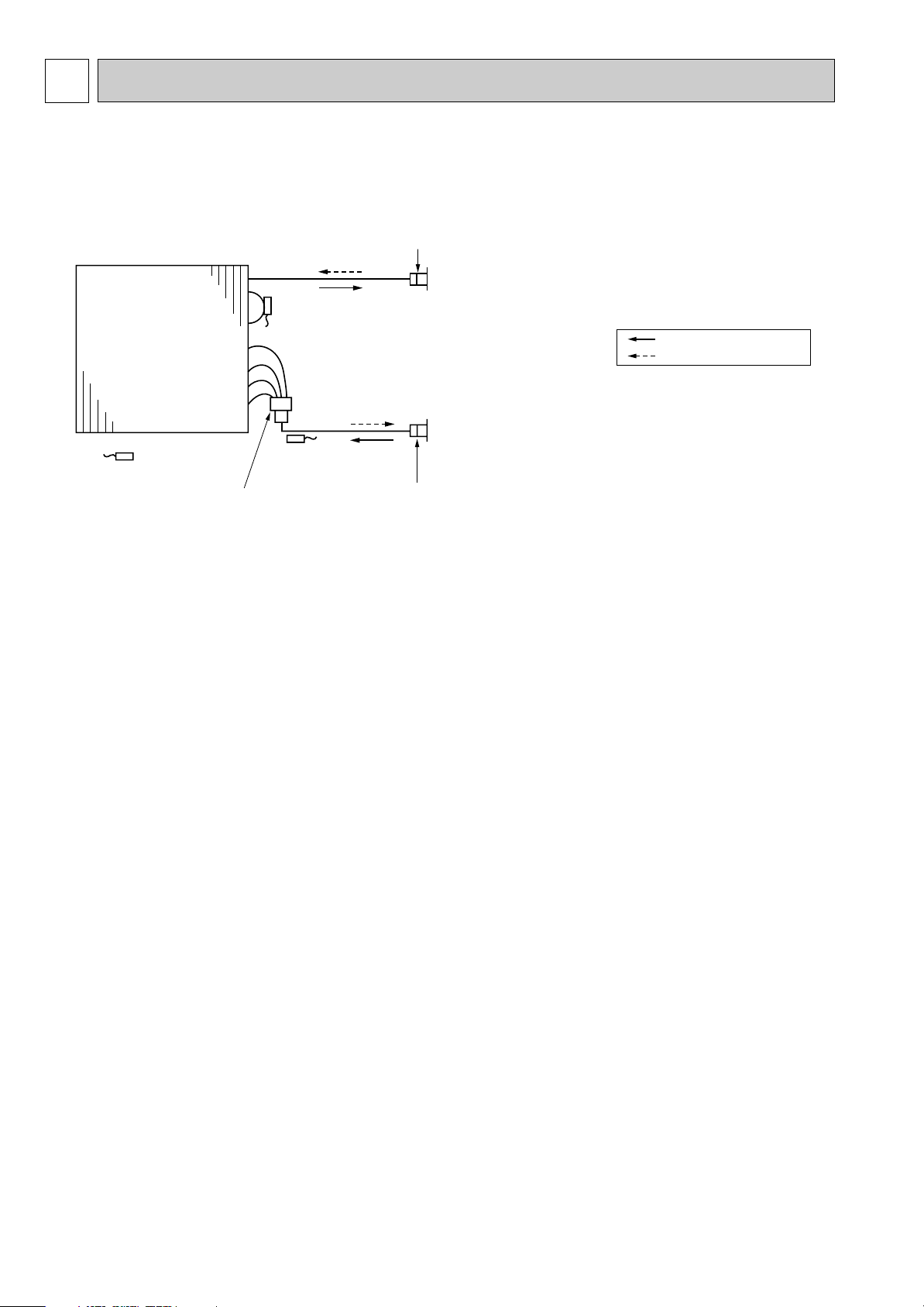

5

Pipe temperature

thermistor/liquid

(RT12)

Distributor

with strainer

#50

Condenser/evaporator

temperature thermistor

(RT13)

Room temperature

thermistor (RT11)

Refrigerant flow in cooling

Refrigerant flow in heating

Strainer

#50

Strainer

#50

Heat exchanger

Refrigerant GAS pipe connection

(Flare)

Refrigerant LIQUID pipe connection

(Flare)

REFRIGERANT SYSTEM DIAGRAM

SLZ-A09AR.TH

SLZ-A12AR.TH

SLZ-A18AR.TH

8

Page 9

6

Operation lamp

Mis-wiring1

blinking

2

blinking

Indoor-outdoor

signal error

Wiring between the indoor and

outdoor is coming off.

