Mitsubishi SLZ-A09AR.TH, SLZ-A12AR.TH, SLZ-A18AR.TH Service Manual

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

ON/OFF

RESET

TOO

WARM

TOO

COOL

MODE

AUTO COOL

DRY

HEAT

FAN

VANE

SELECT

TIME

h

TECHNICAL & SERVICE MANUAL

No. OC302

Series SLZ

Ceiling Cassettes

R410A

Indoor unit

[Model names] [Service Ref.]

SLZ-A09AR SLZ-A09AR.TH

SLZ-A12AR SLZ-A12AR.TH

SLZ-A18AR SLZ-A18AR.TH

•This manual does not cover

outdoor units. When servicing

them, please refer to the

service manual No.OC304

and this manual in a set.

CONTENTS

1. PART NAMES AND FUNCTIONS ········2

2. SPECIFICATIONS·································3

3. OUTLINES AND DIMENSIONS············5

4. WIRING DIAGRAM ·······························7

5.

REFRIGERANT SYSTEM DIAGRAM

INDOOR UNIT

6. TROUBLESHOOTING ··························9

7. 4-WAY AIR FLOW SYSTEM ···············16

8. DISASSEMBLY PROCEDURE ···········18

9. PARTS LIST········································21

REMOTE CONTROLLER

·········8

1

ON/OFF

RESET

TOO

WARM

TOO

COOL

MODE

AUTO COOL

DRY

HEAT

FAN

VANE

SELECT

TIME

h

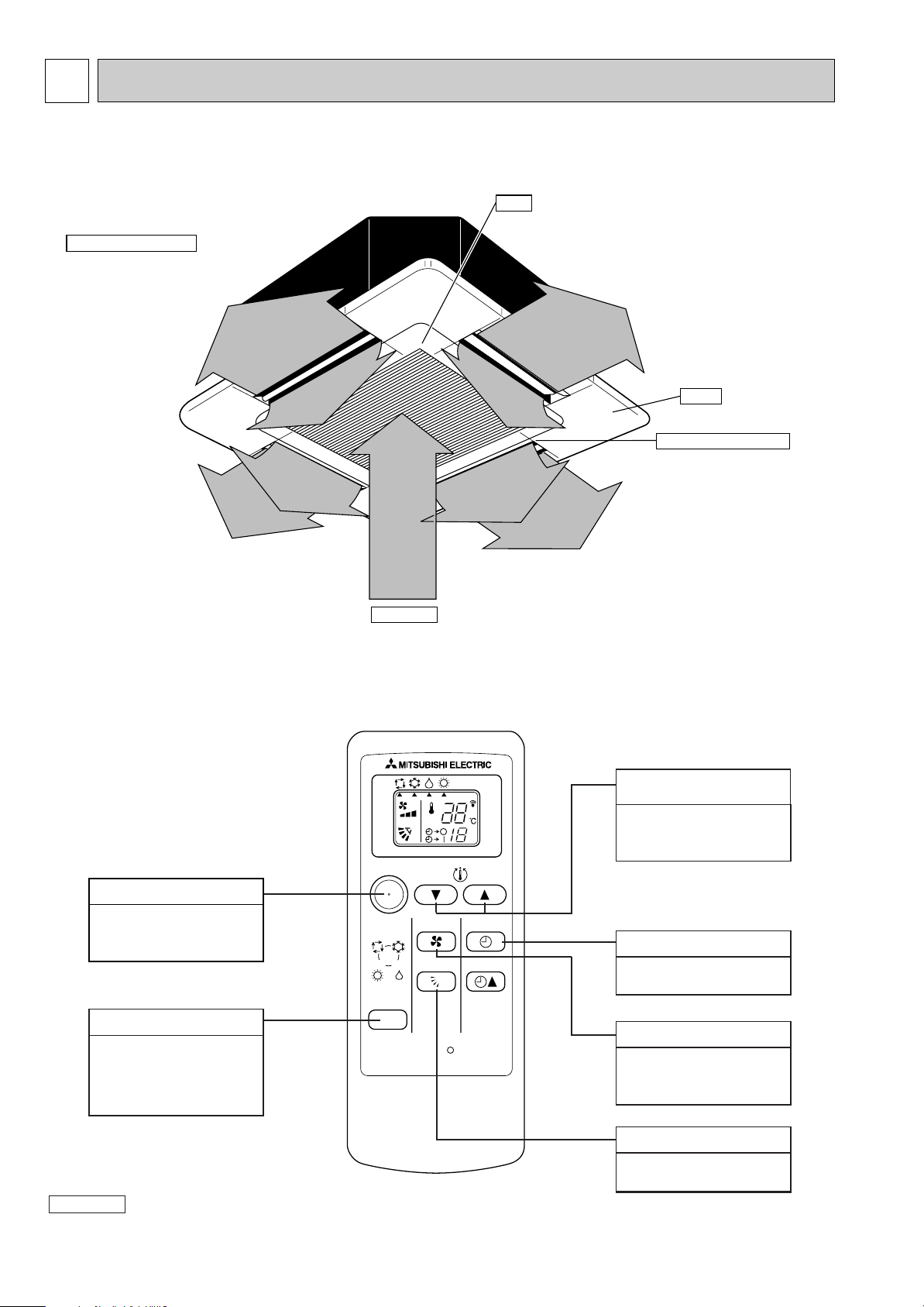

PART NAMES AND FUNCTIONS

Indoor Unit

SLZ-A09AR.TH

SLZ-A12AR.TH

SLZ-A18AR.TH

Horizontal Air Outlet

Sets airflow horizontal automatically

during cooling or dehumidifying.

