Page 1

Page 2

Before attempting to operate this product, you should

thoroughly read and fully understand all the contents of this

manual.

Administrators and supervisors shall not instruct anyone to

operate or inspect this machine unless he/she is familiar

with all the contents of this document.

USERS MANUAL

III

Page 3

i

For Your Safety

- This manual must be thoroughly read and understood by all operators before they attempt

to use SDP-Eco 1630 III.

- This manual provides general guidelines, precautions and warnings for the safe operation

of this machine. Very serious accidents may occur if this machine is utilized without

following this manual and we shall bear absolutely no liability or responsibility for the

consequences.

- The warning labels for hazard prevention area attached to dangerous parts or areas of

the machine. Study and understand all the specific dangers involved and how they can

be avoided.

- Keep this manual available and near the machine at all times so that it can be

immediately referred to whenever necessary.

- Look up the name, address and phone number of our nearest dealer or branch office

(listed on the back page of this manual), and post the information prominently for quick

reference.

- Please make sure that this manual reaches everyone charged with operating this

machine.

Machine operators must thoroughly read Chapter 1. Do not turn on the machine's power

supply until all of the precautions have been read and understood. Very serious

accidents may occur if this instruction is not observed.

Administrators and supervisors shall not instruct anyone to operate or inspect the SDPEco 1630 III unless he/she is familiar with all the contents of this document.

Warning

Page 4

Compliance with CISPR Rules

This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

Compliance with FCC Rules

Notice for the USA

This machine has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the machine is operated in a

commercial environment. This machine generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this machine in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at their own expense.

Changes or modifications not expressly approved by Mitsubishi Paper Mills Limited could

void the user's authority to operate the machine.

Notice for Canada

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing

Unit Regulations.

Cet appareil numérique de la Class A respecte toutes les exigences du Règlement sur le

matériel brouilleur du Canada.

When export the machine

International transfer of this product, any of its parts, components and/or software must be

carried out in compliance with the relevant laws and ordinance of the country of export and

the country of product end-use. We do not assume any responsibility of liability for product

transferred without regard to proper export/import regulations or procedures.

Limit of responsibility

Please note that machine specifications are subject to change without notice for updates and

improvements. This may cause inconsistencies between the contents of this manual and

the machine you currently possess.

We shall not be held responsible for any damage caused by conditions beyond our control

such as customer modification, disassembly or misuse of our machine, programs or

software, or their use in a defective or deficient environment.

We assume no responsibility or liability for any damage or consequential and/or indirect

losses resulting from any accident or malfunction that might occur during the operation of

this machine.

Copyright

©2005: Mitsubishi Paper Mills Limited.

The copyright for this entire manual belongs to Mitsubishi Paper Mills Limited.

Copying, reprinting, or reproduction of this manual in whole or in part in any medium without

our express consent infringes upon the copyright and the rights of the publisher.

ii

Page 5

iii

Introductory Note

Thank you very much for choosing our product. We sincerely hope that you will enjoy using

the SDP-Eco 1630 III, and fully utilize all its functions and capabilities.

This users manual describes how to safely operate this machine and explains all the basic

procedures for data setting, maintenance, inspections, etc.

As noted below, however, it is the client's obligation to obtain or prepare all the necessary

material safety data sheets ("MSDS") for any chemical substances used during the client's

operation on this machine. Although great care has been taken in preparing this manual, if

you find that certain points seem unclear or in error, please contact Mitsubishi Paper Mills

Limited.

This manual contains the following sections:

Chapter 1 "On Safety"

This chapter describes instructions to be observed for the safest possible operation of the product.

Please make sure to read this chapter before turning on the power to the product.

Chapter 2 to 6

These chapters provide relevant knowledge and reference information for machine operation.

Please read them carefully before attempting to operate the machine.

Chapter 7 to 9

These chapters describe daily maintenance procedures and troubleshooting methods as well as

supplying various technical information. Please read through them as necessary.

Page 6

iv

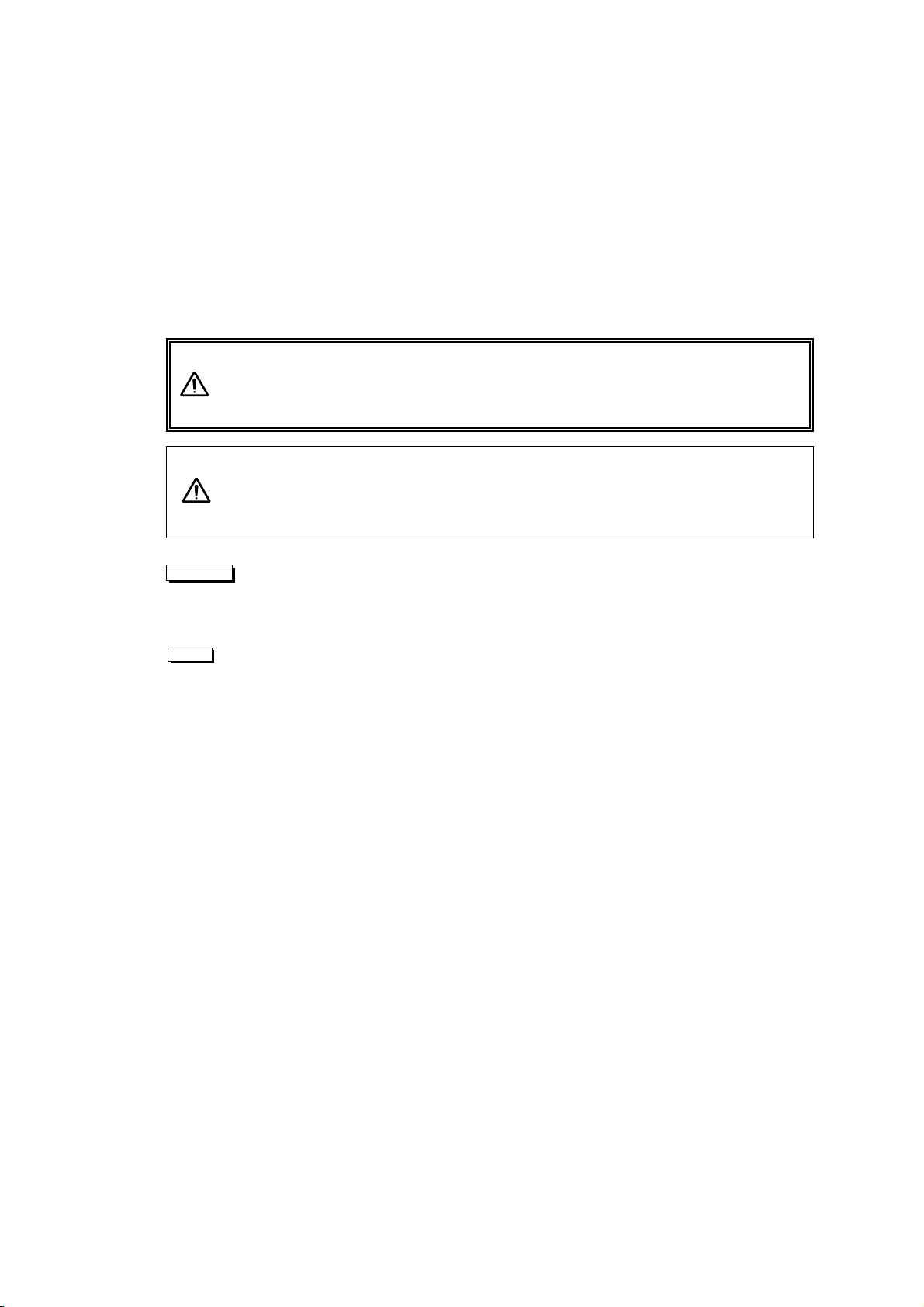

About this manual

In this manual, important supplementary remarks are classified as either WARNINGs,

CAUTIONs, Cautions, or Notes.

Since remarks under WARNING and CAUTION headlines call attention to conditions and

operations that may result in accidents or physical injuries, be sure to thoroughly read and

observer their instructions.

Indicates a potentially hazardous situation which, if not

avoided or properly handled, could possibly result in

death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided or properly handled, could possibly result in

minor or moderate injury.

Indicates a situation that could either cause damage to the machine,

destroy data necessitate extensive reduplicated effort. Strictly follow the

noted instructions.

Provides supplementary information or information to prevent incorrect

operations.

Warning

Caution

Caution

Note

Page 7

v

Contents

Chapter 1 On Safety

1.1 When using the machine ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••1

1.2 Warning labels and attachment positions ••••••••••••••••••••••••••••••••••••••••••••4

1.3 Handling processing chemicals ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••6

1.4 Before connecting the power cable•••••••••••••••••••••••••••••••••••••••••••••••••••••8

1.5 Operation precautions ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••9

1.6 Precautions during transport and installation •••••••••••••••••••••••••••••••••••••10

1.7 SDP-Eco 1630 III Installation ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••10

1.8 Maintenance ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••12

1.9 Machine disposal••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••13

Chapter 2 Names of Machine Components and Parts

2.1 Main unit ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••15

2.2 Operation panel••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••17

2.3 Safety switch••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••18

Chapter 3 Handling plates

3.1 Plate setting •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••19

3.2 Plate end processing ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••23

Chapter 4 Operation

4.1 Cable connection check••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••25

4.2 Turning ON the power switch••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••26

4.3 Initialization ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••26

4.4 Data input for the set plate (This procedure is necessary when

loading the plate.)•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••27

4.5 Execution of Pre. Feed command (This procedure is necessary

when loading the plate.)••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••28

4.6 Exposure••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••29

4.7 Processor section•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••31

4.8 Collecting exposed plates •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••34

4.9 Turning OFF the power supply and inspection at shutdown •••••••••••••••34

Page 8

vi

Chapter 5 Menus and panel displays

5.1 User menu •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••37

5.2 Panel operation ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••39

Chapter 6 User menu

6.1 Plate data•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••41

6.2 Laser menu ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••42

6.3 Pre. Feed menu •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••44

6.4 Image Data menu•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••44

6.5 Mode menu ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••44

6.6 Maintenance menu •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••45

6.7 Rinse •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••45

Chapter 7 Maintenance

7.1 Cutter blade replacement••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••47

7.2 Cylindrical lens cleaning •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••48

7.3 Filter cleaning•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••49

7.4 Punch dust removal••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••50

7.5 Cleaning the processor section •••••••••••••••••••••••••••••••••••••••••••••••••••••••••51

7.6 Cleaning the washing tank••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••59

7.7 Replacing the diffusion sheet (SLM-EAC, SLM-EST)•••••••••••••••••••••••••63

7.8 List of expendable parts••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••65

7.9 How to order parts••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••65

Chapter 8 Message

8.1 Message ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••67

8.2 Displaying and clearing errors•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••67

8.3 Status display•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••68

8.4 Warning display••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••68

8.5 List of error messages ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••69

8.6 Jam removal procedure ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••71

Chapter 9 Specifications

9.1 Basic specifications ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••73

9.2 Overview diagram ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••74

Page 9

Chapter1 On Safety

- 1 -

Chapter 1 On Safety

SDP-Eco 1630 III was designed and manufactured with special attention to

safety considerations. However, it is impossible either to eliminate all

potential sources of danger from such products or to anticipate all possible

hazards and misuses. It is therefore critical that you both familiarize

yourself, all your operators and other relevant personnel with all of the noted

precautions, countermeasures and related procedures, and take maximum

care when operating this machine.