Difference of wiring polarity

between the indoor and outdoor.

Trouble of the outdoor inverter

P.C. board.

Check the wiring out between the indoor and

outdoor.

Check the outdoor inverter P.C. board. Refer to the

TECHNICAL & SERVICE MANUAL of outdoor unit.

Trouble of the Indoor controller

board.

Exchange the Indoor controller board.

Pipe temperature thermistor

/ Liquid.

Mis-connecting of the pipe

temperature thermistor / Liquid.

Reinsert the connector (CN21).

Trouble of the pipe temperature

thermistor / Liquid.

Trouble of the Indoor controller

board.

Exchange the Indoor controller board.

Check the resistance value of the thermistor.

Room temperature

thermistor

Mis-connecting of the room

temperature thermistor.

Reinsert the connector (CN20).

Trouble of the room temperature

thermistor.

Trouble of the Indoor controller

board.

Exchange the Indoor controller board.

Check the resistance value of the thermistor.

Condenser / evaporator

temperature thermistor

Mis-connecting of the condenser /

evaporator temperature thermistor.

Reinsert the connector (CN29).

Trouble of the condenser / evaporator

temperature thermistor.

Trouble of the Indoor controller

board.

Exchange the Indoor controller board.

Check the resistance value of the thermistor.

Drain sensor Mis-connecting of the indoor drain

sensor

Reinsert the connector (CN31).

Trouble of the indoor drain sensor

Trouble of the Indoor controller

board.

Exchange the Indoor controller board.

Check the resistance value of the thermistor.

Phenomenon

Blinking

frequency

Cause Countermeasure

TROUBLESHOOTING

6-1. Cautions on troubleshooting

(1) Before troubleshooting, check the followings:

1Check the power supply voltage.

2Check the indoor/outdoor connecting wire for mis-wiring.

(2) Take care the followings during servicing.

1 Before servicing the air conditioner, be sure to first turn off the remote controller to stop the main unit, and then turn

off the breaker.

2 When removing the indoor controller board, hold the edge of the board with care NOT to apply stress on the

components.

3 When connecting or disconnecting the connectors, hold the housing of the connector. DO NOT pull the lead wires.

6-2. Trouble display

Blinking frequency of operation lamp shows the details of trouble of the indoor and the outdoor units.

(1) Incase of being indicated irregularity on the self diagnoses.

9

To be continued on the next page.

Page 10

3

blinking

5,7,10

blinking

6

blinking

9

blinking

Freezing protection is

working.

1) Short cycle of air cycle

2) Dirty air filter

3) Damaged fan

4) Abnormal refrigerant

1) Clear obstructions from air cycle.

2) Clean the air filter

3) Check the fan

4) Check the refrigerant temperature.

Malfunction of outdoor unit Malfunction of outdoor unit Refer to the TECHNICAL & SERVICE MANUAL

of outdoor unit.

Malfunction of drain pump 1) Malfunction of drain pump

2) Damaged drain sensor

1) Check the drain pump.

2) Check the drain sensor.

(Check the drop of water is on.)

If the resistance is normal, replace the indoor

controller board.

Outdoor thermistor Mis-connecting of the outdoor

thermistor.

Reinsert the connector.

Trouble of the outdoor thermistor.

Trouble of the outdoor inverter P.C.

board.

Exchange the outdoor inverter P.C. board.

Check the resistance value of the thermistor.

Phenomenon

Blinking

frequency

Cause Countermeasure

Not working of remote

controller switch ON/OFF

Short circuit the protecting parts in the

Indoor controller board.

Trouble of the Indoor controller board. Check the Indoor controller board out.

Trouble of the remote controller.

Check the varistor (ZNR1) and fuse (FUSE) out in

the Indoor controller board.

Exchange the remote controller.

Wiring between the indoor and outdoor is

coming off.

Working the Indoor units

and not working the outdoor

units.

Check the wiring out between the indoor and

outdoor.

Difference of wiring polarity between the

indoor and outdoor.

Trouble of the outdoor inverter P.C. board.

Trouble of the contactor (52C). Exchange the contactor.

Check the outdoor inverter P.C. board.

Malfunction of outdoor unit. Refer to the TECHNICAL & SERVICE MANUAL of

outdoor unit.

Fan motor connector is coming off.