Filter

Remove dust and pollutants

from inhaled air

Grille

Auto Air Swing Vane

Disperses airflow up and

down and adjusts the angle

of airflow direction.

Air Intake

Inhales air from room.

Remote controller

SET TEMPERATURE

button

SET TEMPERATURE

button sets and any

desired room temperature.

ON / OFF button

Pushing button starts

operation. Pushing again

stops operation.

MODE SELECT button

This button is used to change

between auto, cooling,

heating and drying operation

modes. (SLZ)

Attention :

● Avoid operation of buttons with fingernails or other sharp objects. Sharp objects may scratch remote controller.

TIMER SELECT button

Used for selecting timed

starting or stopping.

FAN SPEED button

This button is used to set

fan speed to low, medium

or high.

VANE CONTROL button

Used to change the airflow

direction.

2

2

SLZ-A09AR.TH SLZ-A12AR.TH

Indoor model

Function

Power supply

Single phase

230V, 50Hz

600/540/480

10

0.18

40

0.014

0.18

PK6V15-LA

4

38/35/32

650/580/530

3

10

10

10

MPPC

Cooling

91

Heating

92

Single phase

230V, 50Hz

660/600/540

10

0.23

52

0.014

0.23

PK6V20-LE

4

39/37/34

690/630/570

3

10

10

10

MPPC

Cooling

94

Heating

95

Air flow (High/Med./Low)

Power outlet

Running current ✽1

Power input Rated frequency

Dew prevention heater

Power factor ✽1

Fan motor current ✽1

Model

Winding

resistance (at20:)

Width

Height

Depth

Weight

Air direction

Sound level(High/Med./Low)

Fan speed(High/Med./Low)

Fan speed regulator

Thermistor RT11(at25:)

Thermistor RT12(at25:)

Thermistor RT13(at25:)

Remote controller model

K /h

A

A

W

(kW)

%

A

"

mm(in)

mm(in)

mm(in)

kg

dB(A)

rpm

k"

k"

k"

Electrical

data

Fan

motor

Special

remarks

Capacity

Dimensions

WHT-BLK : 407 BLK-BLU : 55

BLU-YLW : 31 YLW-BRN : 30

BRN-RED : 165

UNIT : 570(22-7/16) PANEL : 650(25-9/16)

UNIT : 208(8-3/16) PANEL : 20(13/16)

UNIT : 570(22-7/16) PANEL : 650(25-9/16)

UNIT : 16.5 PANEL : 3

WHT-BLK : 384 BLK-BLU : 111

BLU-YLW : 49 YLW-BRN : 46

BRN-RED : 311

SLZ-A18AR.TH

Single phase

230V, 50Hz

660/600/540

20

0.24

53

0.014

0.24

PK6V20-LF

4

40/38/35

710/650/590

3

10

10

10

MPPC

Cooling

97

Heating

97

WHT-BLK : 317 BLK-BLU : 88

BLU-YLW : 52 YLW-BRN : 45

BRN-RED : 301

1.5+ 440V

250V 3.15A

MSBPC20 12V 250"

POWER SUPPLY : 3P TO OUTDOOR UNIT : 4P

G4A-1A-E-PS 12V DC

145:i2:

240V AC 15W

INDOOR UNIT

Item

Model

Indoor fan capacitor

Fuse

Vane motor

Terminal block

Contactor

Indoor fan motor thermal fuse

Cord Heater

SLZ-A09AR.TH SLZ-A12AR.TH SLZ-A18AR.TH

(C1)

(F11)

(MV)

(TB)

(52C)

(H2)

