Mitsubishi Electric SEZ-KA35, SEZ-KA50, SEZ-KA60, SEZ-KA71VA Installation Manual

Air-Conditioners

SEZ-KA35, KA50, KA60, KA71VA

INSTALLATION MANUAL

For safe and correct use, please read this manual and outdoor unit installation manual thoroughly before

installing the air-conditioner unit.

FOR INSTALLER

E°XEIPI¢IO O¢H°IøN E°KATA™TA™H™

°И· ЫˆЫЩ‹ О·И ·ЫК·П‹ ¯Ъ‹ЫЛ, ‰И·‚¿ЫЩВ ЪФЫВОЩИО¿ ·˘Щfi ЩФ ВБ¯ВИЪ›‰ИФ, О·ıТ˜ О·И ЩФ ВБ¯ВИЪ›‰ИФ

ВБО·Щ¿ЫЩ·ЫЛ˜ ЩЛ˜ ВНˆЩВЪИО‹˜ МФУ¿‰·˜, ЪИУ ·fi ЩЛУ ВБО·Щ¿ЫЩ·ЫЛ ЩЛ˜ ÌÔÓ¿‰·˜ ОПИМ·ЩИЫЩИОФ‡.

POUR L’INSTALLATEUR

English

∂ППЛУИО¿

Contents

1. Safety precautions ................................................................................... 2

2. Selecting the installation location ............................................................. 2

3. Installation diagram & Accessories .......................................................... 3

4. Indoor unit installation .............................................................................. 4

5. Refrigerant piping work ............................................................................ 4

1. Safety precautions

• Please report to or take consent by the supply authority before connection

to the system.

• Be sure to read “Safety precautions” before installing the air conditioner.

• Be sure to observe the cautions specified here as they include important

items related to safety.

• The indications and meanings are as follows.

Warning:

Could lead to death, serious injury, etc.

Warning:

• Do not install it by yourself (customer).

Incomplete installation could cause injury due to fire, electric shock, the unit

falling or leakage of water. Consult the dealer from whom you purchased the

unit or special installer.

• Install the unit securely in a place which can bear the weight of the unit.

When installed in an insufficient strong place, the unit could fall causing injured.

• Use the specified wires to connect the indoor and outdoor units securely and

attach the wires firmly to the terminal board connecting sections so the stress

of the wires is not applied to the sections.

Incomplete connecting and fixing could cause fire.

• Do not use intermediate connection of the power cord or the extension cord

and do not connect many devices to one AC outlet.

It could cause a fire or an electric shock due to defective contact, defective

insulation, exceeding the permissible current, etc.

• Check that the refrigerant gas does not leak after installation has completed.

Caution:

• Perform grounding.

Do not connect the ground wire to a gas pipe, water pipe arrester or telephone

ground wire. Defective grounding could cause an electric shock.

• Do not install the unit in a place where an inflammable gas leaks.

If gas leaks and accumulates in the area surrounding the unit, it could cause

an explosion.

• Install a ground leakage breaker depending on the installation place (where it

is humid).

If a ground leakage breaker is not installed, it could cause an electric shock.

6. Drainage piping work ............................................................................... 6

7. Electrical work .......................................................................................... 6

8. Air filter installation ................................................................................... 9

9. Duct work ............................................................................................... 11

10. Test run .................................................................................................. 11

Caution:

Could lead to serious injury in particular environments when operated incorrectly.

• After reading this manual, be sure to keep it together with the instruction

manual in a handy place on the customer’s site.

: Indicates a part which must be grounded.

Warning:

Carefully read the labels affixed to the main unit.

• Perform the installation securely referring to the installation manual.

Incomplete installation could cause a personal injury due to fire, electric shock,

the unit falling or leakage of water.

• Perform electrical work according to the installation manual and be sure to

use an exclusive circuit.

If the capacity of the power circuit is insufficient or there is incomplete electrical work, it could result in a fire or an electric shock.

• Attach the electrical part cover to the indoor unit and the service panel to the

outdoor unit securely.

If the electrical part cover in the indoor unit and/or the service panel in the

outdoor unit are not attached securely, it could result in a fire or an electric

shock due to dust, water, etc.

• Be sure to use the part provided or specified parts for the installation work.

The use of defective parts could cause an injury or leakage of water due to a

fire, an electric shock, the unit falling, etc.

• Ventilate the room if refrigerant leaks during operation.

If the refrigerant comes in contact with a flame, poisonous gases will be released.

• Perform the drainage/piping work securely according to the installation

manual.

