Mitsubishi SE-1.6AR.TH (-T), SE-2AR.TH (-T), SE-2.5AR.TH (-T), SU-1.6VR.TH (-T), SU-2NR.TH Service Manual

...Page 1

TECHNICAL & SERVICE MANUAL

SPLIT-TYPE, AIR CONDITIONERS

CONTENTS

1. PART NAMES AND FUNCTIONS ········2

2. SPECIFICATIONS·································4

3. OUTLINES AND DIMENSIONS············7

4. WIRING DIAGRAM·······························9

5.

REFRIGERANT SYSTEM DIAGRAM

······12

6. DATA···················································16

7. MICROPROCESSOR CONTROL·······21

8. TROUBLESHOOTING························25

9. DISASSEMBLY PROCEDURE···········31

10. PARTS LIST········································36

11. OPTIONAL PARTS ·····························40

<Indoor unit>

SE-1.6AR.TH

SE-2AR.TH

SE-2.5AR.TH

SE-1.6AR.TH-T

SE-2AR.TH-T

SE-2.5AR.TH-T

No. OC167

[Models]

INDOOR UNIT

The Slim Line.

From Mitsubishi Electric.

REMOTE CONTROLLER

SU-1.6NR.TH

SU-2NR.TH

SU-2.5NR.TH

SU-1.6VR.TH

SU-2VR.TH

SU-2.5VR.TH

SU-1.6VR.TH-T

SU-2VR.TH-T

SU-2.5VR.TH-T

<Outdoor unit>

MITSUBISHI ELECTRIC

12

11

10

9

8

7

6

5

4

3

2

1

29

28

27

26

25

24

23

22

21

20

19

18

TIMER TEMP

TIMER/TEMP.

UP

DOWN

POWER

COOL

ON/OFF

MODE

SELECT

FAN

SPEED

TIMER

MODE

DRY

FAN

HIGH

LOW

AUTO

STOP

START

OUTDOOR UNIT

Series SE

Ceiling Concealed

REVISED EDITION-A

Revision

• SE-1.6AR.TH-T, SE-2AR.TH-T, SE-2.5AR.TH-T,

SU-1.6VR.TH, SU-1.6VR.TH-T, SU-2VR.TH, SU-2VR.TH-T,

SU-2.5VR.TH and SU-2.5VR.TH-T are added.

•Please destroy OC167, if you have.

Page 2

2

1

PART NAMES AND FUNCTIONS

● Indoor Unit

SE-1.6AR.TH SE-1.6AR.TH-T

SE-2AR.TH SE-2AR.TH-T

SE-2.5AR.TH SE-2.5AR.TH-T

Air outlet duct flange

Air outlet

Air intake

(Selecting the either back side or bottom side.)

SU-1.6NR.TH SU-1.6VR.TH SU-1.6VR.TH-T

SU-2NR.TH SU-2VR.TH SU-2VR.TH-T

SU-2.5NR.TH SU-2.5VR.TH SU-2.5VR.TH-T

Air intake

Air outlet

Drain outlet

Piping

Drain hose

● Outdoor Unit

Page 3

3

● Remote controller

SE-1.6AR.TH SE-1.6AR.TH-T

SE-2AR.TH SE-2AR.TH-T

SE-2.5AR.TH SE-2.5AR.TH-T

MITSUBISHI ELECTRIC

12

11

10

9

8

7

6

5

4

3

2

1

29

28

27

26

25

24

23

22

21

20

19

18

TIMER TEMP

TIMER/TEMP.

UP

DOWN

POWER

COOL

ON/OFF

MODE

SELECT

FAN

SPEED

TIMER

MODE

DRY

FAN

HIGH

LOW

AUTO

STOP

START

TIMER / TEMP.

This button is used to

change between display of

room temperature and

display of remaining timer

during "AUTO STOP"

operation. Green lamps

light in selected display

Remaining timer time

display

Lamps display

remaining timer time

or room temperature.

Lamps indicate time

remaining until timer stops

timed operation. Green

lamps corresponding to

remaining number of hours

light.

Room Temperature

display

Lamps display temperature

settings and actual room

temperatures.

● Temperature settings;

Green lamps light.

● Temperature in room;

Green lamps flash.

(Example display readings are for explanations

only ; autual display readings will differ.)

This button is used to

change between low and

high fan speeds. One of

two green lamps lights to

indicate fan speed in effect.

MODE SELECT button

This button is used to

change between cooling,

ventilation and DRY

operation modes. One of

three green lamps lights to

indicate mode in effect.

ON / OFF button

Pushing button starts

operation. Pushing again

stops operation. Green

lamp remains lit during

UP and DOWN buttons

● Temperature control (While "TEMP" green

lamps is lit.)

Use UP and DOWN buttons to set disired

temperature between 18 and 29°C.

● Timed operation (While green "TIMER"

lamp is lit.)

Use UP and DOWN buttons to set timed

operation between one and twelve hours.

TIMER MODE button

Used for selecting timed

starting or stopping. Green

lamps lights to indicate

timer mode selected.

● Pushing UP and Down buttons together for more than two seconds will initiate "trial run" or "inspection" mode. Avoid pushing

these buttons simultaneously during normal operation. Push ON / OFF button to cancel trial run or inspection mode if initiated

by accident.

● All green lamps turn off when air conditioner is stopped.

● Avoid operation of buttons with fingernails or other sharp objects. Sharp objects may scratch operating panel.

Attention :

Settings remain in effect until changed. Air conditioner

can be operated by simply pushing ON /OFF button

once settings have been made.

FAN SPEED button

Display Panel Operating Panel

Page 4

4

SPECIFICATIONS

2

Function

Power supply

Model

Capacity

Dehumidification

Air flow

Running current

Power input

Power factor

Starting current

Compressor motor current

Fan motor current

W

R/h

K/h

A

W

%

A

A

A

W

"

"

"

mm

mm

mm

mm

mm

mm

kg

kg

dB

dB

rpm

rpm

kg

R

k"

k"

k"

Capacity

Outdoor unit

Indoor unit

Electrical

data

Coefficient of performance(C.O.P)

Compressor

Indoor

fan motor

Outdoor

fan motor

Dimensions

Indoor unit

Indoor unit

Width

Height

Depth

Width

Height

Depth

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

RT11(at 25:)

RT12(at 25:)

RT61(at 0:)

Sound level

(Hi)

Fan speed

(Hi)

Fan speed

regulator

Outdoor unit

Outdoor unit

Refrigerant filling capacity(R-22)

Thermistor

Weight

Special

remarks

Model

Output

Winding resistance (at 20:)

Model

Winding resistance (at 20:)

Model

Winding resistance (at 20:)

SU -1.6NR.TH

Single phase, 220V, 60Hz Single phase, 220-240V, 50Hz

Cooling

780

PK6V19-ED

WHT-BLK :251.4 BLK-BLU : 19.9

BLU-YLW :26.5 YLW-RED :63.2

RA6V40-EE

WHT-BLK :130.4

BLK-RED :134.6

SU -1.6VR.TH SU -1.6VR.TH-T

SE -1.6AR.TH SE -1.6AR.TH SE -1.6AR.TH-T

3800

1.5

6.9

1500

99

6.18

2.53

51

740

820

RH-207NHDT

1000

C-R:1.68 C-S:2.78

50

720-770

780-820

1100

270

700

850

605

290

35

38

35

2

1

0.9

MS-56 O 0.52

10

10

33.18

4000

1.6

7.0-6.8

1490-1550

97-95

6.41-6.20

2.68-2.58

RH-247VHAT

1200

C-R:2.13 C-S:3.91

36

35-38

0.72

0.59-0.60

Refrigerant oil

NOTE:Test conditions (JIS)

Cooling : Indoor DB27°C WB19°C

Outdoor DB35°C WB24°C

Page 5

5

Model

NOTE:Test conditions(JIS)

Indoor DB27°C WB19°C

Outdoor DB35°C WB24°C

Capacity

Capacity

Electrical

Data

Current

Input

W

A

W

5200

13.1

2850

NOTE:Test condition(SSA 385/386)

Indoor DB29˚C WB19˚C

Outdoor DB46˚C WB24˚C

WSSA 385/386 can be applied only to Saudi Arabia.

—

—

—

Capacity

Capacity

Electrical

data

Coefficient of performance(C.O.P)

Compressor

Indoor

fan motor

Outdoor

fan motor

Dimensions

Weight

Special

remarks

Dehumidification

Air flow

Running current

Power input

Power factor

Starting current

Compressor motor current

Fan motor current

Model

Output

Winding resistance (at 20:)

Model

Winding resistance (at 20:)

Model

Winding resistance (at 20:)

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Sound level

(Hi)

Fan speed

(Hi)

Fan speed

regulator

Refrigerant filling capacity(R-22)

Refrigerant oil

Thermistor

Function

Power supply

Indoor unit

Outdoor unit

Width

Height

Depth

Width

Height

Depth

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

RT11(at 25:)

RT12(at 25:)

RT61(at 0:)

W

R/h

K/h

A

W

%

A

A

A

W

"

"

"

mm

mm

mm

mm

mm

mm

kg

kg

dB

dB

rpm

rpm

kg

R

k"

k"

k"

SE -2AR.TH SE -2AR.TH SE -2AR.TH-T

SU -2NR.TH

Cooling

Single phase, 220V, 60Hz Single phase, 220-240V, 50Hz

5900

11.5

2500

99

55

10.66

0.84

2.36

NH-33NCDT

1500

C-R:0.92 C-S:1.93

WHT-BLK :161.9 BLK-BLU : 50.3

BLU-YLW :18.7 YLW-RED :47.2

53

890

860

1.65

MS-32(N-1) O 0.85

PK6V32-ED

RA6V50-OF

WHT-BLK :116.4

BLK-RED :111

SU -2VR.TH SU -2VR.TH-T

2.6

1020

10.4-10.2

2250-2350

9.73-9.51

0.67-0.69

2.49-2.38

NH-38VMDT

C-R:1.07 C-S:2.26

1100

270

700

850

605

290

35

55

39

810-850

810-845

2

1

10

10

33.18

MS-32(N-1) O 1.2

5600

98-96

51-55

1700

52

1.6

Page 6

6

Function

Power supply

Model

Capacity

Dehumidification

Air flow

Running current

Power input

Power factor

Starting current

Compressor motor current

Fan motor current

W

R/h

K/h

A

W

%

A

A

A

W

"

"

"

mm

mm

mm

mm

mm

mm

kg

kg

dB

dB

rpm

rpm

kg

R

k"

k"

k"