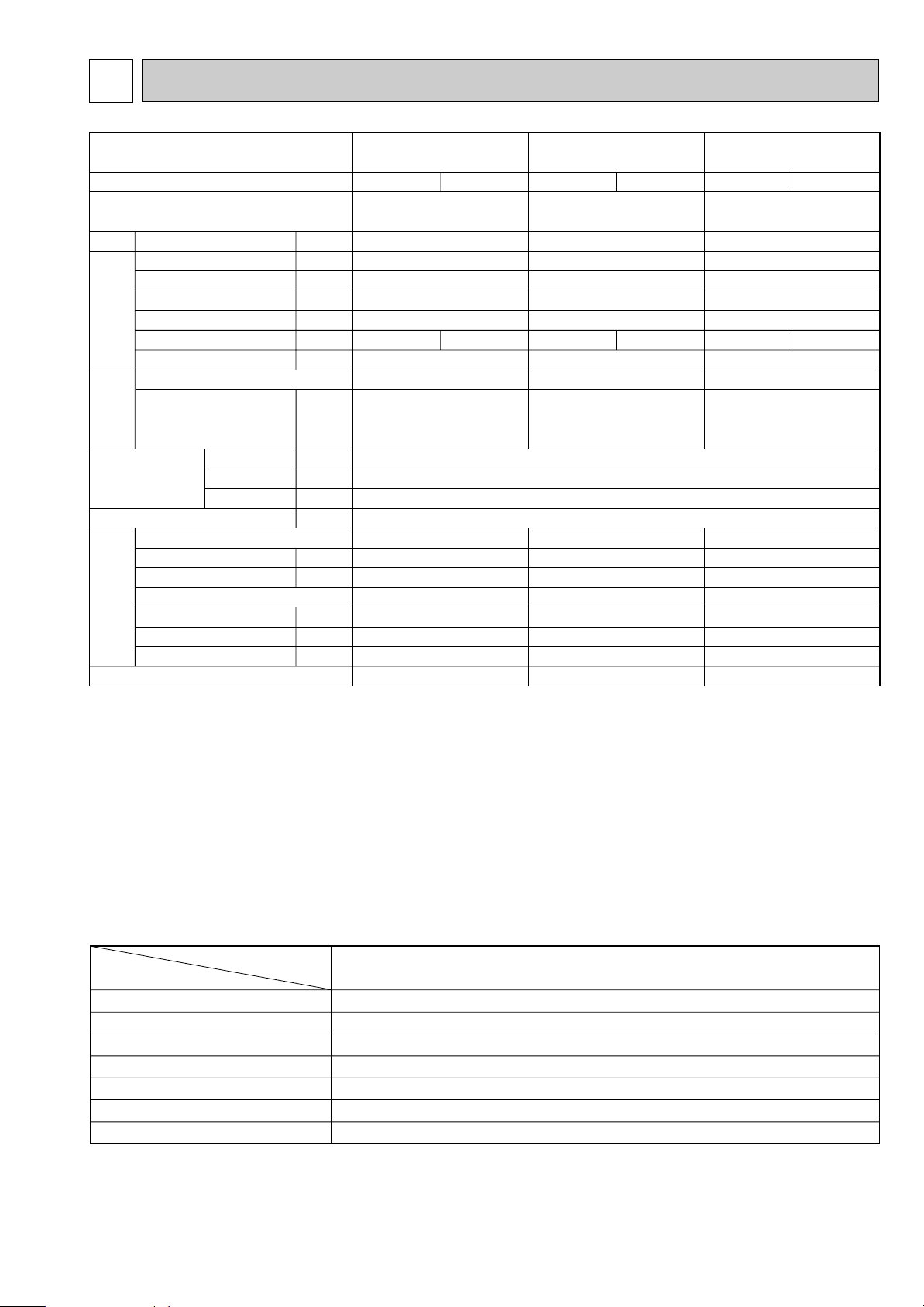

SPECIFICATIONS

NOTE : Test conditions are based on ISO 5151

Cooling : Indoor D.B. 27: W.B. 19:

Heating : Indoor D.B. 20: W.B. 15:

Refrigerant piping length (one way): 5m

✽1 Measured under rated operating frequency.

Specifications and rating conditions of main electric parts

Outdoor D.B. 35: W.B. 24:

Outdoor D.B. 7: W.B. 6:

