Page 1

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF

˚C

CHECK

CHECK MODE

FILTER

TEST RUN

FUNCTION

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

TEMP.

TECHNICAL & SERVICE MANUAL

No. OC303

Series SEZ

Ceiling Concealed

R410A

Indoor unit

[Model names] [Service Ref.]

SEZ-A12AR SEZ-A12AR.TH

SEZ-A18AR SEZ-A18AR.TH

SEZ-A24AR SEZ-A24AR.TH

•This manual does not cover

the following outdoor units.

When servicing them,

please refer to the service

manual No.OC304 and this

manual in a set.

CONTENTS

1. PART NAMES AND FUNCTIONS········2

2. SPECIFICATIONS·································4

3. OUTLINES AND DIMENSIONS············7

Model name

indication

4. WIRING DIAGRAM ·······························8

5.

REFRIGERANT SYSTEM DIAGRAM

········9

6. TROUBLESHOOTING························10

7. DISASSEMBLY PROCEDURE ···········17

INDOOR UNIT

8. PARTS LIST········································20

9. OPTIONAL PARTS·····························22

WIRED REMOTE

CONTROLLER

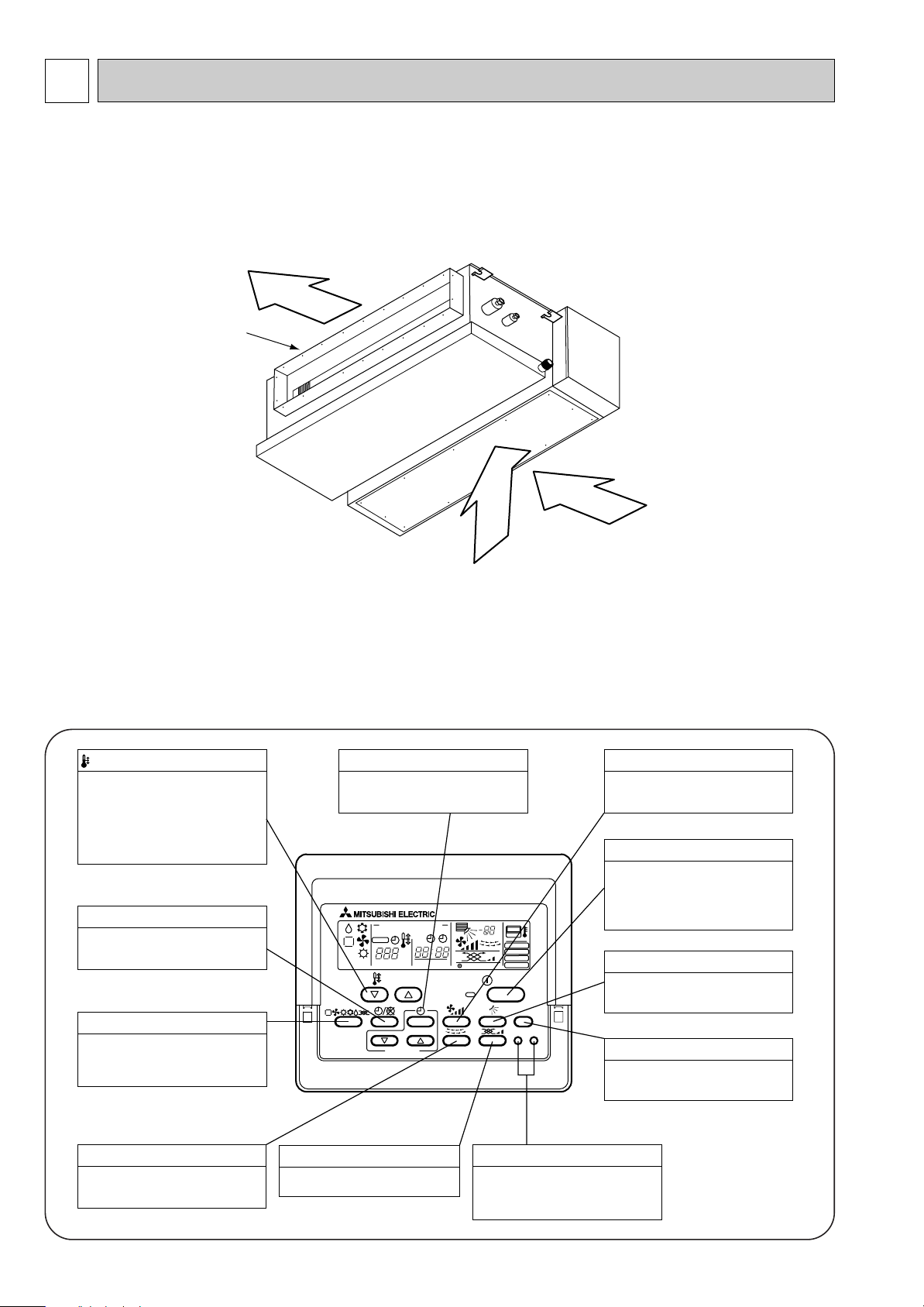

Page 2

1

Air outlet duct flange

Air outlet

Air inlet

(Selecting the either back side or bottom side)

PAR-20MAA

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF

˚C

CHECK

CHECK MODE

FILTER

TEST RUN

FUNCTION

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

FILTER

CHECK TEST

TEMP.

TIMER SET

This sets the ventilation fan speed.

VENTILATION button

Press this button to switch the cooling,

electronic dry (dehumidify), automatic

and heating modes.

OPERATION SWITCH button

This sets the room temperature. The

temperature setting can be performed

in 1: units

Setting range

Cooling 19: to 30:

Heating 17: to 28:

TEMP. ADJUSTMENT button

This switches between continuous

operation and the timer operation.

TIMER button

This switches between the operation

and stop modes each time it is pressed.

The lamp on this button lights during

operation.

ON/OFF button

Only press this button to perform an

inspection check or test operation.

Do not use it for normal operation.

CHECK-TEST RUN button

This switch the horizontal fan motion

ON and OFF.

LOUVER button

AIR DIRECTION button

This resets the filter service indication

display

FILTER button

This sets the current time, start time

and stop time.

TIME SETTING button

This sets the ventilation fan speed.

FAN SPEED button

(Not available for this model.)

(Not available for this model.)

This adjusts the vertical angle of the

ventilation.

(Not available for this model.)

PART NAMES AND FUNCTIONS

Indoor Unit

SEZ-A12AR.TH

SEZ-A18AR.TH

SEZ-A24AR.TH

Wired remote controller

On the controls are set, the same operation mode can be repeated by simply pressing the ON/OFF button.