If there is a defect in the drainage/piping work, water could drop from the unit

and household goods could be wet and damaged.

• Fasten a flare nut with a torque wrench as specified in this manual.

When fastened too tight, a flare nut may broken after a long period and cause

a leakage of refrigerant.

2. Selecting the installation location

2.1. Indoor unit

• Where airflow is not blocked.

• Where cool air spreads over the entire room.

• Where it is not exposed to direct sunshine.

• At a distance 1 m or more away from your TV and radio (to prevent picture from

being distorted or noise from being generated).

• In a place as far away as possible from fluorescent and incandescent lights (so the

infrared remote control can operate the air conditioner normally).

2

• Where the air filter can be removed and replaced easily.

Warning:

Mount the indoor unit into a ceiling strong enough to withstand the weight of

the unit.

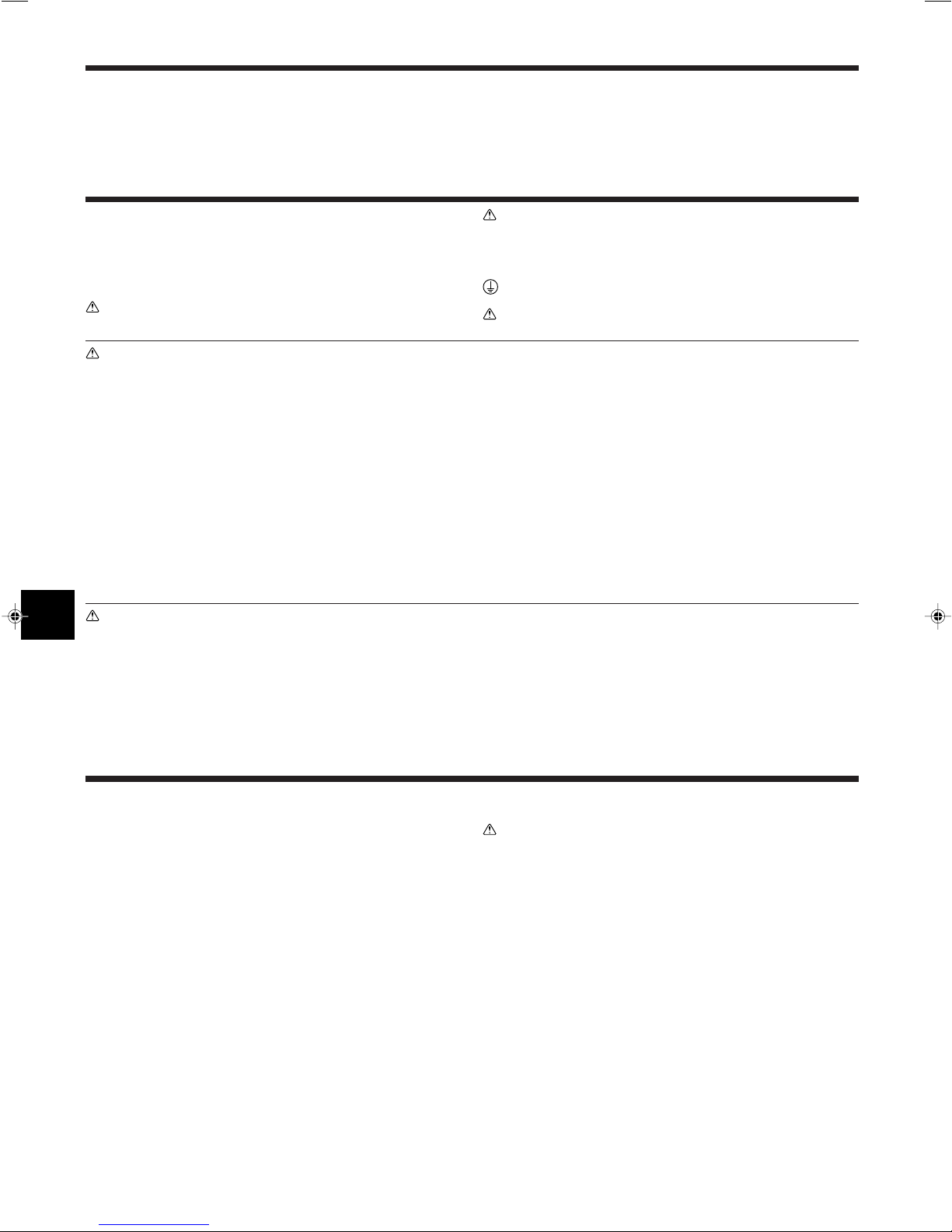

3. Installation diagram & Accessories

42 930

7×100=700100

29

12.5 120

240

77.5

955

21525

H

J

I

G

J

50

27

1016

7×100=700

880

10040

(10)