3

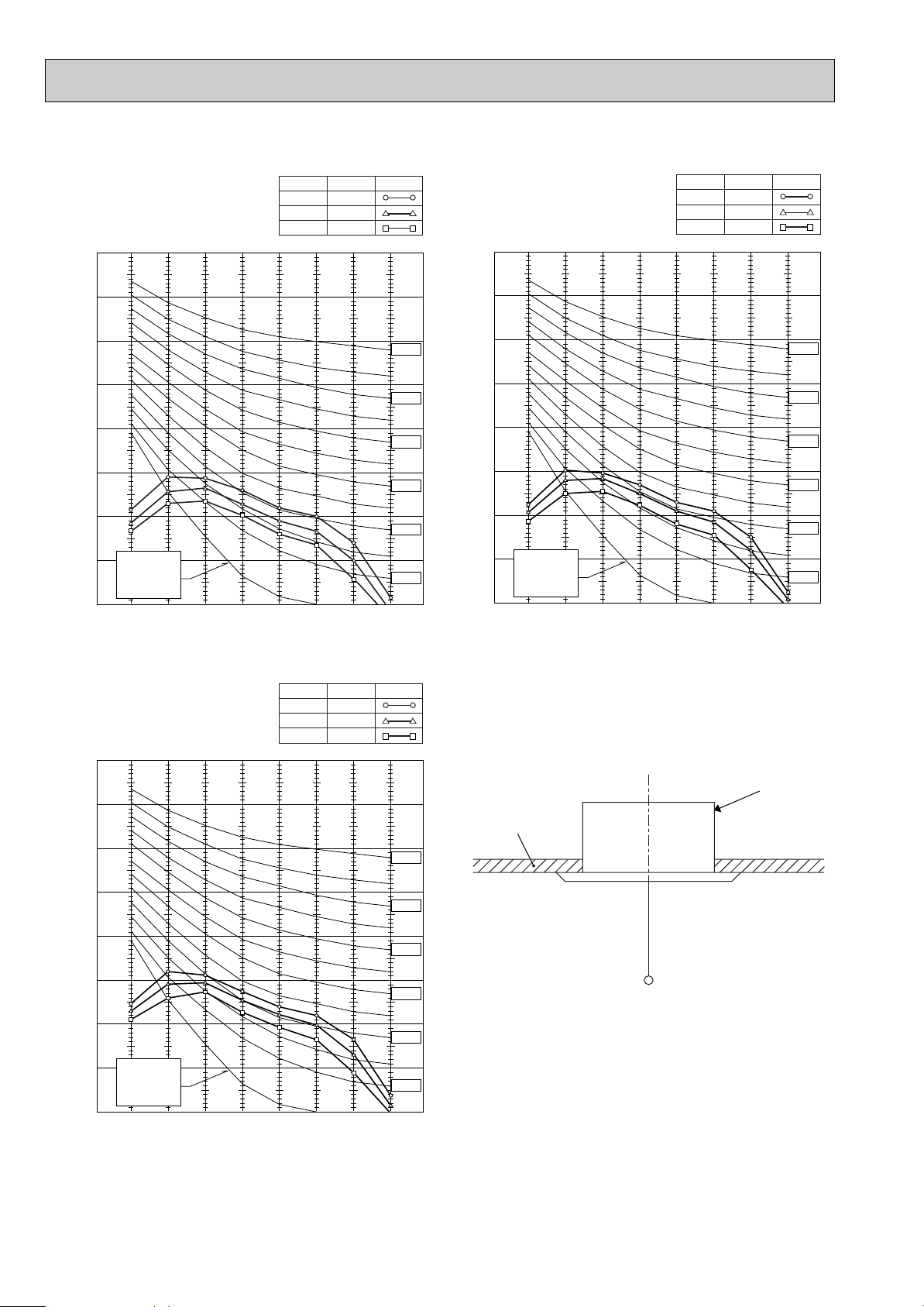

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

SLZ-A12AR.TH

Hi

Me

39

SPL(dB)37LINE

<50Hz>

NOTCH

Lo

34

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

SLZ-A09AR.TH

Hi

Me

38

SPL(dB)35LINE

<50Hz>

NOTCH

Lo

32

NOISE CRITERION CURVES

UNIT

1.5m

MICROPHONE

CEILING

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

SLZ-A18AR.TH

Hi

Me

40

SPL(dB)38LINE

<50Hz>

NOTCH

Lo

35

4

NOTE: The sound level is measured in an anechoic room where echoes are few, when compressor stops. The sound

may be bigger than displayed level under actual installation condition by surrounding echoes. The sound level

can be higher by about 2 dB than the displayed level during cooling and heating operation.