● Operation buttons

2

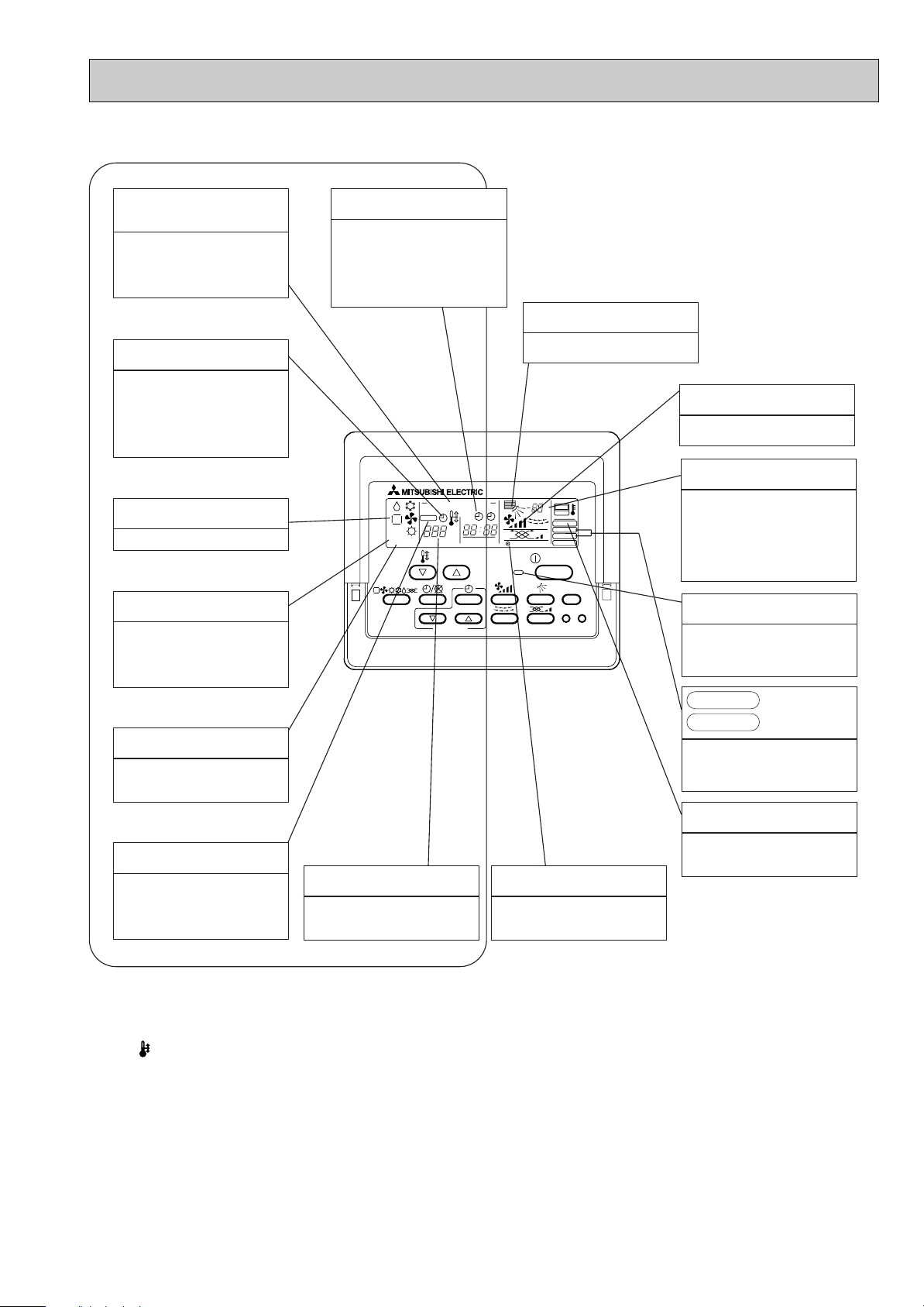

Page 3

● Display

PAR-20MAA

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF

˚C

CHECK

CHECK MODE

FILTER

TEST RUN

FUNCTION

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

FILTER

CHECK TEST

TEMP.

TIMER SET

CENTRALLY

CONTROLLED display

This indicates when the unit is con-

trolled by optional features such as

central control type remote controller.

TIMER display

This indicates when the continuous

operation and time operation modes

are set.

It also display the time for the timer

operation at the same time as when

it is set.

OPERATION MODE display

This indicates the operation mode.

STANDBY display

The [STANDBY] symbol is only dis-

played from the time the heating

operation starts unit the heated air

begins to blow.

DEFROST display

This indicates when the defrost oper-

ation is performed.

CLOCK display

The current time , start time and stop

time can be displayed in ten second

intervals by pressing the time switch

button. The start time or stop time is

always displayed during the timer

operation.

In this display example on the bottom left, a condition where all display lamps light is shown for explanation purposes although this differs

from actual operation.

AIR DIRECTION display

This displays the air direction.

(Not available for this model.)

AIR SPEED display

The selected fan speed is displayed.

ROOM TEMPERATURE display

The temperature of the suction air

is displayed during operation. The

display range is 8°C to 39°C. The

display flashes 8°C when the actual

temperature is less than 8°C and

flashes 39°C when the actual temperature is greater than 39°C.

Operation lamp

This lamp lights during operation,

goes off when the unit stops and

flashes when a malfunction occurs.

This display lights in the check mode

or when a test operation is performed.

CHECK MODE

TEST RUN

display

FILTER display

CHECK display

This indicates when a malfunction

has occurred in the unit which should

be checked.

SET TEMPERATURE display

This displays the selected setting

temperature.

Caution

● Only the Power display lights when the unit is stopped and power supplied to the unit.

● When the central control remote control unit, which is sold separately, is used the ON-OFF button, operation switch button

and TEMP. adjustment button do not operate.

● “NOT AVAILABLE” is displayed when the Air speed button are pressed.This indicates that this room unit is not equipped

with the fan direction adjustment function and the louver function.

● When power is turned ON for the first time, it is normal that “H0” is displayed on the room temperature indication (For max.

2minutes). Please wait until this “H0” indication disappear then start the operation.

POWER display

This lamp lights when electricity is

supplied to the unit.

This lamp lights when the filter need

to be cleaned.