Not rotating the fan in the

indoor unit.

Trouble of the Indoor controller board.

Check the fan motor output of the Indoor

controller

board.

Check the connector out.

Trouble of the fan motor. Check the resistance value between the each tap

of fan motor.

A connector attaching the panel to the body

is not connected.

Horizontal vane doesn't work.

Check if the connector for vane motor is connected.

Connect it.

A connector attaching the panel to the body

is not connected.

Fixing of horizontal vane.

Connect it.

Phenomenon Cause Countermeasure

From the preceding page.

(2) Other case

10

Page 11

Check of indoor controller board and indoor fan motor

Operation lamp blinks once in a fixed period.

Error was found in the signal transmitted or

received between the indoor and outdoor units.

Check the condenser/evaporator

temperature thermistor.

Is the connector CN29 on the

indoor controller board connected?

No

Connection is defective.

Measure the resistance of

condenser/evaporator

temperature thermistor.

Is the connecting wire between

the indoor and outdoor units

No

connected properly?

Connection is defective.

Yes

No

Connection is defective. Connection is defective. Connection is defective.

Are there any devices emitting

noise near the power supply or

the connecting wire between the

Yes

Yes

indoor and outdoor units?

No

Remove the devices.

Turn off the power supply and turn it on again to operate the unit in

cooling or heating mode.

Operation lamp blinks once in a

No

fixed period.

Yes

Normal

Indoor controller board is defective.

Operation lamp blinks twice in a fixed period.

Check the pipe temperature

thermistor / liquid.

Is the connector CN21 on the

indoor controller board connected?

Yes

Measure the resistance

of the pipe temperature

thermistor / liquid.

Check the room temperature thermistor.

Is the connector CN20 on the

indoor controller board connected?

No

Measure the resistance of

room temperature thermistor.

Yes

Check the drain sensor thermistor.

Is the connector CN31 on the

indoor controller board connected?

No

Measure the resistance

of drain sensor.

Yes

Is the resistance 0 (short circuit) or

∞ (open circuit)?

Yes

Condenser/evaporator

temperature thermistor

is defective.

Is the resistance 0 (short circuit) or

∞ (open circuit)?

No

Yes

Pipe temperature

thermistor / liquid

is defective.

No

Room temperature

thermistor is defective.

Turn off the power supply and turn it on again to operate the unit in

cooling mode.

Operation lamp blinks twice in a

No

Normal

fixed period.

Indoor controller board is defective.

Is the resistance 0 (short circuit) or

∞ (open circuit)?

Yes

Yes

No

Drain sensor is defective.

Is the resistance 0 (short circuit) or

∞ (open circuit)?

Yes

No

To be continued on the next page.

11

Page 12

Yes No

No

Yes

No

Yes

No

The switch of remote controller does not work.

Connection is defective.

Indoor controller board is defective.

Is the connecting

wire between the

indoor unit and

the decoration

panel connected

Is the varistor on

the indoor controller

board burnt?

Yes

Replace the varistor.

No

Is the fuse on the

indoor controller

board melted?

Yes

Yes

Replace the fuse.

Check the followings.

•The display on the remote controller does

not appear on the screen.

•The display on the remote controller is dim.

•The indoor unit does not respond to the

remote control signal when the remote

controller is not operated near the signal

receiving section on the unit.

Replace the batteries.

No

Replace the

remote controller.

Does the display appear on the

screen?

Does the indoor unit receive the

remote control signal when the

remote controller is not operated

near the signal receiving section

on the unit?

Indoor fan motor does not rotate.

Measure the resistance of connectors FAN1

and 2 on the indoor controller board.

Connection is defective.

Turn off the power supply and check the connectors

FAN1 and 2 on the indoor controller board visually.

Indoor fan motor is defective.

Are the connectors FAN1 and 2

connected?

Indoor controller board is defective.

Is the resistance 0 (short circuit) or

∞ (open circuit)?

From the preceding page.

12

Page 13

6-3. Test point of indoor controller board

Indoor controller board

Pipe temperature thermistor/liquid (RT12)

Condenser/evaporator

temperature thermistor

(RT13)

Room temperature thermistor (RT11)

Drain sensor (DS)

Power supply

input 220-240V AC

Fuse 250V AC 3.15A

• Room temperature thermistor (RT11)

• Pipe temperature thermistor/liquid (RT12)

• Condenser/evaporator temperature

thermistor (RT13)

< Thermistor for lower temperature >

50

40

30

20

Resistance (K")

10

0

-20 -10 0 10 20 30 40 50

Temperature (:)

13

Page 14

6-4. Trouble criterion of main parts

BLK RED ORNYLW

BLU

BRN

WHT

P

Room temperature

thermistor

(RT11)

Condenser/evaporator

temperature thermistor

(RT13)

Measure the resistance with a tester.