Capacity

Outdoor unit

Indoor unit

Electrical

data

Coefficient of performance(C.O.P)

Compressor

Indoor

fan motor

Outdoor

fan motor

Dimensions

Indoor unit

Indoor unit

Width

Height

Depth

Width

Height

Depth

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

RT11(at 25:)

RT12(at 25:)

RT61(at 0:)

Sound level

(Hi)

Fan speed

(Hi)

Fan speed

regulator

Outdoor unit

Outdoor unit

Refrigerant filling capacity(R-22)

Thermistor

Weight

Special

remarks

Model

Output

Winding resistance (at 20:)

Model

Winding resistance (at 20:)

Model

Winding resistance (at 20:)

SU -2.5NR.TH

Single phase, 220V, 60Hz Single phase, 220-240V, 50Hz

Cooling

3.2

1200

PK6V50-ED

WHT-BLK :101.1 BLK-BLU : 56.1

BLU-YLW :14.7 YLW-RED :34.9

RA6V60-AB

WHT-BLK :81.1 BLK-YLW :92.2

YLW-RED :102.2

SU -2.5VR.TH SU -2.5VR.TH-T

SE -2.5AR.TH SE -2.5AR.TH SE -2.5AR.TH-T

7000

13.6

2920

98

12.52

2.40

54

980

930

NH-38NBDT

1700

C-R:0.83 C-S:1.83

53

860-890

860-890

1100

270

700

850

605

290

35

61

43

2

2

2.15

MS-32(N-1) O 1.2

10

10

33.18

6600

14.0-13.2

3030-3050

98-96

13.11-12.26

2.18-2.16

NH-47VMDT

2200

C-R:0.96 C-S:2.07

56

59

1.08

0.89-0.94

Refrigerant oil

NOTE:Test conditions(JIS)

Indoor DB27°C WB19°C

Outdoor DB35°C WB24°C

Capacity

Capacity

Electrical

Data

Current

Input

W

A

W

6100

16.2

3490

NOTE:Test condition(SSA 385/386)

Indoor DB29˚C WB19˚C

Outdoor DB46˚C WB24˚C

WSSA 385/386 can be applied only to Saudi Arabia.

—

—

—

Page 7

7

OUTLINES AND DIMENSIONS

3

INDOOR UNIT

SE-1.6AR.TH SE-1.6AR.TH-T

SE-2AR.TH SE-2AR.TH-T

SE-2.5AR.TH SE-2.5AR.TH-T

SU-1.6NR.TH SU-1.6VR.TH SU-1.6VR.TH-T

SU-2NR.TH SU-2VR.TH SU-2VR.TH-T

SU-2.5NR.TH SU-2.5VR.TH SU-2.5VR.TH-T

605

29220

50

133

500

161

850

74

30

100

157

35

30

Service panel

Liquid refrigerant

pipe joint

Refrigerant pipe

(flare)

Gas refrigerant

pipe joint

Refrigerant pipe

(flare)

12.7 (SU-1.6NR.TH)

15.88 (SU-2/2.5NR.TH)

6.35 (SU-1.6/2NR.TH)

(SU-1.6/2VR.TH,SU-1.6/2VR.TH-T)

(SU-1.6/2VR.TH,SU-1.6/2VR.TH-T)

9.52 (SU-2.5NR.TH)

(SU-2.5VR.TH,SU-2.5VR.TH-T)

(SU-2/2.5VR.TH,SU-2/2.5VR.TH-T)

Air intake

View A

A

Electrical parts box

Suspension

bolt

pitch

Air outlet

Access door

Service space(It is

necessary to maintain

a working service

area from the ceiling.)

20 mm or more

Access door

Electrical

parts

box

Suspension bolt pitch

Suspension bolt pitch

Drain plug R1 male

Refrigerent pipe(liquid)

{6.35(SE-1.6/2AR.TH)

(SE-1.6/2AR.TH-T)

{9.52(SE-2.5AR.TH)

(SE-2.5AR.TH-T)

Refrigerent pipe(gas)

{12.7(SE-1.6AR.TH)

(SE-1.6AR.TH-T)

{15.88(SE-2/2.5AR.TH)

(SE-2/2.5AR.TH-T)

Unit : mm

OUTDOOR UNIT

350

35

248

Drainage

3holes 16.2

20

290

310

345

10cm or more

If the right/left sides or

back side is vacant,the

front has only to be 50cm

unobstructed.

50cm

or m

ore

If the front or right/left sides

are vacant, the top has only

to be 10cm

10cm or more

unobstructed.

10cm or more

35cm

or m

ore

Page 8

8

REMOTE CONTROLLER

Remote controller cable installation

MITSUBISHI ELECTRIC

12

11

10

9

8

7

6

5

4

3

2

1

29

28

27

26

25

24

23

22

21

20

19

18

TIMER TEMP

TIMER/TEMP.

UP

DOWN

POWER

COOL

ON/OFF

MODE

SELECT

FAN

SPEED

TIMER

MODE

DRY

FAN

HIGH

LOW

AUTO

STOP

START

75

69

108

117

108

96.5

12

90.5

11.6

3.6

33

117

33

Rear side wiring

arrangememt opening

Upper side wiring

arrangement

opening

Fixing hole

83.5

12

86

4.6

46

9.2

MITSUBISHI ELECTRIC

12

11

10

9

8

7

6

5

4

3

2

1

29

28

27

26

25

24

23

22

21

20

19

18

TIMER TEMP

TIMER/TEMP.

UP

DOWN

POWER

COOL

ON/OFF

MODE

SELECT

FAN

SPEED

TIMER

MODE

DRY

FAN

HIGH

LOW

AUTO

STOP

START

Exposed remote controller

cable

Cable can be connected only to the

top of the remote controller.

(Right side, left side, and buttom are

not possible.)

●For exposed remote controller cable installation

Note : The cable for the remote controller has 10m (39ft) length and 12-core with connectors O.D. 5.8.

●For recessed remote controller cable installation

Unit : mm

Remote controller cable

Conduit tube

(local arrangement)

Switch box

(local arrangement)

Set screw (match with switch box),

local arrangement.

Page 9

9

NOTE :1. Since the indoor fan motor (MF) is connected with 50 Hz power, if 60Hz power is used,change the wiring

connection showing fig:*1

Indoor Fan Moter(MF) for 60Hz

2. About the outdoor side electric wiring referto the outdoor unit electric wiring diagram for servicing.

3. Use copper conductors only. (For field wiring)

4. Symbols below indicate.

/:Terminal block, : Connector

How to remove the terminals shown at ”W” mark.

WIRING DIAGRAM

4

P.C BOARD

INTERFACE

BOARDP.C

CONTROLLER

REMOTE

12 12

104B

CN

120

CN

120

CNR

TB

CIRCUIT BREAKER

POWER SUPPLY

~/N

220-240V 220V

50Hz 60Hz

L

N

GRN/YLW

3

RED

W

W

W

W

W

W

W

BRN

2

N

BLU

WHT

GRN/YLW

BLU

TO OUTDOOR

UNIT

CONNECTING

TB

5

CN

104

2

RT11

RT12

3

CN201

2

1

2

CN

112

CN

113

YLW

BLU

BLU

BLU

YLW

TRANS

8

LDCOM

LDC11

LDC12

LDFL

LDFM

LDFH

SR142

SR143

SR144

GRN/YLW

WHT

ORN

RED

BLK

BLK

WHT

4

5

6

1

2

3

7

ELECTRONIC CONTROL P.C BOARD

NR11

C11

52C

RED

ORN

F11

4

3

MF

HIC1

SR141

SR144

RT11

TB

TERMINAL BLOCK

RT12

INDOOR COIL THERMISTOR

HIC1

DC/DC CONVERTER

NR11

MF

52C

F11

SYMBOL

NAME NAME

C11

SYMBOL

FAN MOTOR CAPACITOR

SOLID STATE RELAY

FUSE(3.15A)

COMPRESSOR CONTACTOR

ROOM TEMPERATURE THERMISTOR

VARISTOR

FAN MOTOR

NAMESYMBOL

~

CONTROLLER

REMOTE

220-240V 220V

50Hz 60Hz

220-240V 220V

50Hz 60Hz

”W” shows the terminals with a lock mechanism,so they cannot be removed when you pull the lead wire.

Be sure to pull the wire by pushing the locking lever (project part) of the terminal with a finger.

1Slide the sleeve.

2Pull the wire while pushing the locking lever.

BLUE

YELLOW

60

50

fig: *1

BLUE

SE-1.6AR.TH SE-1.6AR.TH-T

SE-2AR.TH SE-2AR.TH-T

SE-2.5AR.TH SE-2.5AR.TH-T

INDOOR UNIT

Page 10

10

OUTDOOR UNIT

SU-1.6NR.TH

SU-2NR.TH

NOTE :1. Use copper conductors only. (For field wiring)

2. Since the indoor and outdoor unit connecting wires have polarity, connect them according to the numbers

(N,2,3 and ;).

3. Symbols below indicate.

/:Terminal block, : Connector

4. ”w” shows the terminals with a lock mechanism,so they cannot be removed when you pull the lead wire.

Be sure to pull the wire by pushing the locking lever (project part) of the terminal with a finger.

1Slide the sleeve.

2Pull the wire while pushing the locking lever.