3

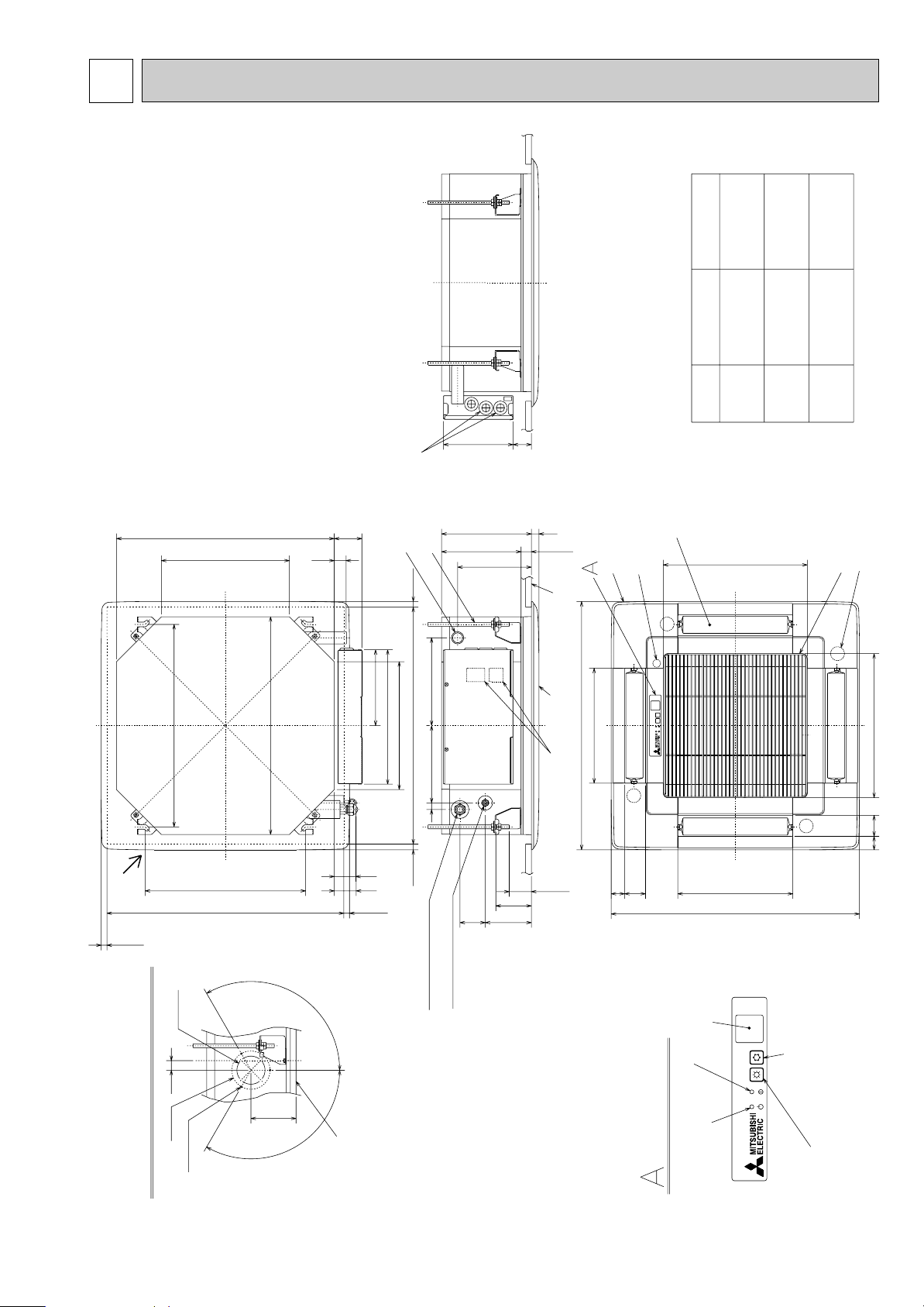

Suspension bolt

M10 or 3/8

(procure locally)

1/4F

flared connection

[6.35mm

1/4F

flared connection

[6.35mm

[9.52mm

flared connection

3/8F

1/2F

flared connection

SLZ-A18AR

SLZ-A12AR

Refrigerent pipe (liquid)

Refrigerent pipe (gas)

Models

SLZ-A09AR

[6.35mm

flared connection

1/4F

Refrigerent pipe

(liquid)

Refrigerent pipe

(gas)

[12.7mm

[9.52mm

flared connection

3/8F

15~37 15~37

576~620

570

530

Grille

Fresh air

intake

Drain pipe

VP-25 connection

(O.D.[32)

Vane motor

Drain hole

V/M

V/M

V/M

V/M

Air intake grille

55 35

35 55

Auto vane

Grille

Air intake hole

Air intake hole

Air outlet hole

Air outlet hole

301

301

Emergency operation

switch(cooling)

Emergency operation switch(heating)

Operation lamp

(WIRELESS PANEL)

