Page 1

Air-Conditioners

SEZ-A12, A18, A24AR

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner

unit.

FOR INSTALLER

English

Page 2

Contents

1. Safety precautions ................................................................................... 2

2. Selecting the installation location ............................................................. 2

3. Installation diagram & Accessories .......................................................... 3

4. Indoor unit installation .............................................................................. 4

5. Refrigerant piping work ............................................................................ 5

6. Drainage piping work ............................................................................... 7

7. Electrical work .......................................................................................... 8

8. Duct work ............................................................................................... 10

1. Safety precautions

• Please report to or take consent by the supply authority before connection

to the system.

• Be sure to read “The following should always be observed for safety” before

installing the air conditioner.

• Be sure to observe the cautions specified here as they include important

items related to safety.

• The indications and meanings are as follows.

Warning:

Could lead to death, serious injury, etc.

Caution:

Could lead to serious injury in particular environments when operated incorrectly.

• After reading this manual, be sure to keep it together with the instruction

manual in a handy place on the customer’s site.

Warning:

• Do not install it by yourself (customer).

Incomplete installation could cause injury due to fire, electric shock, the unit

falling or leakage of water. Consult the dealer from whom you purchased the

unit or special installer.

• Install the unit securely in a place which can bear the weight of the unit.

When installed in an insufficient strong place, the unit could fall causing injured.

• Use the specified wires to connect the indoor and outdoor units securely and

attach the wires firmly to the terminal board connecting sections so the stress

of the wires is not applied to the sections.

Incomplete connecting and fixing could cause fire.

• Do not use intermediate connection of the power cord or the extension cord

and do not connect many devices to one AC outlet.

It could cause a fire or an electric shock due to defective contact, defective

insulation, exceeding the permissible current, etc.

• Check that the refrigerant gas does not leak after installation has completed.

9. Air filter installation ................................................................................. 11

10. Test run .................................................................................................. 13

11. Maintenance .......................................................................................... 14

12. System control (Fig. 12-1) ...................................................................... 15

This Installation Manual describes only for the indoor unit and the connected

outdoor unit of SUZ series.

If the connected outdoor unit is MXZ series, refer to the Installation Manual for

MXZ series.

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Indicates that caution should be taken with rotating parts.

: Indicates that the main switch must be turned off before servicing.

: Beware of electric shock.

: Beware of hot surface.

Warning:

Carefully read the labels affixed to the main unit.

• Perform the installation securely referring to the installation manual.

Incomplete installation could cause a personal injury due to fire, electric shock,

the unit falling or leakage of water.

• Perform electrical work according to the installation manual and be sure to

use an exclusive circuit.

If the capacity of the power circuit is insufficient or there is incomplete electrical work, it could result in a fire or an electric shock.

• Attach the electrical part cover to the indoor unit and the service panel to the

outdoor unit securely.

If the electrical part cover in the indoor unit and/or the service panel in the

outdoor unit are not attached securely, it could result in a fire or an electric

shock due to dust, water, etc.

• Be sure to use the part provided or specified parts for the installation work.

The use of defective parts could cause an injury or leakage of water due to a

fire, an electric shock, the unit falling, etc.

• Ventilate the room if refrigerant leaks during operation.

If the refrigerant comes in contact with a flame, poisonous gases will be released.

Caution:

• Perform grounding.

Do not connect the ground wire to a gas pipe, water pipe arrester or telephone

ground wire. Defective grounding could cause an electric shock.

• Do not install the unit in a place where an inflammable gas leaks.

If gas leaks and accumulates in the area surrounding the unit, it could cause

an explosion.

• Install a ground leakage breaker depending on the installation place (where it

is humid).

If a ground leakage breaker is not installed, it could cause an electric shock.

2. Selecting the installation location

2.1. Indoor unit

• Where airflow is not blocked.

• Where cool air spreads over the entire room.

• Where it is not exposed to direct sunshine.

• At a distance 1 m or more away from your TV and radio (to prevent picture from

being distorted or noise from being generated).

• In a place as far away as possible from fluorescent and incandescent lights (so the

infrared remote control can operate the air conditioner normally).

2.2. Outdoor unit

• Where it is not exposed to strong wind.

• Where airflow is good and dustless.

• Where it is not exposed to rain and direct sunshine.

• Where neighbours are not annoyed by operation sound or hot air.

• Where rigid wall or support is available to prevent the increase of operation sound

or vibration.

• Where there is no risk of combustible gas leakage.

• When installing the unit at a high level, be sure to fix the unit legs.

• Where it is at least 3 m away from the antenna of TV set or radio. (Otherwise,

images would be disturbed or noise would be generated.)

• Perform the drainage/piping work securely according to the installation

manual.

If there is a defect in the drainage/piping work, water could drop from the unit

and household goods could be wet and damaged.

• Fasten a flare nut with a torque wrench as specified in this manual.

When fastened too tight, a flare nut may broken after a long period and cause

a leakage of refrigerant.

• Where the air filter can be removed and replaced easily.

Warning:

Mount the indoor unit into a ceiling strong enough to withstand the weight of

the unit.

• Install the unit horizontally.

Caution:

Avoid the following places for installation where air conditioner trouble is liable to occur.

• Where there is too much machine oil.

• Salty environment as seaside areas.

• Hot-spring areas.

• Where sulfide gas exists.

• Other special atmospheric areas.

