Page 1

191191

6. INVERTER MULTI-SPLIT SYSTEM

ROOM AIR-CONDITIONER[2room]

(Air to air heat pump type)

(OUTDOOR UNIT)

SCM45ZA

(INDOOR UNIT)

SKM22ZA

SKM25ZA

SKM28ZA

SKM32ZA

SKM40ZA

Page 2

192

CONTENTS

6.1 GENERAL INFORMATION ........................................................................193

6.1.1 Specific features ................................................................................. 193

6.1.2 How to read the model name .............................................................193

6.2 SELECTION DATA ..................................................................................... 194

6.2.1 Specifications...................................................................................... 194

6.2.2 Range of usage & limitations............................................................. 198

6.2.3 Exterior dimensions............................................................................199

6.2.4 Piping system...................................................................................... 201

6.2.5 Selection chart .................................................................................... 202

6.3 ELECTRICAL DATA ................................................................................... 203

6.3.1 Electrical wiring ..................................................................................203

6.4 OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER ............. 205

6.5 APPLICATION DATA .................................................................................215

6.5.1 Installation of indoor unit ................................................................... 216

6.5.2 Installation of remote controller ........................................................218

6.5.3 Installation of outdoor unit.................................................................219

6.5.4 Electrical wiring ..................................................................................220

6.5.5 Refrigerant piping ...............................................................................221

6.5.6 Test run and handling instruction .....................................................223

6.6 MAINTENANCE DATA ............................................................................... 224

6.6.1 Trouble shooting .................................................................................224

6.6.2 Servicing ..............................................................................................232

Page 3

193

6.1 GENERAL INFORMATION

6.1.1 Specific features

(1) Equipped with an inverter scroll compressor.

¡Low noise. Low vibration and compact.

(2) The long piping makes the location of the inside and units flexible.

¡No need for additional charge of refrigerant : 20 m

¡Maximum piping length : 30 m

(3) Connectable indoor capacity

Number of connectable units : 1 to 2 units

Total of indoor units (class kW) : 6.5 kW

(4) Indoor units are available with 5 capacities.

5 capacities ········ 22, 25, 28, 32, 40

(5) Inverter (Frequency converter) for multi-steps power control

¡Heating / Cooling

The rotational speed of a compressor is changed in step in relation to varying load, to interlock with the indoor and outdoor unit

fans controlled to changes in frequency, thus controlling the power.

¡Allowing quick heating/cooling operation during start-up period. Constant room temperature by fine-tuned control after the unit

has stabilized.

(6) Fuzzy control

Fuzzy control calculates the amount of variation in the difference between the suction air temperature and the setting temperature

in compliance with the fuzzy rules in order to control the air capacity and the inverter frequency.

(7) Self diagnosis function

We are constantly trying to do better service to our customers by installing such judges that show abnormality of operation as

follows. (See Page 225)

6.1.2 How to read the model name

Example : SK M 25 Z A

Series No.

Inverter and heat pump type.

Product capacity

Multiple system

Model name

SK : Wall mounted type

SC : Outdoor unit

Page 4

194

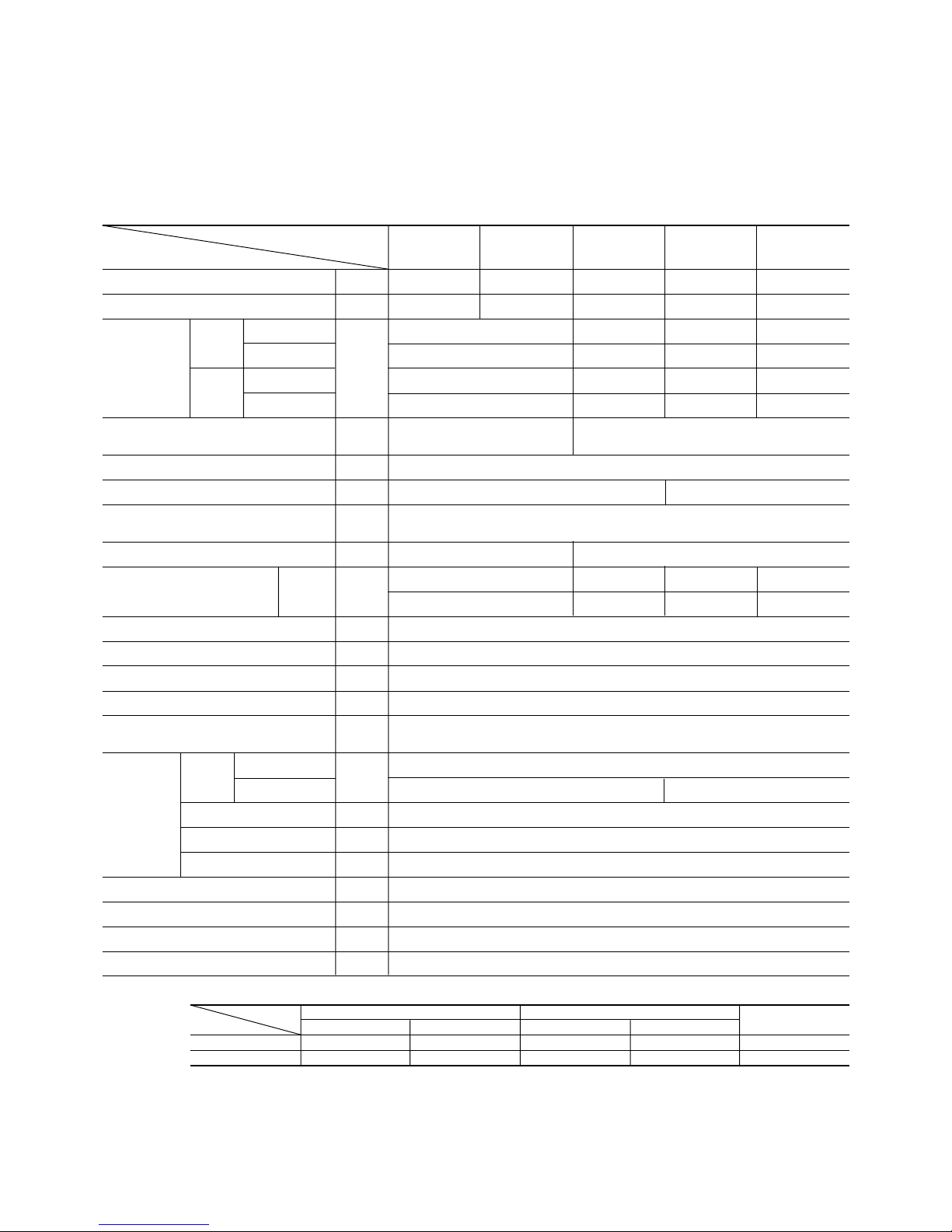

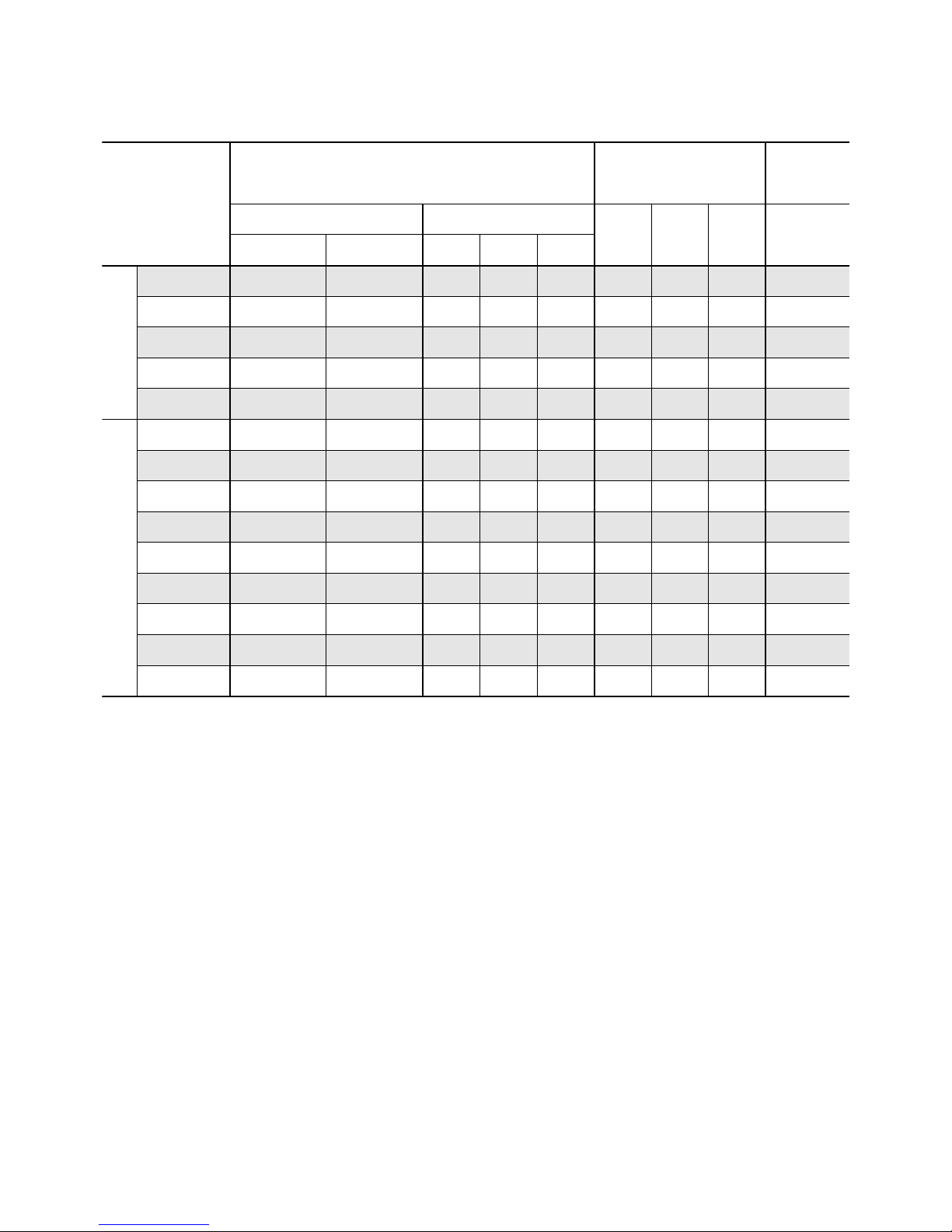

Item

Models

SKM22ZA SKM25ZA SKM28ZA SKM32ZA SKM40ZA

Cooling capacity W 2200 2500 2800 3200 4000

Heating capacity W 3200 3400 4000 4500 5400

Noise level

Cooling

dB

Hi : 38 Lo : 29 Hi : 39 Lo : 31 Hi : 40 Lo : 30 Hi : 42 Lo : 31

Hi : 52 Lo : 43 Hi : 53 Lo : 45 Hi : 54 Lo : 44 Hi : 56 Lo : 45

Heating

Hi : 39 Lo : 30 Hi : 40 Lo : 32 Hi : 41 Lo : 32 Hi : 42 Lo : 32

Hi : 53 Lo : 44 Hi : 54 Lo : 46 Hi : 55 Lo : 46 Hi : 56 Lo : 46

Exterior dimensions

Height × Width × Depth

mm 250 × 750 × 178 275 × 790 × 174

Color Ivory white

Net weight kg 7.5 8.0

Air handling equipment

Fan type & Q’ty

Tangential fan × 1

Motor W 17 18

Cooling 7.0 7.7 9.0 9.5

Air flow (at high)

Heating

CMM

7.5 9.1 10 10

Air filter, Q’ty

Polypropylene net × 2 (Washable)

Operation switch Wireless-Remote controller

Room temperature control M.C thermostat

Pilot lamp RUN (Green), TIMER (Yellow)

Safety equipment

O.D mm (in)

φ 6.35 (1/4″)

φ 9.52 (3/8″) φ 12.7 (1/2″)

Connecting method Flare connecting

Attached length of piping Liquid line : 0.4m Gas line : 0.35m

Insulation Necessary (Both Liquid & Gas lines)

Drain hose Connectable

Accessories (including) Mounting kit

Optional parts —

Outdoor units to be combined SCM45ZA

6.2 SELECTION DATA

6.2.1 Specifications

(1) Indoor unit

Models SKM22ZA, 25ZA, 28ZA, 32ZA, 40ZA

(2) Capacity indicated is the rated capacity with one unit operating under ISO-T1 standards conditions.