3

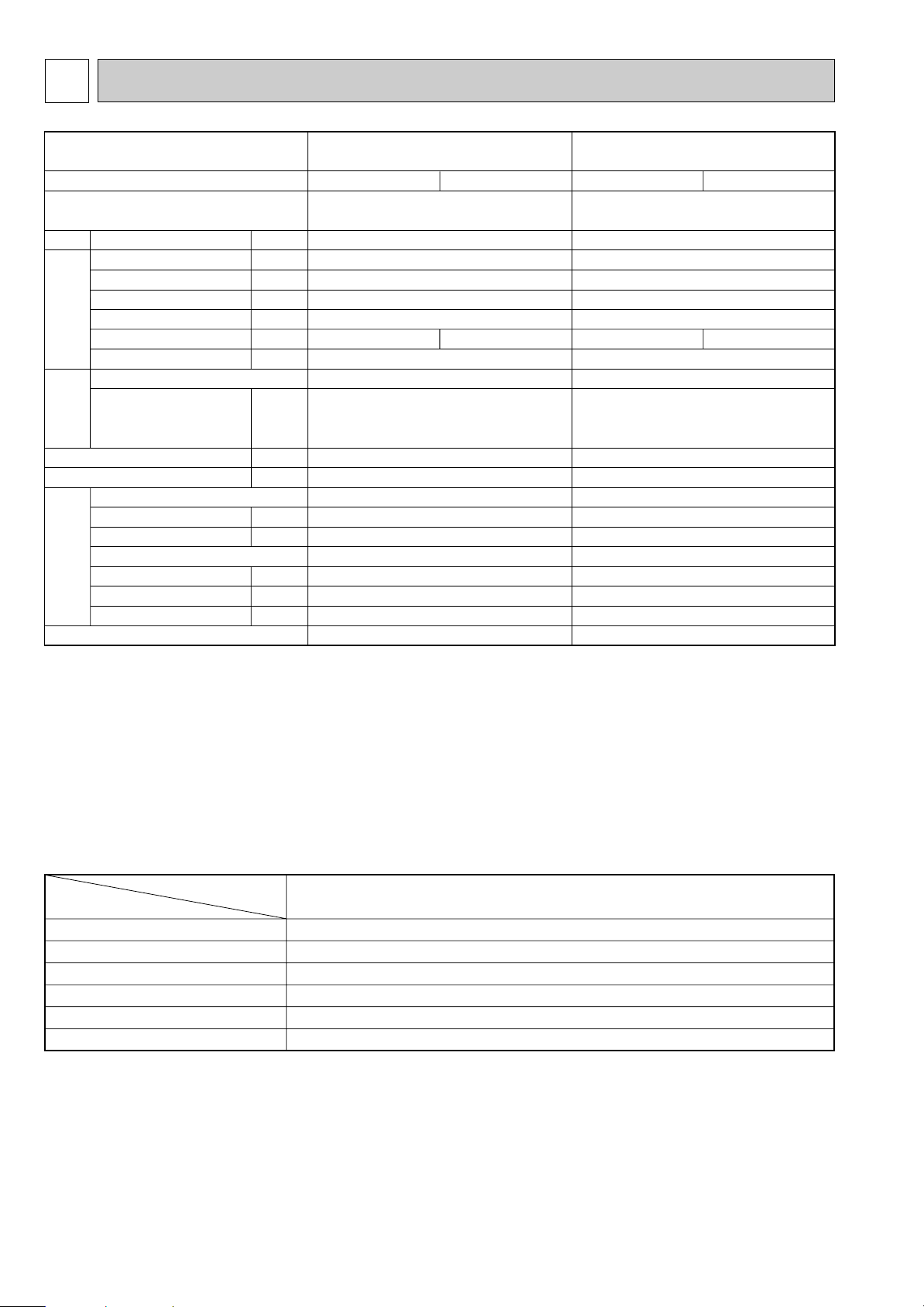

Page 4

2

SEZ-A12AR.TH SEZ-A18AR.TH

Indoor model

Function

Power supply

Single phase

230V, 50Hz

780/600

10

0.21

33

—

0.21

PK6V19-EF

1100o270o700

33.5

1

35/30

770/630

3

10

10

10

PAR-20MAA

Cooling

94

Heating

95

Single phase

230V, 50Hz

1020/720

20

0.27

49

—

0.27

PK6V32-EF

1100o270o700

33.5

1

39/31

840/640

3

10

10

10

PAR-20MAA

Cooling

97

Heating

98

Air flow (High/Low)

Power outlet

Running current ✽1

Power input Rated frequency

Auxiliary heater

Power factor ✽1

Fan motor current ✽1

Model

Winding

resistance (at20:)

Dimensions WoHoD

Weight

Air direction

Sound level (High/Low)

Fan speed (High/Low)

Fan speed regulator

Thermistor RT11 (at 25:)

Thermistor RT12 (at 25:)

Thermistor RT13 (at 25:)

Remote controller model

K /h

A

A

W

A(kW)

%

A

"

mm

kg

dB(A)

rpm

k"

k"

k"

Electrical

data

Fan

motor

Special remarks

Capacity

WHT-BLK : 251.4 BLK-BLU : 19.9

BLU-YLW : 26.5 YLW-BRN : 13.2

BRN-RED : 50.0

WHT-BLK : 161.9 BLK-BLU : 50.3

BLU-YLW : 18.7 YLW-BRN : 8.0

BRN-RED : 39.2

SEZ-A12/18AR.TH : 2.5+ 440V SEZ-A24AR.TH : 3.0+ 440V

250V 3.15A

ERZV10D471

POWER SUPPLY : 3P TO OUTDOOR UNIT : 4P

G4A-1A-E-PS 12V DC

145:i2:

INDOOR UNIT

Item

Model

Indoor fan capacitor

Fuse

Varistor

Terminal block

Contactor

Indoor fan motor thermal fuse

SEZ-A12AR.TH SEZ-A18AR.TH SEZ-A24AR.TH

(C1)

(FUSE)

(ZNR1)

(TB)

(52C)

SPECIFICATIONS

NOTE : Test conditions are based on ISO 5151

Cooling : Indoor D.B. 27: W.B. 19:

Outdoor D.B. 35: W.B. 24:

Heating : Indoor D.B. 20: W.B. 5:

Outdoor D.B. 7: W.B. 6:

Refrigerant piping length (one way): 5m

✽1 Measured under rated operating frequency.

Specifications and rating conditions of main electric parts

4

Page 5

Indoor model

SEZ-A24AR.TH

Function

Power supply

Capacity

NOTE : Test conditions are based on ISO 5151

Air flow (High/Low)

Power outlet

Running current ✽1

Power input Rated frequency

Auxiliary heater

Electrical

data

Power factor ✽1

Fan motor current ✽1

Model

Winding

Fan

motor

resistance (at20:)

Dimensions WoHoD

Weight

Air direction

Sound level(High/Low)

Fan speed(High/Low)

Fan speed regulator

Thermistor RT11 (at 25:)

Thermistor RT12 (at 25:)

Special remarks

Thermistor RT13 (at 25:)

Remote controller model

Cooling : Indoor D.B. 27: W.B. 19:

Outdoor D.B. 35: W.B. 24:

Heating : Indoor D.B. 20: W.B. 15:

Outdoor D.B. 7: W.B. 6:

Refrigerant piping length (one way): 5m

✽1 Measured under rated operating frequency.

K /h

A

A

W

A(kW)

%

A

"

mm

kg

dB(A)

rpm

k"

k"

k"