2

Page 3

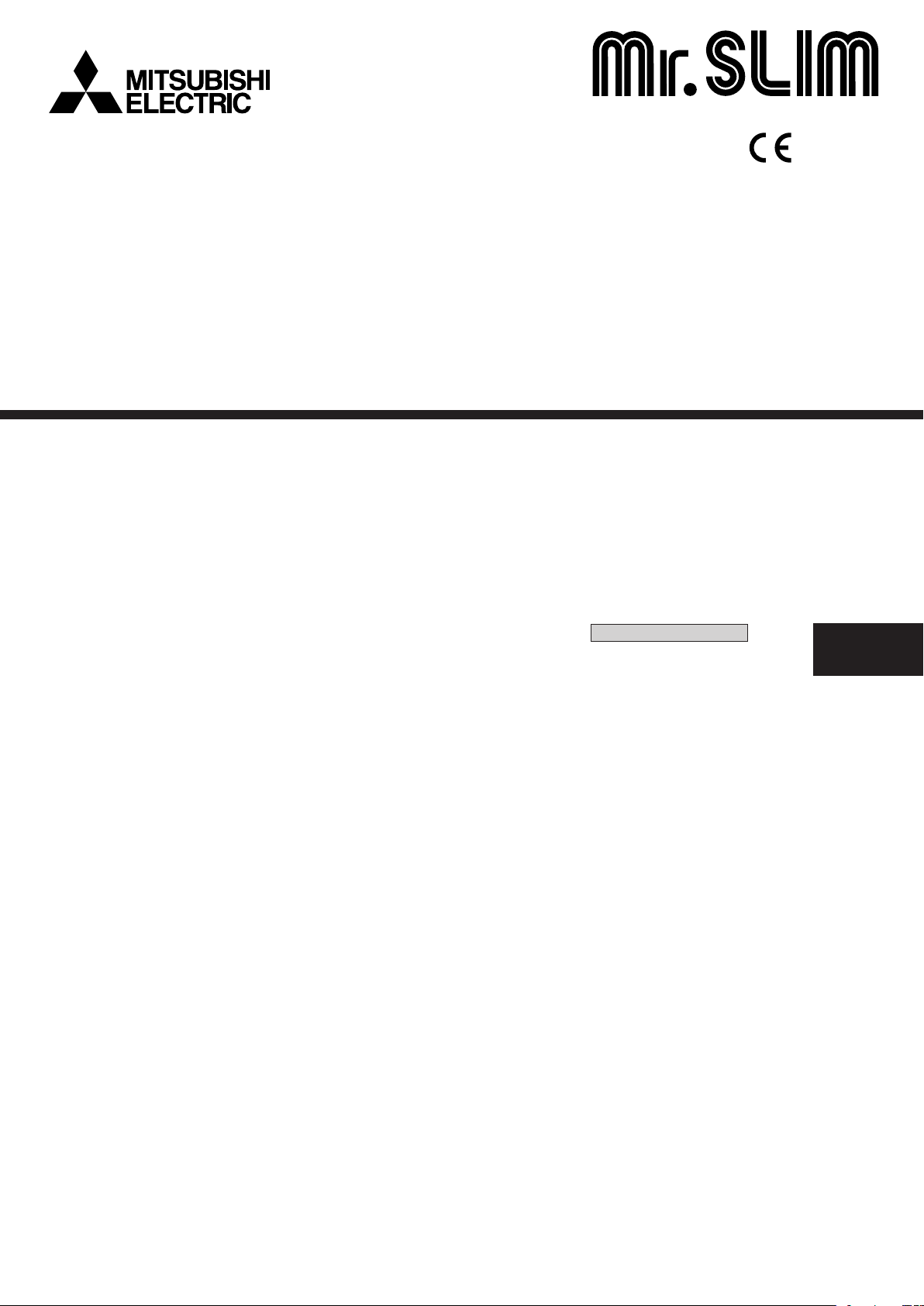

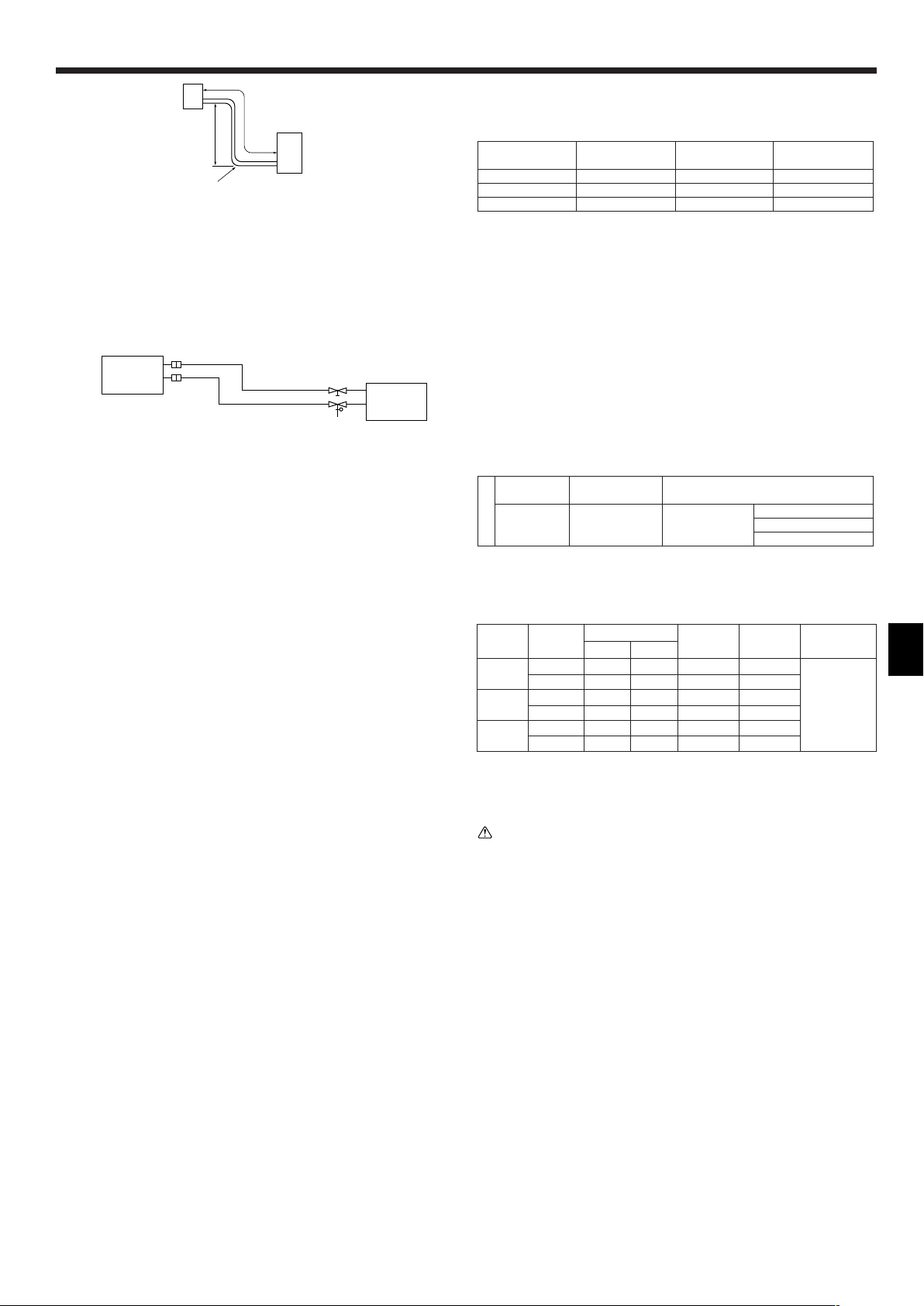

3. Installation diagram & Accessories

A

C

A

C

B

A

D

C

A

B

42 930

7×100=700100

29

12.5 120

240

77.5

955

21525

H

J

I

G

J

50

27

1016

7×100=700

880

10040

(10)

50

60

350

38

680

50

1000

50

1070

150

77

450

150

600

700

2

1

3

0

3

5

6

9

8

3

2

5

7

A

(1070)

270

30

1100

2575

32.5

(10) 50

94 60

350

100

108

25

20

170

A

F

B

C

D

2

E

24012.5

120

25 215

39

77.5

100 7×100=700

955

93051

J

J

■ SEZ-A12/A18/A24AR

Air inlet (rear side) dimensions

9×2-ø2.9 holes

24-ø2.9 holes

20 or more

A

Air inlet (bottom side) dimensions

(mm)

PLATE (A)

24-ø2.9 holes

2×2-ø2.9 holes

Fig. 3-1

3.1. Indoor unit (Fig. 3-1)

1 Air inlet (rear side) *Select the either back side or bottom side

2 Electrical parts box

3 Suspension bolt pitch

5 Access door

6 Service space (It is necessary to maintain a working service area from the ceiling.)

7 Air inlet (bottom side) *Select the either back side or bottom side

8 Suspension bolt M10 or 3/8 (procure locally)

9 Air outlet duct flange

0 Air outlet

A Refrigerant pipe (gas)

■ SUZ-A09/A12AR

■ SUZ-A18/A24AR

Fig. 3-2

B Refrigerant pipe (liquid)

C Wiring entry

D Terminal block

E Drain plug R1 male

F Air outlet duct flange

G In case of bottom side suction, mount the PLATE (A) on the rear side.

H After installation, remove the transportation suppor t PLATE (B).

I PLATE (B) × 2

J Inlet size

3.2. Outdoor unit (Fig. 3-2)

Ventilation and service space

■ SUZ-A09/A12AR

A 100 mm or more

B 350 mm or more

C Basically open 100 mm or more without only obstruction in front and on both sides of the

unit.

D 200 mm or more (Open two sides of left, right, or rear side.)

■ SUZ-A18/A24AR

A 100 mm or more

B 350 mm or more

C 500 mm or more

When the piping is to be attached to a wall containing metals (tin plated) or metal

netting, use a chemically treated wooden piece 20 mm or thicker between the wall

and the piping or wrap 7 to 8 turns of insulation vinyl tape around the piping.

Units should be installed by licensed contractor accordingly to local code requirement.