(Part temperature 10°C ~ 30°C)

Measure the resistance between the terminals with a tester.

(Coil wiring temperature 10°C ~ 30°C)

Pipe temperature

thermistor/liquid

(RT12)

Indoor fan motor

(MF)

Check method and criterion

Part name

Normal

A09AR

Normal

WHT-BLK

BLK-BLU

BLU-YLW

YLW-BRN

BRN-RED

386~428

52~58

29~33

28~32

157~174

A12AR

309~399

107~115

47~51

44~48

299~323

A18AR

305~329

85~92

50~54

43~47

289~313

4.3kΩ~9.6kΩ

Abnormal

Abnormal

Opened or

short-circuited

Opened or short-circuited

Measure the resistance between the terminals using a tester.

(Surrounding temperature 20:~30:)

Measure the resistance between the terminals using a tester.

(Surrounding temperature 20:~30:)

Measure the resistance between the terminals using a tester.

(Surrounding temperature 10:~30:)

Vane motor (MV)

Drain pump (DP)

Drain sensor (DS)

(Refer to the thermistor)

1

2

Yellow

Yellow

1

2

3

Abnormal

Open or short

Normal

0.6k"~6.0k"

NormalConnector Abnormal

300" Open or short

Normal Abnormal

290" Open or short

Orange

Red

White

P : Thermal fuse 145 ± 2˚C

Red — Yellow

Red — Blue

Red — Orange

Red — White

Blue

Yellow

35

1

2

4

M

SLZ-A09AR.TH

SLZ-A12AR.TH

SLZ-A18AR.TH

14

Page 15

<Thermistor Characteristic graph>

-200 20406080

< Thermistor for drain sensor >

Temperature (:)

0

1

2

3

4

5

6

7

8

9

10

Resistance (K")

Thermistor for

lower temperature

•Room temperature thermistor (RT11)

•Pipe temperature thermistor/liquid (RT12)

•Condenser/evaporator temperature

thermistor (RT13)

Thermistor R0=15k' ±3%

Fixed number of B=3480K ± 2%

Rt=15exp { 3480( ) }

1

273+t

1

273

0: 15k'

10: 9.6k'

20: 6.3k'

25: 5.2k'

30: 4.3k'

40: 3.0k'

Thermistor for

drain sensor

< Thermistor for lower temperature >

50

40

30

20

Resistance (K")

10

0

-20 -10 0 10 20 30 40 50

Temperature (:)

Thermistor R0=6.0k' ±5%

Fixed number of B=3390K ± 2%

Rt=6exp { 3390( ) }

1

273+t

0: 6.0k'

10: 3.9k'

20: 2.6k'

25: 2.2k'

30: 1.8k'

40: 1.3k'