WHT-BLK : 101.1 BLK-BLU : 56.1

BLU-YLW : 14.7 YLW-BRN : 6.7

BRN-RED : 28.2

Cooling

98

Heating

Single phase

230V, 50Hz

1200/720

20

0.34

64

—

98

0.34

PK6V50-EF

1100o270o700

33.5

1

43/32

890/660

3

10

10

10

PAR-20MAA

5

Page 6

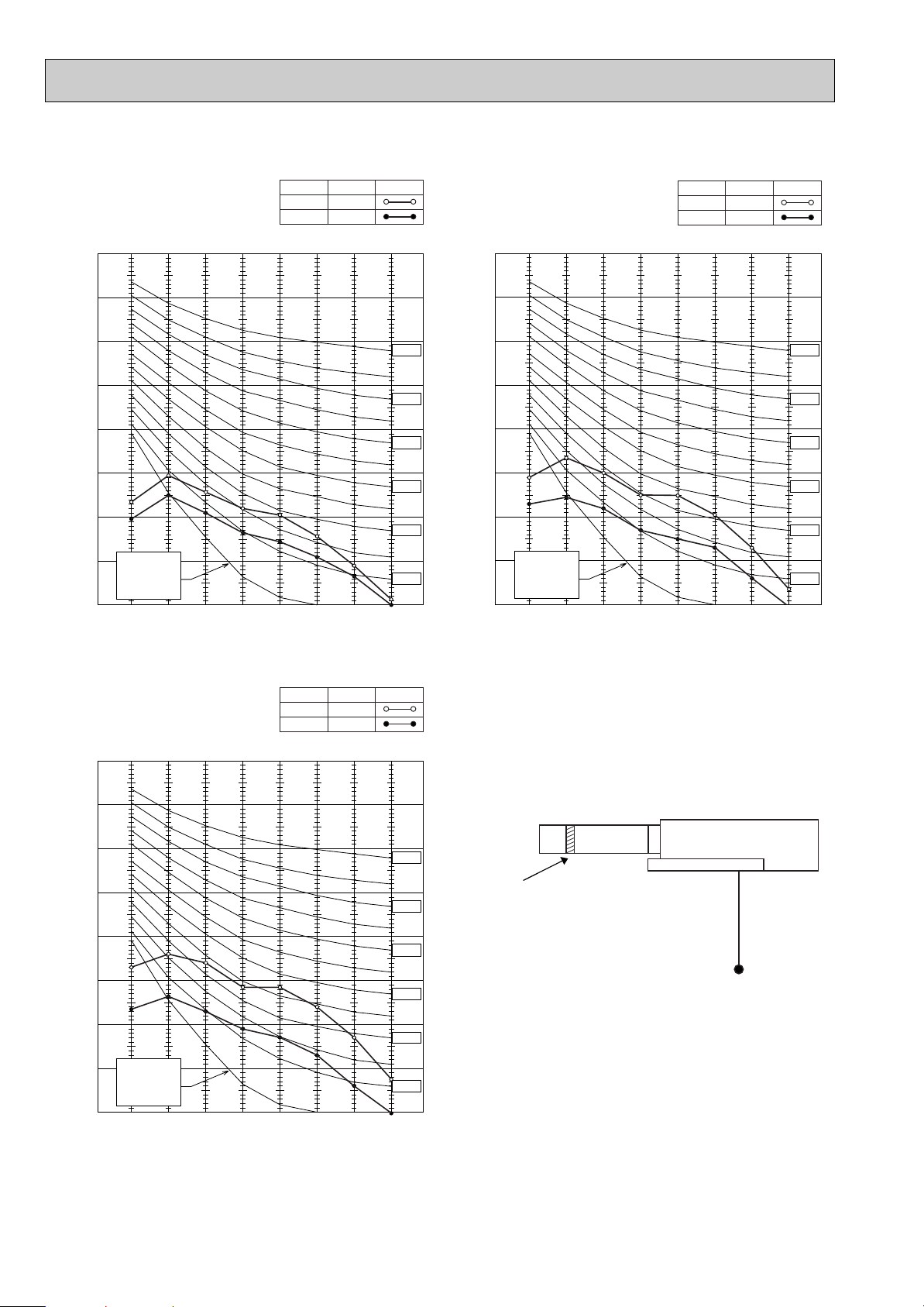

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

SEZ-A18AR.TH

Hi

Lo

39

SPL(dB)

31

LINE

<50Hz>

NOTCH

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

SEZ-A12AR.TH

Hi

Lo

35

SPL(dB)

30

LINE

<50Hz>

NOTCH

NOISE CRITERION CURVES

UNIT

External static

pressure 30Pa

1.5m

MICROPHONE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

TERESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

OCTAVE BAND SOUND PRESSURE LEVEL, dB (0 dB = 0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

SEZ-A24AR.TH

Hi

Lo

43

SPL(dB)

32

LINE

<50Hz>

NOTCH

NOTE: The sound level is measured in an anechoic room where echoes are few, when compressor stops. The sound

may be bigger than displayed level under actual installation condition by surrounding echoes. The sound level

can be higher by about 2 dB than the displayed level during cooling and heating operation.

6

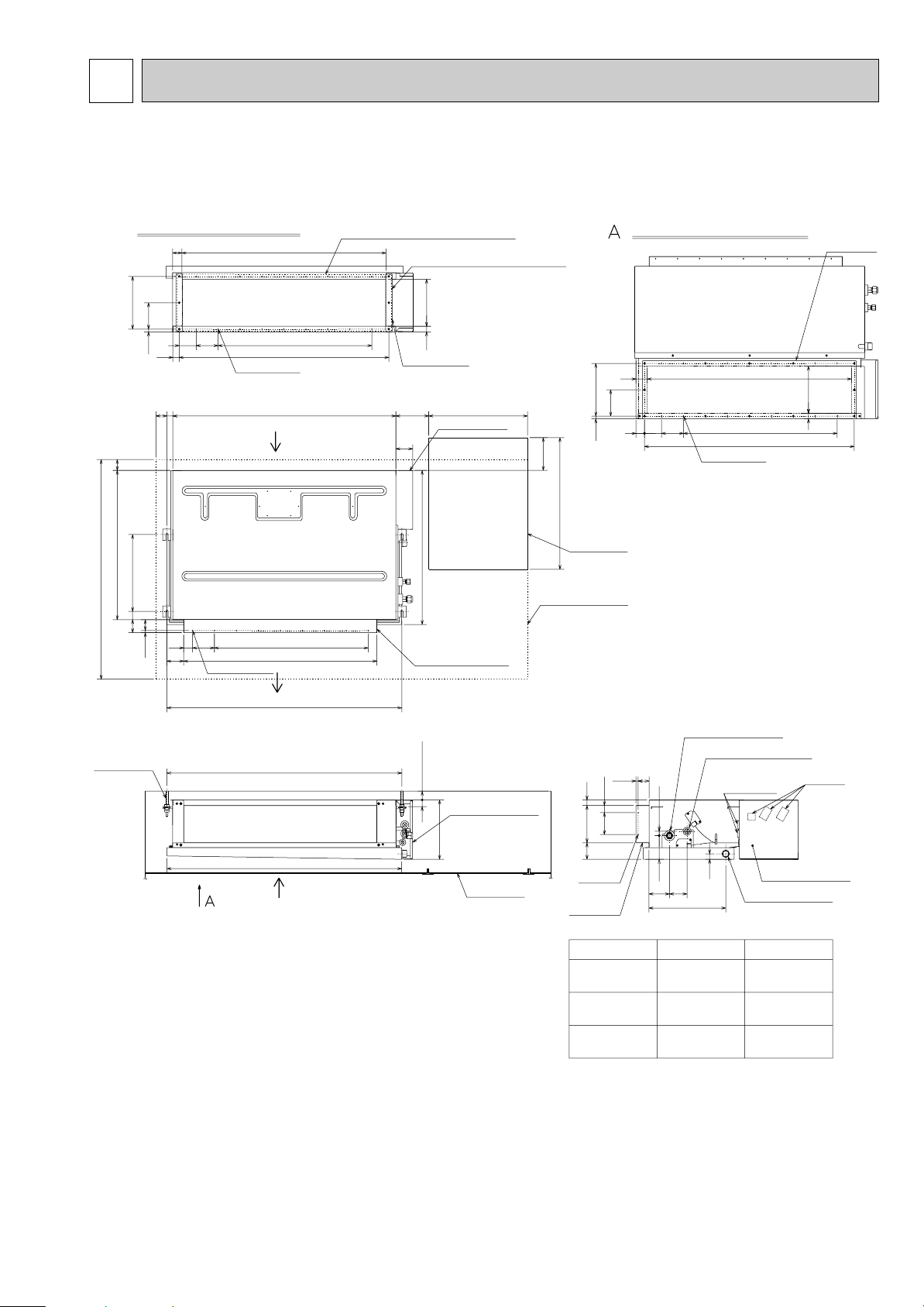

Page 7

3

42 930

Terminal

block

3/8F

flared connection

[9.52mm

[6.35mm

flared connection

1/4F

SEZ-A24AR

SEZ-A18AR

Air outlet

duct flange

Air outlet duct flange

51

25

930

(Inlet size)

PLATE (B) o2

After installation, remove the

transportation support PLATE (B).