3

Page 4

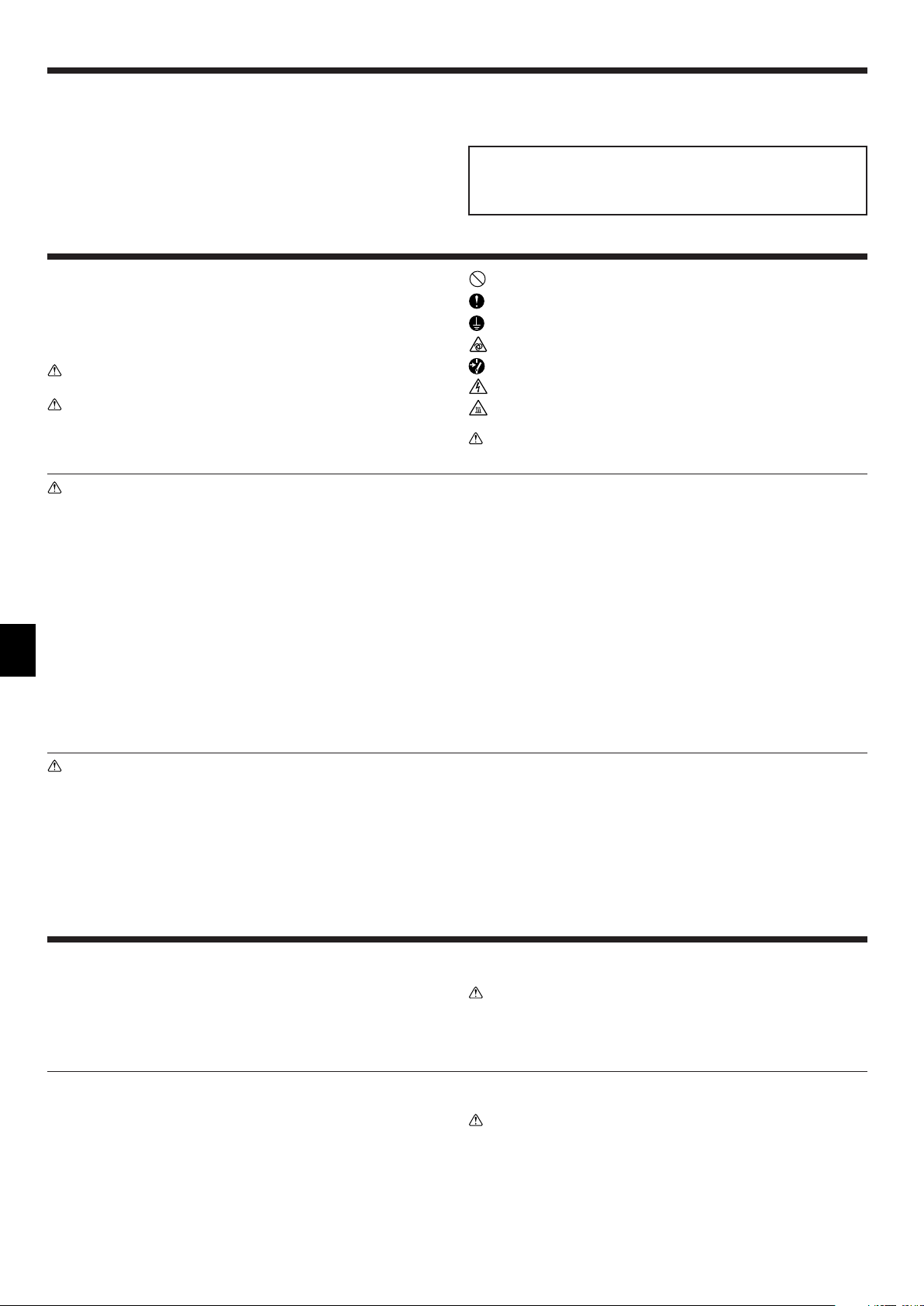

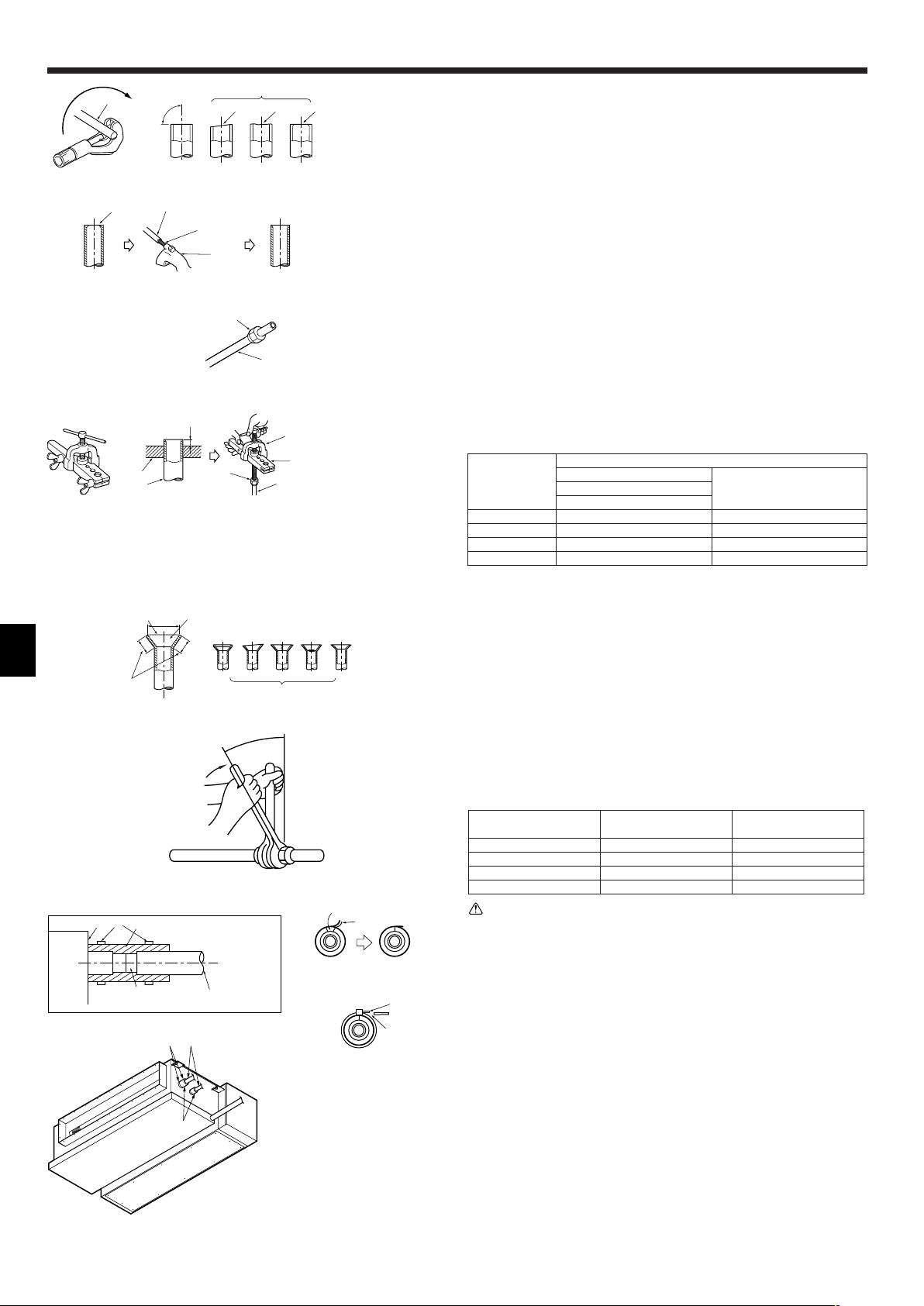

3. Installation diagram & Accessories

G

E

F

ab

b

ce

d

B

A

A

A

B

C

D

350

1070

AB

1

2

3

C

4

Fig. 3-3

4. Indoor unit installation

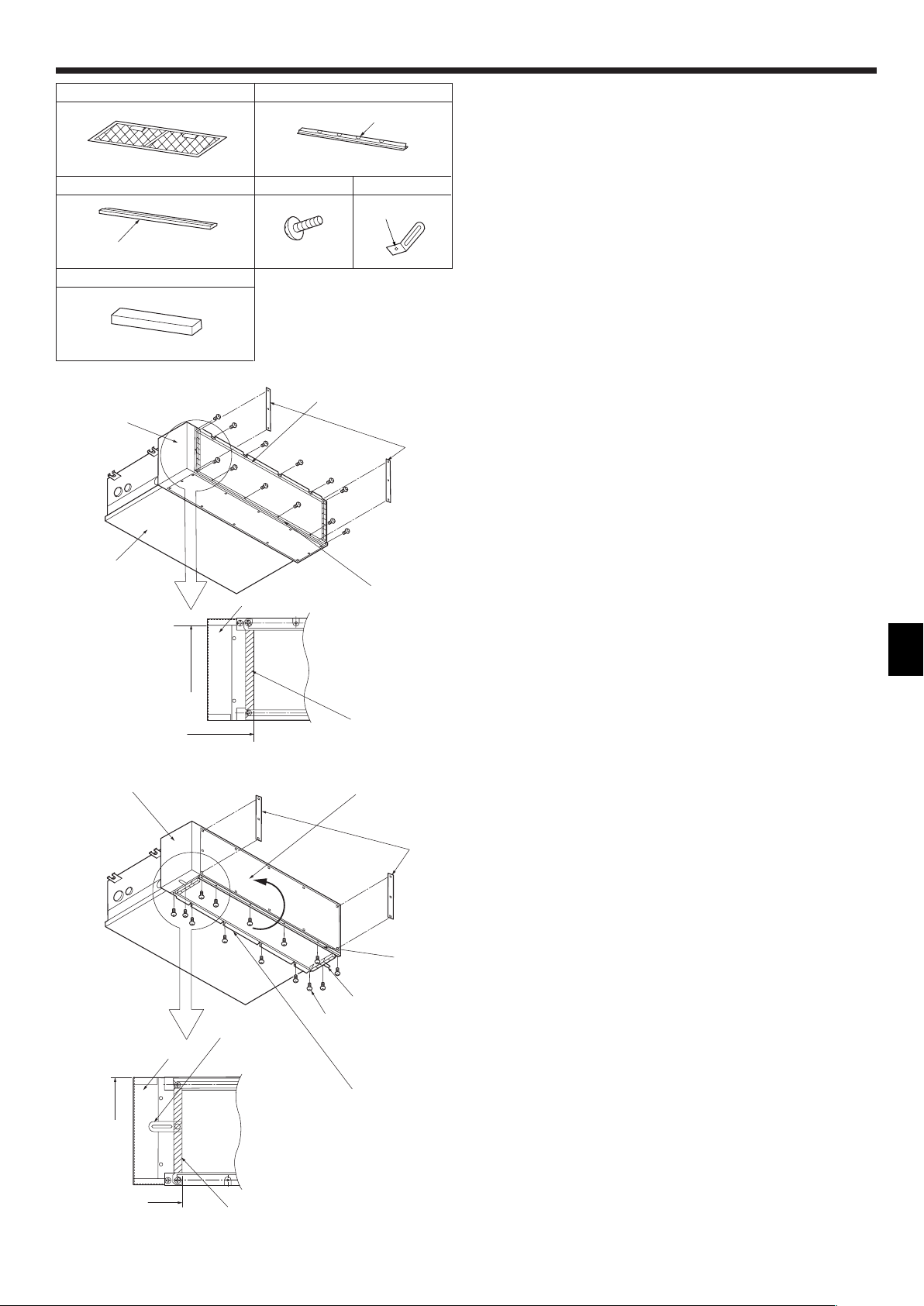

3.3. Checking the indoor unit accessories (Fig. 3-3)

Check that the indoor unit is equipped with the following parts and accessories:

A Refrigerant pipe parts

1 Pipe cover (for refrigerant piping joint)

Small diameter × 1

Large diameter × 1

2 Bands for temporary tightening of pipe cover × 4

B Remote controller parts

3 Parts contained in the cardboard box × 1

Check the contents and read the explanations provided.

C Air filter parts

4 Parts contained in the bag × 1

Check the contents and read the explanations provided.

Refrigerant and drainage pipe sizes

Model SEZ-A12AR SEZ-A18AR SEZ-A24AR

Refrigerant Liquid OD ø6.35 (1/4") OD ø6.35 (1/4") OD ø6.35 (1/4")

pipe Gas OD ø9.52(3/8") OD ø12.7 (1/2") OD ø15.88 (5/8")

Drainage pipe Hard PVC pipe : OD ø26 (1")

4.1. Suspension Structure (Give site of suspension

strong structure.)

4.1.1. Wooden structure (Fig. 4-1)

• Select tie beam (one-story houses) or second-floor girder (two-story houses) as

reinforcement member.

• Use sturdy beams of at least 6 cm square for beam pitch of 90 cm or less or of at

least 9cm square for beam pitch of 90-180 cm.

A Ceiling

B Rafter

C Beam

D Roof beam

Fig. 4-1

Fig. 4-2

Fig. 4-3

4.1.2. Ferro-concrete structures (Fig. 4-2)

Secure the suspension bolts using the method shown, or use steel or wooden hangers, etc. to install the suspension bolts.

E Use inserts rated at 100-150 kg each (procure locally)

F Suspension bolts M10 (3/8") (procure locally)

G Steel reinforcing rod

4.1.3. Installing the suspension bolts

• Check the pitch of the suspension bolts.

• Use the ø10 (3/8") suspension bolts (×4, procure locally).

• Adhere strictly to the length of the suspension bolts.

4.2. Suspending the unit (Fig. 4-3)

Direct suspension method:

Raise the unit and line it up with the suspension bolts, then secure it using both

nuts.

a Air outlet

b Air intake (selecting the either back side or bottom side.)

c Washer (procure locally)

d Nuts (procure locally)

e Suspension bolts (procure locally)

4.3. Transportation support removal (Fig. 4-4)

After installation, completely remove the transportation support because this part

should only be used during transportation.