1.1 When using the machine

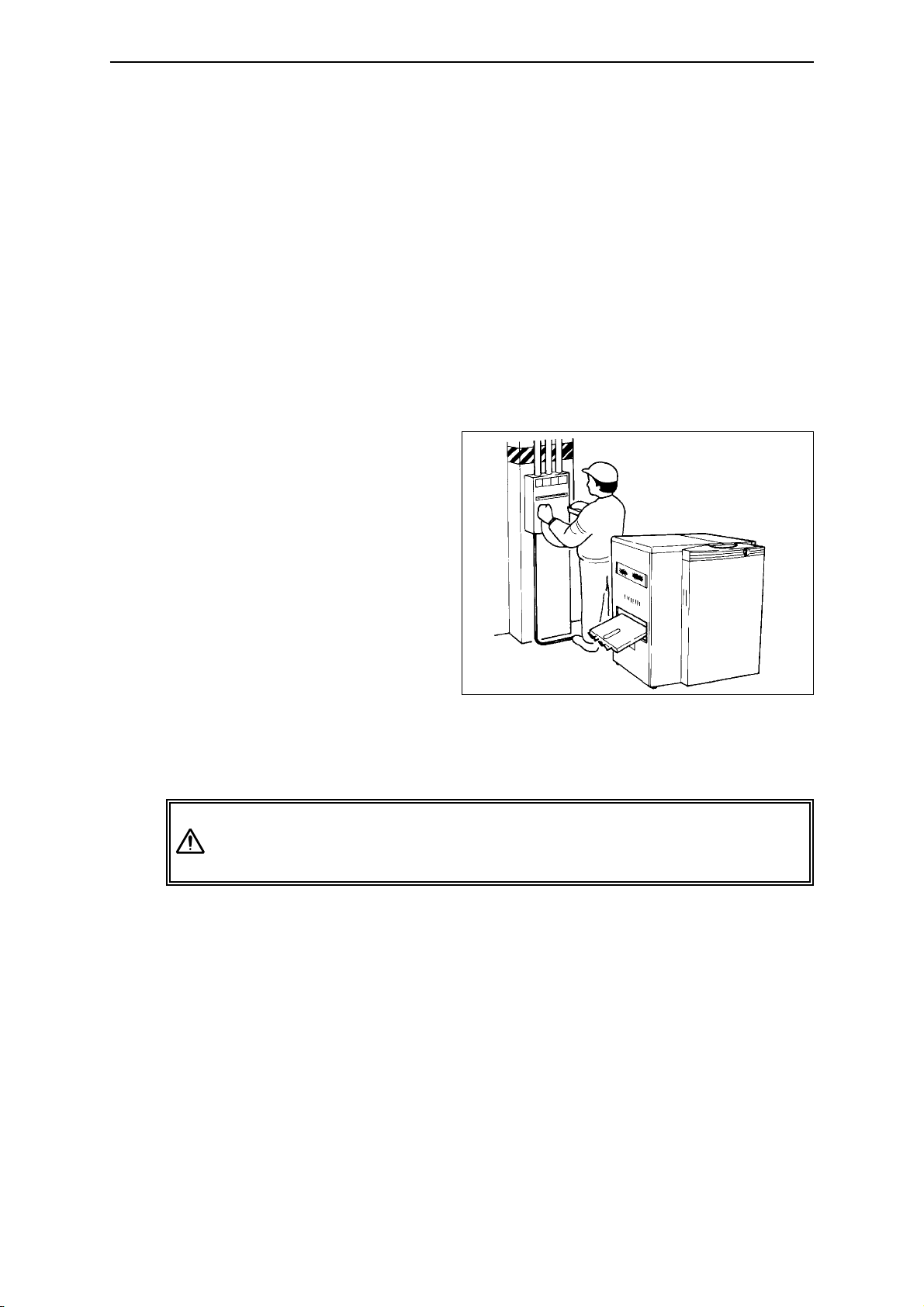

• Grounding connection

- In order to prevent

electric shock at the AC

power supply unit, be

sure to connect the

ground in accordance

with operation site

regulations (resistance:

less than 100 ohms)

using the SDP-Eco 1630

III exclusive wire.

- Even when the user's

present facility outlet can

be with the SDP-Eco 1630 III power plug with ground, make sure that

the ground pole on the outlet is connected with ground in accordance

with operation site regulations (resistance: less than 100 ohms)

Following all relevant local wiring regulations, prepare a grounded

(less than 100 ohms) power supply outlet that can accept this

machine's power plug.

• Power supply

- Prepare a power supply that satisfies all the requirements stipulated in

the specification sheet.

- Always provide circuit breakers for unit or devices that use water or

chemicals.

- Please entrust all wiring, connections and other electrical work to an

authorized electrician.

•

Maintenance and safe passage during emergencies

A minimum of 60 cm clearance is required around the machine at all

times to afford adequate space for maintenance and safe passage during

emergencies. Never allow this space to become blocked with any

objects, wires, or other obstacles.

Warning

Page 10

SDP-Eco1630 III USERS MANUAL

- 2 -

Chapter 1 On Safety

• This machine incorporates a power supply unit.

Do not use a bubble type extinguisher when a fire occurs. It may cause

electric shocks. Place a powder type extinguisher near the machine.

• The SDP-Eco 1630 III is equipped with a leakage circuit breaker.

If a short circuit occurs in the machine, the breaker is automatically

activated and shuts off the circuit.

Occasionally the main unit will not activate when you turn ON the

Power Switch because the leakage breaker inside the main unit

has turned itself OFF.

In such a case, contact your local dealer where you purchased the

machine and ask a service person to check out the condition.

• This machine incorporates high current electrical circuits.

Touching the electrical circuits of this machine with any part of your

body can cause serious injury or death. Please contact the dealer where

you purchased this machine when maintenance or inspections are

required.

•

Safety switches

To ensure operator safety, this machine is provided with safety switches.

If a front door is opened while the machine is running, a safety switch is

activated and operation is immediately stopped.

(Refer to "Chapter 2 Names of Machine Component and Parts".)

Warning

Page 11

Chapter 1 On Safety

• LASER SAFETY.

The SDP-Eco1630 III is certified as a Class 1 laser product under the U.S.

Department of Health and Human Services (DHHS) Radiation

Performance Standard according to the Radiation Control for Health and

Safety Act of 1968. This means that the recorder does not produce

hazardous laser radiation.

Since radiation emitted inside the SDP-Eco1630 III is completely

confined within protective housings and external covers, the laser beam

can not escape from the machine during any phase of user operation.

• CDRH REGULATIONS.

The Center for Devices and Radiological Health (CDRH) of the U.S.

Food and Drug Administration implemented regulations for laser products

on August 2, 1976. Compliance is mandatory for products marketed in

the United States. The level shown in the figure indicates compliance

with the CDRH regulations and must be attached to laser products

marketed in the United States.

•

For European model

The SDP-Eco1630 III is classified as a CLASS 1 LASER PRODUCT in

accordance with IEC Pub 1.1 825 1984.

Ordinary operation will not release laser radiation into the work

environment. Do not remove any of the safety covers for this product or

release any of its interlock switches. Laser radiation may cause injuries to

your body (e.g. weakened eyesight, skin cancer).