50

60

350

38

680

50

1000

50

1070

150

77

450

150

600

700

2

1

3

0

3

5

6

9

24012.5

120

25 215

39

77.5

100 7×100=700

955

93051

J

J

8

3

2

5

7

A

(1070)

270

30

1100

2575

32.5

(10) 50

94 60

350

100

108

25

20

170

A

F

B

C

D

2

E

■ SEZ-KA35/KA50/KA60/KA71VA

Air inlet (rear side) dimensions

24-ø2.9 holes

9×2-ø2.9 holes

20 or more

A

Air inlet (bottom side) dimensions

(mm)

PLATE (A)

24-ø2.9 holes

3.1. Indoor unit (Fig. 3-1)

1 Air inlet (rear side) *Select the either back side or bottom side

2 Electrical parts box

3 Suspension bolt pitch

5 Access door

6 Service space (It is necessary to maintain a working service area from the ceiling.)

7 Air inlet (bottom side) *Select the either back side or bottom side

8 Suspension bolt M10 or 3/8 (procure locally)

9 Air outlet duct flange

0 Air outlet

A Refrigerant pipe (gas)

AB

1

2

Fig. 3-2

3

C

4

2×2-ø2.9 holes

Fig. 3-1

B Refrigerant pipe (liquid)

C Wiring entry

D Terminal block

E Drain plug R1

F Air outlet duct flange

G In case of bottom side suction, mount the PLATE (A) on the rear side.

H After installation, remove the transportation suppor t PLATE (B).

I PLATE (B) × 2

J Inlet size

3.2. Checking the indoor unit accessories (Fig. 3-2)

Check that the indoor unit is equipped with the following parts and accessories:

A Refrigerant pipe parts

1 Pipe cover (for refrigerant piping joint)

Small diameter × 1

Large diameter × 1

2 Bands for temporary tightening of pipe cover × 4

B Remote controller parts

3 Parts contained in the cardboard box × 1

Check the contents and read the explanations provided.

C Air filter parts

4 Parts contained in the bag × 1

Check the contents and read the explanations provided.

Refrigerant and drainage pipe sizes

Model SEZ-KA35VA SEZ-KA50VA SEZ-KA60VA SEZ-KA71VA

Refrigerant Liquid

pipe Gas

Drainage pipe Hard PVC pipe : OD ø26 (1")

OD ø6.35 (1/4") OD ø6.35 (1/4") OD ø6.35 (1/4") OD ø9.52 (3/8")

OD ø9.52(3/8") OD ø12.7 (1/2") OD ø15.88 (5/8") OD ø15.88 (5/8")