Refrigerant

piping

Liquid line

Gas line

Frost protection, Serial error protection

Fan motor error protection

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC 19ºC 35ºC 24ºC ISO-T1, JIS C9612

Heating 20ºC – 7ºC 6ºC ISO-T1, JIS C9612

Sound level

Power level

Sound level

Power level

Page 5

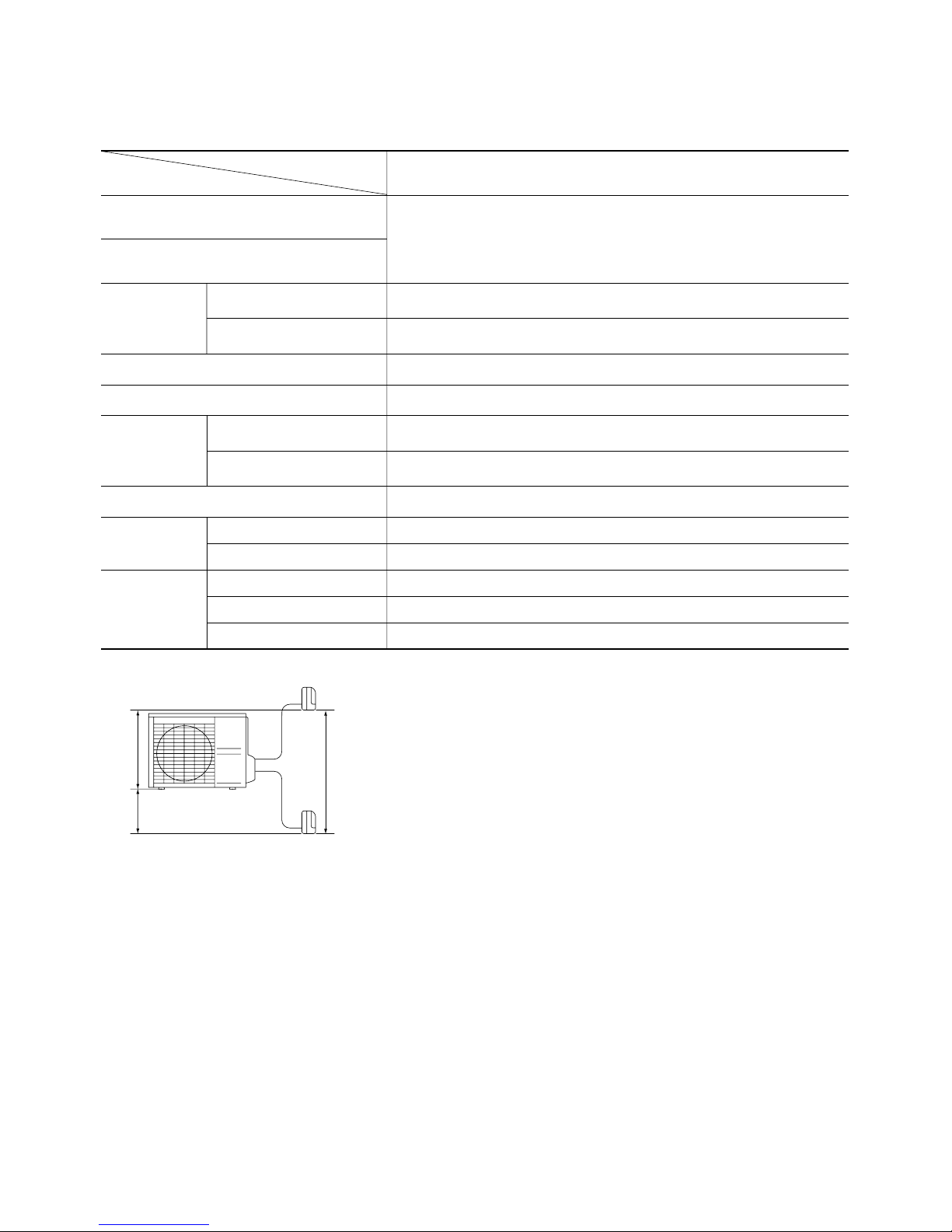

195

Item

Model

SCM45ZA

Cooling capacity W 4500 (2000 ~ 5100)

Heating capacity W 5600 (2200 ~ 6000)

Power source 1 Phase 220/240V 50Hz

Power consumption

Cooling

W

1820 (680 ~ 2050)

Heating 1950 (650 ~ 2190)

Running current

Cooling 8.4/7.7

Heating

A

9.0/8.2

Sound level

Cooling : 46 Heating : 48

Noise level

Power level

dB

Cooling : 60 Heating : 62

Exterior dimensions

Height × Width × Depth

mm

595 × 720 × 290

Color Stucco white

Net weight kg 36

Refrigerant equipment

Compressor type & Q’ty

GR5490FD41 × 1

Motor kW 1.2

Starting method Direct start

Refrigerant control Capillary tubes + Electric expansion valve

Refrigerant kg R22 1.3 (Pre-charged up to the piping length of 20m)

Refrigerant oil R 0.45 (BARREL FREEZE 32SAM)

Air handling equipment

Fan type & Q’ty

Propeller fan × 2

Motor W 24

Air flow (at high) CMM 30

Shock & vibration absorber Rubber (for compressor)

Safety equipment

Size × Core × Number mm (in)

Liquid line: φ 6.35 (1/4″) × 2

Gas line: φ 9.52 (3/8″) × 2

Connecting method Flare connecting

Attached length piping —

Insulation Necessary (Both Liquid & Gas lines)

Power source supply Terminal block (Screw fixing type)

Size × Core number 1.5 mm2 × 4 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included)

Union : (φ 9.52 / φ 12.7) × 1

Installation sheet, Manual instruction

Indoor units to be combined

(2) Outdoor unit

Model SCM45ZA

Compressor overheat protection, Overcurrent protection

High pressure protection, Serial signal error protection

Notes (1) The data are measured at the following conditions.

SKM22, 25, 28, 32, 40 type

Refrigerant

piping

Connection wiring

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC 19ºC 35ºC 24ºC ISO-T1, JIS C9612

Heating 20ºC – 7ºC 6ºC ISO-T1, JIS C9612

(2) The values for capacity and power consumption shown in a range ( ) indicate the minimum and maximum of the range.

(3) If the piping length exceeds 20 m, additional charging is required. (20g/m)

Page 6

196

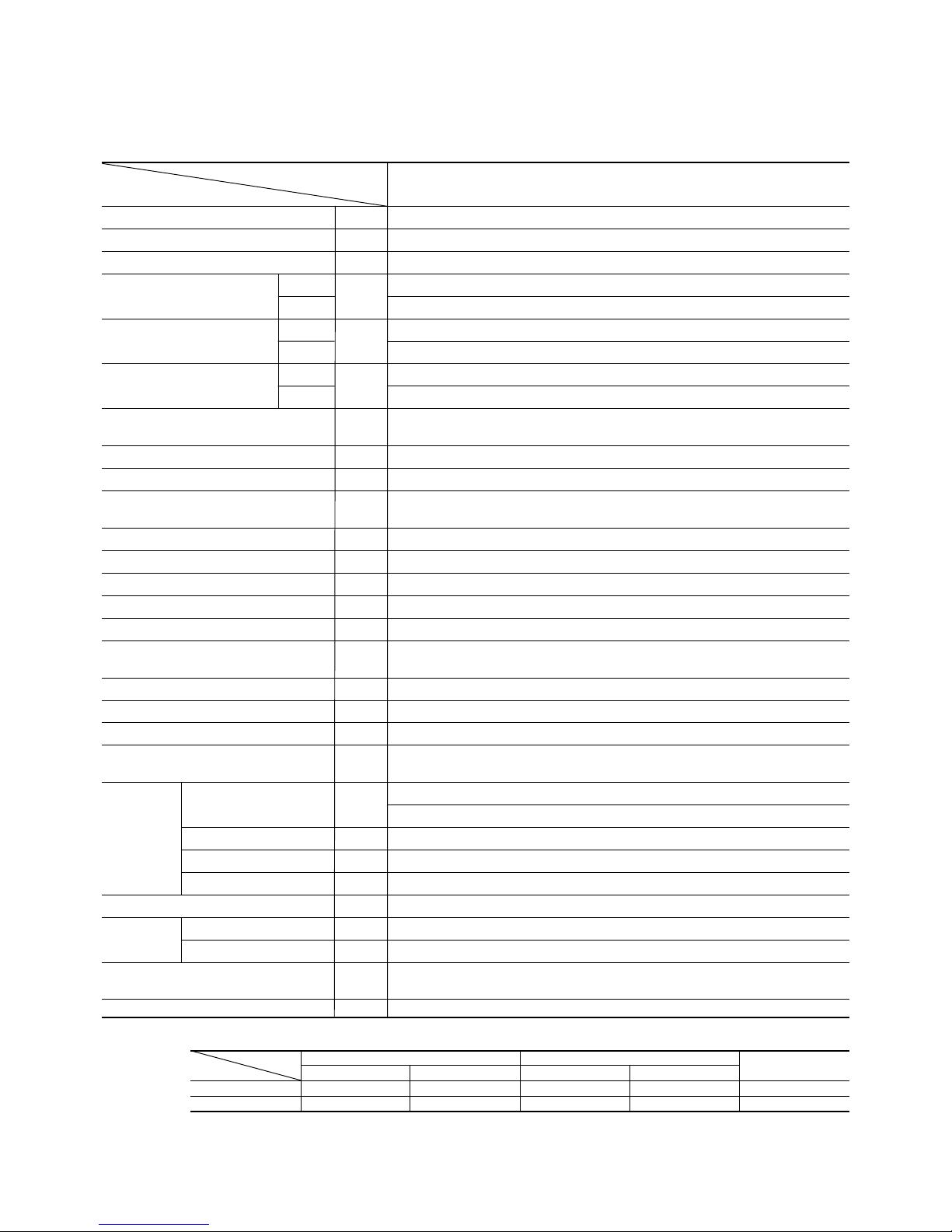

(3) Operation data

¡ The combinations of the indoor units is indicated by numbers. They are read as follows.

(Example) SKM22ZA / 22 SKM40ZA / 40

¡ The capacity of the indoor units is shown by rooms. If this exceeds the maximum capacity of the outdoor unit, the demand

capacity will be proportionally distributed.

¡ If units are to be combined, use the table below to make the proper selection.

(a) Heating

Indoor unit

combination

Heating capacity (kW) Power consumption (W)

Running

current (A)

Room heating capacity (kW) Total capacity (kW)

A room

3.2

3.4

4.0

4.5

5.4

2.8

2.6

2.5

2.3

2.0

2.8

2.6

2.5

2.2

2.8

3.0

3.1

3.3

3.6

2.8

3.0

3.1

3.4

B room Min.

Standard

Max.

Min.

Standard

StandardMax.

1.4

1.4

1.4

1.4

1.4

2.2

2.2

2.2

2.2

2.2

2.2

2.2

2.2

2.2

3.2

3.4

4.0

4.5

5.4

5.6

5.6

5.6

5.6

5.6

5.6

5.6

5.6

5.6

3.9

4.0

4.7

5.6

6.0

6.0

6.0

6.0

6.0

6.0

6.0

6.0

6.0

6.0

400

400

400

400

400

650

650

650

650

650

650

650

650

650

1030

1170

1350

1580

2030

1980

1950

1900

1850

1780

1950

1880

1830

1750

1330

1390

1680

2080

2300

2190

2160

2100

2050

1970

2160

2080

2030

1940

4.73/4.34

5.37/4.92

6.20/5.68

7.25/6.65

9.32/8.54

9.09/8.33

8.95/8.21

8.72/8.00

8.49/7.79

8.17/7.49

8.95/8.21

8.63/7.91

8.40/7.70

8.03/7.37

1

room

2

room

22

25

28

32

40

22+22

22+25

22+28

22+32

22+40

25+25

25+28

25+32

25+40

(220/240V)

Page 7

197

(b) Cooling

Indoor unit

combination

Cooling capacity (kW) Power consumption (W)

Running

current (A)

Room cooling capacity (kW) Total capacity (kW)

A room

2.2

2.5

2.8

3.2

4.0

2.2

2.1

2.0

1.9

1.7

2.25

2.2

2.1

1.8

2.2

2.4

2.6

2.8

3.1

2.25

2.4

2.6

3.0

B room Min.

Standard

Max.

Min.

Standard

StandardMax.