- 3 -

Page 12

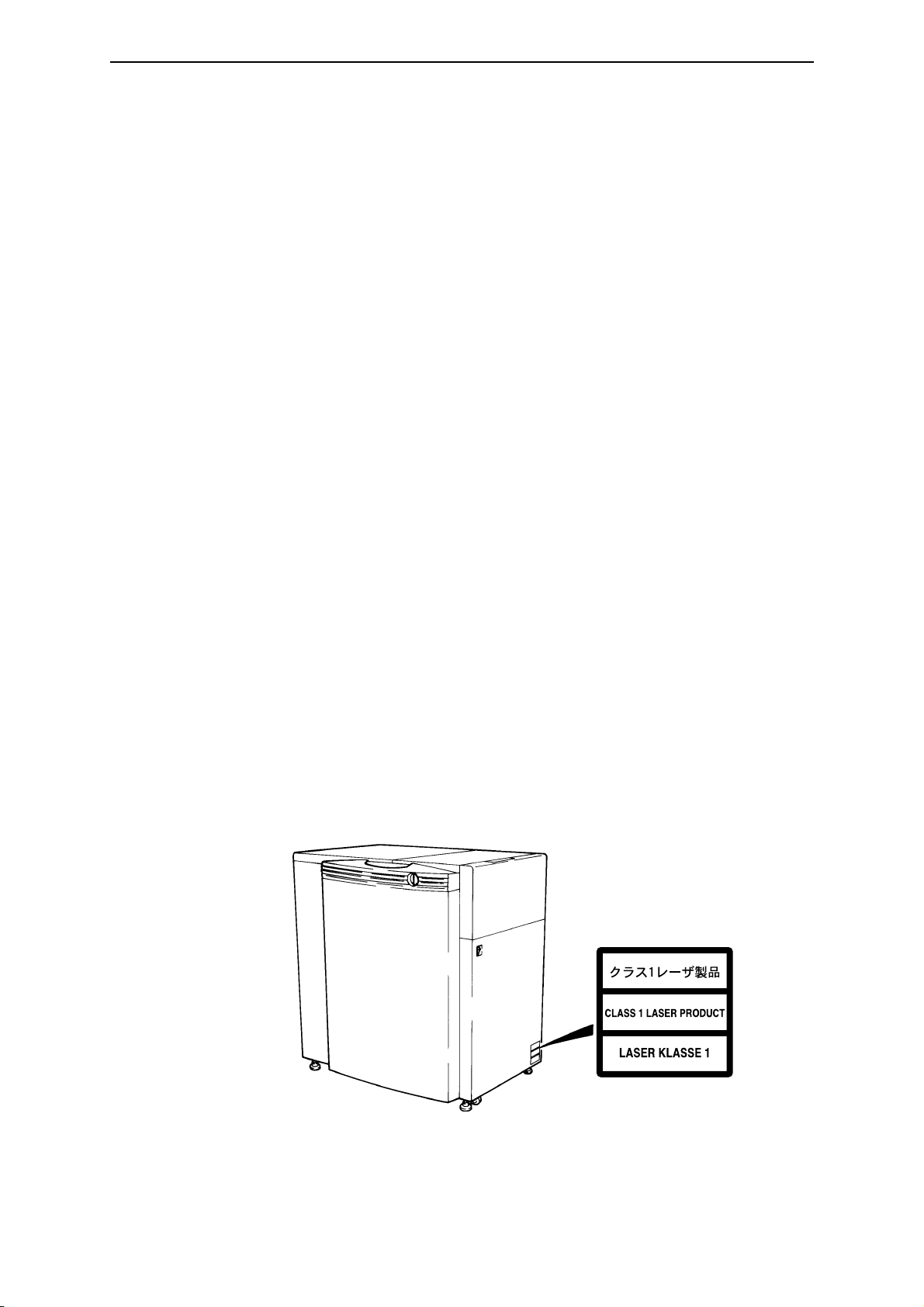

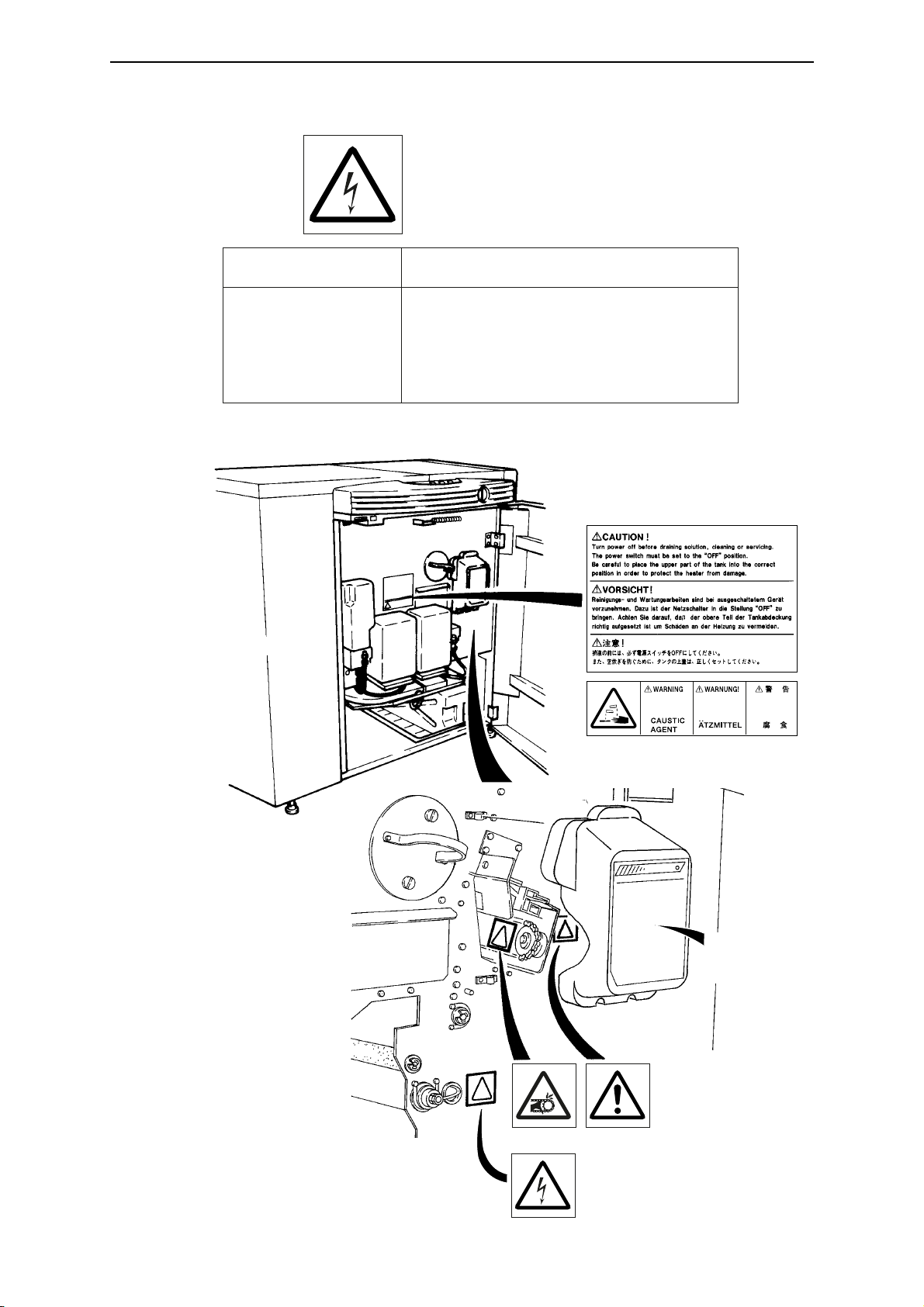

1.2 Warning labels and attachment positions

Warning labels are attached to dangerous parts or areas of the machine. All

operators and maintenance personnel must follow the instructions written on

these labels.

- Do not remove or deface any of these warning labels.

- Labels must always be clearly visible without any obstacles shielding or

obscuring them.

- If a label is removed or defaced, replace it with a new warning label as

soon as possible. Please contact the dealer where you purchased this

machine for new labels.

•

Types of warning labels

Hazard

Safe handling method

Contains processing

chemicals. Direct contact

with these chemicals due

to splashing or overflow

may result in skin.

irritation, blindness, or

burns.

Always wear protective gear such as safety glasses,

rubber gloves, masks, and rubber aprons.

Read all instructions and warnings for processing

chemicals.

Hazard

Hands or fingers may get

caught.

Keep hands, fingers and the rest of the body away

during operation. Always turn OFF the main power

supply and the power switch on the machine before

approaching.

Sections marked with this

label contain functions or

components which could

cause personal injury.

Keep hands, fingers and the rest of the body away

from the machine while it is running. If you must

physically touch the machine, always turn the

power supply OFF beforehand.

Safe handling method

Safe handling methodHazard

SDP-Eco1630 III USERS MANUAL

- 4 -

Chapter 1 On Safety

(1) Caustic

agent

(2) Hazardous

Moving

Section

(3) Caution

Page 13

Chapter 1 On Safety

- 5 -

Chapter 1 On Safety

• The locations of the machine's warning labels are shown below.

(1)

(4) Electric

shock

(2) (3)

(4)

Cutter blade

replacement

procedure

Safe handling methodHazard

There are sections where

the voltages are

dangerously high. Direct

contact with these sections

(marked with this label) can

cause severe shock and

potentially fatal injuries.

The parts or sections marked with this label should

be avoided. Be careful not to touch them with your

bare bands or any part of your body.

Page 14

SDP-Eco1630 III USERS MANUAL

- 6 -

Chapter 1 On Safety

1.3 Handling processing chemicals

The SDP-Eco 1630 III uses processing chemicals to activate and

stabilize exposed plates. The processing chemicals used in this

machine are not generally dangerous to humans, but failure to use

them in the correct manner is dangerous. Be sure to handle all

processing chemicals with care.

Cautions for use of processing chemicals

Inflammation may occur if processing chemicals come in contact

with the eyes or skin, so be sure to wear protective gear (safety

goggles and rubber gloves) when handling the chemicals.

Keep out of reach of children.

What to do in case of emergency

If chemicals come in contact with the eyes, immediately rinse with

clean running water for at least 15 minutes. If the inflammation

persists, consult an eye specialist.

If chemicals come in contact with the skin, immediately rinse under

clean running water.

If chemicals are swallowed, immediately consult a physician.

Report the ingredients of the chemical or solution to the physician.

Cautions for handling waste chemicals

These chemicals have high COD and pH levels (especially the

activator) and cannot be disposed of by simply pouring them down

the drain. Please have processing chemicals removed by a

certified waste management specialist.

Warning

Caution

Caution

Caution

Page 15

Chapter 1 On Safety

- 7 -

Chapter 1 On Safety

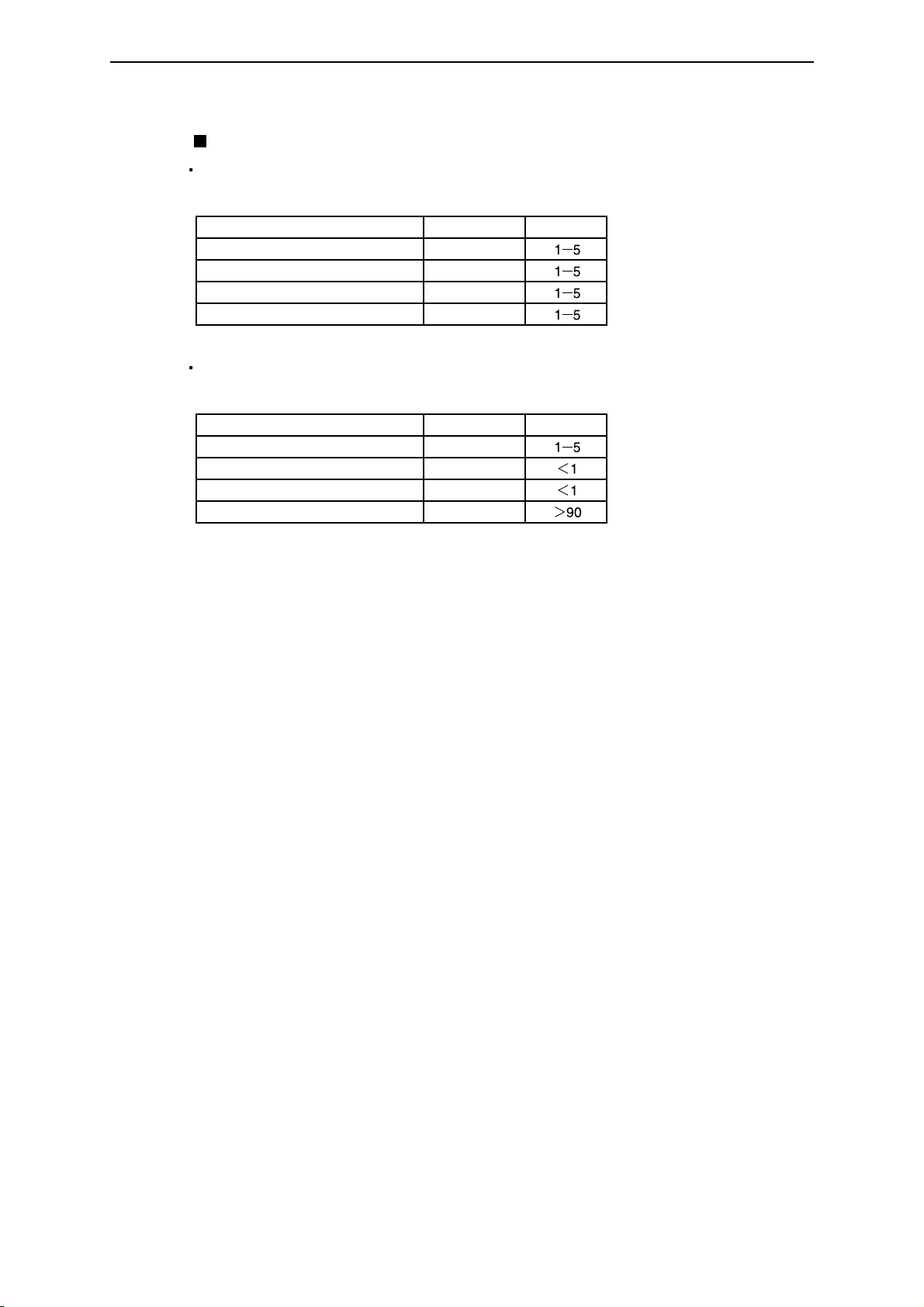

Processing chemical components

Activator (SLM-EAC)

Mixture: (aqueous chemical)

pH: approx. 13.4

Composition CAS No. Percentage

Potassium hydroxide

Potassium sulfite

Sodium sulfite

N-amino ethyl ethanolamine

Stabilizer (SLM-EST)