3

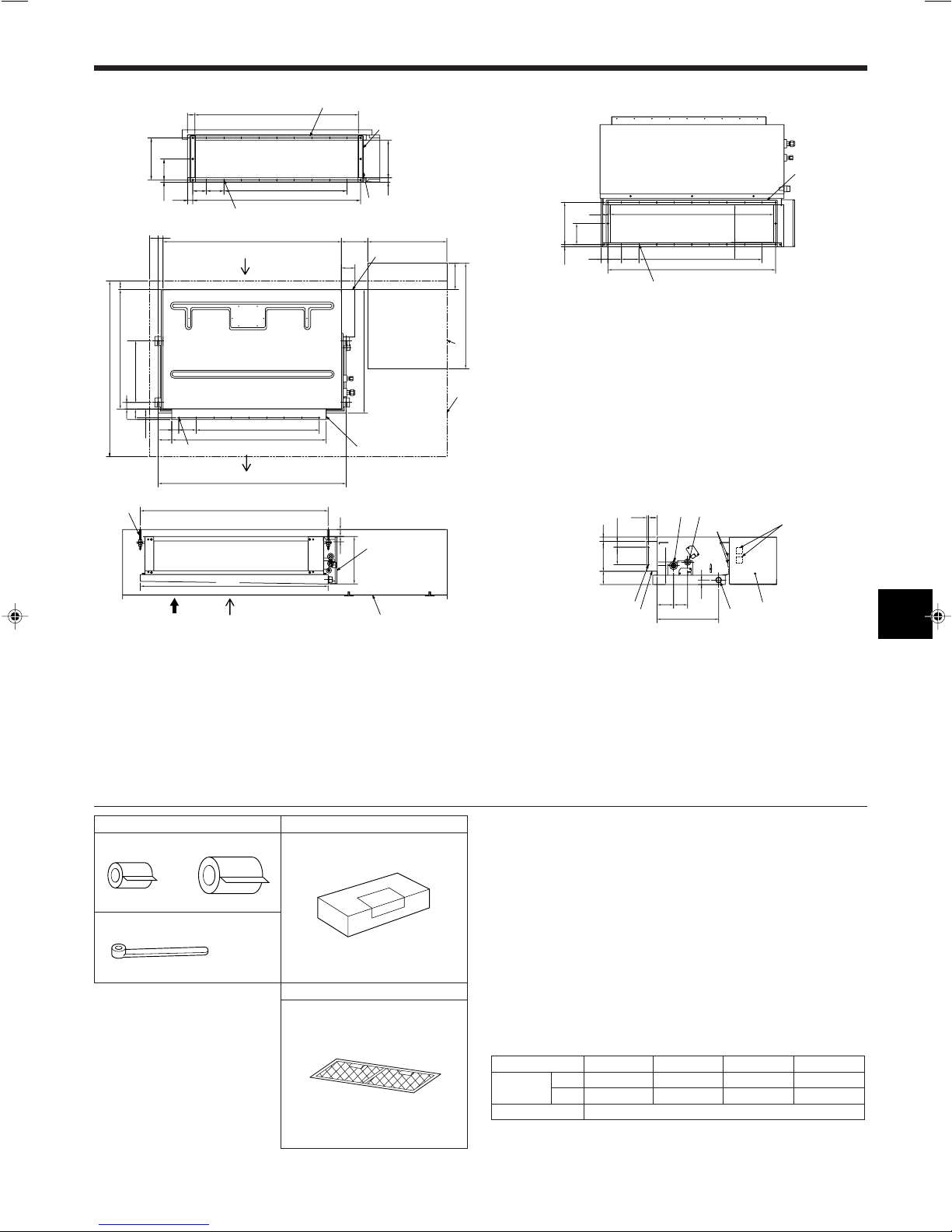

4. Indoor unit installation

G

E

F

ab

b

ce

d

B

A

A

A

B

C

D

350

1070

SEZ-KA35:ø9.52

SEZ-KA50:ø12.7

SEZ-KA60:ø15.88

SEZ-KA71:ø15.88

SEZ-KA35:ø6.35

SEZ-KA50:ø6.35

SEZ-KA60:ø6.35

SEZ-KA71:ø9.52

1

2

Fig. 4-1

Fig. 4-2

4.1. Suspension Structure (Give site of suspension

strong structure.)

4.1.1. Wooden structure (Fig. 4-1)

• Select tie beam (one-story houses) or second-floor girder (two-story houses) as

reinforcement member.

• Use sturdy beams of at least 6 cm square for beam pitch of 90 cm or less or of at

least 9 cm square for beam pitch of 90-180 cm.

A Ceiling

B Rafter

C Beam

D Roof beam

4.1.2. Ferroconcrete structures (Fig. 4-2)

Secure the suspension bolts using the method shown, or use steel or wooden hangers, etc. to install the suspension bolts.

E Use inserts rated at 100-150 kg each (procure locally)

F Suspension bolts M10 (3/8") (procure locally)

G Steel reinforcing rod

4.1.3. Installing the suspension bolts

• Check the pitch of the suspension bolts.

• Use the ø10 (3/8") suspension bolts (×4, procure locally).

• Adhere strictly to the length of the suspension bolts.

4.2. Suspending the unit (Fig. 4-3)

Direct suspension method:

Raise the unit and line it up with the suspension bolts, then secure it using both

nuts.

a Air outlet

b Air intake (selecting the either back side or bottom side.)

c Washer (procure locally)

d Nuts (procure locally)

e Suspension bolts (procure locally)