A 3 screws

B Transportation support

Fig. 4-4

4

Page 5

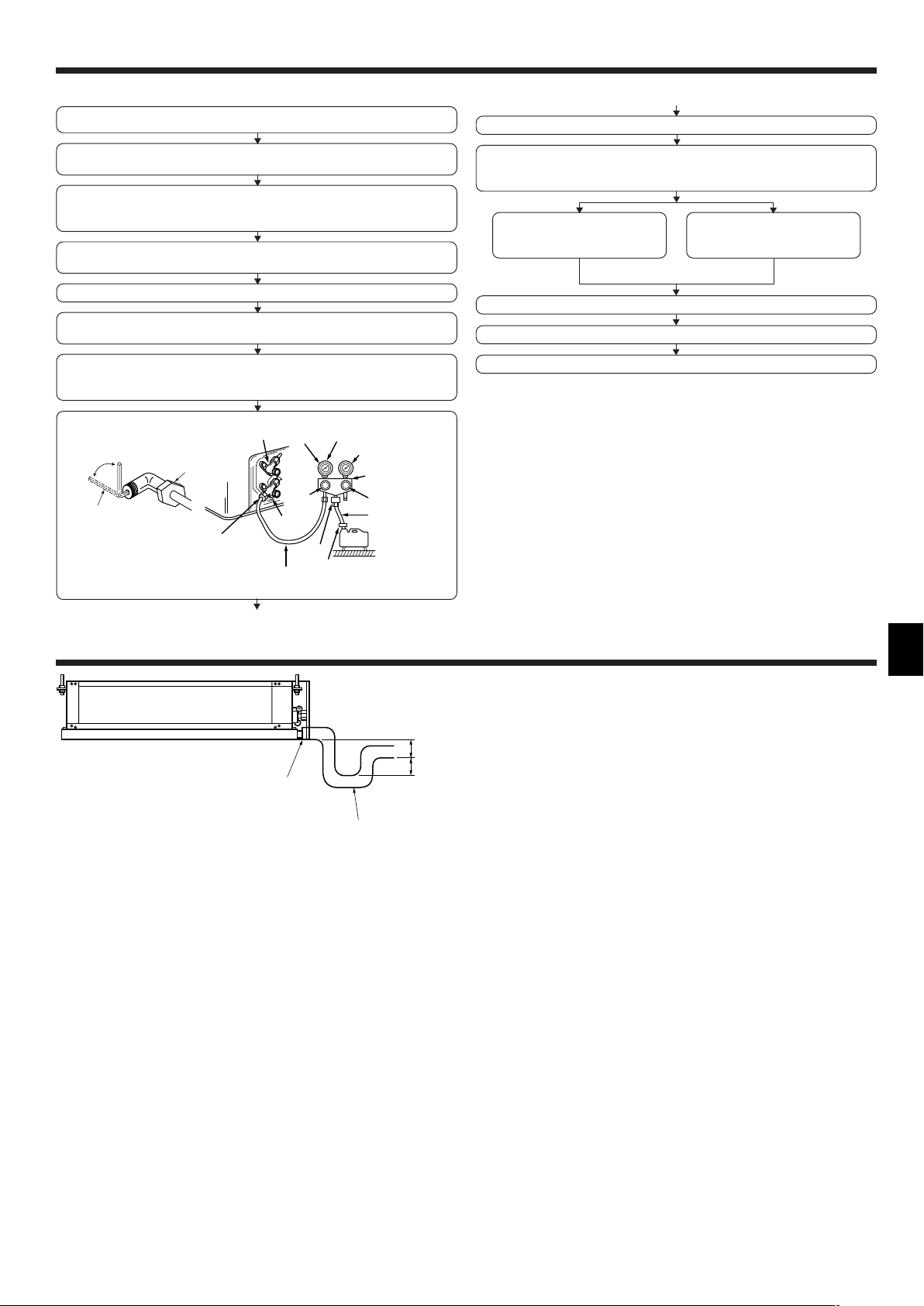

5. Refrigerant piping work

Ø6.35

SEZ-A12:Ø9.52

SEZ-A18:Ø12.7

SEZ-A24:Ø15.88

1

2

b

(C)

(B)

(A)

a

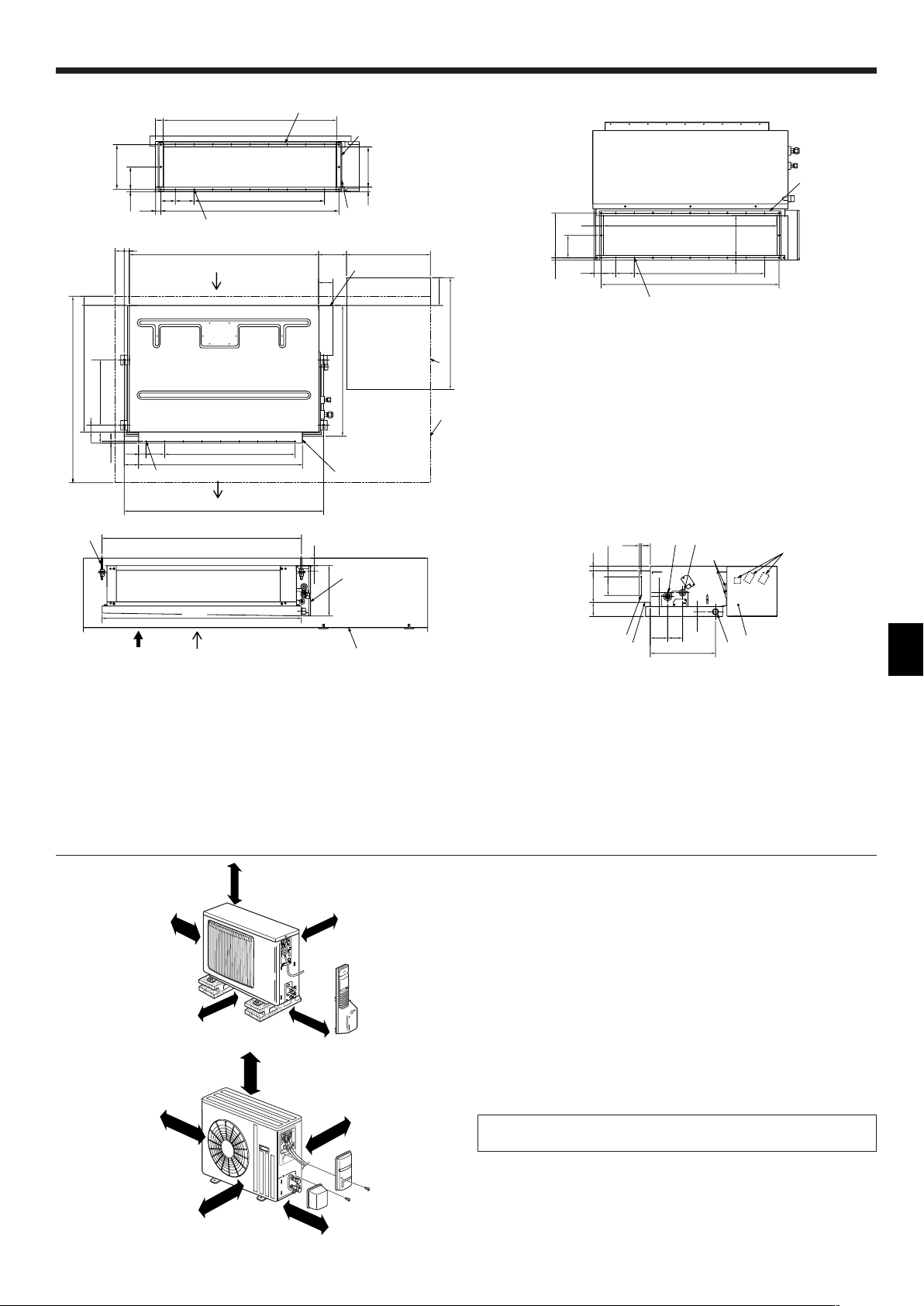

5.1. Refrigerant pipe (Fig. 5-1)

Maximum difference between heights of indoor unit and outdoor unit, the length of

refrigerant piping and the number of bends in piping are within limits shown below.

Fig. 5-1

Fig. 5-2

a Indoor unit

b Outdoor unit

1 Indoor unit

2 Outdoor unit

Models (A) Pipe length (B) Height (C) Number of

SEZ-A12AR max. 20 m max. 12 m max. of 10

SEZ-A18AR max. 30 m max. 15 m max. of 10

SEZ-A24AR max. 30 m max. 15 m max. of 10

*1: Height difference limitations are binding regardless of which unit, indoor or out-

door, is positioned higher.

Avoid the following places for installation where air conditioner trouble is liable to

occur.

• Where there is too much oil such as for machine or cooking.

• Salty environment as seaside areas.

• Hot-spring areas.

• Where sulfide gas exists.

• Other special atmospheric areas.

• This unit has flared connections on both indoor and outdoor sides. (Fig. 5-2)

• Refrigerant pipes are used to connect the indoor and outdoor units as shown in the

figure below.

• Insulate both refrigerant and drainage piping completely to prevent condensation.

• Refrigerant adjustment … If pipe length exceeds 7 m, additional refrigerant (R410A)

charge is required.

(The outdoor unit is charged with refrigerant for 7 m pipe length.)

7 m

maximum

Exceeding

7 m

Pipe length

(one way) difference bends (one way)

No additional

charge required

Additional

charge required

Refrigerant

to be added

–

SEZ-A12AR:30g/m

SEZ-A18AR:50g/m

SEZ-A24AR:50g/m

Piping preparation

• Refrigerant pipes of 3, 5, 7, 10 and 15 m are available as optional items.

(1) Table below shows the specifications of pipes commercially available.

Outside diameter

Model

SEZ-A12AR

SEZ-A18AR

SEZ-A24AR

(2) Ensure that the 2 refrigerant pipes are well insulated to prevent condensation.

(3) Refrigerant pipe bending radius must be 10 cm or more.

Caution:

Using careful insulation of specified thickness. Excessive thickness prevents

storage behind the indoor unit and smaller thickness causes dew drippage.