Mixture: (aqueous chemical)

pH: approx. 6.0

Composition CAS No. Percentage

Phosphate

Tri-ethanol amine

Heavy sodium sulfite

Water

1310-58-3

7646-93-7

7757-82-6

111-41-1

7778-77-0

102-71-6

7631-90-5

7732-18-5

Page 16

SDP-Eco1630 III USERS MANUAL

- 8 -

Chapter 1 On Safety

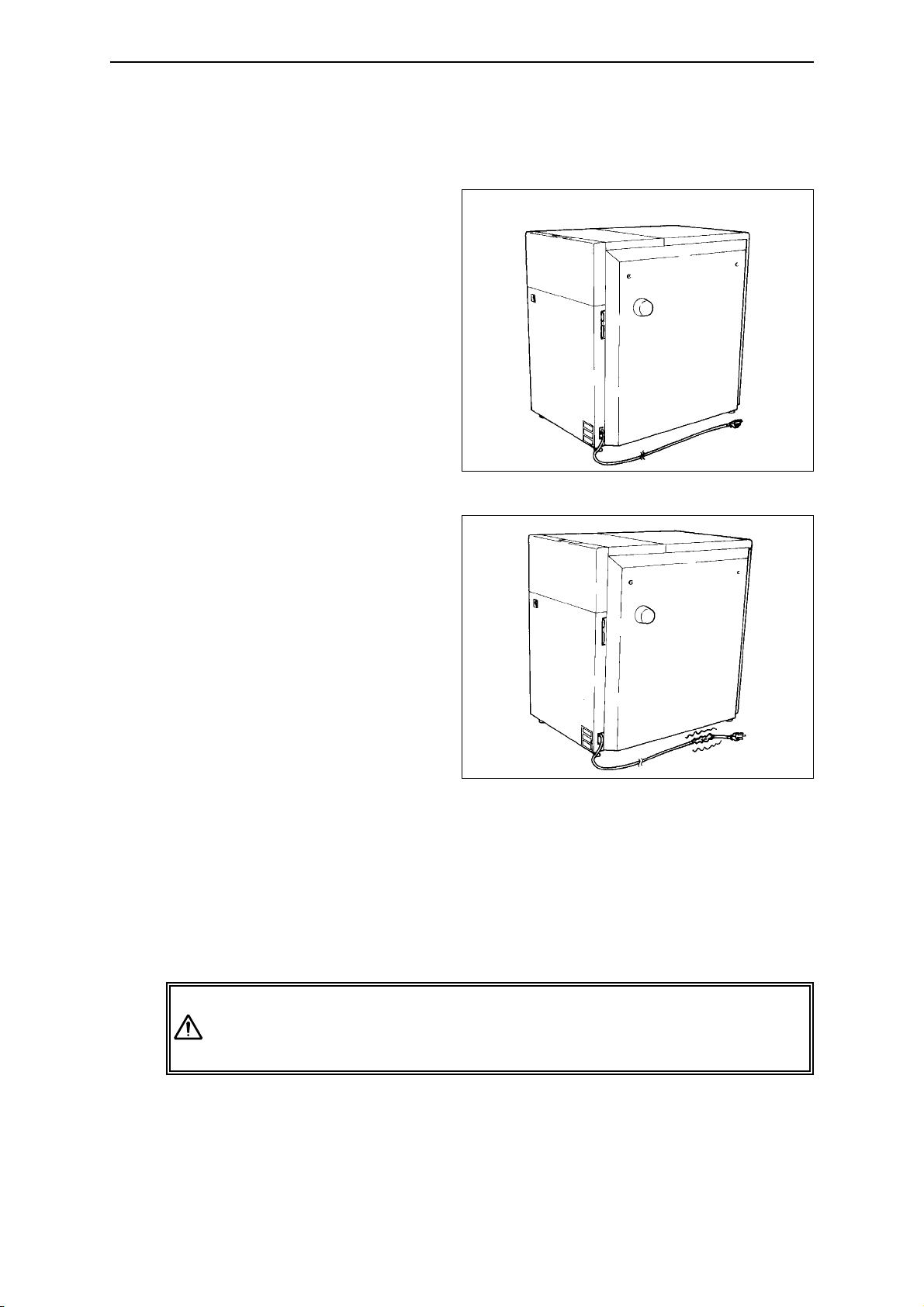

1.4 Before connecting the power cable

• Power supply

- Check that the power

switch on the SDP-Eco

1630 III is turned OFF

before connecting the

power plug to the user's

power outlet. (Refer to

"Chapter 2: Names of

Machine Component and

Parts".)

•

Power cables

- Always use grounded

power cables when

connecting to this

machine.

- If you find anything that

might indicate power

cable damage such as

unusual deformations or

surface flaws, immediately turn OFF the power

supply, pull the power

plug from its outlet and

contact the dealer where you purchased this machine.

- Do not place heavy objects or articles with sharp blades anywhere on the

power cable or forcefully pull at it.

- Never connect the power cable to a shared or overloaded outlet or

distribution socket.

- Please contact our nearest dealer before attempting to extend the power

cable.

If you notice any problems with the power cable such as scratches

or deformities, immediately turn OFF the main power supply switch

and contact the dealer where you purchased this machine.

Power plug with earth wire

Warning

Page 17

Chapter 1 On Safety

- 9 -

Chapter 1 On Safety

1.5 Operation precautions

• Do not turn the machine's power supply ON or start operation until this

manual has been thoroughly read and fully understood.

• All operators must wear appropriate work clothing and should never wear

necklaces, scarves, or other accessories which could be caught by moving

parts and cause accidents.

• Do not operate the machine if you feel in anyway sick, nauseous or

unsteady.

• If you notice that the machine is in any way abnormal, immediately report

the situation to your supervisor for appropriate action.

• The SDP-Eco 1630 III can perform continuous automatic operation, but it

must not be operated continuously without an operator in attendance.

An operator trained to take appropriate initial corrective actions should

always be in attendance to deal immediately with any emergencies that

may arise.

• When your SDP-Eco 1630 III will not be operated for an extended period

of time, be sure to unplug the power cord. Check for any dust or

contamination in the outlet, power plug, and/or the AC power socket on

your SDP-Eco 1630 III at least once a year.

• During operation, do not open any of the unit's doors or covers. Opening

these doors or covers may be hazardous to the safety of operators and

other persons working in the vicinity, and may also damage the machine.

• Power failure

If a power failure occurs due to an external reason, immediately turn OFF

the power switch and the SDP-Eco 1630 III.

When power is recovered, supply power again, referring to "4.2 Turning

ON the power switch".

Appropriate Unacceptable

Cap

Gloves

(or wet hands)

Open cuffs

Loose or dangling necktie

Always avoid clothing, gear, or

accessories that could in any way

be caught up in the machine.

Buttoned

Safety shoes

(preferable)

Items hanging from clothes

Over-long trousers

Slippers or sandals

Page 18

SDP-Eco1630 III USERS MANUAL

- 10 -

Chapter 1 On Safety

1.6 Precautions during transport and installation

• The weight of the SDP-Eco 1630 III is described in "Chapter 9:

Specifications"Make sure the floor is fully capable of handling 2500 N/m

2

(approx. 55 lbs/ft2) or heavier loading before installing the SDP-Eco 1630 III .

•

Transport and installation

This machine's transport and installation must always be handled by

engineers and contractors assigned by Mitsubishi Paper Mills Limited.

We shall bear no responsibility whatever for any unit breakage, damage,

or malfunctions caused by or during transport or installation performed by

anyone other than the above specified personnel. Whenever your

machine must moved, transferred, or reinstalled, please entrust all

procedures to our nearest branch office or dealer.

1.7 SDP-Eco 1630 III Installation

• Installation environment

Installing the machine in the following locations may cause machine damage

or malfunctions. Do not install the machine anywhere that is exposed or

subject to:

* Locations with strong and/or

persistent vibration

* Locations with an uneven

floor

Page 19

Chapter 1 On Safety

- 11 -

Chapter 1 On Safety

* Locations in direct sunlight

* Locations with high

temperature and/or humidity

(outside the normal range of

Temp.: 18 to 28˚C,

Rel.humidity: 50 to 70%)

* Locations where dew

condensation is a factor

* Locations with sudden,

drastic temperature changes

* Locations where excessive dirt,

grime or dust are factors

* Locations in the vicinity of

flammable gases or liquids

* Locations having corrosive

chemical vapors, mists, or

gases

* Locations with a nearby heat

source (such as a radiator or

heater)

* Locations with electrical

interference such as voltage

fluctuations or line noise.

* Locations with devices which

emit sparks or electromagnetic

radiation

•

Ventilation

Please ensure sufficient ventilation during the operation of the equipment to

avoid odor in high density.

Page 20

SDP-Eco1630 III USERS MANUAL

- 12 -

Chapter 1 On Safety

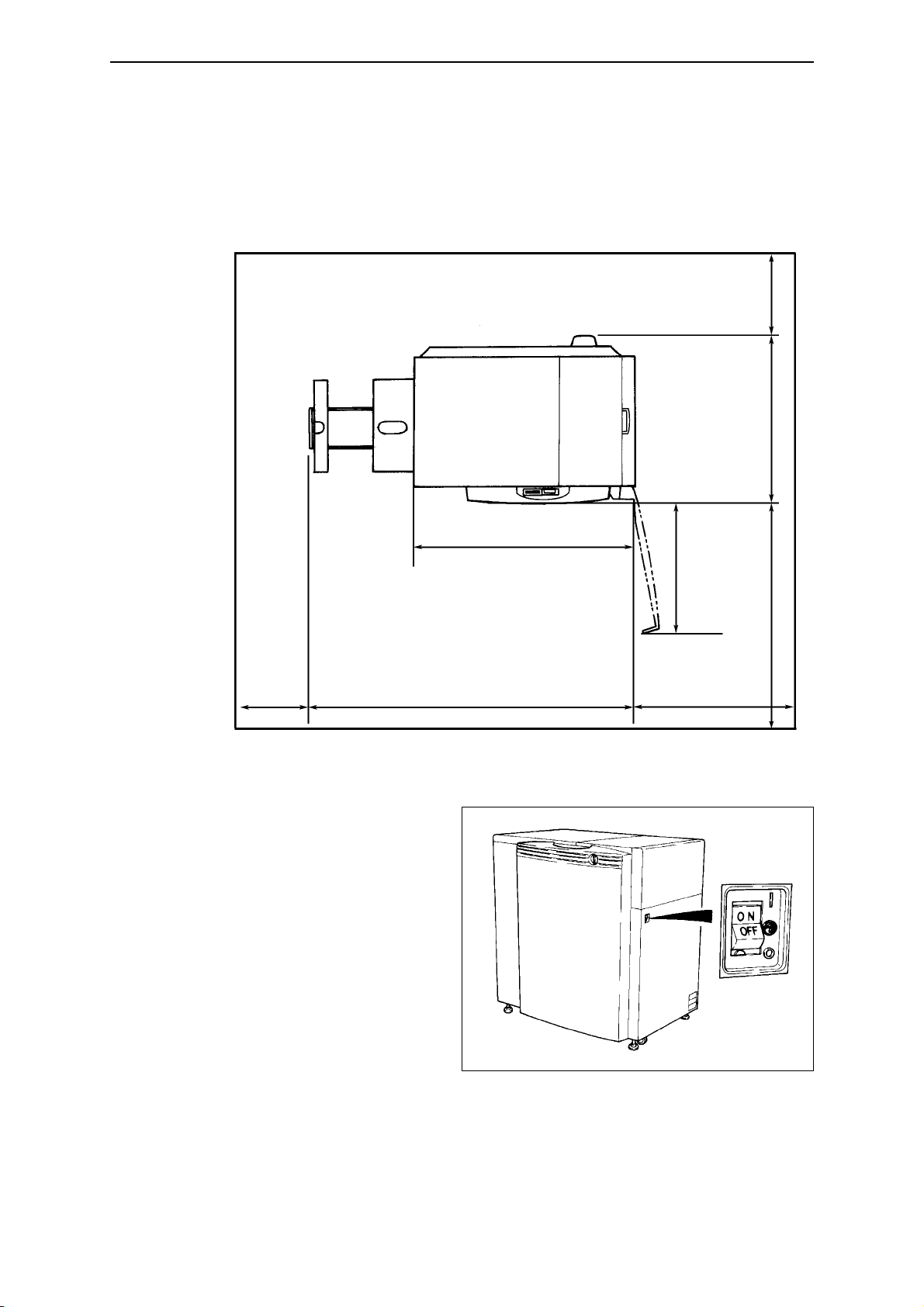

• Installation space

As shown in figure below, clearance is required around the machine at all

times to assure adequate space for maintenance and safe passage during

emergencies.

1.8 Maintenance

• Maintenance that requires tools may only be performed by persons who

have been specially

trained with our authorized

curriculum.