1.1

1.1

1.1

1.1

1.1

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.2

2.5

2.8

3.2

4.0

4.4

4.5

4.6

4.7

4.8

4.5

4.6

4.7

4.8

2.5

2.8

3.0

3.5

4.5

4.7

4.8

4.9

5.0

5.1

4.8

4.9

5.0

5.1

350

350

350

350

350

680

680

680

680

680

680

680

680

680

750

900

1040

1200

1580

1750

1820

1830

1840

1850

1820

1830

1840

1850

900

1040

1150

1360

1850

1950

2020

2030

2040

2050

2020

2030

2040

2050

3.44/3.16

4.13/3.79

4.78/4.38

5.51/5.05

7.25/6.65

8.03/7.37

8.36/7.66

8.40/7.70

8.45/7.74

8.49/7.79

8.36/7.66

8.40/7.70

8.45/7.74

8.49/7.79

1

room

2

room

22

25

28

32

40

22+22

22+25

22+28

22+32

22+40

25+25

25+28

25+32

25+40

(220/240V)

Page 8

198

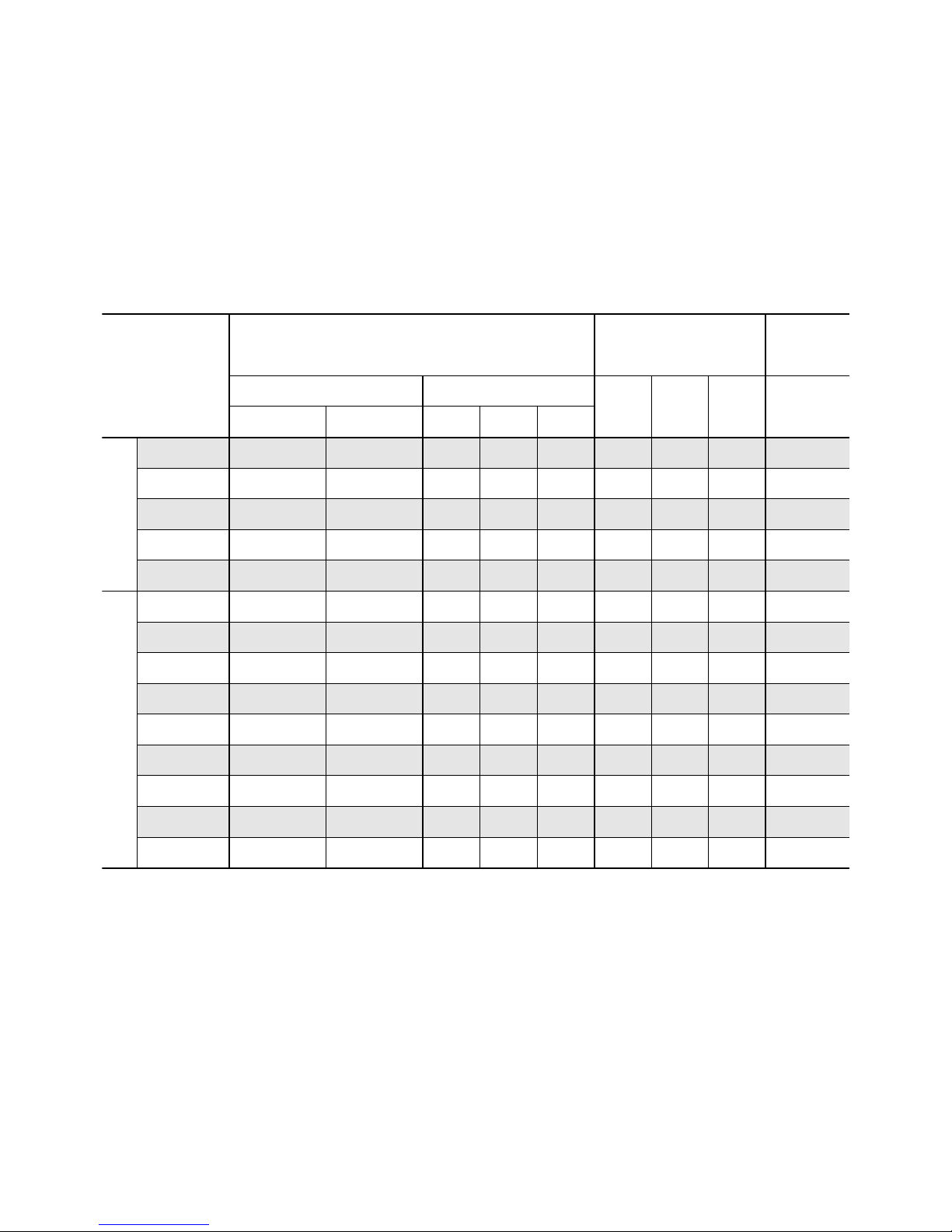

6.2.2 Range of usage & limitations

Indoor intake air temperature

(Upper, lower limits)

Indoor units

that can be

used in

combination

Length for one indoor unit

Total length for all rooms

Max. 25m

Max. 30m

6.5kW

1 to 2 units

SCM45ZA

Refer to the selection chart.

Compressor

stop/start

frequency

Power source

voltage

1 cycle time

Stop time

Voltage fluctuation

Voltage drop during start

Interval unbalance

Difference in height between indoor units (C)

Within ± 3% of rated voltage

Within ±15% of rated voltage

Within ±10% of rated voltage

3 min or more

6 min or more (from stop to stop or from start to start)

Max. 25m

Max. 15m

Max. 10m

Outdoor air temperature

(Upper, lower limits)

Number of connected units

Total of indoor units (class kW)

Difference in

height between

indoor and outdoor

units

When above outdoor unit (B)

When below outdoor unit (A)

Item

Model

A

B

C

Page 9

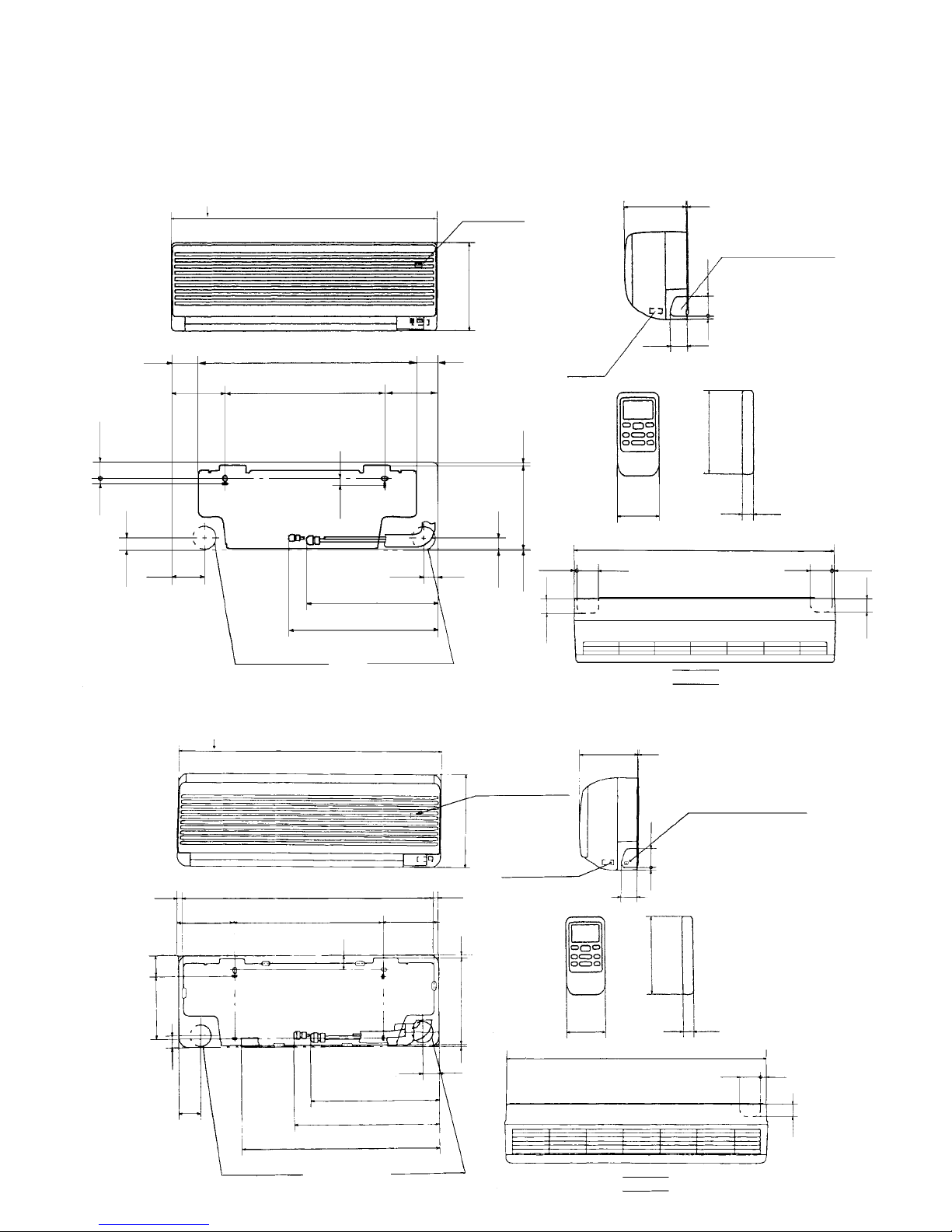

199

6.2.3 Exterior dimensions

(1) Indoor unit

Models SKM22ZA, 25ZA

A

750

75

92

40

60

746.9

7.5

62

62 7.5

16

VIEW A

65615

150

450 150

Room temp.

thermistor

Terminal

block

Piping for Gas (

Ø9.52) 370

Piping for Liquid (

Ø6.35) 420

Piping hole

(

Ø65)

Piping hole

(Ø65)

Piping hole right (left)

178 3

250

4615

19

9236.5

4.5

36

117

40

37

36

569

49

Unit: mm

Model SKM28ZA

A

790

15

67

51

60

62

18

16

780

VIEW A

15 760

170

450 170

Room temp. thermistor

Terminal block

Piping for Gas

(Ø9.52) 390

Piping for Liquid (

Ø

6.35) 440

Drain hose 600 (

Ø

16)

Piping hole

(

Ø

65)

Piping hole

(Ø65)

Piping hole right (left)

Unit: mm

174 3

275

187.5 61

46

9260

117

37

6

36

56

9

49

Page 10

200

Models SKM32ZA, 40ZA

A

790

15

67

51

60

62

18

16

780

VIEW A

15 760

170

450 170

Room temp. thermistor

Terminal block

Piping for Gas

(Ø12.7) 390

Piping for Liquid (Ø6.35) 440

Drain hose 600 (

Ø

16)

Piping hole

(

Ø

65)

Piping hole

(Ø65)

Piping hole right (left)

Unit: mm

174 3

275

187.5 61

46

9260

117

37

6

36

56

9

49

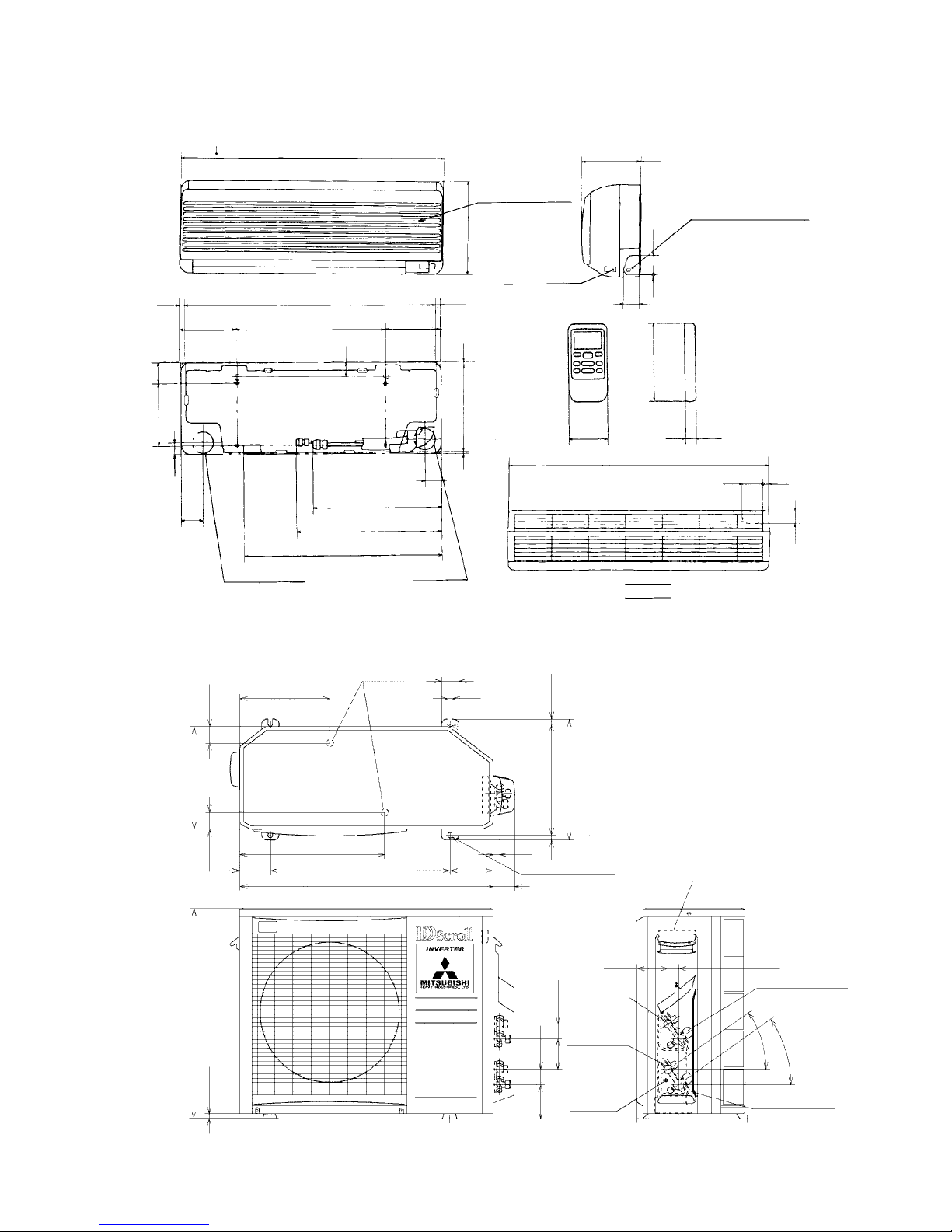

(2) Outdoor unit

Model SCM45ZA

Ground

terminal

Liquid line service

valve B Unit

Liquid line service

valve A Unit

42.5

14 13.5

84.7

96.5 42.5

14.4

595

340

312.5

290

48.1 46.6

88.2

Elongated hole

(2-16×12)