Pipe

For liquid

For gas

For liquid

For gas

For liquid

For gas

mm inch

6.35 1/4

9.52 3/8

6.35 1/4

12.7 1/2

6.35 1/4

15.88 5/8

Min wall

thickness

0.8 mm

0.8 mm

0.8 mm

0.8 mm

0.8 mm

1.0 mm

Insulation

thickness

8 mm

8 mm

8 mm

8 mm

8 mm

8 mm

Insulation

material

Heat resisting

foam plastic

0.045 specific

gravity

5

Page 6

a

dcbef

90°

d

c

b

a

5. Refrigerant piping work

b

a

a

b

e

b

c

d

c

A

a

f

c

b

d

e

b

c

e

g

h

c

i

c

b

a

defgh

i

Fig. 5-3

Fig. 5-4

Fig. 5-5

Fig. 5-6

a Copper tubes

b Good

c No good

d Tilted

e Uneven

f Burred

a Burr

b Copper tube/pipe

c Spare reamer

d Pipe cutter

a Flare nut

b Copper tube

a Flaring tool

b Die

c Copper tube

d Flare nut

e Yok e

5.2. Flaring work

• Main cause of gas leakage is defect in flaring work.

Carry out correct flaring work in the following procedure.

5.2.1. Pipe cutting (Fig. 5-3)

• Using a pipe cutter cut the copper tube correctly.

5.2.2. Burrs removal (Fig. 5-4)

• Completely remove all burrs from the cut cross section of pipe/tube.

• Put the end of the copper tube/pipe to downward direction as you remove burrs in

order to avoid burrs drop in the tubing.

5.2.3. Putting nut on (Fig. 5-5)

• Remove flare nuts attached to indoor and outdoor unit, then put them on pipe/tube

having completed burr removal.

(not possible to put them on after flaring work)

5.2.4. Flaring work (Fig. 5-6)

• Carry out flaring work using flaring tool as shown at the right.

Pipe diameter A (mm)

(mm)

6.35 0 - 0.5 9.1

9.52 0 - 0.5 13.2

12.7 0 - 0.5 16.6

15.88 0 - 0.5 19.7

When the tool for R410A is used

Clutch type

Dimension

+0

B (mm)

-0.4

Firmly hold copper tube in a die in the dimension shown in the table at above.

B

Fig. 5-7

5.2.5. Check (Fig. 5-7)

• Compare the flared work with a figure in right side hand.

• If flare is noted to be defective, cut off the flared section and do flaring work again.

a Smooth all around

b Inside is shining without any scratches

c Even length all around

d Too much

e Tilted

f Scratch on flared plane

g Cracked

h Uneven

i Bad examples

5.3. Pipe connection (Fig.5-8)

• Apply a thin coat of refrigeration oil on the seat surface of pipe.

• For connection first align the center, then tighten the first 3 to 4 turns of flare nut.

• Use tightening torque table below as a guideline for indoor unit side union joint section,

and tighten using two wrenches. Excessive tightening damages the flare section.

Copper pipe O.D. Flare nut O.D. Tightening torque

(mm) (mm) (N·m)

ø6.35 17 14 - 18

ø9.52 22 34 - 42

Fig. 5-8

Be careful of flying flare nut! (Internally pressurized)

Remove the flare nut as follows:

1. Loosen the nut until you hear a hissing noise.

2. Do not remove the nut until the gas has been completely released (i.e., hiss-

3. Check that the gas has been completely released, and then remove the nut.

Outdoor unit connection

Connect pipes to stop valve pipe joint of the outdoor unit in the same manner applied

for indoor unit.

a Indoor unit (main unit)

b 1 Pipe cover

c 2 Band

d Flare joint

6

Fig. 5-9

e Refrigerant pipe and insulating ma-

terial (must be supplied locally)

f Position the pipe cover so that the end

is in firm contact with the main unit.

Fasten it so that there is no clearance.

g Allow no clearance

h Separator sheet

i Cut off the remainder band

• For tightening use a torque wrench or spanner, and use the same tightening torque

Refrigerant pipe insulation (Fig. 5-9)

(1) Peel the separator sheet off the accompanying pipe cover, and wrap it around the

(2) Be sure to fix both ends of the pipe cover using an attachment band (ensure that

(3) Stick vinyl tape on the joint positions.

ø12.7 26 49 - 61

ø15.88 29 68 - 82

Warning:

ing noise stops).

applied for indoor unit.

refrigerant pipe, making sure that the side which is slit faces upwards.

the band’s joint faces upwards).

Page 7

5. Refrigerant piping work

A

B

H

1

H

2

5.4. Purging procedures leak test

PURGING PROCEDURES

Connect the refrigerant pipes (both the liquid and gas pipes) between the indoor

and the outdoor units.

Remove the service port cap of the stop valve on the side of the outdoor unit gas pipe.

(The stop valve will not work in its initial state fresh out of the factory (totally closed

with cap on).)

Connect the gage manifold valve and the vacuum pump to the service port of the

stop valve on the gas pipe side of the outdoor unit.

Run the vacuum pump. (Vacuumize for more than 15 minutes.)

Check the vacuum with the gage manifold valve, then close the gage manifold valve,

and stop the vacuum pump.

Leave it as is for one or two minutes. Make sure the pointer of the gage manifold

valve remains in the same position. Confirm that the pressure gage show -0.101MPa

(-760 mmHg)

Handle

Low

Window

Adapter for

preventing

the back flow

Compound pressure

gauge (for R410A)

Pressure gauge

(for R410A)

Gauge manifold

valve (for R410A)

Handle High

Charge hose

(for R410A)

Vacuum

(or the vacuum

pump

pump with the

function to

prevent the back

flow)

*Close

*Open

Hexagonal wrench

*4 to 5 turns

Stop valve

Stop valve

Service port

-0.101MPa

(-760 mmHg)

Stop

valve

Charge hose

(for R410A)

Remove the gage manifold valve quickly from the service port of the stop valve.

After refrigerant pipes are connected and evacuated, fully open all stop valves on

gas and liquid pipe sides.

Operating without fully opening lowers the performance and causes trouble.

Pipe length :

7 m maximum

No gas charge is needed.

Pipe length exceeding 7 m

Charge the prescribed

amount of gas.

Tighten the cap to the service port to obtain the initial status.

Retighten the cap

Leak test

6. Drainage piping work

Fig. 6-1

H1 : 50 mm or more

H2 : 1/2 H1 or more

6.1. Drainage pipe connection (Fig. 6-1)

Indoor unit’s drainage pipe

• The drainage pipe should be arranged so that the discharge end is lower than the

other end, as shown in the figure opposite.

• Place the trap outside the unit.

• After connecting the drainage pipe, make sure that water is discharged properly

and that there are no leaks.

A Drainage piping connection 1 RP male.

B Tr ap

Outdoor unit drainage pipe connection

When drainage piping is necessary, use the drain pan (supplied as an option).

7

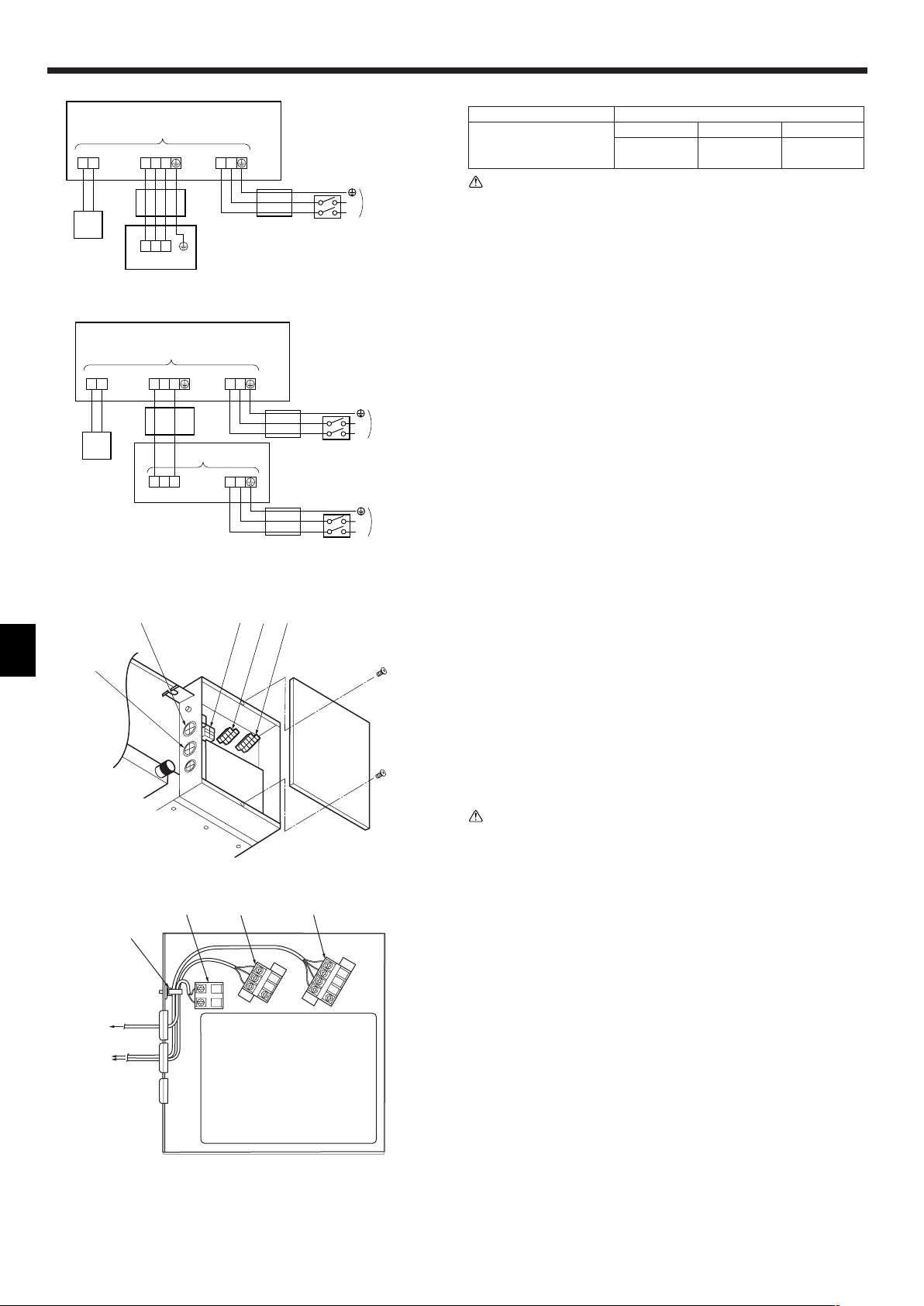

Page 8

7. Electrical work

N

A

B

H

C

F

D

E

A

G

N

2

3

N

2

3

N

L

L

1 2

N

B

C

F

E

N

2

3

12

N

L

L

A

H

A

D

C

E

A

G

N

3

N

F

N

L

L

2

1456

3

4

5

6

0

7

8

9

(1) SEZ-A12AR (1:1 SYSTEM)