• During machine mainte-

nance, the operator must

make it clear that the

machine should not be

turned ON and prevent

any person other than our

authorized technician(s)

from touching the

machine.

• Be sure to turn OFF the power switch and remove the power plug from

the outlet before you start maintenance, cleaning or repairs.

Power switch

(Unit: cm)

40 or

longer

79.5

40 or

longer

70 or longer

146.5

66.9

100

100 or

longer

Page 21

Chapter 1 On Safety

- 13 -

Chapter 1 On Safety

1.9 Machine disposal

• To protect the environment, always commission a special authorized

contractor to dispose of your old machine(s).

• Commission an ordinary contractor to dispose of parts discarded or

replaced during the repair processing.

Page 22

SDP-Eco1630 III USERS MANUAL

- 14 -

Page 23

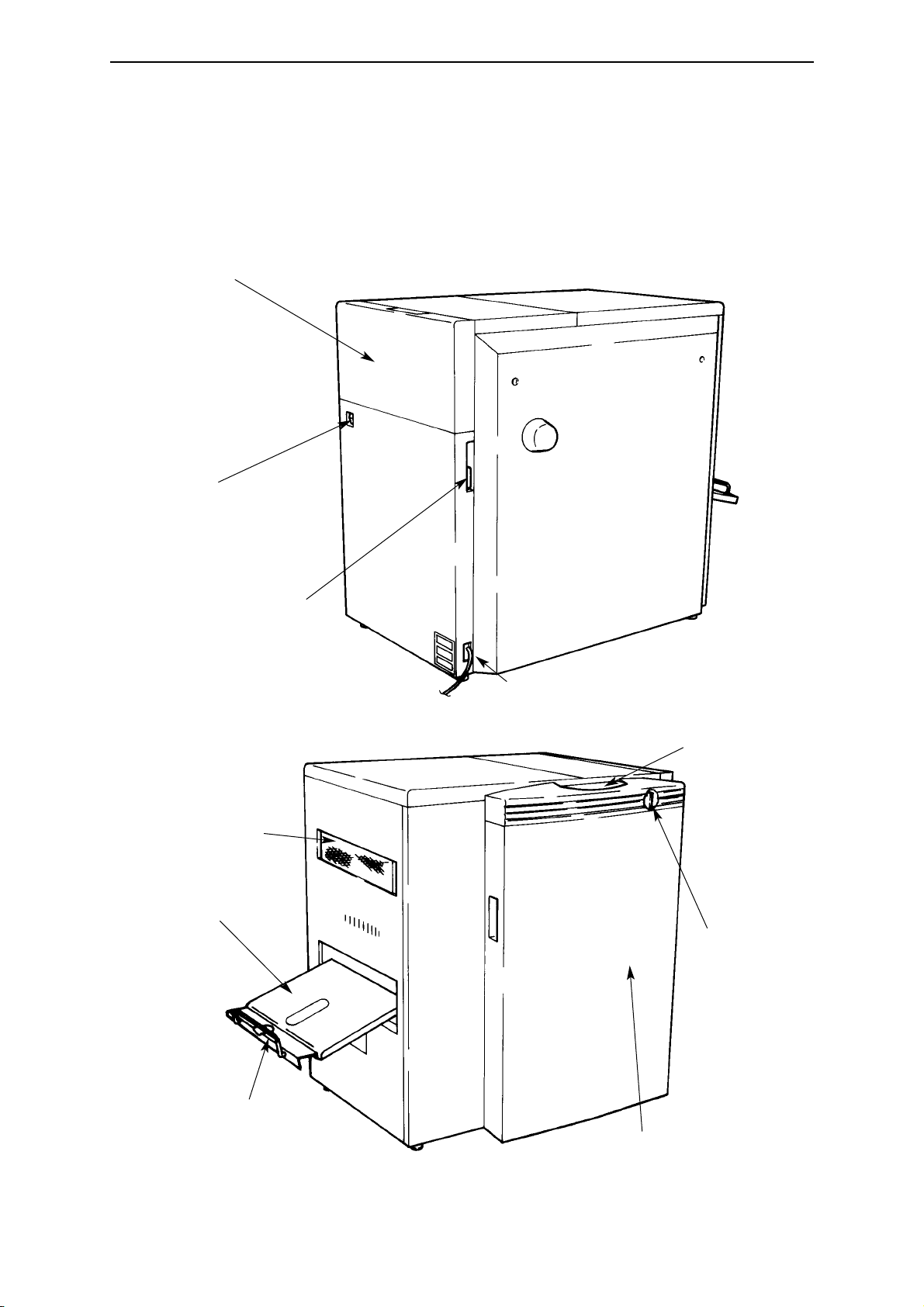

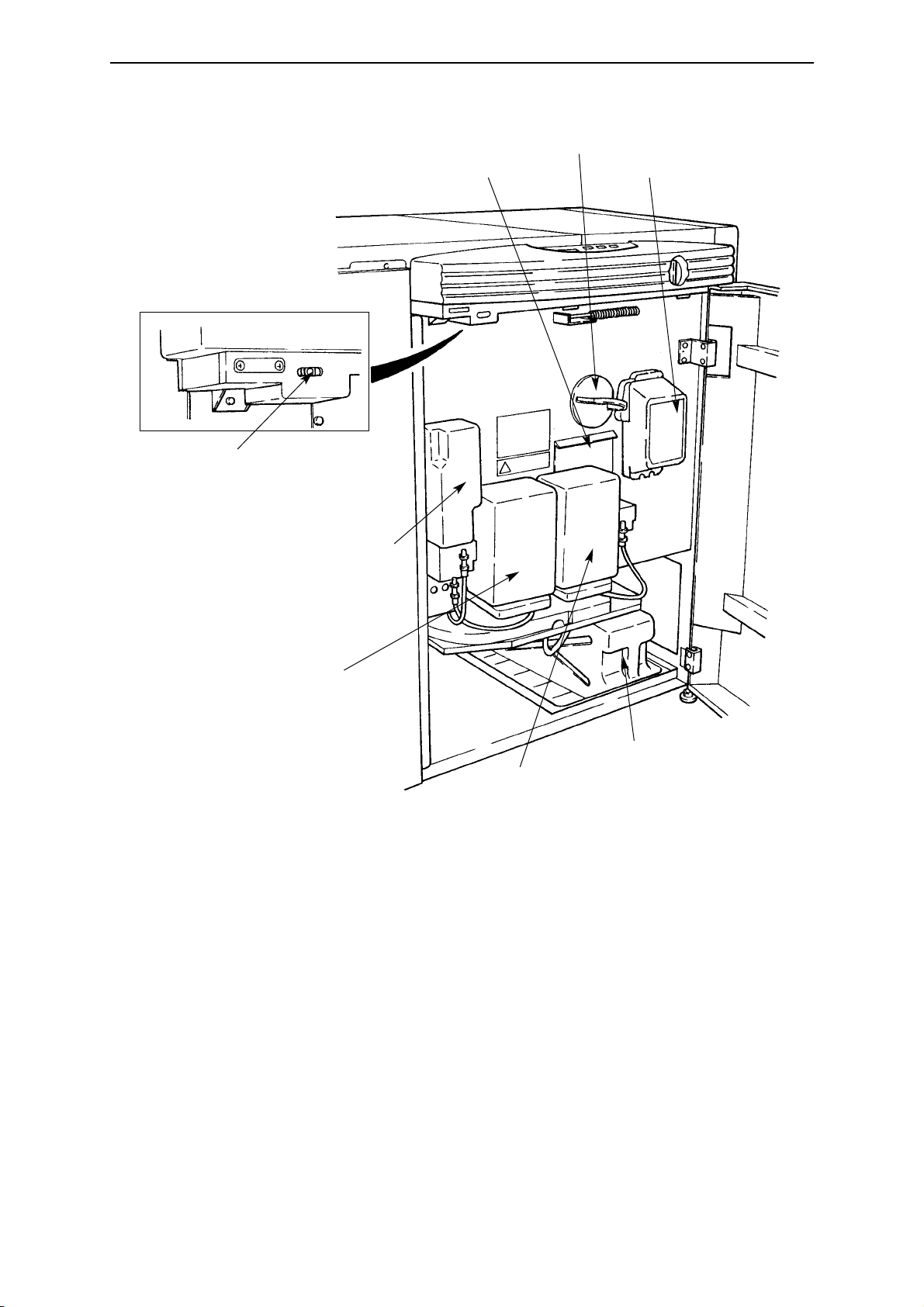

Chapter 2 Names of Machine Components and Parts

Chapter 2 Names of Machine Components and Parts

The SDP-Eco 1630 III consists of the following parts.

2.1 Main unit

- 15 -

Power switch

Plate setting cover

Wide SCSI connector

Operation panel

Front door

Nip roller

clearance handle

Filter

Plate receiving

tray

AC power socket

Arm

Page 24

SDP-Eco1630 III USERS MANUAL

- 16 -

Safety switch

Rinse water

replenisher bottle

EST replenisher

bottle (stabilizer)

EAC replenisher

bottle (activator)

Waste chemical tank

Plate take up unit

Cutter unit

Cylindrical lens

Page 25

Chapter 2 Names of Machine Components and Parts

- 17 -

2.2 Operation panel

(1) Display panel

The operation mode, error messages, and setting values for various

parameters are displayed on this panel.

(2) Power ON/OFF key

The power ON/OFF key is used to turn OFF the power after a processor

cleaning operation. This key is used for the usual ON/OFF operation.

(3) ON LINE lamp

The ON LINE lamp is lit during transmission or standby status between

the SDP-Eco 1630 III and host computer.

(4) LOADED lamp

The LOADED lamp lights when a film is loaded and at its exposure

position.

(5) Stop key (Reset)

The STOP key is used to interrupt the exposure of a plate. If the exposure

is interrupted, the plate will be cut and discharged. This key is also used

to cancel errors and to turn OFF the error buzzer.

(6) key

The key is used to switch the user's mode between remote and local.

Also it returns the menu to the upper level.

(7) Select key

The SELECT key is used to move the cursor or change parameters.

(8) key

The key is used to enter parameters or to execute various

commands.

ENT.

ENT.

MENU

MENU

(2)

(1)

(3)

(4)

(5)

(6)

(7)

(8)

Page 26

SDP-Eco1630 III USERS MANUAL

2.3 Safety switch

This machine is equipped with a safety interlock switch which detects the

front door's open/closed status.(See page 16) If this switch detects that the

front door is open, this machine cannot perform any operations.

If the front door is opened during data transmission from the host

computer, image exposure or plate transfer, all machine operations

stop. This will cause problems with data transfer and in the image data.

Use of controls or adjustment or performance of procedures other

than those specified herein may result in hazardous radiation

exposure. Operations or adjustments other than those specified

herein may result in damage to your body(e.g.weakened eyesight,

skin cancer).

- 18 -

Caution

Warning

Page 27

Chapter 3 Handling Plates

Chapter 3 Handling plates

3.1 Plate setting

1) Open the plate setting cover and,

holding the lever with your thumb,

take the spool shaft out.

2) Refer to your plate width, and

align the edge of the spool plate

boss to the groove in the spool

shaft. The spool shaft grooves are

numbered from outer side in the

following order: 414, 404, 400,

370, 340, 335, 324, 310, 305, 279,

254, and 229.

Red tape is affixed to the

reference side of the

spool shaft.

3) To prevent the reference side of

the spool plate from shifting from

its designated position, insert a

screw driver into the set screw

hole and firmly fix the set screw to

the spool shaft.

Always fix the set screw on the

flat side of the spool shaft.