DEFROST/STAND BY lamp

Receiver

Detail drawing of fresh air intake

Ceiling surface

Cut out hole

[73.4

Burring hole

3-[2.8 hole

[100

118

25

120°

120°

377

377

650

650

Suspension

bolt lower edge

230

18248

Wiring entry

Terminal block

Ceiling surface

235

208

27

+5

0

193

20

93

38~58

66121

17 202

56

57

72

31

Ceiling hole

Suspension bolt pitch

15~37

15~37

576~620

420

570

335

199

352

335

Suspension bolt

pitch

Ceiling hole

OUTLINES AND DIMENSIONS

SLZ-A09AR.TH

SLZ-A12AR.TH

SLZ-A18AR.TH

Unit : mm

5

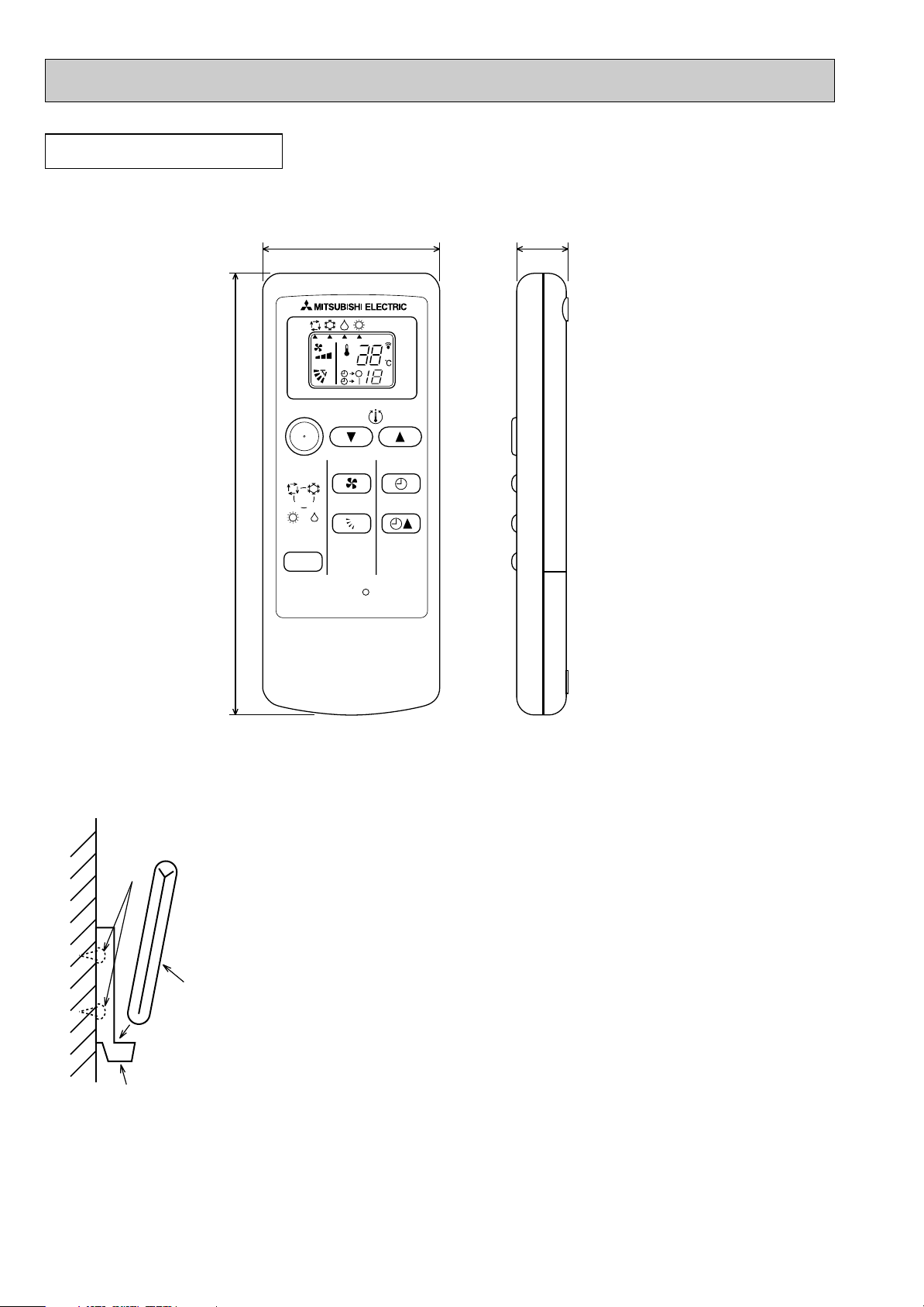

REMOTE CONTROLLER

Installation area

• Area in which the remote controller is not exposed direct sunshine.

• Area in which there is no nearby heating source.

• Area in which the remote controller is not exposed to cold (or hot) winds.

• Area in which the remote controller can be operated easily

• Area in which the remote controller is beyond the reach of children.

Installation method

1 Attach the remote controller holder to the desired location using two tapping screws.

2 Place the lower end of the controller into the holder.

A Wireless remote controller (Accessory)

B Wall

C Remote controller holder (Accessory)

D Fixing screw (Accessory)

• The signal can travel up to approximately 7 meters (in a straight line) within 45

degrees to both right and left of the center line of the receiver.

In addition, the signal may not be received if there is interference of light of fluorescent

lights or strong sunlight.