BLK

BLK

YLW

VLT

26C

BLU

WHT

RED

RED

BLU

WHT

ORN

RED

52C

52C

4

3

2

1

C2

WHT

BLK

ORN

RED

WHT

MF

MC

CR

A2

A1

BLU

F

TB2

L1/1

L3/5

R

C

S

BLK

RED

C1

T1/2

T3/6

BLU

GRN/YLW

2

3

TO INDOOR

UNIT

CONNECTING

W

W

W

TB

220V, 60Hz

220V, 60Hz

THERMAL SWITCH26C

TB2 TERMINAL BLOCKF FUSE(2A)

CR SURGE ABSORBER

TERMINAL BLOCK

COMPRESSOR CONTACTOR52C

TB

FAN MOTOR

(INNER THERMOSTAT)

(INNER THERMOSTAT)

COMPRESSOR

MC

FAN MOTOR CAPACITOR

COMPRESSOR CAPACITOR

C2

C1

NAME

SYMBOL

NAME

SYMBOL

NAME

SYMBOL

MF

N

THERMAL SWITCH26CTB2 TERMINAL BLOCKF FUSE(2A)

CR SURGE ABSORBER

THERMAL REED SWITCH26F1

FAN MOTOR RELAYX1

TERMINAL BLOCK COMPRESSOR CONTACTOR52CTB

FAN MOTOR

(INNER THERMOSTAT)

(INNER THERMOSTAT)

COMPRESSOR

MF

MC

FAN MOTOR CAPACITOR

COMPRESSOR CAPACITOR

C2

C1

NAME

SYMBOL

NAME

SYMBOL

NAME

SYMBOL

YLW

VLT

BLK

CR

A2

A1

26C

BLK

BLU

ORN

BLU

X1

26F1

F

RED

8

7

BLU

RED

WHT

52C

TB2

RED

C2

GRN/YLW

2

3

RED

N

W

W

W

TB

220V, 60Hz

220V, 60Hz

L1/1

L3/5

MC

R

C

S

BLK

RED

C1

WHT

52C

T1/2

T3/6

BLU

TO INDOOR

UNIT

CONNECTING

1

3

5

X1

6

5

4

3

2

1

YLW

MF

YLW

BLK BLK

WHT

RED

ORN

WHT

ORN

RED

SU-2.5NR.TH

Page 11

11

OUTDOOR UNIT

SU-1.6VR.TH

SU-2VR.TH

SU-1.6VR.TH-T

SU-2VR.TH-T

NOTE :1. Use copper conductors only. (For field wiring)

2. Since the indoor and outdoor unit connecting wires have polarity, connect them according to the numbers

(N,2,3 and ;).

3. Symbols below indicate.

/:Terminal block, : Connector

4. ”w” shows the terminals with a lock mechanism,so they cannot be removed when you pull the lead wire.

Be sure to pull the wire by pushing the locking lever (project part) of the terminal with a finger.

1Slide the sleeve.

2Pull the wire while pushing the locking lever.

VLT

YLW

BLU

WHT

WHT

RED

RED

BLU

WHT

ORN

RED

52C

52C

4

3

2

1

C2

WHT

BLK

ORN

RED

WHT

MF

MC

CR

A1

A2

BLU

F

TB2

L1/1

L3/5

R

C

S

BLK

RED

C1

T1/2

T3/6

BLU

GRN/YLW

2

3

TO INDOOR

UNIT

CONNECTING

N

TB

220-240V,50Hz

220-240V,50Hz

W

W

W

YLW

VLT

BLU

ORN

1

3

5

X1

BLU

X1

26F1

F

RED

8

7

BLU

RED

WHT

52C

CR

TB2

WHT

RED

A1

A2

6

5

4

3

2

1

YLW

C2

MF

YLW

BLK BLK

WHT

RED

ORN

WHT

ORN

RED

L1/1

L3/5

MC

R

C

S

BLK

RED

C1

WHT

52C

T1/2

T3/6

BLU

GRN/YLW

2

3

RED

TO INDOOR

UNIT

CONNECTING

N

TB

220-240V,50Hz

220-240V,50Hz

W

W

W

SU-2.5VR.TH

SU-2.5VR.TH-T

TB2 TERMINAL BLOCKF FUSE(2A)

CR SURGE ABSORBER

TERMINAL BLOCK

COMPRESSOR CONTACTOR52C

TB

FAN MOTOR

(INNER THERMOSTAT)

(INNER THERMOSTAT)

COMPRESSOR

MF

MC

FAN MOTOR CAPACITOR

COMPRESSOR CAPACITOR

C2

C1

NAME

SYMBOL

NAME

SYMBOL

NAME

SYMBOL

TB2 TERMINAL BLOCKF FUSE(2A)

CR SURGE ABSORBER

THERMAL READ SWITCH26F1

FAN MOTOR RELAYX1

TERMINAL BLOCK COMPRESSOR CONTACTOR52CTB

FAN MOTOR

(INNER THERMOSTAT)

(INNER THERMOSTAT)

COMPRESSOR

MF

MC

FAN MOTOR CAPACITOR

COMPRESSOR CAPACITOR

C2

C1

NAME

SYMBOL

NAME

SYMBOL

NAME

SYMBOL

Page 12

12

5

REFRIGERANT SYSTEM DIAGRAM

Indoor

heat

exchanger

Outdoor

heat

exchanger

Distributor

(With strainer)

Flared connection

Room temperature

thermistor

Indoor coil

thermistor

Flared connection

Stop valve

Stop valve

(with service port)

Strainer

Strainer

Strainer

Capillary tube

(

[3.0x[1.8xR100

)

Capillary tube

(

[3.0x[1.8xR550

)

Compressor

Refrigerant pipe [12.7

(Option)

(with heat insulator)

Refrigerant pipe

(Option) [6.35

(with heat insulator)

Dis pressure

regulator

INDOOR UNIT

SE-1.6AR.TH

OUTDOOR UNIT

SU-1.6NR.TH

Indoor

heat

exchanger

Outdoor

heat

exchanger

Distributor

(With strainer)

Flared connection

Room temperature

thermistor

Indoor coil

thermistor

Flared connection

Stop valve

Stop valve

(with service port)

Strainer

Strainer

Strainer

Capillary tube

(

[3.0x[2.0xr100

)

Capillary tube

(

[3.0x[2.0xr700

)

Compressor

Refrigerant pipe [15.88

(Option)

(with heat insulator)

Refrigerant pipe

(Option) [6.35

(with heat insulator)

Accumulator

Dis pressure

regulator

INDOOR UNIT

SE-2AR.TH

OUTDOOR UNIT

SU-2NR.TH

INDOOR UNIT

OUTDOOR UNIT

SE-2.5AR.TH

SU-2.5NR.TH

Indoor coil

thermistor

Room temperature

thermistor

Indoor

heat

exchanger

Strainer

Distributor

(With strainer)

Strainer

Refrigerant pipe [15.88

(Option)

(with heat insulator)

Flared connection

Flared connection

Refrigerant pipe

(Option) [9.52

(with heat insulator)

Stop valve

(with service port)

Stop valve

Dis pressure

regulator

Accumulator

Capillary tube

(

[3.0x[2.0xR100

Capillary tube

(

[3.0x[2.0xR600

Compressor

)

Strainer

)

Outdoor

heat

exchanger

Page 13

13

INDOOR UNIT

SE-1.6AR.TH

SE-1.6AR.TH-T

OUTDOOR UNIT

SU-1.6VR.TH

SU-1.6VR.TH-T

Indoor

heat

exchanger

Outdoor

heat

exchanger

Distributor

(With strainer)

Flared connection

Room temperature

thermistor

Indoor coil

thermistor

Flared connection

Stop valve

Stop valve

(with service port)

Strainer

Strainer

Strainer

Capillary tube

(

[3.0x[2.0xr570

)

Compressor

Accumulator

Refrigerant pipe [15.88

(Option)

(with heat insulator)

Refrigerant pipe

(Option) [6.35

(with heat insulator)

INDOOR UNIT

SE-2AR.TH

SE-2AR.TH-T

OUTDOOR UNIT

SU-2VR.TH

SU-2VR.TH-T

INDOOR UNIT

OUTDOOR UNIT

SE-2.5AR.TH

SE-2.5AR.TH-T

SU-2.5VR.TH

SU-2.5VR.TH-T

Indoor coil

thermistor

Room temperature

thermistor

Indoor

heat

exchanger

Distributor

(With strainer)

Strainer

Strainer

Refrigerant pipe [12.7

(Option)

(with heat insulator)

Flared connection

Flared connection

Refrigerant pipe

(Option) [6.35

(with heat insulator)

Stop valve

(with service port)

Stop valve

Compressor

Capillary tube

(

[3.0x[1.8xr800

Strainer

)

Outdoor

heat

exchanger

Indoor coil

thermistor

Room temperature

thermistor

Indoor

heat

exchanger

Distributor

(With strainer)

Refrigerant pipe [15.88

(Option)

(with heat insulator)

Strainer

Strainer

Flared connection

Flared connection

Refrigerant pipe

(Option) [9.52

(with heat insulator)

Stop valve

(with service port)

Dis pressure

regulator

Stop valve

Accumulator

Capillary tube

(

[3.0x[2.0xR100

Capillary tube

(

[3.0x[2.0xR700

Compressor

)

Strainer

)

Outdoor

heat

exchanger

Page 14

14

Models

A: Refrigerant piping

Max.length

15m(49ft)

Max. Height difference *

7m(23ft)

MAX. REFRIGERANT PIPING LENGTH & MAX. HEIGHT DIFFERENCE

SE-1.6AR.TH

SE-1.6AR.TH-T

SE-2AR.TH

SE-2AR.TH-T

SE-2.5AR.TH

SE-2.5AR.TH-T

Length : m(ft)

A

15(49)

Piping size O.D. : mm (in.)

Gas

Liquid

{12.7(1/2)

{6.35(1/4)

{15.88(5/8)

wIt does not matter which unit is higher.

Models

SE-1.6AR.TH

SE-1.6AR.TH-T

SE-2AR.TH

SE-2AR.TH

SE-2AR.TH-T

SE-2.5AR.TH

SE-2.5AR.TH-T

Outdoor unit:

precharged

(up to 7m)

900

1650

Refrigerant piping length (one way)

7m08m159m3010m4511m6012m7513m9014m

105

15m

120

Calculation : og=15g/mo(Refrigerant piping length minus 7m)

If pipe length exceeds 7m, additional refrigerant (Freon 22) charge is required

ADDITIONAL REFRIGERANT CHARGE (R-22 : g)

{9.52(3/8)

2150

1600

SU-1.6VR.TH SU-1.6NR.TH

SU-1.6VR.TH-T

SU-2VR.TH SU-2NR.TH

SU-2VR.TH-T

SU-2.5VR.TH SU-2.5NR.TH

SU-2.5VR.TH-T

Indoor unit

Outdoor unit

SU-1.6VR.TH SU-1.6NR.TH

SU-1.6VR.TH-T

SU-2NR.TH

SU-2VR.TH

SU-2VR.TH-T

SU-2.5VR.TH SU-2.5NR.TH

SU-2.5VR.TH-T

Indoor unit

Outdoor unit

Page 15

15

Run the vacuum pump for more than 15 minutes and at this time confirm that the pressure gauge indicates

-0.1 Mpa (-76 cmHg).

EVACUATION PROCEDURES

Connect the refrigerant pipes (both the liquid and gas

pipes) between the indoor and the outdoor units.

Remove the service port cap of the stop valve on the side of the

outdoor unit gas pipe. (The stop valve will not work in its initial

state fresh out of the factory (totally closed with cap on)).