- 19 -

Lever

Plate setting cover

229 (9)

254 (10)

279 (11)

305 (12)

310 (12 1/5)

Marker

Spool plate

Set screw

Red tape

Spool shaft

Edge of boss

400 (15 3/4)

324 (12 3/4)

335 (13 3/16)

340 (13 3/8)

370 (14 9/16)

404 (15 7/8)

414 (16 3/10)

Caution

Page 28

SDP-Eco1630 III USERS MANUAL

4) Lower a roll of plate (wound in

the same direction as in the figure

on the left) down over the spool

shaft. (The shaft should be

standing vertically with the

reference side of the spool plate as

its base.).

Firmly press the edge of the plate

roll against the spool plate

(reference side) until they touch

equally all around the periphery of

the roll.

5) Firmly snap the contact side of the

spool plate down over the spool

shaft and continue pressing the

plate (contact side) downward to

the edge of the plate roll until

there are no intervening gaps.

Position the contact side of the

spool plate so that its set screw is

positioned 180

o

opposite the one

on the reference side.

The two set screws are

fixed 180

o

opposite each

other to prevent rotational

imbalance due to the

weight of the screws.

- 20 -

Plate

Make sure that the lateral edges

of the plate are still even after

the roll is set on the spool shaft.

Spool plate

(contact side)

Plate

No gaps here.

Spool plate (reference side)

Set screw

(contact side)

Must be located

exactly (180o)

opposite the one

on the reference

side.

Set screw

(reference

side)

Note

Page 29

Chapter 3 Handling Plates

Confirm that there is no gap

between the plate roll and the

spool plate and that the set screw

is placed in the correct position

and then tighten the set screw.

6) Turn ON the power switch to the

main unit. After completion of the

initialization process, grab the

handle on the right side, open the

magazine cover, and load a plate

roll which has been mounted on a

spool shaft.

Refer to "4.1 Cable

connection check", "4.2

Turning ON the power

switch" and "4.3

Initialization" in Chapter 4

"Operation" when turning

ON the main power

switch.

7) Put the spool shaft holder on the

spool set guide and set the guide

into the SDP-Eco 1630 III.

Position the shaft with its red mark

toward the back of the machine

(on the right side).

8) Turn the nip roller clearance

handle (located at the panel

bottom) until it is horizontal. This

cancels the main roller nipping.

Gently insert the plate into the

clearance in the guide roller.

- 21 -

Gently insert the plate.

Turn the nip roller

clearance handle until

it is horizontal.

Note

Page 30

SDP-Eco1630 III USERS MANUAL

A buzzer sounds when you start

inserting the plate. Insert the plate

further until a second buzzer

sounds. At the position where the

buzzer sounds, turn the nip roller

clearance handle back to its

vertical position to close the nip.

Insert the plate edge until

the second buzzer sounds.

If you insert it too far (30

mm or more), the plate

may jam.

Finally, gently holding the right

and left ends of the spool plate

rewind the plate to take up any

slack. Close the plate setting

cover. The plate setting is now

completed.

Skewing or meandering

may occur during feeding

depending on how carelessly the plate was

inserted.

Always insert the plate

evenly, holding its left and

right edges with both

hands.

Follow the procedures "4.4 Data

input for the set plate" and

"4.5 Execution of Pre. Feed

command" to input data for the set

plate. To prepare for the exposure:

Remove any section of the plate

that has been fogged by friction

during preliminary feeding.

- 22 -

Hold the spool plate to rewind the plate.

Tighten the slack on the

plate roll using both hands.

Close the plate setting

cover.

Insert the plate edge until the second buzzer

sounds and secure it there.

Turn the nip roller

clearance handle back

until it is vertical.

Caution

Caution

Page 31

Chapter 3 Handling Plates

3.2 Plate end processing

When plate end is displayed, remove the plate and re-set a new one following

the procedure below.

1) When is displayed on the panel:

The plate ended during exposure, so it is discharged from the processor.

Stop the buzzer by pressing the (reset) key.

After the plate is discharged, press the key to shift to the local mode,

and mount a new plate following the procedure mentioned in "3.1 Plate

setting".

Whether or not data will be

exposed depends on the

amount of exposure data

remaining when the plate end

is detected.

2) When is displayed

on the panel:

Plate ended at the beginning of an

exposure, so the remainder is

shorter than the processor's

minimum transfer length. Please

remove the plate.

1. Open the front door and remove

the plate through the plate removal

port.

2. Close the door and press the

key to return to the local mode.

3. Re-set the plate following the

procedure mentioned in "3.1 Plate

setting".

- 23 -

Cover for the plate

removal port

Plate removal port

<Plate End>

MENU

Note

Pick up plate

Page 32

SDP-Eco1630 III USERS MANUAL

- 24 -

Page 33

Chapter 4 Operation

The SDP-Eco 1630 III is a SCSI device. Turn ON the power switch for this

machine first, and complete its initialization routine. Then turn ON the

power switch to the host computer (RIP computer).

Be sure to turn OFF the power switch to the host computer (RIP computer)

when turning OFF the power switch for this machine.

Never open the front door or plate setting cover unnecessarily. Do

not open the plate setting cover except when replacing the plate roll.

Otherwise, the plate being processed may be adversely exposed. If

the front door is opened while the plate is being fed, it will adversely

affect the plate's image quality and feed state.

4.1 Cable connection check

After checking that the entire system including the host computer (RIP

computer) is shut down, check that all cables are connected correctly. The

figure below shows cable connections and locations. The cables used here

should be SCSI connection dedicated cables.

Do not use cables other than

the provided SCSI cables.

If the cable must be extended,

please purchase the optional

differential unit. This ma-

chine is incorporated with an

active terminator, so that this

differential unit can be

mounted internally.

Chapter 4 Operation

- 25 -

Wide SCSI

connector

Do not open the cover

during operation

Do not open the door

during operation

Caution

Page 34

SDP-Eco1630 III USERS MANUAL

4.2 Turning ON the power switch

Before you turn ON the power switch of the main unit, check the following

points.

1) Processing chemical has been properly supplied to the processor.

2) The front door and plate setting cover are securely closed and the covers

are properly mounted.

In a SCSI, the power switch must be turned ON from the peripheral unit.

First, check that the power switch for the host computer (RIP computer) is

shut down. Then, turn ON the machine power switch.

If any error is detected during initialization after turning ON the power switch, it is

immediately displayed.

4.3 Initialization

When the power switch to the SDP-Eco 1630 III is turned ON, the machine

performs an initialization sequence which includes a number of routines to

confirm that it is ready for normal operation. Checked items include:

- Internal setting check

- Plate mounting check

- Polygon mirror function check

- Waste chemical tank level check

- Activator (EAC) level check

- Stabilizer (EST) level check

- Home position check for each moving part

•

Panel display flow after machine startup

- You can cancel the operations after "Cleaning", during the sequence of this

process, by using the key.

- The "Heating" window informs you if a heater has not yet reached the specified

temperature. ("P" signifies the process heater, and "R", the roller heater.)

- 26 -

Caution

Note

Initializing....

Note

Cleaning

Levels Dryer H/L?

Heating

Cleaning

Start OK

Page 35

4.4 Data input for the set plate (This procedure is necessary when

loading the plate.)

(1) Press the key to display the .

(2) Press the key to display , which is a lower

level of the menu.

(3) Use the key to select the data registration number, plate type, plate

width, or length of plate roll, then press the key to flash the cursor

(indicating mode change).

(4) Press the key after changing the data using the or key.

• Input the plate data and press the key. Press the key once to call

up the display and press the key once more to call up

the display and switch to the on-line mode.

(Example)

1) Selection of Data Memory Channel (From M0 to M3)

Press the key in order to start the

cursor key flashing and select M0 to

M9 using the key or the

key. Press the key to register the

data channel.

2) Selection of plate type (From F100 to F175)

Press the key or the key to

move the cursor to the F100 display

(plate type). Press the key to

start the cursor flashing. Select the

plate type (F175, R175) using the

key or the key and press

the key to register the plate type.

3) Selection of the plate width (From 404 to 414)

Press the key or the key to

move the cursor to the 404 display

(plate width). Press the key to

start the cursor flashing. Select the

plate width using the key or the

key and press the key to

register the plate width.

ENT.

ENT.

ENT.

ENT.

ENT.

ENT.

Start OK

< Plate Data >

MENU

ENT.

Chapter 4 Operation

- 27 -

M0 F175 414 61m

M3 F100 404 37m

If setting

M3

Cursor

M3 F100 404 37m

M3 F175 404 61m

M3 F175 404 61m

M3 F175 414 61m

MENU

ENT.

< Plate Data >

< Plate Data >

M0 R 1 7 5 414 00m

ENT.

Note

ENT.

Page 36

SDP-Eco1630 III USERS MANUAL

- 28 -

4) Inputting the value for the remaining amount of plate (61m to 46m)

Press the key or the key to

move the cursor to the remaining

amount display. Press the key or

the key to start the cursor

flashing. Change the remaining

amount using the key or the

key and register the value with

the key.

*Press the key to return to the original menu when you finish changing settings.

4.5 Execution of Pre. Feed command (This procedure is necessary

when loading the plate.)

Close the plate setting cover after the plate roll is set.

(1) Return the menu to the upper level menu using the key.

(2) Select Pre. Feed (preliminary feeding mode) using the key.

Press the key to move to the lower level menu

for the preliminary feeding mode.

(3) Use the key to set the plate feeding number to either "1" or "3" -- for

"Feed Count 1".

(4) Start preliminary feeding with the key.

- Press the key after the preliminary feeding. Press the key once to

call up the display. Press the key once more to call up the

display and switch to the on-line mode.

- Normally, a preliminary feeding must be performed to remove the fogged area

after loading a new plate.

Start OK

MENU

< Plate Data >

MENU

ENT.

M3 F175 414 61m

M3 F175 414 41m

ENT.

MENU

< Plate Data >

ENT.

MENU

Note

ENT.

Page 37

Chapter 4 Operation

- 29 -

4.6 Exposure

The machine has two exposure modes: remote exposure which performs

exposure using data provided from the host computer, and local exposure

which performs laser test exposure and re-exposure.

•

Remote exposure

After entering remote mode (ON LINE lamp is lit), give the exposure

command through the host computer (RIP computer). While exposure is in

progress, "Exposing ***%" is displayed on the panel display. "***%"

indicates the percentage currently exposed.

[Display during remote exposure]

The panel display changes as shown below during the exposure.

•

Local exposure

[Laser Test Expo.]

(1) Confirmation and input of the plate type, resolution and light intensity

1) Use the key to call up display.

2) Select using the key and press the key.

3) Press the key while is displayed.

4) Plate type, resolution and light intensity are displayed.

(Example) (F175 1200 dpi Light intensity 200)

5) Press the key to change the resolution. Select the desired

resolution from among 12 (1200 dpi), 15 (1500 dpi), 18 (1800 dpi)

and 24(2400dpi) using the key. Register the resolution using

the key.

6) Press the key to move the cursor to the light intensity value

display and then press the key.

7) Change the light intensity value using the key or the key.

Press the key to register the light intensity value.

Press the key to return to the previous menu if no change is necessary or

setting is discontinued.

MENU

Data transmission start

Data transmission end

Image data exposure start

Image data exposure end

Plate is being discharged

Completion

MENU

<Laser>

ENT.

< Plate Data >

Laser Test Expo.

Data Transferring

Exposing 0%

Exposing 100%

Discharging

Complete

ENT.

F175 (1 2) 200

ENT.

Note

ENT.

ENT.

ENT.

Page 38

SDP-Eco1630 III USERS MANUAL

- 30 -

(2) Exposure

1) Press the key to call up display. Move the

cursor to the Laser Test Expo. display and press the key.