A

C

B

D

ON/OFF

RESET

TOO

WARM

TOO

COOL

MODE

AUTO COOL

DRY

HEAT

FAN

VANE

SELECT

TIME

h

57 17.5

140

Unit : mm

6

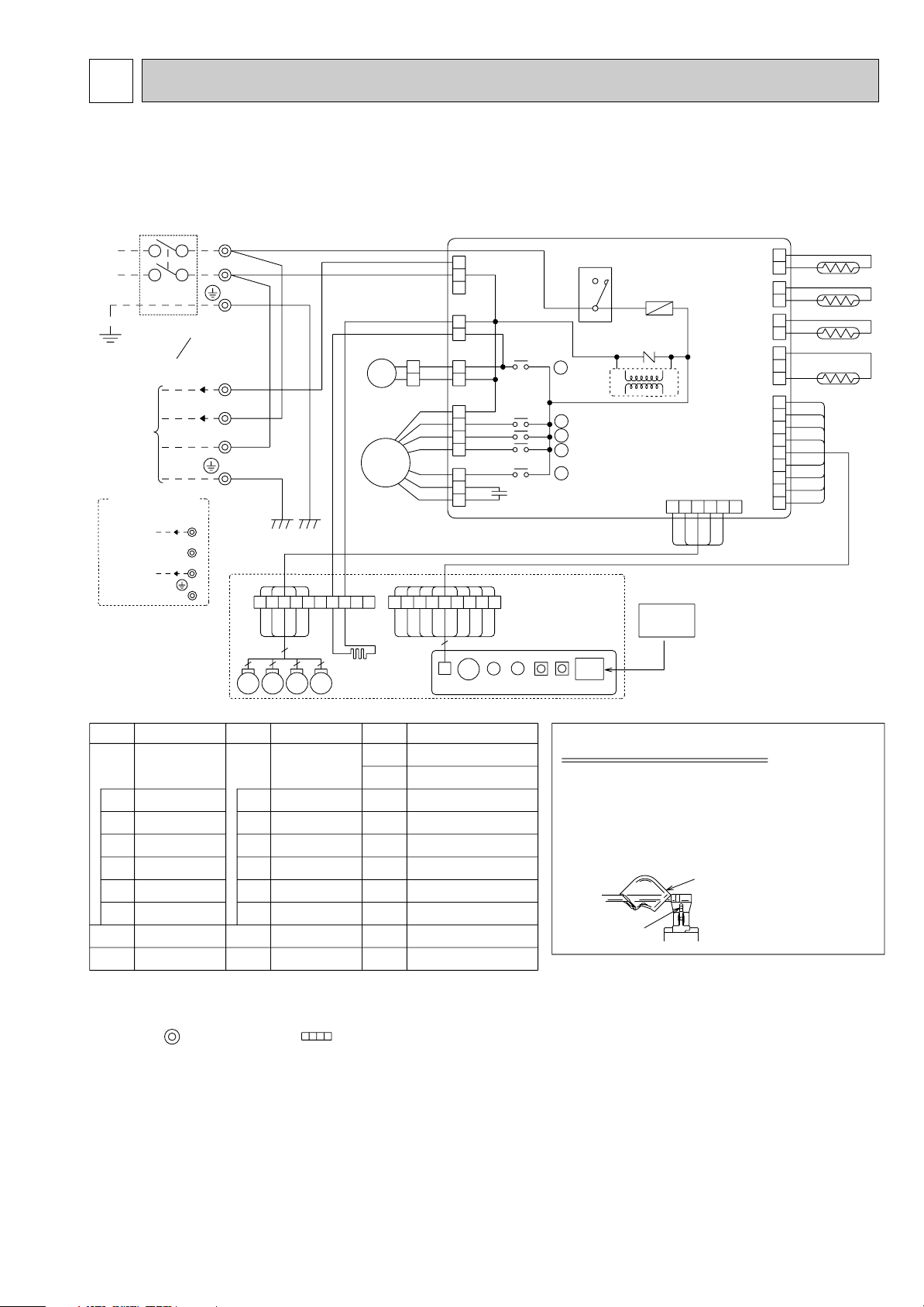

4

GRILLE

FOR A18 (1:1 SYSTEM)

OR MULTI SYSTEM

FOR A09/12

★

★

(1:1 SYSTEM)

TO OUTDOOR

UNIT

CONNECTING

CONDENSER/EVAPORATOR

TEMPERATURE THERMISTOR

RT13

RT13

3

12VDC

★ The 12V DC is NOT always against the ground.

Terminal 3 has 12V DC against terminal N.

However, between 3 and 2, these terminals are NOT electrically insulated by the transformer or other device.

TO OUTDOOR

UNIT

CONNECTING

2

N

TB

TERMINAL BLOCK

MV MV MV MV

CNB

BZ

LED2

LED1

SW1

SW2

RU

W.B

POWER SUPPLY

~/N

220-240V 220V

50Hz 60Hz

FAN MOTOR

CAPACITOR

C1

5

5

5

5

H2

5

BLK

DC13.1V

TRANS

X5

X5

W.R

REMOTE

CONTROLLER

TB

: Connector

: Terminal block

(For field wiring)

2.Use copper conductors only.

3.Symbols below indicate.

PIPE TEMPERATURE

THERMISTOR / LIQUID

RT12

W.R

WIRELESS REMOTE

CONTROLLER

RT11

ROOM TEMPERATURE

THERMISTOR

VANE MOTORMV

FAN MOTOR

MF

DEW PREVENTION

HEATER

H2

DRAIN SENSOR

DRAIN-UP

MACHINE

DP

DS

FUSE

FUSE(3.15A)

w WHT

3

N

2

220-240V~

12VDC

L

3

4

52C

ZNR1

DP

MF

X1

X2

X3

X4

X4

X3

X2

X1

w RED

w BLU

GRN/YLW

w WHT

N

GRN/YLW

TB

CIRCUIT BREAKER

w BLU

1.About the outdoor side electric wiring refer to the outdoor unit electlic wiring diagram for servicing.

How to remove the terminals

shown at "

w " mark.

" w " shows the terminals with a lock mechanism,

so they cannot be removed when you pull the

lead wire. Be sure to pull the wire by pushing

the locking lever (projected part) of the

terminal with a finger.

locking lever

1 Slide the sleeve.

2 Pull the wire

while pushing

the locking lever.

sleeve

NOTES:

9

BUZZER

ZNR1

VARISTOR

NAME

SYMBOLSYMBOL

NAME

SYMBOL

NAME

X1

X2-X5

RELAY(D.PUMP

/D.HEATER)

RELAY

(FAN MOTOR)

COMPRESSOR

CONTACTOR

52C

BZ

LED1

LED2

SW1

SW2

I.B

INDOOR

CONTROLLER

BOARD

W.B

WIRELESS REMOTE

CONTROLLER

BOARD

RU

LED

(RUN INDICATOR)

LED

(HOT ADJUST)

SWITCH

(HEATING ON/OFF)

SWITCH

(COOLING ON/OFF)

RECEVING UNIT

[LEGEND]

FUSE

C1

I.B

RT11

RT12

DS

(2 PHASE)

1

2

BLK

CN29

1

3

1

3

BRN

RED

ORN

YLW

BLU

VLT

GRY

PINK

SKY BLU

YLW

YLW

RED

ORN

YLW

WHT

BLU

1

745

10

89

ORN

RED

BRN

YLW

BLU

WHT

YLW

YLW

BLU

RED

WHT

RED

GRN

WHT

WHT

1

3

5

7

1

3

1

3

5

5

3

1

CNP(PUMP)

CNC

CND(POWER)