PLATE (A)

In case of bottom side suction,

mount the PLATE (A) on the rear side.

39

955

7

o100=700

100

77.5

(Inlet size)

215

Air inlet (bottom side) dimensions

w Select the either

back side or bottom side.

Air inlet (rear side) dimensions

w Select the either back side or bottom side.

29

955

7

o100=70010077.5

240

120

12.5

25

(Inlet size)

(Inlet size)

Air inlet

(bottom side)

24-[2.9 holes

24-[2.9 holes

215

120

12.5 240

450

1/4F

flared connection

[6.35mm

(It is necessary to

maintain a working

service area from

the ceiling.)

150

(10) 50

Electrical parts box

2o2-[2.9

holes

50 880

7

o100=700

100

40

9o2-[2.9 holes

100 32.5

75 170 25

(10) 50

flared connection

[15.88mm

5/8F

flared connection

1/2F

[12.7mm

Refrigerent pipe

(gas)

Refrigerent pipe

(liquid)

1/4F

flared connection

[6.35mm

SEZ-A12AR

Models

1000

50

50

27

1016

77

150

600

Air inlet

(rear side)

Electrical parts box

700

Access door

Service space

Air outlet

38

60

680

350

Suspension bolt pitch

Suspension bolt pitch

1070

Suspension bolt

M10 or 3/8

(procure locally)

(Suspension bolt pitch)

Electrical parts box

(1070)

1100

20 or more

270

30

Access door

Wiring entry

Refrigerent pipe (liquid)

Refrigerent pipe (gas)

Drain plug R1 male

108

20

94 80

25

350

OUTLINES AND DIMENSIONS

SEZ-A12AR.TH

SEZ-A18AR.TH

SEZ-A24AR.TH

Unit : mm

7

Page 8

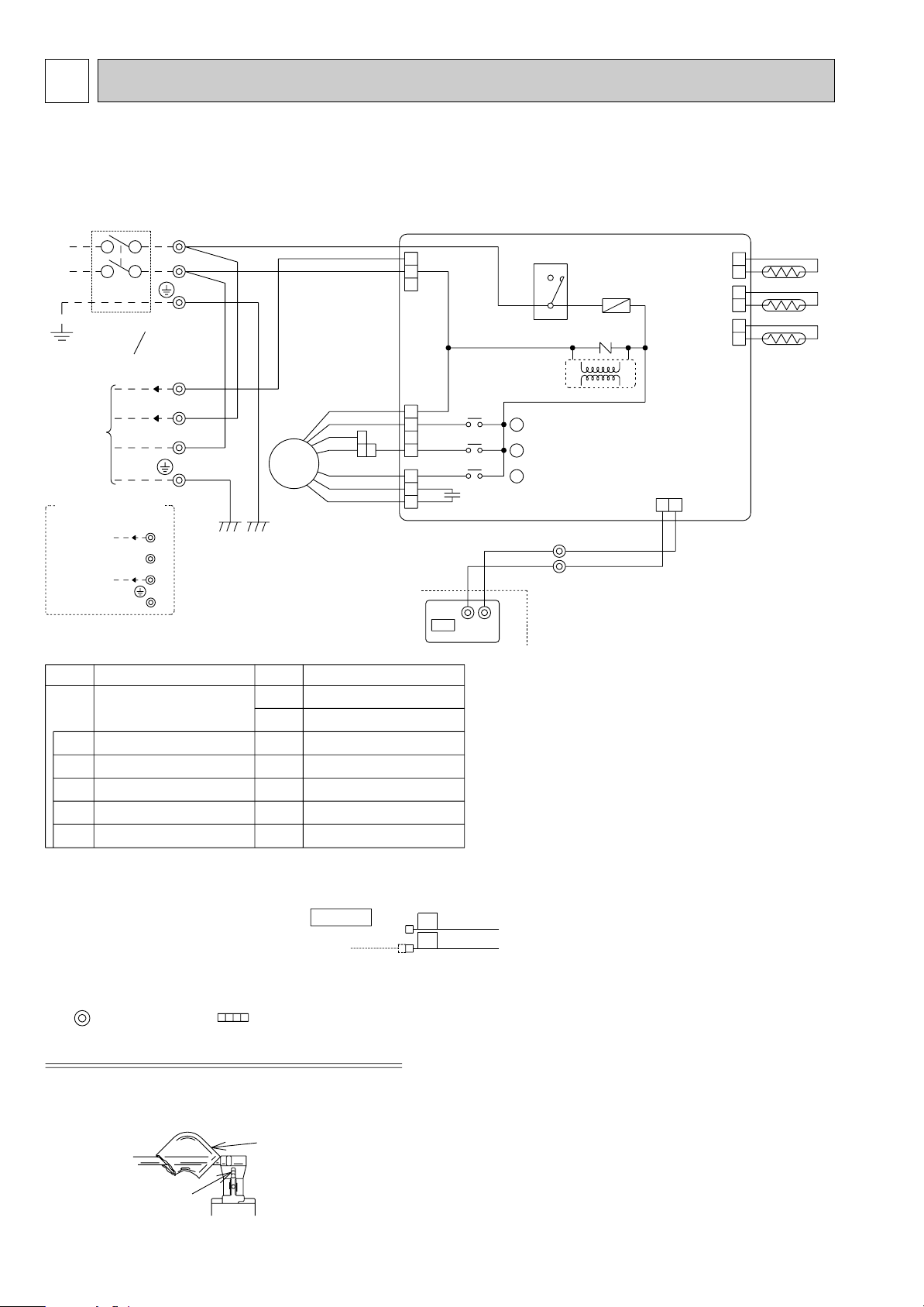

4

FOR A18/24 (1:1 SYSTEM)

OR MULTI SYSTEM

FOR A12

(1:1 SYSTEM)

X5

X4

X2

REMOTE CONTROLLER

BOARD

R.B

RT12

RT11

I.B

RT13

FUSE

X4

X2

ZNR1

52C

4

3

w

TRANS

DC13.1V

BLK

C1

MF

X5

N

w BLU

CIRCUIT BREAKER

TB

GRN/YLW

N

w WHT

GRN/YLW

w BLU

TO OUTDOOR

UNIT

CONNECTING

w RED

L

12VDC

220-240V~

2

N

3

w WHT

TB

POWER SUPPLY

~/N

220-240V 220V

50Hz 60Hz

2

TO OUTDOOR

UNIT

CONNECTING

12V DC

3

[LEGEND]

INDOOR CONTROLLER

BOARD

I.B

52C

COMPRESSOR CONTACTOR

RELAY(FAN MOTOR)

X2,X4,X5

NAME

SYMBOL

NAME

SYMBOL

VARISTOR

ZNR1

FUSE(3.15A)

FUSE

MF

FAN MOTOR

ROOM TEMPERATURE

THERMISTOR

RT11

RT12

PIPE TEMPERATURE

THERMISTOR / LIQUID

C1

FAN MOTOR CAPACITOR

TERMINAL BLOCK

TB

RT13

CONDENSER / EVAPORATOR

TEMPERATURE THERMISTOR

1.Since the indoor fan motor(MF) is connected with 50Hz power,if 60Hz power is used, change the wiring

connection showing fig: *1

Indoor Fan Motor(MF) for 60Hz

2.About the outdoor side electric wiring refer to the outdoor unit electlic wiring diagram for servicing.