2) After Laser Test Expo. display appears, Y N is displayed. Choose

'Y' with the cursor key and press the key. The laser test

exposure will start. (Refer to '6-2 Laser menu')

- When the cursor key is at 'N', press the key to call up the

display.

- After completion of the test exposure, press the key once to call up the

display and press the key oncemore to return to .

- When re-adjustment of the light intensity is necessary, change the light

intensity value following step (1)-6 in the procedure above.

[Exposure Clear]

The image data which remains in the hard disk drive will be re-exposed if

exposure is interrupted during remote exposure (e.g., because of a plate end

signal). It is possible for the hard disk to keep up to 2 separations of image

data. Image data that has been exposed can be re-exposed.

1. Press the key to call up the display.

2. Select the key and press the key to move to the display

for re-exposure.

3. Select in the display. Pressing the key

shows the display for selecting unexposed or exposed data.

4. Pressing the key in the display brings up the

display.

Unexposure EXEC............Image data on the hard disk drive, which has not

yet been exposed.

Exposed EXEC.................Image data which has already been exposed.

Select EXEC and press the key to start

exposure.

5. Select and press the key to erase image data on the

hard disk drive.

- When is displayed, use the key (the red reset key)

to return to the previous window. Then press the key to return to the

window.

- Though the hard disk drive can keep image data for up to 2 separations, you

cannot select the separation data to be output.

< Plate Data >

MENU

Non Exposure Data

MENU

Laser Test Expo.

ENT.

ENT.

Note

ENT.

Laser Test Expo.

<Laser>

MENU

MENU

Start OK

MENU

< Image Data >

< Plate Data >

ENT.

Exposure

Exposure Clear

ENT.

<Exposed EXEC

Unexposure EXEC>

ENT.

Exposure Clear

ENT.

Note

Page 39

Chapter 4 Operation

4.7 Processor section

The processing chemicals are applied to the plate while it is being transferred

in the SDP-Eco 1630 III's built-in processor section. The processor section

also includes a final rinsing process which cleans the developed plates and

thus reduces paper media waste (from processing chemical stains) at the start

of printing.

You must thoroughly read "1.3 Handling processing chemicals".

• Preparing and pouring processing chemical

1) Fasten a replenishment cap on the replenisher bottle which contains the

processing chemical and set it in the tank.

Be sure to set the bottle in the appropriate tank since the SLM-EAC

and SLM-EST cause different (opposing) effects.

• Processing chemical replenishment

As the processing chemical decreases, the liquid level in the tank goes down

and finally the "Empty EST" or "Empty EAC" message appears on the display

(accompanied by a buzzer sound). Replenish the processing chemical

following the procedure below.

Replenish the processing chemical and replace the processing bottle

following the procedure below.

1) Press the key to turn off the buzzer.

2) Open the front door.

3) Add processing chemical from the container (10 liters) to the replenisher

bottle.

4) Put the cap back on the replenisher bottle and set it in the tank.

- 31 -

Rinse water

replenisher

bottle

Washing tank

Waste

water hose

SLM-EST

drainage

hose

SLM-EST

replenisher

bottle

Processor rack

SLM-EST

processing

chemical tank

SLM-EAC

replenisher

bottle

SLM-EAC

processing

chemical tank

SLM-EAC

drainage

hose

Cap

Waste chemical vat

Waste chemical tank

Caution

Caution

Page 40

SDP-Eco1630 III USERS MANUAL

• Processing chemical replacement

Replace the processing chemical every three months regardless of the number

of plates processed.

•

Preparing rinse water

1) Pour approximately 1 liter of water into the rinse water replenisher bottle

and set it in the washing tank.

2) Always make sure that the bottle is filled with water before turning ON

the power switch.

3) After turning ON the power, reset the counter in the <Rinse> menu with

the following operation.

[Procedure]

(1) Push the key to display .

(2) Select using the key, and then push the key.

(3) Using the key, align the cursor to "CLR" in the

menu.

(4) Push the key to reset the counter.

If the washing tank becomes empty of water, this will adversely affect the

plate's image quality. Replenish the rinse water everyday before starting

operation.

Replace the water in the washing tank every month. Replacement

frequency may vary depending on the quality of the water and the

season.

• Confirming the remaining amount of rinse water and replenishment

When the rinse water is running out and needs to be replenished, the "Rinse

Tank Check" message appears in the display, causing the buzzer to sound.

Confirm the remaining amount of rinse water and replenish it as necessary.

1) Press the key to turn the buzzer OFF.

2) Open the front door.

3) Remove the rinse water replenishing bottle and replenish it with rinse

water.

4) Return the rinse water replenishing bottle to its original position, and then

close the front door.

- Pressing the key to delete the above message in the display does not

reset the software counter, causing the message to appear in the display and

the buzzer to sound a while after the key has been pressed. To reset the

counter, open the front door, and then confirm the remaining amount of rinse

water, or display the window in the users menu, and then perform a

counter clearance operation. (For detailed operation, refer to the section

"Preparing Rinse Water.")

<Rinse>

- 32 -

<Rinse>

MENU

< Plate Data >

ENT.

Count 150 CLR

Caution

ENT.

Note

Page 41

Chapter 4 Operation

- If the output data is sent from the host computer to the recorder while

the above warning is being issued, the warning disappears, executing

output operation. After output operation has been completed, the

warning message appears and the buzzer sounds again.

• Handling waste liquid

Scale lines indicating capacity are marked on the waste chemical tank.

Observe the scale line carefully and dispose of the processing chemical before

it reaches the 10-liter line.

When the waste chemical tank is full, the "Waste tank check" message appears

and a buzzer sounds. (Images cannot be read at this time.)

Dispose of the processing chemical following the procedure below.

1) Press the key to turn off the buzzer.

2) Remove the cap from the waste chemical tank and dispose of the waste

chemical in the tank.

3) Put the cap back on the now empty tank and put it back in the waste

chemical vat.

- The waste chemical tank weighs approximately 11 kilograms when it

is full, so please be very careful when handling it. (Refer to "1.3

Handling processing chemicals".)

- Be careful when handling the hose attached to the waste chemical

cap. Using a crimped or twisted hose can cause chemical leakage.

• If the machine is not used for a long period

Before deactivating the machine for a long time (7 days or more),

always drain the water in the rinse water replenisher bottle.

If the machine has not been used for a long time, the processor rack roller may

stick and not rotate smoothly.

Follow the procedure below so that the processor rack roller will rotate

smoothly.

1) Open the front door.

2) Remove the replenisher bottle

from the tank.

3) Hold the handle in the processor

rack section and slightly pull out

the processor rack.

- 33 -

Handle

Processor rack

Caution

Caution

Page 42

SDP-Eco1630 III USERS MANUAL

- 34 -

4.8 Collecting exposed plates

Exposed plates are discharged into the plate receiving tray. The SDP-Eco

1630 II discharges plates image-side down. Adjust the length of the discharge

retainer arm to accommodate the maximum length of the plates used.

It is possible to continuously collect plates (up to 50 consecutive sheets).

However, we cannot guarantee trouble-free collection of such large

numbers of plates if the machine is indiscriminately discharging plates of

different lengths or if the plate type is frequently being changed.

4.9 Turning OFF the power supply and inspection at shutdown

Always, before shutting down the machine, press the power ON/OFF key to

perform the final inspection. When is displayed in the on-line mode,

press the key to return to the local mode and then press the power

ON/OFF key.

The required final inspection includes checking the chemical level in the

waste chemical tank and releasing the plate nip by turning the nip roller

clearance handle to its vertical position. Roller cleaning is also performed

during the final inspection. If this procedure is not followed, transfer errors

may occur or masters exposed on the following day may be stained or marred.

If this procedure is not followed, transfer errors may occur or plates exposed

on the following day may be stained or marred.

It is not necessary to turn ON/OFF the main power for a weekday shut-down.

For weekend inspections: at shut-down, first turn OFF the machine,

completely clean the roller, and finally turn OFF the main power supply (at

the breaker).

MENU

Start OK

4) To rotate the roller, turn the handle

in the direction indicated by the

arrow in the figure.

Rotate the roller with the handle.

Caution

Page 43

Chapter 4 Operation

When shutting down the machine by pressing the power ON/OFF key, the

dehumidifying heater will automatically run unless the main power is also shut

down. The dehumidifying heater attached below the plate setting section inhibits

condensation in the machine by heating plates when humidity is high and

temperature is low. The low temperature keeps the machine away from fire

danger.

During the final inspection, do not open the front door until the display

panel is turned off; otherwise the final inspection will stop in the middle

of the operation.

- 35 -

Note

Caution

Page 44

SDP-Eco1630 III USERS MANUAL

- 36 -

Page 45

Chapter 5 Menus and panel displays

Chapter 5 Menus and panel displays

The display panel shows the performance status of the SDP-Eco 1630 III, its

error messages, etc.

5.1 User menu

- 37 -

Page 46

SDP-Eco1630 III USERS MANUAL

• Operation status

[Remote and local]

In the remote mode, it is possible to expose data transferred from the host

computer (RIP computer). In the local mode, exposure data from the host

computer (RIP computer) cannot be accepted.

The local mode includes a "User menu" (including user maintenance

functions) and a "Maintenance menu".

[User menu]

The "User menu" provides the basic commands necessary to operate the

machine.

[Maintenance menu]

If a command or a dialog for a command that is not included in the User

menu list appears, immediately press the key several times to return

to the User menu. (Do NOT press the key.)

This menu is used to adjust the SDP-Eco 1630 III.

[Standby mode]

In remote mode, if no command is sent to the machine for 10 minutes, it

enters the standby mode.

The standby mode will be canceled whenever a command is given or

when any key on the panel except the key is pressed.

Recovery time will differ depending on whether the machine has been in standby

mode for more than 10 minutes. If the machine was left idle for more than 10

minutes, recovery will take longer because a cleaning routine is performed for

the processor roller.

[Auto power OFF]

When this machine is left in the local mode for two hours, a cleaning

routine is performed for the processor roller and the power is turned OFF

automatically.

- 38 -

MENU

ENT.

Note

Page 47

5.2 Panel operation

• Power ON/OFF key

Press this key to turn OFF the power supply to the machine and shut it

down (after cleaning the processor roller). To re-start the machine, press

the Power ON/OFF key again.

This key only works in the first local status display and does not work at

all in the remote status.

[Final inspection display]

Final inspection

Always press the Power ON/OFF key when the operation ends.

• Remote mode display

The following display appears on the panel while the remote mode is selected.

START OK

The ON LINE lamp is lit while this is displayed.

Pressing the key shows the current state of the plate.

Pressing the key shows the number of images in data remaining on the

hard disk drive.

•

Menu/command selection

Use the key, keys, and key to select menus or

commands. The key brings up the menu level in the remote and local

modes. The keys switch the menu level between remote and local.

The keys are used to shift between commands. Selectable

commands appear with one of their letters underlined. You can select

commands on the right by pressing the right key and commands on the left

with the left key.

Pressing the key when a ">" mark is shown at the right edge of the menu

display shows the next (hidden) menu to the right. (Simply reverse this step

to move to hidden menus on the left.) When you find the desired menu, press

the key. Proceed to the next menu.

ENT.

MENU

ENT.

MENU

Chapter 5 Menus and panel displays

- 39 -

Waste Tank? Nip Free Cleaning Power OFF

HDD 1/2

Amount of image data which has not yet been exposed.

Amount of image data in the hard disk drive.