(2) SEZ-A18/A24AR (1:1 SYSTEM) OR MULTI SYSTEM

7.1. Power supply (Fig. 7-1)

Electrical specification Input capacity Main Switch/Fuse (A)

Power supply SEZ-A12AR SEZ-A18AR SEZ-A24AR

(1 phase ~/N, 220-240V,

50Hz)

Warning:

• Do not use intermediate connection of the power cord, etc. or an extension

cord or connect many devices to one AC outlet. It could cause a fire or electric shock due to defective contact, defective insulation, exceeding the permissible current, etc.

• Supply power should be taken from independently branched circuit. If not, it

could cause a fire.

• A switch with at least 3 mm contact separation in each pole shall be provided

by the air conditioner installation.

A Terminal block

B Indoor unit (Refer to Fig. 7-2)

C Breaker

D 4-core cable ((2) · · · 2-core cable)

10 20 20

E 3-core cable

F Power supply

G Outdoor unit (Refer to Fig. 7-3)

H Remote controller

Fig. 7-1

7.2. Indoor wire connection (Fig. 7-2)

Work procedure

1.Remove 2 screws to detach the electric component cover.

2.Route each cable through the wiring intake into the electric component box. (Procure power cable and in-out connecting cable locally and use remote control cable

supplied with the unit.)

3.Securely connect the power cable and the in-out connecting cable and the remote

control cable to the terminal blocks.

4.Secure the cables with clamps inside the electric component box.

5.Attach the electric component cover as it was.

• Fix power supply cable and indoor/outdoor cable to control box by using buffer

bushing for tensile forse. (PG connection or the like.)

Warning:

• Attach the electrical part cover securely. If it is attached incorrectly, it could

result in a fire, electric shock due to dust, water, etc.

• Use the specified indoor/outdoor unit connecting wire to connect the indoor

and outdoor units and fix the wire to the terminal bed securely so that no

stress is applied to the connecting section of the terminal bed. Incomplete

connection or fixing of the wire could result in a fire.

• The wiring configuration of the indoor unit’s fan motor is for a 50Hz power

supply. The wiring must be reconfigured if a 60Hz power supply is used. Refer

to the wiring diagram for details.

1 Entry for remote controller cable

2 Entry for power supply cable and Indoor-Outdoor connecting cable

3 Cable clamp

4 Remote controller terminal

5 Power supply terminal

6 Indoor/Outdoor unit connecting terminal

7 To remote controller

8 To power supply source

9 To outdoor unit

0 Indoor controller

8

Fig. 7-2

Page 9

7. Electrical work

LN

N

2 3

N

2 3

1

2

5

12

7

6

3

4

65 mm

15 mm

1

2

30

46

30

30120

83.5

A

B

C

F

A

H

C

D

E

G

I

I

I

H

B

J

H

A

AB TB6

B

1

234

ON

1

234

ON

C

LN

N

3

N

2 3

1

2

5

LN

2

5

12

7

6

3

4

(1) SEZ-A12AR (1:1 SYSTEM) (2) SEZ-A18/24AR (1:1 SYSTEM) OR

MULTI SYSTEM

Fig. 7-3

Fig. 7-4

Fig. 7-5

B-1. B-2.

Fig. 7-6

Fig. 7-7

• Perform wiring as shown in the diagram to the lower left. (Procure the cable lo-

cally). (Fig. 7-3)

Make sure to use cables of the correct polarity only.

1 Connecting cable 2 Power supply cable

4 core VVF cable 3 core with ground IEC cord

• SEZ-A12:1.0 mm2 or more • SEZ-A12:1.0 mm2 or more

• SEZ-A18, A24:1.5 mm2 or more • SEZ-A18, A24:1.5 mm2 or more

Colors Colors

N : Blue N : Blue

2 : Brown L : Brown

3 : Red : Green/Yellow

: Green/Yellow

3 Indoor

4 Outdoor

5 Always install an earth longer than other cables

6 Remote controller cable

Wire No × size (mm2) : Cable 2C × 0.69

This wire accessory of remote controller

(wire length : 10m, non-polar)

7 Remote controller

• Connect the terminal blocks as shown in the diagram below. (Fig. 7-4)

1 Loosen terminal screw

2 Terminal bed

(1) Use care not to make mis-wiring.

(2) Firmly tighten the terminal screws to prevent then from loosening.

(3) After tightening, pull the wires lightly to confirm that they do not move.

7.3. Remote controller

7.3.1. For wired remote controller

1) Installing procedures

(1) Select an installing position for the remote controller. (Fig. 7-5)

The temperature sensors are located on both remote controller and indoor unit.

s Procure the following parts locally:

Two piece switch box

Thin copper conduit tube

Lock nuts and bushings

A Remote controller profile

B Required clearances surrounding the remote controller

C Installation pitch

(2) Seal the service entrance for the remote controller cord with putty to prevent

possible invasion of dew drops, water, cockroaches or worms. (Fig. 7-6)

A For installation in the switch box:

B For direct installation on the wall select one of the following:

• Prepare a hole through the wall to pass the remote controller cord (in order to run

the remote controller cord from the back), then seal the hole with putty.

• Run the remote controller cord through the cut-out upper case, then seal the cut-

out notch with putty similarly as above.

B-1. To lead the remote controller cord from the back of the controller:

B-2. To run the remote controller cord through the upper portion:

(3) For direct installation on the wall

C Wall

D Conduit

E Lock nut

F Bushing

G Switch box

H Remote controller cord

I Seal with putty

J Wood screw

2) Connecting procedures (Fig. 7-7)

1 Connect the remote controller cord to the terminal block.

A To the terminal block on the indoor unit

B TB6 (No polarity)

2 Set the dip switch No.1 shown below when using two remote controller’s for the

same group.

C Dip switches

Setting the dip switches

The dip switches are at the bottom of the remote controller. Remote controller Main/

Sub and other function settings are performed using these switches. Ordinarily, only

change the Main/Sub setting of SW No.1. (The factory settings are all “ON”.)

<SW No. 1>

SW contents Main Remote controller Main/Sub setting

ON/OFF

Comment Set one of the two remote controllers at one group to “Main”

<SW No. 2>

SW contents Main When remote controller power turned on

ON/OFF

Comment

Main/Sub

Normally on/Timer mode on

When you want to return to the timer mode when the power is restored

after a power failure when a Program timer is connected, select “Timer

mode”.

<SW No. 3>

SW contents Main Cooling/heating display in AUTO mode

ON/OFF

Comment

Yes/No

When you do not want to display “Cooling” and “Heating” in the Auto

mode, set to “No”.

<SW No. 4>

SW contents Main Intake temperature display

ON/OFF

Comment When you do not want to display the intake temperature, set to “No”.

Yes/No

9

Page 10

A

B

C

B

C

A

7. Electrical work

Q

B C

N

A

M

E

P

H

G

L

JK

F

I

D O

8. Duct work

Fig. 7-8

Fig. 7-9

A Cord clamp.

B Service panel

C Fixing screws

A Loosen terminal screw

B Terminal block

C Lead wire

7.4. Outdoor unit (Fig. 7-8)

• Connect cable from the indoor unit correctly on the terminal-block.

• Use the same terminal block and polarity as is used with the indoor unit.

• For aftercare maintenance, give extra length to connecting cable.

• Both end of connecting cable (extension wire) are peeled off. When too long,

or connected by cutting off the middle, peel off power supply cable to the size

given in the figure.

• Be careful not to contact connecting cable with piping.

Caution:

• Use care not to make mis-wiring. (Fig. 7-9)

• Firmly tighten the terminal screws to prevent them from loosening.

• After tightening, pull the wires lightly to confirm that they do not move.

Warning:

• Be sure to attach the service panel of the outdoor unit securely. If it is not

attached correctly, it could result in a fire or an electric shock due to dust,

water, etc.

• Tighten terminal screws securely.

• Wiring should be done so that the power lines are not subject to tension.

Otherwise, heat may be generated or fire may occur.