1

273

15

Page 16

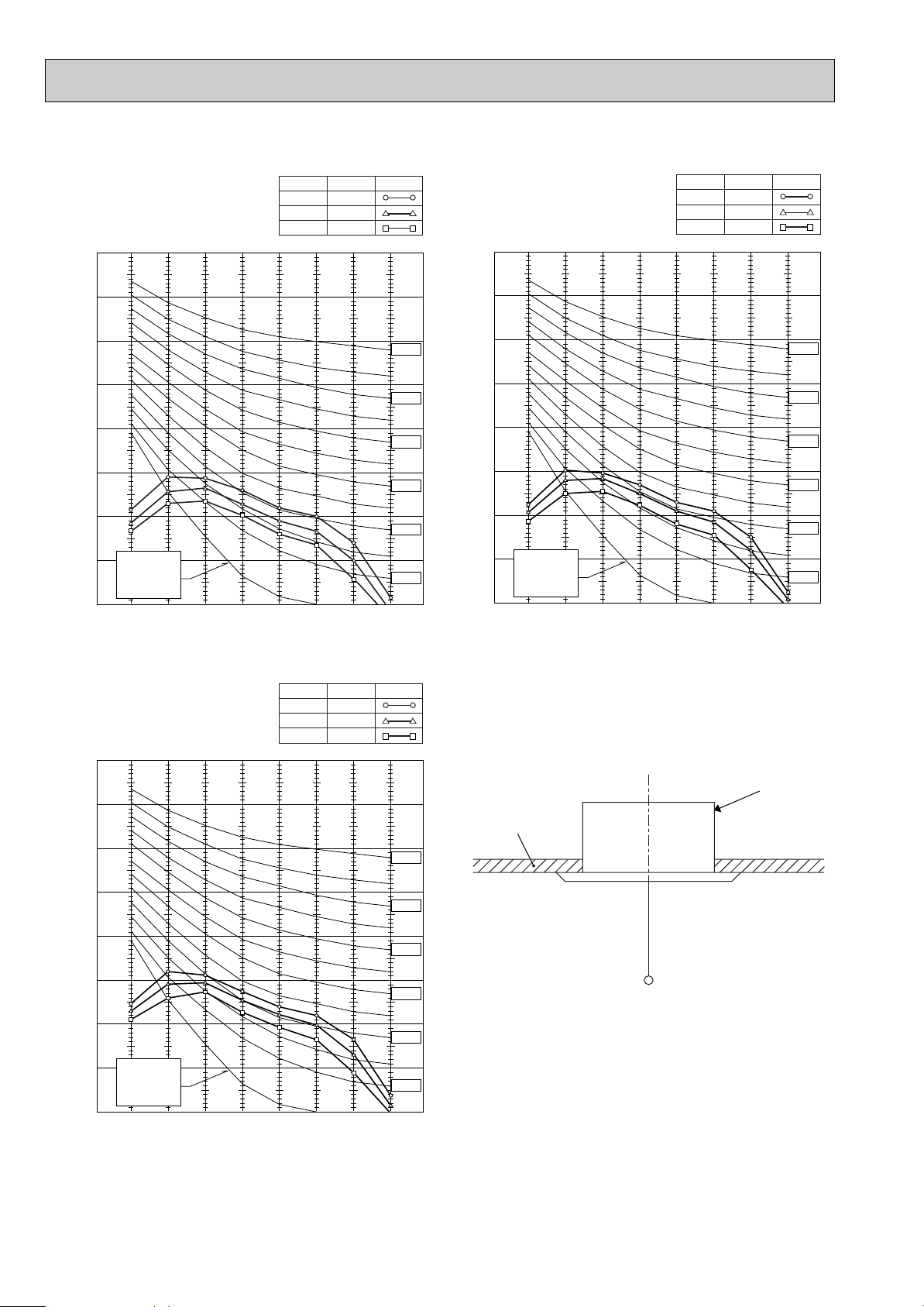

7 4-WAY AIR FLOW SYSTEM

Detail drawing of fresh air intake

Ceiling surface

Refrigerant pipe

Drain pipe

Electrical Box

Cut out hole

[73.4

Burring hole

3-[2.8 hole

[100

118

25

120°

120°

Fresh air intake

Static pressure : P [Pa]

Air flow : Q [m

3

/min]

50

-50

-100

-150

-200

-250

-300

0

0.5 1.0 1.5 2.0 2.5 3.0 3.5

Q

0

B

A

C

1

Curve in the

left praphs.

Duct characteristics

at site

Q

A

EC

2

Q

Qa

AD

3

CN51

Multiple remote

controller adapter

PAC-SA88HA-E

Indoor controller board

Distance between indoor

controller board and relay

must be within 10m.

Be sure to secure insulation

material by tape and such

5

Green

Yellow

Orange

Connector (5P)

Package side

Multiplr remote

controller adapter

PAC-SA88HA-E

Be sure to secure insulation

material by tape and such

Installation at site

CN51

on

indoor unit

board

Red

Brown

1

MB

~

CNPCNCCND FAN2

C1

FAN1

52C

C412

CN51

RC00J590B

7-1. Fresh air intake (Location for installation)

At the time of installation, use the duct holes (cut out) located at the positions shown in following diagram, as and when required.

7-2. Fresh air intake amount & static pressure characteristics

SLZ-A09AR.TH

SLZ-A12AR.TH

SLZ-A18AR.TH

Taking air into the unit

How to read curves

NOTE: Fresh air intake amount should be 20% or less of

whole air amount to prevent dew dripping.

7-3. Interlocking operation method with duct fan (Booster fan)

●Whenever the indoor unit is operating, the duct fun

operates.

(1)Connect the optional multiple remote controller

adapter(PAC-SA88HA-E)to the connector CN51 on the

indoor controller board.

(2)Drive the relay after connecting the 12V DC relay

Use a relay under 1W.