RED

CN31

CN20

CN21

(DRAIN)

(INTAKE)

(LIQUID)

CN90

(WIRELESS)

CN6V

(VANE)

(HEATER)

1

2

3

1

1

2

2

12345

1

2

3

4

5

6

7

8

9

FAN2(FAN)

FAN1(FAN)

BLU

WHT

ORN

RED

YLW

6

WHT

WHT

SKY BLU

PINK

GRY

VLT

BLU

YLW

ORN

RED

BRN

YLW

YLW

236

123456789

w

WIRING DIAGRAM

SLZ-A09AR.TH

SLZ-A12AR.TH

SLZ-A18AR.TH

7

5

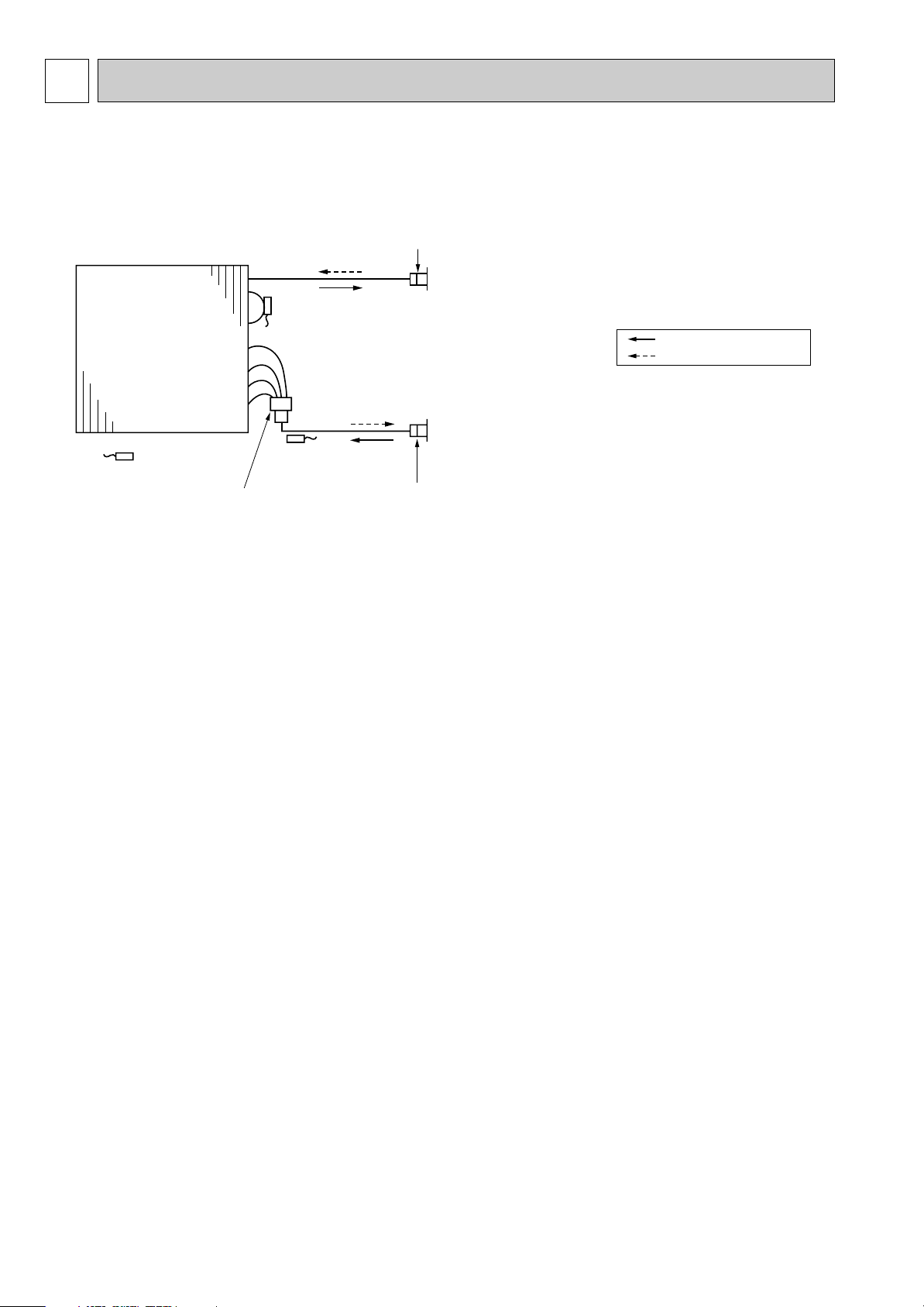

Pipe temperature

thermistor/liquid

(RT12)

Distributor

with strainer

#50

Condenser/evaporator

temperature thermistor

(RT13)

Room temperature

thermistor (RT11)

Refrigerant flow in cooling

Refrigerant flow in heating

Strainer

#50

Strainer

#50

Heat exchanger

Refrigerant GAS pipe connection

(Flare)

Refrigerant LIQUID pipe connection

(Flare)

REFRIGERANT SYSTEM DIAGRAM

SLZ-A09AR.TH

SLZ-A12AR.TH

SLZ-A18AR.TH

8

Loading...

Loading...