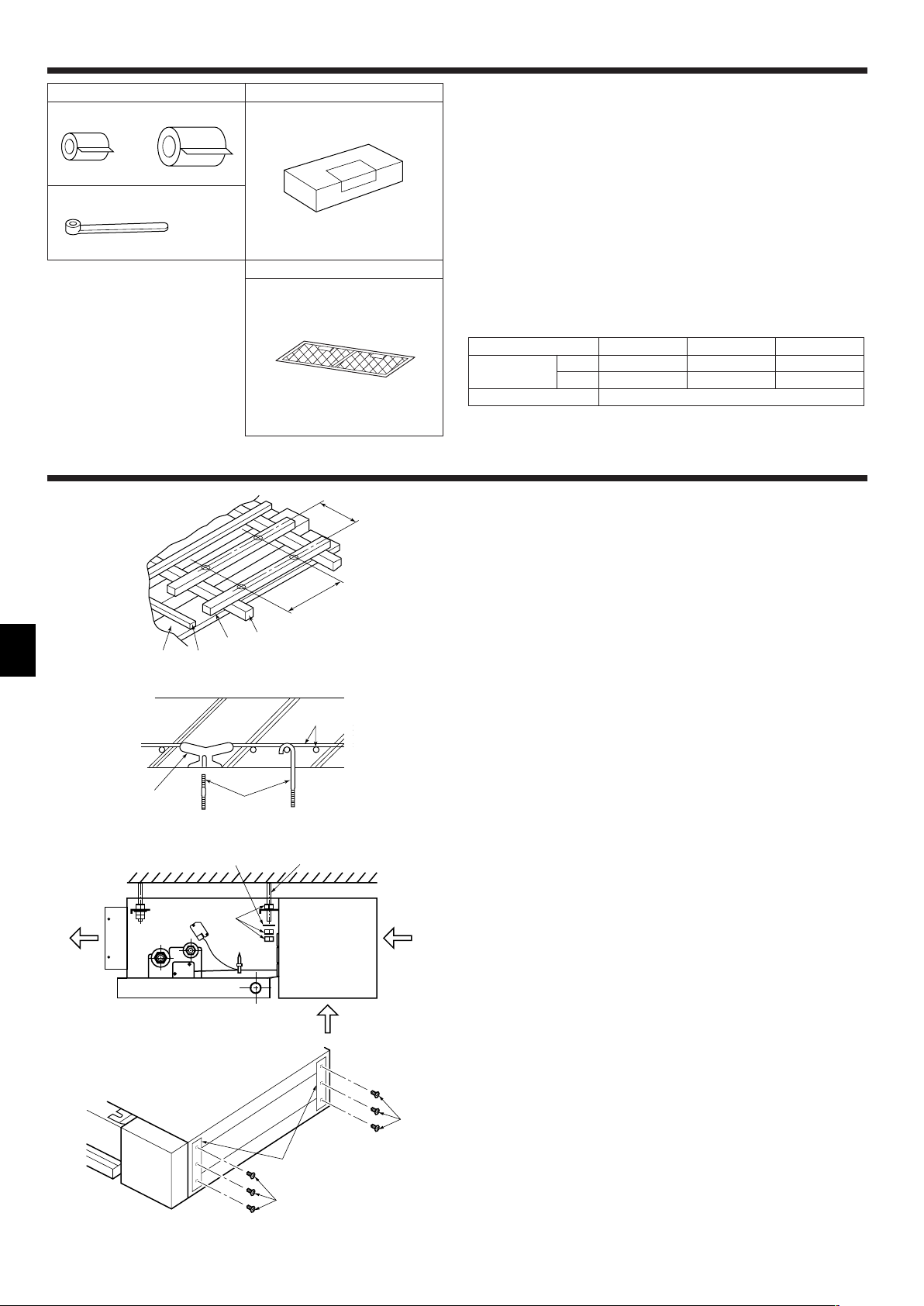

At the time of shippting from factory

In case of bottom-side suction

Remove the panel attached to the bottom

side, and mount it on the rear side.

Fig. 8-1

Use the canvas duct for connecting the indoor unit and the duct. (Fig. 8-1)

Use fire-proof material for the duct parts.

Make sure that the duct has sufficient heat insulation.

A Electrical parts box

B Canvas duct

C Air outlet flange

D Air outlet duct

E Air filter (procure locally)

F Air outlet grille

G Air intake grille

H Ceiling

I Drainage pan

J Air intake

K Air outlet

L Allow clearance to avoid short cycling.

M Indoor unit

N Earth terminal

O Earth cable

P 850 mm or more

Q Safety net (procured locally)

Notes:

• The fan and motor are dangerous if handled during operation. For this

reason, be sure to install the indoor unit at least 850mm from the air intake

grill G.

If it is not possible to put more than 850 mm of distance between the air

intake grill and the indoor unit, install the safety net Q (locally procured).

• Connect the main body of the air conditioner and the duct so that their

potentials are equal.

• Connect an earth cable O from the air outlet flange C to the earth terminal

N. Then, connect another earth cable O from the earth terminal N to the

air outlet duct D.

• Be sure to install an air filter (procure locally) and an air outlet duct.

10

Page 11

9. Air filter installation

A

A

B

C

C

2

1

3

4

A

A

5

4

C

C

4

3

5

6

2

1

12

Cut out

3

Cut out

6

45

Hole

Fig. 9-1

9.1. Confirmation of enclosed parts (Fig. 9-1)

• Please ensure all the parts shown below are present before starting installation.

1 Filter × 1

2 Filter rail × 1

3 Filter rail × 1

4 ST. screw (4 × 10) × 14

5 Clamp × 2

6 Seal × 2

9.2. Filter rail installation (Rear air intake) (Fig. 9-2)

■ Please select air intake direction A or B

1. Transportation support remove (Throw away).

2. Please attach filter rail 2 as per the diagram (screw × 6).

Please connect rails 2 3 carefully.

3. Please attach filter rail 3 as per the diagram (screw × 6).

Please connect rails 2 3 carefully.

4. Seal 6

Upright position here.

A Control box

B Drain pan

C Air tight seal

Level with edge

Fig. 9-2

9.3. Filter rail installation (Bottom air intake) (Fig. 9-3)

1. Transportation support remove (Throw away).

2. Please move the plate position. (Please use the screws removed.)

3. Please attach filter rail 2 as per the diagram (screw × 6).

Please connect rails 2 3 carefully.

4. Please attach filter rail 3 as per the diagram (screw × 6).

Please connect rails 2 3 carefully.

5. Clamp 5 (Attach the clamps 5 with screw × 2)

Upright position here.

6. Seal 6

Upright position here.

A Control box

C Air tight seal

Level with edge

Fig. 9-3

11

Page 12

9. Air filter installation

1

2

B

A

E

D

F

2

1

A

E

D

F

A

F

H

G

E

Fig. 9-4

9.4. Filter installation points (Rear air intake) (Fig. 9-4)

1. Insert the filter into rail 2

2. Hook the filter onto rail 3

A Control box

B Drain pan

D Filter

E Rail 2

F Rail 3

9.5. Filter installation points (Bottom air intake)

(Fig. 9-5)

1. Insert the filter into rail 2

2. Hook the filter onto rail 3

3. Bend the clamp to hold the filter.

A Control box

D Filter 1

E Rail 2

F Rail 3

G Bend

H Clamp 5

Fig. 9-5

12

Page 13

10.Test run

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF

˚C

CHECK

CHECK MODE

FILTER

TEST RUN

FUNCTION

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

FILTER

CHECK TEST

TEMP.

TIMER SET

DEF

HIMG

CB A

ON/OFF

CHECK

FILTER

CHECK TEST

TEMP.

TIMER SET

B

C

A

STAND BY

DEFROST

INDOOR UNIT

ADDRESS NO

ERROR CODE

OA UNIT ADDRESS NO

CENTRALLY CONTROLLED

CLOCK

ON OFF

˚C

1Hr.

NOT AVAILABLE

˚C

CHECK MODE

FILTER

CHECK

FUNCTION

ERROR CODE

OA UNIT ADDRESS NO

STAND BY

DEFROST

INDOOR UNIT

ADDRESS NO

CENTRALLY CONTROLLED

CLOCK

ON OFF

˚C

1Hr.

NOT AVAILABLE

˚C

CHECK MODE

FILTER

CHECK

FUNCTION

a)

D

E

10.1. Before test run

s After completing installation and the wiring and piping of the indoor and outdoor

units, check for refrigerant leakage, looseness in the power supply or control

wiring, wrong polarity, and no disconnection of one phase in the supply.

s Use a 500-volt megohmmeter to check that the resistance between the power

supply terminals and ground is at least 1.0 MΩ.

s Do not carry out this test on the control wiring (low voltage circuit) termi-

nals.

Warning:

Do not use the air conditioner if the insulation resistance is less than 1.0 MΩ.

Insulation resistance

After installation or after the power source to the unit has been cut for an extended

period, the insulation resistance will drop below 1 MΩ due to refrigerant accumulating in the compressor. This is not a malfunction. Perform the following procedures.

1. Remove the wires from the compressor and measure the insulation resistance of

the compressor.

2. If the insulation resistance is below 1 MΩ, the compressor is faulty or the resist-

ance dropped due the accumulation of refrigerant in the compressor.

Fig. 10-1

3. After connecting the wires to the compressor, the compressor will start to warm

up after power is supplied. After supplying power for the times indicated below,

measure the insulation resistance again.

• The insulation resistance drops due to accumulation of refrigerant in the com-

pressor. The resistance will rise above 1 MΩ after the compressor is warmed

up for two to three hours.

(The time necessary to warm up the compressor varies according to atmospheric conditions and refrigerant accumulation.)

• To operate the compressor with refrigerant accumulated in the compressor,

the compressor must be warmed up at least 12 hours to prevent breakdown.

4. If the insulation resistance rises above 1 MΩ, the compressor is not faulty.

Caution:

• The compressor will not operate unless the power supply phase connection

is correct.

• Turn on the power at least 12 hours before starting operation.

- Starting operation immediately after turning on the main power switch can result in

severe damage to internal parts. Keep the power switch turned on during the operational season.

10.2. Test run

The following 3 methods are available.

10.2.1. Using wired remote controller (Fig. 10-1)

1 Turn on the power at least 12 hours before the test run.

2 Press the [TEST] button twice. ➡ “TEST RUN” liquid crystal display

3 Press the [Mode selection] button. ➡ Make sure that wind is blown out.

4 Press the [Mode selection] button and switch to the cooling (or heating) mode.

➡ Make sure that cold (or warm) wind is blown out.