MB: Electromagnetic switch power relay for duct fan.

X: Auxiliary relay (12V DC LY-1F)

between the Yellow and Orange connector lines.

16

Q…Planned amount of fresh air intake

A…Static pressure loss of fresh air

intake duct system with air flow

amount Q

B…Forced static pressure at air condi-

tioner inlet with air flow amount Q

C…Static pressure of booster fan with

air flow amount Q

D…Static pressure loss increase

amount of fresh air intake dust system for air flow amount Q <Pa>

E…Static pressure of indoor unit with air

flow amount Q

Qa…Estimated amount of fresh air

intake with out D <m3/min>

<m

3

/min>

<Pa>

<Pa>

<Pa>

<Pa>

Page 17

7-4. Fixing of horizontal vane

Standard of

horizontal position

Dimension A (mm)

21 25 28 30

Level 30°

(Min.)

Downward 45° Downward 55°

Downward 70°

(Max.)

w Dimension between 21 mm and 30 mm can be arbitrarily set.

Caution

Do not set the dimension out of the range.

Erroneous setting could cause dew drips, smudge on ceiling or malfunction of unit.

<Set range>

.

Horizontal vane of each air outlet can be fixed according to the environment, which is installed.

Setting procedure

1) Turn off a main power supply (Turn off a breaker).

2) Disconnect the vane motor connector of the direction of the arrow with pressing the unlocking button as shown in figure

below.

Electricity insulate the disconnected connector with the vinyl tape.

Vane motor

Vane motor

Connector

Horizontal vane

3) Set a vertical vane of the air outlet, which tries to fixed by the hand slowly within the range in the table below.

Measured standard

position of the grille

Horizontal vane

Unlocking button

17

Page 18

8 DISASSEMBLY PROCEDURE

SLZ-A09AR.TH SLZ-A12AR.TH SLZ-A18AR.TH

OPERATING PROCEDURE PHOTOS&ILLUSTRATIONS

1. Removing the air intake grille

(1) Slide the knob of air intake grille to the direction of the

arrow 1 to open the air intake grille.

(2) Remove the hook for secure belt on air inlet grille from the

panel.

(3) Slide the shaft in the hinge to the direction of the arrow 2

and remove the air intake grille.

2. Removing the fan guard

(1) Open the air intake grille.

(2) Remove the 3 screws of fan guard.

Be careful on removing heavy parts.

Figure 1

Air intake grille

Grille

Air intake grille knob

Photo 1

Fan guard

Screws

3. Removing the panel

(1) Remove the air intake grille. (Refer to 1)

Corner panel (See figure 2)

(1) Remove the screw of the corner.

(2) Slide the corner panel to the direction of the arrow 3, and

remove the corner panel.

Panel (See photo 2)

(1) Disconnect the connector that connects with the unit.

(2) Remove the 2 screws from the panel and loose another 2

screws, which fixed to the oval hole, have different diameter.

(3) Rotate the panel a little to remove the screws.(Slide the

panel so that the screw comes to a large diameter of the

oval hole, which has two different diameters.)

4. Removing the electrical parts

(1) Remove the 2 screws and the control box cover.

<Electrical parts in the control box>

• Indoor controller board (I.B)

• Compressor contactor (52C)

• Fuse (FUSE)

• Varistor (ZNR1)

• Terminal block (TB)

Figure 2

Screw

Corner

panel

Photo 2

Connectors

Screws

Photo 3

Indoor controller board

(I.B)

Corner

panel

Varistor

(ZNR1)

Air intake grille

Panel

Screws

Panel

Indoor

controller box

Compressor contactor

(52C)

18

Fuse

(FUSE)

Terminal blocks

(TB)

Page 19

OPERATING PROCEDURE

PHOTOS&ILLUSTRATIONS

5. Remove the room temperature thermistor (RT11)

(1) Remove the panel. (Refer to 3)

(2) Pull out the room temperature thermistor from the drain

pan.

(3) Remove the 2 screws fixed to the control box cover, and

remove the control box cover.

(4) Remove the connector (CN20) from the indoor controller

board, and disconnect the room temperature thermistor.

6. Remove the drain pan

(1) Remove the panel. (Refer to 3)

(2) Remove the room temperature thermistor and the 2 lead

wires held with fastener; wireless controller board relay

connector (9P red) and panel relay connector (10P white).

(3) Remove the 4 screws fixed to the drain pan, and remove

the drain pan.