19

12

Drain hole

720 62

50

87 510

411.5

256

123

29.7

Terminal block

Gas line service

valve B Unit

Gas line service

valve A Unit

35°

35°

(ø6.35)

(ø6.35)

(ø9.52)

(ø9.52)

Page 11

201

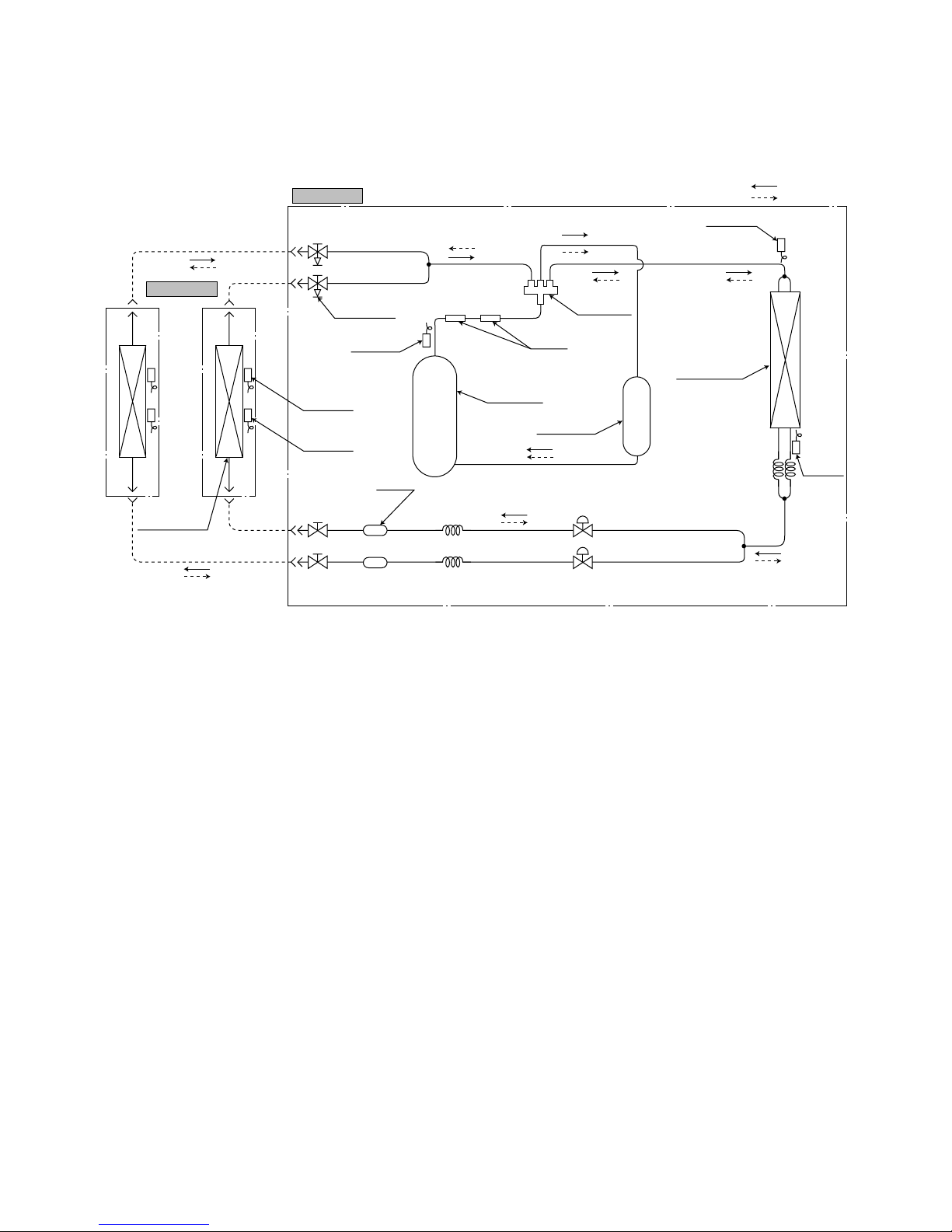

6.2.4 Piping system

Model SCM45ZA

Outdoor unit

Indoor unit

Thermistor

(Th

I

-R)

Thermistor

(Th

I

-A)

Check joint

Thermistor

(Th

O

-D)

Thermistor

(Th

O

-A)

Thermistor

(ThO-R)

Heat exchanger

Heat exchanger

Liquid line

Gas line

(ø6.35)

(ø6.35)

(ø9.52)

(ø9.52)

Strainer

Suction

Accumulator

Compressor

Discharge

Muffler

4 way valve

Service valve

(Liquid)

Capillary tube

Electric

expansion valve

EEVA

EEVB

Cooling cycle

Heating cycle

Service valve

(Gas)

Page 12

202

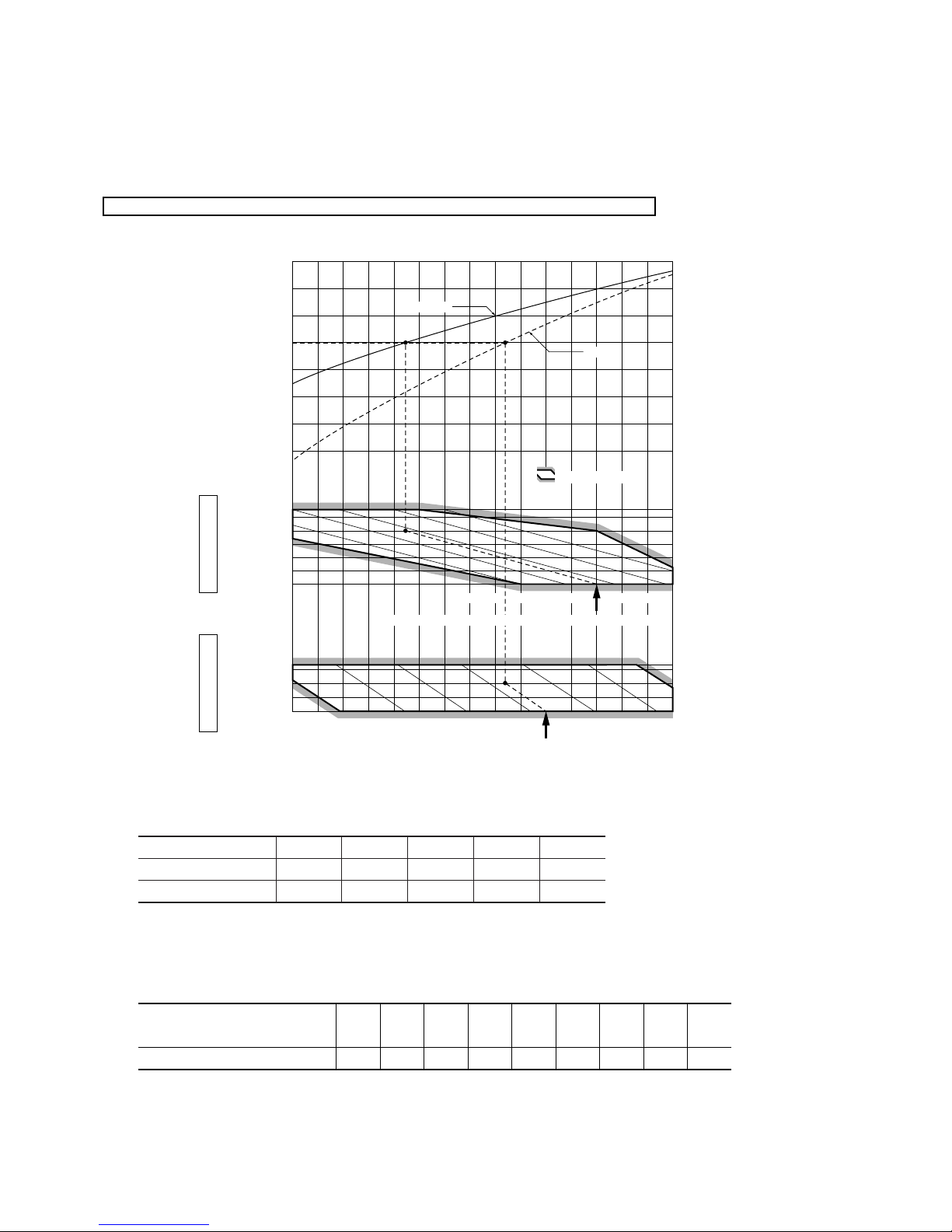

6.2.5 Selection chart

Correct the cooling and heating capacity in accordance with the conditions as follows. The net cooling and heating capacity can be

obtained in the following way.

Net capacity = Capacity shown on specification ✕ Correction factors as follows.

(1) Coefficient of cooling and heating capacity in relation to temperatures

(2) Correction of cooling and heating capacity in relation to one way length of refrigerant piping

It is necessary to correct the cooling and heating capacity in relation to the one way piping length between the indoor and outdoor

units.

(3) Correction relative to frosting on outdoor heat exchanger during heating

In additions to the foregoing corrections (1), (2) the heating capacity needs to be adjusted also with respect to the frosting on the

outdoor heat exchanger.

15

ISO-T1 Standard ConditionOutdoor air W.B. temperature °C W.B.

010-10 -5 5

14 16 18 20 22

15

10

27

25

20

15

20

25

30

35

40

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

43

24

20

ISO-T1 Standard ConditionIndoor air W.B. temperature °C W.B.

Heating

Cooling

Applicable range

Coefficient of cooling &

Heating capacity in

relation to temperature

Cooling operation

Outdoor air D.B.

temperature

°C D.B.

Heating operation

Indoor air D.B.

temperature

°C D.B.