Caution

Page 48

SDP-Eco1630 III USERS MANUAL

• Switch the mode between remote and local

Remote Mode Local Mode

Start OK <Plate Data>

• Shift between commands (Example)

1st hierarchy <Maintenance>

2nd hierarchy Cutter Processor> <Ver SCSI-ID>

• Command execution

There are two types of commands: one which activates machine functions

such as preliminary feeding and cutter-processor commands, and one which is

used, for example, to set numerical values.

For commands in which numerical values can be changed (Example:

Referring to P27 "4.4 Data input for the set plate")

Use the to move the cursor to the numerical value display. Press the

key to start the display flashing and change the displayed value. (In

some modes the numerical value display starts flashing from the time it is first

displayed.)

The or key increases/decreases a numerical value.

Press the key when the desired number appears.

If you wish to reset a value or interrupt the setting procedure, press the

key to return to the upper menu level without changing the currently set value

and re-start the setting procedure from the beginning by selecting the same

command.

For commands in which numerical values can not be changed (Example:

Referring to P28 "4.5 Execution of Pre. Feed command")

Use the to select the desired command. Then press the key to

execute it.

Repeatedly press the key until Start OK is displayed to return to the on-

line mode.

MENU

ENT.

MENU

ENT.

ENT.

ENT.

MENU

MENU

- 40 -

Page 49

Chapter 6 User menu

It is possible to set values affecting the machine's operation state from the user

menu. Note that some settings from the host computer are given priority and

they will be automatically changed if the host computer resets them.

Refer to '5.2 Panel operation' for details on key operation.

6.1 Plate data

The command is used to enter information on the plate to be

loaded.

• Data channel

The data channel stores the plate information. 10 different sets of plate

parameter data can be stored (from M0 to M9). The plate information consists

of plate type, plate width, remaining amount, and the set laser (depends on the

resolution for the respective plate type).

•

Plate type

You can only use the following three types of plates.

• Plate width

Each plate can be set to the following widths (displayed in mm).

< Plate Data >

Chapter 6 User menu

- 41 -

Plate type

Data

channel

Plate width

Remaining

amount

Sample panel display

M1 F175 404 60m

Note

Panel display

F175

F100

R175

Plate model

SDP-FRm175

SDP-FR100

SDP-RR175

Remarks

Polyester base

t 0.175 mm

Polyester base

t 0.100 mm

Paper base

t 0.175 mm

Page 50

SDP-Eco1630 III USERS MANUAL

• Remaining amount of plate

The remaining amount of plate should be set in meter units when you use a

new plate.

The initial setting value is 0 meter.

The remaining amount of plate is shown in 1 meter increments (0 to 75

meters) in the remote mode display

The remaining amount value is calculated by subtracting the exposed plate

length from the plate length set by the operator. The plate length for

preliminary feeding is also subtracted.

However, the accuracy of the remaining length measurement is not

guaranteed. Please regard this value simply as a reference guide.

6.2 Laser menu

The laser menu contains a command to set the laser for exposing the current

plate.

• Resolution setting

(12) ......1200dpi

(15) ......1500dpi

(18) ......1800dpi

(24) ......2400dpi

• Laser setting

From the panel, you can set the exposure laser for each resolution to be used

with the current plate.

1) Set the resolution and laser value.

2) If necessary, expose a trial sheet to adjust the laser.

- 42 -

Sample panel display

Plate type

F175 (12) 200

Resolution

Laser value

Page 51

Chapter 6 User menu

• Laser test exposure

The plate is exposed using a specific pattern to determine the most suitable

laser for each resolution. (The selected resolution is displayed on the panel

display.) The table on the previous page shows the exposure resolution

pattern. Resolution code lines are shown at the bottom of the exposed pattern.

- 43 -

100%

50%

95%

5%

Light intensity

value

10

8

Resolution code lines

1200 dpi ..... 2 lines

1500 dpi ..... 3 lines

1800 dpi ..... 4 lines

2400 dpi ..... 5 lines

0

+8

+10

(Example1200dpi)

Page 52

SDP-Eco1630 III USERS MANUAL

6.3 Pre. Feed menu

Whenever you set a new plate, a "Pre. Feed" operation is performed to

eliminate any fogged sections at the leading edge.

From the display panel, you can select whether to feed 1 or 3 sheets for this

operation. The length of each sheet is 500 mm, so if you perform a 3-sheet

preliminary feed, 1500 mm of plate will be cut, fed and disposed of.

If there are still darkened or fogged areas on the plate, perform another

preliminary feed.

6.4 Image Data menu

The SDP-Eco 1630 III incorporates a hard disk drive buffer to avoid idle time

due to differences in calculation speed between itself and the host, and to

enable quick re-exposure after an exposure was interrupted (e.g., if you use

the stop key or the plate ends).

Data written in the hard disk drive can be exposed or erased in the local mode.

Select the "Exposure" command to expose the data and the "Clear" command

to erase it.

6.5 Mode menu

In this menu, you can operate the punch (option), select a dryer level, and set

the buzzer response for different key operations.

Set the punch to ON to punch plates before image exposure or set it to OFF if

punching is not necessary.

If the machine does not contain a punch unit, the "Un-mounted" message

appears.

• Punch specifications

Two types of punch unit options can be set: the DS punch (for alternately

positionable punch) and the BELL punch.

The distance between punch holes is fixed, so it is impossible to change the

distance depending on the plate width.

[DS punch] [BELL punch]

- 44 -

220

Leading side

Leading side

386.5

Cut line

Dedicated for 335mm width plates

12 x 16

10 x 16

5 x 8

φ

5

Note

Page 53

Chapter 6 User menu

• Dryer level selection

When setting the dryer temperature, you can select either automatic or manual

(Hi or Low). Select the temperature setting which suits your plate type and

the environmental conditions.

If you select automatic setting, the dryer temperature will be set to "Hi" for

FR100 and FRm175 plates, and "Low" for RR175.

• Stand-by mode ON/OFF

Either activate (ON) or deactivate (OFF) the stand-by mode as follows.

ON: The Stand-by mode is active.

OFF: The Stand-by mode is inactive.

6.6 Maintenance menu

This menu is used when a plate is jammed, the processor is operating, etc.

• Cutter

If a plate is jammed in the machine, the cutter can often be used to help free

and discharge the plate. The cutter returns to its original position after cutting

a plate.

• Processor

The processor can be activated independently of the exposure unit.

• VER

This command displays the version numbers of the software in the machine

(MCON software which controls SDP-Eco 1630 III operations and SRAM

software which controls the SCSI interface).

• SCSI-ID

This command allows you to set/reset SCSI-IDs. Note that after changing a

SCSI-ID setting, you must turn OFF the power and reboot the entire system

including the SDP-Eco 1630 III itself.

6.7 Rinse

The machine is provided with the software counter that functions to warn

operators when the rinse water lowers than the designated level. The warning

is issued in a message and does not prevent output operations.

• When the recorder has received the exposure data from the host computer

(RIP computer) while the "Rinse Tank Check" message is displayed, this

message disappears, and then the exposure is performed. After the exposure

has been finished, the "Rinse Tank Check" message is displayed again.

- 45 -

Note

Page 54

SDP-Eco1630 III USERS MANUAL

• The alarm function in this machine has been set to OFF before shipment at

the factory.

(Settings 000 = OFF)

• The consumption rate of rinse water may be different depending on the

settings in the machine. Set the consumption rate with the following

procedure.

[Procedure] (In cases where the current values are changed to "150".)

(1) Push the key to display the window.

(2) Select with the key, and then push the key.

(3) When is displayed, make sure that the cursor is placed

under the setting, and then push the key.

(4) Push either the key (Increase) or the key (Decrease) to set the

settings to "150".

(5) After changing the setting, push the key to confirm the setting.

(6) Push the key two times to display the window.

Use "120 to 160" as a reference value. Adjust the rate of rinse water reduction

depending on the installation conditions of the machine.

(Adjustable range: 50 to 300. Note that using "000" deactivates this function.)

[Notes for adjustment]

(1) When the "Rinse Tank Check" message is displayed.

If the replenishing bottle is empty, decrease the setting.

If there is a lot of rinse water left in the bottle, increase the setting.

(2) To deactivate the software counter function, use "000" as a setting value.

Be sure to reset the counter by "CLR" after you have adjusted the setting.

- 46 -

MENU

< Plate Data >

< Rinse >

Count 150 CLR

Note

MENU

ENT.

ENT.

ENT.

< Plate Data >

Page 55

Chapter 7 Maintenance

Chapter 7 Maintenance

7.1 Cutter blade replacement

If the edge of the cutter becomes notched, chipped or curved after cutting a

plate, the blade must be replaced.

The cutter blade should be replaced regularly both to prevent transfer jams

and problems due to cutting errors, and to maximize the machine's overall

performance.

Always replace the blade after cutting two plate rolls and/or every 30 days

regardless of the number of plates cut.

Replacement procedure

1) Turn OFF the power switch.

2) Open the front door.

3) Remove the cutter unit cover.

4) Insert the cutter blade between

the cutter blade guides (upper

and lower) in the direction

indicated by the arrow in the

figure and secure it in the

designated position.

-Use the accompanying

cutter blade or NT cutter

blades (85 mm), which

are commercially available.

-Align the back side of the

cutter with the cutter

carriage guide and

tighten the set screw with

a coin.

5) Return the cutter unit, cover, and

front door to their original

positions. Turn ON the power

switch and check the cutter's

performance in the maintenance

mode.

Always be careful when handling the cutter blade. Wear safety gloves

to protect your hands from being cut.

- 47 -

Remove the

cutter unit

cover.

Cutter carriage

Set screw

Back side of cutter blade

Cutter blade guide (upper)

Cutter blade guide (lower)

Cutter guide

Caution

Cutter blade replacement

procedure label

Caution

Page 56

SDP-Eco1630 III USERS MANUAL

7.2 Cylindrical lens cleaning

The SDP-Eco 1630 III incorporates a

highly accurate optical system in

which the lens is positioned

extremely close to the exposed

surface.

Therefore, if the lens is soiled with

dirt or dust due to environmental

conditions, for example, it may show

up as a vertical line (white or black).

1)If a vertical line appears, open the

front door, loosen the two screws on

the cylindrical lens unit, and remove

the entire unit by gently pulling it out

toward the operator.

2)Inspect the lens under a bright

fluorescent light to check its

cleanliness and, if there is any dirt or

dust, clean it off with a blower.

Do not use compressed

air when cleaning the

lens.

3)Never touch the lens with your hand

or any kind of tool. These lens can

be easily scratched and may require

replacement.

The plate will be fogged

after you replace the

lens. Before the next

operation, feed one

sheet through the

machine.

4)Re-assemble the cylindrical lens unit,

reversing the previous procedure. Be

sure to firmly re-insert the unit as far

back as it will go into the machine

chassis.

- 48 -

Cylindrical lens

Clean it off with a blower

Remove the

entire unit

by gently

pulling it out

toward the

operator.

Cylindrical lens

unit

Screw

Caution

Caution

Page 57

Chapter 7 Maintenance

7.3 Filter cleaning

Since a clogged filter mesh will seriously affect exposure results, clean the

filter at least every three months.

1) Turn OFF the power supply.

2) Remove the filter frame from the

machine.

3) Remove the filter and cleanse it

with the cleaner (with the frame

attached).

4) Remount the filter frame back in

its original position.

If the filter is not mounted, the cylindrical lens

will immediately be

soiled with dust and dirt.

Also, the plate surface

will become scratched.

- 49 -

Remove the

filter frame

using both

hands.

Clean the filter

using a

cleaner.

Filter

Caution

Page 58

SDP-Eco1630 III USERS MANUAL

- 50 -

7.4 Punch dust removal

When the punch unit (option) is mounted, it is necessary to periodically