Connect the gauge manifold valve and the vacuum pump to the service port of the stop valve on the gas

pipe side of the outdoor unit.

Check the vacuum with the gauge manifold valve, then close the gauge manifold valve, and stop the

vacuum pump.

Leave it as is for one or two minutes. Make sure the pointer of the gauge manifold valve remains in the

same position.

After refrigerant pipes are connected and evacuated, fully open all stop valves

on gas and liquid pipe sides.

Operating without fully opening lowers the performance and causes trouble.

Pipe length :

7m maximum

No gas charge is

needed.

Pipe length

exceeding 7m

Charge the prescribed

amount of gas.

Remove the gauge manifold valve quickly from the service port of the stop

Tighten the cap to the service port to obtain the initial status.

Retighten the cap.

Leak test

Page 16

16

DATA

6

The standard data contained in these specifications apply only to the operation of the air conditioner under normal condition.

Operating conditions vary according to the areas where these units are installed. The following information has been provided to

clarify the operating characteristics of the air conditioner under the conditions indicated by the performance curve.

(1) GUARANTEED VOLTAGE

Rated voltage : ±10% SU-NR(198~242V 60Hz) / SU-VR(198~264V 50Hz)

(2) AIR FLOW

Air flow should be set at MAX.

(3) MAIN READINGS

(1) Indoor intake air wet-bulb temperature : ˚CWB

(2) Indoor outlet air wet-bulb temperature :

˚CWB

(3) Outdoor intake air dry-bulb temperature :

˚CDB

(4) Total input : W

The table of indoor air wet-bulb temperature difference at the bottom on page shows the difference between the

indoor intake air wet-bulb temperature and the indoor outlet air wet-bulb temperature for your reference at service.

How to measure the indoor air wet-bulb temperature difference

1. Attach at least 2 sets of wet-and-dry-bulb thermometers to the indoor air intake as shown in the figure, and at least 2 sets of

wet-and-dry-bulb termometers to the indoor air outlet. The thermometers must be attached to the position where air speed is

high.

2. Attach at least 2 sets of dry-bulb thermometers to the outdoor air intake.

Cover the thermometers to avoid direct rays of the sun.

3. Check that the air filter is cleaned.

4. Open windows and doors of the room.

5. Press the TEST RUN switch to start the COOL MODE.

6. When system stabilizes after more than 15 minutes, measure temperature and take an average temperature.

7. 10 minutes later, measure temperature again and check that the temperature does not change.

Air outlet

Air inlet

Wet-and dry-bulb

thermometers

Dry-bulb

thermometers

BACK VIEW

INDOOR UNIT

OUTDOOR UNIT

SU-NR (60Hz)

SU-VR (50Hz)

SE-1.6AR.TH

SE-1.6AR.TH-T

SE-2AR.TH

SE-2AR.TH-T

SE-2.5AR.TH-T

SE-2.5AR.TH

8.6

7.9

7.2

6.5

5.9

5.2

8.0

7.3

6.7

6.0

5.4

4.8

8.6

7.9

7.4

6.5

5.9

5.2

10.4

8.5

9.5

7.8

8.7

7.1

7.8

6.4

7.0

5.8

6.2

5.1

SE-1.6AR.TH

SE-2AR.TH

10.5

9.6

8.7

7.9

7.1

6.3

SE-2.5AR.TH

Page 17

17

Dry Bulb temperature (˚C)

20

25

30

Relative humidity (%)

50

60

70

(4) OUTDOOR LOW PRESSURE AND OUTDOOR UNIT CURRENT

COOL operation

1 Both indoor and outdoor units are under the same temperature/humidity condition.

2 Air flow should be set at MAX.

0.8

0.7

0.6

0.5

0.4

0.3

15 18 20 25 30 32 35(:)

50 60 70 (%)

Ambient temperature (:) / Ambient humidity (%)

Outdoor low pressure

8

7

6

5

4

3

15 18 20 25 30 32 35(:)

50 60 70 (%)

Ambient temperature (:) / Ambient humidity (%)

Outdoor unit current (A)

8

7

5

6

4

3

(MPa•G)

(kgf/F• G)

220V

SE-1.6AR.TH / SU-1.6NR.TH

3 The unit of pressure has been changed to MPa based on the international system of units(SI unit system).

The converted score against the traditional unit system can be gotten according to the formula below.

1(MPa • G) =10.2(kgf/

f

f

• G)

0.7

0.6

0.5

0.4

0.3

0.2

15 18 20 25 30 32 35(:)

50 60 70 (%)

Ambient temperature (:) / Ambient humidity (%)

Outdoor low pressure

12

11

10

9

8

7

15 18 20 25 30 32 35(:)

50 60 70 (%)

Ambient temperature (:) / Ambient humidity (%)

Outdoor unit current (A)

220V

(MPa•G)

7

6

4

3

2

5

(kgf/F• G)

SE-2AR.TH / SU-2NR.TH

220V

0.7

0.6

0.5

0.4

0.3

0.2

15 18 20 25 30 32 35(:)

50 60 70 (%)

Ambient temperature (:) / Ambient humidity (%)

Outdoor low pressure

14

13

12

11

10

9

8

15 18 20 25 30 32 35(:)

50 60 70 (%)

Ambient temperature (:) / Ambient humidity (%)

Outdoor unit current (A)

(MPa•G)

7

6

4

3

2

5

(kgf/F• G)

SE-2.5AR.TH / SU-2.5NR.TH

Page 18

18

0.7

0.6

0.5

0.4

0.3

0.2

15 18 20 25 30 32 35(:)

50 60 70 (%)

Ambient temperature (:) / Ambient humidity (%)

Outdoor low pressure

11

10

9

8

7

6

15 18 20 25 30 32 35(:)

50 60 70 (%)

Ambient temperature (:) / Ambient humidity (%)

Outdoor unit current (A)

220V

(MPa•G)

7

6

4

3

2

5

(kgf/F• G)

240v

SE-1.6AR.TH / SU-1.6VR.TH

SE-1.6AR.TH-T / SU-1.6VR.TH-T

0.8

0.7

0.6

0.5

0.4

0.3

15 18 20 25 30 32 35(:)

50 60 70 (%)

Ambient temperature (:) / Ambient humidity (%)

Outdoor low pressure

8

7

6

5

4

3

15 18 20 25 30 32 35(:)

50 60 70 (%)

Ambient temperature (:) / Ambient humidity (%)

Outdoor unit current (A)

8

7

5

6

4

3

(MPa•G)

(kgf/F• G)

220v

240v

SE-2AR.TH / SU-2VR.TH

SE-2AR.TH-T / SU-2VR.TH-T

220V

0.7

0.6

0.5

0.4

0.3

0.2

15 18 20 25 30 32 35(:)

50 60 70 (%)

Ambient temperature (:) / Ambient humidity (%)

Outdoor low pressure

14

13

12

11

10

9

8

15 18 20 25 30 32 35(:)

50 60 70 (%)

Ambient temperature (:) / Ambient humidity (%)

Outdoor unit current (A)

(MPa•G)

7

6

4

3

2

5

(kgf/F• G)

240v

SE-2.5AR.TH / SU-2.5VR.TH

SE-2.5AR.TH-T / SU-2.5VR.TH-T

Page 19

19

(5) INDOOR FAN PERFORMANCE AND CORRECTED AIR FLOW

Air flow (K/X)

Recommended range

80

60

40

20

0

15510 2025

External static pressure(Pa)

(1Pa = 0.1mmAq)

Fan Performance

SE-2AR.TH (60Hz)

Corrected Airflow

Capacity

Input

1.0

1.1

1.2

0.8

0.9

510152025

Correction factor

Air flow (K/X)

Air flow (K/X)

Recommended range

80

100

60

40

20

0

15510 2025

External static pressure(Pa)

(1Pa = 0.1mmAq)

Fan Performance

SE-2.5AR.TH (60Hz)

Corrected Air flow

Capacity

Input

0.8

0.9

1.1

1.0

1.2

510152025

Correction factor

Air flow (K/X)

SE-1.6AR.TH (60Hz)

Fan Performance

Recommended range

80

1.3

60

40

20

External static pressure(Pa)

(1Pa = 0.1mmAq)

0

105 7 15 20 25

Air flow (K/X)

1.2

1.1

1.0

Correction factor

0.9

0.8

Corrected Air flow

510152025

Air flow (K/X)

Capacity

Input

Page 20

20

Air flow (K/X)

Recommended range

80

60

40

20

0

15510 2025

External static pressure(Pa)

(1Pa = 0.1mmAq)

Fan Performance

SE-2AR.TH (50Hz)

SE-2AR.TH-T

Corrected Airflow

Capacity

Input

1.0

1.1

1.2

0.8

0.9

510152025

Correction factor

Air flow (K/X)

25

Air flow (K/X)

Recommended range

80

60

40

20

0

105152025

External static pressure(Pa)

(1Pa = 0.1mmAq)

Fan Performance

SE-1.6AR.TH (50Hz)

SE-1.6AR.TH-T

Corrected Air flow

Capacity

Input

1.0

1.2

1.3

1.1

0.8

0.9

5101520

Correction factor

Air flow (K/X)

Air flow (K/X)

Recommended range

80

100

60

40

20

0

15510 2025

External static pressure(Pa)

(1Pa = 0.1mmAq)

Fan Performance

SE-2.5AR.TH (50Hz)

SE-2.5AR.TH-T

Corrected Air flow

Capacity

Input

0.8

0.9

1.1

1.0

1.2

510152025

Correction factor

Air flow (K/X)

Page 21

21

MICROPROCESSOR CONTROL

7

1. COOL operation

(1) Compressor control

1 3-minute time delay

To prevent overload, the compressor will not start within 3 minutes after stop.

2 The compressor runs when the room temperature is higher than the set temperature.

The compressor stops when the room temperature is equal to or lower than the set temperature.

3 The compressor stops in check mode.

(2) Indoor fan control

Indoor fan speed LOW/HIGH depends on the remote controller setting.

(3) Outdoor fan control

POWER ON/OFF with the compressor.

(4) Coil frost prevention

1 Temperature control

When the indoor coil thermistor RT12 reads -1°C or below, the coil frost prevention mode starts immediately.

However the coil frost prevention will not work for 5 minutes after the compressor starts.

During the coil frost prevention compressor stops and the indoor fan operates at the set speed for 5 minutes.

After that, if RT12 still reads or below -1°C, this mode prolonged untill theRT12 reads over -1°C.

After the coil frost prevention stops, units will not enter this mode again at least 5 minutes even RT12 reads -1°C.