Air inlet temperature of

outdoor unit in ˚C WB

Adjustment coefficient

-10

0.95-90.94-70.93-50.91-30.88-10.8610.8730.9251.00

Piping length [m]

Cooling

Heating

7

1.0

1.0

10

0.99

1.0

15

0.975

1.0

20

0.965

1.0

25

0.95

1.0

Page 13

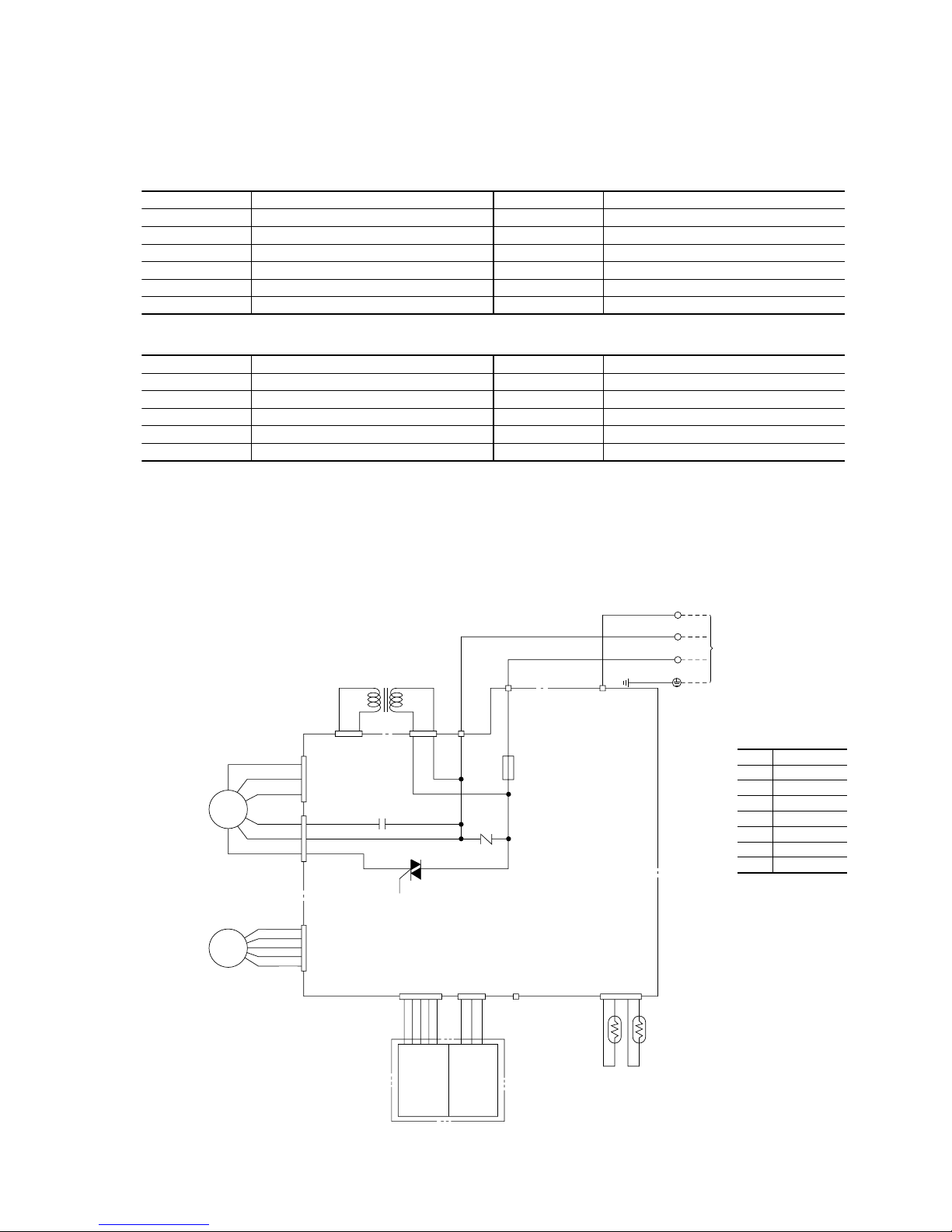

203

RD

WH

BK

JR

F (250V · 3.15A)

Power line

(Outdoor unit)

Black

Blue

Gray

Yellow

Red

White

Purple

Yellow/Green

BK

BL

GR

Y

RD

WH

PP

Y/GN

Color symbol

S

ZNR

CF

I

CNC CNB

TR

FMI

Q

CNM

CNE CND CNG

Display

Wireless

R-Amp

Back up

switch

Printed circuit board

ThI-AThI-R

FMI

SM

COM

CNU

CF

BL

RD RD BK BK

CNW

GR

PP

Y

WH

RD

1

2

Y/GN

3

CM

FM

0

L

DS

EEVA, B

20S

Parts name

Compressor motor

Fan motor

Reactor

Diode stack

Electric expansion valve

4 way valve (coil)

Symbol

Tho-A

Tho-R

Tho-D

LED2

LED1, 3

Parts name

Thermistor (outdoor air temp.)

Thermistor (outdoor H.X temp.)

Thermistor (comp. dome temp.)

Warning lamp (Red)

Serial signal lamp (Green)

Symbol

• Indoor Unit

FM

I

CF

I

SM

TR

ZNR

Parts name

Fan motor

Capacitor (for FM

I

)

Flap motor

Transformer

Varistor

Symbol

Q

F

Th

I

-A

Th

I

-R

Parts name

Fan motor control triac

Fuse

Thermistor (Room temp.)

Thermistor (Indoor H. X temp.)

Symbol

6.3 ELECTRICAL DATA

Meaning of marks

• Outdoor Unit

6.3.1 Electrical wiring

(1) Indoor unit

Models SKM22ZA, 25ZA, 28ZA, 32ZA, 40ZA

Page 14

204

(2) Outdoor unit

Model SCM45ZA

~+

++++

–

~

1

2

3

1

2

3

1

2

Y/GN

Y/GN

WH

BK

BL

WH

BK

RD

Serial A

Serial B

52X2-4

AC·R

AC·S

S. OUT

R. IN

S. IN

G

CNB CNB

LED1 LED3 LED2

(Red)

GY

DS

IC2

P

RDU

WH

BK

Tho-A Tho-R

CND

CNC

CNACNFCNECNA

Tho-D

V

W

N

BL

ORWH

L

WH

BK

UNIT A

UNIT B

Power source

1 Phase

220/240V

50Hz

Printed circuit board

Fuse

250V 25A

Printed circuit board

Power

transistor

CM

20S EEVA FMoEEVB

(Green)

Black

Blue

Gray

Red

White

Orange

Yellow/Green

BK

BL

GY

RD

WH

OR

Y/GN

Color symbol

Page 15

205

FAN SPEED ON/OFF

MODE

TEMP

AIR FLOW

SET TIMER TIMER

ACL

HI POWER

ECONO

CONT

HI POWER

ECONO

ON OFF

TIMER

AUTO

HI

MED

LO

FAN SPEED indicator

Indicators the ¡ for the fan speed which has

been set.

ON-TIMER • OFF-TIMER indicator

FAN SPEED button

Each time the button is pushed, the ¡

indicator is switched over in turn.

HI POWER button

This button changes the HI POWER

operation.

SET TEMPERATURE button

This button sets the room temperature.

ECONOMY button

This button changes the ECONOMY operation.

SET TIMER button

This button sets the ON TIMER time or SLEEP

time.

HI POWER operation indicator

Indicators during HI POWER operation.

ECONOMY operation indicator

Indicators during ECONOMY operation.

Operation switch over indicator

Indicators the ¡ for the operation which has

been set.

AIR FLOW indicator

Indicator selected flap mode.

OPERATION MODE select button

Each time the button is pushed, the ¡

indicator is switched over in turn.

ON/OFF button

This button, when pressed, starts operation

and stops when repressed.

AIR FLOW button

This button changes the flap mode.

TIMER button

The button selects ON TIMER operation,

OFF-TIMER operation or normal operation.

Reset switch

Switch for resetting microcomputer.

RUN

TIMER

INVERTER

TIMER RUN

RUN (HOT KEEP) lamp (green)

• Illuminates during operation.

• Flashs at stop blowing due to the hot keep.

Illuminates during TIMER operation.

TIMER lamp (yellow)

INVERTER

¡ Above figure shows all indications for the purpose of explanation,

but practically only the pertinent parts are indicated.

Heat pump model : [ (AUTO) · (Cool) · (Heat) · (Dry)]

Cooling only model: [ (AUTO) · (Cool) · (Fan) · (Dry)]

6.4

OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER

(1) Remote Controller

(2) Indoor unit indicator

Models SKM22, 25 models

Models SKM28, 32, 40 models

Page 16

206

(3) Back-up switch

When the remote controller become weak, or if the remote controller is lost or malfunctioning, this switch may be used to turn the

unit on and off.

(a) Operation

Push the switch once to place the unit in the automatic mode. Push it once more to turn the unit off.

(b) Detail of operation

Operation starts in the same way as the previous operation.

¡ The flap operation as shown above will be repeated.

Stops at the level position for

one minute.

s

In case of cooling

t

and dry operation

s

In case of heating

t

operation

Sway operation

Sway operation

(4) Flap control

Control the flap by AIRFLOW button on the wireless remote control.

(a) Natural flow (AUTO)

The flap will be automatically set to the angle of air flow best to operation.

1) Starting time of operation

ON/OFF

¡ The flap operation as shown above will be repeated.

Models SKM22, 25 models Models SKM28, 32, 40 models

ON/OFF button

(c) Swing flap

Flap moves in upward and downward directions continuously.

Horizontal

blowing

2) When not operating

The flap returns to the position of air flow directly below, when operation has stopped.

(b) Memory flap (Only case of SKM28, 32, 40 models)

While the flap is operating if the AIRFLOW button is pushed once, it stops swinging at an angle.

As this angle is memorized in the microcomputer, the flap will be automatically set to the angle when next operation is

started.

◆ Recommendable stopping angle of the flap

Slant forward

blowing

COOL•DRY

HEAT

ON/OFF button

Page 17

207

(5) Comfort timer setting

If the timer is set at ON when the operation select switch is set at the cooling or heating, or the cooling or heating in auto mode

operation is selected, the comfort timer starts and determines the starting time of next operation based on the initial value of 15

minutes and the relationship between the room temperature at the setting time (temperature of room temperature thermistor) and

the setting temperature. (Max. 60 minutes)

Operation mode Operation start time correction value (Min.)

3 < Room temp. – Setting temp. 1 < Room temp. – Setting temp. 3 Room temp. – Setting temp. 1

At cooling

+5 No change –5

3 < Setting temp. – Room temp. 2 < Setting temp. – Room temp. 3 Setting temp. – Room temp. 2

At heating

+5 No change –5

Notes (1) At 5 minutes before the timer ON time, operation starts regardless of the temperature of the room temperature thermistor (Th

I-A).

(2) This function does not actuate when the operation select switch is set at the dehumidifying as well as the dehumidifying in the auto mode.

However, the operation of item (1) above is performed during the dehumidifying in the auto mode.

(3) During the pleasant reservation operation, both the operation lamp and timer lamp illuminate and the timer lamp goes off after expiration of the timer, ON setting

time.

Corrects the starting time of next operation by

calculating the temperature difference.

(Example) Heating

Setting temperature

Room temperature

Operation starting time

Time

Setting time

15 min. 10 min. 5 min.

earlier earlier earlier

¡ If the difference (= Setting temperature – Room

temperature) is 4ºC, the correction value is found to be

+5 minutes from the table shown above so that the

starting time of next operation is determined as

follows:

15 min. earlier + 5 min. = 20 min. earlier

↑↑

Current operation Correction value

start time

≤

≤

≤

≤

Capacity control is within the range shown above. If demand capacity of the indoor units exceeds the maximum capacity of the outdoor unit, the demand capacity will be proportionally distributed.

2) Outdoor unit speed control (28 ~ 120 rps)

(6) Cooling operation

(a) Summary

1) Capacity control

Model

Capacity

SCM45ZA

2.0 ~ 5.1 kW

SCM45YA

2.0 ~ 5.1 kW

28 rps or less

More than 28 rps, but 120 rps or less

More than 120 rps

Decision speed

28 rps

28 to 120 rps

120 rps

Indoor unit instruction total speed value

Note (1) The indoor unit instruction total speed value is the total of the values from each unit in item (b).

(b) Mode switching

Within the selected mode, the unit operates using the values shown below which were obtained by multiplying a conversion

coefficient to the indoor unit instruction speed.

Model (Indoor)

Operation Mode

Automatic

High

Medium

Low

Hi power

Econo

28 ~ 58

28 ~ 58

28 ~ 44

28 ~ 30

58

28 ~ 34

28 ~ 68

28 ~ 68

28 ~ 50

28 ~ 32

68

28 ~ 36

28 ~ 88

28 ~ 88

28 ~ 60

28 ~ 30

86

28 ~ 50

28 ~ 96

28 ~ 96

28 ~ 70

28 ~ 34

96

28 ~ 40

28 ~ 110

28 ~ 118

28 ~ 100

28 ~ 40

108

28 ~ 50

22 25 28 32 40

(rps)

Page 18

208

(7) Heating Operation

(a) Summary

1) Capacity control

Model

Capacity

SCM45ZA

2.2 ~ 6.0 kW

28 rps or less

More than 28 rps, but 120 rps or less

More than 120 rps, but 134 rps or less

More than 134 rps

Decision speed

28 rps

28 to 120 rps

120 to 134 rps

134 rps

Indoor unit instruction total speed value

Capacity control is within the range shown above. If demand capacity of the indoor units exceeds the maximum capacity of the outdoor unit, the demand capacity will be proportionally distributed.

2) Outdoor unit speed control (28 ~ 134 rps)

Note (1) The indoor unit instruction total speed value is the total of the values from each unit in item (b).