5 Press the [Fan speed] button. ➡ Make sure that the wind speed is switched.

6 Check operation of the outdoor unit fan.

7 Release test run by pressing the [ON/OFF] button. ➡ Stop

8 After the checks, always turn off the power.

A ON/OFF button

B Test run display

C Indoor temperature liquid line temperature display

D ON/OFF lamp

E Power display

F Error code display

Test run remaining time display

G Set temperature button

H Mode selection button

I Fan speed button

M TEST button

10.3. Self-check

10.3.1. Wired remote controller (Fig. 10-2)

1 Turn on the power.

2 Press the [CHECK] button twice.

3 Set refrigerant address with [TEMP] button if system control is used.

4 Press the [ON/OFF] button to stop the self-check.

Fig. 10-2

• For description of each check code, refer to the following table.

5101 Room temperature thermistor error

5102 RT12, 13 thermistor error

2503 Drain sensor error

2502 Drain pump error

1503 Freezing safeguard operation

0405, 1501, 4210, 5102 Outdoor unit error

6831~6834 Signal error between remote controller and indoor units

6800 Communication error between indoor and outdoor units

8000 No alarm history

F F F F No unit

• On wired remote controller

1 Check code displayed in the LCD.

1 Check code Symptom

A CHECK button

B Refrigerant address

C TEMP. button

D IC: Indoor unit

OC: Outdoor unit

E Check code

13

Page 14

10.Test run

B

A

G

H

K

L

M

I

J

C

D

E

F

RC00J590B

52C

C412

C1

FAN2FAN1CNP

CNCCND

JP14

A

10.4. AUTO RESTART FUNCTION

This model is equipped with the AUTO RESTART FUNCTION.

When the indoor unit is controlled with the remote controller, the operation mode,

set temperature, and the fan speed are memorized by the indoor controller board.

The auto restart function sets to work the moment the power has restored after

power failure, then, the unit will restart automatically.

Notes:

• The operation settings are memorized when 10 seconds have passed after

the remote controller was operated.

Fig. 10-3

11.Maintenance

• If the main power is turned off or a power failure occurs while AUTO START/

STOP timer is active, the timer setting is cancelled. As this model is equipped

with the auto restart function, the air conditioner should start operating at

the same time that a power has restored.

• If the unit has been off with the remote controller before power failure, the

auto restart function does not work as the power button of the remote controller is off.

• To prevent breaker off due to the rush of starting current, systematize other

home appliance not to turn on at the same time.

10.5. Indoor temperature position change function

(Fig. 10-3)

This model is equipped with the indoor temperature position change function. Detection of room temperature can be changed into remote controller’s internal sensor.

1 Power supply is turn off.

2 Cut the JP14 jumper wire of the indoor controller board with a pair of nippers.

A Indoor controller board

A Indoor unit

B Union

C Liquid pipe

D Gas pipe

E Stop valve

F Outdoor unit

G Refrigerant gas cylinder operating valve

Fig. 11-1

H Refrigerant gas cylinder for R410A with

siphon

I Refrigerant (liquid)

J Electronic scale for refrigerant charging

K Charge hose (for R410A)

L Gauge manifold valve (for R410A)

M Service port

11.1. Gas charge (Fig. 11-1)

1. Connect gas cylinder to the service port of stop valve (3-way).

2. Execute air purge of the pipe (or hose) coming from refrigerant gas cylinder.

3. Replenish specified amount of refrigerant, while running the air conditioner

for cooling.

Note:

In case of adding refrigerant, comply with the quantity specified for the refrigerating

cycle.

Caution:

• Do not discharge the refrigerant into the atmosphere.

Take care not to discharge refrigerant into the atmosphere during installation, reinstallation, or repairs to the refrigerant circuit.

• For additional charging, charge the refrigerant from liquid phase of the gas

cylinder.

If the refrigerant is charged from the gas phase, composition change may

occur in the refrigerant inside the cylinder and the outdoor unit. In this case,

ability of the refrigerating cycle decreases or normal operation can be impossible. However, charging the liquid refrigerant all at once may cause the compressor to be locked. Thus, charge the refrigerant slowly.

To maintain the high pressure of the gas cylinder, warm the gas cylinder with warm

water (under 40°C) during cold season. But never use naked fire or steam.

14

Page 15

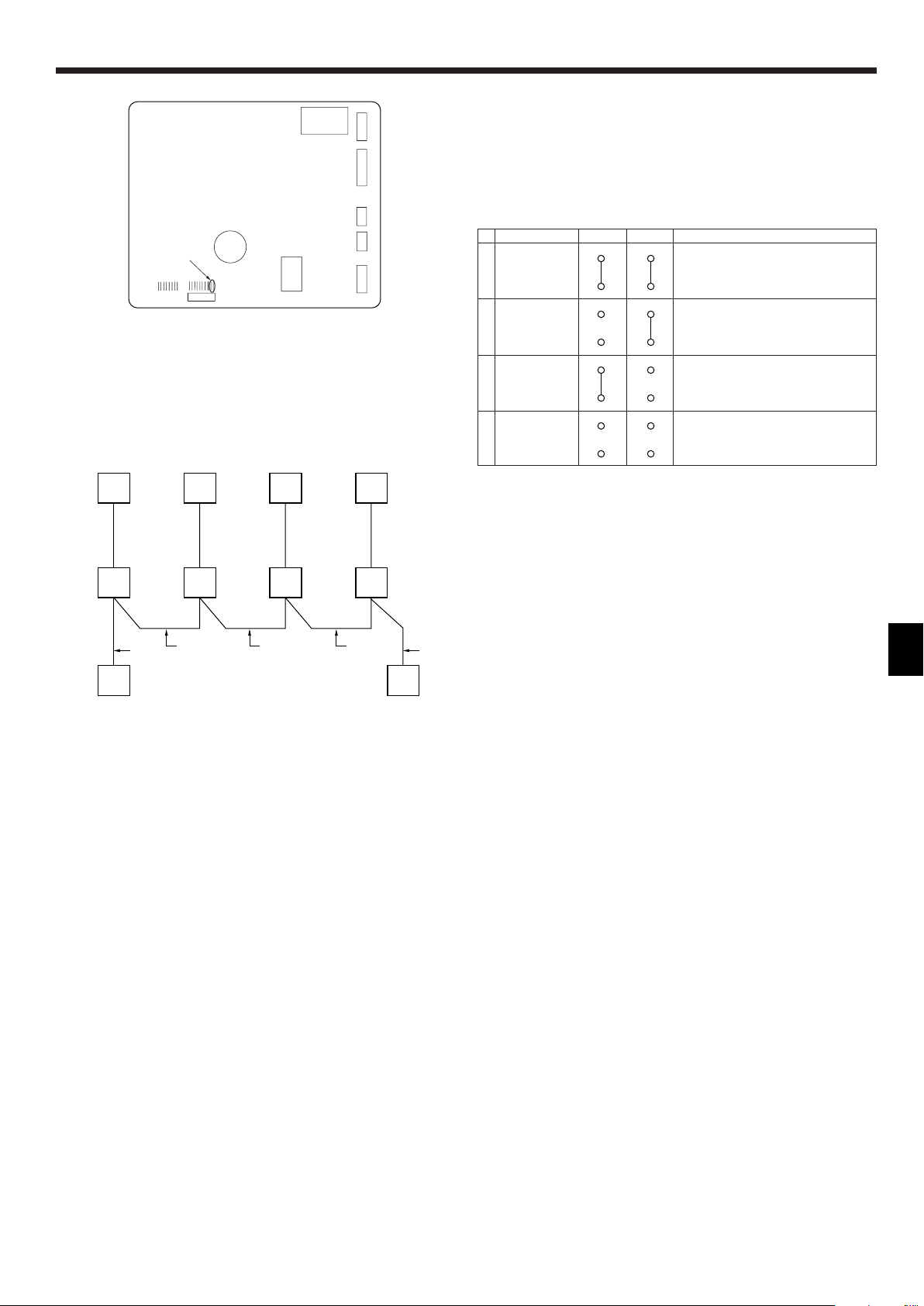

12.System control (Fig. 12-1)

A

BE

C

1

A

BFABGABH

D

1

2 2 2

RC00J590B

52C

C412

C1

FAN2FAN1CNP

CNCCND

JP17,18

I

1 Wiring from the Remote Control

This wire is connected to terminal block for remote controller of the indoor unit (nonpolar).

2 When a Different Refrigerant System Grouping is Used.

Up to 4 refrigerant systems can be controlled as one group using the MA remote

controller. There is need to set up JP17, JP18 jumper wire of indoor controller board.

Note:

In single refrigerant system, there in no need of wiring 2, and there is need to

cut JP17, JP18 jumper wire of indoor controller board.

The total extention of remote control cable is a maximum of 100 m.

JP17 JP18

Refrigerant

E

address = 00

The setup at the time shipment. In single refrigerant system, there is no need to cut JP17, JP18.

A Outdoor unit

B Indoor unit (only SEZ)

C Master remote controller

D Subordinate remote controller

E Standard 1:1 (Refrigerant address = 00)

F Simultaneous two groups (Refrigerant address = 01)

G Simultaneous three groups (Refrigerant address = 02)

H Simultaneous four groups (Refrigerant address = 03)

I Indoor controller board.

Fig. 12-1

Refrigerant

F

address = 01

Refrigerant

G

address = 02

Refrigerant

H

address = 03

Cut the JP17 jumper wire of indoor controller

board with a pair of nipper.

Cut the JP18 jumper wire of indoor controller

board with a pair of nipper.

Cut the JP17, JP18 jumper wire of indoor controller board with a pair of nipper.

15

Page 16

This product is designed and intended for use in the residential,

commercial and light-industrial environment.

The product at hand is

based on the following

EU regulations:

• Low Voltage Directive 73/23/ EEC

• Electromagnetic Compatibility Directive 89/

336/ EEC

Please be sure to put the contact address/telephone number on

this manual before handing it to the customer.

BG79S993H01

HEAD OFFICE: MITSUBISHI DENKI BLDG., 2-2-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

Printed in Thailand

Loading...

Loading...