Fig. 4-3

Fig. 4-4

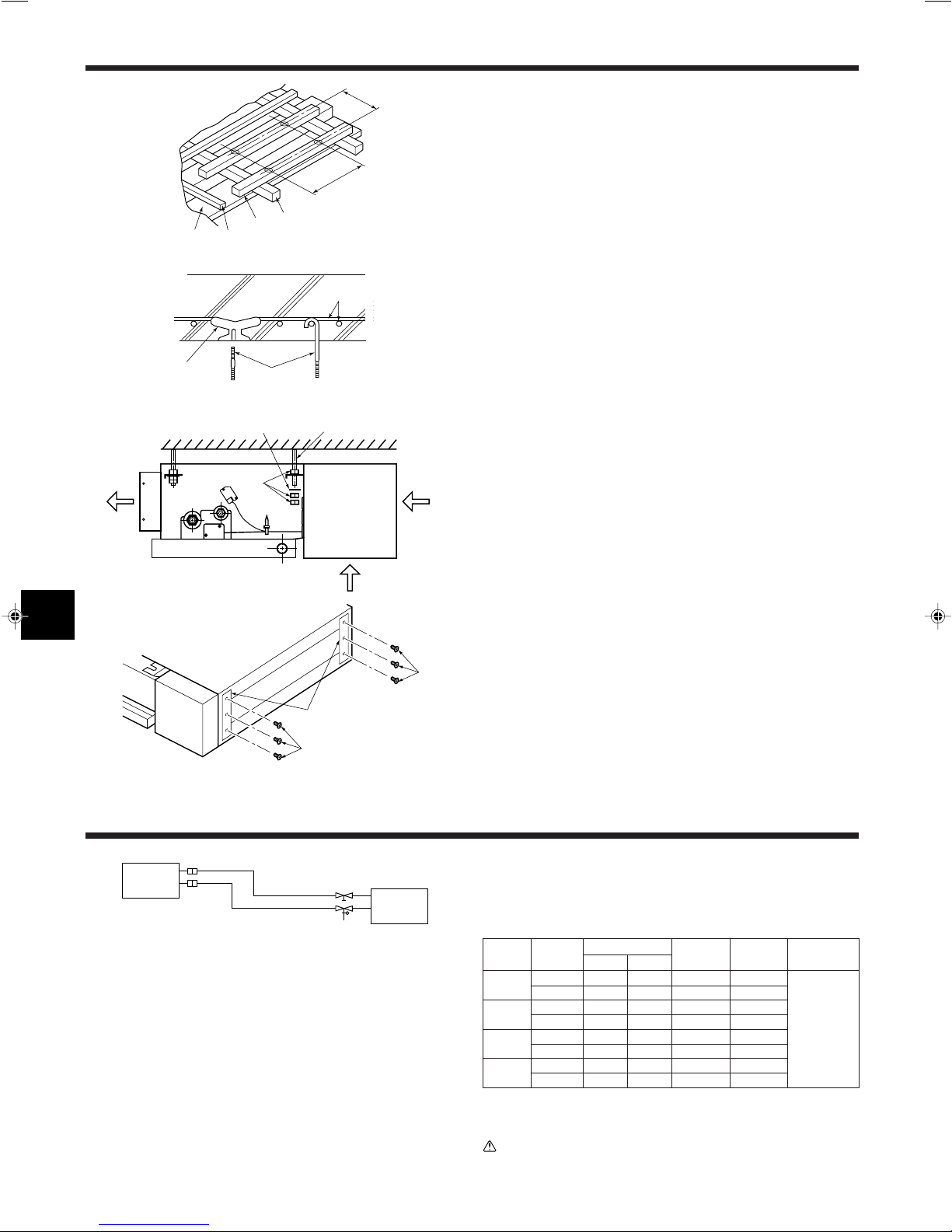

5. Refrigerant piping work

Fig. 5-1

1 Indoor unit

2 Outdoor unit

4.3. Transportation support removal (Fig. 4-4)

After installation, completely remove the transportation support because this part

should only be used during transportation.

A 3 screws

B Transportation support

5.1. Refrigerant pipe (Fig. 5-1)

Piping preparation

• Refrigerant pipes of 3, 5, 7, 10 and 15 m are available as optional items.

(1) Table below shows the specifications of pipes commercially available.

Model

SEZKA35VA

SEZKA50VA

SEZKA60VA

SEZKA71VA

Pipe

For liquid

For gas

For liquid

For gas

For liquid

For gas

For liquid

For gas

Outside diameter

mm inch

6.35 1/4

9.52 3/8

6.35 1/4

12.7 1/2

6.35 1/4

15.88 5/8

9.52 3/8

15.88 5/8

Min. wall

thickness

0.8 mm

0.8 mm

0.8 mm

0.8 mm

0.8 mm

1.0 mm

0.8 mm

1.0 mm

Insulation

thickness

8 mm

8 mm

8 mm

8 mm

8 mm

8 mm

8 mm

8 mm

Insulation

material

Heat resisting

foam plastic

0.045 specific

gravity

4

(2) Ensure that the 2 refrigerant pipes are well insulated to prevent condensation.

(3) Refrigerant pipe bending radius must be 10 cm or more.

Caution:

Using careful insulation of specified thickness. Excessive thickness prevents

storage behind the indoor unit and smaller thickness causes dew drippage.

Loading...

Loading...