(c) Operation of Major Functional Components in Cooling Mode

Functional

components

Operation

Instruction speed

Indoor

unit fan

Compressor

Outdoor unit fan

Electronic

expansion valve

See preceding table

ON

According to instruction speed

According to outdoor unit speed

According to decision

speed

0

(All indoor units)

OFF

According to stop mode

According to mode switching

OFF

0

(Thermostat off units)

ON

All closed

(Thermostat off units)

According to outdoor unit speed

According to mode switching

All closed

(Fan, stop, abnormal stop units)

0

(Fan, stop, abnormal stop units)0 (All units)

ON

First speed or low

OFF

OFF

According to stop mode

Cooling

Thermostat OFF

(All indoor units)

Thermostat OFF

(Some of indoor units)

Fan, stop, abnormal stop

(Some of indoor units)

Failure

(Outdoor Unit)

Fixed

Automatic

(b) Mode switching

Within the selected mode, the unit operates using the values shown below which were obtained by multiplying a conversion

coefficient to the indoor unit instruction speed.

(c) Operation of Major Functional Components in Heating Mode

Model (Indoor)

Operation Mode

Automatic

High

Medium

Low

Hi power

Econo

28 ~ 74

28 ~ 74

28 ~ 50

28 ~ 34

76

28 ~ 42

28 ~ 80

28 ~ 80

28 ~ 58

28 ~ 36

82

28 ~ 44

28 ~ 120

28 ~ 120

28 ~ 86

28 ~ 46

120

28 ~ 60

28 ~ 126

28 ~ 126

28 ~ 92

28 ~ 46

120

28 ~ 54

28 ~ 134

28 ~ 134

28 ~ 126

28 ~ 54

126

28 ~ 64

22 25 28 32 40

(rps)

Functional

components

Operation

Instruction speed

Indoor

unit fan

Compressor

Outdoor unit fan

Electronic

expansion valve

See preceding table

ON

According to mode switching

According to instruction speed

According to outdoor unit speed

According to decision

speed

0

(All indoor units)

OFF

According to stop mode

Hot Keep

Hot Keep

OFF

0

(Thermostat off units)

ON

After 4 minutes all closed: 58 pulse

(Thermostat off units)

According to mode switching

According to instruction speed

According to outdoor unit speed

58 Pulse

(Fan, stop, abnormal stop units)

0

(Fan, stop, abnormal stop units)0 (All units)

ON OFF

Hot Keep

Hot Keep

OFF

According to stop mode

Heating

Thermostat OFF

(All indoor units)

Thermostat OFF

(Some of indoor units)

Fan, stop, abnormal stop

(Some of indoor units)

Failure

(Outdoor Unit)

Fixed

Automatic

Page 19

209

(d) Hot keep operation

If the hot keep operation is selected during the heating operation, the indoor fan is controlled based on the temperature of the

indoor unit heat exchanger (detected with ThI-R, indoor unit heat exchanger thermistor) to prevent blowing of cool wind.

¡ Normal mode (Normal heating operation, operation after HI POWER completion)

1st speed

¡ Values of a, b

AB

At 0 rps command 22 25

Other than 0 rps

17 19

command

Note (1) Refer to the table shown above right for the values A and B.

¡ Hot keep M mode [During HI POWER operation (for 15 min.)]

Indoor fan

Indoor heat exchanger temp. (˚C)

2nd speed

3rd speed

4th speed

5th speed

6th speed

7th speed

1st speed

Indoor heat exchanger temp. (˚C)

2nd speed

3rd speed

4th speed

5th speed

6th speed

7th speed

(e) Defrosting

(i) When the following conditions are met, the defrosting operation will start.

1) During normal operation

a) When 40 minutes has passed since the start of heating or 40 minutes after the last defrosting (based on cumu-

lative operation time of compressor).

b) When the outdoor heat exchanger thermistor (Tho-R) temperature is –2 °C or less for 3 continuous minutes

after 37 minutes have passed.

c) Outdoor temperature thermistor (Tho-A) – outdoor heat exchanger thermistor (Tho-R) temperature

0.44 ×

outdoor temperature thermistor (Tho-A) temperature + A °C or more.

A = Outdoor temperature – 2 °C: 4, outdoor temperature < – 2 °C: 6.

d)When the compressor is operating.

u Or, during heating, defrosting will start when the decision speed counts zero (0) rps for 10 times or more

and all conditions in a), b) and d) have been satisfied.

2) During defrosting acceleration

a) When 40 minutes has passed since the last defrosting (based on cumulative operation time of compressor).

b) When the compressor is operating.

u Or, during heating, defrosting will start when the decision speed counts zero (0) rps for 10 times or more

and all conditions in a) and b) have been satisfied.

Note (1) Defrosting acceleration is when the finishing of the previous defrosting is according to the defrosting conditions of the 10 minutes

that have passed.

Indoor fan

Page 20

210

3) Operation of function component in defrosting

4) Conditions for finishing defrosting

When any of the following conditions is met, the defrosting finishing operation will start.

1 When the temperature of the outdoor heat exchanger thermistor (Tho-R) is 9 °C or more.

2 When 10 minutes has passed after the start of defrosting.

(8) Determining the operating mode

The cooling and heating operating modes are the remote control switch mode that have been previously determined.

If a mode differing from these is selected after this, the selected mode will appear in the display of the remote control, but only the

fan will operate.

A unit

B unit

Cooling

Cooling

Fan Heating

HeatingFan

Cooling

switch

ON

Heating

switch

ON

Heating

switch

ON

Cooling

switch

ON

Heating

switch

ON

Operation Operation

Operation Operation

Operation

Example of operating pattern

Note (1) [ ] indicates currect operation.

1

2

Example

First operation Second operation

Notes

Different mode is

only fan operation.

•

Selected Mode

Cooling

Heating

Remote Control Display

Cooling

Heating

Operation

Cooling

Heating

Selected Mode

Heating

Cooling

Remote Control Display

Heating

Cooling

Operation

Fan

(1)

Fan

Note (1) If the display shows

heating and the operation is fan, Hot Keep

will operate.

Notes (1) Indoor unit fan is

in response to Hot

Keep.

(2) Outdoor unit fan

starts

6

seconds after the start of the

compressor.

80 sec.80 sec.

ON

OFF

OFF

0 rps

According to rps

EEV control

Calculated start

Opening in relation

to conditions

Opening in

relation to

conditions

Defrost end conditions

Start of defrost operation Defrost operation

Fully closed

Defrost end operation

80 rps

Decision speed Decision speedOutdoor unit speed

Outdoor unit fan

Electronic expansion valve

EEVA,B

(Operating unit)

Electronic expansion valve

EEVA,B

(Stopped unit)

4-way valve

200 pulse

When 2 units are operating:

150 pulse

When 1 unit is operating:

200 pulse

Page 21

211

(9) Control and protection functions

(a) Start of protection for compressor

When the decision speed becomes a speed other than 0 rps and when the compressor is starting operation, an inverter

decision speed of 40 rps or less indicates four-way valve switching protection and a speed of 40 rps or more indicates that

protection of the compressor has started.

1) Start of protection for compressor

a) After the compressor has started, the speed of the outdoor unit will reach a maximum value of 56 rps for 1 minute

and 45 seconds.

b) During this time, if the decision speed exceeds 56 rps, operation will be at 56 rps; if it is 56 rps or less, operation will

be at the decision speed or operation with 4-way valve switching protection.

c) The outdoor unit fan speed operates according to outdoor unit speed.

d) If restarting after a thermostat stop, the protection function for the outdoor unit operates and when restarting after

the inverter stop, compressor protection is not started.

e) During the start of protection, current safe and compressor overheat have priority.

2) 4-way valve switching protection

Four-way valve switching protection is performed so that four-way valve switching will be performed smoothly.

a) When the decision speed starts at less than 40 rps, it forces the decision speed to operate at 40 rps for 30 seconds.

b) After 30 seconds, the speed of the outdoor unit is transferred to the decision speed.

c) This function applies to all units starting from an outdoor unit speed of 0 rps.

d) Current safe and compressor overheat protection are enabled even when this function is in operation.

(b) Heating overload protection control

During heating operation, if the outdoor unit is operating at a speed at 28 rps or more and the outdoor temperature is 12 °C or

more for 30 continuous seconds, current safe control is performed.

Operation is restored when the outdoor temperature is 10 °C or less.

(c) Cooling overload protection control

During cooling operation, if the outdoor unit is operating at a speed at 28 rps or more and the outdoor temperature is 39 °C

or more for 3 continuous minutes, current safe control is performed by turning the outdoor fan dial up by 1 unit. Operation is

restored when the outdoor temperature is 38 °C or less.

(d) Heating thermostat OFF control

When there is a heating operation being performed for one room while a heating thermostat OFF is being performed in

another room, the following controls are performed to prevent overheating.

1) This control is performed when all of the following conditions have been satisfied.

a) Compressor: During operation (determined speed 28 rps or more)

b) One room serial signal: Operating mode – heating, command speed: other than 0 rps.

c) Other room serial signal: Operating mode – heating, command speed: 0 rps.

2) Description of control

Start of control

Release of control

58 pulse

4 min

Fully closed

EEV A, B Heating

0 rps compatible

EEV A, B Operating

unit compatible

Outdoor unit fan

According to

outdoor rps

Actual operating speed Decision rps

Outdoor unit speed Decision rps

Functional components Operation of each functional components Remarks

Page 22

212

(e) High pressure cut protection control

The high pressure cut protection operates during heating operations when a “heating 0 rps” serial signal is received from one

of the two operating indoor units.

1 When only one of two operating units sends a “heating 0 rps”signal.

2 min.

0 rps

instruction

A room

B room

Indoor unit

instruction

speed

Functional components Operation of each functional components Remarks

Instruction speed from indoor unit

that has “heating 0 rps”.

Instruction speed for indoor unit

that has “other than heating 0 rps”.

Actual operating speed

Outdoor unit fan

4-way valve

EEVA

EEVB

Calculated rps

0 rps

Calculated rps

0 rps

Fully closed

Decision rps

58 pulse or

EEV control

According to

outdoor rps

OFF

ON

OFF

According to

outdoor rps

According to

outdoor rps

Corresponding expansion valve for

unit with serial signal that has

“heating 0 rps”.

Corresponding expansion valve for

unit with serial signal that has

“other than heating 0 rps”.

2 When decision speed becomes 0 rps during high pressure cut protection control

2 min.

200 pulse

200 pulse

0 rps instruction

Functional components Operation of each functional components Remarks

The sequence for o rps instruction

shows one example.

Actual operating speed

Outdoor unit fan

4-way valve

EEVA

EEVB

Calculated rps

Calculated rps

0 rps

0 rps

Decision rps

0 rps

According to

outdoor rps

OFF

ON

According to

outdoor rps

Fully closed

According to

outdoor rps

Fully closed

OFF

0 rps instruction

A room

B room

Indoor unit

instruction

speed

2 min. 25 sec.

Page 23

213

(f) Low Hz continuous operation protection control

The following controls are performed to return oil to the compressor when the outdoor unit speed of 28 rps or more to 40 rps

or less is continuously operated for 20 minutes.

1) The decision speed is forced to operate at 40 rps for 2 minutes.

2) The outdoor fan and electronic expansion valve are operated according to the outdoor unit speed.

3) If there is an instruction exceeding 40 rps during this forced 40 rps operation, this control ends and the operation

follows that instruction.

(g) Heating low temperature protection control

The following controls are performed when the outdoor unit is in heating operation at a speed other than 0 rps and the outdoor

temperature is 2 °C or less for 1 continuous minute.

1) The outdoor unit fan speed is forced to 5th speed.

2) This control is ended when the outdoor temperature reaches 4 °C or more.

(h) Current safe control

1) When converter in port current is detected at the current sensor (CT) and it exceeds the set amperage, the speed is reduced

2 rps. This is rechecked after one second and if it still exceeds the set amperage, the speed is reduced another 2 rps.

2) If the actual speed operated at 28 rps or less, the inverter is stopped. It is restarted after a 3 minute delay. However, if it

is restarted repeatedly within an interval of 1 hour, it will not start on the 5 times.

(i) Current cut

This detects converter output current at the shunt resistor and if it exceeds the set value, the inverter is stopped. It is restarted

after a 3 minute delay. However, if the current cut operates again when the actual speed is less than 20 rps, it will not start on

the 4 times.

(j) Compressor overheat protection

The detection temperature of the compressor dome thermistor (Tho-D) is used to prevent oil deterioration and damage to the

motor wire due to overheating of the compressor.

1) If Tho-D becomes

125 °C, the inverter is stopped. After the stop mode has been activated, the inverter will be

restarted when Tho-D becomes < 95 °C. However, if it is restarted repeatedly within an interval of 1 hour, it will not

start on the 3 times.