2 Time control

When the three conditions below have been satisfied for 1 hour and 45 minutes, compressor stops for 3 minutes.

a. Compressor has been continuously operating.

b. Indoor fan speed is Low.

c. Room temperature is below 26°C.

When compressor stops ,the accumulated time is canceled and when compressor restarts, time counting starts from

the beginning.

Time counting also stops temporarily when the indoor fan speed becomes High or the room temperature exceeds 26°C.

However, when two of the above conditions (b.And c.) are satisfied again time accumulation is resumed.

<How to operate>

1 Press POWER ON / OFF button.

2 Press MODE SELECT button to set operation mode to COOL.

3 Check lamp is ON and set desired temperature with UP or DOWN but-

ton.

NOTES : 1. When lamp is ON, press TIMER/TEMP button to change the

display to temperature mode.

2. Set temperature changes by 1°C in the range 18 ~ 29°C each time UP

or DOWN button is pressed.

3. The lighting lamp shows the set temperature, and the flashing lamp

shows the room temperature.

When the room temperature is equal to the set temperature, the lamp

keeps lighting, 0.5 seconds brightly and 0.5 seconds faintly.

TIMER

<COOL operation time chart>

W1 Even if the room temperature rise above the set temperature during this period, the compressor will not start until this

period has ended.

MITSUBISHI ELECTRIC

12

11

10

9

8

7

6

5

4

3

2

1

29

28

27

26

25

24

23

22

21

20

19

18

TIMER TEMP

TIMER/TEMP.

UP

DOWN

POWER

COOL

ON/OFF

MODE

SELECT

FAN

SPEED

TIMER

MODE

DRY

FAN

HIGH

LOW

AUTO

STOP

START

TEMP

Thermostat

Indoor fan

Operation starts by

POWER button

ON.

ON

OFF

ON

OFF

Room temperature

becomes equal to

set temperature.

Room temperature

rises above set

temperature.

LOW or HIGHLOW or HIGH

Operation stops by

POWER button

OFF.

Compressor

Outdoor fan

ON

OFF

}

MIN. 3 minutes 1

Page 22

22

2. DRY operation

<How to operate>

1 Press POWER ON / OFF button.

2 Press MODE SELECT button to set operation mode to DRY.

3 Check lamp is ON and set desired temperature with UP or DOWN but-

ton.

NOTES : 1. When lamp is ON, press TIMER/TEMP button to change the

display to temperature mode.

2. Unable to set temperature. POWER ON/OFF are operated by

microprocessor control automatically.

3. The flashing lamp shows the room temperature.

TIMER

<DRY operation time chart> In case of the room temperature of 23: and above.

Example

Thermostat

Indoor fan

Outdoor fan

compressor

1st ON

8min.

1min.

4min.

3min.

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

(1) Setting temperature

Follow the right chart with according to the initial room temperature. When

the room temperature is 13: or under, dry operation does not work.

(2) ON/OFF control

When the room temperature is 23°C or over:

Compressor operates by temperature control and time control.

1 Set temperature is controlled to fall 2°C above from initial set temperature.

2 When the thermostat is ON, the compressor repeats 8 minutes ON and 3 minutes OFF.

When the thermostat is OFF, the compressor repeats 4 minutes OFF and 1 minute ON.

Indoor fan and outdoor fan operate in the same cycle as the compressor.

When the room temperature is under 23°C.

When the thermostat is ON, the compressor repeats 2 minutes ON and 3 minutes OFF.

When the thermostat is OFF, the compressor repeats 4 minutes OFF and 1 minute ON.

(3) Coil frost prevention

The operation is same as that of coil frost prevention during COOL mode.

However the indoor fan speed becomes the set speed or Low.

TIMER TEMP

12

11

10

9

8

7

6

5

4

3

2

1

29

28

27

26

25

24

23

22

21

20

19

18

TIMER/TEMP.

UP

DOWN

POWER

ON/OFF

COOL

MODE

DRY

SELECT

FAN

HIGH

FAN

SPEED

LOW

AUTO

STOP

TIMER

MODE

START

MITSUBISHI ELECTRIC

TEMP

Page 23

23

3. FAN operation

<How to operate>

1 Press POWER ON / OFF button.

2 Press MODE SELECT button to set operation mode to FAN.

NOTES : Temperature can not be set in FAN operation.

MITSUBISHI ELECTRIC

12

11

10

9

8

7

6

5

4

3

2

1

29

28

27

26

25

24

23

22

21

20

19

18

TIMER TEMP

TIMER/TEMP.

UP

DOWN

POWER

COOL

ON/OFF

MODE

SELECT

FAN

SPEED

TIMER

MODE

DRY

FAN

HIGH

LOW

AUTO

STOP

START

(1) Indoor fan control

The indoor fan speed LOW / HIGH depends on the remote controller setting.

Page 24

24

4. TIMER operation

<Timer function>

AUTO STOP ·········Air conditioner stops after the set time lapses.

AUTO START ········Air conditioner starts after the set time lapses.

<How to operate

●

AUTO STOP timer>

1 While lamp is lighting, press TIMER MODE button.

and lamps turn ON.

2 Set the time for the AUTO STOP timer with the UP or DOWN button.

NOTE : The time setting is in 1 hour units up to 12 hours.

3 With the lapse of time, the timer lamps turn OFF one by one, showing the

remaining time.

4 To cancel the AUTO STOP timer and continue operation, press the TIMER MODE

button.

To cancel the AUTO STOP timer and stop operation, press the POWER ON/OFF

button.

<How to operate AUTO START timer>

1 While lamp is OFF, press TIMER MODE button.

and lamps turn ON.

2 Set the time for the AUTO START timer with the UP or DOWN button.

NOTE : The time setting is in 1 hour units up to 12 hours.

3 With the lapse of time, the timer lamps turn OFF one by one, showing the

remaining time.

4 To cancel the AUTO START timer and keep the unit OFF, press the TIMER MODE

button.

To cancel the AUTO START timer and start operation, press the POWER ON /

OFF button.

TIMER

POWER

● POWER

5. TEST RUN

The unit starts the test run by pressing both the UP and DOWN buttons simultaneously for more than two seconds during

lamp ON or the unit OFF.

● The test run automatically stops in 2 hours.

● Set temperature is not displayed during test run.

●

During the test run, the thermo function are as below.

● Room temperature is displayed by the flashing green lamp when TIMER/TEMP button is pressed.

● The test run can be released by pressing the POWER ON / OFF or the TIMER MODE button.

TIMER

Initial 30 minutes

Thermo ON at the all time

Since 30 minutes passed to terminating of the

test run

Thermo ON/OFF as 24: of setting

temperature

6. SERVICE FUNCTION

AUTO RESTART FUNCTION

Operating the J2 Jumper line on the remote control Interface P.C.board of the indoor unit.

The function can set the auto restart function.(See page 29.) wAuto restart setting on the shipping.

J2 = Auto restart

No J2 = No auto restart

TIMER TEMP

TIMER/TEMP.

29

12

28

11

27

10

26

9

25

8

24

7

23

6

22

5

21

4

20

3

19

2

18

1

UP

DOWN

POWER

COOL

DRY

FAN

HIGH

LOW

AUTO

STOP

START

MITSUBISHI ELECTRIC

ON/OFF

MODE

SELECT

FAN

SPEED

TIMER

MODE

TIMER

Page 25

25

TROUBLESHOOTING

8

1. Cautions on troubleshooting

(1) Before troubleshooting, check the followings:

1Check the power supply voltage.

2Check the indoor/outdoor connecting wire for mis-wiring.

(2) Take care the followings during servicing.

1 Before servicing the air conditioner, be sure to first turn off the remote controller to stop the main unit, and then turn

off the breaker.

2 When removing the electronic control P.C. board, hold the edge of the board with care NOT to apply stress on the

components.

3 When connecting or disconnecting the connectors, hold the housing of the connector. DO NOT pull the lead wires.

Page 26

26

2. Self diagnostic function

(1) When trouble occurs during operation, the unit stops and enters the self-diagnotic mode, and displays the trouble

location with the timer lamps on the remote controller. All the other lamps are OFF.

(2) To activate the self-diagnostic function for service, press the UP and DOWN buttons simultaneously for more than two

seconds during operation with lamp ON.

(3) The timer lamps show the latest trouble. Trouble data is memorised unit the nest trouble occurs, even when the breaker

turns OFF. To clear the memory, press the UP and DOWN buttons simultaneously for more than two seconds during

the test run.

(4) All buttons except the POWER ON/OFF button are unavailable during the self-diagnostic mode.

(5) To release the self-diagnostic mode, press the POWER ON/OFF button.

TEMP.

12

11

10

9

8

7

6

5

1

2

3

4

(Indicates that the unit is in self-diagnostic mode)

TIMER TEMP.

29 Remote controller interface signal error

28

27 Indoor thermistor abnormally

26

25

24

23

22

18

19

20

21

Page 27

27

3. Trouble shooting

(1) In case of being indicated irregularity on the self diagnoses

No Phenomenon Cause Countermeasure

29 Remote controller interface

signal error

Mis-wiring of the Interface

P.C.board.

Reinsert the wiring connector of the Interface

P.C.board.

Trouble of the Interface P.C.board.

Exchange the Interface P.C.board.

Trouble of the Indoor P.C.board. Exchange the Indoor P.C.board.

27

Indoor coil thermistor Mis-connecting of the Indoor coil

thermistor.

Reinsert the connector (CN112).

Trouble of the Indoor coil

thermistor.

Room temperature

thermistor

Trouble of the Indoor P.C.board.

Check the resistance value of the thermistor.

Mis-connecting of the room

temperature thermistor.

Exchange the Indoor P.C.board.

Reinsert the connector (CN113).

Trouble of the room temperature

thermistor.

Trouble of the Indoor P.C.board.

Exchange the Indoor P.C.board.

Check the resistance value of the thermistor.

(2) Other case

Phenomenon

Cause

Countermeasure

Not working of remote

controller switch ON/OFF

Mis-connecting the remote control wiring. Reinsert the connector of remote control wiring.

Mis-connecting the Interface P.C.board.

Reinsert the wiring connector of Indoor P.C.board

and Interface P.C.board.

Short circuit the protecting parts in the

Indoor P.C.board.

Check the varistor(NR11) and fuse(F11) out in the

Indoor P.C.board.

Trouble of the Interface P.C.board.

Check the Interface P.C.board out.

Trouble of the Indoor P.C.board.

Working the Indoor units and

not working the outdoor

units.