(4) Remove the fan guard. (Refer to 2)

7. Removing the pipe temperature thermistor/liquid (RT12)

and condenser/evaporator temperature thermistor (RT13)

(1) Remove the panel. (Refer to 3)

(2) Remove the drain pan. (Refer to 6)

(3) Disconnect the indoor coil thermistor from the holder.

(4) Remove the 3 screws fixed to the piping cover, and

remove the piping cover. (See photo 9)

(5) Remove the 2 screws fixed to the control box cover, and

remove the control box cover.

Photo 4

Screw

Room

temperature

thermistor

(RT11)

Screw

Photo 5

Control box

Fan guard

Control box

Connectors

Drain plug

Screw

Drain pan

Screw

Pipe temperature thermistor/liquid (RT12)

(6) Remove the connector (CN21) from the indoor controller

board, and disconnect the pipe temperature thermistor/liquid.

Condenser/evaporator temperature thermistor (RT13)

(6) Remove the connector (CN29) from the indoor controller

board, and disconnect the condenser/evaporator temperature

thermistor.

8. Remove the fan motor (MF)

(1) Remove the panel. (Refer to 3)

(2) Remove the drain pan. (Refer to 6)

(3) Remove the nut and the washer from the turbo fan, and

remove the turbo fan.

(4) Remove the 2 screws fixed to the control box cover, and

remove the control box cover.

(5) Disconnect the connectors of the (fan 1) and the (fan 2)

from the indoor controller board.

(6) Remove the 3 screws fixed to the piping cover, and

remove the piping cover. (See photo 9)

(7) Remove the 6 screws fixed to the flat plate, and remove

the flat plate.

(8) Disconnect the lead wires to the direction of the fan motor,

and remove the 3 nuts of the fan motor.

Pipe temperature

thermistor/liquid

(RT12)

Photo 6

Screws

Lead

wires

Screw

Flat plate

Condenser/evaporator

temperature thermistor

(RT13)

Screw

Nut

Nut

Fan motor

(MF)

Nut

Screws

19

Page 20

OPERATING PROCEDURE PHOTOS&ILLUSTRATIONS

9. Removing the drain pump (DP) and drain sensor (DS)

(1) Remove the panel. (Refer to 3 )

(2) Remove the drain pan. (Refer to 6)

(3) Remove the 2 screws fixed to the control box cover, and

remove the control box cover.

(4) Remove the connectors of the (CNP) and the (CN31)

from the indoor controller board.

(5) Remove the 1 screw fixed to the cover, and remove the

cover.

(6) Disconnect the lead wires to the direction of the drain

pump.(See photo 7)

(7) Remove the 3 screws of the drain pump.

(8) Cut the drain hose band, pull out the drain hose from the

drain pump.

(9) Pull out the drain pump.

(10) Remove the drain sensor and the holder.

10. Removing the heat exchanger

(1) Remove the panel. (Refer to 3 )

(2) Remove the drain pan. (Refer to 6)

(3) Remove the nut and the washer from the turbo fan, and

remove the turbo fan.

(4) Remove the 2 screws fixed to the control box cover, and

remove the control box cover.

(5) Disconnect the connectors of the (fan 1) and the (fan 2)

from the indoor controller board.

(6) Remove the 3 screws fixed to the piping cover, and

remove the piping cover. (See photo 9)

(7) Remove the pipe temperature thermistor/liquid and

condenser/evaporator temperature thermistor. (Refer to 7)

(8) Disconnect the lead wires to the direction of the fan motor.

(9) Remove the 1 coil support screw, the 2 inside coil screws

(See photo 10), and the 4 outside coil screws (See photo 9)

from the heat exchanger, and remove the heat exchanger.

Photo 7

Control

box

Photo 8

Drain

hose

Screw

Photo 9

Coil

screws

Screws of

piping cover

Piping cover

Screw

Drain sensor (DS) Drain pump (DP)

Fixing band

Cover

Lead wires

Lead wires

Screws

Control box

Coil

screws

Control box

20

Photo 10

Coil screws

Coil

support

Coil

support

Screw

Heat exchanger

Page 21

PARTS LIST9

No.

Parts No.

Specification

Remarks

(Drawing No.)