2) When 105 °C

Tho-D < 125 °C, the following outdoor unit speed controls are performed.

(k) Serial transmission abnormality protection

If the compressor is operating with an outdoor speed other than 0 rps and a serial signal cannot be received from all indoor

controls with outdoor controls having serial signals other than “stop - 0 rps” continuously for 1 minute and 55 seconds, the

inverter is stopped.

After the inverter has been stopped, it will be restarted after the compressor start delay if a serial signal can be received again

from the indoor control.

Compressor doom temperature (°C)

Notes (1) If the temperature of the compressor dome is 105 °C or more and less than 125 °C, the outdoor unit speed is reduced by 8 rps.

(2) After 20 seconds, if the temperature of the compressor dome has decreased, it is lowered 2 rps. If the temperature has risen or is

the same, it is lowered another 8 rps.

(3) If the temperature of the compressor dome is 95 °C or more and less than 105 °C, the speed of the outdoor unit is maintained. If

operation is maintained at the same speed for 6 minutes or more or if the temperature is 95 °C or less, control is returned to

normal operation.

6 minutes of more has passed

(3)

6 minutes of more has passed

(3)

6 minutes of more has passed

(3)

Lower limit 28 rps

8 rps

12510595

8 rps or 2 rps

(2)

8 rps or 2 rps

(2)

0 rps

Decision speed

Inverter

Page 24

214

(l) Compressor lock

If the motor for the compressor does not turn a half a turn approximately 0.3 seconds after it has been started, it is determined

that a compressor lock has occurred and the inverter is stopped.

(m) Compressor dome thermistor broken wire protection control

1) When the outdoor unit speed is other than 0 rps and after the compressor has started to operate, if after 10 minutes there

is a compressor dome thermistor temperature10-second interrupt signal (less than 7 °C), it is immediately placed in

stop mode and restarted. (This detection is only performed once when the compressor is on.)

2) If an error continues for 4 times continuously, a permanent stop is made. (Restoration requires resetting the power

supply.)

(n) Outdoor unit failure

This is a function for determining when there is trouble with the outdoor unit during air conditioning.

The inverter is stopped if any one of the following in item 1), 2) is satisfied. Once the unit is stopped by this function, it is not

restarted.

1) When the input current is measured at 1 A or less for 3 continuous minutes or more.

2) If the outdoor unit sends a 0 rps signal to the indoor unit 3 times or more within 20 minutes of the power being turned on.

(o) Stop mode (Decision speed is 0 rps, when the protection function for the outdoor controller is operating,

when restarting due to operation change)

(10) Regulation of outdoor air flow

(a) The fan operates as follows according to the speed of the outdoor unit. (Except during defrost.)

(b) If the outdoor unit fan motor speed is 300 rpm or less for 30 seconds or more continuously, the compressor and outdoor unit

fan are stopped.

Functional

components

Operation

Outdoor unit

speed

Actual operating

speed

Outdoor unit fan

E EVA

4-way valve

E EVB

Cooling Heating

Operation of outdoor unit protection function, if restarting

when recovering from thermostat stop and switching operations.

If stopping due to an indoor unit instruction and if permanent stop.

Cooling Heating

Stop instructions

All stop Stop instructions All stop 0 rps instructions Restart Stop instructions Restart

Decision

rps

0

Outdoor

rps

0

According to

outdoor rps

0

ON

OFF

EEV

control

Fully

closed

EEV

control

Fully

closed

3 min.

3 min.

3 min.

2 min.

2 min. 25 sec.

200 pulse

200 pulse

55 sec.

3 min.

3 min.

3 min.

2 min.

2 min. 25 sec.

200 pulse

200 pulse

2 min.

55 sec.

2 min. 25 sec.

200 pulse

200 pulse

2 min.

2 min. 25 sec.

200 pulse

200 pulse

Outdoor unit speed

Outdoor fan speed

Fuzzy auto

when starting

1st speed

Less than 80

2nd speed

80 or more and

less than 100

3rd speed

100 or more

and less than 120

4th speed

120 or more

5th speed

Page 25

215

6.5 APPLICATION DATA

SAFETY PRECAUTIONS

¡ Please read these “Safety Precautions” first then accurately execute the installation work.

¡ Though the precautionary points indicated herein are divided under two headings,

WARNING and CAUTION , those points

which are related to the strong possibility of an installation done in error resulting in death or serious injury are listed in the

WARNING section. However, there is also a possibility of serious consequences in relationship to the points listed in the

CAUTION section as well. In either case, important safety related information is indicated, so by all means, properly observe all

that is mentioned.

¡ After completing the installation, along with confirming that no abnormalities were seen from the operation tests, please explain

operating methods as well as maintenance methods to the user (customer) of this equipment, based on the owner’s manual.

Moreover, ask the customer to keep this sheet together with the owner’s manual.

WARNING

¡ This system should be applied to places as households, residences and the like. Application to inferior environ-

ment such as engineering shop could cause equipment malfunction.

¡ Please entrust installation to either the company which sold you the equipment or to a professional contractor.

Defects from improper installations can be the cause of water leakage, electric shocks and fires.

¡ Execute the installation accurately, based on following the installation manual. Again, improper installations can

result in water leakage, electric shocks and fires.

¡ For installation, confirm that the installation site can sufficiently support heavy weight. When strength is insuffi-

cient, injury can result from a falling of the unit.

¡ For electrical work, please see that a licensed electrician executes the work while following the safety standards

related to electrical equipment, and local regulations as well as the installation instructions, and that only exclusive use circuits are used.

Insufficient power source circuit capacity and defective installment execution can be the cause of electric shocks

and fires.

¡ Accurately connect wiring using the proper cable, and insure that the external force of the cable is not conducted

to the terminal connection part, through properly securing it improper connection or securing can result in heat

generation or fire.

¡ Take care that wiring does not rise upward, and accurately install the lid/service panel. It’s improper installation

can also result in heat generation or fire.

¡ When setting up or moving the location of the air conditioner, do not mix air etc. or anything other than the

designated refrigerant (R22) within the refrigeration cycle.

Rupture and injury caused by abnormal high pressure can result from such mixing.

¡ Always use accessory parts and authorized parts for installation construction. Using parts not authorized by this

company can result in water leakage, electric shock, fire and refrigerant leakage.

¡ Ventilate the work area when refrigerant leaks during the operation.

Coming in contact with fire, refrigerant could generate toxic gas.

¡ Confirm after the foundation construction work that refrigerant does not leak.

If coming in contact with fire of a fan heater, a stove or movable cooking stove, etc., refrigerant leaking in the

room could generate toxic gas.

CAUTION

¡ Execute proper grounding. Do not connect the ground wire to a gas pipe, water pipe, lightning rod or a telephone

ground wire.

Improper placement of ground wires can result in electric shock.

¡ The installation of an earth leakage breaker is necessary depending on the established location of the unit.

No installing an earth leakage breaker may result in electric shock.

¡ Do not install the unit where there is a concern about leakage of combustible gas.

The rare event of leaked gas collecting around the unit could result in an outbreak of fire.

¡ For the drain pipe, follow the installation manual to insure that it allows proper drainage and thermally insulate it

to prevent condensation. Inadequate plumbing can result in water leakage and water damage to interior items.

Page 26

216

6.5.1 Installation of indoor unit

(a) Caution for installation

1) The system should be applied to places as households, residences and the like.

2) The equipment shall be installed in accordance with national wiring regulations.

3) The connection to the fixed wiring of the mains supply must be made via a double pole isolating switch with a contact

gap of at least 3mm in each pole.

4) When the outdoor unit has a possibility of being overturned or being displaced and fall from its original installation

position, the outdoor unit should be fixed in its position by the use of anchor bolts or wires.

(b) Installation of indoor unit

1) Fixing of installation Board

Outdoor side

5°

ø65

Indoor side

Wall thickness × 1.5cm

Sleeve

Sleeve Inclined plate

Sealing plate

Putty

Pipe

Assembled state

¡ Drill a hole with a 65 whole

core drill.

¡ Find the inside wall structures (pillar, etc.) and secure

the board after checking the horizontal level.

Unit: mm

¡ When the pipe is connected at the rear, cut off the lower and the right

side portions of the sleeve collar (as shown by the broken line.)

Reference hole

450

Level surface

matching mark

¡ Horizontal level adjustment of the board is conducted

with four temporarily tightened screws.

¡Adjust so that the board will be horizontal with the

reference hole in the center.

2) Drilling of holes and fixture of sleeve (Option ports)

¡The connecting wires may touch the metal inside the wall and cause danger so it is necessary to always use the sleeve.

Installation space (Indoor unit)

Models SKM22, 25 models Models SKM28, 32, 40 models

Indoor unit

[Front View]

Installation board

50

Service

space

100

15

Service

space

15

760

450170 170

5

260

9

40 Service space

Service space

15

61187.5

36

67

51

Gas pipe 390

Liquid pipe 440

Drain hose 600

(Connection hole outside diameter ø16)

Position for the hole in the wall ø65

Position for the hole in the wall ø65

50

75 615

450

60

100

40

Gas pipe 370

Liquid pipe 420

92

ø65

ø65

9

40

236.54.5

36

36

15

19

15

46

Service space

Position for the

hole in the wall

Position for the

hole in the wall

Service space

Service space

Service

space

Indoor unit

Installation

board

150

150

Page 27

217

3) Mounting of interconnecting wires (Field wiring)

a) Remove the lid.

b) Remove the terminal block cover.

c) Connect the connection wire securely to the terminal block.

Cautions when piping from the left and the rear center of the unit

Earth terminal

Terminal block

Wiring clamp

Cover

Lid

Pipe

Drain hose

Left Side Piping

Left rear piping Right rear piping

Right

Rear

Under

Left rear

Left

Left side piping

[Procedure for exchanging the drain hose.]

Right side piping

1.Remove the drain hose.

2.Remove the drain cap.

3.Insert the drain cap.

4.Connect the drain hose.

Right Side Piping

The piping can be removed from

the rear, left, left rear, right and

from under the unit.

¡ Tape only the portion that runs through the wall.

Always tape the crossover wires with the pipe.

¡ Loosen and remove the

spring-type clamp.

¡ Remove with your

hand or a pair of pliers.

¡

Use a hexagonal wrench

to correctly insert the

drain cap which was

removed in 2.

Caution: Be careful

because if the cap is not

inserted property, water

leak may occur.

¡ Loosen the spring-type

clamp and securely

insert the drain hose.

Caution: Be careful

because if the cap is not

inserted properly, water

leak may occur.

¡ Hold the bottom of the pipe and change its direction

before stretching it and shaping it.

Wall

Gutter

Pipes storage area

¡ When conducting the central rear piping, use

a nipper to cut out knock-out holes in the

installation board.

¡ Do not place the power supply cords

above the gutter, because the air

conditioner is structured in a way where

condensation on the back side is

collected in to the drain pan before

drainage.

Removed by pressing in the

section with the broken lines

and pulling it towards the arrow.

Use cables for interconnection wiring to avoid loosening of the wires.

CENELEC code for cables Required field cables.

H05 RNR4G1.5 (Example)

H Harmonized cable type

05 300/500 volts

R Natural-and/or synth. rubber wire insulation

N Polychloroprene rubber conductors insulation

R Stranded core

4 Number of conductors

G One conductor of the cable is the earth conductor (yellow/green)

1.5 Section of copper wire (mm

2

)

[Top View]

1) Connect the connection wire securely to the terminal block. If the

wire is not affixed completely, contact will be poor, and it is dangerous as the terminal block may heat up and catch fire.

2) Take care not to confuse the terminal numbers for indoor and out-

door connections.

3) Affix the connection wire using the wiring clamp.

d) Attach the terminal block cover.

e) Attach the lid.

4) Shaping the pipe and drain hose

[Shaping the pipe] [Taping of the exterior]

Page 28

218

Drainage

Too high It curves like a wave.

under 5 cm

Smell from

sewerage drains.

The end of the

drain hose is

touching the

water.

The gap to the

ground is less

than 5 cm.

The end of the

drain hose is

touching the

sewage drains.

Drain hose

Extension drain hose

when a part of the extension drain hose is indoors

Shielding pipe

Indoor unit

Hook (2 locations)

Installation

board

Instalation

board

Indoor unit

base lower hook

Wall

Installing steps

1. Hook the upper part

of the indoor unit to

the installation board.

2. The unit can be

installed simply by

gently pushing in the

lower part.

¡ The drain hose must be fit with a downward slope.

¡ Do not set the drain hose like the following illustrations.

¡ Pour water in the drain pan below the heat exchanger and confirm that the water is drained outside.

¡ If the extension drain hose is indoors, make sure it is insulated using a shielding pipe (not supplied).