3.Use copper conductors only. (For field wiring)

4.Symbols below indicate.

: Terminal block : Connector

How to remove the terminals shown at " w " mark.

sleeve

1Slide the sleeve.

2Pull the wire while pushing the locking lever.

locking lever

" w " shows the terminals with a lock mechanism, so they cannot be removed when you pull the lead wire.

Be sure to pull the wire by pushing the locking lever (projected part) of the terminal with a finger.

NOTES:

60

BLUE

YELLOW

50

fig: *1

BLUE

BLU

TRANSMISSION WIRE

DC12V

2

1

TB

CN2

R.B

1

BLU

BLU

2

TB

(REMOCON)

BLU

CN22

21

2

2

1

1

(LIQUID)

(INTAKE)

CN21

CN20

RED

WHT

CN29

BLK

2

1

(2 PHASE)

FAN1

FAN2(FAN)

RED

CND(POWER)

(FAN)

5

3

1

7

5

3

1

WHT

WHT

BLU

YLW

1

3

5

WHT

BRN

RED

ORN

★

★

★ The 12V DC is NOT always against the ground.

Terminal 3 has 12V DC against terminal N.

However, between 3 and 2, these terminals are

NOT electrically insulated by the transformer or

other device.

WIRING DIAGRAM

SEZ-A12AR.TH

SEZ-A18AR.TH

SEZ-A24AR.TH

8

Page 9

5

Pipe temperature

thermistor/liquid

(RT12)

Distributor

with strainer

#50

Condenser/evaporator

temperature thermistor

(RT13)

Room temperature

thermistor (RT11)

Refrigerant flow in cooling

Refrigerant flow in heating

Strainer

#50

Strainer

#50

Heat exchanger

Refrigerant GAS pipe connection

(Flare)

Refrigerant LIQUID pipe connection

(Flare)

REFRIGERANT SYSTEM DIAGRAM

SEZ-A12AR.TH

SEZ-A18AR.TH

SEZ-A24AR.TH

9

Page 10

6

PAR-20MAA

ON/OFF

ERROR CODE

CHECK

CHECK MODE

FILTER

CHECK TEST

TEMP.

TIMER SET

A

B

C

ERROR CODE

CHECK

CHECK MODE

CHECK

CHECK MODE

DE

• For description of each check code, refer to the following table.

5101

5102

2503

2502

1503

0405, 1501, 4210, 5102

6831~6834

6800

– – – –

F F F F

Room temperature thermistor error

RT12, RT13, Outdoor thermistor error

Drain sensor error

Drain pump error

Freezing safeguard operation

Outdoor unit error

Signal error between remote controller and indoor units

Communication error between indoor and outdoor units

No alarm history

No unit

1 Check code Symptom

• On wired remote controller

1 Check code displayed in the LCD.

TROUBLESHOOTING

6-1. Cautions on troubleshooting

(1) Before troubleshooting, check the followings:

1 Check the power supply voltage.

2 Check the indoor/outdoor connecting wire for mis-wiring.

(2) Take care the followings during servicing.

1 Before servicing the air conditioner, be sure to first turn off the remote controller to stop the main unit, and then turn

off the breaker.

2 When removing the indoor controller board, hold the edge of the board with care NOT to apply stress on the

components.

3 When connecting or disconnecting the connectors, hold the housing of the connector. DO NOT pull the lead wires.

6-2. Self-check function

Wired remote controller

(1) Turn on the power.

(2) Press the [CHECK] button twice.

(3) Set refrigerant address with [TEMP] button

if system control is used.

(4) Press the [ON/OFF] button to stop the

self-check.

AA

CHECK button

BB

Refrigerant address

CC

TEMP button

DD

IC : Indoor unit

OC : Outdoor unit

EE

Check code

10

Page 11

6-3. Trouble shooting

Mis-wiring6800

5102

5101

Indoor-outdoor

signal error

Wiring between the indoor and

outdoor is coming off.

Difference of wiring polarity

between the indoor and outdoor.

Trouble of the outdoor inverter

P.C. board.

Check the wiring out between the indoor and

outdoor.

Check the outdoor inverter P.C. board. Refer to the

TECHNICAL & SERVICE MANUAL of outdoor unit.

Trouble of the Indoor controller

board.

Exchange the Indoor controller board.

Pipe temperature thermistor

/ Liquid.

Mis-connecting of the pipe

temperature thermistor / Liquid.

Reinsert the connector (CN21).

Trouble of the pipe temperature

thermistor / Liquid.

Trouble of the Indoor controller

board.

Exchange the Indoor controller board.

Check the resistance value of the thermistor.

Room temperature

thermistor

Mis-connecting of the room

temperature thermistor.

Reinsert the connector (CN20).

Trouble of the room temperature

thermistor.

Trouble of the Indoor controller

board.

Exchange the Indoor controller board.

Check the resistance value of the thermistor.

Condenser / evaporator

temperature thermistor

Mis-connecting of the condenser /

evaporator temperature thermistor.

Reinsert the connector (CN29).

Trouble of the condenser / evaporator

temperature thermistor.

Trouble of the Indoor controller

board.

Exchange the Indoor controller board.

Check the resistance value of the thermistor.

Phenomenon

Check

code

Cause Countermeasure

1503

0405

1501

4210

Freezing protection is

working.

1) Short cycle of air cycle

2) Dirty air filter

3) Damaged fan

4) Abnormal refrigerant

1) Clear obstructions from air cycle.

2) Clean the air filter

3) Check the fan

4) Check the refrigerant temperature.

Malfunction of outdoor unit Malfunction of outdoor unit Refer to the TECHNICAL & SERVICE MANUAL

of outdoor unit.

Outdoor thermistor Mis-connecting of the outdoor

thermistor.

Reinsert the connector.

Trouble of the outdoor thermistor.

Trouble of the outdoor inverter P.C.

board.

Exchange the outdoor inverter P.C. board.

Check the resistance value of the thermistor.

(1) In case of being indicated irregularity on the self diagnoses

11

Page 12

(2) Other case

Not working of remote

controller switch ON/OFF

Short circuit the protecting parts in the

Indoor controller board.

Trouble of the Indoor controller board. Check the Indoor controller board out.

Wiring between the indoor and the wired

remote controller is coming off.

Check the wiring between the Indoor and the wired

remote controller.

Trouble of the remote controller.

Check the varistor (ZNR1) and fuse (FUSE) out in

the Indoor controller board.

Exchange the remote controller.

Wiring between the indoor and outdoor is

coming off.

Working the Indoor units

and not working the outdoor

units.

Check the wiring out between the indoor and

outdoor.

Difference of wiring polarity between the

indoor and outdoor.

Trouble of the outdoor inverter P.C. board.

Trouble of the contactor (52C). Exchange the contactor.

Check the outdoor inverter P.C. board.