Trouble of the remote controller. Exchange the remote controller.

Wiring between the indoor and outdoor is

coming off.

Check the wiring out between the indoor and

outdoor.

Difference of wiring polarity between the

indoor and outdoor.

Exchange the contactor.

Trouble of the contact(52C)

Not rotating the fan in the

indoor unit.

Trouble of the compressor(MC) and

outdoor fan motor(MF).

Check the compressor and fan motor out.

Frequency switching connector is coming

off.

Fan motor connector is coming off.

Check the connector out.

Check the frequency (50Hz/60Hz) in the indoor

unit.

Trouble of the Indoor P.C.board. Check the fan motor output of the Indoor

P.C.board.

Trouble of the fan motor.

Check the resistance value between the each tap

of fan motor.

Check the Indoor P.C.board out.

Page 28

28

Indoor coil thermistor (RT12)

Room temperature thermistor (RT11)

0

0

10

20

30

40

10 20 30 40 50 60

Temperature ( C)

Resistance (K')

(1). Indoor electronic control P.C. board

Fan motor power supply 220 - 240V AC

75643218

Lo

60Hz

Hi

Fuse 250V AC 3.15A

Power supply

input 220-240V AC

12V DC

5V DC

+

–

+

–

Time short point

Indoor coil thermistor (RT12)

Lo

50Hz

Room temperature thermistor (RT11)

4. Test point of P.C.board

Page 29

29

(2) Remote controller interface P.C. board

AUTO RESTART

FUNCTION

+ JP17= 5V DC

+ JP16=12V DC

– JP15= 0V DC

To

Indoor electronic

control P.C.board

To REMOTE CONTROLLER

Page 30

30

Measure the resistance between the terminals with a tester.

(Coil wiring temperature10°C ~ 30°C)

Compressor

Room

temperature

thermistor

5. Trouble criterion of main parts

Part name

Indoor coil

thermistor

Indoor fan

motor

Outdoor fan

motor

Check method and criterion

Measure the resistance with a tester.

(Part temperature 10°C ~ 30°C)

Measure the resistance between the terminals with a tester.

(Coil wiring temperature -10°C ~ 40°C)

Measure the resistance between the terminals with a tester.

(Coil wiring temperature -10°C ~ 40°C)

Figure

C

S

R

BLK

RED

WHT

BLK RED ORNYLW

BLU

WHT

GRN

YLW

P

Normal

8kΩ ~ 20kΩ

Abnormal

Opened or short-circuited

Normal

NR

1.52~

1.87

Ω

2.41~

2.96

Ω

2

0.81~

1.00

Ω

1.70~

2.09

Ω

C-R

C-S

Normal

Abnormal

Opened or

short-circuited

2AR

WHT-BLK

Normal

Abnormal

Opened or

short-circuited

102 ~ 126Ω

97.9 ~ 120Ω

2NR/2VR

WHT-BLK

BLK-RED

1.6NR/1.6VR

115 ~ 141Ω

118 ~ 146Ω

1.6AR

155.5~168.2Ω241.4~261.2Ω

BLK-BLU

48.3~52.3Ω19.0~20.6Ω

BLU-YLW

17.8~19.4Ω25.4~27.5Ω

YLW-RED

45.2~49.0Ω60.6~65.6Ω

Abnormal

Opened or

short-circuited

1.6/2NR

1.6/2VR

BLK

RED ORN

WHT

MAIN

AUX

P

: Inner protector

p

2.5

0.73~

0.90

Ω

1.61~

1.98

Ω

71.5 ~ 87.5Ω

90.1 ~ 110.2Ω

2.5NR/2.5VR

BLK-YLW

80.8 ~ 99.4Ω

2.5NR

2.5VR

BLKYLW

RED ORN

WHT

MAIN

AUX.2

AUX.1

P

SE-1.6AR SU-1.6NR SU-1.6VR

SE-2AR SU-2NR SU-2VR

SE-2.5AR SU-2.5NR SU-2.5VR

2.5AR

97.0~105Ω

53.8~58.3Ω

14.0~15.3Ω

33.4~36.2Ω

VR

1.87~

2.30

Ω

3.44~

4.22

Ω

1.6

NR

VR

0.94~

1.16

Ω

1.99~

2.44

Ω

NR

VR

0.84~

1.04

Ω

1.82~

2.24

Ω

Page 31

31

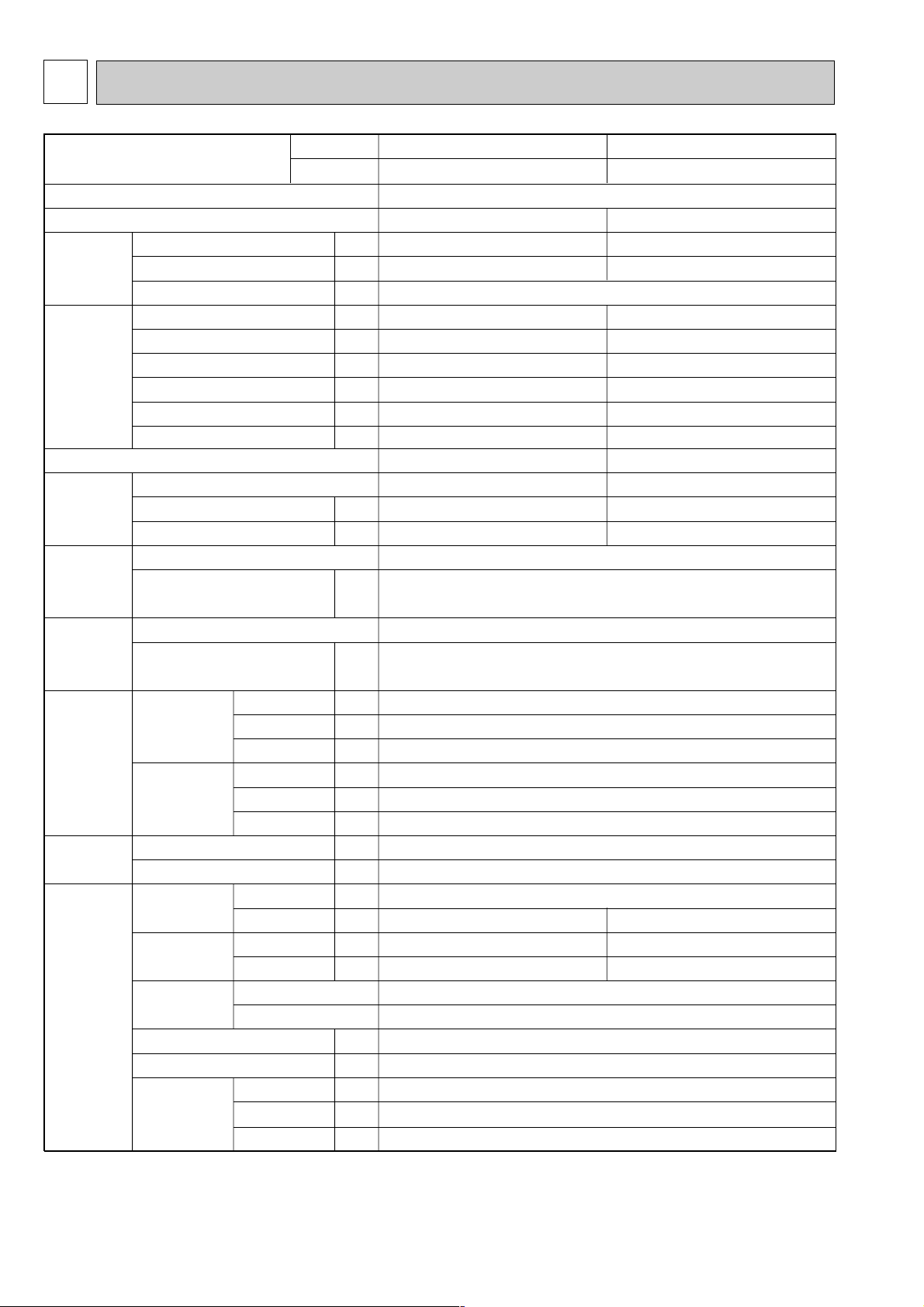

1. Removing the electrical parts

(1) Remove the 2 screws and the electrical parts cover.

(See Photo 1.)

● Indoor controller board

● Transformer

● Run capacitor

● Fuse (3.15A)

● Terminal block

(See Photo 2.)

DISASSEMBLY PROCEDURE9

Indoor Unit : SE-1.6AR.TH SE-2AR.TH SE-2.5AR.TH

SE-1.6AR.TH-T SE-2AR.TH-T SE-2.5AR.TH-T

OPERATING PROCEDURE

PHOTOS

2. Removing the indoor coil thermistor(RT12)

(1) Remove the electrical parts cover.

(See Photo 1.)

(2) Remove the 2 screws and the service panel.

(See Photo 1.)

(3) Remove the thermister (RT12) from the holder.

(See Photo 3.)

(4) Disconnect the connector (CN112) from the indoor

controller board and pull the lead wire of thermistor

(RT12) out.

Drain pan

Electrical parts cover

Service panel

Front Panel

Set screws

(for drain pan)

Fuse

Set screws

Terminal block

Transformer

Run capacitor

Thermistor

(RT12)

Photo 2.

Photo 3.

Photo 1.