5) Securing the Indoor Unit to the Installation Board

6.5.2 Installation of remote controller

(1) Mounting method of battery

Uncover the remote control switch, and mount the batteries (UM-4 × 2 pieces) in

the body regularly.

(Fit the poles with the indication marks, , & . without fail)

(2) Fixing to pillar or wall

(a) Conventionally, operate the remote control switch by holding in your hand.

(b) In the case of stationary operation service as by mounting on the holder for

the remote control switch, make sure that the locating place is satisfactory

for access service before installing it.

(c) Avoid installing it on a clay wall etc.

Cover

Battery

Holder (remote control switch)

Adjust the installation to vertical attitude.

Avoid projecting the screw head.

Wood screw

ø3.5 × 16

Page 29

219

Air inlet

Service

space

()

Air inlet

Air

Outlet

Note (1) If the wall is higher than 1.2 m or a ceiling is

present, distances larger than indicated in the above

table must be provided.

300

Air inlet Air inlet

Air inlet

Air

Outlet

Air

Outlet

Air

Outlet

80 mm or more

180 mm or more

75 mm or more

80 mm or more

280 mm or more

80 mm or more

280 mm or more

250mm or more

Air inlet

(2) Installation of outdoor unit

(a) Make sure that sufficient space for installation and service is secured.

(b) Fix the leg sections of the unit on a firm base which will not play.

Attach cushion pads, etc. between the unit and the mounting fixtures not to transmit vibration to the building.

(c) Attach a drain elbow, etc. under the drain port of the bottom plate to guide drain water.

(Drain elbow should not be used where days when temperature drops below 0°C continue for several days. Draining may be

disturbed by frozen water.)

(d) When installing the unit at a higher place or where it could be toppled with strong winds, secure the unit firmly with

foundation bolts, wire, etc.

6.5.3 Installation of outdoor unit

(1) Selection of installation location

(Please install with the customer’s consent in a location that follows the conditions listed below.)

(a) Where the following installation space is available, and where air does not gather.

(b) Where rain and sunlight do not directly hit the unit, and where there is enough air circulation.

(c) Also, where the unit cannot be buried by snow.

A location which can sustain the weight of the unit, and where noises and vibrations are not enhanced.

(d) Where blasts of cold or hot air and noise do not bother the neighbors.

(e) Where the unit does not receive heat radiation from other heat sources.

(f) Where there are no obstructions (animals, plants, etc.) to the suction inlet and blowing outlet.

(g) Where water may drain out.

(h) Please avoid the following locations.

1) Where there is constant exposure to harsh winds such as the top floors of a building. Also, locations with exposure to

salty air.

2) Where there are oil splashes, vapor, and smoke.

3) Where there are possibilities of flammable gas leaks.

(i) Installation space (on a flat surface)

If there are no open space to install the unit, and it must be

installed in a location where there are obstructions such as a

wall to the suction inlet and the blowing outlet, please observe the following points. In such cases, please also be aware

that the performance of the cooling/heating system may decline by approximately 10%.

Page 30

220

6.5.4 Electrical wiring

Power source

UNIT A

1212 3

123

UNIT B

UNIT A UNIT B

123

123

Out side

In side

Earth

leakage

breaker

Circuit

breaker

Power source

12

Earth

leakage

breaker

Circuit

breaker

[POWER SUPPLY CODE]

CENELEC code for cables required field cables.

H05RNR3G 4.0

(e) After connecting the power supply wires, make sure to secure the wires with wiring clamps.

(2) Connecting the outside/inside crossover wires

(a) Ensure that crossover wiring is matched with crossover piping in A and B rooms.

(b) The length of the crossover wires should be under 25 m. If it longer than 25 m, signal errors between the units may occur and

cause the operation to shut down.

(c) Use the crossover wires specified below. Different wires may cause heat generation and fire. Do not to use unspecified wires.

[INTERCONNECTING WIRING CODE]

CENELEC code for cables required field cables.

H05RNR4G 1.5

(d) Make sure the terminal numbers on the terminal board of the indoor and outdoor connections are correct.

(e) After connecting the crossover wires to the terminal board, use wiring clamps to secure the wiring.

Use cables for interconnection wiring to avoid loosening of the wires.

CENELEC code for cables Required field cables.

H05 RNR3G4.0 (Example)

H Harmonized cable type

05 300/500 volts

R Natural-and/or synth. rubber wire insulation

N Polychloroprene rubber conductors insulation

R Stranded core

3 Number of conductors

G One conductor of the cable is the earth conductor (yellow/green)

4.0 Section of copper wire (mm

2

)

SCM45ZA

SCM45YA

25A

25A

(1) Connection of the power lines

(a) This multi-type room air conditioner receives its power from outside.

(b) It is necessary to use a single phase 200/240 V 50 Hz for the power supply.

(c) An earth leakage breaker and a circuit breaker must be installed.

Their capacities are listed below.

(d) Use the power supply wires specified below. Different wires may cause heat generation and fire. Do not to use unspecified

wires.

Never bundle, wind or treat the power wires. Otherwise, heat or fire may be generated.

Page 31

221

* If the total length for all the rooms exceeds the length of chargeless refrigerant pipe,

additionally charge with refrigerant according the item 4.

¡The diameter of the refrigerant pipe:

¡Outdoor unit and the total connectable indoor units (class kW):

Liquid side

Gas side

2.2 · 2.5 · 2.8kW

ø 9.52 · t 0.8

3.2 · 4.0kW

ø 12.7 · t 0.8

ø 6.35 · t 0.8

Class of indoor unit (kW)

Diameter of joint pipe

Model

SCM45ZA

SCM45YA

Total of indoor units (class kW)

6.5kW

6.5kW

(2) Connection of refrigerant piping

¡ The service valve corresponding to each indoor unit is as illustrated in the right figure.

¡ Changing the gas side piping size

If the piping connection for the gas side of the outdoor unit does not match the piping size

of the indoor unit, use the parts provided for variable connections to make the joint.

Variable diameter joint (provided): ø9.52 → ø12.7 (1 piece)

[Examples of use of variable diameter joints]

Connection of indoor unit of Class 4.0 to A unit.

¡ Securely fit the copper packing between the service valve and the variable diameter joint to prevent shifting.

¡ Cover the pipes with tape so that dust and sand do not enter the pipe until they are connected.

[Connection of pipes]

¡ When connecting the pipes to the outdoor unit, be careful about the discharge of fluorocarbon gas or oil.

¡ Make sure to match the pipes between the indoor unit and the outdoor unit with the correct service valves.

(1) Preparations

¡ Remove the flare nut (from both

liquid and gas sides).

¡ Remove the flare nut (from both

liquid and gas sides).

¡Fit the removed flare nut to the joint pipe, and then flare it.

A dimensions

Liquid side:

ø 6.35: ø 9 ~ ø 9.5

Gas side:

ø 9.52: ø 13.2 ~ ø 14

ø 12.7: ø 16.2 ~ ø 17

Gas

Gas

side

service

valve

Liquid

Liquid

side

service

valve

Service valve

for room B

Service valve

for room A

ø9.52

ø9.52

ø6.35 pipe

ø12.7 pipe

Indoor unit

4.0 kW class

Liquid side service valve (ø6.35)

Gas side service

valve (ø9.52)

Copper packing Variable diameter joint (ø9.52–ø12.7)

Service valve

for room A

Indoor

Remove

Push

Outdoor

Remove

Push

90+0.5˚

A

A

B

C

Length for one indoor unit

Total length for all rooms

Lower installation spot of the indoor unit A

Upper installation spot of the indoor unit B

Maximum height difference of the indoor units C

Length of chargeless refrigerant pipe

*

Height

difference

Under 25m

Under 30m

Under 15m

Under 10m

Under 25m

20m

6.5.5 Refrigerant Piping

(1) Limit

The maximum permissible length of the refrigerant pipes for the outdoor units, and the maximum permissible height difference for

the outdoor units are as shown below.

Page 32

222

(3) Air purging

(a) Remove the cap on both gas and liquid sides before starting operation.

(b) After completing the operation, do not forget to tighten the cap (gas may leak).

(c) Conduct air purging for all connected indoor units.

(2) Connection

Indoor Outdoor

¡ Secure the nut with a specified tightening

torque to avoid any gas leaks.

¡ Secure the nut with a specified tightening

torque to avoid any gas leaks.

¡ When air purging with a vacuum pump,

secure the nut with a specified tightening

torque to avoid any gas leaks.

¡ When air purging with a refrigerant from

an outdoor unit, just temporarily secure the

nut.

¡ Specified tightening torques are as follows:

Liquid side (ø 6.35): 17mm in width across flat of the flare nut: 15.7-19.6 N·m (1.6-2.0 kgf·m)

Gas side (ø 9.52): 22mm in width across flat of the flare nut: 29.4-39.2 N·m (3.0-4.0 kgf·m)

Gas side (ø 12.7): 24mm in width across flat of the flare nut: 39.2-49.0 N·m (4.0-5.0 kgf·m)

Note: Fully open the service valves (on both liquid and gas sides) after completing air purging

Liquid side

Gas side

Liquid side

Gas side

(4) Additional refrigerant charge

(a) When the total refrigerant pipe length for all the rooms exceeds the length of the uncharged pipe (20m), additional refrigerant

is required.

(If 20m or less, additional charge is not required.)

(b) For this multi type room air conditioner, it is not necessary to charge the refrigerant for the total maximum length in all the

rooms.

*1: Charge amount at the time of shipment.

(c) Ensure that there are no gas leaks from the pipe joints by using a leak detector or soap water.

1 Secure all flare nuts on both indoor and outdoor sides to prevent leaks from

the pipes.

2 Connect the service valves, charge hose, manifold valve and vacuum pump

as shown in the right figure.

3 Fully open the handle Lo for the manifold valve, and pump a vacuum for 15

minutes. Ensure that the meter is indicating -0.1 MPa (-76cmHg).

4 After vacuuming, fully open the service valve (both liquid and gas sides)

with a hexagon wrench.

5 Ensure that there are no gas leaks from the joints in the indoor and outdoor

units.

6 Repeat the above steps 1 ~ 5 for all connected indoor units.

Open

Open

Vacuum pump

Charge hose

Charge hose

Handle Lo

Handle Hi

Manifold

valve

Pressure

gauge

Compound

pressure

gauge

-0.1 MPa

(-76cmHg)

Model

SCM45ZA

SCM45YA

Charged pipe length

(Amount of uncharged

refrigerant) *1

Maximum total pipe length for all rooms

(Maximum amount of refrigerant)

On site additional charge

20g/m1300g 1500g

Procedure

To protect the global environment, use a vacuum pump that do not release flourocarbon gas into the atmosphere.

When a vacuum pump cannot be used due to certain conditions for installation, sufficient refrigerant is available for air

purging with refrigerant for the outdoor unit.

Page 33

223

(5) Heat insulation for joint

Heat insulation for joints

Position so

the slit

comes on top.

Vinyl tape

Cover the joint with

insulation material

for the indoor unit

and tape it.

Tapping screw

Drain hose

Exterior tape

Crossover wires

Pipes

Pipe clamp

Apply exterior tape and shape along

the place where the pipes will be routed. Secure to the wall with a pipe

clamp. Be careful not to damage the

pipes and the wires.

(2) Test run

(a) Carry out the test run for each unit individually. (If 2 units are tested at the same time, wrong wiring and wrong pipe

connections cannot be checked.)

(b) After each individual test, run the units in all the rooms simultaneously and check the units.

(c) Test both the cooling and the heating.

(Three-minute restart preventive timer)

When the air conditioner is restarted or when changing the operation, the unit will not start operating for approximately 3

minutes. This is to protect the unit and it is not a malfunction.

Beware of wrong connections in refrigerant piping and wiring

¡ Make sure to match the piping and wiring from each unit to the outdoor unit.

¡ Be careful because if connections are wrong, normal operation cannot be achieved and may damage the compressor.

[Correct connections] [Example of wrong connections]

A unit

A

B

B unit

Outdoor

unit

Indoor unit

Indoor unit

Piping

Wiring

A unit

A

B

B unit

Outdoor

unit

Installation test check points

Check the following points again after completion of the installation, and before turning on the power. Conduct a test

run again and ensure that the unit operates properly. At the same time, explain to the customer how to use the unit and

how to take care of the unit following the instruction manual.

After installation Test run

The power supply voltage is correct as the rating.

No gas leaks from the joints of the service valve.

Power cables and crossover wires are securely inserted and fixed

to the terminal board.

Each indoor and outdoor unit is properly connected (no wrong

wiring or piping).

Service valve is fully open.

Refrigerant has been additionally charged (when the total pipe