Malfunction of outdoor unit. Refer to the TECHNICAL & SERVICE MANUAL of

outdoor unit.

Fan motor connector is coming off.

Not rotating the fan in the

indoor unit.

Trouble of the Indoor controller board.

Check the fan motor output of the Indoor

controller

board.

Check the connector out.

Trouble of the fan motor. Check the resistance value between the each tap

of fan motor.

A connector attaching the panel to the body

is not connected.

Horizontal vane doesn't work.

Check if the connector for vane motor is connected.

Connect it.

A connector attaching the panel to the body

is not connected.

Fixing of horizontal vane.

Connect it.

Phenomenon Cause Countermeasure

12

Page 13

Check of indoor controller board and indoor fan motor

Check code : 6800

Error was found in the signal transmitted or

received between the indoor and outdoor units.

Is the connecting wire between

the indoor and outdoor units

No

Connection is defective.

connected properly?

Are there any devices emitting

noise near the power supply or

the connecting wire between the

Yes

Yes

Remove the devices.

Turn off the power supply and turn it on again to operate the unit in

cooling or heating mode.

Operation lamp blinks once in a

No

Normal

fixed period.

Yes

Indoor controller board is defective.

indoor and outdoor units?

No

Check code : 5101

Check the room temperature thermistor.

Is the connector CN20 on the

indoor controller board connected?

No

Connection is defective.

Yes

Room temperature

thermistor is defective.

Turn off the power supply and turn it on again to operate the unit in

cooling mode.

No

Normal

Measure the resistance of

room temperature thermistor.

Is the resistance 0 (short circuit) or

∞ (open circuit)?

Operation lamp blinks twice in a

fixed period.

Indoor controller board is defective.

Yes

No

Yes

13

Page 14

Yes

No

Yes

No

No

Yes

Yes

No

Measure the resistance

of the pipe temperature

thermistor / liquid.

Indoor controller board is defective.

Check the pipe temperature

thermistor / liquid.

Turn off the power supply and turn it on again to operate the unit in

cooling mode.

Connection is defective.

Is the connector CN21 on the

indoor controller board connected?

Pipe temperature

thermistor / liquid

is defective.

Is the resistance 0 (short circuit) or

∞ (open circuit)?

No

Yes

Yes

No

Measure the resistance of

condenser/evaporator

temperature thermistor.

Check the condenser/evaporator

temperature thermistor.

Is the connector CN29 on the

indoor controller board connected?

Refer to the TECHNICAL &

SERVICE MANUAL of

outdoor unit.

Is the error of indoor unit?

Connection is defective.

Condenser/evaporator

temperature thermistor

is defective.

Is the resistance 0 (short circuit) or

∞ (open circuit)?

Normal

Operation lamp blinks twice in a

fixed period.

Check code : 5102

Yes

No

Yes

No

Indoor fan motor does not rotate.

Measure the resistance of connectors FAN1

and 2 on the indoor controller board.

Connection is defective.

Turn off the power supply and check the connectors

FAN1 and 2 on the indoor controller board visually.

Indoor fan motor is defective.

Are the connectors FAN1 and 2

connected?

Indoor controller board is defective.

Is the resistance 0 (short circuit) or

∞ (open circuit)?

14

Page 15

6-4. Test point of indoor controller board

•Room temperature thermistor (RT11)

•Pipe temperature thermistor/liquid (RT12)

•Condenser/evaporator temperature

thermistor (RT13)

0

10

20

30

40

50

-20 -10 0 10 20 30 40 50

< Thermistor for lower temperature >

Temperature (:)

Resistance (K")

Indoor controller board

Pipe temperature thermistor/liquid (RT12)

Condenser/evaporator

temperature thermistor

(RT13)

Room temperature thermistor (RT11)

Drain sensor (DS)

Power supply

input 220-240V AC

Fuse 250V AC 3.15A

15

Page 16

6-5. Trouble criterion of main parts

BLK RED

GRN

YLW

ORNYLW

BLU

BRN

WHT

P

Room temperature

thermistor

(RT11)

Condenser/evaporator

temperature thermistor

(RT13)

Measure the resistance with a tester.

(Part temperature 10°C ~ 30°C)

Measure the resistance between the terminals with a tester.

(Coil wiring temperature 10°C ~ 30°C)

P : Thermal fuse

145 ± 2˚C

Pipe temperature

thermistor/liquid

(RT12)

Indoor fan motor

(MF)

Check method and criterion

Part name

Normal

A12AR

Normal

WHT-BLK

BLK-BLU

BLU-YLW

YLW-BRN

BRN-RED

241.4~261.2Ω

19.0~20.6Ω

25.4~27.5Ω

12.6~13.7Ω

47.9~51.9Ω

A18AR

155.5~168.2Ω

48.3~52.3Ω

17.8~19.4Ω

7.6~8.3Ω

37.6~40.7Ω

A24AR

97.0~105Ω

53.8~58.3Ω

14.0~15.3Ω

6.3~6.9Ω

27.0~29.3Ω

8kΩ~20kΩ

Abnormal

Abnormal

Opened or

short-circuited

Opened or short-circuited

SEZ-A12AR.TH

SEZ-A18AR.TH

SEZ-A24AR.TH

16

Page 17

DISASSEMBLY PROCEDURE7

SEZ-A12AR.TH

SEZ-A18AR.TH

SEZ-A24AR.TH

OPERATING PROCEDURE PHOTOS

1. Removing the electrical parts

(1) Remove the 2 screws and the electrical parts cover.

(See Photo 1.)

● Indoor controller board (I.B)

● Compressor contactor (52C)

● Fuse (FUSE)

● Varistor (ZNR1)

● Terminal block (TB)

(See Photo 2.)

Photo 1.

Service panel

(Pipe temperature

thermistor / liquid)

Electrical

parts cover

2. Removing the pipe temperature thermistor (RT12)

(1) Remove the electrical parts cover.

(Refer to 1.)

(2) Remove the 2 screws and the service panel.

(See Photo 3.)

(3) Remove the thermistor (RT12) from the holder.

(See Photo 4.)

(4) Remove the connector (CN21) from the indoor

controller board and pull the white wire of thermistor

(RT12) out.

3. Removing the condenser / evaporator temperature

thermistor (RT13)

(1) Remove the electrical parts cover.

(Refer to 1.)

(2) Remove the 2 screws and the service panel.

(See Photo 3.)

(3) Remove the thermistor (RT13) from the holder.

(See Photo 4.)

(4) Remove the connector (CN29) from the indoor

controller board and pull the black wire of thermistor

(RT13) out.

Drain

pan

Service panel

(Condenser / evaporator

temperature thermistor)

Photo 2.

Terminal block

Indoor controller board

Photo 3.

Screws

Service

panel

Set screws

(for drain pan)

Compressor contactor

Photo 4.

Set screws

Front panel

Indoor

controller box

Varistor

Fuse

Pipe temperature

thermistor / liquid

(RT12)

17

Screws

Condenser / evaporator

temperature thermistor (RT13)

Page 18

OPERATING PROCEDURE

PHOTOS

4. Removing the room temperature thermistor (RT11)

(1) Remove the electrical parts cover.

(Refer to 1.)

(2) Remove the front panel at fan side. (12 screws)

(See Photo 1.)

(3) Remove the thermistor (RT11) from the separator (panel).