Page 32

32

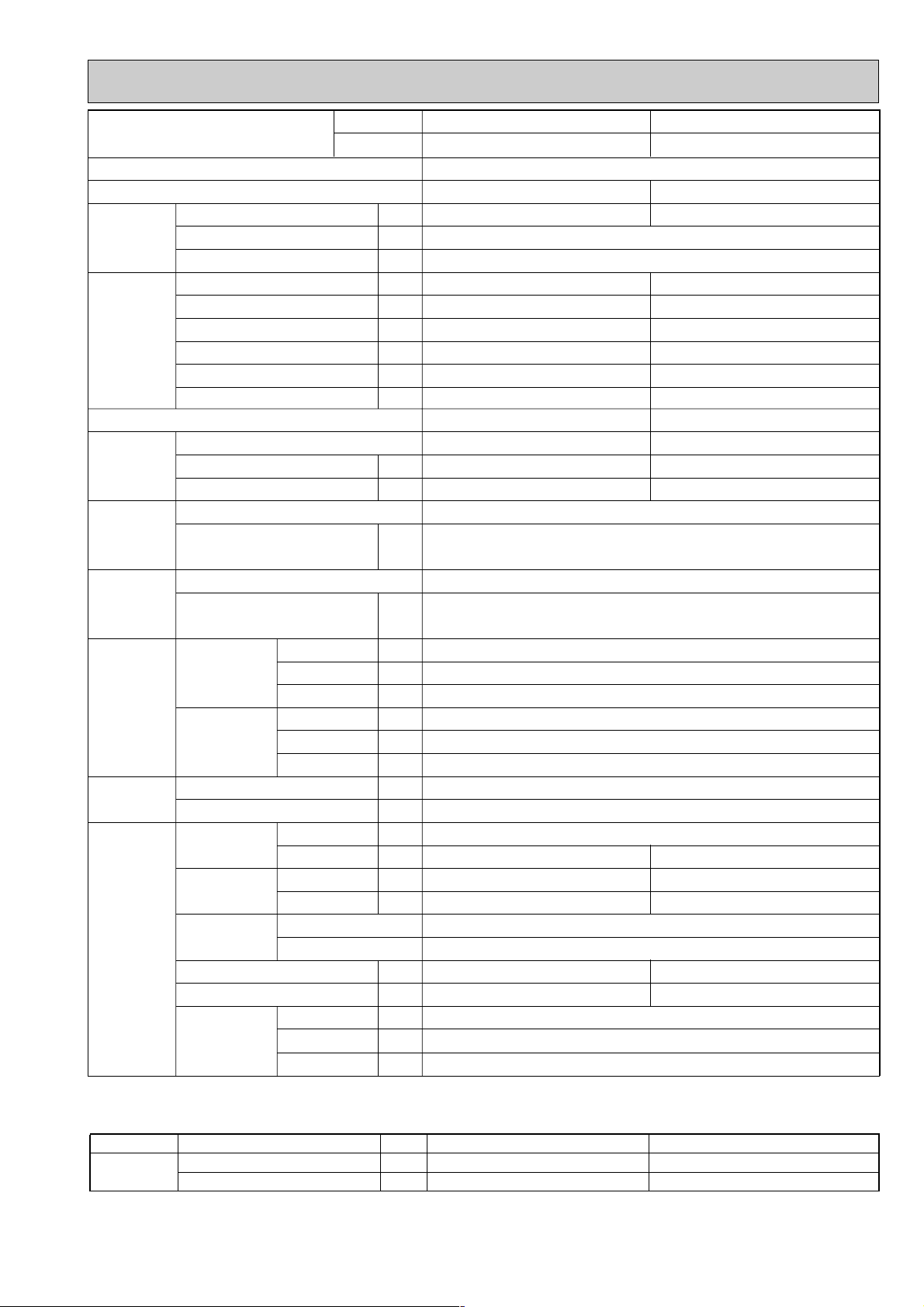

3. Removing the room temp. thermistor(RT11)

(1) Remove the electrical parts cover.

(See Photo 1.)

(2) Remove the front panel at fan side.(12 screws)

(See Photo 1.)

(3) Remove the thermister (RT11) from the fan casing.

(See Photo 4.)

(4) Disconnect the connector (CN113) from the indoor

controller board and pull the lead wire of thermistor

(RT11)out.

PHOTOS

OPERATING PROCEDURE

4. Removing the sirocco fan and the fan motor.

(1) Remove the electrical parts cover.

(See Photo 1.)

(2) Remove the front panel at fan side.(12 screws)

(See Photo 1.)

(3) Disconnect the fan motor connector from the indoor

controller board.

(See Photo 2.)

(4) Remove the thermistor (RT11) from the fan casing.

(See Photo 4.)

(5) Undo the 4 claws and remove the fan claws.(down side)

<Either left or right>

(See Photo 4.)

(6) Remove the motor bands. (A screw each on left and

right.)

(See Photo 4.)

(7) Disconnect the earth wire.(from the fan motor leg.)

(See Photo 5.)

(8) Remove the fan motor and the sirocco fan by assembly.

(See Photo 5.)

(9) Unscrew the setting screw and remove the sirocco fan.

<Either left or right>

(See Photo 5.)

Set screw

Earth wire

Motor bands

Thermistor

(RT11)

Claws

Screws

Fan casing

Fan motor

Claws

Photo 4.

Photo 5.

Page 33

33

5. Removing the drain pan

(1) Unscrew each set screw on the right and left, and

remove the drain pan pushing it toward the back.

(See Photo 1.)

PHOTOS

OPERATING PROCEDURE

6. Removing the heat exchanger

(1) Remove the drain pan.

(See Photo 1.)

(2) Remove the under flange at heat exchanger side.

(16 screws)

(See Photo 6.)

(3) Remove the 4 screws of heat exchanger.( 2 screws

each on left and right)

(See Photo 7.)

(4) Remove the service panel.( 3 screws )

(See Photo 7.)

(5) Put the heat exchanger down to the fan motor and pull it

toward you.

(See Photo 7.)

Screws

Under flange

Screws

(for heat exchanger)

Service panel

Screws

(for service panel)

Heat exchanger

Photo 6.

Photo 7.

Page 34

34

OPERATING PROCEDURE PHOTOS

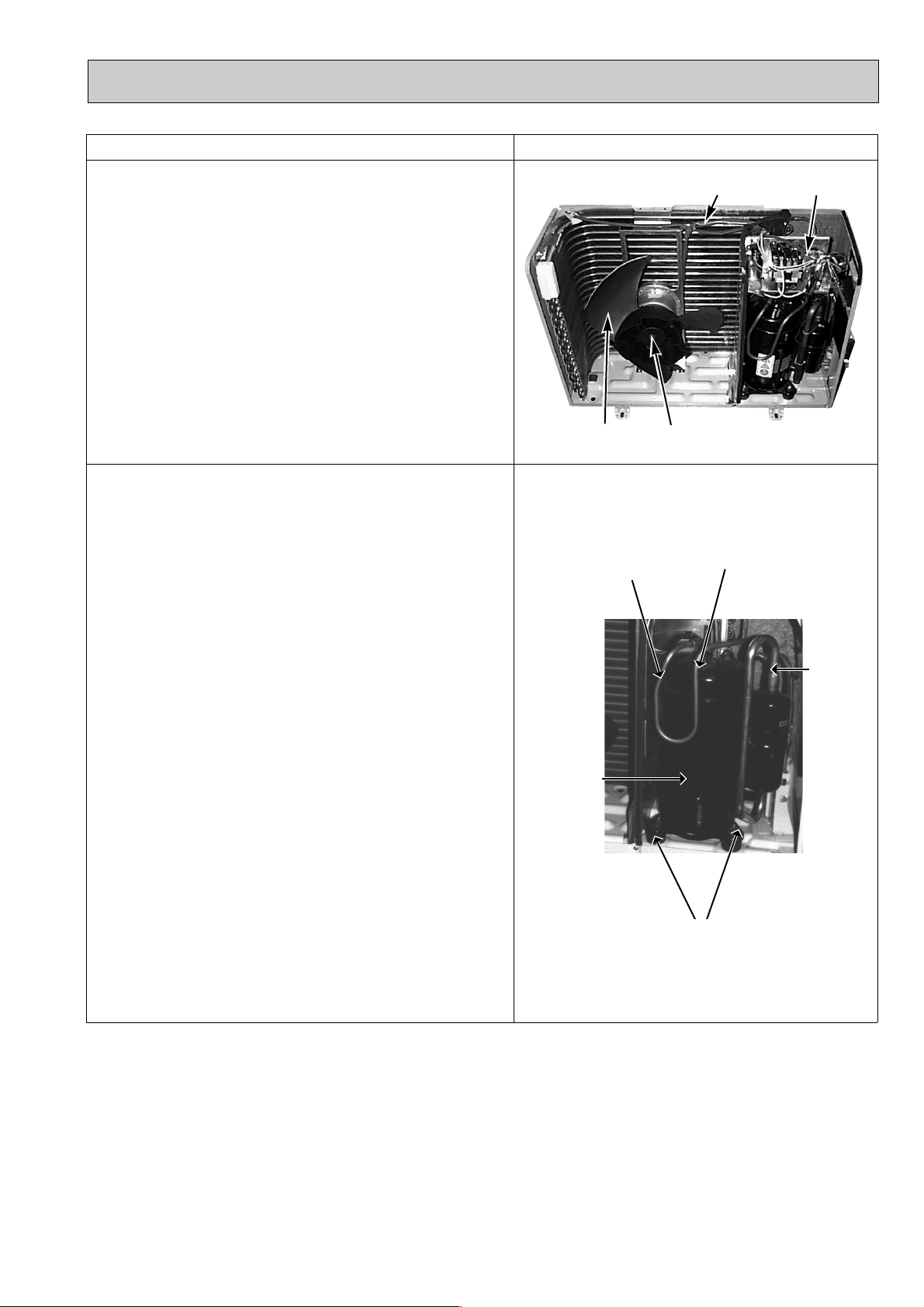

1. Removing the cabinet

(1) Remove the screws of the cabinet.

(2) Hold the bottom of the cabinet on the both side to remove

the cabinet.

2. Removing the electrical parts

(1) Remove the cabinet.(Refer to 1)

(2) Remove the following parts.

•Compressor capacitor(C1)

•Outdoor fan capacitor(C2)

•Terminal block(TB,TB2)

•Fan motor relay(X1)[For SU-2.5NR.TH, SU-2.5VR.TH and

SU-2.5VR.TH-T]

•Contactor(52C)

•Fuse(F)

Outdoor Unit : SU-1.6NR.TH SU-2NR.TH SU-2.5NR.TH

SU-1.6VR.TH SU-2VR.TH SU-2.5VR.TH

SU-1.6VR.TH-T SU-2VR.TH-T SU-2.5VR.TH-T

Photo 1

Photo 3

Photo 2

Screws

Screws

Service

panel

Compressor

run capacitor

Compressor

Contactor

Terminal bed

Fuse

Page 35

35

OPERATING PROCEDURE

PHOTOS

3. Removing the outdoor fan motor

(1) Remove the cabinet. (Refer to 1)

(2) Unconnect the connector remove the clamp of fan motor

lead wire.

(3) Remove the propeller nut and remove the propeller.

(4) Remove screws fixing the fan motor.

4. Removing the compressor

(1) Remove the cabinet. (Refer to 1)

(2) Remove the soundproof felt.

(3) Remove the terminal cover on the compressor

(4) Remove the electrical assembly.

(Refer to 2)

(5) Release gas from the refrigerant circuit.

(6) Disconnect the welded part of the discharge pipe

(7) Disconnect the welded part of the suction pipe.

(8) Remove nuts fixing the compressor.

(9) Remove the compressor.