Unit

Amount

Wiring

Diagram

Symbol

Recom-

mended

Q'ty

Price

1

2

3

4

5

6

7

8

9

10

1

1

4

4

1

1

4

8

4

4

W.B

MV

E07 103 003

E07 103 317

E07 103 037

E07 103 975

E07 103 100

E07 103 010

E07 103 303

E07 103 044

E07 103 031

E07 103 032

AIR OUTLET GRILLE

WIRELSS REMOTE CONTROL BOARD

AUTO VANE

CORNER PANEL

AIR FILTER

INTAKE GRILLE

VANE MOTOR

VANE BUSH

GEAR (V)

GEAR (M)

Parts name

SLP-2AL

Q'ty/set

PANEL PARTS

SLP-2AL

1

10

9

8

3

2

7

4

5

6

21

Page 22

FUNCTIONAL PARTS

ON/OFF

RESET

TOO

WARM

TOO

COOL

MODE

AUTO COOL

DRY

HEAT

FAN

VANE

SELECT

TIME

h

SLZ-A09AR.TH

SLZ-A12AR.TH

SLZ-A18AR.TH

22

23

1

3

2

3

22

21

4

20

5

19

18

17

6

16

15

7

8

9

10

24

11

25

12

13

14

22

Page 23

No.

1

E07 104 290

2

E07 104 124

3

E07 104 808

4

E07 105 124

E07 140 620

5

E07 141 620

E07 142 620

6

E07 104 105

E07 140 300

7

E07 105 300

E07 106 300

8

E07 104 816

9

E07 104 502

10

E07 104 097

11

E07 104 700

12

E07 104 308

13

E07 104 520

14

E07 104 524

15

E07 104 648

16

E07 140 309

17

E07 104 307

18

E07 104 702

19

E07 104 266

20

E07 104 241

21

E07 104 355

22

E07 104 809

23

E07 104 006

24

E07 140 426

25

E02 527 083

Parts nameParts No. Specification

BASE

DRUM-1

LEG-1

DRUM-2

I

NDOOR HEAT EXCHANGER

INDOOR HEAT EXCHANGER

INDOOR HEAT EXCHANGER

MOTOR MOUNT

INDOOR FAN MOTOR

INDOOR FAN MOTOR

INDOOR FAN MOTOR

FLAT PLATE

TURBO FAN

SPL WASHER

DRAIN PAN

ROOM TEMPERATURE THERMISTOR

FAN GUARD

DRAIN PLUG

COIL SUPPORT

CONDENSER / EVAPORATOR

TEMPERATURE THERMISTOR

PIPE TEMPERATURE THERMISTOR / LIQUID

DRAIN HOSE

DRAIN SENSOR

SENSOR HOLDER

DRAIN PUMP

LEG-2

COVER (DRUM)

WIRELESS REMOTE CONTROLLER

REMOTE CONTROLLER HOLDER

PK6V15-LA

PK6V20-LE

PK6V20-LF

Q'ty/set

SLZ-

A12A09 A18

AR.TH

1

1

2

1

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

Unit

Price

Amount

Wiring

Symbol

MF

MF

MF

RT11

RT13

RT12

DS

DP

W.R

Recom-

mended

Q'ty

Remarks

(Drawing No.)

1

1

1

1

2

2

1

1

1

1

3PCS/SET

3

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

Diagram

23

Page 24

ELECTRICAL PARTS

No.

Parts No.

Parts name

Specification

Remarks

(Drawing No.)

Unit

Amount

Wiring

Diagram

Symbol

Recom-

mended

Q'ty

Price

1

2

3

4

5

6

E07 140 340

E02 127 382

E02 661 385

E02 367 377

E02 257 375

E07 140 447

E07 141 447

E07 142 447

COMPRESSOR CONTACTOR

FUSE

VARISTOR

TERMINAL BLOCK

TERMINAL BLOCK

INDOOR CONTROLLER BOARD

INDOOR CONTROLLER BOARD

INDOOR CONTROLLER BOARD

52C

FUSE

ZNR1

TB

TB

I.B

I.B

I.B

250V 3.15A

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Q'ty/set

SLZ-

A12A09 A18

AR.TH

3P

4P

SLZ-A09AR.TH

SLZ-A12AR.TH

SLZ-A18AR.TH

6

N

2

220-240V~

3

N

220-240V

L

TO OUTDOOR

UNIT

POWER

SUPPLY

5

1 324

CCopyright 2004 MITSUBISHI ELECTRIC ENGINEERING CO., LTD.

Distributed in Mar. 2004 No.OC302 PDF 8

Made in Japan.

HEAD OFFICE : MITSUBISHI DENKI BLDG., 2-2-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

New publication, effective Mar. 2004.

Specifications subject to change without notice.

Loading...

Loading...