(See Photo 6.)

(4) Disconnect the connector (CN20)from the indoor

controller board and pull the lead wire of

thermistor (RT11) out.

Photo 5.

Photo 6.

Fan motor

Claws

Claws

Motor bands

Screws

Fan casing

Fan casing

Fan motor

Separator

(panel)

Room temperature

thermistor (RT11)

5. Removing the sirocco fan and the fan motor (MF).

(1) Remove the electrical parts cover.

(Refer to 1.)

(2) Remove the front panel at fan side.(12 screws)

(See Photo 1.)

(3) Disconnect the fan motor connector (FAN1, FAN2) from

the indoor controller board.

(See Photo 2.)

(4) Undo the 4 claws and remove the fan claws.(down side)

<Either left or right>

(See Photo 5.)

(5) Remove the motor bands.

<A screw each on left and right.>

(See Photo 5.)

(6) Disconnect the earth wire from the fan motor leg.

(See Photo 7.)

(7) Remove the fan motor and the sirocco fan by assembly.

(See Photo 7.)

(8) Unscrew the setting screw and remove the sirocco fan.

<Either left or right>

(See Photo 7.)

Photo 7.

Set screw

Earth wire

18

Page 19

OPERATING PROCEDURE

6. Removing the drain pan

(1) Unscrew each set screw on the right and left, and

remove the drain pan pushing it toward the the back.

(See Photo 1.)

7. Removing the heat exchanger

(1) Remove the drain pan.

(Refer to 1.)

(2) Remove the Under flange at heat exchanger side.

(16 screws)

(See Photo 8.)

(3) Remove the 4 screws of heat exchanger.( 2 screws

each on left and right)

(See Photo 9.)

(4) Remove the thermistor (RT12) from the holder.

(Refer to 2.)

(5) Remove the thermistor (RT13) from the holder.

(Refer to 3.)

(6) Remove the service panel.( 3 screws )

(See Photo 9.)

(7) Put the heat exchanger down to the fan motor and

pull it toward you.

(See Photo 9.)

Photo 8.

PHOTOS

Screws

Under flange

Photo 9.

Screws

(for heat exchanger)

Heat exchanger

Service

panel

Screws

(for service panel)

19

Page 20

PARTS LIST8

No.

Parts No.

Parts name

Specification

Remarks

Unit

Amount

Wiring

Diagram

Symbol

Recommended

Q'ty

Q'ty/set

Price

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

LEFT SIDE PANEL

SIROCCO FAN

FAN MOTOR RUBBER MOUNT

FAN MOTOR

FAN MOTOR

FAN MOTOR

ROOM TEMPERATURE THERMISTOR

FRONT PANEL

DRAIN PAN

PIPE TEMPERATURE THERMISTOR / LIQUID

INDOOR HEAT EXCHANGER

INDOOR HEAT EXCHANGER

INDOOR HEAT EXCHANGER

RIGHT SIDE PANEL

SEPARATOR ASSY

LEFT LEG

BASE

RIGHT LEG

E07 039 086

E07 039 500

E02 179 505

E07 039 300

E07 040 300

E07 041 300

E07 143 308

E07 039 000

E07 039 700

E07 143 309

E07 136 307

E07 143 620

E07 144 620

E07 145 620

E07 143 085

E07 143 293

E07 039 809

E07 039 290

E07 039 808

(Drawing No.)

MF

MF

MF

RT11

RT13

RT12

PK6V19-EF

PK6V32-EF

PK6V50-EF

SEZ-

A18AR.THA12AR.TH A24AR.TH

<2PCS/SET>

1

2

2

1

1

1

1

1

1

1

1

1

2

1

2

1

2

2

1

1

1

1

1

1

1

1

1

2

1

2

1

2

2

1

1

1

1

1

1

1

1

1

2

1

2

CONDENSER / EVAPORATOR

TEMPERATURE THERMISTOR

INDOOR UNIT

STRUCTURAL PARTS

SEZ-A12AR.TH

SEZ-A18AR.TH

SEZ-A24AR.TH

14

13

12

11

1

10

2

3

Part number that is circled is not shown in the illustration.

9

8

7

4

5

20

6

Page 21

L

N

3

N

N

3

2

TO OUTDOOR

UNIT

POWER

SUPPLY

TO REMOTE

CONTROLLER

No.

Parts No.

Parts name

Specification

250/3.15A

4P

3P

2P

Remarks

(Drawing No.)

Unit

Amount

Wiring

Diagram

Symbol

Recommended

Q'ty

Q'ty/set

Price

1

2

3

4

5

6

7

8

9

10

INDOOR CONTROLLER BOARD

INDOOR CONTROLLER BOARD

INDOOR CONTROLLER BOARD

COMPRESSOR CONTACTOR

FUSE

VARISTOR

TERMINAL BLOCK

TERMINAL BLOCK

TERMINAL BLOCK

REMOTE CONTROLLER

REMOTE CONTROLLER CABLE

CONTROLLER COVER

E07 143 447

E07 144 447

E07 145 447

E07 140 340

E02 127 382

E02 661 385

E02 257 375

E02 367 377

E02 007 375

E07 136 426

E07 018 089

E07 039 449

I.B

I.B

I.B

52C

FUSE

ZNR1

TB

TB

TB

R.B

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

SEZ-

A18AR.THA12AR.TH A24AR.TH

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF

˚C

CHECK

CHECK MODE

FILTER

TEST RUN

FUNCTION

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

TEMP.

INDOOR UNIT

ELECTRICAL PARTS

SEZ-A12AR.TH

SEZ-A18AR.TH

SEZ-A24AR.TH

1

7

6

5

8

9

4

Part numbers that is circled is not shown in the illustration.

2

21

3

Page 22

9

OPTIONAL PARTS

9-1. REFRIGERANT PIPES

The air conditioner has flared connections its indoor and outdoor sides.

Please use the optional extension pipe as follows.

Applied unit

SEZ-A12AR.TH

SEZ-A18AR.TH

SEZ-A24AR.TH

Models Pipe length

MAC-680PI

MAC-681PI

MAC-682PI

MAC-683PI

MAC-684PI

MAC-670PI

MAC-671PI

MAC-672PI

MAC-673PI

MAC-674PI

MAC-860PI

MAC-861PI

MAC-862PI

MAC-863PI

MAC-864PI

3m

5m

7m

10m

15m

3m

5m

7m

10m

15m

3m

5m

7m

10m

15m

Cross-section A-Gas

Pipe size O.D.mm (in.)

B-liquid

{9.52

(3/8)

{12.7

(1/2)

{6.35

(1/4)

{15.88

(5/8)

Insulation

CD

{27

{31

{21

{27

Additional

refrigerant

charge

R410A (g)

0

60

150

300

0

40

100

200

0

40

100

200

9-2. AIR FILTER

Applied unit

SEZ-A12AR.TH

SEZ-A18AR.TH

SEZ-A24AR.TH

Models

PAC - 1000 FT

22

Page 23

Page 24

HEAD OFFICE : MITSUBISHI DENKI BLDG., 2-2-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

CCopyright 2004 MITSUBISHI ELECTRIC ENGINEERING CO., LTD.

Distributed in Mar. 2004 No. OC303 PDF 8

Made in Japan.

New publication, effective Mar. 2004.

Specifications subject to change without notice.

Loading...

Loading...