Photo 5

Terminal cover

Compressor

Discharge

pipe

Suction

pipe

Compressor nuts

Photo 4

Fan motor cable

Connector

Propeller fan

Propeller fan nut

Page 36

36

PARTS LIST10

SE-1.6

SE-2.5

1

1

1

1

1

2

2

1

1

2

2

1

1

1

1

1

1

1

1

2

2

1

1

2

2

1

1

1

1

1

1

1

1

2

2

1

1

2

2

1

1

1

SE-2

AR.TH AR.TH-T

No.

Parts No.

Parts name

Specification

Remarks

Unit

Amount

Wiring

Diagram

Symbol

Recom-

mended

Q'ty

Q'ty/set

Price

1

2

3

4

5

6

7

8

9

10

11

12

13

14

FRONT PANEL

RIGHT SIDE PANEL

LEFT SIDE PANEL

BASE

FAN MOTOR

FAN MOTOR

FAN MOTOR

SIROCCO FAN

RUBBER MOUNT

INDOOR HEAT EXCHANGER

INDOOR HEAT EXCHANGER

INDOOR HEAT EXCHANGER

DRAIN PAN

RIGHT LEG

LEFT LEG

INDOOR COIL THERMISTOR

ROOM TEMPERATURE THERMISTOR

SEPARATOR ASSY

E07 039 000

E07 051 085

E07 039 086

E07 039 290

E07 051 300

E07 052 300

E07 053 300

E07 039 500

E02 179 505

E07 039 620

E07 040 620

E07 041 620

E07 039 700

E07 039 808

E07 039 809

E07 039 307

E07 039 308

E07 039 293

(Drawing No.)

RT12

RT11

MF

MF

MF

STRUCTURAL PARTS

SE-1.6AR.TH

SE-2AR.TH

SE-2.5AR.TH

SE-1.6AR.TH-T

SE-2AR.TH-T

SE-2.5AR.TH-T

12

8

9

1

6

7

11

3

4

2

5

13

INDOOR UNIT

14

Part number that are circled is not shown in the illustration.

Page 37

37

ELECTRICAL PARTS

SE-1.6AR.TH

SE-2AR.TH

SE-2.5AR.TH

SE-1.6AR.TH-T

SE-2AR.TH-T

SE-2.5AR.TH-T

SE-1.6 SE-2 SE-2.5

AR.TH AR.TH-T

No.

Parts No.

Parts name

Specification

Remarks

(Drawing No.)

Unit

Amount

Wiring

Diagram

Symbol

Recom-

mended

Q'ty

Q'ty/set

Price

1

2

3

4

5

6

7

8

9

10

11

12

CABLE(FOR BOARD)

REMOTE CONTROLLER CABLE

COMPRESSOR CONTACTOR

TERMINAL BLOCK

TERMINAL BLOCK

FUSE

VARISTOR

REMOTE CONTROLLER

REMOTE CONTROLLER COVER

ELECTRONIC CONTROL P.C. BOARD

ELECTRONIC CONTROL P.C. BOARD

ELECTRONIC CONTROL P.C. BOARD

REMOTE CONTROLLER P.C. BOARD

CONTROLLER COVER

1

1

1

1

1

1

1

1

1

1

1

1

E07 039 087

E07 027 089

E02 138 340

E02 367 377

E02 229 375

E02 127 382

E02 085 385

E07 027 426

E07 027 088

E07 051 450

E07 052 450

E07 053 450

E07 051 454

E07 039 449

52C

TB

TB

F11

NR11

L,N,

3,2,N,

3.15A

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

8921 11 10

4

5

3

6

INDOOR UNIT

Part number that are circled is not shown in the illustration.

Page 38

38

OUTDOOR UNIT

STRUCTURAL PARTS

SU-1.6NR.TH

SU-2NR.TH

SU-2.5NR.TH

SU-1.6VR.TH

SU-2VR.TH

SU-2.5VR.TH

SU-1.6VR.TH-T

SU-2VR.TH-T

SU-2.5VR.TH-T

2

89

32315 17 16 24 4 22

51918 1

10

No.

Parts No.

Parts name

Specification

Remarks

Unit

Amount

Wiring

Diagram

Symbol

Recommended

Q'ty

Q'ty/set

Price

CABINET

BACK PANEL(OUT)

BACK PANEL(OUT)

SERVICE PANEL

BASE

BASE

BASE

FAN MOTOR

FAN MOTOR

FAN MOTOR

FUSE HOLDER

COMPRESSOR CONTACTOR

COMPRESSOR CONTACTOR

COMPRESSOR CONTACTOR

COMPRESSOR CONTACTOR

FAN MOTOR CAPACITOR

COMPRESSOR CAPACITOR

COMPRESSOR CAPACITOR

COMPRESSOR CAPACITOR

COMPRESSOR CAPACITOR

TERMINAL BLOCK

E02 141 232

E02 140 233

E07 054 233

E02 141 245

E02 138 290

E02 140 290

E02 176 290

E02 141 301

E02 144 301

E02 147 301

E07 001 241

E07 057 340

E07 058 340

E07 042 340

E07 012 340

E02 138 351

E02 082 353

E02 079 353

E07 058 353

E02 089 353

E02 209 374

(Drawing No.)

52C

52C

52C

52C

C2

C1

C1

C1

C1

TB

SU

-1.6SU-2SU-2.5SU-1.6SU-2SU-2.5

NR.TH VR.TH VR.TH-T

S-N11EX

S-N18EX

S-N11EX

S-N18EX

3.0MF-440VAC

50MF-440VAC

30MF-440VAC

40MF-440VAC

35MF-440VAC

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

MF

MF

MF

1

2

3

4

5

6

7

8

9

10

Page 39

39

Part number that are circled is not shown in the illustration.

No.

Parts No.

Parts name

Specification

Remarks

Unit

Amount

Wiring

Diagram

Symbol

Recom-

mended

Q'ty

Q'ty/set

Price

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

TERMINAL BLOCK

FUSE(OUT)

SURGE ABSORBER

THERMAL REED SWITCH

PROPELLER FAN

COMPRESSOR RUBBER MOUNT

COMPRESSOR RUBBER MOUNT

MOTOR SUPPORT

MOTOR SUPPORT

MOTOR SUPPORT

GRILLE(OUT)

OUTDOOR HEAT EXCHANGER

OUTDOOR HEAT EXCHANGER

OUTDOOR HEAT EXCHANGER

FAN MOTOR RELAY

DIS PRESSURE REGULATOR

STOP VALVE(GAS)

STOP VALVE(GAS)

STOP VALVE(LIQUID)

STOP VALVE(LIQUID)

COMPRESSOR

COMPRESSOR

COMPRESSOR

COMPRESSOR

COMPRESSOR

COMPRESSOR

ACCUMULATOR

STRAINER

STRAINER

STRAINER

STRAINER

CAPILLARY TUBE

CAPILLARY TUBE

CAPILLARY TUBE

CAPILLARY TUBE

CAPILLARY TUBE

CAPILLARY TUBE

CAPILLARY TUBE

THERMAL SWITCH

E07 056 374

E02 095 382

E07 042 384

E02 229 381

E02 141 501

E02 075 506

E02 138 506

E02 138 515

E02 139 515

E02 140 515

E02 141 521

E02 138 630

E02 141 630

E02 147 630

E02 288 343

E02 069 644

E02 140 661

E02 150 661

E02 139 662

E02 176 662

E02 271 900

E07 058 900

E02 177 900

E07 042 900

E07 043 900

E02 042 900

E07 058 932

E07 057 933

E07 059 933

E02 205 933

E02 236 933

E02 138 936

E02 271 936

E02 283 936

E02 147 937

E07 057 936

E02 140 936

E07 055 936

E07 057 305

(Drawing No.)

TB2

F

CR

26F1

X1

MC

MC

MC

MC

MC

MC

SU

-1.6SU-2SU-2.5SU-1.6SU-2SU-2.5

NR.TH VR.TH,VR.TH-T

3RUBBER

4RUBBER

RH-207NHDT

NH-33NCDT

NH-38NBDT

RH-247VHAT

NH-38VMDT

NH-47VMDT

[3.0O[2.0OR700

[3.0O[1.8OR550

[3.0O[2.0OR600

[3.0O[2.0OR100

[3.0O[1.8OR100

[3.0O[1.8OR800

[3.0O[2.0OR570

2A

26C

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

Page 40

HEAD OFFICE MITSUBISHI DENKI BLDG.MARUNOUCHI TOKYO100-8310 TELEX J24532 CABLE MELCO TOKYO

CCopyright 1998 MITSUBISHI ELECTRIC ENGINEERING CO., LTD.

Issued in Oct.1998. No. OC167 REVISED EDITION-A 1461

Issued in Aug.1998. No. OC167 396

Printed in Japan.

New publication, effective Oct. 1998.

Specifications subject to change without notice.

OPTIONAL PARTS

11

1. REFRIGERANT PIPES

The air conditioner has flared connections its indoor and outdoor sides.

Please use the optional extension pipe as follows.

3. AIR FILTER

Applied unit

SE-1.6AR.TH SE-1.6AR.TH-T

SE-2AR.TH SE-2AR.TH-T

SE-2.5AR.TH SE-2.5AR.TH-T

Models

PAC - 1000 FT

Applied unit

SE-1.6AR.TH

SE-1.6AR.TH-T

SE-2AR.TH

SE-2AR.TH-T

Models Pipe length

Pipe size O.D.mm (in.)

Cross-section A-Gas

{12.7

(1/2)

{15.88

(5/8)

{6.35

(1/4)

{27

{31

{21

{27

0

45

120

0

45

120

B-liquid

Insulation

CD

3m

5m

7m

10m

15m

3m

5m

7m

10m

15m

MAC-680PI

MAC-681PI

MAC-682PI

MAC-683PI

MAC-684PI

MAC-670PI

MAC-671PI

MAC-672PI

MAC-673PI

MAC-674PI

Additional

refrigerant

charge

R-22(g)

SE-2.5AR.TH

SE-2.5AR.TH-T

0

45

120

3m

5m

7m

10m

15m

MAC-860PI

MAC-861PI

MAC-862PI

MAC-863PI

MAC-864PI

{9.52

(3/8)

2. REMOTE CONTROLLER EXTENSION CABLE

When installing the remote controller at a distance from the air conditioner, use the designated extension cable with

connector.

Part No.

Length

PAC-905EC

12m

PAC-906EC

20m

PAC-918EC

30m

PAC-919EC

50m

Loading...

Loading...